Production method of human milk fat substituted grease

A technology of breast milk fat and production method, applied in the production/processing of edible oil/fat, milk replacer, dairy products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

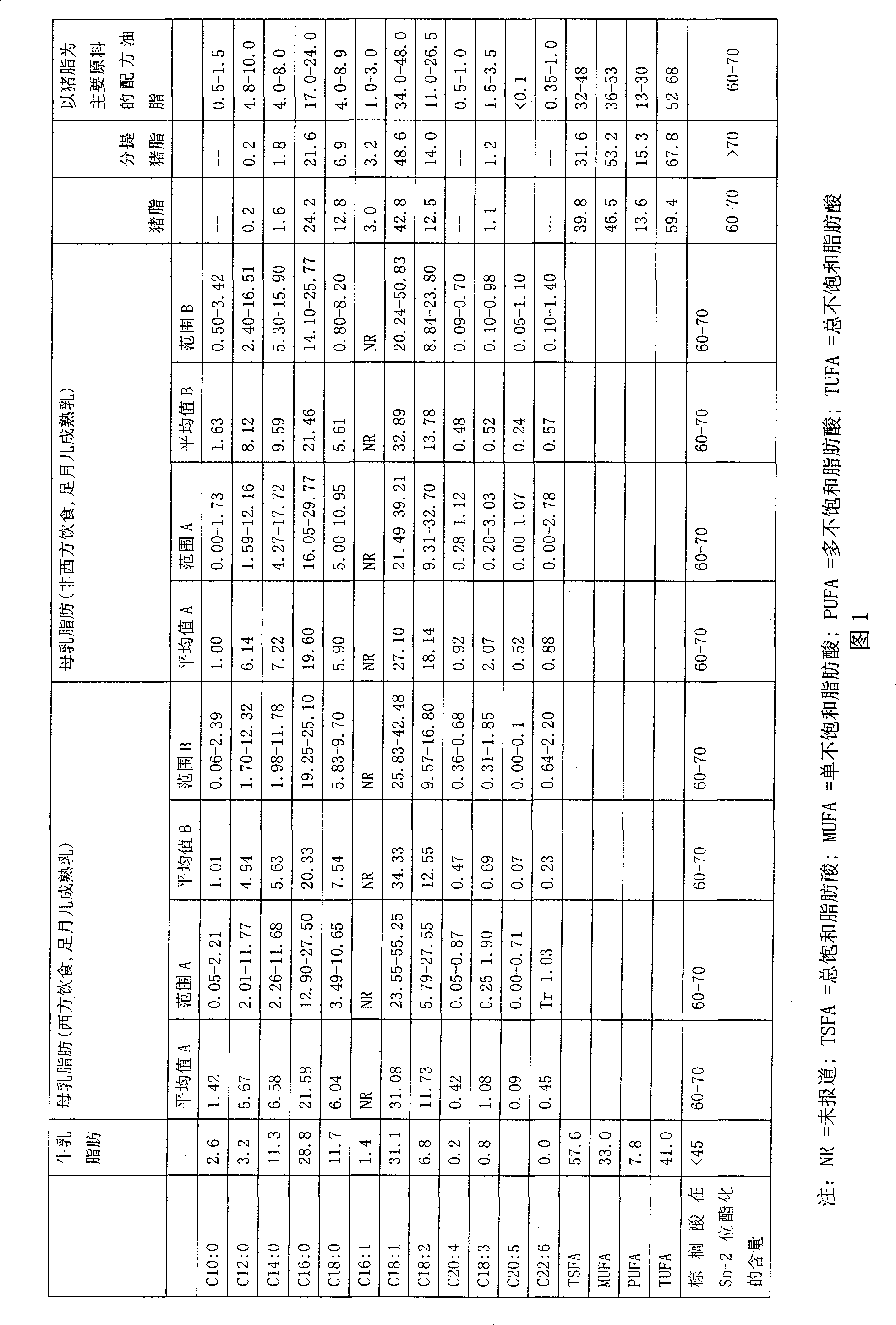

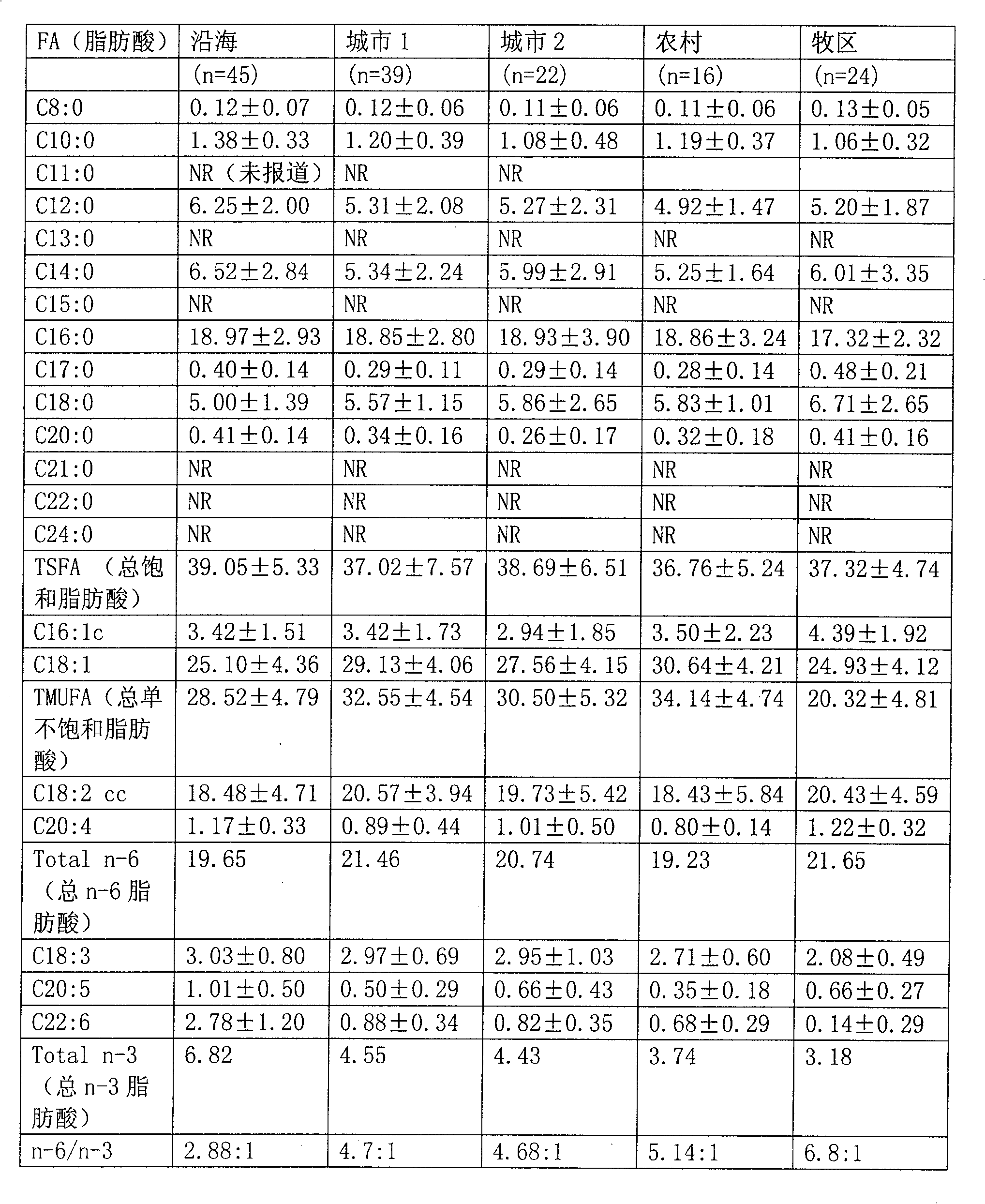

Method used

Image

Examples

Embodiment 1

[0043] Embodiment one: the preparation of high OPO (containing OPL) fractionation lard

[0044] Raw lard: iodine value (IV): 66.4

[0045] Melting point: 33.1°C; OPO (including OPL)%: 39.8 The fractionation process is as follows:

[0046] Heat the raw lard to 50-60°C, stabilize it for 20 minutes, then cool down to 25°C at a rate of 4-6°C / hour, then cool down to 19-17°C at a rate of 1.5-2.5°C / hour, and crystallize at constant temperature After 5-10 hours, stir all the above-mentioned processes, and finally return to the temperature of 0-1°C, and start to separate after stabilization. The initial filtration pressure is 6bar, and stop after pressurizing to 12bar. The liquid target product with OPO (including OPL) content of 85.3% - fractionated lard was obtained, with a yield of 49.7%.

Embodiment 2

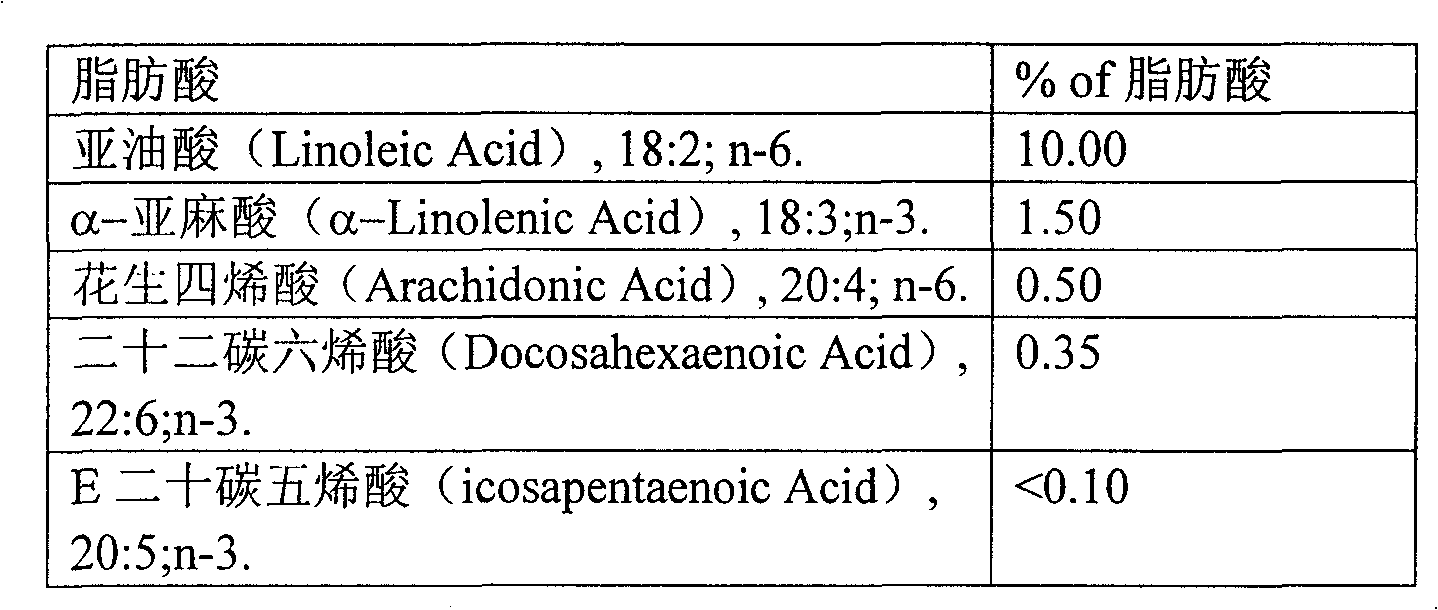

[0047] Example 2: Preparation of breast milk fat substitute oil

[0048] The fractionated lard obtained in Example 1 was mixed with several other oil raw materials according to the ratio shown in Table 5 to make 1 kg of blended oil, which was then subjected to a refining process, wherein the refining deodorization temperature was 235° C. and the residence time was 50 minutes to produce a The fatty acid composition and triglyceride structure are similar to breast milk fat and the breast milk fat substitute oil whose trans acid content is less than 1%, its fatty acid composition is shown in Table 6.

[0049] Grease type

[0050] table 5

[0051] In Table 5, palm oil and milk fat are "other animal and vegetable oils" in the raw material formula.

[0052] Mixed oil (%)

[0053] Table 6

Embodiment 3

[0055] The result of Example 1 is mixed with lard and soybean oil, palm oil (iodine value is 50.5), coconut oil, and deep-sea fish oil in the ratio shown in Table 7 to make 1kg blended oil, and then through the refining process, wherein in the deodorization stage According to the conditions of temperature 235°C, residence time 50 minutes, and vacuum degree 2.3mbar, breast milk fat substitute oil was obtained, and its key indicators are shown in Table 8.

[0056] Grease type

[0057] Table 7

[0058] In Table 7, palm oil is "other animal and vegetable oils" in the raw material formula.

[0059] Mixed oil (wt%)

[0060] Table 8

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com