Weft knitting cloth and production method thereof

A fabric and weft knitting technology, used in weft knitting, textiles, papermaking, knitting, etc., can solve problems such as loss of physical and chemical properties, impact on service life, yarn breakage, etc., to increase functionality, improve service life, and maintain softness sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: A reflective weft-knitted fabric

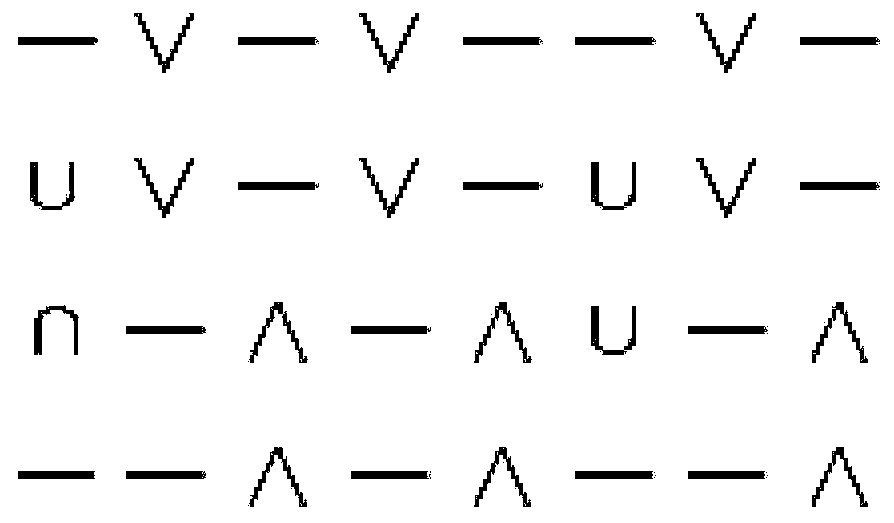

[0049] The weft-knitted fabric includes 1 fabric unit, which is obtained by circular weaving of 8 stitches of a weft-knitting double-sided machine; the dial needles and cylinder needles of the weft-knitting double-sided machine adopt a 12-needle arrangement, and the triangular configuration diagram of the fabric unit Such as figure 1 shown.

[0050] Among them, the 1st and 6th roads are woven with nylon, and the rest of the roads are woven with spandex and polyester.

[0051] Among them, the 1-3 road forms the first separating net, and the 1st road connects with the 2nd road to form the upper surface coil and the 3rd road to form the lower surface coil; the fabric structure of the 1-3 road weaving includes the upper and lower surfaces and The three-layer structure of the middle layer.

[0052] Routes 4 and 5 respectively form the upper and lower surfaces of the hollow channel. Because of the separation net structure on b...

Embodiment 2

[0056] Embodiment 2: A kind of reflective weft-knitted fabric

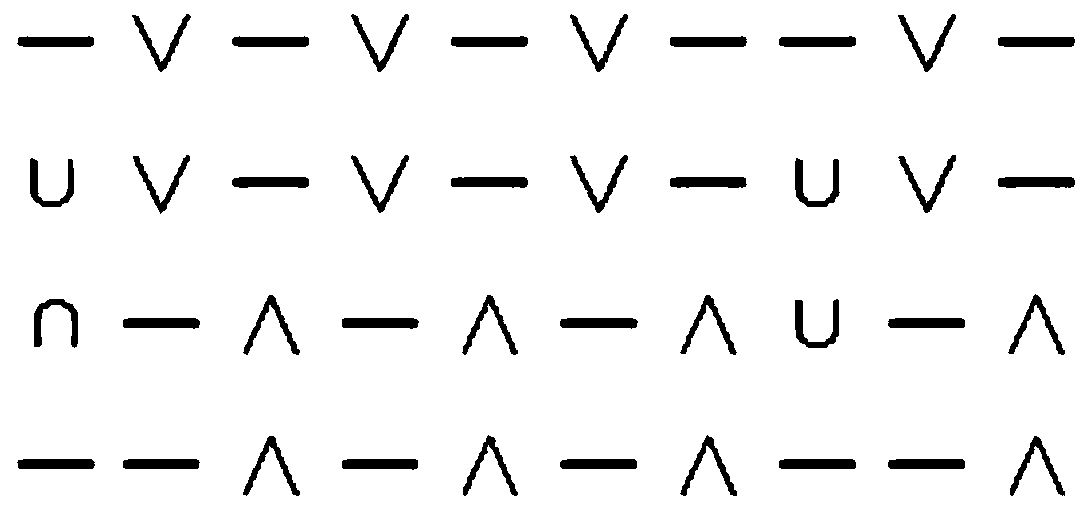

[0057] The weft-knitted fabric is obtained by weaving 10 stitches on a weft-knitting double-sided machine; the dial needle and the cylinder needle adopt a 12-needle arrangement, and the triangle configuration diagram is as follows figure 2 shown.

[0058] Among them, the 1st and 8th routes are woven with nylon, and the rest of the routes are woven with spandex and polyester.

[0059] Among them, the 1-3 road forms the first separating net, and the 1st road connects with the 2nd road to form the upper surface coil and the 3rd road to form the lower surface coil; the fabric structure of the 1-3 road weaving includes the upper and lower surfaces and The three-layer structure of the middle layer.

[0060] Routes 4, 5, 6 and 7 respectively form the upper and lower surfaces of the hollow channel, forming two hollow units. Because in the separating net structure on both sides, there is yarn interlocking in the middle...

Embodiment 3

[0064] Embodiment 3 A kind of antibacterial weft knitted fabric

[0065] The weft-knitted fabric is woven with 10 stitches on a weft-knitting double-sided machine; the dial needle and cylinder needle adopt a 12-needle arrangement, and the triangle configuration diagram is as follows Figure 11 shown.

[0066] Among them, the 1st and 8th routes are woven with nylon, and the rest of the routes are woven with spandex and polyester.

[0067] Among them, the 1-3 road forms the first separating net, and the 1st road connects with the 2nd road to form the upper surface coil and the 3rd road to form the lower surface coil; the fabric structure of the 1-3 road weaving includes the upper and lower surfaces and The three-layer structure of the middle layer.

[0068] Routes 4, 5, 6 and 7 respectively form the upper and lower surfaces of the hollow channel, forming two hollow units. Because in the separating net structure on both sides, there is yarn interlocking in the middle (filled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com