Centrifugal switch of split-phase motor

A centrifugal switch and phase-splitting technology, which is applied to electric switches, starters of single-phase induction motors, motor generators/starters, etc., can solve problems such as increasing noise, increasing intervals, and accelerating wear of contact parts , to reduce wear and reduce noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

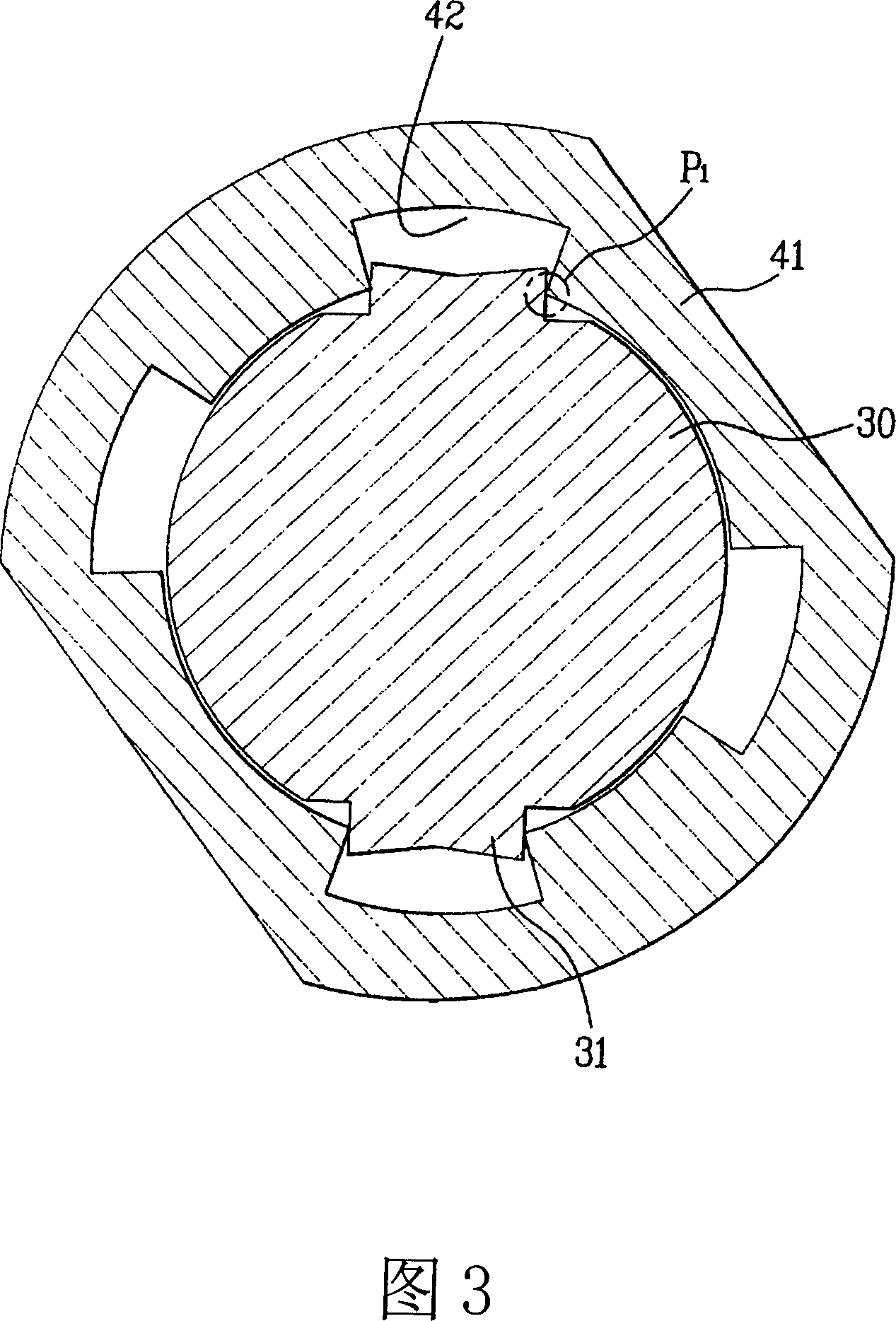

[0030] Referring to accompanying drawing 4 below, the centrifugal switch of the split-phase motor in the present invention is described.

[0031] As shown in Figure 4, the above-mentioned centrifugal switch 200 includes: a sleeve 210, which is inserted into the limiter 110 of the shaft 100, and a flange portion 213 is formed on its outer peripheral surface; The outside of the cylinder 210 is movably inserted along the axial direction of the above-mentioned sleeve 210, and when it reaches a predetermined position, the circuit of the auxiliary coil 12 is disconnected; the centrifugal actuator 230 is formed with at least two or more, and in When the shaft 100 rotates, it is opened outward by the centrifugal force generated; the tension spring 240 generates an elastic restoring force in the direction of converging on the centrifugal actuator 230 .

[0032] At this time, as shown in FIG. 5 , the inner surface of the sleeve 210 is formed with a locking groove 211 , and the locking g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com