Oil suspension preparation using resin-based vegetable oil as carrier and preparation method thereof

A technology of turpentine-based vegetable oil and carrier, applied in botany equipment and methods, plant growth regulators, biocides, etc., can solve the problems of easy rancidity, competition with the people, high price, etc., and achieve good stability and safety High, low toxicity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

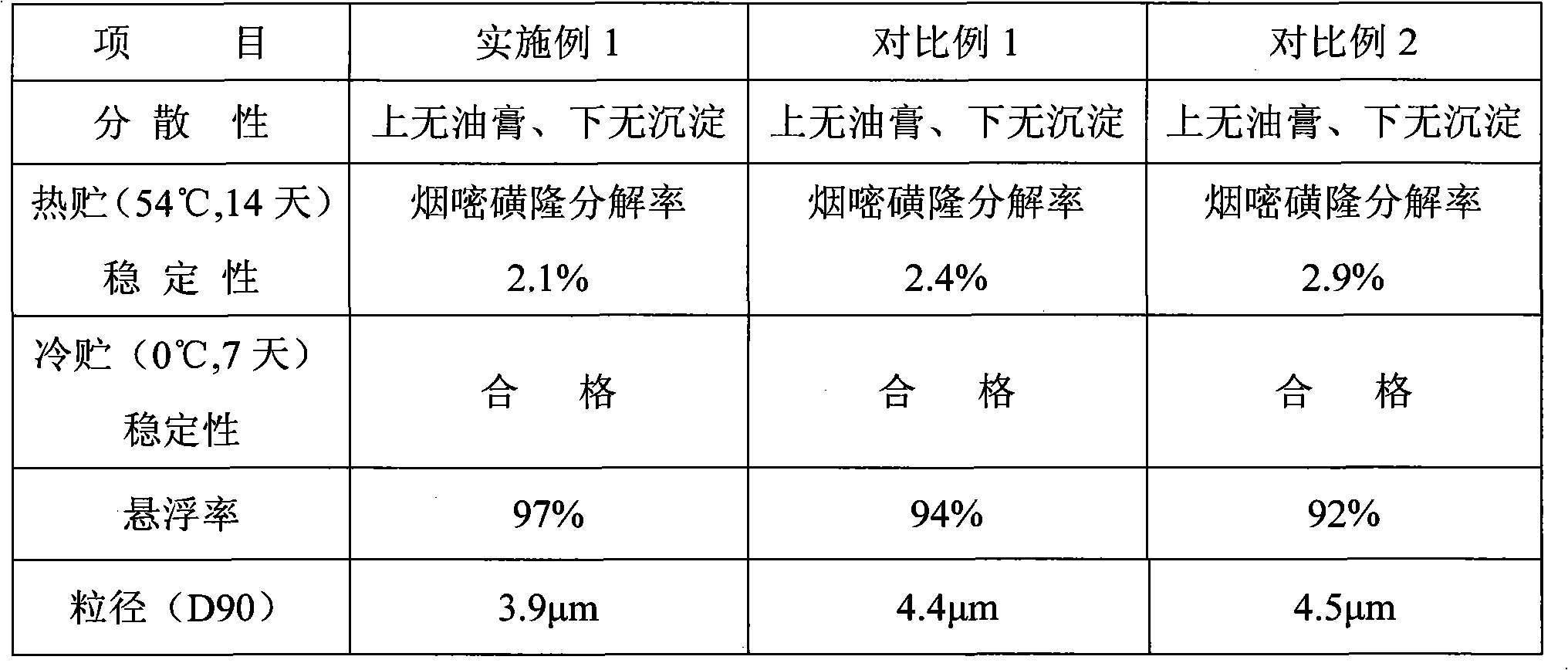

Embodiment 1

[0039] Nicosulfuron 40kg, polyoxyethylene polyoxypropylene block copolymer 15kg, sorbitan oleate 10kg, polycarboxylate 20kg, attapulgite 50kg, polysiloxane 1kg, rosin-based vegetable oil 864kg .

[0040] Preparation:

[0041] 1) After mixing nicosulfuron, polyoxyethylene polyoxypropylene block copolymer, sorbitan oleate, polycarboxylate, attapulgite, polysiloxane, and rosin-based vegetable oil, Placed in a high-speed shear ball mill;

[0042] 2) High-speed shearing ball milling until 90% of the particle size is less than 4 μm to form 4% nicosulfuron oil suspension preparation.

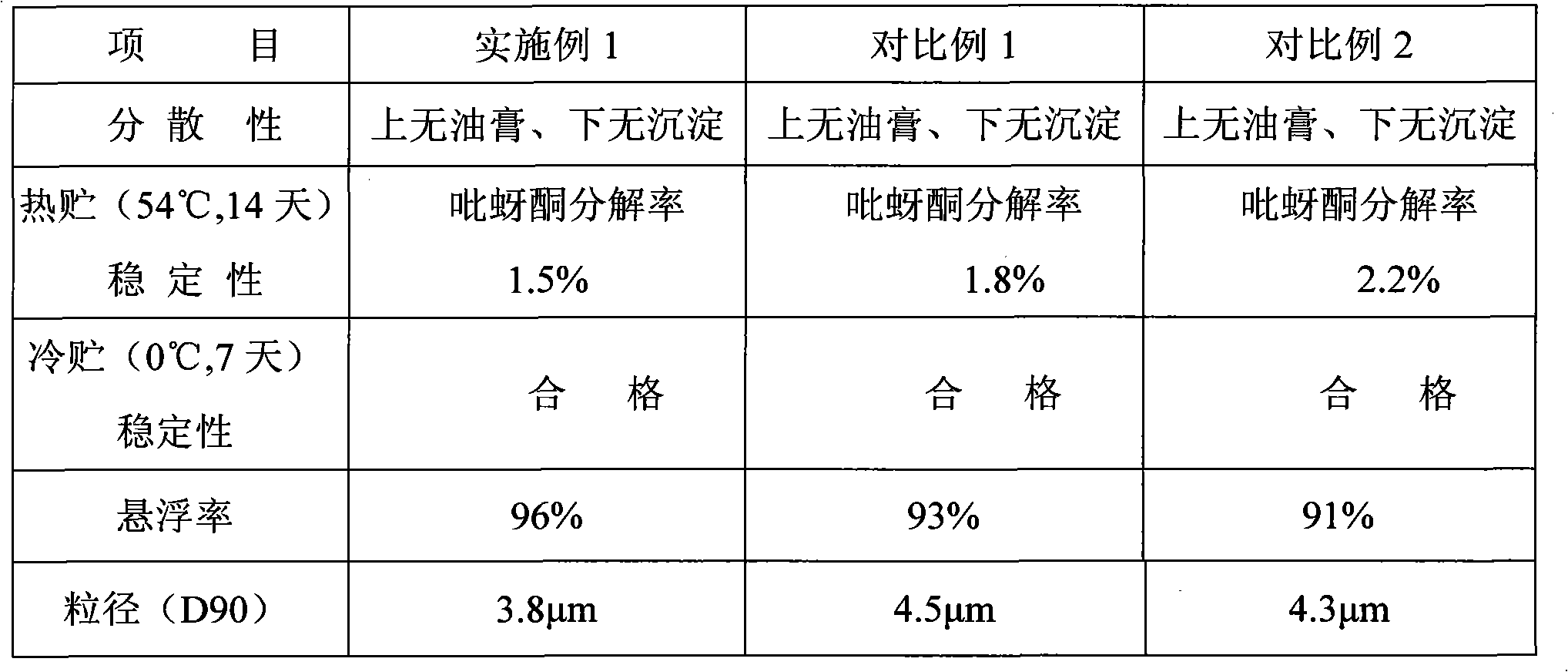

Embodiment 2

[0052] Penoxsulam 25kg, polyoxyethylene polyoxypropylene block copolymer 25kg, alkylbenzene sulfonate 10kg, polycarboxylate 20kg, hydroxyethyl cellulose 30kg, polysiloxane 2kg, rosin-based vegetable oil 888kg .

[0053] Preparation:

[0054] 1) After mixing penoxsulam, polyoxyethylene polyoxypropylene block copolymer, alkylbenzene sulfonate, polycarboxylate, hydroxyethyl cellulose, polysiloxane, and rosin-based vegetable oil, Placed in a high-speed shear ball mill;

[0055] 2) High-speed shear ball milling until 90% of the particle size is less than 4 μm to form 2.5% penoxsulam oil suspension preparation.

Embodiment 3

[0057] Nicosulfuron 10kg, acetochlor 490kg, fatty alcohol polyoxyethylene ether 50kg, sorbitan monooleate 20kg, polymer grafted lignosulfonate 80kg, polysiloxane 1kg, rosin-based vegetable oil 349kg

[0058] Preparation:

[0059] 1) After mixing nicosulfuron, acetochlor, fatty alcohol polyoxyethylene ether, sorbitan monooleate, polymer grafted lignosulfonate, polysiloxane, and turpentine-based vegetable oil, place in In high-speed shear ball milling equipment;

[0060] 2) High-speed shearing ball milling until 90% of the particle size is less than 4 μm to form 50% nicosulfuron-acetochlor oil suspension preparation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com