Three-dimensional (3D) printing robot system based on magneto-rheological materials and Three-dimensional (3D) printing method based on magneto-rheological materials

A robotic system, 3D printing technology, applied in printing and other directions, can solve the problems of manufacturing speed, product accessibility and safety, multiple colors and molding accuracy and quality problems, and achieve fast printing speed, low printing cost, high precision high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

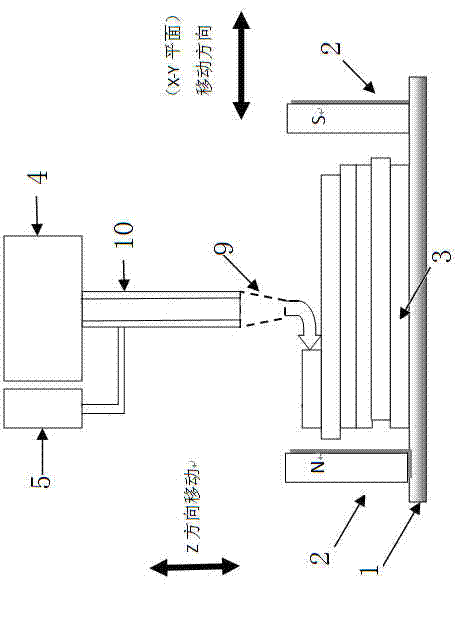

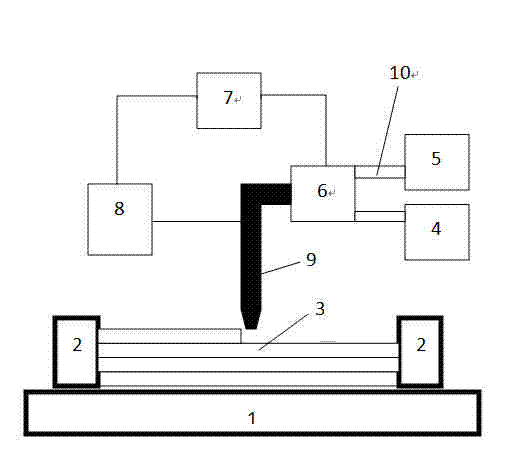

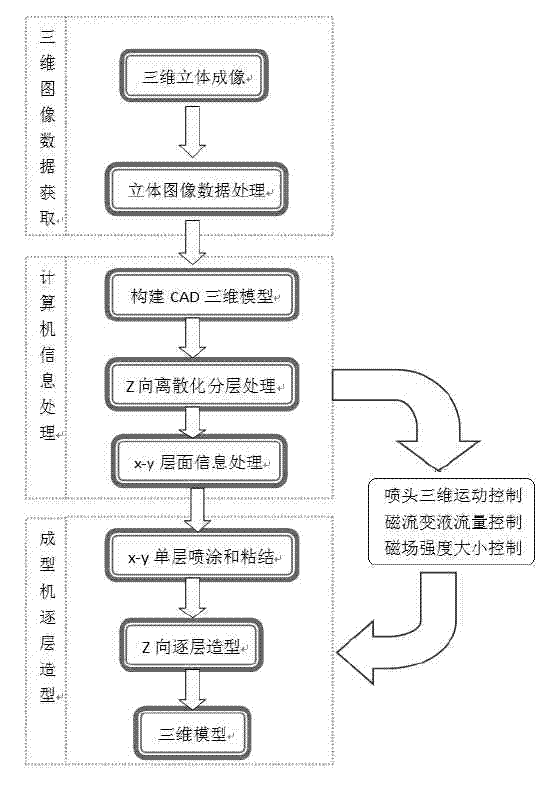

[0051] Fig. 1 is a schematic diagram of a nozzle device for 3D printing rapid prototyping based on magnetorheological fluid, and Fig. 2 is a schematic diagram of a device for 3D printing rapid prototyping based on magnetorheological fluid, as shown in the figure: the magnetorheological material based on magnetorheological material provided by the present invention 3D printing robot system, including 3D stereoscopic imaging system, computer 3D stereoscopic image processing system and 3D printing rapid prototyping device;

[0052] The three-dimensional stereoscopic imaging system is used to obtain the three-dimensional data extraction of the entity, and provide it to the computer three-dimensional stereoscopic image processing system;

[0053] The computer three-dimensional image processing system is used to construct three-dimensional data extracted by a three-dimensional imaging system into a three-dimensional image, and digitally process the three-dimensional image to form a c...

Embodiment 2

[0085] The difference between this embodiment and embodiment 1 is only:

[0086] The principle of 3D printing rapid prototyping provided by the present invention is based on the magnetorheological effect of magnetorheological materials.

[0087] The solution to the technical problem of 3D printing in the present invention is to add a binder or dope solid particles, and solidify and form at a low temperature. Adhesives commonly used in industry include polyvinyl alcohol adhesives, polyvinyl formal adhesives, polyvinyl acetate adhesives, epoxy resins, synthetic rubbers, polyurethanes, acrylate adhesives, heterocyclic high Molecular binder.

[0088] The 3D printing robot of the present invention is a humanoid robot. The head is a computer-controlled system for processing three-dimensional images.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com