Real-time monitoring method for three-dimensional space operating posture position of scraper conveyer

A technology of scraper conveyor and three-dimensional space, which is applied in the direction of conveyor control device, conveyor, conveyor objects, etc., and can solve the problems of not obtaining the shape of the vertical working surface of the scraper conveyor, and not considering complex working conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be further described below.

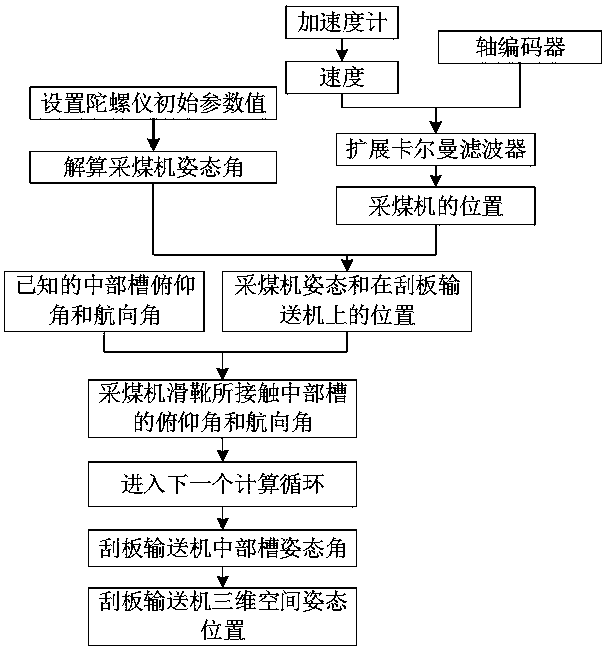

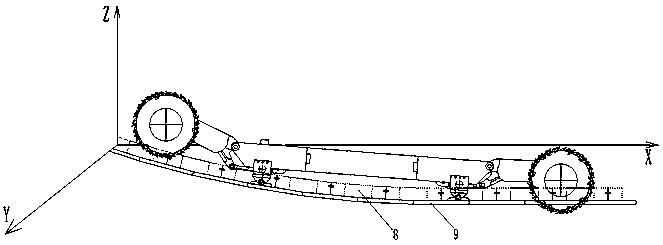

[0029] A method for real-time monitoring of the three-dimensional space running attitude position of a scraper conveyor, wherein the three-dimensional space shape detection of the scraper conveyor includes a horizontal working surface and a vertical working surface. Under the complex working condition of the uneven bottom plate of fully mechanized mining face, the pitch angle and heading angle of the middle groove of each section of scraper conveyor can be detected accurately by using the established shape calculation method.

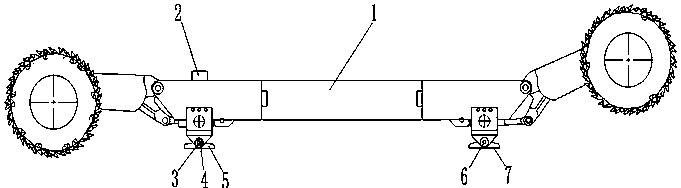

[0030] Taking the middle trough where the shearer was in operation as the origin, establish a coordinated monitoring coordinate system between the shearer and the scraper conveyor, and measure the distance between the left sliding shoe of the shearer and the fuselage of the shearer with two front and rear sliding shoes when the shearer starts to operate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com