Electric automatic differential lock

A differential lock, electric technology, applied in the field of automobile drive train, can solve problems such as difficult to grasp and use flexibly, cumbersome, loss of differential, etc., and achieve the effect of easy promotion and use, convenient operation and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

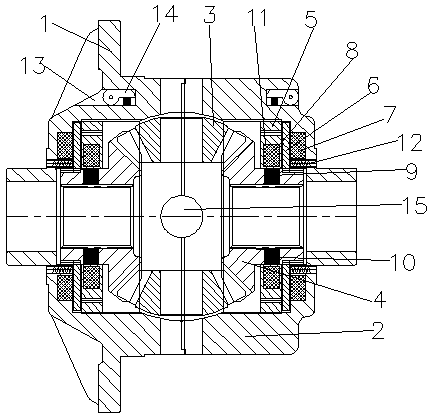

[0016] refer to figure 1 As shown, the electric automatic differential lock includes a large differential lock case 1, a small differential lock case 2 set on one end of the large differential lock case 1, and a small differential lock case 2 installed on the large differential lock case 1 and the small differential lock case 2. Between the planetary gear 3 fixed by the cross shaft 15, a side gear 4 is respectively arranged in the large differential lock case 1 and the small case 2 of the differential lock, and each side gear 4 meshes with the planetary gear 3 respectively. The gear 4 is provided with a plurality of alternator permanent magnets 9 with positive and negative poles arranged alternately, the side gear 4 is covered with a generator iron core 5 and a generator coil 8, and the differential lock shells 1 and 2 are equipped with an electromagnet coil 7 And the friction plate 6, the friction plate 6 is arranged between the generator iron core 5 and the electromagnet coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com