Rectangular Pre-stressed reinforced concrete hollow pile with internal thread or internal groove and method for processing hollow pile

A technology of reinforced concrete and rectangular piles, applied in sheet pile walls, manufacturing tools, infrastructure engineering and other directions, can solve problems such as overturning, poor safety, and weak bonding force, and achieve low cost, strong bonding force, and safety. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

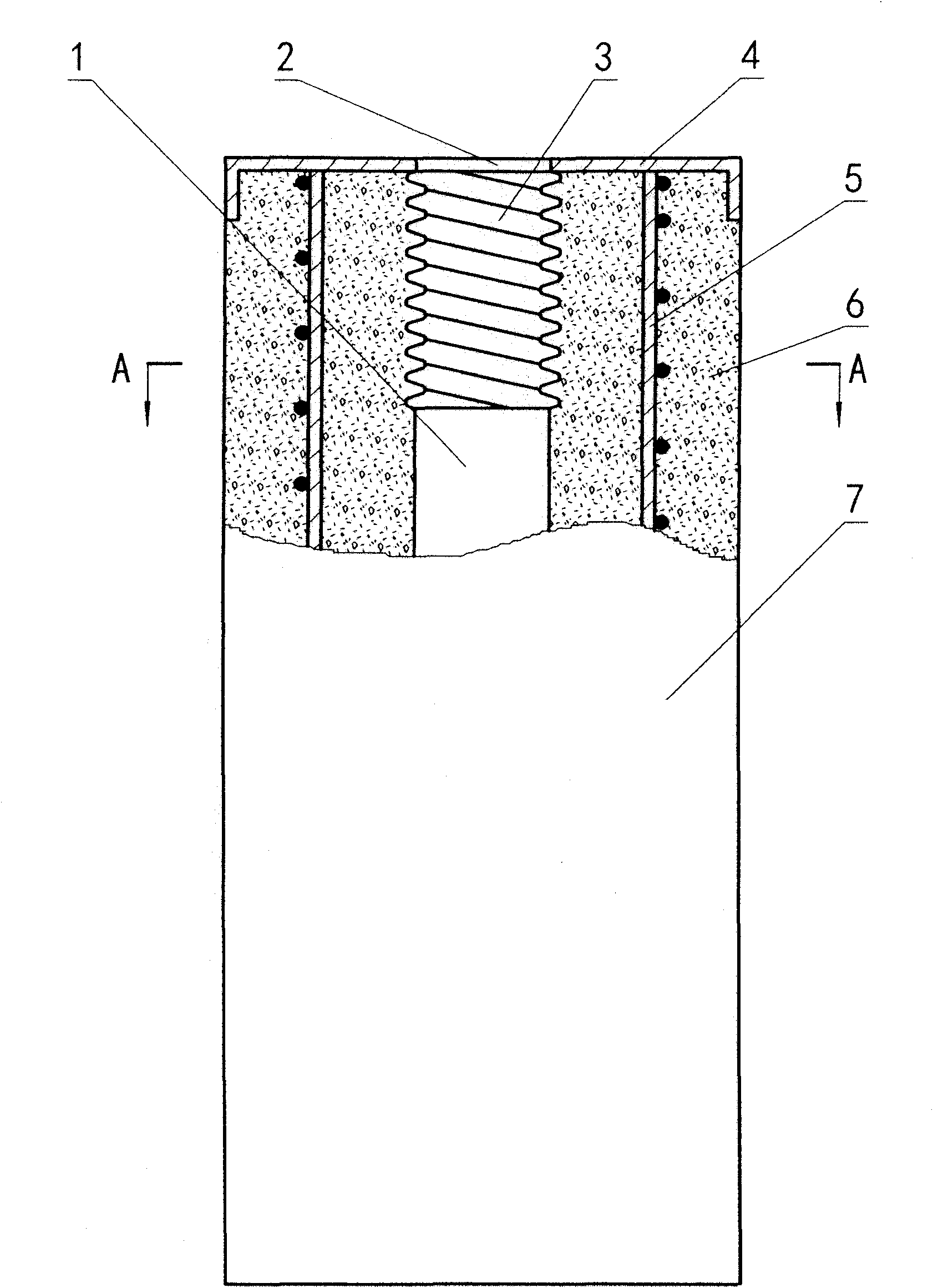

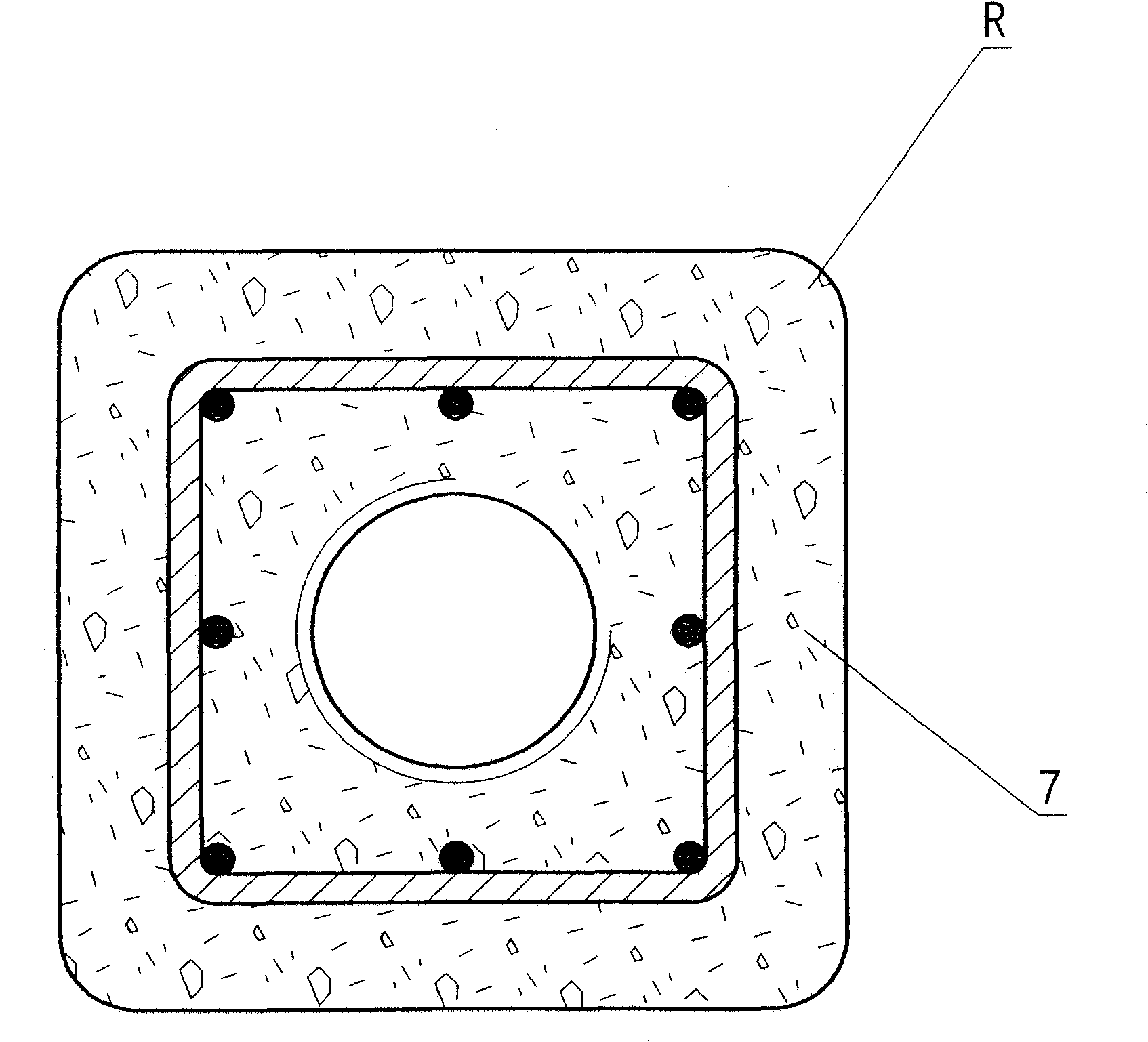

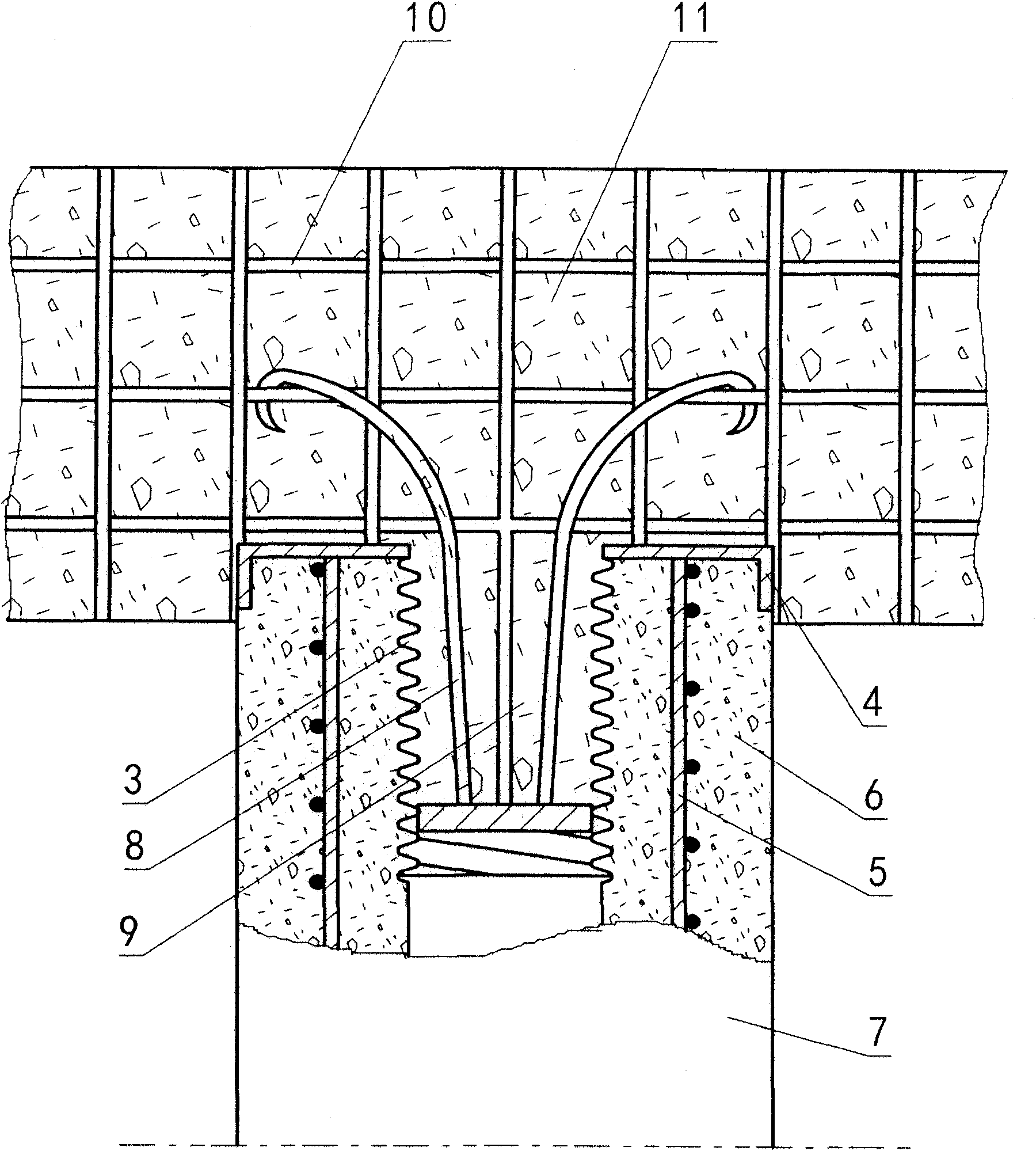

[0039] figure 1Among them, it includes a square pile body 7 and a square metal end plate 4, the shape of the four corners of the square pile body 7 is four equal circular arcs, the square pile body 7 contains a steel cage 5, concrete 6, and the square pile body 7 There is a through hole 1 in the center of the pile body in the axial direction, and the square metal end plates 4 are arranged at both ends of the square pile body 7, corresponding to the center hole 1 of the pile body on the square pile body 7, and the square metal end plates 4 Also be provided with metal end plate central round hole 2, be provided with welding bevel on the periphery of square metal end plate 4, be provided with anchor hole symmetrically on square metal end plate 4; The arc radii of the two corners are equal, which is convenient for the prestressed reinforced concrete hollow square pile to be demoulded smoothly from its processing mold during the processing process, while ensuring that the corners o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com