Stereoscopic vision detecting method for measuring three-dimensional morphology on strong reflection surface

A technology of three-dimensional shape and stereo vision, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as fringe image distortion, and achieve the effect of simple method, high measurement accuracy and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

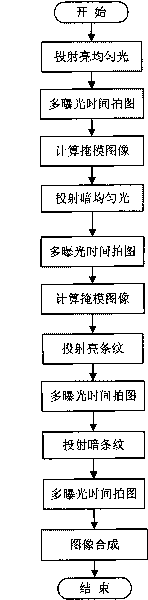

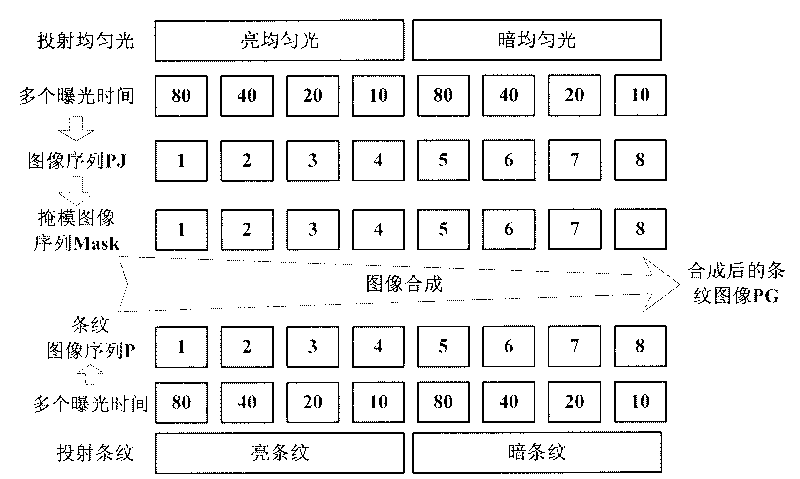

[0032] The present invention is a stereo vision detection method for three-dimensional shape measurement of strongly reflective surfaces. On the basis of the traditional stereo vision detection based on sinusoidal fringe projection, light and dark fringe projection, multiple exposure time image acquisition, and high dynamic range image synthesis are added. And other new technologies to overcome the saturation of the fringe image caused by the strong reflective surface or the fringe image is too dark, and effectively avoid the distortion of the fringe image. The specific implementation steps are as follows,

[0033] (1) Project bright uniform light first, take images with multiple exposure times respectively, and store them in the image sequence PJ in sequence, then project dark uniform light, take images with multiple exposure times respectively, and store them in the image sequence PJ sequentially. Bright uniform light has the same brightness as the brightest part of the brig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com