Patents

Literature

68results about How to "Maintain physical and chemical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for extracting tobacco essence perfume

InactiveCN1899141AImprove qualityImprove inner qualityTobacco treatmentEssential-oils/perfumesFlavorReflux

The tobacco flavor extracting process includes the following steps: 1. crushing tobacco and setting in extracting tank; 2. adding solvent in 2-16 times the weight of tobacco to the extracting tank; 3. decompression reflux extracting at 20-60deg.c temperature and 0.020-0.098MPa vacuum degree for 1-8 hr; and 4. separating the liquid extract through filtering, and decompression concentrating the filtrate at vacuum degree of 0.020-0.098MPa to obtain the tobacco flavor of density 1.1-1.4g / ml. The extracting process is simple, safe, environment friendly, high in extracting efficiency and low in production cost, and the extracted tobacco flavor has the physical and chemical properties of natural tobacco components and may be added to cigarette to improve flavor, raise quality and lower tar.

Owner:宋光泉 +1

Preparation method and application of hydroxysafflor yellow A

ActiveCN102702150AReduce lossesReduce moisture contentOrganic chemistryChromatographic separationFreeze-drying

The invention discloses a preparation method for extracting, separating and purifying hydroxysafflor yellow A from a Chinese medicinal material safflower at high yield and purity. The method comprises the following steps of: performing ultrasonic water extraction on the safflower medicinal material, separating by using HZ801 macroporous adsorption resin, performing LH-20 sephadex chromatographic separation, performing ultrafiltration, and performing freeze drying. The content of the prepared hydroxysafflor yellow A dry powder is 99.8 percent, and the yield of the hydroxysafflor yellow A is 62.7 percent.

Owner:ZHEJIANG YONGNING PHARMA

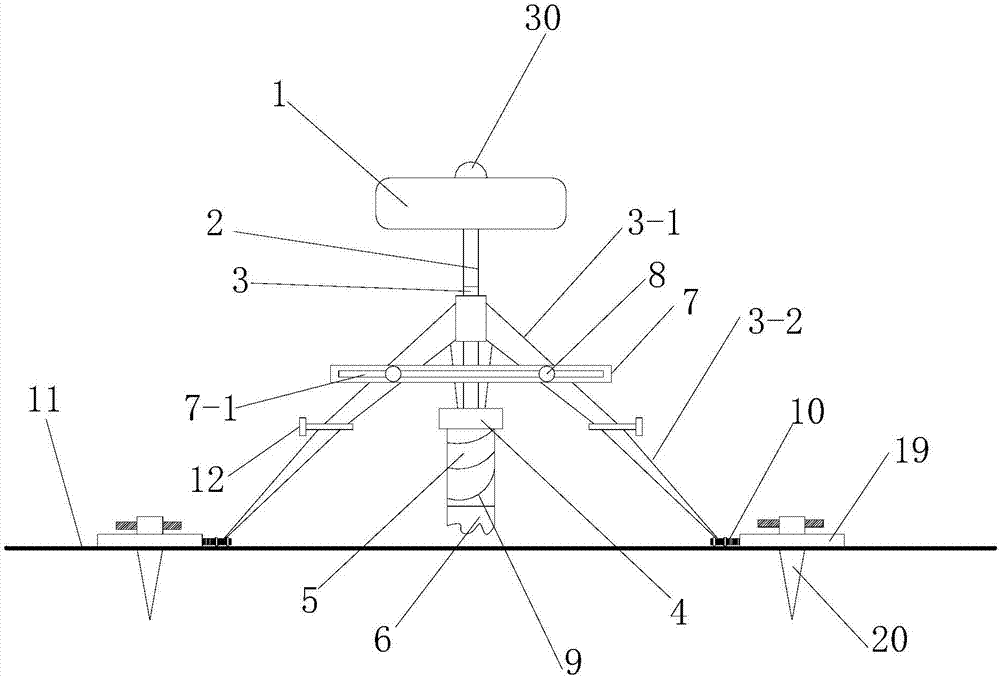

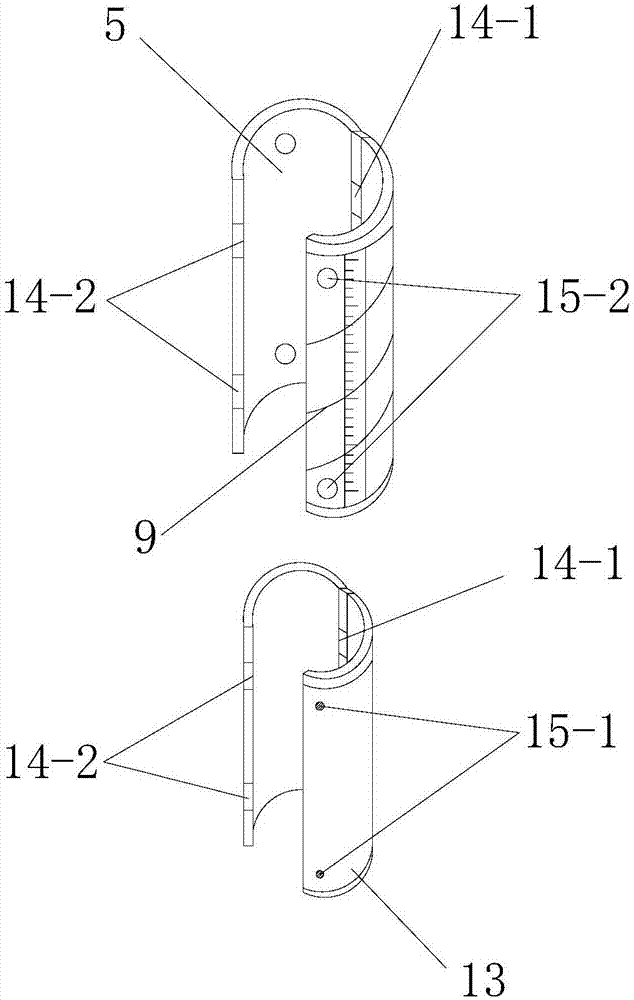

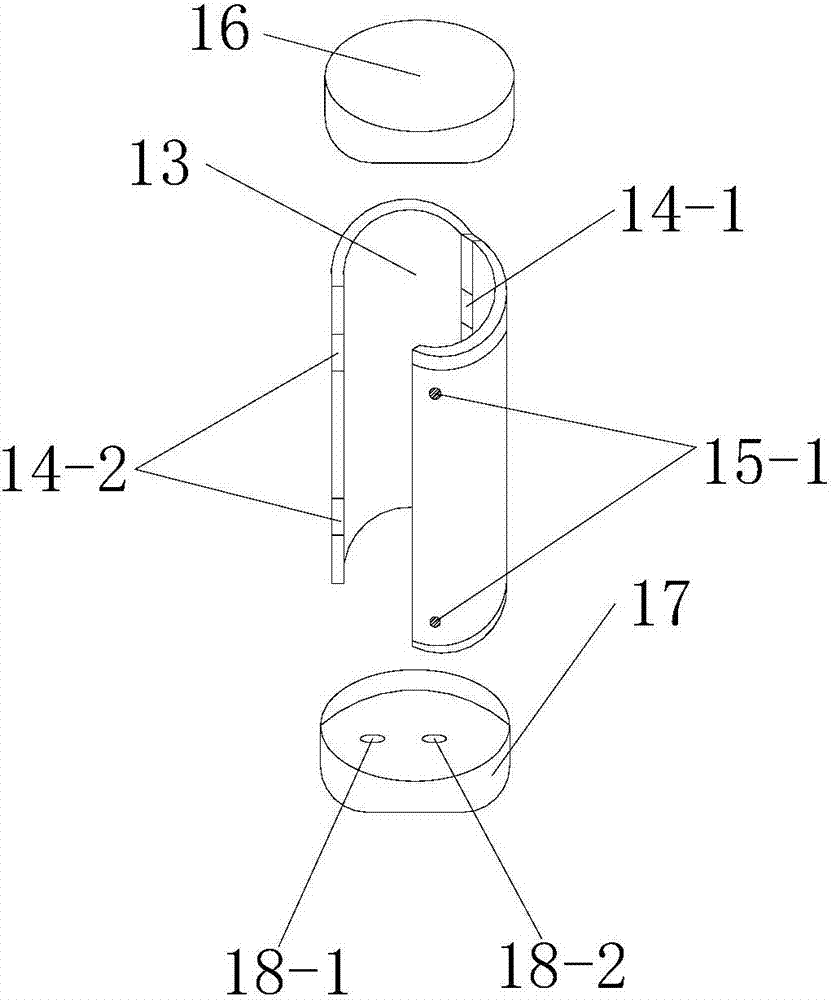

Soil sample collecting device

Owner:BAOJI UNIV OF ARTS & SCI

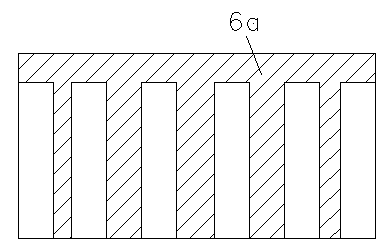

Conductive geomembrane and preparation method thereof

ActiveCN103103993ANo electrical damageGuarantee personal safetySynthetic resin layered productsFoundation testingGeomembranePhysical performance

The invention discloses a conductive geomembrane. The conductive geomembrane is characterized by comprising at least a seepage-proofing layer and a conducting layer. The seepage-proofing layer and the conducting layer are arranged in sequence. The seepage-proofing layer and the conducting layer are combined together. The conducting layer is placed on the bottom layer. The thickness of the conducting layer is 0.01-0.05mm and the resistance value of the conducting layer is 103-105 ohm. The seepage-proofing layer is an insulating layer. The resistance value of the external insulation surface of the insulating layer is more than 108 ohm. The bottom layer of the conductive geomembrane has good electrical conductivity and the upper layer of the conductive geomembrane has good insulating property and the physical performance of the conductive geomembrane is not influenced with the electrical conductivity. Physical and chemical performance of a high density polyethylene geomembrane is kept. Holes and defects of the finished laid geomembrane are convenient and quick to check out with combination of electric leakage detection, and welding and repairing can be timely conducted. Therefore, the quality of a seepage-proofing and water-proofing project is guaranteed.

Owner:QINGDAO BEIMEI OIL & GAS ENVIRONMENTAL PROTECTION TECH CO LTD

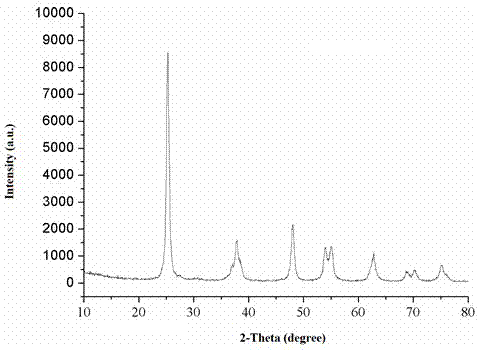

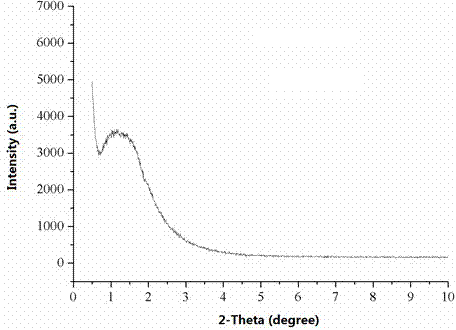

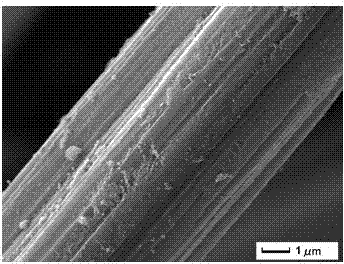

Preparation method of carbon fiber-loaded mesoporous titania

ActiveCN103696235AImprove surface activityHigh porosityCarbon fibresMesoporous materialAdvanced composite materials

The invention discloses a preparation method of carbon fiber-loaded mesoporous titania, and belongs to a carbon fiber surface modification technology. An activated carbon fiber is adopted as a load body, and the mesoporous titania is loaded on the surface of the carbon fiber by sol-gel reaction by virtue of a guiding role of a template. The method has the advantages that titania-modified carbon fiber which has a mesoporous structure, is controllable in load capacity, and uniform in distribution, and has a phase in an anatase structure can be prepared, and high specific surface area of the mesoporous material is beneficial to improvement of interface bonding between a carbon fiber reinforcement and a base material. Thus, the mechanical property of the carbon fiber composite material is improved further. Meanwhile, the preparation method has important significance in expansion of application of the carbon fiber in the structure-energy storage integrated multifunctional composite material. The preparation method can be applied to the technical fields such as an advanced composite material, energy storage, absorption and the like.

Owner:JIANGSU UNIV

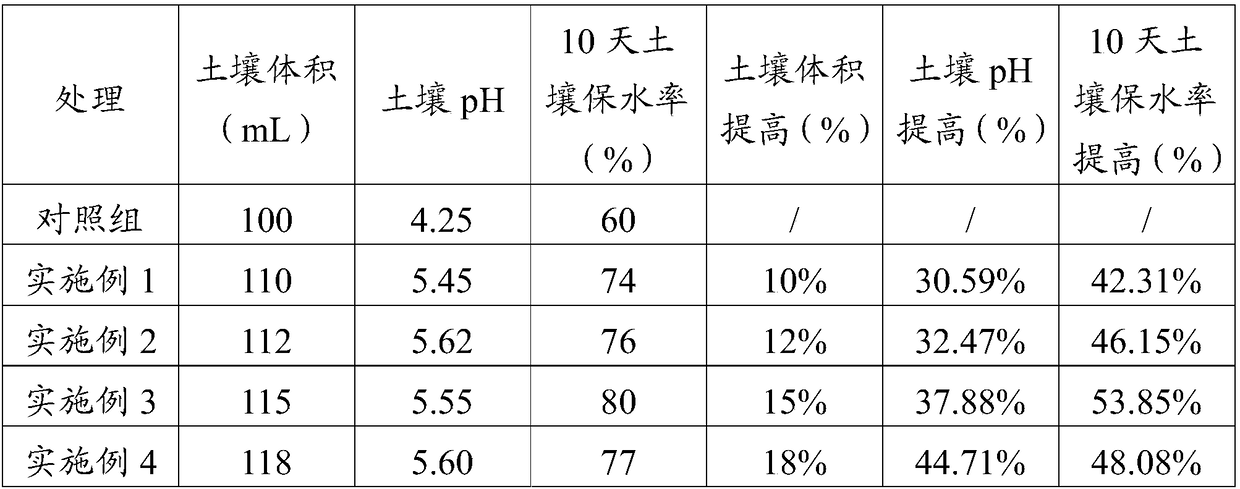

Remediation method of alkaline soil

InactiveCN109220039AReduce alkalinityGood characterSuperphosphatesCalcareous fertilisersAlkalinitySoil characteristics

The invention provides a remediation method of alkaline soil, and relates to the technical field of soil improvement. The method comprises the steps of (1), soil preparation; (2), soil loosening agentapplication; (3), soil improving fertilizer application. According to the method, the alkaline soil is restored through the steps of soil preparation, soil loosening agent application, soil improvement fertilizer application and the like to reduce soil alkalinity, improve soil characteristics, loosen soil, increase soil fertility to gradually improve soil alkalinization, soil sterilization and fertilizer addition are conducted while the soil alkalinity is reduced, and the method is a remediation method which has the effects of alkaline soil conditioning agent and value improving and synergism.

Owner:广西百乐德农业投资有限公司

Highly heat-conducting phase change heat storage material and preparation method therefor

InactiveCN105154021AHigh thermal conductivityFast heat absorption and releaseHeat-exchange elementsPorosityVoid ratio

The invention discloses a highly heat-conducting phase change heat storage material and a preparation method therefor. The heat storage material is prepared by compounding 67.5% by mass of paraffin, 7.5% by mass of expanded graphite and 25% by mass of through-hole foamed aluminum. The melting point of selected paraffin in the materials is 40-60 DEG C, and the porosity of the selected through-hole foamed aluminum in the materials is over 90%. The material has the advantages that the material is fast in heat absorption and heat release speed and great in heat storage, and is not varied in shape after phase change.

Owner:JIANGSU QIZHENG NEW ENERGY

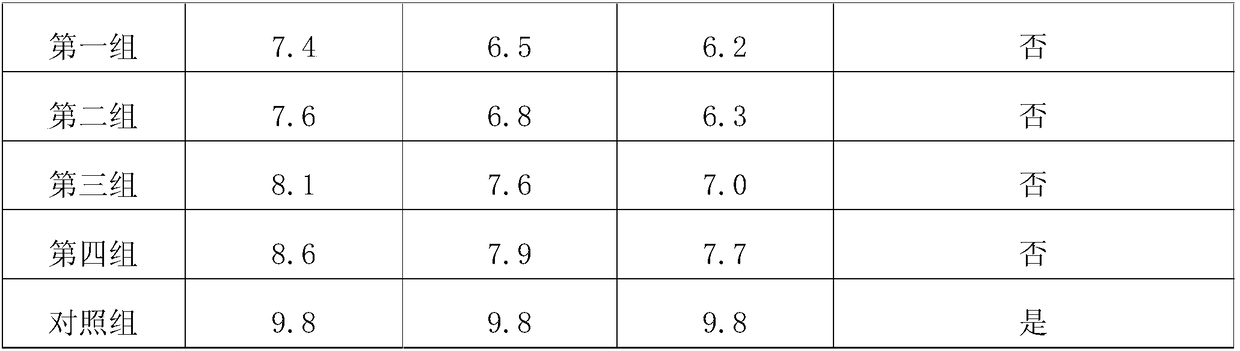

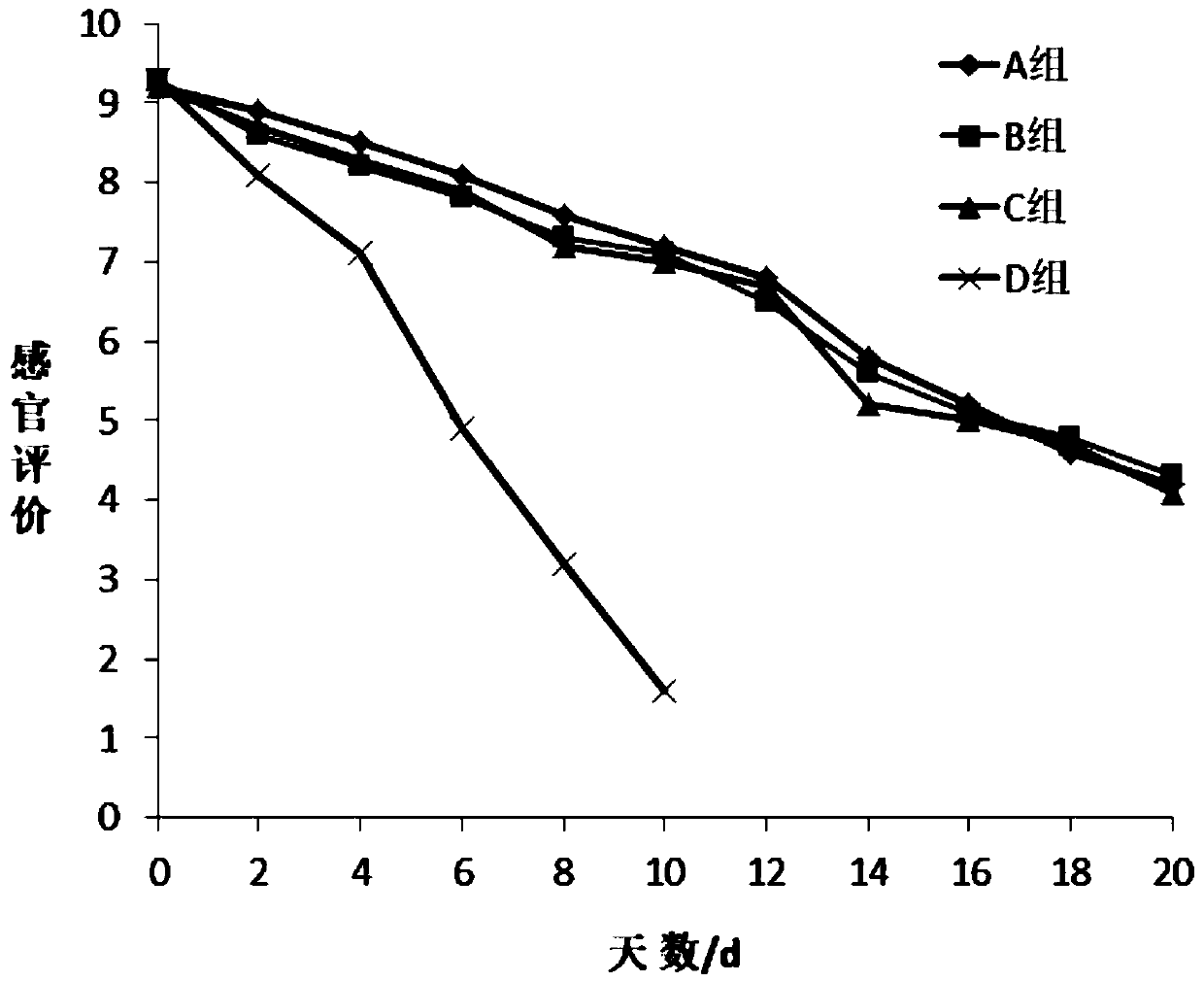

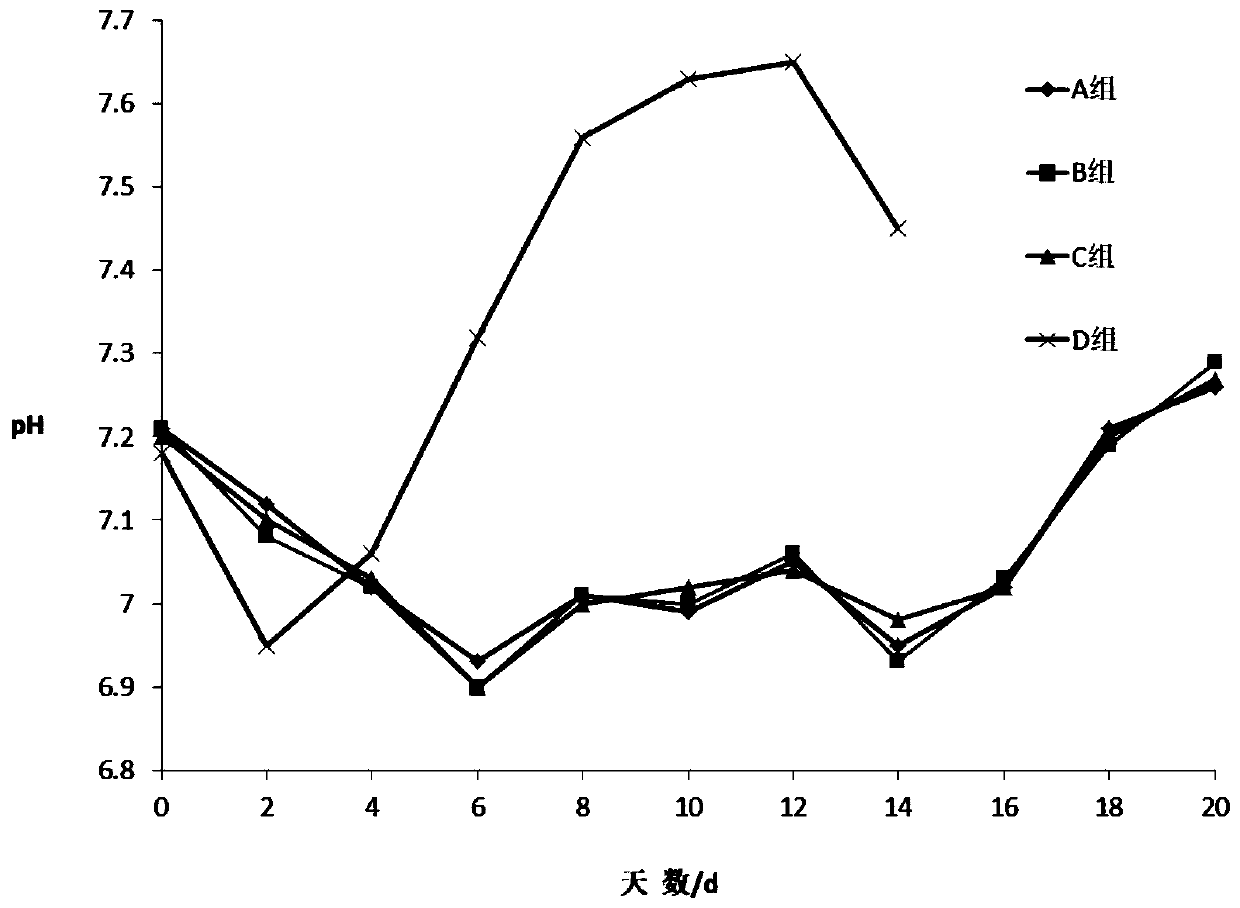

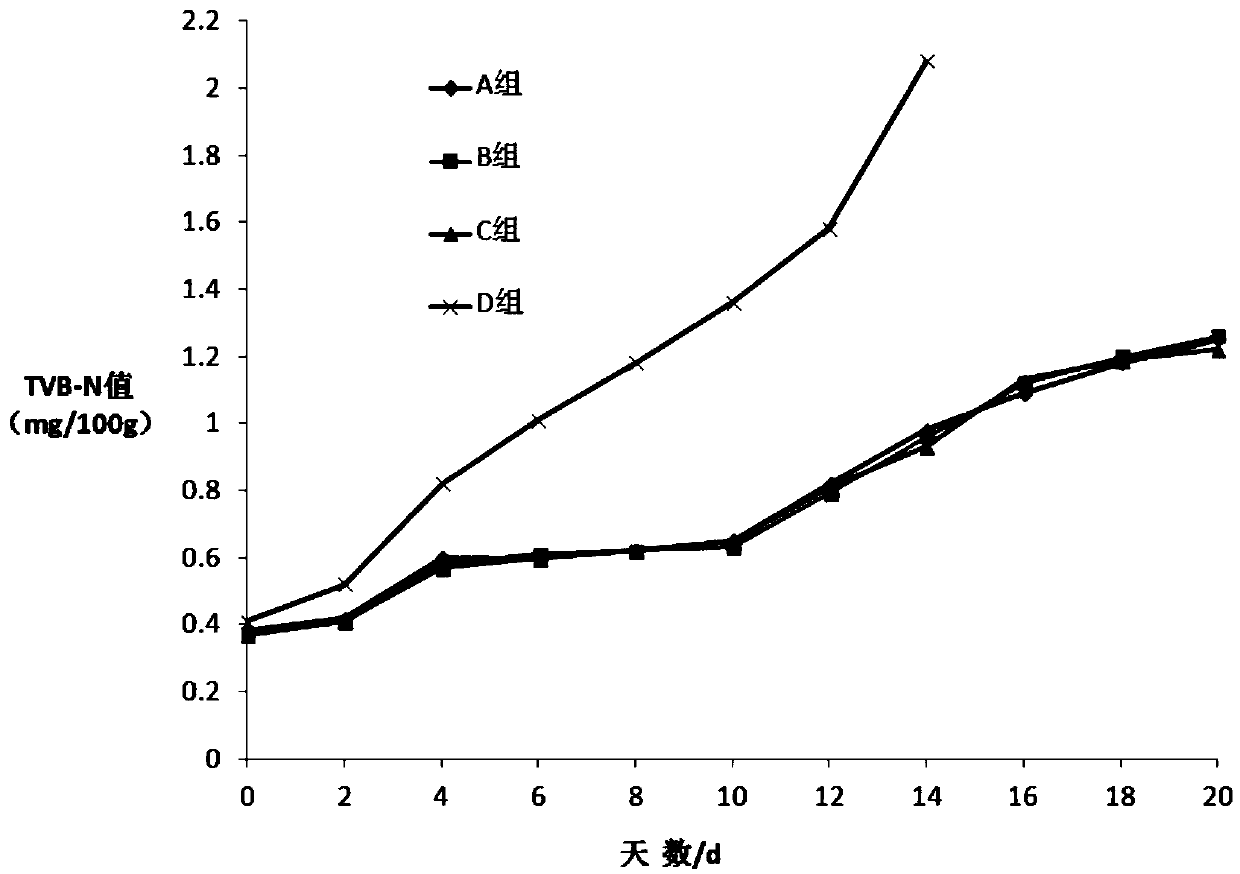

Coating and partial freezing preservation method for hairtail

ActiveCN109566718AAvoid crackingInhibition of reproductionFood freezingMeat/fish preservation by freezing/coolingOperabilityPreservation methods

The invention discloses a coating and partial freezing preservation method for hairtail. The method comprises the following steps of (1) carrying out pretreatment; (2) carrying out sterilization; (3)carrying out surface dewatering; (4) carrying out dipping and coating; (5) carrying out vacuum cooling and drying; (6) carrying out low-temperature quick-freezing; and (7) carrying out partial freezing cold storage. The coating and partial freezing preservation method for the hairtail has the advantages that the hairtail is preserved through a combined coating and partial freezing preservation technology, the steps are simple, the operability is high, the juice loss rate in the unfreezing process of the hairtail can be decreased, the physicochemical properties and the sensory quality of the hairtail can be well maintained, and the shelf life of storage and sale of the hairtail in the partial freezing state can be obviously prolonged.

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

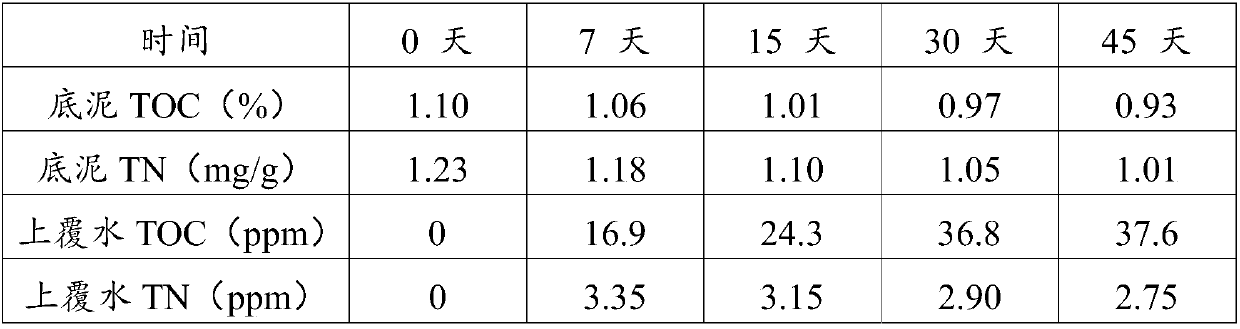

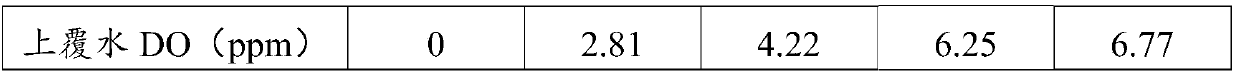

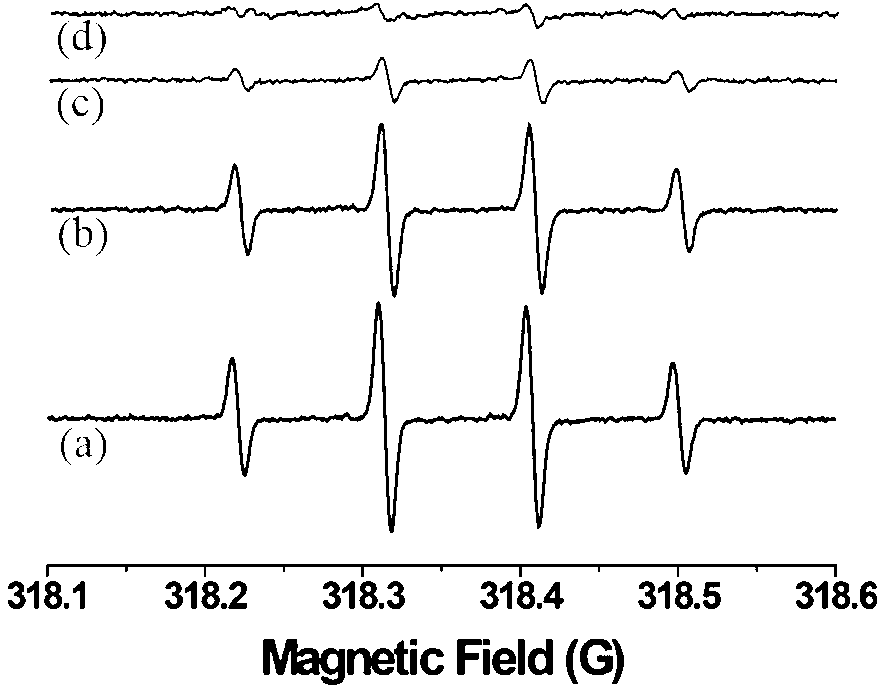

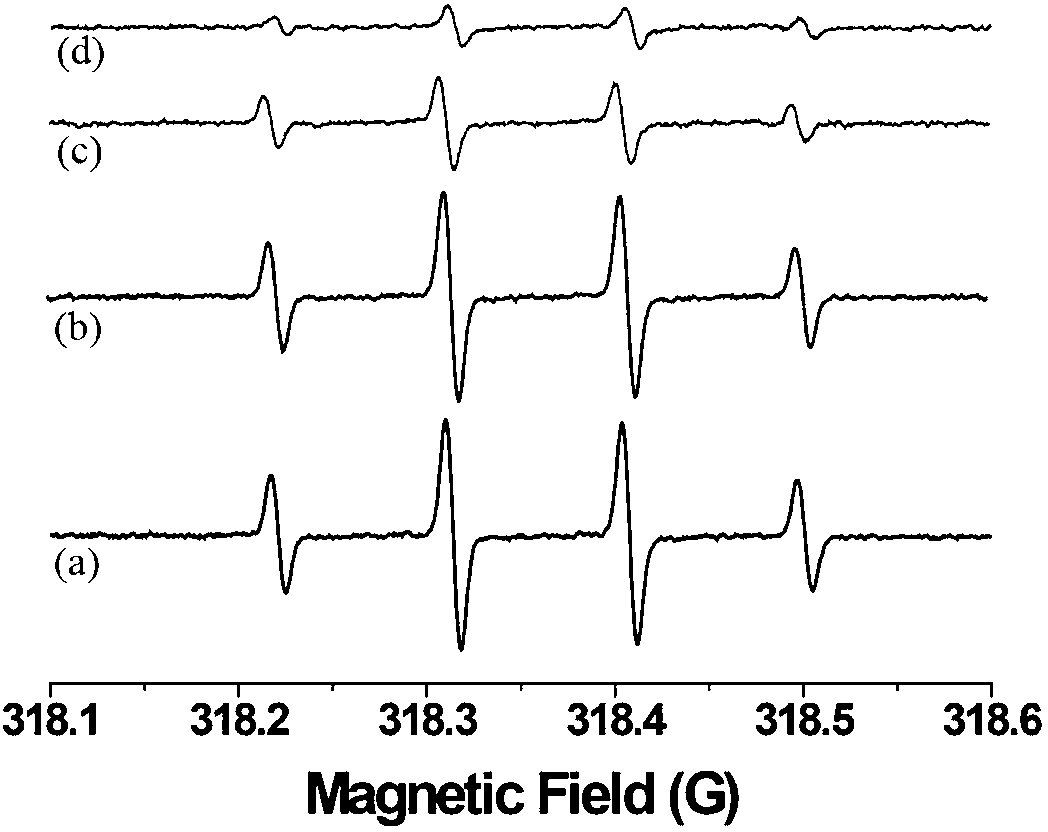

Method for river channel restoration

ActiveCN109607940AMaintain physical and chemical propertiesIncrease dissolved oxygen concentrationWater resource protectionWater treatment parameter controlHoneycomb likeChemical property

The invention provides a method for river channel restoration. The method comprises the following steps: (1) extracting 2 to 10 cm of sediment from the surface layer of river sediment; (2) placing a honeycomb-like filling material into the river sediment, wherein the upper end of the honeycomb-like filling material is 5 to 10 cm higher than the plane of the river sediment; (3) mixing the extractedsediment in the step (1) with calcium nitrate, a solid bio-stimulant, denitrifying bacteria, photosynthetic bacteria, ammonifying bacteria and nitrifying bacteria, and injecting an obtained mixture into the honeycomb-like filling material; and (4) planting submerged plants and elodea nuttallii which absorb ammonia nitrogen onto a river channel. The method for river channel restoration provided bythe invention combines microbial restoration and plant restoration, can significantly remove TOC and TN in the sediment, can maintain the physical and chemical properties of overlying water, increases the dissolved oxygen concentration of the overlying water, controls the TN concentration of the overlying water, and prevents eutrophication.

Owner:GUANGZHOU WATER CONSERVANCY & HYDROPOWER STATION CONSTR ENG

Pleiotropic fullerene-vitamins-water-soluble macromolecular ternary complex and preparation method thereof

ActiveCN103169730AHas antioxidant activityHas anticancer activityAntibacterial agentsPowder deliveryTernary complexPolymer science

The invention discloses a preparation method of a pleiotropic fullerene-vitamins-water-soluble macromolecular ternary complex. The preparation method comprises the following steps of: forcibly mixing fullerene powder, vitamins and water-soluble molecules; then adequately stirring the mixed material in water; and filtering to obtain a transparent filtrate and evaporating to obtain a water-soluble fullerene / vitamine complex. Based on an antioxidant and antibacterial fullerene-water-soluble macromolecular system already invented, vitamins with antioxidation and anti-cancer activity are further introduced to the fullerene-water-soluble macromolecular system so as to obtain a multifunctional water-soluble complex system with antioxidation, antibacterial property and anti-cancer characteristic. The complex has wide application prospect in the fields of cosmetic, biomedicine and the like.

Owner:XIAMEN FUNANO NEW MATERIAL TECH COMPANY +1

Hybrid material containing metal organic framework material, and preparation method thereof

PendingCN109721737AUniform growthUniform grain sizeOther chemical processesDispersed particle separationMetal-organic frameworkAdsorption separation

The invention relates to a hybrid material containing a metal organic framework material, and a preparation method thereof. The preparation method comprises: (1) carrying out acid treatment on an aluminosilicate carrier, washing to achieve a neutral state, and drying; (2) immersing the carrier in an organic ligand solution, and impregnating; (3) transferring the material into a reactor containinga copper salt solution while supplying a trimesic acid solution, and carrying out stand treatment at a low temperature; and (4) transferring the reactor into a drying oven, drying, taking the mixtureout of the reactor, filtering, washing, and drying to obtain the hybrid material containing the metal organic framework material. According to the present invention, the copper-based metal organic framework material HKUST-1 in the hybrid material grows uniformly, and the hybrid material has high ethylene adsorption capacity and selective ethylene / ethane adsorption separation effect, and further has good mechanical strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

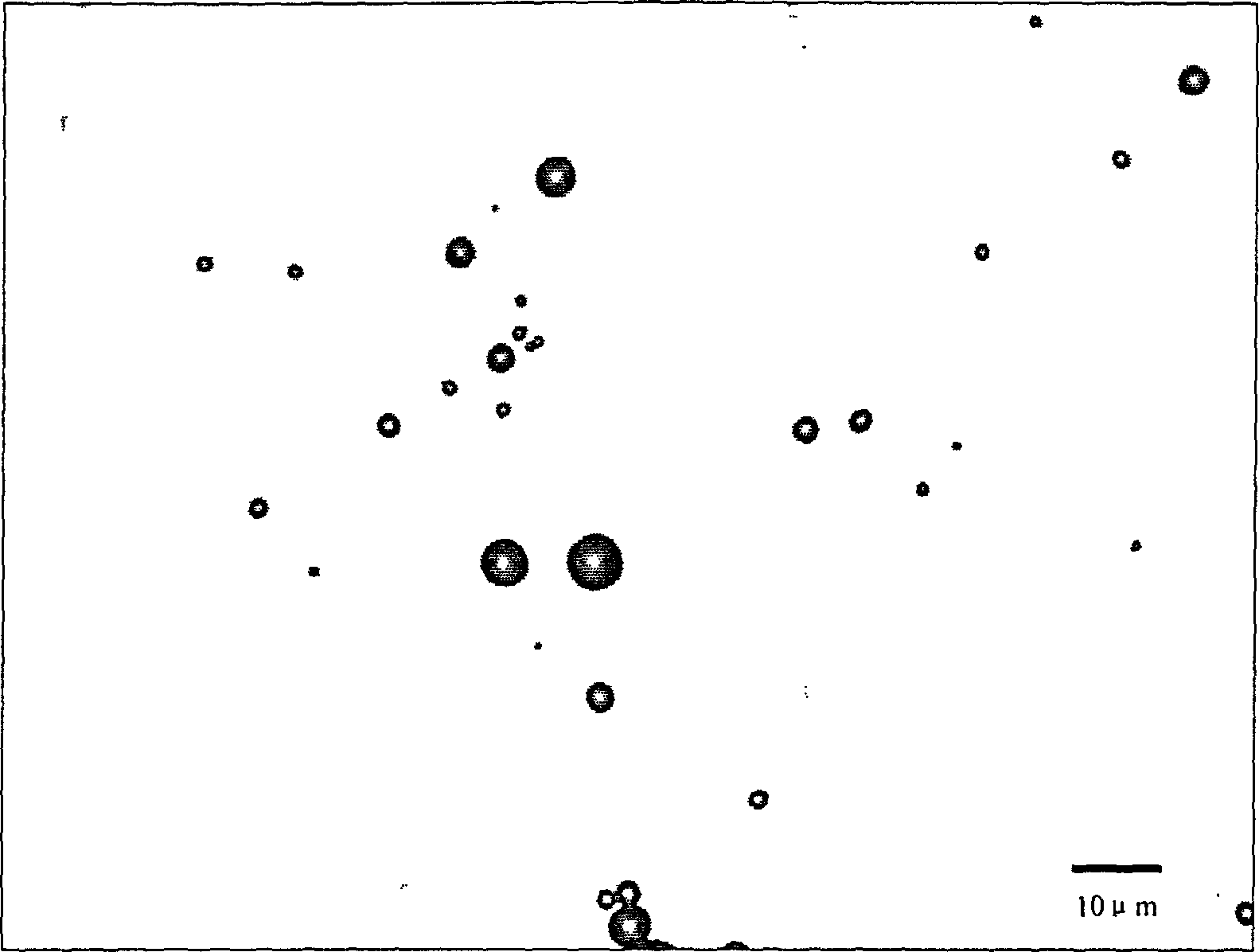

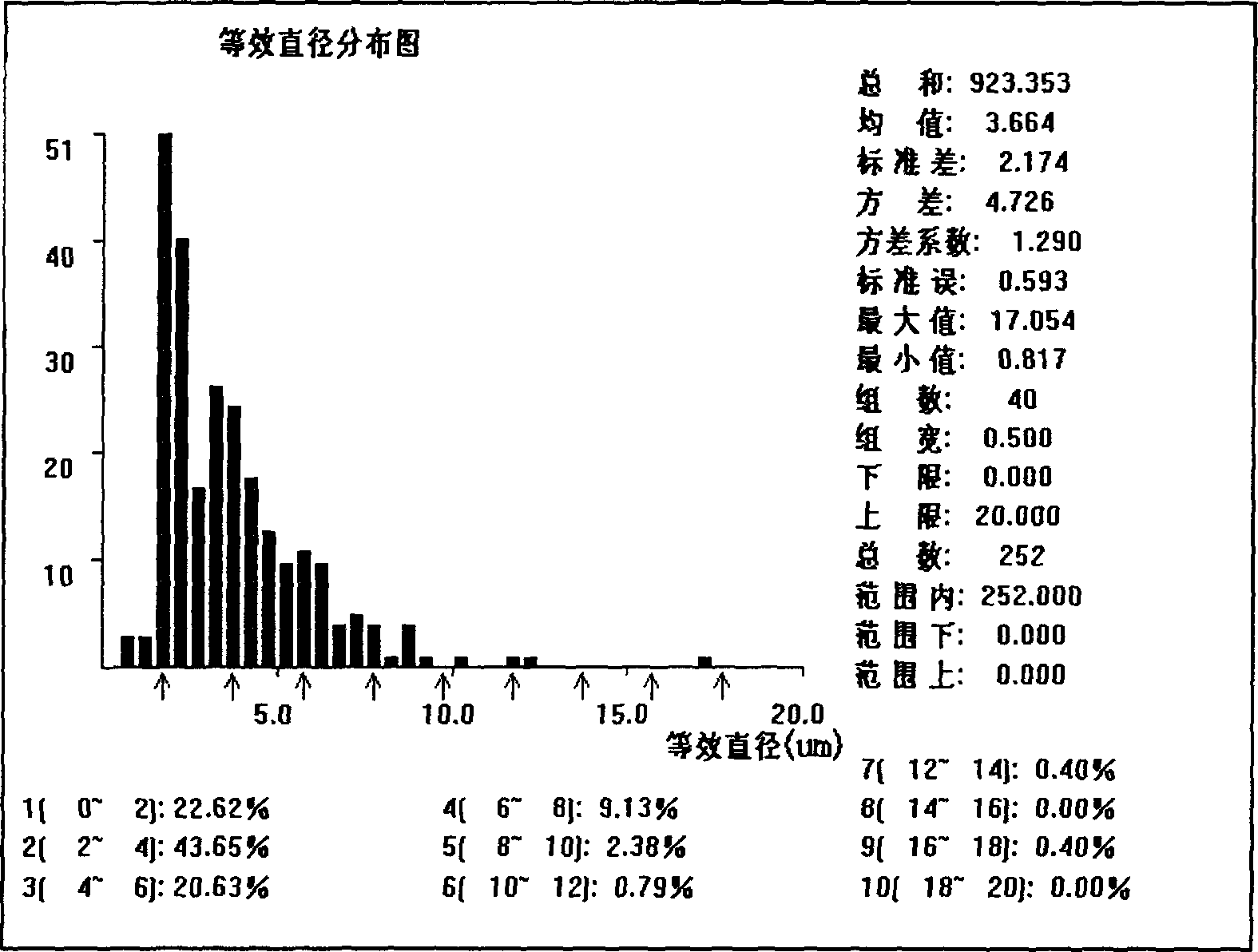

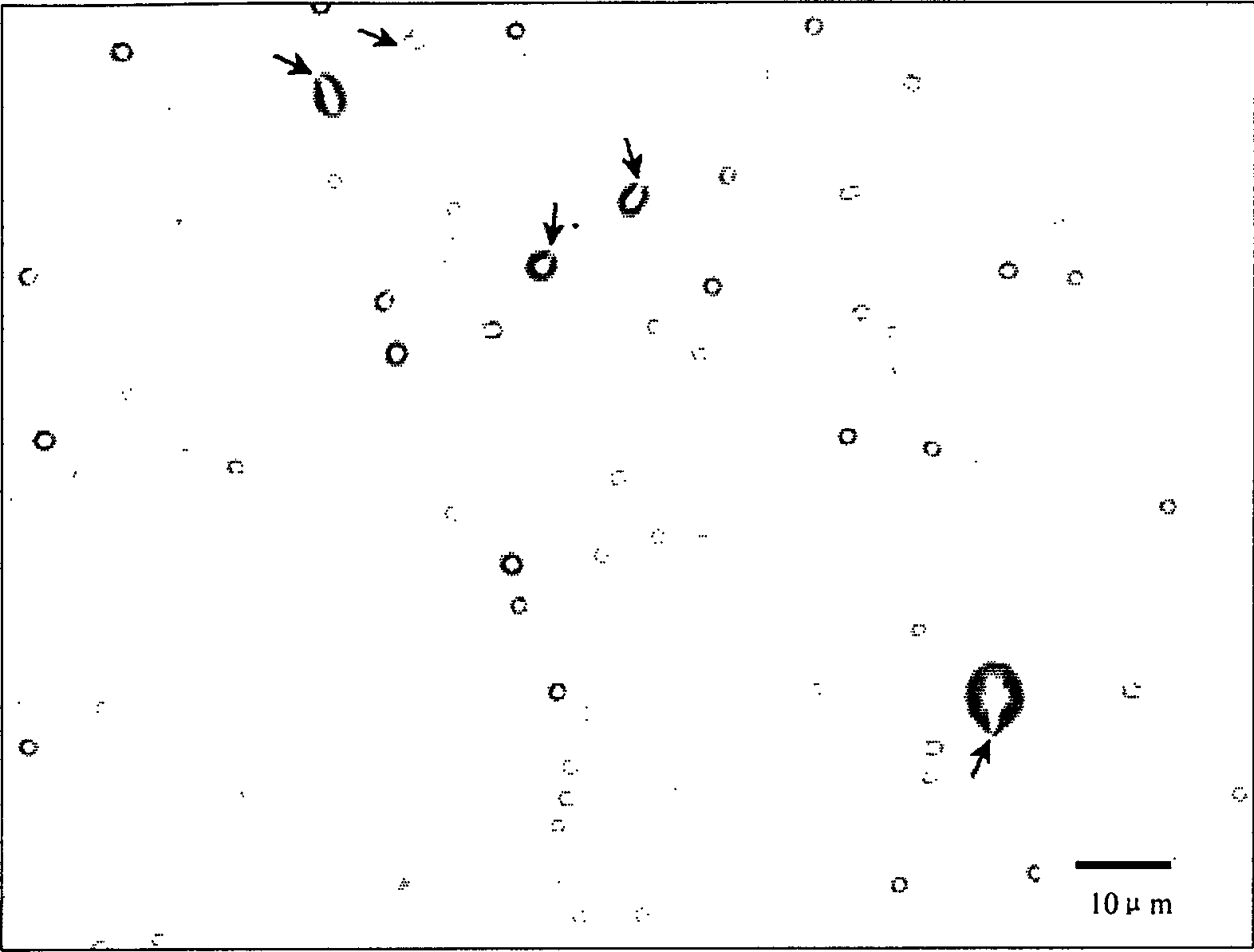

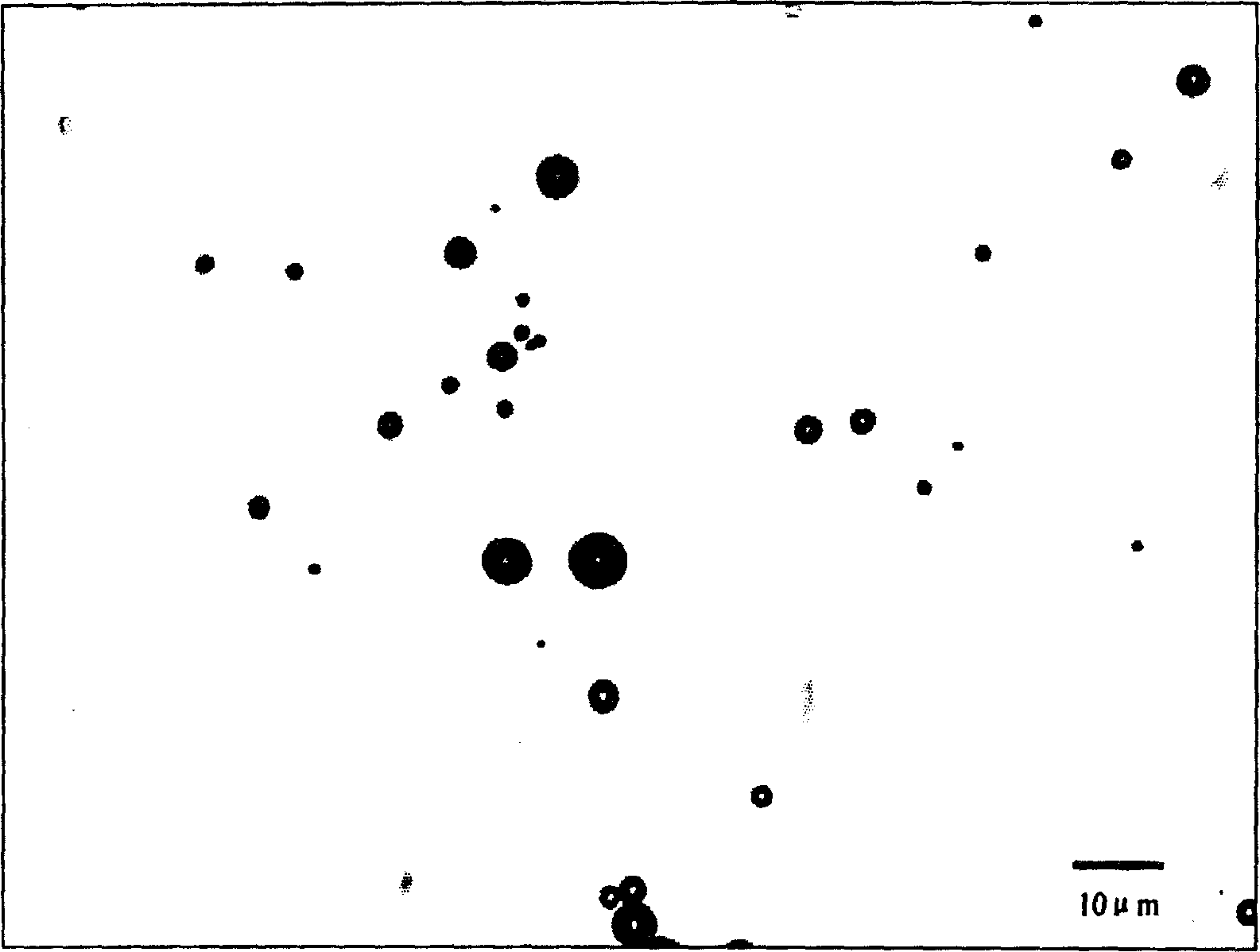

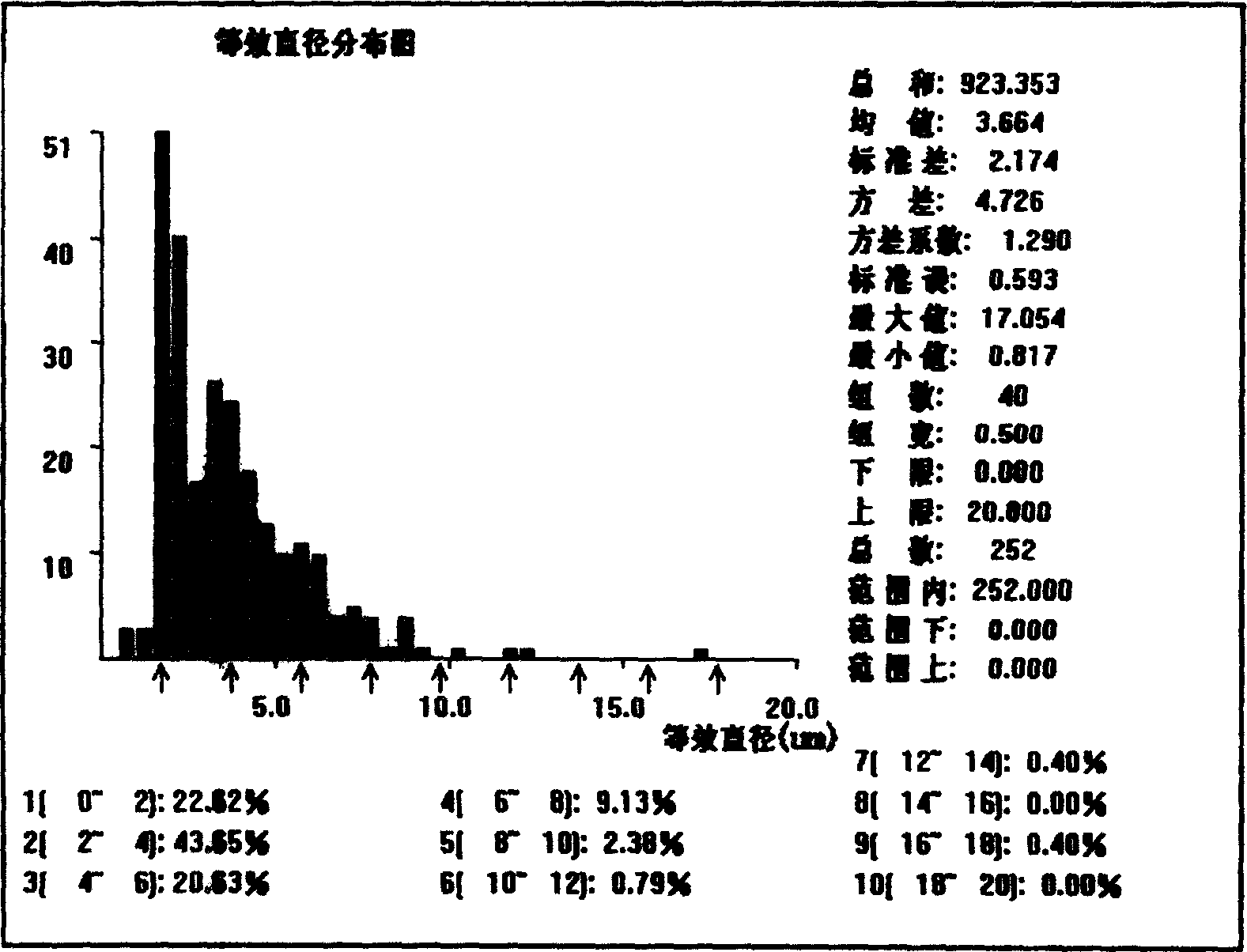

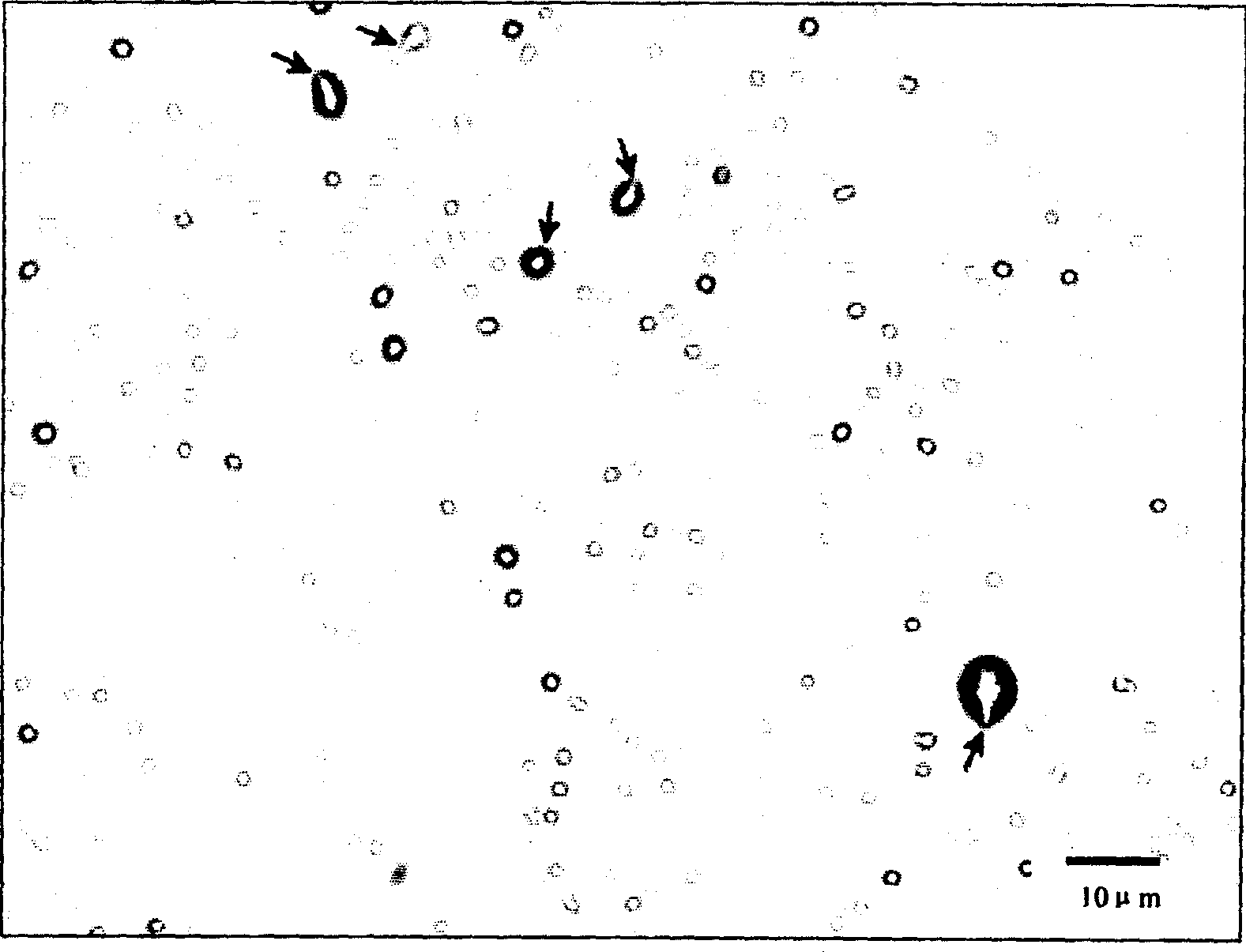

Method and use of closed hydrophilic and lipophilic liquid-phase hollow capsules with cores

InactiveCN1613504AStable contrast-enhanced ultrasound interfaceLow costEmulsion deliveryMicroballoon preparationLiquid crystalSmall particle

A process for preparing the vesicles in liquid phase used for intravenous oxygen transfer includes such steps as dissolving the filming material in chloroform and / or methanol, vacuumizing, spray drying at the transfer temp from gel state to liquid crystal state to generate film on the biodegradable water-soluble small particles, loading them in container, vacuumizing, sealing, filling gas and water medium at the temp lower than the transfer temp from gel state to liquid crystal state, and manual waving until said small particles are dissolved to form the hydrophilic-lipophilic self-enclosed small vesicles.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

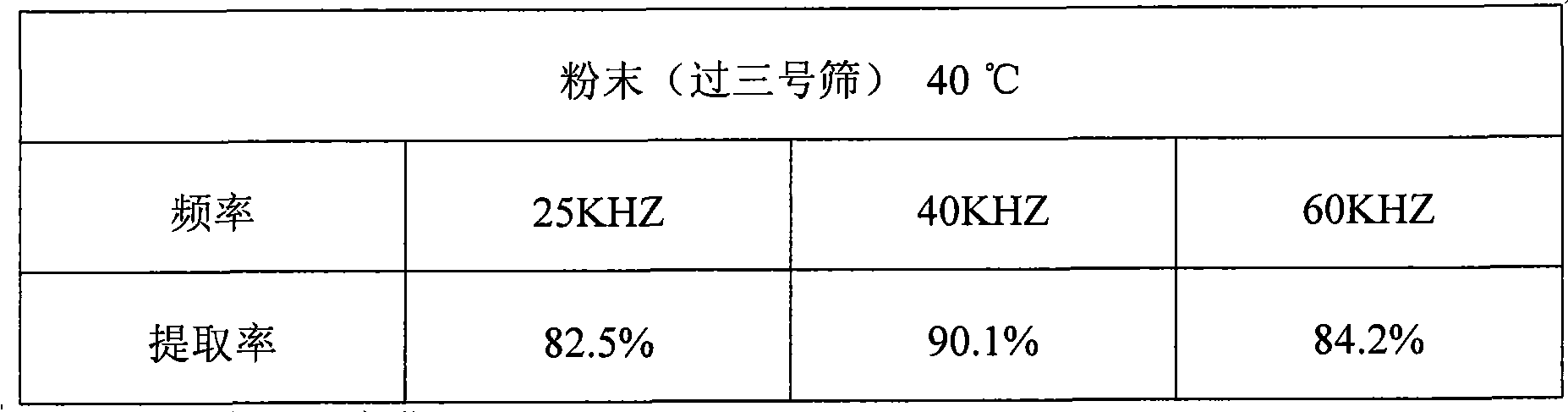

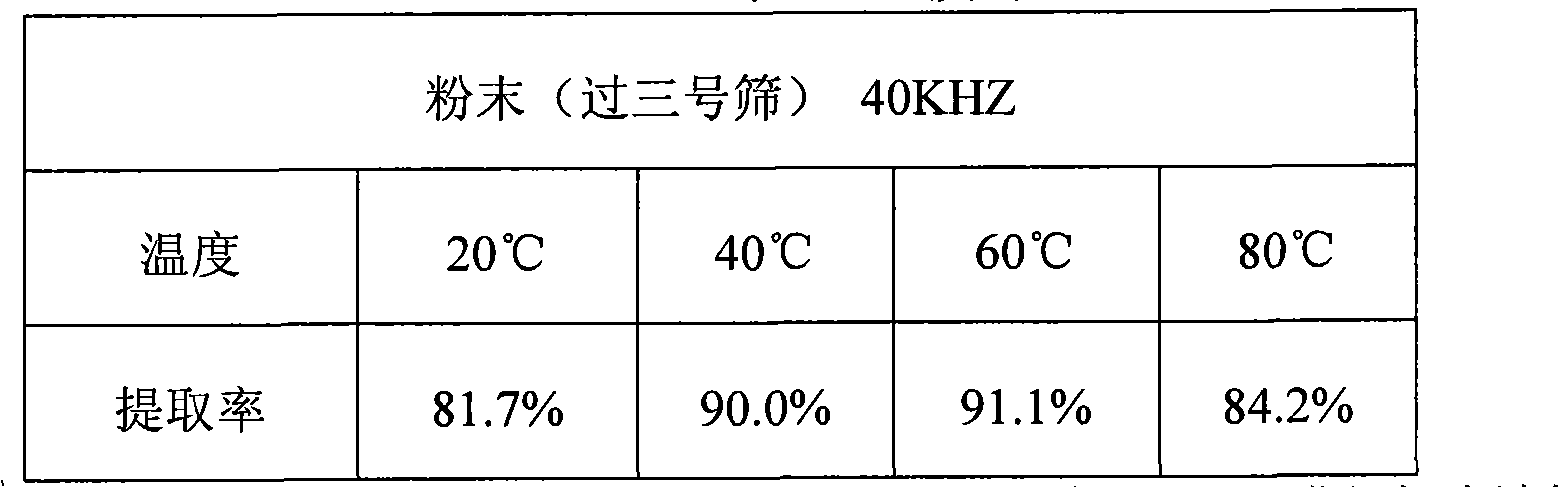

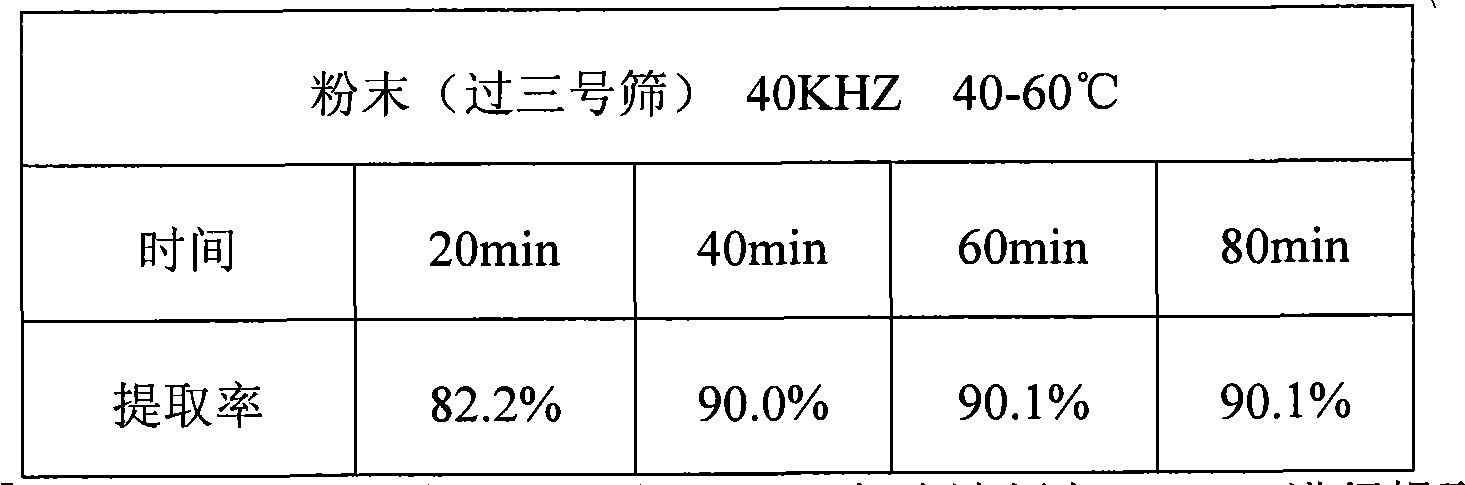

Preparation method of kudzu root isoflavone powder

InactiveCN102783647AImprove solubilityMaintain physical and chemical propertiesOrganic active ingredientsNervous disorderEmulsionPueraria lobata isoflavone

The invention discloses a preparation method of kudzu root isoflavone powder. The preparation method of the kudzu root isoflavone powder includes: using kudzu roots as raw materials, drying, smashing, adding ethanol, then adding cellulose and protease to perform enzymolysis, decompressing and concentrating, and freezing and drying to obtain kudzu root isoflavone; mixing the kudzu root isoflavone, beta-cyclodextrin and soybean lecithin, adding water to make 1000mL kudzu root isoflavone emulsion, and performing ultrasonic processing for 20 minutes; atomizing the kudzu root isoflavone emulsion which is processed by ultrasonic into liquid drops through a spray gun, freezing and curing rapidly after the liquid drops are contacted with compressed nitrogen, placing cured samples in a vacuum freeze drying apparatus to be dried, and obtaining the kudzu root isoflavone powder. The kudzu root powder manufactured by the method fills the blank that no kudzu root powder exists on the domestic market, enzyme treatment is matched with digestion so as to extract flavonoid materials effectively, processing steps are reduced, efficiency is improved, kudzu root flavone can be kept maximally by using a spray freeze drying technique, and products with high economic value and health care value can be obtained.

Owner:JIANSU MAOBAO GEYE CO LTD

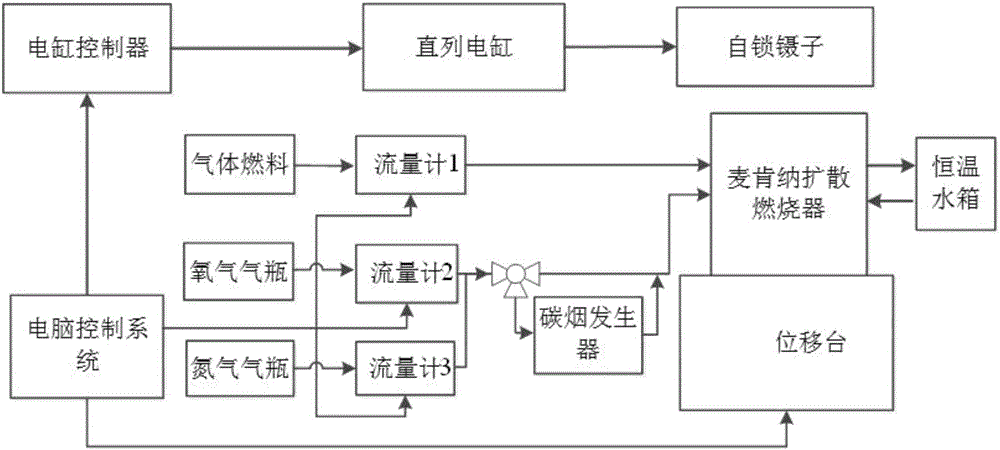

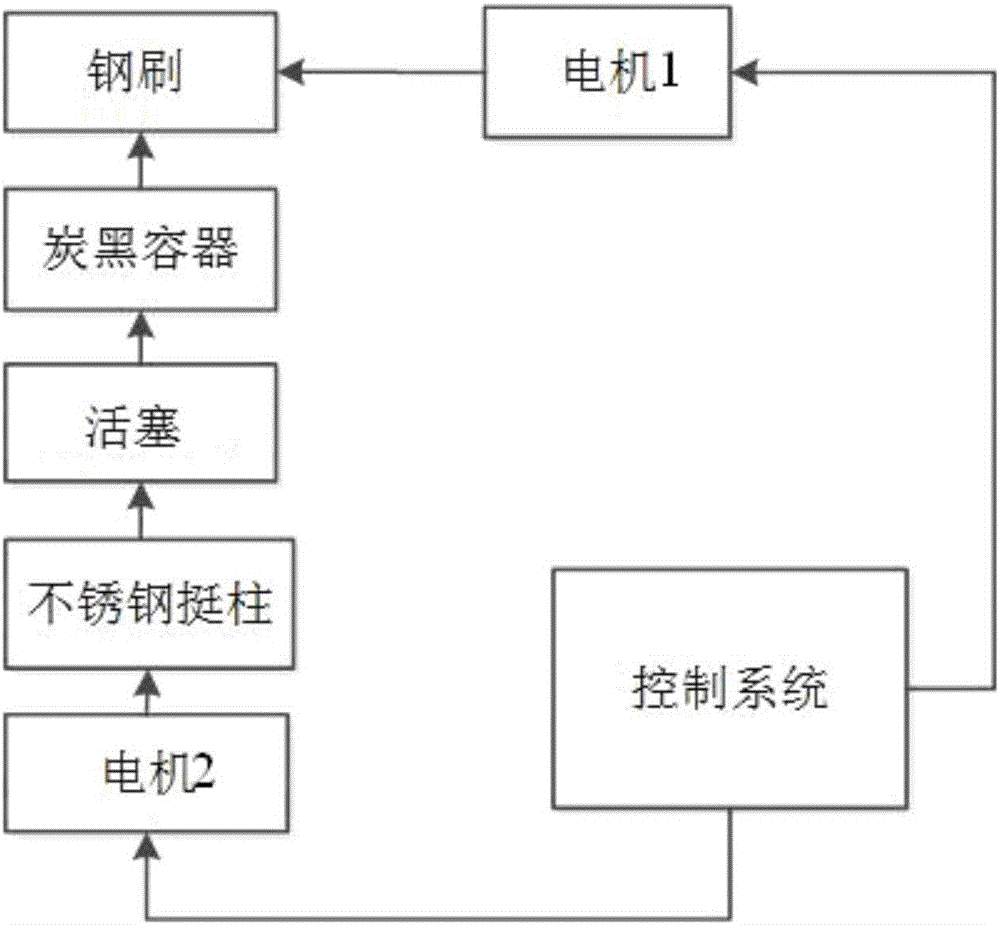

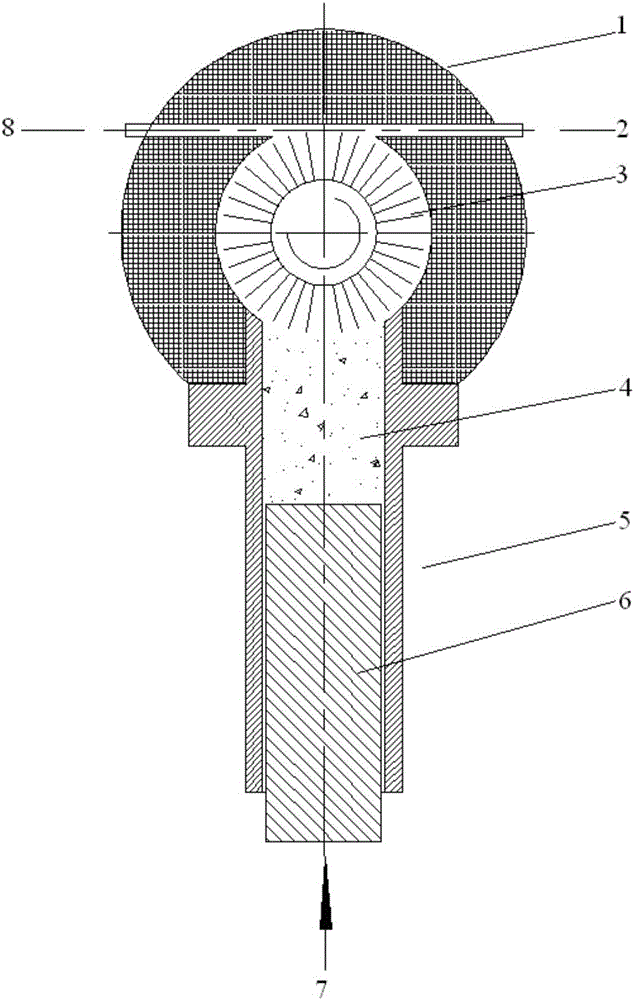

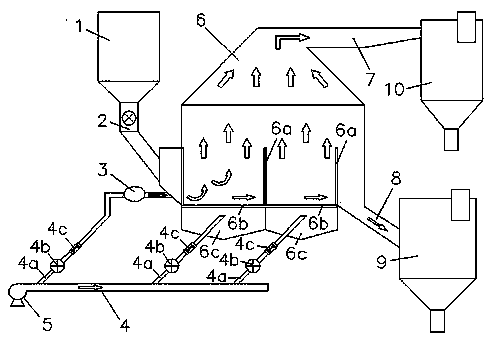

Simulation system and method capable of reproducing soot evolution characteristics under post-injection strategy of engine

ActiveCN106092588ASimplified backspray strategyFast resamplingChemical analysis using combustionEngine testingSteel tubePost injection

The invention discloses a simulation system capable of reproducing soot evolution characteristics under a post-injection strategy of an engine, which comprises a soot generator, an electric cylinder controller, a computer control system, a Mckenna diffusion combustor fixed on a displacement bench and a pair of self-locking tweezers arranged above the Mckenna diffusion combustor, and is characterized in that a central steel pipe of the Mckenna diffusion combustor is connected to a gaseous fuel source through a pipeline, air inlet pores of a plurality of metal sintered plates at the periphery of the Mckenna diffusion combustor are all connected to an air inlet main pipeline which is connected with a nitrogen gas cylinder and an oxygen gas cylinder; a coiled pipe is connected to a constant temperature water tank; an in-line electric cylinder connected with the self-locking tweezers realizes connection with the electric cylinder controller through a motor and a programming data line, and model carbon black in a carbon black container is taken into a gas channel through a rotating steel brush under driving of a piston. The simulation system disclosed by the invention can facilitate to simplify research for formation and conversion mechanisms of soot generated under the post-injection strategy of the engine, thereby providing a scientific basis for preventing atmosphere environment pollution.

Owner:TIANJIN UNIV

Prep. of vegetable fiber biological filler

InactiveCN1448347AHigh strengthImprove deodorization rateDispersed particle separationSustainable biological treatmentVegetable fibersBiomass c

The present invention belongs to the field of biological treatment of water gas. Organic plant fiber and durable component are soaked fully with water, stirred, molded to form, and dried in 10-1500 Pa pressure and -40 to 60 deg.c temperature to obtain biological stuffing. The biological stuffing has good microecological environment suitable for microbes to grow, great amount of biomass per unitarea, proper water maintaining amount and other advantages. The method of the present invention has high production efficiency, and the prepared biological stuffing has high deodorizing efficiency and long service life and may be used in purifying waste gas containing various effluvial components.

Owner:CHINA PETROLEUM & CHEM CORP +1

Soil conditioner and fertilizer comprising same

InactiveCN108558572AIncrease the granular structureImprove water retentionCalcareous fertilisersNitrogenous fertilisersAlkali soilSodium Bentonite

The invention discloses a soil conditioner and a fertilizer comprising the same. The soil conditioner consists of the following components in percentages by mass: 20-50% of mineral resource potassiumfulvic acid, 20-30% of alginic acid or alginate, 10-30% of medium trace element chelate and 10-30% of bentonite. According to the soil conditioner, soil granular structures are increased by high-activity short carbon-chain micromolecule structures of active mineral resource potassium fulvic acid; and meanwhile, by the alkalinity of the soil conditioner, acid soil and saline-alkali soil can be subjected to acid-alkali buffering and conditioning, and nutrients in soil are activated. The soil conditioner is further added with the alginic acid and the bentonite, the water retention effect of the soil is improved, the soil granular structures can be increased further, substitution capacity of the soil is increased, and therefore, the soil buffering effect is improved.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

Dry method selective solid material separation device

InactiveCN103433216AMaintain physical and chemical propertiesWon't breakGas current separationEngineeringVolumetric Mass Density

The invention discloses a dry method selective solid material separation device, and belongs to the technical field of material gravity separation methods. An outlet in the bottom of a fluidization separation bed of the separation device is connected with a high-density material storage bin through a conveying pipeline. An outlet in the top of the fluidization separation bed of the separation device is connected with a low-density material storage bin through an upper portion air channel. An air conveying main pipe connected with an air blower is provided with air conveying branch pipes. One air conveying branch pipe is connected with an outlet pipeline of a feeding device through an air connecting box. The other air conveying branch pipes are respectively connected with an air bellow at the bottom of the fluidization separation bed. According to the dry method selective solid material separation device, a physical method is applied to separation of solid mixed materials, the form of water-soluble substances in the materials can not be damaged, intrinsic physicochemical properties of the materials can be kept, the separated materials can be further utilized, secondary pollution is avoided in the whole separation process, and the dry method selective solid material separation device has the best environmental-friendly effect. Meanwhile, the dry method selective solid material separation device is simple in structure, easy and convenient to operate and manage, free of adding other separation media, low in cost, and applicable to the separation of a majority of materials with different densities.

Owner:中能东讯新能源科技(大连)有限公司 +1

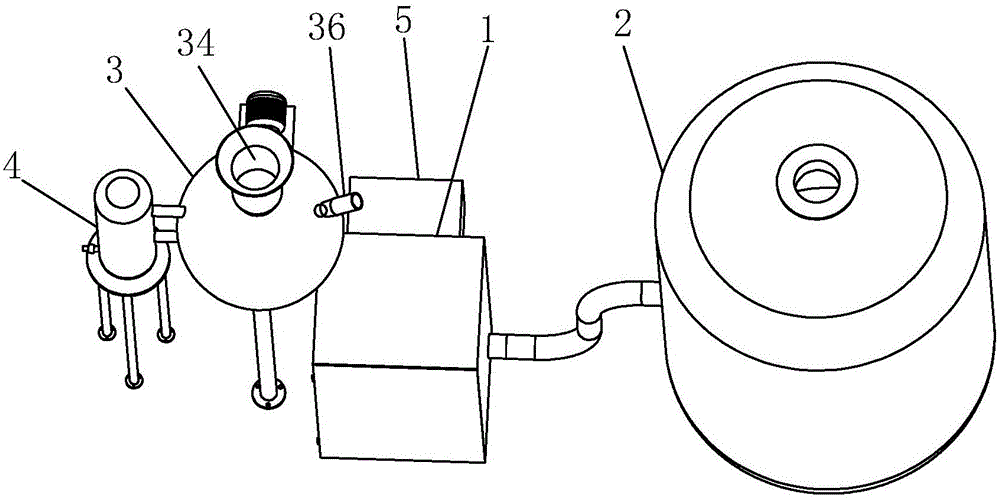

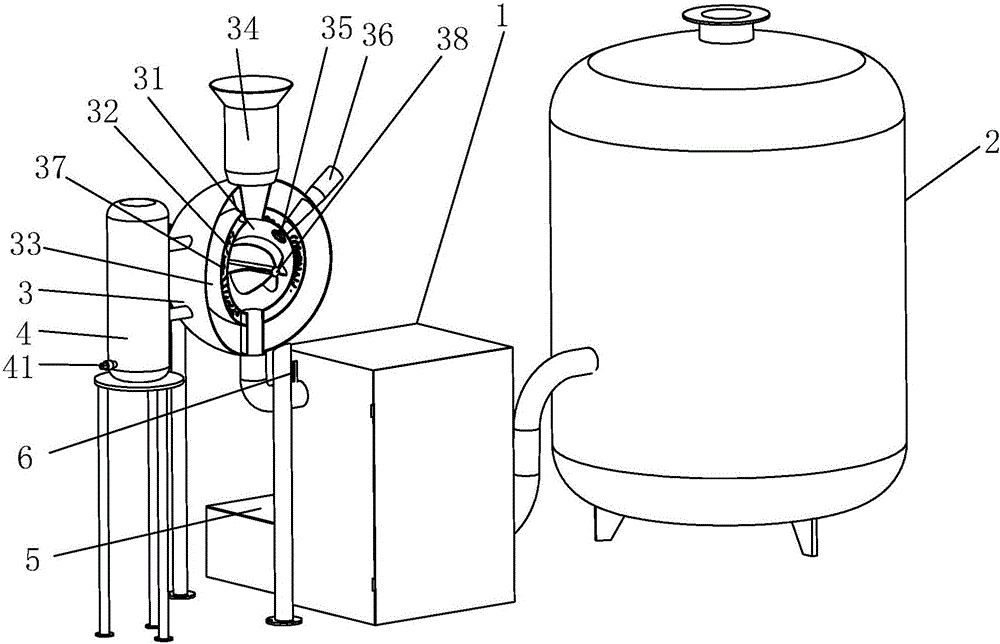

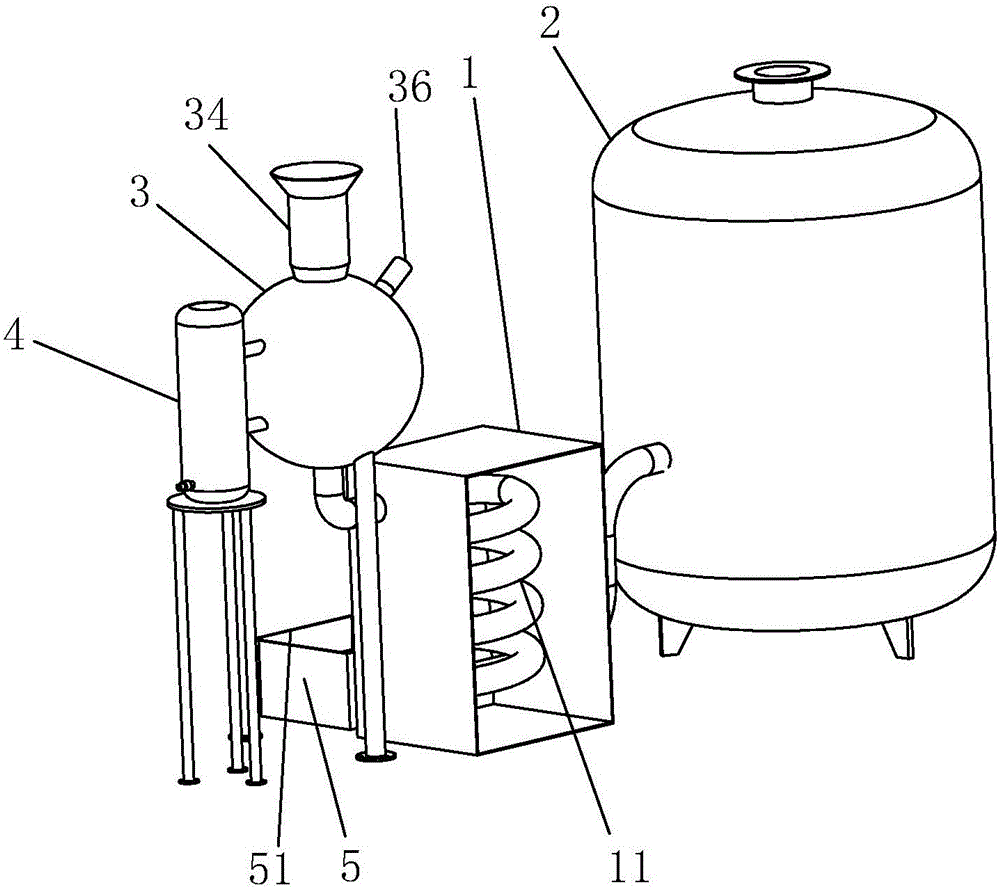

2-EAQ (2-ethylanthraquinone) synthesis device and technology

ActiveCN106045838AJoin slowlyMaintain physical and chemical propertiesOrganic compound preparationQuinone preparation2-EthylanthraquinoneProcess engineering

The invention discloses a 2-EAQ (2-ethylanthraquinone) synthesis device and technology. The technical scheme is characterized in that the 2-EAQ synthesis device comprises a tubular reactor, a hydrolysis kettle and a sphere mixer, wherein a feed chute allowing a solid material to be fed is formed in the sphere mixer; a sprinkling nozzle for jetting a fluid material is arranged in the sphere mixer; a feed tube communicated with the sprinkling nozzle is further arranged on the sphere mixer; the sphere mixer is communicated with one end of the tubular reactor, and the other end of the tubular reactor is communicated with the hydrolysis kettle; with the adoption of the sprinkling mode of the sprinkling nozzle, fuming sulphuric acid is added more slowly, so that the temperature in the sphere mixer is prevented from being increased to be too high due to too high mixing speed of the materials during mixing of the materials, the temperature in a mixing process is controlled to be in a safe mixing temperature range of the two materials, and the mixing process is safer and more stable.

Owner:吉林紫瑞新材料有限公司

Bioactive filtering material for water treatment and baking technology thereof

InactiveCN1546398AHigh strengthHigh porositySustainable biological treatmentFiltration separationSulfonateFoaming agent

A biologically active filtering material for water treatment and its roasting process by using clay as the principal raw material for the biologically active filtering material, charging lignin sulfonate plasticizing agent and polyvinyl alcohol foaming agent, wherein the biological activity is achieved through roasting process and biological modification. The advantages of the invention are strong biological adhesion, high performance of film suspension, good current fluidized form, easy backwash and strong dirt-blocking capability.

Owner:SHANDONG UNIV +1

Highly-heat-conductive shaped phase-change heat-storage material and preparation method thereof

InactiveCN105154017AImprove thermal conductivityFast heat absorption and releaseHeat-exchange elementsParaffin oilsGraphite

The invention discloses a highly-heat-conductive shaped phase-change heat-storage material and a preparation method thereof. The heat-storage material is prepared from compounding paraffin, expanded graphite and porous foamed copper, wherein the mass percentage of the paraffin accounts for 74.88%; the mass percentage of the expanded graphite accounts for 8.32%; the mass percentage of the porous foamed copper accounts for 16.8%; the melting point of the paraffin selected in the above-mentioned materials is in the range of 40 DEG C to 60 DEG C; and the voidage of the porous foamed copper selected in the above-mentioned materials is more than 98%. The material has the advantages of rapid heat-absorption and heat-release efficiencies, large heat storage capacity, and invariant shape after phase change.

Owner:JIANGSU QIZHENG NEW ENERGY

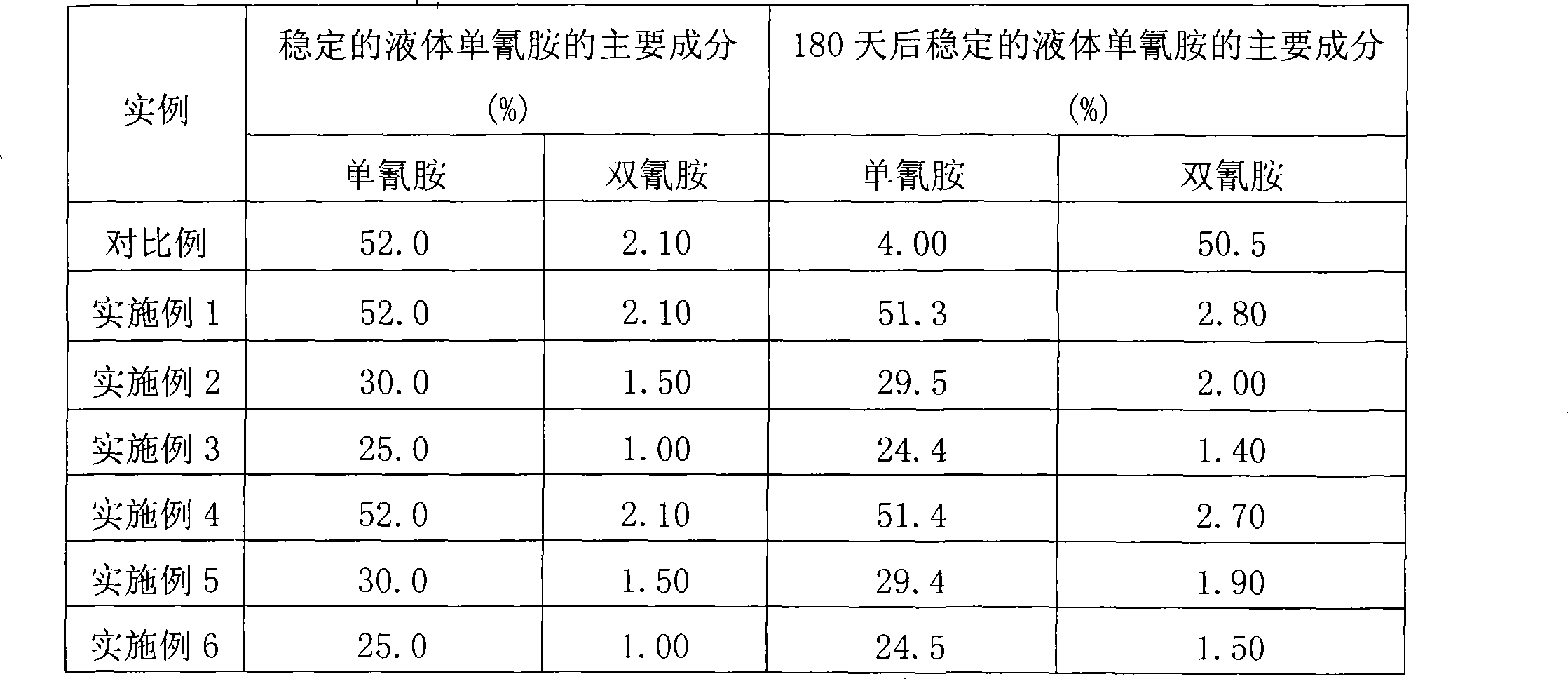

Stabilizing agent of liquid single-cyandiamide and method for producing stable liquid single-cyandiamide

InactiveCN101428821AMaintain physical and chemical propertiesSolve storage problemsCyanamideAcetic acidStable state

The invention belongs to the field of chemical engineering, and particularly relates to a stabilizer for liquid cyanamide and a method for preparing stable liquid cyanamide. The stabilizer for liquid cyanamide can be acetic acid or metacetonic acid. The method for preparing stable liquid cyanamide comprises steps as follows: liquid cyanamide is put into a container with a stirring device; the stabilizer with the liquid cyanamide weight 0.01-5.0% is added slowly in stirring; the temperature of the liquid cyanamide in the container is controlled to be the natural environmental temperature; and the liquid cyanamide with stable performance is obtained. A large amount of experiments show that proper acetic acid or metacetonic acid is added into liquid cyanamide to be the stabilizer, so that liquid cyanamide can be in a very stable state at the natural environmental temperature, all of the physicochemical properties of liquid cyanamide are kept, and the long-term problems of storage and transportation of liquid cyanamide at the natural environmental temperature are solved.

Owner:宁夏大荣化工冶金有限公司

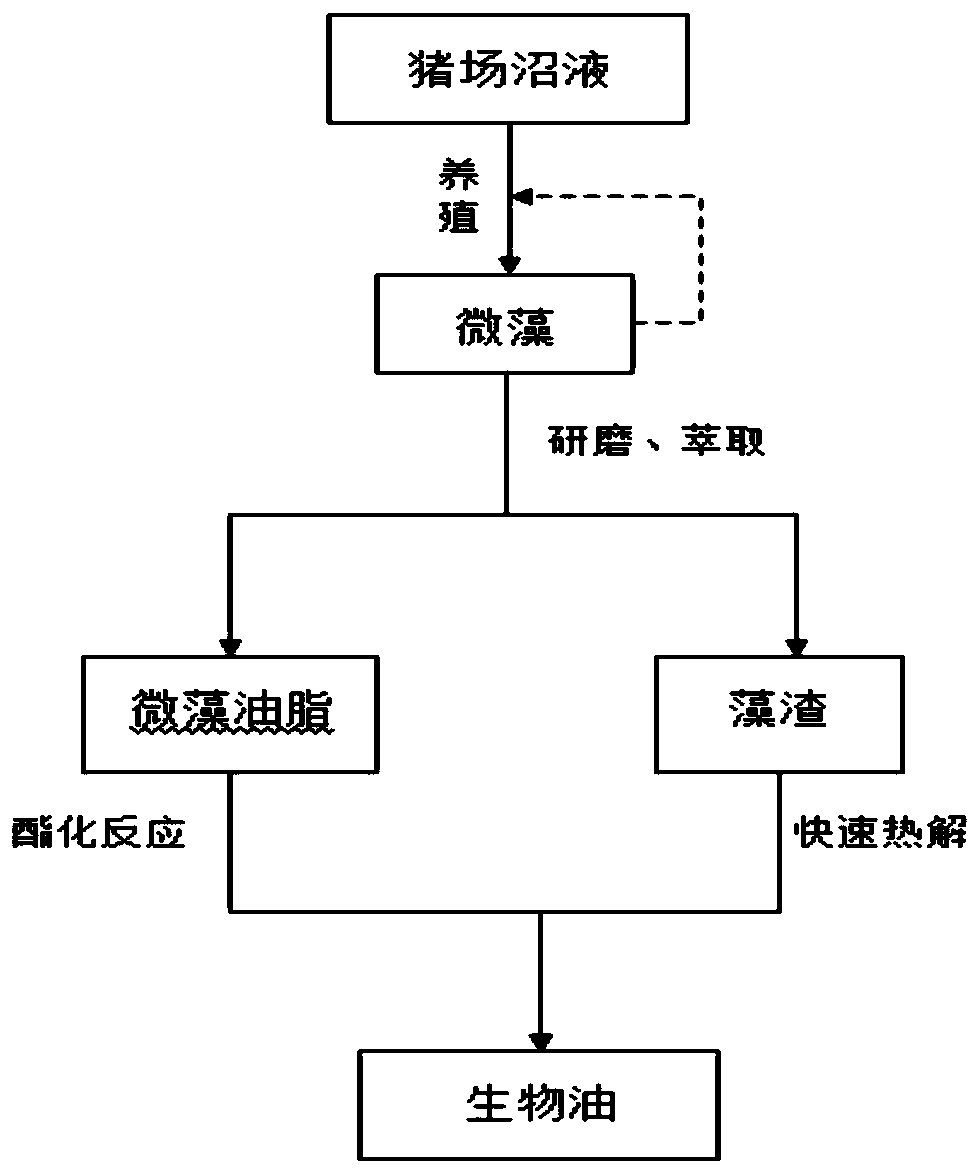

Method for cultivating microalgae with pig farm biogas slurry and making full use of microalgae to produce bio-oil

InactiveCN111500465AEasy to prepareIncrease valueFatty acid esterificationUnicellular algaePig farmsOil and grease

The invention provides a method for culturing microalgae with pig farm biogas slurry and making full use of the microalgae to produce bio-oil. The method comprises the following steps of: preparing a5-20% microalgae culture solution by using the pig farm biogas slurry, and inoculating the microalgae into the culture solution for culturing; grinding the microalgae cultured by the pig farm biogas slurry and quartz sand according to a certain mass ratio, and adding an organic solvent for extraction to realize extraction of microalgae grease and preparation of microalgae residue; carrying out esterification reaction on the microalgae grease to obtain bio-oil; and pyrolyzing the microalgae residue in a cracking device at 300-800DEG C in an atmosphere of inert gas to prepare the bio-oil again.On the basis of the existing pig manure biogas engineering, the pig farm biogas slurry is used for culturing microalgae, so that purification treatment of the pig farm biogas slurry is realized, and alarge amount of biomass energy is accumulated; by adding the additives into the biogas slurry, the growable biomass and grease content of microalgae in the biogas slurry are improved; and through full utilization of the microalgae, the energy utilization potential of the biogas slurry and the microalgae is improved, and the energy problem is relieved to a certain extent.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Metal substrate highly heat-conducting heat storage material and preparation method therefor

InactiveCN105154022AHigh thermal conductivityFast heat absorption and releaseHeat-exchange elementsPorosityHeat conducting

The invention discloses a metal substrate highly heat-conducting heat storage material and a preparation method therefor. The heat storage material is prepared by compounding 75% by mass of paraffin and 25% by mass of through-hole foamed aluminum. The melting point of selected paraffin in the materials is 40-60 DEG C, and the porosity of the selected through-hole foamed aluminum in the materials is over 90%. The material has the advantages of being fast in heat absorption and heat release speed and great in heat storage.

Owner:JIANGSU QIZHENG NEW ENERGY

Novel inorganic composite high-thermal-conductivity phase-change heat storage material and preparation method thereof

InactiveCN106701027AMaintain physical and chemical propertiesHigh phase change enthalpyHeat-exchange elementsPorositySuper absorbent

The invention discloses a novel inorganic composite high-thermal-conductivity phase-change heat storage material and a preparation method thereof. The heat storage material is prepared from, in percentage by mass, 83.2% of crystal salt hydrate, 0.8% of an SAP (super absorbent polymer) and 16% of porous aluminum through composition, and the porosity of selected porous aluminum in the materials is 90% or higher. The material has the advantages that the heat absorption and release speeds are high, the heat storage capacity is high, and the appearance is unchanged after phase change.

Owner:ZHENJIANG XINMENGXI ENERGY TECH

Weft knitting cloth and production method thereof

The invention provides weft knitting cloth and a preparation manner thereof. The weft knitting cloth comprises an upper surface, a lower surface and a middle layer. The middle layer of the cloth comprises connecting threads and core-through yarn, the connecting threads are hooked and connected between the upper surface and the lower surface in the weft direction, and division grids are formed by the connecting threads and upper surface and lower surface yarn hooked and connected with the connecting threads. Fabric units including hollow channels are formed by the adjacent division grids, the upper surface and the lower surface, the core-through yarn is arranged in the hollow channels in a penetrating manner, and the fabric units are woven by a double-face machine. By means of the structure, the core-through yarn is wrapped in the fabric units, the functional core-through yarn is not connected with other yarn any more, the structure of the functional core-through yarn is not destroyed in the weaving process, and functionality and original physical and chemical properties are kept. Meanwhile, much functional core-through yarn can be added into the cloth, and overall functionality offabric is increased; and meanwhile, the functional core-through yarn does not appear on the surface of the weft knitted cloth, the softness of the fabric surface is kept, and the service life of the functional cloth is also prolonged.

Owner:FUJIAN HUAFENG NEW MATERIALS

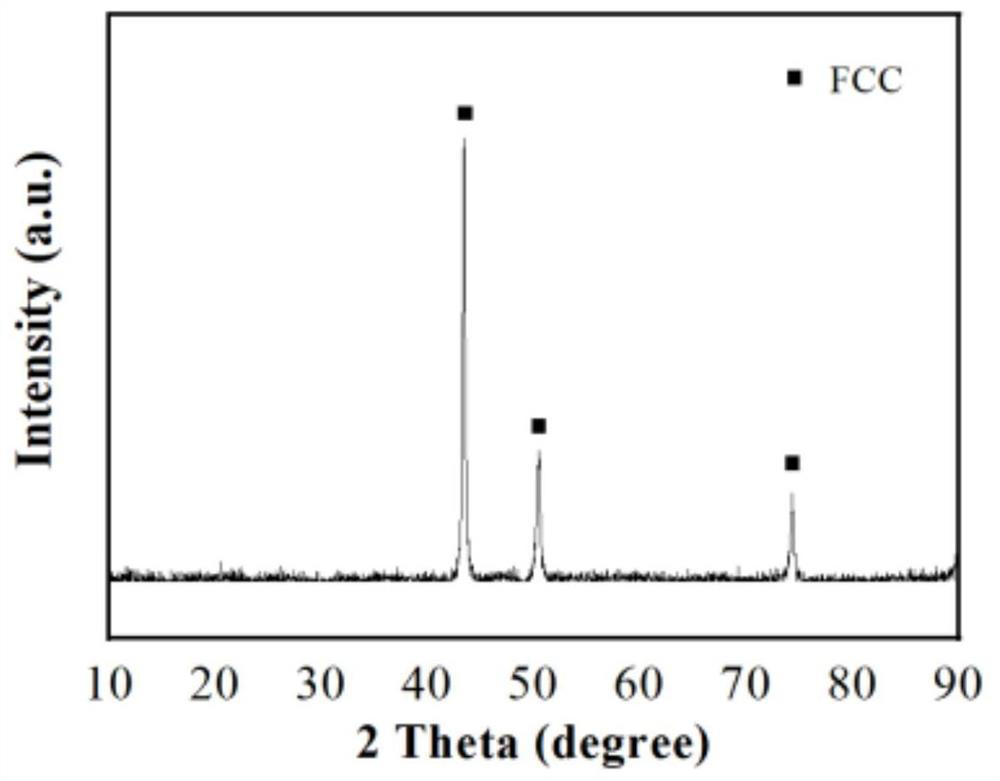

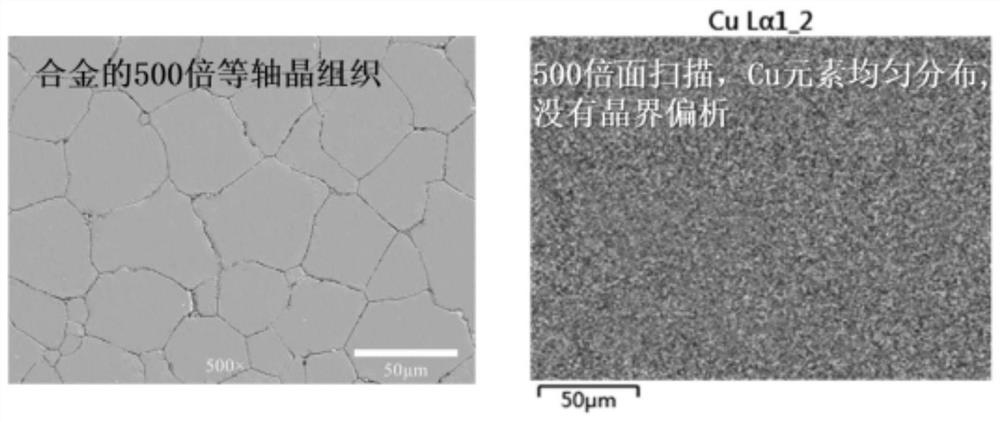

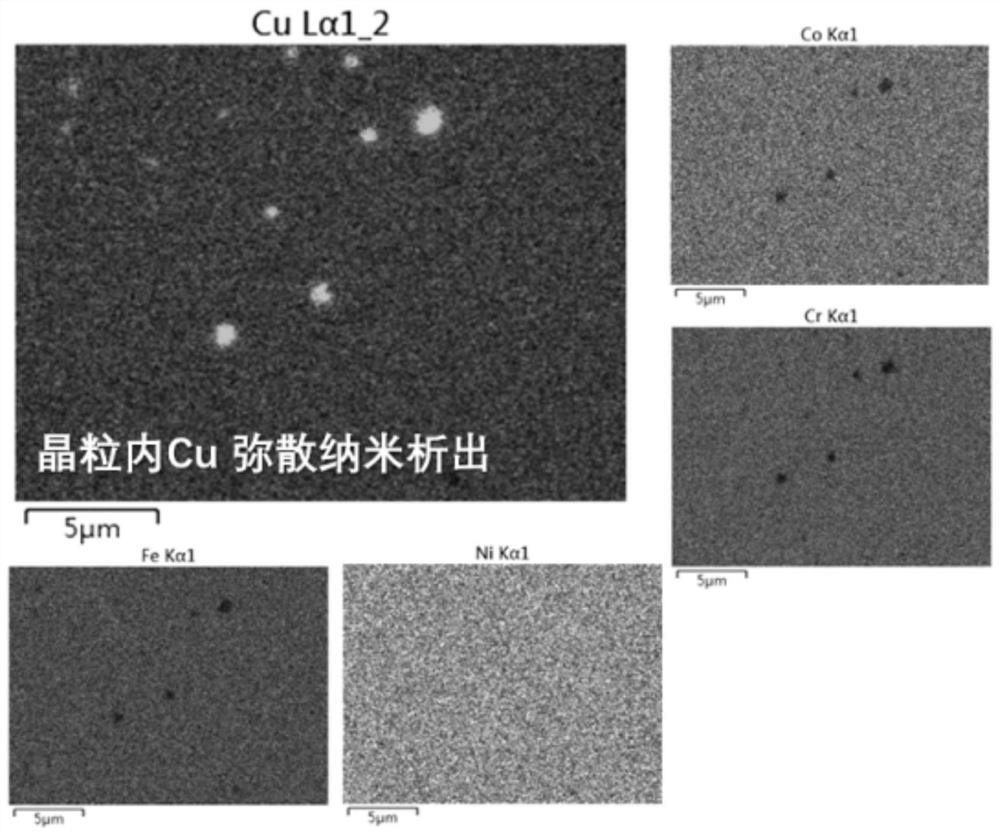

Preparation method of multifunctional ocean engineering alloy

ActiveCN113481397AAchieve corrosion resistanceAchieve high plasticityTransportation and packagingMetal-working apparatusFree energiesAlloy

The invention discloses a preparation method of a multifunctional ocean engineering alloy. Through coupling of a multi-principal alloy structure, structural entropy and temperature and through powder metallurgy and heat treatment, the intersolubility between elements and the free energy of an alloy system are regulated and controlled, Cu grain boundary segregation is eliminated, and uniform and dispersed nano precipitation of the antifouling element Cu in the corrosion-resistant and high-plasticity multi-principal alloys is realized. The preparation method is simple and controllable to operate, and the prepared material has plasticity higher than 75%, high yield strength, excellent corrosion resistance and antifouling property and has important application prospects in the field of ocean engineering.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +2

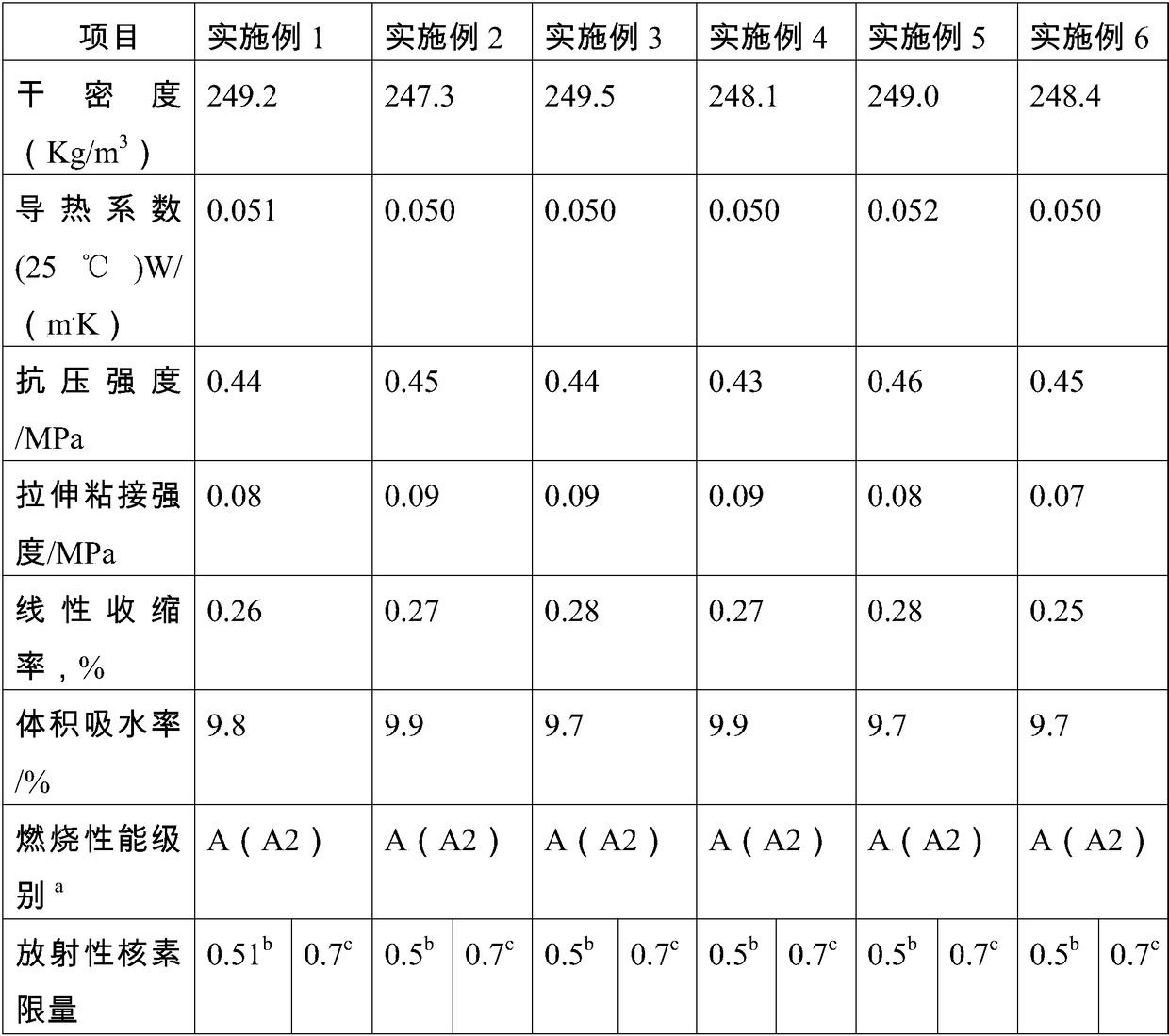

Preparation method of inorganic heat preservation paste

InactiveCN108546077APrevent collapseMaintain physical and chemical propertiesMaterials sciencePolypropylene fiber

The invention discloses a preparation method of inorganic heat preservation paste, comprising the following steps: S1, putting polypropylene cellosilk into a water vat, scattering, adding into a pullvat, adding a proper amount of water into the pull vat, putting the pull vat under a stirrer, stirring, controlling a head of a stirring paddle to approach the bottom of the pull vat, adding an aid, aperformance additive and mica powder in sequence during stirring, supplementing a proper amount of water, and continuously stirring; S2, adding glass beads into the pull vat, stirring, and increasingthe height of the paddle; putting floating beads, paste beads and horn meal into the pull vat in sequence, supplementing a proper amount of water, and stirring until a dry mass disappears; S3, lowering the head of the stirring paddle to approach the bottom of the pull vat, shoveling off materials remaining inside the pull vat, continuously stirring, supplementing a proper amount of water, stirring, supplementing a proper amount of water, and continuously cleaning an edge; S4, pulling the pull vat to be below a lifter, lifting, pouring into a packing bag, weighing, sealing, sewing a pack, andwarehousing after inspection.

Owner:长兴贝斯德邦建材科技有限公司

Bioactive filtering material for water treatment and baking technology thereof

InactiveCN1220543CHigh strengthHigh porositySustainable biological treatmentFiltration separationSulfonateFoaming agent

A biologically active filtering material for water treatment and its roasting process by using clay as the principal raw material for the biologically active filtering material, charging lignin sulfonate plasticizing agent and polyvinyl alcohol foaming agent, wherein the biological activity is achieved through roasting process and biological modification. The advantages of the invention are strong biological adhesion, high performance of film suspension, good current fluidized form, easy backwash and strong dirt-blocking capability.

Owner:SHANDONG UNIV +1

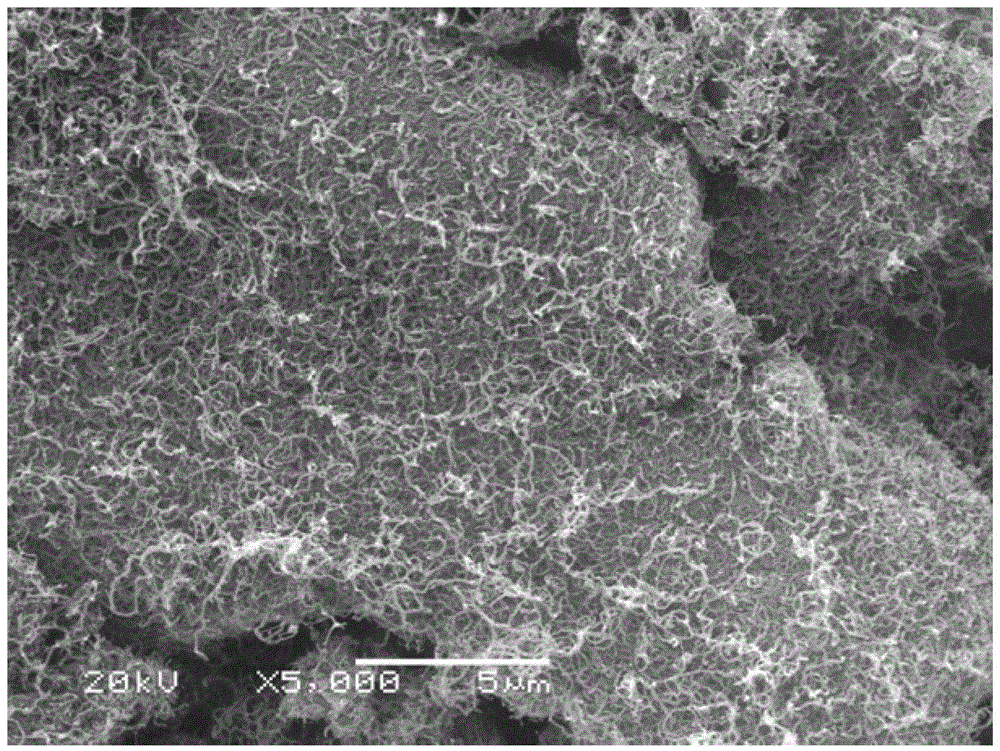

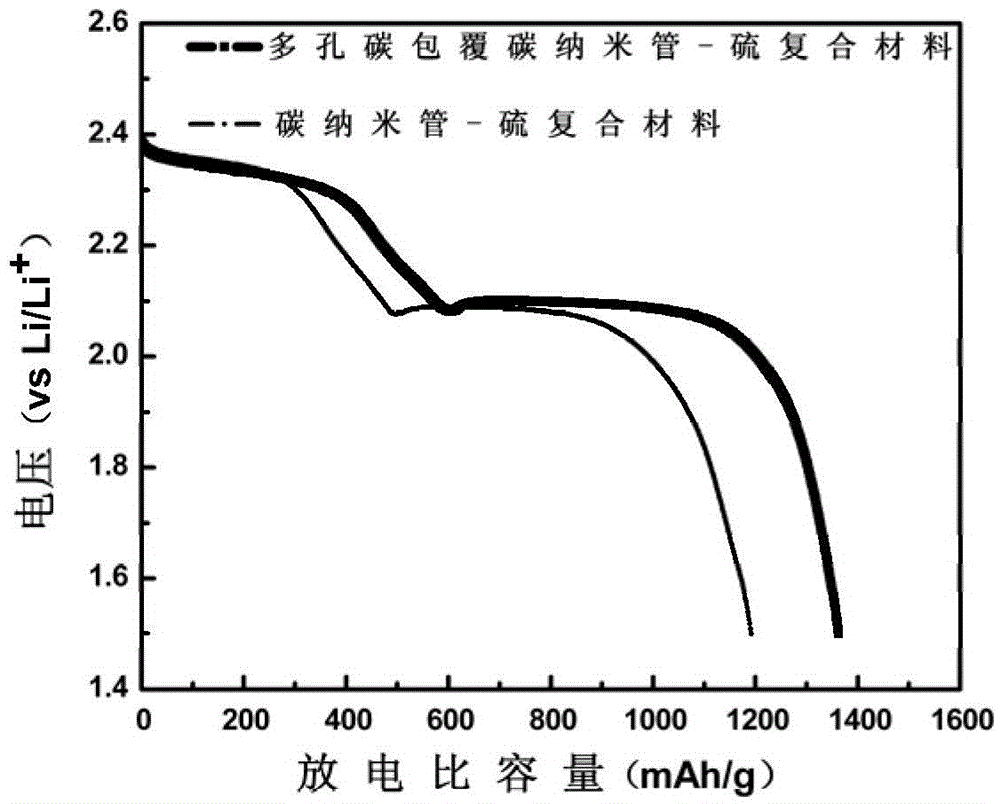

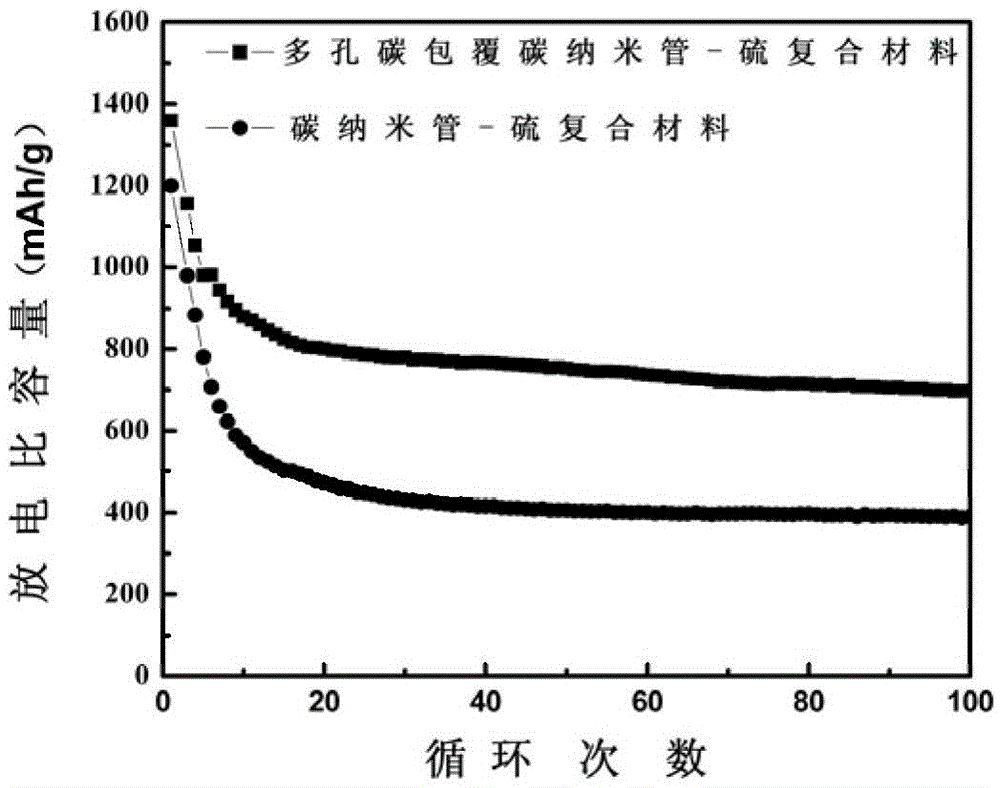

A sulfur/porous carbon-coated carbon nanotube composite positive electrode material for lithium-sulfur batteries and its preparation method

ActiveCN103500820BGood ion transmission abilityImprove conductivityMaterial nanotechnologyCell electrodesMicro nanoPorous carbon

The invention discloses a sulfur / porous carbon-coated carbon nano tube compound positive material for a lithium-sulfur battery and a preparation method thereof. The lithium-sulfur battery compound positive material is formed by compounding a carbon nano tube compound carbon material coated with porous carbon with a micro-nano structure and elemental sulfur. The preparation method comprises the following steps of: firstly coating poly-dopamine on the surface of a carbon nano tube; then carrying out high temperature carbonization, and compounding with the elemental sulfur to obtain the compound positive material. The preparation method disclosed by the invention has the advantages of easiness for operation and low cost. The prepared lithium-sulfur battery compound positive material is high in sulfur utilization ratio and greatly enhances the cycle property of the lithium-sulfur battery.

Owner:CENT SOUTH UNIV

Method and use of closed hydrophilic and lipophilic liquid-phase hollow capsules with cores

InactiveCN1285383CStable contrast-enhanced ultrasound interfaceDamage reliefEmulsion deliveryMicroballoon preparationLiquid crystallineOxygen

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com