Patents

Literature

45 results about "Contact print" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A contact print is a photographic image produced from film; sometimes from a film negative, and sometimes from a film positive or paper negative. In a darkroom an exposed and developed piece of photographic film or paper is placed emulsion side down, in contact with a piece of photographic paper, light is briefly shone through the negative or paper and then the paper is developed to reveal the final print.

Contact print methods

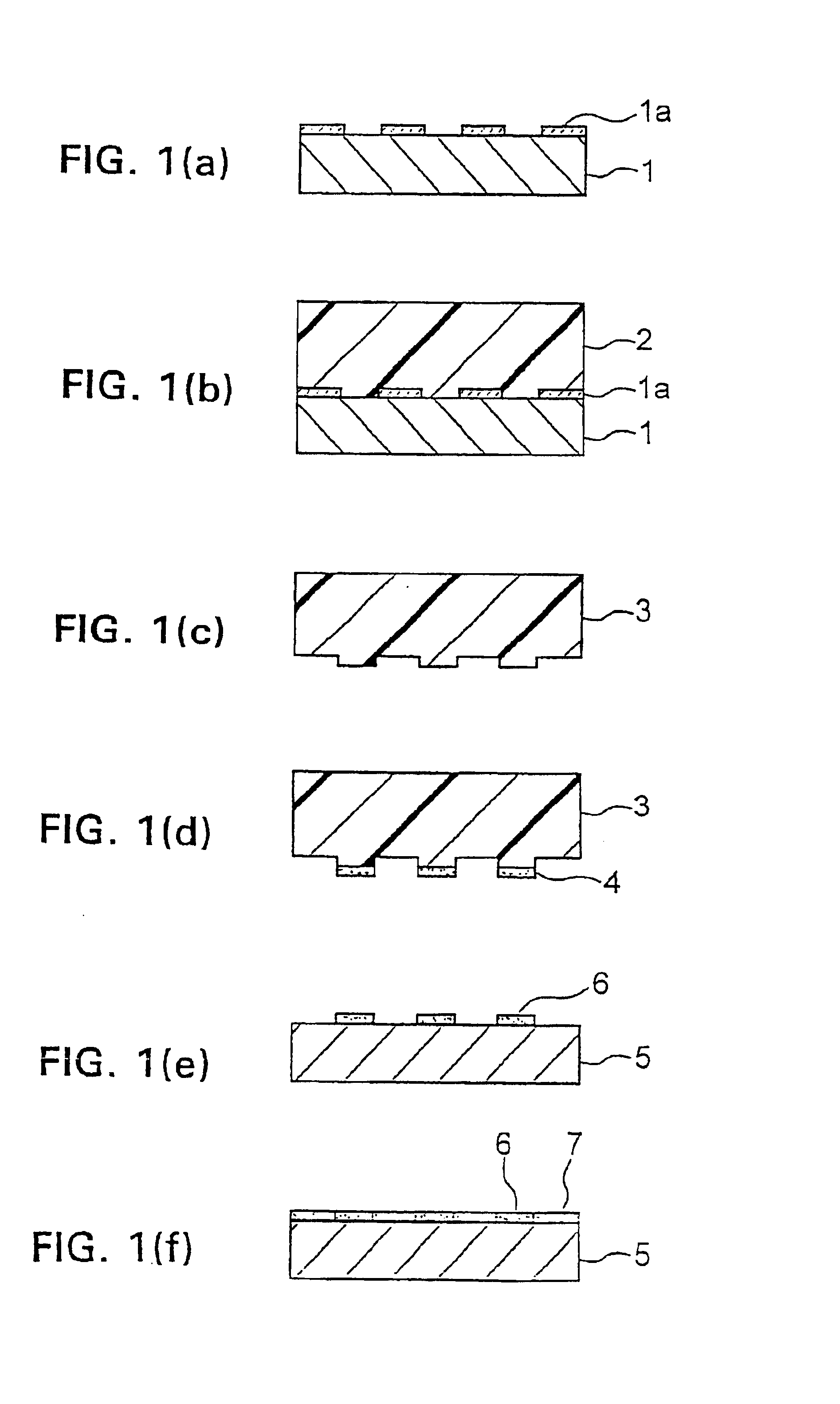

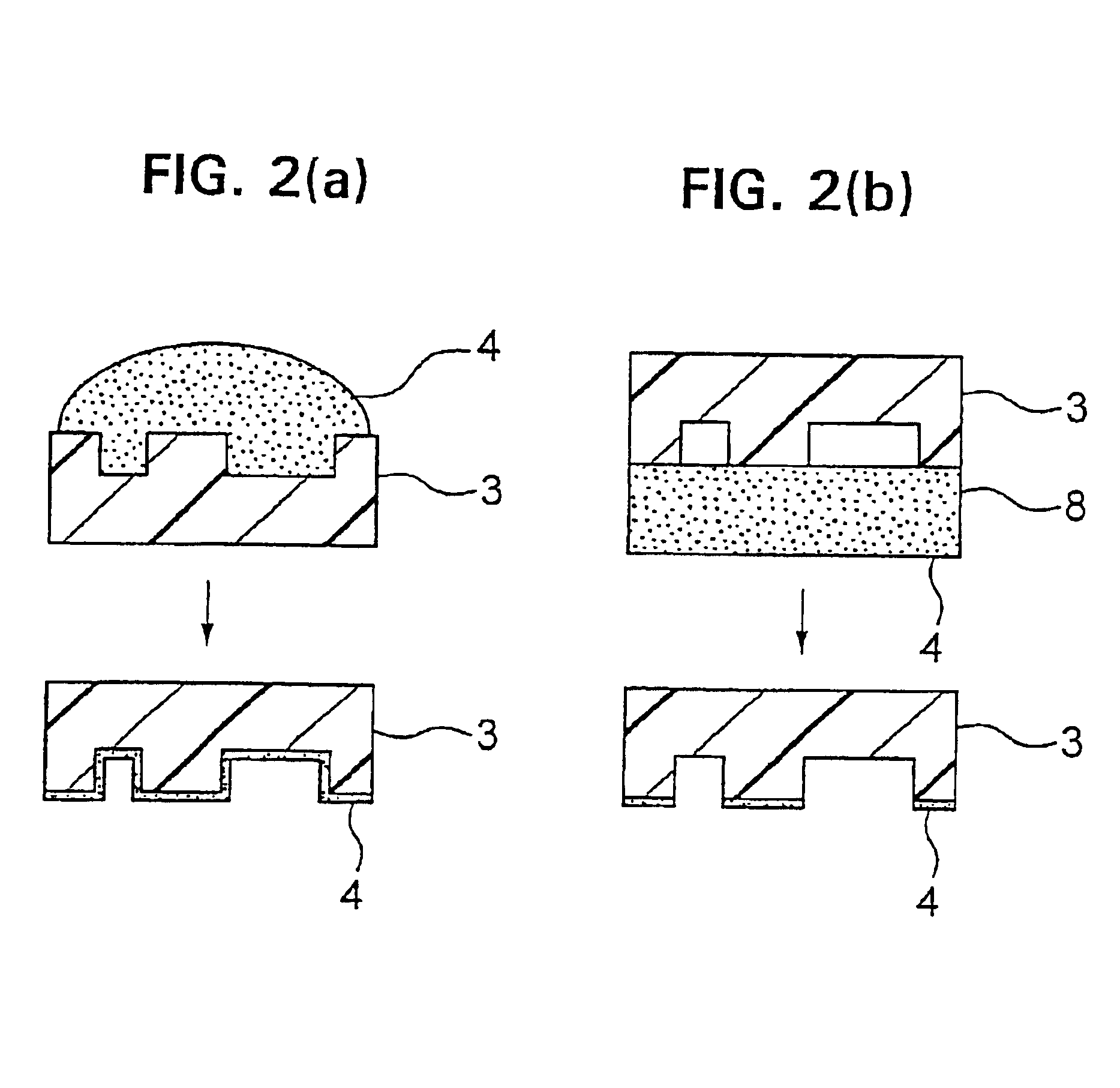

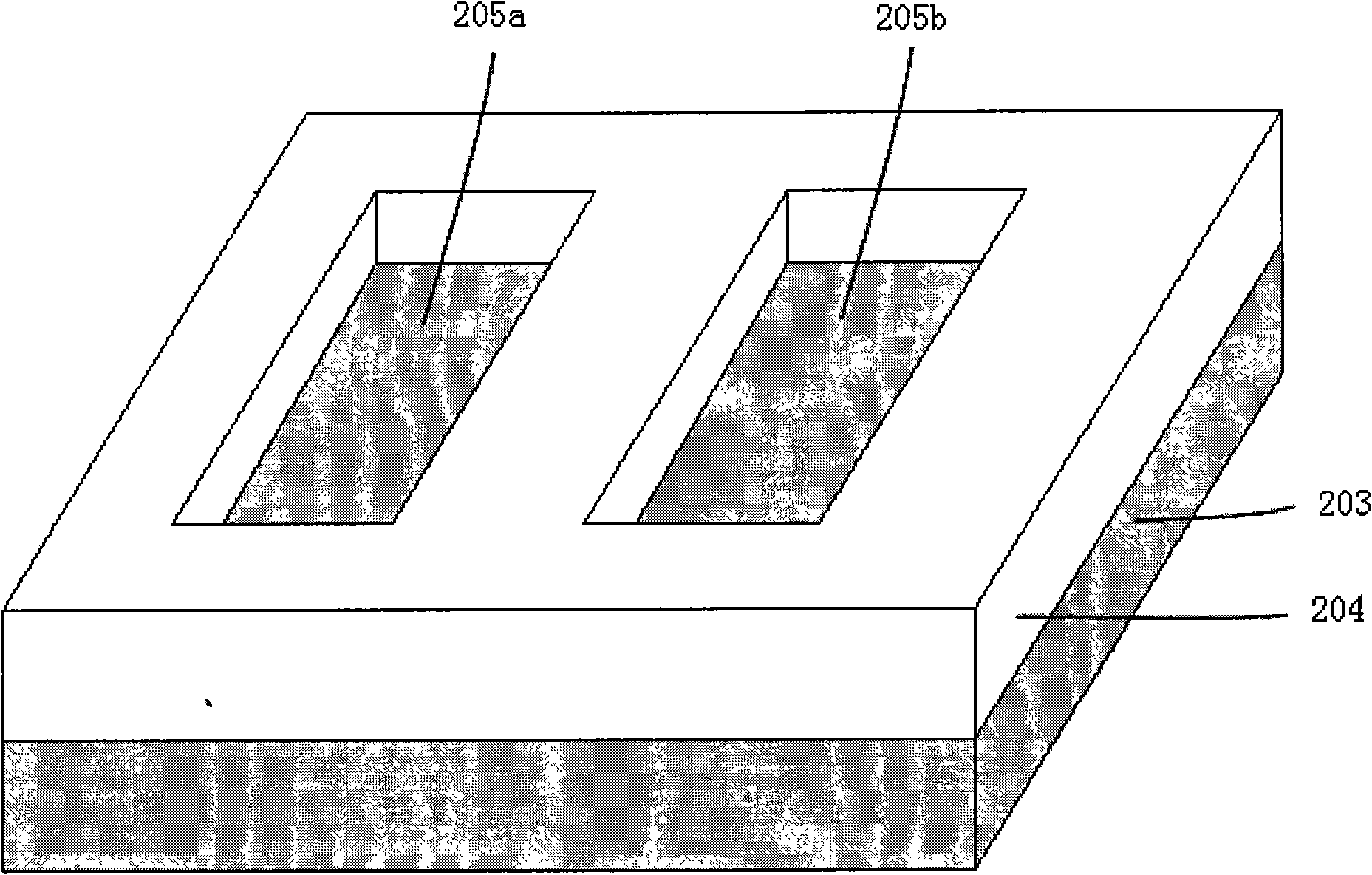

InactiveUS6957608B1High definitionImprove printing effectMechanical working/deformationSolid-state devicesContact printSolvent

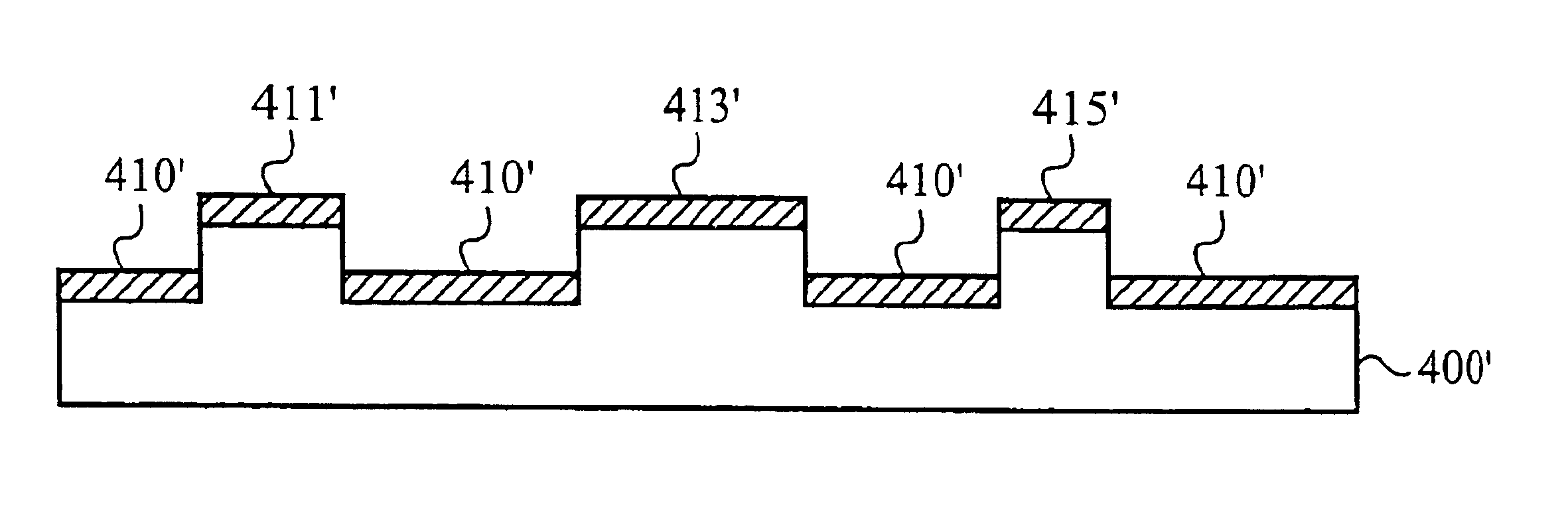

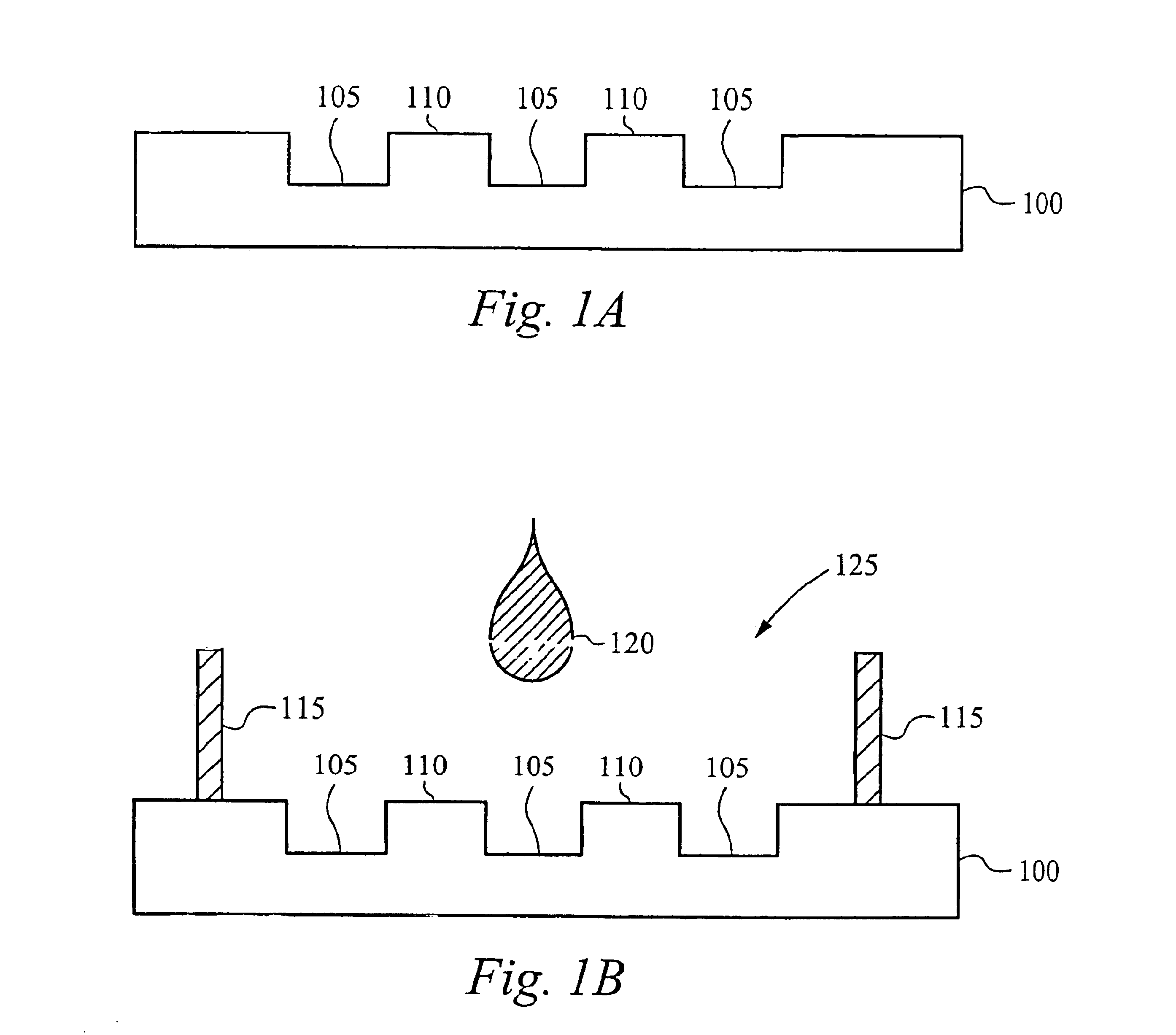

A method of and device for controlled printing using liquid embossing techniques is disclosed. In accordance with the embodiments of the invention a stamp comprises a differentiated embossing surface with protruding and recessed surfaces to enhance the ability of the stamp to selectively displace liquid ink from a print surface and / or remove solvent from the liquid in a soft curing process. A stamp with differentiated surfaces is fabricated by selectively coating, or otherwise treating the protruding features, the recessed features, or a combination thereof, such that the surface energies and / or wettability of the protruding surfaces and the recessed surfaces are differentiated.

Owner:KOVIO

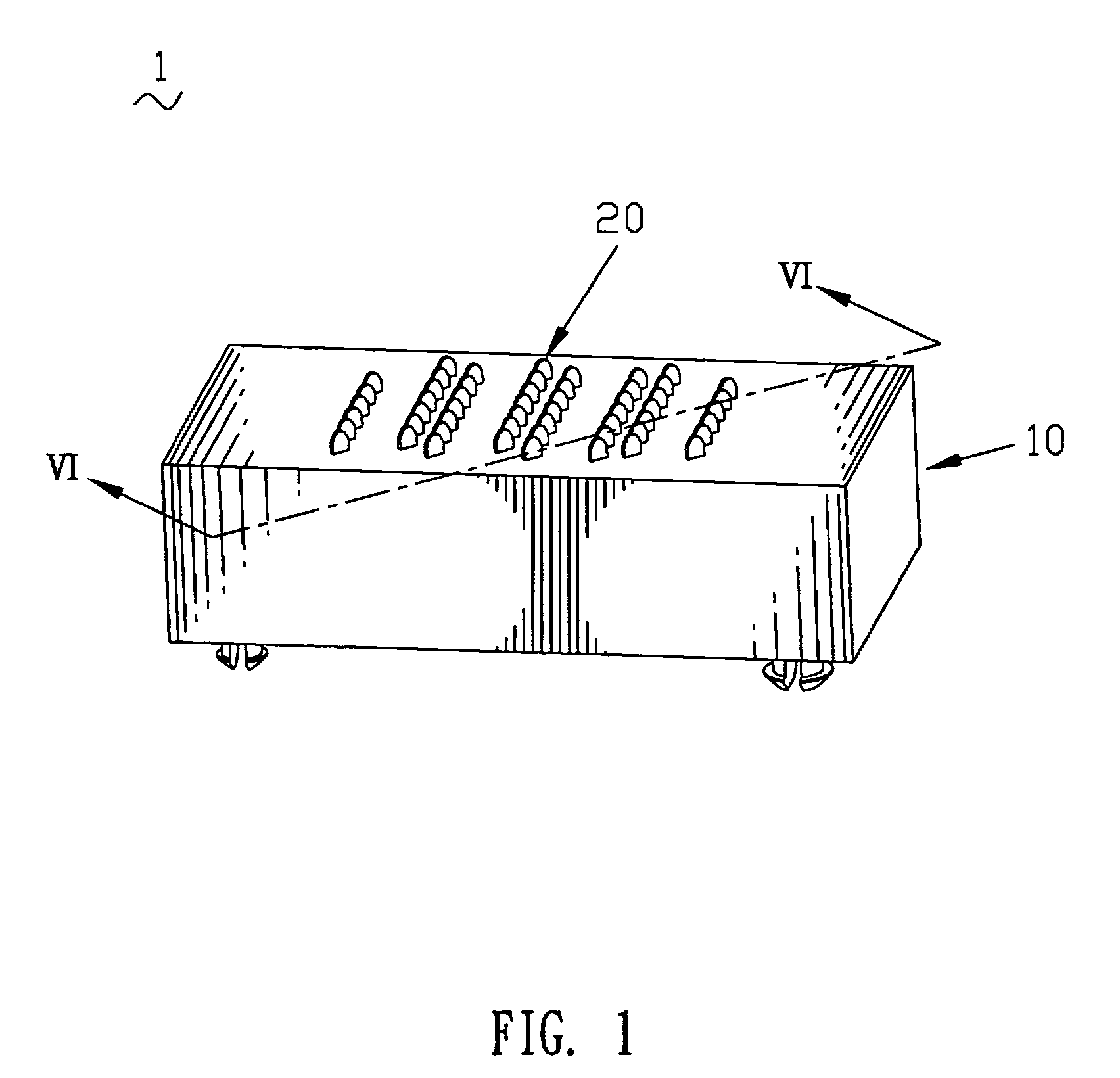

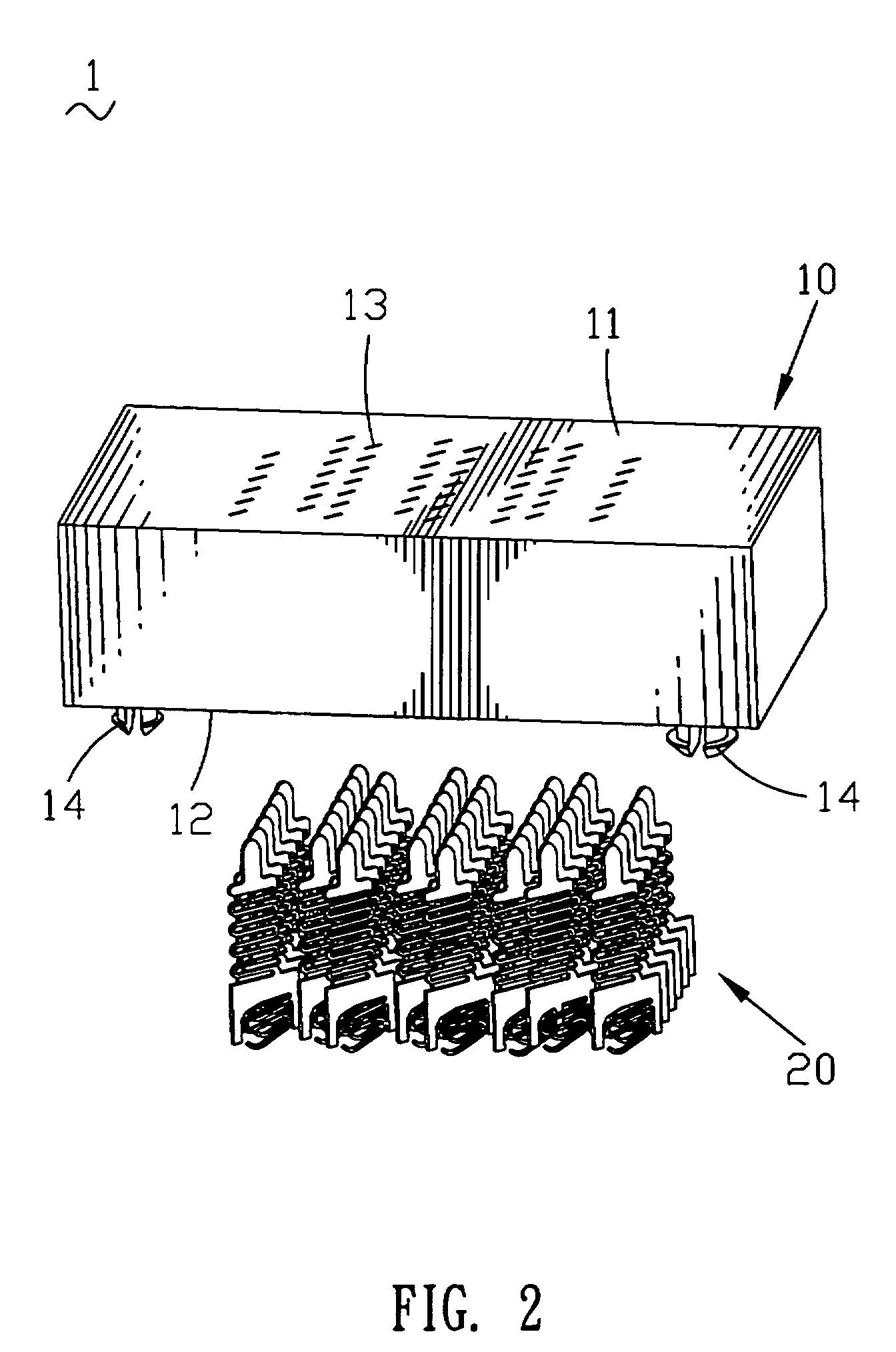

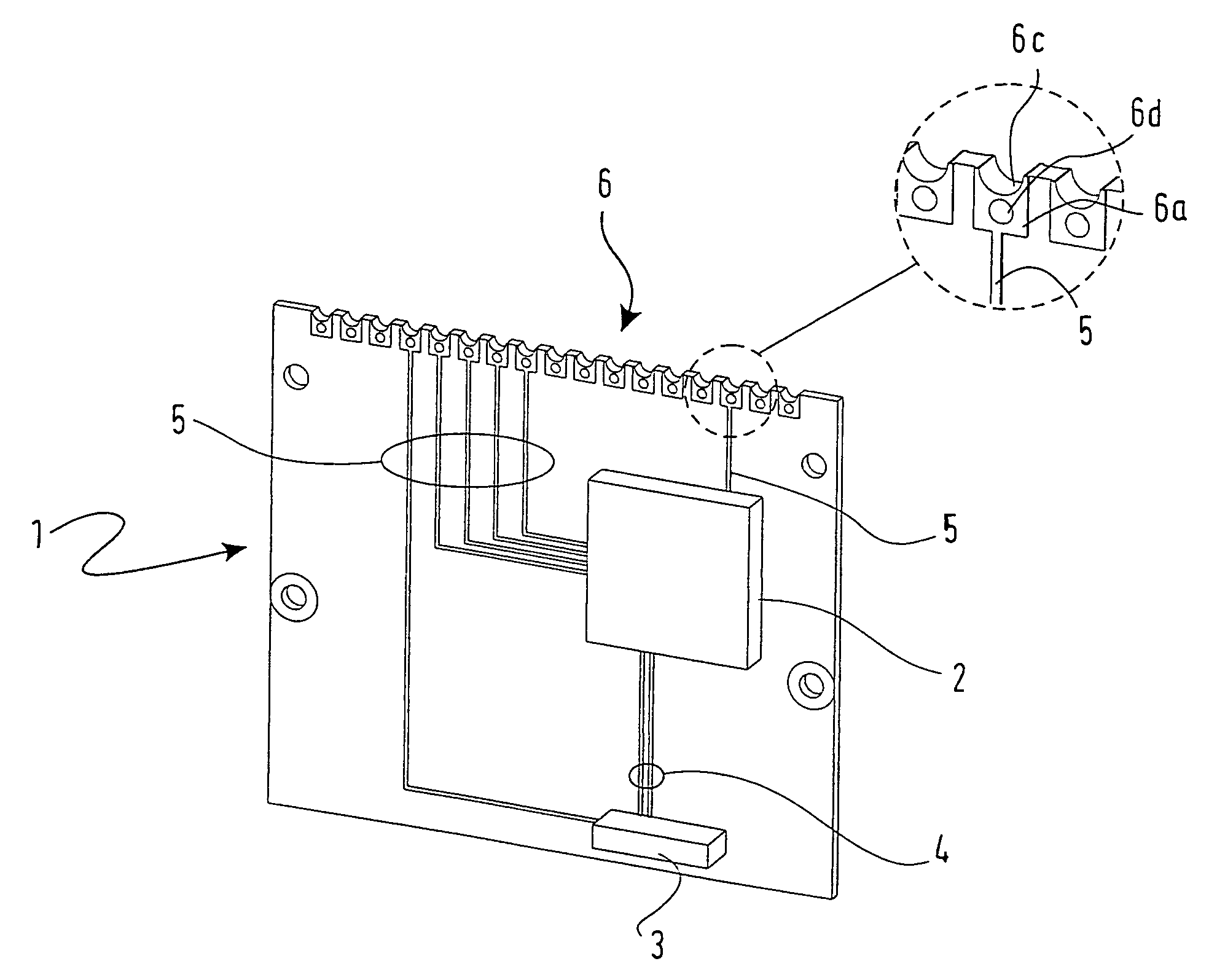

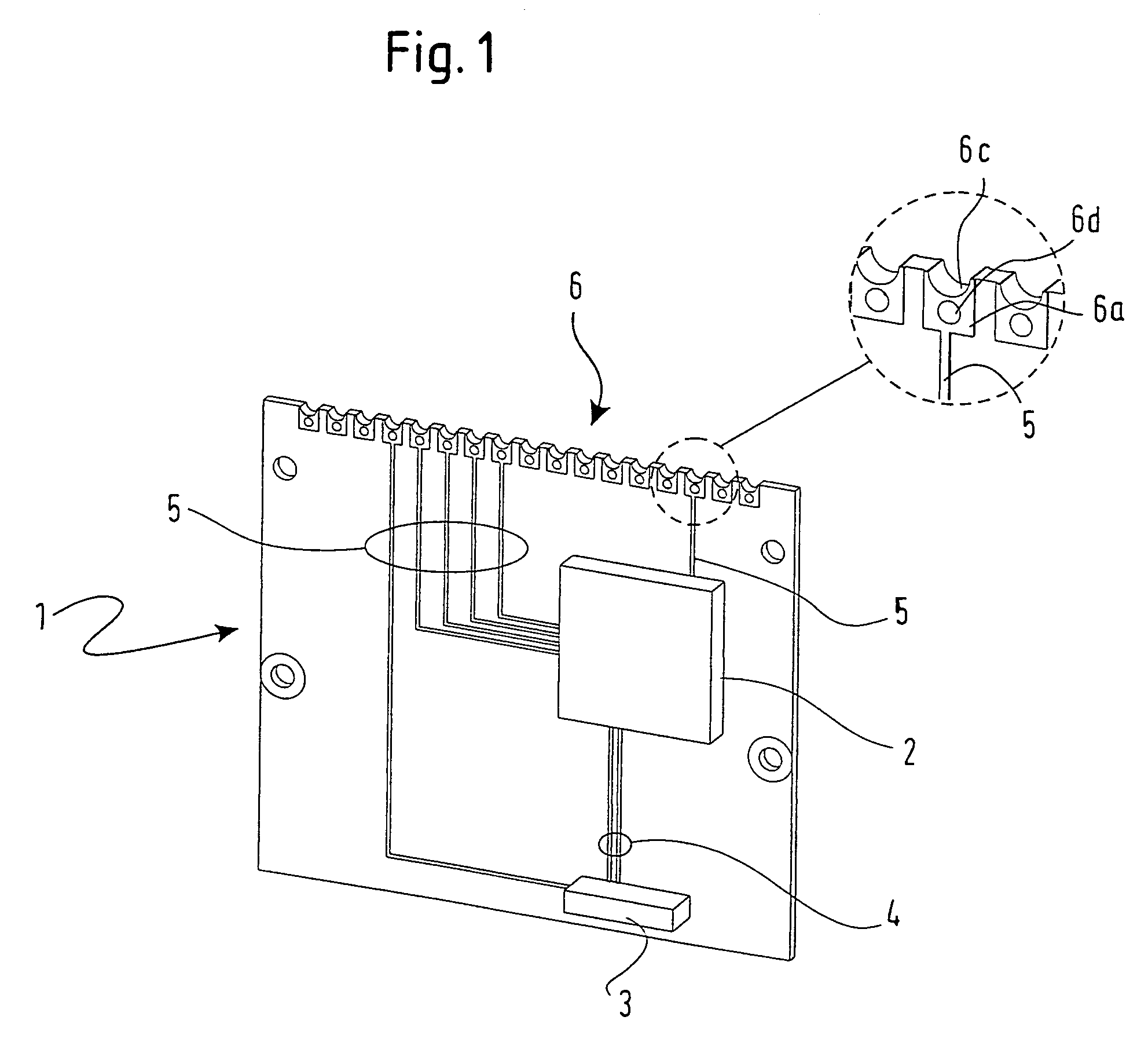

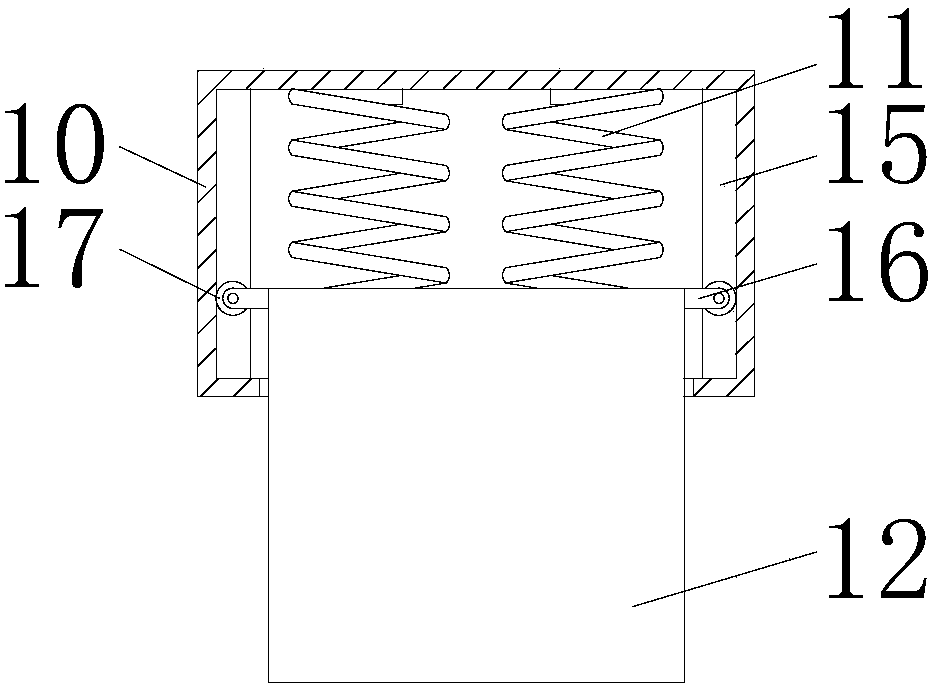

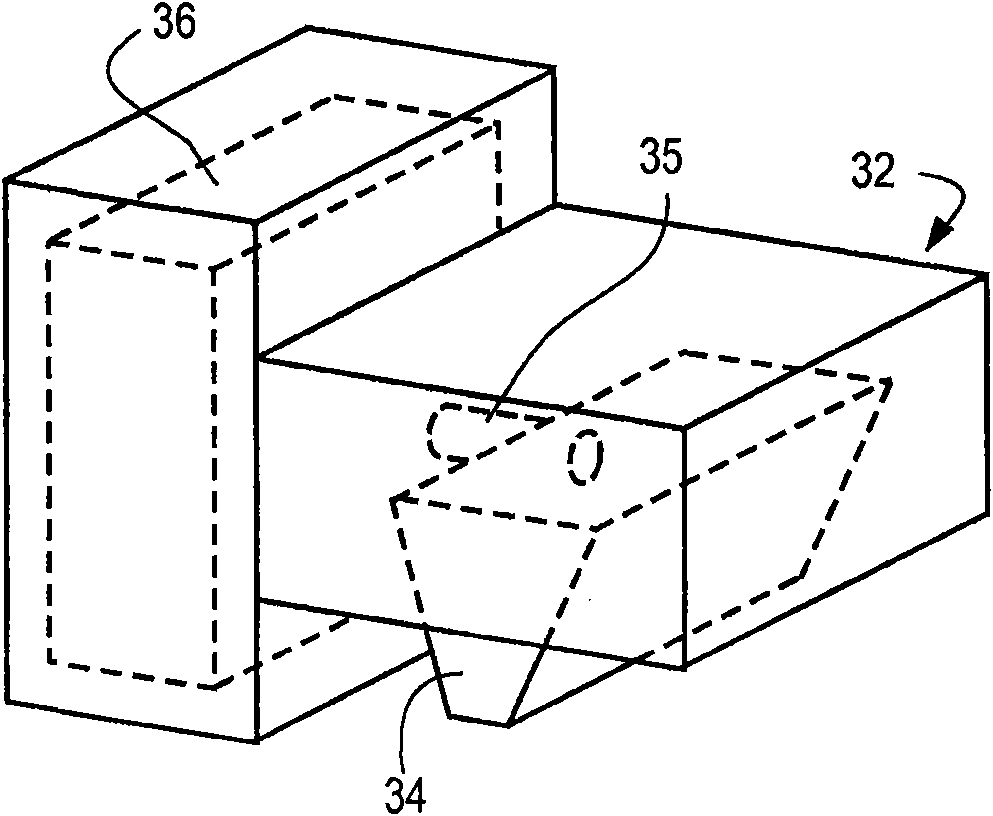

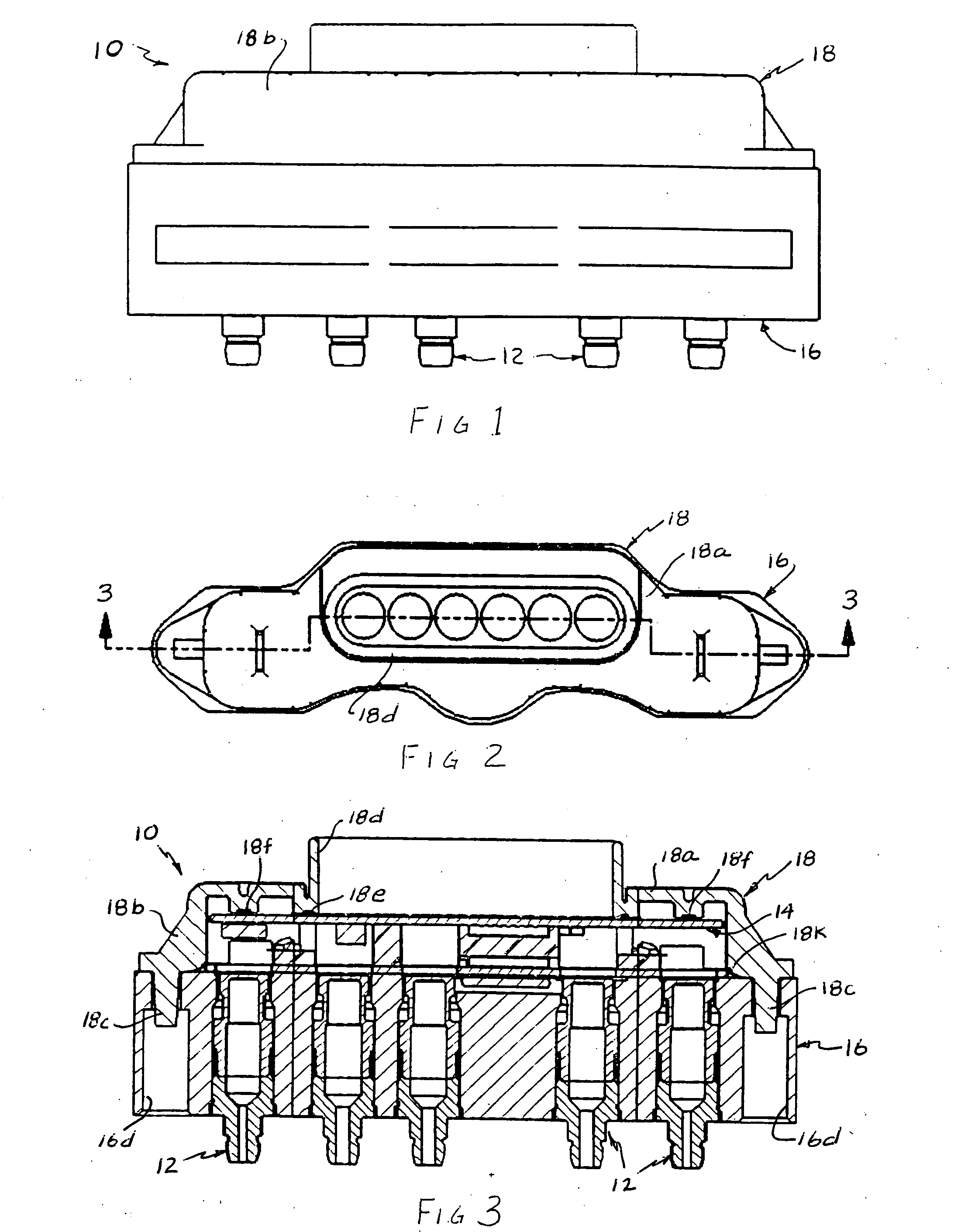

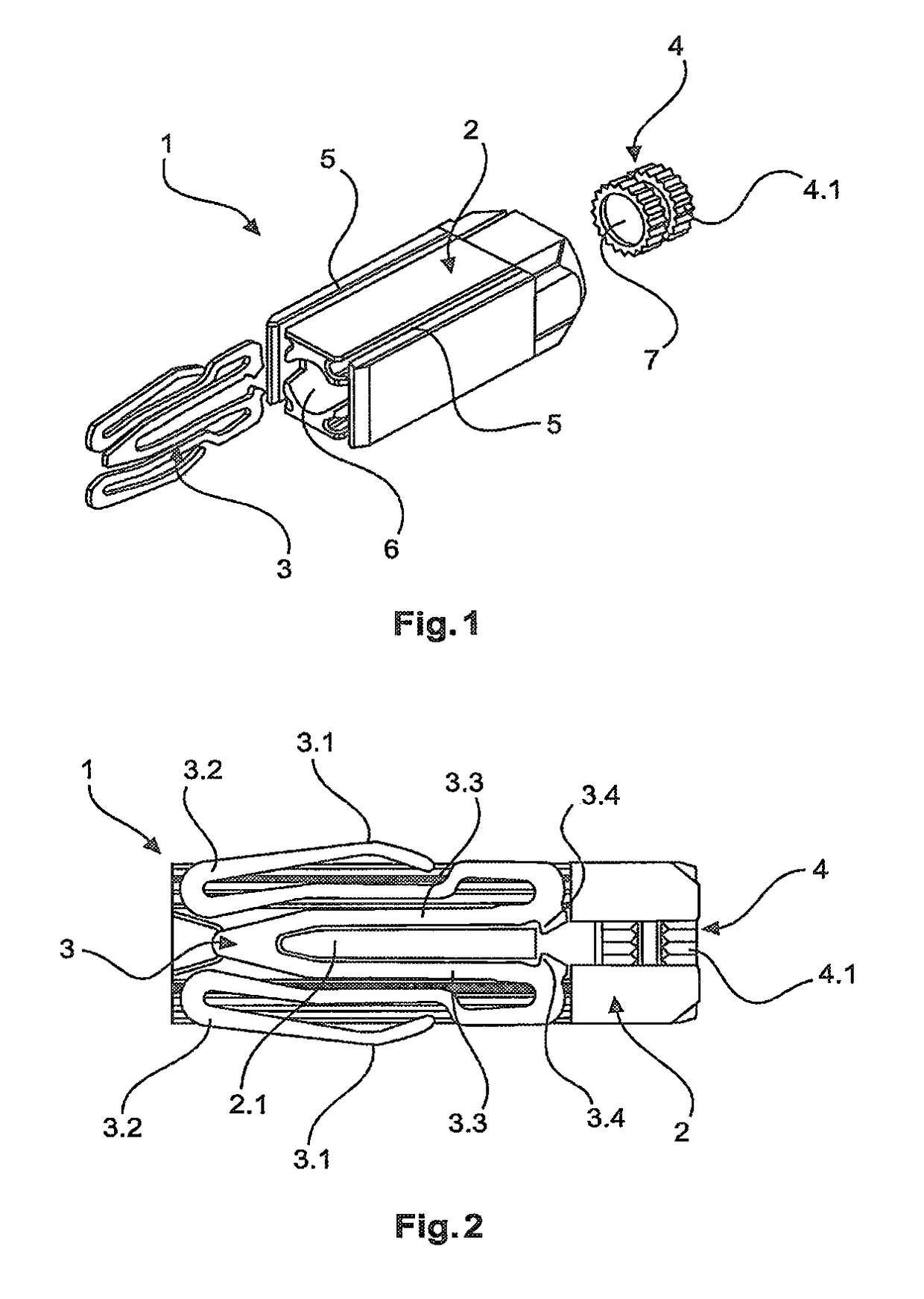

Board to board connector

InactiveUS7270550B1Easy to disassembleSignal transmission is stableCoupling contact membersPrinted circuitsBoard-to-board connectorContact print

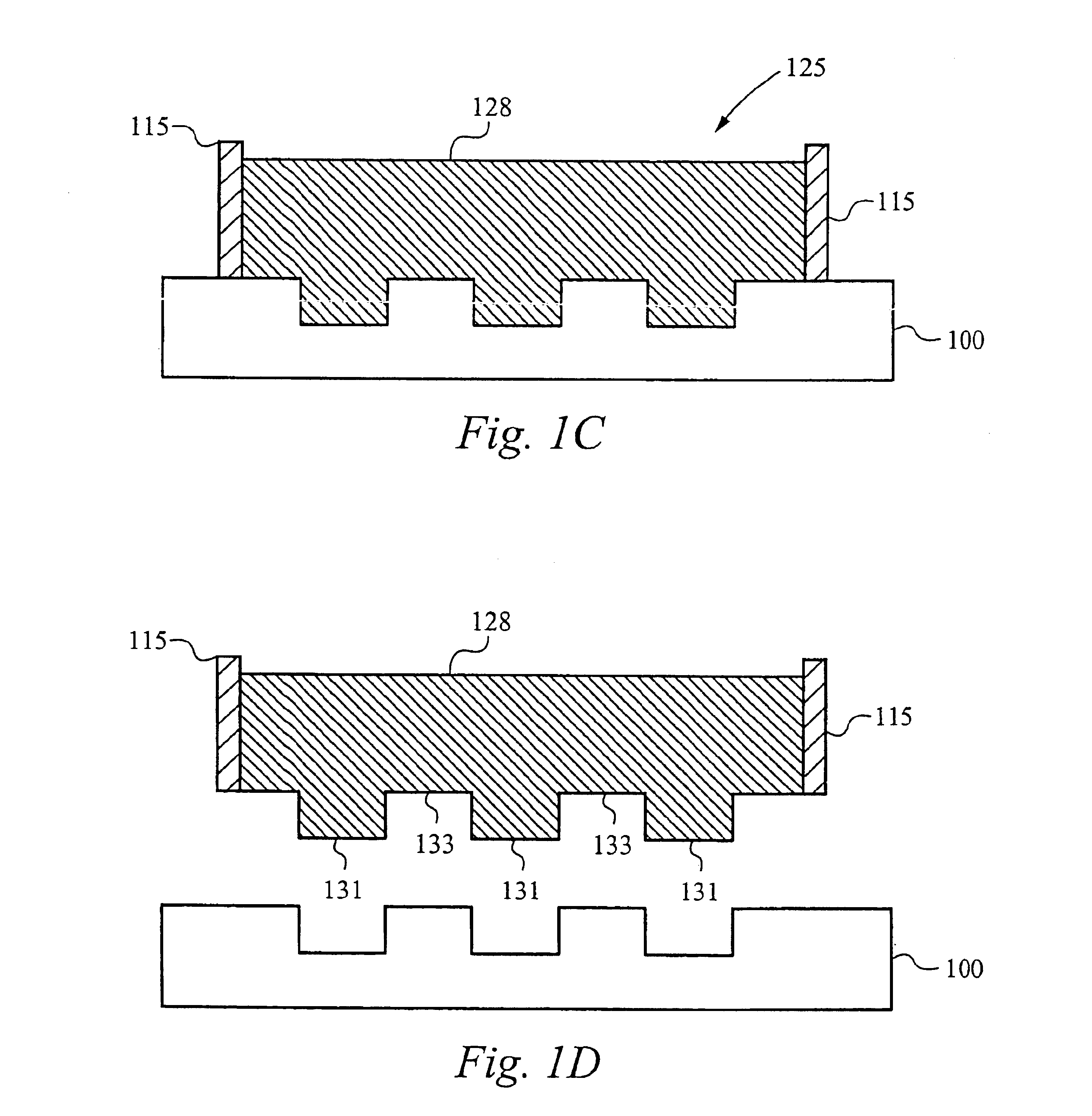

A board to board connector includes a dielectric housing and a plurality of terminals. The dielectric housing has an upper surface, a bottom surface and a plurality of terminal passages which pass through the upper surface and the bottom surface. Each terminal is received in each terminal passage respectively. Each terminal has a fixed holding portion. A compressed portion extends from the lower end of the fixed holding portion. The compressed portion has a second contact portion protrudes out from the bottom surface of the dielectric housing. A winding portion extends from the upper end of the fixed holding portion. A first contact portion extends from the top of the winding portion and protrudes out from the upper surface of the dielectric housing. The board to board connector utilizes the elastic force which is supplied by the compressed portion and the winding portion to ensure the terminals contact printed circuit boards stably so as to assure the transmitting of the signal is stably.

Owner:CHENG UEI PRECISION IND CO LTD

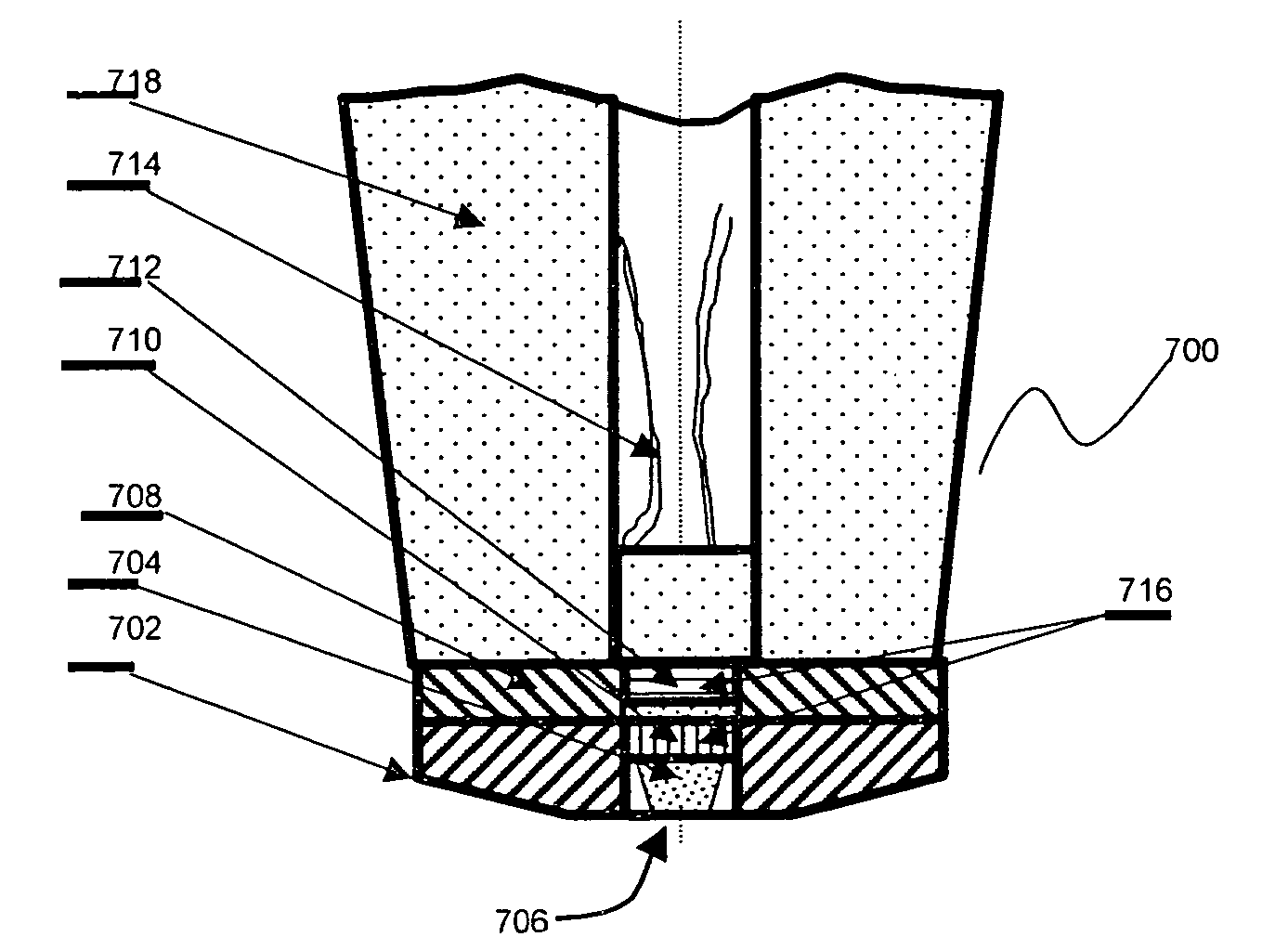

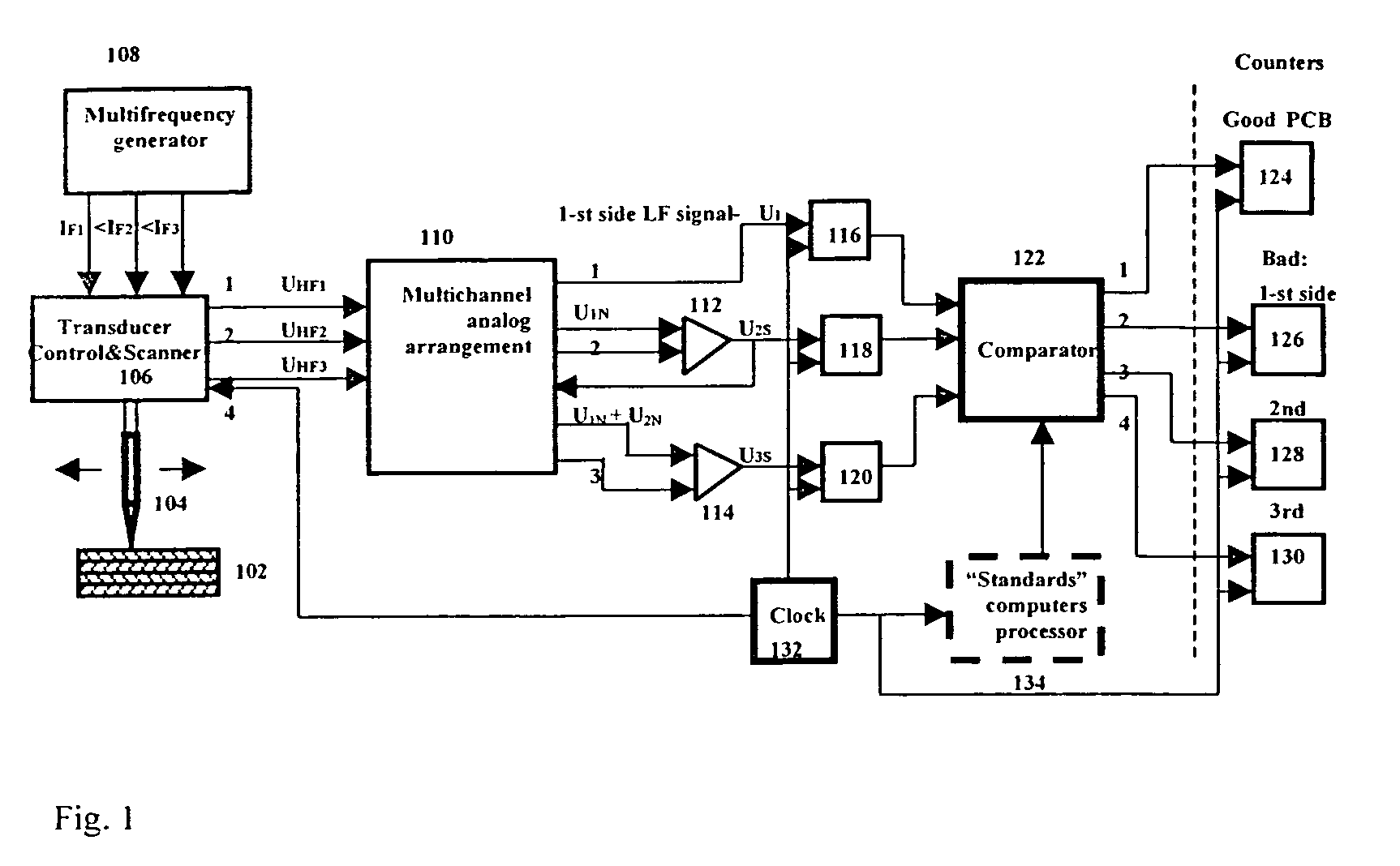

Methods and devices for eddy current PCB inspection

InactiveUS6975108B2Sharp focusEasy to detectHysteresis curve measurementsMaterial magnetic variablesPrinted circuit boardElectromagnetic testing

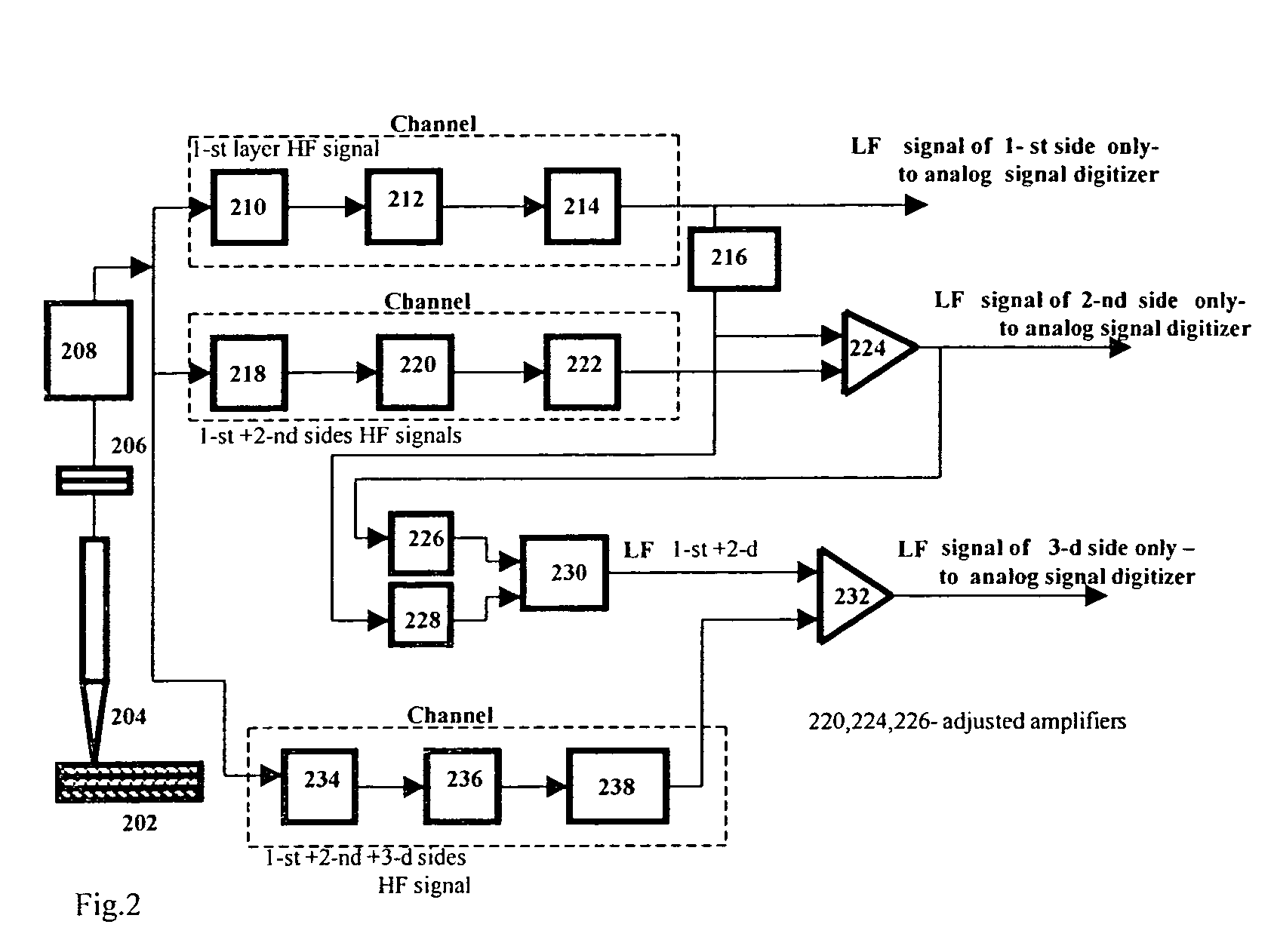

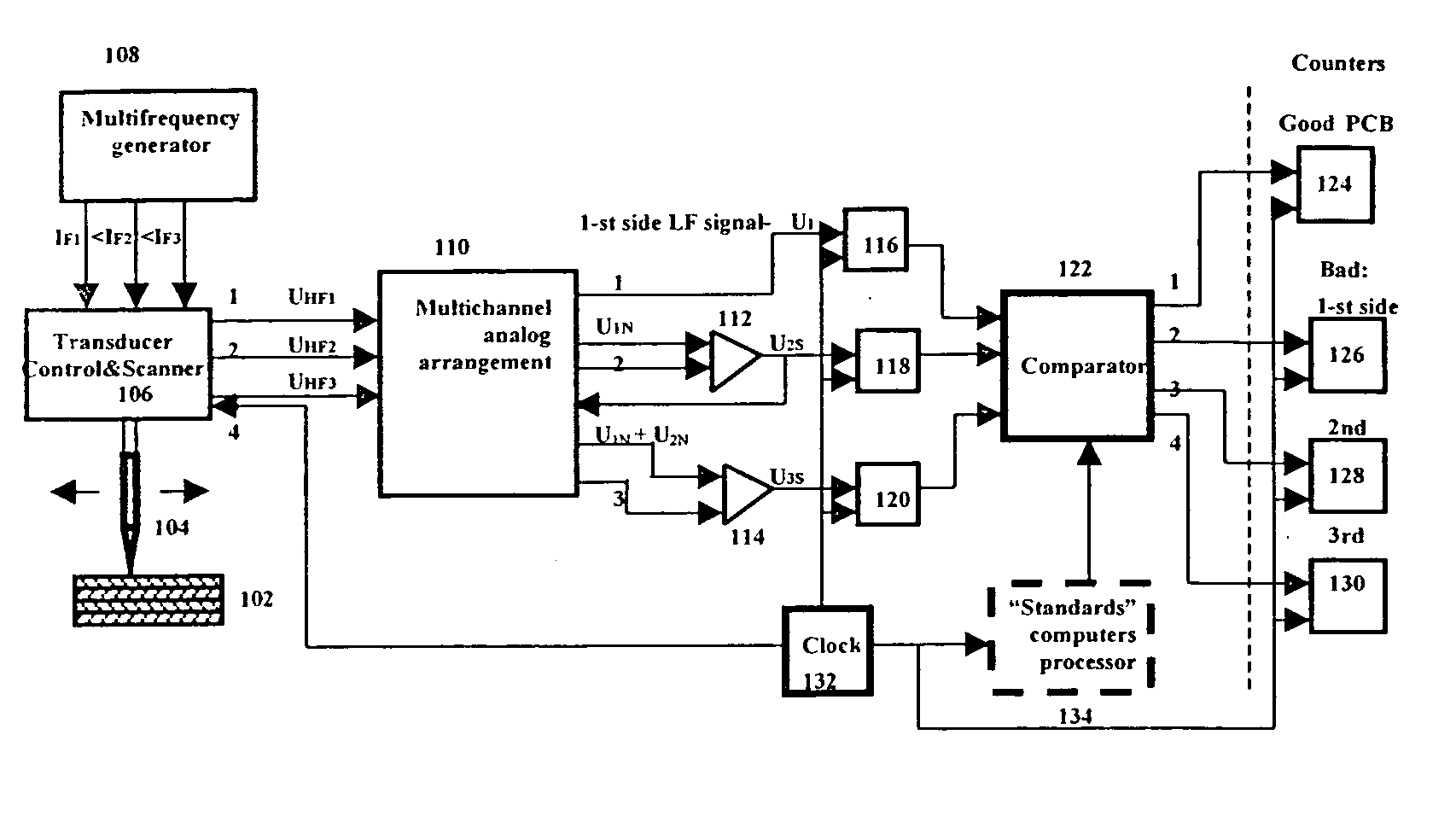

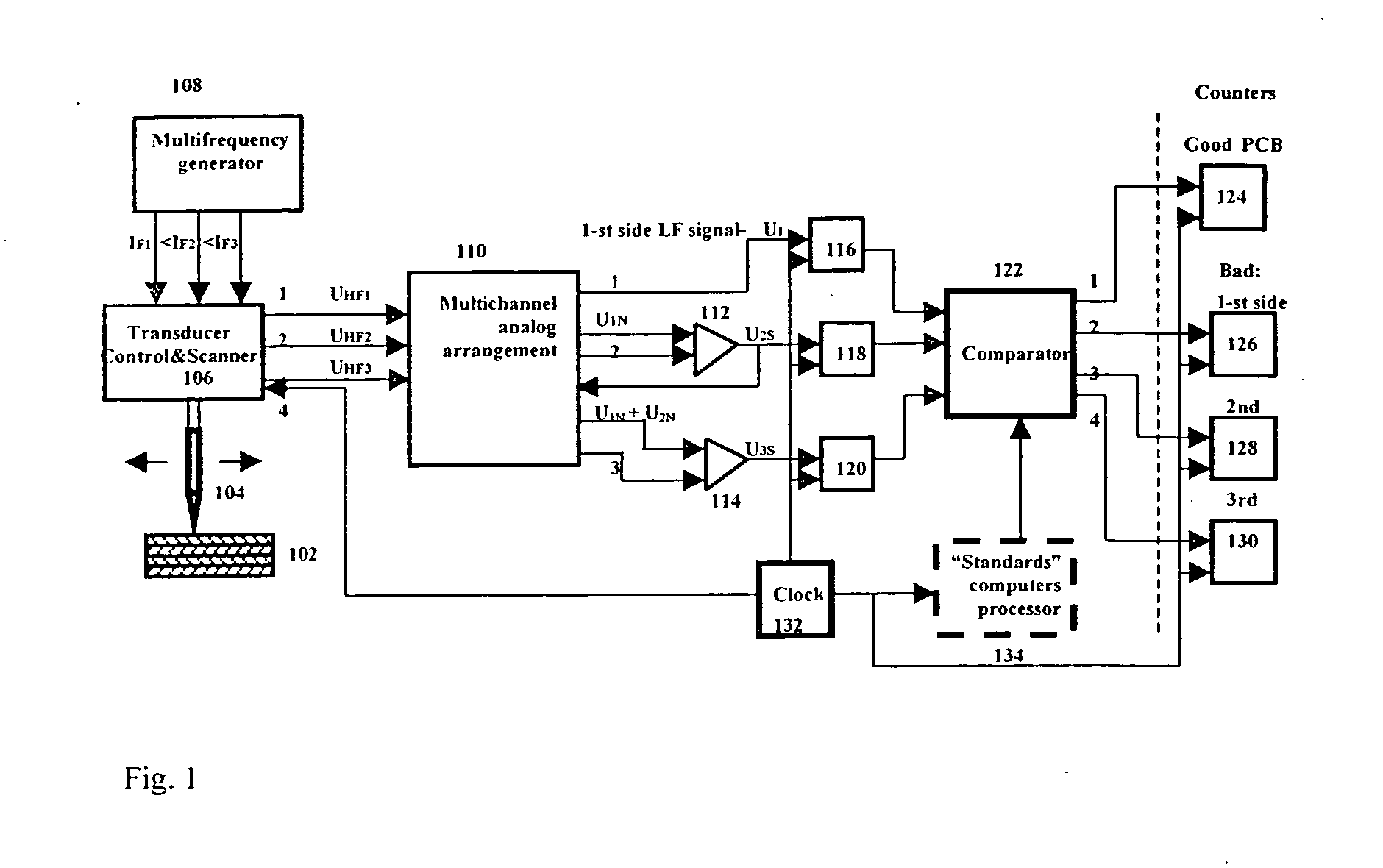

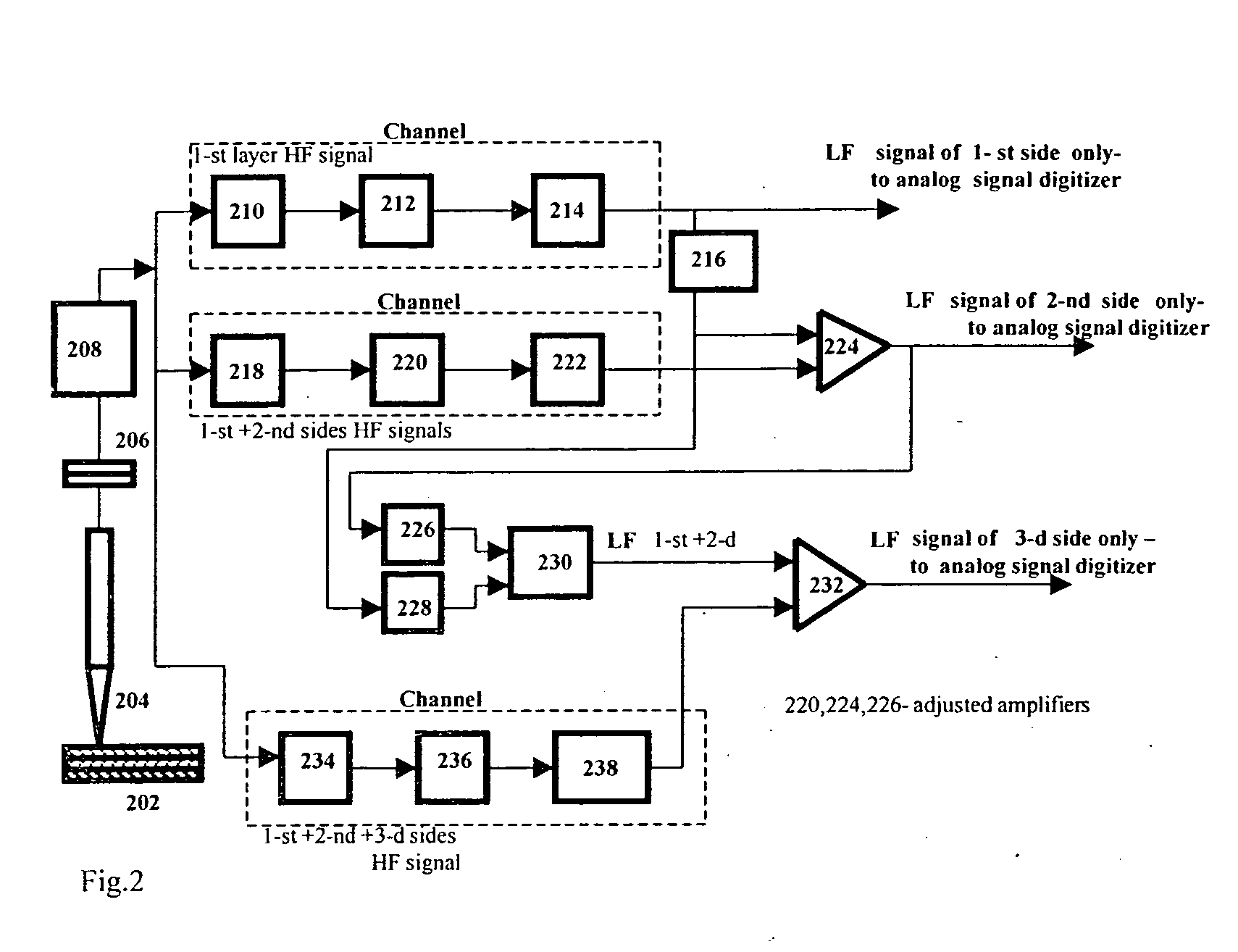

A non-contact printed circuit board (PCB) electromagnetic testing system comprises at least one high resolution transducer operative to induce multi-frequency, multi-amplitude eddy currents in a tested PCB, each such transducer including both a high frequency excitation coil that serves also as a sensing coil and a direct current (DC) bias coil operative to provide an optimal transducer operating regime; a multi-frequency generator for providing AC and DC bias signals to each transducer; and a control mechanism for driving the transducer. Optionally, the system further comprises an external ferrite concentrator that enhances a magnetic field flux focus and depth of focus on the inspected PCB. The multi-frequency, multi-amplitude methods enable three-dimensional mapping of various features in the PCB with both high sensitivity and high resolution in respective operating regimes.

Owner:BILIK YULI +2

Methods and devices for eddy current PCB inspection

InactiveUS20050104585A1Defect correctionQuick testHysteresis curve measurementsMaterial magnetic variablesPrinted circuit boardElectromagnetic testing

A non-contact printed circuit board (PCB) electromagnetic testing system comprises at least one high resolution transducer operative to induce multi-frequency, multi-amplitude eddy currents in a tested PCB, each such transducer including both a high frequency excitation coil that serves also as a sensing coil and a direct current (DC) bias coil operative to provide an optimal transducer operating regime; a multi-frequency generator for providing AC and DC bias signals to each transducer; and a control mechanism for driving the transducer. Optionally, the system further comprises an external ferrite concentrator that enhances a magnetic field flux focus and depth of focus on the inspected PCB. The mutli-frequesncy, multi-amplitude methods enable three-dimensional mapping of various features in the PCB with both high sensitivity and high resolution in respective operating regimes.

Owner:BILIK YULI +2

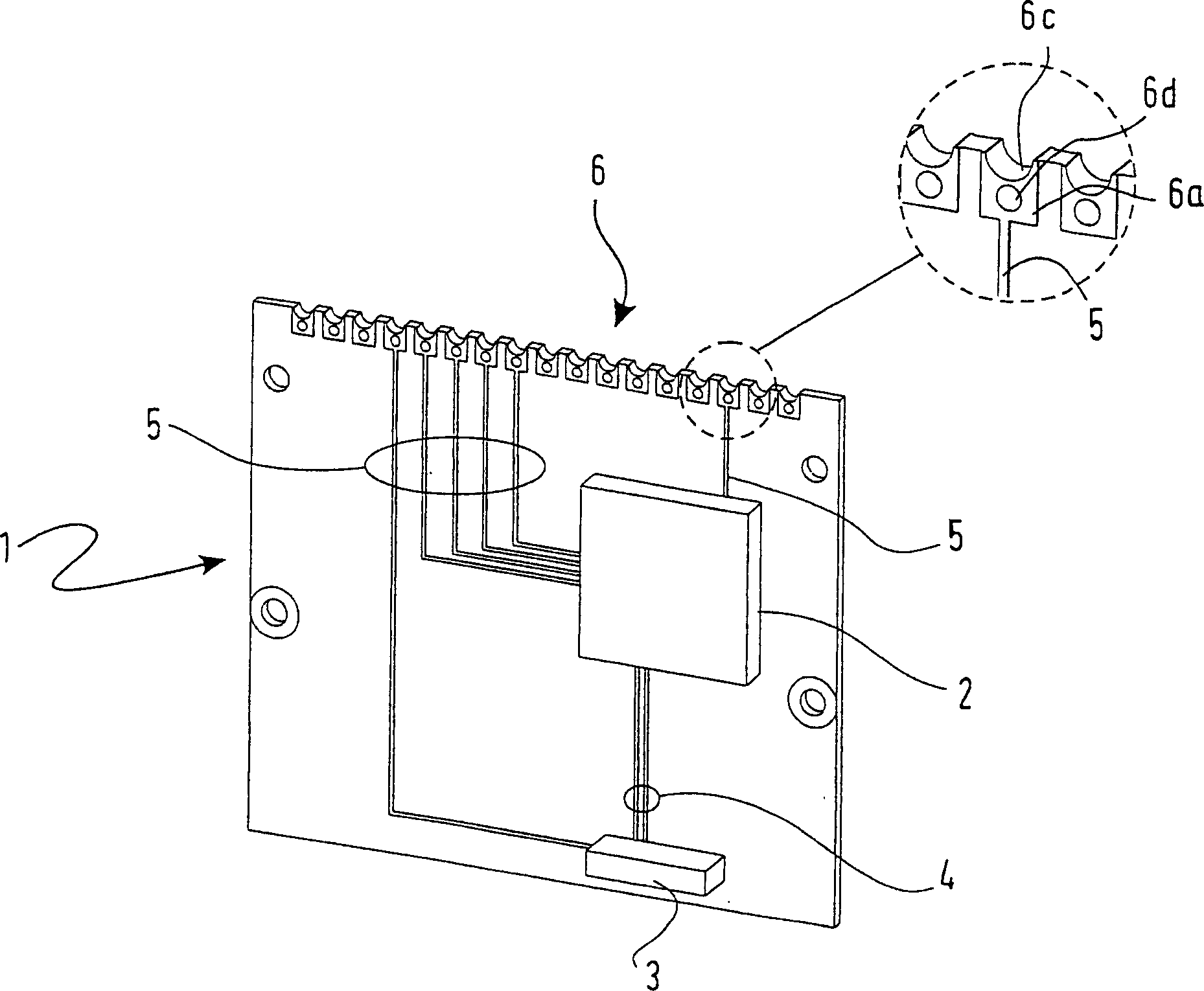

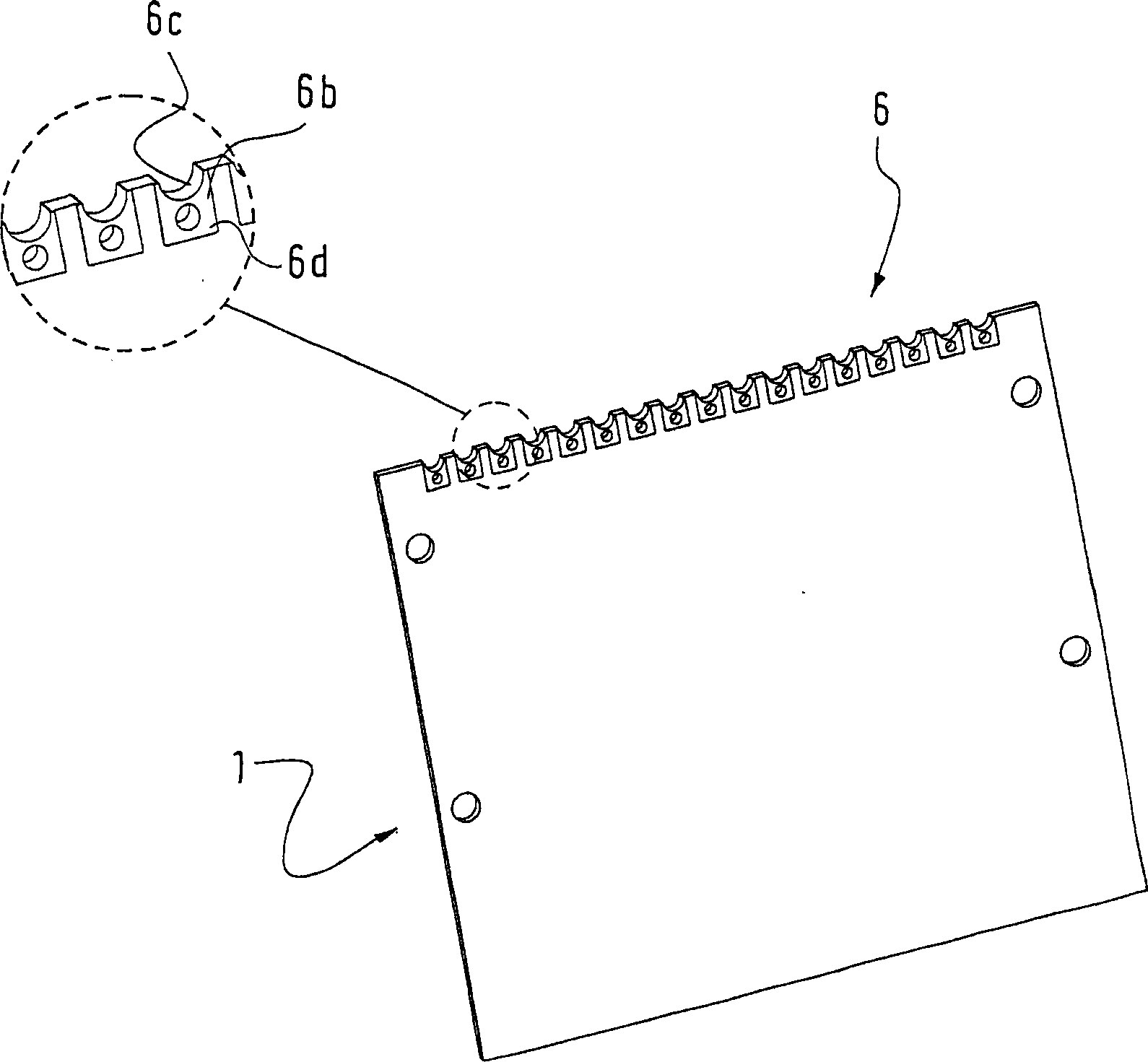

Electrical contacting method

ActiveUS7155815B2Mechanical stabilitySave spacePrinted circuit assemblingLine/current collector detailsElectrical conductorContact print

A method for contacting printed conductors terminating at the edge of a circuit board with printed conductors of a MID component includes: on a panel which includes the circuit board, producing the printed conductors of the circuit board in a layout in which the printed conductors are extended past a partition line which defines the edge of the circuit board; providing the panel with through holes along the partition line in the region of the printed conductors; electroplating through the through holes; isolating the circuit board from the panel; and positioning the circuit board in relation to the MID component and soldering the printed conductors of the circuit board to the printed conductors of the MID component. Rear electrical contacting areas are provided on a back side of the panel near the partition line, and the printed conductors are connected to the rear electrical contacting areas via the through holes.

Owner:NOVAR PLC

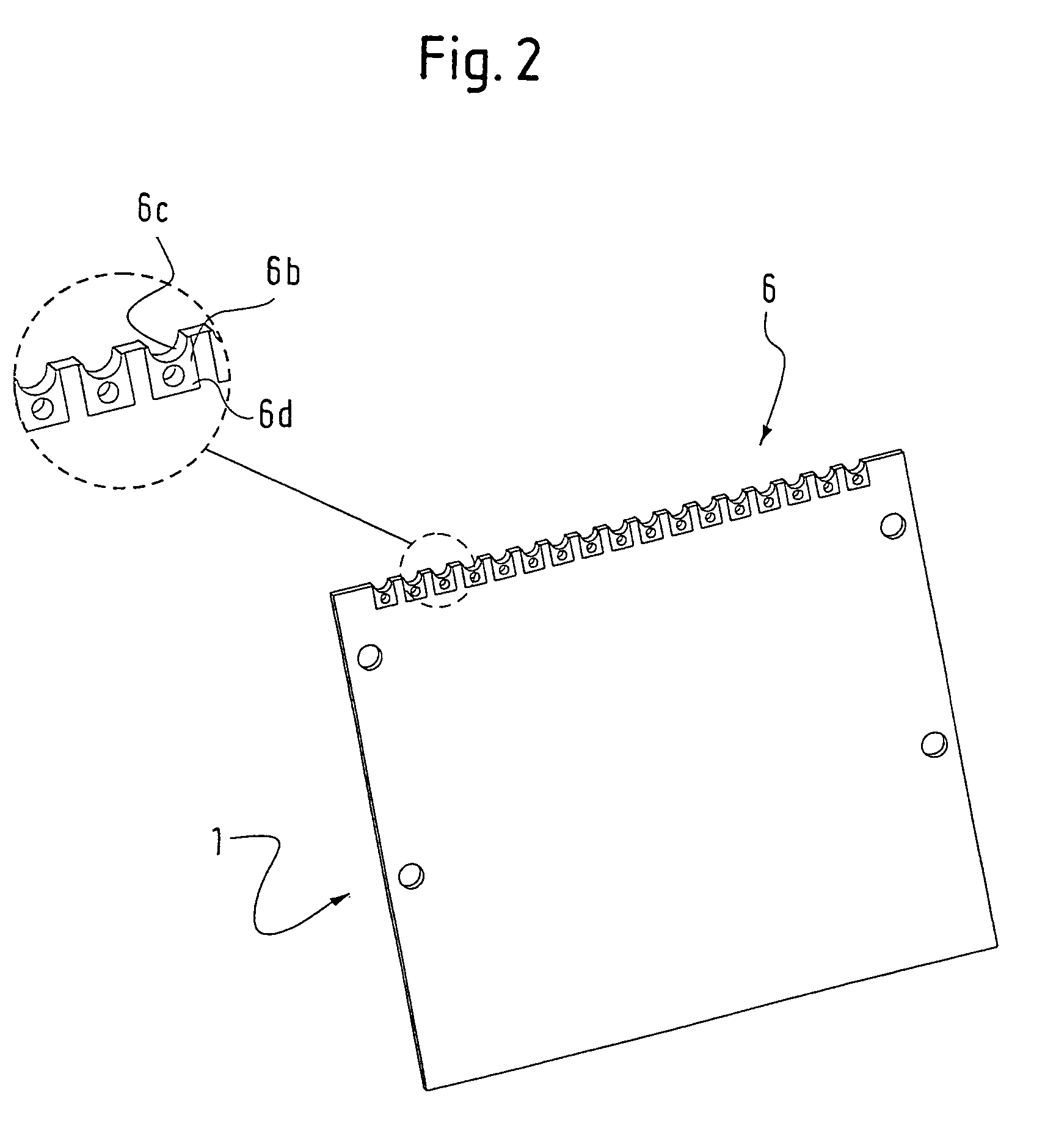

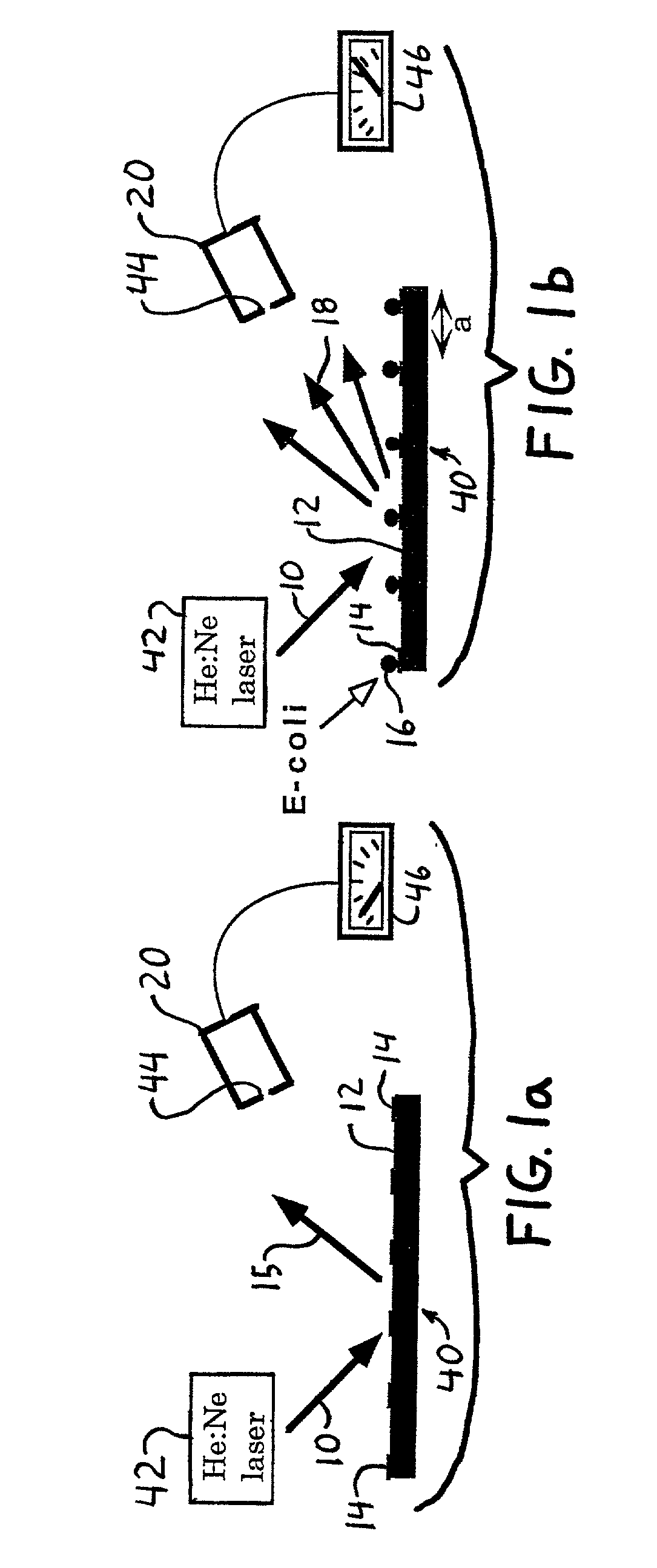

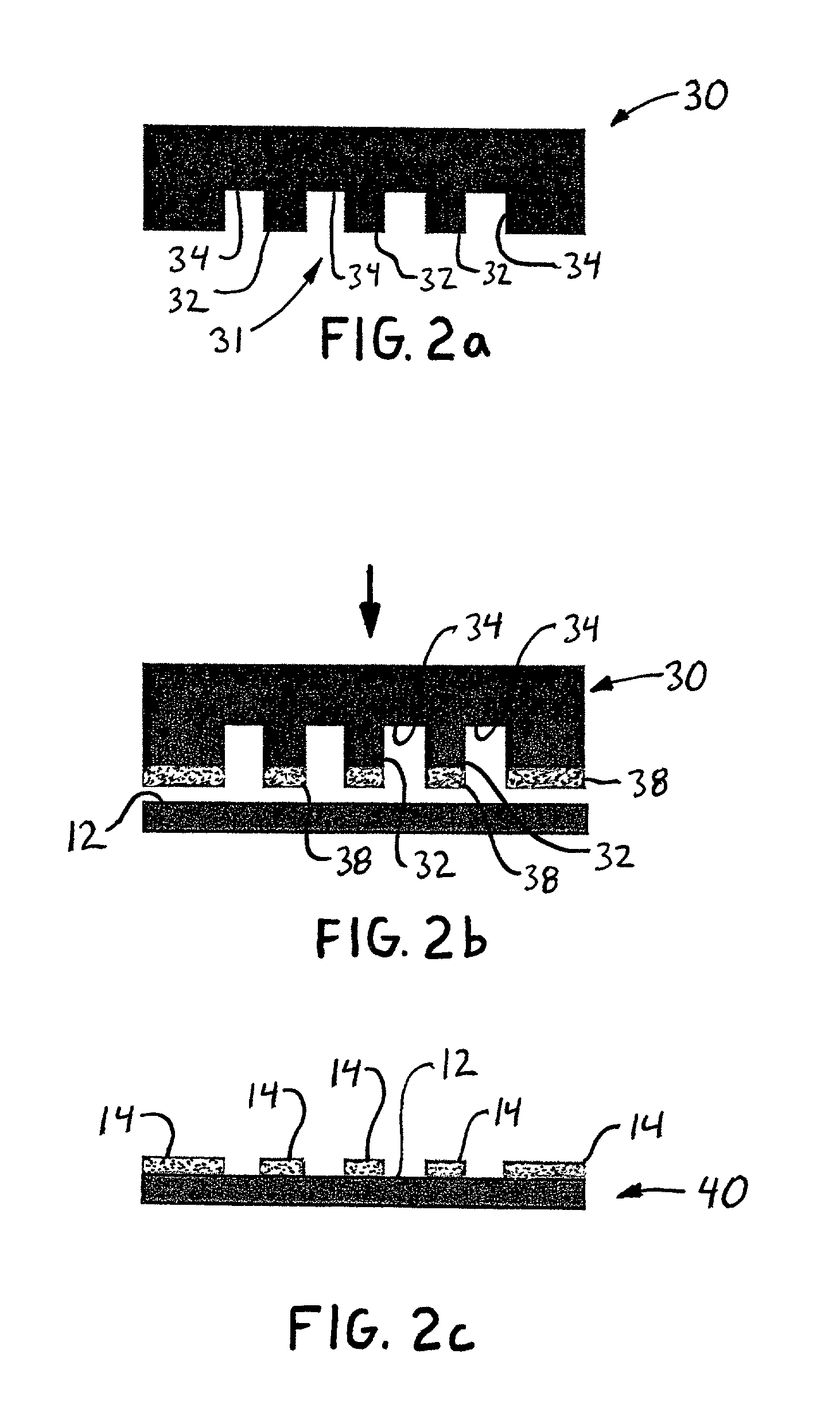

Diffraction-based cell detection using a micro-contact-printed antibody grating

InactiveUS20020037593A1Material nanotechnologyScattering properties measurementsMicrocontact printingEscherichia coli

An optical biological detector is able to bind specific targeted bacterial cells by stamping an antibody grating pattern onto a silicon surface. The antibody grating alone produces insignificant optical diffraction, but upon immunocapture of the targeted cells, the optical phase change produces a diffraction pattern. Micro-contact printing provides a method for placing the antibody grating pattern directly onto a substrate surface with no additional processes or binding chemicals. Antibodies or other biologically active material may be stamped directly onto clean native oxide silicon substrates with no other chemical surface treatments. Direct binding of the antibodies to the silicon occurs in a way that still allows them to function and selectively bind antigen. The performance of the sensor was evaluated by capturing Escherichia coli O157:H7 cells on the antibody-stamped lines and measuring the intensity of the first order diffraction beam resulting from the attachment of cells. The diffraction intensity increases in proportion to the cell density bound on the surface.

Owner:CORNELL RES FOUNDATION INC

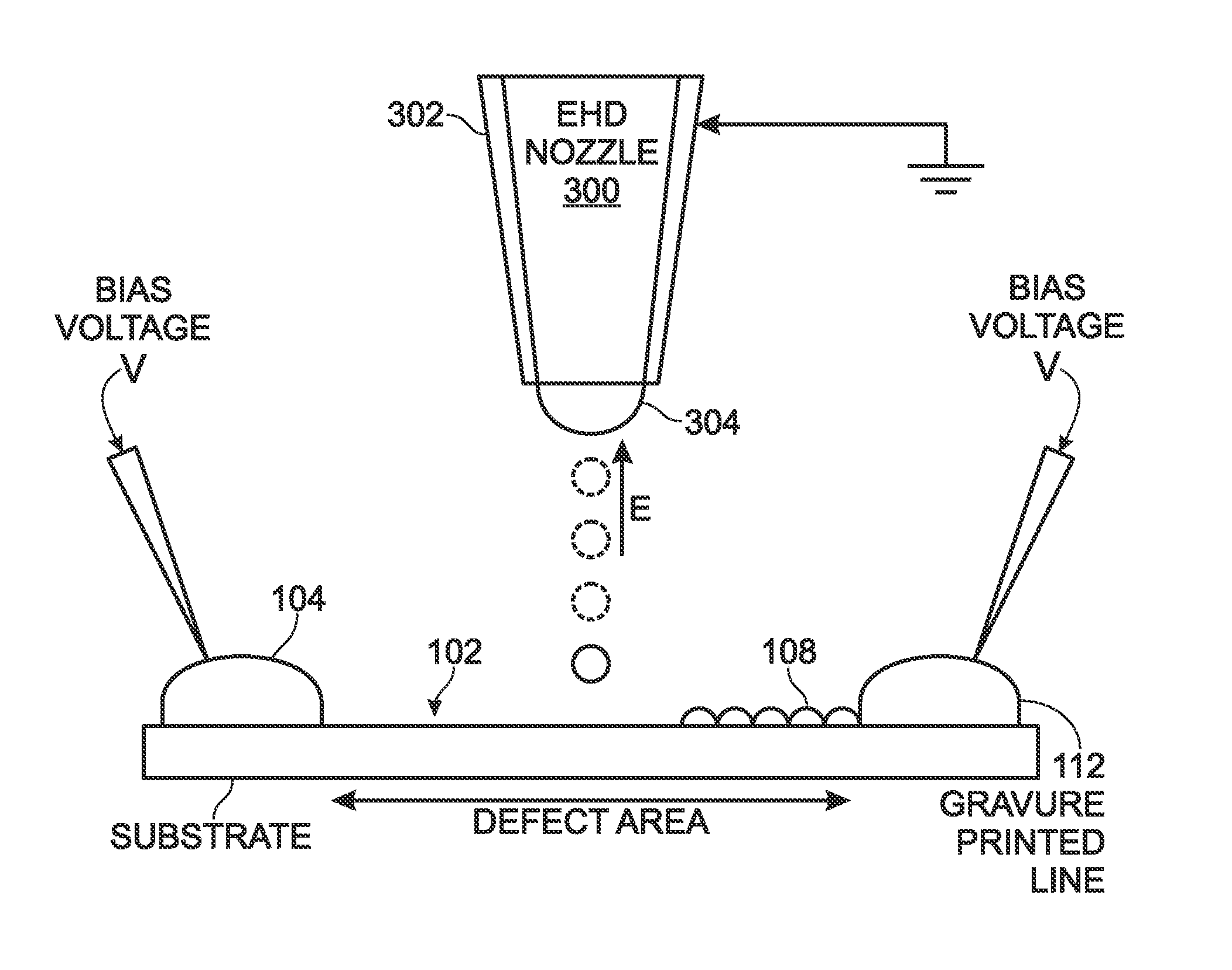

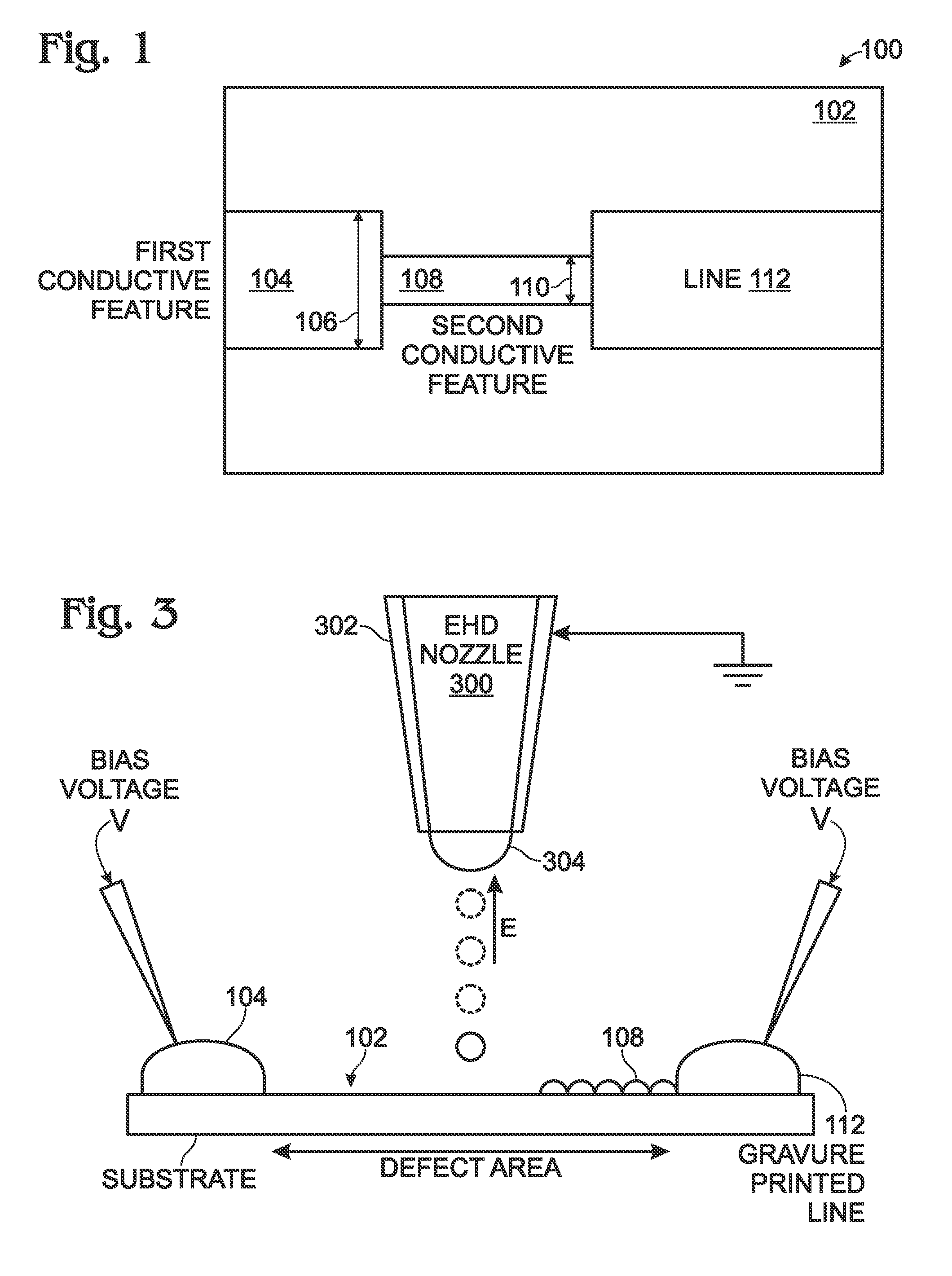

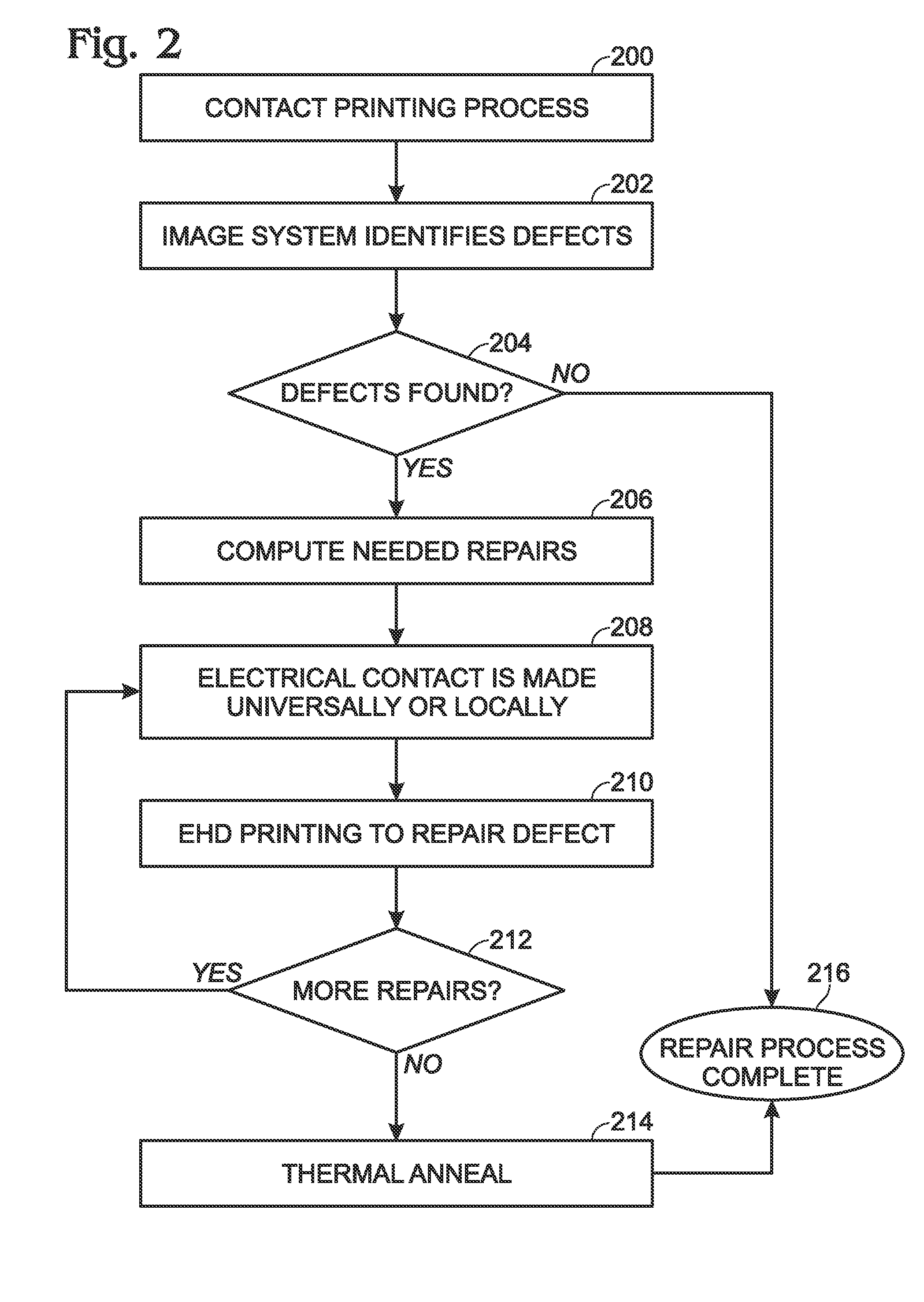

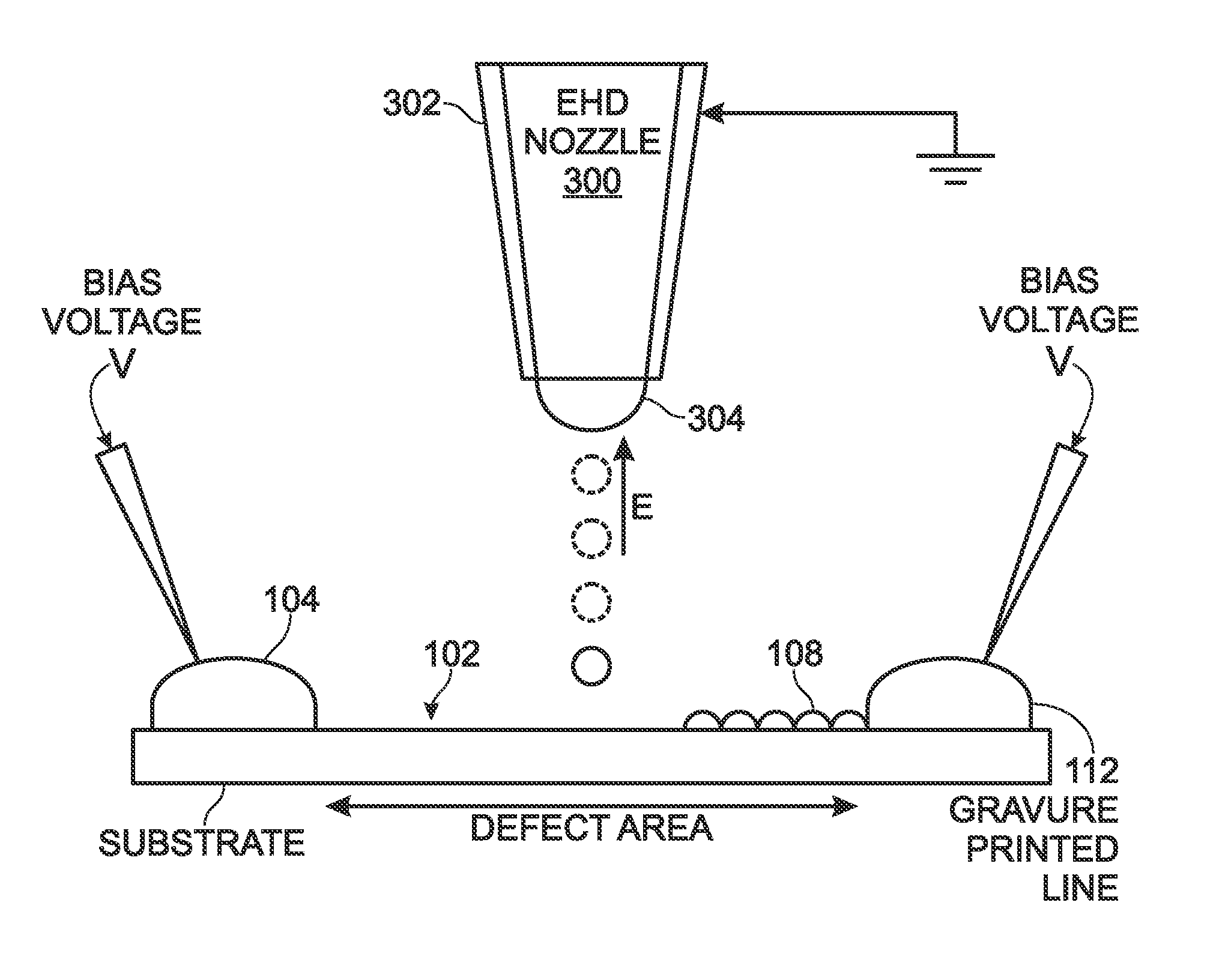

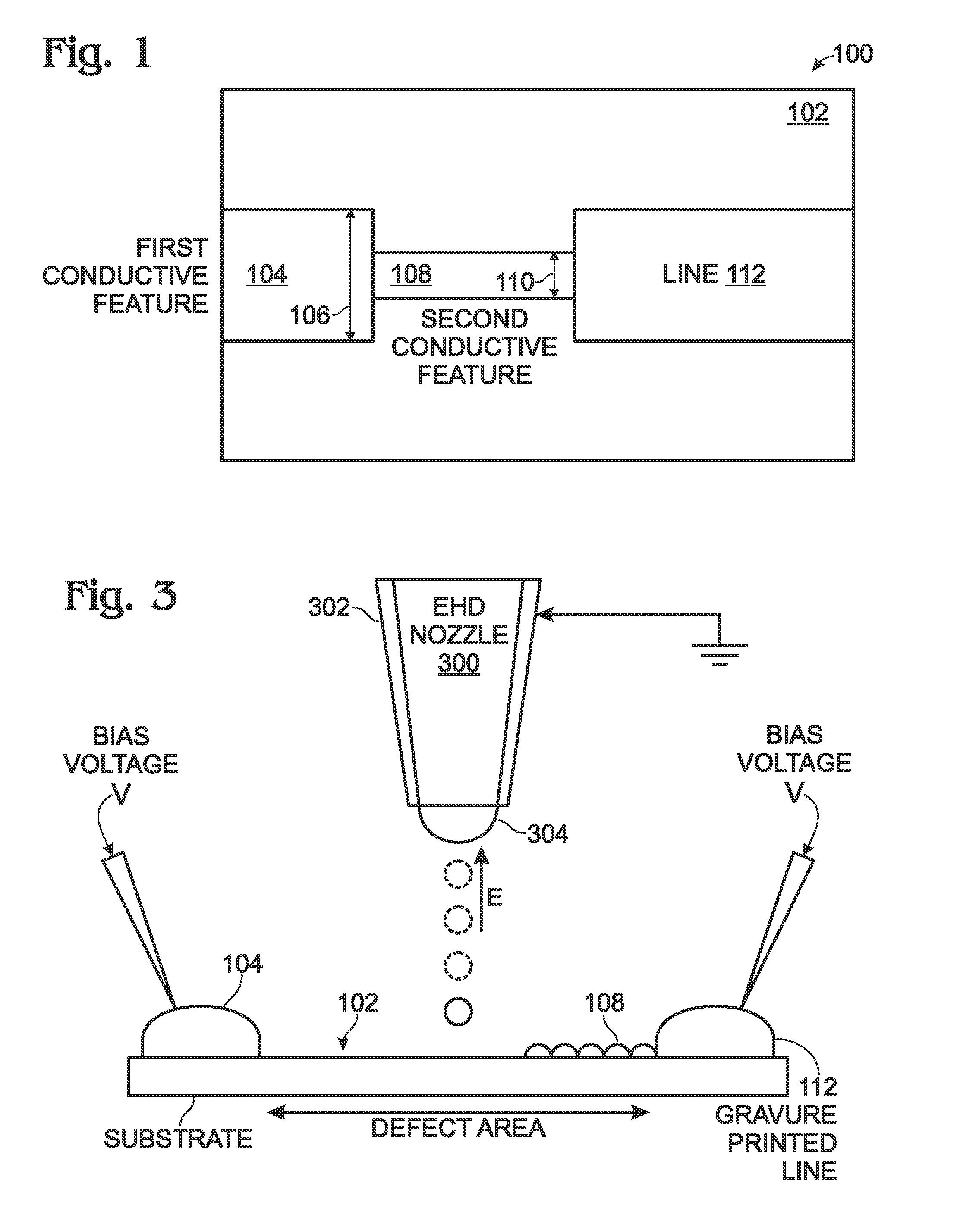

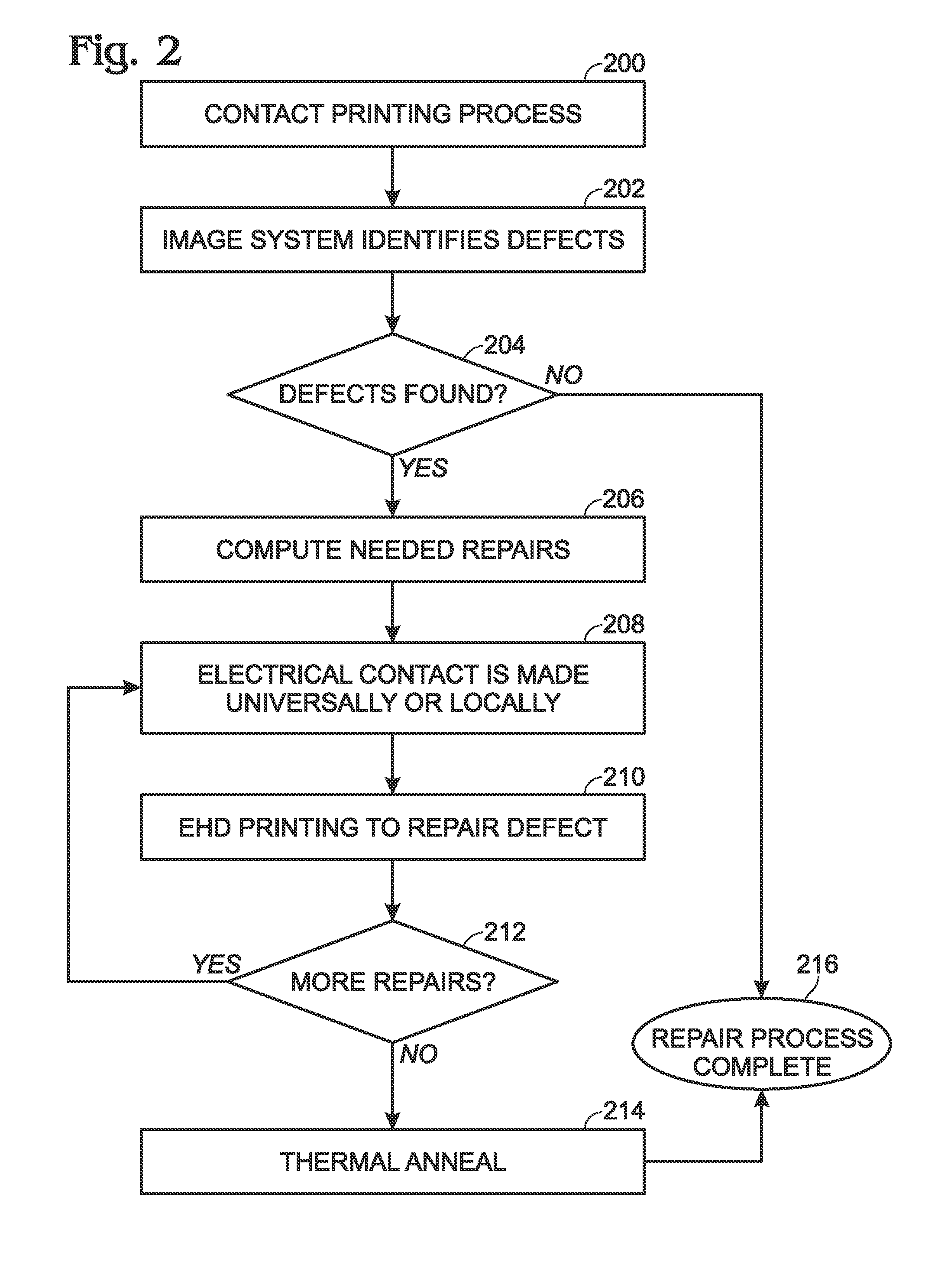

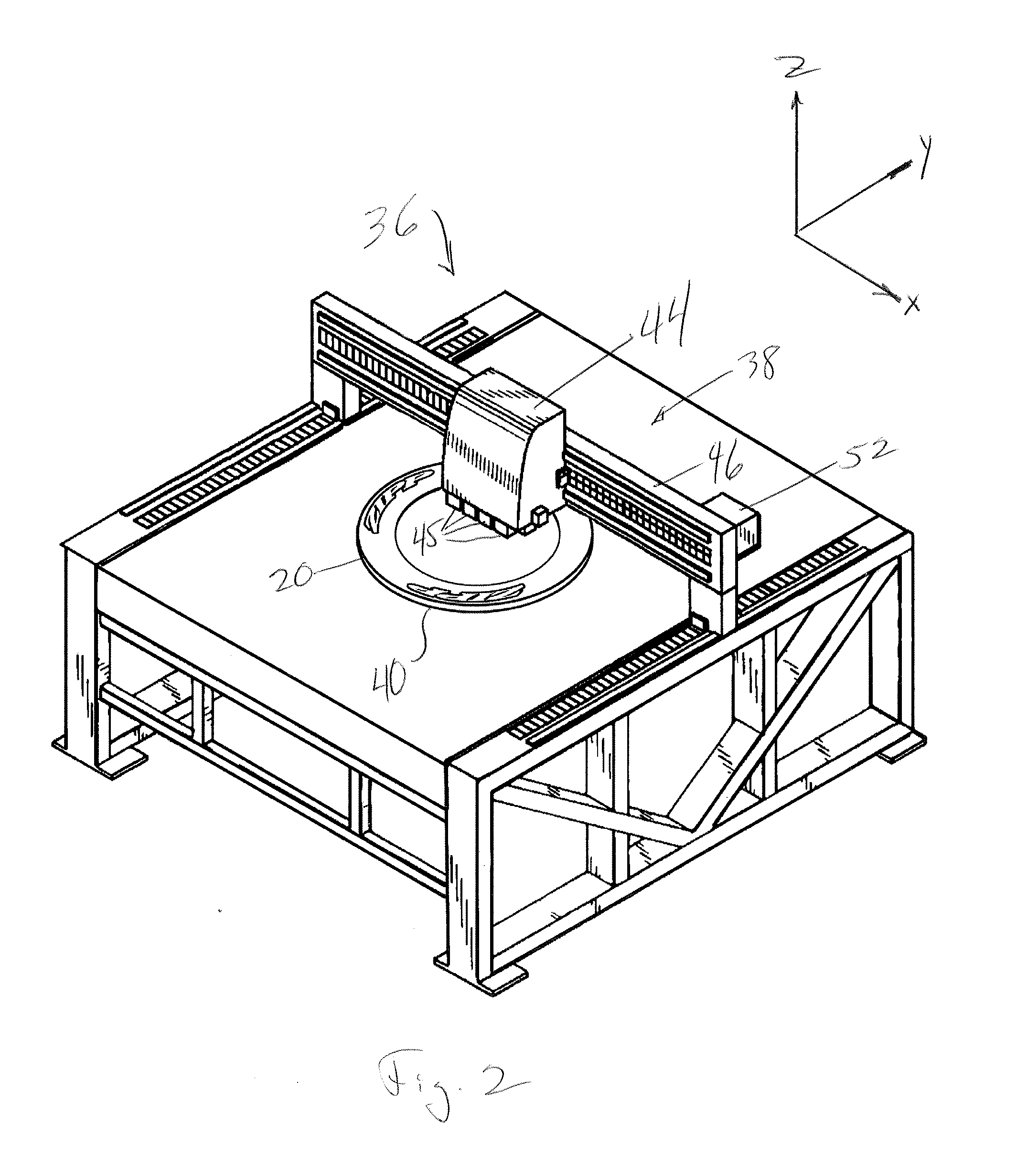

Electrohydrodynamic (EHD) printing for the defect repair of contact printed circuits

ActiveUS9198299B2Reduce discontinuityConductive pattern formationPrinted circuits repair/correctingEngineeringContact print

A method is provided for repairing defects in a contact printed circuit. The method provides a substrate with a contact printed circuit formed on a substrate top surface. After detecting a discontinuity in a printed circuit feature, a bias voltage is applied to at least one of a first region of the printed circuit feature or a second region of the printed circuit feature. The bias voltage may also be applied to both the first and second regions. An electric field is formed between the bias voltage and an ink delivery nozzle having a voltage potential less than the bias voltage. Conductive ink is attracted into the electric field from the ink delivery nozzle. Conductive ink is printed on the discontinuity, forming a conductive printed bridge. Typically, the ink delivery nozzle is an electrohydrodynamic (EHD) printing nozzle.

Owner:SHARP KK

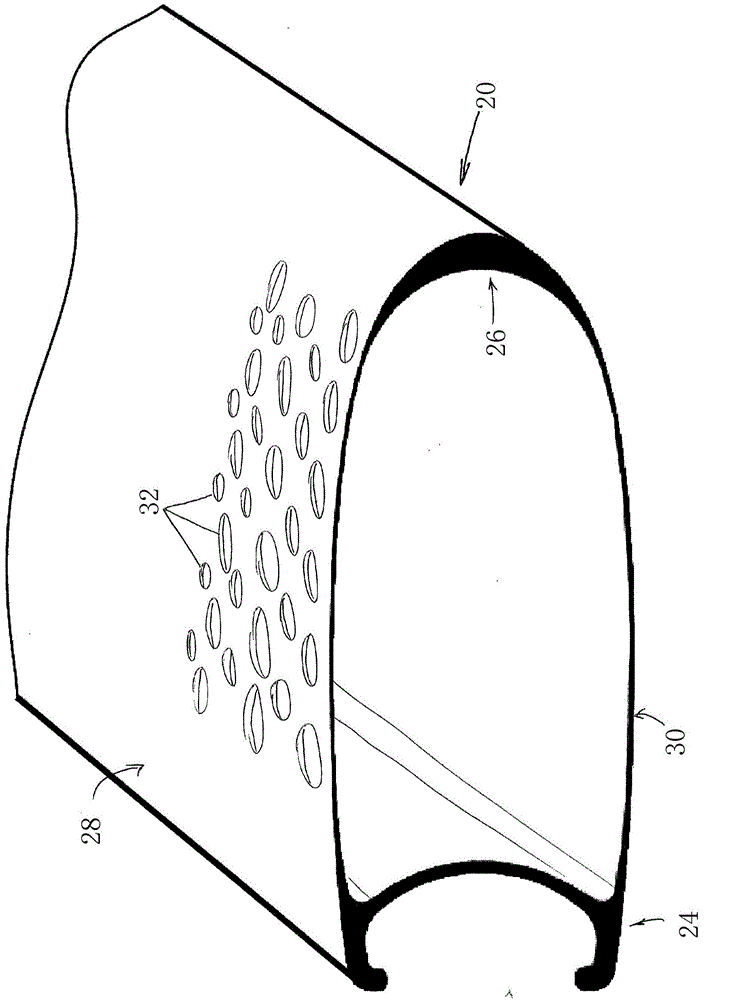

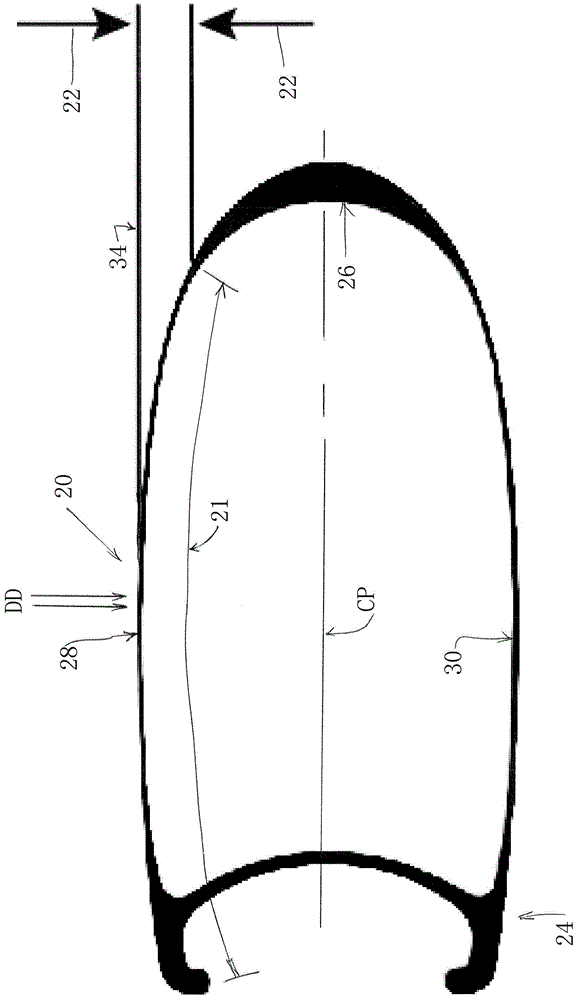

Vehicle rim with print graphics and methods of making

The present invention relates to a vehicle rim with print graphics and methods of making. A rim is provided for a bicycle wheel having an axis about which the wheel rotates and a center plane normal to the axis, including a tire-engaging portion located at an outer perimeter of the rim. An inner perimeter portion is located radially inwardly from the tire-engaging portion. The rim includes a first sidewall and a second sidewall spaced from the first sidewall. The first and second sidewalls extend between the tire-engaging and inner perimeter portions. An image receiving area is located on each of the first and second sidewalls and a non-contact printed graphic is disposed on at least some of the image receiving area.

Owner:SRAM CORPORATION

Electrohydrodynamic (EHD) Printing for the Defect Repair of Contact Printed Circuits

ActiveUS20140158399A1Fix bugsReduce discontinuityElectrolysis componentsVolume/mass flow measurementPrinting inkContact print

A method is provided for repairing defects in a contact printed circuit. The method provides a substrate with a contact printed circuit formed on a substrate top surface. After detecting a discontinuity in a printed circuit feature, a bias voltage is applying to at least one of a first region of the printed circuit feature or a second region of the printed circuit feature. The bias voltage may also be applied to both the first and second regions. An electric field is formed between the bias voltage and an ink delivery nozzle having a voltage potential less than the bias voltage. Conductive ink is attracted into the electric field from the ink delivery nozzle. Conductive is printed ink on the discontinuity, forming a conductive printed bridge. Typically, the ink delivery nozzle is an electrohydrodynamic (EHD) printing nozzle.

Owner:SHARP KK

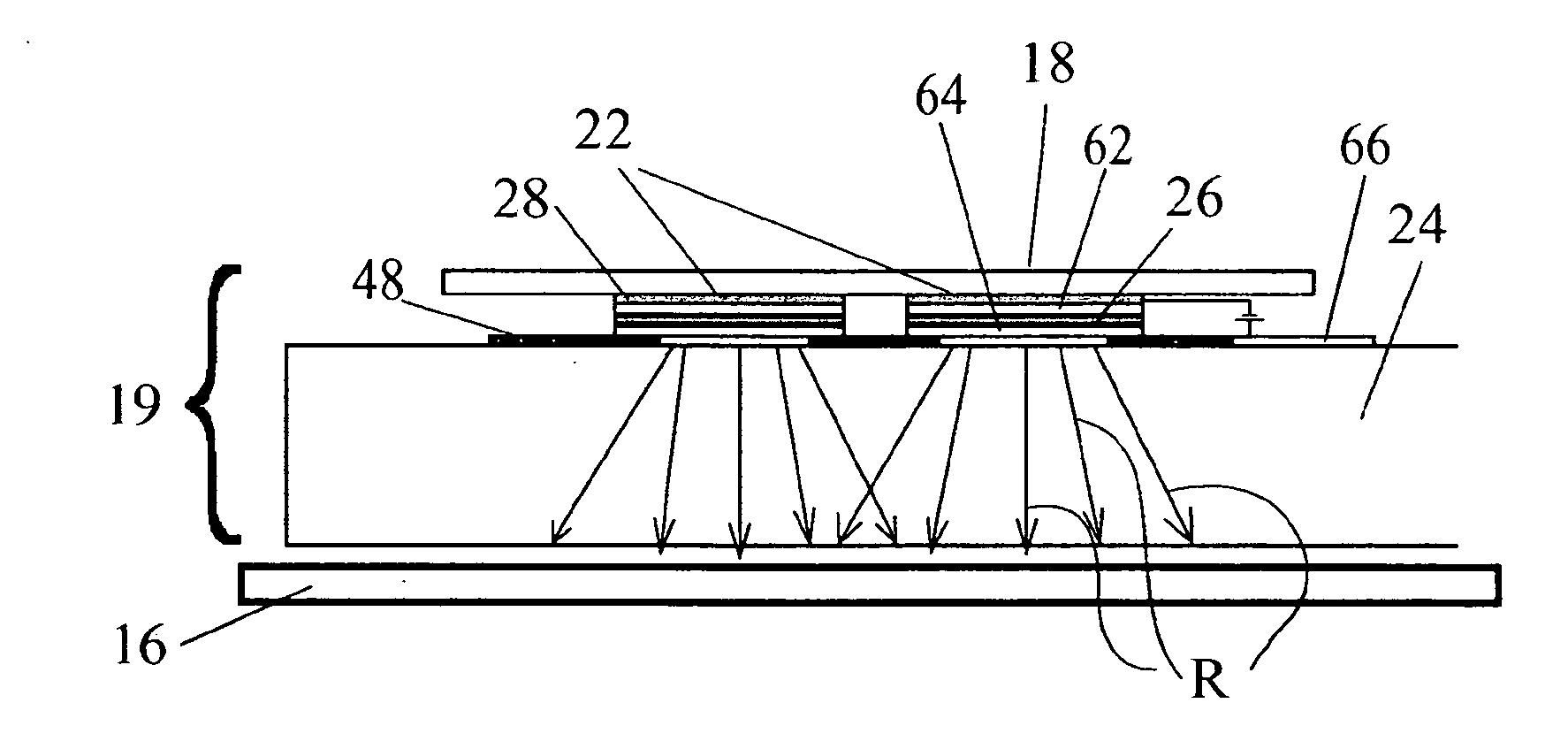

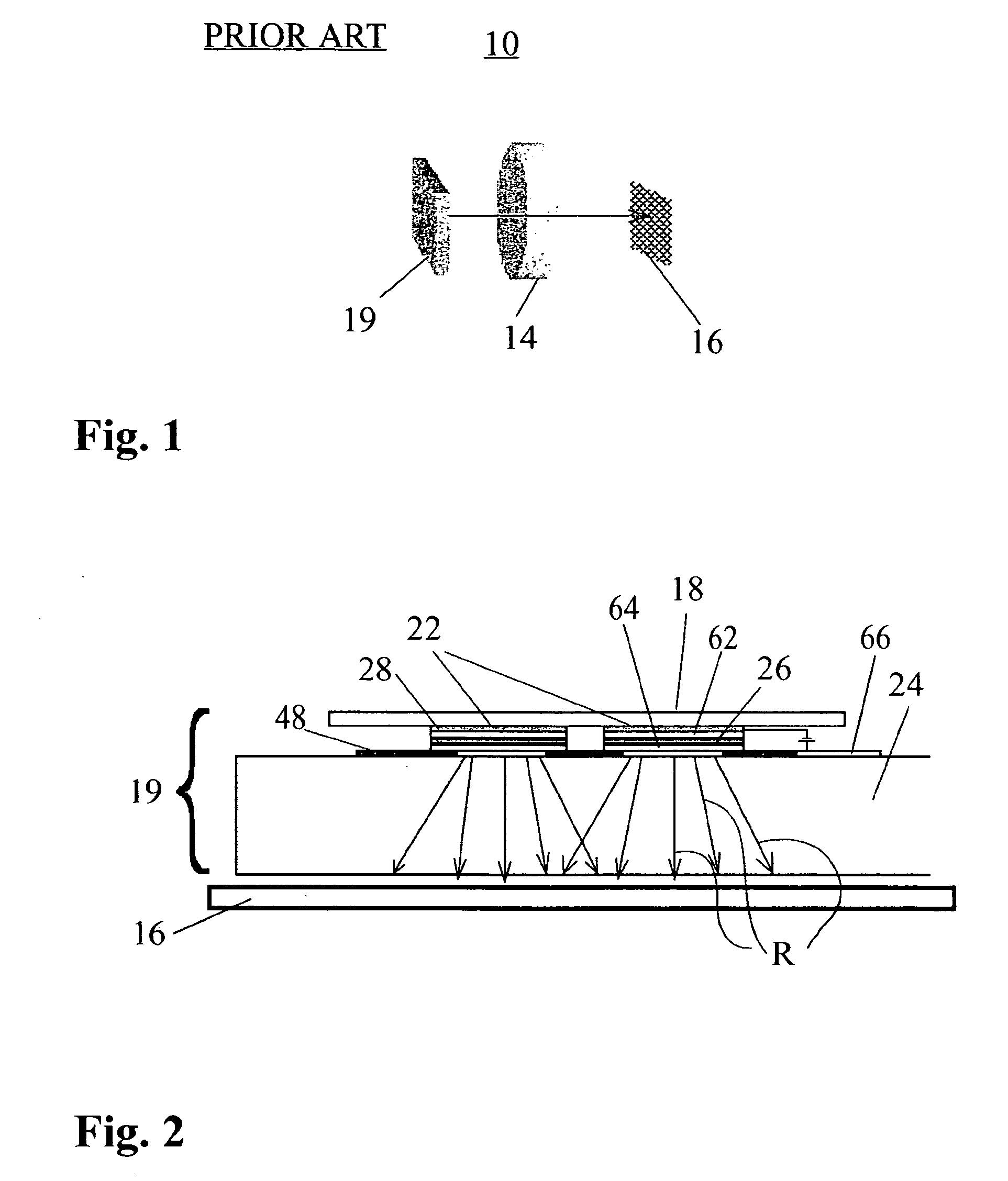

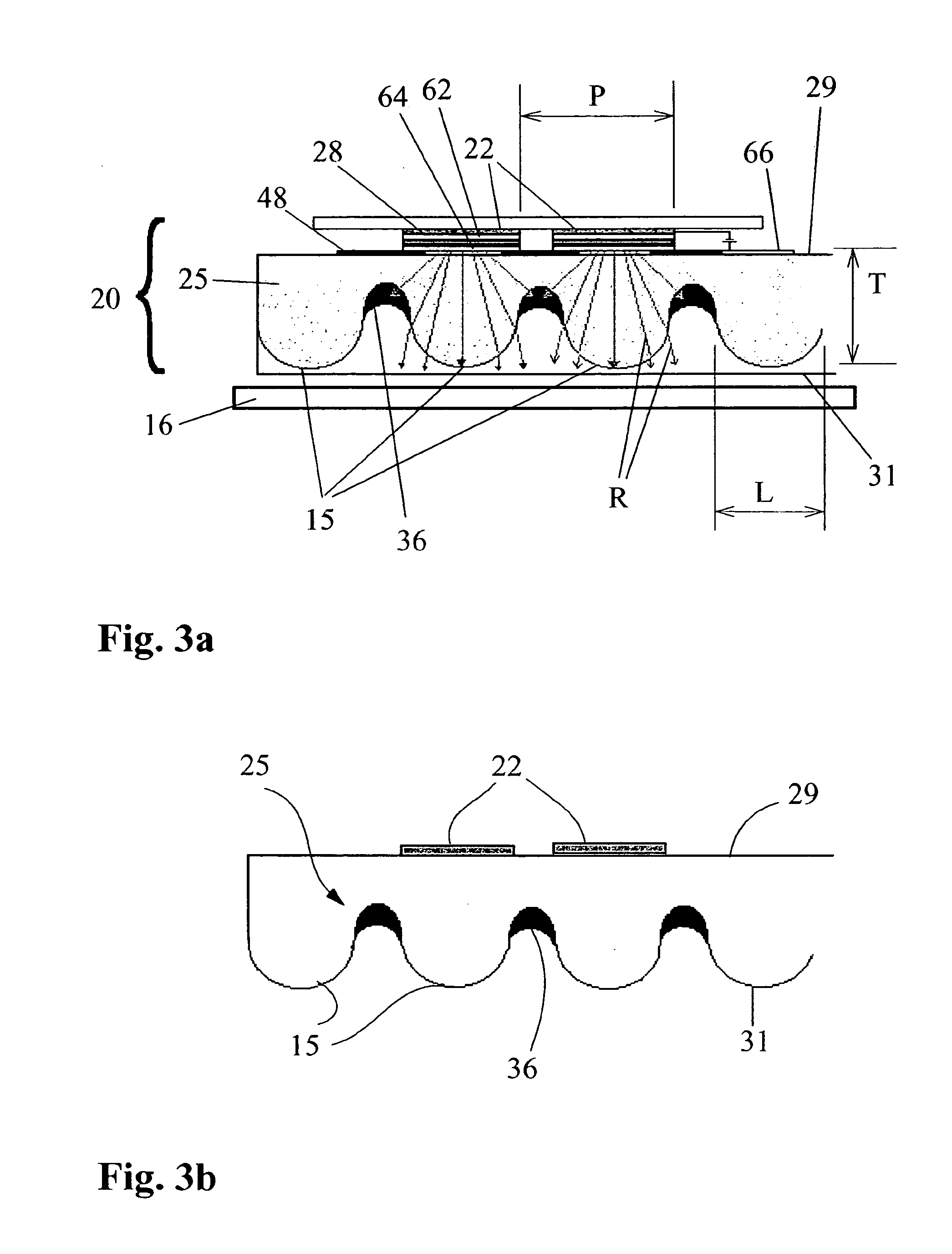

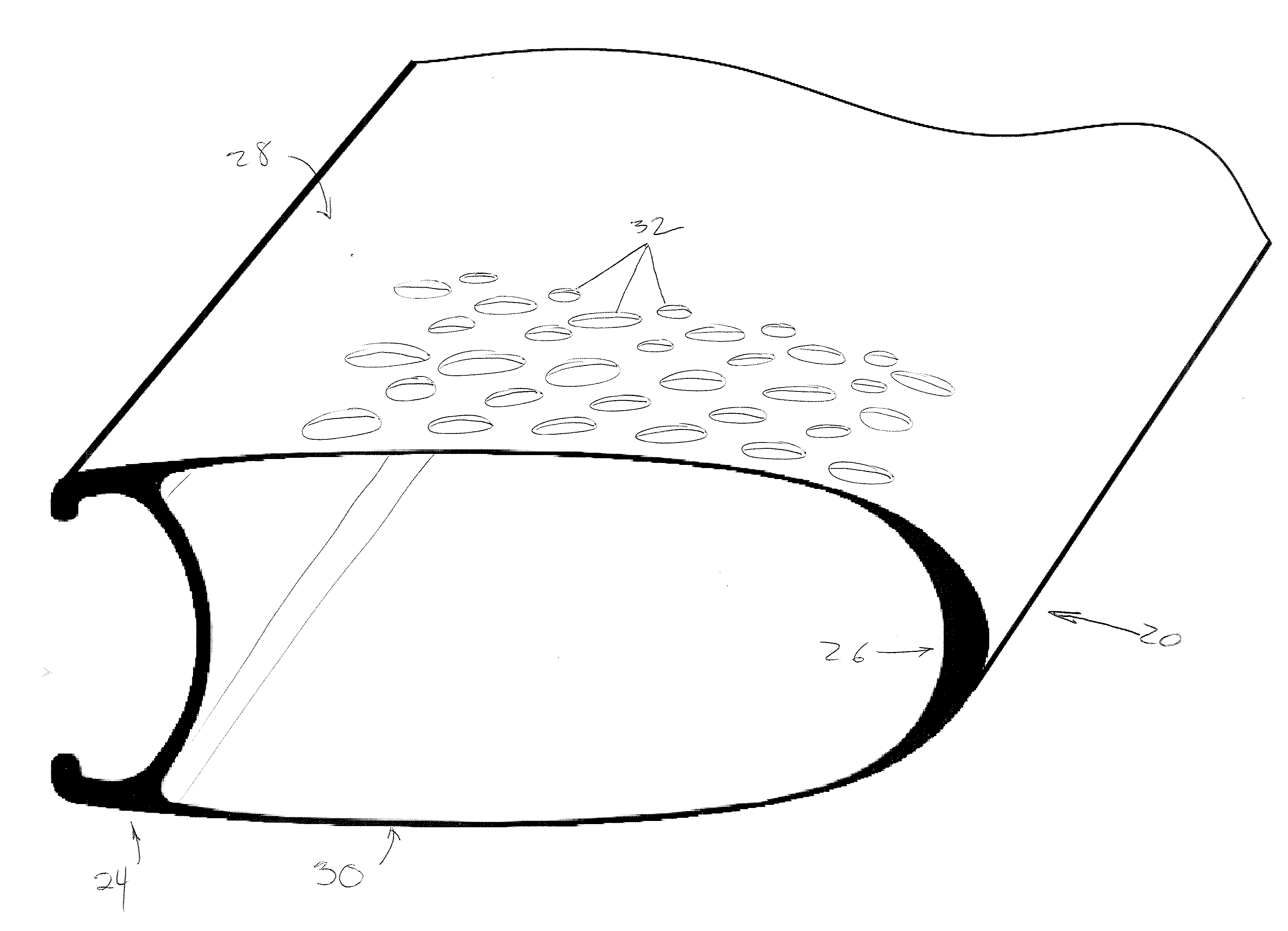

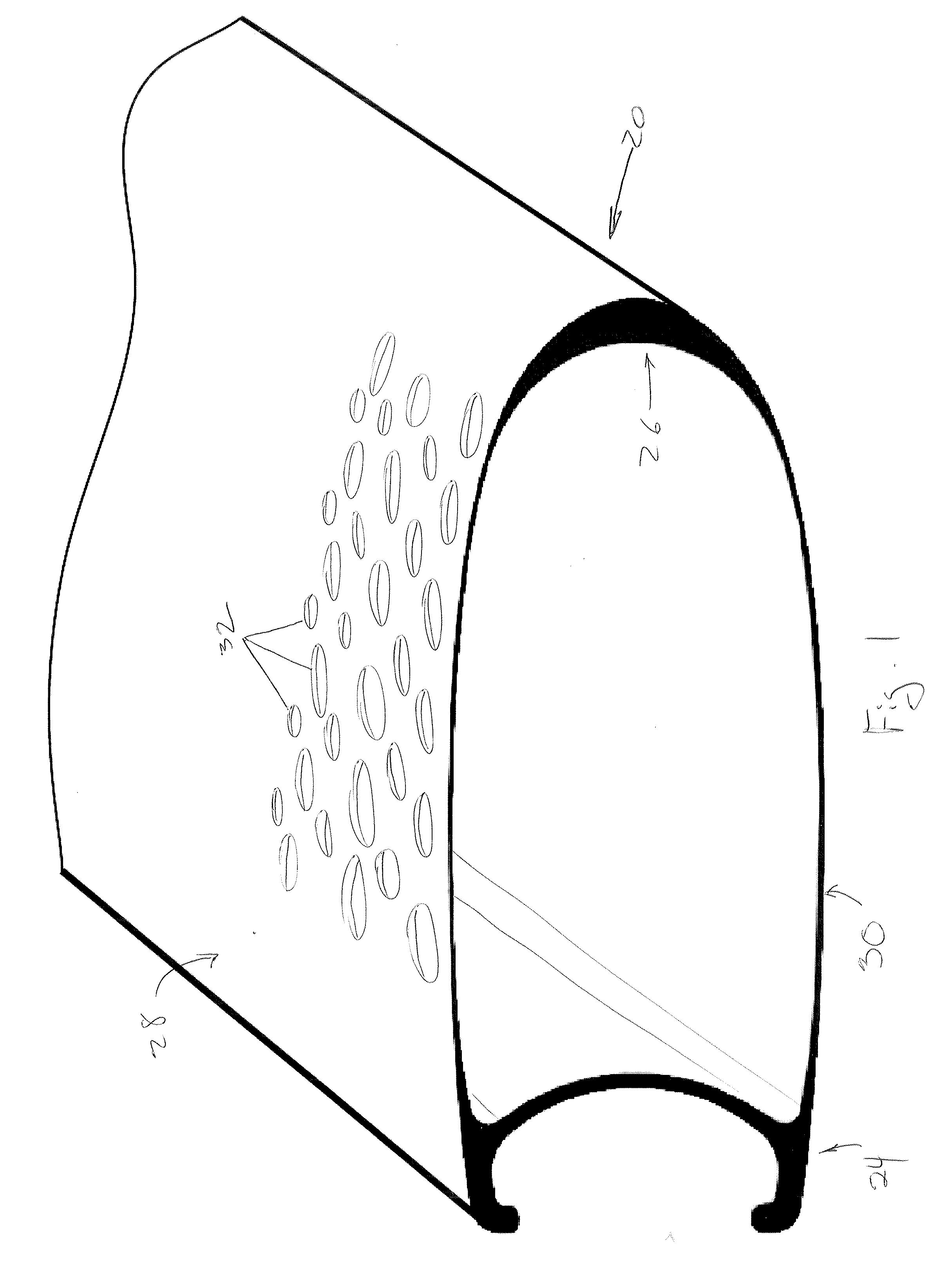

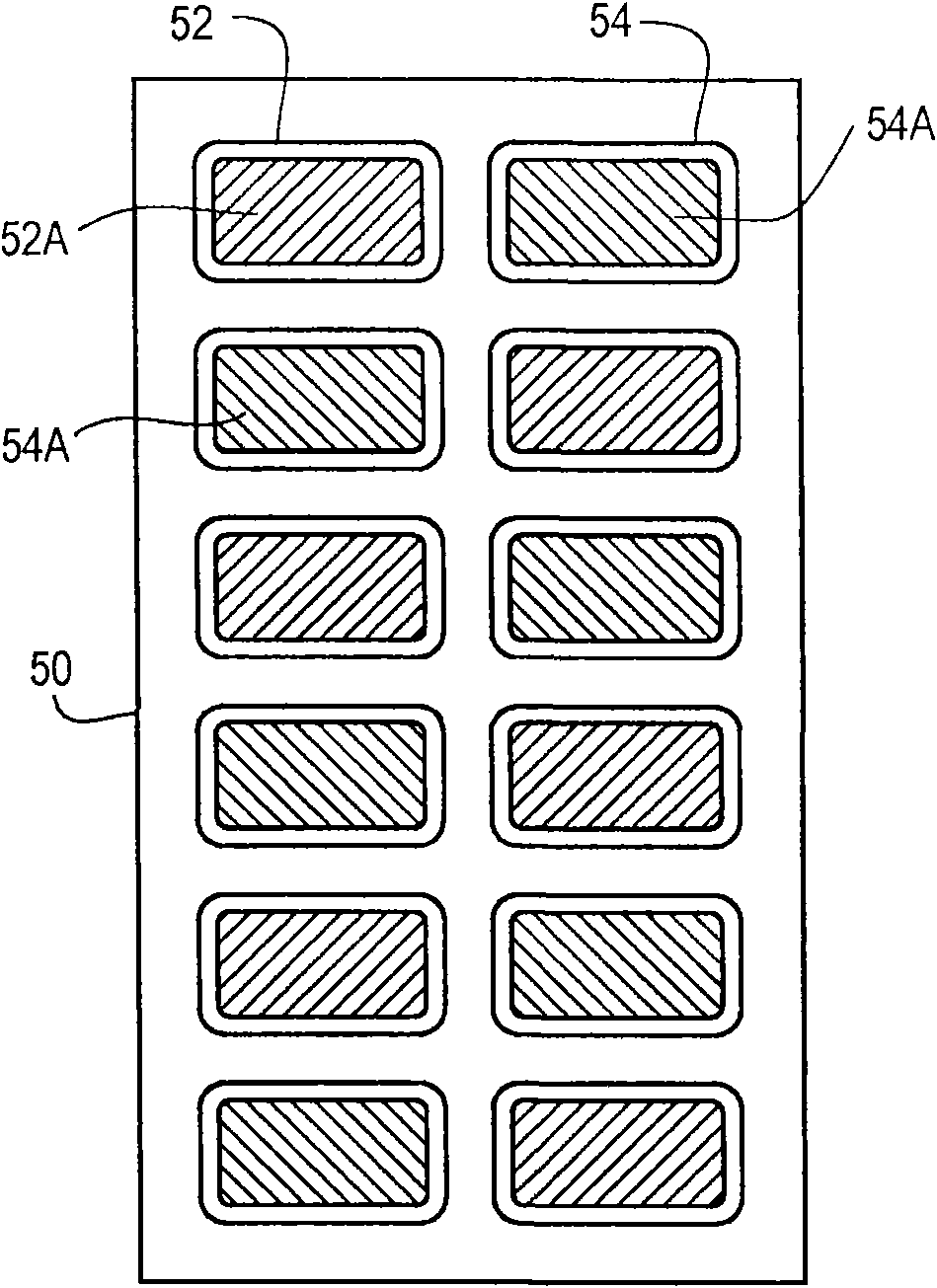

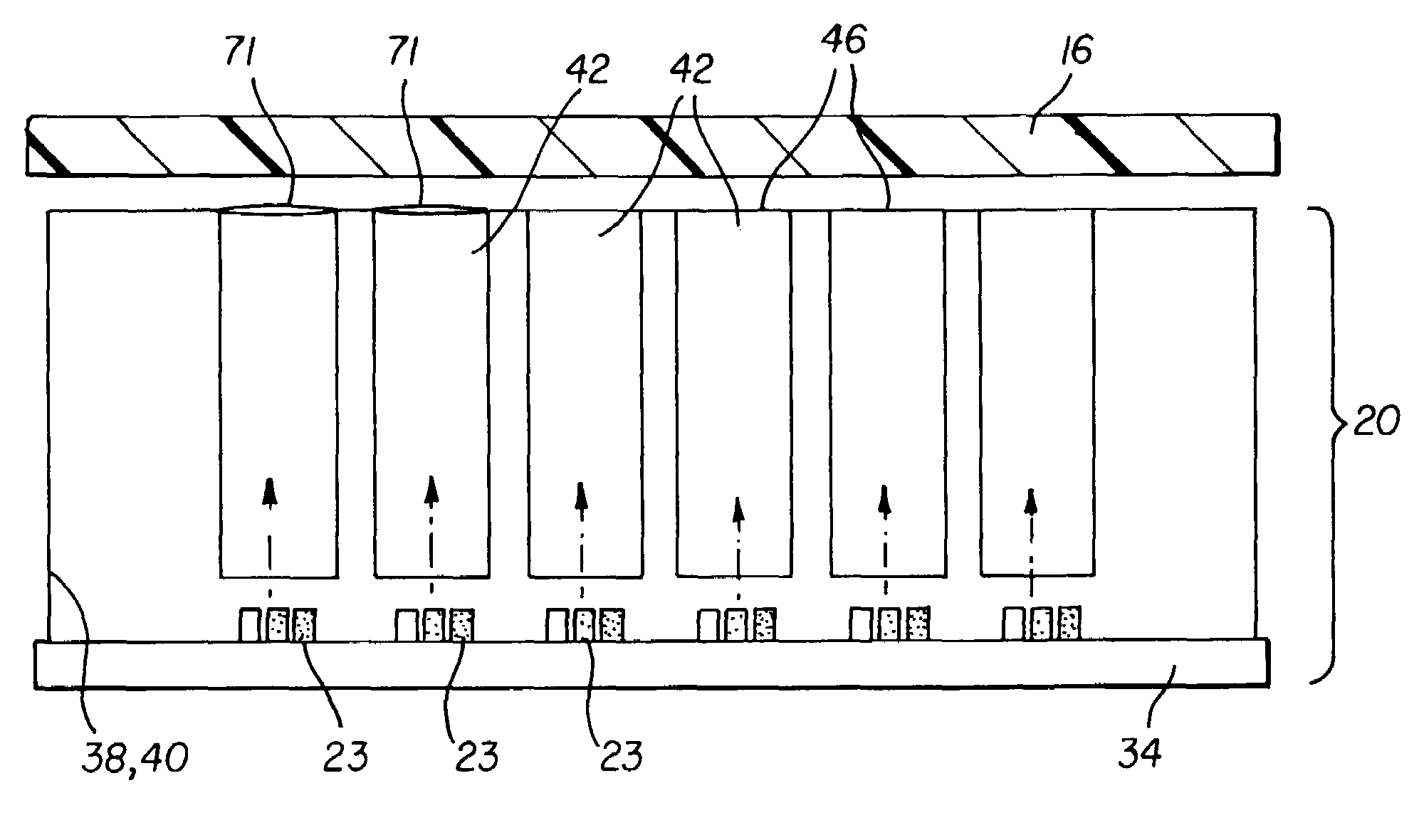

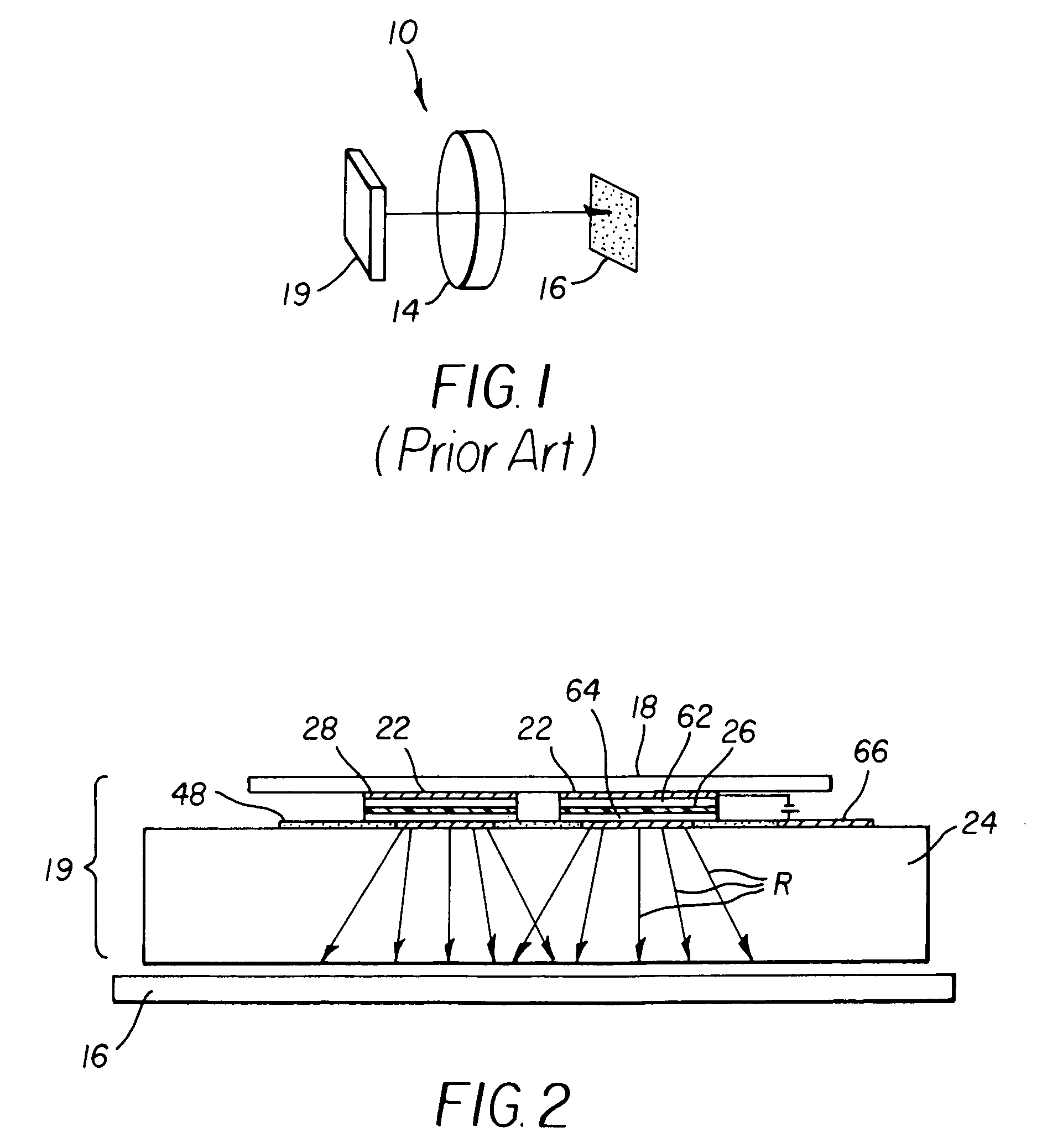

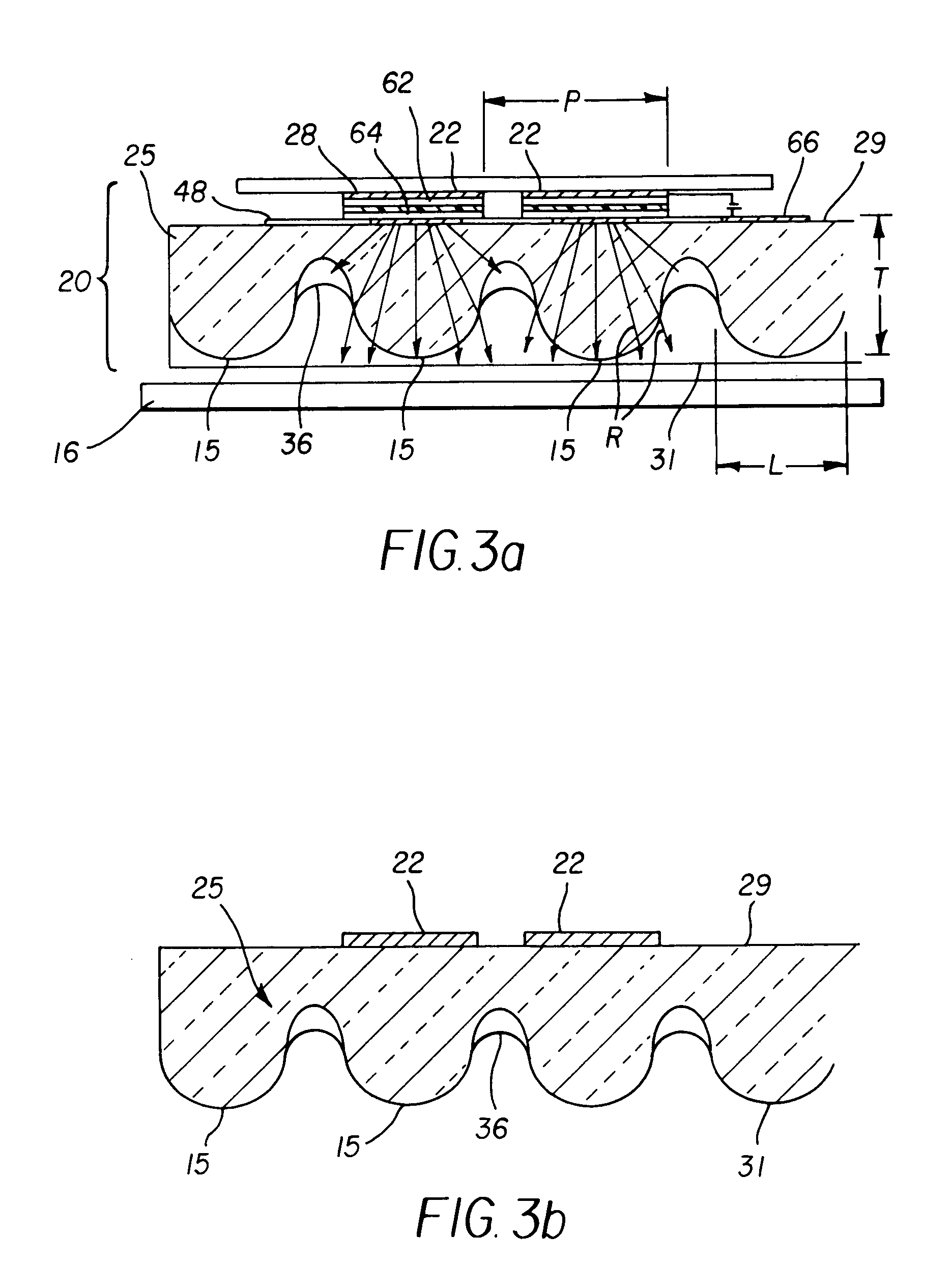

Printer using direct-coupled emissive array

InactiveUS20050243161A1Easy to useImprove sharpnessSolid-state devicesSemiconductor/solid-state device manufacturingFiberDigital data

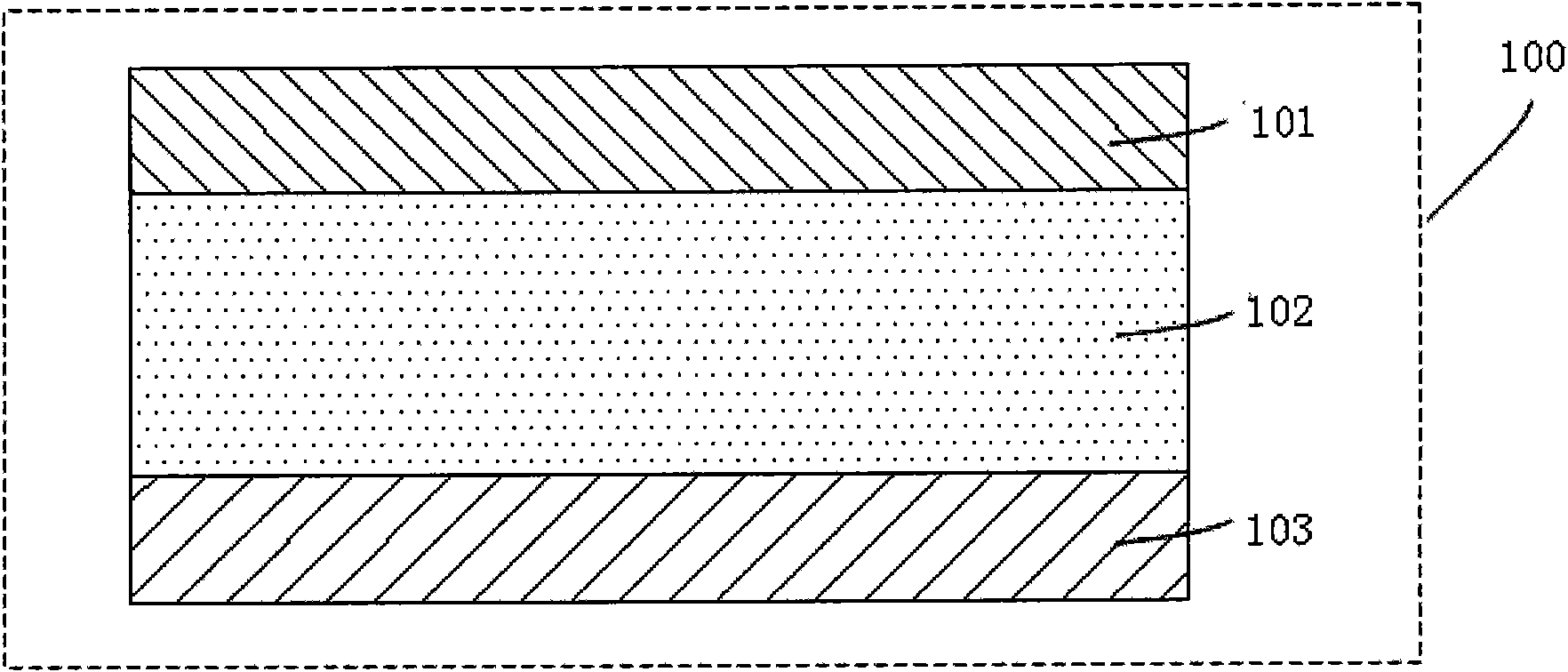

A contact printing apparatus (100), using a direct-coupled emissive array (20) of individual light emitting pixels (22), forms an image from digital data onto a photosensitive medium (16). The direct-coupled emissive array (20) is fabricated on an optically coupled substrate (25) that provides light-directing elements, such as a lenslet array or fiber optic faceplate (40) for directing light from emitter pixels (22) to print pixel (71) locations on the photosensitive medium (16).

Owner:EASTMAN KODAK CO

Vehicle rim with print graphics and methods of making

InactiveUS20140265538A1Reduce weightInherent efficiencyRimsDecorative surface effectsGraphicsEngineering

Owner:SRAM CORPORATION

Process for contact printing of patterns of electroless deposition catalyst

InactiveUS20060236884A1High resolutionLow costLiquid/solution decomposition chemical coatingConductive pattern formationElectroless depositionContact print

A process comprising the step of: contact printing a pattern of an electroless deposition catalyst via a hydrophilic phase to a receiving medium, wherein said electroless deposition catalyst requires no activation prior to electroless deposition.

Owner:AGFA GEVAERT AG

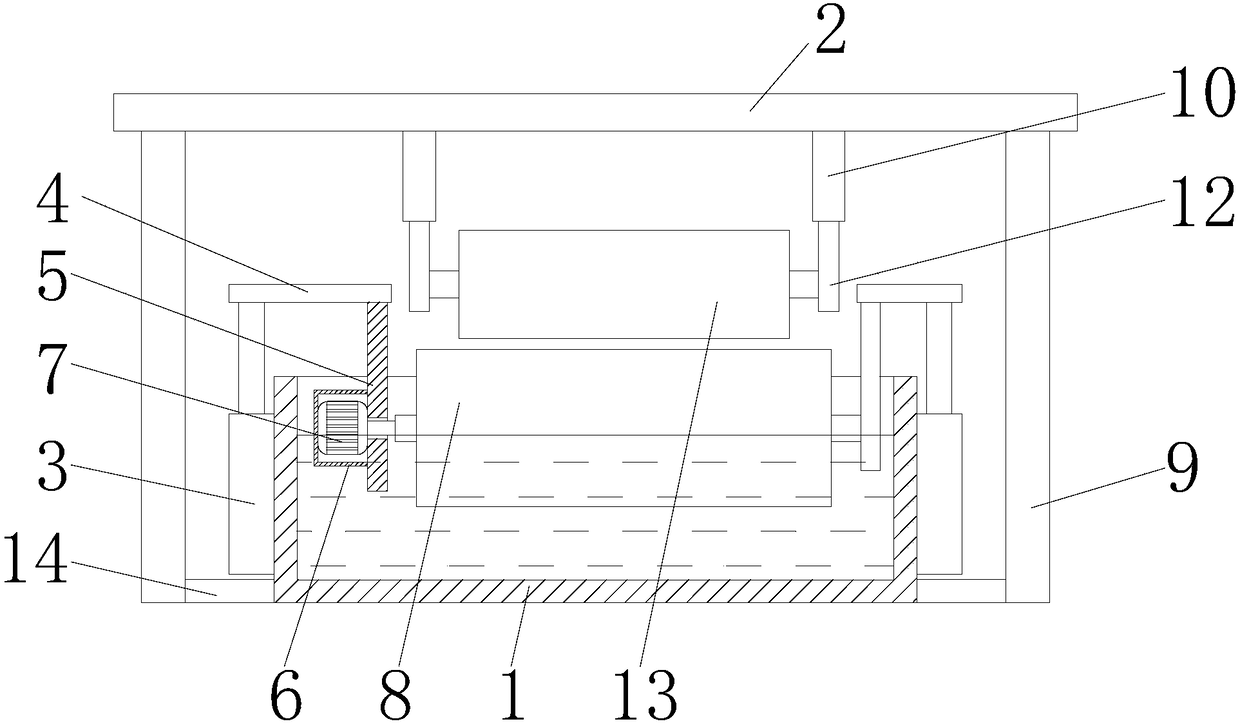

Printing and dyeing equipment high in printing and dyeing quality

InactiveCN108468167AImprove printing and dyeing qualityClose contactTextile treatment machine arrangementsLiquid/gas/vapor textile treatmentContact printEngineering

The invention discloses printing and dyeing equipment high in printing and dyeing quality. The equipment comprises a dye box and a transverse plate, the dye box is located below the transverse plate,the two sides of the dye box are both fixedly connected with an electric retractable rod, the top of each electric retractable rod is fixedly connected with a connecting plate, the bottom of each connecting plate is fixedly connected with a vertical plate, and the bottom of each vertical plate extends to an inner cavity of the dye box; a motor box is fixedly connected with the positions, in the inner cavity of the dye box, on the surfaces of the vertical plates; a motor is fixedly connected with the positions, in an inner cavity of the motor box, on the surfaces of the vertical plates. Materials are extruded through an extrusion roller, so that the materials are in close contact with a printing and dyeing roller, the printing and dyeing quality of the materials is improved, and the problems are solved that when printing and dyeing equipment performs contact printing on the materials through the printing and dyeing roller, the height of the printing and dyeing roller cannot be adjusted,accordingly the printing and dyeing roller cannot be in close contact with the materials, and the printing and dyeing quality of the materials is reduced.

Owner:叶侃

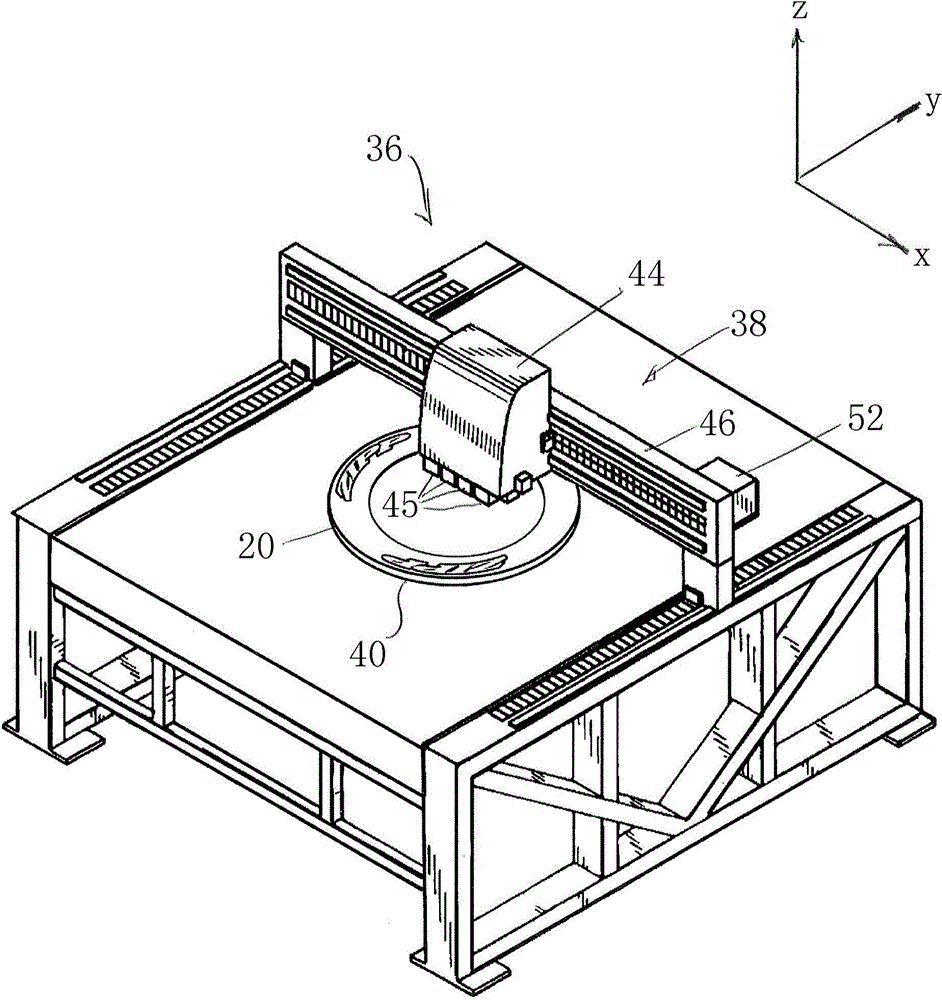

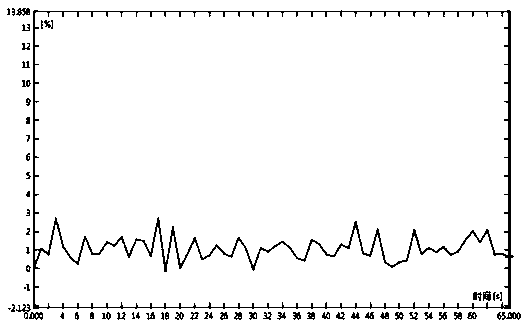

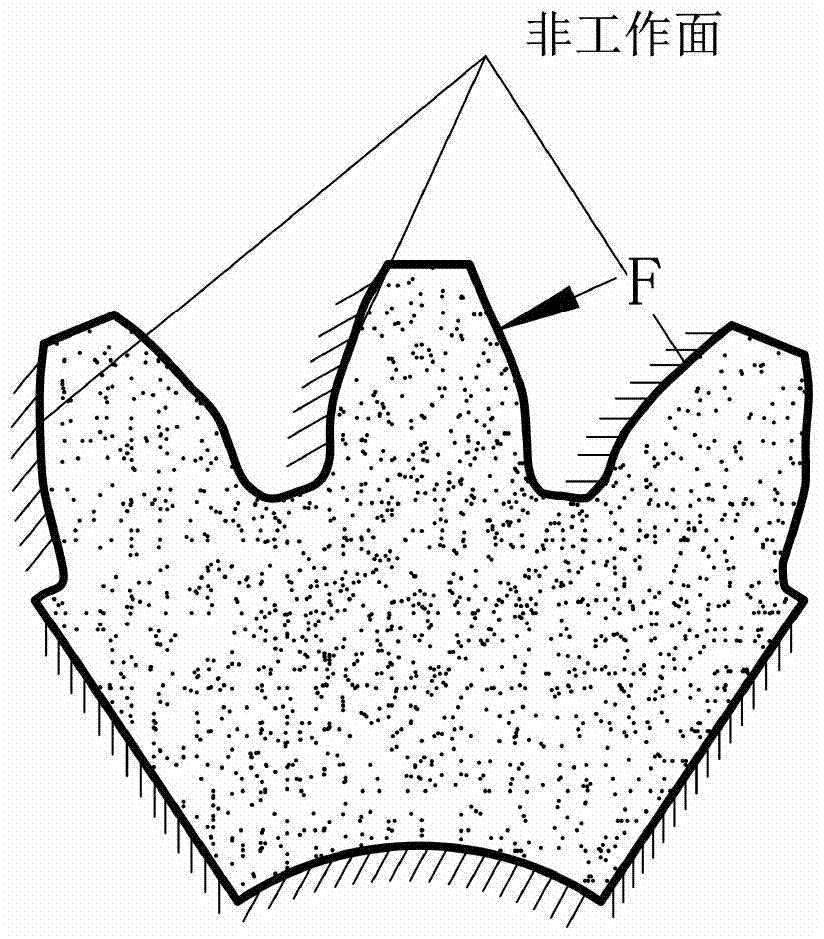

Online testing device and testing method for full-field deformation in contact print of rubber tire tread rubber material

PendingCN108956300AEasy to adjustSolve the difficulty of buildingMaterial strength using tensile/compressive forcesRubber materialFull field

The invention relates to an online testing device and testing method for full-field deformation in the contact print of a rubber tire tread rubber material. The online testing device comprises a support platform, a linear loading adjustment mechanism, a rotation loading adjustment mechanism, an adaptive clamping mechanism and a vision detection system, wherein the linear loading adjustment mechanism and the vision detection system are fixedly connected on the support platform according to a certain location relationship; the linear loading adjustment mechanism and the rotary loading adjustmentmechanism are fixedly connected; the adaptive clamping mechanism is fixedly connected with a pressure sensor; and the pressure sensor is fixedly connected with a torque sensor. The device can completely simulate stress deformation of a tire tread rubber material of a tire in the contact print under various work conditions, can solve the problems that a single-point contact measurement mode of anexisting tire tread rubber material in the contact print is difficult to implement, has a large testing result error and cannot acquire full-field deformation characteristics of the tire tread rubbermaterial in the contact print by a non-contact vision measurement method, has the characteristic of concise structure, and is easy to control and adjust.

Owner:JILIN UNIV

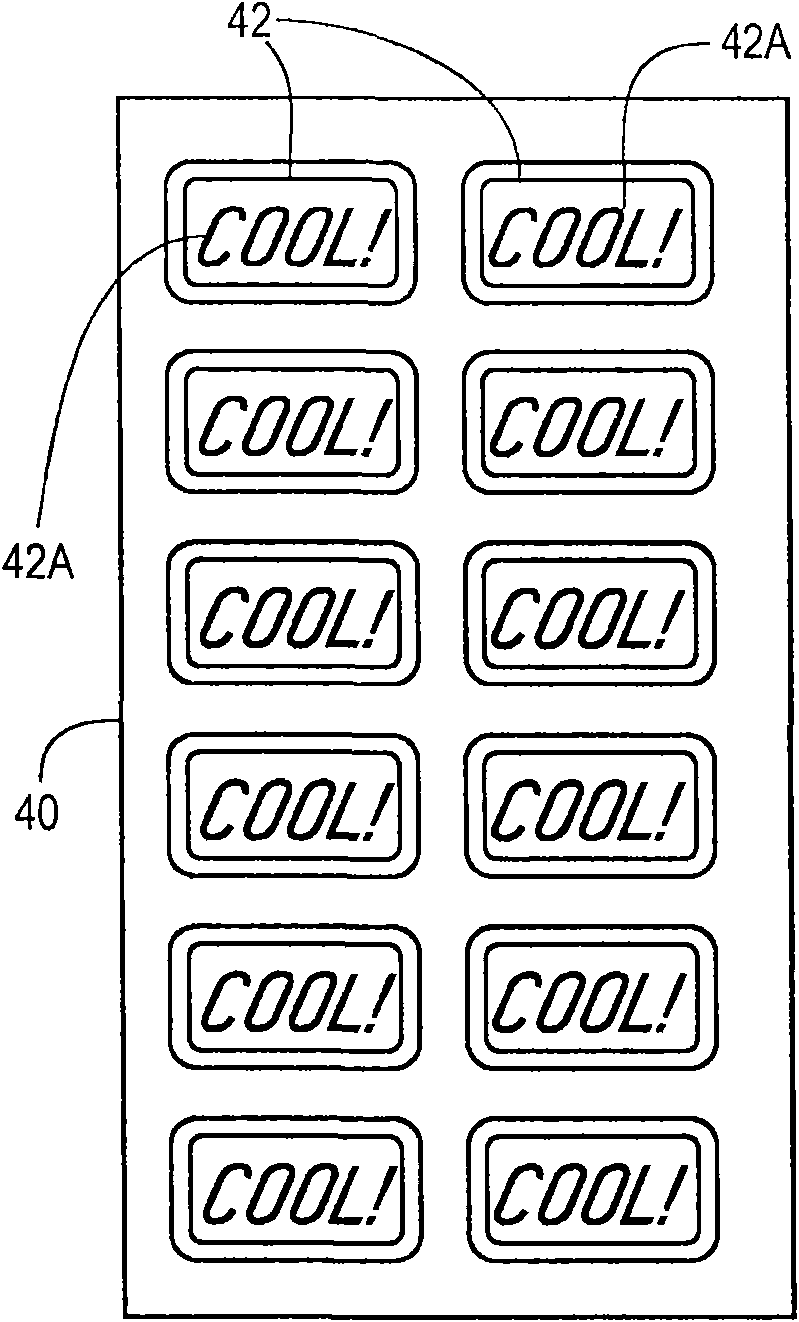

Non-contact printed comestible products and apparatus and method for producing same

InactiveCN101557714AIncrease stimulationIncrease happinessReady-for-oven doughsConfectioneryContact printPrinting ink

The present disclosure provides an apparatus and method for packaging a non-contact printed edible substrate as well as the resultant packaged product. The packaging apparatus may include a non-contact printer, a carrier, and a package located at a discharge position. The carrier may be constructed and arranged to transport the edible substrate from the print position to the package and orient same in the package so that the printed ink indicia is visible through at least a portion of a panel of the package. At a print position, the non-contact printer is constructed and arranged to apply an edible ink indicia to an edible substrate. The packaging apparatus may form a packaged product having a plurality of compartments where at least one compartment at least partially defined by a panel. The interior of the compartment contains at least one edible substrate comprising a surface and a printed edible ink indicia on the surface so that the ink indicia is visible through at least a portion of the panel.

Owner:WM WRIGLEY JR CO

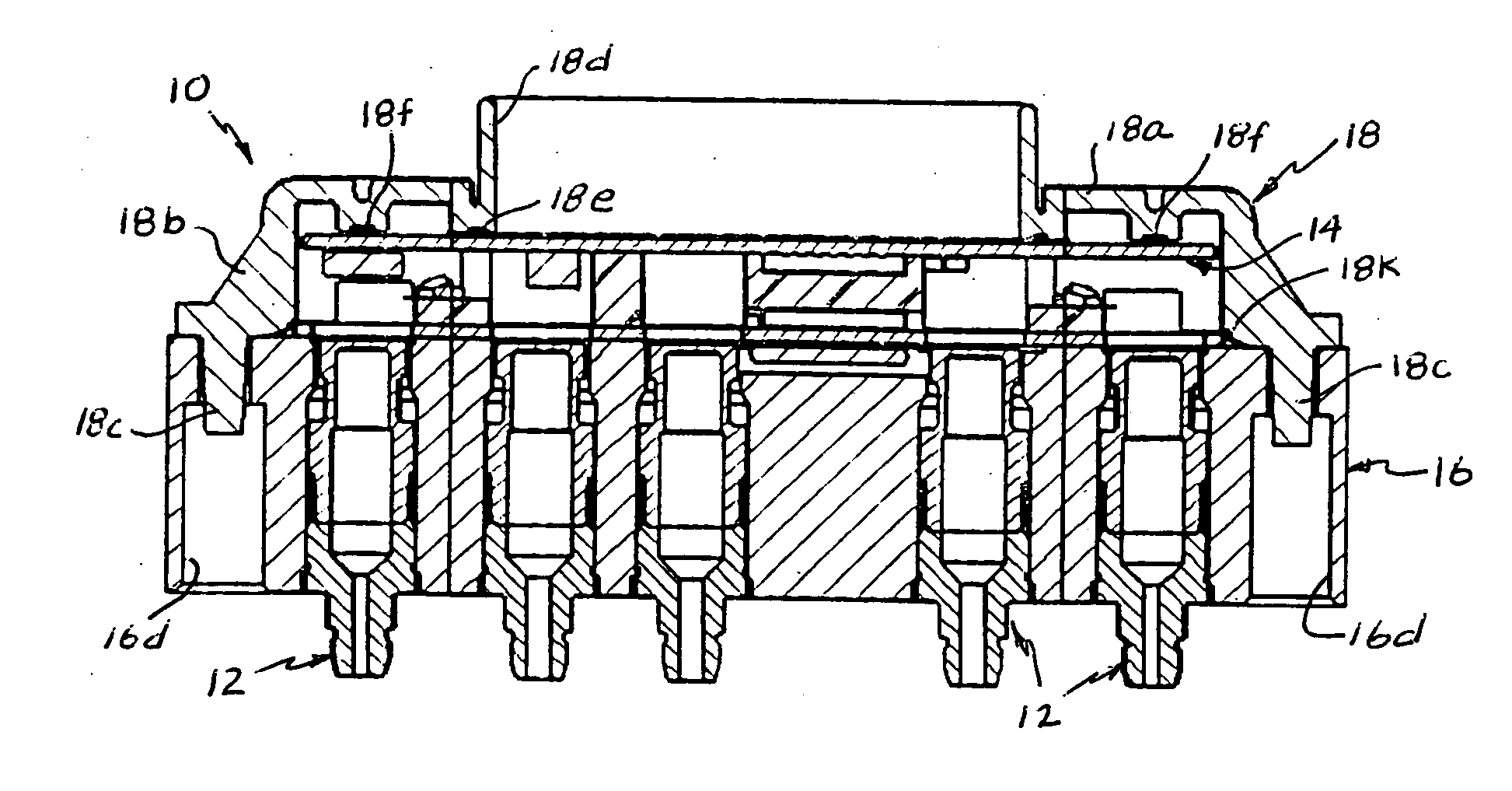

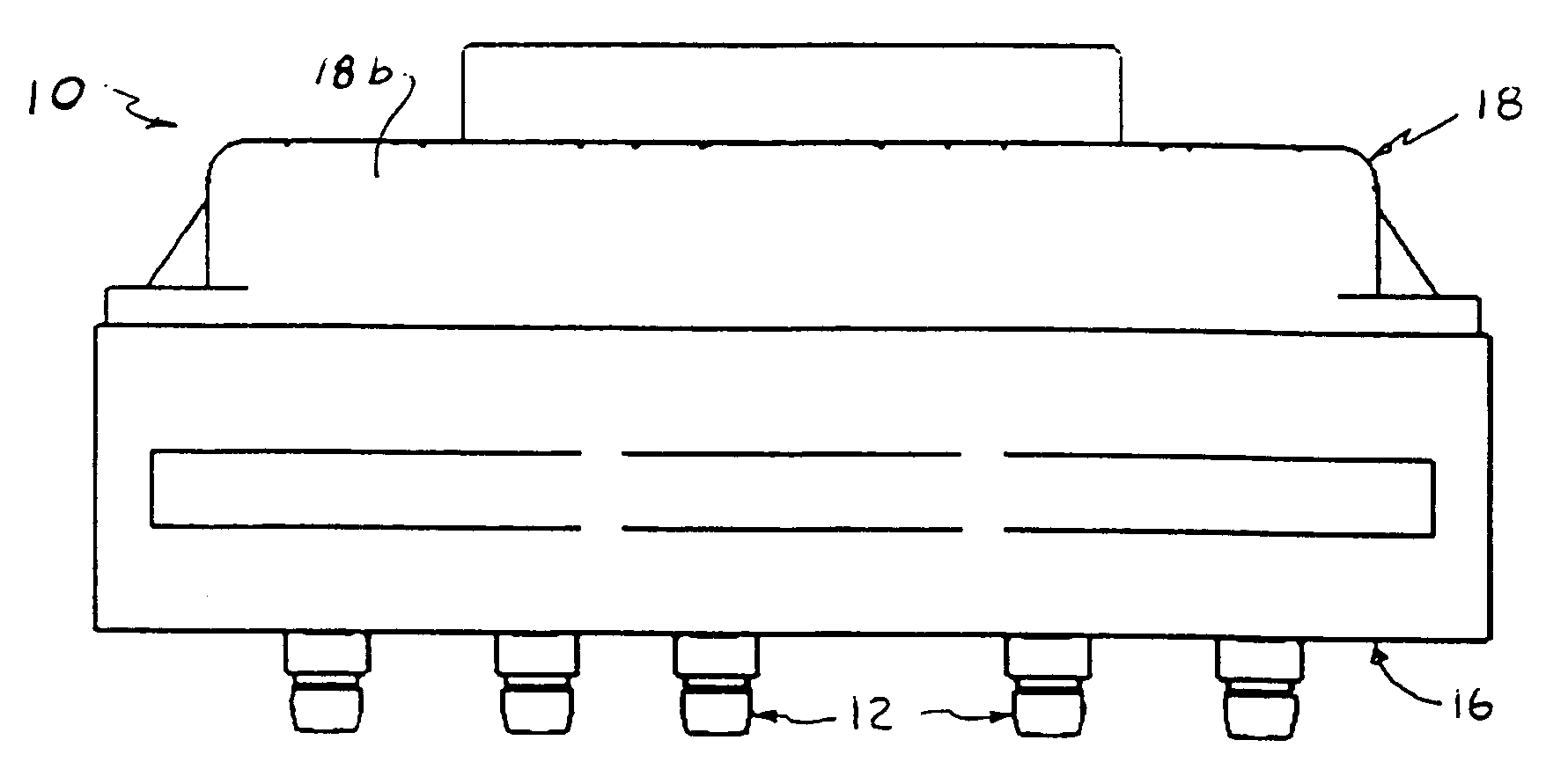

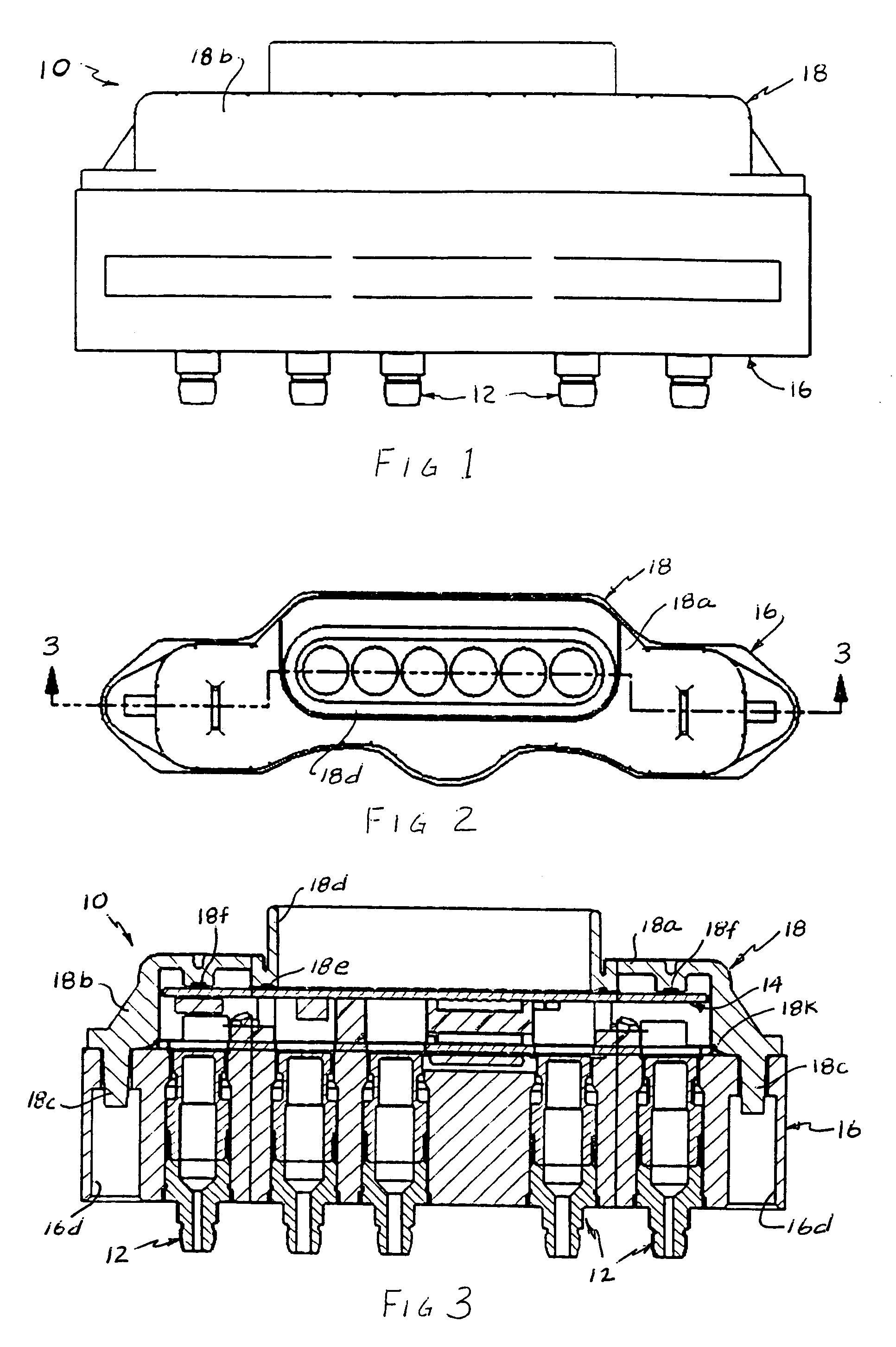

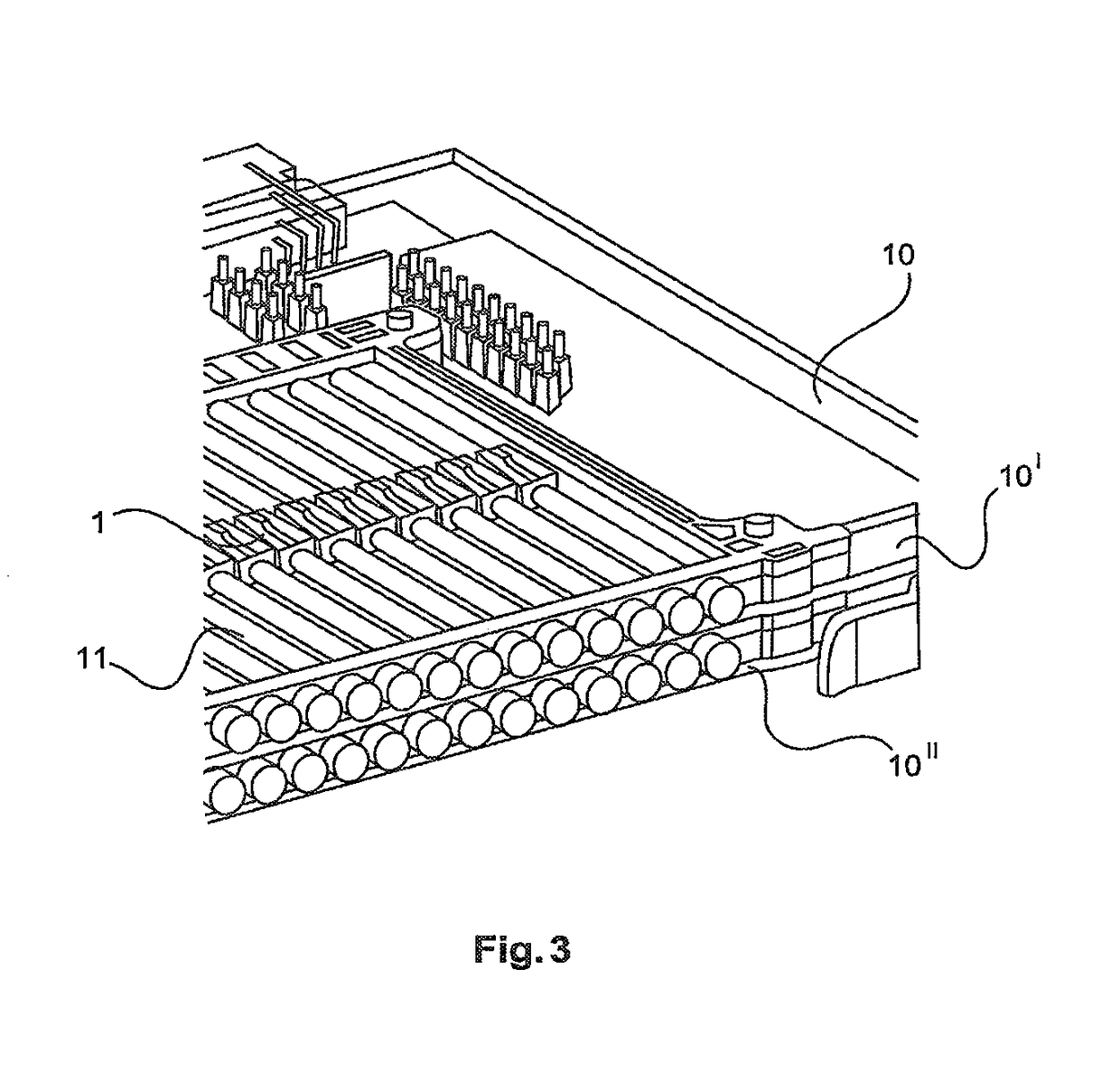

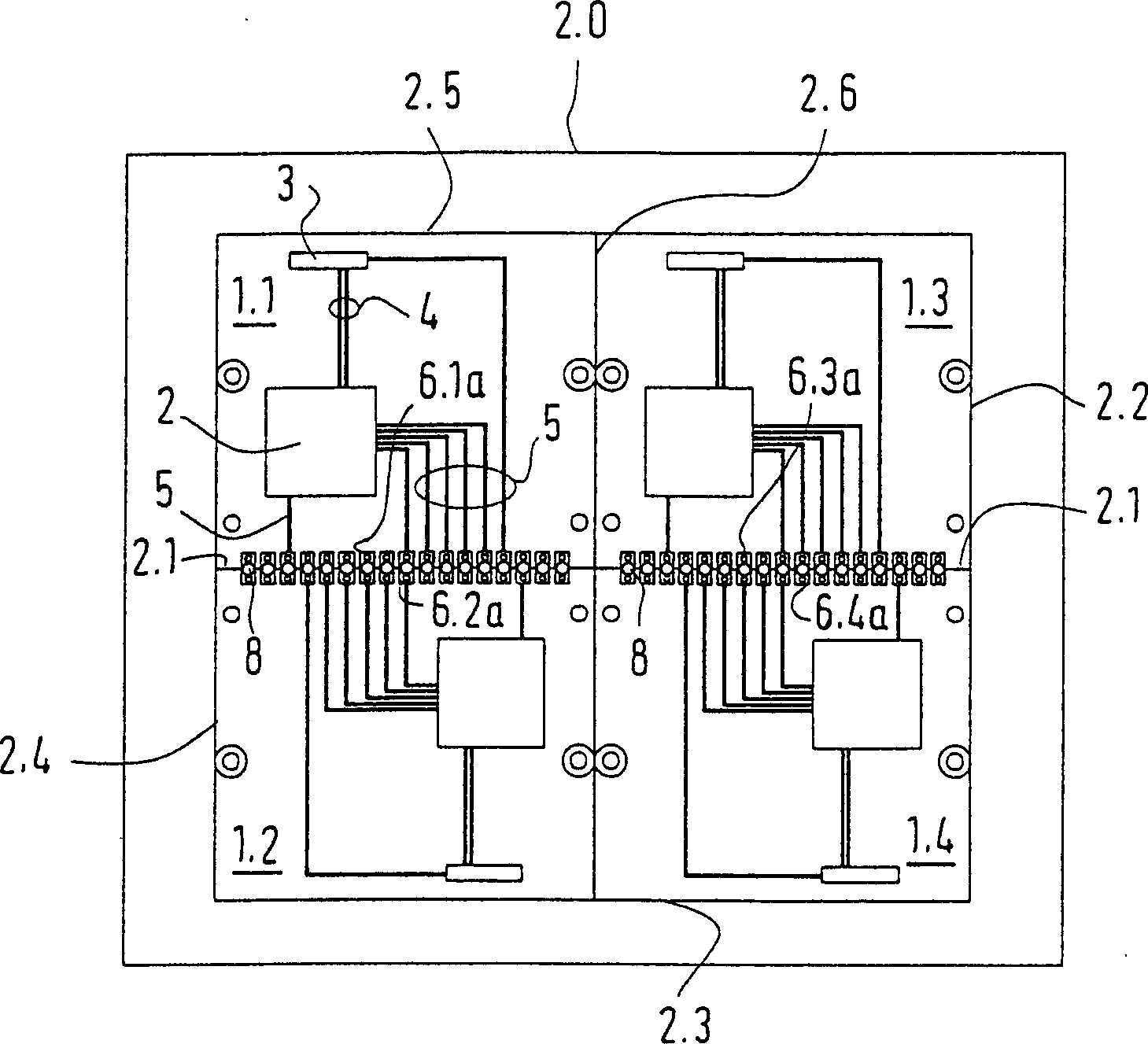

Multi-channel pressure sensing apparatus

ActiveUS20060016266A1Low costEasy to integrateFluid pressure measurement by electric/magnetic elementsMultiple fluid pressure valves simultaneous measurementContact padFlexible circuits

A multi-channel pressure sensor module (10) for integration in a hydraulic / electrical control unit of a vehicular braking system is shown. A body or manifold (16) mounts a plurality of strain gauge sense element assemblies (12) each having a port for connection to a fluid pressure source to be monitored. An electronic module assembly (14) has a contact printed circuit board (24) and a sense element printed circuit board (22) sandwiching a spacer / support member (20) and electrically coupled together by a flexible circuit board (26). The spacer / support member (20) is formed with pockets (20e, 20f) for receipt of discrete electronic components and to provide access to wire bond pads (22c) and sense element openings (22b). First and second sets of guide posts (20c, 20d) extend from the spacer / support member for alignment of the circuit boards as well as the electronic module assembly on the base. A cover (18) is received on the base over the electronic module assembly and provides access to contact pads of the contact printed circuit board through a shroud (18d).

Owner:SENSATA TECHNOLOGIES INC

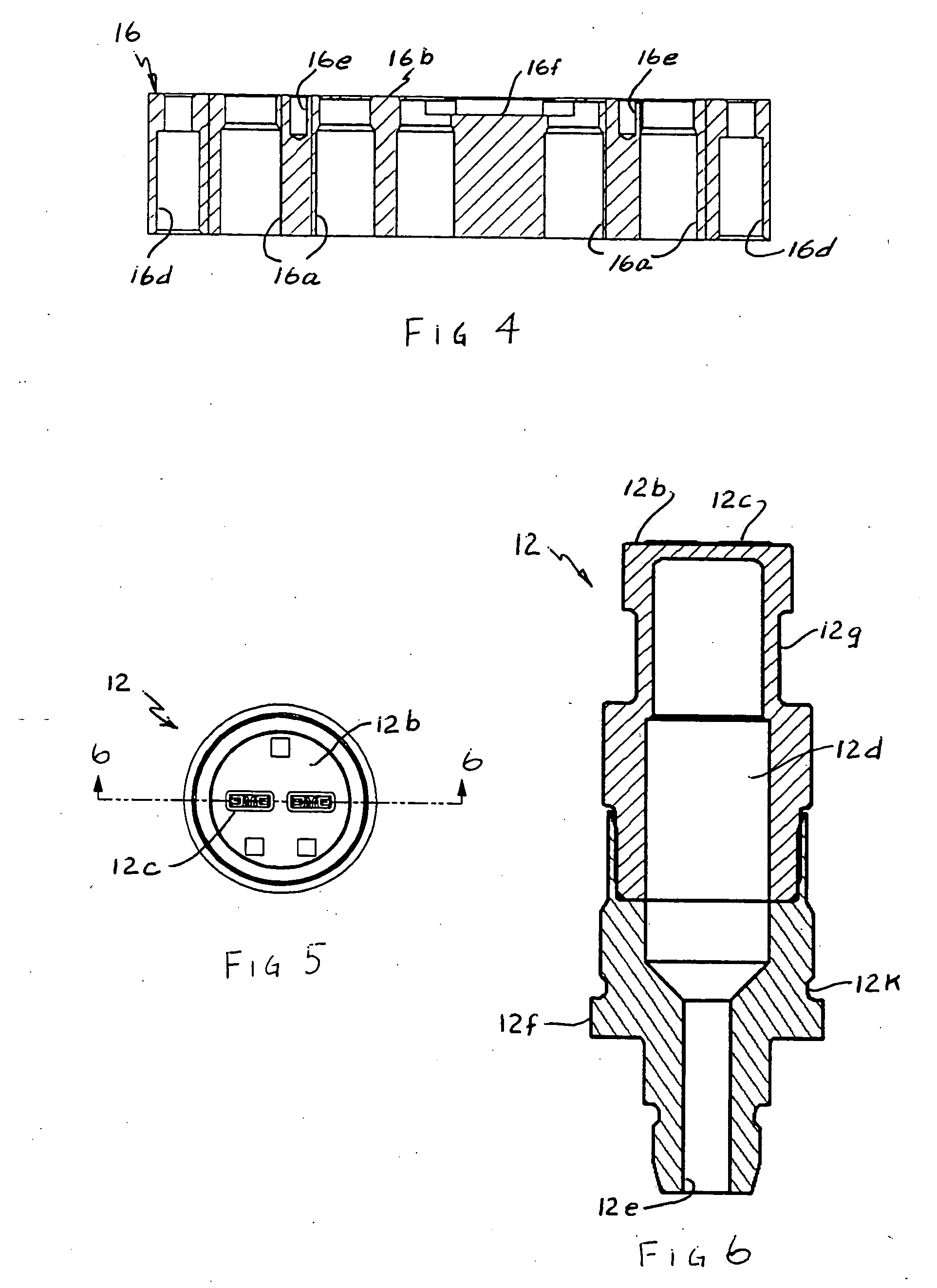

Automatic typography printing system by user directly contacting printing factory

InactiveCN106845949AEnable self-service designEasy to produceReservationsOffice automationUser needsPersonalization

The invention relates to the field of printing, in particular to an automatic typography printing system by a user directly contacting a printing factory. The existing printing service has the defects that the communication efficiency between the user and the printing factory is lower; when a common user needs to manufacture the self personalized real professional printing product, multiple steps are required; the difficulty in operation is high, and the cost is high; along with the popularizing of mobile equipment, such as smart phones, the user time is fragmented, and the common user cannot easily and consistently improve the self personalized printing product layout design. The automatic typography printing system has the advantages that by utilizing software technique, the user can enjoy the professional service experiences in the fragmented time; the self-help printing is realized through the self selection and arrangement of the user, the personalizing requirement of the user is met, and the printing cost is reduced.

Owner:北京悦博晟文化传播有限公司

Process for contact printing of pattern of electroless deposition catalyst

InactiveCN101208207ALiquid/solution decomposition chemical coatingConductive pattern formationElectroless depositionContact print

A process comprising the step of: contact printing a pattern of an electroless deposition catalyst via a hydrophilic phase to a receiving medium, wherein said electroless deposition catalyst requires no activation prior to electroless deposition.

Owner:AGFA GEVAERT AG

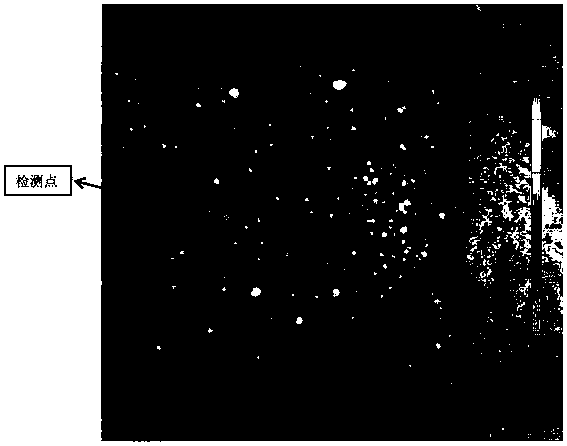

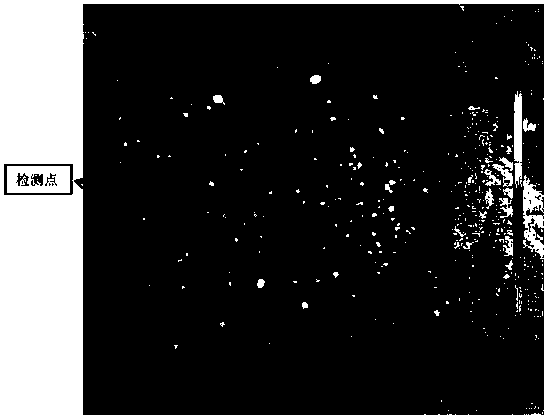

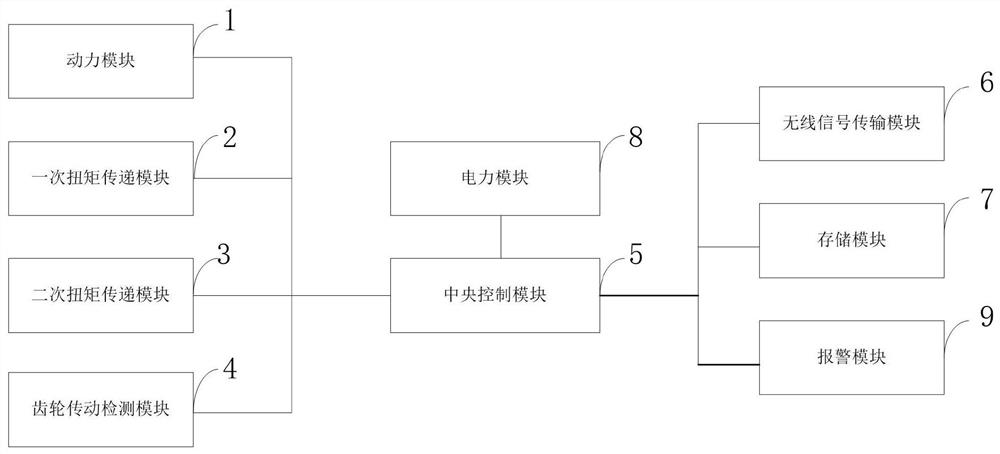

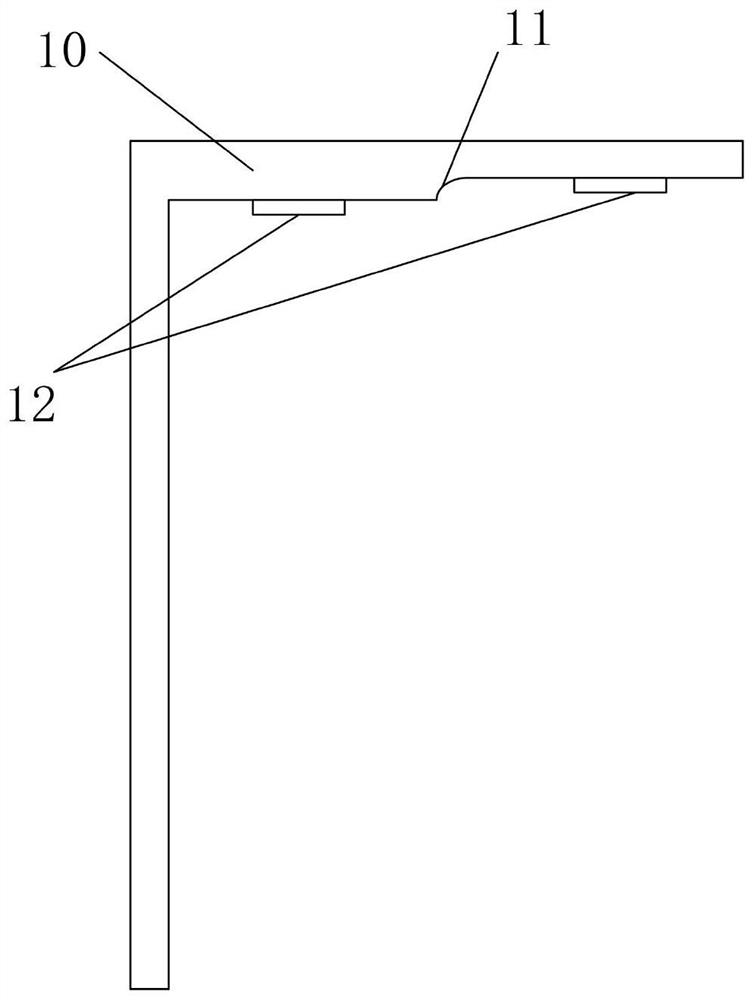

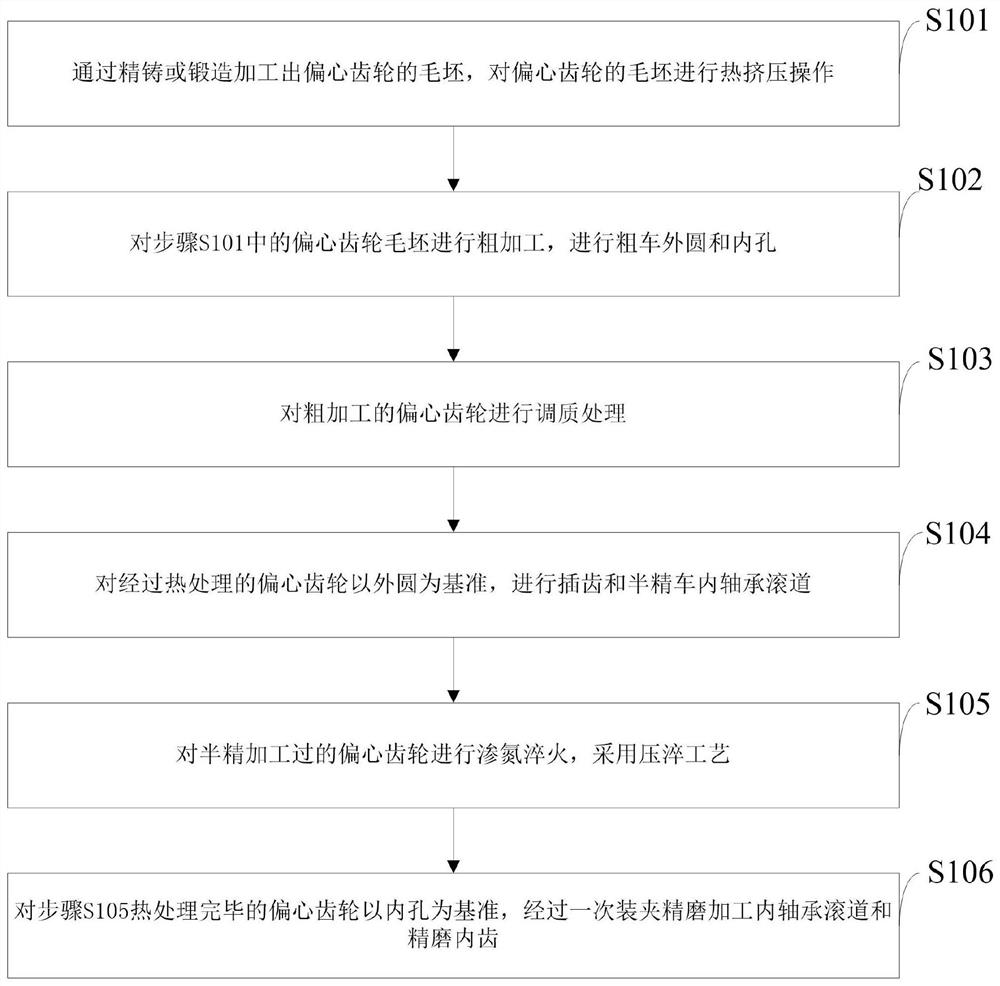

Robot precise joint speed reducer

InactiveCN111745632ATimely detection of transmission errorsEasy to controlProgramme-controlled manipulatorJointsGear wheelReduction drive

The invention belongs to the technical field of robots, and discloses a robot precise joint speed reducer. The robot precise joint speed reducer comprises a power module, a primary torque transmissionmodule, a secondary torque transmission module, a gear transmission detection module, a central control module, a wireless signal transmission module, a storage module, an electric power module and an alarm module. According to the robot precise joint speed reducer, the front surface and the back surface of an eccentric gear assembly are engaged with the contact print through a collection micro camera, the collected contact print image is denoised through an image processing unit, the collected front surface and the back surface of the eccentric gear assembly are engaged with the contact print through an image measurement unit to be measured and recorded, the processing result is compared and analyzed with a preset threshold value, so that the transmission error and the abrasion state ofmeshing of a rigid gear and an output shaft can be found in time, precision control is facilitated, and by means of the machining method of the eccentric gear assembly, the machining precision of therigid gear can be improved, and the service life is prolonged.

Owner:WEIFANG UNIVERSITY

Multi-channel pressure sensing apparatus

ActiveUS7007552B2Low costEasy to integrateFluid pressure measurement by electric/magnetic elementsMultiple fluid pressure valves simultaneous measurementContact padFlexible circuits

A multi-channel pressure sensor module (10) for integration in a hydraulic / electrical control unit of a vehicular braking system is shown. A body or manifold (16) mounts a plurality of strain gauge sense element assemblies (12) each having a port for connection to a fluid pressure source to be monitored. An electronic module assembly (14) has a contact printed circuit board (24) and a sense element printed circuit board (22) sandwiching a spacer / support member (20) and electrically coupled together by a flexible circuit board (26). The spacer / support member (20) is formed with pockets (20e, 20f) for receipt of discrete electronic components and to provide access to wire bond pads (22c) and sense element openings (22b). First and second sets of guide posts (20c, 20d) extend from the spacer / support member for alignment of the circuit boards as well as the electronic module assembly on the base. A cover (18) is received on the base over the electronic module assembly and provides access to contact pads of the contact printed circuit board through a shroud (18d).

Owner:SENSATA TECHNOLOGIES INC

Sliding element for contacting printed circuit boards

ActiveUS10148026B2Without high expenditureNot sensitive to malfunctionNon-rotary current collectorCoupling contact membersElectrical conductorContact print

A sliding element for electrically contacting conductor paths on two facing printed circuit boards is provided. The sliding element comprises a main body, at least one electrical contact element, and a through-going opening provided for accepting a threaded stud. An internal thread in the through-going opening allows the sliding element to move linearly along the threaded stud when the threaded stud is rotated. By moving the sliding element along the threaded stud, different conductor paths on the printed circuit boards are brought into electrical contact with one another.

Owner:HARTING ELECTRIC GMBH & CO KG

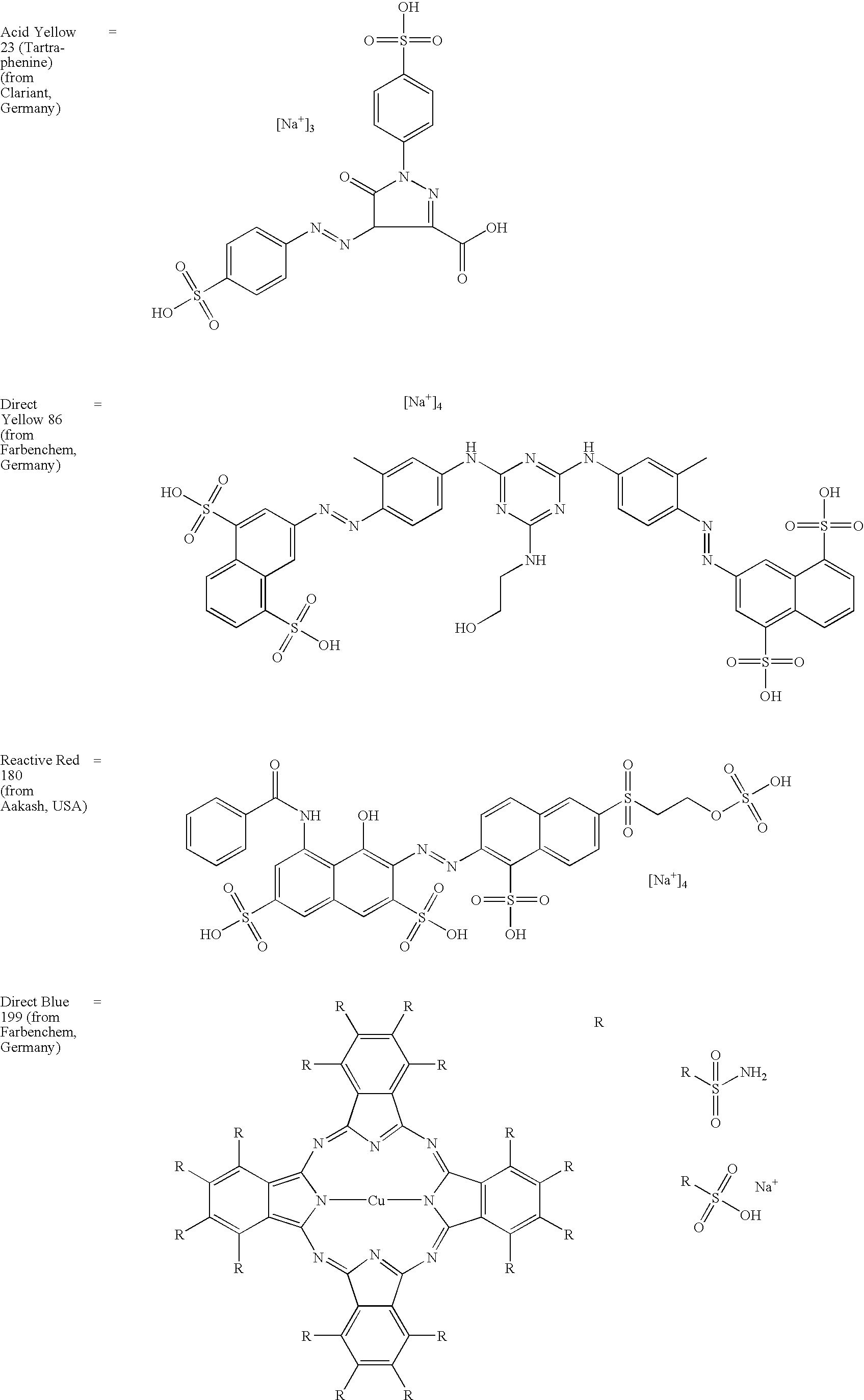

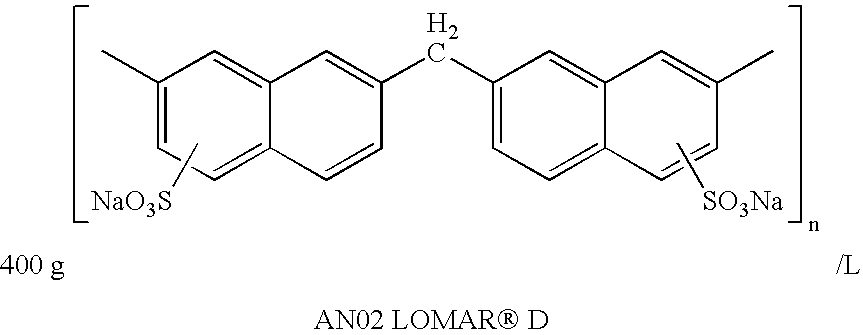

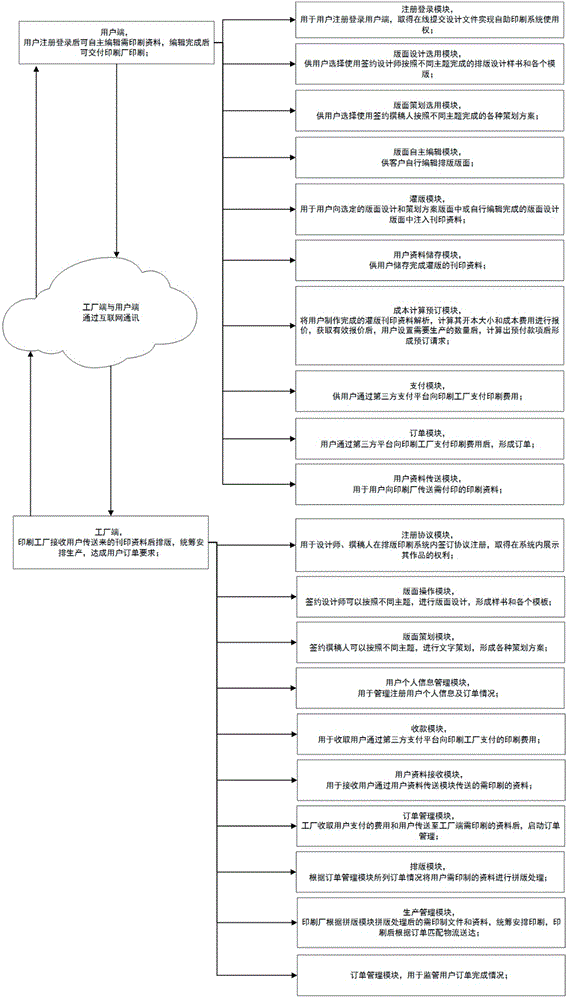

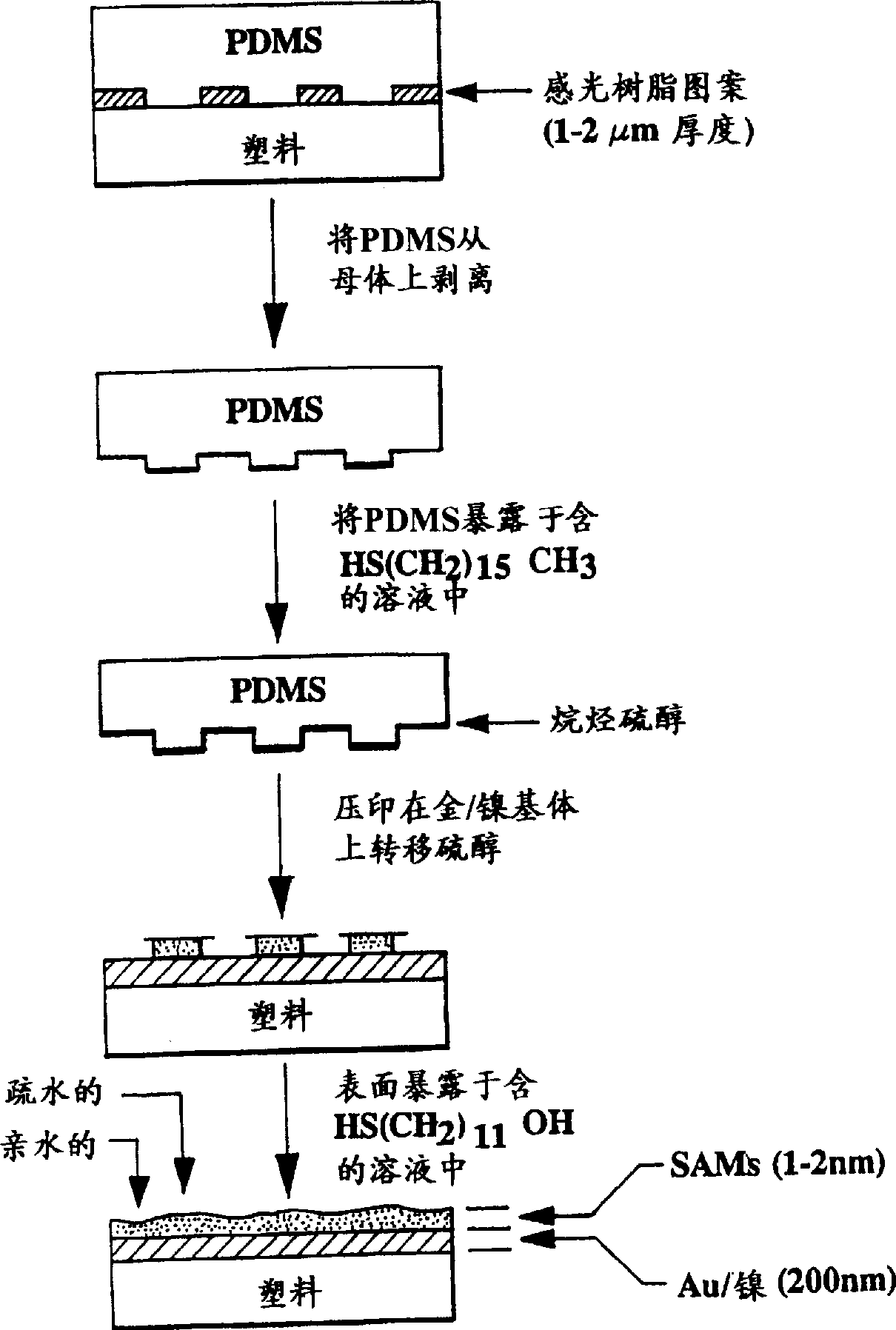

Method of contact printing on gold coated films

InactiveCN1244265ALow costEasy to handleMaterial nanotechnologyLiquid surface applicatorsOptical diffractionAnalyte

The present invention comprises methods of contact printing of patterned, self-assembling monolayers of alkanethiolates, carboxylic acids, hydroxamic acids, and phosphonic acids on metallized thermoplastic films, the compositions produced thereby, and the use of these compositions. Patterned self-assembling monolayers allow for the controlled placement of fluids thereon which contain a chemically reactive, indicator functionality. The optical sensing devices produced thereby when the film is exposed to an analyte and light, can produce optical diffraction patterns which differ depending on the reaction of the self-assembling monolayer with the analyte of interest. The light can be in the visible spectrum, and be either reflected from the film, or transmitted through it, and the analyte can be any compound reacting with the fluid on the self-assembling monolayer. The present invention also provides a flexible support for a self-assembling monolayer on gold or another suitable metal.

Owner:KIMBERLY-CLARK WORLDWIDE INC

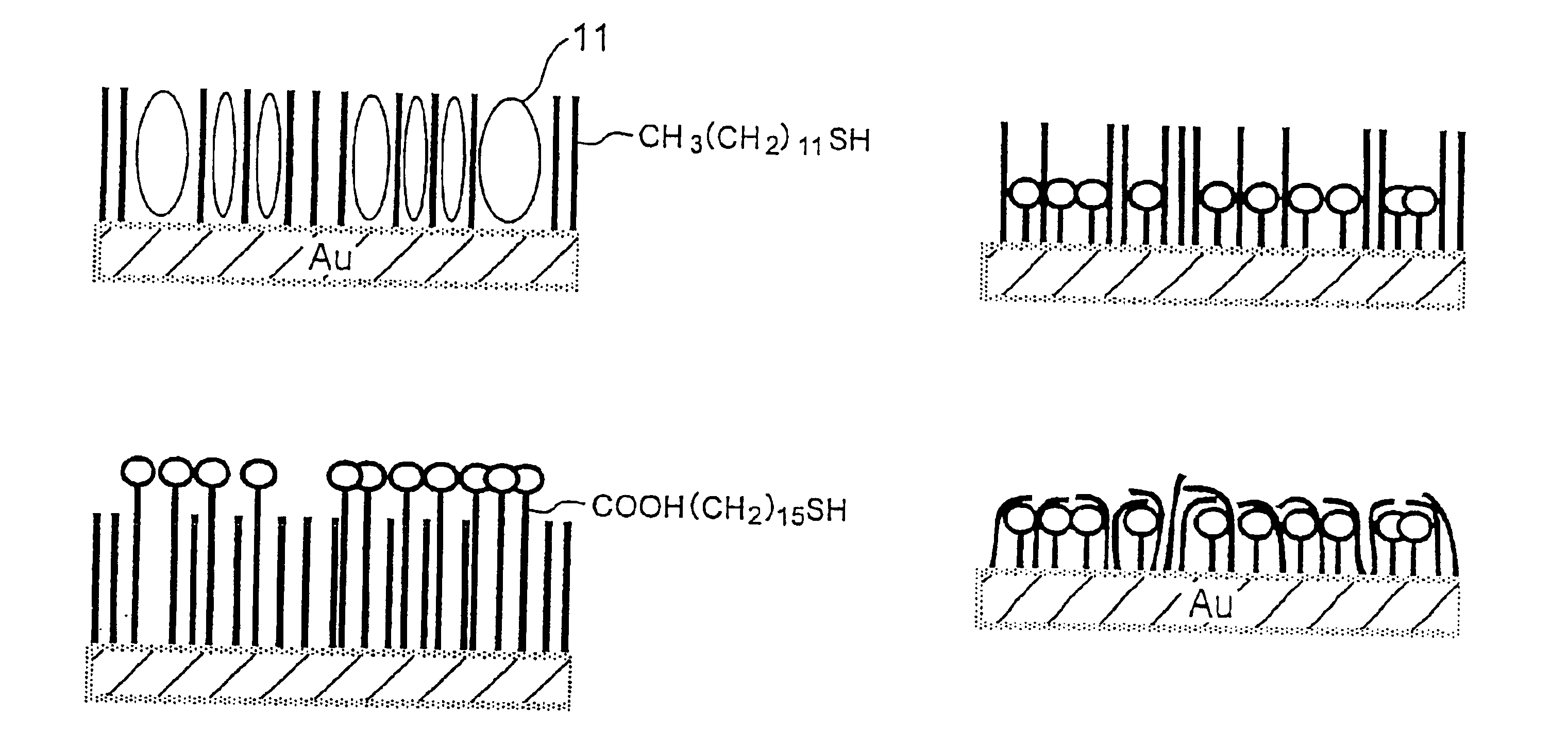

Patterning method with micro-contact printing and its printed product

InactiveUS6868786B2Increase contrastPlaten pressesDecorative surface effectsMicrocontact printingChain length

A patterning method for micro-contact printing involves the steps of: applying a resin on a master having projected patterns, hardening the resin and thereafter removing the hardened resin from the master to make a stamp of the resin; applying a molecular ink including hydrophobic molecules dispersed in a solvent on the stamp; forming micro-contact printed patterns of the hydrophobic molecular layer on a substrate by means of the stamp on which the molecular ink is applied; dipping the substrate with micro-contact printed patterns in a hydrophilic molecule solution dispersed in a solvent to give chemical modification to the areas of the surface of the substrate around the micro-contact printed patterns, the solution including hydrophilic molecules having a chain length shorter than the chain length of hydrophobic molecules included in the molecular ink is used as the hydrophilic molecule solution. According to the method, printed products having micro-contact printed patterns of a molecular level are obtained with a contrast between the micro-contact printed patterns and the area of the surface of the substrate around the micro-contact printed patterns.

Owner:DAI NIPPON PRINTING CO LTD

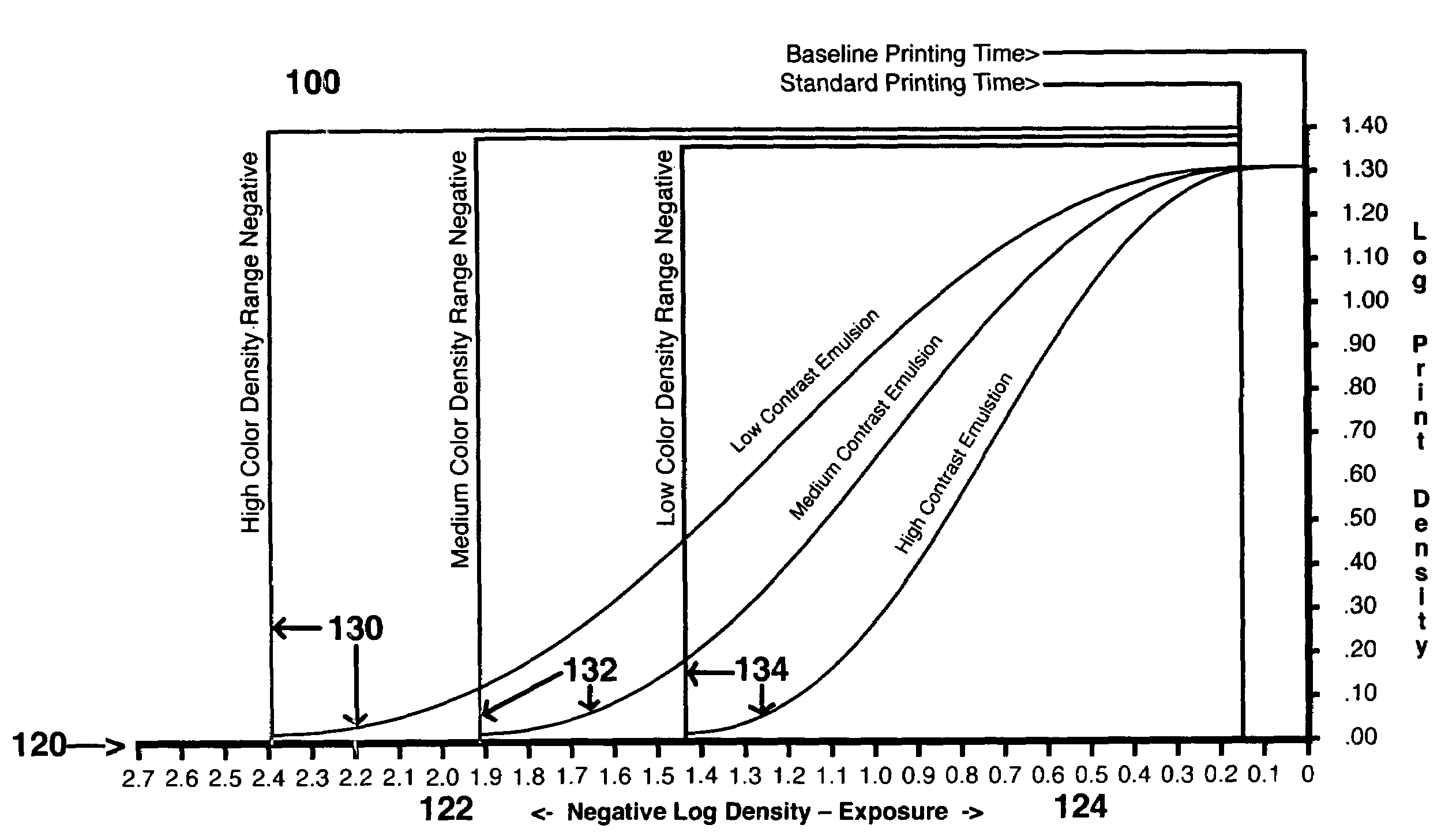

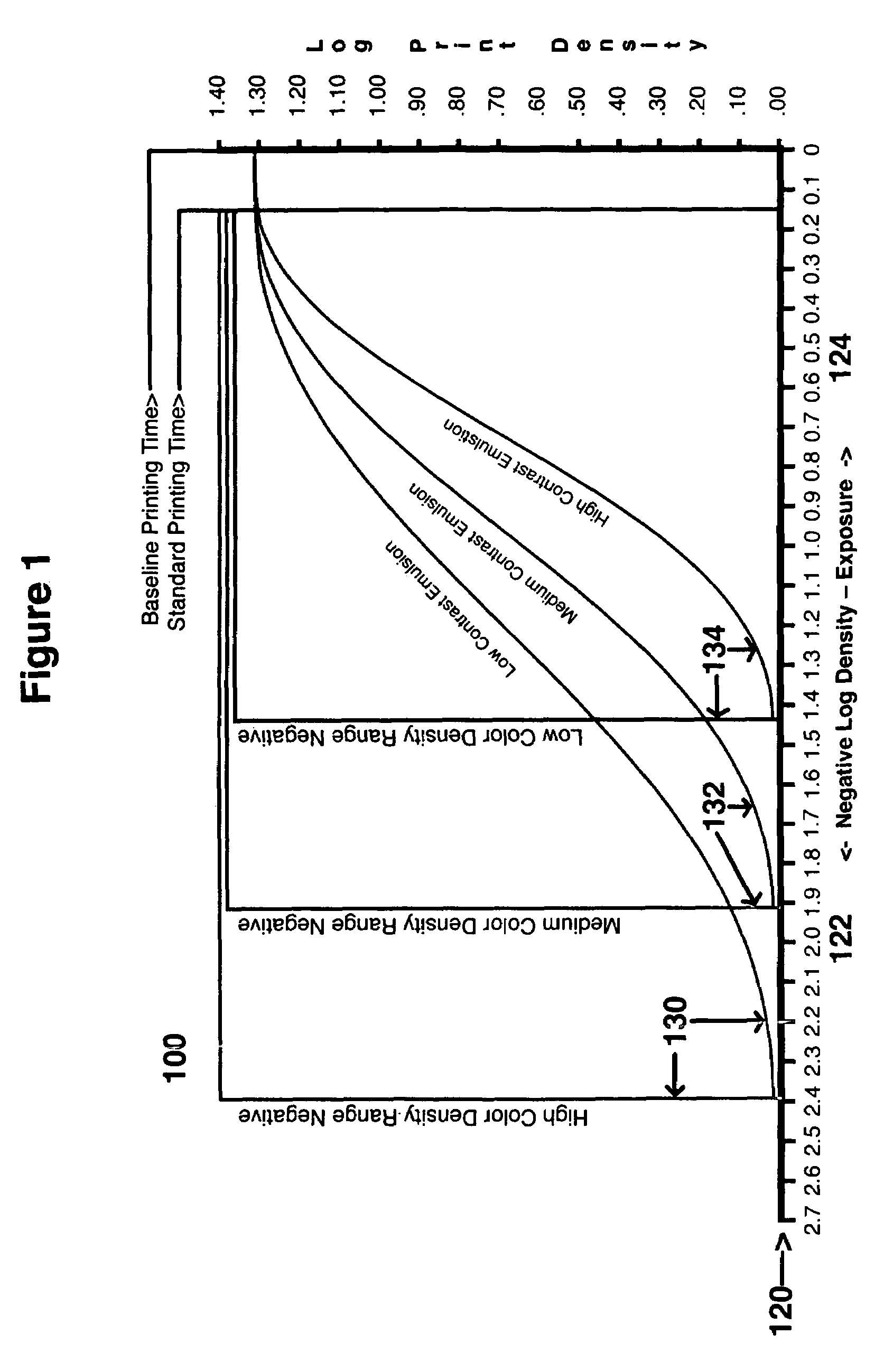

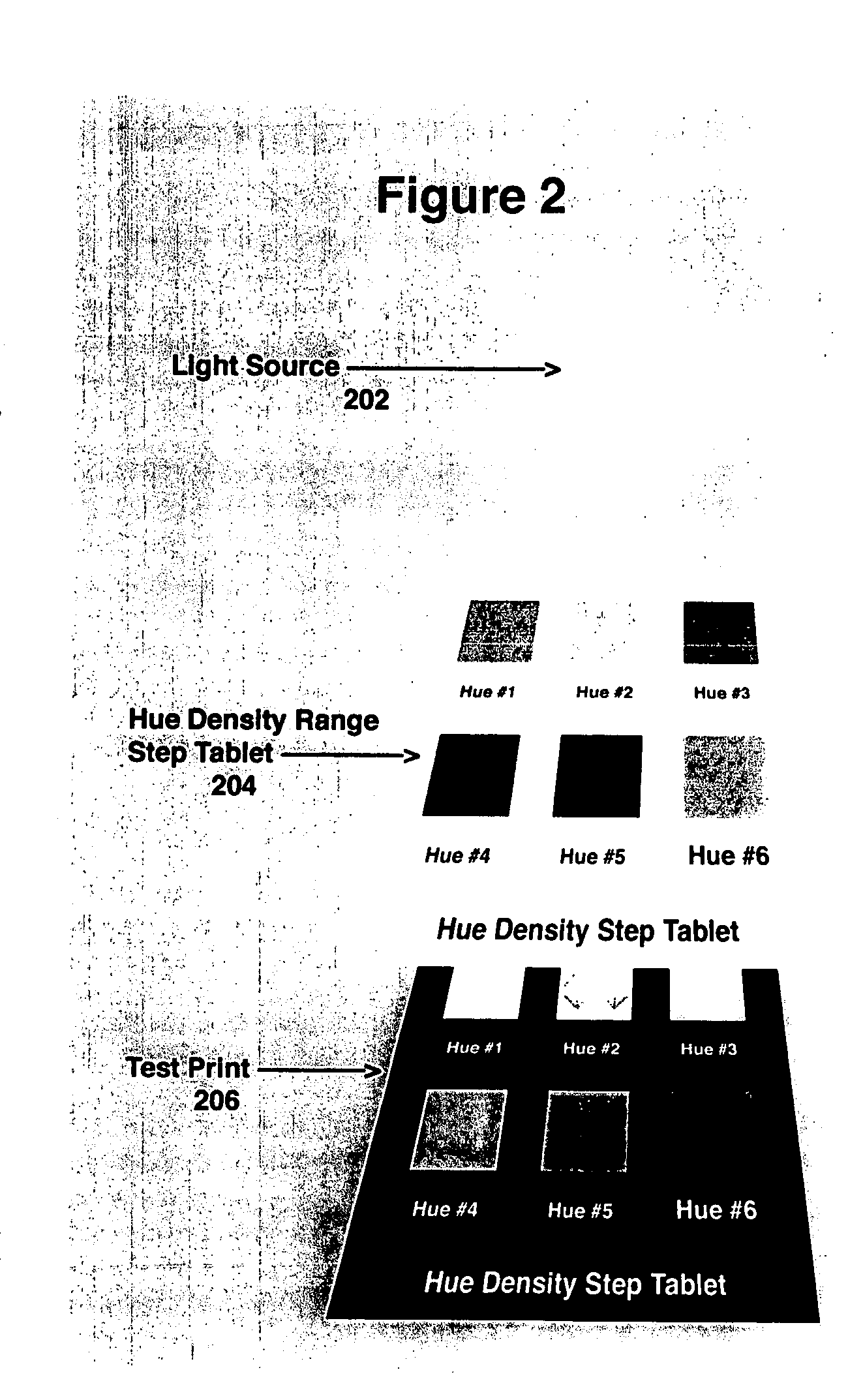

Density range control in a photograph by variation of hue density range of the negative

A negative density range control system uses color hue contrast to provide a print of a picture, by comparing the relationship between negative hue density and print emulsion density requirement and providing an appropriate density for a printing process, whether converting a positive digital image to negative digital image with a specific hue density color or making a print by contact printing a hue density negative rendered from a digital image file.

Owner:NELSON MARK

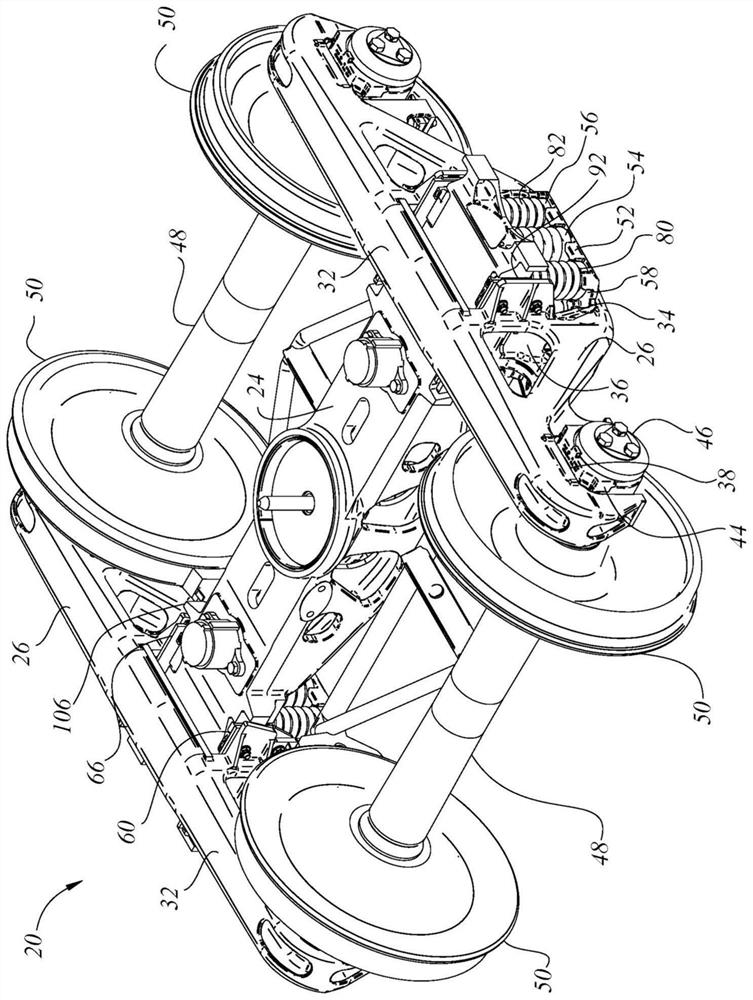

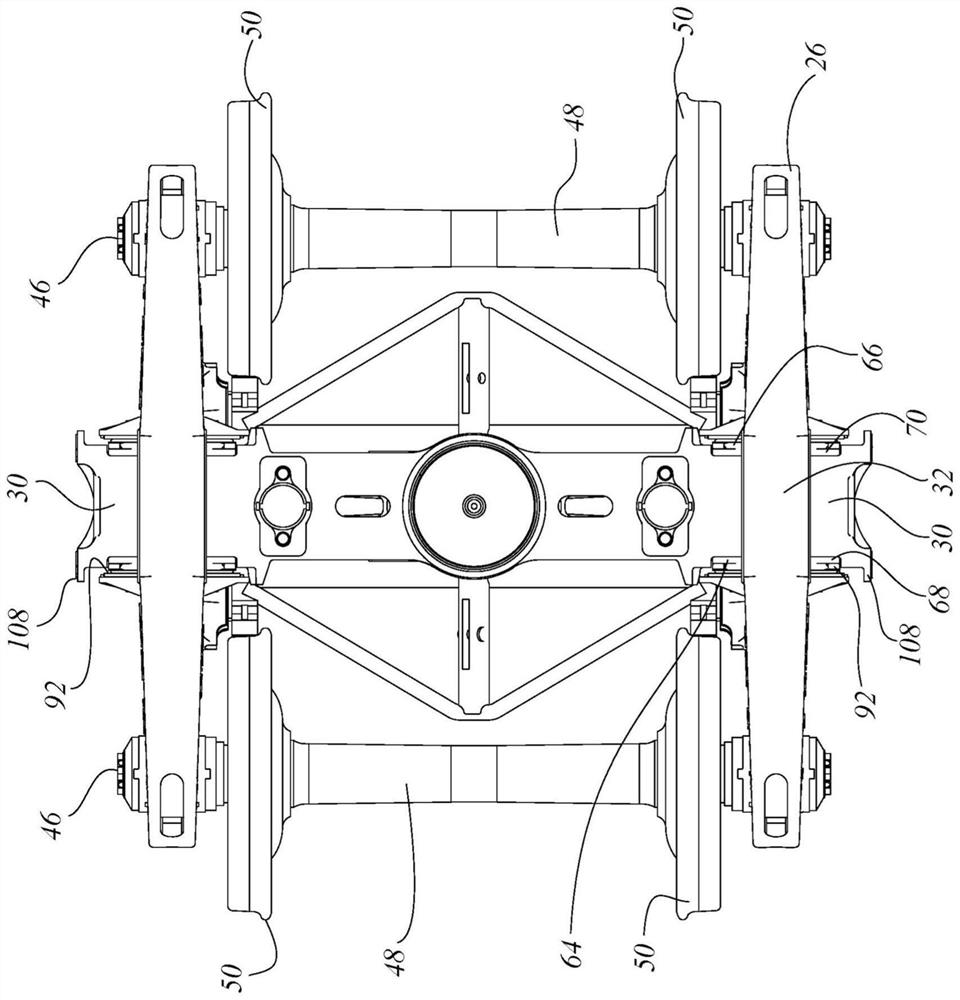

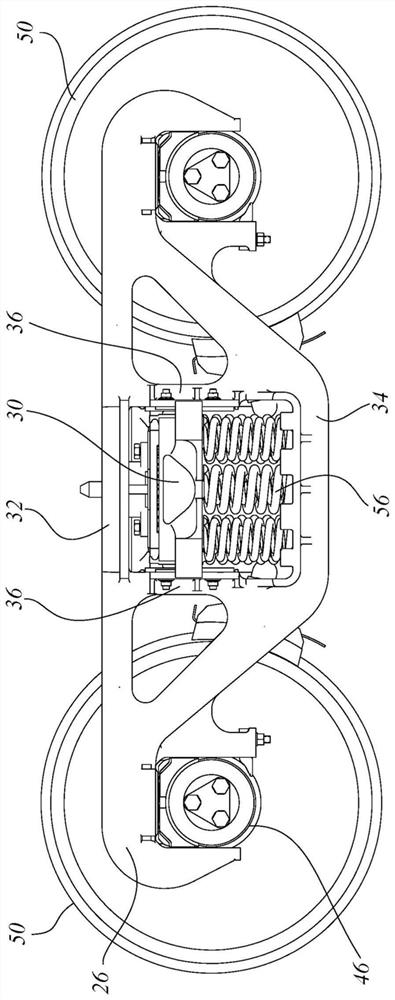

Railway vehicle bogie damper wedge fitting

A damper wedge for a railway vehicle bogie is provided. The damper wedge has a friction member that rides on a wear plate of a side frame column of a railway vehicle bogie. The damper wedge block is provided with a non-metal abrasion surface; a spring seat engaged in use with a spring of the railway vehicle bogie; and a sloped damper wedge surface having a primary angle alpha and a secondary angle beta. The spring seat is provided with an axial center line. The inclined damper wedge surface has a curvature. The curvature has an operating point. The damper wedge has a reference plane perpendicular to the non-metallic wear surface and including the axial centerline. The axial centerline intersects the inclined damper wedge surface at an intersection point that is the center of the contact footprint. And the working point is positioned in a central area of the contact print or the working surface print.

Owner:NATIONAL STEEL CAR

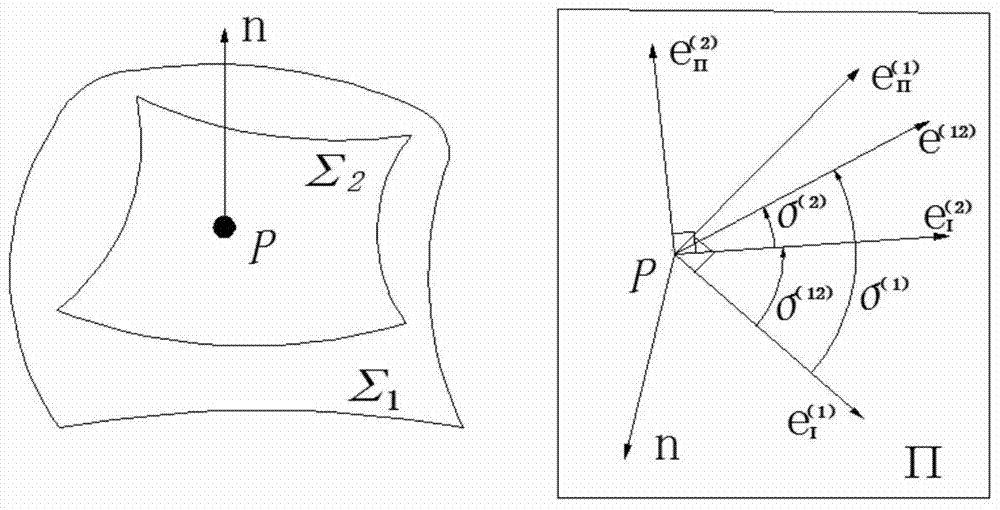

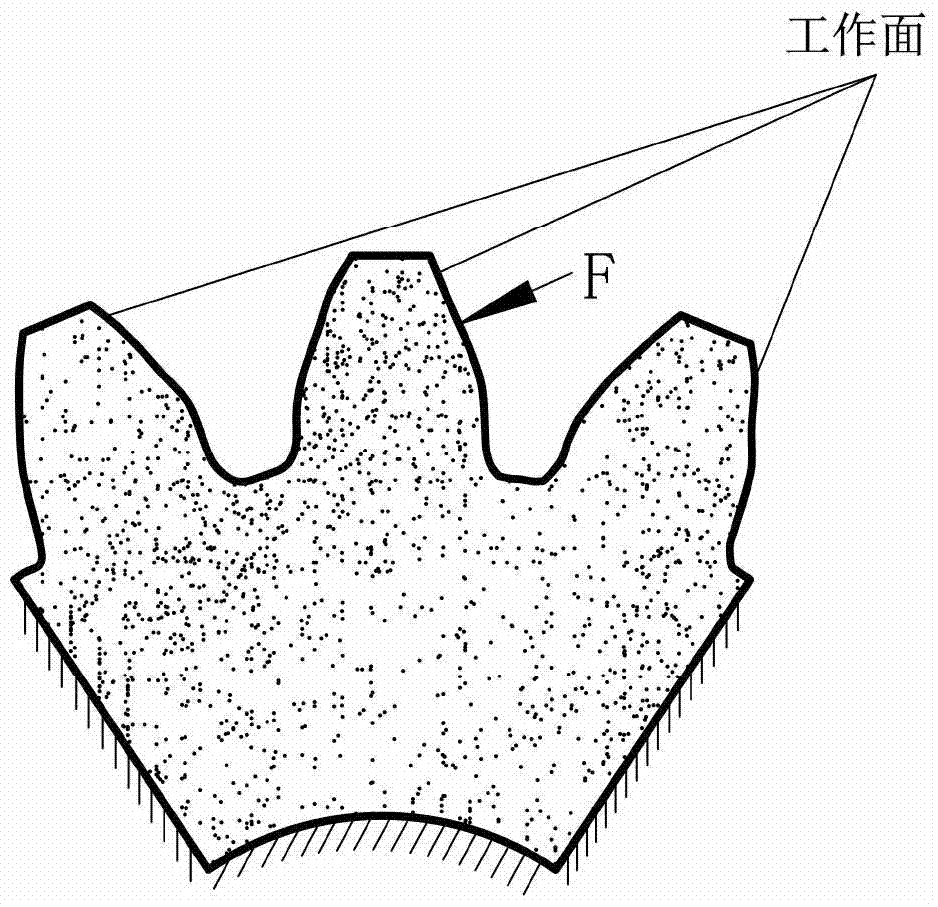

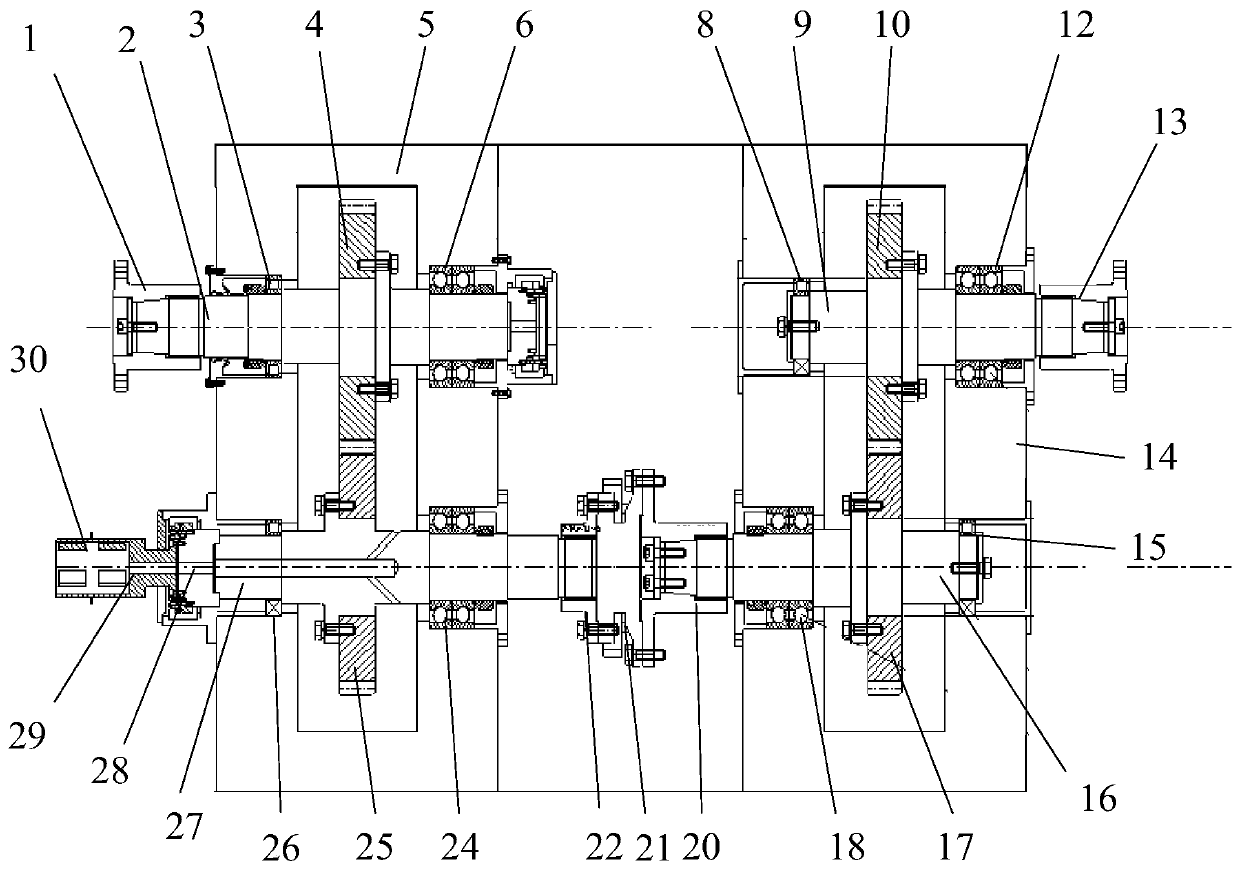

An Improved Contact Analysis Method for Tooth Loading

ActiveCN104408220BCalculations are precise and easySpecial data processing applicationsStress distributionElement model

The present invention discloses a modified method for gear teeth loading contact analysis. The method obtains a tooth surface equation and a normal vector equation of the gear through geometric calculation based on deformation compatibility conditions; and performing gear teeth contact analysis with no load on such basis to obtain contact prints and transmission error by the gear engagement, principal curvature and principal direction of the tooth surfaces, and derivative method curvature of the tangent tooth surfaces, thereby establishing a relation within the size of the contact oval, the amount of compression of the tooth surface, and the load; determining load distribution of the gear by combining with Hertz theoretical formula and a flexibility coefficient method, considering effect from an installing error and a supporting error, and nonlinearity of the contact flexibility coefficient; and according to a load distribution result among the teeth, using the Hertz formula to calculate a tooth surface pressure distribution and a contact stress distribution at a certain moment of the large and small gears, and using a three-dimensional finite element model to perform stress calculation to obtain a reliable bending stress. The gear teeth loading contact analysis method plays an important role in design, calculation and application of the technical field of gears.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Printer using direct-coupled emissive array

InactiveUS7224379B2Low-cost componentEasy to useSolid-state devicesSemiconductor/solid-state device manufacturingFiberDigital data

Owner:EASTMAN KODAK CO

Electrical contacting method

A method for contacting printed conductors terminating at the edge of a circuit board with printed conductors of a MID component includes: on a panel which includes the circuit board, producing the printed conductors of the circuit board in a layout in which the printed conductors are extended past a partition line which defines the edge of the circuit board; providing the panel with through holes along the partition line in the region of the printed conductors; electroplating through the through holes; and positioning the circuit board in relation to the MID component and soldering the printed conductors of the circuit board to the printed conductors of the MID component. Rear electrical contacting areas are provided on a back side of the panel near the partition line, and the printed conductors are connected to the rear electrical contacting areas via the through holes.

Owner:NOVAR PLC

Involute cylindrical gear comprehensive test device applied to dynamic and quasi-static tests

The invention discloses an involute cylindrical gear comprehensive test device applied to dynamic and quasi-static tests, and belongs to the technical field of gear transmission. The device comprisesa main test component, an auxiliary test component, a torsion sensor, a transmission shaft and a digital remote test system. According to the device provided by the invention, the low-speed quasi-static test on transmission error, contact print and tooth root stress of the involute cylinder and the high-speed dynamic test on vibration performance and boundary temperature of the involute cylinder can be performed, the test function of the involute cylinder test device is broadened, and the replacement, installation and debugging time and costs are effectively reduced.

Owner:CHINA NORTH VEHICLE RES INST

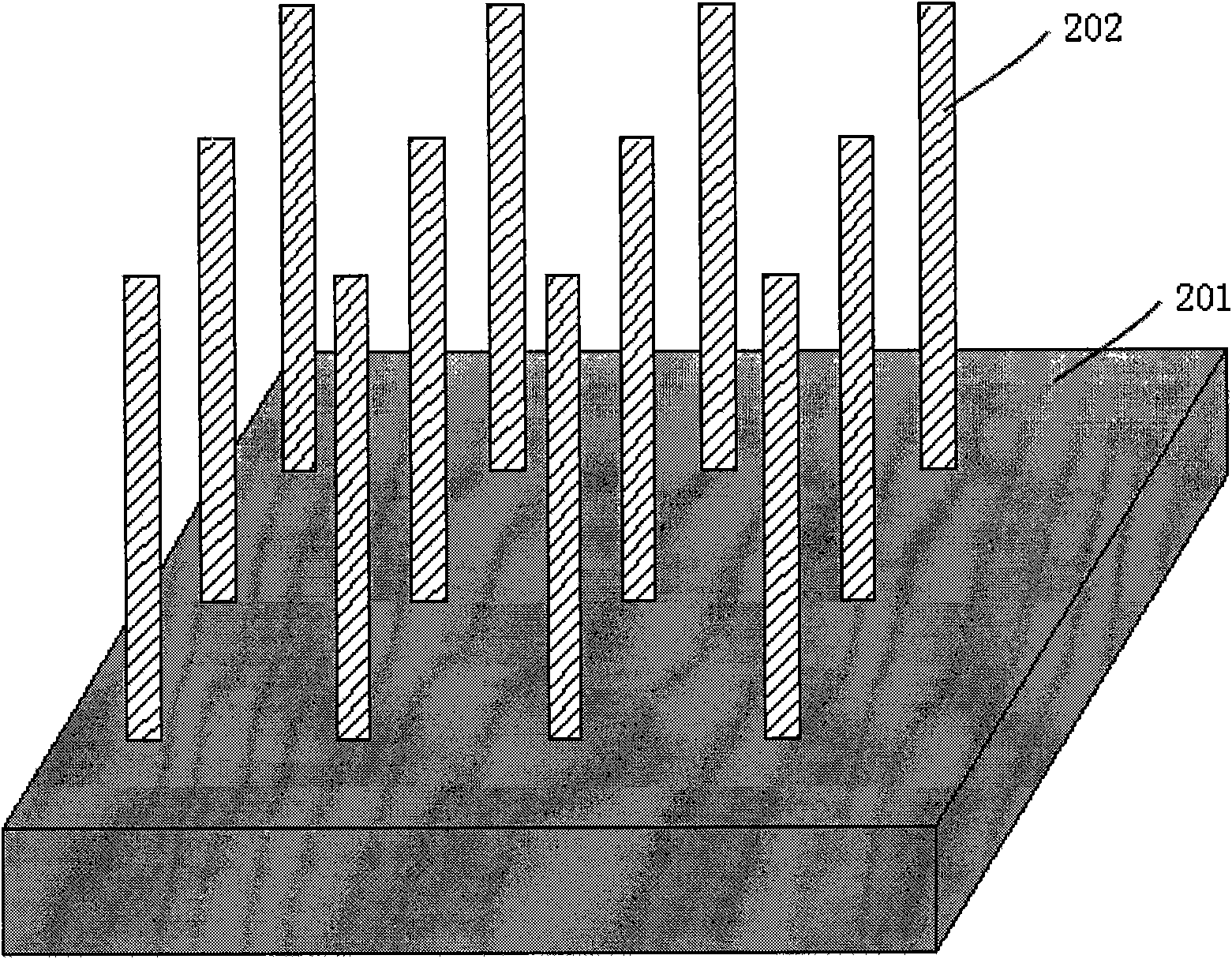

Resistive random access memory used in flexible circuits and production method thereof

InactiveCN101789439AAvoid high temperatureRealize the process is simpleSemiconductor/solid-state device detailsSolid-state devicesStatic random-access memoryHigh density

The invention, which belongs to the technical field of nonvolatile memories, discloses a resistive random access memory used in flexible circuits and a production method thereof. The invention utilizes contact printing to form two layers of high-density metal nanowires arranged perpendicular to one another, the metal nanowires are used as the electrodes of the resistive random access memory, and thereby an ultrahigh-density resistive random access memory array can be formed; meanwhile, the invention utilizes polymer material to form a p-n junction structure and a storage unit in the resistive random access memory, so that high temperature is avoided, and therefore the resistive random access memory can be integrated in a flexible circuit. The invention has the advantages of simple implementation technique, low cost and the like and does not need high-temperature annealing, and moreover, the invention is applicable to printed circuits.

Owner:FUDAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com