Three-dimensional printing molding preparation method for porous ceramic for filtration

A technology of porous ceramics and three-dimensional printing, which is applied to ceramic forming machines, ceramic products, filtration and separation, etc., can solve the problems of high production cost of consumables and high structural complexity of printing equipment print heads, and achieve low manufacturing cost, simple structure, and easy preparation The effect of low technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

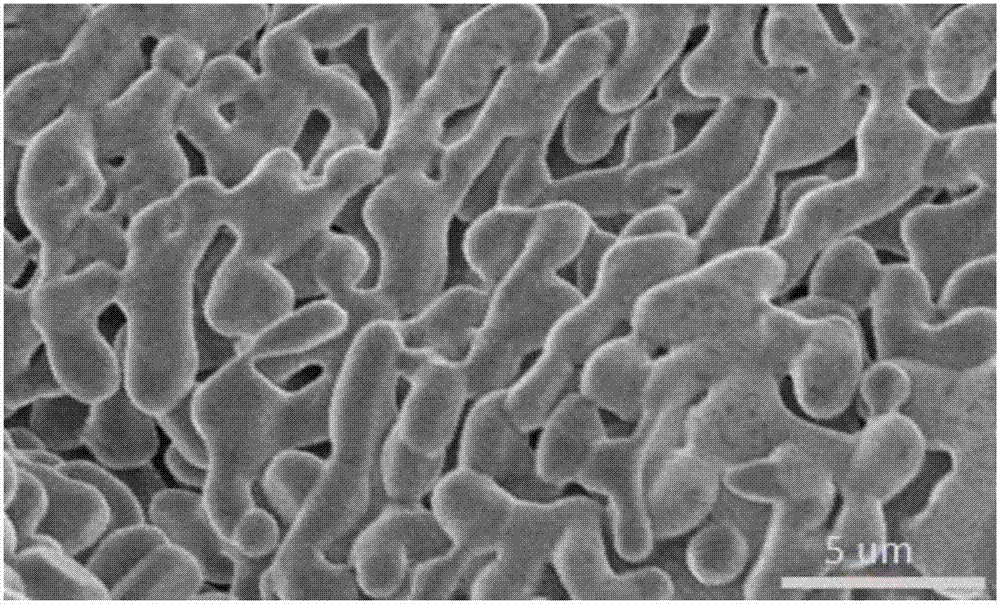

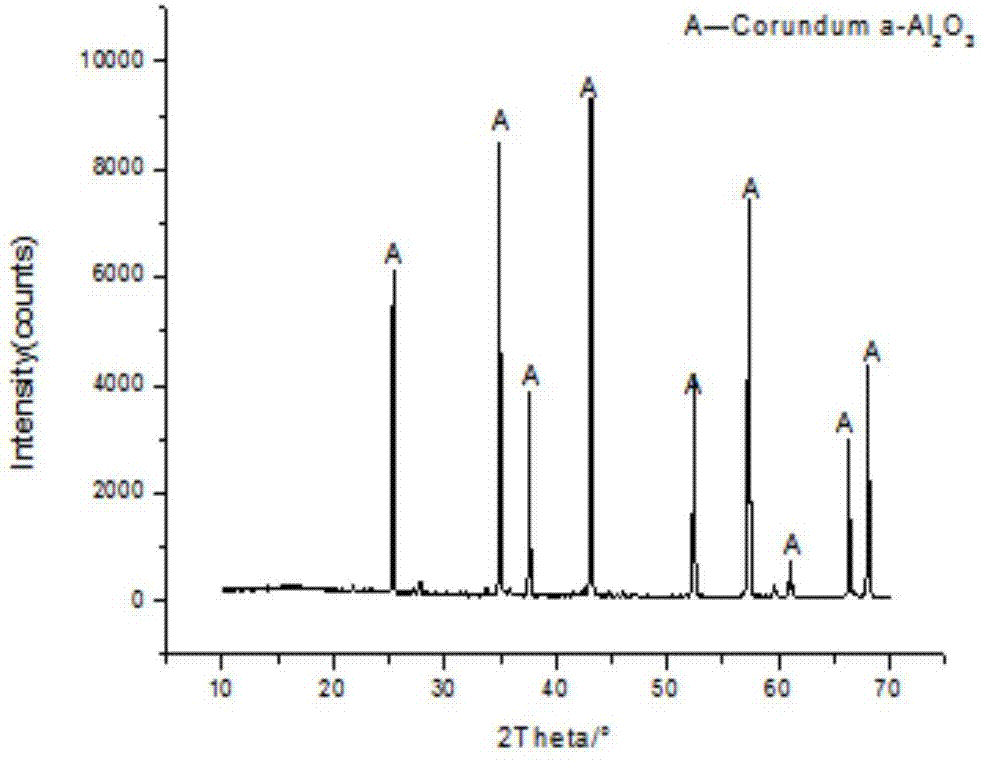

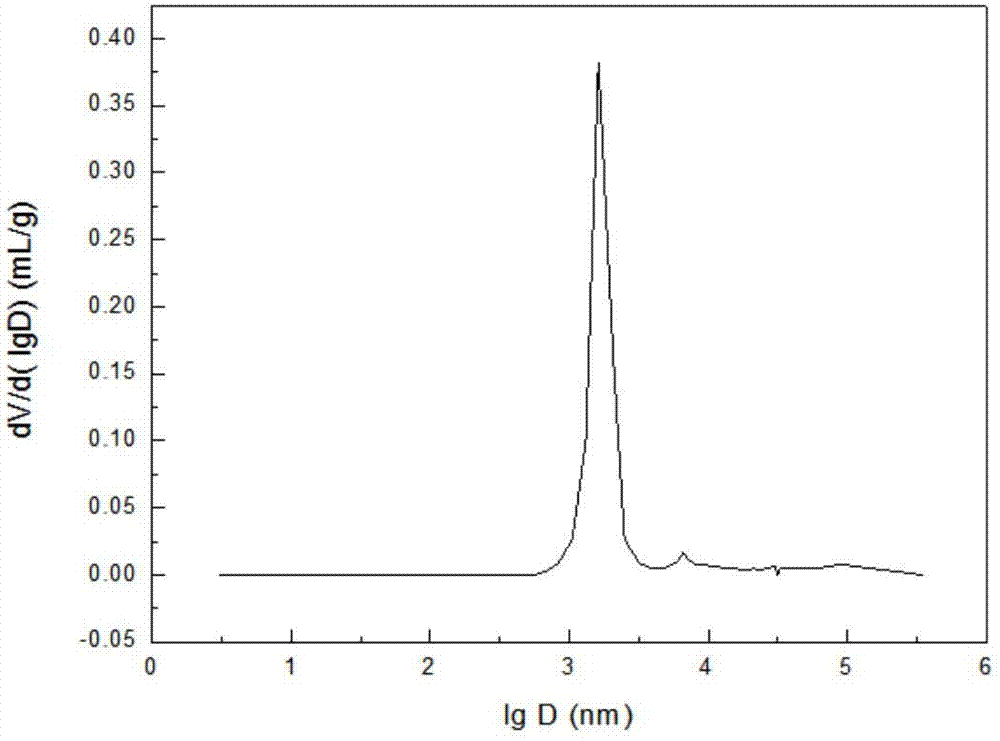

[0040] A kind of corundum (α-Al 2 o 3 ) three-dimensional printing preparation method of porous ceramics, the process is as follows Figure 4 As shown, the specific steps are as follows:

[0041] (1) Preparation of ceramic materials for three-dimensional printer printing, the steps are as follows:

[0042] 1) Take α-Al with an average particle size of 0.5-100 μm 2 o 3 300g of powder, 5-25g of magnesium oxide, titanium dioxide and silicon dioxide mixture (sintering aid) with an average particle size of 0.5-50μm, 7.5-30g of starch (pore-forming agent) with an average particle size of 0.5-100μm; these solid powders Add them together to the mixer for mixing, so that the different powders can be mixed evenly.

[0043] 2) Get 6-18g of 10wt% PVA solution (binder), mix it with 50-100g of deionized water, and gradually add the mixed solution into a mixer, and stir it evenly with the solid powder; Mix 3-9g of butyl ester (plasticizer) and 3-9g of polypropylene glycol with a molecu...

Embodiment 2

[0052] A three-dimensional printing and molding preparation method of quartz porous ceramics for filtration, the process is as follows Figure 4 As shown, the specific steps are as follows:

[0053] (1) Preparation of ceramic materials for three-dimensional printer printing, the steps are as follows:

[0054] 1) Take 300g of quartz powder with an average particle size of 5-15μm, 5-25g of anorthite-clay mixture with an average particle size of 1-5μm, and polymethyl methacrylate (pore-forming agent) with an average particle size of 5-15μm 7.5 -30g; and these solid powders are added to the mixer for mixing, so that the different powders are evenly mixed.

[0055] 2) Mix 6-24g of 3.5wt% carboxymethyl cellulose solution (binder) with 50-100g of deionized water, and gradually add the solution into a mixer, and stir evenly with the solid powder; Dibutyl diformate (plasticizer) 3-9g and polypropylene glycol with a molecular weight of 400 (lubricant) 3-9g (lubricant) and absolute eth...

Embodiment 3

[0061] A preparation method for three-dimensional printing and molding of silicon carbide porous ceramics for filtration, the process of which is as follows Figure 4 As shown, the specific steps are as follows:

[0062] (1) Preparation of ceramic materials for three-dimensional printer printing, the steps are as follows:

[0063] 1) Take 300g of silicon carbide powder with an average particle size of 100-300μm, 25-50g of albite-clay mixture with an average particle size of 10-50μm, and 7.5-30g of sucrose powder (pore-forming agent) with an average particle size of 30-100μm ; and these solid powders are added together into the mixer for mixing, so that the different powders are evenly mixed.

[0064]2) Take 8-24g of 3.5wt% polyacrylamide solution (binder) and mix with 50-80g of deionized water, and gradually add the mixed solution into the mixer, and mix it evenly with the solid powder; Triol (plasticizer) 4-10g and polyethylene glycol 4-10g (lubricant) with a molecular weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com