Gap magnetic adsorption type curved surface morphology detection robot and curved surface morphology measuring method

A magnetic suction, robot technology, applied in the field of mobile robots, can solve the problems of manual detection, no image acquisition and transmission functions, and high processing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

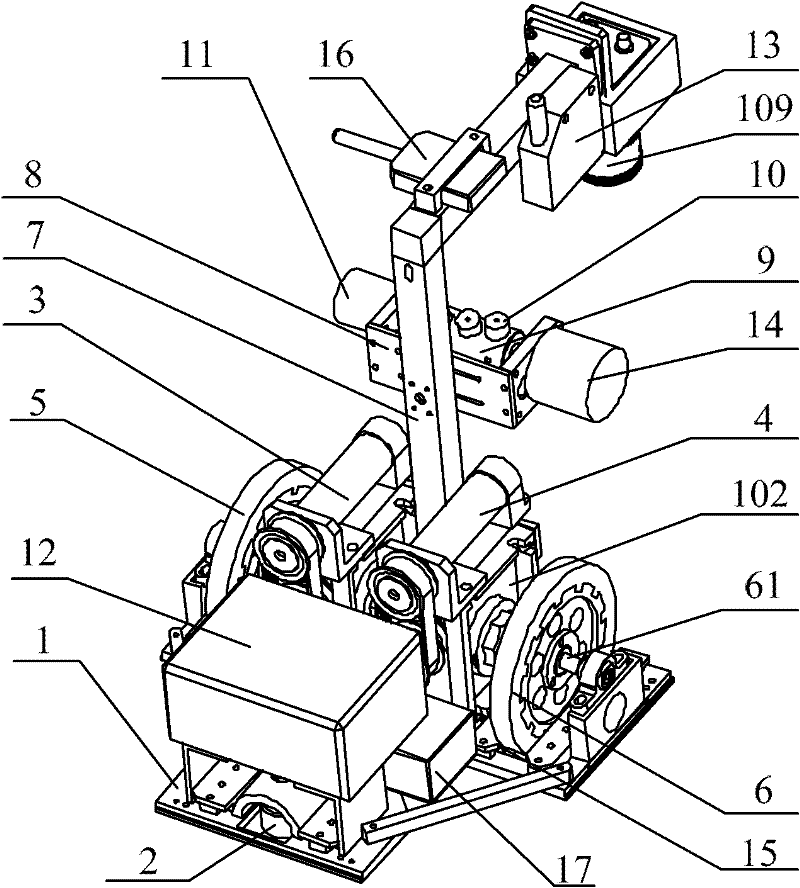

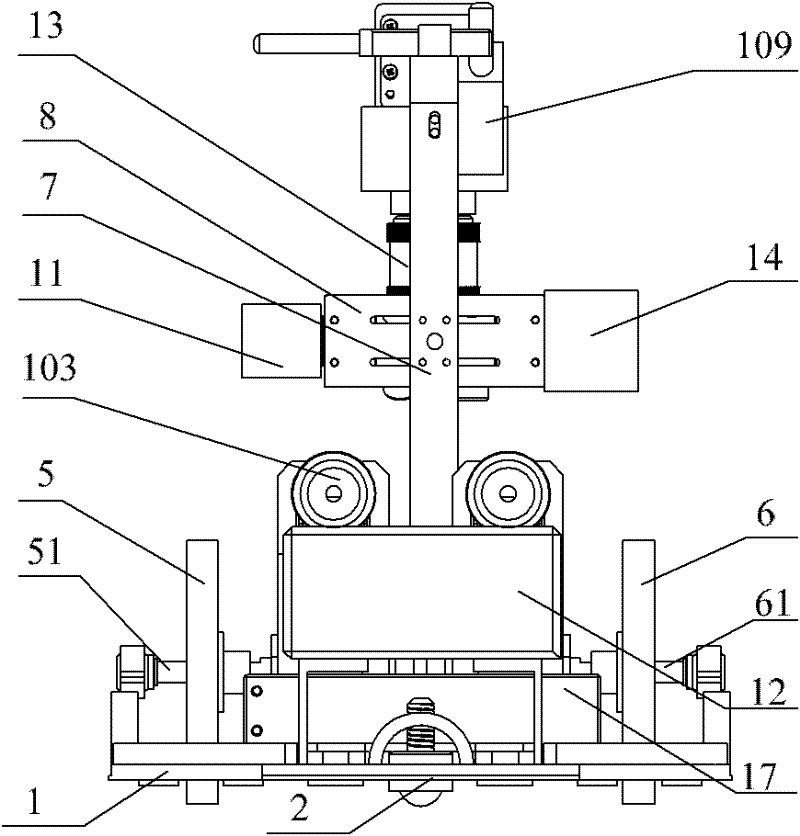

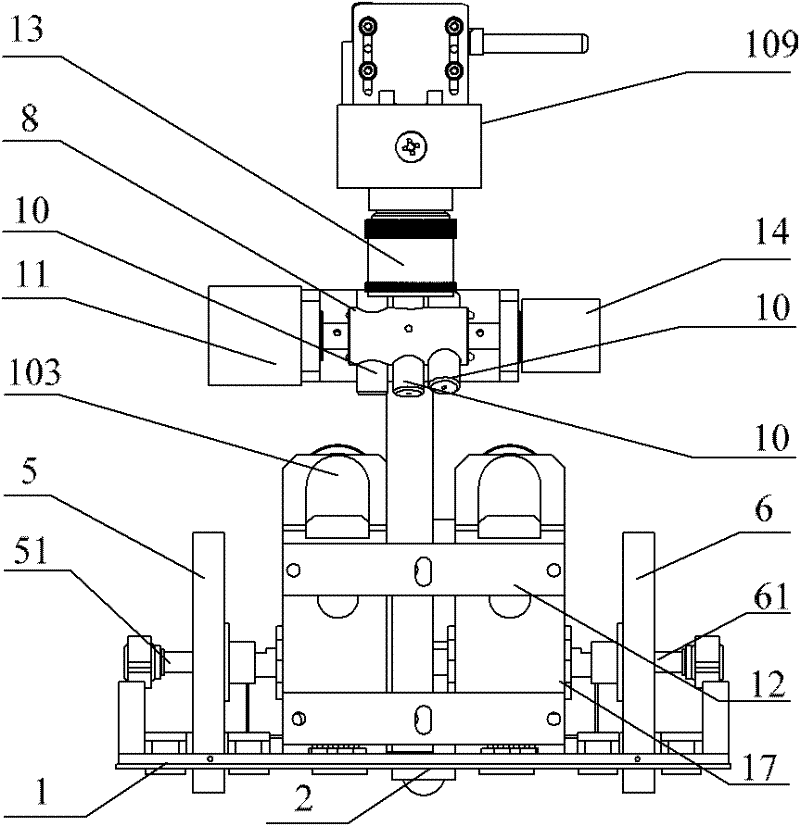

[0056] An embodiment of a gap magnetic suction type curved surface shape detection robot designed by the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 shown. The robot includes three major parts: a wheeled mobile platform, a detection component and a control system. 61. The first driving wheel 5, the second driving wheel 6 and the permanent magnet 15; the detection components include a detection bracket 7, a scanning frame 8, a scanning rotation axis 9, a line laser 10, a third motor 11, and a camera 13 , an image acquisition module and an angle sensor 14; the control system includes a motor drive circuit and a controller 12; the universal wheel 2 is fixed under the chassis 1; the first motor 3 and the second motor 4 Respectively fixedly connected with the chassis 1; the first rotating shaft 51 is sleeved in the chassis 1, the output shaft of the first motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com