Patents

Literature

2056 results about "Super absorbent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Absorbent structures comprising coated super-absorbent polymer particles

ActiveUS7108916B2Synthetic resin layered productsCellulosic plastic layered productsParticulatesSuper absorbent

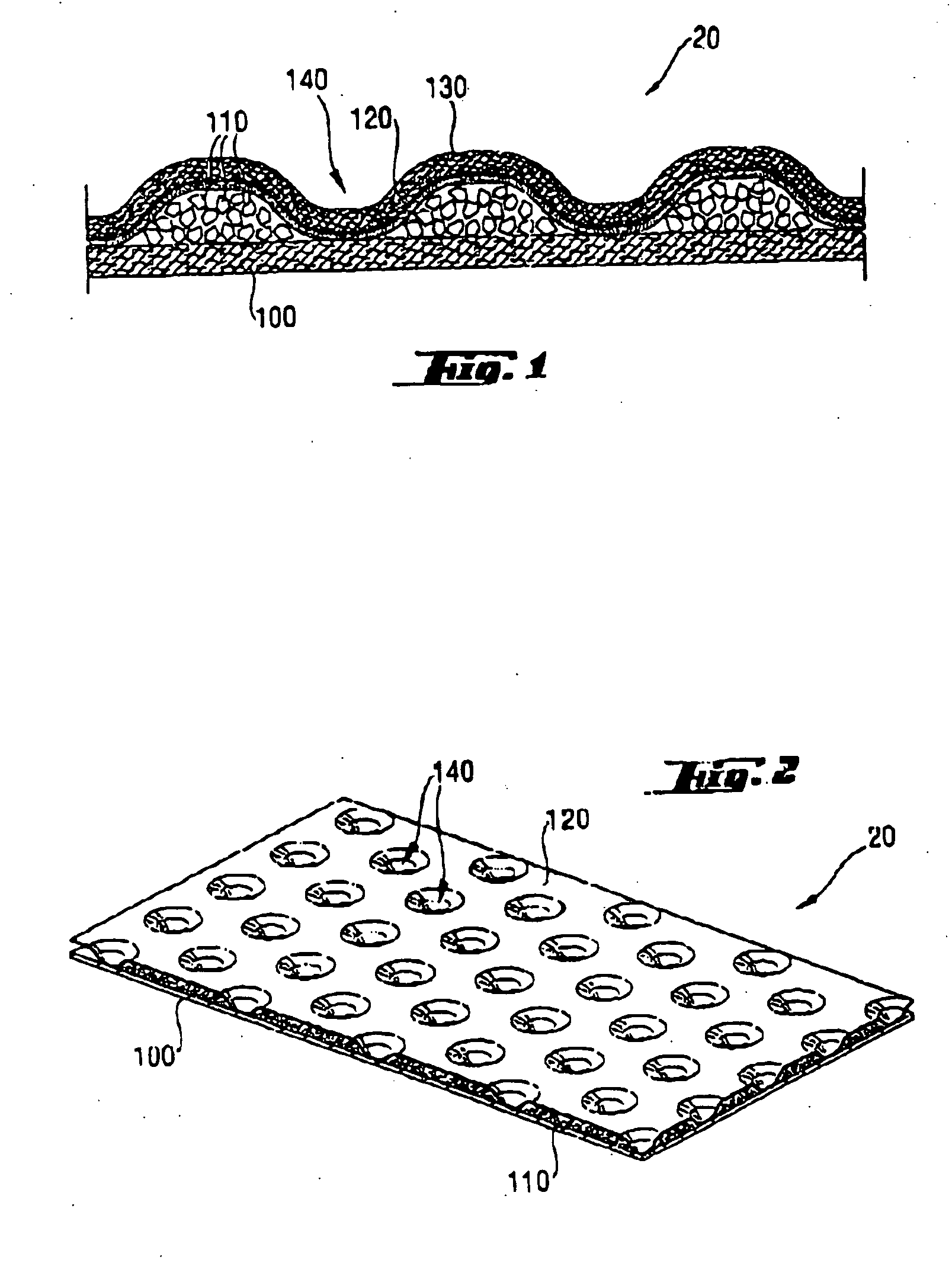

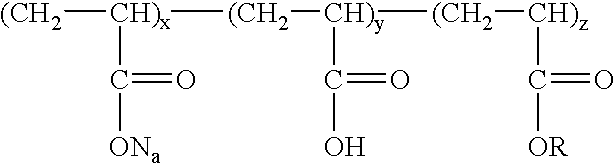

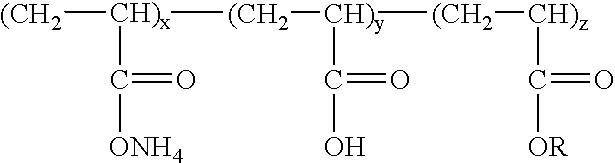

This invention is directed to super-absorbent material, which comprises a super absorbent polymer core that is coated with an organic, polar coating agent, and whereby the particulate super-absorbent material has a contact angle and a corresponding cos CAm (as defined herein), whereby the cos CAm is more than 0.3, and whereby, when said coating agent is in the form of particles, said coating agent particles have a (weight) mean particle size of from 0.001 to 1 micron. The material is useful for absorbent structures and absorbent articles (comprising such structures). The coated super-absorbent material is typically present in said absorbent structure at least at a concentration of 50% by weight of the structure, preferably even 80% or even 90%. The invention also provides a process for making the absorbent material.

Owner:THE PROCTER & GAMBLE COMPANY

Absorbent structures comprising coated super-absorbent polymer particles

This invention is directed to super-absorbent material, which comprises a super absorbent polymer core that is coated with an organic, polar coating agent, and whereby the particulate super-absorbent material has a contact angle and a corresponding cos CAm (as defined herein), whereby the cos CAm is more than 0.3, and whereby, when said coating agent is in the form of particles, said coating agent particles have a (weight) mean particle size of from 0.001 to 1 micron. The material is useful for absorbent structures and absorbent articles (comprising such structures). The coated super-absorbent material is typically present in said absorbent structure at least at a concentration of 50% by weight of the structure, preferably even 80% or even 90%. The invention also provides a process for making the absorbent material.

Owner:THE PROCTER & GAMBLE COMPANY

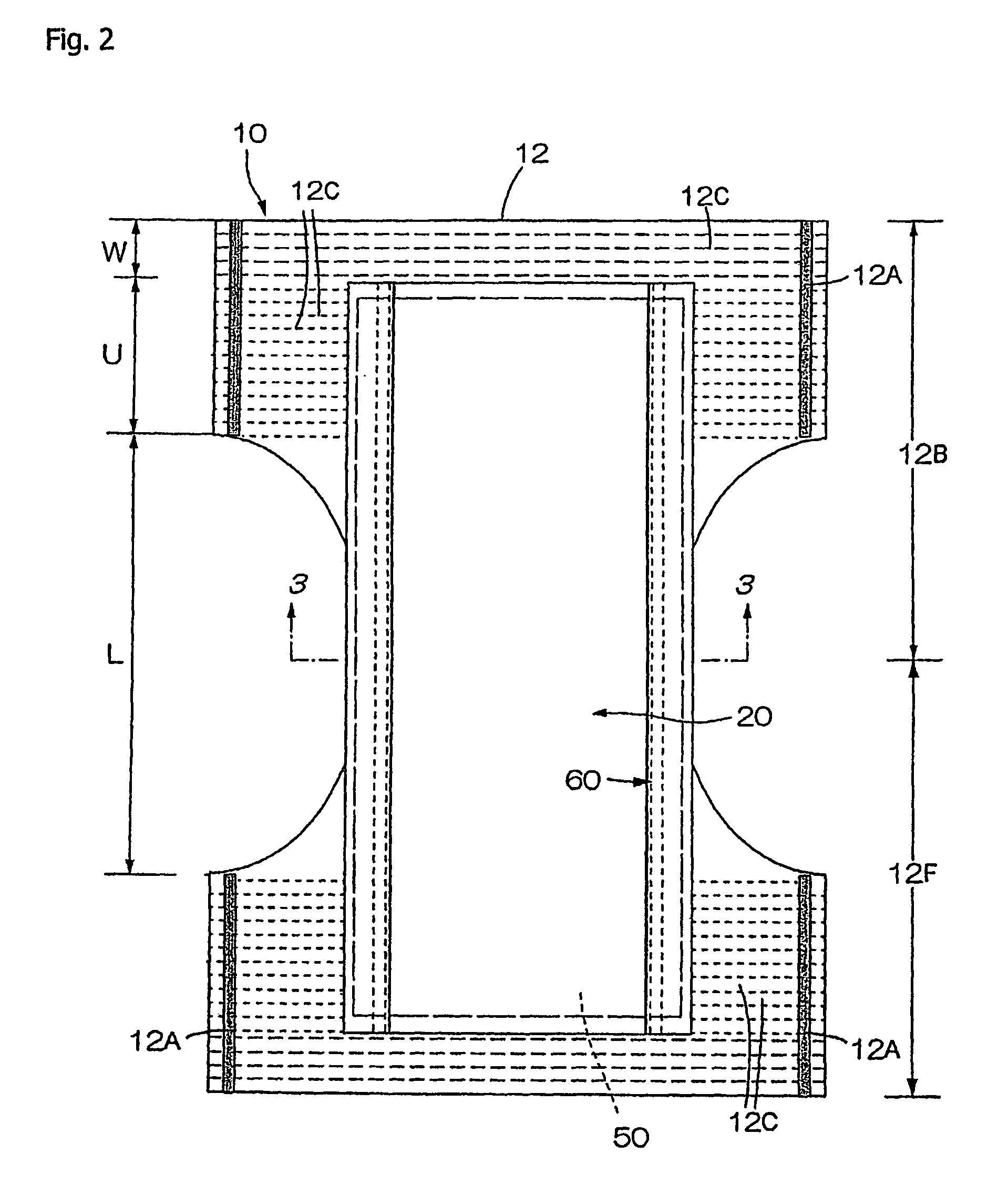

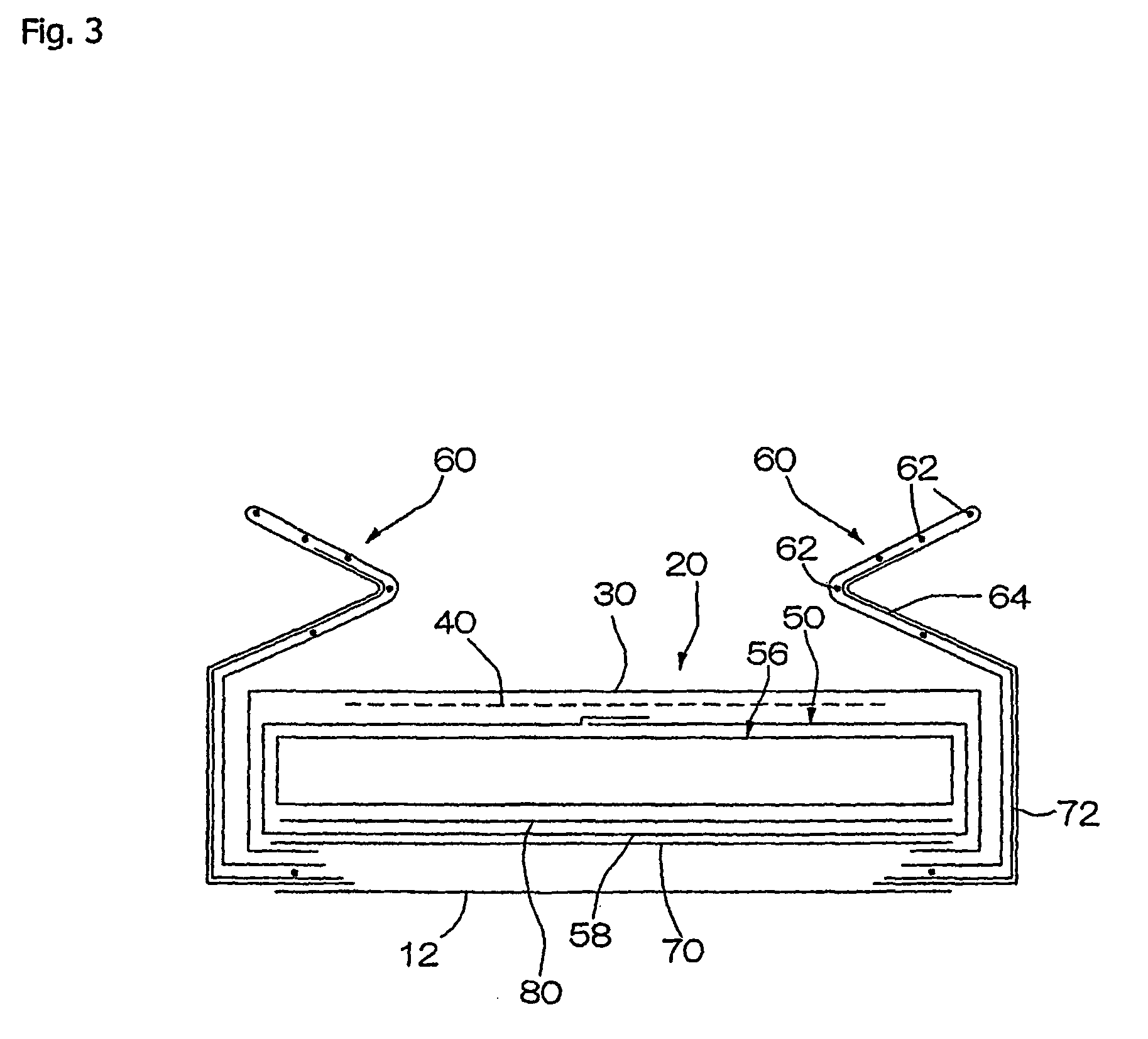

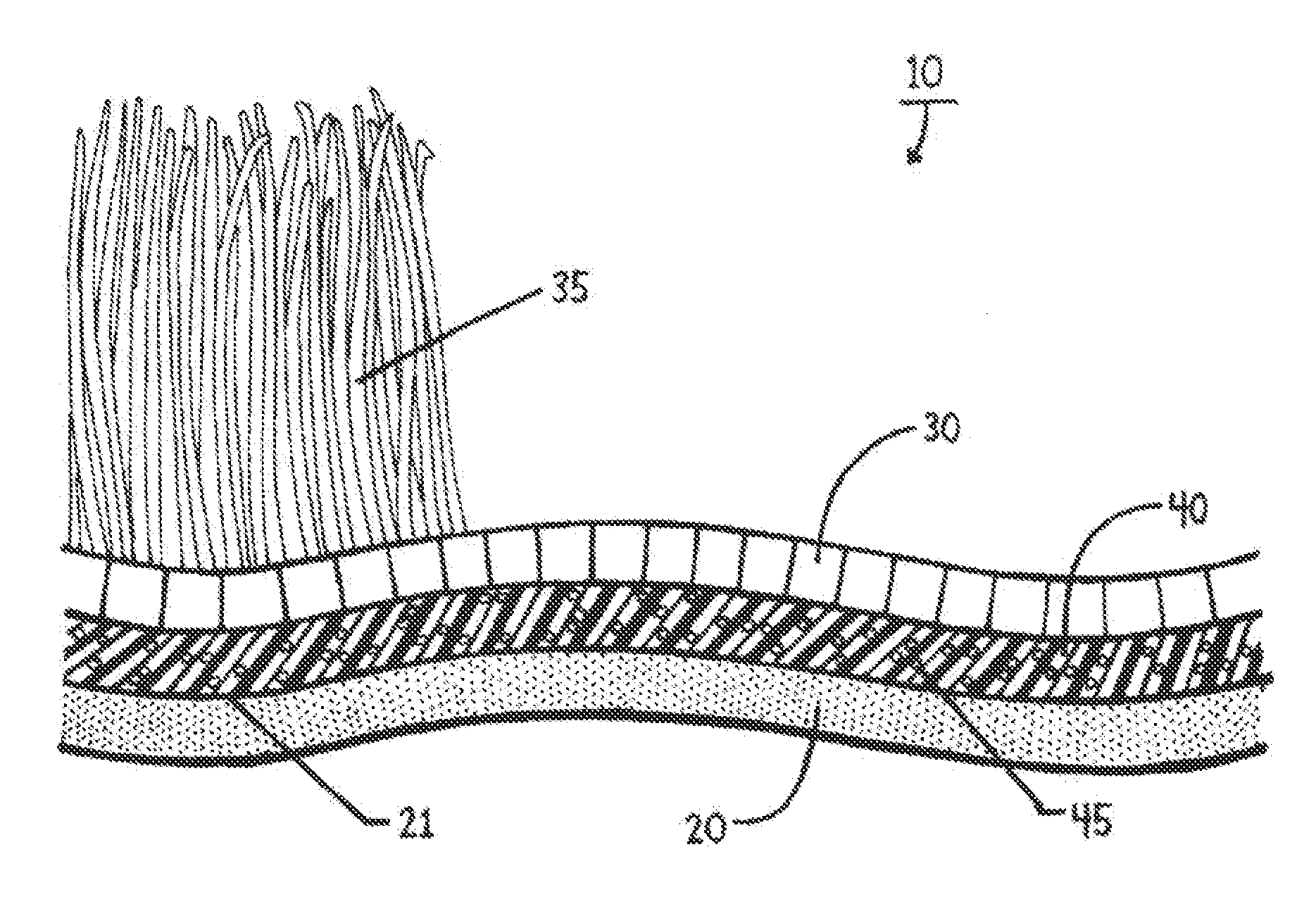

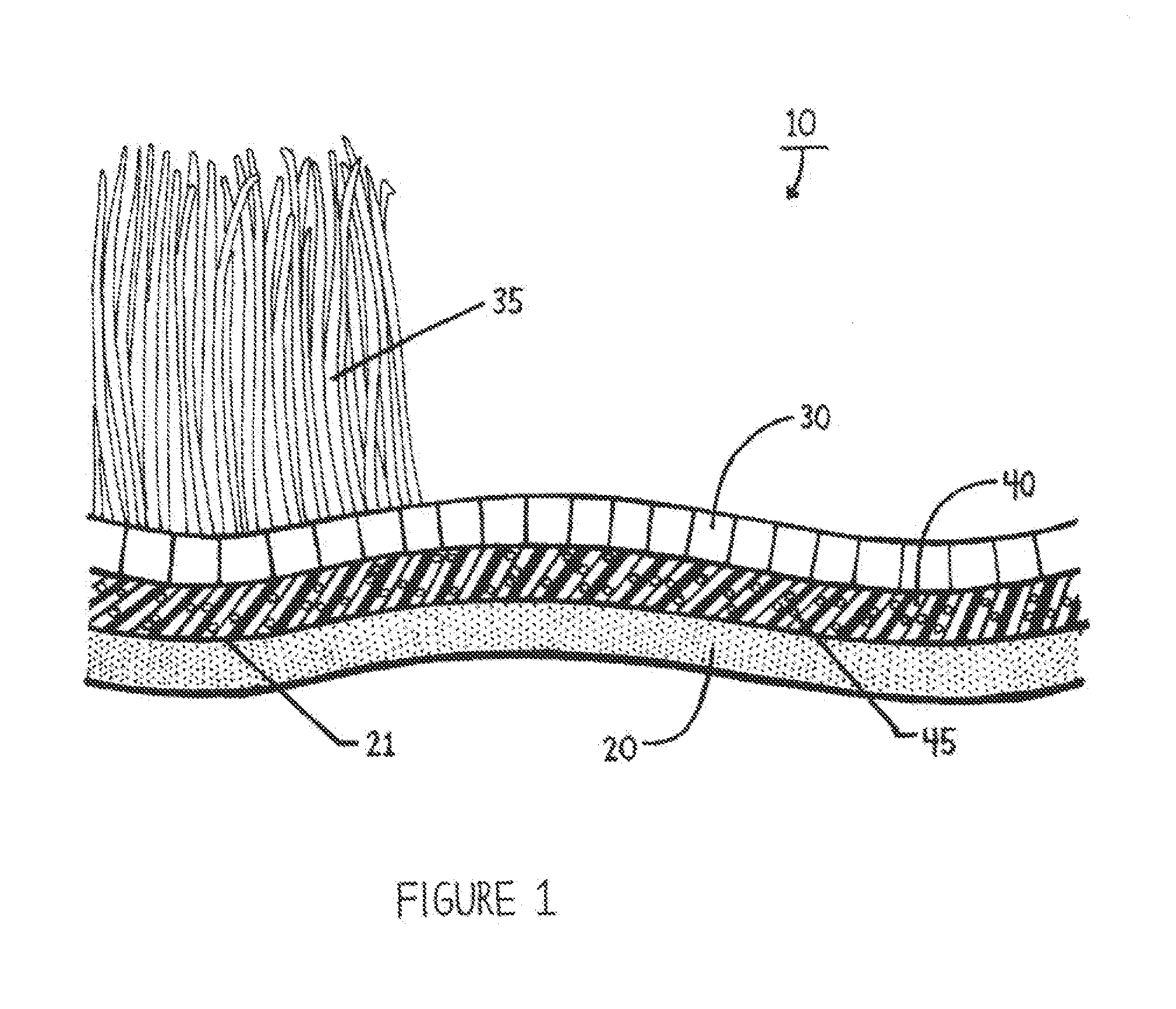

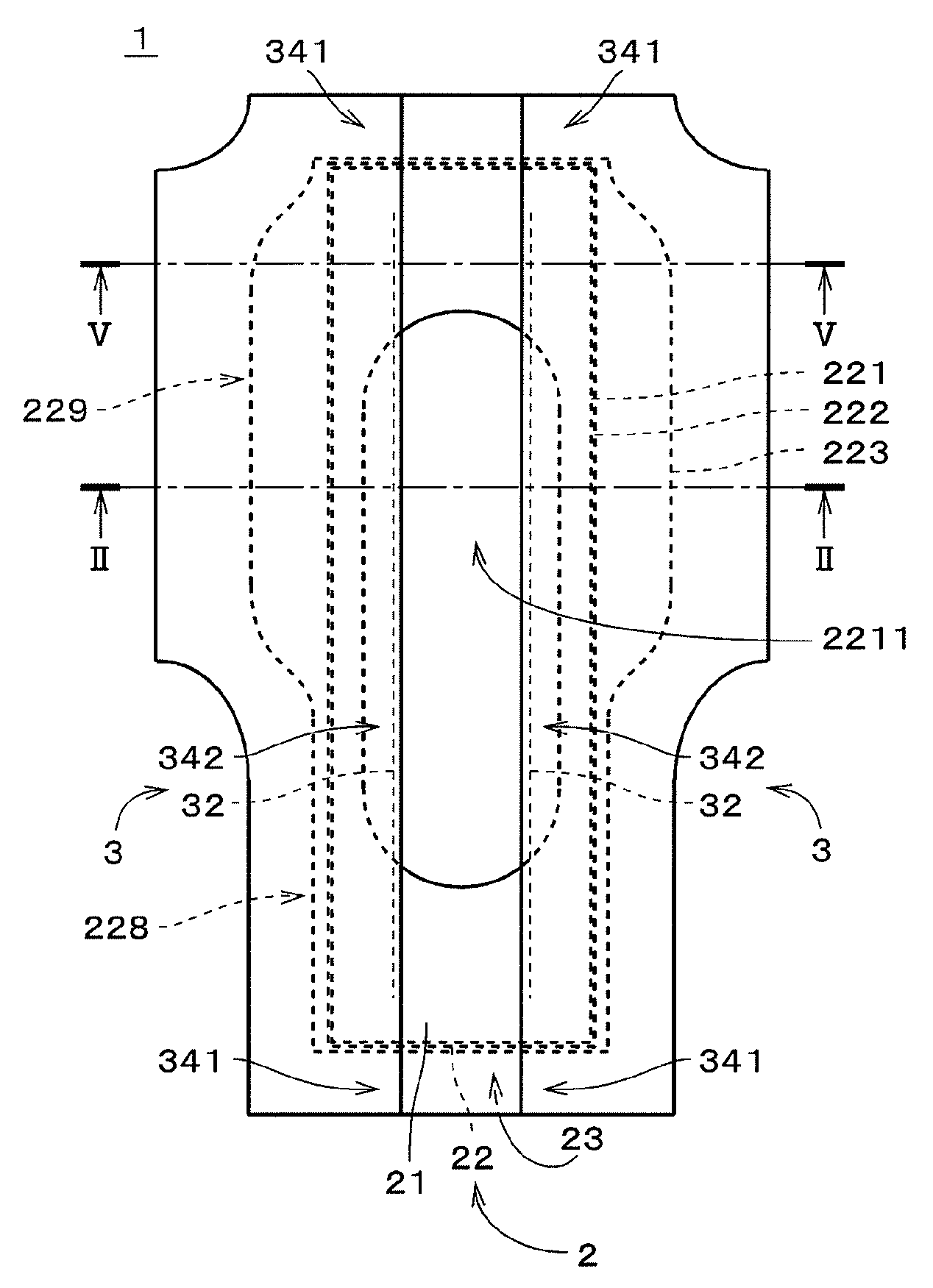

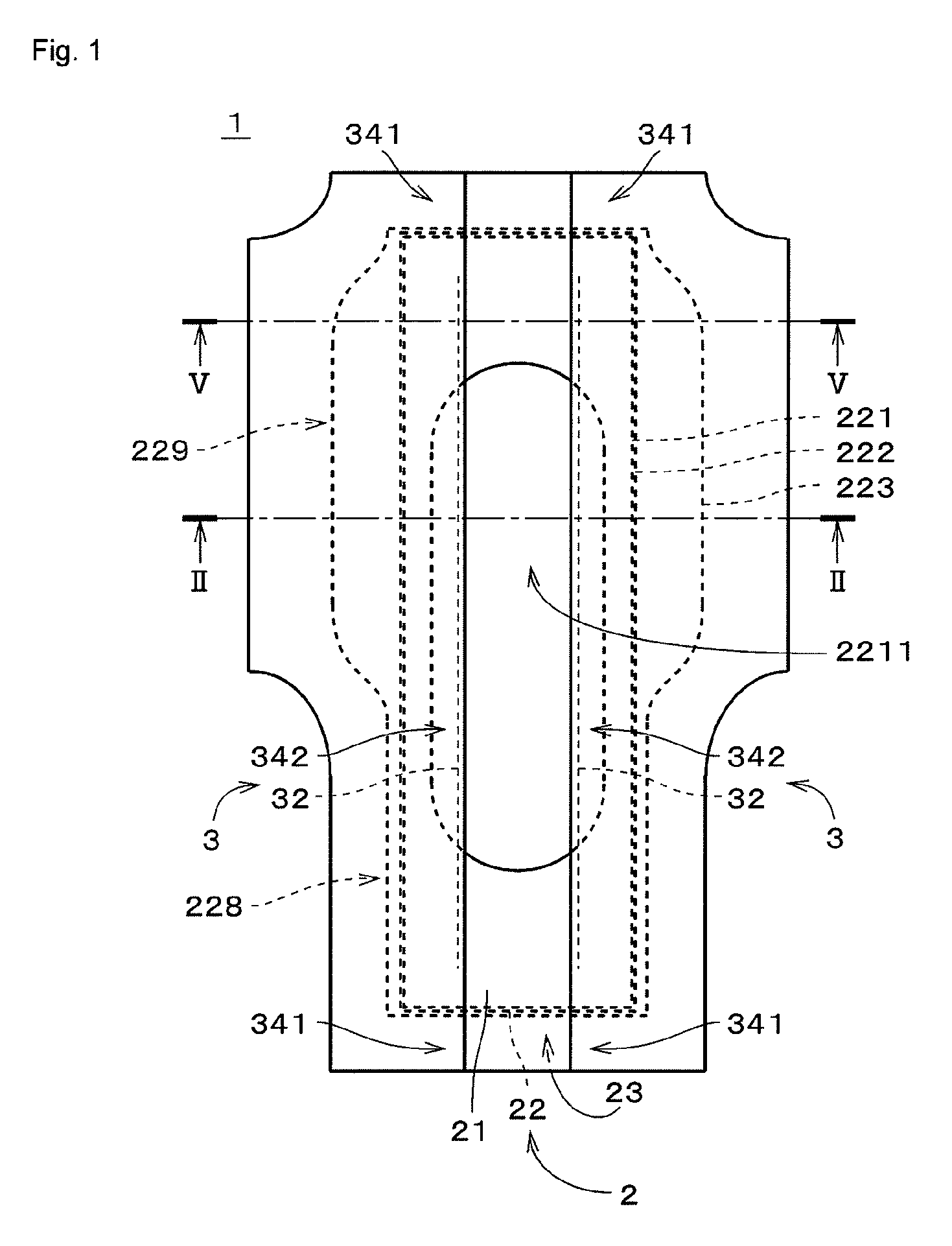

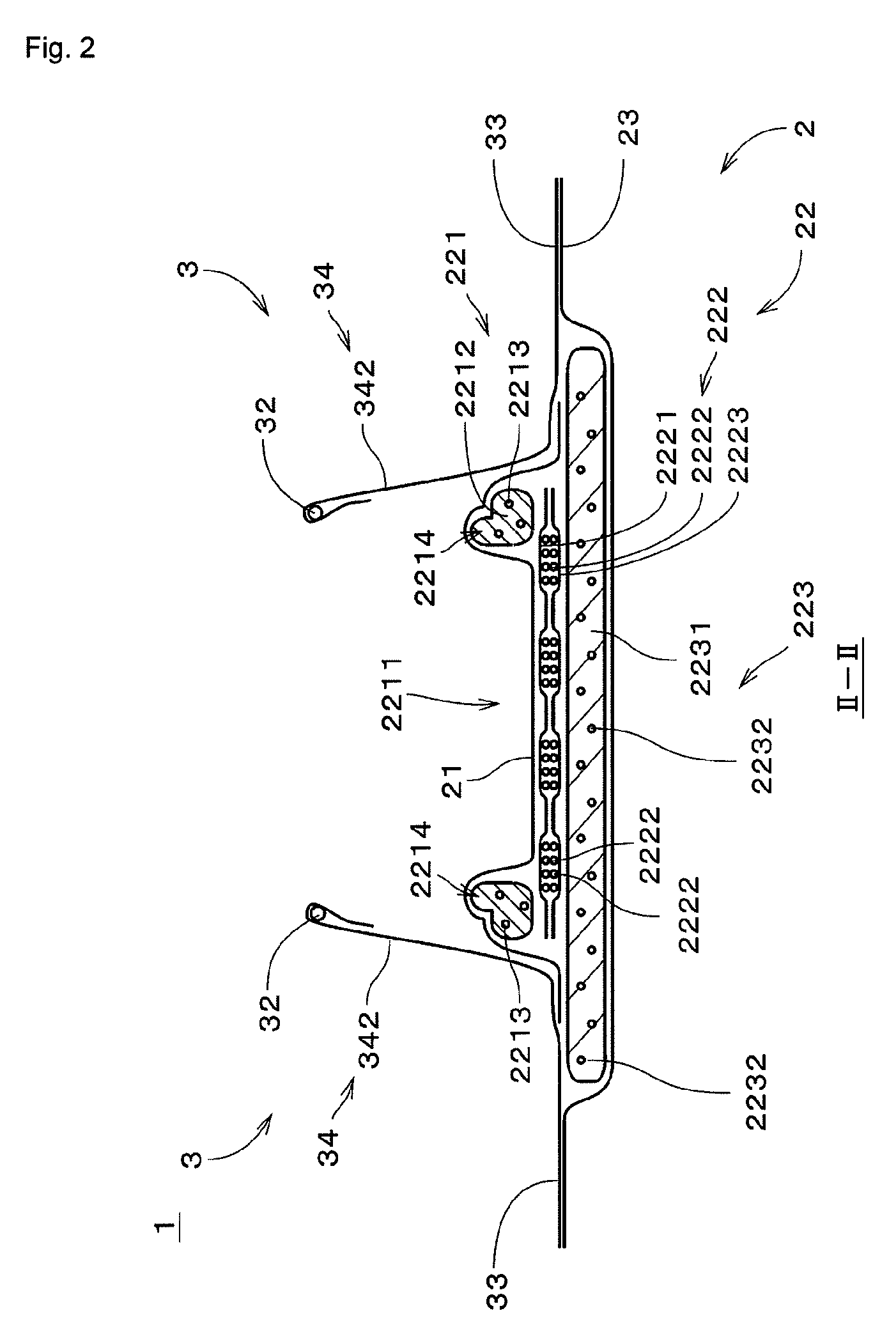

Manufacturing facility of absorbent body, absorbent body and absorbent article

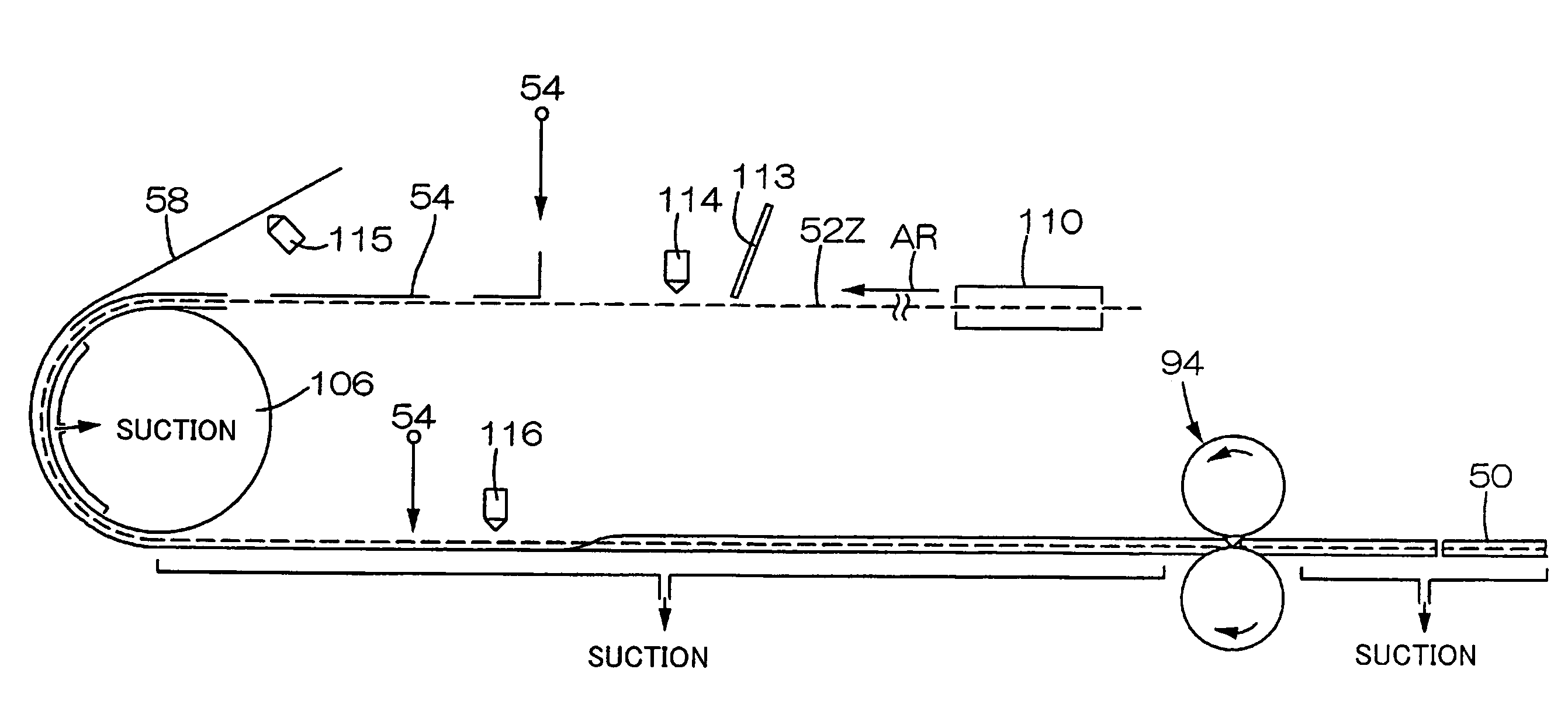

ActiveUS7717150B2Prevent characteristicsDifficult to moveLamination ancillary operationsManual label dispensersFiber bundleSuper absorbent

A shuffling hand feeling and unwanted non-uniform absorption characteristics in the case of using a tow (fiber bundle) are prevented.An absorbent body includes a fiber aggregate 21 formed by opening the tow, a super absorbent polymer 54, and a sheet covering these components; and includesthe super absorbent polymer 54 bonded to the sheet 58 with an adhesive that is applied in a continuous plane to the entire surface or the substantially entire surface of at least the portion to be provided with the super absorbent polymer 54 in this sheet 58.

Owner:DAIO PAPER CORP

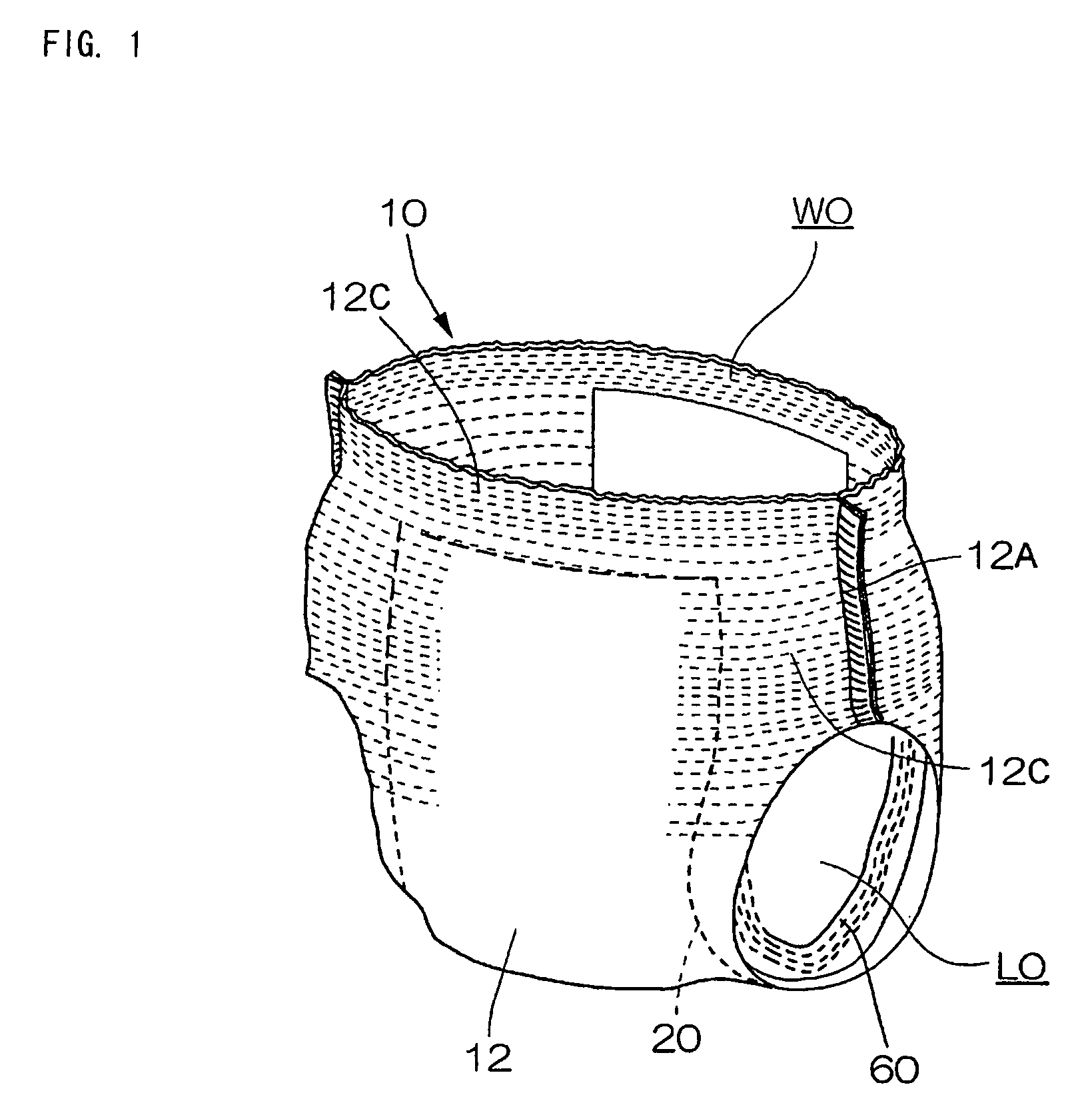

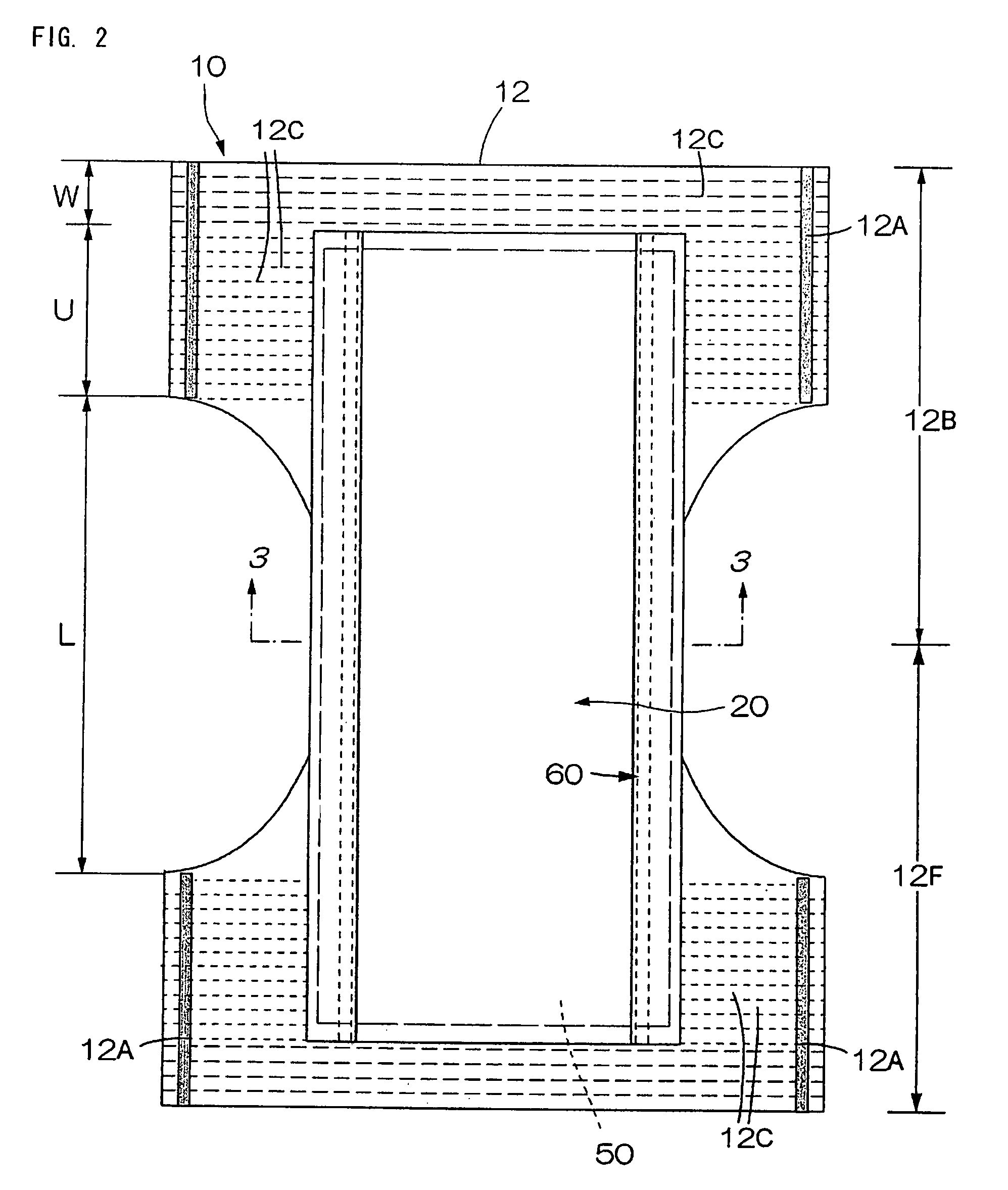

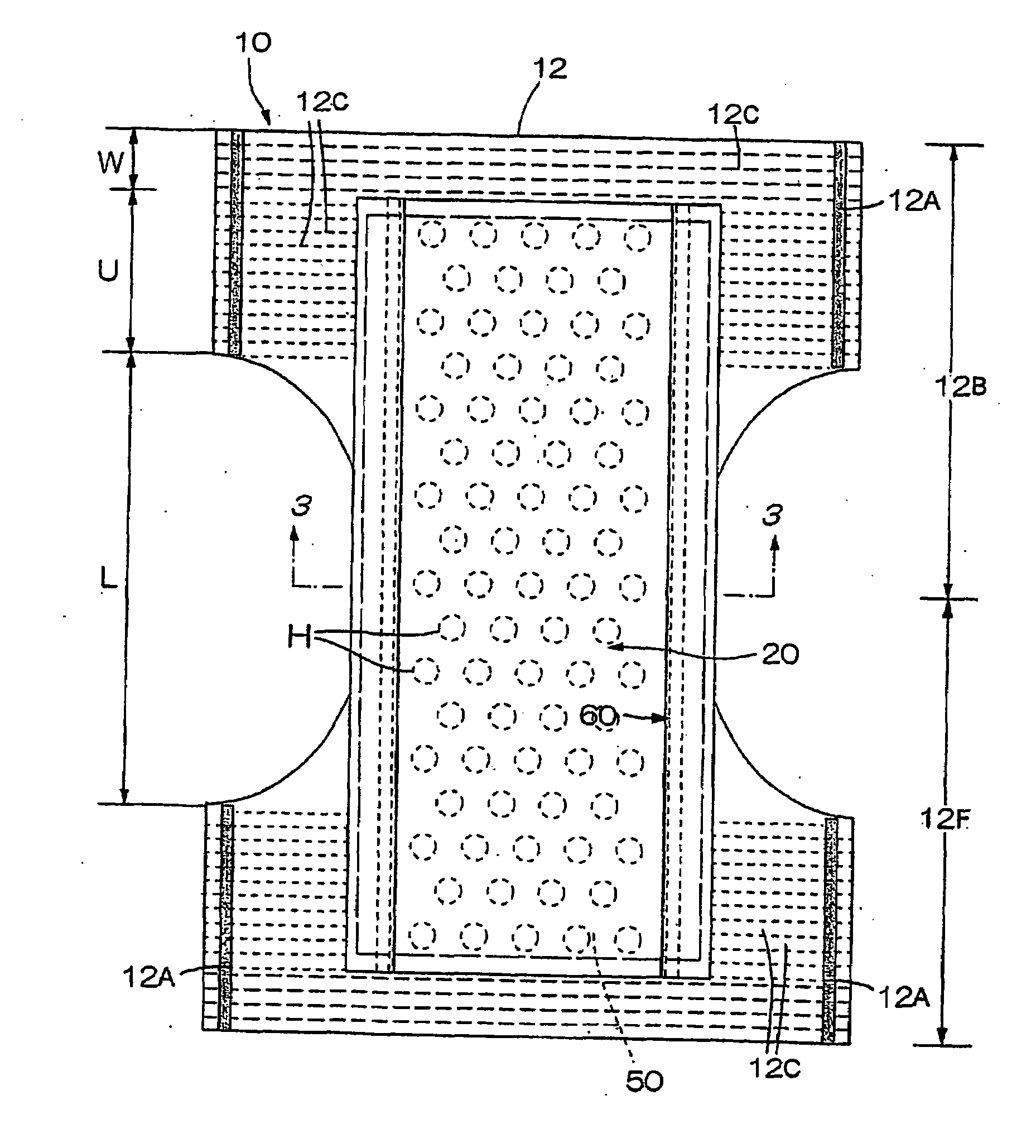

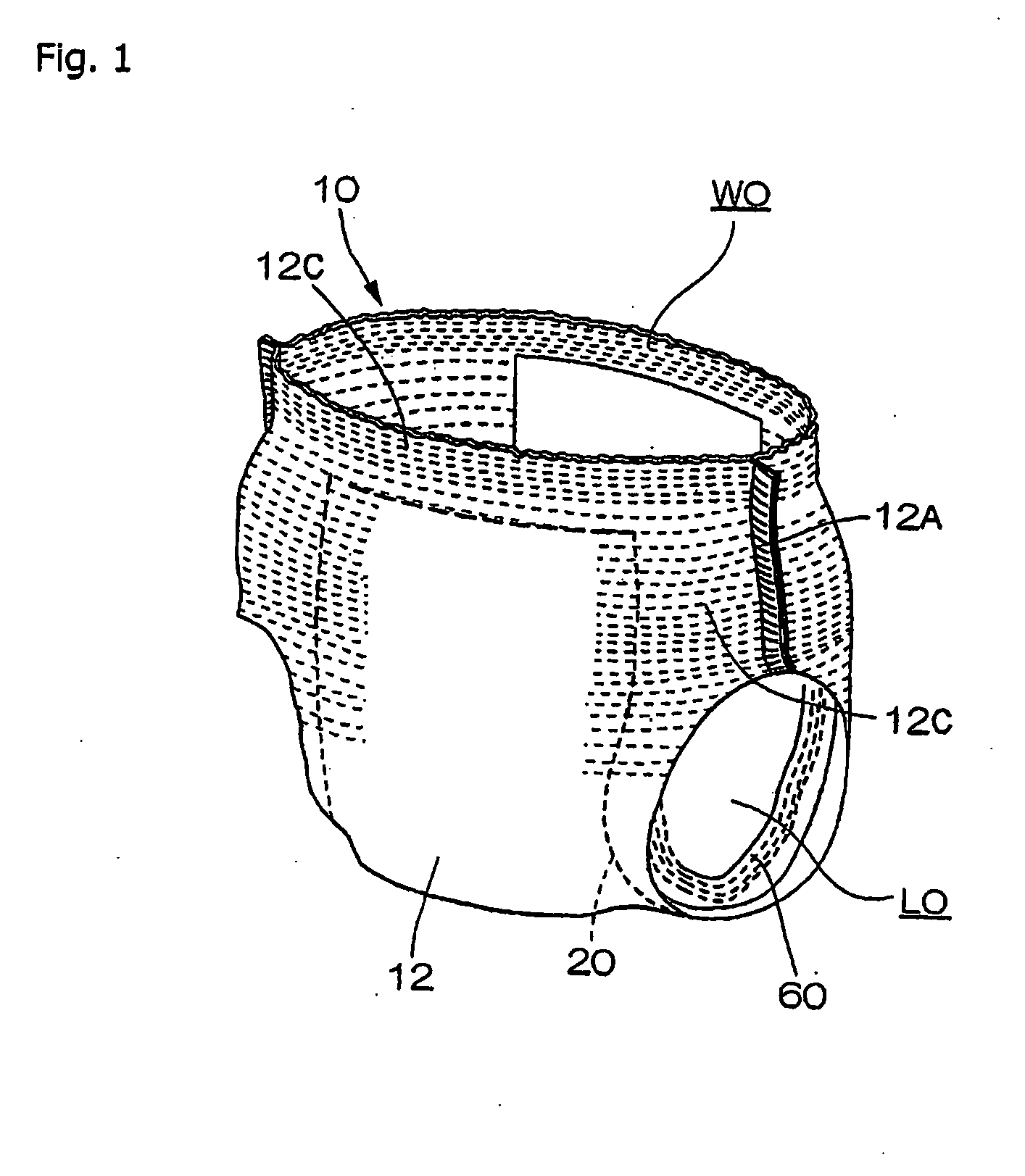

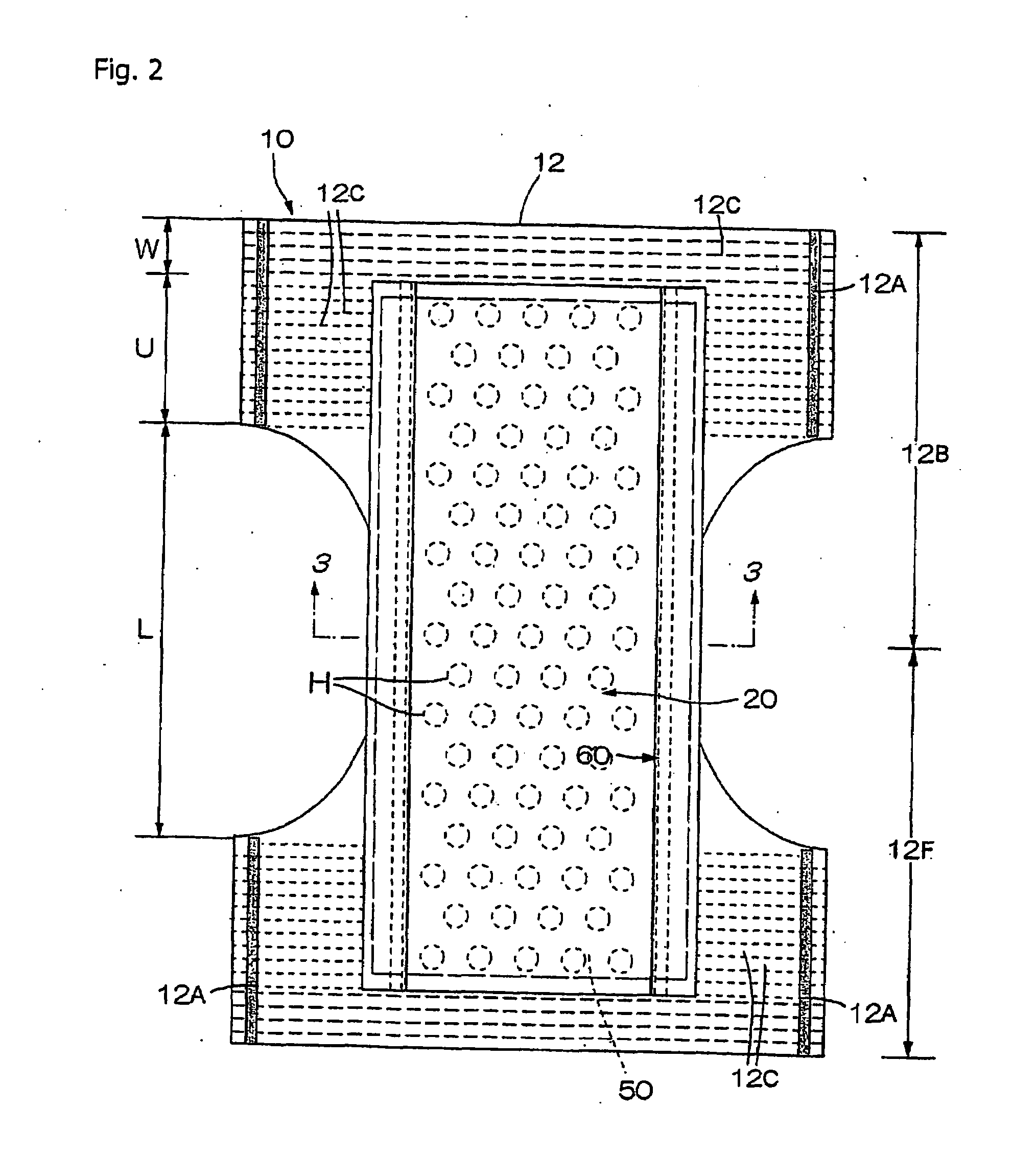

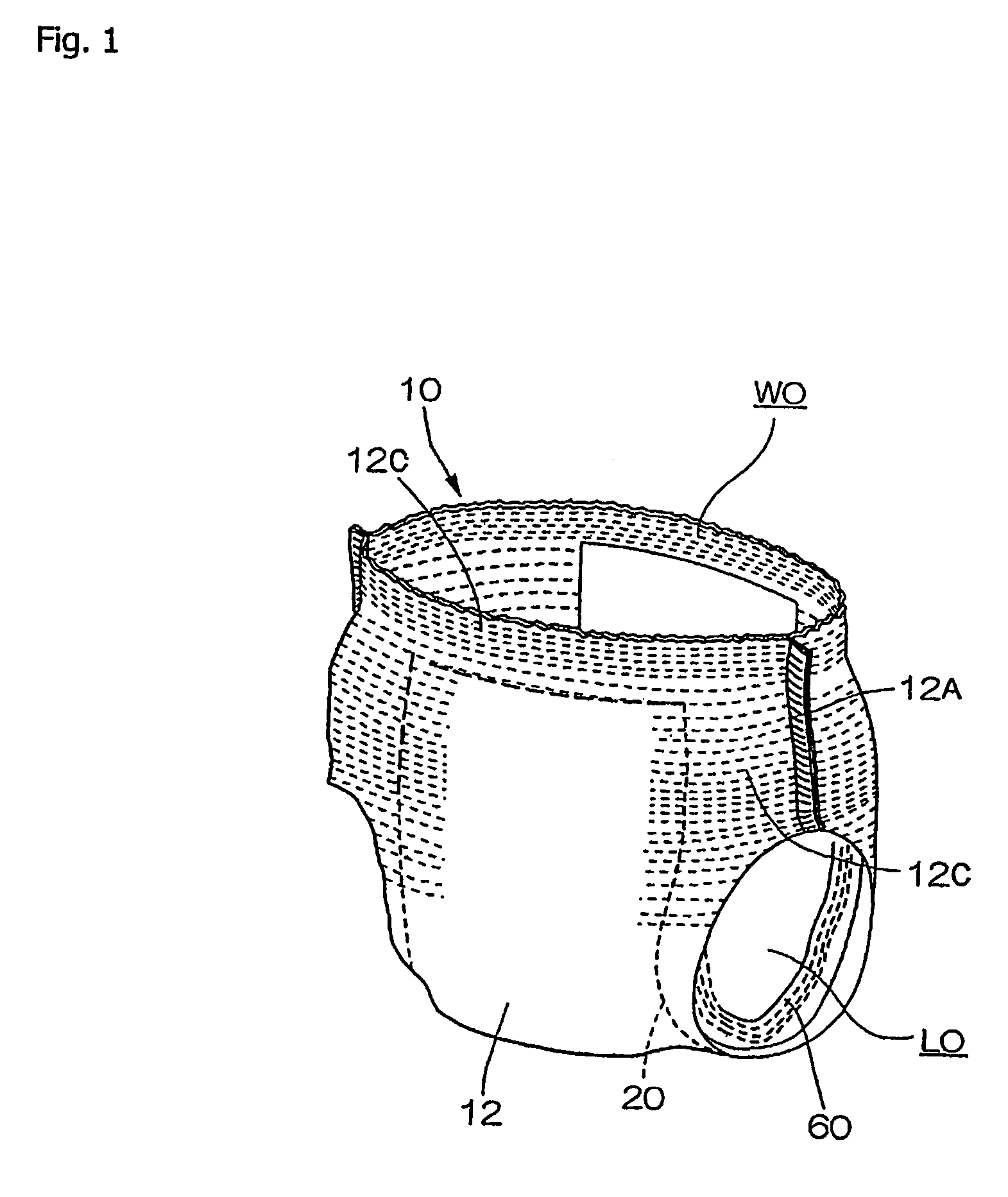

Paper Diaper

[Problem to be Solved] To prevent shingly hand feeling and unintentional bias of absorption characteristics in the case of using tow (fiber bundle).[SOLUTION] An absorption element having a super absorbent polymer 54, comprising a fiber aggregate formed by opening tow 21, a super absorbent polymer 54 and a wrapping sheet 58 for wrapping them, wherein the whole face or almost whole face of part provided at least with the super absorbent polymer 54 in the sheet 58 is applied with an adhesive in a continuous plane, which is bonded to the sheet 58 with the adhesive.

Owner:DAIO PAPER CORP

Absorbent article

InactiveUS7884259B2High amount of water absorptionReduce usageLayered productsBaby linensFiberAdhesive

An absorbent article including a fiber aggregate formed by opening the tow, a super absorbent polymer particle, and a sheet covering these components. The super absorbent polymer particle are bonded to the sheet with an adhesive that is applied in a continuous plane to the entire surface or the substantially entire surface at least at the portion to be provided with the super absorbent polymer particle in this sheet.

Owner:DAIO PAPER CORP

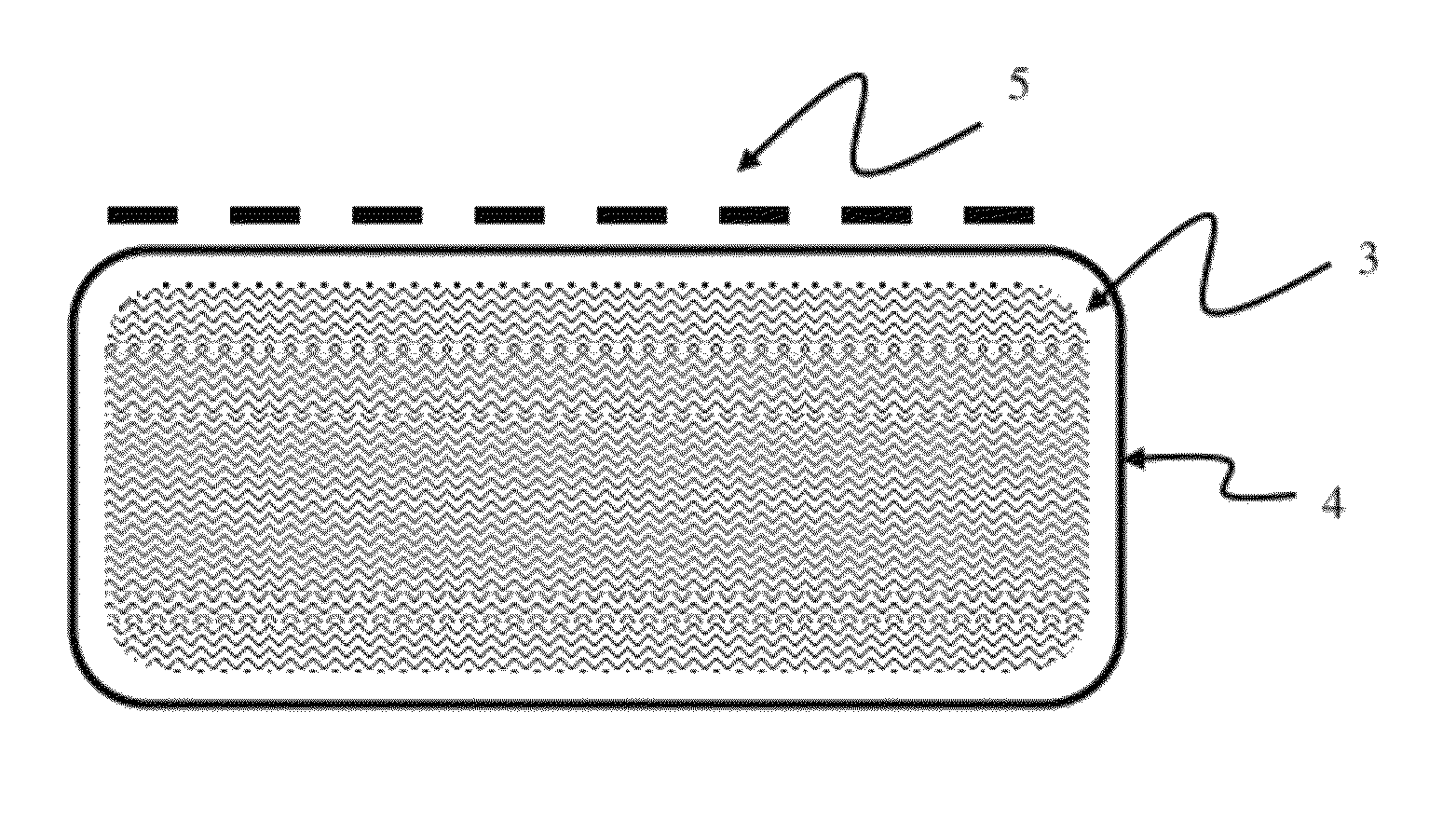

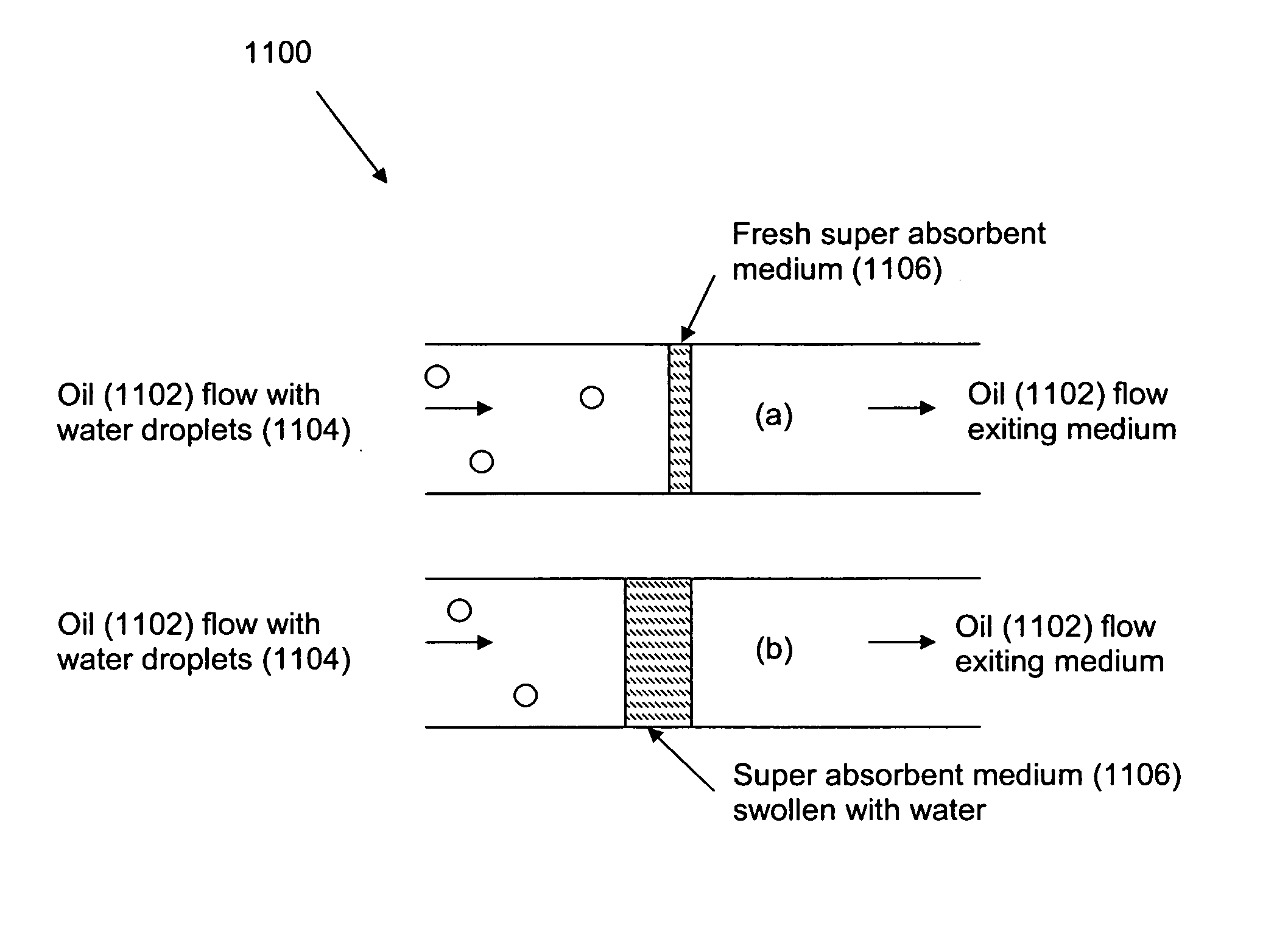

Super absorbent containing web that can act as a filter, absorbent, reactive layer or fuel fuse

ActiveUS20090065436A1Avoid introducingRapidly stop flowDispersed particle filtrationLayered productsParticulatesFiber

The web of the invention can comprise a super absorbent layer that can act as an moisture sensitive fuel shut-off valve, absorbent, adsorbant or reactant. The web of the invention can comprise a super absorbent fabric or layer made of a superabsorbent particle or fiber. The web can comprise a nanofiber layer having dispersed within the nanofiber layer a super absorbent particulate and optionally a second particulate material that can act as an absorbent, adsorbant or reactant. Fluid, gas or liquid, that flows through or by the assemblies of the invention can have any gas, liquid or solid material dispersed or dissolved in the fluid interact with the super absorbent particulate. If needed these materials can also react with, be absorbed by, or adsorbed onto, the active particulate within the nanofiber layer. The structures of the invention can act simply as flow-by reactive, absorptive, or adsorptive layers with no filtration properties, or the structures of the invention can be assembled into filters that can filter particulate from a mobile fluid in a flow-through mode while simultaneously reacting, absorbing, or adsorbing materials from the mobile fluid.

Owner:DONALDSON CO INC

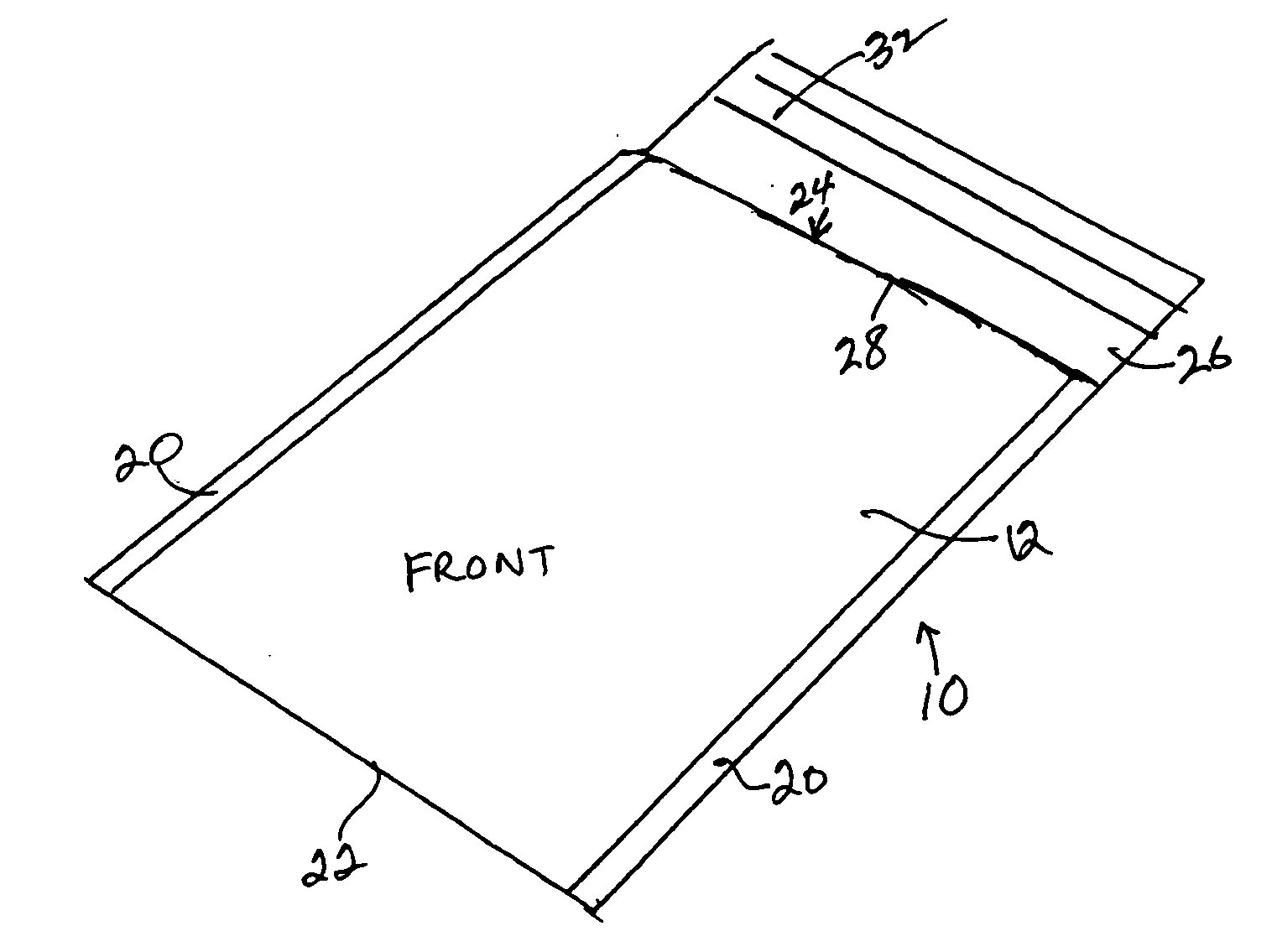

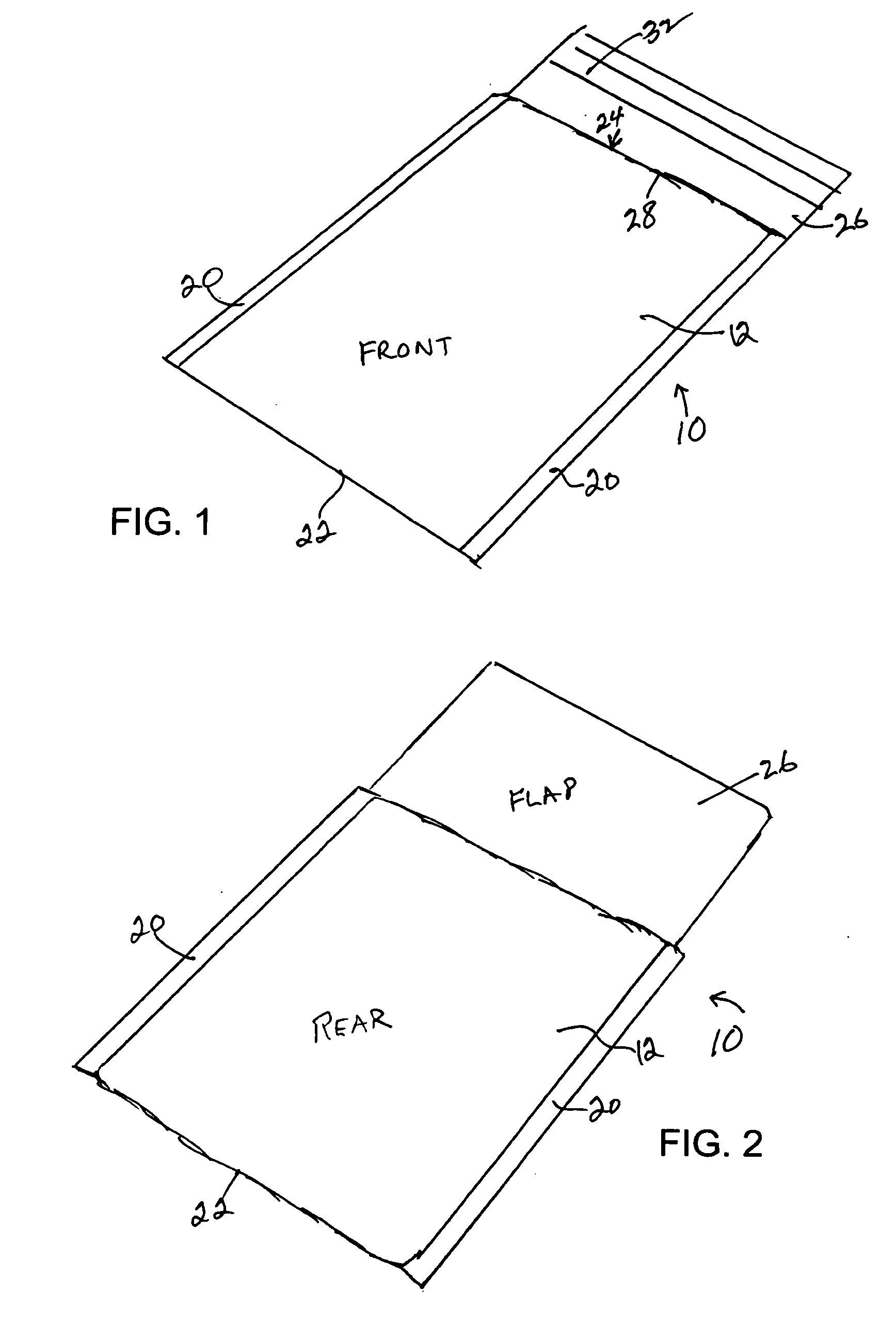

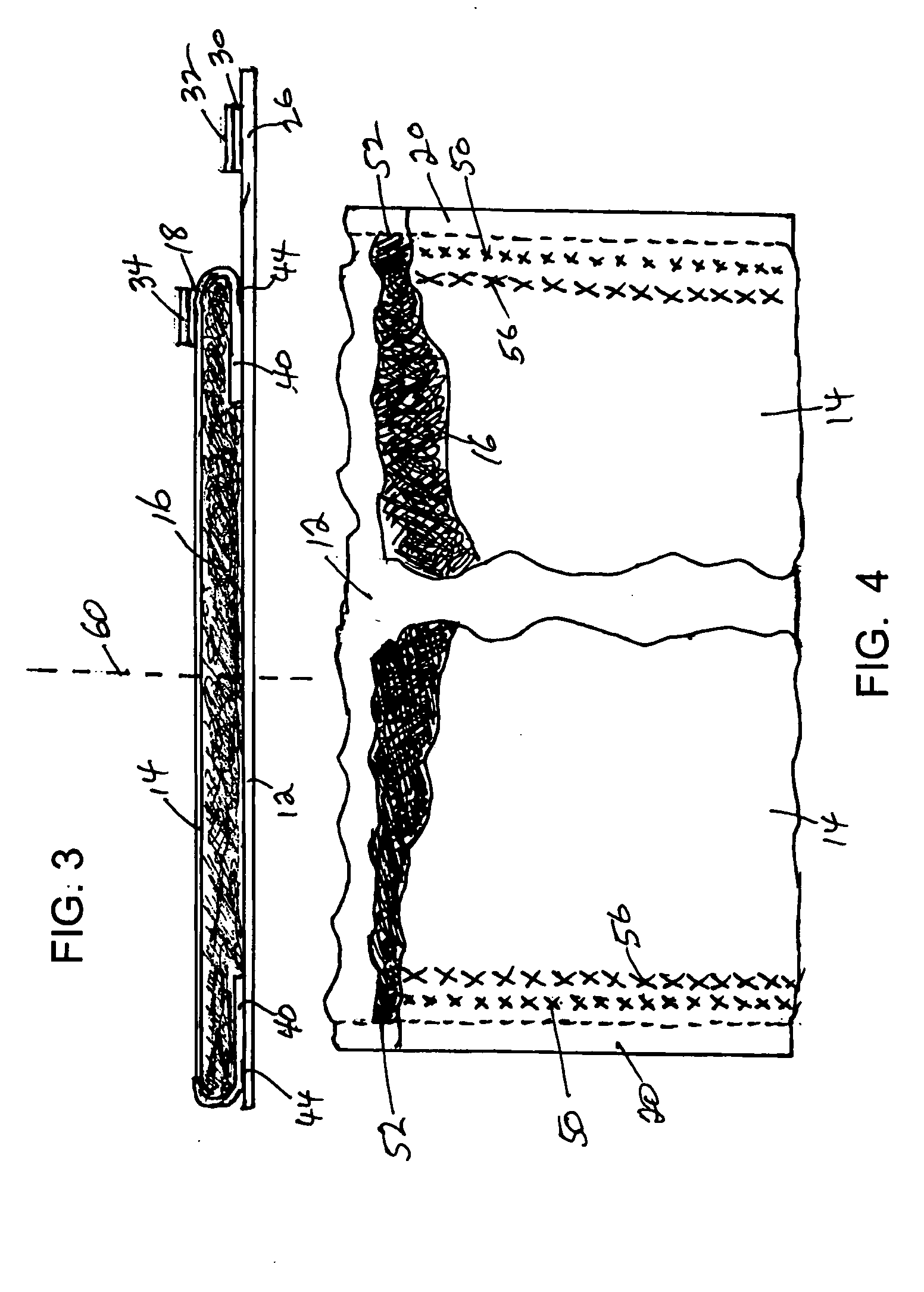

"green" temperature- controlled mailer

A mailer has an outer, longitudinally extending, biodegradable film with lateral edges folded on itself to form a pocket having an opening and sealable by a flap. An assembly is composed of an inner, longitudinally extending, biodegradable film having lateral edges and a longitudinal extending pad composed of textile cuttings and microbial and super-absorbent powders. The inner film extends longitudinally around the pad and is attached to the pad. The assembly is positioned in the pocket with the inner film being sealed to the outer film adjacent the opening to the pocket trapping the pad between the outer and inner films. Sealing tape is mounted on the inner film adjacent to the pocket to seal the pocket closed. The lateral edges of both the outer and inner films, which extend laterally beyond the pad, are heat sealed together.

Owner:MILLER DRAYTON

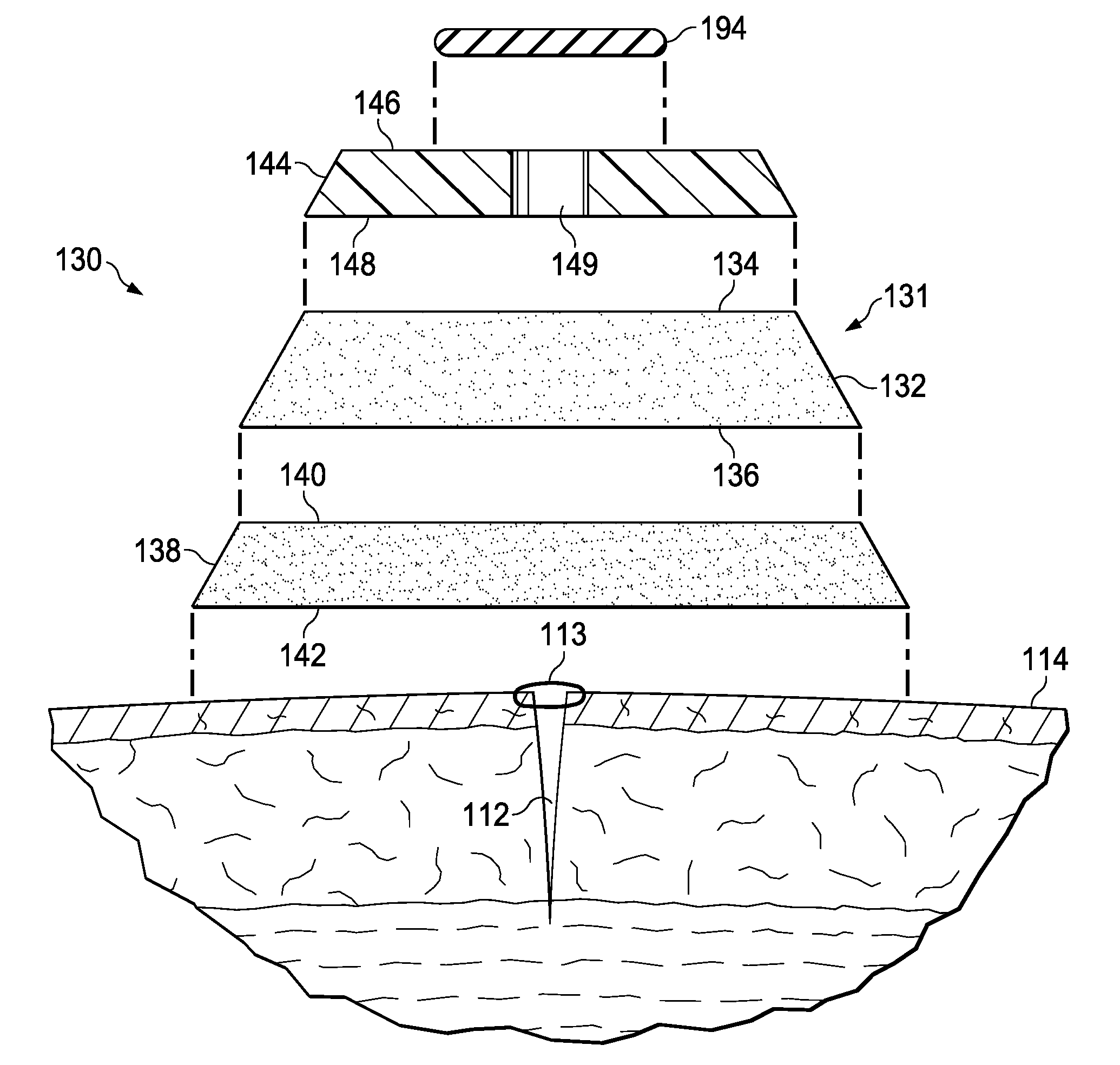

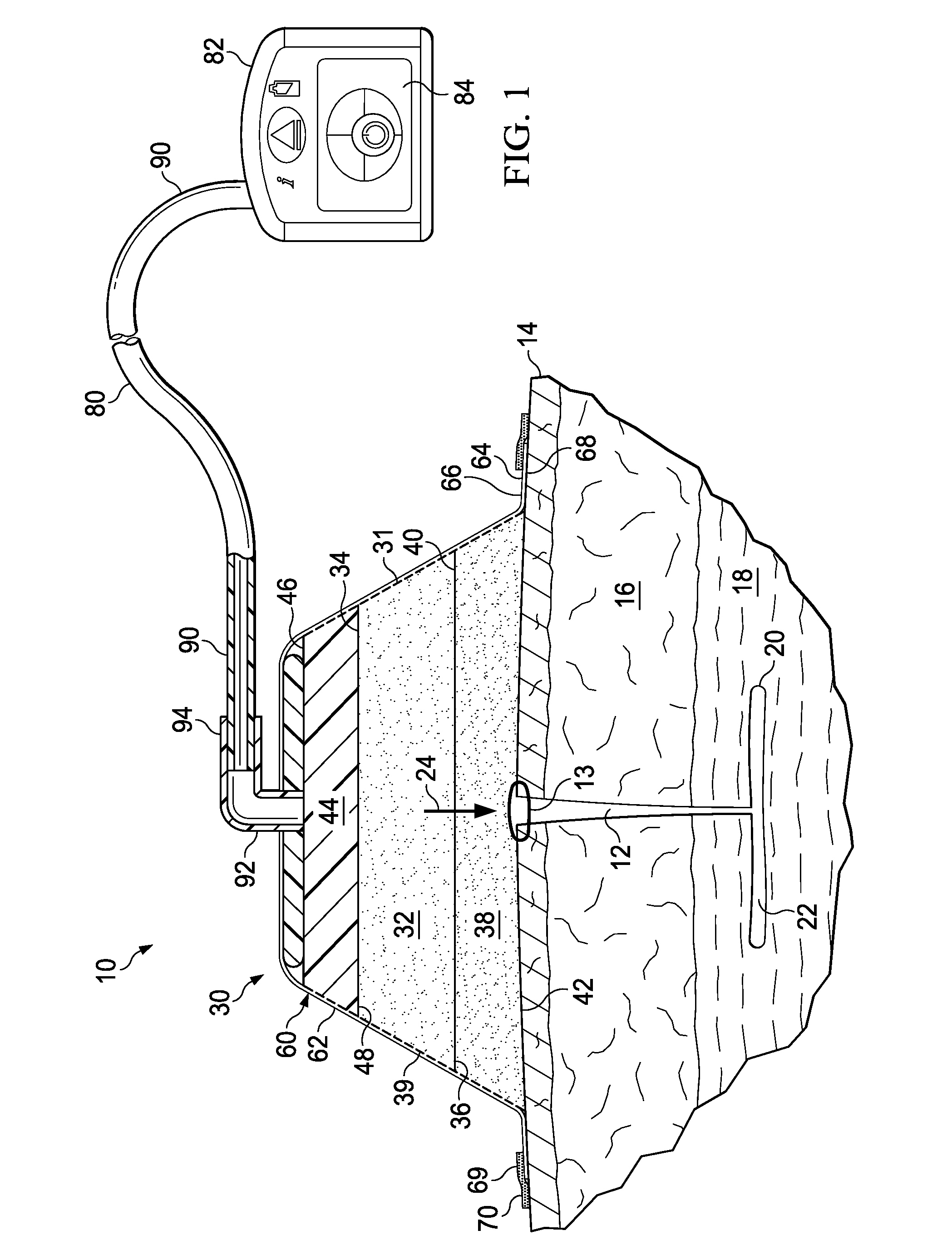

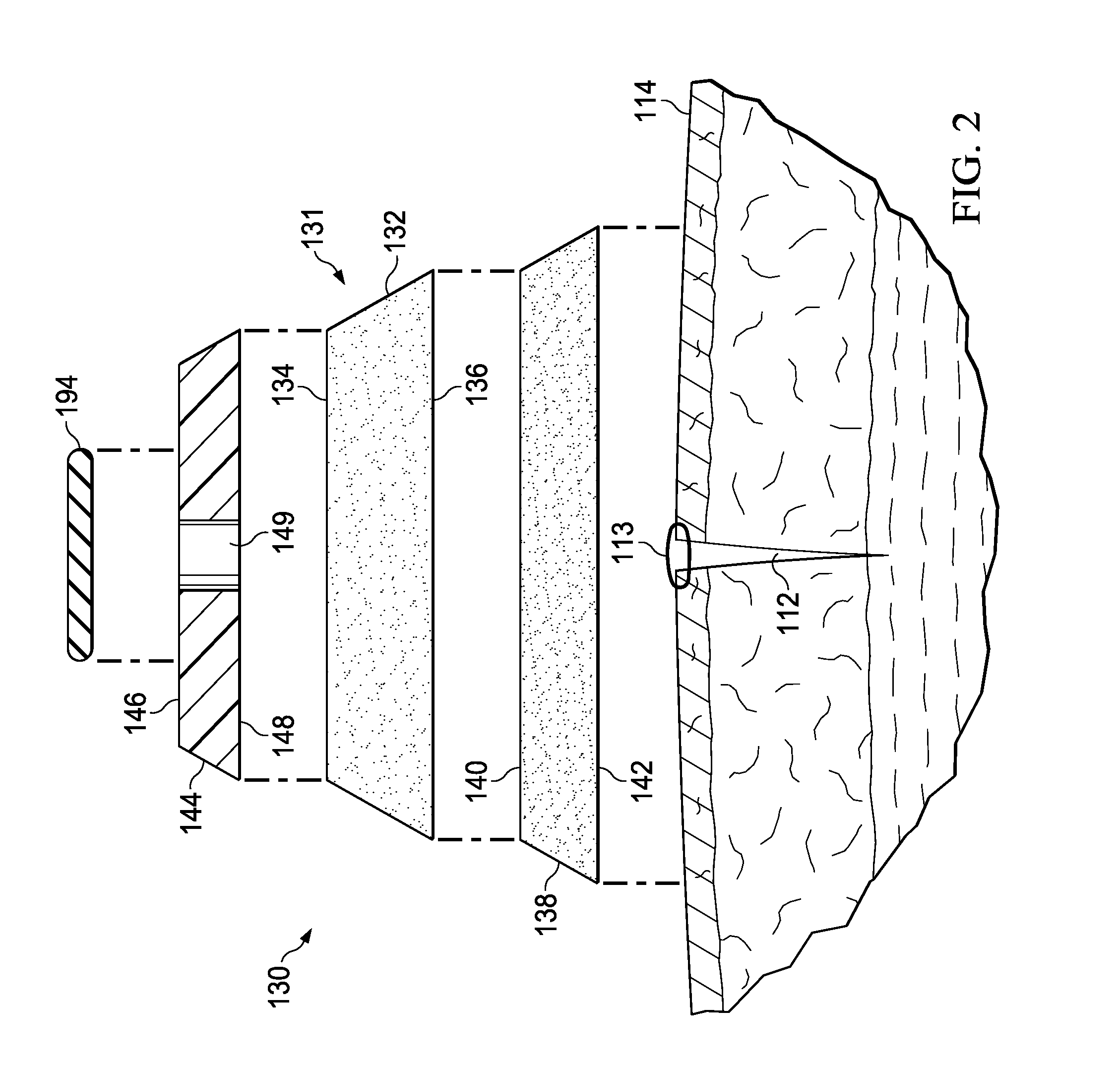

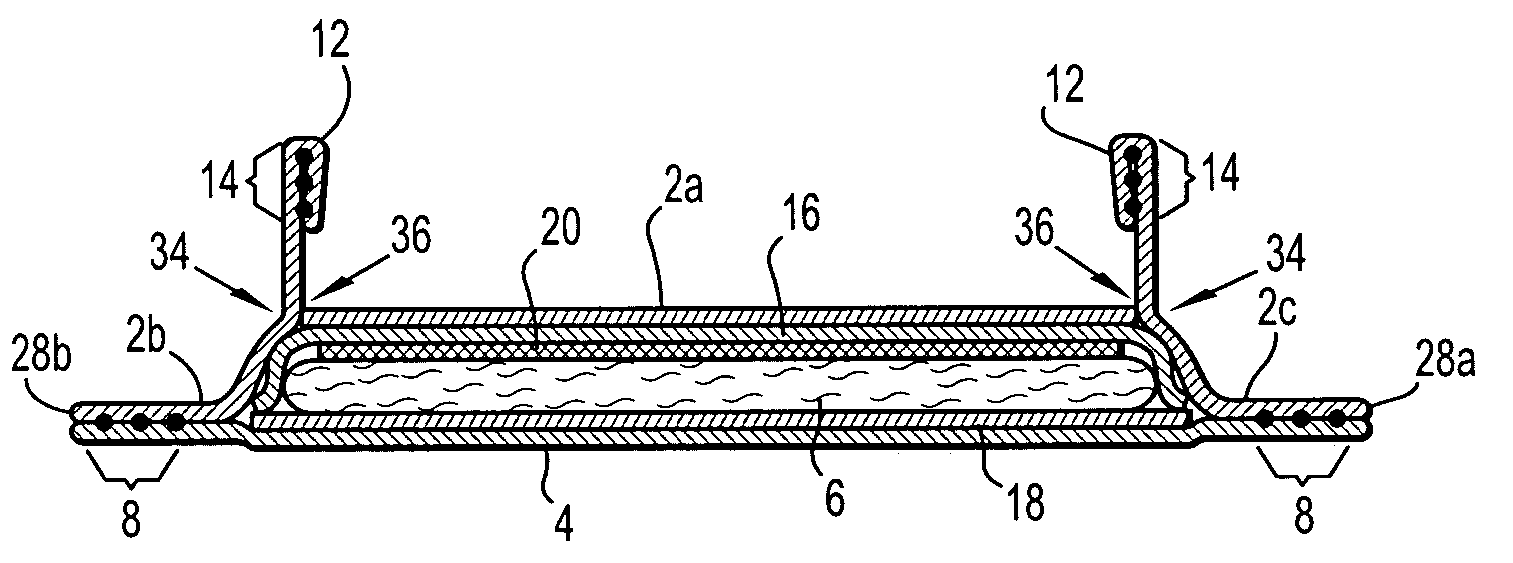

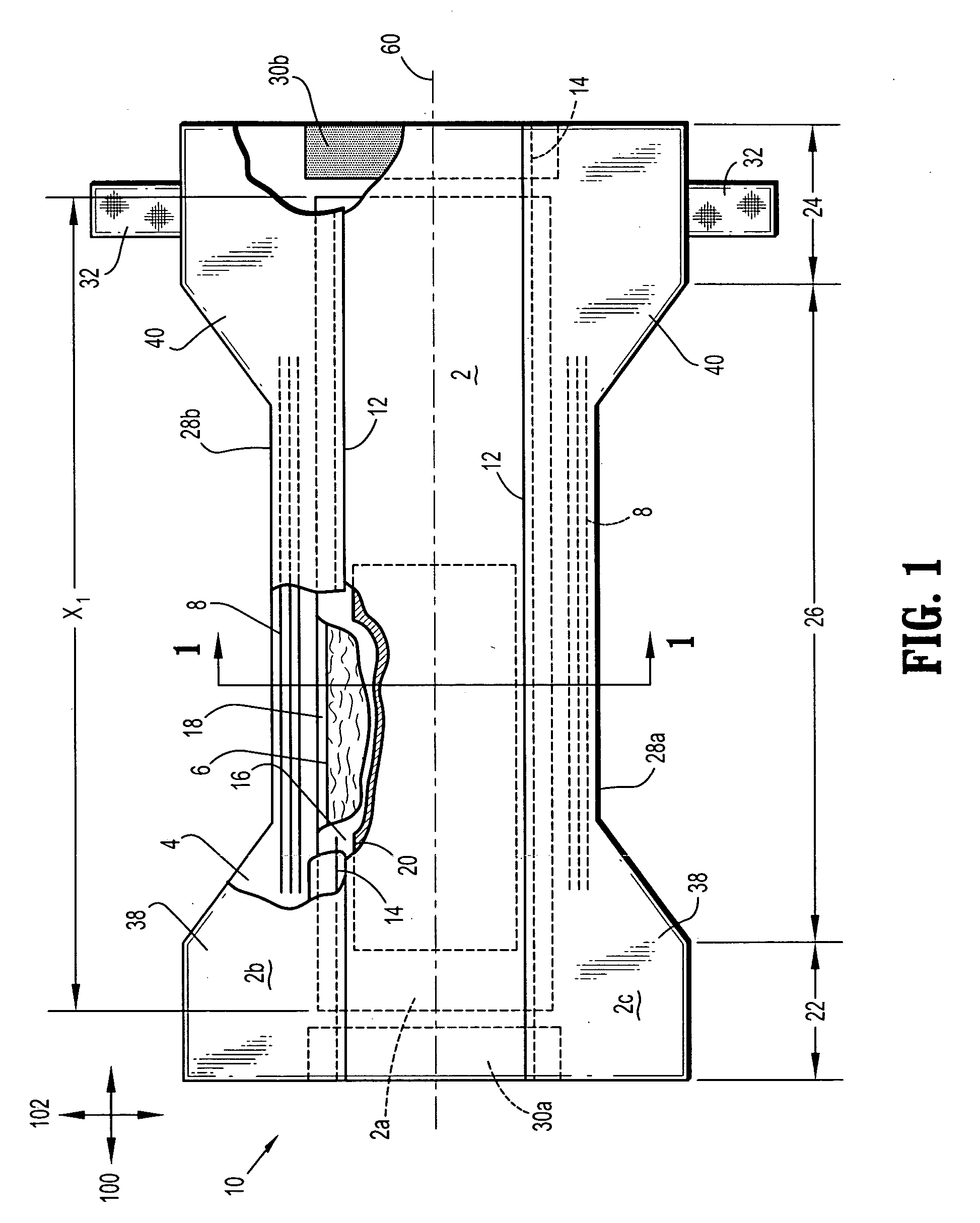

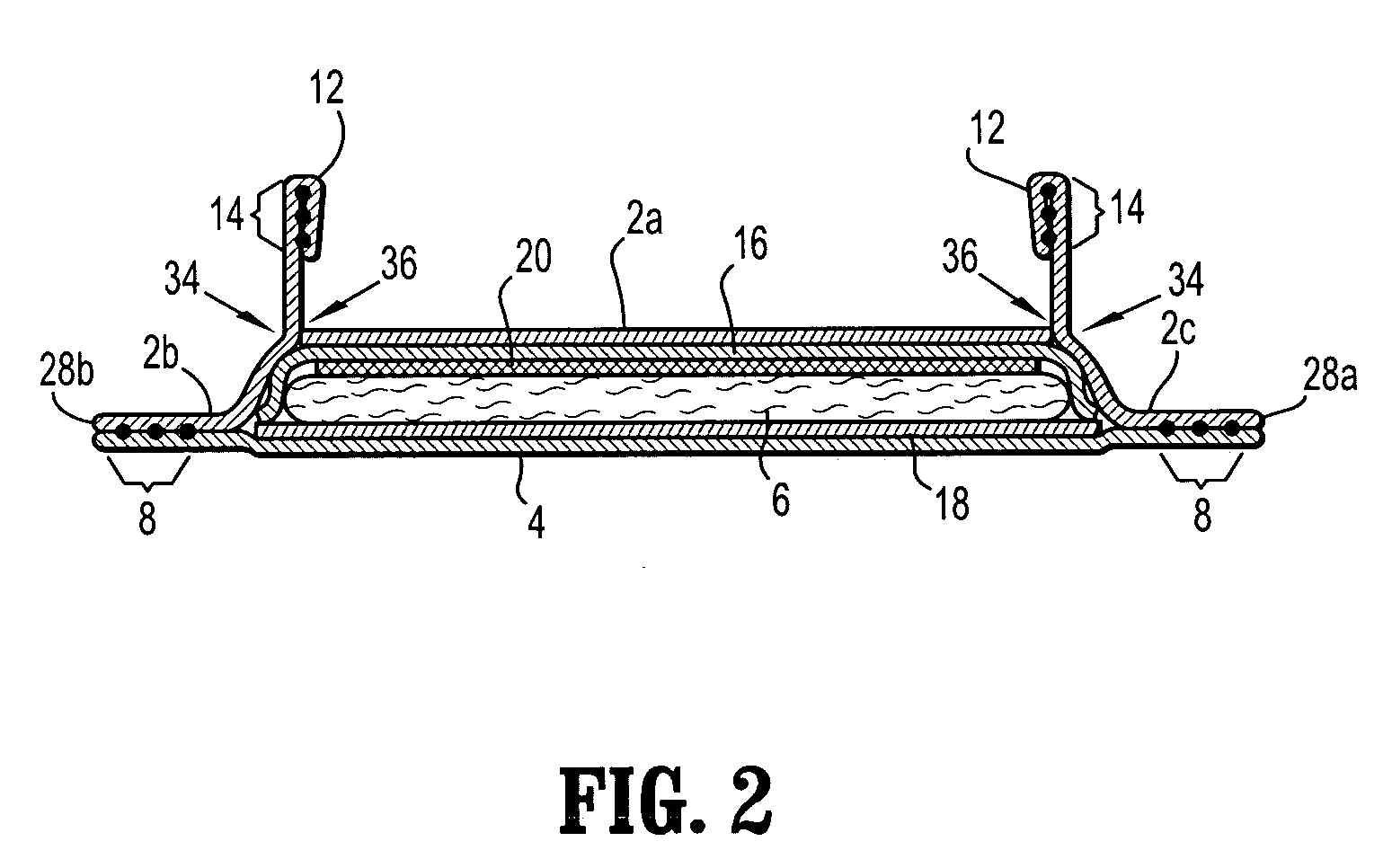

Super-absorbent, reduced-pressure wound dressings and systems

A super-absorbent dressing assembly for use with a reduced-pressure wound treatment system includes a breathable, fluid restricted dry layer for placement against a wound, a super-absorbent layer, and a non-breathable layer, and a drape extending over the non-breathable layer. A reduced-pressure interface is available to fluidly couple the super-absorbent layer to a reduced-pressure subsystem. The super-absorbent dressing assembly preferably supplies a compressive force when placed under reduced pressure. A reduced-pressure treatment system uses a super-absorbent bolster to treat wounds, e.g., linear wounds.

Owner:3M INNOVATIVE PROPERTIES CO

Absorbent structures comprising coated super-absorbent polymer particles

This invention is directed to super-absorbent material, which comprises a super absorbent polymer core that is coated with an organic, polar coating agent, and whereby the particulate super-absorbent material has a contact angle and a corresponding cos CAm (as defined herein), whereby the cos CAm is more than 0.3, and whereby, when said coating agent is in the form of particles, said coating agent particles have a (weight) mean particle size of from 0.001 to 1 micron. The material is useful for absorbent structures and absorbent articles (comprising such structures). The coated super-absorbent material is typically present in said absorbent structure at least at a concentration of 50% by weight of the structure, preferably even 80% or even 90%. The invention also provides a process for making the absorbent material.

Owner:THE PROCTER & GAMBLE COMPANY

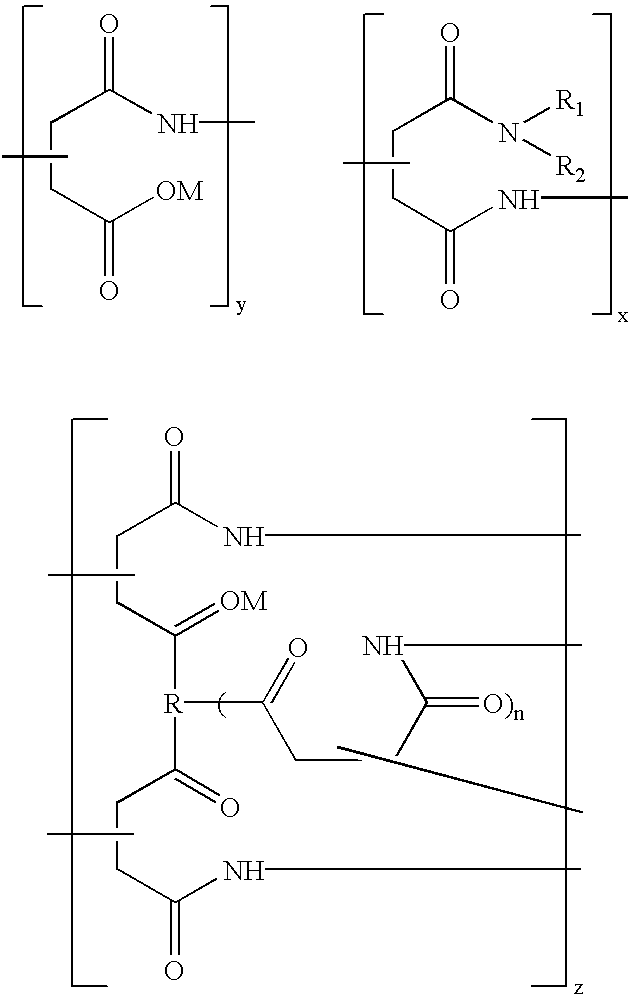

In vivo use of water absorbent polymers

InactiveUS6908609B2Reduce the amount requiredReduce the numberBiocideSynthetic polymeric active ingredientsFecesRemove blood

The subject invention is a method and material for removing fluid from the intestinal tract of a host and may be useful in treating animals or human patients suffering from fluid overload states. In one embodiment, the subject method involves ingesting an enterically coated non-systemic, non-toxic, non-digestible, water absorbing polymer which absorbs fluid while passing through the intestinal tract. The polymer is excreted in the feces wherein the polymer and absorbed fluid is removed from the body. Preferred polymers include super absorbent acrylic acid polymers, preferably provided in bead form. The polymers may include functional groups for selectively removing blood borne waste products, e.g. urea, from the G.I. tract.

Owner:RELYPSA INC

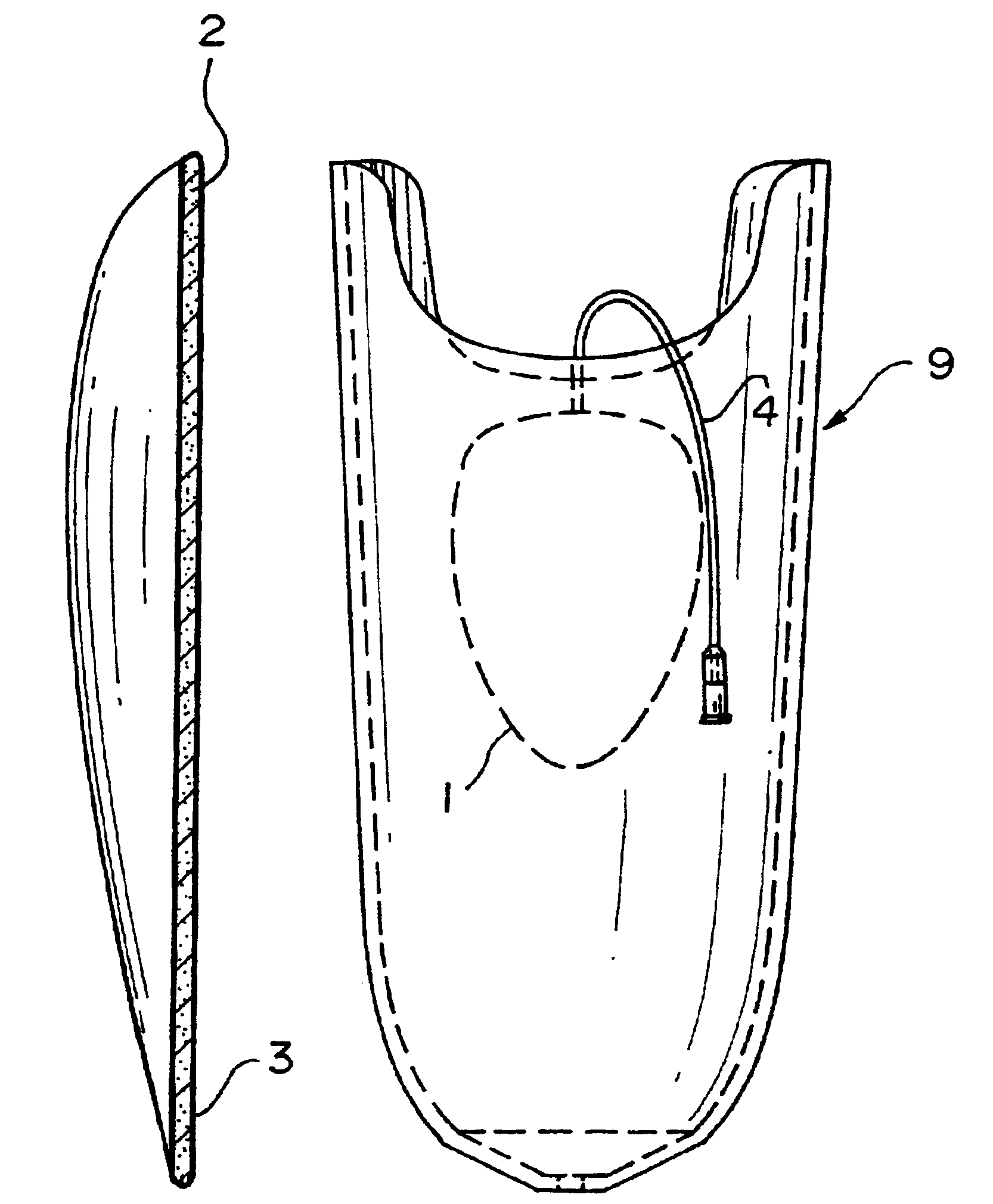

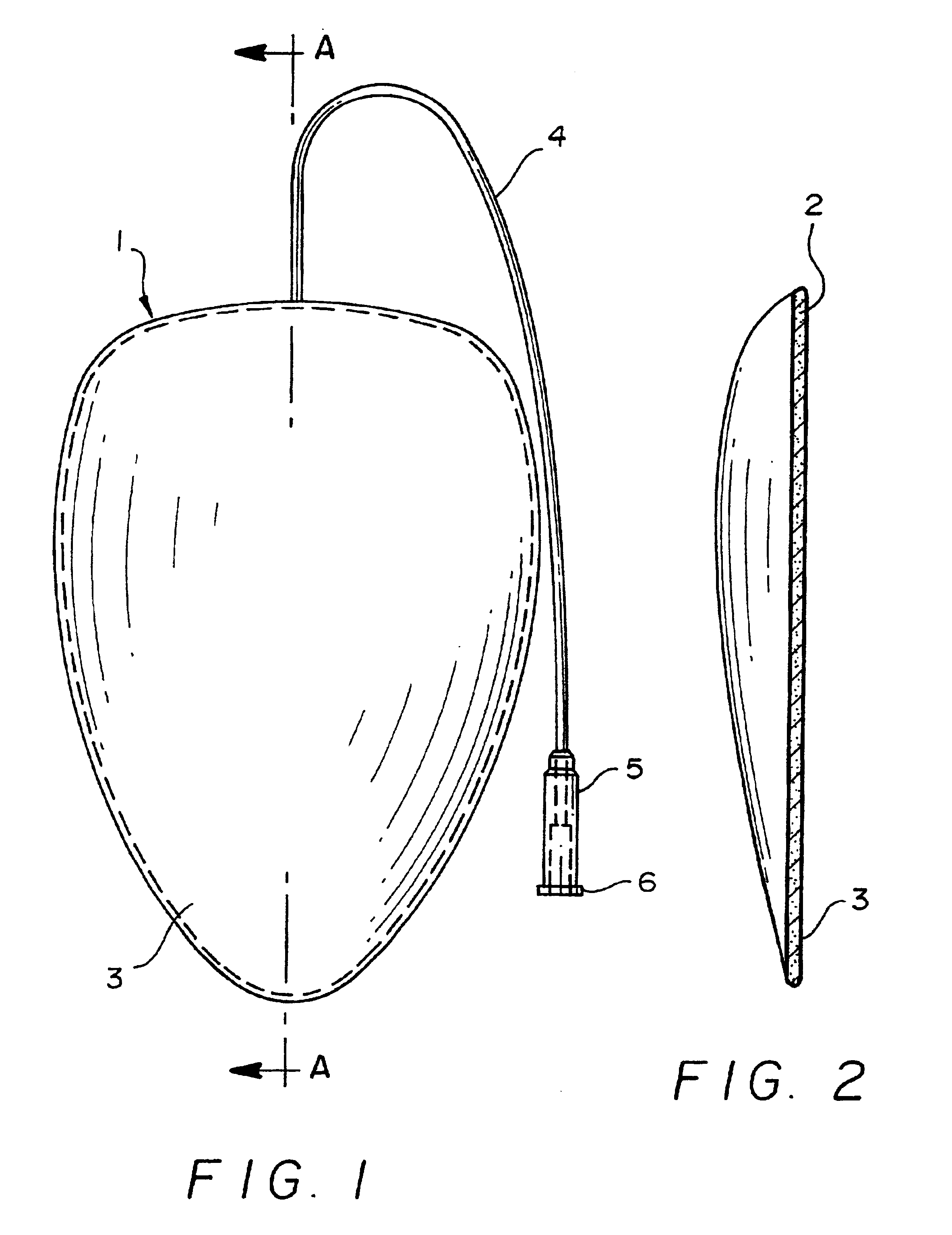

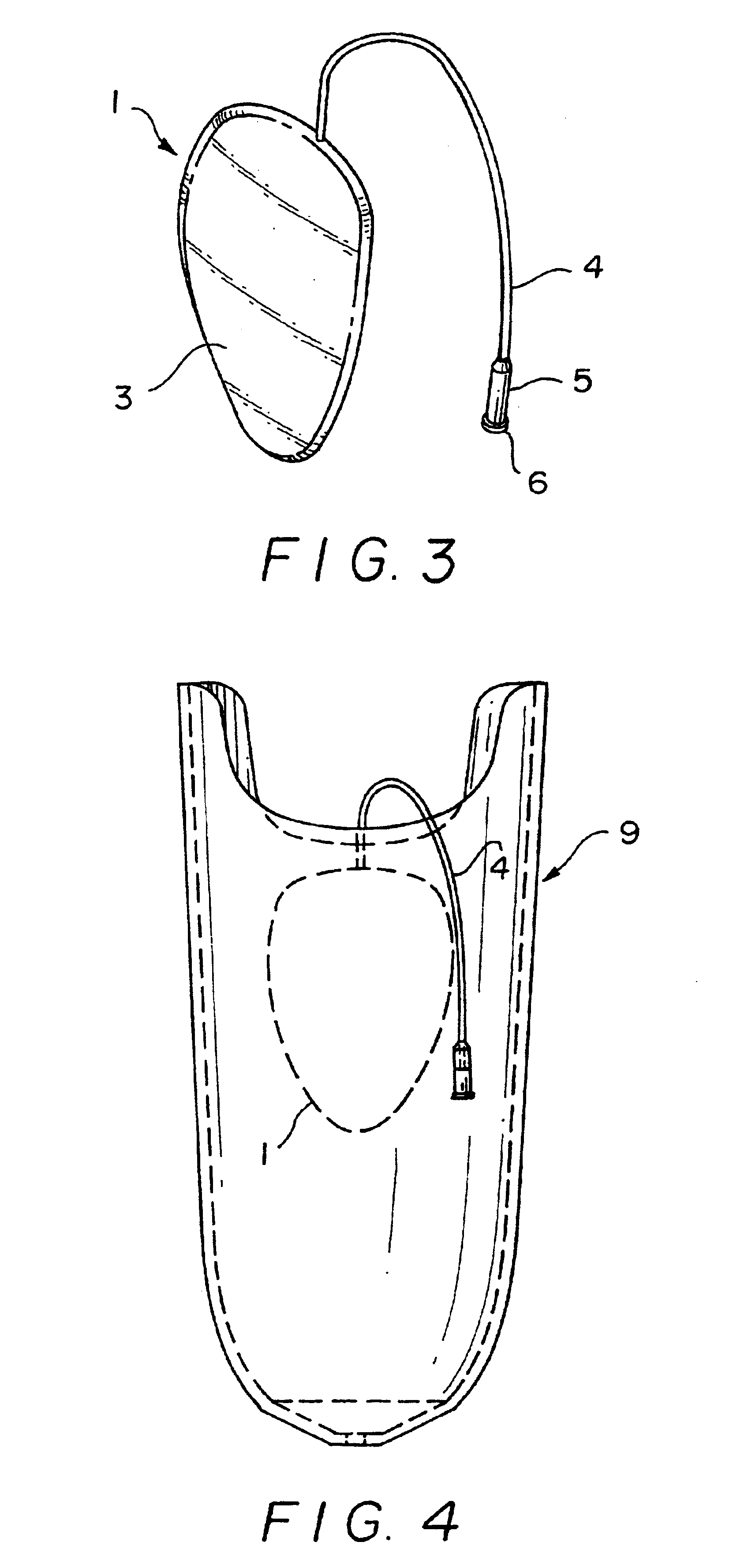

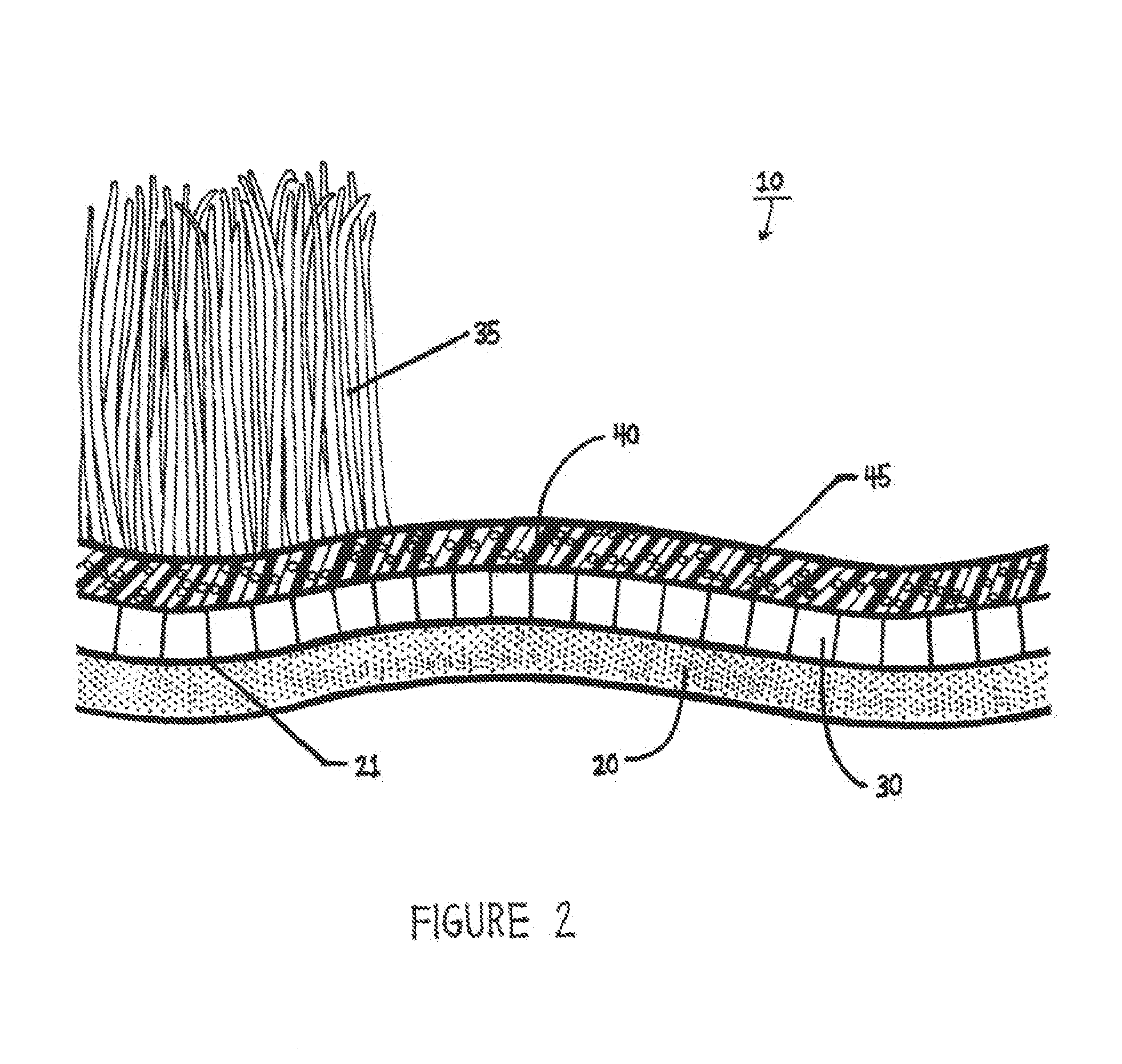

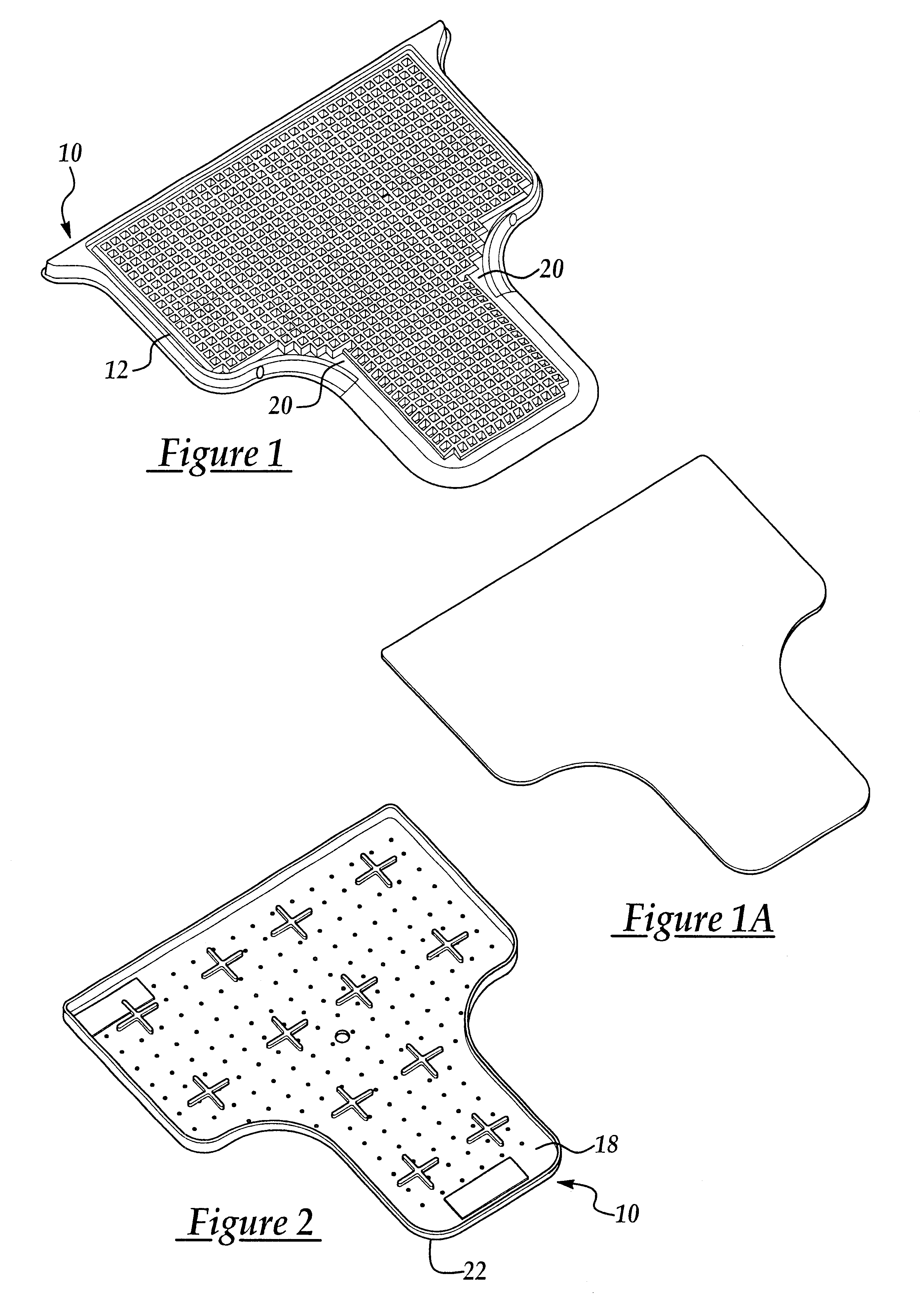

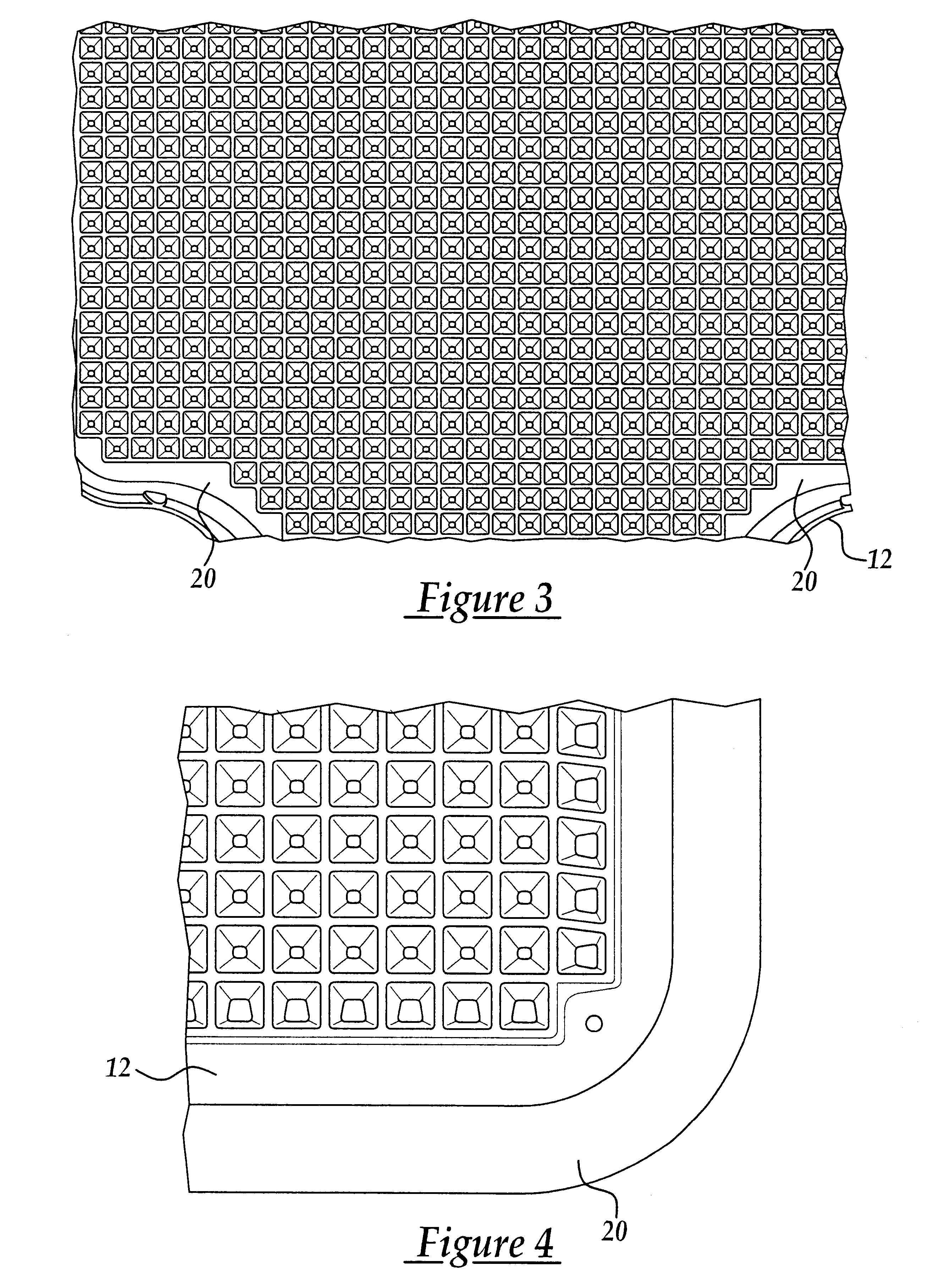

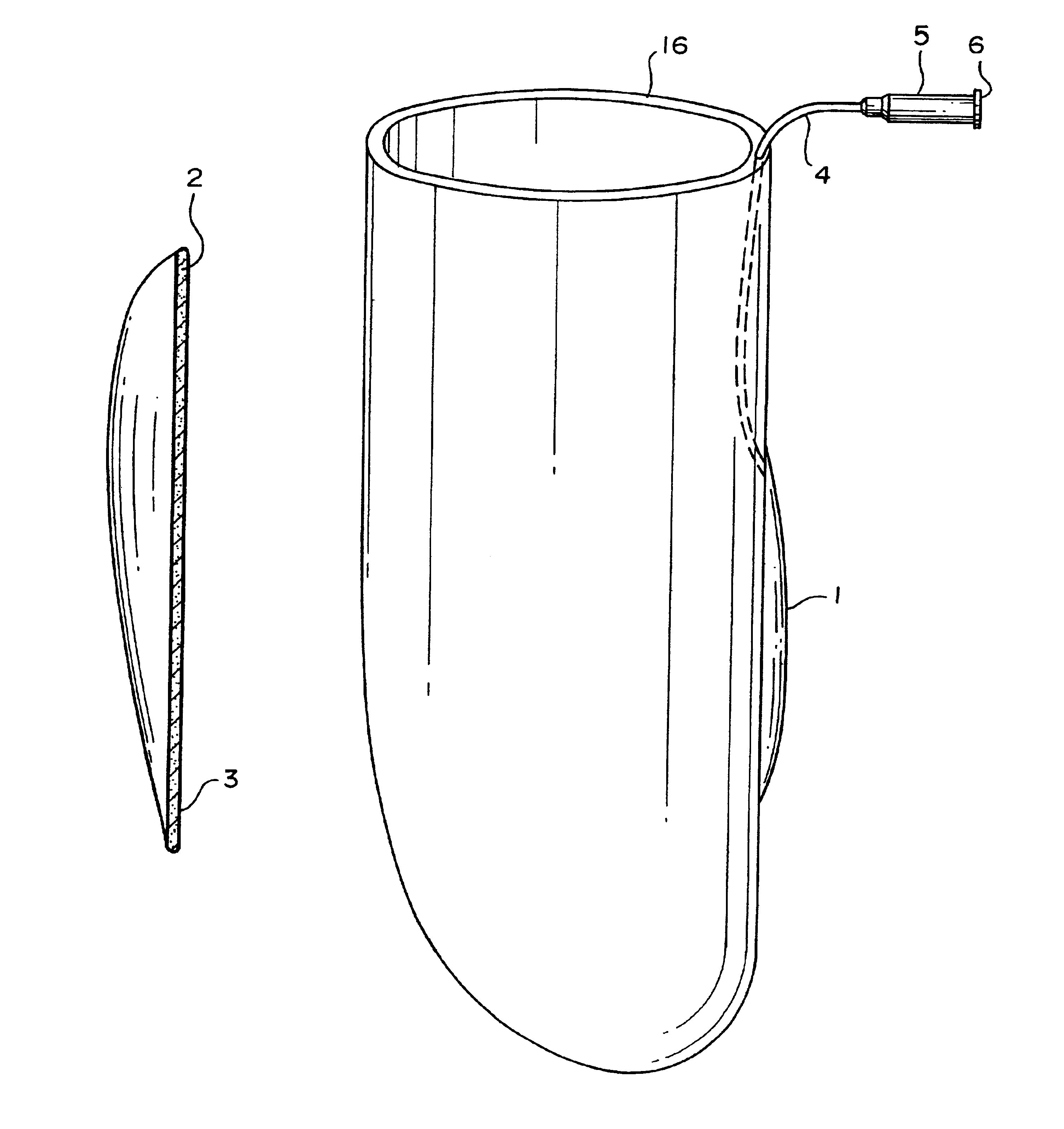

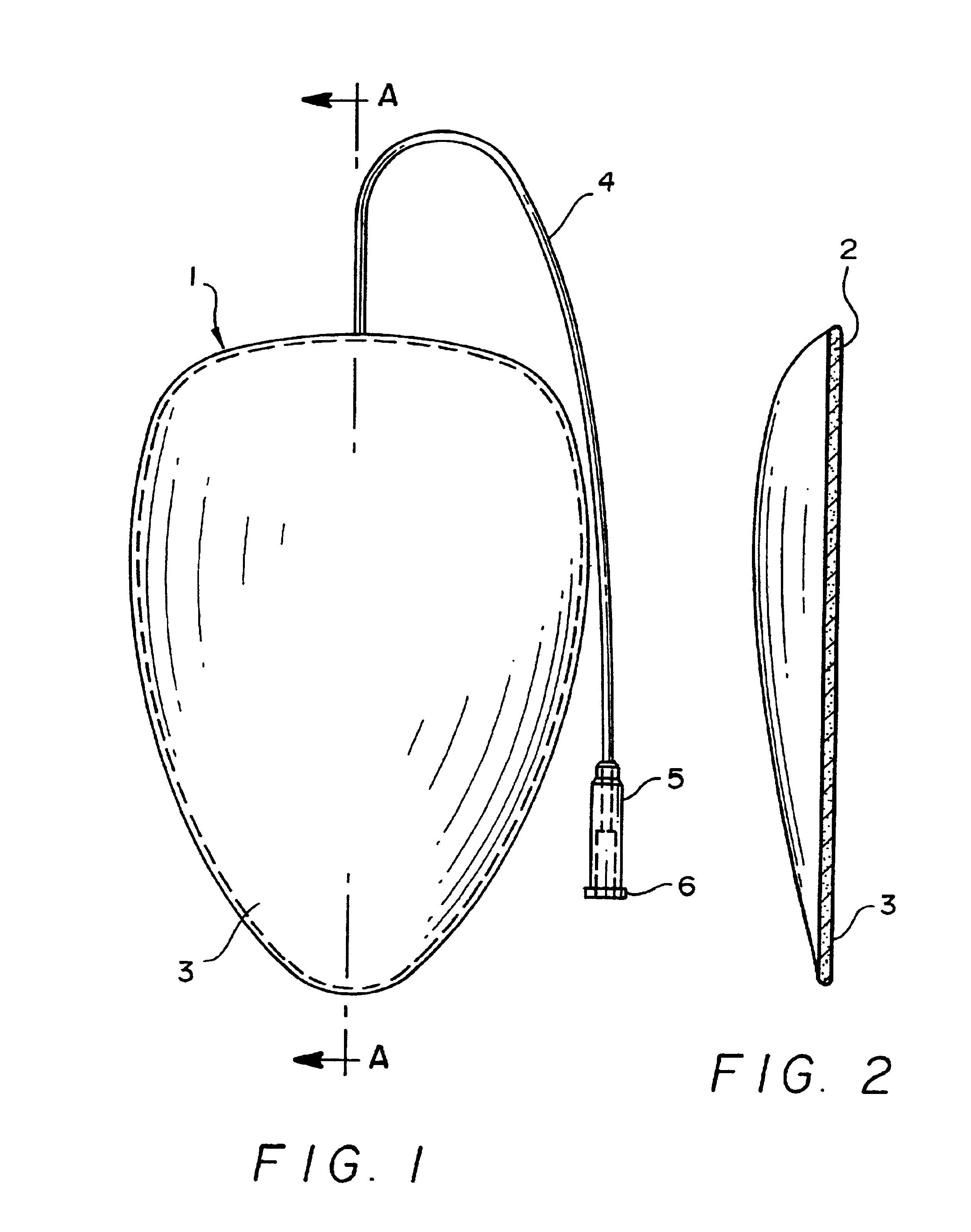

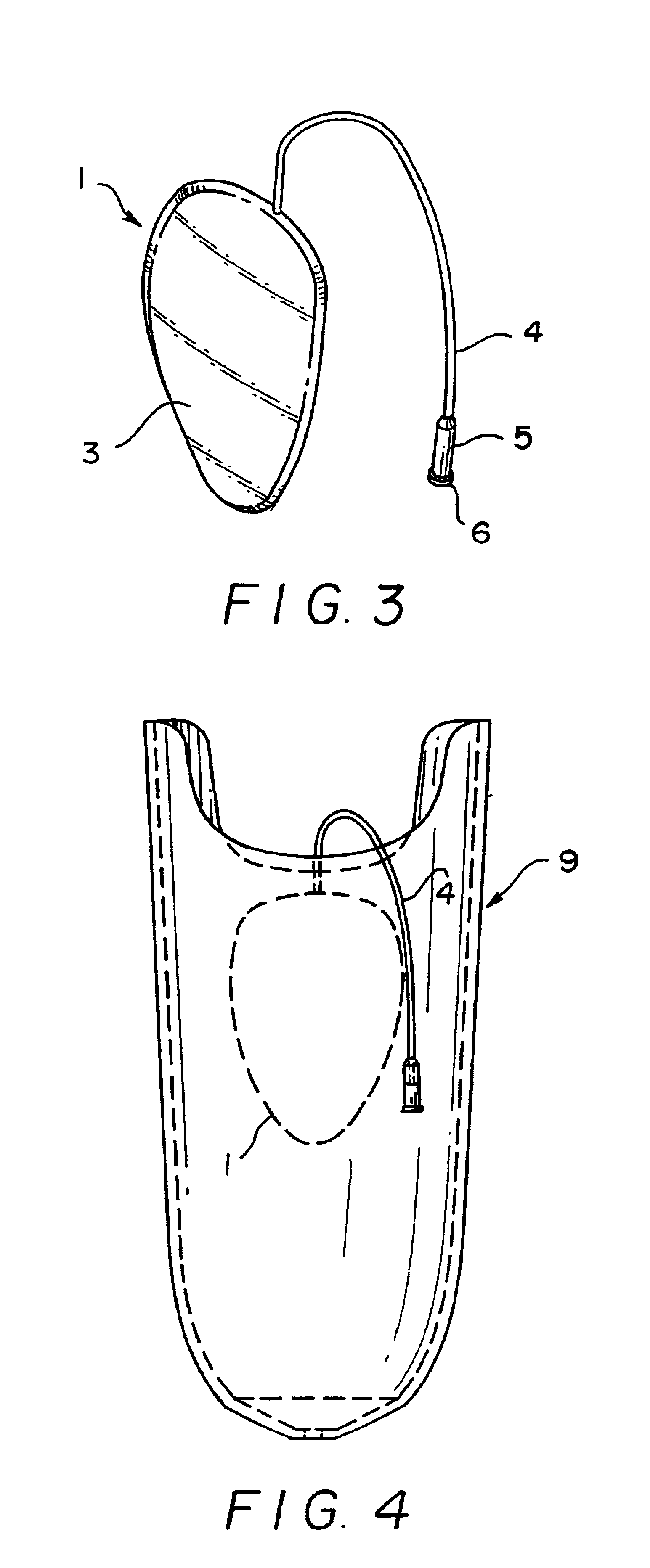

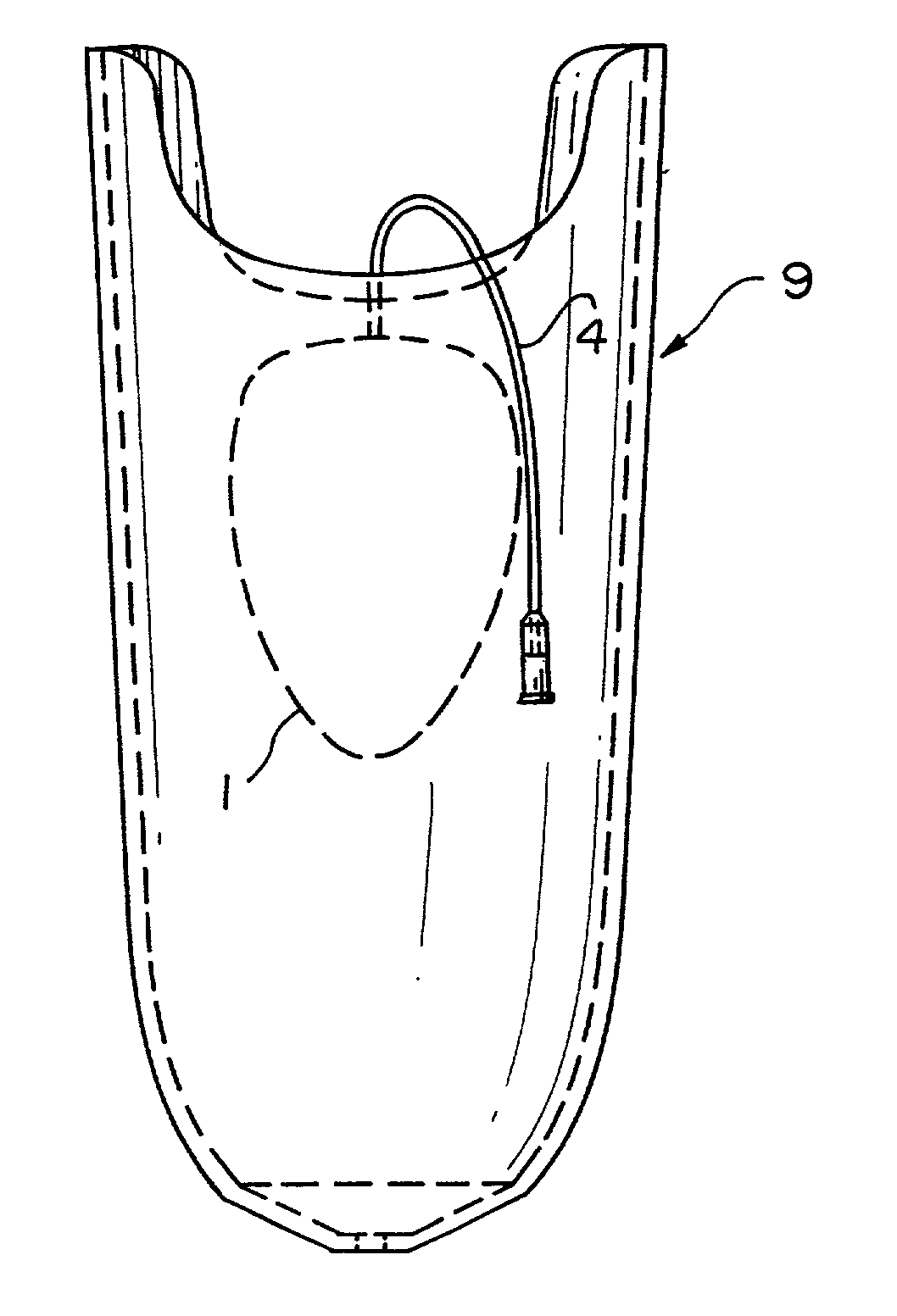

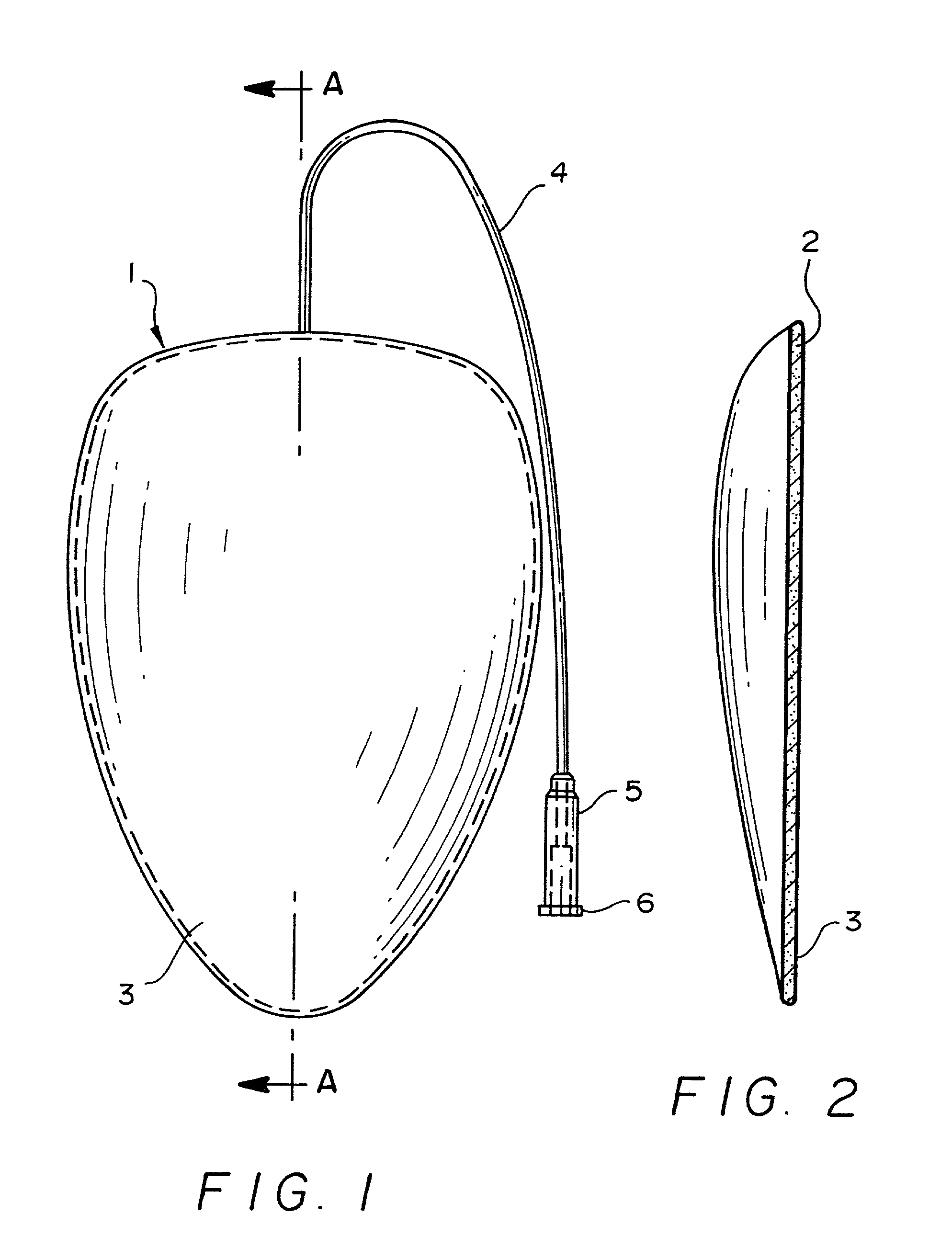

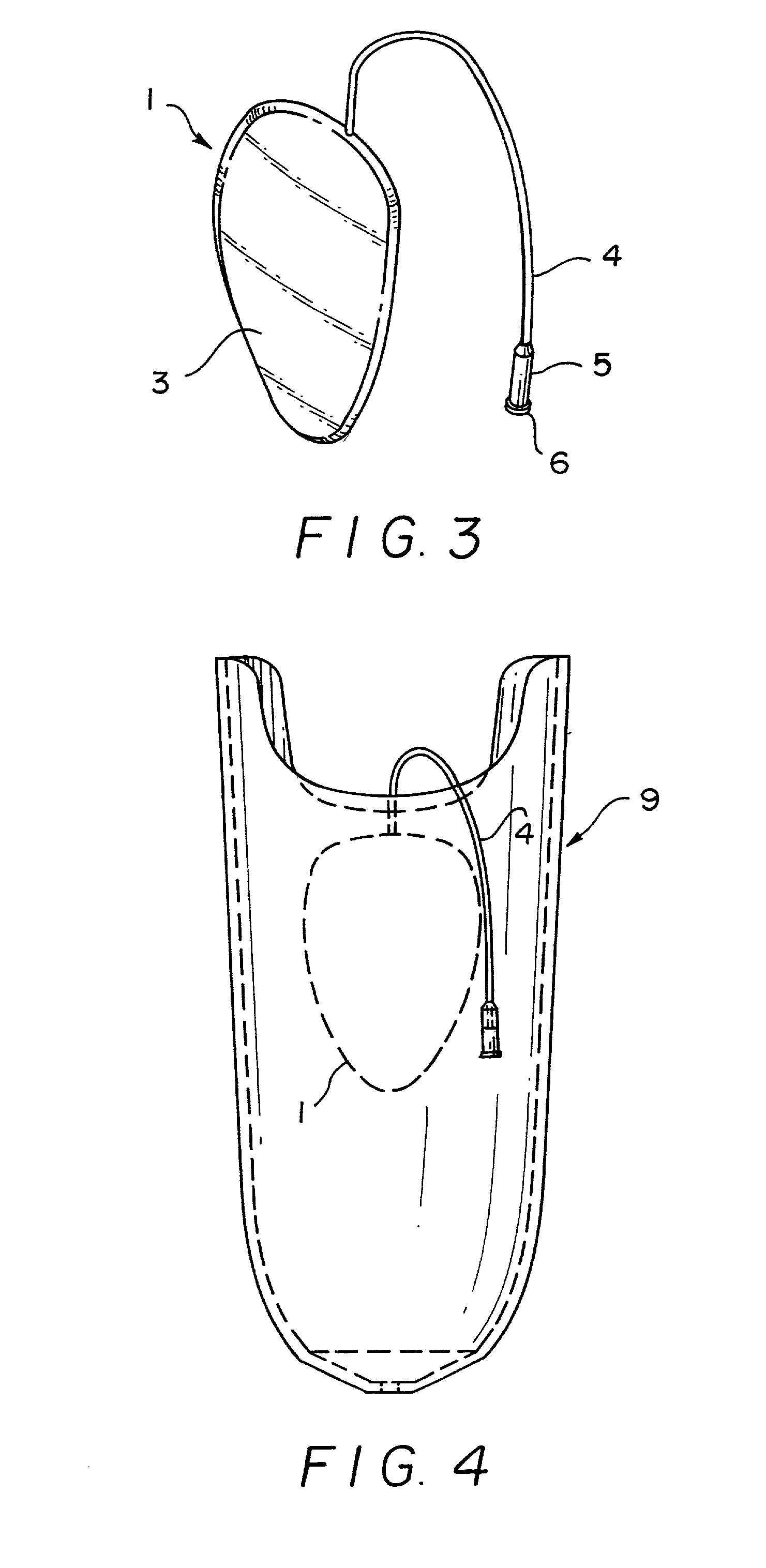

Artificial limb socket containing volume control pad

A volume control pad is provided for use in the socket of an artificial limb. The volume control pad has a core surrounded by a flexible shell. The core includes super absorbent polymer particles which form a gel Upon the addition of water thereto. The volume control pad includes a tube for the introduction of water into the core portion of the pad. The volume control pad provides a simple and inexpensive means for adjusting the conformance of the socket around the residual limb from an initial swollen condition to a further point in time in which the swelling has diminished.

Owner:KAUPTHING BANK

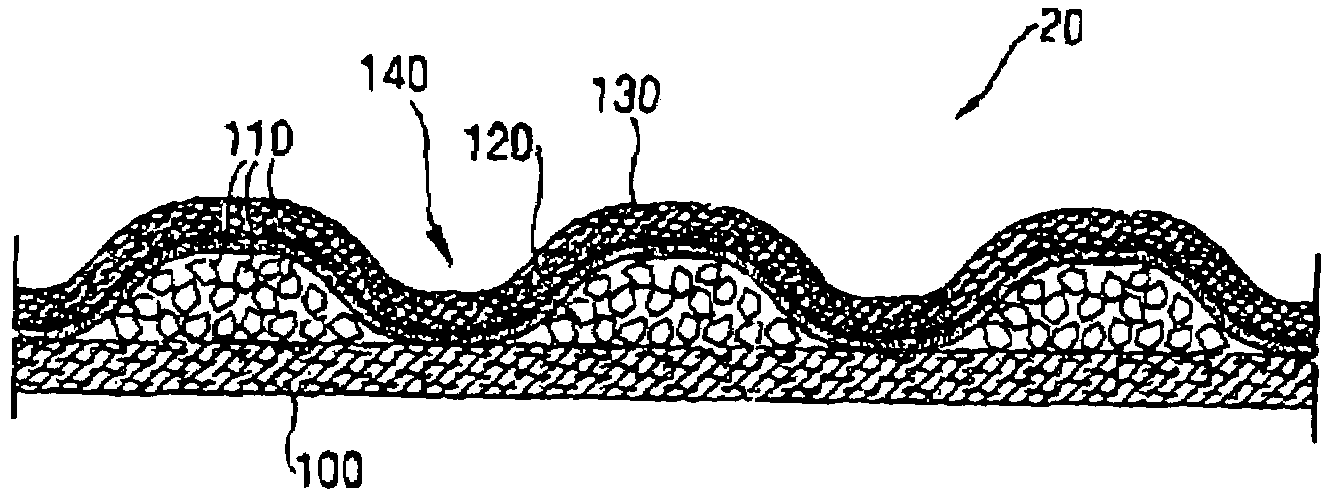

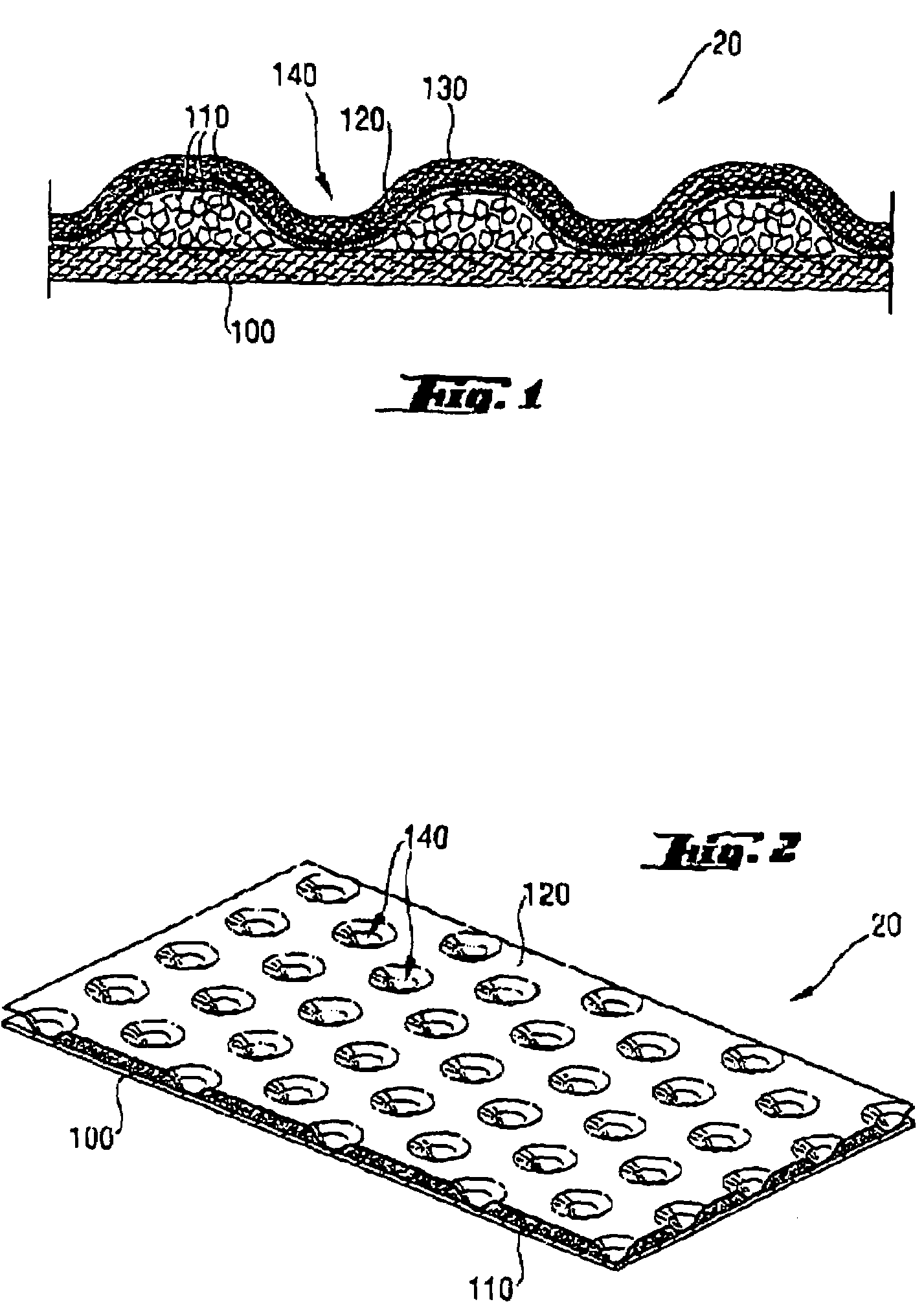

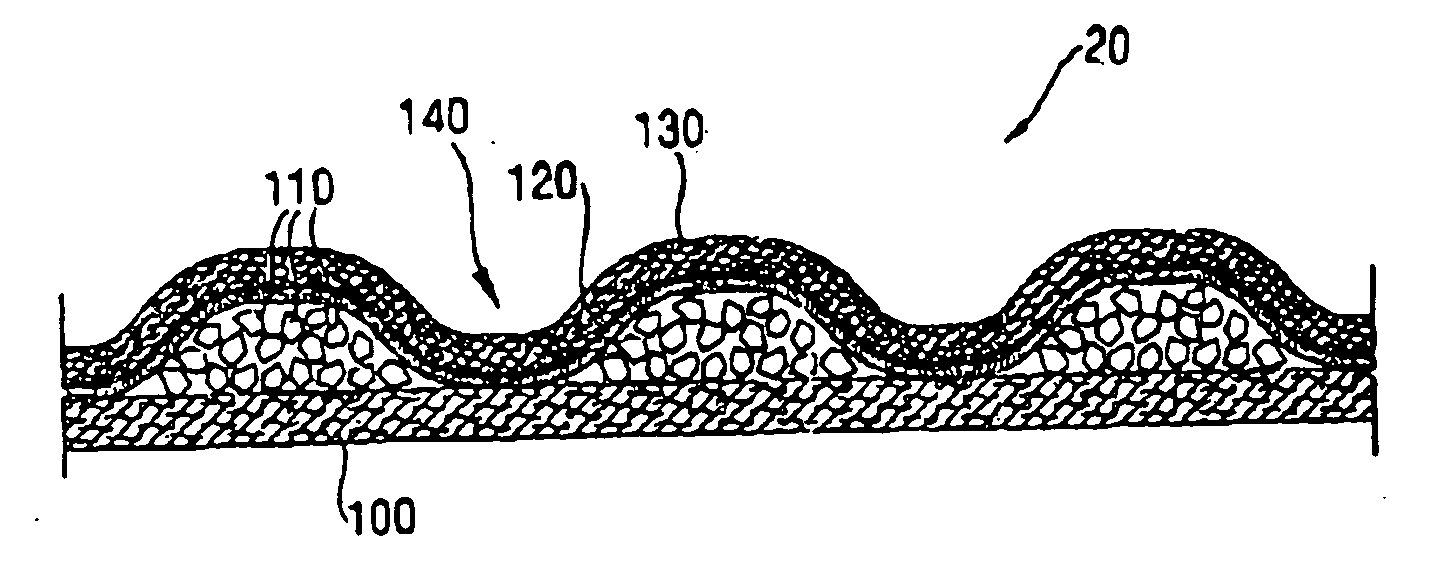

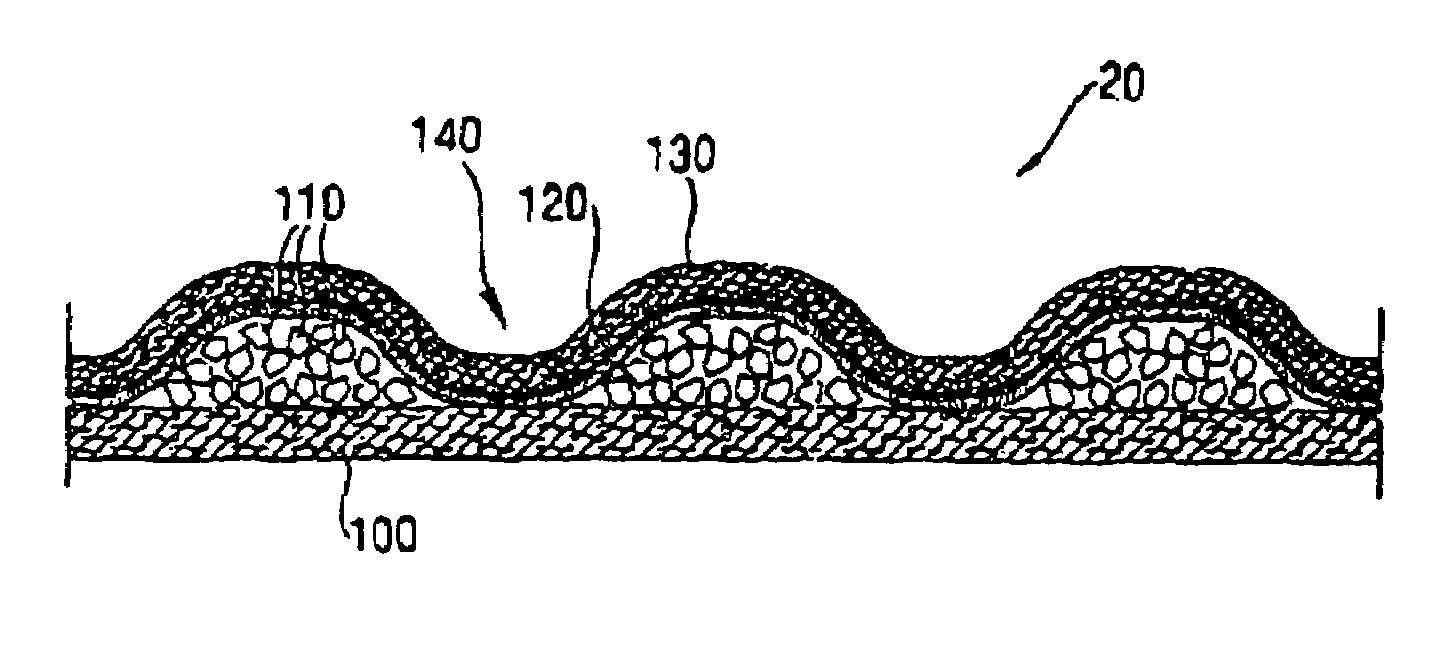

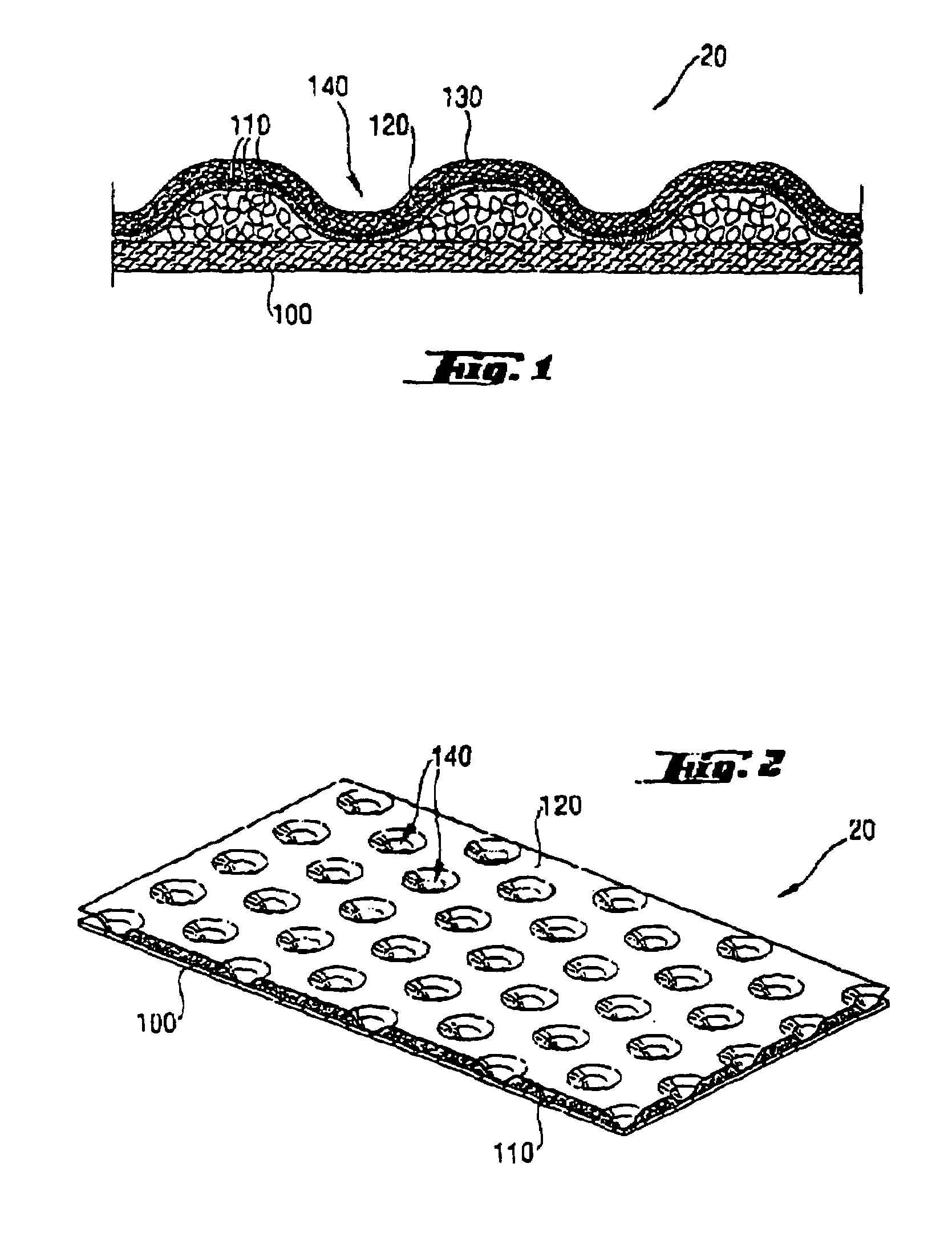

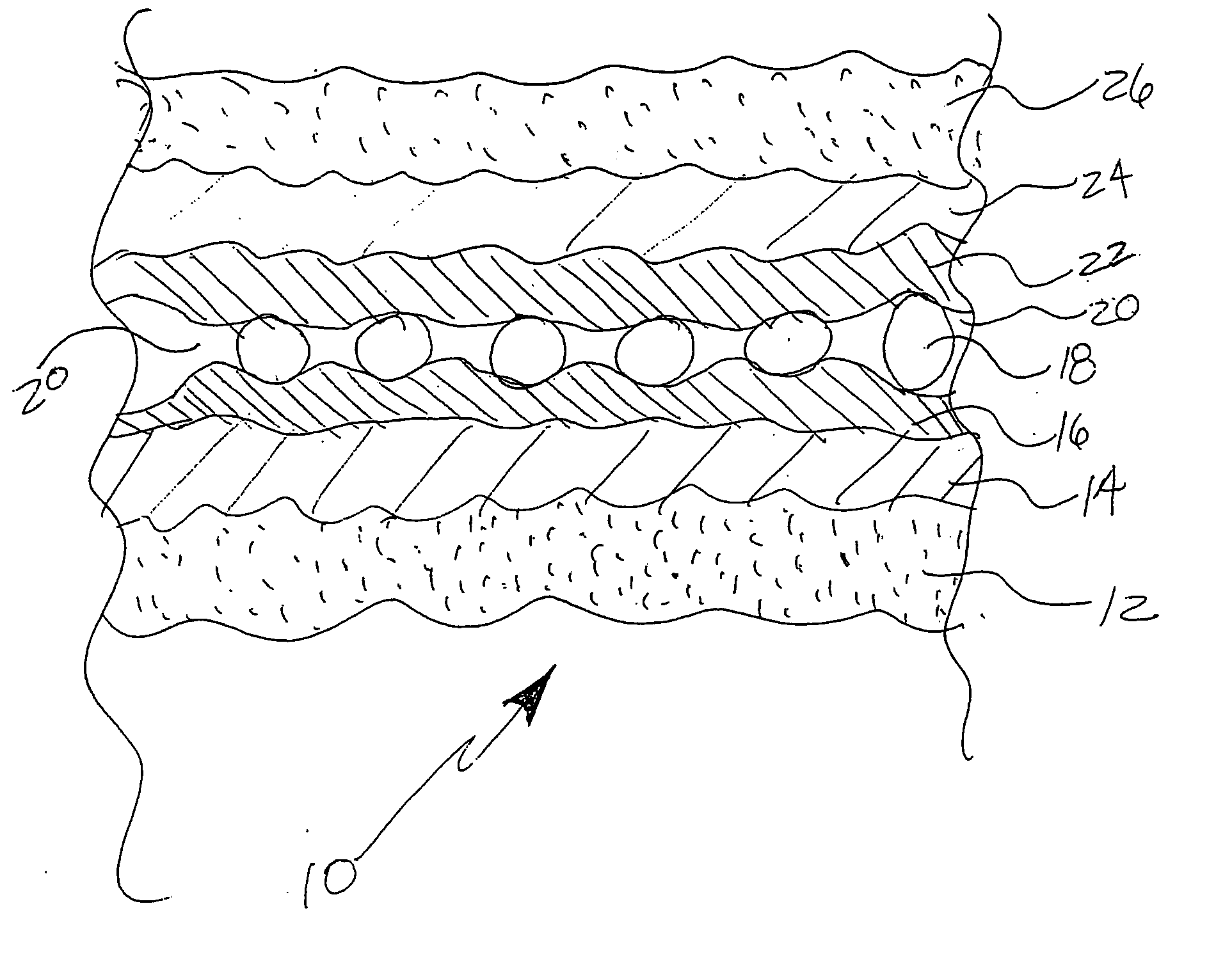

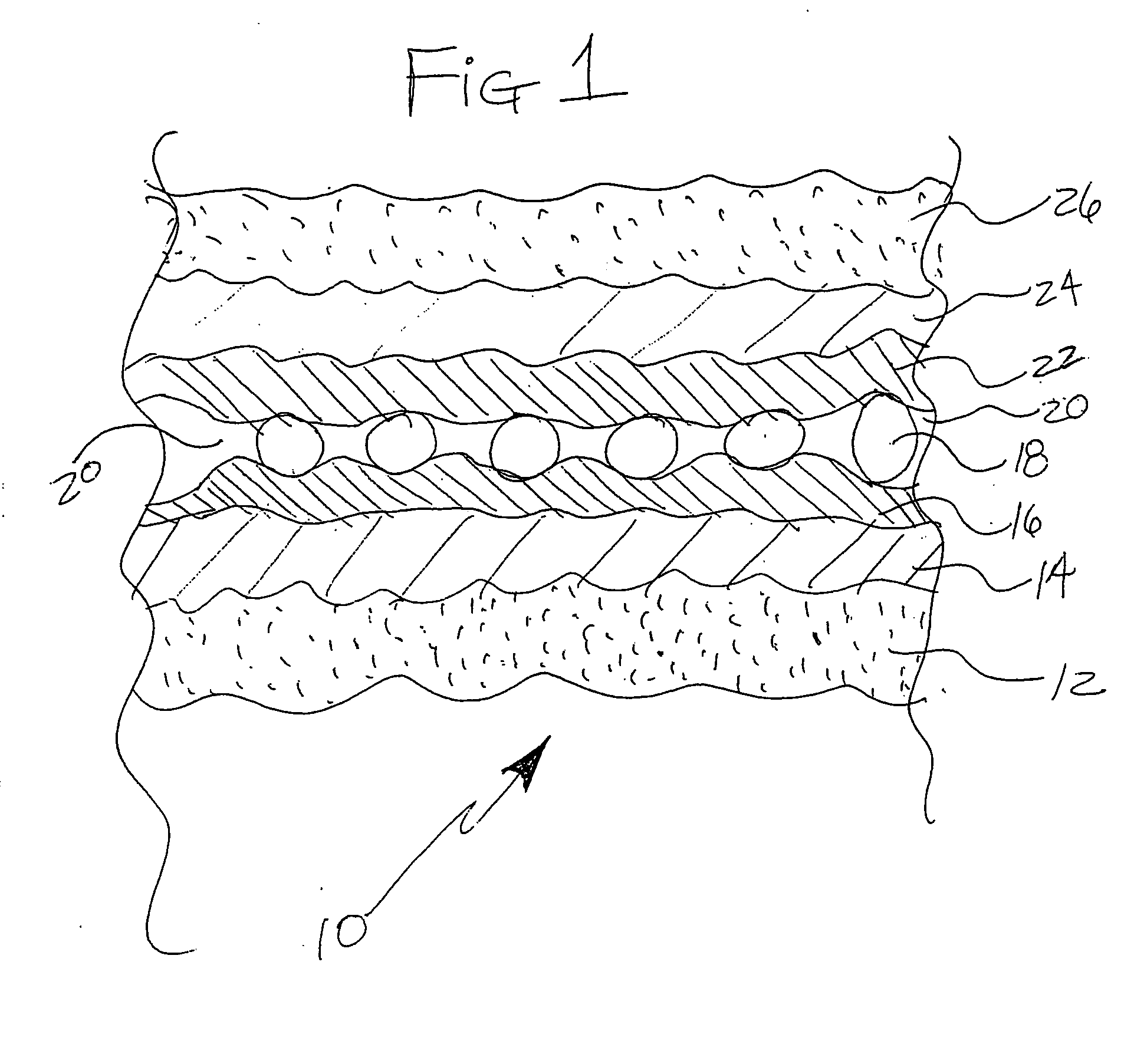

Multi-layer structure for supporting dispersed super absorbent polymeric material

InactiveUS20050118383A1Prevent seepageReadily availableLayered productsPedestrian/occupant safety arrangementTreatment feverSuper absorbent

A multi-layer structure containing an evenly dispersed super absorbing polymer to be used for fabric covered cooling, wetting, and fire deterrent applications. Such multi-layer structure incorporates a laminate super-absorbing polymer within various layers and pockets to maintain an even distribution of super-absorbing polymer within the fabric layers. Various applications such as cooling neckbands, fever reducing suits, house-covering fire deterrent blankets and other personal cooling devices are disclosed.

Owner:CARGILL LYNN E +2

Synthetic turf having cooling layer

The present invention describes a synthetic turf having super absorbent materials in order to keep the synthetic turf cooler than conventional synthetic turfs. The present invention also provides for synthetic turf infill cooling particles comprising a layer of water-absorbing material coating a foundation comprising a core substrate. In one embodiment, the cooling particle is comprised of a core particle or substrate, which is coated with a water-absorbing material. In one embodiment, the water-absorbing material is a super absorbent polymer.

Owner:SAPTURF

Absorbent product with low dryness index

The embodiments provide an absorbent garment, such as a disposable diaper, incontinent pad, sanitary napkin, and the like, that has an absorbent core that provides for a long term dryness profile. The dryness profile reflects real world long term usage of absorbent products. Such new absorbent garments can be constructed with absorbent cores containing synthetic fibers and super absorbent particulates.

Owner:LITVAY JOHN D

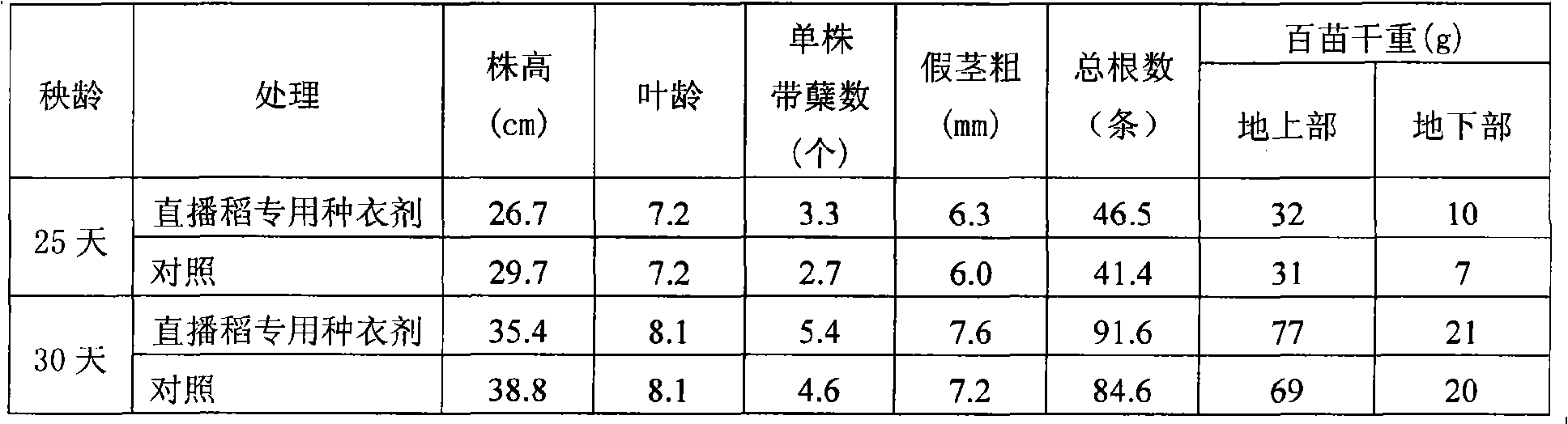

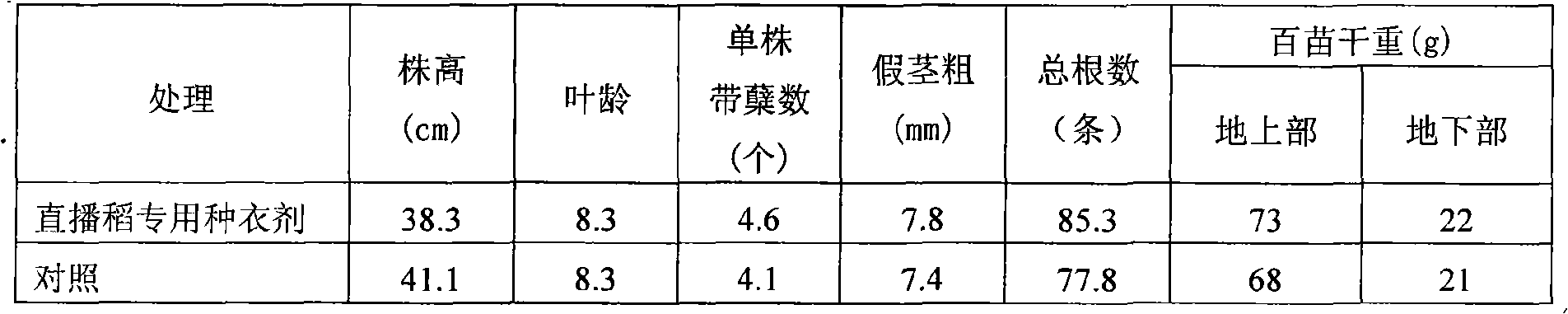

Seed coating agent special for direct seeding rice

InactiveCN101310582AEfficiently regulate changes in moisture contentRegulating changes in moisture contentSeed coating/dressingDiseaseAdditive ingredient

The invention discloses a seed coating agent specially used for direct seeding rice, which is characterized in that the seed coating agent mainly contains the following ingredients by weight: 2 to 8 percent of super absorbent resin, 1 to 5 percent of oxygenates, 0.1 to 0.5 percent of sparrow and rat destruction agent , 0.5 to 2 percent of bactericide, 0.5 to 2 percent of pesticide, 0.02 to 0.2 percent of plant growth regulator, 3 to 10 percent of trace element fertilizer and the margin is special type mineral clay. The powder raw materials are crushed to more then 100 meshes and are mixed evenly, the mixture is coated on the surfaces of rice seeds by a seed-coating method for direct sowing, thus clay sacculus integrating 'a small water reservoir, a small oxygen reservoir, a small drug storage and a small fertilizer storage' are formed around the rice seeds and at the roots of seedlings; the seed coating agent has the effects of preserving and providing water, ventilating and providing oxygen, promoting seedling emergency, preventing diseases and killing pests, preventing mice and destructing sparrows, strengthening seedlings and roots and increasing production. The seed coating agent is also characterized by low dosage, low cost, simple and convenient operation, and the like, thereby being applicable to coating rice seeds which are directly sowed both on flooded paddy fields and dry paddy fields.

Owner:JIANGSU LIXIAHE REGION AGRI RES INST

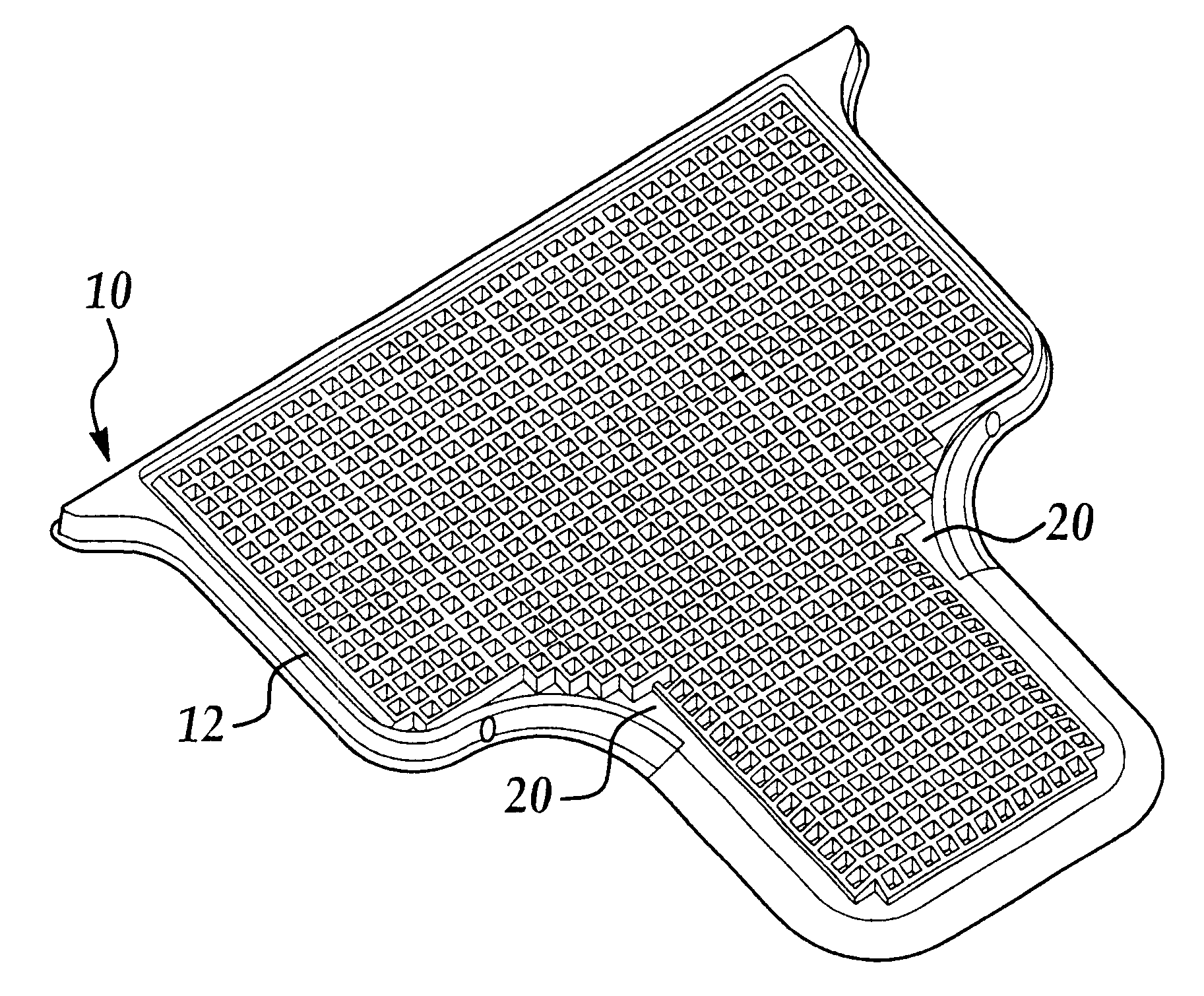

Surface protection system mat

A surface protection system consisting of three pieces, (1) cartridge-top, (2) absorbent core, and (3) base unit. The cartridge-top, made of semi-flexible material with a waffle grid design of drainage holes, traps and directs liquid spills into the absorbent core. The core is a thin layer of material attached to the entire underside of the cartridge-top, forming one unit. The core material, consisting of cotton-fluff and a super-absorbent polymer or fiber, holds and wicks the liquid away from the surface, turning it into a jell. The cartridge-top is snapped onto the top of the base unit covering it completely. It is disposed via routine trash collection during maintenance (usually weekly) and replaced by a fresh one. The base unit is also made of semi-flexible material and is extremely durable. It is placed on the floor under a urinal and secured to the floor to prevent its accidental displacement.

Owner:WRIGHT RICKIE J +1

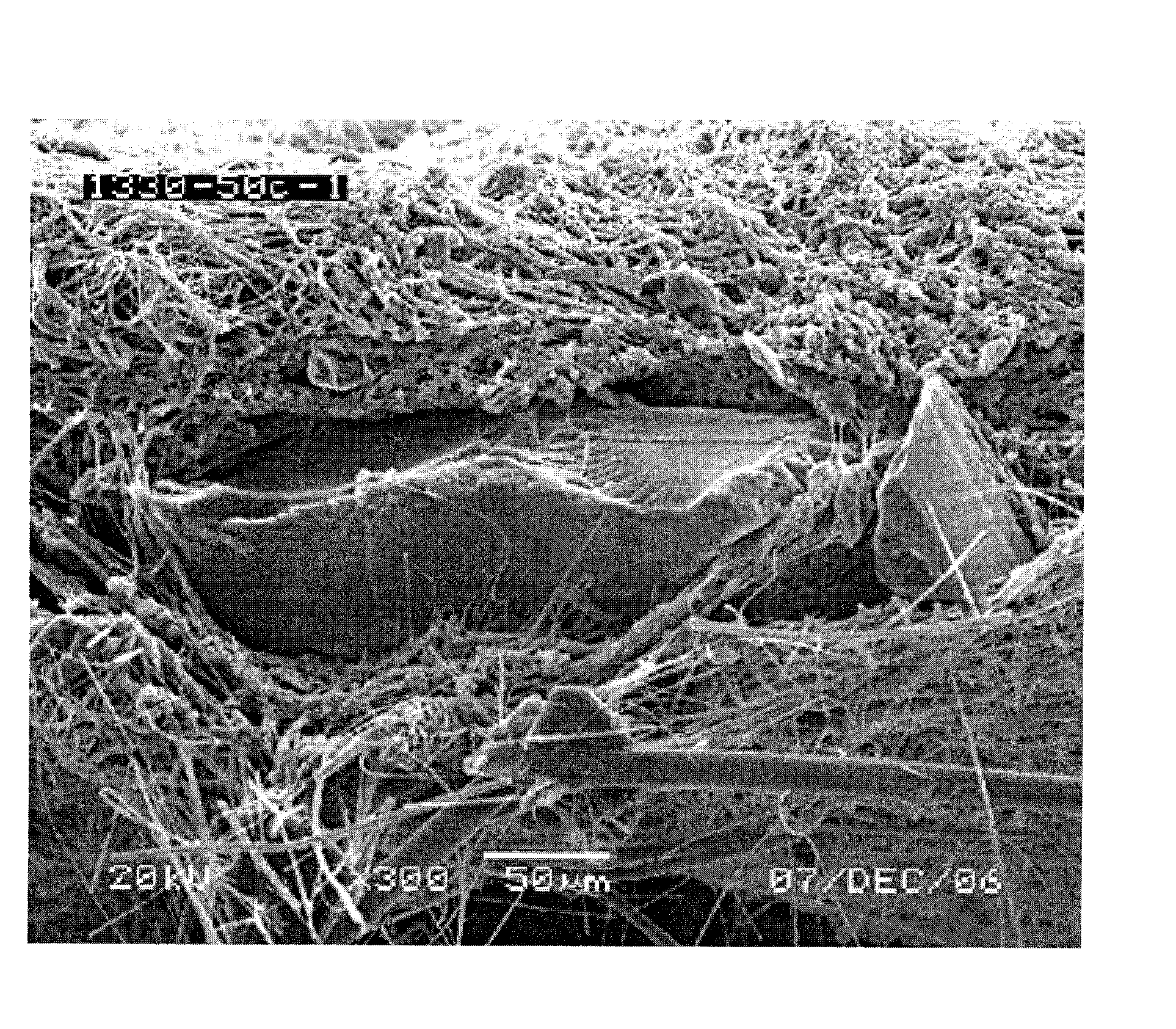

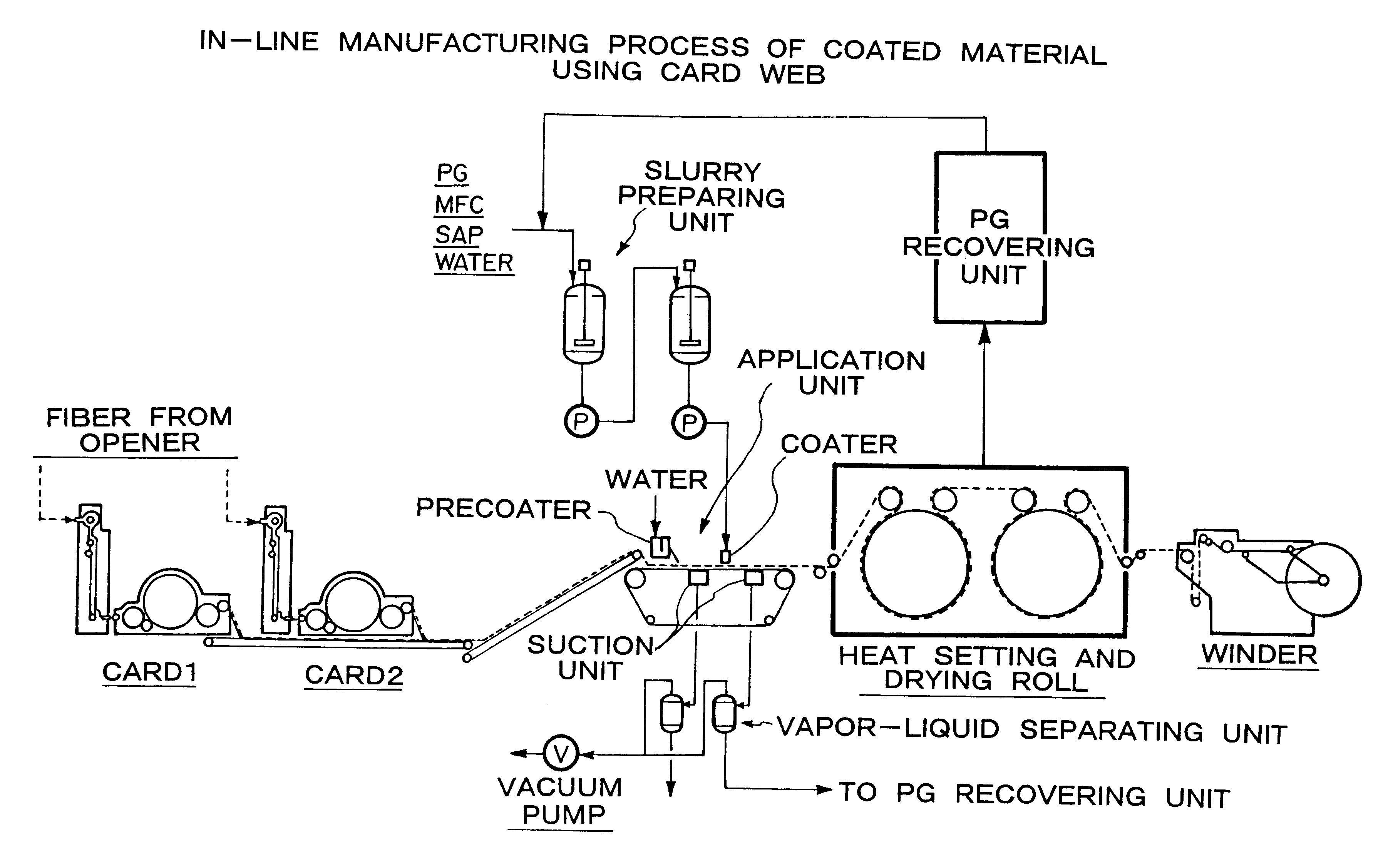

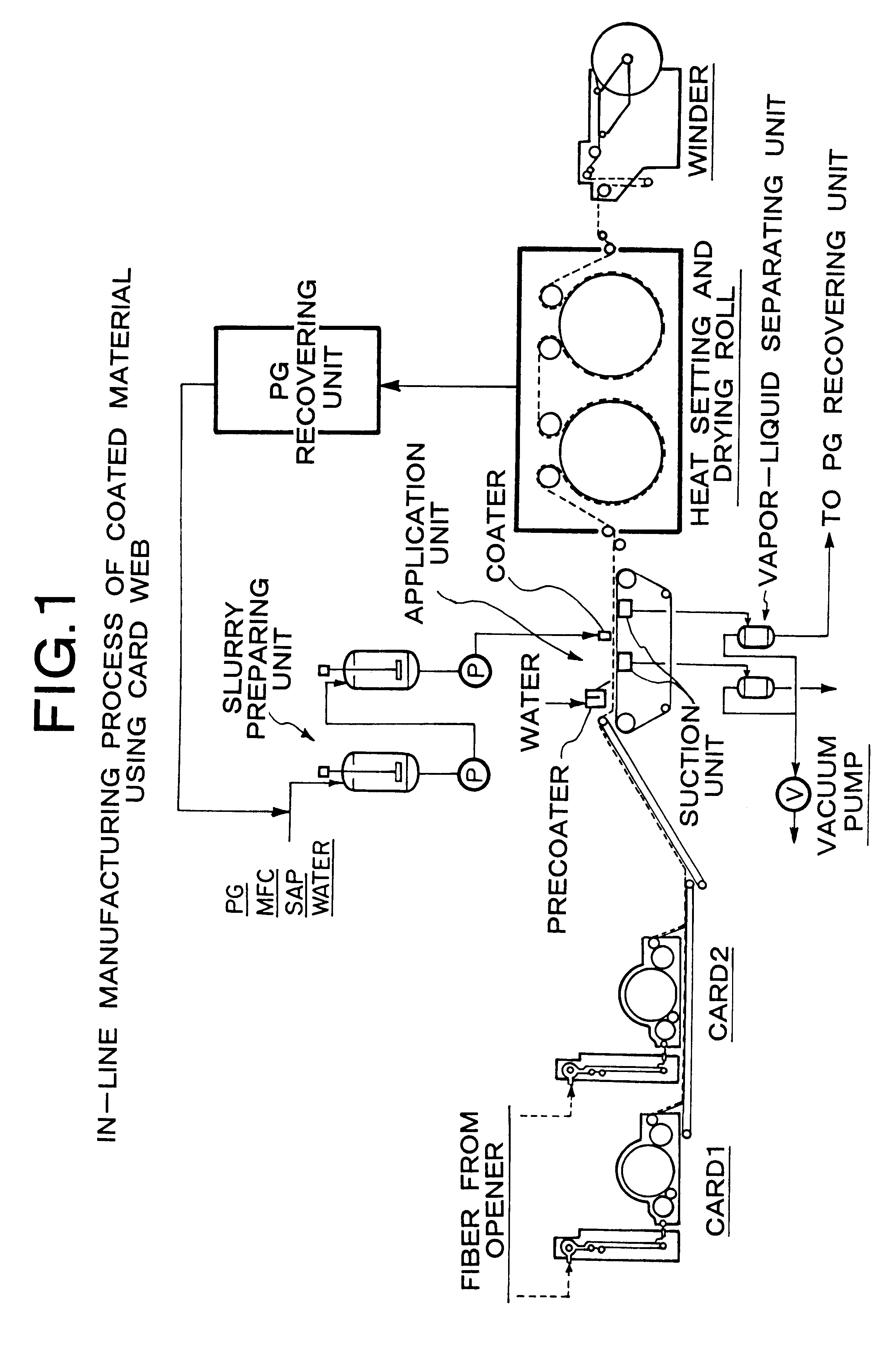

Super water-absorbent composite and method for preparation thereof

InactiveUS6540853B1Low costBenefit is optimisedNon-fibrous pulp additionWood working apparatusFiberPolymer science

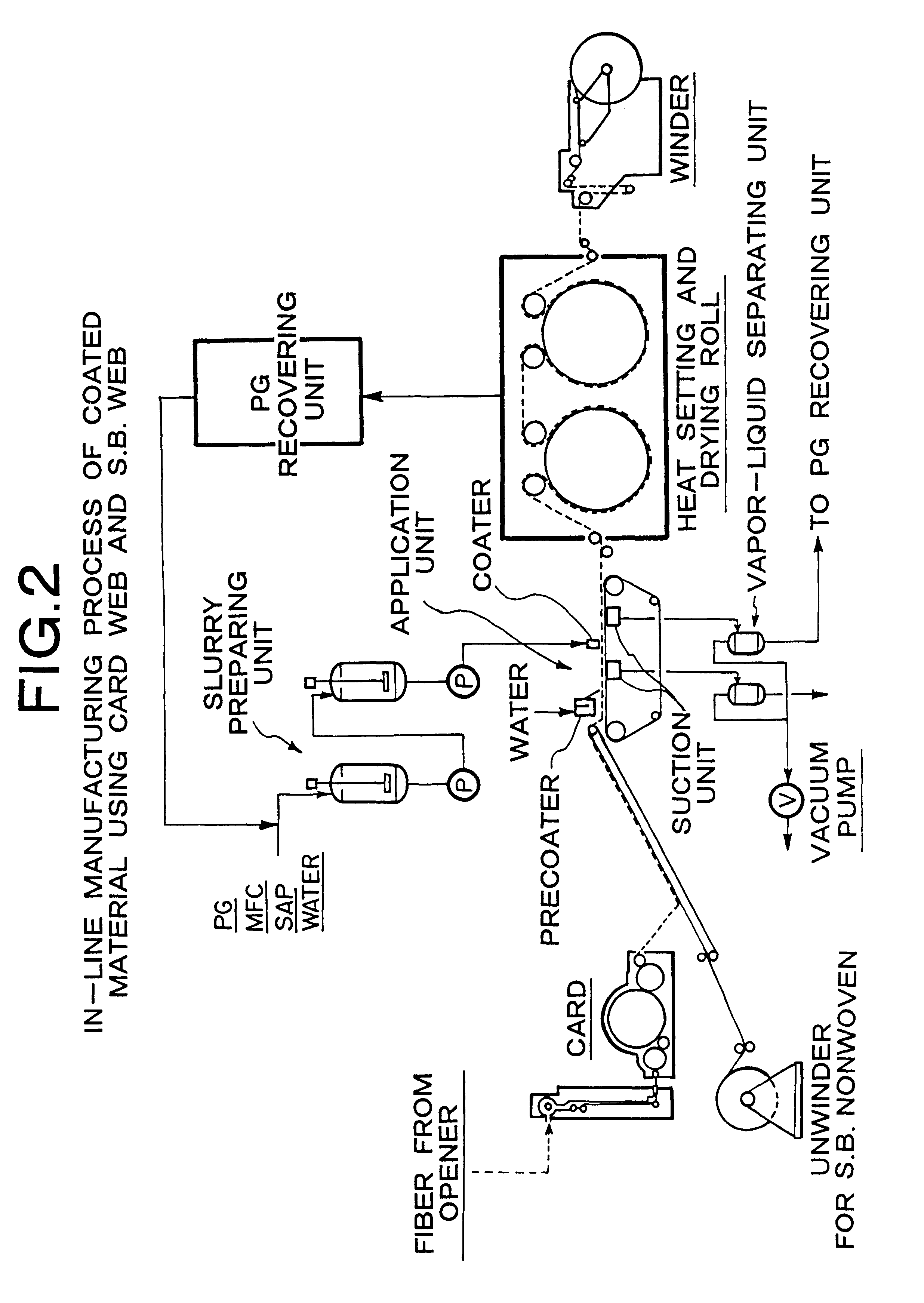

An absorbent composite sheet mainly consisting of a fibrous substrate web, a super absorbent polymer, and a bonding component bonding both of them with each other, wherein (a) the fibrous substrate web is a non-bonded web with a few of the constituent fibers bonded with each other, (b) a liquid mixture system is used of a medium mainly consisting of the super absorbent polymer and the bonding component, (c) a composite web is formed by adding the liquid mixture system to the fibrous substrate web, and (d) a liquid component is separated from the composite web so that fixing of the super absorbent polymer to the fibrous substrate web and bonding of the webs of the fibrous substrate web with one another are carried out at the same time. Methods of manufacturing such absorbent composite sheets are also provided.

Owner:DSG INT LTD

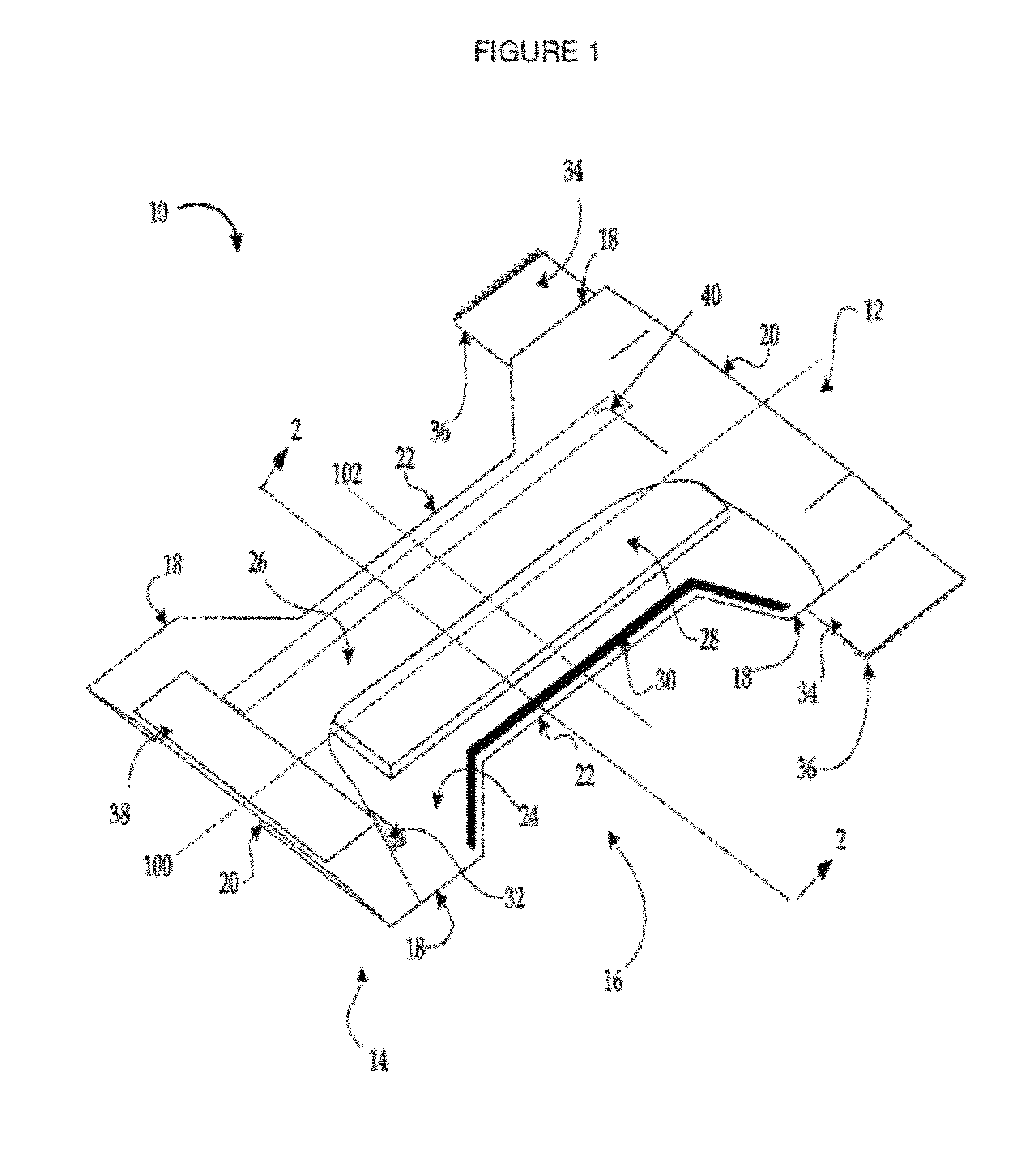

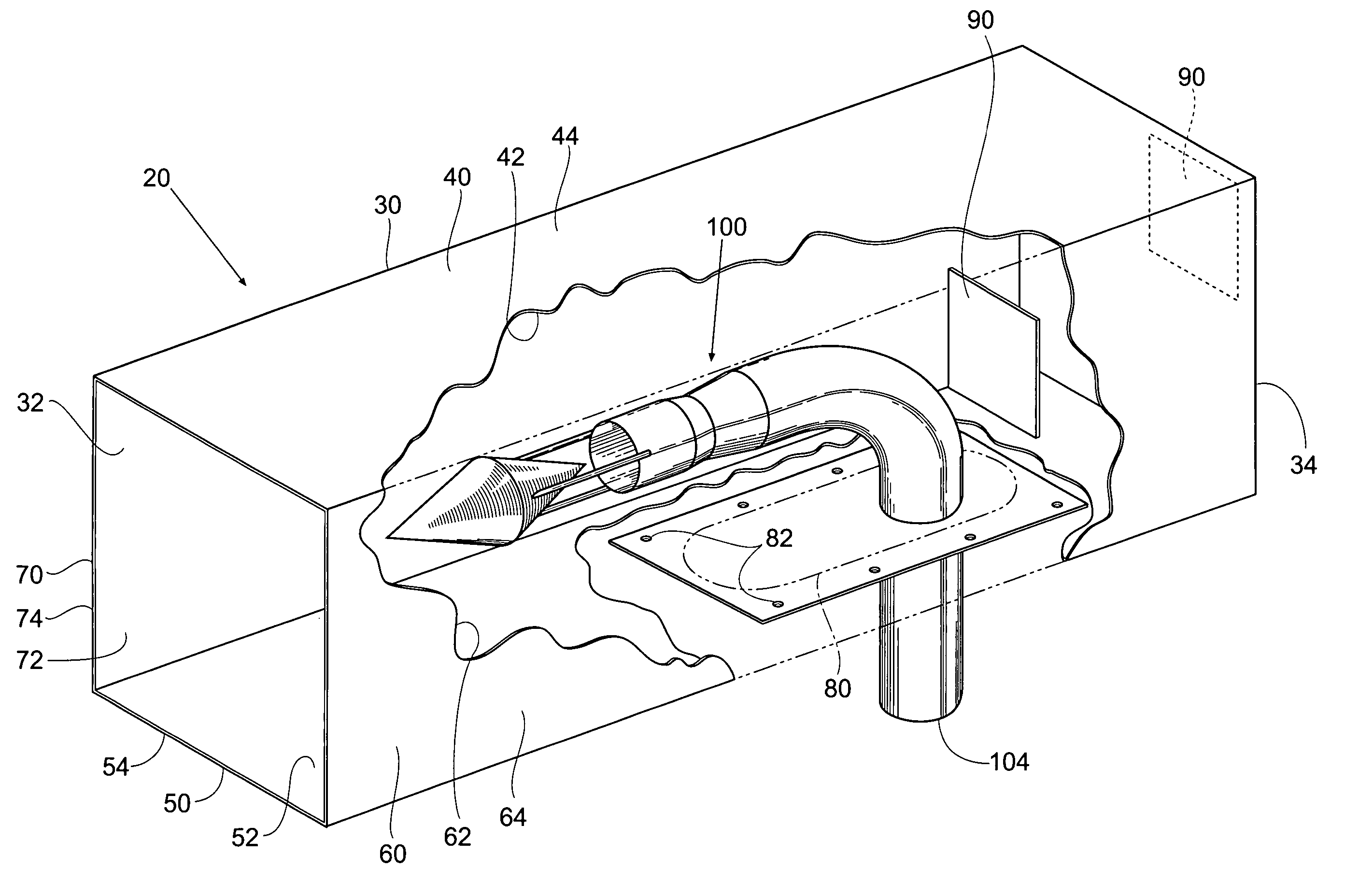

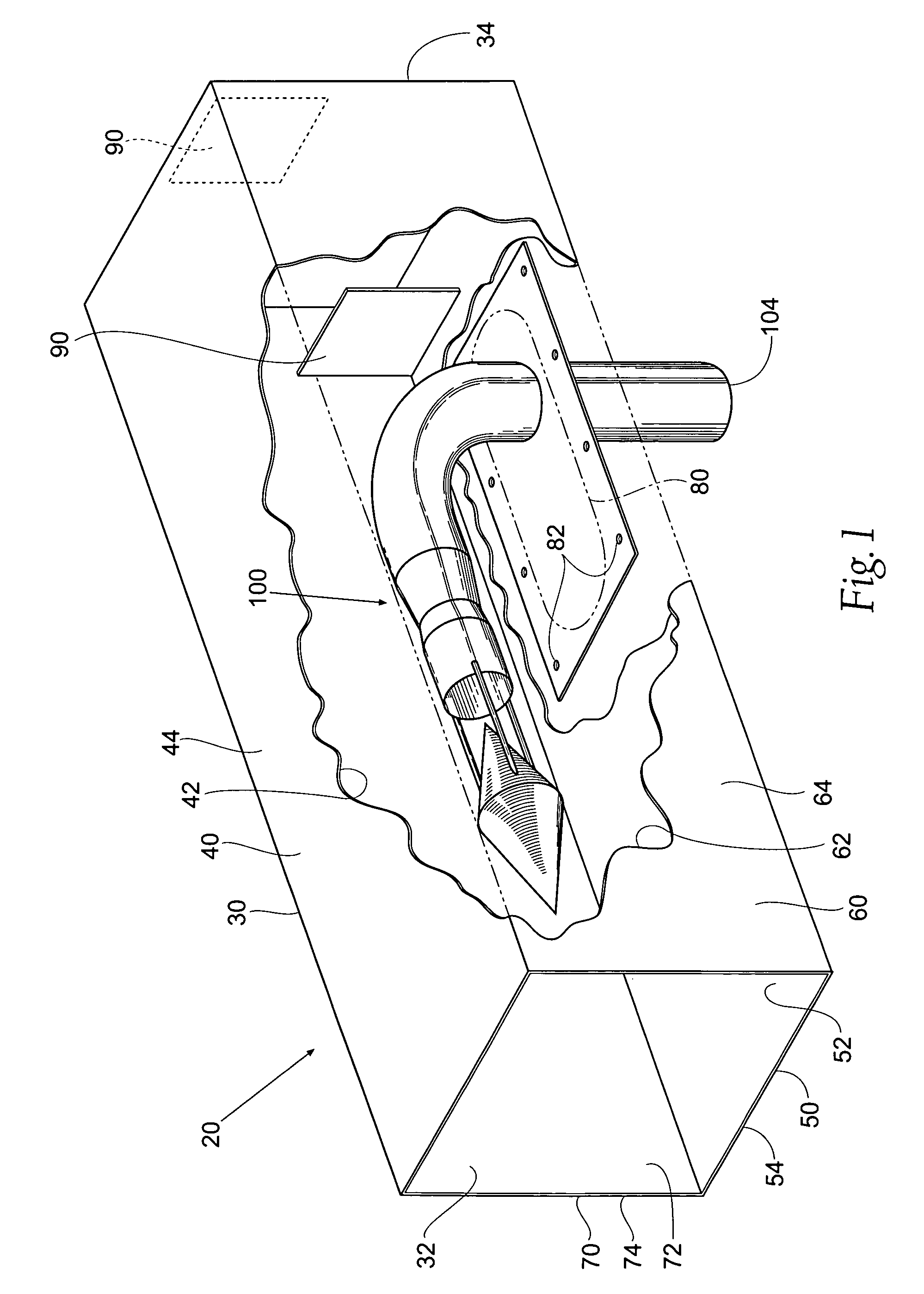

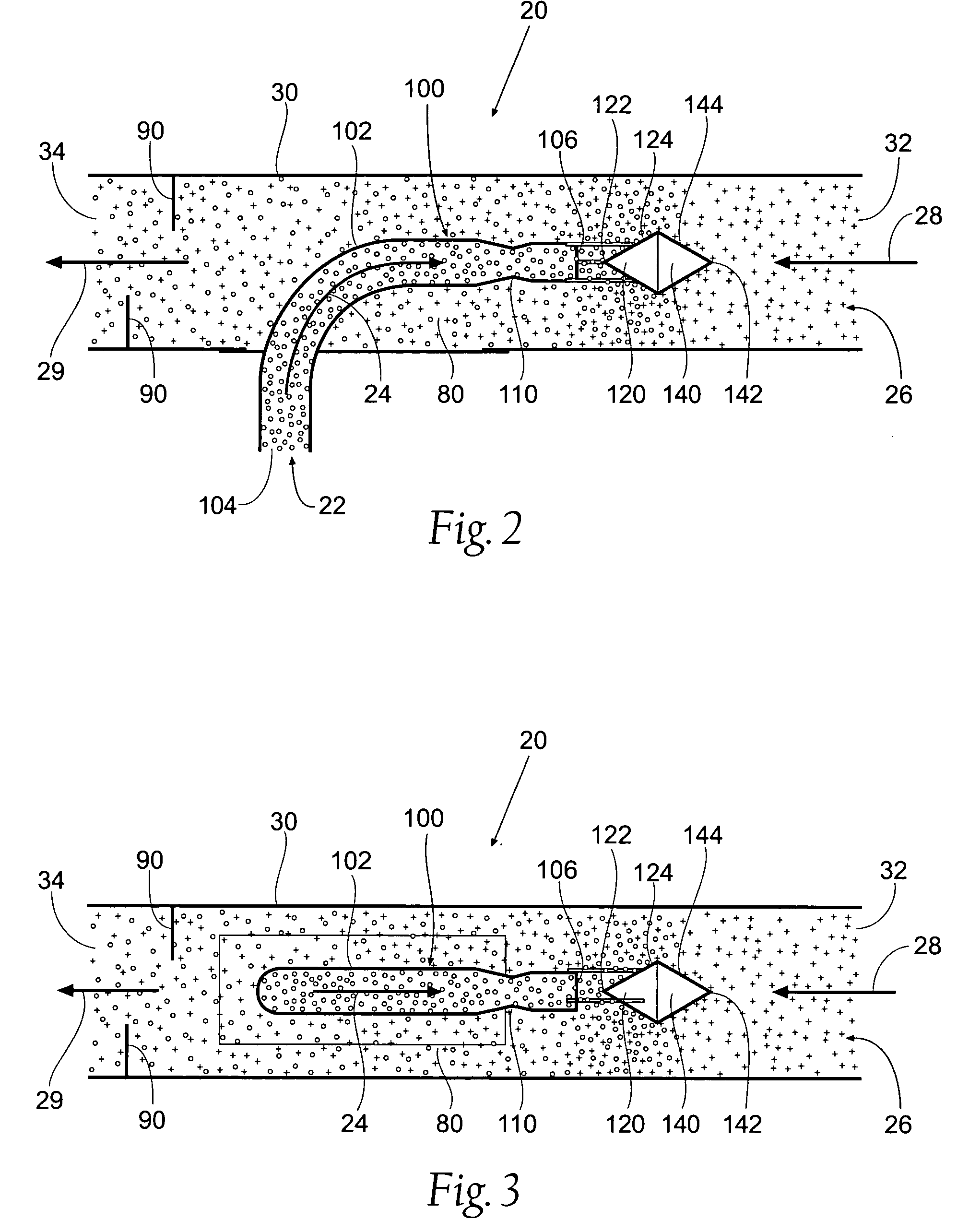

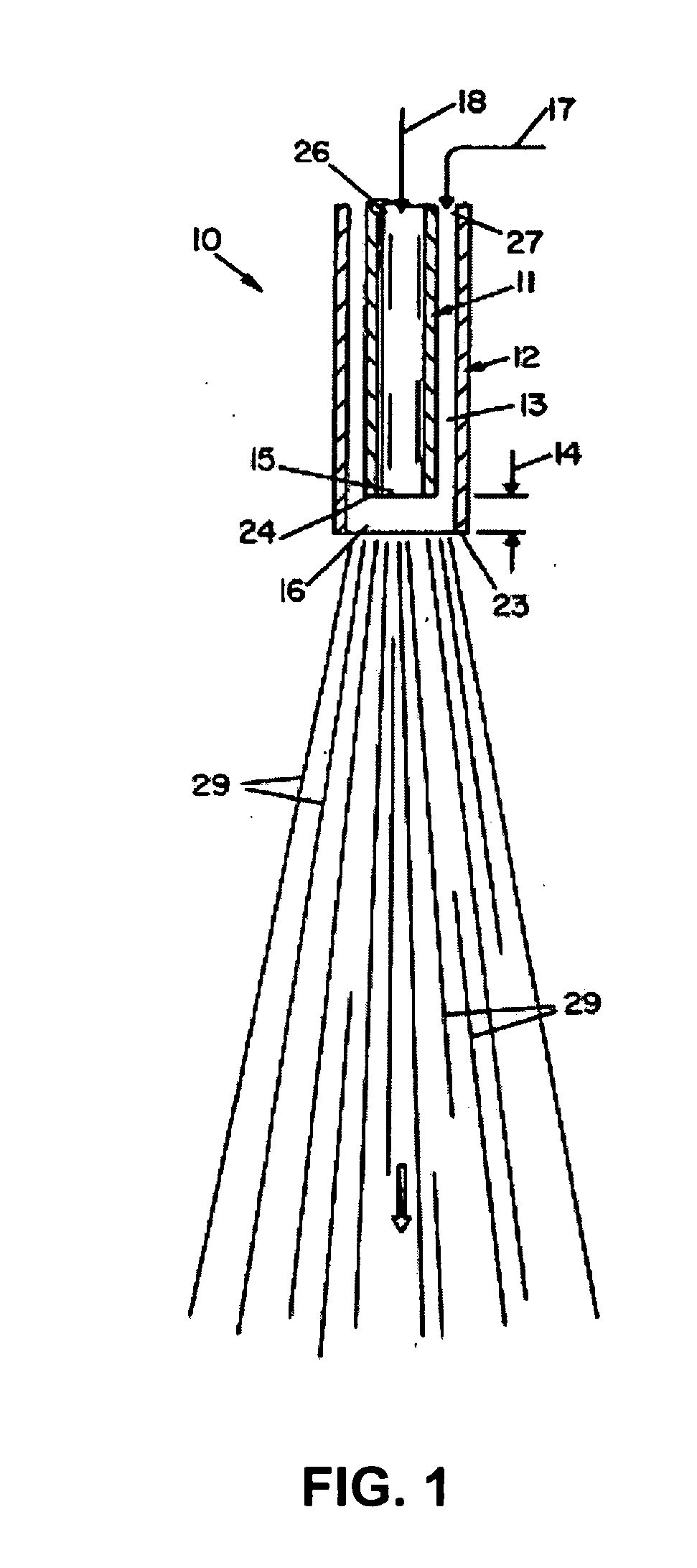

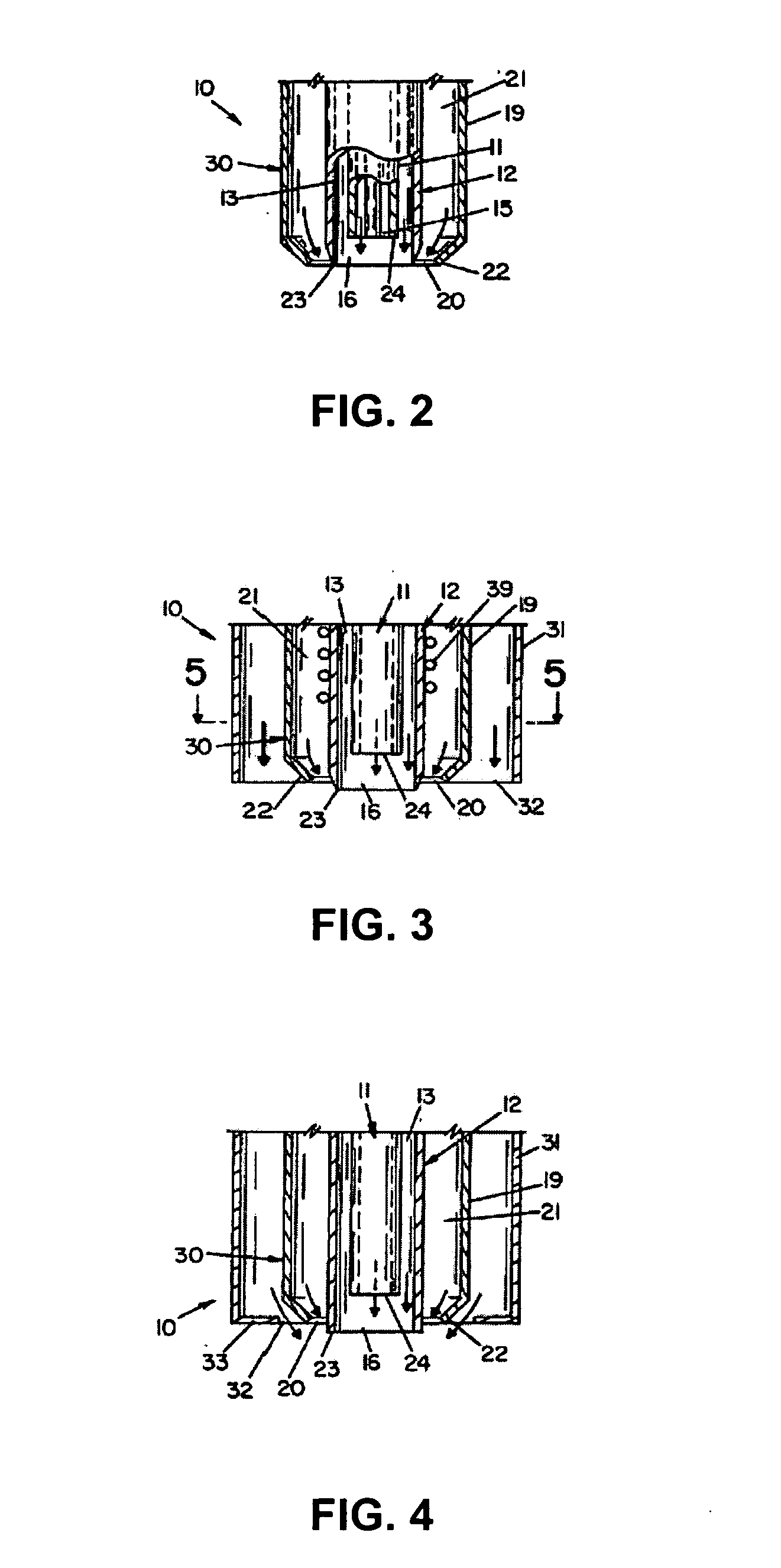

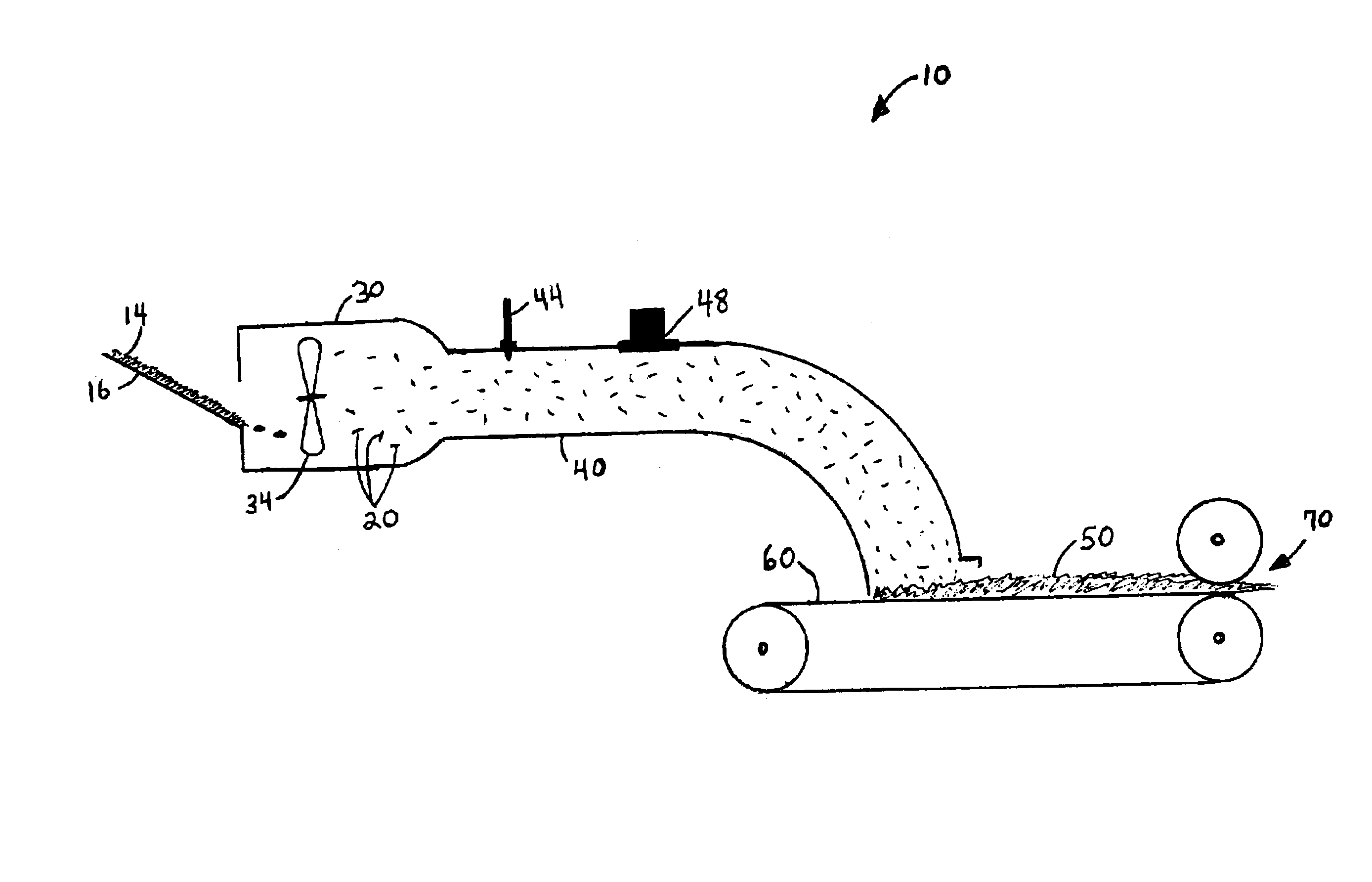

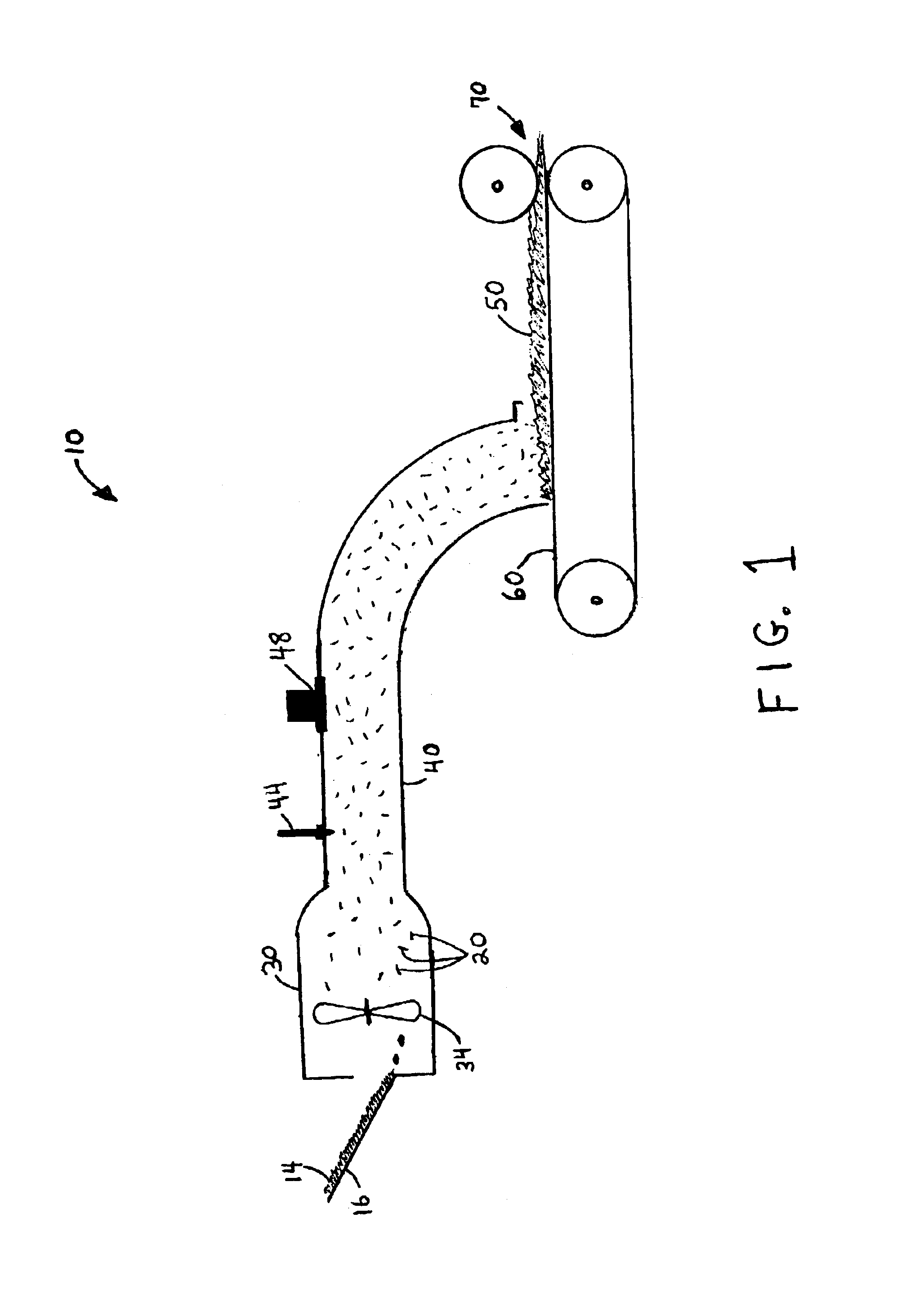

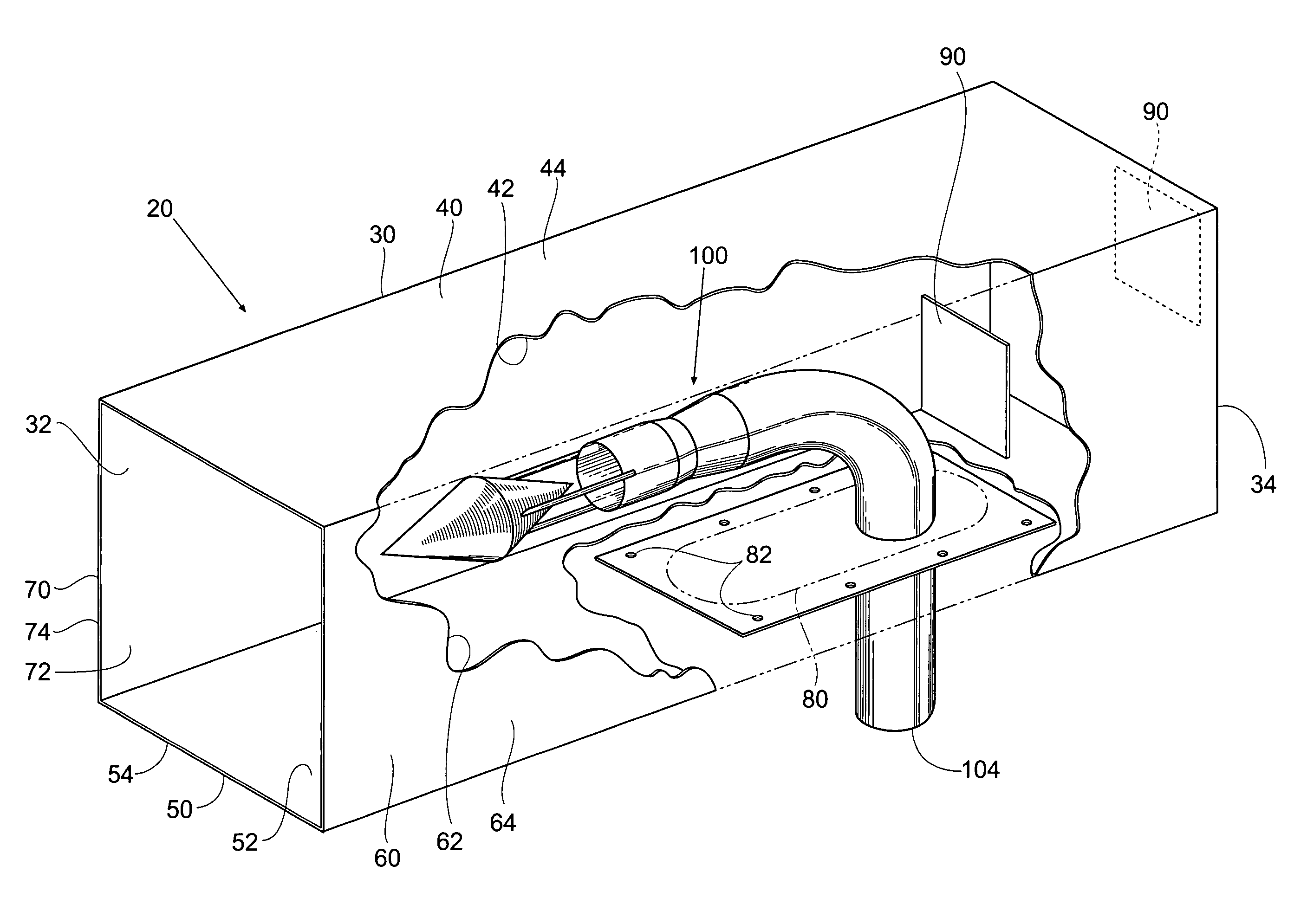

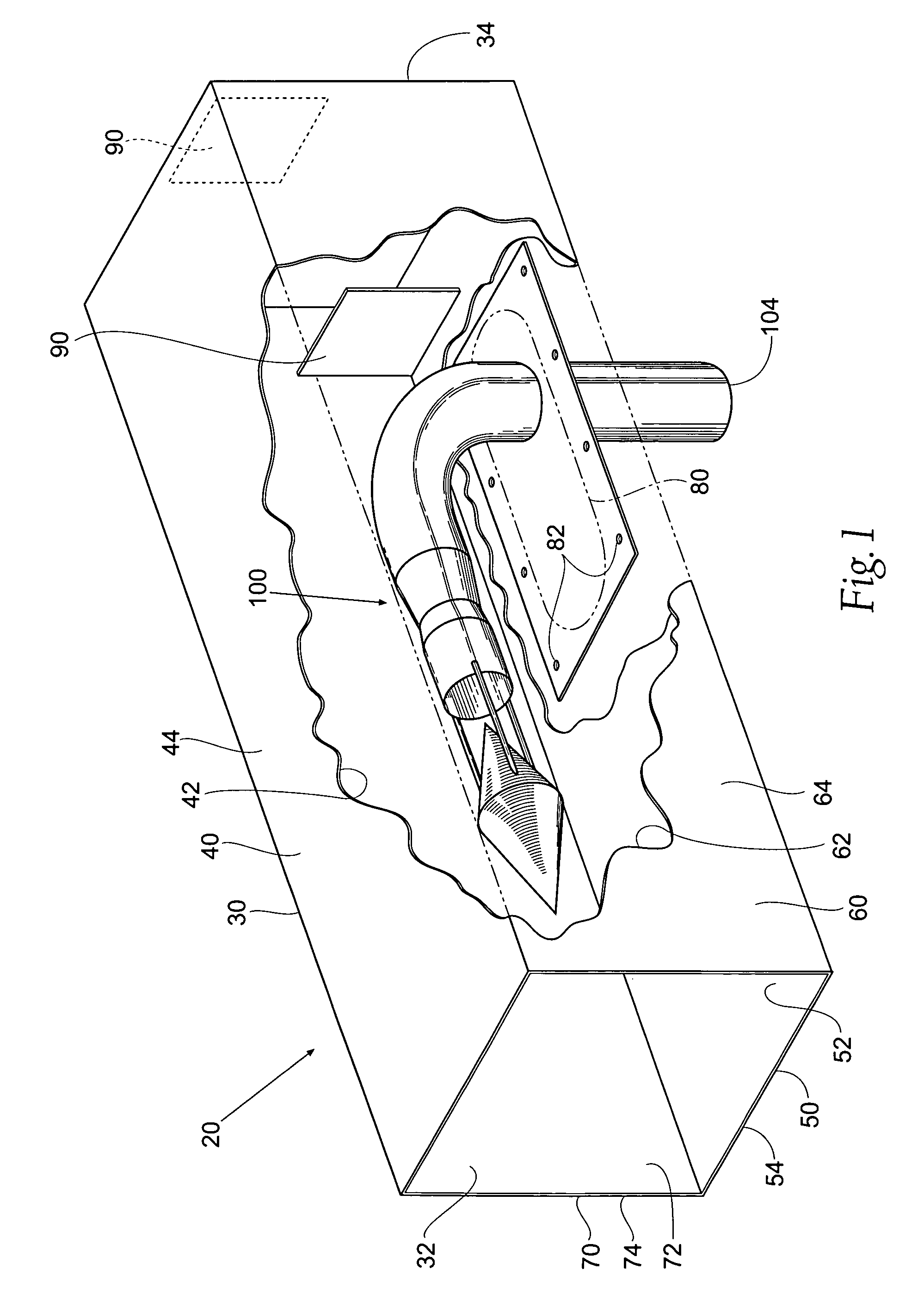

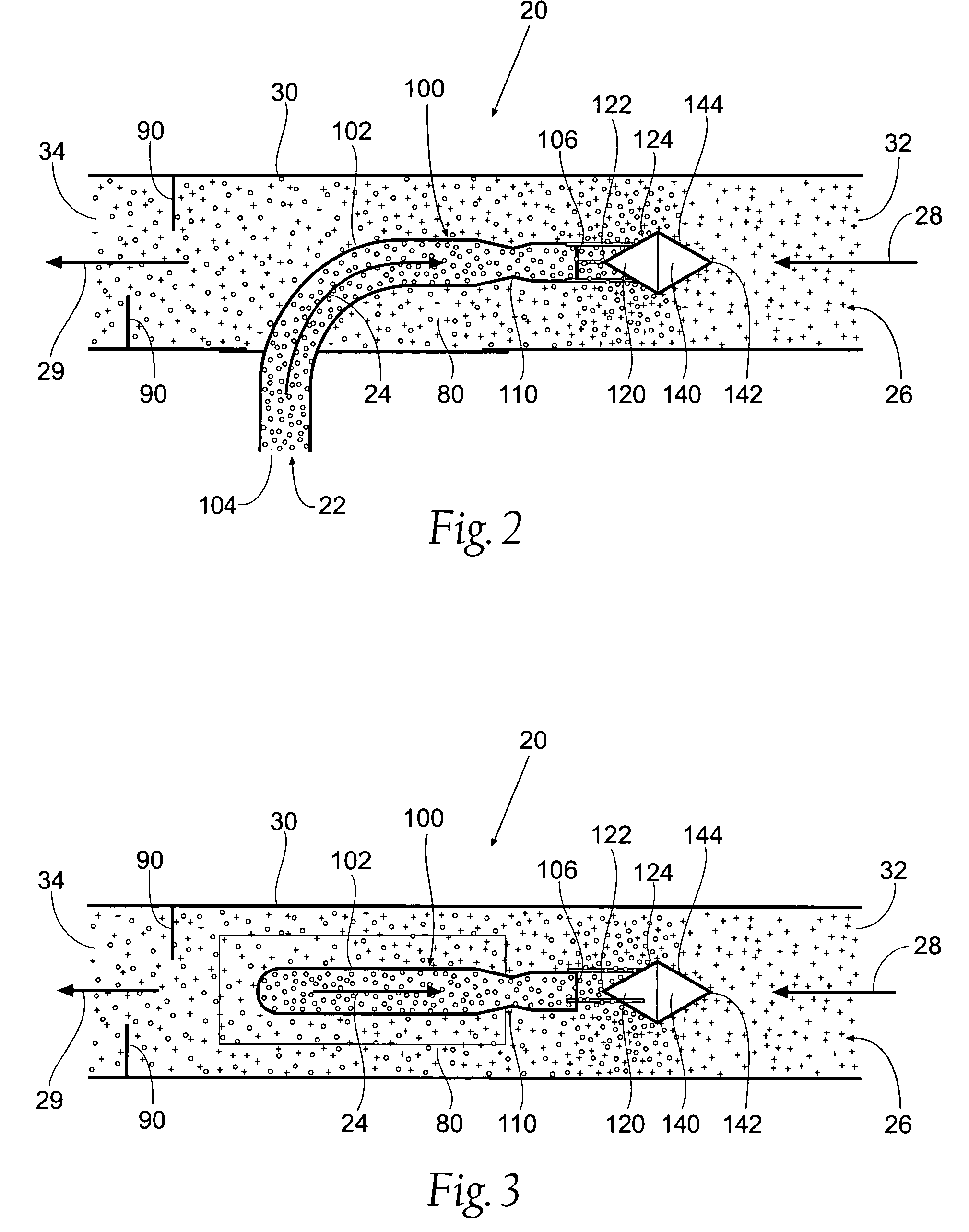

Super absorbent distribution system design for homogeneous distribution throughout an absorbent core

InactiveUS20050234412A1Achieve effectEnhancing objectiveCeramic shaping apparatusBaby linensDistribution systemSuper absorbent

A super absorbent distribution system for homogenous distribution throughout an absorbent core is disclosed. A super absorbent material is injected into a stream of absorbent fluff at an opposite direction to that of the stream of absorbent fluff. The super absorbent is blasted into the peak and outer surface of a cone shaped super absorbent barrier. The oncoming absorbent fluff also contends with a similarly shaped absorbent fluff barrier. The super absorbent material slows down as it hits the super absorbent barrier and oncoming fluff, then stops, then reverses direction and flows with the absorbent fluff as a homogenous distribution of super absorbent material and absorbent fluff. The combination of super absorbent material and absorbent fluff may encounter baffle members to further distribute the super absorbent material and absorbent fluff.

Owner:CURT G JOA

Artificial limb socket containing volume control pad

InactiveUS6936073B2Improve consistencySimple and inexpensiveArtificial legsArtificial handsSuper absorbentResidual limb

A volume control pad is provided for use in the socket of an artificial limb. The volume control pad has a core surrounded by a flexible shell. The core includes super absorbent polymer particles which form a gel upon the addition of water thereto. The volume control pad includes a tube for the introduction of water into the core portion of the pad. The volume control pad provides a simple and inexpensive means for adjusting the conformance of the socket around the residual limb from an initial swollen condition to a further point in time in which the swelling has diminished.

Owner:KAUPTHING BANK

Artificial limb socket containing volume control pad

InactiveUS20020040248A1Simple and inexpensiveMinimizes pain and discomfortArtificial legsArtificial handsSuper absorbentResidual limb

A volume control pad is provided for use in the socket of an artificial limb. The volume control pad has a core surrounded by a flexible shell. The core includes super absorbent polymer particles which form a gel upon the addition of water thereto. The volume control pad includes a tube for the introduction of water into the core portion of the pad. The volume control pad provides a simple and inexpensive means for adjusting the conformance of the socket around the residual limb from an initial swollen condition to a further point in time in which the swelling has diminished.

Owner:KAUPTHING BANK

Fibrous self-sealing components

InactiveUS20030099576A1High aspect ratioSuitable characteristicAnalysis using chemical indicatorsSamplingFiberPipette

The invention relates to gas- or liquid permeable materials that seal when exposed to water, and to methods of making such materials. In general, materials of the invention comprise super-absorbent fibers. The invention further relates to devices comprising self-sealing media including, but not limited to, pipette tips.

Owner:INPUT OUTPUT INC +1

Paper sepiolite sustained-release antibacterial cat litters

InactiveCN103348922AGood antibacterial effectImprove adsorption capacityAnimal housingCarboxymethyl celluloseSodium phosphates

Owner:WUHU LEISURELY NURSING SUPPLIES POLYTRON TECH INC

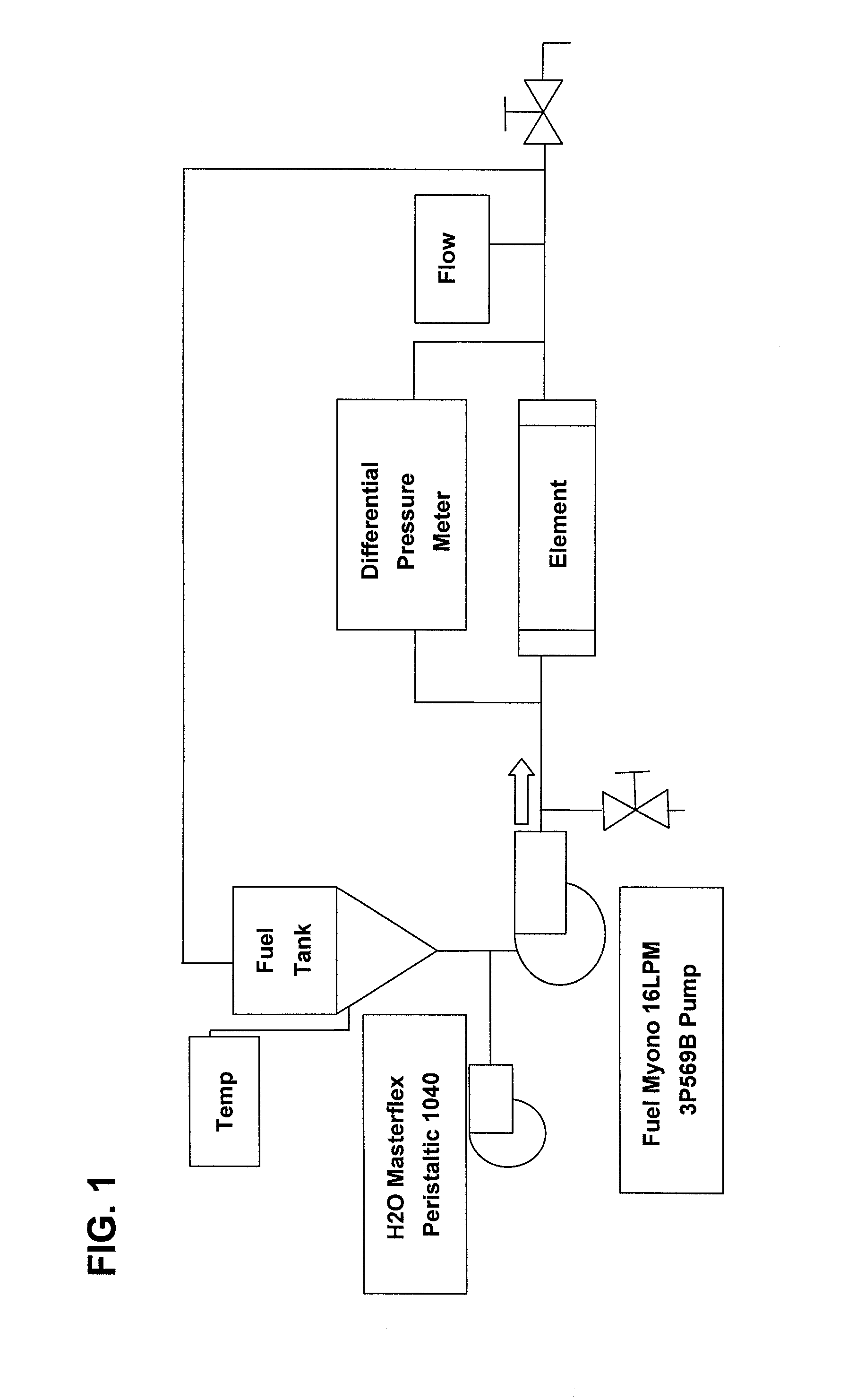

Method and apparatus for removal of water and/or water-based compounds from organic liquids or vice-versa

ActiveUS20070062855A1Efficient and complete removal of waterReduce leakageMaterial nanotechnologyWater/sewage treatment by ion-exchangeWater basedFiber

The present invention relates to methods and apparatus for removing water and / or water-based compounds from organic liquids / fluids. In one embodiment, the present invention relates to methods and apparatus that utilize fibrous media that contains, is impregnated, or is formed from at least one super absorbent compound, where the fibrous media is formed from nanofibers.

Owner:THE UNIVERSITY OF AKRON

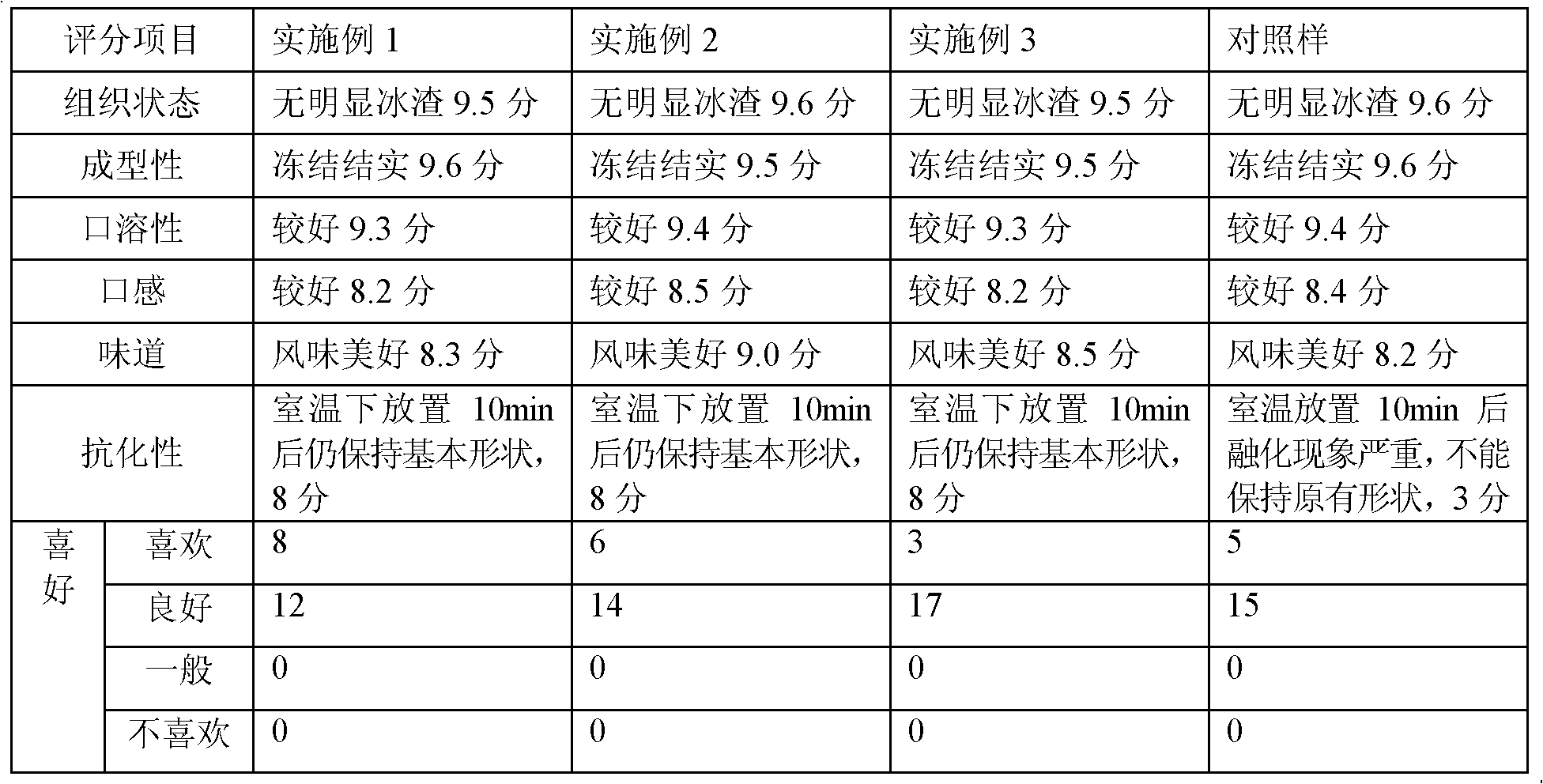

Self-expanding ice-cream and production method thereof

The invention provides self-expanding ice-cream and a production method thereof. The self-expanding ice-cream comprises, by total weight, 35%-80% of light cream, 0.1-5% of thickener, and 0.1%-5% of super absorbent polymer, wherein the thickener is from one or a plurality of gelatin, sodium alginate and carrageen, and the super absorbent polymer is from one or a plurality of locust bean gum, xanthan gum, gellan gum and guar gum. In addition, milk fat content of the ice-cream is 15%-25%. The production method of the self-expanding ice-cream includes: whipping light cream of the ice-cream ingredients until expansion rate of the light cream reaches 60%-85%; mixing the light cream with other ingredients to make ice-cream liquid; and pouring the ice-cream liquid into a mould prior freezing into the finished ice-cream. The ice-cream can have certain expansion rate and good organization and taste with no coagulating needed in production of the self-expanding ice-cream, and the ice-cream is excellent in forming performance, oral thawing performance and thawing resistance.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

In vivo use of water absorbent polymers

InactiveUS20050036983A1Improving fluid absorbing performanceLess interferenceMetabolism disorderDigestive systemMedicineRemove blood

The subject invention is a method and material for removing fluid from the intestinal tract of a host and may be useful in treating animals or human patients suffering from fluid overload states. In one embodiment, the subject method involves ingesting an enterically coated non-systemic, non-toxic, non-digestible, water absorbing polymer which absorbs fluid while passing through the intestinal tract. The polymer is excreted in the feces wherein the polymer and absorbed fluid is removed from the body. Preferred polymers include super absorbent acrylic acid polymers, preferably provided in bead form. The polymers may include functional groups for selectively removing blood borne waste products, e.g. urea, from the G.I. tract.

Owner:SORBENT THERAPEUTICS

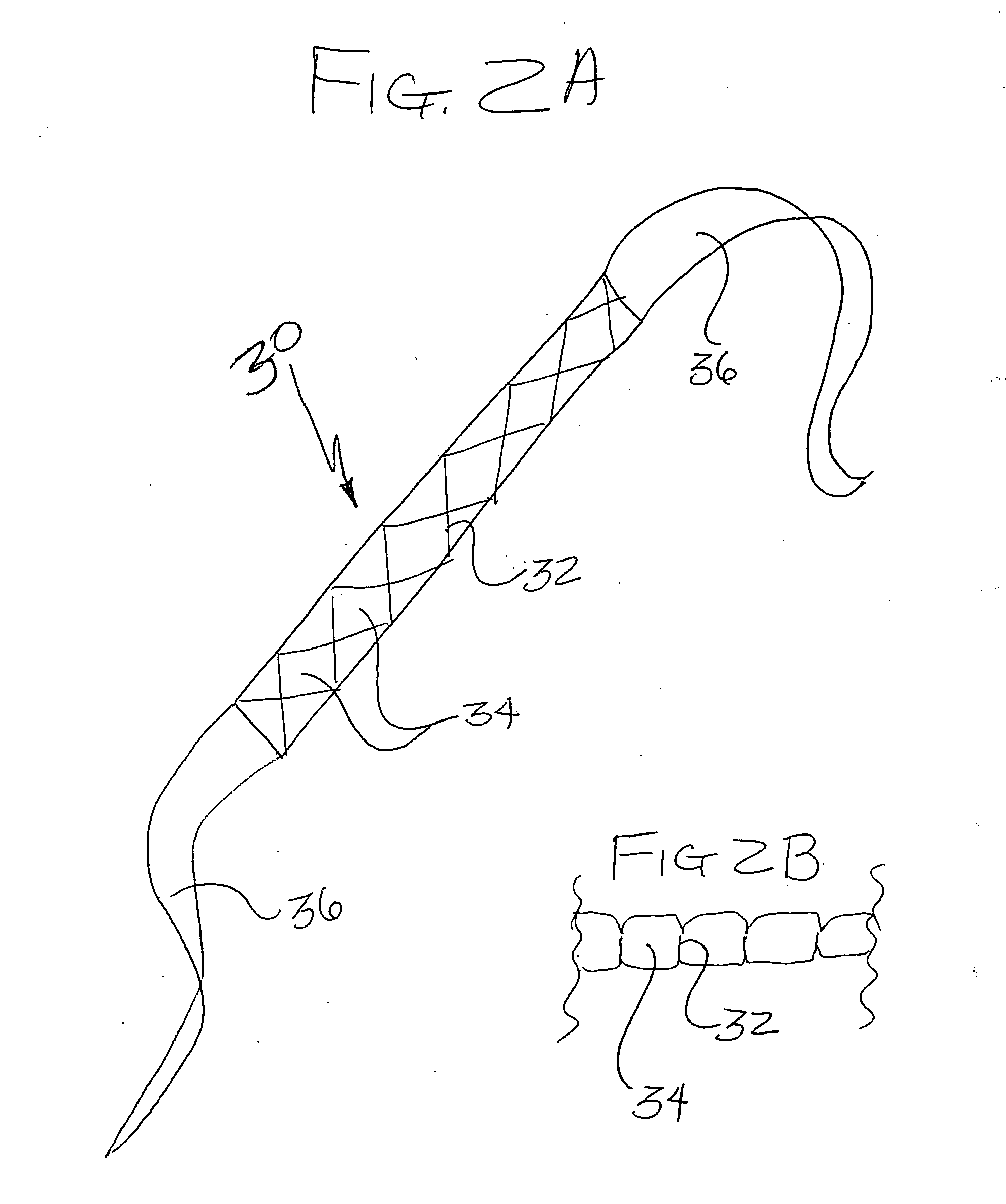

Tow-based absorbent articles with a single casing sheet

An absorbent article is provided that includes a liquid pervious top layer and an absorbent core of synthetic tow fibers. A casing layer is disposed to surround the core such that super absorbent particles are disposed therebetween. The casing layer is bonded with the core to form a predetermined pattern. The pattern is configured for containment of super absorbent particles. A liquid impervious back layer is also included, wherein the casing layer is disposed between the top layer and the back layer. Alternatively, the absorbent article has an absorbent core of polypropylene tow fibers and a polypropylene casing sheet that encloses the core such that super absorbent particles are disposed therebetween. The casing sheet is ultrasonically bonded, or embossed, to the core to form a predetermined pattern. The pattern defines pockets that are configured for containment of the super absorbent particles.

Owner:FIRST QUALITY RETAIL SERVICES

Absorbent product

In an absorbent part of an absorbent product, super absorbent materials located between two sheets in an absorbent area swell by absorption of moisture of excrement, and spaces extending in a longitudinal direction from an opening, which is formed at a portion of upper absorbent layer facing the crotch region of a wearer, are formed between a non-absorbent area where the super absorbent materials do not exist and the upper absorbent layer and between the non-absorbent area and a lower absorbent layer. In the absorbent product, through the spaces, moisture of excrement in the second excretion and later can be quickly diffused over a wide area along the longitudinal direction of the absorbent part, and the moisture of excrement can be absorbed in a wide area of the absorbent part. As a result, it is possible to maintain high absorbing ability in multiple excretions in the absorbent product.

Owner:LIVEDO CORP

Method for making fibrous web materials

Disclosed herein is a method for making fibrous web materials which may be used in or as absorbent core materials for absorbent products. The method involves providing loose fibers, entraining the fibers in a moving airstream, treating the fibers with an energy-activatable pre-polymer composition and subjecting the fibers to activation energy to initiate cross-linking of the composition. The fibers are collected on forming surface to form a fibrous web. The fibers may be treated with the composition while entrained in the moving air or after being collected on the forming surface, or in an alternate embodiment by treating with the composition a mat of fibers from which the loose fibers are provided. The fibrous web material may comprise cellulosic fibers such as pulp, and / or synthetic fibers such as staple fibers, and / or super absorbent materials.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Super absorbent distribution system design for homogeneous distribution throughout an absorbent core

InactiveUS7303708B2Enhancing objectiveCeramic shaping apparatusBaby linensDistribution systemSuper absorbent

A super absorbent distribution system for homogenous distribution throughout an absorbent core is disclosed. A super absorbent material is injected into a stream of absorbent fluff at an opposite direction to that of the stream of absorbent fluff. The super absorbent is blasted into the peak and outer surface of a cone shaped super absorbent barrier. The oncoming absorbent fluff also contends with a similarly shaped absorbent fluff barrier. The super absorbent material slows down as it hits the super absorbent barrier and oncoming fluff, then stops, then reverses direction and flows with the absorbent fluff as a homogenous distribution of super absorbent material and absorbent fluff. The combination of super absorbent material and absorbent fluff may encounter baffle members to further distribute the super absorbent material and absorbent fluff.

Owner:CURT G JOA

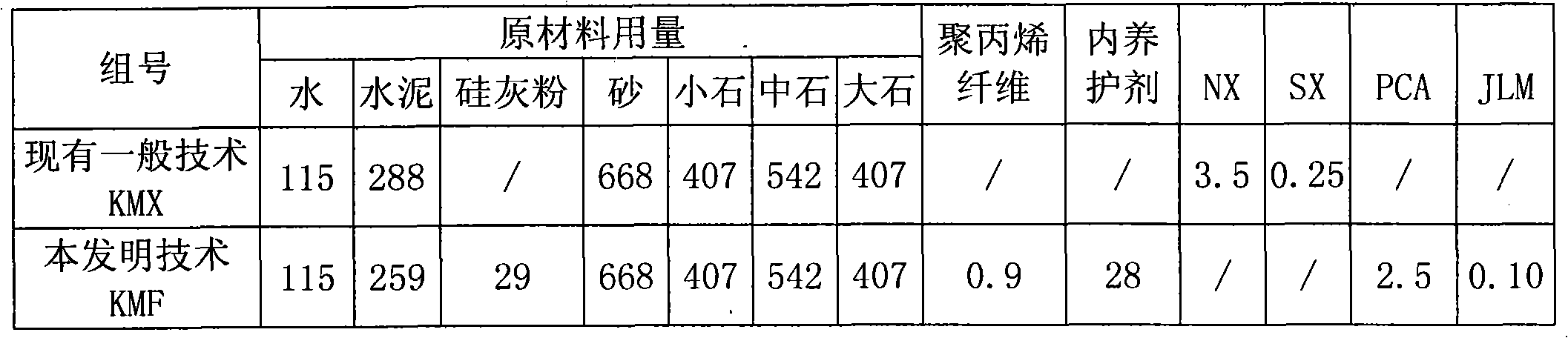

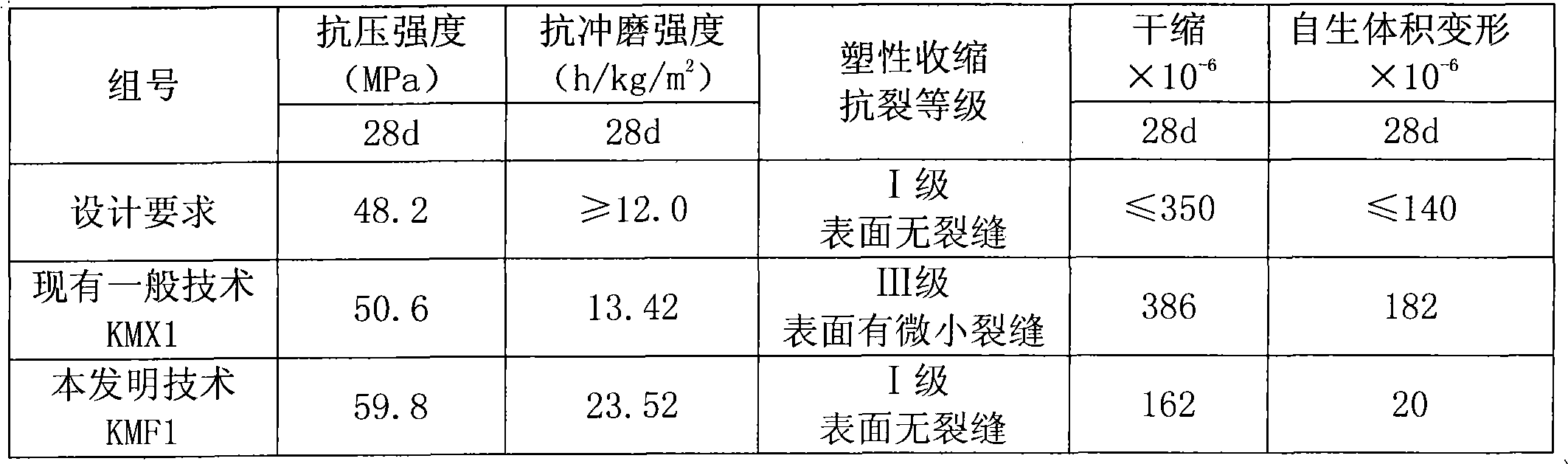

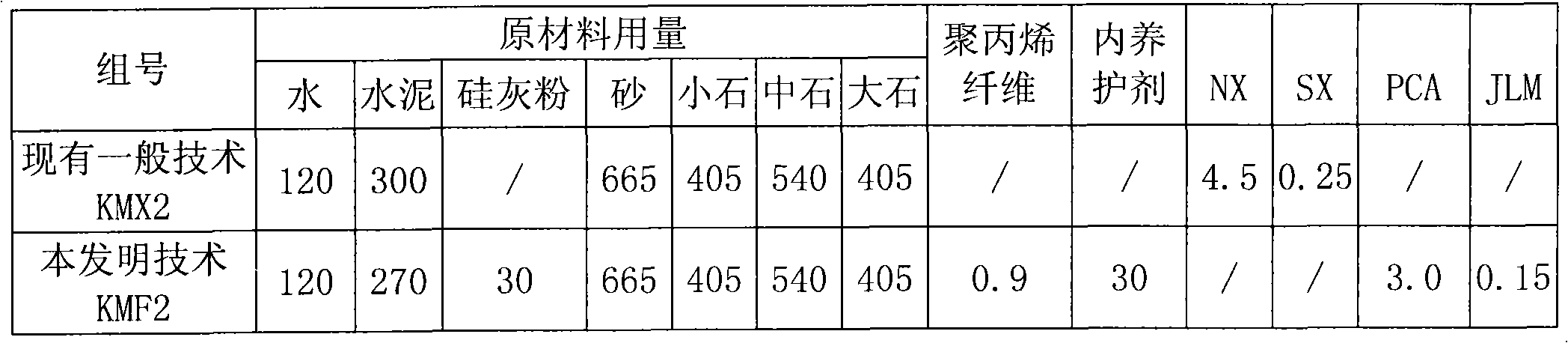

Crack-resistant abrasion-resistant hydraulic concrete and preparation method thereof

InactiveCN102010160AImprove performanceImprove abrasion resistanceSolid waste managementCrack resistanceVolume deformation

The invention discloses crack-resistant abrasion-resistant hydraulic concrete and a preparation method thereof. The hydraulic concrete comprises materials of cement, sand, stones, a polypropylene fiber, a water reducing agent, an air entraining agent and water, and is characterized in that: an internal curing agent and silica fume powder are added; by adopting the internal curing agent as a super absorbent resin, internal maintenance of the concrete is enhanced, the concrete shrinkage is reduced, the abrasion resistance of the concrete is improved, and the crack resistance of the concrete is improved; by adopting the silica fume powder, the concrete mixture performance and abrasion resistance are improved, the comprehensive utilization of industrial wastes and resource and energy conservation are realized, and the environment is protected; and taking concrete at C40 strength grade as an example, the abrasion resistance is 23.52h / kg / m<2>, the early plastic shrinkage crack resistance reaches the first grade, cracks are not formed on the surface of the concrete, an air shrinkage value within 28 days is 162*10<-6>, and the autogenous volume deformation within 28 days is 20*10<-6>. The technical scheme is simple in technical operation, readily available in raw materials, lower in production cost and better in economic and social benefits.

Owner:广西壮族自治区水利科学研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com