Uniform powder discharging device

A uniform and powder technology, applied in the field of uniform feeding device, can solve the problems of reduced production efficiency, energy consumption, increased machine loss, dust problems, etc., and achieve the effect of improving dispersion efficiency, convenient feeding speed, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

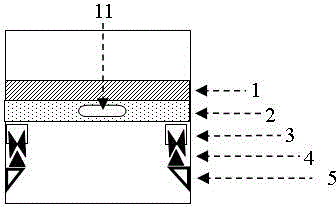

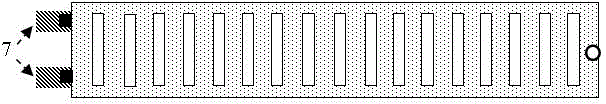

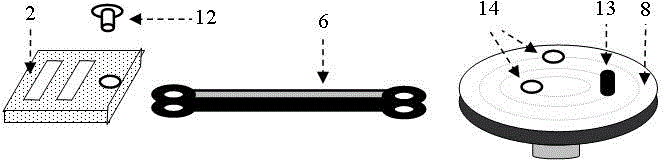

[0021] Embodiment 1: As shown in the figure, the device is composed of a fixed grid, a movable grid, a pulley, a guide rail and a guide rail bracket, a movable connecting rod, a spring, a disc with an eccentric shaft, a motor and a feeding box, and the The guide rail bracket 5 fixes two sets of guide rails 4 in parallel on the two inner sidewalls of the rectangular blanking box 10, and two or more pairs of pulleys 3 are symmetrically fixed respectively under the both sides of the mobile grid 2, and the pulleys 3 Fall on the guide rail 4; fix one end of the spring 7 on the side wall of the blanking box, and one end is connected to one end of the moving grid 2; one end of the connecting rod 6 is connected to the eccentric shaft on the disc 8, and the center of the disc 8 Fixed on the rotating shaft of the motor 9, the other end of the connecting rod 6 passes through the hole 11 on the side wall of the feeding box 10 and is connected with the moving grid; finally, the fixed grid i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com