Patents

Literature

393 results about "Milk fat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

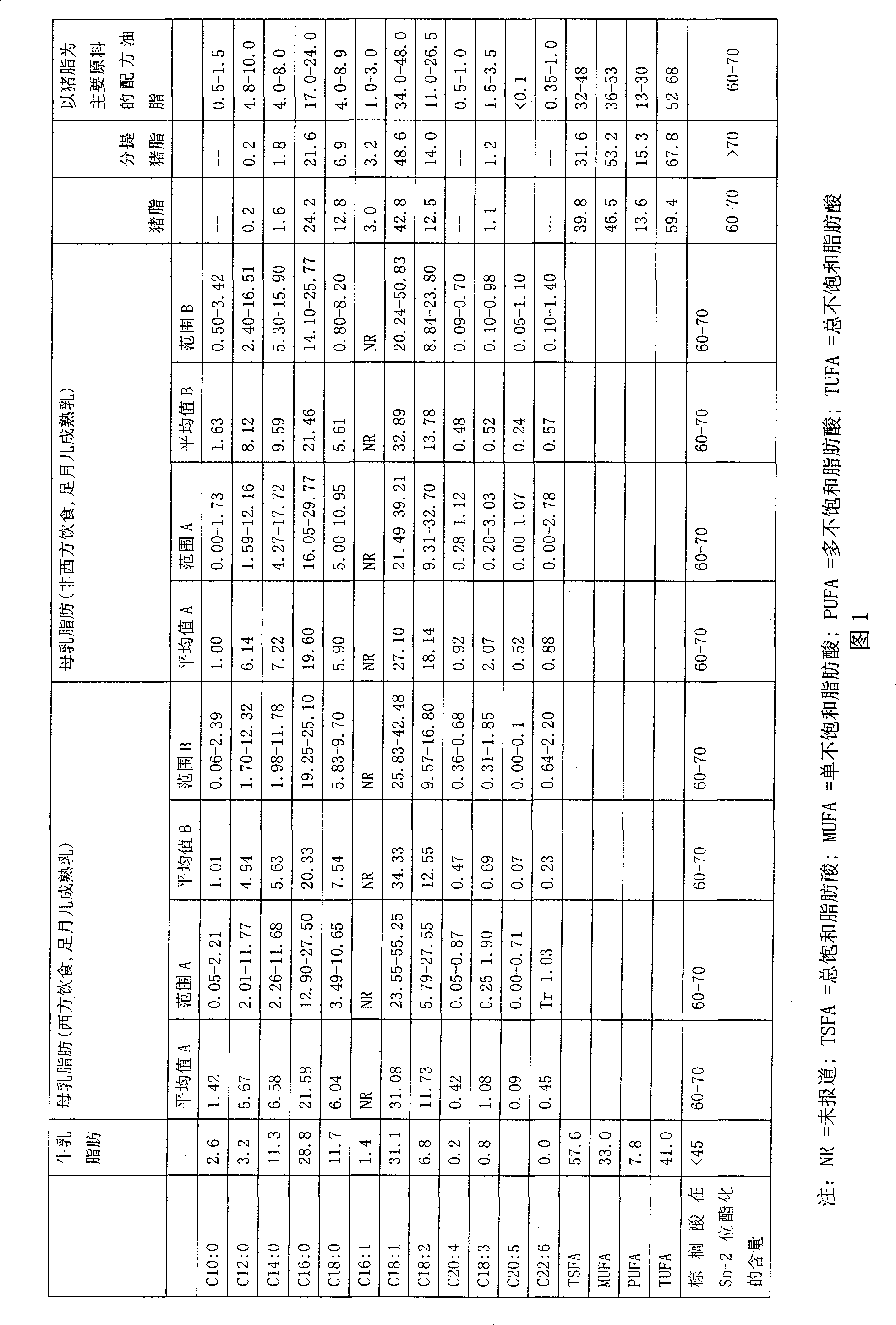

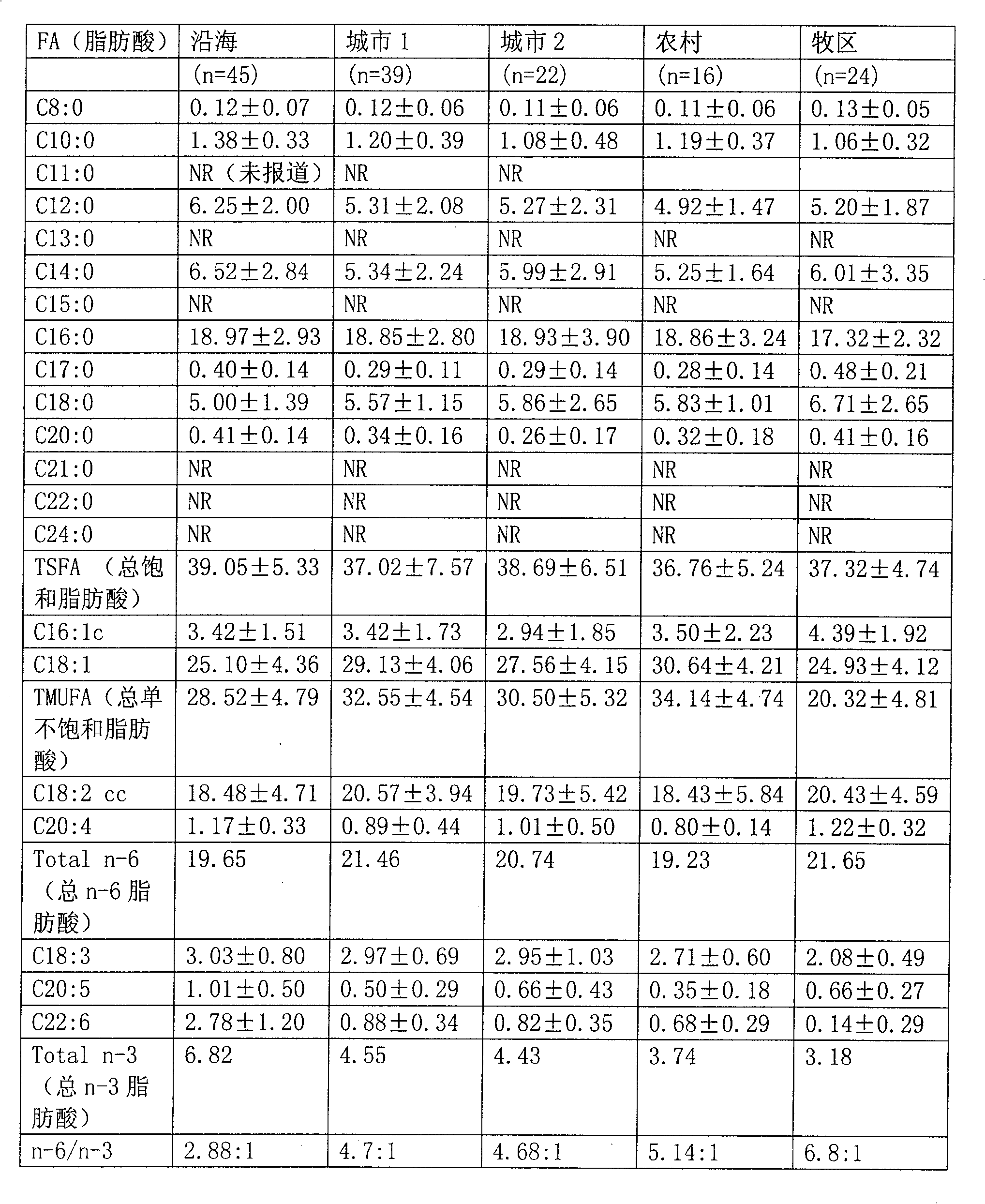

Milk contains approximately 3.4% total fat. Milk fat has the most complex fatty acid composition of the edible fats. Over 400 individual fatty acids have been identified in milk fat. However, approximately 15 to 20 fatty acids make up 90% of the milk fat.

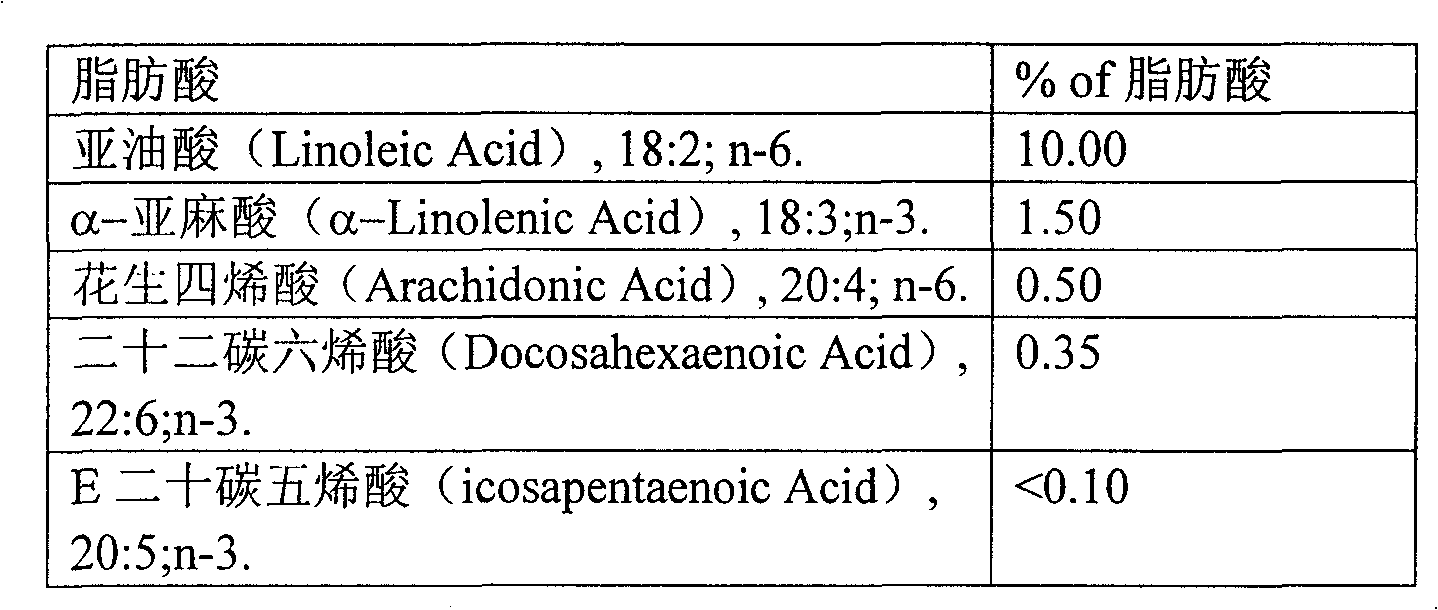

Lipid composition for infant formula and method of preparation

InactiveUS6034130AImprove stabilityBiocideFatty acid esterificationDocosahexaenoic acidLipid composition

Synthetic lipid composition in which the content and the distribution of the fatty acids are similar to those of human milk fat, containing less than 2% by weight of free fatty acids, in which palmitic acid is predominantly at the 2-position of the triacylglycerols and the arachidonic and docosahexaenoic acids are distributed between the 1-, 2- and 3-positions and in particular predominantly at the 2-position of the triacylglycerols.

Owner:NESTEC SA

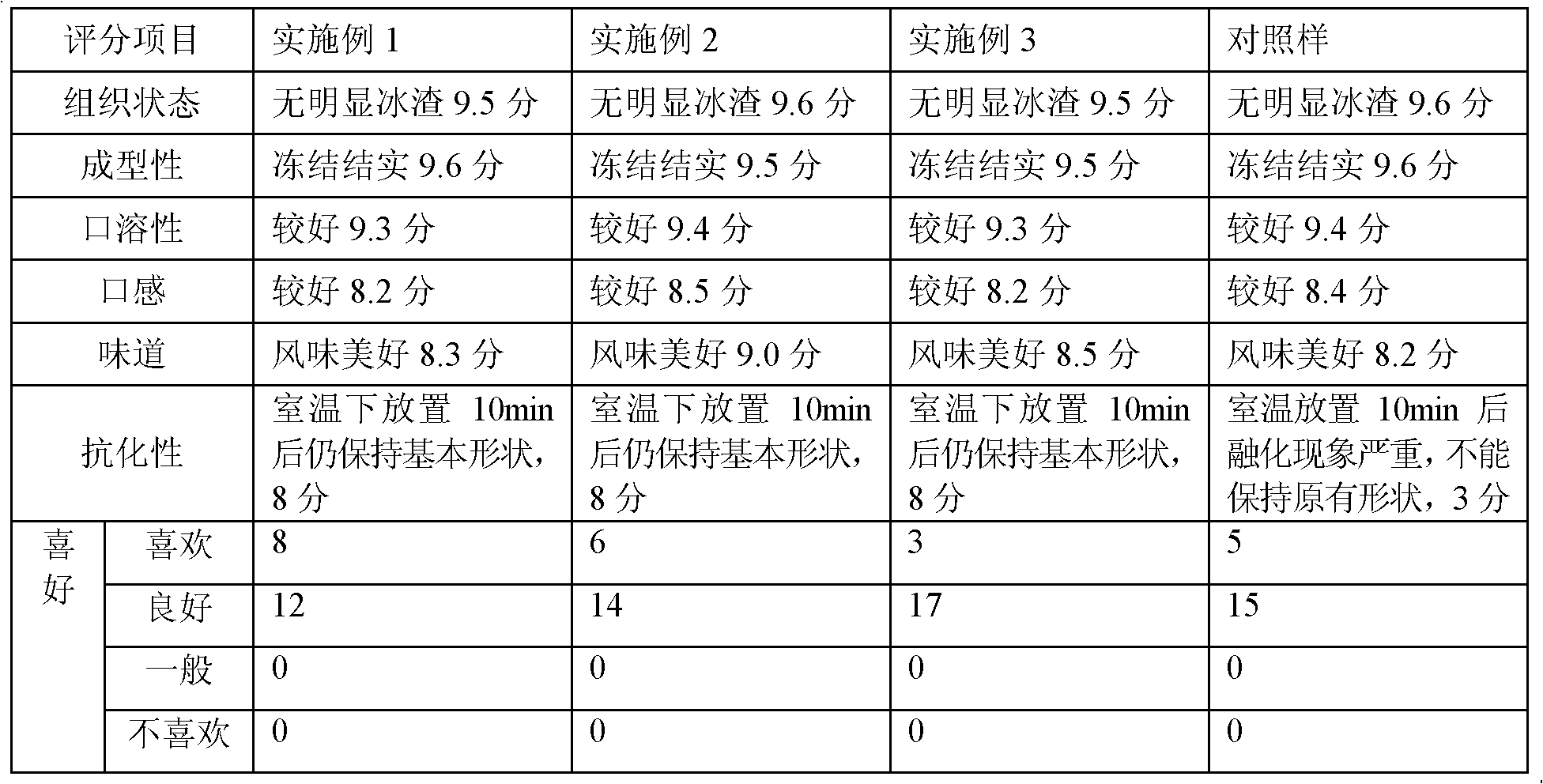

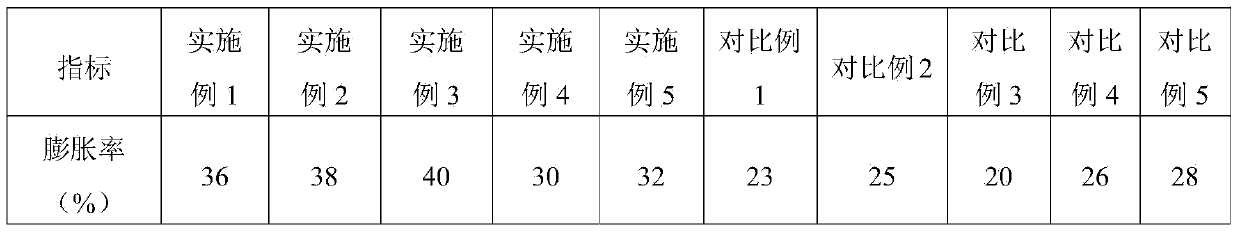

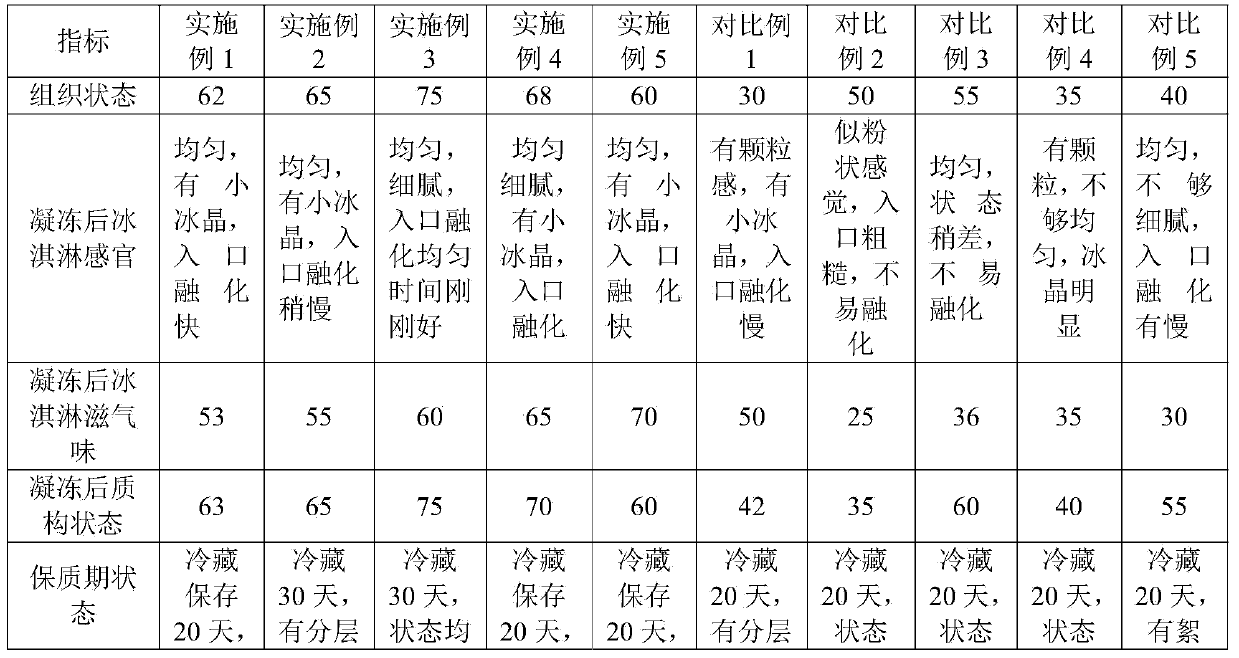

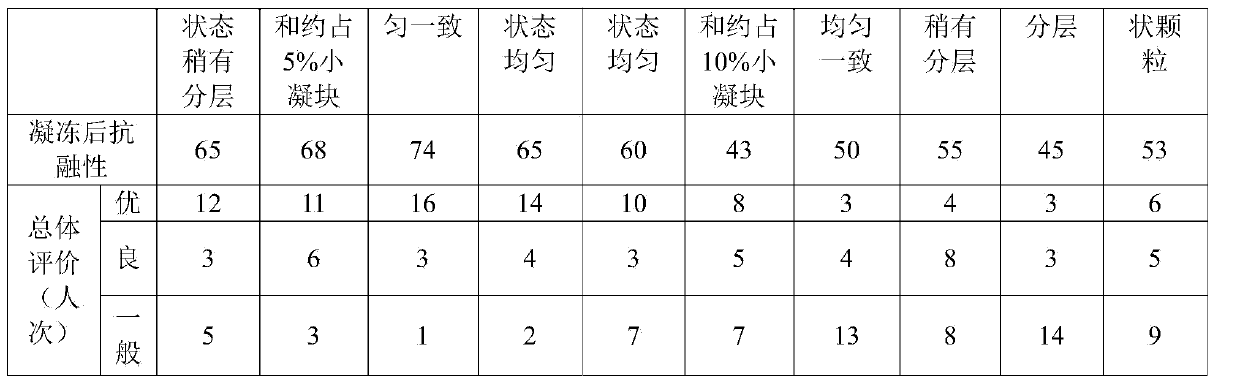

Self-expanding ice-cream and production method thereof

The invention provides self-expanding ice-cream and a production method thereof. The self-expanding ice-cream comprises, by total weight, 35%-80% of light cream, 0.1-5% of thickener, and 0.1%-5% of super absorbent polymer, wherein the thickener is from one or a plurality of gelatin, sodium alginate and carrageen, and the super absorbent polymer is from one or a plurality of locust bean gum, xanthan gum, gellan gum and guar gum. In addition, milk fat content of the ice-cream is 15%-25%. The production method of the self-expanding ice-cream includes: whipping light cream of the ice-cream ingredients until expansion rate of the light cream reaches 60%-85%; mixing the light cream with other ingredients to make ice-cream liquid; and pouring the ice-cream liquid into a mould prior freezing into the finished ice-cream. The ice-cream can have certain expansion rate and good organization and taste with no coagulating needed in production of the self-expanding ice-cream, and the ice-cream is excellent in forming performance, oral thawing performance and thawing resistance.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Preparation method of grease with humanized structure

ActiveCN102776077AHuge market potentialHigh number of reusesMilk preparationFatty acid esterificationVegetable oilMolecular rearrangement

The invention discloses a preparation method of grease with a humanized structure. The preparation method comprises the following steps: carrying out intra-molecular rearrangement reaction to palm oil with palmitic acid content of higher than 50% under the action of catalyst to obtain Sn-2 locus triglyceride with palmitic acid content of higher than 50%; and carrying out ester exchange reaction to the Sn-2 locus triglyceride with palmitic acid content of higher than 50% with mixed fatty acid or non-glyceride under the action of 1,3 locus Specificity lipase, and then subjecting the reaction product to after treatment, so as to obtain the grease with humanized structure, wherein the mixed fatty acid is mixture of at least two selected from the group consisting of decanoic acid, lauric acid,myristic acid, palmitoleic acid, stearic acid, oleic acid, linoleic acid and linolenic acid. The vegetable oils are used as the raw material according to the method, so the safety is high; the preparation process is simple, the reaction time is short, the enzyme dosage is low, and the cost is low; and the prepared grease with the humanized structure is very similar to the beast milk fat in the composition of fatty acid and the structural distribution of triglyceride, so the grease can be added in infant formula or formula foods and used as breast milk fat substitute.

Owner:ZANYU TECH GRP CO LTD

Smearing cheese analogue and preparation method thereof

The invention discloses a smearing cheese analogue and a preparation method thereof. The smearing cheese analogue comprises the following raw materials, by weight: 15%-28% of vegetable fat, 0.2%-1.3% of a stabilizer, 0.2%-1% of an emulsifier, 5% -18% of a plant protein powder, 3%-10% of a modified starch and 45%-65% of water. The smearing cheese analogue completely uses non milk-derived ingredients as raw materials, most of which are composed of plant ingredients, does not contain cholesterol, lactose or milk fat, can satisfy consumers requiring no cholesterol or saturated fat and consumers having lactose intolerance, and is a quite healthy food. The smearing cheese analogue with light flavor is very suitable for the taste of Chinese consumers, uses the raw materials with wide sources, and has a strong price advantage. The preparation method is simple, uses easily available factory equipment, and can be applied to scale and industrial production.

Owner:BRIGHT DAIRY & FOOD

Human Milk Fat Substitutes

ActiveUS20080193624A1Produced cost-effectivelyReduce lossesFatty acid esterificationFood preparationVegetable oilTriglyceride

Disclosed are human milk fat (HMF) substitutes, processes for their preparation, uses thereof and fat blends and infants formulae containing them. A fat base composition of the invention comprises a mixture of vegetable-derived triglycerides, with less than 50% of the fatty acid residues bonded at the sn-2 position being saturated; and / or with the amount of saturated fatty acid residues bonded at the sn-2 position of the glycerol backbone less than about 43.5% of the total amount of saturated fatty acid residues. Typically, substantially all of the saturated fatty acids bonded at the sn-2 position of the glycerol backbone are palmitic acid residues. Also disclosed are substitute HMF compositions comprising a blend of at least 25% or at least 30% of the said fat base composition of the invention with up to 75%, or respectively up to 70%, of at least one vegetable oil. Processes for preparing the fat base compositions and blend are also disclosed. Further disclosed are infant formulas comprising the fat base composition or substitute human milk fat composition.

Owner:ENZYMOTEC

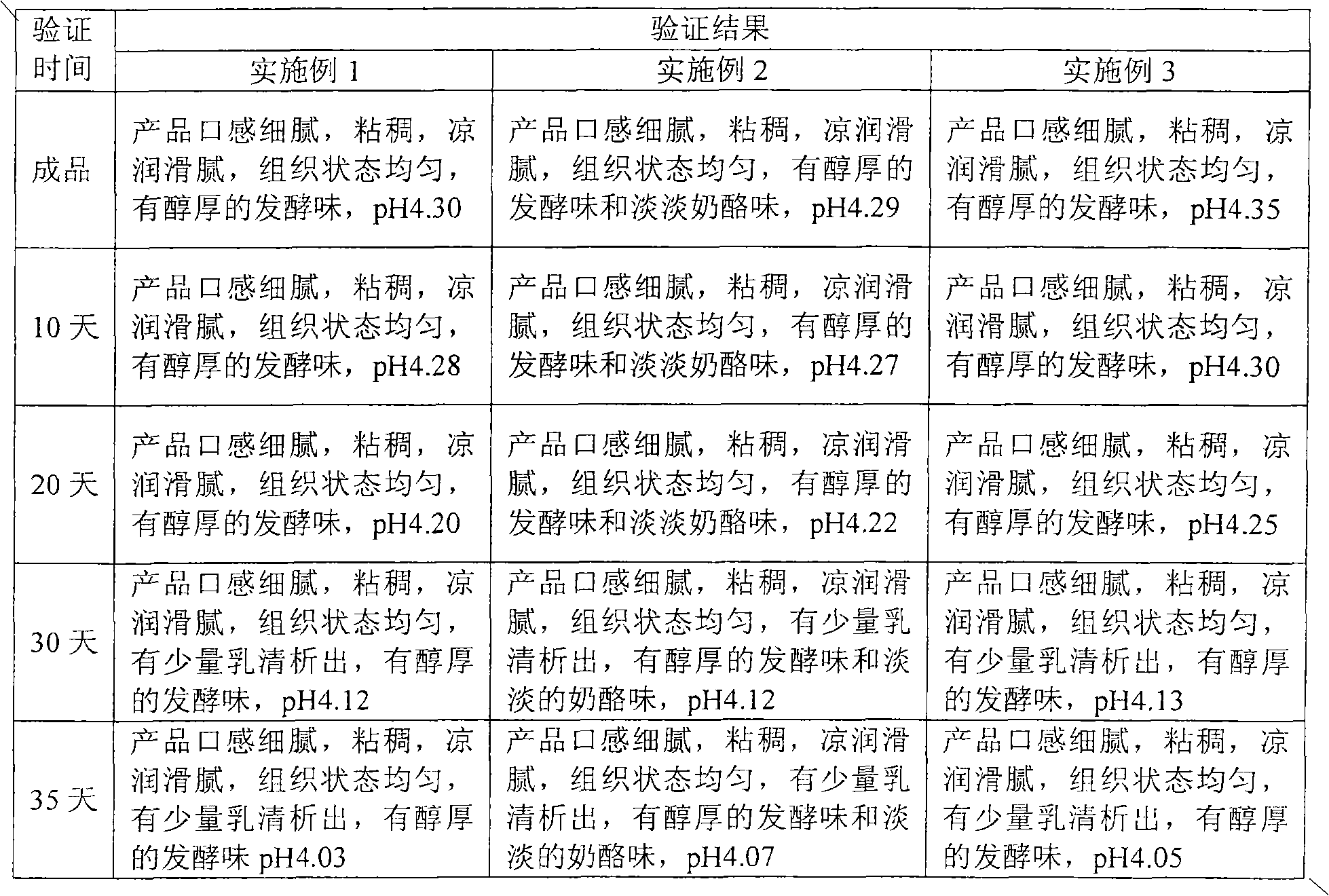

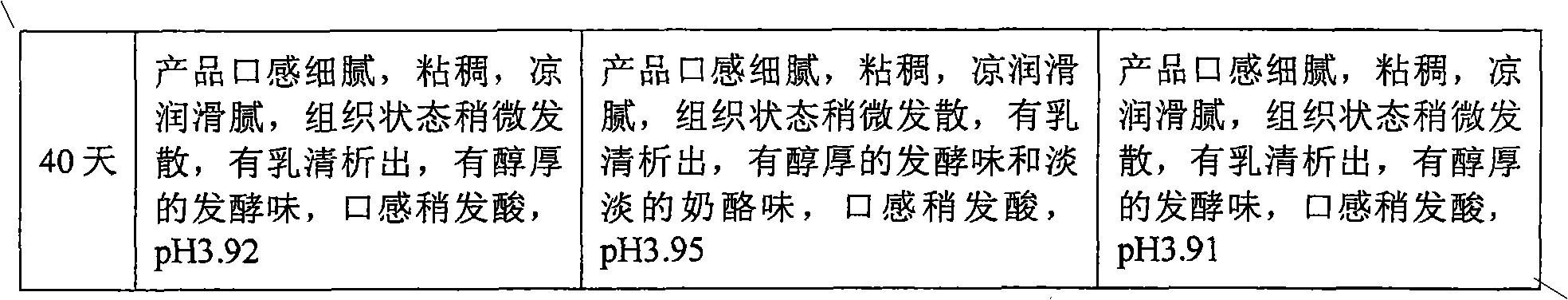

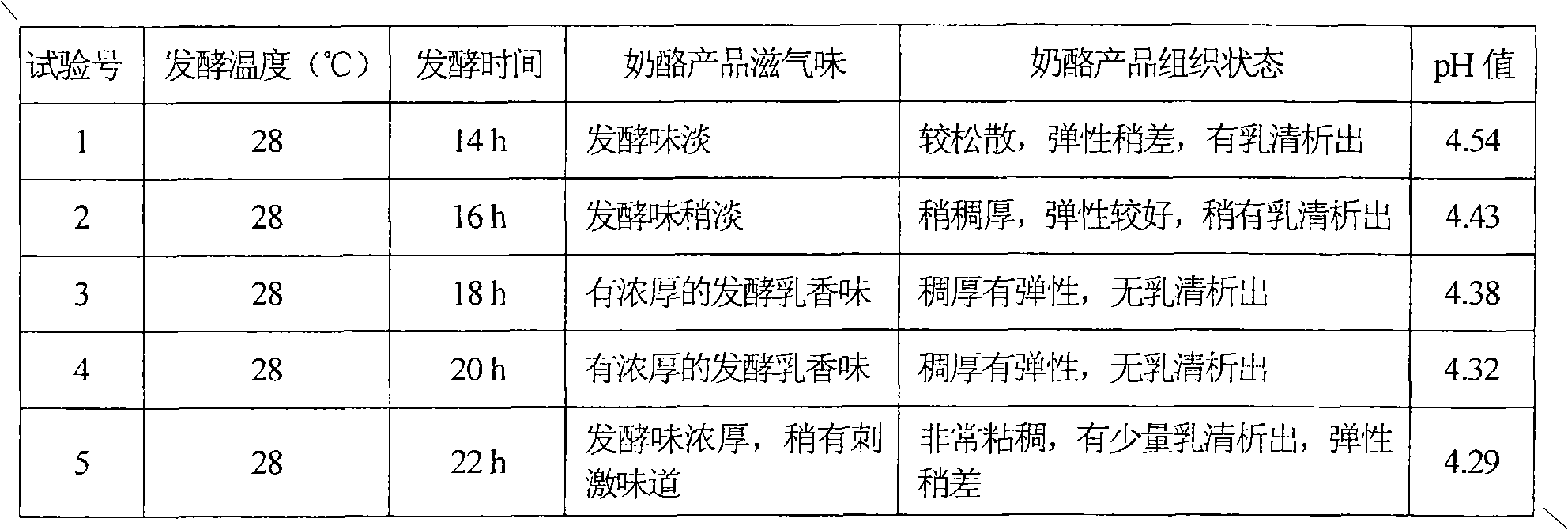

Cheese and preparation method thereof

ActiveCN101961054AGood shelf life stabilityUnique tasteCheese manufactureFood preparationFlavorEmulsion

The invention provides a cheese and a preparation method thereof. The method comprises the following steps of: preparing a feed liquid, wherein milk fat content of the feed liquid is 6 to 8 percent, the lactoprotein content is 5.5 to 7.5 percent, and the total solid matter is 27 to 30 percent; homogenizing and sterilizing the feed liquid, then adding a specific amount of leaven and rennin, preserving the heat at the temperature of between 28 and 30 DEG C and fermenting for 18 to 20 hours; stirring the feed liquid to break emulsion when fermentation time is up, and the pH value of the fermented feed liquid is 4.2 to 4.5; and then refining and reducing the temperature to below 20 DEG C, and then filling the feed liquid to obtain the cheese finished product. The cheese obtained by the method has the advantages of unique taste, flavor and texture, rich yeast taste, basically no irritating taste and smell, delicate mouthfeel of the product, uniform and consistent texture, and stable quality.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

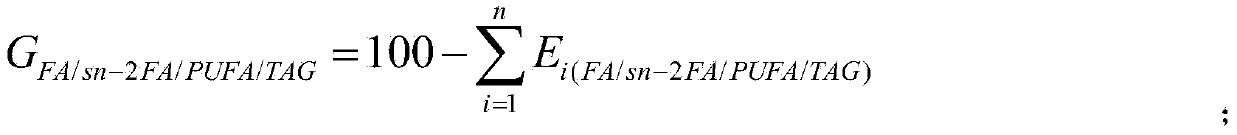

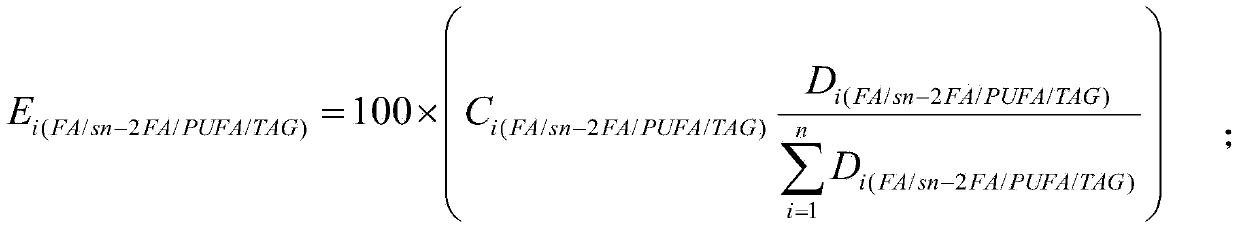

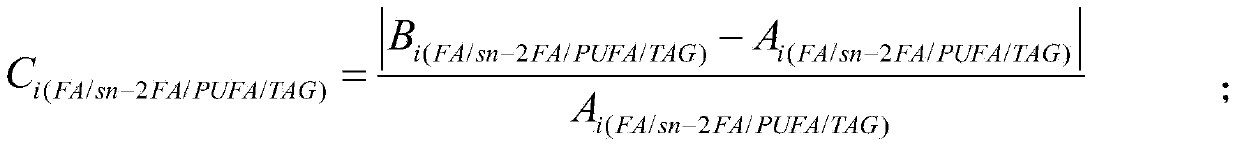

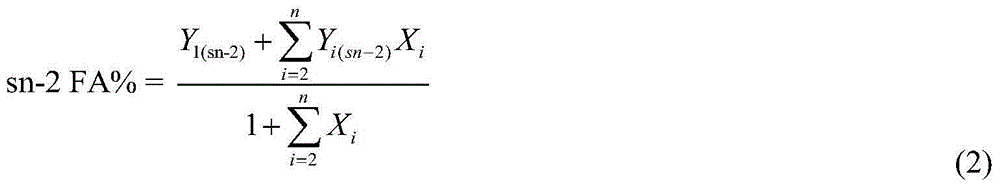

Preparation method of human milk substitute fat based on triglyceride composition and evaluating method of human milk substitute fat

The invention discloses a preparation method of a human milk substitute fat based on a triglyceride composition and an evaluating method of the human milk substitute fat. The preparation method comprises the following steps: with lard oil as a base raw material, adding sunflower seed oil, canola oil, palm kernel oil, palm oil, microbial oil and algae oil in the lard oil according to a certain proportion in accordance with composition and distribution of fatty acid of human milk fat to obtain mixed oil similar to the human milk fat on the composition and distribution of the fatty acid; and by adopting specific lipase at 1 and 3 sites as catalysts, and similarities between of mixed oil and human milk fat in aspects of composition and distribution of the fatty acid, composition of polyunsaturated fatty acids and triglyceride as indexes, adjusting the composition of the triglyceride of the mixed fat by using a manner of lactone exchanging to obtain a product with relatively high similarity to the human milk fat on the composition of the triglyceride. The human milk substitute fat is obtained by adopting physical mixing and enzyme catalysis ester exchange manners, the production cost can be greatly reduced, and the relatively high similarity is achieved for the product and the human milk fat.

Owner:无锡益语科技发展有限公司

Lipid Preparation for Enhancing Mineral Absorption

ActiveUS20080058415A1Promote absorptionEnhancement of formationBiocideSpread compositionsEnzymatic synthesisBone density

Disclosed is a dietary ingredient comprising at least one edible lipid which does not inhibit mineral absorption, enhances mineral absorption and intake, particularly a chemically or enzymatically synthesized synthetic oil, particularly glyceride-based lipid with high levels of mono- or polyunsaturated fatty acids at positions sn-1 and sn-3 of the glycerol backbone, vegetable- and plant-derived oil, such as flax and canola oils, short and medium chains lipid, preferably MCT and an oil mimicking the triglyceride composition of human mother's milk fat and its various uses.The dietary ingredient is particularly intended for use in enhancing calcium absorption and in the prevention and / or treatment of disorders associated with depletion of bone calcium and bone density, prevention and treatment of osteoporosis, for the enhancement of bone formation and bone mass maximization and for the enhancement of bone formation in infants and young children.

Owner:ENZYMOTEC

Cream cheese and preparation method thereof

InactiveCN101167500ABroaden sources of raw materialsStable textureCheese manufactureStaphylococcus lactisAdditive ingredient

The invention relates to a cream cheese and a preparation method thereof. The technical scheme is to use milk fat raw material: 15-85%; whole milk: 10-80%; milk protein raw material: 1-10%; carbohydrate raw material: 1-10%. The present invention expands the raw material source of the cream cheese, uses milk protein raw material, carbohydrate raw material and stabilizer as ingredients, forms a stable texture without whey precipitation, and omits the process step of removing whey. The invention uses lactic acid bacteria including diacetyl lactis streptococcus to mix and ferment the ingredients of cream cheese, so that the product can form a new flavor.

Owner:TIANJIN UNIV OF SCI & TECH

Preparation method of human milk alternative fat combining enzymatic acidolysis and physical mixing

The invention discloses a preparation method of human milk alternative fat combining enzymatic acidolysis and physical mixing. The preparation method mainly comprises the following two steps: S1, adjusting the composition (greater than 1%) of a plenty of fatty acids of catfish oil or a fractionation product of the catfish oil by virtue of acidolysis; and S2, adjusting the composition of trace fatty acids (less than 1%) of an enzymatic product by virtue of physical mixing. The raw materials catfish oil or the fractionation product of the catfish oil used by the method are wide in source and low in price, and contain a relatively high content of sn-2 palmitic acid and a relatively low content of total palmitic acid. In the acidolysis reaction, the free fatty acids used is small in proportion, and in the process, the composition and distribution of the plenty of fatty acids are emphasized at the same time as well as the composition of trace fatty acids containing polyunsaturated fatty acids with medium carbon chains and long carbon chains. The obtained product is highly similar to human milk fat and has a relatively huge market application prospect.

Owner:JIANGNAN UNIV

Natural milk flavored essence base material prepared by hydrolyzing milk fat by using lipase and production method thereof

ActiveCN102067977APlay a role in flavoringIntrinsic quality improvement and enhancementFood preparationFlavorHydrolysate

The invention discloses a natural milk flavored essence base material prepared by hydrolyzing milk fat by using lipase and a production method thereof. The method comprises the step of adding the lipase into a milk fat system to hydrolyze to obtain a hydrolysate, and is characterized in that the milk fat system is prepared by a method comprising the steps of: adding the milk fat into water or enzymolysis buffer solution, mixing the milk fat and the water or the enzymolysis buffer solution, raising the temperature to be between 70 and 90 DEG C, keeping the temperature for 15 to 40 minutes, reducing the temperature to be between 35 and 55 DEG C, adjusting the pH value of solution to be between 4.5 and 7.5, and then performing mechanical emulsification. The invention improves a method for producing a milk flavored essence base material by taking cream as a raw material and utilizing the hydrolysis of the lipase, and obtains the milk flavored essence base material with stronger, fuller and more impressive milk flavor, more natural and softer fragrance, and more natural trend by improving reaction conditions. Compared with products prepared by the conventional process, the natural milkflavored essence base material can increase the fragrance by 100 to 200 times, and remarkably improve the inner quality of fragrance-increased products. Moreover, the natural milk flavored essence base material has the advantages of low production cost, simple process, high edible safety, and 'pollution-free' production process.

Owner:BRIGHT DAIRY & FOOD

Human milk substitute fat composition

The invention discloses a human milk substitute fat composition which is prepared from natural grease or modified grease as a raw material. On the basis of composition and distribution of fatty acids of human milk fat and the composition of triglyceride, the fat composition is prepared by mixing the grease and is similar with the human milk fat in the aspects of the composition and distribution of fatty acids of human milk fat and the composition of triglyceride. The similarity of the substitute fat composition with human milk fat in the aspects of the composition and distribution of fatty acids of human milk fat and the composition of triglyceride is evaluated through a human milk substitute fat model, which proves that the similarity of fatty acids is higher than 90%, the similarity of sn-2 fatty acid is higher than 80% and the similarity of triglyceride is higher than 60%. The total similarity of the substitute fat composition with the human milk fat is more than 70%.

Owner:JIANGNAN UNIV

Acidic milk pudding and preparation method thereof

ActiveCN102511745AFix stability issuesExtended shelf lifeFood preparationMilk puddingAcidity regulator

The invention belongs to the field of milk product processing, and relates to an acidic milk pudding and a preparation method thereof. The acidic milk pudding has a pH value of 4.2 to 4.4 and comprises: by weight, 7 to 10% of white sugar or one or more sweeteners, 1 to 2% of anhydrous milk fat, 0.3 to 0.6% of one or more stabilizing agents, an appropriate amount of one or more acidity conditioning agents and the balance milk. The one or more acidity conditioning agents are added into a milk pudding so that the acidic milk pudding having the characteristics of long quality guarantee period and good uniformity and stability is obtained.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

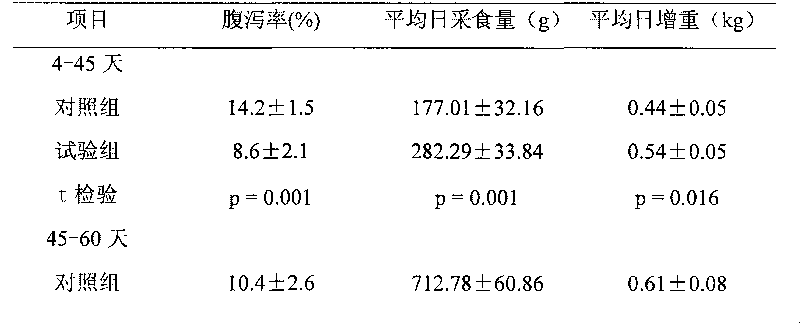

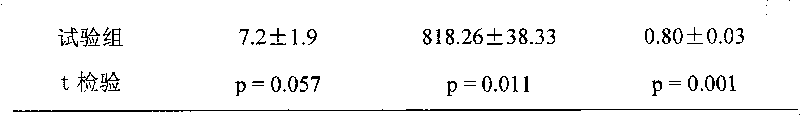

Antidysenteric early-weaning calf opening material

ActiveCN101692879AImprove palatabilityReduce the incidence of diarrheaFeeding-stuffFood processingGeneration rateSucrose

The invention discloses a highly-effective antidysenteric early milk-fat calf opening material, which comprise the following weight shares: granule materials B- 60-80, tabletting corn 17-36 and molasses 2-4, wherein the granule materials B comprises materials with the following weight shares: corn 45-60, soya bean waste 10-20, fermentation soya bean waste 4-10, swelling soybean 0-5, concentrated soybean protein 0-5, whey powder 5-10, molasses 1-3, saccharose 1-2, amylaceum 1-2, lycine 0.8-1.0, acimetion 0.05-0.15, calcium hydrogen orthophosphate 1.5-2.5, stone powder 0.8-1.2, salt 0.4-0.8, calf premix 1-1.4, acidating agent 0.2-0.4, antioxidant 0.05 and moderate 0.05. The method for preparing calf opening material comprises firstly adopting secondary cubing technology to process granule materials, then, evenly mixing particle food and tabletting corn, and then, spraying molasses on the surfaces of particle food and tabletting corns. Animal test results show that the calf opening material has better palatability, can effectively prompt animals to take in feed, achieves early-weaning within 45 days, can effectively control the loose bowel movement generation rate of calves, and prompts the growth of calves.

Owner:BEIJING JIUZHOU DADI BIOLOGICAL TECH GRP

Production method of human milk fat substituted grease

The invention provides a method for preparing breast milk fat which replaces oil and fat. The method comprises the steps of: mixing oil and fat with the C16:0 content being higher than 20% and the esterifying rate of C16:0 in a Sn-2 position being higher than 70% as the main raw materials, oil and fat with an intermediate carbon chain fatty acid (C8:0, C10:0 and C12:0) content being higher than 50%, oil and fat with the n-3 unsaturated fatty acid content being higher than 5% and / or the n-6 unsaturated fatty acid content being higher than 20% and other animal and vegetable oils at a certain proportion, and refining. The fatty acid composition and the triglyceride structure of the prepared oil and fat for replacing the breast milk fat are similar to those of the breast milk fat. The content of the trans-fatty-acid is lower than 1.0%. The prepared oil and fat has mild taste; and is suitable for the preparation of the infant formulation food.

Owner:杨晓光

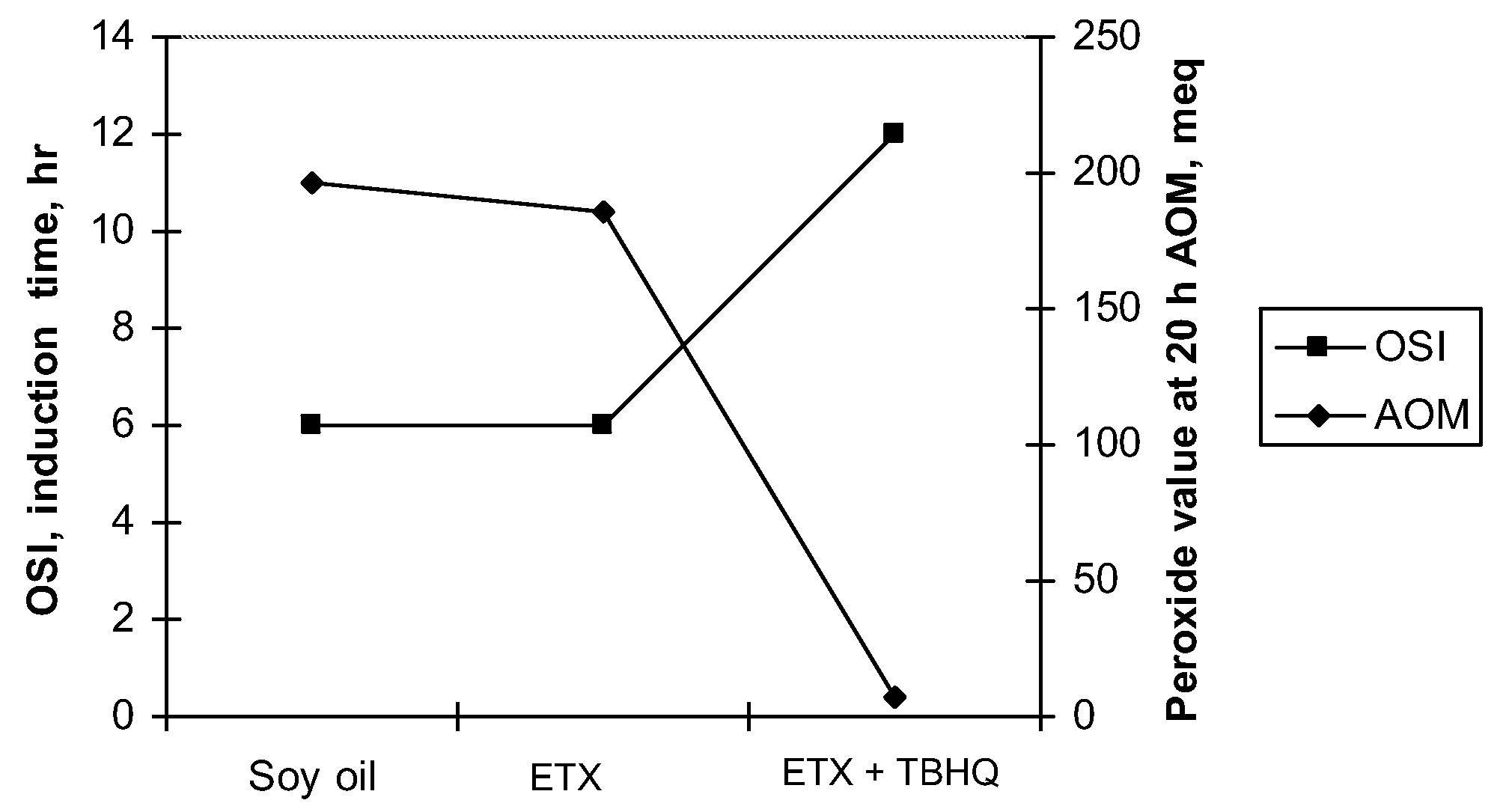

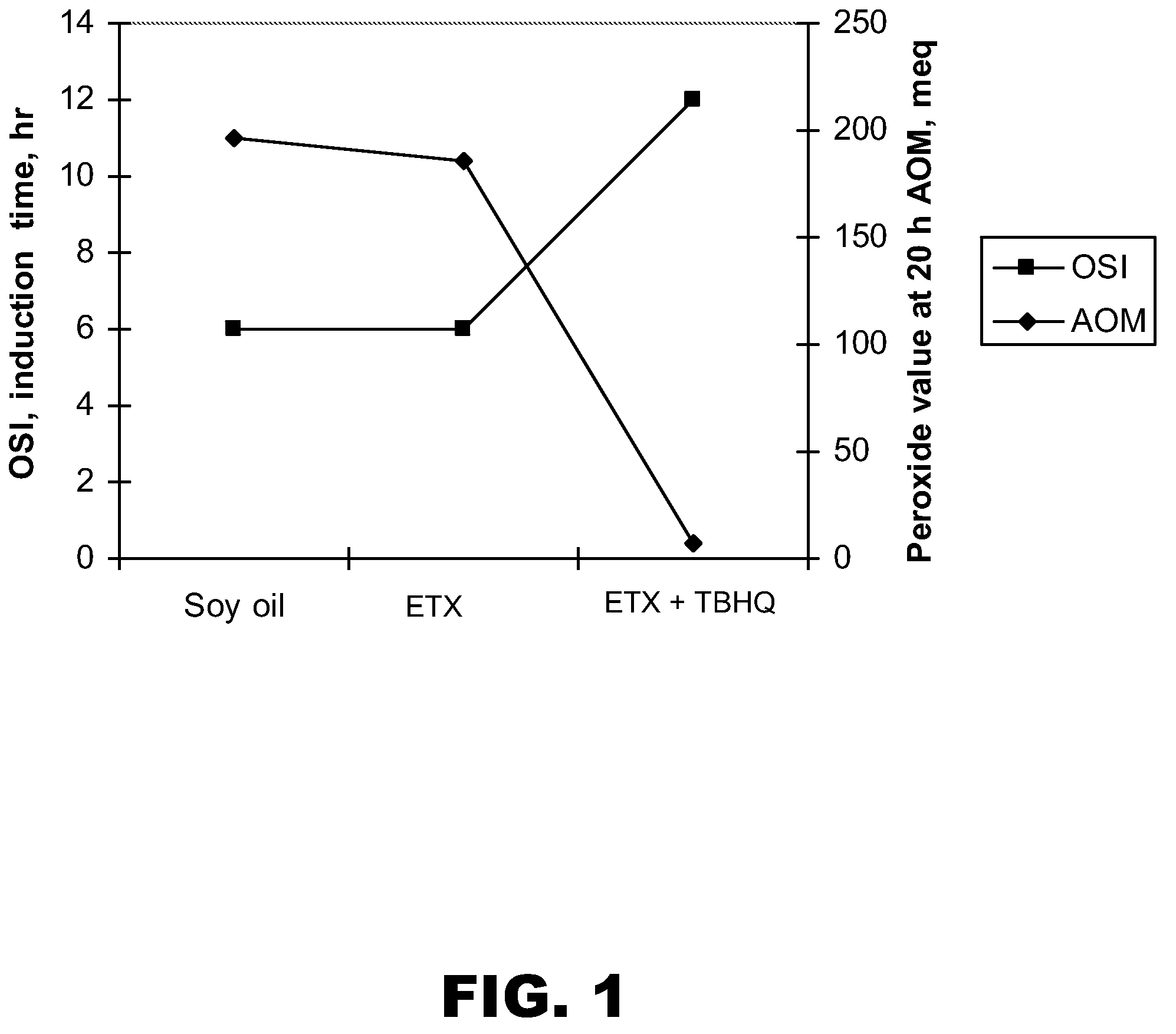

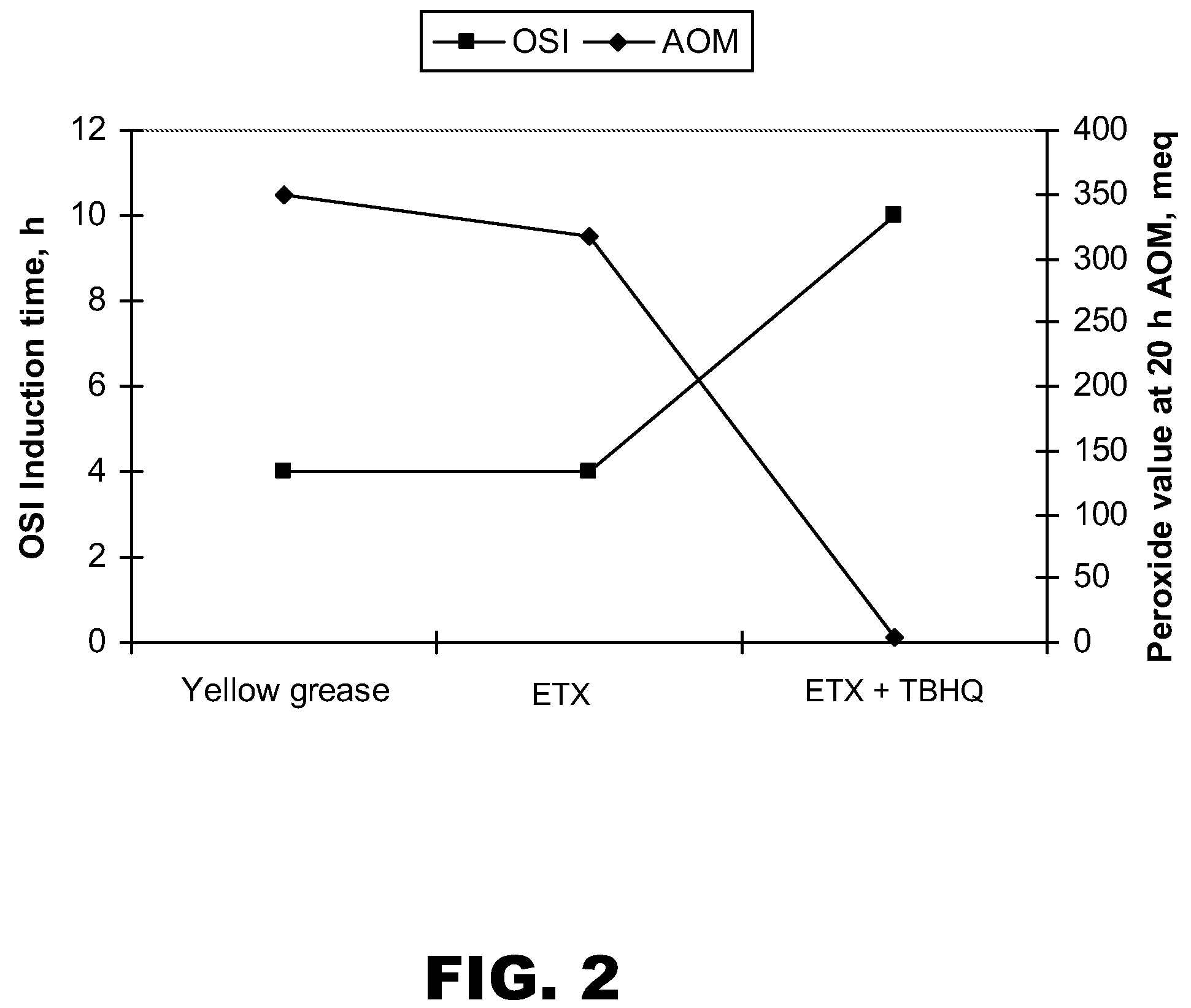

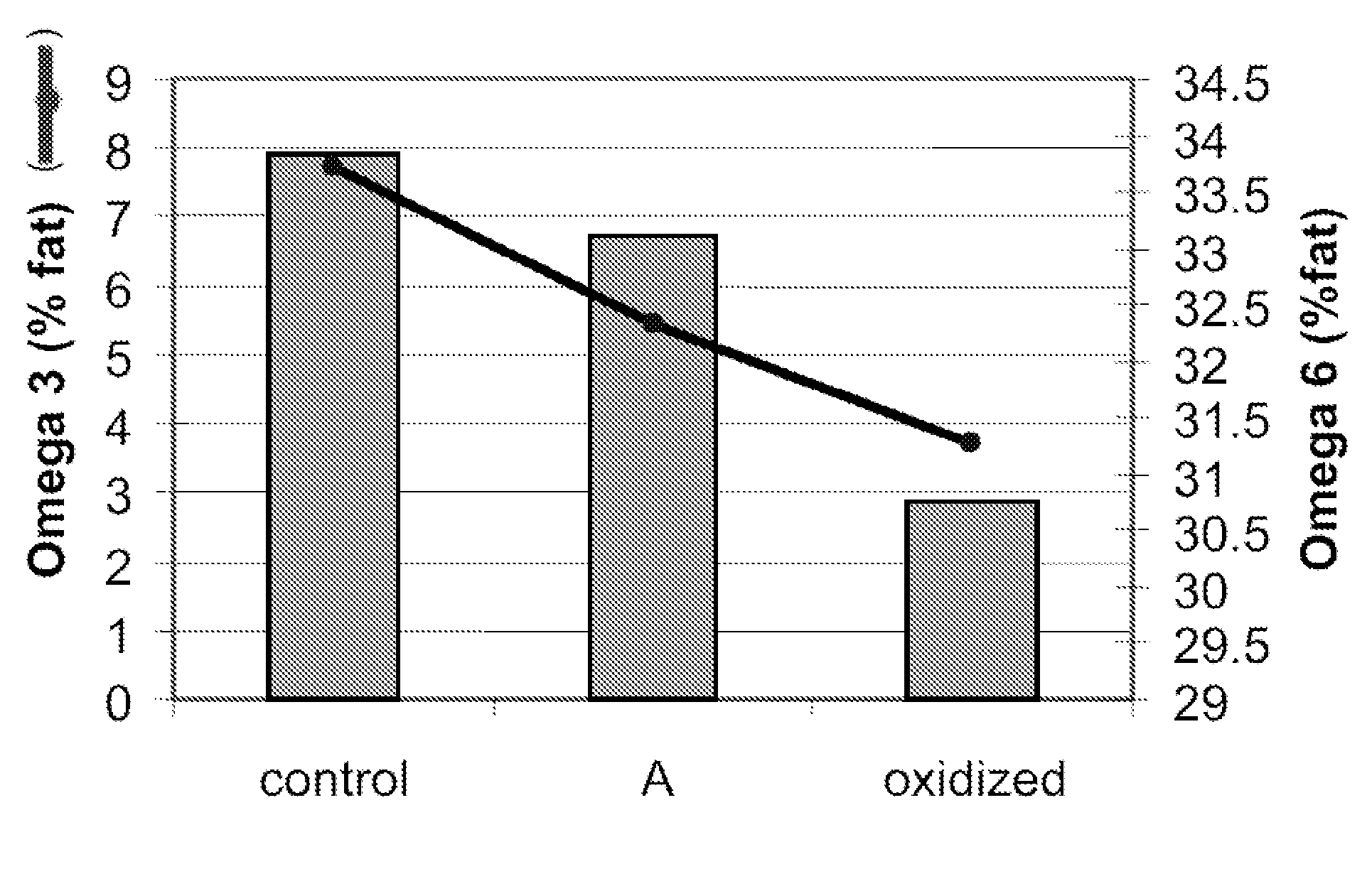

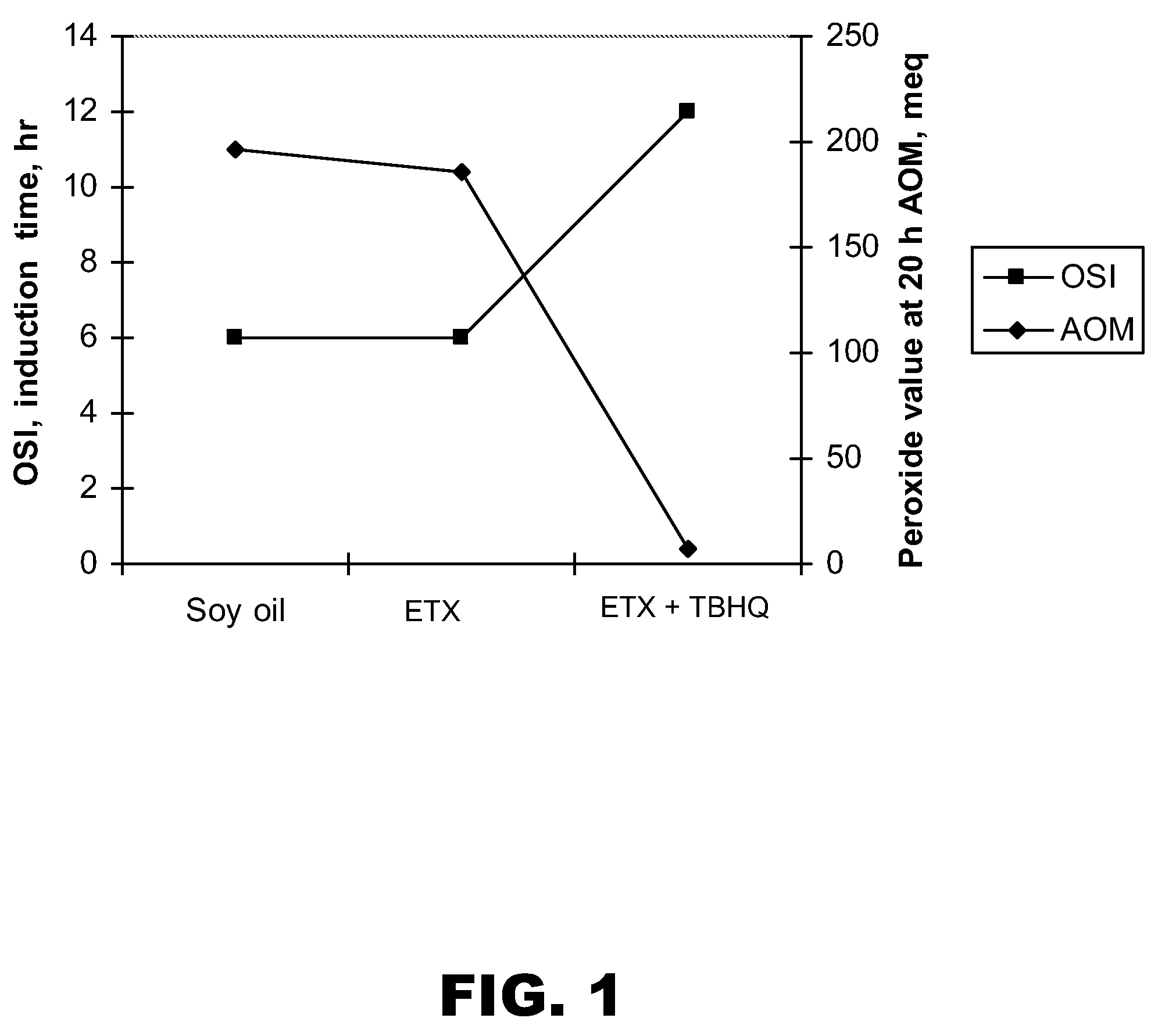

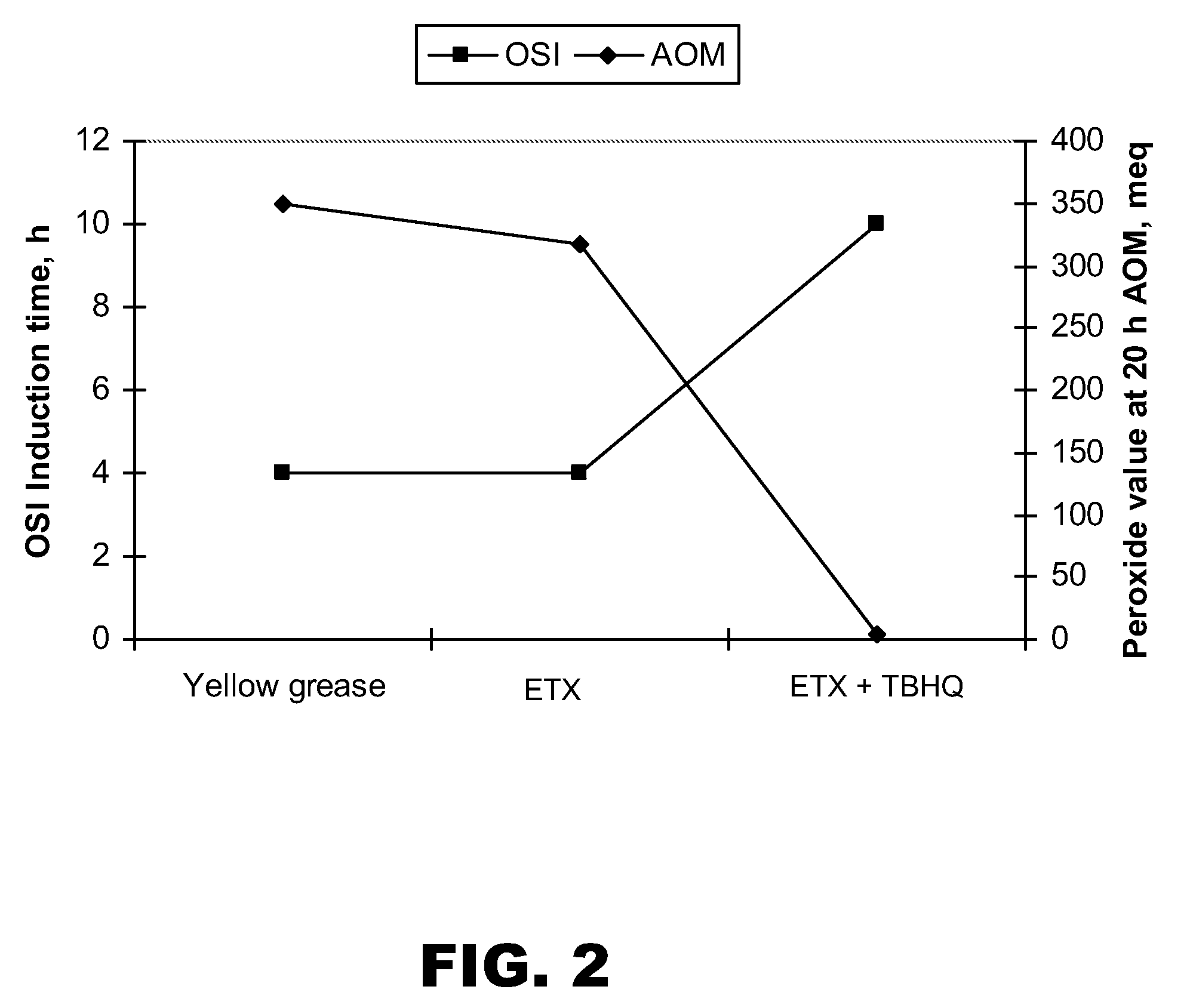

Antioxidant combinations for use in ruminant feed rations

ActiveUS20080015217A1Increasing nutrient digestionReduce oxidationBiocideMetabolism disorderWater sourceAntioxidant

The present invention provides a combination of antioxidants that effectively stabilize different types of fats utilized in a ruminant diet. When included in a ruminant feed ration or water source, the antioxidant combination typically increases nutrient digestion, such as fiber and protein, improves rumen fermentation, improves microbial growth, improves microbial efficiency, increases milk production and / or milk fat, improves antioxidant status of the ruminant, and attenuates the negative effects of some fats in the ruminant animal.

Owner:EW NUTRITION CAROTENOID TECH SA

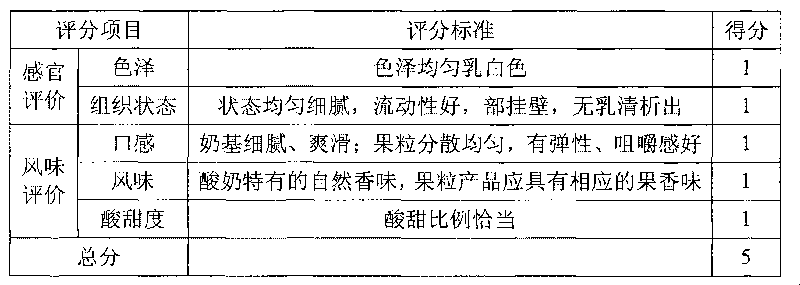

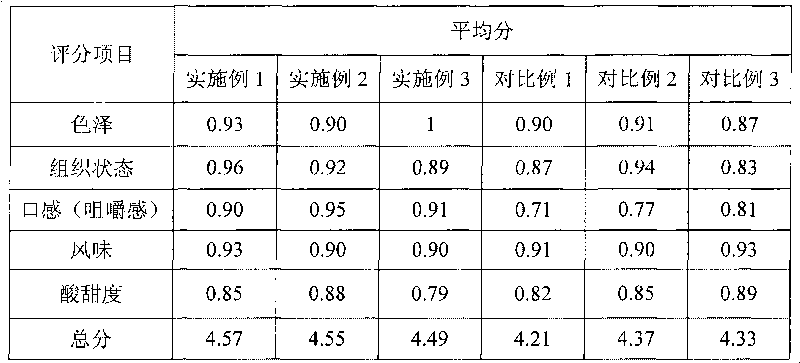

Drinking yoghourt and making method thereof

The invention provides drinking yoghourt and a making method thereof. The drinking yoghourt comprises the following ingredients: 18.5-25% of total solid matter, 2.5-3.0% of milk fat and 2.3-2.7% of milk protein; the drinking yoghourt of the invention also comprises the ingredient of sweetening agent of which the sweetness is equal to that of 6-9% of cane sugar. The drinking yoghourt of the invention is made through the steps of mixing all ingredients, homogenizing, sterilizing, cooling, inoculating lactic acid bacteria fermentation agent and homogenizing fermented yoghourt material. In the invention, by reasonably selecting and proportioning the formula of the drinking yoghourt and controlling proper production process, the drinking yoghourt obtained by production has good flowability, and simultaneously has good flavor and mouth feel and good stability.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Ice cream slurry and preparation method thereof

The invention discloses ice cream slurry and a preparation method thereof. The ice cream slurry comprises the following raw materials in percentage by mass: 2-8% of milk fat, 8-16% of lactoprotein, 5-25% of sweetening agent, 0.1-1% of emulsifier, 0.1-1% of thickening agent and water. The preparation method comprises the following steps: mixing the raw materials, namely uniformly mixing the milk fat, the lactoprotein, the sweetening agent except white granulated sugar and water at a temperature of 30-40 DEG C, heating up to 60-70 DEG C to obtain a solution A, and uniformly mixing the solution A with the emulsifier, the thickening agent and the white granulated sugar to completely dissolve all raw materials; carrying out secondary homogenization; sterilizing at a sterilizing temperature of 110-130 DEG C for 10-30 seconds; cooling; and carrying out sterile filling to obtain the ice cream slurry. The ice cream slurry disclosed by the preparation method disclosed by the invention is long in quality guarantee period, convenient to use, uniform in product state, free of layering or bleeding phenomenon, excellent in flavor and fragrance and capable of ensuring delicate taste and fresh flavor of ice cream.

Owner:BRIGHT DAIRY & FOOD CO LTD

Antioxidant combinations for use in feed rations to increase milk production and milk fat

The present invention provides a combination of antioxidants that effectively stabilize different types of fats utilized in a ruminant diet. When included in a ruminant feed ration or water source, the antioxidant combination typically increases nutrient digestion, such as fiber and protein, improves rumen fermentation, improves microbial growth, improves microbial efficiency, increases milk production and / or milk fat, improves antioxidant status of the ruminant, and attenuates the negative effects of some fats in the ruminant animal.

Owner:EW NUTRITION CAROTENOID TECH SA

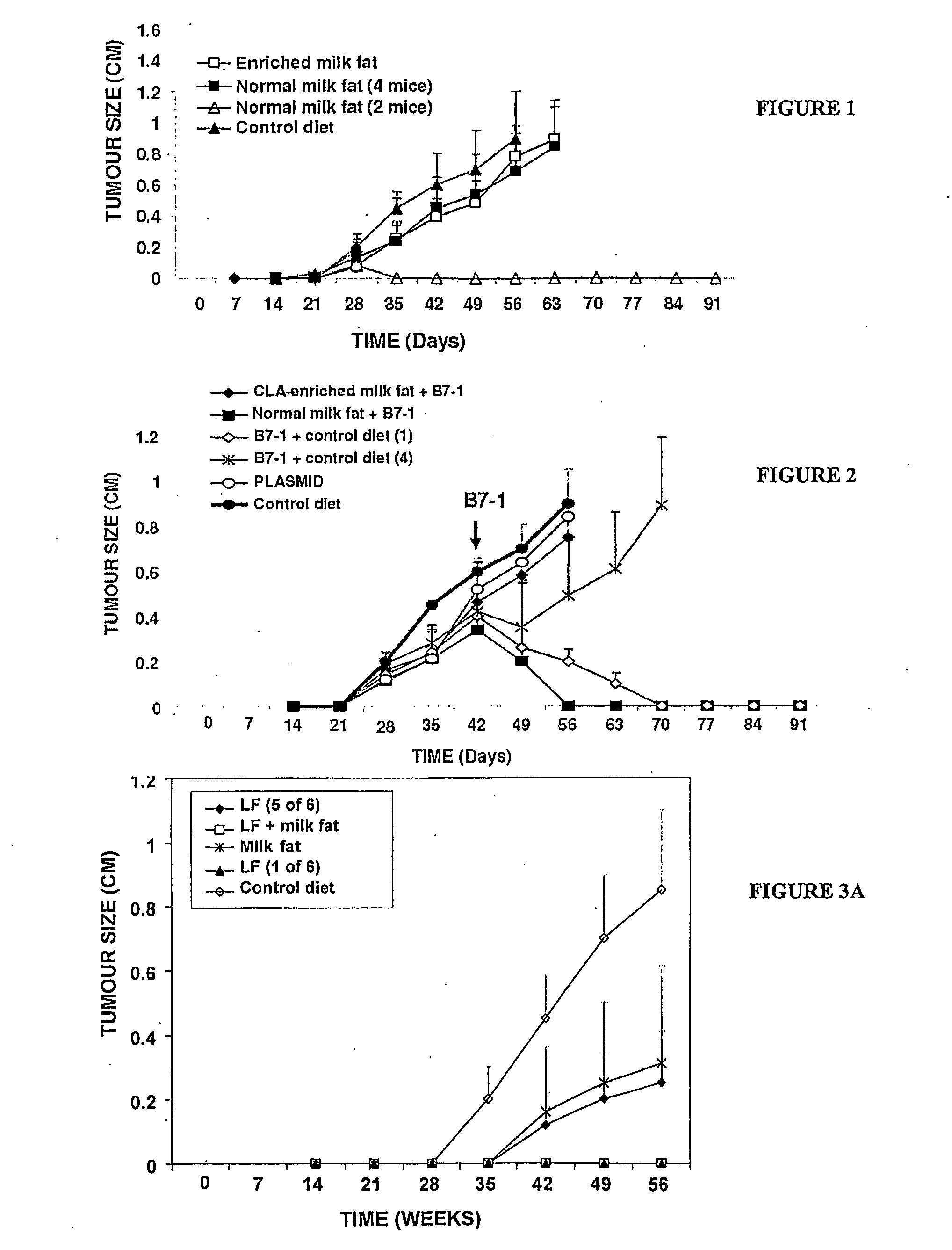

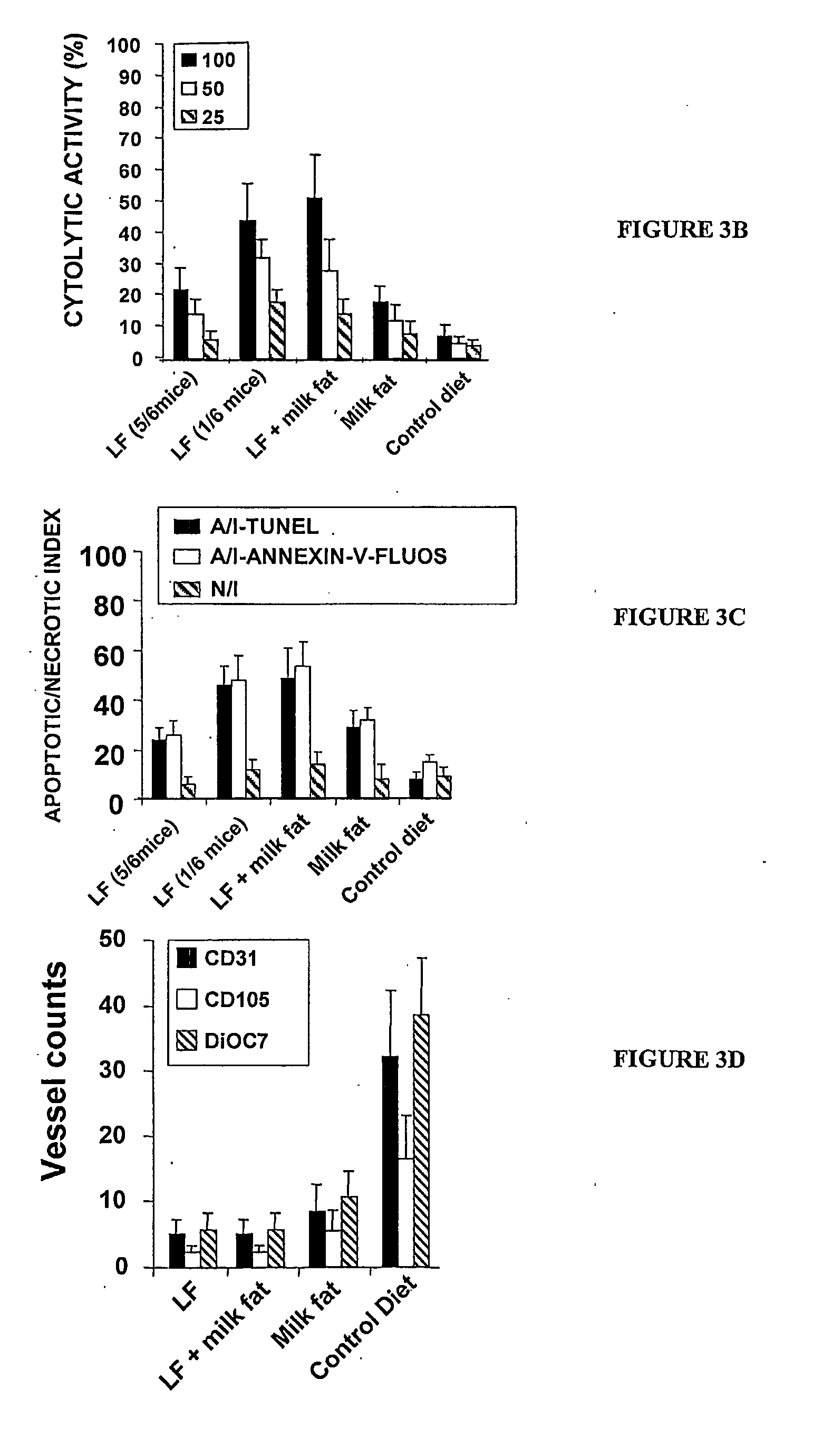

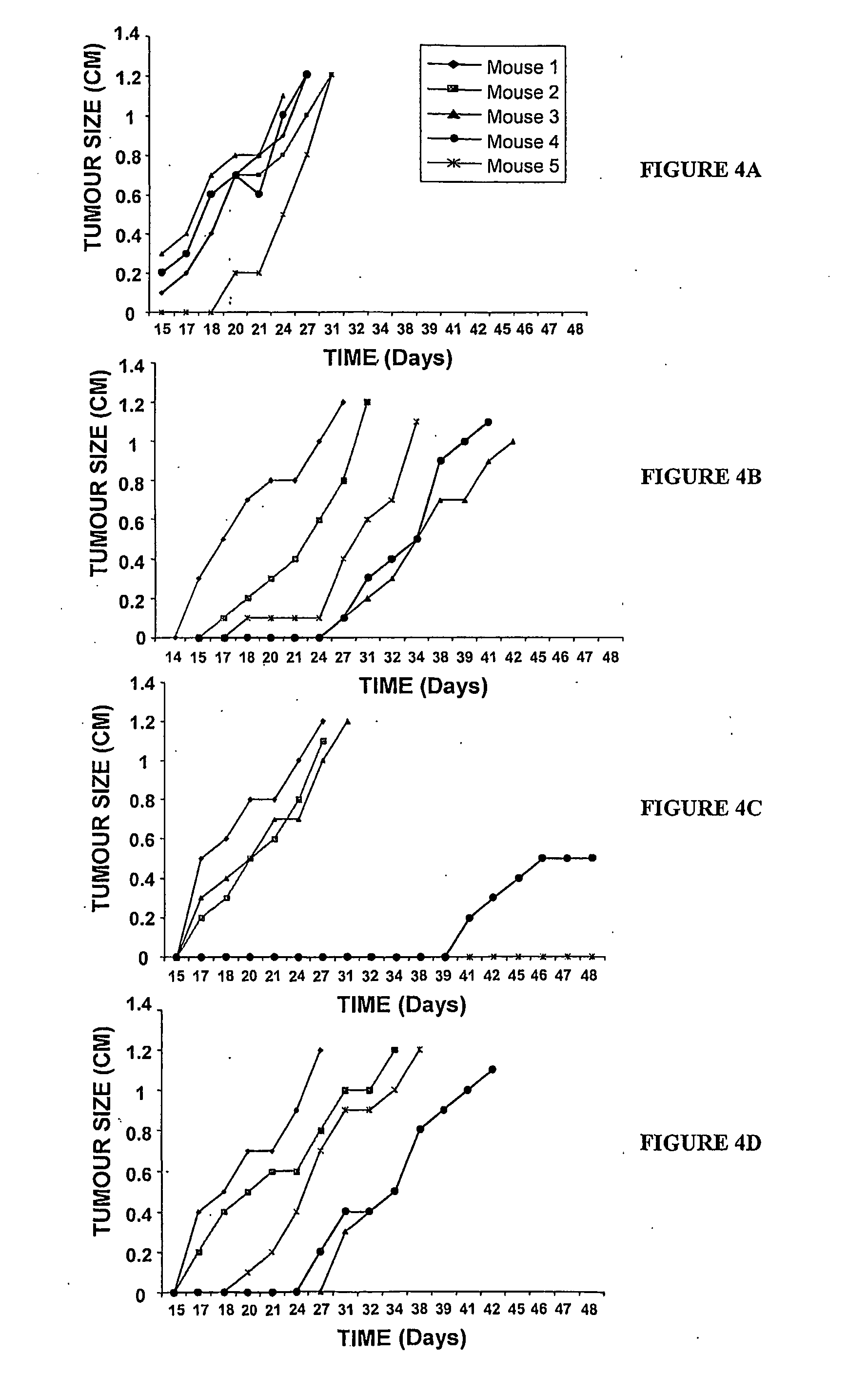

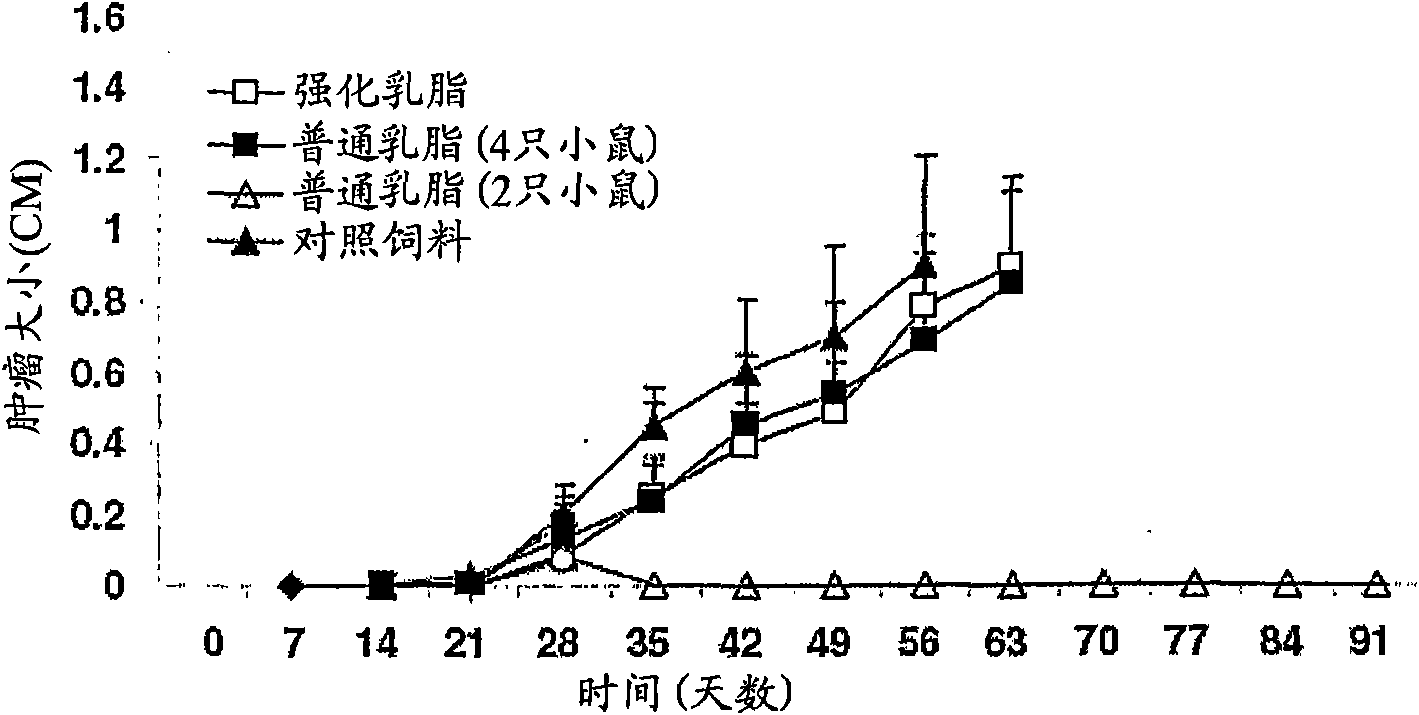

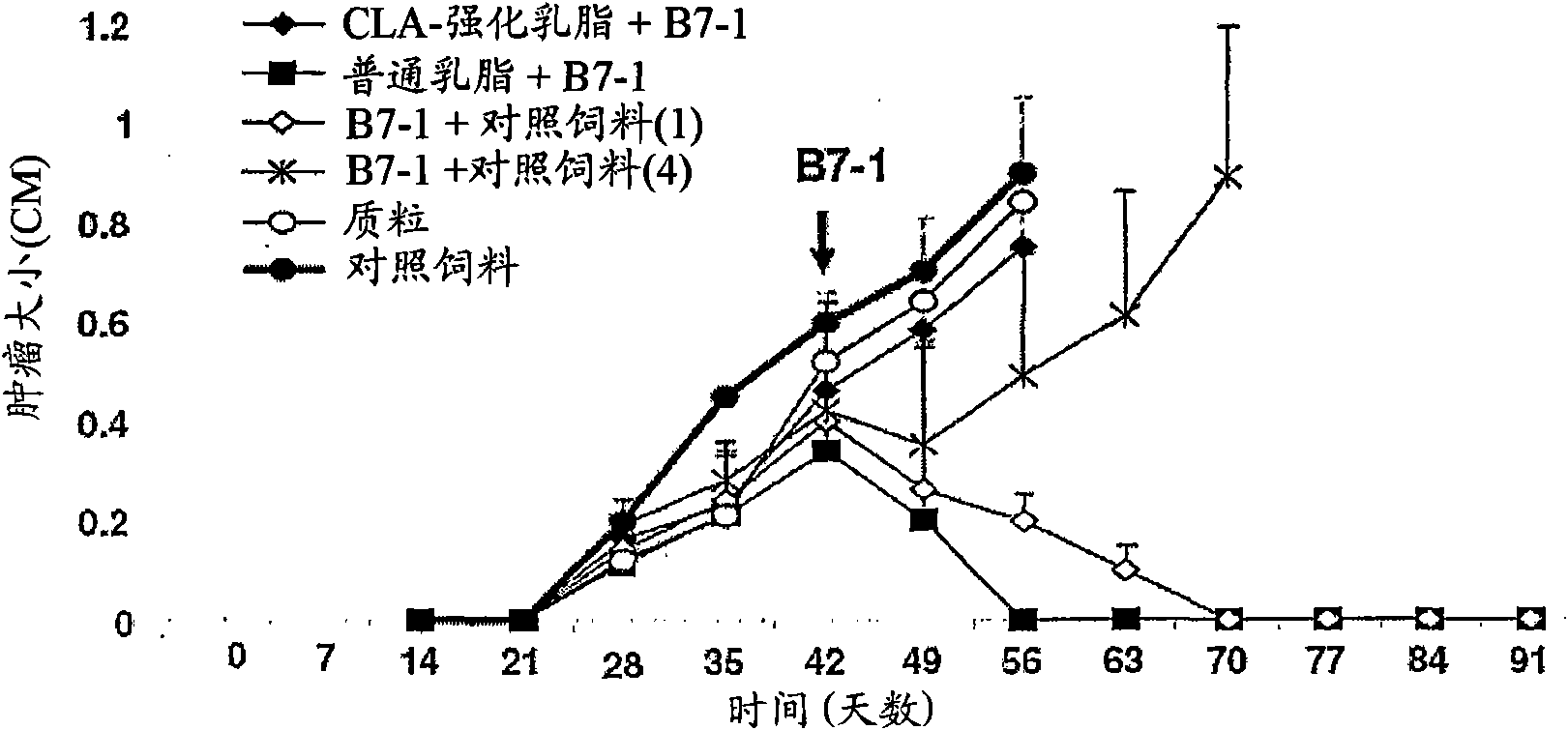

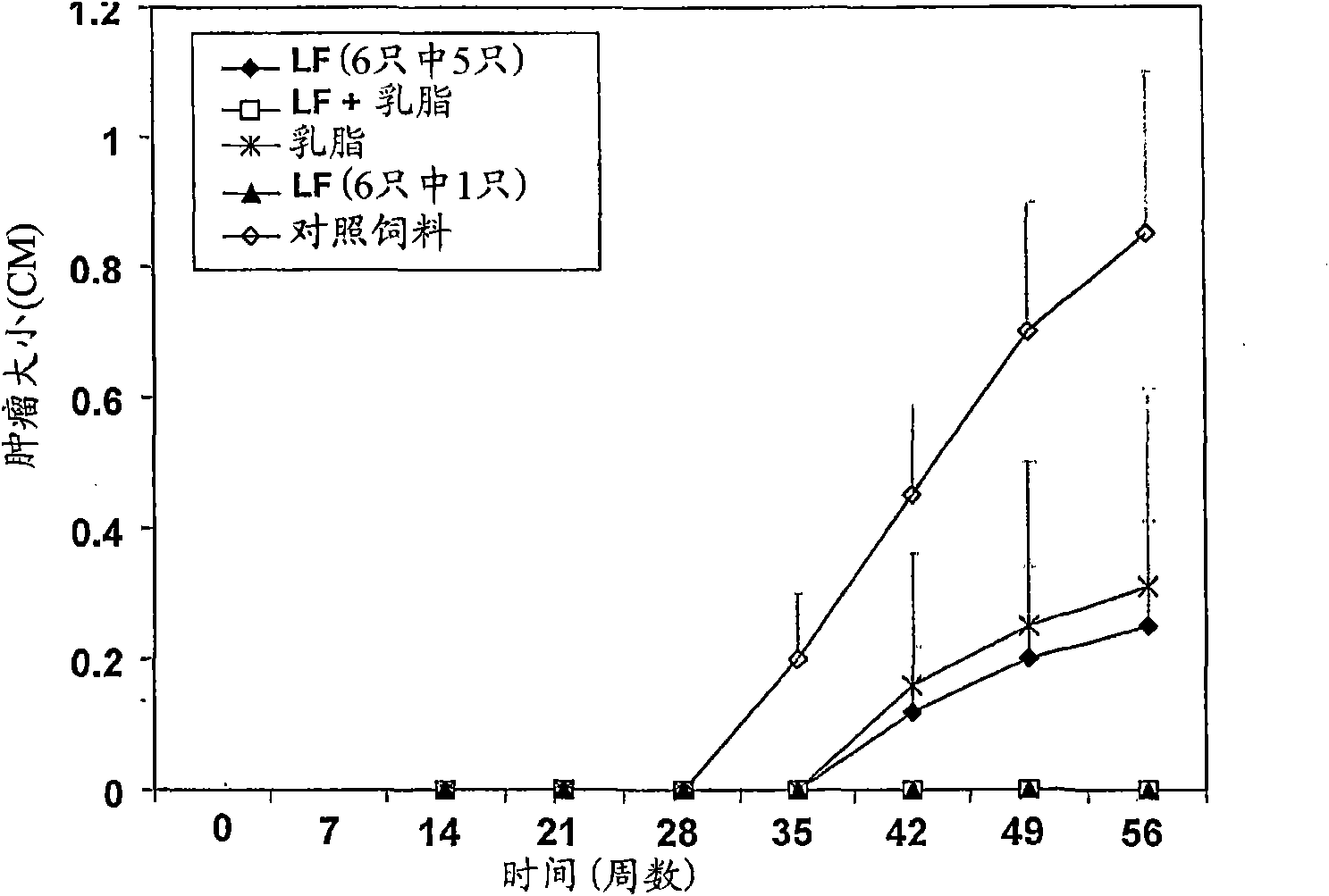

Methods of immune or hematological enhancement, inhibiting tumour formation or growth, and treating or preventing cancer, cancer symptoms, or the symptoms of cancer treatments

InactiveUS20110182943A1Increase productionImprove the level ofBiocideNervous disorderCancer preventionRed blood cell

The present invention relates to administration of milk fat or a milk fat analogue, optionally with at least one additional therapeutic factor, preferably lactoferrin or metal ion lactoferrin, preferably iron lactoferrin, preferably bovine lactoferrin, preferably iron bovine lactoferrin, or a metal ion functional variant or functional fragment thereof, to inhibit tumour formation or growth, maintain or improve one or more of the white blood cell count, the red blood cell count, or the myeloid cell count, reduce cachexia, mucositis, and anemia, stimulate the immune system and treat or prevent cancer and the symptoms of cancer and side-effects of cancer therapies. The methods and medicinal uses of the invention may be carried out by employing dietary (as foods or food supplements), nutraceutical or pharmaceutical compositions. Compositions useful in the methods of the invention are also provided.

Owner:FONTERRA COOP GRP LTD

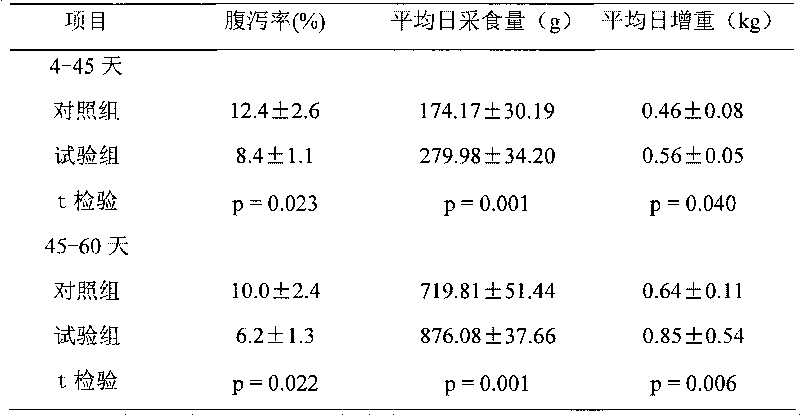

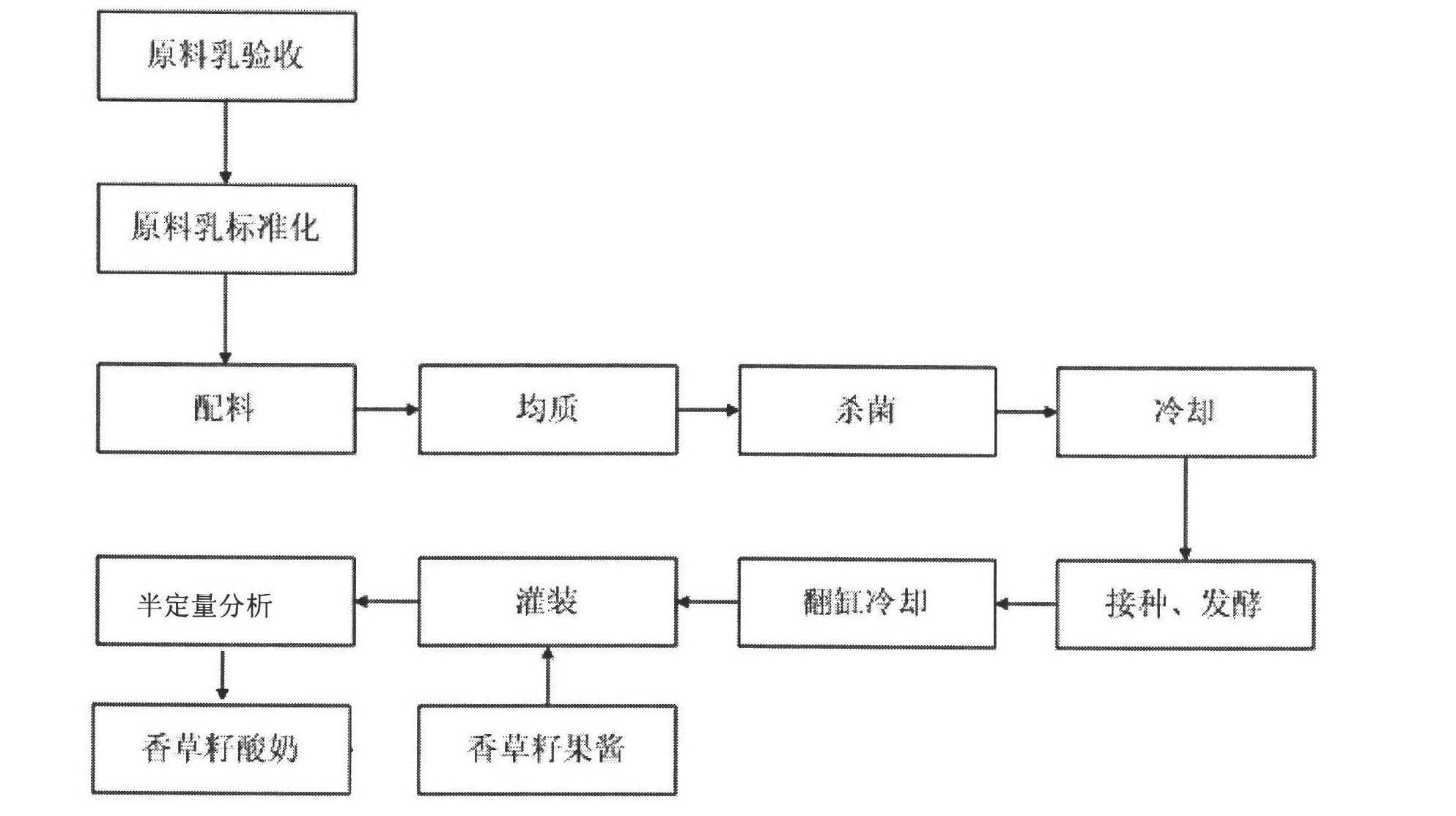

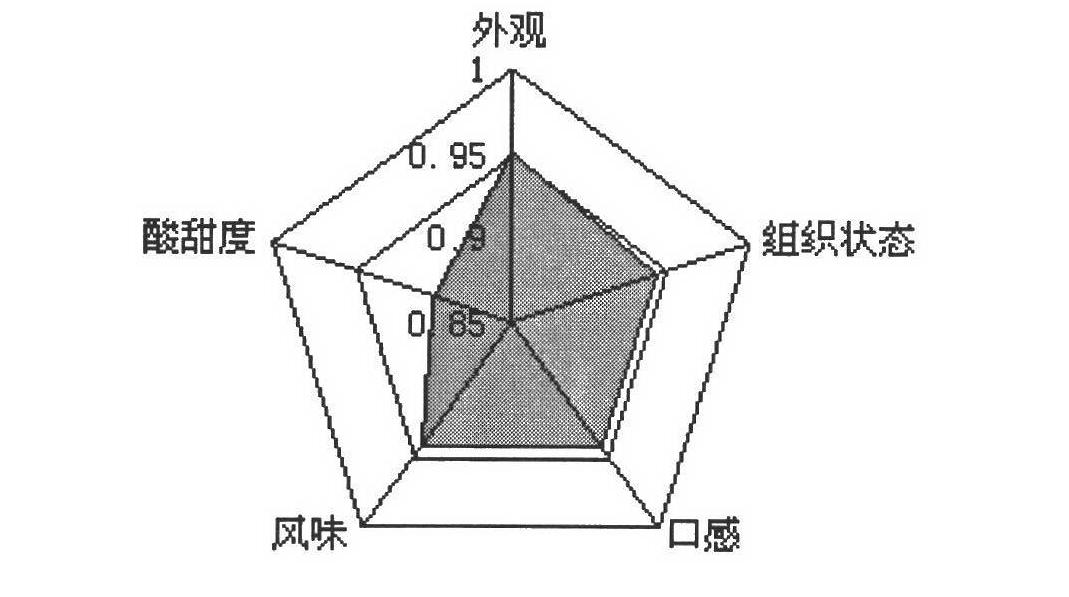

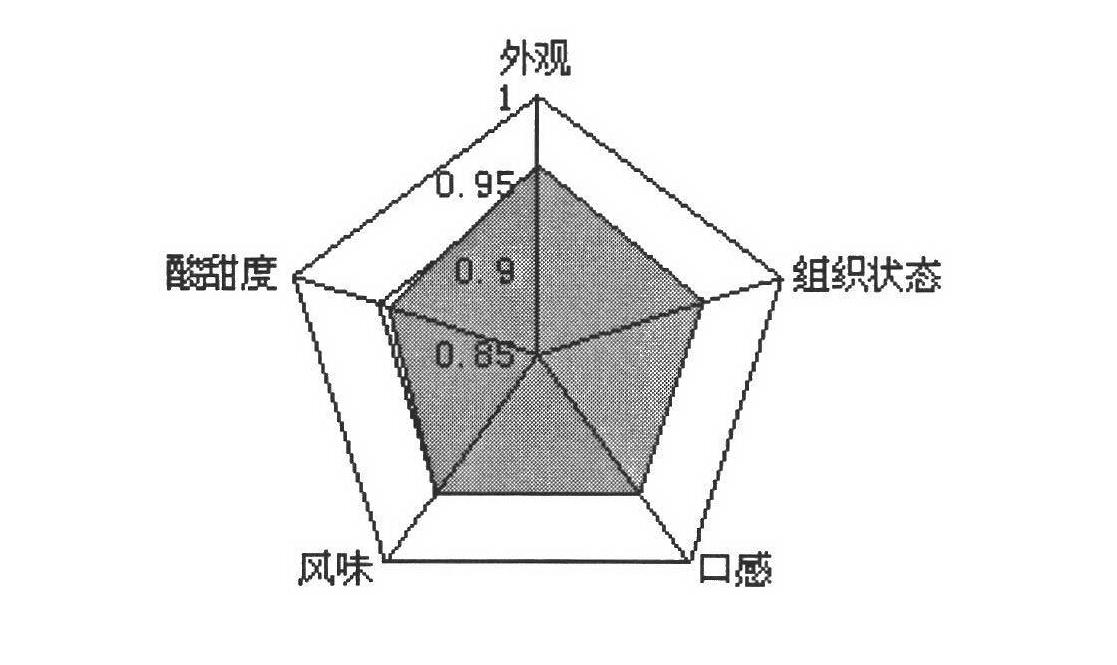

Vanilla-seed fermented milk and formulation, preparation method as well as semiquantitative analysis method thereof

The invention discloses a raw material formulation for vanilla-seed fermented milk, which includes raw milk, lactalbumin powder, a milk-fat product, a sweet substance, a thickening agent, zymogen and vallina-seed jam with viscosity not being higher than 10cm / (20 DEG C, 60s); and the invention discloses a semiquantitative analysis method for addition of the jam, which comprises steps of 1) covering vanilla-seed fermented milk uniformly on an entire filter-paper surface; 2) drying filter-paper surface with the vanilla-seed fermented milk for 15 to 40 minutes; and 3) comparing with a series standard sample. The invention also discloses a preparation method of the vanilla-seed fermented milk, which comprises the steps of: 1, mixing the fermented milk and the vanilla-seed jam to be canned; and 2, implementing the analysis according to the semiquantitative analysis method and fetching the vanilla-seed fermented milk reaching the target addition of the jam. The invention also discloses the vanilla-seed fermented milk prepared through the preparation method. The vanilla-seed fermented milk combines the light fermented flavor of the fermented milk and the fragrance of the vanilla and has rich color, the addition of the jam can be semiquantitatively monitored, the quality of different product batches is stable, and the market potential is remarkable.

Owner:BRIGHT DAIRY & FOOD

Yogurt smoothie kit and methods for making the same

InactiveUS20140295030A1Improved microbial stabilityImprove survivabilityMilk preparationFrozen sweetsEngineeringSugar

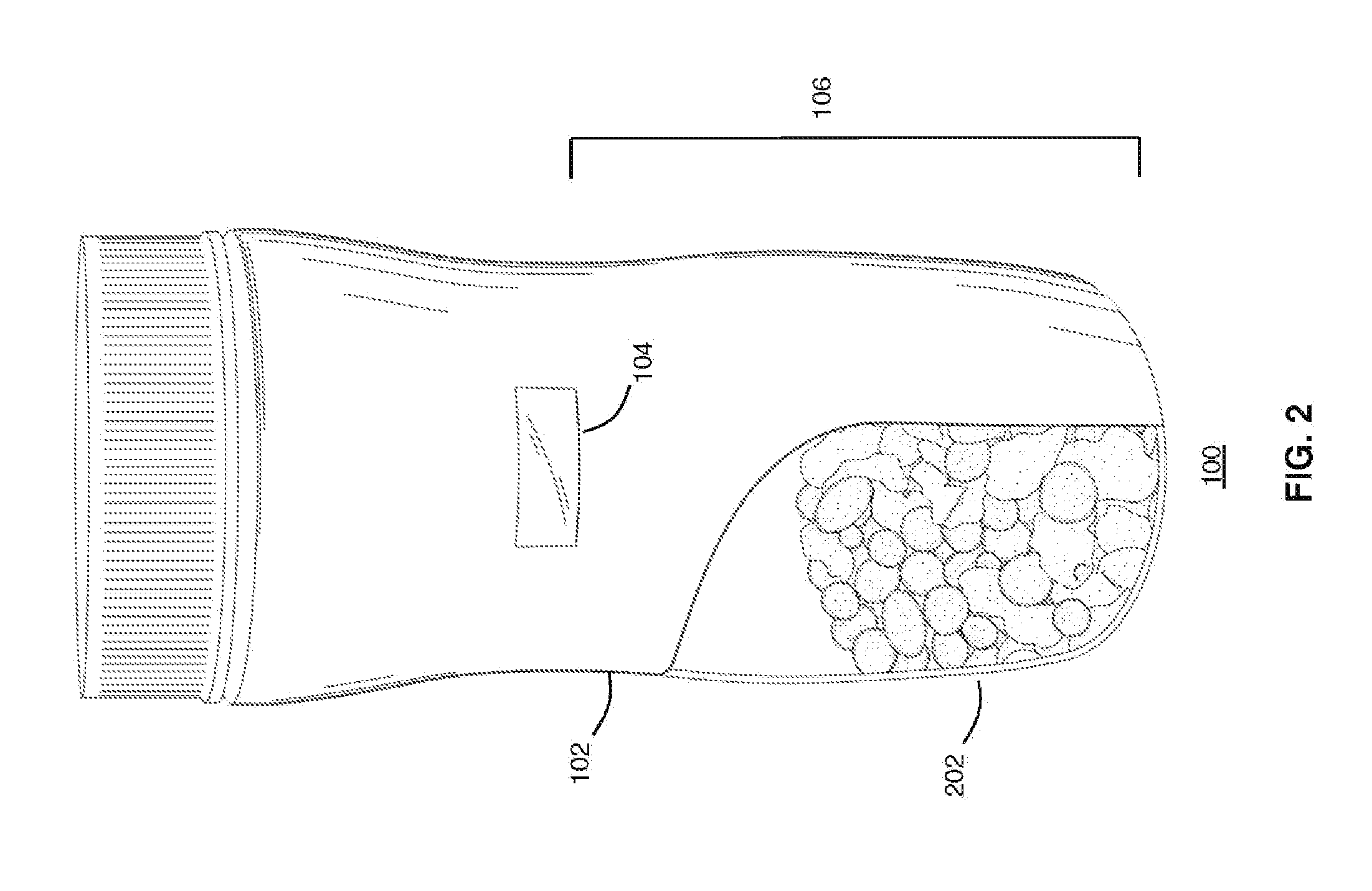

A yogurt smoothie kit for use in preparing yogurt smoothies, when combined with mixing liquid, is provided herein. The kit includes a container having an inner volume, an open top end, a closed bottom end, and a demarcation positioned between the top end and the bottom end, the inner volume divided by the demarcation into an upper volume above the demarcation and a lower volume below the demarcation. The kit further includes, inside the container, a plurality of frozen yogurt pellets, the frozen yogurt pellets each having at least milk proteins, milk fat, yogurt bacterial cultures, sugar, and a stabilizer mix.

Owner:CARGILL INC +1

Yolk essence and preparation method thereof

ActiveCN104222992AIncrease the fragranceRich aromaAcidic food ingredientsFood preparationYolkSolvent

The invention discloses yolk essence and a preparation method thereof. The preparation method comprises the following steps: taking yolk raw material, adding water and saccharose, uniformly mixing, sterilizing, introducing in aspergillus oryzae and aroma-producing yeast for fermentation, treating by a colloid mill to obtain yolk fermentation broth; adding mixed amino acids, thiamine, anhydrous milk fat and a solvent into the yolk fermentation broth, performing thermal reaction to obtain a yolk reactant; and adding yolk base, modified starch and xanthan gum in the yolk reactant, mixing uniformly, treating by the colloid mill to obtain paste yolk essence. According to the invention, natural yolk is used as the raw material, and the essence with the yolk flavor is prepared through microbial fermentation action and thermal reaction technology, the fragrance is rich and real, the cost is low, and the yolk essence has a great application market.

Owner:广东华谷香料科技有限公司

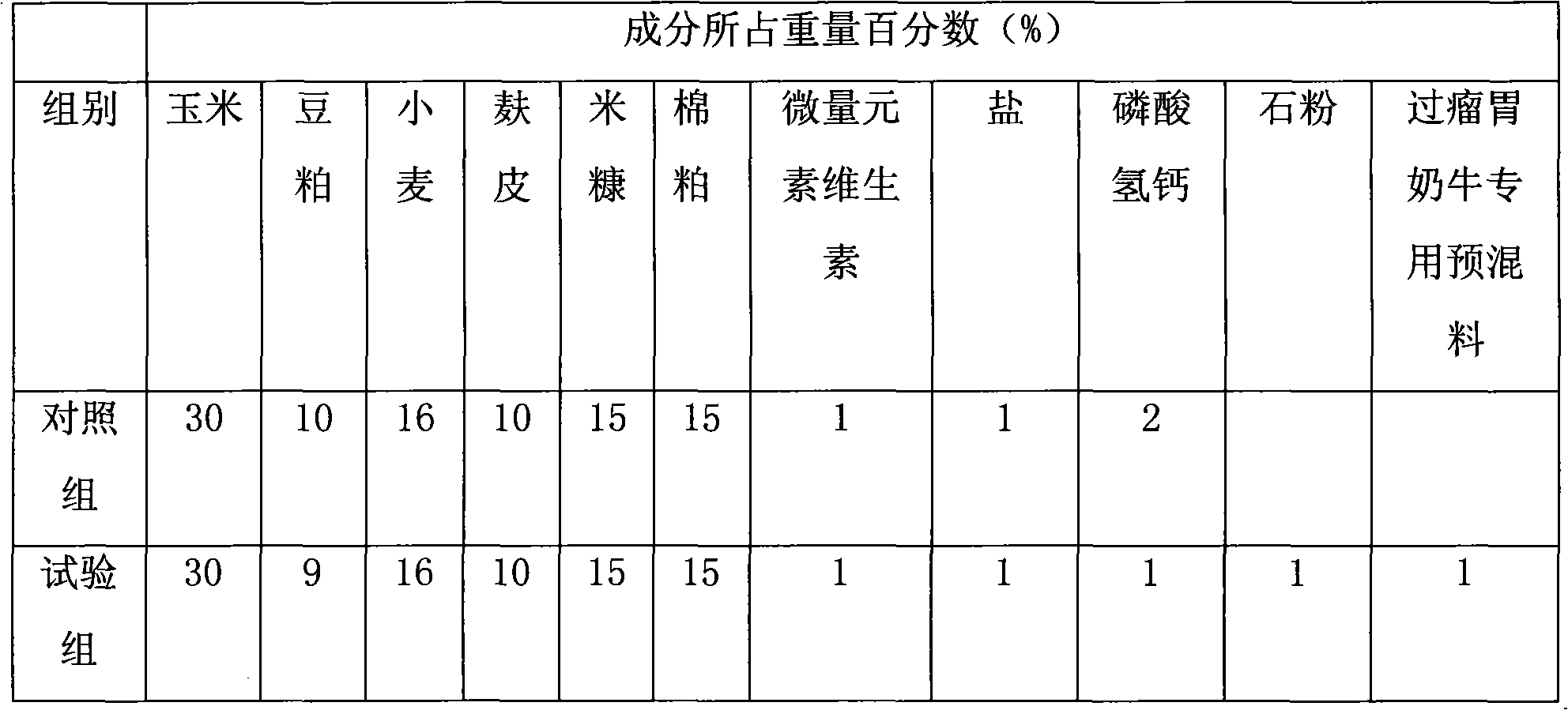

Premix material special for by-pass cow and preparation method thereof

InactiveCN101331921AExpand sourceImprove bioavailabilityAnimal feeding stuffAccessory food factorsPhytaseBetaine

The invention relates to a special premix compound for rumen bypass cows and a preparation method thereof. The formula of the premix compound is that every kilogram contains 100 to 150g of lysine, 10 to 20g of methionine, 15 to 30g of betaine, 100 to 250mg of folic acid, 15 to 30g of choline, 50 to 100g of phytase, 50 to 100g of non-starch polysaccharide enzyme and hydrogenated palm powder. The preparation method is that firstly a stainless steel stirrer is used for heating water at 50 to 60 DEG C and dissolving the hydrogenated palm powder; other materials are added and mixed evenly; then the materials are placed to be cooled. The special premix compound for rumen bypass cows can increase milk yield, improve milk fat percentage and milk protein, reduce the dosage of calcium hydrogen phosphate, eliminate anti-nutritional factors, widen feed sources and can improve the health of cows.

Owner:PUTIAN JINRIXING BIOTECH DEV CO LTD

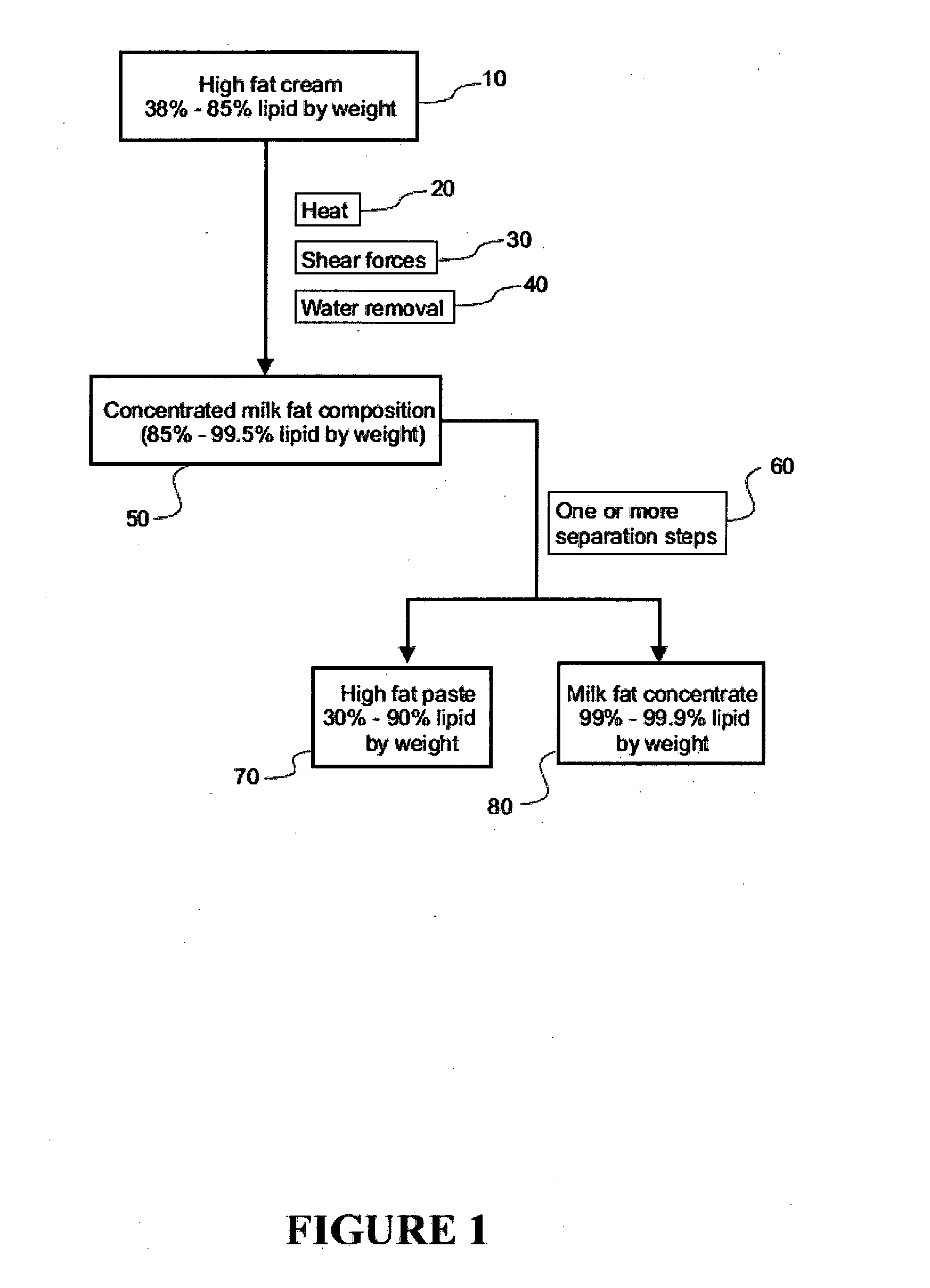

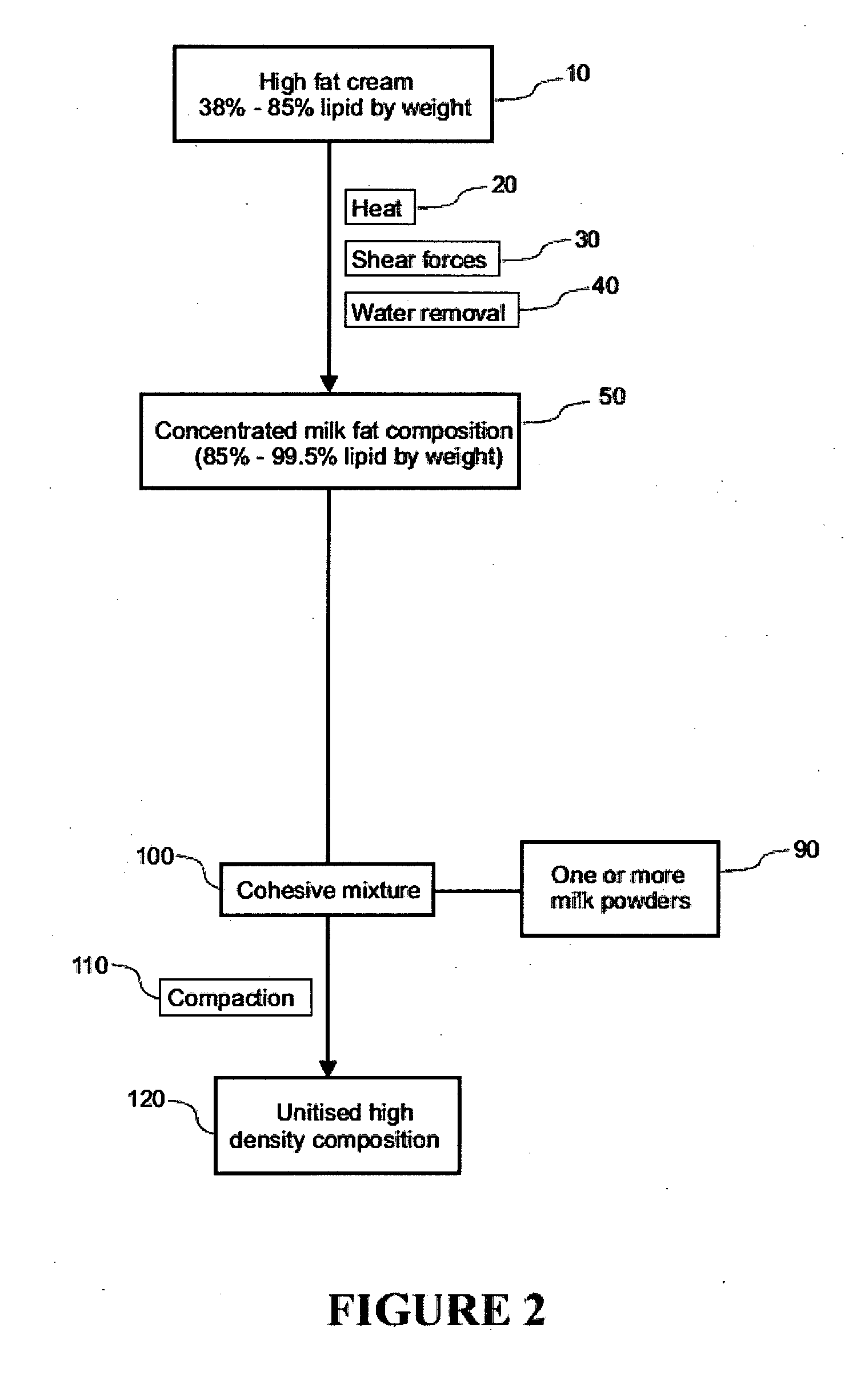

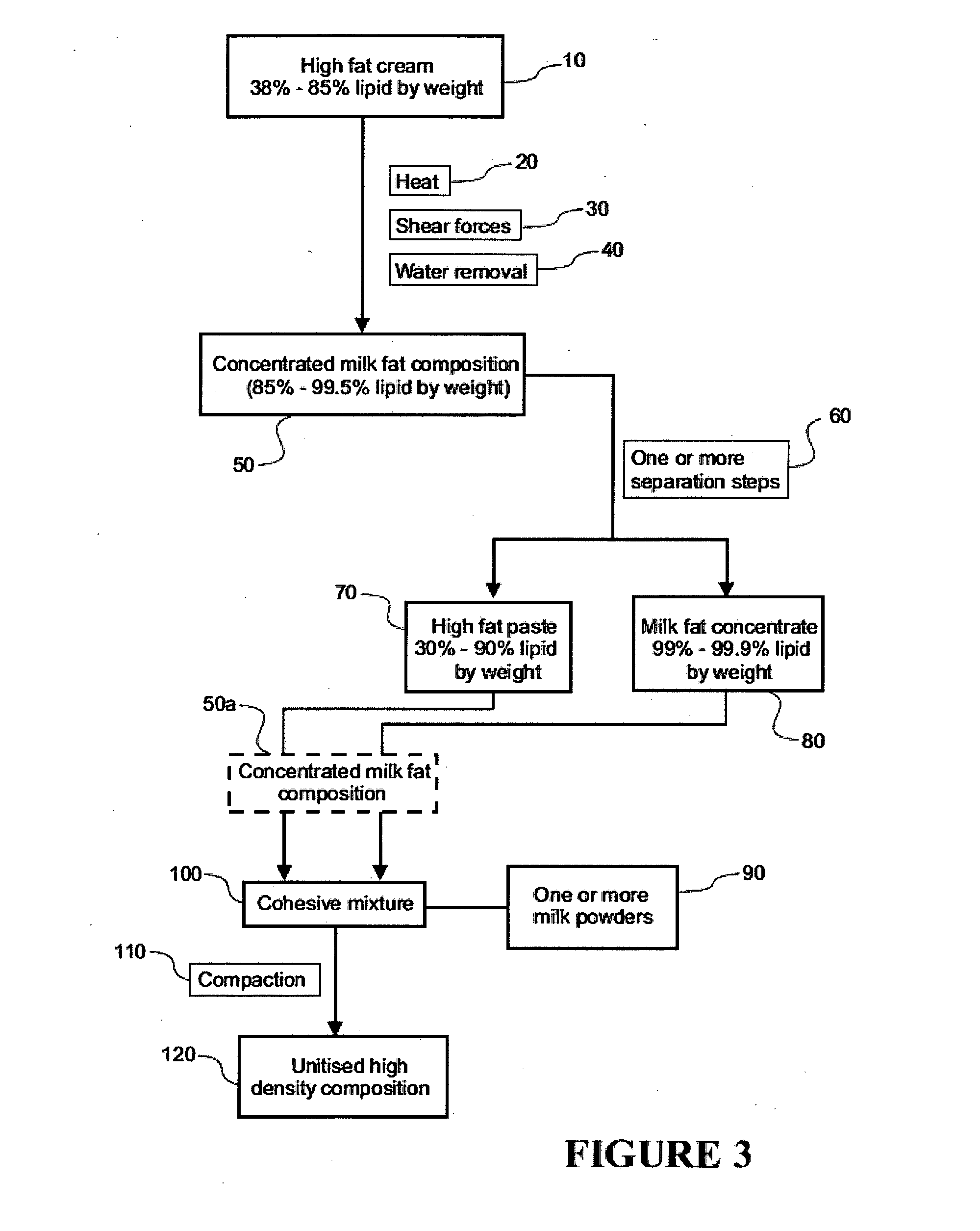

Production of concentrated milk fat compositions and unitised high density compositions

The present application is directed to a method comprising; heating high fat cream, subjecting the high fat cream to shear forces, and removing water to provide a milk fat composition being a water-in-oil emulsion and comprising about 85-99.5% lipid and moisture content of about 0.05-15%. A method comprising the separation of concentrated milk fat to provide a high fat paste comprising about 1 to about 90% by weight lipid, about 0.1 to about 20% by weight moisture, and about 0.5 to about 35% phospholipid, and a milk fat concentrate comprising about 99 to about 99.9% lipid is also disclosed. In addition a method of producing a unitised high density composition comprising; providing a mixture comprising one or more liquid or semi-liquid milk fat compositions, and one or more milk powders, and compacting the mixture to produce a unitised high density composition is disclosed.

Owner:MACKERETH ANTONY RAYMOND +2

Method for manufacturing cheese flavor milk essence bases

The invention discloses a method for manufacturing cheese flavor milk essence bases. The method includes steps of fermenting whole-milk powder by the aid of lactic acid bacteria and rhizopus oryzae to obtain milk fermented broth; adding milk fat into the milk fermented broth and carrying out enzymatic hydrolysis on the milk fermented broth by the aid of lipase and protease to obtain milk enzymatic hydrolysis liquid; adding amino acid, reducing sugar and solvents into the milk enzymatic hydrolysis liquid, and enabling the amino acid, the reducing sugar, the solvents and the milk enzymatic hydrolysis liquid to carry out thermal reaction to obtain the cheese flavor milk essence bases. The method has the advantages that procedures for manufacturing the cheese flavor milk essence bases are natural, generated aroma is natural, harmonious and mellow, the cheese flavor milk essence bases have certain heat resistance and can be applied to milk beverage, baking food and home cooking food, and accordingly the method has a broad market prospect.

Owner:广州市天滋优生物科技有限公司

Two-section type process for preparing natural essence with milk flavor

InactiveCN102318809ASolve the weak aromaSolve the erraticAnimal feeding stuffAccessory food factorsBiotechnologyFlavoring essences

The invention discloses a two-section type process for preparing natural essence with milk flavor, which comprises the following steps of: A, gentle flavor-producing enzymolysis: cream is put into a reaction vessel and is heated to the temperature of 90-95 DEG C, and the temperature is lowered to 35-60 DEG C after the temperature of 90-95 DEG C is kept for 10-15 min; the Ph is 6-8, and the cream is extracted for 10min-15min through ultrasound; then milk-flavor raw materials and / or milk-flavor essence base are added, are uniformly stirred and mixed, and then are sterilized; according to 5%-15% of the weight of the mixed substrate, lipase and protease are added; and enzymolysis is conducted for 7-22h at the temperature of 35-60 DEG C; B, high-temperature flavor-incensing reaction: after the enzymolysis is finished, the temperature of enzymolysis reaction liquid is raised to 90-95 DEG C, an organic solvent is slowly dropped into the liquid according to 3-10% of the weight of the substrate, and the mixed liquid reacts for 2-4h, after the liquid is cooled, the liquid is filtered and separated after natural settling; and the essence with milk flavor is obtained. The essence with milk flavor, prepared by the process, can simulate milk-flavor taste and has strong taste of natural milk fat, and soft flavor, can improve the mouth feeling and the flavor-staying ability, and is suitable for mass production and application.

Owner:成都大帝汉克生物科技有限公司

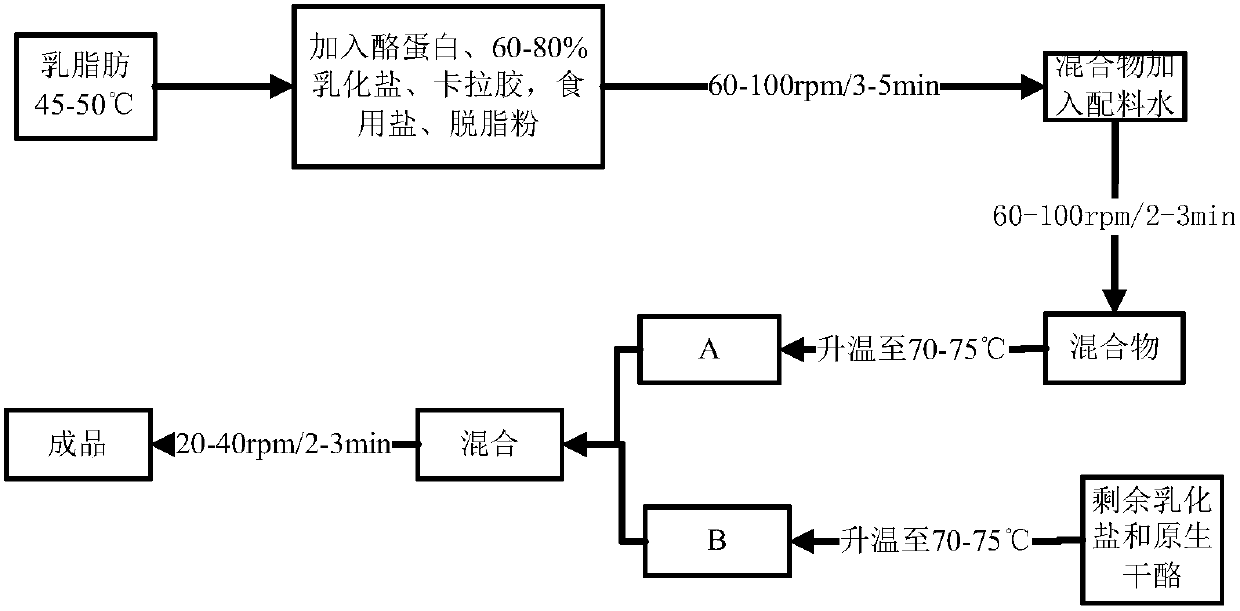

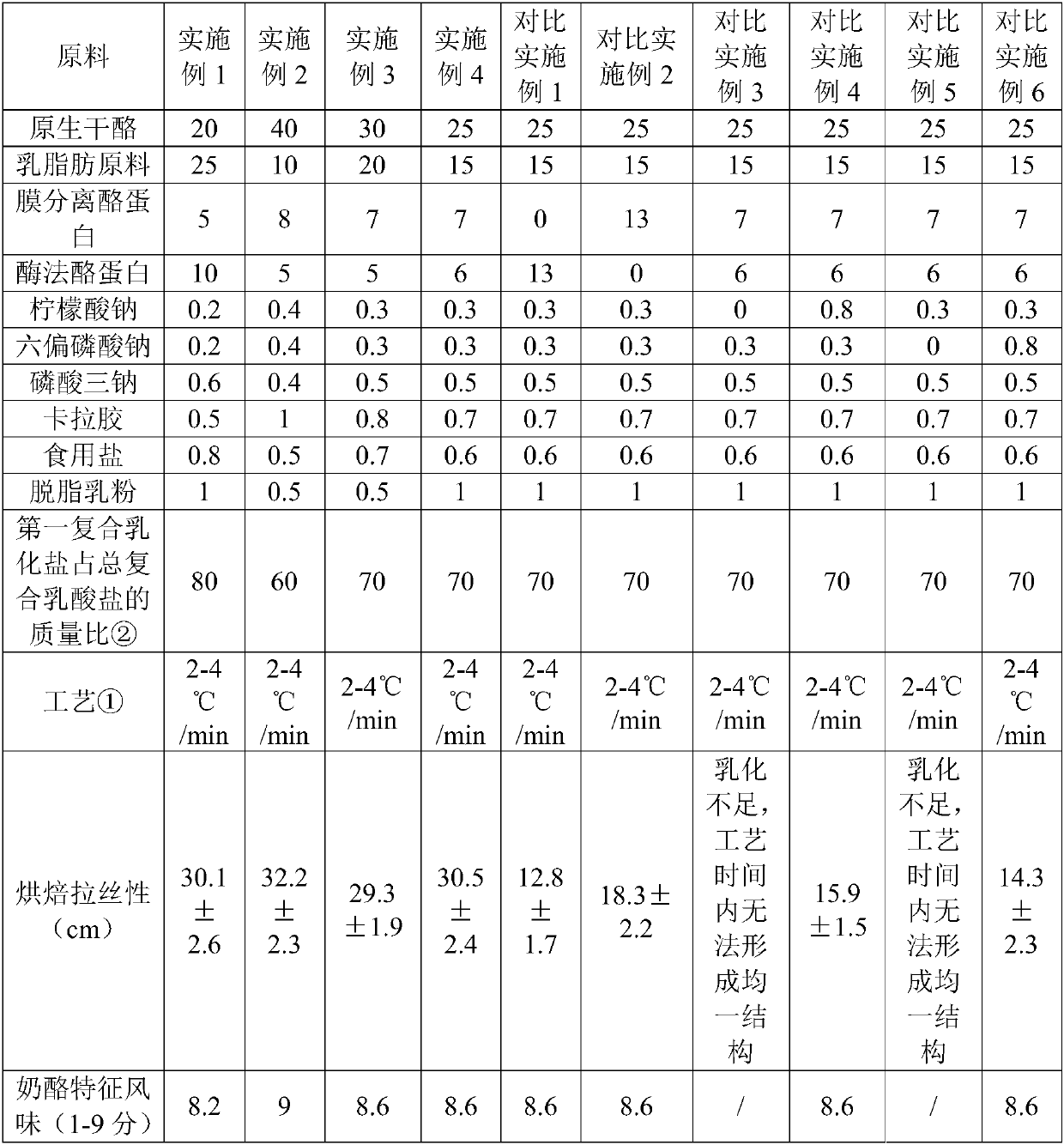

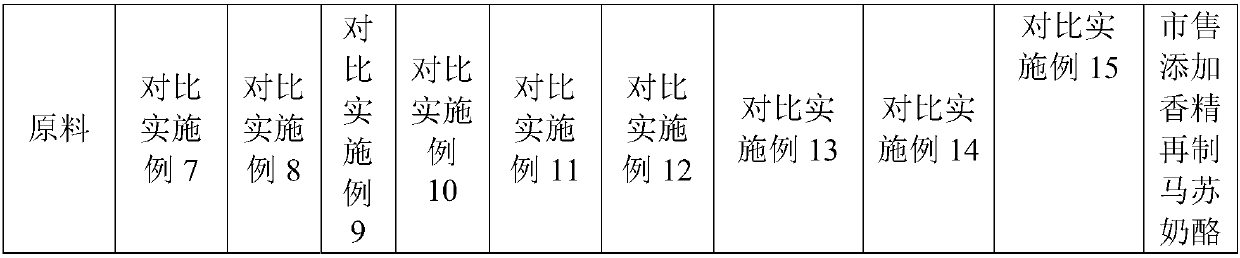

Processed cheese and preparation method thereof

The present invention provides processed cheese. The processed cheese comprises the following raw materials: 20-40 parts by weight of mature raw cheese, 10-25 parts by weight of milk fat raw materials, 5-10 parts by weight of membrane separated casein, 5-10 parts by weight of enzymatic method casein, 1.0-1.2 parts by weight of compound emulsified salt, 0.5-1 part by weight carrageenan, 0.5-0.8 part by weight of edible salt, 0.3-1.0 part by weight skim milk powder, and the balance of water, and the compound emulsified salt is 0.2-0.4 part by weight of sodium citrate, 0.2-0.4 part by weight of sodium hexametaphosphate and 0.4-0.6 part by weight of trisodium phosphate. The processed cheese is stable in structure, good in baking and drawing properties, free of essence, and full of cheese characteristic flavor.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

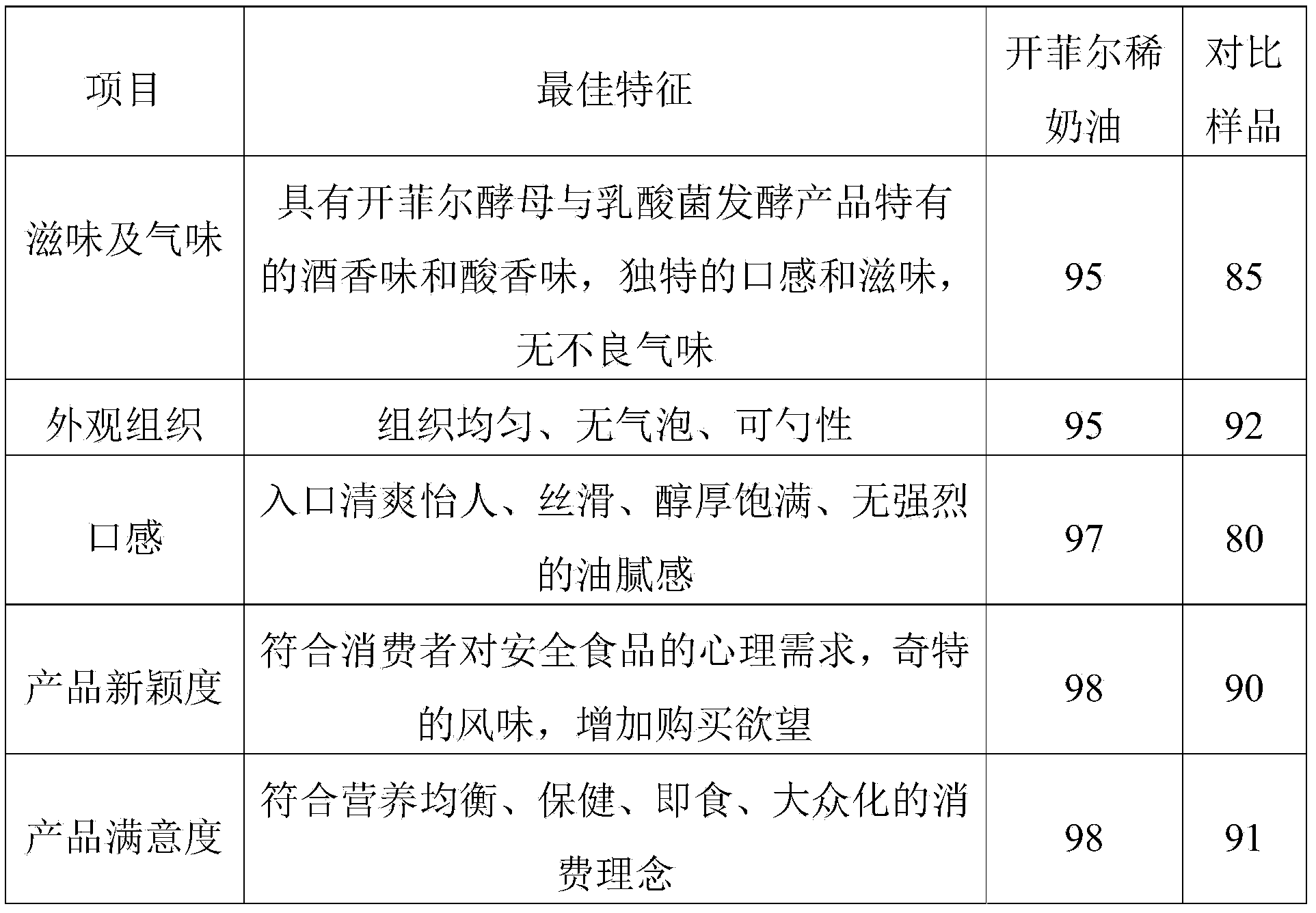

Kefir fermented single cream and preparation process thereof

ActiveCN103828929ACater to strong demandRetain nutritional valueCream preparationLeuconostoc mesenteroidesLactobacillus acidophilus

The invention relates to kefir fermented single cream and a preparation process of the kefir fermented single cream. The process comprises the following steps: (1) homogenizing uniformly-mixed raw materials, sterilizing and cooling, wherein the raw material components comprise 80-100wt% of single cream and 0-20wt% of white granulated sugar; and (2) inoculating a kefir fermenting strain and fermenting at 30-37 DEG C for 10-30 hours to obtain the kefir fermented single cream. The kefir fermented single cream is one or the combination of more strains of streptococcus thermophilus, lactobacillus bulgaricus, lactobacillus acidophilus, lactococcus lactis lactic acid subspecies, lactococcus lactis milk fat subspecies, lactococcus lactis diacetyl subspecies and lactic acid bacillus leuconostoc mesenteroides. The kefir fermented single cream has a thick texture; no additive is added and the kefir fermented single cream still has good stability; the preparation process is simple and a continuous agitating process is reduced; a temperature control range of fermentation is wide so that the kefir fermented single cream is good for industrial production.

Owner:BRIGHT DAIRY & FOOD CO LTD

Methods of immune or hematological enhancement, inhibiting tumour formation or growth, and treating or preventing cancer, cancer symptoms, or the symptoms of cancer treatments

The present invention relates to administration of milk fat or a milk fat analogue, optionally with at least one additional therapeutic factor, preferably lactoferrin or metal ion lactoferrin, preferably iron lactoferrin, preferably bovine lactoferrin, preferably iron bovine lactoferrin, or a metal ion functional variant or functional fragment thereof, to inhibit tumour formation or growth, maintain or improve one or more of the white blood cell count, the red blood cell count, or the myeloid cell count, reduce cachexia, mucositis, and anemia, stimulate the immune system and treat or prevent cancer and the symptoms of cancer and side-effects of cancer therapies. The methods and medicinal uses of the invention may be carried out by employing dietary (as foods or food supplements), nutraceutical or pharmaceutical compositions. Compositions useful in the methods of the invention are also provided.

Owner:FONTERRA COOP GRP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com