A method for interconnecting lead wires in metal shells

A metal shell and metal technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve reliability problems and other problems, and achieve the effects of high reliability, no external current damage, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention provides a method for interconnecting lead wires in a metal shell, comprising:

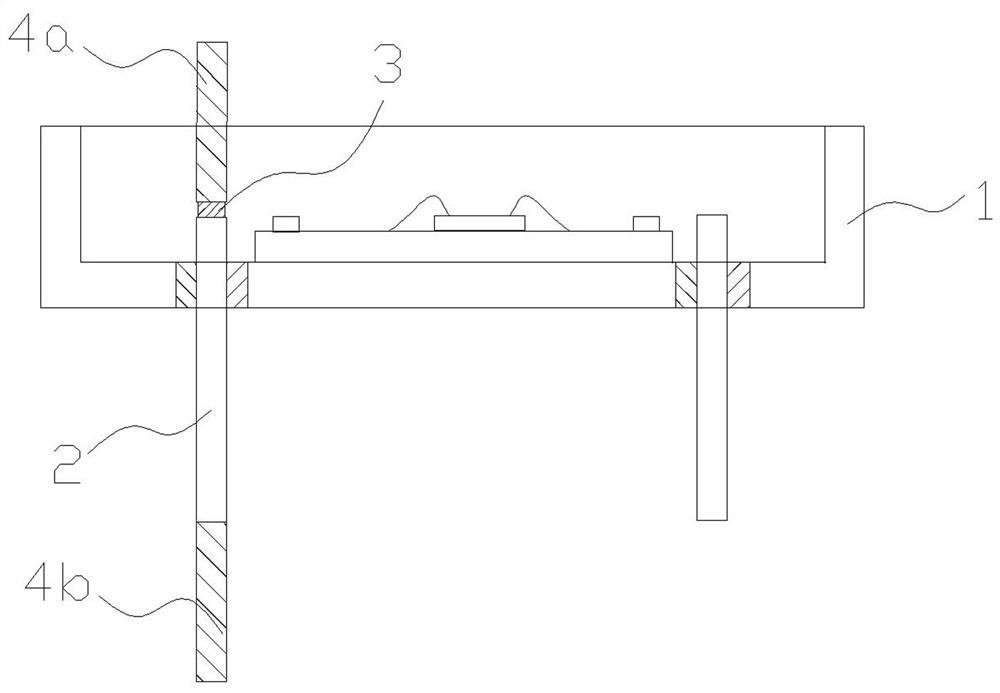

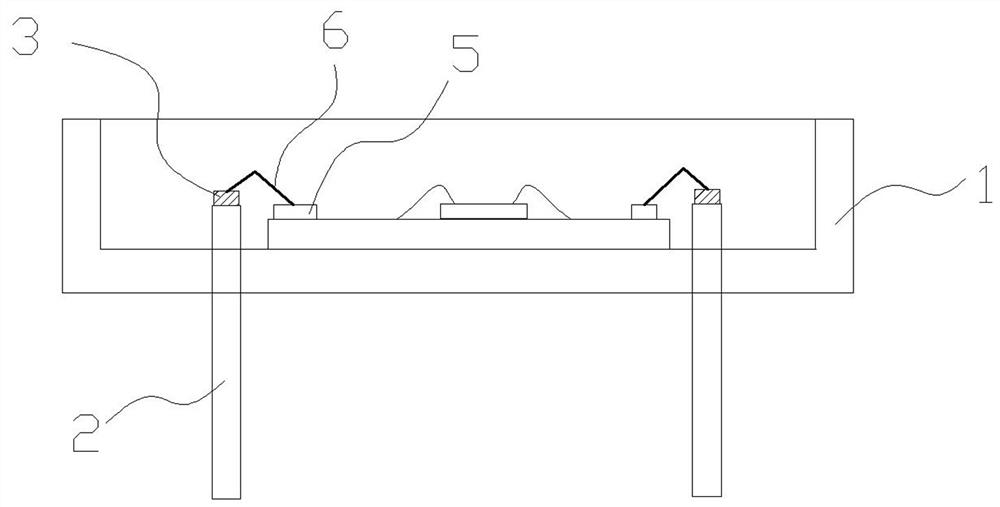

[0020] a. If figure 1 As shown, through the spot welding process, the metal transition pad 3 is assembled on the end surface of the lead post 2 of the metal shell 1;

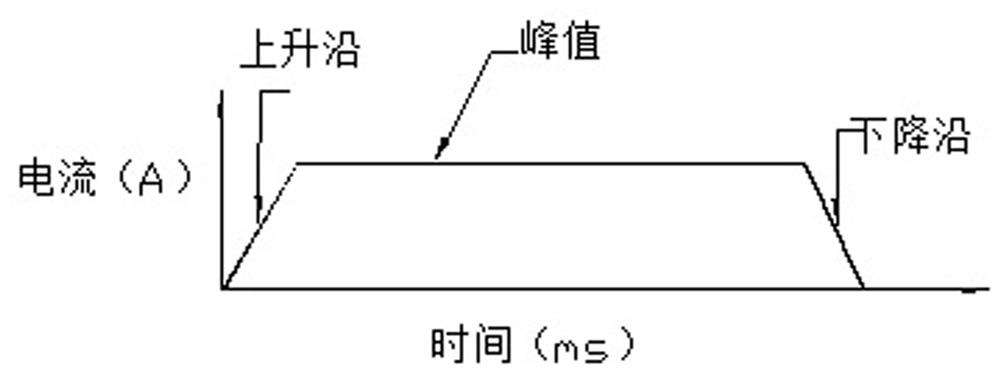

[0021] Micro-gap parallel spot welding or butt welding can be used for spot welding. The spot welding equipment is M3-20 DC spot welding device; the welding process can be decomposed into three steps. The gap parallel spot welding head is directly above the welding point; secondly, the micro-gap parallel spot welding head contacts and applies a certain pressure on the surface of the wire to be welded, and the spot welding equipment outputs a specific current to both the parallel positive electrode 4a and the parallel negative electrode 4b as required At the end, a strong current flows through the welding area, and the electric energy is converted into heat energy, which instantly forms a metal nugget at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com