Driving roller for belt line

A technology for driving rollers and wires, applied in the field of roller friction, can solve the problems of reducing the service life of the track, increasing the labor time of workers, delaying the processing efficiency of products, etc., to achieve the effect of enhancing processing efficiency, reducing working time of employees, and increasing tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

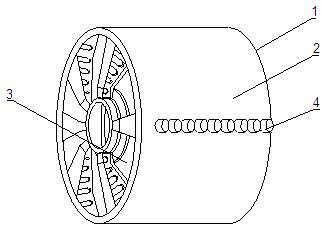

[0045]Such asFigure 1-10As shown, the present invention provides a belt wire drive drum including a drive drum body 1, and the drive drum body 1 includes a foreign shield 2, and the outer sheave 2 is provided with a cooling device 3, and the cooling device 3 includes a ring 31. The outer surface of the outer cover 2 is fixedly connected to the damper 4, and the damper column 4 includes a U-shaped sleeve 41.

[0046]In the present embodiment, the temperature of the outer retaining ring 2 is lowered by the cooling device 3 to reach the high temperature environment between the alleviated outer sheath 2 and the track, and the shock absorbing column 4 increases friction between the track and the outer sheath 2. Force, increase the use of strip floral on the surface of the track.

[0047]Such asFigure 1-10As shown in the present embodiment, it is preferable that the friction layer 45 includes a guard 451, and a fixed block is fixedly connected to the outer surface of the guard plate 451, and th...

Embodiment 2

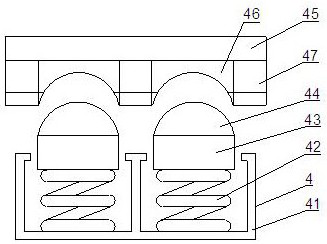

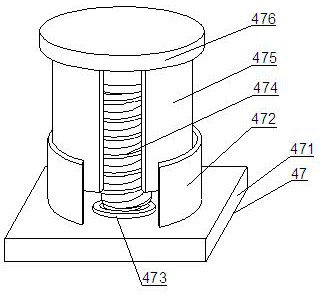

[0050]Such asFigure 1-10As shown in the basis of the first embodiment, the present invention provides a technical solution: preferably, the inner surface of the U-shaped sleeve 41 is fixedly coupled to the spring 122, and the spring 1 42 is fixedly connected to the haterflainer 43. The outer surface of the haterflower 43 is fixed to the outer surface of the thermal conductive layer 44, and the outer surface of the heat conductive layer 44 is attached to the outer surface of the internal arc block 46, and the friction layer 45 is fixedly connected. The exterior surface is fixedly connected to the damper spring 47, by providing the inner arc block 46 on the outer surface of the friction layer 45, and then connect the heat conductive layer 44 inside the damper 4 and the inner arc block during rotation. 46 will generate a pressure on the thermally conductive layer 44, and use the spring 42 to reverse the internal arc block 46 to increase the tightness between the two, and then use the c...

Embodiment 3

[0052]Such asFigure 1-10As shown, in the basis of the first embodiment, the present invention provides a technical solution: preferably, the inner surface of the retaining ring 31 is fixedly connected to the water pipe 32, and the outer surface of the water pipe 32 is provided with waterproof rubber blocks 33, and the water pipe 32 The surface is fixedly connected to the surface of the water absorbing roller 34, and the water pipe 35 is fixed to the outer surface of the ladle 31, and the water pipe 32 includes a water tube 321, the outer surface of the sheath 31. The inner surface of the connecting hole 322 and the inner surface of the water tube 321 is provided on the upper surface, and the drain port 324 is provided on one end of the water tank 323, and the water source is performed through the water tube 323, and then the water source is directed to the water source. On the surface of the connecting hole 322, the internal water source is guided by the water guide roller 34, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com