Patents

Literature

5656results about "Forme preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

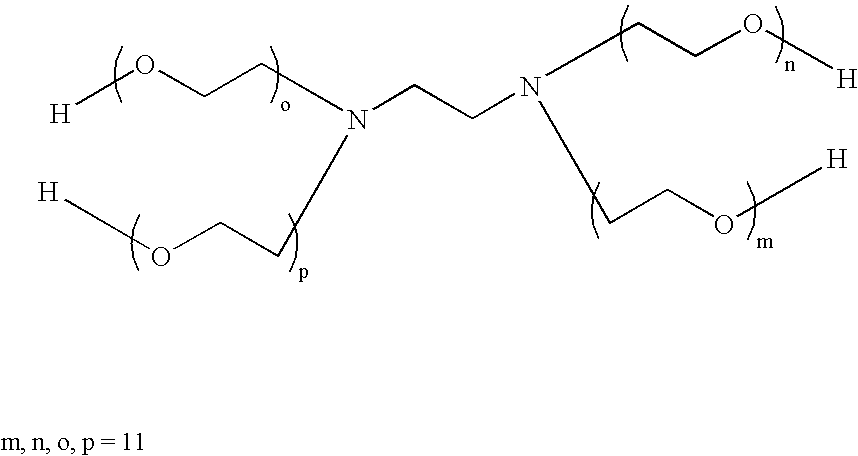

On-press developable IR sensitive printing plates using binder resins having polyethylene oxide segments

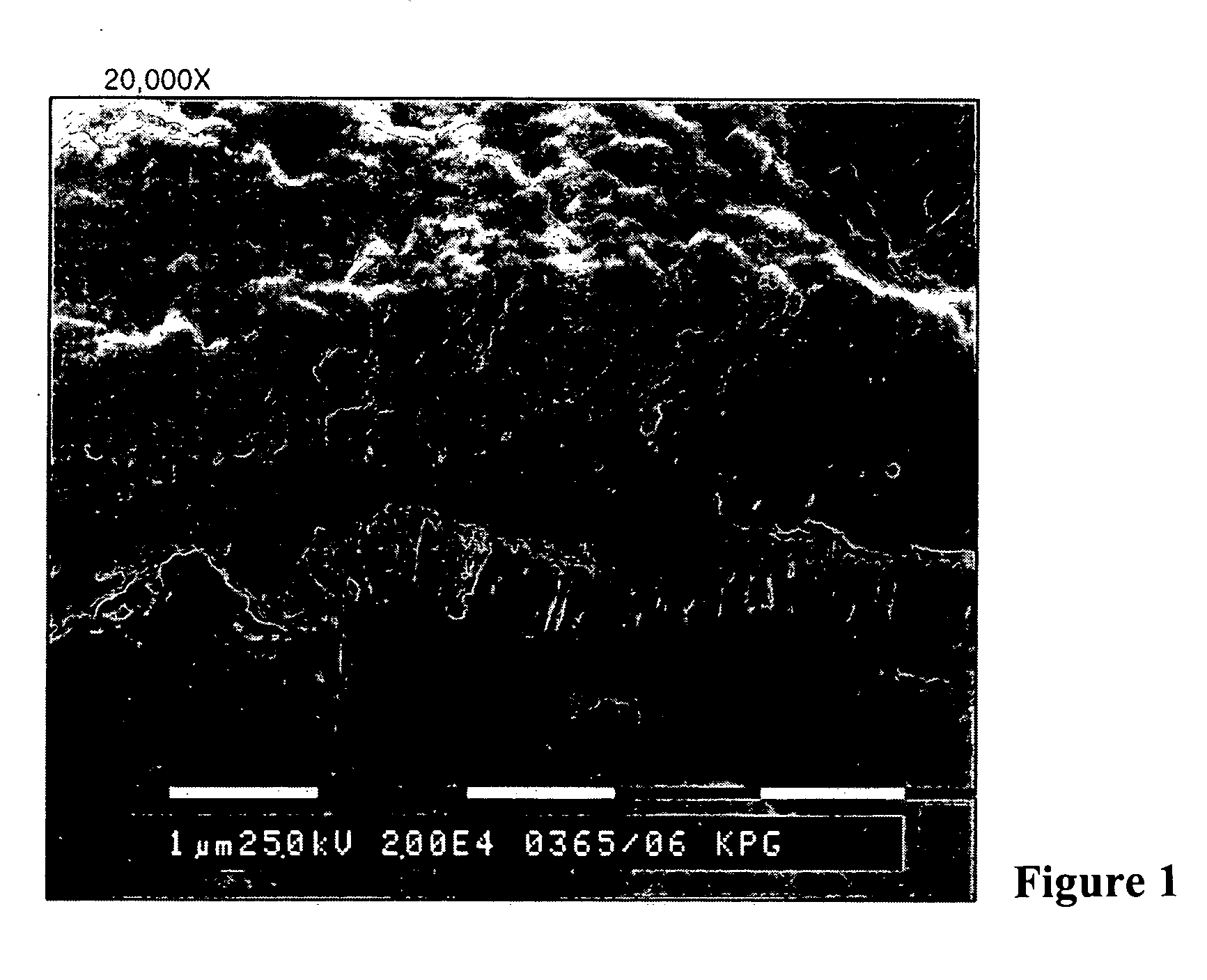

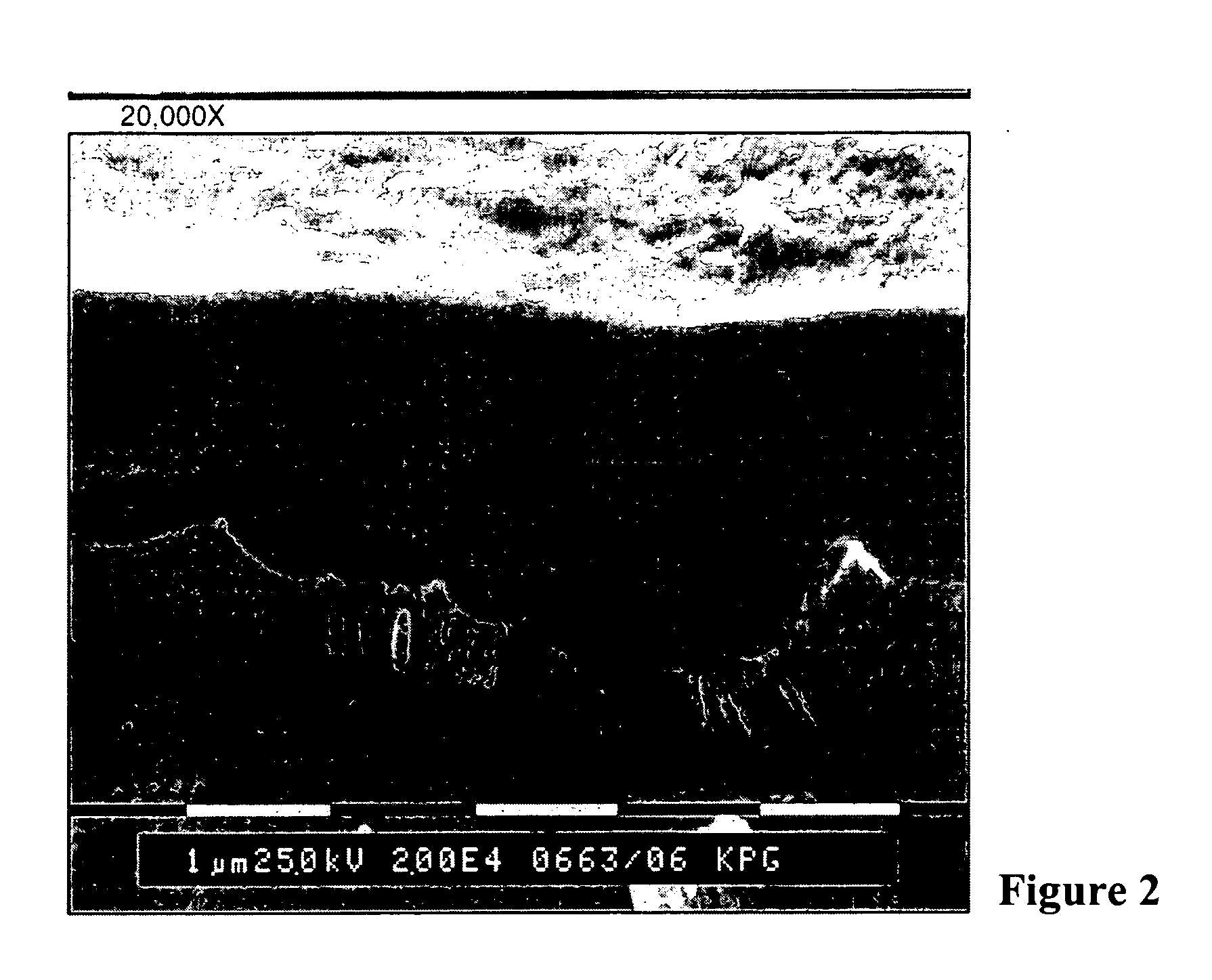

InactiveUS6899994B2Prevent steppingRadiation applicationsSemiconductor/solid-state device manufacturingPolymer sciencePolyethylene oxide

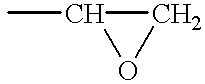

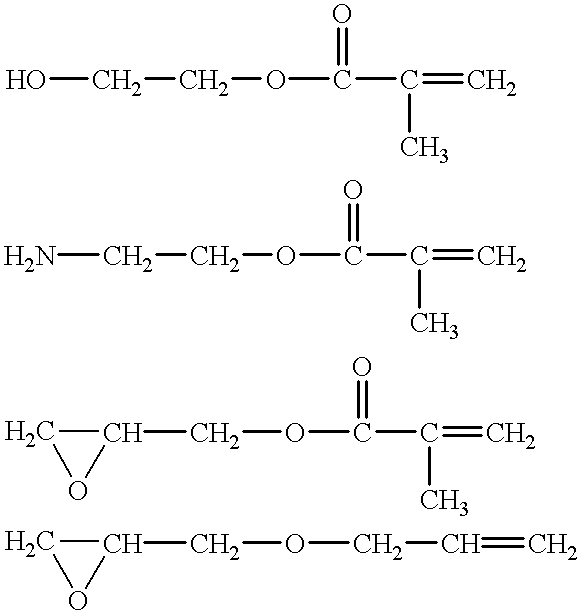

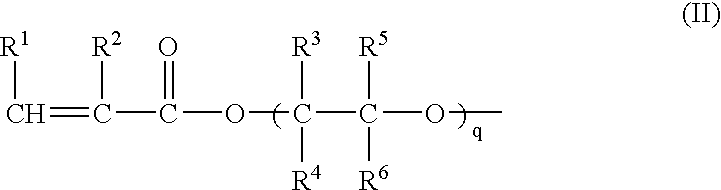

The present invention relates to a polymerizable coating composition suitable for the manufacture of printing plates developable on-press. The coating composition comprises (i) a polymerizable compound and (ii) a polymeric binder comprising polyethylene oxide segments, wherein the polymeric binder is selected from the group consisting of at least one graft copolymer comprising a main chain polymer and polyethylene oxide side chains, a block copolymer having at least one polyethylene oxide block and at least one non-polyethylene oxide block, and a combination thereof. The invention is also directed to an imageable element comprising a substrate and the polymerizable coating composition.

Owner:KODAK POLYCHROME GRAPHICS

Radiation-sensitive compositions and imageable materials

InactiveUS7153632B1Maintaining photo speedMaintaining visible print outPhotosensitive materialsRadiation applicationsPolymer sciencePolymer

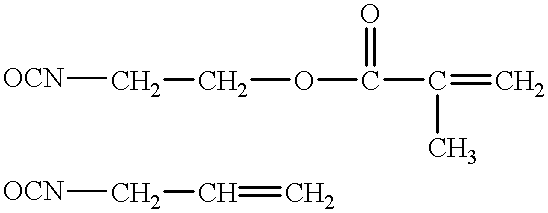

A radiation-sensitive composition includes a radically polymerizable component that comprises carboxy groups, an initiator composition to generate radicals, and a polymeric binder comprising poly(alkylene oxide) segments and optionally pendant cyano groups. This composition can be used to prepare imageable elements such as negative-working, on-press developable printing plate precursors.

Owner:EASTMAN KODAK CO

Imageable element with solvent-resistant polymeric binder

InactiveUS20050003285A1Enhances on-press solvent resistanceProlong lifeRadiation applicationsSemiconductor/solid-state device manufacturingSolventPendant group

The present invention provides an imageable element including a lithographic substrate and an imageable layer disposed on the substrate. The imageable layer includes a radically polymerizable component, an initiator system capable of generating radicals sufficient to initiate a polymerization reaction upon exposure to imaging radiation, and a polymeric binder having a hydrophobic backbone and including both constitutional units having a pendant cyano group attached directly to the hydrophobic backbone, and constitutional units having a pendant group including a hydrophilic poly(alkylene oxide) segment. When the imageable element is imaged and developed, the resulting printing plate may exhibit improved on-press solvent resistance and longer press life.

Owner:KODAK POLYCHROME GRAPHICS

Water-developable infrared-sensitive printing plate

ActiveUS20050123853A1Semiconductor/solid-state device manufacturingPhotosensitive material auxillary/base layersPendant groupAqueous solution

The present invention provides an imageable element including a lithographic substrate and an imageable layer disposed on the substrate. The imageable layer includes a radically polymerizable component, an initiator system capable of generating radicals sufficient to initiate a polymerization reaction upon exposure to imaging radiation, and a polymeric binder having a hydrophobic backbone and including constitutional units having a pendant group including a hydrophilic poly(alkylene oxide) segment. The imageable element can be developed using an aqueous developer solution. Alternatively, the imageable element can be developed on-press by contact with ink and / or fountain solution.

Owner:KODAK POLYCHROME GRAPHICS

Contact print methods

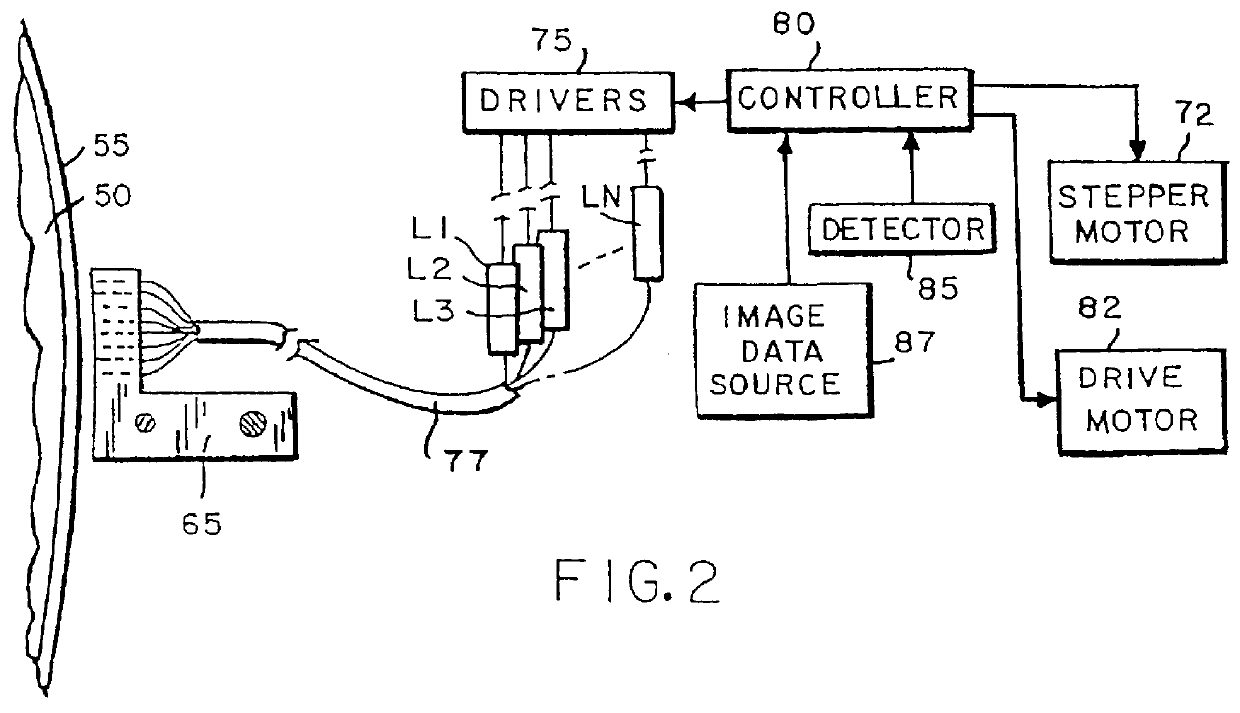

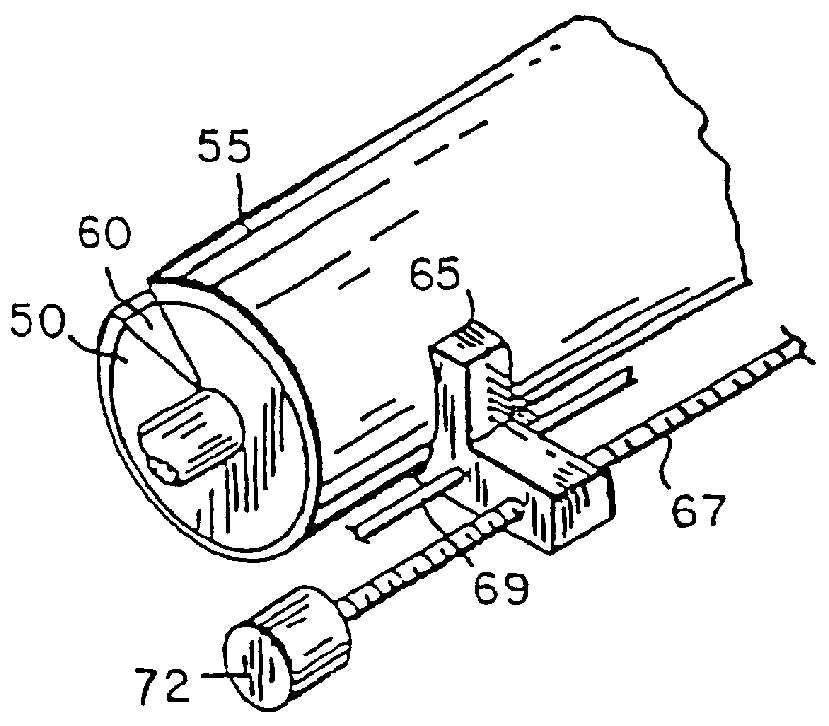

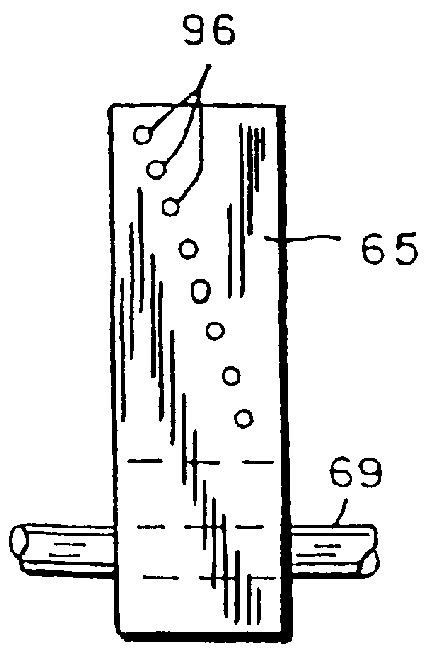

InactiveUS6957608B1High definitionImprove printing effectMechanical working/deformationSolid-state devicesContact printSolvent

A method of and device for controlled printing using liquid embossing techniques is disclosed. In accordance with the embodiments of the invention a stamp comprises a differentiated embossing surface with protruding and recessed surfaces to enhance the ability of the stamp to selectively displace liquid ink from a print surface and / or remove solvent from the liquid in a soft curing process. A stamp with differentiated surfaces is fabricated by selectively coating, or otherwise treating the protruding features, the recessed features, or a combination thereof, such that the surface energies and / or wettability of the protruding surfaces and the recessed surfaces are differentiated.

Owner:KOVIO

Negative Working, Heat-Sensitive, Lithographic Printing Plate Precursor

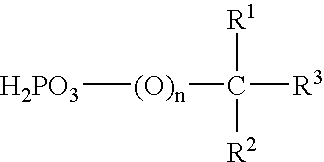

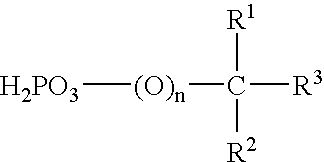

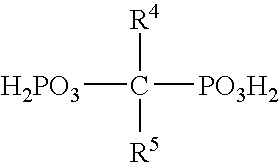

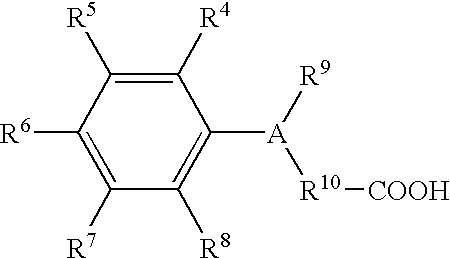

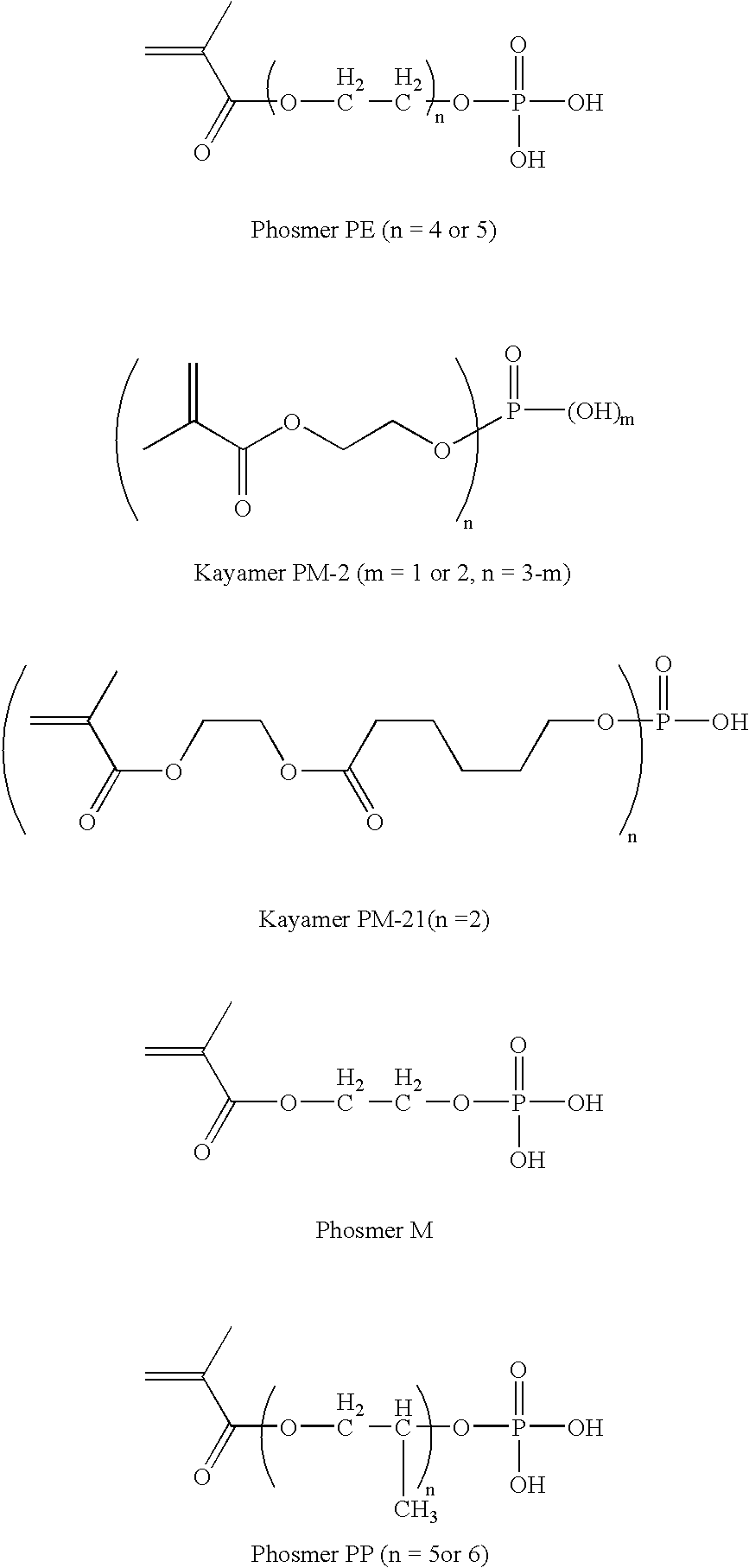

ActiveUS20080213696A1Number of defectSize of defectPhotosensitive materialsDuplicating/marking methodsSimple Organic CompoundsPhosphoric acid

A heat-sensitive negative-working lithographic printing plate precursor includes on a grained and anodized aluminum support a coating including hydrophobic thermoplastic polymer particles, a hydrophilic binder, and an organic compound, wherein the organic compound includes at least one phosphonic acid group or at least one phosphoric acid group or a salt thereof.

Owner:AGFA OFFSET BV

Negative-acting no-process printing plates

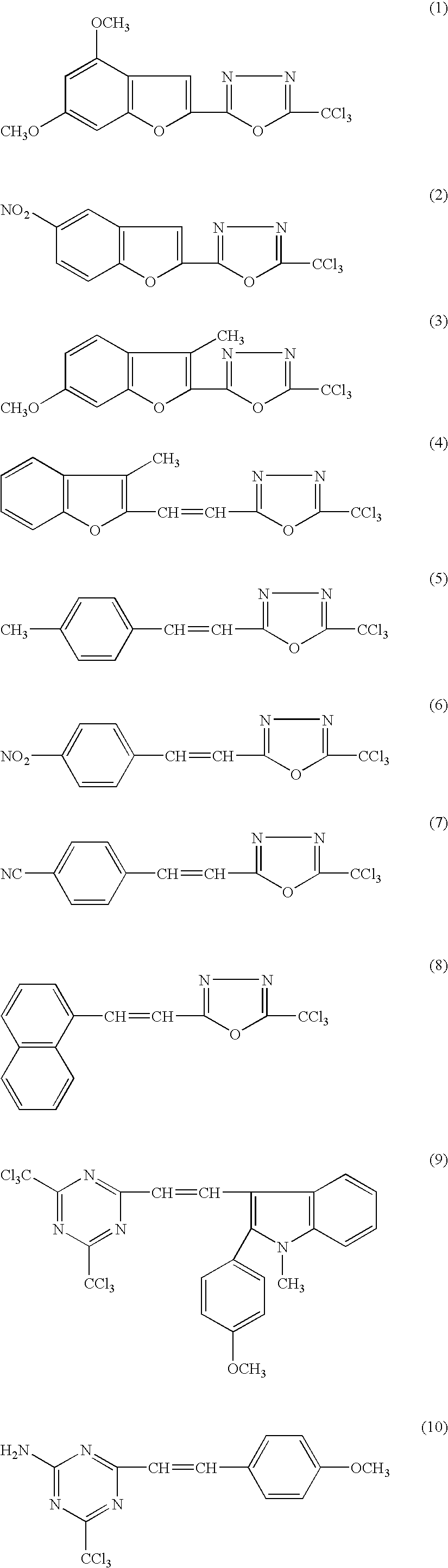

InactiveUS6027857APhotosensitive materialsPhotosensitive material processingFunctional monomerOligomer

A photosensitive composition is prepared containing a polymer of the formula B(X)(Y) wherein B represents an organic backbone, each X independently is an acidic group or salt thereof and each Y independently is a photocurable group and a photoinitiating compound or compounds. Preferably, free-radically polymerizable multi-functional monomer and / or oligomer is added to the photosensitive composition. The photosensitive composition can be coated on a suitable substrate for planographic printing plate applications. Imagewise irradiation causes the light struck regions to photocure, becoming insoluble in aqueous and organic mediums, while the non-light struck regions remain highly soluble / dispersable. Printing plates of this construction do not require processing prior to being run on a press.

Owner:3M CO

High speed negative-working thermal printing plates

Negative working thermally imageable elements useful as lithographic printing plate precursors and methods for their use are disclosed. The elements have a substrate, a layer of imageable composition over the substrate, and, optionally, an overcoat layer over the layer of imageable composition. The imageable composition has an allyl-functional polymeric binder. Optimum resolution and on-press performance can be attained without a post-exposure bake. The elements do not require a post-exposure bake and can be used in on-press development applications.

Owner:KODAK POLYCHROME GRAPHICS

Method of making a photopolymer printing plate

ActiveUS20050266349A1High degree of polymerizationImage deteriorationPhotosensitive materialsDuplicating/marking methodsPhotopolymerEngineering

A method of making a lithographic printing plate comprising the steps of: a) providing a lithographic printing plate precursor comprising (i) a support having a hydrophilic surface or which is provided with a hydrophilic layer, (ii) a photopolymerizable coating on said support, b) image-wise exposing said coating in a plate setter, c) developing the precursor, thereby removing the non-exposed areas of the coating from the support, whereby the developing step is carried out off-press in a gumming unit by treating the coating of the precursor with a gum solution.

Owner:AGFA OFFSET BV

Negative-acting no-process printing plates

InactiveUS6171735B1Platen pressesSemiconductor/solid-state device manufacturingFunctional monomerOligomer

Owner:3M INNOVATIVE PROPERTIES CO

Printing plates using binder resins having polyethylene oxide segments

InactiveUS20050170286A1Prevent steppingRadiation applicationsSemiconductor/solid-state device manufacturingPolymer sciencePolyethylene oxide

The present invention relates to a polymerizable coating composition suitable for the manufacture of printing plates, which may be developable on-press. The coating composition comprises (i) a polymerizable compound and (ii) a polymeric binder comprising polyethylene oxide segments, wherein the polymeric binder is selected from the group consisting of at least one graft copolymer comprising a main chain polymer and polyethylene oxide side chains, a block copolymer having at least one polyethylene oxide block and at least one non-polyethylene oxide block, and a combination thereof. The invention is also directed to an imageable element comprising a substrate and the polymerizable coating composition.

Owner:EASTMAN KODAK CO

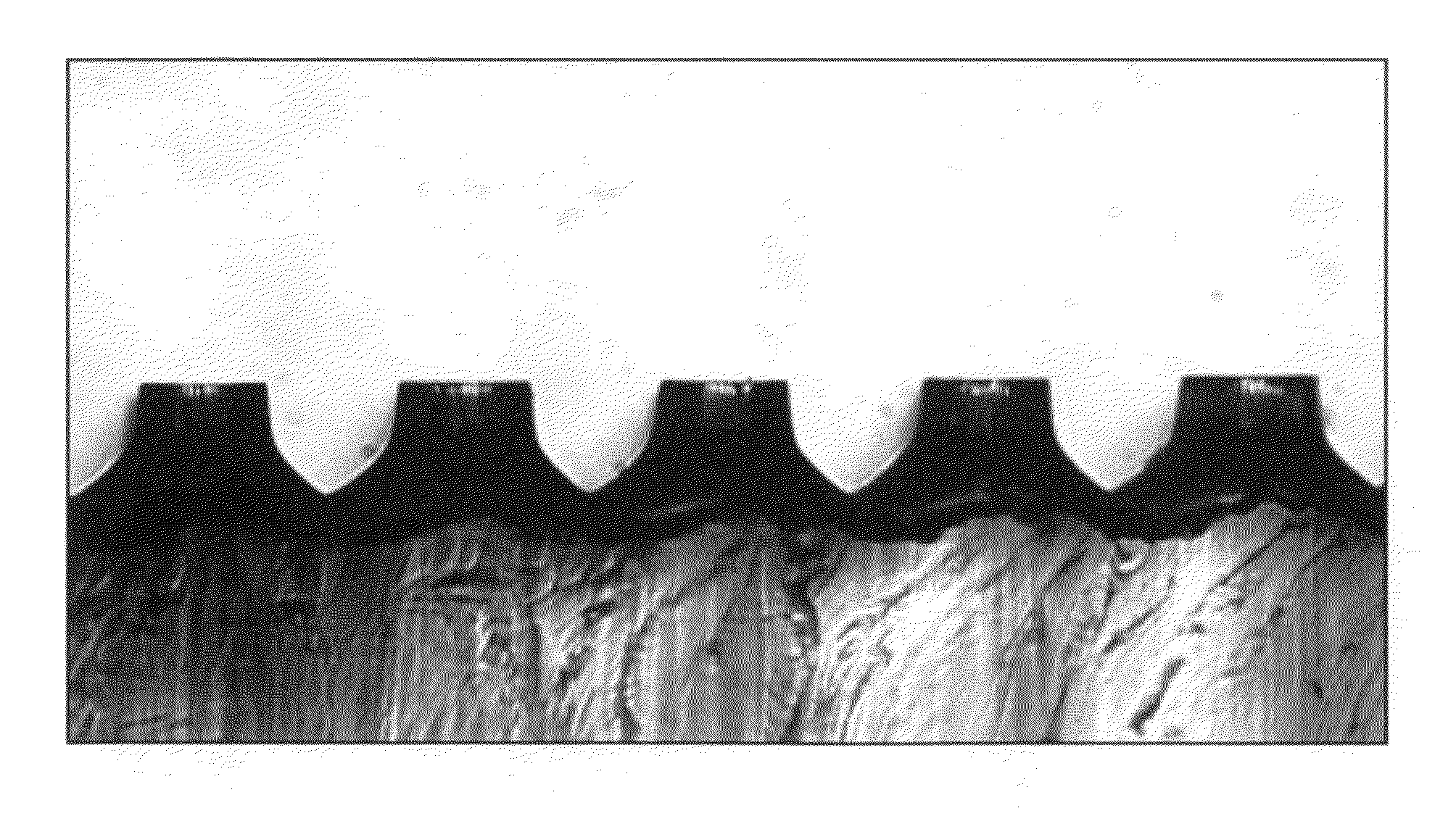

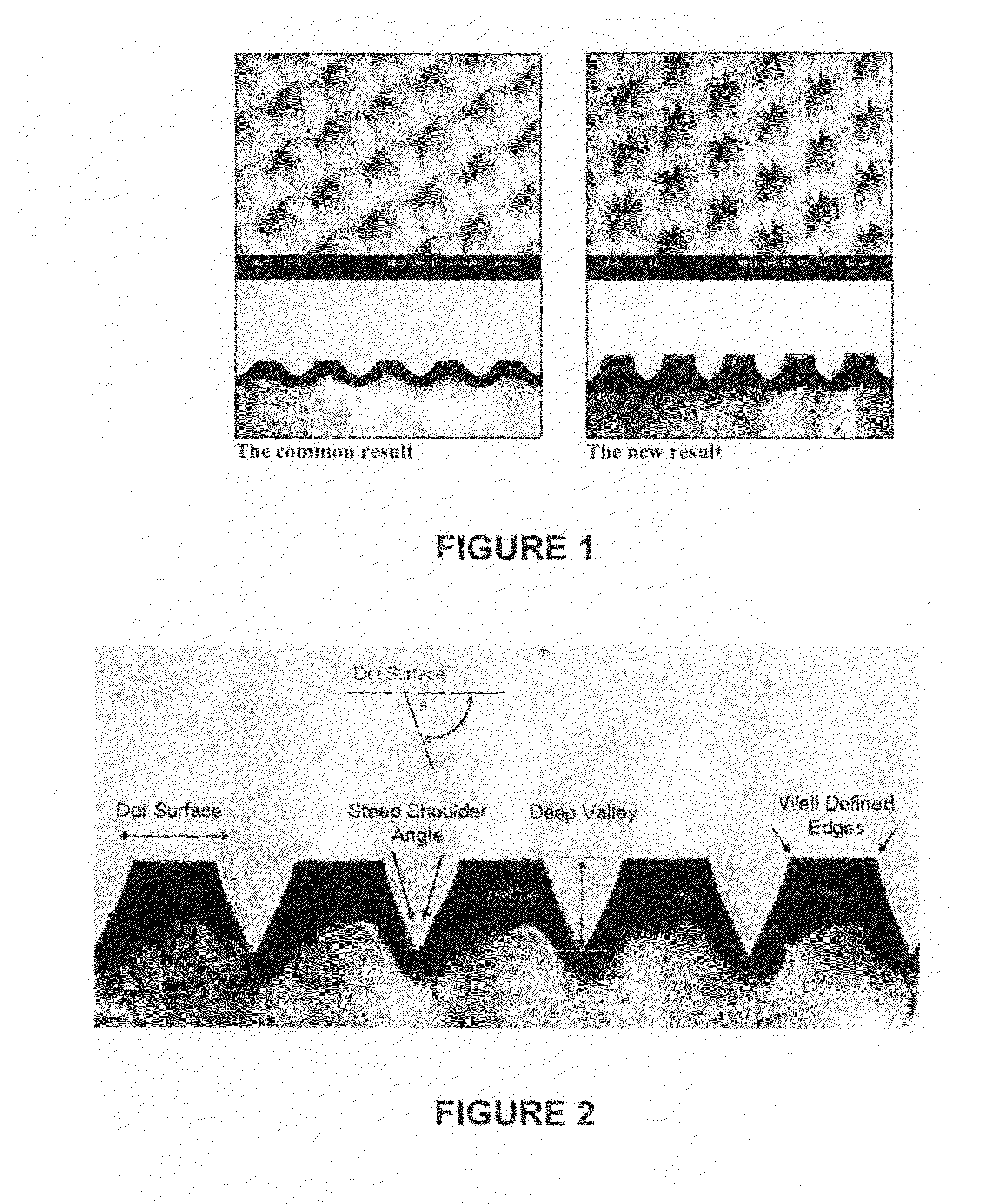

Method of improving print performance in flexographic printing plates

ActiveUS20110079158A1Promote resultsReduces print flutingLayered productsPlate printingCross-linkEngineering

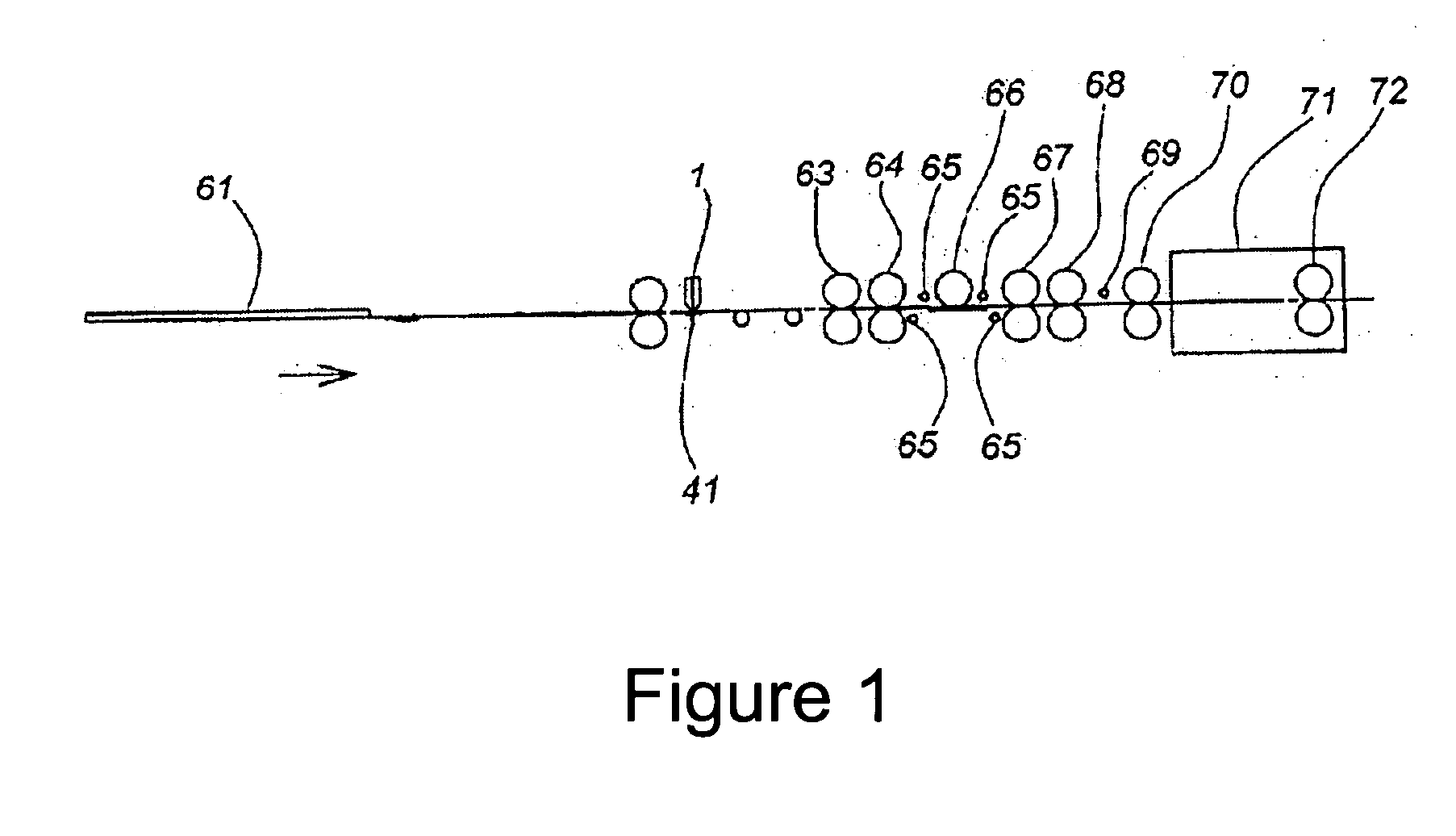

A method of making a relief image printing element from a photosensitive printing blank is provided. A photosensitive printing blank with a laser ablatable layer disposed on at least one photocurable layer is ablated with a laser to create an in situ mask. The printing blank is then exposed to at least one source of actinic radiation through the in situ mask to selectively cross link and cure portions of the photocurable layer. Diffusion of air into the at least one photocurable layer is limited during the exposing step and preferably at least one of the type, power and incident angle of illumination of the at least one source of actinic radiation is altered during the exposure step. The resulting relief image comprises a plurality of dots and a dot shape of the plurality of dots that provide optimal print performance on various substrates, including corrugated board.

Owner:MACDERMID PRINTING SOLUTIONS

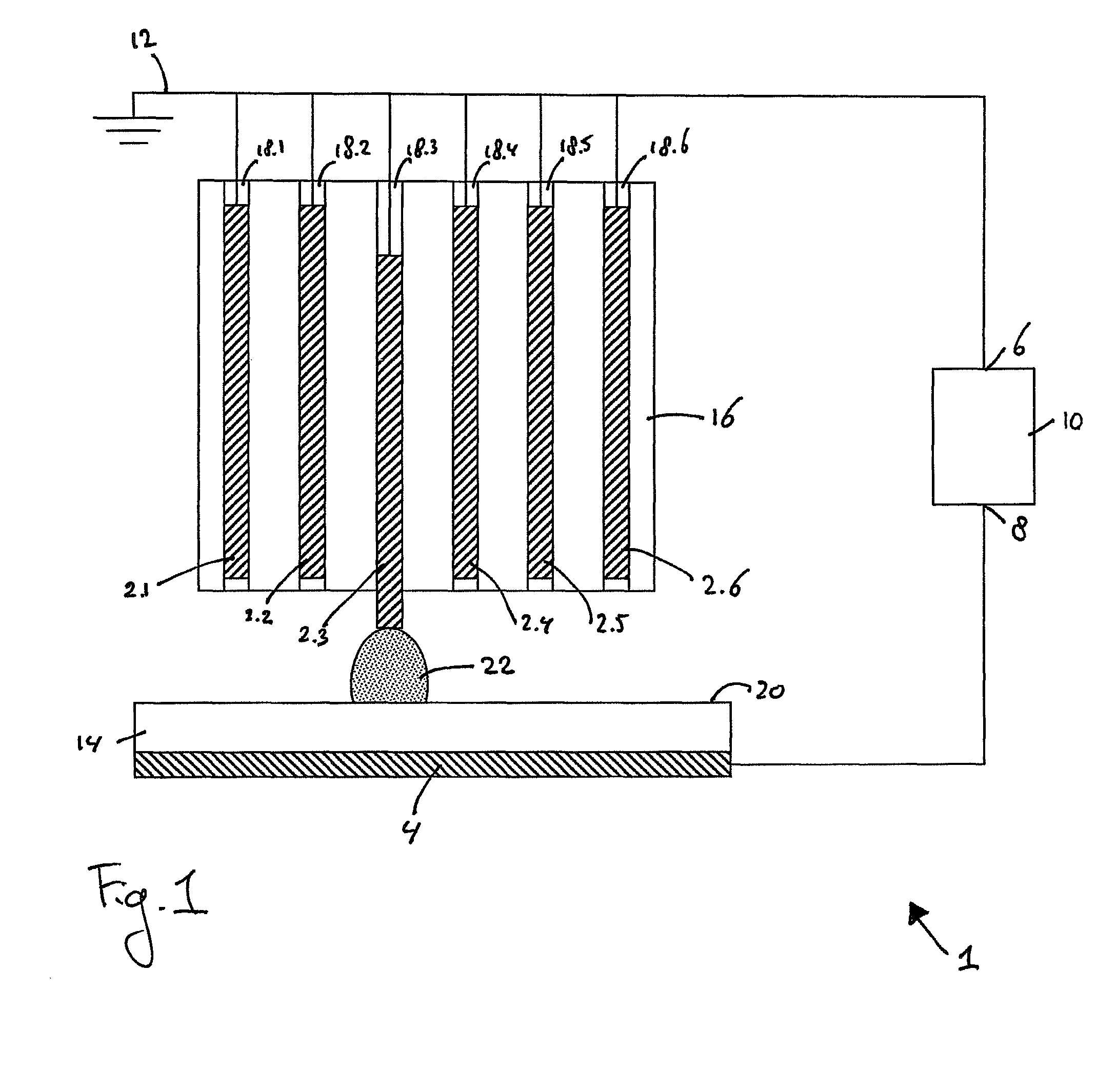

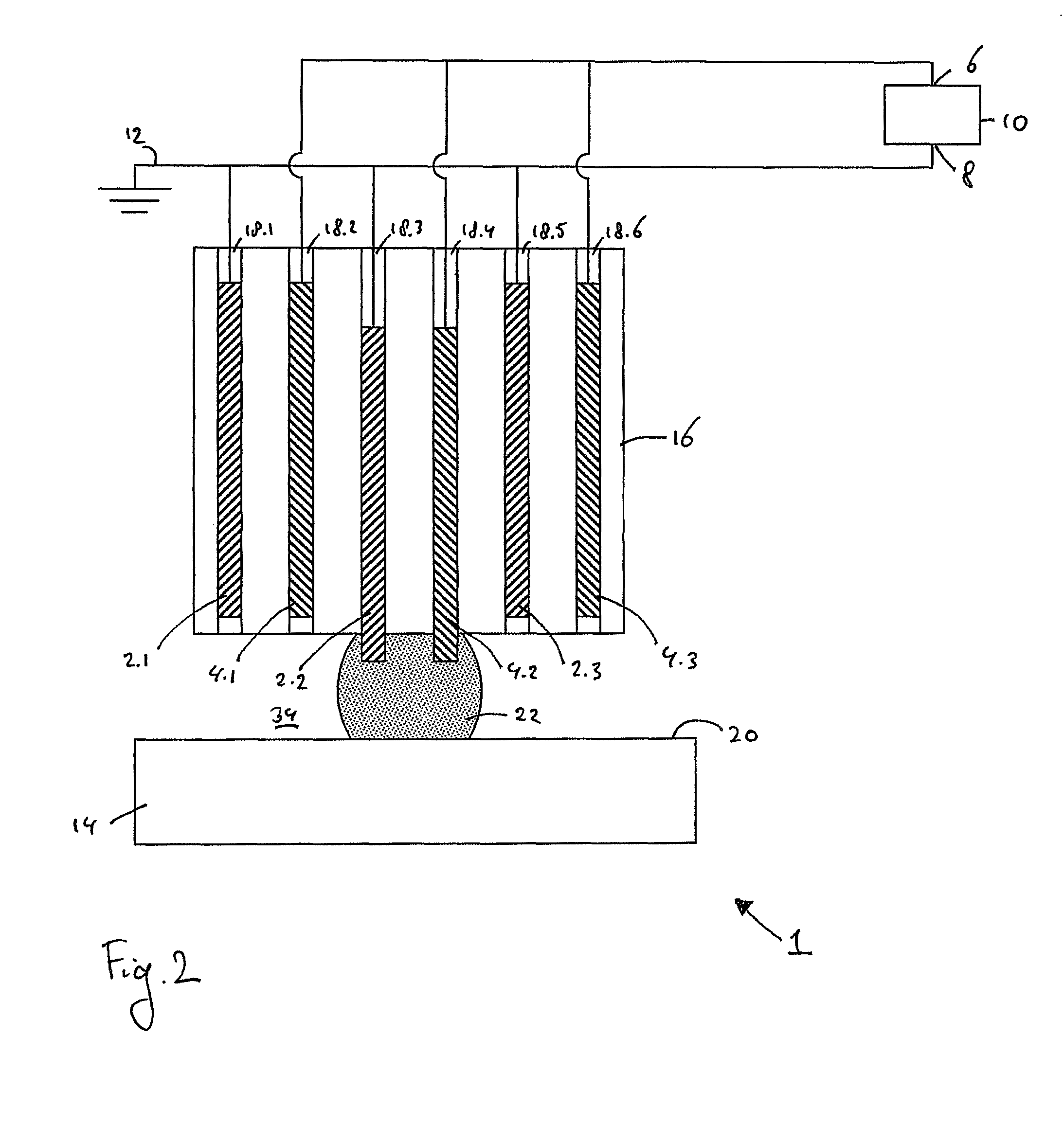

Device for generating a plasma discharge for patterning the surface of a substrate

InactiveUS8702902B2Easy to controlLong electrode lifeDecorative surface effectsSemiconductor/solid-state device manufacturingHigh pressureHigh voltage source

Device for generating a plasma discharge for patterning the surface of a substrate, comprising a first electrode having a first discharge portion and a second electrode having a second discharge portion, a high voltage source for generating a high voltage difference between the first and the second electrode, and positioning means for positioning the first electrode with respect to the substrate, wherein the positioning means are arranged for selectively positioning the first electrode with respect to the second electrode in a first position in which a distance between the first discharge portion and the second discharge portion is sufficiently small to support the plasma discharge at the high voltage difference, and in a second position in which the distance between the first discharge portion and the second discharge portion is sufficiently large to prevent plasma discharge at the high voltage difference.

Owner:VISION DYNAMICS HLDG

Method of making a lithographic printing plate

ActiveUS8232043B2High degree of polymerizationQuality improvementPlaten pressesPhotosensitive materialsInter layerEngineering

A method of making a lithographic printing plate includes the steps of a) providing a lithographic printing plate precursor including (i) a support having a hydrophilic surface or which is provided with a hydrophilic layer, (ii) a coating on the support including a photopolymerizable layer, and, optionally, an intermediate layer between the photopolymerizable layer and the support, b) image-wise exposing the coating in a plate setter, c) optionally, heating the precursor in a preheating unit, and d) developing the precursor off-press in a gumming unit by treating the coating of the precursor with a gum solution, thereby removing the non-exposed areas of the coating from the support, wherein the coating further includes a compound capable of interacting with the support, the compound being present in the photopolymerizable layer and / or in the intermediate layer.

Owner:AGFA OFFSET BV

Imageable element with solvent-resistant polymeric binder

InactiveUS7261998B2Enhances on-press solvent resistanceProlong lifeRadiation applicationsSemiconductor/solid-state device manufacturingPolymer scienceBackbone chain

The present invention provides an imageable element including a lithographic substrate and an imageable layer disposed on the substrate. The imageable layer includes a radically polymerizable component, an initiator system capable of generating radicals sufficient to initiate a polymerization reaction upon exposure to imaging radiation, and a polymeric binder having a hydrophobic backbone and including both constitutional units having a pendant cyano group attached directly to the hydrophobic backbone, and constitutional units having a pendant group including a hydrophilic poly(alkylene oxide) segment. When the imageable element is imaged and developed, the resulting printing plate may exhibit improved on-press solvent resistance and longer press life.

Owner:KODAK POLYCHROME GRAPHICS

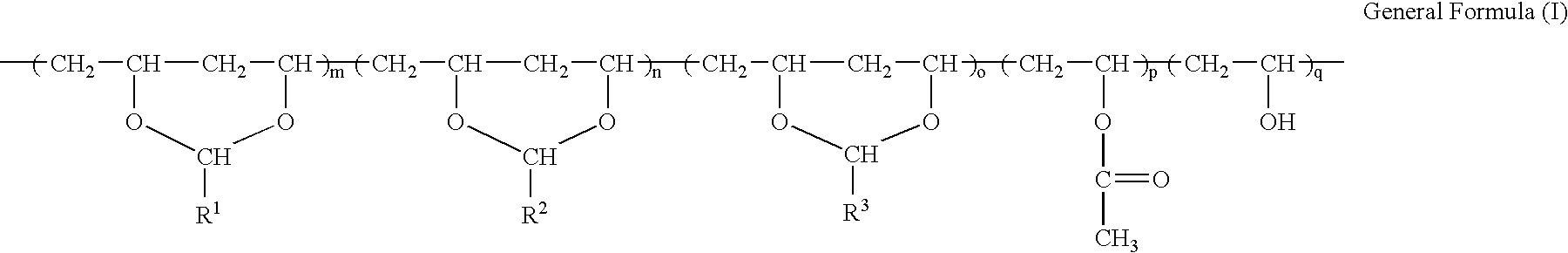

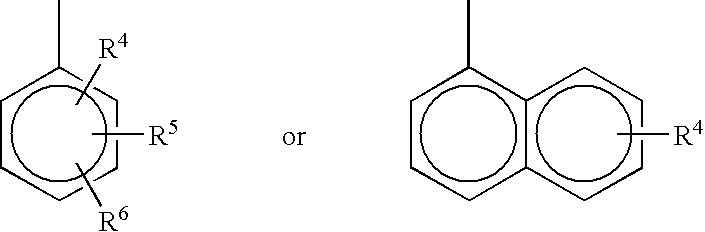

Light-sensitive lithographic printing plate

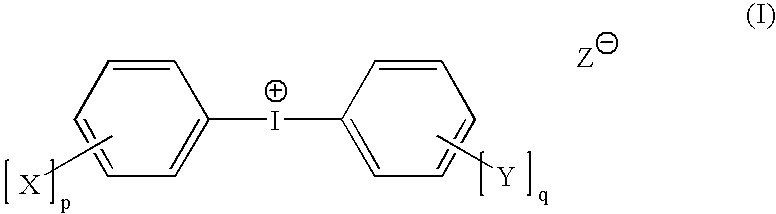

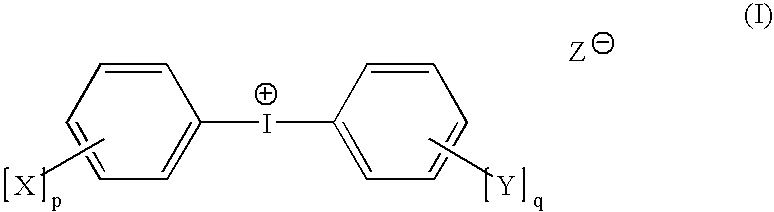

InactiveUS20050214677A1High developing latitudeExcellent printing durabilityPhotosensitive materialsLithographyOrganic acidPlanographic printing

A light-sensitive lithographic printing plate comprising a hydrophilic substrate provided thereon with a layer sensitive to infrared light rays comprising (A) a polymer represented by the following general formula (I); (B) an organic acid and / or a cyclic acid anhydride; and (C) a light-heat conversion substance. The light-sensitive lithographic printing plate is excellent in the both printing durability and the developing latitude.

Owner:FUJIFILM HLDG CORP

Method for making a lithographic printing plate involving on press development

InactiveUS6030750AImprove printing effectSemiconductor/solid-state device manufacturingPlate printingEngineeringPrinting press

The present invention provides a method for making a lithographic printing plate comprising the steps of: (1) image-wise exposing to light an imaging element comprising (i) on a hydrophilic surface of a lithographic base an image forming layer comprising hydrophobic thermoplastic polymer particles capable of coalescing under the influence of heat and dispersed in a hydrophilic binder and (ii) a compound capable of converting light to heat, said compound being comprised in said image forming layer or a layer adjacent thereto; (2) and developing a thus obtained image-wise exposed imaging element by mounting it on a print cylinder of a printing press and supplying an aqueous dampening liquid and / or ink to said image forming layer while rotating said print cylinder.

Owner:EASTMAN KODAK CO

Method of preparing negative-working radiation-sensitive elements

ActiveUS7175969B1Excellent developabilityReduced background stainingPhotosensitive materialsRadiation applicationsSide chainMoisture

A method of preparing negative-working, single-layer imageable elements improves their storage stability in a humid environment. The method includes enclosing the coated imageable elements in a water-impermeable sheet material that substantially inhibits the transfer of moisture to and from the imageable element. Such imageable elements include a radiation-sensitive composition that includes a radically polymerizable component, an initiator composition to provide radicals upon exposure to imaging radiation, a radiation absorbing compound, and a polymeric binder having poly(alkylene glycol) side chains.

Owner:EASTMAN KODAK CO

Lithographic printing plate precursor and lithographic printing method

InactiveUS20050170282A1Photomechanical apparatusPhotosensitive material auxillary/base layersLaser exposureEngineering

An on-press development or non-processing (non-development) type lithographic printing plate precursor capable of giving a printout image having a large lightness difference, and a lithographic printing method using this lithographic printing plate precursor are provided, a lithographic printing plate precursor comprising a support and a photosensitive-thermosensitive layer capable of recording an image by infrared laser exposure, the lithographic printing plate precursor being capable of performing a printing by loading on a printing press without passing through a development processing step after recording an image, or by recording an image after loading on a printing press, wherein said photosensitive-thermosensitive layer comprises (1) an infrared absorbent and (2) a discoloring agent or discoloration system capable of generating a color change upon exposure; and the lithographic printing method performing a printing using the above-described lithographic printing plate precursor.

Owner:FUJIFILM CORP

Negative-working radiation-sensitive compositions and imageable materials

ActiveUS7524614B2Improve solubilityIncrease speedPhotosensitive materialsRadiation applicationsRadiation sensitivityPlanographic printing

A radiation-sensitive composition includes a radically polymerizable component and an iodonium borate initiator composition capable of generating radicals sufficient to initiate polymerization of the free radically polymerizable component upon exposure to imaging radiation. The iodonium borate composition includes a particular diaryliodonium borate compound having organic substituents to provide a sum of at least 6 carbon atoms on the iodonium cation phenyl rings. This composition can be applied to a suitable substrate to provide a negative-working imageable element with improved digital speed and good shelf life and that can be imaged to provide lithographic printing plates. The imaged elements can be developed either on-press or off-press using alkaline developers.

Owner:EASTMAN KODAK CO

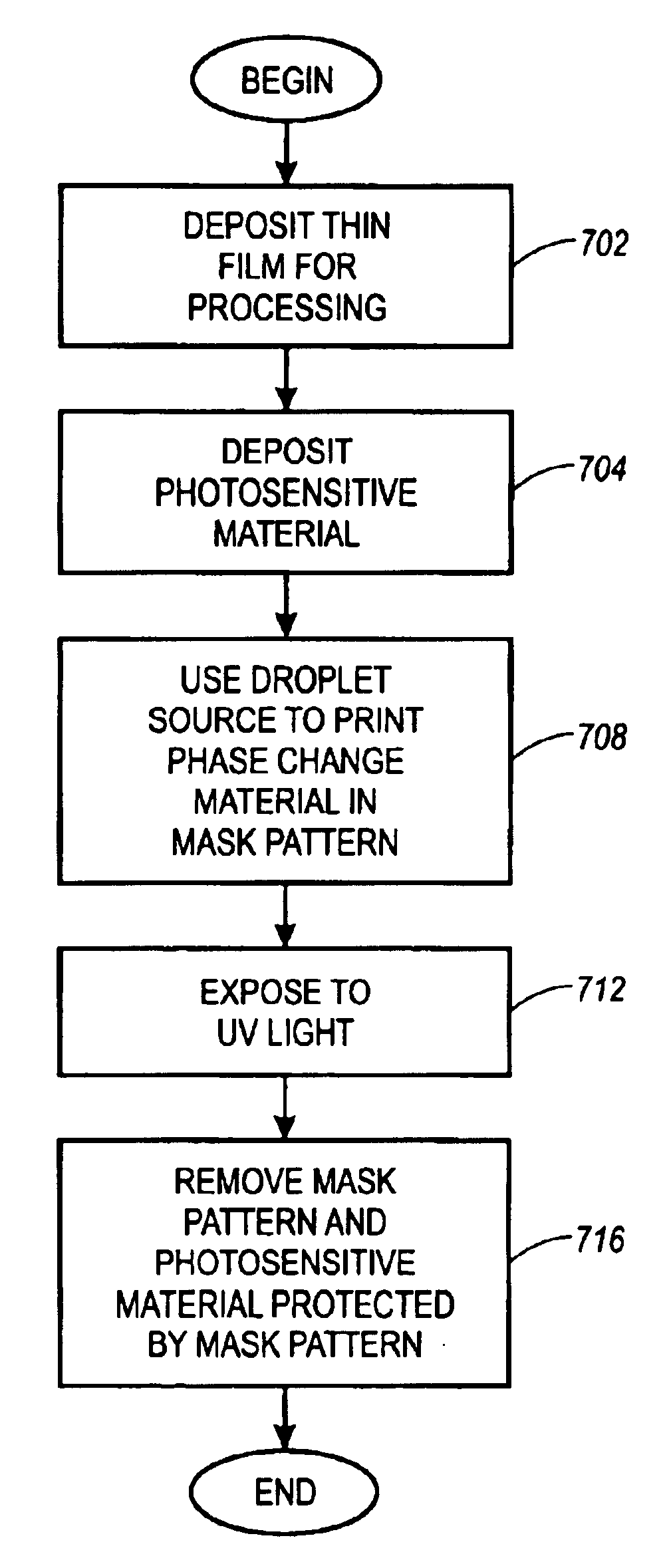

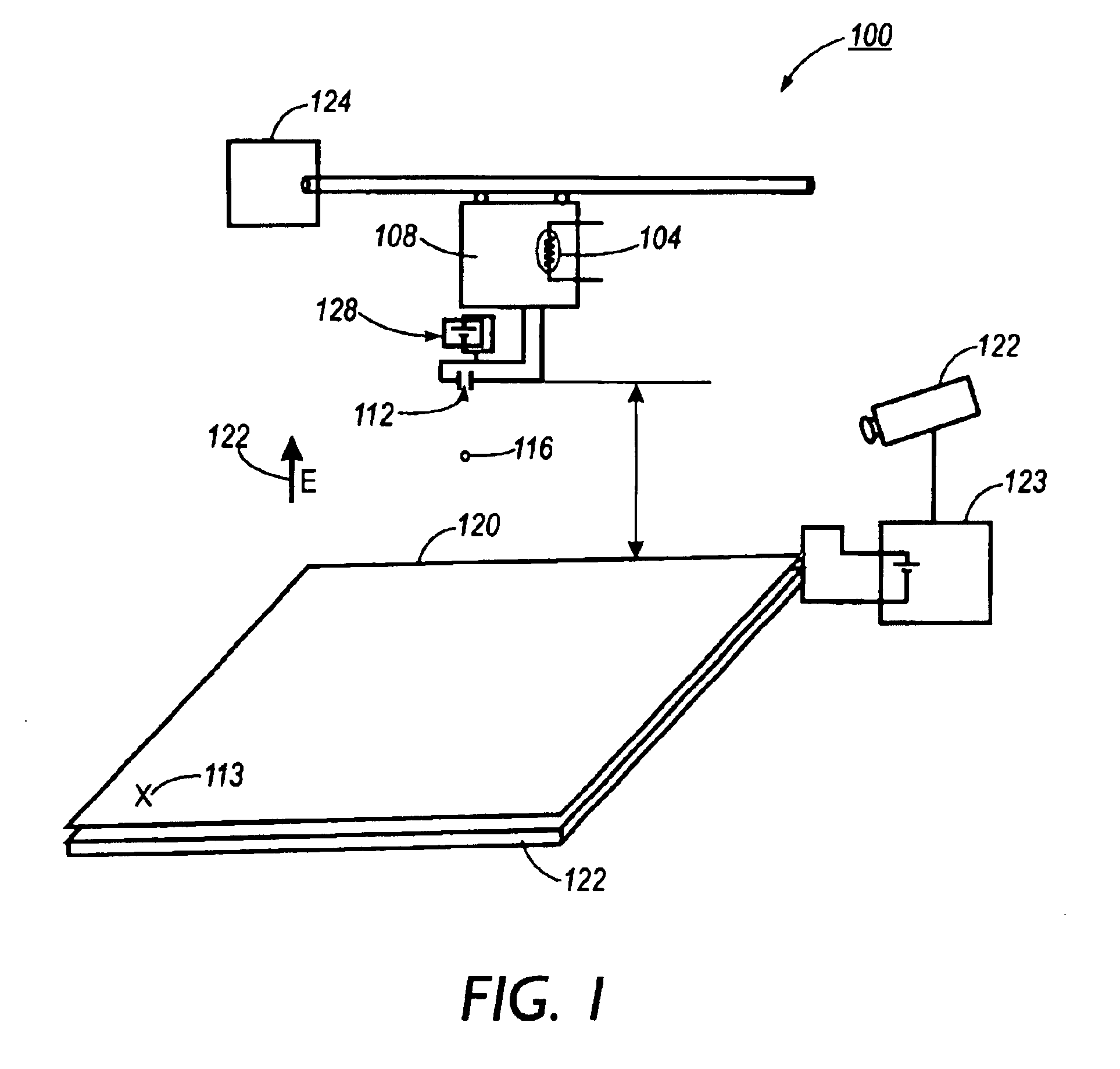

Method for printing etch masks using phase-change materials

InactiveUS6872320B2Decorative surface effectsDuplicating/marking methodsPhase changePhase-change material

A method and system for masking a surface to be etched is described. A droplet source ejects droplets of a masking material for deposit on a thin-film or other substrate surface to be etched. The temperature of the thin-film or substrate surface is controlled such that the droplets rapidly freeze upon contact with the thin-film or substrate surface. The thin-film or substrate is then etched. After etching the masking material is removed.

Owner:XEROX CORP

Method for developing multilayer imageable elements

InactiveUS20050162505A1Recording apparatusSemiconductor/solid-state device manufacturingEngineeringStochastic screening

A method for forming an image by imaging and developing a multi-layer imageable element, in which the developer is fresh developer and the developer is not reused, is disclosed. Much smaller variation in dot percentage is obtained when each imaged imageable element is developed in fresh developer than when the developer is reused to develop additional imaged imageable elements. The method is especially suited to the formation of images using stochastic screening. Either a solvent based developer or a high pH developer may be used.

Owner:KODAK POLYCHROME GRAPHICS

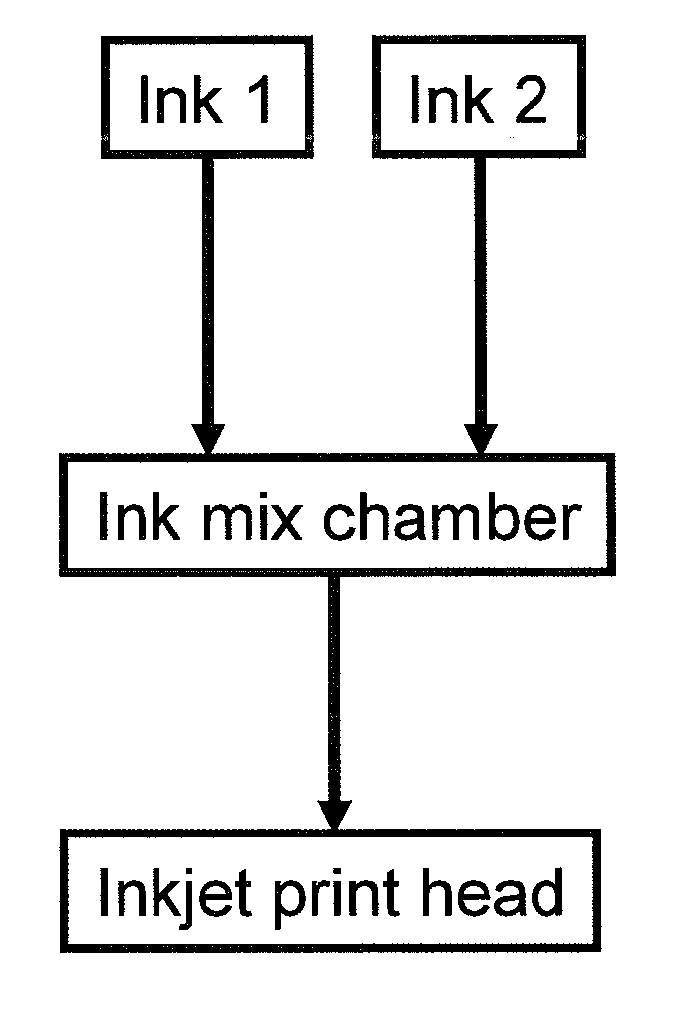

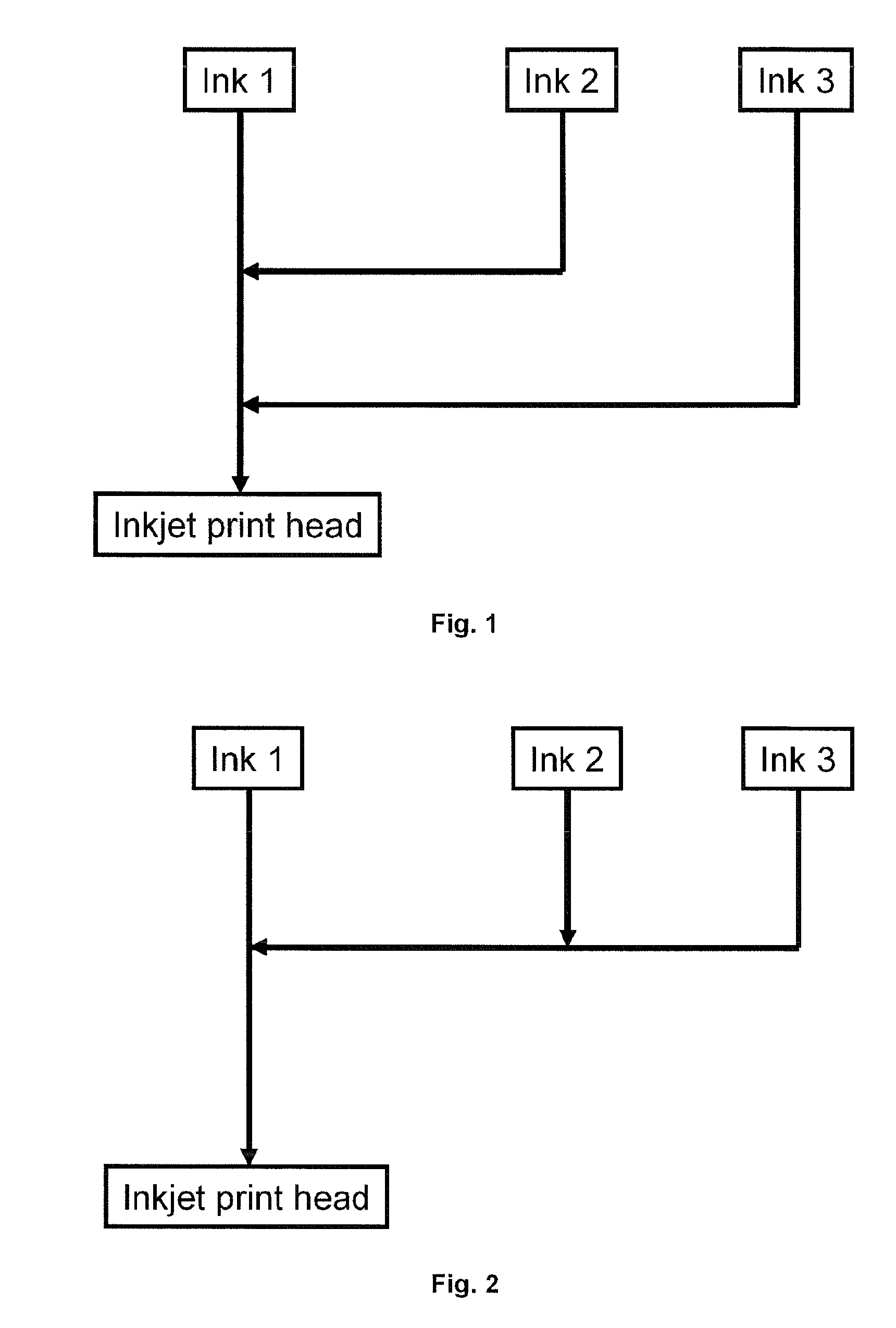

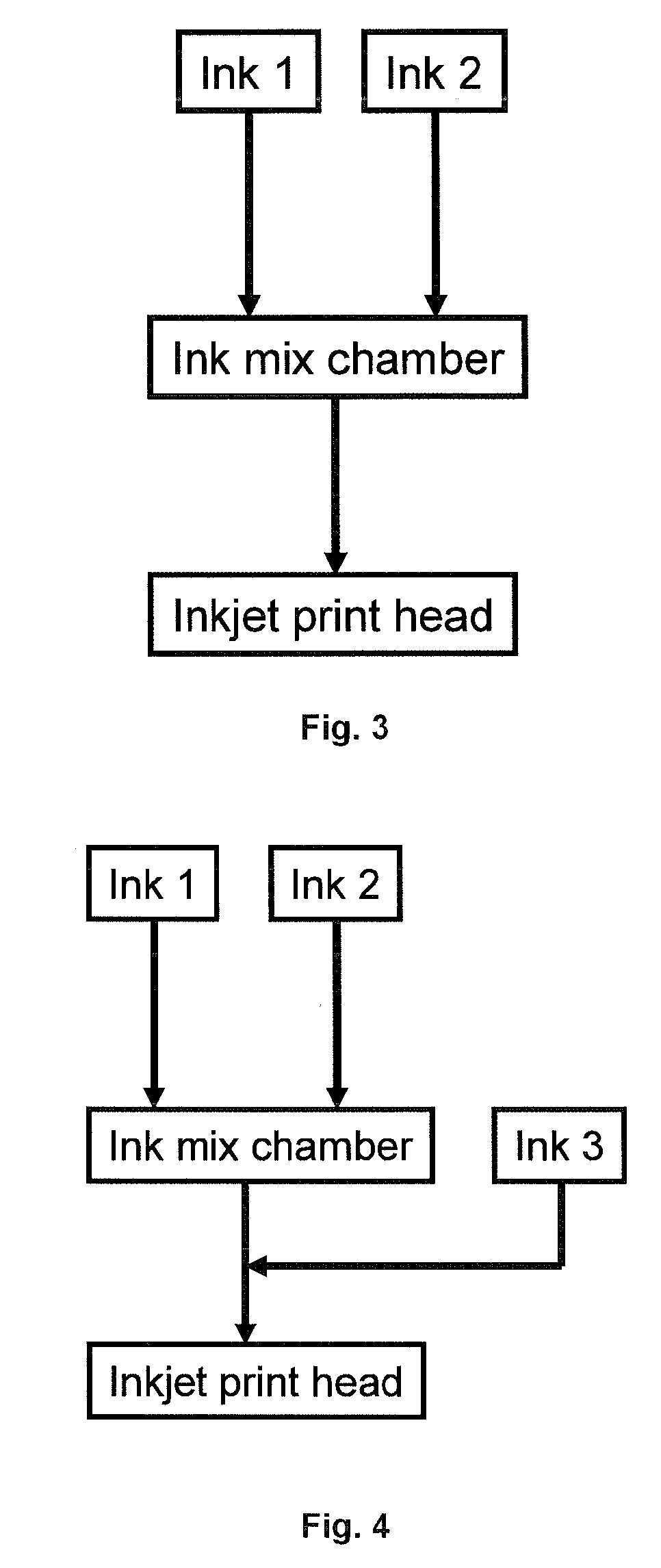

3d-inkjet printing methods

InactiveUS20100007692A1Altered physical propertyImprove adhesionAdditive manufacturing apparatusPattern printingEngineeringElectron

A 3D-inkjet printing method includes the steps ofa) providing two or more fluids having a different composition to an inkjet printer;b) mixing the two or more fluids in a controlled amount;c) jetting the mixture of the two or more fluids with the inkjet printer onto a support;d) at least partially curing the jetted mixture by actinic radiation or electron beam; ande) repeating steps b) to d) in order to build a 3D-relief on the support. The method is capable of printing 3D-objects with inkjet fluid sets in an inkjet printer.

Owner:AGFA NV

Thermosensitive lithographic printing plate

InactiveUS7108956B2Favorable image formationHigh sensitivityPhotosensitive materialsSemiconductor/solid-state device manufacturingPolymer scienceWater insoluble

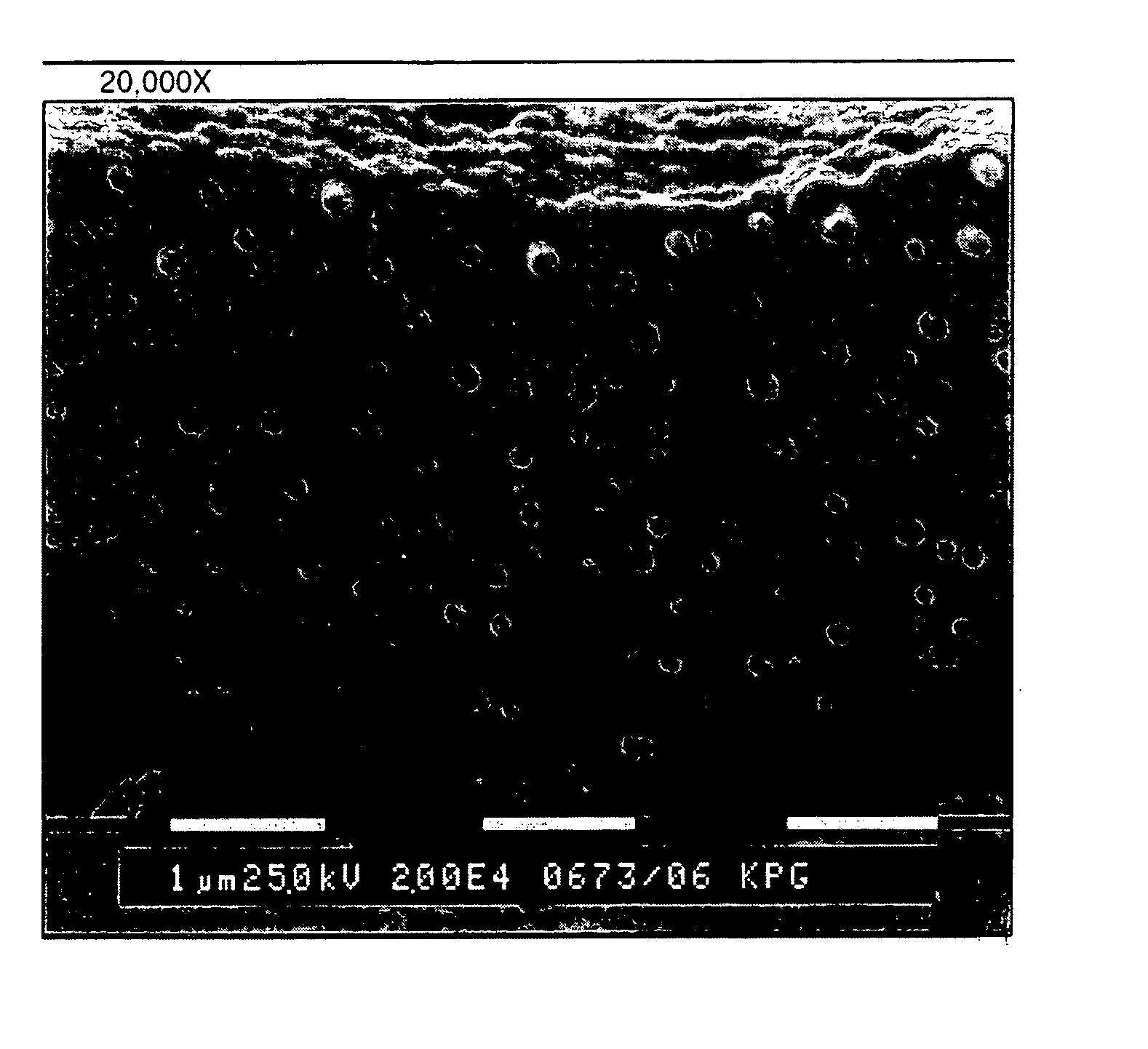

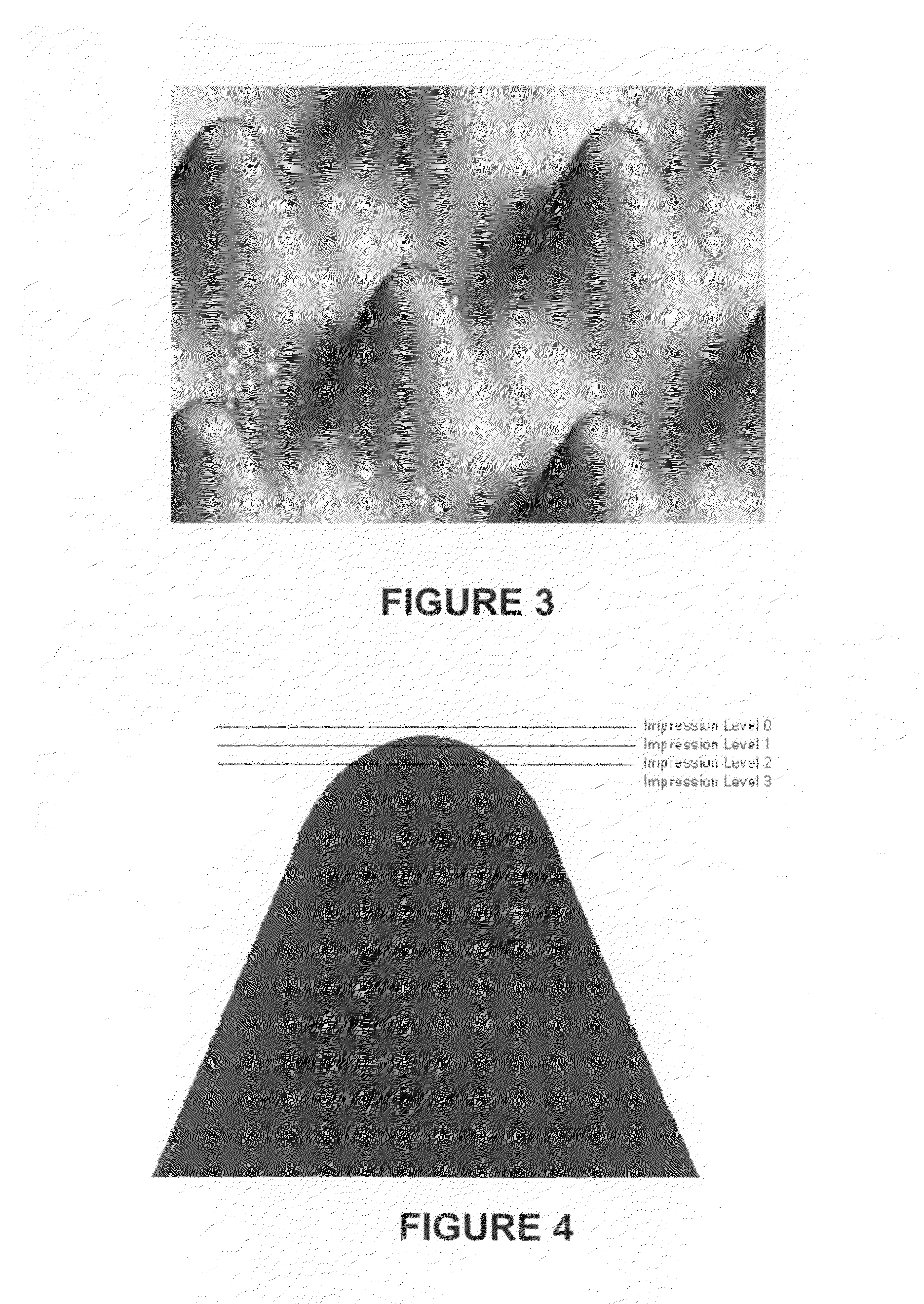

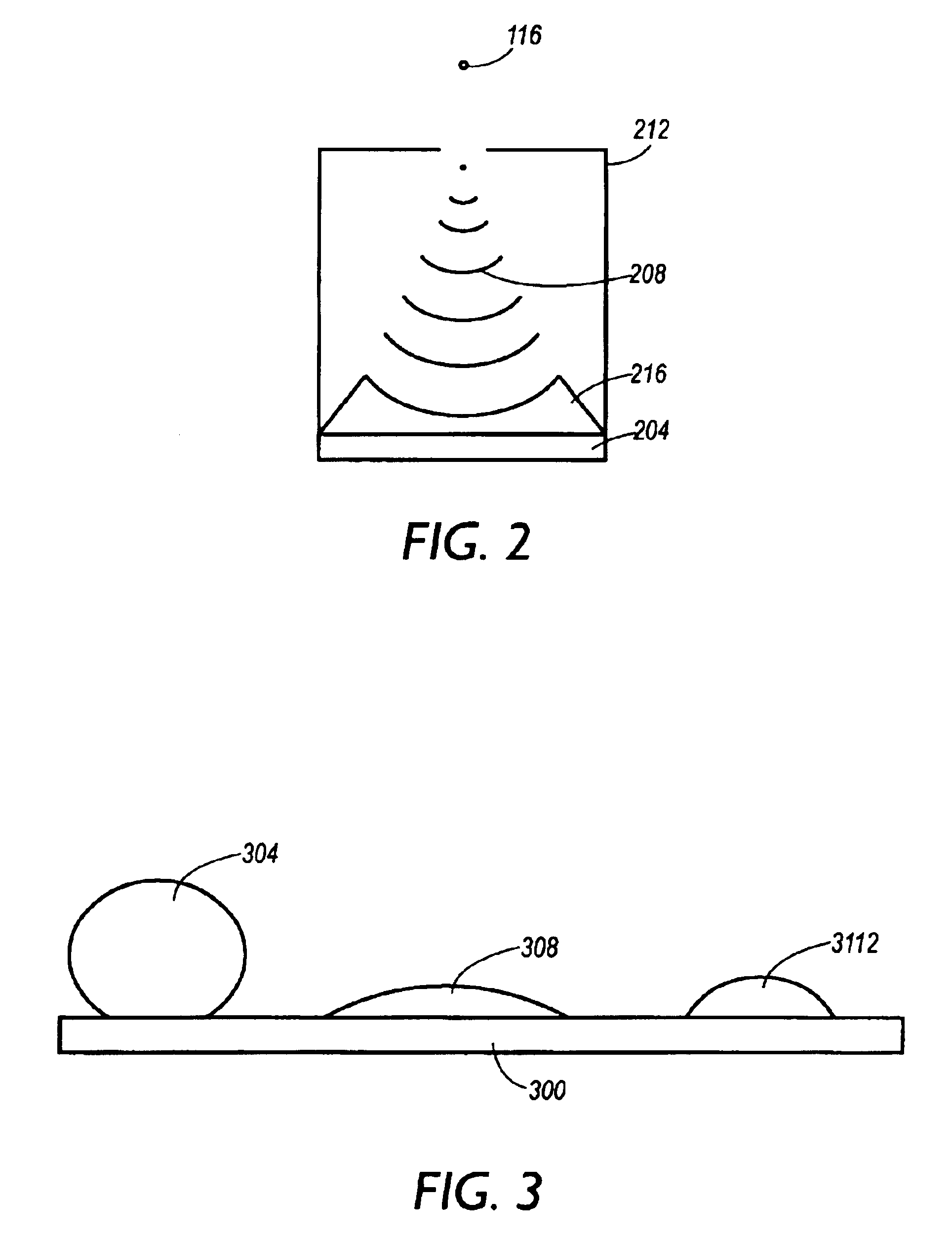

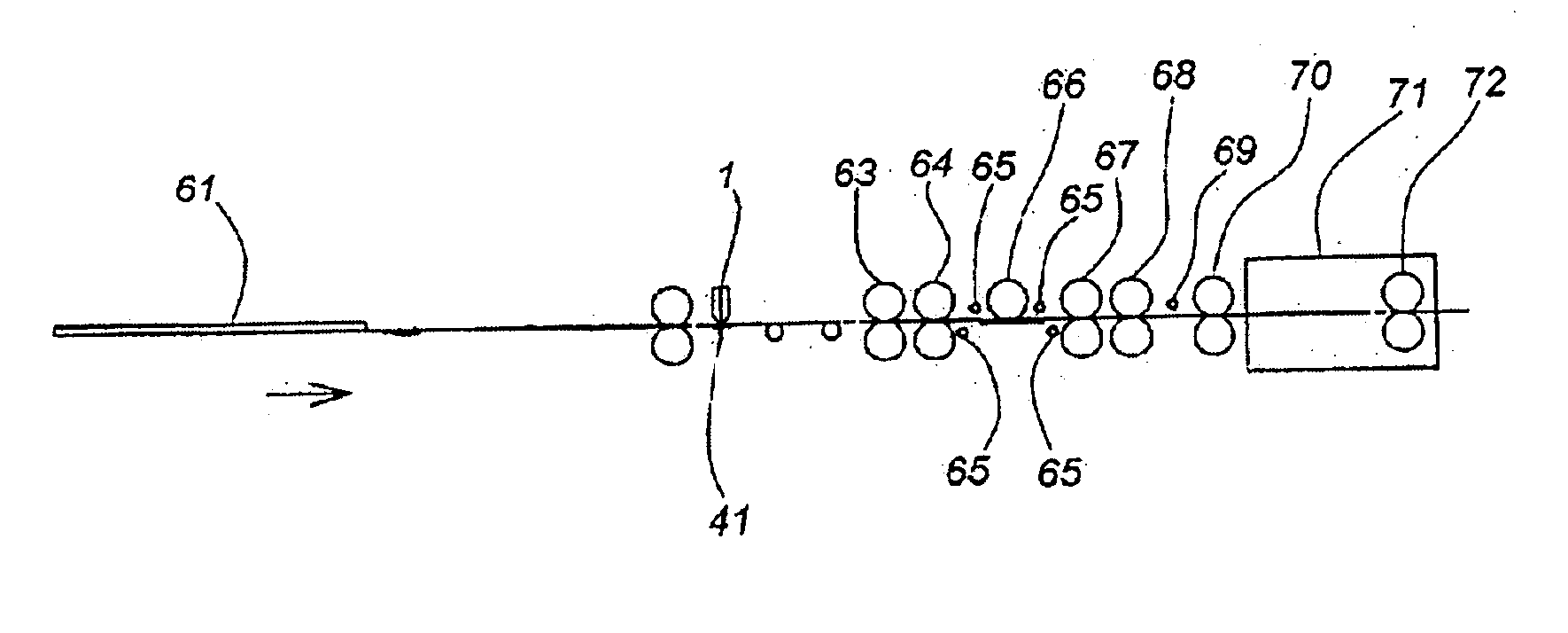

A thermosensitive lithographic printing plate comprising: a hydrophilic support; a lower layer comprising a water-insoluble and alkali-soluble resin; and an upper thermosensitive layer comprising a water-insoluble and alkali-soluble resin and an infrared absorbing dye, whose dissolution in an alkaline aqueous solution increases upon exposure, wherein a surface of the upper thermosensitive layer has protrusions caused by ununiformity of thickness of the upper thermosensitive layer in a proportion of 0.1 or more and not more than 7 per μm2 or the upper thermosensitive layer comprises at least two alkali-soluble resins having a different dissolution speed in an alkaline aqueous solution from each other, and the at least two alkali-soluble resin cause phase separation from each other.

Owner:FUJIFILM HLDG CORP +1

Method of producing a relief image for printing

ActiveUS20050227182A1Low costHigh imaging sensitivityRadiation applicationsSemiconductor/solid-state device manufacturingEngineeringRadiation

The present invention involves a method for making a relief image. A film that includes a carrier sheet and an imageable material is used to form a mask image that is opaque to a curing radiation. In one embodiment, the mask image is formed on the carrier sheet while in another embodiment, the mask image is formed on a receptor sheet. The mask image is then transferred to a photosensitive material, such as a flexographic printing plate precursor. The resulting assembly is exposed to the curing radiation resulting in exposed and unexposed areas of the photosensitive material. The carrier sheet or the receptor sheet may be removed from the mask image either before or after exposure to the curing radiation. Finally, the photosensitive material and mask image assembly is developed with a suitable developer to form a relief image.

Owner:KODAK POLYCHROME GRAPHICS +1

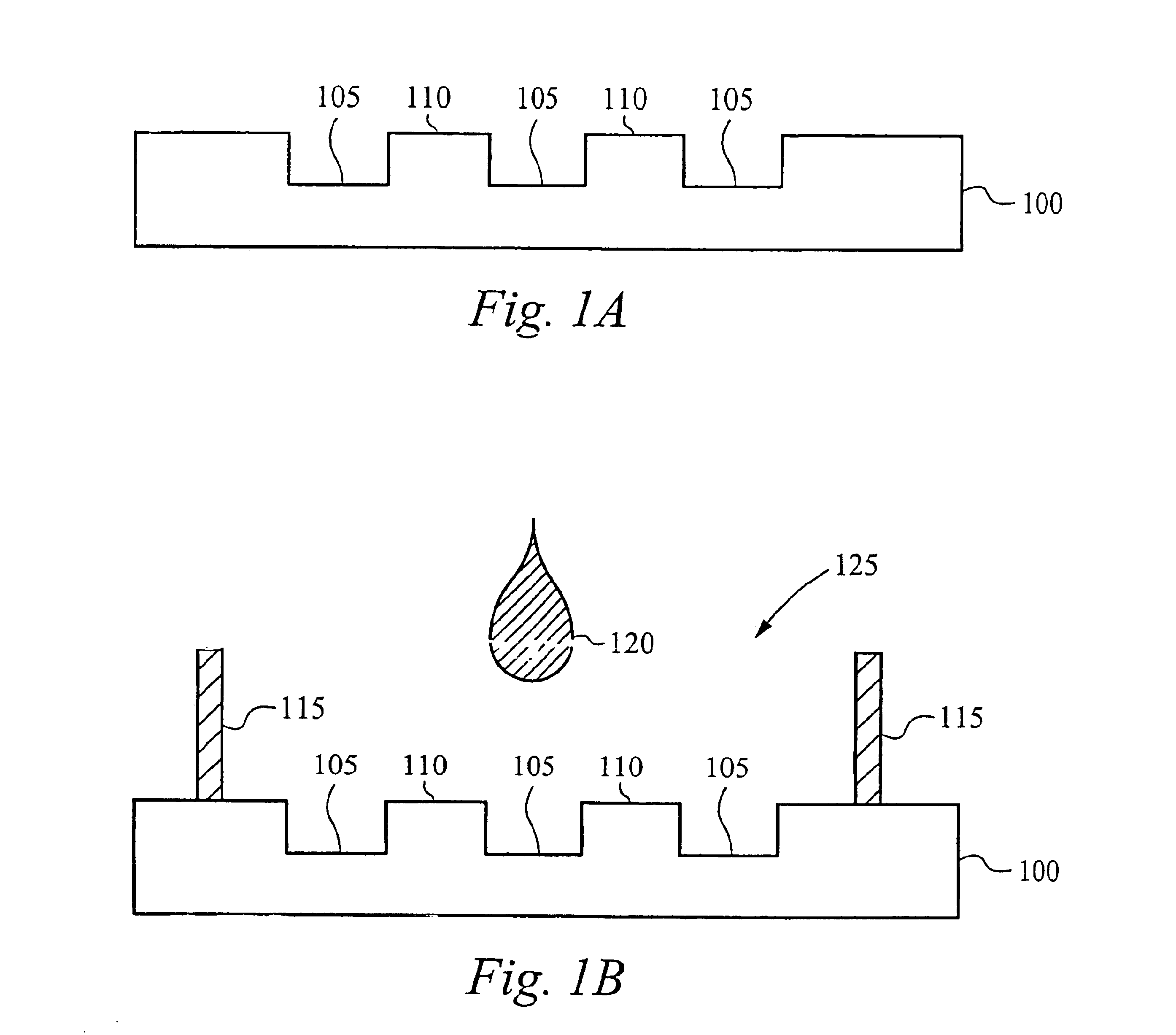

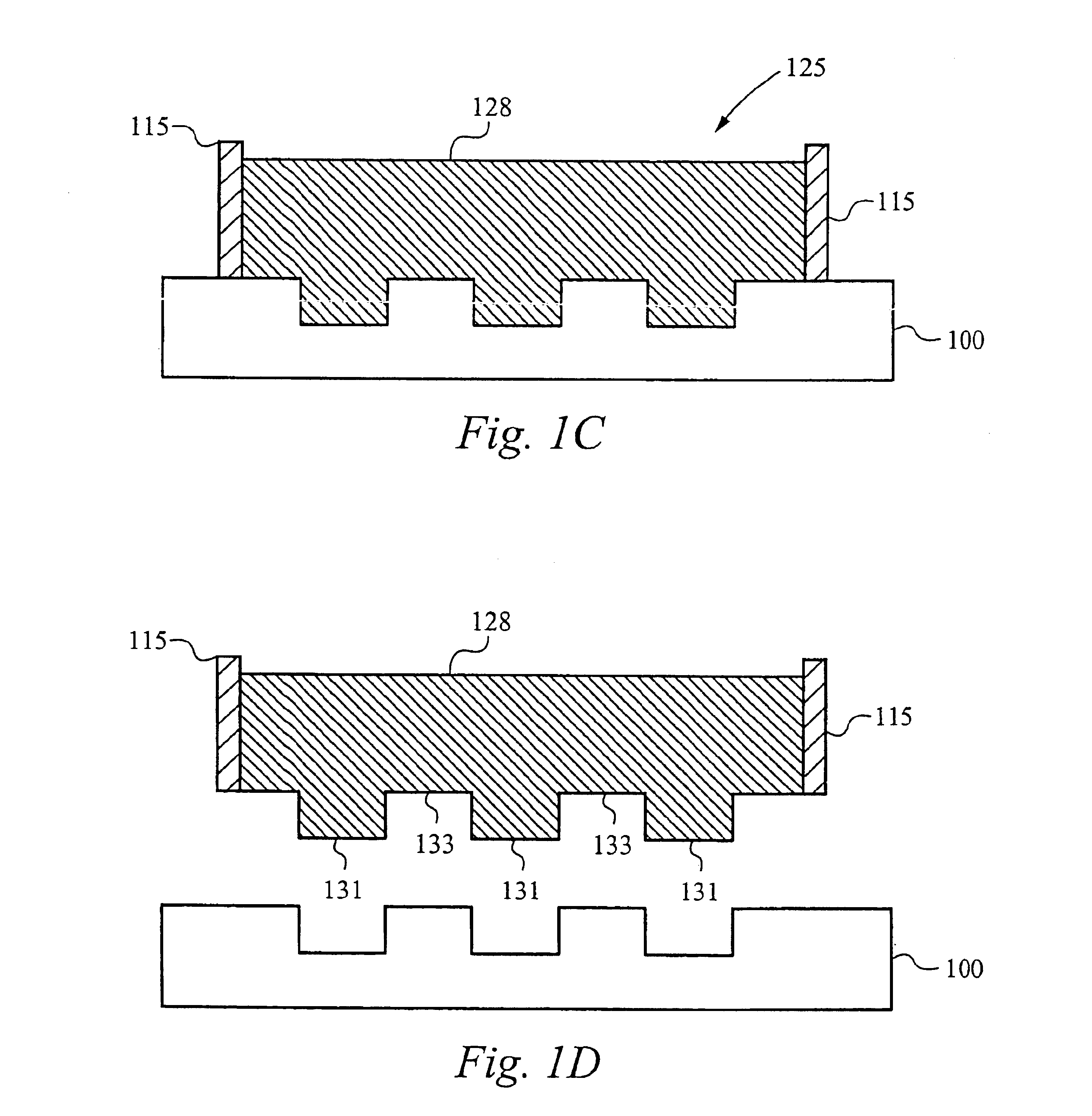

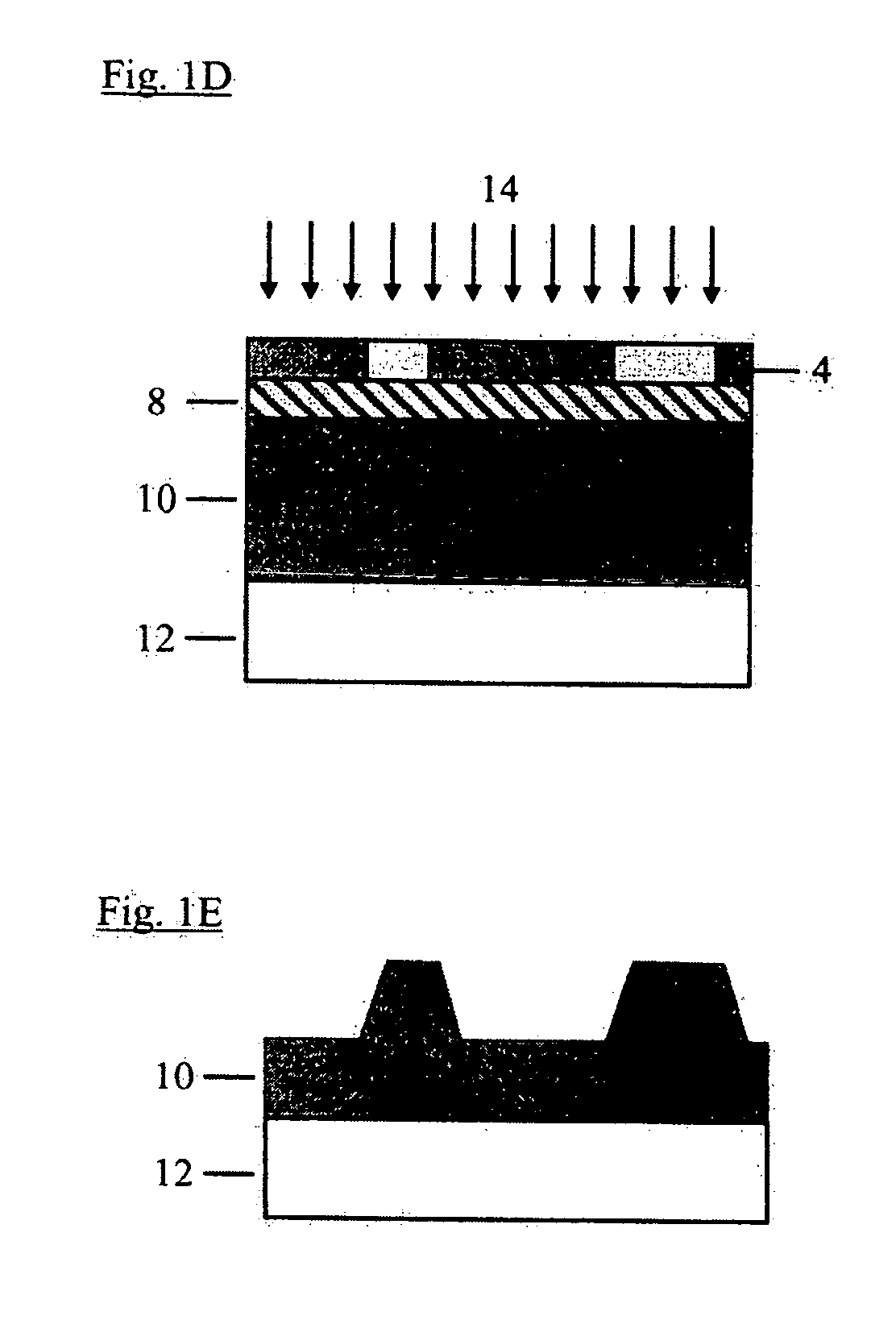

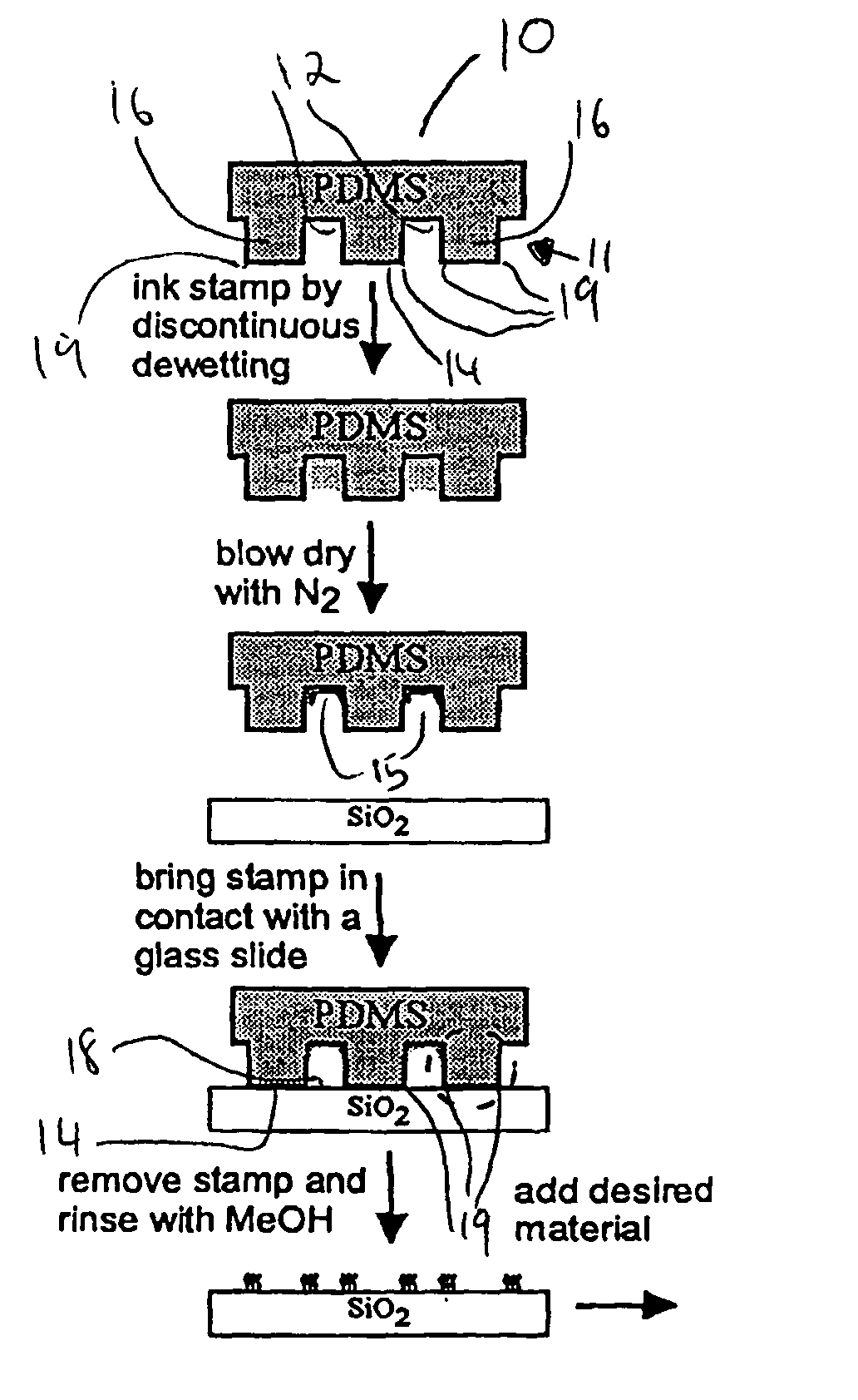

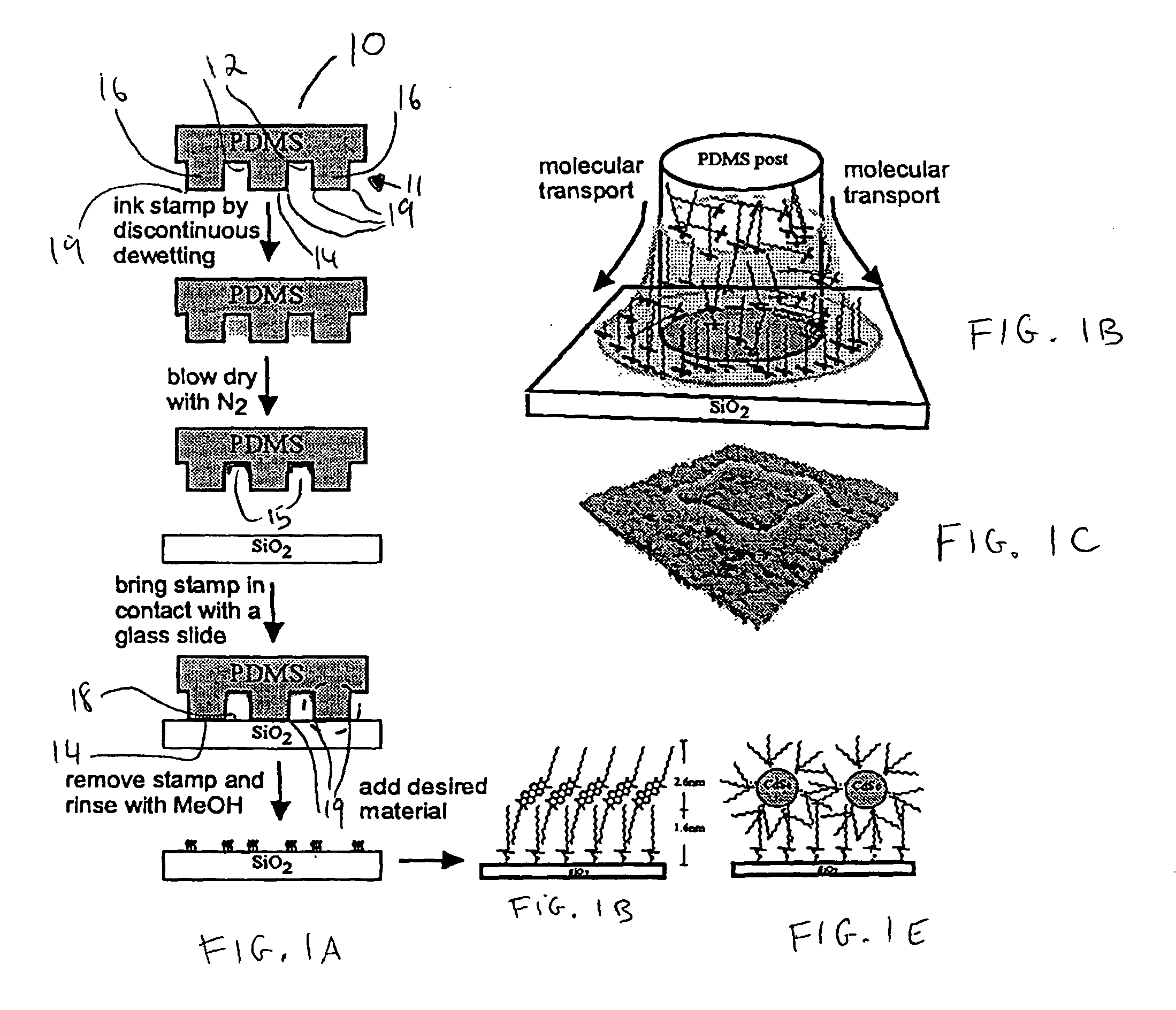

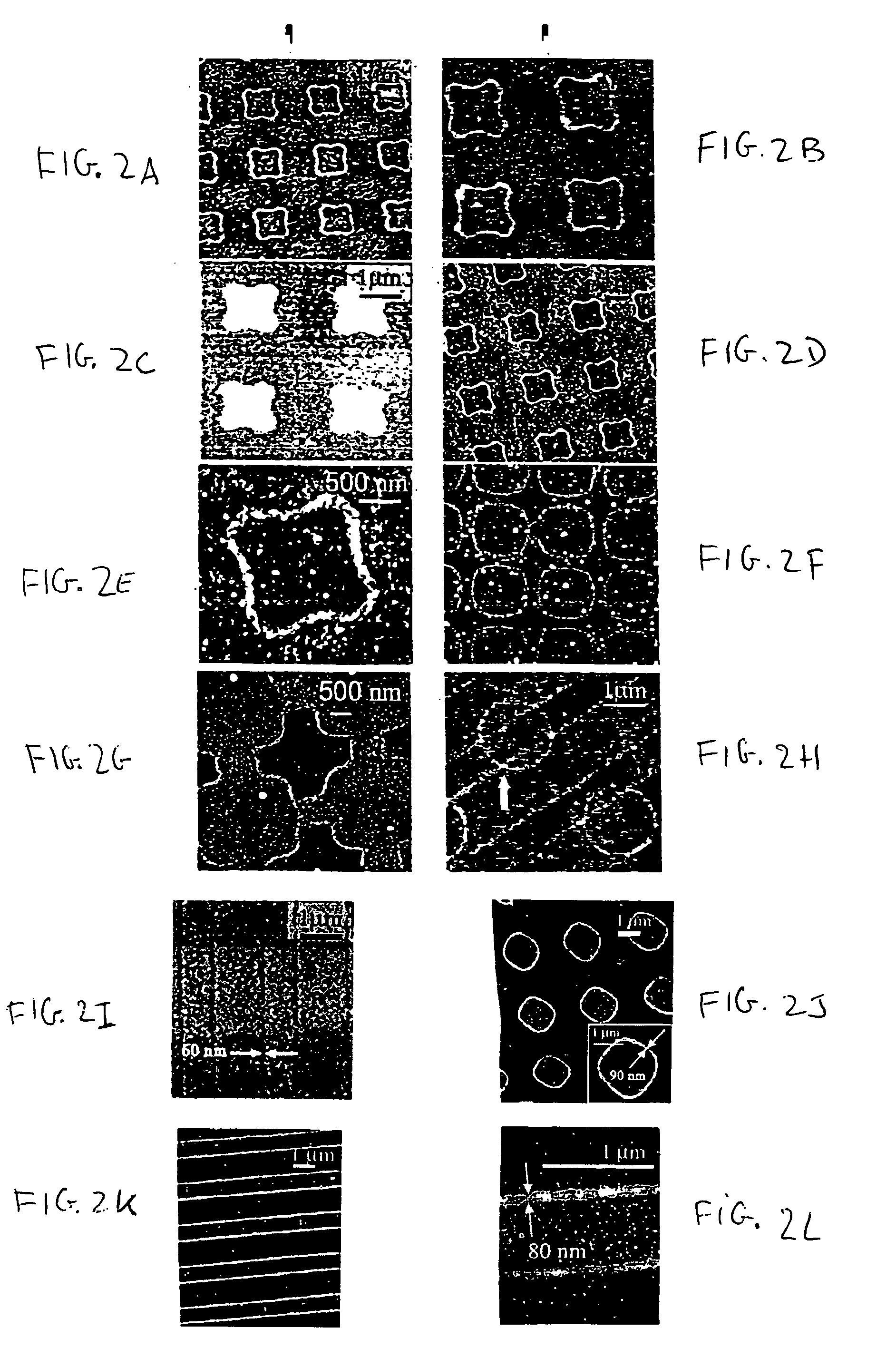

Edge transfer lithography

InactiveUS20050120902A1Wide applicabilitySmall feature sizeMaterial nanotechnologyDecorative surface effectsImage resolutionEngineering

A method for applying a nanoscale resolution pattern of a molecular link onto a surface of a substrate is disclosed. The method referred to as edge transfer lithography, comprises providing a stamp structure (10) having a surface (11) with at least one protruding feature (16). Each protruding feature (16) has a stamp surface of a respective predefined shape at a protruding end thereof. Each protruding feature and its stamp surface are bounded by at least one edge (19), which edge intersects the surface of the stamp structure to form a recess. A solution of the molecular ink and a solvent is applied of the surface of the stamp structure (10) are such that the solution dewets from the surface of the stamp structure (10) is then dried to evaporate the solvent.

Owner:ADAMS DAVID +1

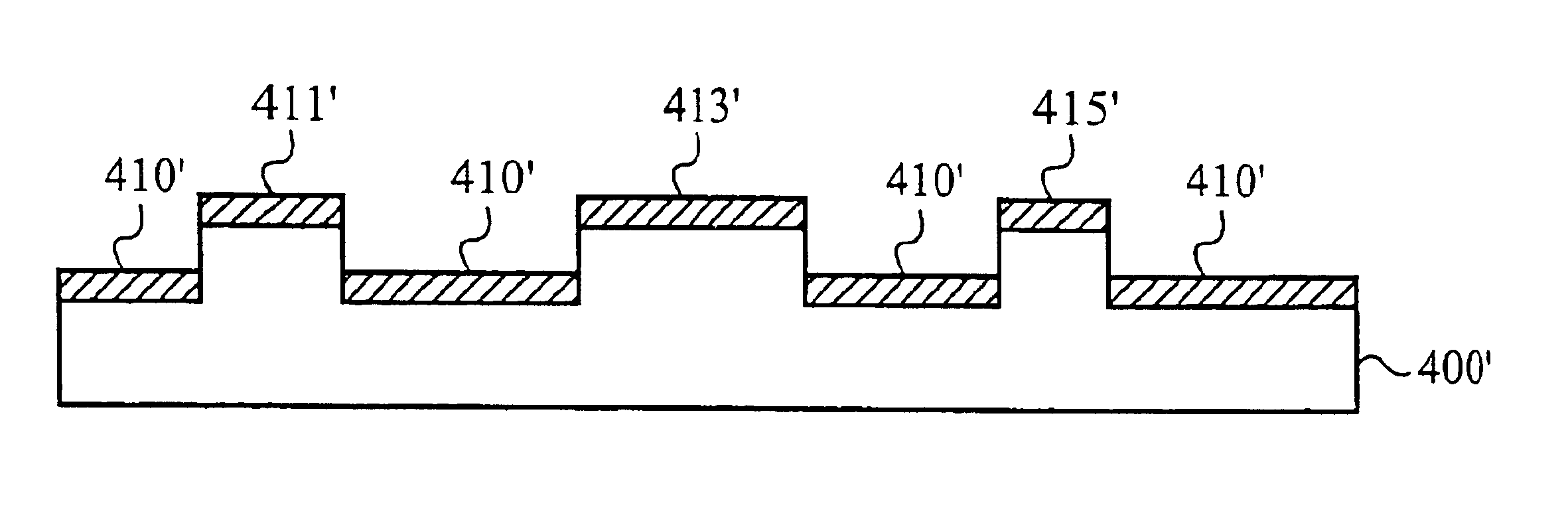

Elastomeric mask and use in fabrication of devices

An elastomeric mask is provided that allows deposition of a variety of materials through mask openings. The mask seals effectively against substrate surfaces, allowing simple deposition from fluid phase, gas phase, and the like or removal of material using gaseous or liquid etchants. The mask then can be simply peeled from the surface of the substrate leaving the patterned material behind. Multi-layered mask techniques are described in which openings in an upper mask allow selected openings of a lower mask to remain un-shielded, while other openings of the lower mask are shielded. A first deposition step, following by re-orientation of the upper mask to expose a different set of lower mask openings, allows selective deposition of different materials in different openings of the lower mask. Pixelated organic electroluminescent devices are provided via the described technique.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE +1

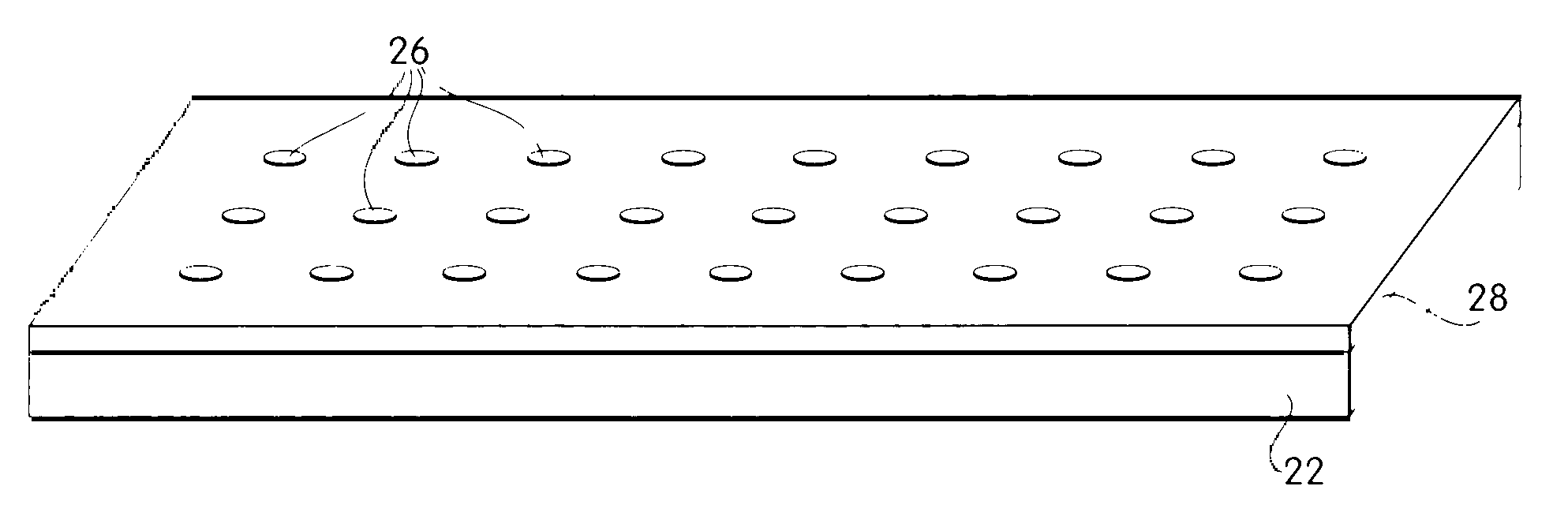

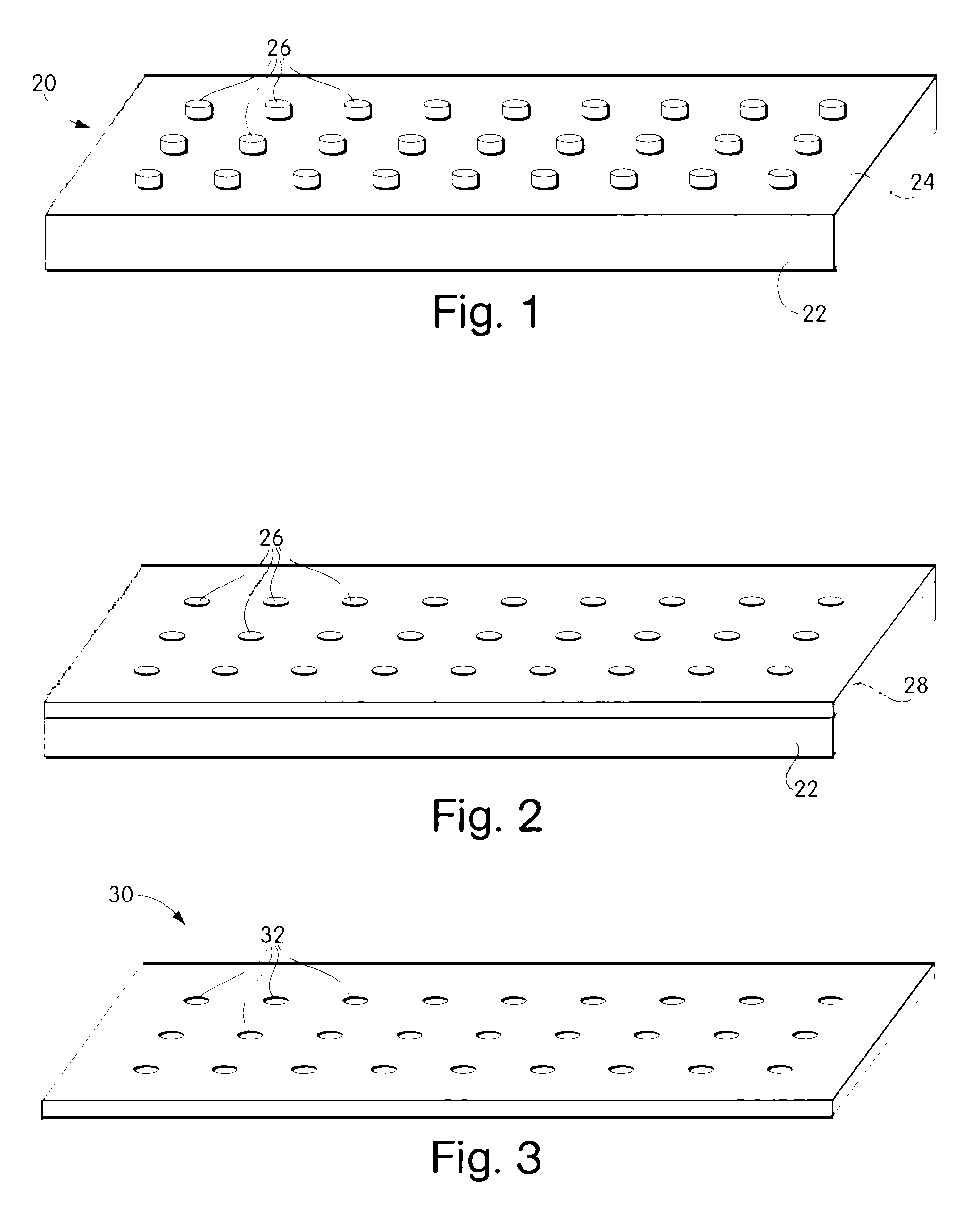

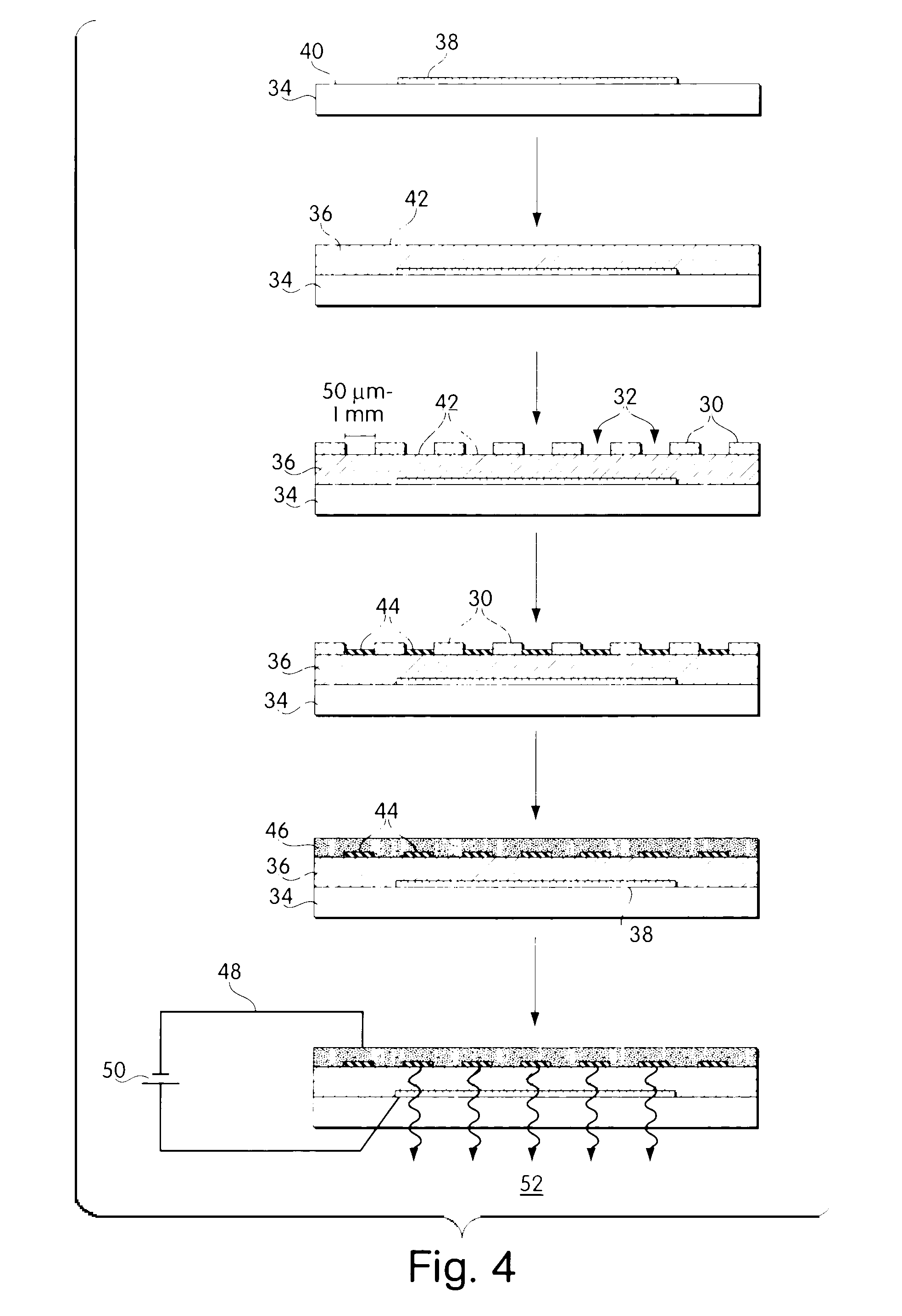

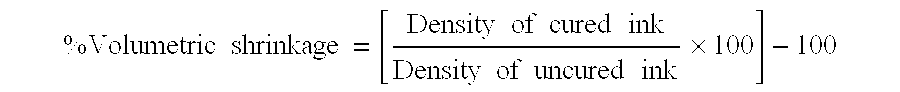

Method for manufacturing a flexographic printing master

InactiveUS20060055761A1Fast and simple and environmentalImprove image qualityPlate printingHand compositionOligomerPolymer science

A method for manufacturing a flexographic printing master comprising the steps of: (a) providing an ink-receiver surface; (b) jetting a curable jettable fluid on the ink-receiver surface characterized in that the curable jettable fluid comprises at least one photo-initiator, at least one monofunctional monomer, at least 5 wt % of a polyfunctional monomer or oligomer and at least 5 wt % of a plasticizer both based on the total weight of the curable jettable liquid capable of realizing a layer after curing having an elongation at break of at least 5%, a storage modulus E′ smaller than 200 MPa at 30 Hz and a volumetric shrinkage smaller than 10%.

Owner:AGFA NV

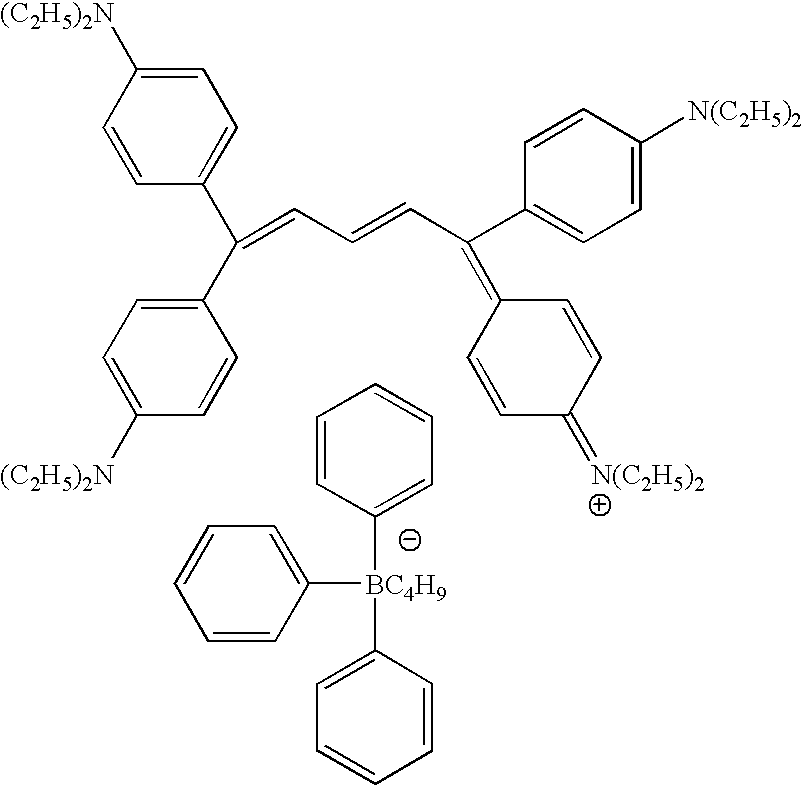

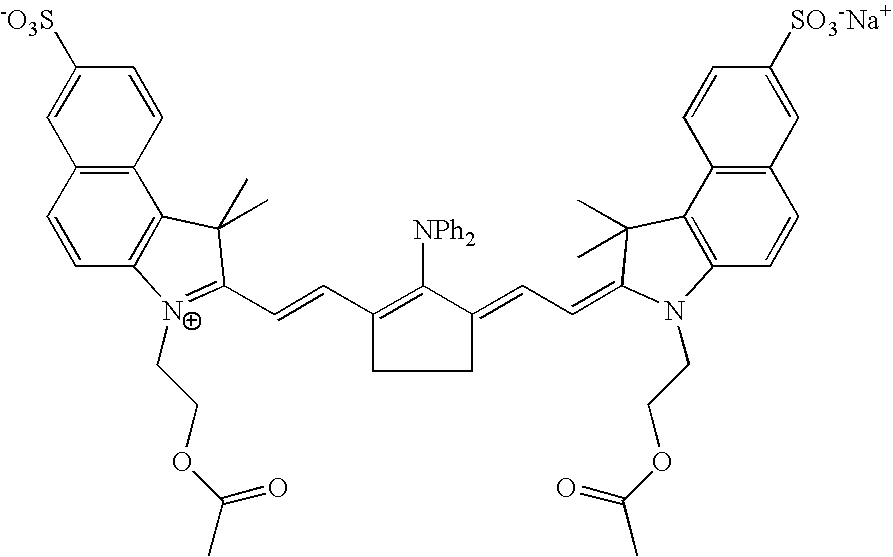

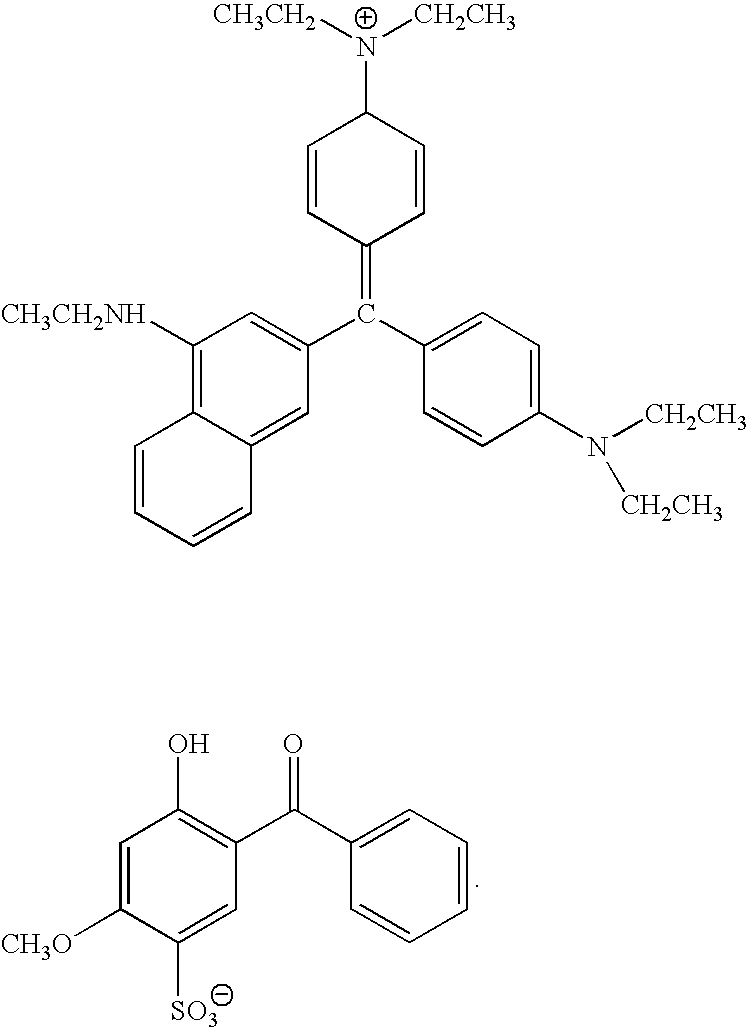

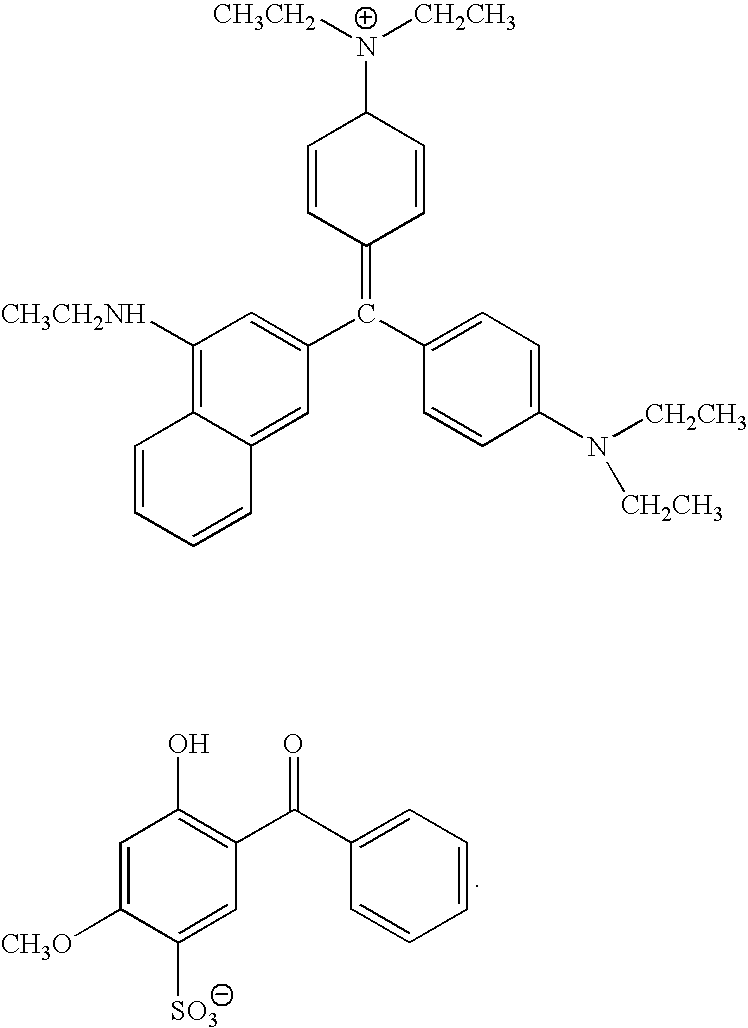

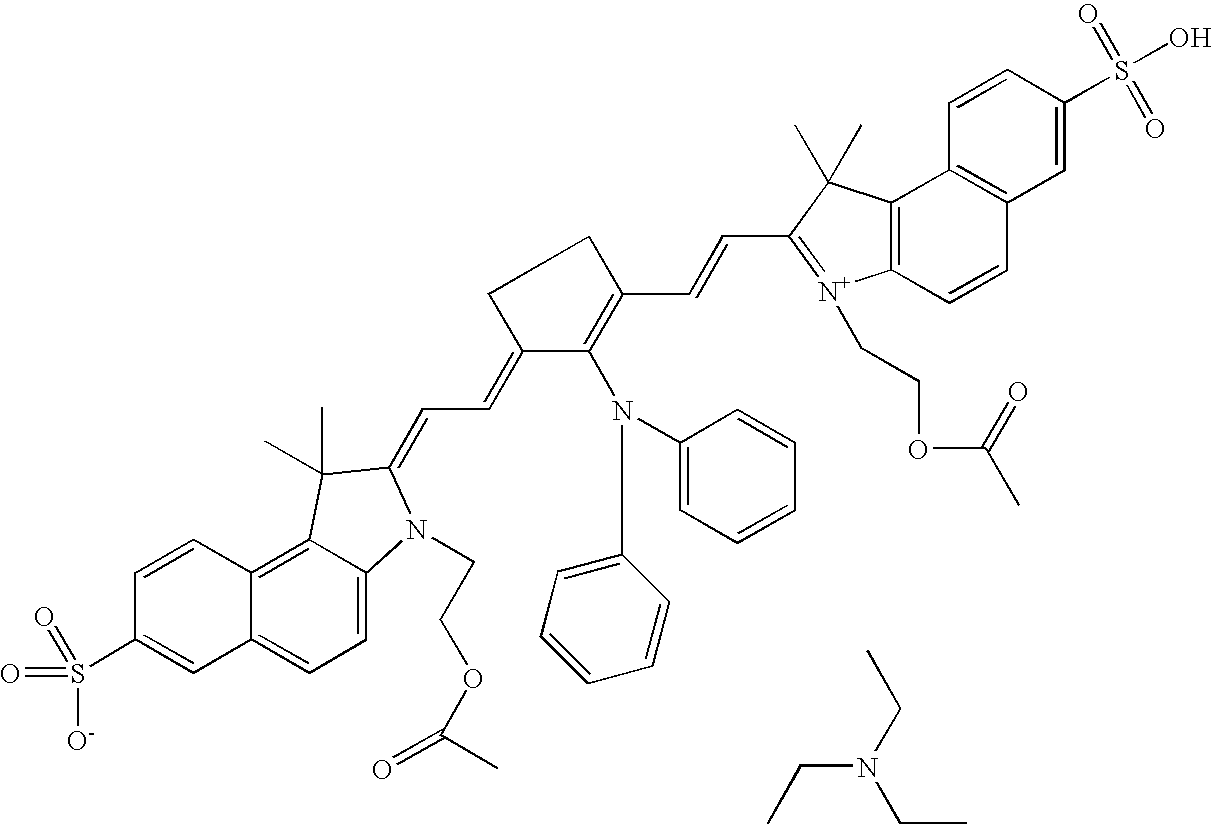

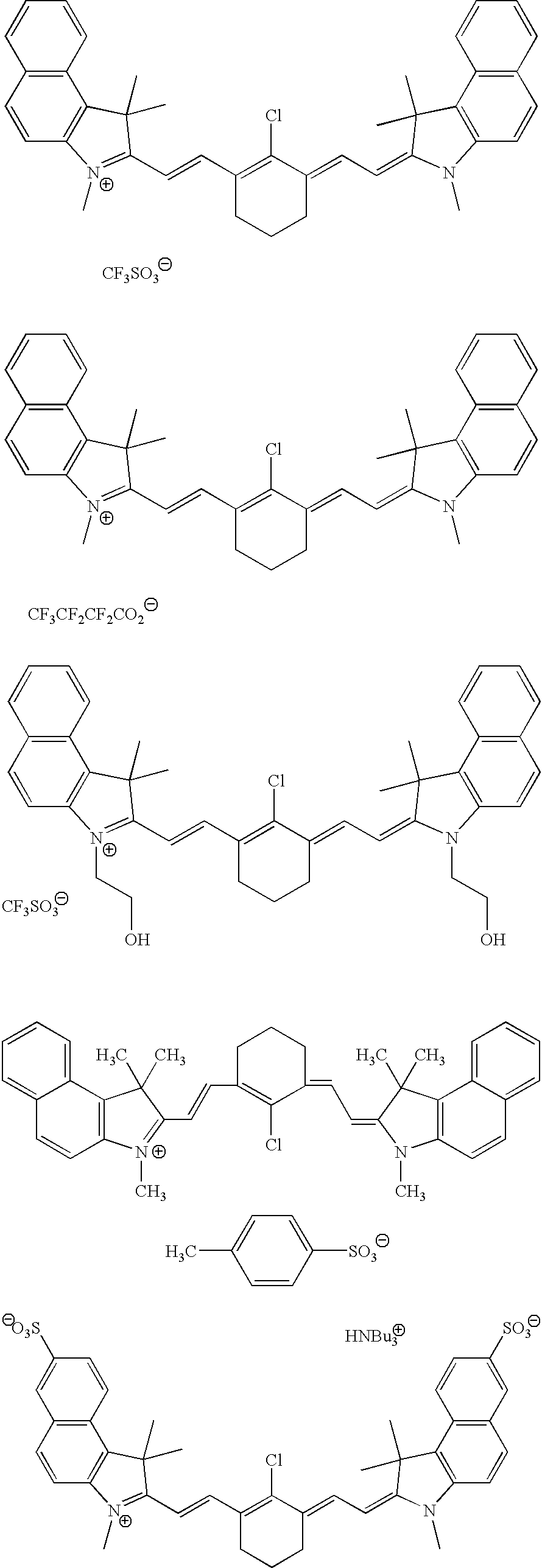

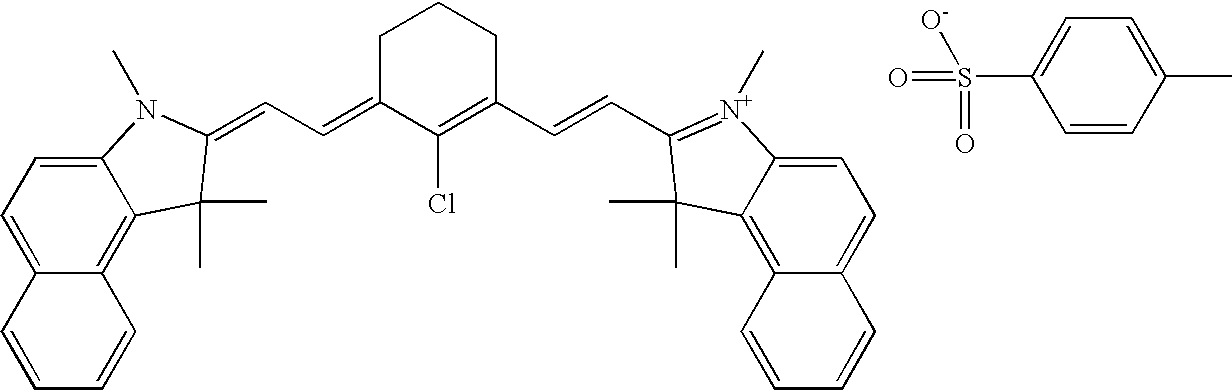

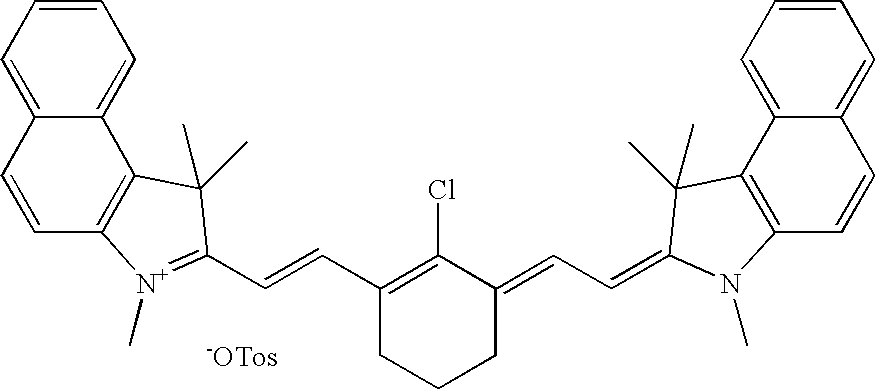

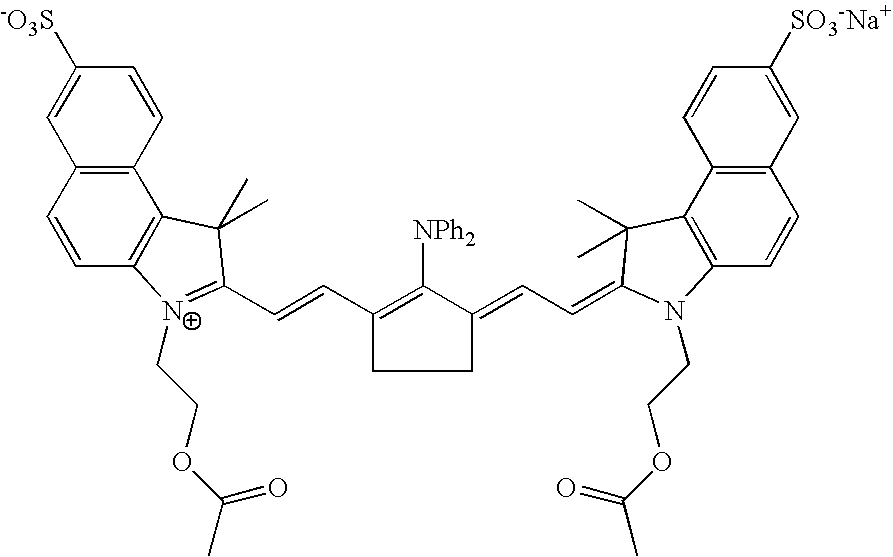

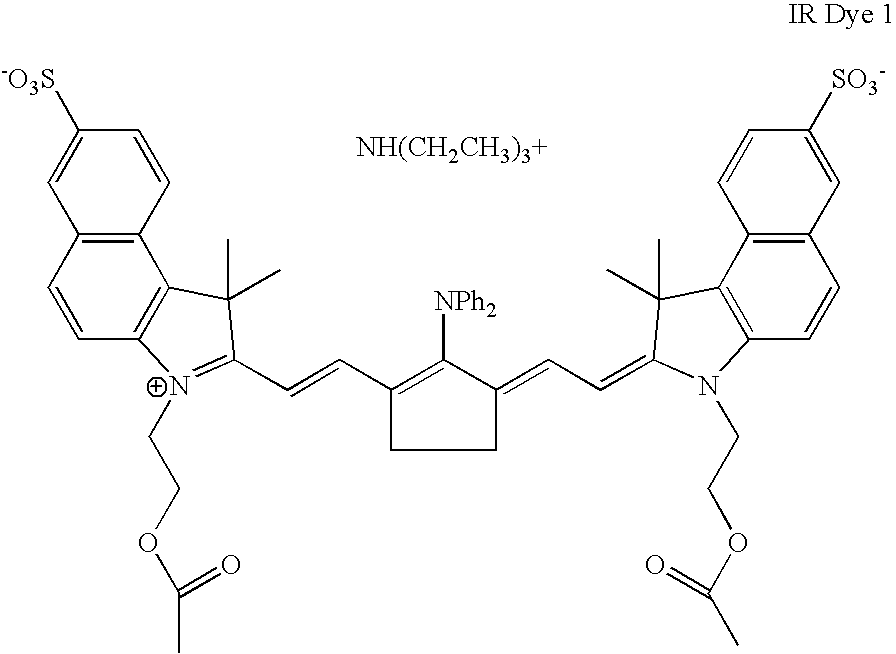

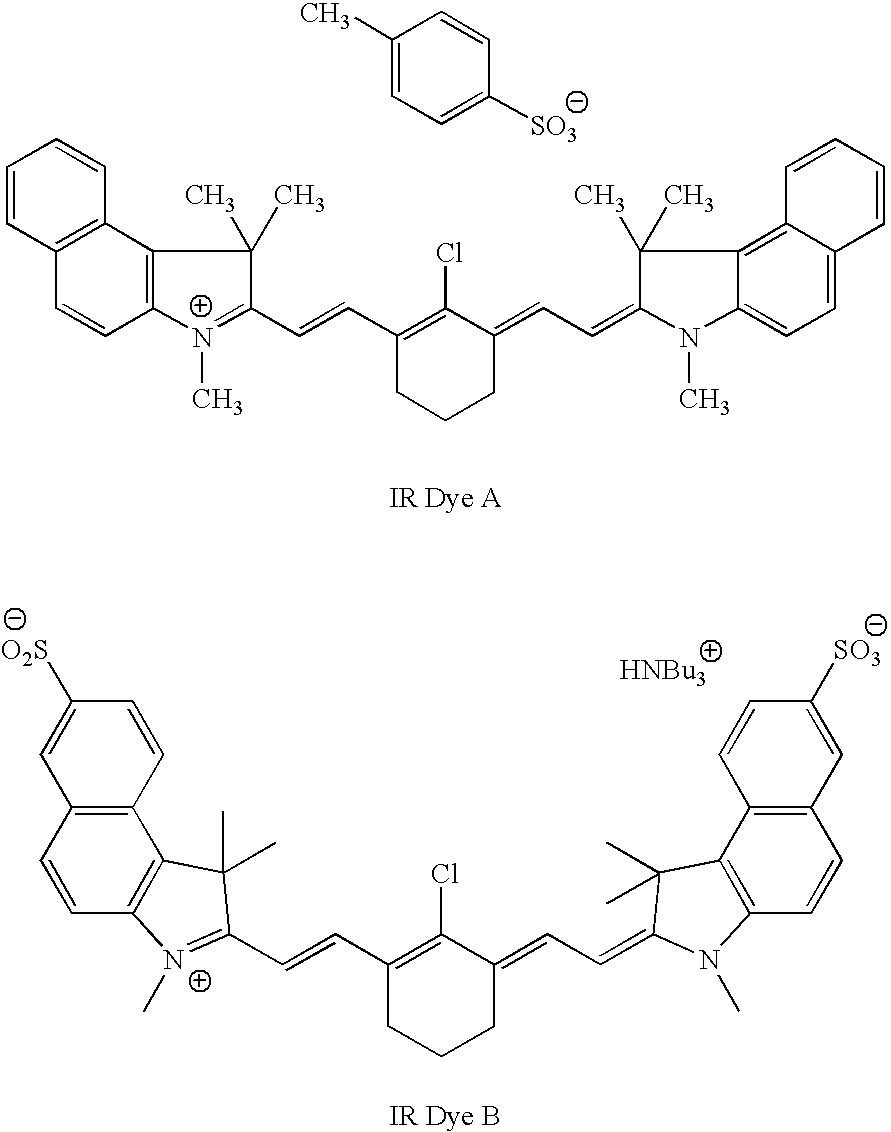

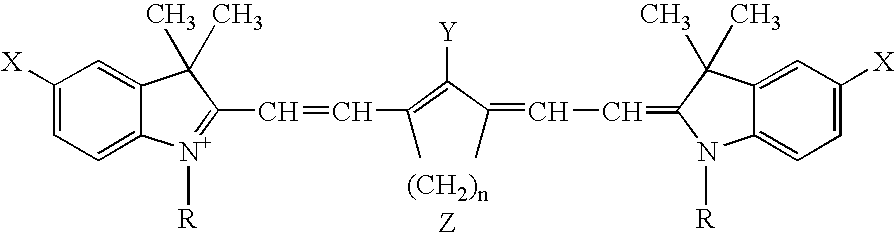

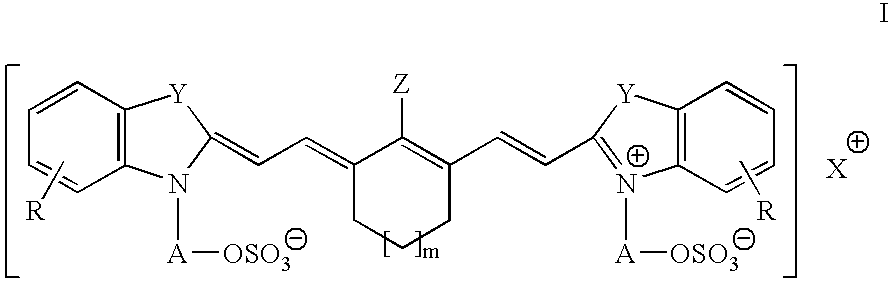

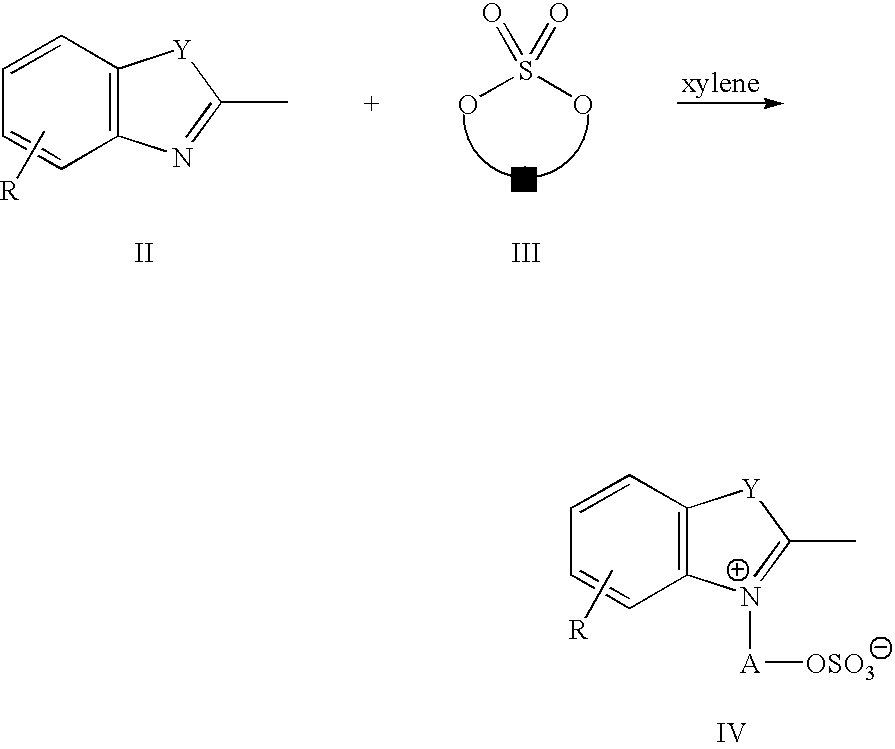

Infrared absorbing compounds and their use in imageable elements

Infrared absorbing compounds are disclosed. The compounds are co-polymers that comprise covalently attached ammonium, sulfonium, phosphonium, and / or iodonium cations, and infrared absorbing cyanine anions that have two to four sulfonate groups and / or sulfate groups, and / or infrared absorbing oxonol anions. The infrared absorbing compounds can be used in aqueous developable lithographic printing plate precursors.

Owner:KODAK POLYCHROME GRAPHICS

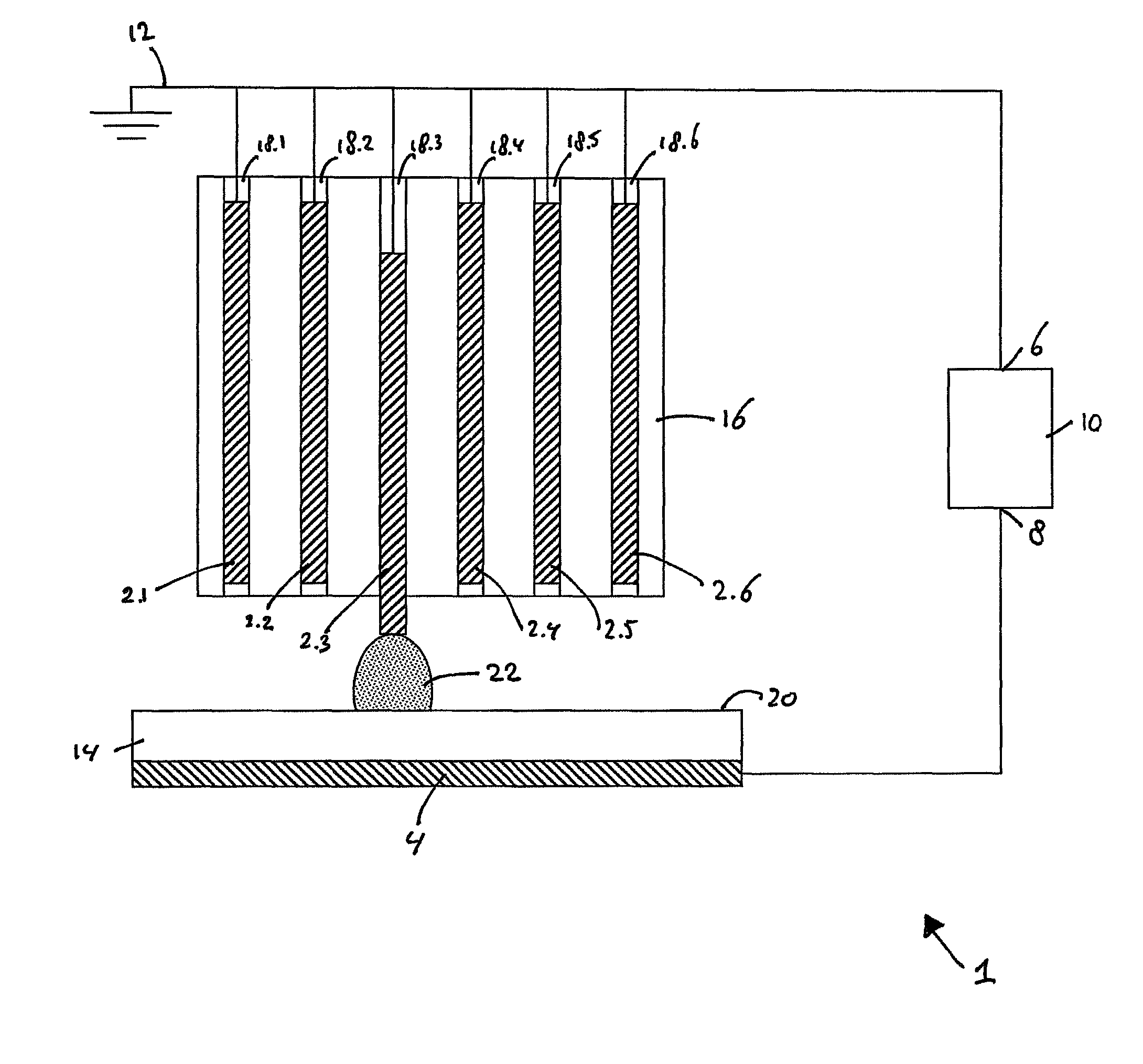

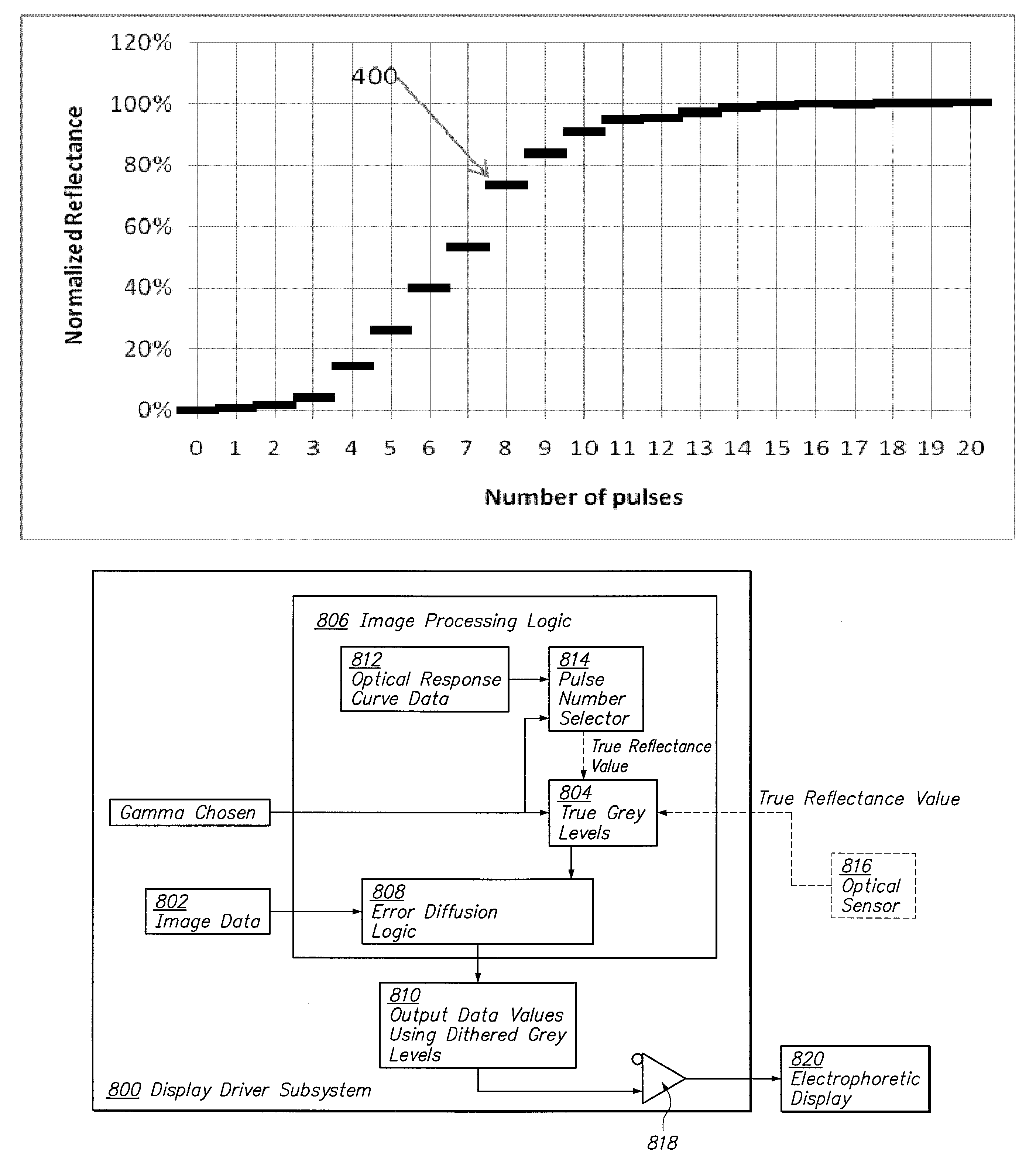

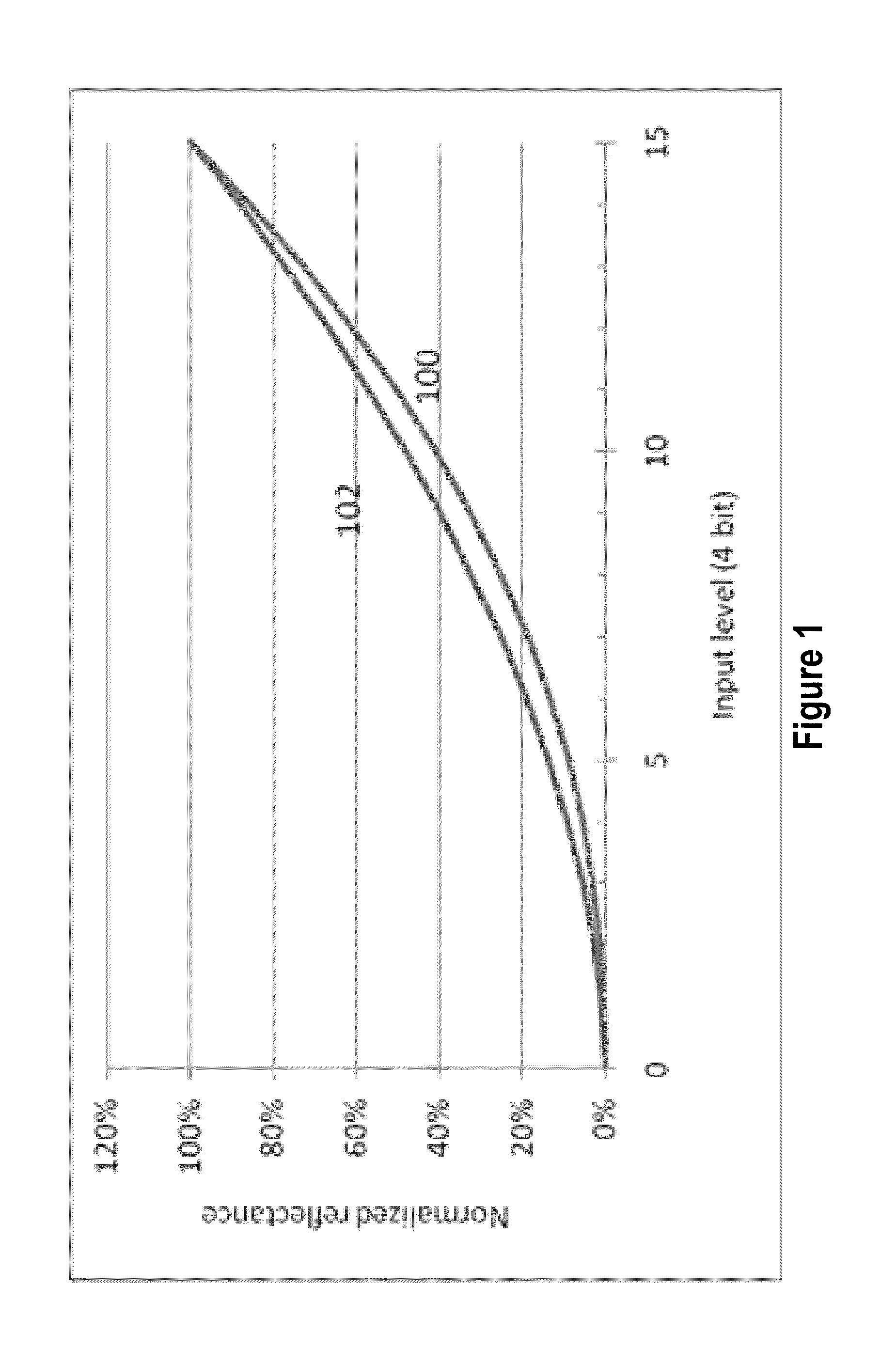

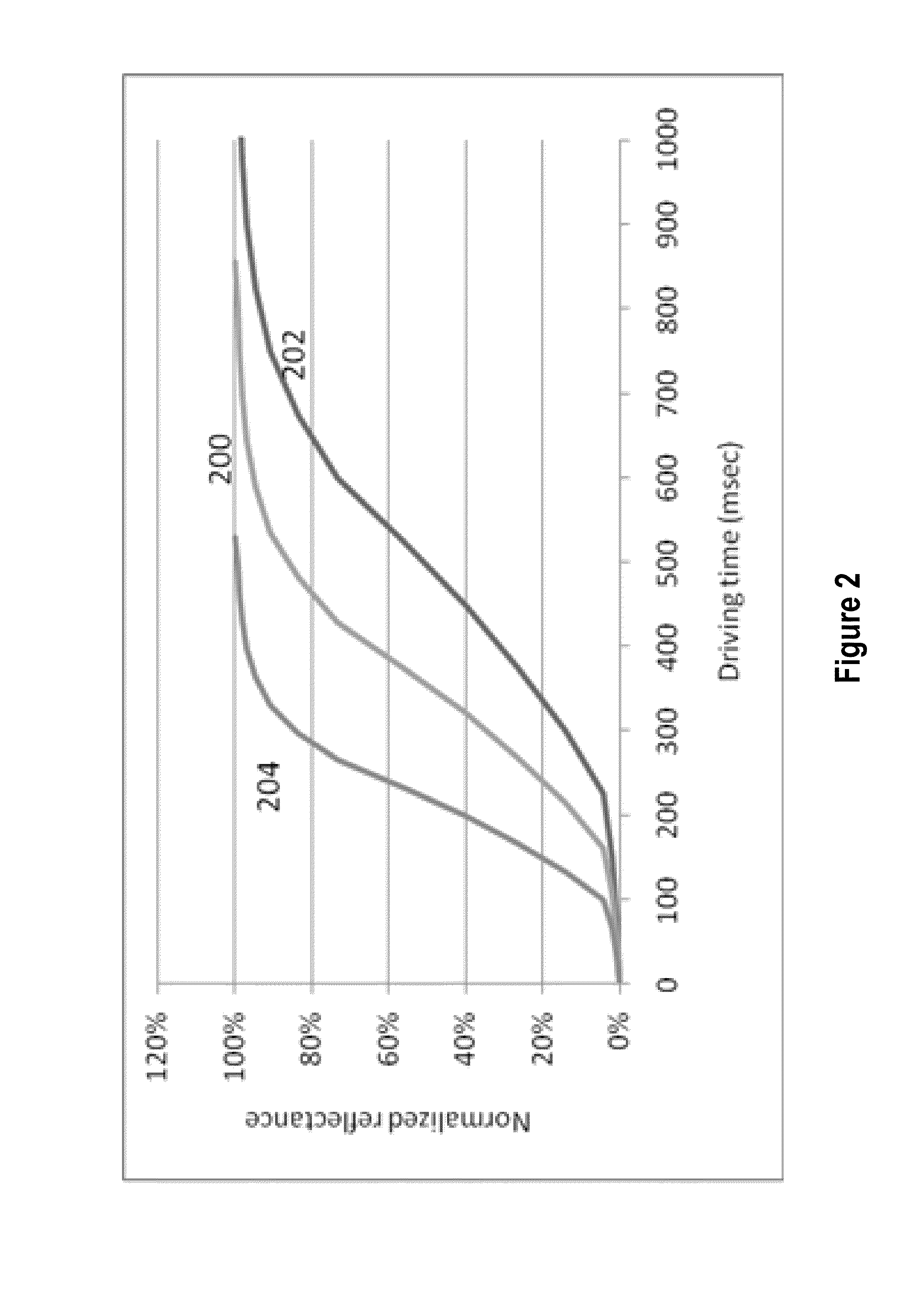

Gamma adjustment with error diffusion for electrophoretic displays

ActiveUS8456414B2Improve display qualityComplex to useCathode-ray tube indicatorsVisual presentationImaging processingDisplay device

Embodiments are directed to image processing methods to improve display quality while using a limited number of pulses and to correct the error between the reflectance and the desired gamma. The complexity of the hardware used for driving a display device may then be reduced to minimum. In addition, in various embodiments the method can also be used to compensate for the change of an optical response curve due to batch variation, temperature change, photo-exposure or aging of the display device.

Owner:E INK CORPORATION

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com