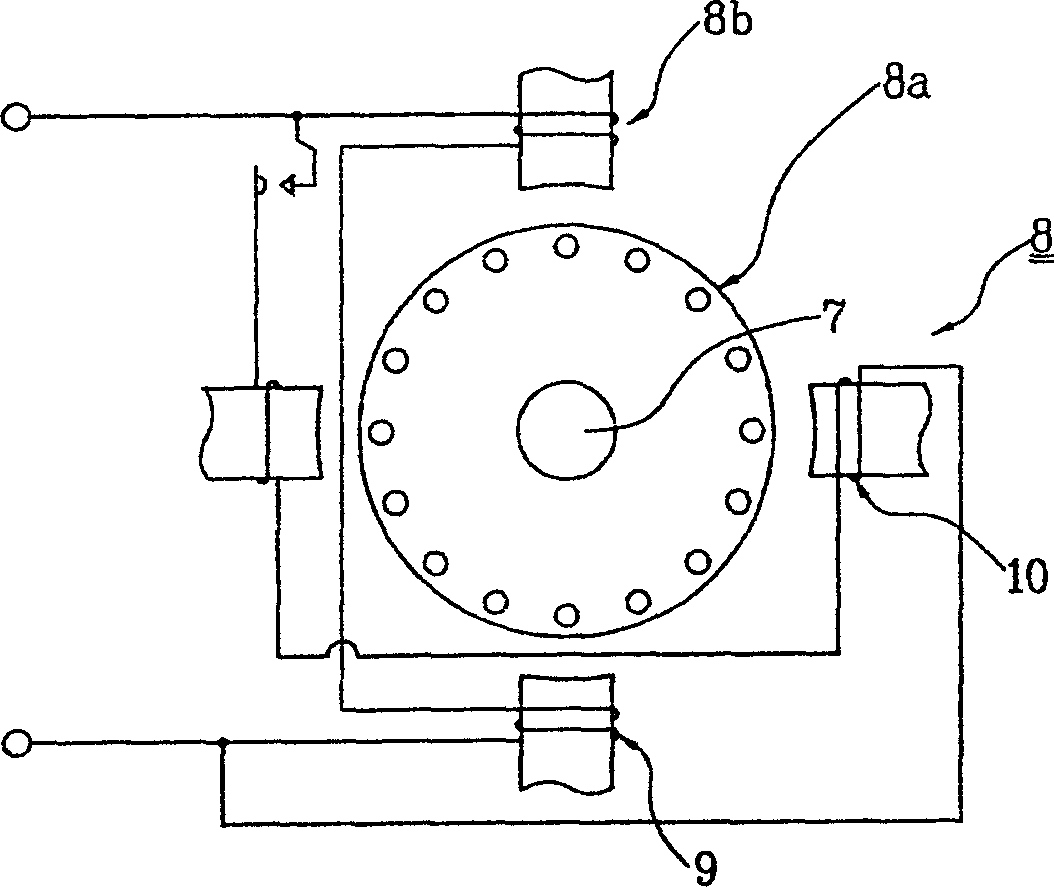

Structure of centrifugal switch

A centrifugal, switching technology, applied in electrical switches, electrical components, circuits, etc., can solve problems such as noise generation, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

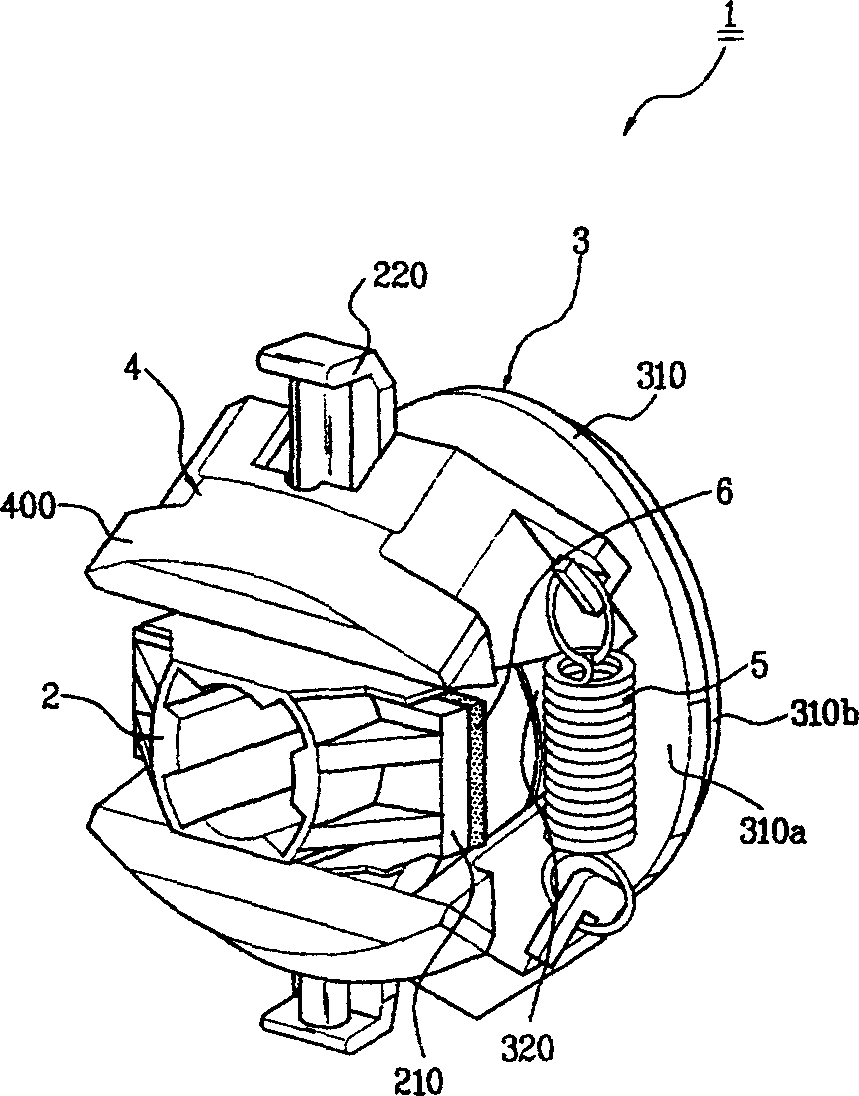

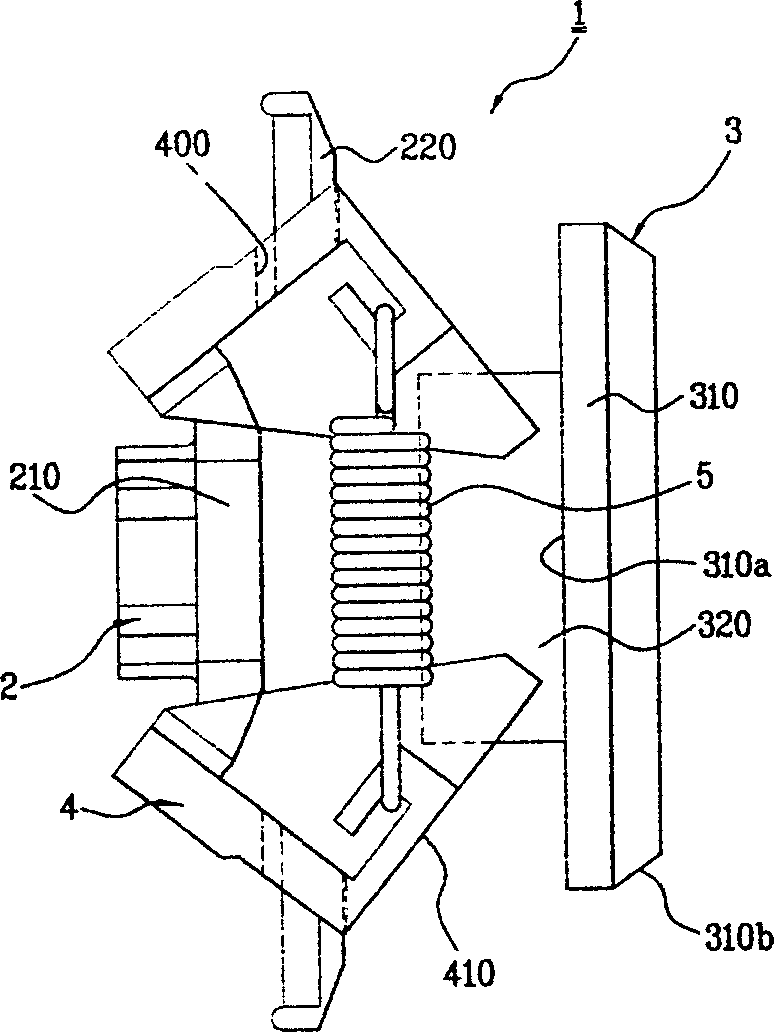

[0029] The structure of the centrifugal switch of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments:

[0030] In the following description, the same parts as the prior art refer to the prior art and use the same symbols.

[0031] Such as image 3 , Figure 4a and Figure 4b As shown, the centrifugal switch designed by the present invention includes: the crankshaft 7 of the motor passes through, and a flange 210 is arranged on one side end, and the two sides in the direction that the flange 210 is perpendicular to the crankshaft of the motor Cylinder type hollow shaft 2 extending to form guide arm 220; Equipped with inserting behind flange 210 of hollow shaft 2, shaft mechanism 320 moving along the axis direction of hollow shaft 2 and along the radius at the rear end of shaft mechanism 320 The sliding block 3 of the bushing 310 formed by extending in the direction; while forming the through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com