Patents

Literature

784results about How to "Avoid high temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

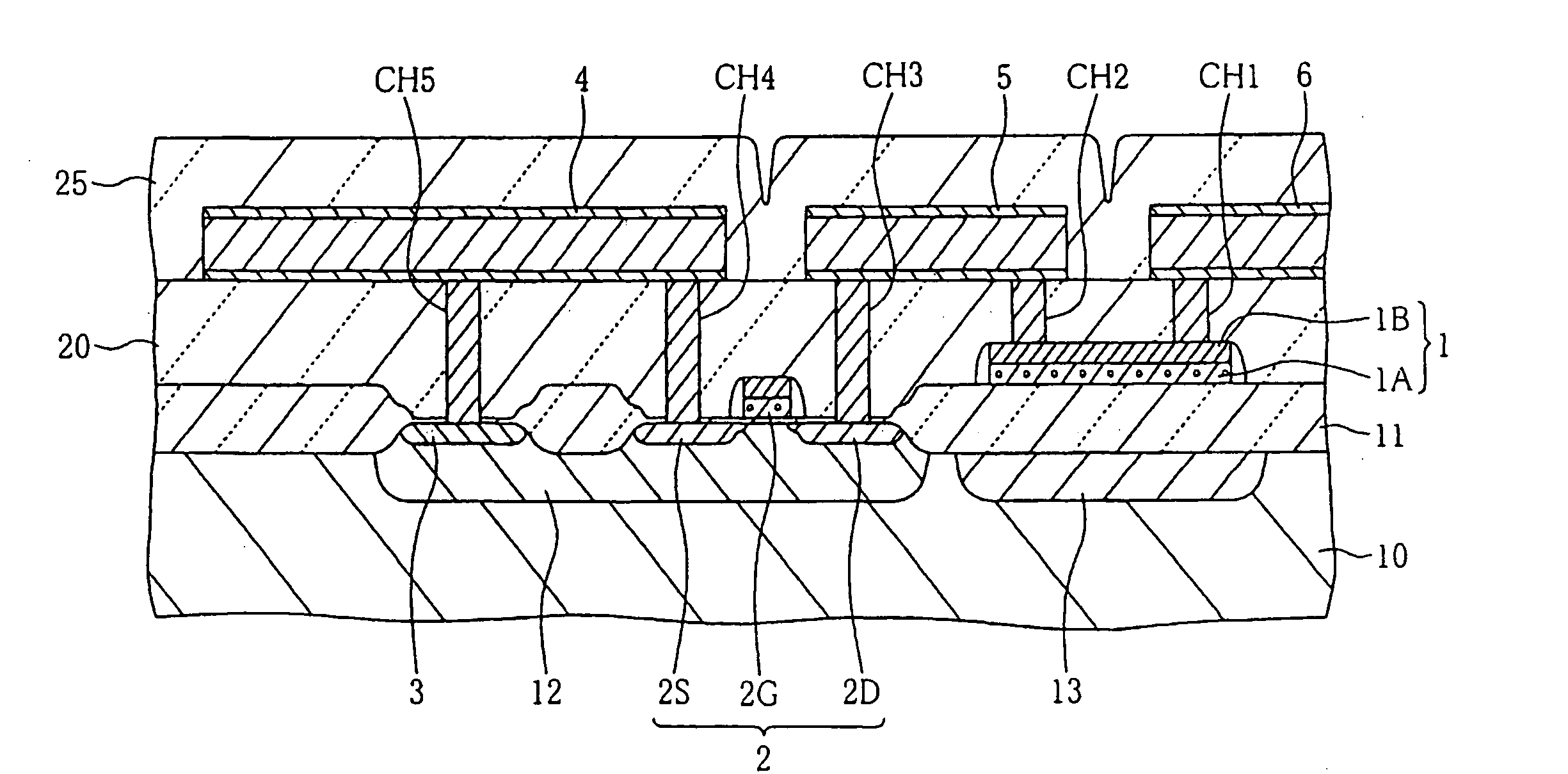

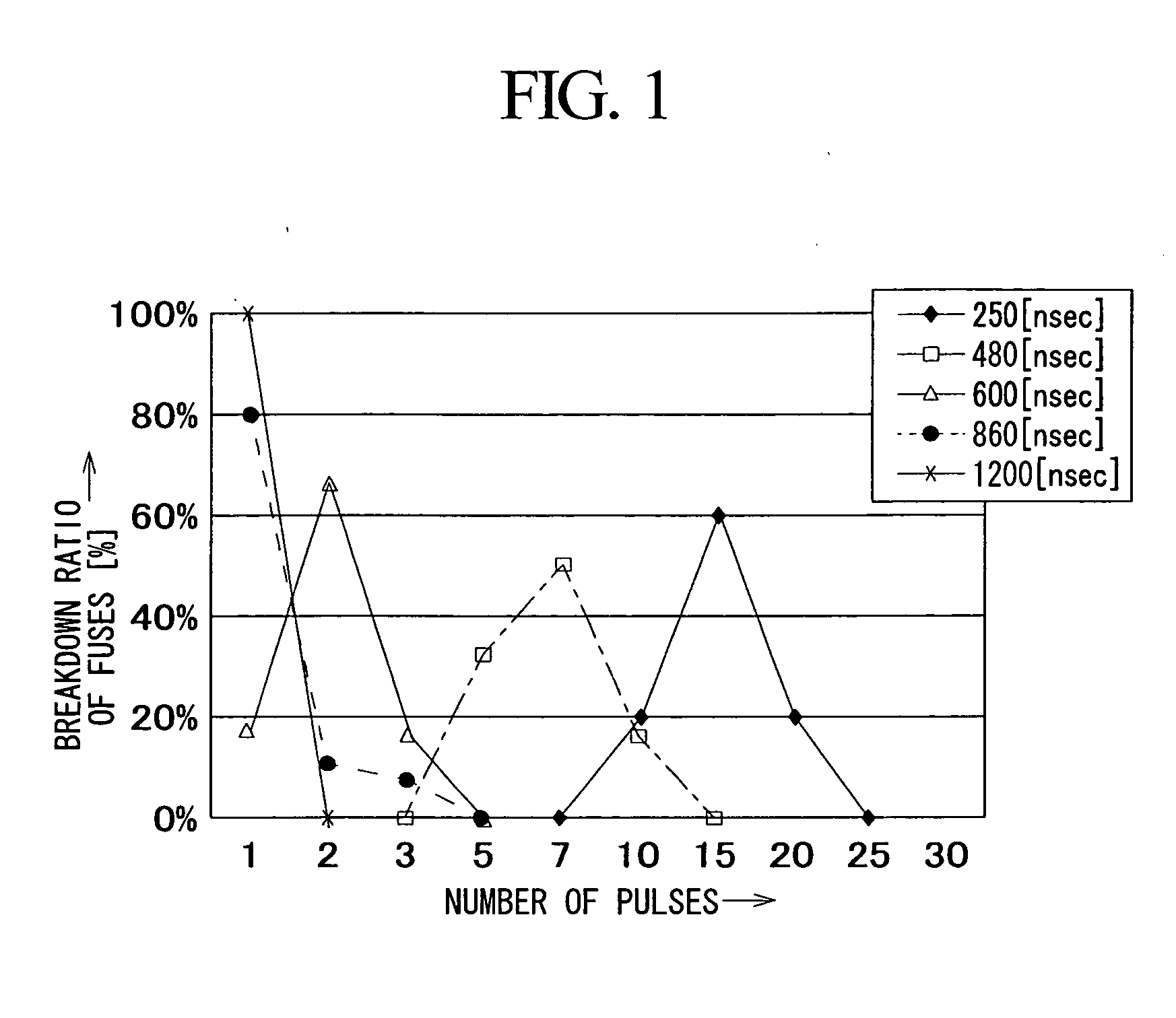

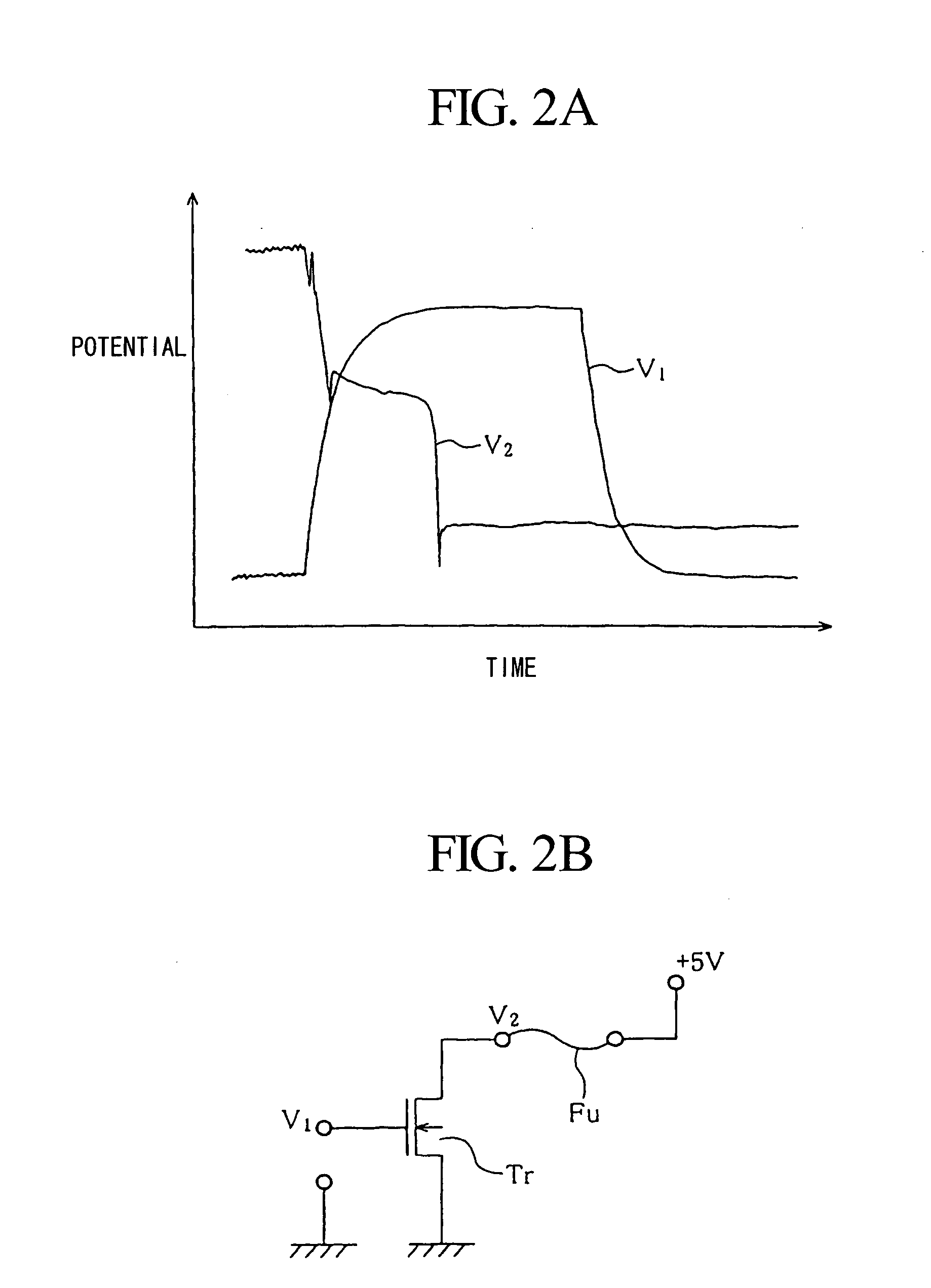

Fuse breakdown method adapted to semiconductor device

InactiveUS20070007621A1Increase distanceInhibit degassingTransistorSemiconductor/solid-state device detailsDevice materialEvaporation

A plurality of pulses each having relatively low energy are consecutively applied to a subject fuse to cause breakdown, wherein the total energy of pulses is set in light of a prescribed breakdown threshold, which is calculated in advance. The subject fuse has a pair of terminals and an interconnection portion that is narrowly constricted in the middle so as to realize fuse breakdown with ease. A pulse generator generates pulses, which are repeatedly applied to the subject fuse by way of a transistor; then, it stops generating pulses upon detection of fuse breakdown. Side wall spacers are formed on side walls of fuses, which are processed in a tapered shape so as to reduce thermal stress applied to coating insulating films. In addition, pulse energy is appropriately determined so as to cause electro-migration in the subject fuse, which is thus increased in resistance without causing instantaneous meltdown or evaporation.

Owner:YAMAHA CORP

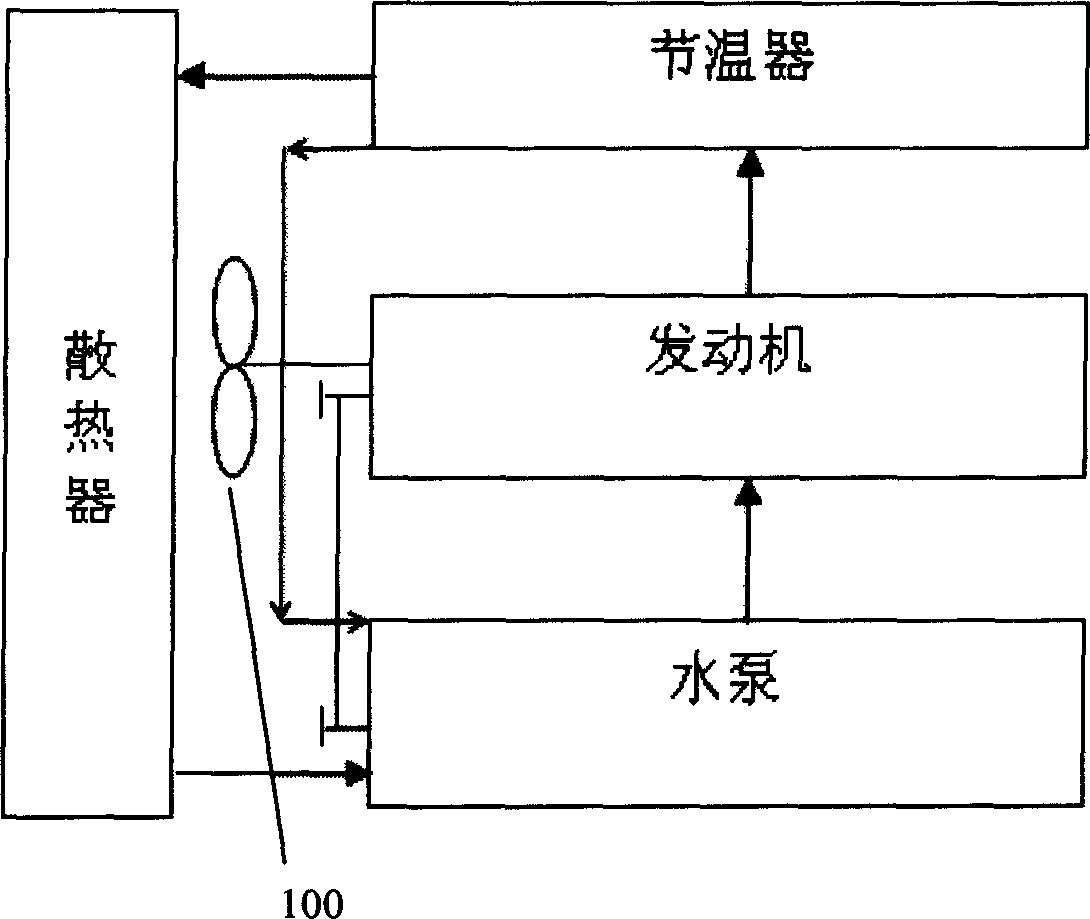

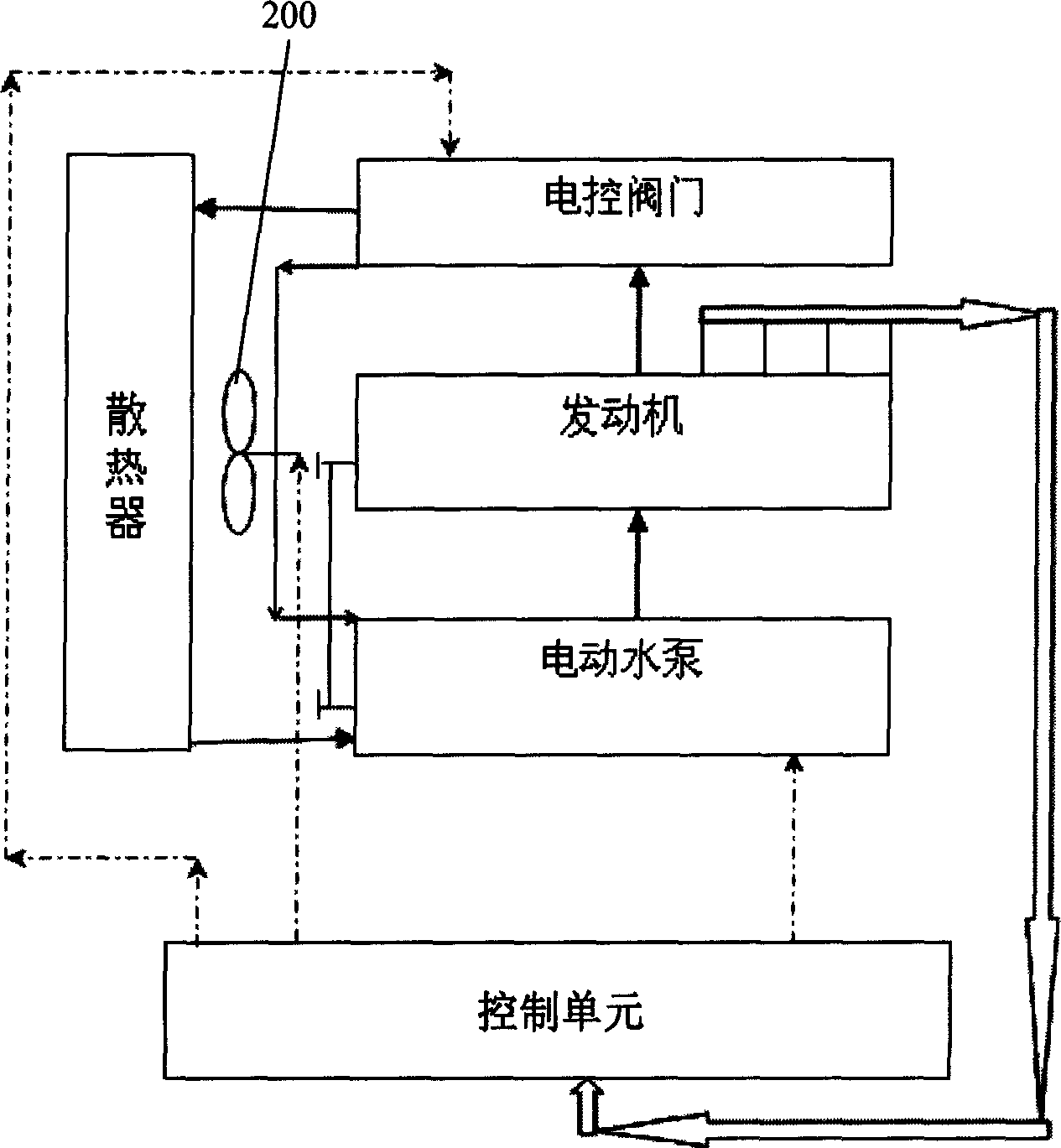

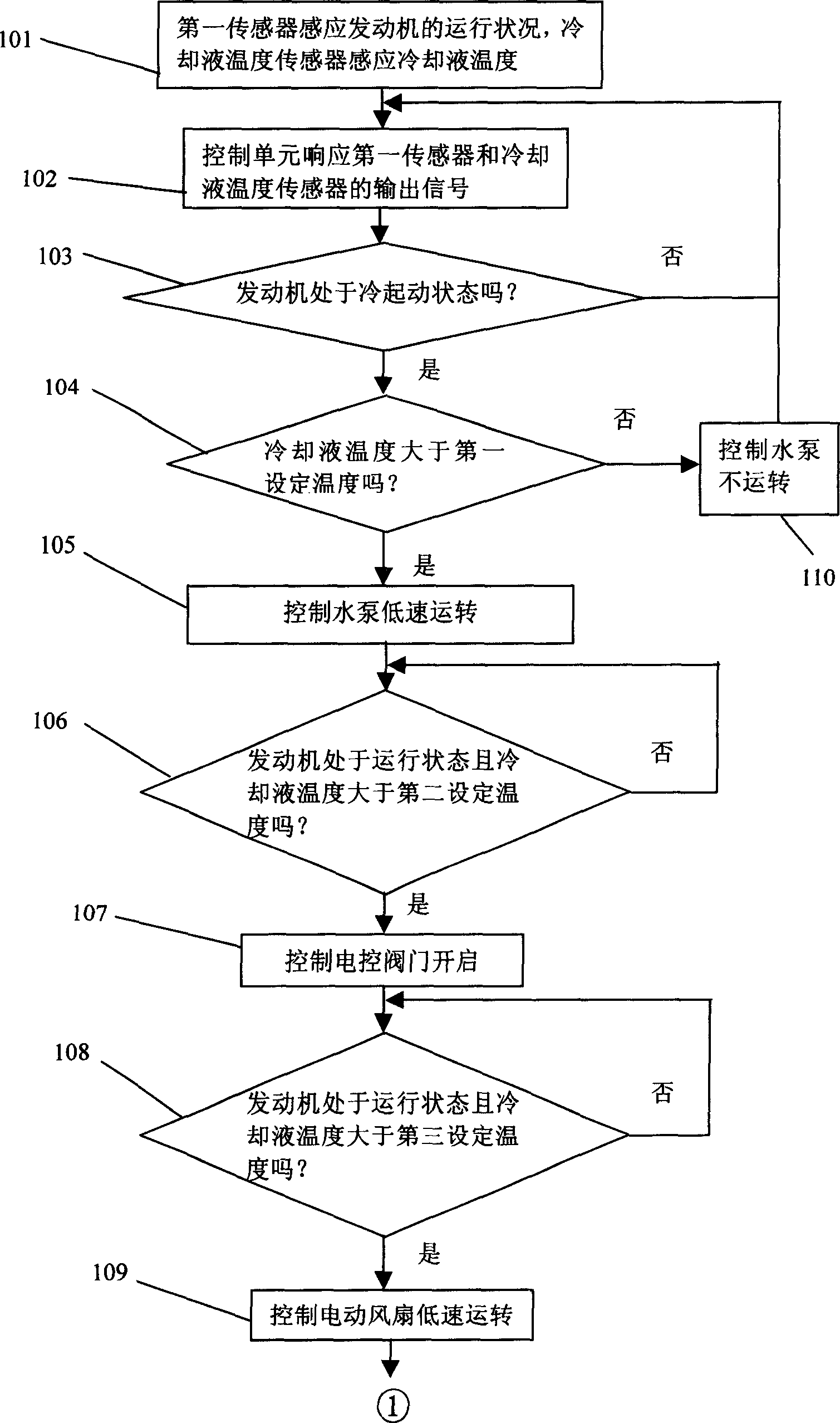

Water cooling system of engine and cooling method thereof

InactiveCN1884804AIncrease starting speedReduce exhaust pollutionLiquid coolingCoolant flow controlLiquid temperatureEngineering

The invention relates to an engine water cooling system and relative cooling method, wherein the first sensor senses the working condition of engine; the cooling liquid temperature sensor senses the temperature of cooling liquid inside the engine; the control unit responds the signals of first sensor and the cooling liquid temperature sensor, to control the electric water pump to operate when the temperature of cooling liquid is higher than the first preset temperature when the engine starts, to drive the cooling liquid to cool the engine, to improve the starting property of engine and the discharging property of heating machine; and the electric controller based on the operation parameter of engine and the temperature of cooling liquid, controls the switch of electric valve, the electric water pump and the rotation speed of electric fan, to control the circulation and the flux of cooling liquid, and the cooling ability of cooling fan, to improve the property of engine.

Owner:BYD CO LTD

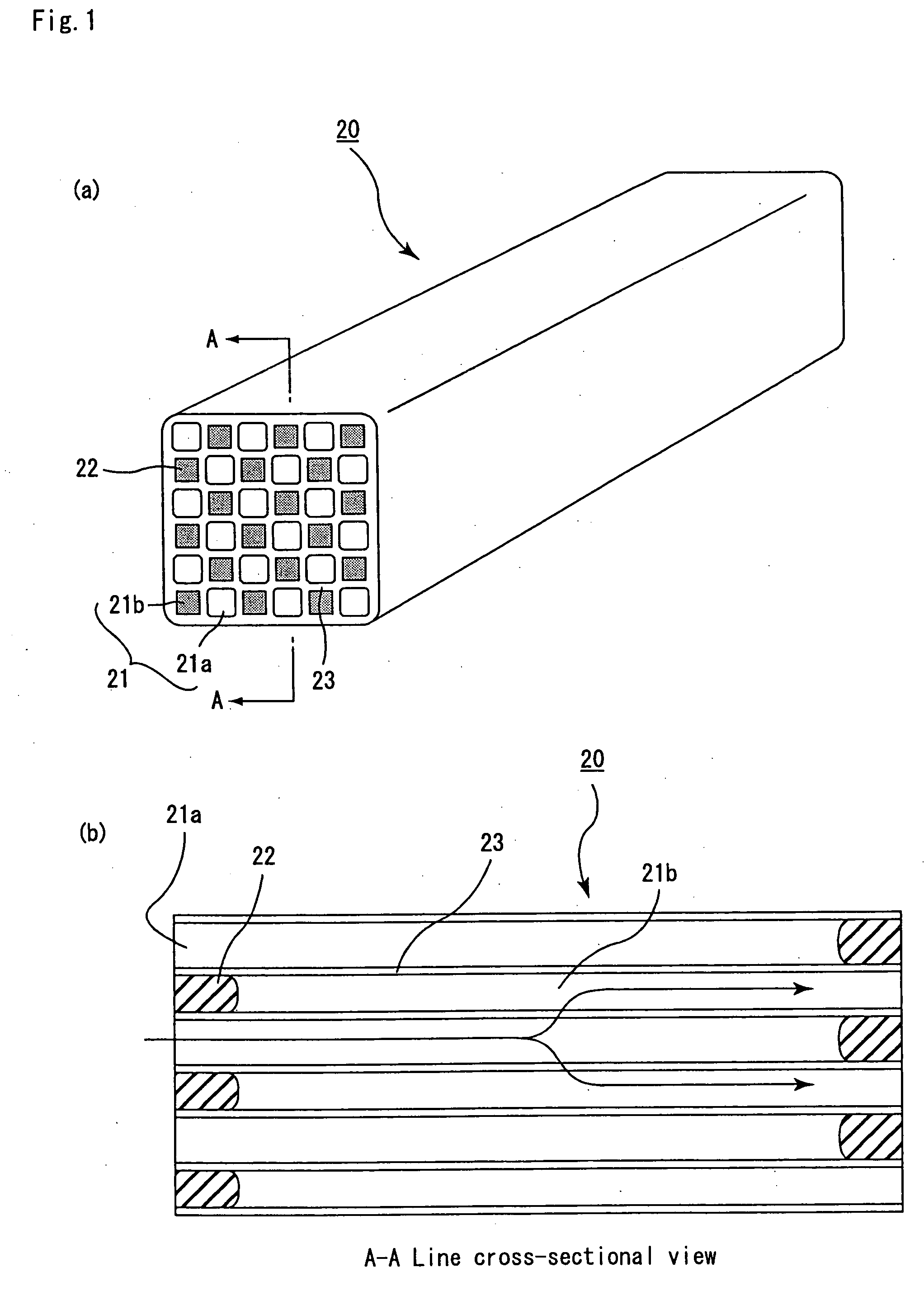

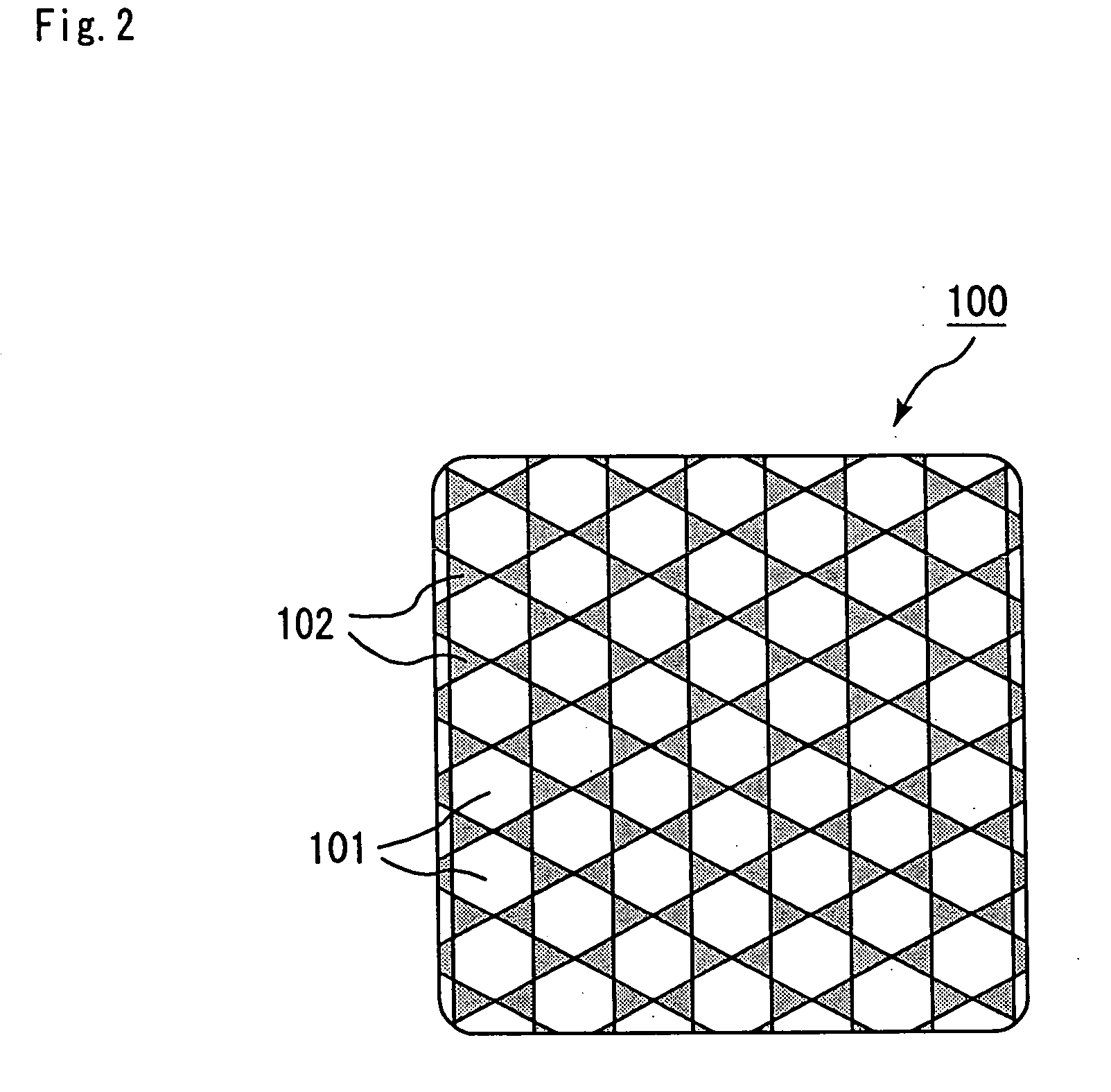

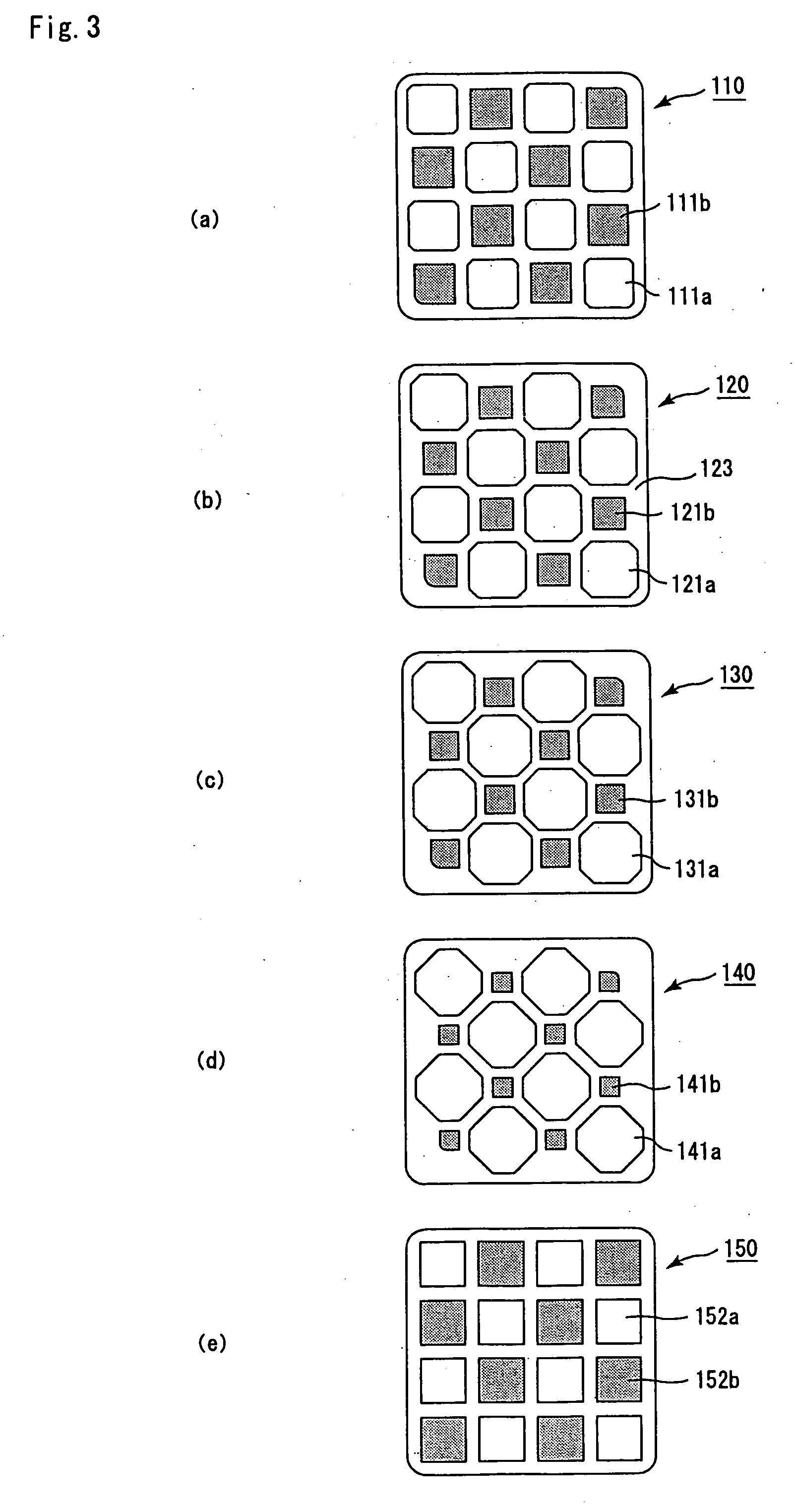

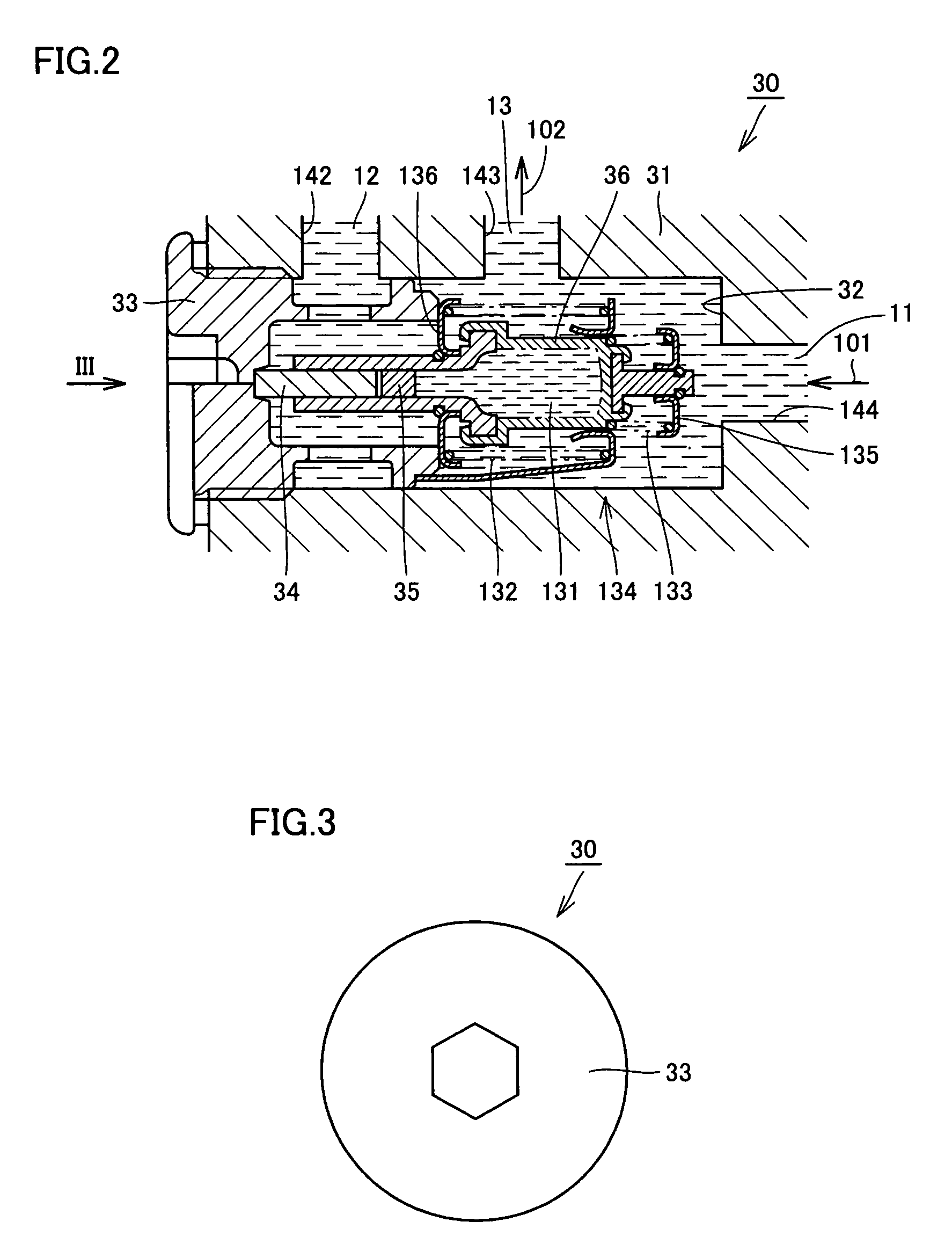

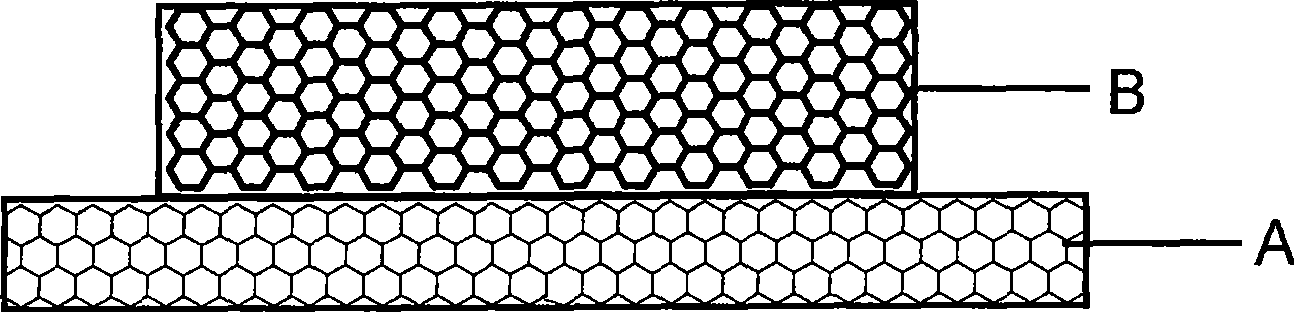

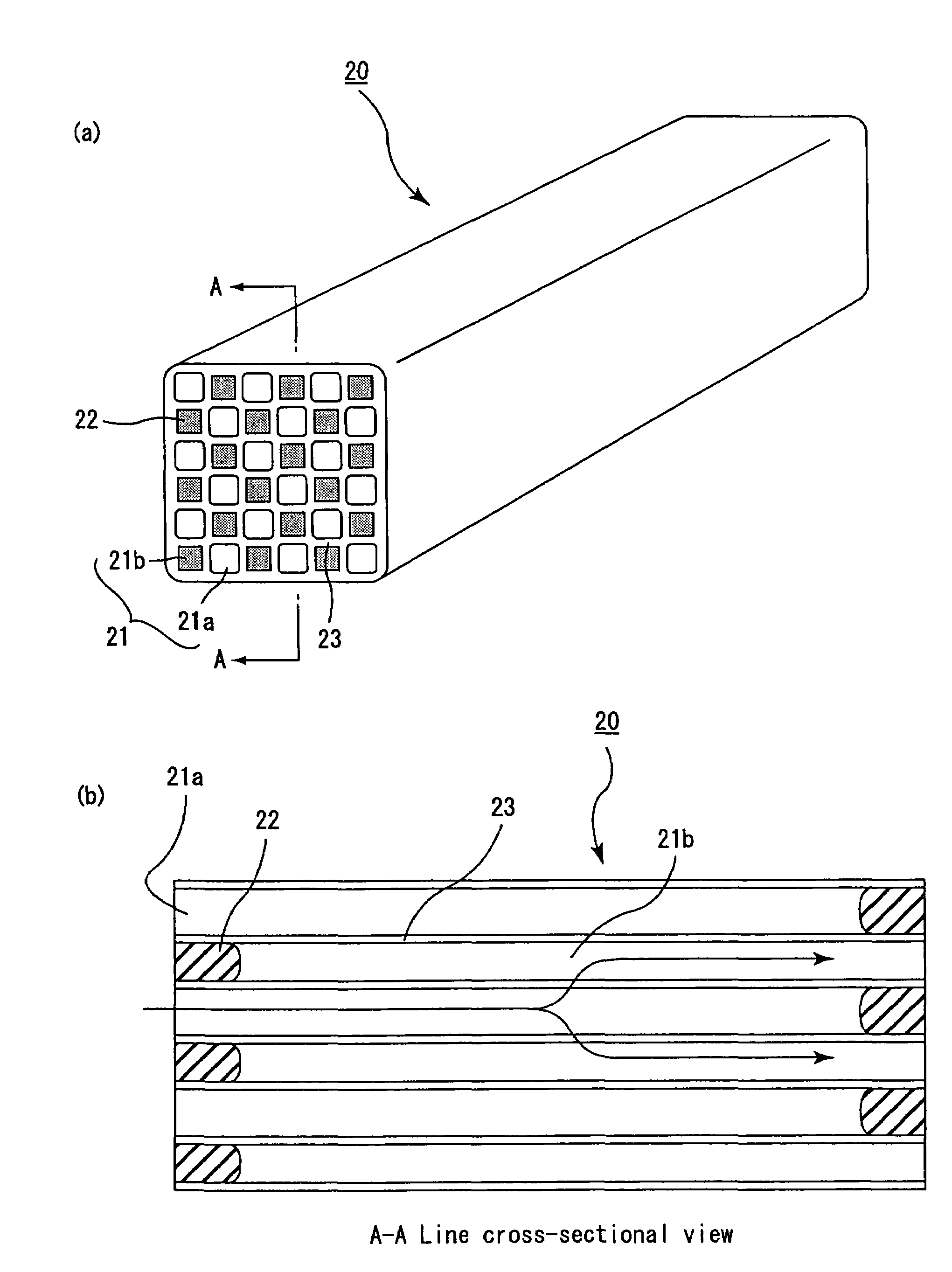

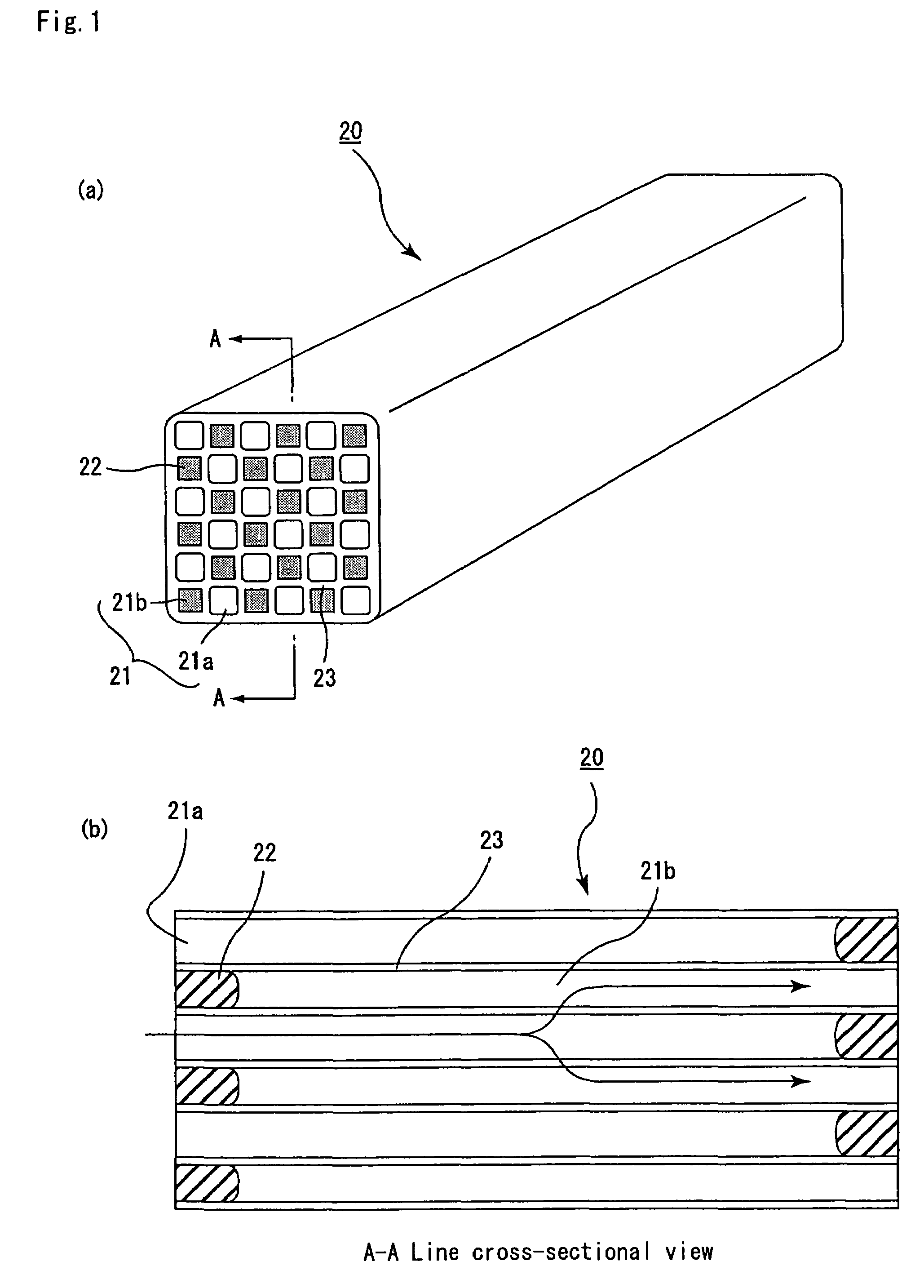

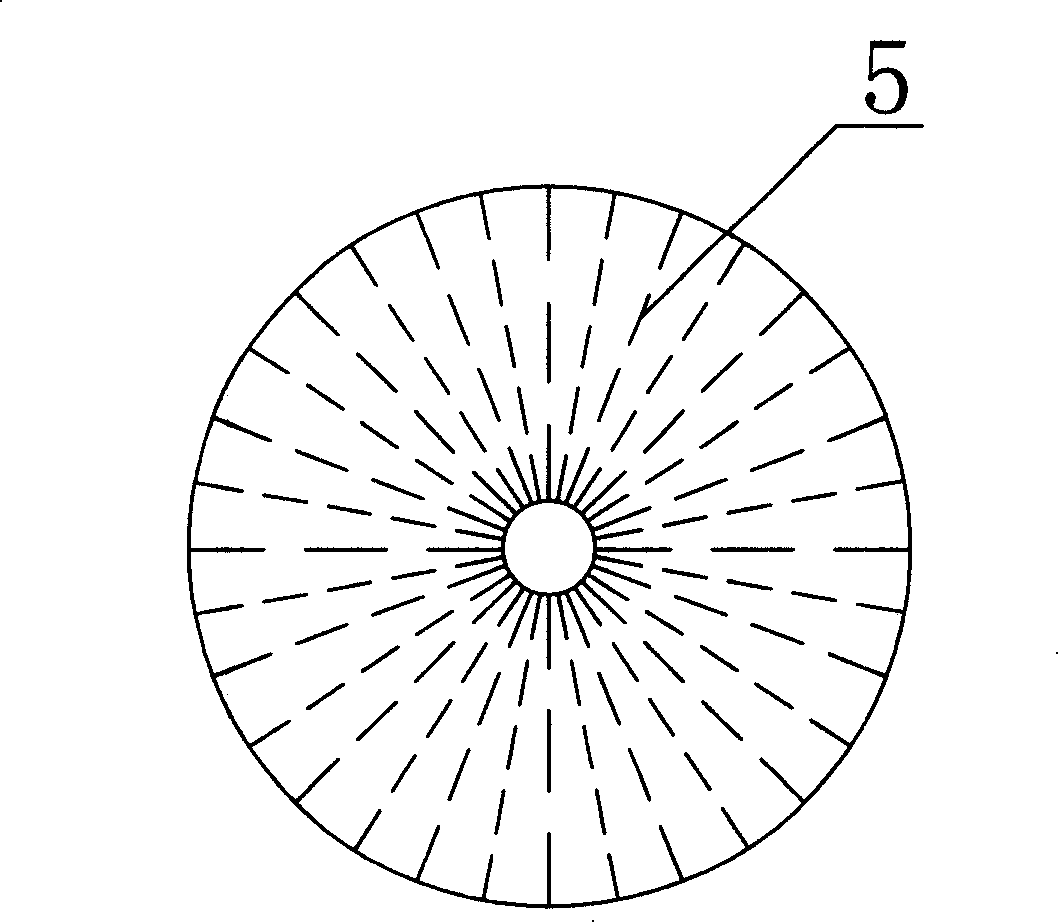

Honeycomb structure body

ActiveUS20060159602A1InhibitionReduce thermal stressCombination devicesCatalyst carriersHoneycomb structurePorous ceramics

An object of the present invention is to provide a honeycomb structural body which makes it possible to prevent a thermal stress from concentrating on plugs for sealing a group of inlet-side through holes and the vicinity thereof during a regenerating process, and consequently to prevent occurrence of cracks. The honeycomb structural body of the present invention is a pillar-shaped honeycomb structural body mainly made of porous ceramics, in which a plurality of through holes are placed in parallel with one another in the length direction with a partition wall interposed therebetween. Herein, the through holes are constituted by a group of inlet-side through holes, whose ends are sealed by plugs at the outlet side such that the total sum of areas on cross sections perpendicular to the length direction is made relatively greater, and a group of outlet-side through holes, whose ends are sealed by plugs at the inlet side such that the total sum of areas on the cross sections thereof is made relatively smaller. Supposing that the aperture rate on the inlet side is X (%) and that the total sum of thermal capacities of the plugs which seal the group of inlet-side through holes at 500° C. per 11.8 cm2 of the end face on the outlet side containing the group of the outlet-side through holes is represented by Y(J / K), the relationship indicated by the following inequalities (1) and (2) is satisfied. 0.0157X−0.0678<Y<1.15X−5 (1) 35≦X≦60 (2)

Owner:IBIDEN CO LTD

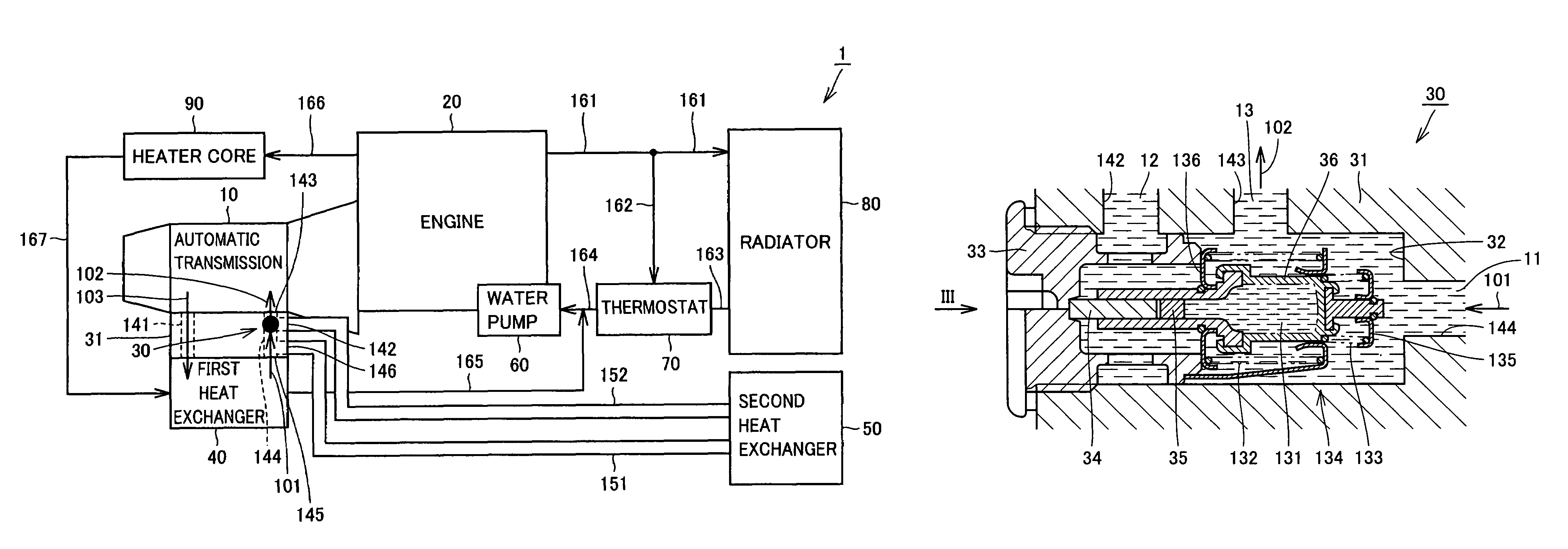

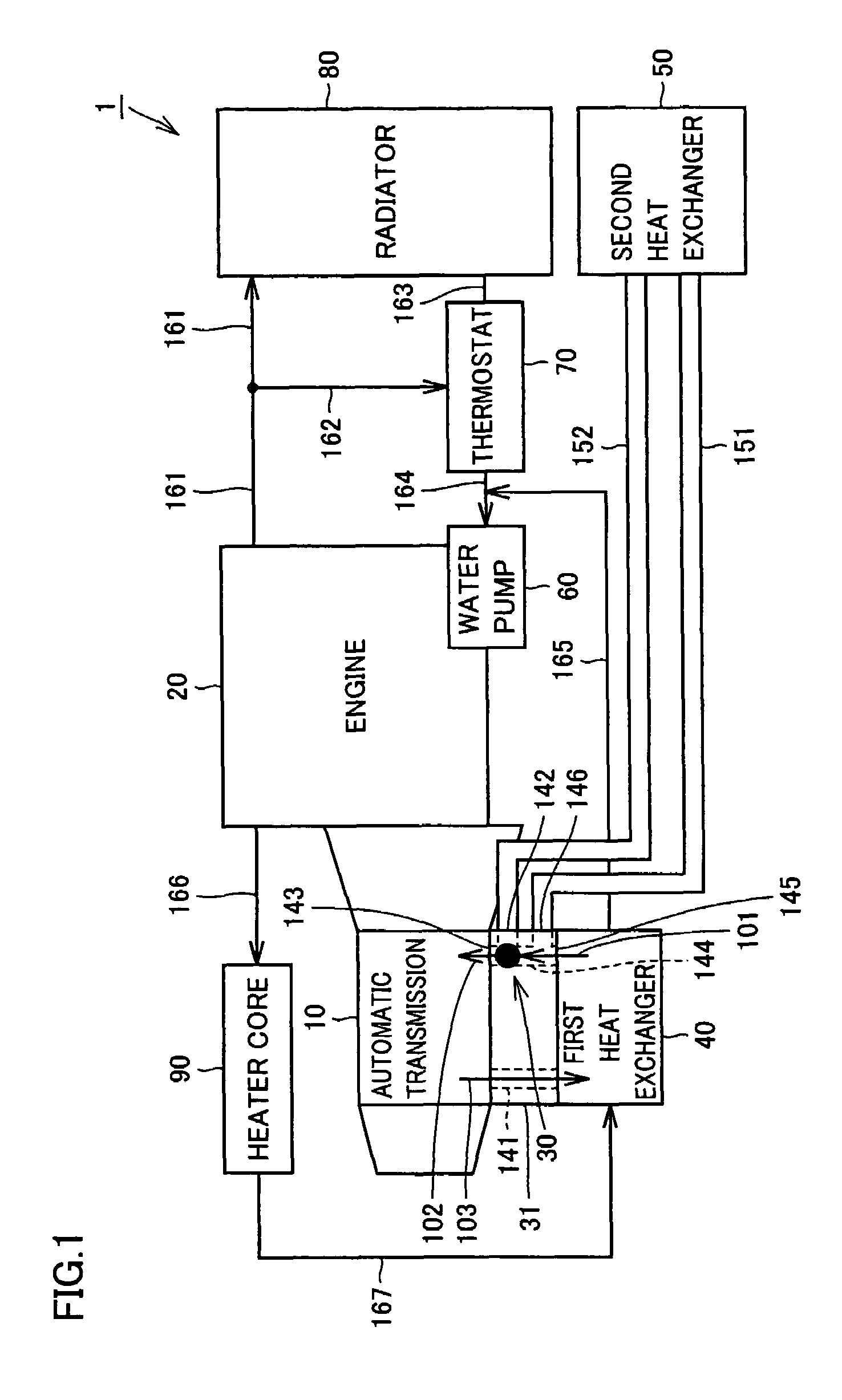

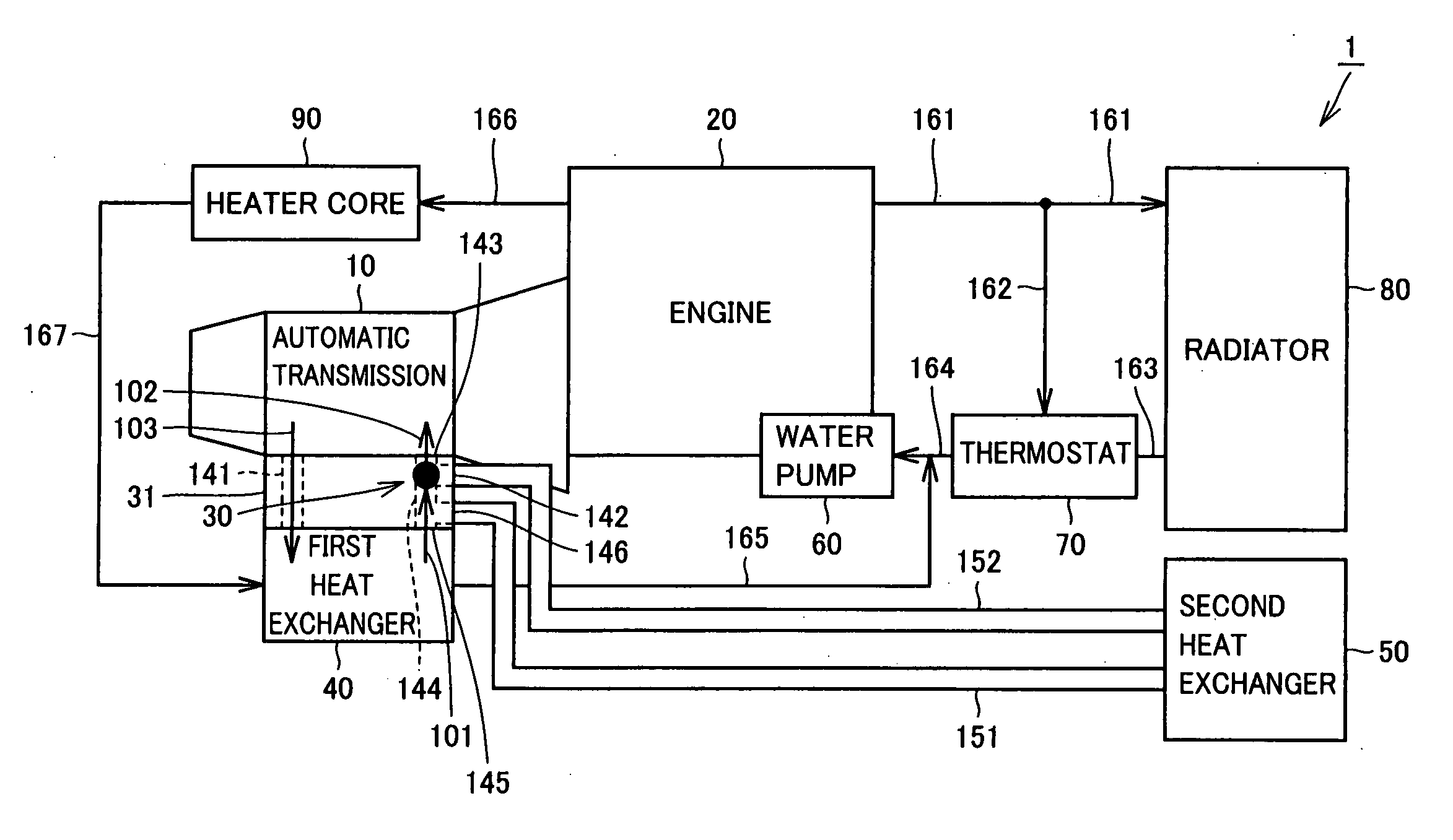

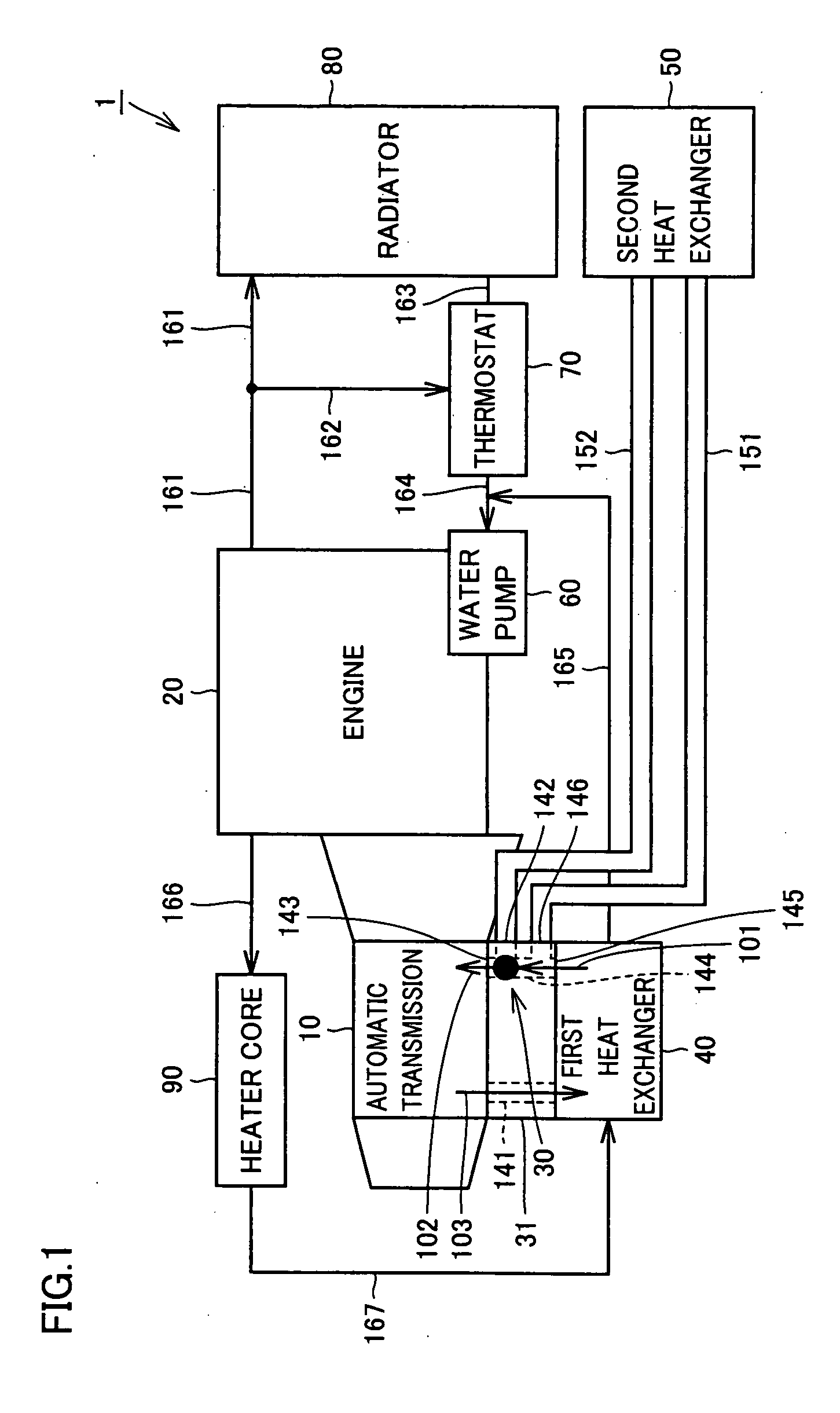

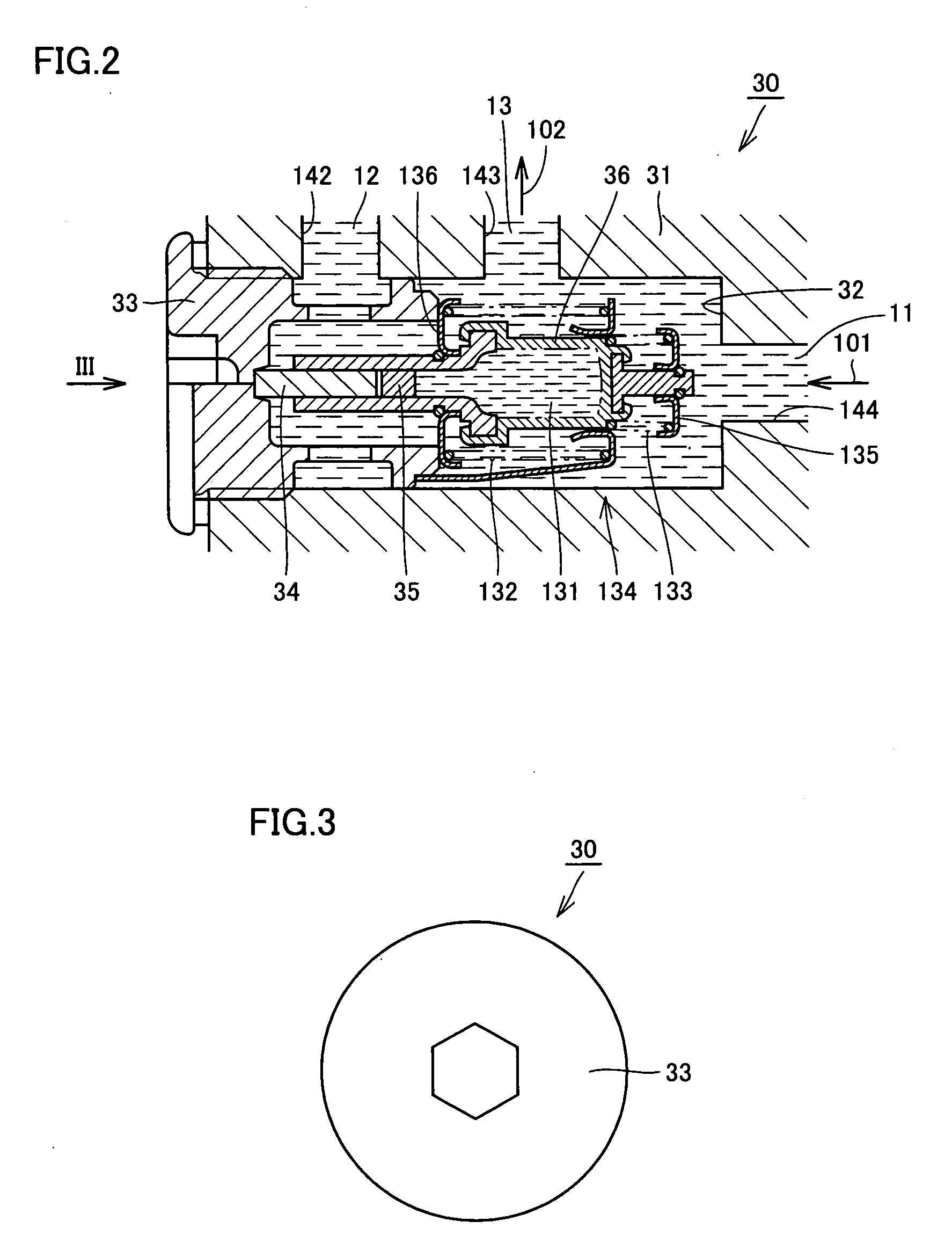

Heat exchanger structure of automatic transmission

InactiveUS7665513B2Heat radiationRapid temperatureTemperature control without auxillary powerGearboxesAutomatic transmissionEngineering

A heat exchanger structure of an automatic transmission stabilizing a temperature of oil is provided. A heat exchanger structure of an automatic transmission includes an automatic transmission, a first heat exchanger provided on an upstream side and a second heat exchanger provided on a downstream side, each capable of cooling oil ejected from the automatic transmission, and a thermo valve capable of supplying oil subject to heat exchange by at least one of first and second heat exchangers to the automatic transmission. When a temperature of the oil is relatively low, the thermo valve supplies oil passed through the first heat exchanger to the automatic transmission and shuts off a flow of oil from the second heat exchanger to the automatic transmission. When a temperature of the oil is relatively high, the thermo valve supplies oil passed through first and second heat exchangers to the automatic transmission.

Owner:TOYOTA JIDOSHA KK

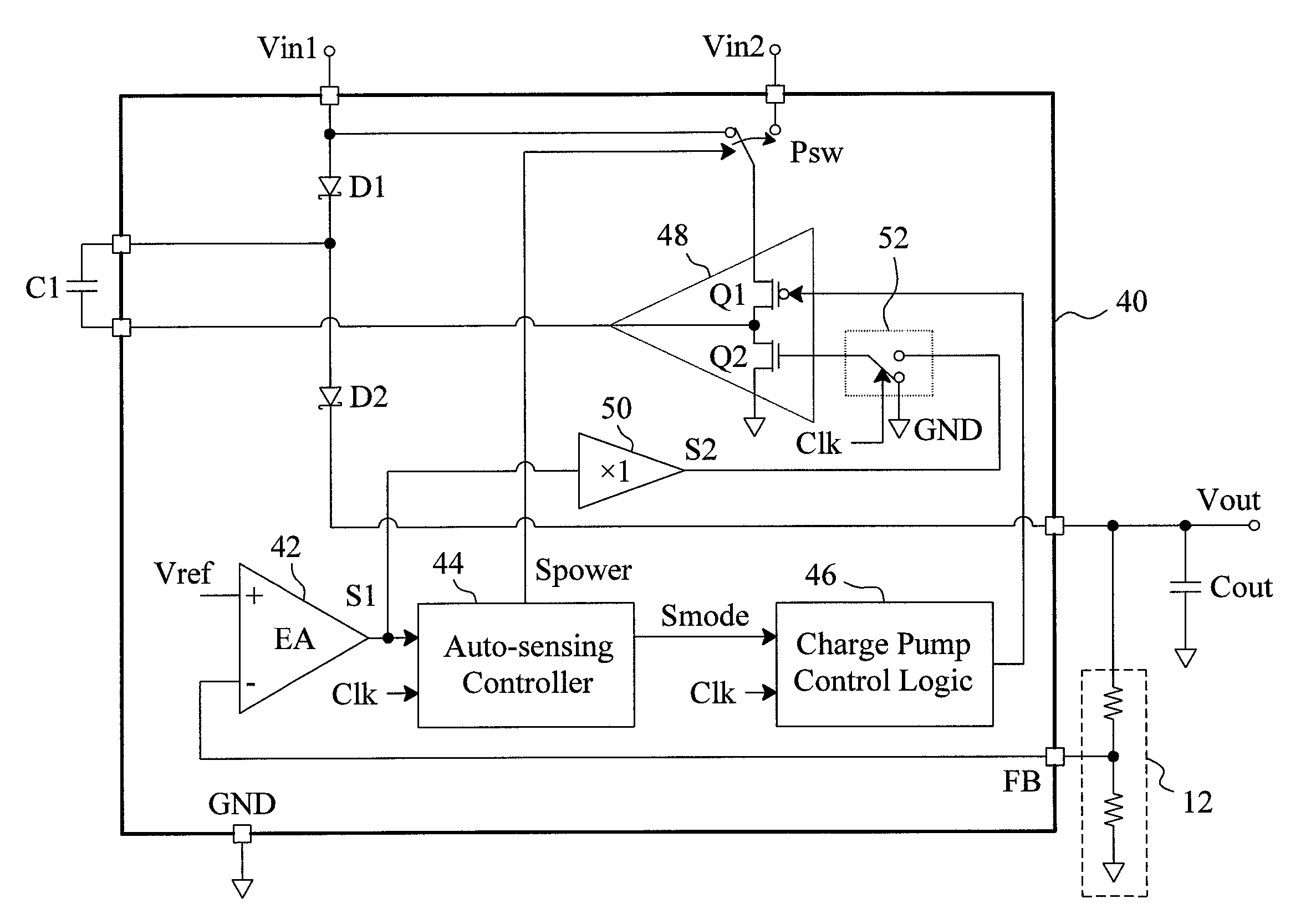

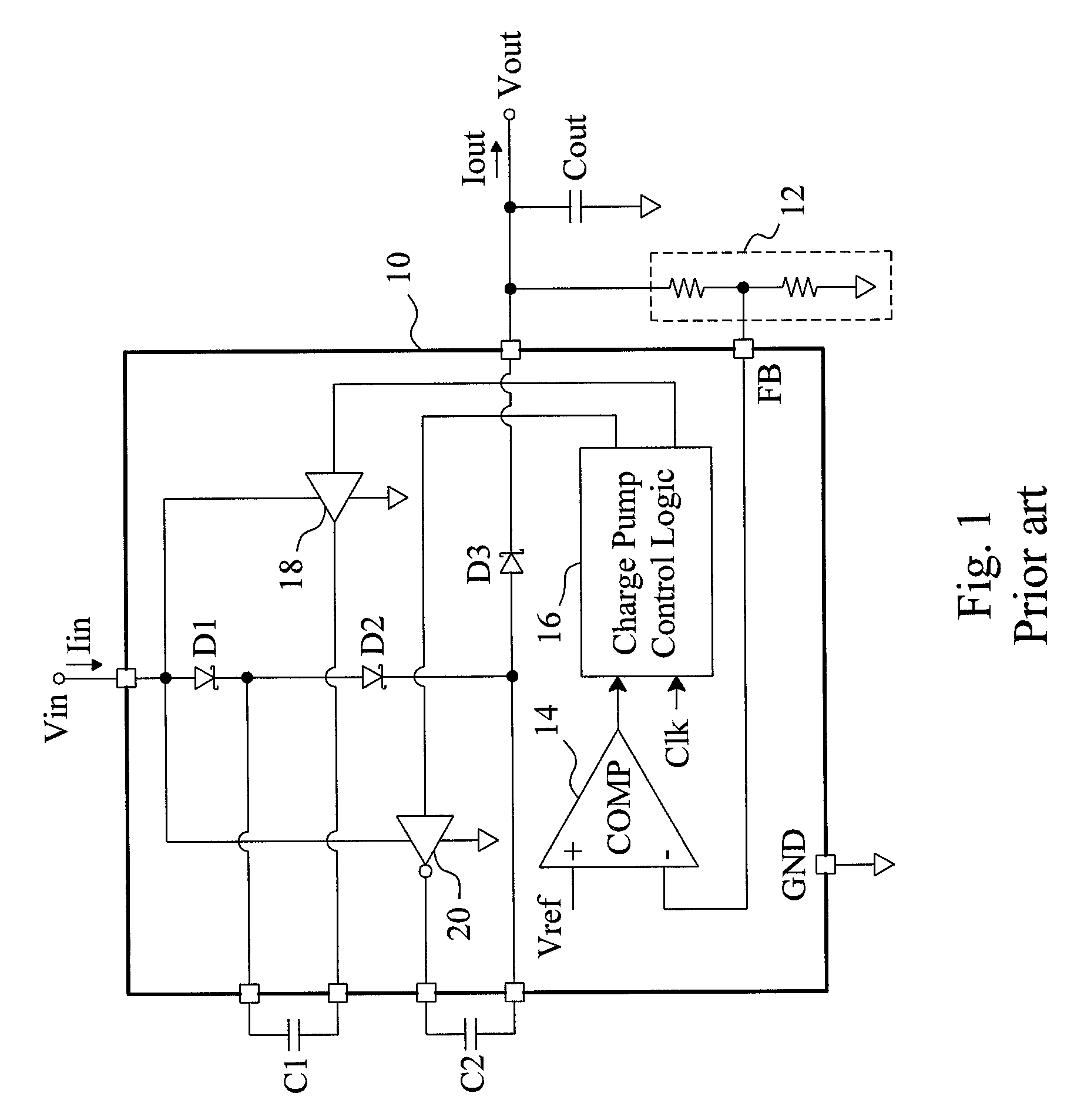

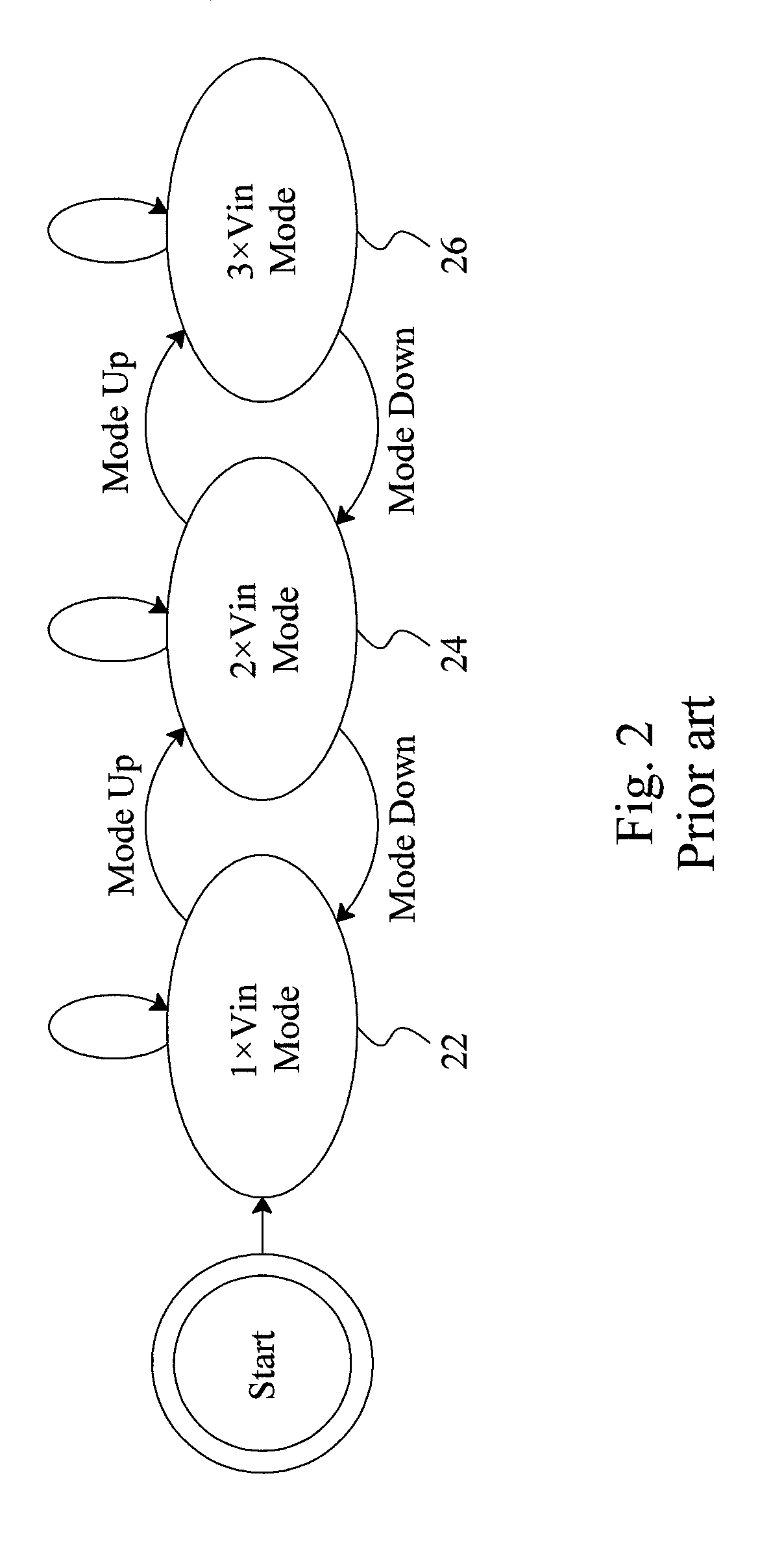

Efficiency and thermal improvement of a charge pump by mixing different input voltages

InactiveUS8193853B2Improve charging efficiencyReduce heatAc-dc conversionApparatus without intermediate ac conversionOperation modeControl circuit

Owner:RICHTEK TECH

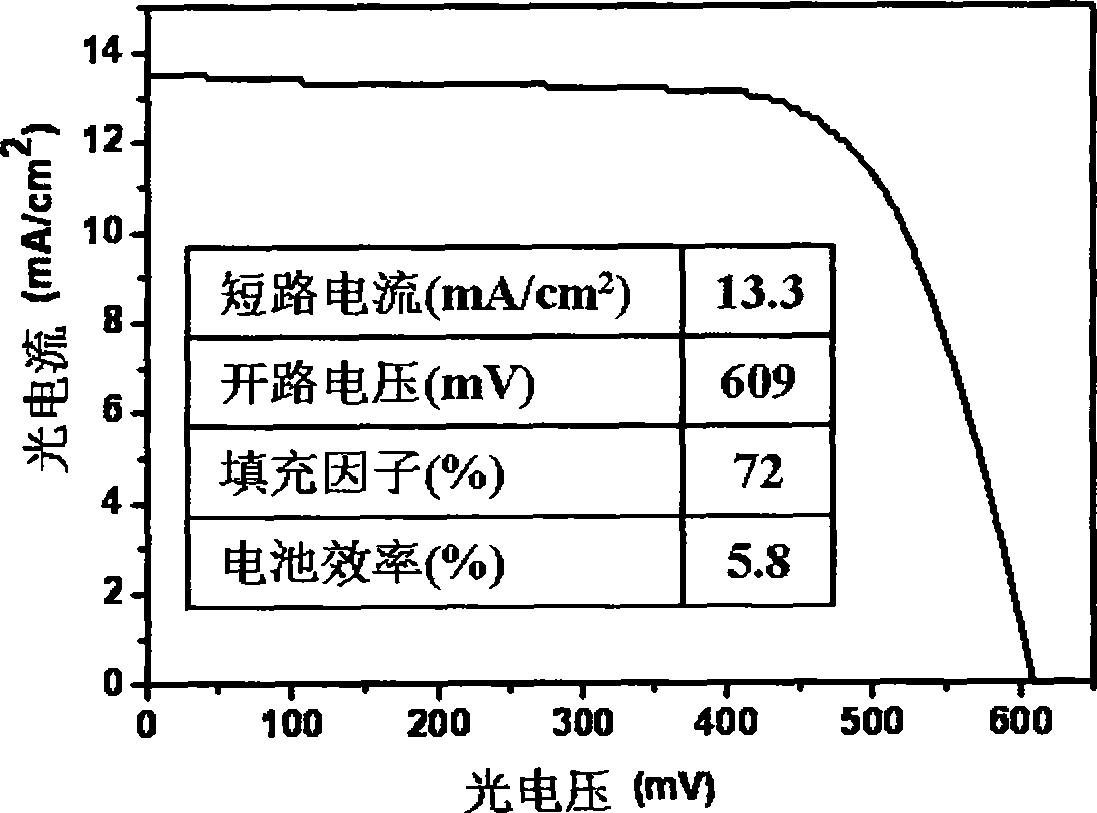

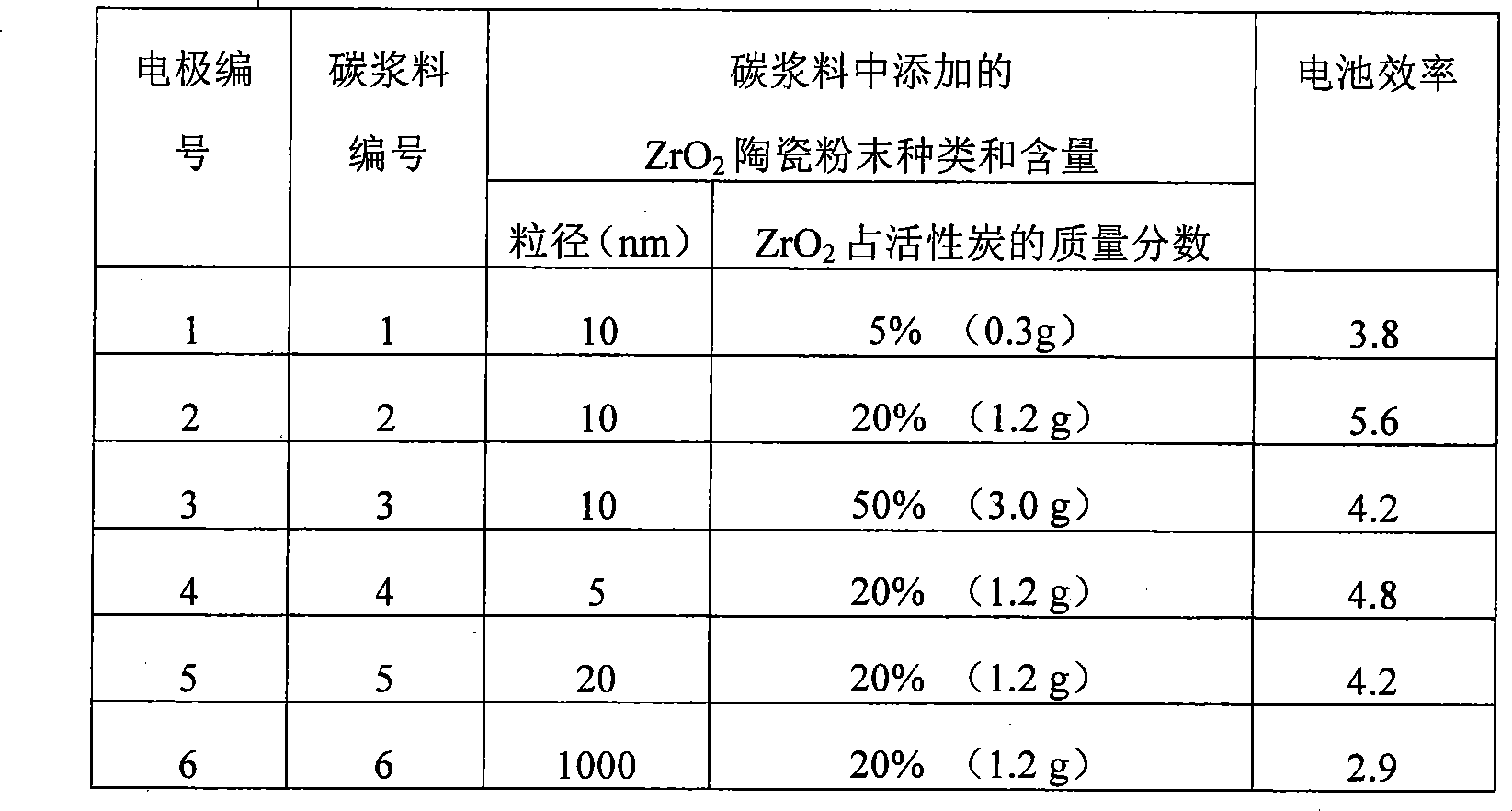

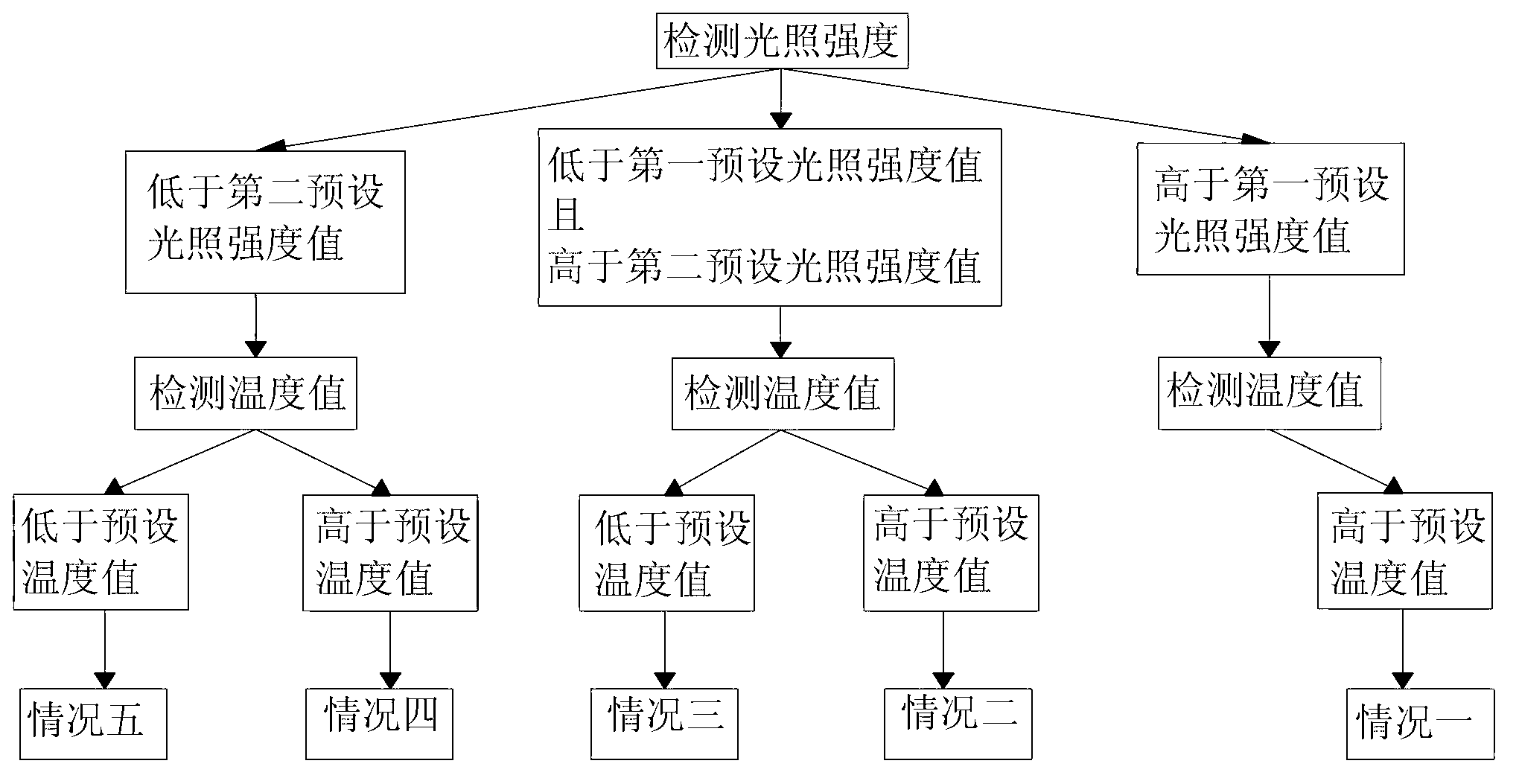

Full carbon counter electrode dye-sensitized solar cell and preparing method

ActiveCN101388294AGood mechanical properties such as friction resistanceImprove mechanical propertiesLight-sensitive devicesElectrode manufacturing processesElectrical batteryFilm coating

The invention relates to an all carbon counter electrode for a dye-sensitized solar cell and a process for preparation, wherein the all carbon counter electrode is formed by a carbon substrate A and a carbon catalytic active layer B which is coated on the carbon substrate. The process for preparing the all carbon counter electrode comprises firstly dispersing carbon catalytic active material and making into carbon paste according to the process of preparing carbon paste disclosed by the patient closure number CN101188257A, then transferring to the clean carbon substrate A through the methods of screen painting, spread coating, rotary film coating, film dropping or Czochralski method, and finally preparing the all carbon counter electrode through drying or kilning. The all carbon electrode of the invention can reduce series resistance and interface resistance, thereby increasing the short-circuit current (Jsc), filling factor (FF) and photoelectric transformation efficiency of the dye-sensitized solar cell. The substrate material adopted by the all carbon counter electrode of the invention has smaller resistance, can reduce using or avoid using metal flow concentration leads, and simplifies preparation technology.

Owner:深圳市华物光能技术有限公司

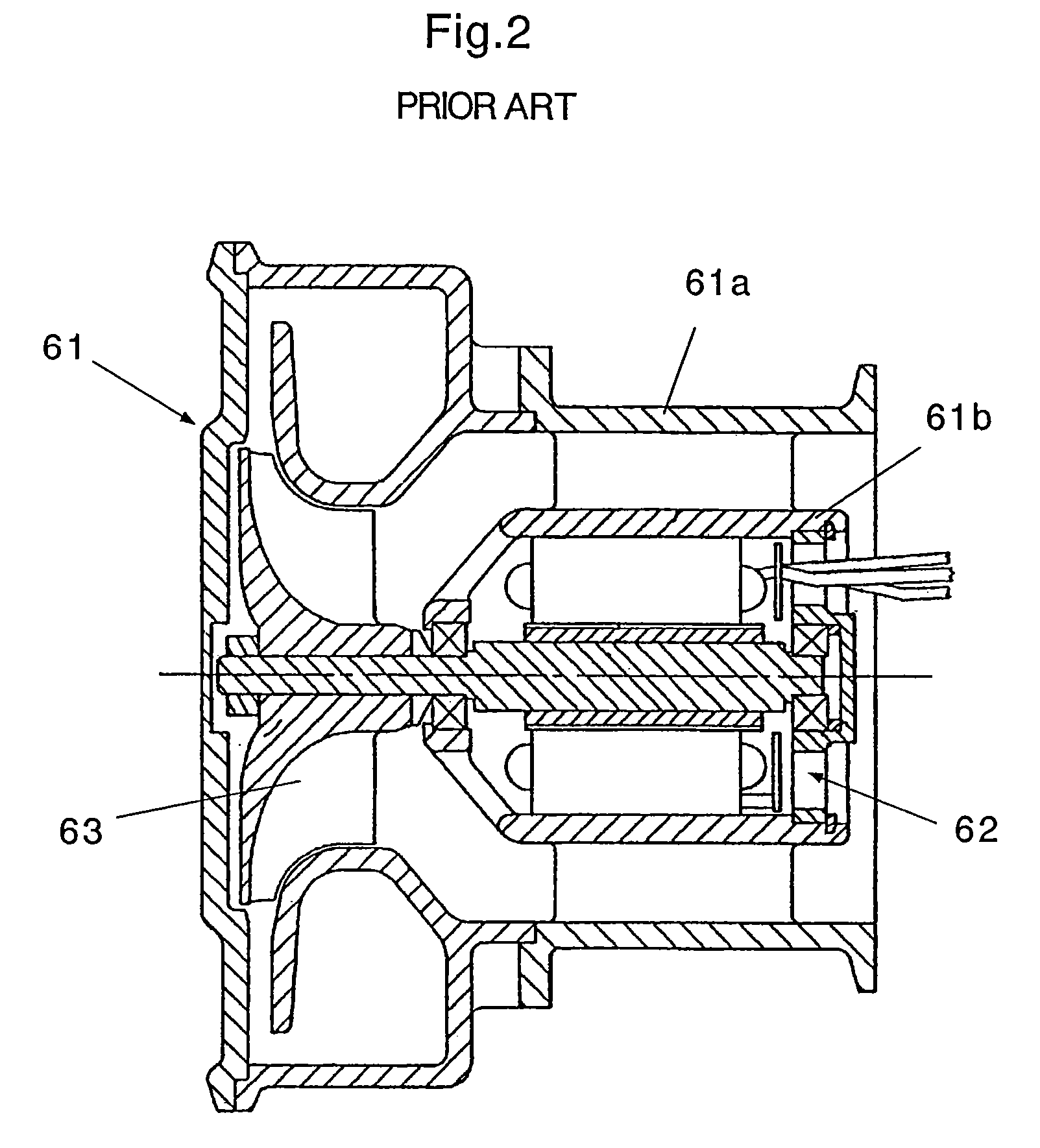

Heat exchanger structure of automatic transmission

InactiveUS20060060346A1Temperature stabilityHeat radiationGearboxesTemperatue controlAutomatic transmissionEngineering

A heat exchanger structure of an automatic transmission stabilizing a temperature of oil is provided. A heat exchanger structure of an automatic transmission includes an automatic transmission, a first heat exchanger provided on an upstream side and a second heat exchanger provided on a downstream side, each capable of cooling oil ejected from the automatic transmission, and a thermo valve capable of supplying oil subject to heat exchange by at least one of first and second heat exchangers to the automatic transmission. When a temperature of the oil is relatively low, the thermo valve supplies oil passed through the first heat exchanger to the automatic transmission and shuts off a flow of oil from the second heat exchanger to the automatic transmission. When a temperature of the oil is relatively high, the thermo valve supplies oil passed through first and second heat exchangers to the automatic transmission.

Owner:TOYOTA JIDOSHA KK

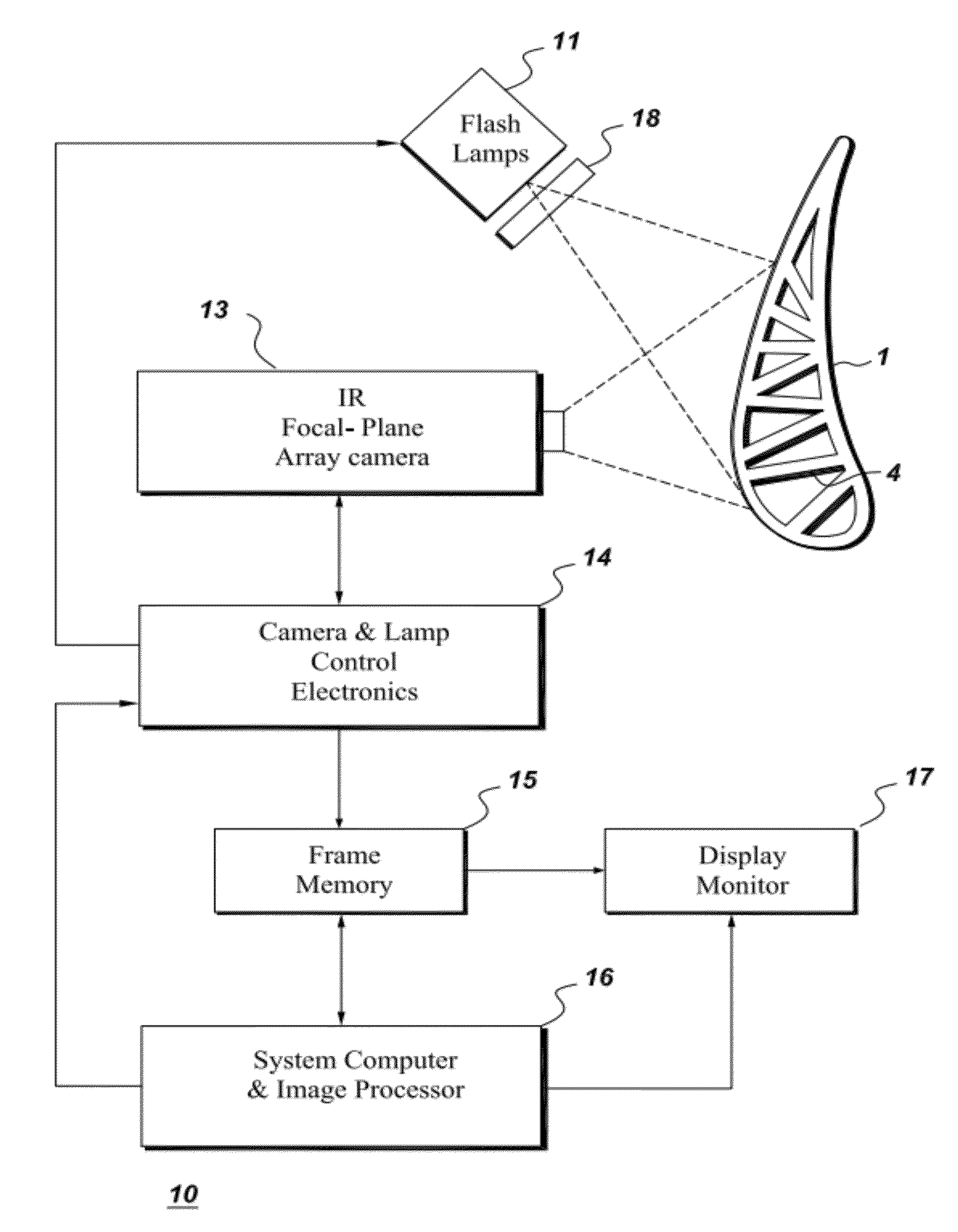

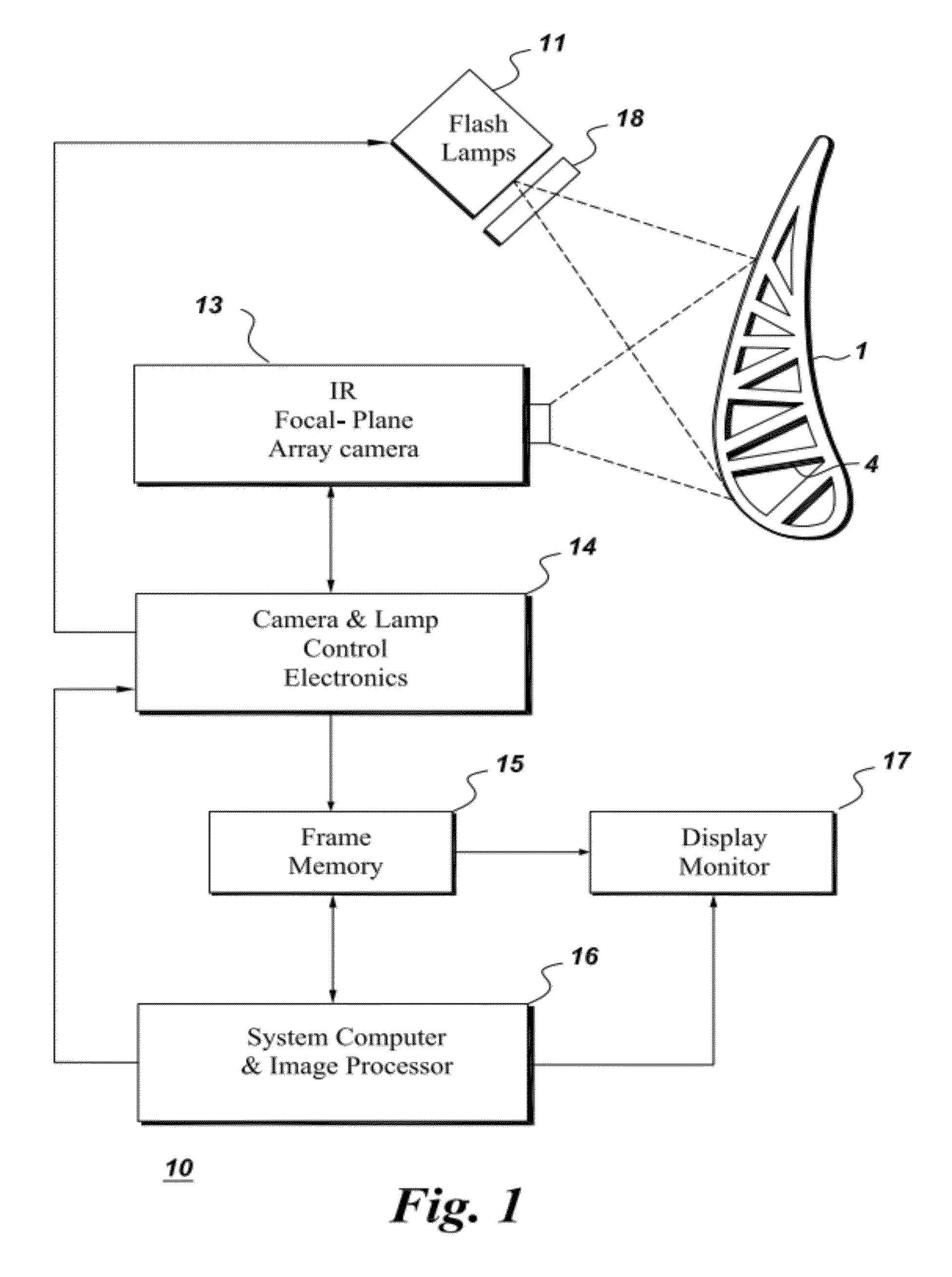

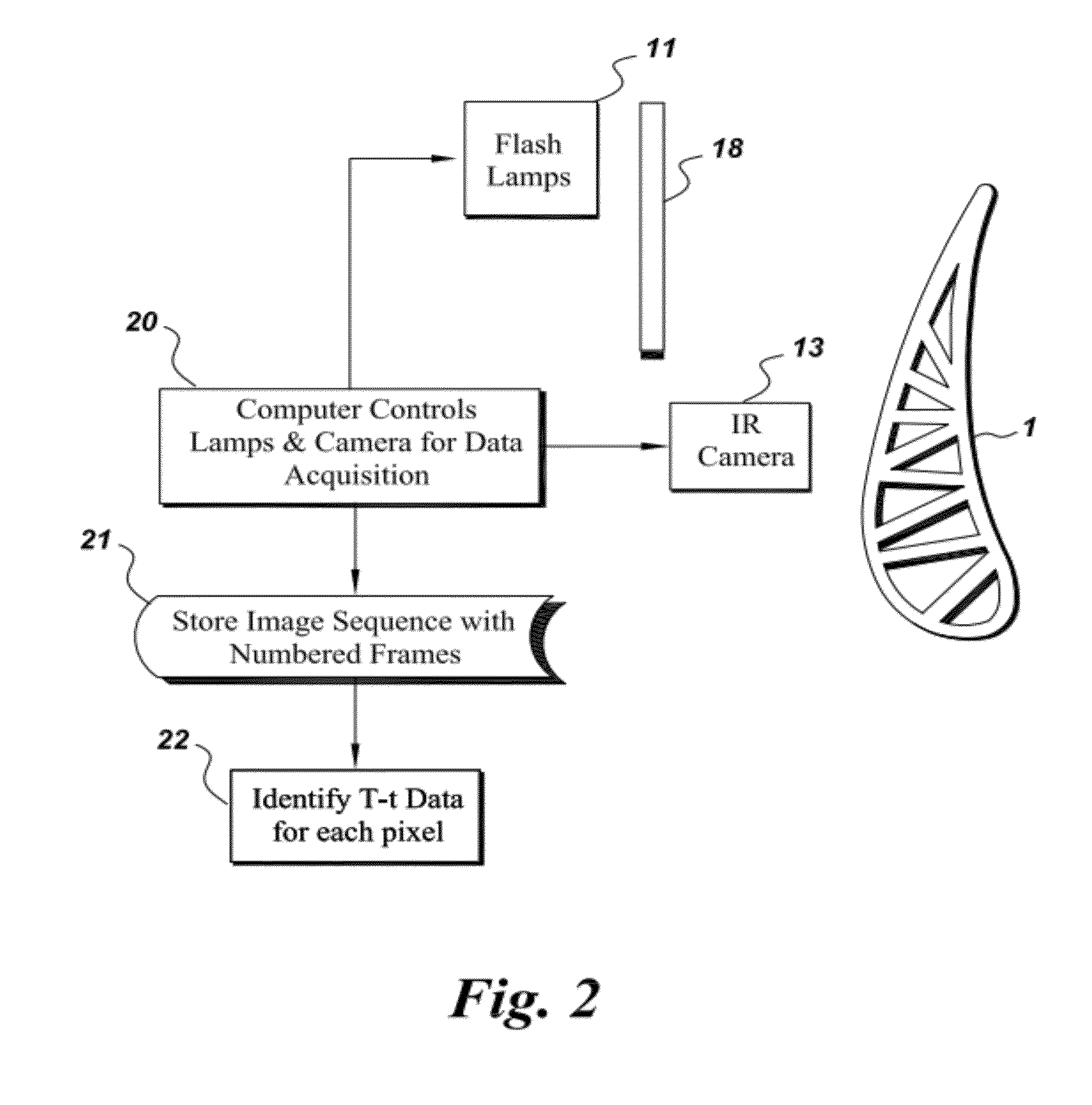

Thermal imaging method and appratus for evaluating coatings

InactiveUS20120050537A1Avoid high temperatureTelevision system detailsDigital computer detailsVariable thicknessCoated surface

An apparatus is provided for determining variable thickness of a coating on a surface of a substrate using in part a flash-lamp source, capable of generating a thermal pulse at the coating surface, and a image capture and processing device capable of capture sequential image frames of the coating surface, whereas each sequential image frame corresponds to an elapsed time and comprises a pixel array, and wherein each pixel of the array corresponds to a location on the coating surface. A method of calculating coating thickness is also provided.

Owner:GENERAL ELECTRIC CO

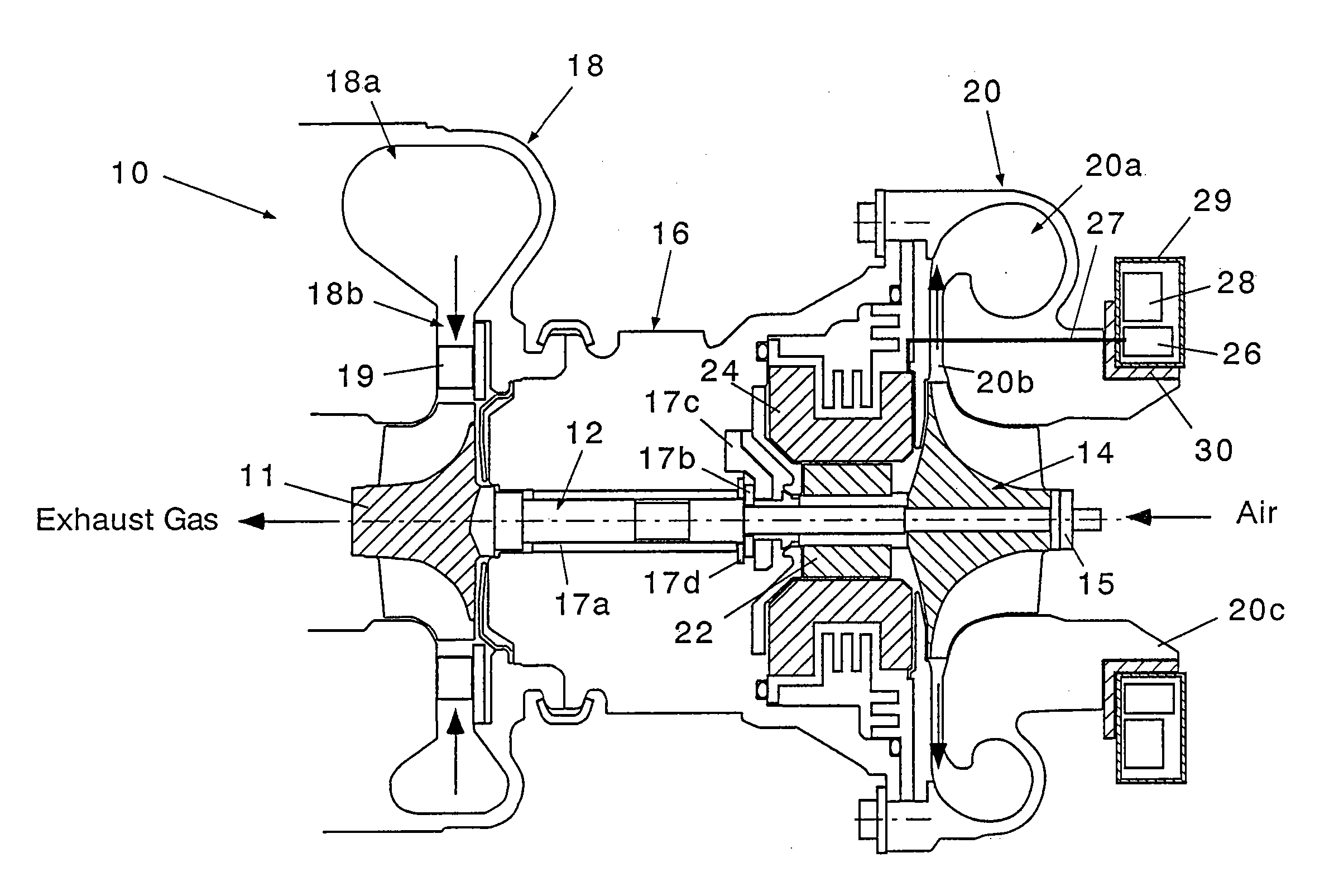

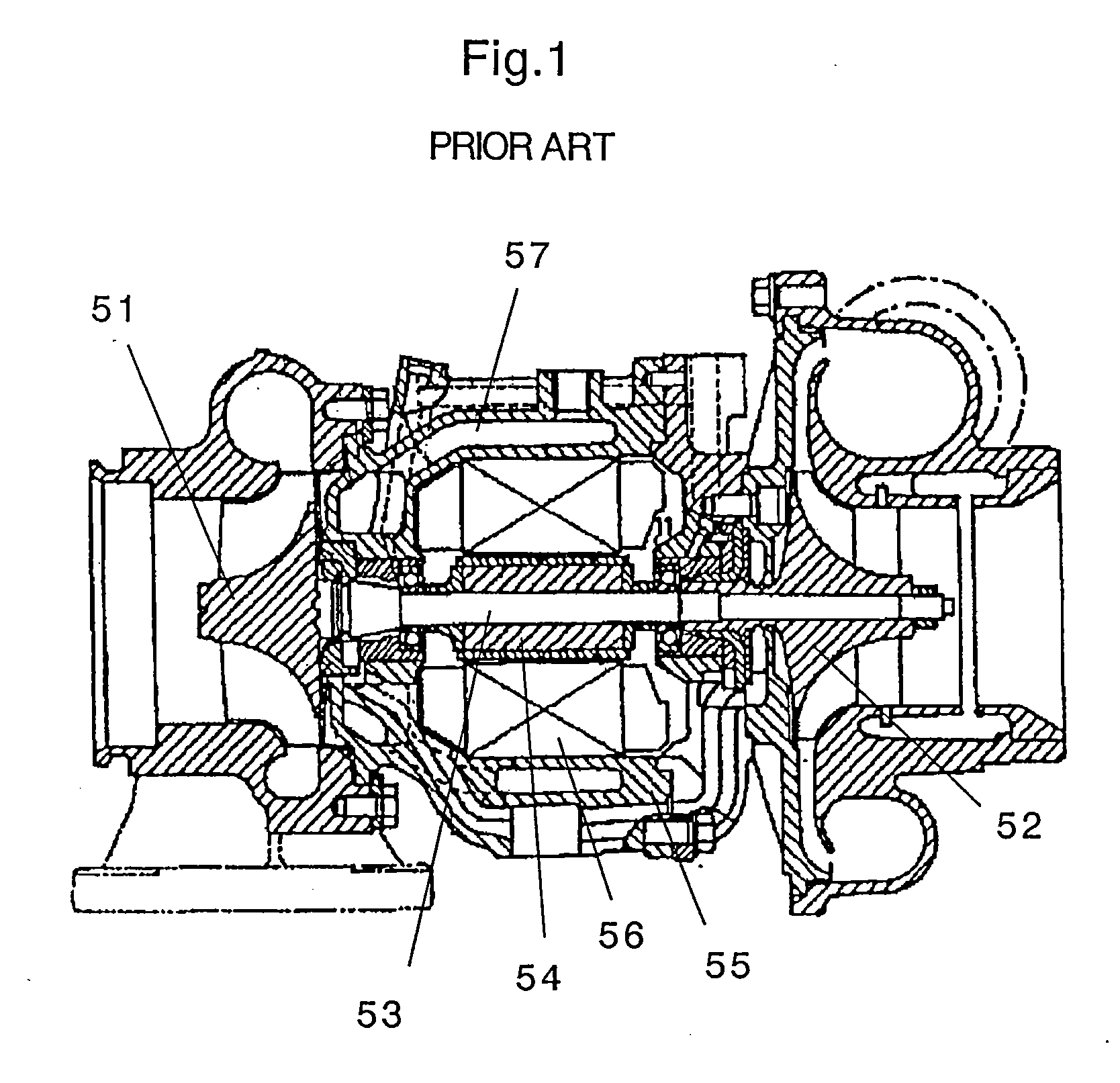

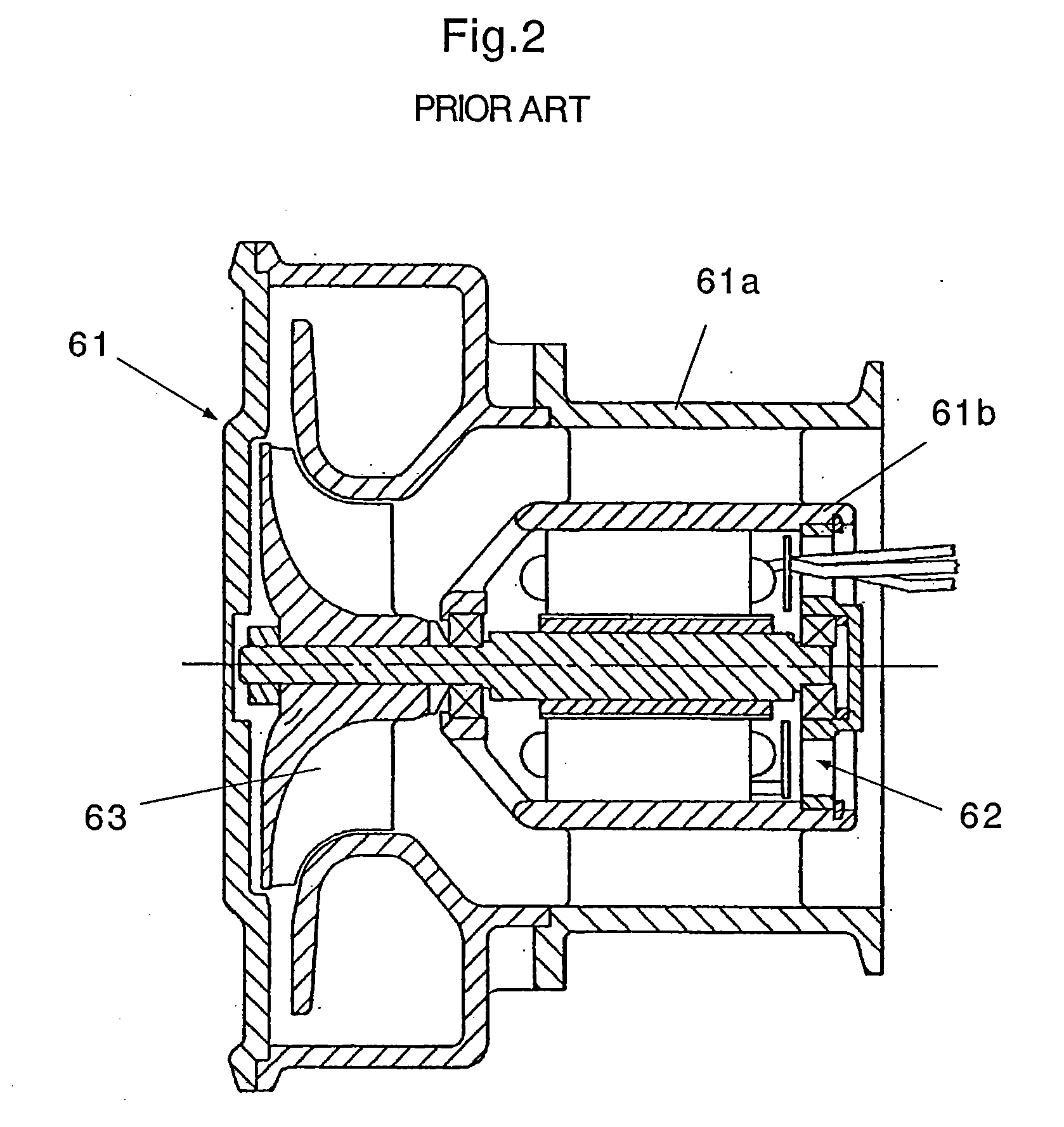

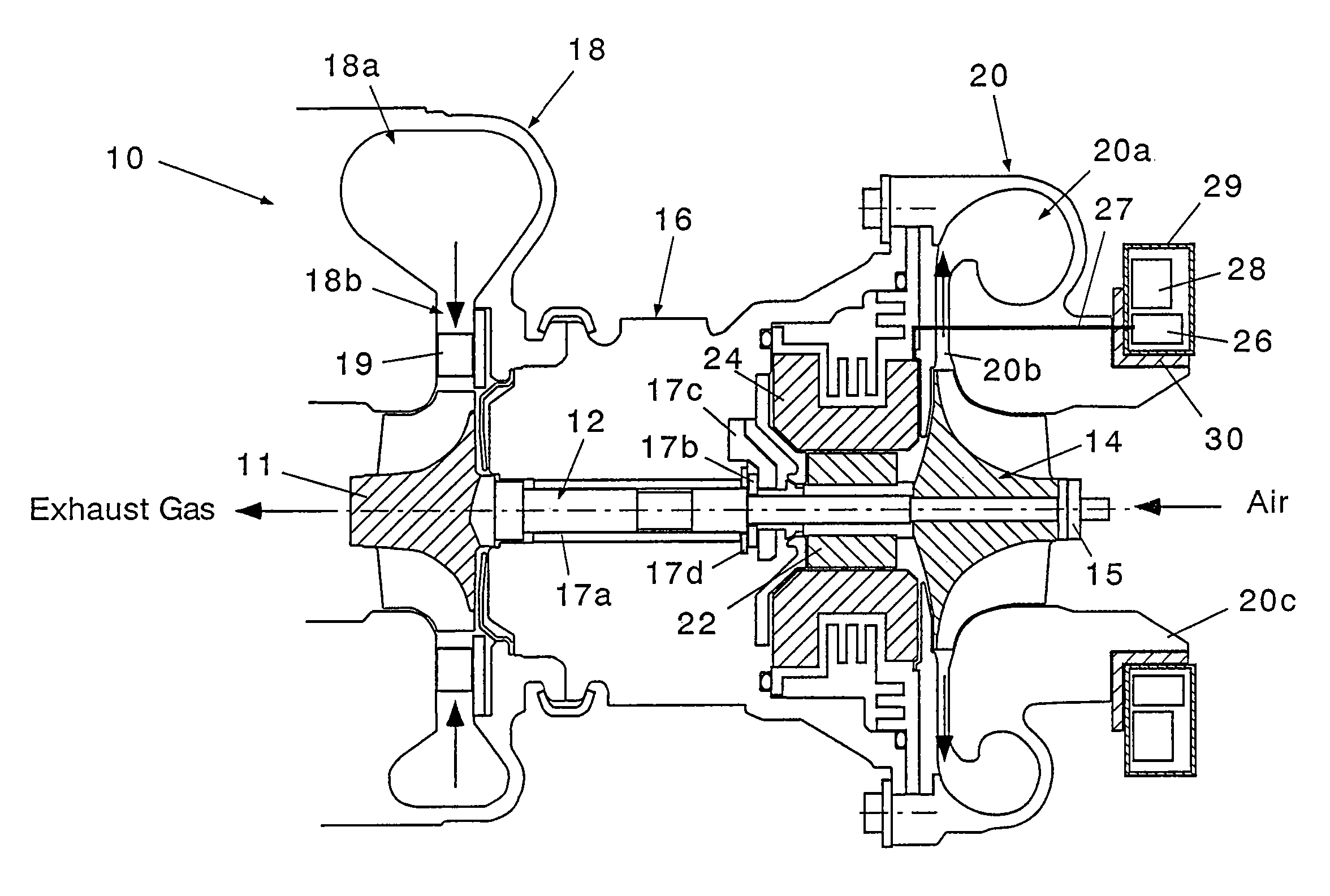

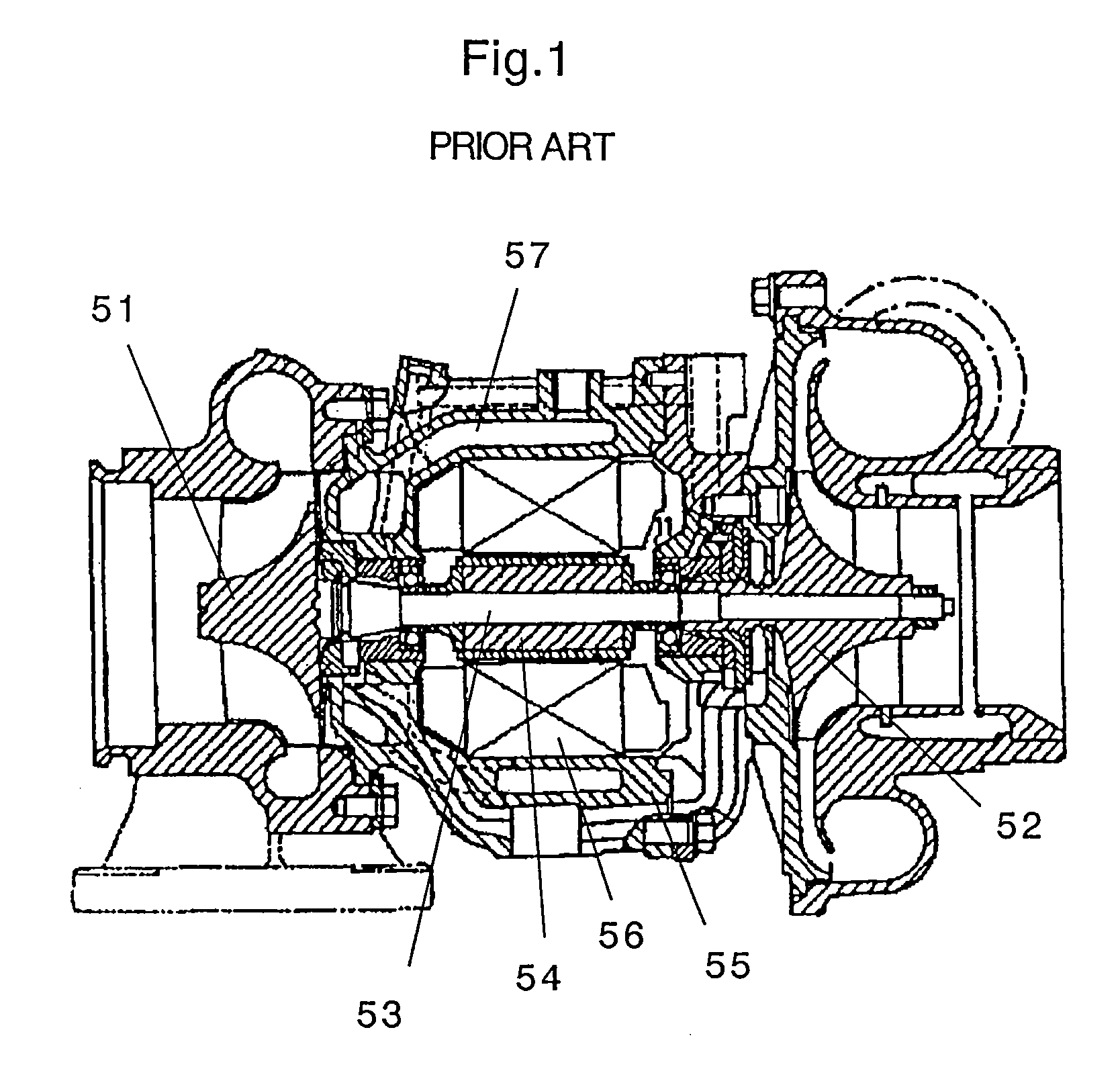

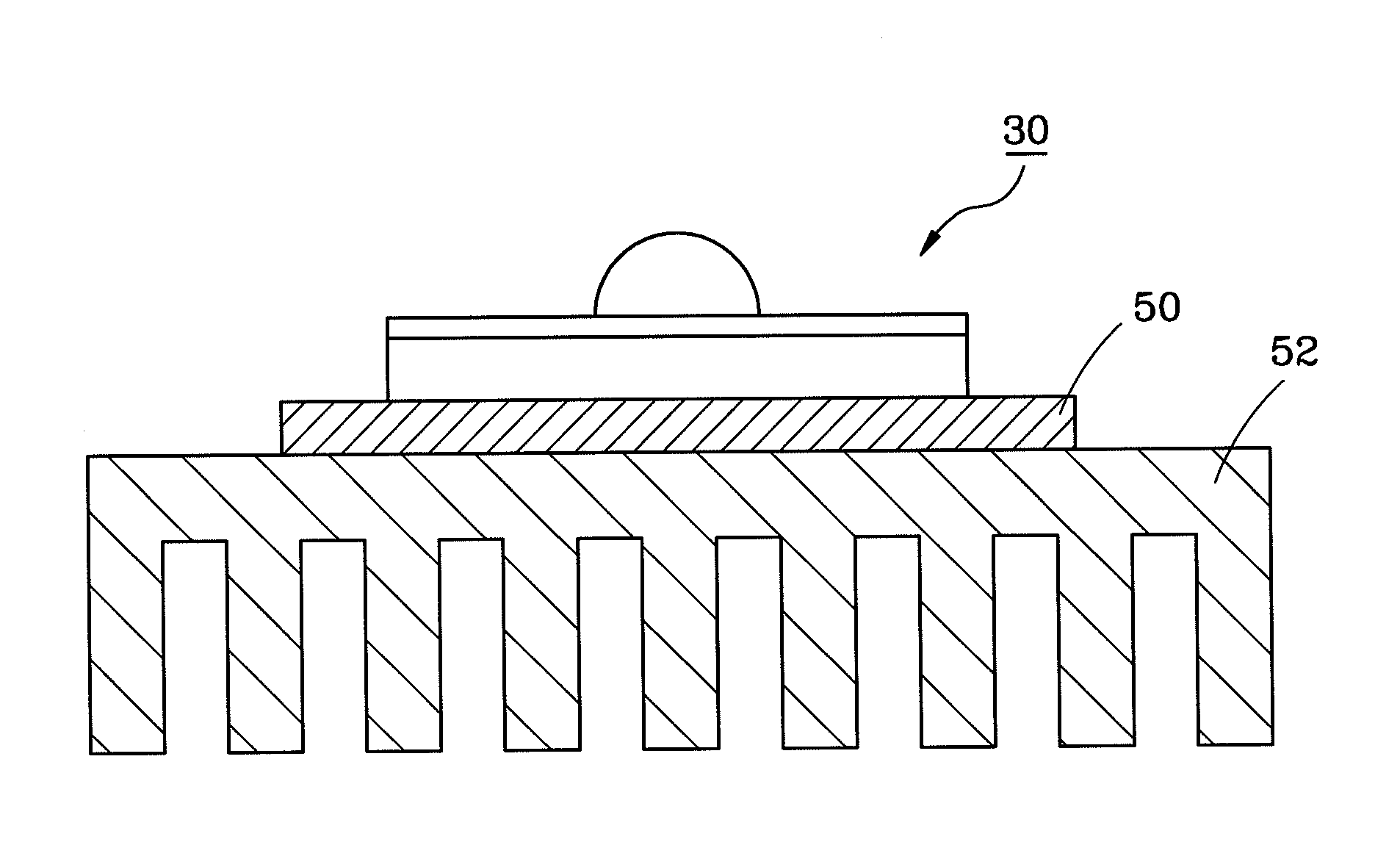

Motor-driven supercharger

ActiveUS20070108772A1Reduce power lossAvoid high temperatureInternal combustion piston enginesEngine manufactureMotor driveVoltage inverter

There are provided with a motor rotor (22) fixed to a turbine shaft (12) and rotating together with the turbine shaft, a motor stator (24) surrounding the motor rotor and fixed within a bearing housing (16), an inverted (26) converting a dc power into an ac power, and an inverter controller (28) controlling a frequency and a voltage of the ac power by the inverter. The inverter and the inverter controller are accommodated in a driver container (29), and are coupled to a compressor housing (20) by an insulating coupling member (30).

Owner:IHI CORP

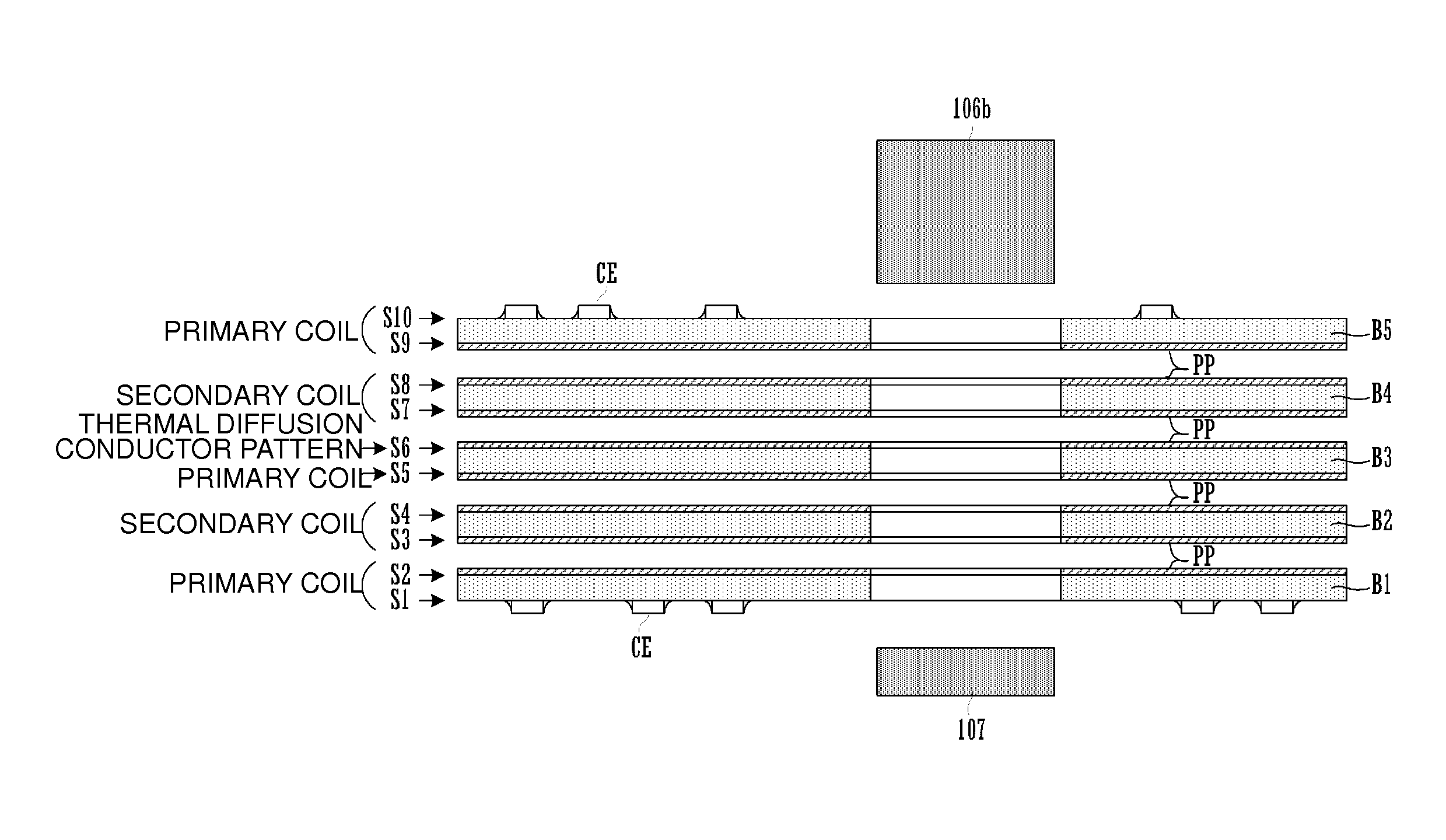

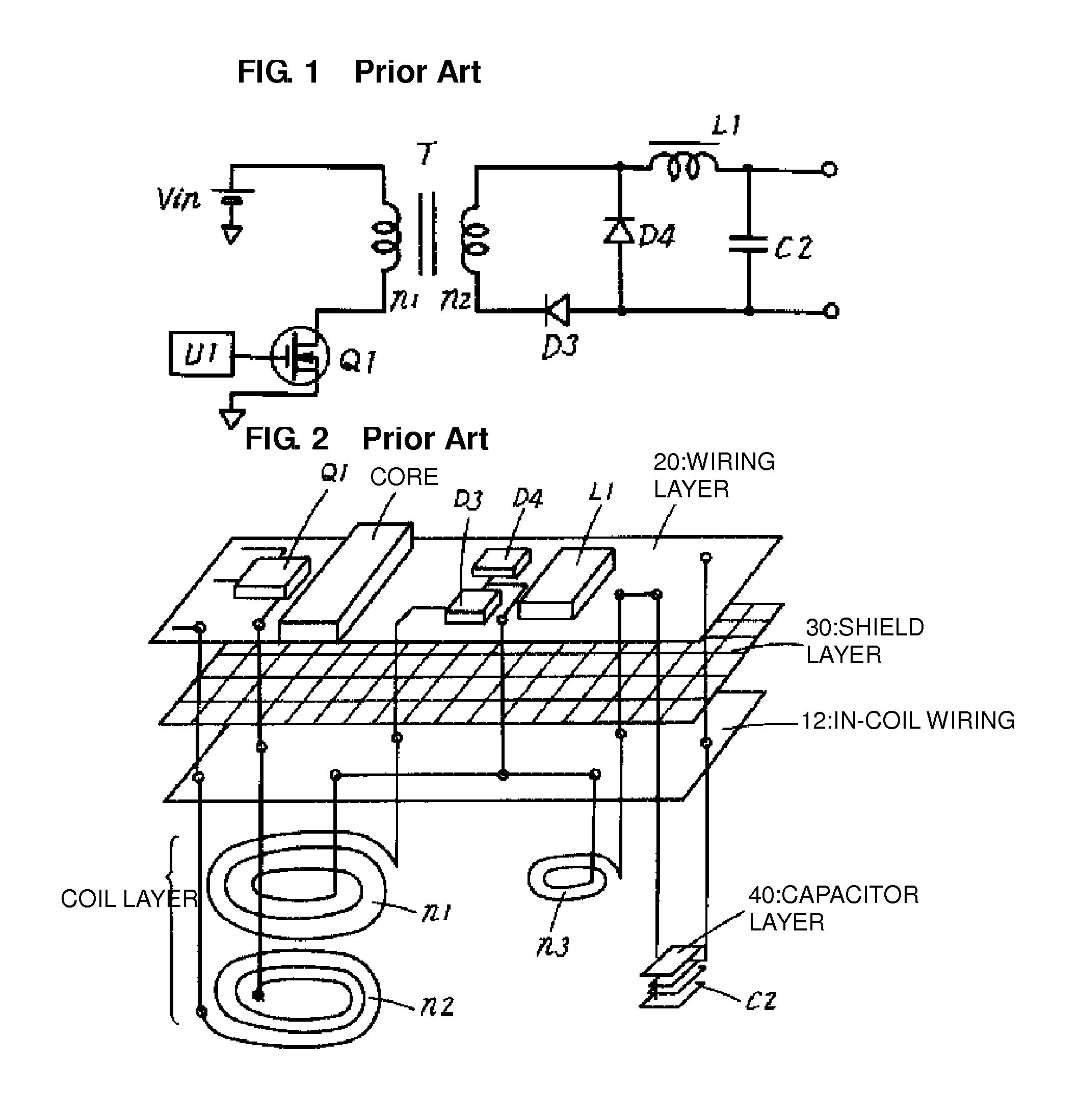

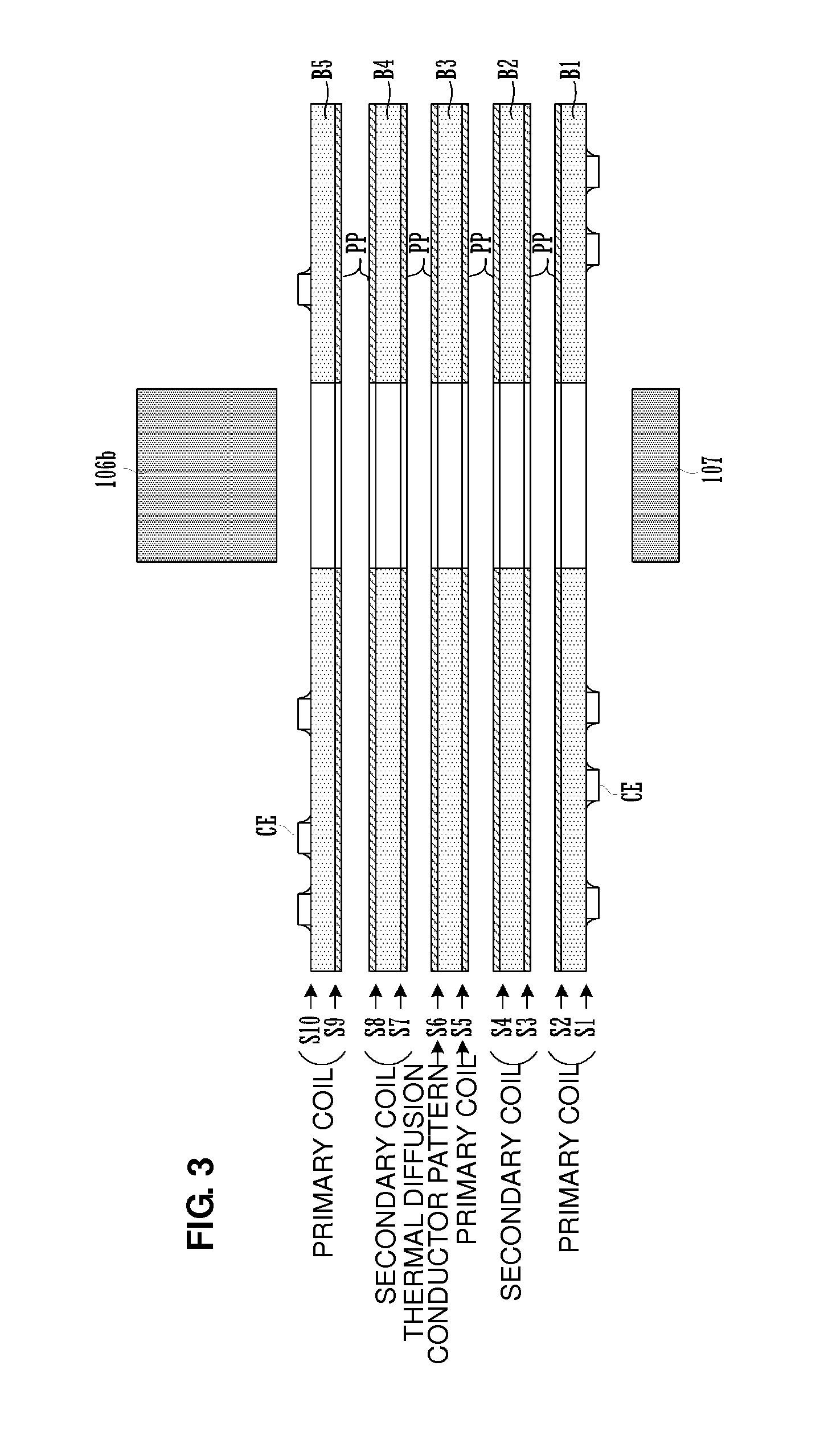

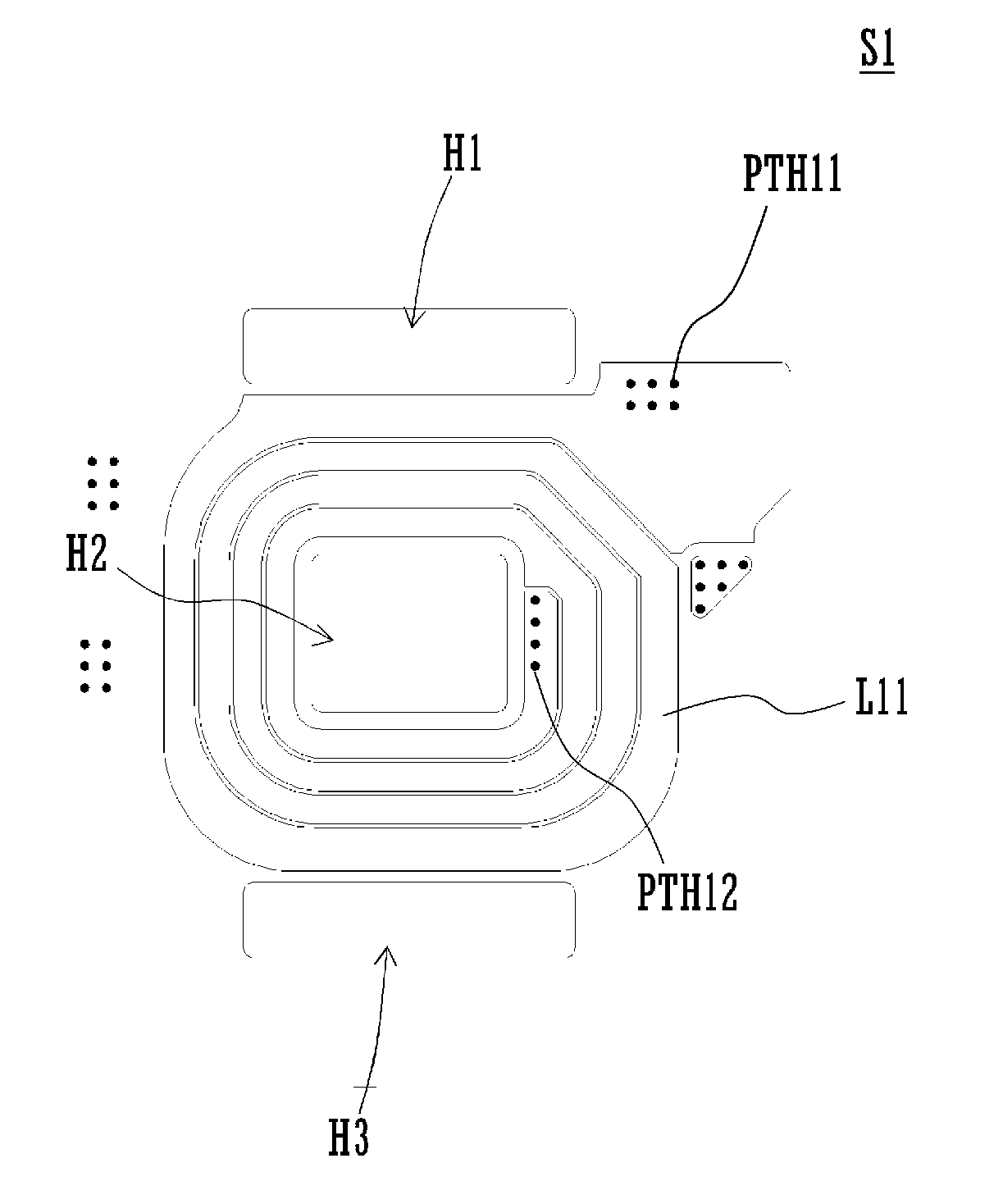

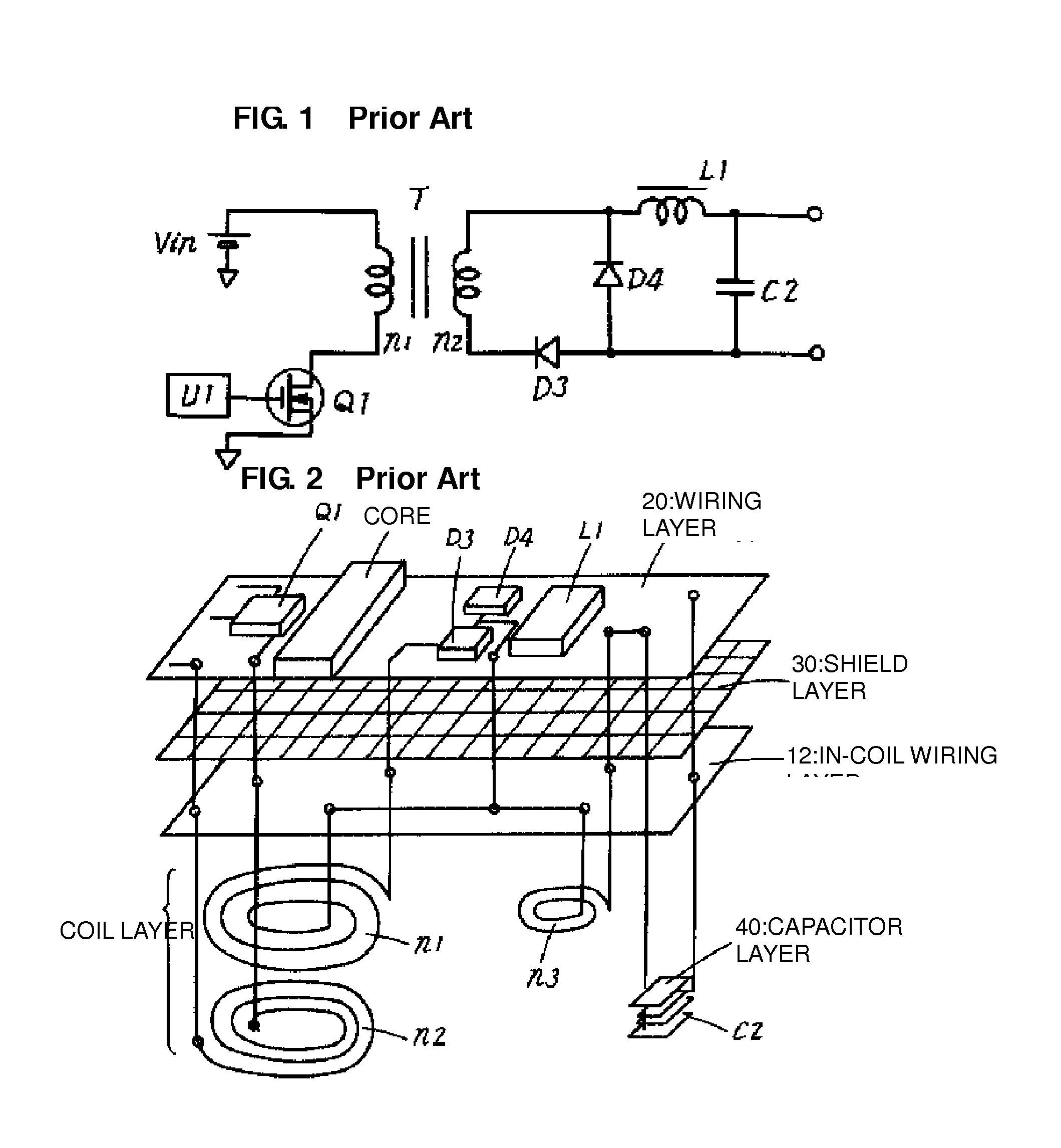

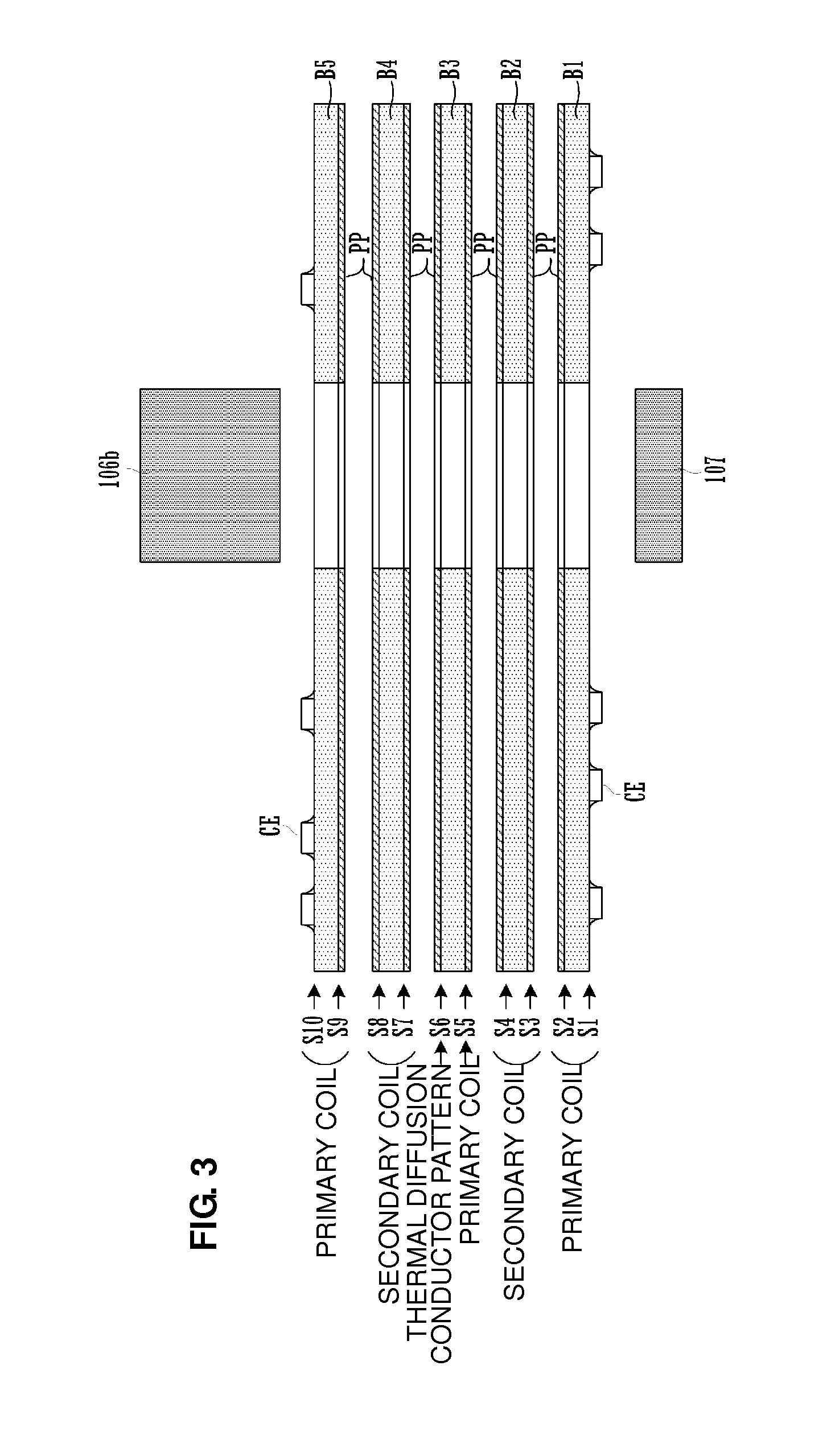

Coil-integrated switching power supply module

ActiveUS8334747B2Reduce thermal resistanceEffective diffusionTransformers/inductances coolingPrinted circuit aspectsElectrical conductorComputer module

A coil-integrated switching power supply module that provides an improved heat radiation effect to keep the temperature of the entire coil-integrated switching power supply module to a lower value includes a thermal diffusion conductor pattern arranged around a hole through which a magnetic core extends on a layer. The thermal diffusion conductor pattern continuously extends in areas where coil conductor patterns are located on other layers and outside areas where the coil conductor patterns are located on the other layers. In addition, the thermal diffusion conductor pattern includes slits at portions thereof and does not define a closed loop around the hole through which the magnetic core extends.

Owner:MURATA MFG CO LTD

Motor-driven supercharger

ActiveUS7352077B2Reduce power lossAvoid high temperatureInternal combustion piston enginesEngine manufactureMotor driveAlternating current

Owner:IHI CORP

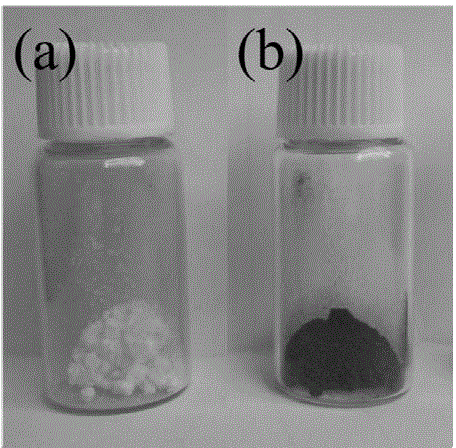

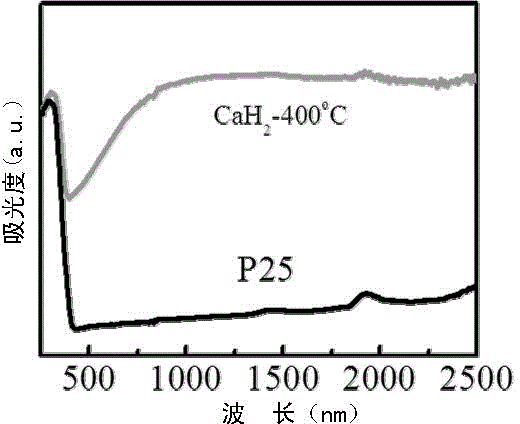

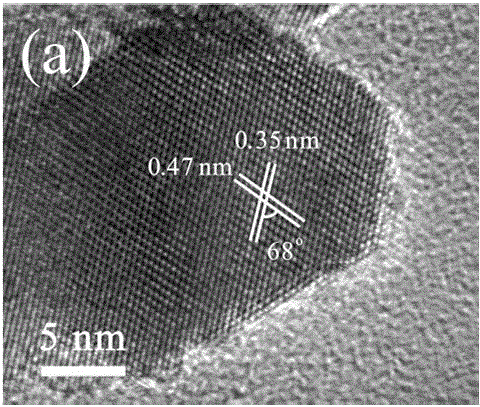

Method for preparing black titanium dioxide by contact type reduction method

ActiveCN104941614AImprove catalytic performanceCrystal phase controllableCatalyst activation/preparationMixed materialsContact type

The invention relates to a method for preparing black titanium dioxide by a contact type reduction method. The method comprises preparation by a solid and liquid contact type reduction method. A method provided by the invention comprises the following steps: in a negative-pressure or inert atmosphere, heating a mixed material of reducing agents and titanium dioxide to 200-800 DEG C, keeping the stipulated time, reducing titanium dioxide to obtain black titanium dioxide, wherein the reducing agents are metal oxide, metal hydroboron, and / or high-activity metal. Another method provided by the invention comprises the following steps: dispersing titanium dioxide into water, adding reducing agents into water with dispersed titanium dioxide, stirring for the stipulated time, and reducing so as to obtain black titanium dioxide, wherein the reducing agents are metal hydride, metal hydroboron, and / or high-activity metal. Titanium dioxide prepared by the invention has wide application prospect in the fields of dye-sensitized solar cells, hydrogen generation by water photolysis, and the like.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Honeycomb structural body

ActiveUS7517502B2InhibitionReduce thermal stressCombination devicesCatalyst carriersStress concentrationPore diameter

An object of the present invention is to provide a honeycomb structural body which makes it possible to prevent a thermal stress from concentrating on plugs for sealing a group of inlet-side through holes and the vicinity thereof during a regenerating process, and consequently to prevent occurrence of cracks. The honeycomb structural body of the present invention is a pillar-shaped honeycomb structural body mainly made of porous ceramics, in which a plurality of through holes are placed in parallel with one another in the length direction with a partition wall interposed therebetween. Herein, the through holes are constituted by a group of inlet-side through holes, whose ends are sealed by plugs at the outlet side such that the total sum of areas on cross sections perpendicular to the length direction is made relatively greater, and a group of outlet-side through holes, whose ends are sealed by plugs at the inlet side such that the total sum of areas on the cross sections thereof is made relatively smaller. Supposing that the aperture rate on the inlet side is X (%) and that the total sum of thermal capacities of the plugs which seal the group of inlet-side through holes at 500° C. per 11.8 cm2 of the end face on the outlet side containing the group of the outlet-side through holes is represented by Y(J / K), the relationship indicated by the following inequalities (1) and (2) is satisfied.0.0157X−0.0678<Y<1.15X−5 (1)35≦X≦60 (2)

Owner:IBIDEN CO LTD

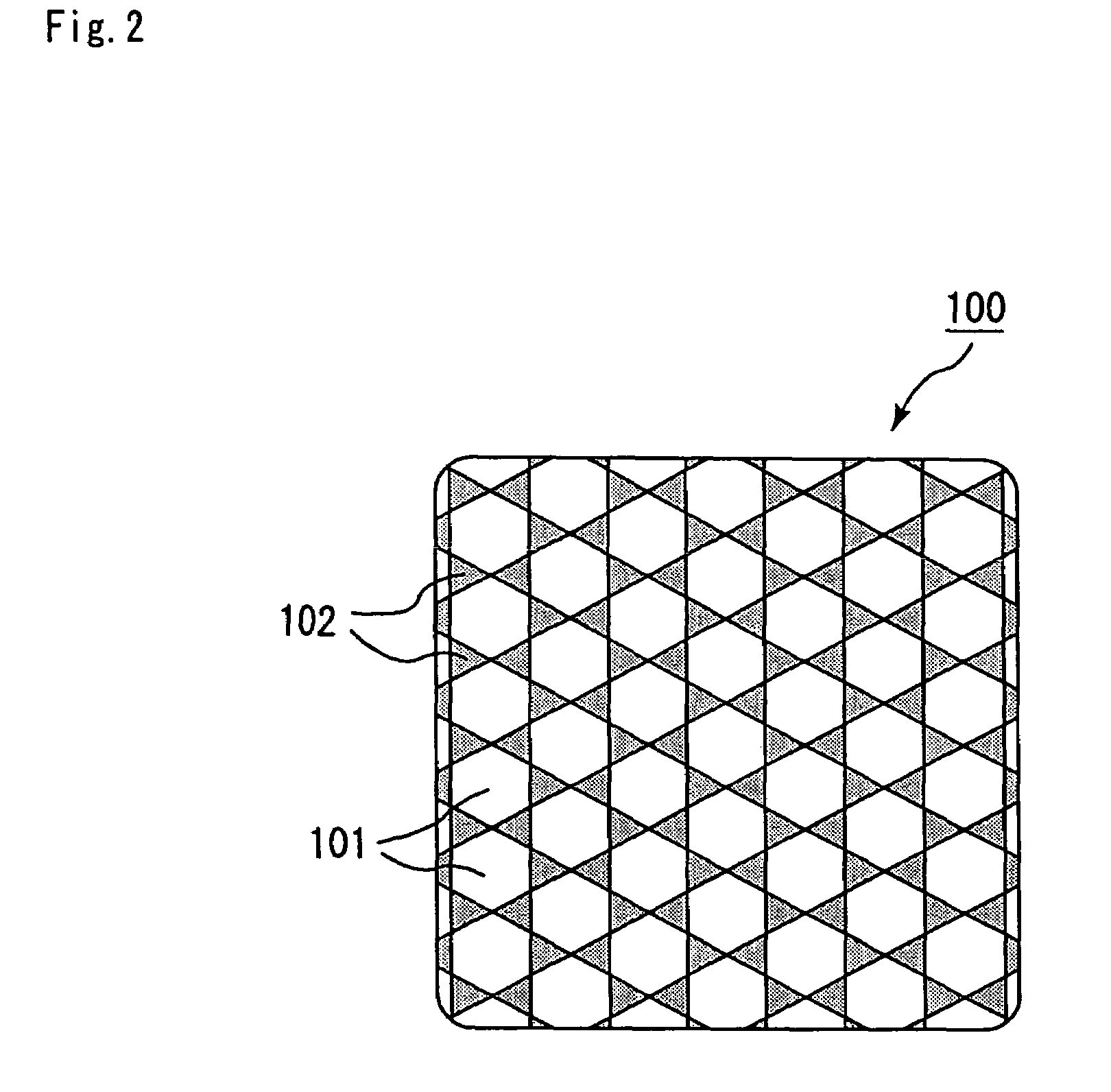

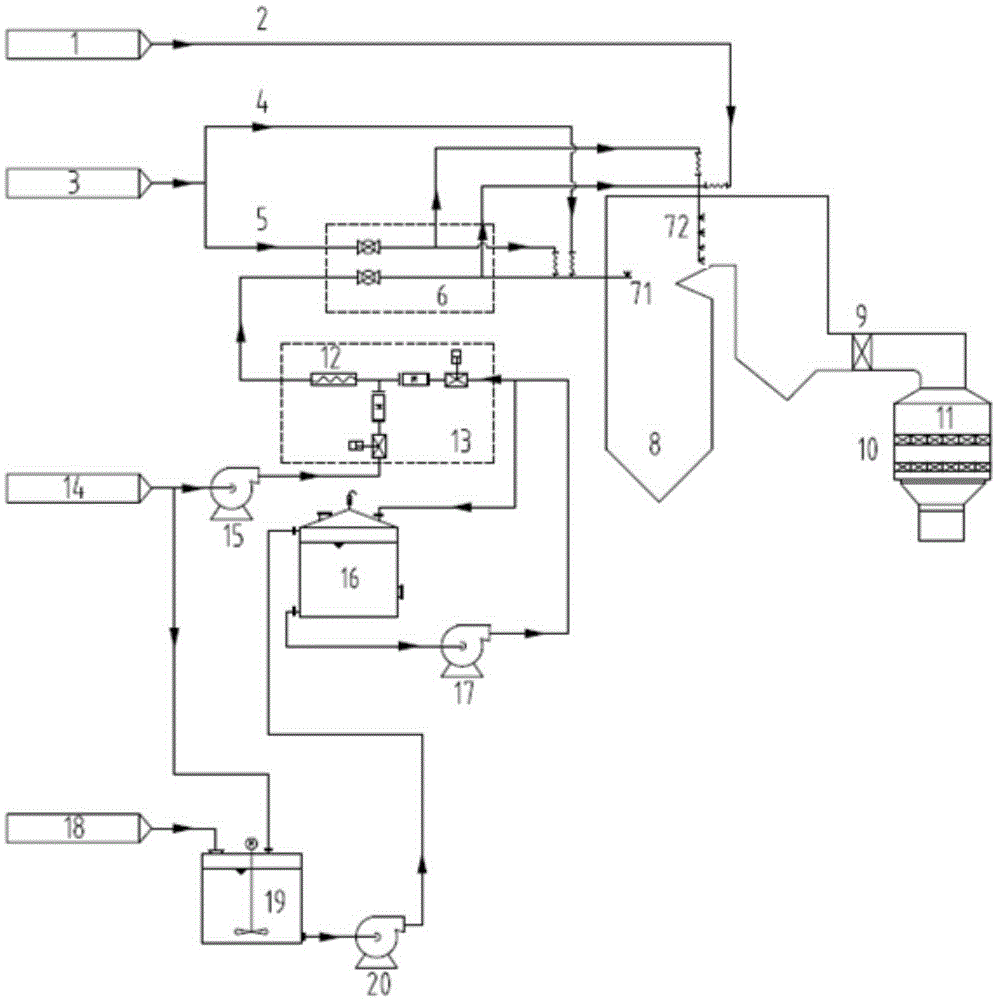

Coal-fired boiler SNCR and SCR combined denitration system and method thereof

ActiveCN105289233AImprove mixing uniformityImprove distribution uniformityLighting and heating apparatusDispersed particle separationBoiler furnaceProcess engineering

The invention relates to a coal-fired boiler SNCR and SCR combined denitration system. The denitration system comprises a boiler SNCR reaction system and a SCR reactor; the boiler SNCR reaction system comprises the boiler, an urea solution distribution module and a metering module, and an urea injection system and an urea supply system which are connected with the urea solution distribution module and the metering module; the urea injection system comprises multilayer-designed short spray guns with upper elevation in a 25m to 40m scope in a boiler furnace combustion zone, and multilayer-designed porous long spray guns having an furnace arch with the boiler, wherein, in each layer, at least one porous long spray gun vertically stretches into the boiler, and extends and passes through the cross section; the SCR reactor is connected with a boiler tail through a flue gas mixer; in the SCR reactor, the multilayer cellular catalyst can be arranged at a space between a coal economizer and an air preheater. According to the method, a mol ratio of ammonia nitrogen in an inlet cross section of the SCR catalyst is uniformly distributed, and denitration efficiency of the SCR reactor is enhanced.

Owner:CHINA HUANENG GRP CO LTD +1

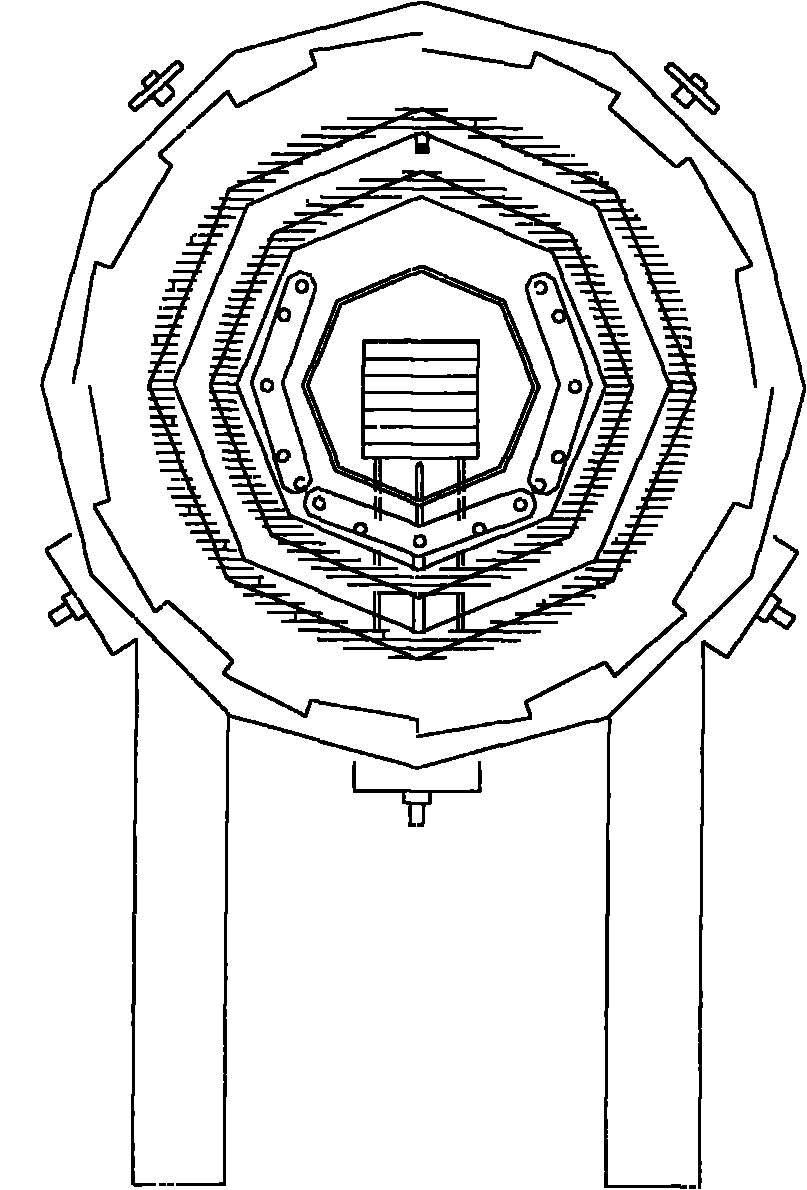

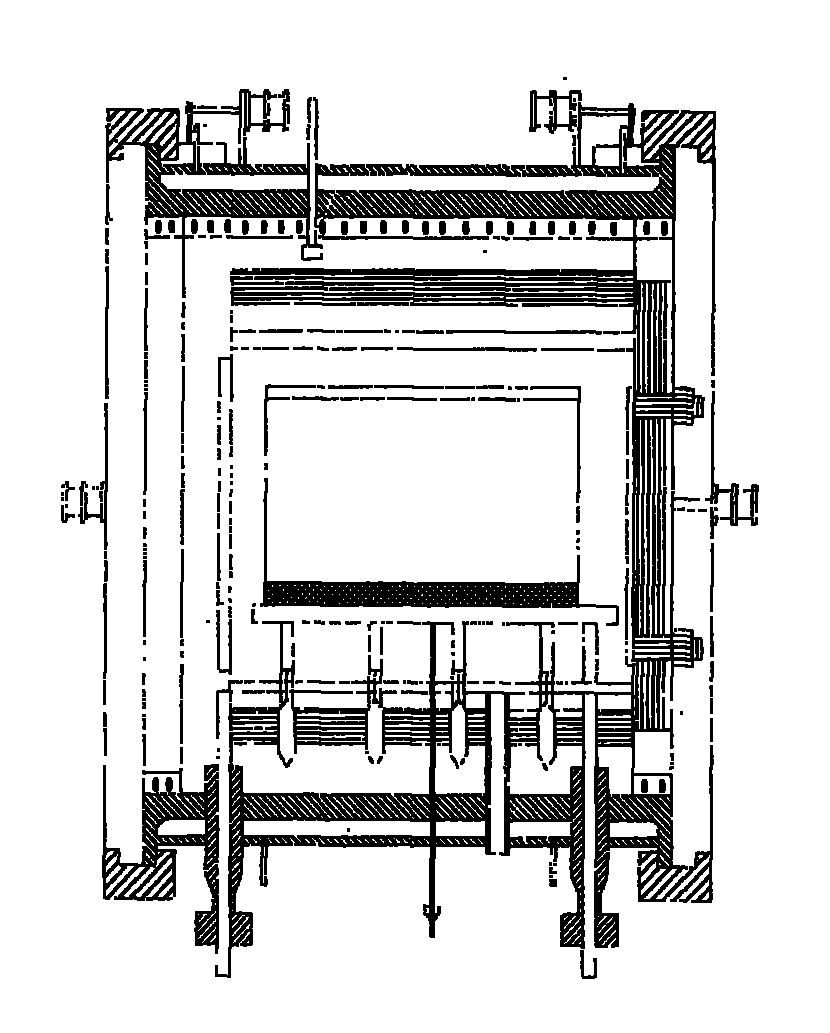

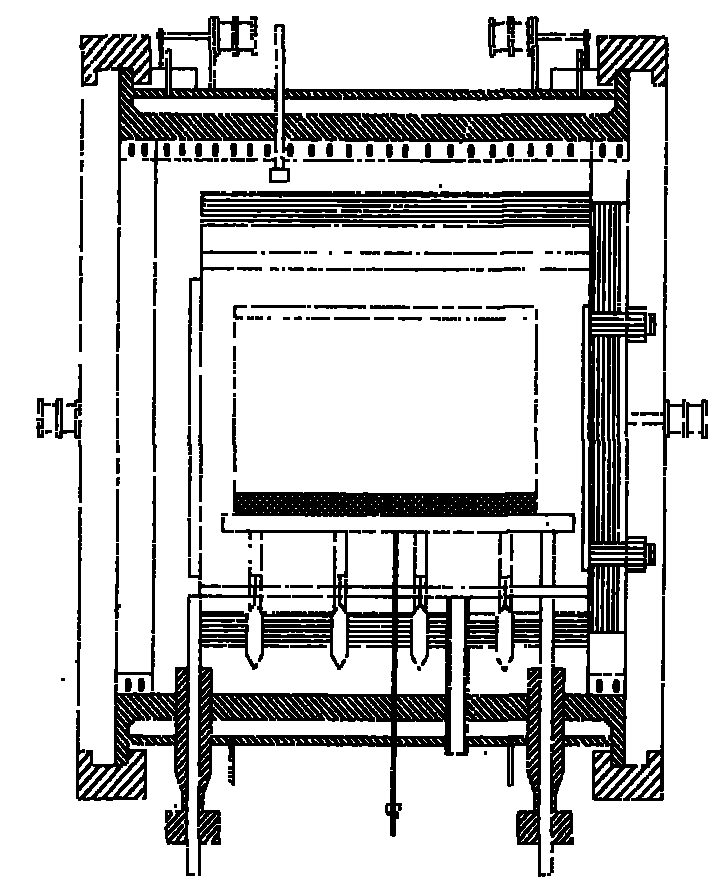

Pressure sintering furnace

InactiveCN101788226AAchieve elastic compressionSolve elastic compression problemsFurnace componentsMuffle furnacesCouplingDistribution system

The invention relates to a pressure sintering furnace used for producing hard alloys. The pressure sintering furnace comprises a furnace shell, a vacuum system, an air distribution system, a heating and thermal-insulating device, a compression system, a cooling system and a decompression device. The pressure sintering furnace is characterized in that the furnace shell is a horizontal cylinder provided with a double-wall water jacket, the furnace door on the furnace shell has a quick-opening hydraulic side-rotating structure, the furnace door of the furnace shell comprises a thermal-insulating door on the external layer of the furnace and a graphite door on the internal side of the furnace, the opening of the furnace door is controlled by a hydraulic locking device with a door-closing air cylinder, the door-closing air cylinder is provided with an elastic coupling device, and the thermal-insulating door of the furnace door is a boss thermal-insulating door. The pressure sintering furnace has stable performance and low cost and safety production can be realized by using the pressure sintering furnace, thus the uniformity of temperature field distribution in the furnace can be effectively improved and the qualification rate of products can be more than 90%.

Owner:ZHUZHOU CEMENTED CARBIDE EQUIP

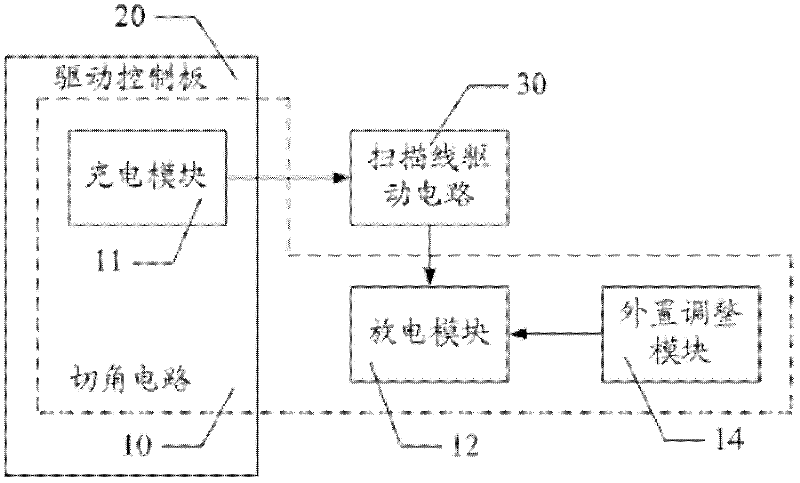

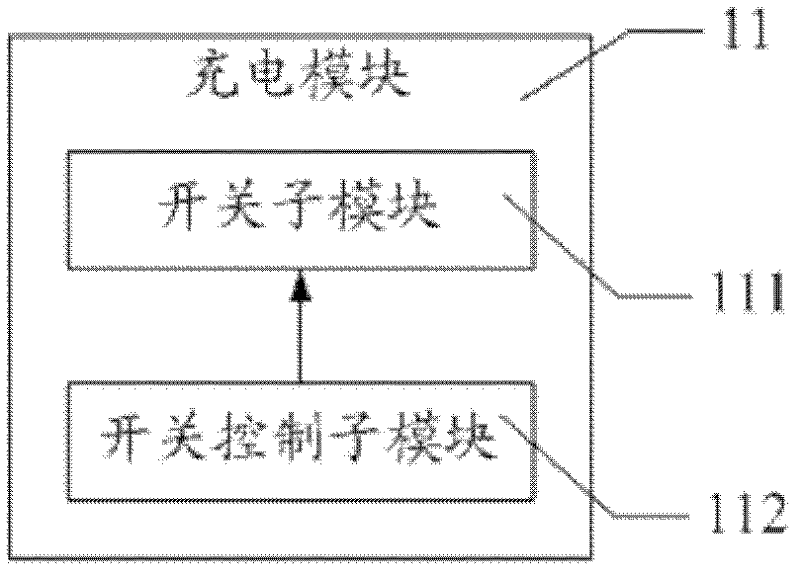

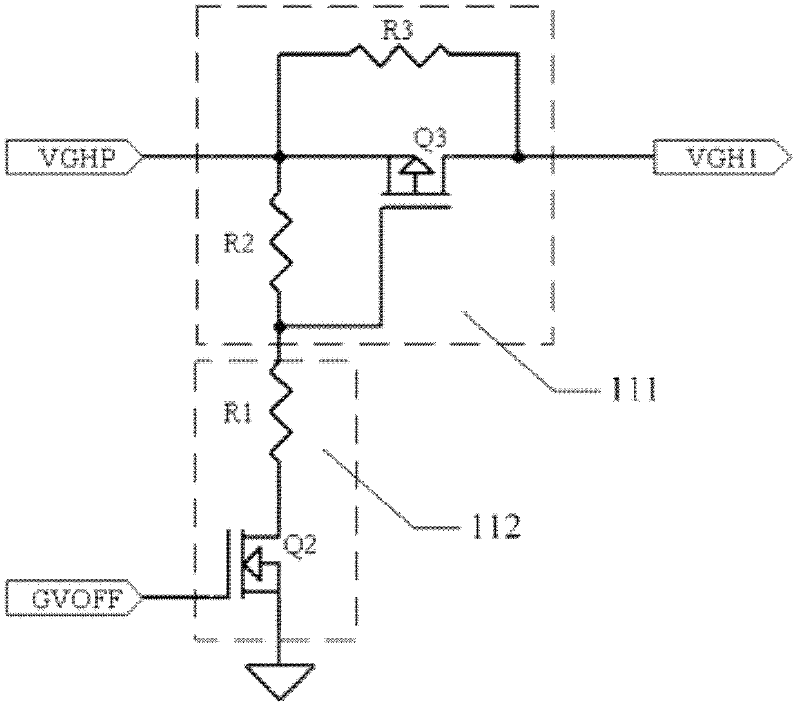

Corner-cutting circuit in LCD (Liquid Crystal Display) driving system

ActiveCN102314846AReduce load discharge chargeAvoid Crowded ArrangementsCathode-ray tube indicatorsParasitic capacitorCapacitance

The invention discloses a corner-cutting circuit in an LCD (Liquid Crystal Display) driving system, which is connected with a plurality of scanning-line driving circuits and comprises a charging circuit, a plurality of discharging modules and a plurality of external adjusting modules, wherein the charging circuit is integrated on a control plate and is used for receiving the input of a direct-current driving voltage and outputting an opening voltage for charging the scanning-line driving circuits; the discharging modules are respectively integrated on each scanning-line driving circuit and are used for controlling the corresponding scanning-line driving circuit to be discharged; and the external adjusting modules are respectively and externally connected to the external part of each scanning-line driving circuit, are connected with the corresponding discharging modules and are used for adjusting the discharging modules to control the discharging speeds of the scanning-line driving circuits. In the invention, the size of a variable resistor which is externally connected onto a discharging resistor is regulated according to the size of the respective parasitic capacitor of each scanning-line driving circuit to further adjust the discharging slope of the corresponding scanning-line driving circuit, so that the corner-cutting circuit is applicable to the scanning-line driving circuits with different parasitic capacitors.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for extracting natural rose essential oil from rose

The invention relates to a method for extracting natural rose essential oil from fresh rose, which comprises: pretreating the rose, placing the pretreated rose into flavor-extracting petroleum ether, performing repeated leaching and filtration, removing residue, and obtaining leachate; distilling the flavor-extracting petroleum ether in the leachate, and obtaining an extract; adding the extract into ethanol for dissolution, freezing and filtration, removing undissolved substances, and obtaining an alcohol extract; and concentrating the alcohol extract under vacuum, removing the ethanol, and obtaining the rose essential oil. The essential oil extracted by the method maintains the special flavor of the rose; the method has rich resources of raw materials, fully utilizes the prior resources, and has simple technique and low cost; and the obtained product has unique flavor and long flavor lasting time, and is an ideal additive of food, cosmetics and the like.

Owner:庆阳市康惠玫瑰发展有限责任公司

Method for processing cold-making green tea

InactiveCN102726553AAvoid high temperaturePreserve the flavorPre-extraction tea treatmentFlavorChemistry

The invention discloses a method for processing cold-making green tea, comprising the following steps of: deactivating enzymes of fresh tea leaves by a vacuum microwave method, carrying out vitrification, followed by ultramicro crushing, carrying out vacuum freeze drying, crushing caking tea, packing by the use of a tea filter bag, and carrying out vacuum packing by the use of a plastic-aluminum bag for external packing, so as to prepare the cold-making green tea product. The vacuum microwave method for deactivating enzymes has advantages of rapid speed for killing enzyme and low action temperature; ultramicro crushing after vitrification realizes full crushing of tea under the low-temperature condition; and vacuum packing avoids oxidation, moisture absorption and browning of the product during the storage process. The cold-making green tea has advantages of good color, excellent flavor and rapid cold-making speed.

Owner:FUJIAN AGRI & FORESTRY UNIV

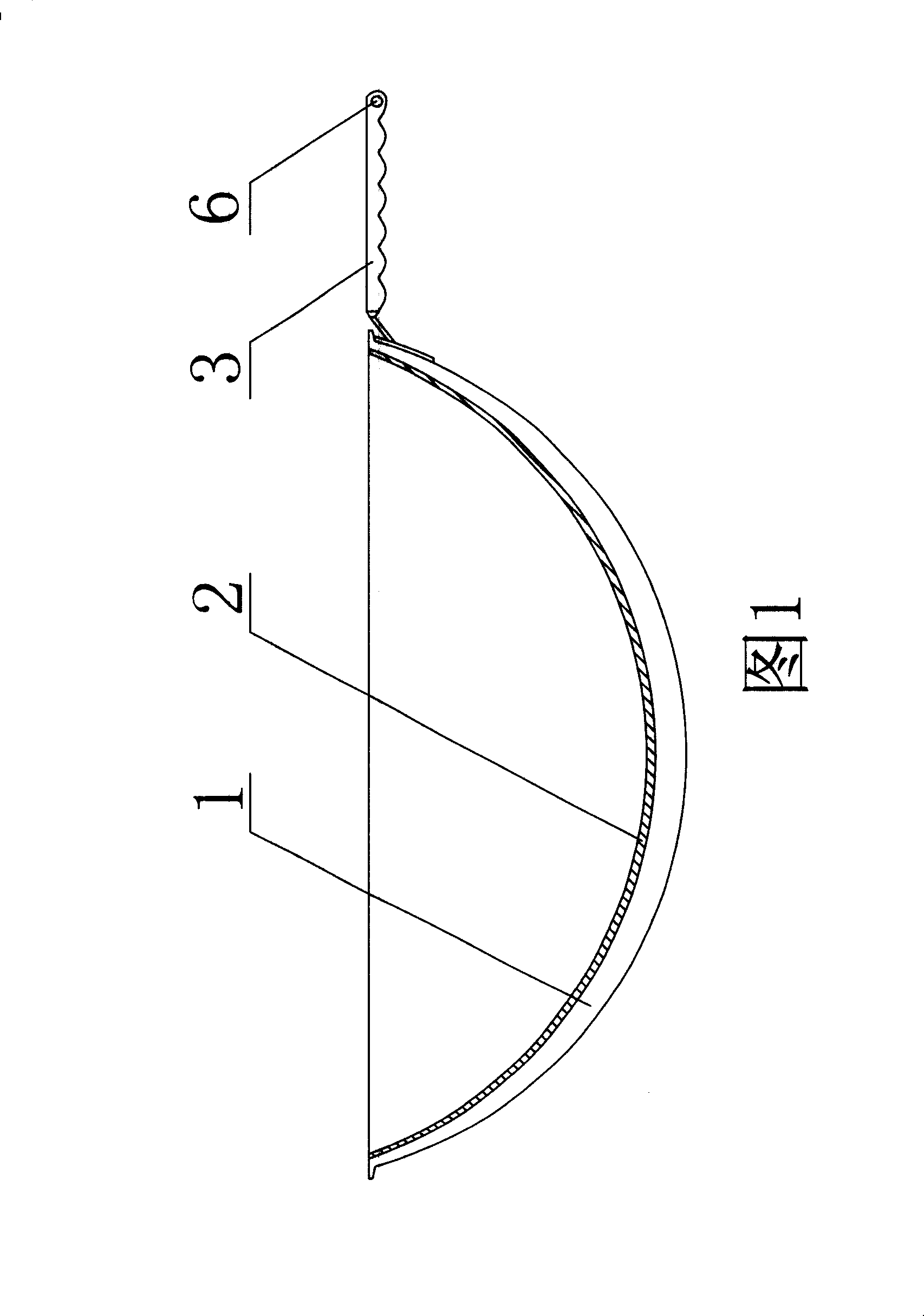

Fume-less cooker

InactiveCN101234001AIncrease the surface heating areaIncrease profitCooking-vessel materialsFrying pansConvex structureMetallurgy

The invention discloses an oil-free and smoke-free pan which comprises a pan body and a uniform heating layer of which thermal conductivity is lower than the thermal conductivity of the pan body. The uniform heating layer is arranged on the inner surface of the pan body. The invention adopts an aluminium alloy or magnesium alloy pan body with relatively high thermal conductivity, thus realizing a rapid heating. Furthermore, a purple sand ceramic uniform heating layer with relatively low thermal conductivity is sintered or a stainless steel uniform heating layer is compounded on the inner surface of the pan body to dissipate local high temperature on the pan body to the whole uniform heating layer, which ensures that no local high temperature, oil and smoke is produced in the pan, thus saving energy. A plurality of small convex structures are arranged on the uniform heating layer. Air is in a groove between the convex structures and the air is expanded after being heat, which results in the separation of food and the pan body to have physically non-stick effect. Compared with original immersion coating, the physical non-stick structure has better non-stick effect. A helical structure is adopted on the outer surface of the pan body, thereby increasing outer surface area of the pan body and improving energy utilization rate.

Owner:胡金高

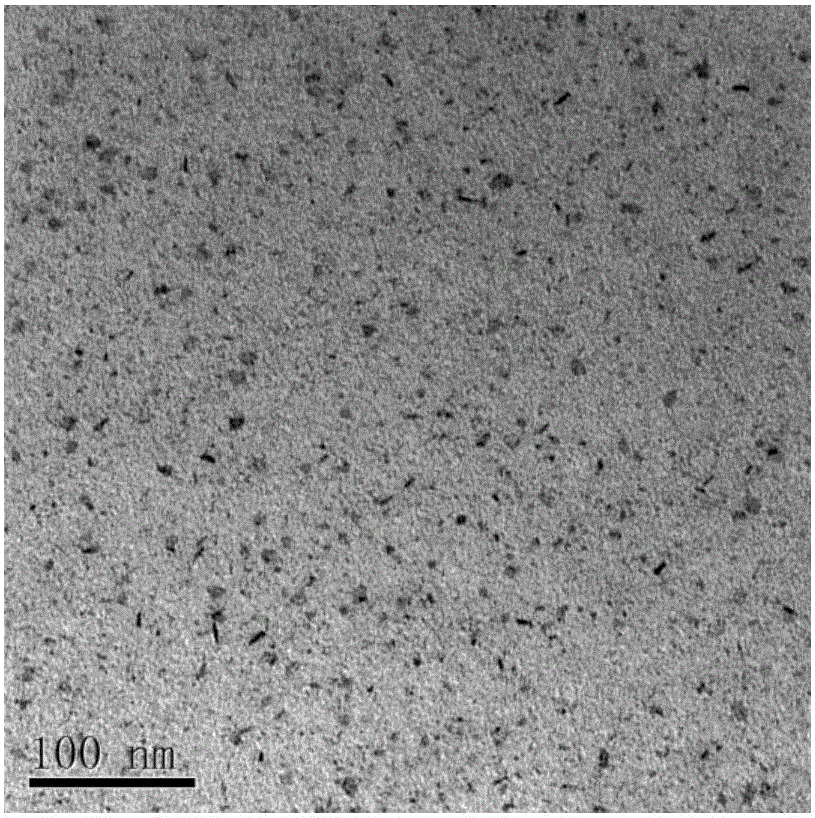

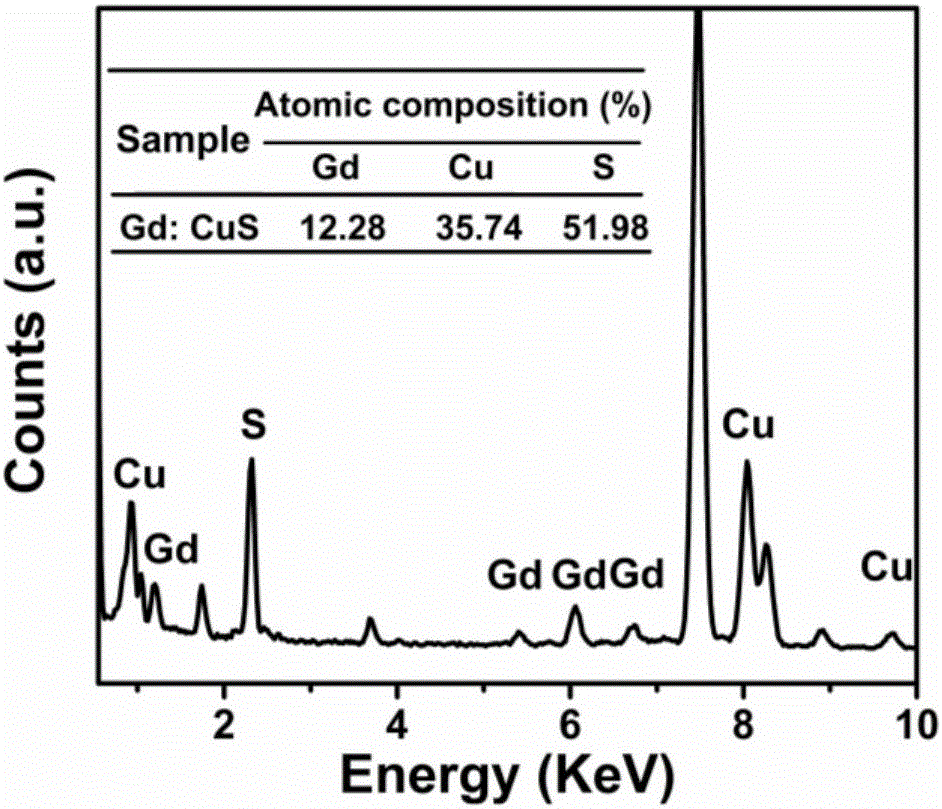

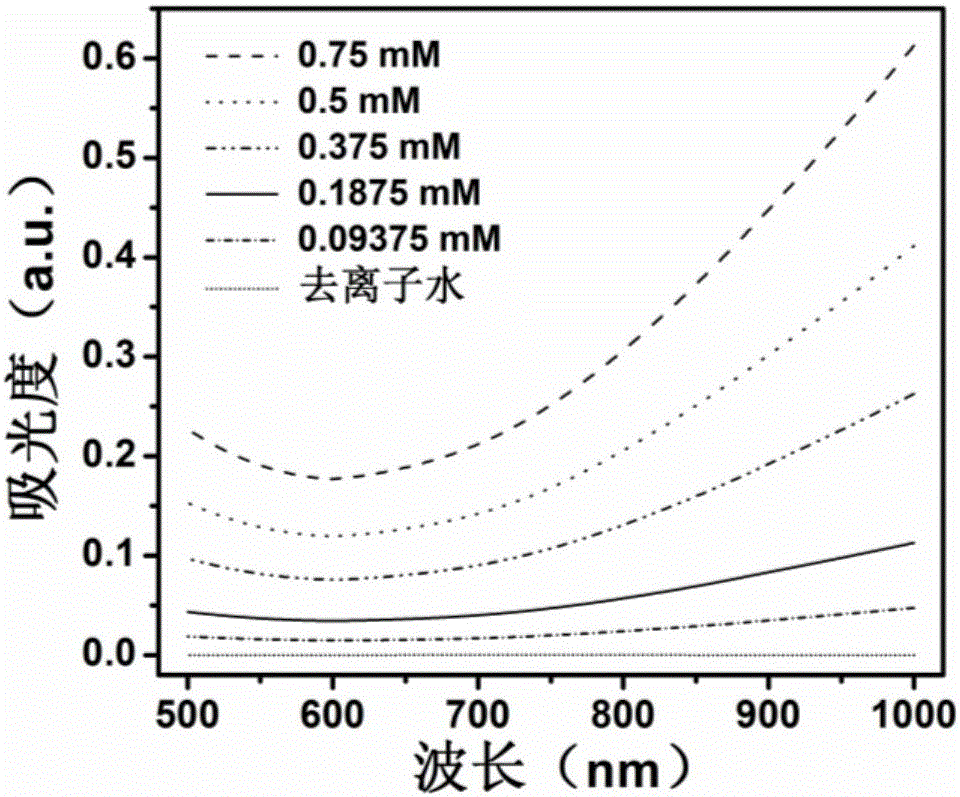

Protein biological template-based gadolinium-doped copper sulfide nano-particles and preparation method thereof

InactiveCN105999309AAvoid practicalityAvoid high temperatureEnergy modified materialsGeneral/multifunctional contrast agentsFreeze-dryingCopper salt

Owner:TIANJIN UNIV

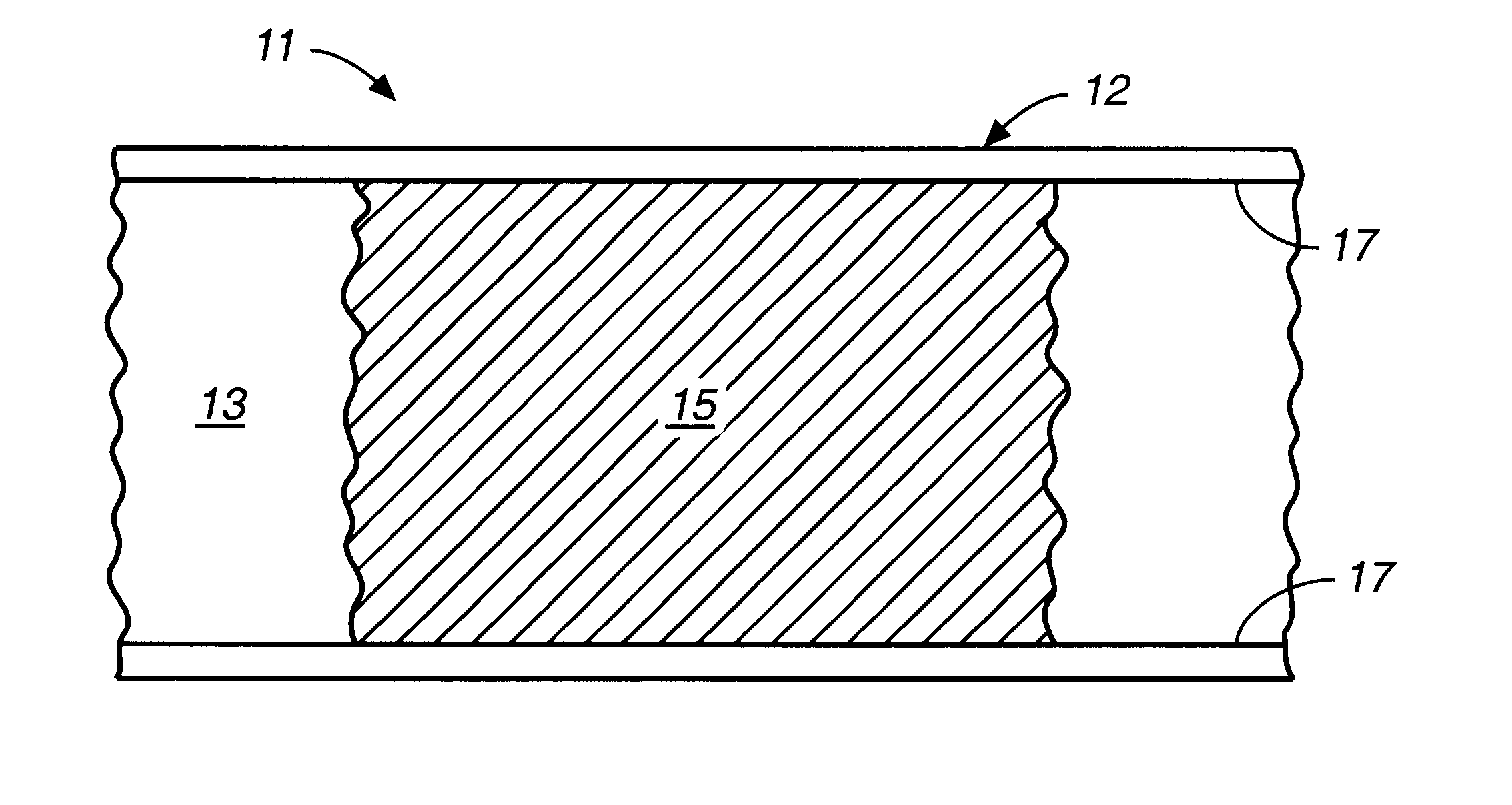

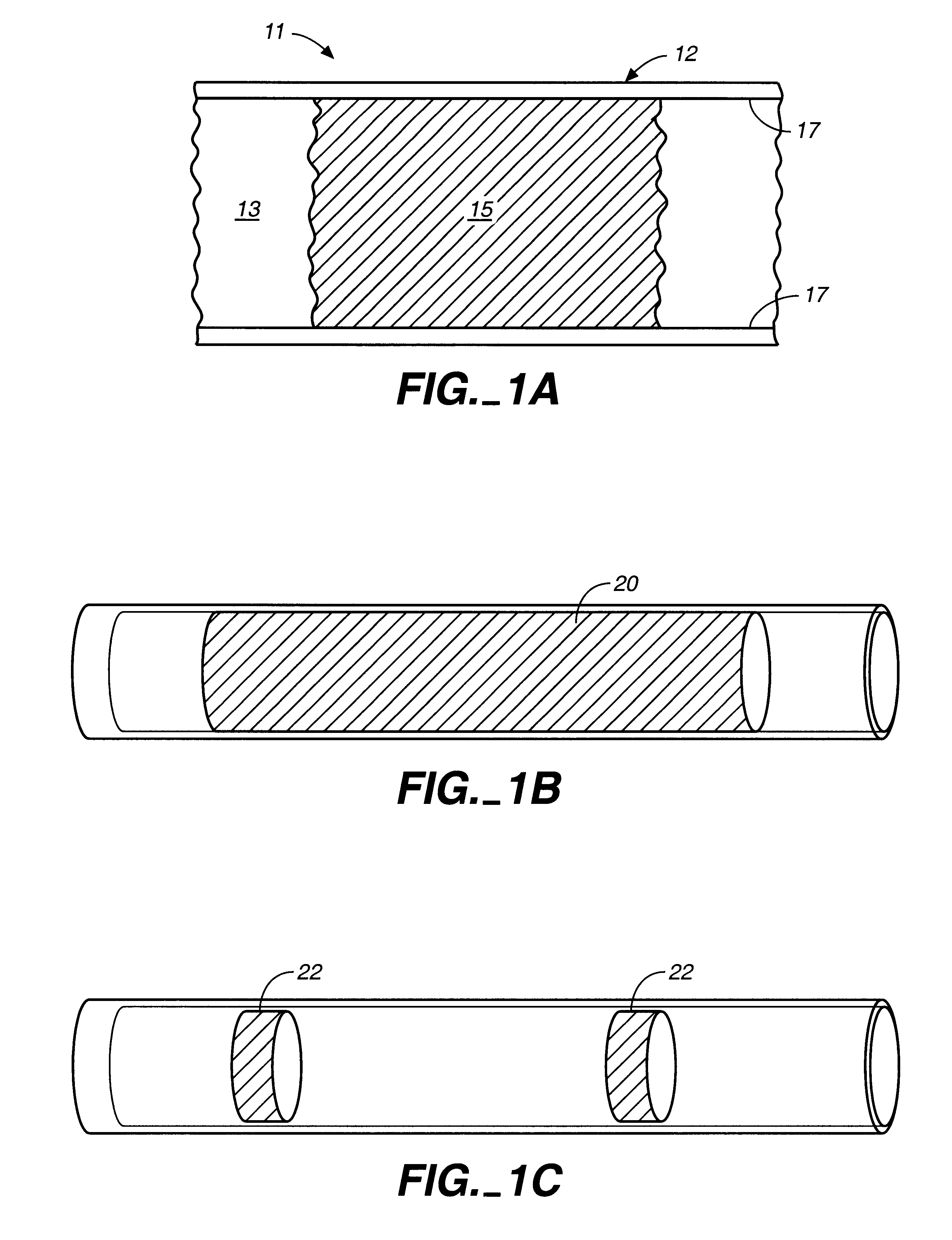

Separation column having a photopolymerized sol-gel component and associated methods

InactiveUS6875348B2Preparation of a separation columnEasy to prepareIon-exchange process apparatusComponent separationAnalyteFrit

A separation column and a method of preparing the separation column are provided. The separation column includes a separation channel and a porous matrix in the channel. The porous matrix includes a metal organic polymer, such as a photopolymer. The porous matrix can be a separation medium adapted to separate a sample of analytes or a frit adapted to retain a separation medium in the channel.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

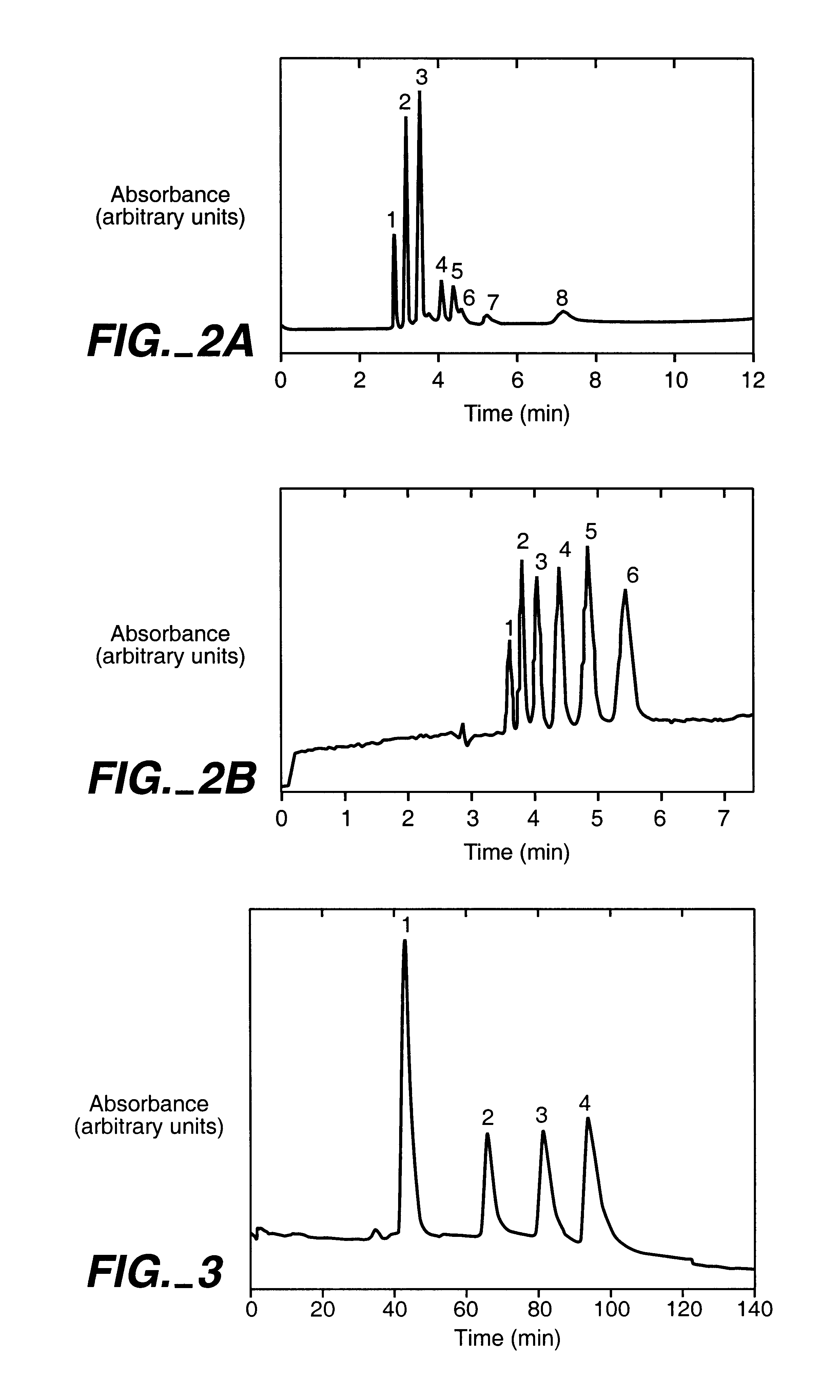

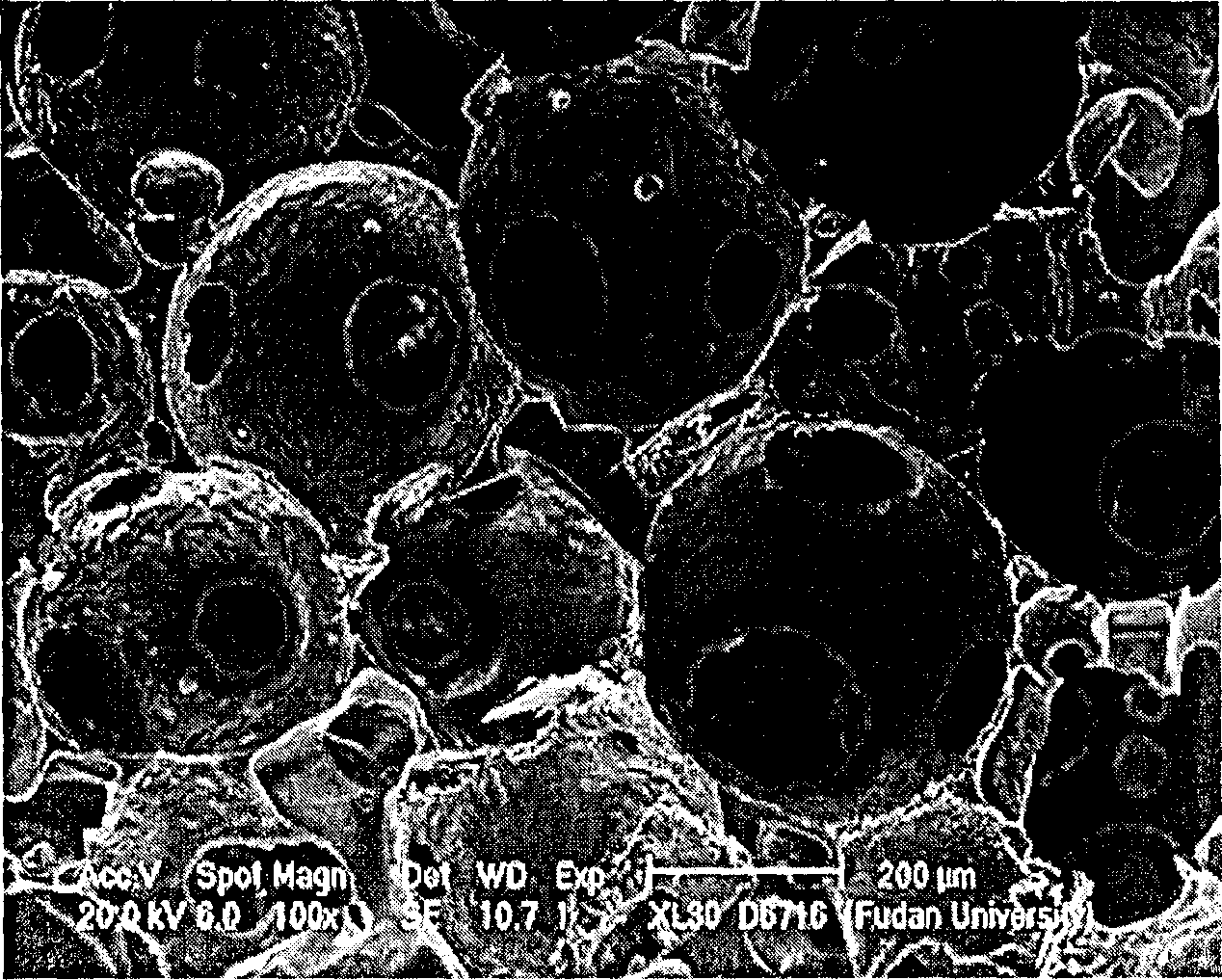

Porous rack with spherical pores and its molding prepn process

InactiveCN1486754ALiquidGood shape retentionPharmaceutical containersMedical packagingSpherical poreBiological materials

The present invention belongs to the field of polymer material and biological material technology, and is especially one porous rack with spherical pores and its molding preparation process. The 3D porous rack is prepared with polymer material as base material and through molding at normal temperature. The simple process may be used in preparing both rack with simple and regular outer appearance and rack with complicated and irregular outer appearance. The prepared porous rack may be relatively thick and has regular spherical pore structure of porosity over 90%, and the pores are communicated mutually and homogeneously distributed. The rack has high mechanical strength, and is suitable as 3D porous cell rack in tissue engineering and in other application fields.

Owner:FUDAN UNIV

Coil-integrated switching power supply module

ActiveUS20120112866A1Reduce thermal resistanceEffective diffusionTransformers/inductances coolingPrinted circuit aspectsElectrical conductorClosed loop

A coil-integrated switching power supply module that provides an improved heat radiation effect to keep the temperature of the entire coil-integrated switching power supply module to a lower value includes a thermal diffusion conductor pattern arranged around a hole through which a magnetic core extends on a layer. The thermal diffusion conductor pattern continuously extends in areas where coil conductor patterns are located on other layers and outside areas where the coil conductor patterns are located on the other layers. In addition, the thermal diffusion conductor pattern includes slits at portions thereof and does not define a closed loop around the hole through which the magnetic core extends.

Owner:MURATA MFG CO LTD

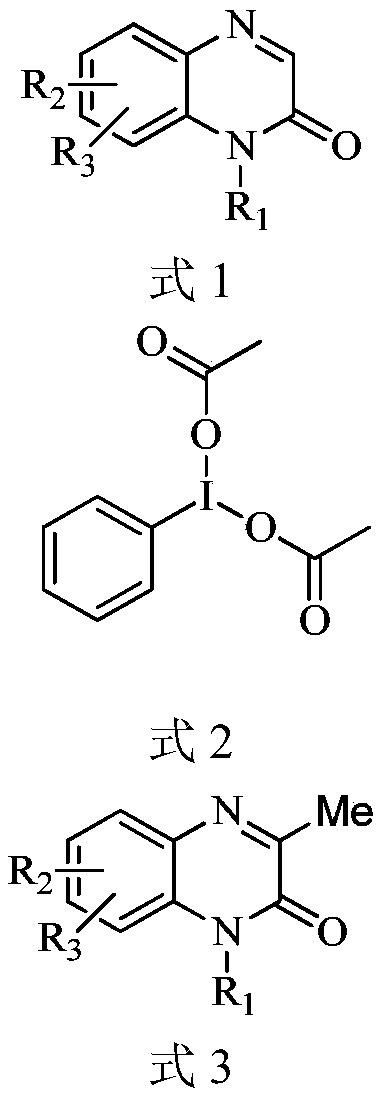

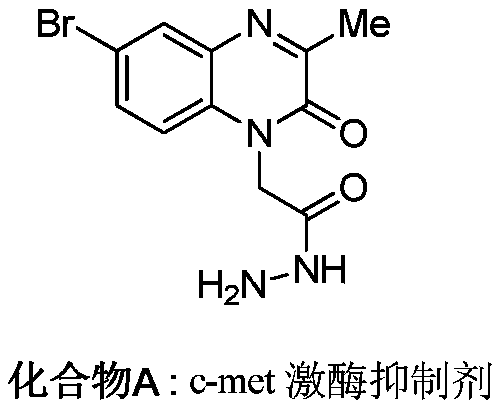

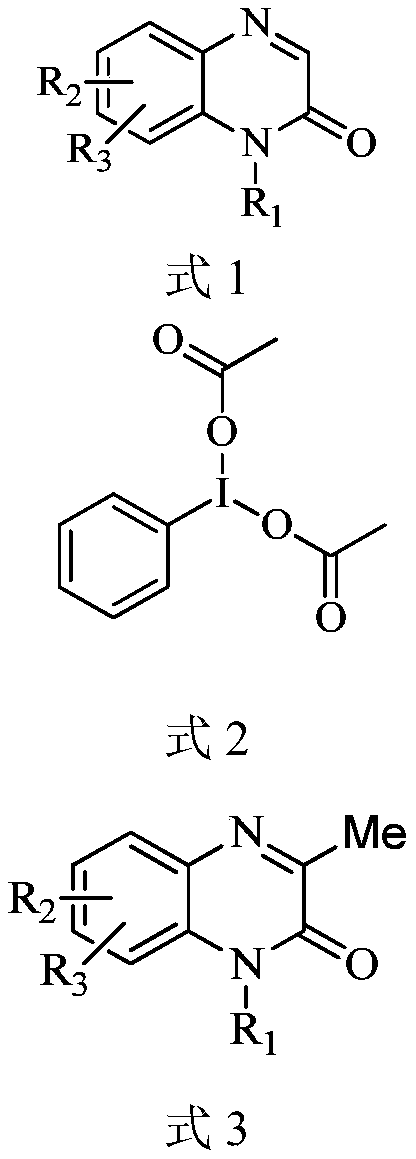

Preparation method of 3-methylquinoxaline-2(1H)-one compounds

InactiveCN109988117AAvoid pollutionImprove reaction efficiencyOrganic chemistryState of artQuinoxaline

The invention discloses a preparation method of 3-methylquinoxaline-2(1H)-one compounds. The preparation method comprises the step of performing a visible light catalytic reaction on a quinoxaline ketone compound and iodobenzene diacetate under the action of a photocatalyst so as to obtain 3-methylquinoxaline ketone compounds. Compared with the prior art, the synthesis method has the advantages that (1) the adopted quinoxaline-2(1H)-one derivative raw material is cheap and easily available so that reduction of the cost is facilitated; (2) the reaction can be carried out under irradiation at room temperature, the conditions are mild, and the product is obtained in one step, so that the reaction yield is high, the operation is environmentally friendly, and industrial production is facilitated; and (3) the method has good applicability to functional groups, and multiple 3-methylquinoxaline ketone compound derivatives can be obtained.

Owner:HUNAN UNIV OF SCI & ENG

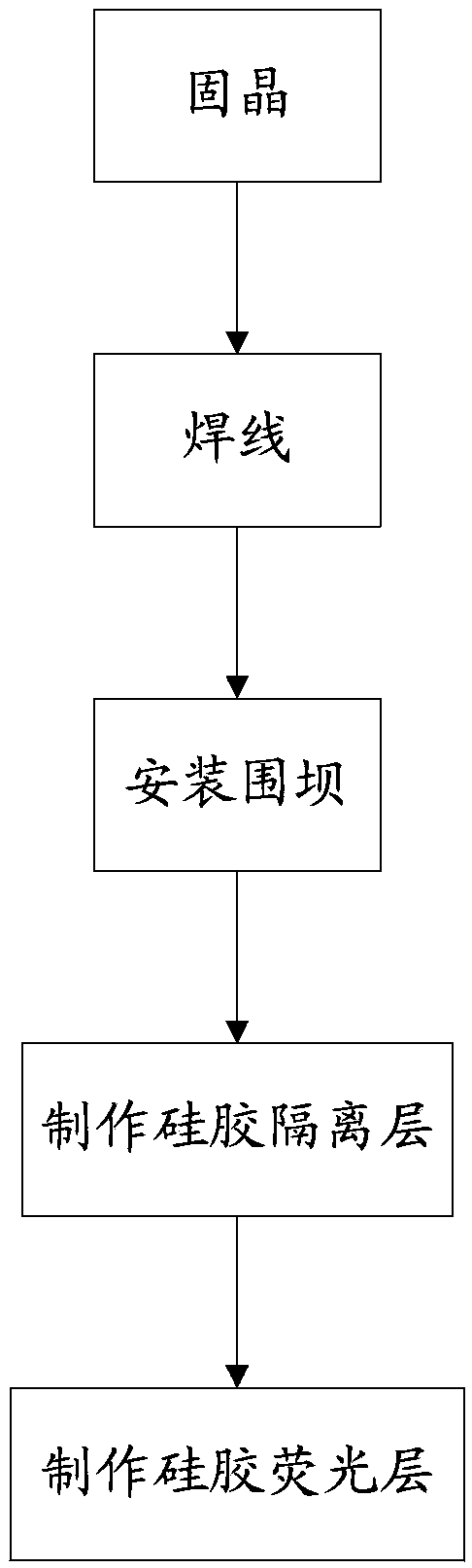

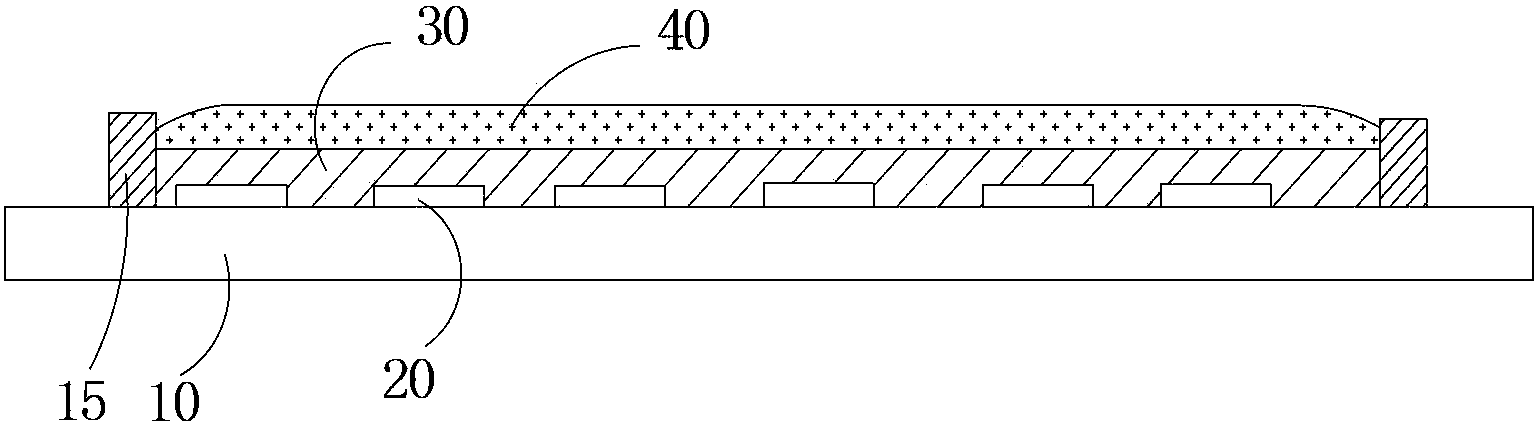

Manufacturing method of isolation type COB light source module

InactiveCN103413885AExtended service lifeAvoid high temperatureSemiconductor devicesFluorescenceEngineering

The invention discloses a manufacturing method of an isolation type COB light source module. The manufacturing method of the isolation type COB light source module comprises the steps of crystal fixing, namely a crystal fixing position on a substrate is coated with liquid crystal fixing glue, an LED chip is attached to the crystal fixing position, and then the substrate is roasted; wire welding, namely one end of a gold wire is welded on a welding disc of the crystal fixing position, and the other end of the gold wire is welded on the electrode of the LED chip; surrounding dam installing, namely organic silica gel is dispersed on the substrate to form an annular surrounding dam; silica gel isolating layer manufacturing, namely liquid silica gel is dropped in the surrounding dam, and the substrate is roasted to enable the liquid silica gel to be solidified to form a silica gel isolating layer; silica gel fluorescent layer manufacturing, namely fluorescent powder and the liquid silica gel are evenly mixed to obtain liquid fluorescent silica gel, the liquid fluorescent silica gel is dropped onto the silica gel isolating layer, and the substrate is roasted to enable the liquid fluorescent silica gel to be solidified to form a silica gel fluorescent layer. The manufacturing method of the isolation type COB light source module has the advantages that the service life of the LED chip can be prolonged and light emitting quality can be optimized.

Owner:GUANGZHOU LEDTEEN OPTOELECTRONICS CO LTD

Machining method for deep hole reducing inner cavity

InactiveCN104001958AImprove rigidityGuaranteed accuracyBoring/drilling machinesSmall amplitudeSurface roughness

The invention relates to a machining method for a deep hole reducing inner cavity. Variable cross-section machining is carried out by the adoption of small amplitude, small cutting-in and ultrasonic frequency vibration through turning and clamping, the surface roughness of a workpiece is reduced, and the dimensional accuracy of the workpiece is improved. According to the machining method, the step of repeated cutter feeding and retreating processing for machining the complex deep hole reducing inner cavity part is changed, the machining time is effectively shortened, and the machining quality of the complex deep hole reducing inner cavity part is improved.

Owner:HARBIN DONGAN ENGINE GRP

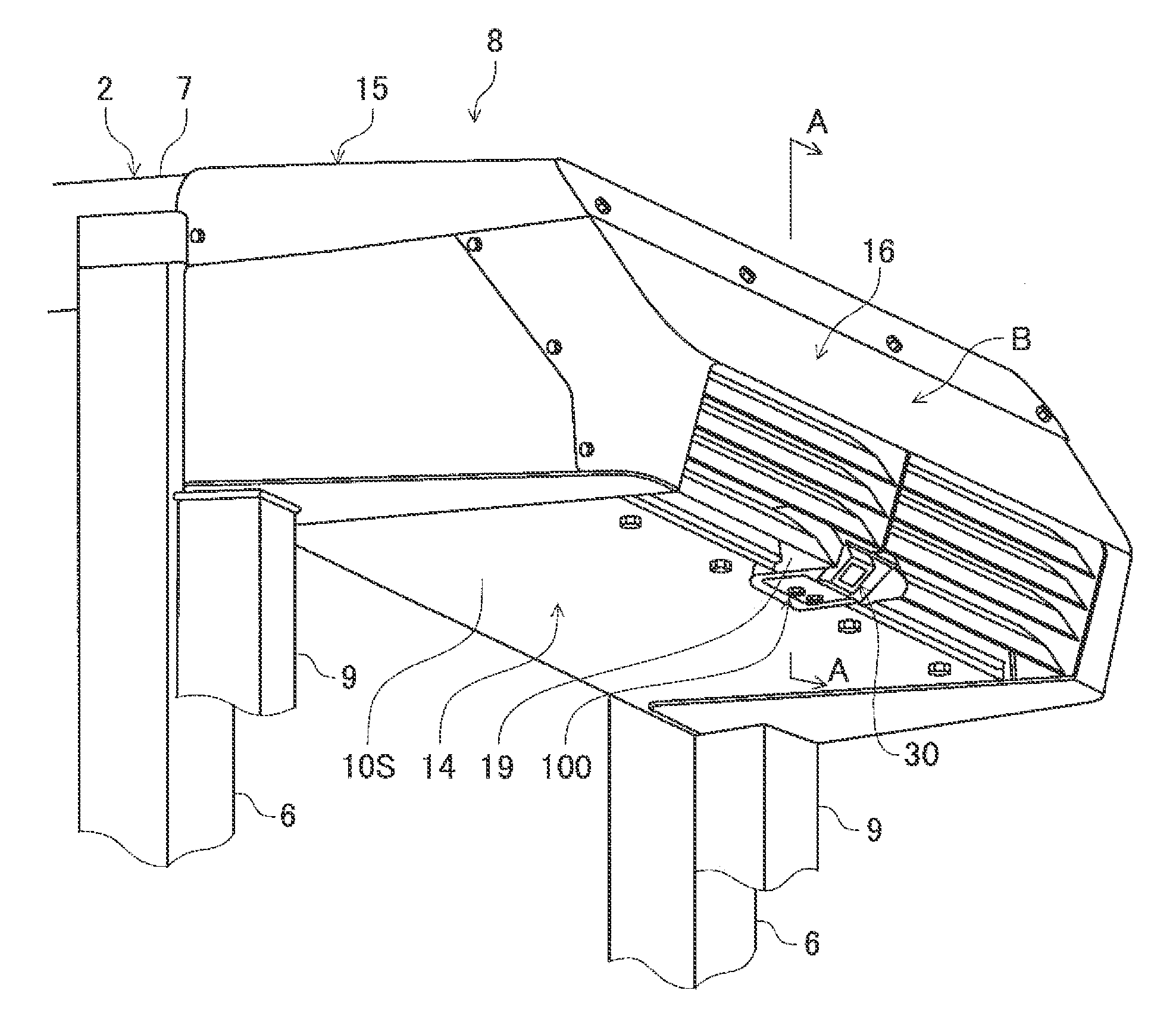

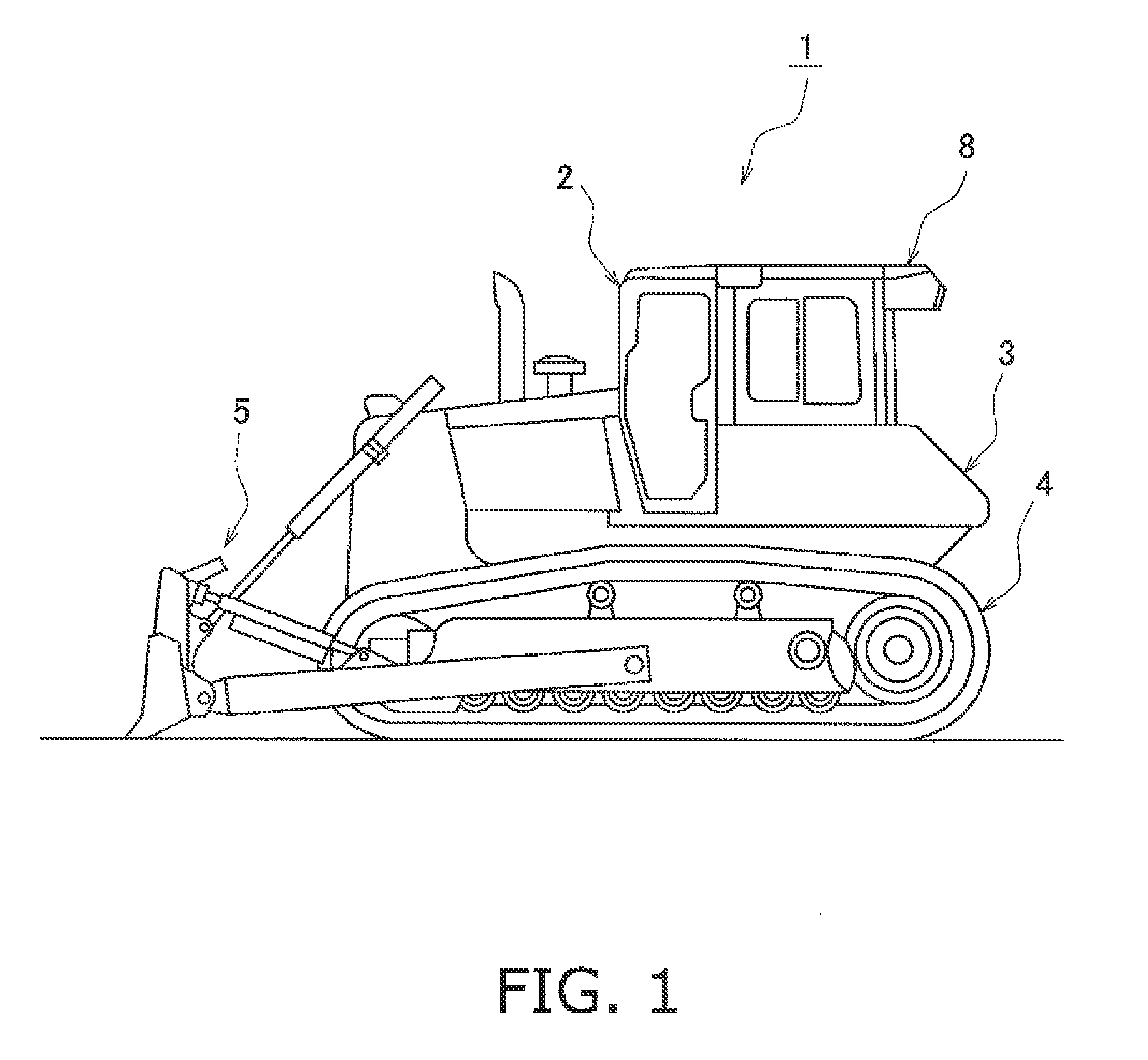

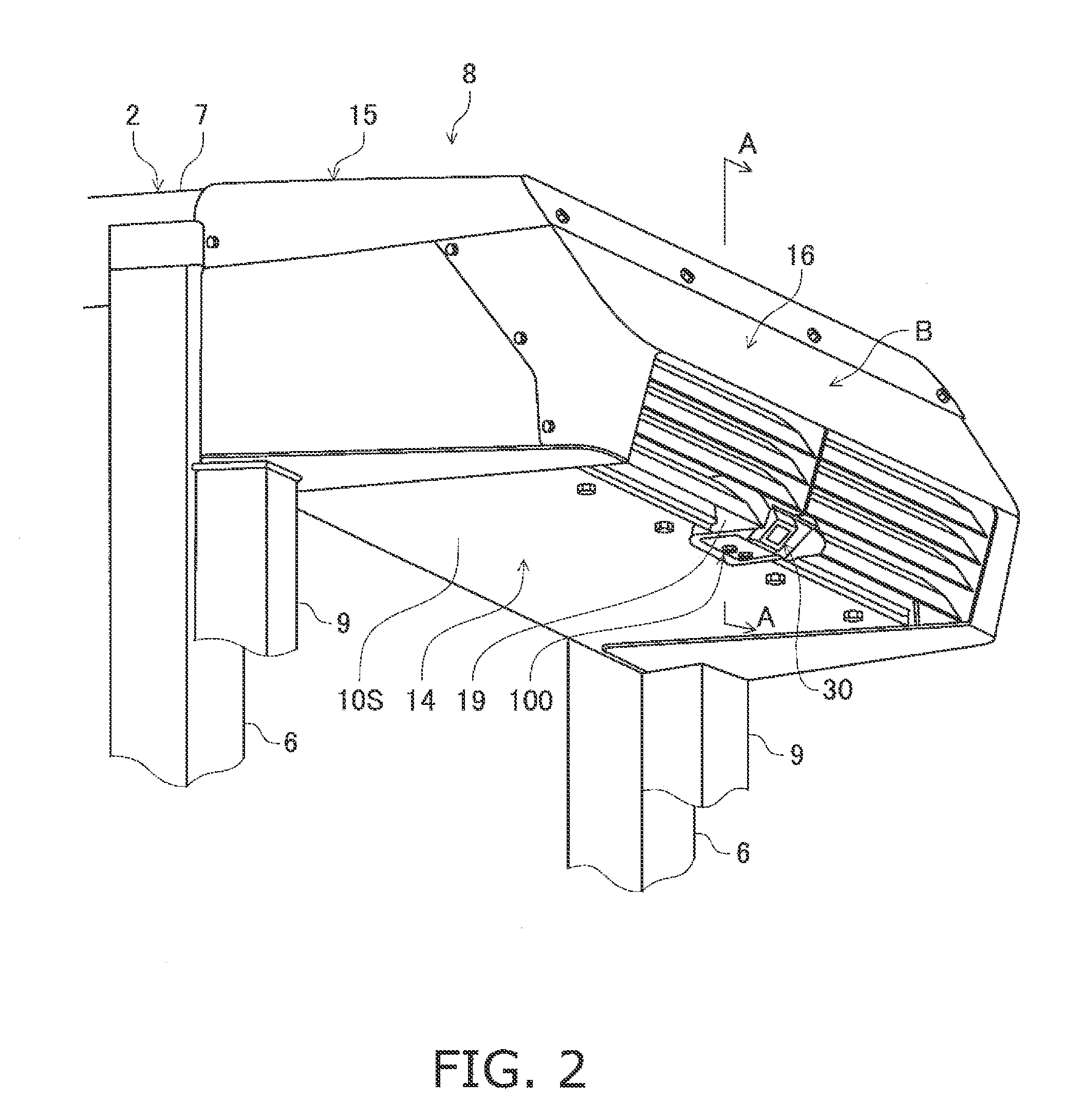

Work vehicle equipped with rear monitoring camera apparatus

ActiveUS20120146361A1Less chance of damageIncrease temperatureVehicle seatsAir-treating devicesEngineering

Owner:KOMATSU LTD

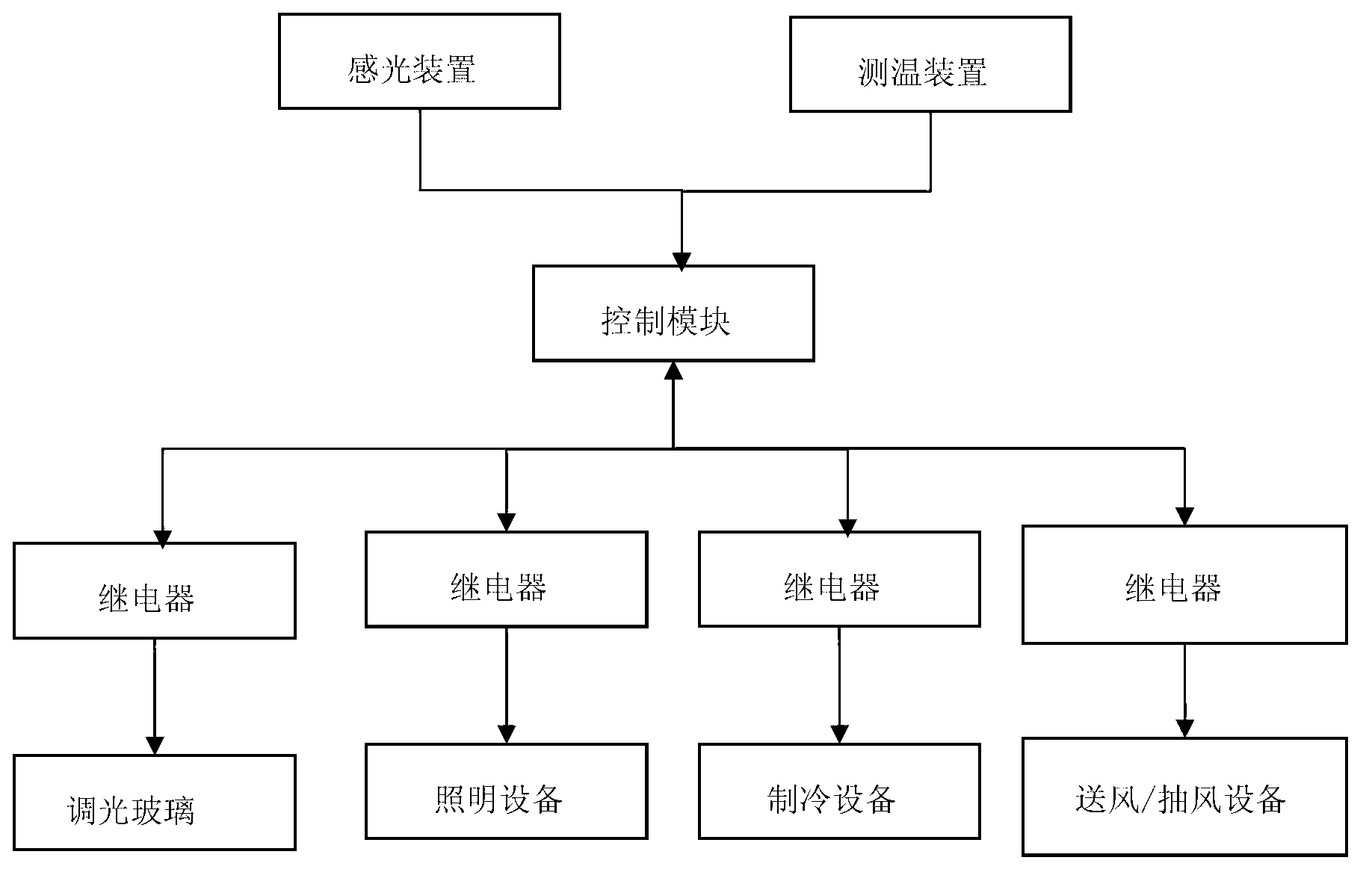

Light adjustment and temperature adjustment control system and control method for sightseeing lift

ActiveCN103072852AEnsure visibilityIsolated irradiationElevatorsBuilding liftsLight sensingControl system

The invention discloses a light adjustment and temperature adjustment control system for a sightseeing lift, which belongs to the technical field of lift control systems. The light adjustment and temperature adjustment control system comprises a detection module, a control module and an output module, wherein both the detection module and the output module are connected with the control module; the output module comprises electrically-controlled liquid crystal light adjusting glass which is connected with the control module; and the detection module comprises a light sensing device which is connected with the control module. The invention further discloses a light adjustment and temperature adjustment control method for the sightseeing lift. According to the system and the method, the control module is used for transmitting a processing result signal to the output module when illumination intensity is very high and is higher than a first preset illumination intensity value according to the detection of the light sensing device, and the electrically-controlled liquid crystal light adjusting glass is closed and is driven to enter a light insulating and heat insulating state, so that strong sunlight irradiation is insulated, the generation of high temperature in a lift car due to irradiation is avoided, the consumed electric energy of an air conditioner is reduced, and the aims of saving energy and protecting environment are fulfilled.

Owner:HITACHI ELEVATOR CHINA

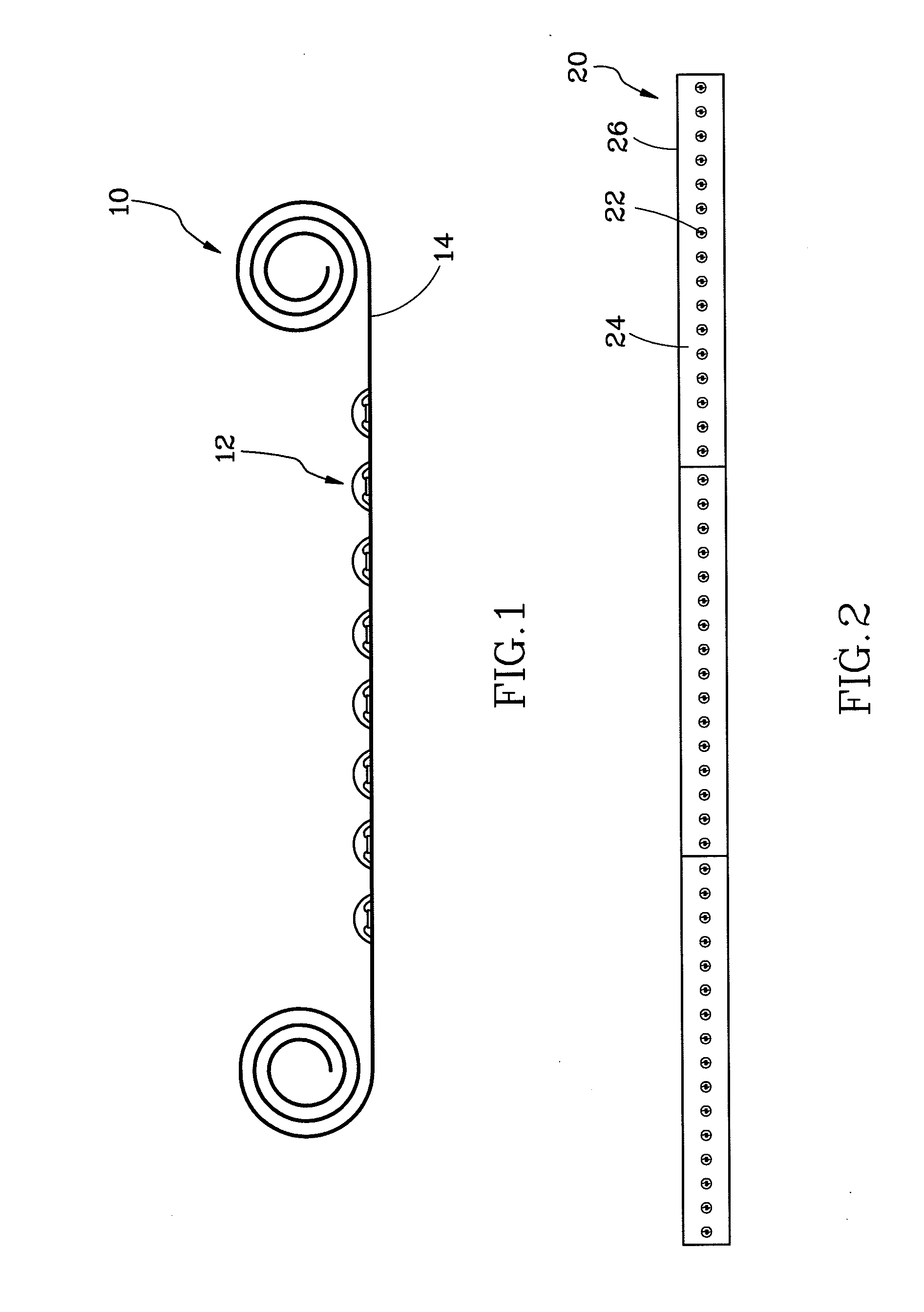

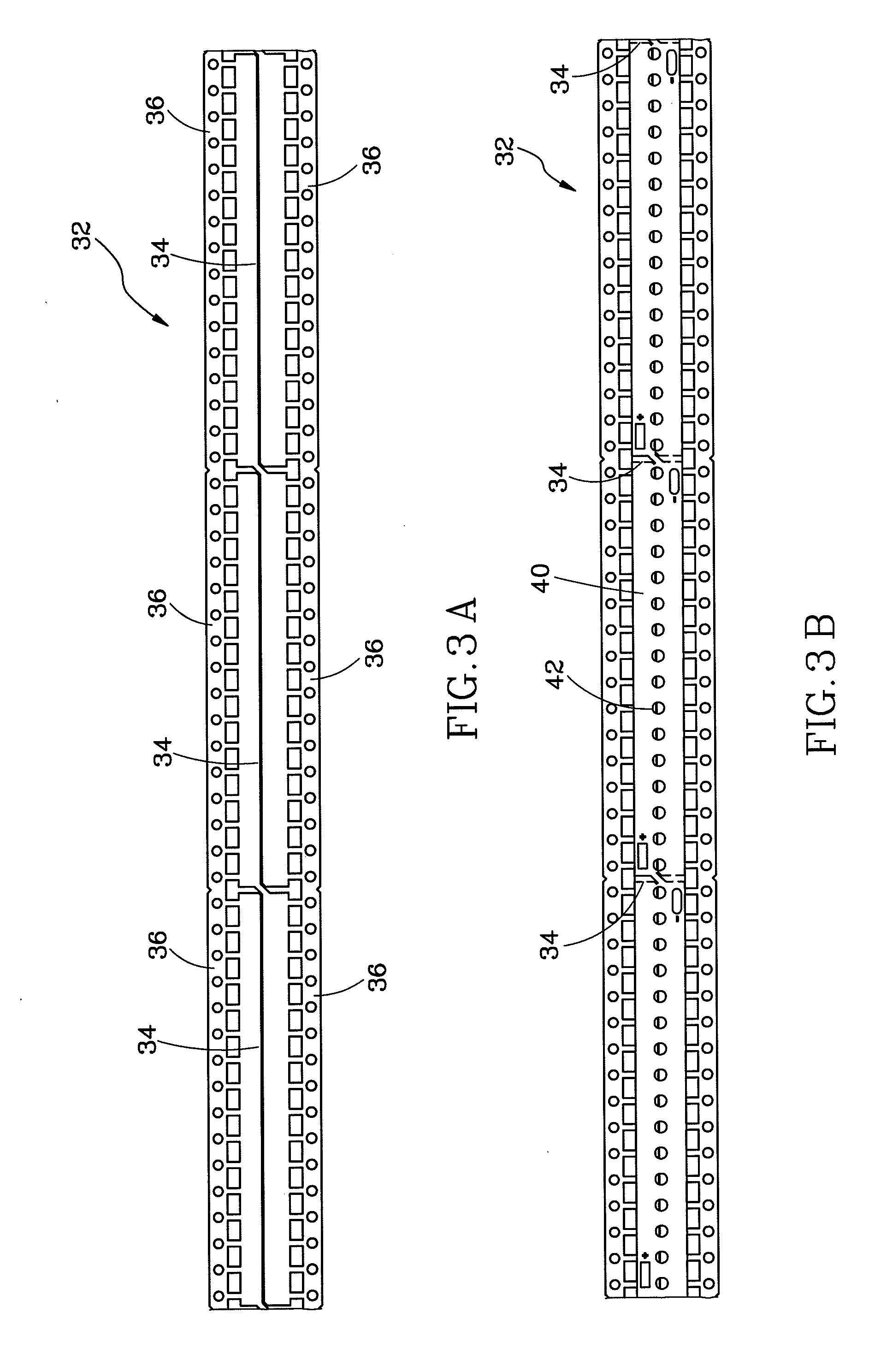

LED lamp strip and manufacturing process thereof

ActiveUS20120228645A1Reduce production cost and timeAvoid high temperaturePoint-like light sourceElongate light sourcesEngineeringLead frame

A process of manufacturing an LED lamp strip includes the steps of forming a plurality of through holes on an adhesive tape, mounting the adhesive tape to a top side of a scrollable lead frame, bonding a plurality of LED chips to the top side of the scrollable lead frame according to the positions of the through holes, packaging the LED chips respectively, and finally cutting the scrollable lead frame. In light of this, the LED lamp strip can be produced under the circumstances of low production cost and less production time.

Owner:LINGSEN PRECISION INDS

Color toner for developing electrostatic image, comprising first linear polyester and second non-linear polyester as binder resin

InactiveUS6506530B1Sharply melting propertySuppress changesDevelopersPolyester resinPolymer chemistry

Owner:MINOLTA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com