Electronic actuator of single-phase asynchronous electric motor

A starting switch, single-phase asynchronous technology, applied to the starter of a single single-phase induction motor, motor generator/starter, etc., can solve the problems of large volume, short service life and poor operation reliability of the electronic starting switch, and achieve High instantaneous power, long life, reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

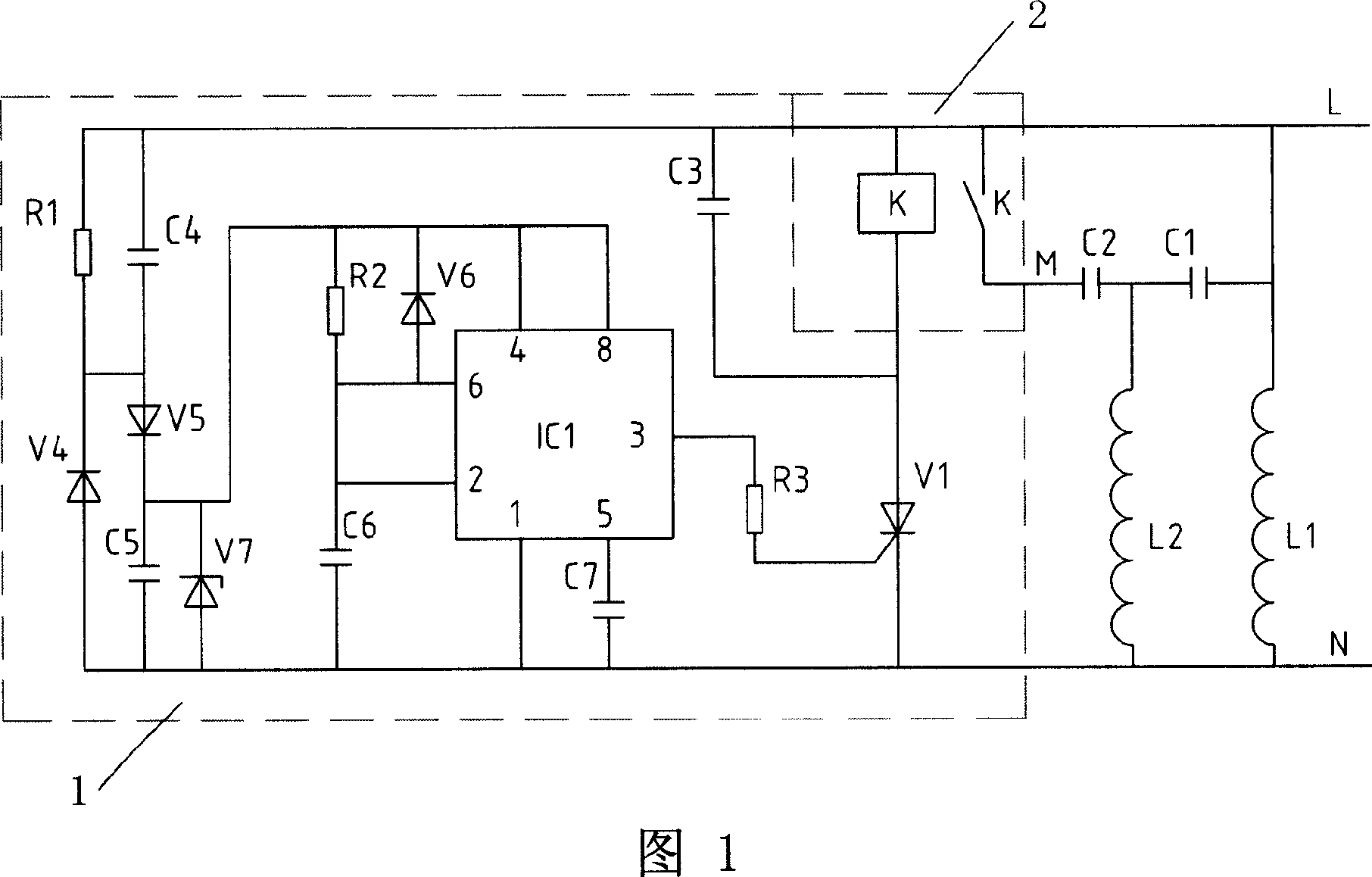

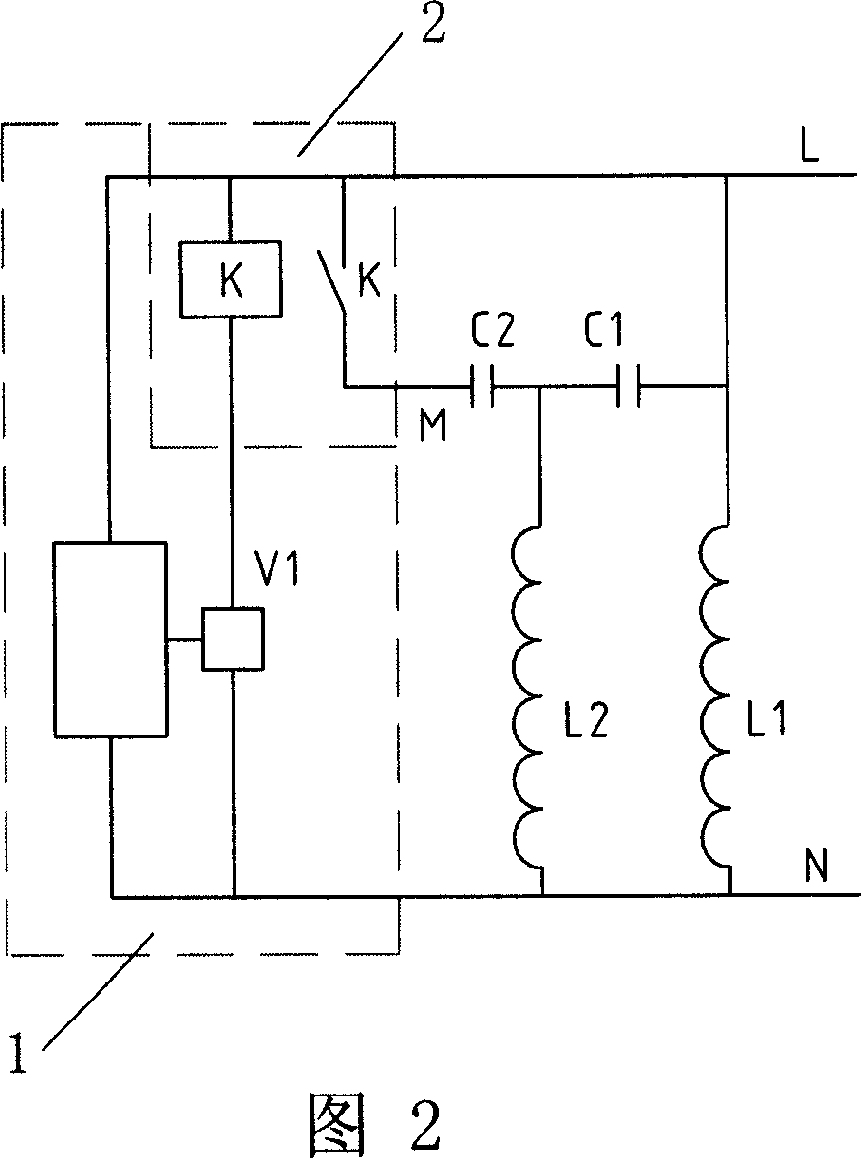

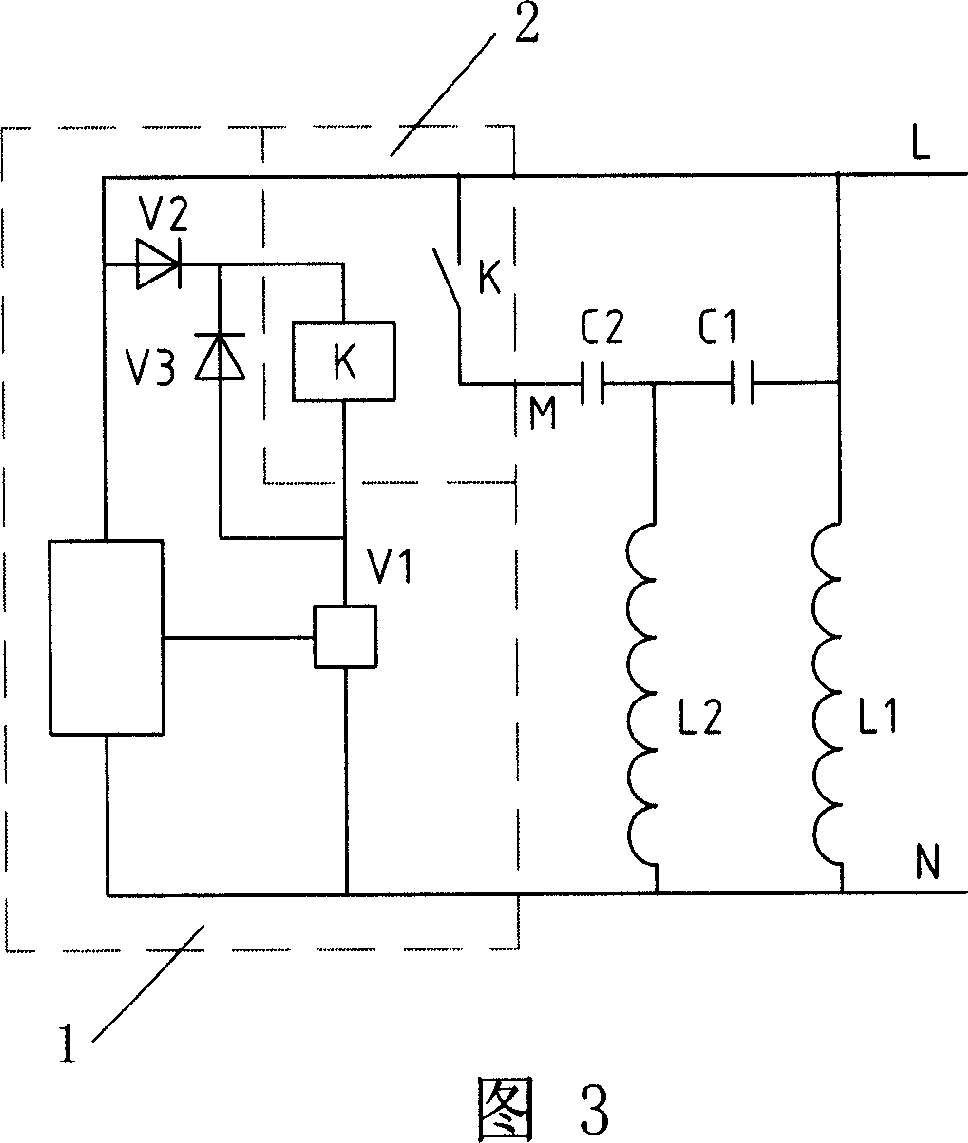

[0037] Embodiment 1: Referring to Fig. 1 and Fig. 4, an electronic start switch for a single-phase asynchronous motor includes an electromagnetic relay 2, an electronic control circuit 1 for controlling the pull-in and break-off of the relay, and the moving contact of the relay K Connected between the auxiliary winding L2 of the motor and the power supply; the rated duty system of the relay K is a duty cycle in which the energized time and the non-energized time cycle alternately, and the relay cannot reach thermal balance during the energized time; the coil of the relay K is connected to the The high-voltage semiconductor switch V1 is connected in series, and the high-voltage semiconductor switch V1 is connected to the mains power supply. The peak value of the rated operating voltage of the relay K coil and the peak value of the mains power supply voltage are approximately equal in absolute value.

[0038] In the electronic control circuit 1, the commercial power supply is con...

Embodiment 2

[0042] Embodiment 2: Referring to Fig. 1 and Fig. 4, according to the instruction manual of the original relay in embodiment 1, the highest working voltage of the coil of the original relay under the uninterrupted duty system is V 1 =48×1.2=57.6(V). It can be estimated from the electrical principle that the effective value of the relay is V 2 = Under the working voltage of 220V, the allowable power-on duration rate is about

[0043] q≤(V1 / V2) 2 ×100%=(57.6 / 220) 2 ×100%≈6.9%. Here it is assumed that the temperature of the relay coil is the same under the two working systems.

[0044] When the operating condition of the relay modified in embodiment 1 is changed to the frequency of motor starting operation as n=120 times / hour, the duration of each starting process is t=2 seconds, and the operating voltage of the relay coil is still the mains alternating current 220V The pulsating voltage obtained after the voltage is half-wave rectified and filtered by a 4.7μf capacitor, throu...

Embodiment 3

[0046] Embodiment 3: The relay in Embodiment 1 is still used, and the relay is started from a cold state, and the pulsating voltage obtained by applying a commercial AC 220V voltage to the coil after half-wave rectification and filtering by a 4.7 μf capacitor. After 12 seconds, the temperature rise of the relay coil reaches 50°C, and the temperature of the surrounding environment is 35°C. This is an example of short-time work. Explain that in the short-time duty system, the same relay, which allows the motor to start the process, takes longer than the intermittent cycle duty system.

[0047] In other words, compared with the intermittent duty cycle, the same motor starting time and the same relay power, the volume of the short-time duty relay can be made smaller.

[0048] The above implementation plan is realized by transforming the original relay. Of course, it is not the best solution, but it can already meet the needs of starting the single-phase double-value capacitor asy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com