Preparation method of flexible silicon dioxide aerogel

A technology of silica and airgel, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problems of long time (usually more than 2 days, low connection strength of product skeleton structure, etc.), and shorten the preparation time , improve performance, improve the effect of preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, a preparation method of flexible silica airgel, which includes the following steps: weighing raw materials, the molar ratio of TEOS, MTES, DEDMS, ethanol, water, CTAB, hydrochloric acid and ammonia water is 0.045:0.242:0.021 : 1.65: 3.67: 0.00027: 0.00012: 0.01, the ethanol is absolute ethanol, the water is deionized water, the concentration of hydrochloric acid is 0.12mol / L, and the concentration of ammonia water is 2.5mol / L.

[0033] S1. Dissolving CTAB in a mixed solvent at a temperature of 40° C. to obtain a mixed solution. The mixed solvent includes ethanol, water and hydrochloric acid.

[0034] S2, adding TEOS, MTES and DEDMS to the mixed solution sequentially under stirring condition, carrying out hydrolysis reaction, mixing and stirring to obtain silica sol.

[0035] S3, adding ammonia water dropwise to the silica sol under stirring conditions, performing polycondensation reaction, mixing and stirring to obtain silica gel.

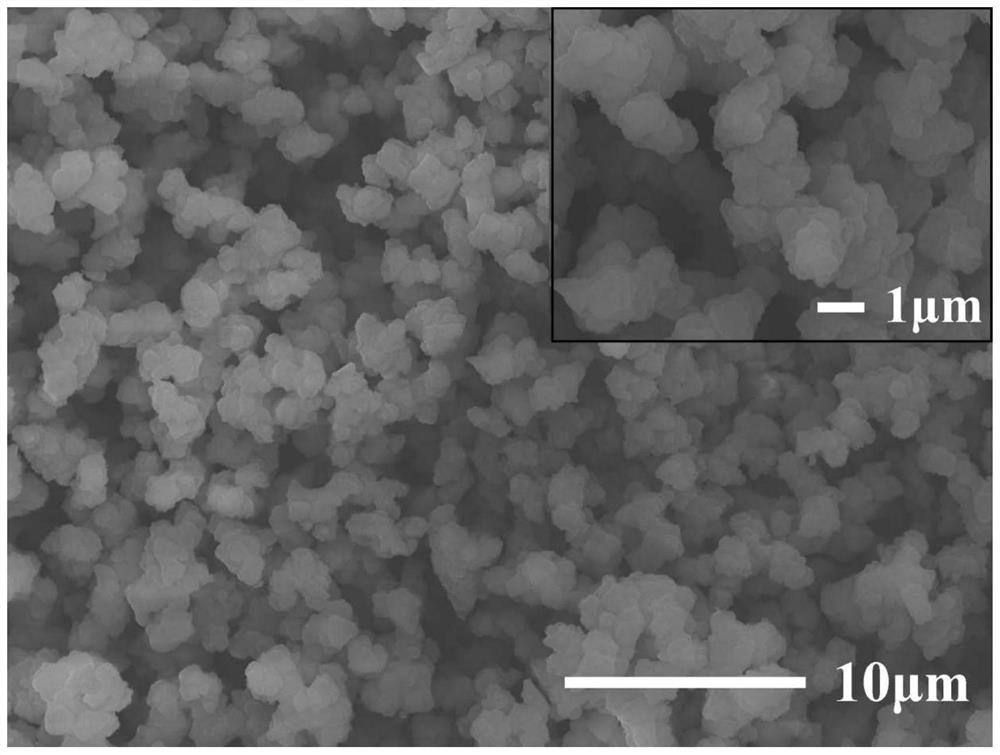

[0036] S4, aging the s...

Embodiment 2

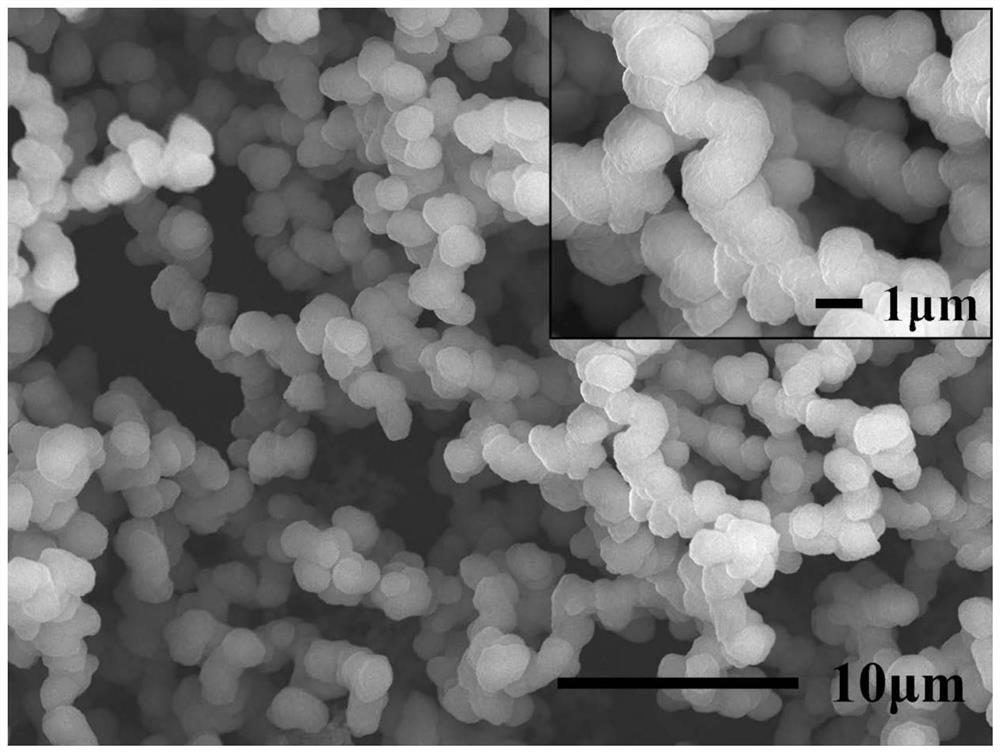

[0038] Embodiment 2, a preparation method of flexible silica airgel, the ratio of raw material components, hydrolysis reaction, polycondensation reaction operation is the same as that of Embodiment 1, the difference is the aging treatment and drying treatment, the aging temperature of the aging treatment is 30 °C, the aging time is 6 hours, and the drying treatment specifically includes: first drying at a temperature of 40 °C for 2 hours, and then drying at a temperature of 60 °C for 3 hours. The obtained flexible silica airgel was observed with a scanning electron microscope, and the airgel skeleton was a coarse structure.

Embodiment 3

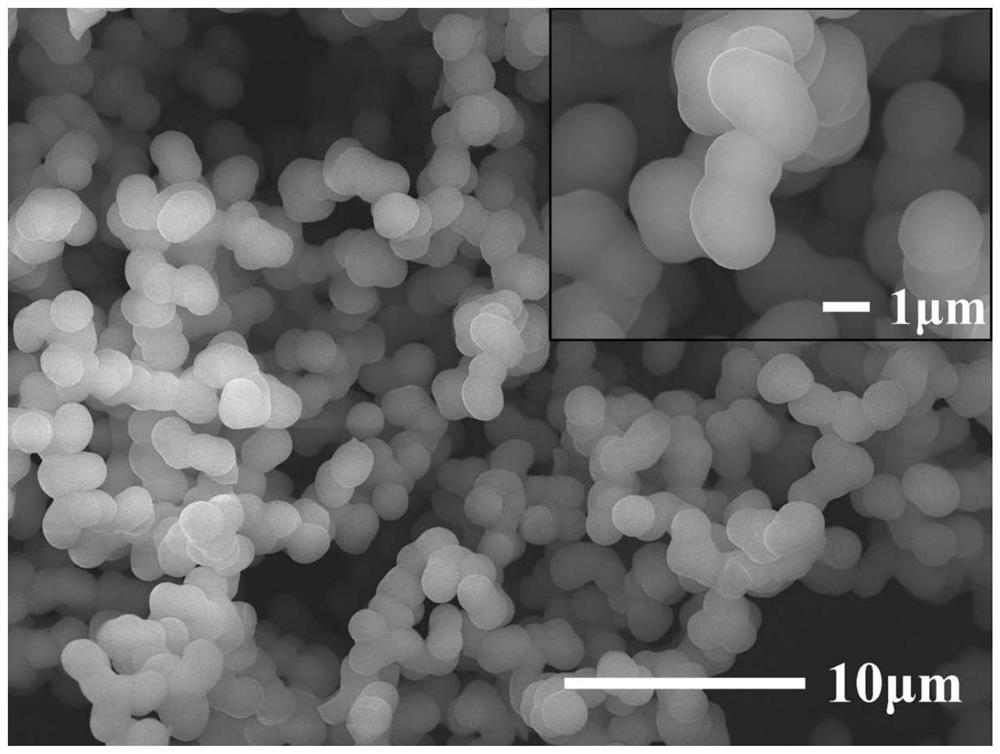

[0039] Embodiment 3, a preparation method of a flexible silica airgel, the ratio of raw material components, hydrolysis reaction, polycondensation reaction operation is the same as the embodiment 1, the difference is the aging treatment and drying treatment, the aging temperature of the aging treatment is 50 °C, the aging time is 3 hours, and the drying treatment specifically includes: firstly drying at a temperature of 45 °C for 1.5 hours, and then drying at a temperature of 80 °C for 1 hour. The obtained flexible silica airgel was observed with a scanning electron microscope, and the airgel skeleton was a coarse structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com