Steel plate feeding trolley in elevator production process

A technology of production process and feeding carts, which is applied in the direction of trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of lower production efficiency, expensive truss manipulators, and high costs of small and medium-sized enterprises, and achieve the effect of avoiding the problem of slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

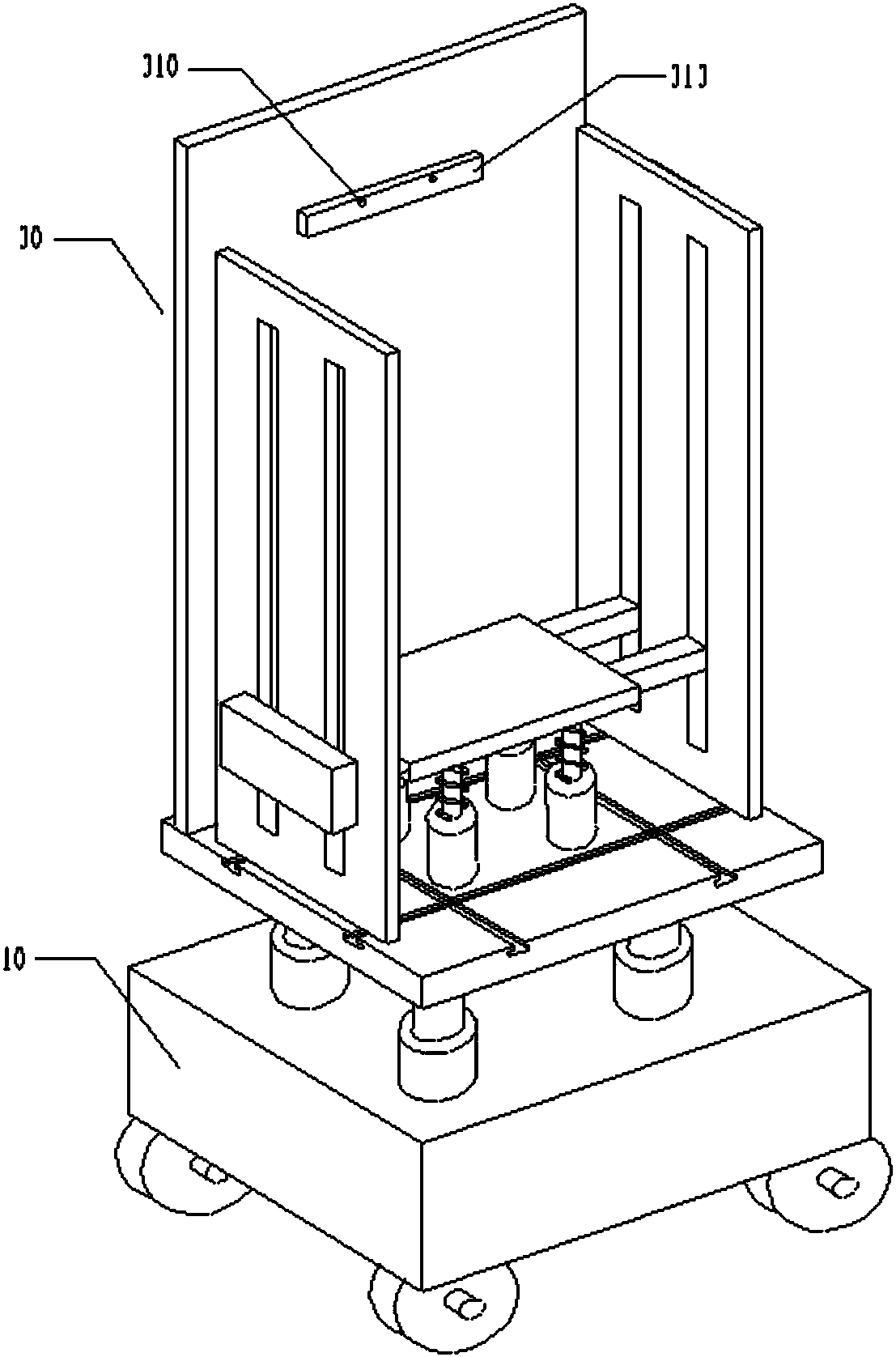

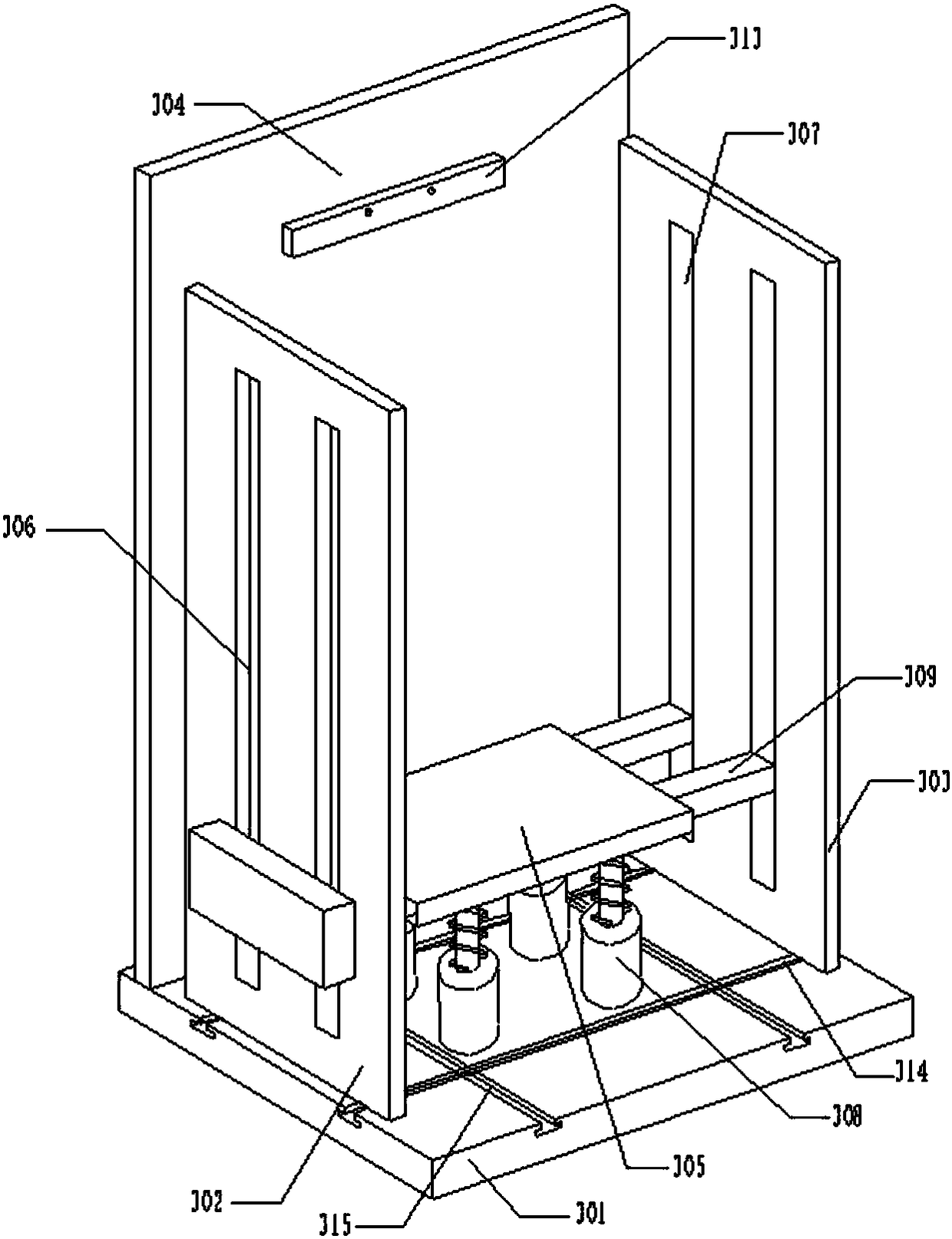

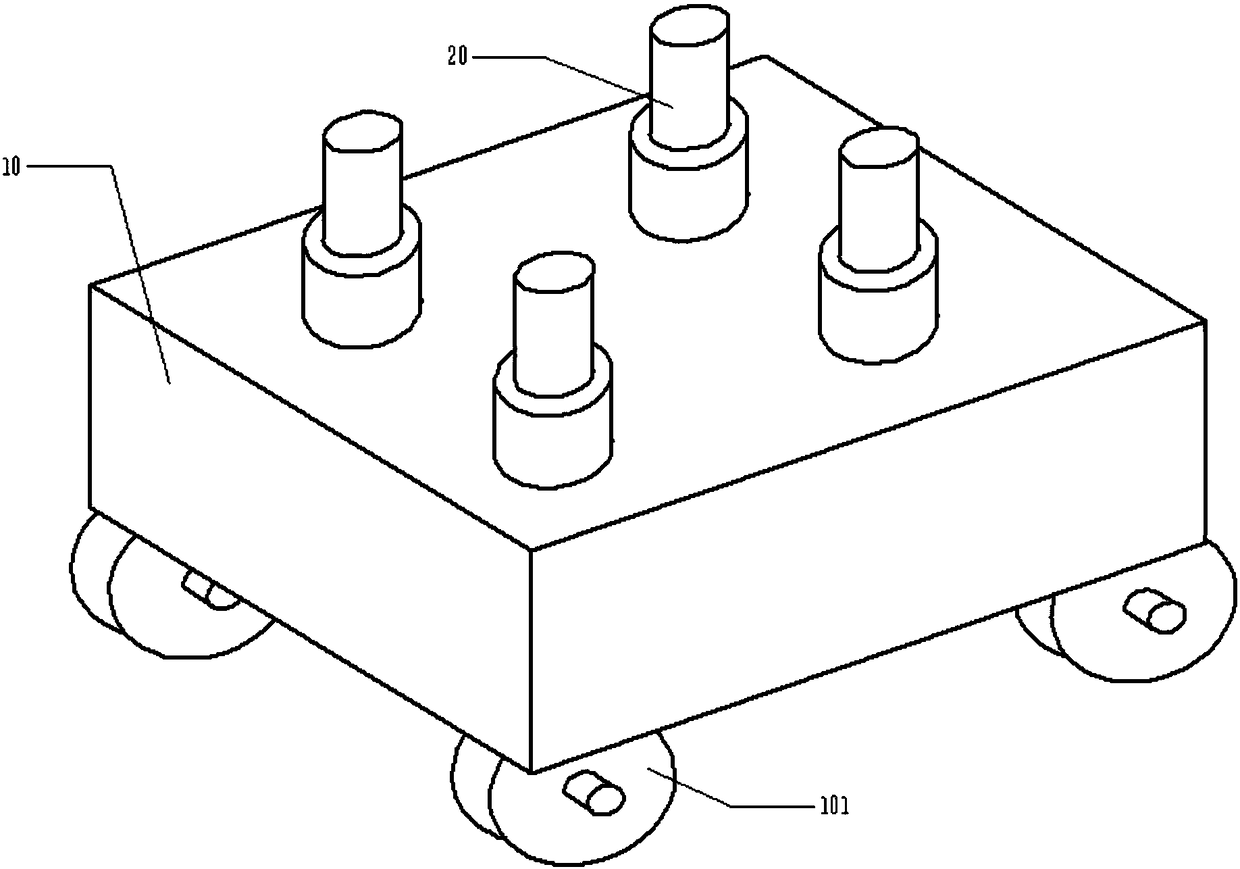

[0027] Such as Figure 1-Figure 4 As shown, a steel plate feeding car in the elevator production process includes a car body base 10, a lifting part 20, a discharging part 30 and a control part 40. The car body base 10 is provided with a lifting part 20, and the top of the lifting part 20 is provided with a The material part 30 and the control part 40 are disposed on the discharge part 30 , and the control part 40 is configured to be electrically connected to the lifting part 20 , and the control part 40 controls the lifting of the lifting part 20 .

[0028] The lifting part 20 is set as four groups of vertical telescopic devices evenly arranged, and the telescopic devices can assist in adjusting the height of the discharging part 30, so that it can better adapt to the height of different equipme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com