Patents

Literature

216results about How to "Convenient speed adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Speed control of brushless DC motors

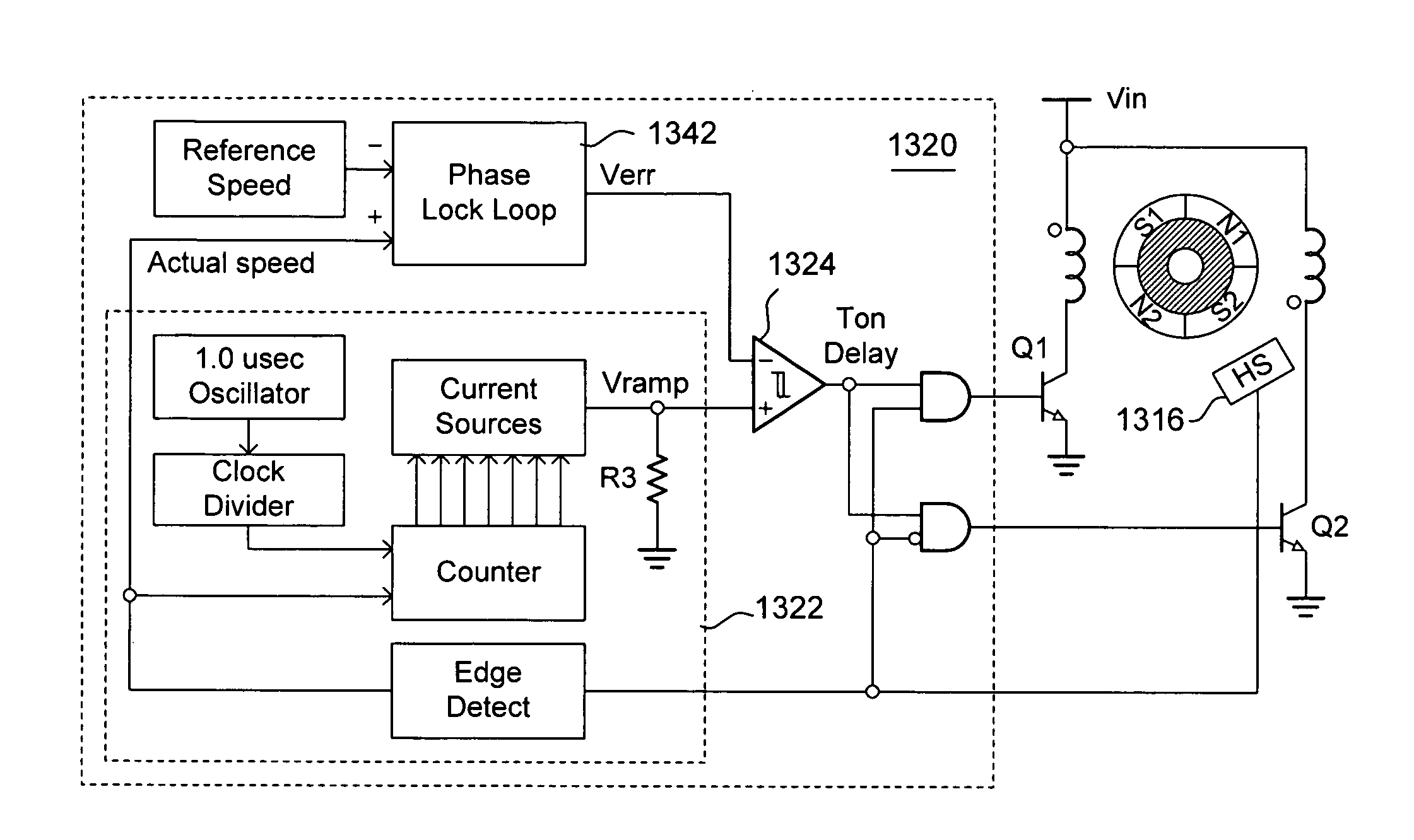

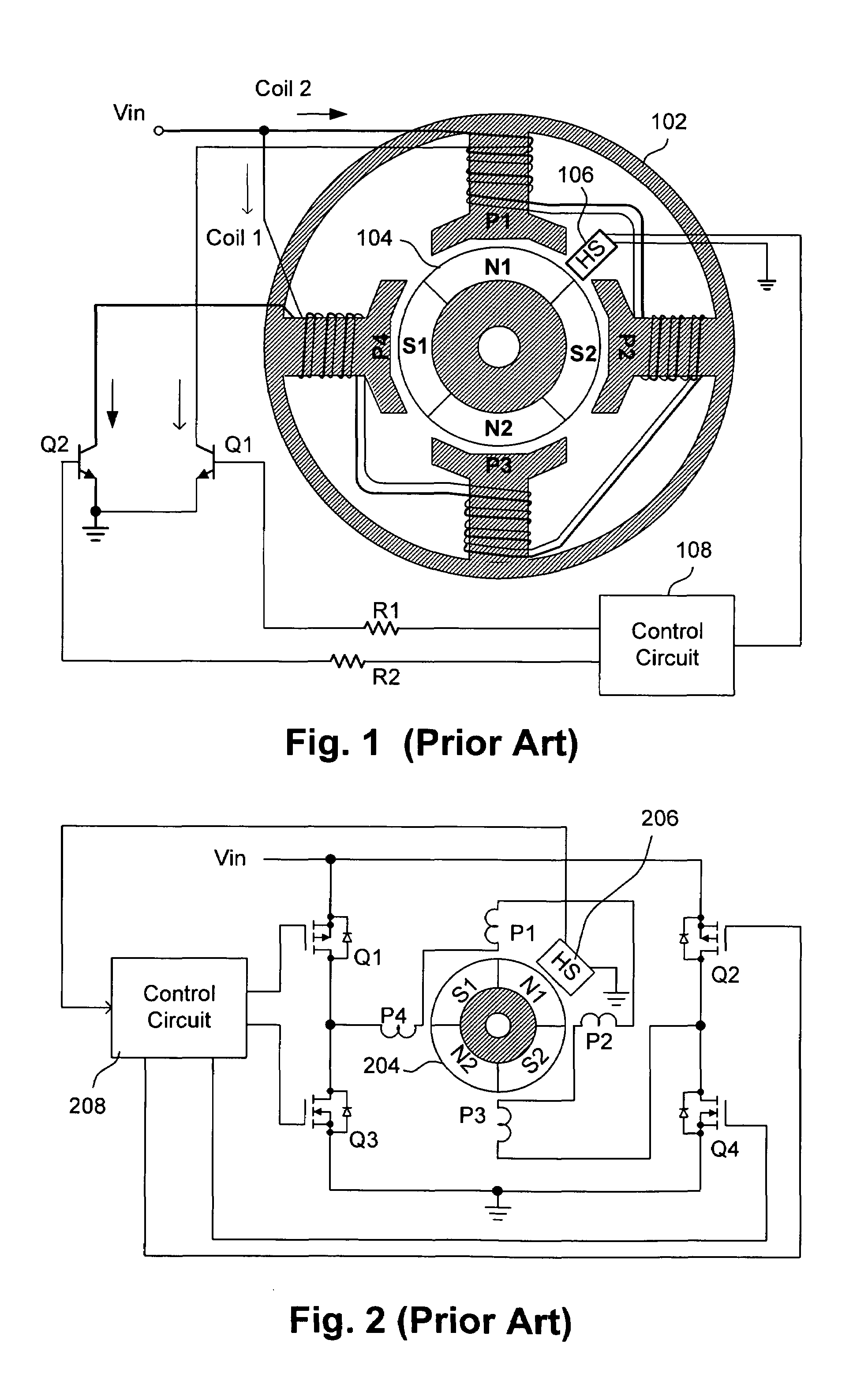

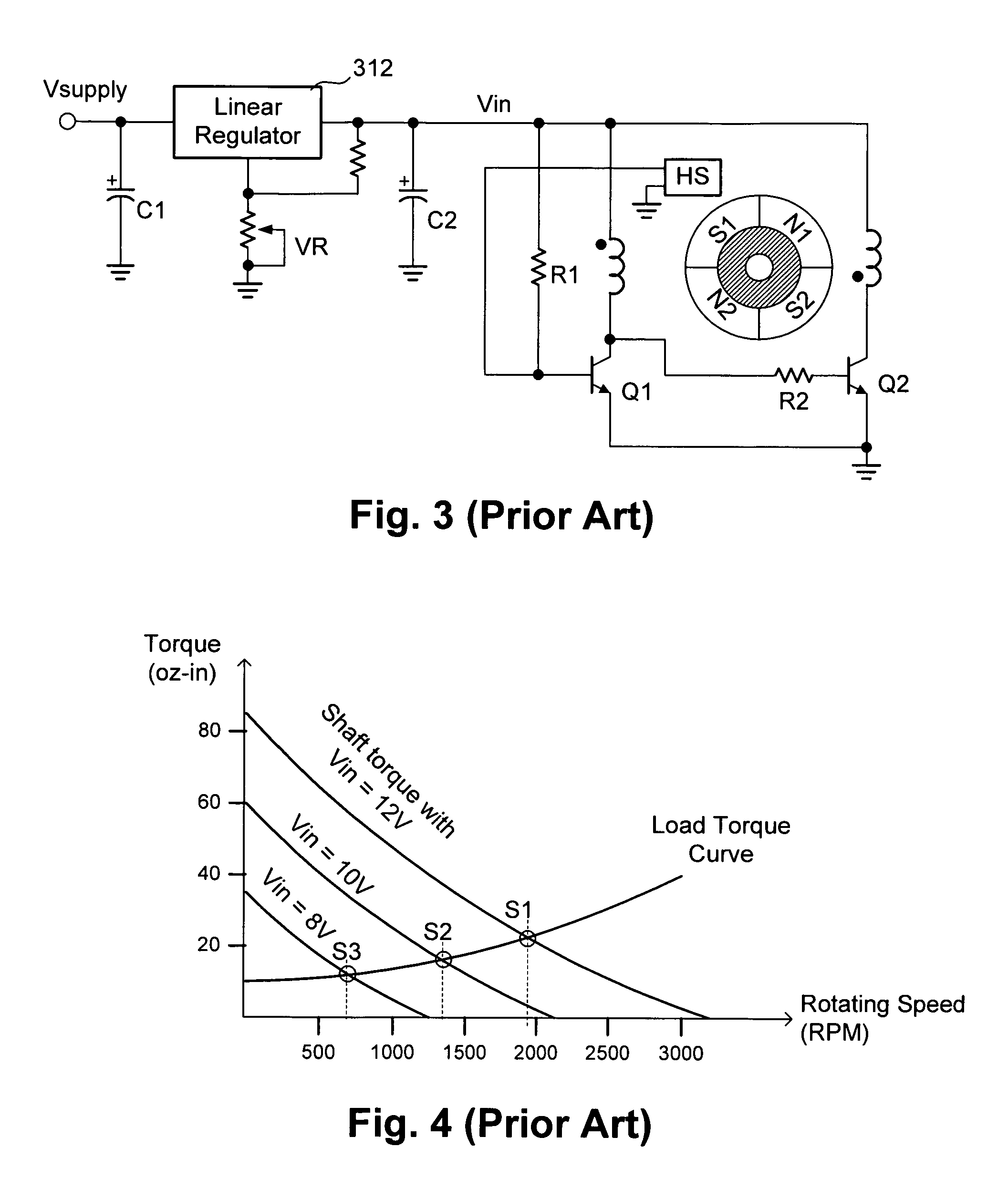

InactiveUS7259531B1Convenient speed adjustmentEliminate degradationAC motor controlSynchronous motors startersEngineeringControl circuit

The speed control apparatus comprises a plurality of Hall sensors, a plurality of switches, a turn-on control circuit, and a gate drive logic. The Hall sensors are configured to detect magnetic rotor sections of a poly-phase brushless DC motor at different positions. The switches apply voltages on a plurality of windings to respectively produce magnetic north or south on stator poles of the poly-phase BLDC motor. The turn-on control circuit generates a conduction time reduction after each output transition of the Hall sensors. The gate drive logic separately turns on or turns off the switches according to different output transitions of the Hall sensors to respectively apply voltages on the windings with the conduction time reduction.

Owner:GREEN MARK TECH

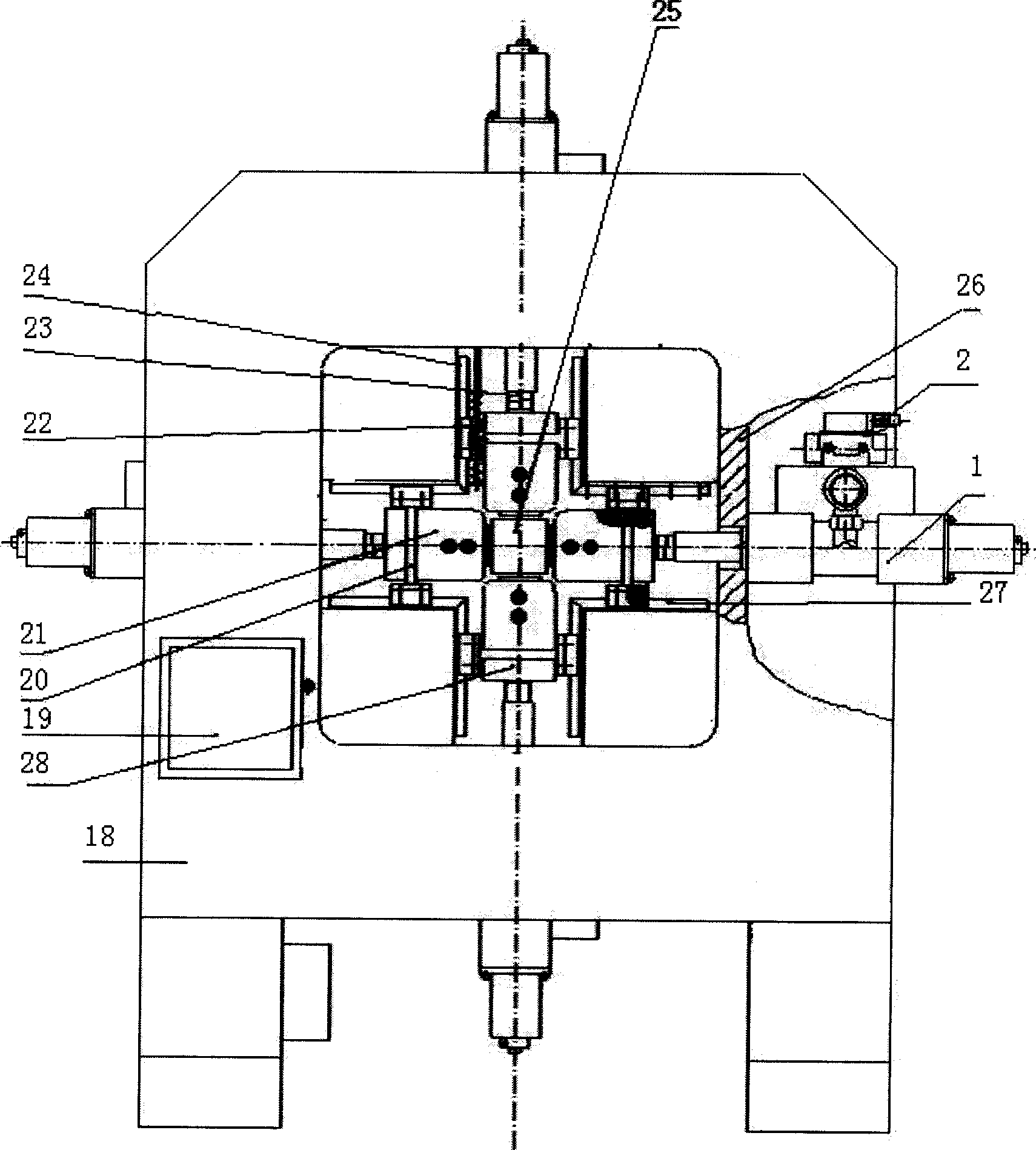

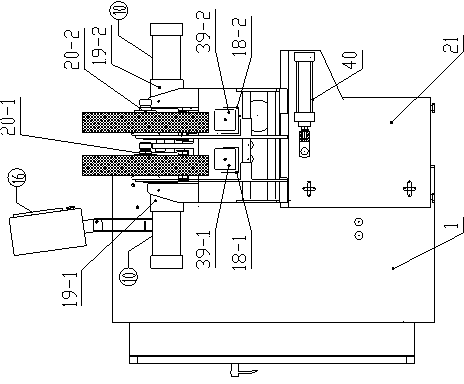

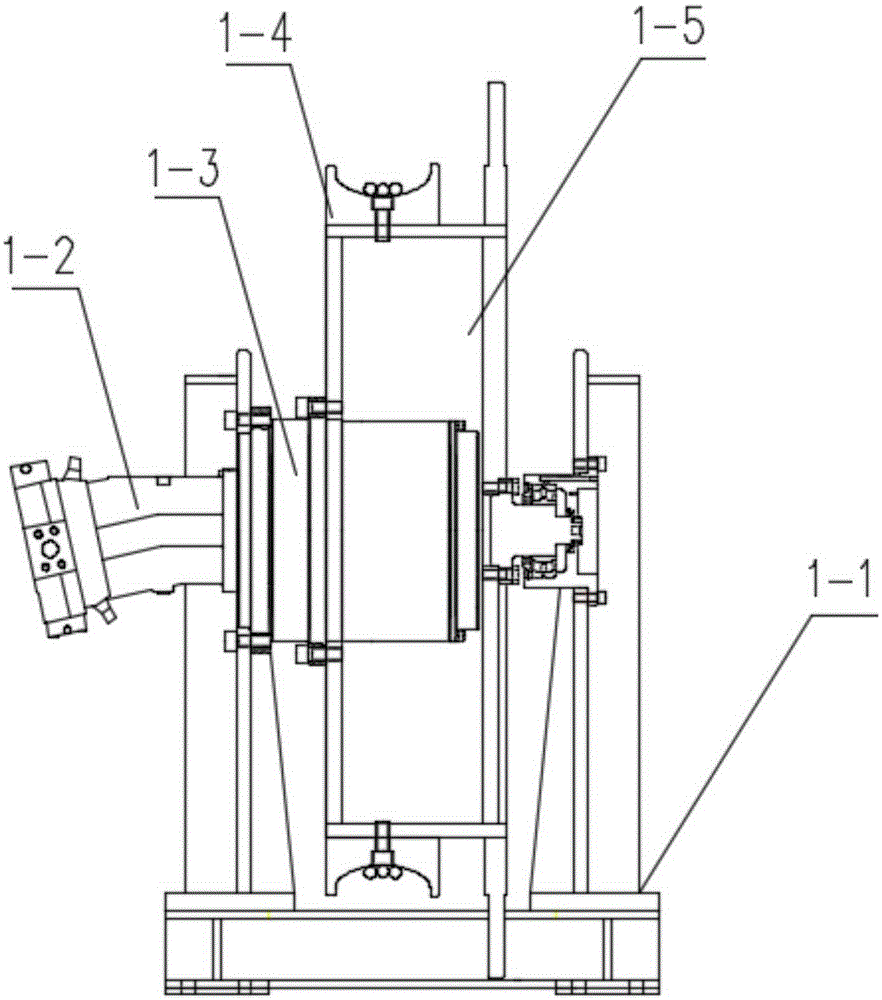

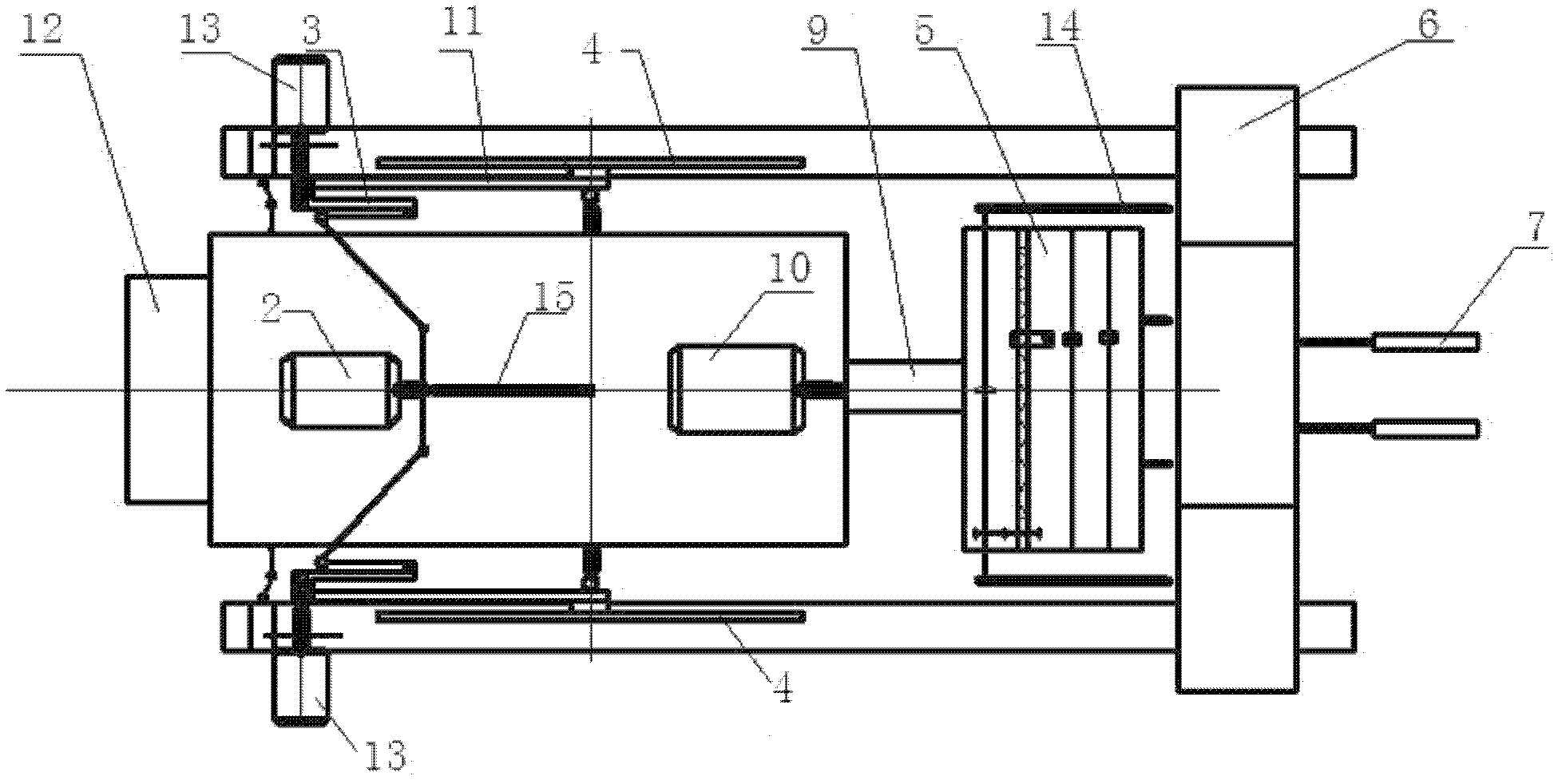

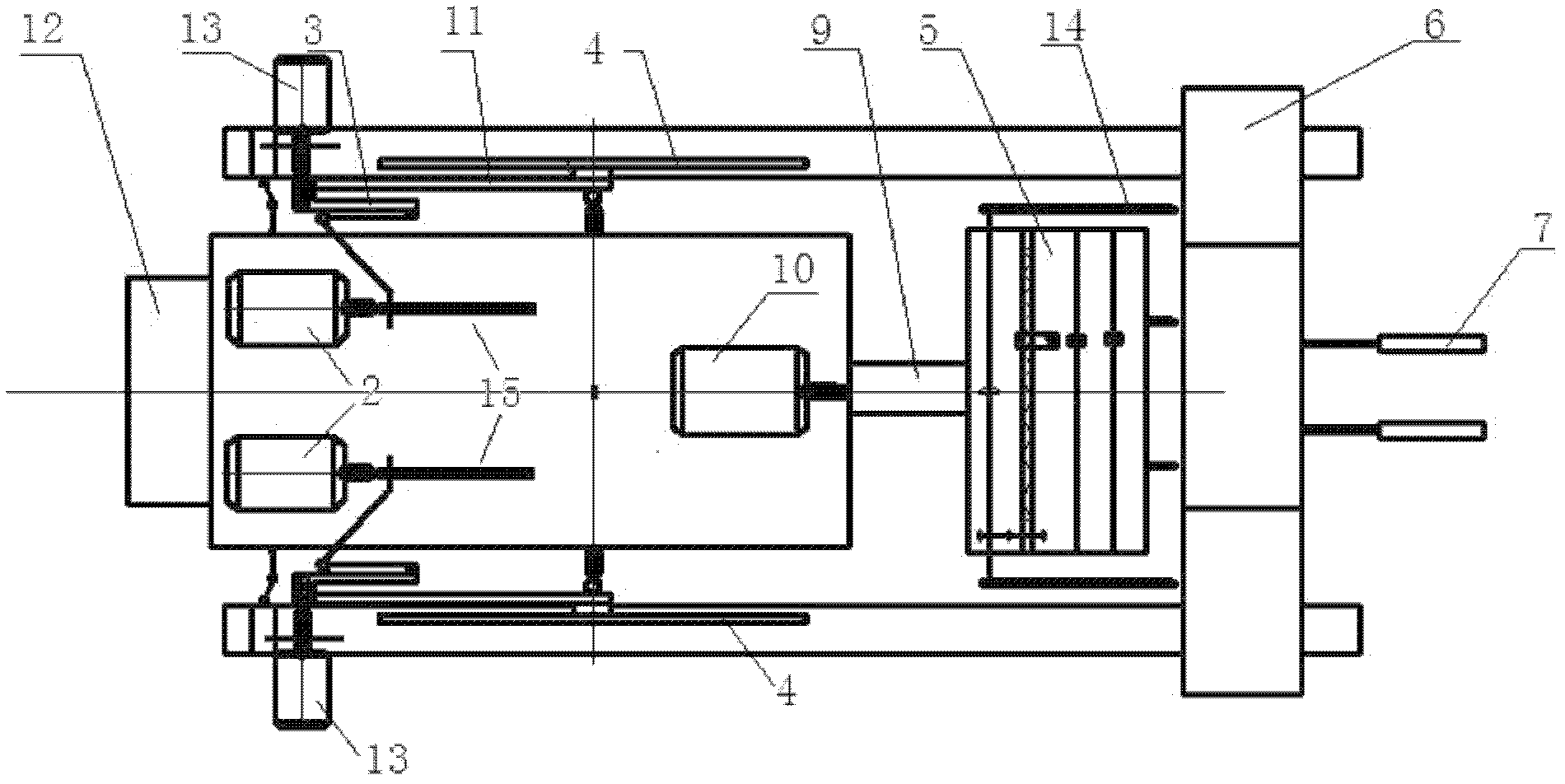

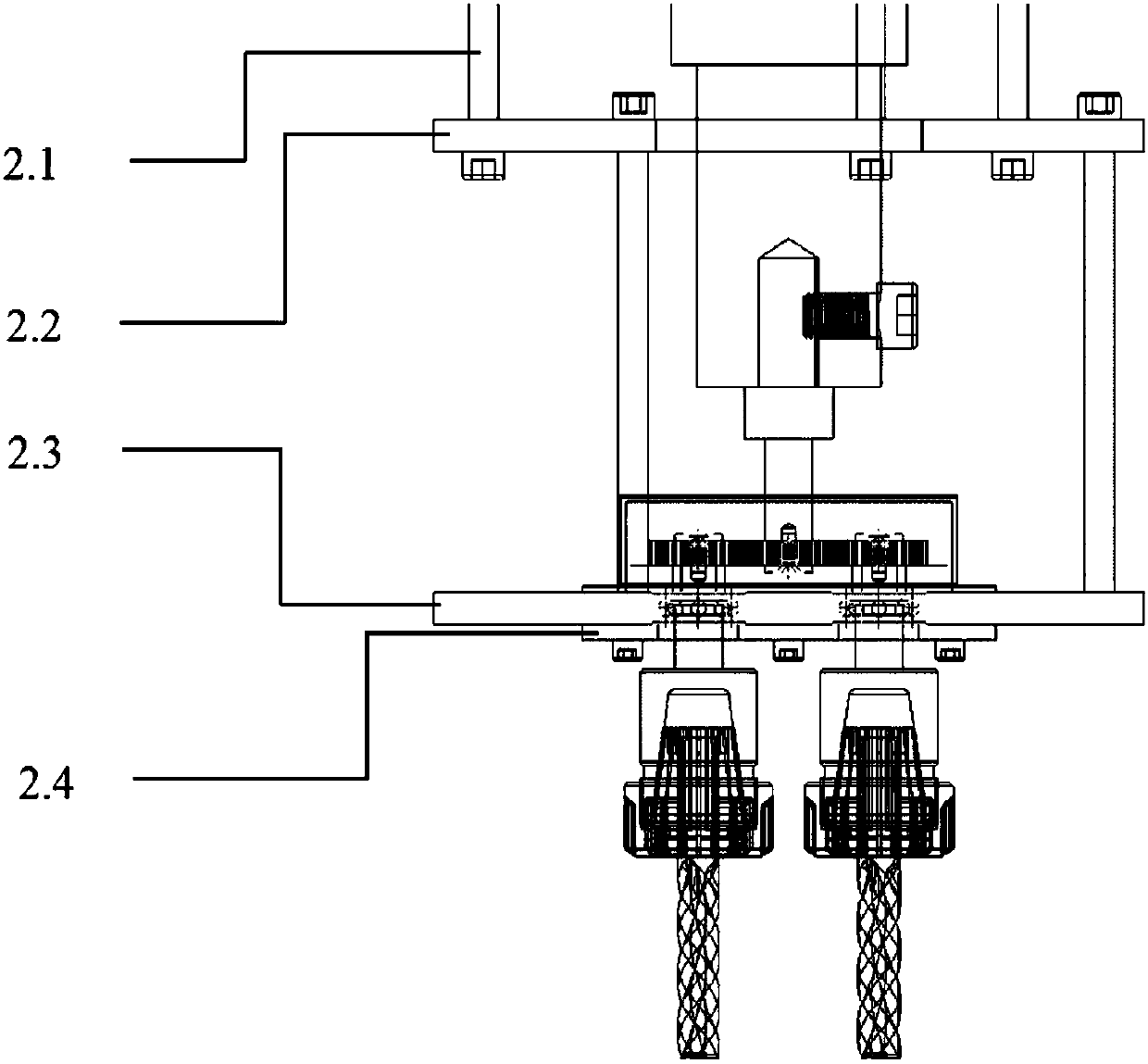

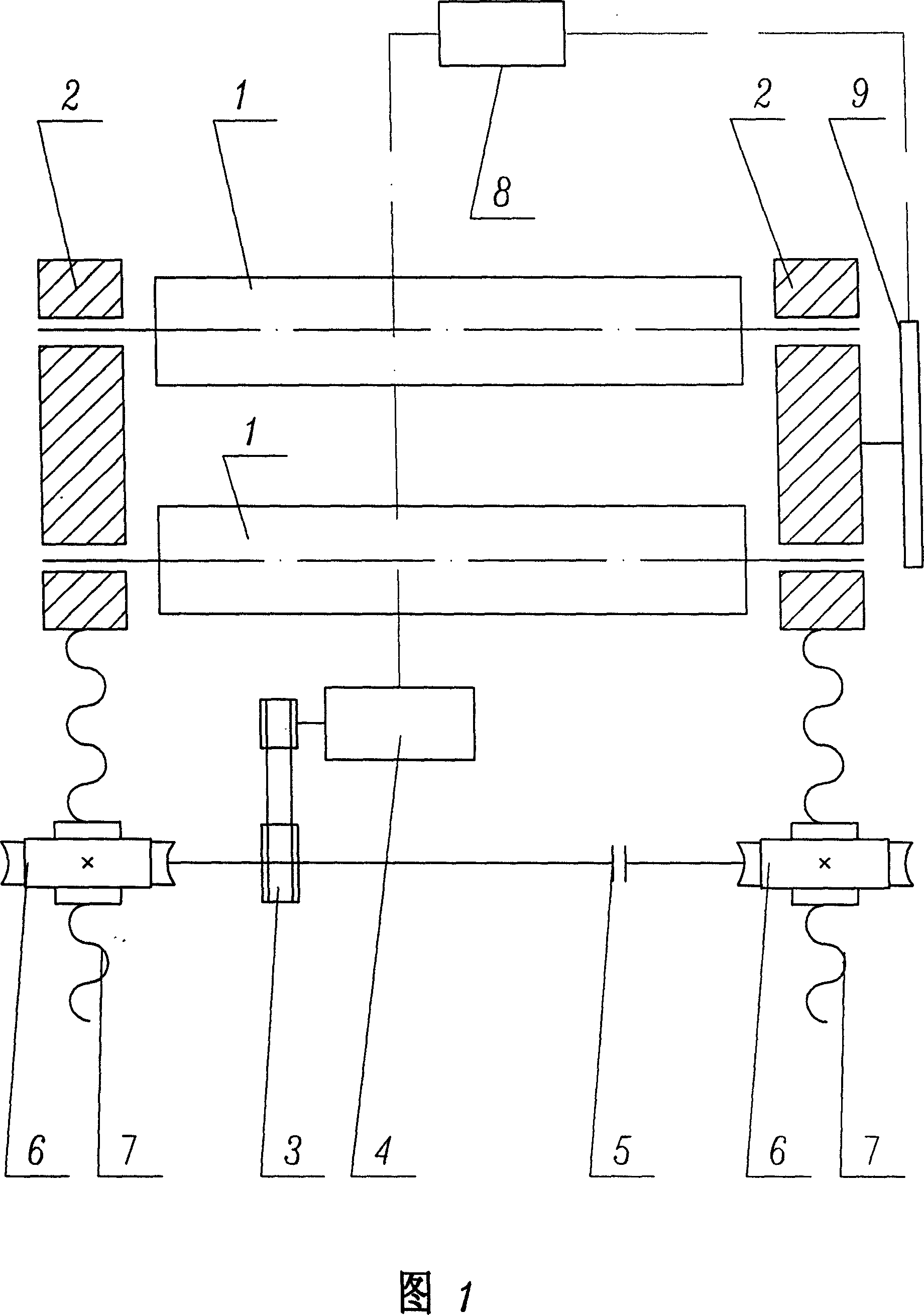

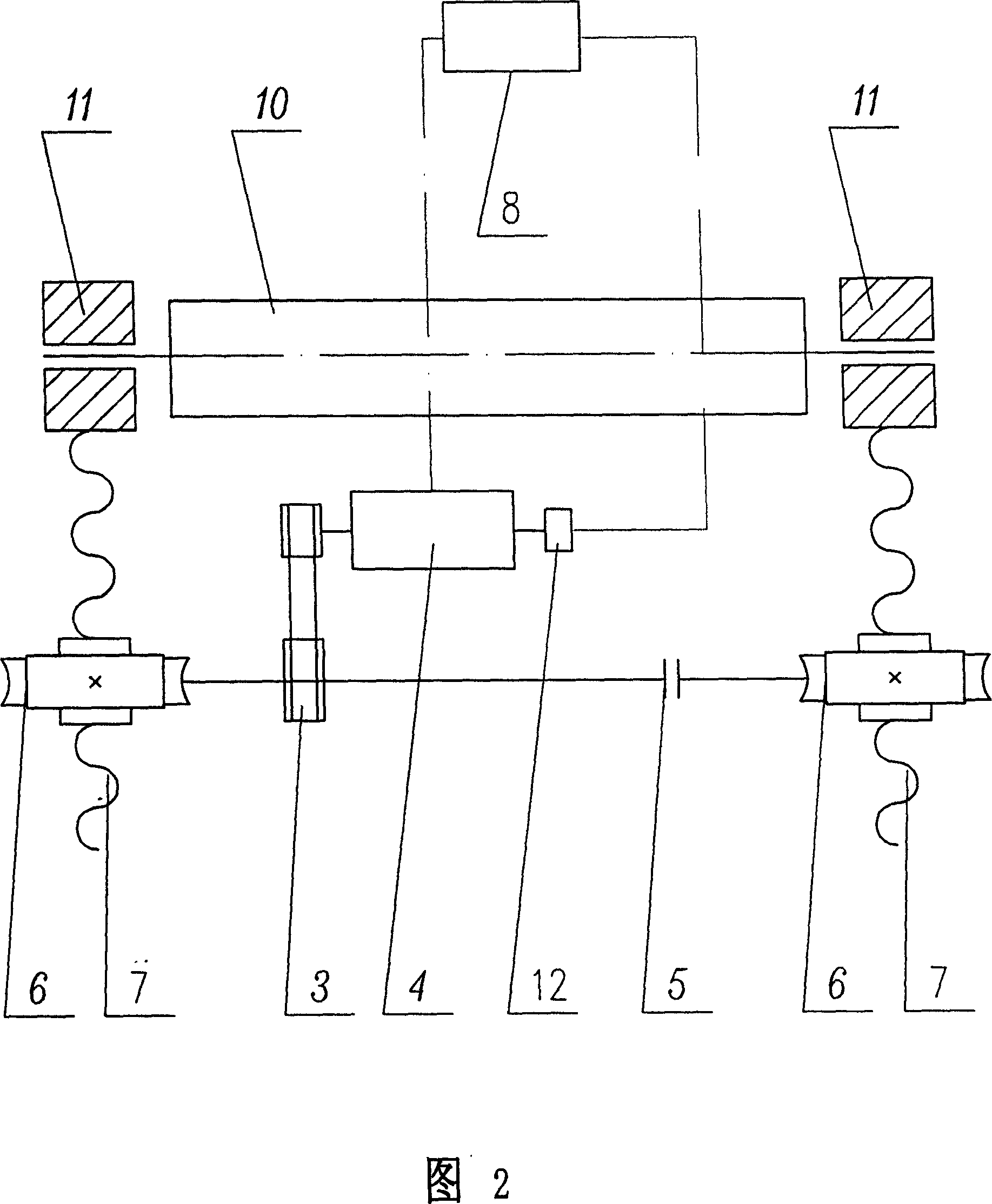

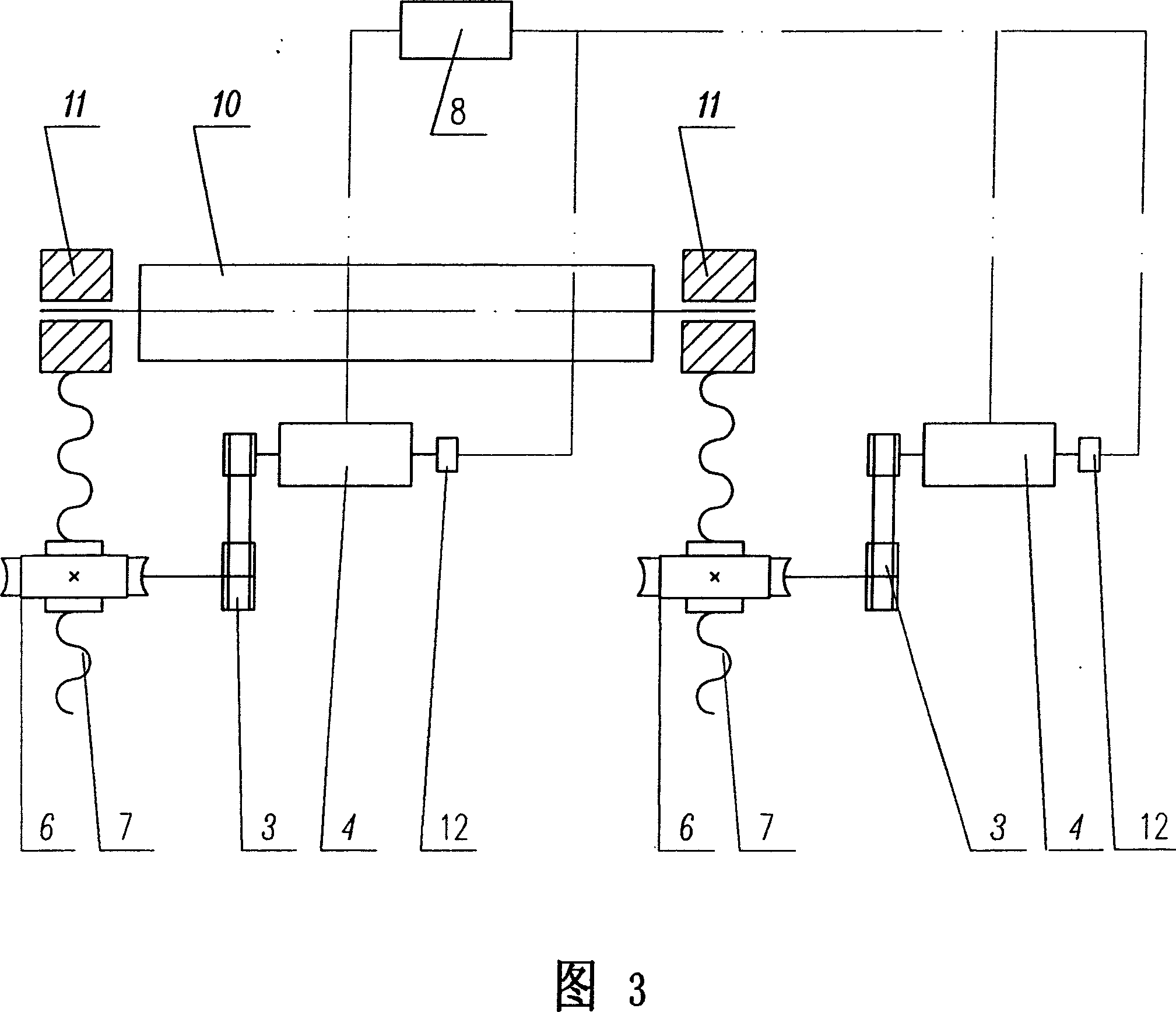

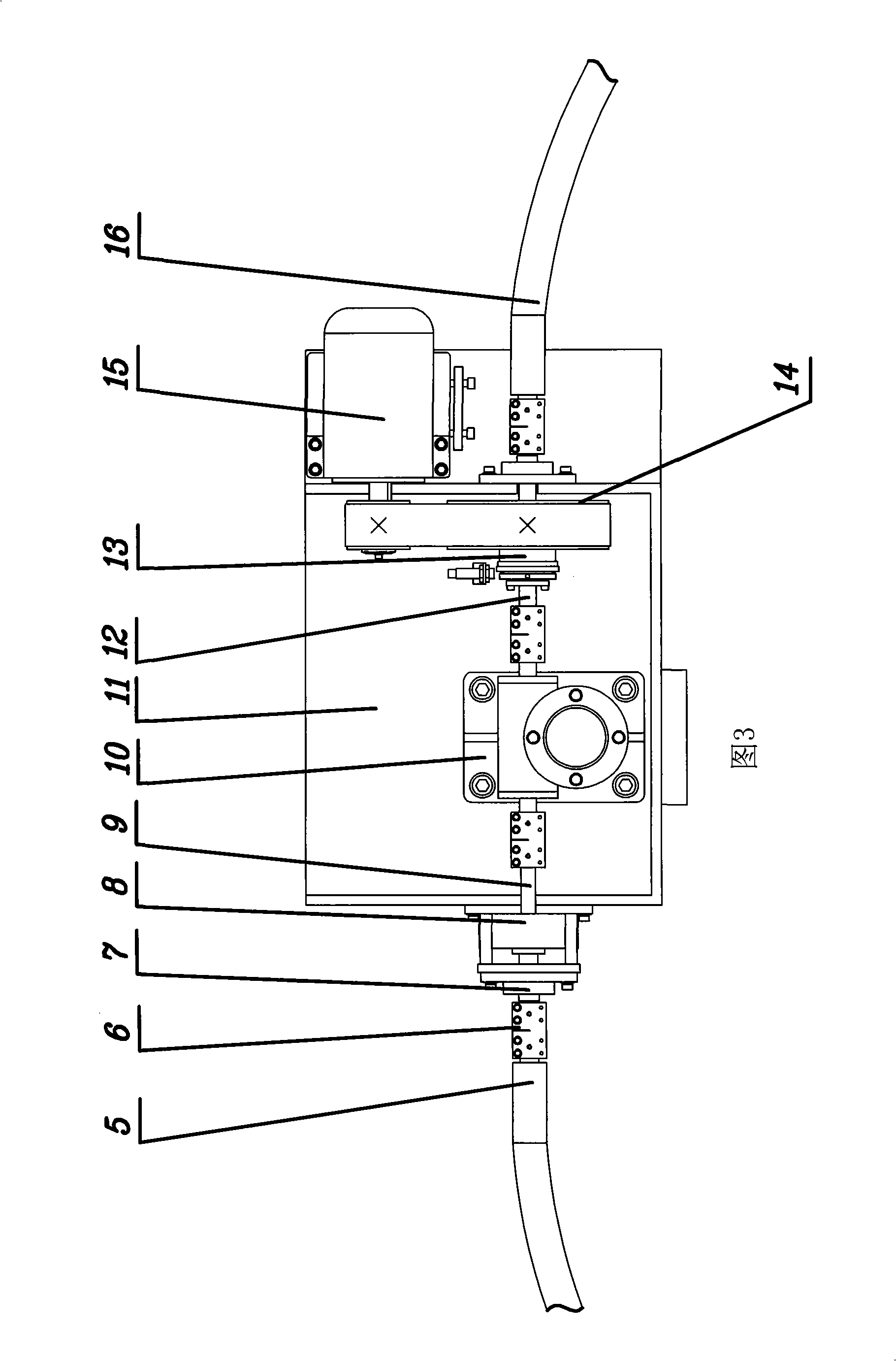

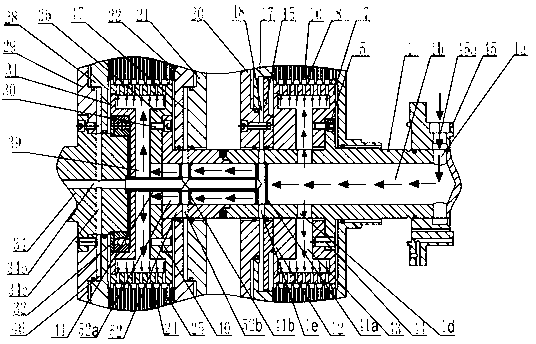

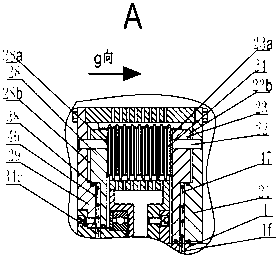

Vertical double-shaft four-cylinder electro-hydraulic servo testing machine

InactiveCN1865910ARapid responseQuick change shockMaterial strength using tensile/compressive forcesControl systemElectro hydraulic

The vertical dual-shaft four-cylinder electrohydraulic servo testing machine comprises: a hydraulic pressure drive for dual-direction stress filed, a four-cylinder drive fit to any loading path, a differential close-loop servo system, a function generator fit to different waves, a position transfer device fit to assemble the test piece, a guide plate and linear rail to ensure co-shaft and avoid bending. This invention is very convenient.

Owner:TSINGHUA UNIV +1

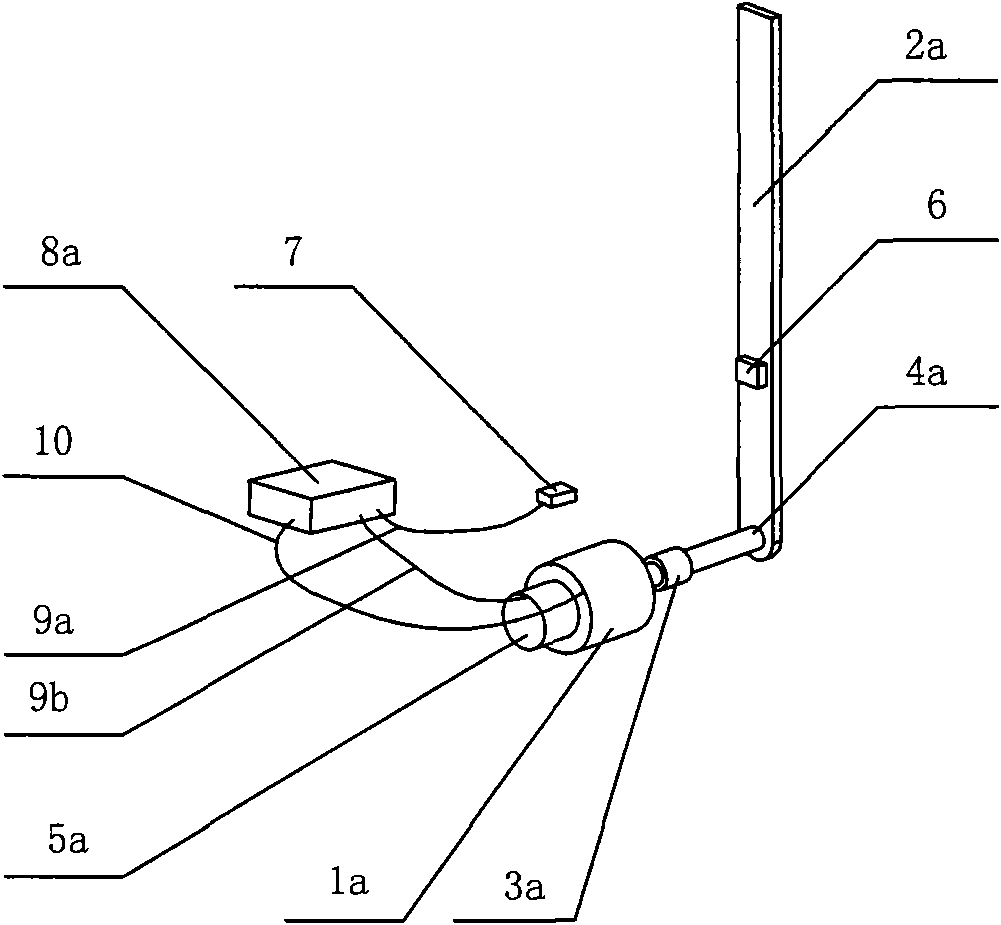

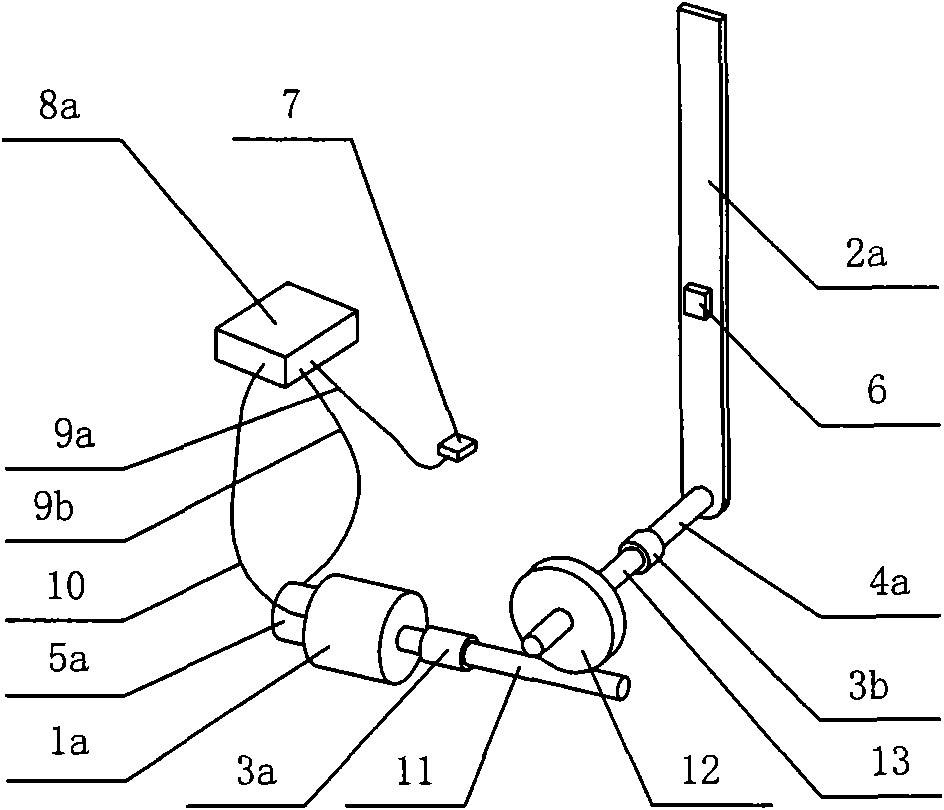

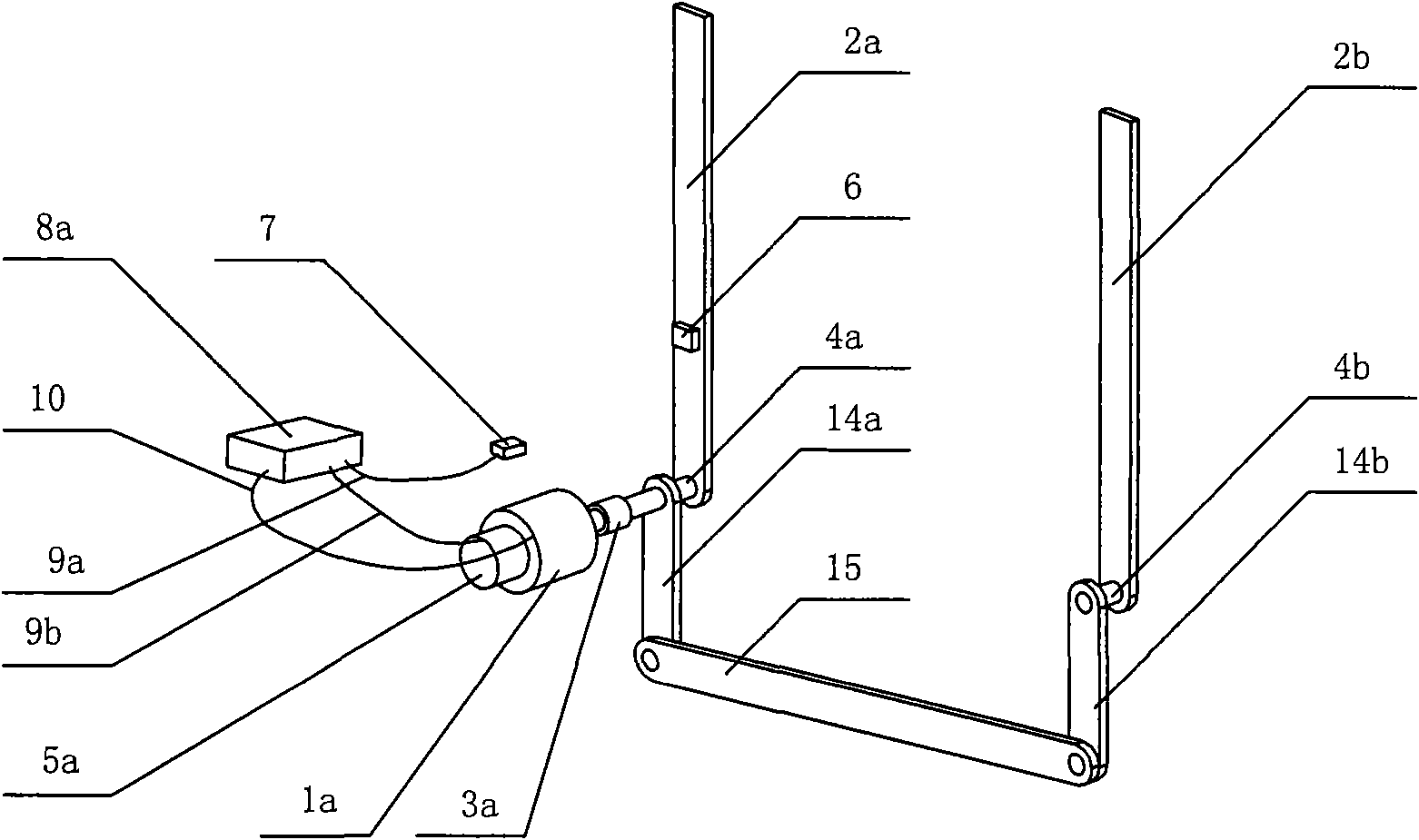

Electric windshield wiper of automobile and control method thereof

InactiveCN101875342ASimple mechanical structureExtended service lifeProgramme controlComputer controlWindscreen wiperMotor shaft

The invention relates to an electric windshield wiper of automobile and a control method thereof; the electric windshield wiper of automobile comprises a first servo motor and a first wiper arm; the output of the first servo motor is connected with the first wiper shaft through a first shaft joint; the first wiper shaft is provided with the first wiper arm; the first wiper arm swings along the rotation of the first wiper shaft; the motor shaft of the servo motor is provided with a first position detection device; the first wiper arm is provided with magnetic steel; a magnetic induction element is installed at the corresponding position on the automobile; the first position detection device and the magnetic induction element transmit the detected position signal to a first servo controller; and the first servo controller controls the first servo motor and drives the first wiper arm to swing. The electric windshield wiper has simple structure and low cost, and screen wiper can swing discretionarily between 0 and 180 degrees with the protection function of stopping rotating; the speed can be adjusted without level, and the electric windshield wiper has high reliability and long service life.

Owner:HANGZHOU SES MACHINERY

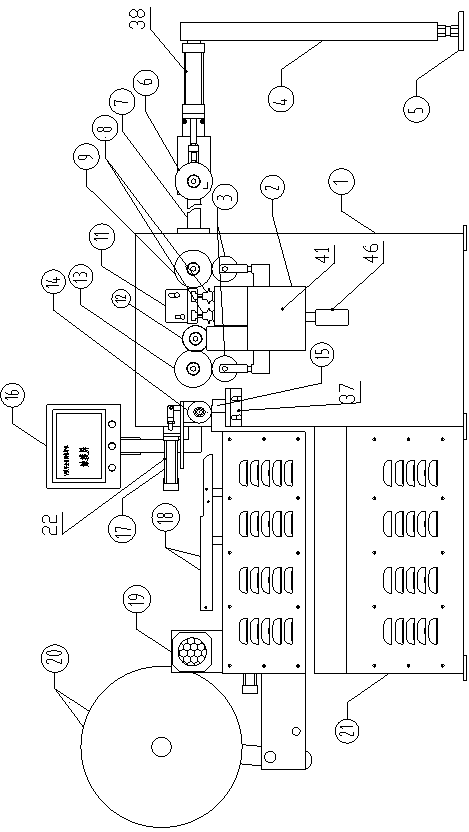

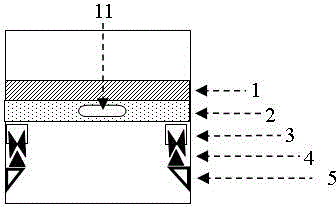

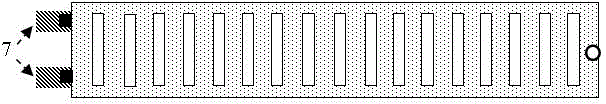

Digital full-automatic V-belt wrapping machine

InactiveCN103963327ANo difference in proficiencyReduce physical laborBeltsEngineeringMechanical engineering

The invention discloses a digital full-automatic V-belt wrapping machine which comprises a case; a feeding box is connected with the left side of the case; two cloth distribution scrolls, two guiding-open devices and two cloth guiding grooves are sequentially connected onto the feeding box from left to right; an automatic cut-off assembly and machine heads are sequentially connected onto the case from left to right; a tensioning assembly is connected with the right side of the case; the two cloth distribution scrolls, the two guiding-open devices and the two cloth guiding grooves are respectively arranged in parallel; the automatic cut-off assembly comprises a blade fixing seat, a long blade, a cut-off air cylinder and a disk blade; the long blade is fixedly connected onto the blade fixing seat; the disk blade is connected onto the cut-off air cylinder; the cut-off air cylinder is horizontally arranged; the limiting position of the disk blade in moving right is above the long blade. The digital full-automatic V-belt wrapping machine has the advantages that manual labor is reduced, the production efficiency is improved, the new worker training is eliminated, the proficiency and the working efficiency of new workers and veteran workers make no difference at all, and one worker can operate two machines when a long belt is processed.

Owner:要银安

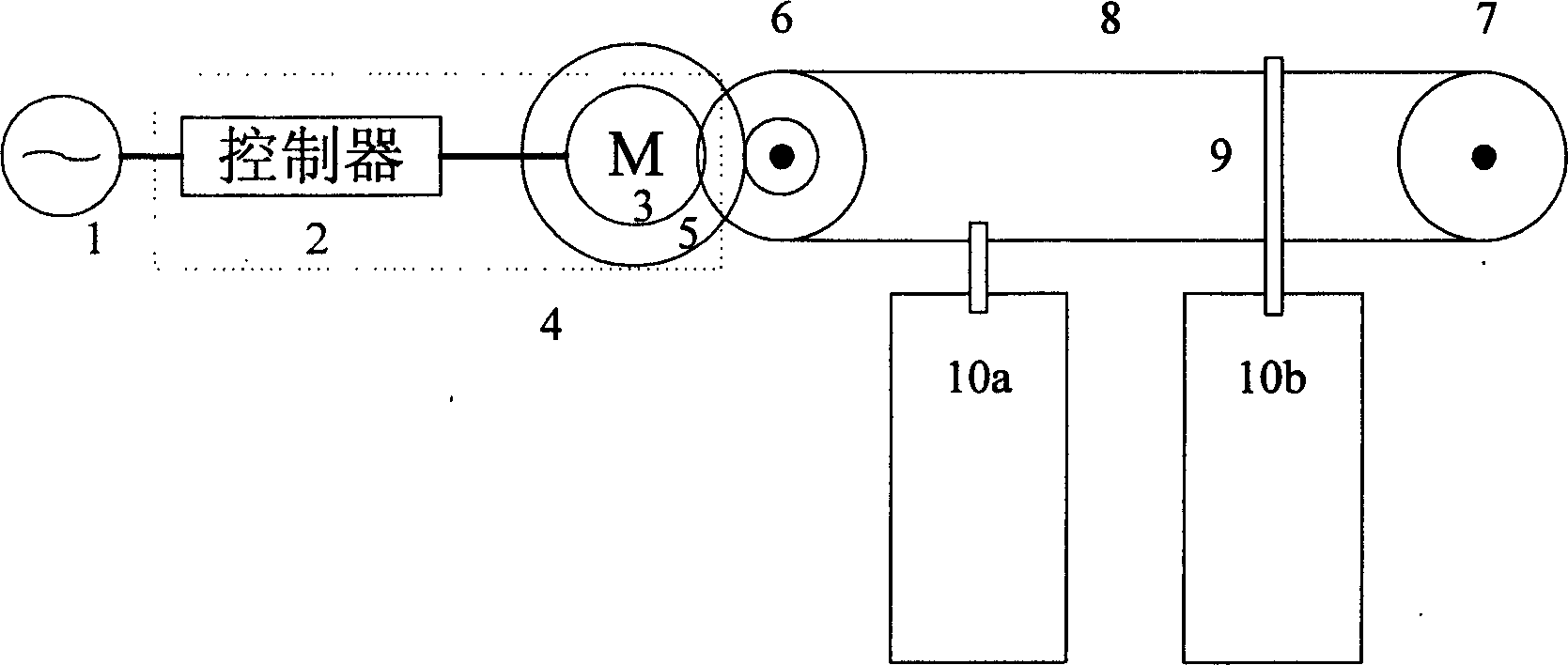

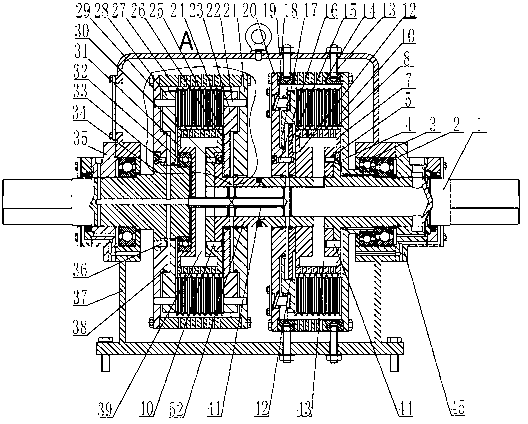

Gear free elevator door driving device with permanent-magnet synchronous motor

InactiveCN1907832AConvenient speed adjustmentWide speed rangeBuilding liftsMotor speedSynchronous motor

The invention relates to a device for controlling the open and close of lifter door, especially a lifter door switch controller with non-gear speed reducer, wherein the controller via the rotor position signal output by the increment coder or other position sensor uses the spatial voltage vector impulse modulation (SVPWM) frequency-variable speed adjustment, to control the magnetic-permanent synchronous motor, to generate stable electromagnetic torque, to flexibly and smoothly adjust the size and direction of motor speed in large range; and said controller uses the position signal to find the position and speed of lifter door, to switch the lifter door, via preset smooth speed curvature. The inventive driver has high efficiency, low cost, and non-gear speed reducer.

Owner:TIANJIN UNIV

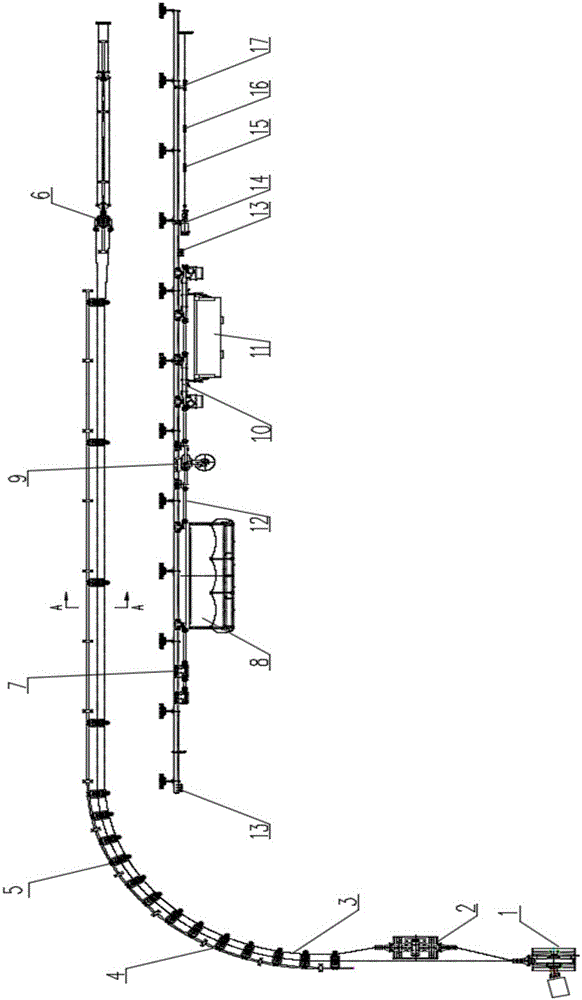

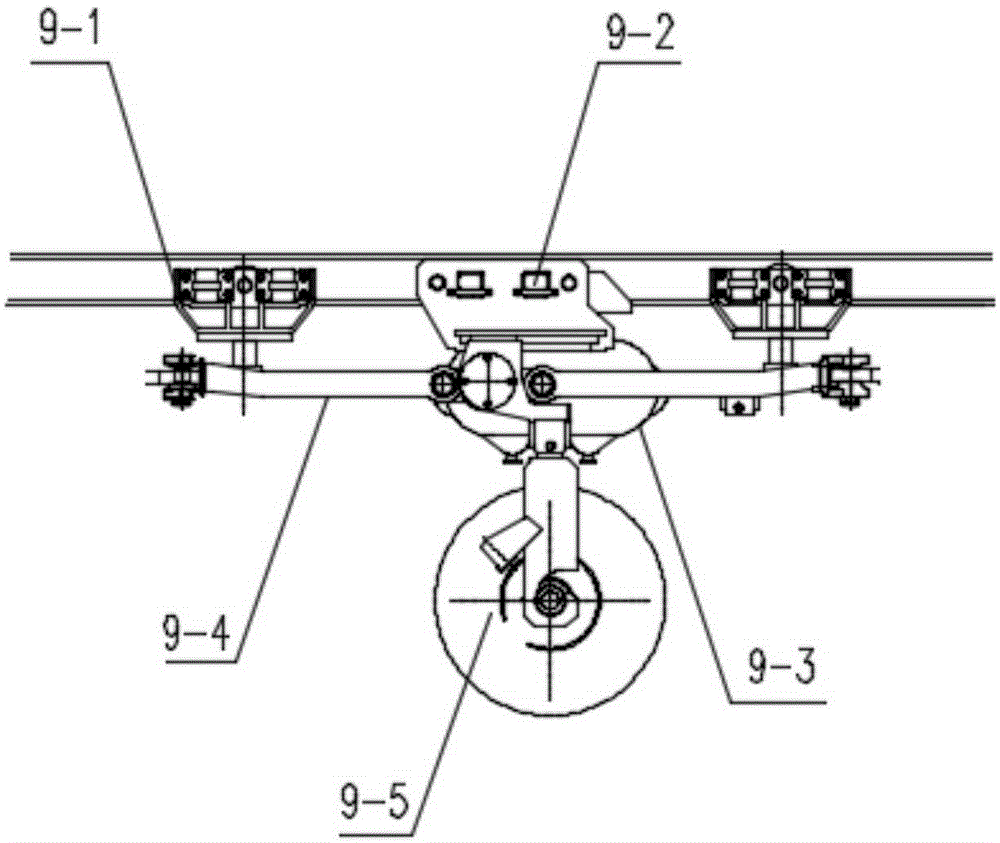

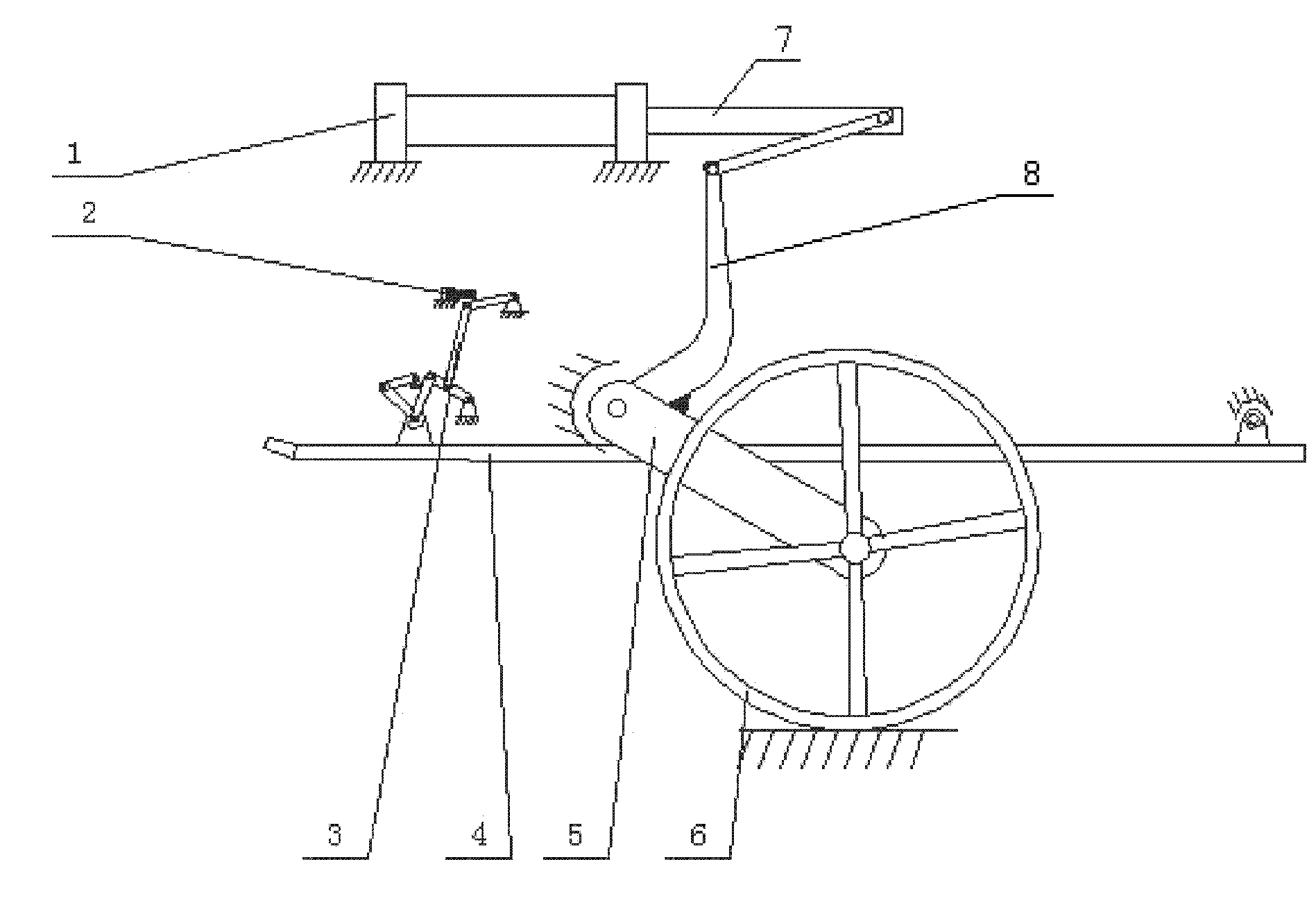

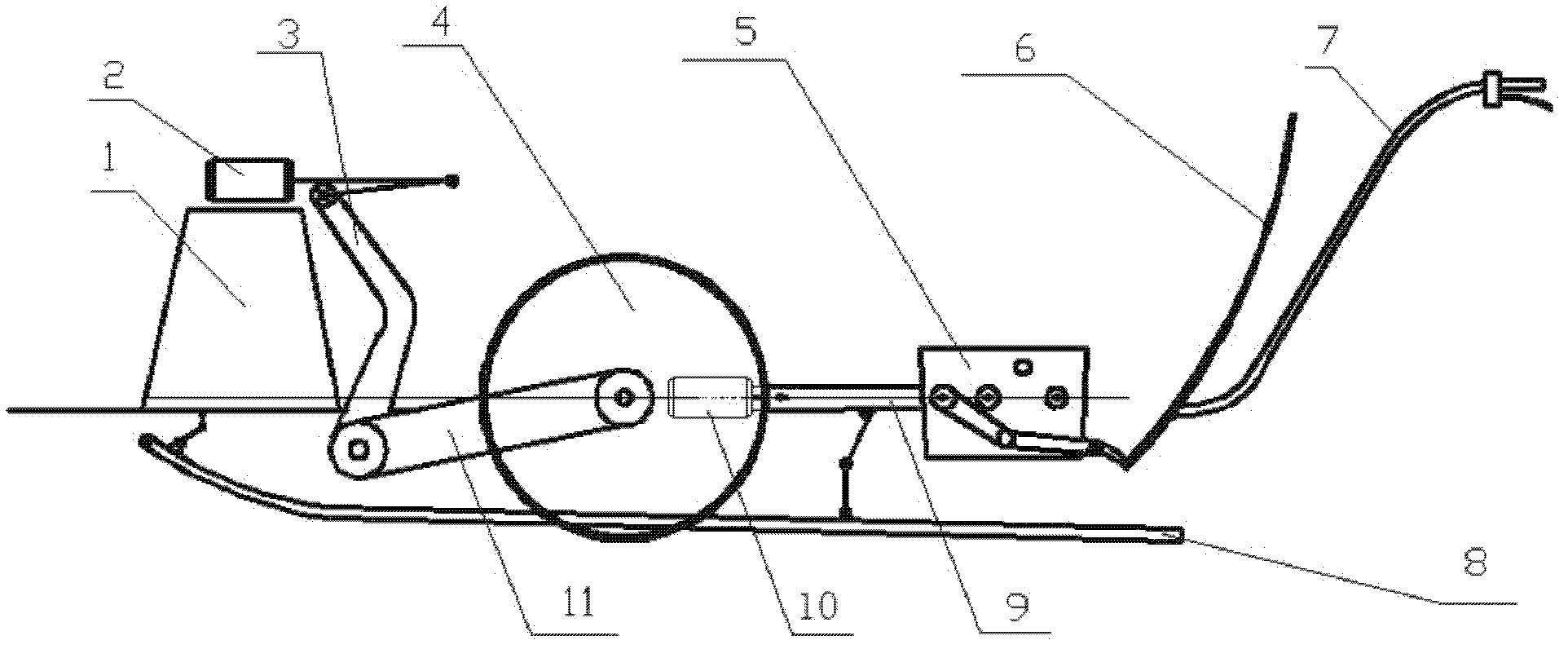

Monorail crane transportation system pulled by steel wire rope of hydraulic winch

InactiveCN105174053ARealize continuous transportationEasy constructionEarth drilling and miningUnderground transportTowerWinch

The invention discloses a monorail crane transportation system pulled by a steel wire rope of a hydraulic winch. The monorail crane transportation system comprises a suspended rail, a steel wire rope, the hydraulic winch, a tensioning tower, a rotary station, a tractor, a braking vehicle, a manual vehicle and a hoisting beam, wherein the steel wire rope penetrates through the hydraulic winch and the tensioning tower and penetrates through wheel guide frames and the rotary station to form a closed endless rope; the head and tail parts of the steel wire rope are fixedly connected with the tractor; in a transportation process, a monorail crane is pulled and controlled by the steel wire rope to operate; the braking vehicle, the manual vehicle, the tractor and the hoisting beam are suspended on the suspended rail and are in sliding connection with the suspended rail; the tractor is connected with the manual vehicle and the hoisting beam respectively through pull rods; and the manual vehicle is connected with the braking vehicle through a pull rod. The monorail crane transportation system is driven by the hydraulic winch, has a compact structure and a reasonable layout and is simple to operate, and the speed is convenient to regulate; endless speed regulation is realized, and transportation links and post workers are reduced; and security coefficients in the transportation process are improved.

Owner:徐州华东机械有限公司

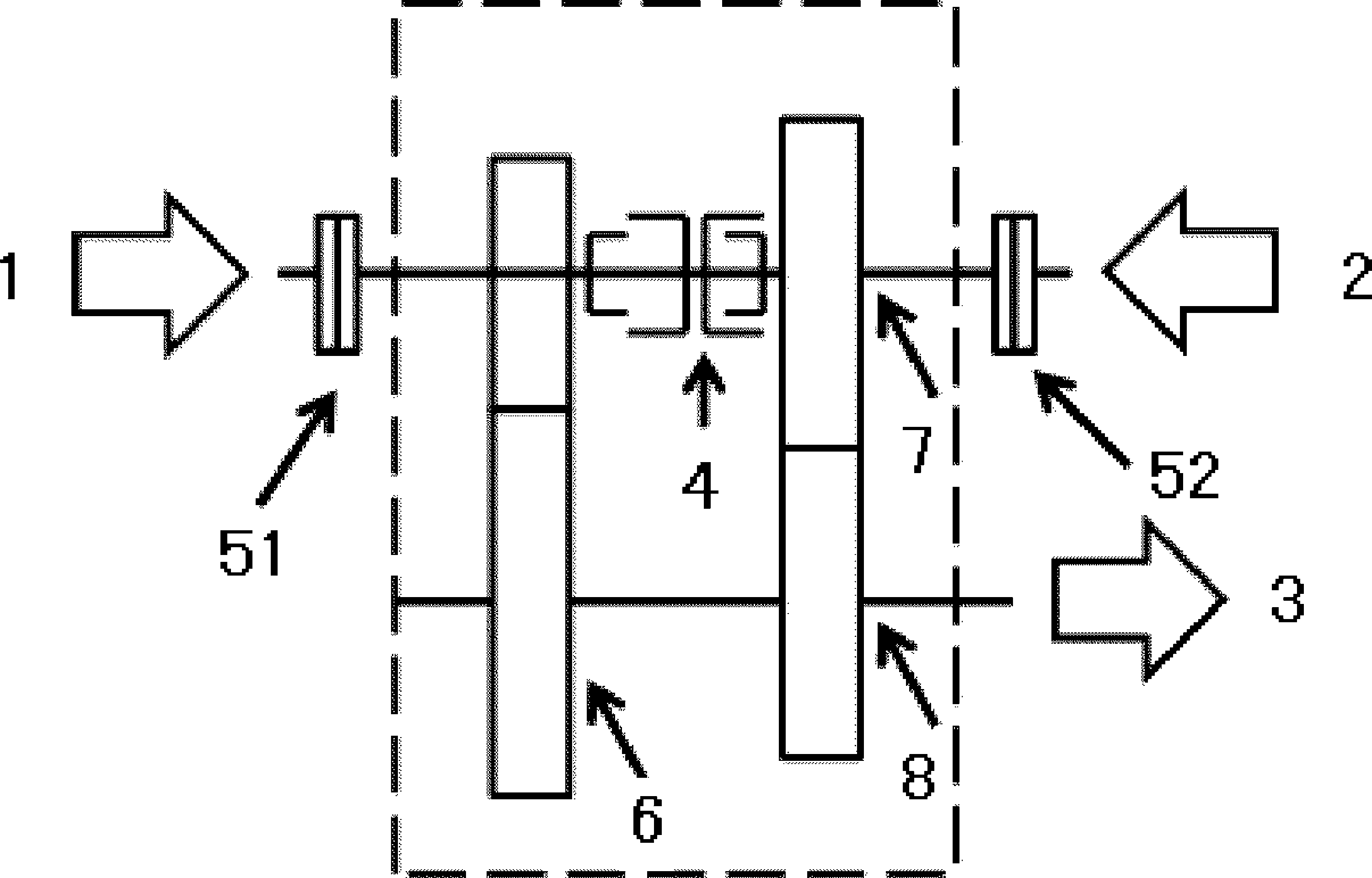

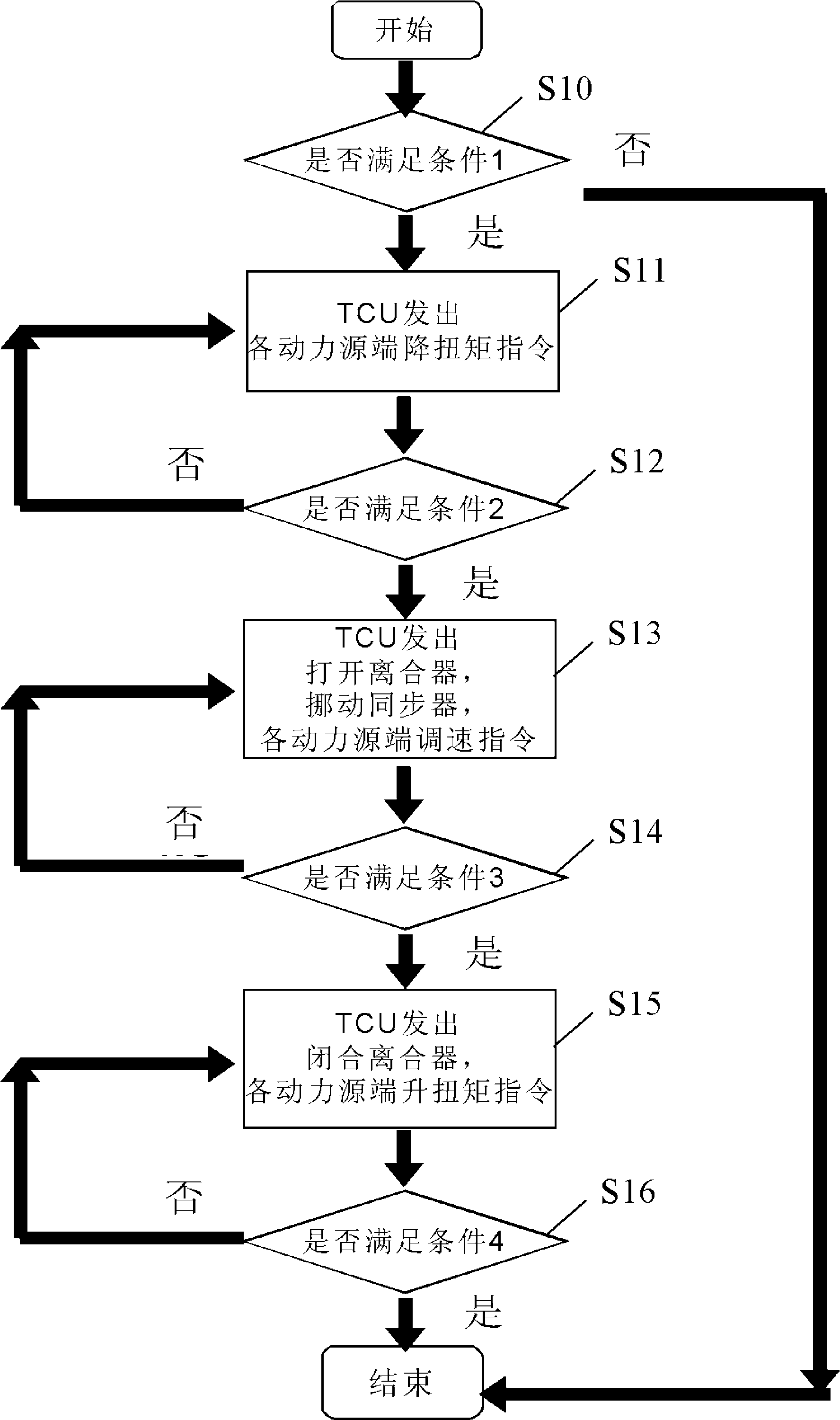

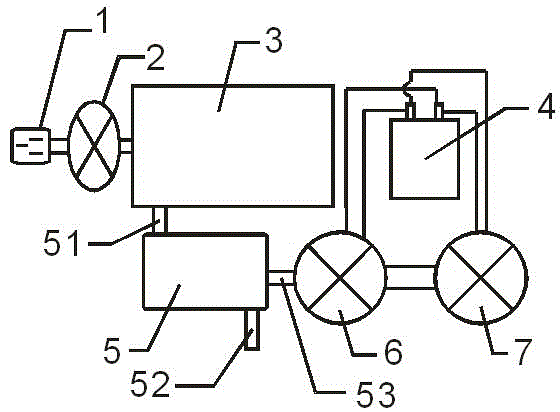

Multi-power-source coordinated control method used during gear shifting of hybrid electric vehicle

InactiveCN104118421AOptimize lifting torqueConvenient speed adjustmentHybrid vehiclesPlural diverse prime-mover propulsion mountingClutchEngineering

A multi-power source coordinated control method in the gear shifting process of a hybrid automobile; the power of each power source is respectively coupled to a gearbox input shaft (7) via respective clutches (51, 52) of a first power source end (1) and a second power source end (2), and is transferred to a constant meshing gear (6) of a corresponding gear via a synchronizer (4), and then transferred to the vehicle wheels through a gearbox output shaft (8) and then through the gear. The method comprises the steps of: a TCU receives a signal instruction of a gear required by the automobile; transmitting a torque reduction instruction to each power source and determining whether the torque is reduced to be within a target torque range; transmitting instructions for clutch release and synchronizer moving, and for each power source end to adjust speed; when determining that the synchronizer is in place and each power source end has completed speed adjustment, transmitting instructions for clutch engagement, and for each power source end to increase torque, and determining whether the torque is increased to be within a target torque range, thus completing gear shifting. The present invention subdivides torque control at each control stage in a gear shifting process, optimizes torque increase and reduction by each power source, and avoids jerking and bumping caused by inconsistency or rapid change of torque.

Owner:SAIC MOTOR

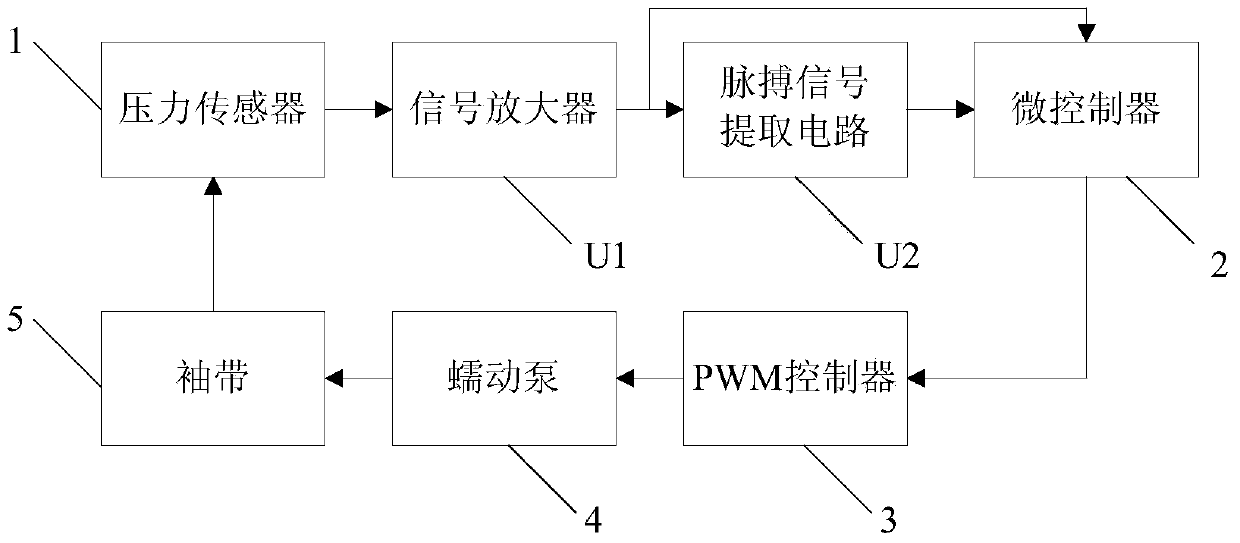

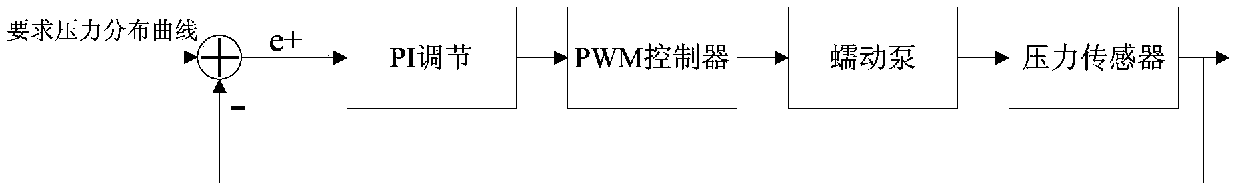

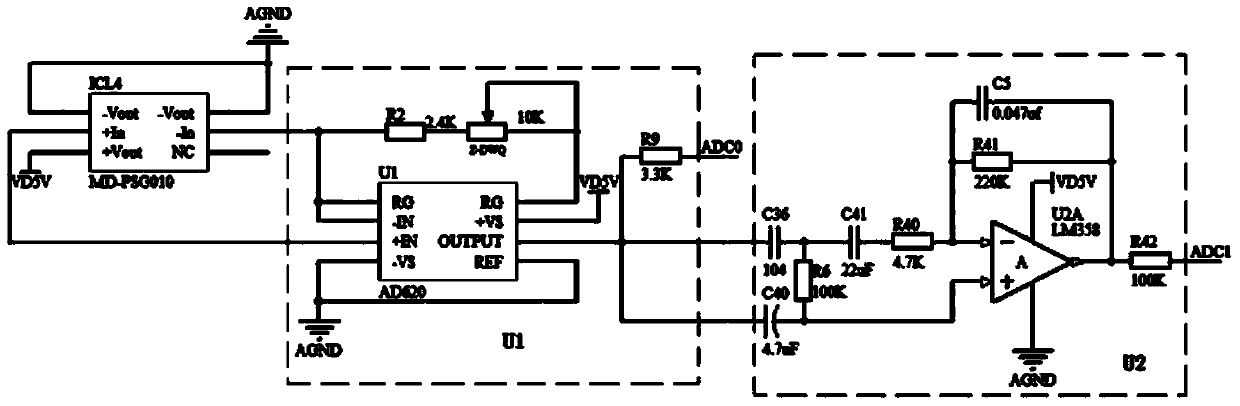

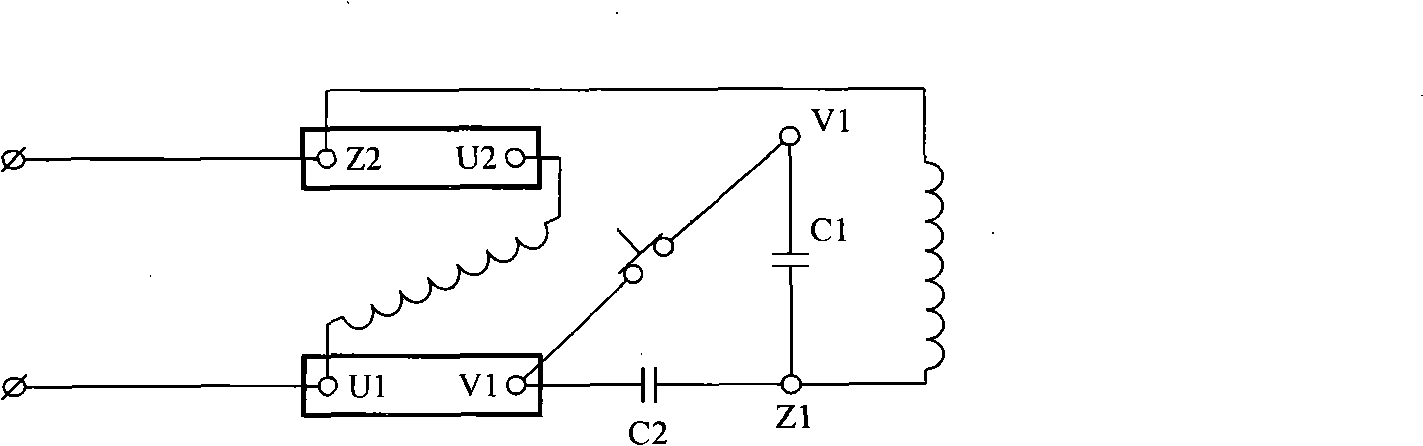

Pressure control circuit and control method for blood pressure measurement

The invention relates to a pressure control circuit and control method for blood pressure measurement. The control circuit comprises a pressure sensor, a signal processing circuit, a microcontroller, a PWM (pulse-width modulation) controller and a peristaltic pump. The pressure sensor is connected with the input end of the signal processing circuit, the output end of the signal processing circuit is connected with the input end of the microcontroller, the output end of the microcontroller is connected with the input end of the PWM controller, and the output end of the PWM controller is connected with the peristaltic pump; the pressure sensor collects mixed signals of pressure and pulse waves, the signal processing circuit receives the mixed signals and has the same processed to acquire pressure feedback signals and pulse wave signals, the pressure feedback signals and the pulse wave signals are sent to the microcontroller, and the microcontroller sends control signals to the PWM controller after being subjected to comparison and PI adjustment, the PWM controllers sends out the PWM signals with the corresponding pulse width to complete control of the peristaltic pump. Compared with the prior art, the pressure control circuit and control method has the advantages that the pressure can be effectively controlled to change uniformly during measurement, and measurement precision is improved.

Owner:SHANGHAI UNIV OF ENG SCI

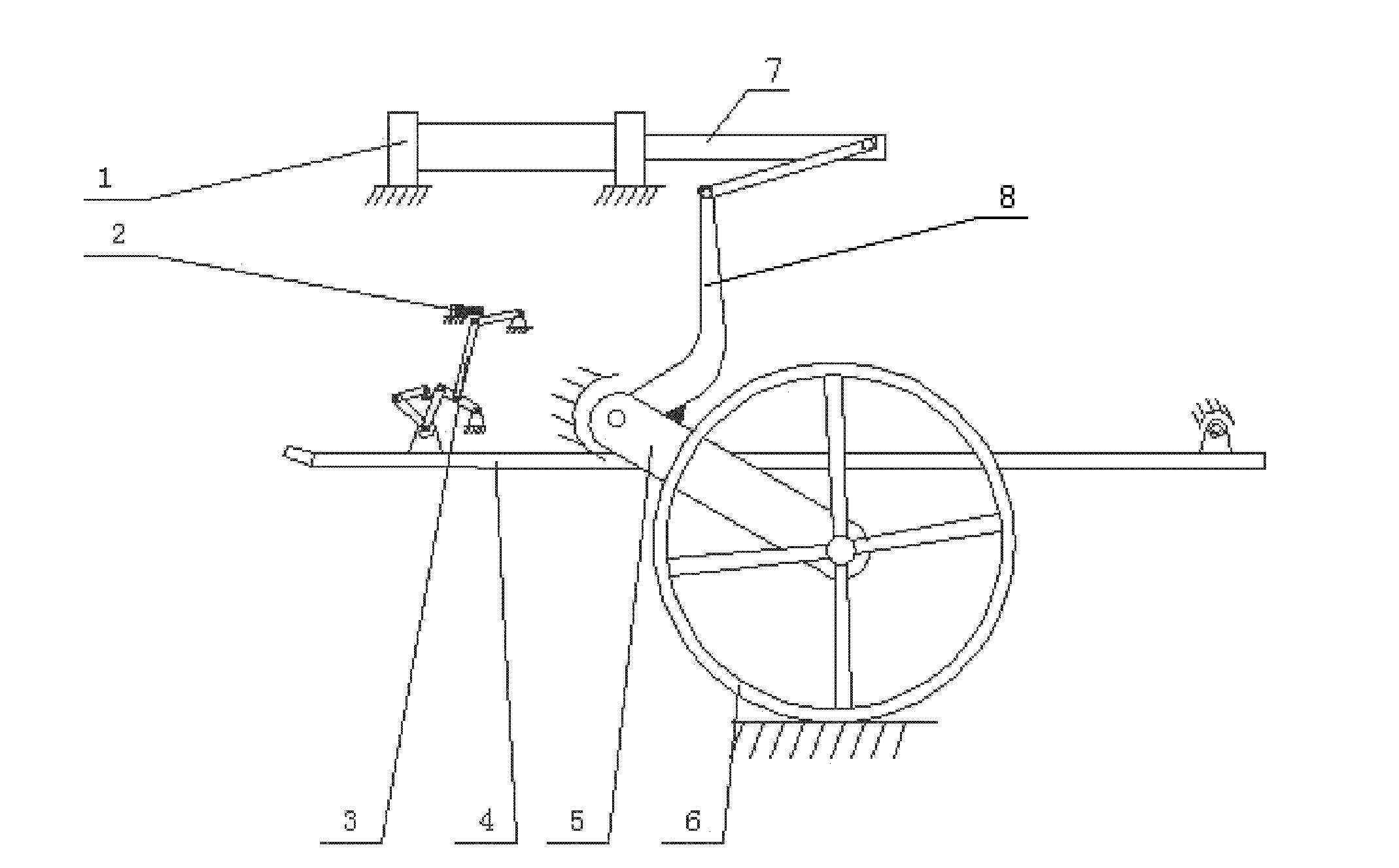

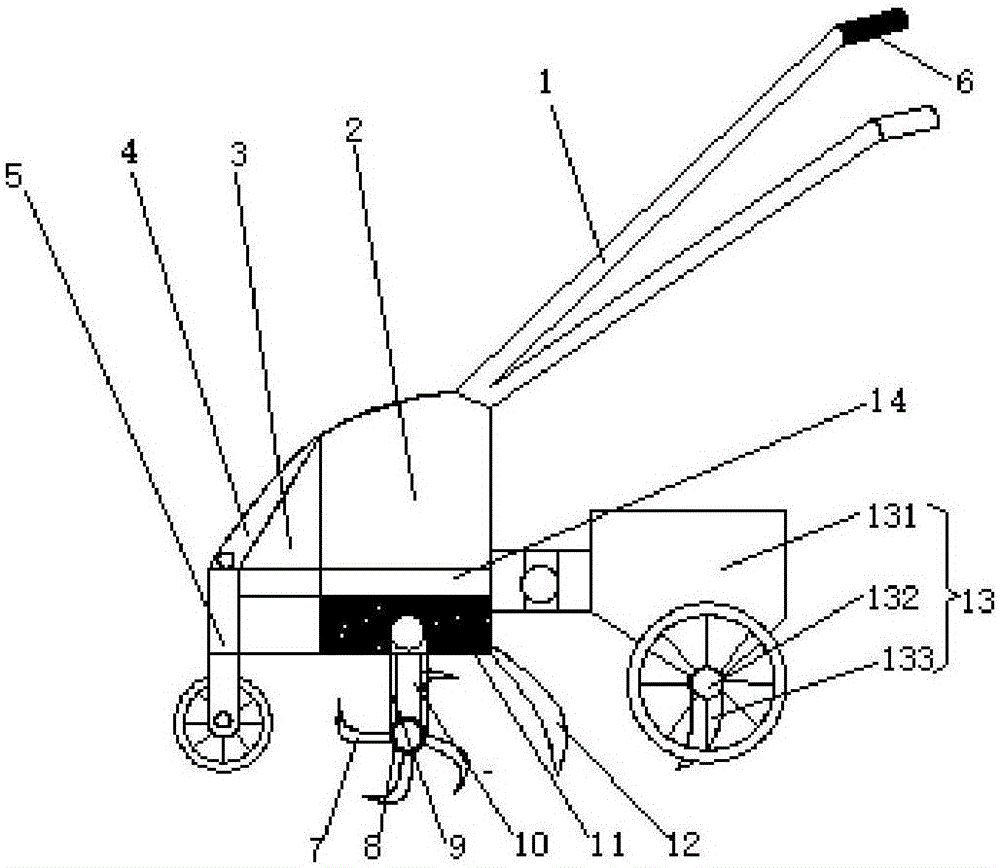

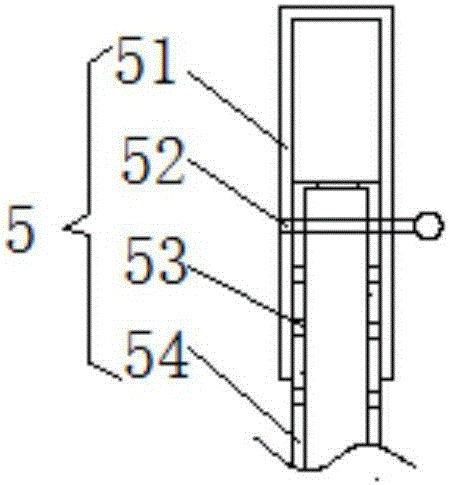

Electric profiling mechanisms of paddy rice transplanter

InactiveCN102487643AConvenient speed adjustmentGood power controlTransplantingKnowledge FieldSelf locking

The invention discloses electric profiling mechanisms of a paddy rice transplanter. The invention relates to the field of paddy rice transplanter apparatus researches. Existing hydraulic profiling mechanisms of double-wheel 4-row automatic paddy rice transplanters have problems such as complicated mechanism and low efficiency. Also, existing hydraulic profiling mechanisms can not be adapted to complicated paddy field environments with deep mud. The profiling mechanisms provided by the invention are based on an electric paddy rice transplanter. A left profiling mechanism and a right profiling mechanism are independently driven by 2 motors, such that the transplanters can keep balanced with a mud surface in a paddy field with an uneven hardground, and transplanting quality can be ensured. Profiling driving motors have a self locking function in a shut-down situation. For saving energy, the motors are in a standby state when not triggered. Also, a manual adjusting function is provided. Adriving mechanism of the mechanical hydraulic profiling mechanisms is simplified to a large extent, the volume of the transplanter is reduced, and the weight of the transplanter is reduced.

Owner:SOUTH CHINA AGRI UNIV

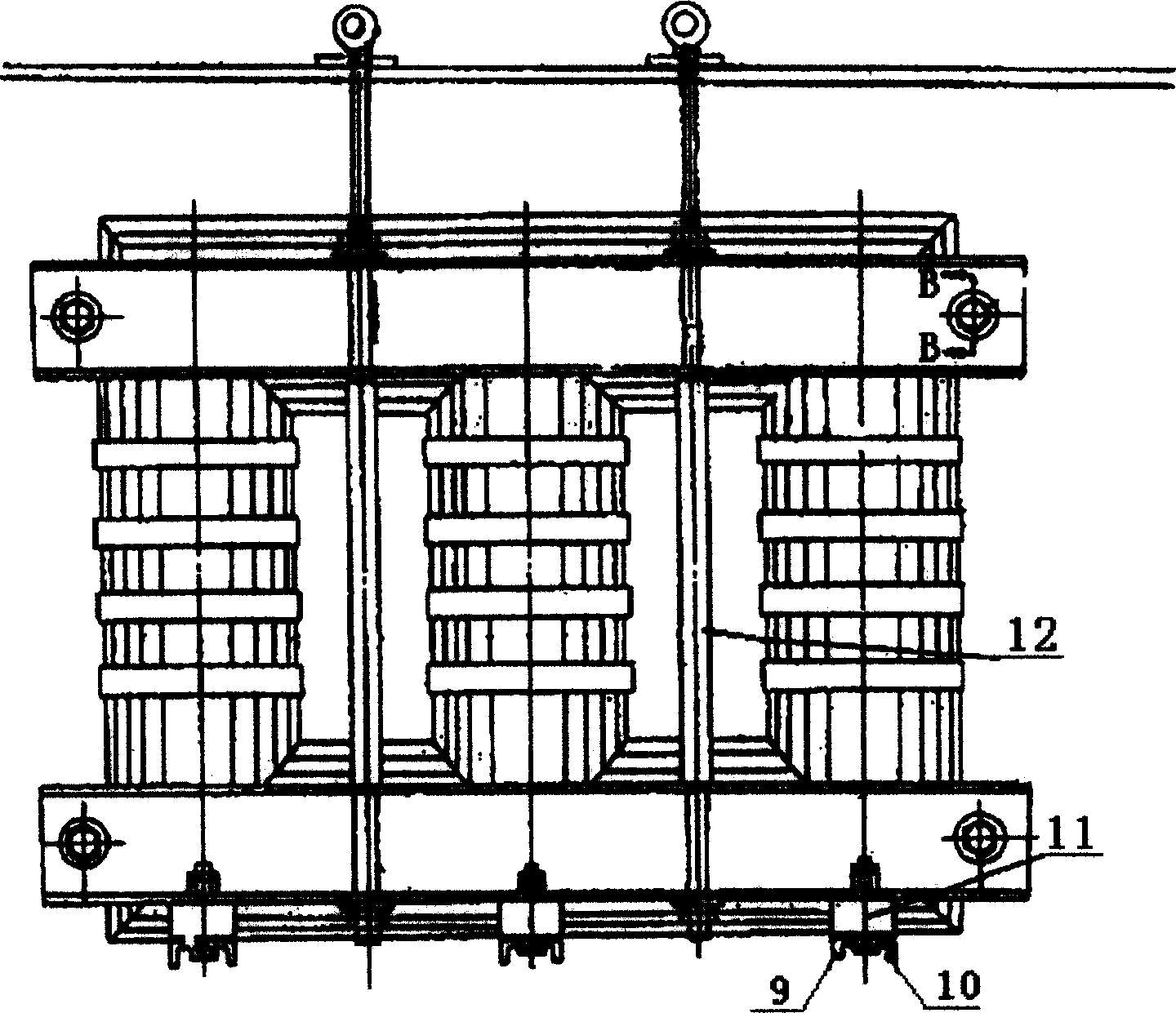

Offshore platform transformer

ActiveCN1758387AReduce lossHigh mechanical strengthTransformers/inductances coolingTransformers/inductances coils/windings/connectionsTransformerLow voltage

This invention relates to a transformer on a sea platform, in which, its winding is formed by multiple transposed conductors, longitudinal gas channels are set between high voltage coils, formation bracing strips are used to isolate the windings and the insulation tube to form axial gas channels, which are formed between low voltage coils and between coils and the high voltage tube, a top-blown cooling fan is set at the bottom of the coils, bracing plates are used to fix many places between a core post and the internal winding filled with insulation bars, the places between internal and external windings are fixed by bracing strips, an U-steel and a square iron are welded to an iron yoke, multiple pairs of screw rods are used to locate the top of the device and the shell and positions between the bottom of the device and the shell are fixed by foot screws and the side wall of the shell is welded with locating round bars.

Owner:北京新特电气有限公司

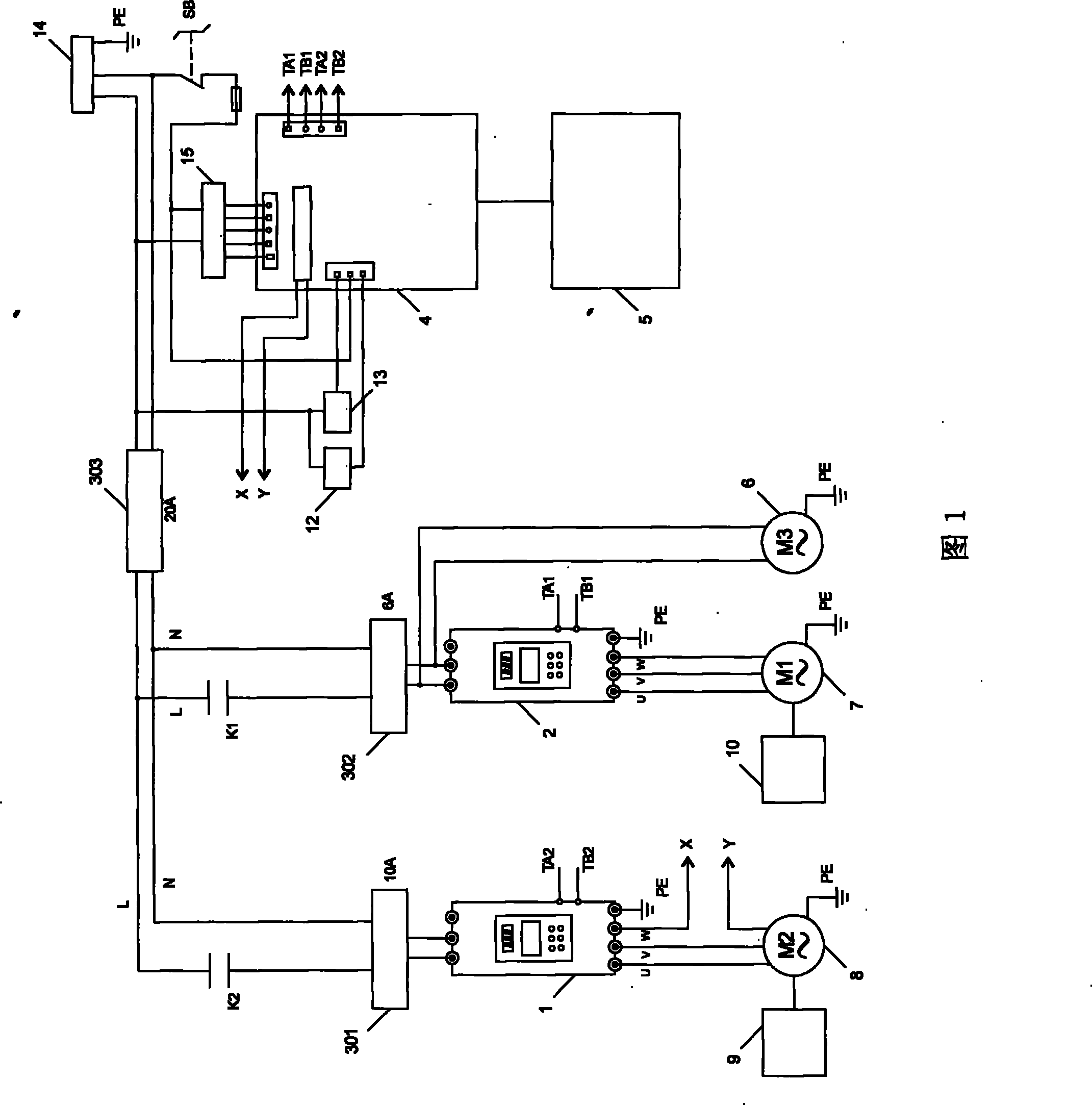

Multi-motor driven rice transplanting machine and control method thereof

The invention discloses a multi-motor driven rice transplanting machine and a control method thereof and belongs to the technical field of new energy agricultural machinery. By adopting power of storage batteries, the invention solves the problems of large size and weight, complicated transmission mechanism, inflexibility in control, high maintenance and running cost, pollutions of noise and waste gas, and the like of a traditional rice transplanter driven by an oil-fired engine; and not only are the above problems solved, but also travelling waterwheel driving motors, a profiling mechanism driving motor and a rice transplanting mechanism driving motor are controlled independently by a controller, so that the functions that the machine turns at a small radius, a profiling mechanism is standby in an energy-saving manner, the distances between transplanted seedlings can be adjusted in a wide range, and the like can be realized. The invention is suitable for China with the practical characteristics of vast population and limited farmland, shortage of energy, large agricultural acreage in mountainous areas and hills, disperse land masses and the like and meets the requirements of the national modern agriculture for novel rice transplanting machines.

Owner:SOUTH CHINA AGRI UNIV

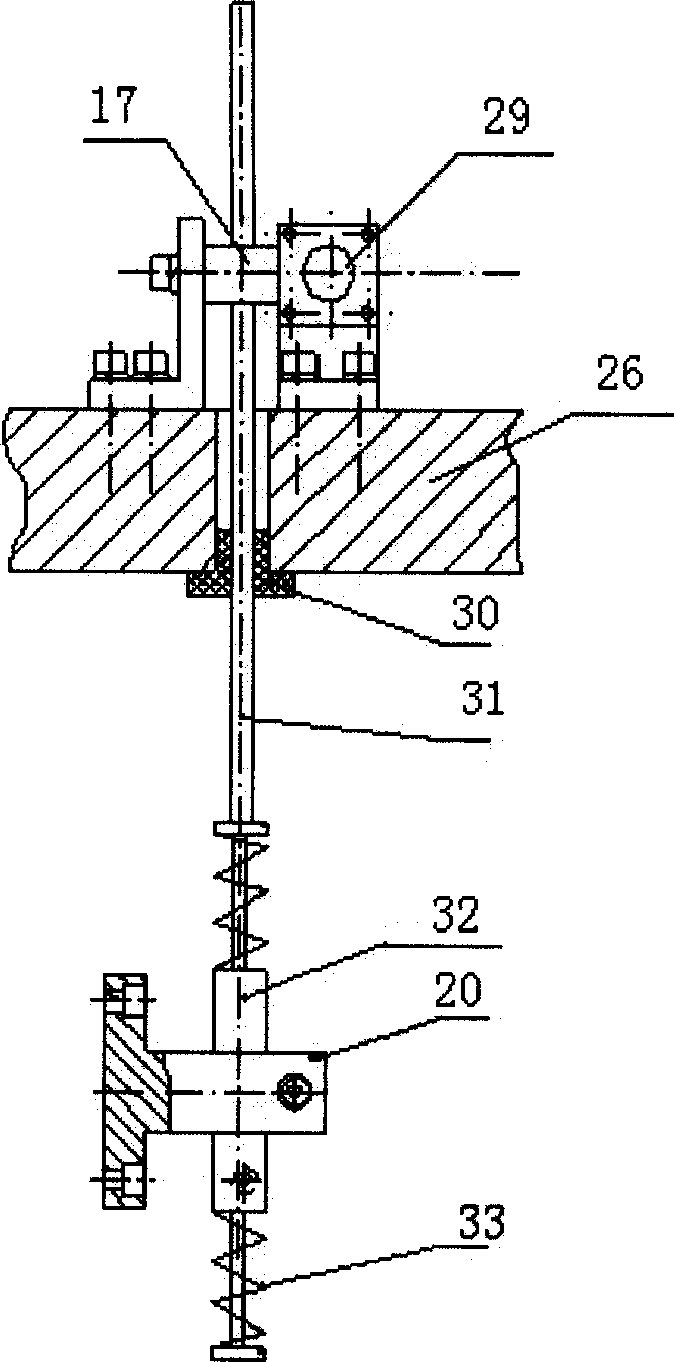

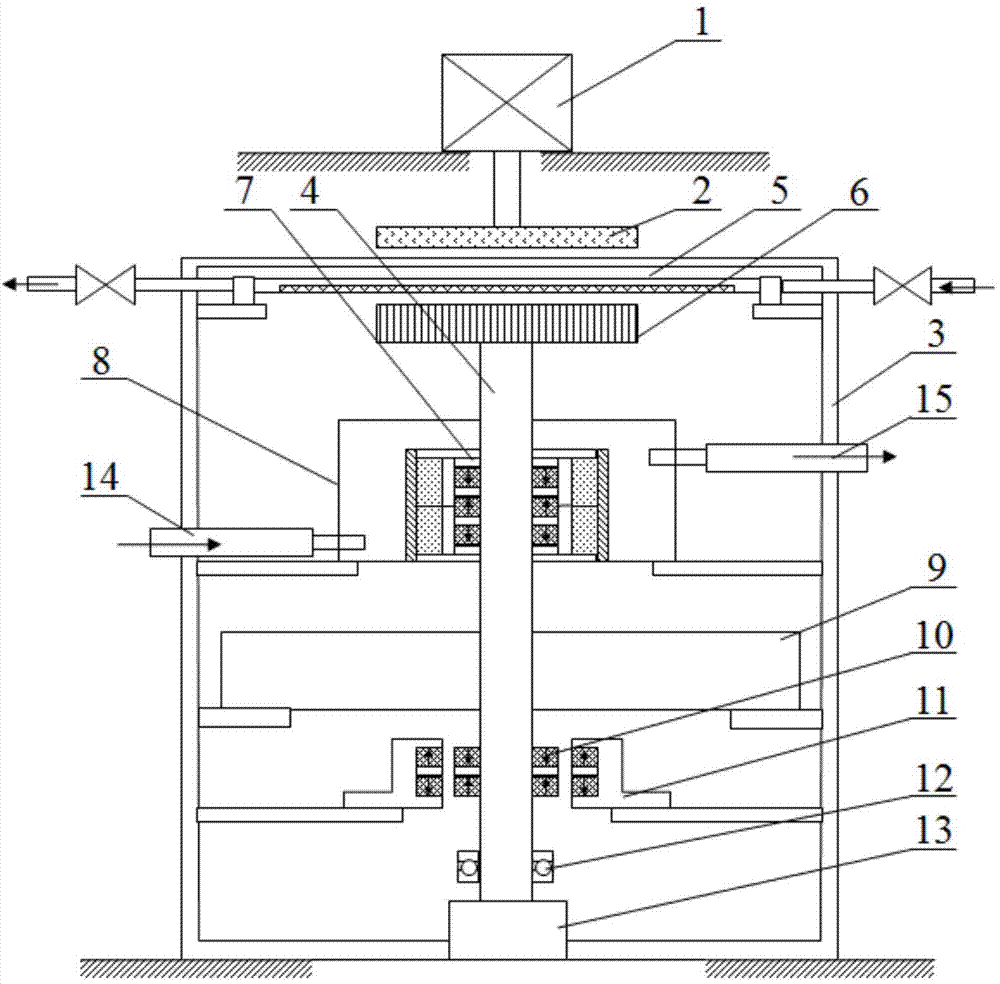

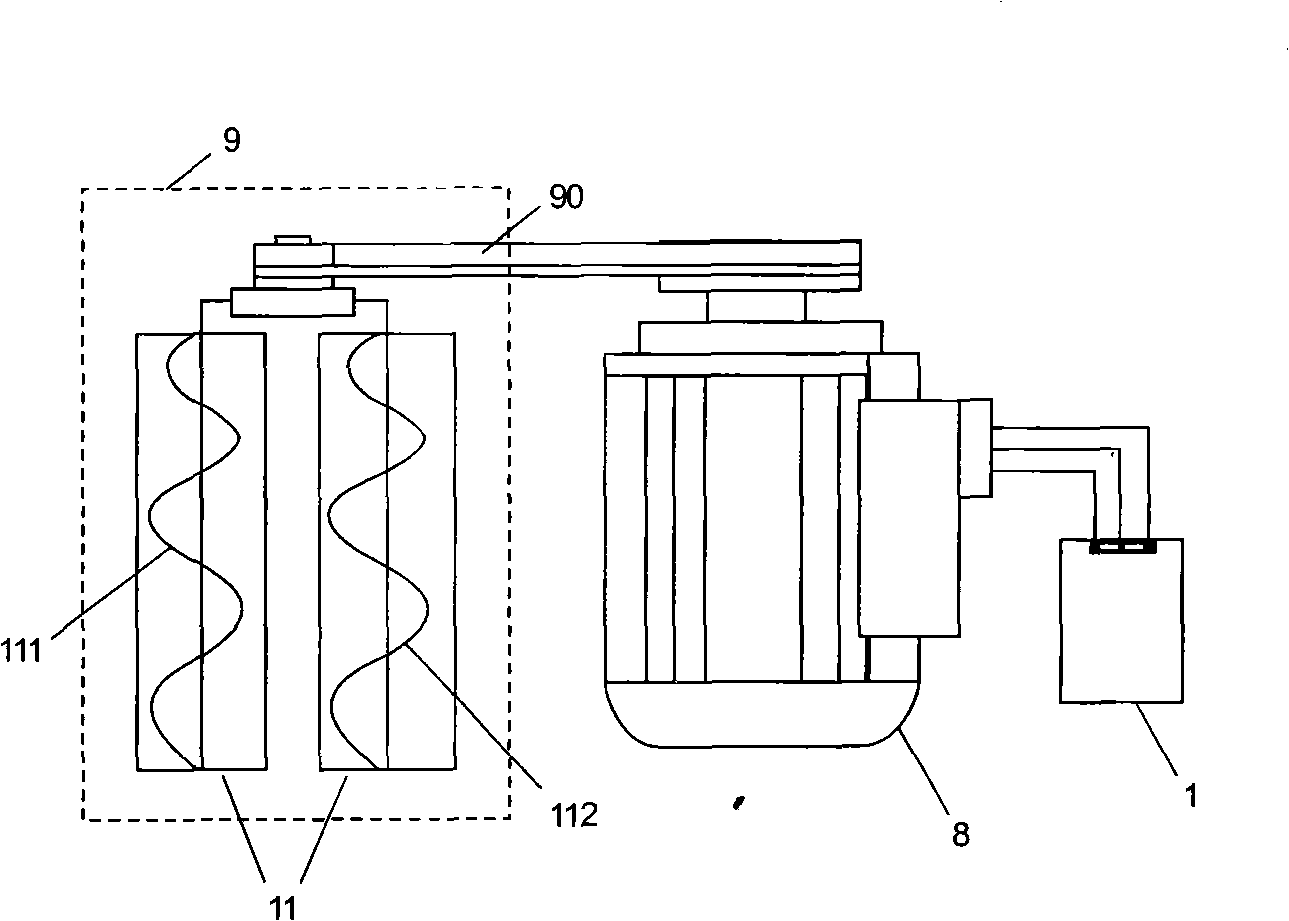

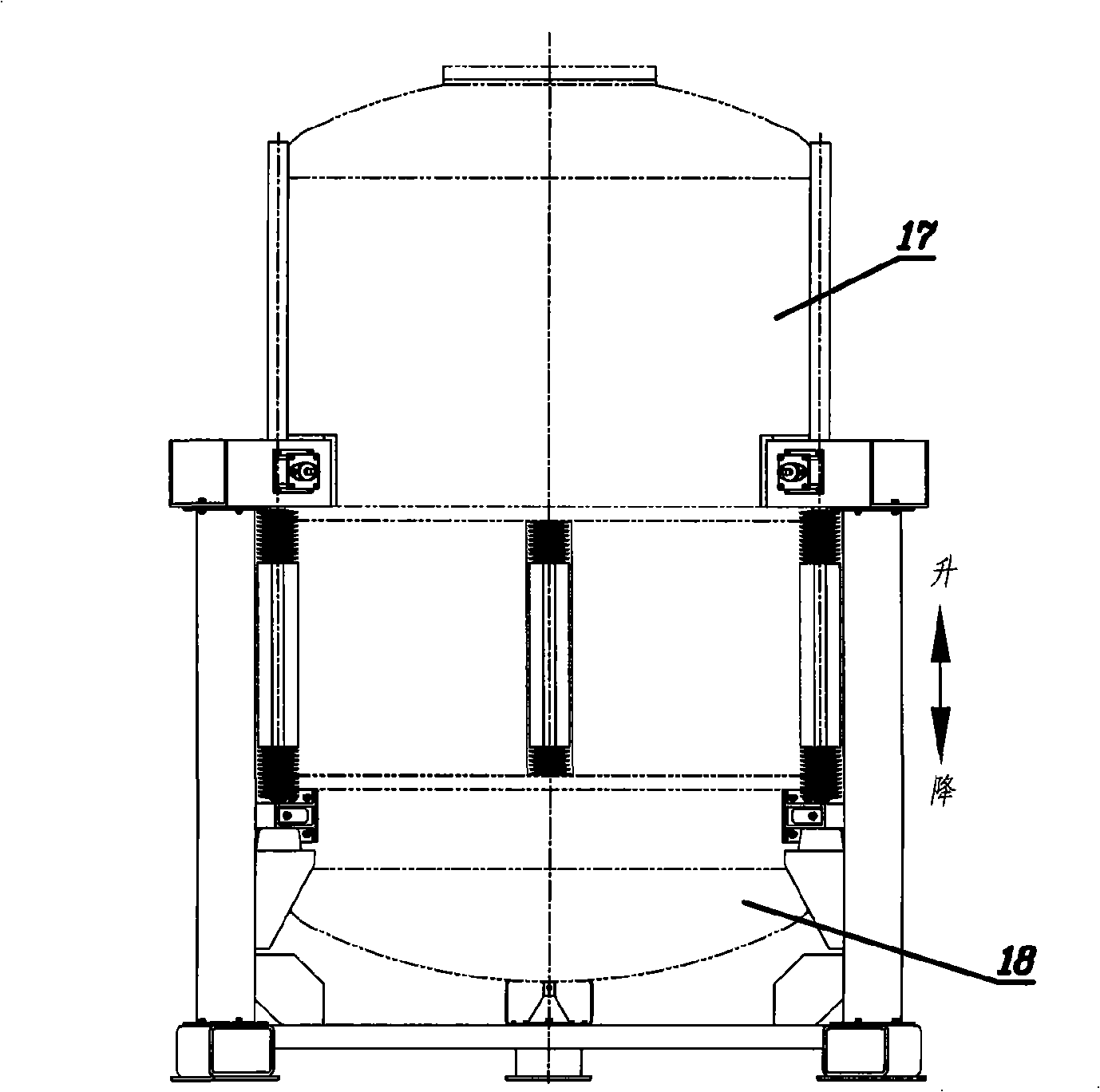

High-temperature superconductive flywheel energy storage system based on permanent magnetic drive

InactiveCN104734414AReduce no-load lossImprove system efficiencyMechanical energy handlingPermanent magnet rotorMagnetic field coupling

A high-temperature superconductive flywheel energy storage system based on permanent magnetic drive comprises a drive part, a superconductive magnetic shielding mechanism and an energy storage part. The drive part, the superconductive magnetic shielding mechanism and the energy storage part are vertically and sequentially arranged in the axial direction. The superconductive magnetic shielding mechanism and the energy storage part are located in a seal cavity (3), the drive part is located outside the seal cavity (3), and the energy storage part is isolated from the drive part. The seal cavity (3) can provide a vacuum environment for the energy storage part. The drive part provides energy for the energy storage part. The superconductive magnetic shielding mechanism is a switch starting or stopping energy input and enabling magnetic field coupling between a permanent magnet disc of the drive part and a metal disc of the energy storage part to be communicated or separated. The end face of the superconductive magnetic shielding mechanism keeps parallel and coaxial with the end face of the permanent magnet disc of the drive part and the metal disc of the energy storage part. The energy storage part stores energy transmitted by the drive part, and a high-temperature superconductive bearing of the energy storage part comprises a permanent magnet rotor and a superconductive stator.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

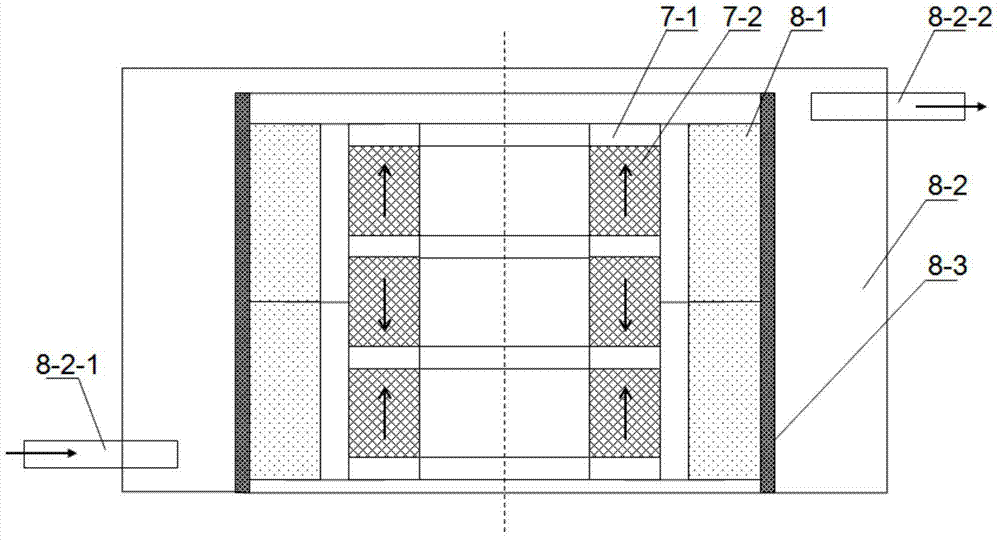

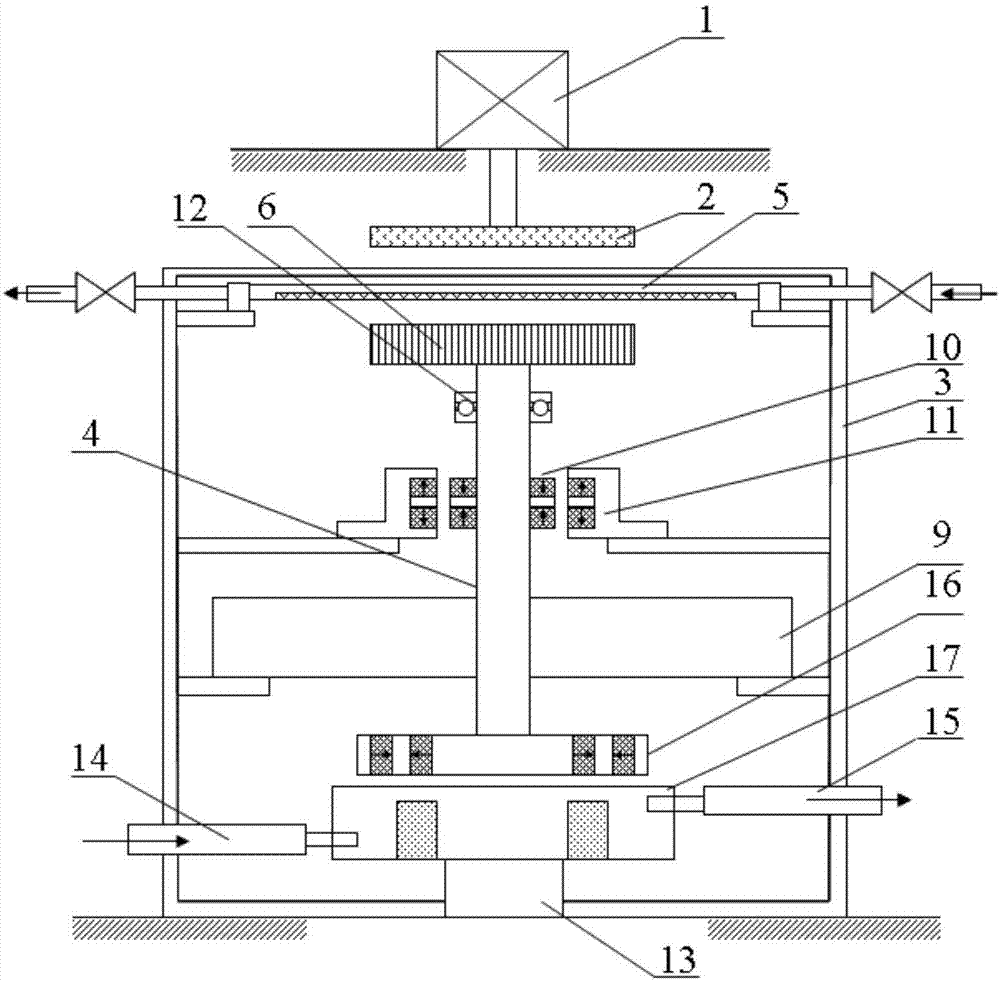

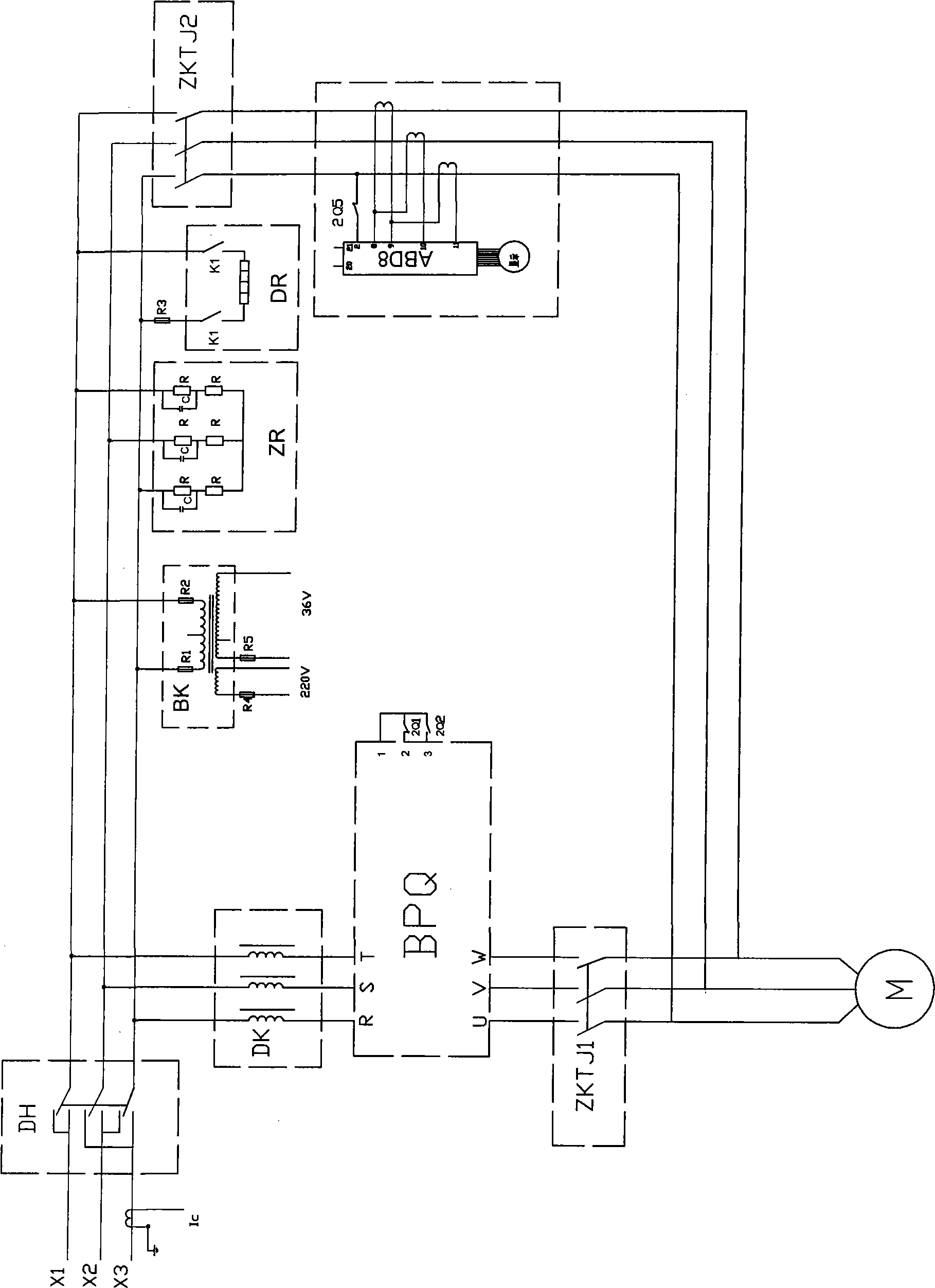

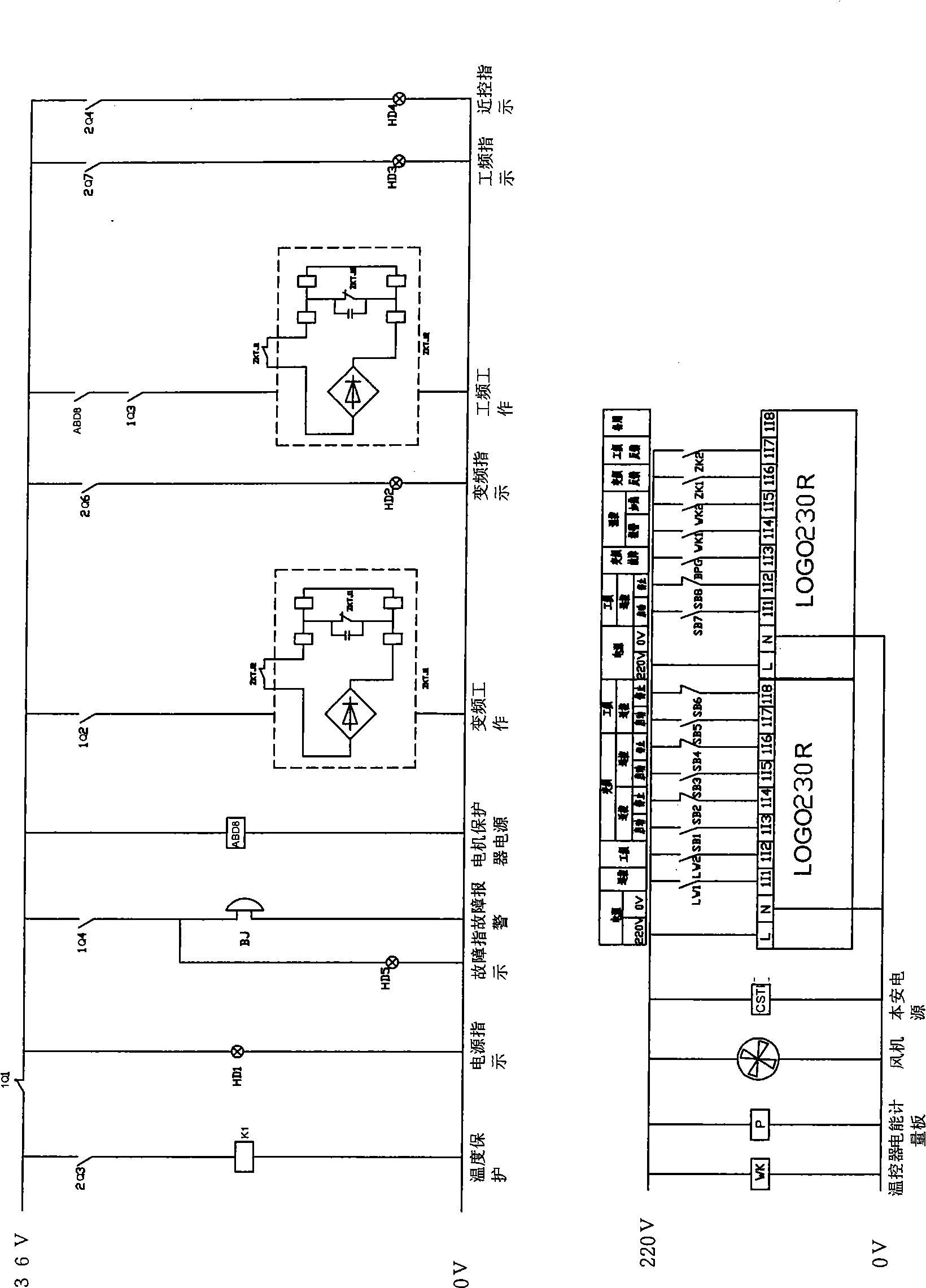

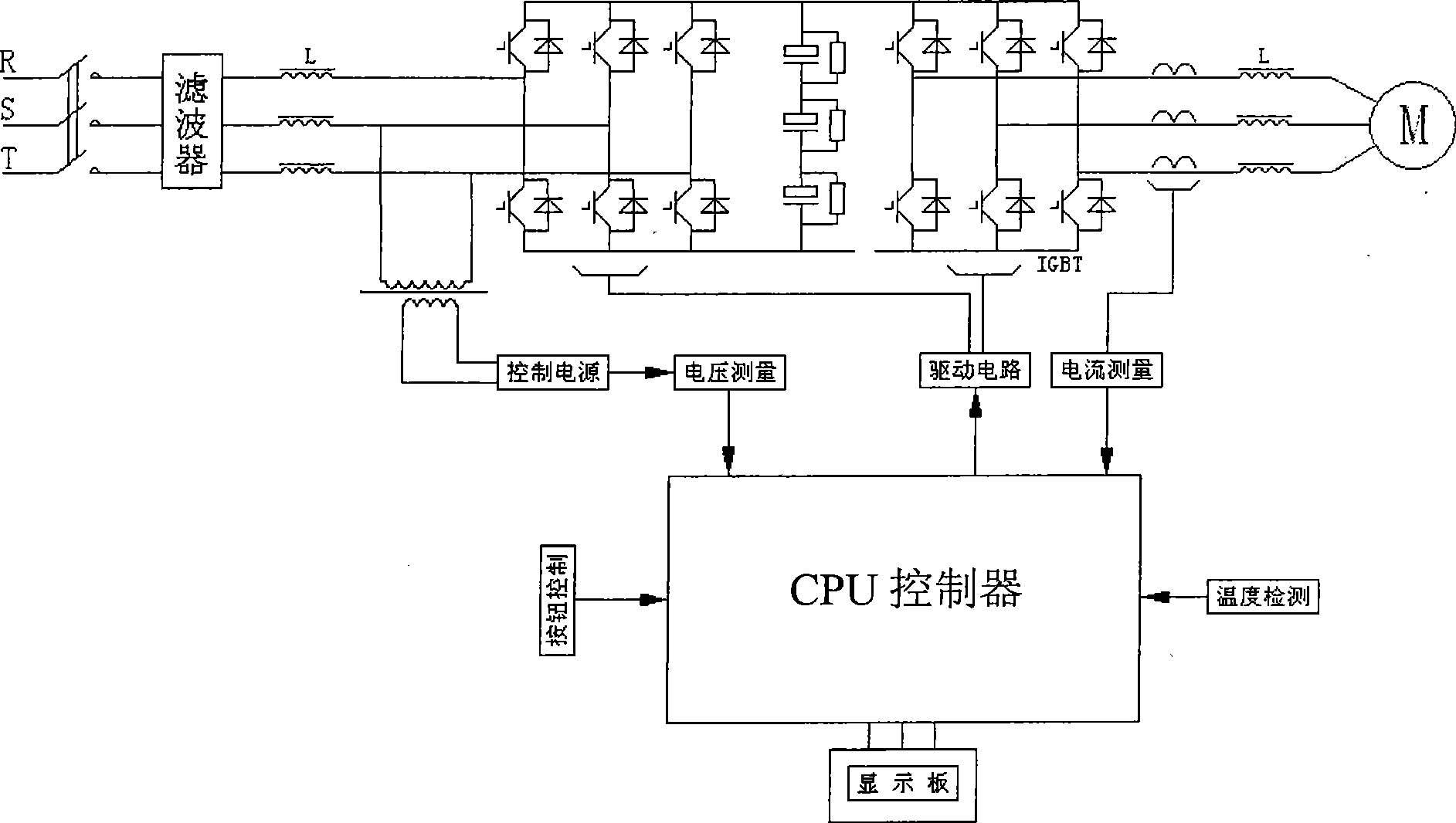

Mine flameproof and intrinsic safety type variable frequency speed control device

InactiveCN101534091AWith dustproofEasy to prevent dustAC motor controlEmergency protective circuit arrangementsFrequency changerDust control

The invention relates to a mine flameproof and intrinsic safety type variable frequency speed control device, which comprises a frequency converter consisting of a three-phase rectifier, a filtering capacitor and an IGBT inverter, a control device, and a flameproof case body, wherein the control device comprises an isolating switch, a power frequency and secondary control loop, and a variable frequency and control loop. The variable frequency speed control device has a variable frequency operating mode and a power frequency operating mode, and gives priority to the variable frequency operating mode complemented with the power frequency operating mode, thus the variable frequency speed control device not only can regulate the speed and save energy better, but also has the advantages of dust control, moisture protection, flame protection, and the like; and the variable frequency speed control device adopts digital display, which not only has a function of remote and approach controls, but also has functions of displaying electric energy, namely displaying load electric energy clearly, and temperature control, and has protection functions of surge protection, open phase protection, over voltage protection, under-voltage protection, and the like. The variable frequency speed control device can be applied to underground places with coal dust or gas coal dust explosion in coal mines to perform controls of starting, stopping and variable frequency speed control on a three-phase flameproof motor, and performs various protections on the motor. The variable frequency speed control device adopts a variable frequency speed control method which is advanced and can be widely popularized.

Owner:范鑫焱

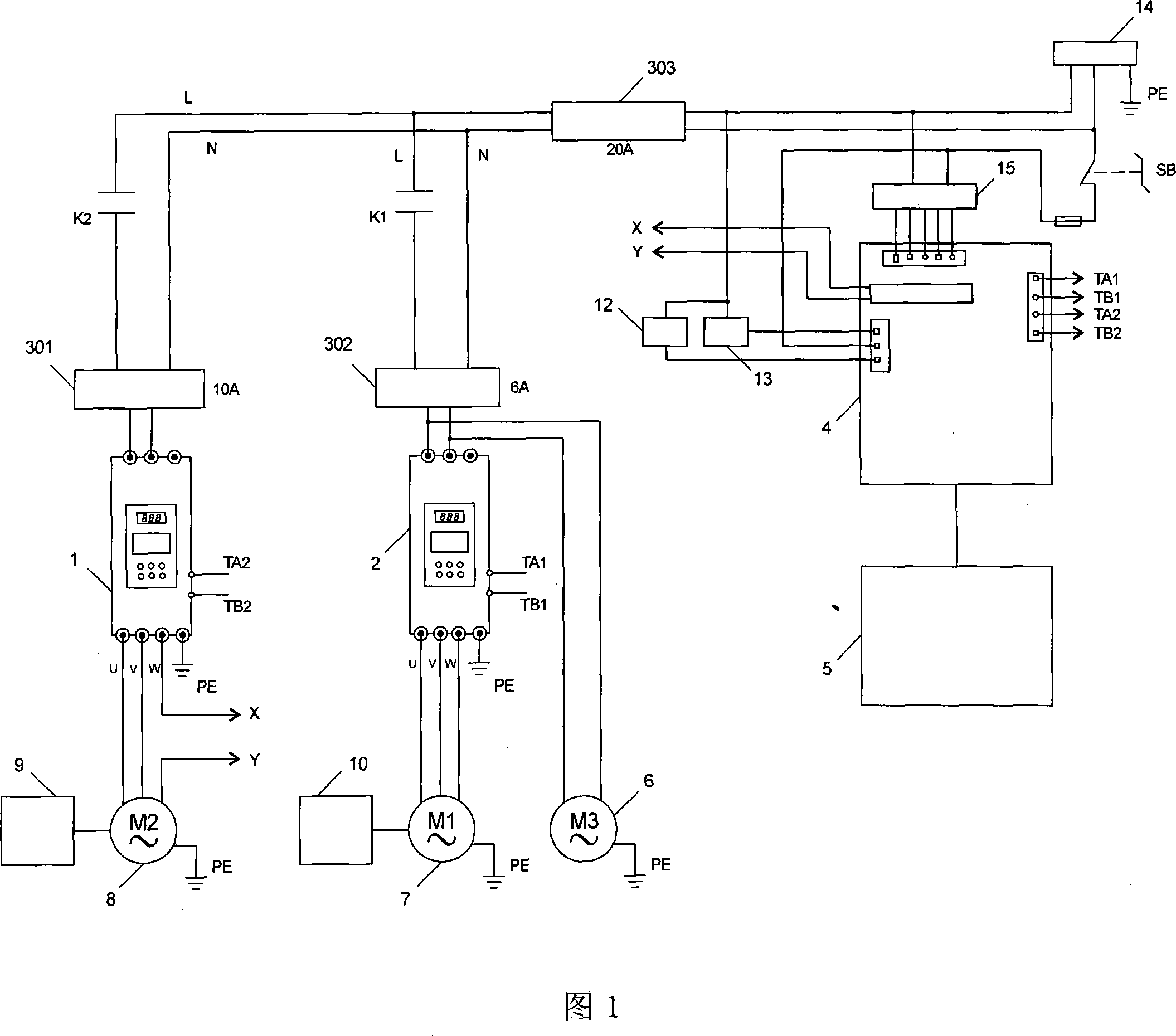

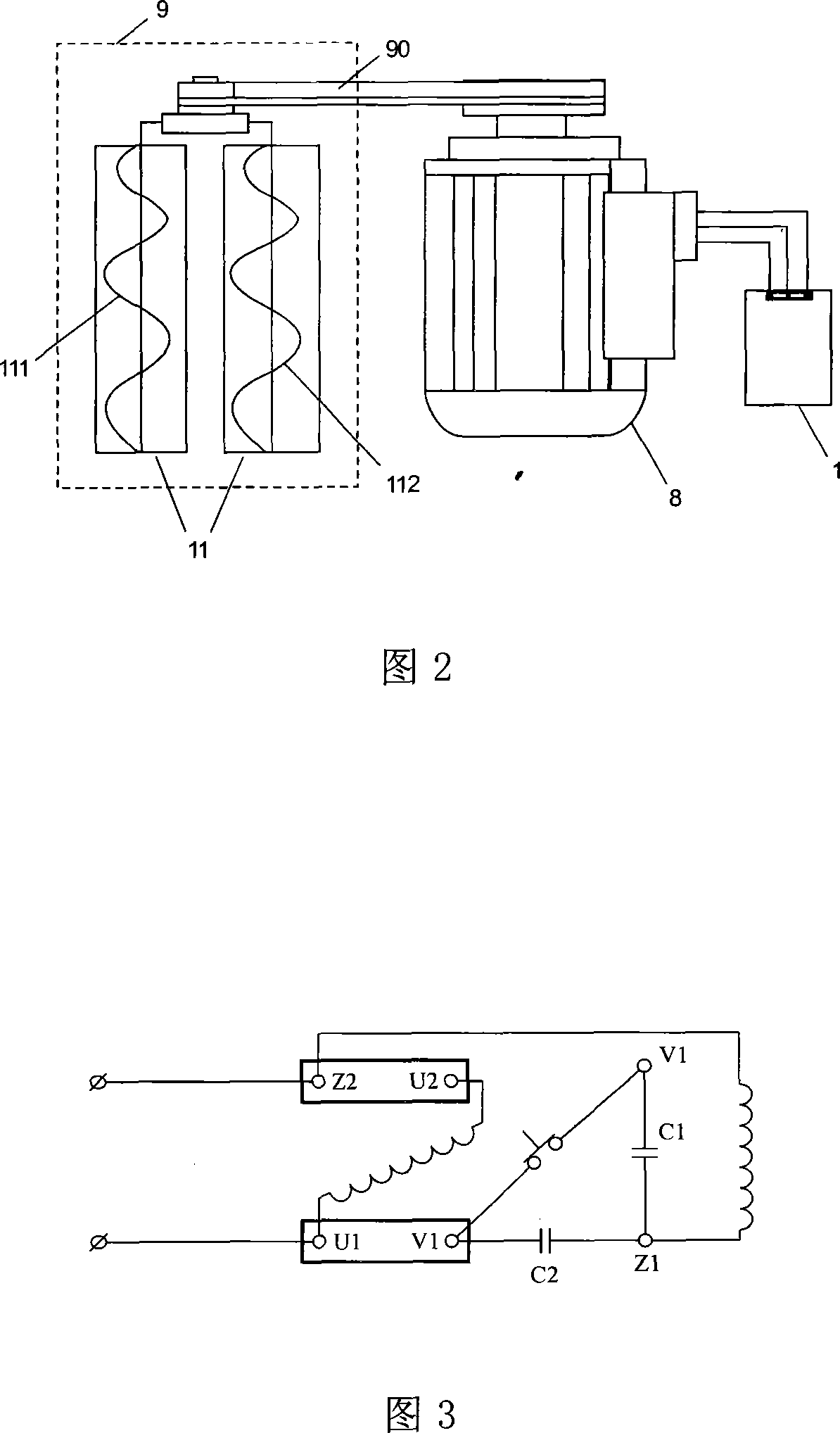

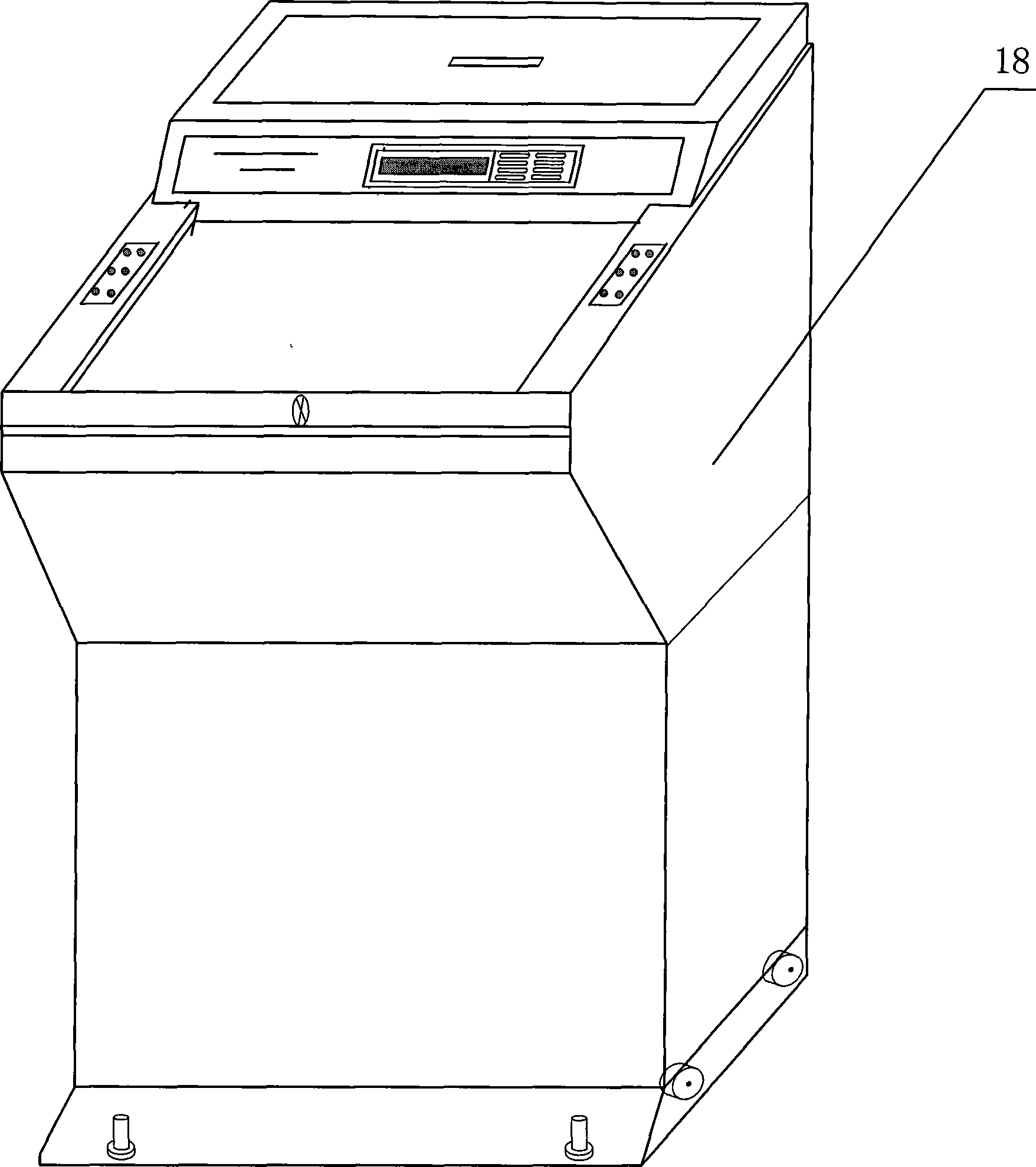

Soft ice cream machine with the frequency conversion control function

InactiveCN101138379AImprove noiseConvenient speed adjustmentFrozen sweetsMotor driveFrequency conversion

The present invention discloses a soft ice cream machine with the control function of frequency conversion; the present invention comprises a power interface, a mixing motor, a mixer, a refrigeration motor, a refrigeration device and a first frequency conversion control; the power output of the mixing motor drives the mixer to provide power for the refrigeration motor through the power interface; the refrigeration motor provides power for the refrigeration device; the mixing motor is a three-phase squirrel-cage asynchronous motor; the power interface is connected with the first frequency conversion control and the output of frequency conversion of the first frequency conversion control controls the a three-phase squirrel-cage asynchronous motor. The present invention provides a soft ice cream machine equipped with the driving function of frequency conversion; in the process of mixing paste, the soft ice cream machine has little noise and is convenient for timing; the starting torque is stable with high efficiency and the paste of ice cream is homogeneous.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +1

Uniform powder discharging device

InactiveCN104477673AEasy to adjustImprove dispersion efficiencyLoading/unloadingAdditive ingredientEngineering

The invention relates to a uniform powder discharging device. The uniform powder discharging device is formed by a fixed grid, a moving grid, a pulley, a guide rail, a guide rail support, a flexible connecting rod, a spring, a disc with an eccentric shaft, a motor and a discharging box. The uniform powder discharging device can uniformly discharge powder in a cabin within a large area, is beneficial to follow-up homogenization of powder and other materials, can timely and conveniently change the discharging speed due to the fact that the rotation speed of a motor or a connecting position of the flexible connecting rod and the eccentric shaft on the motor disc is adjusted through stepless speed change and is beneficial to control the ingredient proportion according to production requirement, simple in manufacture, conveniently design the discharging scattering area according to the requirements and applicable to powder distribution which is good in mobility and not easy to bulge.

Owner:TONGJI UNIV

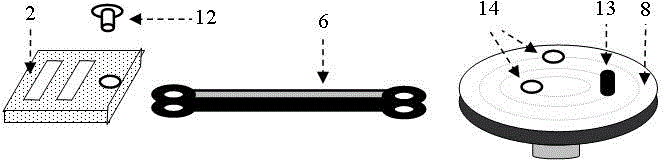

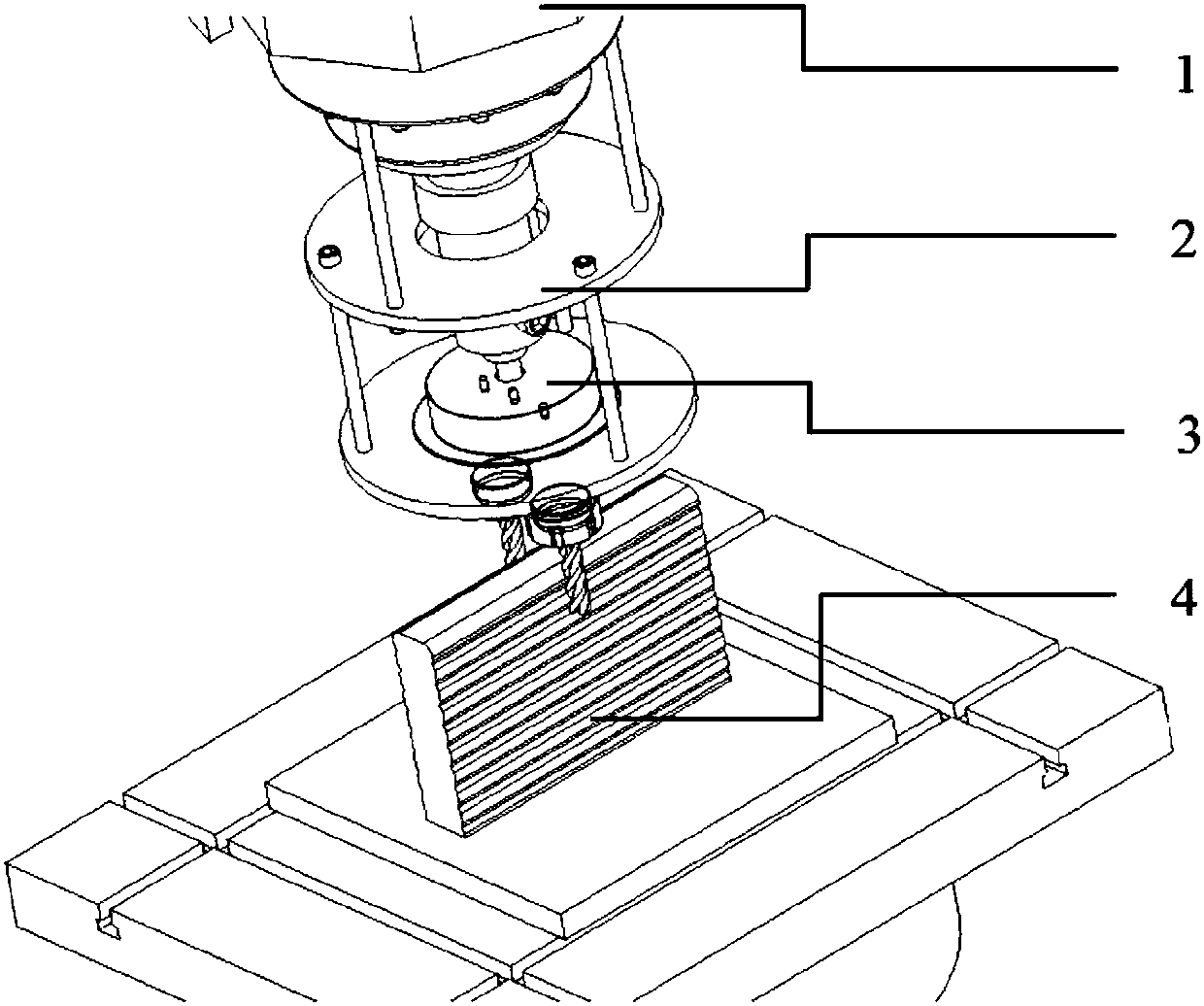

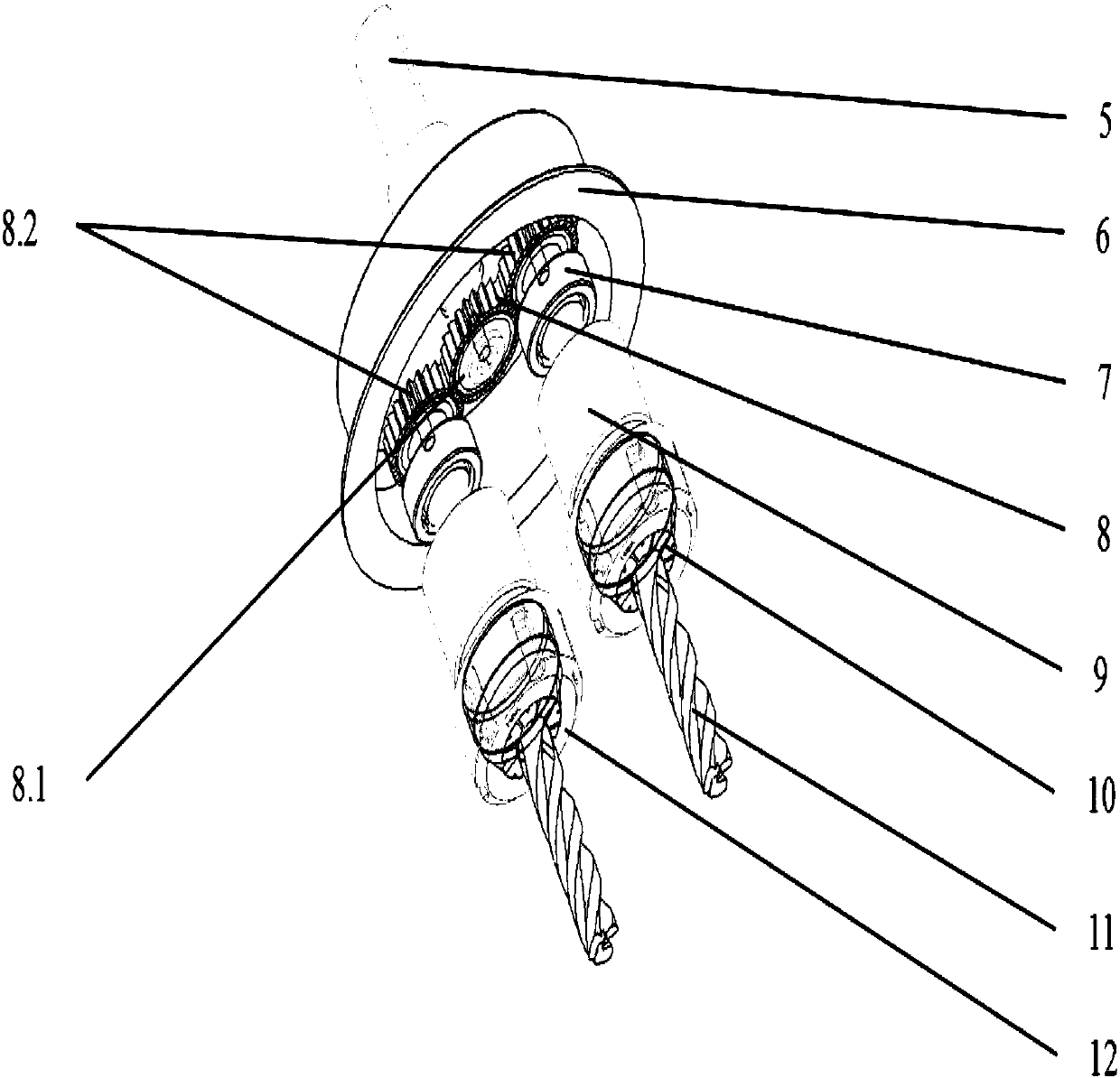

Robot milling double-shaft compound cutter device and method

ActiveCN107855569ASimple structureEasy to installMilling machinesMilling equipment detailsGear driveMilling cutter

The invention relates to a robot milling double-shaft compound cutter device and a method, and belongs to the field of cold and hot compound working in machining. The device consists of a robot driving unit, a connecting bracket, a compound cutter device and a machined workpiece. The compound cutter device comprises a robot connecting shaft, an upper cover, a bearing, a gear set, a shank, a springchuck, milling cutters and a shank cap. The robot driving unit drives the milling cutters in the compound cutter device to rotate to machine the machined workpiece. The robot driving unit is fixedlyconnected with the robot connecting shaft of the compound cutter device to drive a driving gear. The driving gear drives two driven gears to oppositely rotate, so that the two milling cutters are driven to oppositely rotate to realize synchronous milling of double shafts by double side surfaces of the machined workpiece. The device is simple in structure, convenient to install and lower in cost, and replaces the milling cutters to change the side surface sizes of the machined workpiece, namely the thickness of a wall, so as to achieve the machining precision and the surface quality requirements.

Owner:BEIJING UNIV OF TECH

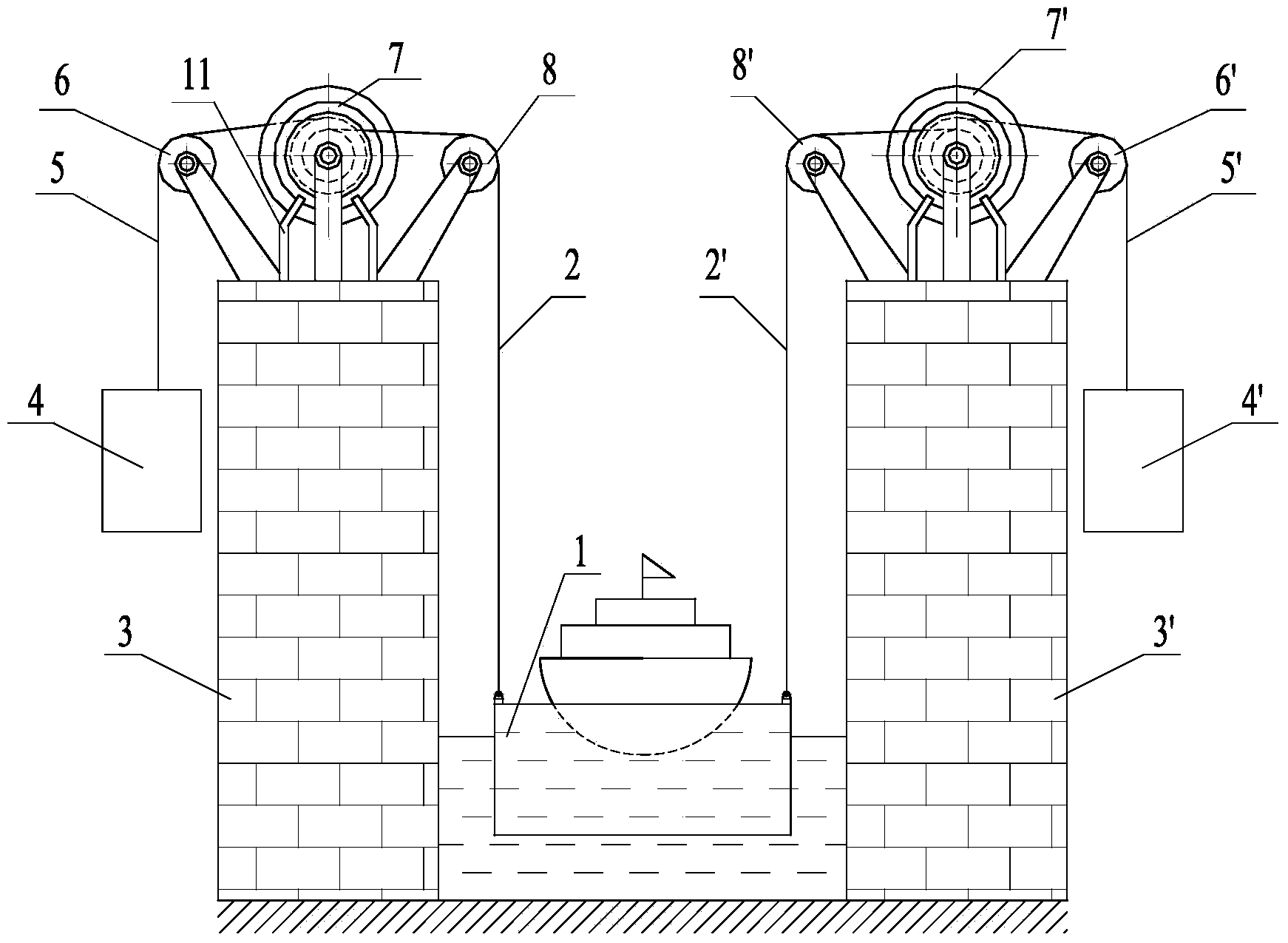

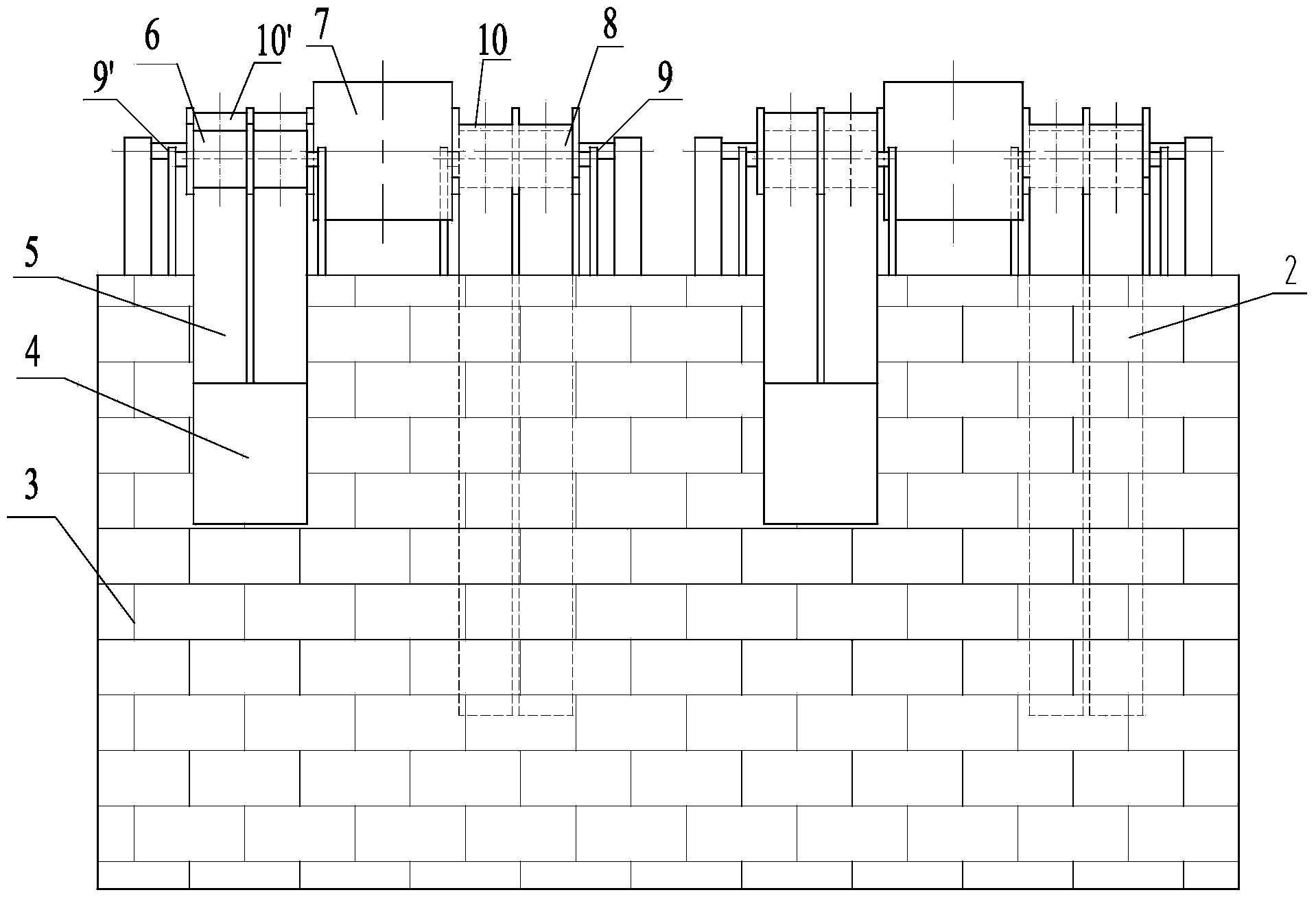

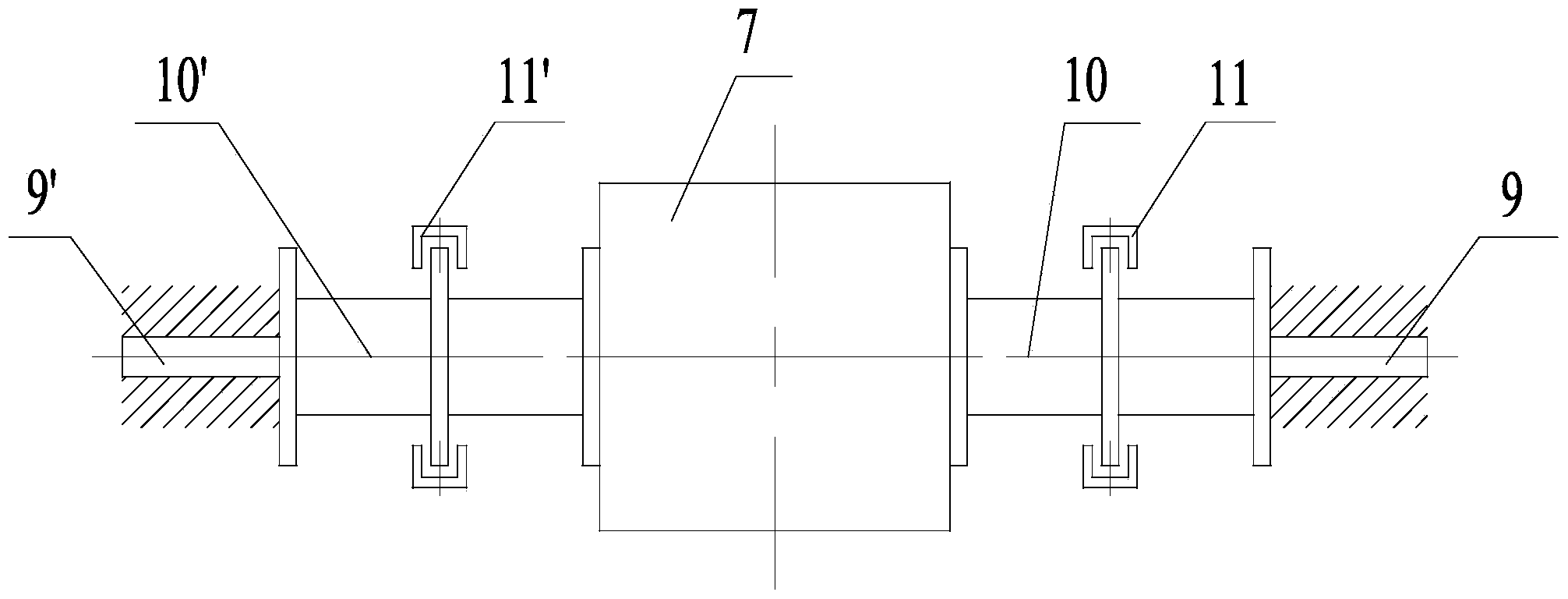

Ship lifting device

ActiveCN103758100ASimple structureConvenient speed adjustmentVertical ship-liftingMarine engineeringLeather belt

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Grooving type longitrorse compound ultrasonic motor

ActiveCN104124893ASimple structureEasy to makePiezoelectric/electrostriction/magnetostriction machinesMechanical engineeringUltrasonic motor

The invention provides a grooving type longitrorse compound ultrasonic motor which is composed of a stator, a rotor and a precompression mechanism. The precompression mechanism comprises a spring, a hoop and a bearing. The stator comprises a piezoelectric ceramic piece and a stator base body, the upper end and the lower end of the piezoelectric ceramic piece are provided with stator driving ends, the stator is pressed at the stator driving ends through the spring and is locked through the hoop, the bearing penetrates the stator and the rotor, the piezoelectric ceramic piece adheres to the outer surface of the stator base body and stimulates longitrorse compound vibration on particles of the driving ends, a motion track of the particles on the end face of the stator is an oval, and the stator drives the rotor to rotate through friction. The grooving type longitrorse compound ultrasonic motor improves torsion amplitude and can accurately adjust the longitrorse amplitude proportional relations.

Owner:SHANGHAI JIAO TONG UNIV

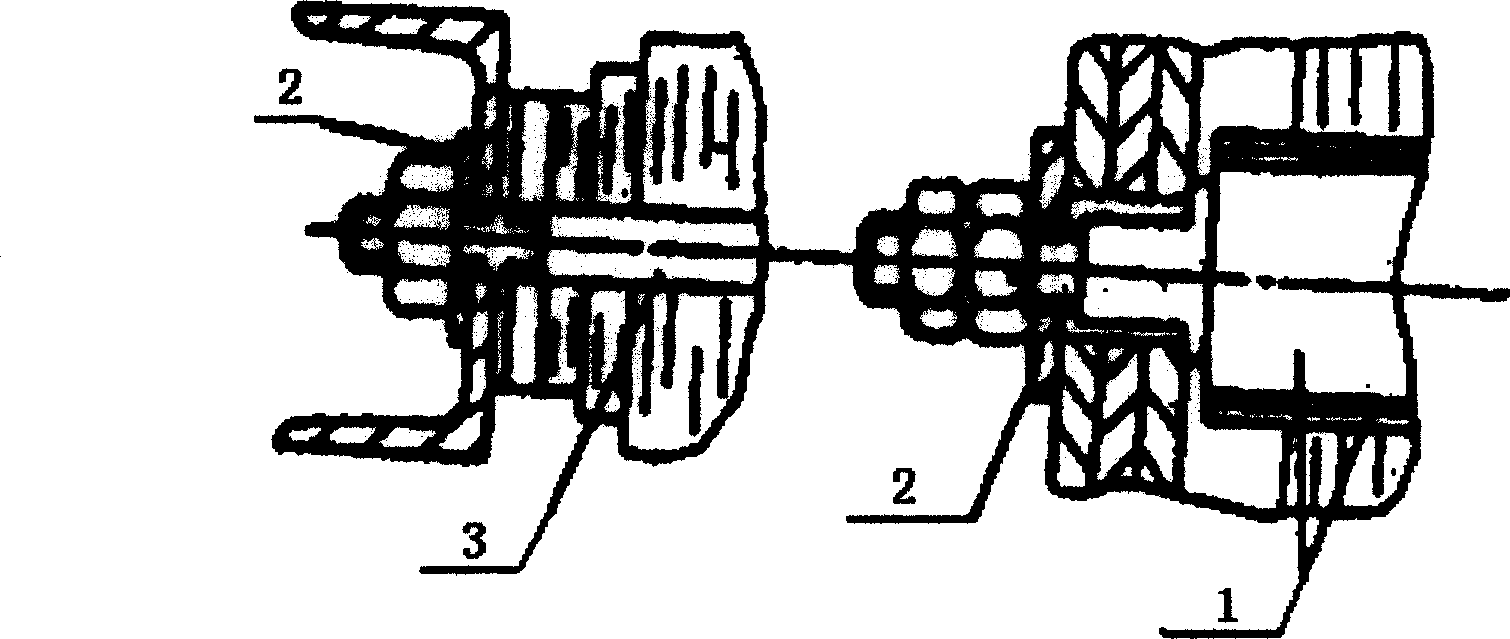

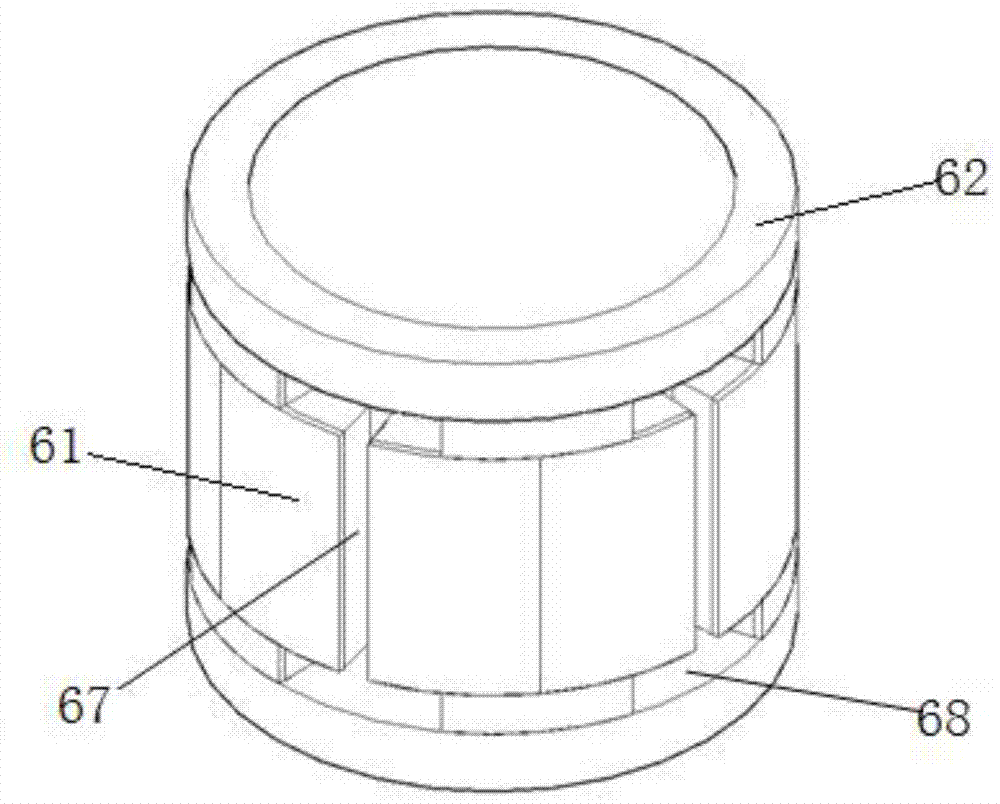

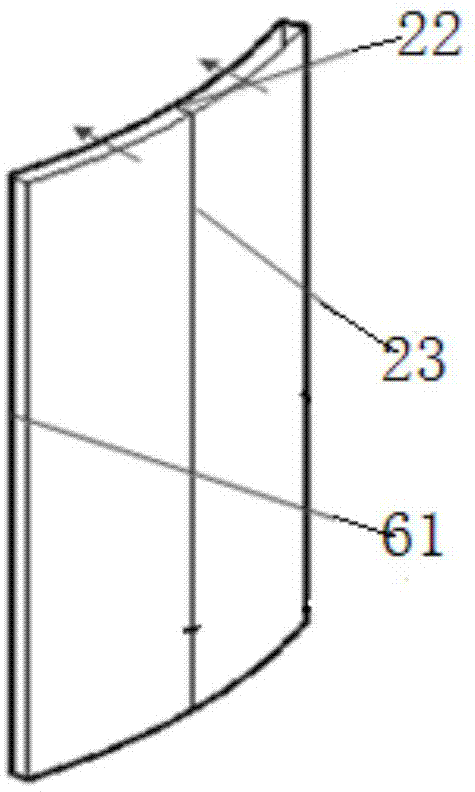

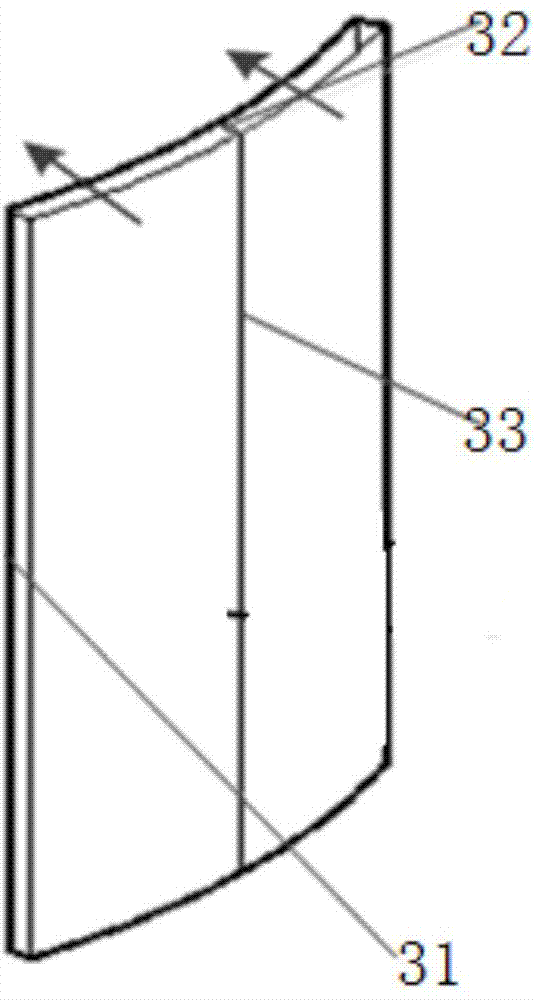

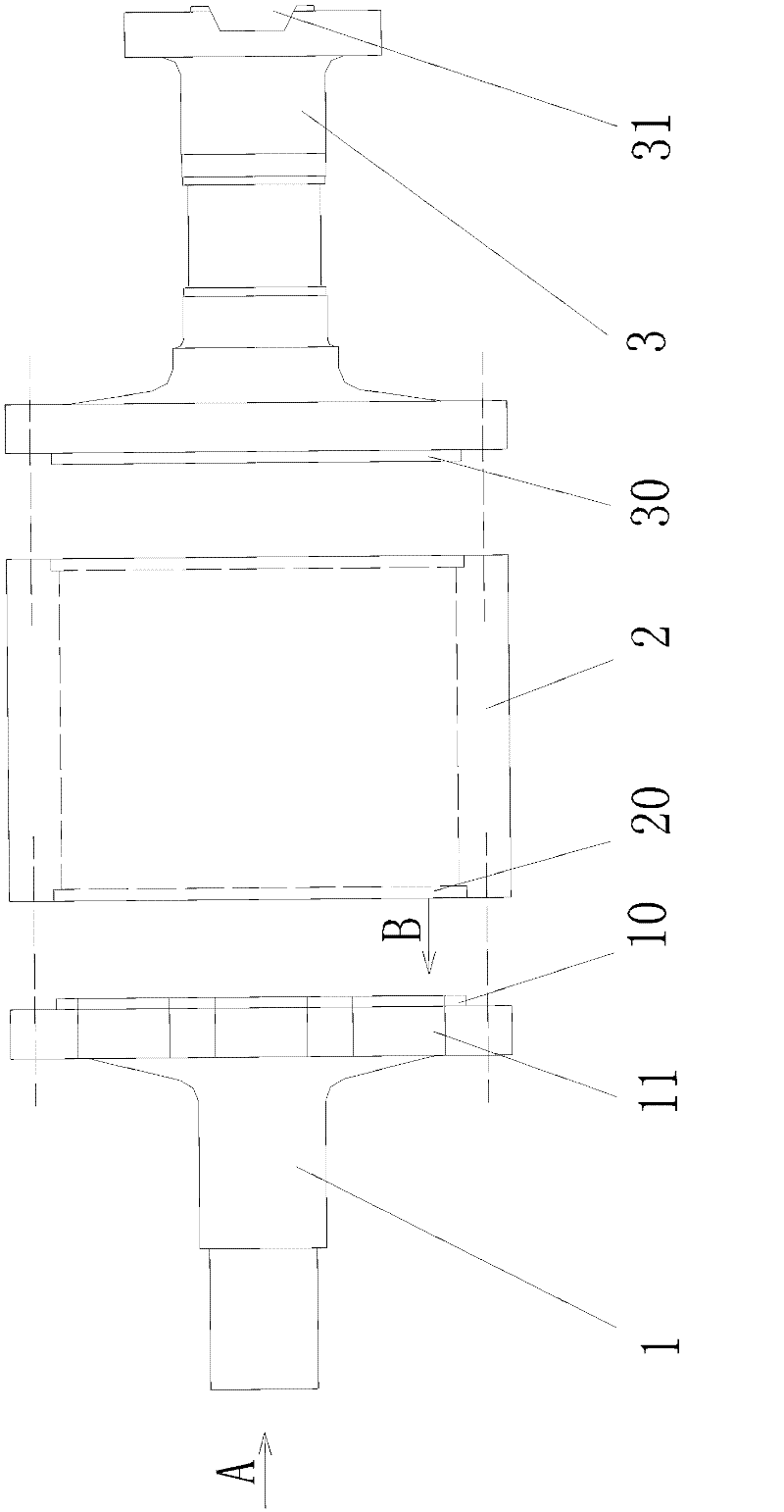

Large-scale motor combined type rotation shaft and assembling method thereof

ActiveCN102195396ASmall moment of inertiaConvenient speed adjustmentManufacturing dynamo-electric machinesMechanical energy handlingEngineeringMechanical engineering

The invention relates to a large-scale motor combined type rotation shaft and an assembling method thereof. The rotation shaft comprises a non-load end shaft, a hollow shaft and a load end shaft which are connected in sequence, wherein the two ends of the hollow shaft are provided with concave seam allowances respectively and a plurality of screw holes and a plurality of positioning pin holes aredistributed along the circle of the hollow shaft; the end surface of the non-load end shaft and the end surface of the load end shaft which are connected to the hollow shaft are provided with convex seam allowances which are matched with the concave seam allowances, screw holes and positioning pin holes; and the non-load end shaft and load end shaft are assembled through the concave seam allowances and the convex seam allowances on the hollow shaft and are tightly and fixedly connected to the hollow shaft by a screw and a positioning pin in an axial fixing way. According to the large-scale motor combined type rotation shaft and the assembling method, the situation that a nut of a rotor loosens in the running process is prevented effectively and the working reliability of the rotor is improved greatly; meanwhile, the alignment and adjustment of the combined shaft centre are more accurate and the operation is more convenient, so that the electrical property of the motor and the rotor balance are guaranteed and the problem of superstandard mechanical vibration is solved.

Owner:上海电气集团上海电机厂有限公司

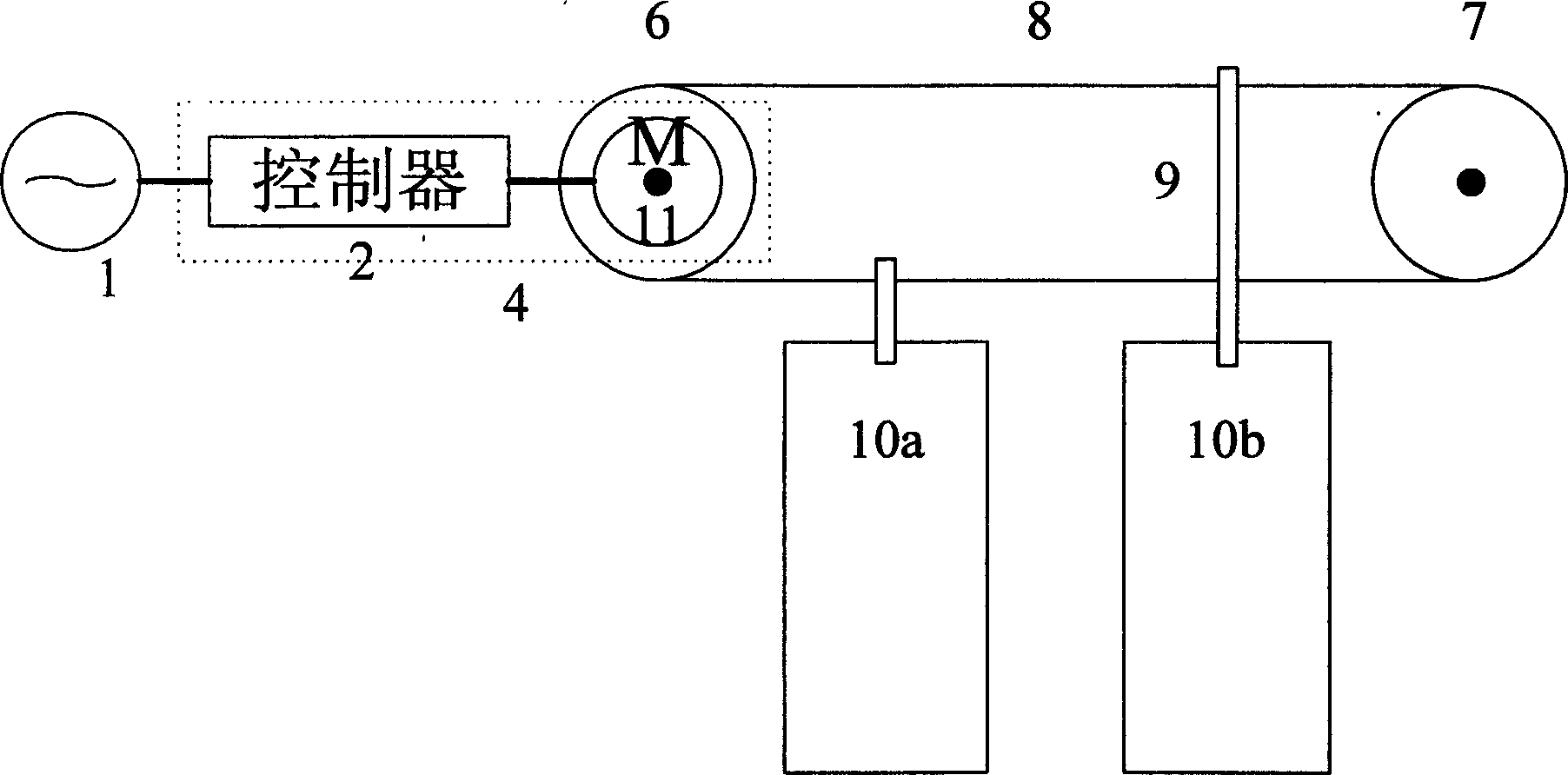

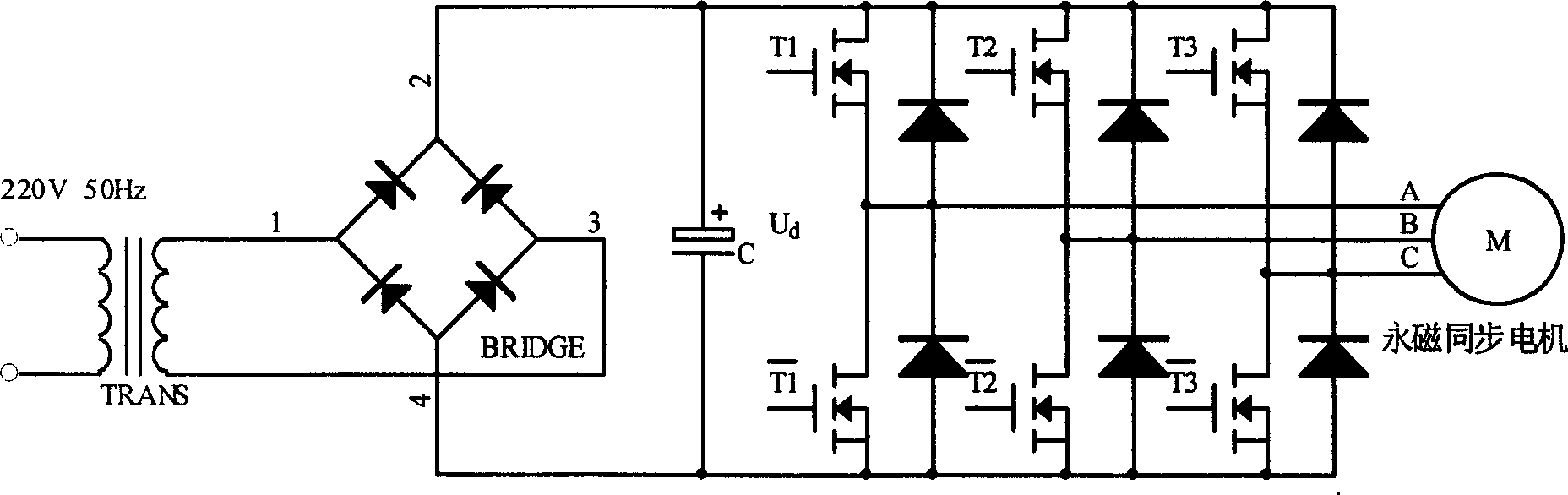

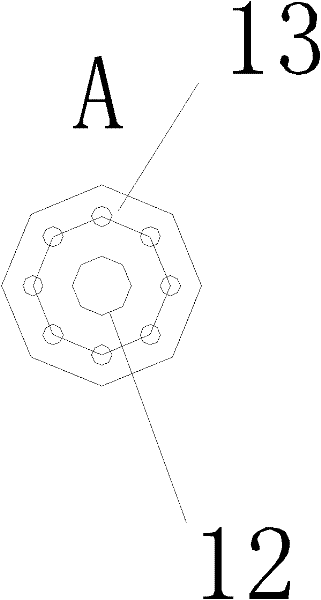

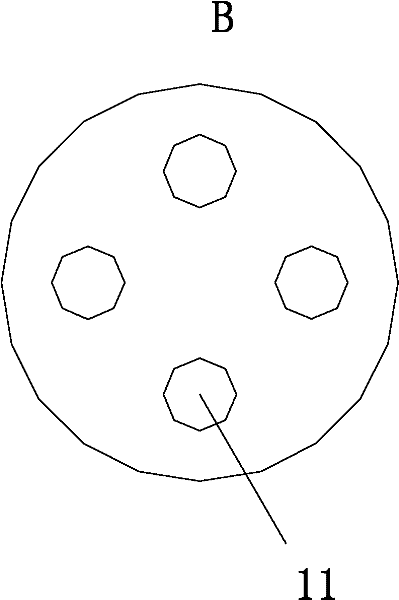

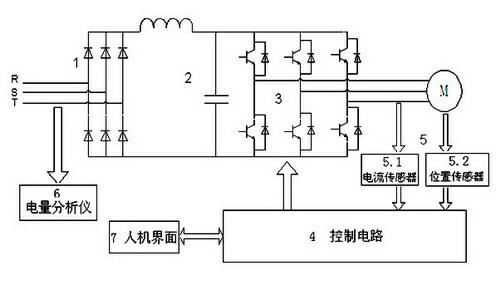

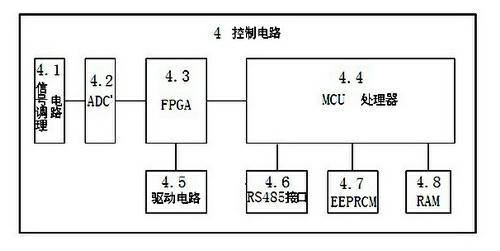

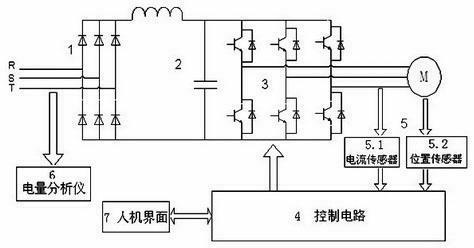

Variable frequency speed regulation control device and variable frequency speed regulation control method for flotation machine

InactiveCN102624301AConvenient speed adjustmentEfficient startAC motor controlSingle motor speed/torque controlHuman–machine interfaceDrive motor

The invention relates to a variable frequency speed regulation control device and a variable frequency speed regulation control method for a flotation machine. The device comprises a rectification circuit, a filtering circuit, an inversion circuit, a control circuit, a sensor, an electric quantity analyzer and a human-computer interface, wherein the rectification circuit is connected with the inverter circuit through the filtering circuit; the permanent magnet motor M is connected with the inversion circuit; the control circuit is connected with the permanent magnet motor M through the sensor, and is also connected with the inversion circuit and the human-computer interface ; and the electric quantity analyzer is connected with the rectification circuit. The control method comprises the following steps of: setting rotating speed, detecting a position signal, detecting a current signal, regulating the rotating speed and performing failure alarming and processing. The device and the method have the advantages that: the permanent magnet direct drive motor of the flotation machine is controlled to be randomly regulated within a rotating speed range, and optimal flotation rotating speed can be conveniently set according to actual conditions by a user; and the most power-saving economical rotating speed of the device can be realized by regulating output current under a material-free light-load working condition, and remarkable energy-saving effects can be achieved.

Owner:武汉长海电气科技开发有限公司

Air powered vehicle

InactiveCN104309494ASimple structureLow costPropulsion using engine-driven generatorsVehicular energy storageFuel tankPower equipment

The invention relates to an air powered vehicle comprising a power supply plugging wire, an air compressor, a compressed air tank, an auxiliary battery, a fluid power engine, direct-current engines, a direct-current motor, an engine gas inlet, an engine gas outlet, an engine drive shaft, a frame and a frame body. According to the air powered vehicle, an existing hybrid power vehicle or pure electric vehicle is optimized, fuel power equipment is omitted, an electric drive system is retained, the majority of batteries are detached, and the space for installing the batteries and an oil tank is used for installing the compressed air tank. During inflation, the power supply plugging wire is connected to a power supply or ordinary power supply socket, after the air compressor is connected to the power supply through the power supply plugging wire, and the compressed air tank is inflated; when the four direct-current engines of a vehicle body are connected to four wheels of the vehicle body respectively, a differential is further omitted, and the vehicle is an actual four-wheel drive vehicle and a complete electric powered and controlled vehicle without a mechanical transmission system.

Owner:SUZHOU SAIPA SOLAR TECH CO LTD

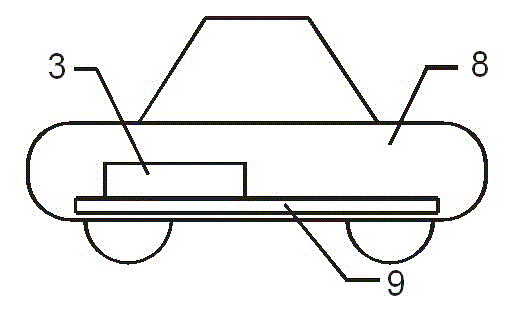

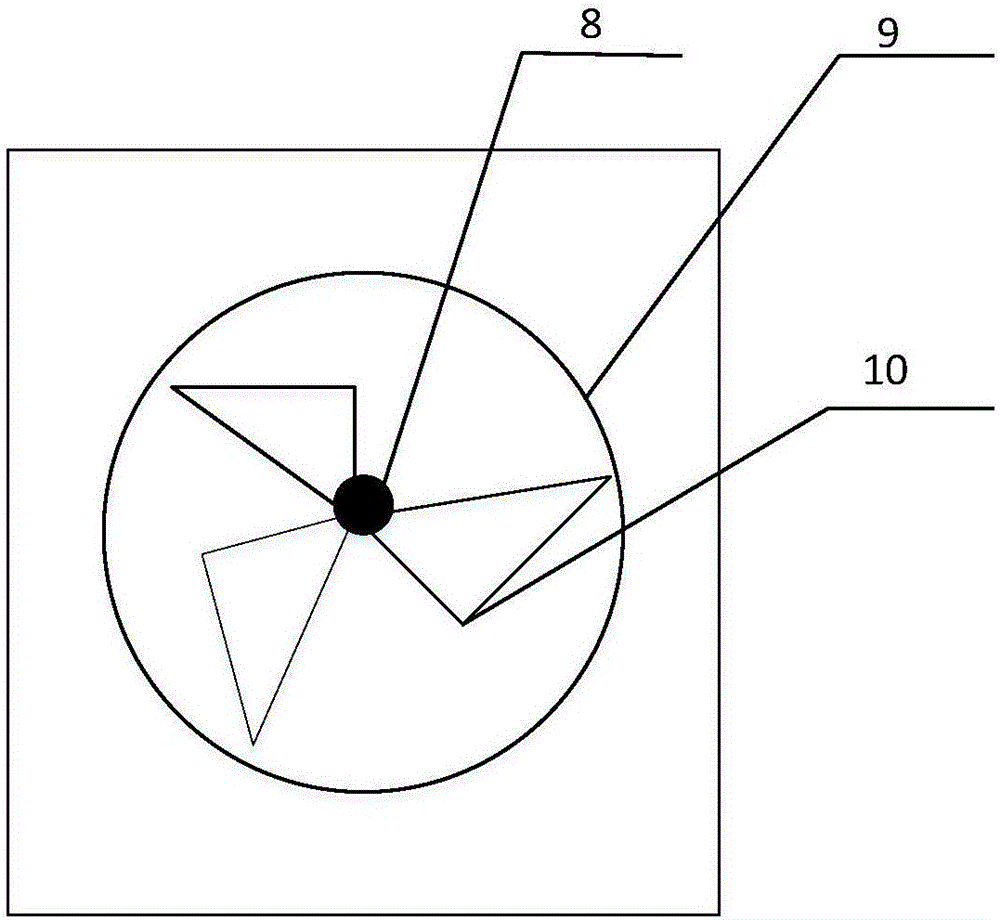

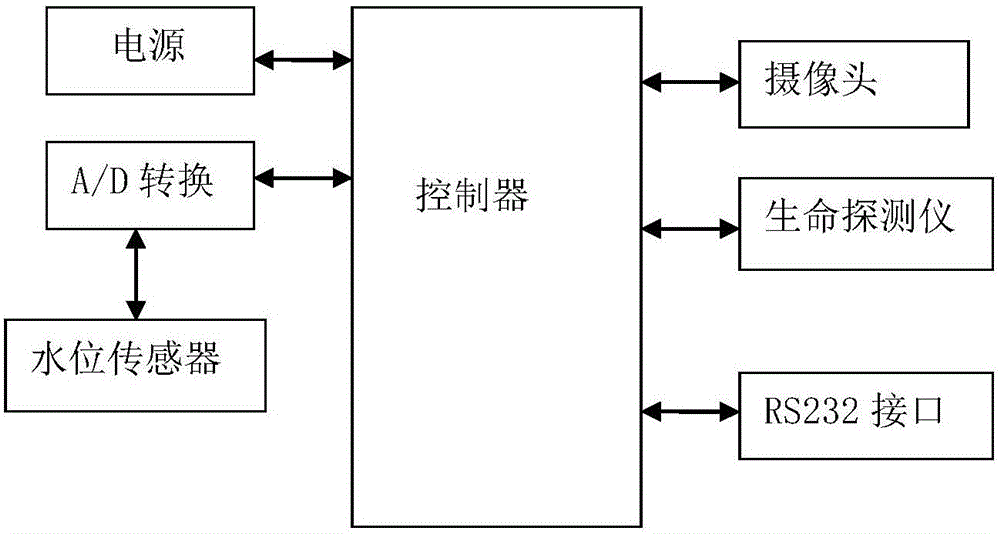

Amphibious ship-shaped searching robot

InactiveCN106240261AReduce resistanceIncrease speedAmphibious vehiclesVessel safetyStopped workSimulation

The invention discloses an amphibious ship-shaped searching robot. Liquid level information is detected by a water level sensor and sent to a controller, and the controller judges the environment where the amphibious ship-shaped searching robot is located; if the robot is on the land, car wheels work, a propeller II does not work and retracts into a hollowed-out cabin through a telescopic rod II, and the amphibious ship-shaped searching robot starts searching trapped persons through a life detection instrument and a camera; and if the robot is on the water, the car wheels stops working, and both a propeller I and the propeller II work. The propeller I rotates in the air, air is filled with an air cushion through an inflation channel and an air blower, and buoyancy for the amphibious ship-shaped searching robot under water is provided; and meanwhile, the propeller II extends out of the hollowed-out cabin through the telescopic rod II and rotates under water, propelling force for driving the amphibious ship-shaped searching robot on the water surface is provided, and the amphibious ship-shaped searching robot starts searching the trapped persons through the life detection instrument and the camera.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Device for automatic controlling final position of moving element

A device used for automatically controlling position of movable component is prepared for setting displacement transducer on movable component, connecting said displacement transducer to input of data collection module through signal line and output of data collection module to input of CPU microprocessor, connecting output of CPU microprocessor separately to motor change-pole module (MCPM) and input of motor frequency conversion module and output of MCPM to various change-pole interface of change-pole multi-speed motor as well as output of MCPM to low speed pole interface of change-pole multi-speed motor.

Owner:张挺胜

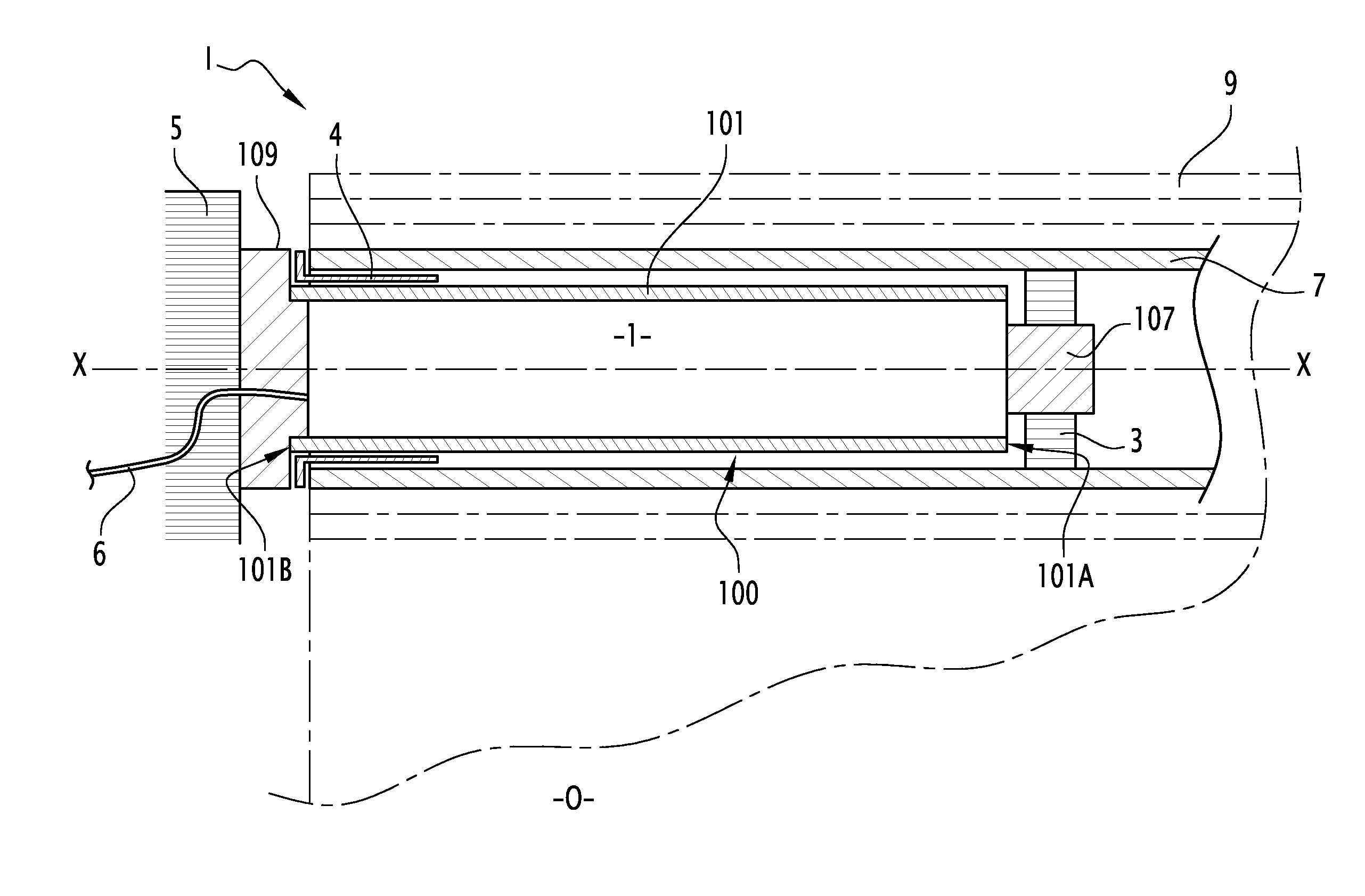

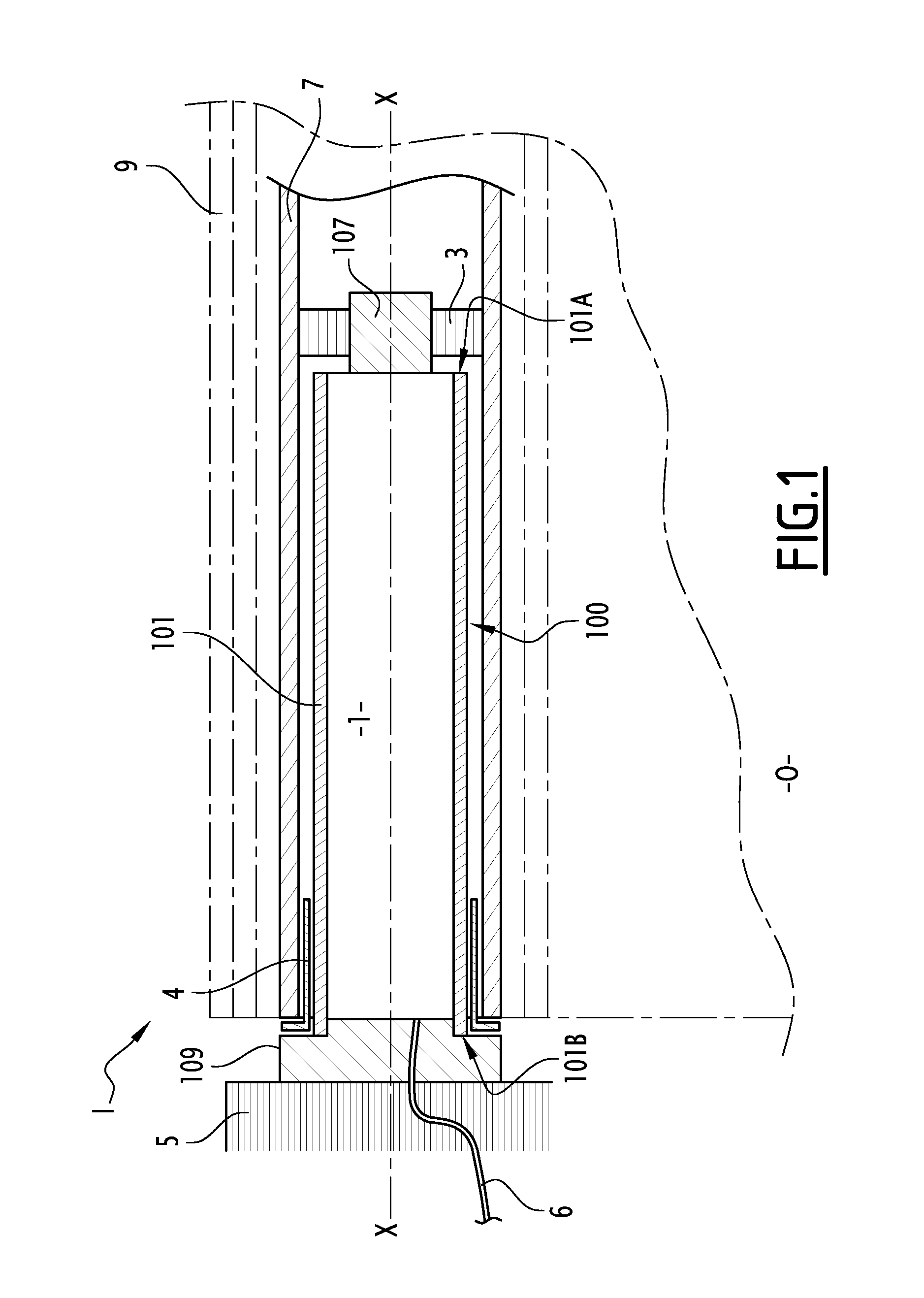

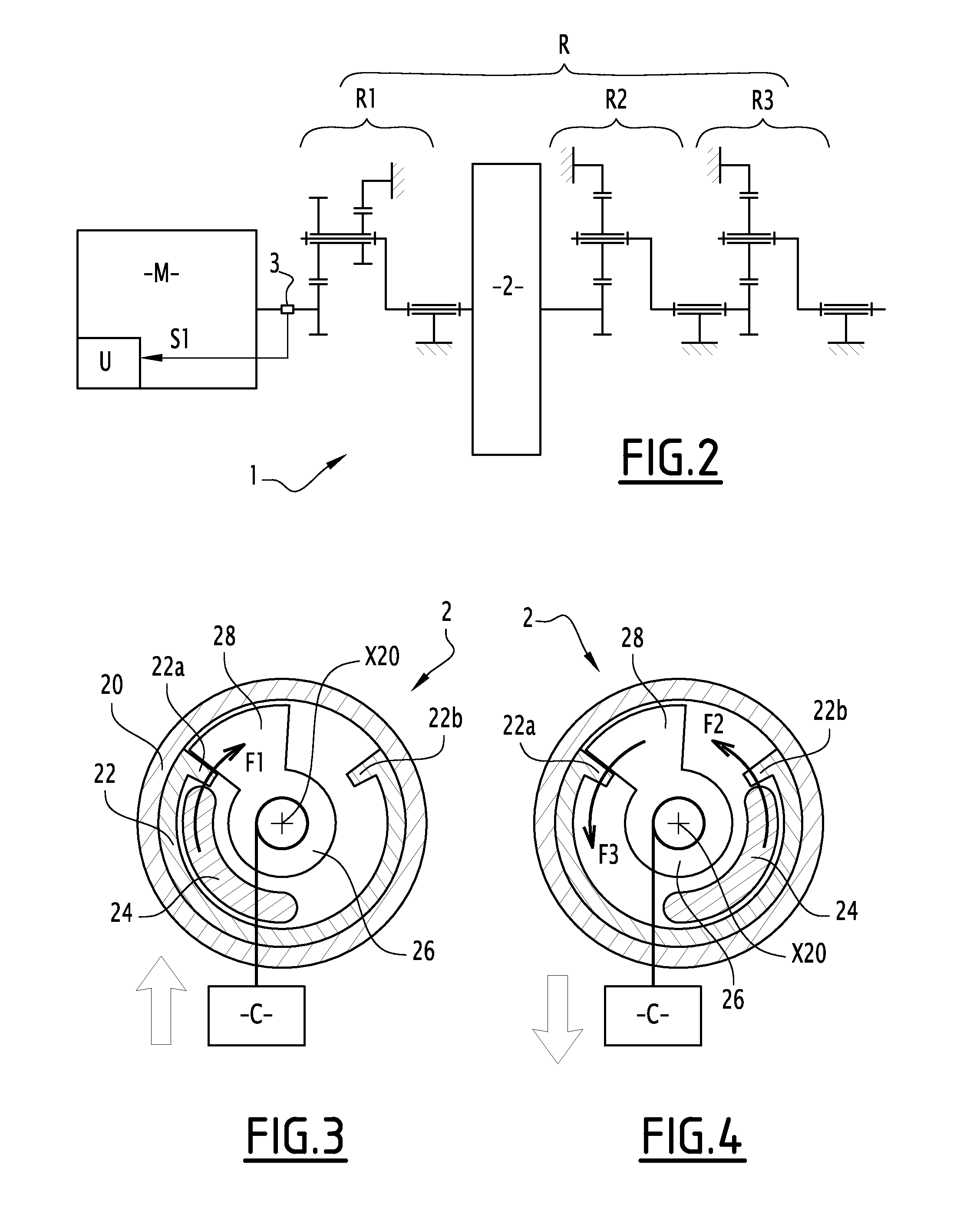

Actuator for driving a home-automation screen and installation comprising such an actuator

ActiveUS20150008801A1Easy to controlLoad is generatedDoor/window protective devicesDC commutatorEngineeringDrag torque

This actuator for driving a home-automation screen includes an electric motor (M), a reduction gear (R) for transmitting the movement of the motor to the home-automation screen and a brake. The actuator includes a direct current electronic switching motor (M) and a mechanical brake (2) having a continuous drag torque.

Owner:SOMFY ACTIVITES SA

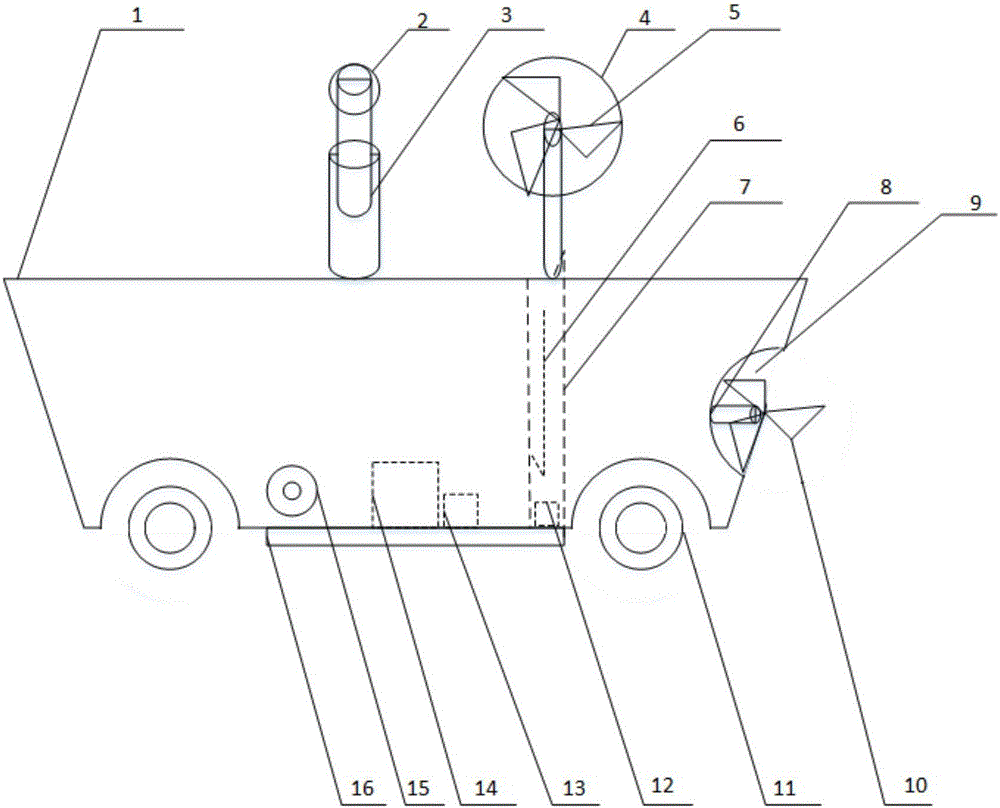

Electronic scarifier for garden

The invention discloses an electric scarifier for gardens. A storage battery is arranged on the upper right side of the main body of the fuselage, a motor is arranged on the lower part of the main body of the fuselage, and a bracket is installed on the bottom of the main body of the fuselage. Rotating shaft, the described rotating shaft is provided with loosening tool, and one end of rotating shaft is equipped with gear, and described gear is connected with motor by connecting belt, and the left side of described fuselage main body is provided with toolbox, and the left side of described toolbox There is a telescopic adjustment device on the side, the lower end of the telescopic adjustment device is equipped with a bracket wheel, the top of the main body of the fuselage is provided with two groups of handle rods, and the handle of the left handle rod is equipped with a switch. The right side of the main body is movably connected with the seeding device through a fixed frame. The garden electric scarifier can meet the management requirements of nurseries, flowers, gardens and other facilities and can adapt to the space constraints in the greenhouse, and has good steering and operational flexibility.

Owner:贵州开阳兴茂农业开发有限责任公司

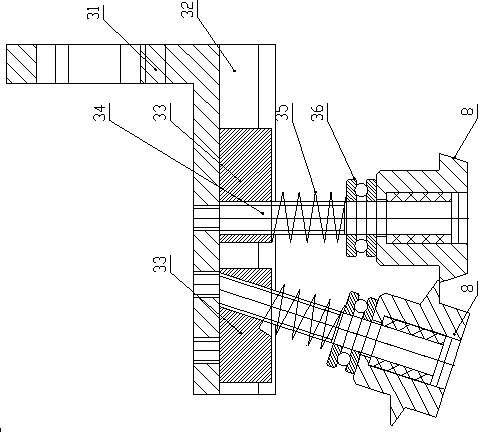

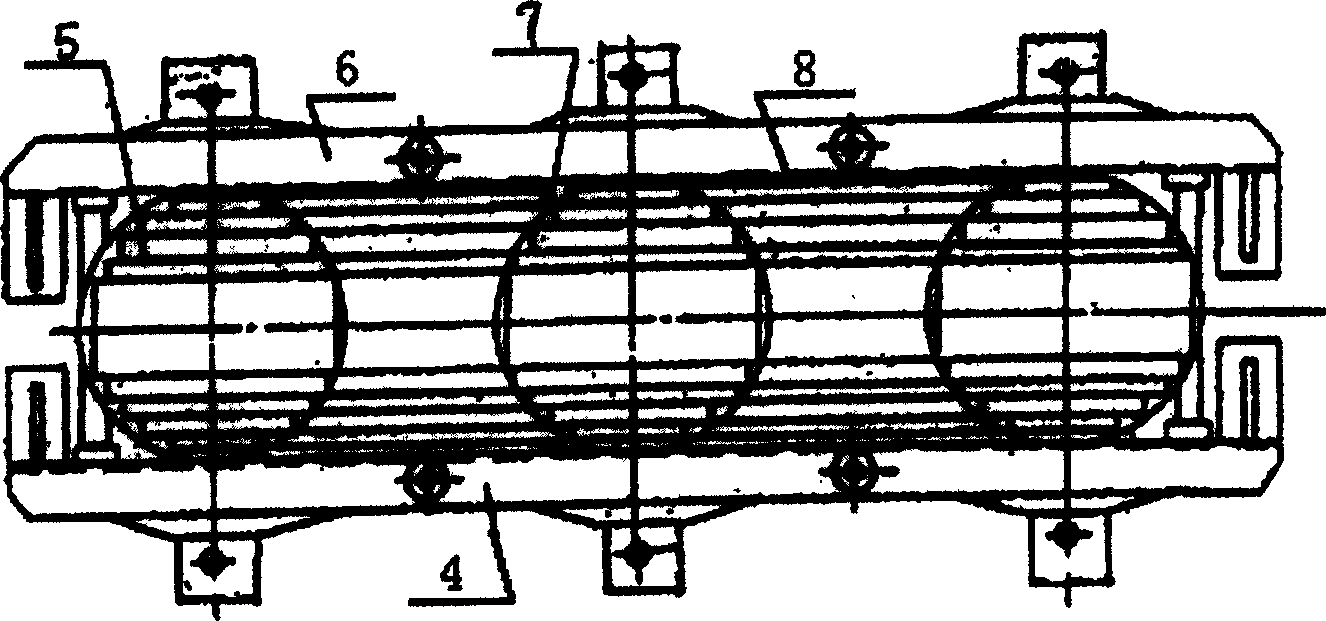

Novel hydro-viscous transmission device

InactiveCN103075449AIngenious ideaSimplify the assembly processLiquid resistance brakesCoupling-brake combinationStatic frictionPiston

The invention discloses a hydro-viscous transmission device, which comprises a box body, a speed regulating mechanism and a braking mechanism, wherein the speed regulating mechanism comprises a speed regulating shaft, a speed regulating shaft transparent cover, a driving friction plate, a driven friction plate, a driven drum, a driven disc, a first piston cylinder, a third piston cylinder and a first control oil pipe, and the braking mechanism comprises a braking shaft, a braking shaft transparent cover, a movable friction plate, a static friction plate, a braking drum, a braking disc, a second piston cylinder, a fourth piston cylinder, a second control oil pipe and a third control oil pipe. The hydro-viscous transmission device has the advantages that the ingenious structure is adopted, the design is simple and reasonable, a stepless speed regulation function of a hydro-viscous speed regulating clutch and a braking speed reduction function of a hydro-viscous brake can be simultaneously realized on a set of device, in addition, the work speed regulating performance and the service life of the device can be obviously improved and prolonged, and the hydro-viscous transmission device is particularly suitable for occasions that a high-power work machine simultaneously needs two kinds of work conditions of speed regulation and braking.

Owner:ZHEJIANG UNIV

Soft ice cream machine with the frequency conversion control function

InactiveCN101138379BImprove noiseConvenient speed adjustmentFrozen sweetsMotor driveFrequency conversion

The present invention discloses a soft ice cream machine with the control function of frequency conversion; the present invention comprises a power interface, a mixing motor, a mixer, a refrigeration motor, a refrigeration device and a first frequency conversion control; the power output of the mixing motor drives the mixer to provide power for the refrigeration motor through the power interface;the refrigeration motor provides power for the refrigeration device; the mixing motor is a three-phase squirrel-cage asynchronous motor; the power interface is connected with the first frequency conversion control and the output of frequency conversion of the first frequency conversion control controls the a three-phase squirrel-cage asynchronous motor. The present invention provides a soft ice cream machine equipped with the driving function of frequency conversion; in the process of mixing paste, the soft ice cream machine has little noise and is convenient for timing; the starting torque is stable with high efficiency and the paste of ice cream is homogeneous.

Owner:SHENZHEN OCEAN POWER INDUSTRIAL CO LTD +1

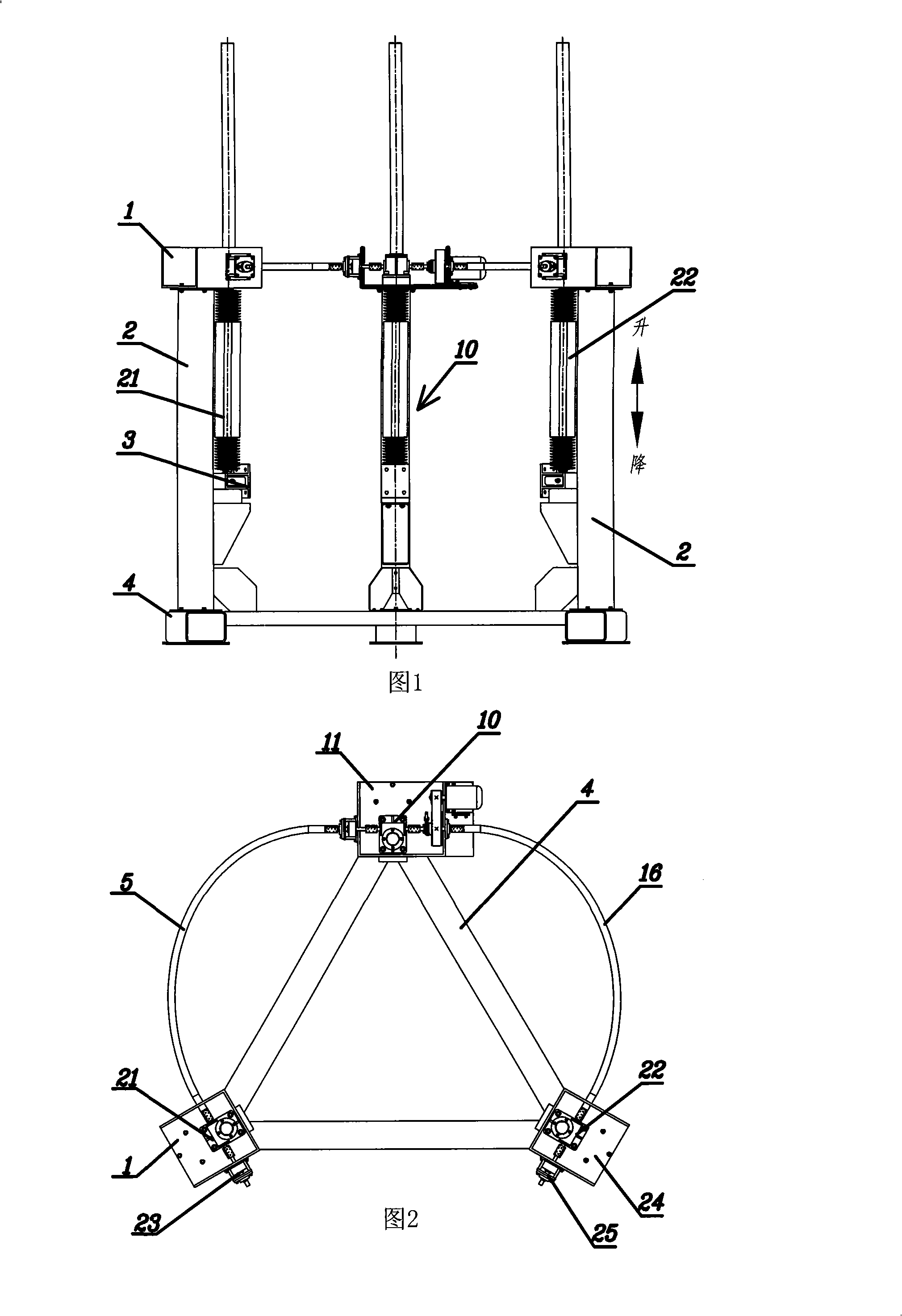

Multi-point synchronization lifting mechanism composed of steel wire flexible shaft

The invention relates to a multipoint synchronous lifting mechanism composed of a steel wire flexible shaft. Three upright columns distributed as equilateral triangle are arranged on a base of the multipoint synchronous mechanism; three screw lifter are respectively arranged on permanent seats of the corresponding upright columns tops; one end of a drive shaft of a first and a second screw lifter is provided with a brake and the other end is connected with one end of the corresponding steel wire flexible shaft by a coupling; one end of a drive shaft of third screw lifter is connected with one end of the brake shaft by the coupling and the other end of the brake shaft is connected with the other end of the same steel wire flexible shaft by the coupling; the other end of the drive shaft of the third screw lifter is connected with one end of a large synchronous belt wheel shaft, and the other end of the wheel shaft is connected with the other end of another steel wire flexible shaft by the coupling; the large synchronous belt wheel shaft is connected with a large synchronous pulley by a torque limiter and the large synchronous pulley is connected with a main shaft of a DC motor by a transmission pair. The multipoint synchronous lifting mechanism has the advantages of high synchronous precision, simple structure, low cost, high reliability, low noise, convenient speed regulation, simple installation and convenient matainance.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

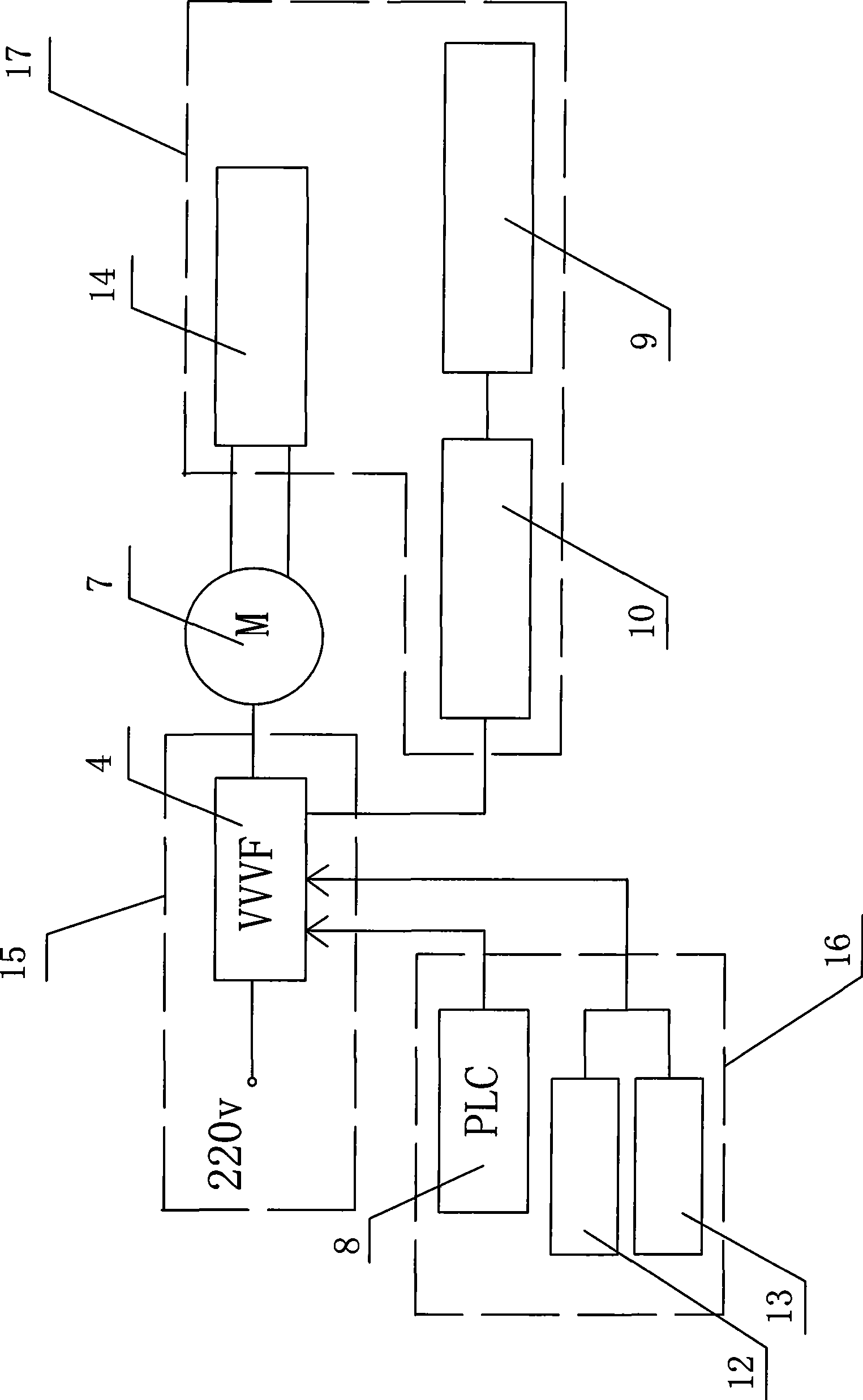

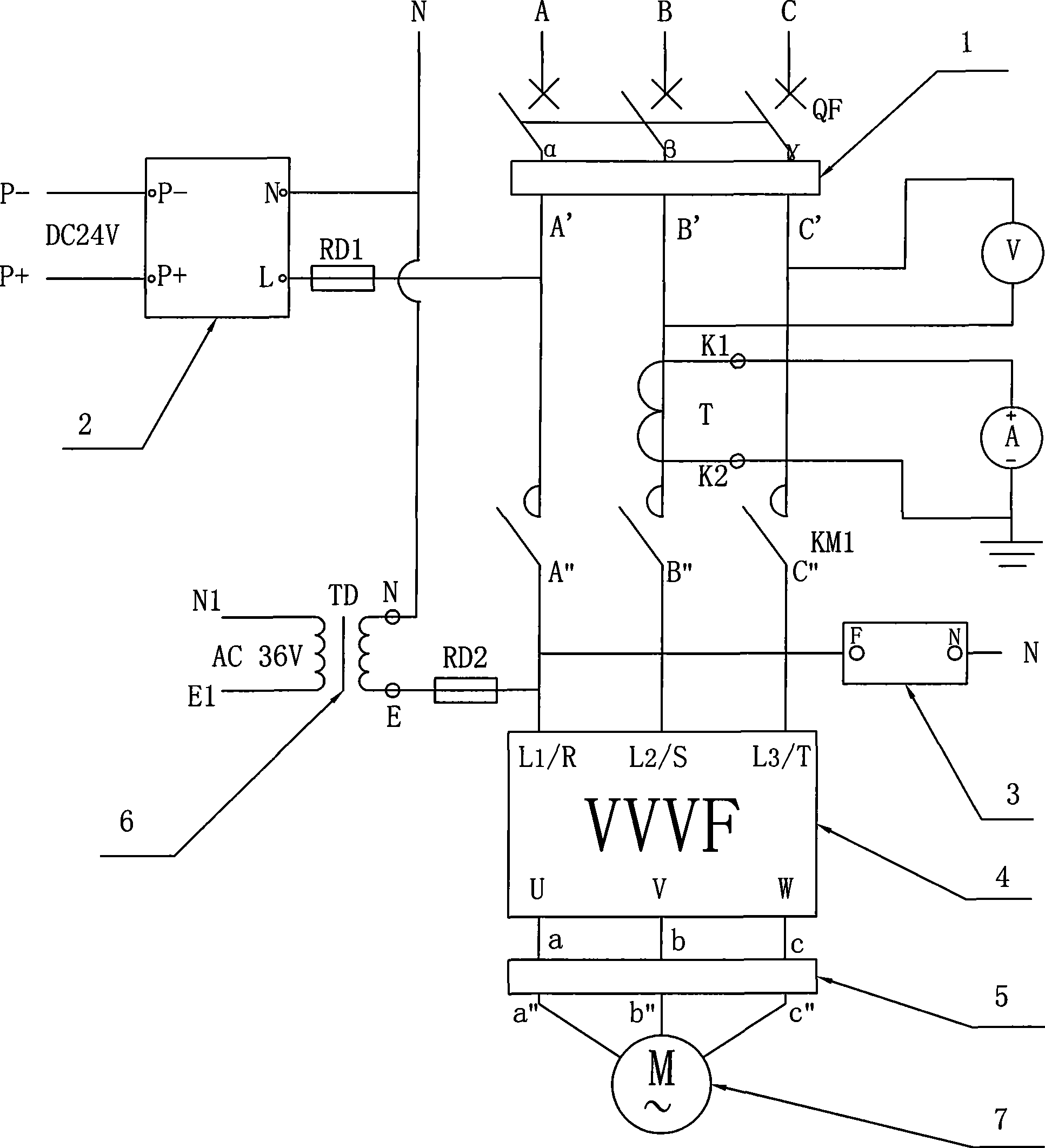

Vertical lathe workstation control system

InactiveCN101474760AEliminate shockStable power supplyAutomatic control devicesFeeding apparatusFrequency changerAlternating current

A vertical lathe worktable control system comprises a cabinet body, a main circuit, an auxiliary control circuit and a braking circuit, wherein the main circuit, the auxiliary control circuit and the braking circuit are installed in the cabinet body. In the main circuit, alternating-current three-phase four-wire is connected with a power source input end of transducer VVVF through a combination switch QF, an input power source filter and an alternating-current contactor KM1. The output of main circuit is connected with a main electric motor through an output power source filter. A PLC programmable controller is the core of auxiliary control circuit. A braking unit comprises a transducer braking mechanism, a braking resistor box, a first transducer frequency setting potentiometer, a second transducer frequency setting potentiometer, a second transducer inching frequency setting potentiometer, a transducer frequency meter and an electromagnetic brake. The transducer VVVF is connected with the transducer braking mechanism. The vertical lathe worktable control system of the invention has the advantages of simple structure, strong reliability, convenient speed adjustment, energy consumption saving, increased operation speed and increased cutting efficiency. The vertical lathe worktable control system of the invention can be widely used on the cutting mechanical device.

Owner:SHENYANG LIGONG UNIV

Brake-type liquid viscosity transmission device

InactiveCN103075450AIngenious ideaSolve complexityCoupling-brake combinationLiquid viscosityControl system

The invention discloses a brake-type liquid viscosity transmission device which comprises a box body, a speed governing mechanism and a brake mechanism, wherein the speed governing mechanism comprises a first shaft, a second shaft, a second shaft transparent cover, a driving friction plate, a driven friction plate, a driven drum, a driven plate, a first piston cylinder and a first control oil pipe; the brake mechanism comprises a brake shaft, a brake shaft transparent cover, a moving friction plate, a static friction plate, a brake drum, a brake plate and a second piston cylinder. According to the brake-type liquid viscosity transmission device, the idea is ingenious, the stepless speed governing function of a liquid viscosity speed governing clutch and the braking and speed reduction functions of a liquid viscosity brake are realized on the same set of device; a same set of oil pressure control system is adopted, the working conditions of the speed governing mechanism and those of the brake mechanism are mutually corresponding and collaborated, so that not only can the torque be transmitted to the transmission system as required and can the output rotating speed be adjusted steplessly, but also adjustable moment of resistance can be applied, the system is in a half-braked state for a long time, and the mutual coordination and controllability of the speed governing and the braking of the transmission system are realized.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com