Soft ice cream machine with the frequency conversion control function

A technology of soft ice cream and frequency conversion control, which is applied in frozen desserts, food science, and applications. It can solve problems such as loud noise, motor damage, and easy magnetic gap generation, and achieve stable starting torque, prevent malfunction, and facilitate speed regulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

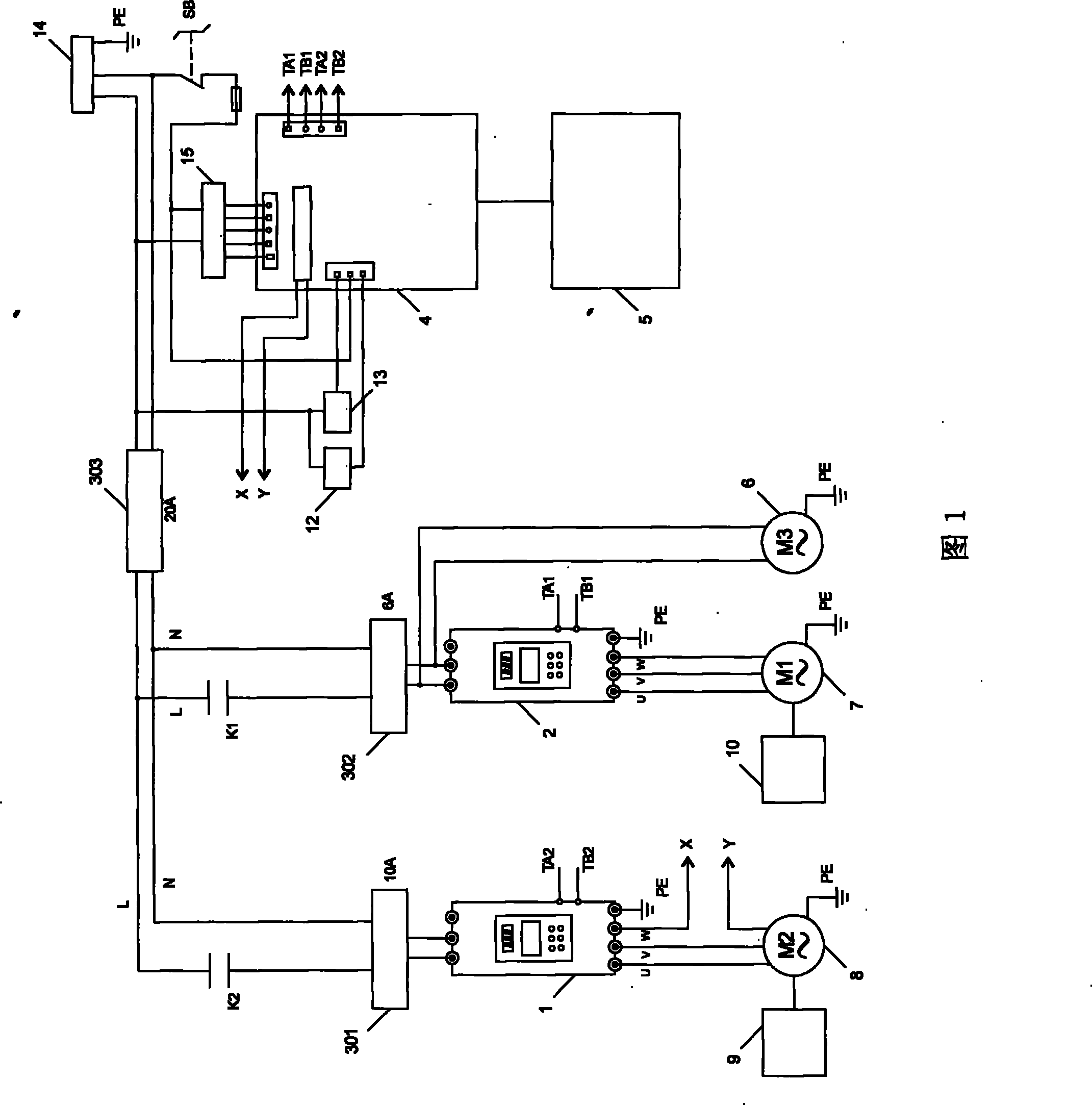

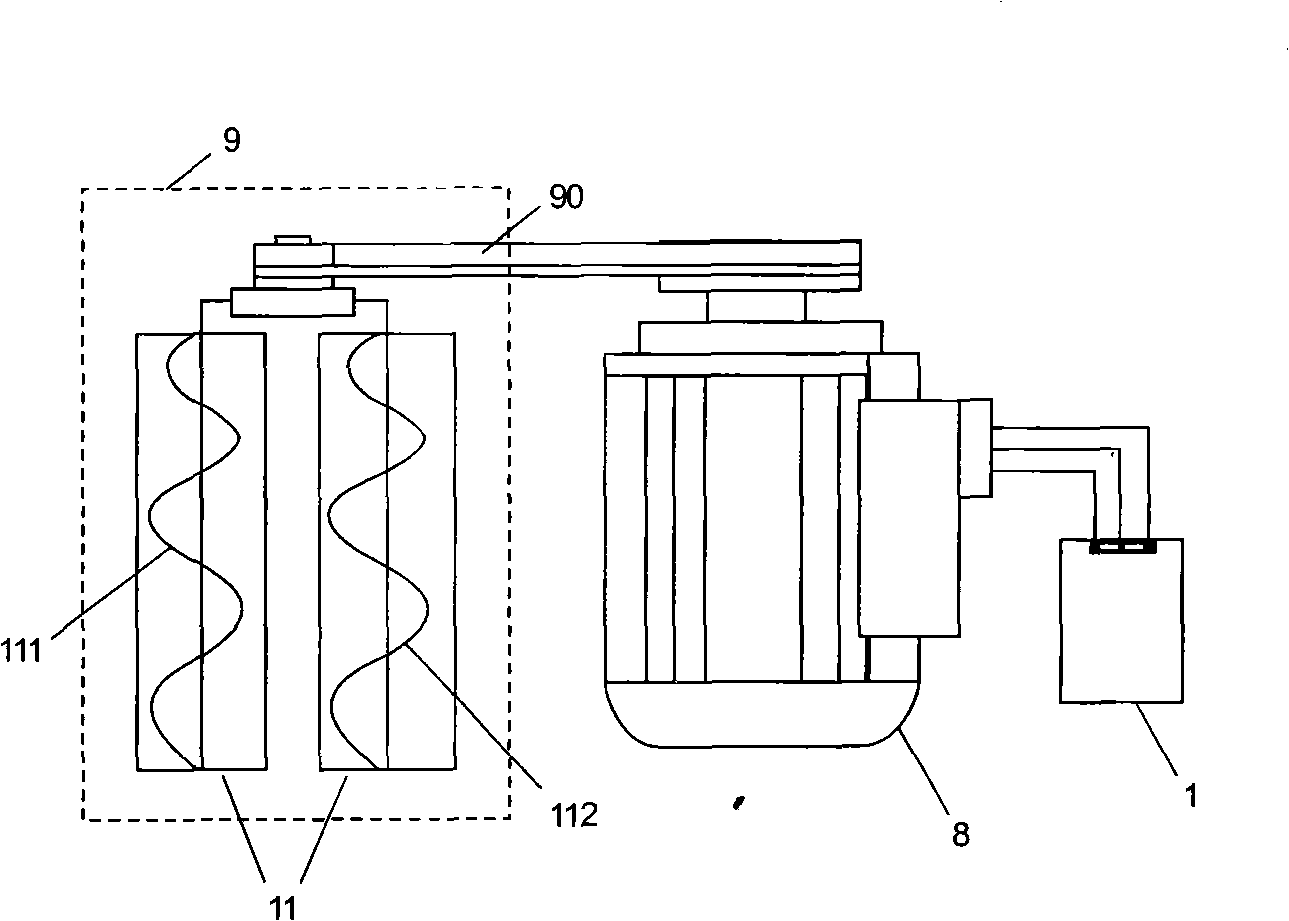

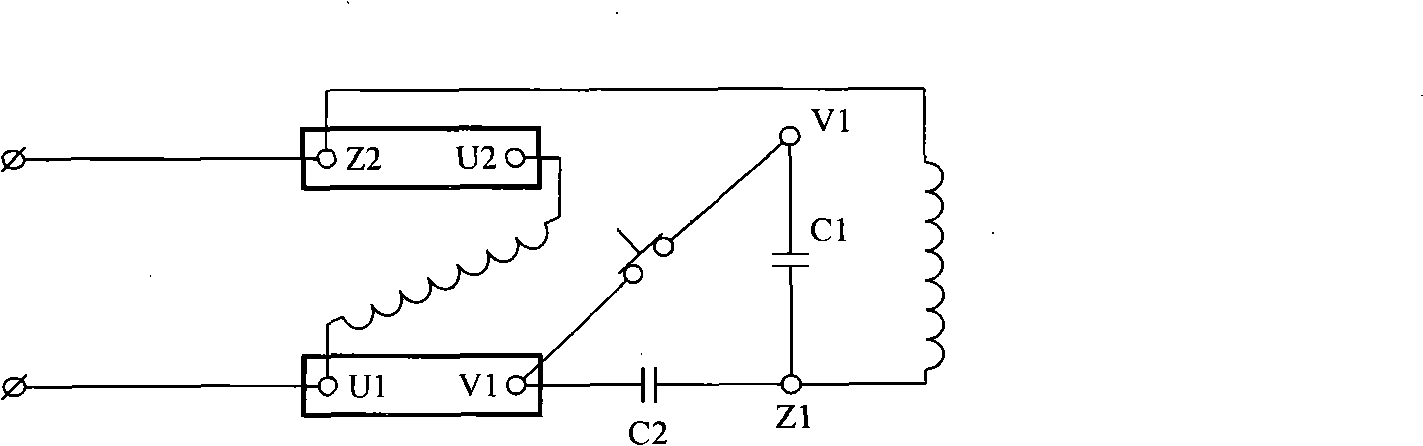

[0019] Please also refer to Figure 1 and figure 2 , The soft ice cream machine with frequency conversion control function includes a power unit, a stirring device 9 and a refrigeration device 10. The structure of the power plant is shown in Figure 1, including the first frequency converter 1, the second frequency converter 2, the first electromagnetic filter 301, the second electromagnetic filter 302, the third electromagnetic filter 303, the first relay 12, the first Two relays 13, refrigeration motor 7, condensing fan motor 6, stirring motor 8, main controller 4 and display 5; the first relay 12 has a main contact switch K2, and the second relay 13 has a main contact switch K1. Wiring according to the wiring diagram of the soft ice cream machine system shown in Figure 1: electrically connect the power interface 14, the third electromagnetic filter 303, the main contact switch K2 of the first relay 12, and the first electromagnetic filter in sequence 301. The first frequenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com