Preparation method of carbon fiber-loaded mesoporous titania

A technology of mesoporous titanium dioxide and titanium dioxide, which is applied in the fields of carbon fiber, fiber treatment, textiles and papermaking, etc., can solve problems such as the influence of titanium dioxide microstructure, morphology and crystal form, small specific surface area, and performance impact of composite materials, etc. Achieve the effect of improving load strength, large specific surface area and controllable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

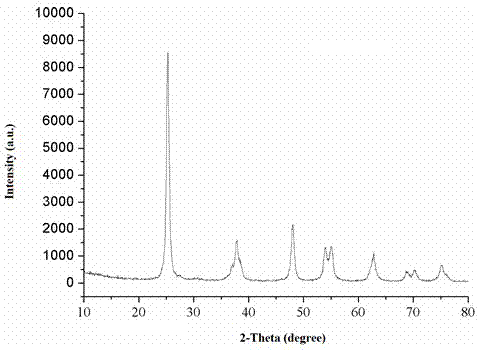

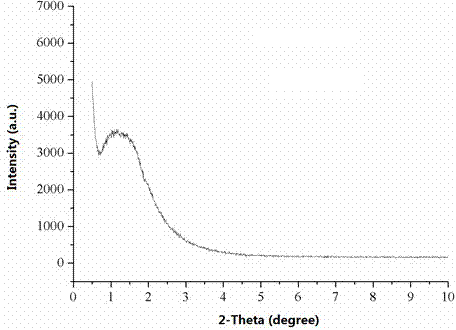

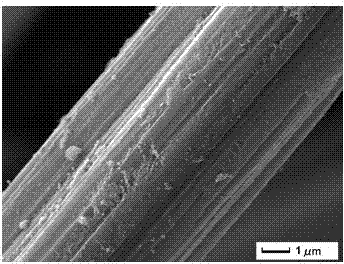

Embodiment 1

[0022] Make solution A with 3.4g tetrabutyl titanate, 0.58g P123 and 5ml absolute ethanol, then make solution B with 2.5ml absolute ethanol, 0.045ml deionized water and 0.098g concentrated hydrochloric acid. Solution B was slowly added to solution A, and continued to stir for 1 hour to obtain a light yellow transparent sol; the activated carbon fiber was immersed in the sol, and after standing for 0.5 hour, it was pulled, and the carbon fiber was taken out and placed in the air to slowly gel; then the loaded The carbon fiber with gel was dried in an oven, treated at 50°C for 24 hours, and then continued at 120°C for 6 hours; the dried sample was placed in a tube furnace and heat-treated at 350°C for 5 hours to obtain a surface Carbon fibers loaded with mesoporous titania.

Embodiment 2

[0024] Make solution A with 3.4g tetrabutyl titanate, 1.16g P123 and 8ml absolute ethanol, then make solution B with 4ml absolute ethanol, 0.09ml deionized water and 0.5g concentrated hydrochloric acid. The solution was slowly added to solution A, and continued to stir for 1.5 hours to obtain a light yellow transparent sol; the activated carbon fiber was immersed in the sol, and after standing for 1 hour, it was pulled, and the carbon fiber was taken out and placed in the air to slowly gel; then the loaded The gelled carbon fibers were dried in an oven, treated at 70°C for 20 hours, and then continued at 120°C for 12 hours; the dried samples were placed in a tube furnace and heat-treated at 400°C for 3 hours to obtain the surface-loaded medium. Porous titanium dioxide carbon fiber.

Embodiment 3

[0026] Make solution A with 3.4g tetrabutyl titanate, 2.32g P123 and 16ml absolute ethanol, then make solution B with 8ml absolute ethanol, 1.8ml deionized water and 0.98g concentrated hydrochloric acid. The solution was slowly added to liquid A, and continued to stir for 3.5 hours to obtain a light yellow transparent sol; the activated carbon fibers were immersed in the sol, stood for 1.5 hours and then pulled, and the carbon fibers were taken out and placed in the air to slowly gel; then the loaded The carbon fiber with gel is dried in an oven, treated at 100°C for 6h, and then continued at 120°C for 24h; the dried sample is placed in a tube furnace and heat-treated at 500°C for 2h to obtain the surface load. Carbon fibers of mesoporous titania.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com