Method for preparing high-strength double-network hydrogel stent by virtue of 3D printing

A 3D printing and hydrogel technology, applied in the fields of medical science, prosthesis, additive processing, etc., can solve the problems that are not conducive to the construction of fine and complex tissue scaffold structures, slow polymer chemical cross-linking reactions, and limitations, generally about several 100 microns to several millimeters, etc., to achieve good mechanical properties, low printing cost, and fine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) 1.5g sodium alginate (SA), 15g N,N-dimethylacrylamide (DMAA) polymer monomer, 0.0029g ketoglutaric acid (KA) photoinitiator, 0.0093g N,N′ -Methylenebisacrylamide (MBAA) crosslinking agent and deionized water were mixed evenly to 100ml, and then the above 100ml mixed solution was slowly added to a beaker containing 22.5g of HA with a particle size of 20nm, and stirred evenly. Prepared as a mixed sol;

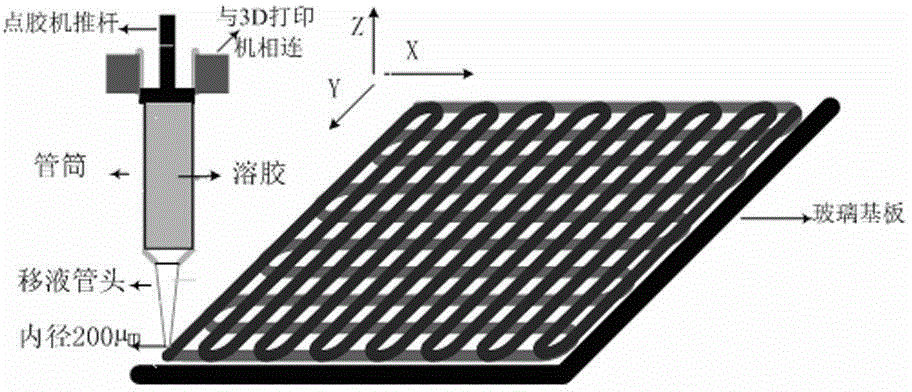

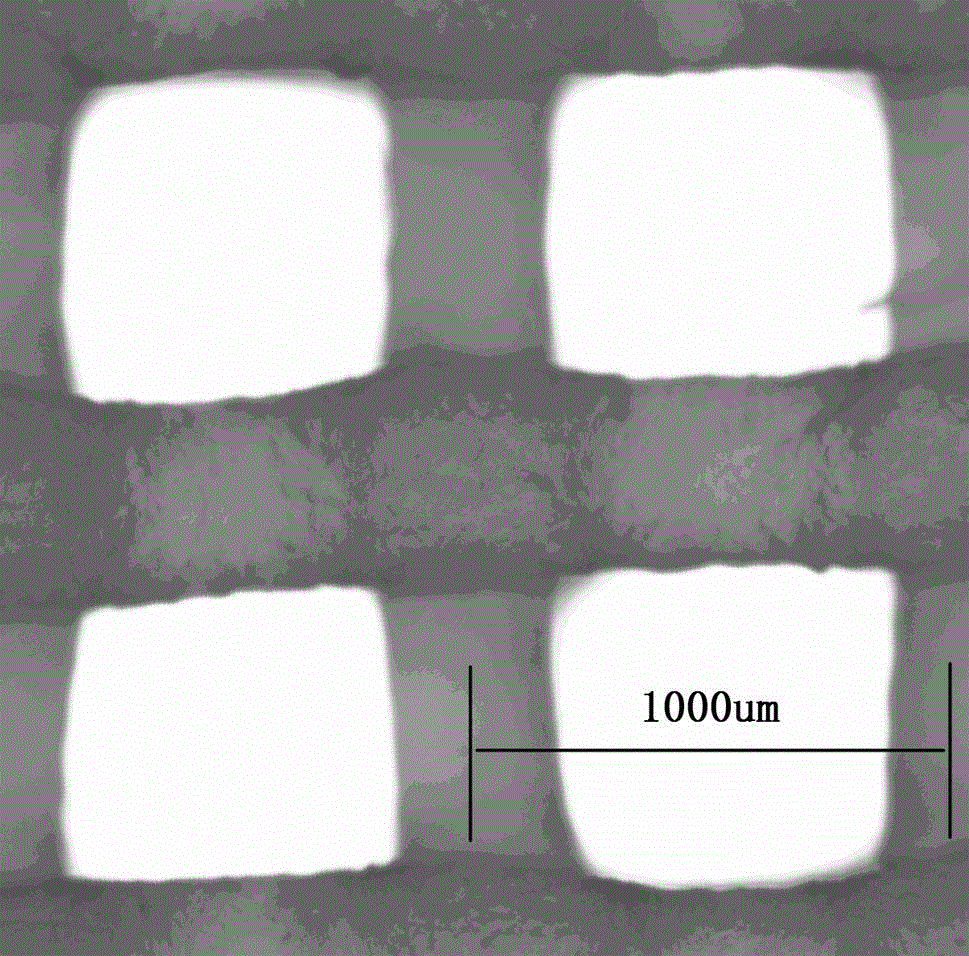

[0043] (2) Preforming of the hydrogel scaffold: use the model The Loctite ? The robot dispensing machine of 200D Benchtop Robot extrudes the mixed sol prepared in step (1) under the selected technical parameters, and 3D prints out the sol support with fine structure. Among them, the technical parameters selected by the robot dispensing machine are:

[0044] Dispenser extrusion rate (volume flow rate) 0.048ml / min

[0045] XY axis platform moving speed 180mm / min

[0046] Z-axis step height 0.4mm

[0047] Needle diameter 100μm;

[0048] (3) Put the printed sol scaff...

Embodiment 2

[0051] (1) 1.8g sodium alginate (SA), 19.8g N,N-bismethacrylamide (DMAA) polymer monomer, 0.0029g ketoglutaric acid (KA) photoinitiator, 0.0093g N,N ′-Methylenebisacrylamide (MBAA) cross-linking agent and deionized water are mixed evenly to 100ml, and then the above 100ml mixed solution is slowly added to a beaker containing 32.4g of HA with a particle size of 80nm, and stirred evenly , formulated into a mixed sol;

[0052] (2) Preforming of the hydrogel scaffold: using a Sistema Dosificador Ultra 2800 robotic dispensing machine, extrude the prepared mixed sol described in step (1) under the selected technical parameters, and 3D print out a fine The structure of the sol support, in which the technical parameters selected by the robot dispensing machine are:

[0053] Dispenser extrusion rate (volume flow rate) 0.072ml / min

[0054] XY axis platform moving speed 250mm / min

[0055] Z-axis step height 0.6mm

[0056] Needle diameter 200μm;

[0057] (3) Put the printed sol scaff...

Embodiment 3

[0061] (1) 2.0g sodium alginate (SA), 24g N,N-bismethacrylamide (DMAA) polymer monomer, 0.0029g ketoglutaric acid (KA) photoinitiator, 0.0093g N,N′ - Methylenebisacrylamide (MBAA) cross-linking agent and deionized water were mixed evenly to 100ml, and then the above 100ml mixed solution was slowly added to a beaker containing 40g of HA with a particle size of 200nm, stirred evenly, and prepared into a mixed sol;

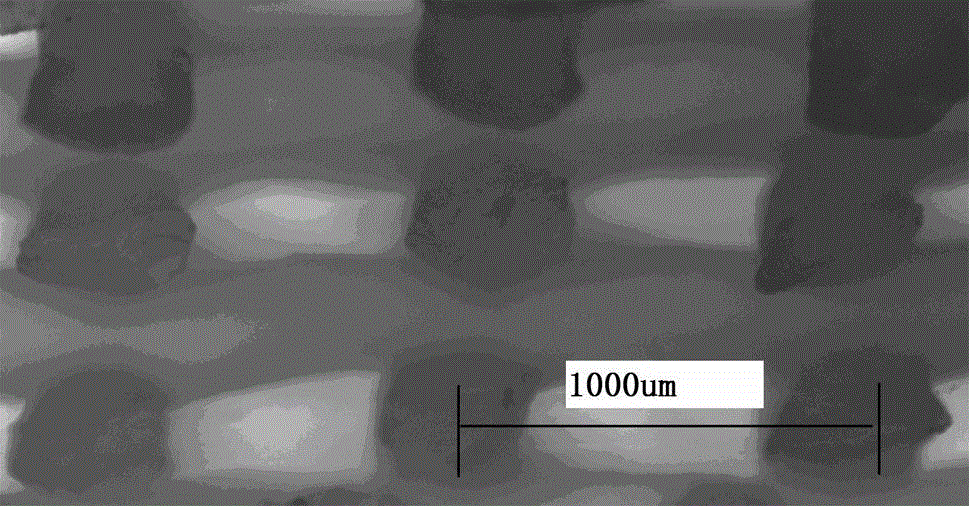

[0062] (2) Preforming of the hydrogel scaffold: use the model The Loctite ? The robot dispensing machine of 400D Benchtop Robot extrudes the mixed sol prepared in step (1) under the selected technical parameters, and 3D prints out the sol support with fine structure, wherein the technical parameters selected by the robot dispensing machine for:

[0063] Dispenser extrusion rate (volume flow rate) 0.090ml / min

[0064] XY axis platform moving speed 220mm / min

[0065] Z-axis step height 0.5mm

[0066] Needle diameter 500μm;

[0067](3) Place the printed sol s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear viscosity | aaaaa | aaaaa |

| Modulus | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com