Depth tracking device for logging while drilling

A logging-while-drilling, depth-tracking technology, applied in surveying, earth-moving, wellbore/well components, etc., can solve the problems of no depth sensor installed in place, inability to collect depth signals, and steel cable slippage, etc., to achieve maintenance and supply. The effect of fast delivery, accurate tracking and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

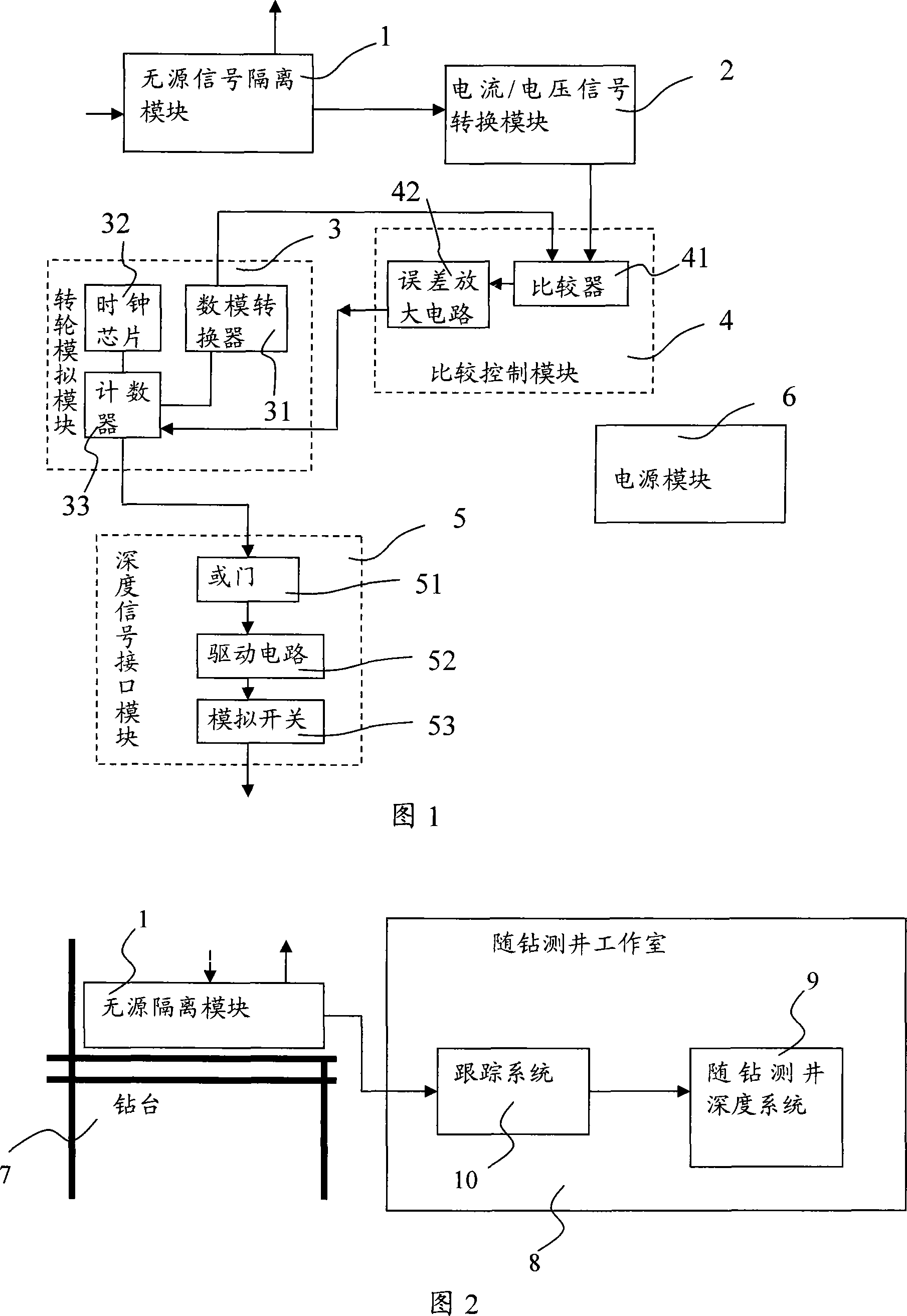

[0017] In order to detect without a depth sensor, it is necessary to use the hook height signal output by the electronic driller system of the offshore oil drilling platform, and the hook height signal is a 4-20mA current signal. Therefore, it is necessary to design a device to convert the height signal into a velocity signal that can be recognized by the logging-while-drilling depth system.

[0018] Below, the depth tracking device while drilling according to the present invention will be described in detail with reference to the accompanying drawings.

[0019] As shown in FIG. 1 , the present invention includes: a passive signal isolation module 1 , a current / voltage signal conversion module 2 , a wheel simulation module 3 , a comparison control module 4 , a depth signal interface module 5 and a power supply module 6 .

[0020] Passive signal isolation module 1 converts the hook height 4-20mA signal output by the electronic driller system of the offshore oil drilling platfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com