A groove for exhausting smoke and covering pipelines

A technology for pipelines and troughs, applied in vertical pipelines, buildings, building components, etc., can solve problems such as through cracks at joints, difficult to change to house use, difficult to mechanize, etc., to achieve safe connection and easy installation and guidance Valve, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

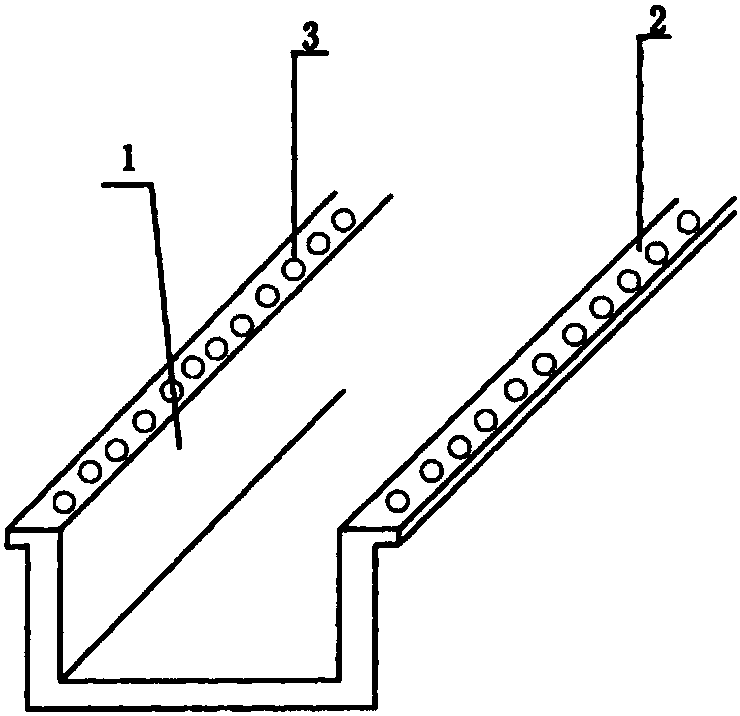

[0026] Such as figure 1 As shown, this type of groove is composed of a groove body A1 and an inlay edge 2. The groove body A1 is a cylindrical body or a table-shaped body with two opposite sides that are not connected but connected at both ends. The inlay edge 2 is formed on the opposite sides of the groove body A1. The outwardly extending edge designed at the outer corner of the edge; the inlaid edge 2 is provided with several through holes A3. The inlay edge 2 is designed to have the same thickness from inside to outside.

example 2

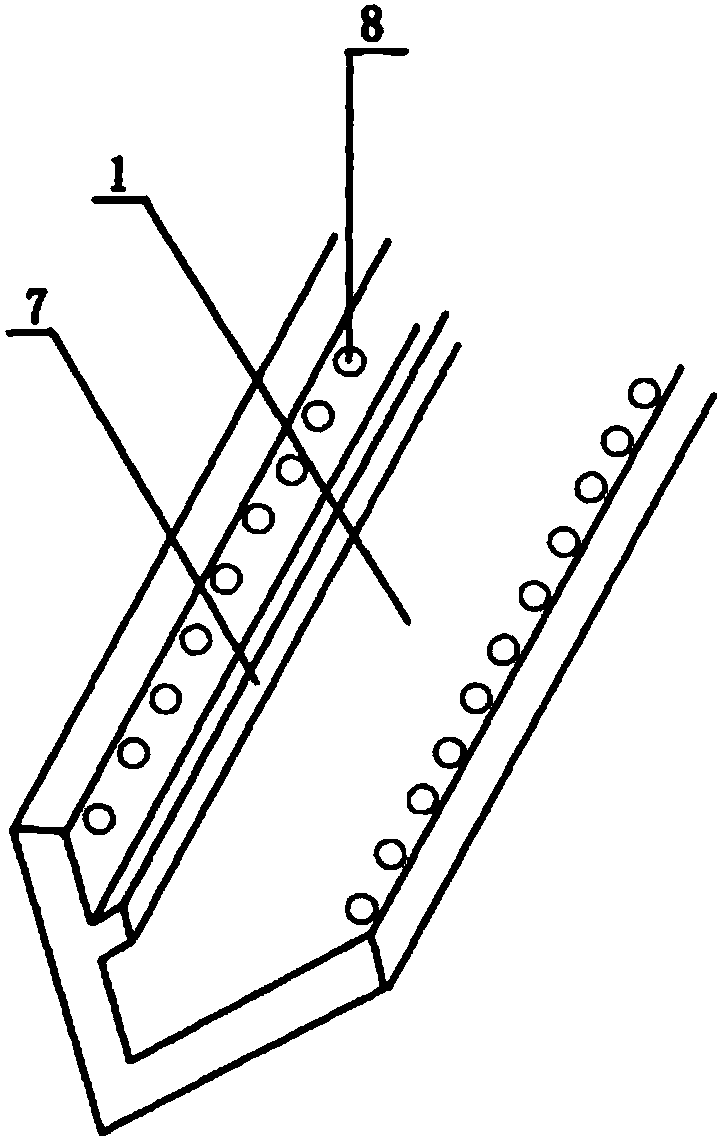

[0028] Such as figure 2 As shown, the type groove is only composed of the groove body A1, and several through holes B8 are arranged at the edge of the groove body A1. A reinforcing rib B7 parallel to the axial direction of the tank A1 is provided on the inner wall or the outer wall of the tank A1 .

example 3

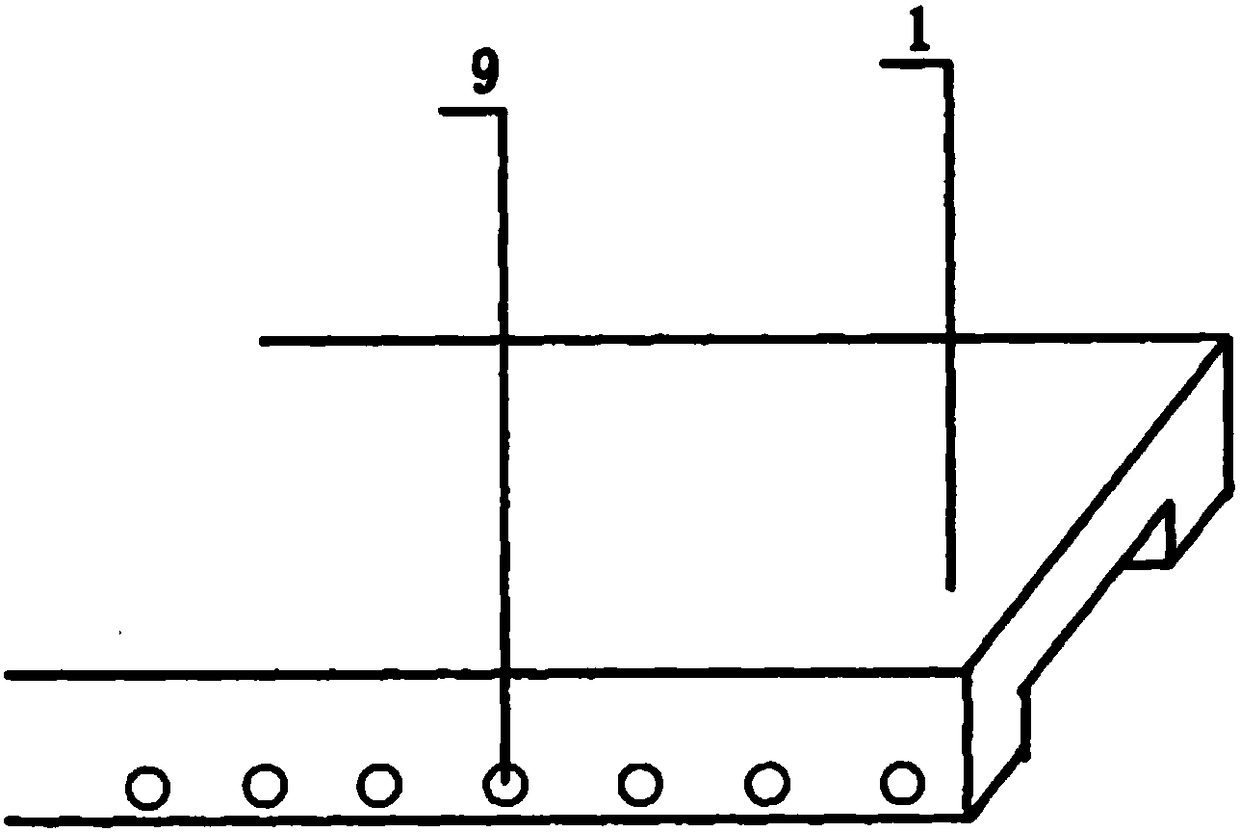

[0030] Such as image 3 As shown, several holes B9 are provided at the edge of the tank A1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com