Patents

Literature

146 results about "Centrifugal switch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A centrifugal switch is an electric switch that operates using the centrifugal force created from a rotating shaft, most commonly that of an electric motor or gasoline engine. The switch is designed to activate or de-activate as a function of the rotational speed of the shaft.

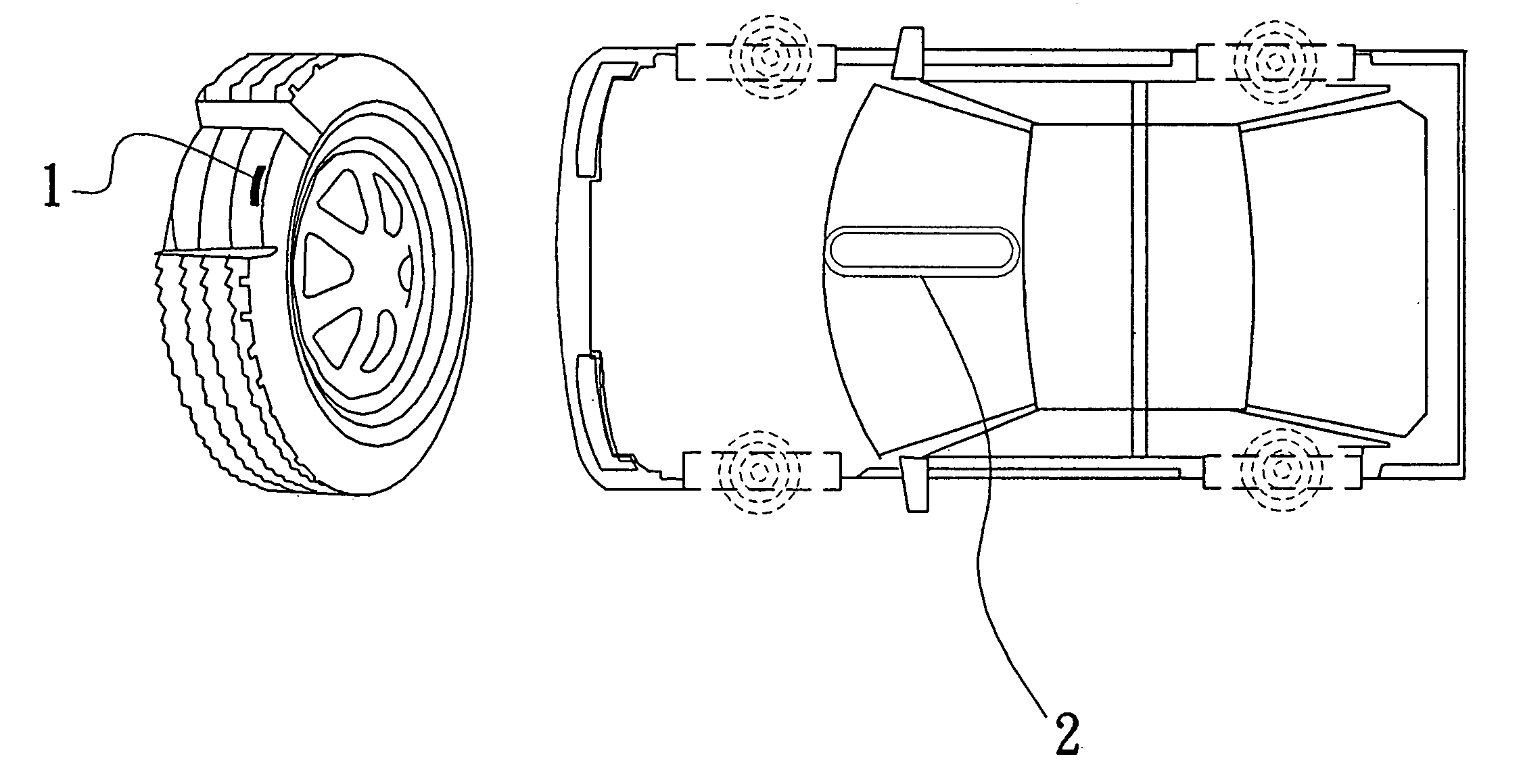

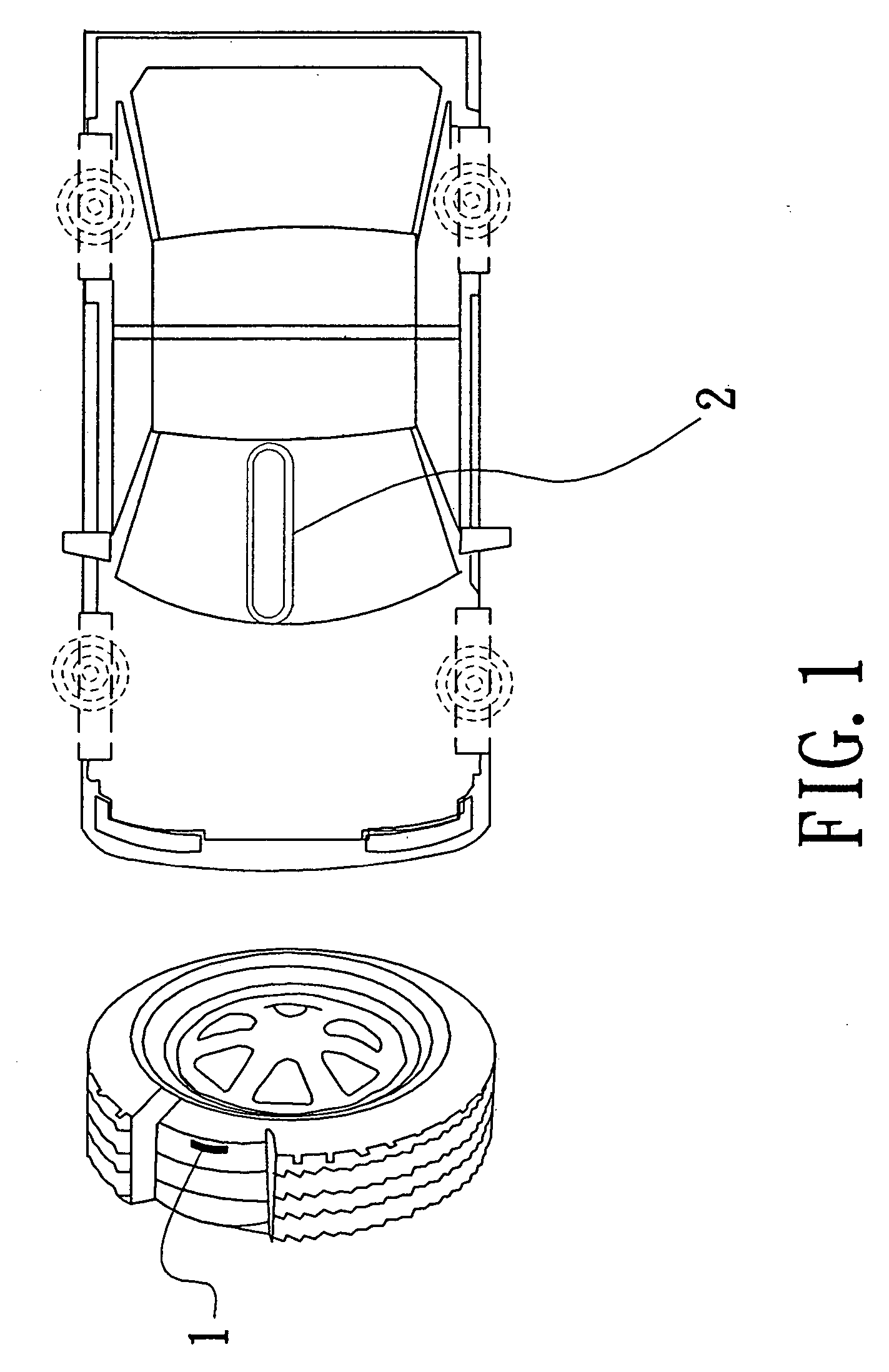

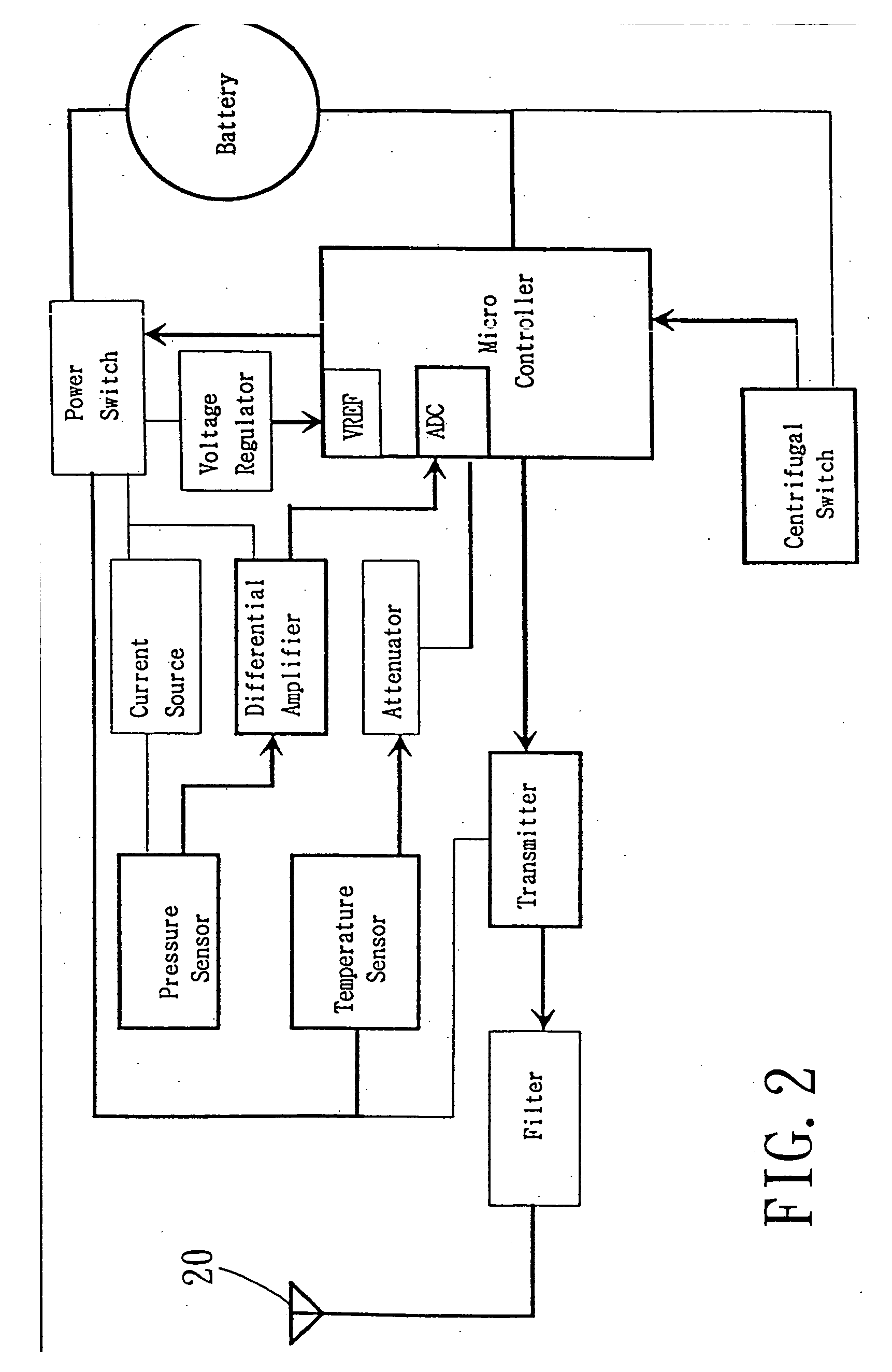

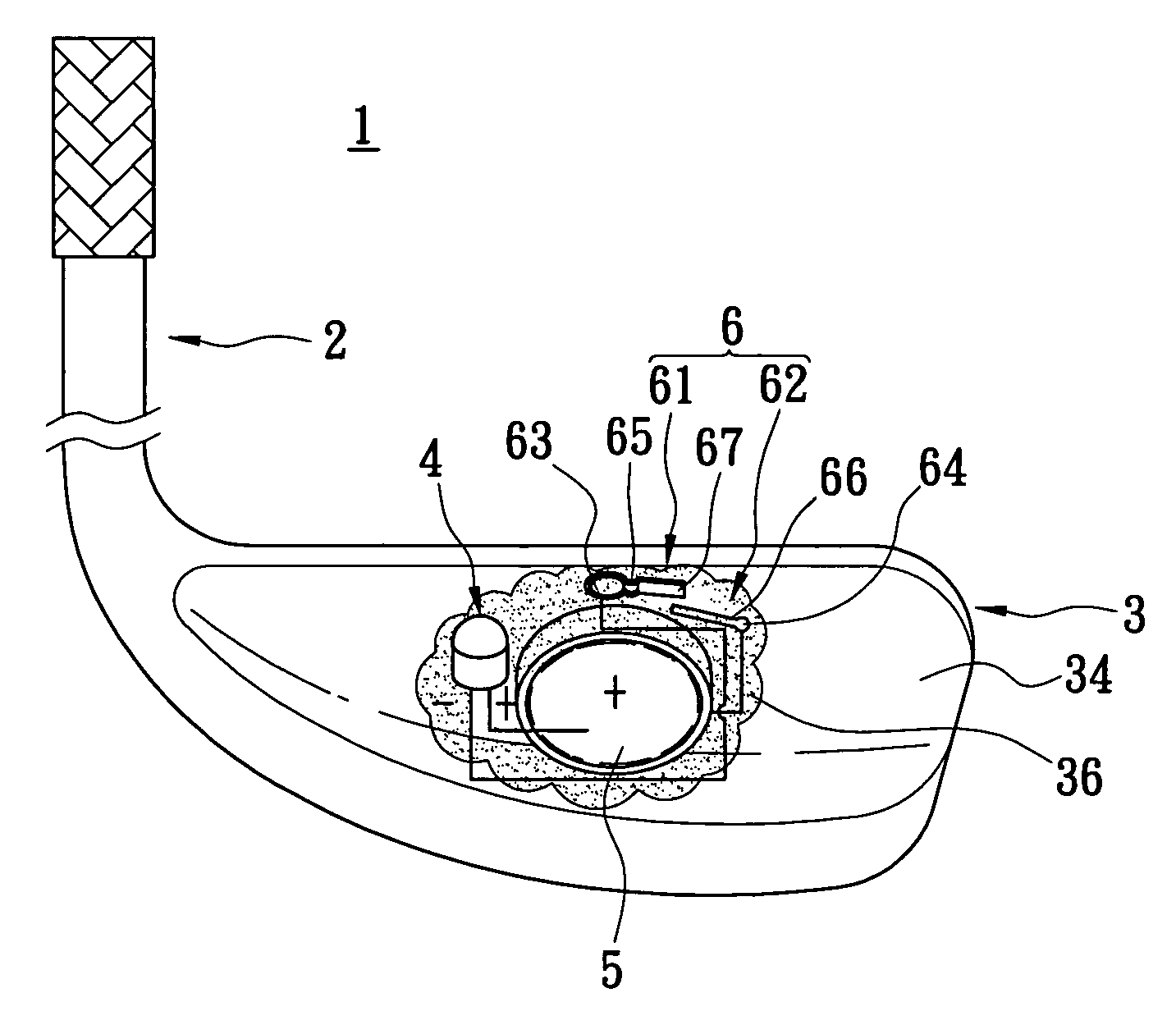

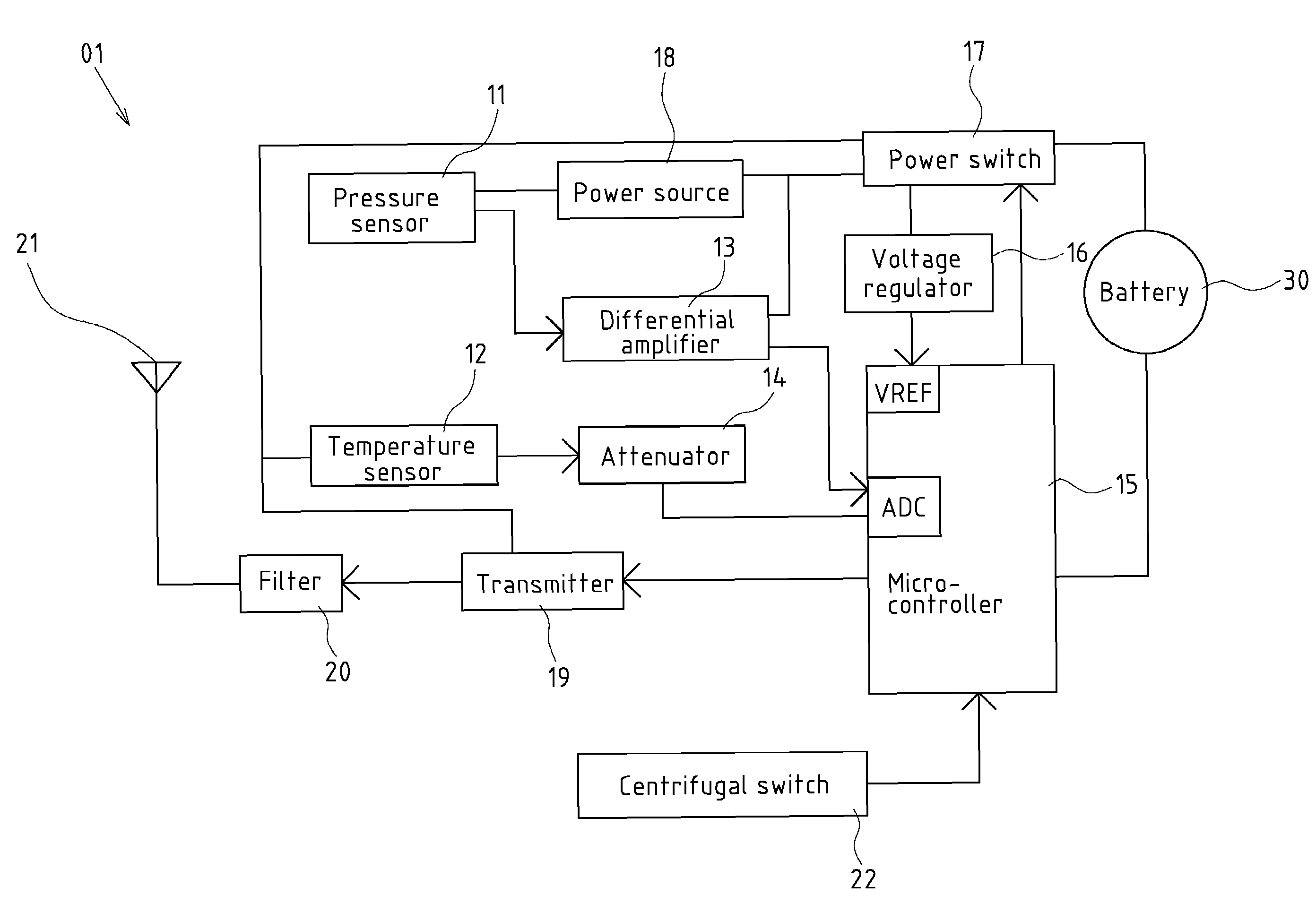

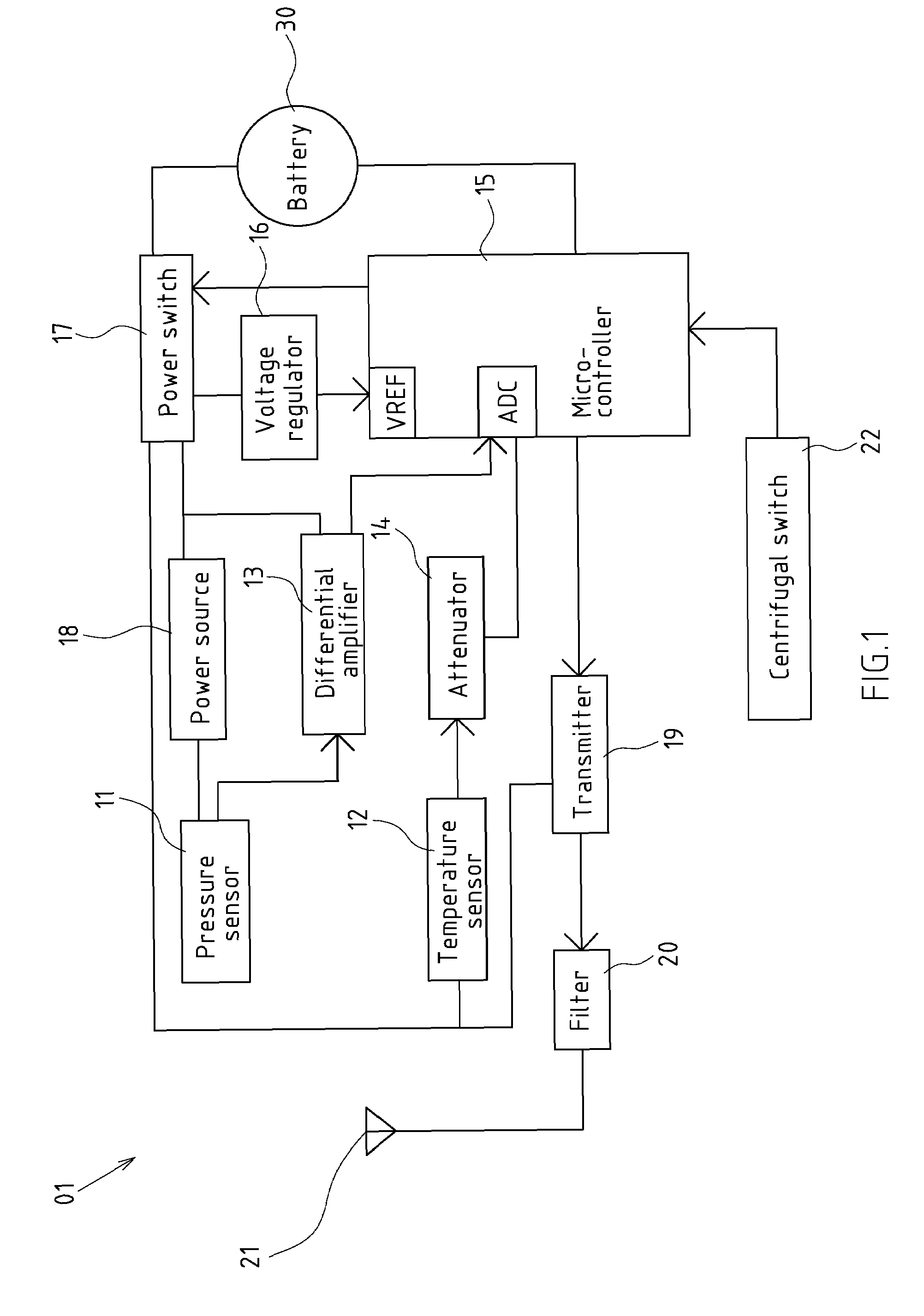

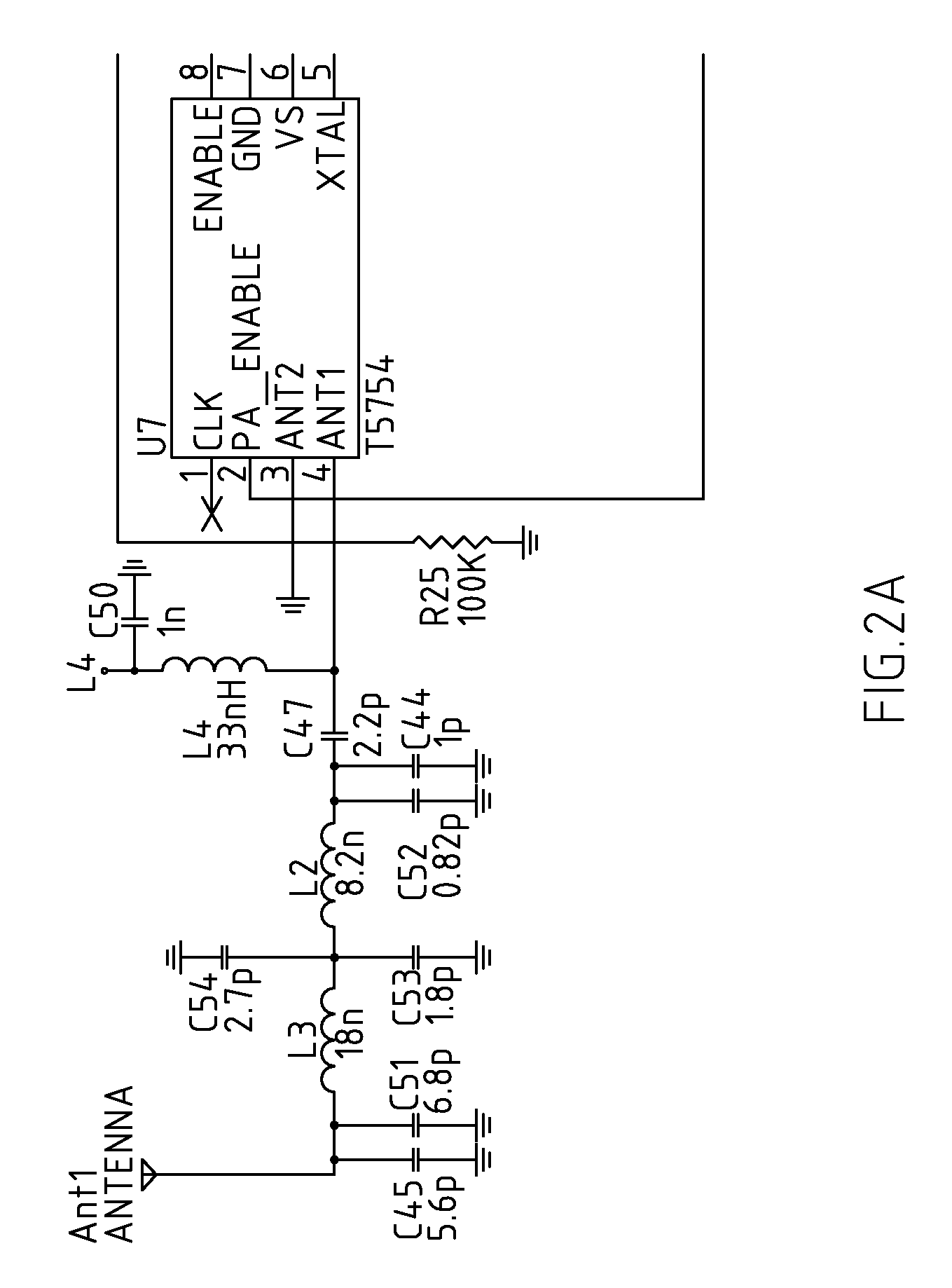

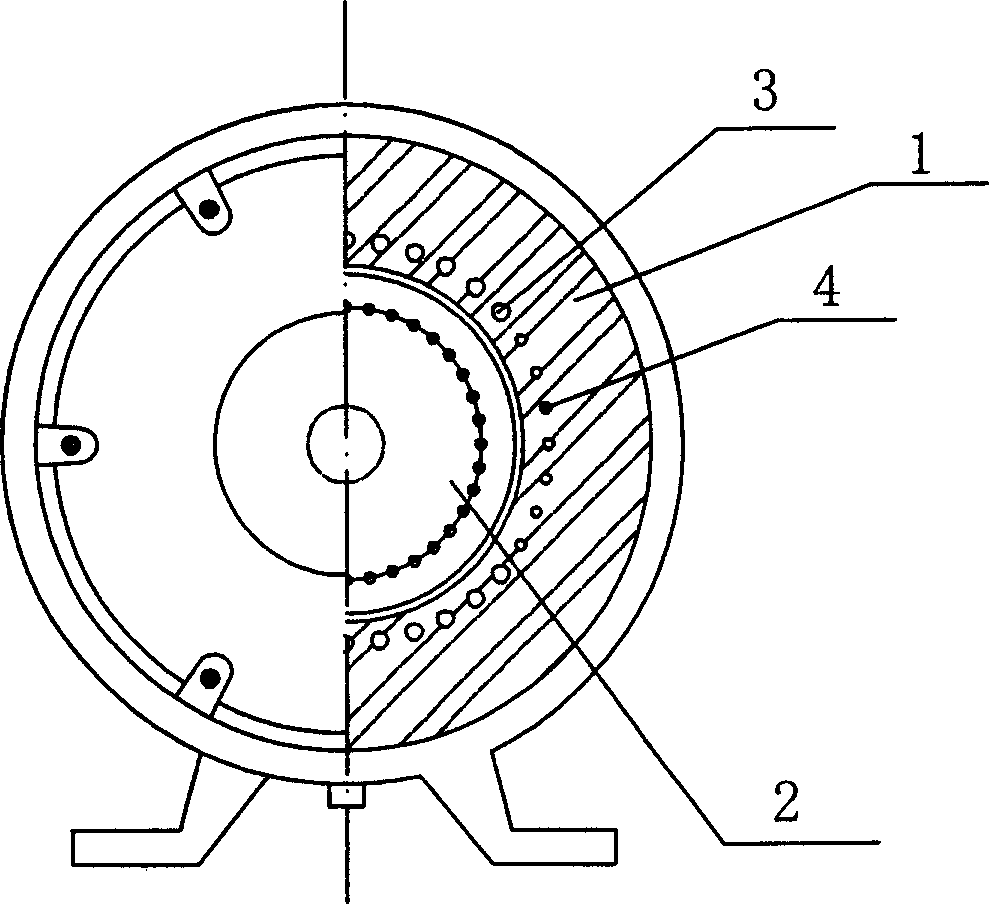

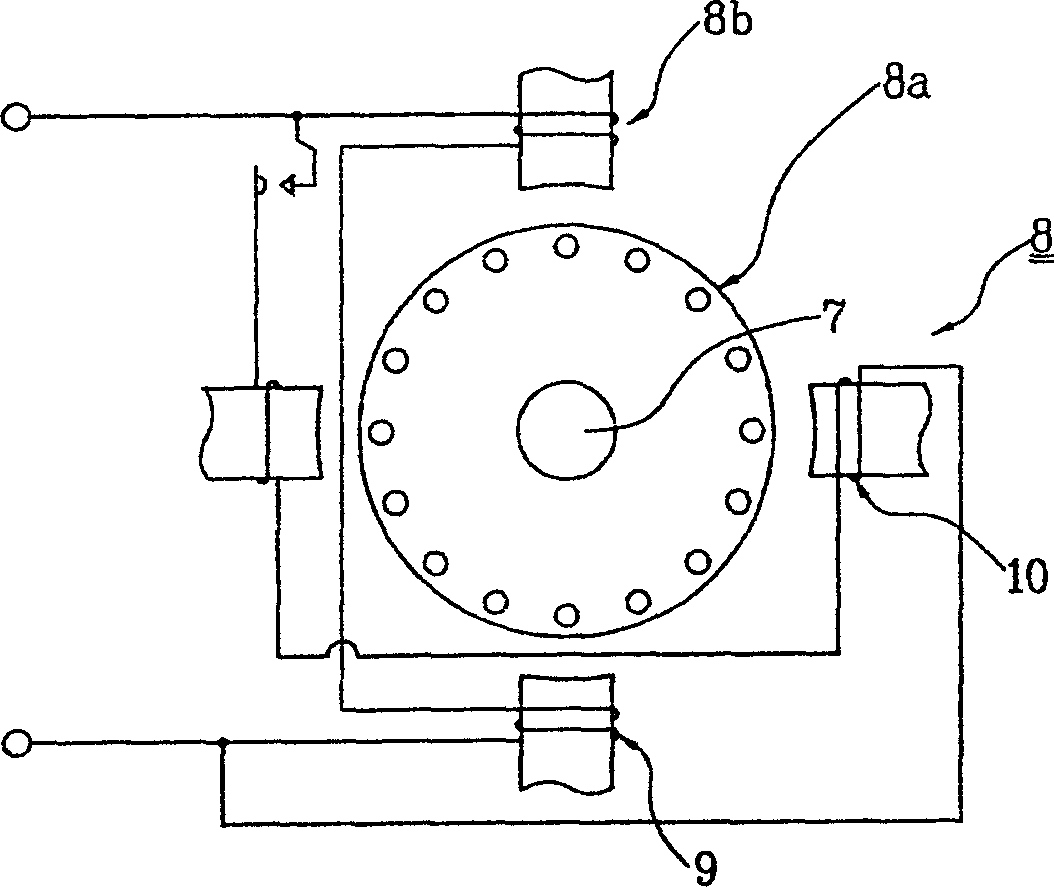

Wireless tire pressure and temperature monitoring system

InactiveUS20050274442A1Effective monitoringEnsure traffic safetyTyre measurementsTyre-inflating valvesDriver/operatorTemperature monitoring

A wireless tire pressure and temperature monitoring system comprises a wireless monitor and transmitter unit installed on the wheel rim and a digital receiver and display unit equipped near the driver's seat. The wireless monitor and transmitter unit further includes a pressure sensor; a temperature sensor; a differential amplifier connected to the pressure sensor, an attenuator connected to the temperature sensor; a micro controller for calculating and processing the pressure signal received from the differential amplifier and the temperature signal received from the attenuator; a transmitter for transmitting the signals to the digital receiver and display unit via a filter and a resonant antenna so that the driver is able to be informed of the tire stability of the vehicle to assure traffic security. A centrifugal switch connected to the micro controller is actuated to start monitoring when the vehicle speed exceeds a defined range (10 km / hr˜20 km / hr), and stop monitoring after the vehicle speed drops down below the aforesaid range for about five minutes.

Owner:ASIA PACIFIC MICROSYST

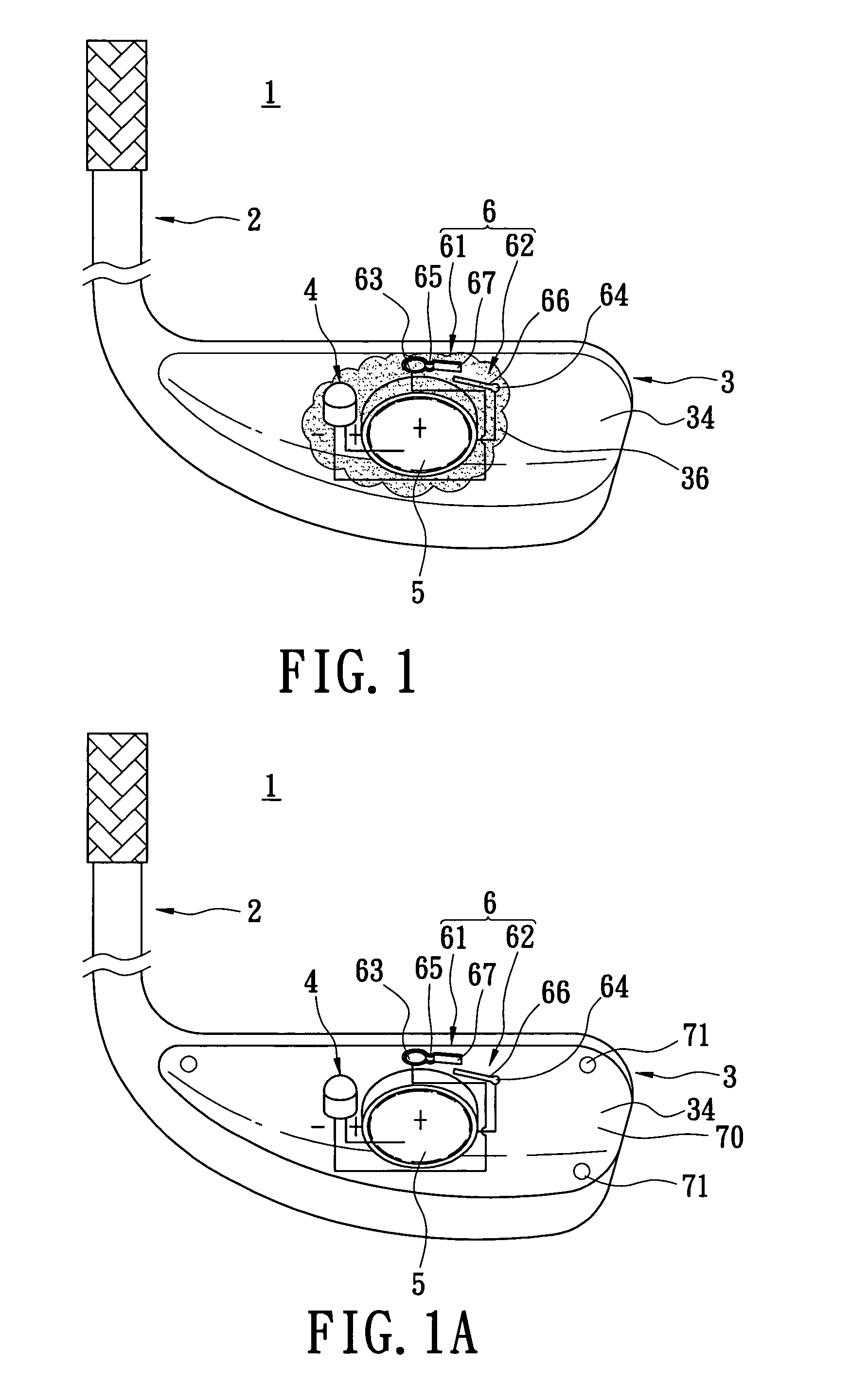

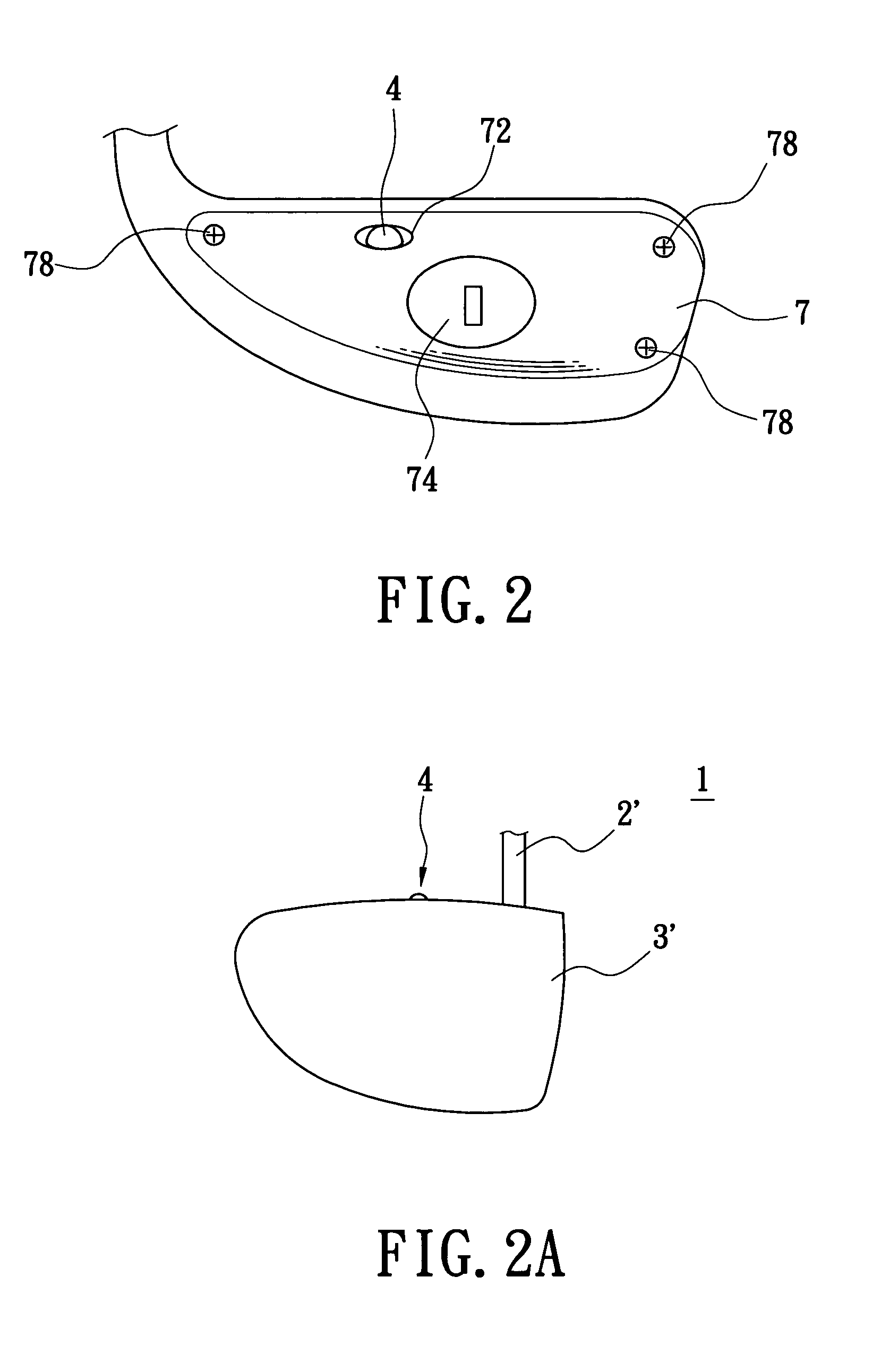

Golf club for showing swing condition

A golf club for showing swing condition has a shaft and a head connecting to the shaft, and the head having a striking face. The golf club has a visible illuminant that is mounted on the head and exposed outside the head with an upward angle. A battery is for providing electrical power to the light. A centrifugal switch that is actuated by centrifugal force is mounted on the head opposite the striking face for controlling a circuit between the battery and the illuminant. Thereby the illuminant will light by a predetermined-strength centrifugal force during swinging the golf club for investigating the body harmony and strength-exerting condition of golfer.

Owner:HU CHIN TE +1

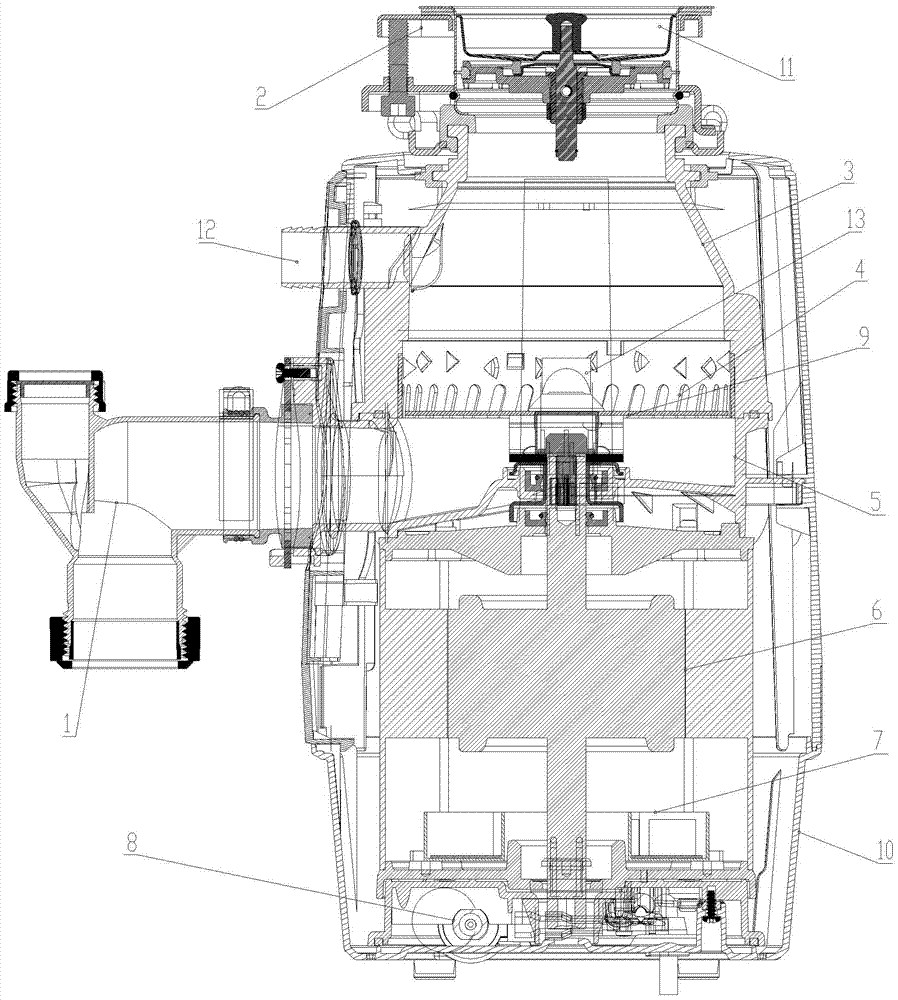

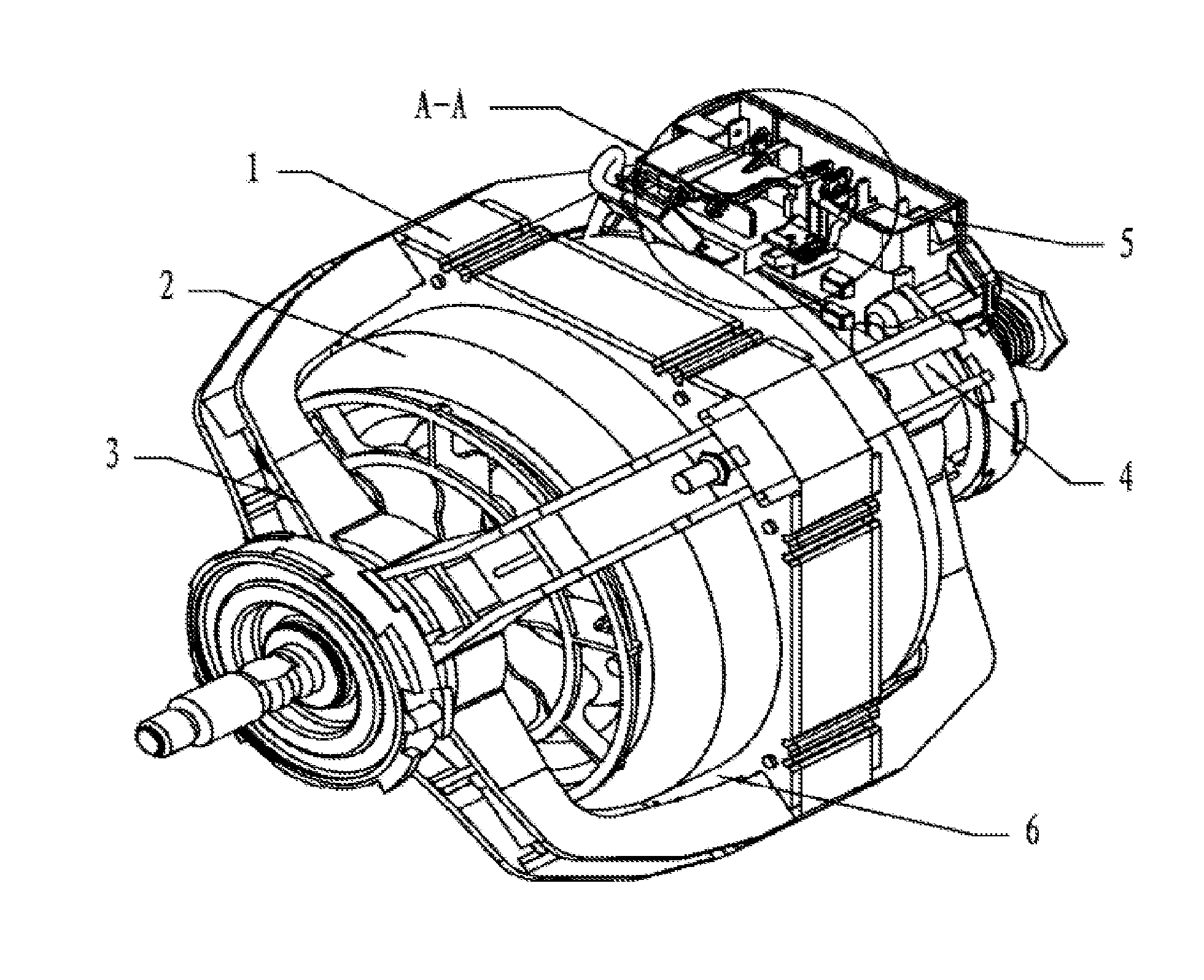

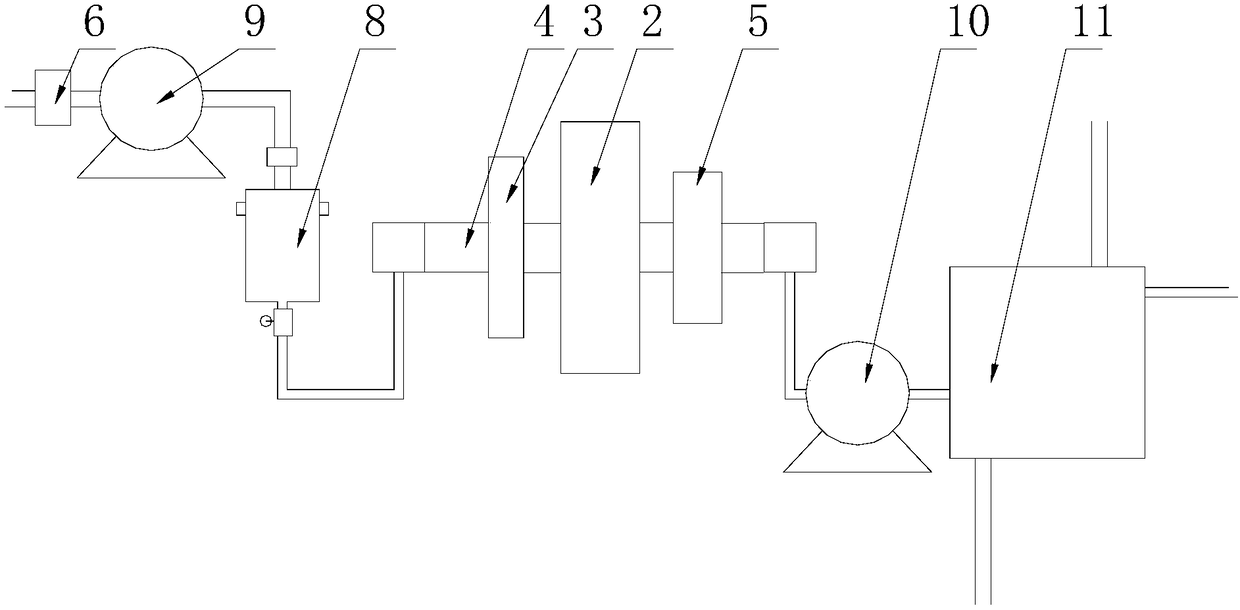

Food waste disposer and control method thereof

ActiveCN105435917AEasy to useAvoid processing powerDomestic plumbingGrain treatmentsSynchronous detectionConductor Coil

The invention discloses a food waste disposer and a control method thereof. The food waste disposer comprises a food waste inlet, a grinding device, a motor (6) and an electronic centrifugal switch (7), wherein food waste enters the grinding device through the food waste inlet; the motor (6) is connected to the grinding device and drives the grinding device to grind the entered food waste and discharge the ground food waste; the electronic centrifugal switch (7) is connected to the motor (6), the running state of the motor (6) is ensured by synchronously detecting the current value and the voltage value of the motor (6), and further the connection or disconnection of the main winding and / or secondary winding of the motor (6) is controlled according to the running state of the motor (6). According to the scheme, the food waste disposer can overcome the defects of inconvenience in use, short service life and poor universality in the prior art and realize the beneficial effects of convenience in use, long service and good universality.

Owner:GREE ELECTRIC APPLIANCES INC

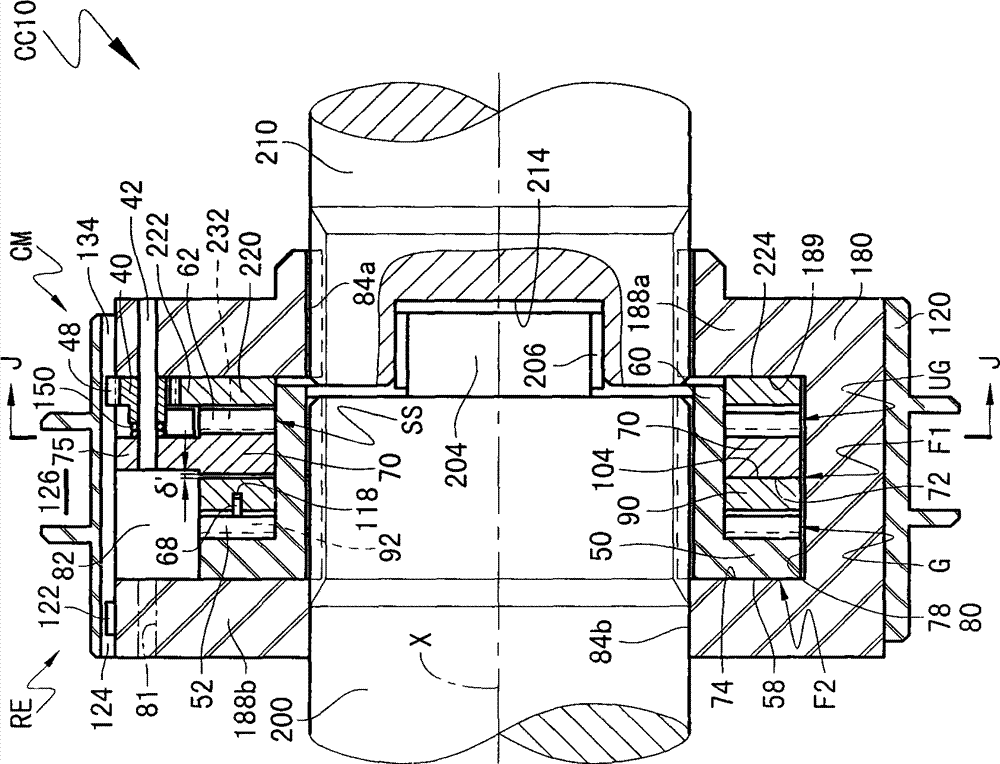

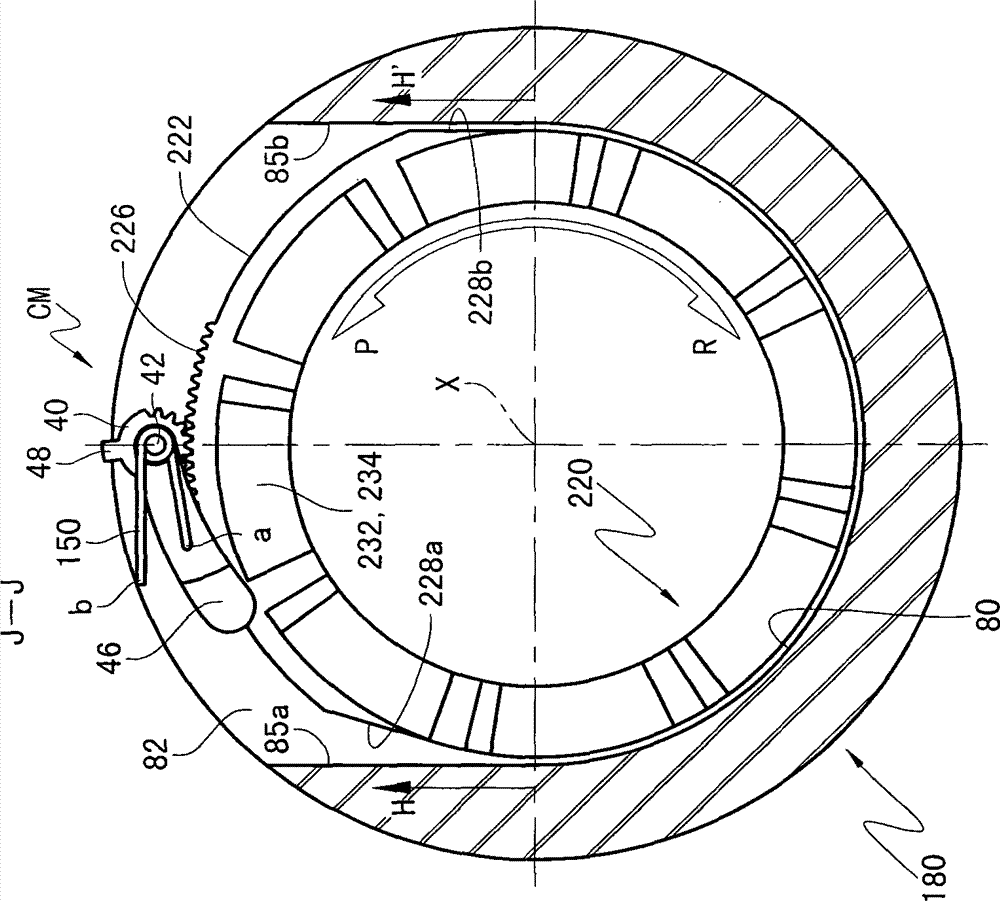

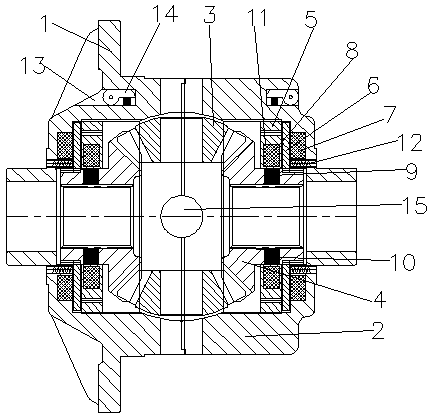

Space wedge type centrifugal clutch capable of rapidly acting, dual clutch transmission with clutch and operation method thereof

InactiveCN102777512ASimple structureQuick and responsive actionGearing controlAutomatic clutchesAutomatic transmissionHigh intensity

The invention discloses a centrifugal clutch, which comprises a full contact type self-excitation space wedge mechanism which is irrelevant to centrifugal force, a rotary guide type stepless supporting mechanism for driving a wedge mechanism to wedge or remove the wedge in a trigger mode, and a centrifugal actuating mechanism which responses to the centrifugal force to actuate the supporting mechanism. The clutch has high-intensity torque capacity irrelevant to the rotating speed and accurate and sensitive responsiveness; and moreover, the working conditions can be circularly changed along with monotonous ascending or descending of the rotating speed. When the clutch is used for a dual clutch transmission, the centrifugal clutch can adaptively finish gear-shifting operations of all forward gears, and any operating gear-shifting mechanism is not required. When the dual clutch is a space wedge type friction clutch, the whole complex and expensive hydraulic system can be completely abandoned; and meanwhile, because the gear-shifting operation is not required, the operating mode of the transmission is simplified, only the output rotating speed is required to be detected, and a secondary clutch which corresponds to the dual clutch in the dual clutch is engaged according to the rotating speed.

Owner:洪涛

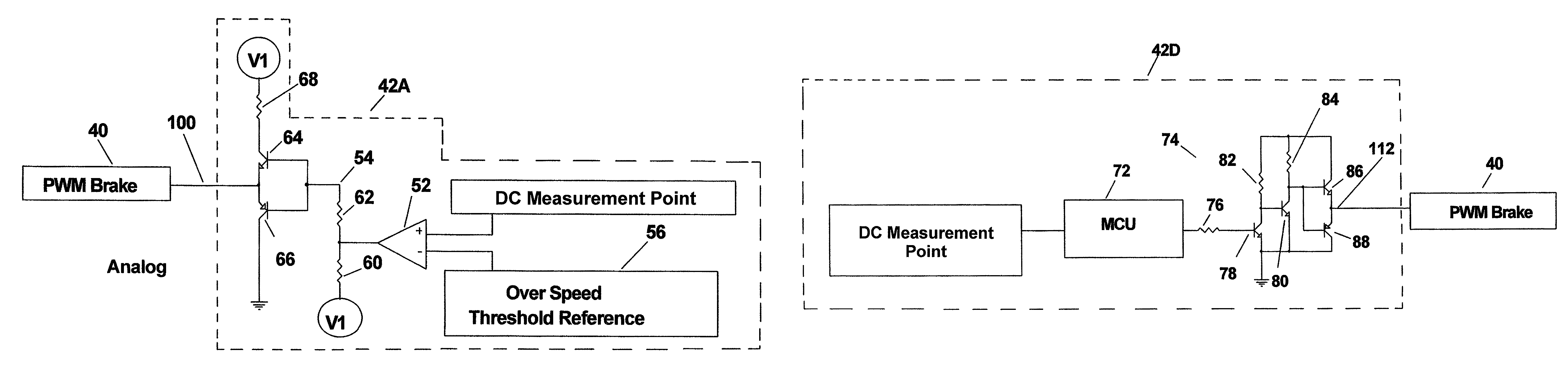

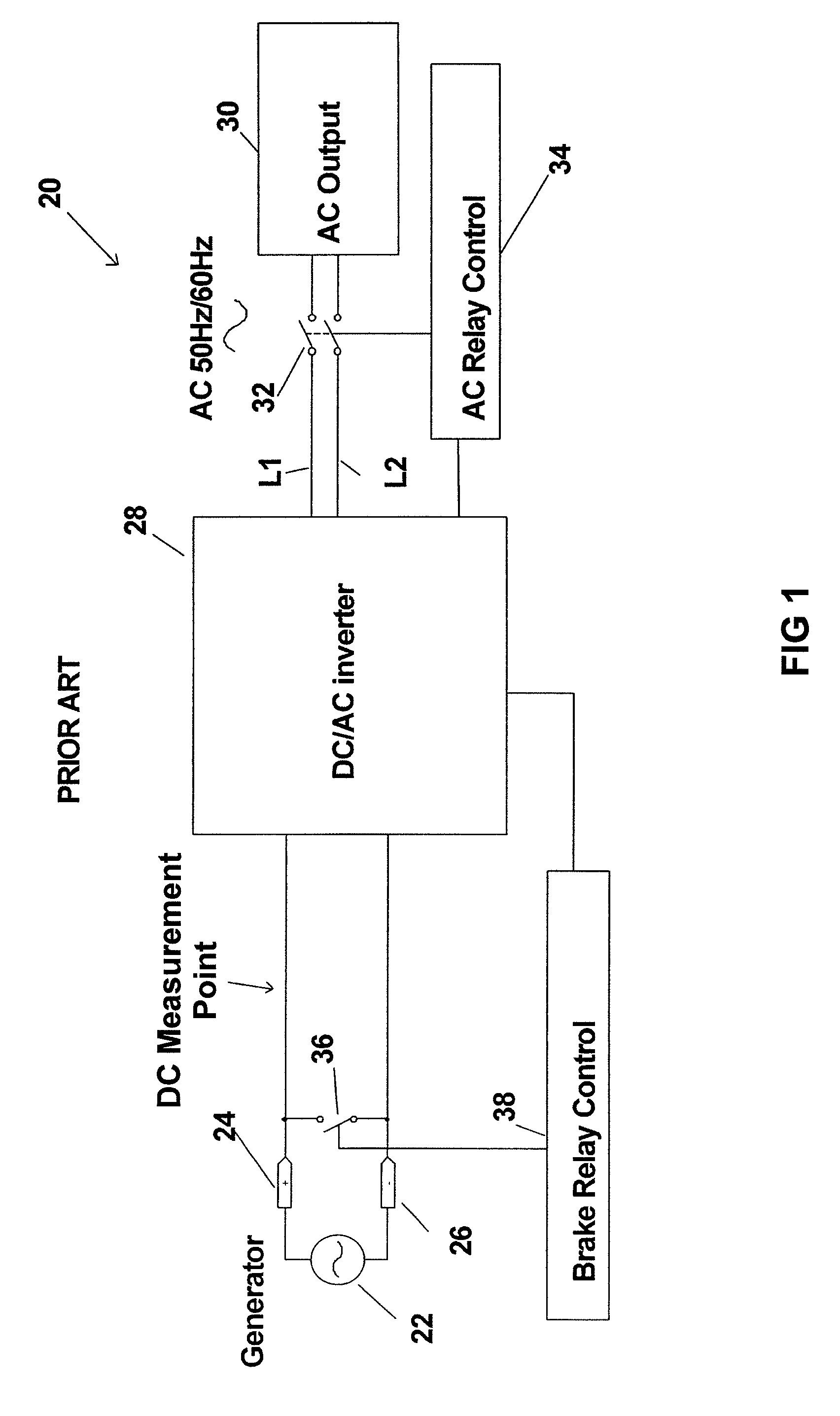

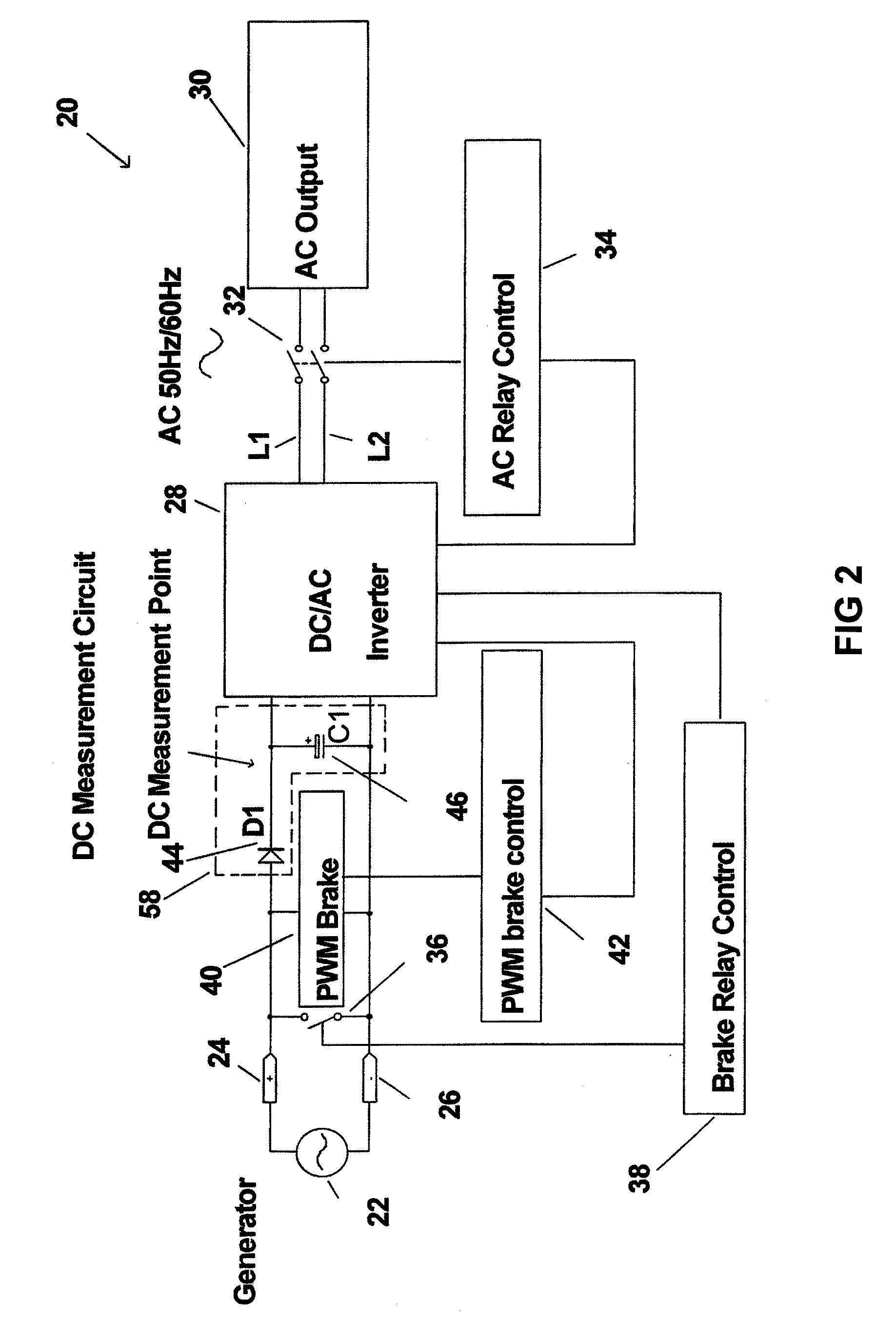

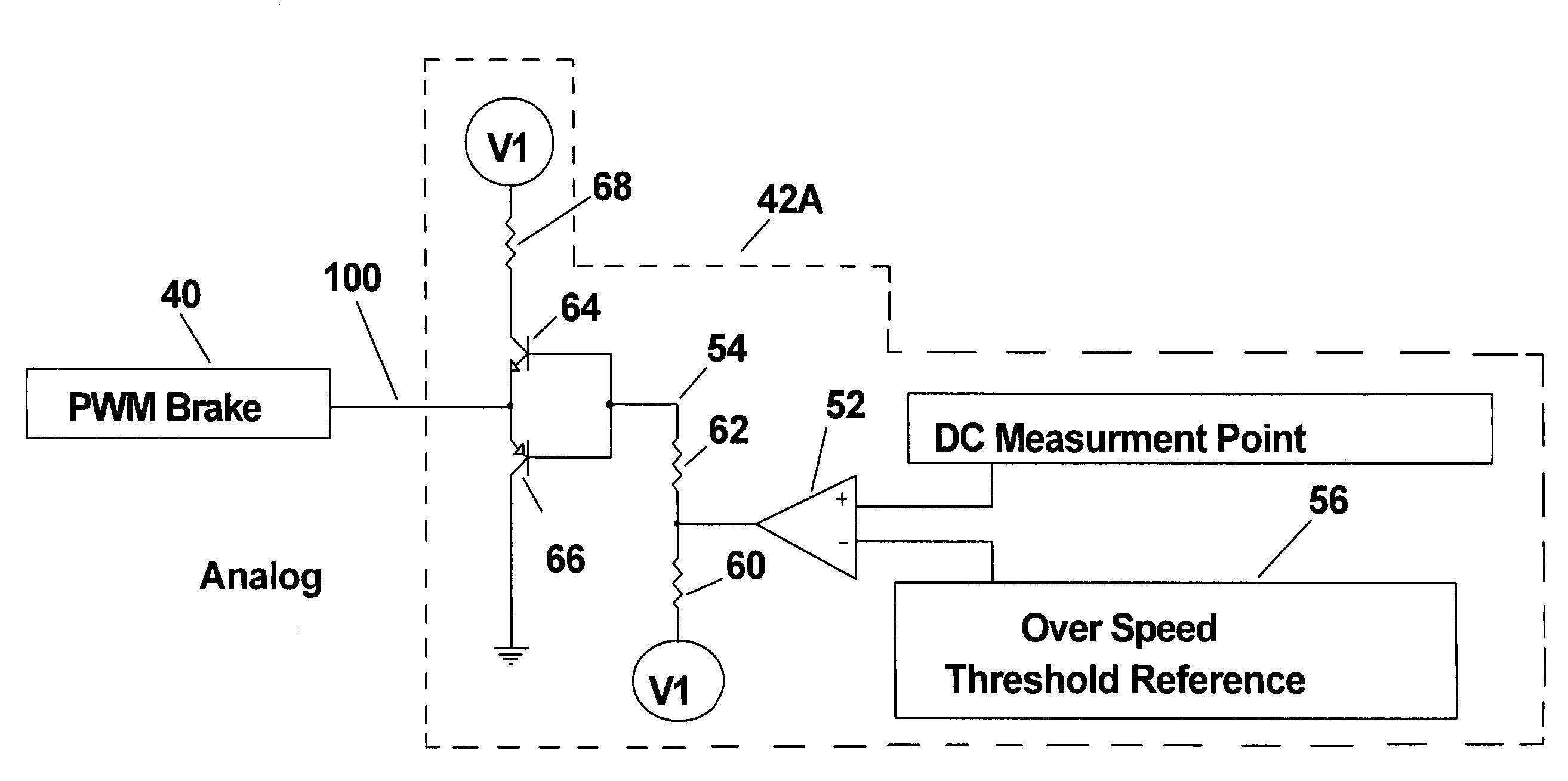

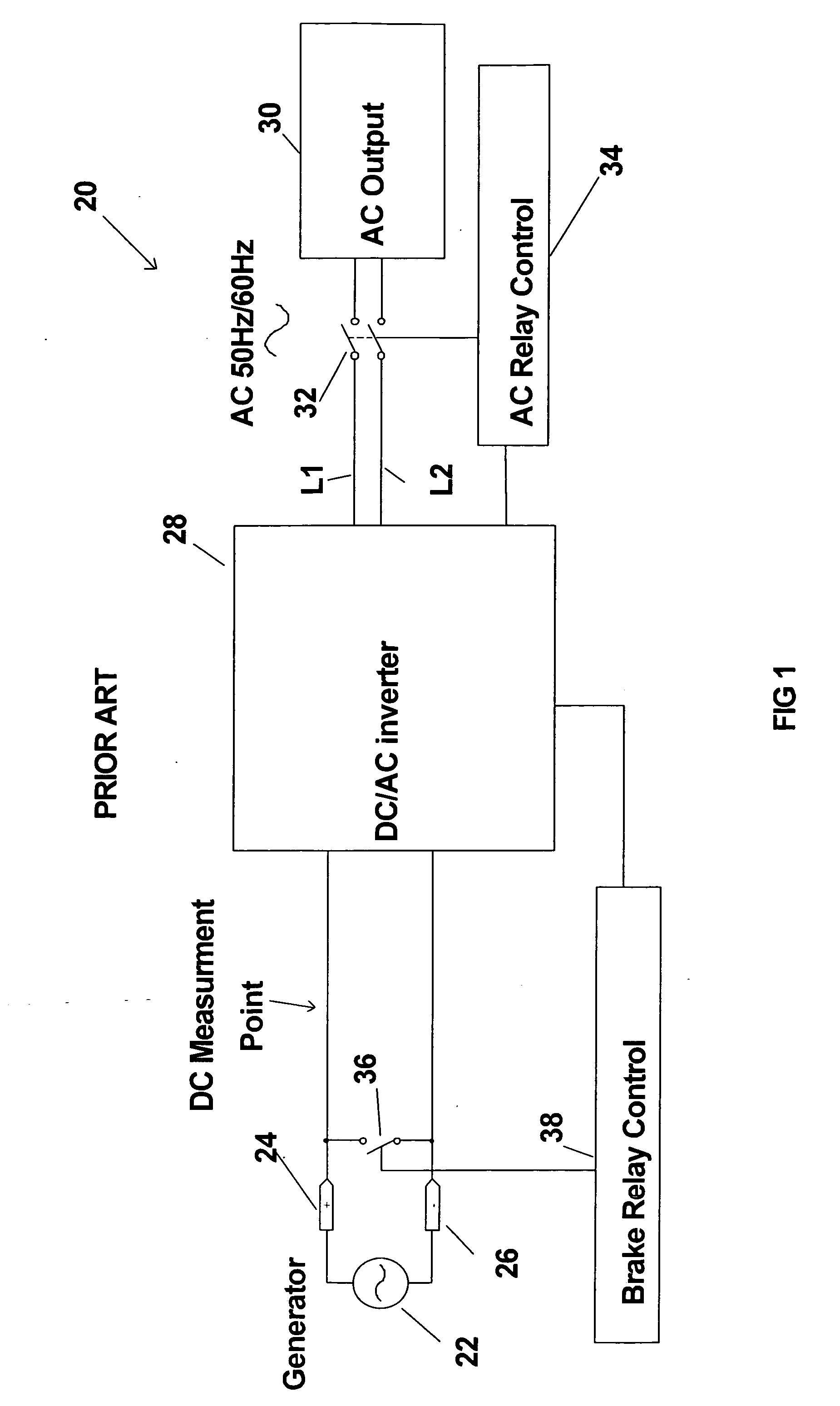

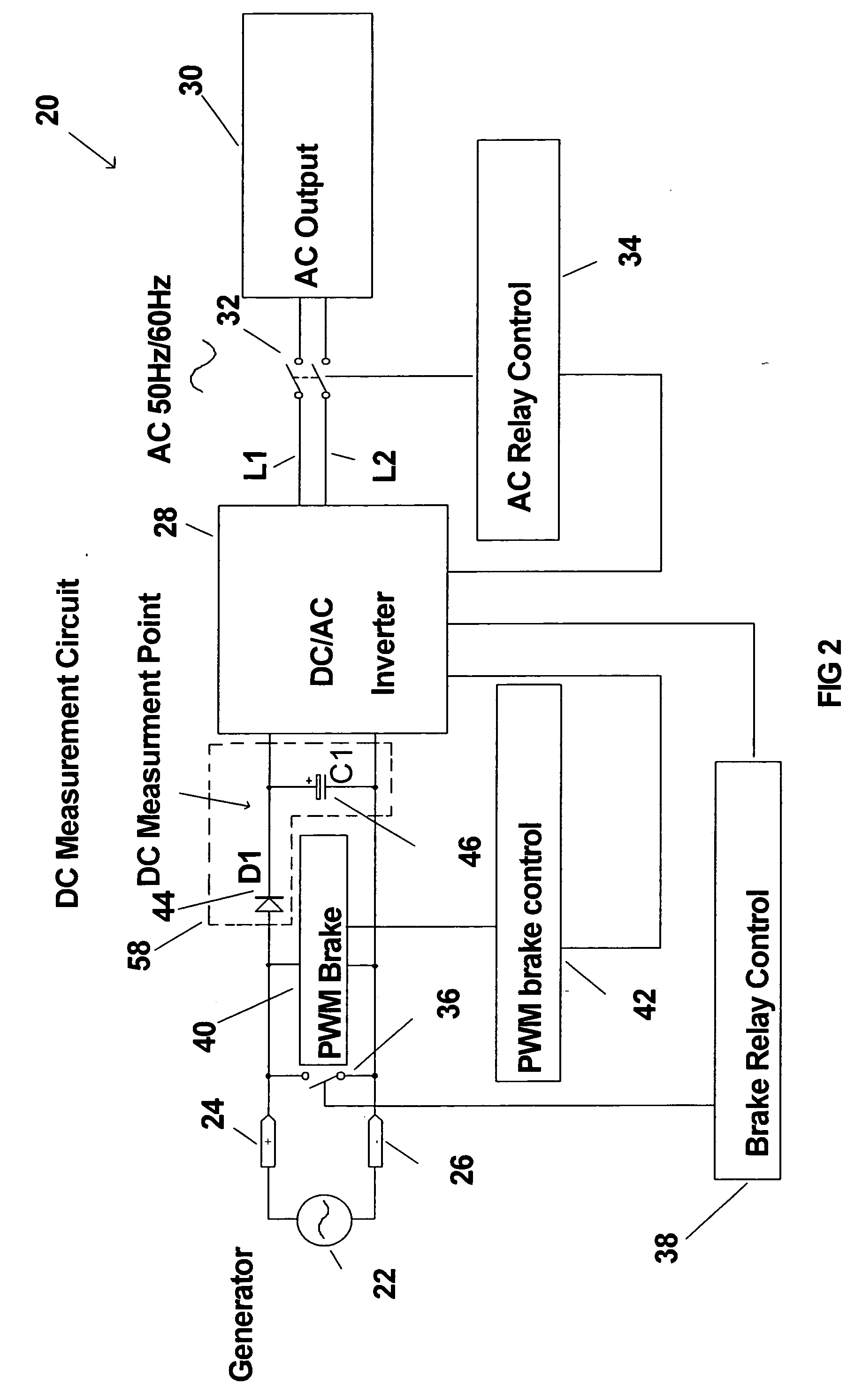

Speed sensing circuit for a wind turbine generator

InactiveUS7816801B2Minimize actuationEliminate needRotational speed controlWind motor controlElectric cablesElectric generator

A protection circuit for a wind turbine generator that includes a PWM Brake that works in conjunction with known Brake Relays is disclosed. The Brake Relay is used to short the generator output terminals at a first threshold voltage. The PWM Brake includes one or more switching devices, coupled across the generator output. The PWM Brake is under the control of a PWM Brake Control Circuit which actuates the PWM Brake at a second threshold voltage that is relatively lower than the first threshold voltage. In accordance with an important aspect of the invention, the PWM Brake Control Circuit includes a novel speed sensing circuit for providing a signal representative of the speed of the turbine generator The novel speed sensing circuit eliminates the need to mount a speed sensor on the pole top mounted turbine generator. As such, the need for adding cabling from the pole top mounted wind turbine generator is eliminated. The novel speed sensing circuit provides a signal representative of the rotational speed of the turbine generator based upon the duty cycle of a pulse width modulated (PWM) signal that is derived from the drive signal developed by the PWM Control Circuit. This signal is used to alternatively actuate and close the Brake Relay to minimize actuation of the centrifugal switch.

Owner:INT COMPONENTS

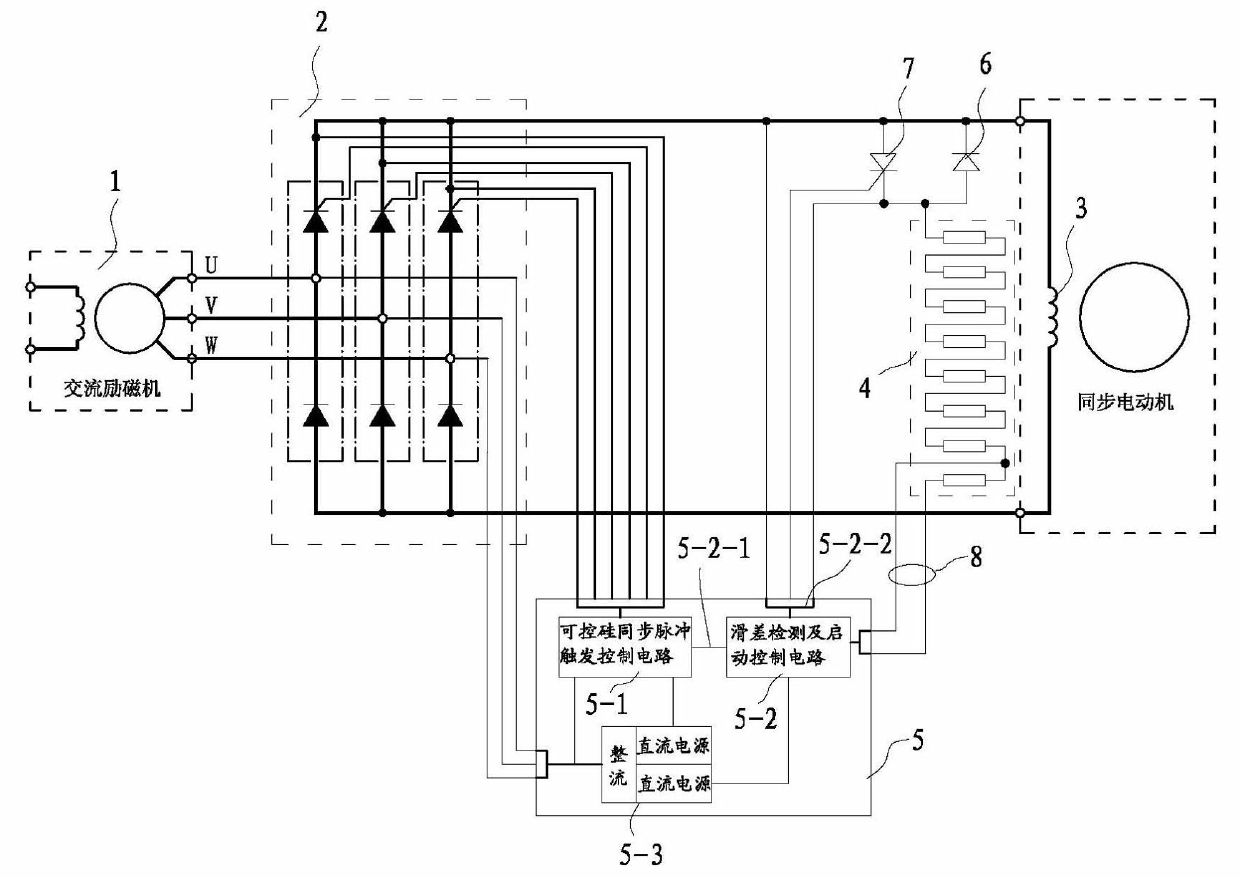

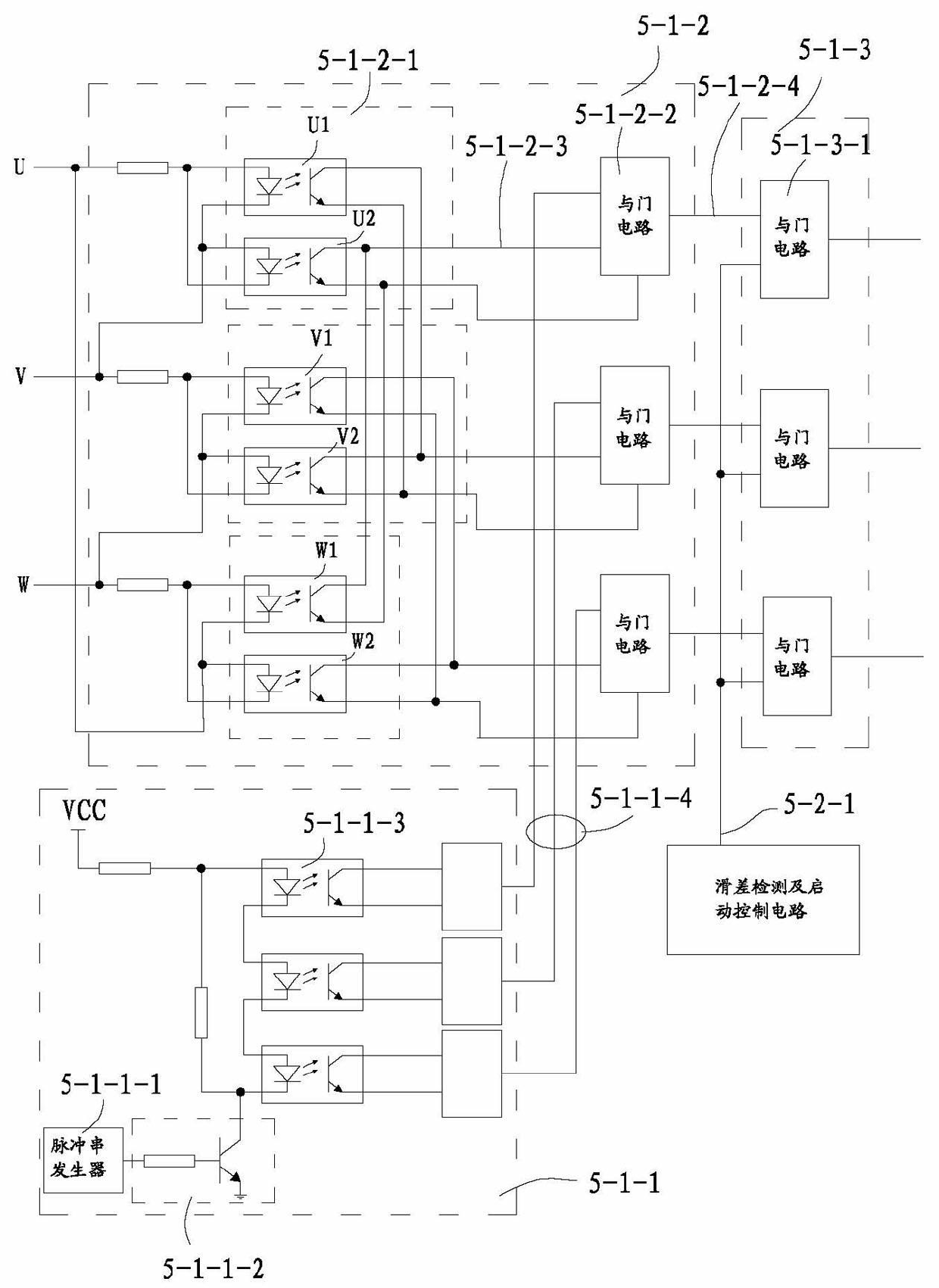

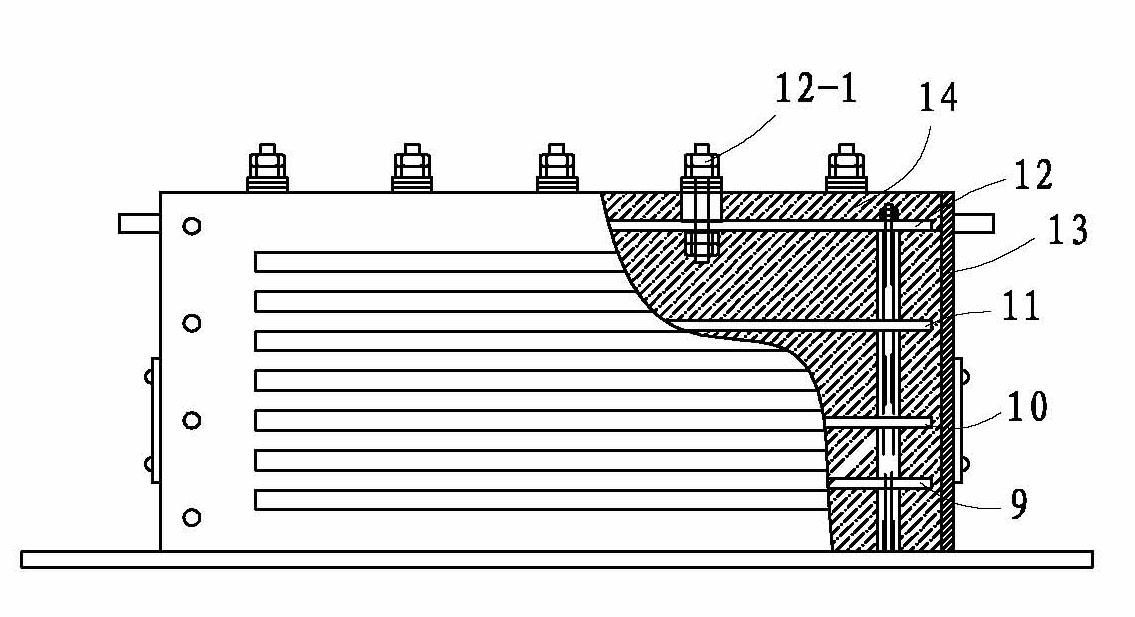

Rotatable master control module of brushless synchronous motor

ActiveCN102170257AAvoid damageSolve the high maintenance rateStarter arrangementsSilicon-controlled rectifierEpoxy

Owner:BEIJING QIANFENG TECH

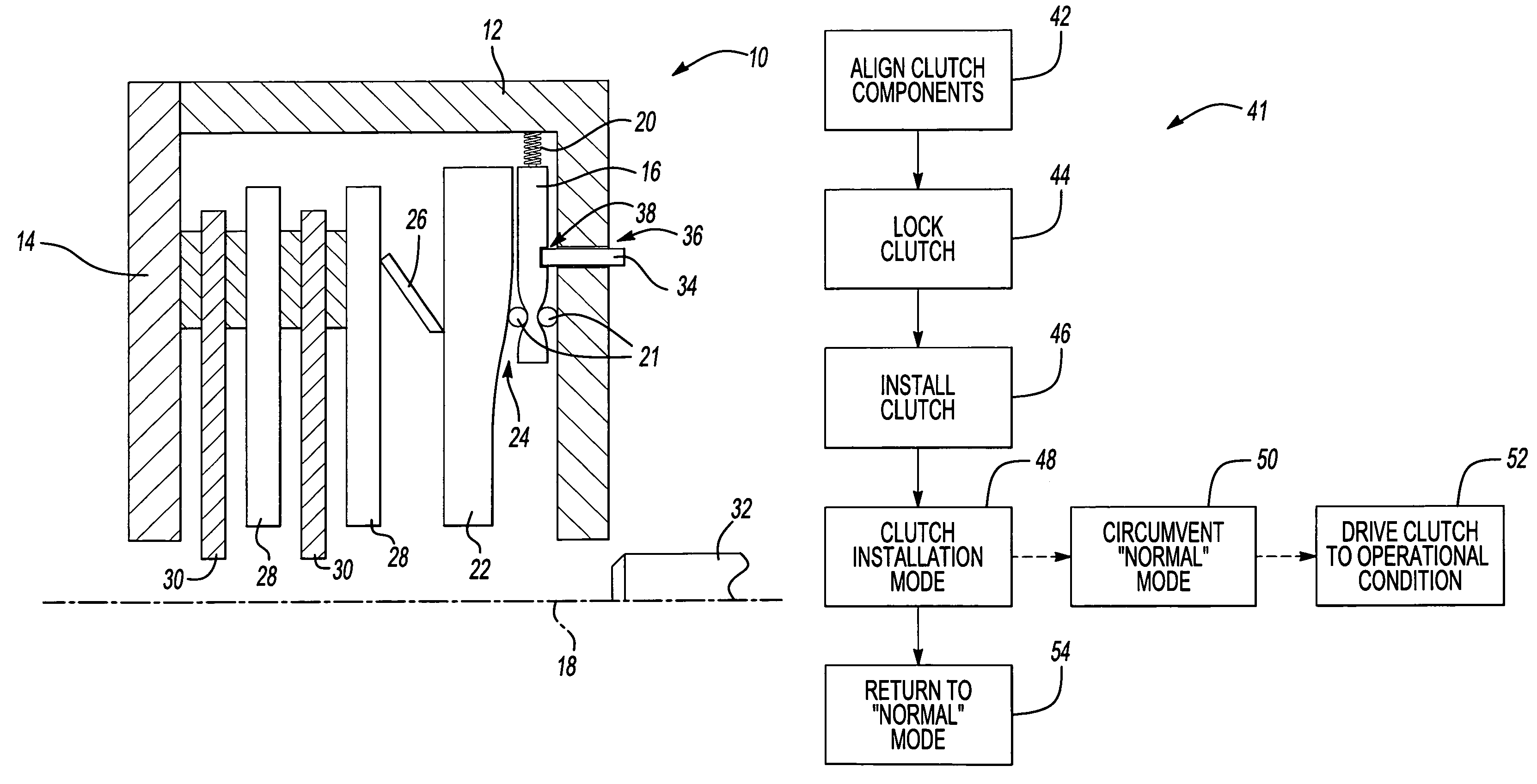

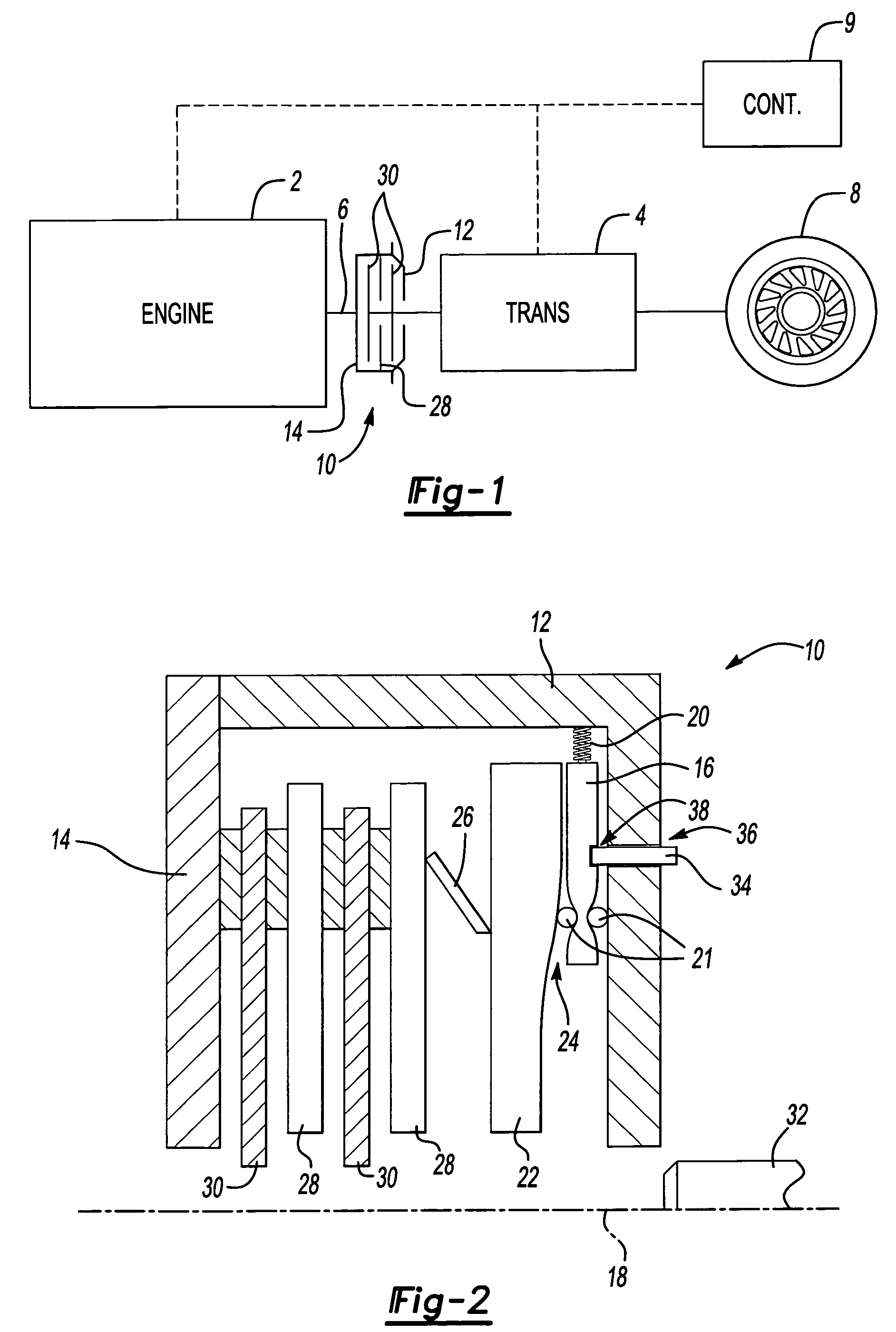

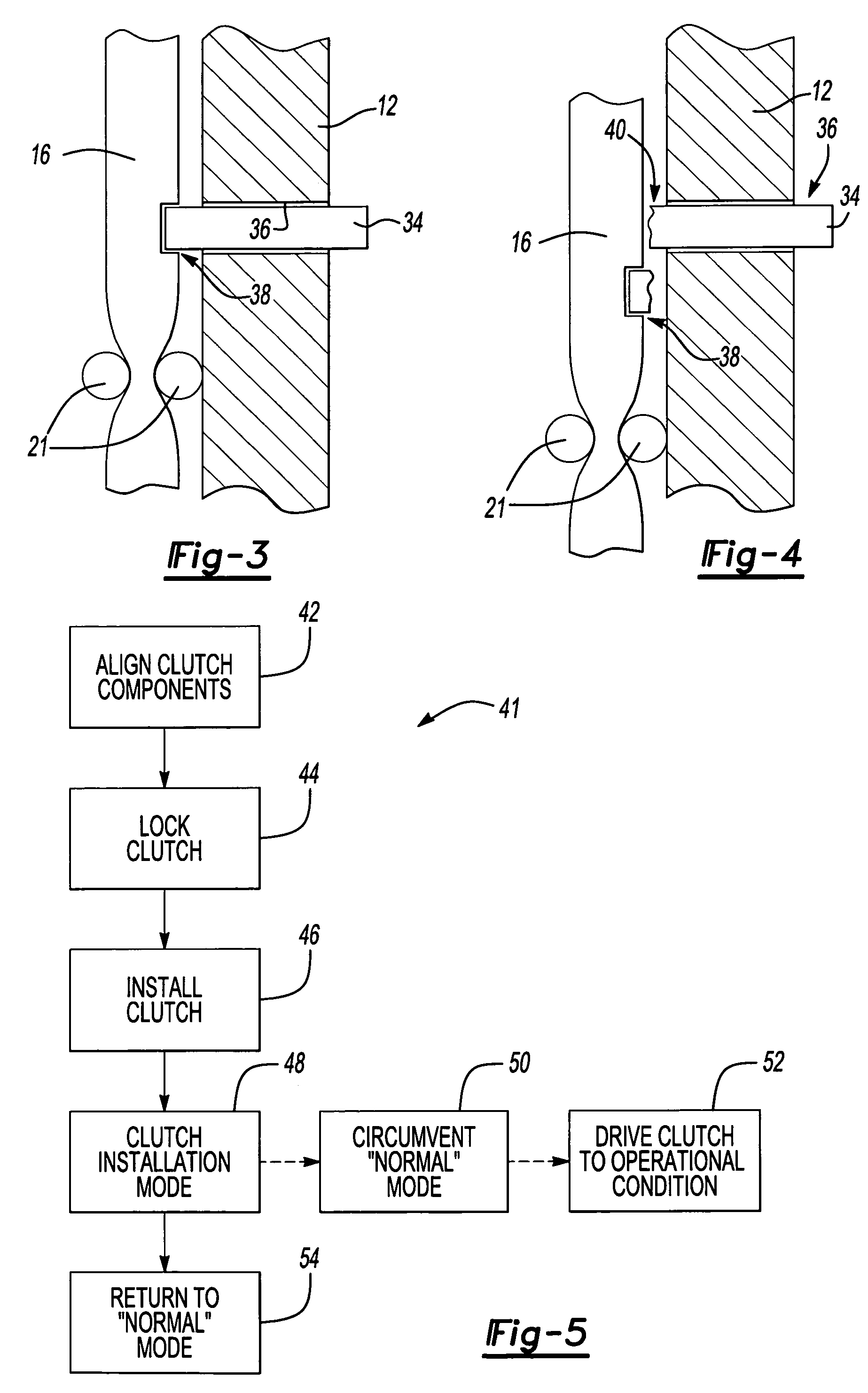

Disabling engine speed limiters during centrifugal clutch installation

InactiveUS7314430B2Simple and cost-effectiveMechanical actuated clutchesEngine controllersRev limiterOperation mode

A master clutch includes a pressure plate adjacent to a friction disc. A centrifugal weight forces the pressure plate and friction disc into engagement when in a desired install position. A locking device retains the centrifugal weight in the desired installed position. A controller sends an electronic command to a system component, such as an engine, to disengage the locking device. In one example, the electronic command may be an engine speed command that is above an engine speed limit in a normal vehicle operating mode. Commanding the engine to run at a speed greater than the typical engine speed limit moves the centrifugal weight out of the desired installed position making the master clutch operational.

Owner:ARVINMERITOR TECH

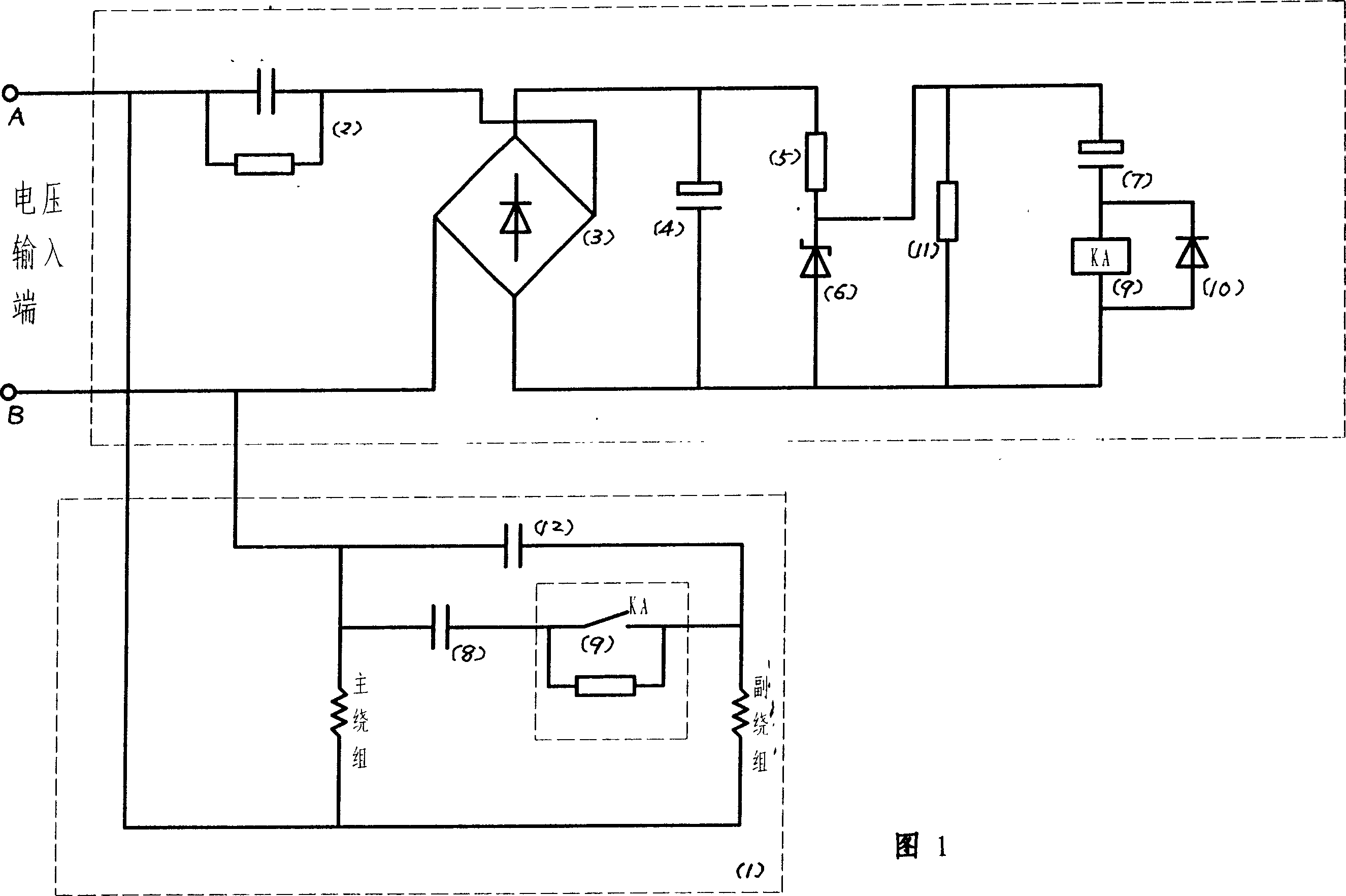

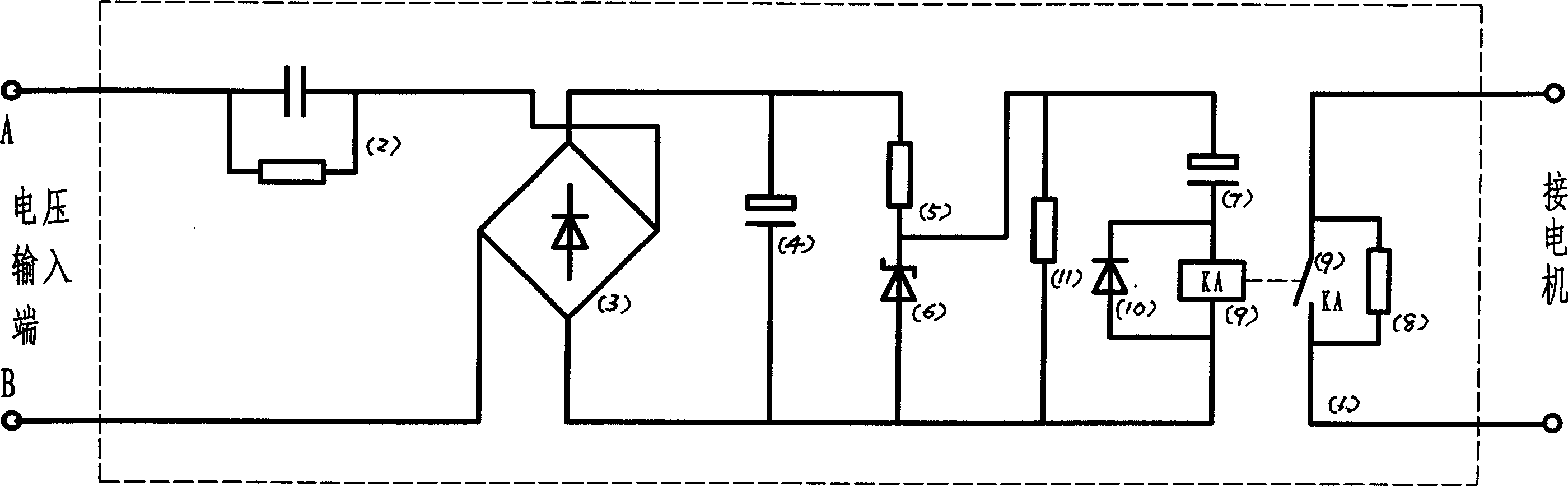

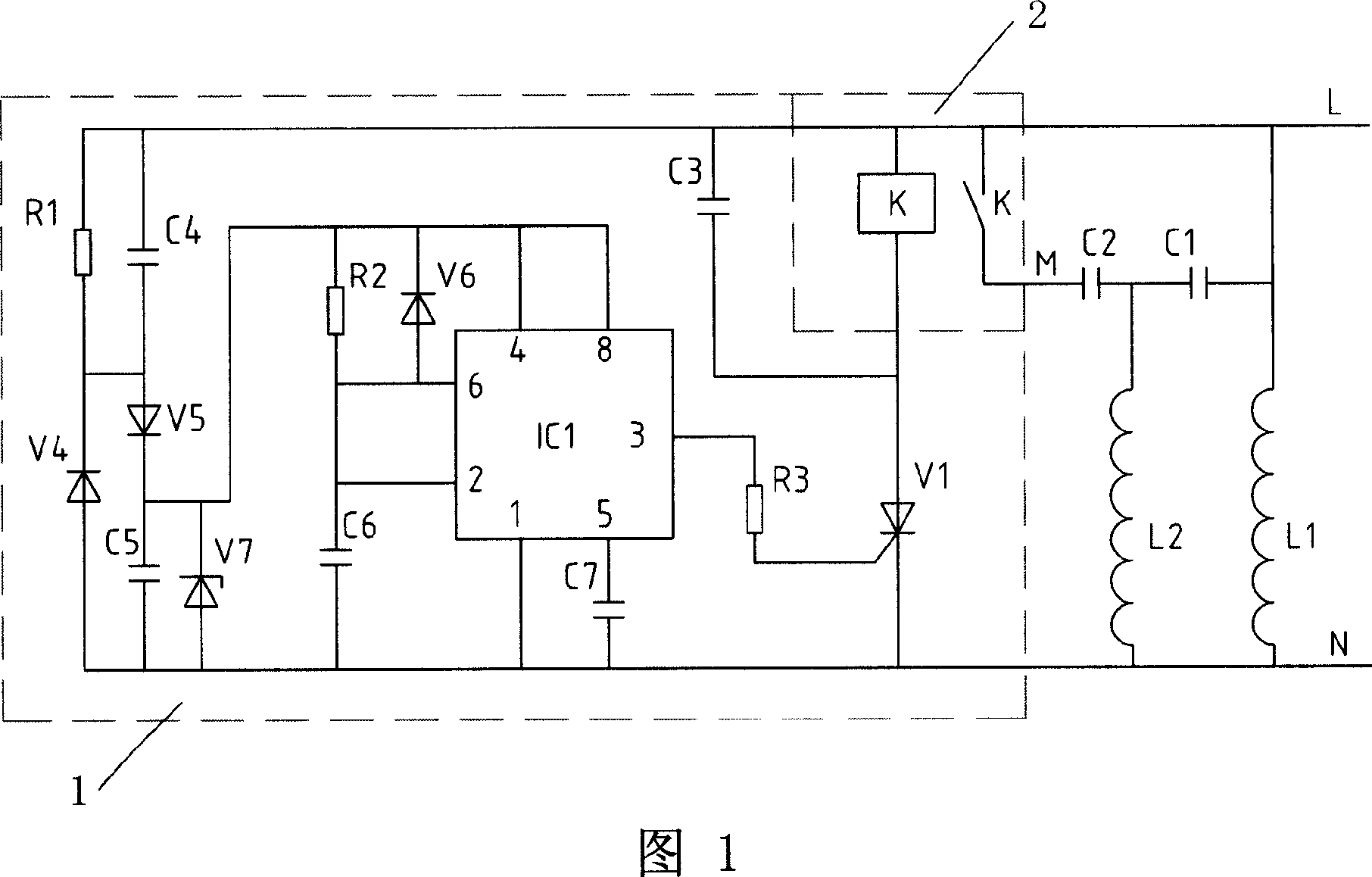

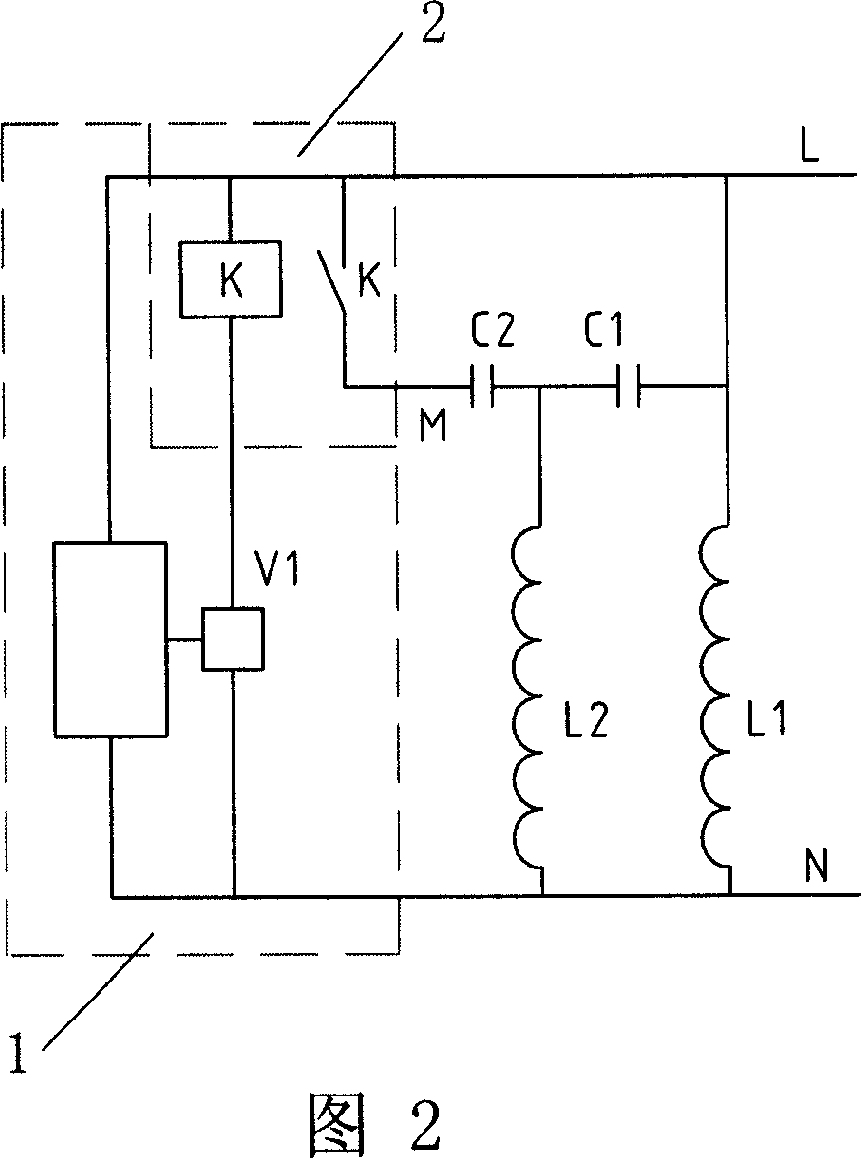

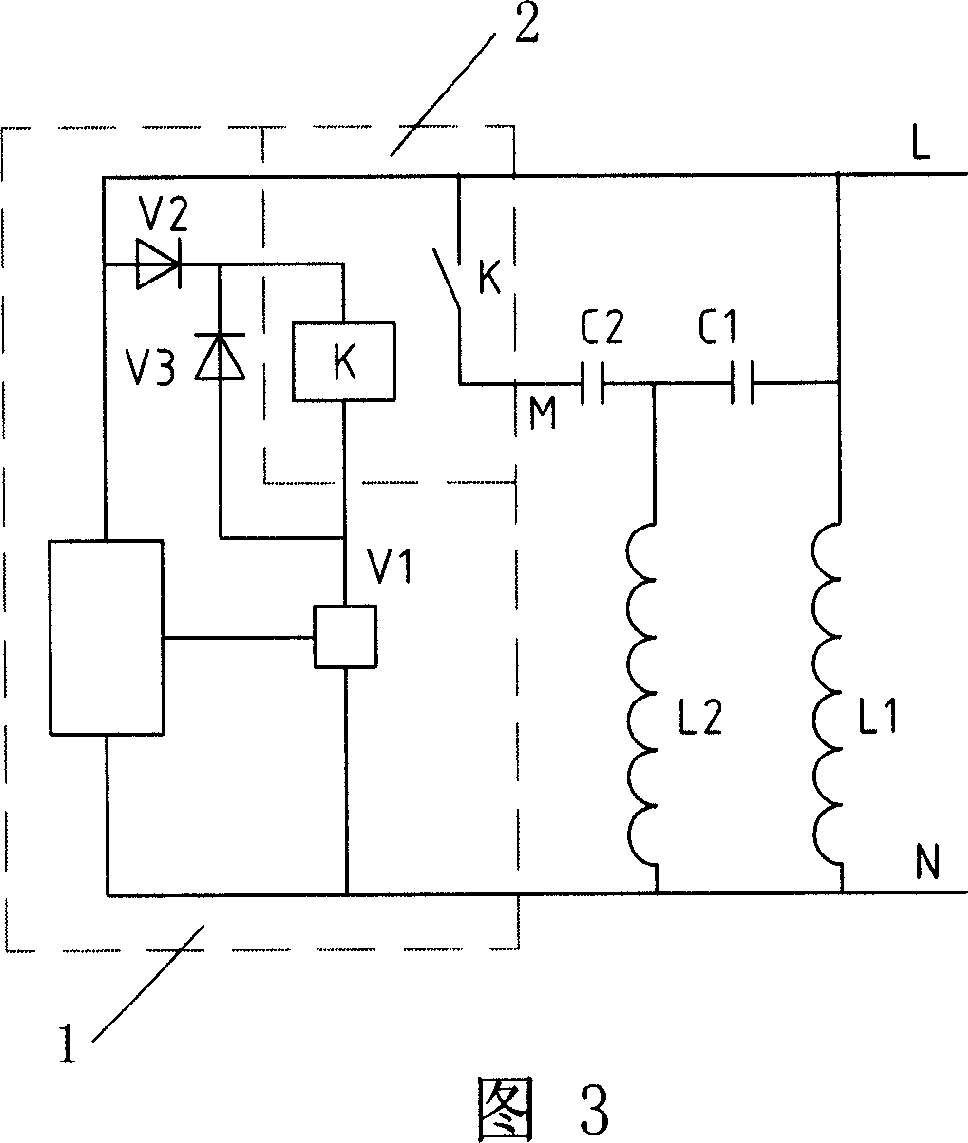

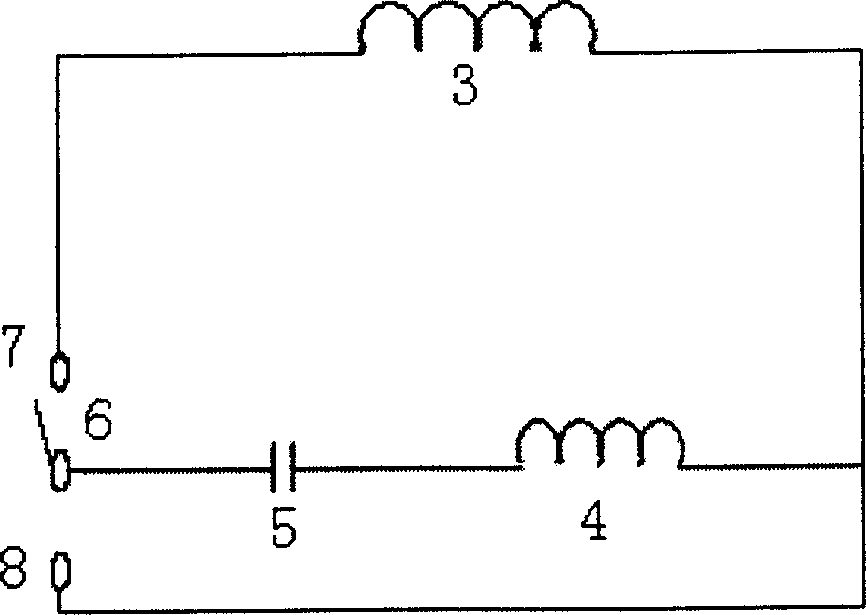

Single-phase AC motor starting method

InactiveCN1767350AImprove performanceAvoid burnsSingle-phase induction motor startersElectricityCapacitance

The invention relates to an operating method of a single-phase ac motor in the field of motor technology. The method connects a circuit and a coil group circuit of the motor on the single-phase ac commercial power, which comprises: designing a resistance capacity parallel circuit connected with one end of the ac commercial power, adding a rectifying circuit on the output end of the resistance capacity parallel circuit and the other end of the ac commercial power, paralleling a filter capacity on the output end of the rectifying circuit, paralleling a voltage regulating circuit which is formed by resistance and voltage regulating pipe on the filter capacity, paralleling a large capacity and a series circuit of the relay coil on the output end of the voltage regulating pipe, connecting an open contact and a start unit of the relay on the coil group circuit of the motor.

Owner:QINGDAO D& D ELECTRO MECHANICAL TECH

Novel speed sensing circuit for a wind turbine generator

InactiveUS20070268002A1Minimize actuationEliminate needRotational speed controlWind motor controlTurbineControl circuit

A protection circuit for a wind turbine generator that includes a PWM Brake that works in conjunction with known Brake Relays is disclosed. The Brake Relay is used to short the generator output terminals at a first threshold voltage. The PWM Brake includes one or more switching devices, coupled across the generator output. The PWM Brake is under the control of a PWM Brake Control Circuit which actuates the PWM Brake at a second threshold voltage that is relatively lower than the first threshold voltage. In accordance with an important aspect of the invention, the PWM Brake Control Circuit includes a novel speed sensing circuit for providing a signal representative of the speed of the turbine generator The novel speed sensing circuit eliminates the need to mount a speed sensor on the pole top mounted turbine generator. As such, the need for adding cabling from the pole top mounted wind turbine generator is eliminated. The novel speed sensing circuit provides a signal representative of the rotational speed of the turbine generator based upon the duty cycle of a pulse width modulated (PWM) signal that is derived from the drive signal developed by the PWM Control Circuit. This signal is used to alternatively actuate and close the Brake Relay to minimize actuation of the centrifugal switch.

Owner:INT COMPONENTS

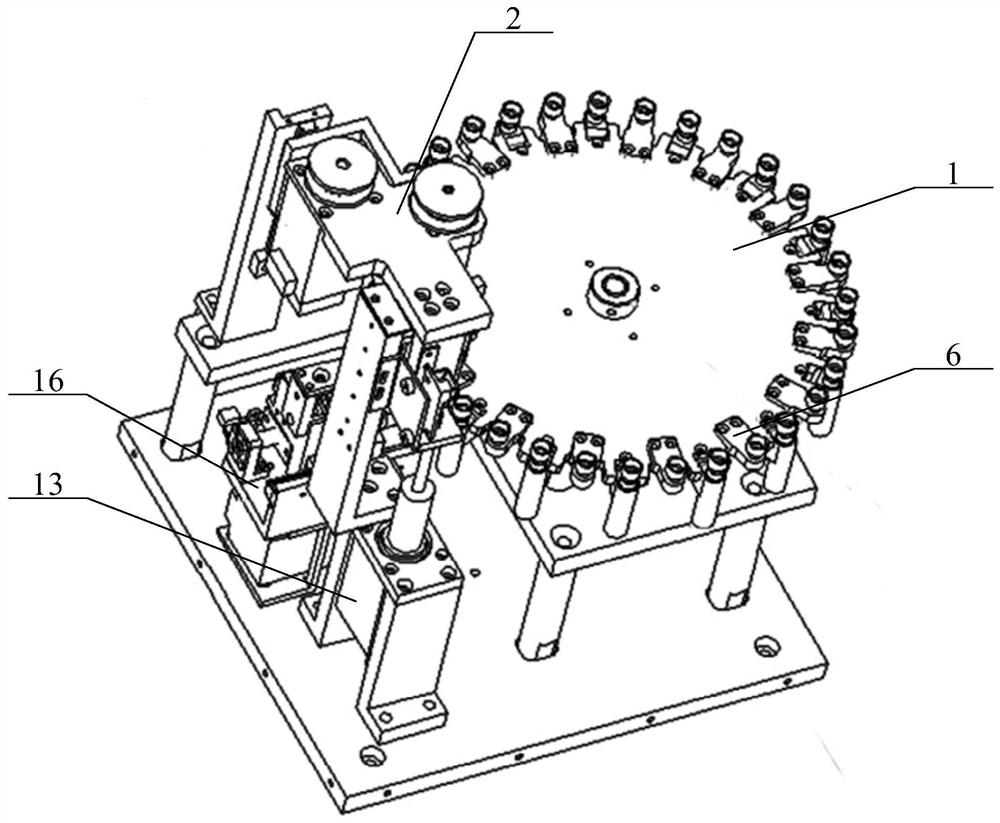

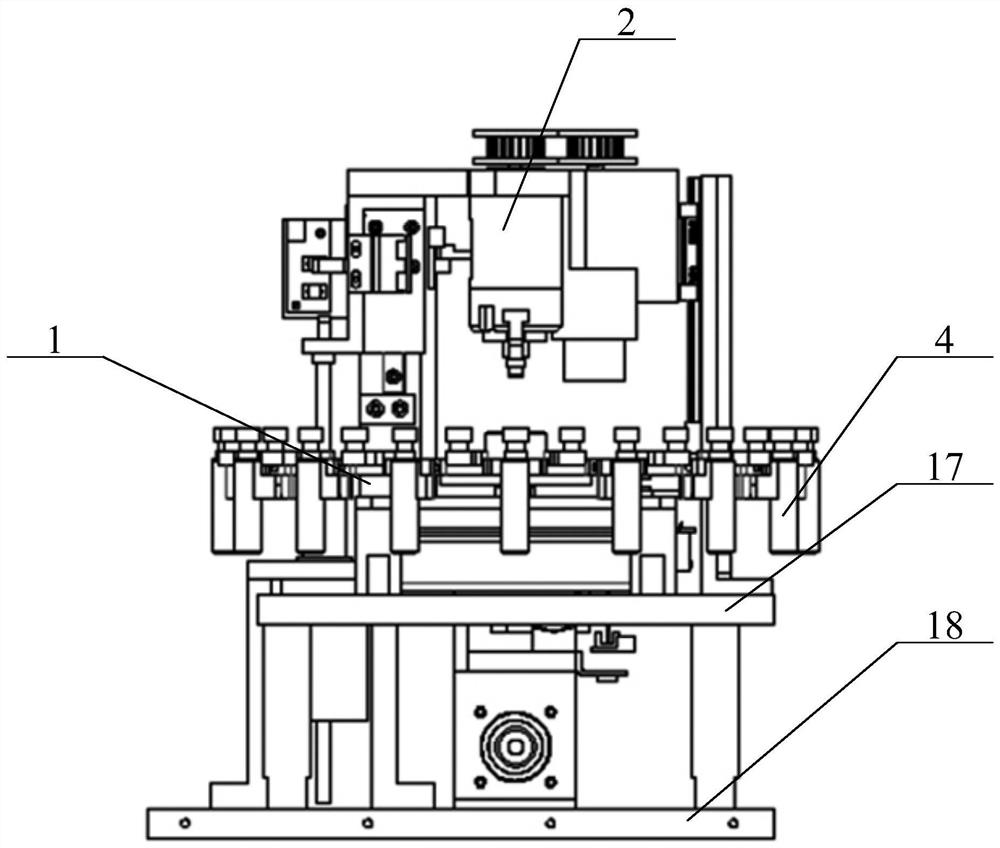

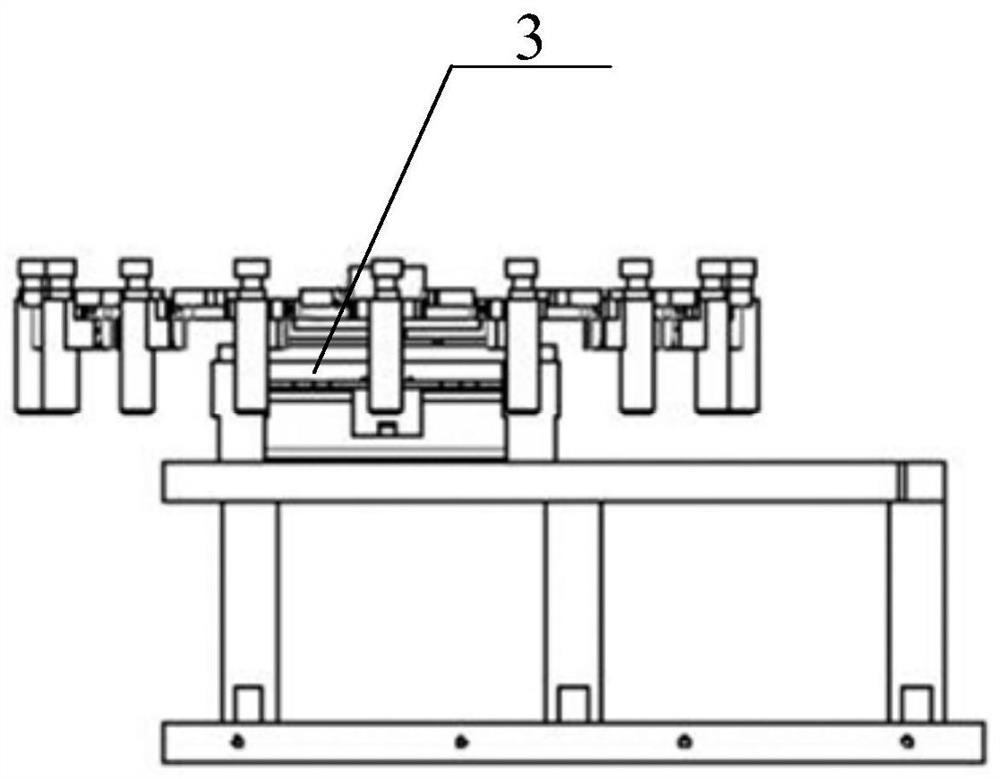

Molecular detection centrifugal opening and closing cover device

ActiveCN113072018AConvenient centrifugationCentrifugal realizationThreaded caps applicationTight-fitting lid removalEngineeringApparatus instruments

The invention provides a molecular detection centrifugal opening and closing cover device, and relates to the technical field of medical instruments. The device comprises a rotating disc, a cover opening and closing assembly and a rotation driving component. A test tube is placed on a rotating disc, a rotating mode of the rotation driving component is started, the test tube is moved to the position below a grabbing part, the grabbing part of the cover opening and closing assembly is used for driving a bottle cover on the test tube to move, and cover opening or cover closing operation is completed; and a centrifugal mode of the rotation driving component is started, the rotating disc rotates at a high speed to drive the test tube to do centrifugal motion, a reagent in the test tube can be centrifuged conveniently, the cover opening and closing function can be achieved, the reagent can be centrifuged, more functions are achieved, and the technical problems that an existing test tube cover opening and closing device can only achieve automatic cover opening and closing and is single in function in the prior art are solved.

Owner:HANGZHOU BIOER TECH CO LTD

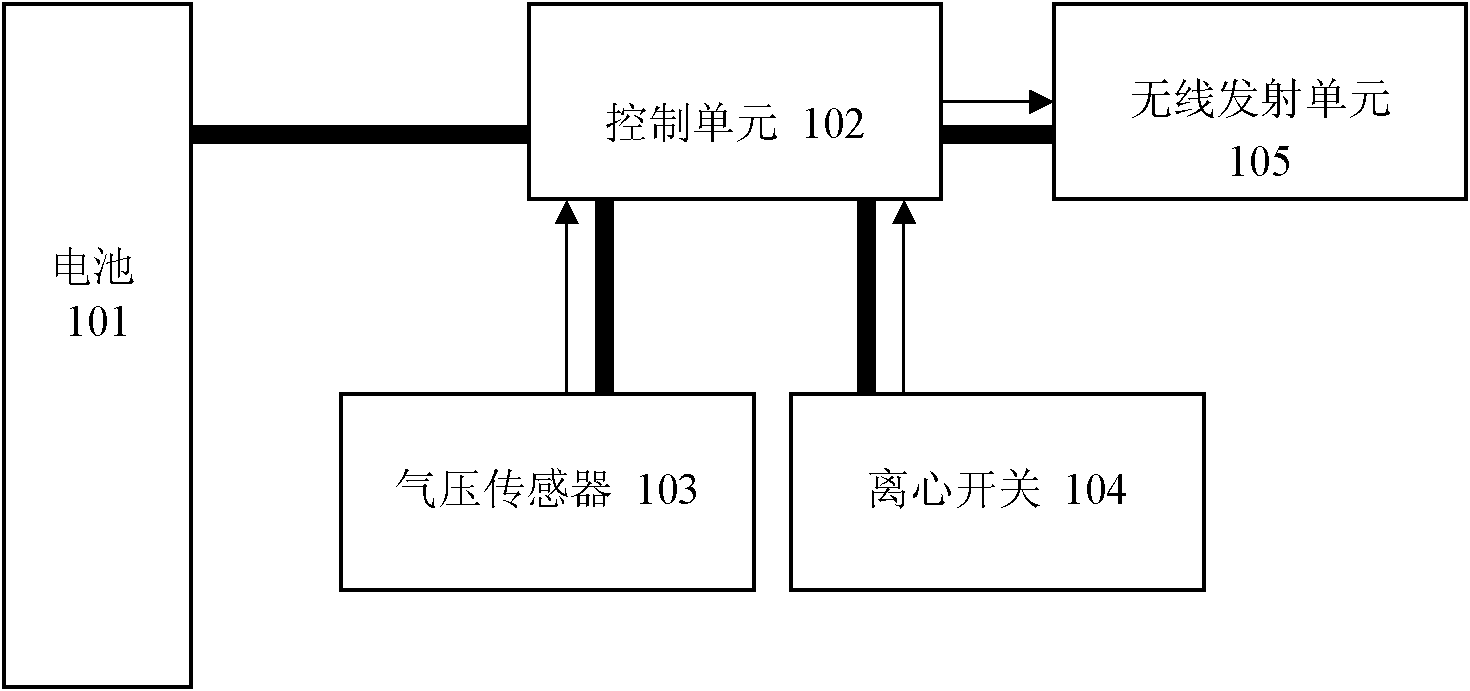

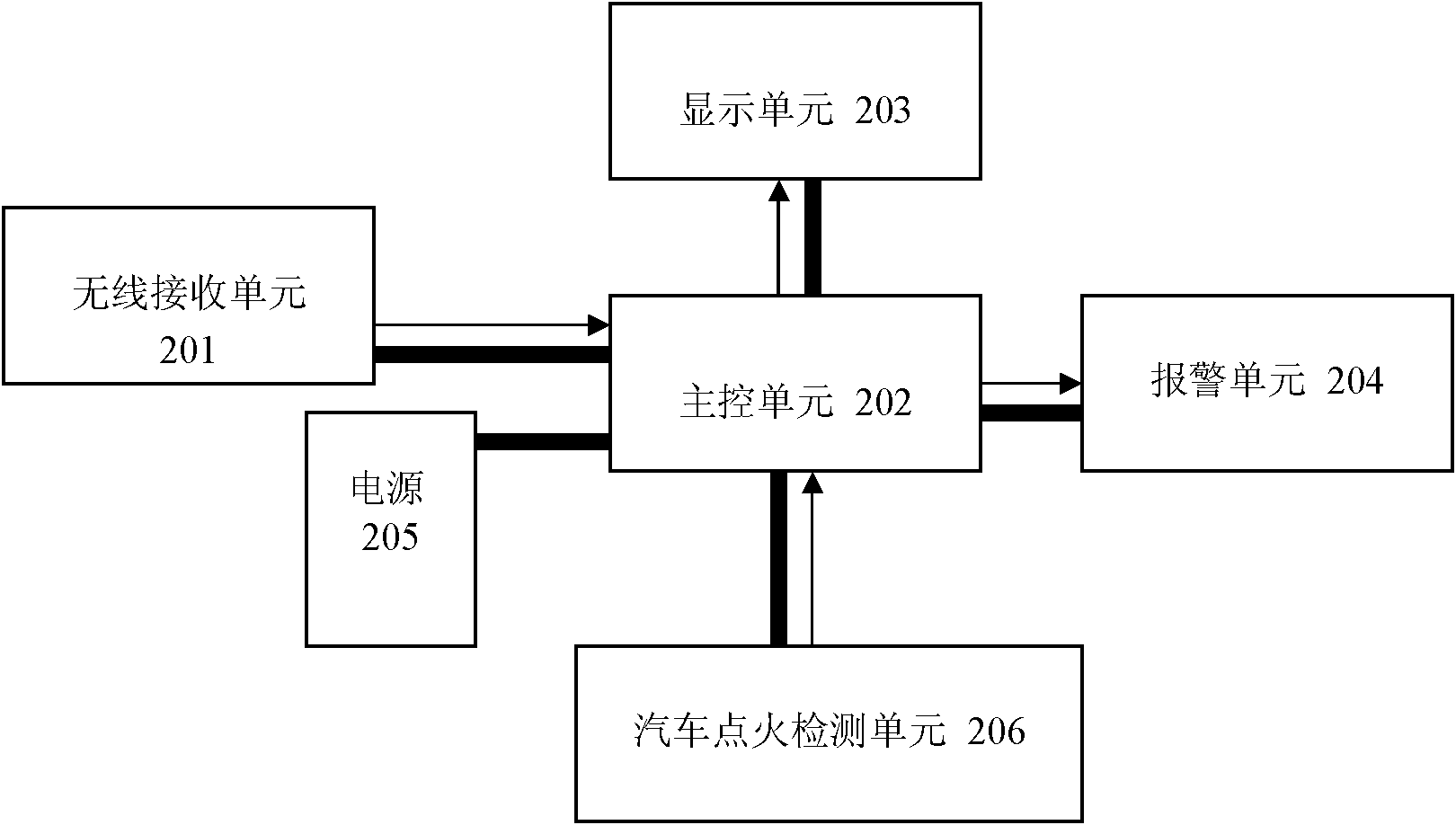

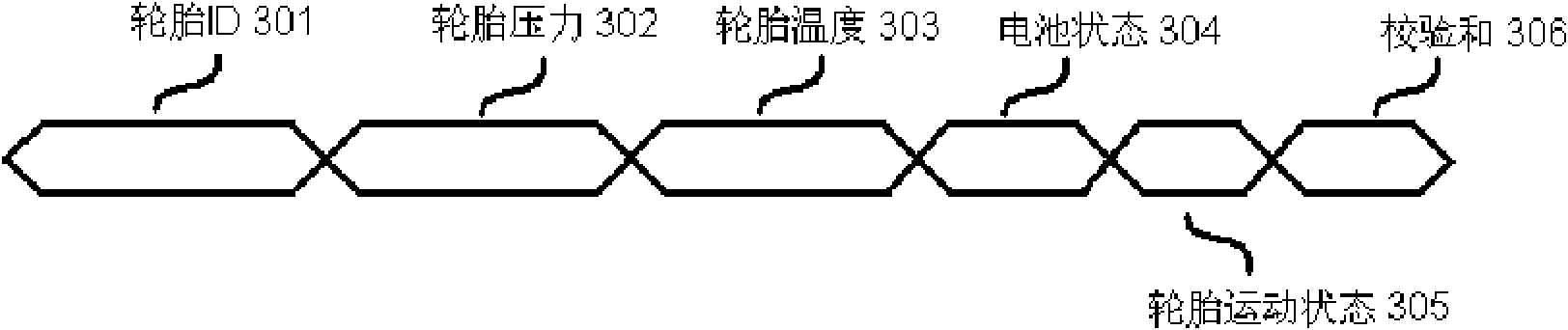

Vehicle and anti-theft method of tyre of vehicle

InactiveCN102529602ATo achieve the purpose of anti-theftCar anti-theft purpose is goodAnti-theft devicesTyre measurementsWireless transmissionData signal

The invention relates to a vehicle and an anti-theft method of a tyre of the vehicle. The anti-theft method comprises the steps: a front end device is arranged in the tyre and comprises an air pressure sensor (103), a centrifugal switch (104) and a wireless transmission unit (105); a vehicle body is provided with a center device, and the center device comprises a wireless receiving unit (201) and a vehicle ignition detecting unit (206); when the tyre is detected to be in a motion state by the centrifugal switch (104), the wireless transmission unit (105) transmits data signals comprising the motion state of the vehicle; and the center device receives the data signals through the wireless receiving unit (201), and when the vehicle is detected to be in a non-ignition state according to the data signals comprising the motion state of the vehicle and the vehicle ignition detecting unit (206), alarm or remote alarm can be processed. The anti-theft method disclosed by the invention not only can be used for preventing the tyre from being stolen, but also can be further used as a novel vehicle illegal motion detection method for preventing the vehicle from being stolen.

Owner:秦榆

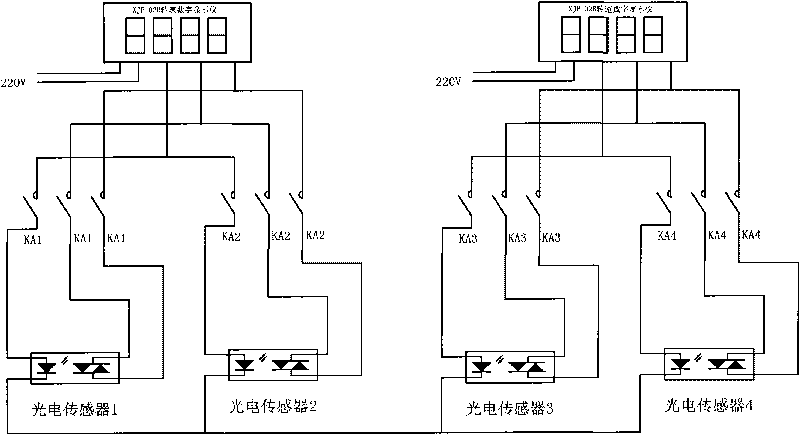

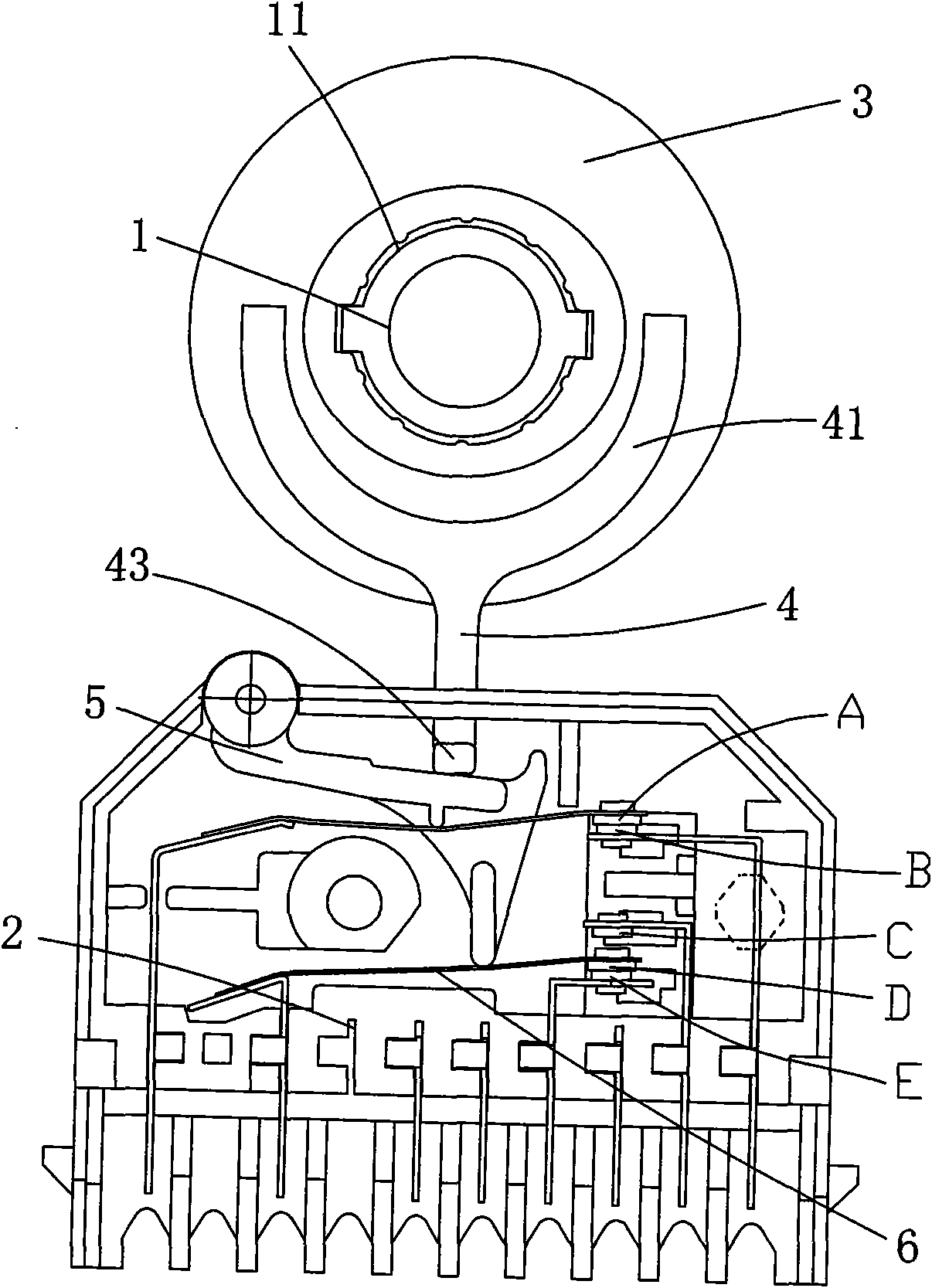

Single-phase motor centrifugal switch tester

ActiveCN101726703AEffective detection of starting speedCircuit interrupters testingDynamo-electric machine testingLow voltageElectric machine

The invention relates to a single-phase motor centrifugal switch tester which comprises an outer casing, a detecting circuit, an exterior power supply interface, a centrifugal switch inserting point and a rotation speed display, wherein the exterior power supply interface is simultaneously connected with a reducing transformer, a converter, the rotation speed display and a controlled sub circuit. The low-voltage output end of the reducing transformer is connected with the input end of a sorting circuit, the output end of the sorting circuit is connected with the centrifugal switch, and the centrifugal switch is connected in series with a switch detecting relay. The converter is connected with a variable-frequency motor through a motor starting switch. The variable-frequency motor is provided with a speed-testing sensor, and the speed-testing sensor is connected with the rotation speed display. The controlled sub circuit comprises a switch detecting normally open contact, a control push button and a motor starting relay which are sequentially connected in series. The switch detecting normally open contact is linked with the switch detecting relay, and the motor starting switch is linked with the motor starting relay. The invention can effectively detect the starting rotation speed of the centrifugal switch when in disconnection.

Owner:慈溪威力电机制造有限公司

Wireless tire pressure and temperature detecting system

InactiveUS7541919B1Save powerPractical and convenientVisible signalling systemsTyre measurementsWirelessCentrifugal switch

Owner:MOBILETRON ELECTRONICS

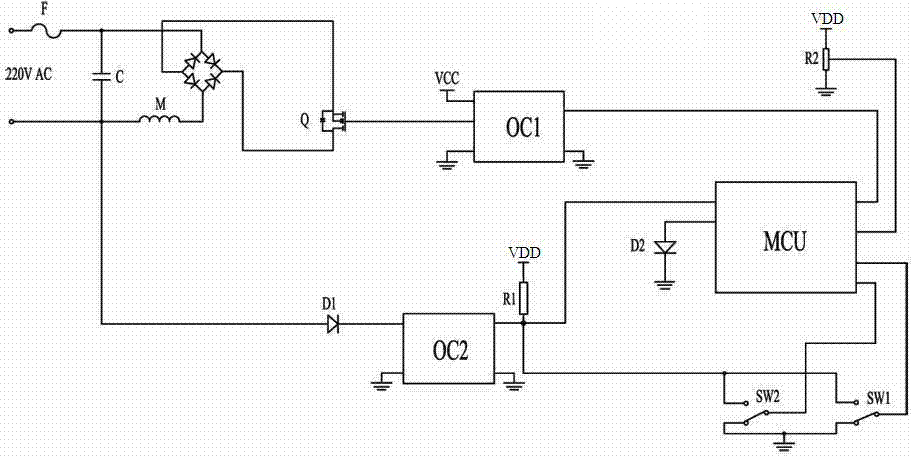

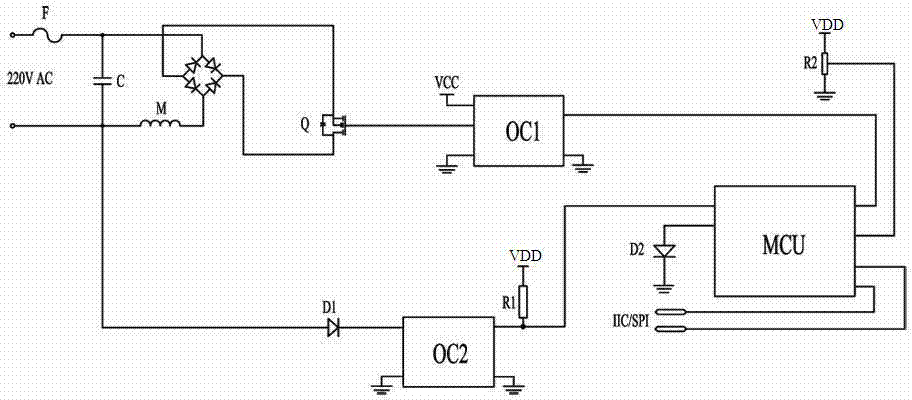

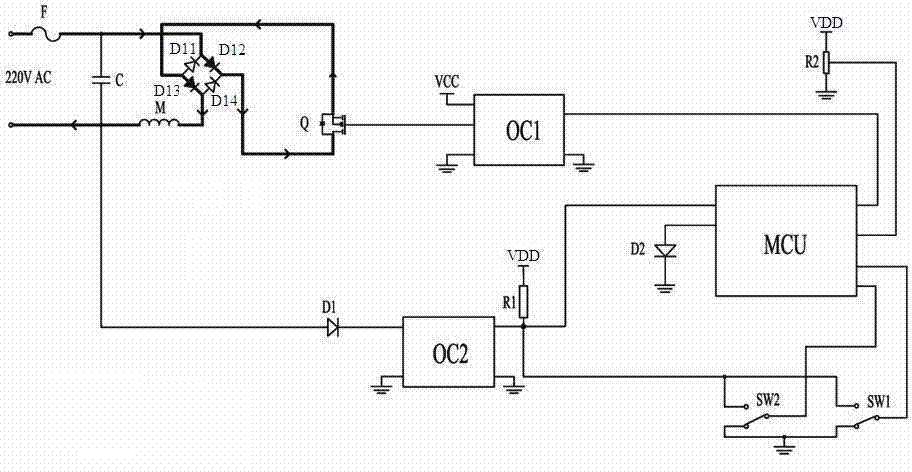

Single-winding single-phase AC motor control module

InactiveCN103618493AStart and stop at willClearly understand the technical solutionAC motor controlPolyphase induction motor starterCapacitanceEngineering

The invention relates to a single-winding single-phase AC motor control module which comprises a single-phase AC motor winding. An inlet end of the single-phase AC motor winding is connected with one end of an external AC power supply, an outlet end of the single-phase AC motor winding is connected with an AC input end of a rectifier bridge, the other AC input end of the rectifier bridge is connected with the other end of the external AC power supply, a DC output end of the rectifier bridge is connected with one end of a driver, the other DC output end of the rectifier bridge is connected with the other end of the driver, and a control end of the driver is used for receiving PWM signals sent by a processing unit. According to the single-winding single-phase AC motor control module, a conventional single-phase AC motor secondary winding, a starting capacitor and a centrifugal switch are eliminated, and the defects that the secondary winding has to be arranged in the running process, running of the capacitor causes power decrease, starting currents are too large instantly, silicon controlled pressure regulating speed change low harmonic waves pollute power grids, default-phase type frequency modulation and speed regulation cost is high and output power is low are overcome.

Owner:孙鲁西

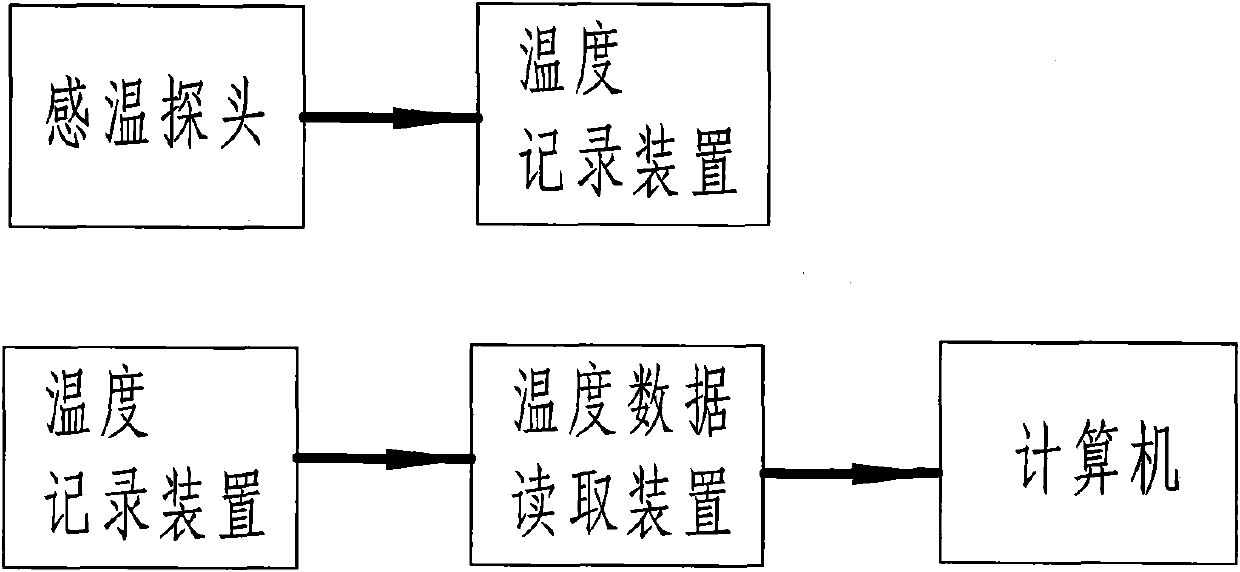

Method for measuring temperature of inner ring and outer ring of bearing between double-rotor engine rotors

InactiveCN101949741ASolve the problem of temperature online measurementThermometers using electric/magnetic elementsUsing electrical meansStopped workEngineering

The invention belongs to the technical field of air engines, disclosing a method for measuring the temperature of an inner ring and an outer ring of a bearing between double-rotor engine rotors. A mode of collecting stored data on line and reading data off line is adopted, a small temperature measuring system is utilized, the rotation speed of a rotor shaft is taken as the control parameter of a centrifugal switch so as to control the collection storage of temperature data, and a heat insulating material is used for covering a temperature recording device installed in the small temperature measuring system in the engine. After the rotor shaft of the engine stops working, the temperature recording device is removed; then a temperature data reading device is connected; the temperature data reading device is connected to a computer via a USB interface to read temperature data and realize the measurement of the temperature of the inner ring and the outer ring of the bearing between the rotors in the process of high-speed rotation at high temperature under the condition of oil mist surrounding.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

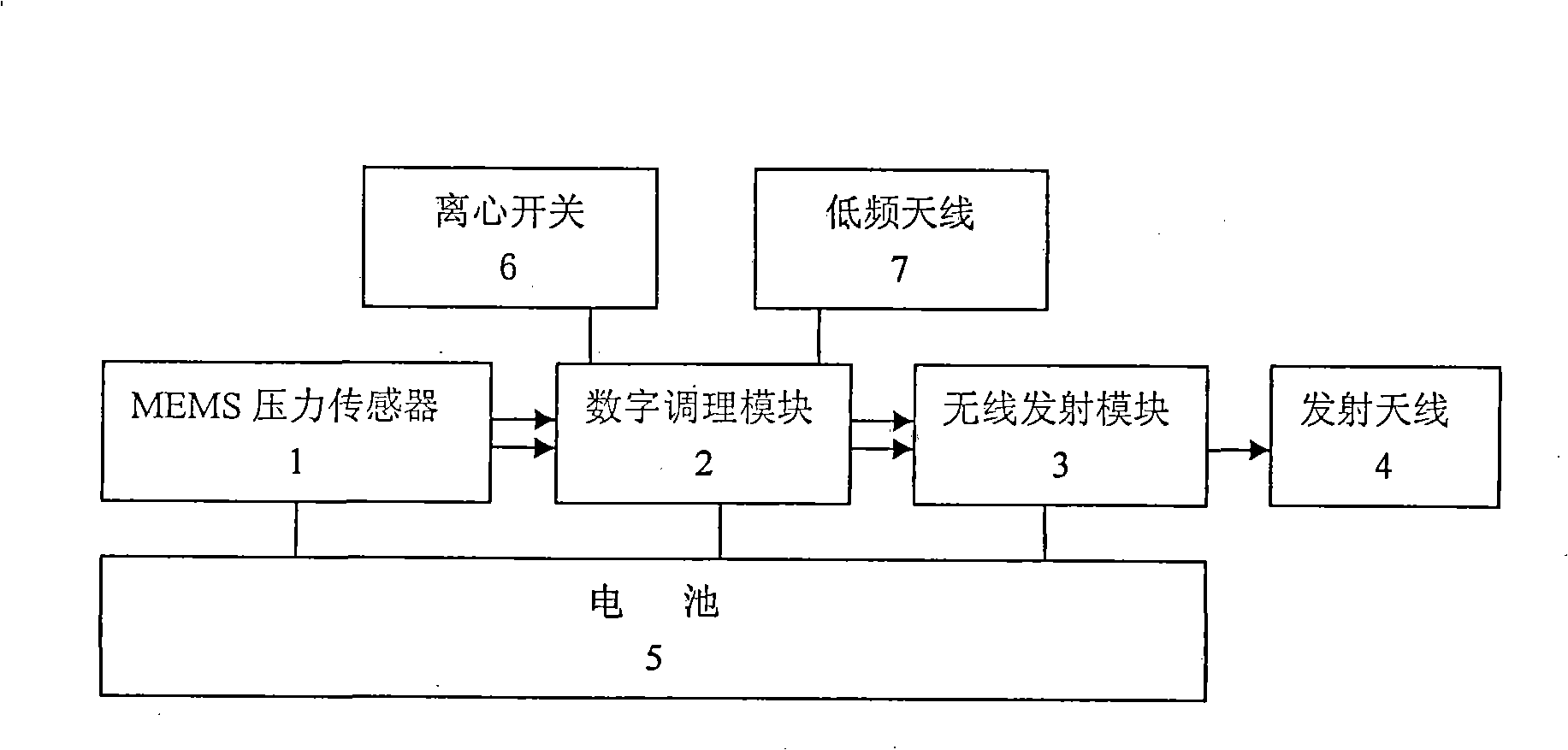

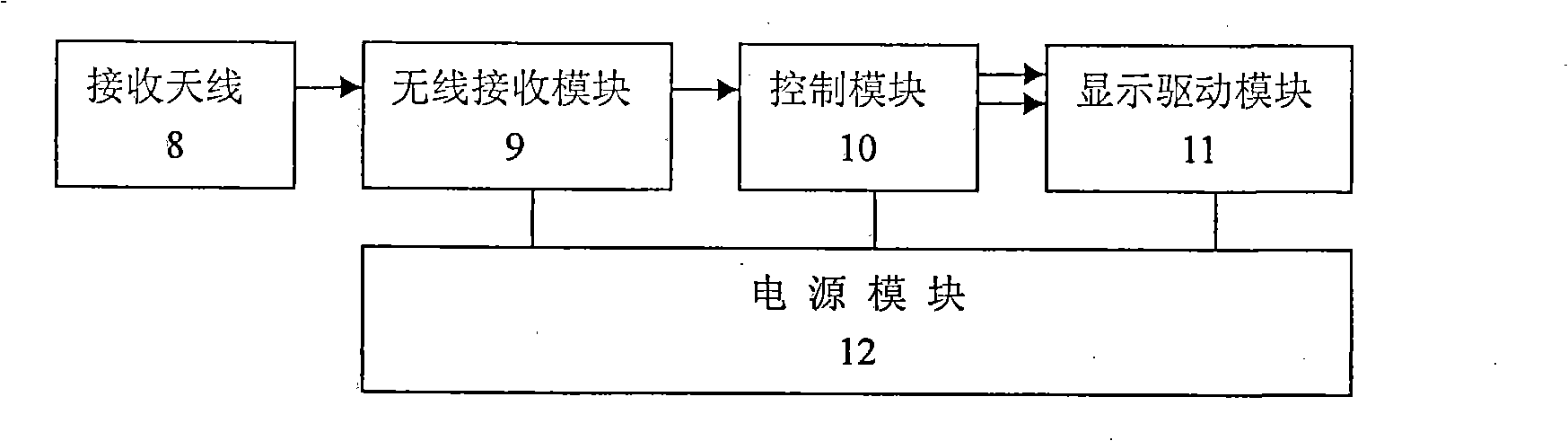

Tire pressure monitoring system for motorcycle tyre

InactiveCN101348060AReduce energy consumptionSolution to short lifeElectric signal transmission systemsTyre measurementsLine sensorMotorcycle tyre

The invention provides a tire pressure monitoring system for motorcycle tires, which essentially comprises a wireless sensor, a central receiver and a display; wherein, the wireless sensor is built-in type. An MEMS pressure sensor, a centrifugal switch and a low-frequency antenna are connected with a numerical signal modulation module; the numerical signal modulation module is connected with a wireless transmitting module; the wireless transmitting module is connected with a transmitting antenna; the central receiver is arranged inside a motorcycle; a receiving antenna is connected with a wireless receiving module; the wireless receiving module is connected with a control module; the control module is connected with a display driving module; the display driving module is connected with the display; the display is integrated in a motorcycle dash board. The system has the advantages of adopting a wireless way to monitor the tire pressure of the tires of the motorcycle in a real-time manner and adopting the MEMS pressure sensor and the centrifugal switch to ensure the tire pressure monitoring system to be reliable, durable, low in energy consumption and long in service life and have the function of display alarm.

Owner:上海飞恩微电子有限公司

Electric automatic differential lock

InactiveCN103277484ASolve slippagePrevent magnetic fieldDifferential gearingsControl theorySpeed limit

The invention discloses an electric automatic differential lock comprising a differential lock large shell, a differential lock small shell nested at one end of the differential lock large shell, and a planet gear. The planet gear mounted between the differential lock large shell and the differential lock small shell is fixed through a cross shaft. Each of the differential lock large shell and the differential lock small shell is provided with an axle shaft gear inside. Both the axle shaft gears mesh with the planet gear. Each axle shaft gear is provided with a plurality of generator permanent magnets with alternately arranged positive and negative poles inside. A generator core and a generator coil are sleeved outside the axle shaft gears. An electromagnet coil and a friction plate are disposed in each of the differential lock large shell and the differential lock small shell. Regulating springs and screws are disposed between each electromagnet coil and one of the differential lock large shell and the differential lock small shell. Each of the differential lock large shell and the differential lock small shell is provided with a speed-limiting eccentric switch. Through the structure, the problem that an automobile idles due to skidding of a single wheel is solved, and the automobile can be freed of the dangerous situation and driven normally. The electric automatic differential lock has the advantages of simple structure, convenience in use and operation, low failure rate, high stability and convenience in popularization.

Owner:优必胜(福建)机械工业有限公司

Electronic actuator of single-phase asynchronous electric motor

InactiveCN1941602AReduce volumeIncrease instantaneous powerSingle-phase induction motor startersTransformerHigh pressure

The invention is concerned with electron start switch of single-phase asynchronous motor, which relates to electromagnetism relay and electron control circuit for controlling the close and disconnection of the said relay. It uses the special work character for the relay of the motor with a low holding ratio in the work condition, to offer a kind of relay with break and continue period work state or short time work state designed for electron start switch of single-phase asynchronous motor. The rating work voltage of relay is high voltage and supplied by city voltage without reducing voltage through transformer. The relay has large instantaneous power and long life-time in small volume. The said electron start switch of single-phase asynchronous motor is suit for fixing and maintaining with low cost and high dependability.

Owner:蔡宗法

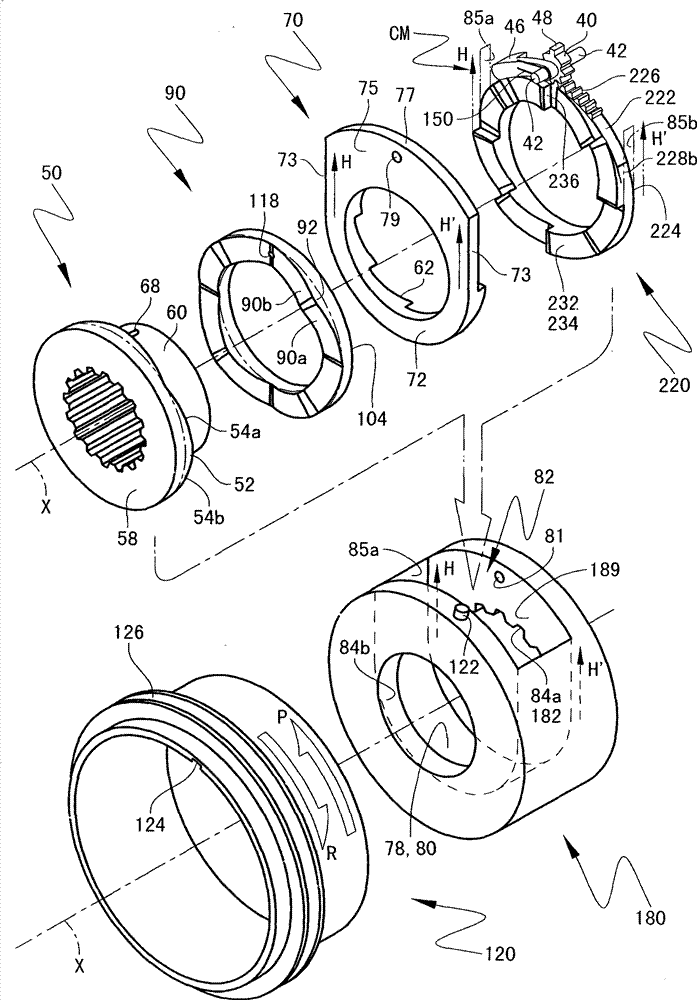

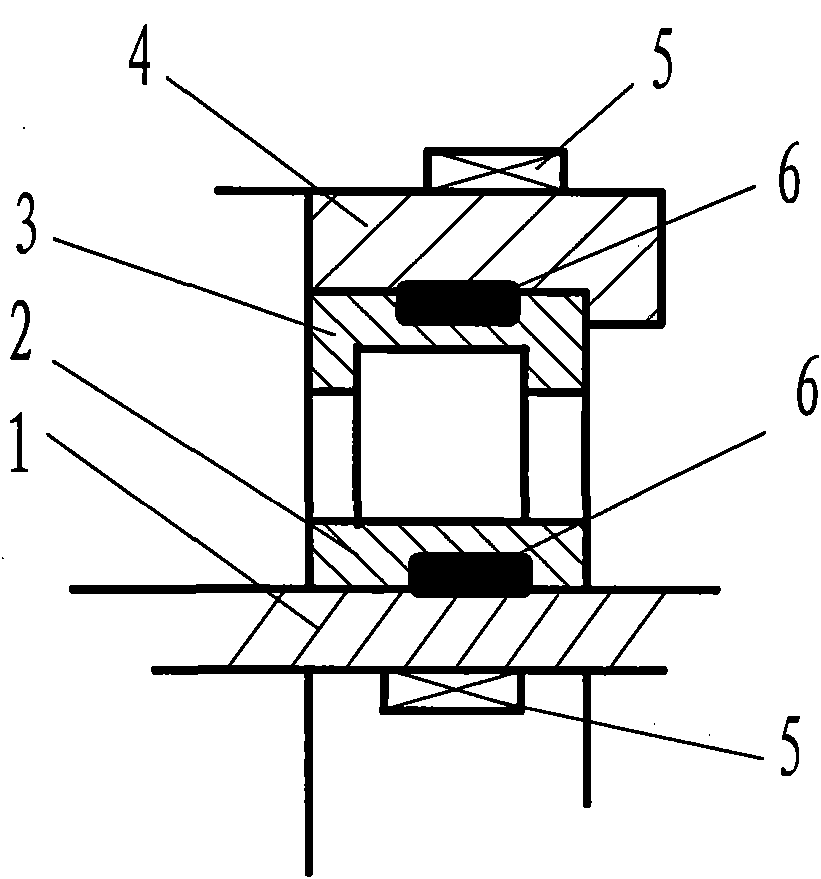

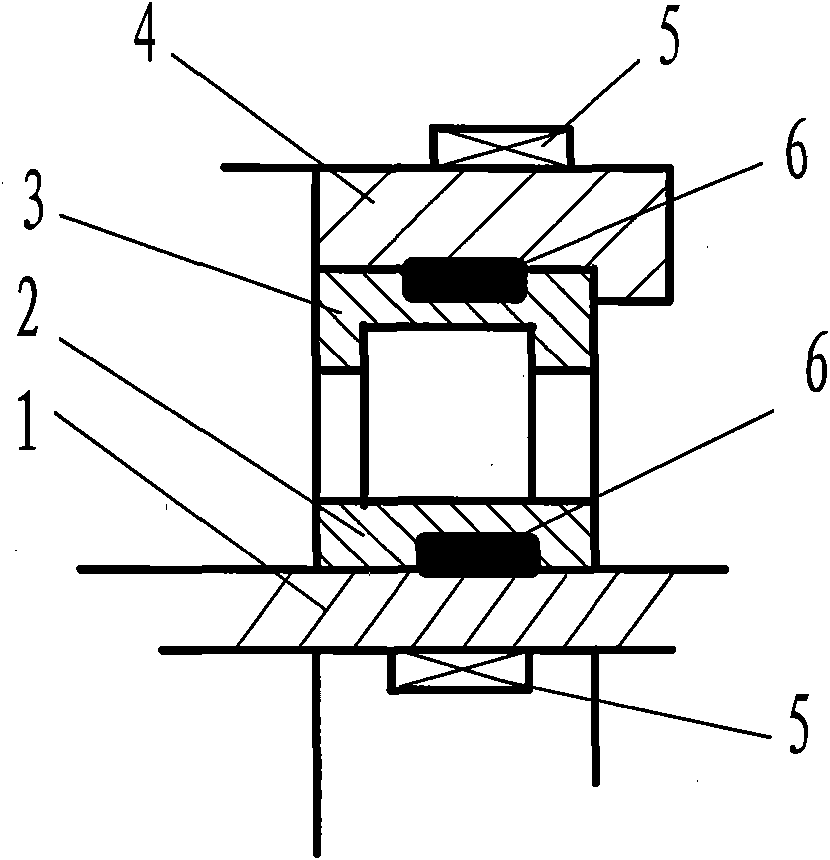

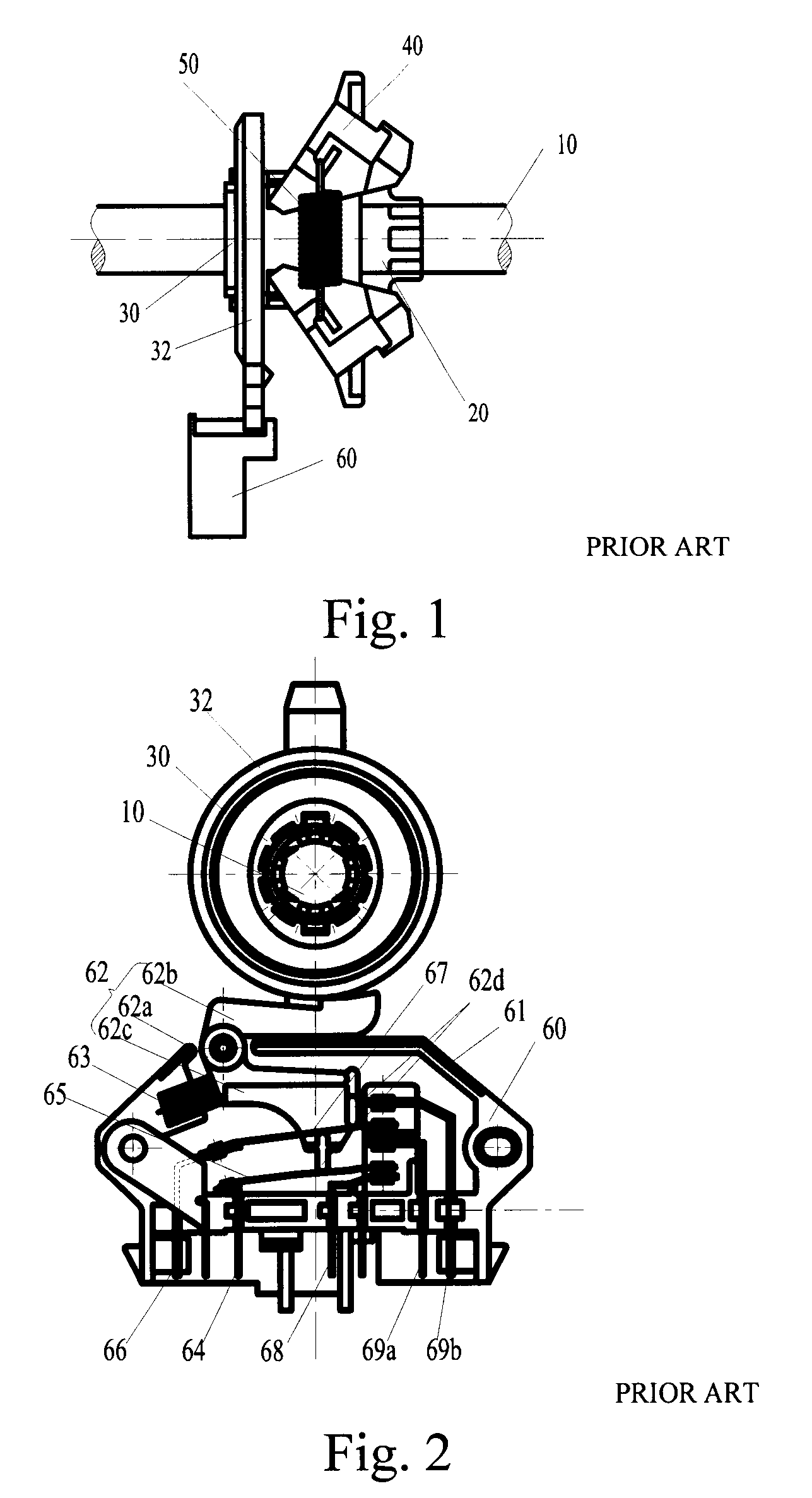

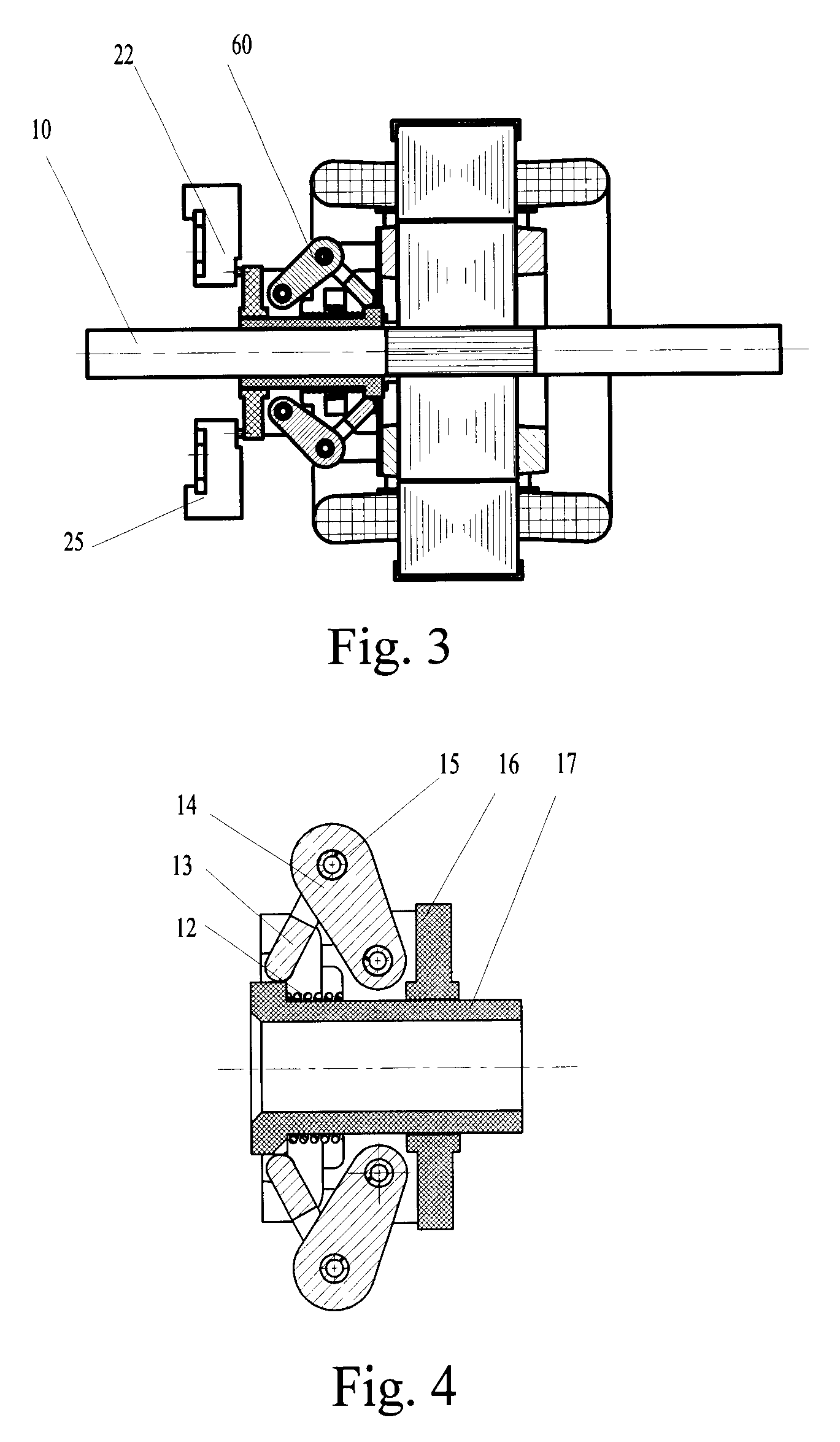

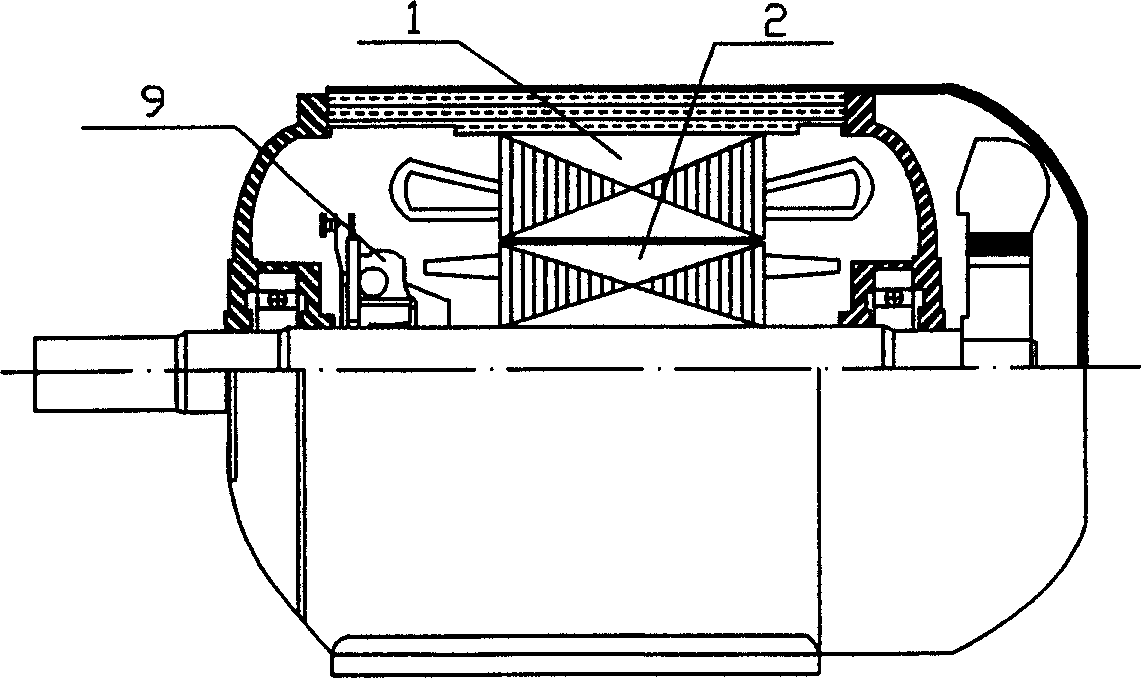

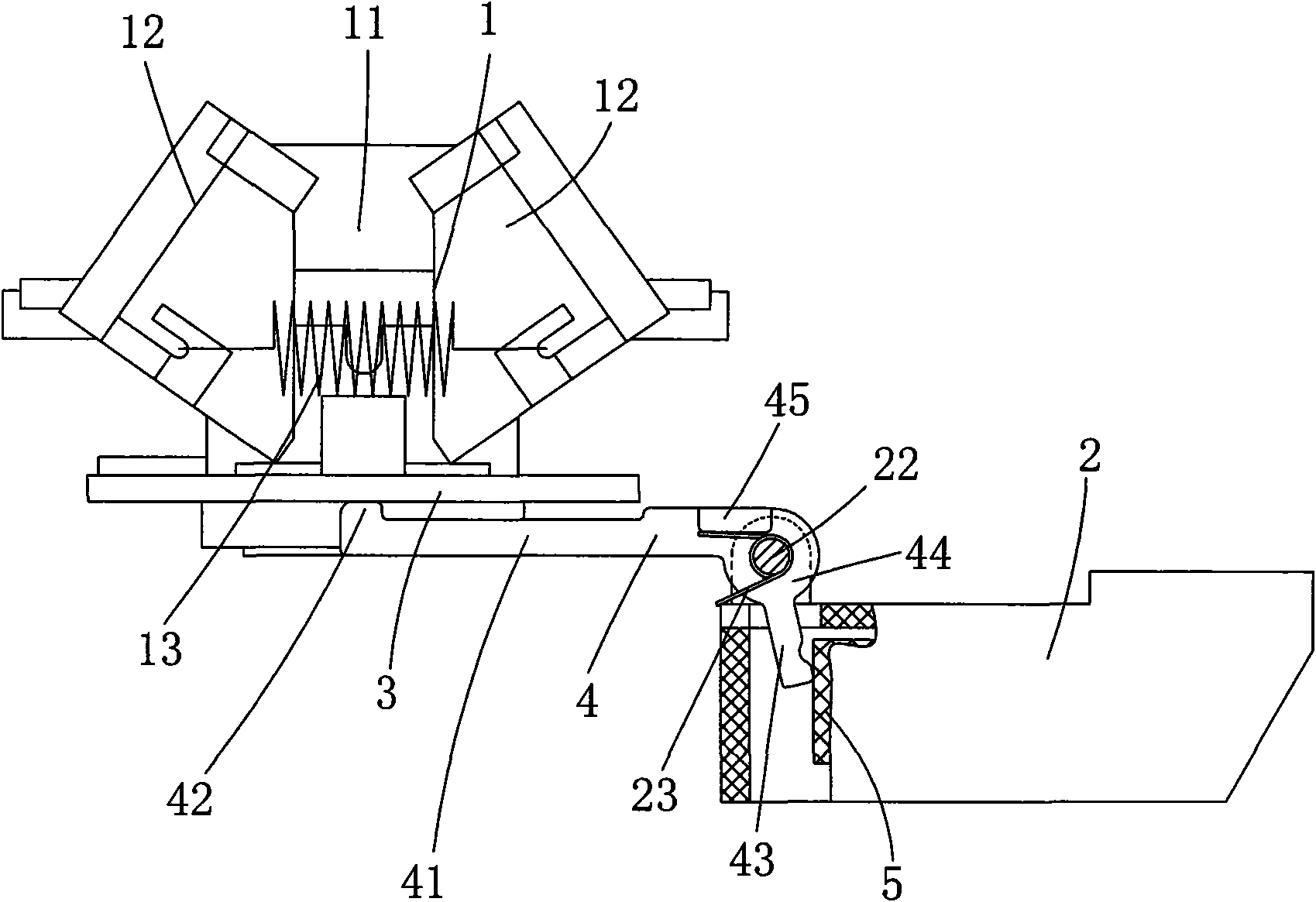

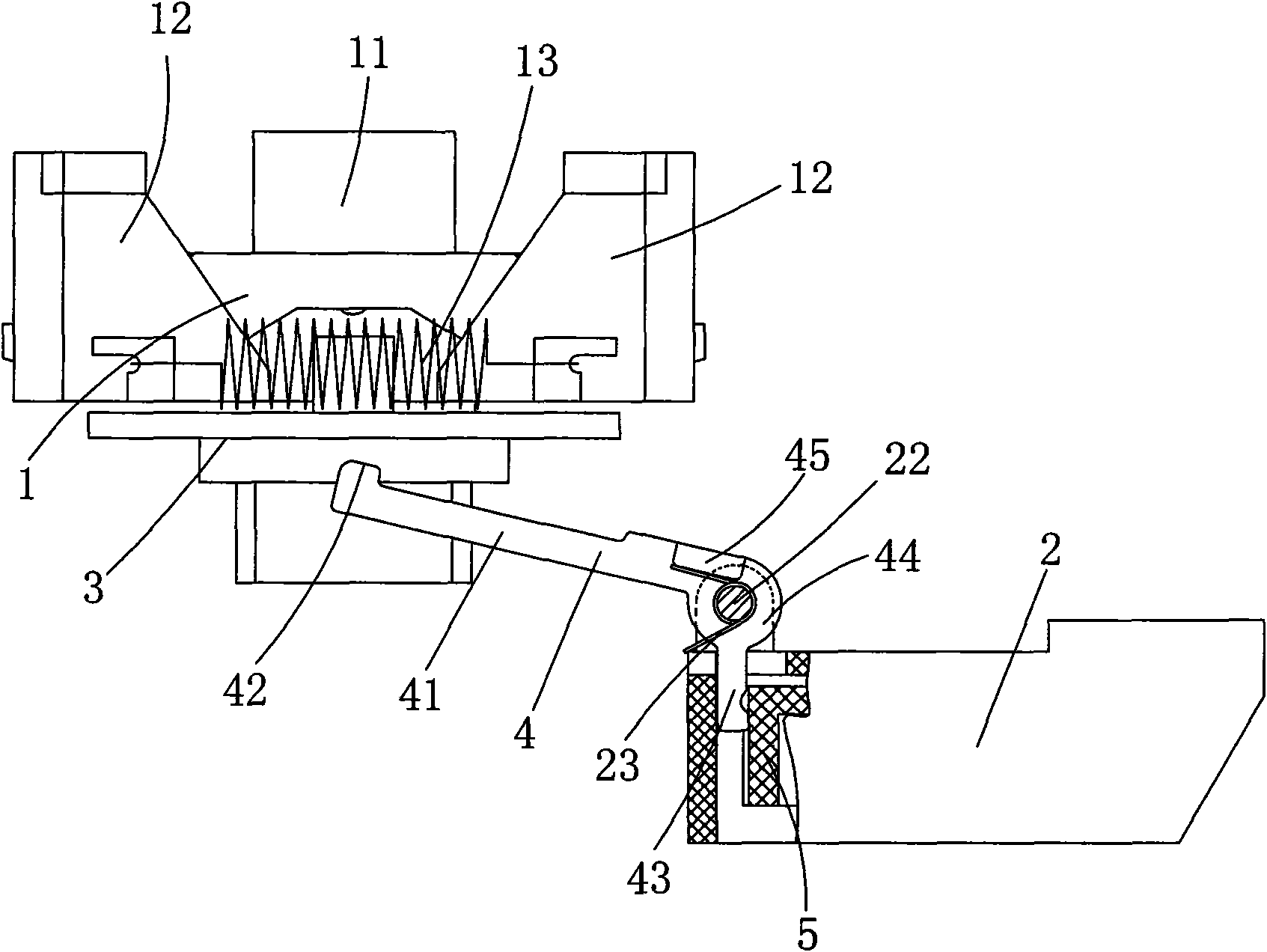

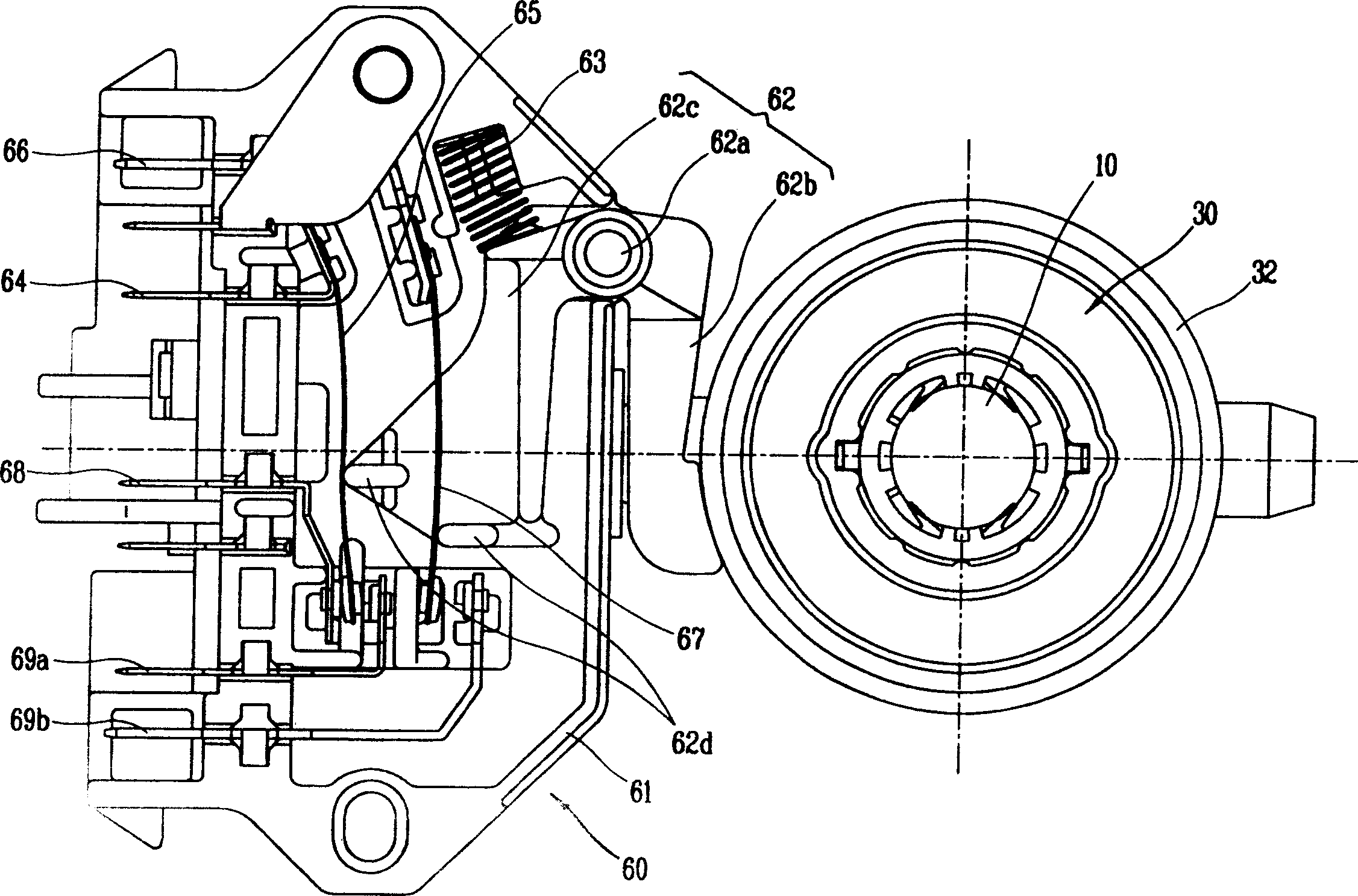

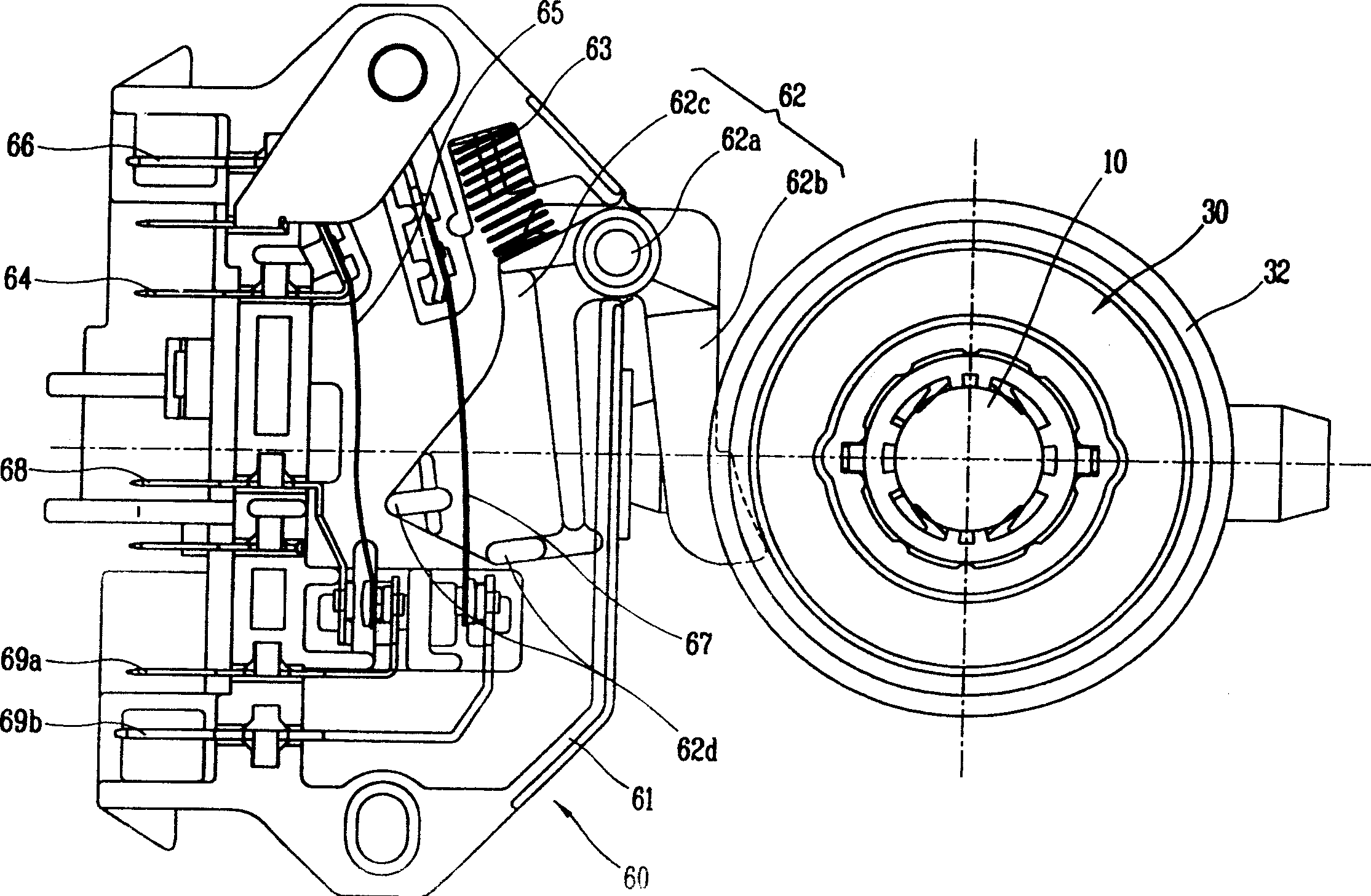

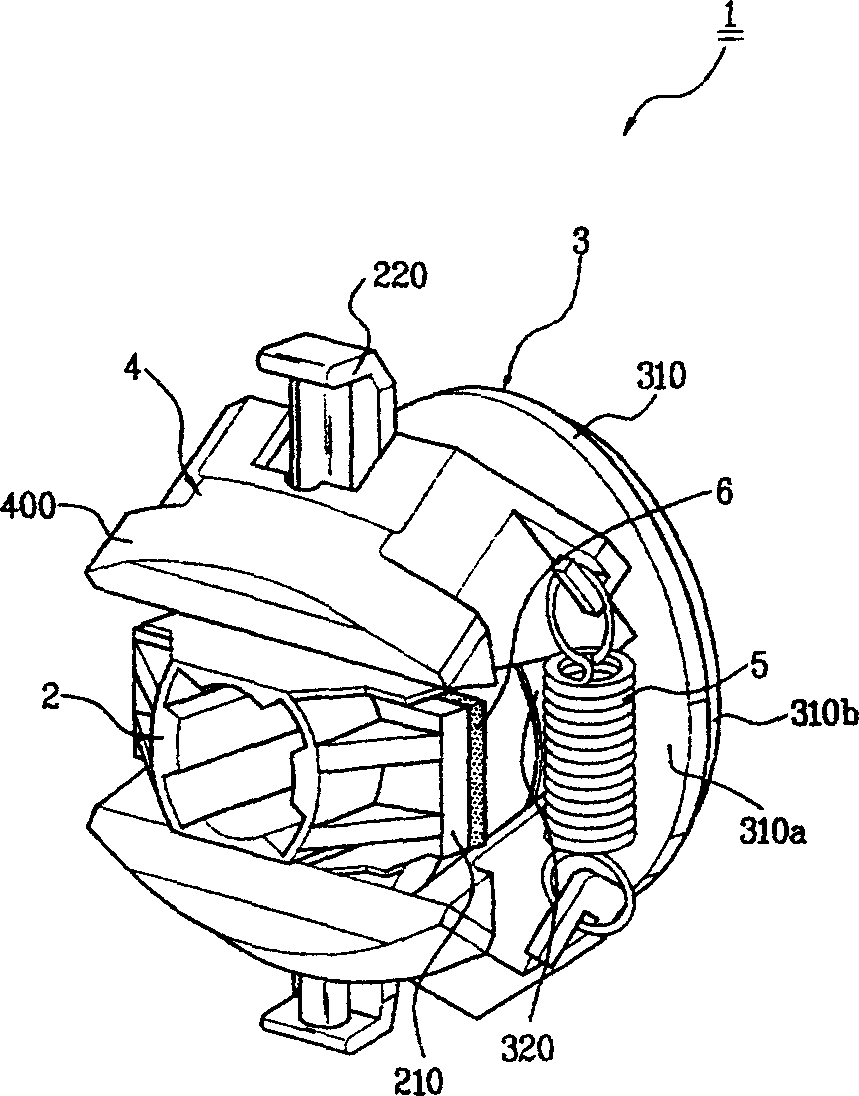

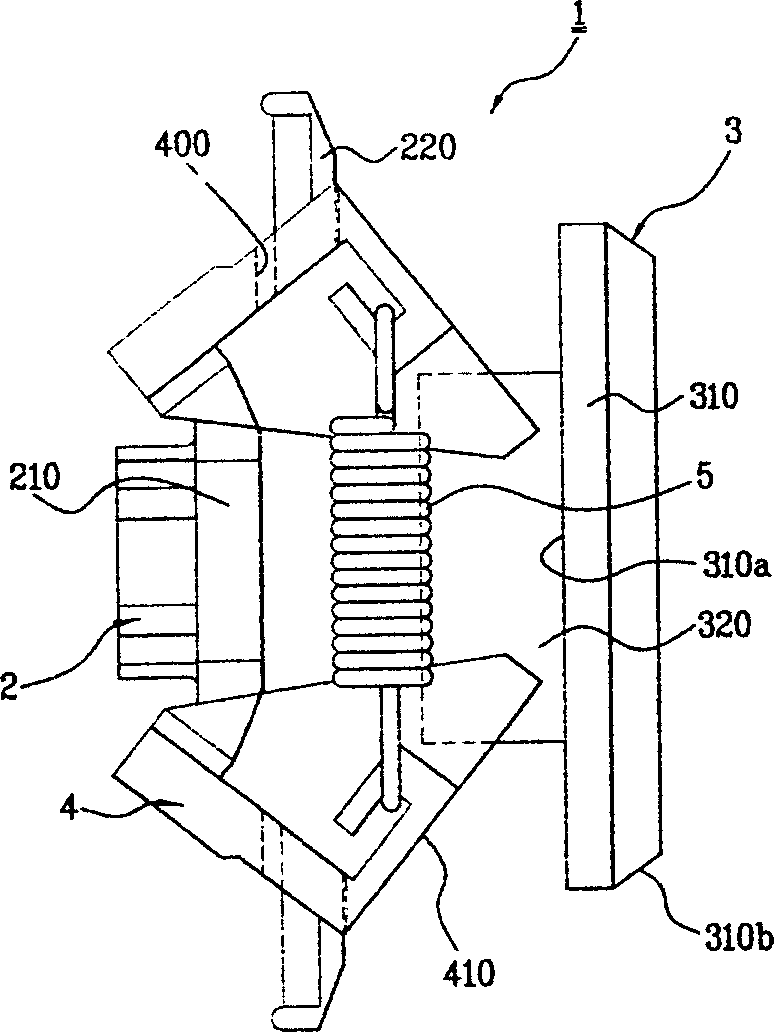

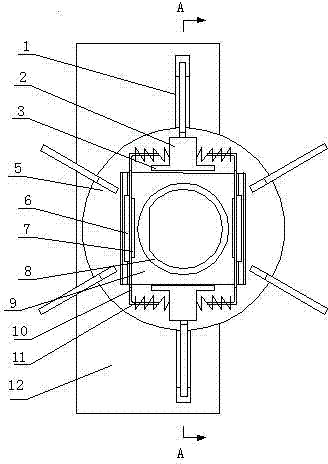

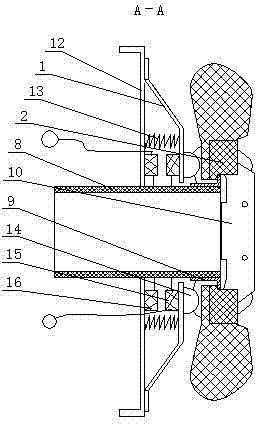

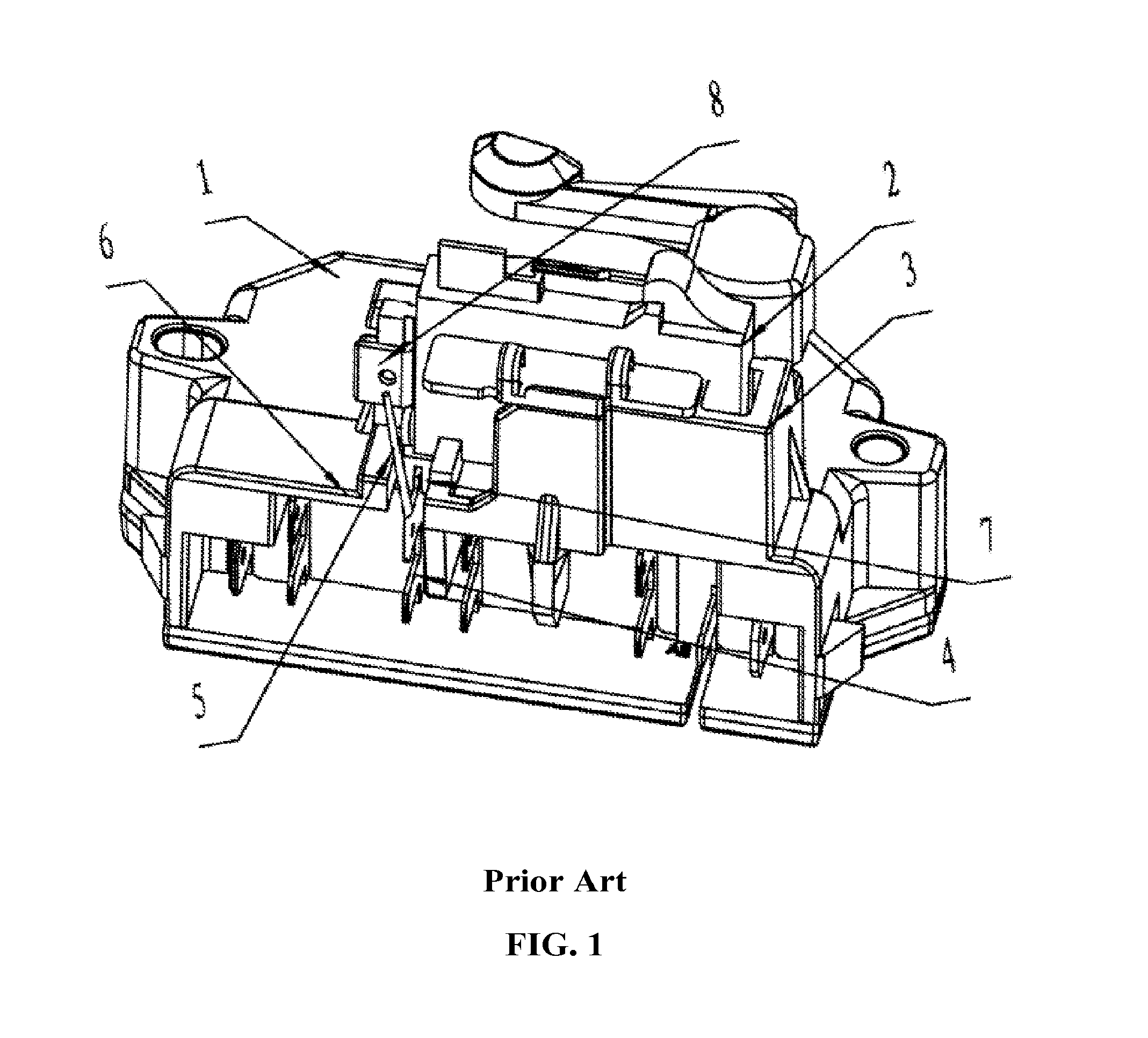

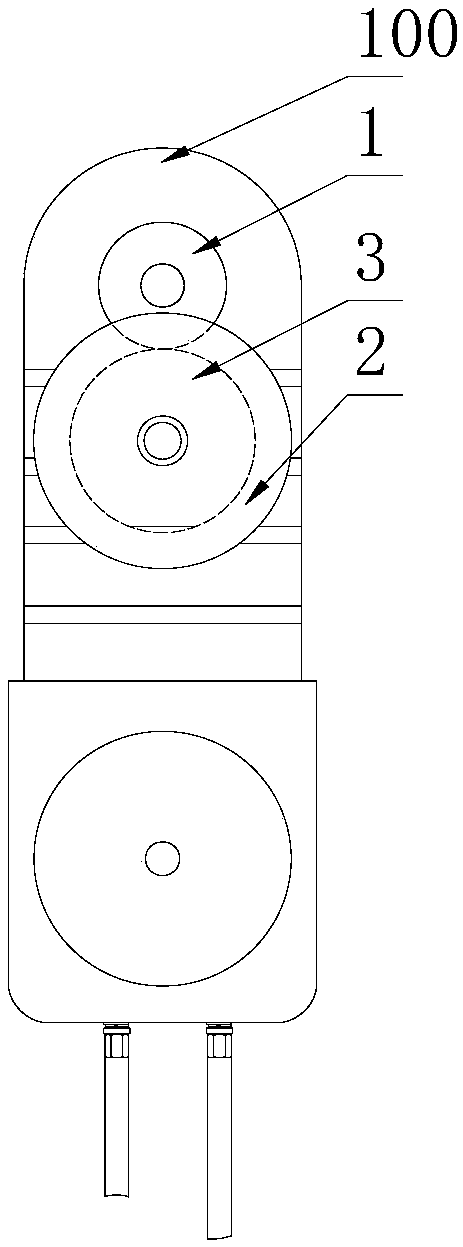

Centrifugal Switching Device of Single-Phase Induction Motor

ActiveUS20090159418A1Overcome defectsSmooth rotation without making any noiseSingle-phase induction motor startersAC motor controlConductor CoilFerrite core

A centrifugal switching device of a single-phase induction motor includes a centrifuge and pressure switches. The centrifuge includes a centrifugal sleeve, a centrifugal base, shaft coupling blocks, and a spring. The spring is directly fitted on the centrifugal base. Under a centrifugal force generated by the rotation of the motor, shaft coupling blocks I and II slide axially against an axial force of the spring, thus forcing an axial end surface of the centrifugal sleeve to be separated from contacts of the pressure switches, such that a starting winding of a stator ferrite-core coil of the single-phase induction motor is disconnected and a heater is turned on. The shaft coupling blocks I and II adopt a design with round transition, central sliding contact, and smooth rotation, thereby achieving a simple structure, convenient mounting, and safety usage.

Owner:HUAN YIJUN

Saturable single-phase asynchronous motor

InactiveCN1758510AIncrease fluxImprove efficiencyAsynchronous induction motorsCapacitanceConductor Coil

A magnetic-assist mono-phase asynchronous motor includes a base, a bearing, a stator and a rotor, among which, the stator is composed of a stator core, a primary winding and an assistant winding, the stator core is mounted on the base, the primary and assistant windings are winded on the core and form an angle of one electric degree, the primary winding is connected with the mono-phase supply, the rotor is composed of a rotor core, winding and a shaft and the core is fixed on the shaft, the rotor winding is winded on the core, the shaft is mounted on the end cover by the bearing, the assistant winding and a serial condenser compose a sub-winding branch, a single-pole double-throw centrifugal starter is composed of a connection post, an upper touch point and a lower touch point connected with both ends of the primary winding and both ends of the assistant winding branch are connected with the connection post and the lower touch point.

Owner:ZHEJIANG UNIV OF TECH

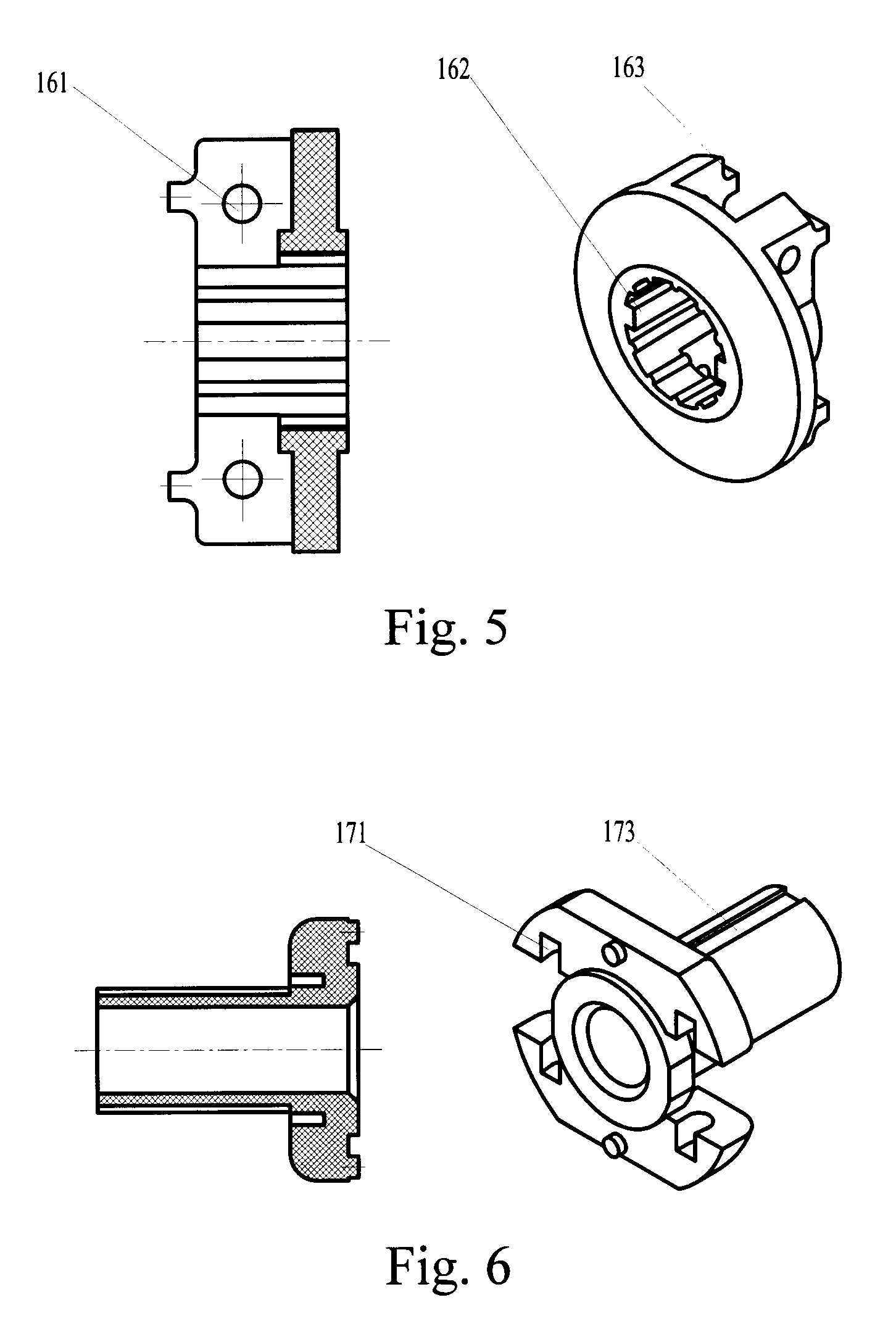

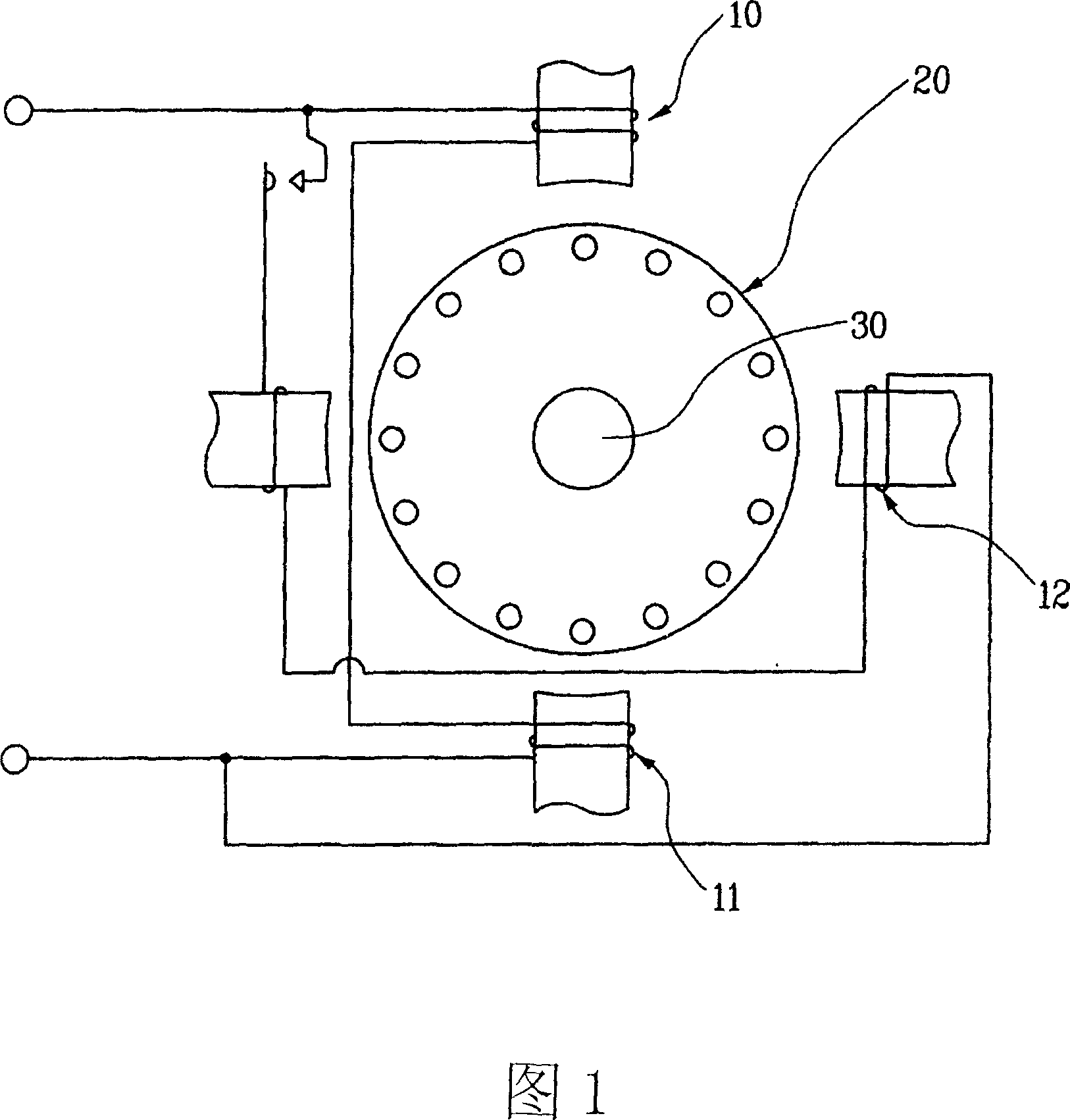

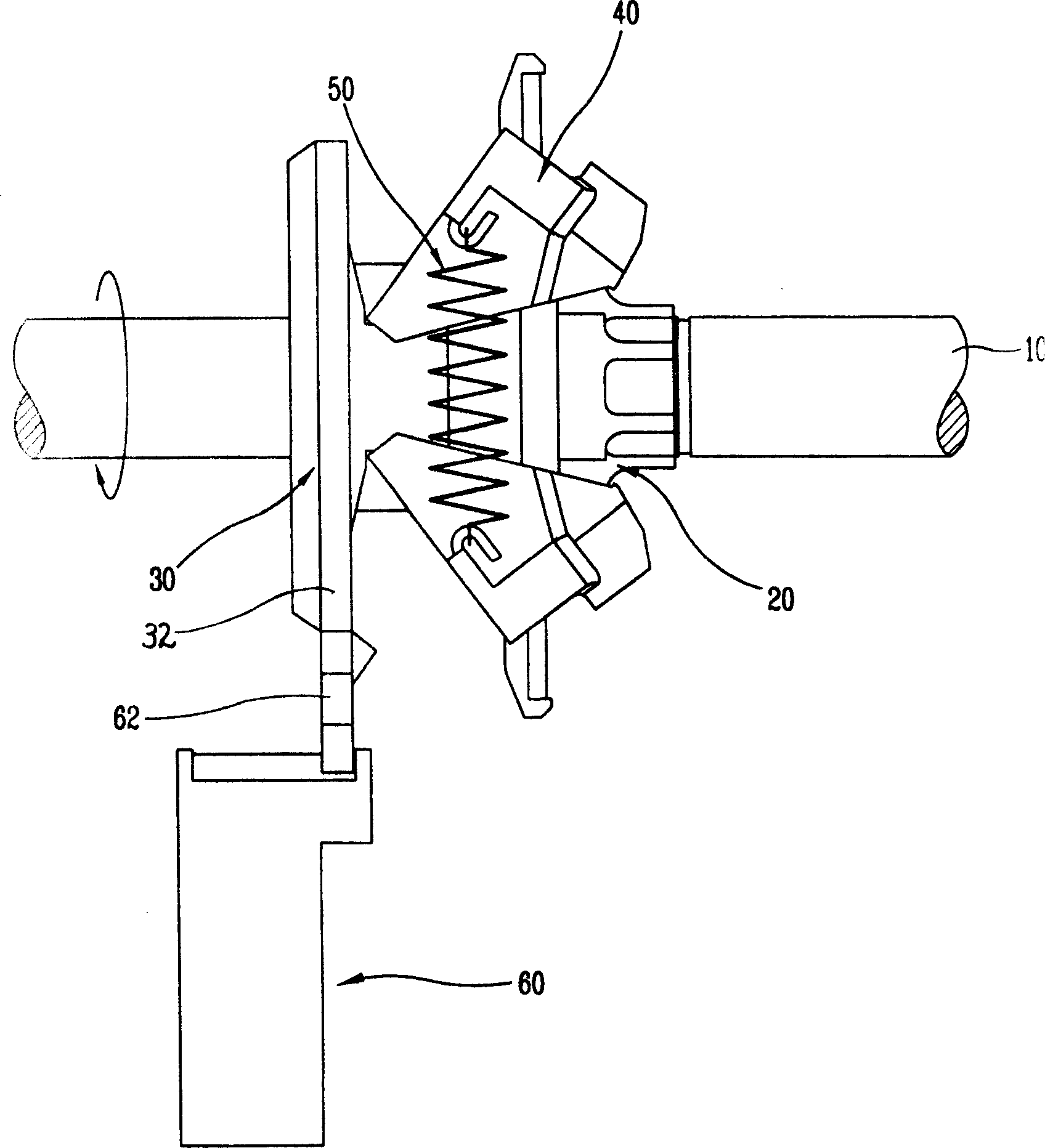

Centrifugal switch suitable for motor driving

InactiveCN101587797AGuaranteed uptimeHigh strengthDynamo-electric motors/converters startersElectric switchesPole pieceEngineering

A centrifugal switch suitable for motor driving comprises a centrifuge and a wire box body; the centrifuge is set with an axially flexible sliding bushing glidingly matched with a shaft; the wire box body is provided with a contact pole piece set in which clutching of contacts is controlled by front end of a movable rod which is rotatably matched with the wire box body; the centrifugal switch further includes a toggle rod whose middle part is rotatably matched with one side at bottom of the wire box body and is reset by a torque spring; front end of the toggle rod contacts bottom end face of the sliding bushing, and the toggle rod rotates under control of the sliding bushing; further, tail end of the toggle rod is collided with the movable rod. This invention achieves functions as follows: it ensures stable operation of the movable rod since end face of the sliding bushing is regarded as working surface for switching contacts; it simplifies structure of the centrifugal switch and enhances strength of the toggle rod in adoption of the integrative toggle rod, and further prolongs service life of the whole centrifugal switch; further, it reduces complexity of installment and enhances convenience for daily maintenance since the integrative toggle rod is adopted.

Owner:NINGBO ZHENHAI MICRO ELECTRIC MOTORS FACTORY

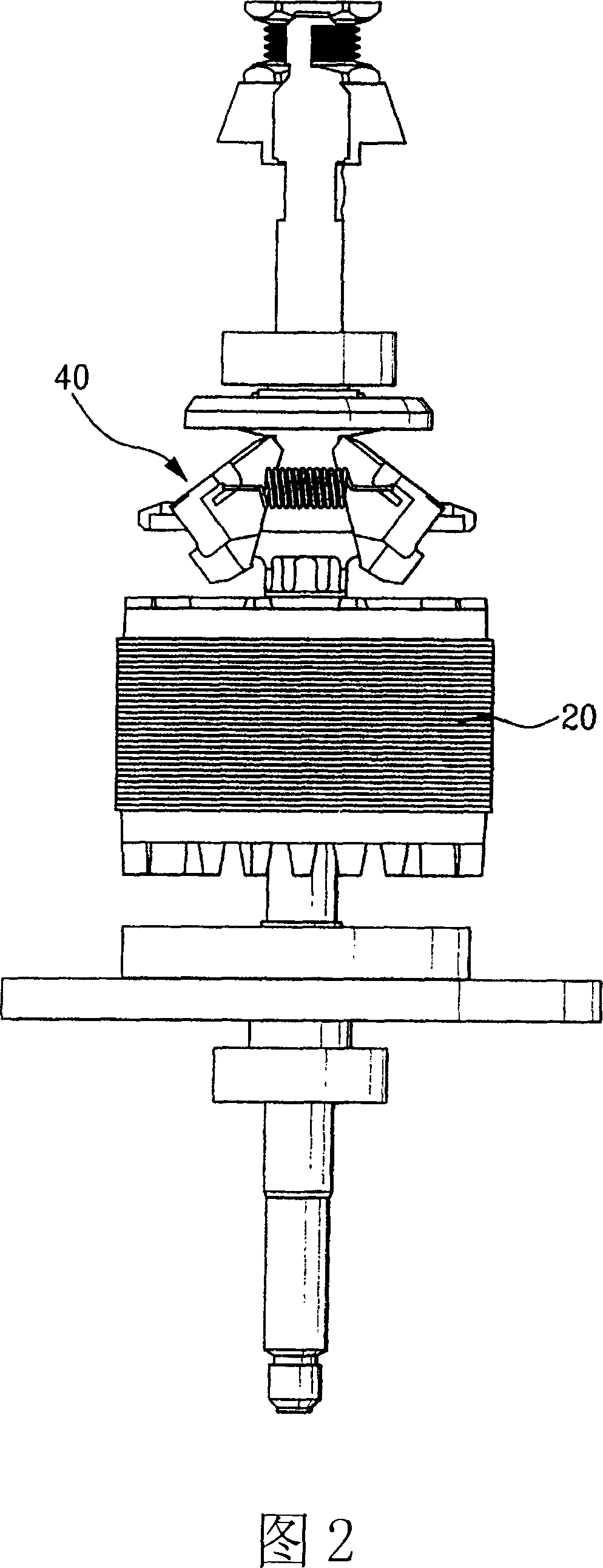

Centrifugal switch of split-phase motor

InactiveCN1979713AReduce wear and tearReduce noiseSingle-phase induction motor startersElectric switchesEngineeringActuator

A kind of centrifugal switch of split-phase motor, includes: sleeve, it is inserted into the limitative units of axis, and forms a flange part over its outer circumference; sliding block, it lies in the outer side of above-said sleeve, and is inserted movably along the axis direction of above-said sleeve, and then disconnect the assistant coil circuit when it arrives in the given position; the centrifugal actuator, it must be 2 pieces at least or more, and opens outwards under the centrifugal force it produces when the above-said axis rotates; stretch spring, it will produce elastic resilience along the direction in which it converges the above-side centrifugal actuator, and a groove is formed inside of the sleeve, the groove contacts with the two sides of the above-said limitative units in the rotary direction. The invention will reduce maximally the wear and tear of the contacting position where it is produced by axis and centrifugal switch, and reduce the noise also.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

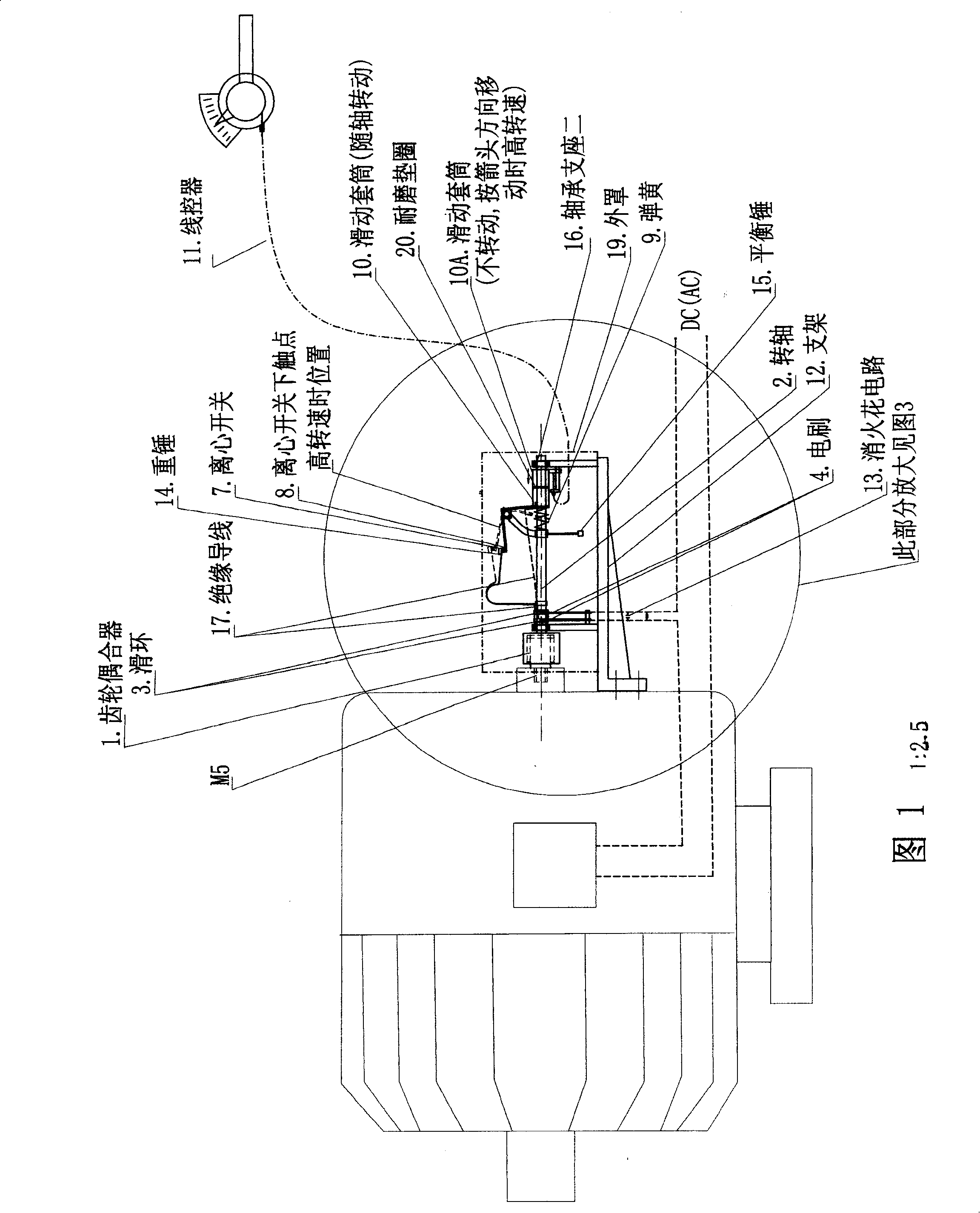

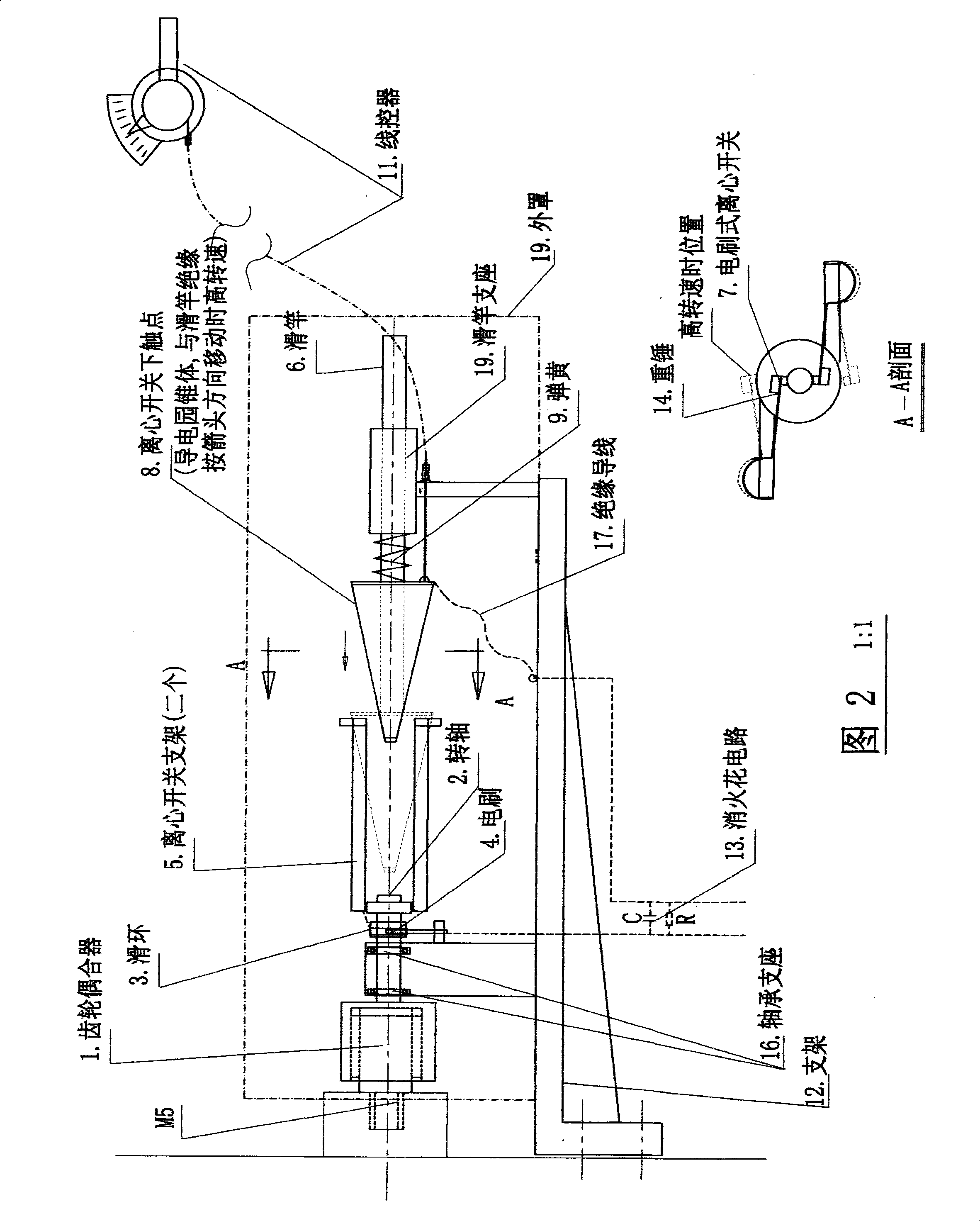

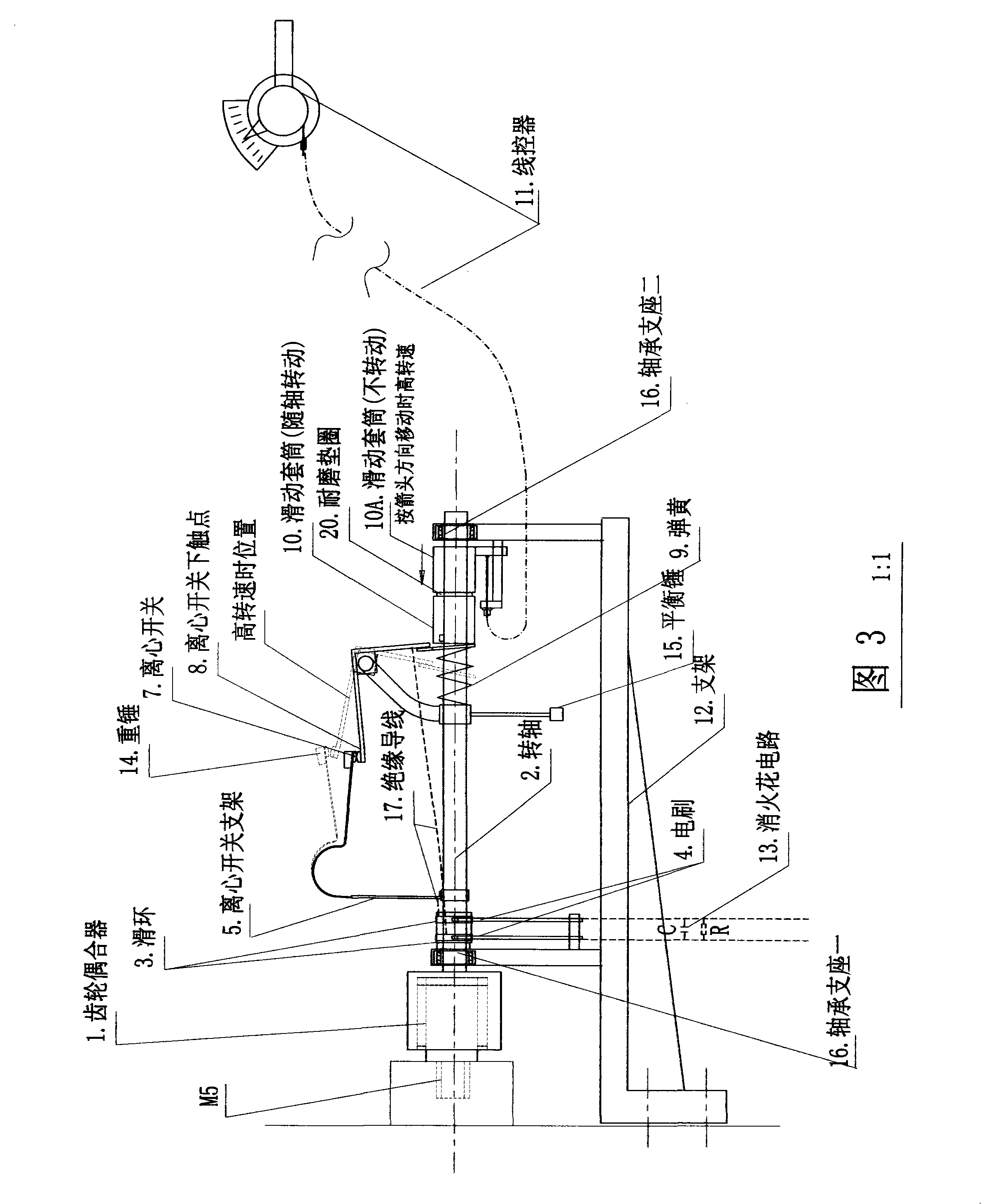

Acentric timing and speed-stabilized motor

The invention provides a speed regulating and stabilizing motor capable of controlling the rotate speed of the motor accurately and is mainly used for the stepless speed regulation and stabilization of ordinary DC motors and AC motors. The invention mainly comprises a centrifugal speed regulator which is fixed on a projecting shaft at the tail of the motor. When a motor shaft rotates, a centrifugal switch on the centrifugal speed regulator is driven to rotate at the same time by the gear coupling. When the rotate speed of the motor surpasses the presetting value, the centrifugal switch is off; otherwise, the centrifugal switch is on. The input current of the motor flows through an electric brush and the centrifugal switch is used to control the on and off time, thereby controlling the rotate speed of the motor. The rotate speed is regulated by the drive-by-wire or a servo-actuator to regulate the pressure of the centrifugal switch; if the pressure is great, the rotate speed is regulated to be high; if the pressure is small, the rotate speed is regulated to be slow. The application of a thyristor amplifying circuit to a large-sized motor ensures that the motor with high voltage and great current can be controlled even if the current flowing through the centrifugal switch and the voltage are small.

Owner:李待言

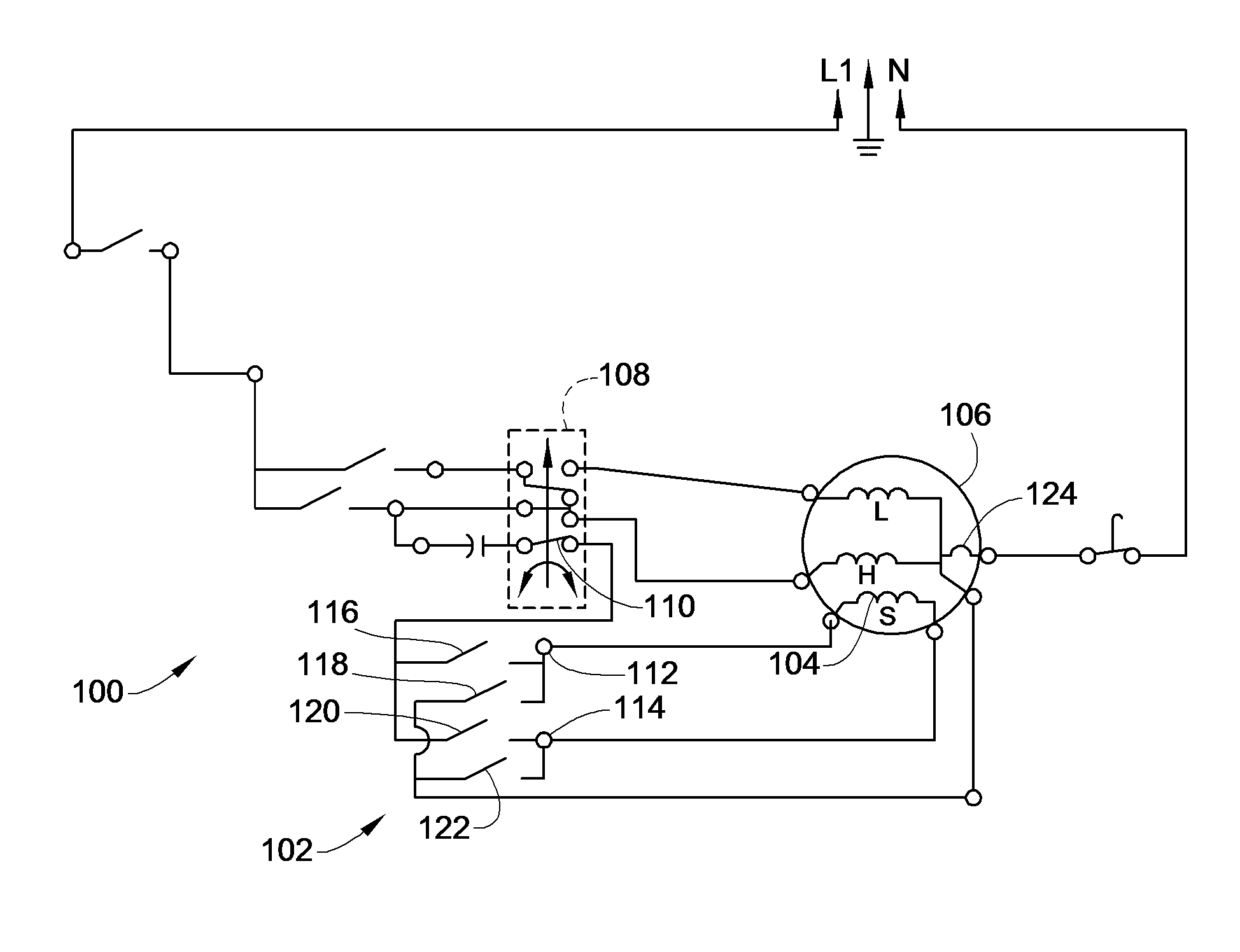

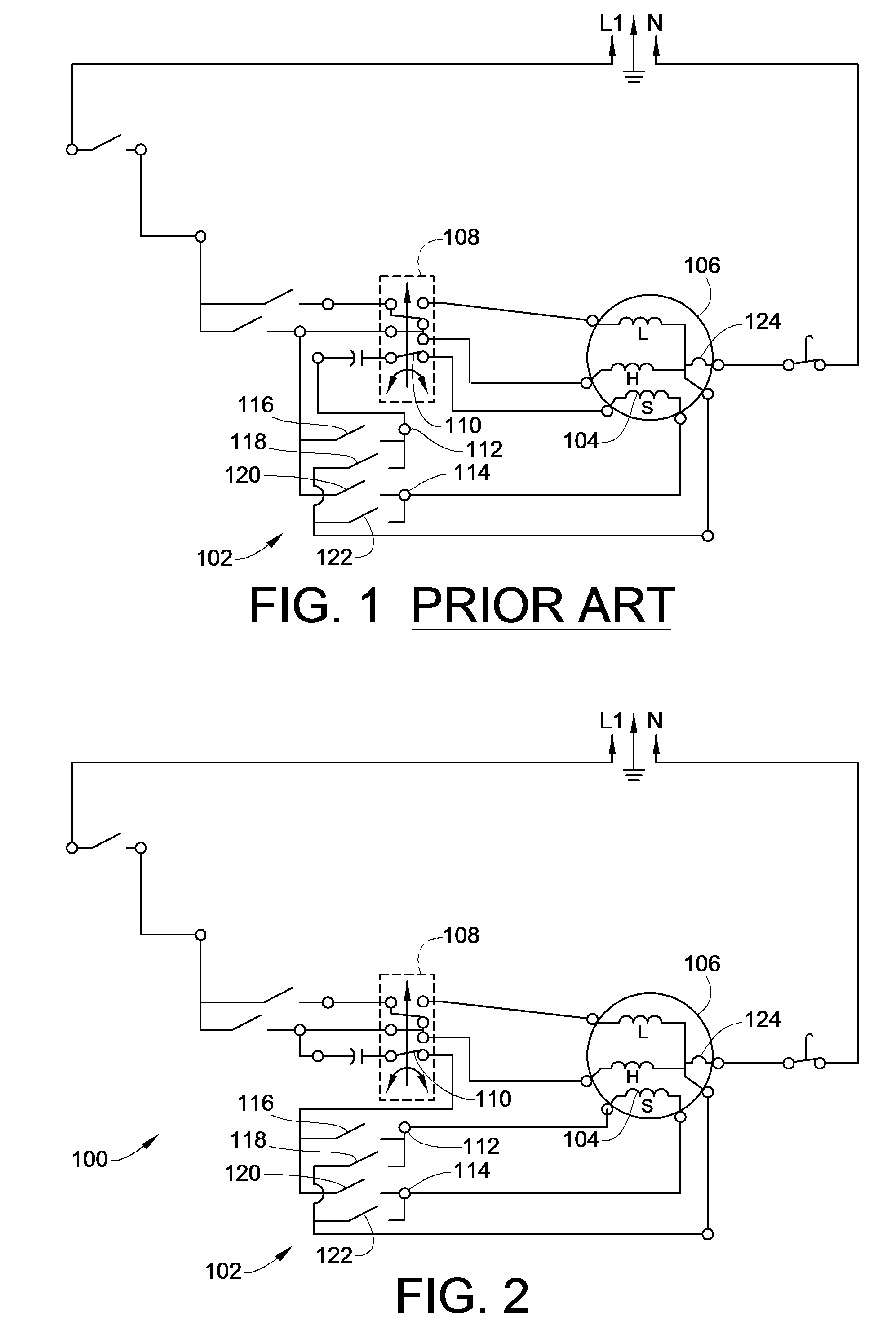

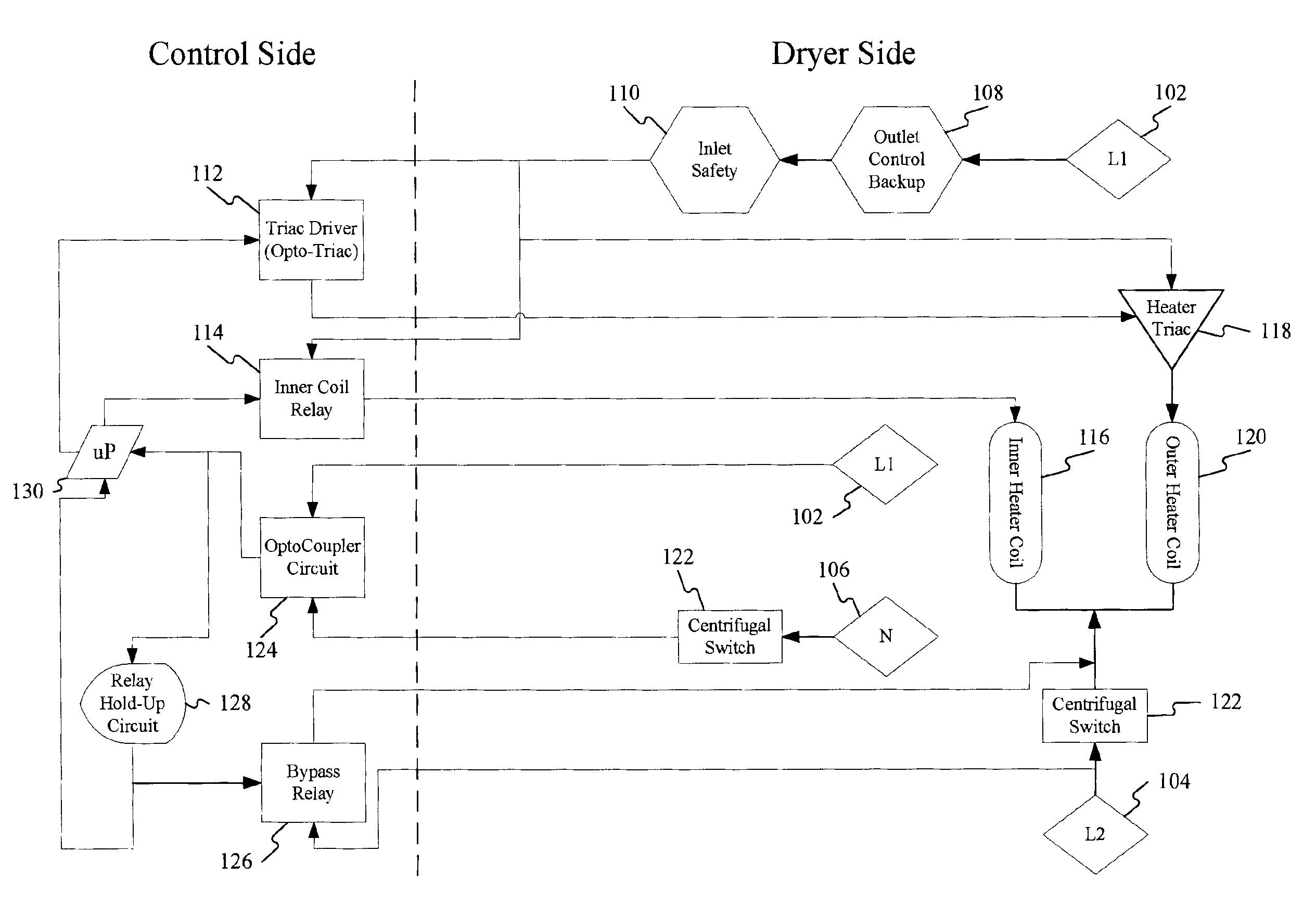

Washing Machine Wiring to Reduce Mechanical Timer Contact Welding

InactiveUS20100171449A1Control circuitryCost of controlSingle-phase induction motor startersAc-dc conversion without reversalInduction motorElectric machine

A control circuit for a washing machine that avoids contact bounce short circuit failures is provided. A washing machine that utilizes an induction motor including a starting winding used to start rotation of the motor at the beginning of a cycle. Such washing machines require that the motor be operated in both directions during different cycles. To enable such operation, a mechanical timer uses a pair of single pole, double throw switches in a switching assembly to reverse the L1 and neutral connections to the starter winding. To avoid the contact shorting problem, the control wiring runs either the L1 or neutral side of the voltage source, or both, through the centrifugal switch to open the input contact(s) once the motor has reached its operating speed. Then, if the switching assembly has L1 and N contacts touching at the same time, it will not result in a dead short.

Owner:ROBERTSHAW CONTROLS CO

Centrifugal switch structure of single phase induction motor

InactiveCN1705054AExtend your lifeAvoid damageStarter detailsElectric switchesEngineeringConductor Coil

A centrifugal switch structure for single phase induction motor consisting of axial moveable axle collar slide block, moveable switch containing first leaf spring switch in shell for switching on / off main and sub windings, moveable lever rotary hinged in shell and located at first leaf spring switch and rotation according to pressurization state of axle collar, fixing slot for executing on / off action. Said invention can prevent the damage of contact by smelting contact.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

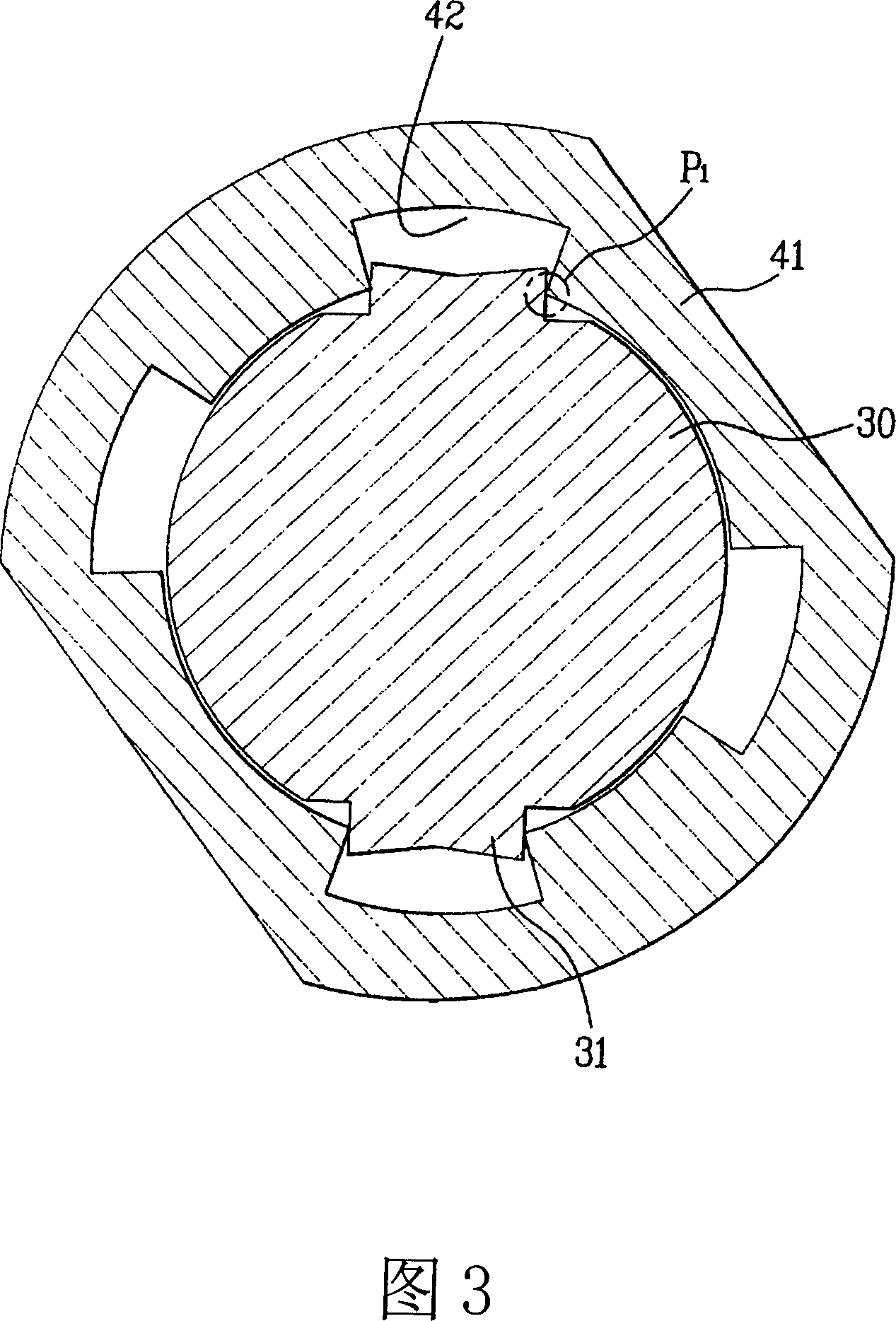

Structure of centrifugal switch

The invention discloses a structure of centrifugal switch, including: a cylinder type hollow shaft with a motor shaft through, arranged with a flange and formed with guide arms; a shaft mechanism inserted in the back of the flange of the hollow shaft and moving in the axial direction of the hollow shaft and a slide block situated at the back end of the shaft mechanism and forming a shaft lining in the radial direction; the centrifugal brakes with the guide arms passing through the through hole, arranged the left and right sides of the shaft mechanism of the slide block in a hinging mode at the same time and able to turn, and opened under the action of centrifugal force; an extension spring linking two-side centrifugal brakes, making them approach to each other as they are not acted by the centrifugal force and providing return force; a buffer pad provided on the contact surface between the slide block and hollow shaft or on the shaft lining of the slide block. It uses the buffer pad to effectively reduce the produced noise as the brakes act and improve the reliance of the products.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

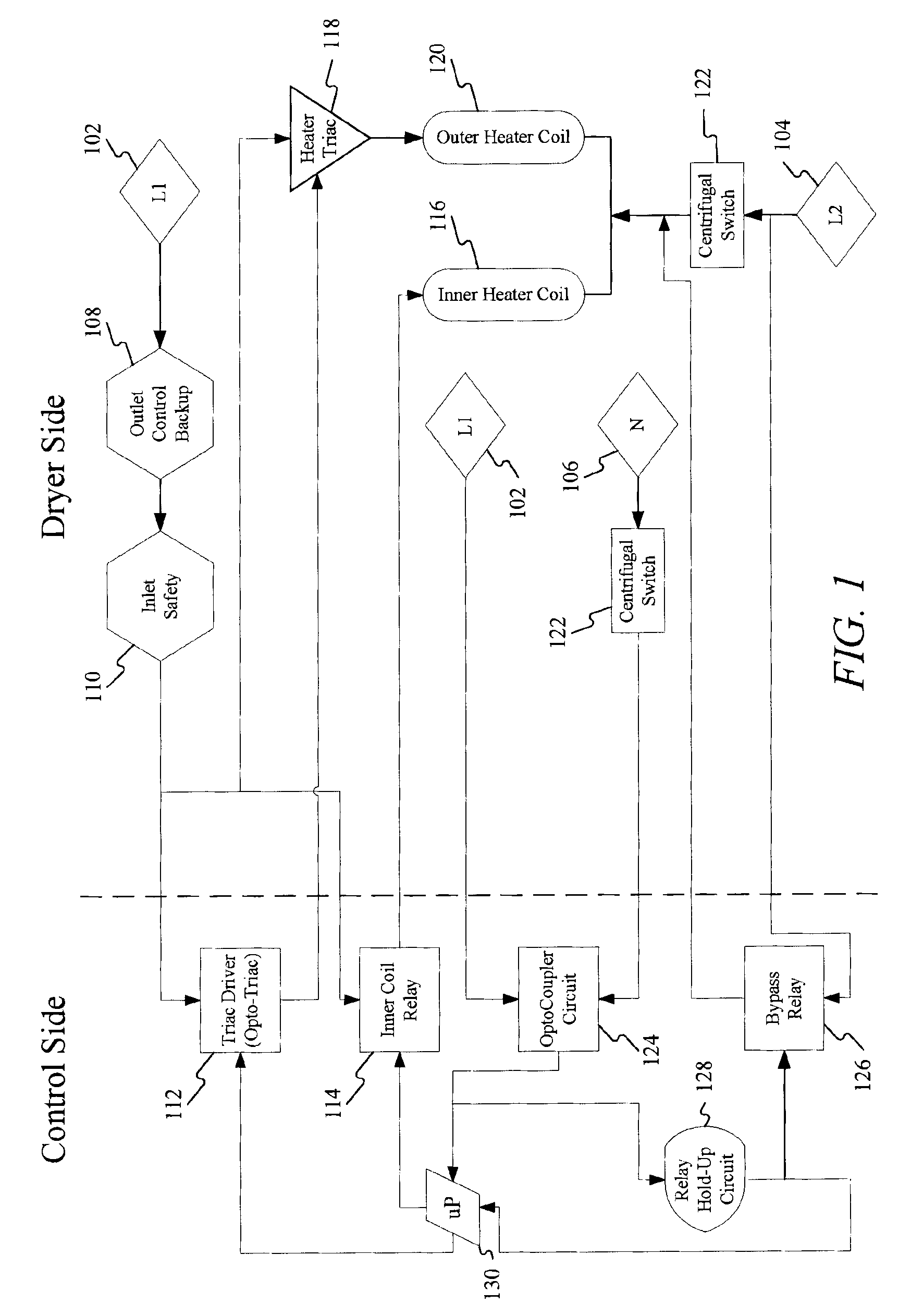

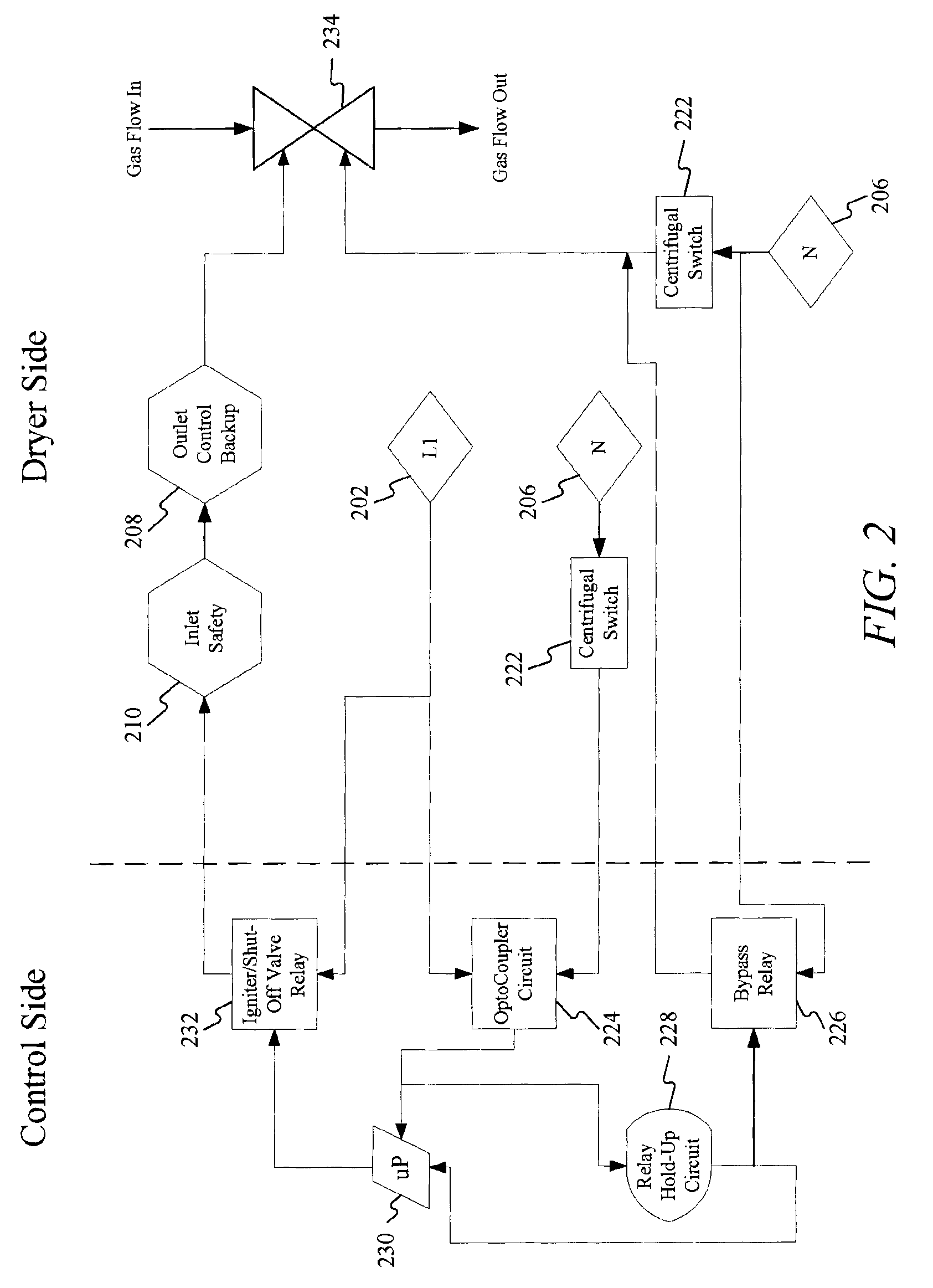

Centrifugal switch bypass for reverse tumble dryers

Owner:HAIER US APPLIANCE SOLUTIONS INC

Fan-type motor centrifugal switch

The invention discloses a fan-type motor centrifugal switch which relates to the field of an electric appliance switch. The fan-type motor centrifugal switch is provided with a rotating shaft, wherein the rotating shaft is provided with a fan impeller; the upper side and the lower side of the front side surface of the fan impeller are provided with bidirectional spring seats; the spindle on the front side of the fan impeller is provided with a centrifugal counter weight snap-gauge; the centrifugal counter weight snap-gauge is clamped between the two spring seats; the left end part and the right end part of the centrifugal counter weight snap-gauge are hinged with centrifugal plates; the upper end part and the lower end part of each centrifugal plate are provided with elastic sheathing arms; the centrifugal plate and the centrifugal counter weight snap-gauge are hinged with the each other; each elastic sheathing arm is sheathed with a closed spring; the other end of the closed spring is abutted against the spring seats; the rear side of the fan impeller is provided with an insulation plate; and a return spring and a travel switch are arranged between the insulation plate and the travel switch. According to the fan-type motor centrifugal switch disclosed by the invention, each component can be made of ABS (acrylonitrile butadiene styrene) plastic products, and the production and the use of materials are both environment-friendly and free from pollution. The fan-type motor centrifugal switch has the advantages of small volume, light weight, cost saving, low structural requirement on a motor shaft, manpower saving, low cost, convenience in installing and maintaining and high effective use ratio of the inside of a motor body, and the improvement of power of the motor.

Owner:李荣华

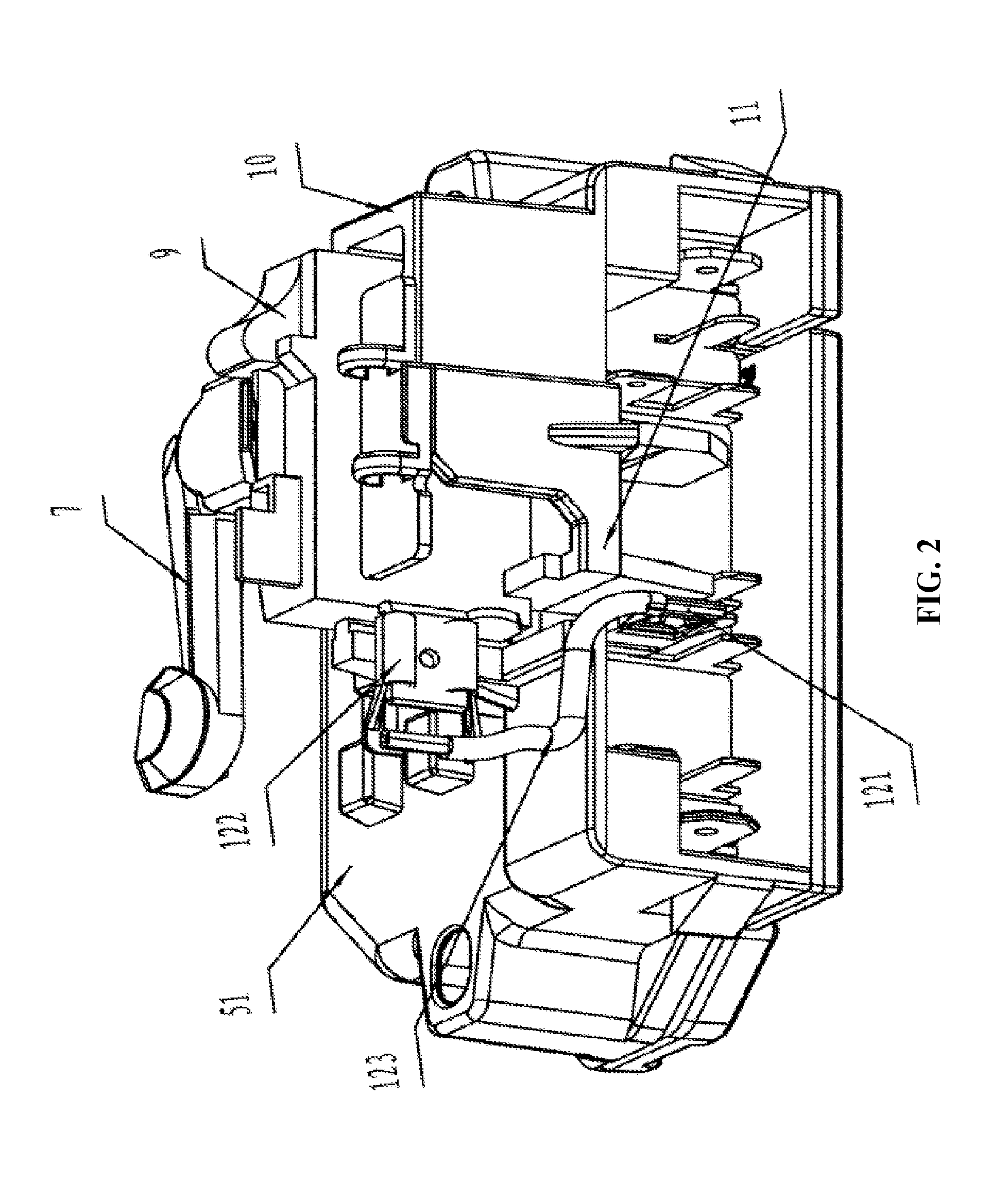

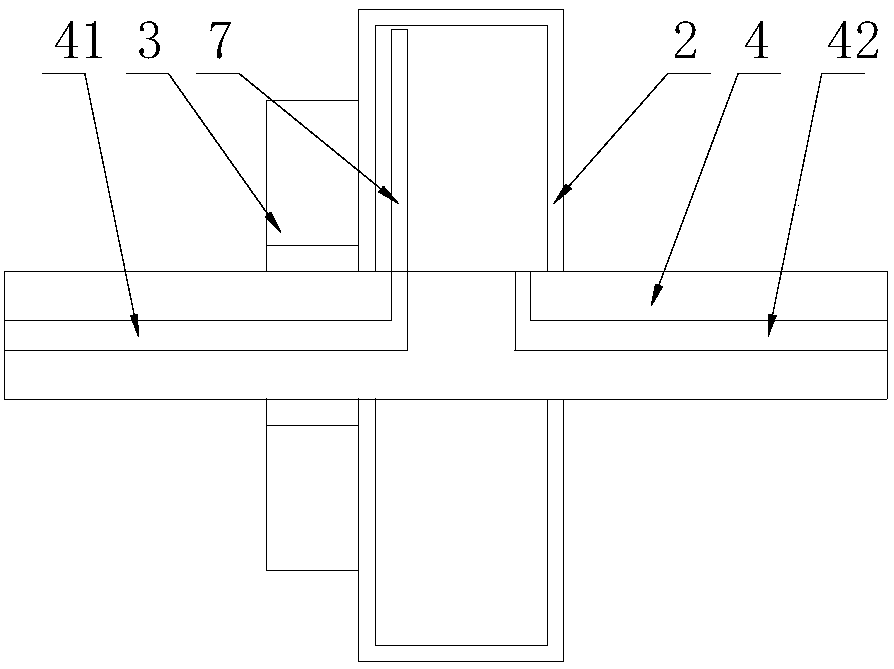

Terminal box for centrifugal switch of motor and motor with the same

ActiveUS8362663B2Simple structureEasy to assemble and disassembleCasings/cabinets/drawers detailsThermal switch detailsElectricityThermostat

A terminal box, including at least a box (51) having a receiving part (10), a movable control rod (7), multiple electric contacts (8), a thermostat (9) having a terminal (91), and a wiring mechanism (12). The movable control rod (7) is disposed on the box (51) and partially extends therefrom. The electric contacts (8) are disposed in the box (51). The thermostat (9) is disposed on end surface of the box (51). The receiving part (10) operates to receive the thermostat (9). One end of the electric contact (8) extends from the box (51) and forms a connecting part (81). A separating plate (11) is disposed between the connecting part (81) and the thermostat (9). One end of the wiring mechanism (12) is connected to the connecting part (81), and the other end thereof bypasses the outside of the separating plate (11) and is connected to the terminal (91). If the thermostat experiences temperature detection failure, users of the motor can easily remove the wiring mechanism, and timely switch off the power supply connected to the motor via an external protection circuit thereby preventing the motor from being burned out.

Owner:ZHONGSHAN BROAD OCEAN MOTOR MFG

Power take-off device with alarm maintenance function

InactiveCN108361369APromote repairLow integrationGear lubrication/coolingGearing controlMechanical AbnormalityEngineering

The invention discloses a power take-off device with an alarm maintenance function. The power take-off device comprises a centrifugal drive gear, a centrifugal cylinder, a centrifugal gear, a centrifugal shaft, a rotation speed sensor, a temperature sensor and a buzzer alarm. Sealing end covers are arranged at the two ends of the centrifugal cylinder, the sealing end covers are fixedly installed on the centrifugal shaft, and the centrifugal gear is fixedly installed on the centrifugal shaft. The centrifugal shaft, at both sides of the centrifugal cylinder, is installed on a bracket through bearings. A rotation speed sensor is arranged on the centrifugal shaft, and the rotation speed sensor is connected with the buzzer alarm through a controller. An inlet of a lubricating oil inlet pump isconnected with a lubricating oil outlet on a shell of the power take-off device through a pipeline, and the temperature sensor is arranged on the pipeline between the inlet of the lubricating oil inlet pump and the lubricating oil outlet on the shell of the power take-off device. The rotation speed sensor and the temperature sensor of the temperature power take-off device with the alarm maintenance function can effectively monitor the internal temperature abnormality and the mechanical abnormality of the power take-off device, and give a timely alarm.

Owner:HUBEI SENYU GEAR DRIVE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com