Patents

Literature

208 results about "Three dimensional morphology" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

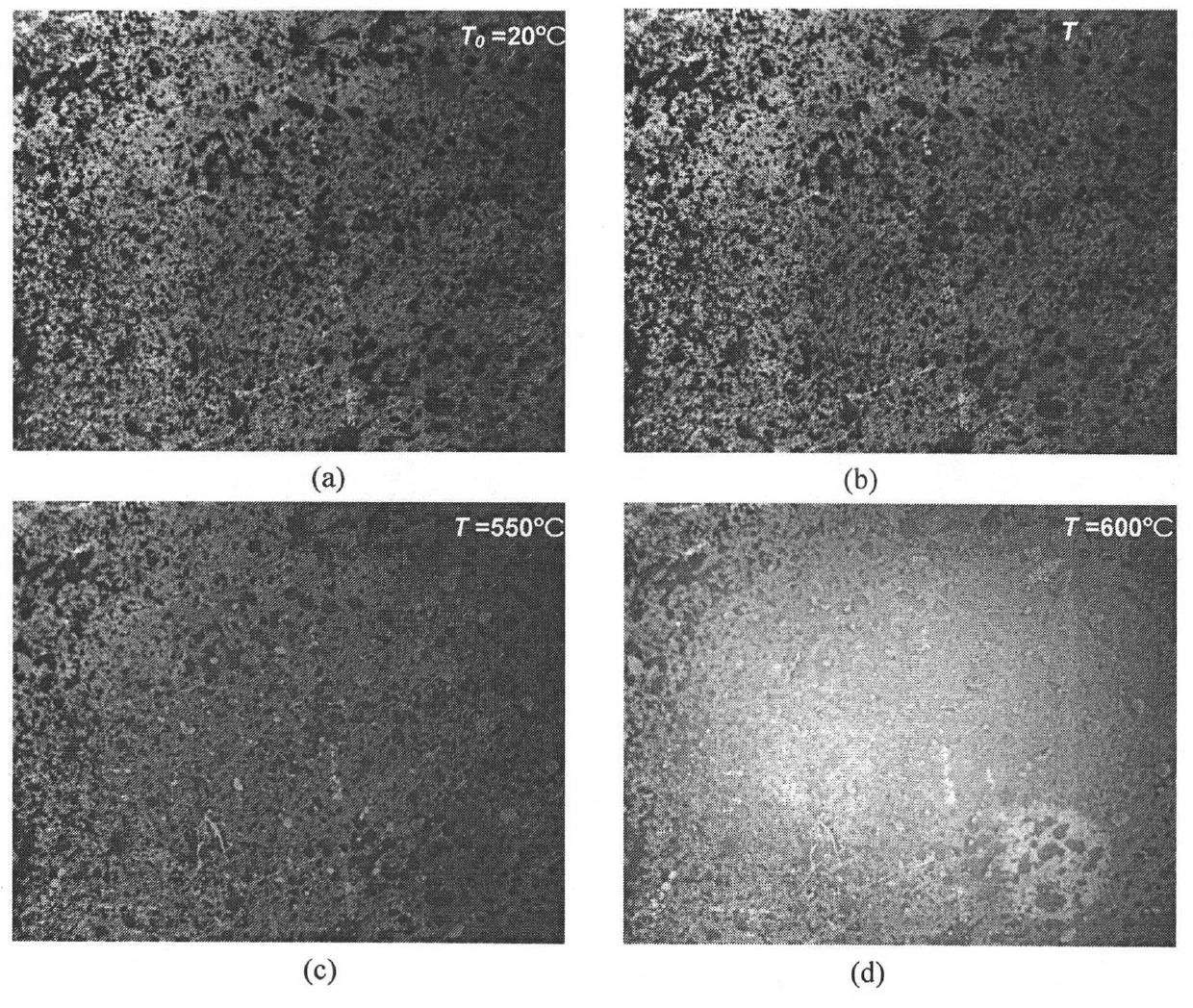

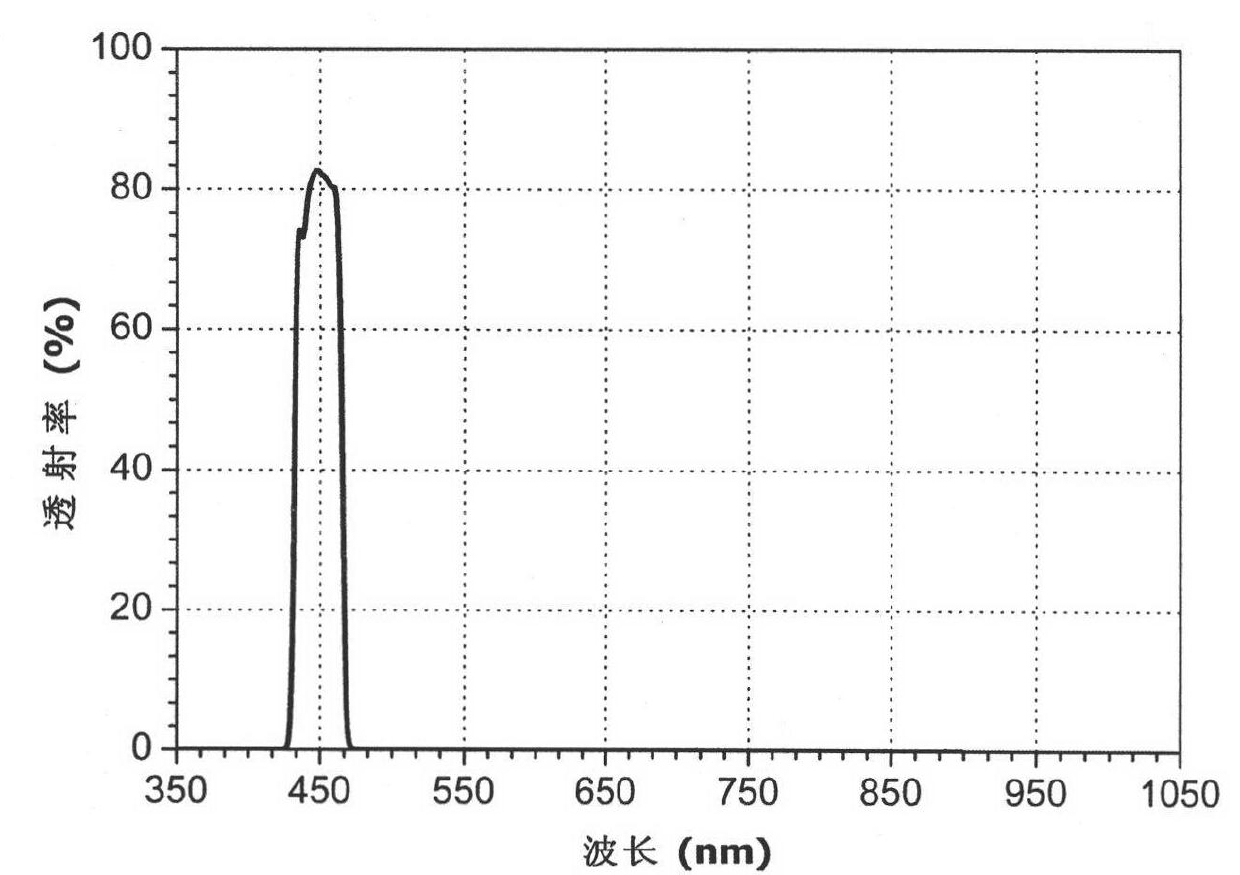

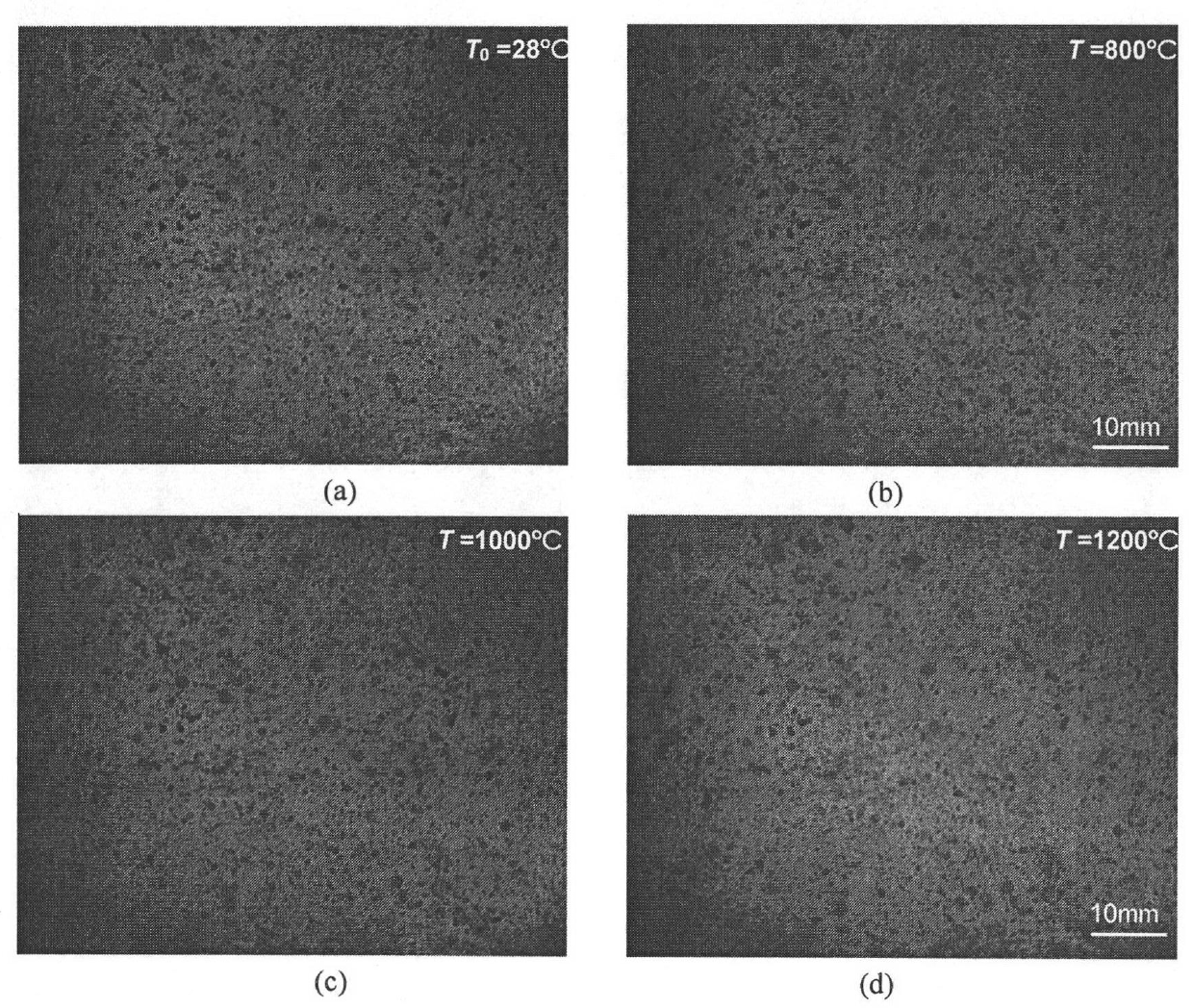

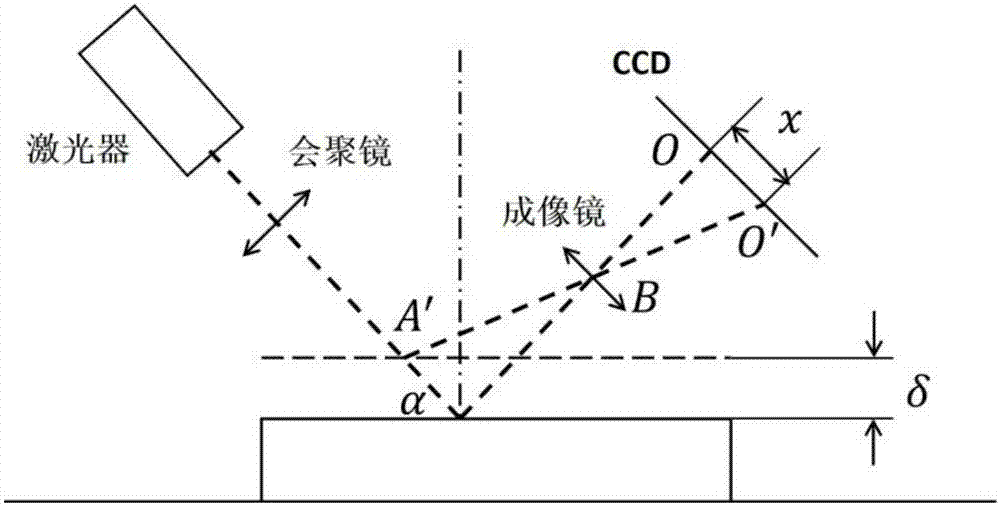

High-temperature three-dimensional digital image related measurement system and measurement method

The invention discloses a high-temperature three-dimensional digital image related measurement system and a high-temperature three-dimensional digital image related measurement method. The system comprises a digital camera, an imaging lens, band-pass optical filter, a monochromatic light source, a calibration board, a support system and a computer, wherein the support system consists of a triangular bracket, a guide rail and a translation stage; and the computer is used for acquiring a digital image and performing analysis processing. The measurement method comprises five steps. In the system, the band-pass optical filter is arranged in front of the imaging lens of the digital camera, so that the influence of the thermal radiation of a high-temperature object on the brightness enhancement of an acquired image of the camera can be reduced effectively. In the measurement, a measured object is lighted by adopting the monochromatic light source of which the lighting wavelength is positioned in a band-pass range of the band-pass optical filter. By using the system and the method, a brilliant image of the surface of the high-temperature object at the surface temperature of over 500 DEG C is acquired, wherein the image can be directly analyzed and processed by a three-dimensional digital image related method to acquire the three-dimensional morphology of the surface of the high-temperature object and a three-dimensional deformation field under the action of a thermal load. The system has a compact structure, is convenient to operate, and has a wide application range and high measurement precision.

Owner:BEIHANG UNIV

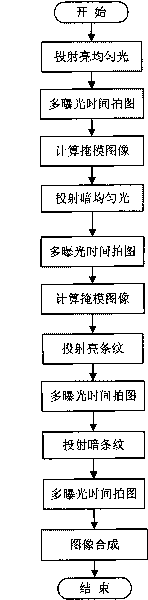

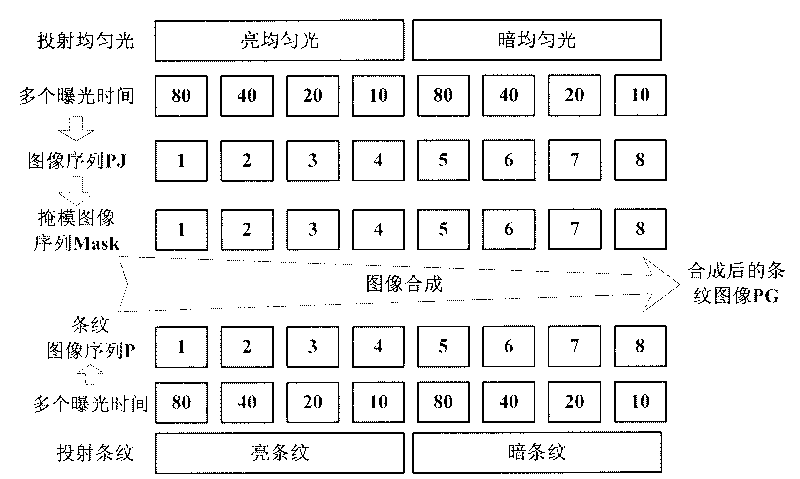

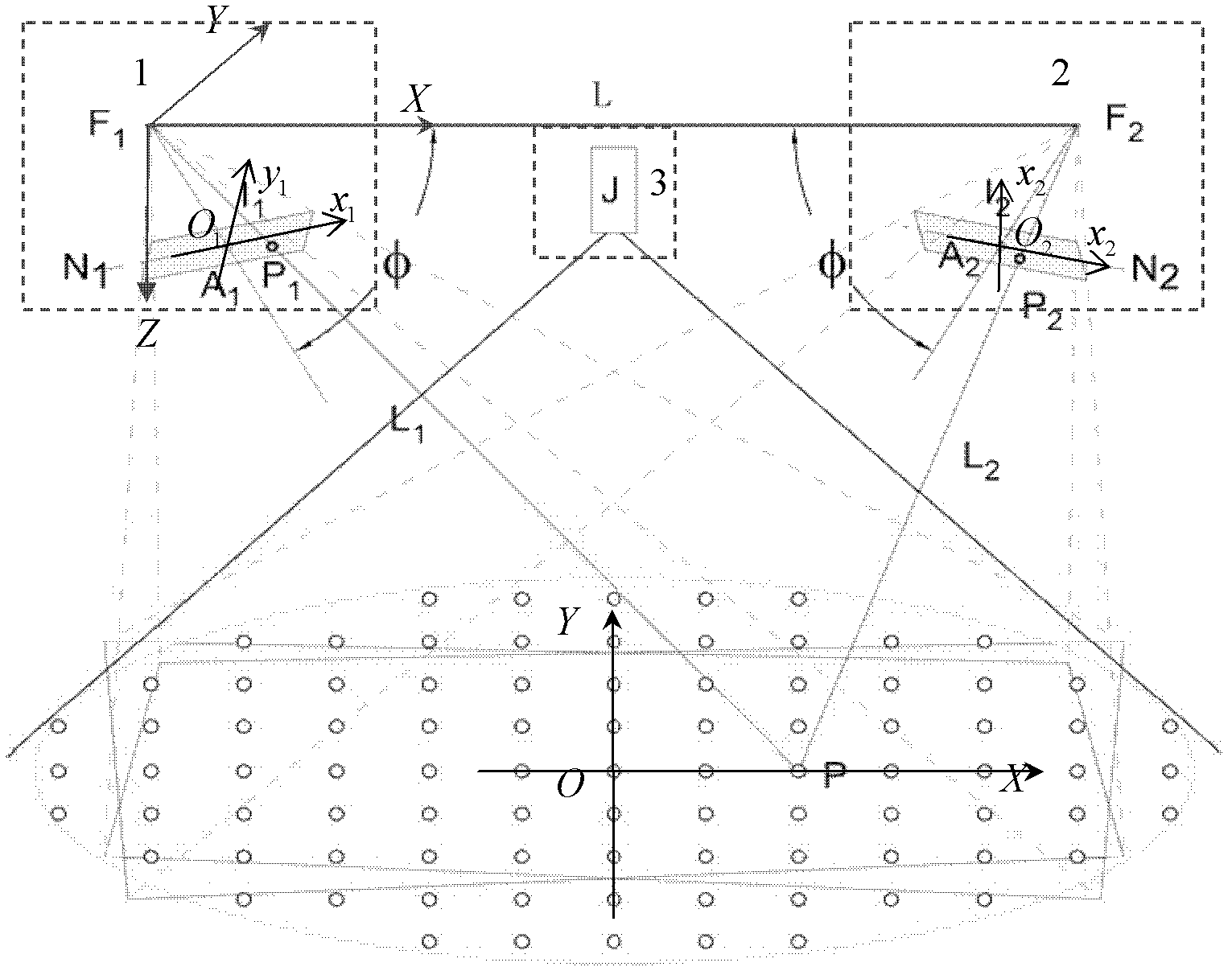

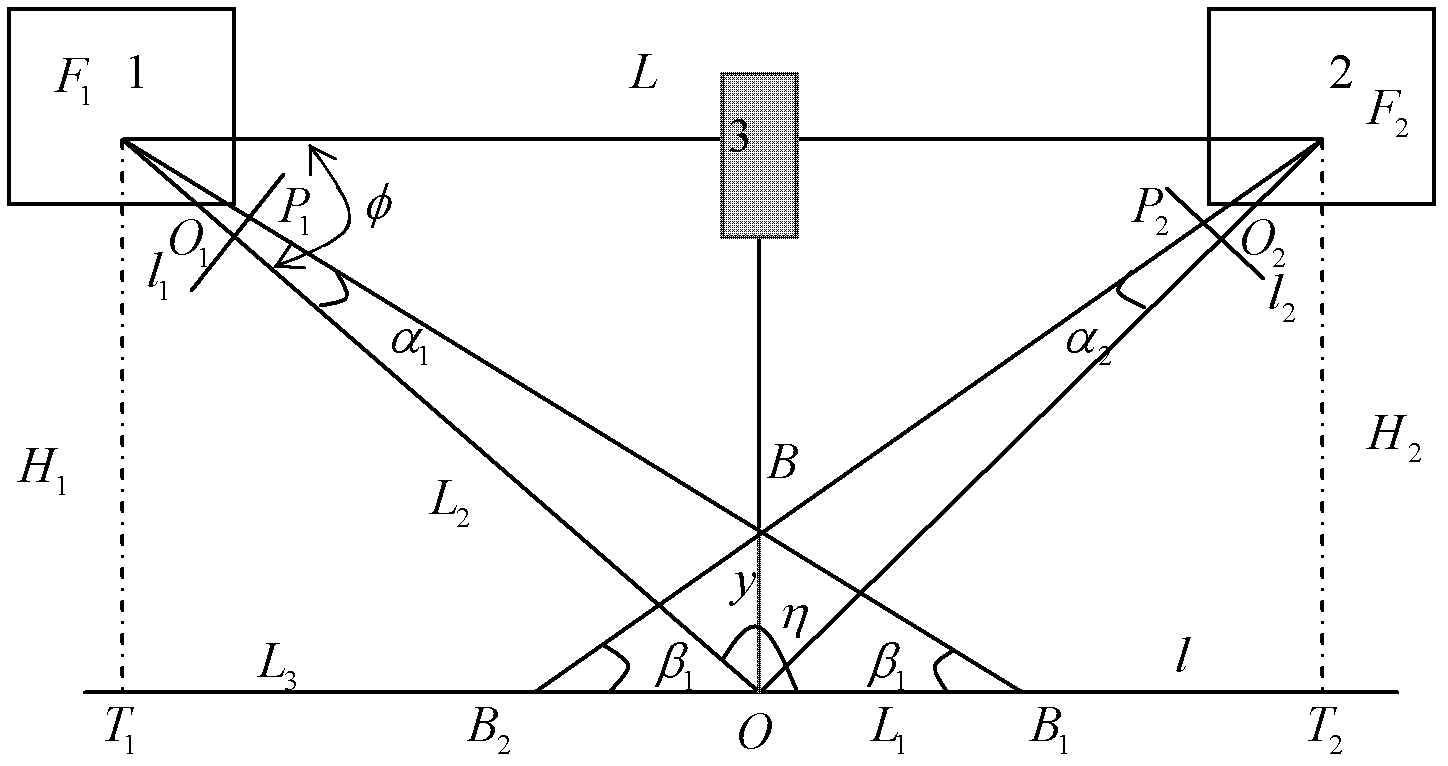

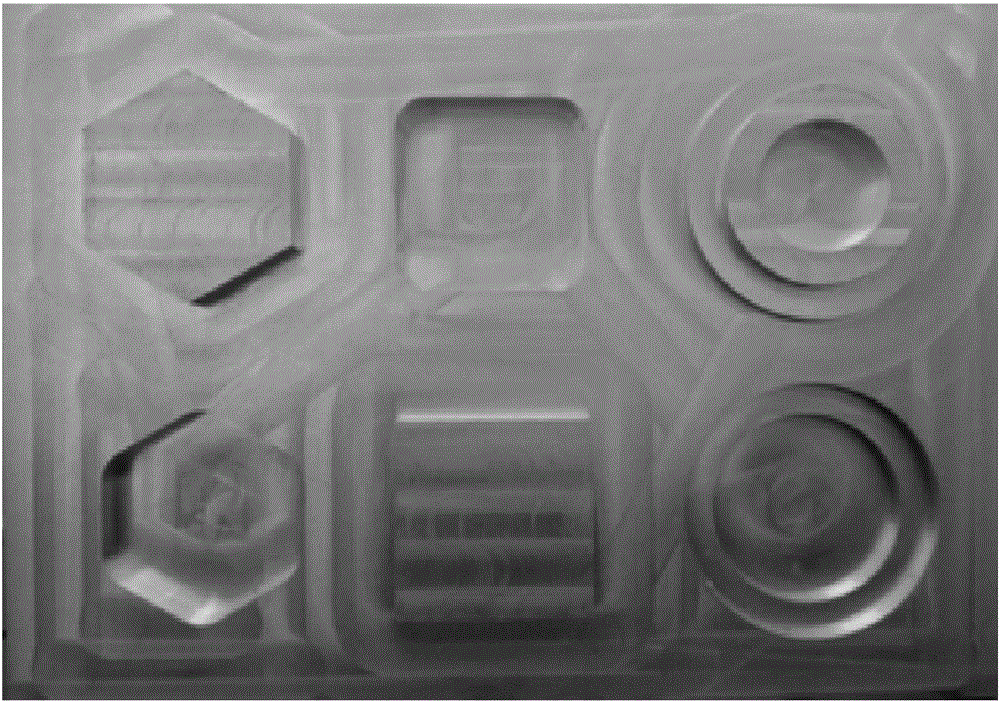

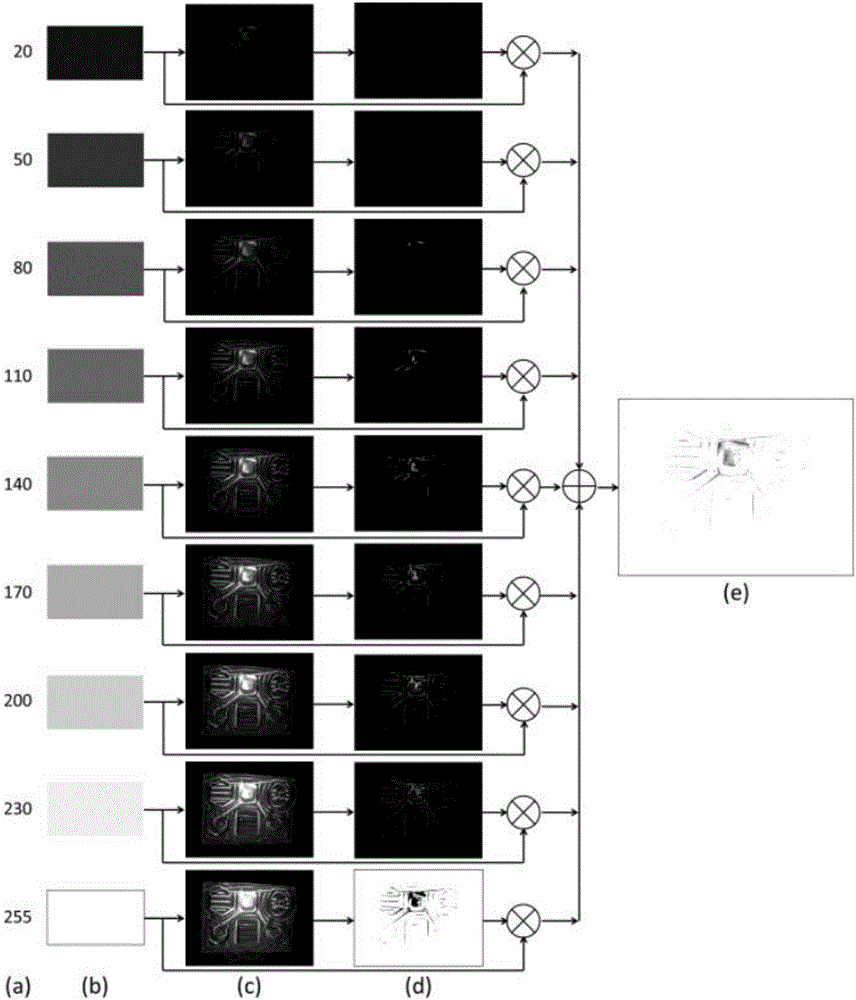

Stereoscopic vision detecting method for measuring three-dimensional morphology on strong reflection surface

InactiveCN101694375AGuaranteed measurement accuracySimple methodUsing optical meansThree dimensional morphologyStereo matching

A stereoscopic vision detecting method for measuring three-dimensional morphology on a strong reflection surface is provided. A traditional stereoscopic vision detecting method based on the sine stripe projection comprises steps of stripe projection, image collection, phase resolving, stereoscopic matching and three-dimensional recurrence, and the invention adds new technologies, such as bright-dark stripe projection, image collection in long exposure time, image synthesis within high dynamic range and the like in the steps of the strip projection and the image collection, which overcomes saturated or darker stripe images caused by the strong reflection surface, and can realize the non-contact optical measurement of three-dimensional morphology on the strong reflection surface such as metal. The detecting method has the characteristics of simpleness, flexibility and excellent reliability, and can be used for the optical non-contact measurement of three-dimensional morphology on the strong reflection surface such as metal.

Owner:BEIHANG UNIV

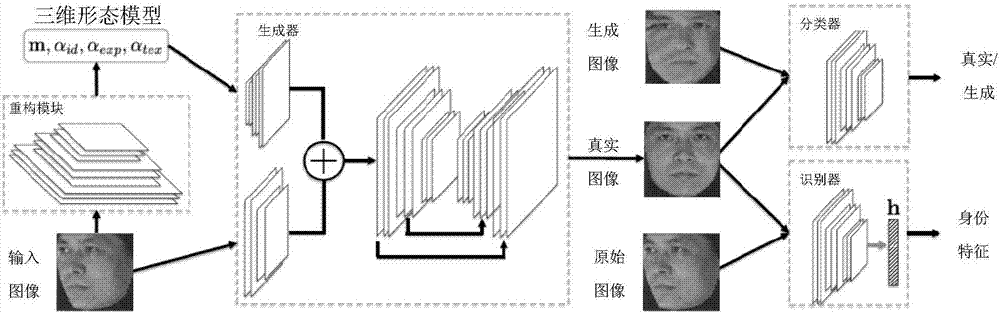

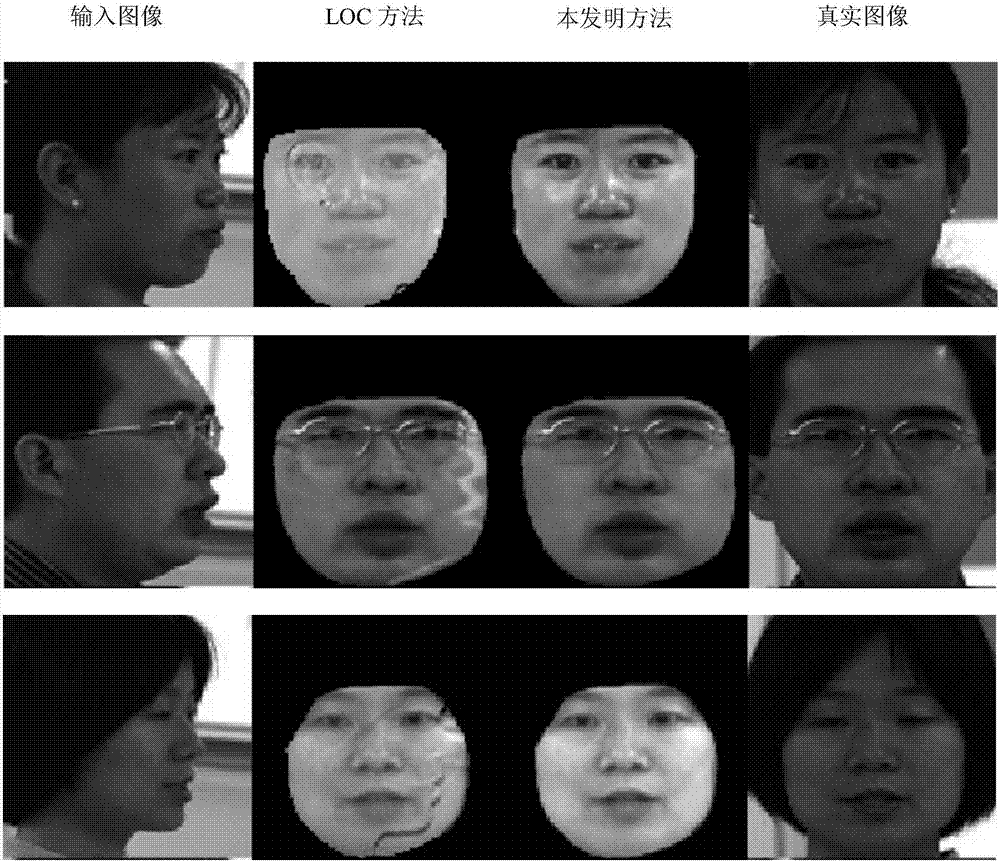

Large-amplitude face straightening method by means of adversarial network and three-dimensional morphological model

The invention provides a large-amplitude face straightening method by means of an adversarial network and a three-dimensional morphological model. The main content of the large-amplitude face straightening method by means of an adversarial network and a three-dimensional morphological model includes a reconstruction module, a generation network and classification module, and an identification module. The large-amplitude face straightening method by means of an adversarial network and a three-dimensional morphological model includes the steps: a generator generates a forward front face image by taking a non-forward front face image as input, and at the same time a classifier tries to determine whether the image is a real image and utilizes the fed back information to promote the image generated from the generator to be more close to the real image, and at the same time an identification engine is used to maintain the original identity characteristics in the input image. The large-amplitude face straightening method by means of an adversarial network and a three-dimensional morphological model can process the non forward face, especially a large-amplitude deflected face image, can provide a generation network and a morphological model to straighten the face, and can greatly improve the effect of face identification and straightening at the same time.

Owner:SHENZHEN WEITESHI TECH

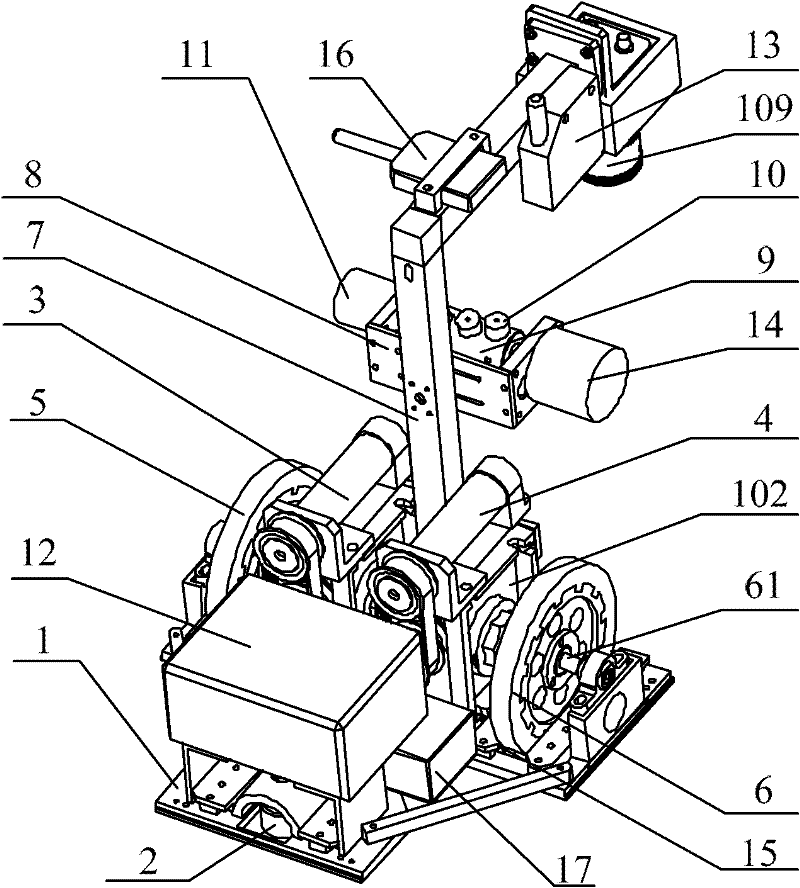

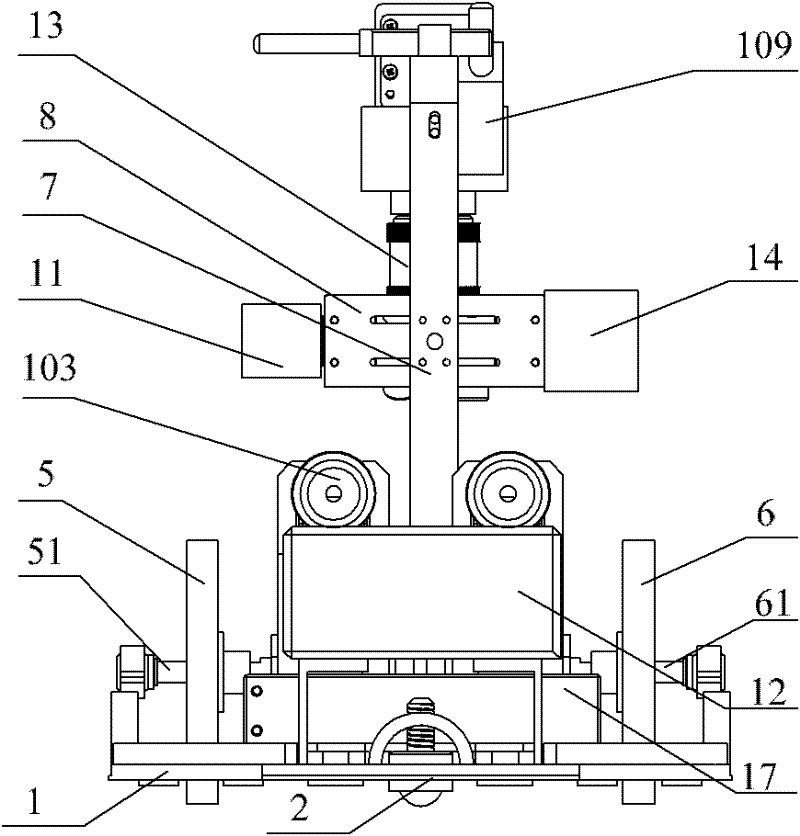

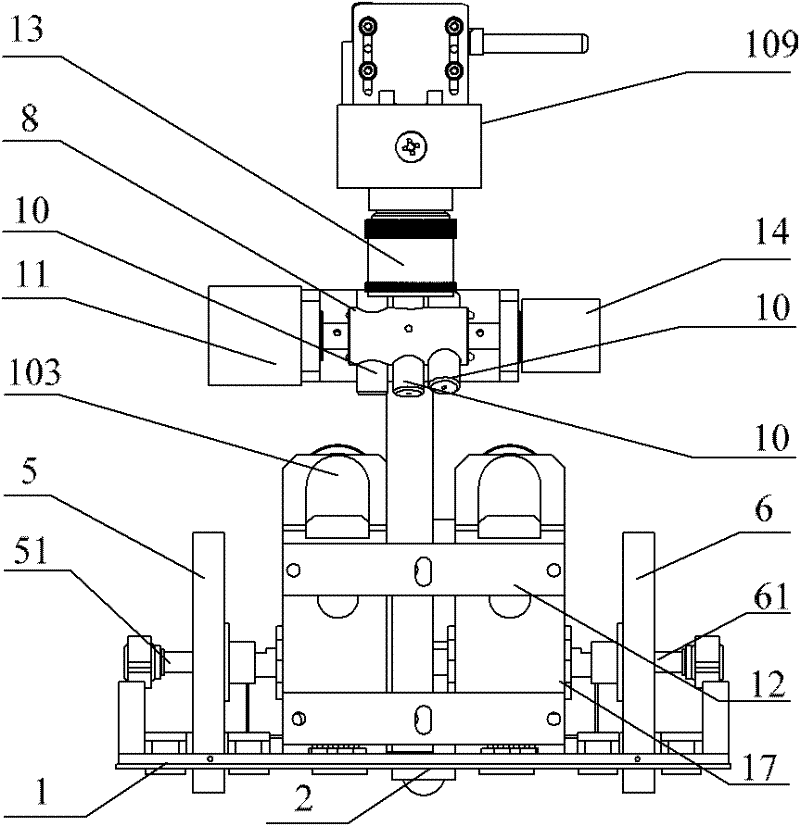

Gap magnetic adsorption type curved surface morphology detection robot and curved surface morphology measuring method

InactiveCN102221330AAdvantages and Notable ImprovementsFlexible movementUsing optical meansVehiclesMotor driveThree dimensional morphology

The invention provides a gap magnetic adsorption type curved surface morphology detection robot and a curved surface morphology measuring method, belonging to the mobile robot and machine vision measuring technology field. The robot comprises two driving wheels, a universal wheel, three motors, a straight line laser, a motor-drive circuit, a controller, a camera, an angle sensor, a permanent magnet body and like. By utilizing gap permanent magnetism adsorption principle and a curved surface adaptive scheme of arranging magnetic patch at the surrounding of the wheels symmetrically in a concentration way, that the robot is adsorbed on a magnetic conductive curved surface with different curvature and can move flexibly is realized. A plurality of straight line laser beams which are rotated to different angles are projected to a surface to be measured. The camera is used to shoot sequence image of the surface to be measured with laser stripes. Combined with distance detected by a laser range finder, three dimensional morphology of the surface is detected. Through a wireless video transmission module, video is transmitted to a host computer to display. The robot provided in the invention has the advantages of compact structure, flexible movement, and large adaptation curvature scope, and especially is suitable for all position three dimensional morphology detection of magnetic conductive curved surface workpiece in a narrow space.

Owner:WUXI RES INST OF APPLIED TECH TSINGHUA UNIV +1

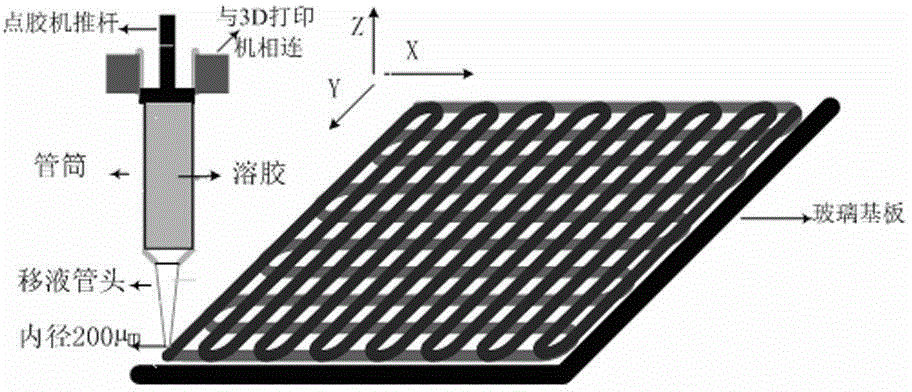

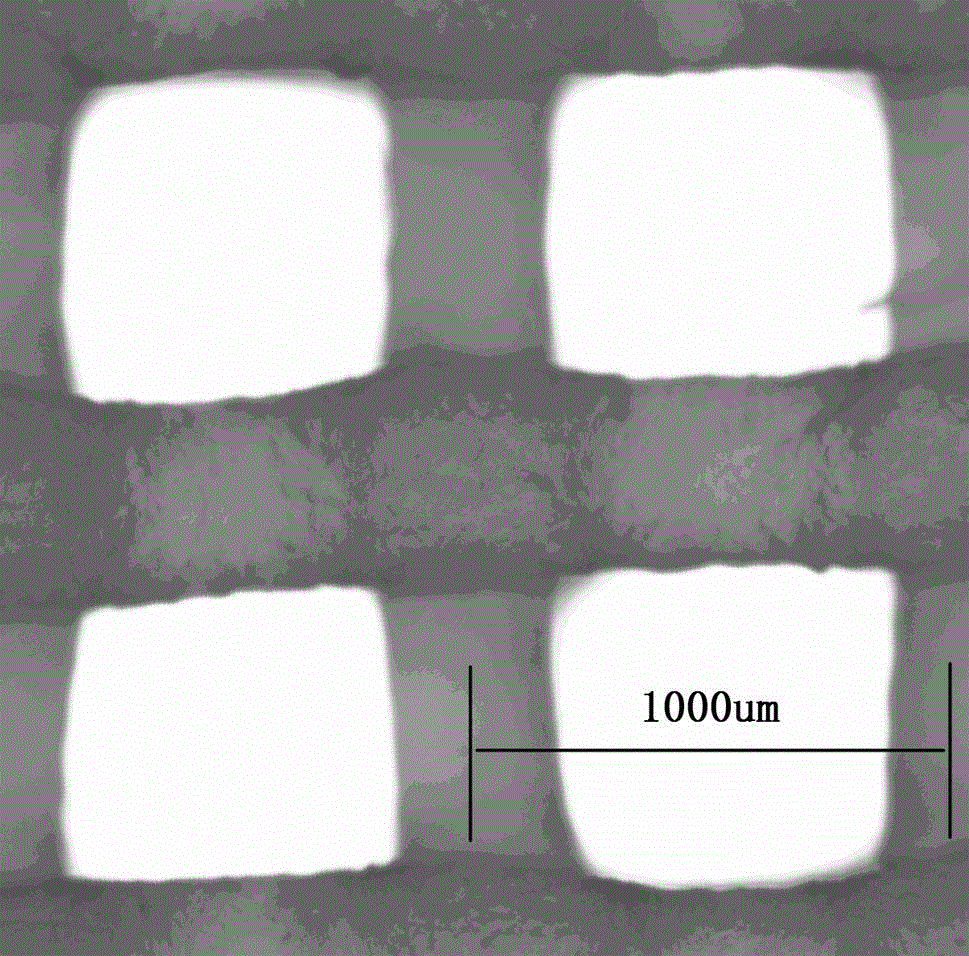

Method for preparing high-strength double-network hydrogel stent by virtue of 3D printing

InactiveCN104628936ANo collapseObvious collapse phenomenonAdditive manufacturing apparatusProsthesisCross-linkUltraviolet lights

The invention discloses a method for preparing a high-strength double-network hydrogel stent by virtue of 3D printing. The method comprises the following steps of adding a polymer monomer N, N-dimethyl acrylamide, an initiator, a crosslinking agent and sodium alginate (SA) into deionized water to form a solution and adding inorganic powder hydroxyapatite to obtain a sol; controlling and extruding the sol by a robot dispenser, and carrying out 3D printing molding to obtain a sol stent; placing the sol stent under ultraviolet light so that the monomer in the stent is subjected to photopolymerization and chemical cross-linking reaction to form a layer of chemically cross-linked network pre-molded hydrogel stent; immersing the pre-molded hydrogel stent into a CaCl2 aqueous solution so that SA in the stent is subjected to physical crosslinking to form a second layer of physically cross-linked network so as to obtain the hydrogel stent having physically and chemically cross-linked double-network. The hydrogel stent prepared by the method has higher mechanical strength and fine internal structure, and the three-dimensional morphology of the stent can be conveniently regulated and controlled to adapt to the complex application requirements of tissue engineering materials.

Owner:HUBEI UNIV OF TECH

Three-dimensional detection and welding seam inflection point identifying method for multilayer multiple welding seams of robot

ActiveCN107876970AGuaranteed accuracy requirementsEnsure real-time requirementsProgramme-controlled manipulatorLaser beam welding apparatusFeature vectorThree dimensional morphology

The invention discloses a three-dimensional morphology detection and welding seam inflection point identifying method for multilayer multiple welding seams of a robot. The three-dimensional detectionand welding seam inflection point identifying method comprises the following steps that 1, a camera, line structural light and the robot are calibrated; 2, a welding seam structure light image is obtained and processed; and 3, the three-dimensional spatial morphology of the multilayer multiple welding seams is obtained, and inflection point characteristics are identified, specifically, the processcomprises the following steps that 3.1, the eigenvector of a calculated hessian matrix during extraction of a center line is recorded; 3.2, according to the direction of the eigenvector, the threshold value of the eigenvector difference is set to identify inflection points of the multilayer multiple welding seams; and 3.3, according to model data calculated in the step 1, the sub-pixel coordinatevalue of the center line under a camera coordinate system is converted to be under a robot coordinate system and serves as the three-dimensional data of the welding seam surface for being used for robot welding. According to the three-dimensional detection and welding seam inflection point identifying method for the multilayer multiple welding seams of the robot, the precision is high, the reliability is high, and real-time performance is good.

Owner:ZHEJIANG UNIV OF TECH

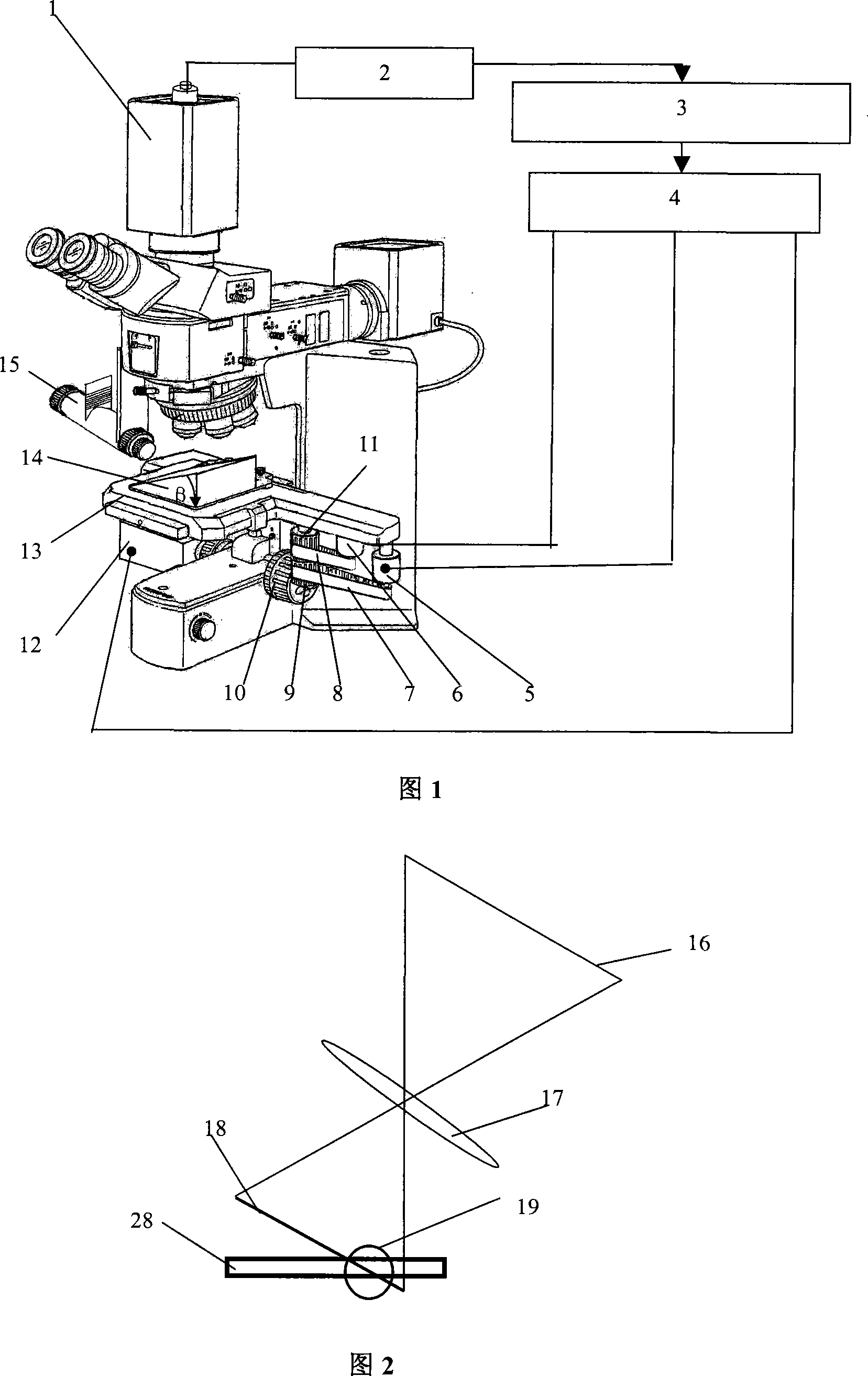

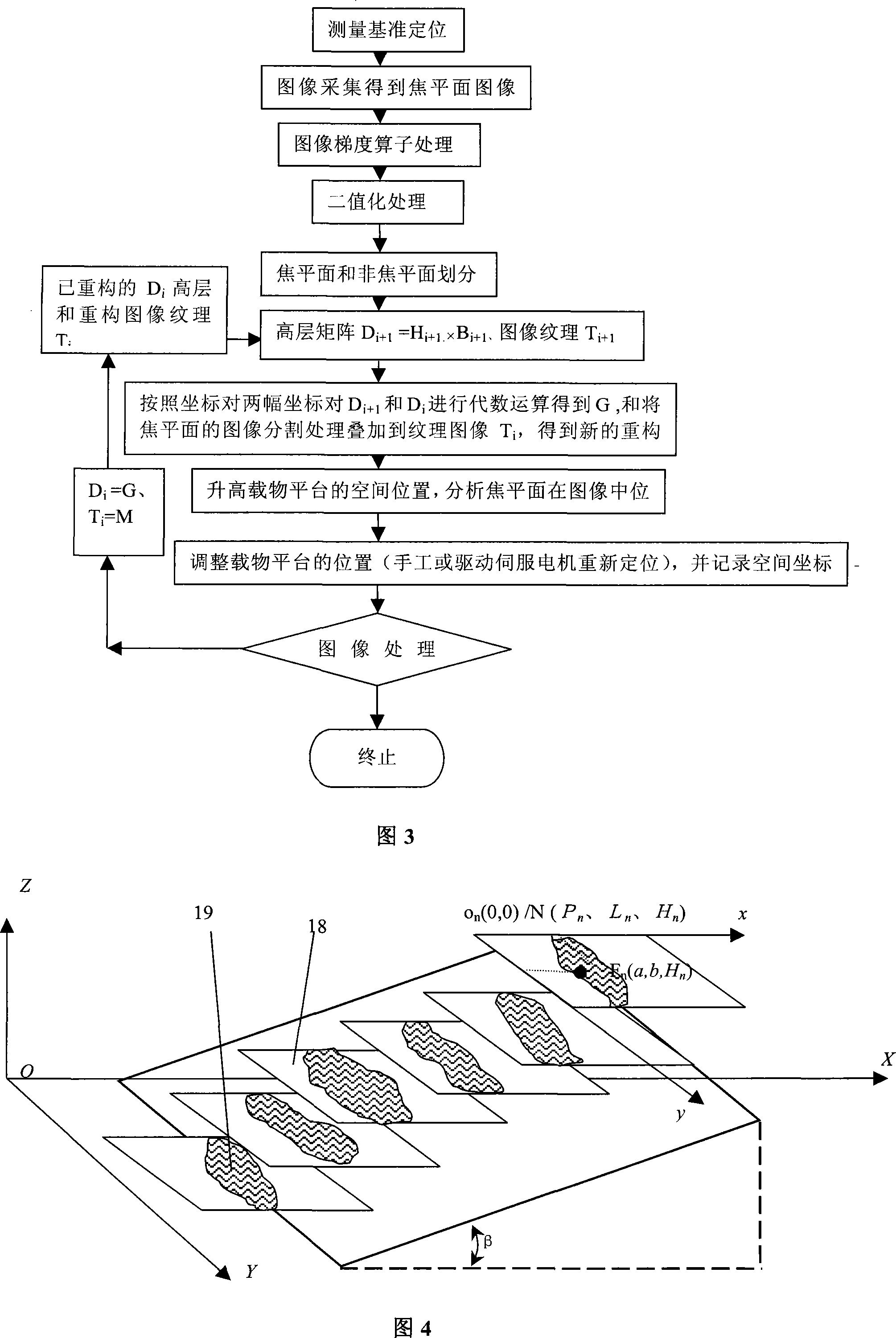

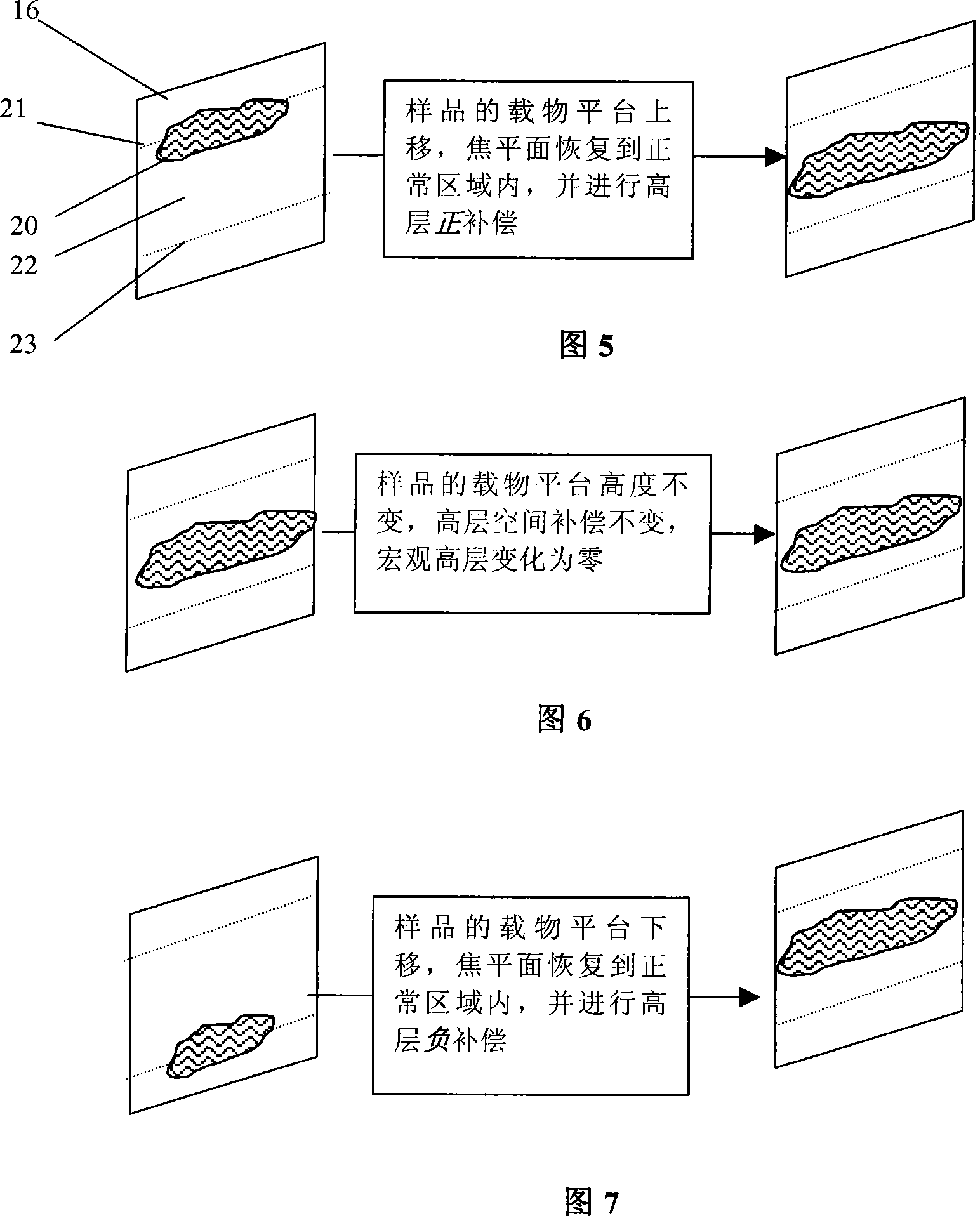

Three-dimensional microcosmic appearance inclined scanning method and apparatus

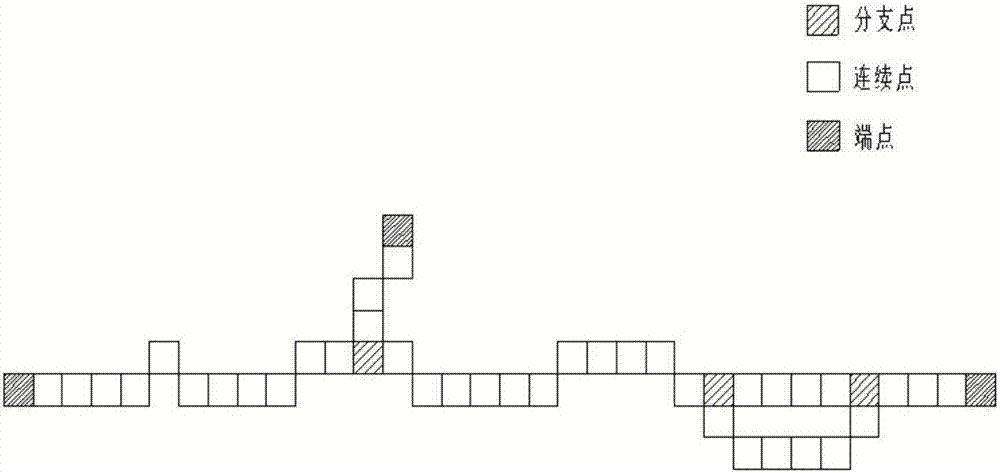

InactiveCN101226052AReduce scan timeSolve the slow scanning speedUsing optical means3D modellingThree dimensional morphologyDrift angle

The invention relates to a three-dimensional micro-morphology oblique scanning method and a corresponding device. The method is characterized in that the position of a focus object is adjusted by three stepping motors controlled by a computer, ensuring the object always at the central place in the oblique scanning and obtaining image texture and high-level information of the focus surface of the object, then obtaining a lager three-dimensional morphology image through synthesis and restructure. The device comprises the computer, a microscope and a camera (1); wherein, the camera is arranged on the microscope, an object-carrying platform (13) of the microscope is provided with an object-carrying wedge-shaped platform (14), the object-carrying wedge-shaped platform and a drift angle of the object-carrying platform forms a oblique focus surface when the drift angle Beta is 5 to 40 degrees, the three-dimensional movement space coordinate of the object and the image of the camera at the space coordinate are inputted to the computer at the same time, then restructuring the three-dimensional micro-morphology high-level and texture information on the basis. The three-dimensional micro-morphology oblique scanning method and a corresponding device has the advantages of avoiding useless work in non-focus area, reducing scanning time and improving scanning speed and efficiency.

Owner:武汉交通科技研究院有限责任公司

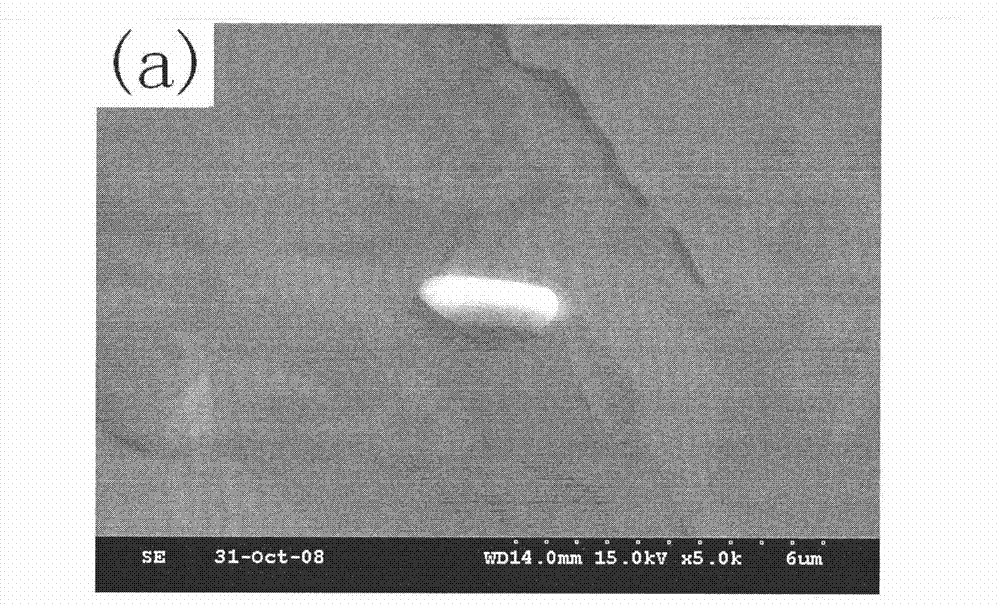

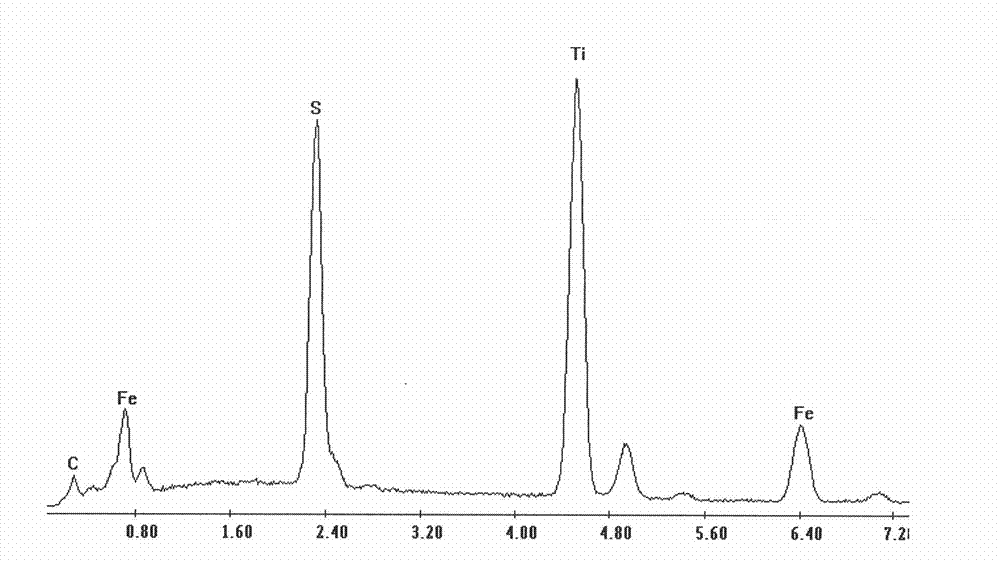

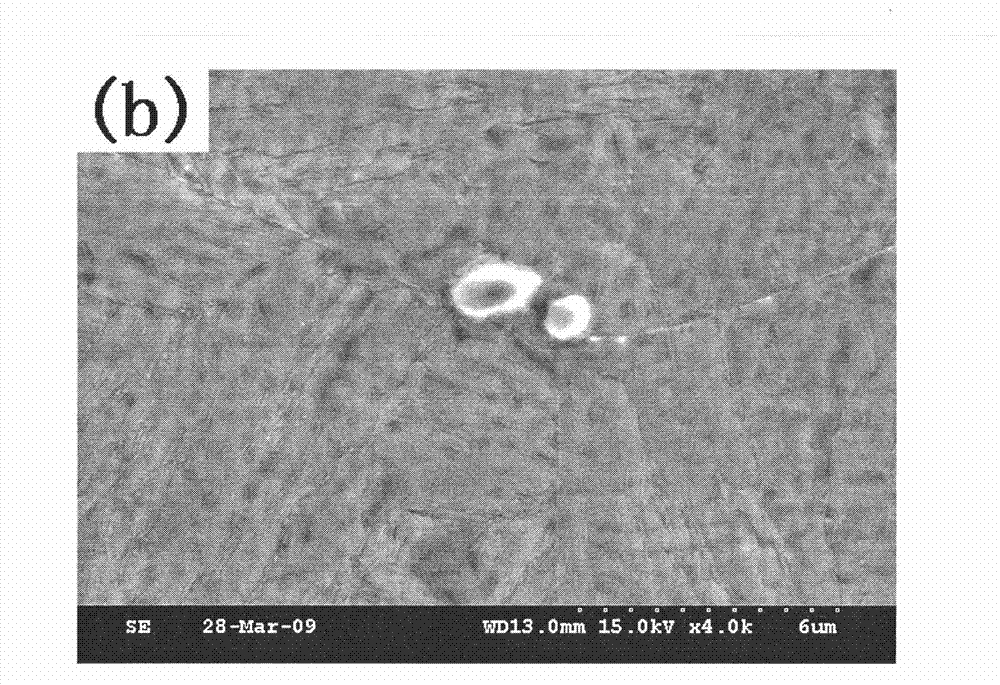

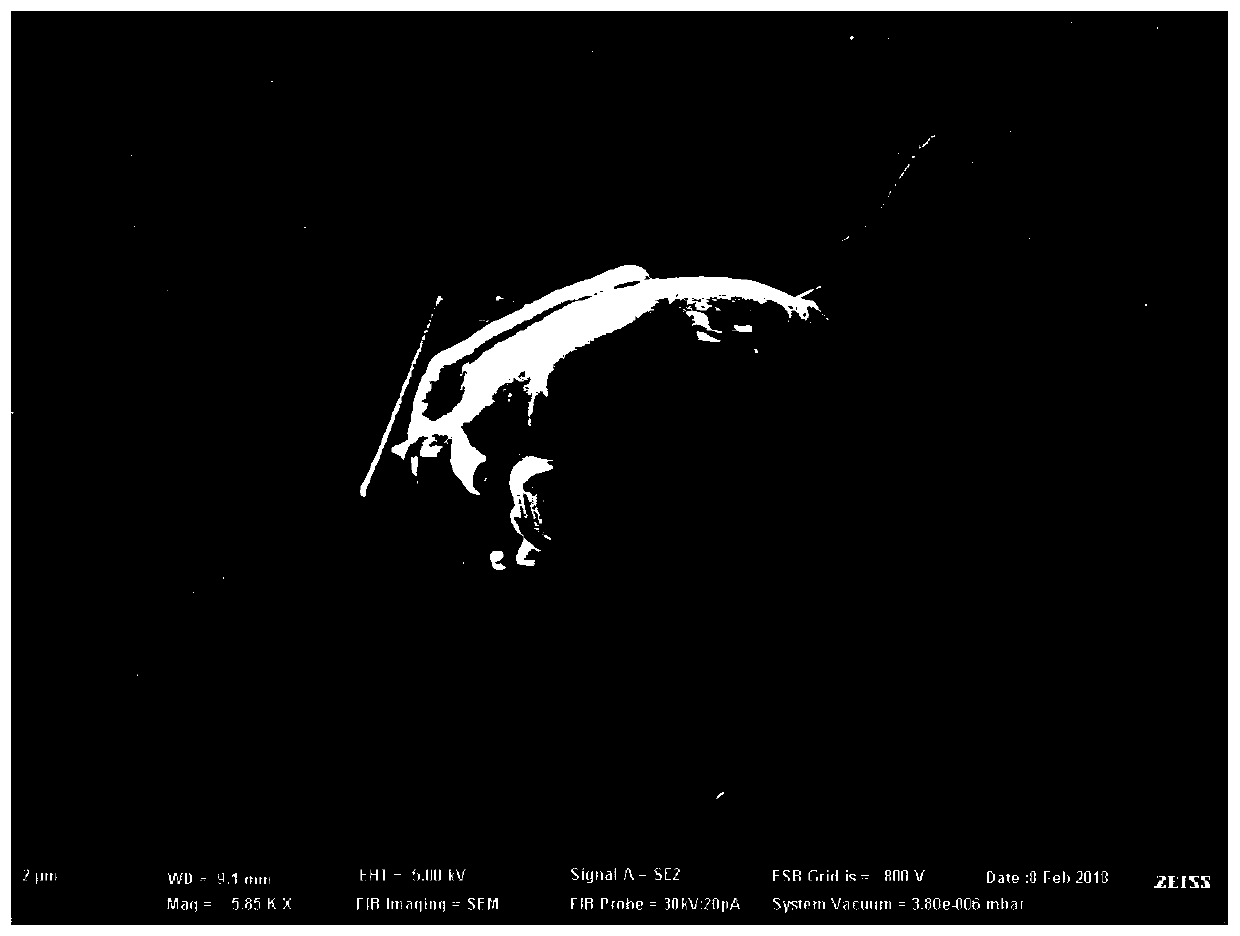

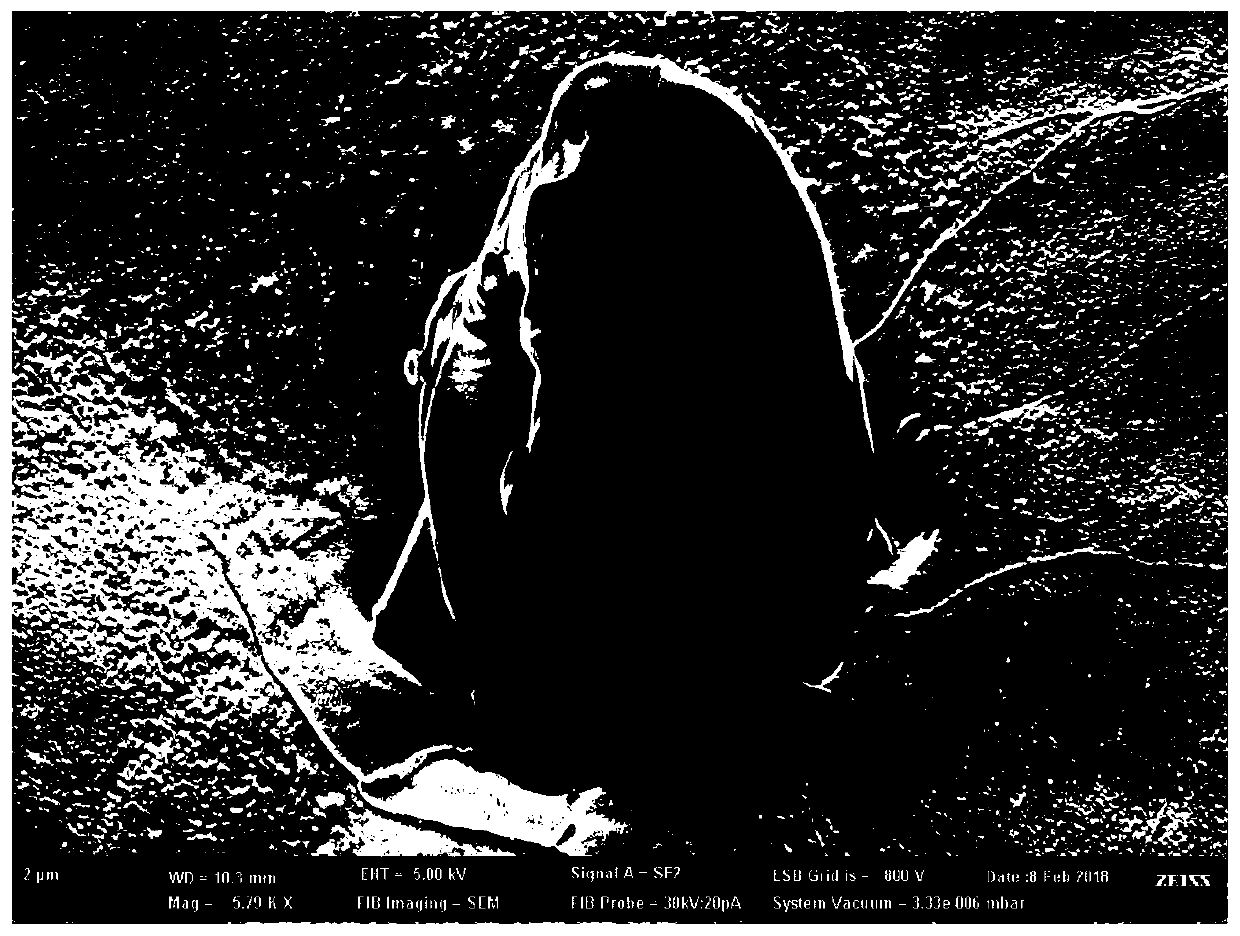

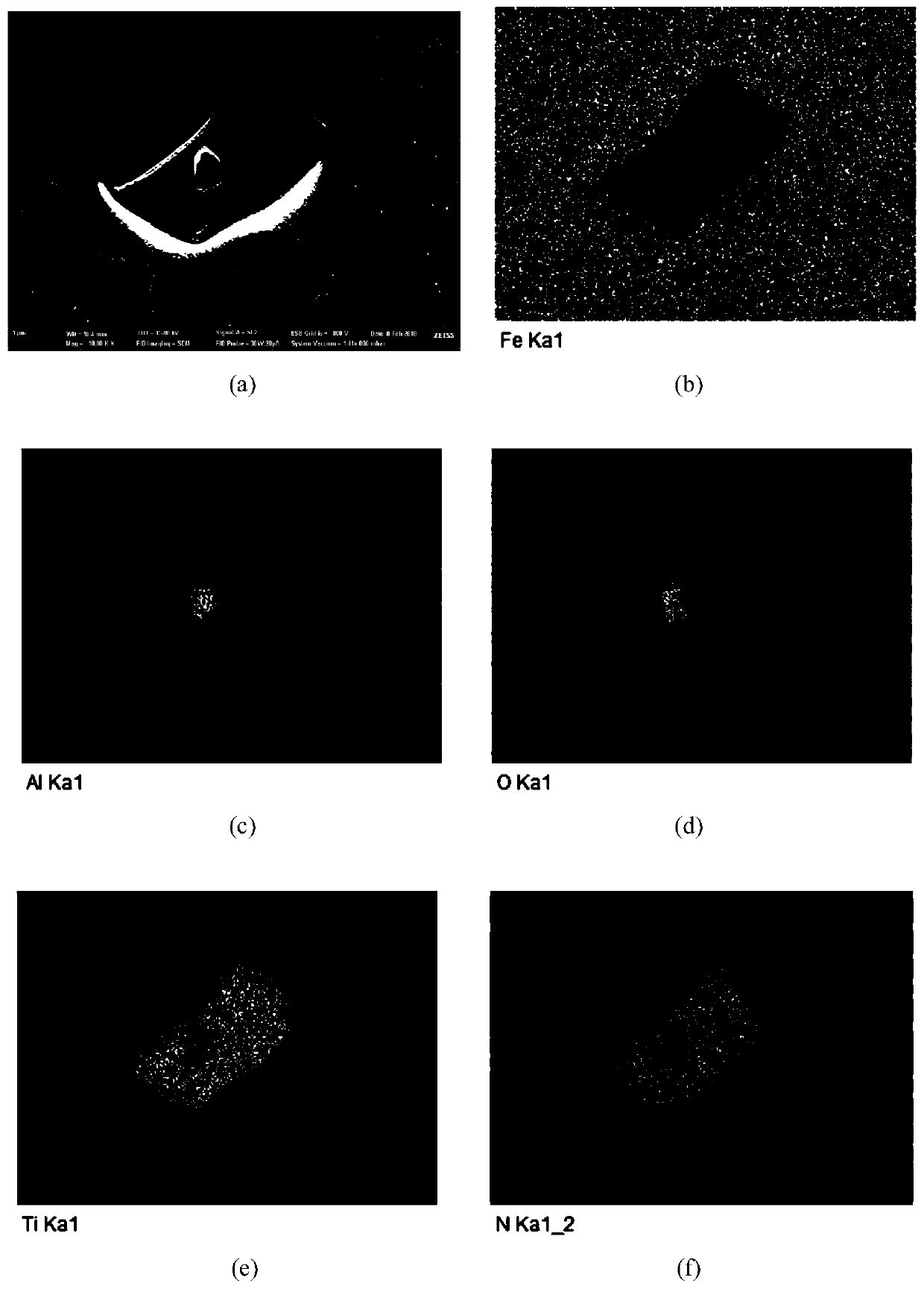

Method for observing in-situ morphologies of nonmetallic inclusions in steel

InactiveCN102879412ATrue form completeThe real shape is fully presentedPreparing sample for investigationMaterial analysis by measuring secondary emissionSpectroscopyGlycerol

The invention relates to a method for observing the in-situ morphologies of the nonmetallic inclusions in steel. The method is characterized by comprising the following steps: a metallographic specimen is prepared and a surface to be observed is polished to be a plane; the superficial electrolytic corrosion is performed on an electrochemical polishing apparatus, an electrolyte is as follows: 5% (v / v) HCl (hydrogen chloride)+5%(v / v) glycerol+1% (v / v) citric acid methanol solution, and the setup parameters of the electrochemical polishing apparatus are as follows: the current density is 0.02A to 0.10A / cm<2>, the electrolytic temperature is from below 15 DEG C to below 5 DEG C, and the electrolytic time is 20 to 40s; a rubber rod is utilized for slightly wiping off the corrosive products on an electrochemical polishing surface of a test sample after the electrochemical polishing, the surface of the test sample is dried by a blow drier, and the nonmetallic inclusions are highlighted on an electrolytic etched surface of the test sample, so that the true morphologies of the nonmetallic inclusions with the different dimensions are completely displayed; and the morphologies of the nonmetallic inclusions are observed by a scanning electron microscope and an energy disperse spectroscopy. The method for observing in-situ morphologies of nonmetallic inclusions in steel provided by the invention has the advantages that the sample is prepared simply, the period is short, the analysis speed is fast, and the constituents and the varieties of the nonmetallic inclusions can be determined accurately by observing the three-dimensional morphologies and dimensions of the nonmetallic inclusions.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

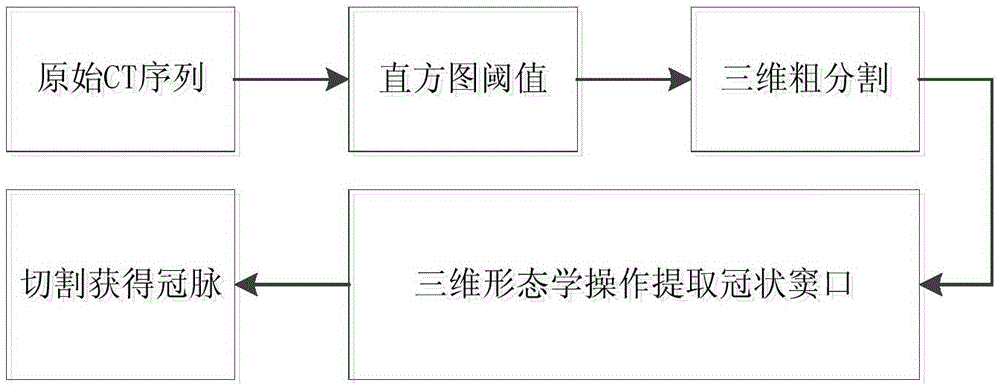

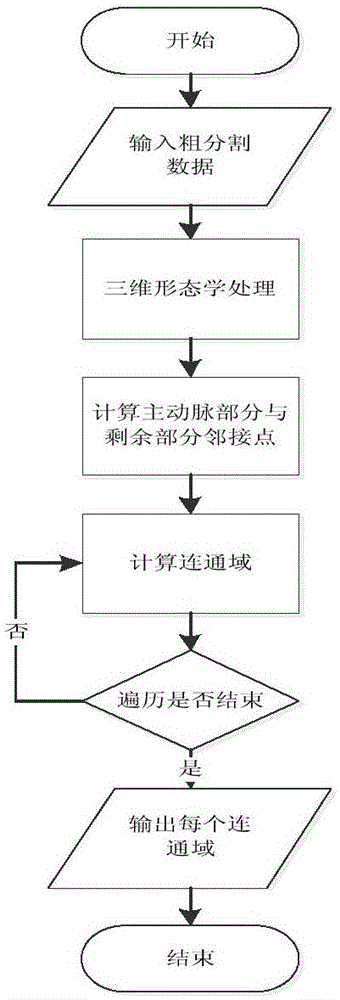

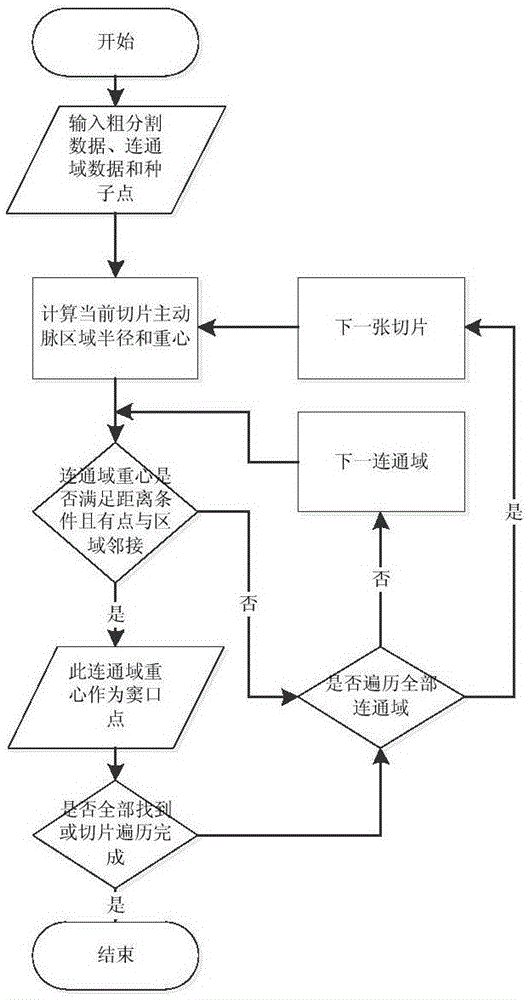

Coronary artery automatic extraction method based on three-dimensional morphology

The present invention discloses a coronary artery automatic extraction method based on three-dimensional morphology. The method comprises the steps of (S1) obtaining image data, sorting images orderly according to obtainment times, and carrying out histogram transformation on the sorted images, (S2) carrying out three-dimensional coarse segmentation on a transformed image, carrying out three-dimensional morphology processing on the gray scale value of a split coronary artery image, and obtaining a communication domain formed by neighbor points through calculating the neighbor points of an aorta area and a corroded area, and (S3) traversing all neighbor points, after execution is completed, outputting the communication domain of each neighbor point, executing the process of cutting a coronary artery image, searching the opening point of the coronary artery from the inputted three-dimensional coarse segmentation data and the communication domain data of all neighbor points, and completing cutting of the coronary artery image.

Owner:CHONGQING UNIV +1

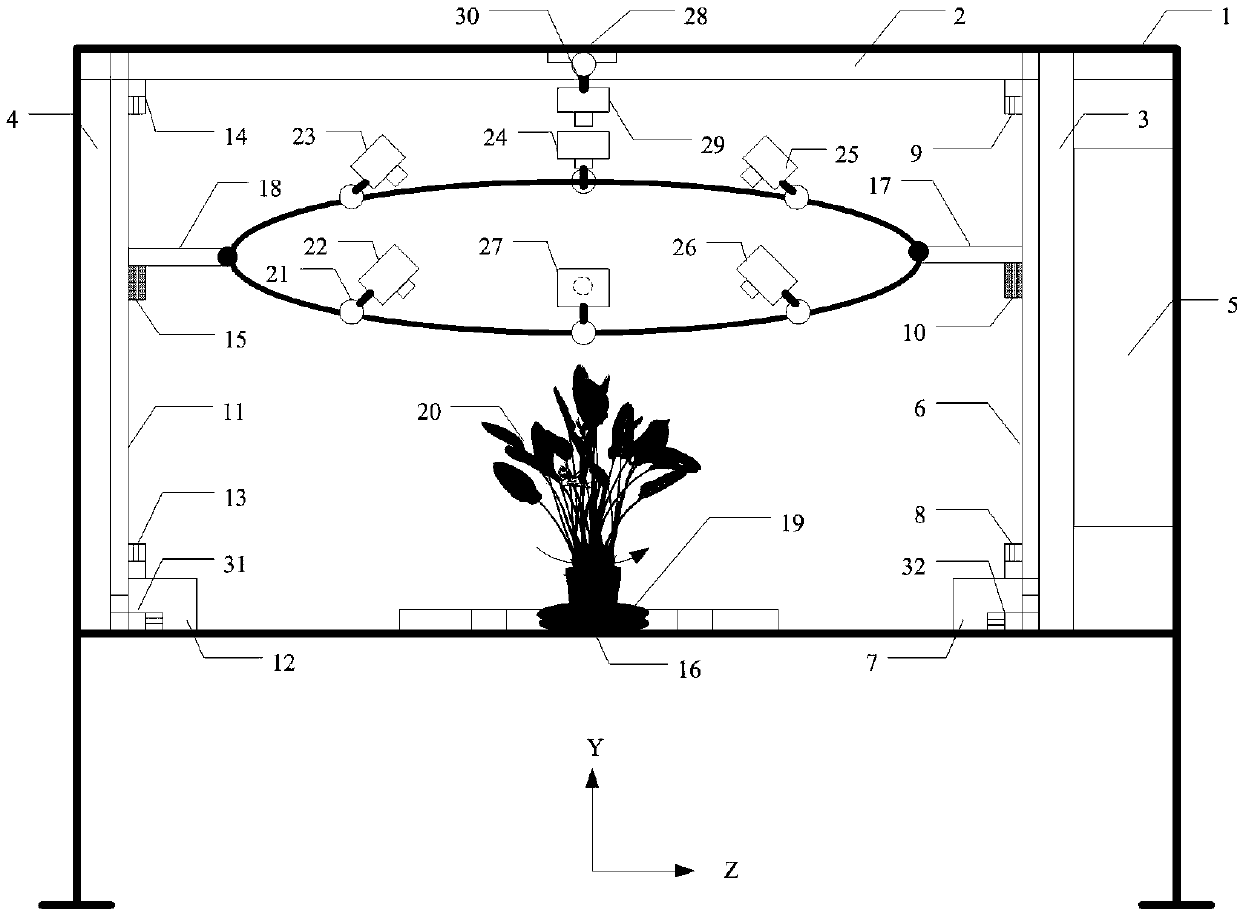

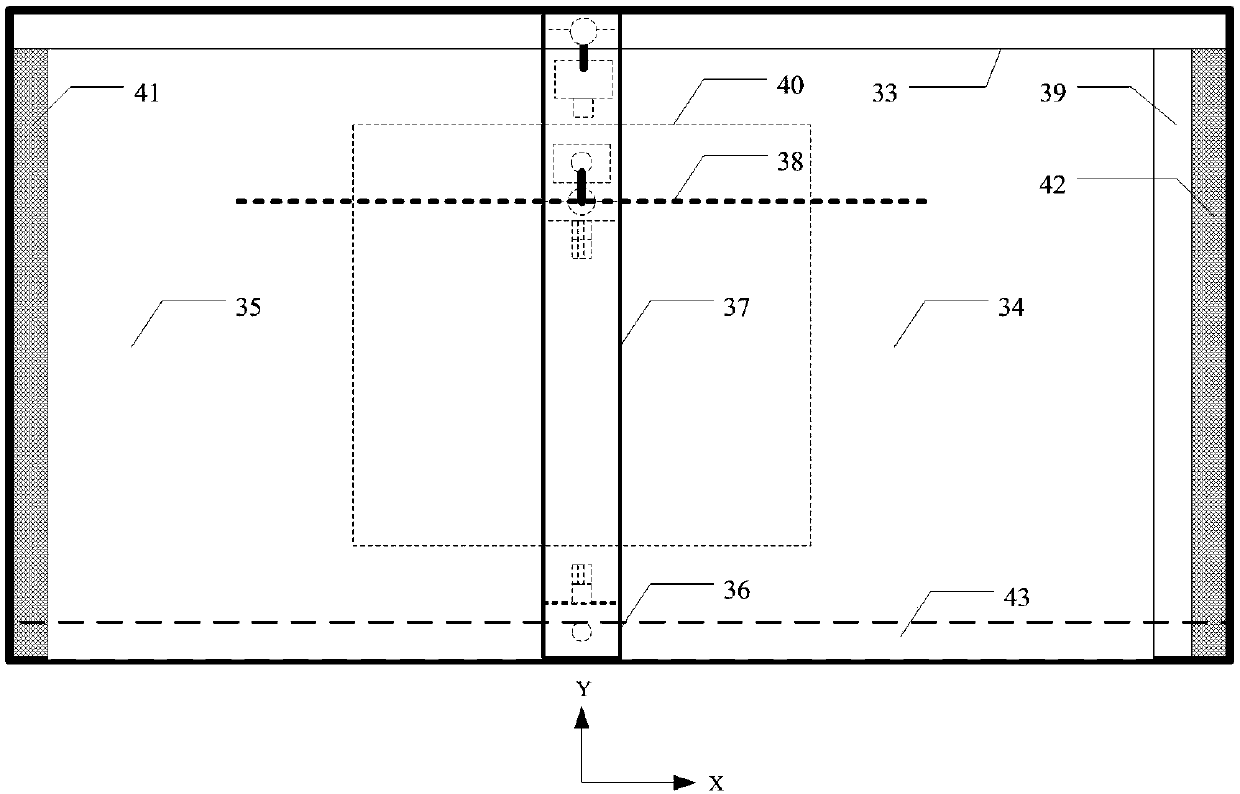

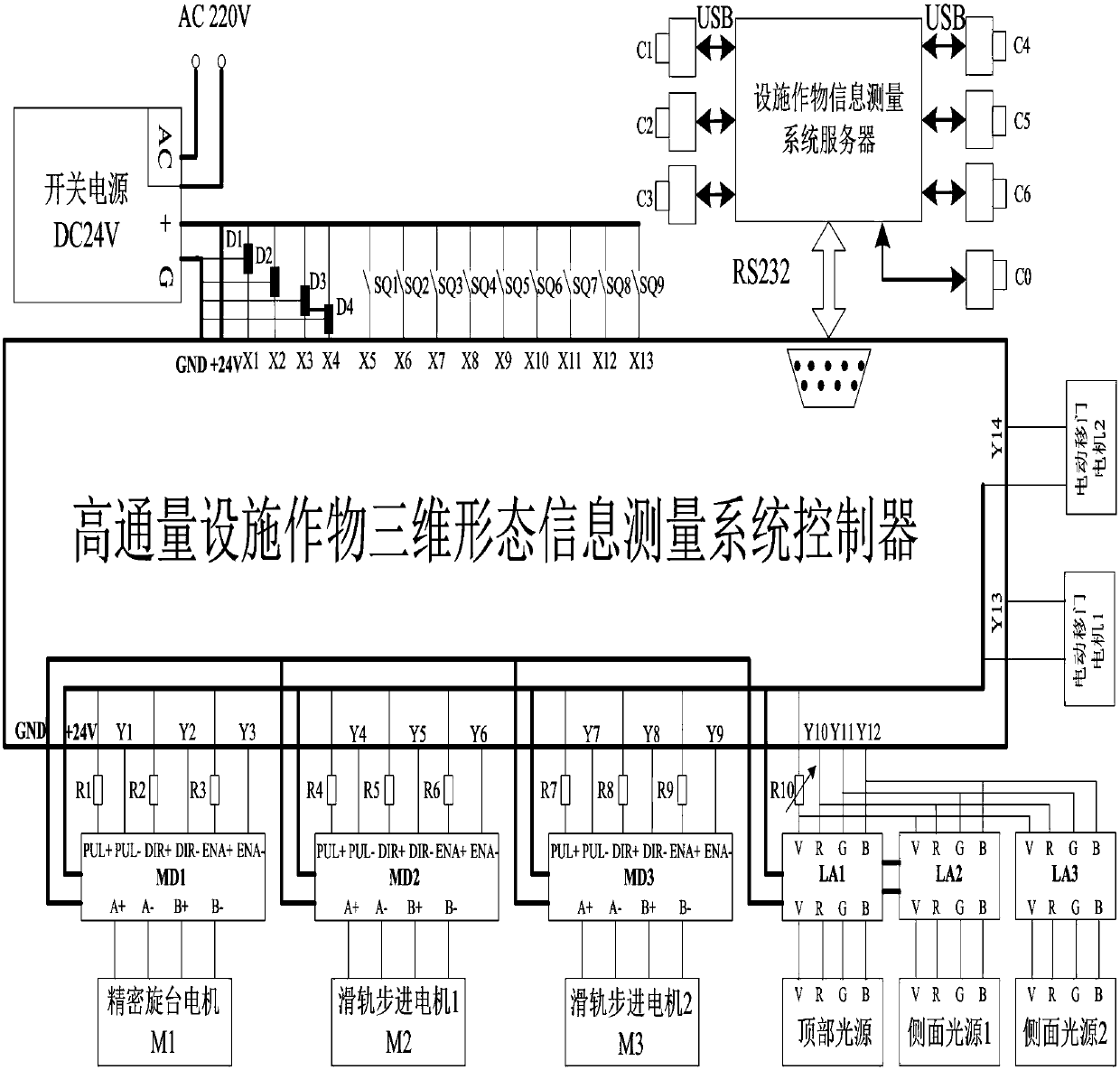

High-throughput facility crop three-dimensional morphology information measurement system based on space carving technique

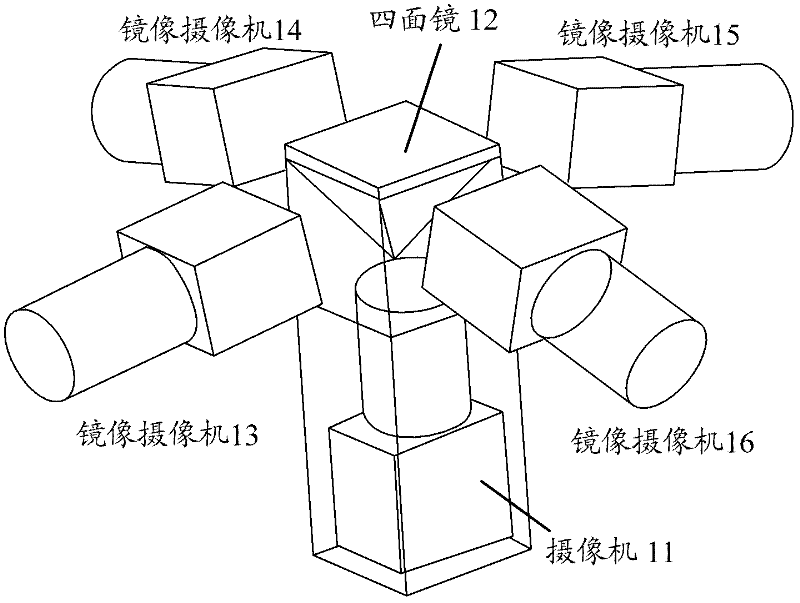

ActiveCN107869962AEnables high-speed imagingHigh measurement accuracyColor measuring devicesUsing optical meansEngineeringVision sensor

The invention discloses a high-throughput facility crop three-dimensional morphology information measurement system based on a space carving technique. The measurement system is characterized in thatthe system comprises a rectangular imaging chamber, the imaging chamber is made of aluminum profiles, six surfaces of the imaging chamber are closed, and an RGB (red, green and blue) LED (light-emitting diode) adjusting light source, a vision sensor, a precision rotating table, a sliding rail platform, a laser distance measuring sensor, a light screen sensor, an imaging system control cabinet, a server computer and crop three-dimensional morphology information measurement image processing software are mounted in the imaging chamber.

Owner:NANJING AGRICULTURAL UNIVERSITY

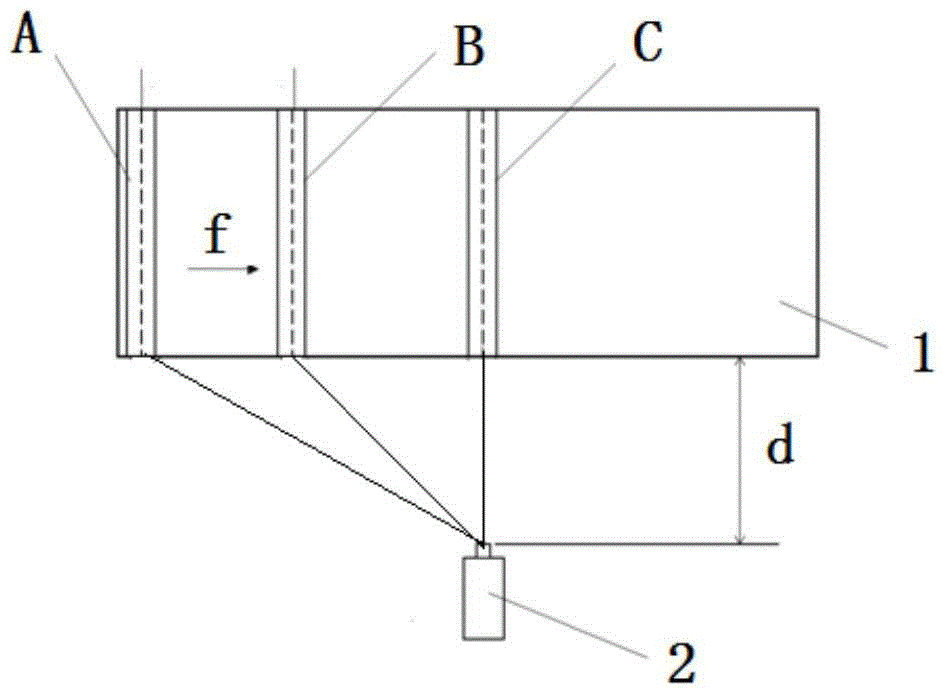

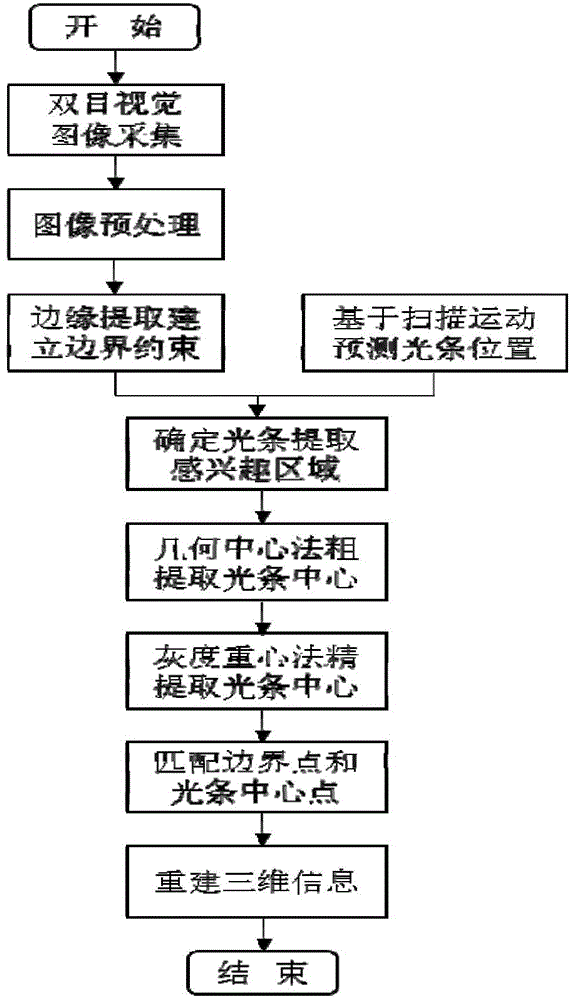

Binocular vision three-dimensional morphology measurement method based on time and space constraints

ActiveCN104930985AImprove measurement efficiencyHigh measurement accuracyUsing optical meansLaser scanningLaser light

The invention provides a binocular vision three-dimensional morphology measurement method based on time and space constraints, which belongs to the technical field of computer vision measurement. The binocular vision three-dimensional morphology measurement method based on time and space constraints is for the surface morphology of a large composite structure component, and uses a laser scanning binocular vision measurement system to carry out image acquisition and image processing. Edge information is extracted. The constraints are established. Time dimension information is combined to predict the position of a light strip. An appropriate interested extraction area is established. Laser light strip centers corresponding to left and right light stripe images are fast and accurately extracted. The light stripe center information in a boundary constraint is retained. The light stripe center information beyond the constraint is removed. The retained light strip center information and boundary information are matched and reconstructed. Ultimately, complete three-dimensional morphology information is restored. The method provided by the invention has the advantages of improved measurement efficiency, high measurement accuracy, complete detection information and fast operation speed, and can realize the three-dimensional morphology measurement of the surface of a large part.

Owner:DALIAN UNIV OF TECH

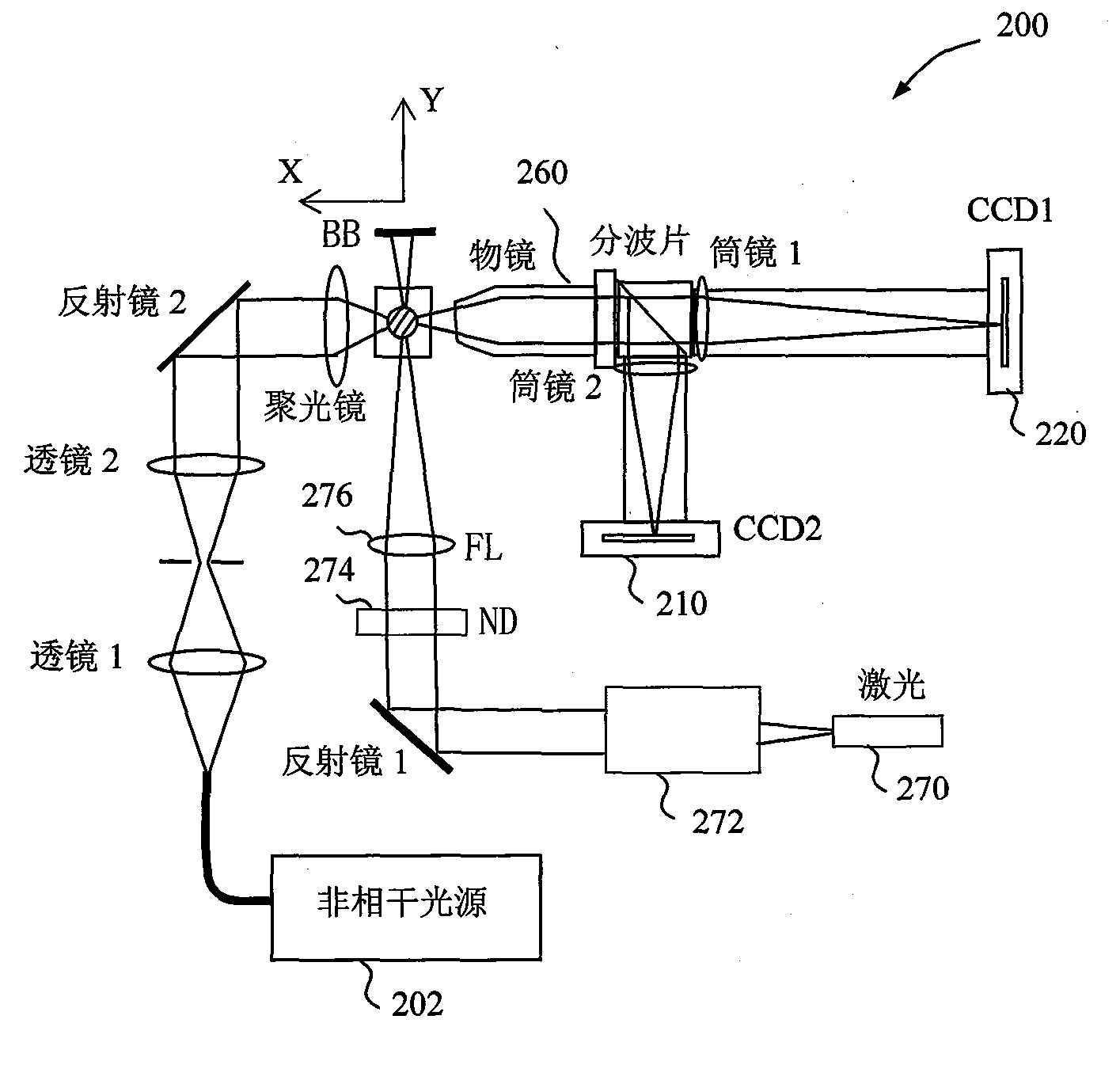

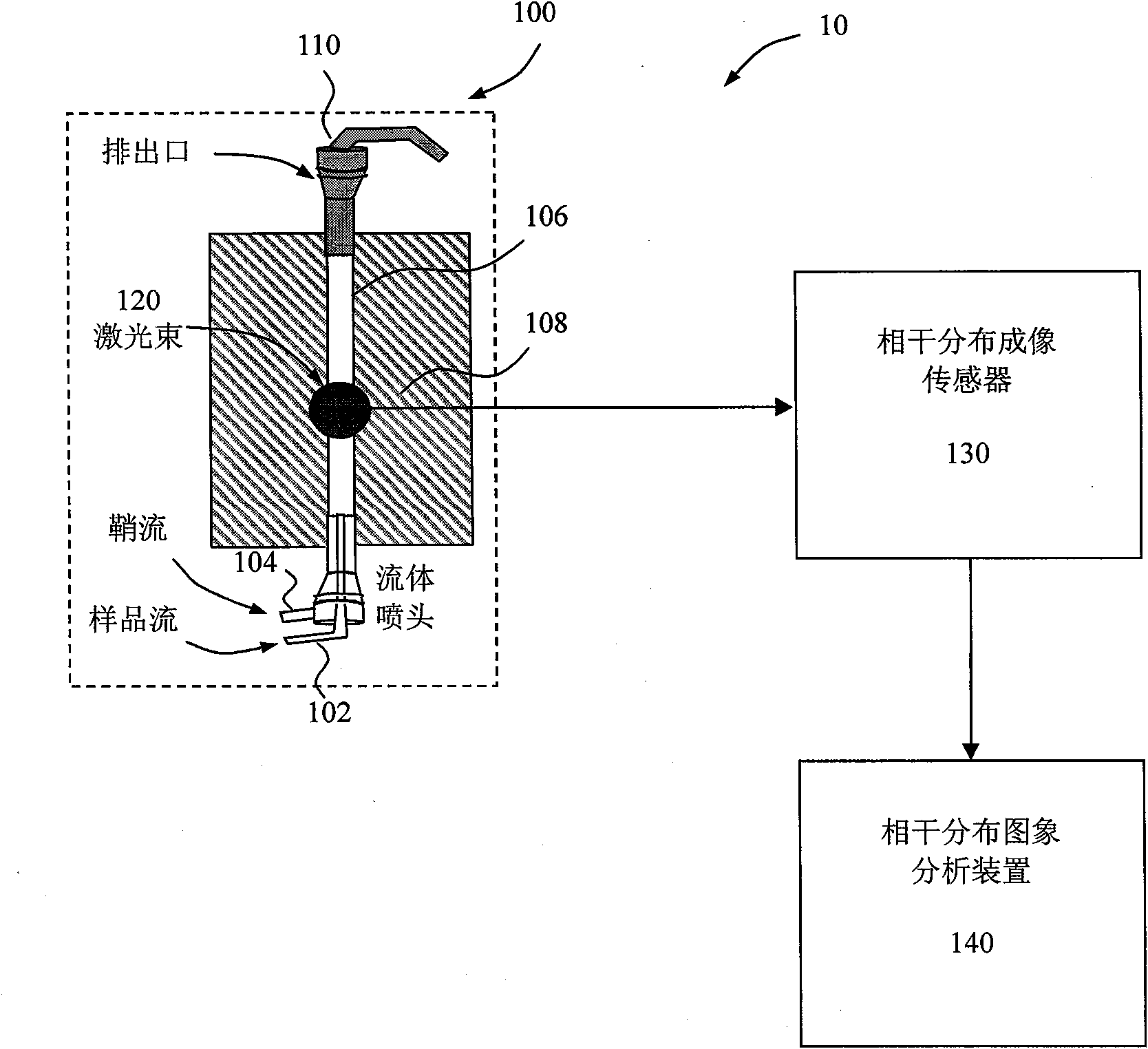

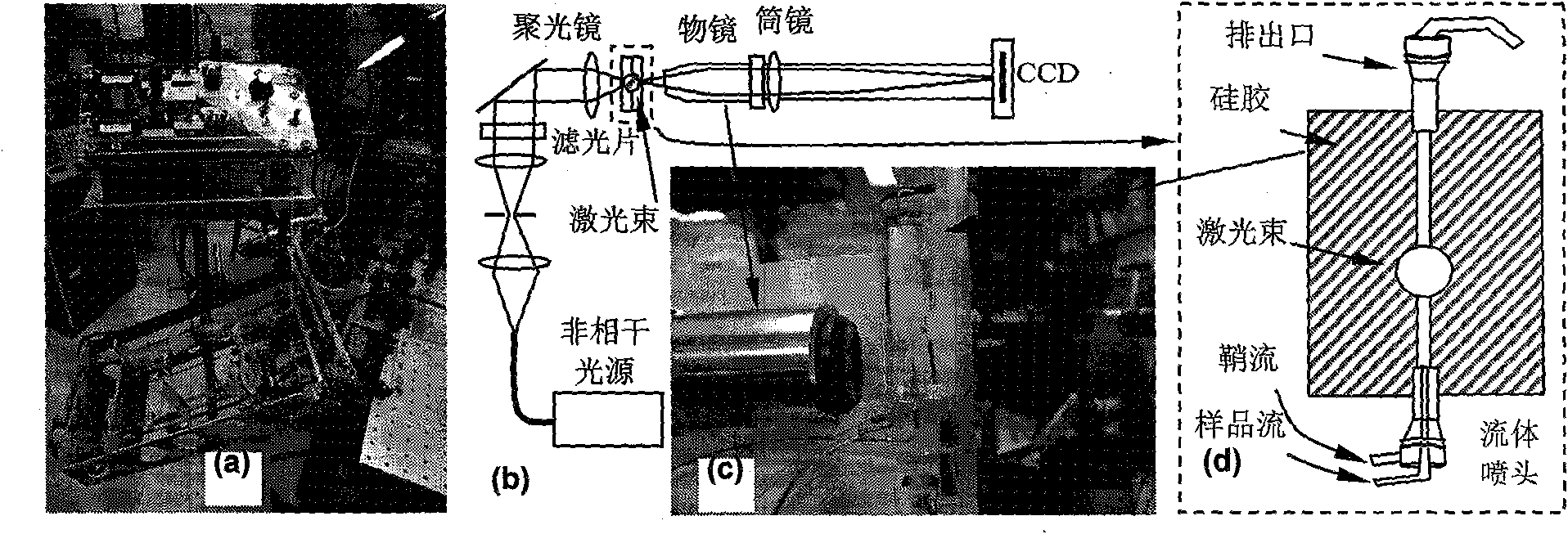

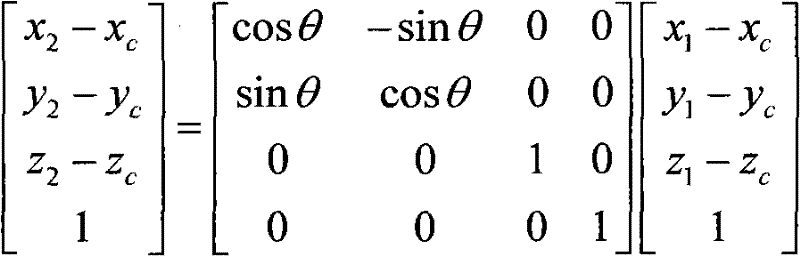

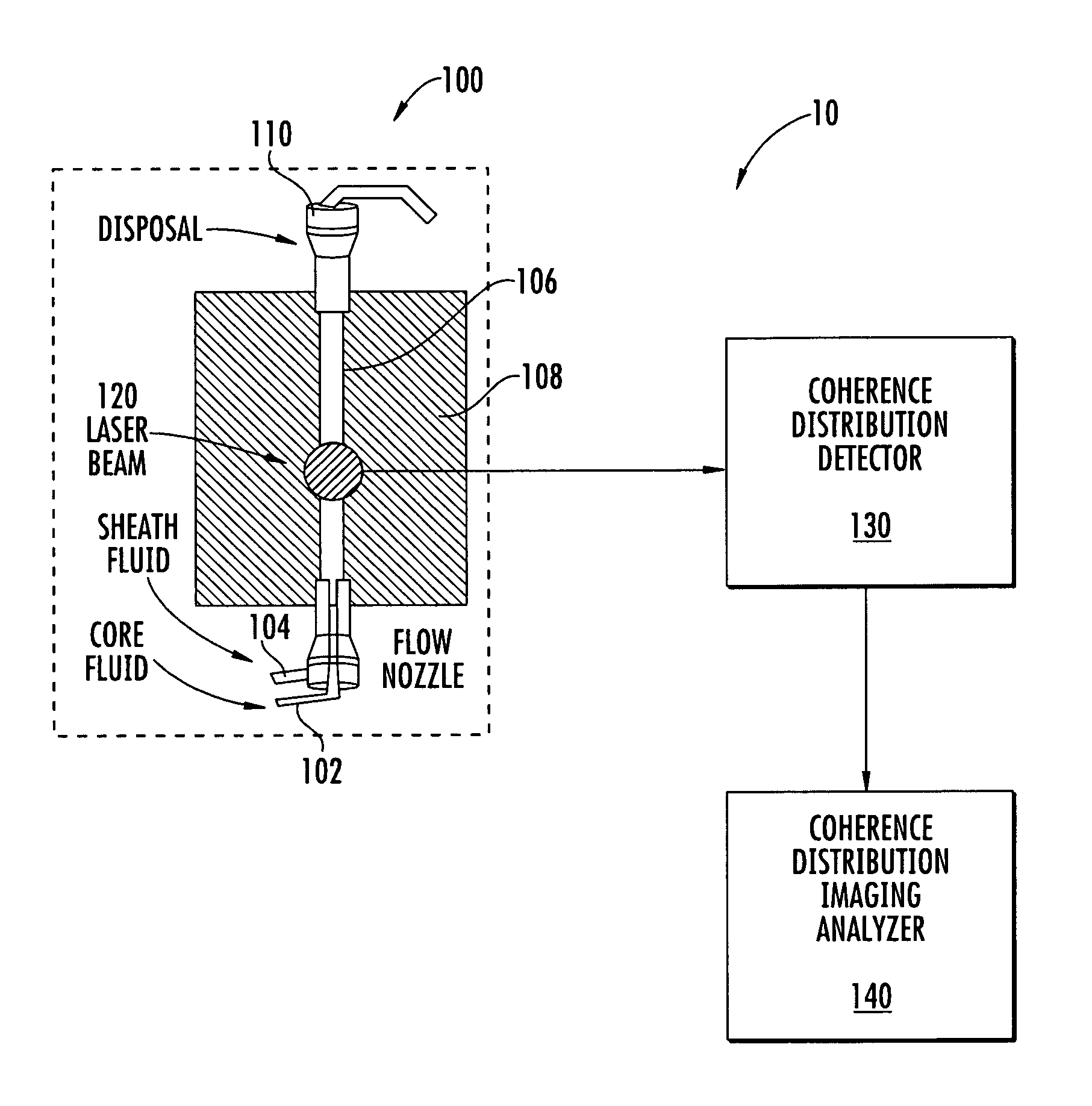

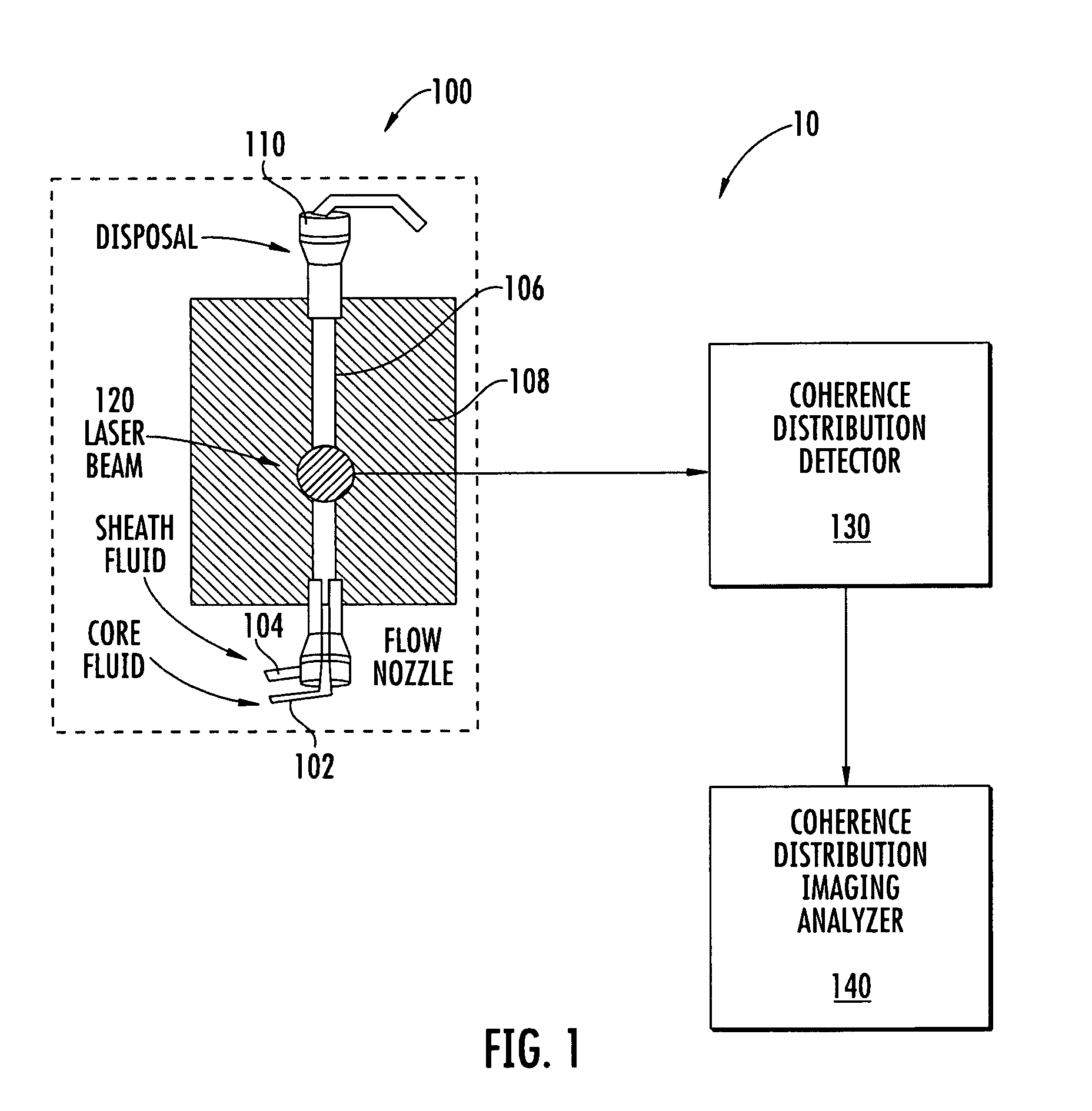

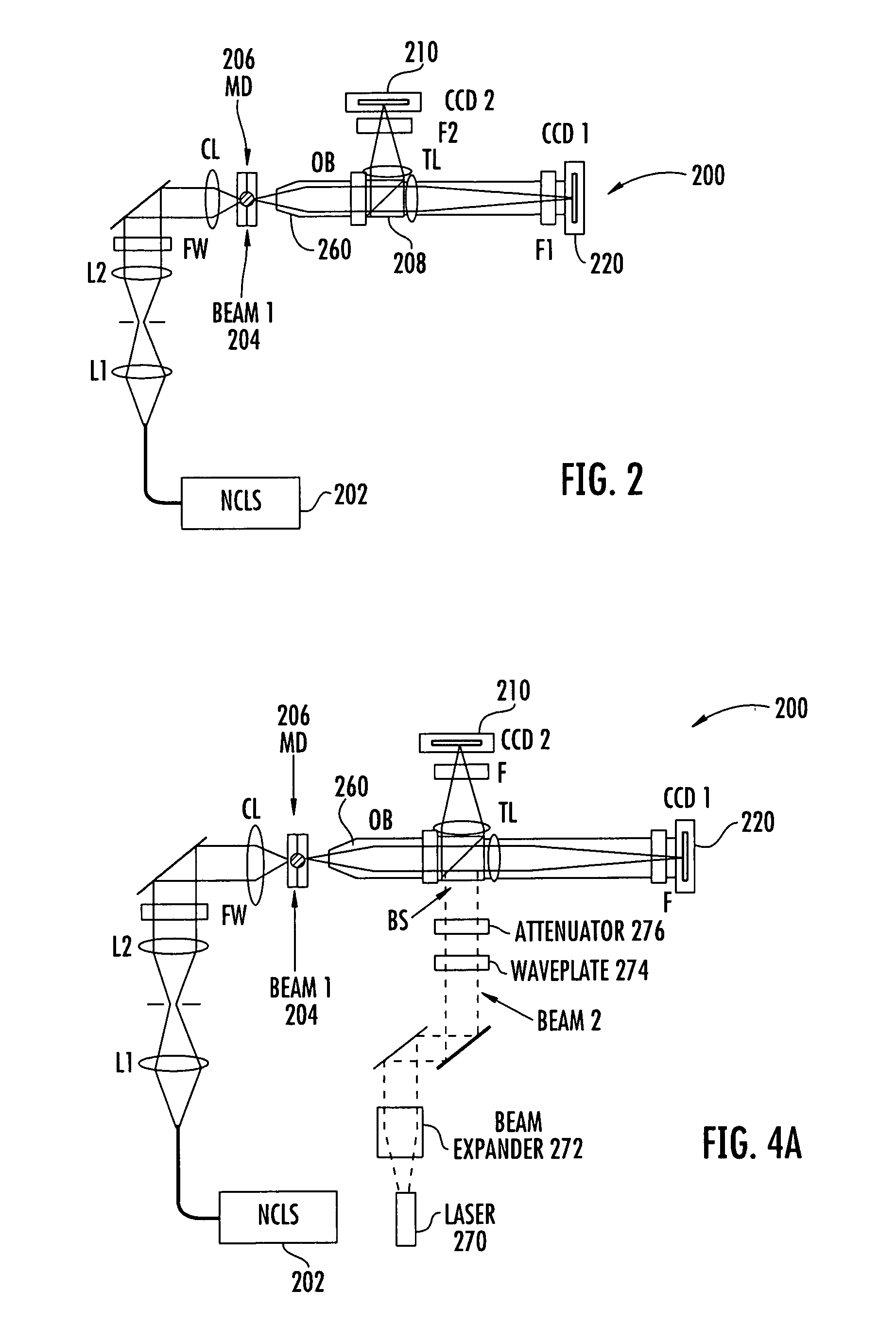

Flow cytometer apparatus for three dimensional diffraction imaging and related methods

The invention relates to a flow cytometer system for detection of three dimensional diffraction image and a method program product. The system includes a fluid controller configured to form a hydrodynamically focused flow stream including an outer sheath fluid and an inner core fluid; a coherent light source configured to illuminate a particle in the inner core fluid; a detector configured to detect a spatially coherent distribution of elastically scattered light from the particle excited by the coherent light source; an analyzing module configured to extract a three-dimensional morphology parameter of the particle from a spatially coherent distribution of the elastically scattered light. The method includes forming the hydrodynamically focused flow stream including the outer sheath fluid and the inner core fluid; illuminating one particle in the inner core fluid with the coherent light source; elastically detecting scattered light from the particle that is excited by the coherent light source; and extracting a three-dimensional morphology parameter of the particle from a spatially coherent distribution of the elastically scattered light. According to the invention, it is possible to perform single-particle analysis to a polulation containing a plurality of particles in a multi-dimensional feature space.

Owner:EAST CAROLINA UNIVERISTY

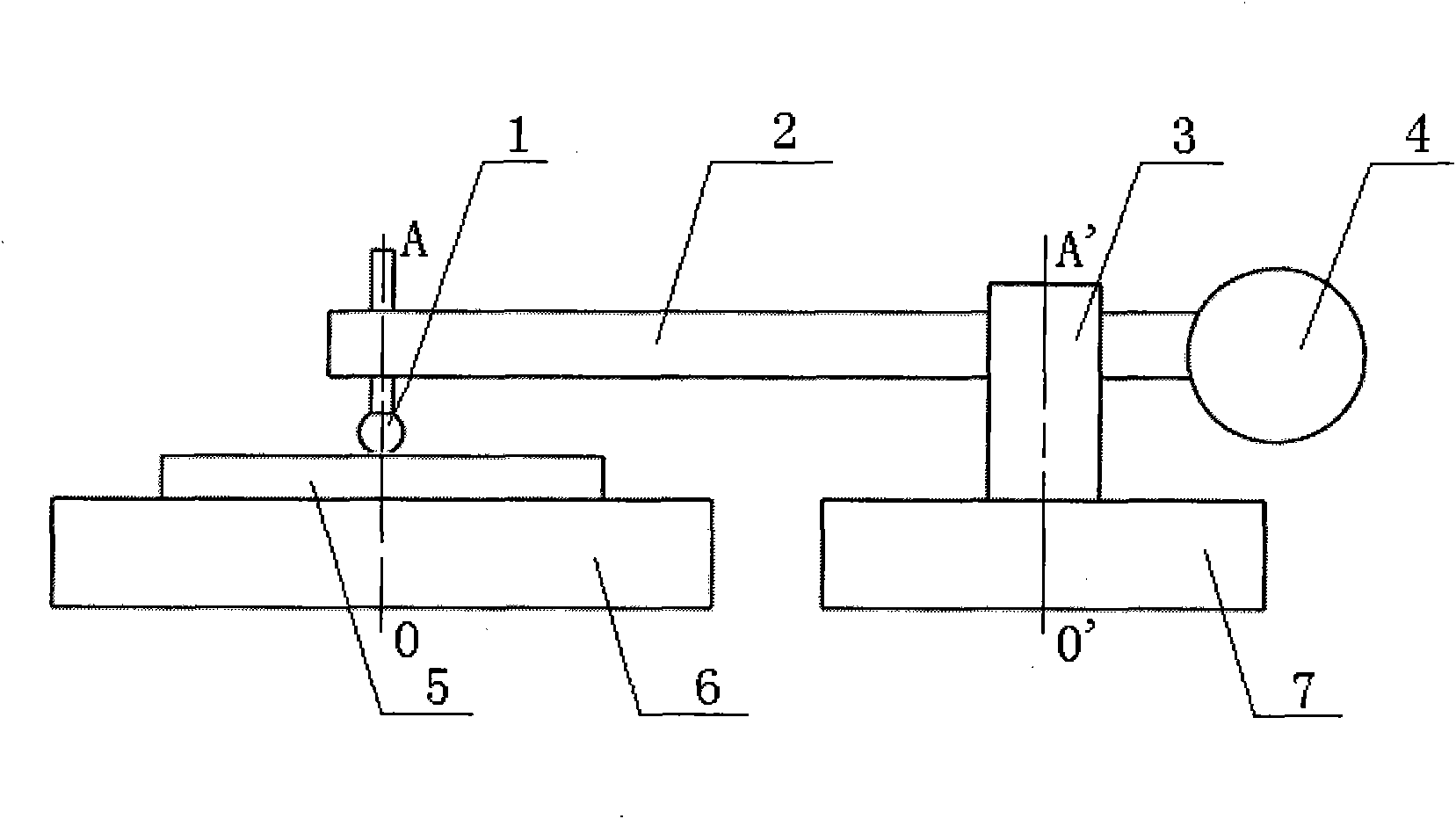

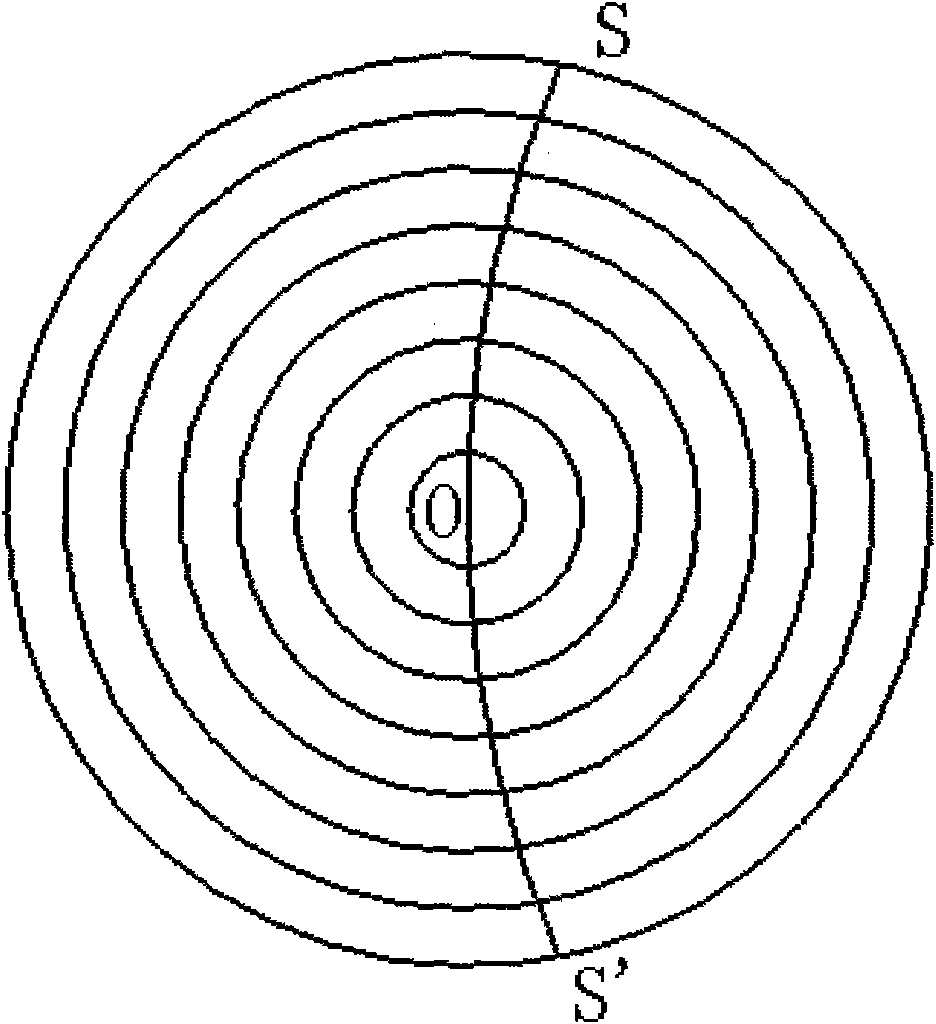

Swing arm type three-dimensional contourgraph

InactiveCN101936699ASolve the problem that only two-dimensional contours can be measuredSolution rangeMechanical counters/curvatures measurementsMechanical roughness/irregularity measurementsThree dimensional morphologyEngineering

The invention relates to a swing arm type three-dimensional contourgraph which comprises a measuring head system, a transverse arm, an upright post, a counter weight, a measured plane element, a workpiece turntable and a transverse arm turntable, wherein one end part of the upright post is arranged in a mounting hole of the transverse arm turntable and fixedly connected with the transverse arm turntable, and the transverse arm is arranged in another end part mounting hole of the upright post; one end part of the transverse arm is provided with the counter weight, while the other end part of the transverse arm is provided with the measuring head system; the measured plane element is arranged on the workpiece turntable; a detection end of the measuring head system is in contact with the measured plane element; and the transverse arm and the upright post are used for finishing the rotating motion of the measuring head system; and the counter weight is used for balancing the measuring head system and the transverse arm so as to guarantee the transverse arm turntable to maintain stable rotation. The contourgraph can be used for the measurement and the analysis of the three-dimensional surface profile of a heavy-caliber high-precision plane element, wherein measurable parameters comprise three-dimensional morphologies, two-dimensional morphologies, PV (Peak Value), RMS (Root Mean Square) and three-dimensional morphological volumes.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

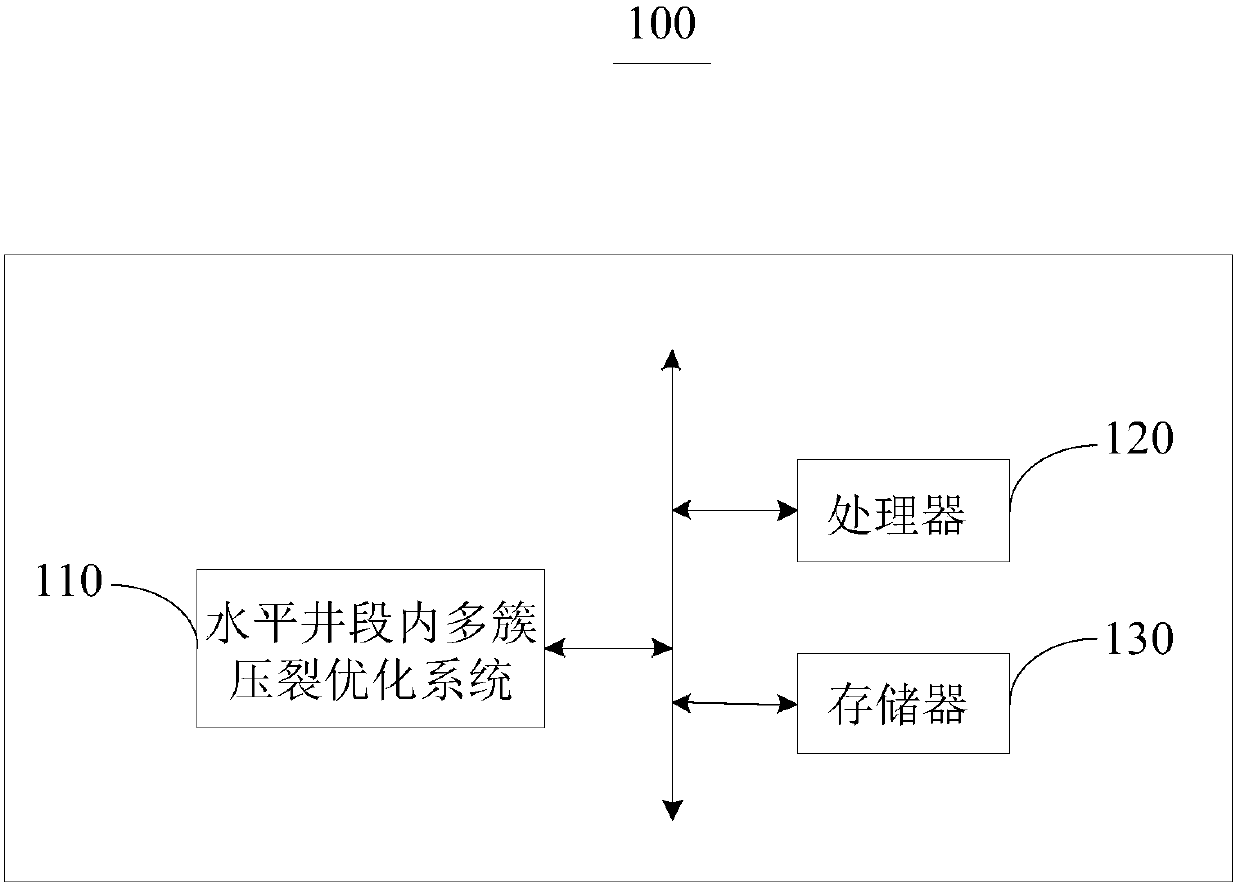

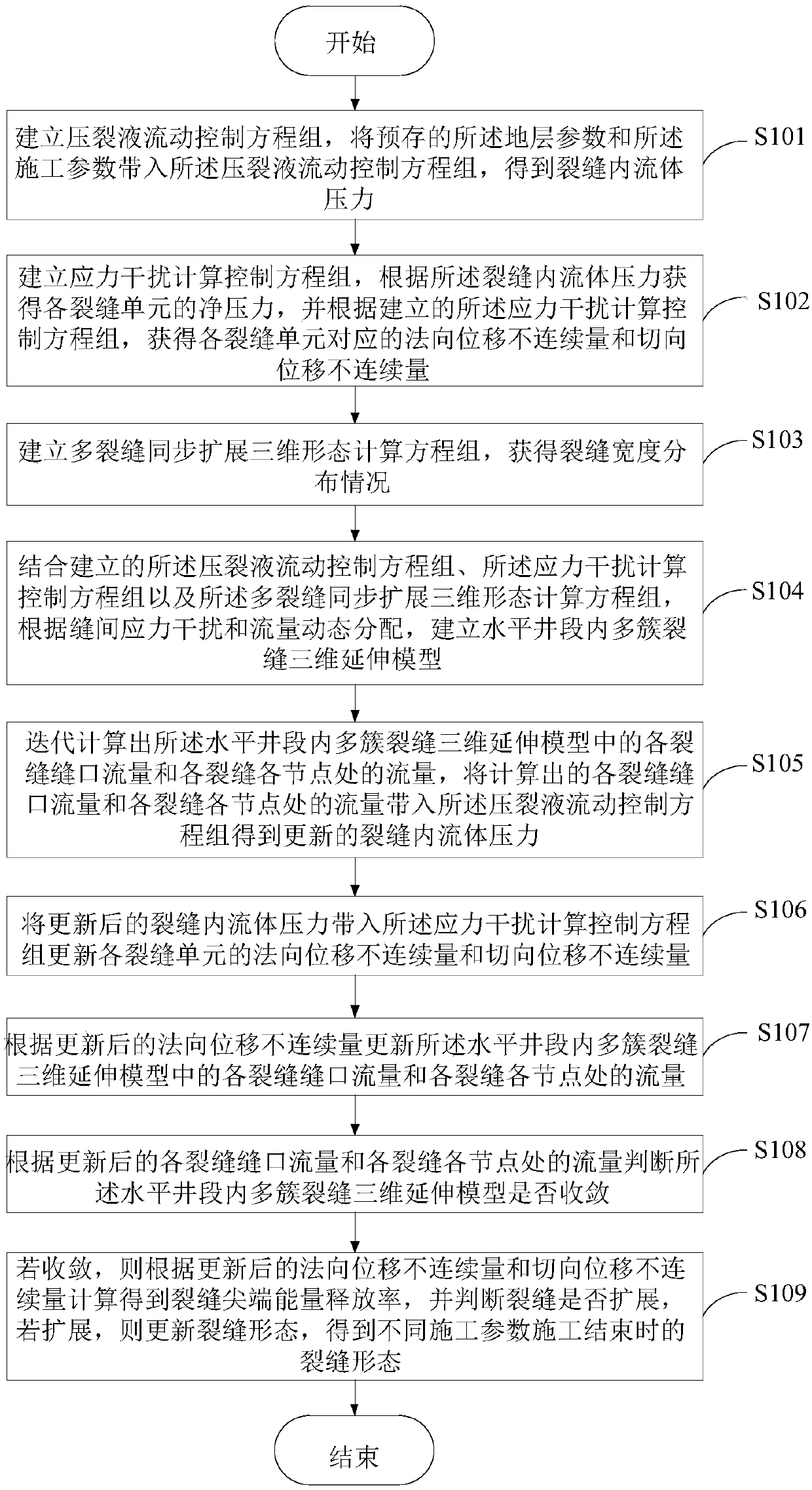

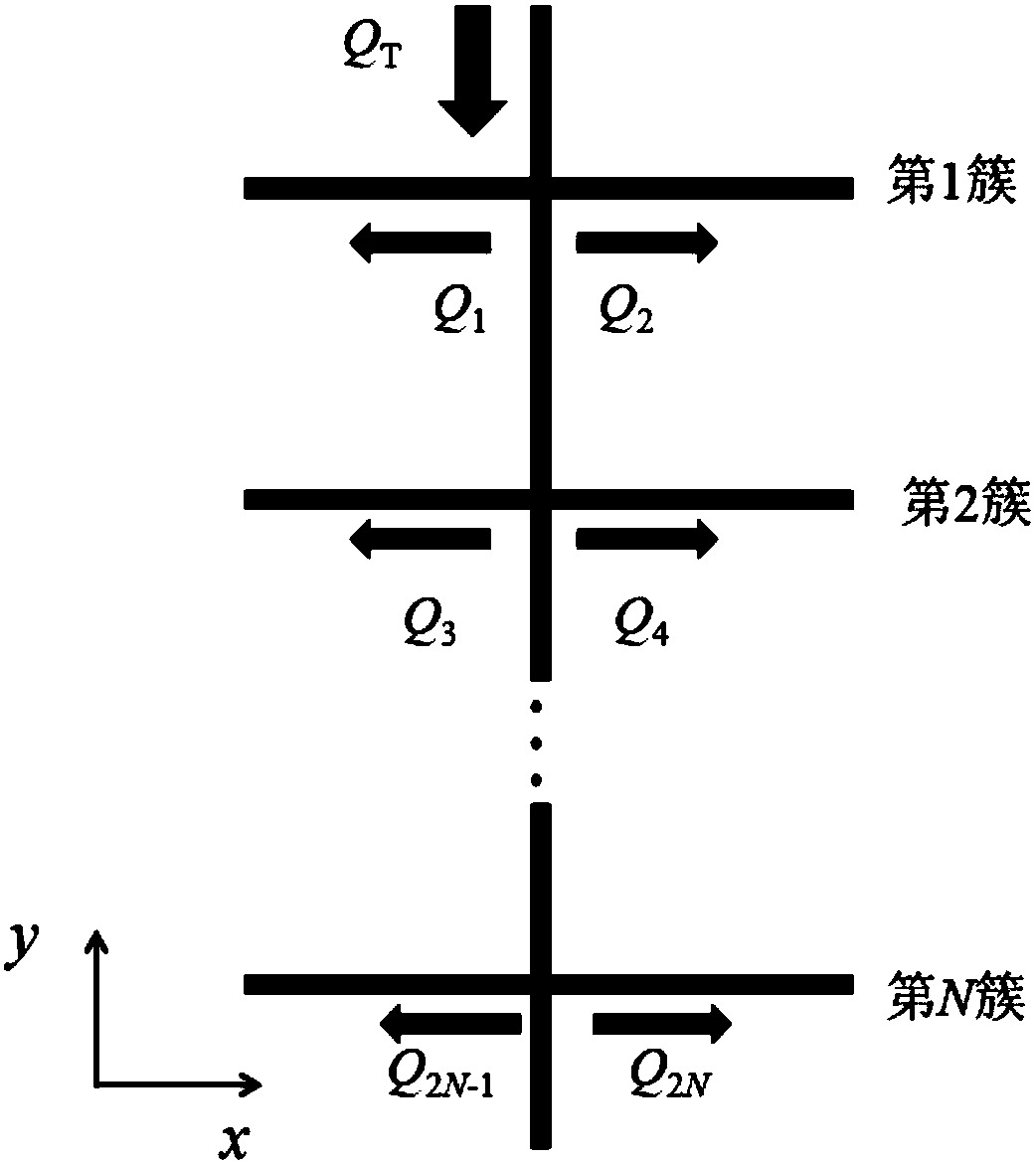

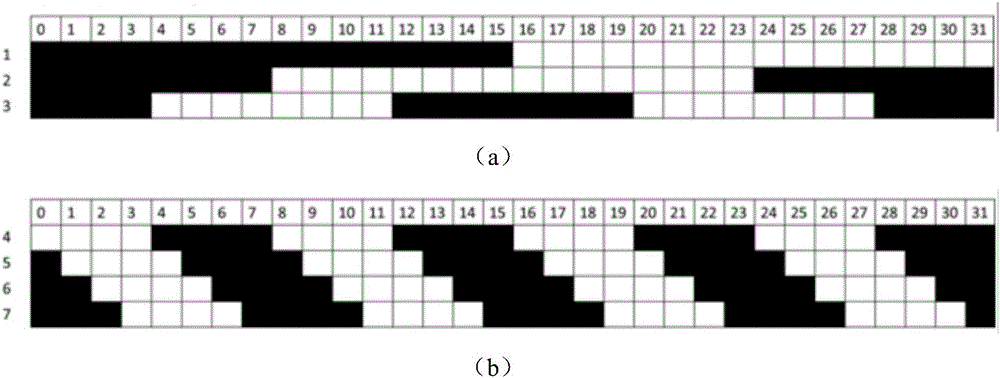

Method and system for optimizing multi-cluster fracturing in horizontal well section

ActiveCN107203667AImprove convenienceData processing applicationsFluid removalThree dimensional morphologyMulti cluster

An embodiment of the invention provides a method and system for optimizing multi-cluster fracturing in a horizontal well section and applies to an apparatus for optimizing multi-cluster fracturing in a horizontal well section. The method includes: constructing a fracturing fluid flow control equation set, a stress interference calculation control equation set and a multi-fracture synchronous expansion three-dimensional morphology calculation equation set according to stratum parameters and multiple construction parameter sets, and constructing, on such basis, an internal multi-cluster fracture three-dimensional expansion model of a horizontal well section by considering inter-fracture stress and dynamic flow distribution; simulating fracture morphology under different construction parameters according to the constructed internal multi-cluster fracture three-dimensional expansion model of the horizontal well section so as to optimize construction parameters. The method and system according to the invention consider multiple influence factors to establish the internal multi-cluster fracture three-dimensional expansion model of the horizontal well section, and good optimization is achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for measuring three-dimensional terrain in river model test

InactiveCN102538763AQuality improvementAdjust shooting rangeWater resource protectionWater resource assessmentDigital videoTerrain

The invention belongs to the technical field of hydraulic measurement and in particular relates to a method for measuring a three-dimensional terrain. A key technology for the river model test is characterized in that: deformation of a river channel is monitored in real time in the river model test of hydraulic engineering. The method comprises the following steps of: on the basis of a binocular stereo vision principle, by using an image pick-up technology, a laser matrix light source tracing technology and a three-dimensional terrain reconstruction technology, measuring the three-dimensional morphology of a bed surface in the river model test in real time; integrating a digital video camera, a laser rectangular lattice tracing light spot transmitting device and a computer; by installing a system in a set mode, correcting camera parameters and projecting laser lattice light spots to the bed surface, tracing the bed surface of a river model, acquiring an image of the bed surface, and extracting and matching laser tracing points of a river bed in an economic, safe and high-quality mode; by using a computational formula, computing three-dimensional space coordinates of laser tracing light spots on the bed surface; and on the basis of the computer, by taking the three-dimensional space coordinates of all laser tracing light spots on the bed surface as media, generating a terrain map of the river model.

Owner:TSINGHUA UNIV

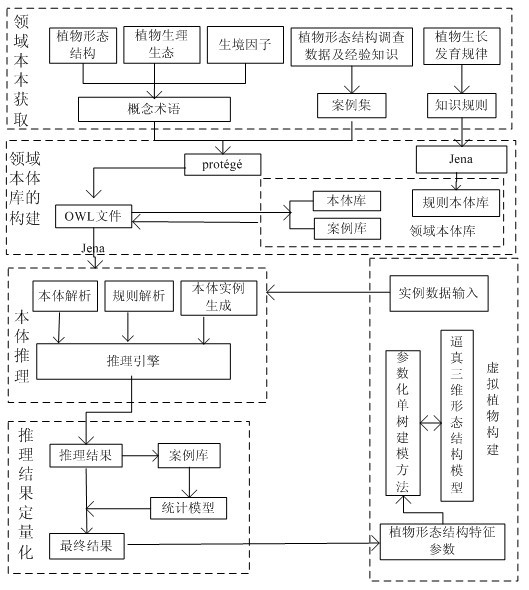

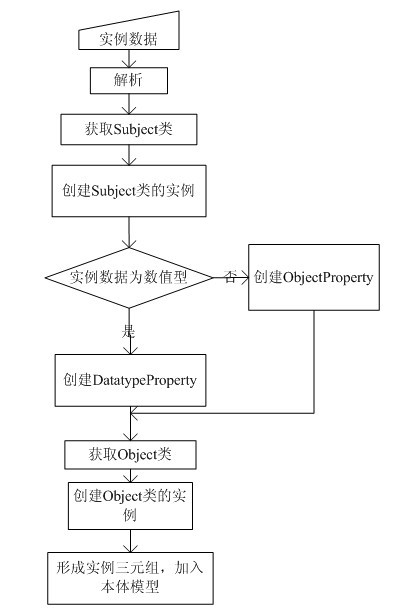

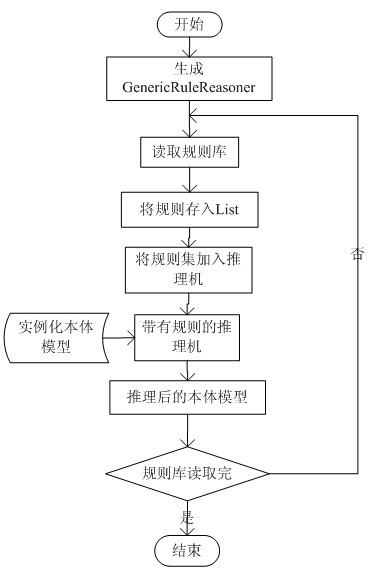

Individual plant wood modeling method driven by domain ontology

The invention discloses an individual plant wood modeling method driven by domain ontology, belonging to the intersection filed of an ontology method and plant modeling. The individual plant wood modeling method is characterized by including the steps as follows: firstly obtaining the morphological structure characteristics, the habitat domain concept terms and the growth rhythm of a plant, and creating a plant domain concept ontology base by utilizing an ontology tool protege and a plant growth rhythm ontology base by utilizing a semantic network developing tool Jena; then creating a three-dimensional morphological structure model base of the plant in different growth stages by utilizing a parameterization individual-tree modeling method; and later obtaining the morphological characteristic parameters of the plant by utilizing ontology reasoning according to the morphological structure characteristics or the habitat, the growth stages and the phenological period description of the plant, and creating a vivid three-dimensional morphological structure model by utilizing the parameterization individual-tree modelling method. By utilizing the individual plant wood modeling method, a user with less botany knowledge can create a model confirming to the characteristics of botany, or a botanist creates a vivid three-dimensional model in a short time.

Owner:FUZHOU UNIV

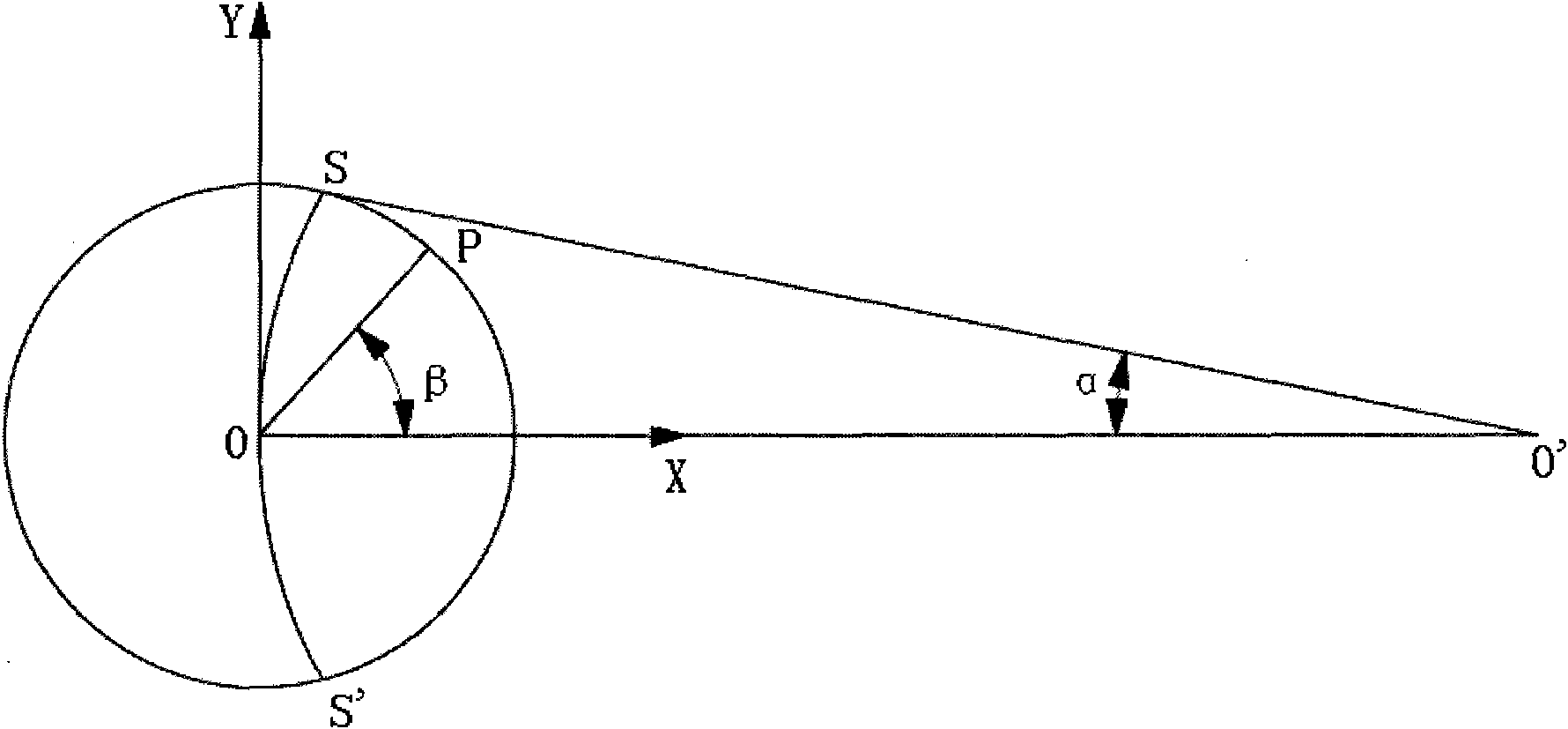

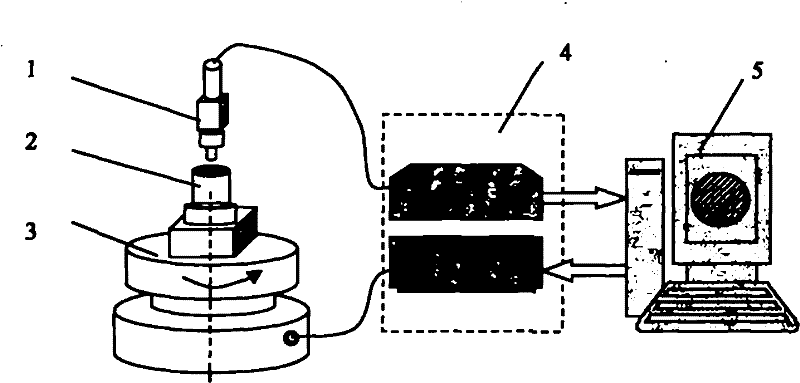

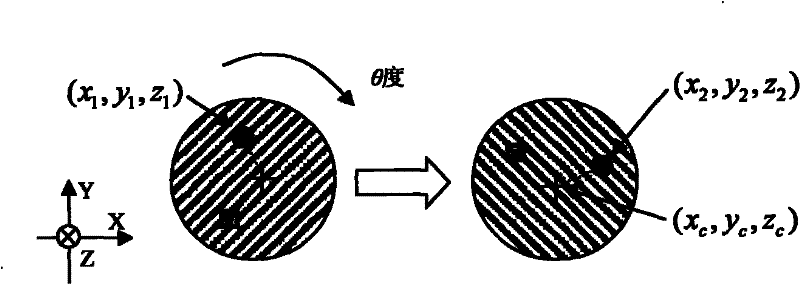

Morphology registration analysis-based method for detecting precision of precise main shaft rotation

ActiveCN102252617AHigh precision requirementsRealize measurementMeasurement/indication equipmentsUsing optical meansThree dimensional morphologyControl system

The invention provides a morphology registration analysis-based method for detecting precision of precise main shaft rotation. A surface sample is installed on a to-be-detected precise main shaft; a control system controls the to-be-detected precise main shaft to be at a position at an angle theta; surface morphology graphs of the surface sample are collected in order, wherein the surface morphology graphs are obtained when the to-be-detected precise main shaft at complete circumference positions. A morphology data registration analysis processing system analyzes the plurality of surface morphology graphs and error evaluation is simultaneously carried out. According to the invention, a morphology of a surface sample that makes rotation with a precise main shaft is measured and subsequent morphology registration is analyzed and processed; there is no high precision requirement on the surface sample; and an expensive standard external circle profile or a complex testing system and a testing process are not needed. If a two-dimensional morphology / image sensor is selected for utilization, a radial rotation error of the main shaft can be measured; If a three-dimensional morphology measurement sensor is selected for usage, radial and axial rotation errors of the main shaft can be measured simultaneously. The utilization of a measurement sensor with high resolution enables main shaftrotation error detection with nanometer-level precision to be realized.

Owner:HARBIN INST OF TECH

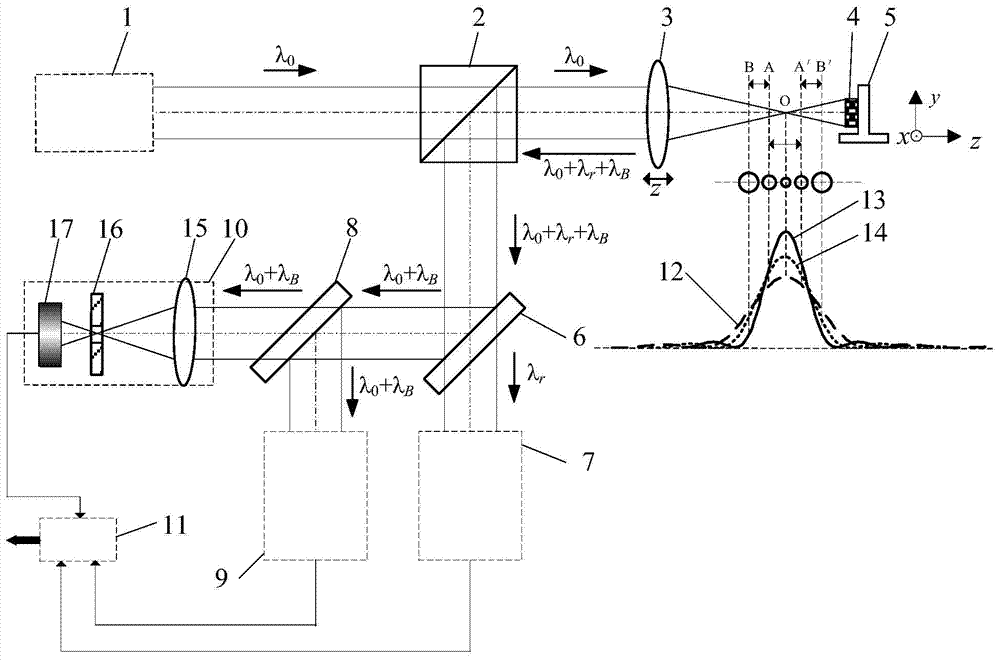

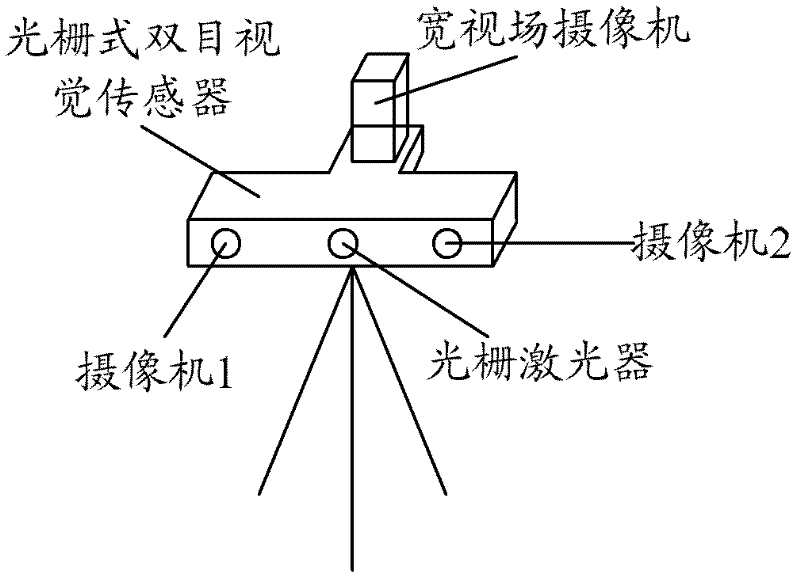

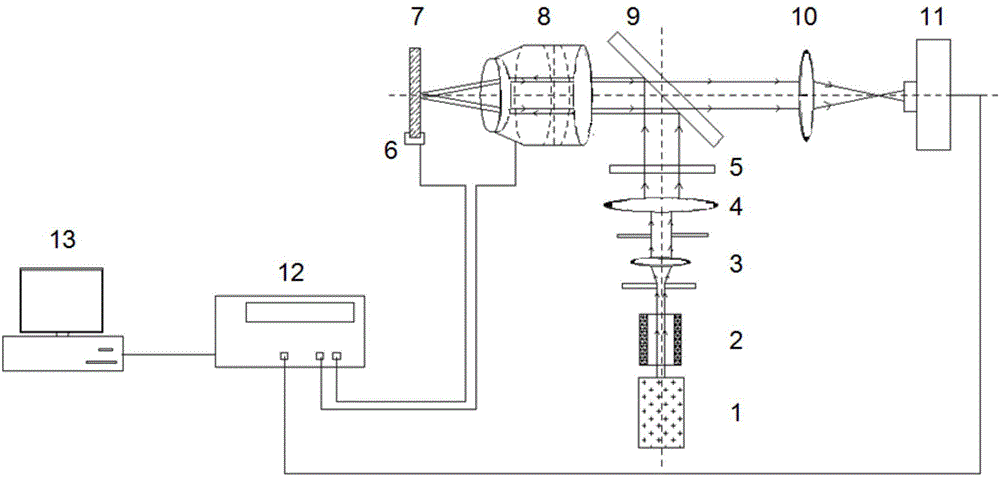

Laser confocal Brillouin-Raman spectral measurement method and apparatus

ActiveCN103940800AGood size controlEasy to testRaman scatteringElectricityThree dimensional morphology

The invention belongs to the technical field of microscopic imaging and spectral measurement and relates to a high resolution spectral imaging and detection method and apparatus which combine confocal microscopic technology and spectral detection technology together, realize integration of images and spectrums and are used for three dimensional morphology reconstruction and micro-area morphological performance parameter measurement of a variety of samples. The method and apparatus utilize Rayleigh light abandoned by a traditional confocal Raman system and confocal technology for detection of the position of a sample, employs a spectral detection system for spectral detection and uses Brillouin diffusion light abandoned by a traditional confocal Raman detection technology to test properties like elasticity and piezoelectricity of a material, thereby realizing measurement of micro-area high spatial resolution morphological parameters of a sample. The method and apparatus provided by the invention have the advantages of accurate positioning, high spatial resolution, high spectral detection sensitivity, controllable measured spot size, etc. and have wide application prospects in fields like biomedicine, evidence collection of court, micro and nano-fabrication, material engineering, engineering physics, precise metering and physical chemistry.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

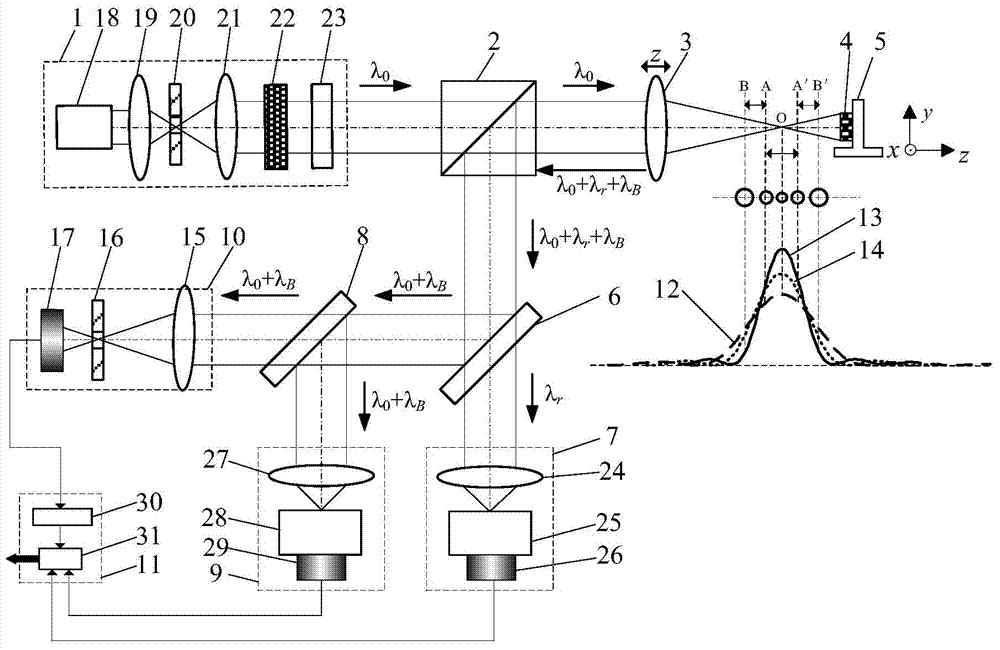

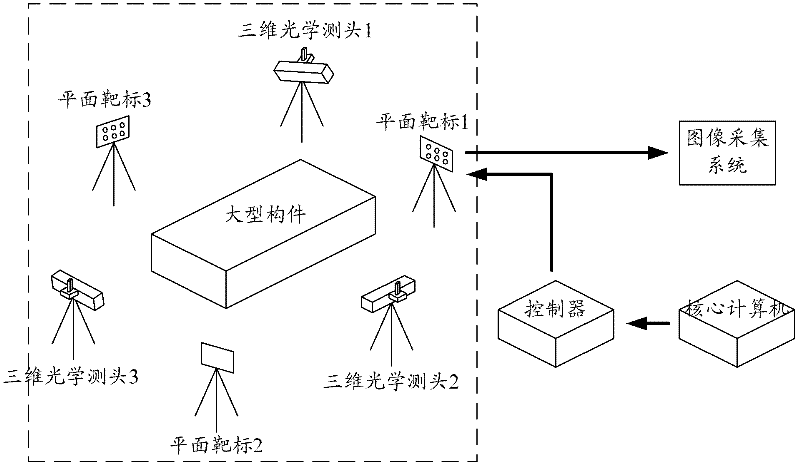

Object surface three-dimensional morphology multi-sensor flexible dynamic vision measurement system and method

InactiveCN102506758ALittle influence on measurement accuracyRealization of Flexible Dynamic Visual MeasurementUsing optical meansGratingVision sensor

The invention discloses an object surface three-dimensional morphology multi-sensor flexible dynamic vision measurement system and method. The object surface three-dimensional morphology multi-sensor flexible dynamic vision measurement system comprises a plurality of three-dimensional optical measuring heads and plane targets, a controller, a image acquisition system and a core computer, wherein the three-dimensional optical measuring heads and the plane targets are arranged around an object to be measured; each three-dimensional optical measuring head comprises a grating type binocular vision sensor and a wide field camera; the core computer controls a characteristic point of each plane target to be lighted through the controller, the wide field camera measures the plane targets around the wide field camera, the grating type binocular vision sensor measures a surface three-dimensional morphology of the object to be measured; and with the plane targets in common vision fields of the wide field cameras as mediums, local three-dimensional data obtained through the measurement of the grating type binocular vision sensors are unified to a global coordinate system. According to the invention, the problems of large influence to dynamic measurement precision by a site vibration environment due to rigid connection among the vision sensors in the traditional multi-vision-sensor measurement system.

Owner:BEIHANG UNIV

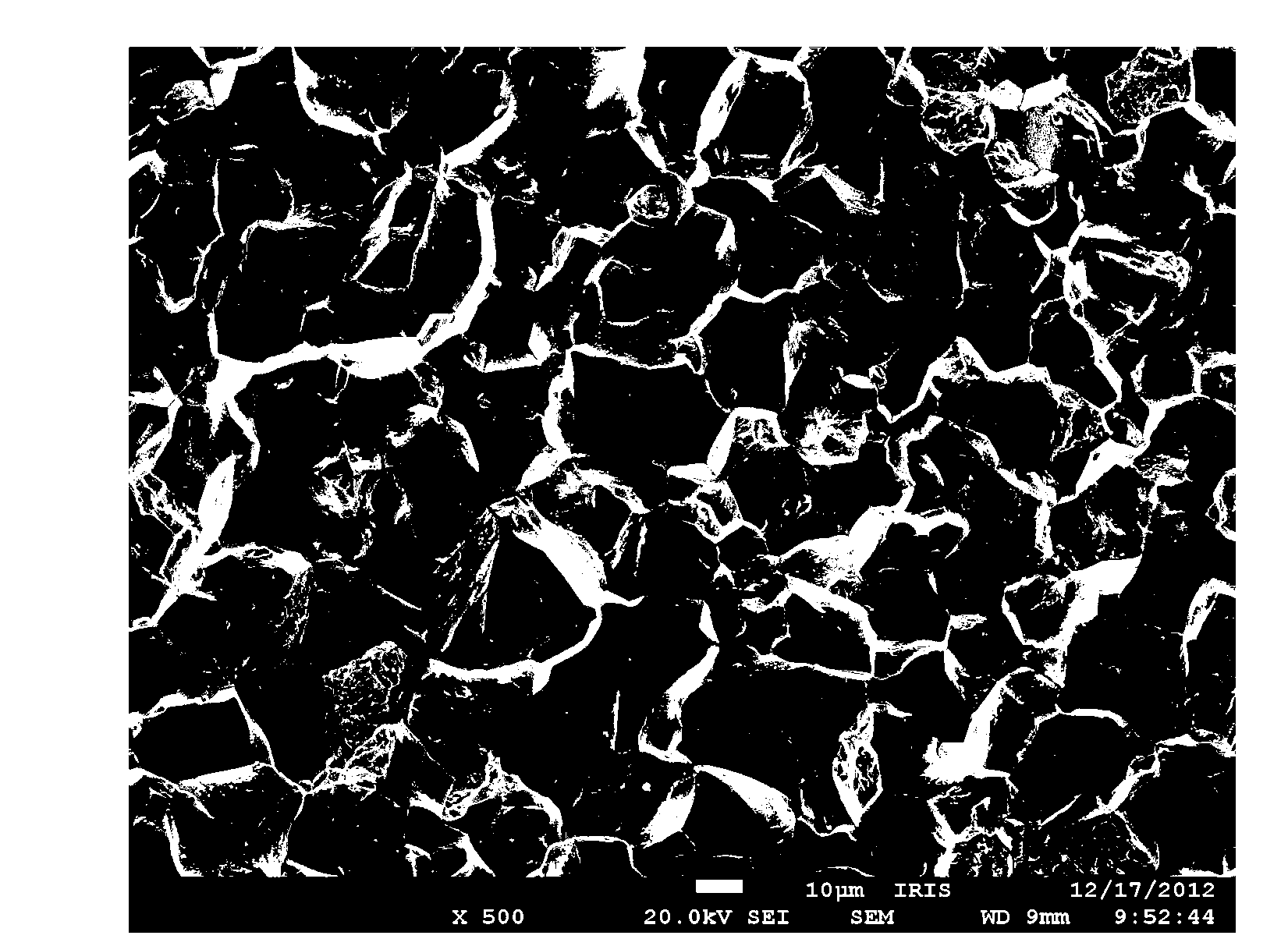

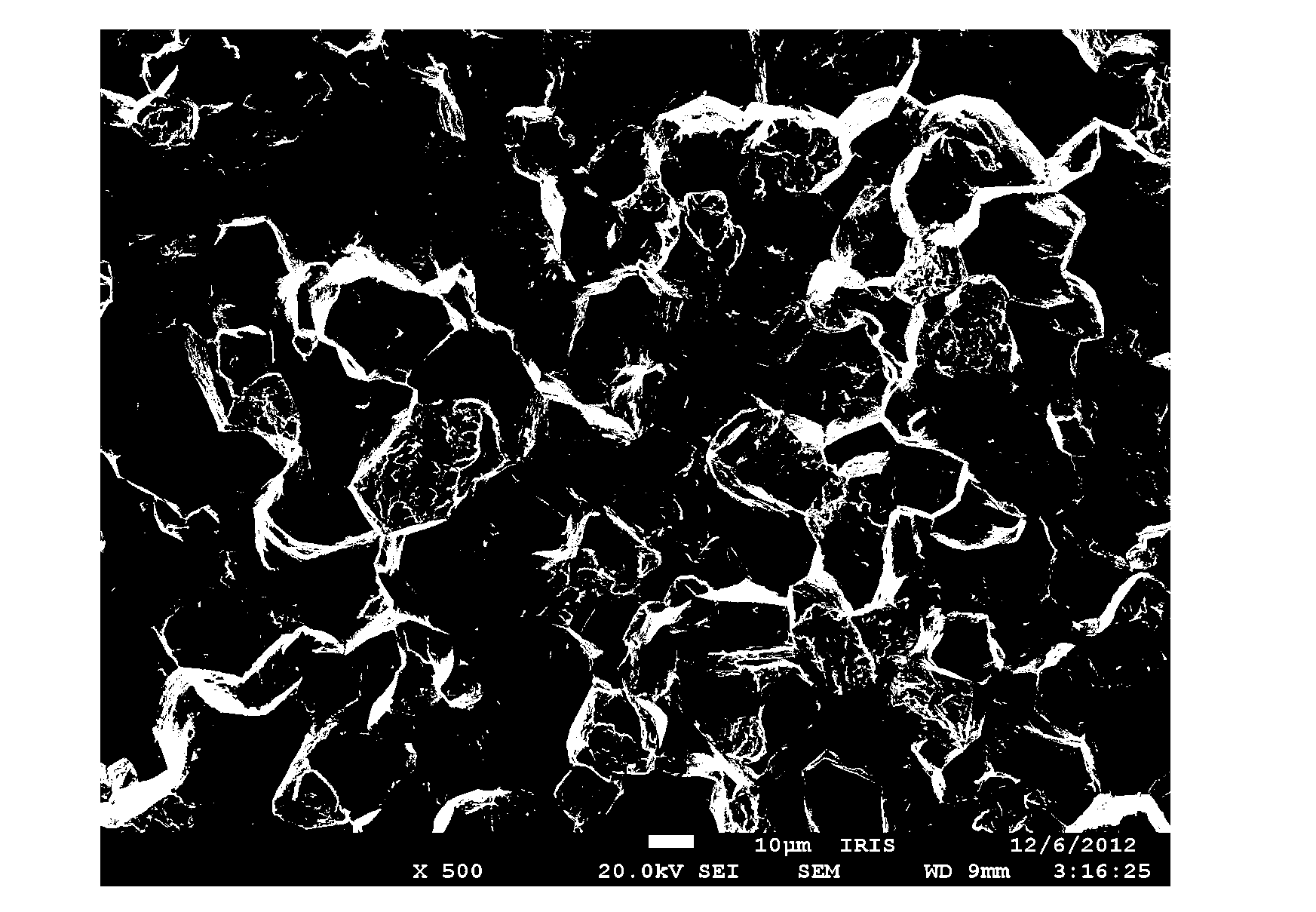

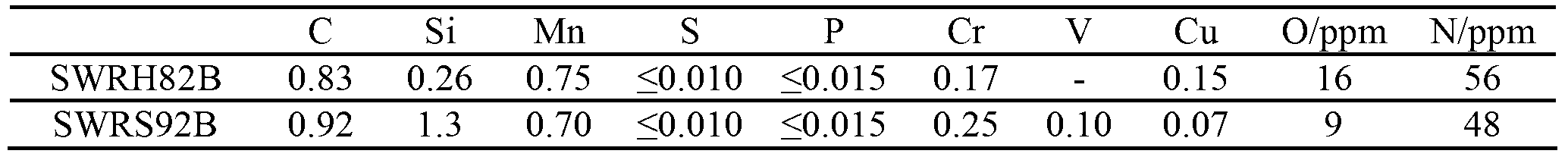

High-carbon steel wire rod austenite crystal grain size measuring method

ActiveCN103257098AThree-dimensional appearanceAccurately measure the sizeParticle size analysisWire rodAustenite grain

The invention discloses a high-carbon steel wire rod austenite crystal grain size measuring method. The method comprises the following steps of: firstly, horizontally cutting a plurality of notches vertical to the length direction of a wire rod; then, heating the wire rod with the notches in a heating furnace so as to enable the wire rod to be austenitized completely, wherein the heating temperature is generally 860 DEG C-1300 DEG C; then, placing the heated wire rod rapidly into cold water for quenching treatment; and finally, breaking a quenched sample along the notches, photographing fractures cracking along crystals by a scanning electron microscope, observing the three-dimensional morphologies of crystal grains on the fractures directly by the scanning electron microscope, and measuring the sizes of the crystal grains. The method provided by the invention can be used for preparing samples simply, does not require corrosion, is high in success rate, and can accurately determine the sizes of the high-carbon steel wire rod austenite crystal grains.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Flow cytometer apparatus for three dimensional difraction imaging and related methods

ActiveUS9013692B2Scattering properties measurementsLuminescent dosimetersThree dimensional morphologyParticle physics

A flow cytometer assembly includes a fluid controller configured to form a hydrodynamically focused flow stream including an outer sheath fluid and an inner core fluid. A coherent light source is configured to illuminate a particle in the inner core fluid. A detector is configured to detect a spatially coherent distribution of elastically scattered light from the particle excited by the coherent light source. An analyzing module configured to extract a three-dimensional morphology parameter of the particle from a spatially coherent distribution of the elastically scattered light.

Owner:HU XIN HUA

Color confocal three-dimensional morphology measuring method and system

InactiveCN109373927ATime consuming to solveFast measurementUsing optical meansThree dimensional morphologyObject point

The invention relates to a color confocal three-dimensional morphology measuring method and system. A polychromatic light source is employed and a relationship between wavelength colors and displacement is obtained through axial dispersion, so that a time consuming problem caused by axial scanning is solved and the measuring speed is increased. A stray signal of a focal plane is obtained is filtered through a small hole and a sharp signal located at the focal plane is obtained, so that the high axial resolution is realized. A color camera is used as the data receiving end and thus all height information of the surface of the measured object in the view field can be obtained by shooting once, so that the measuring speed is increased. The color confocal three-dimensional morphology measuringmethod is especially suitable for the color confocal parallel scanning system. According to the invention, the height information extraction of the measured object point is completed only by one imaging; and the three-dimensional topographical feature of the measured object surface is obtained by combining the two-dimensional information provided by the two-dimensional displacement system. Therefore, a novel path is provided for detection of the three-dimensional morphology of the surface of the object.

Owner:HUAQIAO UNIVERSITY

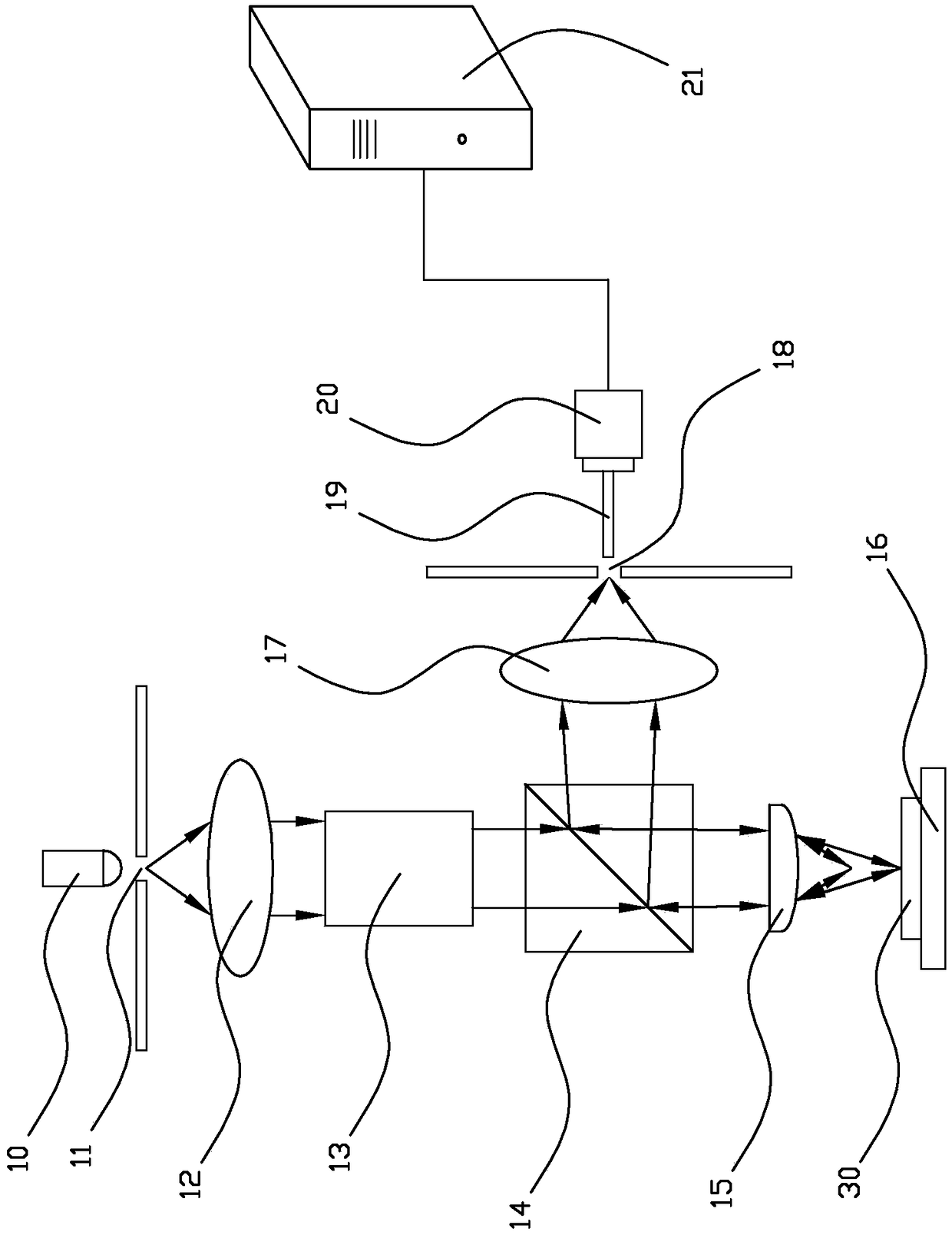

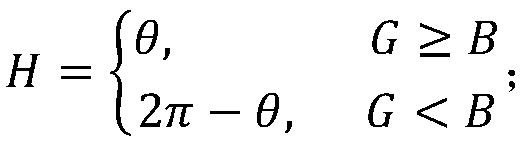

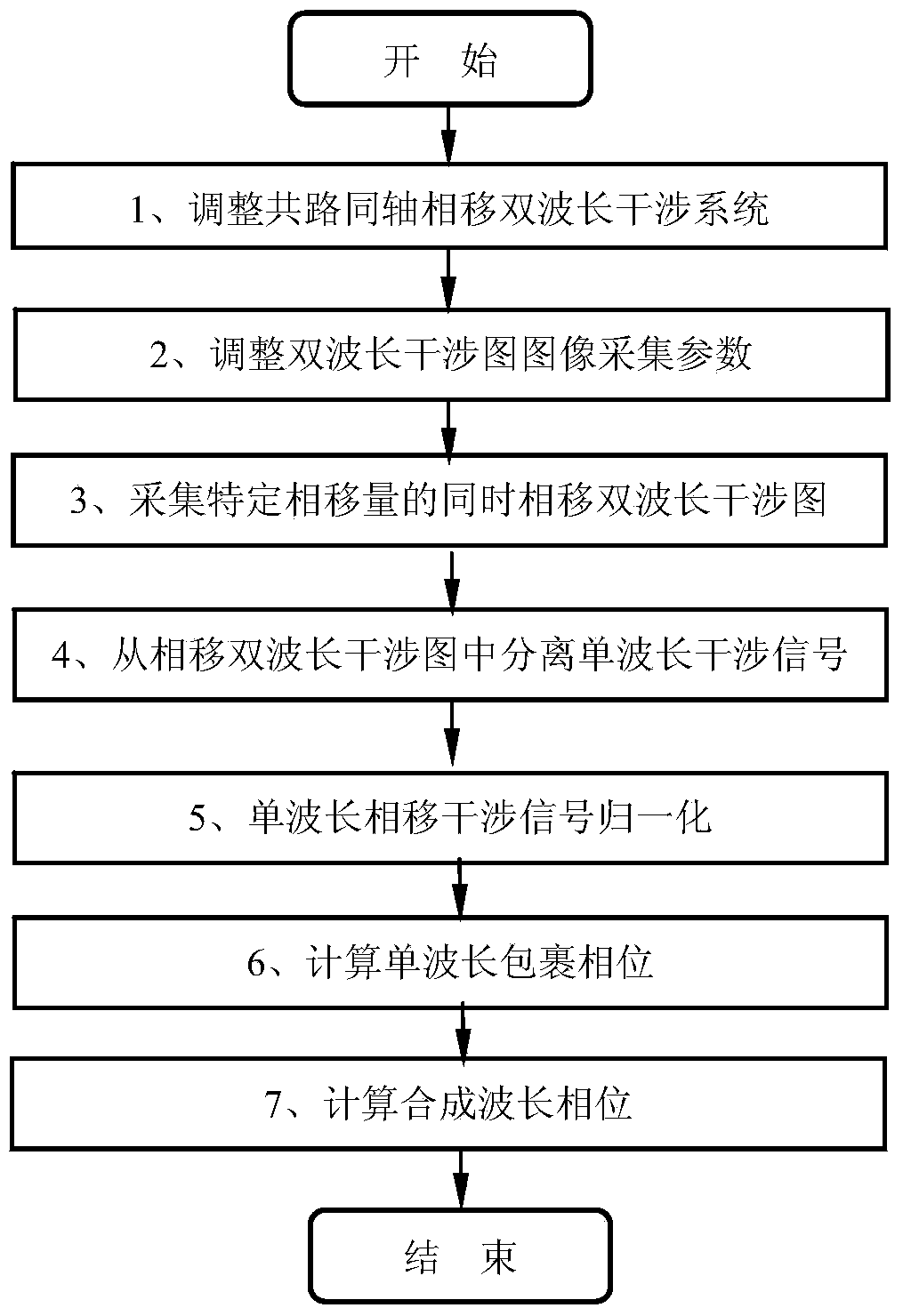

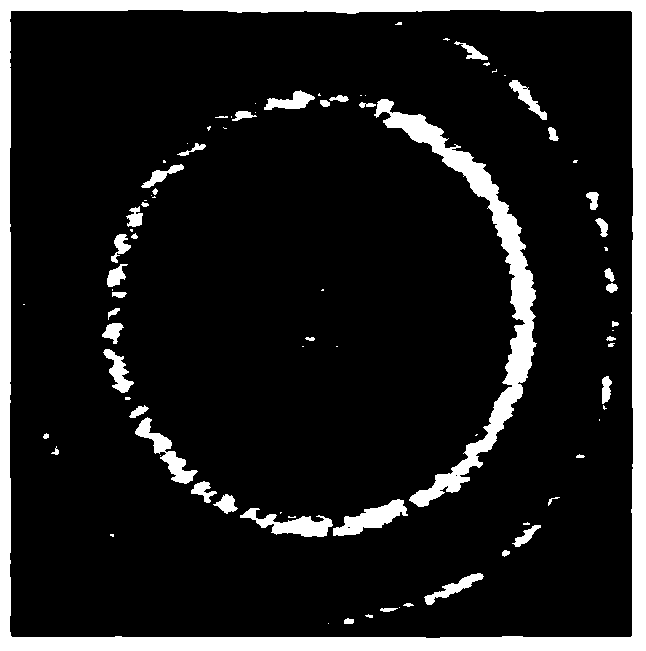

Single-monochrome-CCD phase shift dual-wavelength interferometry method based on specific phase shift amount

InactiveCN104236452ASimple measurement systemReduced measurement timeUsing optical meansPhase shiftedThree dimensional morphology

The invention discloses a single-monochrome-CCD phase shift dual-wavelength interferometry method based on a specific phase shift amount. The method includes the steps that first, a common-path coaxial dual-wavelength interference system is constructed, the laser with the wavelength of lambda1 and the laser with the wavelength of lambda2 are made to enter the interference system, and the lasers with the two wavelengths are adjusted to form interference patterns along a totally same path; second, a single monochrome CCD is adjusted to collect parameters of the dual-wavelength interference patterns; third, the dual-wavelength phase shift interference patterns generated by the two wavelengths at the same time are collected by the single monochrome CCD; fourth, two single-wavelength phase shift interference signal patterns with the background eliminated are separated from the collected dual-wavelength phase shift interference patterns; fifth, normalization processing is performed on the two separated single-wavelength phase shift interference signal patterns; sixth, single-wavelength wrapped phase graphs at the wavelength of lambda1 and the wavelength of lambda2 are calculated; seventh, synthetic wavelength phases with the wavelength of lambda1 and the wavelength of lambda2 are calculated, and thus three-dimensional morphology information of the surface of an object to be measured is obtained. The method is simple and easy to perform.

Owner:SOUTH CHINA NORMAL UNIVERSITY

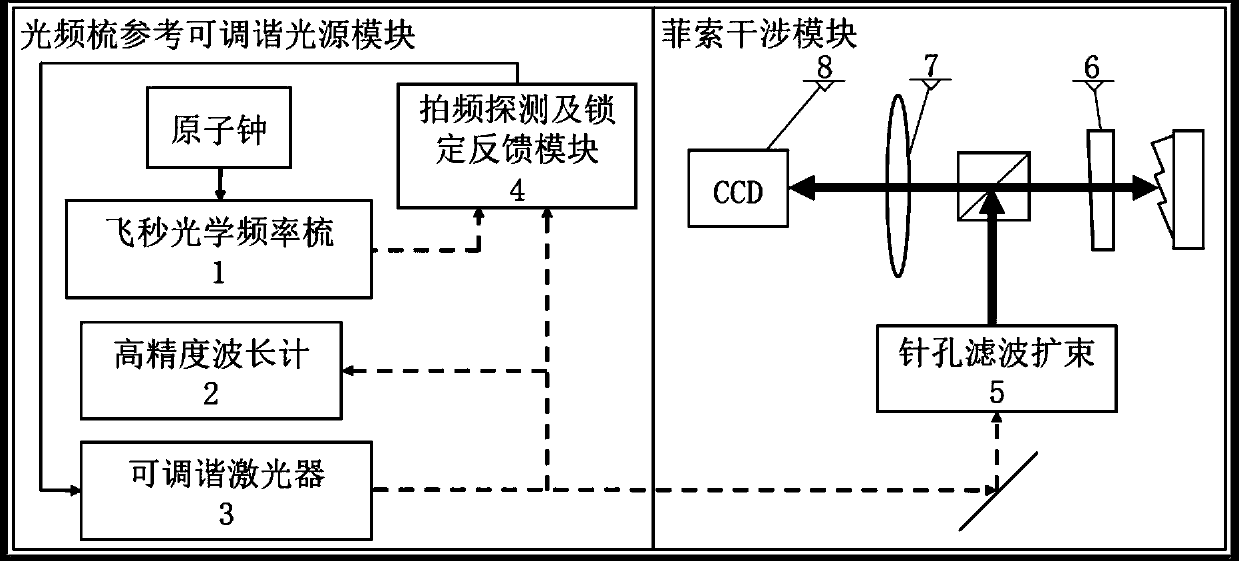

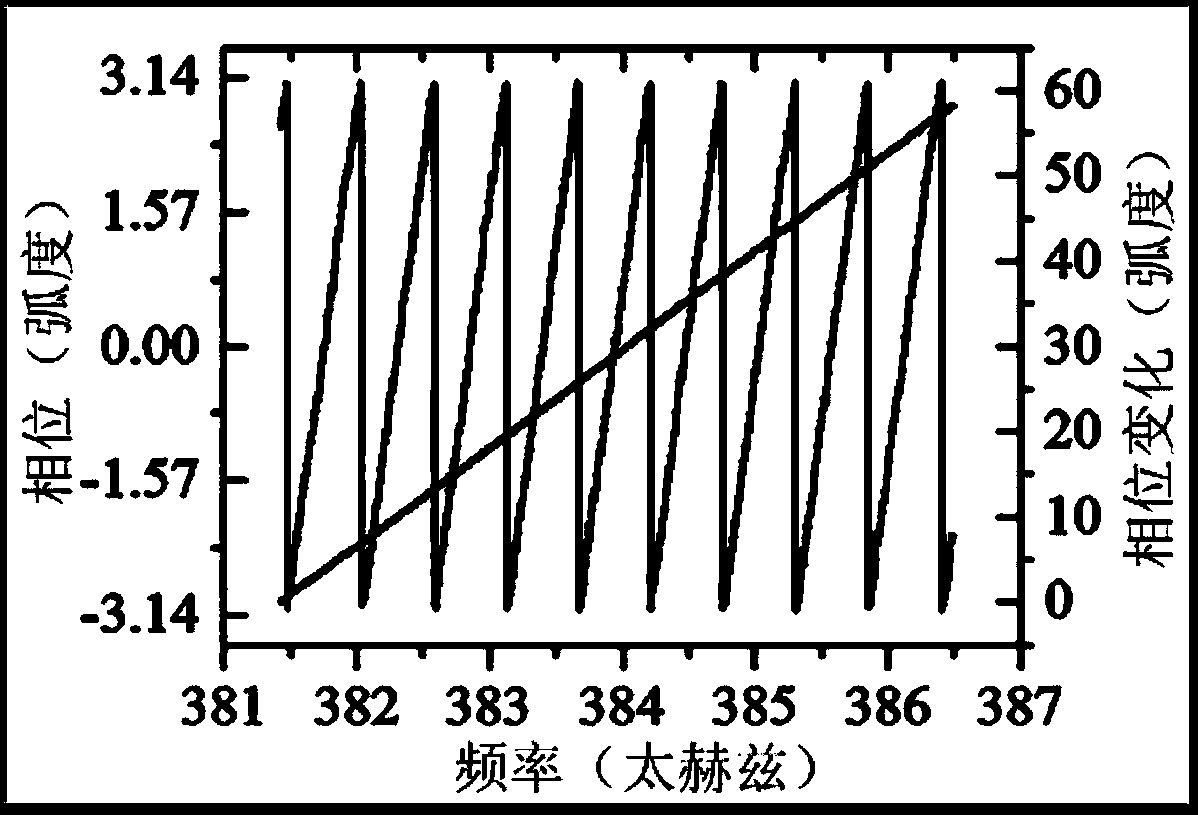

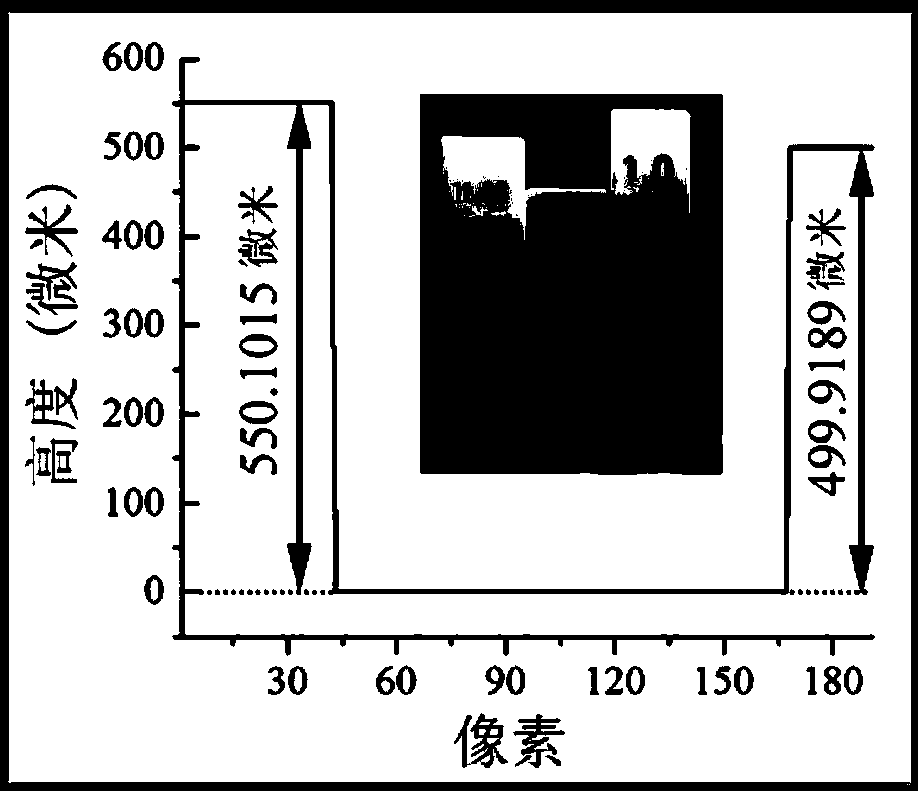

Wavelength scanning three dimensional morphology measurement system of optical frequency comb reference

ActiveCN107063125AQuick measurementHigh precisionUsing optical meansObservational errorOptical frequencies

A wavelength scanning three dimensional morphology measurement system of optical frequency comb reference comprises an optical frequency comb reference tunable light source module and a Fizeau interferometer module, the optical frequency comb reference tunable light source module comprises a femtosecond optical frequency comb, a wavemeter, a tunable laser and a beat frequency detection and locking feedback module, and the femtosecond optical frequency comb provides the optical frequency reference capable of tracing back to an atomic clock. According to the present invention, a set of tunable light source system which can is tunable in a large range and has the very high frequency stability, is realized, a measurement error caused by the light source frequency stability is reduced substantially, and by introducing a Fourier transform phase measurement method in the Fizeau interferometer module, the measurement time is reduced, and the phase measurement precision is improved. The wavelength scanning three dimensional morphology measurement system of the present invention can measure the three dimensional morphology of the surface of an object accurately, does not have the strict requirements and limit for the height variation of the object, realizes the comprehensive measurement precision not more than 20 nanometers, and has the stronger versatility.

Owner:TSINGHUA UNIV

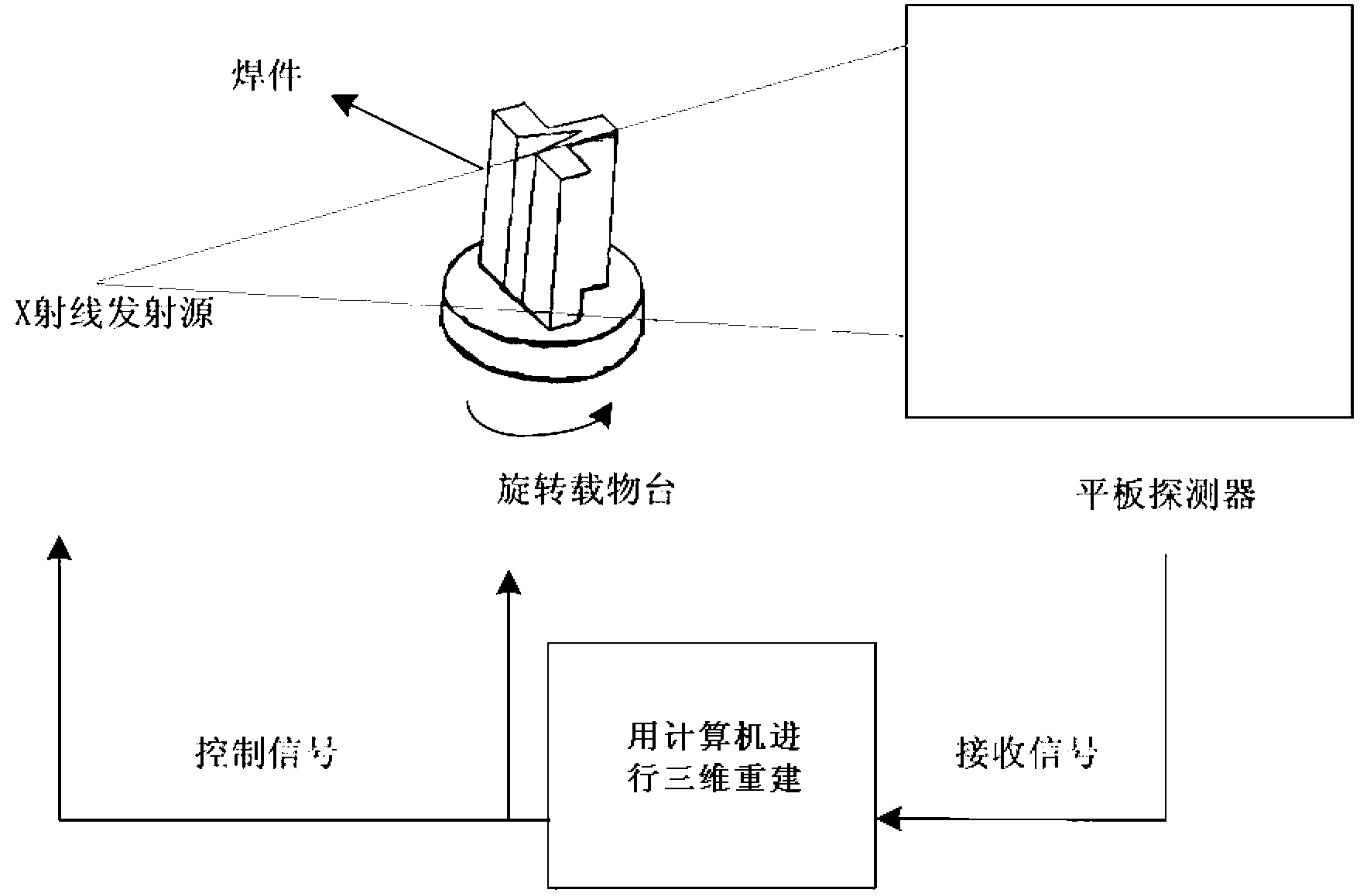

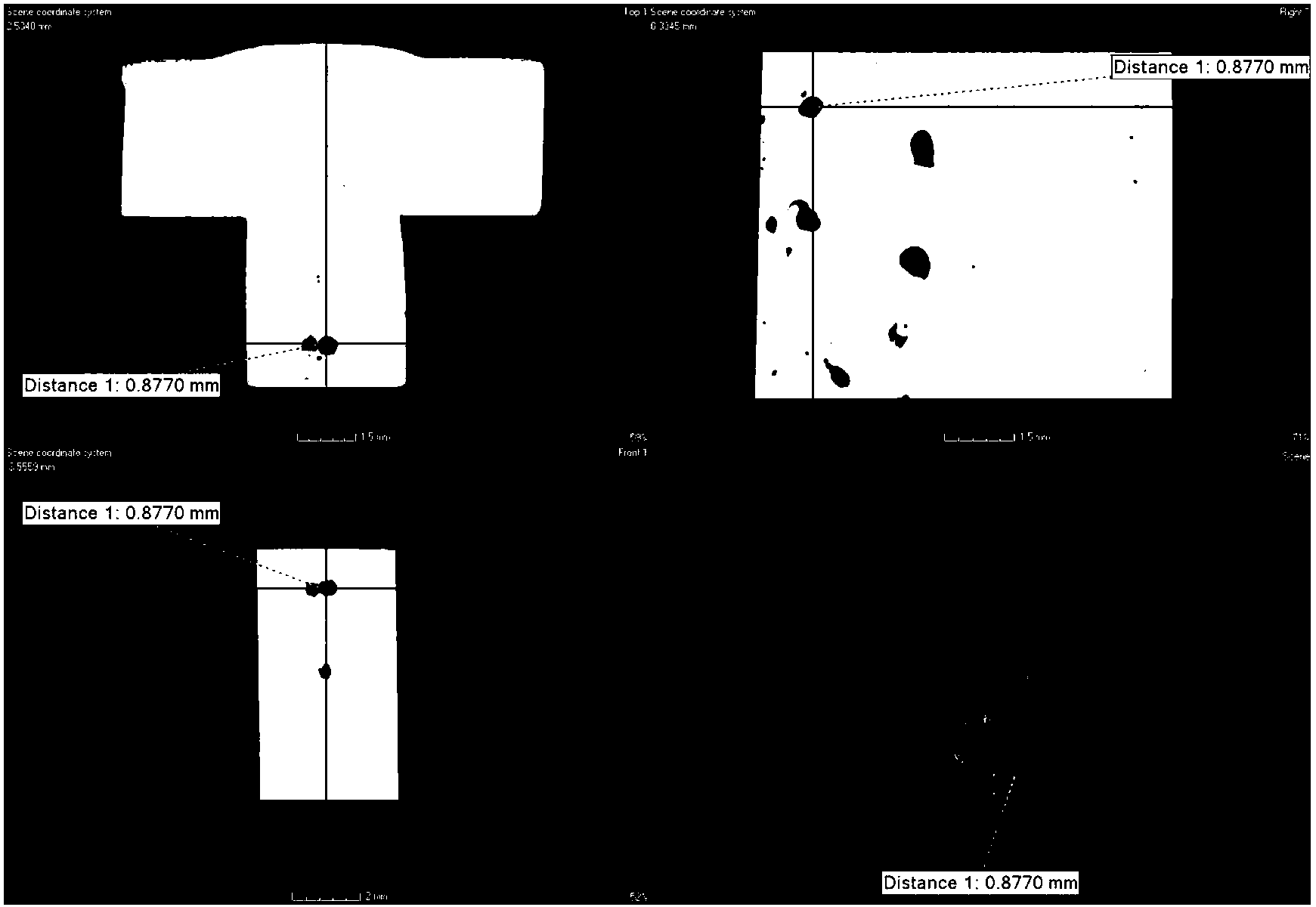

New non-destructive detection method for morphology and distribution of pores in welding seam

InactiveCN103234990AReduce sensitivityPrecise positioningMaterial analysis by transmitting radiationFractographyX-ray

The present invention discloses a new non-destructive detection method for morphology and distribution of pores in welding seam. According to the method, a novel Nano-CT tomography system is adopted to detect a weldment, an X-ray source is adopted to carry out 360 DEG scanning on the welding component, a certain degree of attenuation can be generated when X rays penetrate through the weldment, energy attenuation of the X rays passing through the pores in a welding seam can be significantly lower than energy attenuation of the surrounding rays, a flat panel detector is adopted to receive transmission energies of different degrees of the attenuations so as to obtain multiple groups of tomography scanning images, and three-dimensional reconstruction is performed on the multiple groups of the tomography data to obtain a three-dimensional detection image of pore defect in the welding seam. The detection method has the following characteristics that: resolution is high, imaging is intuitive, the method is not affected by a weldment material type, a shape, a structure and other factors, important information such as a three-dimensional morphology, a pore size, a spatial distribution characteristic and the like of the pores in the welding seam can be obtained, and important significance is provided for pore classification, defect assessment and other aspects, wherein the important information such as a three-dimensional morphology, a pore size, a spatial distribution characteristic and the like is difficult obtained by using the conventional method.

Owner:SHANGHAI JIAO TONG UNIV

Device and method for detecting uniformity of infrared optimal material

InactiveCN103558221ARealize detectionAccurate detectionOptically investigating flaws/contaminationThree dimensional morphologyLight beam

The invention discloses a device and method for detecting the uniformity of an infrared optimal material. The device is characterized by adopting a uniform infrared light beam generating device comprising an infrared light source, a stray light shielding pipe, a collimation part and a beam expanding part, wherein incident light is reflected by 90 DEG by an infrared beam splitter, reflected incident light is focused onto a material to be detected through a varifocus lens; a light beam reflected by the material to be measured is transmitted to an infrared sensor through the varifocus lens, the infrared beam splitter and a focusing lens, and the uniformity evaluation of a non-transparent visible light infrared optical material to be detected is realized through processing an infrared signal. Compared with a conventional method and device for evaluating the infrared optical material, the method and the device for evaluating the uniformity of the infrared optical material, disclosed by the invention, are capable of obtaining morphology and position information of a defect within a certain depth of a field of a focusing surface inside the infrared optical material to be detected can be obtained, and obtaining three-dimensional morphology and position information of the defect inside the infrared optical material to be detected, so that a fine evaluation function of the uniformity of the infrared optical material is realized.

Owner:WUHAN UNIV OF TECH

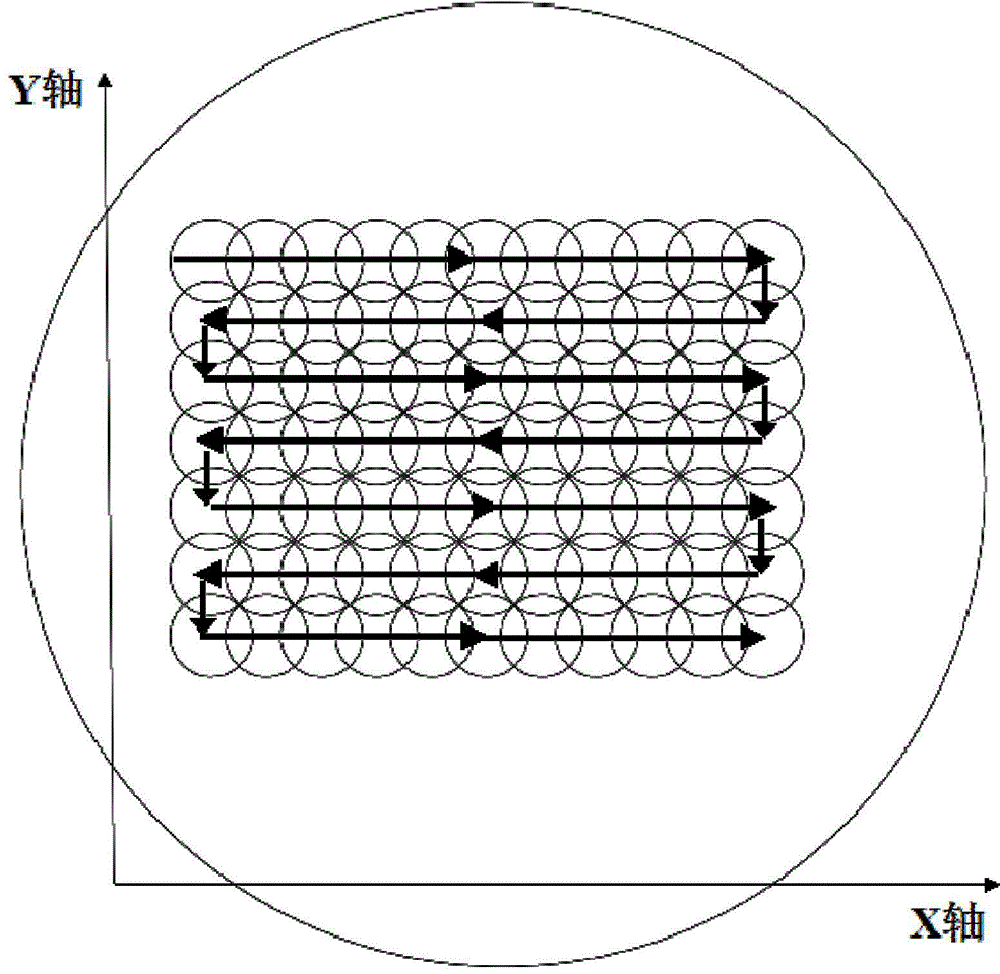

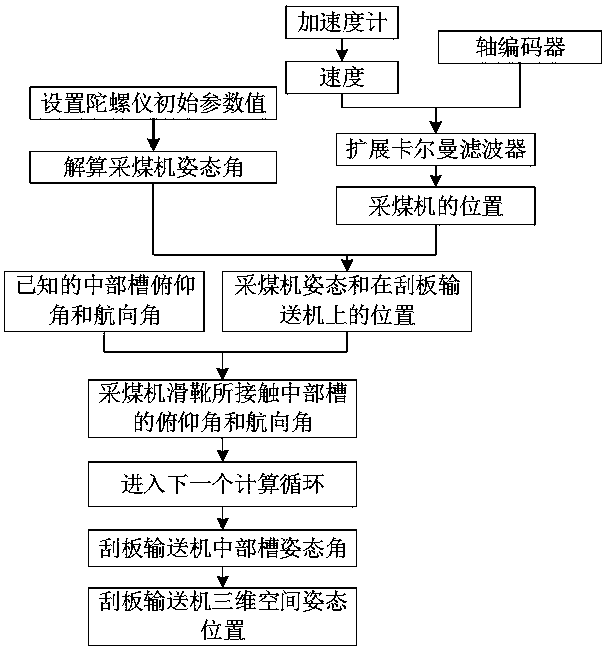

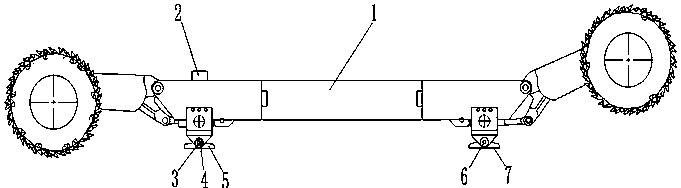

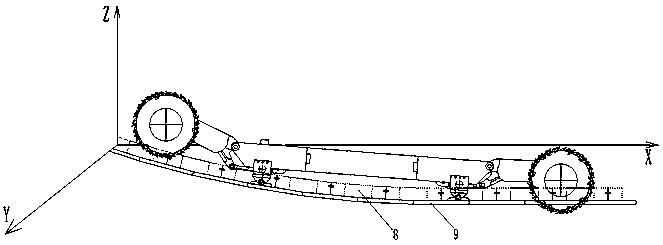

Real-time monitoring method for three-dimensional space operating posture position of scraper conveyer

ActiveCN109018851AReal-time monitoring of dynamic fluctuationsSo as not to damageAngle measurementConveyorsThree dimensional morphologyThree-dimensional space

The invention discloses a real-time monitoring method for the three-dimensional space operating posture position of a scraper conveyer. The real-time monitoring method comprises the steps that under the condition of the complex working condition that bottom plates of coal mine down-hole fully mechanized mining faces are not flat, pitch angles and course angles of all middle grooves of the scraperconveyer are accurately detected through a morphological calculation method; and through the coal mining machine body pitch angles and course angles and coal mining machine position information whichare obtained during operating of a coal mining machine on the scraper conveyer through calculation, a mathematical model is calculated through the built three-dimensional morphology, the actual morphology of the scraper conveyer conduct fully mechanized mining on the horizontal working face and the vertical working face is obtained in a calculating system, and thus the three-dimensional space actual operating posture position of the scraper conveyer is displayed in a monitoring system. According to the real-time monitoring method, the dynamic fluctuant change of the scraper conveyer on the vertical working face and the horizontal working face can be monitored in real time, a large quantity of sensors do not need to be mounted, thus the situation that the scraper conveyer is damaged due tothe large bent angle can be avoided, normal work of the scraper conveyer is ensured, the information is provided for height adjusting of a lower roller of the coal mining machine and pushing of a hydraulic support, and operating reliability of the scraper conveyer for the fully mechanized mining faces is ensured.

Owner:山西量界数字科技有限公司

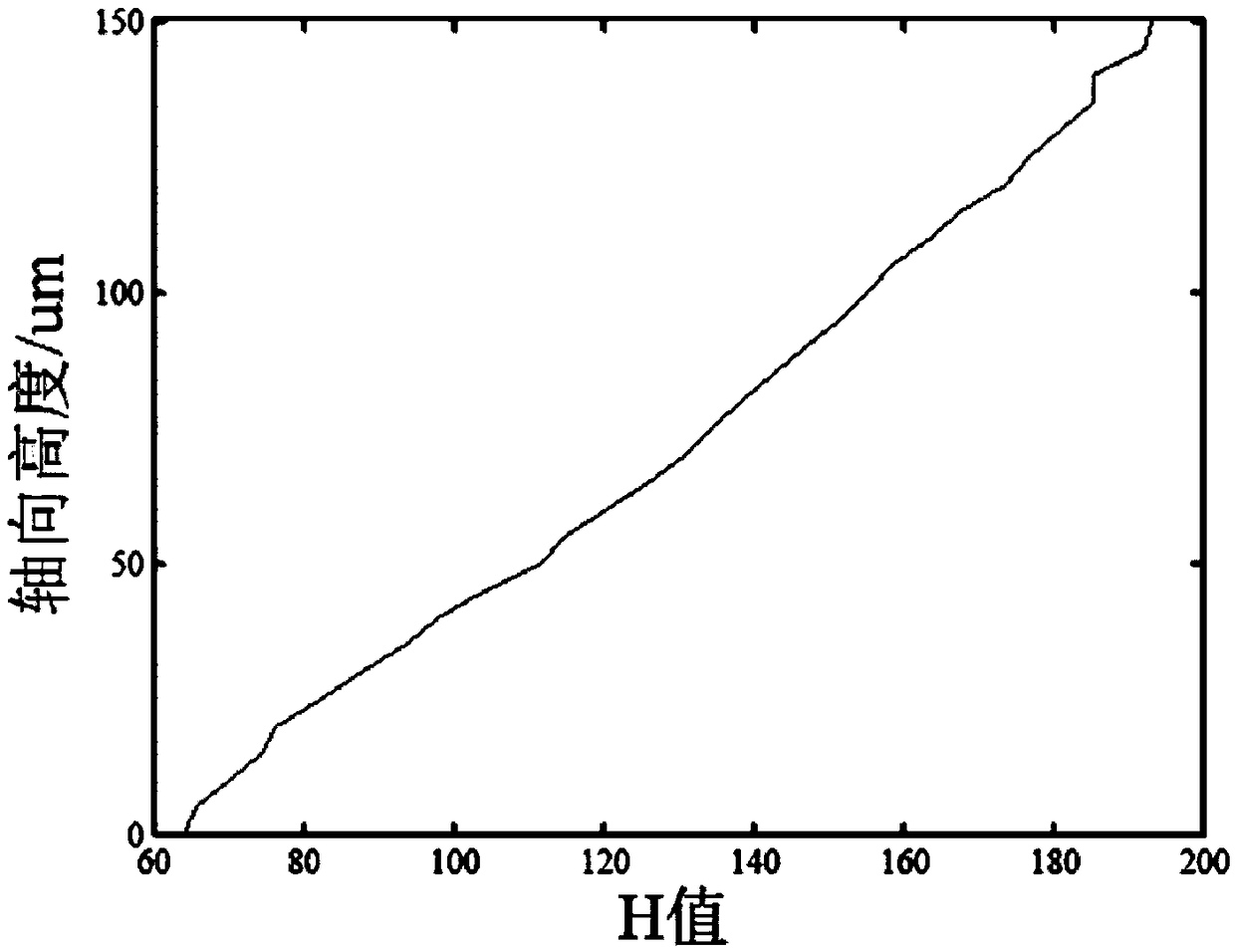

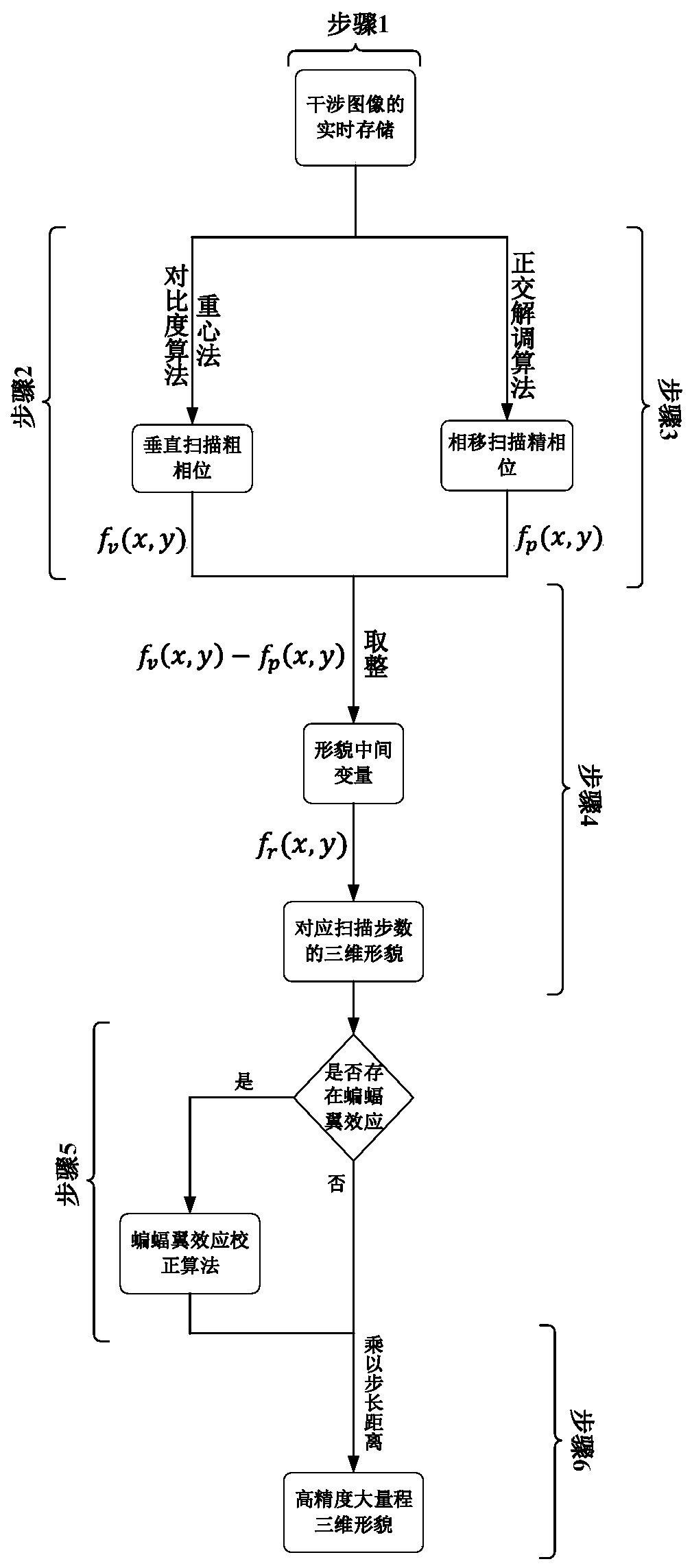

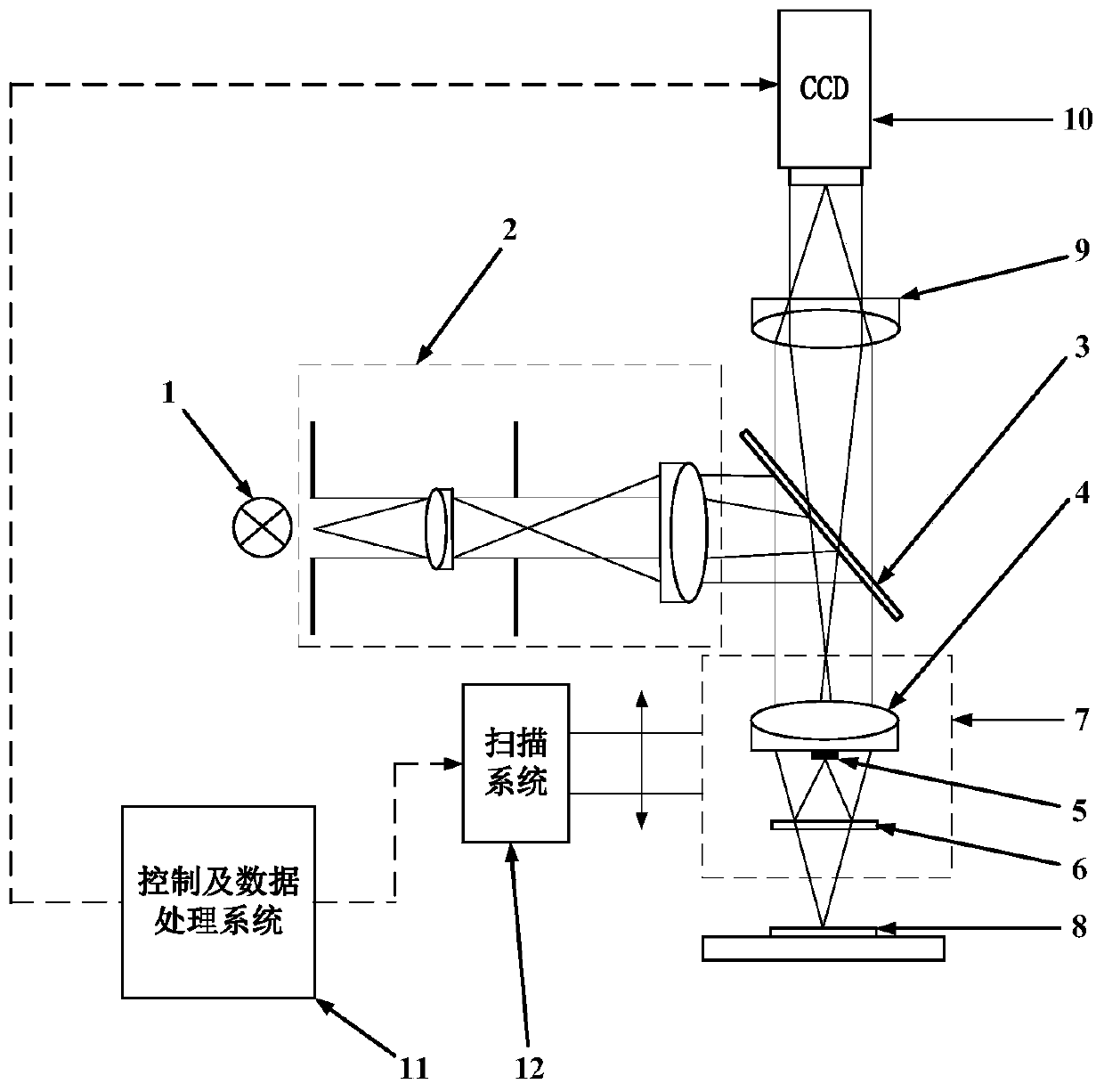

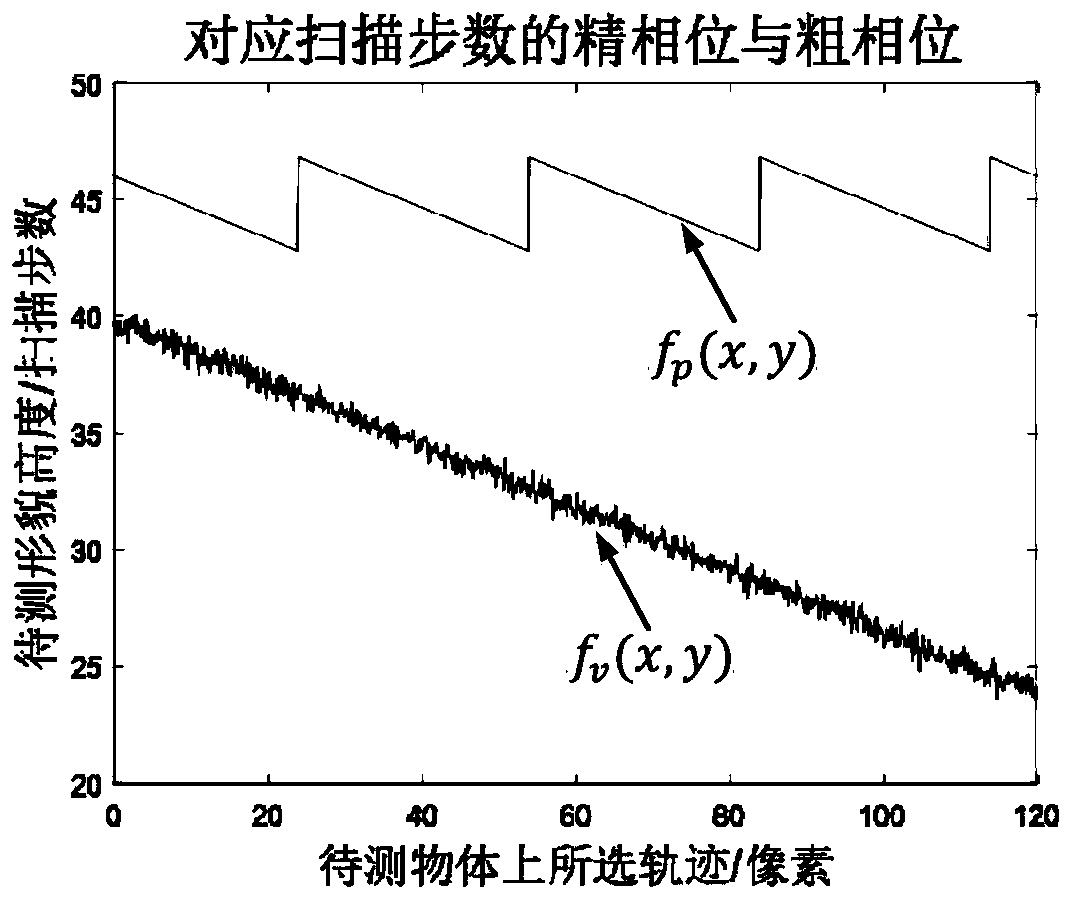

High-precision short coherent light three-dimensional morphology rapid measuring algorithm

ActiveCN109751971AShort timeExact phase resultUsing optical means3D modellingEnvironmental noiseElectricity

The invention discloses a high-precision short coherent light three-dimensional morphology rapid measuring algorithm. The high-precision short coherent light three-dimensional morphology rapid measuring algorithm comprises the steps that firstly piezoelectric ceramics are driven to perform time sequence perpendicular scanning according to pi / 2 phase position stepping quantities within a certain scanning length, and an interference pattern is stored according to each corresponding stepping quantity; the interference patterns are calculated and processed and blended into the process of time sequence perpendicular scanning interference pattern storing to realize rapid measuring; the interference patterns are recorded complete while time sequence perpendicular scanning is carried out, contractratio solution of various pixel point phase shift scanning refined phase and the multiple interference patterns in airspace is completed. The contract ratio of the multiple interference patterns areprocessed to obtain a perpendicular scanning coarse phase; then, the phase shift scanning refined phase is fused with the perpendicular scanning coarse phase to obtain a three-dimensional morphology measuring result; and finally, batwing errors of a sample to be measure generated at edges of step morphology are judged and removed by adopting a two-dimension discrete difference algorithm to obtaina high-precision three-dimensional morphology measuring result. The high-precision short coherent light three-dimensional morphology rapid measuring algorithm is simple, the speed is high, the precision and confidence level is high, and environmental noise resistance capacity is high.

Owner:NANJING UNIV OF SCI & TECH

Three-dimensional analysis method for non-metallic inclusions in metal material

PendingCN110174426ASolve the problem of analyzing 3D topographySolve the analysis problemMaterial analysis using wave/particle radiationThree dimensional morphologyNon-metallic inclusions

The present invention discloses a three-dimensional analysis method for non-metallic inclusions in a metal material. The method comprises the following steps: 1) cutting, grinding and polishing a to-be-analyzed sample to obtain a sheet sample; 2) electrolyzing the observation surface of the sheet sample to erode off one layer of the metal material, and make non-metallic inclusions not be eroded byelectrolysis to protrude from the observation surface and remain in situ on the sheet sample, and cleaning the sheet sample; and 3) placing the sheet sample processed in the step 2) on the sample table of the micro-instrument, adjusting the angle of the sample table, and observing the non-metallic inclusions from right above and side above angles to obtain a three-dimensional morphology of the non-metallic inclusions. According to the method provided by the present invention, information of the non-metallic inclusions and the surrounding matrix in the sample can be retained, and cooperated with the sample table to tilt, the three-dimensional distribution and morphology of the non-metallic inclusions can be observed from multiple angles, so that the difficulty of the preparation of the three-dimensional non-metallic inclusion analysis sample is effectively solved.

Owner:武汉钢铁有限公司

Three-dimensional measurement method suitable for bright surface

ActiveCN106091986AAvoid saturationRestore accuratelyUsing optical meansThree dimensional morphologySignal-to-noise ratio (imaging)

The invention discloses a three-dimensional measurement method suitable for a bright surface. According to images synthesized through uniform-light patterns and coordinate mapping, an optimal projection gray value of each pixel point in a stripe pattern is adaptively adjusted, when the method is used for measuring three-dimensional morphology comprising large-scope reflectivity change, for a bright area with high reflectivity, image saturation can be avoided, for a dark area with low reflectivity, a quite high signal-to-noise ration can be maintained, finally, clear stripe pattern images can be obtained, and the three-dimensional morphology of a measured object can be accurately restored.

Owner:SHAOGUAN COLLEGE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com