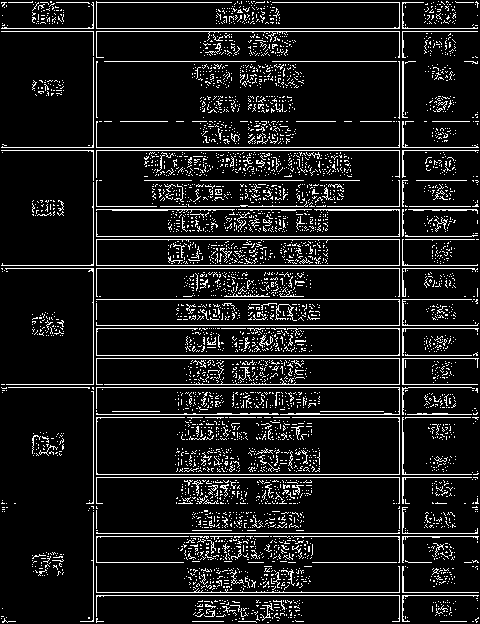

Patents

Literature

169results about How to "Advantages and Notable Improvements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

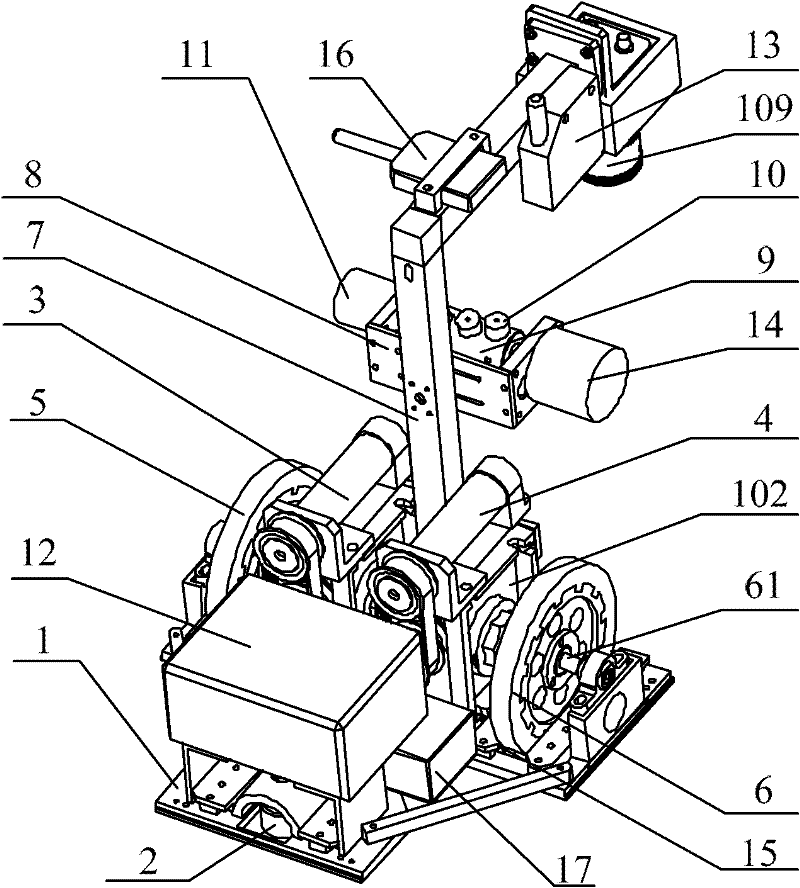

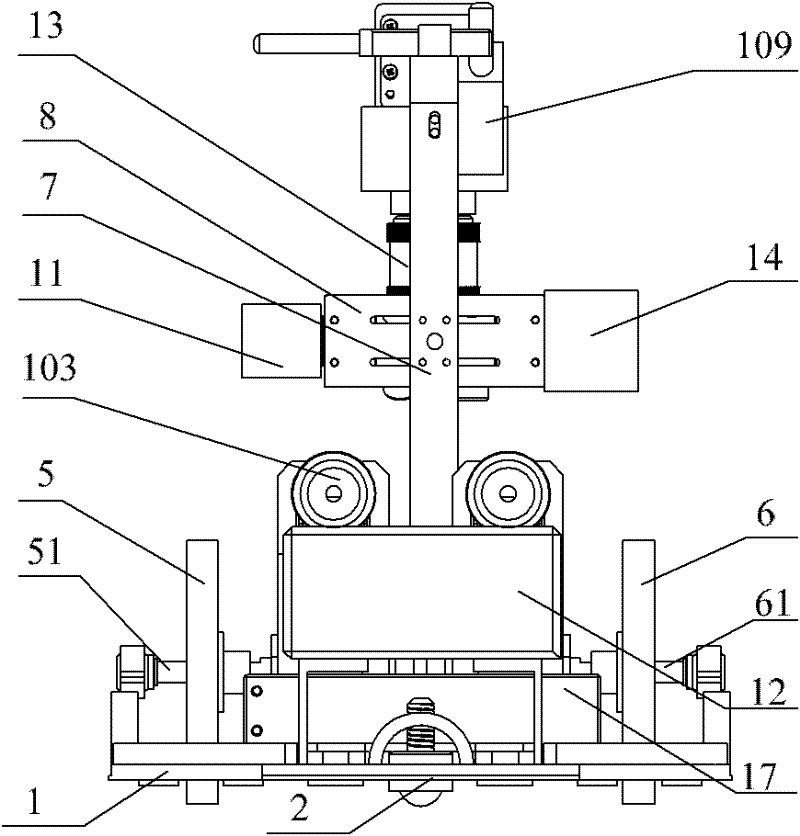

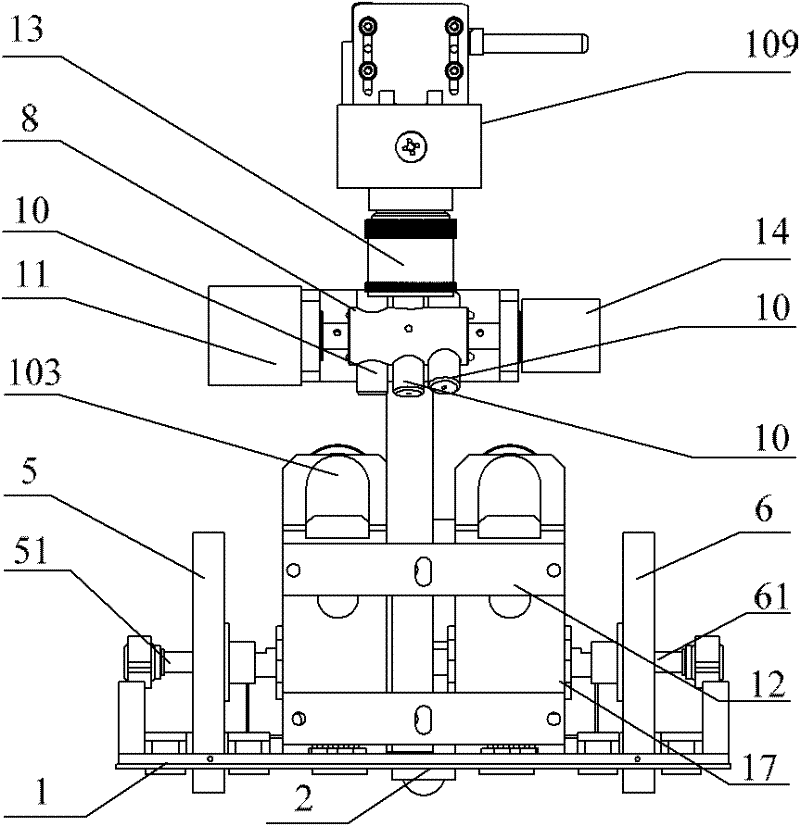

Gap magnetic adsorption type curved surface morphology detection robot and curved surface morphology measuring method

InactiveCN102221330AAdvantages and Notable ImprovementsFlexible movementUsing optical meansVehiclesMotor driveThree dimensional morphology

The invention provides a gap magnetic adsorption type curved surface morphology detection robot and a curved surface morphology measuring method, belonging to the mobile robot and machine vision measuring technology field. The robot comprises two driving wheels, a universal wheel, three motors, a straight line laser, a motor-drive circuit, a controller, a camera, an angle sensor, a permanent magnet body and like. By utilizing gap permanent magnetism adsorption principle and a curved surface adaptive scheme of arranging magnetic patch at the surrounding of the wheels symmetrically in a concentration way, that the robot is adsorbed on a magnetic conductive curved surface with different curvature and can move flexibly is realized. A plurality of straight line laser beams which are rotated to different angles are projected to a surface to be measured. The camera is used to shoot sequence image of the surface to be measured with laser stripes. Combined with distance detected by a laser range finder, three dimensional morphology of the surface is detected. Through a wireless video transmission module, video is transmitted to a host computer to display. The robot provided in the invention has the advantages of compact structure, flexible movement, and large adaptation curvature scope, and especially is suitable for all position three dimensional morphology detection of magnetic conductive curved surface workpiece in a narrow space.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

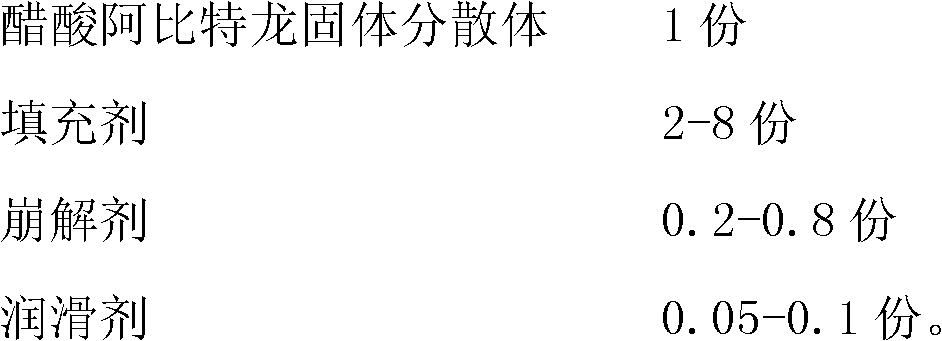

Solid dispersion and tablets comprising abiraterone acetate, and preparation methods thereof

ActiveCN103070828AAdvantages and Notable ImprovementsGood water solubilityOrganic active ingredientsPowder deliverySolubilityMedicine

The invention relates to a solid dispersion and tablets comprising abiraterone acetate, and preparation methods thereof. The solid dispersion is prepared through the steps that: abiraterone acetate and povidone with a weight ratio of 1:0.5-4 are dissolved in chloroform; and reduced-pressure drying is carried out, such that the solid dispersion is obtained. The tablets comprises 1 part of the abiraterone acetate solid dispersion, 2-8 parts of a filling agent, 0.2-0.8 parts of a disintegrating agent, and 0.05-0.1 parts of a lubricant. According to the invention, a micronization technology and a solid dispersion technology are creatively combined, such that abiraterone acetate water solubility is greatly improved. Therefore, abiraterone acetate can be rapidly dissolved in gastrointestinal tract body fluids.

Owner:SHANDONG NEWTIME PHARMA

Method for preparing nutrient dried bean curds

InactiveCN102885165AAdvantages and Notable ImprovementsInhibit growthCheese manufactureFood scienceMicroorganismDry bean

The invention discloses a method for preparing nutrient dried bean curds. The method comprises the following steps of: (1) soaking selected fresh soybeans into a special soak solution for 8 to 13 hours; (2) grinding the fresh soybeans in the presence of water to obtain soybean milk of which the particle size is smaller than 3 micrometers, and filtering; (3) boiling the soybean milk twice and thencurdling the boiled soybean milk, solidifying, molding and pressing; (4), rinsing by using a sodium carbonate (Na2CO3) solution, wherein the treatment temperature is between 85 and 95 DEG C, and the treatment time is 3 to 6 minutes; and (5), marinating, performing centrifugal dewatering, drying, cooling, packaging and sterilizing to obtain the nutrient dried bean curds. By the method, microorganisms can be effectively prevented from growing after products are packed, so that the shelf life of the dried bean curds is prolonged.

Owner:ANHUI RENRENFU BEAN IND

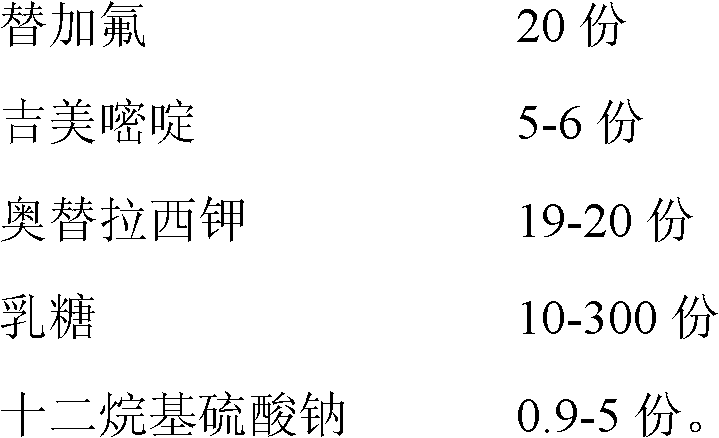

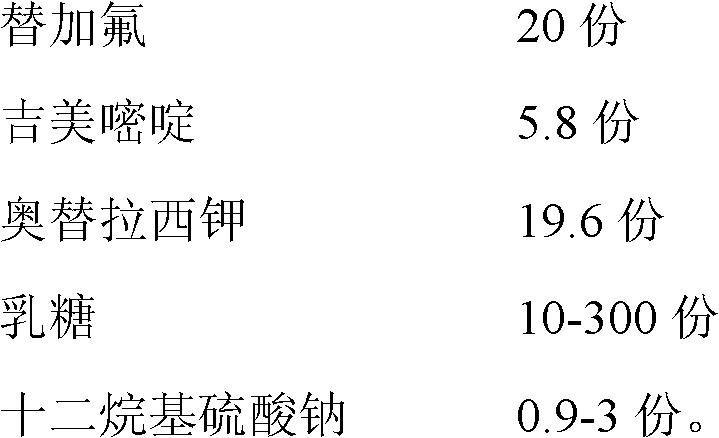

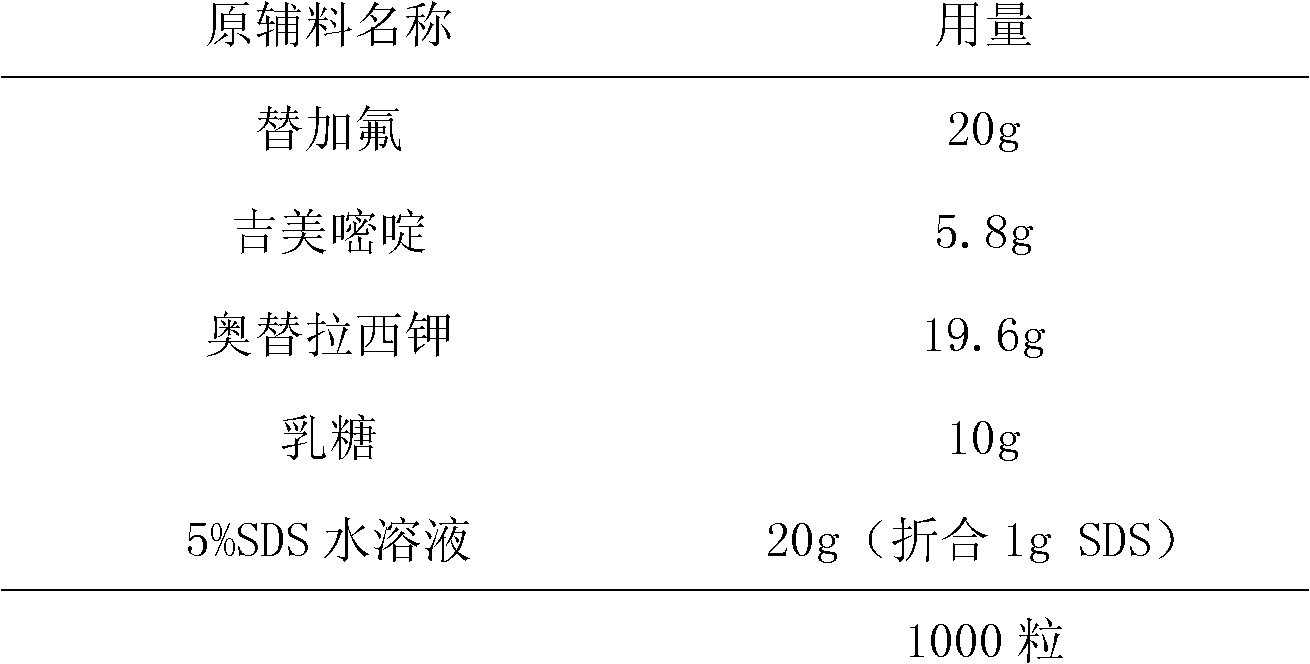

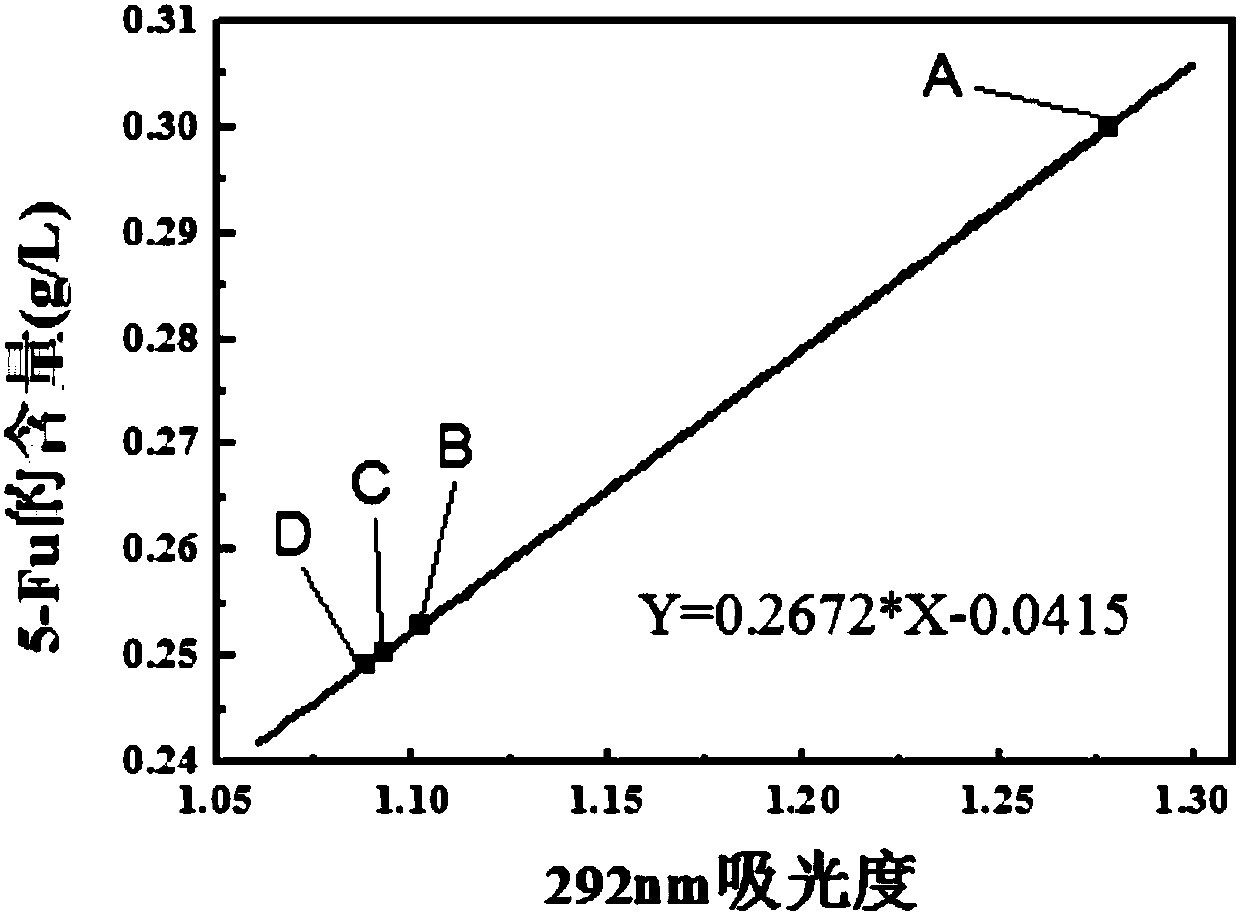

Capsule preparation containing tegafur, gimeracil and potassium oxonate

ActiveCN102302499AAdvantages and Notable ImprovementsReduce dosageCapsule deliveryAntineoplastic agentsPotassium oxonateActive component

The invention refers to a capsule preparation containing tegafur, gimeracil and potassium oxonate. The capsule preparation comprises the following components by weight parts: 20 parts of tegafur, 5-6 parts of gimeracil, 19-20 parts of potassium oxonate, 10-300 parts of lactose, and 0.9-5 parts of sodium dodecyl sulfate. According to the invention, the use level of the surfactant of sodium dodecylsulfate is greatly reduced on the premise of guaranteeing rapid dissolving-out of active components in the preparation, so that the irritation of the capsule preparation to the human gastrointestinaltract is decreased and the medicine compliance of a patient is increased.

Owner:鲁南新时代生物技术有限公司

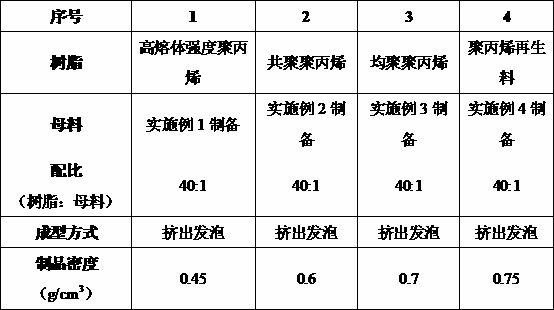

Polypropylene resin foam concentrate and preparation method thereof

ActiveCN102604223AAdvantages and Notable ImprovementsImprove melt strengthMasterbatchPolymer science

The invention relates to a polypropylene resin foam concentrate and a preparation method thereof. The foam concentrate is prepared by taking irradiation modified polypropylene resins as basic raw materials through the steps of adding additives such as a chemical foaming agent, a nucleating agent and a lubricant and the like into the basic raw materials, and uniformly mixing the mixture in a high-speed mixer; and then, adding the obtained mixture into a tandem extruder to carry out extrusion and granulation, thereby obtaining the polypropylene resin foam concentrate. The polypropylene resin foam concentrate provided by the invention can be applied to the extrusion of polypropylene foamed sheets, foamed pipes and foamed profiles; the polypropylene resin foam concentrate is high in modulus of foaming products, good in heat resistance, uniform in foaming hole, and adjustable in density, thereby opening up a new way for the extrusion and foaming of polypropylenes.

Owner:上海萍青工贸有限公司

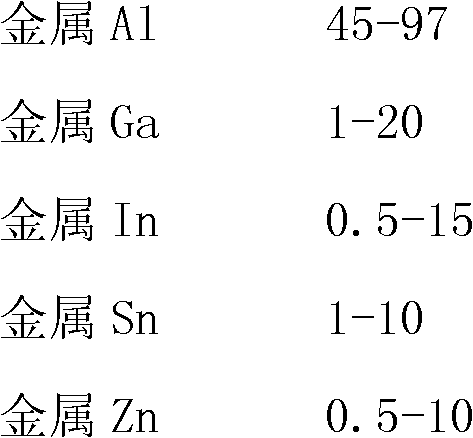

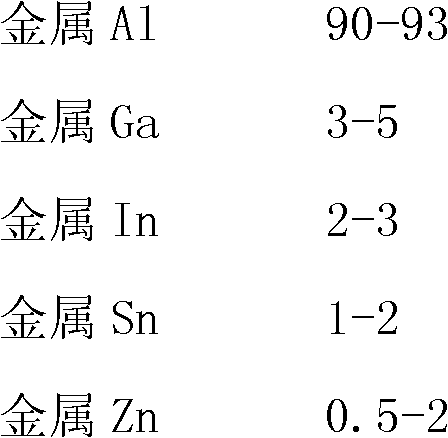

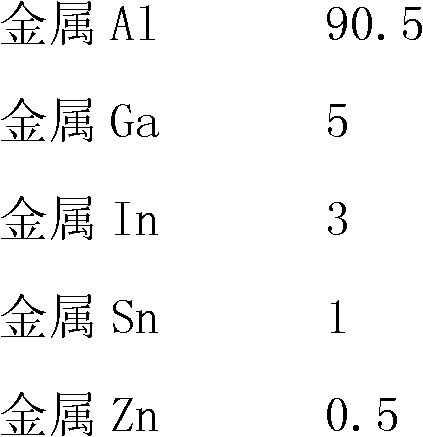

Al-Ga-In-Sn-Zn alloy as well as preparation method and application thereof

The invention relates to an Al-Ga-In-Sn-Zn alloy as well as a preparation method and an application thereof. The alloy is prepared from the following components by weight percent according to a mechanical alloying technique: 45-97wt% of metal Al, 1-20wt% of metal Ga, 0.5-15wt% of metal In, 1-10wt% of metal Sn and 0.5-10wt% of metal Zn. The alloy of the invention can directly react with water at the temperature of larger than or equal to zero DEG C so as to realize the effect of rapidly producing hydrogen; and hydrogen-producing rate reaches more than 90% of a theoretical value, and the reaction rate reaches 200ml / min.s, thereby meeting the dynamic powder requirement of hybrid electric vehicle travelling and greatly improving the utilization rate of gasoline.

Owner:HUBEI UNIV OF TECH

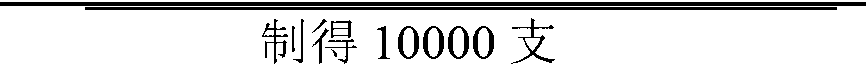

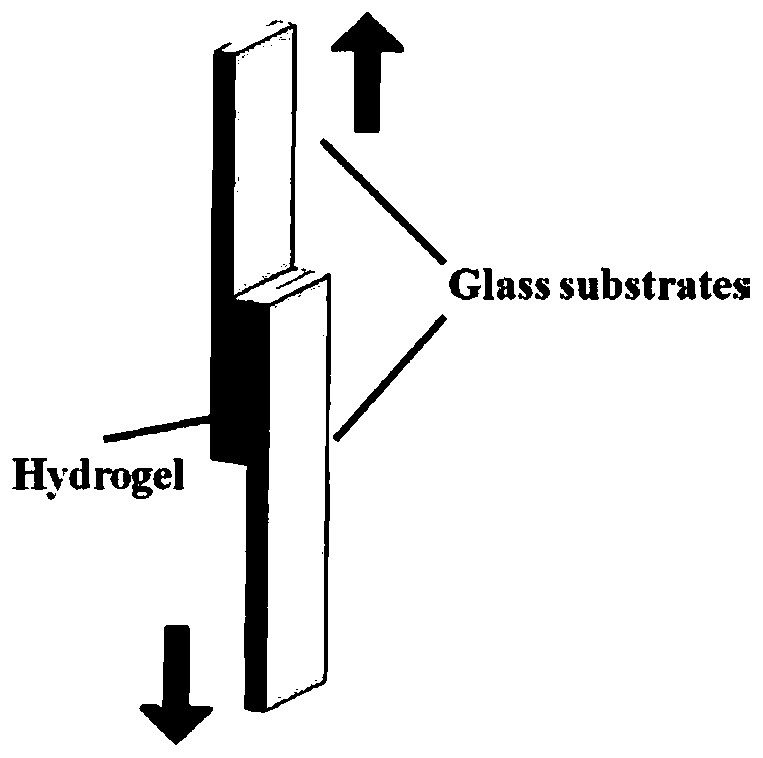

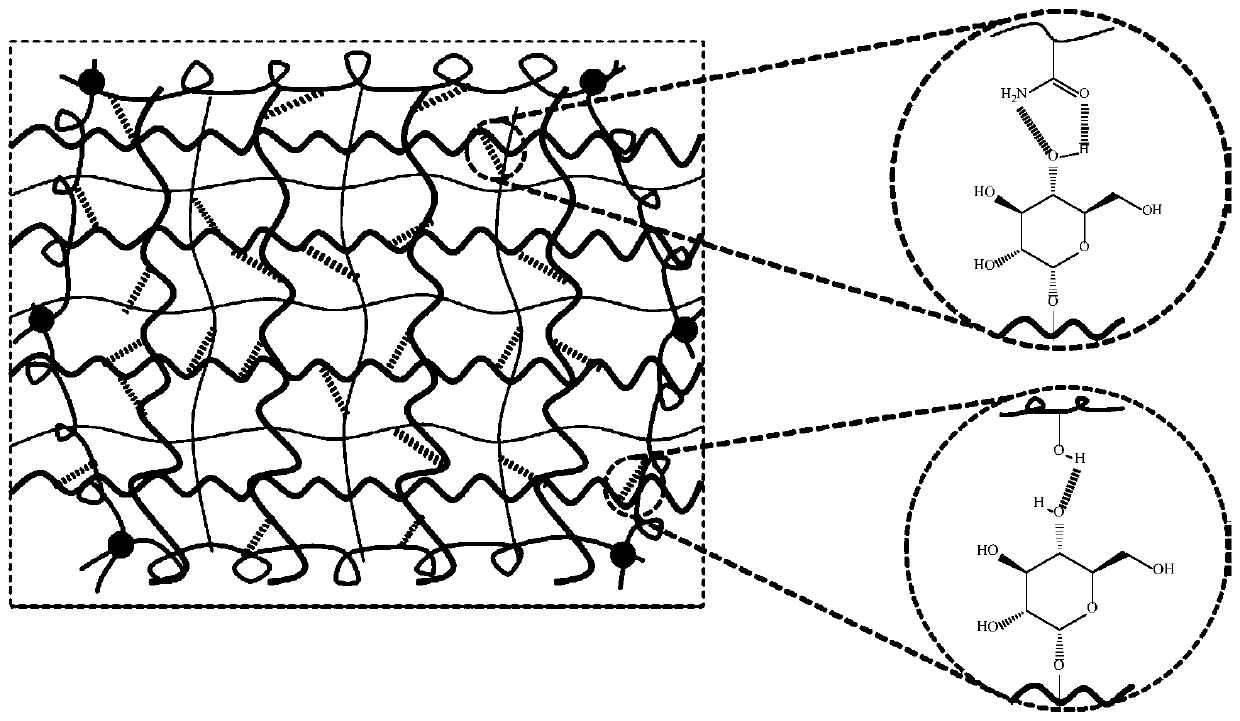

Preparation method for polyacrylamide-acrylic acid-VDT physical-crosslinking high-strength hydrogel

ActiveCN107814957AAdvantages and Notable ImprovementsSimple preparation processHydrogenHigh intensity

The invention discloses a preparation method and a use method of polyacrylamide-acrylic acid-VDT physical-crosslinking high-strength hydrogel. The preparation method comprises the steps: firstly, fully stirring acrylamide, VDT and acrylic acid in dimethyl sulfoxide to obtain an even mixed solution; thermally initiating the mixed solution at a certain temperature to obtain soft preformed gel; thensoaking the soft preformed gel in a water solution of ferric nitrate nonahydrate; forming multi-hydrogen bonds from the VDT, and forming physical-crosslinking high-strength hydrogel through a metal coordination interaction formed by ferric ions and carboxyl. The hydrogel material has the performance of quickly and selectively forming strong hydrogen bonds with target molecules in the water solution, adsorbing the target molecules of specific structures and gathering the target molecules. A preparation process of the preparation method disclosed by the invention has the advantage of simplenessand convenience in operation; furthermore, product performance is excellent; meanwhile, the hydrogel can be applied to the fields of matter separation and purification, sensing technologies, analysistechnologies and the like.

Owner:HUBEI UNIV OF TECH

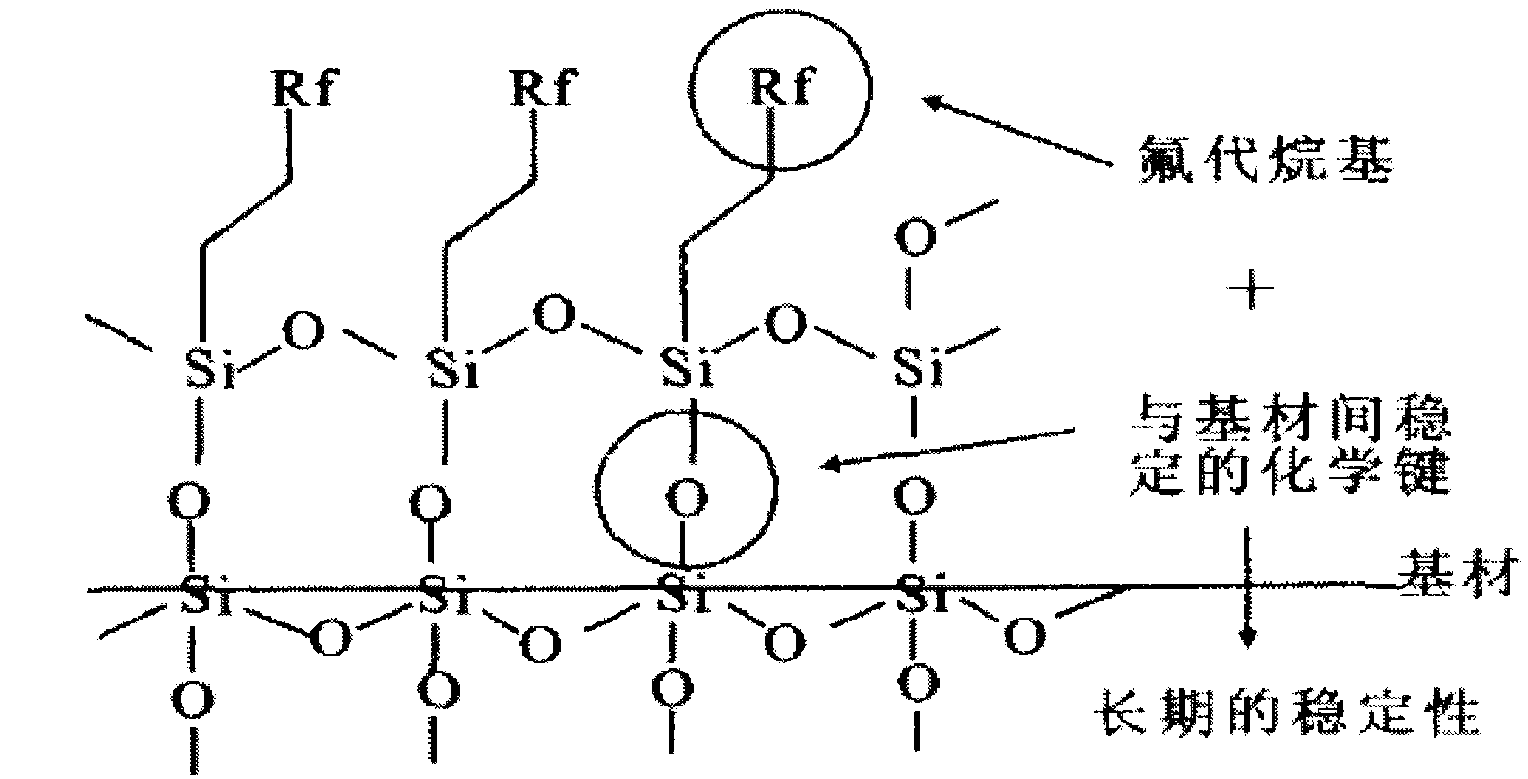

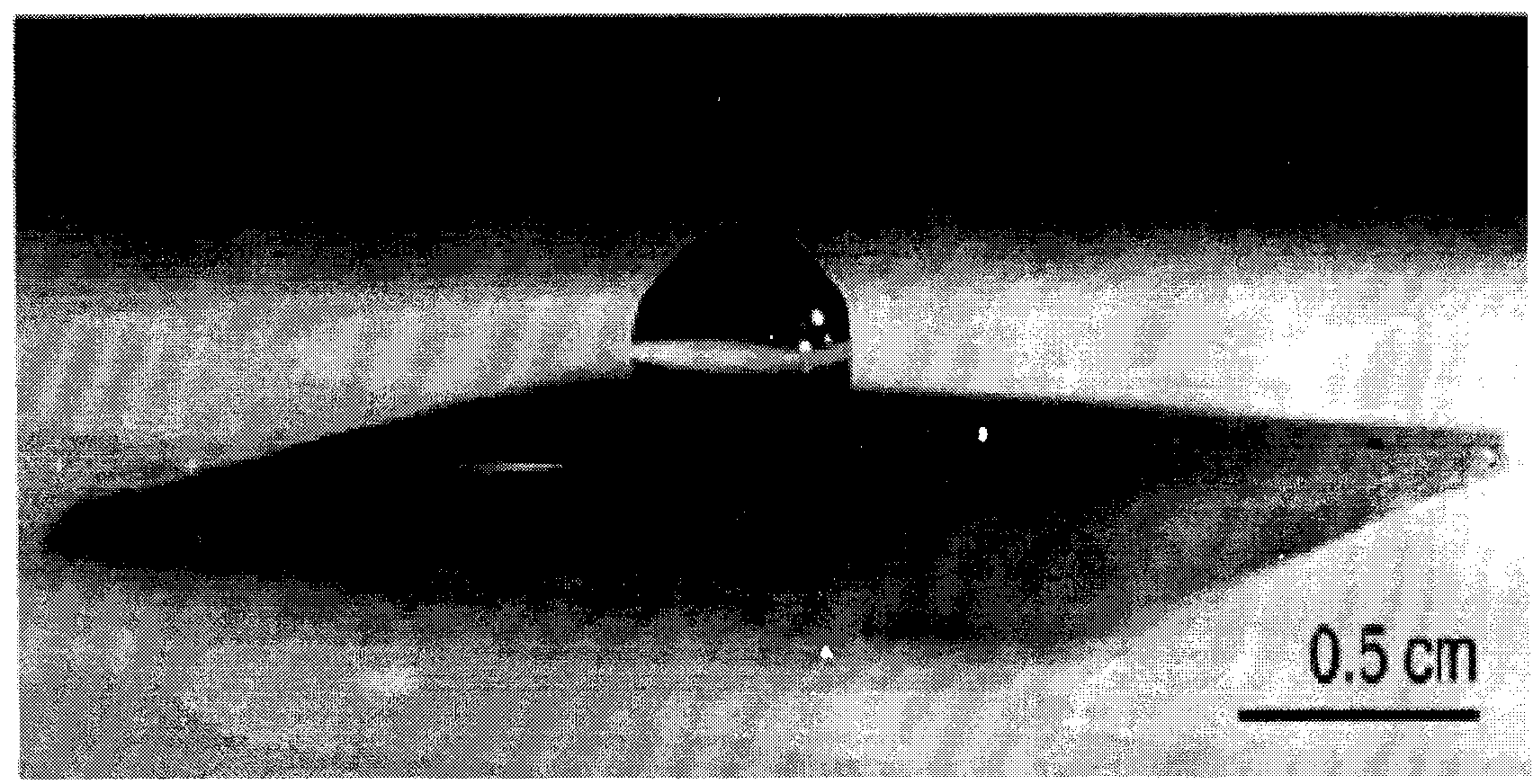

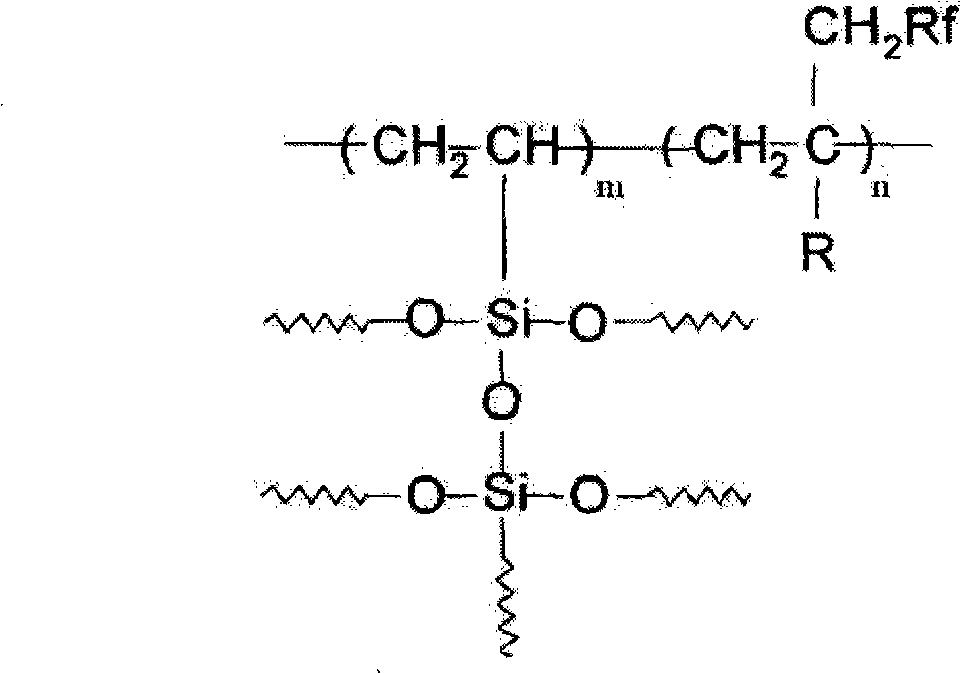

Anti-fouling wear-resisting transparent fluorine-silicone polymer material and preparation method thereof

InactiveCN102911314AReduce manufacturing costSimple production processAntifouling/underwater paintsPaints with biocidesSilicon oxygenSpray coating

The invention relates to an anti-fouling wear-resisting transparent fluorine-silicone polymer material and a preparation method thereof. The fluorine-silicone polymer material contains perfluoroalkyl and silicon-oxygen alkyl. The preparation method comprises the steps of adding an unsaturated monomer containing fluorine, an unsaturated siloxane monomer, a reaction solvent, an initiator, auxiliaries and bactericide into a high pressure reactor; and under the protection of nitrogen, heating and warming, controlling the pressure of the reactor, adjusting stirring, carrying out constant-temperature stirring reaction for 8-16 hours, and then fast cooling to room temperature. The fluorine-silicone polymer material can be coated on the surface of substrates such as glass, metal, plastic and the like in modes of spray coating, roll coating, wiping and the like to achieve the effectively waterproof, oil-proof, anti-fouling and wear-resisting effects.

Owner:XIAMEN MINGDA TECH

Method for producing five-cereal coarse cereal recombinant food

The invention discloses a method for producing a five-cereal coarse cereal recombinant food. The method comprises the following steps of: cleaning raw materials, drying, crushing and sieving with an 80-mesh sieve; and weighing the raw materials in a specific ratio, mixing uniformly, tempering, extruding by using a single-screw extrusion machine, cutting, and drying to obtain the five-cereal coarse cereal recombinant food. According to the method, five-cereal coarse cereals are developed deeply, so that sensory indexes of smells, colors, tastes and the like of products are similar to those of rice, so that the aims of 'refining of coarse grain' and 'the matching of staple grain and the coarse grain' are fulfilled, and the value of agricultural products of the five-cereal coarse cereals and the like is improved.

Owner:ANHUI YANZHIFANG FOOD

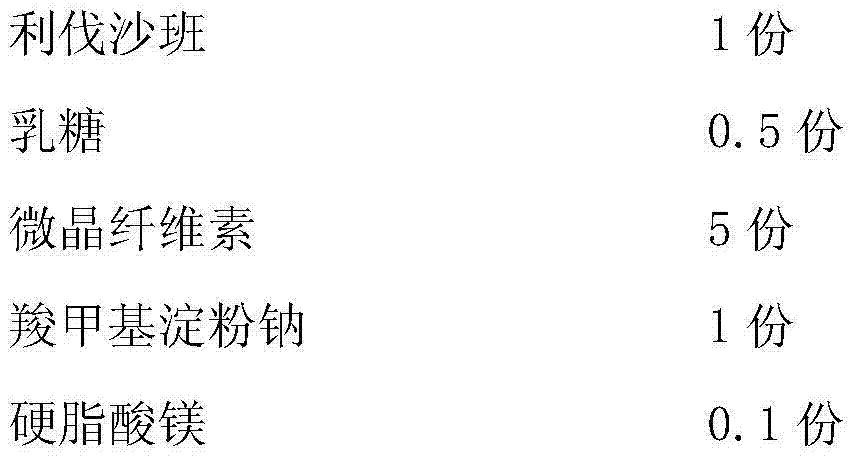

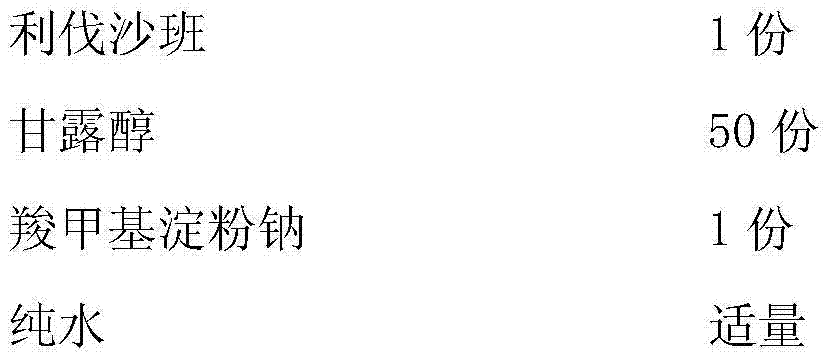

Rivaroxaban-containing tablets

ActiveCN104721156AAdvantages and Notable ImprovementsSignificant progressOrganic active ingredientsPill deliverySucroseFiller Excipient

The present invention discloses rivaroxaban-containing tablets, which are prepared from a raw material containing micronized rivaroxaban and an auxiliary material containing a water soluble filler, wherein a weight ratio of the rivaroxaban to the water soluble filler is 1:0.5-50, and the water-soluble filler is one or a plurality of materials selected from lactose, mannitol, sorbitol and sucrose. According to the present invention, the hydrophilicity of the rivaroxaban is significantly improved, the rapid dissolution the rivaroxaban in the gastrointestinal tract body fluid is easily achieved, the preparation process is simple, the operation is convenient, and the method is suitable for industrial large-scale production.

Owner:SHANDONG NEWTIME PHARMA

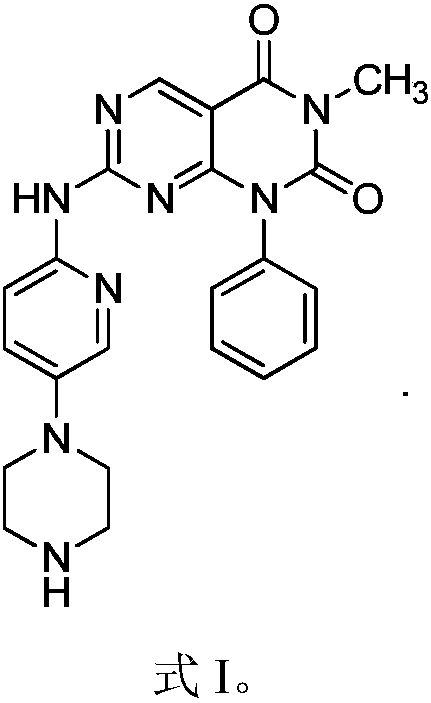

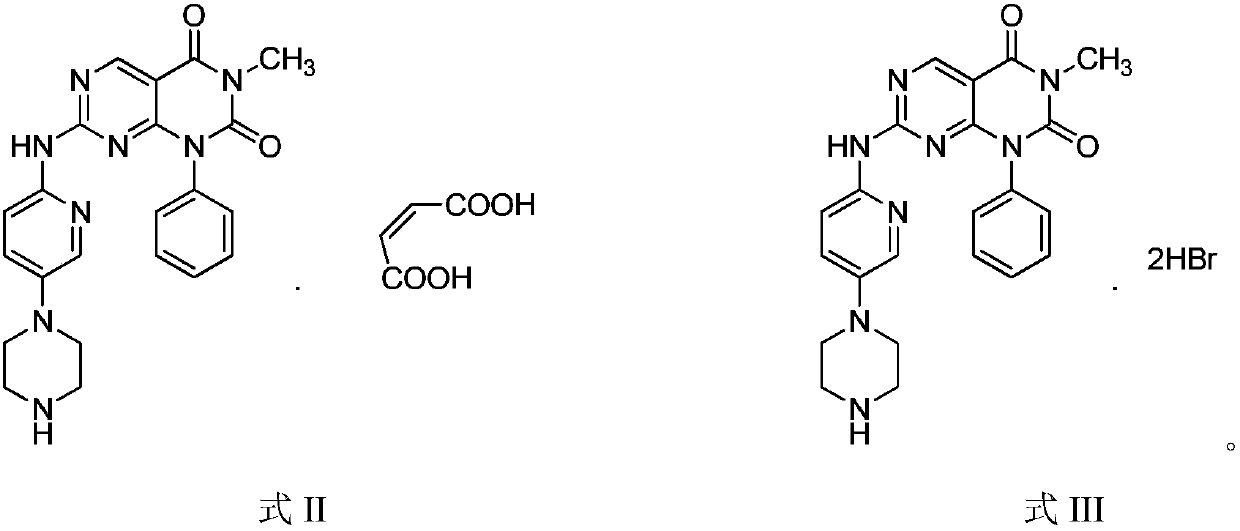

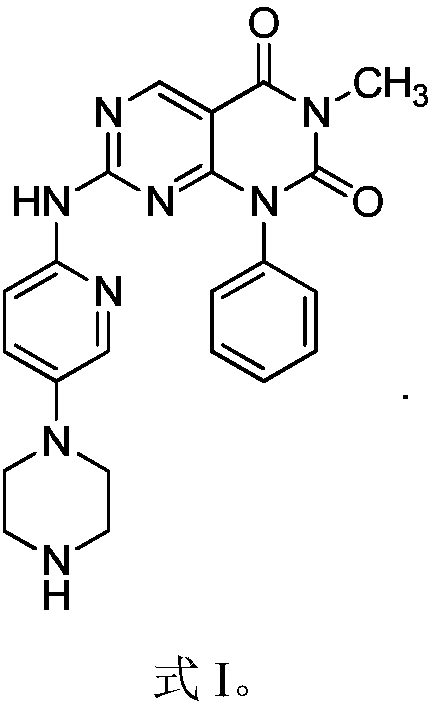

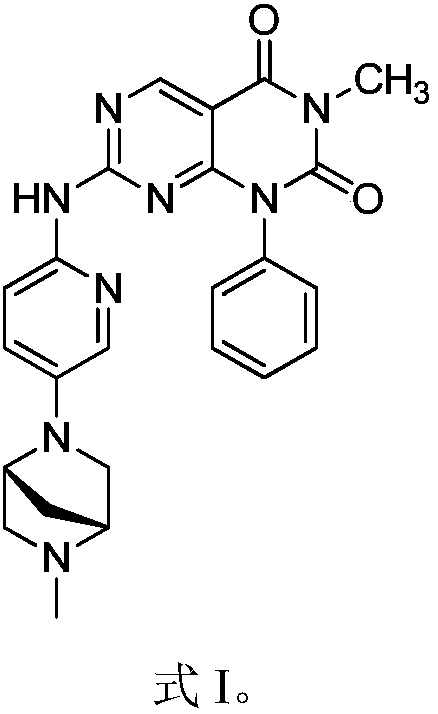

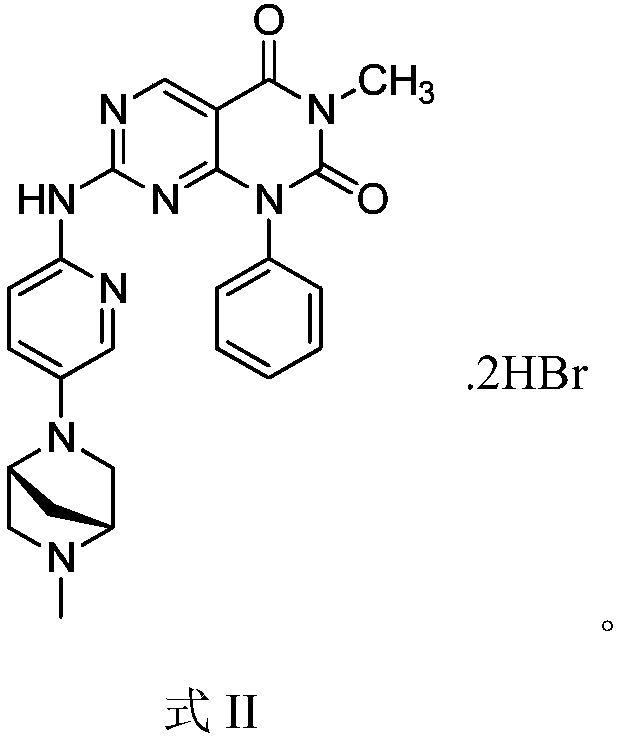

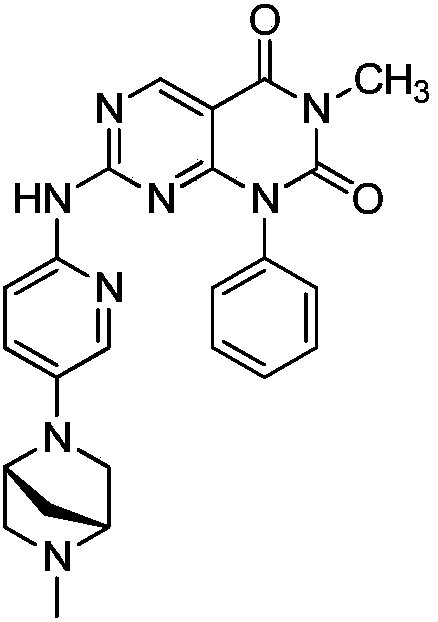

Pharmaceutical composition prepared by combining paclitaxel with CDKS kinase inhibitor for use

InactiveCN107929276AAdvantages and Notable ImprovementsSignificant progressOrganic active ingredientsAntineoplastic agentsHigh dosesBULK ACTIVE INGREDIENT

The present invention provides a combined pharmaceutical composition of paclitaxel and CDKS kinase inhibitors, comprising active ingredients and pharmaceutically acceptable excipients, characterized in that: the active ingredients are composed of paclitaxel and CDK4 / 6 kinase represented by formula I Inhibitors or pharmaceutically acceptable salts thereof, the mass ratio of paclitaxel and CDK4 / 6 kinase inhibitors or pharmaceutically acceptable salts thereof in the active ingredient is (2‑8):1. The pharmaceutical composition has good anticancer curative effect and low toxic and side effects; due to the sensitivity of CDK4 / 6 kinase inhibitors to paclitaxel, the combination of the two produces a synergistic effect, thereby reducing the clinical dosage of capecitabine and reducing the large dosage Toxic and side effects produced by using capecitabine can improve the safety index of clinical treatment and have good clinical application prospects.

Owner:南京众慧网络科技有限公司

Taxol and CDKS kinase inhibitor anti-tumor combined pharmaceutical composition

InactiveCN108125944AGood anticancer effectSmall side effectsOrganic active ingredientsAntineoplastic agentsSide effectPaclitaxel

The invention provides a taxol and CDKS kinase inhibitor anti-tumor combined pharmaceutical composition. The pharmaceutical composition comprises active components and pharmaceutically acceptable auxiliary materials, and is characterized in that the active components comprise taxol and a CDK4 / 6 kinase inhibitor or pharmaceutically salt; and the mass ratio of the taxol to the CDK4 / 6 kinase inhibitor or pharmaceutically salt in the active components is (2-8):1. The pharmaceutical composition is high in anti-tumor efficacy and low in toxic and side effect; and as the CDK4 / 6 kinase inhibitor has sensibility for the taxol, the combination of the CDK4 / 6 kinase inhibitor and taxol has a synergistic effect, the clinical dose of xeloda is reduced, toxic and side effect caused by the use of large dose of xeloda is reduced, the clinical treatment safety index is improved, and the pharmaceutical composition has a good clinical application prospect.

Owner:南京众慧网络科技有限公司

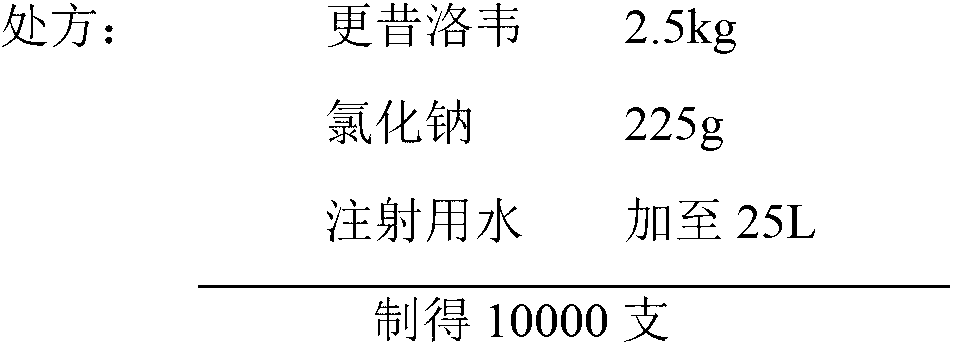

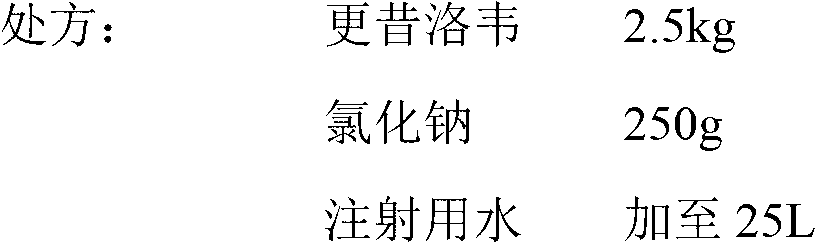

Ganciclovir for injection and preparation method thereof

ActiveCN103054819AAdvantages and Notable ImprovementsImprove yieldPowder deliveryInorganic non-active ingredientsMedicineFreeze-drying

The invention discloses ganciclovir for injection and a preparation method thereof. The preparation is formed by regulating the pH of a solution containing ganciclovir and sodium chloride to 10.0-11.5 by adopting a pH regulator, and freezing and drying repetitively. The freeze-dried powder injection of the ganciclovir for injection has the advantages of high yield, good re-dissolubility, more stable quality and the like; change of related substances during the period of accelerated test is not obvious; and the ganciclovir for injection is safer for clinical application.

Owner:BEIJING WANPENGLANGGE PHARMA TECH

Preparation method of high-strength and high-adhesion branched starch composite hydrogel with strong hydrogen bonding effect

The invention discloses a preparation method of a high-strength and high-adhesion branched starch composite polyacrylamide / polyvinyl alcohol hydrogel with a strong hydrogen bonding effect, the methodcomprises the following steps: branched starch, polyvinyl alcohol, polymer monomer acrylamide and a photoinitiator are dissolved to obtain a uniform mixed solution, firstly, the uniform mixed solution is initiated under the condition of ultraviolet light, so that the acrylamide is polymerized, micro-crystals are formed in a polyvinyl alcohol network in the freezing and unfreezing process, a multi-hydrogen bond interaction can be formed between molecular chains of the branched starch and molecular chains of the polyacrylamide and molecular chains of the polyvinyl alcohol, and under the doubleactions of multiple hydrogen bonds and the micro-crystals, multi-physical-bond cooperative cross-linking is realized. The preparation process is simple and convenient to operate, and the prepared hydrogel has relatively high mechanical strength and excellent adhesion property on the surface of glass, and can be used as a preferred material of a soft robot.

Owner:HUBEI UNIV OF TECH

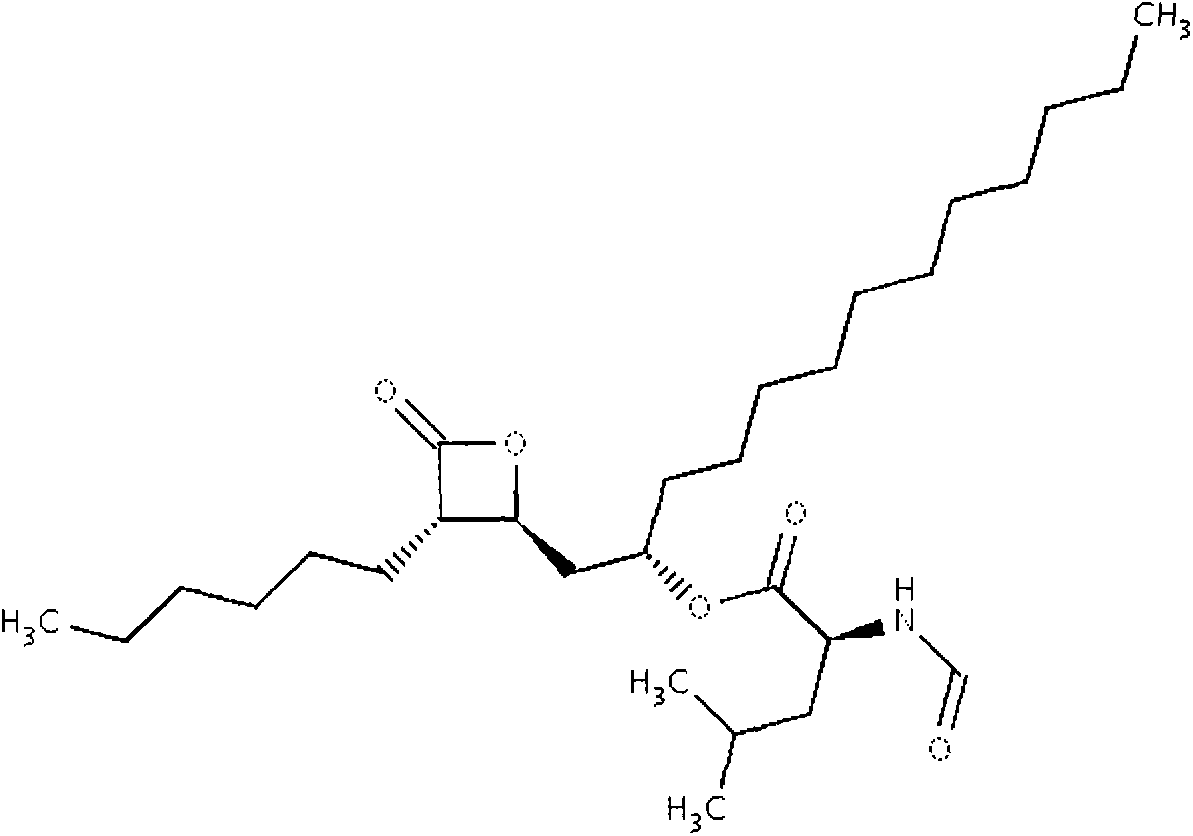

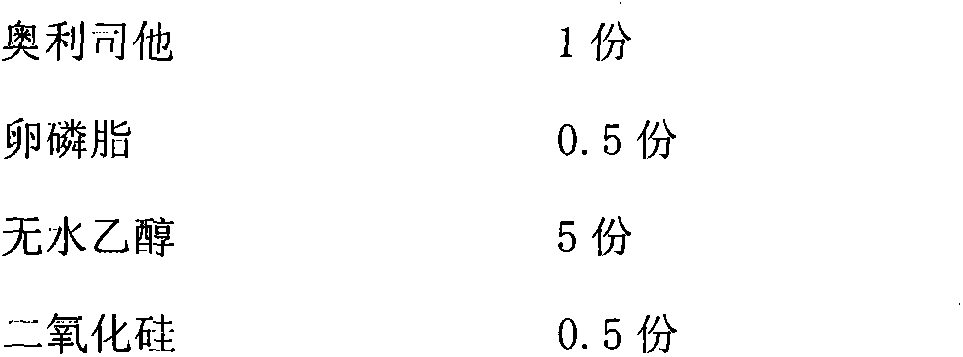

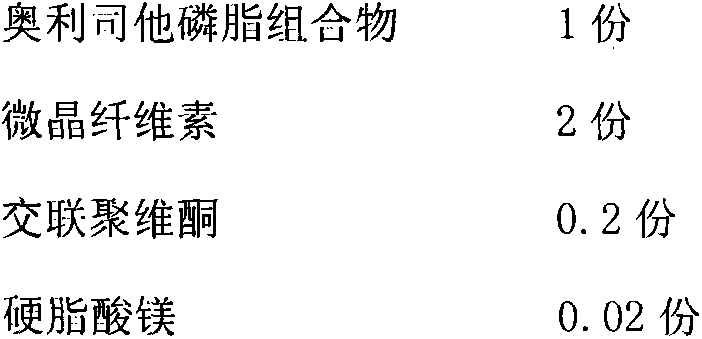

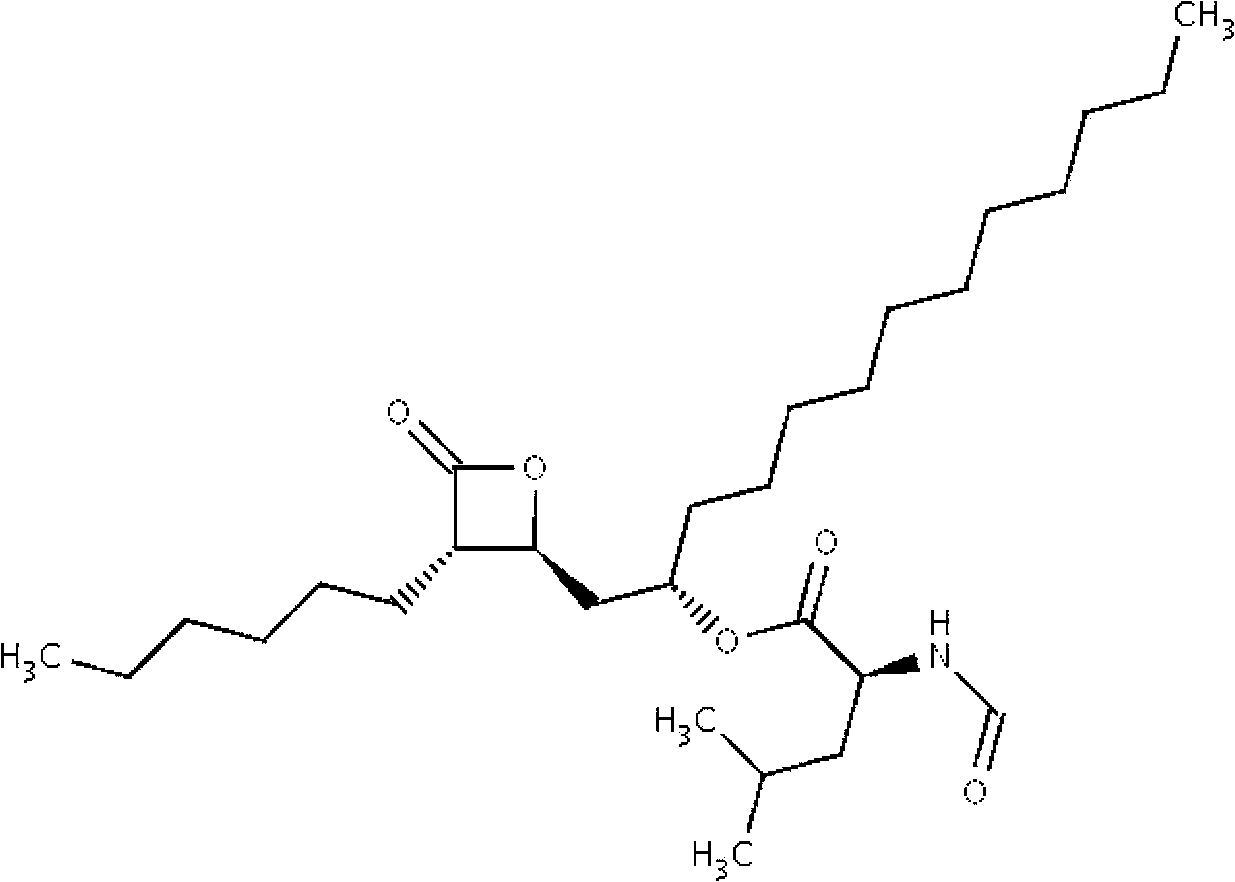

Orlistat tablet and preparation method thereof

InactiveCN103006601APromote dissolutionGood stabilityOrganic active ingredientsMetabolism disorderPharmaceutical AidsMedicinal chemistry

The invention discloses an orlistat-containing tablet and a preparation method thereof. The orlistat-containing tablet is prepared by directly tabletting a silicon dioxide-containing orlistat phospholipid composition and pharmaceutic adjuvants, wherein the weight ratio of orlistat to phospholipid to silicon dioxide which are contained in the silicon dioxide-containing orlistat phospholipid composition is 1:(0.5-1.5): (0.5-3). The orlistat-containing tablet disclosed by the invention solves the problems of tabletting sticking and poor storage stability of the conventional process of the orlistat and enhances the in-vivo dissolvability of the orlistat.

Owner:QINGDAO UNIV

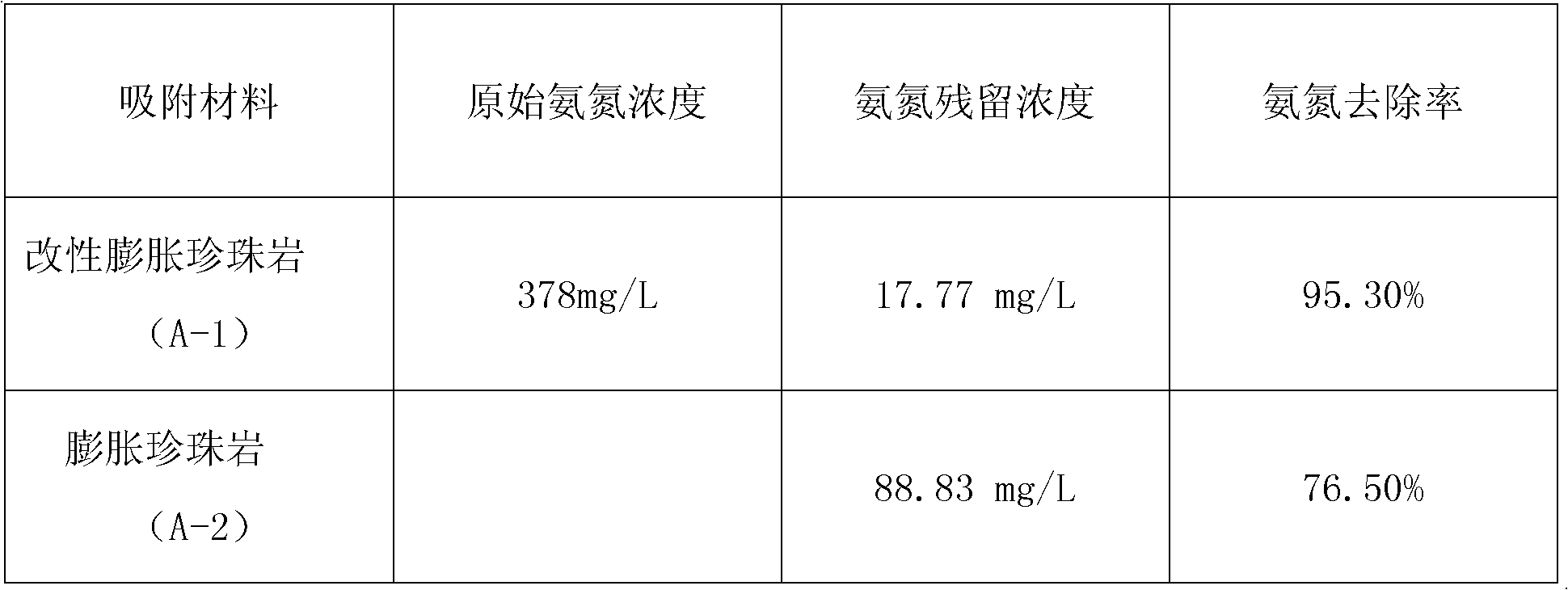

Modified expanded perlite for treating low-concentration ammonia-nitrogen wastewater and wastewater treatment method

ActiveCN102614826AAdvantages and Notable ImprovementsImprove adsorption efficiencyOther chemical processesSilicon compoundsHydrogenAdsorption reaction

The invention relates to modified expanded perlite for treating low-concentration ammonia-nitrogen wastewater and a wastewater treatment method. The method includes steps of placing the modified expanded perlite into an adsorption reaction groove or tank with upper and lower water inlet and outlet openings; tamping the adsorption reaction groove or tank to form a fixed absorption reaction bed; and feeding the low-concentration ammonia-nitrogen wastewater into the fixed absorption reaction bed from an upper water inlet tube port after the pH (potential of hydrogen) of the low-concentration ammonia-nitrogen wastewater is adjusted to a range from 7 to 9, and draining the low-concentration ammonia-nitrogen wastewater from a lower water drainage tube port. Accordingly the purpose of treating the wastewater is achieved. The modified expanded perlite is simple, and is low in cost and suitable for treating the low-concentration ammonia-nitrogen wastewater.

Owner:WUHAN XINGTIANYU ENVIRONMENTAL ENG

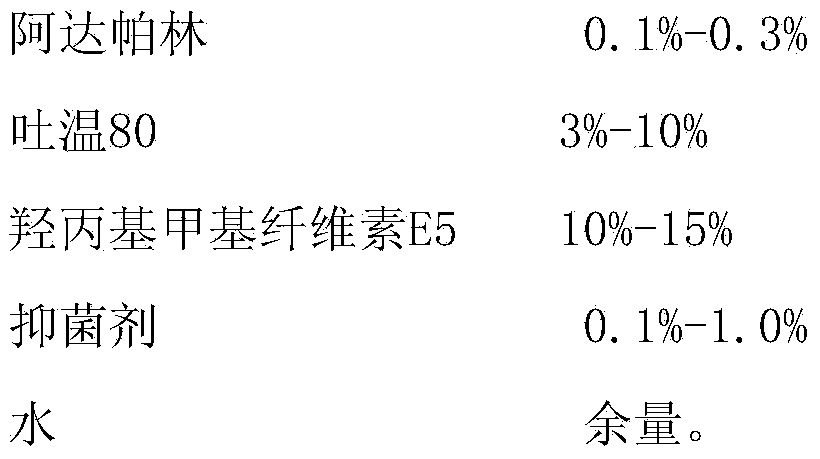

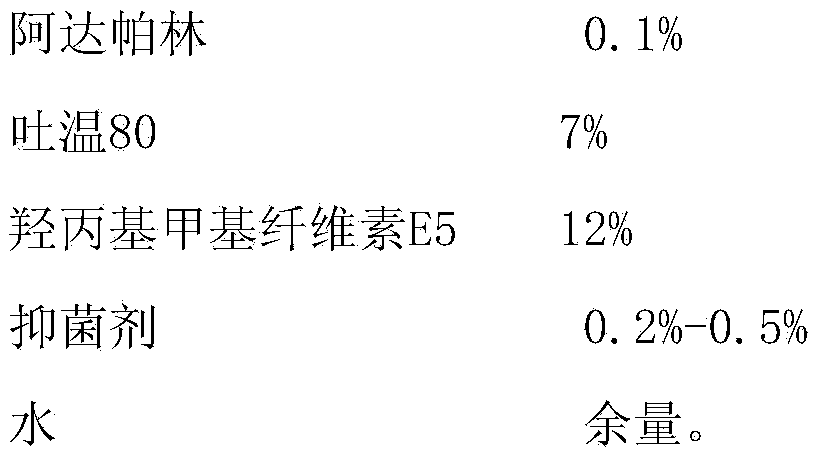

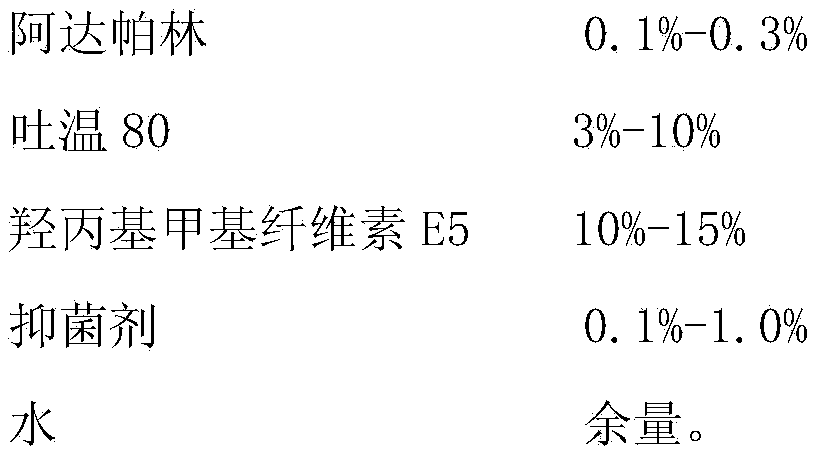

Adapalene gel and method for preparing same

ActiveCN103417473AAdvantages and Notable ImprovementsAvoid reactionOrganic active ingredientsAerosol deliveryGel basedMethyl cellulose

The invention discloses adapalene gel and a method for preparing the same. The adapalene gel which is a preparation comprises adapalene and accessories. The adapalene is an active ingredient, and the accessories include hydroxypropyl methyl celluloses E5 and tween 80. The adapalene gel and the method have the advantages that the hydroxypropyl methyl celluloses E5 are added into a formula and can replace carbomer to be used as a gel base material, the adapalene can be isolated and prevented from being in contact with packing materials of the gel owing to a film forming property of the hydroxypropyl methyl celluloses E5, accordingly, the problem that metal ions react with an existing active ingredient is fundamentally solved, and long-term storage and storage are facilitated.

Owner:江苏小林制药有限公司

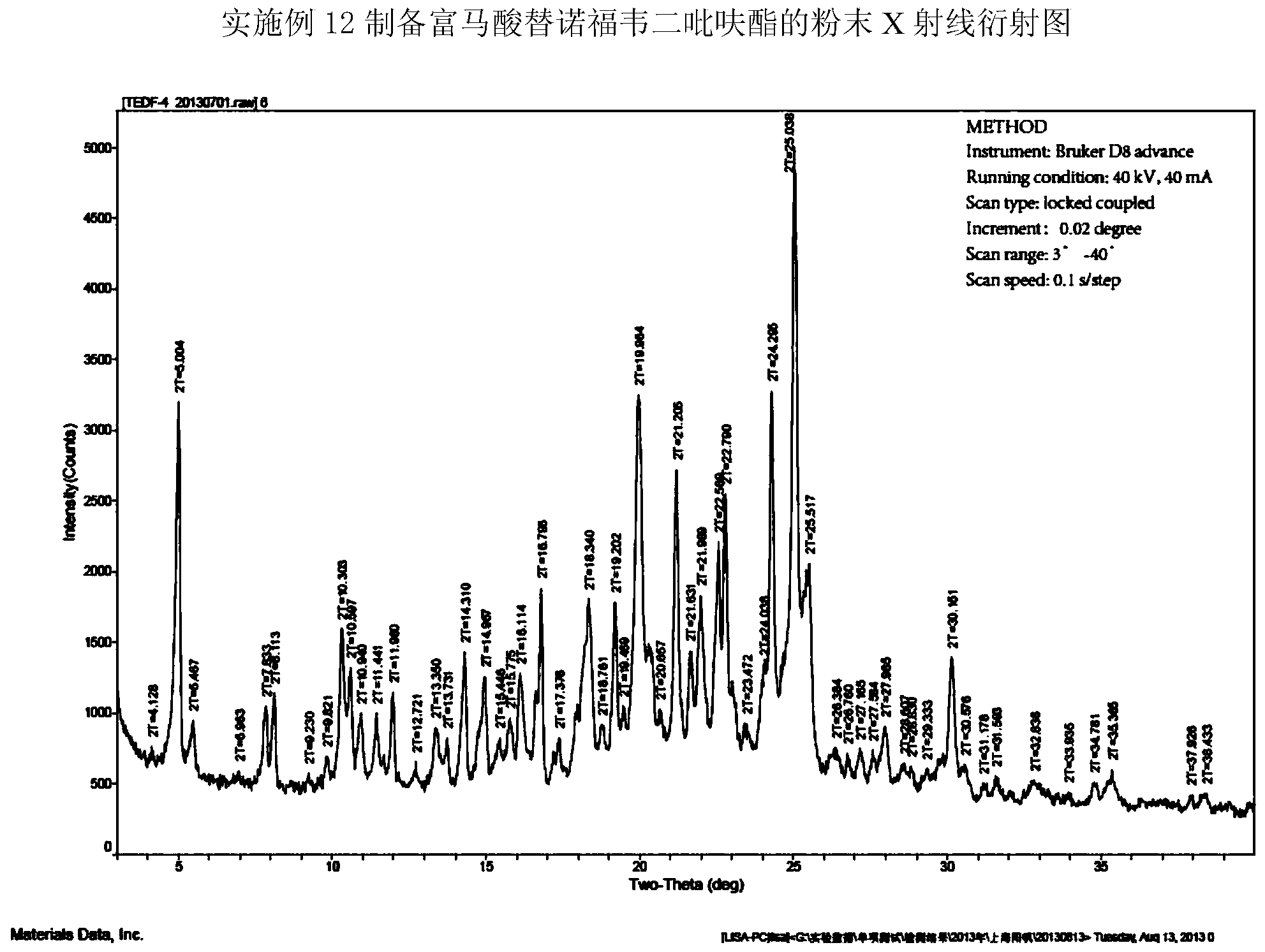

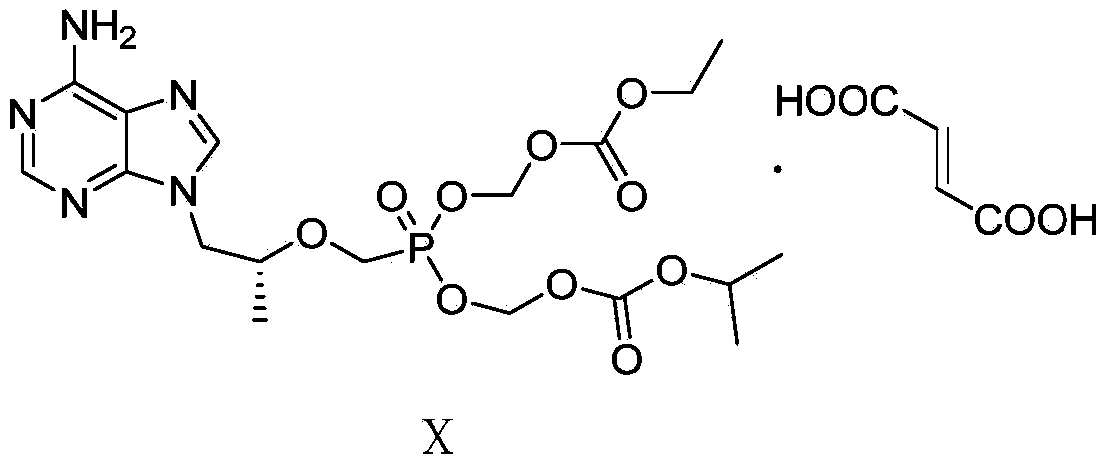

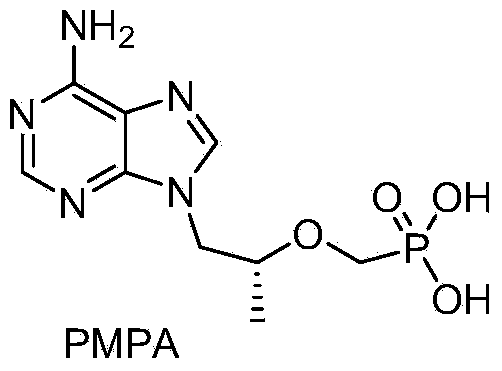

Tenofovir disoproxil fumarate and preparation method thereof

ActiveCN103641858AAdvantages and Notable ImprovementsSignificant progressGroup 5/15 element organic compoundsAntiviral drugDimethyl methylphosphonate

The invention relates to an antiviral drug tenofovir disoproxil fumarate and a novel preparation method thereof, belonging to the field of medicines. Content of related substances in the tenofovir disoproxil fumarate, especially content of impurity K is effectively lowered by taking toluenesulfonyloxy diethyl methylphosphonate as a starting material through hydrolysis, condensation and salifying. Moreover, the preparation method is gentle in reaction condition, low in production cost, simple and convenient to operate, and suitable for large-scale industrial production.

Owner:湖南千金湘江药业股份有限公司

Coarse cereal electuary and preparation method thereof

InactiveCN103719998AAdvantages and Notable ImprovementsSignificant progressFood preservationLipidic food ingredientsVegetable oilThirst

The invention discloses a coarse cereal electuary and a preparation method thereof. The electuary is mainly prepared from the following raw materials in parts by weight: 100 parts of buckwheat powder, 50-150 parts of coix seed powder, 50-150 parts of yam powder, 20-60 parts of black soybean powder, 30-50 parts of dried orange peel, 20-40 parts of vegetable oil, 10-20 parts of peanut and 5-10 parts of walnut. The electuary obtained by deep processing on the raw materials by adopting the method disclosed by the invention has the effects of tonifying spleen, reducing phlegm, calming liver, suppressing yang, clearing heat, resolving thirst, reducing internal heat, nourishing stomach, protecting liver and enhancing vitality and has the advantages that the contained various nutritional ingredients are mutually coordinated and cardiovascular diseases can be prevented at the same time.

Owner:安徽省徽州印象农业科技有限责任公司

Orlistat oral solid preparation and preparation method thereof

ActiveCN103505453AAdvantages and Notable ImprovementsAvoid disadvantagesOrganic active ingredientsMetabolism disorderMedicineDissolution

The invention discloses an orlistat oral solid preparation. The orlistat oral solid preparation is prepared by the steps of melting a low-melting point polymer and orlistat, then extruding out particles by an extruder, and mixing the particles and other accessories. By adopting the preparation disclosed by the invention, adverse factors in a preparation process caused by extremely low melting point of the orlistat are avoided, and the preparation can be made into various pharmaceutically common dosage forms. Moreover, the tablet preparation prepared by the invention is fast in dissolution and has great advantages over the prior art.

Owner:SHANDONG NEWTIME PHARMA

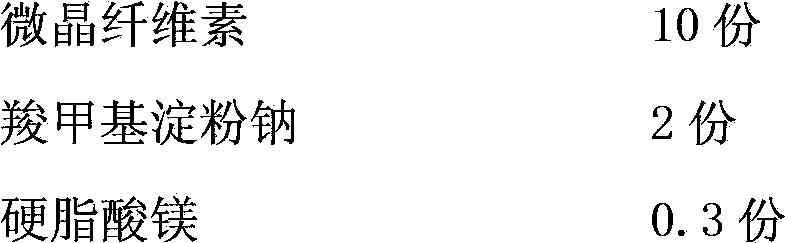

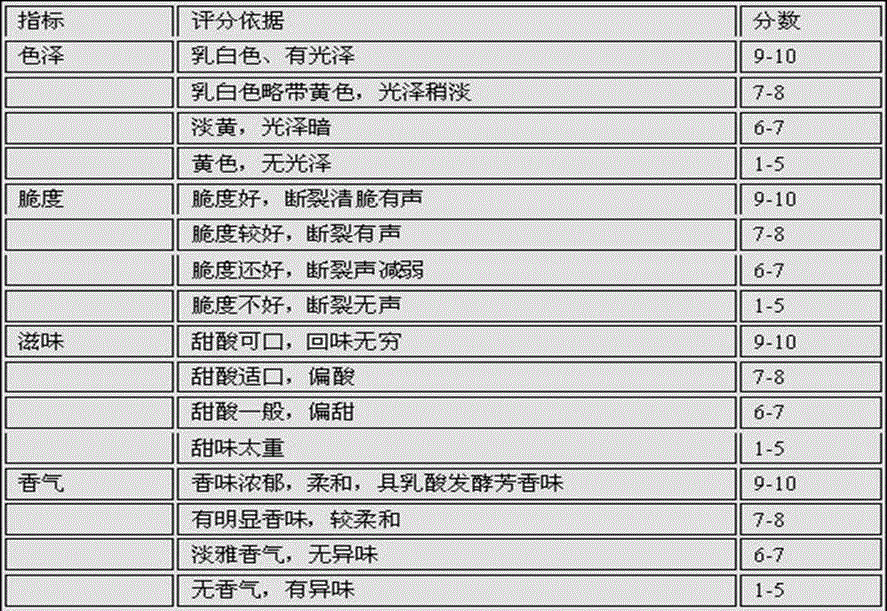

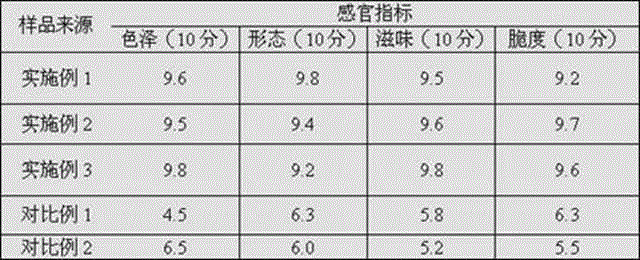

Preparation method of fermented aggregate-containing crispy pastry

ActiveCN104082372AAdvantages and Notable ImprovementsExcellent Calcium Supplement FoodDough treatmentBakery productsBiotechnologyNutrition

The invention discloses a preparation method of fermented aggregate-containing crispy pastry, and belongs to the technical field of food. The fermented aggregate-containing crispy pastry is prepared by the following steps: (1) preparing aggregate enzymolysis solution; (2) fermenting the enzymolysis solution; (3) homogenizing fermentation liquid and flour and other materials; (4) shaping and quickly freezing; (5) performing low-temperature vacuum frying dehydration; (6) de-oiling. By the preparation method, the fermented aggregate-containing crispy pastry prepared from calcium, phosphorus, beneficial microorganisms and other substances obtained during enzymolysis and fermentation of aggregate has the calcium content of 12.5-13.0%, the phosphorus content of 6.2-6.9%, the protein content 12.5-14.0mg / Kg and the amino acid content 0.85-0.90mg / Kg, has the calcium-phosphorus ratio of 2: 1 which is the optimal ratio for body absorption, is crispy in mouthfeel and rich in nutrition and is excellent calcium-supplementing food.

Owner:HUBEI UNIV OF TECH

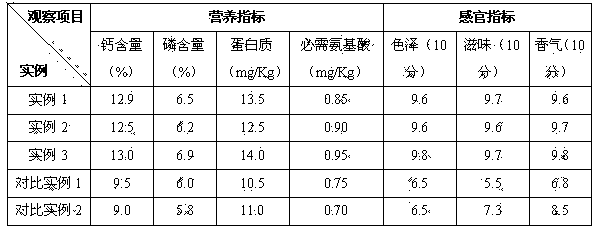

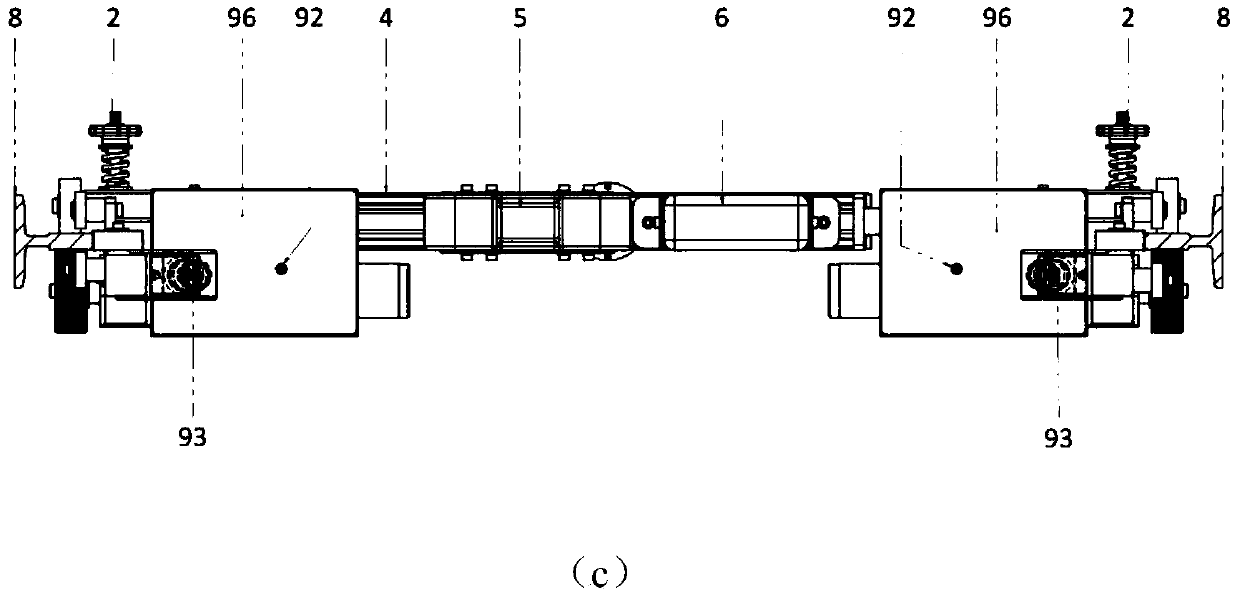

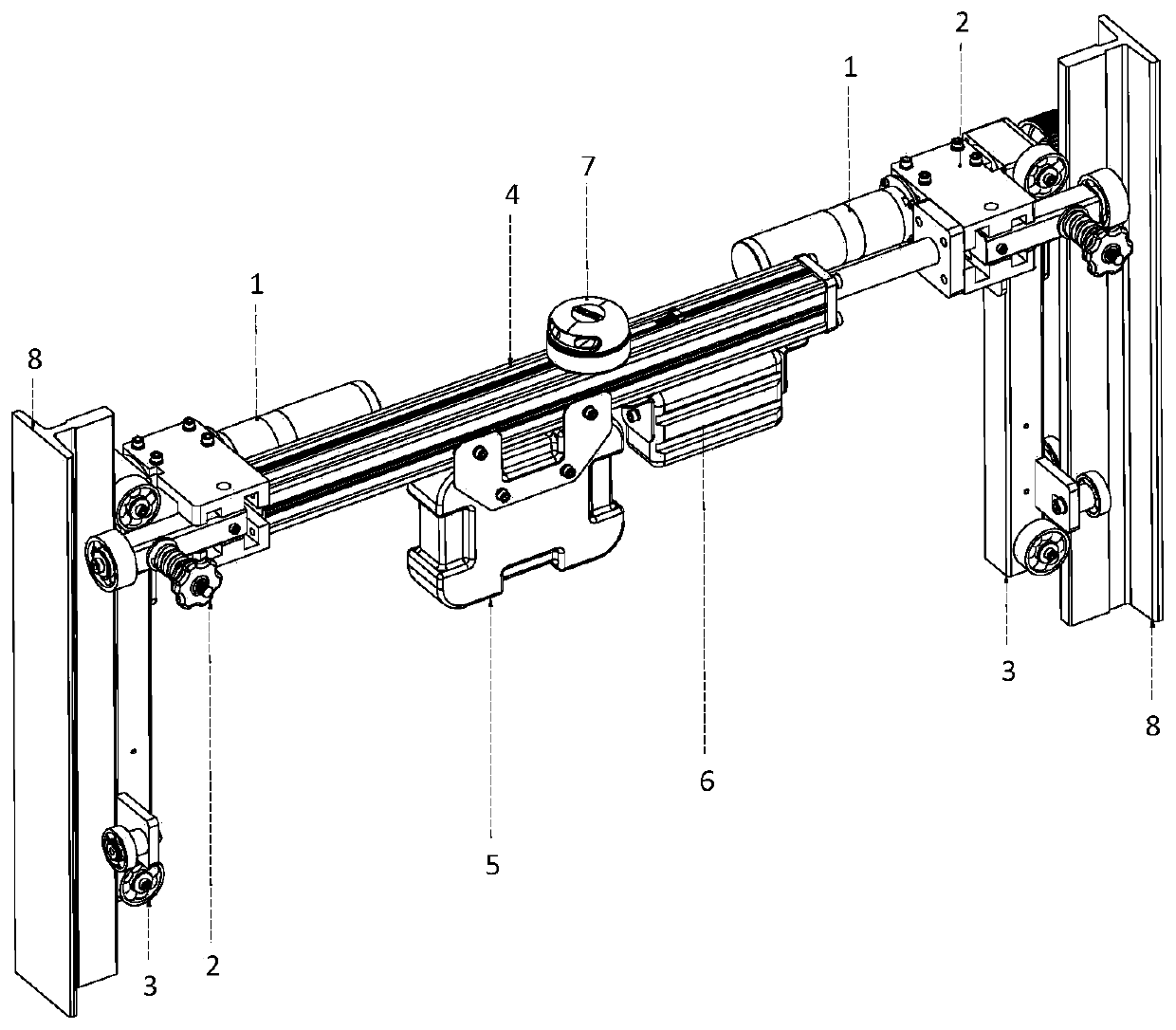

Elevator guide rail quality detecting device and method

ActiveCN111170121AAvoid insufficient frictionAvoid damageElevatorsElectromagnetic wave reradiationImage resolutionClassical mechanics

The invention relates to an elevator guide rail quality detecting device which comprises two plumb lasers independently fixed on the ground, a reflector and a camera. The reflector is fixed below thebottom bodies of grippers on the two sides of an elevator guide rail crawling robot; the camera is fixed on the inner side of a stabilizing arm unit; a pair of traction wheels and a pair of gripper wheels of the elevator guide rail crawling robot always cling to the elevator guide rail and crawl along the guide rail; the laser rays of the plumb lasers separately shine to the positions near to thecenter of the reflector; the camera shoots laser points generated on the reflector without stop; guide rail quality variation is directly converted into position changes of the reflector and the camera in the horizontal direction; and the straightness and other quality conditions of the elevator guide rail can be measured through treating each crawling information of the robot and the position data of the laser points. The elevator guide rail quality detecting device is convenient to use and mount and easy to operate, and has the advantages of being low in cost, high in resolution, measuring precision and efficiency and wide in building applicable range.

Owner:QINGDAO UNIV

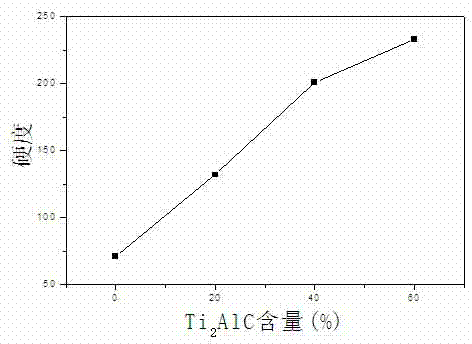

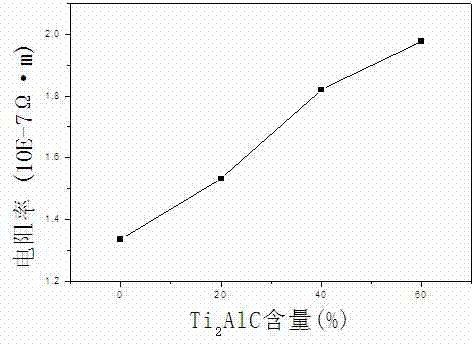

Cu-Ti2 AlC functionally gradient material and preparation method thereof

InactiveCN103085395AAdvantages and Notable ImprovementsImprove thermal shock resistanceCeramic layered productsMetal layered productsAdditive ingredientGradient material

The invention relates to a preparation method of a Cu-Ti2 AlC functionally gradient material. The preparation method is characterized in that a composite material which contains pure Cu or main ingredient Cu is formed at one side of the prepared gradient material; the compound which contains pure Ti2AlC or main ingredient Ti2AlC is arranged at the other side of the prepared gradient material; 1-4 interlayers are arranged; the contents of Cu and Ti2AlC change in gradient along with the thickness direction, and gradually change along with the performance; the hardness and strength of the material are obviously improved along with the direction from Cu to enriched Ti2AlC; the oxidation resistance and the anti-high temperature performance are improved; the wear-resisting property and the elastic modulus are gradually improved; and the toughness, the electric conductivity and the thermal conductivity are obviously improved along the direction from Ti2AlC to enriched Cu. The material has significance as to a special environment which has different operational performances as to different contact surfaces; the material is prepared from Cu and Ti2AlC powder used as raw materials in a manner of hot-pressed sintering under certain atmosphere after evenly mixing and layered charging, wherein the sintering temperature is 800-1000 DEG C; the heating rate is 8-20 DEG C / min; the pressure is 20-40 MPa; and heat preservation time is 0.5-3 hours. By adopting a hot-pressed sintering method, the prepared gradient material is high in compactness, excellent in performance, and good in industrialized prospect.

Owner:HUBEI UNIV OF TECH

Temsirolimus for injection and preparation method thereof

ActiveCN103099806AAdvantages and Notable ImprovementsImprove stabilityOrganic active ingredientsAntineoplastic agentsAlcoholFreeze-drying

The invention belongs to the technical field of pharmaceutical preparations, and concretely relates to temsirolimus for injection and a preparation method thereof. The preparation method comprises dissolving a prescribed amount of temsirolimus and an anti-oxidant in anhydrous alcohol, mixing uniformly, adding a dispersant, re-mixing uniformly, freeze drying and removing the ethanol to obtain the temsirolimus. The preparation provided by the invention is few in prescription component; and the preparation method is convenient and easy, improves disadvantages of complex technology in present prescription, and greatly minimizes components such as alcohols and the like that may cause injection pain, thereby being relatively safe and reliable.

Owner:SHANDONG NEWTIME PHARMA

Forcing culture method of German iris 'black knight'

The invention discloses a forcing culture method of German iris 'black knight'. The method includes following steps: 1), choosing iris potted flowers more than one year old, healthy in growth and uniform in growing trend, fertilizing after flowering in early May is finished and flower bud differentiation at the end of September is basically completed, wherein the fertilizing proportion meets a formula N:P:K=20:20:20; 2), placing the potted flowers in a greenhouse about 90 days before the expected flowering period from the beginning of October when flower buds distinguishable by naked eyes are formed to the beginning of December, and controlling culture conditions for flower forcing. By the method, florescence of the German iris 'black knight' can be effectively brought forward, and by fertilizing and controlling time for greenhouse flower forcing and greenhouse culture conditions, the florescence can be effectively brought forward to expected New Year's Day and Spring Festival, and a basis is provided for development of lunar-new-year German iris 'black knight'.

Owner:武汉市林业果树科学研究所

Fermented crystal allium chinense and preparation method thereof

InactiveCN104473081AShort preparation cycleQuality improvementLactobacillusFood preparationBacilliDesalination

The invention discloses fermented crystal allium chinense and a preparation method thereof. The preparation method is mainly characterized in that a certain proportion of mixedlactic acid bacteria are used for fermenting processed allium chinense, and a product is obtained after seasoning, packaging and sterilizing. Quantitative mixed viable bacteria such as lactobacillus plantarum, lactococcuslact is and lactobacillus brev is are added to allium chinense so as to ferment allium chinense, so that the preparation period of a fermented allium chinense product is shortened, the quality is improved, the salt use amount is reduced simultaneously, a desalination process is omitted, and the cost is reduced.

Owner:HUBEI UNIV OF TECH

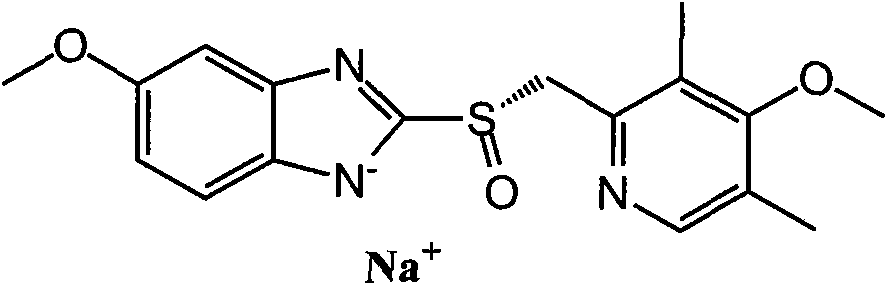

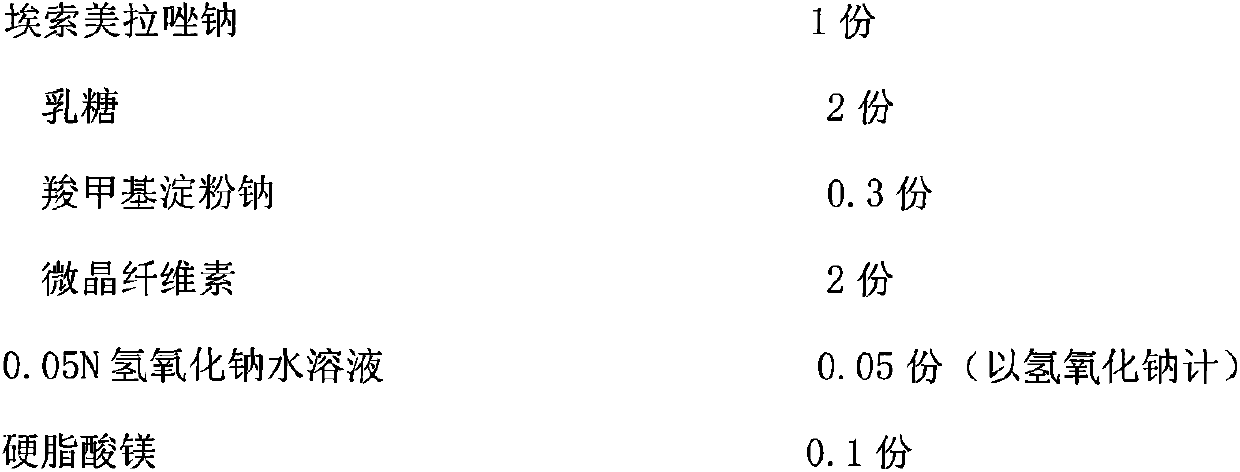

Esomeprazole sodium enteric-coated tablet and preparation method thereof

The invention discloses an esomeprazole sodium enteric-coated tablet, which is obtained by coating a tablet core with an isolation coating and an enteric coating in sequence. The tablet core is composed of esomeprazole sodium, sodium hydroxide, a filler, a disintegrating agent and a lubricating agent, wherein the weight ratio of the esomeprazole sodium to the sodium hydroxide is 1: (0.05-0.45). According to a preparation method, through dissolving an alkaline material in a solvent, the esomeprazole sodium and a pharmaceutic adjuvant mixture are used for granulating; not only is the addition amount of the alkaline material greatly reduced, but also consistency of an alkaline environment in the tablet core is guaranteed; and the stability of medicine is improved.

Owner:QINGDAO UNIV

Potherb mustard-pickled product and low-salt fast pickling method thereof

ActiveCN104172038AAdvantages and Notable ImprovementsReduce nitrite levelsFood preparationBiotechnologyMicrobiology

The invention discloses a potherb mustard-pickled product and a low-salt fast pickling method of the potherb mustard-pickled product. The potherb mustard-pickled product is prepared by adopting a low-salt fermentation pickling technology three times, low-salt fermentation pickling is performed at different temperatures in the first time and the second time, a mixture of garlic, ginger, red hot chili pepper and pricklyash peel is added in the third time and then lactobacillus plantarum is inoculated for performing low-salt fermentation pickling. By adopting the low-salt fermentation pickling technology three times, the content of nitrites in potherb mustard is reduced, the pickling period is shortened, and the potherb mustard and other auxiliary materials can be fully fermented, so that the quality and the flavor of the potherb mustard are improved.

Owner:HUBEI UNIV OF TECH

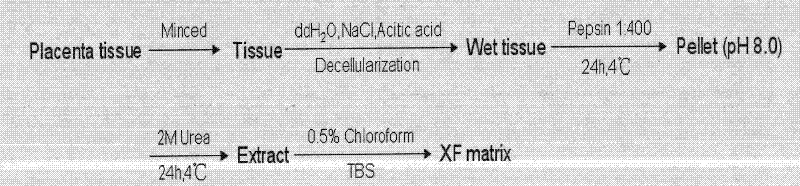

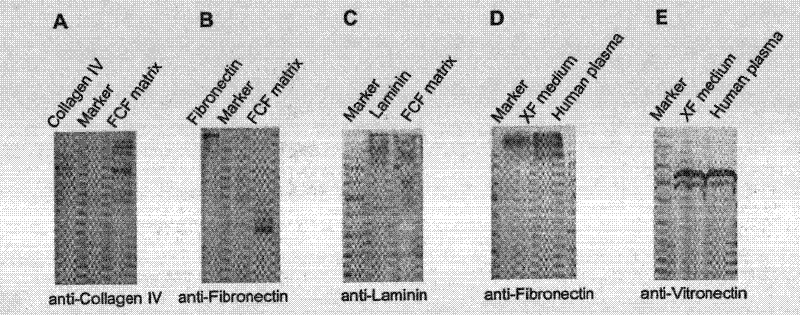

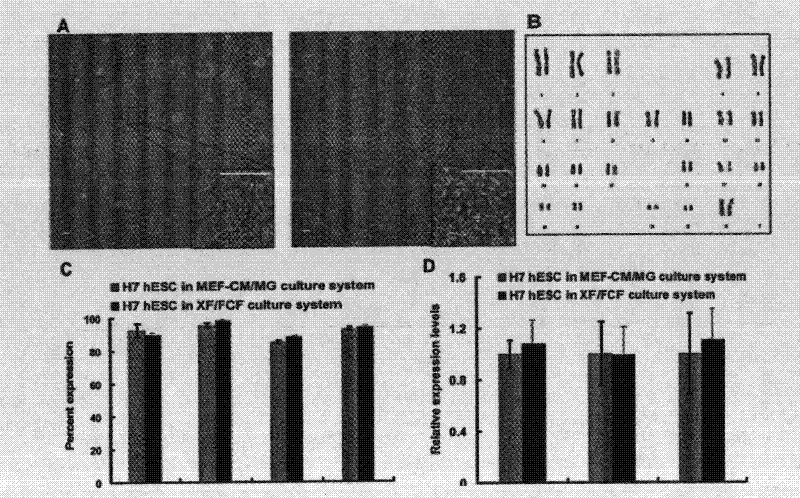

Novel animal source-free and feed layer-free human pluripotent stem cell culture system

InactiveCN102586176AAdvantages and Notable ImprovementsSignificant progressArtificially induced pluripotent cellsNon-embryonic pluripotent stem cellsCell-Extracellular MatrixECM Protein

The invention relates to a novel animal source-free and feed layer-free human pluripotent stem cell culture system. Extracellular matrix protein, namely a humanized matrix, which can support long-term culture of human embryonic stem cells and is extracted from placenta by a pepsase digestion and urea extraction method, a component prepared from human plasma by a NaCl precipitation method is prepared into a humanized medium, and the humanized medium and the humanized matrix form the animal source-free and feed layer-free culture system together. The culture system can maintain the potentialityof self-renewal and differentiation of human embryonic stem cells for a long term, and an animal source-free human induced pluripotent stem cell clone can be established in the culture system, so theanimal source-free and feed layer-free culture system which is low in cost and suitable for amplification culture lays a foundation for clinical application of pluripotent stem cells.

Owner:INSITUTE OF BIOPHYSICS CHINESE ACADEMY OF SCIENCES

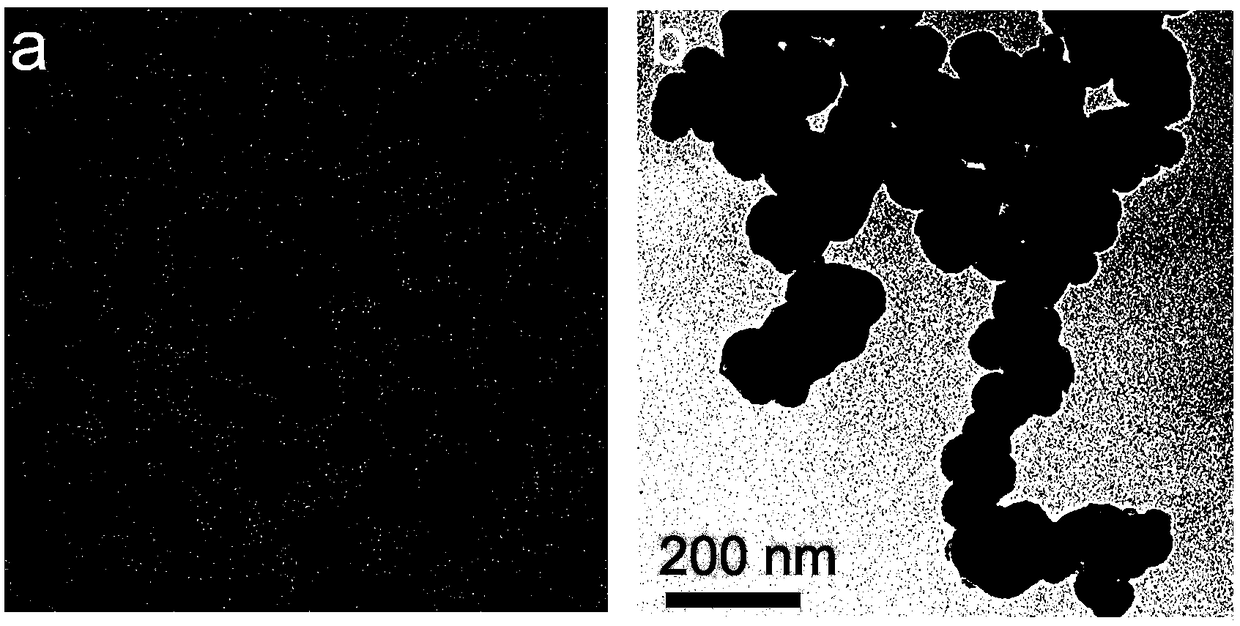

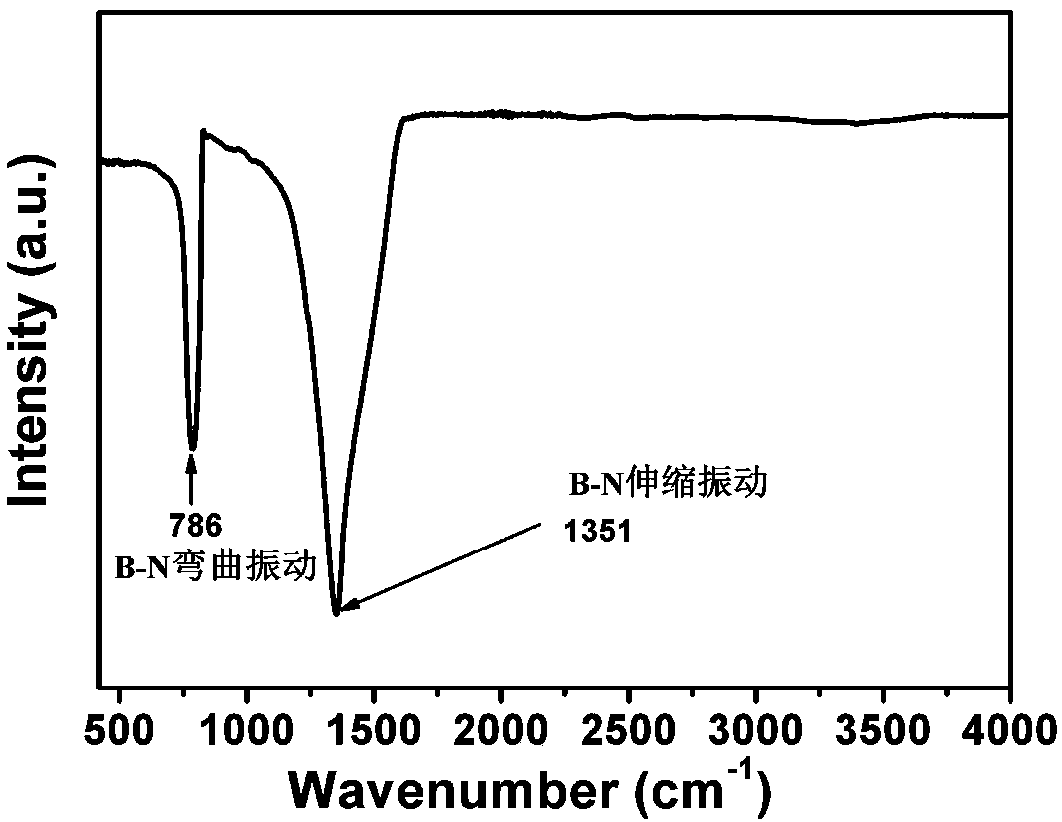

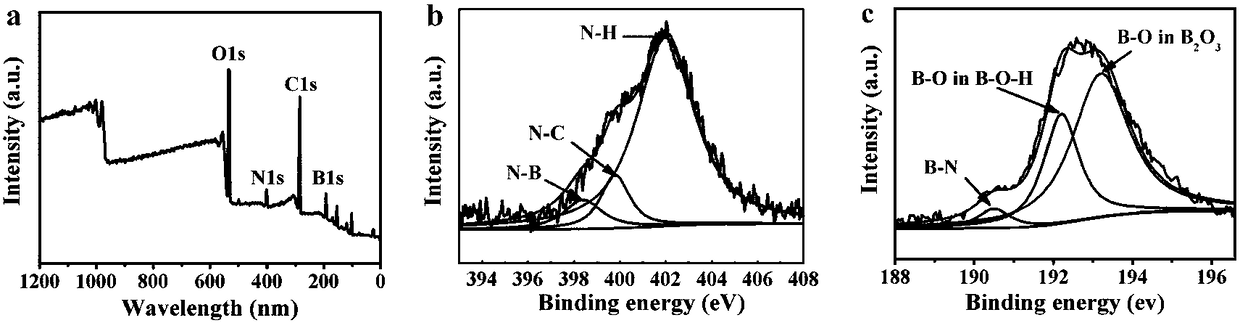

Preparation method for ultrathin boron nitride nanosheets and dispersion liquid thereof

ActiveCN108529574AAdvantages and Notable ImprovementsSignificant progressNitrogen compoundsNanotechnologyFreeze-dryingBoron nitride

The invention belongs to the technical field of nano materials and relates to a preparation method of ultrathin boron nitride nanosheets and dispersion liquid thereof. A one-step hydrothermal method is adopted for preparing the ultrathin boron nitride nanosheets in a laboratory; inexpensive boric acid and ammonia water as used as raw materials and subjected to a hydrothermal reaction for a certainperiod of time to prepare a boron nitride quantum dot solution which is simultaneously modified with amino groups and hydroxyl groups; the boron nitride quantum dot solution is cooled, placed under room temperature for one week, filtered and washed to obtain white transparent boron nitride crystals; the boron nitride crystals are added into ultrapure water, the mixture above is slowly heated to 60-80 DEG C, and the boron nitride crystals are gradually dissolved to obtain a colorless and transparent solution, namely the dispersion liquid of the ultrathin boron nitride nanosheets. Ultrathin boron nitride nanosheet powder can be obtained after the dispersion liquid is freeze-dried. The method has the advantages that the cost is low, the process is easy, and industrial production is facilitated; the obtained ultrathin boron nitride nanosheets are uniform in size distribution, high in crystallinity and good in dispersibility in an aqueous solution.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com