Patents

Literature

268results about How to "Fast printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

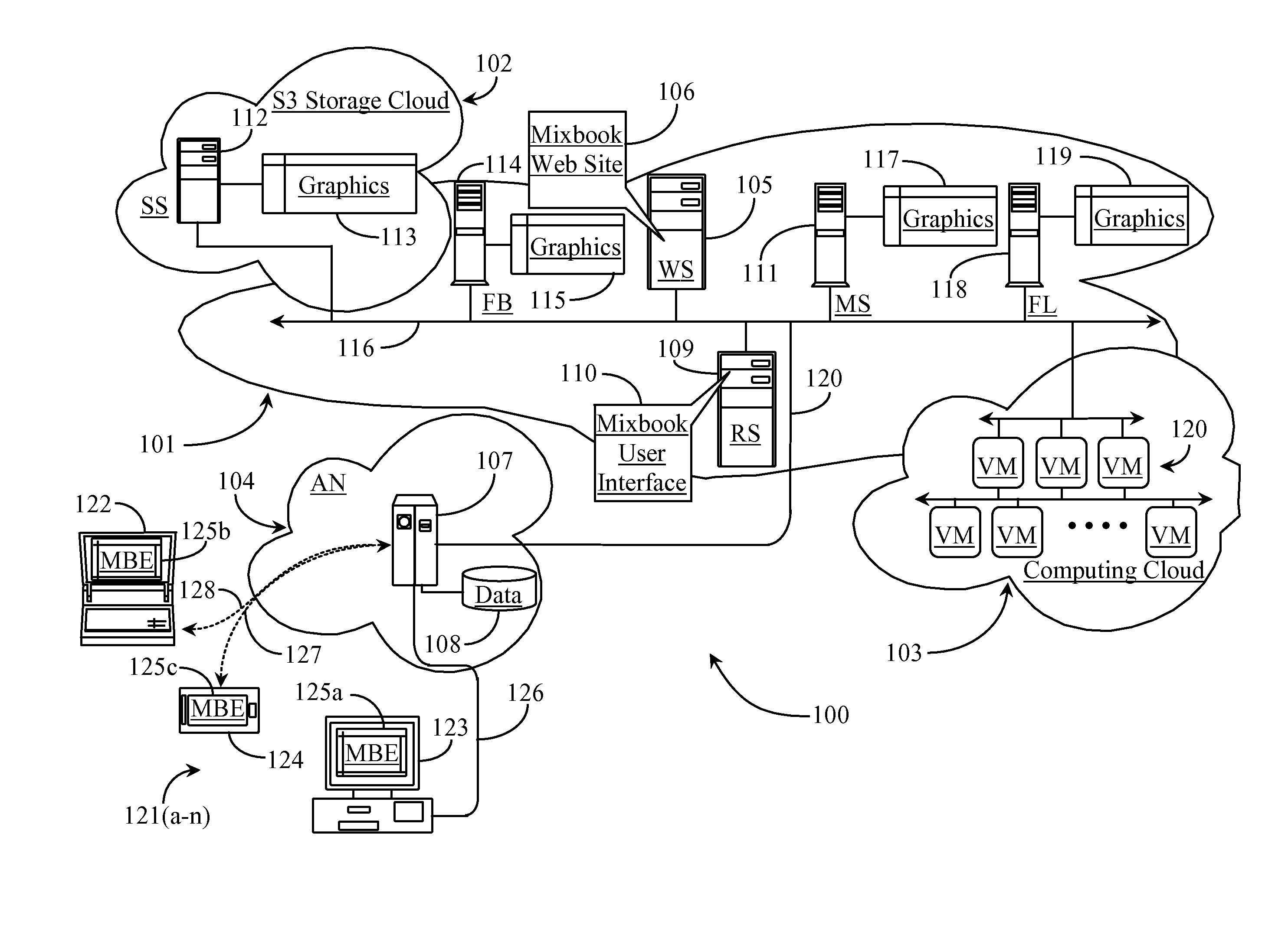

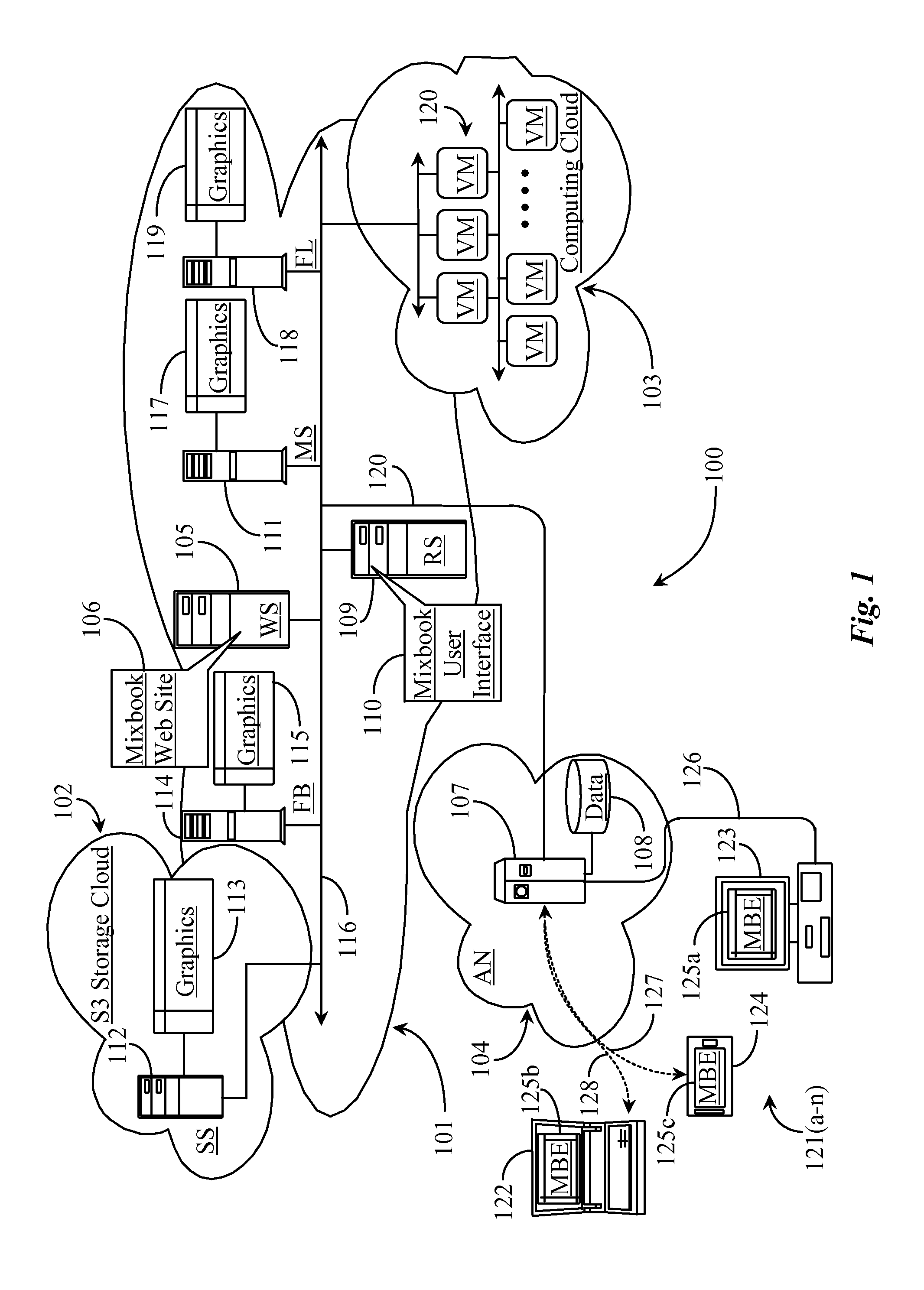

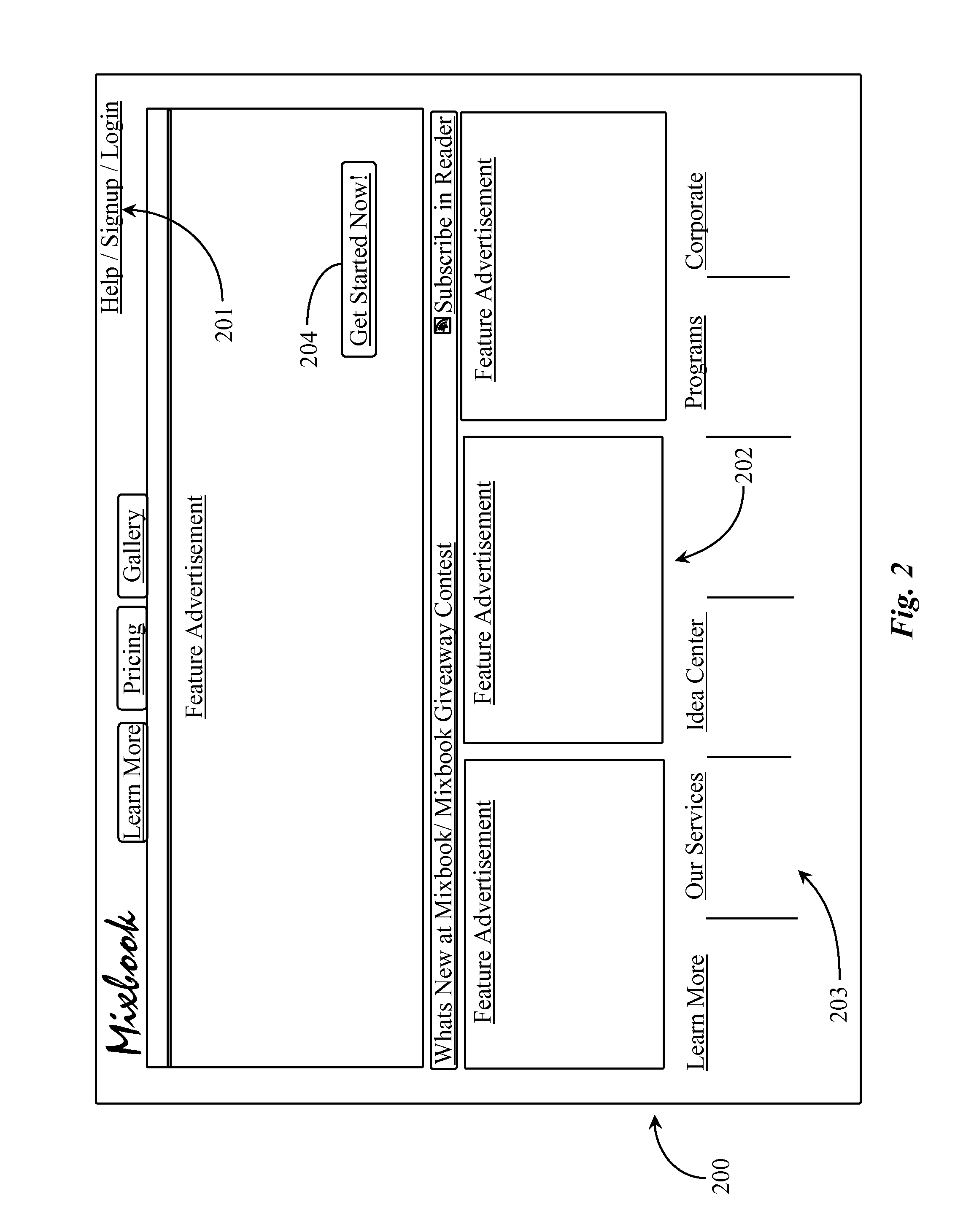

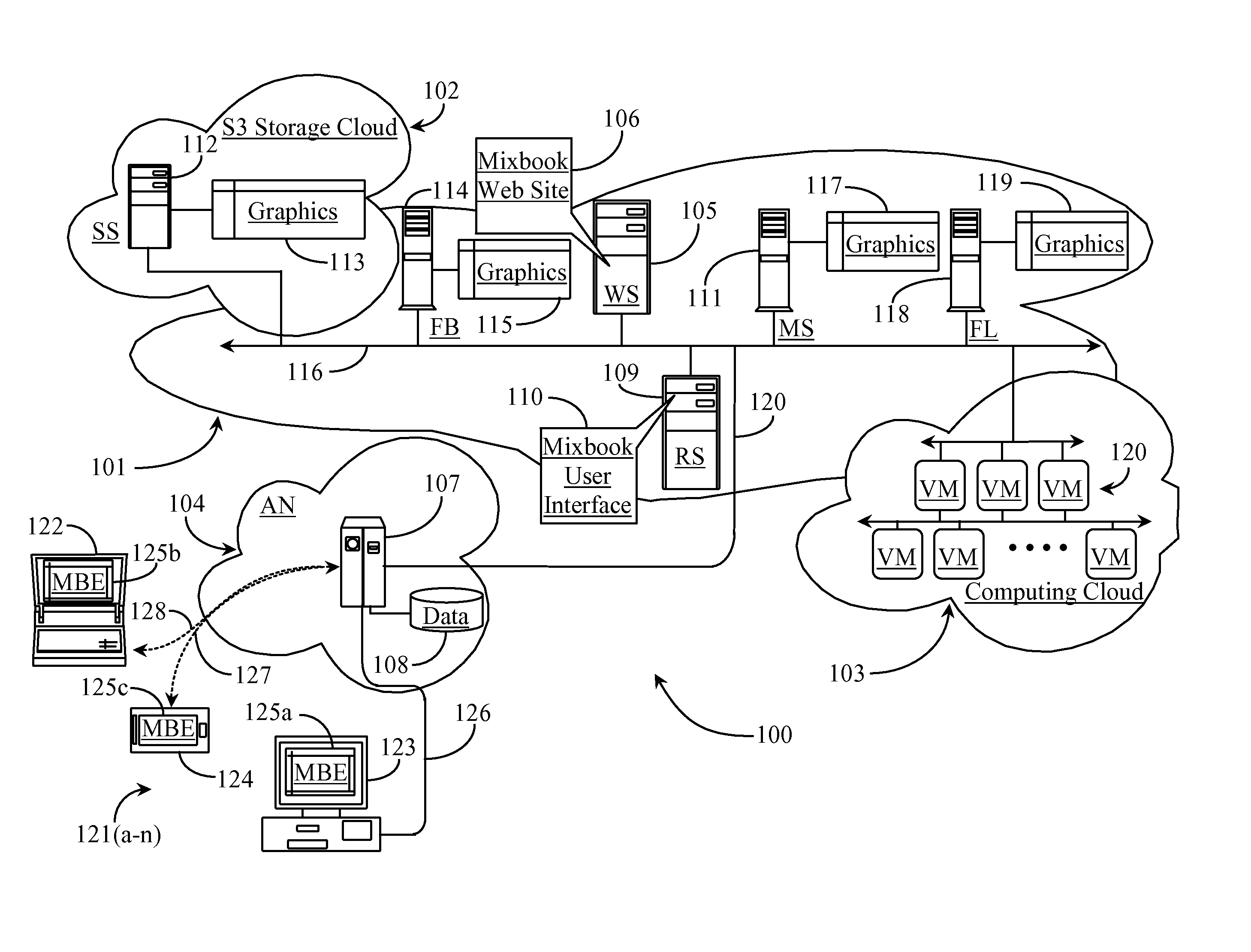

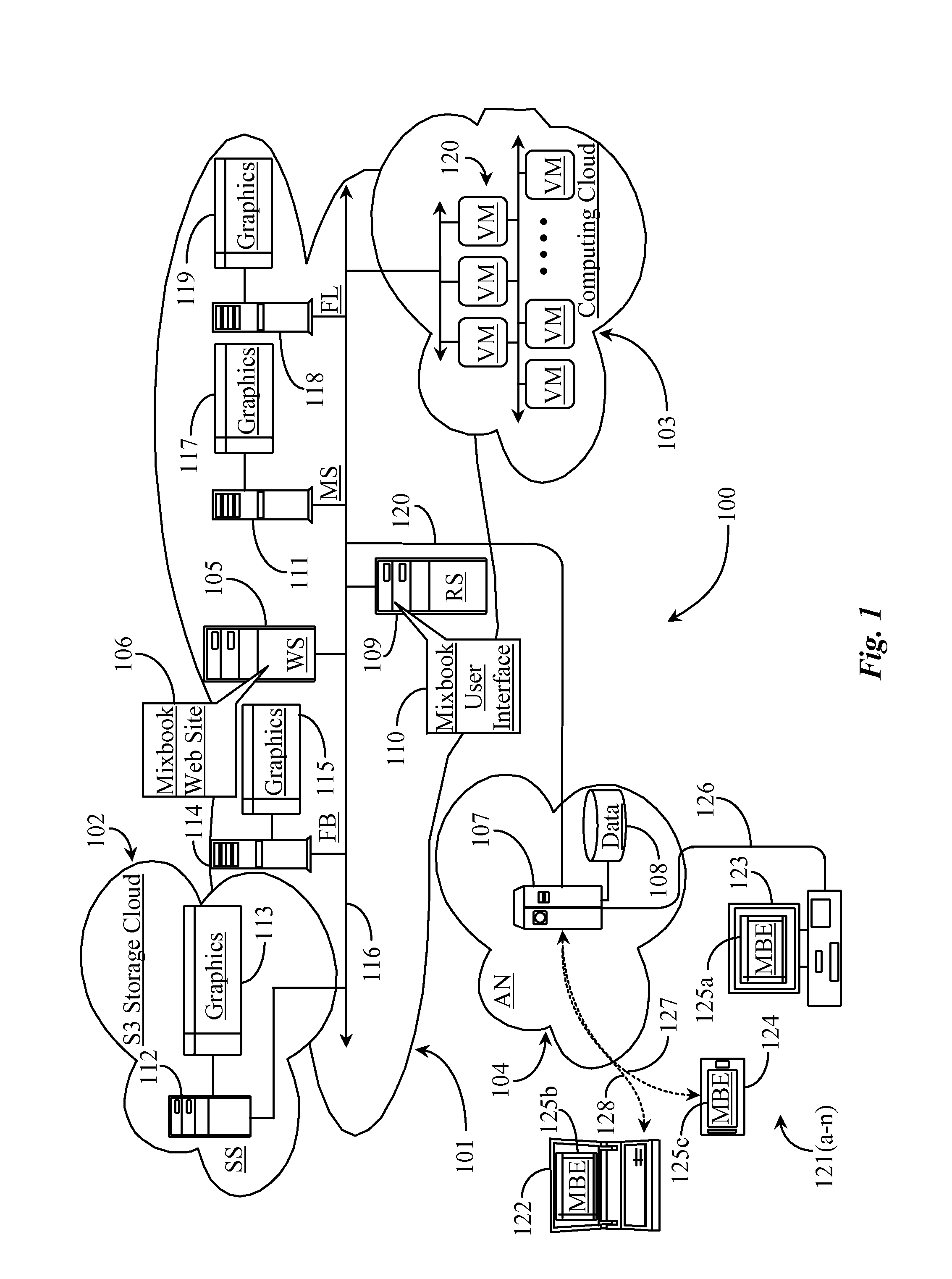

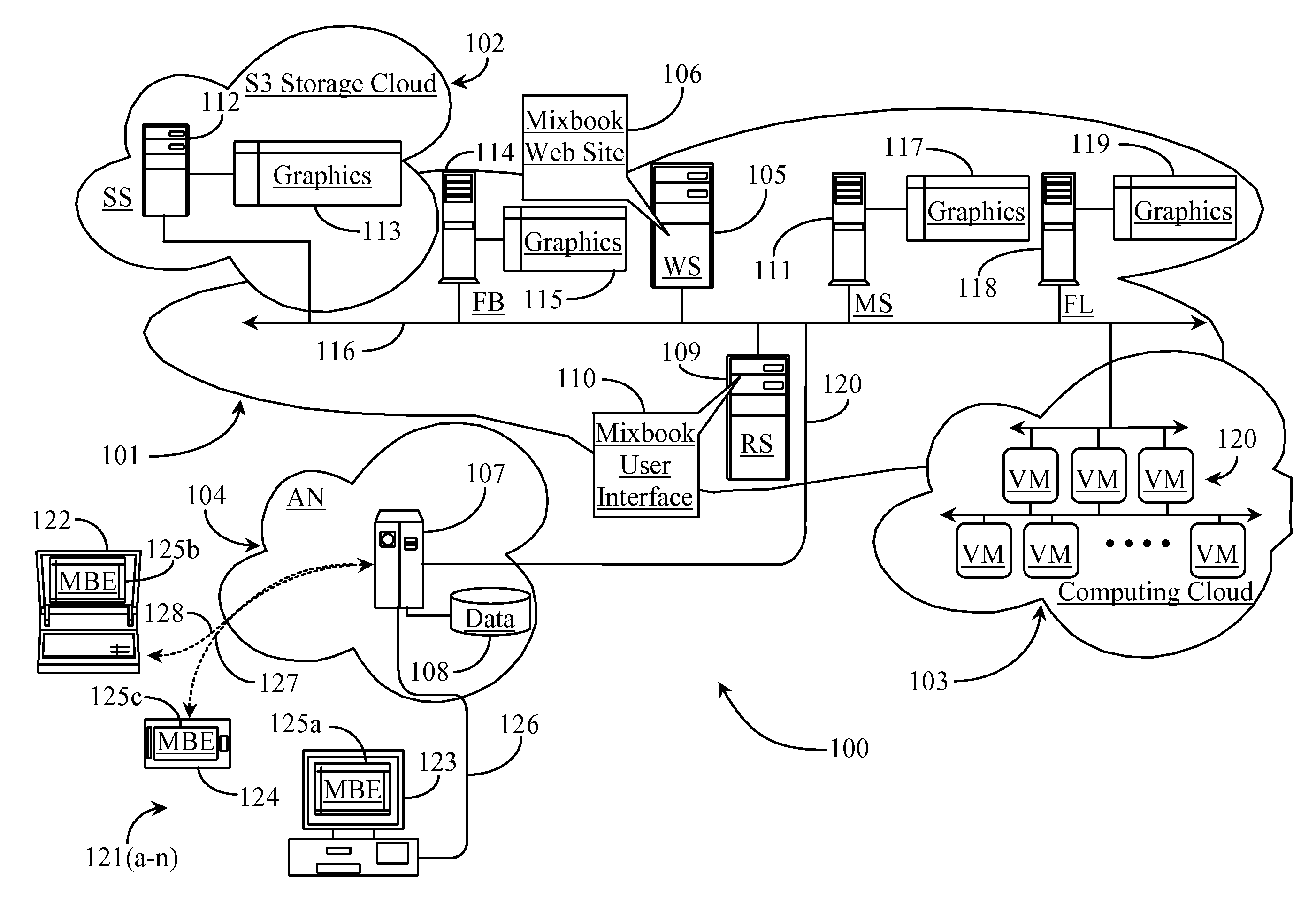

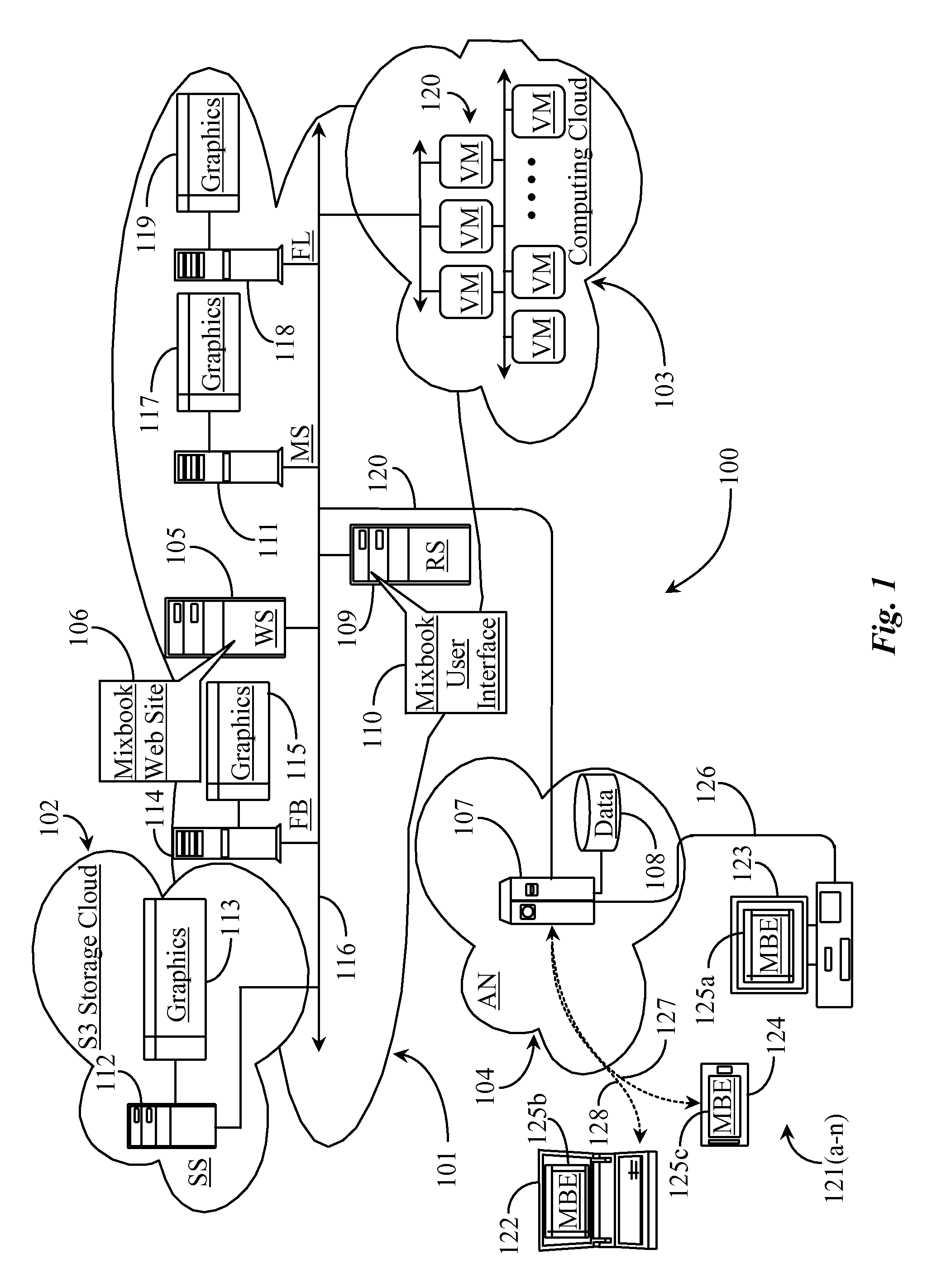

System and Methods for Creating and Editing Photo-Based Projects on a Digital Network

ActiveUS20110167353A1Quickly populateFast printingCharacter and pattern recognitionStill image data indexingGraphicsGraphical user interface

A system for creating and editing image and or text-based projects includes a server connected to a data network, the server having access to a digital medium containing an executable graphics user interface (GUI) accessible by computer browser, at least one data repository residing on the network, the repository accessible to the server, the repository containing images, and product-related graphics, a print configuration engine implemented in software residing on and executable from the digital medium or another accessible medium, the print configuration engine for rendering image and or text-based products for printing, and at least one bi-directional communication channel established between a computing appliance running a version of the GUI while connected to the network and a server managing the data repository.

Owner:INTERACTIVE MEMORIES

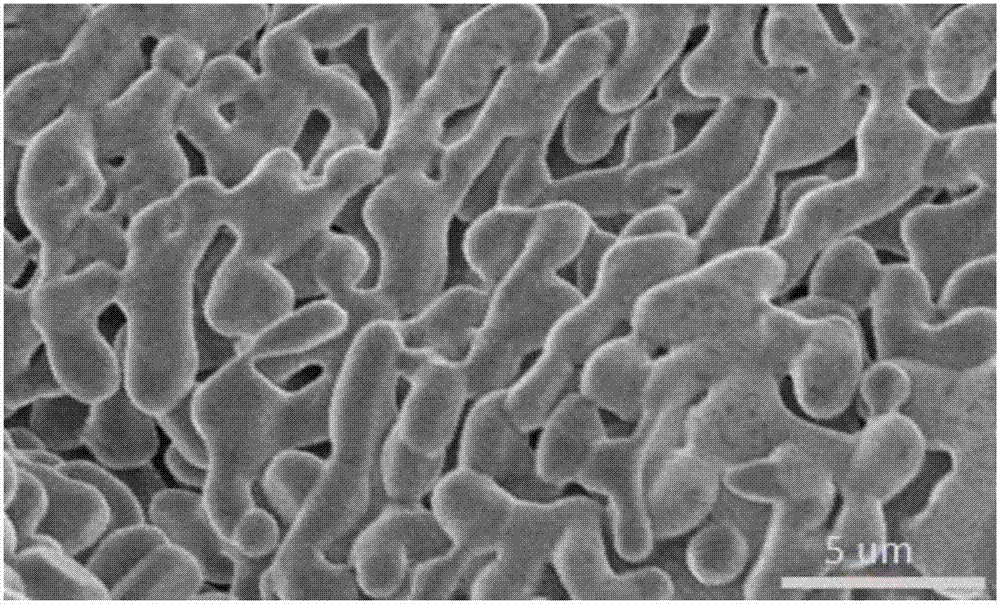

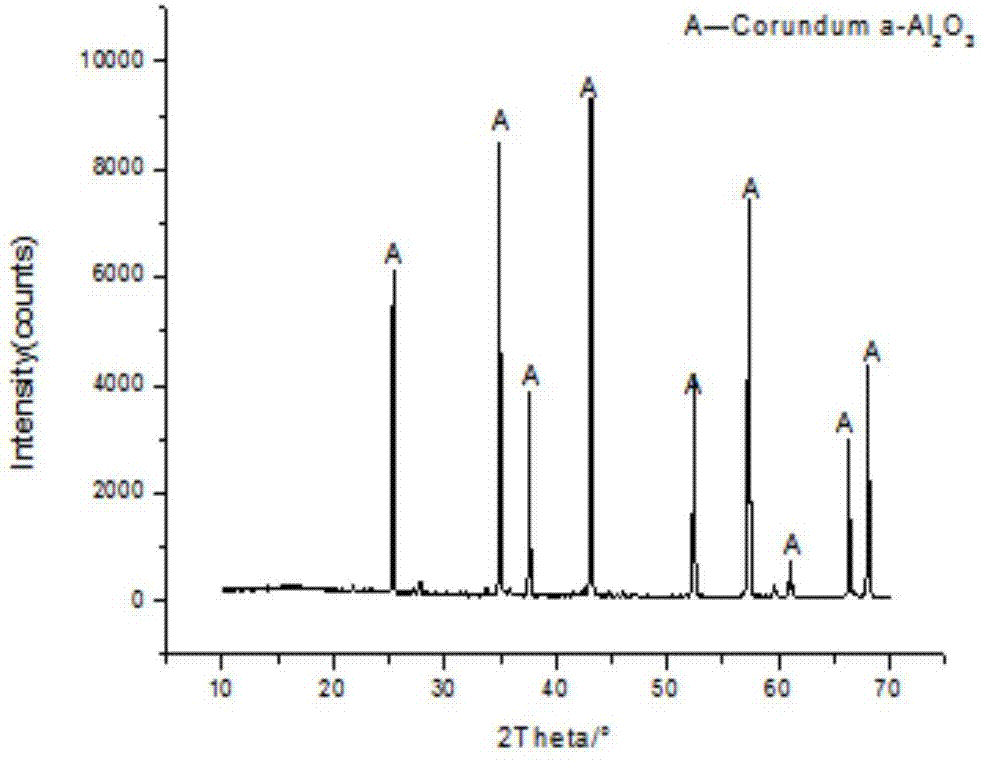

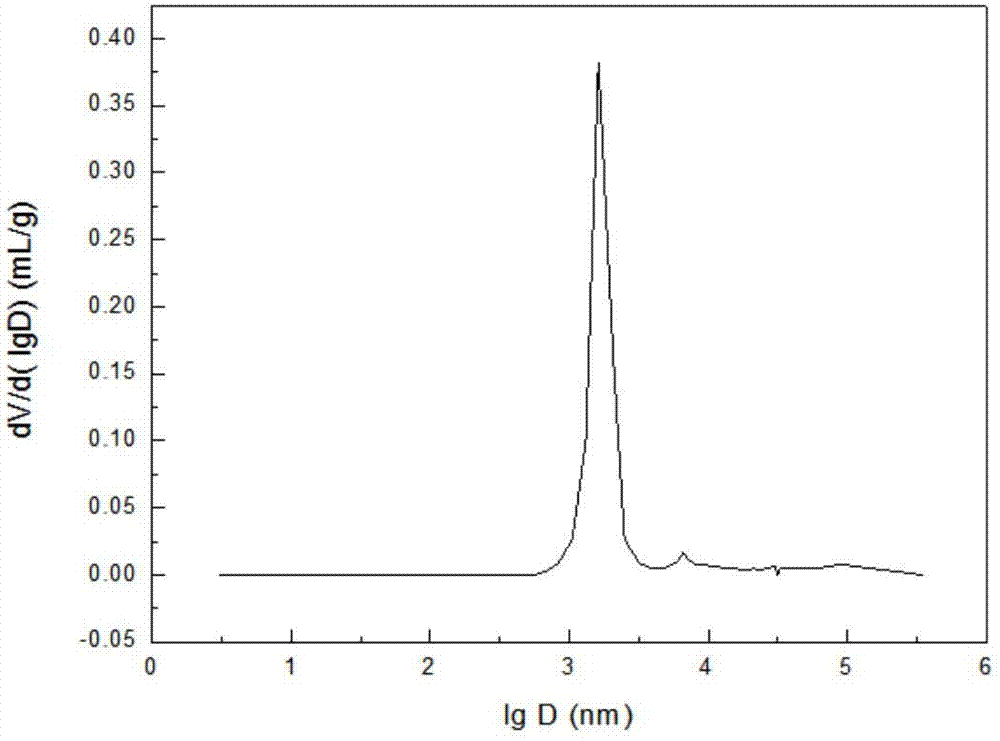

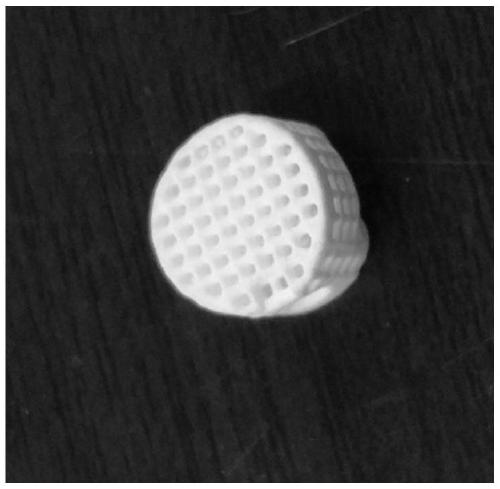

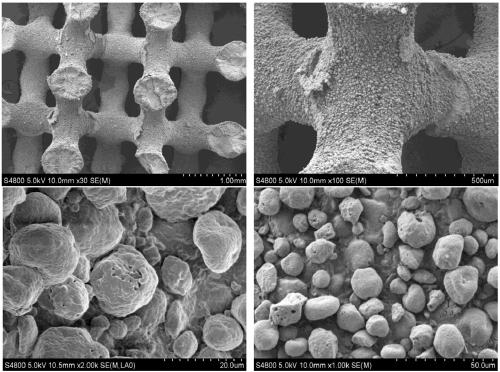

Three-dimensional printing molding preparation method for porous ceramic for filtration

InactiveCN107098717ALoose connectionHigh precisionAdditive manufacturing apparatusDispersed particle filtrationShrinkage rateFiltration

The invention discloses a three-dimensional printing molding preparation method for a porous ceramic for filtration. The method comprises the following steps: S1 preparing a ceramic material for printing in a three-dimensional printer; S2 printing a porous ceramic green body through the three-dimensional printer by using the prepared printing ceramic material; and S3; conducting drying, rubber discharging and sintering on the printed porous ceramic green body to obtain a porous ceramic with a specific shape structure. The three-dimensional printing molding preparation method has the beneficial effects that ceramic particles are loose in connection, the density of the ceramic green body is low, the shrinkage rate after sintering is large, and the defects such as deformation and cracking are easy to occur, and the mechanical properties of the prepared products are lower; and a generated loose porous structure has larger pore size in pores, and the pore size and porosity are difficult to control through a molding process parameter. The ceramic material for printing according to the invention fully mixes solid powder with liquid additive, the ceramic particles are connected closely and the components are uniform, and the printed ceramic green body has high precision and good mechanical performance.

Owner:WUHAN UNIV OF TECH

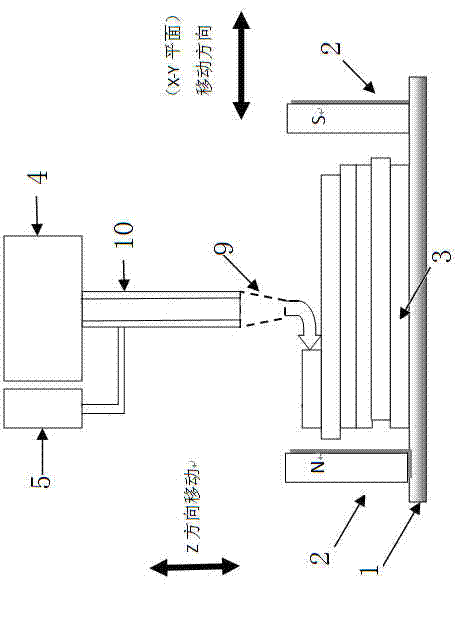

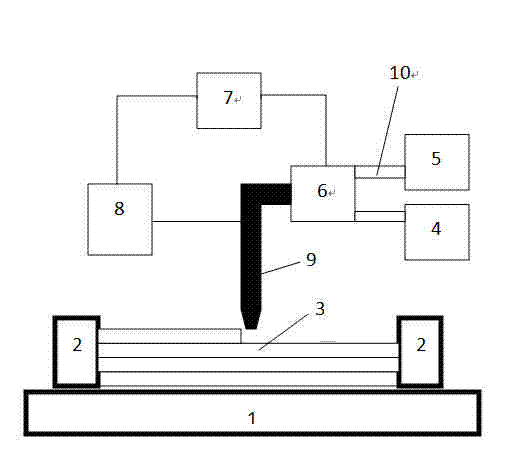

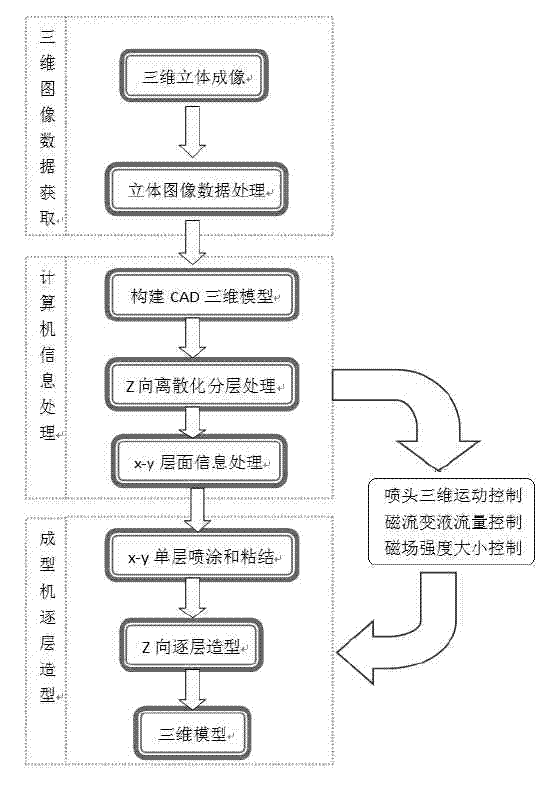

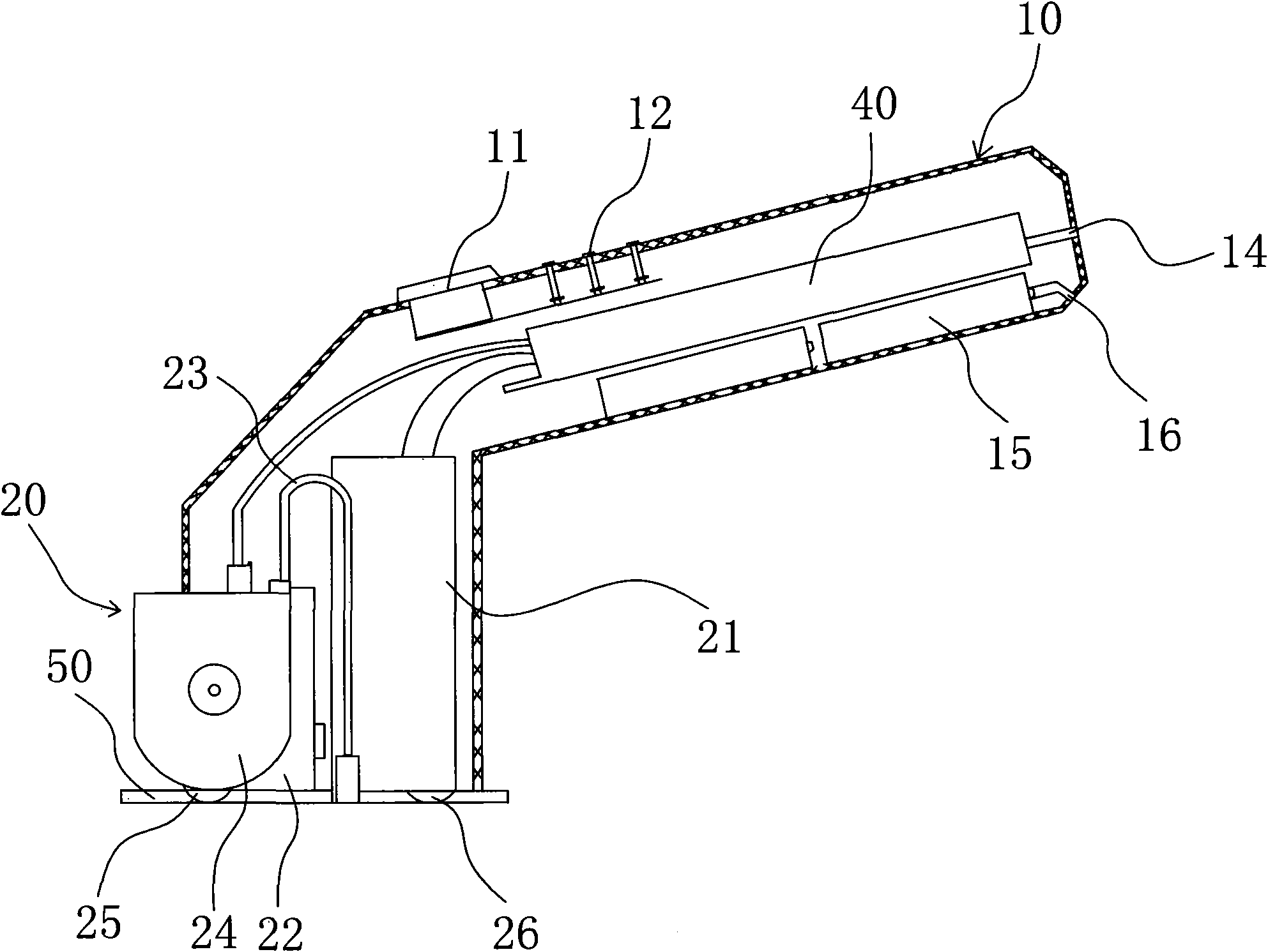

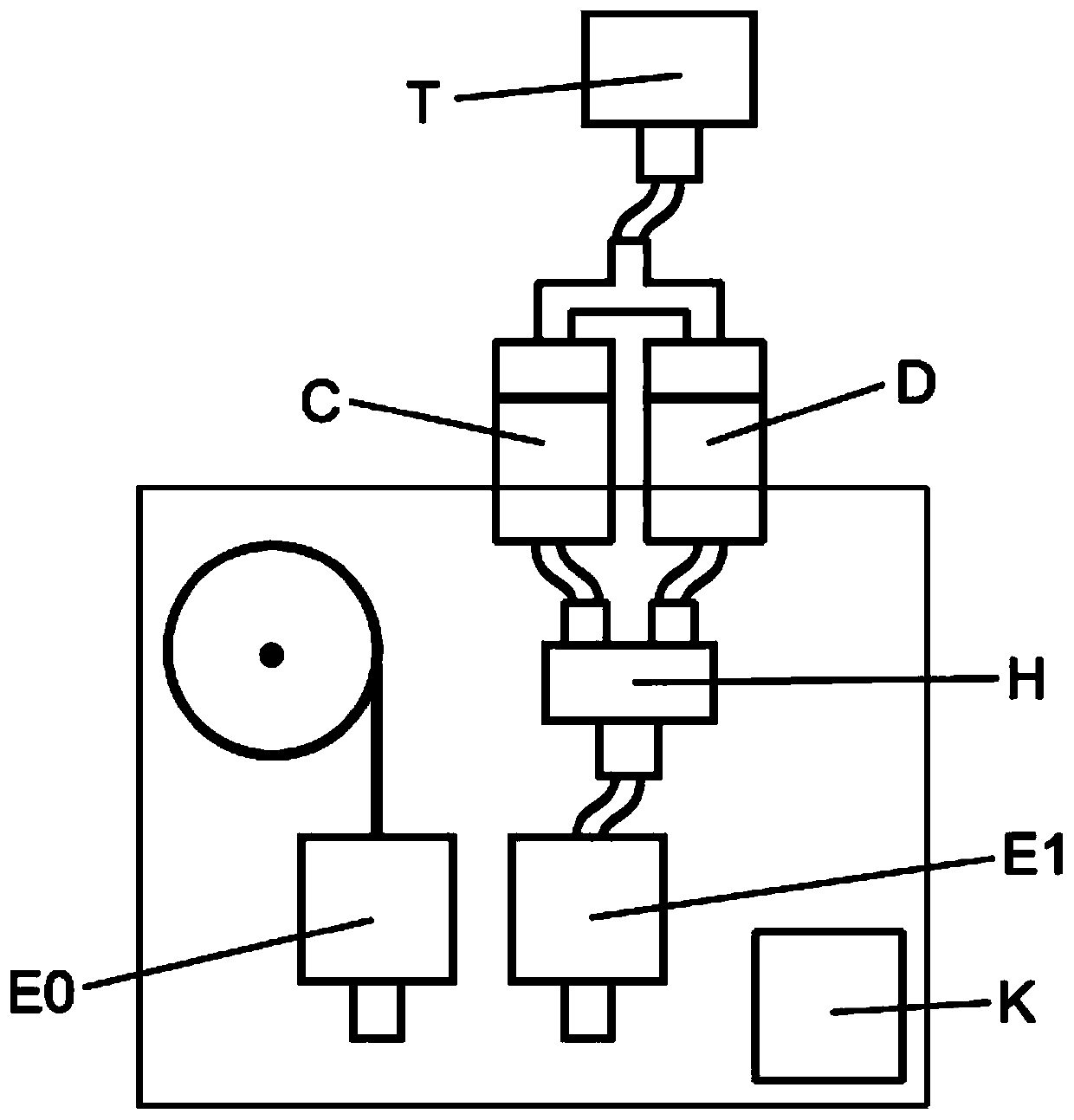

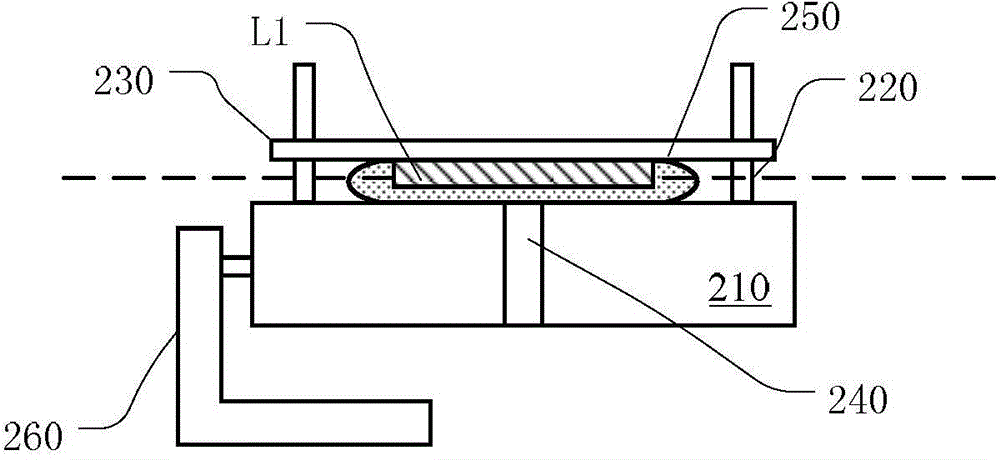

Three-dimensional (3D) printing robot system based on magneto-rheological materials and Three-dimensional (3D) printing method based on magneto-rheological materials

The invention discloses a three-dimensional (3D) printing robot system based on magneto-rheological materials and a 3D printing method based on the magneto-rheological materials, and particularly relates to the 3D printing robot system based on the magneto-rheological materials and the 3D printing method based on the magneto-rheological materials. The 3D printing robot system based on the magneto-rheological materials and the 3D printing method based on the magneto-rheological materials combines a 3D stereoimaging technology and a rapid forming technology based on a magneto-rheological effect, can directly read 3D image data, then prints layer by layer and conducts solidifying forming, and finally forms a 3D entity model. The 3D printing robot system based on the magneto-rheological materials is based on the 3D stereoimaging technology, a magneto-rheological technology, a fine control technology, a digitalizing image technology and the like, and comprises a 3D stereoimaging system, a computer 3D image processing software, a mechanical arm 3D moving system, a magneto-rheological material flow quantity control system, a dye mixing and control system, a magnetic generating and regulating system and the like. a designer aims to design a man-machine interactive system which massively produces models or products and has the advantages of being low in cost, simple and fast, individual and digital.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

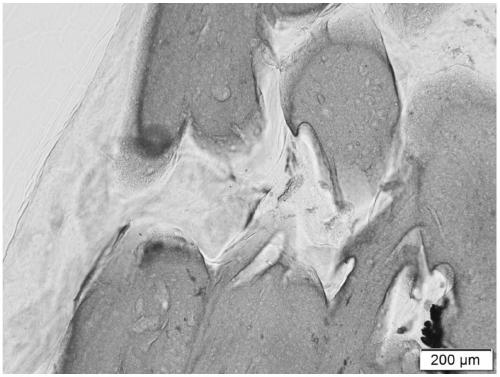

Calcium phosphate bone induction biological ceramic stent based on photocuring 3D printing technology and preparation method thereof

PendingCN109650909AHigh solid contentLow viscosityAdditive manufacturing apparatusCeramic shaping apparatusCalcium biphosphateDispersity

The invention discloses a calcium phosphate bone induction biological ceramic stent based on a photocuring 3D printing technology and a preparation method thereof, and belongs to the field of biomedical materials. Through the method, ceramic paste which is high in content of solid, low in viscosity and good in dispersity and fluidity can be effectively prepared. Through the photocuring 3D printingtechnology and follow-up degreasing sintering, the bone induction porous calcium phosphate ceramic stent with an internal penetrating pore structure can be prepared, wherein the shape, size, porosityand macroscopic morphology of the bone induction porous calcium phosphate ceramic stent can be accurately controlled, and the bone induction porous calcium phosphate ceramic stent is used for bone tissue repairing and filling and individualized repairing.

Owner:SICHUAN UNIV

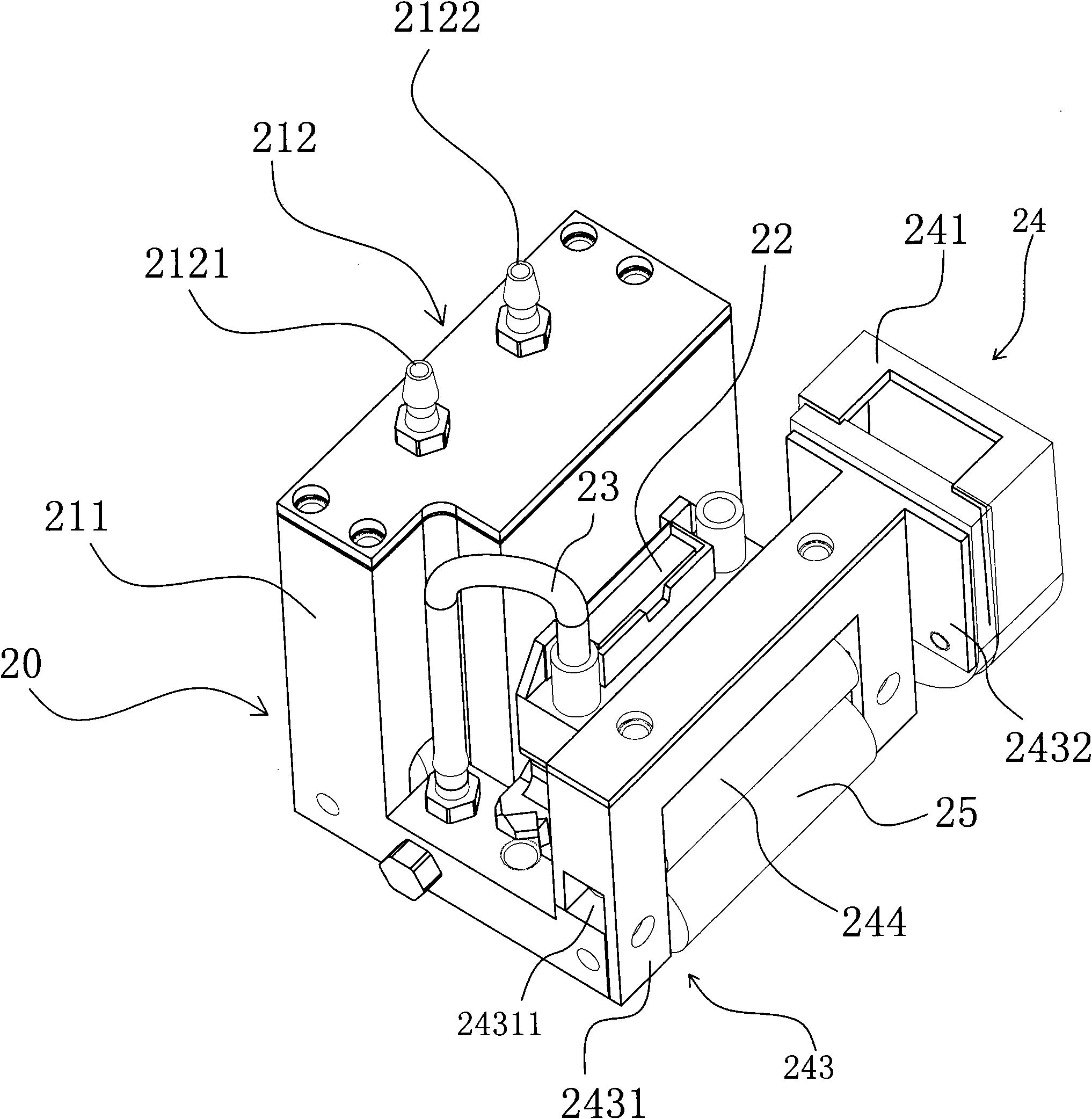

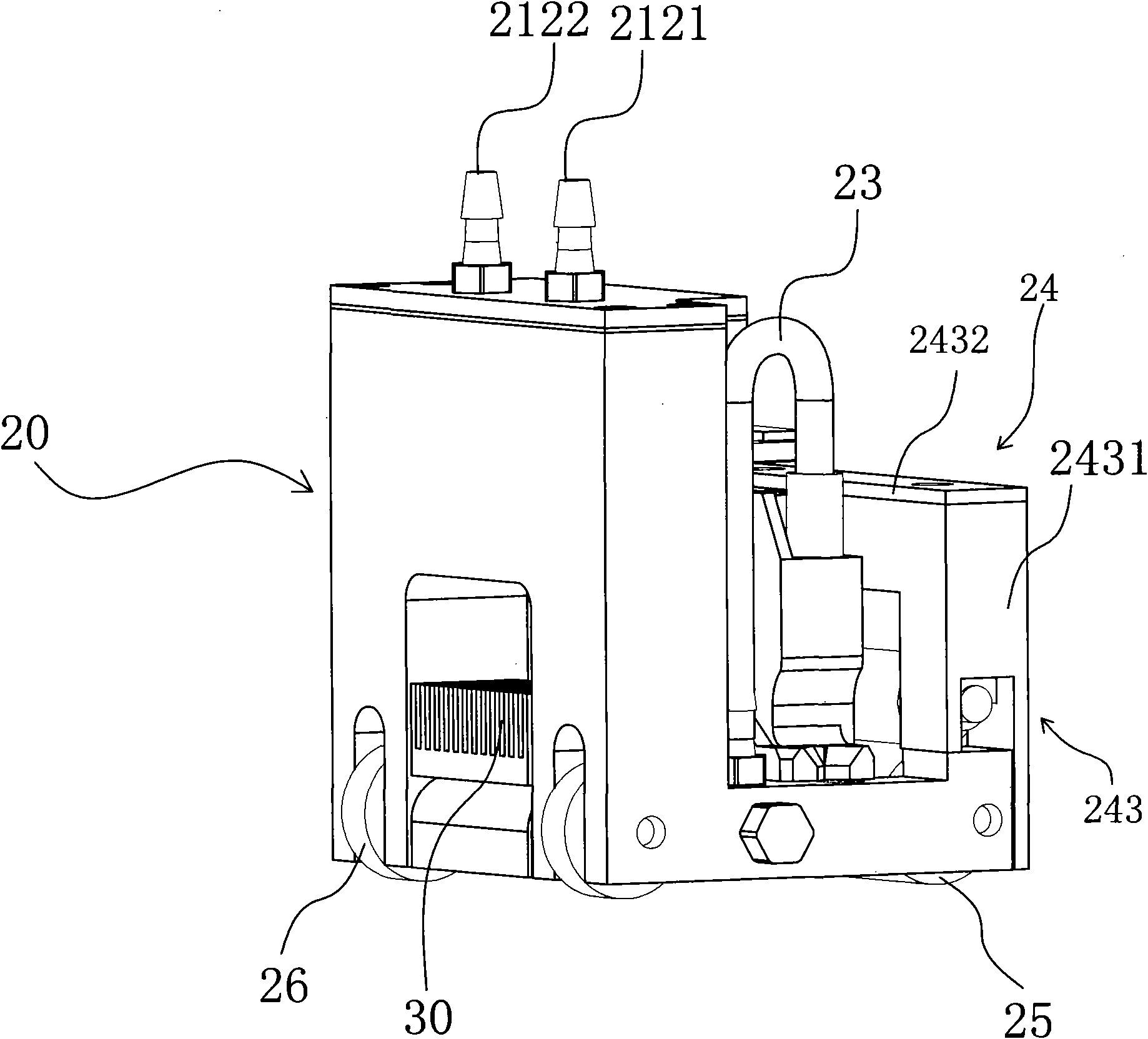

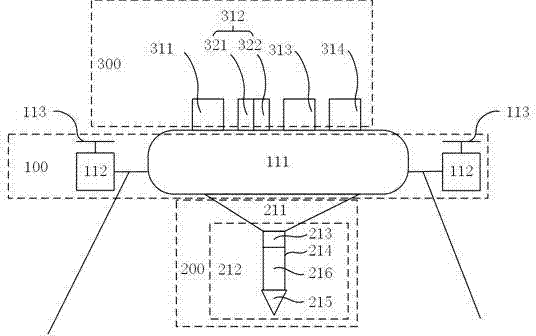

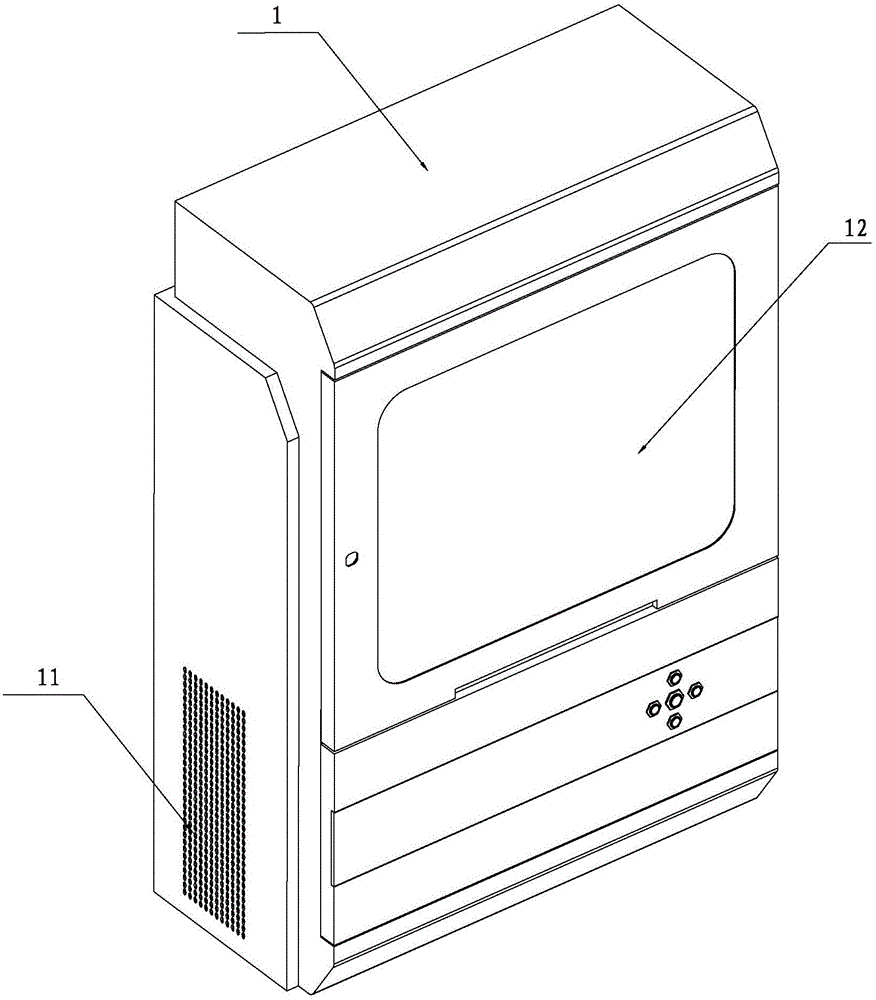

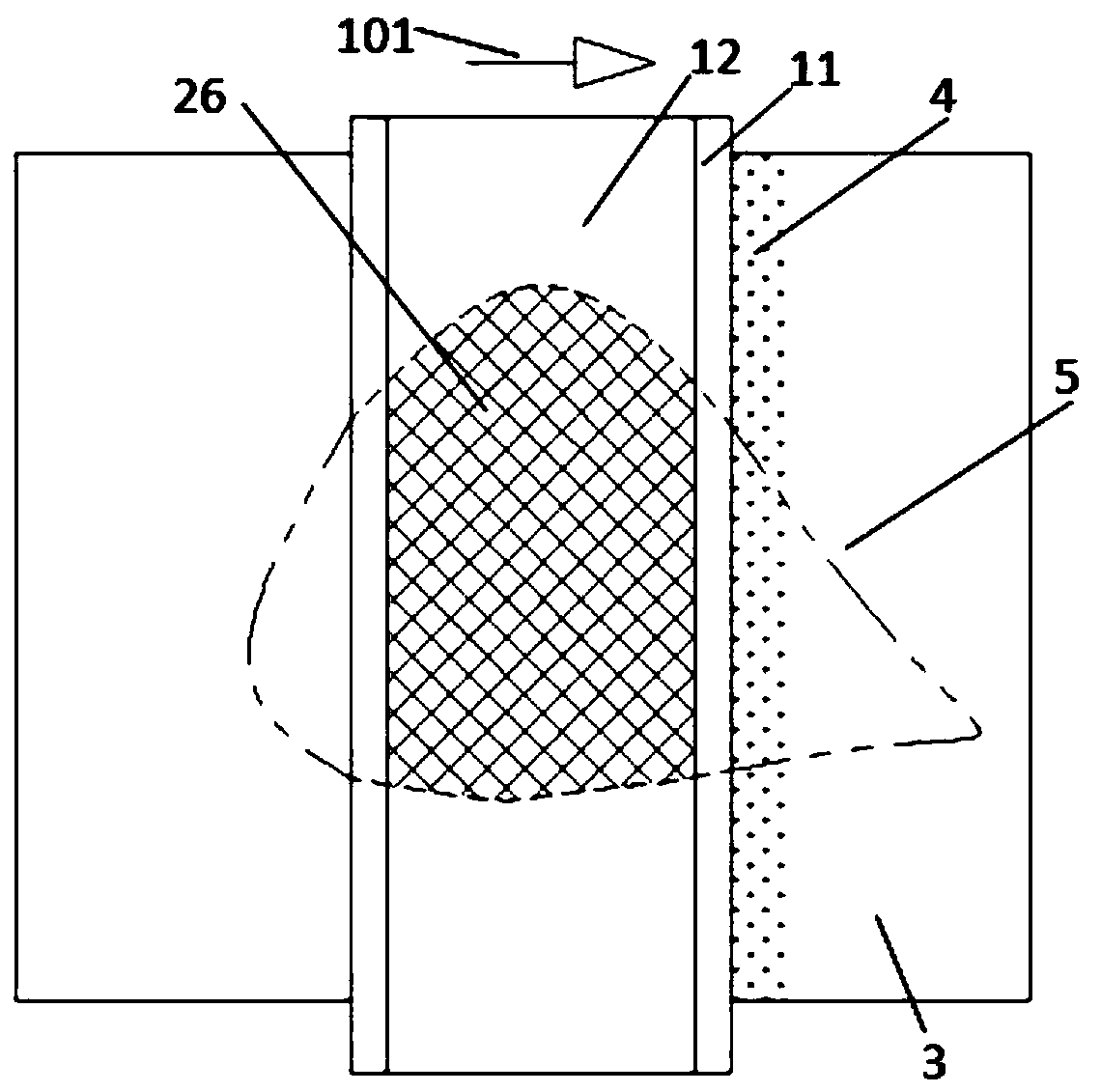

Hand-held ink-jet printer

The invention discloses a hand-held ink-jet printer, which comprises a handle (10), wherein the handle is provided with a display screen (11), a control key (12), a memory cell selection and display unit (13) and a USB interface (14); an inkjet device (20) is arranged at the front end of the handle (10), and comprises an ink box (21), a nozzle (22), an ink tube (23) and a rotary encoder (24); a front roller (25) and a rear roller (26) are arranged at the bottom of the inkjet device; an ultraviolet curing lamp (30) is arranged on the lower end of the inkjet device (20); a control circuit (40) is arranged in the handle (10), comprises a master control chip, and a memory (42) and a USB communication unit (43) which are connected with the master control chip (41), and can be connected with a computer through the USB interface (14). The hand-held ink-jet printer has the characteristics of small and exquisite volume, convenient carrying, hand-held operation, no need of setting types, the real-time update of ink-jet printed contents and the capacity of instantly curing ink in an ink-jet printing process.

Owner:陈亿善

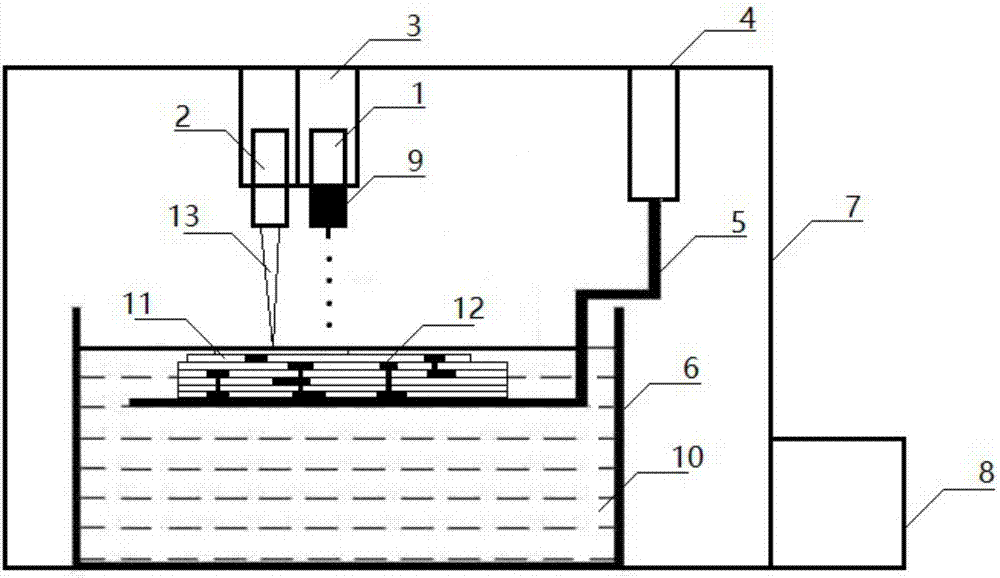

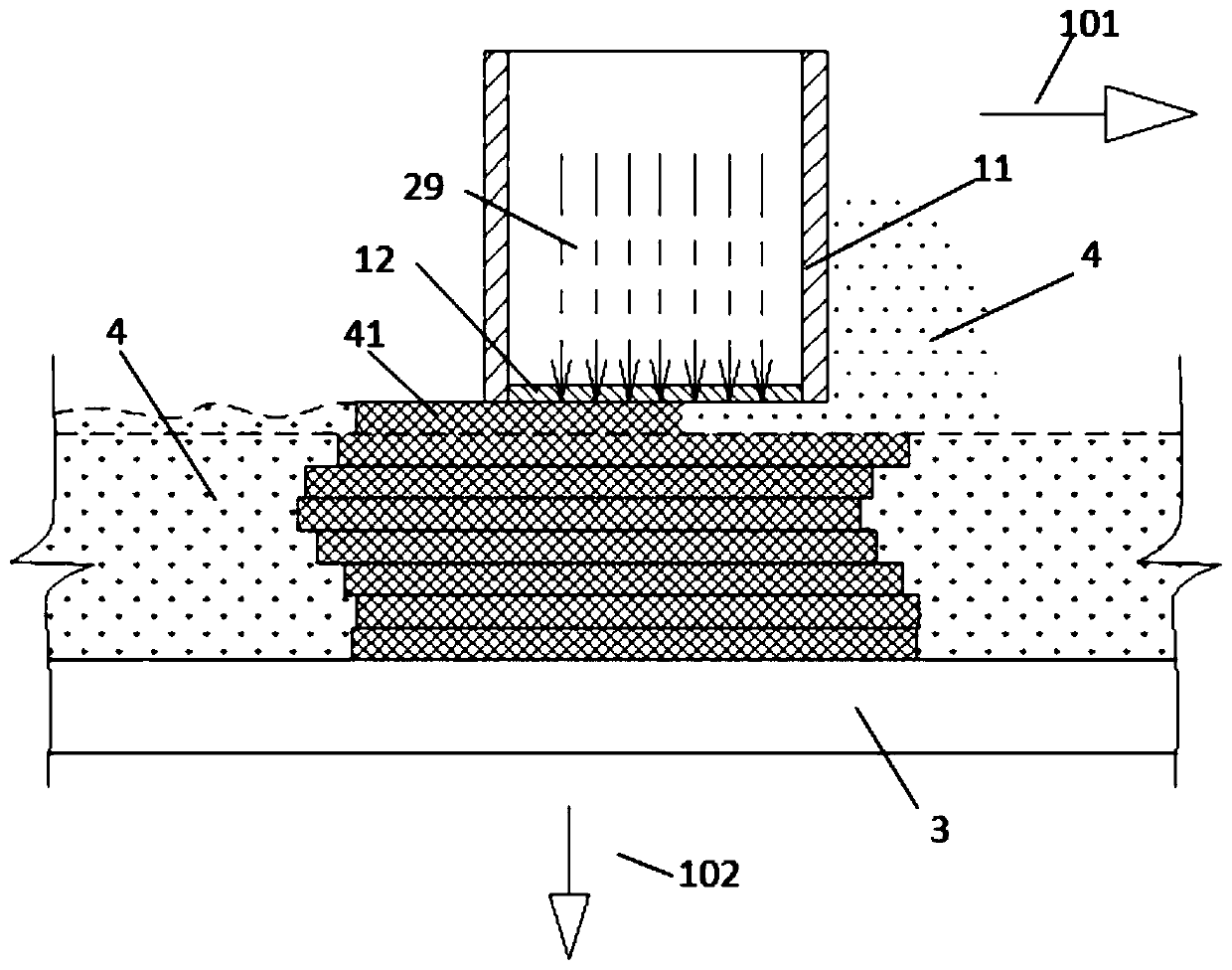

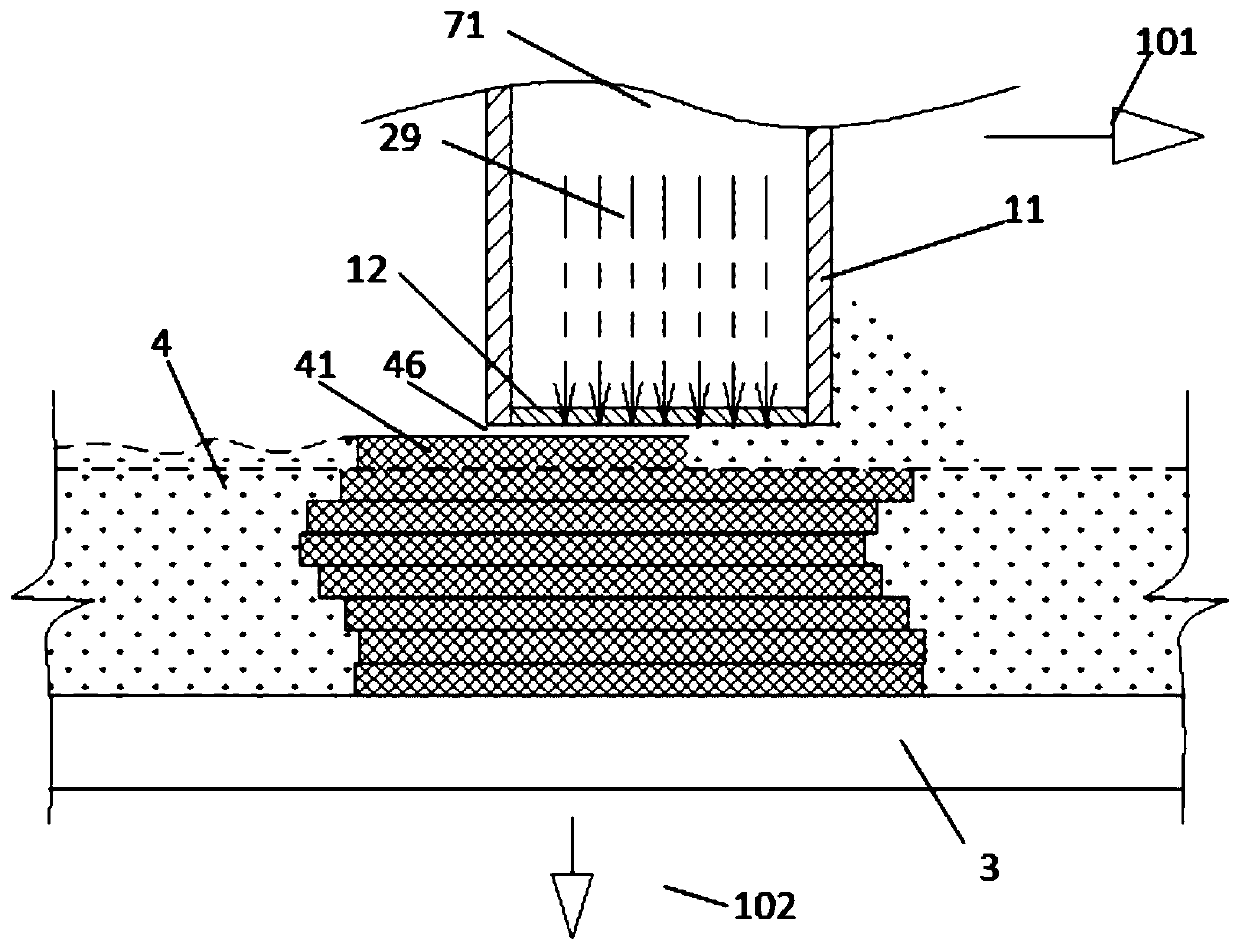

High-efficiency metal 3D printing equipment and method

ActiveCN106925783AHigh precisionLow costAdditive manufacturing apparatusIncreasing energy efficiencySpray nozzleEngineering

The invention discloses high-efficiency metal 3D printing equipment and a method, and belongs to the technical field of 3D printing. Through such measures as separation of a supply system of metal 3D printing equipment from a discharge system, separation of a printing forming area from a cooling medium, positioning of the supply system out of a forming room and capability of controlling the size of a discharge port of a nozzle according to sizes of products, based on direct melt supply and cooling medium cooling, the high-efficiency metal 3D printing equipment and method adopt 3D printing to form high-quality metal products with high efficiency and low cost, and in particular, are suitable for high-efficiency formation of large metal products. The 3D printing equipment is flexible in mechanism actions, fast in operating speed, high in flexibility, high in sensitivity and low in manufacturing cost; the 3D printing forming process is high in efficiency; process parameters are liable to control; and the metal products formed by printing are excellent in quality and repeatability and low in production cost.

Owner:UNIV OF SCI & TECH BEIJING

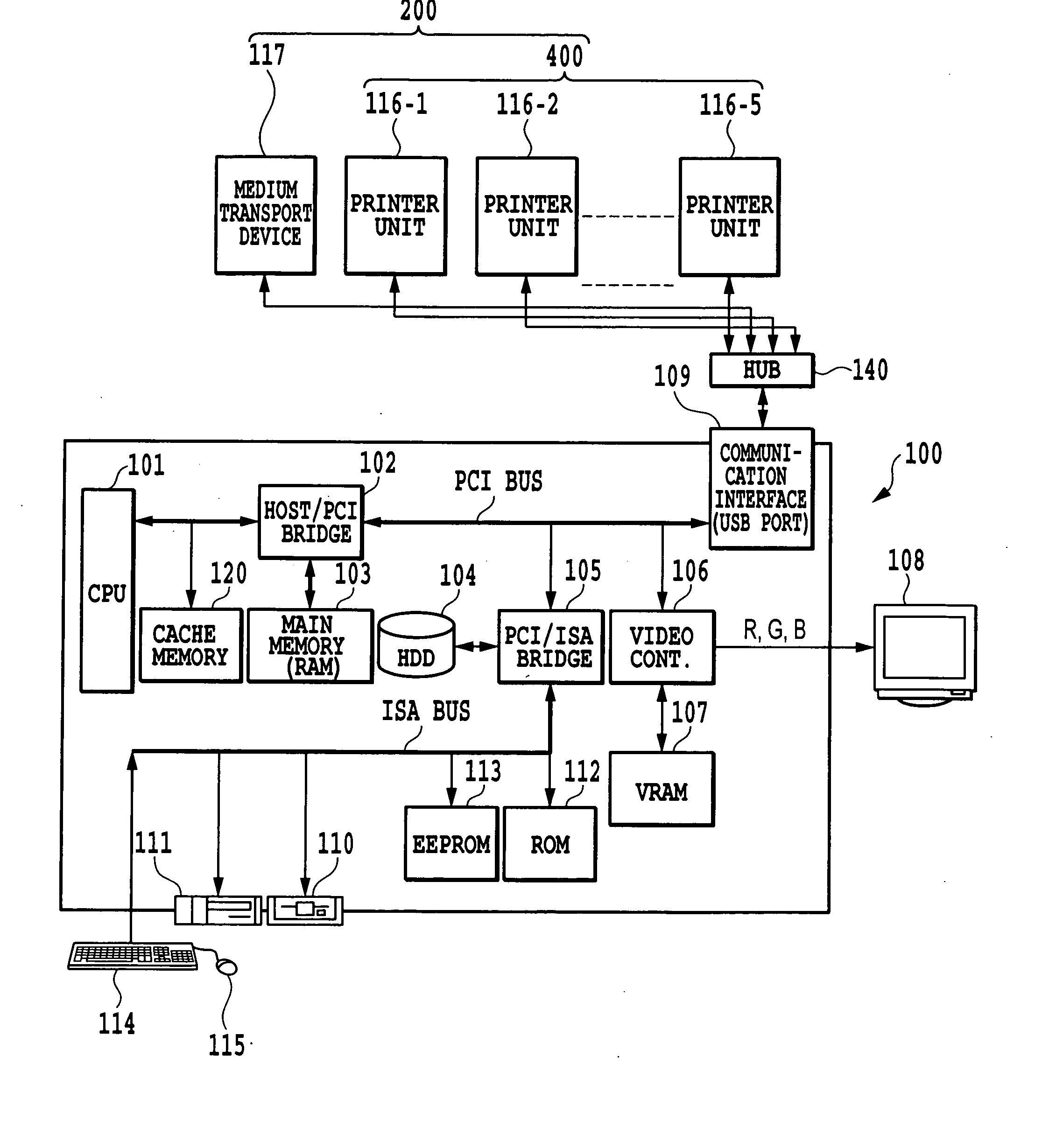

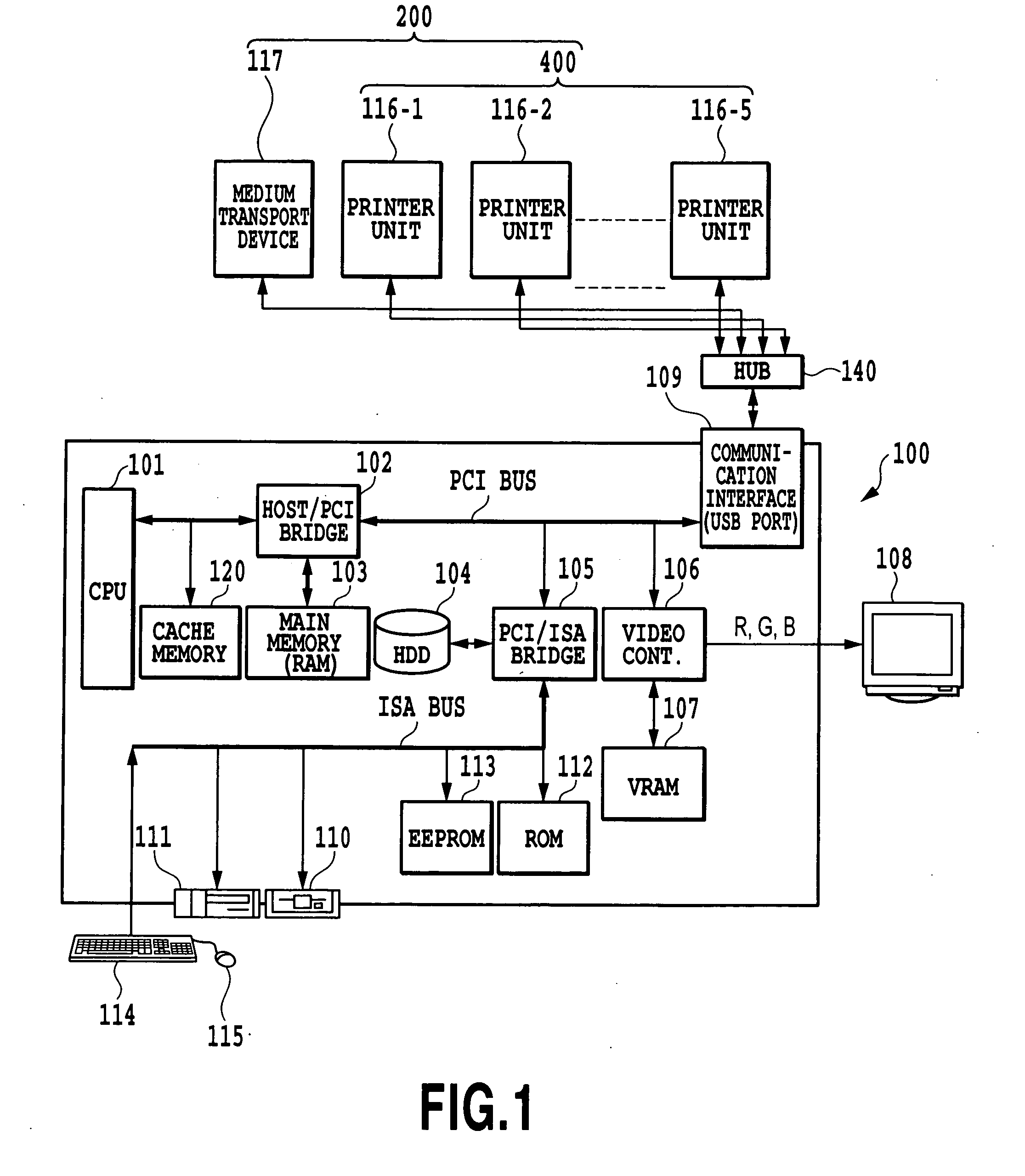

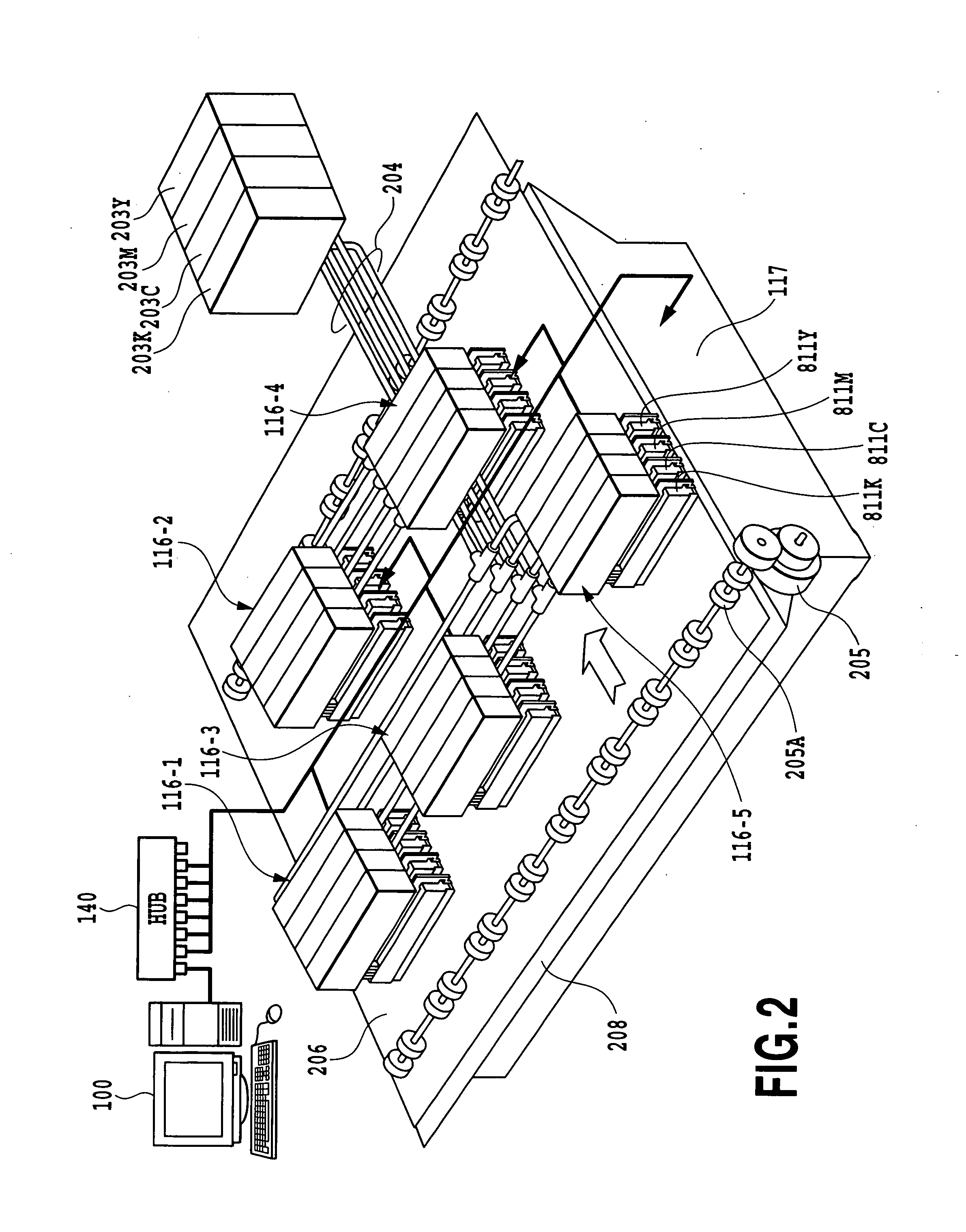

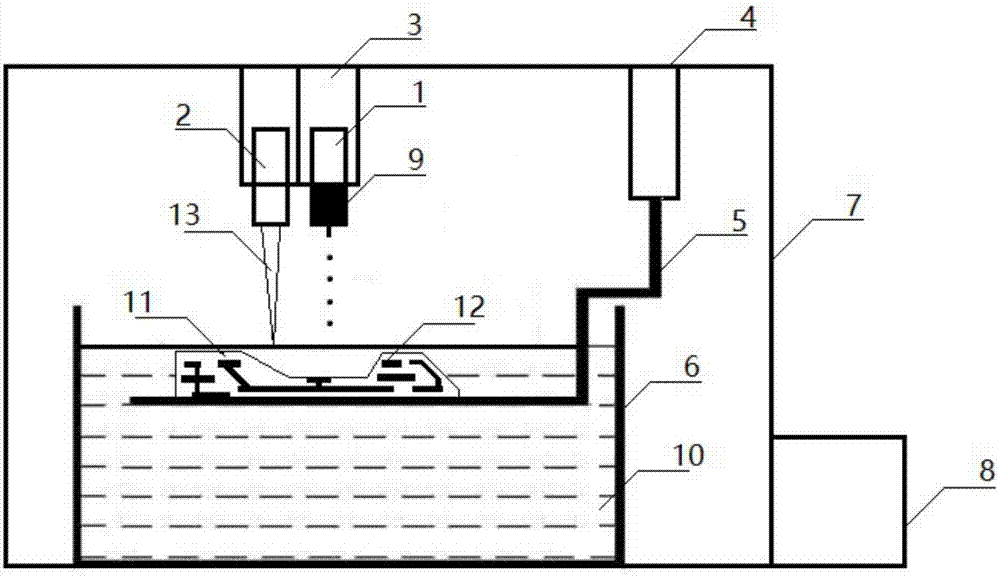

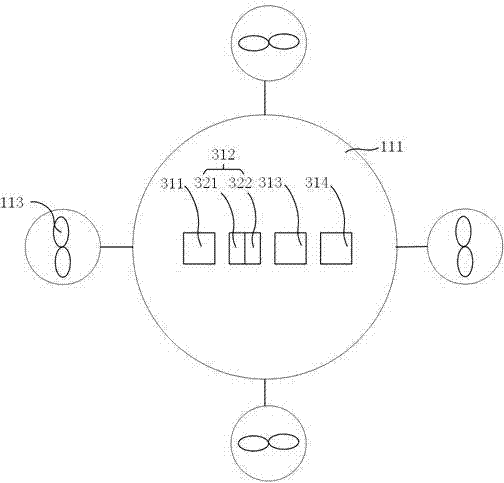

Image Forming Device, Printer Complex System and Medium Conveying Device for the Device, Information Processing Unit for Supplying Image Data to the Image Forming Device, and Image Forming System and Image Forming Method Provided with These

InactiveUS20070263244A1Quickly and easily copeFast printingTypewritersOther printing apparatusImage segmentationEngineering

To meet a demand for changing a print medium size, particularly for increasing the size of print medium while at the same time satisfying the demand for higher printing speed. To that end, a plurality of printer units (116), which are spatially independent of each other (separate from each other) and also independent in the signal system and the ink system, are arranged in an appropriate layout to allow for a line-sequential printing. An information processing device (100) divides a generated image into a plurality of pieces of print data and transfers them to the plurality of printer units. A transport device (117) is installed to feed a large-sized print medium to an area where the plurality of printer units are arranged. The transport device transfers to each of the plurality of printer units a print timing signal corresponding to the position of each printer unit.

Owner:COPYER

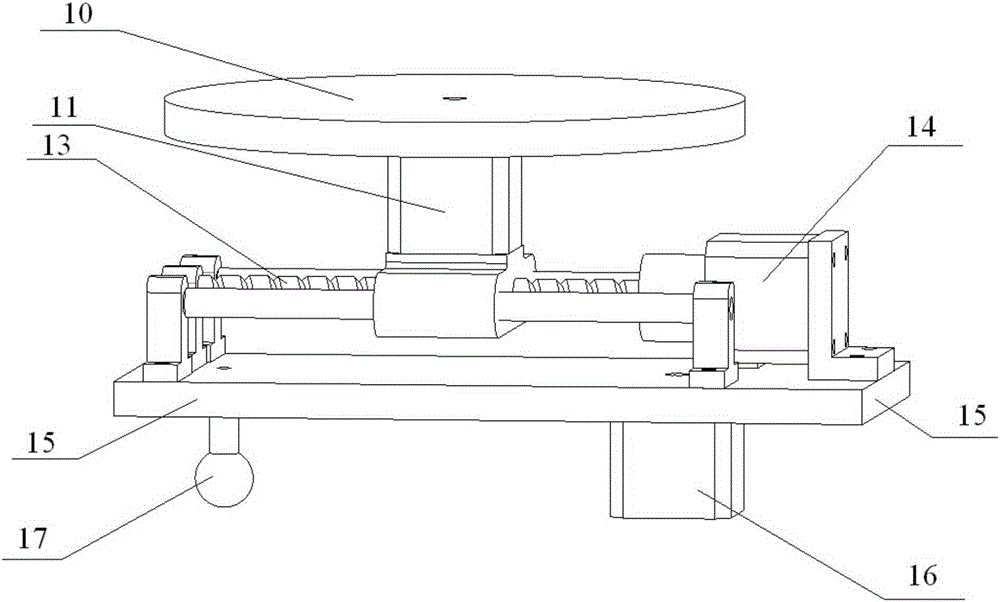

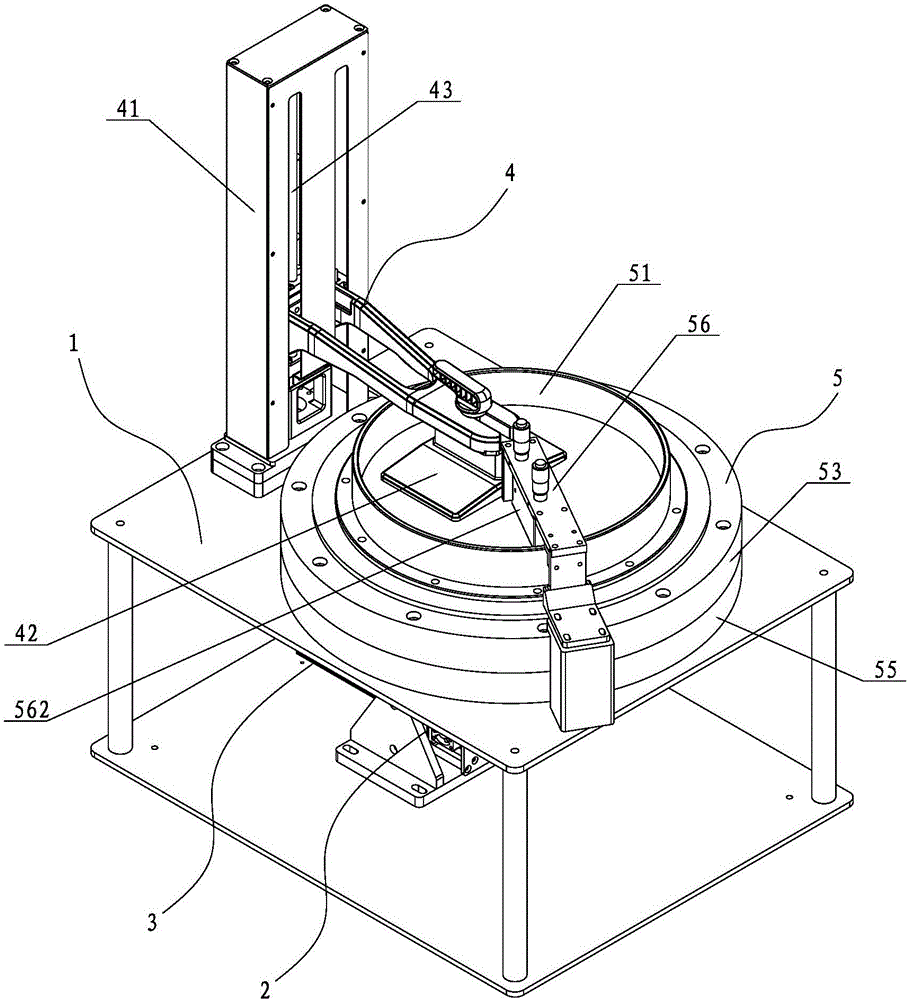

3D printer based on polar coordinates

ActiveCN105291439AImproved Surface Dimensional AccuracyEasy to moveAdditive manufacturing apparatusRectangular coordinatesEngineering

The invention provides a 3D printer based on polar coordinates. The 3D printer comprises a bottom plate, a workbench arranged on the bottom plate and capable of moving in a plane according to the polar coordinates, and a printing head having an adjustable distance with the workbench. The 3D printer provided by the invention realizes the completion of printing of the printing head for any curve and straight line in a working stroke under a coordinate system through the workbench, and has the advantages that the printing speed is fast, the curved surface dimensional accuracy of the printed parts is high, and the surface quality is also greatly improved; and meanwhile, the 3D printer provided by the invention is simple in structure, small in size and large in working range, the movement amounts of the printing head and the workbench during curved surface printing are much smaller than those under a rectangular coordinate system, the noise is also greatly reduced, and the service life is longer.

Owner:四川康铭智能装备科技有限公司

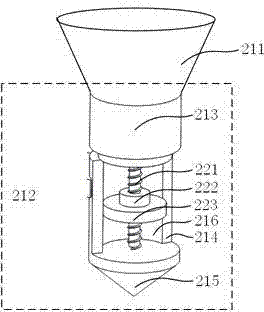

Casting type 3D printer

The invention relates to the field of a 3D printer, and provides the casting type 3D printer. The 3D printer comprises a 3D transmission mechanism, a Z-axis platform and a controller. The Z-axis platform is fixed on the end portion of the 3D transmission mechanism and comprises a metal or plastic smelting furnace. The metal or plastic smelting furnace comprises a feed device, a furnace body, an electric valve, a quantitative output pump and a nozzle, wherein the furnace body is used for smelting printing supplies of the 3D printer, and the controller is used for controlling the transmission of the 3D transmission mechanism, the temperature of a heating layer and the flow of the quantitative output pump. According to the technical scheme, the casting type 3D printer has the advantage of being high in printing speed.

Owner:中山科普斯特电源技术有限公司

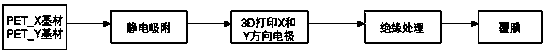

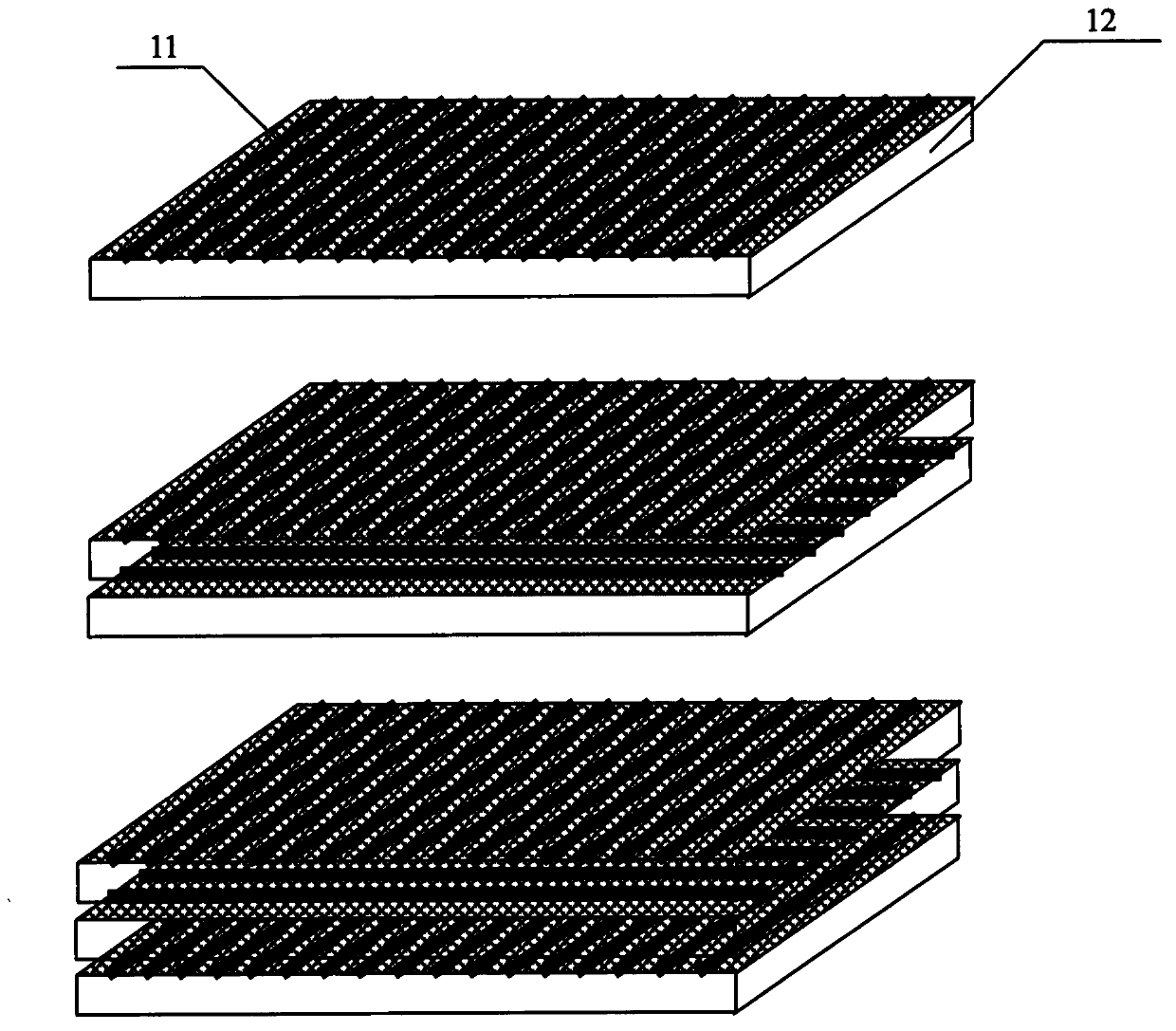

Manufacturing process of projection type capacitive touch screen

InactiveCN103440074AReduce wasteReduce processInput/output processes for data processingAdhesiveEngineering

The invention discloses a manufacturing process of a projection type capacitive touch screen. The current large-size capacitive touch screen has the problems that the production process is complex, the rate of finished products is low, the cost is high, the size of the screen can not be customized and the bending can not be achieved. The manufacturing process comprises the following steps that firstly a PET_X film and a PET_Y film are respectively placed on a 3D (three dimensional) printing platform; secondly, a machine arm sticks a flexible tail-whipping circuit board on the PET_X film, the back surface of the flexible tail-whipping circuit board is coated with adhesive, and one side with a conductive gold finger is upwards; the films enter electrostatic absorption equipment, and static electricity can be uniformly distributed on the films by the equipment; then the films enter 3D printing equipment for printing; finally insulating treatment and film lamination are carried out. The manufacturing process disclosed by the invention has the advantages that the screen can be bent, and can be stuck on the surface of curved glass or the surface of irregularly-shaped glass.

Owner:UC NANO TECH CO LTD

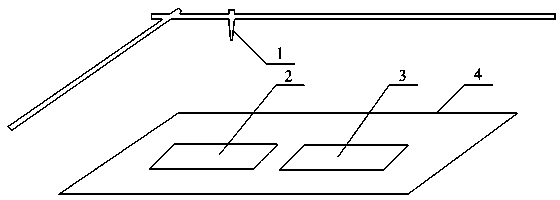

3D printed controllable porous hydroxyapatite bioceramic stent and preparation method thereof

InactiveCN110272273AHigh solid contentLow viscosityAdditive manufacturing apparatusBone implantPorosityUltraviolet

The invention relates to a 3D printed controllable porous hydroxyapatite bioceramic stent and a preparation method thereof. The method comprises the steps that hydroxyapatite paste used for a hydroxyapatite bone tissue bioceramic stent is prepared; a TPMS porous structure is established by using three-dimensional modeling software, and a model structure is adjusted to obtain a TPMS porous structure model with the porosity of 60%-95%, and is saved in an STL format; an STL format model with macroscopic pores is introduced into a photocurable printer; photocuring printing parameters are adjusted, so that the hydroxyapatite paste is stacked layer by layer for superposition moulding to obtain a bioceramic stent biscuit; the bioceramic stent biscuit is put into an ultraviolet curing box for secondary curing, and is placed in a muffle sintering furnace for degreasing and calcination to obtain the porous hydroxyapatite bone tissue bioceramic stent with high density. The prepared porous hydroxyapatite bone tissue stent has a pore structure with high connectivity, has inorganic components consistent with the inorganic components of the human bone, and has excellent biological properties.

Owner:SHANGHAI INST OF TECH

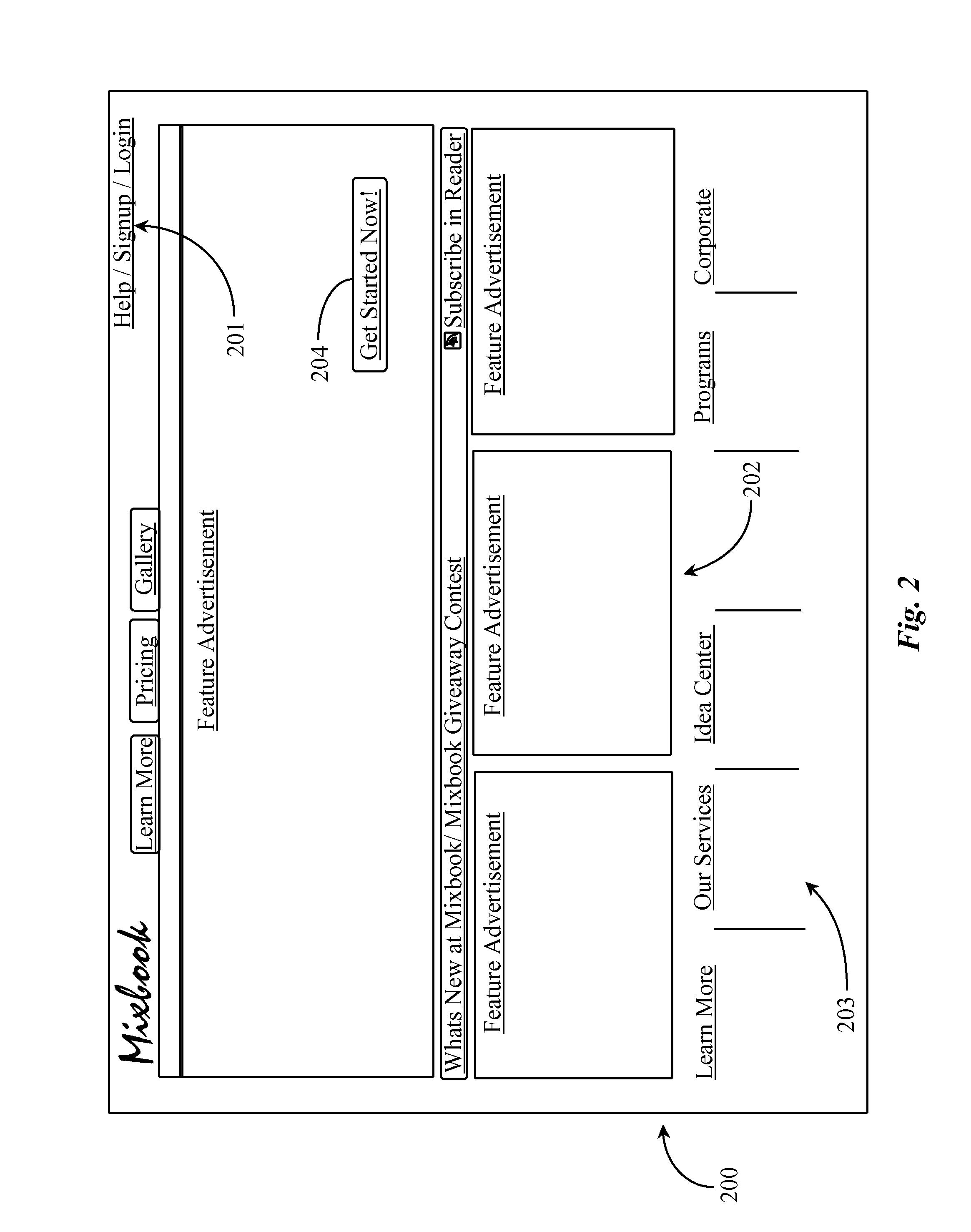

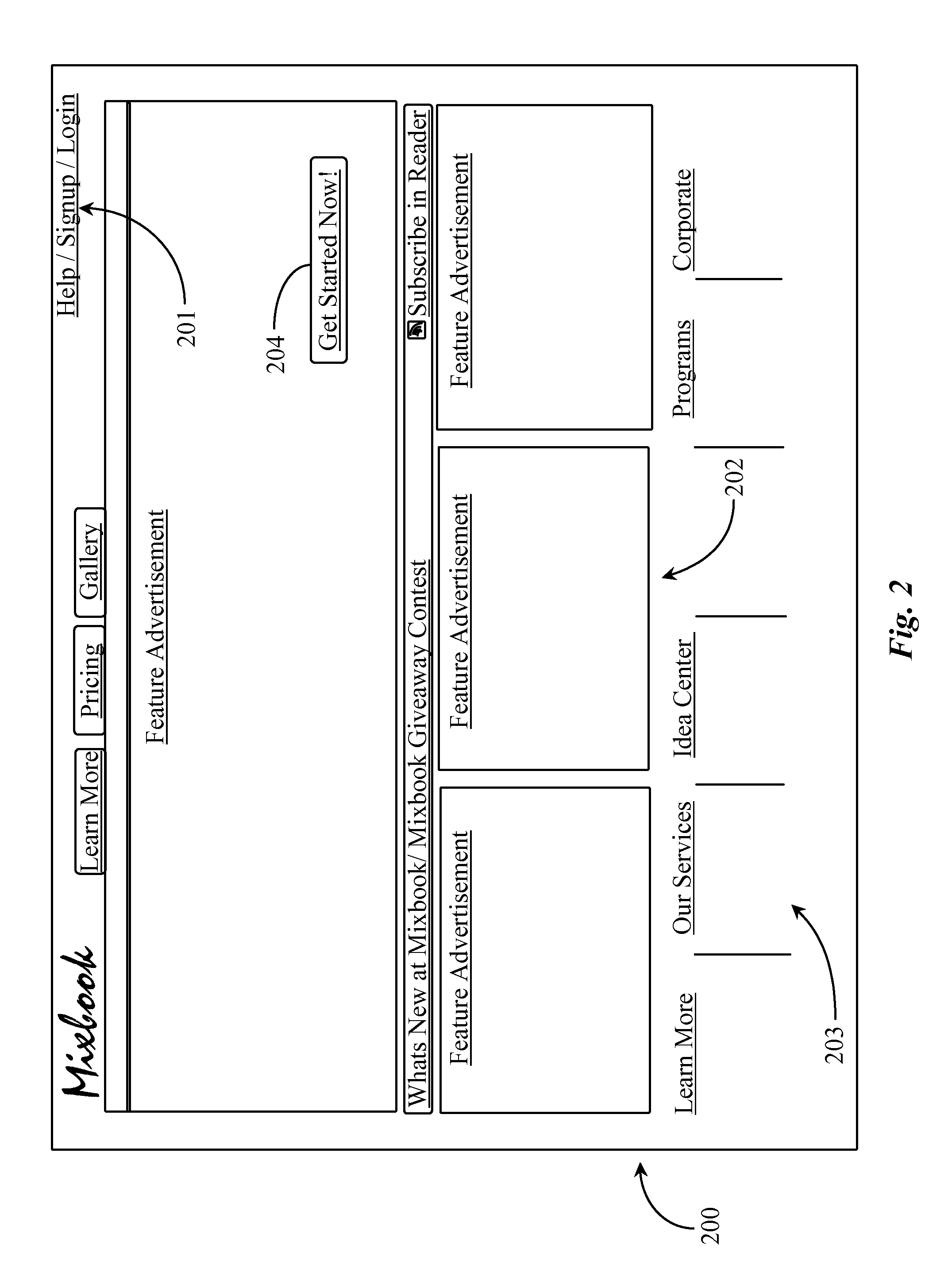

Print Configuration Engine for Enabling Online Printing of Projects Created in an Online Collage-Based Editor

ActiveUS20110013226A1Improve efficiencyReduce printing errorsStill image data indexingCharacter and pattern recognitionGraphicsGraphical user interface

A print configuration engine implemented in software residing on and executable from a digital medium, the print engine integrated with a graphics user interface (GUI) for creating and editing photo-based projects over a data network, the print engine including a communications link to a compatible print server and printer connected to the data network, a print queue for queuing printing tasks, and an image tiling module. The print engine automatically senses if the pixel size of an image is greater than a pre-defined image size threshold for high resolution printing and if so tiles the image and saves the individual image tiles to memory for later reconstitution.

Owner:INTERACTIVE MEMORIES

Manufacturing equipment and manufacturing method of metal and nonmetal composite additive

ActiveCN107471632AGuaranteed uptimeSolve the problem of not being able to print metalAdditive manufacturing apparatus3D object support structuresControl systemLiquid state

The invention provides manufacturing equipment of metal and nonmetal composite additive. The manufacturing equipment comprises a liquid-state metal inkjet device, a light emitter, a multi-shaft moving device, a printing platform, a lifting device, a photocuring material groove, a frame and a control system; a positive projection of the printing platform in the lifting direction is positioned in the photocuring material groove; and the liquid-state metal inkjet device and the light emitter are positioned above the printing platform. The invention further provides a manufacturing method of the metal and nonmetal composite additive. The method can effectively solve the problem of incapability of printing metal and nonmetal composite structures in traditional 3D printing, and can be used for quick customized processing of multi-layer, special-shaped or complex-structured electronic circuits. The printed composite structures are stable and high in precision; the method is easy to manufacture complicated via hole and blind hole structures in precise electronic circuits; and photocuring materials are adopted to achieve higher printing speed compared with plastic FDM.

Owner:BEIJING DREAM INK TECH CO LTD

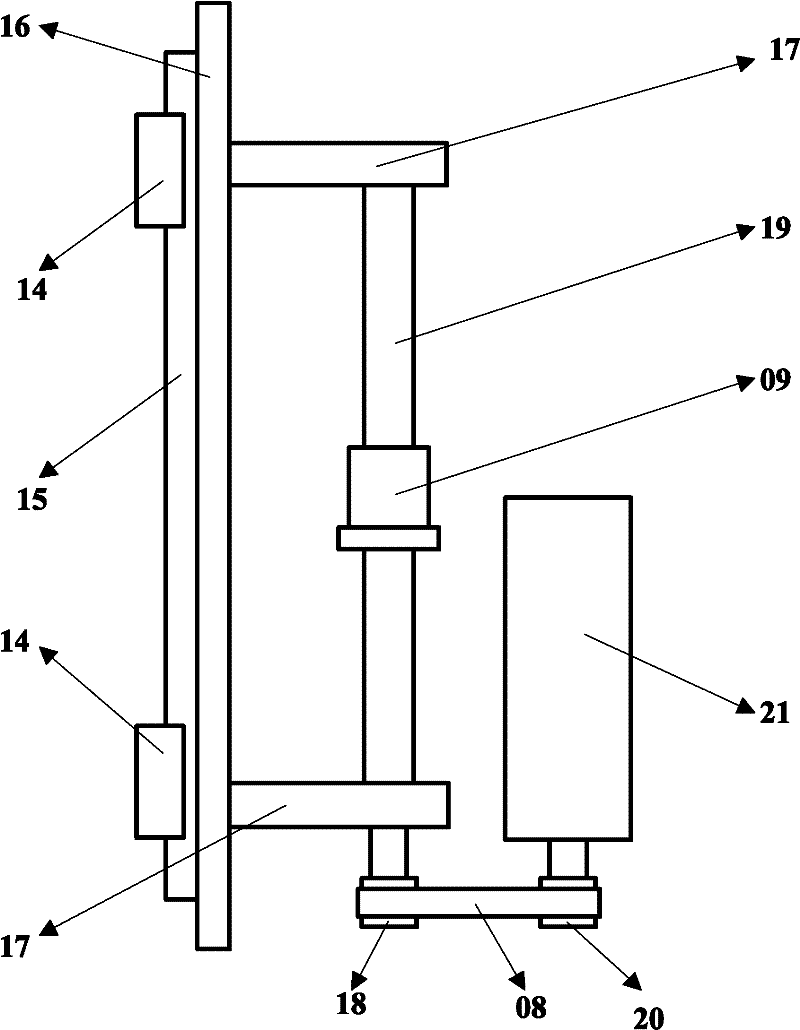

Flying 3D printing robot

The invention relates to a flying 3D printing robot. The flying 3D printing robot comprises an omni-directional mobile platform mechanism, a Z-axis elevating system, a 3D printing mechanism and feedback / communication / control circuits. The flying 3D printing robot is characterized in that the Z-axis elevating system is arranged on and fixedly connected with the omni-directional mobile platform mechanism; the 3D printing mechanism is arranged on and fixedly connected with the Z-axis elevating system; the feedback / communication / control circuits are all mounted on the omni-directional mobile platform mechanism; and the feedback / communication / control circuits control the omni-directional mobile platform mechanism and the Z-axis elevating system to drive the 3D printing mechanism to realize printing of three-dimensional long-strip objects without dimensional limits. The flying 3D printing robot has the characteristics of compact structure, a small size, exemption from dimensional limits on to-be-printed objects of traditional 3D printer, high movement flexibility and a fast printing speed; cooperation and communication among a plurality of printing robots are simultaneously realized, and 3D printing efficiency is further improved; and the flying 3D printing robot is especially applicable to low-cost and high-efficiency printing of great-distance long-strip objects like walls of buildings.

Owner:SHANGHAI UNIV

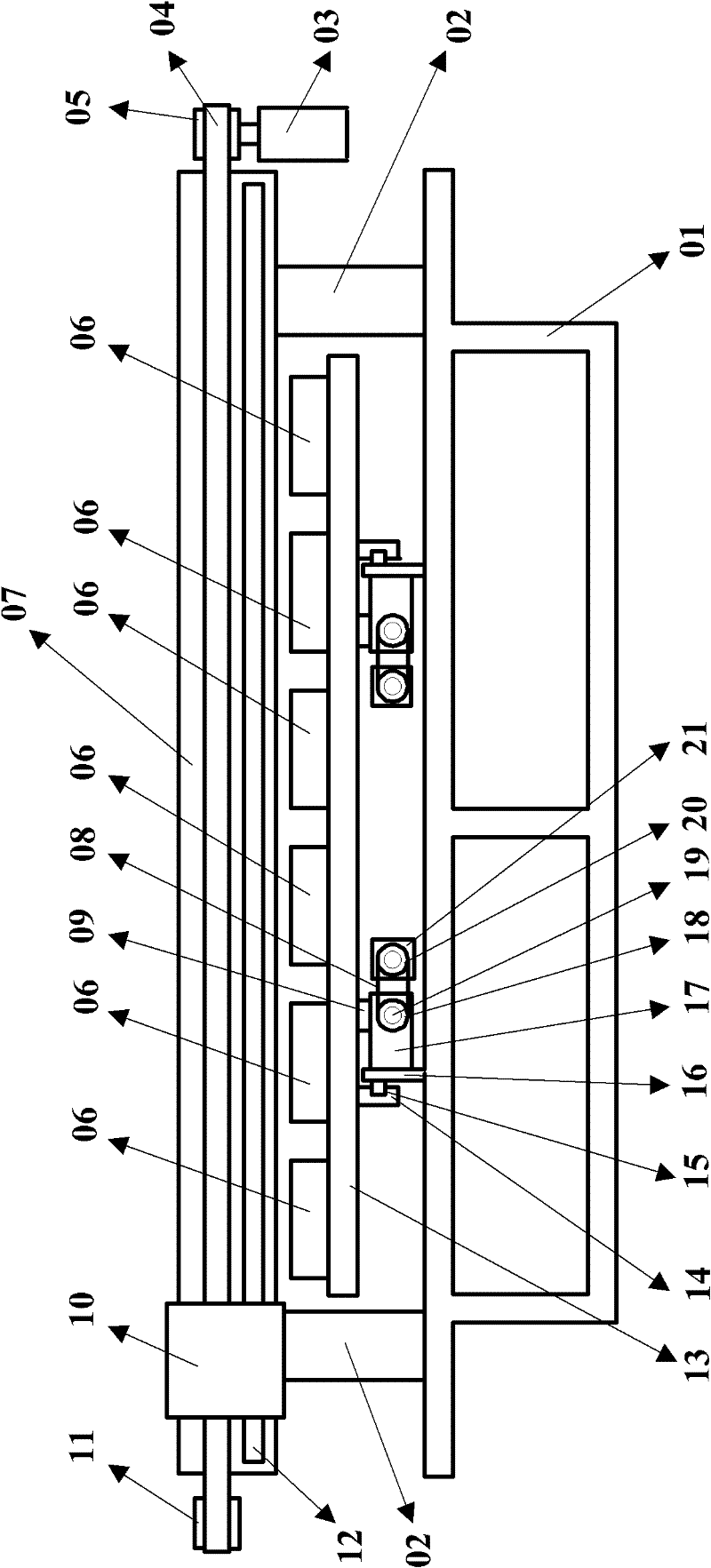

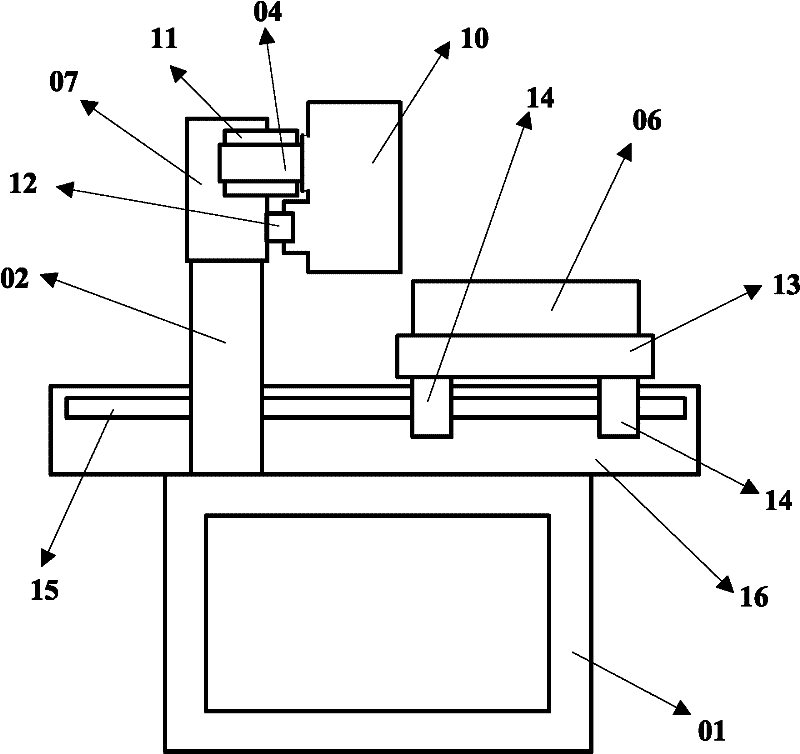

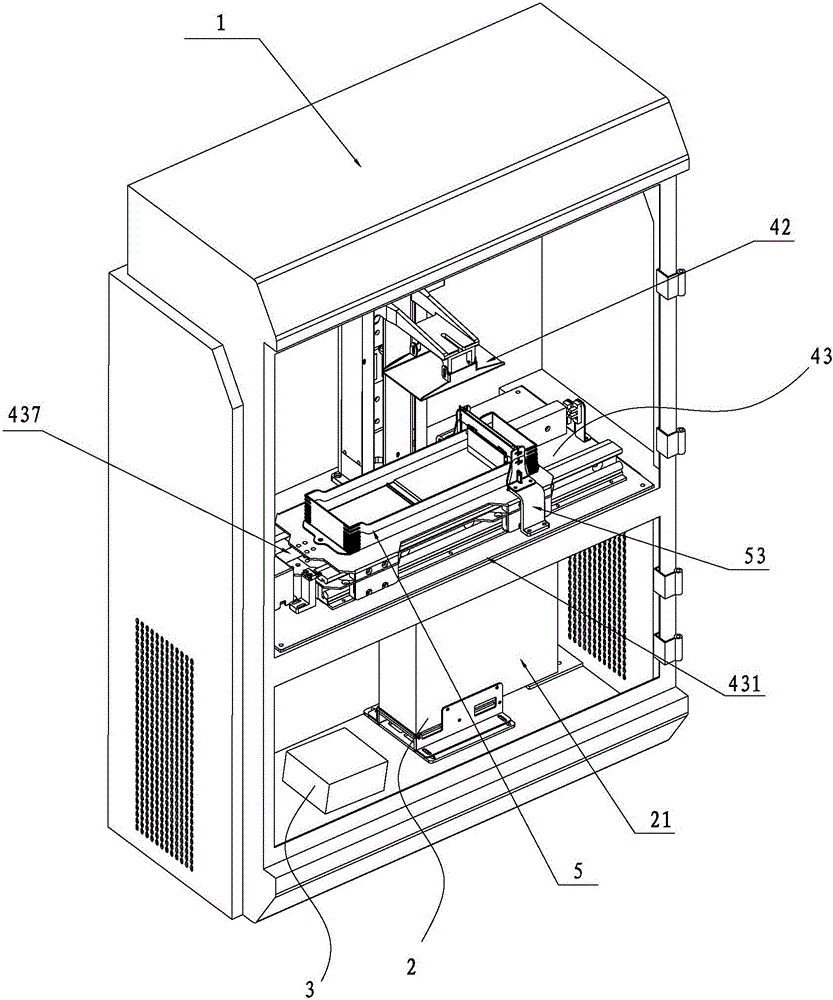

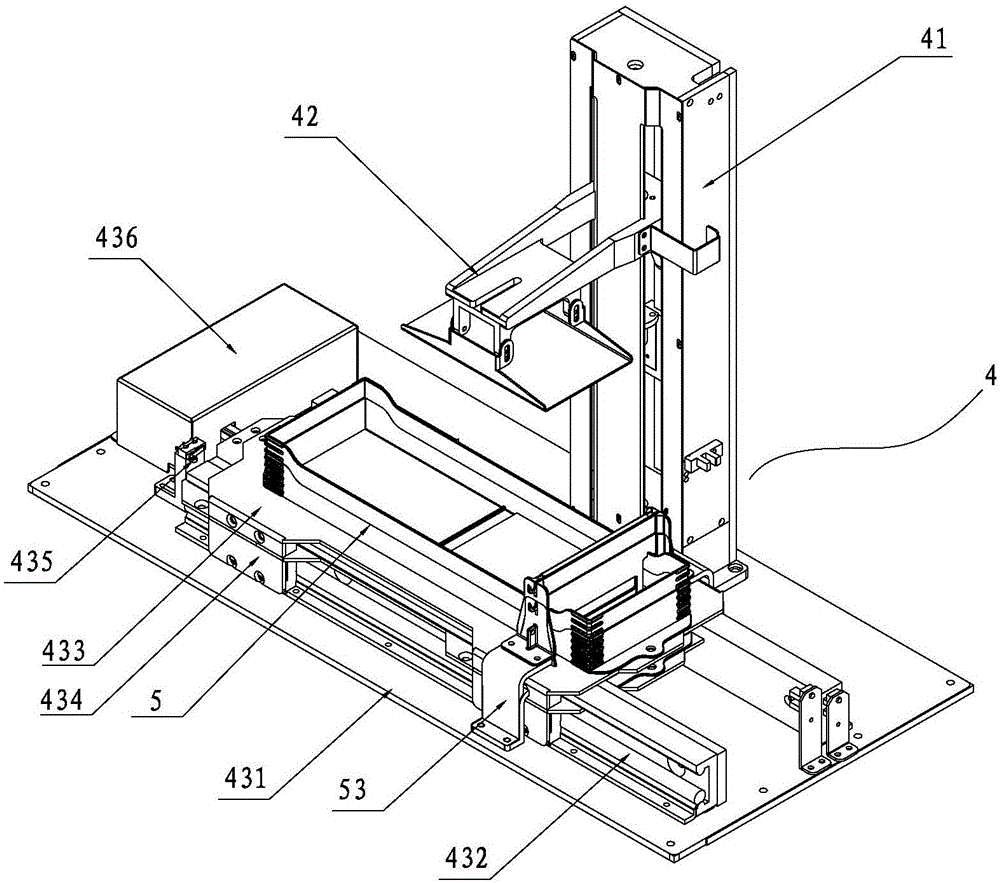

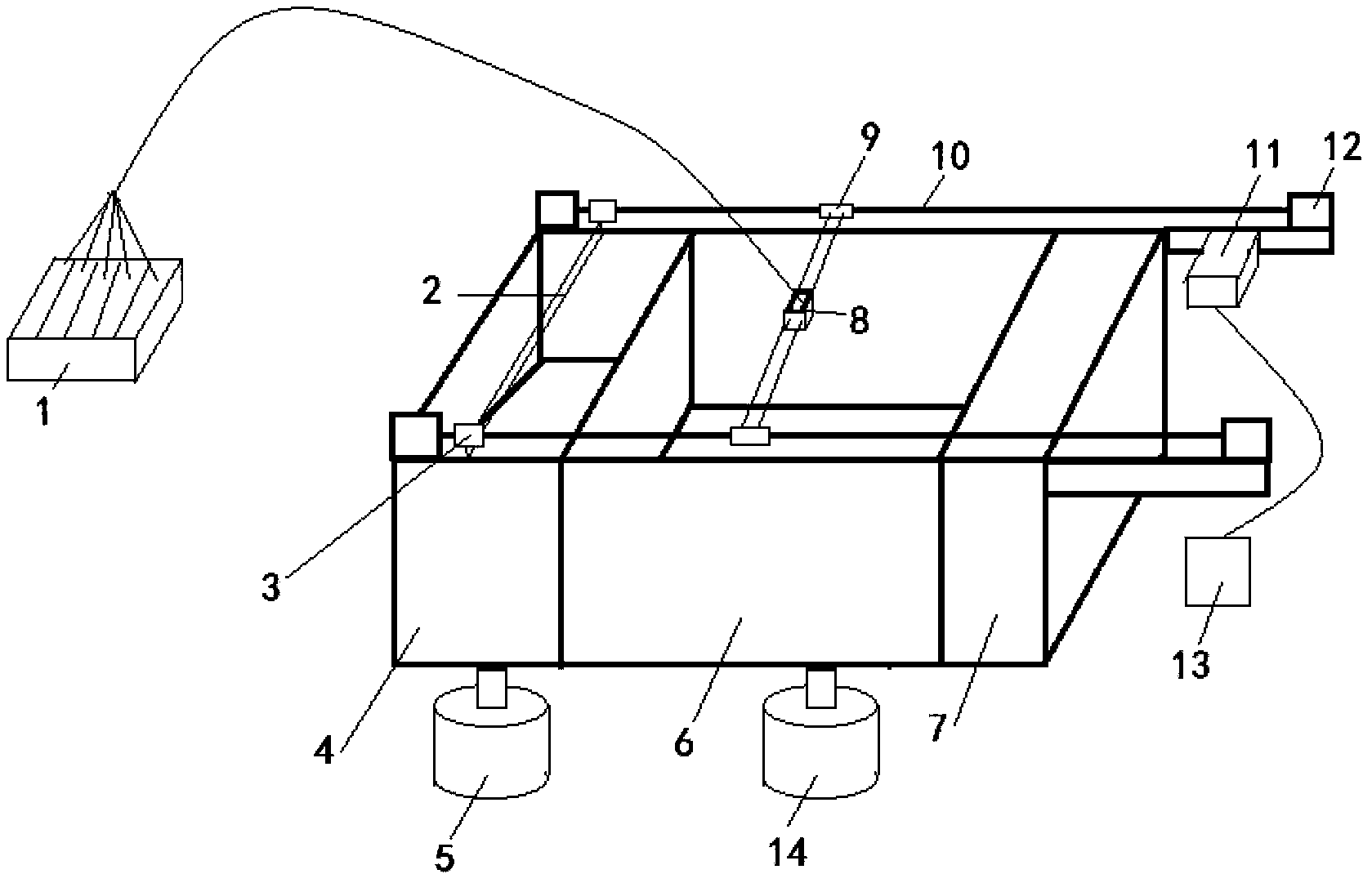

Digital printing machine and digital printing system

ActiveCN102173201AFast printingImprove efficiencyTypewritersOther printing apparatusDigital printingEngineering

The embodiment of the invention discloses a digital printing machine and a digital printing system, wherein the digital printing machine comprises a frame, a printing spray head, a mobile platform and at least two workbenches mounted on the mobile platform for mounting matters to be printed, as well as at least one mobile platform transmission device connected with the mobile platform for driving the mobile platform to move, and a printing spray head transmission device connected with the printing spray head for driving the printing spray head to move; and the mobile platform transmission device and the printing spray head transmission device are mounted on the frame. By adopting the technical scheme provided by the embodiment of the invention, the printing speed is beneficial to improving, and the printing productivity is upgraded.

Owner:SHENZHEN RUNTIANZHI DIGITAL EQUIP

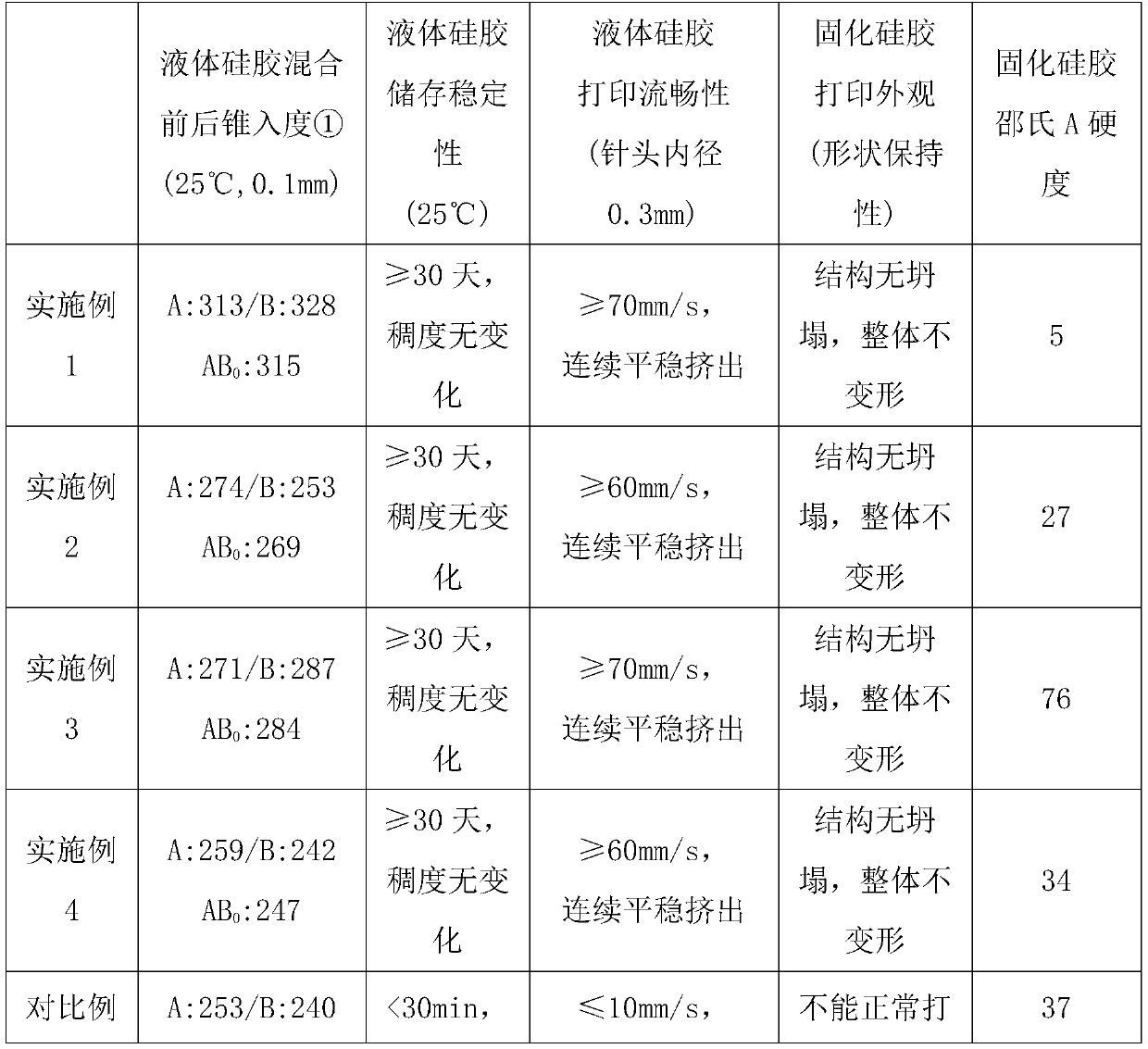

Dual component liquid silica gel for 3D printing and printing method thereof

ActiveCN110128833ASolve problems that are difficult to 3D printIncrease elasticityAdditive manufacturing apparatus3D object support structuresOrganic solventPolyol

The invention discloses a dual component liquid silica gel for 3D printing and a printing method thereof. The liquid silica gel comprises a component A and a component B. The component A comprises following components in parts by weight: 100 parts of vinyl polysiloxane, 0.01 to 5 parts of a hydrosilylation catalyst, 1 to 10 parts of polyether polyol, and 1 to 10 parts of fumed silica. The component B comprises following components in parts by weight: 100 parts of vinyl polysiloxane, 1 to 50 parts of hydrogen containing polysiloxane, 0.01 to 5 parts of a hydrosilylation inhibitor, 1 to 10 partsof polyether polyol, and 1 to 10 parts of fumed silica. During the printing process, the thickness of the liquid silica gel does not change, the structure is not deformed, an onsite heat treatment isnot needed, only post sectioned thermosetting moulding is needed, the printing technology is simplified, and the printing cost is reduced. The liquid silica gel does not contain any organic solvent or photosensitive component, is very safe and nontoxic, and 3D products prepared from the liquid silica gel can be applied to fields, which have high safety requirements, such as children toys, food, medicines, and the like.

Owner:SOUTH CHINA UNIV OF TECH

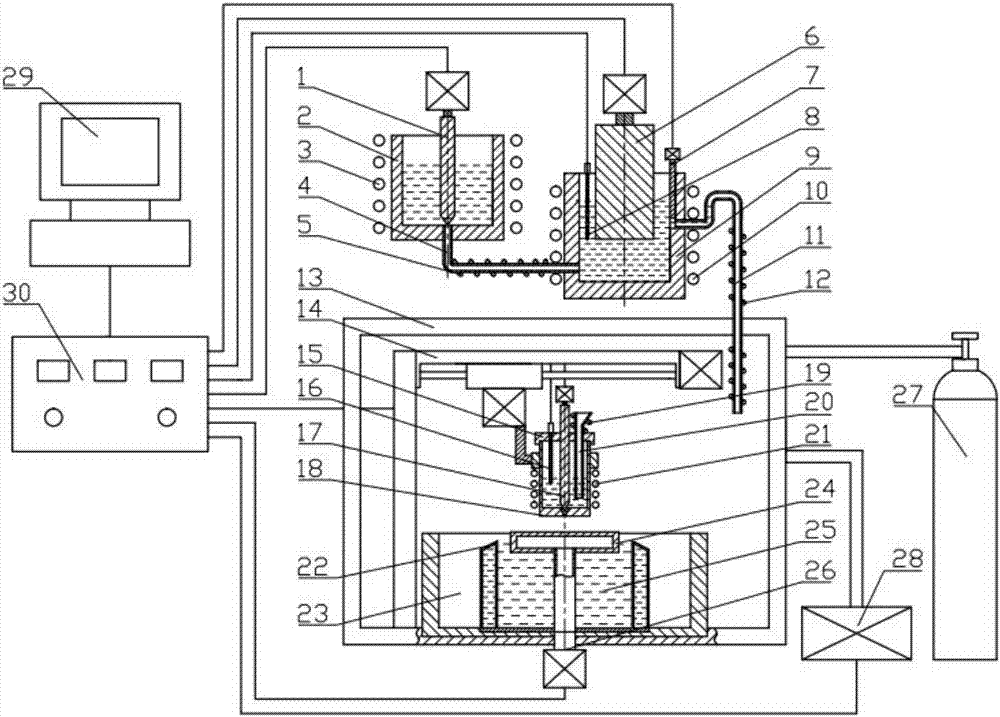

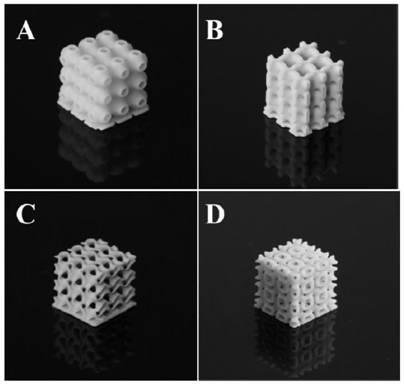

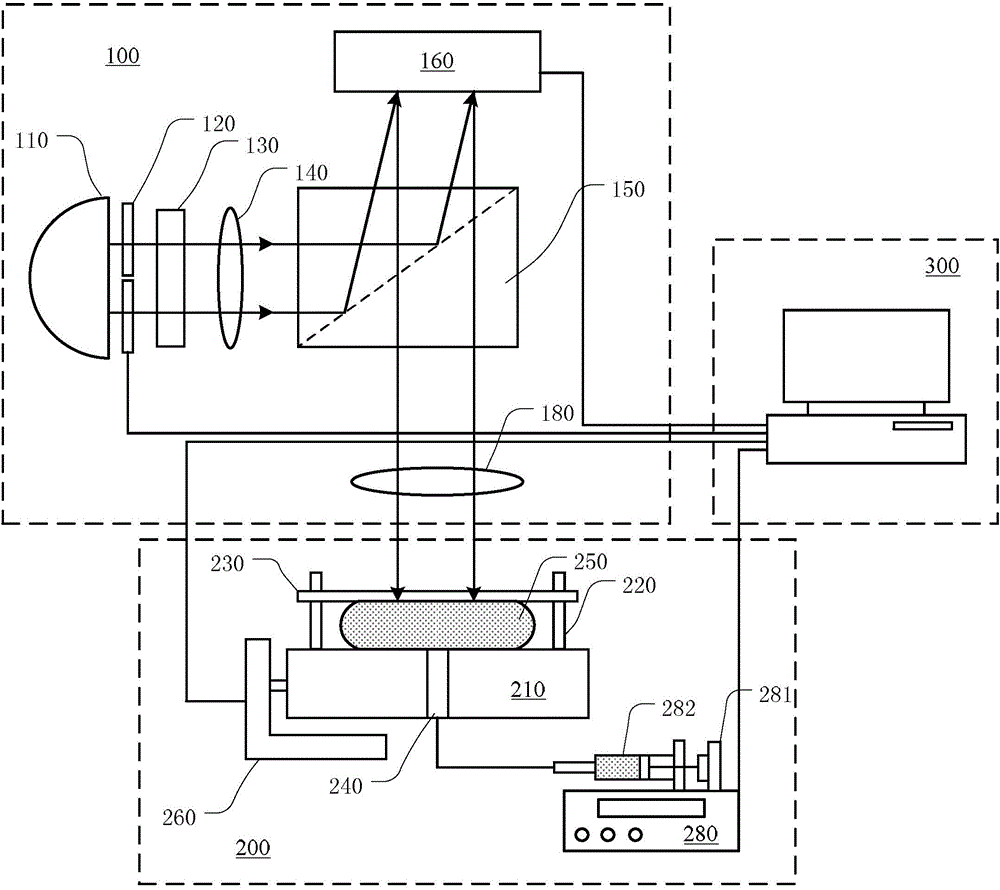

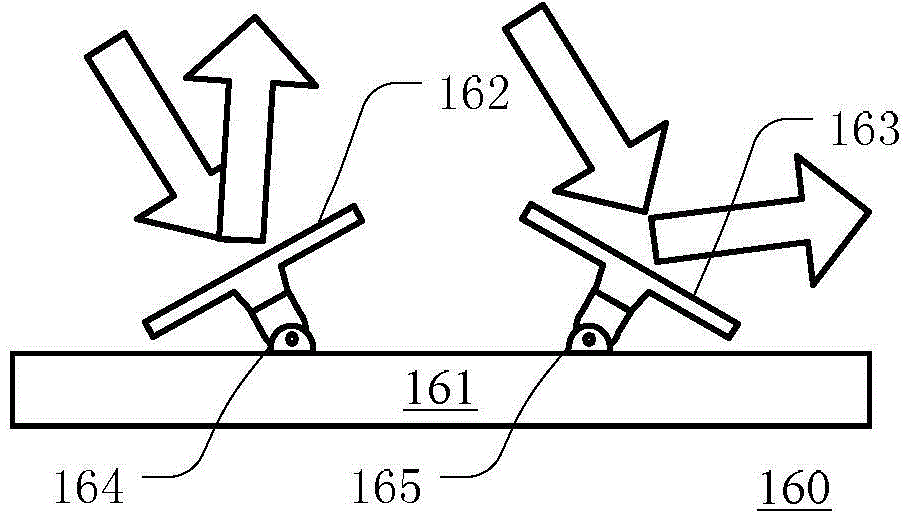

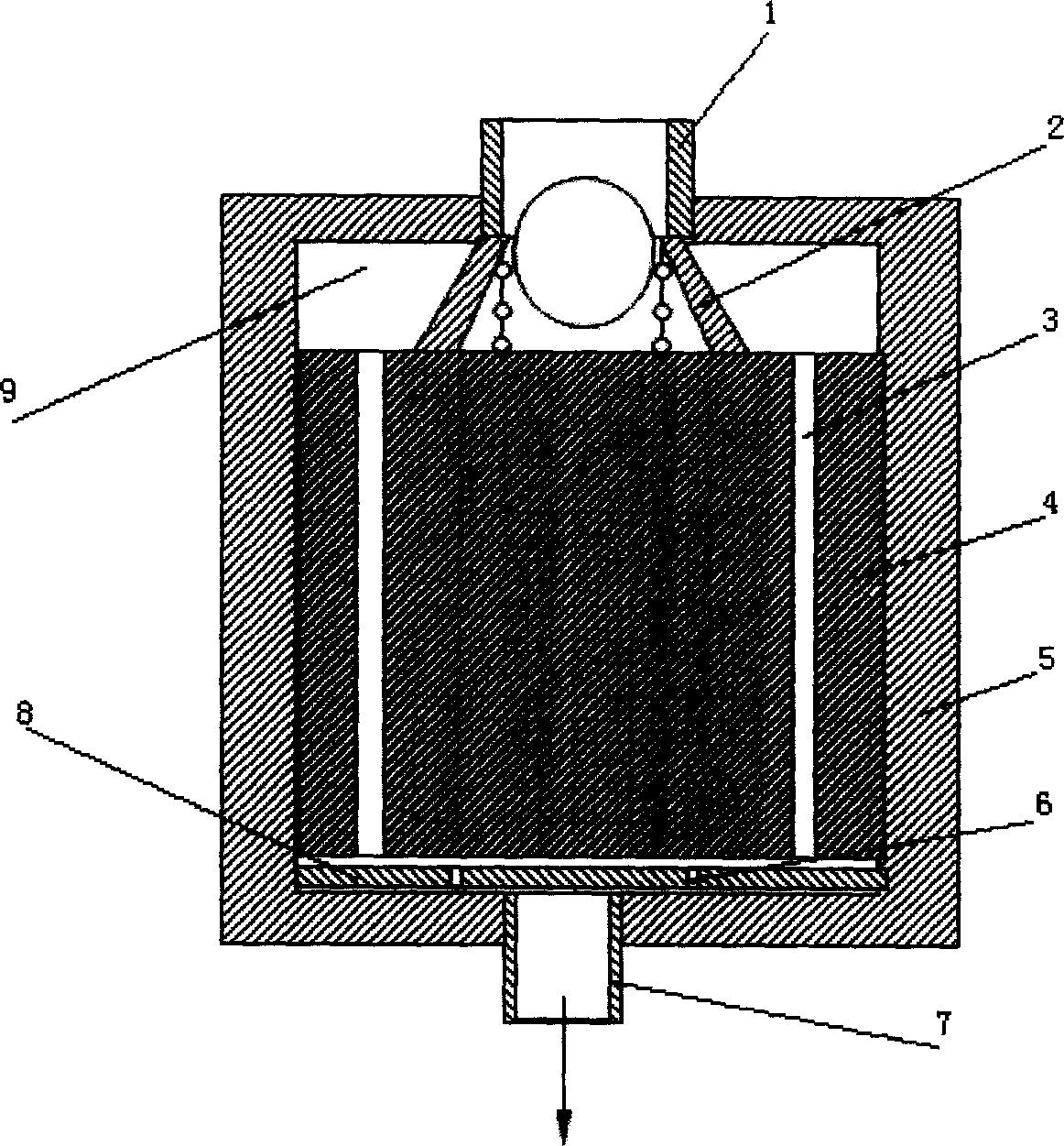

Light-cured printing equipment and method

ActiveCN104589651AFast printingAvoid split layer phenomenonAdditive manufacturing apparatusEngineeringLight cure

The invention discloses light-cured printing equipment and a method for forming a three-dimensional structure in photosensitive hydrogel according to an image stored in a computer. The light-cured printing equipment comprises a digital projection unit used for projecting the image into a photosensitive hydrogel layer, a photosensitive hydrogel curing unit used for providing the photosensitive hydrogel to form the photosensitive hydrogel layer and curing the photosensitive hydrogel in the photosensitive hydrogel layer according to the projected image layer by layer and a computer control unit used for providing the image to the digital projection unit and controlling imaging position of the projected image in the photosensitive hydrogel layer, wherein the photosensitive hydrogel curing unit consists of a guide rod and a bearing sheet which moves along the guide rod, and the lower surface of the bearing sheet is used for limiting the upper liquid level of the photosensitive hydrogel layer. The light-cured printing equipment is capable of printing the three-dimensional structure with high accuracy and high speed.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

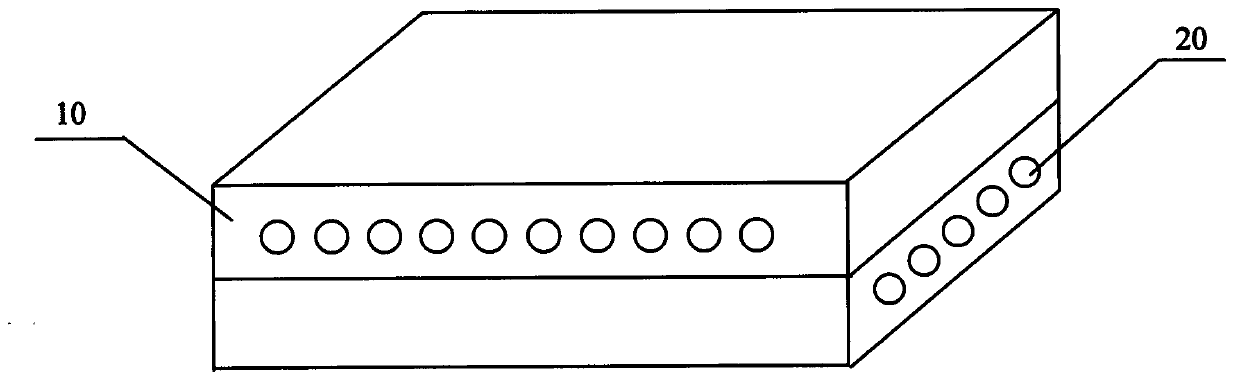

Preparation method of porous sound absorption structure composite material

The invention discloses a preparation method of a porous sound absorption structure composite material. The method comprises the following steps: stacking 3-5 layers of pre-woven high-performance fiber cloth, printing 10-40 parallel three-dimensional straight pipelines on the high-performance fiber cloth by wax materials, PLA (polylactic acid) environment-friendly materials and the like through a 3D printer respectively in the middle of each layer, wherein the pipelines between the two adjacent layers are spatially orthogonal, the diameter of each pipeline is 1 mm to 3 mm, and the distance between the central lines of the two adjacent layers of prefabricated pipelines is 2 mm to 4 mm; injecting epoxy resin, forming by a molding process, and heating in a drying oven at 40-200 DEG C until the 3D pipeline printing materials are fully volatilized or molten to obtain the porous sound absorption structure composite material. The 3D printer used in the preparation process of the porous sound absorption structure composite material is high in printing speed and precision and stable in performance, the printing materials easily volatilized or molten when being heated are used, a preparation process of through holes is greatly simplified, and the price of the printing materials is low; the prepared porous sound absorption structure composite material integrates structural material and sound absorption performances, and is simple in construction process, low in cost and excellent in performances such as good sound absorption effect, corrosion resistance, environmental protection, light weight, high strength and high product size stability.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

Slide 3D printing device and printing method thereof

ActiveCN105150534AGood surface printing qualityHigh printing precisionAdditive manufacturing apparatusMotor driveEngineering

Owner:SHAOXING FAST REAL ELECTRONICS TECH CO LTD +1

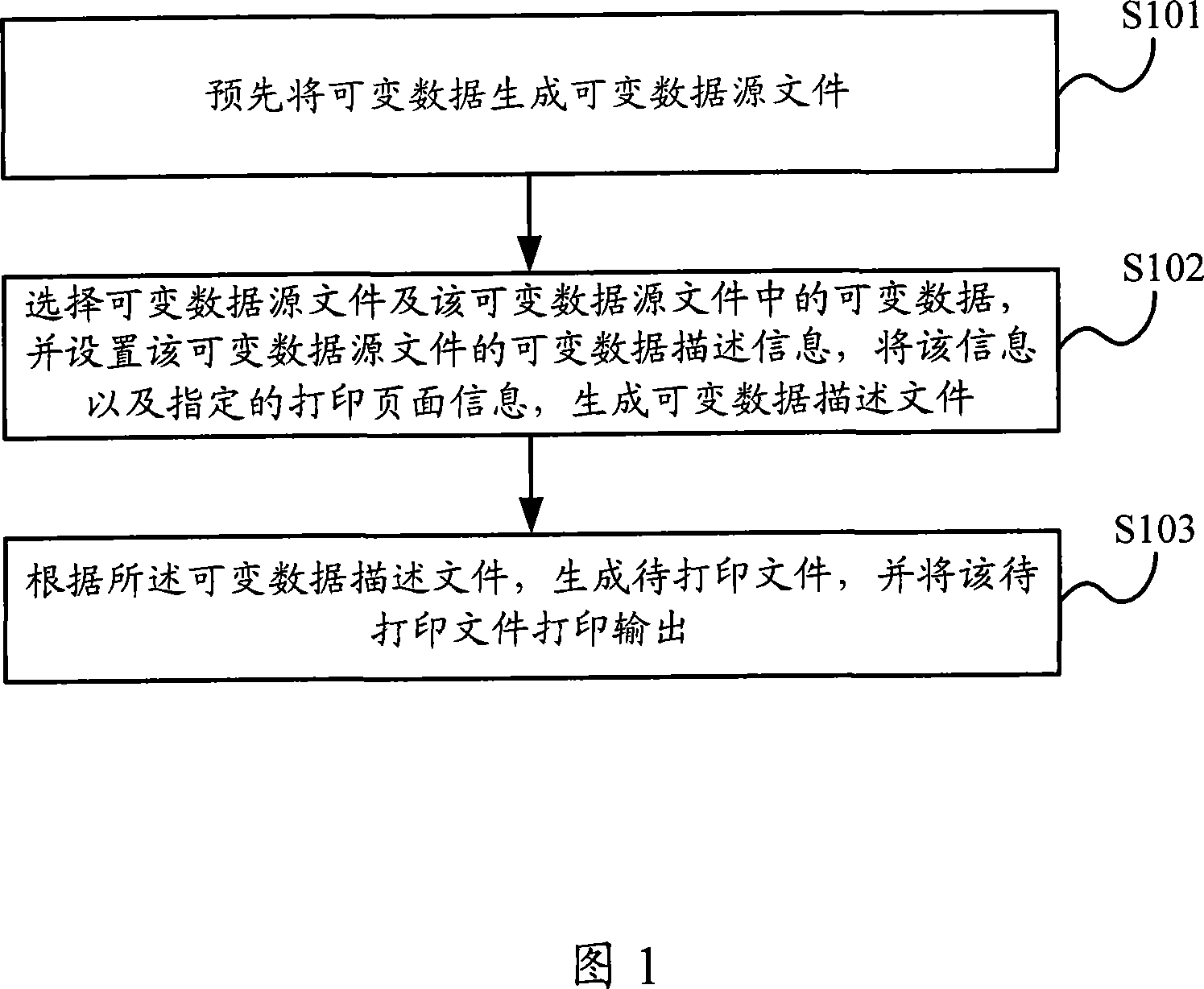

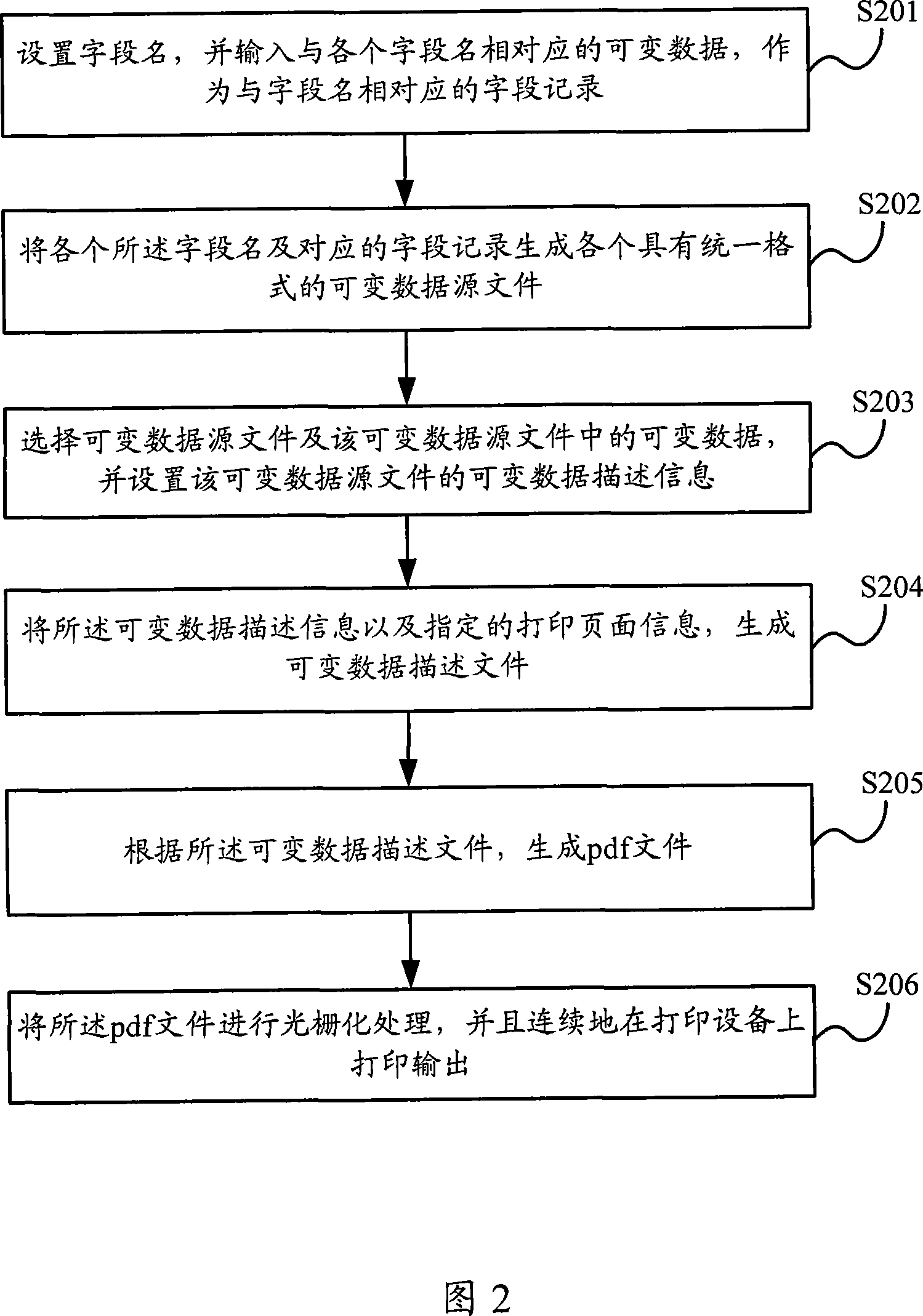

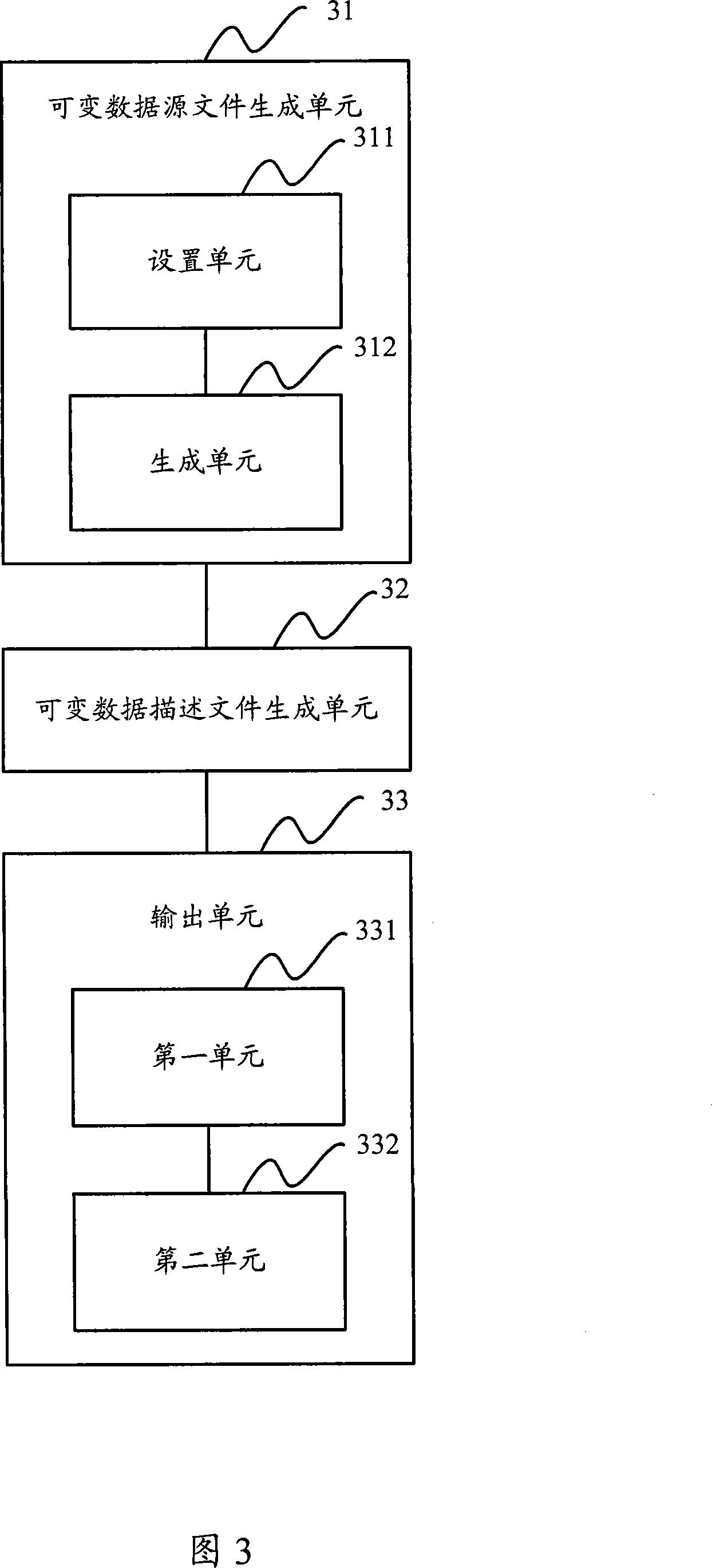

Variable data print-out method and device

InactiveCN101122845ARealize printoutEasy to operateSpecial data processing applicationsDigital output to print unitsPresent methodData source

The present invention discloses a variable data print method and device to achieve a variable data print plan with an simple operation, a high efficiency, a large volume of data processed and a moderate function. The method changes the variable data into a variable data source file with a unified format. The present method includes the following steps: a variable data source file and the variable data in the source file are selected. The descriptive information of the variable data in the source file is set. And a variable data descriptive file is generated out of the descriptive information and the designated page information to be printed. Based on the variable data descriptive file, an armed print file is generated and then printed out. The present invention applies to the variable data print.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

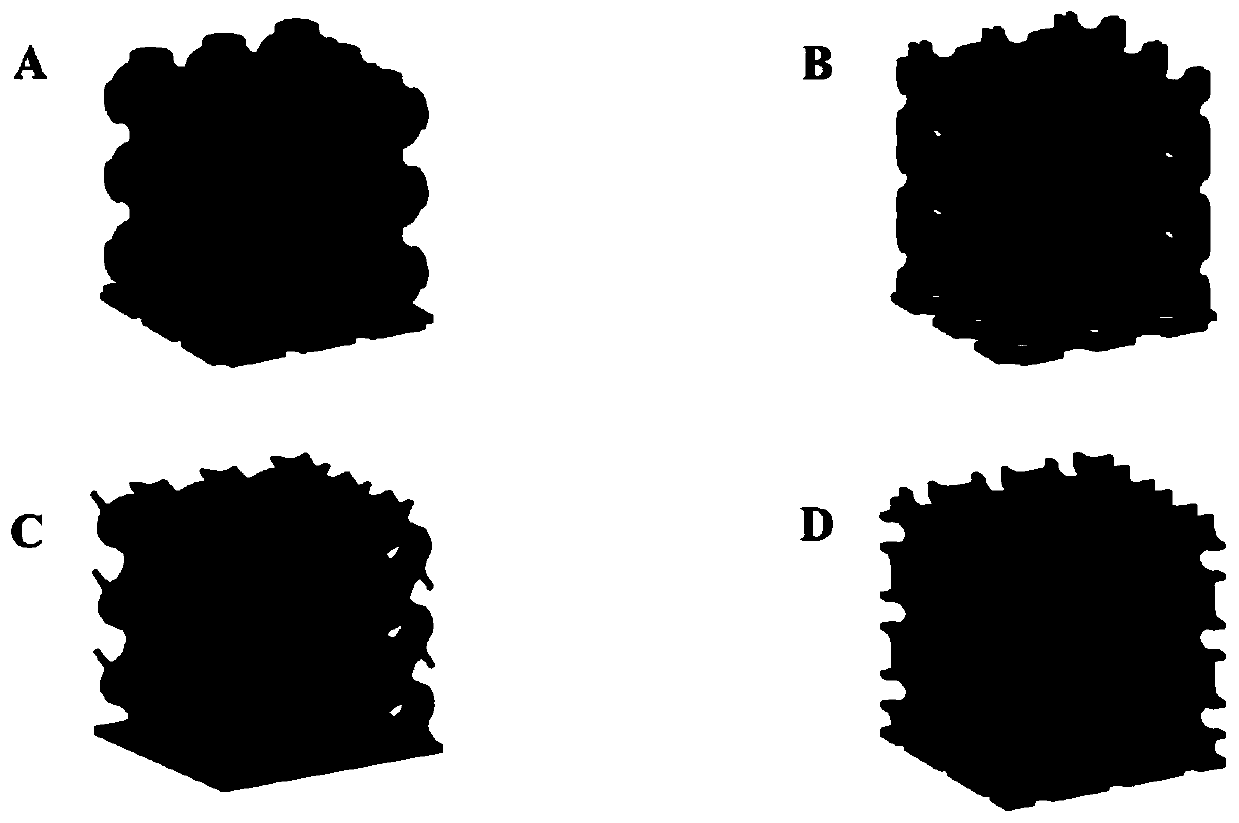

Application of Dimensional Printing Effects to Items Created in a Collage-Based Editor

InactiveUS20110013211A1Quickly populateFast printingDigitally marking record carriersCharacter and pattern recognitionComputer graphics (images)Keyboard shortcut

In a photo collage editor implemented in software residing on and executable from a digital medium, a method for configuring a project for three dimensional printing includes the steps (a) displaying in the editor, a page canvas for editing, (b) selecting or highlighting an image or item on the page canvas, (c) invoking a dimensional print effect configuration interface by selecting an interactive button on a toolbar displayed automatically as a result of step (b) or by implementing keyboard shortcut to execute the interface, and (d) selecting an option for applying one or more three dimensional effects from the interface.

Owner:INTERACTIVE MEMORIES

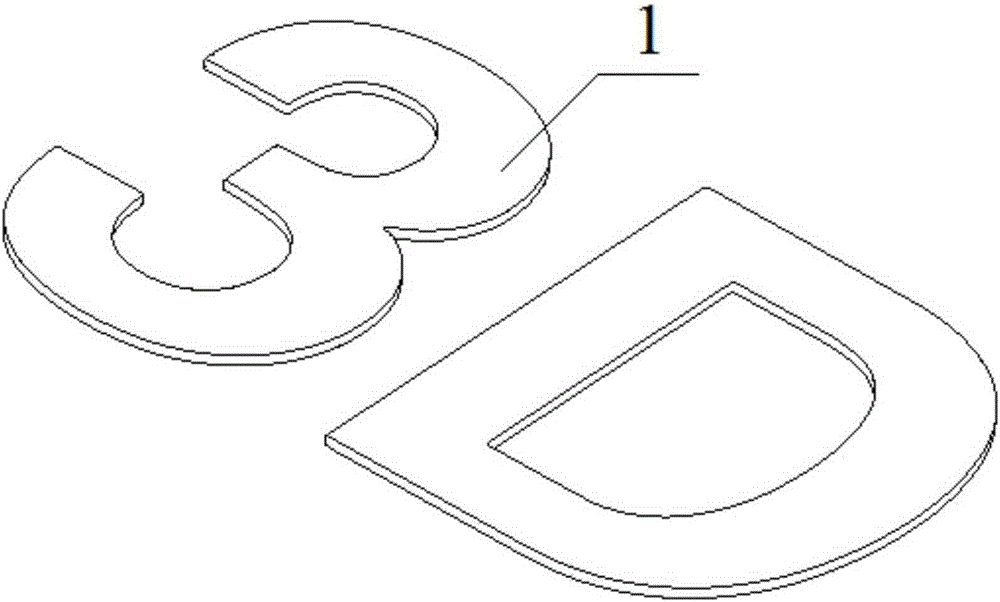

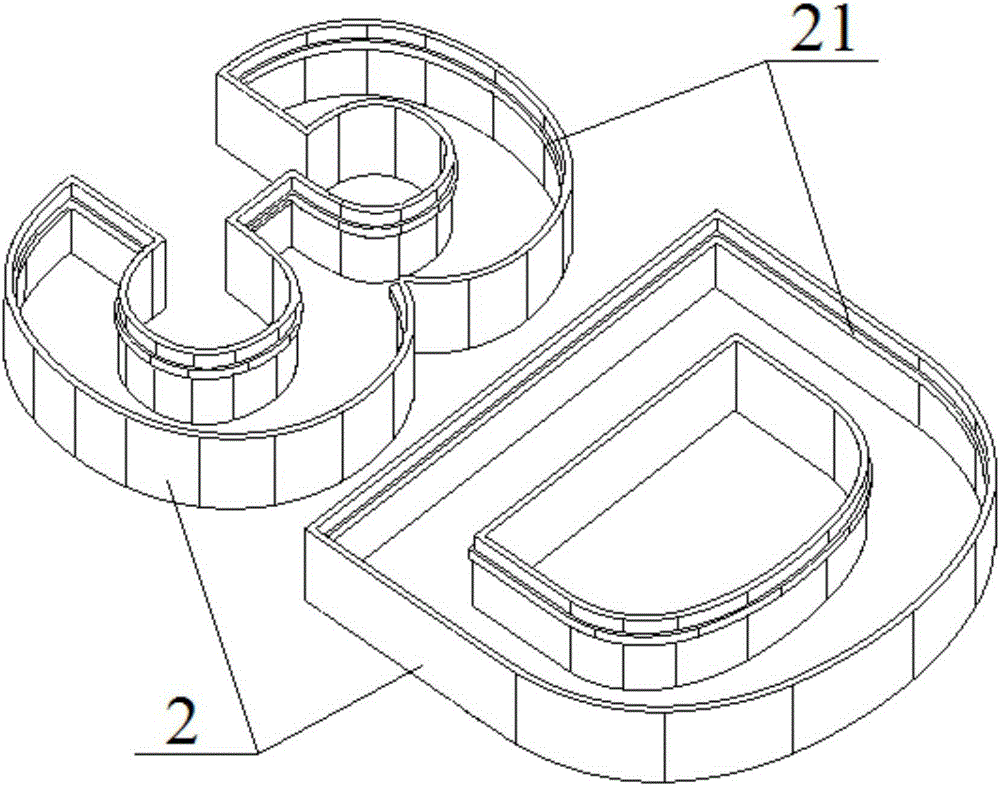

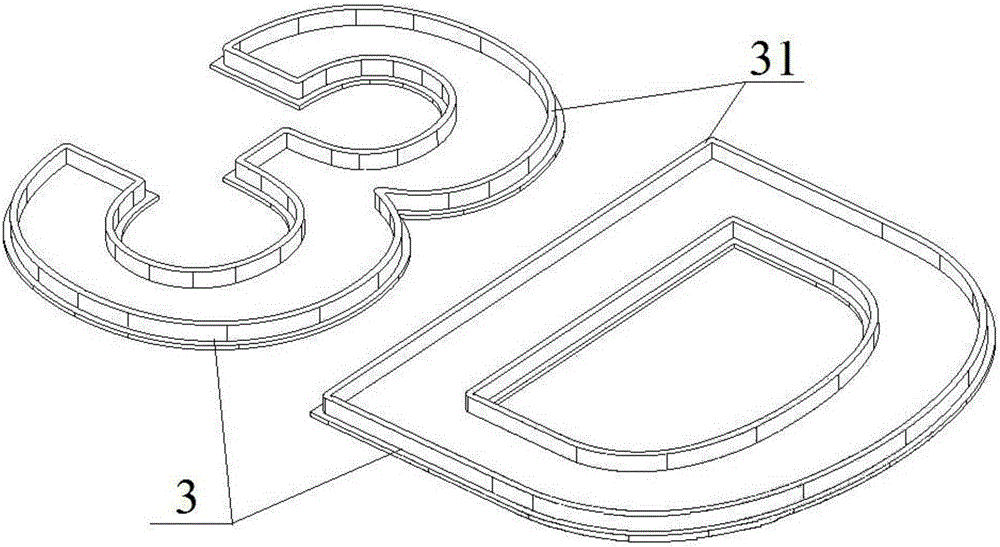

3D printing method of luminous words

ActiveCN105328903AImprove printing accuracyFast printingAdditive manufacturing apparatusEngineeringTypeface

The invention aims to provide an efficient and energy-saving 3D printing method of luminous words. The 3D printing method of the luminous words includes the technical steps that 1, a drawing is designed and a model is made; 2, a luminous word panel is carved; 3, a vertical wall and a lamp panel are printed; 4, a light source is pasted; and 5, assembling is performed. The method has the beneficial effects of being high in printing precision and printing speed, easy to operate, nontoxic, dustfree, environment-friendly, efficient, capable of saving cost and the like. The obtained luminous words are easy to assemble and disassemble and convenient to maintain later, have flexible and varied patterns and styles and have a wider application range. The demands of various occasions can be met by matching colors of the words at will.

Owner:钱宏江

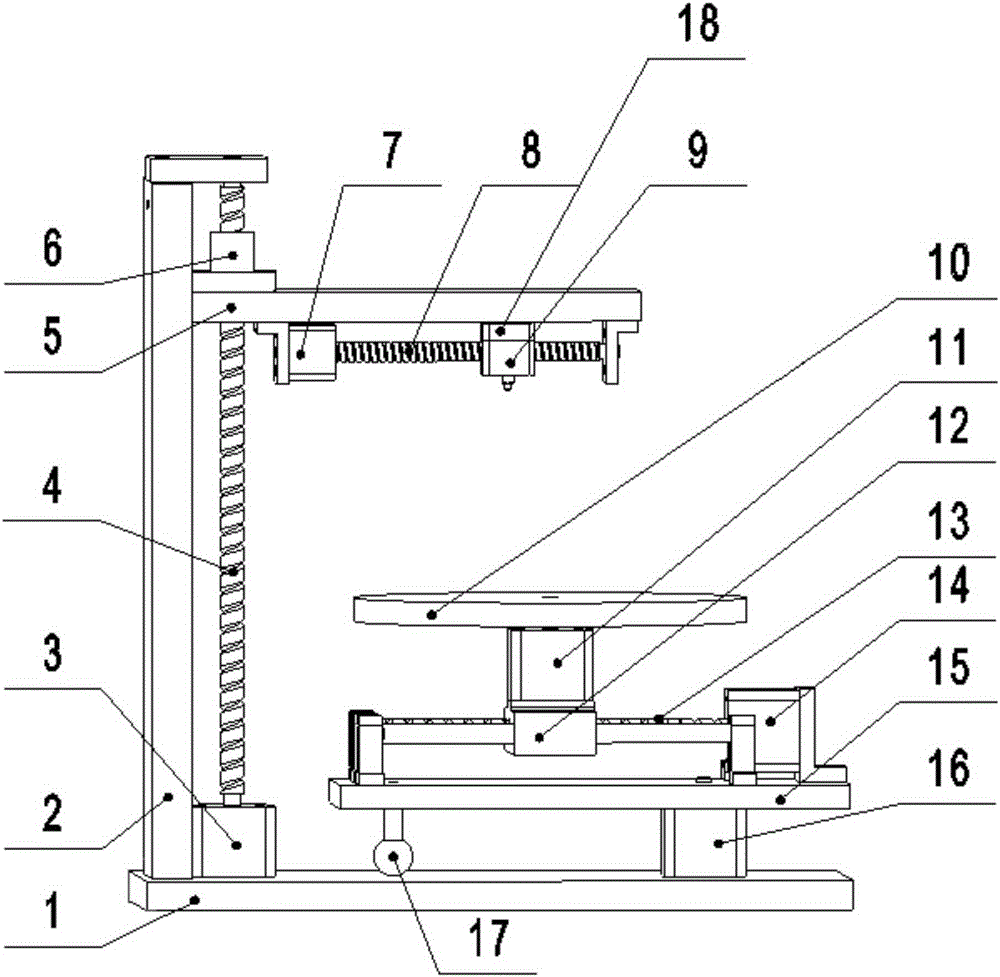

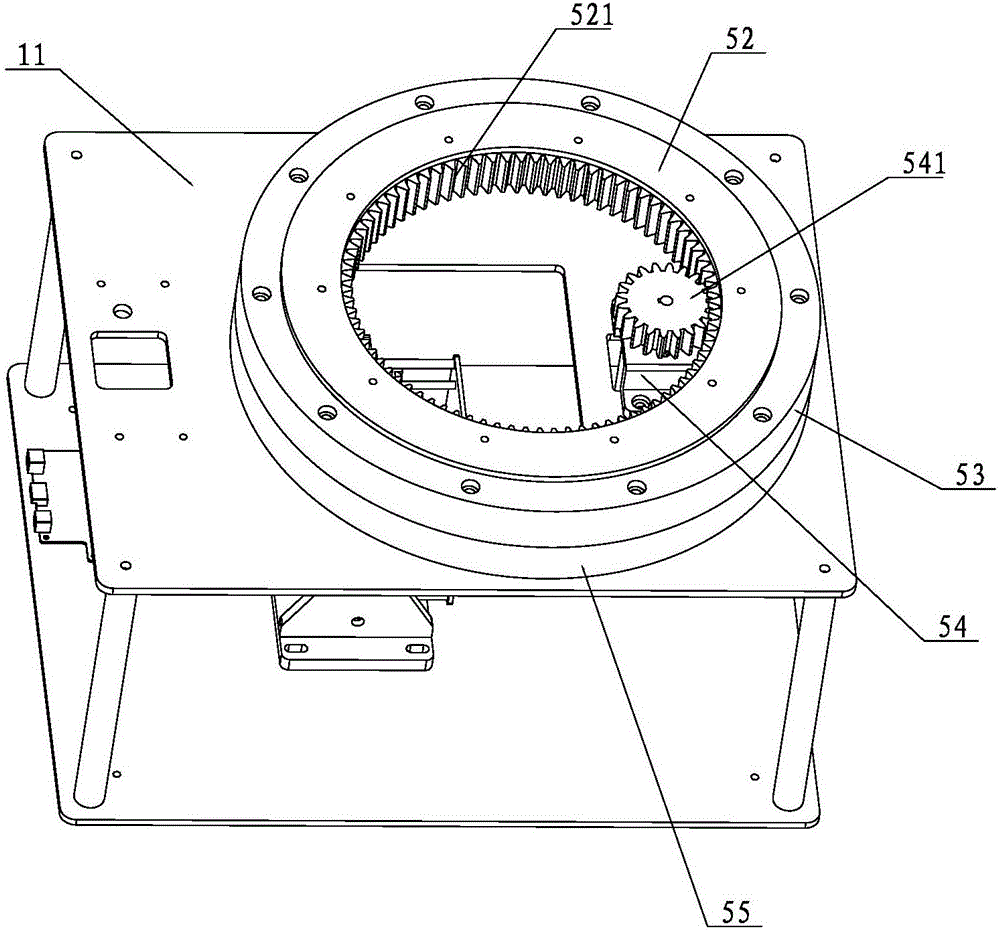

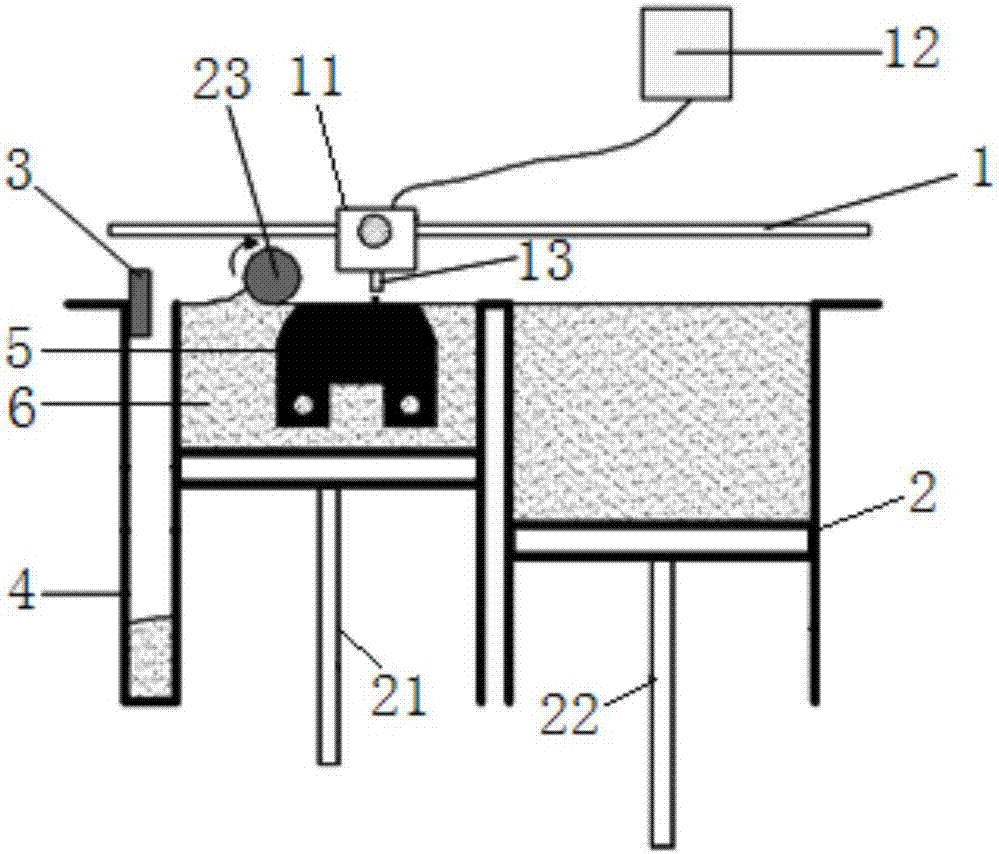

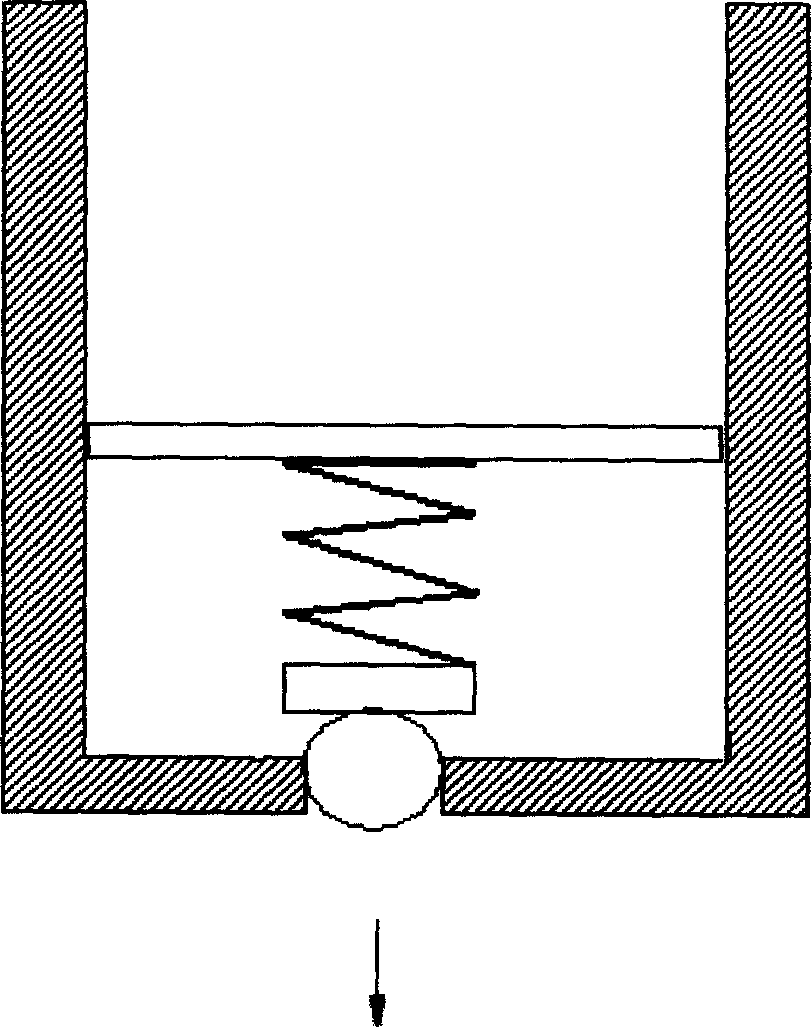

3D printing device and printing method

InactiveCN106476114AExtended service lifeUniform and accurate curing thicknessAdditive manufacturing apparatusCeramic shaping apparatusEngineeringViscosity

The invention discloses a 3D printing device and a printing method. The 3D printing device comprises a base, an exposure mechanism, a control mechanism, a printing mechanism and a liquid containing mechanism, wherein the printing mechanism and the liquid containing mechanism are arranged on the base; the printing mechanism is composed of a module group and a printing platform installed on the module group in a sliding manner; the liquid containing mechanism is composed of a material groove used for containing a printing solution, a drive component used for driving the material groove to rotate and a scraper component used for processing the printing solution; the bottom of the material groove is a bottom plate which is completely or partly transparent; an exposure hole of the exposure mechanism corresponds to the printing platform; and light for exposure and curing directly illuminates the printing platform through the transparent bottom of the material groove. The 3D printing device and the printing method can carry out printing with the high-viscosity printing solution and has the characteristics of rapidness in printing speed, high accuracy, long service life, convenience in operation and the like.

Owner:SHAOXING FAST REAL ELECTRONICS TECH CO LTD

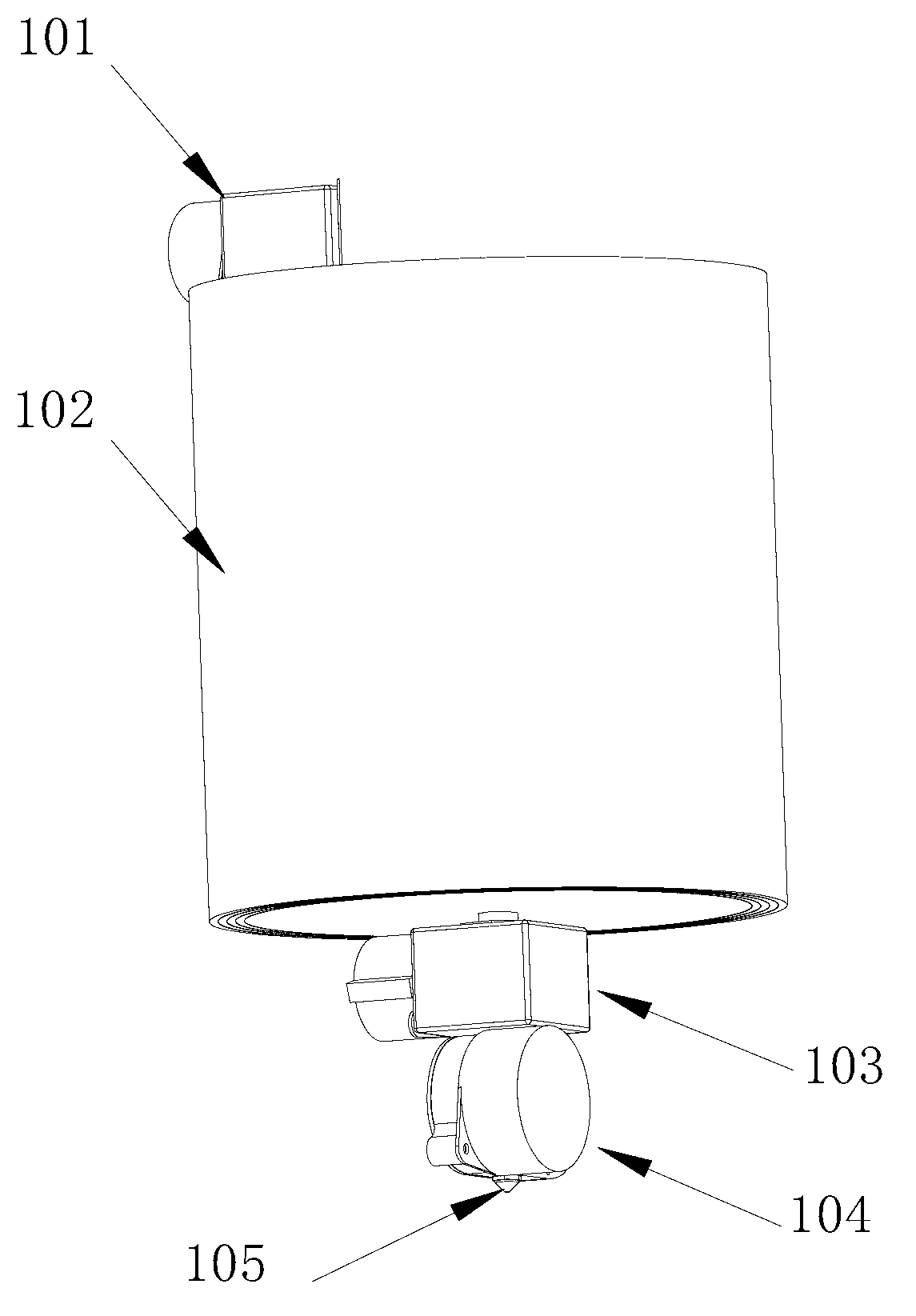

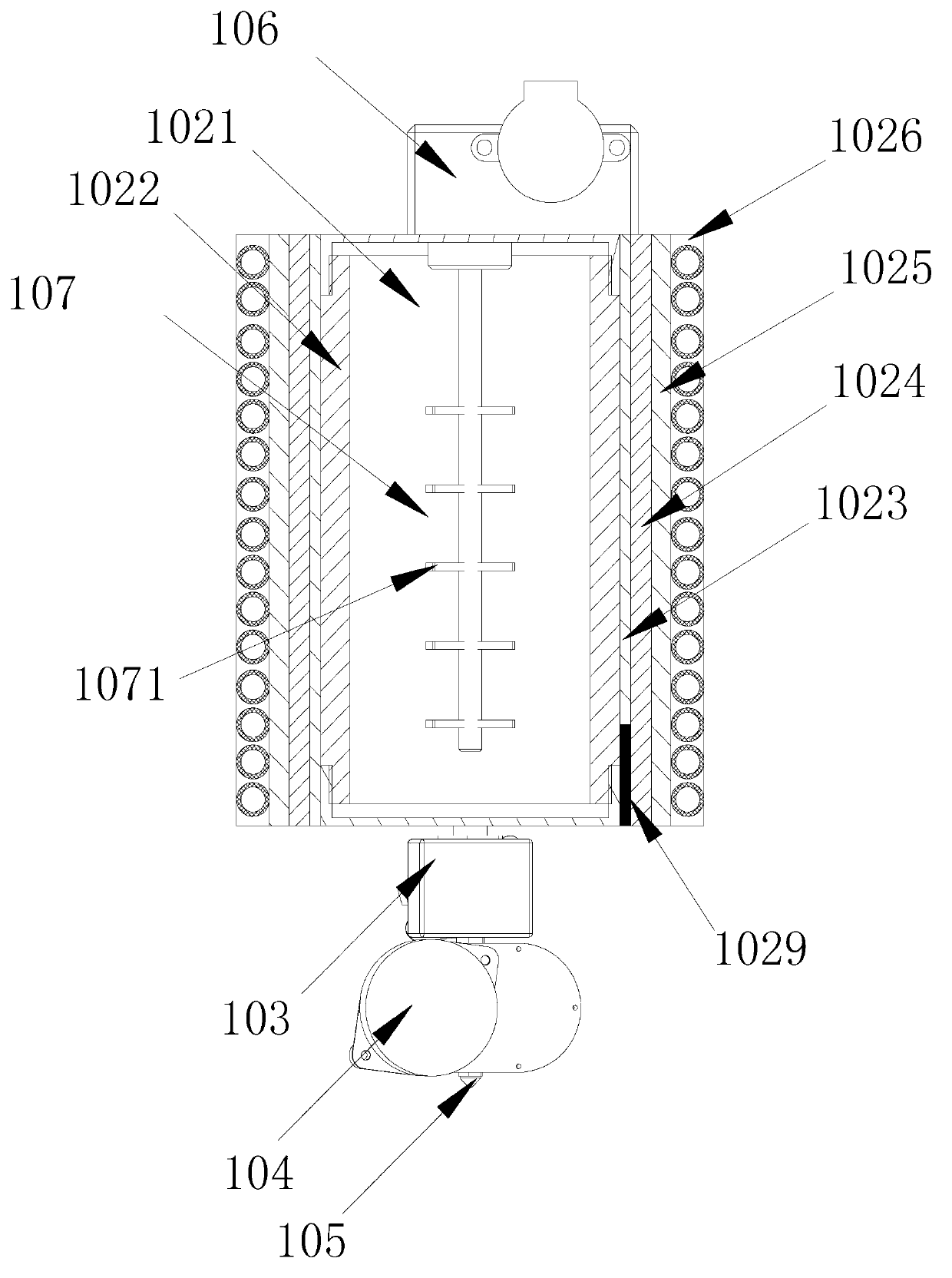

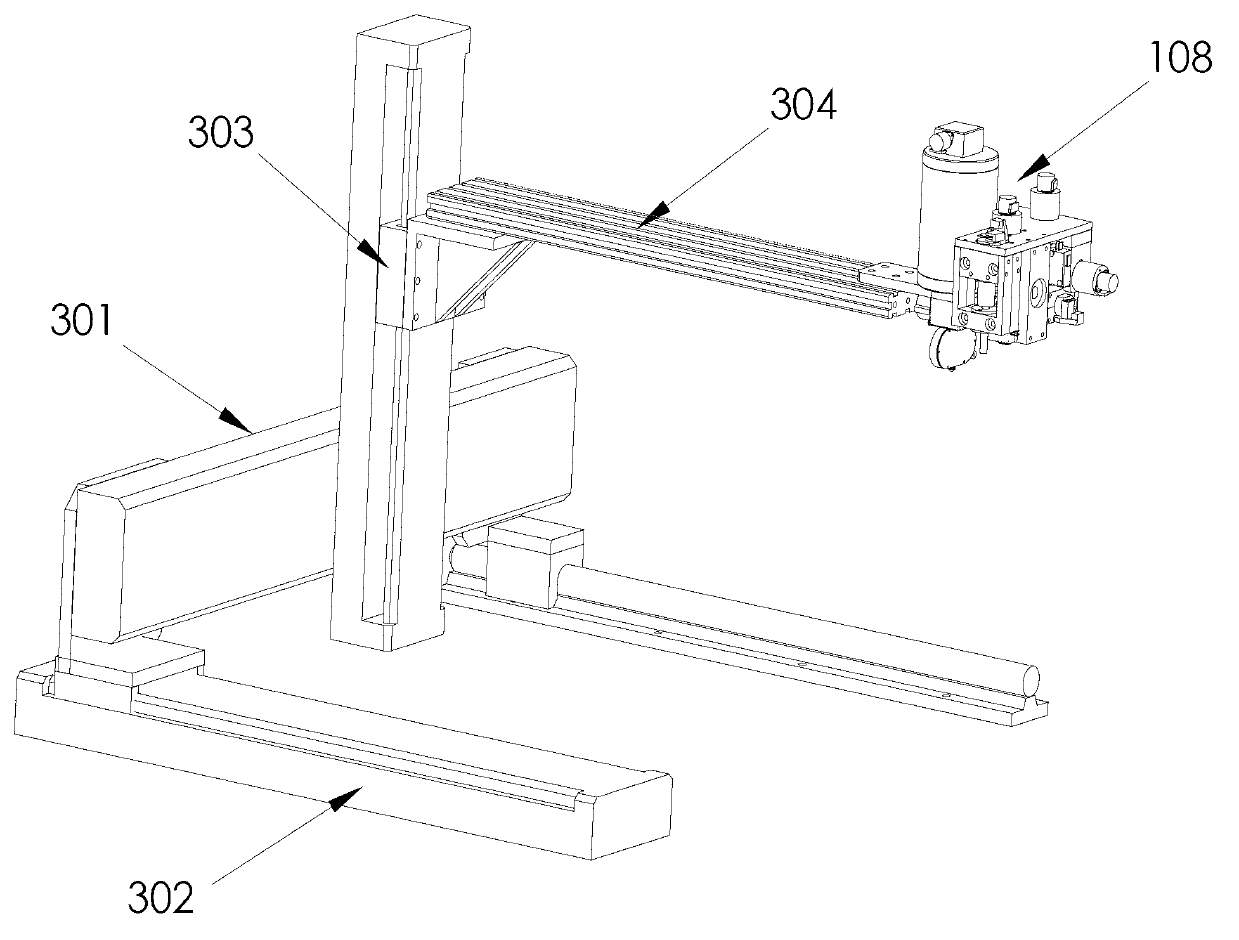

3D printing system

InactiveCN106965427AHigh precisionRich materialAdditive manufacturing apparatusManufacturing data aquisition/processingSprayerEngineering

The invention belongs to the technical field of rapid proto-typing and discloses a 3D printing system. The 3D printing system comprises an ink-jet printer, a printing drive controller and a rapid proto-typing platform, wherein the ink-jet printer comprises a shell, a printer main board, a first drive mechanism, a printer cross beam, a binder supply box and a first sprayer; the first sprayer is installed on the printer cross beam; the binder supply box is connected with the first sprayer; the printer main board drives the first sprayer to move along the X axis and controls the first sprayer to spray binders towards powder; the printing drive controller drives the printer cross beam to move along the Y axis; the rapid proto-typing platform comprises a supporting frame, a proto-typing cylinder, a powder cylinder and a powder spreading roller; and the powder spreading roller is installed on the printer cross beam and consistent with the printer cross beam in longitudinal direction. Various kinds of parts can be formed when the binder is sprayed, high-performance plastic parts can be formed by directly spraying and printing resin, selectable materials are more diverse than FDM and SLA, the cost is low, and precision is high.

Owner:HUAZHONG UNIV OF SCI & TECH

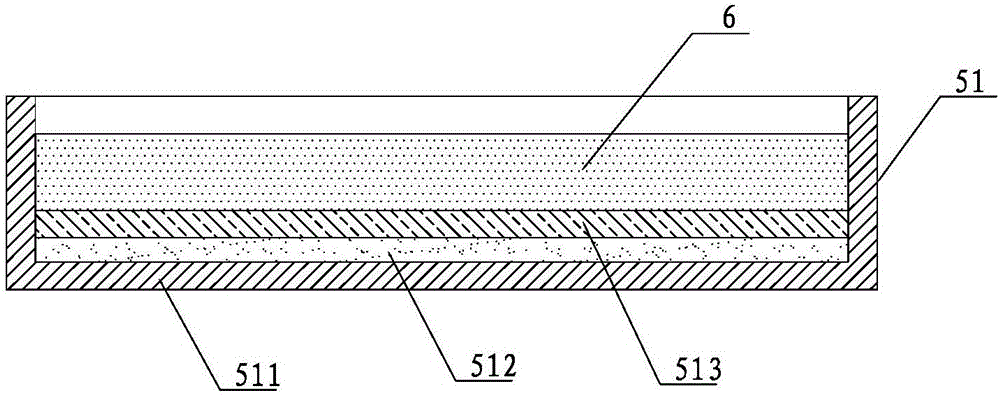

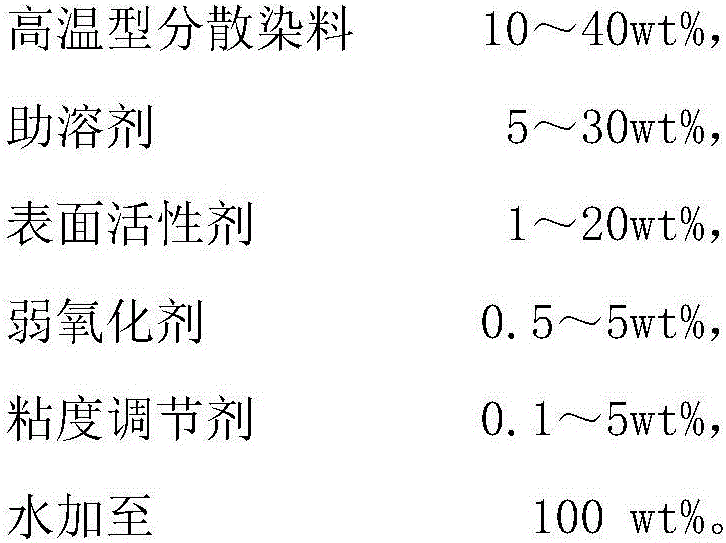

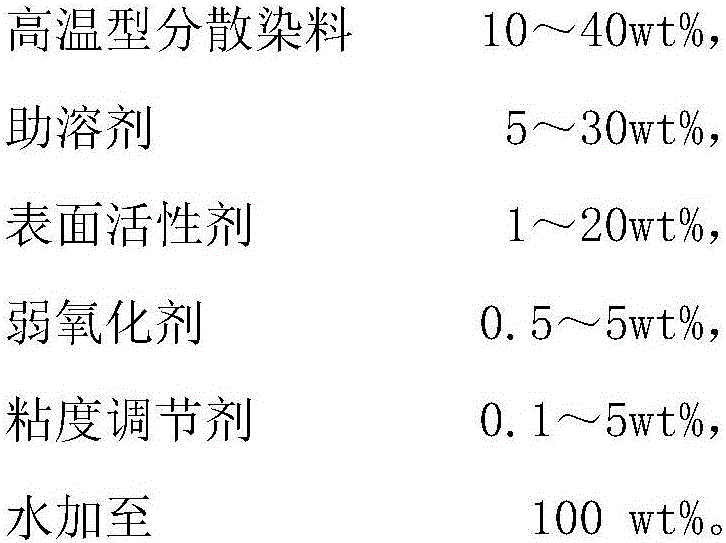

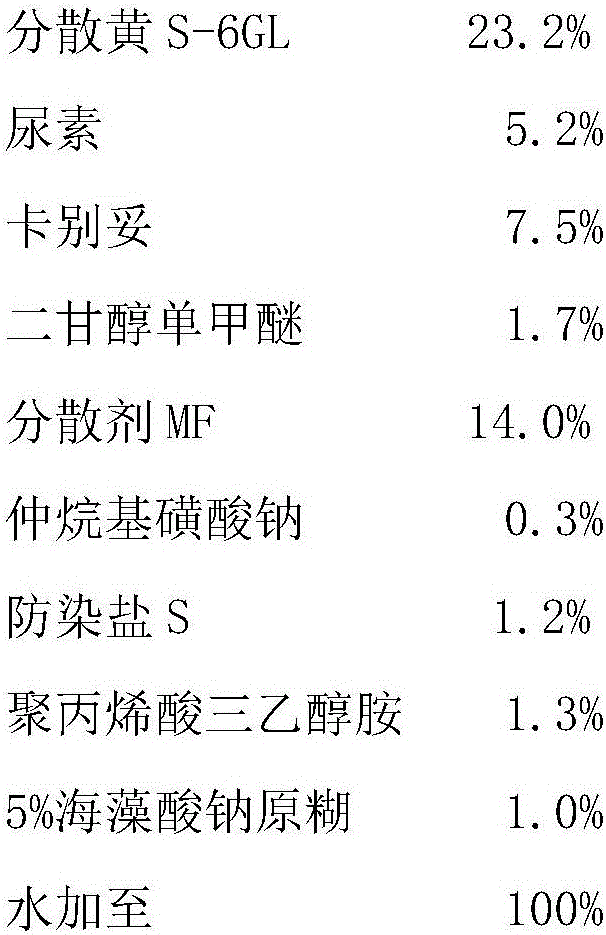

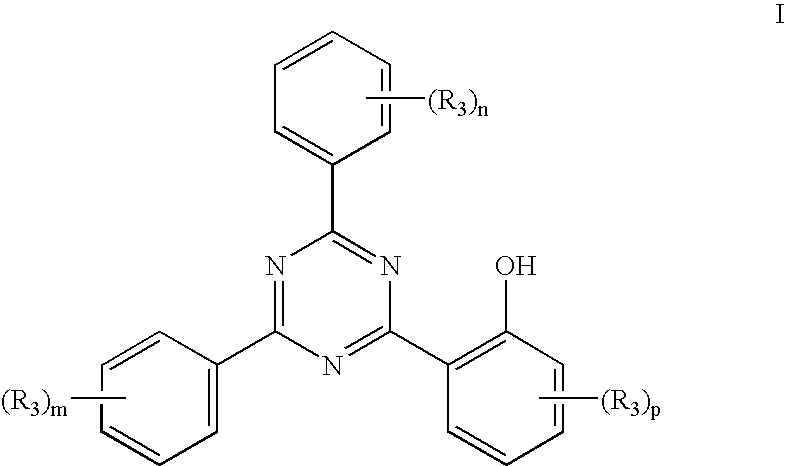

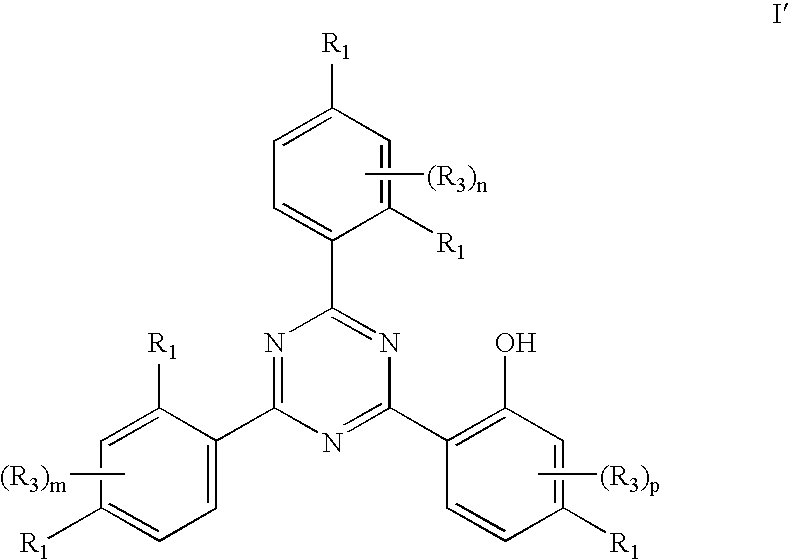

Intaglio direct printing or flexo direct printing technology for polyester fabric and application of weak dispersion solvent ink in technology

InactiveCN106192454AAchieve digital printing effectRich color gradationInksDyeing processPolyesterEngineering

The invention provides an intaglio direct printing or flexo direct printing technology for polyester fabric and application of weak dispersion solvent ink in the technology. The novel printing mode that the weak dispersion solvent ink is directly printed on polyester fabric through an intaglio printing machine or a flexo printing machine is adopted, and meanwhile an intaglio direct printing or flexo direct printing weak dispersion solvent ink constitution matched with the novel printing mode of polyester fabric and a preparing method of the intaglio direct printing or flexo direct printing weak dispersion solvent ink are provided. Operation is simple, only the intaglio printing machine or the flexo printing machine needs to be added on the aspect of technological equipment, and then operation can be carried out with existing technological equipment of printing and dyeing factories; for factories with polyester fabric heat transfer printing technological equipment, heat shaping equipment or steaming equipment and opening washing equipment need to be additionally purchased.

Owner:ZHEJIANG YIDE CHEM

Process of transferring transferable protection overcoat to a dye-donor element

InactiveUS6942956B2Enhancing the gloss of the final printLow line timeDiffusion transfer processesRadiation applicationsPolymer scienceInorganic particle

Owner:KODAK ALARIS INC

Three-dimensional color high-speed printer

The present invention relates to a three-dimensional color high-speed printer, which comprises a moving printing sprayer, a color distribution ink supply box, a work tank, a computer and a peripheral circuit, wherein the work tank comprises a powder supply tank, a forming tank and an overflow tank, the powder supply tank, the forming tank and the overflow tank are laterally and sequentially arranged side by side, a lifting powder supply plate is arranged inside the powder supply tank, a lifting production platform is arranged inside the forming tank, two lateral bracket guide rails are flatly arranged on the work tank, the longitudinal ink roller device capable of laterally moving along the lateral bracket guide rails is arranged on the two lateral bracket guide rails, the two lateral bracket guide rails are further provided with longitudinal guide rails capable of laterally moving, the moving printing sprayer is movably arranged on the longitudinal guide rail, and the material outlet of the color distribution ink supply box is connected with the material inlet of the moving printing sprayer through an ink supply pipe. The three-dimensional color high-speed printer has characteristics of simple structure, easy operation, broad application range, good environmental protection, capability of outputting vibrant color model, and achievement of time-saving and rapid automated operation and easily-used printing process.

Owner:SHAANXI HENGTONG INTELLIGENT MACHINE

Jet printing method for textile and special nozzle therefor

InactiveCN1804208AImprove printing qualityFast printingDyeing processPrintingMicrocomputerControl signal

The invention relates to a method to print on textile and its special nozzle. Wherein, colleting the quantity and coordinate need on pattern with microcomputer; manual preparing opposite color liquids to inject into opposite slurry tanks; horizontal moving the nozzle according to control signal from microcomputer; feeding the textitle to work bench; forcing the dyestuff through feeding pipe and one-way valve into top surface of rotating core in inner cavity; using control signal from microcomputer to drive step motor of nozzle rotating and rotating core; then, forcing the dyesutff flowing into the inlet hole then the gap between rotating hole and bottom plate, and flowing into the outlet hole through concave slot on bottom plate, finally high-speed spraying on the textile.

Owner:周永先

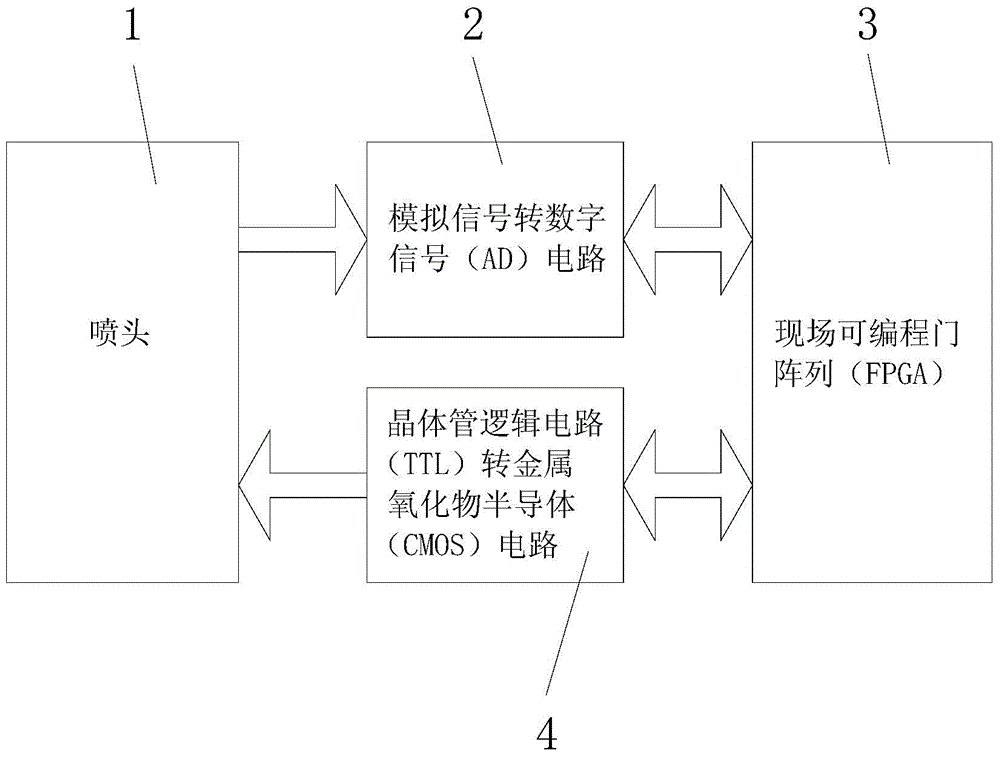

High-speed ink-jet printing module

ActiveCN104002557AAutomate the processMeet the needs of portabilityTypewritersFpga chipElectrical and Electronics engineering

The invention discloses a high-speed ink-jet printing module. The high-speed ink-jet printing module comprises a field-programmable gate array (FPGA) chip control part, a first circuit, a second circuit and a printing spraying head. The FPGA chip control part is connected with the printing spraying head through the first circuit and the second circuit respectively, the FPGA chip control part drives the printing spraying head to work through the second circuit, and the FPGA chip control part controls printing data of the printing spraying head and the time sequence of the spraying head. According to the high-speed ink-jet printing module, when the printing spraying head is used for printing a two-dimensional code, and the spraying head can finish high-precision printing without making contact with paper. The printing module is simple in structure, the printing speed is high, stability is good, and operation and maintenance are convenient.

Owner:SHANGHAI GOOAO ELECTRONIC TECHNOLOGY CORP

Photocuring 3D printing system and printing method

ActiveCN110901058AFast printingLarge light transmission areaAdditive manufacturing apparatus3D object support structuresLight beam3D modeling

The invention relates to a photocuring 3D printing system and a printing method. The photocuring 3D printing system comprises a material carrier and a spreader. The spreader is of a scraper structure;at least part of the spreading side of the spreader is a light-transmitting area; and the spreader and the material carrier generate relative translation motion to lay a photosensitive printing material on the material carrier opposite to the light transmitting area. When the laid photosensitive printing material is in the extruded state, the light beam transmits through the light transmitting area and selectively irradiates the photosensitive printing material of the spreading side of the light transmitting area according to the information of a three-dimensional model to be printed to forma curing layer. The spreader and the material carrier can move vertically relative to each other, the distance between the spreader and the material carrier is increased in the printing process and the curing layer forms a curing model on the material carrier. Material spreading and illumination curing can be synchronously carried out, the 3D printing speed and printing precision can be improved,the application range is wider and the equipment cost and the production cost can be reduced..

Owner:YUANZHI TECH SHANGHAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com