Patents

Literature

71 results about "Flavoring extract" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beanilla Vanilla Extract (Single-Fold 1X) Beanilla Vanilla Extract is our in-house proprietary blend of select Bourbon and Tahitian vanillas used to create an equal balance of flavor and aroma.

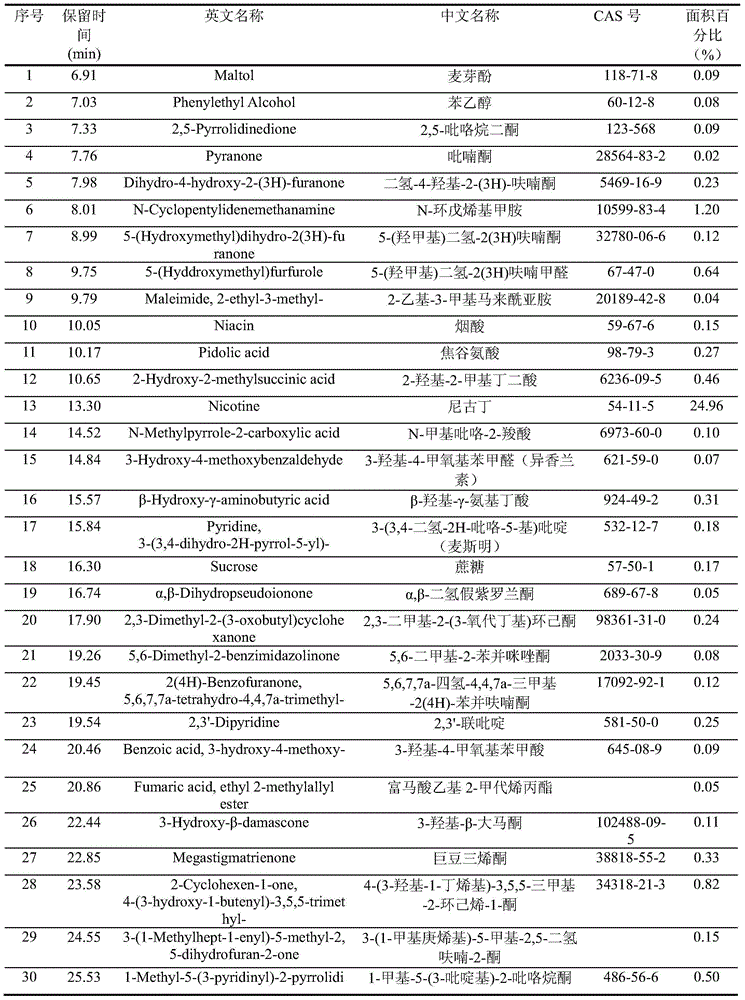

Method for extracting tobacco essence perfume

InactiveCN1899141AImprove qualityImprove inner qualityTobacco treatmentEssential-oils/perfumesFlavorReflux

The tobacco flavor extracting process includes the following steps: 1. crushing tobacco and setting in extracting tank; 2. adding solvent in 2-16 times the weight of tobacco to the extracting tank; 3. decompression reflux extracting at 20-60deg.c temperature and 0.020-0.098MPa vacuum degree for 1-8 hr; and 4. separating the liquid extract through filtering, and decompression concentrating the filtrate at vacuum degree of 0.020-0.098MPa to obtain the tobacco flavor of density 1.1-1.4g / ml. The extracting process is simple, safe, environment friendly, high in extracting efficiency and low in production cost, and the extracted tobacco flavor has the physical and chemical properties of natural tobacco components and may be added to cigarette to improve flavor, raise quality and lower tar.

Owner:宋光泉 +1

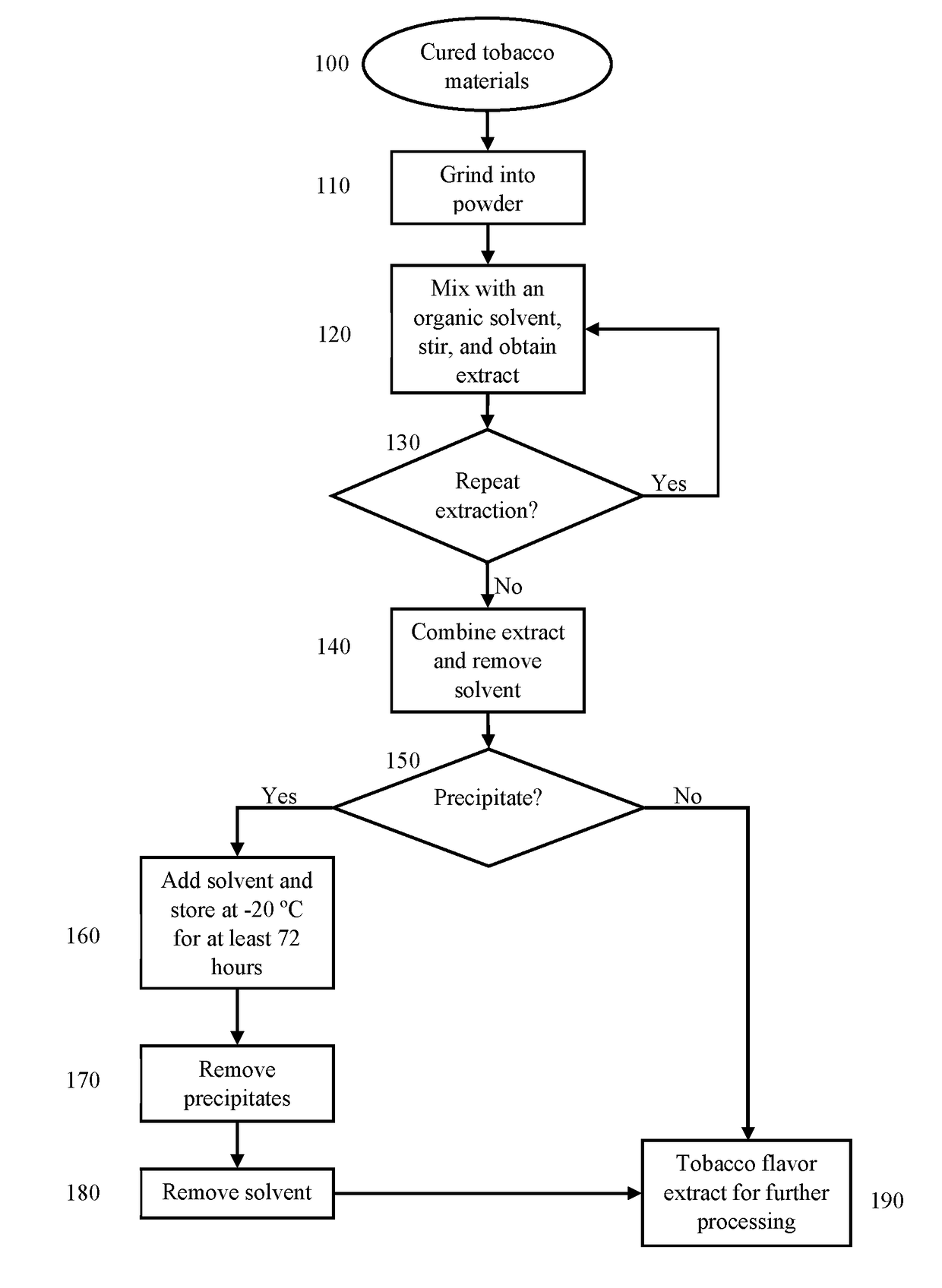

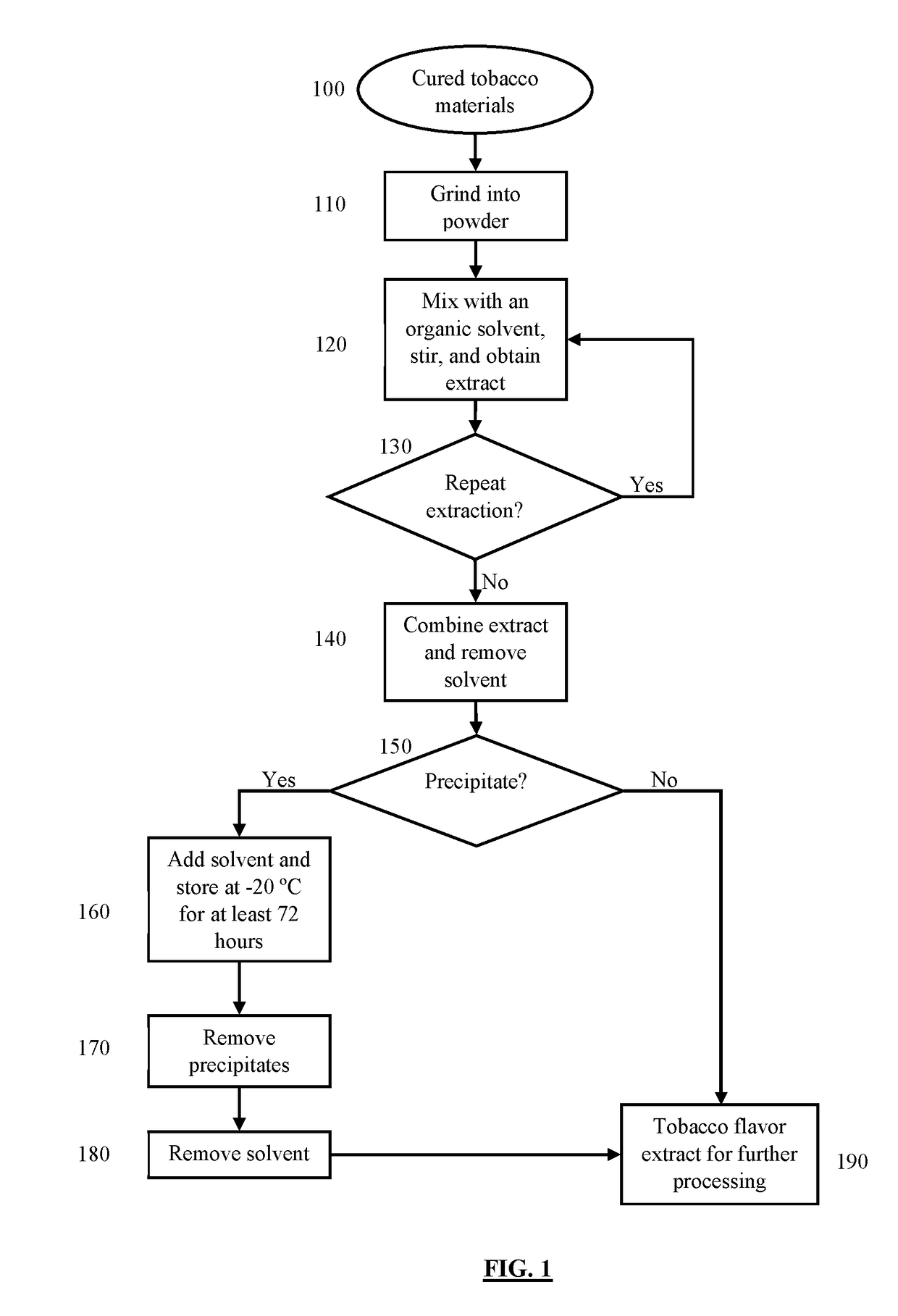

Tobacco flavor extract with reduced tsnas

InactiveUS20170231267A1Tobacco treatmentSolvent extractionFlavoring extractTobacco-specific nitrosamines

A method for preparing a tobacco flavor extract from cured tobacco materials. The tobacco flavor extract has reduced level of tobacco specific nitrosamines (TSNAs) and / or nicotine. The tobacco flavor extract is suitable for use in an electronic smoking device to provide a tobacco taste for a user of the electronic smoking device. The method preserves volatile and semi-volatile flavor components that can be released during a low-temperature vaporization process occurring in the electronic smoking device.

Owner:HUABAO USA INC

Method for extracting natural rose essential oil from rose

The invention relates to a method for extracting natural rose essential oil from fresh rose, which comprises: pretreating the rose, placing the pretreated rose into flavor-extracting petroleum ether, performing repeated leaching and filtration, removing residue, and obtaining leachate; distilling the flavor-extracting petroleum ether in the leachate, and obtaining an extract; adding the extract into ethanol for dissolution, freezing and filtration, removing undissolved substances, and obtaining an alcohol extract; and concentrating the alcohol extract under vacuum, removing the ethanol, and obtaining the rose essential oil. The essential oil extracted by the method maintains the special flavor of the rose; the method has rich resources of raw materials, fully utilizes the prior resources, and has simple technique and low cost; and the obtained product has unique flavor and long flavor lasting time, and is an ideal additive of food, cosmetics and the like.

Owner:庆阳市康惠玫瑰发展有限责任公司

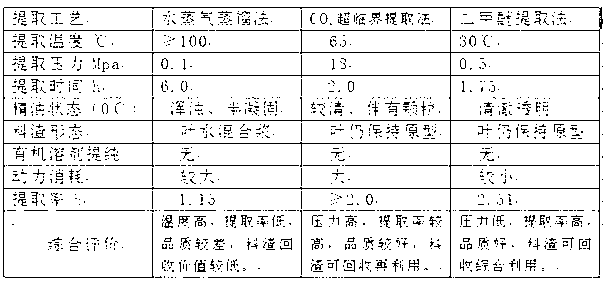

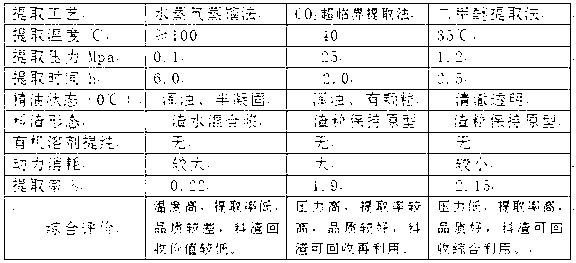

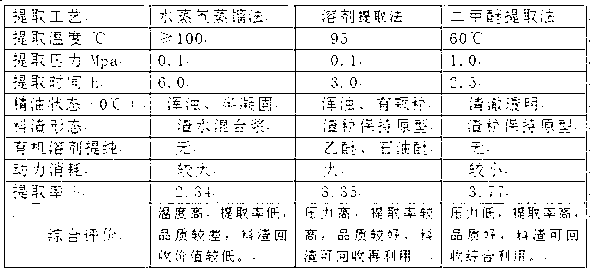

Method for extracting natural flavor with dimethyl ether

The invention relates to a method for extracting a natural flavor with dimethyl ether, which comprises the following steps: making leaves, fruits, flowers and seeds of aromatic plants into a pulp and freeze-drying the pulp, or cleaning and drying stems, barks and roots of aromatic plants, and pulverizing and granulating; sending the freeze-dried material or pulverized and granulated material into an extraction tank, extracting to obtain an extracting solution by using dimethyl ether as a flavor extracting agent, filtering the extracting solution to remove granular impurities, pumping to an evaporation tank, and separating the extracting solution under reduced pressure with a compressor; and carrying out rough separation on the residues after the separation under reduced pressure, carrying out fine separation with a molecular distillation instrument, and distilling by 2-5 stages to obtain the aromatic essential oil. The invention overcomes the defect of low efficiency in the traditional method and the defect of high cost in the supercritical method; the used dimethyl ether extracting agent is odorless and smellless, so the invention has the advantages of no environment pollution, low price and high extraction efficiency; and the obtained plant essential oil is clear and transparent, contains little wax, and overcomes the defects of high water content, high wax content and high oxidative deterioration tendency in the traditional plant essential oil.

Owner:LANZHOU UNIVERSITY

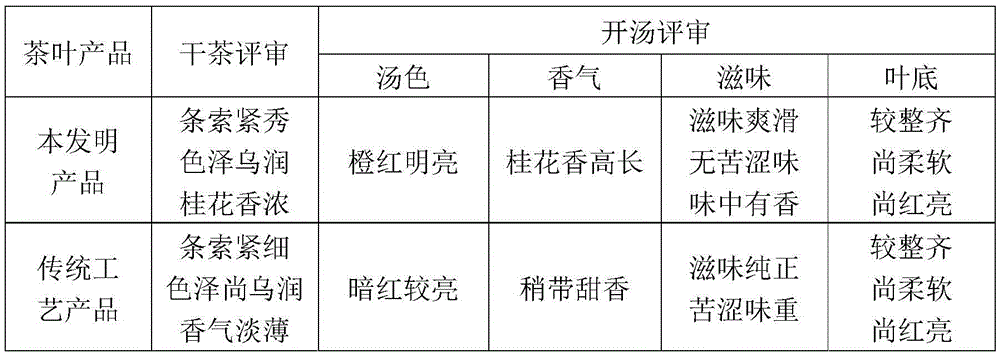

Method for processing black tea with osmanthus fragrance by fresh tea leaves in summer and autumn

ActiveCN105638958AImprove qualityReduce processing costsPre-extraction tea treatmentTea flavoringFlavoring extractBlack tea

The invention provides a method for processing black tea with osmanthus fragrance by fresh tea leaves in summer and autumn. On the basis of existing black tea preparation processes of withering, rolling, fermenting, initial drying, composite drying and the like, with the fresh tea leaves suitable for preparing the black tea in summer and autumn as raw materials, the black tea with the osmanthus fragrance is prepared by the techniques of fresh tea leaves withering, osmanthus water-extract concentrated solution adding, rolling, fermenting, initial drying, composite drying, natural osmanthus essential oil addition, fragrance fixation and the like through a technology of adding the osmanthus fragrance and a flavor extract. Aiming at the disadvantages of low utilization rate of fresh tea leaves in summer and autumn, relatively poor quality, indistinctive taste and fragrance and the like, the processing technology is improved; and the prepared black tea has the quality advantages of tight and slender strips, black color and luster, orange red and bright soup after being brewed, smooth taste and long osmanthus fragrance. By the processing method, the black tea is excellent in interior quality and unique in fragrance; and the problem that fresh tea leaves resources in summer and autumn are wasted and black tea export in China is hindered are greatly relieved.

Owner:HUNAN AGRICULTURAL UNIV

Method for extracting liquorice flavoring extract for cigarette additive from glycyrrhizic-acid produced waste liquid

InactiveCN101921656AMeet the requirements of the development of circular economySave resourcesTobacco treatmentEssential-oils/perfumesLicorice acidGLYCYRRHIZA EXTRACT

The invention discloses a method for extracting a liquorice flavoring extract for a cigarette additive from glycyrrhizic-acid produced waste liquid, belonging to a production method of the cigarette additive. The method sequentially comprises the following steps of: (1) neutralization: adjusting the pH value of the glycyrrhizic-acid produced waste liquid to 7-8; (2) primary membrane impurity removal: processing the waste liquid by adopting inorganic ceramic membrane separating equipment with the bore diameter of 30-100 nm and then collecting filter liquid; (3) electro-osmosis desalination: desalinating by utilizing an electro-osmosis device to reduce the conductivity of the filter liquid to 2500-3000 mus / cm; (4) secondary membrane refined concentration: carrying out refined concentration by using a nanofiltration membrane separating device, wherein a membrane element is a nanofiltration membrane with the separating bore diameter of 1-2 nm; and (5) spray drying: carrying out spray drying on the refined concentrate to obtain liquorice flavoring powder for the cigarette additive. The method is scientific and reasonable, is convenient to operate, easy to implement and can obtain the extract with high purity, and thus, the method is suitable for serving as the cigarette additive.

Owner:HUBEI CHINA TOBACCO IND

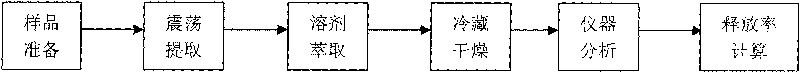

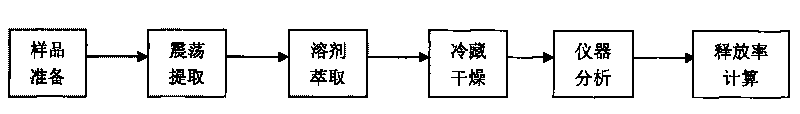

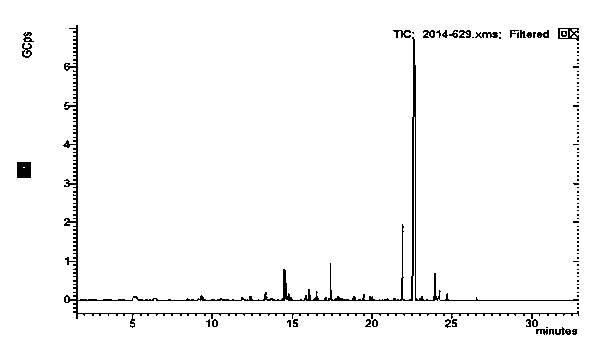

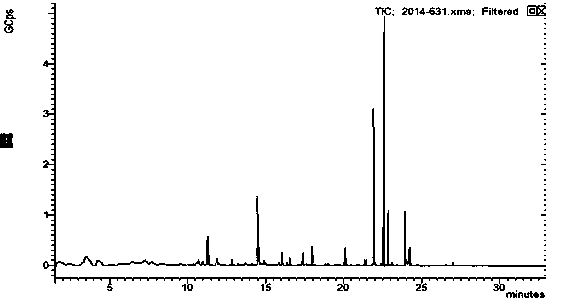

Method for measuring release rate of non-polar or low-polar flavor component in smoke-free tobacco product

ActiveCN101718757AComponent separationPreparing sample for investigationFlavoring extractMethylene Dichloride

The invention discloses a method for measuring the release rate of a non-polar or low-polar flavor component in a smoke-free tobacco product, which is mainly used for determining the release rate of the non-polar or low-polar flavor component in the smoke-free tobacco product by performing preliminary treatment and apparatus analysis on the smoke-free tobacco product. The method specifically comprises the following steps: weighing two parts of equivalent smoke-free tobacco products, adding artificial saliva and a methylene dichloride standard substance solution respectively, sealing and oscillating the mixture, extracting saliva extract twice with the equivalent methylene dichloride standard substance solution, combining the extract liquors, drying the combined extract liquor for cold storage and then feeding a sample in a concentration way; performing separation and detection on an extracted component with GC and GC-MS, retrieving and determining the content of the non-polar or low-polar flavor component according to a retaining time and a mass spectrum database, and comparing the content of the extracted component in the saliva with the content of the directly extracted component of the methylene dichloride solution so as to obtain the release rate of the flavor extracted component of the smoke-free tobacco product. The method has the advantages of simple process, high analysis speed, good accuracy, unlimited sample physical state and the like.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Roasted eel seasoning juice and preparation method thereof

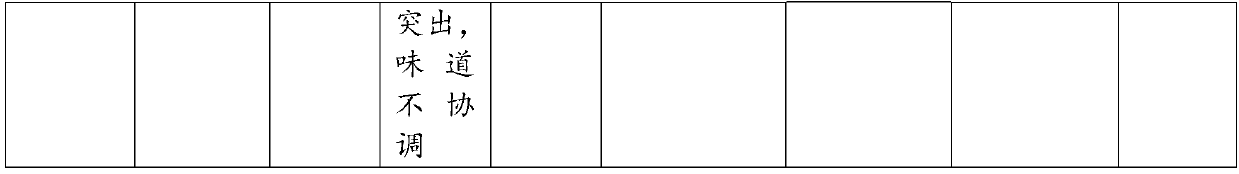

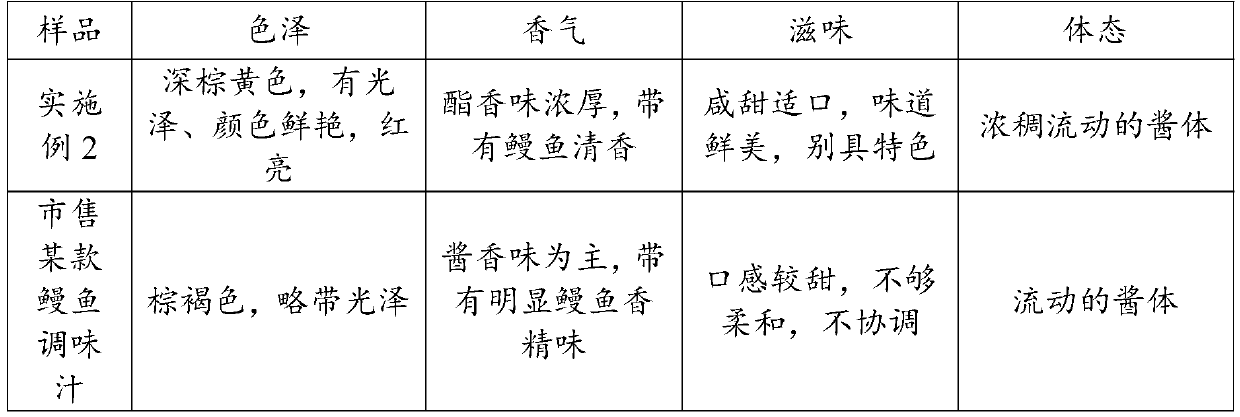

The present invention provides a roasted eel seasoning juice and a preparation method thereof. The preparation method comprises the following steps: blending and sterilizing: sterilized and clarified raw juice soy sauce is inhaled into a high level tank for standby application, the soy sauce is poured into a blending and sterilizing pot, according to an accessory material table, each batch includes eel flavor extract, raw material soy sauce, water, juice, water, mirin, glucose syrup, white granulated sugar, high fructose corn syrup, edible alcohol, monosodium glutamate, and food additive, the accessory materials are put into the blending and sterilizing pot to conduct blending, finally the raw materials are stirred evenly, the blended and qualified soy sauce is heated to 95-98 DEG C and maintained for 60 min, and the heated soy sauce is immediately filled when the soy sauce is still hot; and filling: firstly filling devices and packaging equipment are cleaned and sterilized respectively, when the sterilization meets the requirements, the roasted eel seasoning juice is filled into the packaging equipment, and the filled roasted eel seasoning juice is immediately pressed with a lid for sealing. The sauce flavor of the roasted eel seasoning juice is thicker and has a unique flavor of the roasted eels, can eliminate the smell of meat, increase the fresh flavor and sweetness, add color, and increase smoothness, is easy to be adhered to the roasted eel meat, does not decompose once being heated, and is longer in staying time, and easier to be penetrated into the inner of the roasted eel meat.

Owner:CHANGLE JUQUAN FOOD

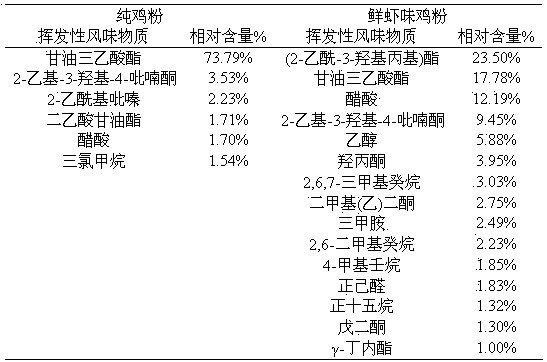

Preparation method of boiling-resistant type chicken powder with natural fresh shrimp flavor

The invention relates to a preparation method of boiling-resistant type chicken powder with natural fresh shrimp flavor, belonging to the field of seasoning processing. According to the method, fresh shrimps are taken as raw material to prepare a shrimp flavor extract, the existing chicken powder is utilized, and the method comprises the following steps: pulping the fresh shrimps, carrying out enzymolysis and enzyme deactivation, centrifuging, carrying out thermal reaction for aroma enhancement, carrying out vacuum concentration, blending the product with pure chicken powder and the like, and carrying out microwave freezing and drying to obtain the final product. The chicken powder processed by the method adopts an enzymolysis technology, a technology of aroma enhancement by Maillard thermal reaction, and a microwave freezing and drying technology, so that the natural fresh shrimps are real and rich in flavor and delicious in taste; furthermore, an embedding technology is adopted, so that the boiling resistance of products can be improved; after the boiling-resistant type chicken powder is cooked for 2 hours, the proportion of the freshening amino acid content is increased by 12.5% compared with the proportion of the pure chicken powder; the boiling-resistant type chicken powder comprises main volatile characteristic flavor substances including esters, ketones and acids, and the relative content of the main volatile characteristic flavor substances is more than 75%.

Owner:JIANGNAN UNIV +1

Composite condiment and producing method thereof

InactiveCN101253967APromote digestion and absorptionIncrease nutritionFood preparationFlavorMonosodium glutamate

The invention discloses a compound seasoning and a production method thereof, and is characterized in that the seasoning consists of the following ingredients by weight percentage: fresh shrimp extract through zymohydrolysis 10%-25%, monosodium glutamate 43%-58%, flavor ribonucleotide 1.5%-1.6%, flavor extract from spicy ingredients 0.5%-1%, and other ingredients 30%; the seasoning further consists of other auxiliary ingredients by the weight percentage as follows: sugar 1%-5%, essence 0.5%-1%, maltodextrin 6.5%-8%, and starch 18%-20%. The production method comprises the steps of cleaning the fresh shrimp, pulverizing, subjecting the pulverized shrimp to zymohydrolysis, filtering, concentrating in a vacuum, extracting, preparing and blending, drying and packing. The novel compound seasoning has unique flavor, high nutritional value, high freshness and good taste, and can replace monosodium glutamate and essence of chicken.

Owner:宁波米氏实业有限公司

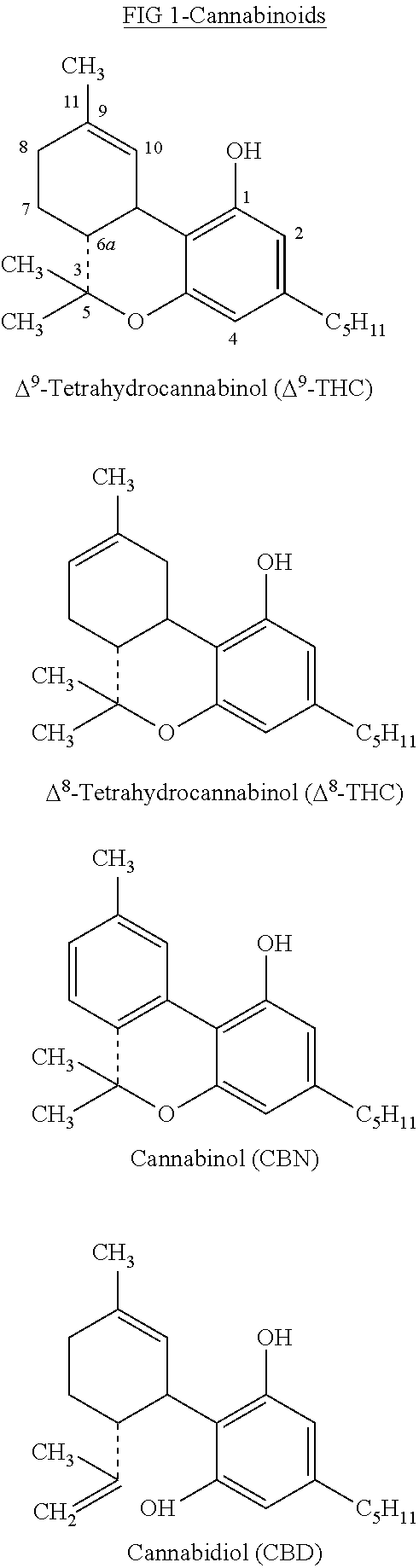

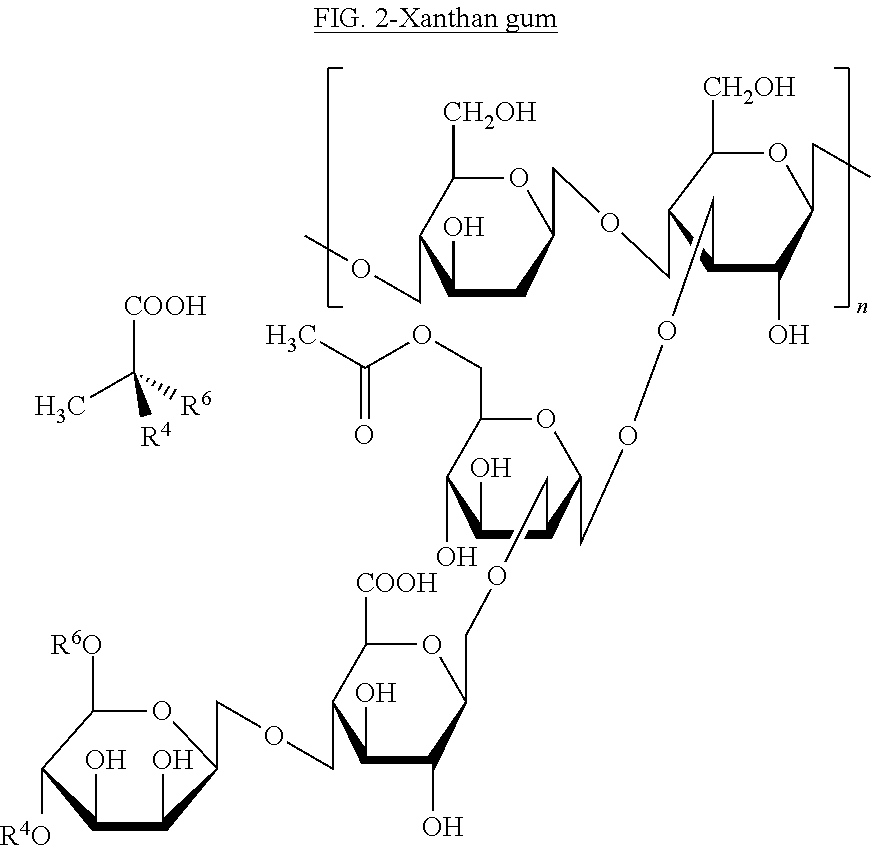

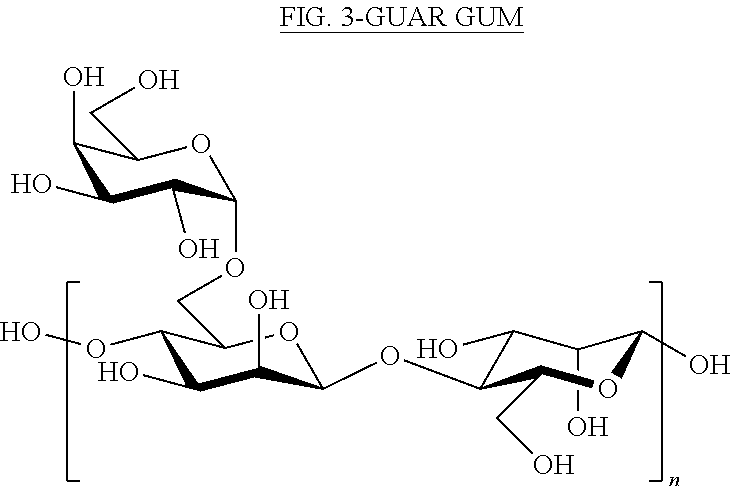

Cannabis infused sweeteners and elixirs

A cannabis infused sweetener comprising cannabis oil; at least one emulsifying agent selected from the group consisting of xantham gum, guar gum, lecithin, carrageen, monoglycerides, natural emulsifiers and organic emulsifiers that are safe for ingestion by humans; and a sweetener; and a cannabis infused elixir comprising cannabis oil; at least one emulsifying agent; a sweetener and flavoring extracts or fruit syrups; both the sweeteners and the elixirs are bio-available, fast acting and highly metabolizable.

Owner:SRE WELLNESS INC

Process combination for preparing fresh tea flavor extract

The invention mainly relates to process combination for preparing a fresh tea flavor extract, in particular to the process combination for preparing a fresh tea flavor green or black tea extract from fresh tea without fixing at a low temperature by crushing, homogenization, centrifuging, microfiltration and membrane concentration processes.

Owner:广州泽力医药科技有限公司

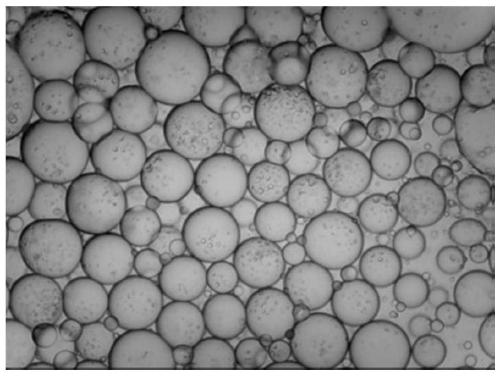

Method for preparing high-stability tobacco natural flavor extract

InactiveCN110387287ANatural aromaNo volatile lossTobacco preparationEssential-oils/perfumesFlavorFlavoring extract

The invention relates to a method for preparing a high-stability tobacco natural flavor extract. The method comprises the following steps: extracting out essential oil easy to volatile in tobacco by using a vapor distillation process, further filtering a tobacco water extract, performing vacuum concentration, returning the extracted essential oil into the concentration liquid, adding concentratedchick-pea yellow slurry, performing high-intensity homogenization emulsion so as to obtain an oil-in-water emulsion, enabling flavor essential oil to be uniformly distributed in a flavor concentrationliquid in a nano oil droplet manner, and increasing the volume ratio of emulsion-system tobacco essential oil, so as to prepare a semisolid tobacco extract product. By adopting the technical scheme,the tobacco essential oil and the extraction concentration liquid are combined and emulsified, and the flavor of the extract is completely derived from a tobacco raw material, so that the flavor is natural; and in addition, as the tobacco essential oil easy to volatile is wrapped in an emulsion water phase in the oil droplet manner, volatilization loss of the flavor of the tobacco flavor extract in storage and use can be effectively reduced.

Owner:HENAN CIGARETTE IND TOBACCO SLICE

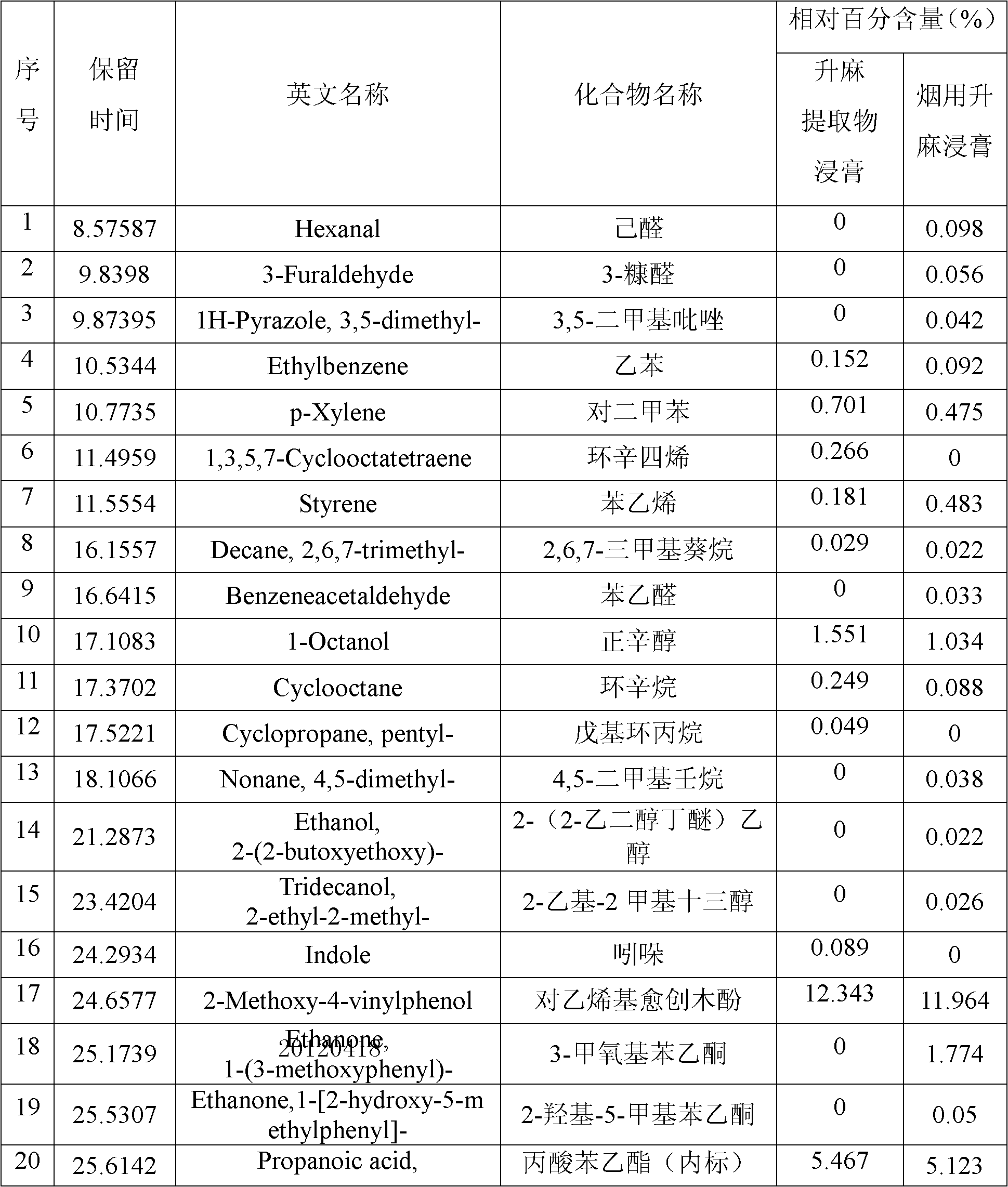

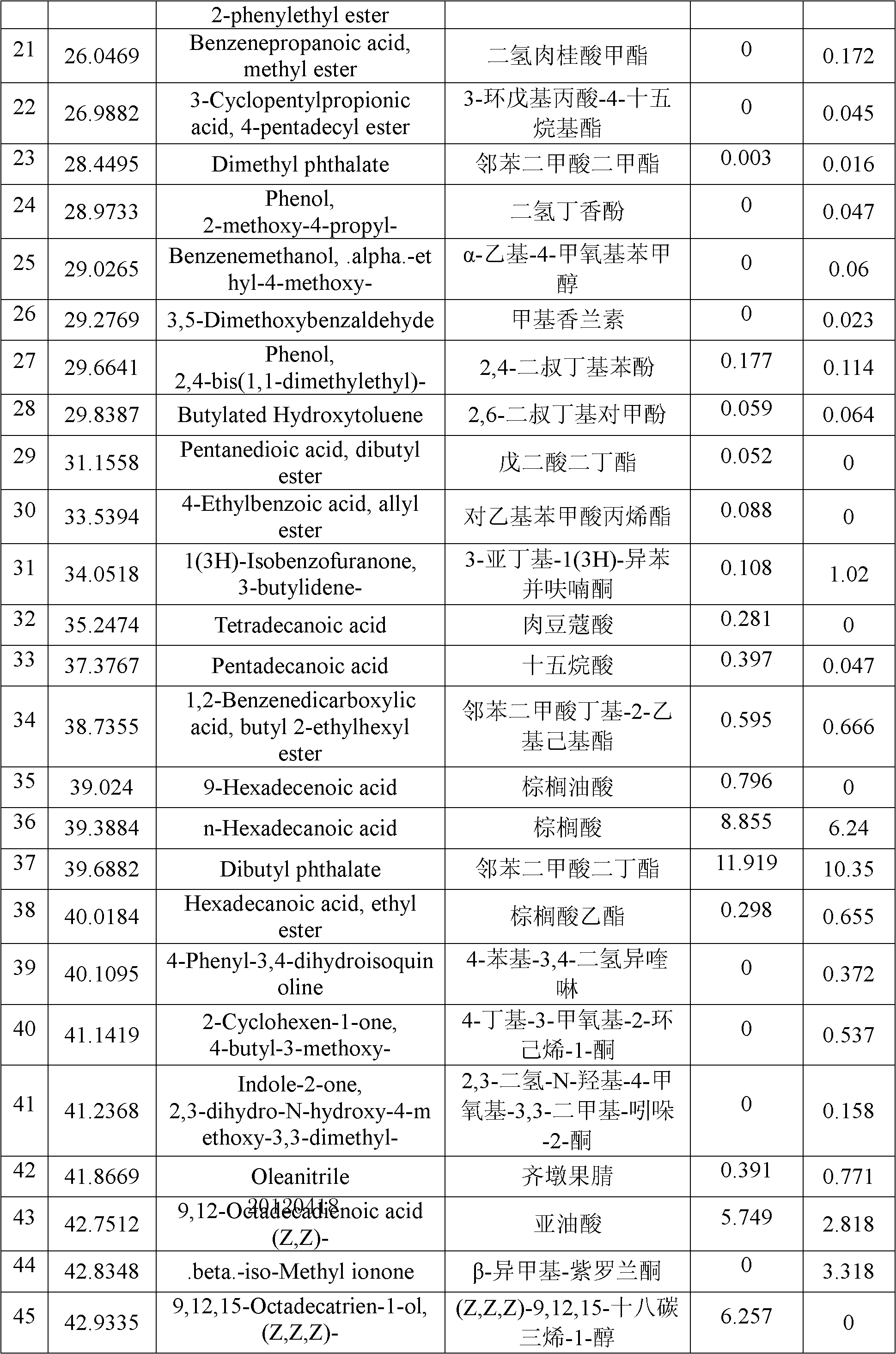

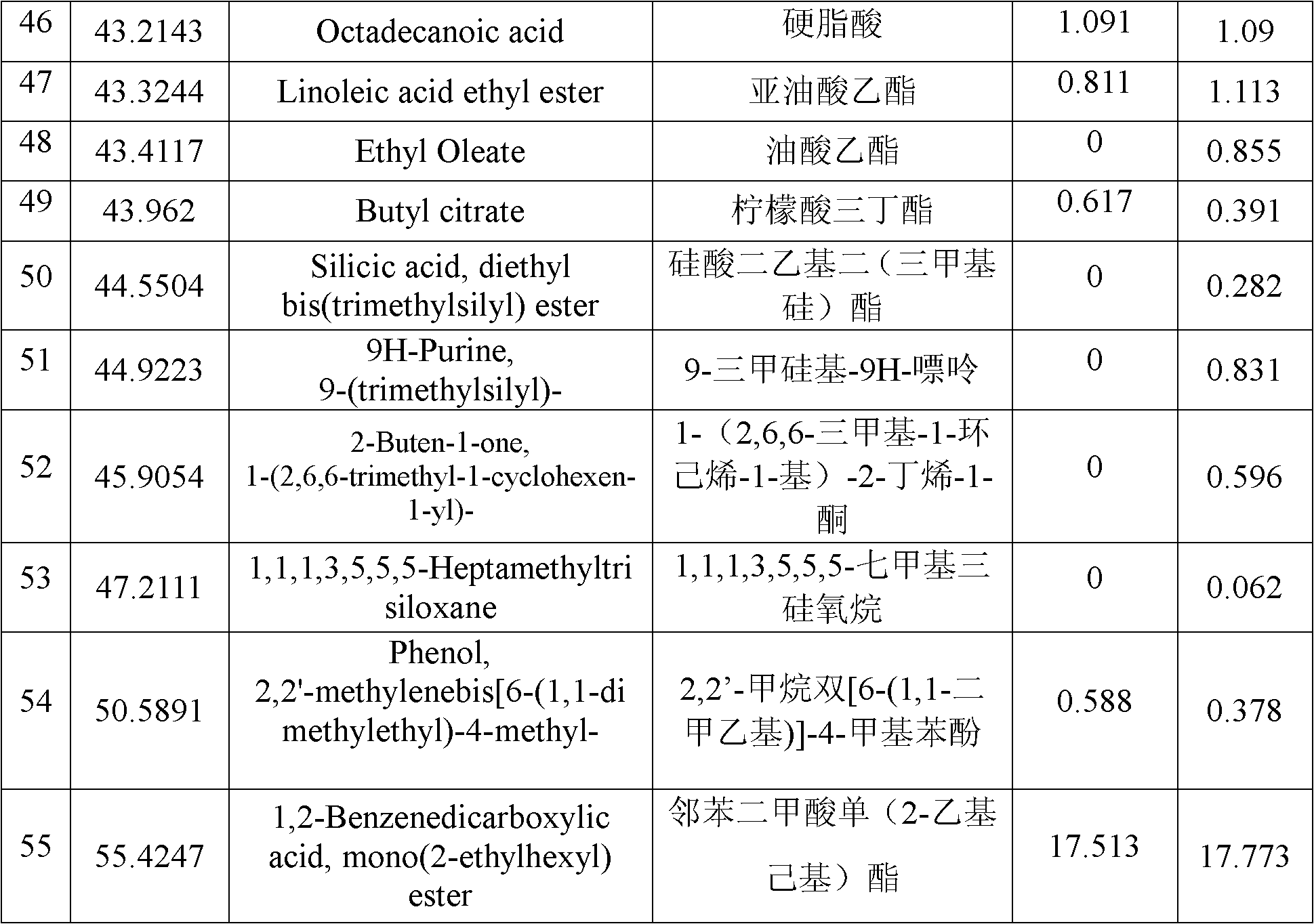

Bacillus methylotrophicus and preparation method as well as application of tobacco cimicifugae extract

InactiveCN102618475AWide variety of sourcesNatural, environmentally friendly and harmlessTobacco preparationBacteriaFlavoring extractMicroorganism

The invention discloses bacillus methylotrophicus, wherein the name of the strain is bacillus methylotrophicus VJ4-1 with a collection number of CCTCC NO: M 2012004. The invention provides biotransformation of tobacco rhizoma cimicifugae extract by using microbial bacillus methylotrophicus and application of the tobacco rhizoma cimicifugae extract to tobacco. Natural tobacco flavor can be produced by fermenting rhizoma cimicifugae through microbial strain. The method has the advantages of simple process, wide source of raw materials, environmental friendliness and harmlessness in a productionprocess and industrial application prospect; and the obtained natural flavor extract can be directly used for flavoring of tobacco, has the advantages of coordination with smoke, light sweet flowery flavor, rich aroma, softness, comfort, good aftertaste and capability of improving smoke flavor and can be mixed with other tobacco essence and perfumes for use.

Owner:HUBEI CHINA TOBACCO IND

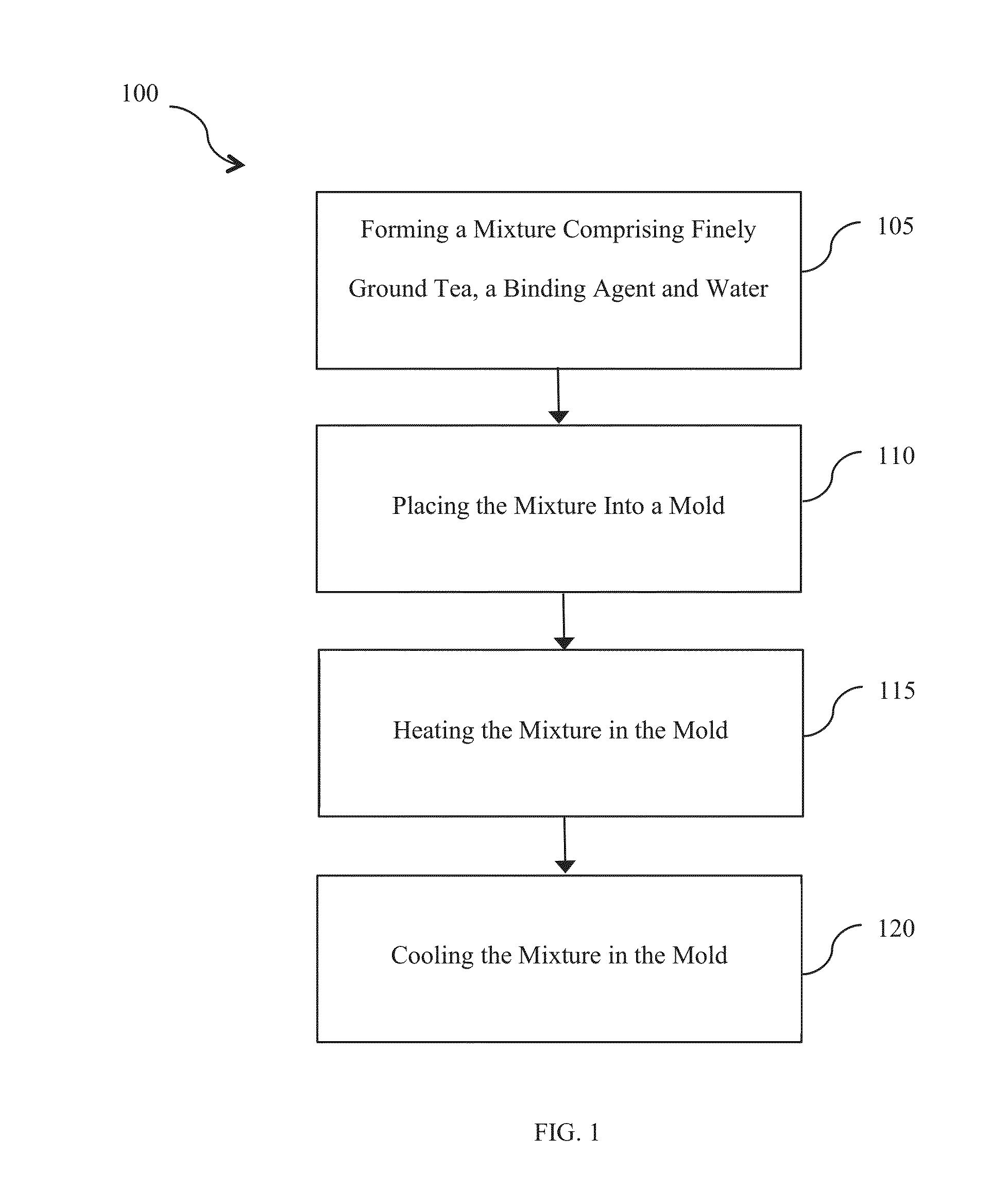

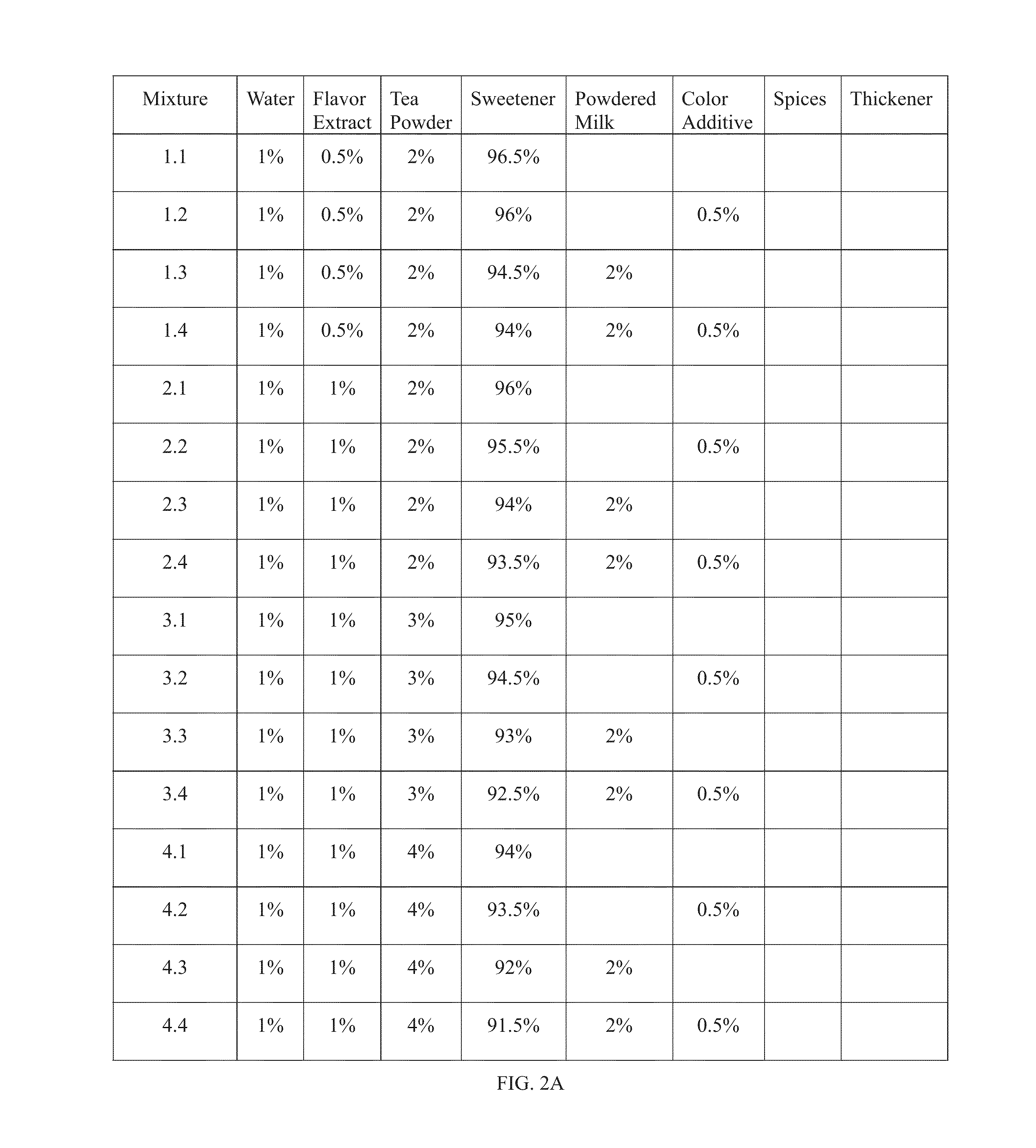

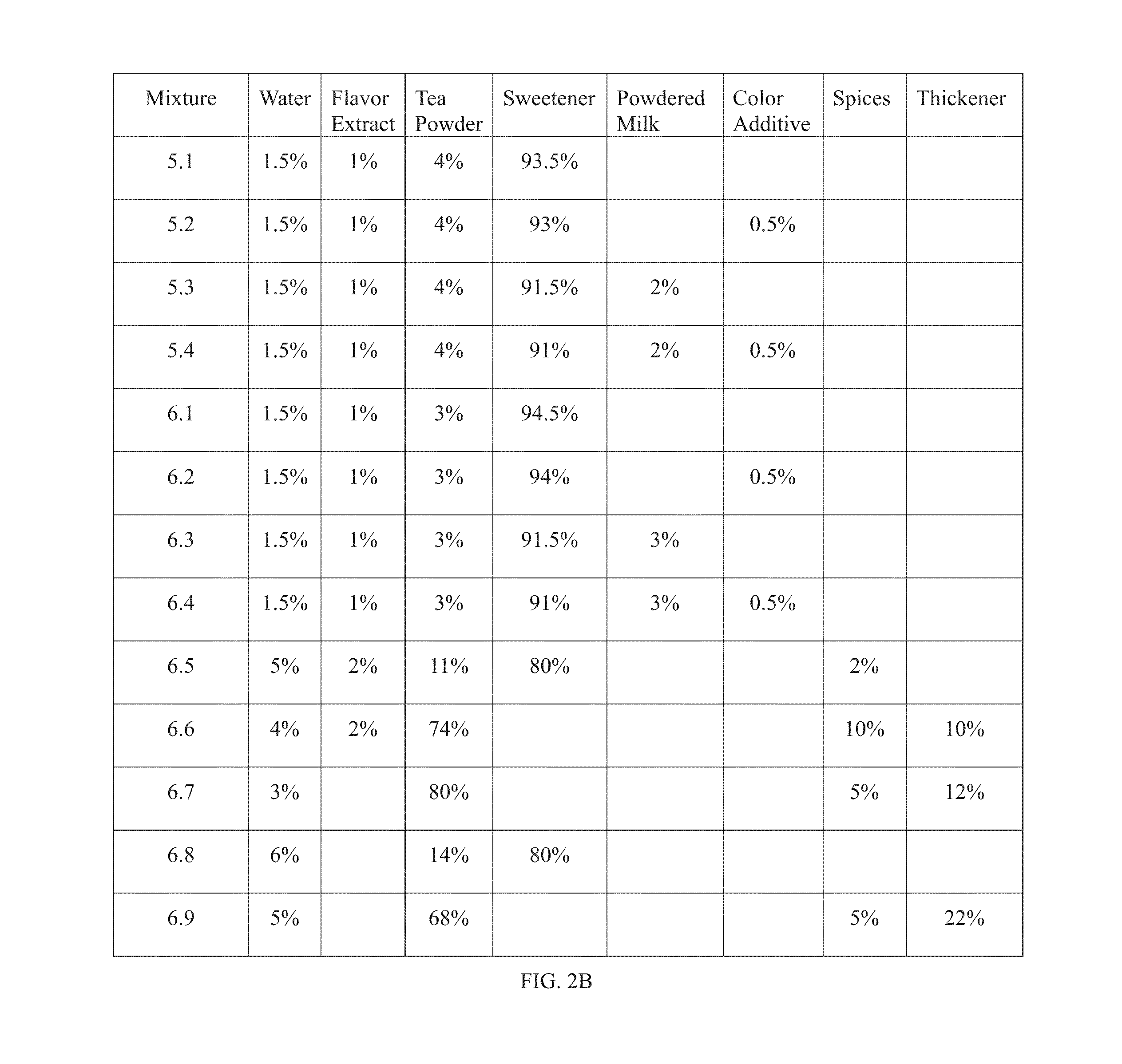

Tea solid composition and process of making the same

ActiveUS20160135476A1Convenient and efficient way of makingDesired nutritive valuePre-extraction tea treatmentTea extractionFlavoring extractFlavor

A tea solid composition comprising a mixture of finely ground tea, a binding agent and water, wherein the mixture forms a tea solid composition in response to heating and subsequent cooling in a mold. The tea solid composition may further include at least one ingredient selected from the group consisting of a sweetener, a ground spice, a flavor extract, a powdered milk product, a color additive and a thickener.

Owner:HUMBLE TEA INC

Oral health composition

ActiveUS20190269607A1Improve health benefitsCosmetic preparationsToilet preparationsFlavoring extractOral health

An ingestible oral health composition has synergistic proportions of active ingredients consisting of: baking soda; guava leaves; turmeric; black pepper; erythritol or xylitol; coconut oil; and vegetable glycerin with a natural flavor extract. The oral health composition may be in the form of a tablet, a powder, a paste, or a suspension. The oral health composition provides superior cleaning and control of oral health problems. The oral health composition can be ingested to provide health benefits to the entire body.

Owner:MARINO MONICA NIKITA

Method for applying tobacco flavor extracted from tobacco branches to snus

The invention discloses a method for applying tobacco flavor extracted from tobacco branches to suns. The method includes pretreating different types of tobaccos, drying tobacco branches of flue-cured tobacco under a low temperature of 40-60 degrees, air drying tobacco branches of burley tobacco and cigars in a ventilating room, sterilizing pretreated dried tobacco branches through UV light, grinding the sterilized tobacco branches into 10-80 meshes, adding crushed samples into a supercritical fluid extraction kettle, adding entrainer having a concentration of 60%-100%, carrying out carbon dioxide supercritical fluid extraction carbon dioxide under an extraction temperature of 40-65 degrees and extraction pressure of 200-350bars, adding extract product of the tobacco branches in snus at a mass proportion of 0.1%-0.3%. The method applies tobacco flavor extracted from tobacco branches through supercritical fluid technology to suns, which solves the problem of insufficiency of raw materials, ensures the safety of snus, minimizes environmental pollution and prevents resources waste.

Owner:CHINA TOBACCO SICHUAN IND CO LTD +1

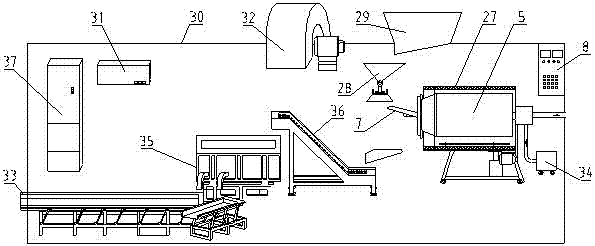

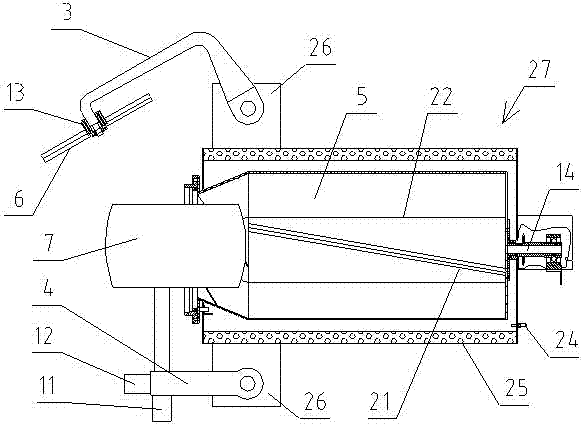

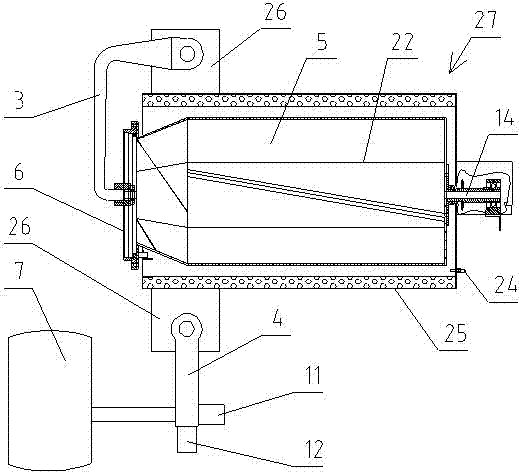

Complete equipment for tea clean automatic fine processing and processing method thereof

ActiveCN102783526ACompact and smooth shapeColor emerald greenPre-extraction tea treatmentFlavoring extractState of art

The invention discloses complete equipment for tea clean automatic fine processing and a processing method thereof; the complete equipment comprises a drum type automatic cooling-roasting flavor-extracting machine and a tea vibrating screening machine which are disposed in a closed case and are connected with each other through a tea lifting conveyer; an automatic quantitative feeding device is connected in front of the tea cooling-roasting flavor-extracting machine; an air inlet, an air outlet and a tea discharging port are disposed on the case wall of the closed case; the complete equipmentfor tea clean automatic fine processing is also provided with an automatic control system; the automatic control system is connected with and controls the automatic quantitative feeding device, the drum type automatic cooling-roasting flavor-extracting machine, the tea lifting conveyer, and the tea vibrating screening machine. The invention effectively solves the problem of great dust of tea fineprocessing equipment in the prior art, wherein the problem can not only damage body health of production workers, but also cause potential safety accidents such as dust explosion and the like; and the provided complete equipment for tea clean automatic fine processing is clean, safe, high in production efficiency, and can realize automatic production.

Owner:苏和生

Preparation method of internal heat-relieving oyster sauce

InactiveCN108464485AAdd flavorImprove the shortcomings of easy to get angryNatural extract food ingredientsFood flavoringsFiltration

The invention discloses a preparation method of an internal heat-relieving oyster sauce. The method comprises the following steps: uniformly mixing oysters with secondary fermentation liquor, conducting fermentation at room temperature, taking out the oysters, boiling the fermented oysters in water, concentrating decoction, adding edible salt, soy sauce, starch and white granulated sugar, and conducting one-time blending to obtain a one-time blended solution for later use; uniformly mixing orychophragmus violaceus, lentinus edodes, garlic, chicken and crab meat, and conducting boiling and concentration to obtain seasoning extract for later use; and uniformly mixing the one-time blended solution with the seasoning extract, and conducting homogenization and boiling sterilization. According to the invention, the fermented oysters are decocted to obtain a normal oyster juice, and the juice is subjected to filtration, concentration and blending, and then seasonings are added according to aformula, and the obtained oyster sauce is stored or transported at normal temperature. With the addition of the chicken, the crab meat and dried small shrimps, the flavor of the oyster sauce is increased. The oyster sauce is used as a food seasoning, tastes delicious, and can improve appetite. Meanwhile, the addition of the fermentation liquor made from components such as aloe and chrysanthemums,the disadvantage that oyster sauces are easy to cause internal heat is improved, and the oyster sauce is suitable for wide population.

Owner:李峰

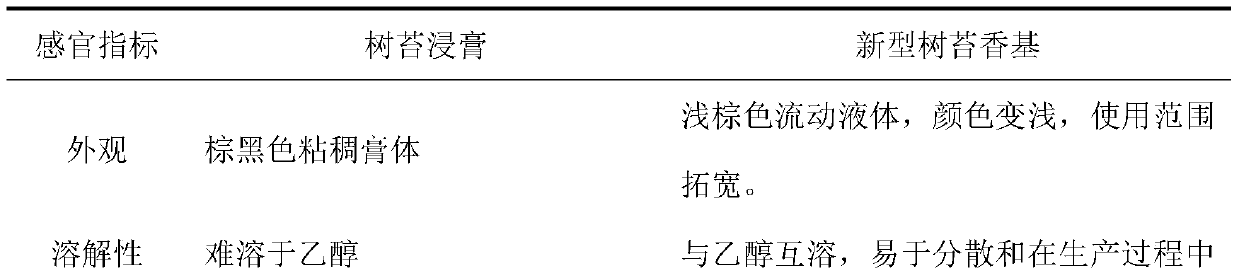

Essence and its preparation process of tree moss extract

ActiveCN105838502BKeep natural propertiesEase of industrial mass productionEssential-oils/perfumesCinnamyl acetatePyrazine

Owner:CHINA TOBACCO JIANGSU INDAL

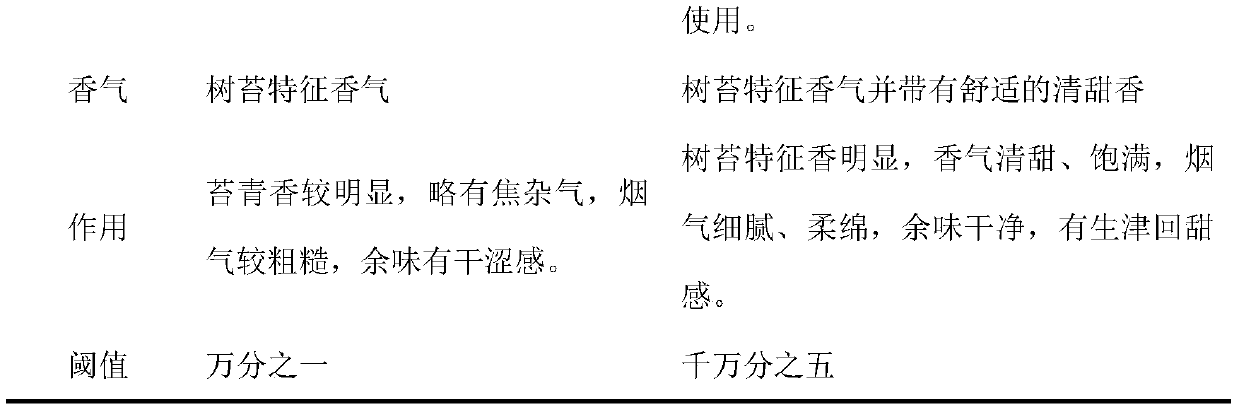

Preparation method of eel polypeptide flavor extract, eel polypeptide flavor extract and eel sauce

PendingCN111329025AReduce manufacturing costGood colorSugar food ingredientsFood ingredient as flavour affecting agentBiotechnologyMaillard reaction

The invention discloses a preparation method of an eel polypeptide flavor extract, the eel polypeptide flavor extract and an eel sauce. The preparation method of the eel polypeptide flavor extract comprises the following step of: carrying out microbial fermentation, a Maillard reaction and an extraction separation process on a machining by-product obtained after main meat tissues of eels are excised. A seasoning, i.e., the eel sauce, is prepared by the obtained eel polypeptide extract; the prepared seasoning not only can be directly used for being eaten together with rice or bread and is nutrient and convenient, but also can be used for cooking seasoning so as to reinforce fragrances and delicious tastes of dishes and improve attraction of the dishes. The invention implements a novel process research of preparing a polypeptide and flavor substance by seafood by-products, develops a scientific utilization and machining method of the seafood machining by-products, and provides a novel approach for sufficient utilization of such category of resources.

Owner:WUYI UNIV

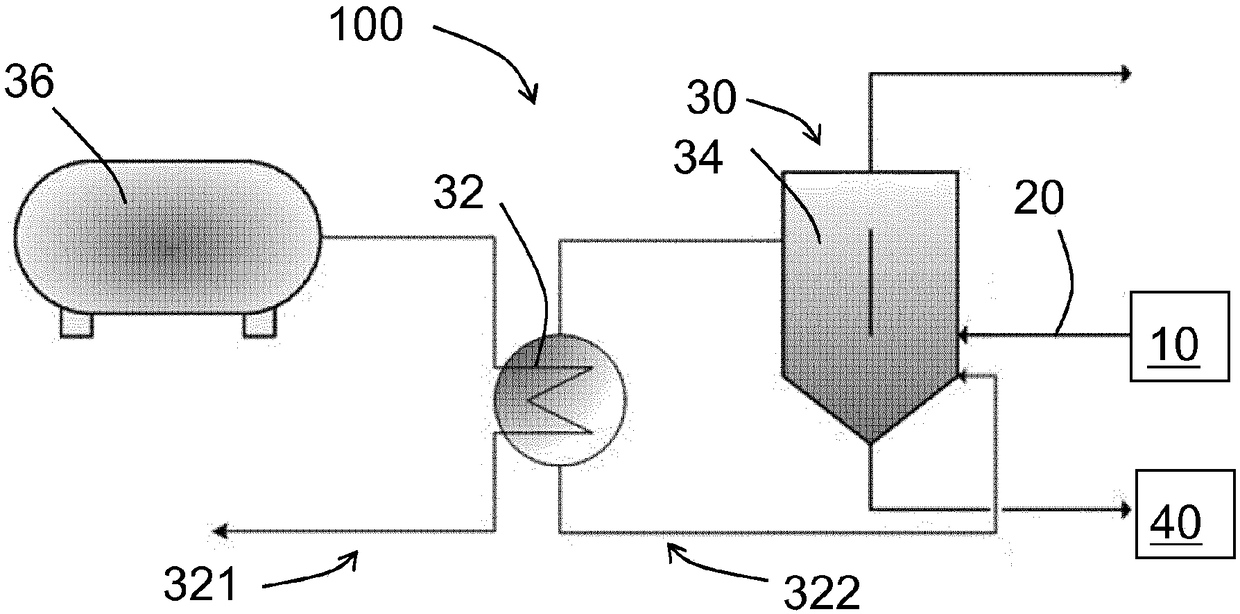

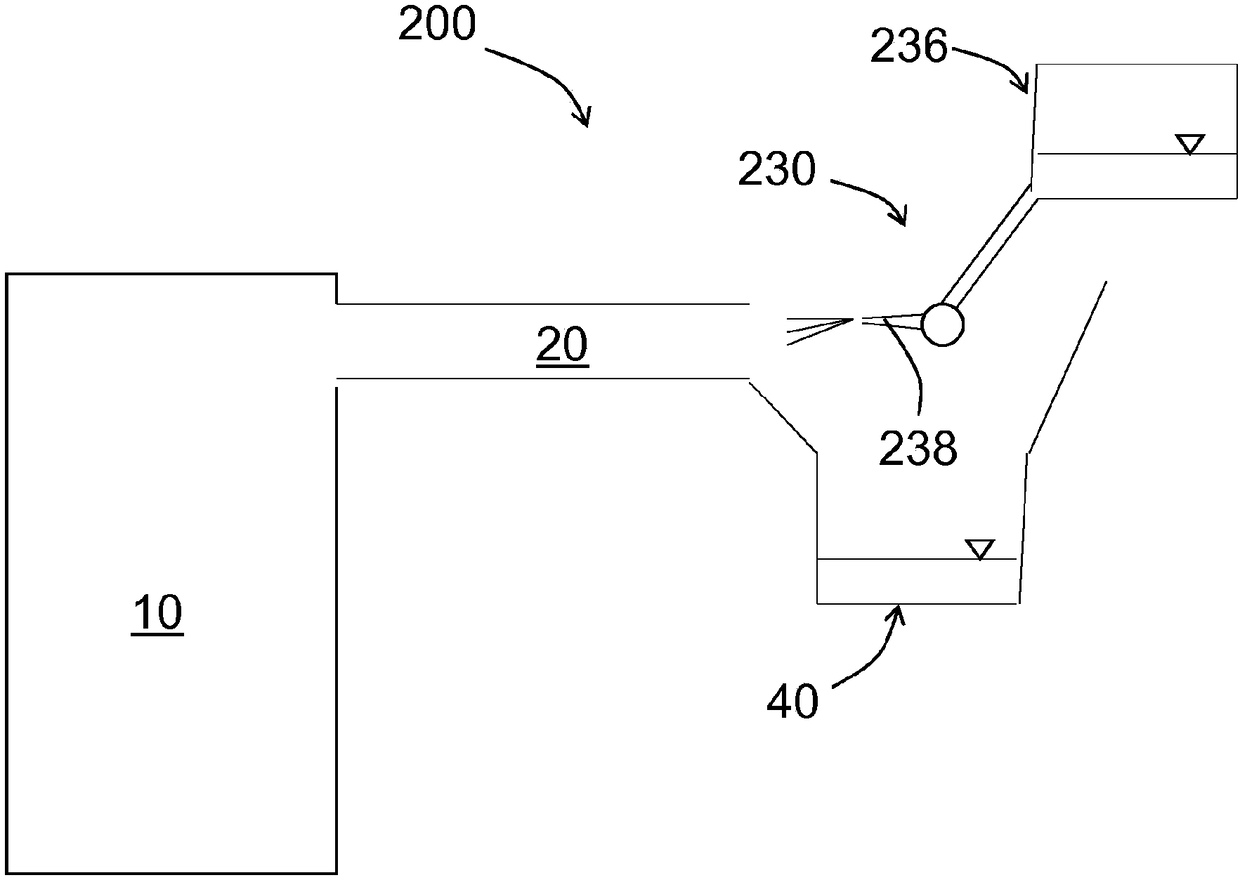

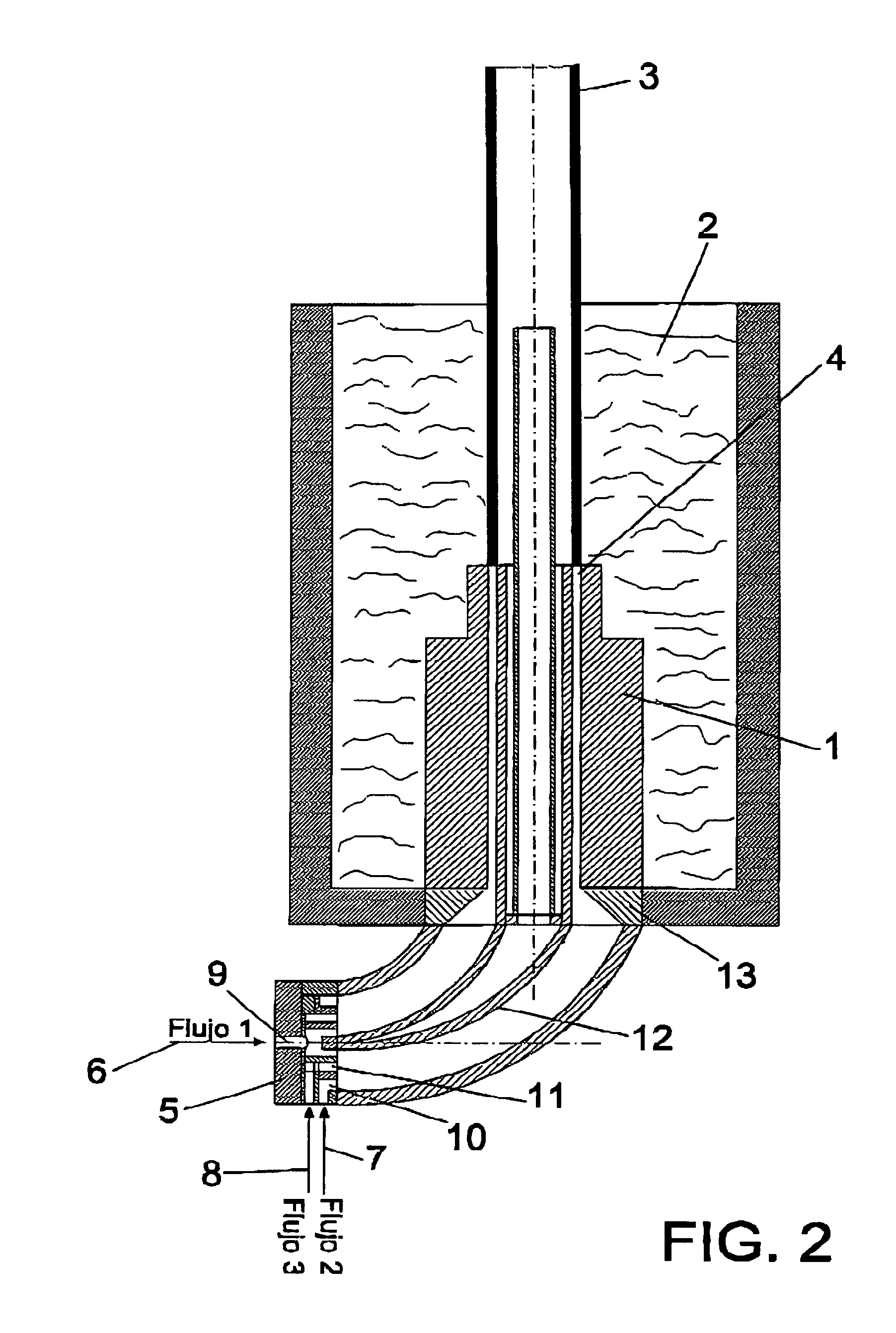

Process and apparatus to obtain tobacco flavor extracts

ActiveCN108347993AAchieve flammabilityAvoid complainingTobacco preparationSolidificationFlavorFlavoring extract

The present invention relates to a process to obtain tobacco flavor extracts, the process comprising: conditioning a mixture of tobaccos in a primary tobacco manufacture heating the mixture of tobaccoto a temperature comprised between about 30 degrees Celsius and about 90 degrees Celsius for a time interval comprised between about 30 seconds and about 1 hour; recovering emissions produced by themixture conditioning; and obtaining at least one flavor extract from the recovered emissions. The present invention also relates to an apparatus to obtain tobacco flavor extracts.

Owner:PHILIP MORRIS PROD SA

Preparation method of strong-flavor type mayonnaise

InactiveCN108541935AWith Chinese sauce flavorGreat tasteFood ingredient as mouthfeel improving agentFood additiveMonosodium glutamate

The present invention discloses a preparation method of a strong-flavor type mayonnaise. The strong-flavor mayonnaise is prepared from the following raw materials in weight ratios: 54.12% of water, 21.65% of soybean oil, 7.22% of white granulated sugar, 7.22% of eggs, 1.08% of edible salt, 0.72% of apple juice, 3.61% of spices, 4.35% of food additives and 0.03% of edible essence. The preparation method includes the following steps: weighing 20 grams of water, 20 grams of soybean oil and 10 grams of spices for flavor extracting at a high temperature of 120 DEG C for 30 minutes, and cooling themixture to obtain mixture A; evenly stirring water, white granulated sugar, eggs, edible salt, apple juice, monosodium glutamate, DL-malic acid, xanthan gum, citric acid, lactic acid, potassium sorbate, capsicum oleoresin, ethylene diaminetetraacetic acid, edible essence and mixture A to form mixture B; evenly mixing soybean oil, hydroxypropyl distarch phosphate and xanthan gum to form mixture C;and slowly adding the mixture C into the mixture B during the stirring process with an egg beating machine, and continuously stirring the mixture B and the mixture C for 5-10 minutes, thereby obtaining the strong-flavor mayonnaise. The invention uses high-temperature and high-pressure concentrating and flavor-extracting technology to extract flavor components from the spices, and the flavor is strong and lasting.

Owner:中山美斯佳食品有限公司

Preparation method of flavored motherwort paste

InactiveCN104189071AReduce churnReduce processing stepsSexual disorderPlant ingredientsFlavoring extractMotherwort

The invention discloses a preparation method of flavored motherwort paste. The preparation method comprises the following steps: 1) taking raw materials and adding water to soak for 3 to 5 hours; 2) cutting up motherwort soaked in the step 1), adding water to decoct the soaked motherwort for 2 times each for 1 to 3 hours, combining decoction, and filtering; 3) cutting up angelica, prepared radix rehmanniae, radix paeoniae alba and ligusticum wallichii soaked in the step 1), adding water to decoct the soaked angelica, prepared radix rehmanniae, radix paeoniae alba and ligusticum wallichii for 2 times each for 2 to 4 hours, combining the decoction and filtering; 4) taking the filtrate in the step 3) and adding brown sugar, heating to 100 to 150 DEG C, dissolving, mixing uniformly and concentrating to flavored extract of which the relative density is 1.10 to 1.50g / cm<3>; 5) taking the filtrate in the step 2), and adding the flavored extract in the step 4) to be concentrated into the flavored motherwort paste of which the relative density is 1.21 to 1.25g / cm<3> at the temperature of 80 to 85 DEG C. According to the preparation method disclosed by the invention, effective components in the motherwort are not destroyed in a preparation process of the flavored motherwort paste, so as to improve the rate of qualified products.

Owner:上海海虹实业(集团)巢湖今辰药业有限公司

Edible fungus clear soup hotpot base material and production method thereof

InactiveCN108651947AGreat tasteExtended shelf lifeFood ingredient as thickening agentFood preservationBiotechnologyMonosodium glutamate

The invention provides an edible fungus clear soup hotpot base material and a production method thereof. The edible fungus clear soup hotpot base material is prepared from the following raw materialsin parts by weight: 100-150 parts of composite edible oil, 300-400 parts of fresh-fragrant flavor extract of edible fungi, 100-120 parts of fresh flavor extract of livestock, poultry and aquatic products, 70-120 parts of table salt, 50-80 parts of monosodium glutamate, 50-80 parts of disodium 5'-ribonucleotide (I+G), 0.2-0.6 part of carrageenan, 0.2-0.6 part of xanthan gum, 0.5-1 part of guar gum,0.5-1 part of sodium carboxymethyl cellulose, 0.5-1.5 parts of sucrose fatty acid ester, and 0.5-1.5 parts of glyceryl mono-and distearate. The hotpot base material is rich in nutrients, convenient to eat, delicious in taste, strong in flavor, obvious in edible fungus flavor, and safe in product quality.

Owner:JIANGXI BAICAOYUAN IND

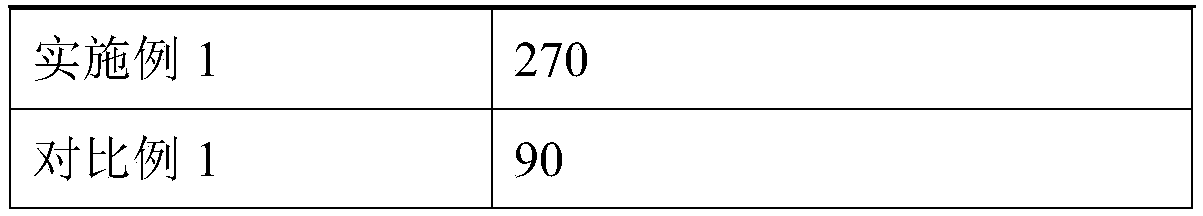

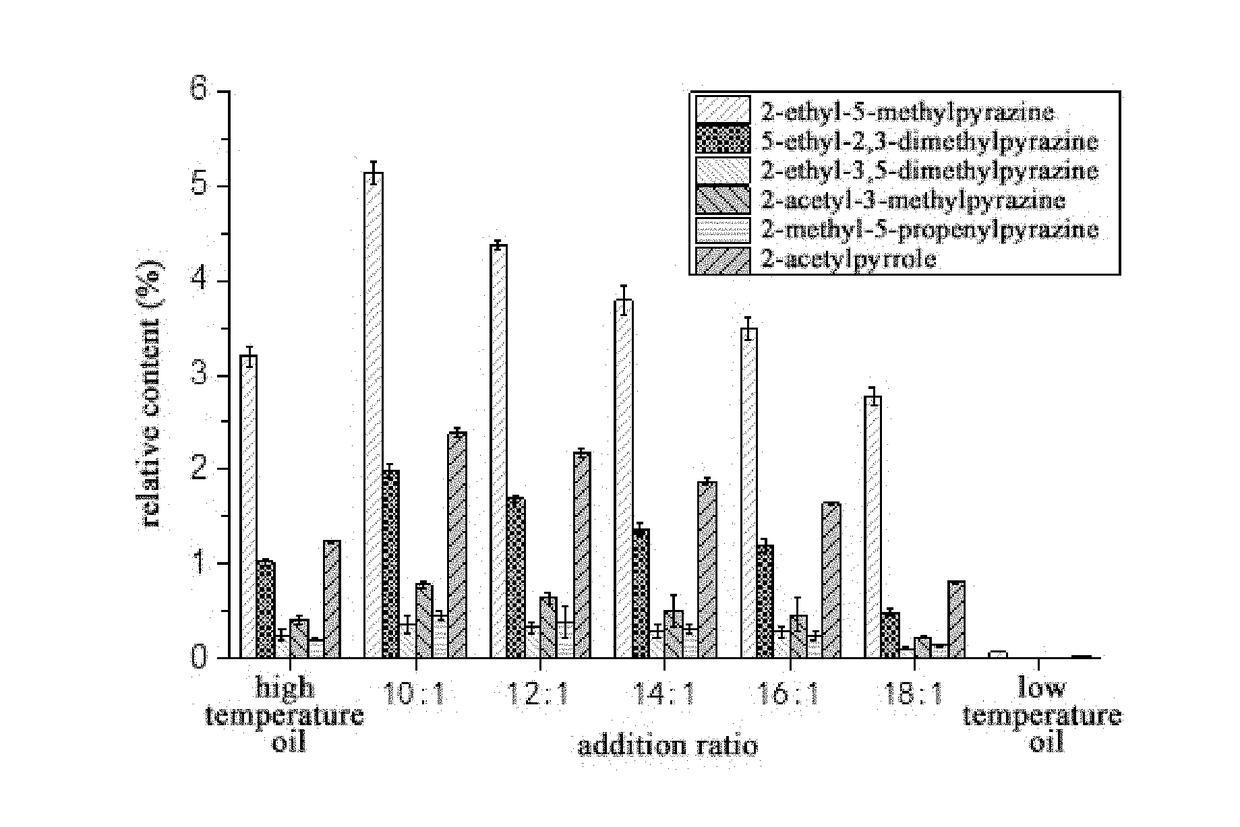

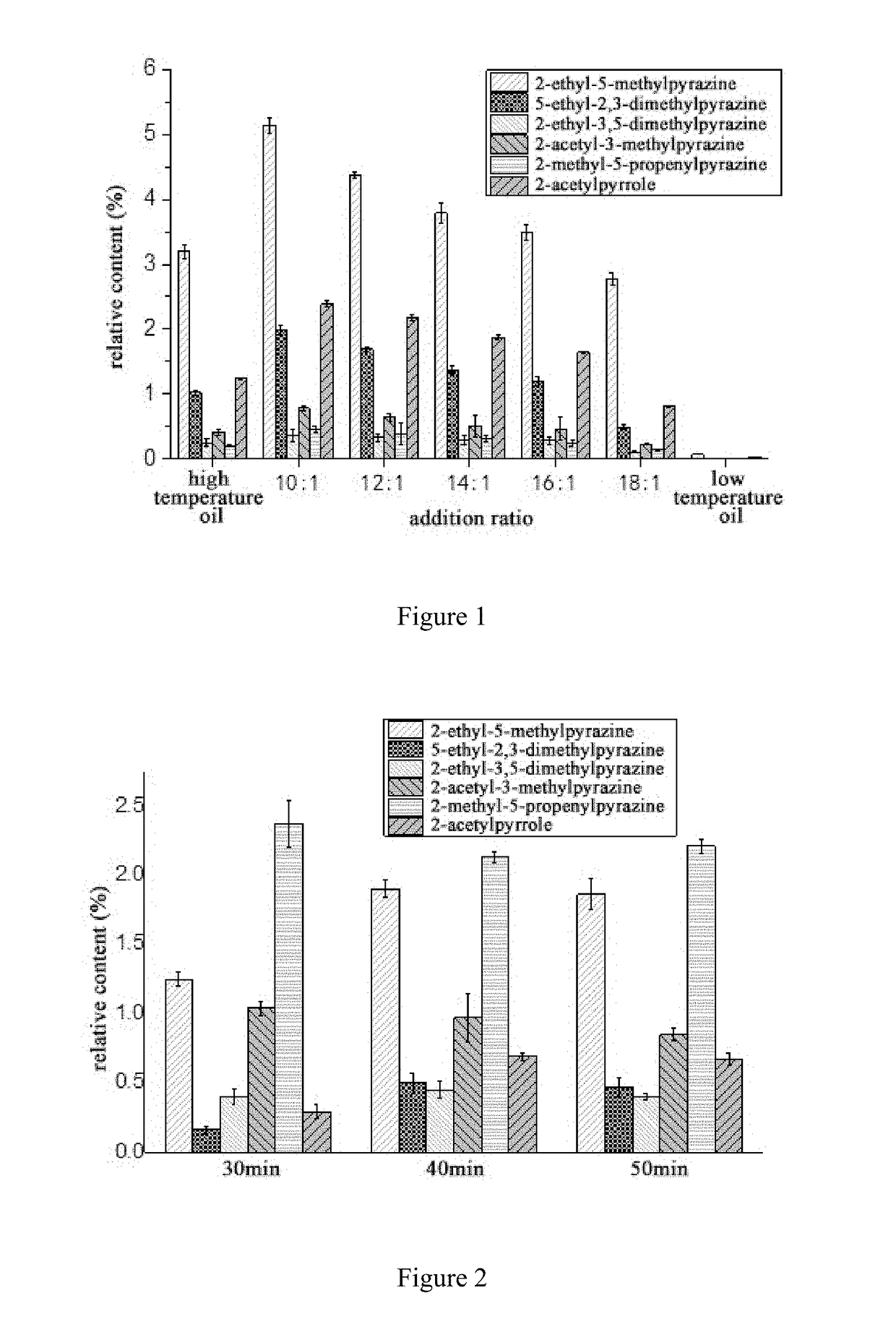

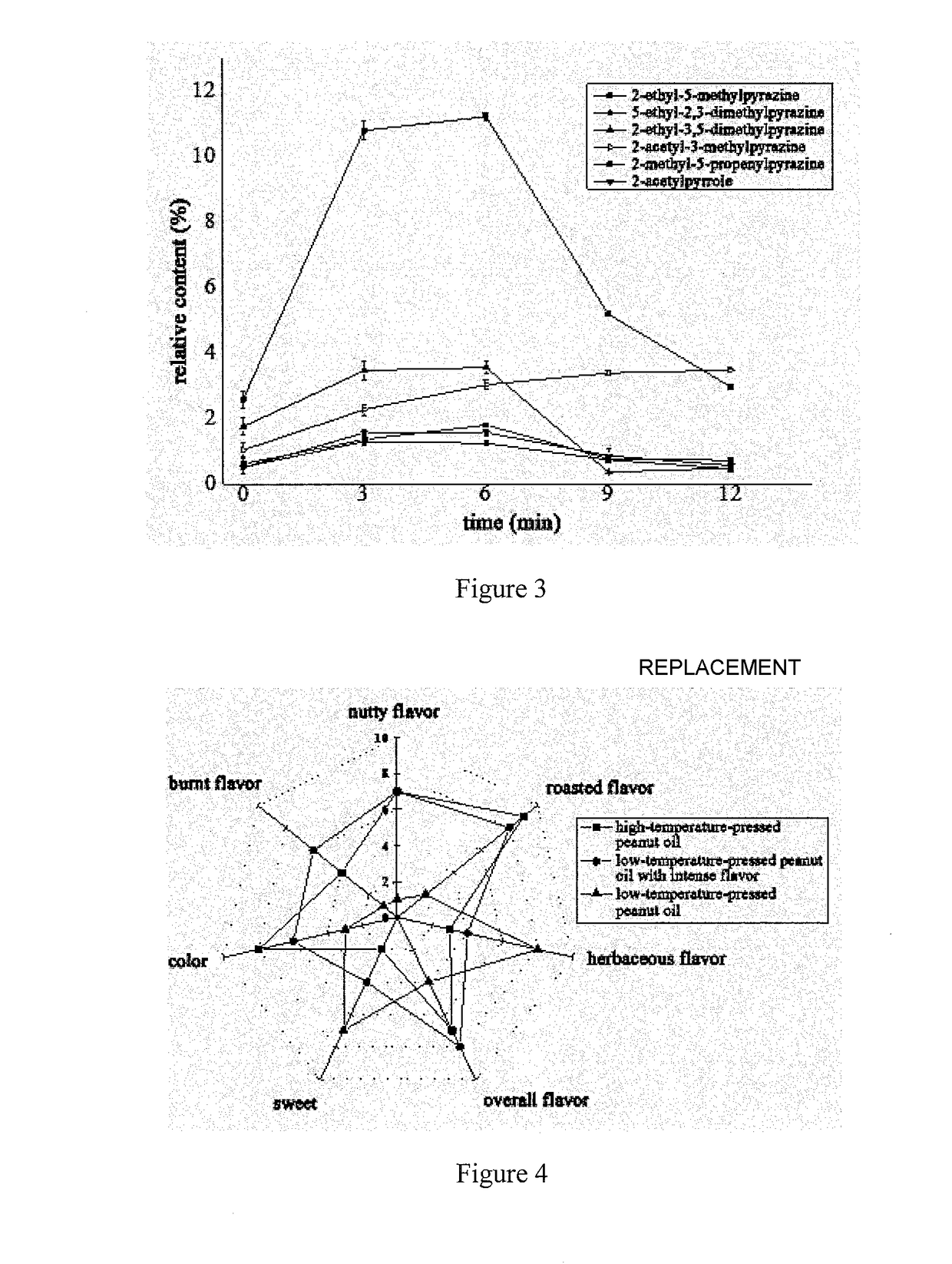

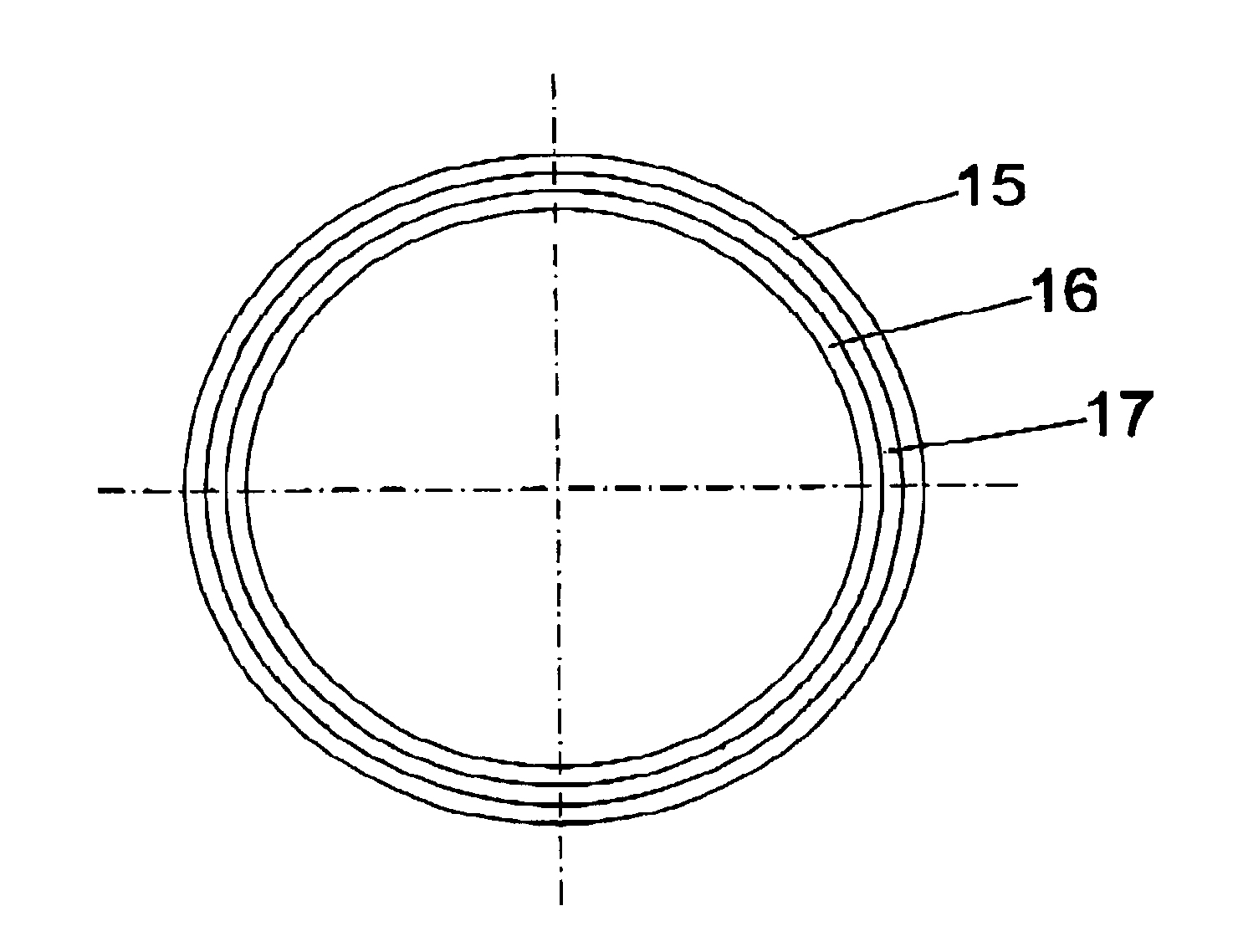

Flavor extract of low-temperature-pressed peanut cake and method for using the same

ActiveUS20180295868A1Add flavorEasy to operateProtein composition from vegetable seedsFood ingredient as flavour affecting agentFlavorFlavoring extract

The present invention provides a flavor extract of low-temperature-pressed peanut cake which is extracted from low-temperature-pressed peanut cake. In the flavor extract, the content of pyrazines flavor substances is not less than 55%, and the content of the aldehydes substances is not more than 15%. The present invention also provides a method for improving the flavor of peanut oil by using the flavor extract of the low-temperature-pressed peanut cake. The flavor extract extracted from peanut cake according to the present invention, which contains 55% or more pyrazines flavor substances, can not only improve the flavor of low-temperature-pressed peanut oil significantly, but also retain the original quality and color of the low-temperature-pressed peanut oil when it is added to low-temperature-pressed peanut oil.

Owner:INST FOR APPL OF ATOMIC ENERGY CHINESE ACAD OF AGRI SCI

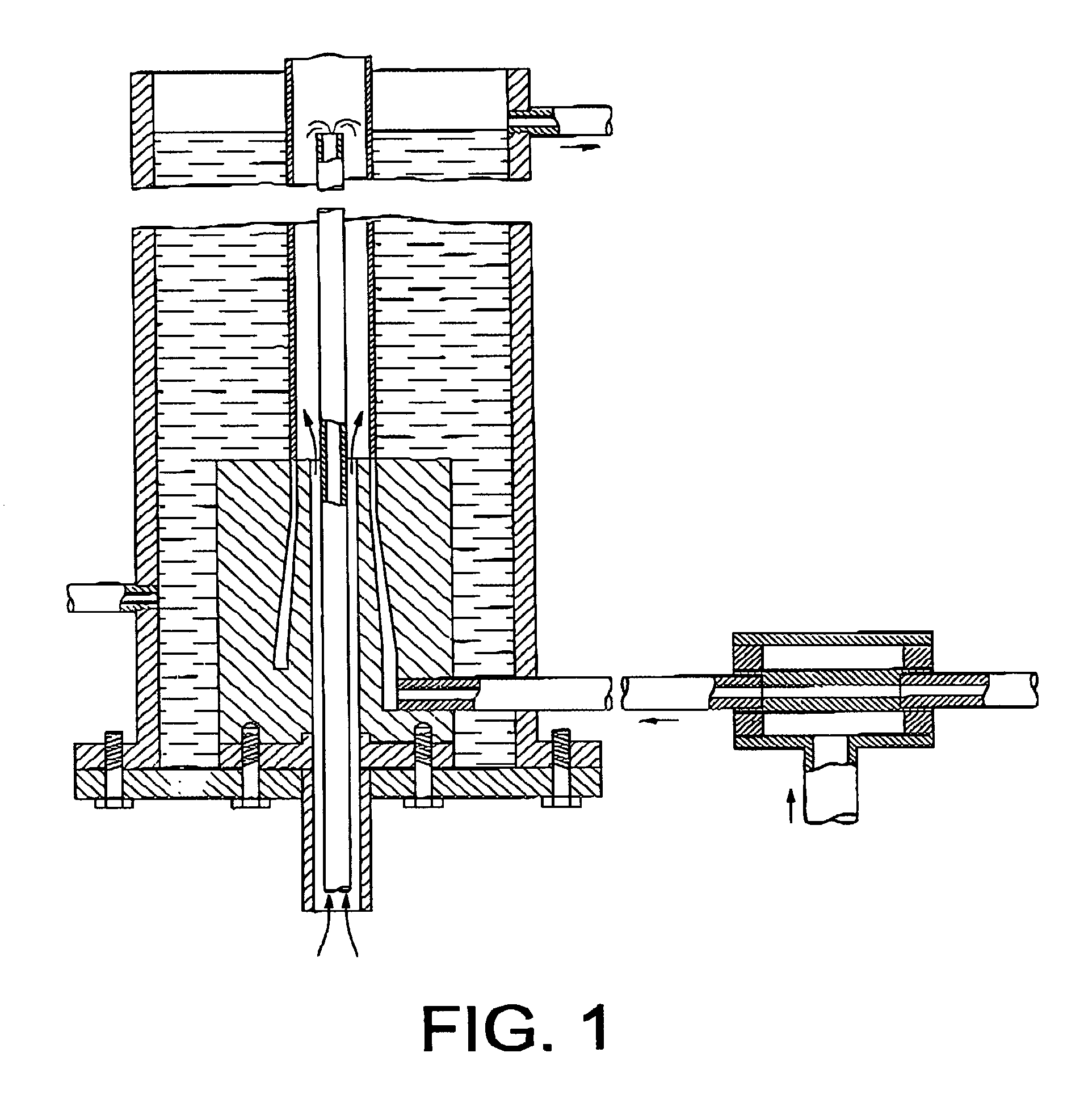

Multilayered cellulose casing, method of manufacture thereof and extrusion head for obtaining said casing

ActiveUS7622173B2Reduce the ratioEconomic advantageWrappers shrinkageLayered productsFlavoring extractEngineering

Cellulose casing for sausages, comprising at least three concentric layers of regenerated cellulose, of which the two layers in contact with the outside, that is, those with the greatest and smallest diameter respectively are made of colorless, transparent viscose, and in which the internal layer or layers are made of regenerated cellulose to which is added other substances such as pigments, fumes, flavor extracts, spices or plastic proteins.The object of the invention is a manufacturing method for the cellulose casing obtained by extrusion of at least three concentric layers of regenerated cellulose. Also object of the invention is the circular viscose extrusion head used in manufacturing the cellulose casing for sausages.

Owner:VISCOFAN INDA NAVARRA DE ENVOLTRAS CELULOSICAS

Mosquito repellent

InactiveCN103875731AReduce pollutionHarm reductionBiocidePest repellentsAdditive ingredientDiethyl ether

The invention discloses a mosquito repellent which comprises the following raw materials in parts by weight: 18-20 parts of clove oil, 7-10 parts of eucalyptus oil, 15-17 parts of howood leaf oil, 18-20 parts of aromatic alcohol, 3-5 parts of a propellant, 7-9 parts of eupatorium liquor and 27-30 parts of mosquito repellent flower flavor extract. The preparation method comprises the following steps: leaching at room temperature for 1-2 hours by using a 60-70 percent solution which contains ethanol and diethyl ether and is 5-6 times the total mass of the clove, eucalyptus and howood leaf, raising the temperature to be 80-90 DEG C, boiling and extracting for 2-3 hours, adding inert gas carbon dioxide for extracting to obtain mixed essential oil of the clove oil, eucalyptus oil and howood leaf oil. By adoption of the pure natural Chinese herbal medicine compositions such as clove, eucalyptus and howood leaf, the harm is slight, drug resistance to mosquitoes is avoided, the mosquito repellent flower flavor extract is a mosquito repellent component extracted from the pure natural plants, and the mosquito repellent is safe to people and livestock and slight in environmental pollution.

Owner:施焱

Screen cleaning agent and preparation method thereof

InactiveCN108148684AClean thoroughlyGood synergyNon-ionic surface-active compoundsOrganic detergent compounding agentsCoconut diethanolamideCleansing Agents

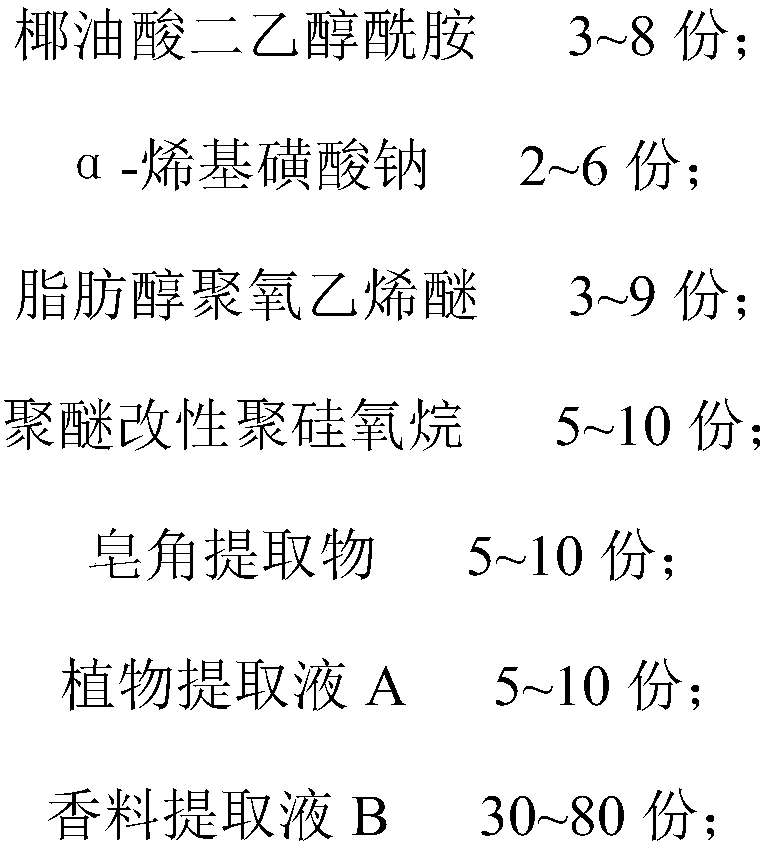

The invention provides a screen cleaning agent and a preparation method thereof. The screen cleaning agent is prepared from the following materials: coconut diethanolamide, sodium alpha-olefin sulfonate, fatty alcohol polyoxyethylene ether, polyether modified polysiloxane, a saponin extract, a plant extract, and a flavor extract. In the formula of the screen cleaning agent provided by the invention, an aromatic bacteriostatic agent and a traditional Chinese medicine plant bacteriostatic agent are innovatively added to be matched to remove bacteria, and the natural saponin extract and a mild surfactant are used as decontamination components, so that the dust and bacteria adsorbed on the screen can be thoroughly cleaned and a protective film can be formed on the surface of the screen after use.

Owner:WUHU WANJIANG INTPROP OPERATION CENT CO LTD

Preparation method of eel polypeptide flavor extract, eel polypeptide flavor extract and eel sauce

ActiveUS20210282437A1Strong aromaOutstanding flavorSugar food ingredientsFood ingredient as flavour affecting agentBiotechnologyMaillard reaction

The disclosure relates to a preparation method of eel polypeptide flavor extract, the eel polypeptide flavor extract, and the eel sauce. The preparation method of the eel polypeptide flavor extract includes the following steps: obtained by using eel processing by-products, eel cutting off the main meat tissues, successively performing microbial fermentation, Maillard reaction and extraction and separation processes. The eel polypeptide extract obtained above is used to making a condiment eel sauce. The eel sauce is nutritious and convenient, it can be used directly for table eating or served as cooking condiments to enhance the aroma and taste of dishes and increase the attractiveness of dishes. The disclosure realizes a new technological research on the preparation of polypeptide and flavor products, opens up a scientific utilization and processing method of seafood processing by-products, and provides a new way for making full use of such resources.

Owner:WUYI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com