Elevator guide rail quality detecting device and method

A technology for elevator guide rails and detection devices, which is applied in the direction of measuring devices, radio wave measurement systems, and measuring instruments, can solve the problems of elevator guide rail quality problems that are difficult to solve, there are few methods with high degree of automation, and it is difficult to achieve precision, etc., to achieve The effect of solving slippage, easy data processing, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

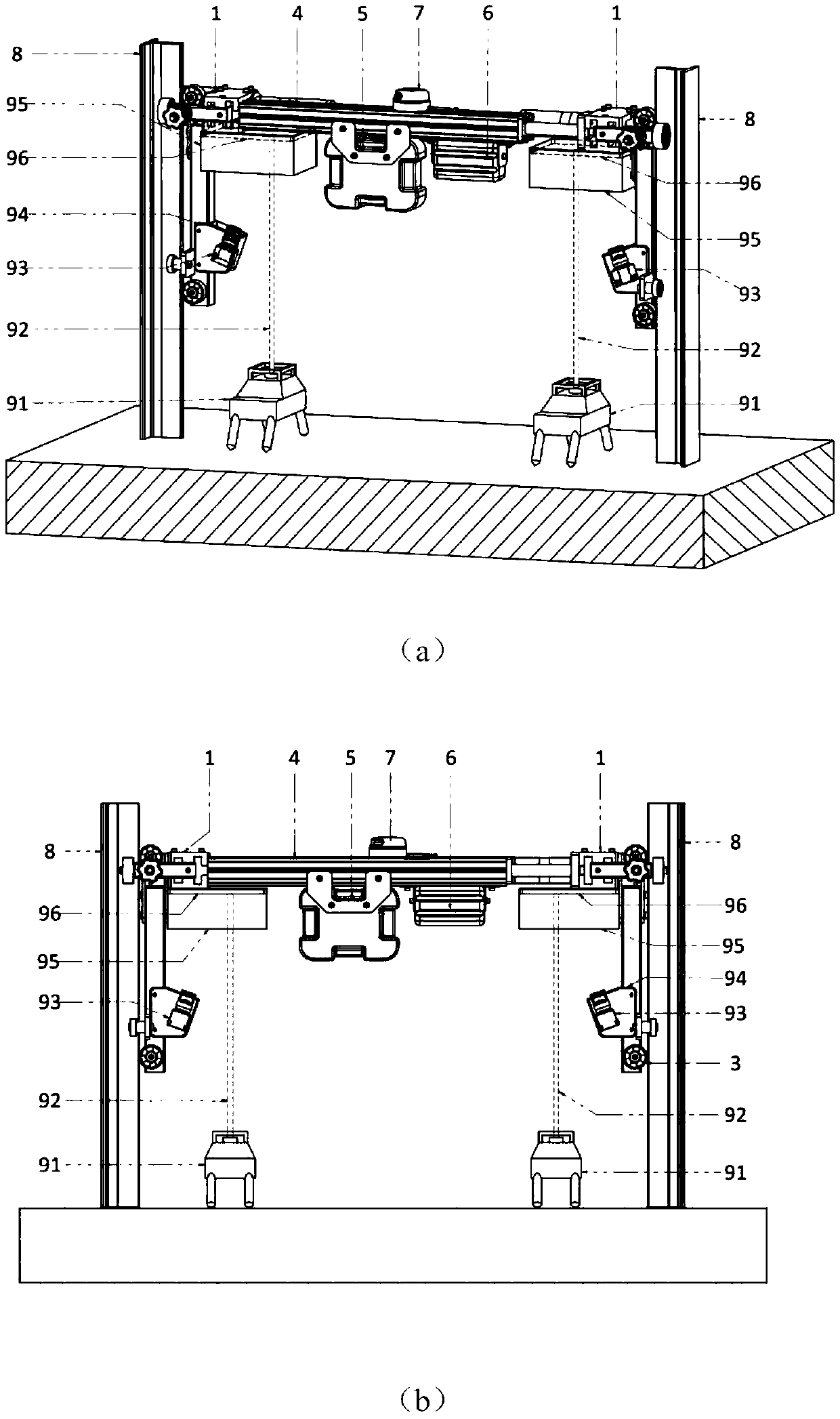

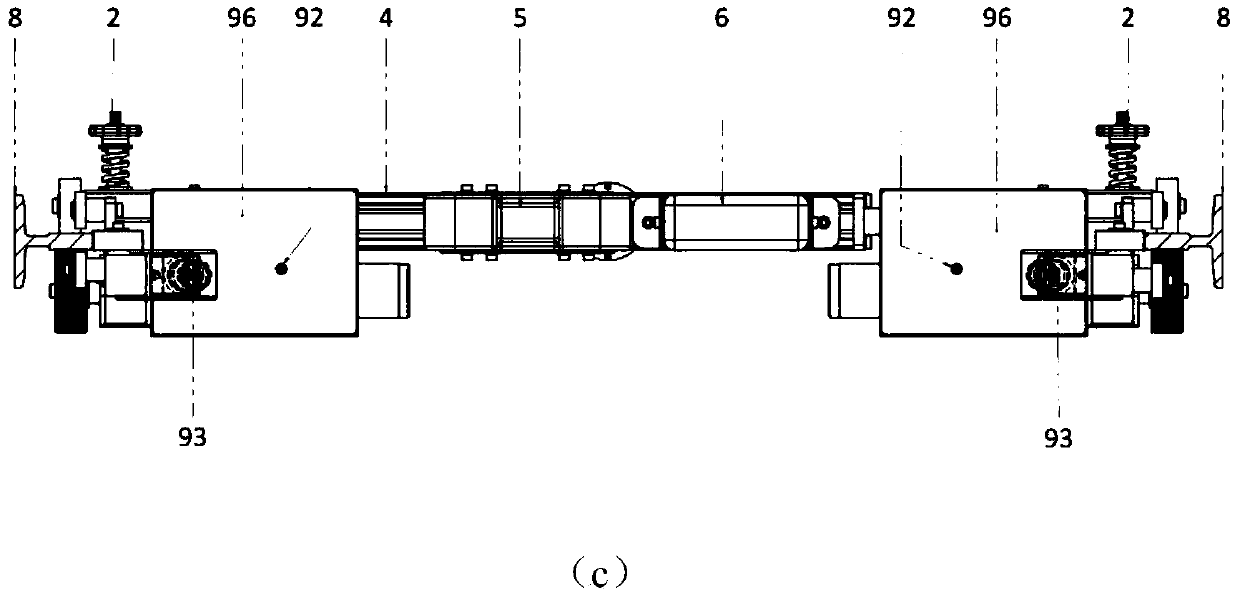

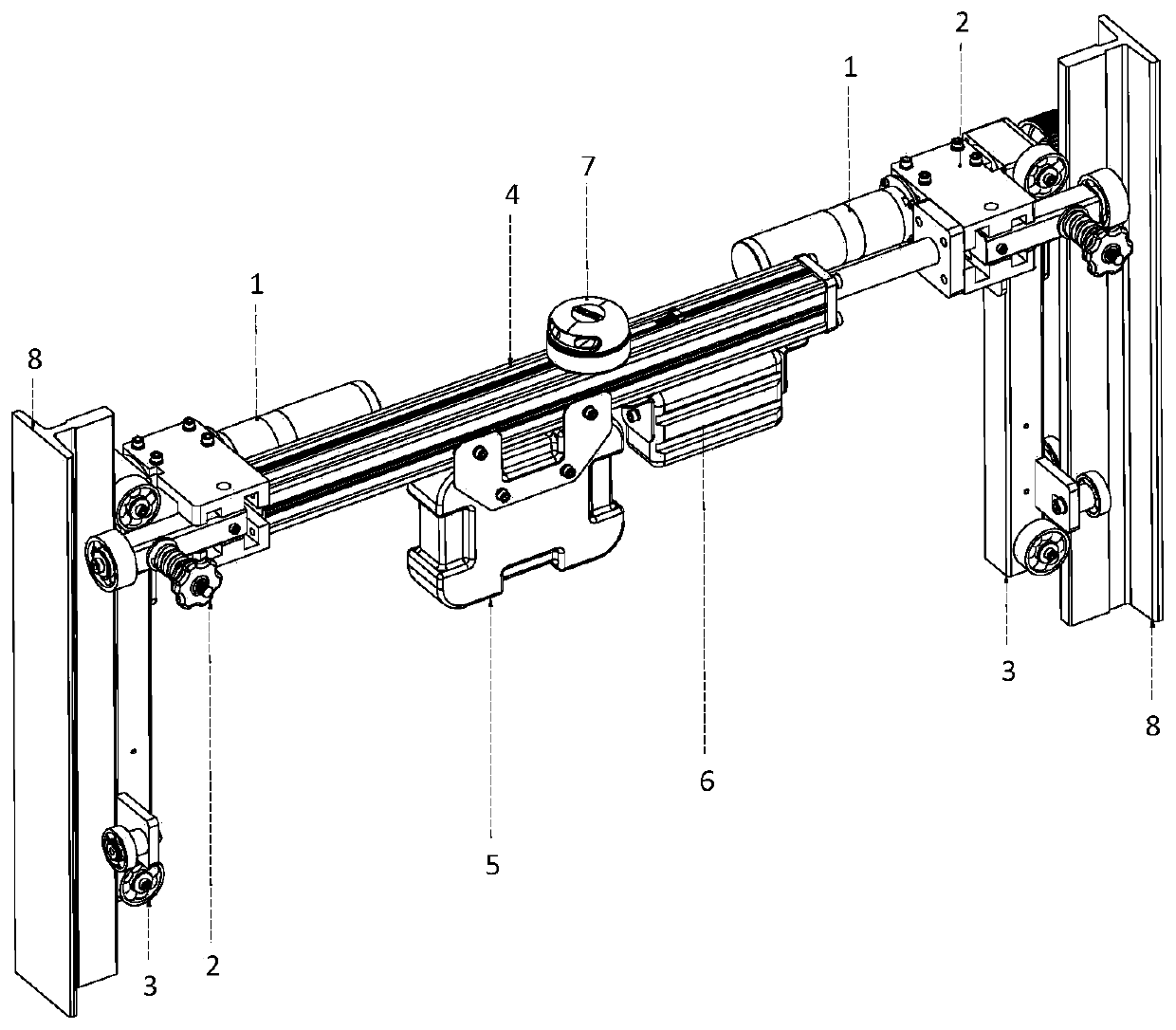

[0065] This embodiment provides an elevator guide rail quality detection device and method, such as figure 1 (a), (b) and (c), the two independent self-leveling plumb lasers 91 are fixed on the ground, and emit two mutually independent, vertical, and ground-stationary laser rays 92 upwards, As a reference line, shoot to the position near the center of the reflector 96 that is connected to the grabber bottom body 23 on both sides of the elevator guide rail crawling robot; there are four light baffles 95 perpendicular to the reflector around the reflector 96, which can reduce The influence of external light on the laser point on the reflector makes the measurement result more accurate and the data processing easier; the camera 93 is fixed on the camera mount 94, and the camera mount 94 is fixed on the stable arm unit 3; The traction wheel 11 and the gripper wheel 25 are always close to the elevator guide rail and climb along the guide rail, so the quality variation of the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com