Shuttle-type connecting clamp for zero-force electric wire

A technology for power wires and connecting clips, which is applied in the direction of conductive connection, electrical component connection, connection, etc., can solve the problems of large contact resistance of parallel grooved wire clips, many disconnection accidents, and rapid electrical erosion damage, and achieves low connection resistance. , Easy installation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

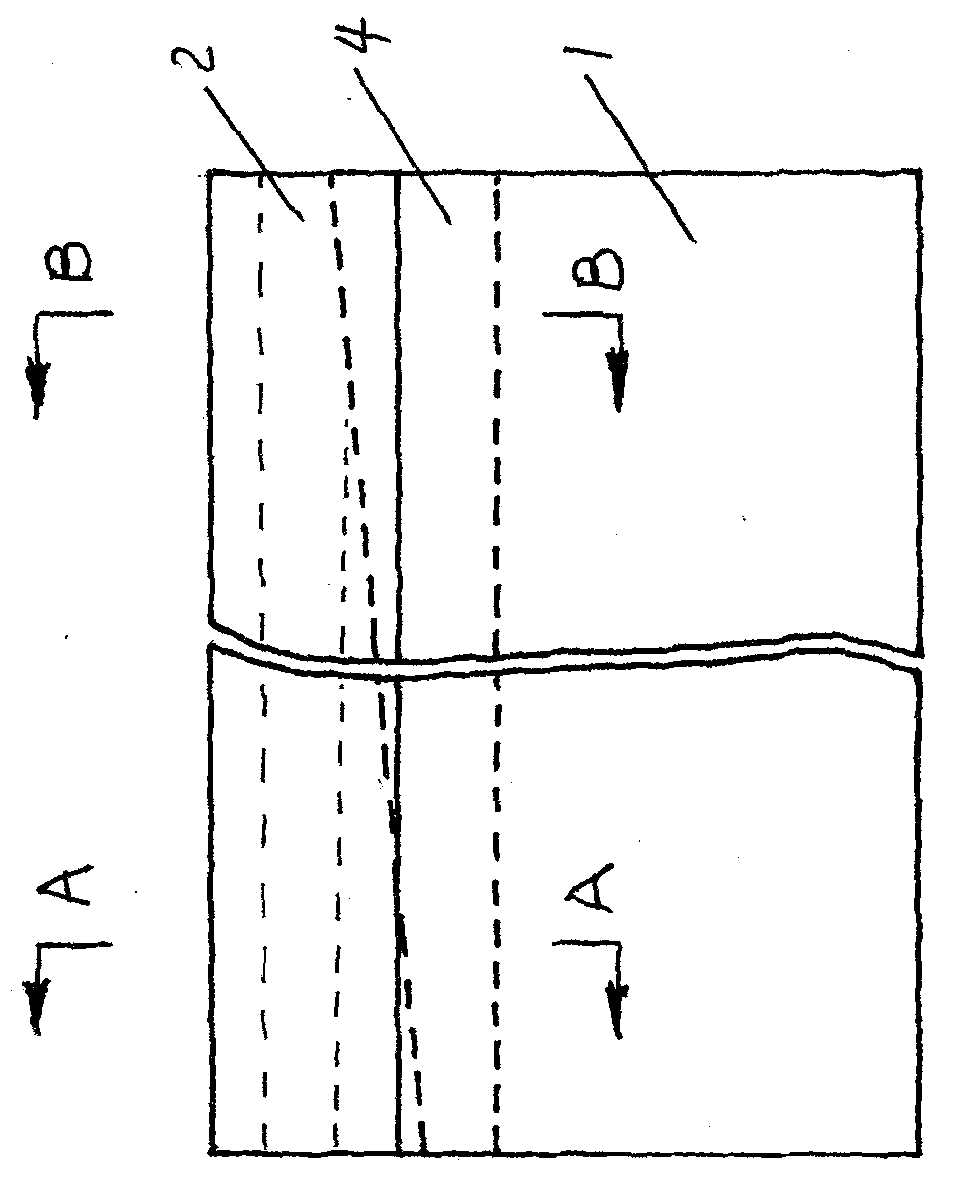

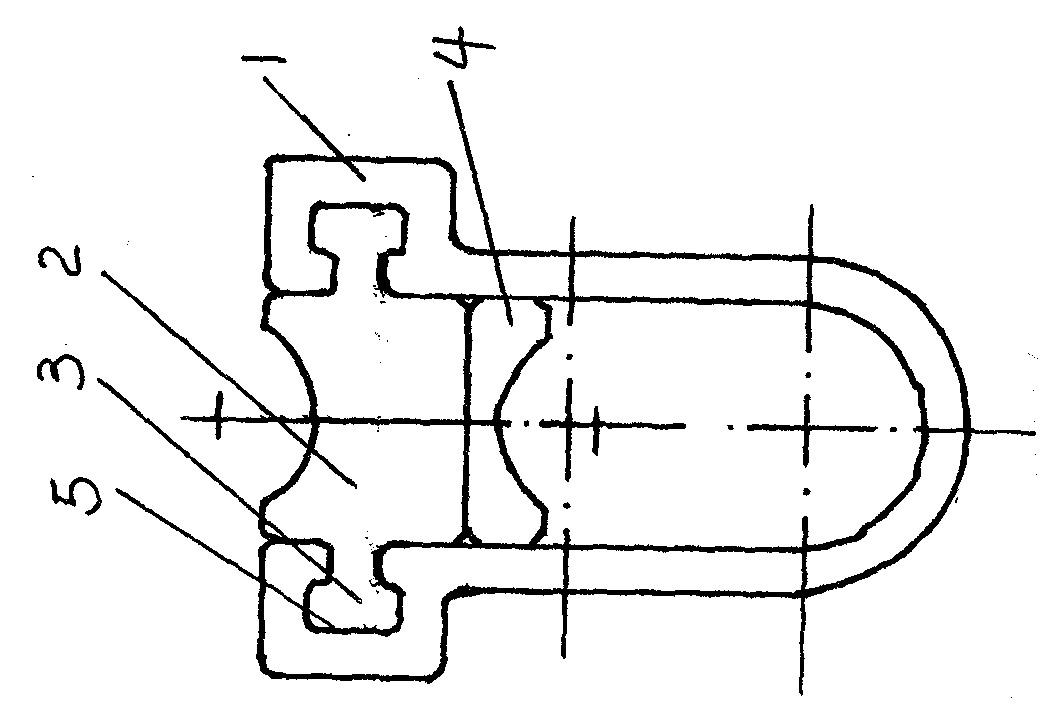

[0027] Figures 1 to 5 As shown: the shuttle-shaped connecting wire clamp for power wires without force, the wire clamp body 1 is a long wire clamp body with a "U" shape in cross section, and the left and right sides of the "U" shape on the upper mouth of the wire clamp body 1 The side clamp body is symmetrically provided with longitudinal concave groove 5, the opening of the concave groove 5 is in the cavity inside the "U"-shaped clamp body 1, the cross section of the concave groove 5 is ear-shaped, and the wire clamp body The upper opening of 1 is provided with a wedge-shaped connection insert 2 inserted longitudinally into the "U"-shaped wire clip body, and the inserts on the left and right sides of the wedge-shaped connection insert 2 are symmetrically provided with longitudinal convex ribs 3, convex ribs 3 and concave Corresponding to the groove 5, the convex rib 3 is inserted into the concave groove 5 and the cross section of the convex rib 3 matches the cross section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com