Method for extracting tobacco essence perfume

A technology of flavors and fragrances and extraction methods, which is applied in the direction of essential oils/spices, tobacco, processed tobacco, etc., can solve the problems of chemical structure damage of natural flavor components, loss of flavor components, long process time, etc., to achieve rich aroma and maintain Physical and chemical properties, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of extracting process of tobacco essence and fragrance, it is characterized in that the method is:

[0024] 1) Selecting a mixture of tobacco leaves, tobacco stems and tobacco dust with a water content of 5% by mass, pulverizing, and putting the pulverized tobacco into an extraction tank;

[0025] 2) adding a solvent in the extraction tank, the solvent is water, and the mass ratio of tobacco to solvent is 1:10;

[0026] 3) extract and reflux under reduced pressure for 3 hours at a temperature of 50°C and a vacuum of 0.098Mpa, and pass in compressed nitrogen for interstitial airflow stirring;

[0027] 4) The extract is separated through a 300-mesh sieve, the filtrate is collected, and concentrated under reduced pressure to a specific gravity d of the sample under a vacuum of 0.098Mpa 4 20 It is 1.25g / ml, and the concentrate is tobacco flavor and fragrance.

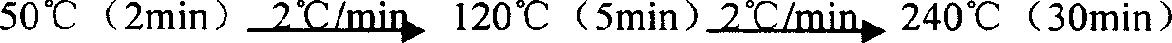

[0028] The above-mentioned concentrate is carried out component analysis:

[0029] A. Qualitative and q...

Embodiment 2

[0098] A kind of extracting process of tobacco essence and fragrance, it is characterized in that the method is:

[0099] 1) Select tobacco leaves with a water content of 20% by mass, shred them, and put the shredded tobacco into an extraction tank:

[0100] 2) adding a solvent in the extraction tank, the solvent is water, and the mass ratio of tobacco to solvent is 1:16;

[0101] 3) extract and reflux under reduced pressure for 8 hours at a temperature of 60°C and a vacuum of 0.02Mpa. During the process of extraction and reflux, compressed nitrogen gas is introduced 4 times to carry out interstitial airflow stirring;

[0102] 4) The extract is separated by a titanium rod core, the filtrate is collected, and concentrated under reduced pressure to a specific gravity d of the sample under a vacuum of 0.02Mpa 4 20 It is 1.4g / ml, and the concentrate is tobacco flavor and fragrance.

[0103] Carry out the component analysis of concentrate by the method for embodiment 1.

Embodiment 3

[0105] A kind of extracting process of tobacco essence and fragrance, it is characterized in that the method is:

[0106] 1) selecting tobacco stems or tobacco powder mixture with a water content of 10% by mass, pulverizing after fermentation, and putting the pulverized tobacco into an extraction tank;

[0107] 2) adding a solvent in the extraction tank, the solvent is water, and the mass ratio of tobacco to solvent is 1:2;

[0108] 3) extraction and reflux under reduced pressure for 1 hour at a temperature of 60°C and a vacuum of 0.03Mpa, and mechanical stirring;

[0109] 4) The extract is separated by a titanium rod core, the filtrate is collected, and concentrated under reduced pressure to a specific gravity d of the sample under a vacuum of 0.03Mpa 4 20 It is 1.1g / ml, and the concentrate is tobacco flavor and fragrance.

[0110] Carry out the component analysis of concentrate by the method for embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com