Patents

Literature

718results about How to "Reduce printing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-based intaglio ink equal to plate engraving ink and uses thereof

ActiveCN101284965AOptimizing physical fastnessNo pollutionInksOther printing apparatusScreen printingSolubility

The invention is equivalent to water soluble intaglio ink of plate engraving ink and / or equivalent to water-soluble screen printing ink of the ink, suitable for a gravure printing machine. The ink has the advantages of nontoxicity, tastelessness, nonflammable property, water solubility, non-environmental pollution and rapid drying; the printing effect of the obtained presswork is the same as or equivalent to the printing effect of the plate engraving presswork; the materialized firmness of the presswork is superior to the materialized firmness of the plate engraving presswork; the ink is low in printing cost and suitable for printing secure and confidential documents with deep printing lines, such as bank notes, securities, stamps, food packing, etc.

Owner:北京万垟防伪技术有限责任公司 +2

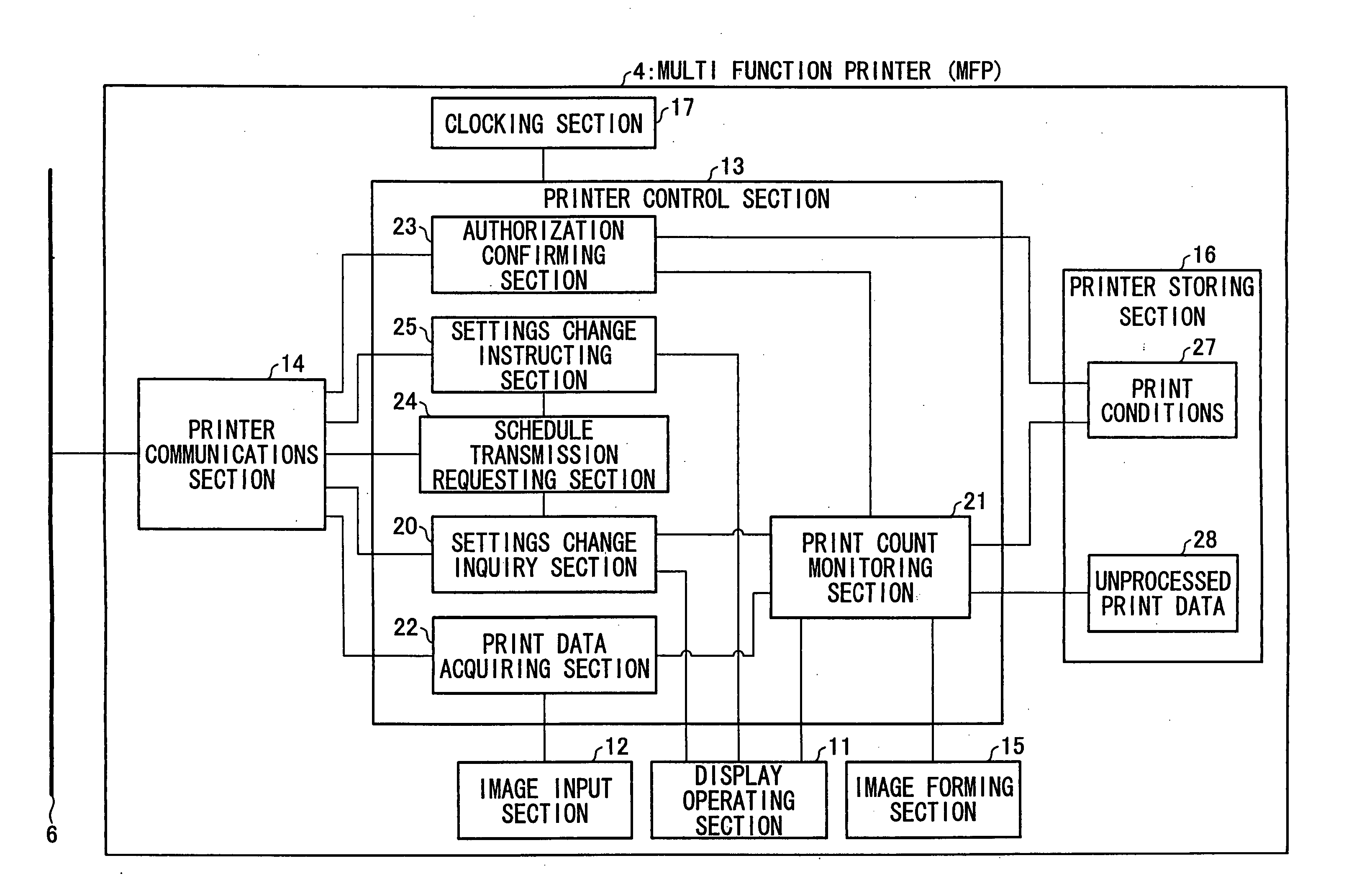

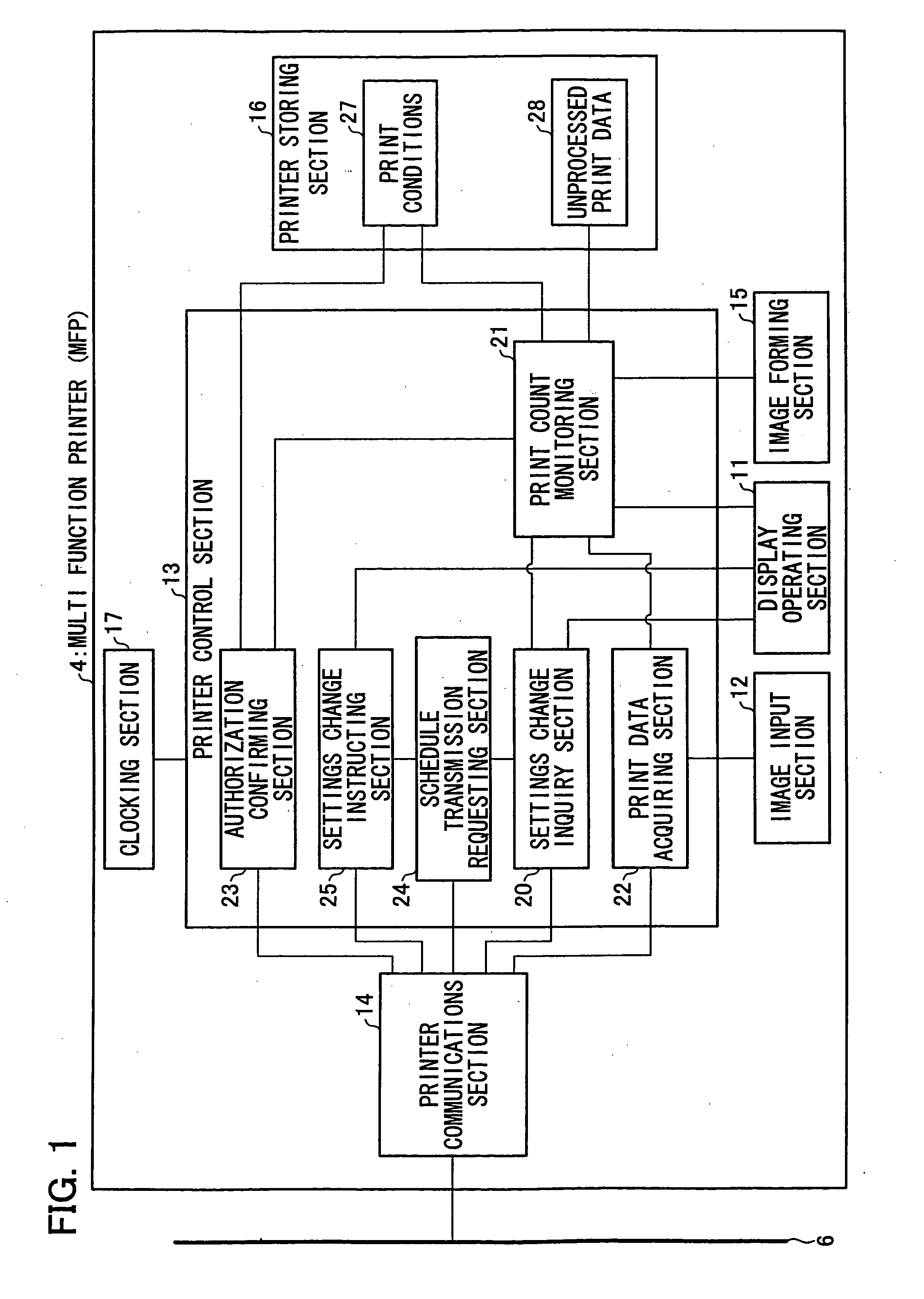

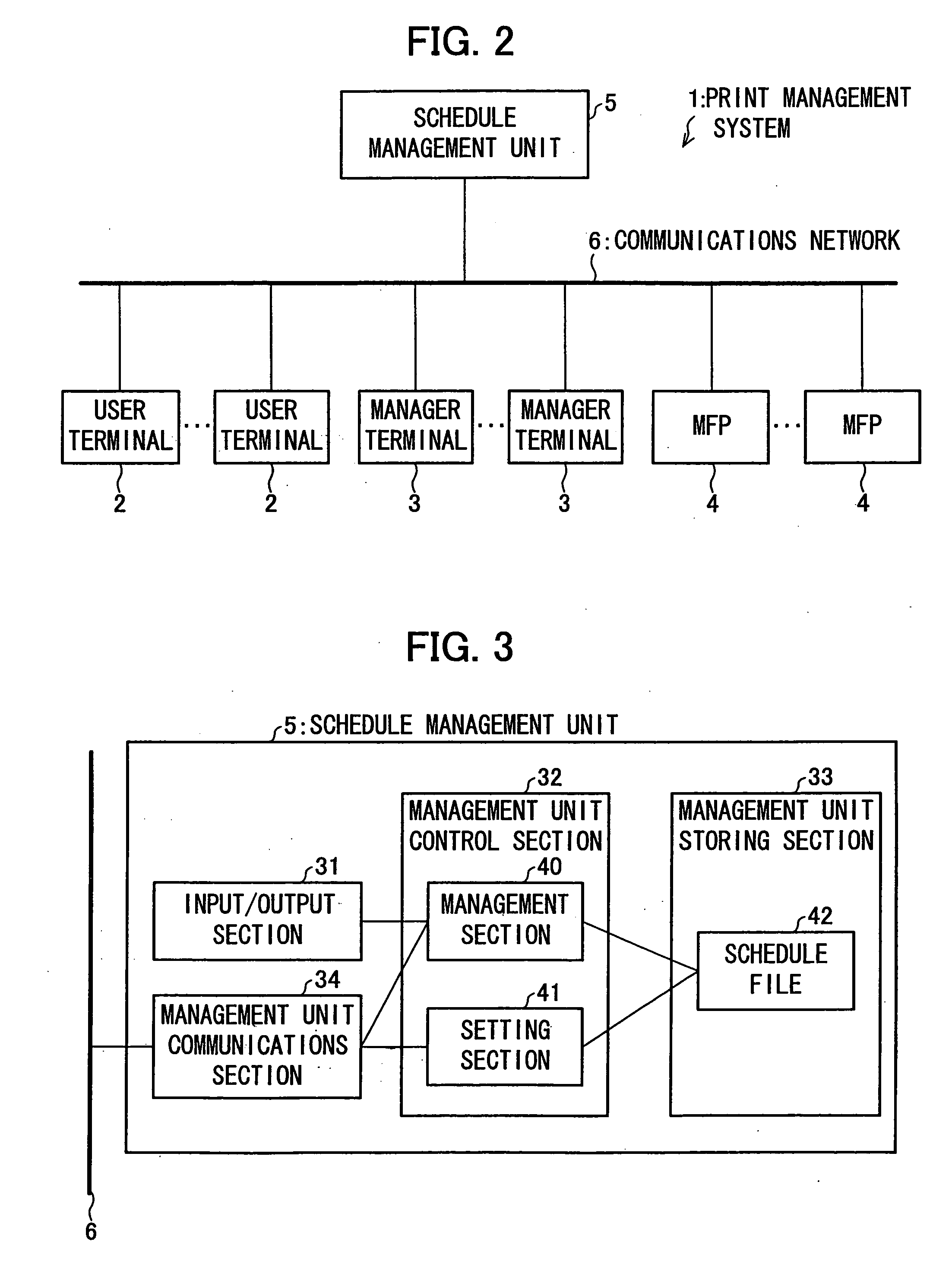

Printing apparatus, print control program, and storage medium storing the print control program

InactiveUS20050275867A1Low costNo wasteful print job carried out by the userDigital computer detailsVisual presentationComputer printingAuthorization

In a multi function printer, an upper limit of printable sheets is set for each user requesting a print job. The multi function printer includes a settings change instructing section for making an inquiry to a manager terminal whether to authorize changing the upper limit as requested by a user, and an authorization confirming section for confirming a reply to the inquiry, and changing the upper limit if the manager terminal authorizes the change. This reduces the cost of print job, and enables a print job to be efficiently carried out by changing print restrictions as required by the print job.

Owner:SHARP KK

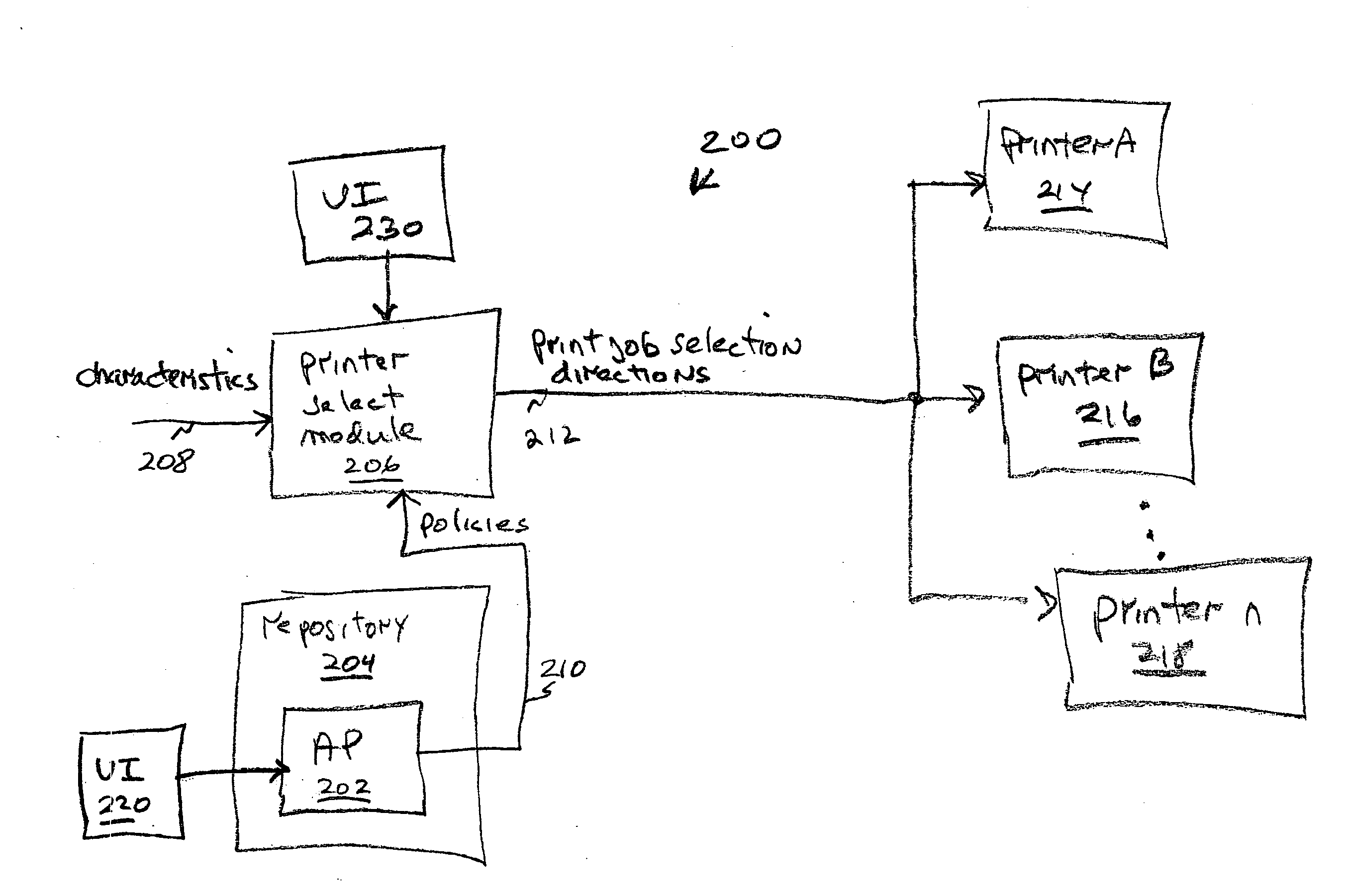

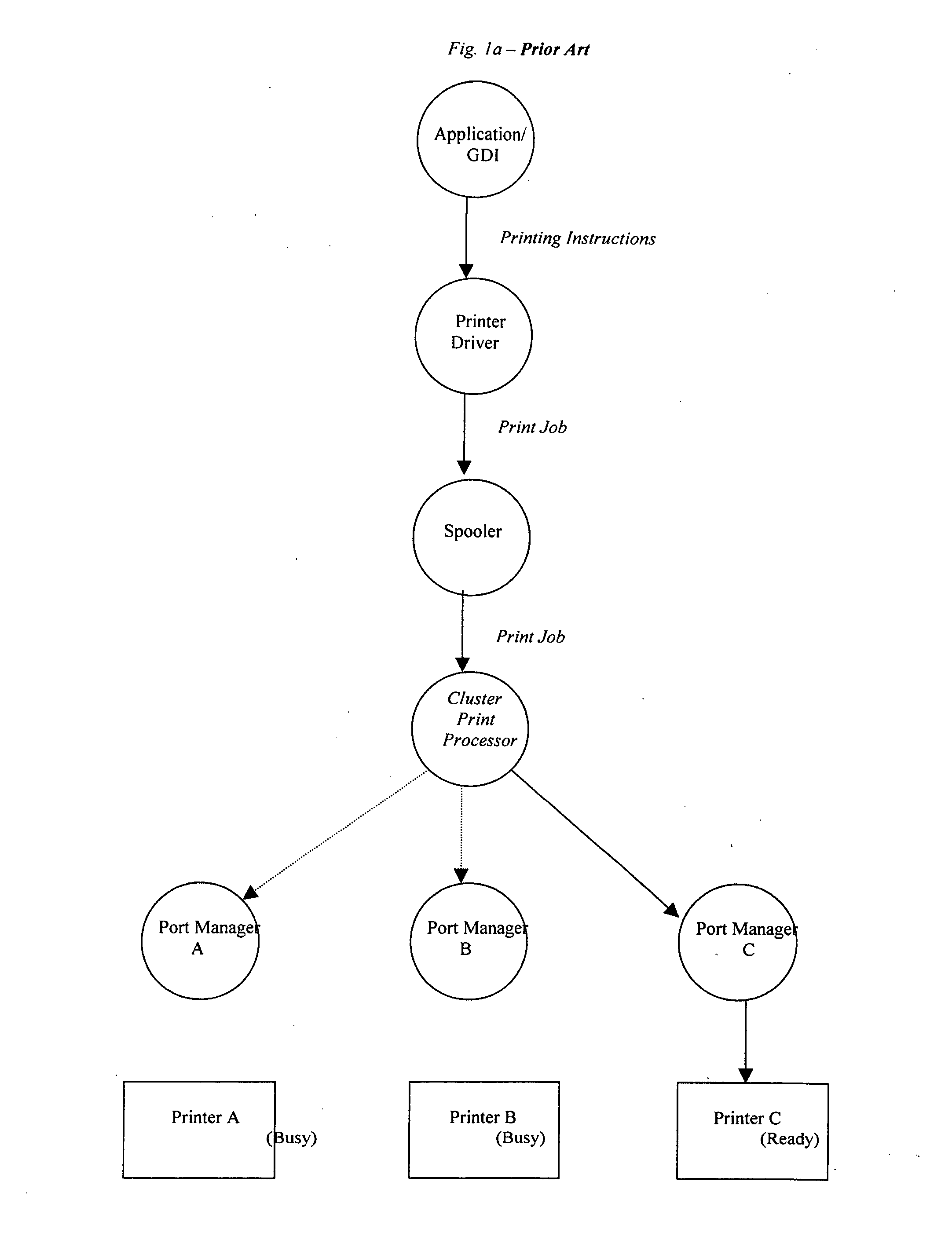

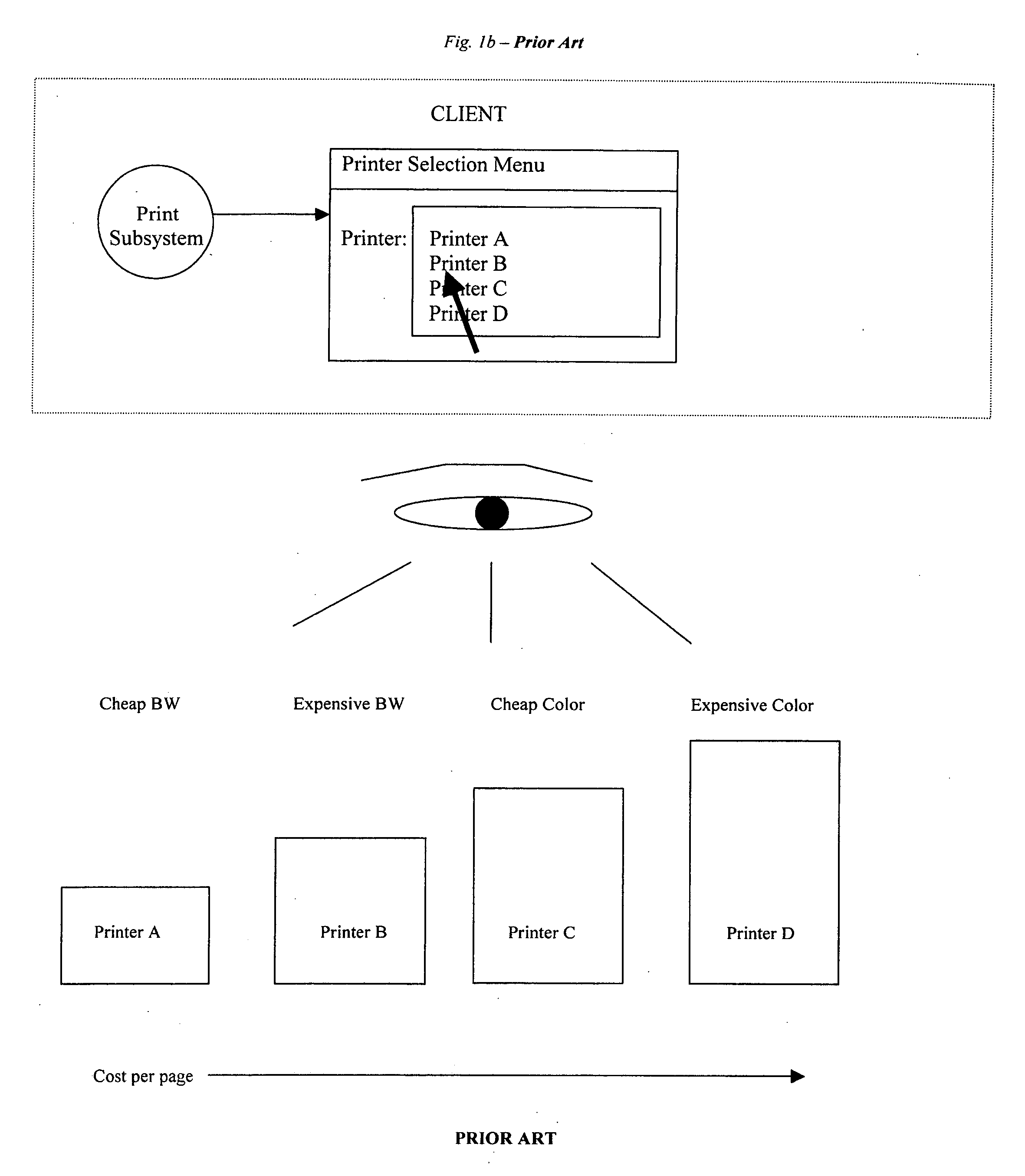

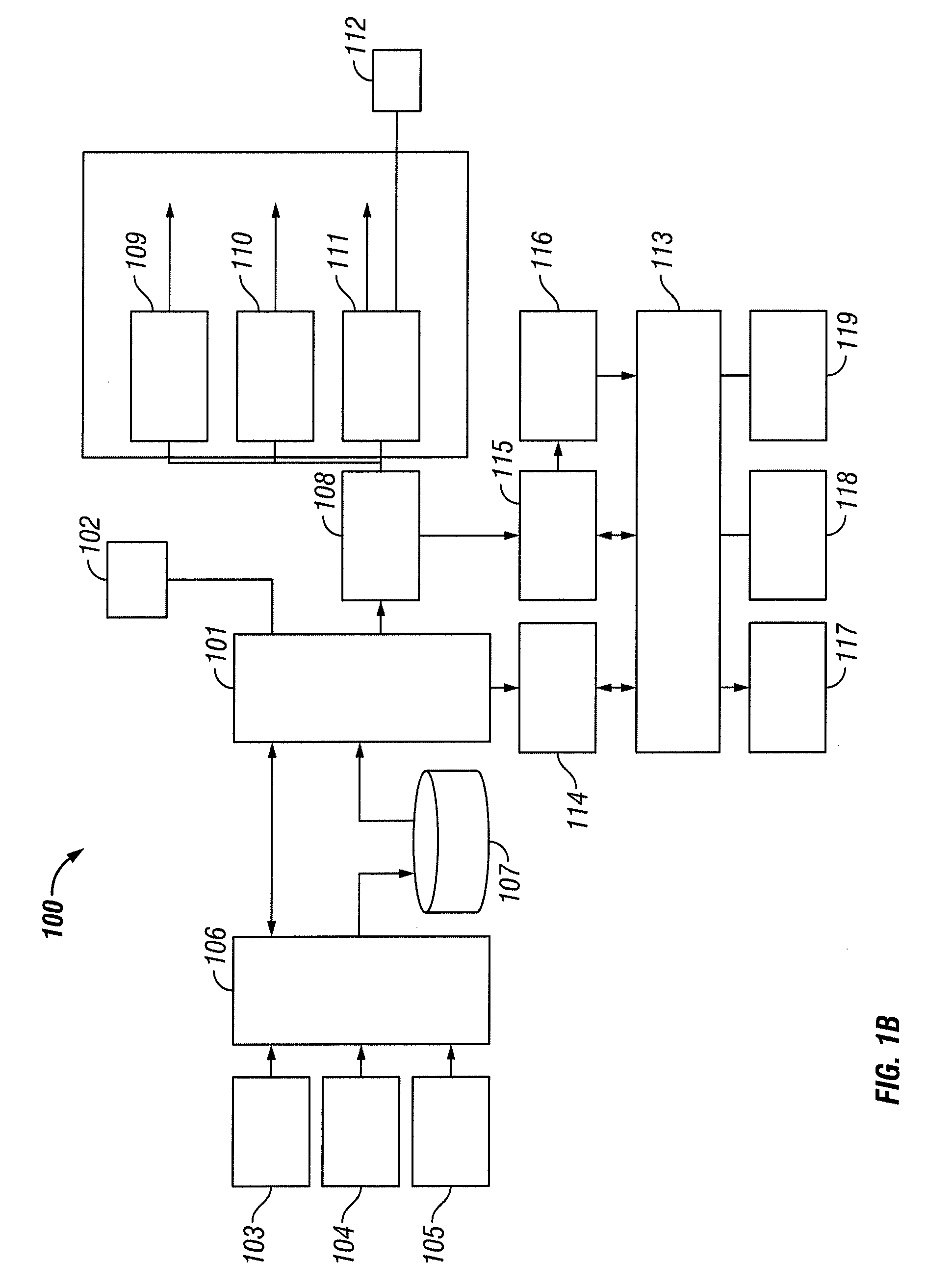

Printer pool administration policy

ActiveUS20050102442A1Reduce printing costsLow costDigital computer detailsDigital output to print unitsOperation schedulingComputer printing

A system and method are provided for managing printer selection in a network of connected printers. The method comprises: accepting a print job; determining characteristics of the print job; selecting a printer in response to a programmable administrative policy that cross-references user-defined usage criteria to print job characteristics; and, sending the print job to the selected printer. The administrative policy is programmed to be responsive to print job characteristics such as user identity, client identity, the document processing application sourcing the print job, the document format, media, document complexity, color / BW, rendering, content, job scheduling, and printer capabilities such as stapling, duplex printing, or hole punching.

Owner:PATOIS TELECOM LIMITED LIABILITY

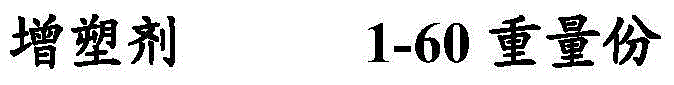

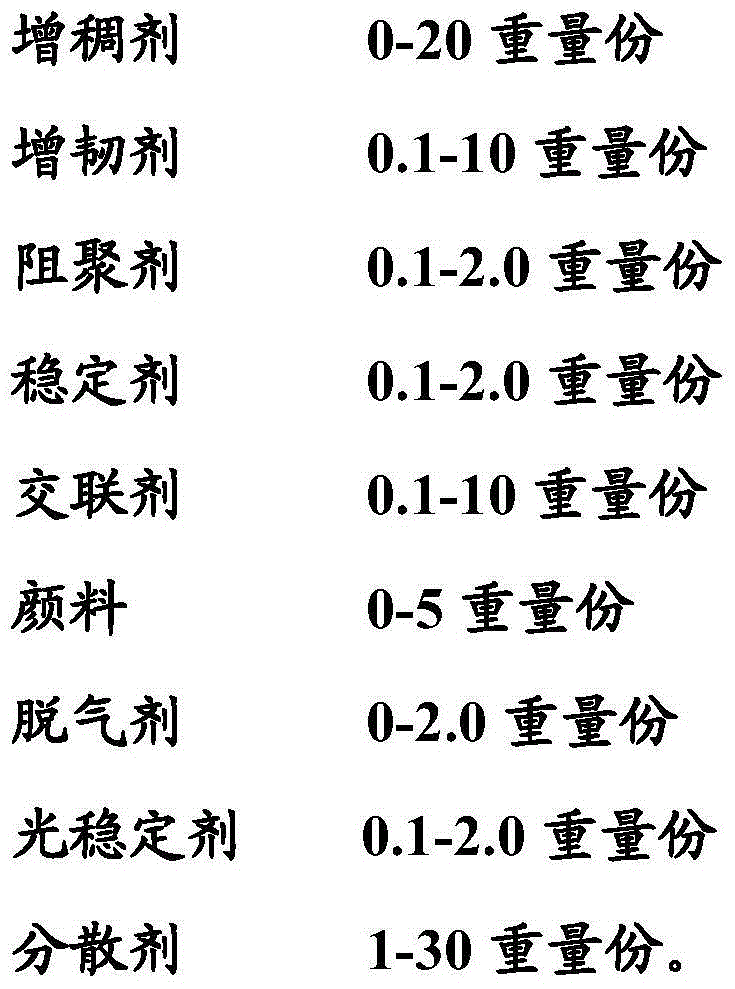

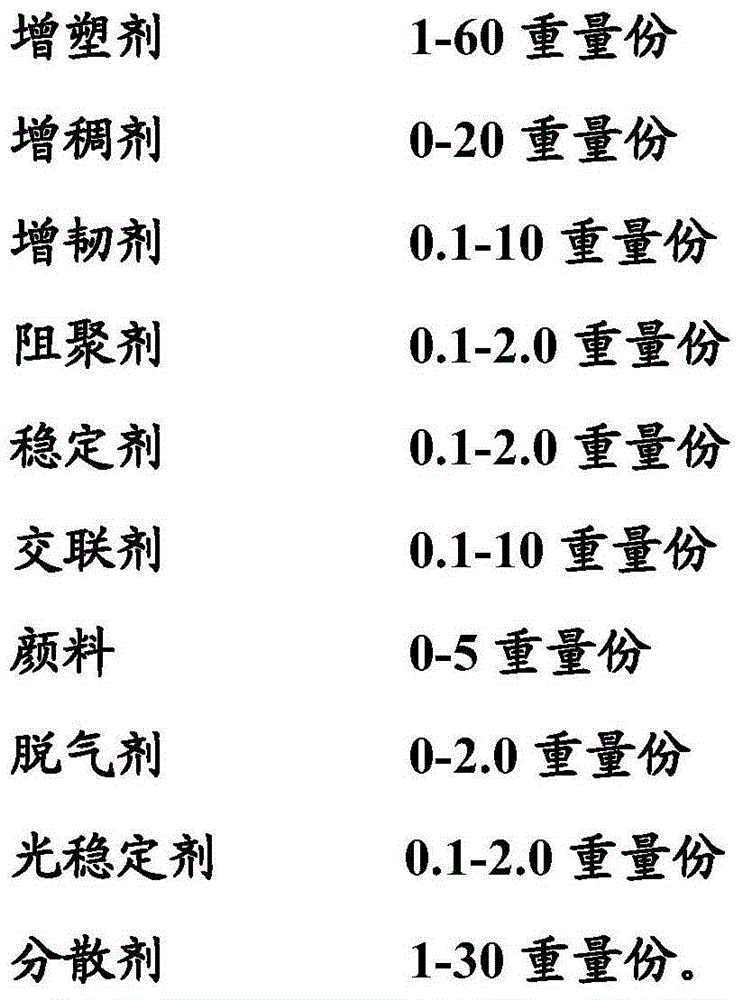

3D printing composition, preparation and application methods and product thereof

The invention discloses a 3D printing composition, its preparation and application methods and a product thereof. According to the material, cyanoacrylate and a powder material are used as main bodies; a solvent is added to adjust fluidity of the material; and simultaneously, certain amounts of a plasticizer, a thickener, a flexibilizer, a stabilizer, a cross-linking agent, a pigment, a degassing agent and the like are contained to raise stability of the material and mechanical property of a printing product. As the material is a liquid and solidification process of the material is controlled by controlling conditions such as environment humidity, temperature and the like during printing, an ink-jet printing head which has been developed comparatively mature at present can be used for printing. The composition provided by the invention has characteristics of high printing precision, fast forming speed and low cost. Meanwhile, a printing product has high mechanical strength. The composition is a novel green 3D printing material.

Owner:INST OF CHEM CHINESE ACAD OF SCI

UV-oxide hybrid drying type engraving intaglio printing ink

ActiveCN101250354AAchieve dryingWell mixedInksOther printing apparatusPulp and paper industryPrinting ink

The invention relates to UV-oxidation mixing drying type incising gravure printing ink, which is prepared through firstly producing by rolling UV drying components and oxidation drying components assisting volatilization drying, penetration drying and complex drying effect, and evenly mixing according to 1%-99% proportion of UV drying component and 99%-1% oxidation drying components assisting volatilization drying, penetration drying and complex drying effect. The printing ink of the invention conducts UV drying in the process of printing, instantly realizes partial drying of printing ink to form a drying ink film, can finish oxidation drying and assisting volatilization drying, penetration drying and complex drying effect to achieve the complete drying of printing ink. The printing ink solves the technical problems that thick ink film existing in current UV drying incising gravure printing ink is incomplete, complete drying can not be realized in the natural storage process, and has the advantages of economical, energy-saving and environment-friendly.

Owner:CHINA BANKNOTE PRINTING & MINTING

Photogravure ink equal to cut ink and its application

This invention relates to a photograghic intaglio printing ink which equals to carving intaglio printing ink. It can be used in photographic intaglio printer, and its outstanding feature is that the price of the printer is cheap, lithographic cost is low, and the post-treatment step of sewage during printing process is unneeded, so the sewage from carving intaglio printing ink printing process is eradicated completely and with no environmental pollution, and the printing ink is no waste and its non-offset performance is very good. It dries quickly, so it shortens the production cycle and saves the production buildings and land. The color of ink of its printing is of distinct hierachical structure and strong stereoscopic feeling. Its printing effect is the same as that of carving intaglio printings. The physicochemical fastness of its printing is superior to that of carving intaglio printings. Its printing cost is low.

Owner:北京万防伪技术有限责任

Greenbooks

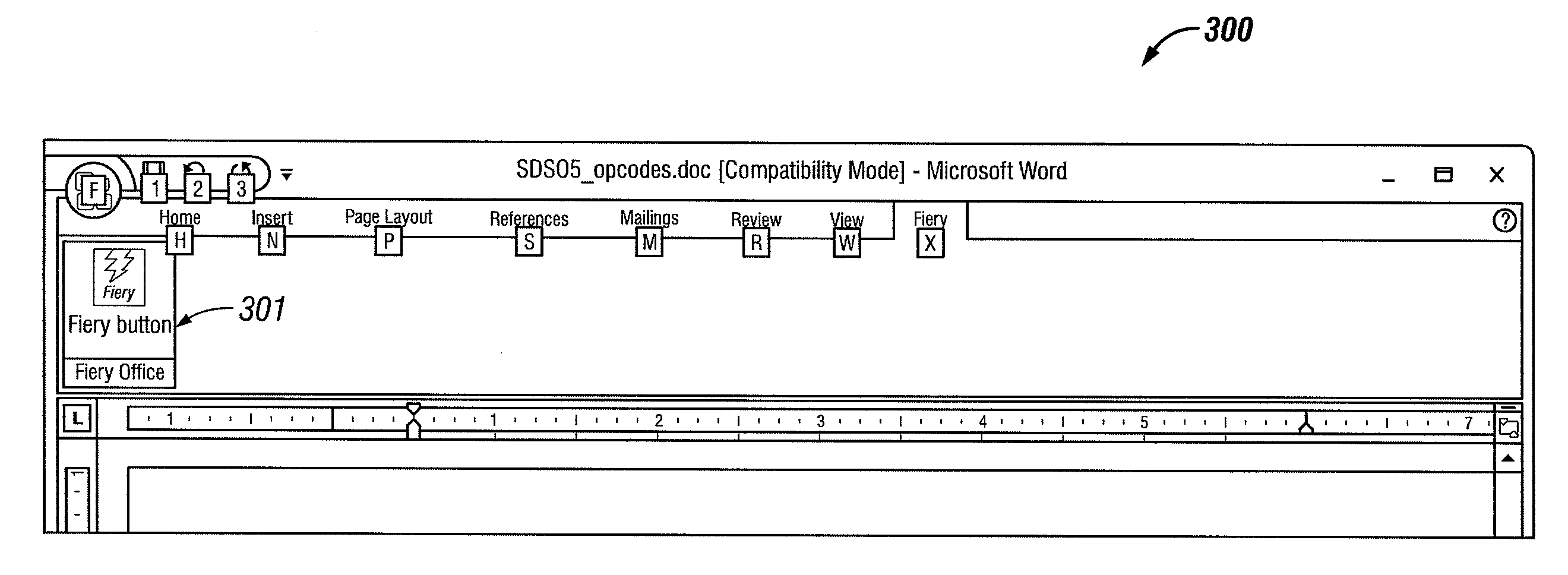

ActiveUS20110032562A1Reduce the amount requiredReduce usageDigital output to print unitsEnvironmentally friendlyArchitecture of Integrated Information Systems

A computer architecture that integrates desktop productivity applications with various visualization engines and various output engines allowing visualization, modification and formatting of the ultimate output from the application. Methods for accomplishing content visualization, editing and formatting in light of one or more printing option are also provided. Methods and apparatus are also provided for environmentally-friendly printing in booklet form.

Owner:FIERY LLC

UV (Ultra Violet) offset printing ink and preparation method thereof

The invention relates to UV (Ultra Violet) offset printing carrier oil, connection UV offset printing gloss oil and preparation methods thereof. The offset printing ink comprises UV offset printing carrier oil and connection UV offset printing gloss oil, wherein the UV offset printing carrier oil is prepared from a polyester acrylate oligomer, filling, a reactive diluent, a high-viscosity additive, and the like by firstly adding a dispersant and resin, grinding the filling to a qualified degree of fineness and then adding the active diluent, a photoinitiator and the high-viscosity additive to stir and disperse together at a high speed, the connection UV offset printing gloss oil is prepared from a high-functional urethane acrylate oligomer, a dual-functional urethane acrylate oligomer, a photoinitiator, a leveling agent, and the like by stirring at a high speed, filtering, and the like. The offset printing ink and the method enable a printed product to generate the special concentration effect so as to obtain various special surface printing effects.

Owner:惠州深赛尔化工有限公司

Flux for lead-free solder and soldering Method

ActiveUS20090308496A1Inhibition formationIncrease costPrinted circuit assemblingCooking-vessel materialsPhosphateNitrogen atmosphere

A soldering flux which is suitable as a no-clean post flux in flow soldering and which can prevent the formation of whiskers which tends to occur when soldering electronic parts to a printed circuit board using a lead-free solder (such as Sn-3.0Ag-0.5Cu) having a higher Sn content and a higher melting point than the eutectic solder contains, in addition to a rosin as a base resin and an activator, 0.2-4 mass % of at least one compound selected from acid phosphate esters and derivatives thereof. The formation of whiskers can be more effectively prevented by carrying out soldering in a nitrogen atmosphere.

Owner:SENJU METAL IND CO LTD +1

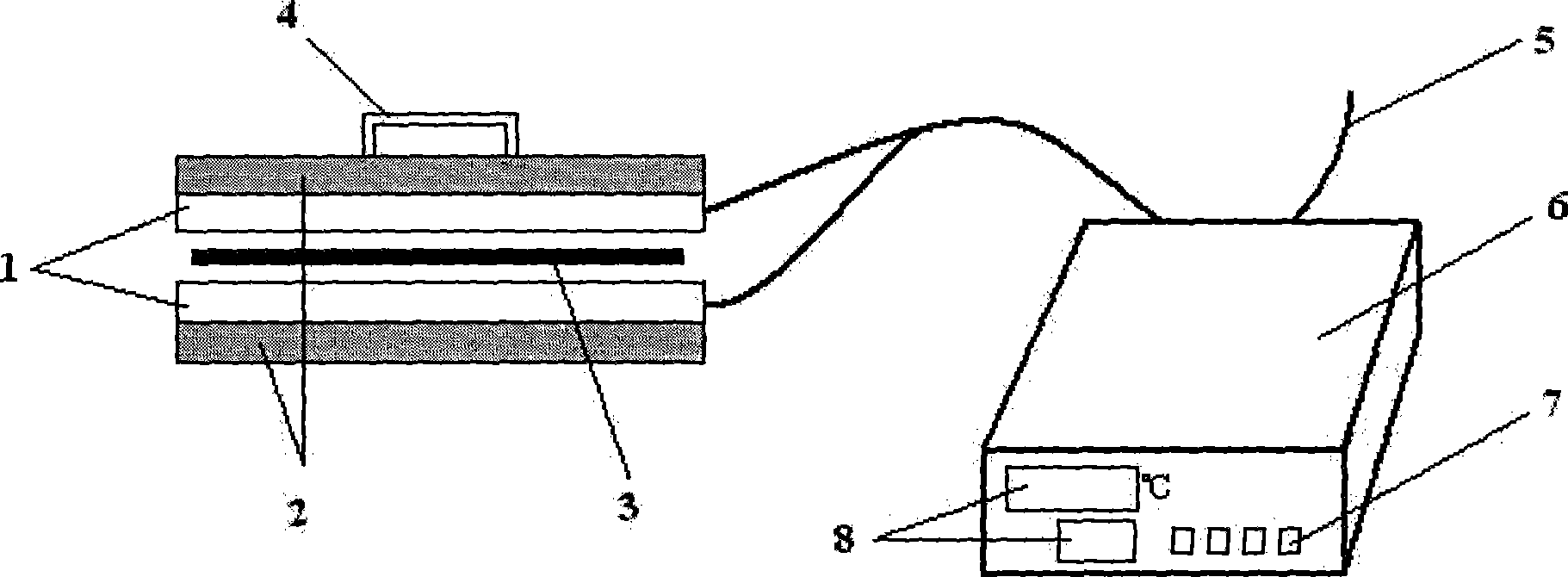

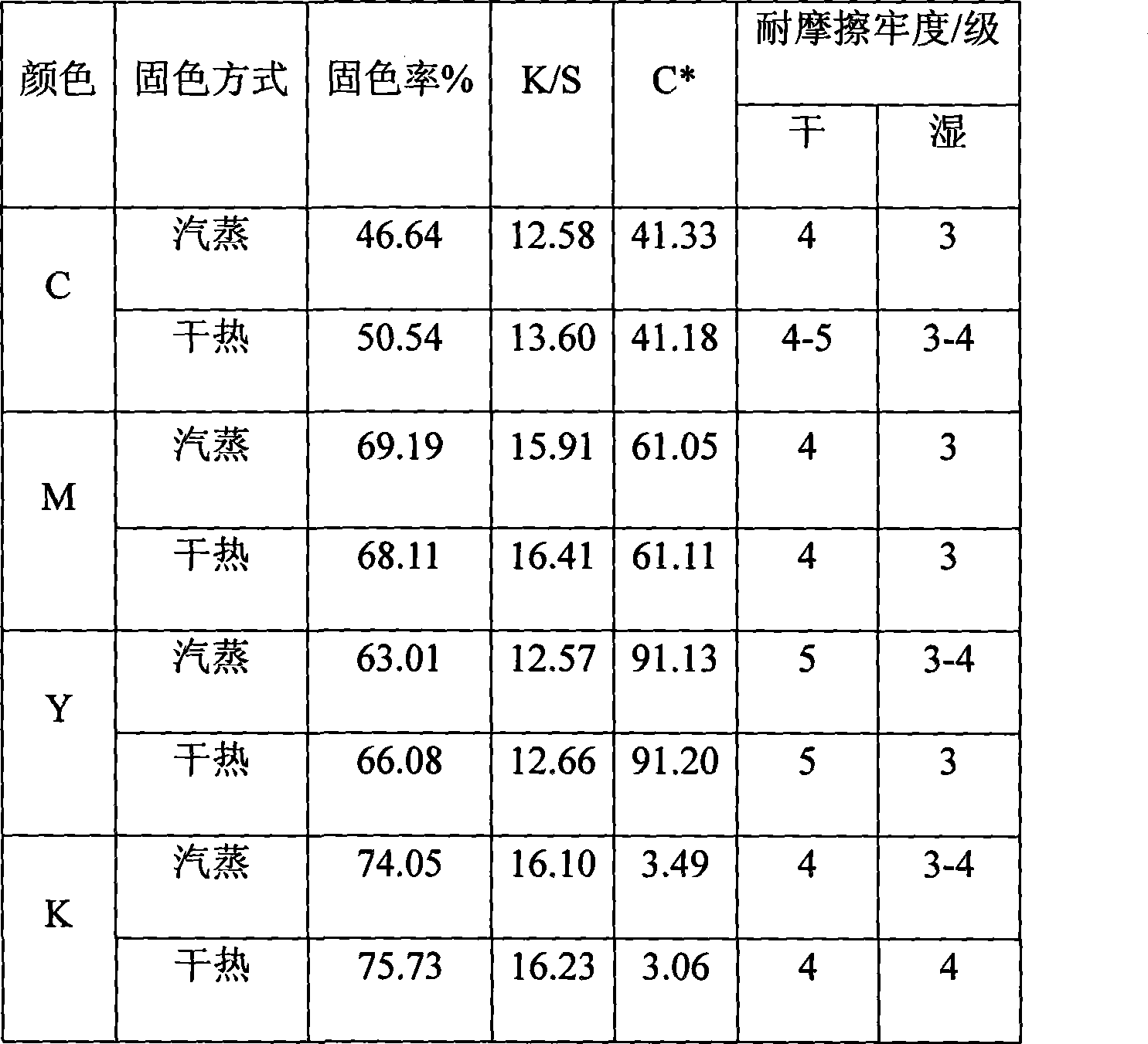

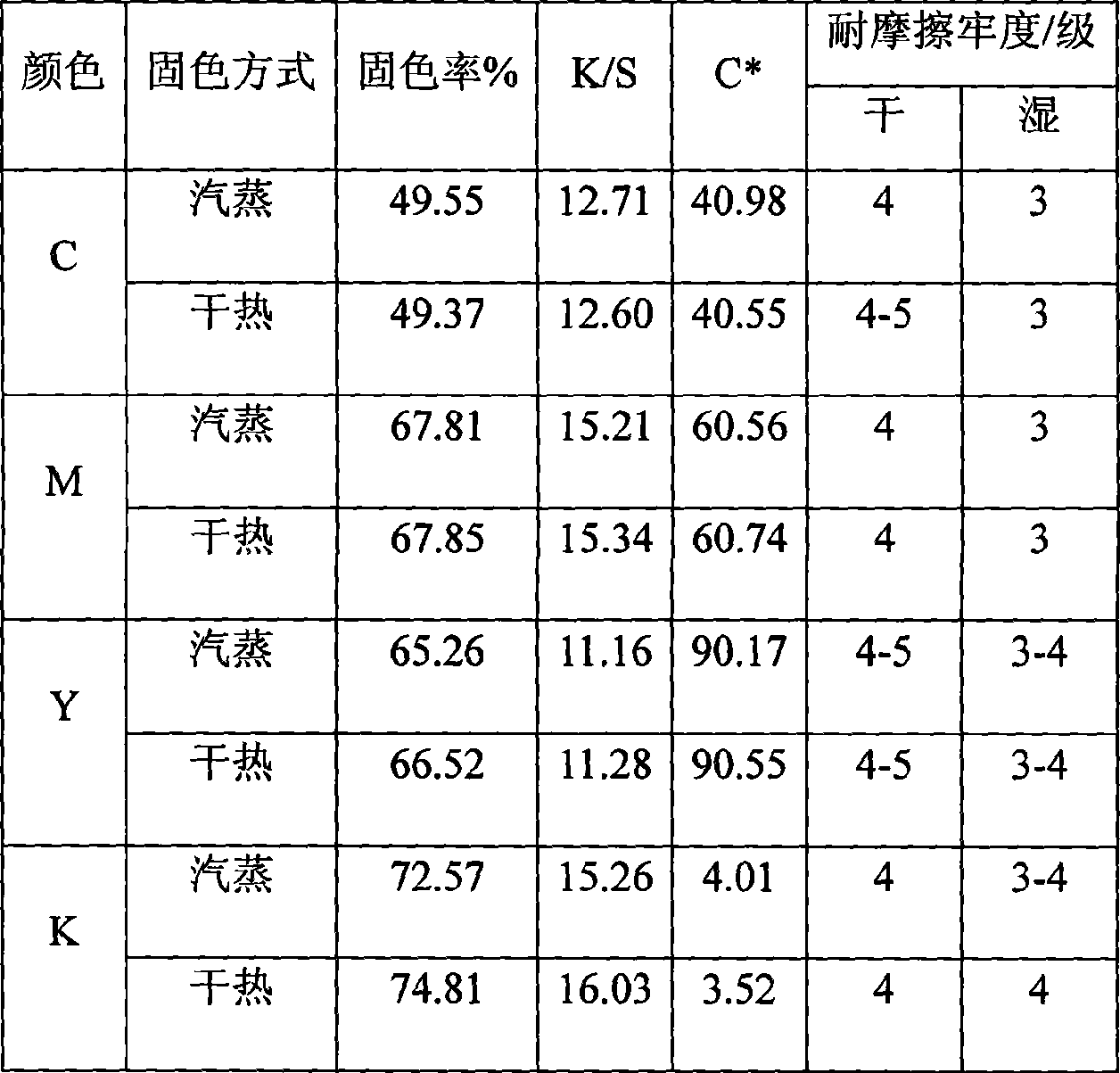

Fixation method and apparatus for inking and printing on cotton with active ink

InactiveCN101381934AHigh color fixing rateImprove color vividnessHeating/cooling textile fabricsDyeing processEngineeringDry heat

The invention relates to a method and a device for fixing cotton fabric reactive ink inkjet printing. The method comprises the following: (1) a step of pretreating fabric, which is to make thickener into stock thickener, dissolve alkaline agent, urea and antifoaming agent in water, add the alkaline agent, the urea and the antifoaming agent to the stock thickener, evenly mix the mixture so as to form a pretreatment solution, pad the fabric with the pretreatment solution and then dry the fabric; (2) a step of performing inkjet printing, which is to adopt reactive dye ink to perform inkjet printing to the pretreated fabric on a digital inkjet printing machine; and (3) a step of after-treating the fabric, which is to adjust humidity of the jet-printed fabric for 4 hours, adopt a contact-type dry-heat fixation device, regulate the temperature of a heating plate to be between 150 and 160 DEG C, set the treatment time to be between 40 and 80 seconds, complete fixation through contact-type dry-heat treatment, wash and dry or air the fabric, so as to obtain a finished product. The invention has the advantages of convenient operation of technological process, strong flexibility and high fixation rate, and solves the problems existing in small-batch steaming fixation.

Owner:DONGHUA UNIV

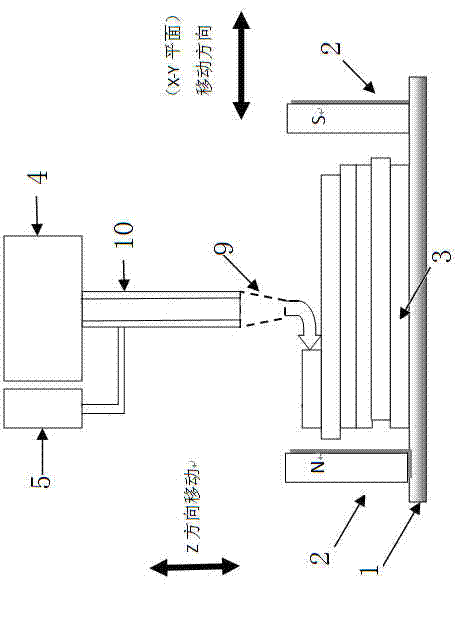

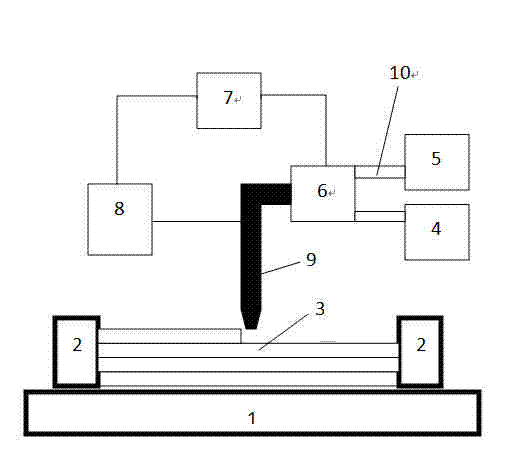

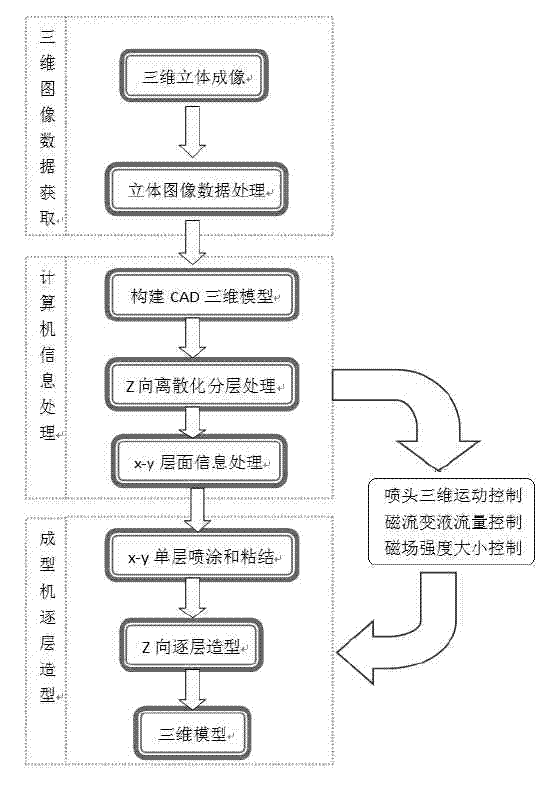

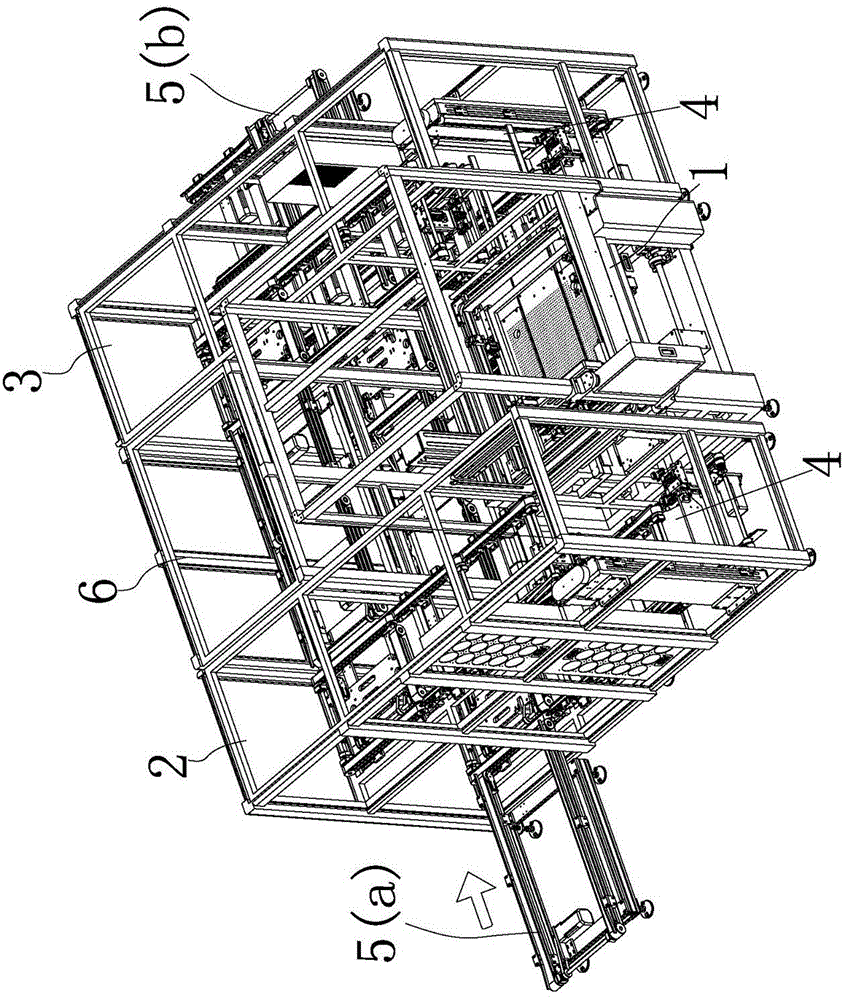

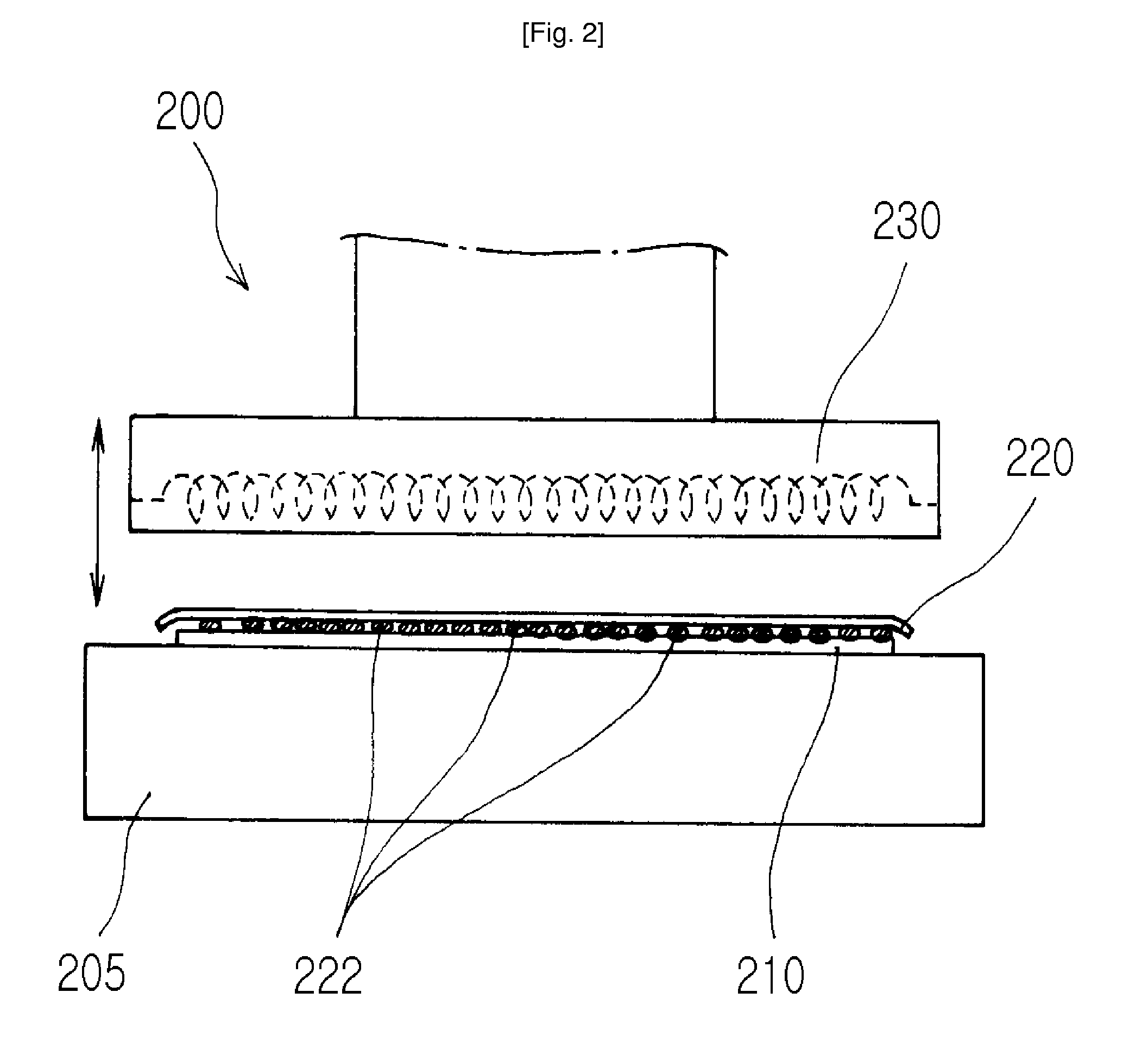

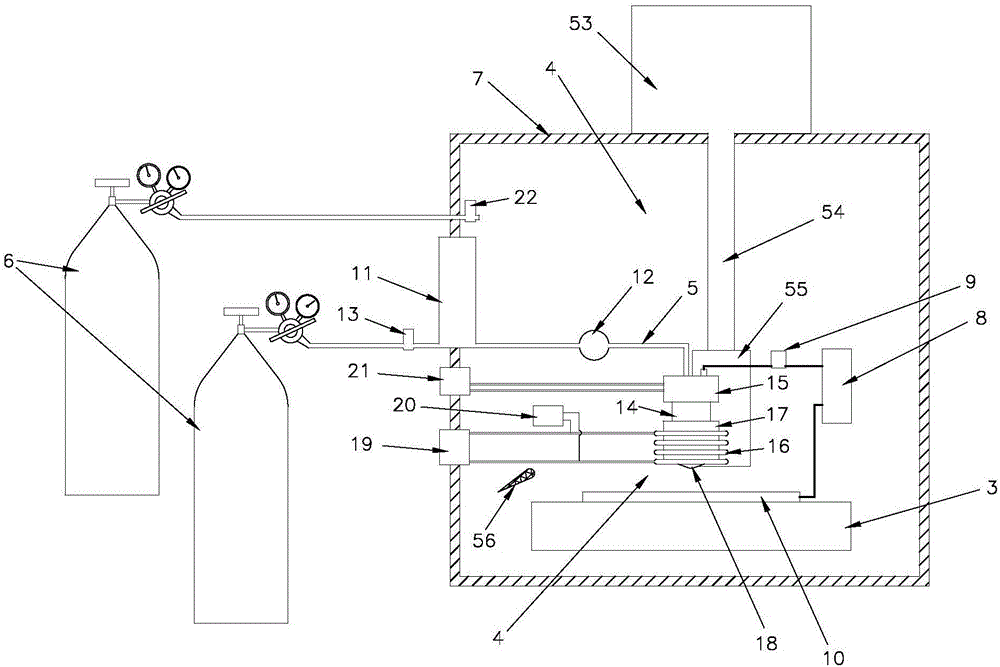

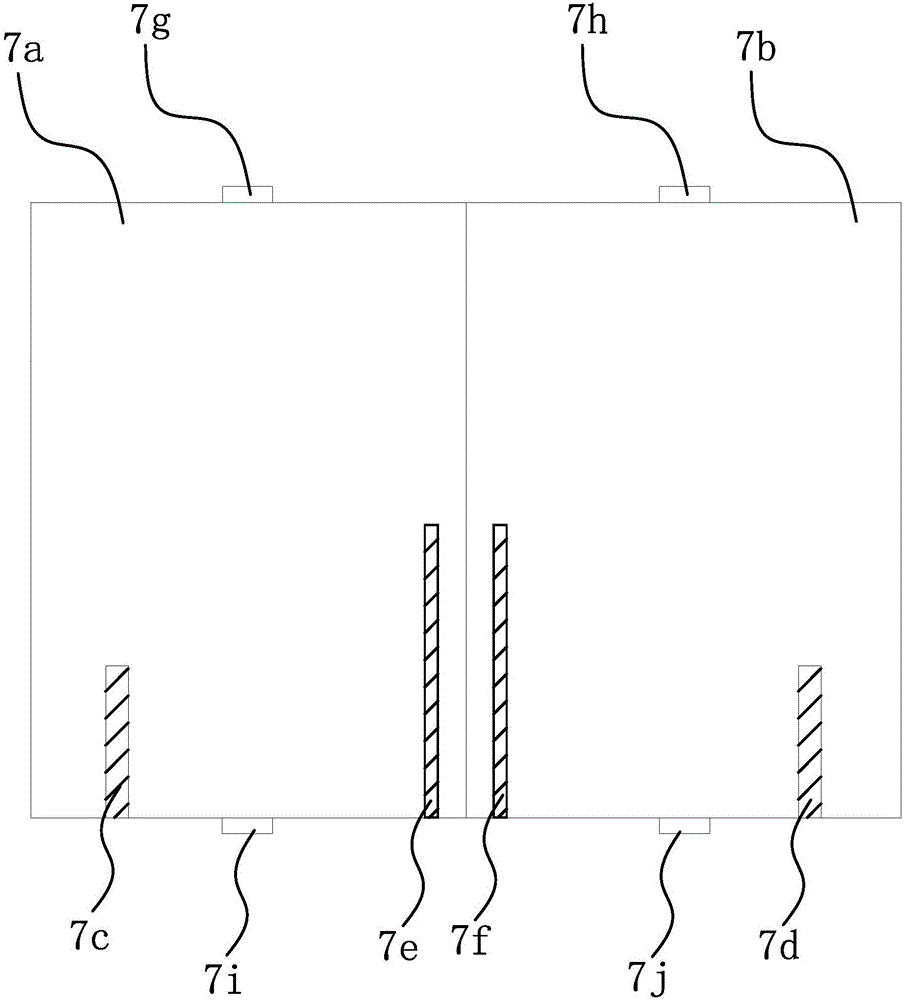

Three-dimensional (3D) printing robot system based on magneto-rheological materials and Three-dimensional (3D) printing method based on magneto-rheological materials

The invention discloses a three-dimensional (3D) printing robot system based on magneto-rheological materials and a 3D printing method based on the magneto-rheological materials, and particularly relates to the 3D printing robot system based on the magneto-rheological materials and the 3D printing method based on the magneto-rheological materials. The 3D printing robot system based on the magneto-rheological materials and the 3D printing method based on the magneto-rheological materials combines a 3D stereoimaging technology and a rapid forming technology based on a magneto-rheological effect, can directly read 3D image data, then prints layer by layer and conducts solidifying forming, and finally forms a 3D entity model. The 3D printing robot system based on the magneto-rheological materials is based on the 3D stereoimaging technology, a magneto-rheological technology, a fine control technology, a digitalizing image technology and the like, and comprises a 3D stereoimaging system, a computer 3D image processing software, a mechanical arm 3D moving system, a magneto-rheological material flow quantity control system, a dye mixing and control system, a magnetic generating and regulating system and the like. a designer aims to design a man-machine interactive system which massively produces models or products and has the advantages of being low in cost, simple and fast, individual and digital.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

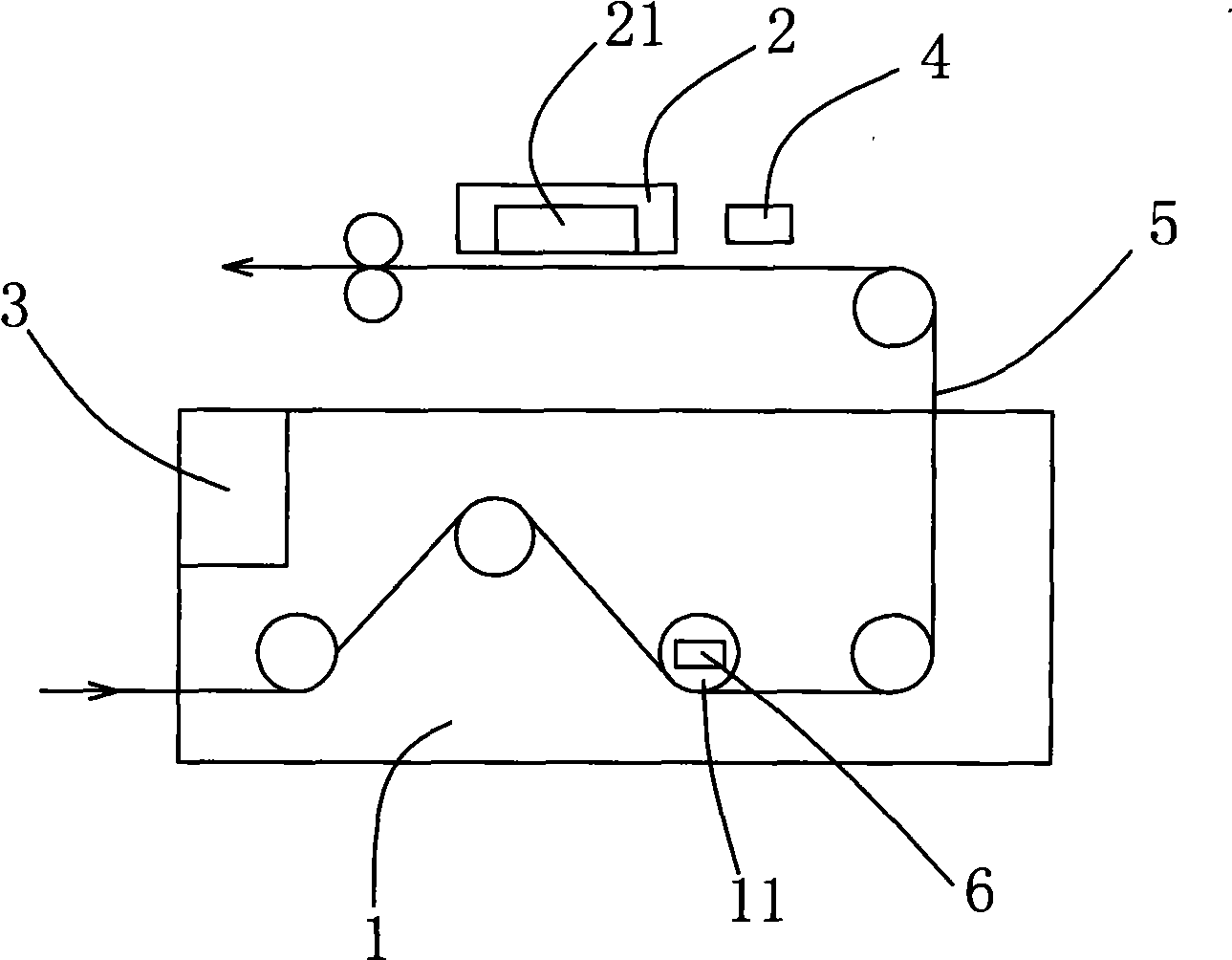

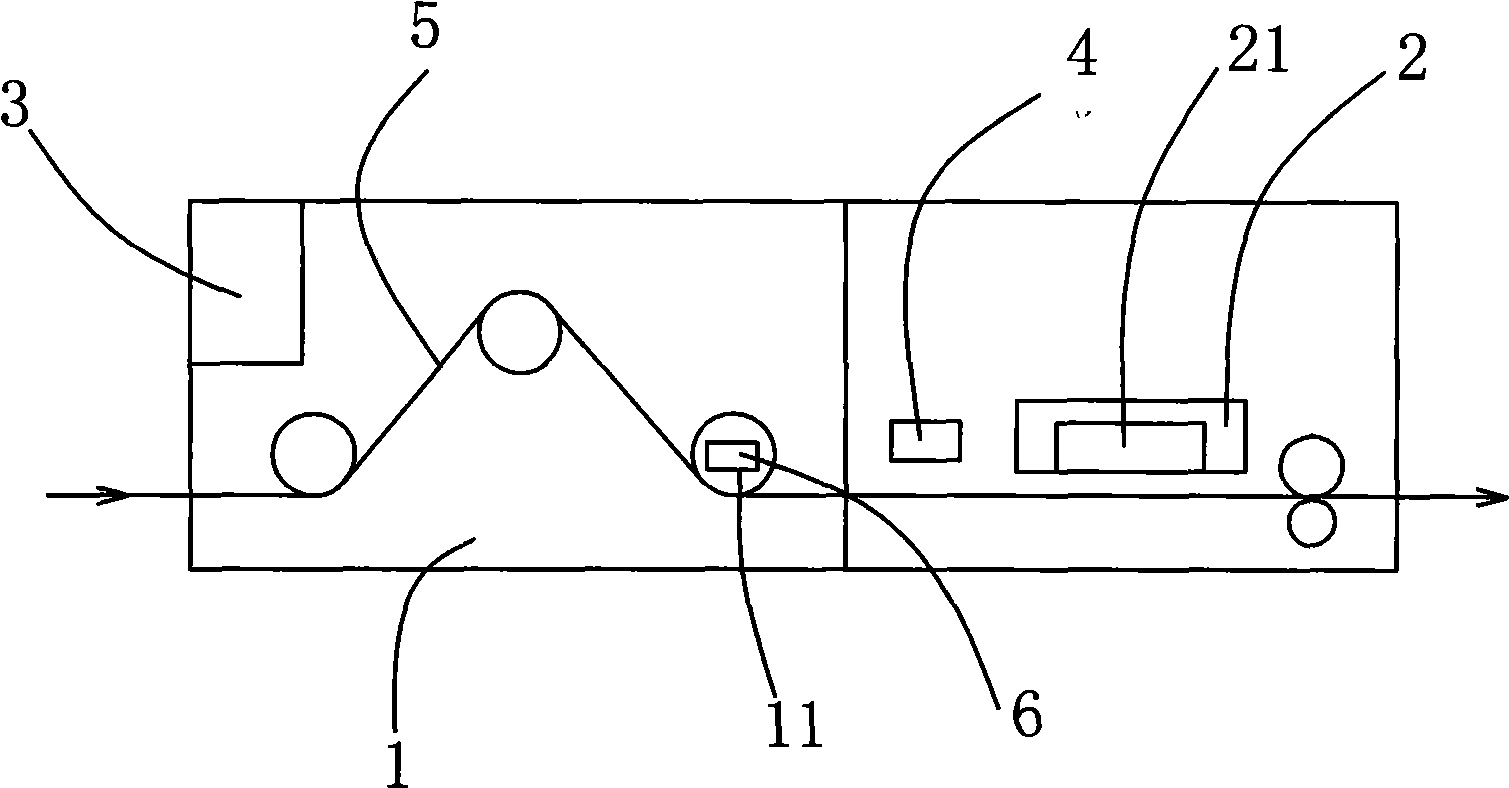

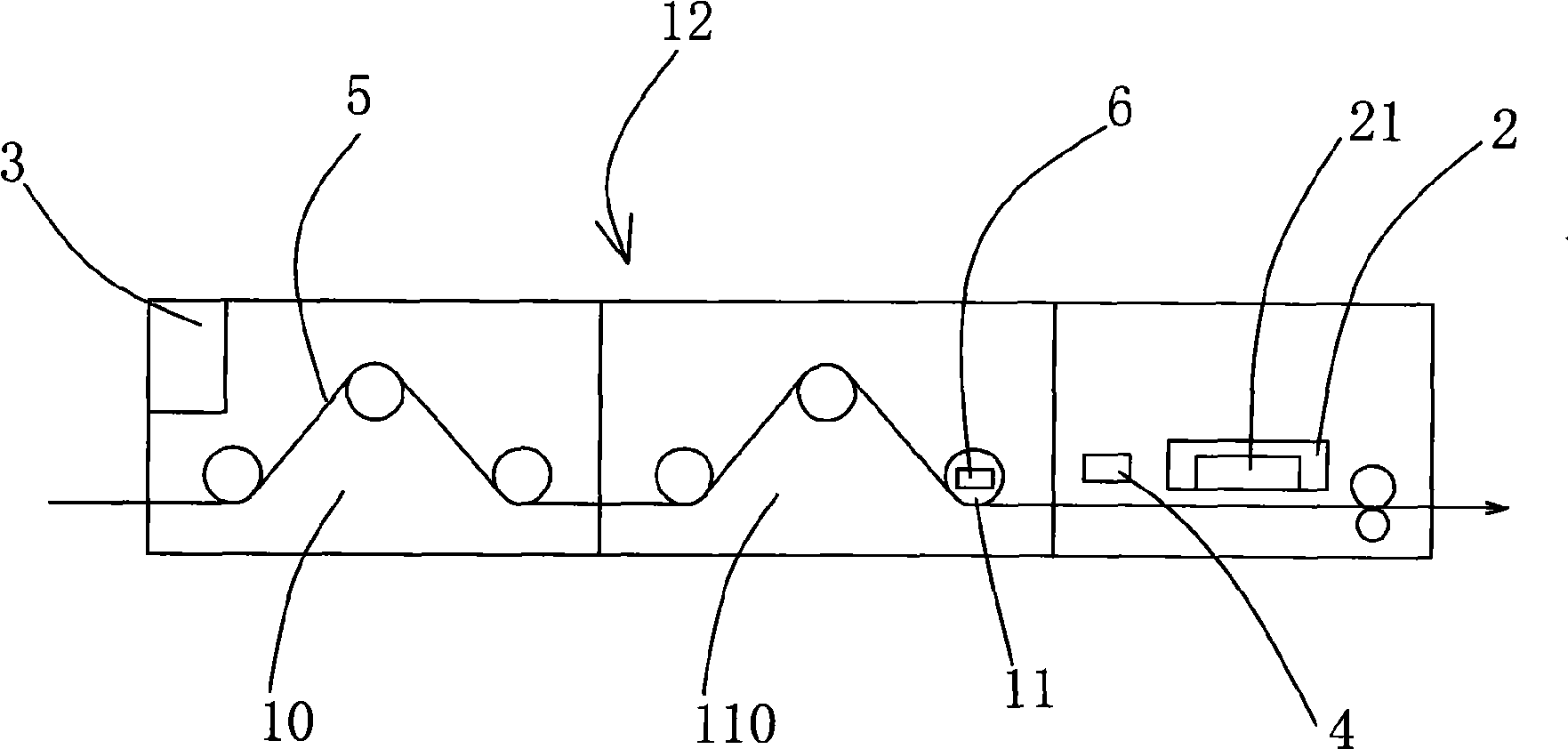

Method for realizing changing content on-line print and mixing digital printing system

ActiveCN101519000AMeet the requirements of mass printingReduce printing costsTypewritersRotary pressesInformation controlDigital printing

The invention relates to a method for realizing changing content on-line print on a rotary press and a mixing digital printing system. The method comprises the following steps: providing a multicolor ink-jet digital printing unit on the rotary press; providing a central control unit to enable a continuous printing stock to pass through an ink-jet region of an ink-jet head of the multicolor ink-jet digital printing unit with the running speed equal to that of the rotary press; carrying out ink jet by the ink-jet head after the multicolor ink-jet digital printing unit receives a color patch information control electrical signal; controlling a predetermining position of the ink-jet head on the continuous printing stock according to a printing position control electrical signal and a printing content information control electrical signal; jetting predetermining characters or / and patterns; and jetting ink by the ink-jet head with the ink-jet speed adapted to the running speed of the continuous printing stock according to the rotary code control electrical signal. The invention can not only carry out large-scale printing, but also realize the changing content on-line printing on the rotary press on the basis of the synchronous on-line print of changeable contents.

Owner:SHENZHEN ZHENGXINYUAN INDAL

Method for printing patterns on finished product shoe in three-dimension way

InactiveCN102511975AThe purpose of expanding salesSimple processShoemaking devicesTypewritersEconomic benefitsEngineering

The invention relates to a method for printing patterns on a finished product shoe in a three-dimension way and belongs to the field of finished product shoe processing. The method comprises the following steps of: (1) carrying out computer treatment on electronic digital pictures to be printed; (2) spraying early-stage treatment liquid on vamp materials; (3) sheathing the finished product shoe onto a three-dimension manufacture tool, supporting the vamp printing part into a plane, fixing the plane and placing the sheathed finished product shoe in a position with a distance being 2 to 3cm under a printing spray head; (4) setting the parameters of a printing machine and calling out the pictures by machine operation software for printing; (5) directly printing the electronic digital pictures to be printed onto the finished product shoe through the printing machine; and (6) carrying out finished product baking, placing the finished product shoe printed with the electronic digital pictures into a baking oven to be baked, taking out the finished product shoe after the finished product shoe is baked, and obtaining the finished product shoe with the electronic digital pictures printed on the vamp. The method is used for printing the patterns on the finished product shoe in the three-dimension way, the patterns printed on the vamp are very stable and firm, the patterns are clear, the precision is high, the quality is good, the processing work procedures are few, and the economic benefits are good.

Owner:邓健

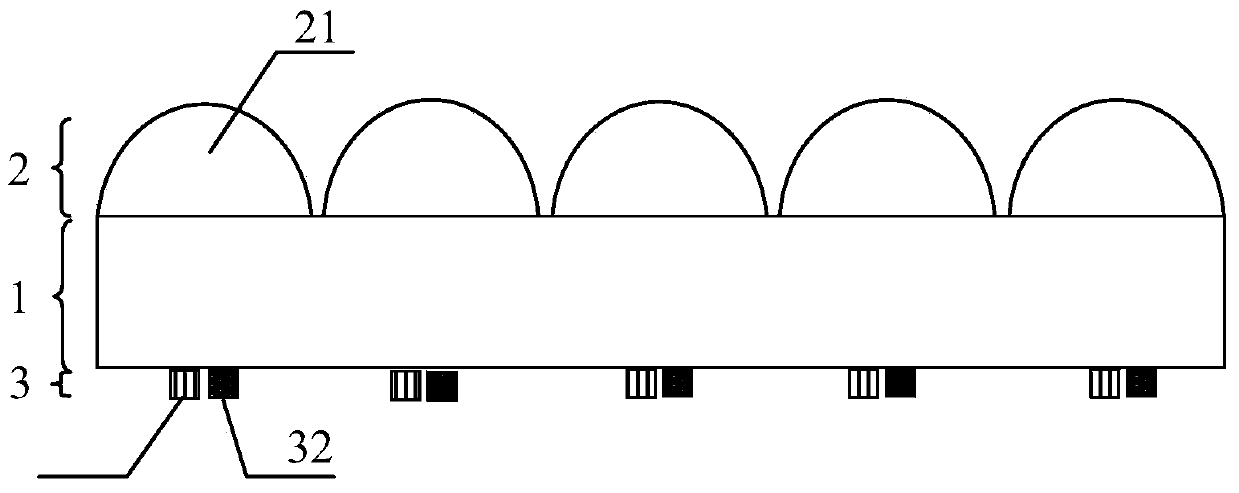

Colored dynamic three-dimensional moire image thin film based on micro printing and preparation method thereof

ActiveCN104191860AIncrease manufacturing difficultyPreserve Horizontal ParallaxInformation cardsDynamic patternMicro lens array

The invention discloses a colored dynamic three-dimensional moire image thin film based on micro printing and a preparation method of the colored dynamic three-dimensional moire image thin film. The moire image thin film comprises a transparent base material layer, a micro-lens array layer located on one side of the transparent base material layer, and a micro-pattern array layer located on the other side of the transparent base material layer. The micro-lens array layer comprises a plurality of micro-lenses arranged in an array. The micro-pattern array layer comprises a plurality of micro-patterns which are arranged in an array and are different in color. The array arrangement of the micro-lenses is matched with the array arrangement of the micro-patterns. The moire image formed by the moire image thin film is characterized by being colored, dynamic and three-dimensional, and an observer can directly observe a colored three-dimensional dynamic pattern without any special observation skills under any luminous environment.

Owner:SUZHOU UNIV +1

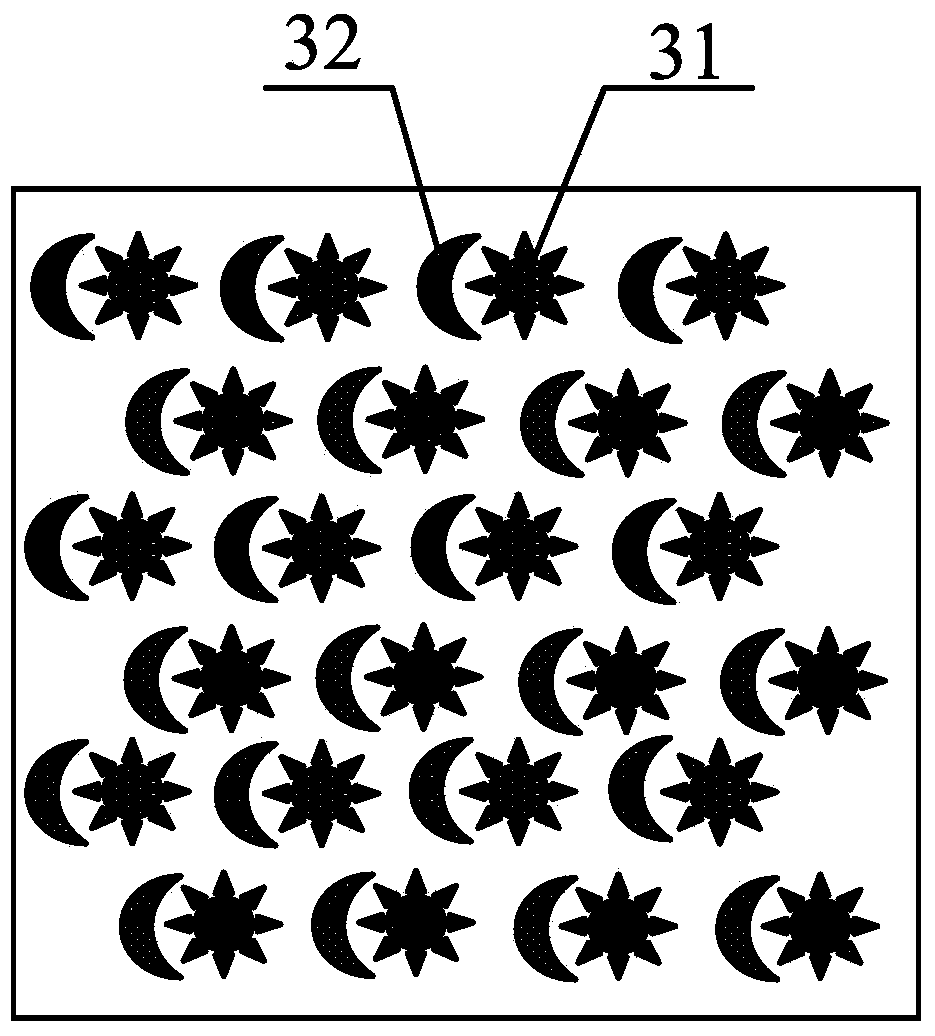

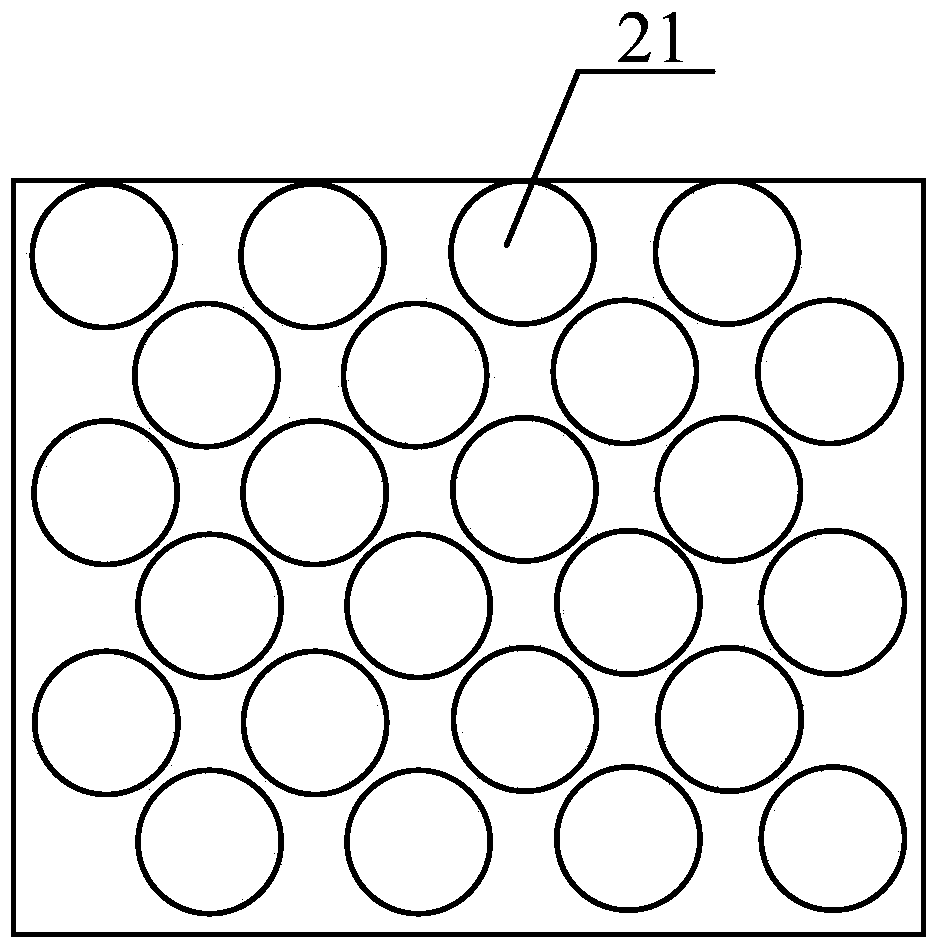

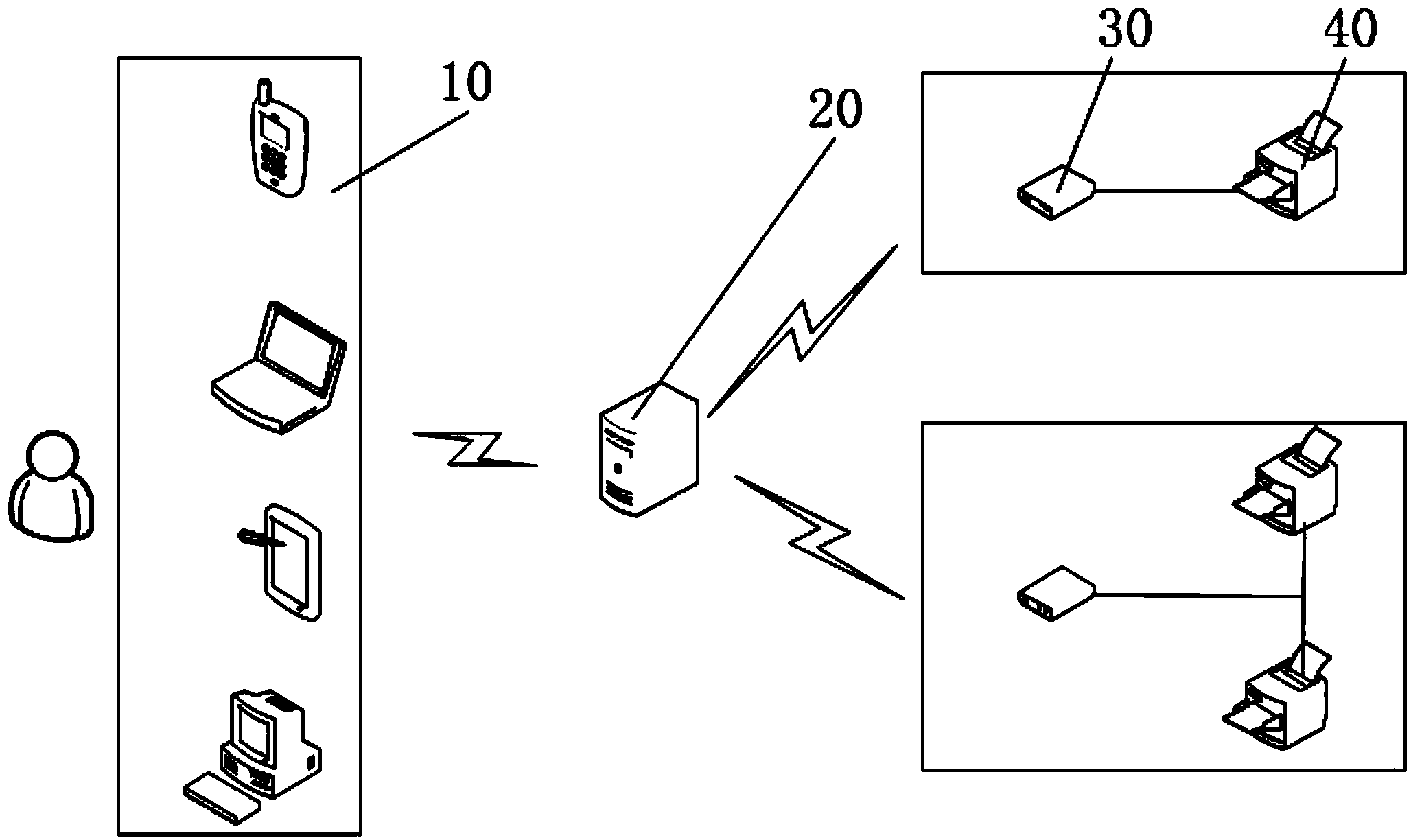

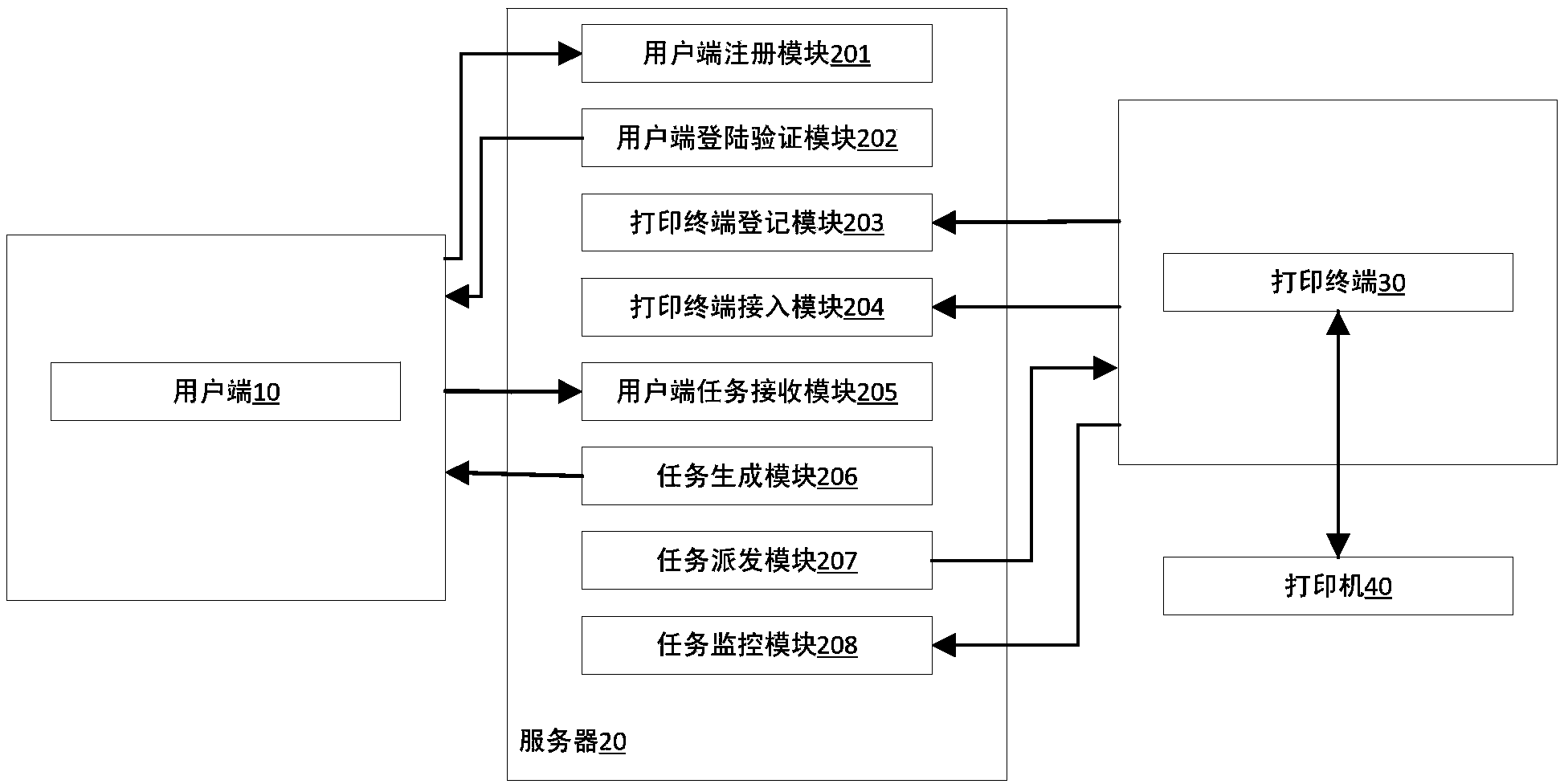

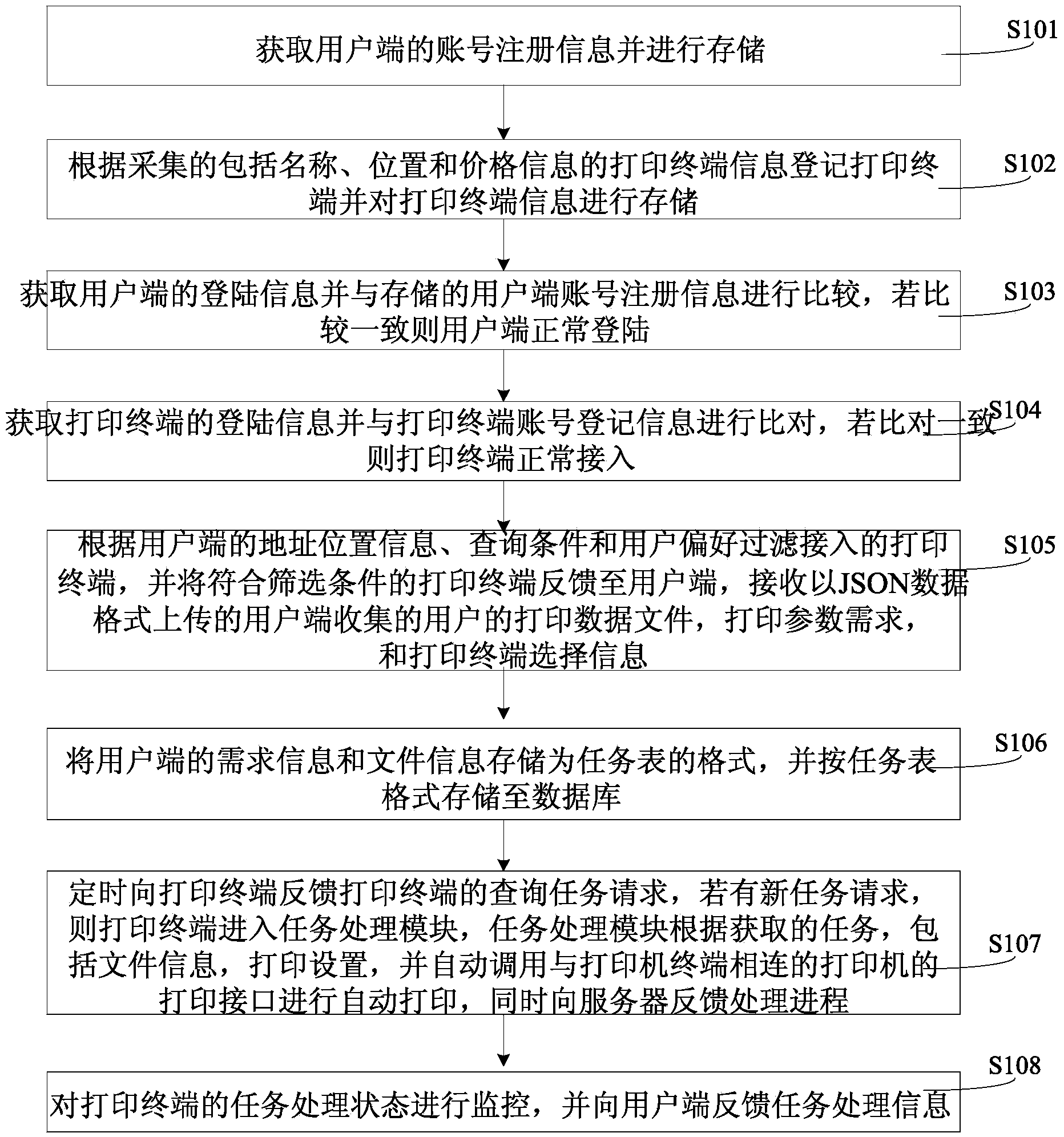

System and method for automatic printing of user side remote multi-selection printing terminals

InactiveCN104035734AImprove printing efficiencyReduce printing costsDigital output to print unitsLocal area networkEngineering

The embodiment of the invention discloses a system and method for automatic printing of user side remote multi-selection printing terminals. The system comprises a user side, a server, the printing terminals and printers. Each printing terminal corresponds to at least one printer. The user side and the printing terminals are located in different local area networks. The server comprises a user side registration module, a printing terminal check-in module, a printing terminal connecting module, a user side log-in verification module, a user side task receiving module, a task generating module, a task distributing module and a task monitoring module. The user side task receiving module is used for filtering the connected printing terminals according to address position information of the user side, the inquiry conditions and user preference and feeding the printing terminals meeting the screening conditions back to the user side. Tasks are generated through one of the printing terminals checked in the server by the user side through the position service. After the printing terminal receives the tasks, printing is conducted automatically.

Owner:HANGZHOU PENGYUAN NETWORK TECH

Positioning method based on location base point, specific mark, and related device and method

InactiveCN106507285AReduce printing costsLow costWireless commuication servicesLocation information based servicePosition dependentTerminal equipment

The invention provides a positioning method based on a location base point. Through arrangement of a plurality of location base points and corresponding markers, the markers can be identified in a visual range, can transmit signals in a limited distance range and stores information which only can be read in the limited distance range, or the information only can be written into the markers in the limited distance range. A mobile terminal device can obtain directly available location information as a current location according to the identified, read, received and written information and can directly display and provide location related map, navigation or guide, direction service and so on. The method can be applied to scenic spot guide, market shopping guide, indoor and cave navigation, and so on. Relatively convenient and accurate positioning can be realized. The extracted specific markers containing the directly available location information can be used for marking the locations of places, geographical names, addresses or location codes and are applicable to location information release, exchange and sharing. An application method and an application system are further expanded.

Owner:宁波亿拍客网络科技有限公司

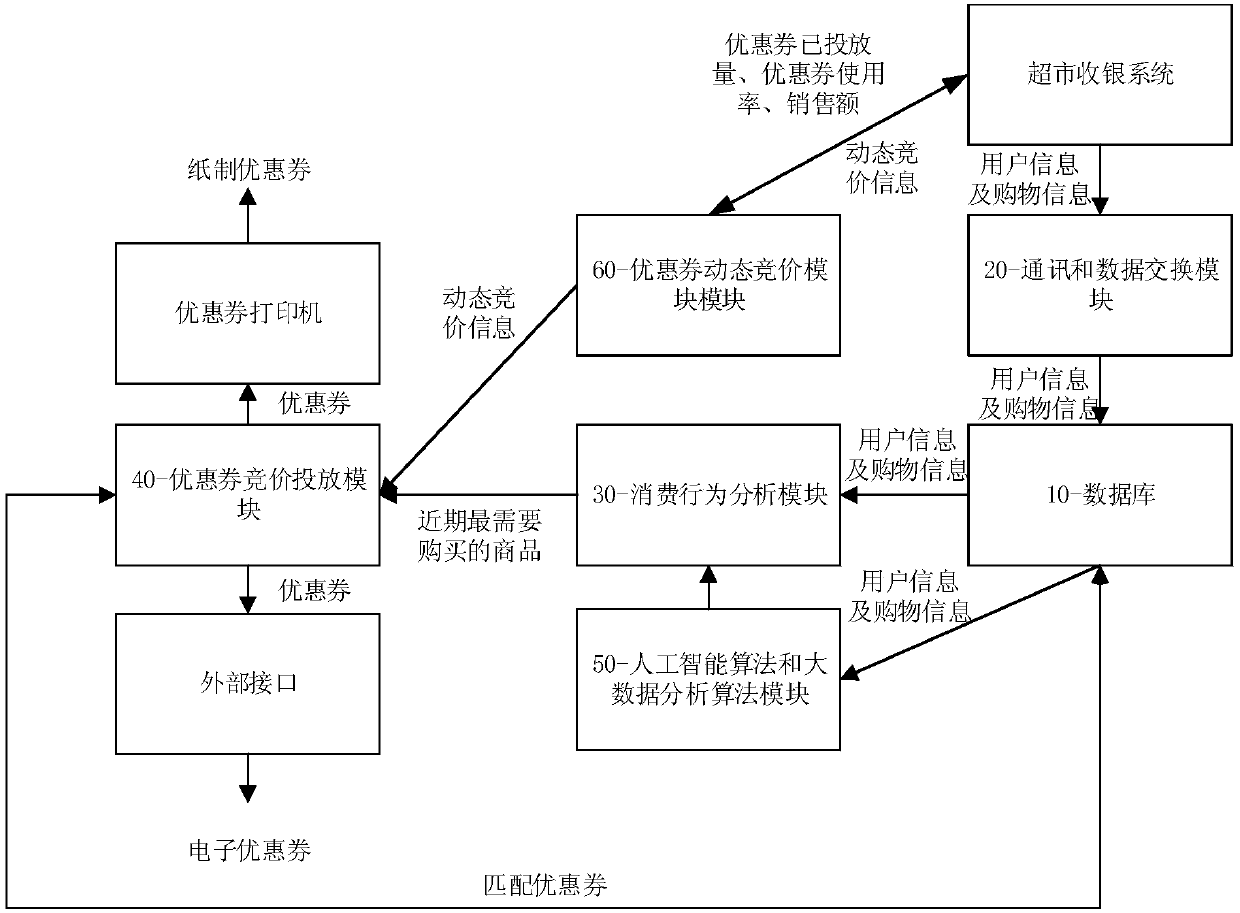

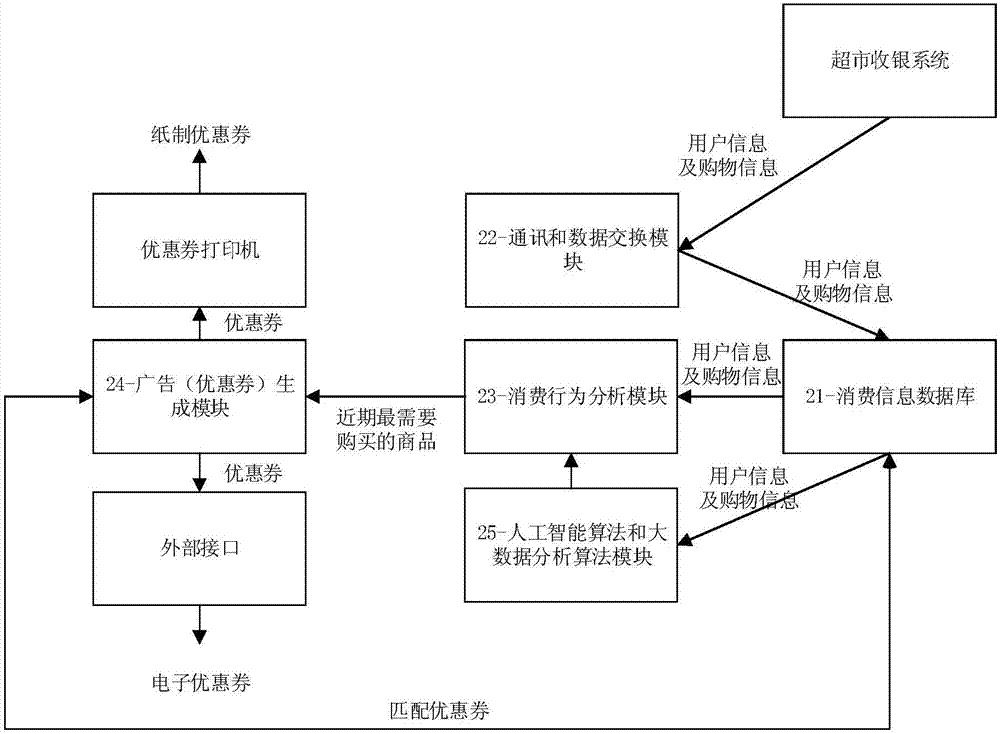

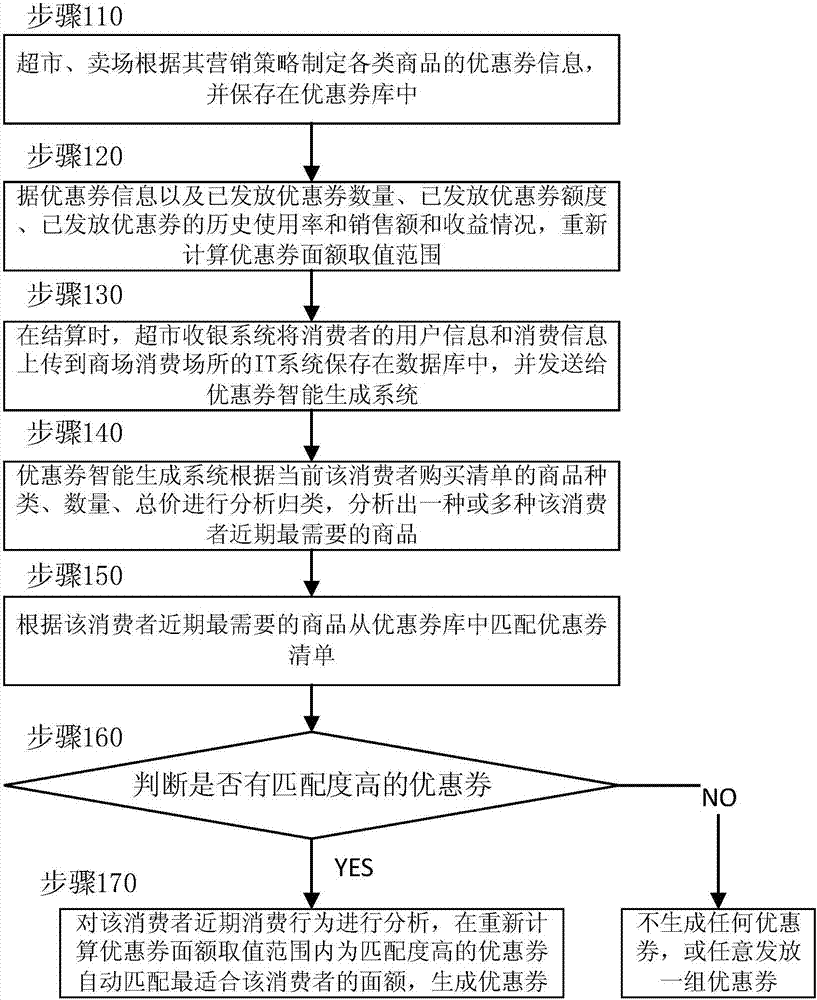

Discount coupon delivery method and system

InactiveCN107862549AImprove precision delivery efficiencyAvoid inconvenienceMarket data gatheringLibrary scienceData library

The invention discloses a method and system for putting coupons. The method includes: merchants formulate a list of commodity coupons according to their marketing strategies and store them in a coupon library; and shopping information, and stored in the database; through the analysis of the consumer's historical shopping data and this shopping information, one or more commodities that the consumer needs to buy most recently; The purchased products are matched with the coupon list from the coupon library, and the coupon list with a high degree of matching with the products that consumers need to buy most recently is screened out; in the coupon list, the coupons of the preset number of merchants with the highest bid are automatically selected, And send it to the cash register system of the store. The present invention expands the source of advertising profit for the provider of the system and the owner of the supermarket, goods and shopping malls, avoids various inconveniences to consumers caused by blindly distributing various types of coupons, and improves consumer experience.

Owner:北京翰宁智能科技有限责任公司

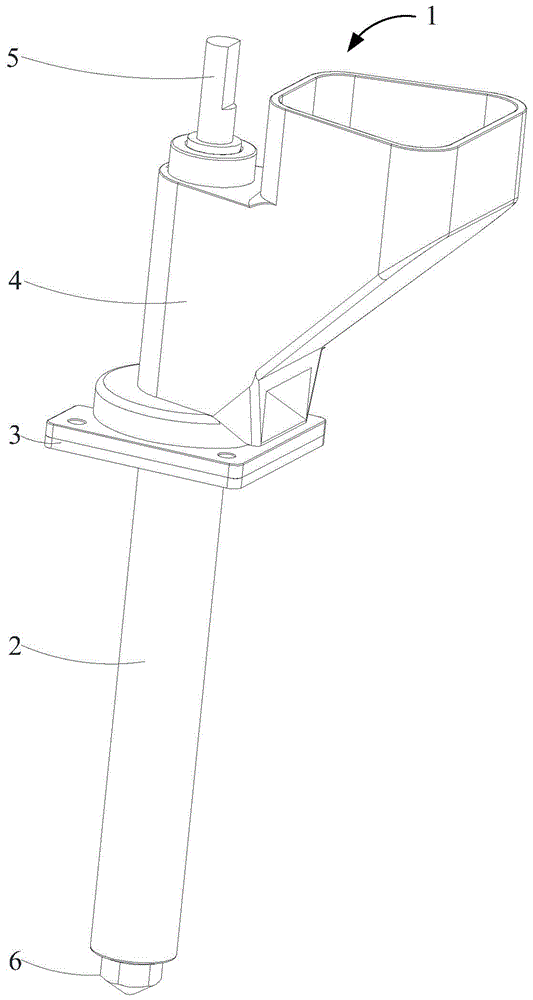

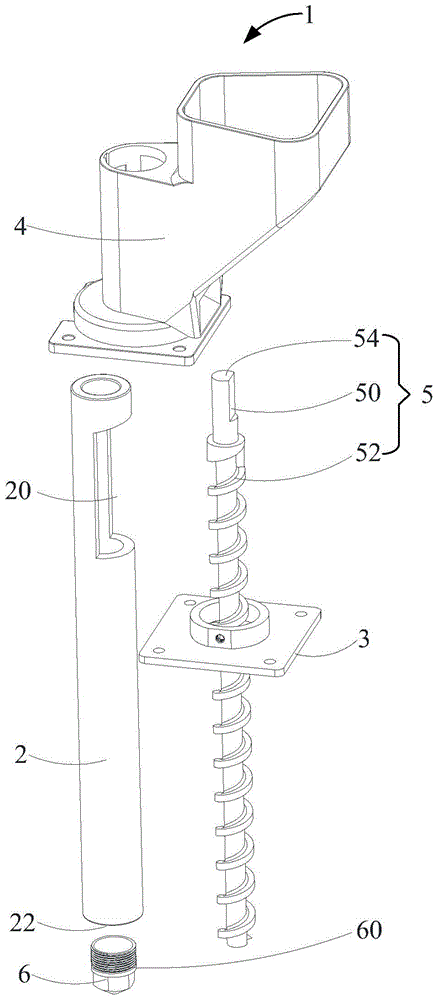

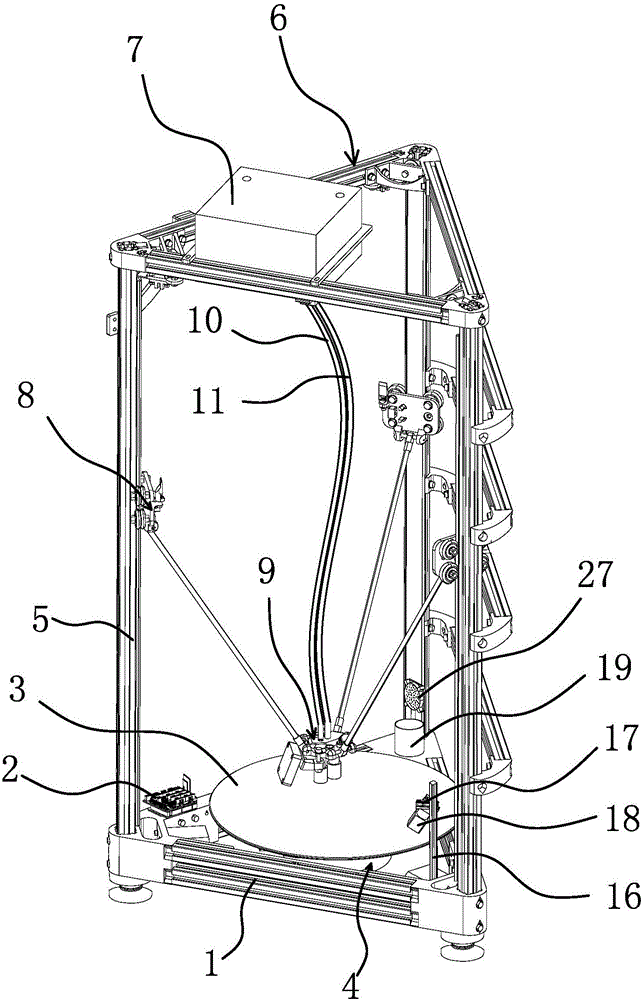

Printer nozzle, 3D printer and forming method

ActiveCN105666640ALower usage limitLower requirementCeramic shaping apparatusMaterials processing3d printer

The invention discloses a printer nozzle, a 3D printer and a forming method. The printer nozzle is used for the 3D printer, and comprises a charging barrel, a screw rod and a hopper. A part of the screw rod is accommodated in the charging barrel. The screw rod is arranged rotatablely relative to the charging barrel. The hopper is arranged in the charging barrel, is communicated with the charging barrel, and is provided with a feeding opening used for feeding. The printer nozzle can be used for processing printing materials of different shapes, so that the printing materials are not limited to a wire material or a strip material, the limitation to material use is overcome, the requirements on materials are reduced, the cost of processing the materials into wires or strips is reduced, the 3D printing cost is reduced.

Owner:SHENZHEN SOONGON TECH

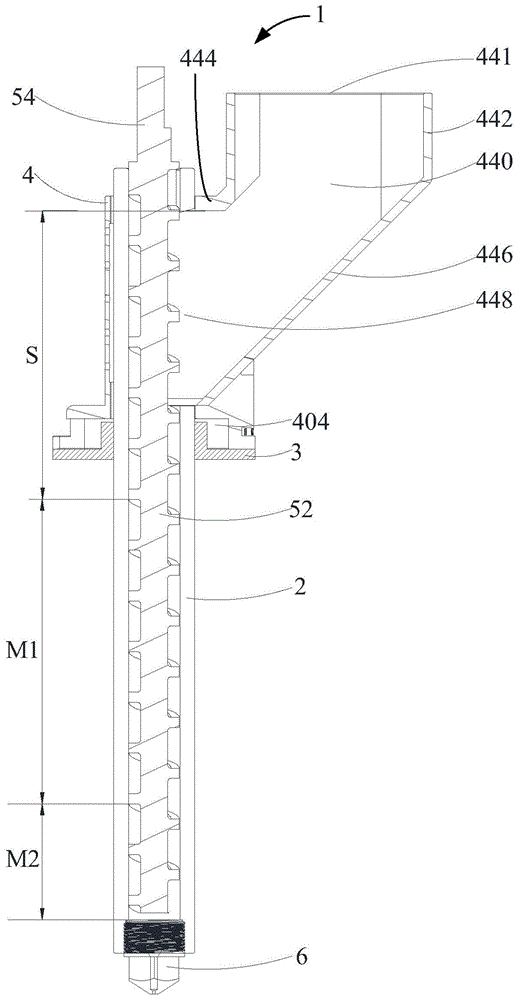

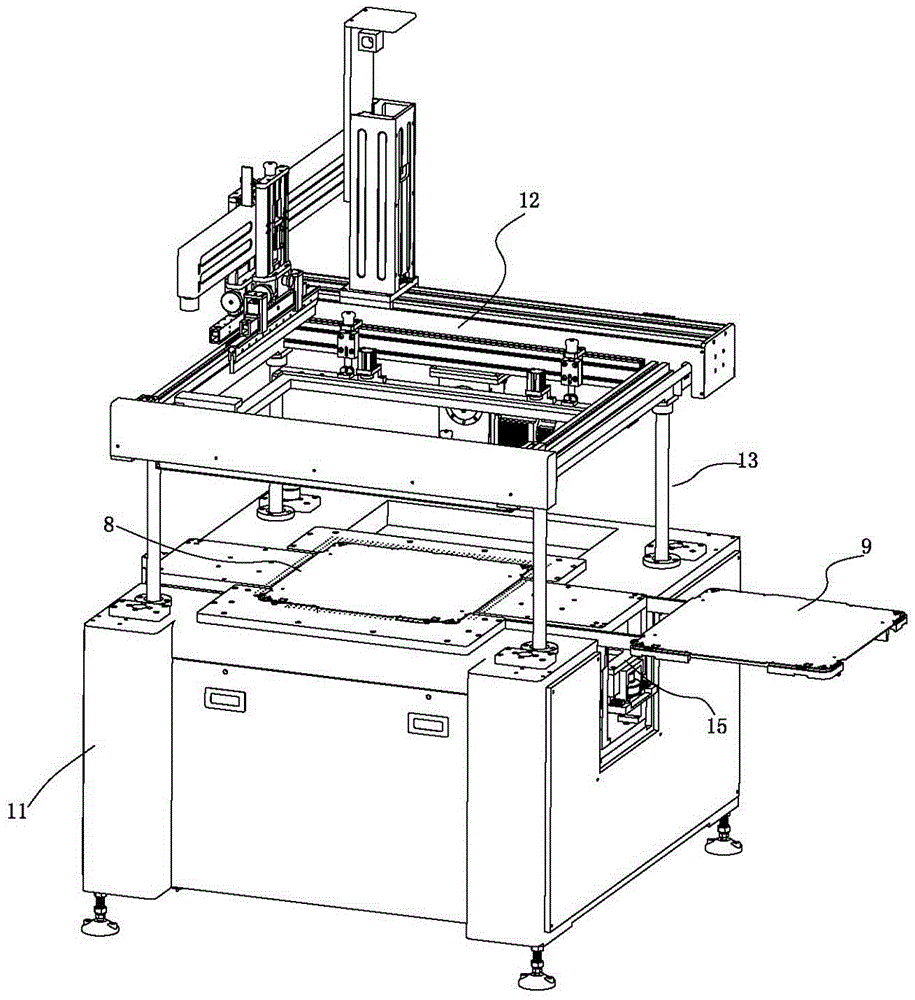

Full-automatic screen printing machine

The invention discloses a full-automatic screen printing machine comprising a control system, a rack, a printing assembly, a feeding mechanism, a material receiving mechanism, a circulating conveying mechanism and two conveying devices. The feeding mechanism and the material receiving mechanism are each internally provided with a plurality of conveying channels; joints between the feeding mechanism and the printing assembly and between the material receiving mechanism and the printing assembly are each provided with a vertical transfer device; the vertical transfer devices are used for transferring material carrying plates between all the layers of conveying channels and / or are used for transferring material carrying plates between the conveying channels and the printing assembly; a moving and loading assembly is arranged at the lower end position of the printing assembly; a printing positioning device is further arranged in a matched printing area of the lower end of the printing assembly; and the positions of the material carrying plates are corrected through the printing positioning device, and the printing assembly is made to complete accurate printing. According to the full-automatic screen printing machine, the feeding mechanism and the material receiving mechanism surround the printing assembly, the double-layer conveying channels are arranged in the feeding mechanism and the material receiving mechanism, the online plate number storage amount of the printing machine is increased, the functions of one printing machine are increased and extended, the full-automatic screen printing machine is suitable for multi-color printing of different category requirements, and the printing machine is high in utilizing rate and production efficiency and low in cost.

Owner:庄统壹 +1

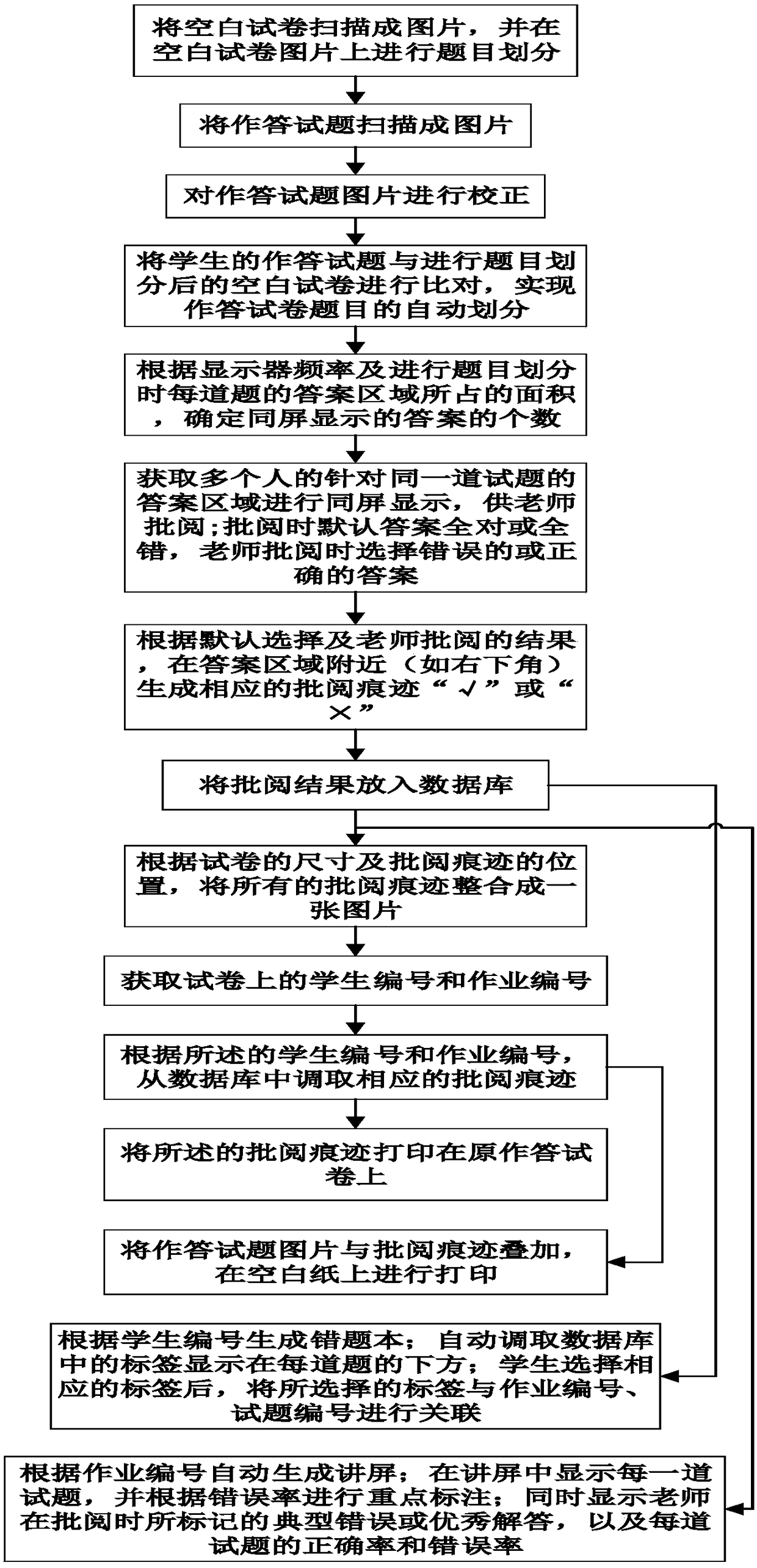

Electronic paper inspection method

InactiveCN108229361AReduce the difficulty of implementationReduce printing costsData processing applicationsCharacter and pattern recognitionComputer scienceInspection time

The invention discloses an electronic paper inspection method. The method comprises the following steps of: S1, scanning answered questions into a picture; S2, carrying out title division on the answered question picture; S3, carrying out same-screen display on same answer areas of a plurality of students so that a teacher can read over the answer areas; and S4, printing the answered paper with reading marks. According to the method, marked reading is realized, answer sheets do not need to be manufactured, and recognition points do not need to be set during the reading, so that the implementation difficulty is greatly reduced and the printing cost is saved; and moreover, same-screen display is carried out on the same answer areas of a plurality of students so that a teacher can read over the answer areas, thereby greatly improving the reading efficiency. Mass data statistics indicates that compared with read-over method in the prior art, the electronic paper inspection method has the effect of shortening the paper inspection time by two thirds.

Owner:北京摩数教育科技有限公司

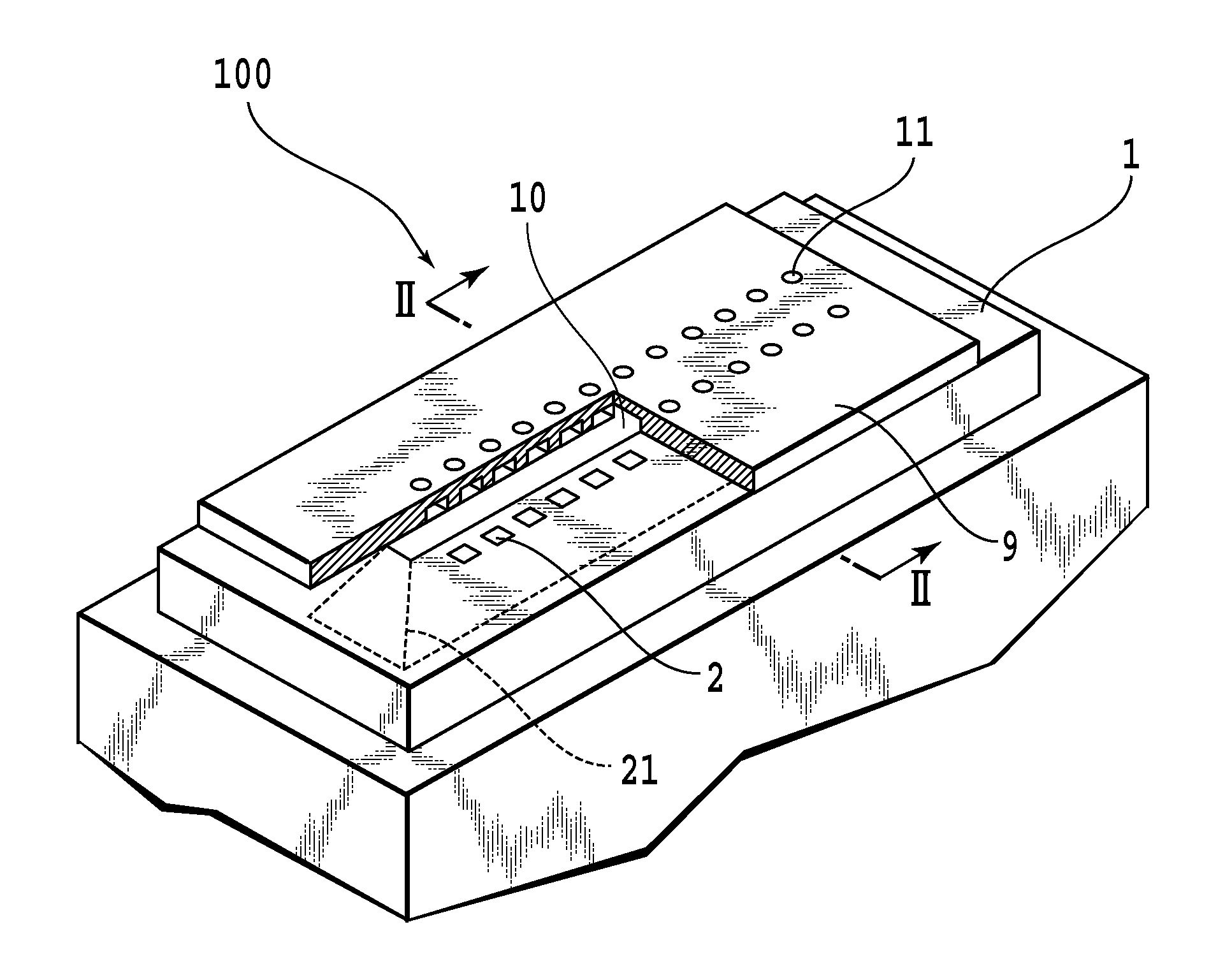

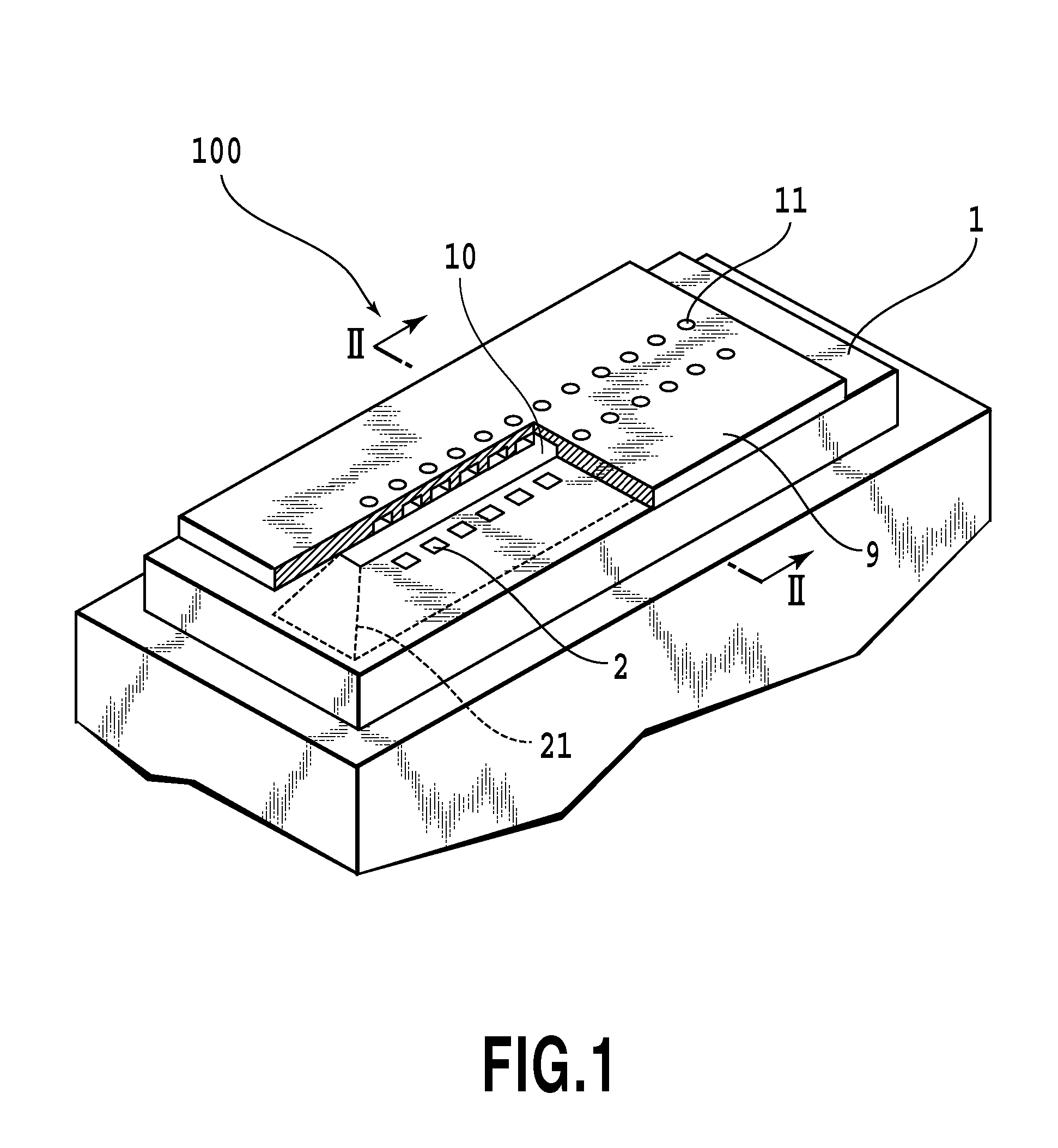

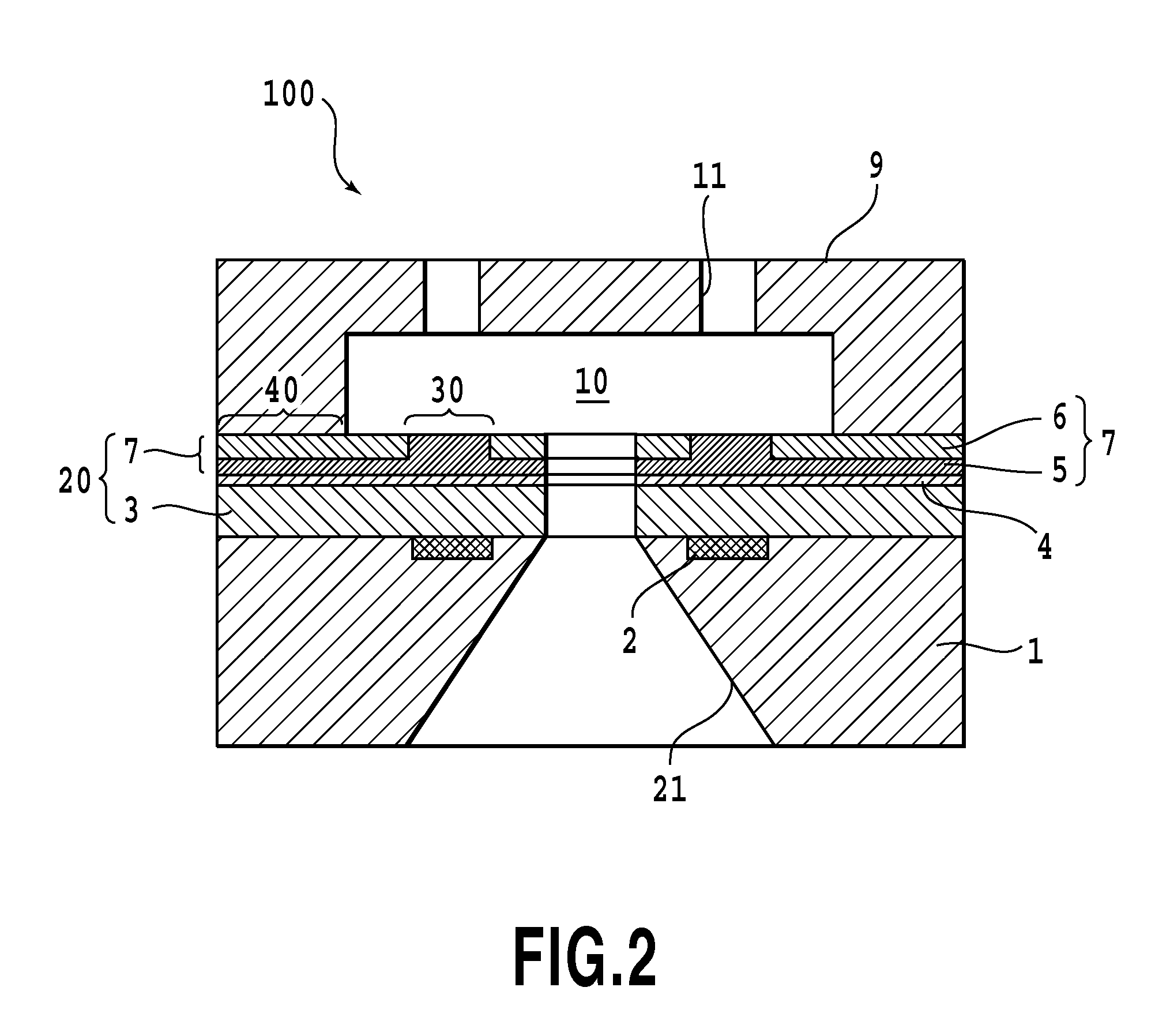

Liquid ejection head and method of manufacturing the liquid ejection head

InactiveUS20090315956A1Simple manufacturing processReduce manufacturing costVacuum evaporation coatingSputtering coatingEngineeringOxide

To provide a print head that simplifies the manufacture process of a print head and reduces the manufacturing cost while preventing the peeling-off between a substrate and a flow passage forming member in the print head, and a method of manufacturing the print head. In the print head of the present invention, a protective layer is formed in a flow passage forming member side portion in a heat generating portion 2. The protective layer 20 contains a noble metal. Then, in the flow passage forming member side portion in the protective layer 20, the surface thereof is made of an oxide of a noble metal except in a portion corresponding to the heat generating portion 2, while in the portion corresponding to the heat generating portion 2 on the flow passage forming member side in the protective layer 20, the surface thereof is made of the noble metal.

Owner:CANON KK

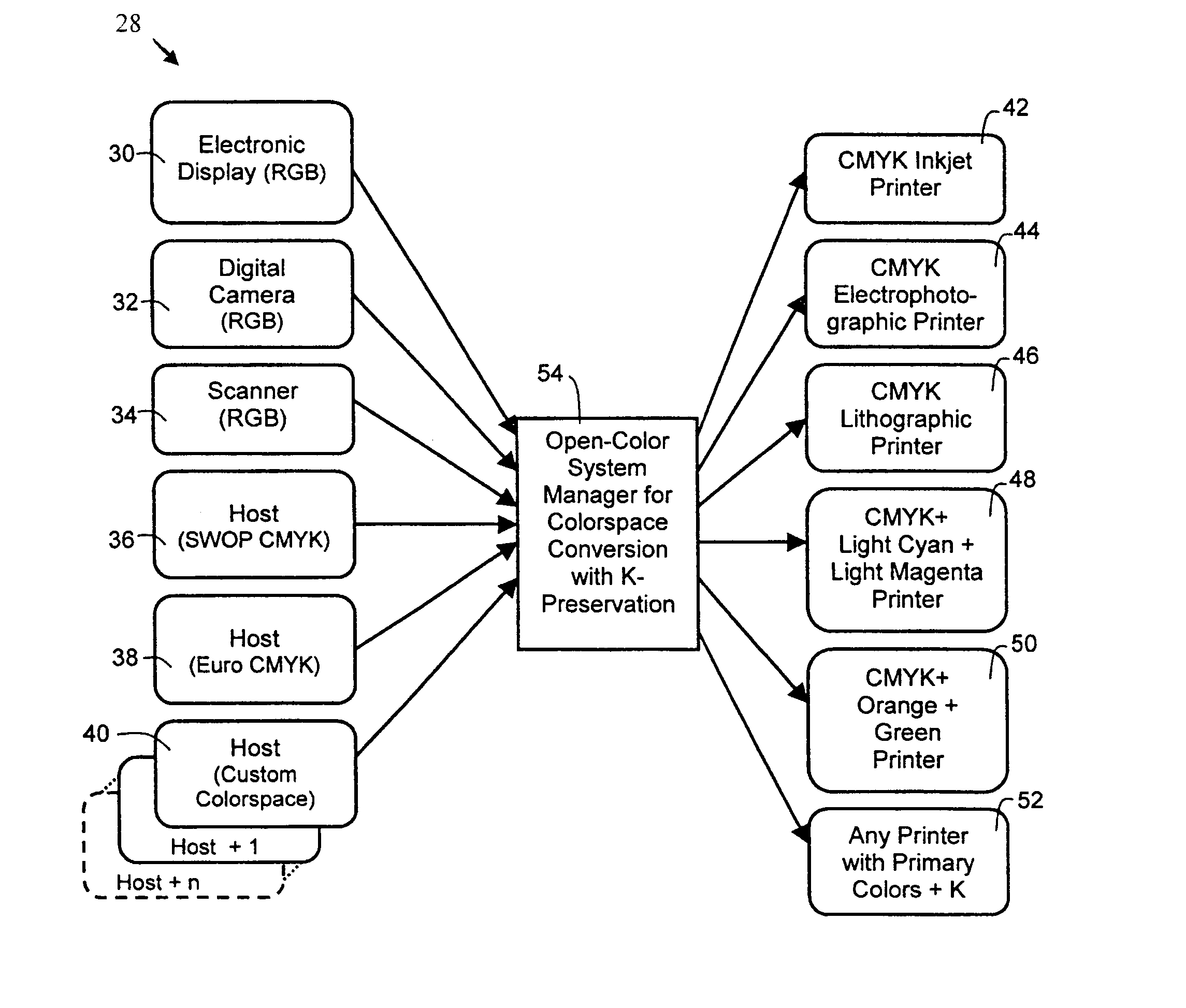

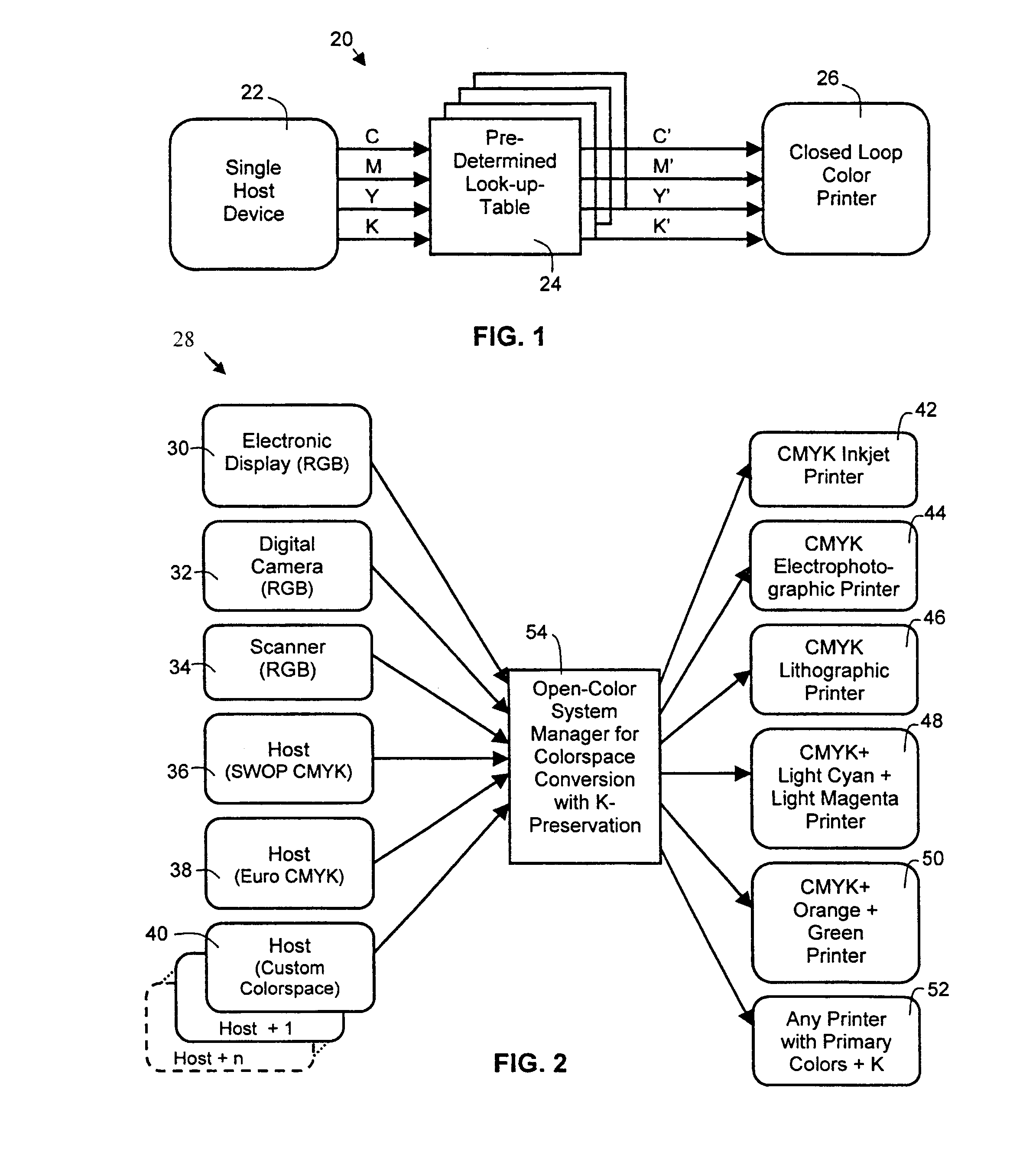

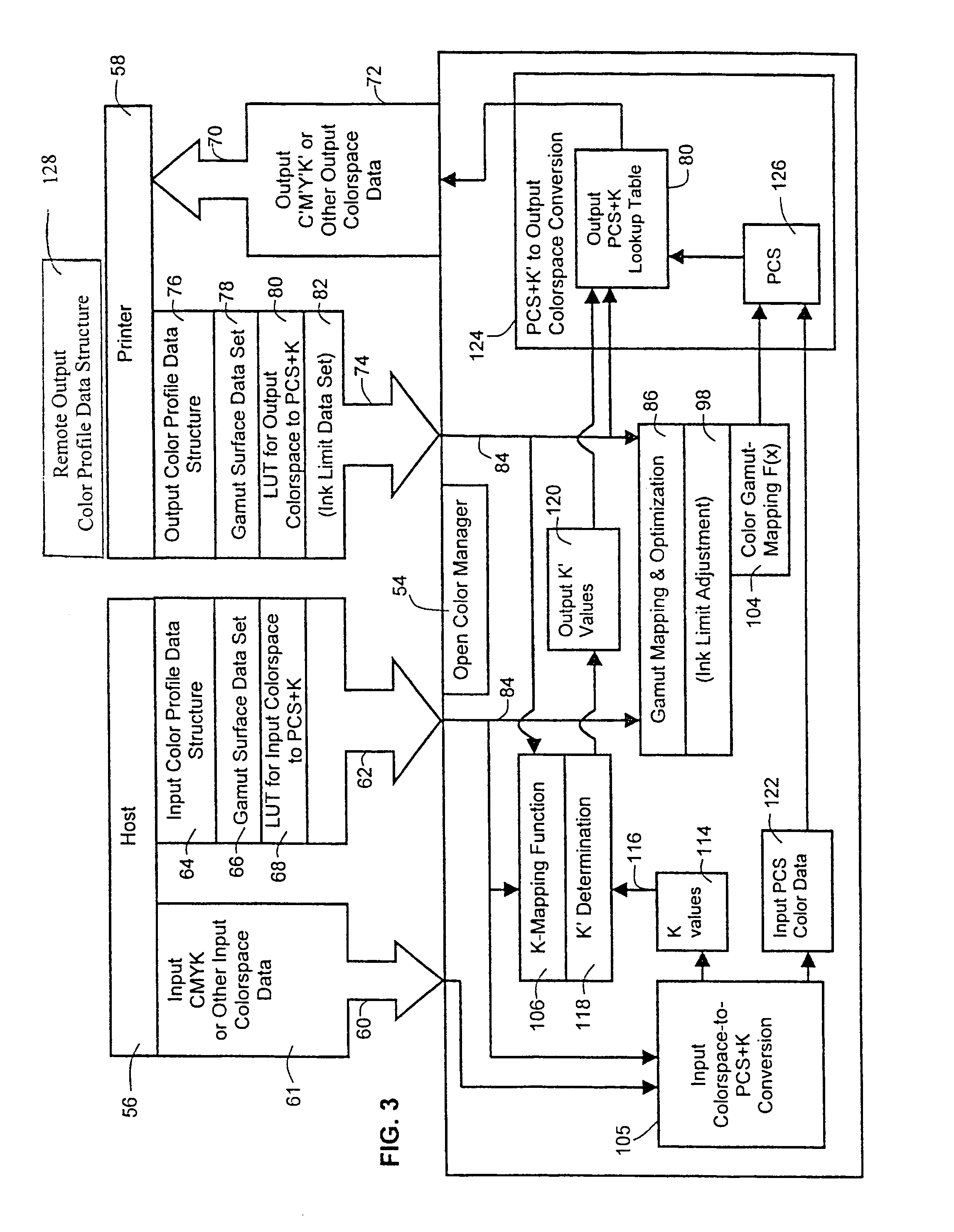

Color space transformation with black preservation for open color management

InactiveUS7046393B2Preserving black channel informationHigh color accuracyDigitally marking record carriersDigital computer detailsData setOutput device

An open color management system allows any of a plurality of input color devices to share data with any of a plurality of output color devices. The color management system includes a networked connection space for input and output device communication, an input color profile for each input device, an output color profile for each output device, and an open color manager which links a given input device with a selected output device. When linking devices, an input color space dataset having black plus multiple color channels is parsed with the input and output color profiles at a job time to create an output color space dataset having black plus multiple color channels for imaging by the output device without degrading color accuracy while preserving black channel information. A method for open color management and an open color manager for use in an open color management system are also provided.

Owner:HEWLETT PACKARD DEV CO LP

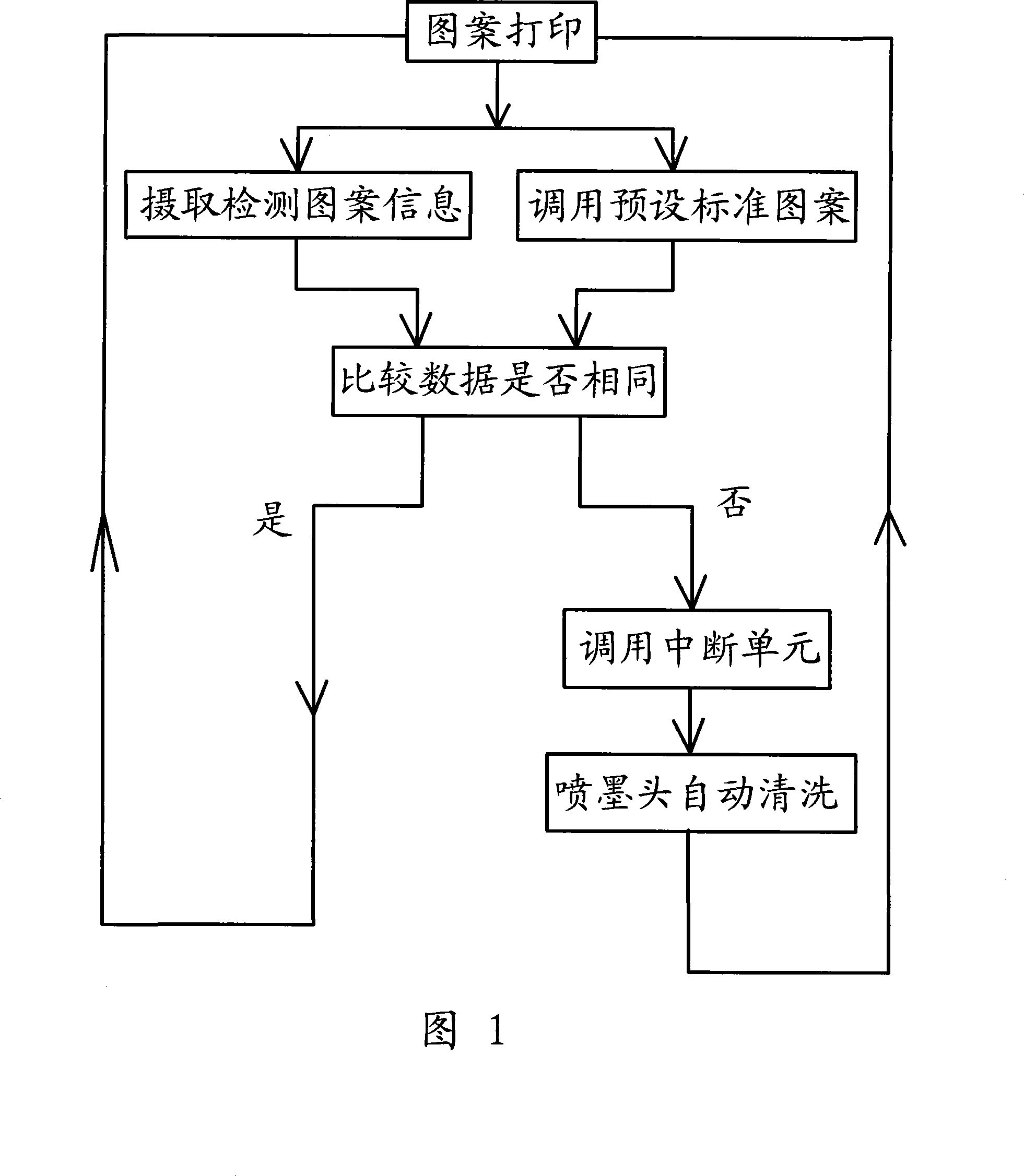

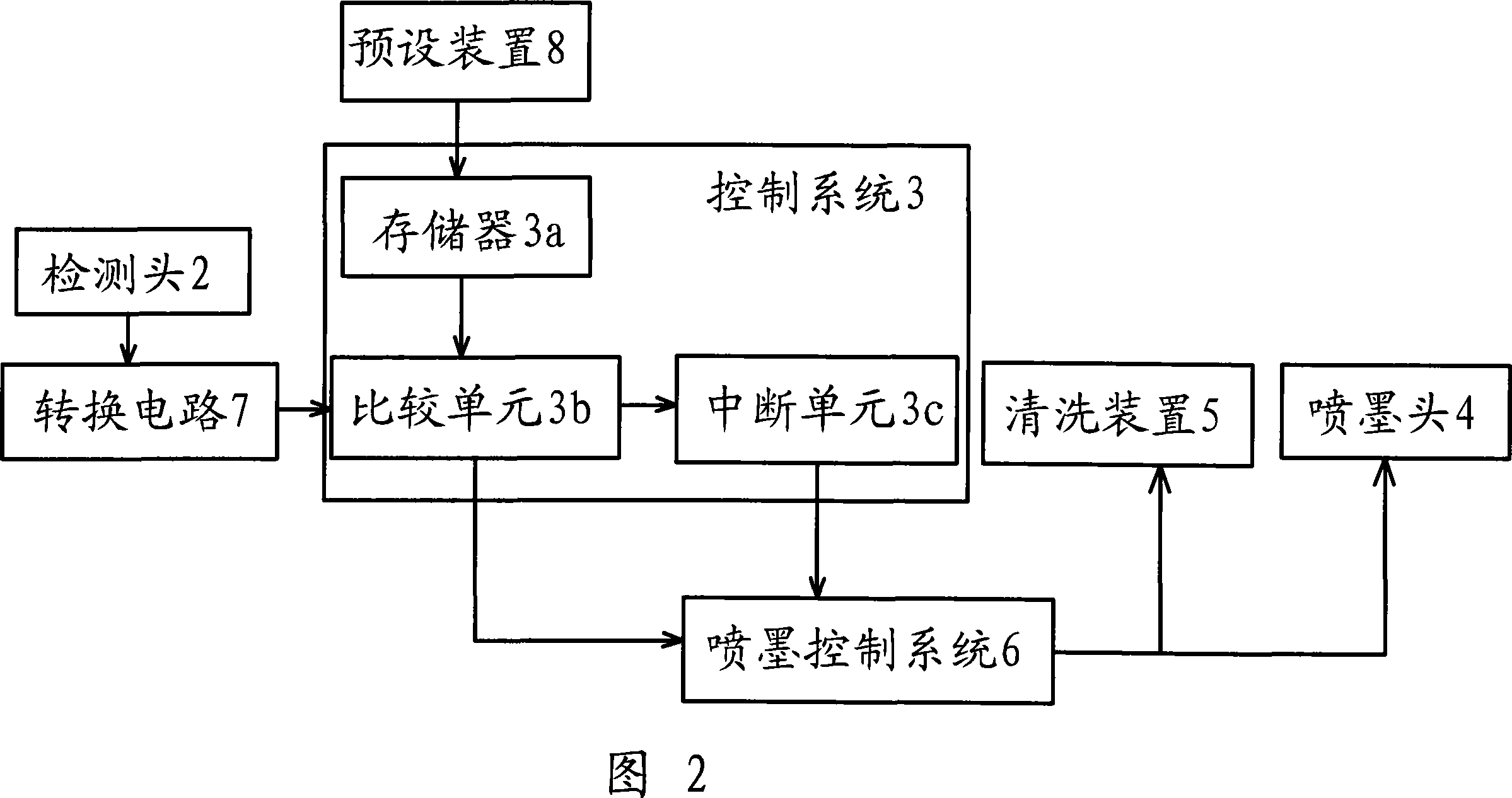

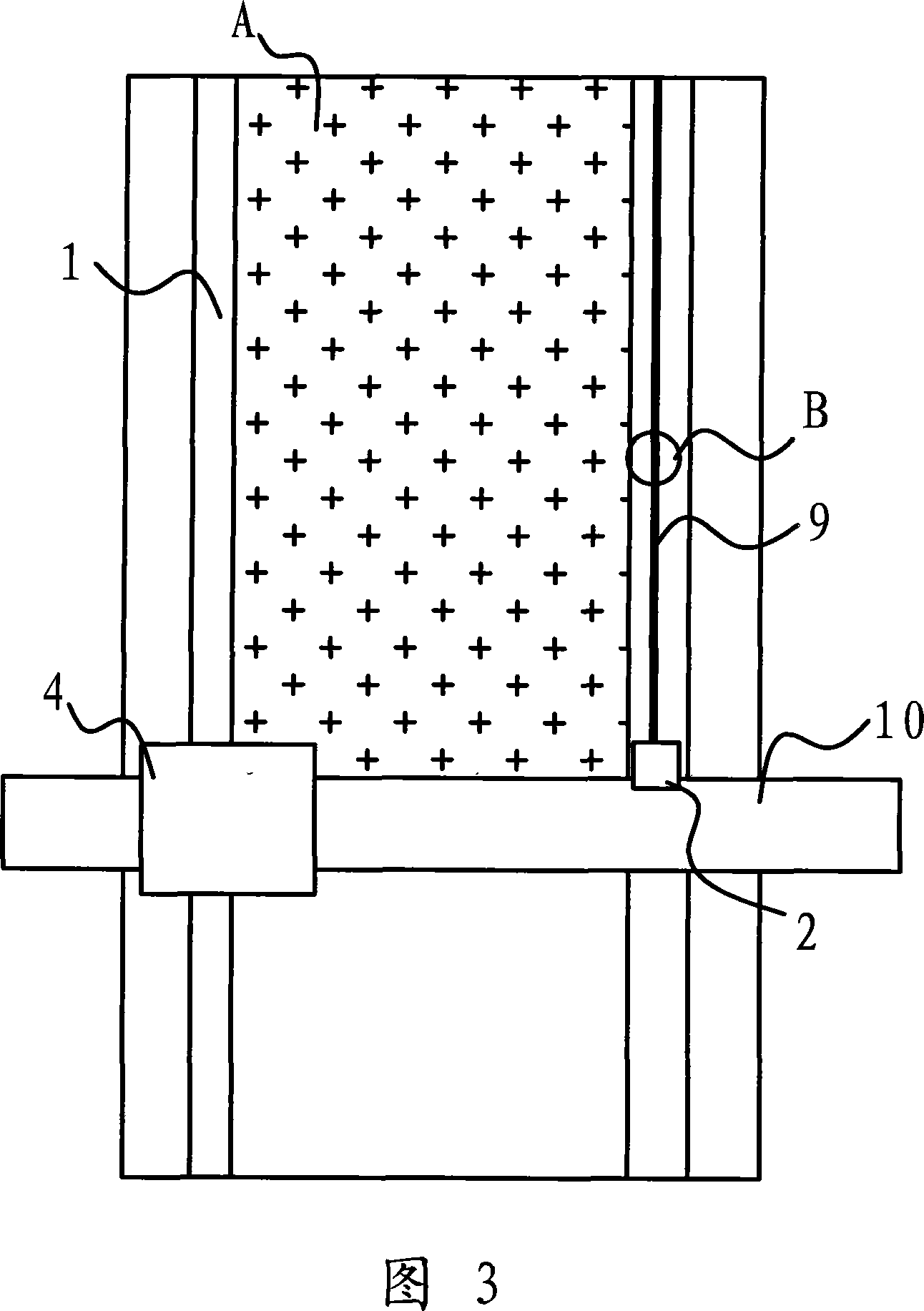

Automatic monitoring method for printing machine ink-jet head and device thereof

InactiveCN101168326AHigh degree of automationEasy to cleanOther printing apparatusReference patternsEngineering

The invention relates to an automatic monitoring method and a device for an inkjet head of a printer. In this method, the collected detection pattern information is compared with the pre-stored standard pattern information. If the two are consistent, the printer will continue to print; Clean the inkjet head. After the cleaning process is completed, move the inkjet head back to the printing area and restart the printing operation. Compared with the prior art, the cleaning of the inkjet head in the present invention is not carried out regularly according to the preset time, but decides whether to clean according to the real-time working state of the inkjet head. It has high degree of automation, obvious cleaning effect and good working stability. It can monitor the working status of the inkjet head in real time, and clean the inkjet head in time according to the monitoring results. The data processing volume is small and the processing speed is fast. features.

Owner:HANGZHOU HONGHUA DIGITAL TECH

Method for preparing printing paste of compound modified starch with adjustable viscosity

This invention is a productive method of printing paste, it is a complex starch its viscosity is adjustable. It contains: Carboxymethylated starch, and inter-connected carboxymethylated starch, and complex them to produce it. This complex starch is a complex denaturation starch use to reactive dyes, its adjustable viscosity range may be expanded, be useful to printing and starching.

Owner:JIANGNAN UNIV

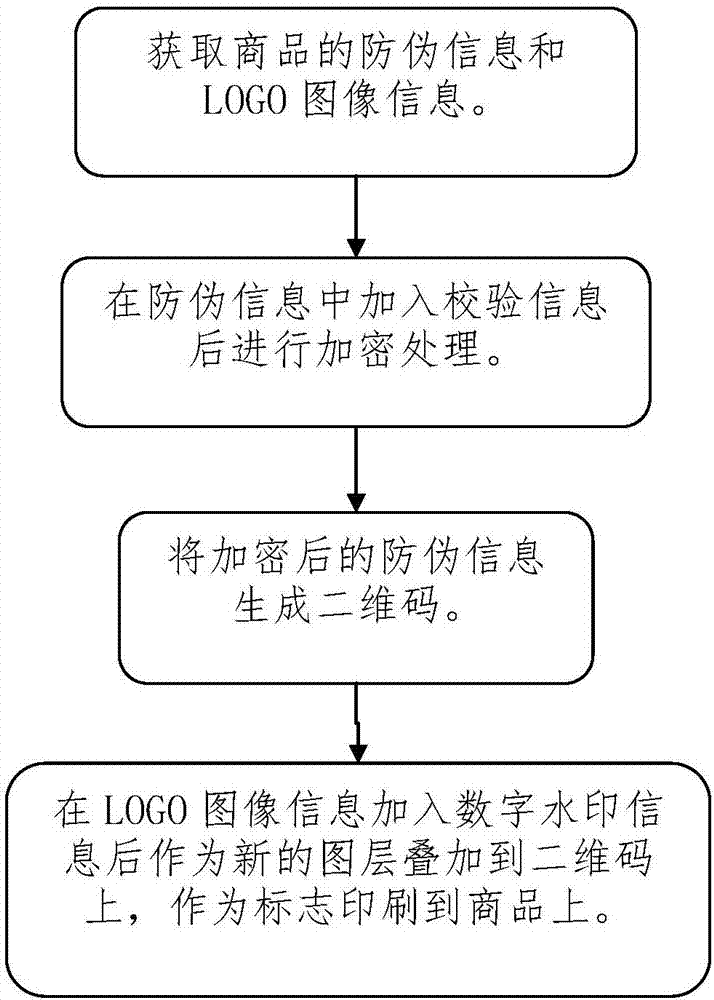

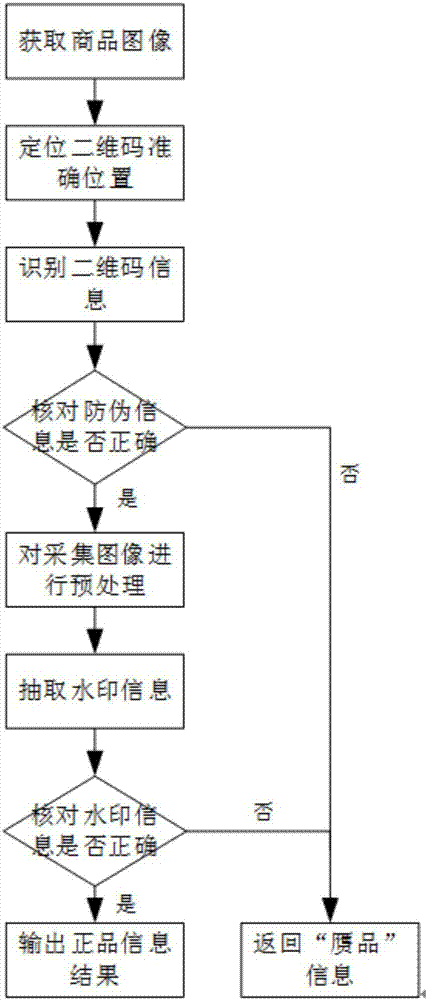

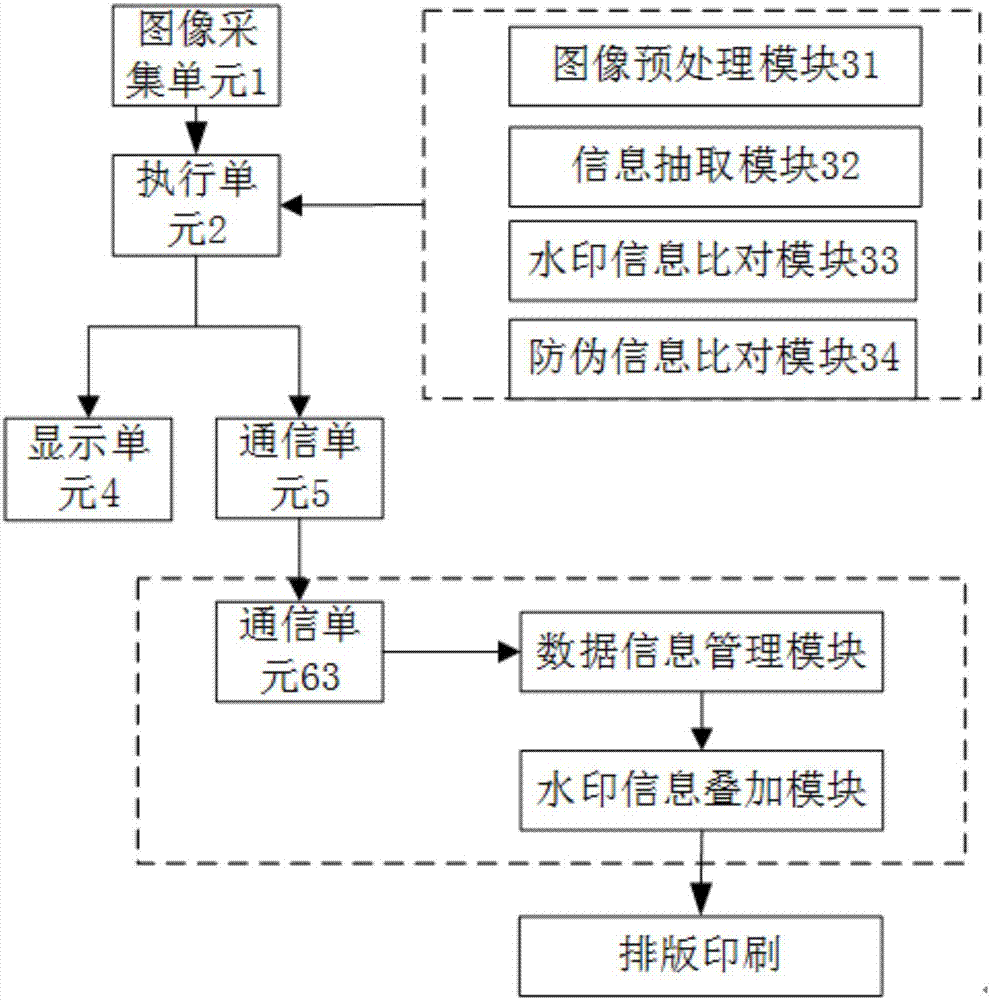

Two-dimensional code superposition digital watermarking method, identification method and identification system thereof

PendingCN106960411AImprove securityIncrease the difficulty of copyingImage data processing detailsCommerceDigital watermarkingLight source

The invention relates to a two-dimensional code superposition digital watermarking method, an identification method and an identification system thereof. The two-dimensional code superposition digital watermarking method comprises the following steps of firstly, acquiring anti-fake information and LOGO image information of a commodity; then adding verification information into the anti-fake information and then carrying out encryption processing; and then generating a two-dimensional code through encrypted anti-fake information; and finally, adding digital watermarking information in the LOGO image information, then taking as a new layer and superposing to the two-dimensional code so as to form a new image, and then taking as a sign and printing on the commodity. The printed commodity can acquire decomposition which is basically consistent with the decomposition of an original image on a visual sense aspect under a standard visible light source. Anti-fake information copy difficulty and an anti-fake coefficient are high so that non-authoritative copy can be prevented. Based on a condition that a commodity printing flow is not changed, commodity printing cost is reduced. Simultaneously, the verification information and the anti-fake information of encryption processing are added so that extraction robustness is increased. Digital watermarking is added in a LOGO image so that safety is high and an anti-fake capability is high too.

Owner:DANDE IMAGE MASTER CO LTD ZHUHAI

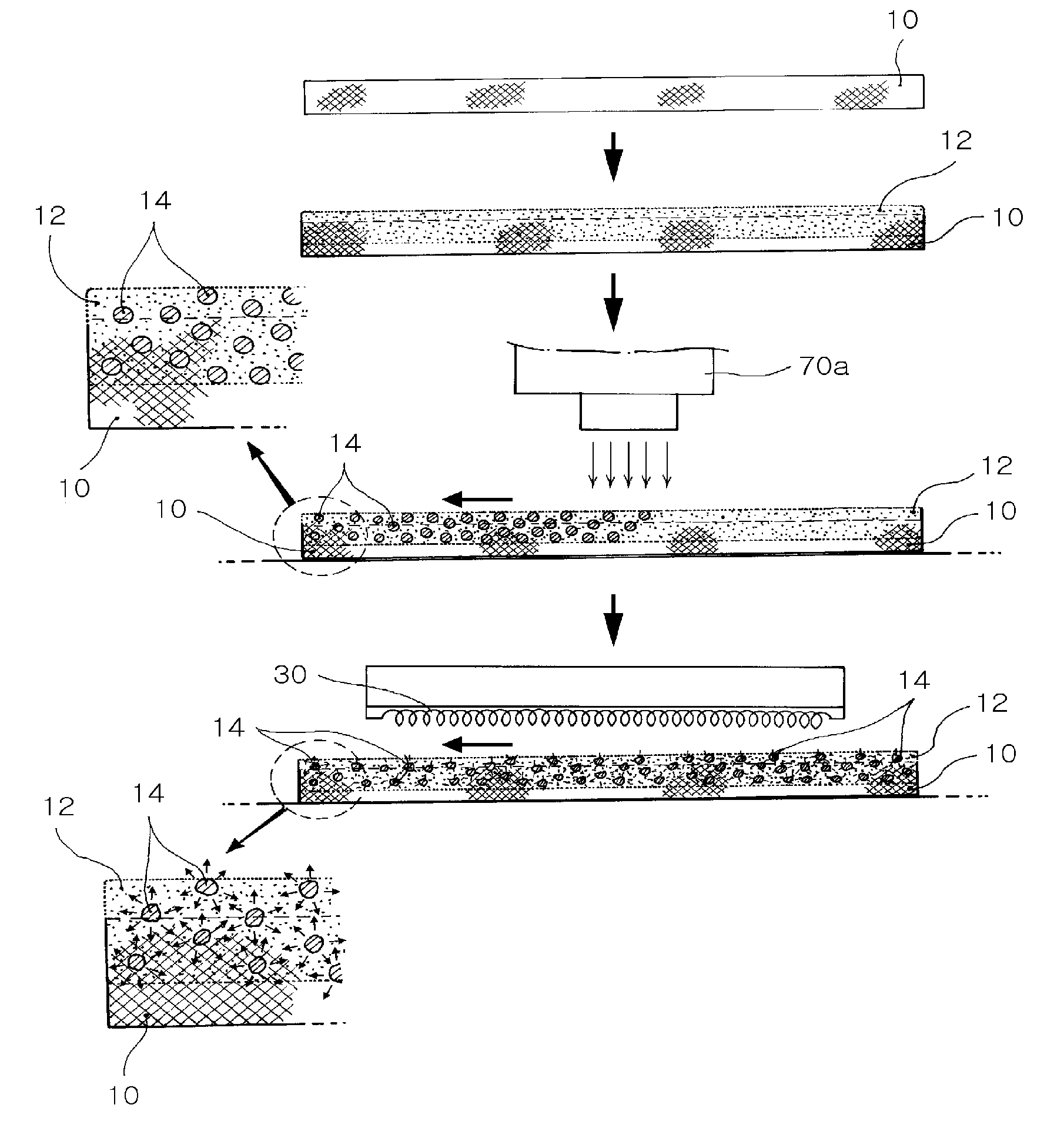

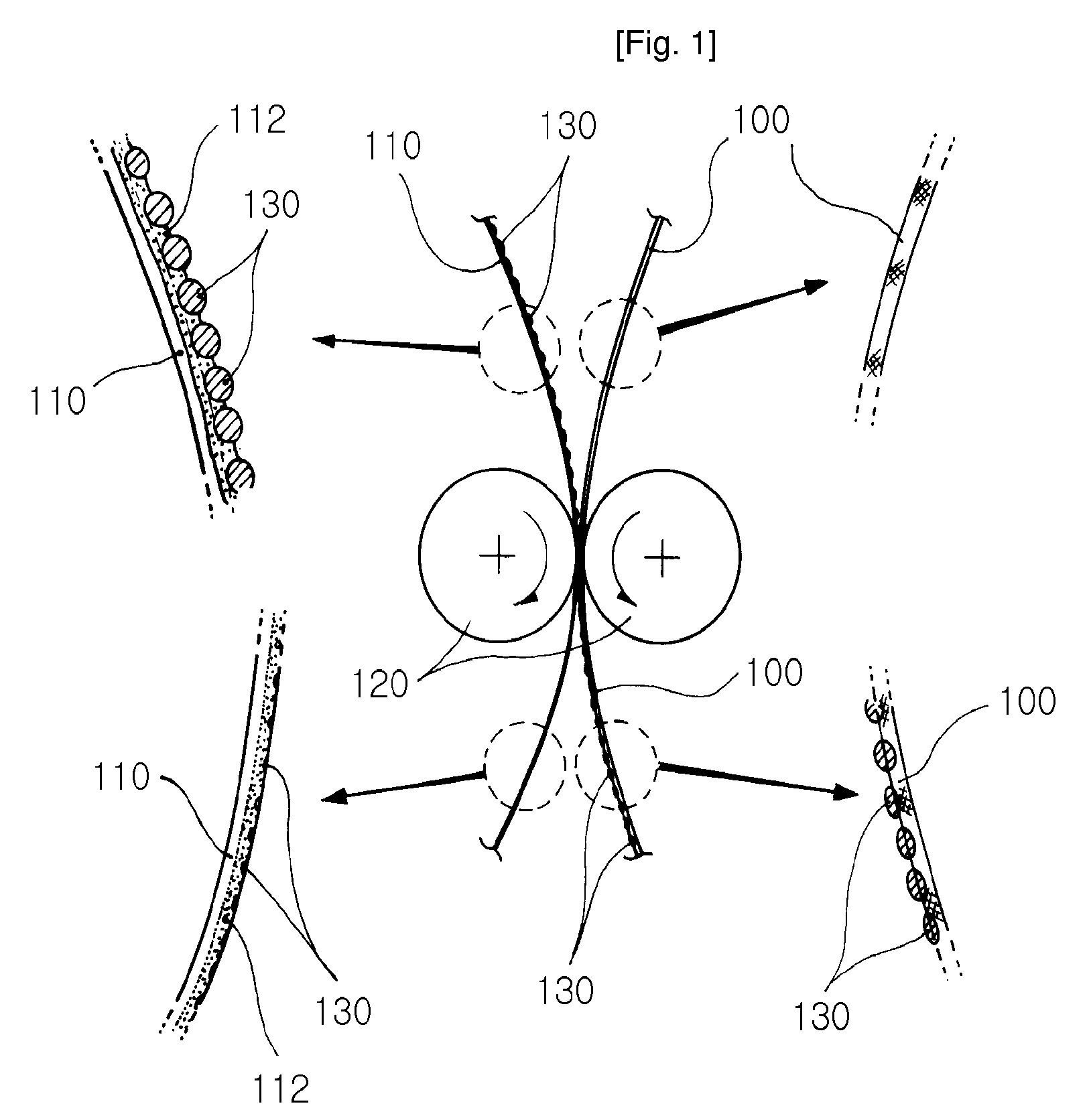

Method and Apparatus for Non-Contact Type Direct Dye-Sublimation Printing

InactiveUS20080095940A1Small and simple structureImprove productivityTransfer printingTransfer printing processEngineeringThermostat

An apparatus and method of printing patterns, an ornamental design or a picture on a printing object using a heat transfer or sublimation transfer technology are provided. In the non-contact type direct dye-sublimation printing method, and agent treatment layer is formed in a printing object, and solid sublimation dye is carried in the agent treatment layer by spraying liquid sublimation dye on the agent treatment layer to allow a transfer image to be infiltrated into the agent treatment layer and hardening the liquid sublimation dye infiltrated into the agent treatment layer. The transfer image is printed on the printing object by sublimating the dye carried on the agent treatment layer and infiltrating the sublimated dye into enlarged pores of a texture of the printing object by heating the printing object. The non-contact type direct dye-sublimation printing apparatus can be manufactured in a simple structure and a small size by omitting a pressing plate, a thermostat and other relating parts that are required in a process for depressing an intermediate transfer medium, thereby reducing the facility costs and the initial investing costs and to provide a printing method using such a printing apparatus.

Owner:KOSTECH INC +1

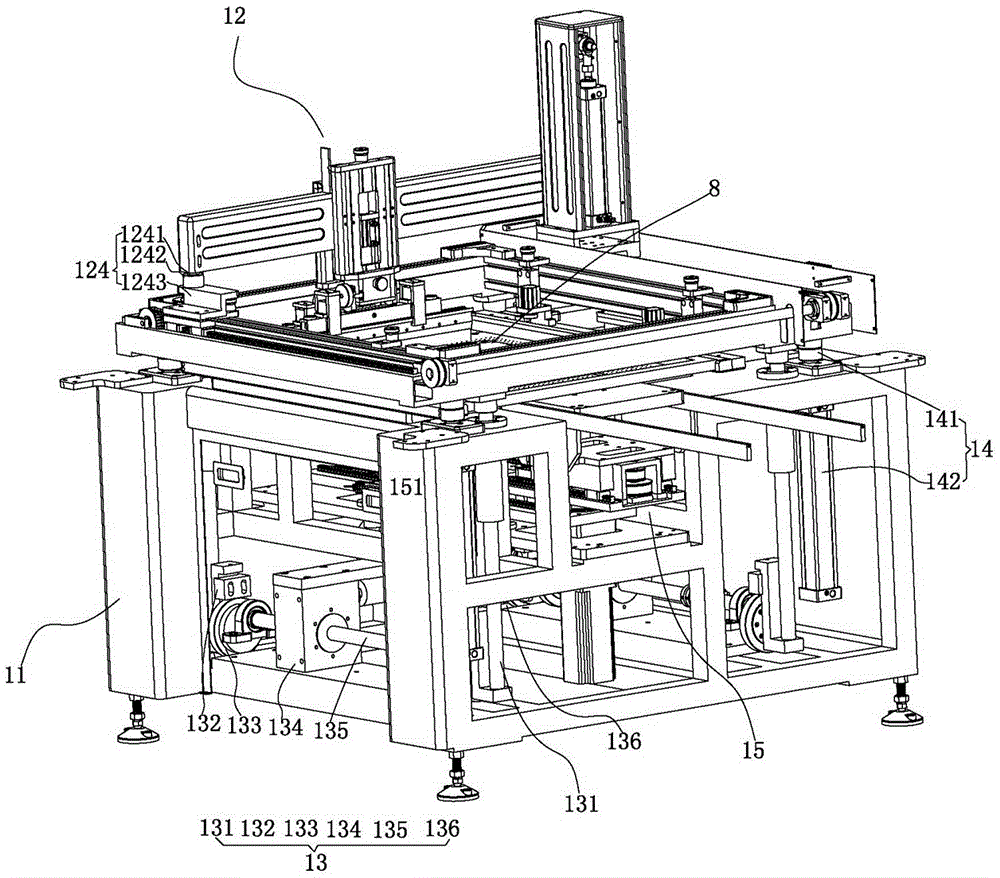

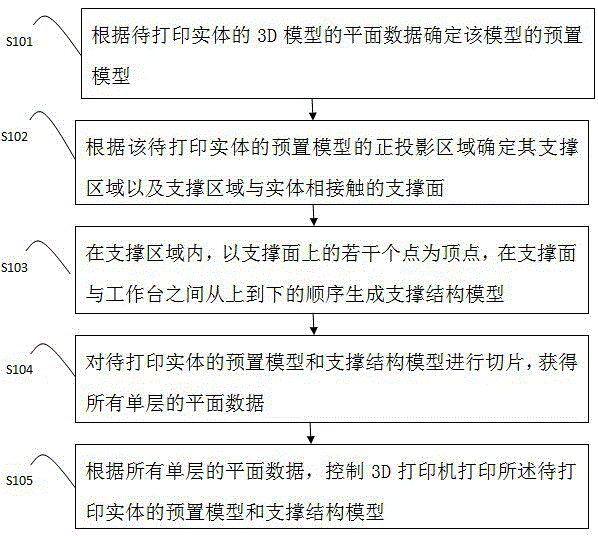

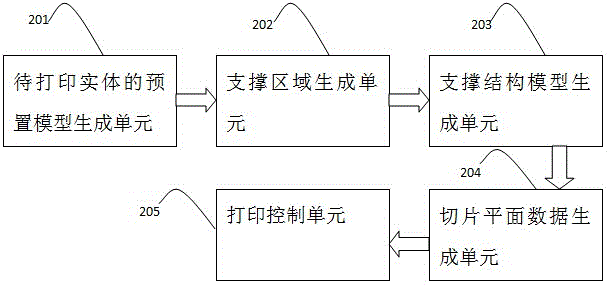

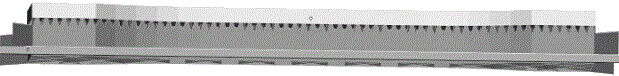

Generating method and generating system for support of additive manufacturing

ActiveCN105643943AReduce consumptionEasy to peelAdditive manufacturing apparatus3d printerComputer science

The invention discloses a generating method and a generating system of a support of additive manufacture. The generating method includes determining a preset model of a 3D model according to planar data of the 3D model of an entity to be printed; determining the support area and the support side of the supporting area contacting with the entity according to the orthographic projection area of the preset model of the entity to be printed; generating a support structure model from top to bottom between the support side and a worktable by taking a plurality of points on the support side as peaks within the support area; cutting the preset model of the entity to be printed and the support structure model to obtain plane data of each single layer; controlling a 3d printer to print the preset model and the support structure model of the entity to be printed. The generating method and the generating system are good in printing effect, and cost fewer materials, and printed parts are high in strength.

Owner:周宏志

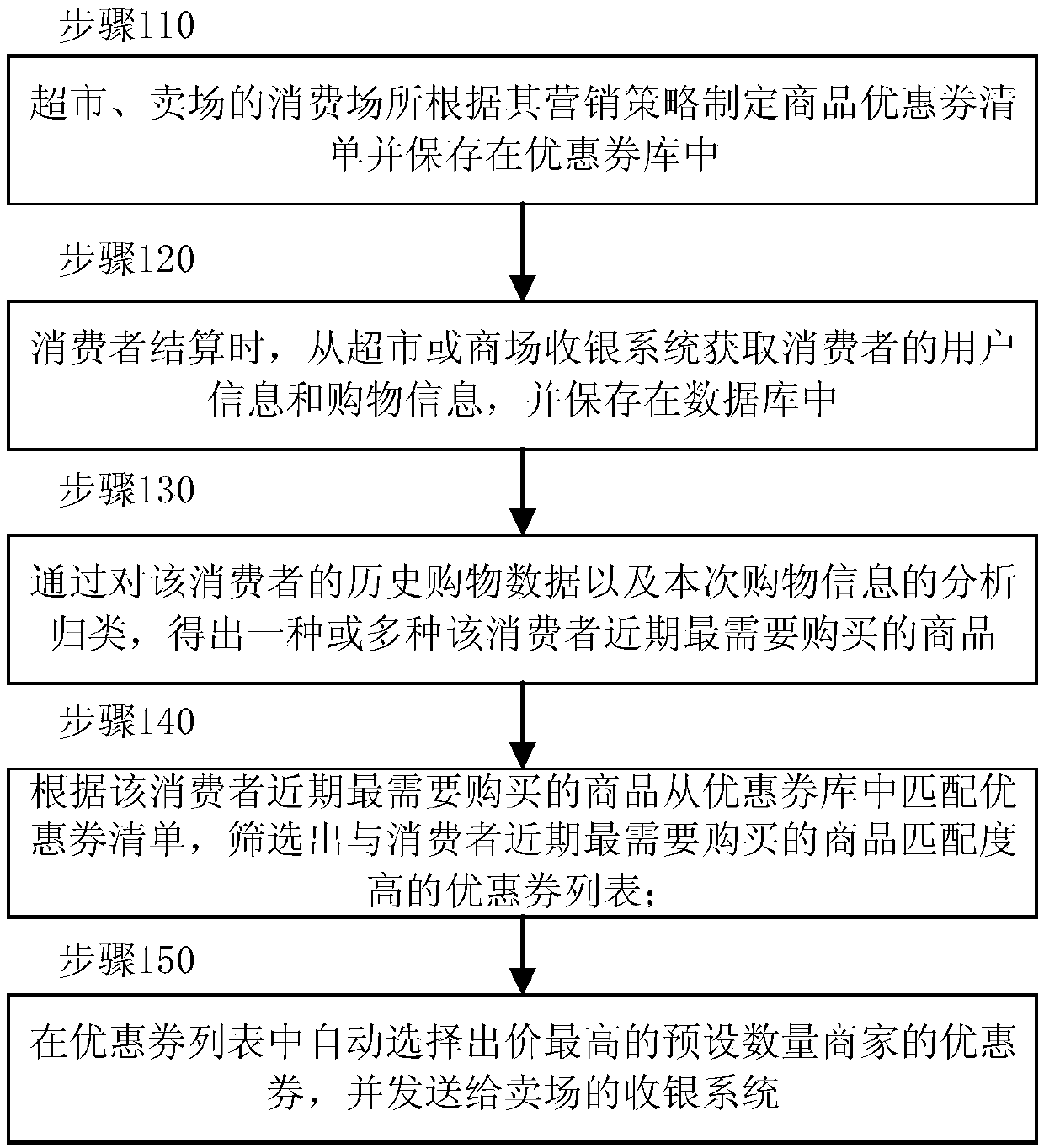

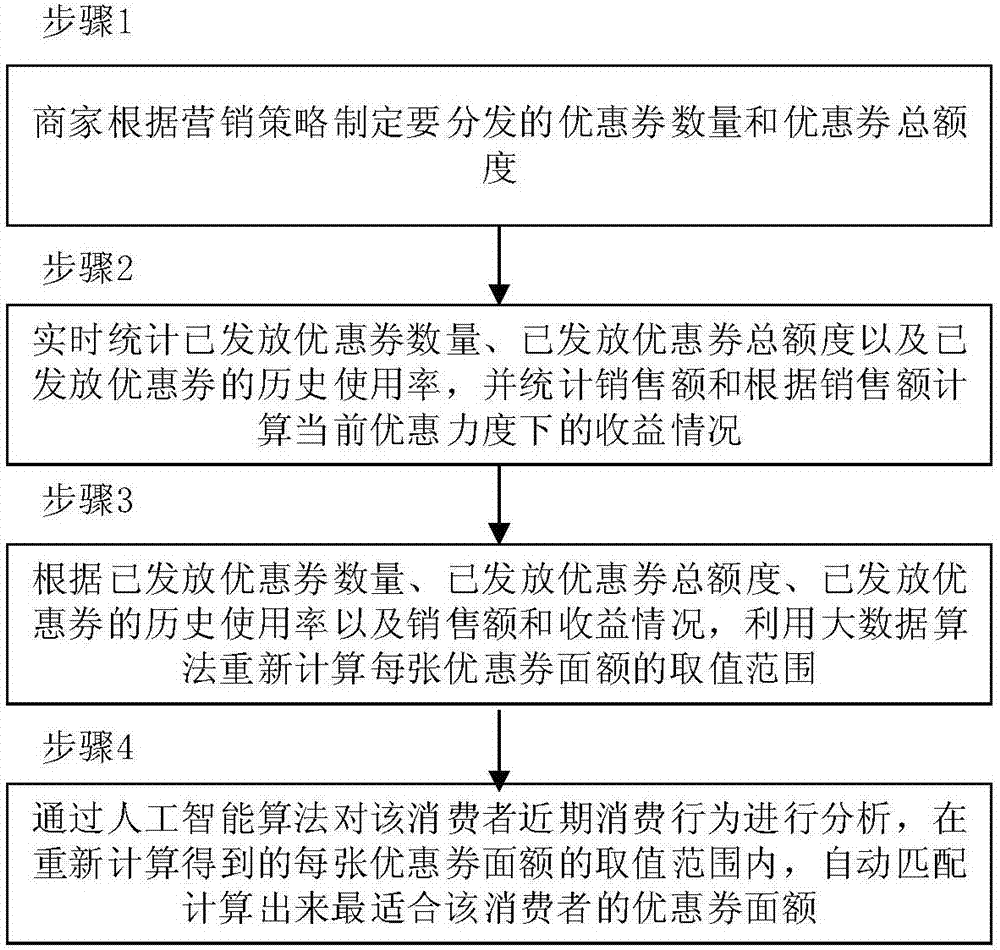

Dynamic generation method of supermarket coupon denomination

InactiveCN107886356AIncrease usageImprove precision delivery efficiencyMarket data gatheringPaymentBusiness development

The invention discloses a method for dynamically generating the denomination of coupons in a supermarket, which includes: the merchant formulates the quantity of coupons to be distributed and the total amount of coupons according to the marketing strategy; The historical usage rate of issued coupons, and statistics of sales and calculation of the income under the current discount based on sales; based on the number of issued coupons, the total amount of issued coupons, the historical usage rate of issued coupons, and sales and revenue, use big data algorithms to recalculate the value range of each coupon face value; analyze the consumer's recent consumption behavior through artificial intelligence algorithms, and within the recalculated value range of each coupon face value, Automatic matching calculates the most suitable coupon denomination for the consumer. The invention automatically changes the face value of coupons according to the market reaction and income situation, so as to ensure the maximization of income.

Owner:北京翰宁智能科技有限责任公司

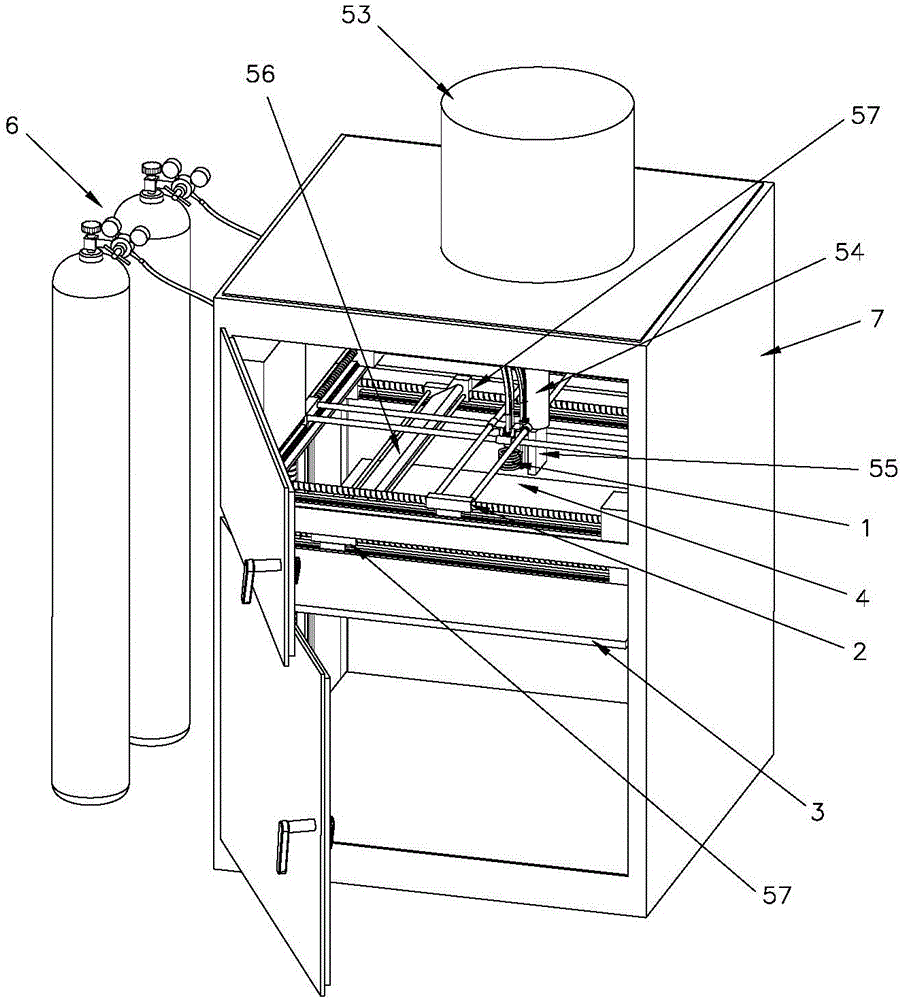

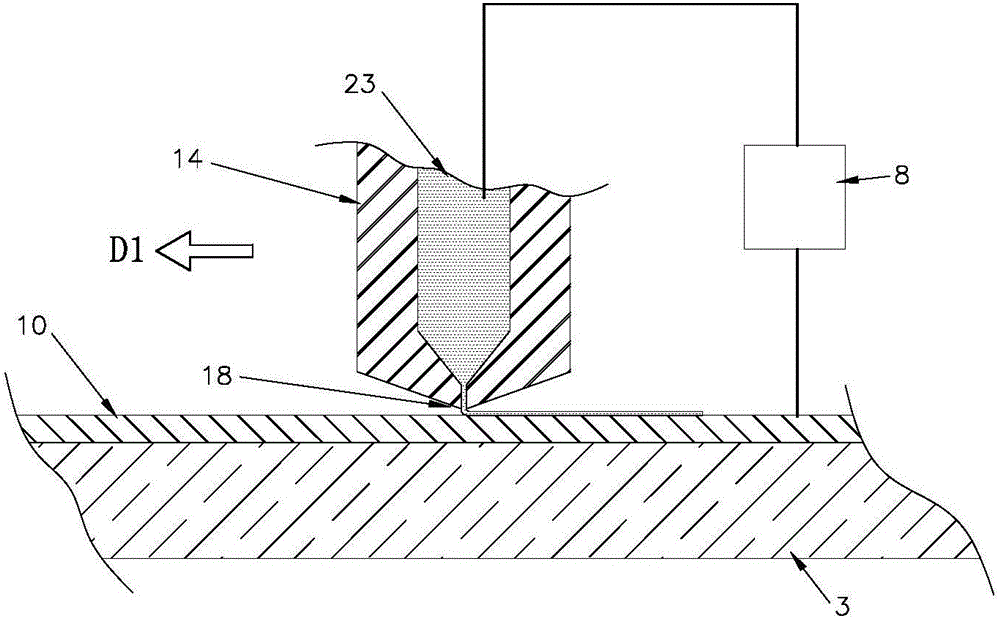

Metal three-dimensional printing method and equipment

ActiveCN106180709APlay a supporting roleReduce printing costsAdditive manufacturing apparatusIncreasing energy efficiencyUltimate tensile strengthMaterials science

The invention discloses a metal three-dimensional printing method and equipment. A core method of the method comprises the following steps of putting molten or softened and flowable metal into a forming area used by three-dimensional printing equipment, converting the molten or softened and flowable metal without flowability into printed and formed metal, accumulating the molten or softened and flowable metal on the printed and formed metal until a to-be-printed object is formed, and forming the to-be-printed object by the accumulated printed and formed metal. The metal three-dimensional printing method is characterized by comprising the following steps of accumulating the molten or softened and flowable metal and the printed and formed metal in a partial area of the forming area; accumulating powder in the partial area of the forming area; and taking the accumulated powder as an auxiliary support, and providing support for the to-be-printed object. A metal part with a complex shape and structure can be manufactured, and the generated metal part is high in strength, is high in density and is high in forming precision; a large metal part can be printed; and the equipment is simple in structure and is low in cost.

Owner:NANJING TAITAO INTELLIGENT SYST CO LTD

3D printer

ActiveCN105856578AShorten the timeImprove printing efficiencyAdditive manufacturing apparatusInformation processingEngineering

The invention provides a 3D printer and belongs to the technical field of 3D printing. The problem in the prior art that the 3D printer is low in printing efficiency is solved. The 3D printer comprises a base, and an information processing system which is arranged on the base and is used for controlling the 3D printer, wherein a printing platform on which a printing material is arranged is arranged on the base; a rotating mechanism which can drive the printing platform to rotate is arranged between the base and the printing platform; a plurality of mounting holes are formed in the base; upright posts are fixed in the mounting holes; top racks which correspond to the base are fixed at the upper ends of the upright posts; a storage box used for storing the printing materials is arranged on the top racks; printing nozzles used for printing are arranged among the upright posts; a lifting mechanism which can control the printing nozzles to ascend or descend is arranged between the printing nozzles and the upright posts; the printing nozzles are arranged above the printing platform; and a recycling device capable of recycling wastes produced by printing and a cleaning device capable of cleaning the printing nozzles are arranged on the base. The 3D printer disclosed by the invention has the advantage of high printing efficiency.

Owner:QINGDAO XINGKANG 3D TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com