Improved structure of dispersion disc

A technology of improved structure and dispersing disk, which is applied to mixers with rotating stirring devices, mixers, mixing methods, etc., can solve the problems of low mixing efficiency of dispersing disks, long dispersion time, and differences in shearing action strength, etc., to achieve improved Effect of dispersion efficiency and dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

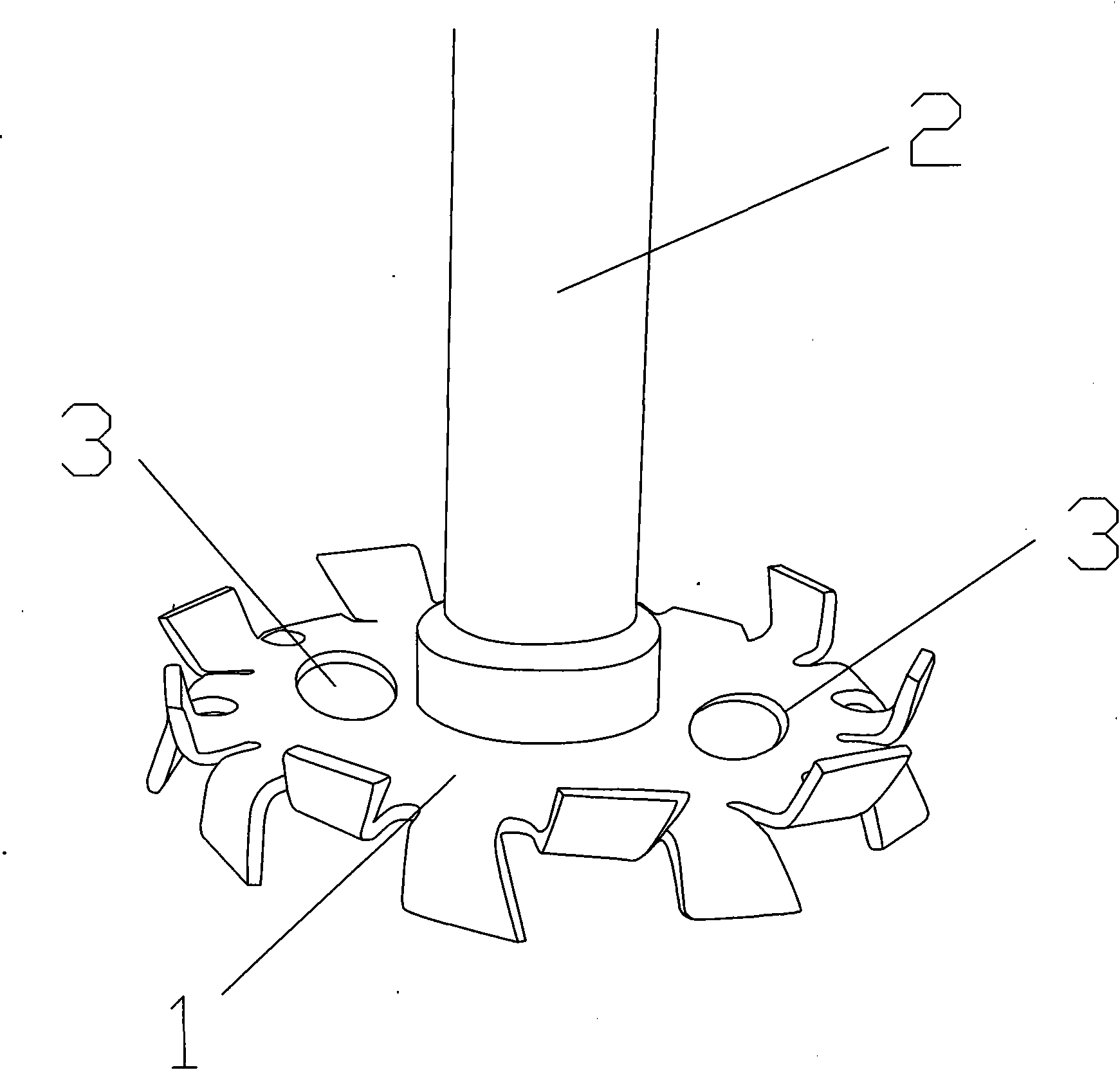

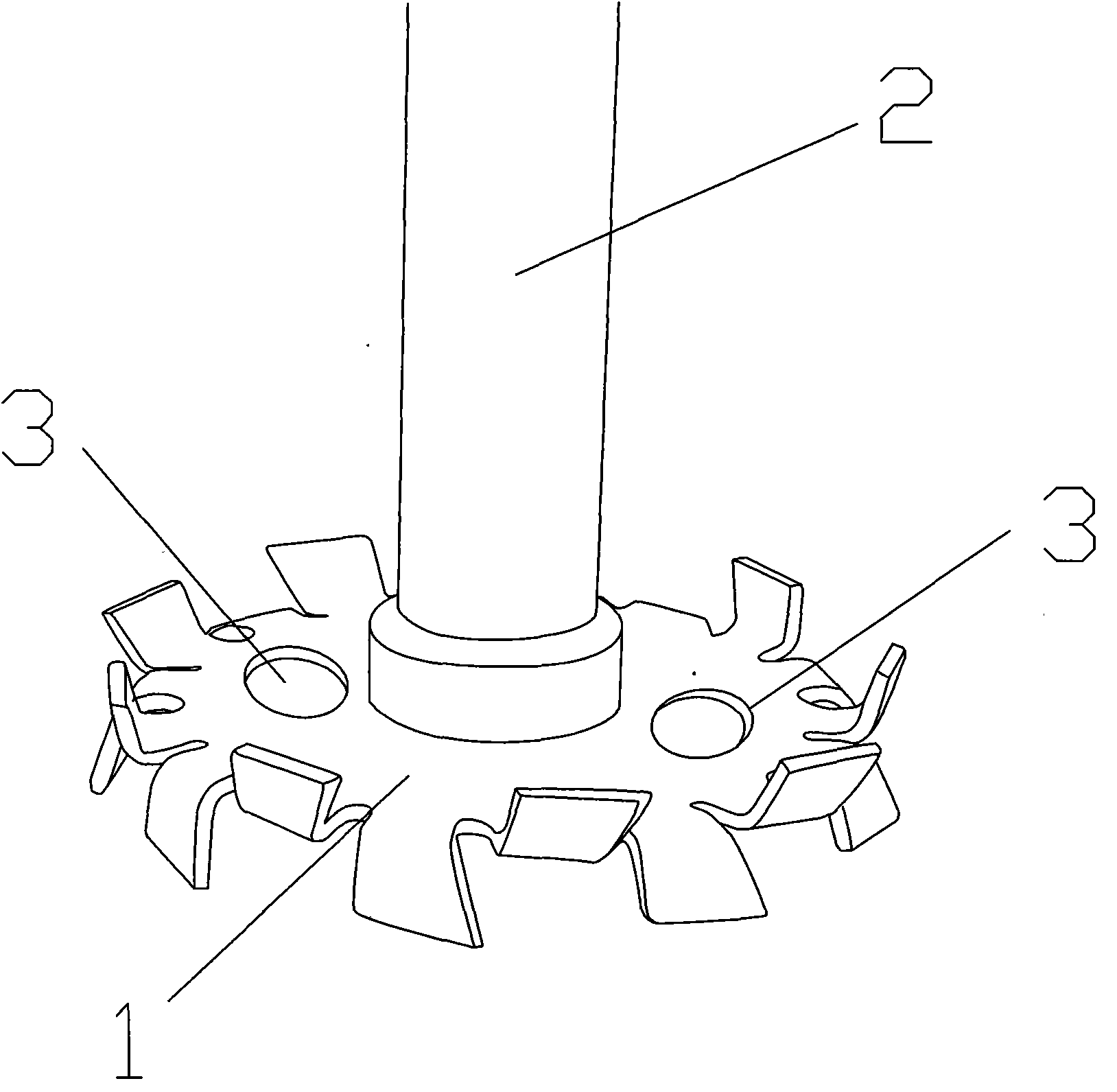

[0011] An improved structure of a dispersing disc, one end of the stirring shaft 2 is fixedly connected to the center of the dispersing disc 1, and a pair of circular holes 3 are arranged symmetrically on the surface of the dispersing disc 1 opposite to the center of the dispersing disc and away from the stirring shaft. The radii of the shaped holes 3 are both 1 / 2 of the radius of the dispersing disk, and the centers of the pair of circular holes 3 are all located at 1 / 2 of the radius of the dispersing disk.

Embodiment 2

[0013] An improved structure of a dispersing disc, one end of the stirring shaft 2 is fixedly connected to the center of the dispersing disc 1, and two pairs of circular holes 3 are symmetrically arranged on the surface of the dispersing disc 1 opposite to the center of the dispersing disc and away from the stirring shaft. The radii of the pair of circular holes 3 are both 1 / 3 of the radius of the dispersing disk, and the centers of the two pairs of circular holes 3 are located at 1 / 2 of the radius of the dispersing disk.

Embodiment 3

[0015] An improved structure of a dispersing disc, one end of the stirring shaft 2 is fixedly connected to the center of the dispersing disc 1, and three pairs of circular holes 3 are symmetrically arranged on the surface of the dispersing disc 1 opposite to the center of the dispersing disc and away from the stirring shaft. The radii of the circular holes 3 are all 1 / 4 of the radius of the dispersing disk, and the centers of the three pairs of circular holes 3 are all located at 1 / 2 of the radius of the dispersing disk.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com