Patents

Literature

422results about How to "Improve dispersion efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

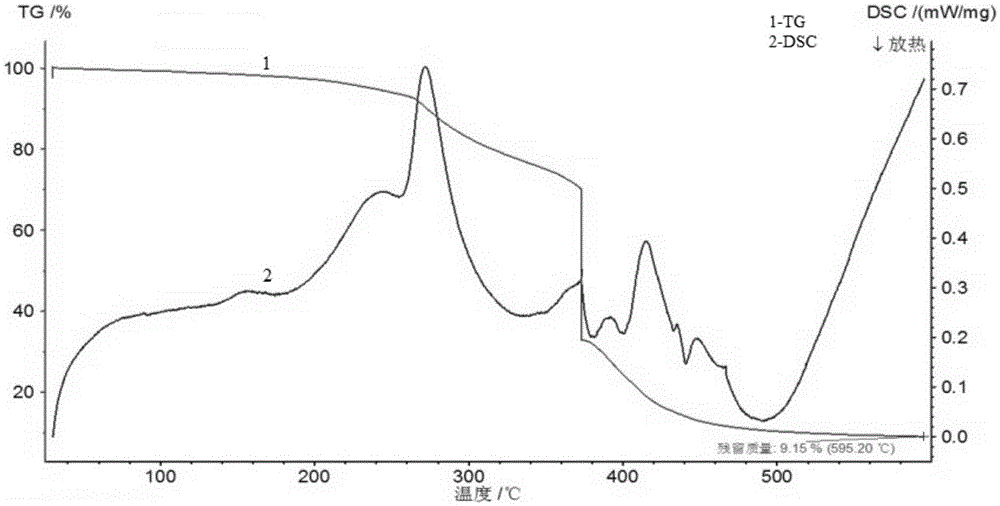

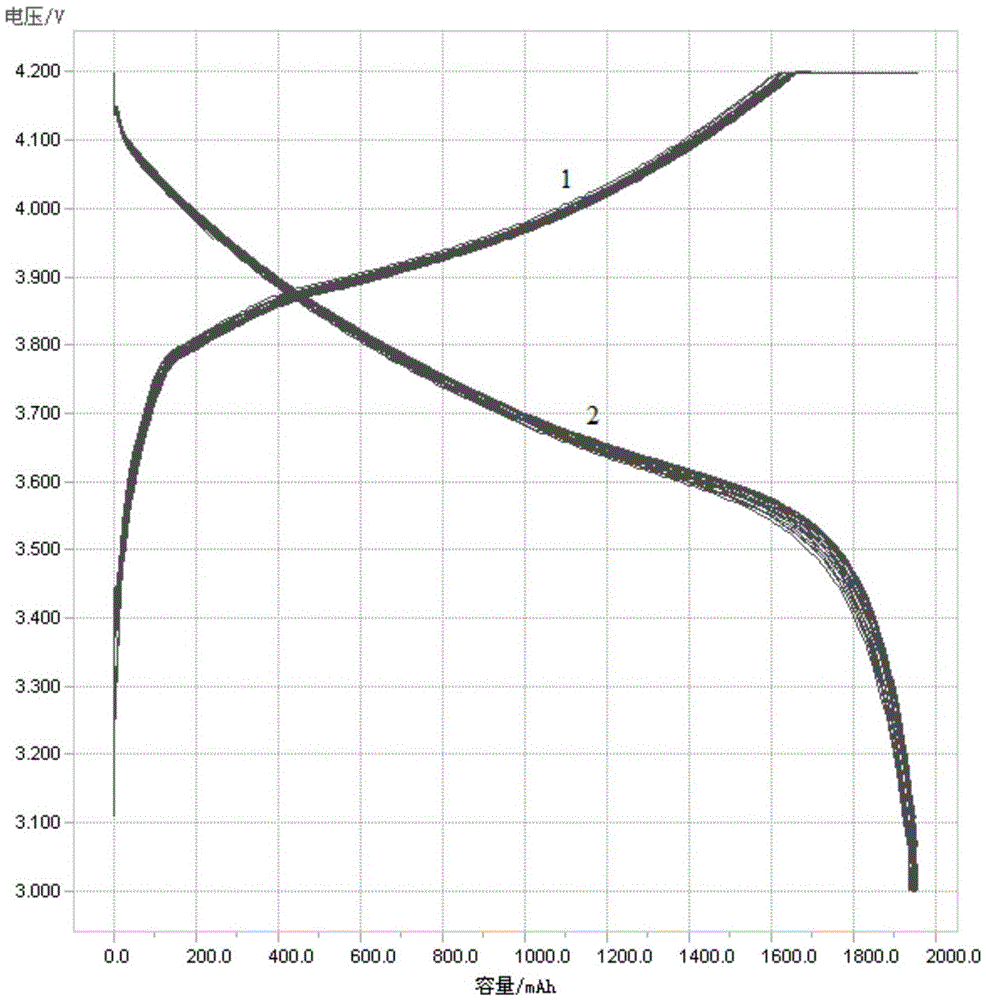

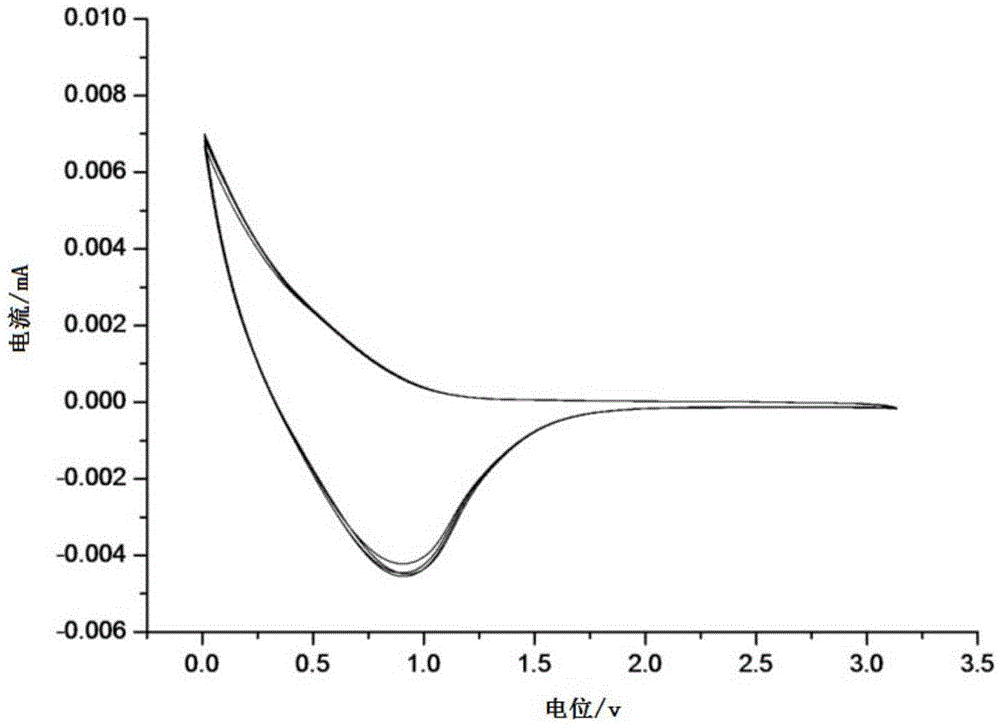

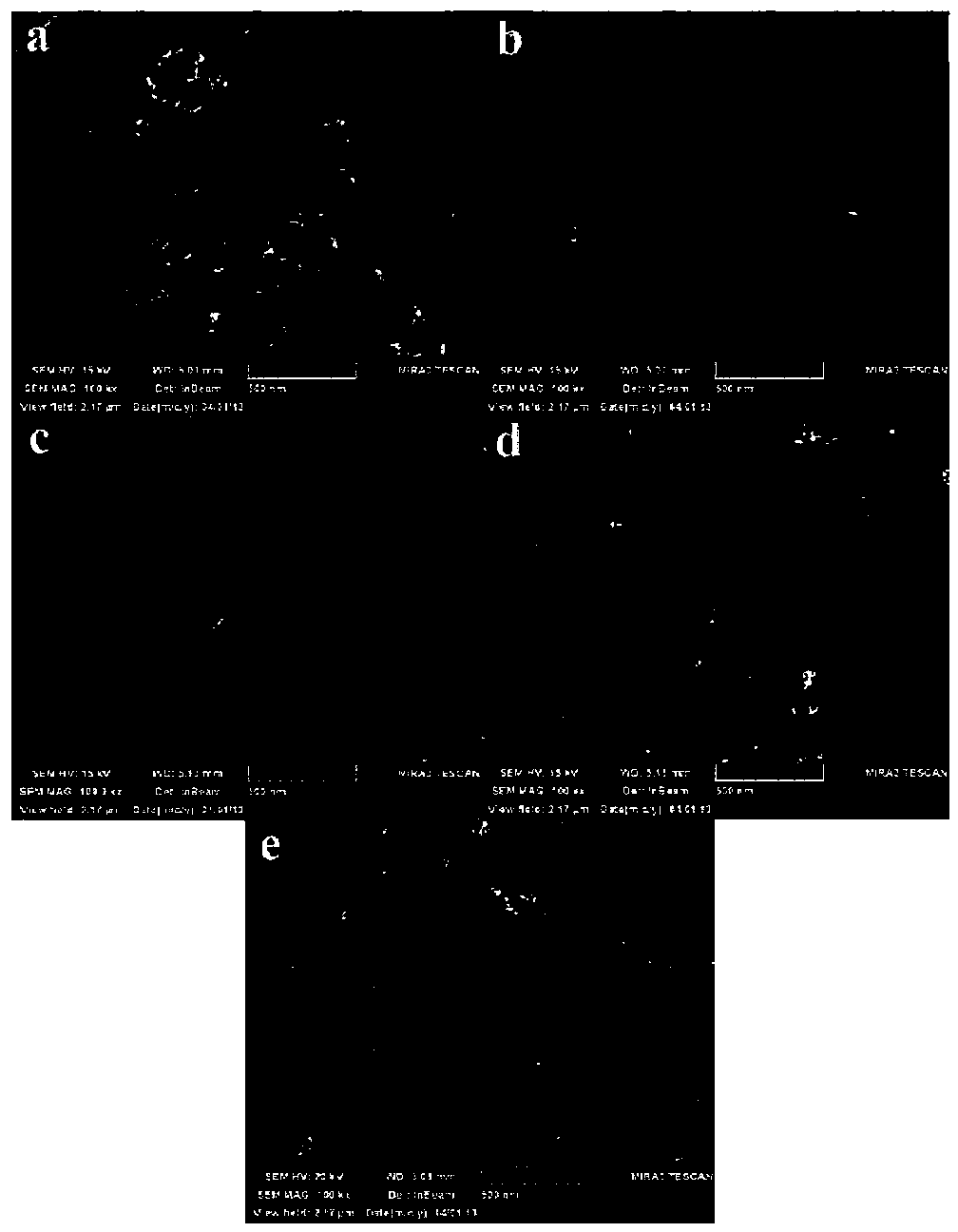

Anode aqueous binder of lithium ion battery and preparation method thereof

InactiveCN105576284ASimplify operation stepsShort reaction timeFinal product manufactureCell electrodesWater solubleLithium electrode

The invention belongs to the lithium ion battery technical field, discloses an anode aqueous binder of a lithium ion battery and a preparation method thereof. The preparation method of the anode aqueous binder of the lithium ion battery comprises follow specific steps: successively adding reactivity emulsifier, water soluble acrylic acid monomers, oil soluble acrylic acid monomers and initiator solution, mixing evenly, taking the mixture as base solution, heating up to initiate polymerization, keeping stirring, dripping the mixture of the water soluble and oil soluble acrylic acid monomers and the initiator solution, reacting, thus preparing the anode aqueous binder of the lithium ion battery. According to the anode aqueous binder and the preparation method of the invention, the problems that the anode aqueous binder of the lithium ion battery is high in viscosity and low in dispersion efficiency are solved; and the anode aqueous binder of the lithium ion battery prepared by the invention is low in viscosity and dosage, has excellent dispersion performance in electrode materials such as graphite and has excellent battery capacity exerting performance and cycle performance.

Owner:BLUE OCEAN & BLACK STONE TECH CO LTD FUJIAN

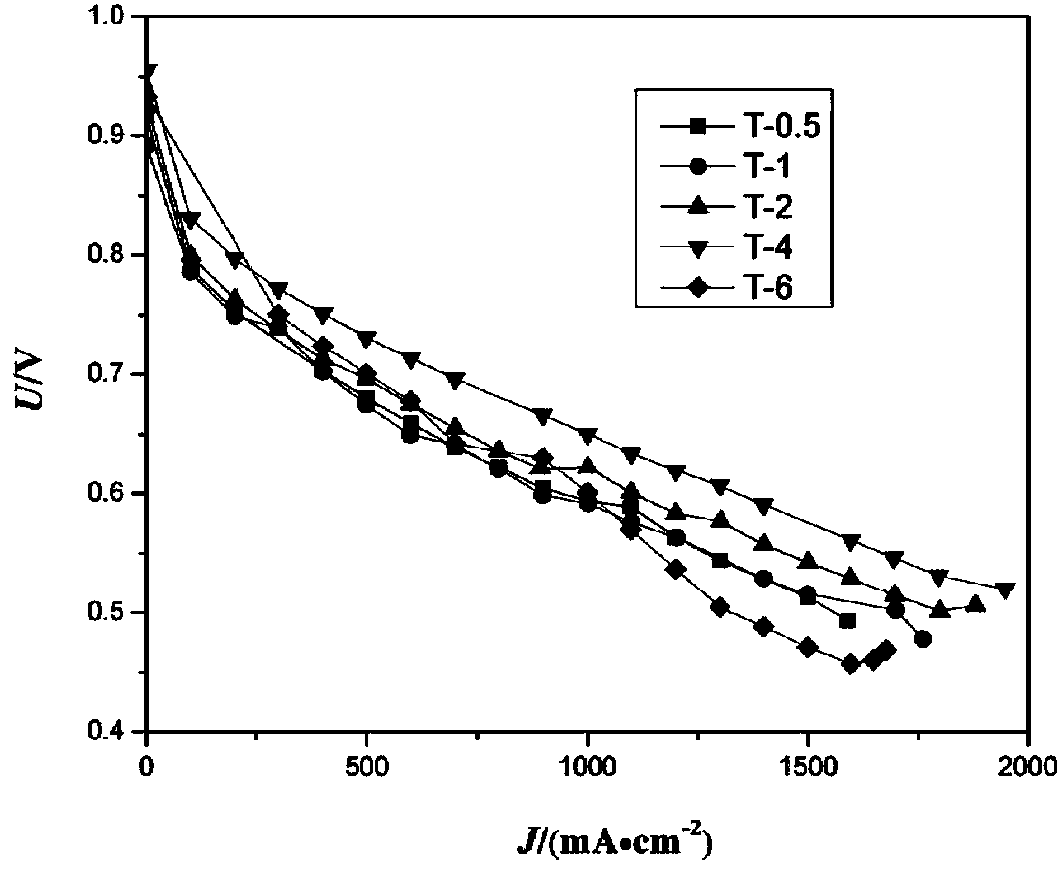

Membrane electrode for fuel cell and preparation method thereof

InactiveCN103515622AShorten dispersion timeImprove dispersion efficiencyFinal product manufactureCell electrodesSolventCatalysis

The invention discloses a membrane electrode for a fuel cell, and a preparation method and a packaging method thereof. A catalysis layer of the membrane electrode provided by the invention is composed of a catalyst slurry on a proton exchange membrane. The catalyst slurry comprises a catalyst, a binder, a disperse solvent, a thickening agent and an additive, and the catalyst is one selected from a Pt catalyst or a Pt alloy catalyst. The preparation method of the membrane electrode provided by the invention comprises the steps of preparation of the catalyst slurry for the membrane electrode, coating of the catalyst slurry and assembly of the membrane electrode. The preparation method of the catalyst slurry provided by the invention can shorten disperse time of the slurry and increase disperse efficiency, and the obtained catalyst slurry can realize transfer rate of 100% in a membrane electrode subassembly preparation process by a transfer printing method, so as to substantially increase utilization rate of the catalyst and electrochemical performance of the membrane electrode and effectively reduce the production cost of the fuel cell.

Owner:TSINGHUA UNIV +1

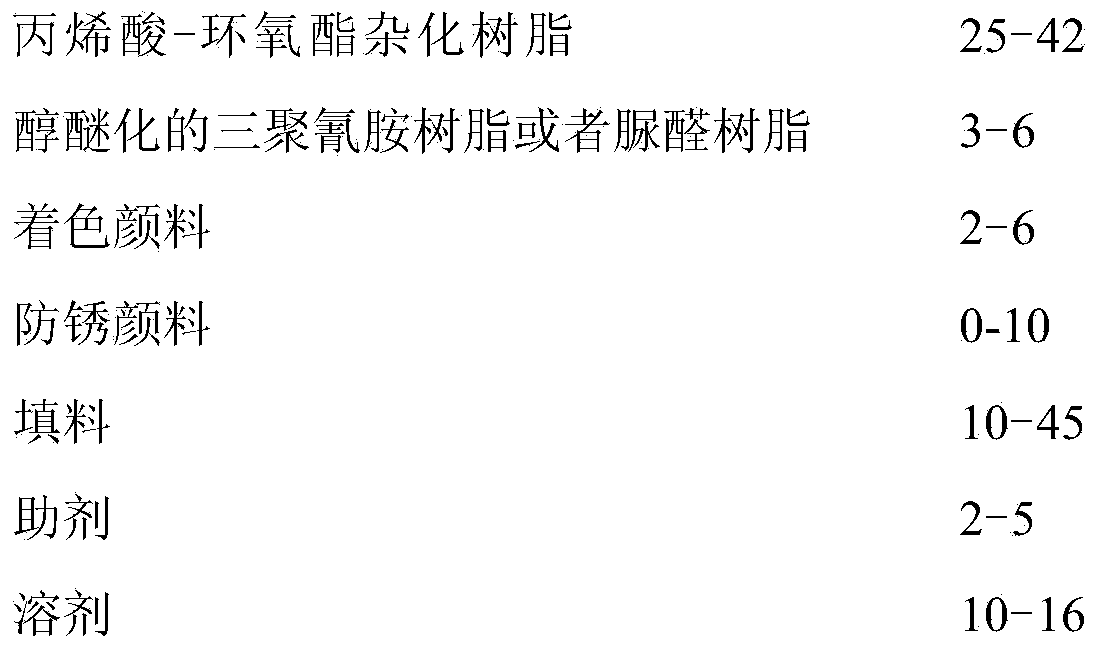

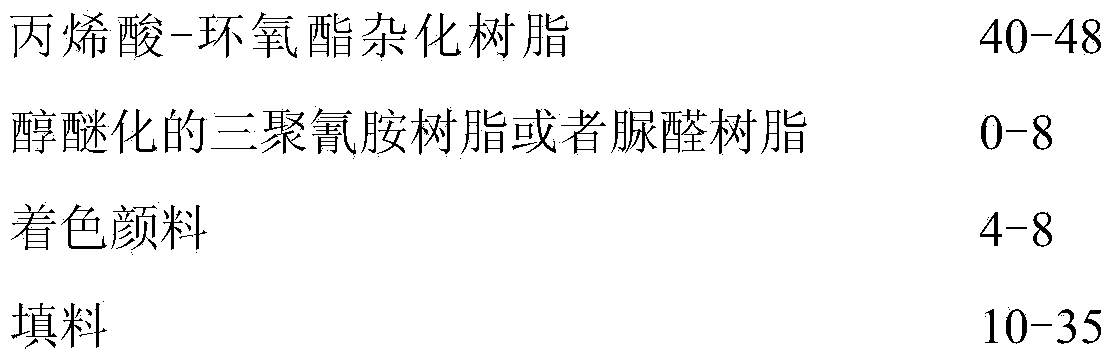

Acrylic acid-epoxy ester hybrid resin and coatings thereof

The invention provides an acrylic acid-epoxy ester hybrid resin. The acrylic acid-epoxy ester hybrid resin is prepared by reacting an epoxy resin and aliphatic acid under the action of a catalyst so as to prepare epoxy ester and then adding acrylic monomers and an initiator under certain conditions. A self-drying type antirust coating can be prepared with the acrylic acid-epoxy ester hybrid resin provided by the invention as a main film forming substance; a dried anticorrosive coating can also be prepared, especially coatings for curtain spraying sliver-coated mirrors, color films and aluminum mirrors; the coatings can meet coating process requirements of a wide-curtain spraying and coating production line with a maximum length of 3 m and are completely dried when baked at a temperature of 130 to 150 DEG C for 5 to 3 min, a film obtained after complete drying has excellent anticorrosion performance, can resist CASS, dampness, dryness and water with a temperature of 60 DEG C for more than 240 h, satisfy requirements of edging and texturing process of a downstream client and do not suffer from edge blackening and corrosion of clad layers.

Owner:常州市弘可利办公用品有限公司 +1

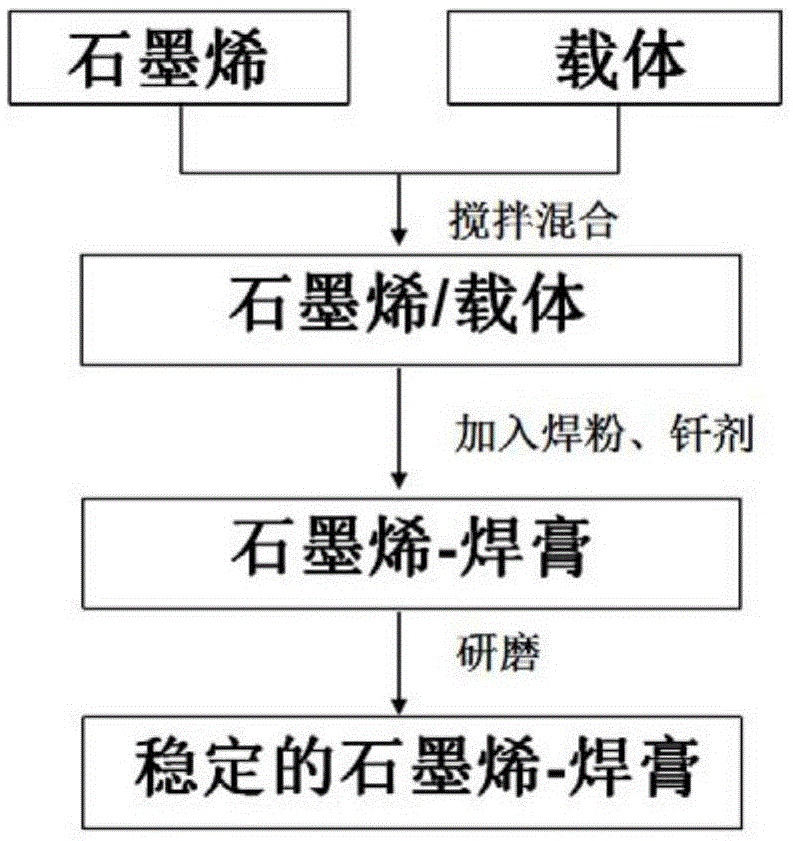

Silver brazing paste and preparation method thereof

ActiveCN105643148AImprove the problem of poor thermal and electrical conductivityAccelerates the brazing processWelding/cutting media/materialsSoldering mediaElectricityGraphite

The invention provides silver brazing paste and a preparation method thereof. The method comprises the following steps: (1) graphene is dispersed in a carrier with a certain viscosity to obtain a graphene / carrier dispersion system; (2) silver welding powder and a brazing agent are added in the graphene / carrier dispersion system to obtain a graphene / carrier / silver welding powder / brazing agent mixed system; and (3) the mixed system, obtained in the step (2), is grinded to obtain the high heat conductivity and high electricity conductivity type solver brazing paste with uniformly dispersed graphene. The silver brazing paste can effectively solve the problems of weak electricity and heat conductivity and long welding time in traditional welding paste. The method has such advantages as simple operation and high practicability, and greatly improves all performances of the traditional welding paste.

Owner:研迈电子材料(上海)有限公司

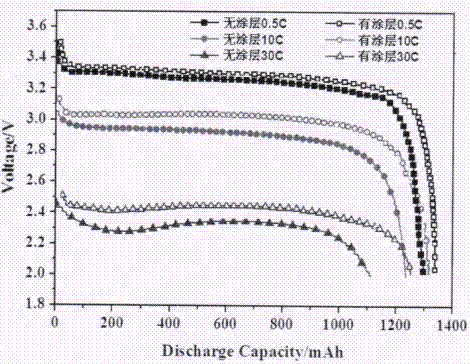

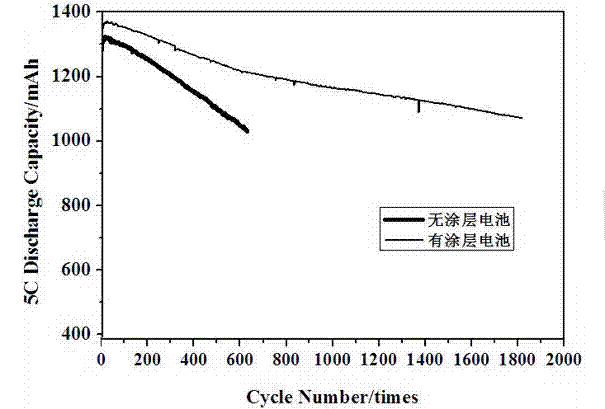

Lithium ion battery anode functional coating and preparation method thereof

ActiveCN102757700AReduce the presence of air bubblesEasy to processCell electrodesElectrically-conductive paintsLow speedSlurry

The invention provides a lithium ion battery anode functional coating and a preparation method thereof. A dispersing agent NMP (N-methyl-pyrrolidone) is stirred by a planetary stirrer at a high speed till the temperature reaches 40 to 50 DEG C; a certain proportion of a binding agent PVDF (Polyvinylidene Fluoride) is added to enable the solid content of a binding agent solution to be 1.2 to 3.5 percent; low-speed revolution is performed and then high-speed rotation is started; cold circulating water is received to control the temperature of the slurry below 50 DEG C; stirring is preformed for 2 to 6 h; a carbon black conductive agent (conductive carbon) is added to enable the solid contend of the slurry to be 20 to 30 percent; stirring is performed for 2 to 4 h; the slurry is transferred into a high-efficiency dynaflow ultrasonic slurry mixer to be subjected to ultrasonic dispersion for 1 to 2 h; after the preparation is finished, the slurry passes through a 200-mesh screen stencil and is sprayed through a spraying machine, wherein the spraying thickness is controlled within 3 to 5 Mum; and after the spraying is finished, a coated pole piece is baked for 12 to 14 h at 110 plus or minus 3 DEG C, wherein dry nitrogen is filled for replacement once each two hours, so as to obtain the lithium ion battery anode functional coating. The replacement of a current collector with an anode aluminium foil material by a current collector with the functional coating can greatly improve the electrochemical properties of lithium ion batteries.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

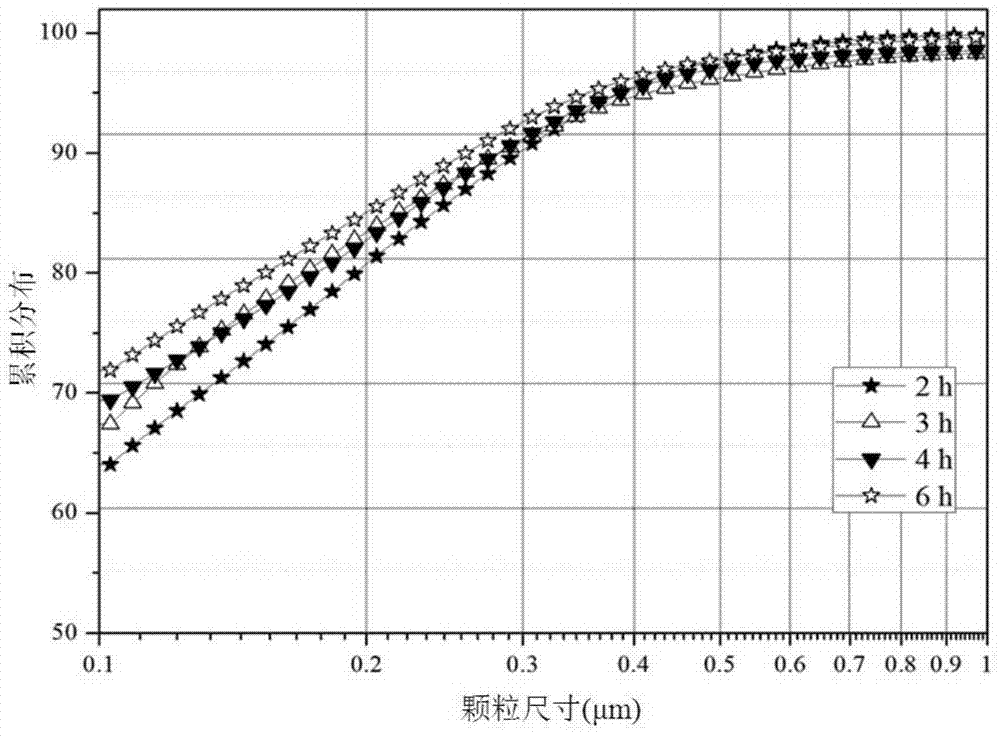

Preparation methods of illite/montmorillonite clay nanometer slurry and illite/montmorillonite clay nanometer powder

InactiveCN103588214AImprove stabilityGood anti-sedimentationMaterial nanotechnologySilicon compoundsDispersityHigh energy

The invention discloses preparation methods of illite / montmorillonite clay nanometer slurry and illite / montmorillonite clay nanometer powder and belongs to the field of development and preparation of nanometer materials. The preparation method of the illite / montmorillonite clay nanometer powder comprises the following steps: (1) mechanically breaking natural illite / montmorillonite clay mineral; (2) soaking in water so as to obtain illite / montmorillonite clay slurry; (3) adjusting the pH value of the illite / montmorillonite clay slurry, puddling and dispersing; (4) sieving the puddled and dispersed slurry by using a 50-mesh sieve; (5) removing iron from the slurry; (6) chemically bleaching the slurry; (7) grinding the bleached slurry by adopting a high-energy density stirred mill so as to obtain nanometer slurry; (8) adding a dispersing agent to the nanometer slurry to carry out dispersing treatment; (9) adding a modifying agent to the slurry to carry out swelling treatment; (10) evaporating and drying; and (11) carrying out mechanical pulverization so as to obtain the illite / montmorillonite clay nanometer powder in the end. The illite / montmorillonite clay nanometer powder prepared by the method can reach the nanoscale and has good powder uniformity and dispersity.

Owner:SOUTH CHINA UNIV OF TECH +1

Children coating and preparation method thereof

The invention provides a children coating and a preparation method of the children coating. The children coating provided by the invention comprises the following raw materials: wood fibers, a purified emulsion, kieselguhr, an anion additive, titanium dioxide, triple superphosphate powder, a dispersing agent, a wetting agent, a defoaming agent, a thickening agent, a preservative, a mildew preventive and tap water and the like. The wood fibers are added into the environmentally-friendly children coating by the invention so as to change the structure and the texture of a surface of a paint film, thereby feeling soft and smooth; and in addition, the porosity of the paint film is improved by the wood fibers in the paint film, the breathable performance is good, the quantity of heat and the transmission capacity of voice are reduced, and a good humidifying function can be created by the gaps of the paint film.

Owner:ZHEJIANG ZHIQIANG PAINT

Lithium ion battery aqueous binding agent and preparation method thereof

ActiveCN108598486ASolve environmental problemsImprove mechanical stabilityCell electrodesSecondary cellsSynthesis methodsLatex particle

The invention discloses a lithium ion battery aqueous binding agent. The lithium ion battery aqueous binding agent comprises emulsion and latex particles, wherein the latex particles are dispersed inthe emulsion and are of three-layer structures, an inner core comprises a polymer with low glass-transition temperature, an intermediate transition layer comprises a polymer with a middle glass-transition temperature, a shell layer comprises a polymer with high glass temperature, and the three-layer structure gradually becomes hard from soft from inside to outside, the solid content of the emulsion accounts for 5-30%, and the mass ratio of the inner core polymer, the intermediate transition layer polymer and the shell layer polymer is (5-30):(20-60):(30-60). In the lithium ion battery aqueousbinding agent obtained by the invention, the binding agent takes water as a dispersion medium, and the problem of environmental protection of the binding agent for a lithium battery is solved; with the synthesis method of the inner core, the transition layer and the shell, the emulsion of the prepared binding agent is good in mechanical stability, and a demulsification phenomenon such as agglomeration during the dispersion process cannot be generated; and the binding agent is relatively low in surface tension, and the dispersing efficiency and the film formation performance are greatly improved.

Owner:李强

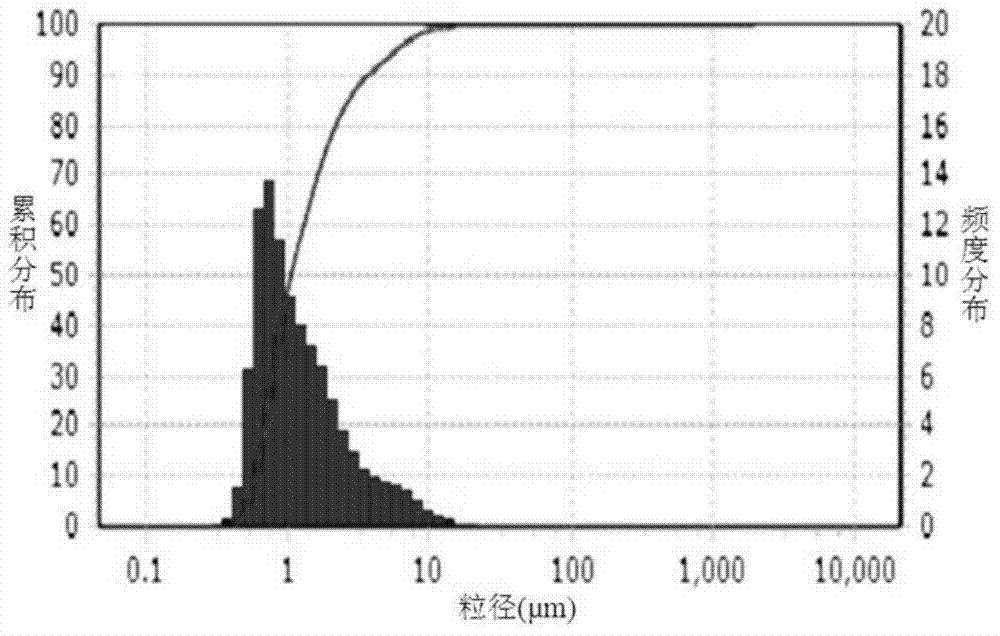

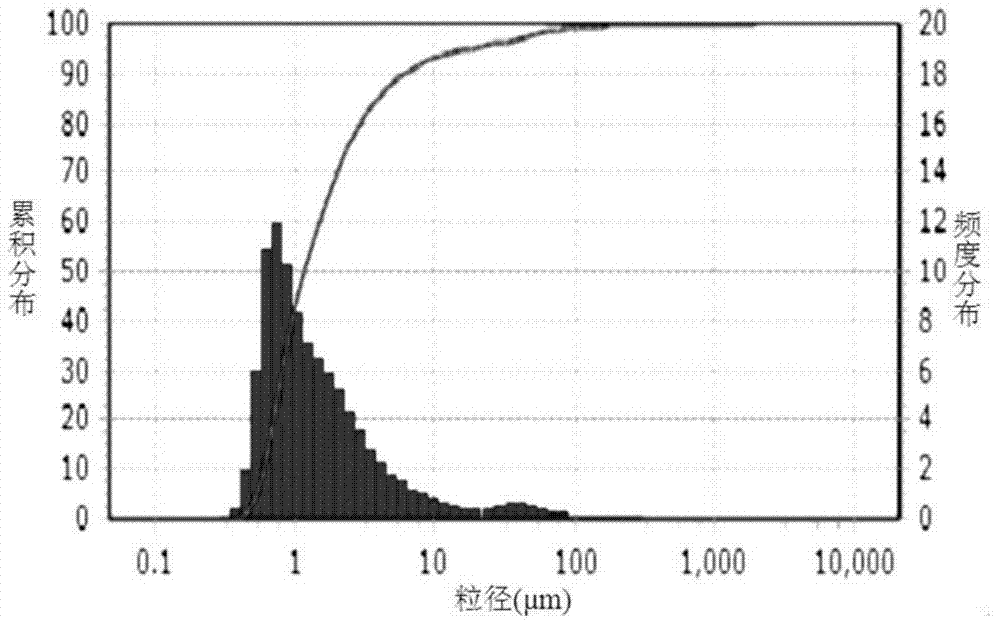

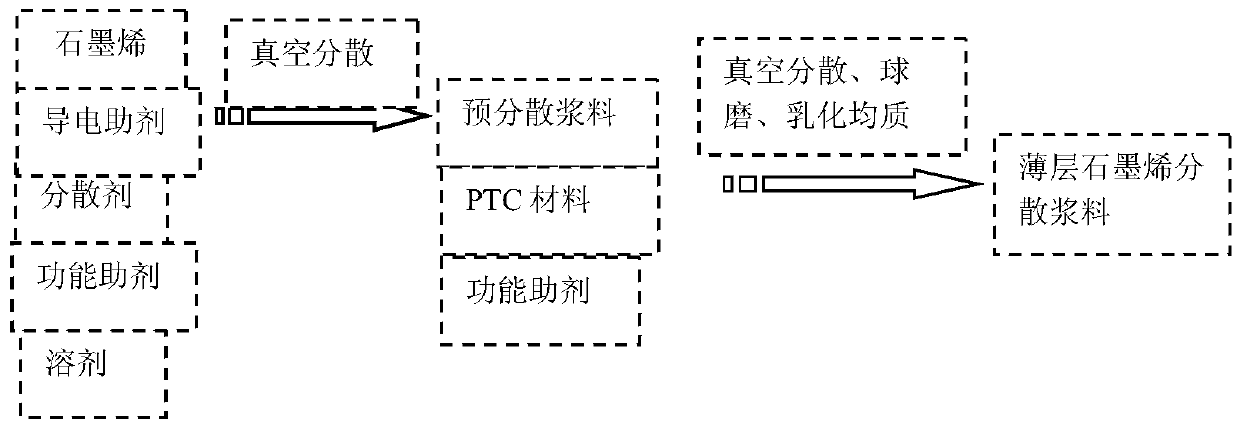

Thin layer graphene-based dispersion slurry, and preparation method and application thereof

InactiveCN110070955ASolve for uniformityFix compatibility issuesElectrode carriers/collectorsSecondary cellsDispersion stabilityThin layer

The invention discloses a thin layer graphene-based dispersion slurry, and a preparation method and application thereof. The thin layer graphene-based dispersion slurry contains 1 to 10wt% of thin layer graphene, 1 to 10wt% of a conductive auxiliary agent, 1 to 20wt% of a PTC material, 0.5 to 5wt% of a functional auxiliary and residual solvent. The preparation method comprises the following stepsof forming a thin layer graphene alkenyl pre-dispersion slurry by high-speed dispersion of the thin layer graphene, the conductive auxiliary agent, the functional auxiliary agent and the solvent; adding PTC material into the thin layer graphene alkenyl pre-dispersion slurry, and obtaining a thin layer graphene-based dispersion slurry after high-speed dispersion, ball milling and homogeneous emulsification dispersion. The dispersion slurry provided by the invention, when applied to a coating, can improve the dispersion efficiency and dispersion stability of graphene in the coating that has hightemperature sensitivity and PTC strength, and is important to improve safety in the application of current collector coating of energy storage devices and electric heating coating.

Owner:苏州格瑞丰纳米科技有限公司

Water-soluble ink compositions, their manufacturing method and use

This invention relates a water soluble ink that utilizes dyes, protective glue, dispersant, leveling agent, emulsifier and water absorbing resin to prepare. This invention also relates to the making method of the water soluble ink and its utilization in printing, watercolor and paper keir. The product of this invention can overcome the oxidation decoloring phenomenon of colorful paper and rice paper when meeting water or ultraviolet irradiation; the decoloring phenomenon of traditional Chinese painting and watercolor painting; the ink marks of the characters are bright, the color is proper and the writing is smooth, the intensity is proper, the fragrance is moderate and it is dry quickly and decreases the environmental pollution.

Owner:李联江

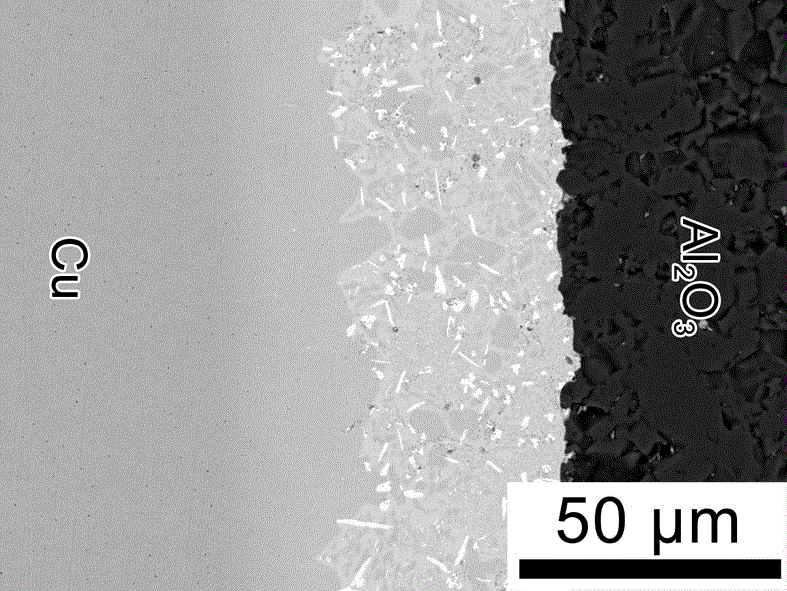

Ceramic substrate and copper clad foil low-temperature connecting soldering paste and production process thereof

InactiveCN106312361AImprove wettabilityQuality assuranceWelding/cutting media/materialsSoldering mediaActive agentSolvent

The invention relates to the field of electronic packaging, in particular to a ceramic substrate and copper clad foil low-temperature connecting soldering paste for a powder module and a production process thereof. The soldering paste is composed of brazing filler metal powder and scaling powder; the brazing filler metal powder is tin-silver-copper-titanium powder, the mass fraction of the Sn in the tin-silver-copper-titanium powder ranges from 35%-50%, the mass fraction of the Ag in the tin-silver-copper-titanium powder ranges from 15%-35%, the mass fraction of the Cu in the tin-silver-copper-titanium powder ranges from 20%-40%, and the mass fraction of the Ti in the tin-silver-copper-titanium powder ranges from 4%-8%; and the scaling powder mainly comprises, by weight, 24%-35% of rosin, 45%-50% of a solvent, 2%-6% of a corrosion inhibitor, 8% of an active agent, 6% of a thixotropic agent and 4%-15% of a thickening agent. According to connection of a ceramic substrate and copper, the process can be simplified, the connecting temperature can be remarkably reduced, the heat stress and the interface voidage are accordingly reduced, and the connector quality is accordingly improved.

Owner:HARBIN INST OF TECH AT WEIHAI

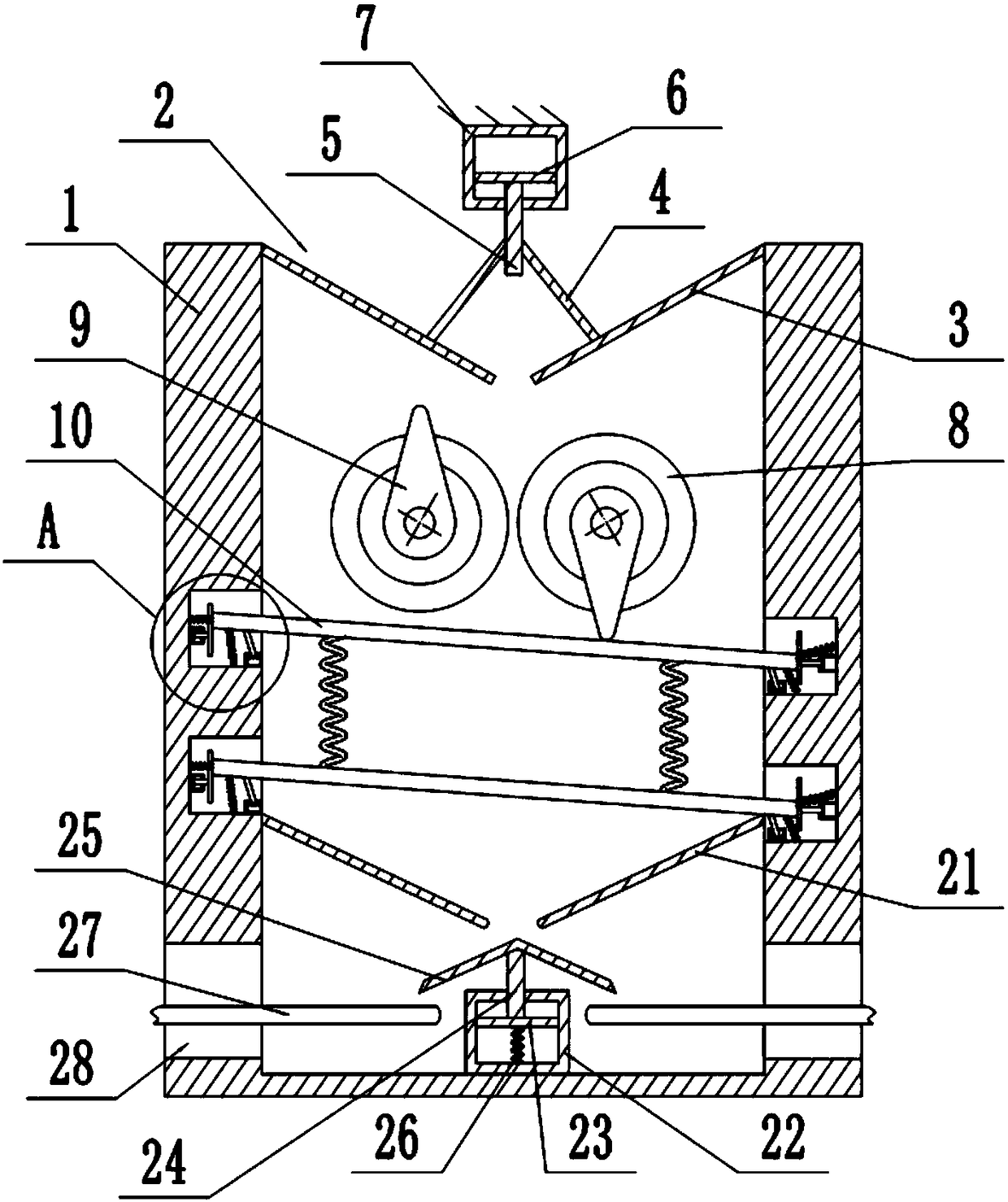

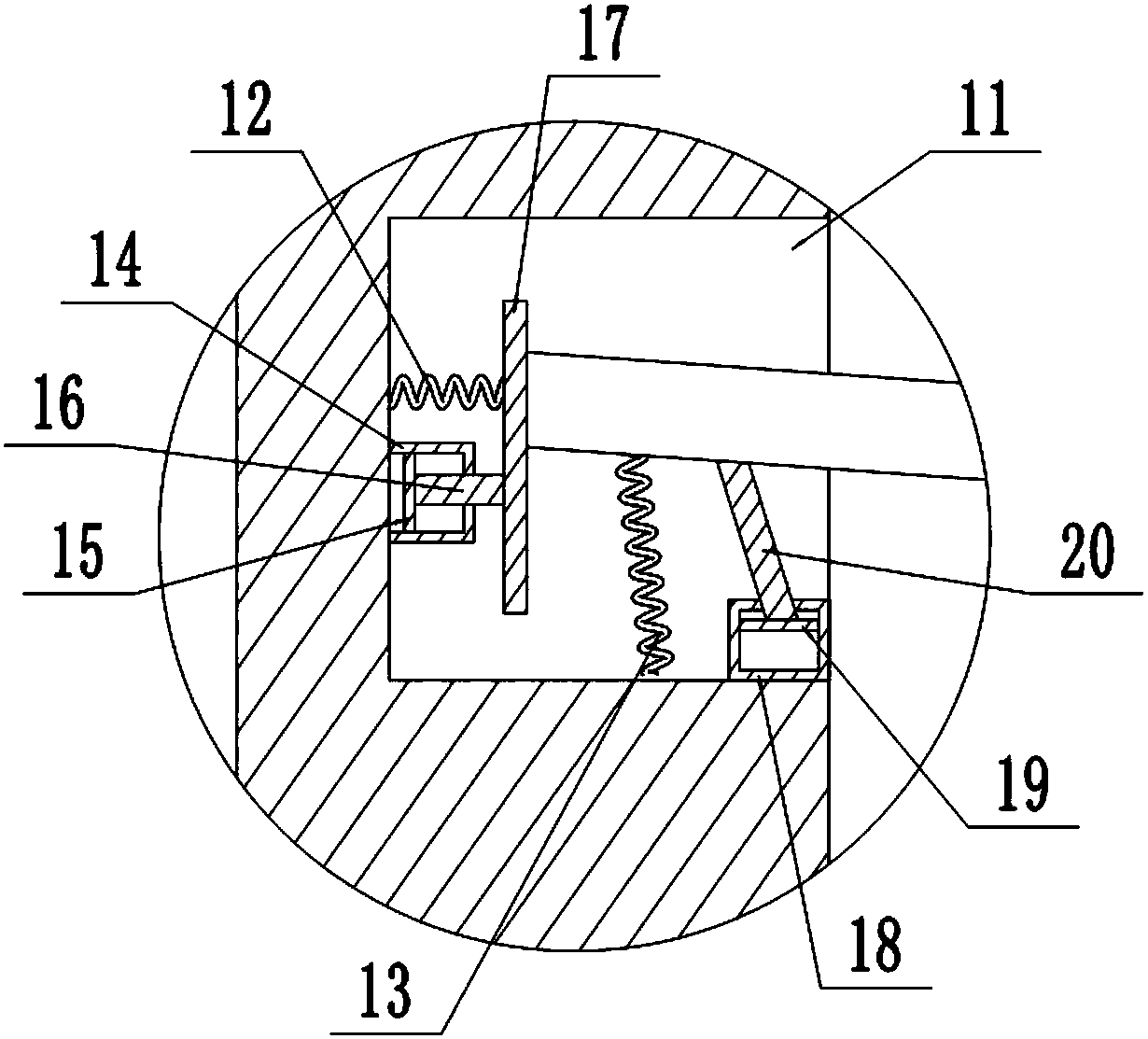

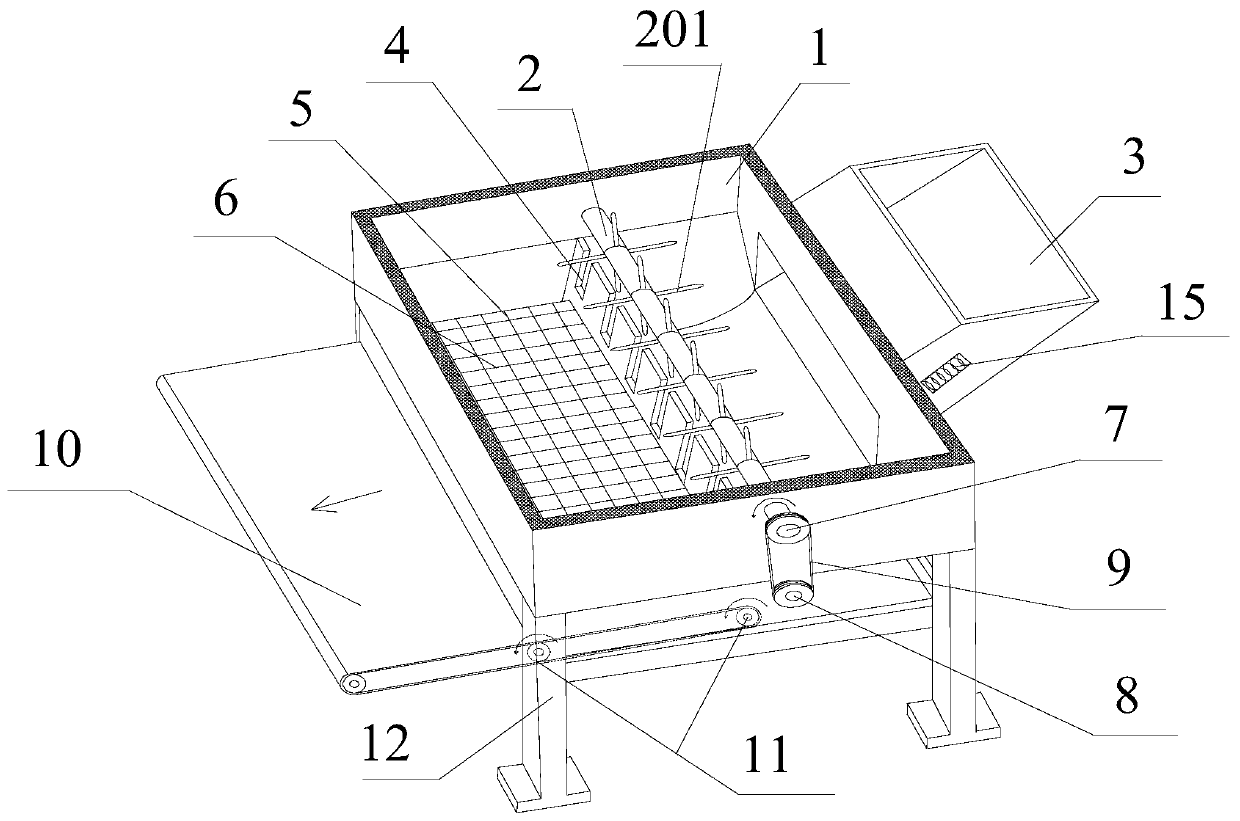

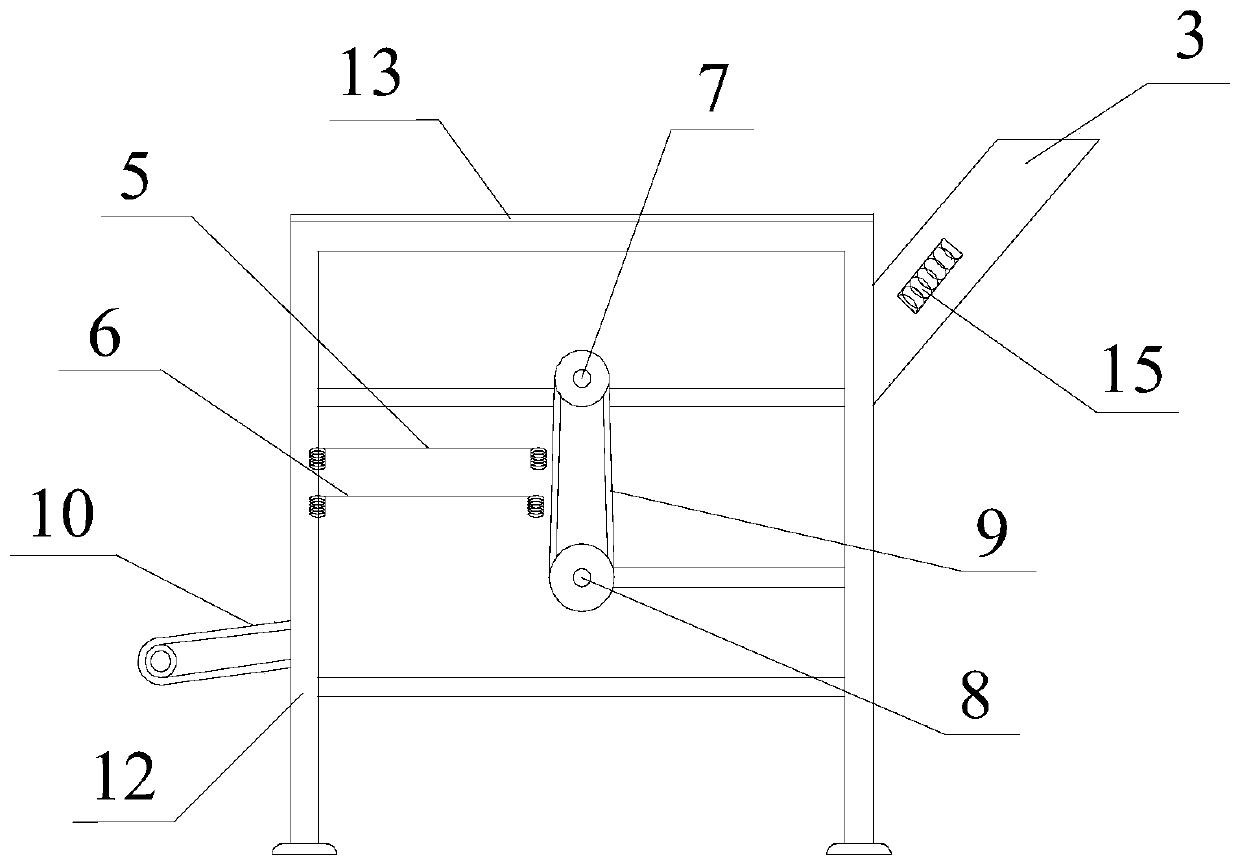

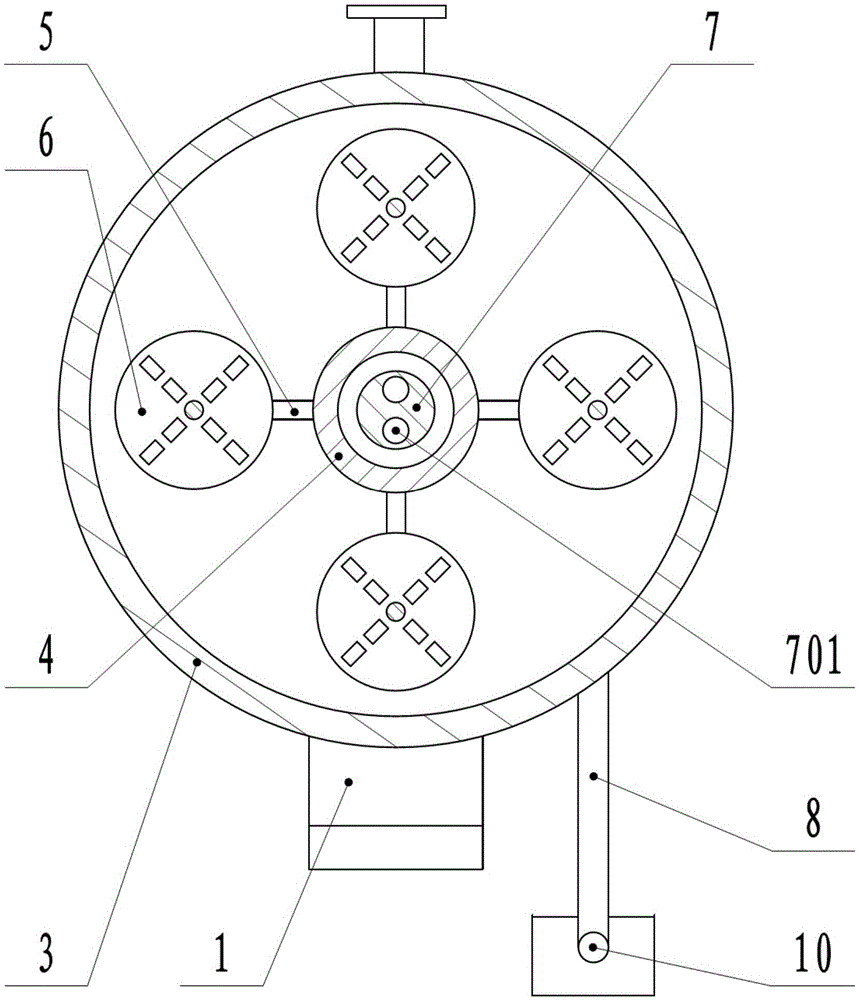

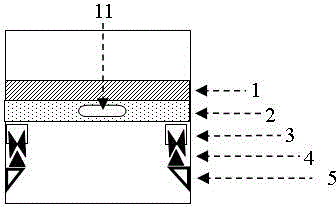

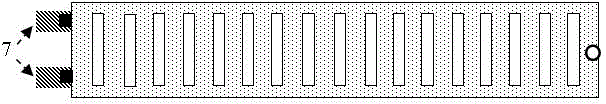

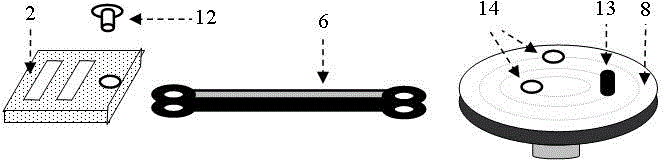

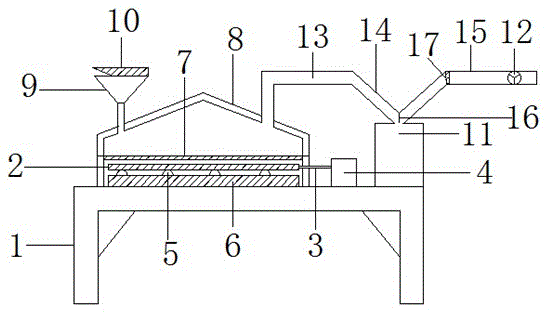

Screening machine

ActiveCN108262091AImprove dispersion efficiencyImprove screening efficiencySievingScreeningEngineeringHigh load

The invention relates to the field of material screening, and discloses a screening machine. The screening machine comprises a machine body; a feed port is formed in the top of the machine body; opening and closing plates are hinged to the two ends of the feed port, and are commonly connected with an adjusting device for adjusting a feeding quantity; two crushing rollers are mounted at the top ofthe machine body; cams are mounted on rotating shafts of the two crushing rollers; two screens are movably connected into the machine body; multiple connecting springs are arranged between the two screens; support devices and shaking devices are arranged at the left and right ends of the two screens; the shaking devices can be triggered when one ends of the screens are pressed down; a gathering port is formed in the bottom of the machine body; an induction device is arranged below the gathering port; and the induction device cooperates with the adjusting device. The screening machine can adjust the feeding quantity of materials according to a discharge quantity of the materials, prevents the phenomenon of low screening efficiency caused by higher loads of the screens, and can gradually scatter the materials to prevent accumulation of the materials on the screens.

Owner:ZUNYI LUXIN MACHINERY CO LTD

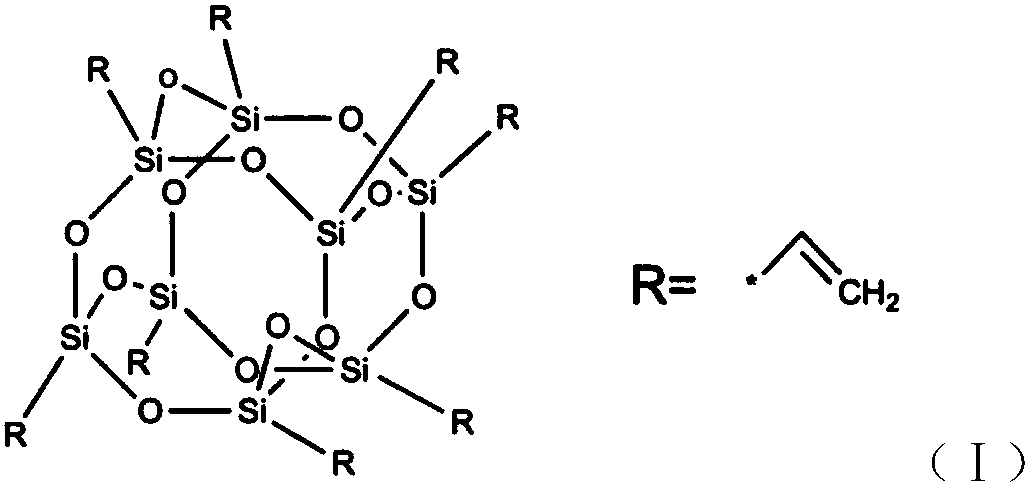

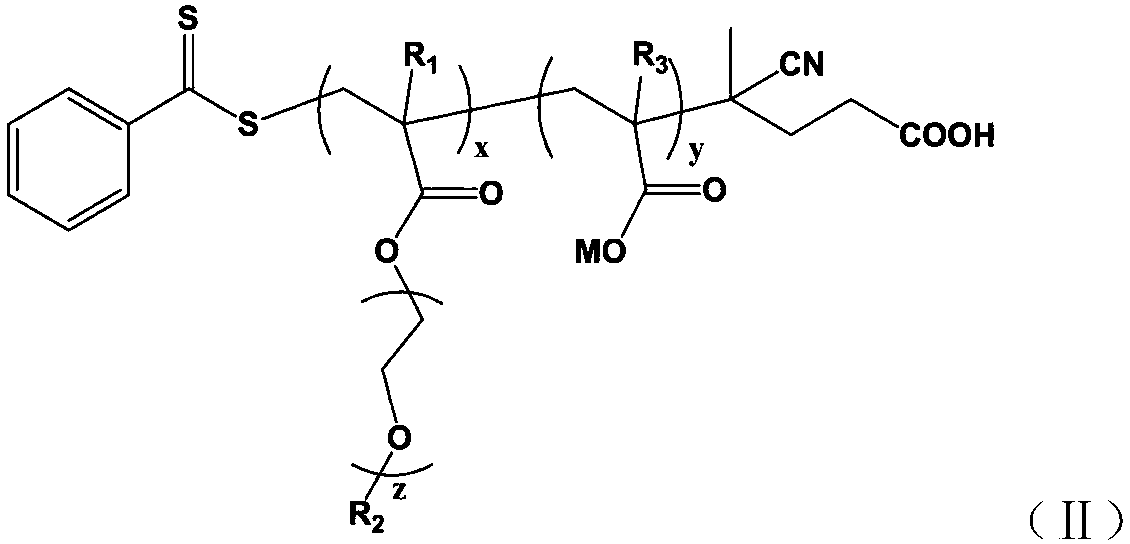

Preparation method and applications of composite super-early strength admixture

The invention discloses a composite super-early strength admixture preparation method, which comprises: dissolving octavinyl POSS and a block polycarboxylic acid A containing a thiol group in a tetrahydrofuran solvent, carrying out a thiol-alkenyl click chemistry reaction under the action of a catalyst, and carrying out rotary evaporation to remove the tetrahydrofuran solvent after completing thereaction so as to obtain a POSS-based star block polycarboxylic acid water-reducing agent; and at a temperature of 20-40 DEG C, simultaneously adding a soluble calcium salt B aqueous solution and a soluble silicate C aqueous solution into the POSS-based star block polycarboxylic acid water-reducing agent in a dropwise manner at a uniform speed, and carrying out thermal insulation for 2-5 h after completing the adding so as to obtain the composite super-early strength admixture. According to the present invention, the POSS core inorganic nanometer structure material in the composite super-earlystrength admixture can achieve the compounding of the polycarboxylic acid water-reducing agent and the nanometer material, such that the dispersion efficiency of the inorganic nanometer structure material is high, the inorganic particles are stable and do not easily settle, the early strength is easily increased, and the transportation cost can be reduced.

Owner:JIANGSU SOBUTE NEW MATERIALS +3

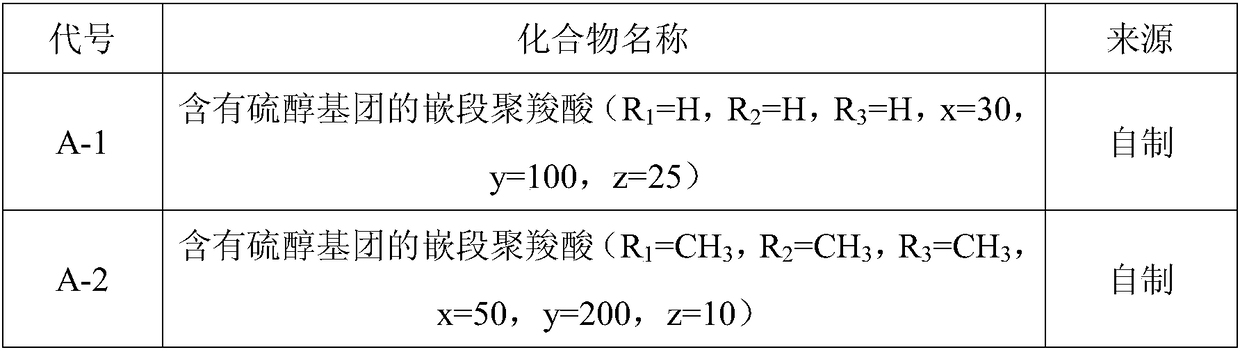

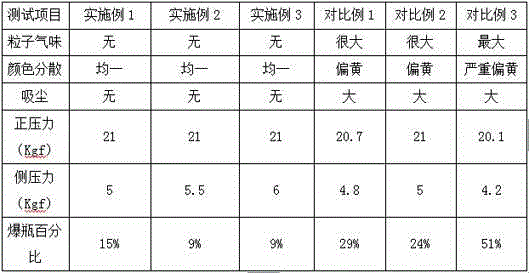

Ultrafine talcum powder and polypropylene filling color masterbatch and preparation method thereof

The invention relates to ultrafine talcum powder and polypropylene filling color masterbatch and a preparation method thereof. The ultrafine talcum powder and polypropylene filling color masterbatch comprises the following raw materials by weight percent: 0.05-5% of pigment, 50-80% of ultrafine talcum powder, 10-40% of polypropylene, 2-10% of fatty glyceride and 0.5-2% of porous inorganic silicon. The production efficiency and the dispersion performance of the ultrafine talcum powder and polypropylene filling color masterbatch are improved, and the ultrafine talcum powder and polypropylene filling color masterbatch is applied to a polypropylene product to endow the product with high luster degree, good heat resistance and characteristics of no smell and dust absorption prevention.

Owner:广东波斯科技股份有限公司

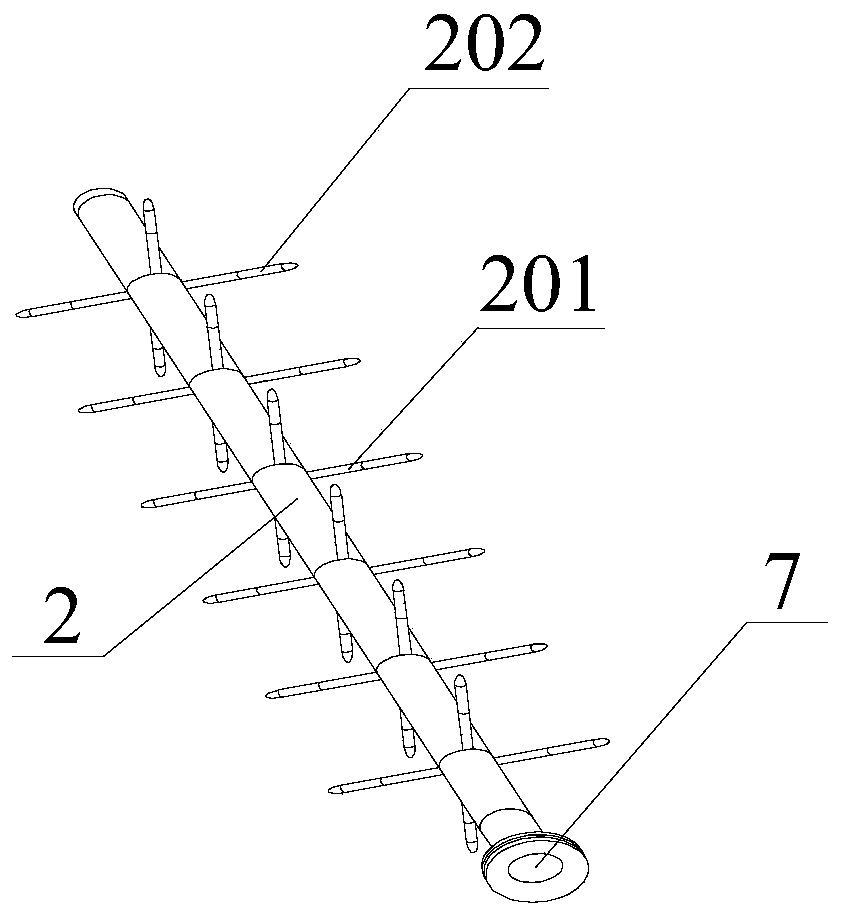

Steel fiber dispersing machine for preparing fiber concrete

The invention discloses a steel fiber dispersing machine for preparing fiber concrete. The steel fiber dispersing machine comprises a stock bin, wherein a feeding hopper is arranged on the side wall of the stock bin, the interior of the stock bin is divided into a material shifting cavity and a dispersing cavity by a partition plate, an output port of the feeding hopper communicates with the shifting cavity, a shifting device is arranged in the shifting cavity, a material outlet is formed in the bottom of the dispersing cavity, an vibrating assembly is fixed on the material outlet, a pluralityof shifting units are arranged on the periphery outer wall of the rotating shaft along the axis of the rotating shaft, a plurality of shifting tooth grooves are formed in the partition plate, each shifting unit is composed of a plurality of shifting teeth, the rotating shaft is rotated anticlockwise, when the shifting teeth drive the steel fibers to move to the vibrating assembly, and then the shifting tooth penetrate through the material shifting tooth grooves to be moved into the shifting cavity again so as to realize continuous stirring. According to the technical scheme, a conventional latticed screen is not adopted during dispersion, and a two-stage vibrating screen plate is designed, so that secondary dispersion of the steel fibers is realized, and bending or damage of the steel fibers in the dispersing process is avoided while blockage of the steel fibers is avoided.

Owner:SOUTHWEST PETROLEUM UNIV

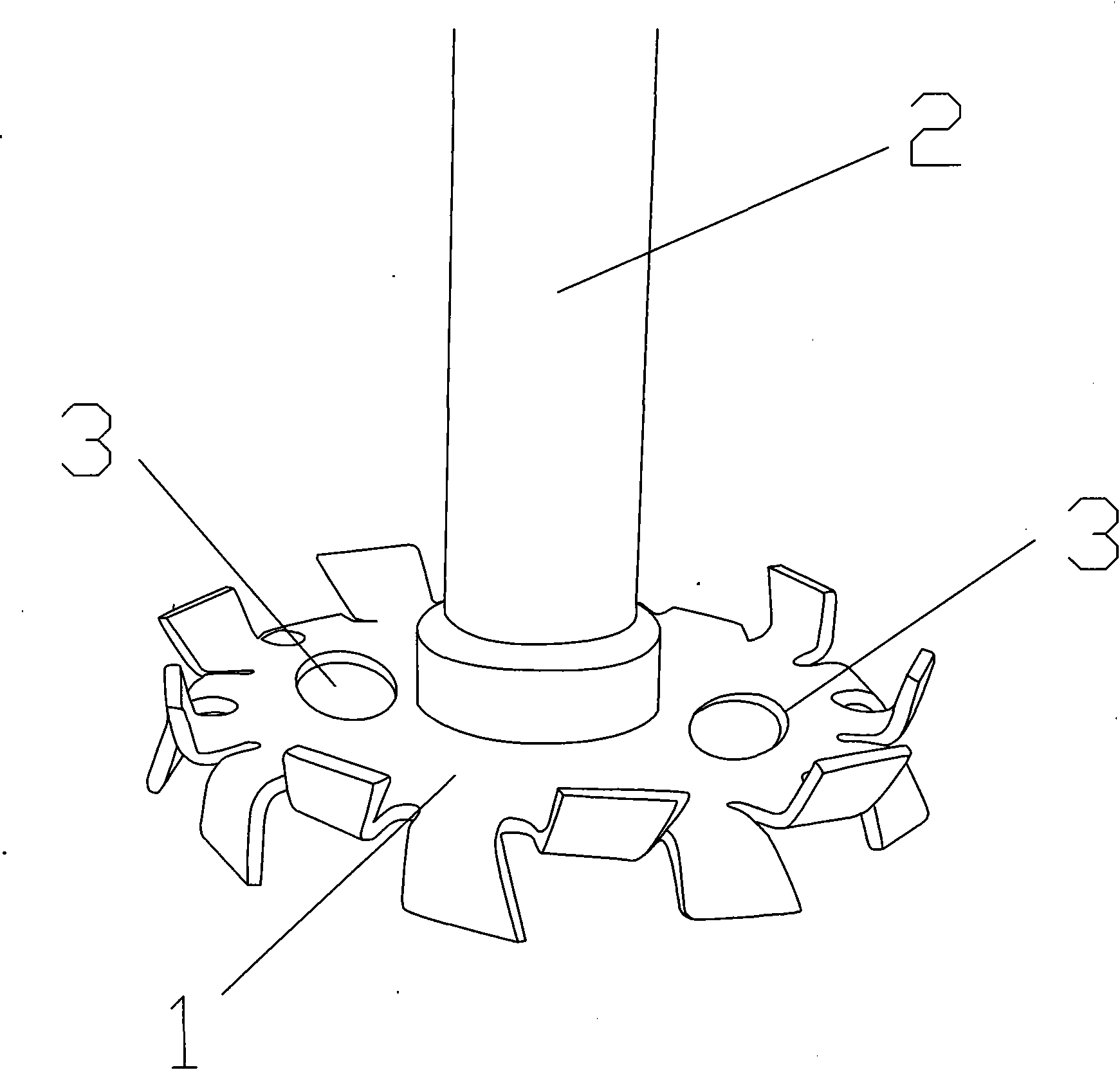

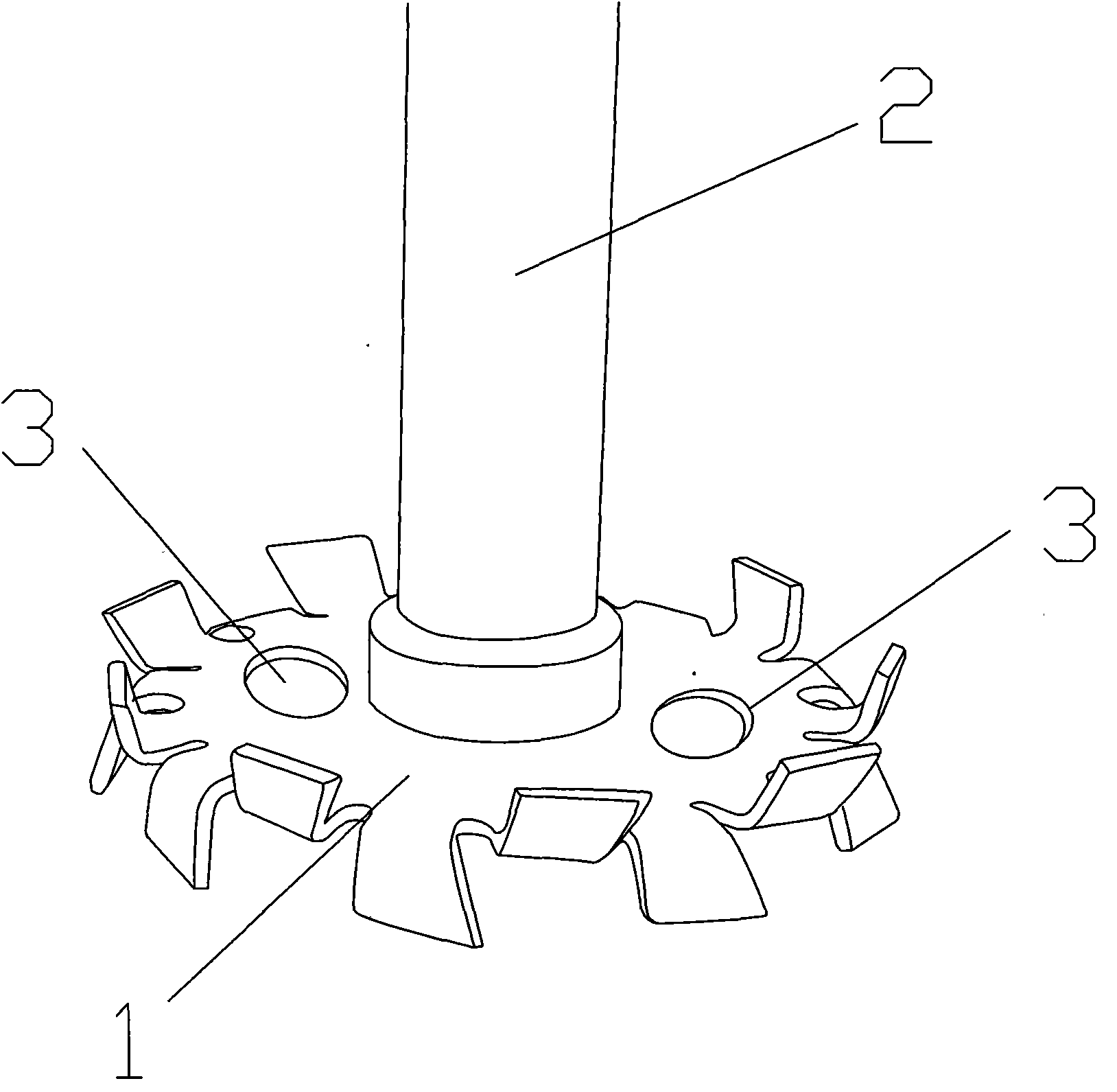

Improved structure of dispersion disc

InactiveCN101972611AImprove dispersion efficiency and dispersion effectImprove dispersion efficiencyRotary stirring mixersTransportation and packagingEngineeringUniform property

The invention discloses an improved structure of a dispersion disc. A plurality of pairs of circular holes are regularly arranged on the dispersion disc, and each pair of circular holes are respectively and symmetrically distributed relative to a stirring shaft on the dispersion disc. Thus, an upper flow field and a lower flow field on the dispersion disc can form a continuous circulating flow field. When a material is stirred at a high speed, the material can be rapidly and uniformly mixed, and the dispersion efficiency and the dispersion effect of the material can be greatly increased. The improved dispersion disc is especially applicable to the preparation of large-scale high-viscosity liquid materials with uniform properties and large mixed volume more than 10 cubic meters.

Owner:SUZHOU SUNMUN TECH CO LTD

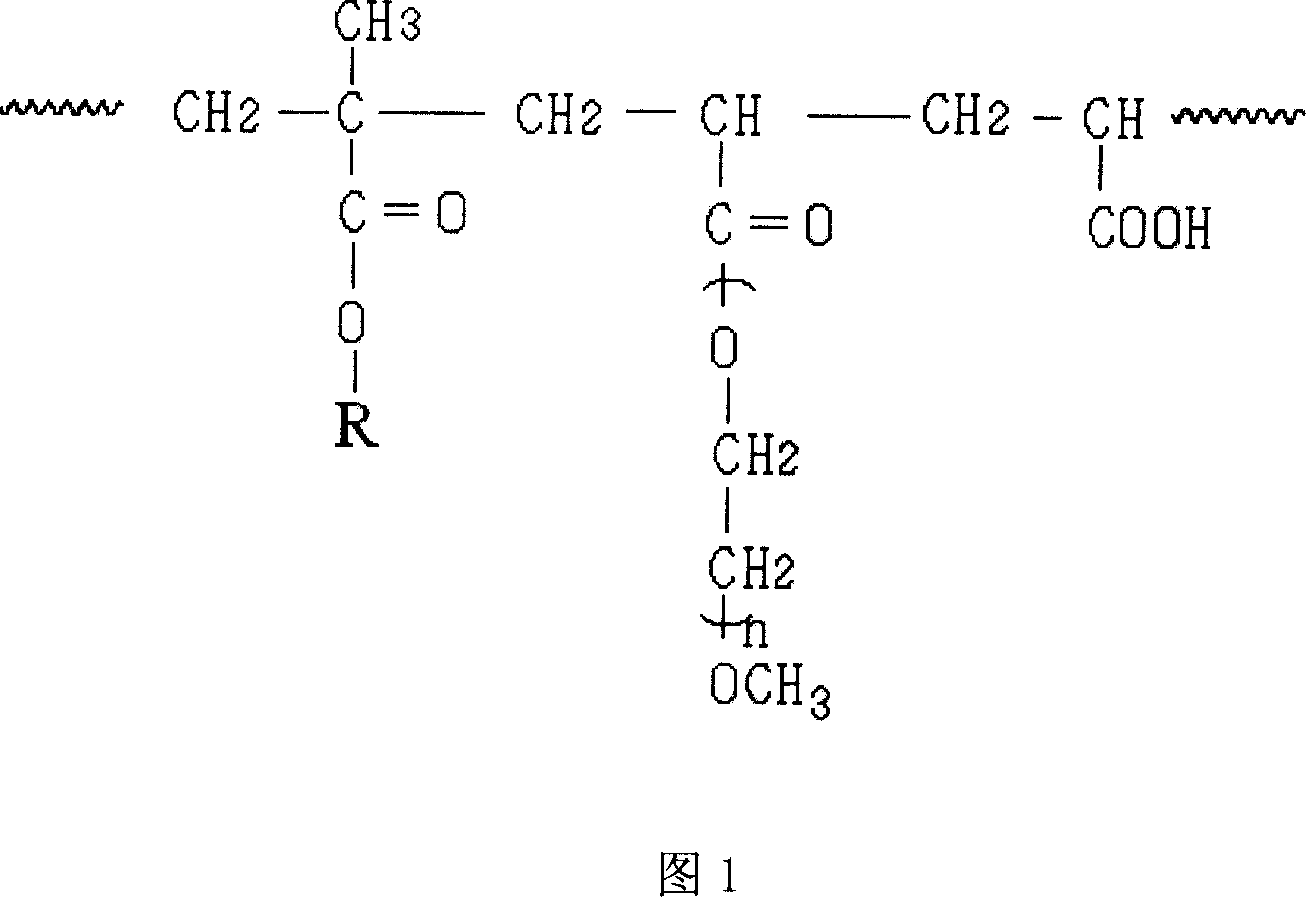

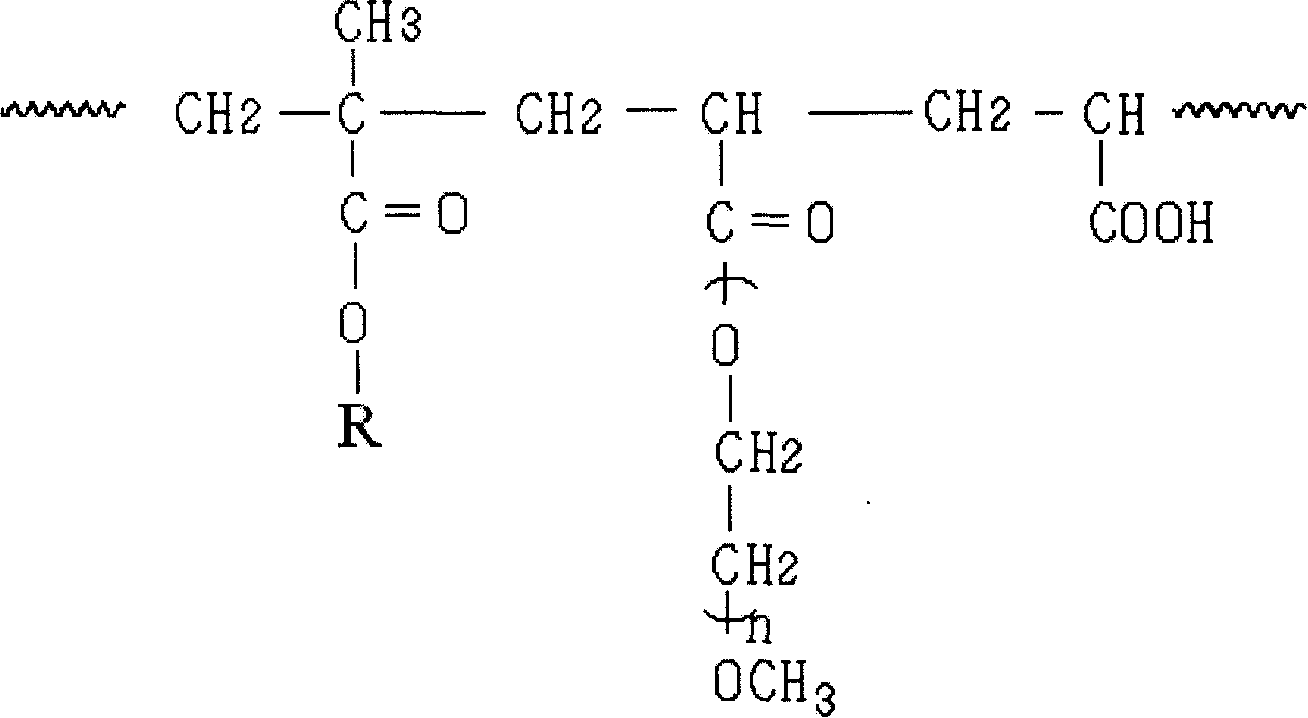

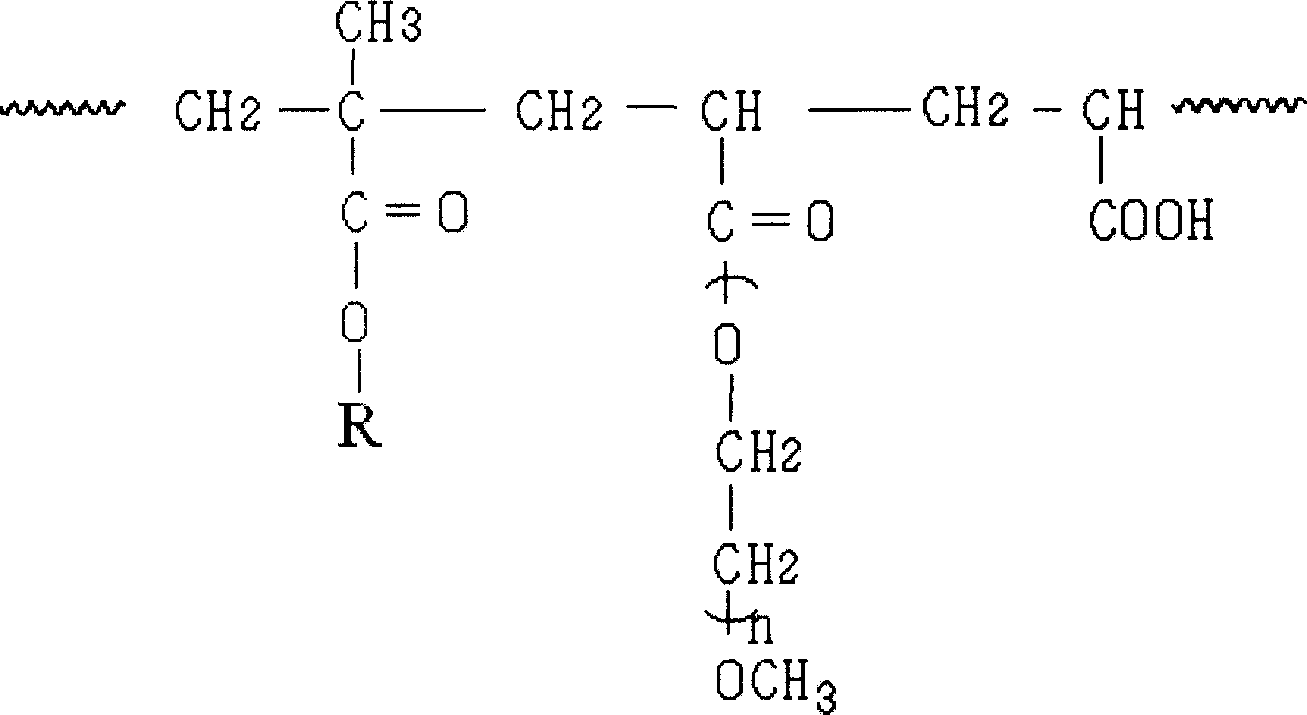

High molecular dispersant agent and its preparing method

InactiveCN101045199AImprove dispersion efficiencyImprove performanceTransportation and packagingMixingEthylene glycolPigment

A high-molecular disperser with 7.2-7.5 centipoises as characteristic viscosity features that the methoxy ethanediol is used as hydrophilic chain segment playing the space stabilizing role and the ester radical is used as anchor group of pigment. Its preparing process includes such steps as synthesizing coarse product, purifying and preparing final product.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD

Sanitary napkin with multiple efficacies such as dysmenorrheal alleviation and antibiosis

InactiveCN106420174AHigh specific surface areaHigh emissivityMedical devicesSanitary towelsAntibiosisEngineering

The invention provides a sanitary napkin with multiple efficacies such as dysmenorrheal alleviation and antibiosis. By arrangement of a multi-layer structure, the functions of sanitary napkin is reasonably regulated so that the sanitary napkin can meet more demands. The combined addition of folium artemisiae argyi essential oil and bamboo charcoal fiber adds antibiosis and peculiar smell removal function; the addition of far-infrared nano-particles and nano-tourmaline powder provides health care functions such as alleviating dysmenorrheal, increasing immunity and promoting microcirculation besides antibiosis and peculiar smell removal.

Owner:潘鳘同

Aqueous high weather-proof matt exterior wall emulsion paint and preparation method thereof

InactiveCN103409023ALess detection finenessSmall smellEmulsion paintsPolymer scienceDefoaming Agents

The invention discloses an aqueous high weather-proof matt exterior wall emulsion paint and a preparation method thereof. The emulsion paint comprises the following components by weight: 30-40 parts of emulsion, 0.2-0.5 part of an organosilicone hydrophobic agent, 2-8 parts of diatomite, 4-7 parts of sericite powder, 20-25 parts of titanium dioxide, 6-14 parts of a calcium carbonate powder, 0.4-0.7 part of a dispersant, 0.1-0.3 part of a wetting agent, 0.3-0.6 part of a defoaming agent, 0.1-0.3 part of an antifreeze, 1.5-2 parts of a coalescing agent, 0.4-0.9 part of a thickening agent, 0.2-0.5 part of a leveling agent, 0.1-0.3 part of a preservative, 0.1-0.3 part of a mildew preventive and 20-30 parts of water. The preparation method provided by the present invention comprises steps of: pre-blending, grinding disperse, and addition of emulsion and auxiliary agent, etc. The aqueous high weather-proof matt exterior wall emulsion paint provided by the invention has advantages of soft texture, flattening and fine paint film surface, and soft matt effect.

Owner:ZHEJIANG ZHIQIANG PAINT

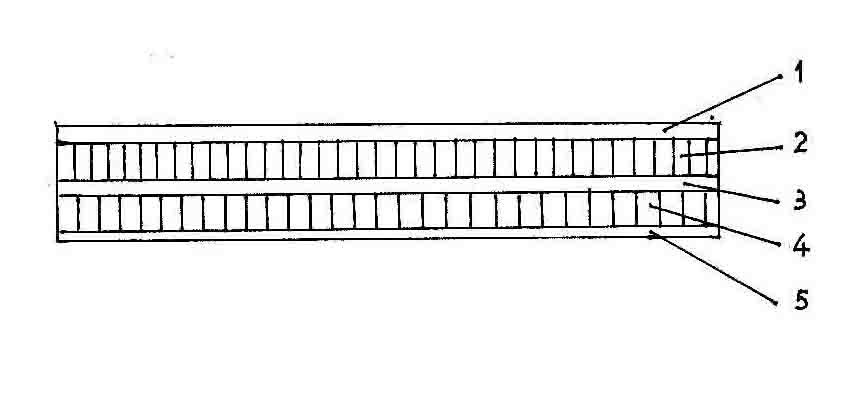

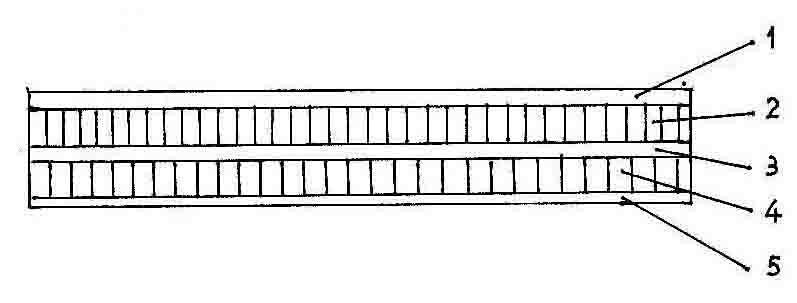

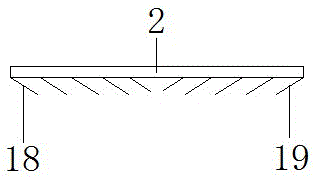

Composite honeycomb sandwich structure floor

InactiveCN102080439AImprove dispersion efficiencyGet the most out of optimizationLayered productsFlooringHoneycombMaterials science

The invention relates to a composite honeycomb sandwich structure floor. The composite honeycomb sandwich structure floor comprises upper skin, a honeycomb sandwich and lower skin and is characterized in that: the honeycomb sandwich consists of an upper honeycomb core and a lower honeycomb core; middle skin is arranged between the upper honeycomb core and the lower honeycomb core; the upper skin is arranged above the upper honeycomb core; the lower skin is arranged below the lower honeycomb core; and compressive strength or density of the lower honeycomb core is lower than that of the upper honeycomb core. The composite honeycomb sandwich structure floor has the advantage of improving from-top-to-bottom dispersing efficiency of concentrated load or impact load by adopting the structure of the upper skin, the middle skin, the lower skin, the upper honeycomb core and the lower honeycomb core according to the characteristic that the concentrated load or the impact load are transmitted from the upper skin to the lower skin along the height direction to perform load dispersion, so that the lower honeycomb core can adopt the honeycomb with compressive strength or density of lower than that of the upper honeycomb core, optimization effect of each resource in the structure is completely exerted, and weight and cost are reduced.

Owner:SHENYANG AIRCRAFT CORP +1

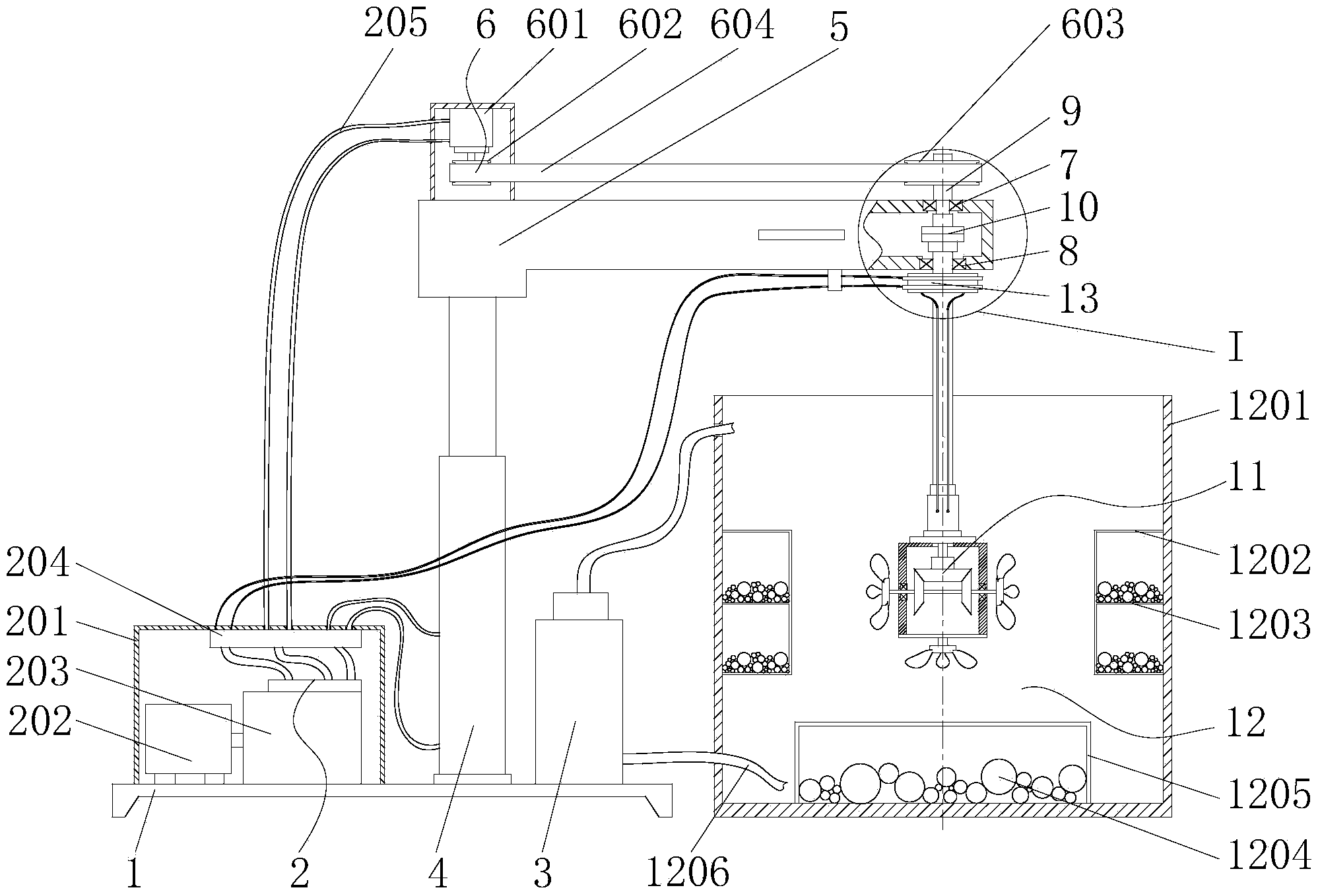

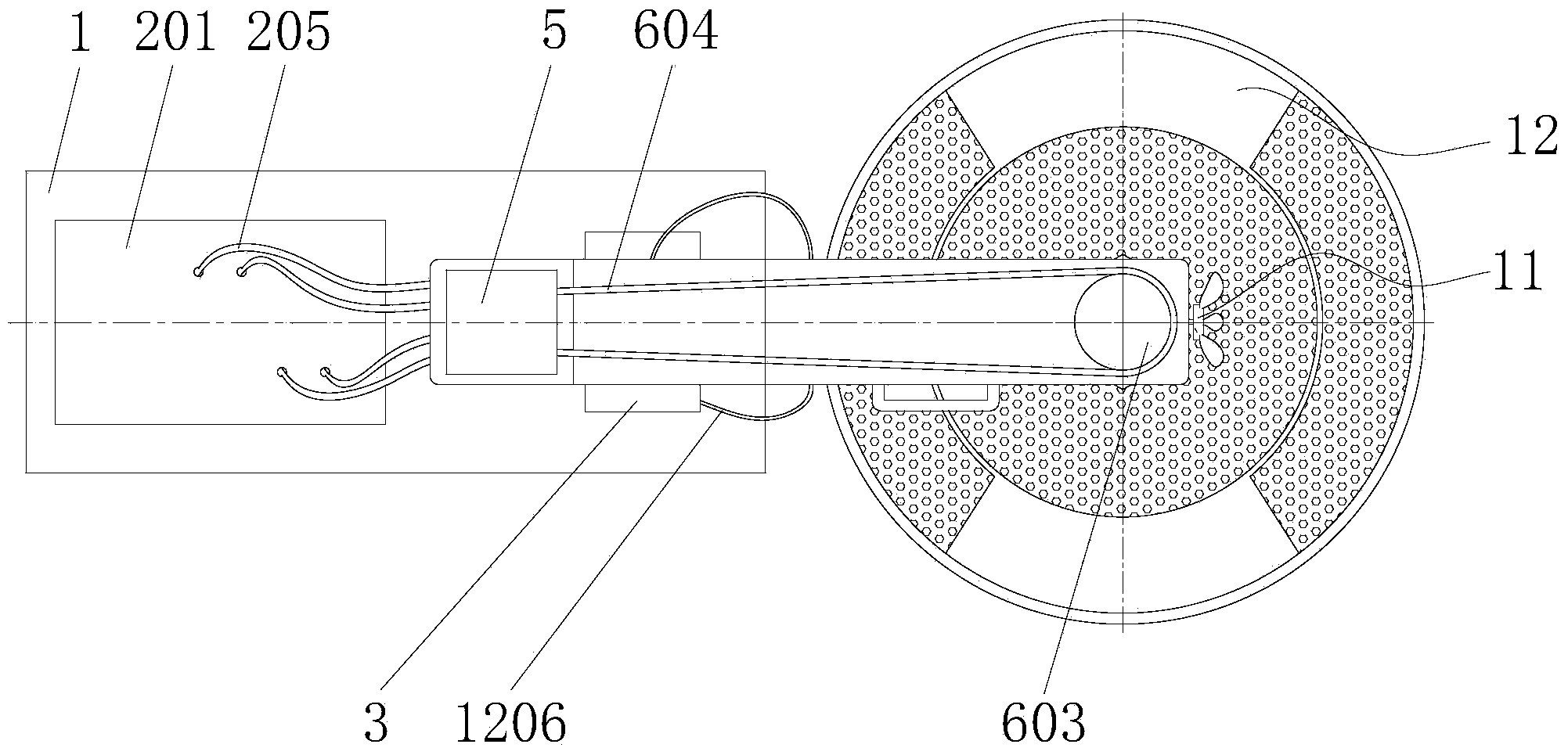

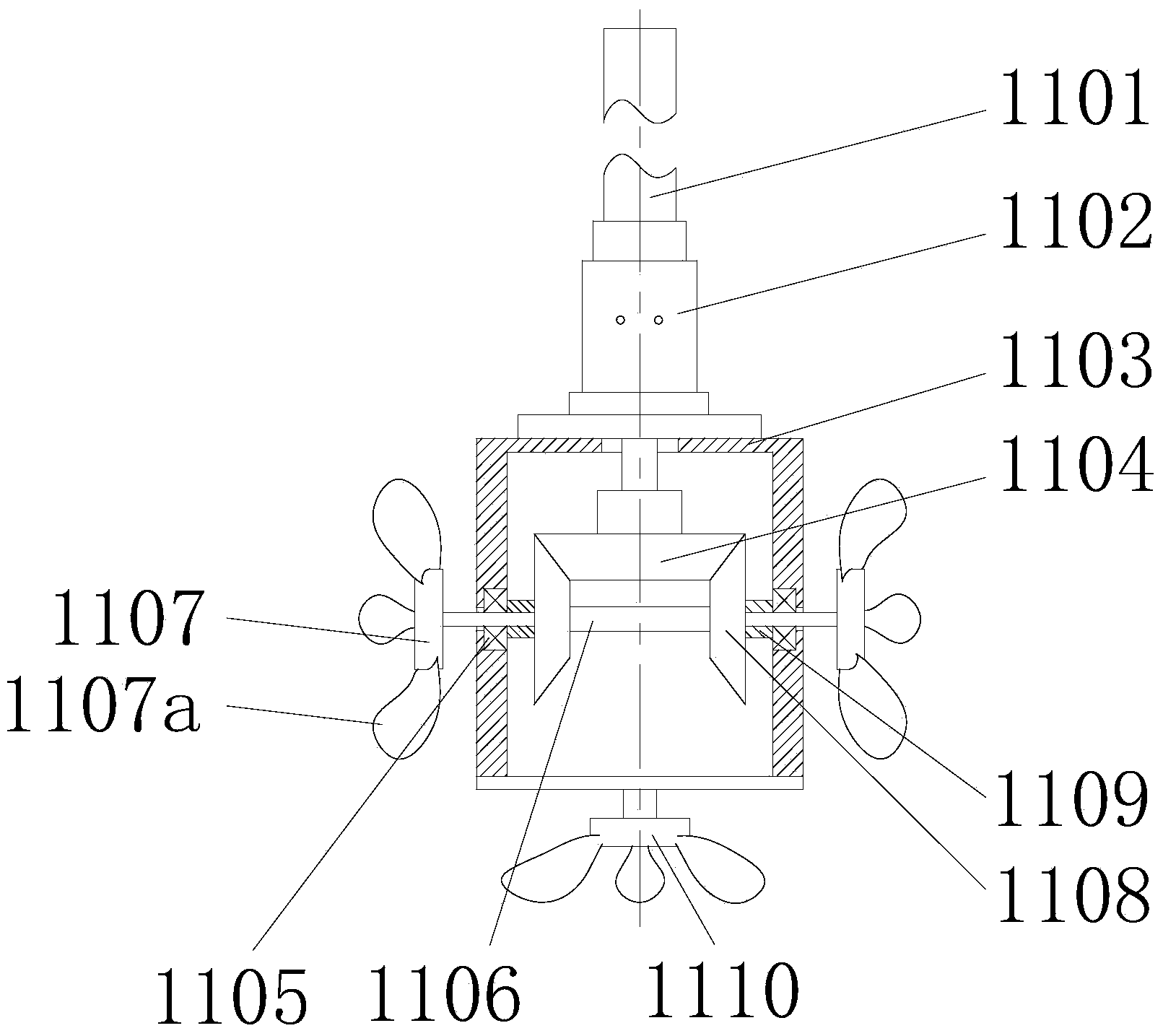

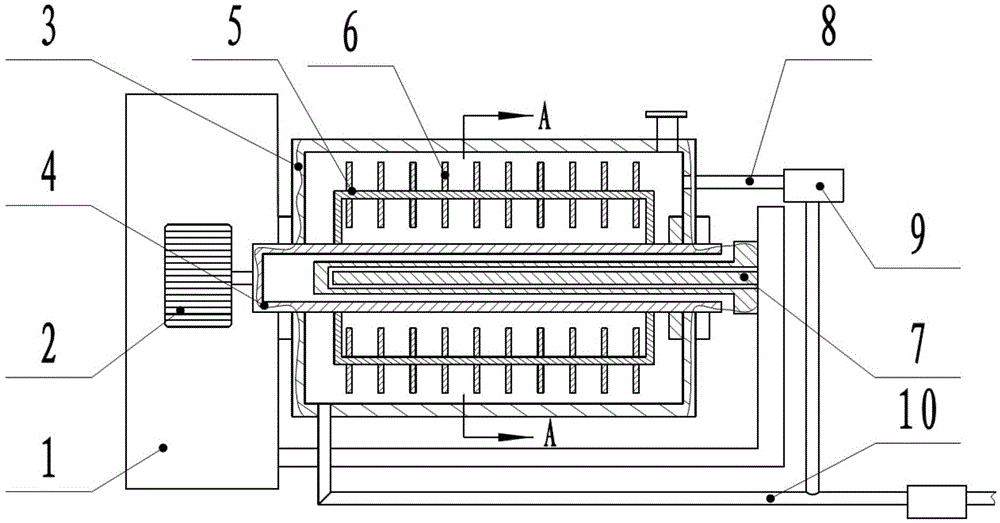

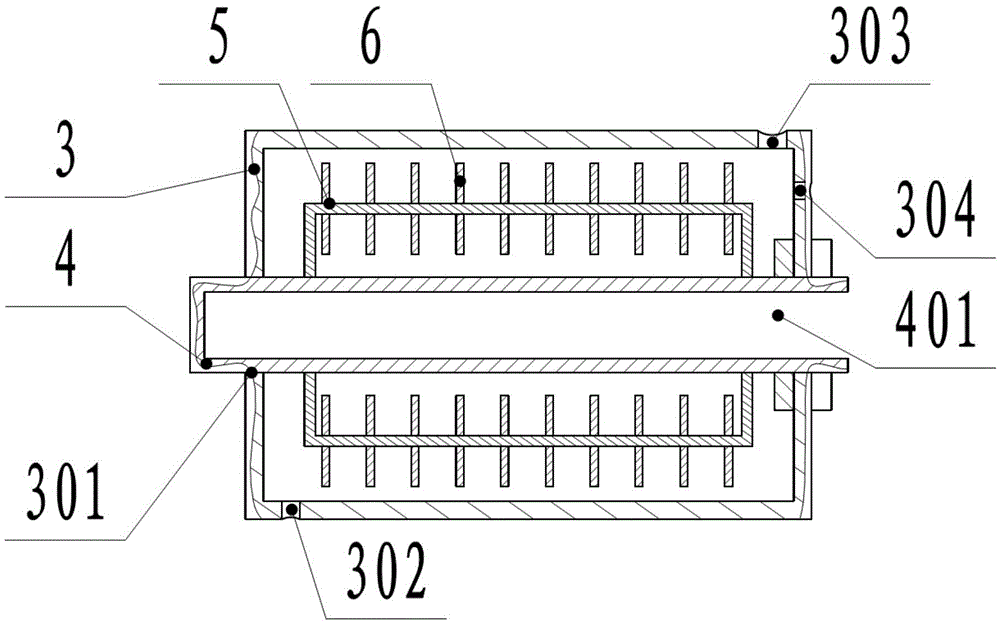

Coating dispersion grinding miller

InactiveCN103464250AReasonable structureImprove dispersion efficiencyGrain treatmentsHydraulic cylinderHydraulic motor

The invention relates to a coating dispersion grinding miller. The coating dispersion grinding miller comprises a base, wherein the left side of the base is provided with a hydraulic pump station, the right side of the base is provided with a pump I, the middle of the base is provided with a hydraulic cylinder, a radial arm is arranged on the top of the hydraulic cylinder, and a power device is arranged above a cantilever; the upper and lower surfaces of the right end of the radial arm are respectively provided with a bearing I and a bearing II, the bearing I is internally provided with a positioning shaft, and a coupler is connected below the positioning shaft; a dispersion device is arranged below the right end of the cantilever, a dispersing device comprises a rotating shaft, a hydraulic motor I, a gear box body, a bevel gear wheel, a bearing, a bevel gear shaft, two bevel pinions and two fixed sleeves; the upper part of the dispersion device is fixedly provided with a conversion valve, and a grinding barrel is arranged on the outer side of the dispersing device. The coating dispersion grinding miller provided by the invention has the advantages that the structure is reasonable, the dispersion efficiency is high, the grinding effect is obvious, the operation is convenient, and a condition that the dispersion and the grinding are simultaneously performed is realized.

Owner:安徽美诺新材料科技有限公司

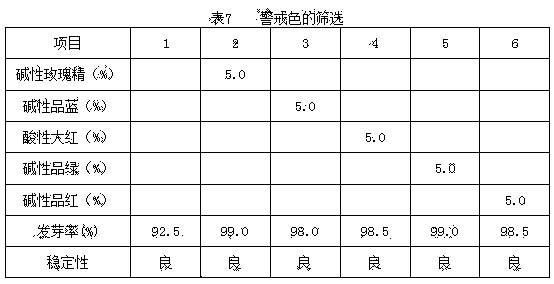

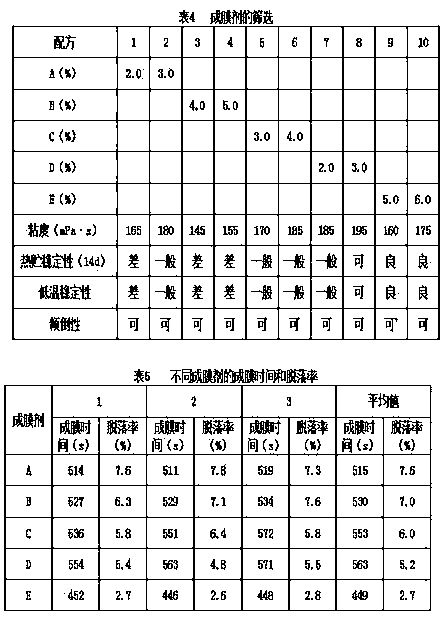

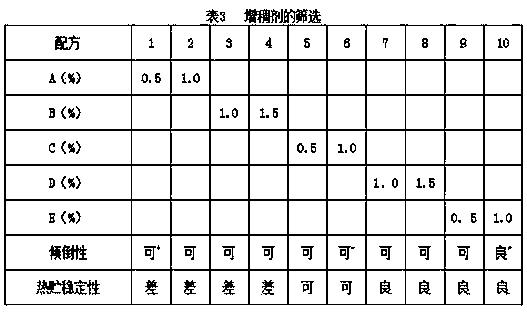

Suspended seed coating for preventing and curing corn smut and preparation method thereof

ActiveCN104255774AGood control effectNot easy to develop resistanceBiocideFungicidesBiotechnologySmut

The invention discloses a suspended seed coating for preventing and curing corn smut and a preparation method thereof. The suspended seed coating for preventing and curing corn smut is characterized by being prepared from the following raw materials in percentage by weight: 3.0-7.0% of imidacloprid, 7.0-12.0% of thiram, 0.2-0.6% of diniconazole, 1.5-2.5% of wetting dispersant, 0.5-1.5% of thickening agent, 2.0-6.0% of antifreezing agent, 0.1-0.3% of preservative, 2.0-6.0% of film-forming agent, 3.0-7.0% of warning colouration, 1.0-5.0% of microelements and the balance of water. The suspended seed coating disclosed by the invention is free of harmful effect on the emergence of seedlings and growth of corn, medicine is wrapped around seeds in a concentrated manner, and the medicine is slowly released. The average control effect for corn underground insects is 77.5%-83.5%, the control effect for head smut is 81.7%-88.4%, and the average growth rate is 16.4%-22.6%.

Owner:WUWEI CHUNFEI CROP SCI & TECH

Sand mill

The invention provides a sand mill. The sand mill comprises a rack, a motor, a grinding cylinder, a main shaft, multiple dispersion disc supports, multiple dispersion discs, a cooling core and a return pipe. The motor is fixedly connected to the rack. The grinding cylinder is arranged on the right side of the motor and fixedly connected with the rack. The center of the grinding cylinder is provided with a through hole, the left side of the bottom of the grinding cylinder is provided with a feeding opening, the right side of the top of the grinding cylinder is provided with a discharging opening, and the upper portion of the right side of the grinding cylinder is provided with an overflow opening. One end of the main shaft is fixedly connected with the motor, the other end of the main shaft is provided with a blind hole, and the main shaft is connected with the grinding cylinder. The dispersion disc supports are evenly and fixedly connected to the periphery of the main shaft. The dispersion discs are arranged on each dispersion disc support in parallel. The cooling core is arranged in the blind hole and fixedly connected with the rack. One end of the return pipe is connected with the overflow opening, and the other end of the return pipe is connected with the feeding opening. By the adoption of the technical scheme, pigment near the main shaft is good in fluidity, the pigment flows through the overflow opening and flows in or out of the grinding cylinder circularly to be fully ground in the flowing process, the pigment is fully dispersed and evenly mixed, and the dispersion efficiency is improved.

Owner:TIANJIN CITY JIUYUE TECH

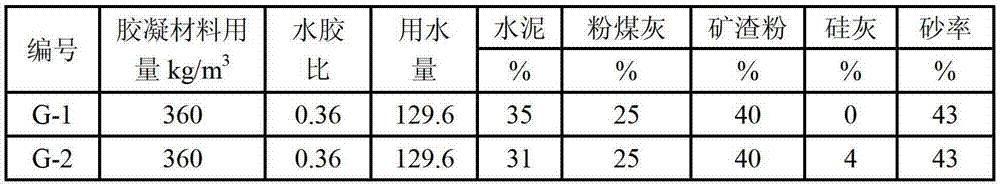

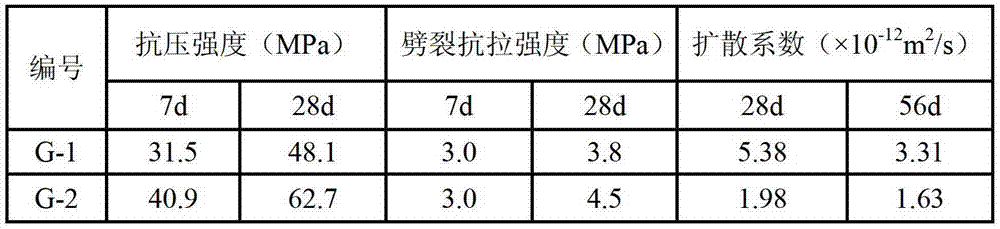

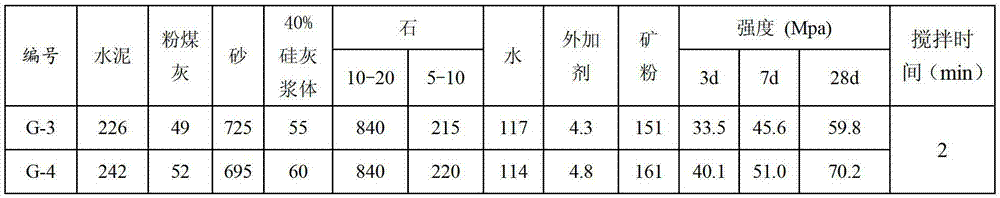

Silicon mortar material as well as preparation and applications thereof

ActiveCN103193405AImprove dispersion efficiencyHigh strengthSolid waste managementSilica fumeMass content

The invention discloses a silicon mortar material. The formula of the silicon mortar material comprises raw materials of silica fume, water, a retarder and an acidifier, wherein the mass ratio of silica fume to water is 1:(0.9-2.5), the mass content of the retarder is 0.01-0.06% of the silicon mortar material, and the mass content of the acidifier is 0.01-0.05% of the silicon mortar material. The environment-friendly and high-efficiency silicon mortar material is prepared by taking silica fume as raw materials and applied to preparing concrete. The method is simple in technique, the prepared silicon mortar can be widely applied to various concretes, and to important projects of harbor projects, water-conservancy dam projects, nuclear power projects, highways and railways and the like having higher requirements on the concrete, and can also be used as common concrete for replacing cement. The prepared silicon mortar material is beneficial to reduction of the environment pollution caused by directly using silica fume, the dispersion efficiency of silica fume in the concrete can be improved, and the strength, permeability resistance, chemical corrosion resistance and the like of the concrete can be obviously enhanced.

Owner:CCCC FOURTH HARBOR ENG INST +3

Modified chlorosulphonated polyethylene rubber paint for steel storage tank and preparation method thereof

InactiveCN101294016AImprove dispersion efficiencyHigh viscosityLarge containersEpoxy resin coatingsSodium BentoniteN-Butanol

The invention relates to a modified chlorosulfonated polyethylene rubber coating used for steel storage tanks and a preparation method thereof. The coating comprises a component A and a component B, wherein the component A is composed of chlorosulfonated polyethylene rubber, dimethylbenzene, trimethylbenzene, titanium white powder, talc powder, fluorocarbon-modified polyacrylamide and organic bentonite; and the component B is composed of bisphenol-A epoxy resin, dimethylbenzene, n-butanol, diphenyl guanidine (manufactured by Dongbei Auxiliary general factory, Shenyang) and ethylenethiourea. The component A and the component B are mixed and cured to form a coating film before application. The coating is excellent in physical property, chemical resistance, salt spray resistance and light fastness, and can be used for the surface protection and coating of steel storage tanks in various corrosive environments.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +1

Uniform powder discharging device

InactiveCN104477673AEasy to adjustImprove dispersion efficiencyLoading/unloadingAdditive ingredientEngineering

The invention relates to a uniform powder discharging device. The uniform powder discharging device is formed by a fixed grid, a moving grid, a pulley, a guide rail, a guide rail support, a flexible connecting rod, a spring, a disc with an eccentric shaft, a motor and a discharging box. The uniform powder discharging device can uniformly discharge powder in a cabin within a large area, is beneficial to follow-up homogenization of powder and other materials, can timely and conveniently change the discharging speed due to the fact that the rotation speed of a motor or a connecting position of the flexible connecting rod and the eccentric shaft on the motor disc is adjusted through stepless speed change and is beneficial to control the ingredient proportion according to production requirement, simple in manufacture, conveniently design the discharging scattering area according to the requirements and applicable to powder distribution which is good in mobility and not easy to bulge.

Owner:TONGJI UNIV

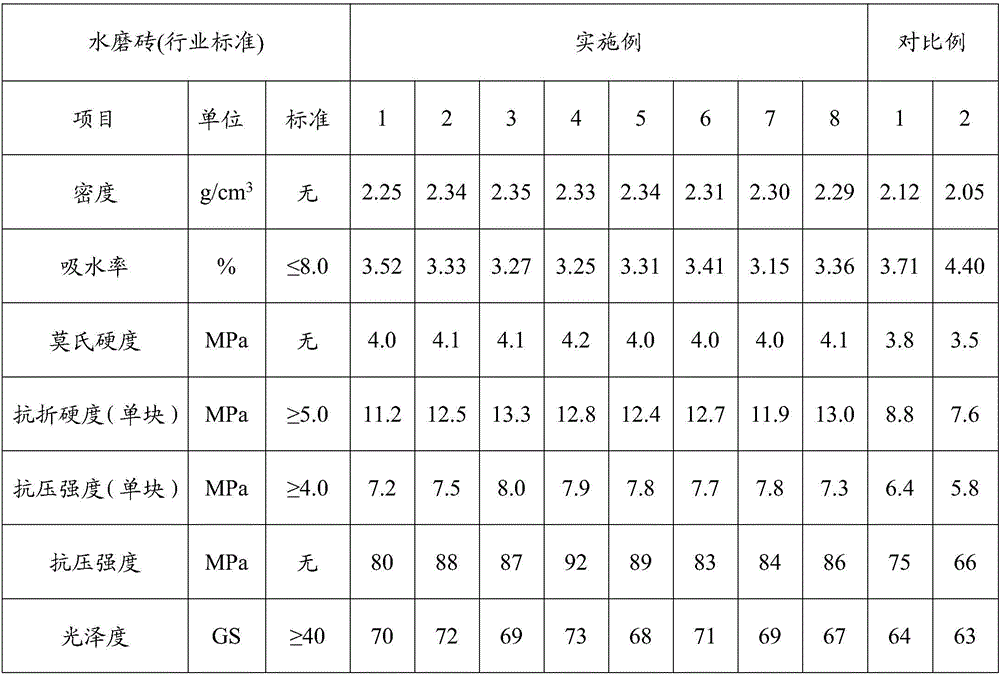

Artificial marble having decorative effect and manufacturing method thereof

The invention relates to the field of architectural decoration / finishing materials, and particularly relates to an artificial marble slab having a decorative effect and a manufacturing method thereof. The artificial marble slab having a decorative effect comprises sulfoaluminate cement, white quartz sand, water-based polycarboxylic acid water-reducing agent, water-based organosilicon defoaming agent, pigment and concrete antishrinking agent. The manufacturing method of the artificial marble slab having a decorative effect comprises the following steps: proportionally preparing mortar, defoaming, performing vibration compaction, netting to obtain a blank, then drying, demolding, and maintaining. According to the invention, the artificial marble slab having a decorative effect has favorable hardness, abrasion strength, shear strength, folding strength and weather resistance, low internal porosity and clear texture; the manufacturing method is short in maintenance time and low in mixing water consumption in the construction process, effectively compensates for dimensional instability caused by shrinkage of cement, and improves the demolding convenience; and the manufacturing method greatly improves the production efficiency and lowers the operating cost of production.

Owner:JIANGSU WONIUSHAN THERMAL INSULATION & WATERPROOF TEHNOLOGY

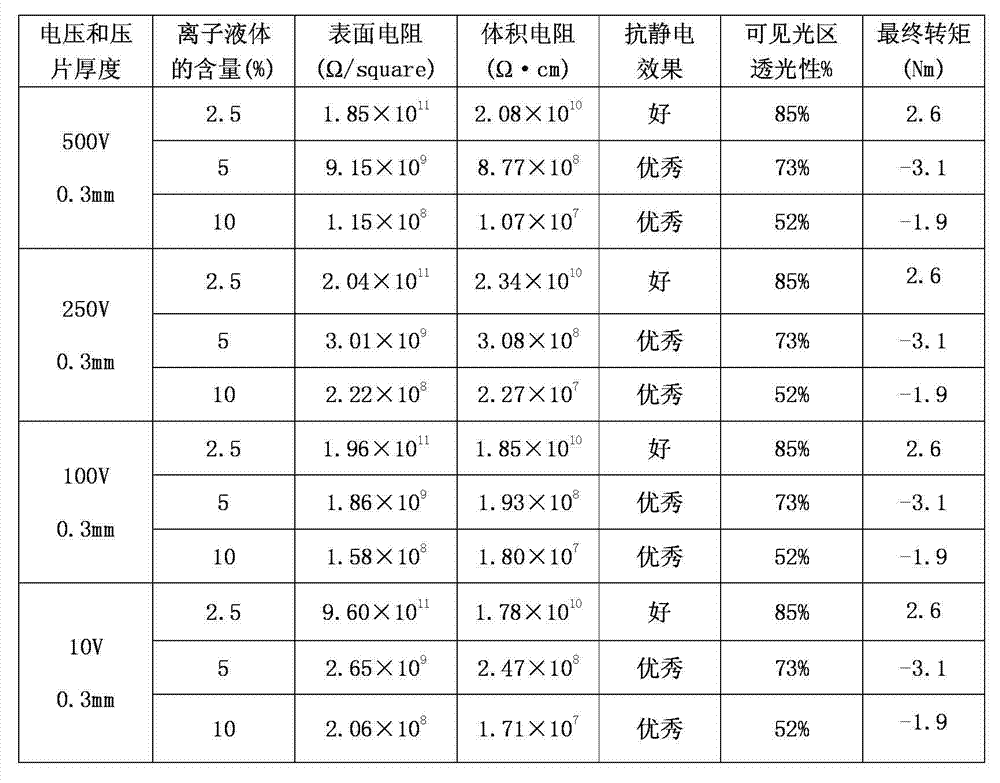

Permanent antistatic polycarbonate composite and preparation method thereof

InactiveCN103242635AHigh transparencyHigh decomposition temperatureEnvironmental resistancePolyolefin

The invention relates to a permanent antistatic polycarbonate composite and a preparation method thereof. The permanent antistatic polycarbonate composite comprises the following components in percentage by weight: 99%-87.5% of polycarbonate, 0.5% of fluoro-substitution polyolefin additives, 0.5%-10% of antistatic agents and 0.1%-2% of other auxiliary agents. The preparation method comprises the following steps of: firstly placing the polycarbonate, the fluoro-substitution polyolefin additives and ionic liquid into an internal mixer, and melting and blending at 260 DEG C till uniform mixing; and carrying out melt extrusion on a mixed material obtained through the processing of the process through a double-screw extruder, granulating, and then drying. The obtained permanent antistatic polycarbonate composite has the advantages of good product penetrability, excellent antistatic property, less influence of air humidity on the antistatic property of a material, lasting antistatic property, simple process, convenience for processing, small usage amount of the ionic liquid antistatic agents and the other auxiliary agents and less influence on the self impact resistance and formability of the polycarbonate, meets the requirement for environment protection, is nontoxic and harmless in raw material and is discovered that no toxic element exists through chemical analysis.

Owner:ZHEJIANG JAVA SPECIALTY CHEM CO LTD

Method for preparing C/SiC material brake disc by carbon fiber prepreg tape

ActiveCN107573075AEnabling Content ProgrammabilityControllable areal densityFriction liningFiberCarbon fibers

A method for preparing a C / SiC material brake disc by a carbon fiber prepreg tape comprises the following steps: clipping the carbon fiber prepreg tape into a short carbon fiber tape with the length of 3-10 mm and pressing the short carbon fiber tape into a brake disc blank; carbonizing the blank to obtain a carbon / carbon preform; and finally carrying out carburizing treatment to obtain a product.Carburizing treatment comprises the steps of placing the carbon / carbon preform in a graphite crucible; heating the carbon / carbon preform for 0.5-2 hours at the temperature of 1,550-1,650 DEG C undervacuum or in an inert atmosphere; and then cooling the carbon / carbon preform in a furnace to finish carburizing treatment. A C / SiC composite material has the advantages of low cost, short process period, pollution-free preparation process, simplicity and controllability and the like on preparation of the carbon / carbon preform, and is expected to be extensively applied to a C / SiC composite brake disc.

Owner:LUOYANG INST OF SCI & TECH

Pigment dispersing machine

ActiveCN105642414AReasonable structural designAvoid wastingSievingScreeningElectric machineryPhotopigment

The invention relates to pigment production equipment, in particular to a pigment dispersing machine. A screen is connected to an eccentric motor through a slide rod; slide wheels are connected under the screen; a slide rail matched with the slide wheels is mounted on an engine base; a grinding screen is mounted over the screen, and the grinding screen is mounted on the engine base through an upright tube; a dustproof cover is mounted above the engine base and the grinding screen; a charge hole and an air exhausting pipe are connected on the dustproof cover, and the charge hole is in the shape of horn mouth; a material recycling box is connected under the air exhausting pipe through a pipeline; and an air exhausting fan is mounted in the air exhausting pipe. According to the pigment dispersing machine, the air exhausting pipe is more reasonable in structural design; when pigment dust circulates in the air exhausting pipe, the pigment dust drops into the bottom of a V-shaped pipeline under the action of a baffle plate in a middle pipeline, and then, enters the material recycling box for being recycled, so that material waste is avoided, and quantity of dust particles exhausted into the environment can be reduced, and therefore, the pigment dispersing machine is more environmentally-friendly.

Owner:JIANGSU GLORY CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com