Conductive geomembrane and preparation method thereof

A geomembrane and conductive layer technology, applied in chemical instruments and methods, sea area engineering, water conservancy engineering, etc., can solve the problems of anti-seepage, negative impact of waterproof effect, consuming a lot of manpower and material resources, pollution, etc., to save testing costs and time, prevent electric shock accidents, and ensure personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

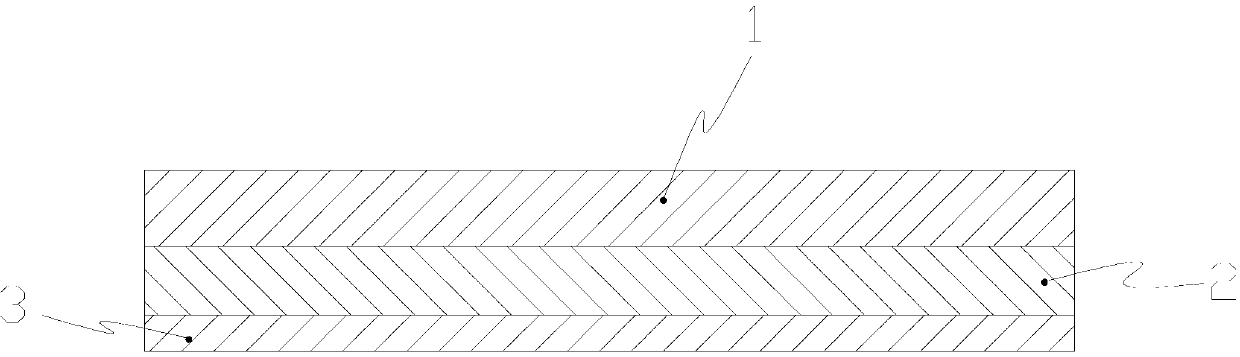

[0015] combine figure 1 , a conductive geomembrane, composed of a first anti-seepage layer 1, a second anti-seepage layer 2 and a conductive layer 3 arranged in sequence, the first anti-seepage layer, the second anti-seepage layer and the conductive layer are combined together; in In the state of use, the first anti-seepage layer, the second anti-seepage layer and the conductive layer are respectively used as the uppermost layer (upper surface layer), middle layer and lowermost layer (lower surface layer) of the geomembrane. The thickness of the first anti-seepage layer is 0.1-0.5 mm, the thickness of the second anti-seepage layer is 0.4-2.0 mm, and the thickness of the conductive layer is 0.01-0.05 mm. Both the above-mentioned first anti-seepage layer and the second anti-seepage layer are made of high-density polyethylene, and the conductive layer is made of high-density polyethylene containing conductive carbon black. The resistance value of the above-mentioned conductive l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com