Patents

Literature

892 results about "High complexity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The complexity of a physical system or a dynamical process expresses the degree to which components engage in organized structured interactions. High complexity is achieved in systems that exhibit a mixture of order and disorder (randomness and regularity) and that have a high capacity to generate emergent phenomena.

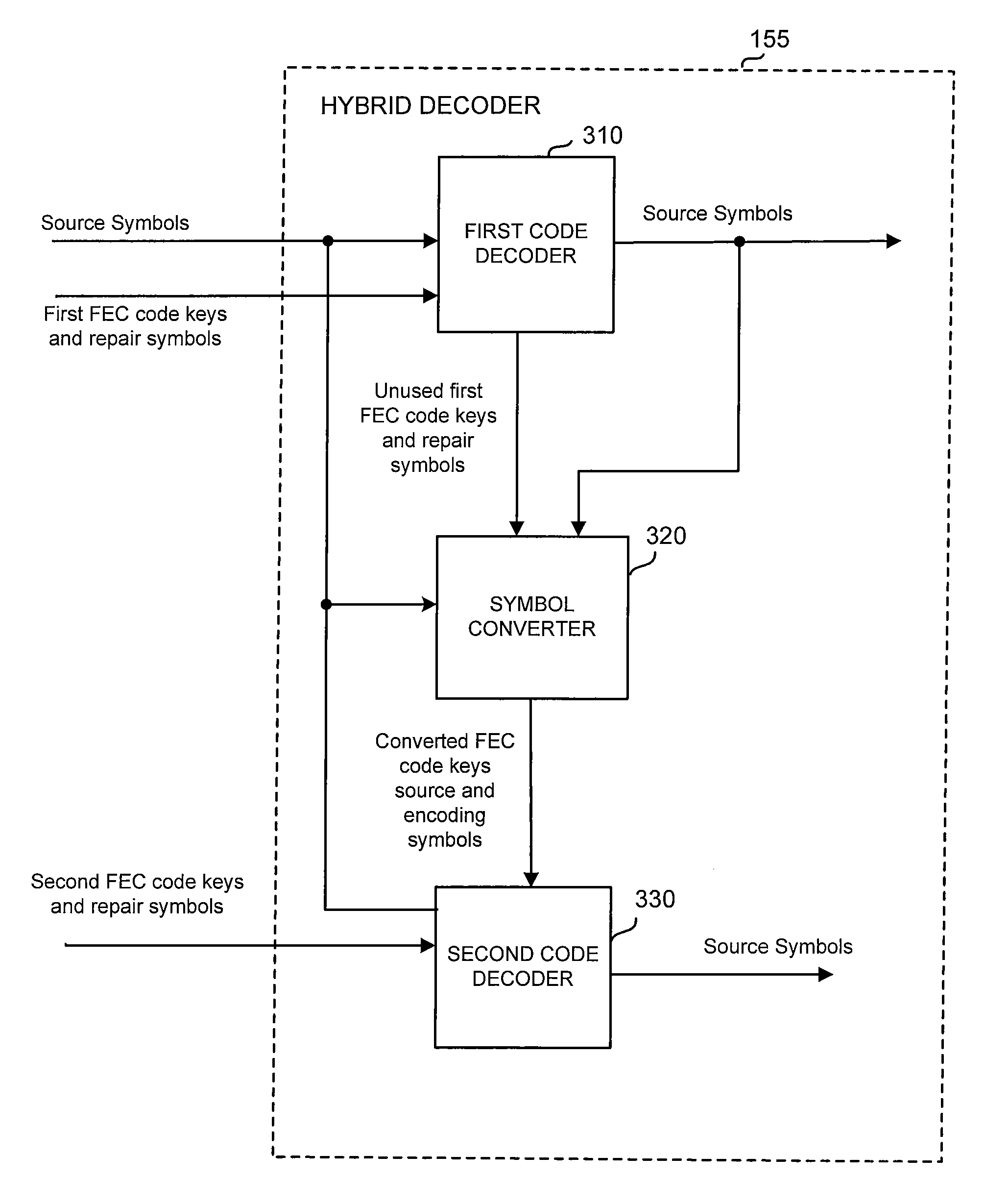

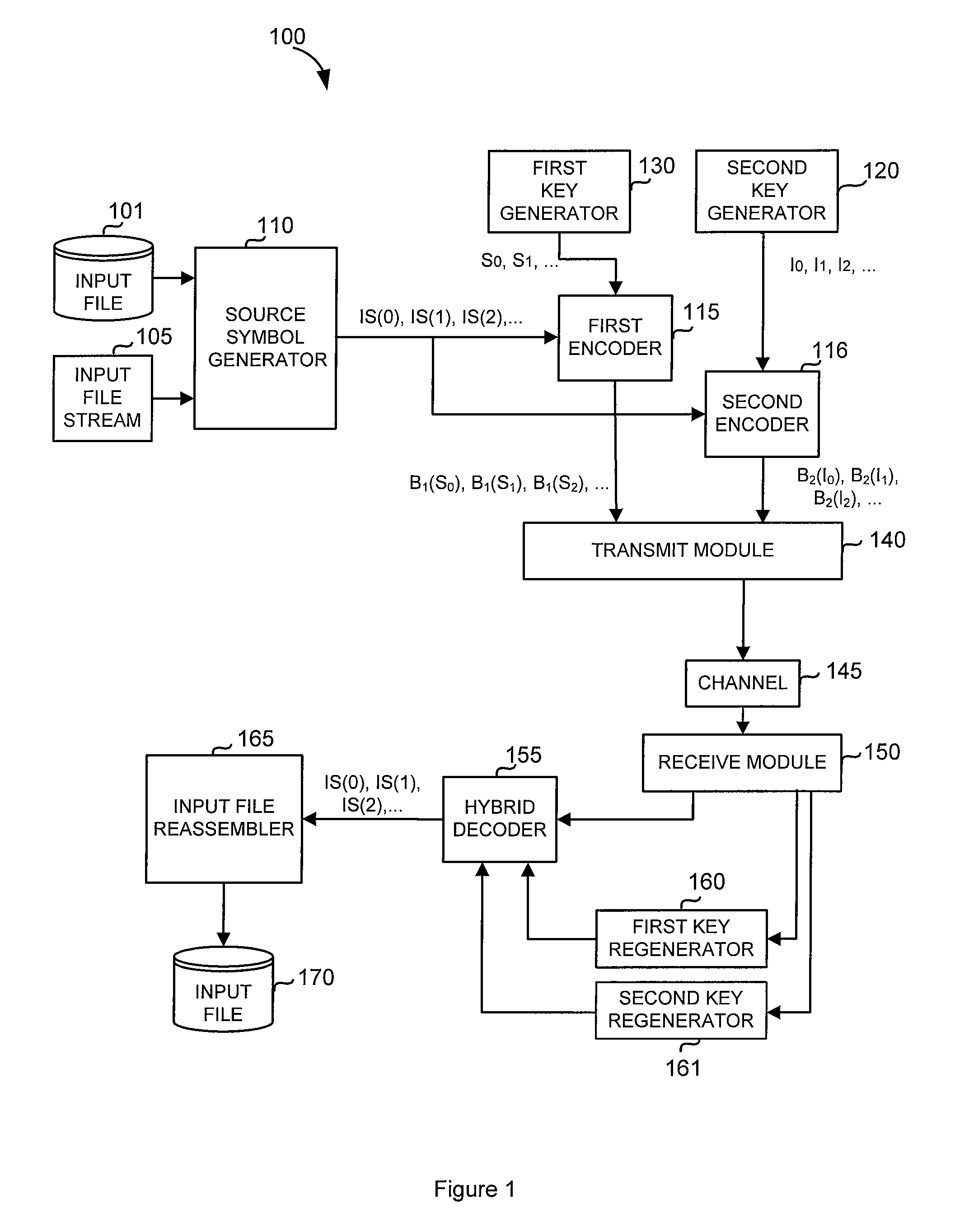

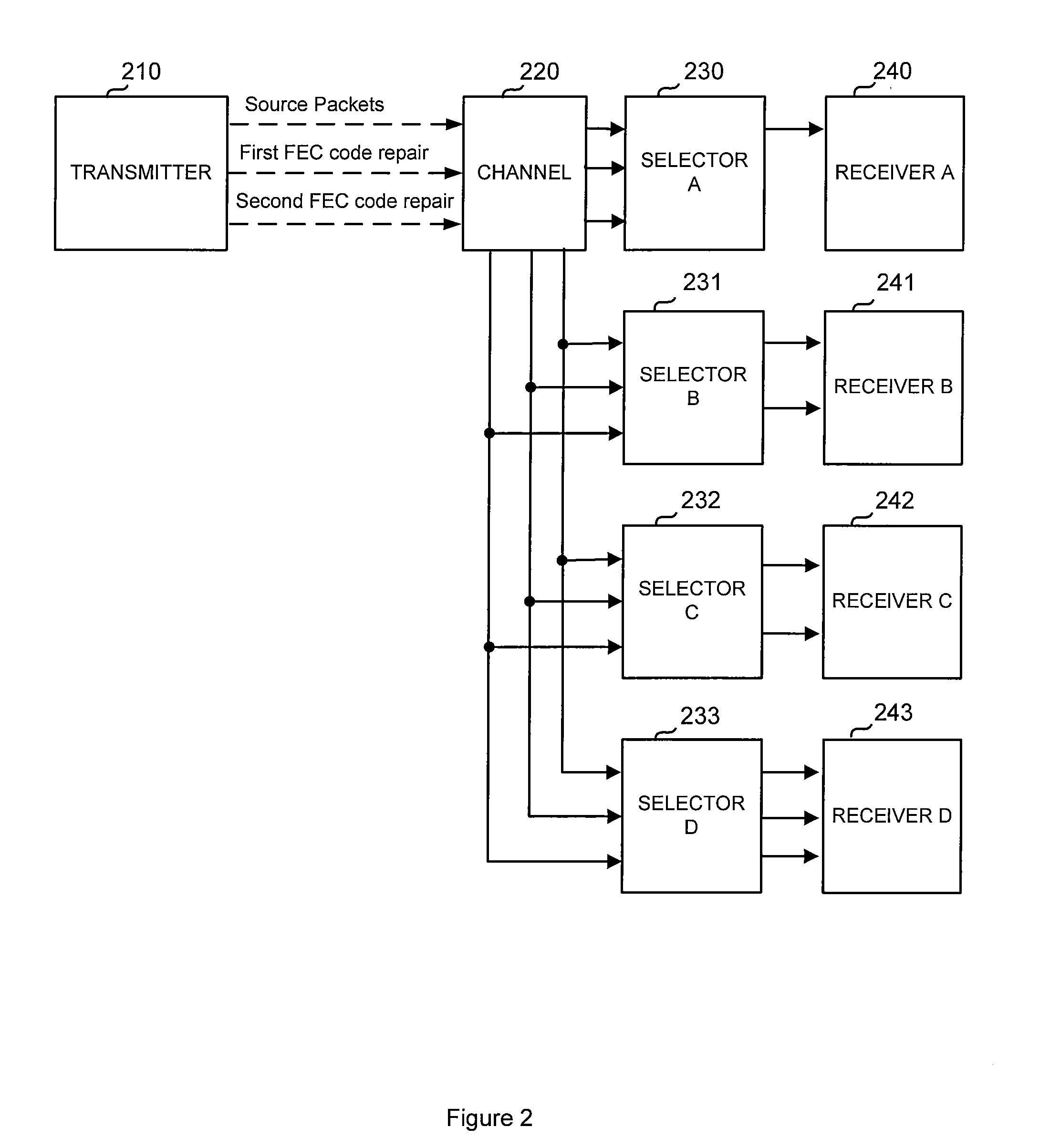

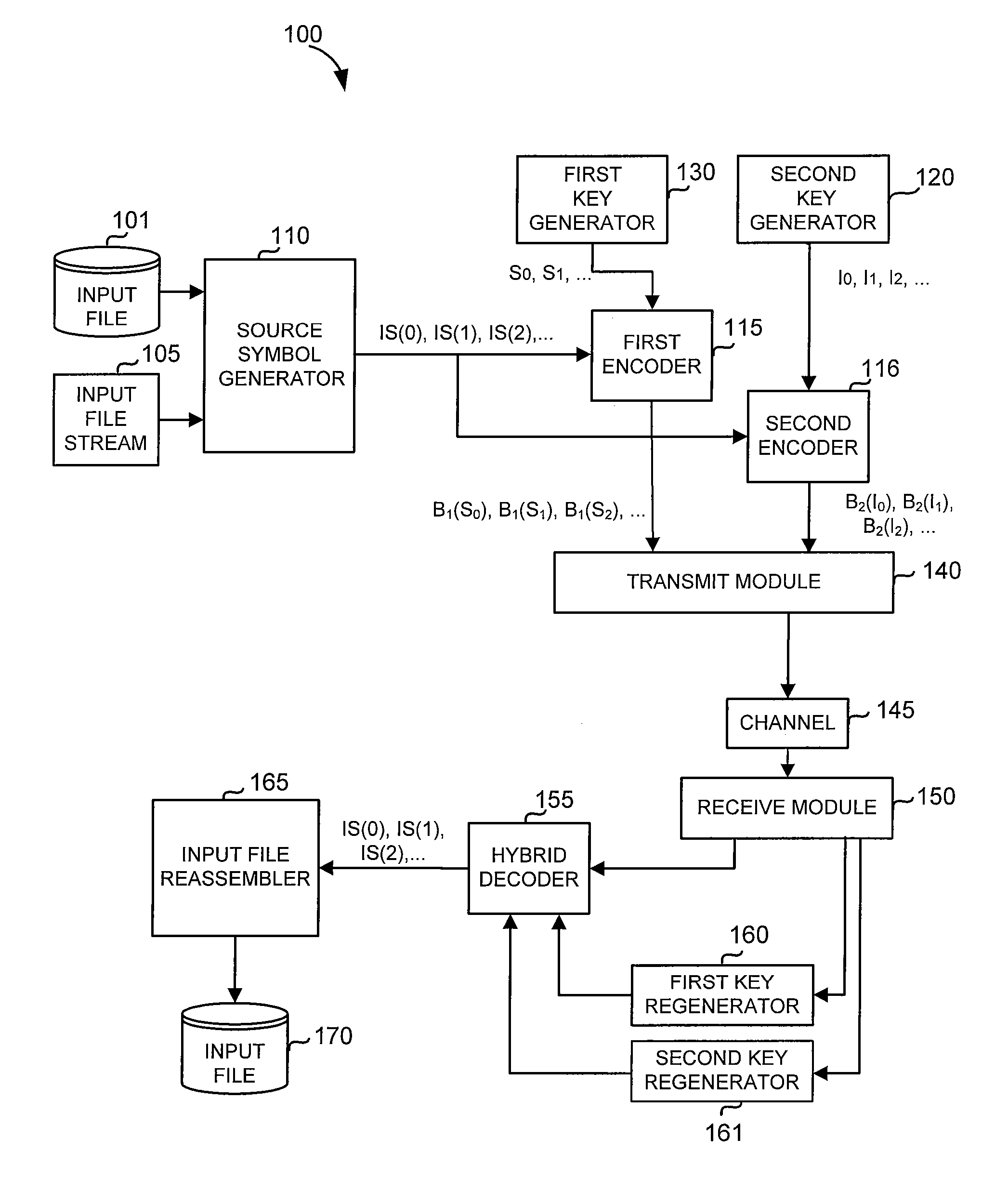

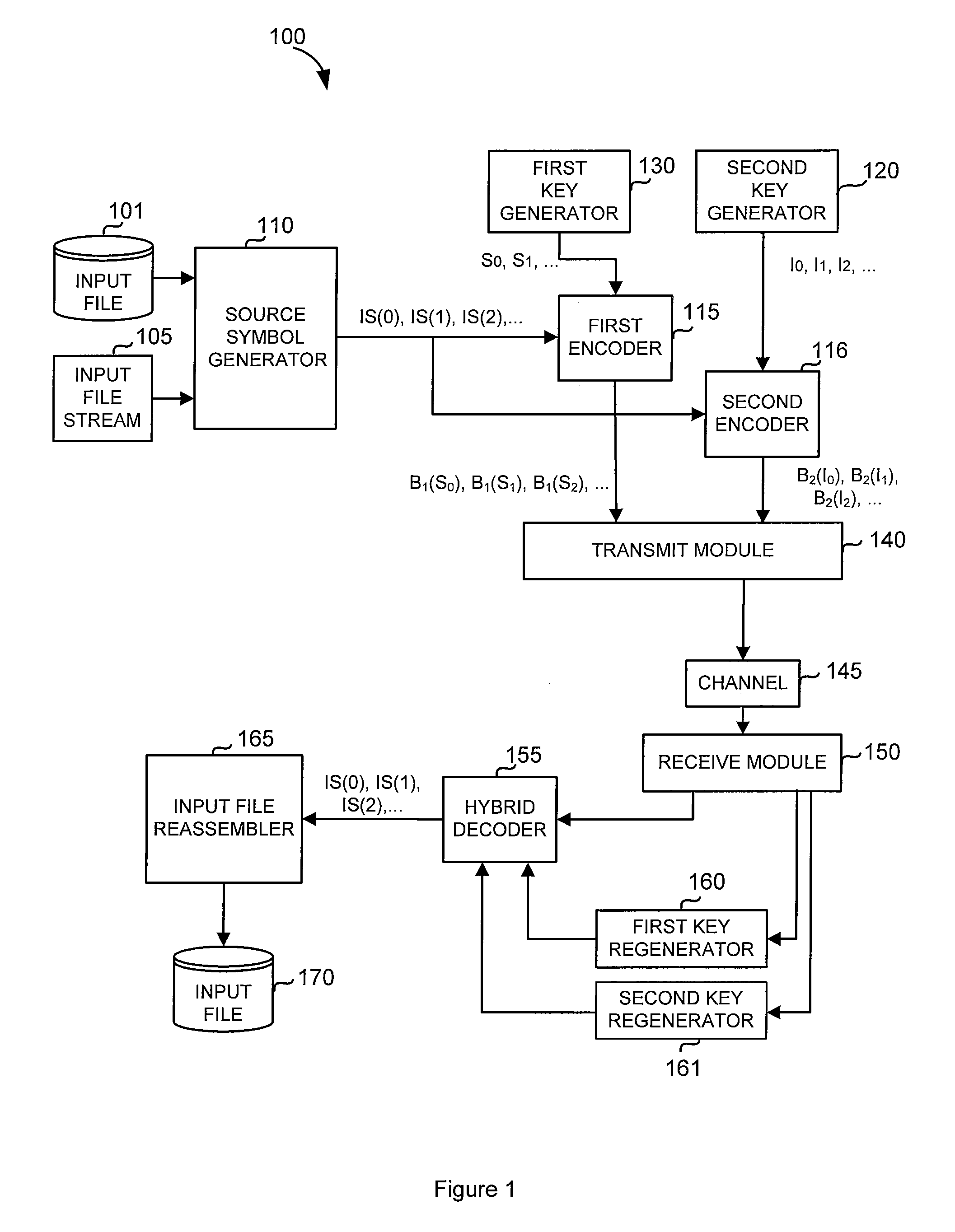

Code generator and decoder for communications systems operating using hybrid codes to allow for multiple efficient users of the communications systems

InactiveUS7971129B2Error protectionImprove errorData representation error detection/correctionError preventionComputer hardwareCommunications system

Owner:QUALCOMM INC

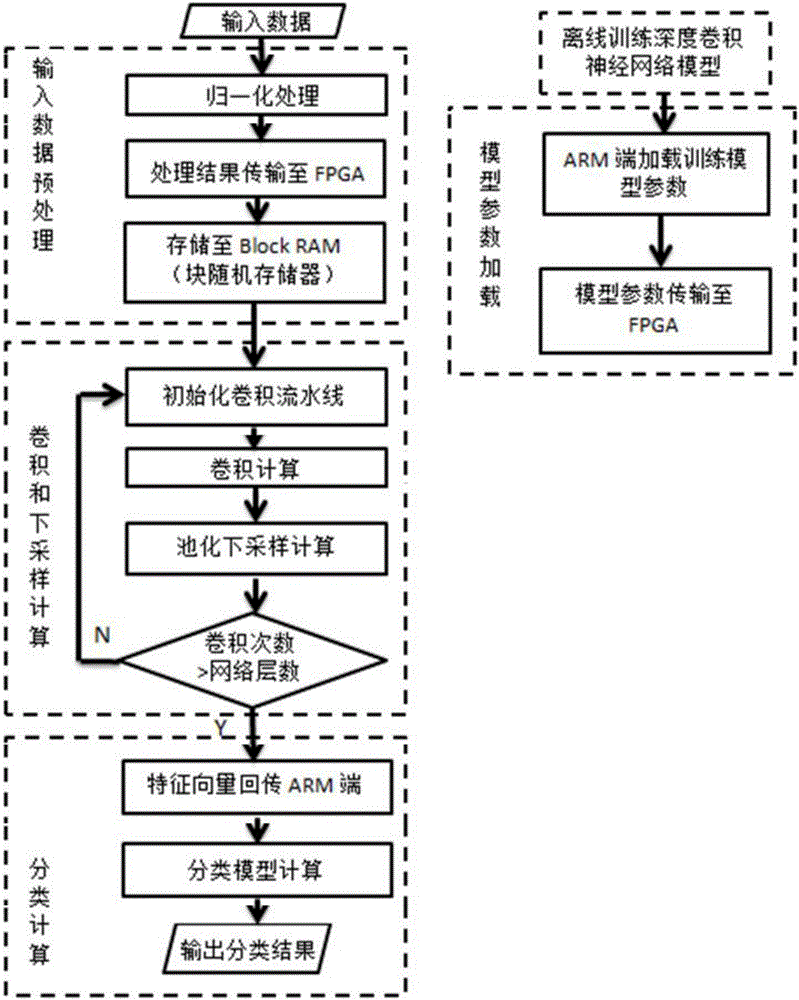

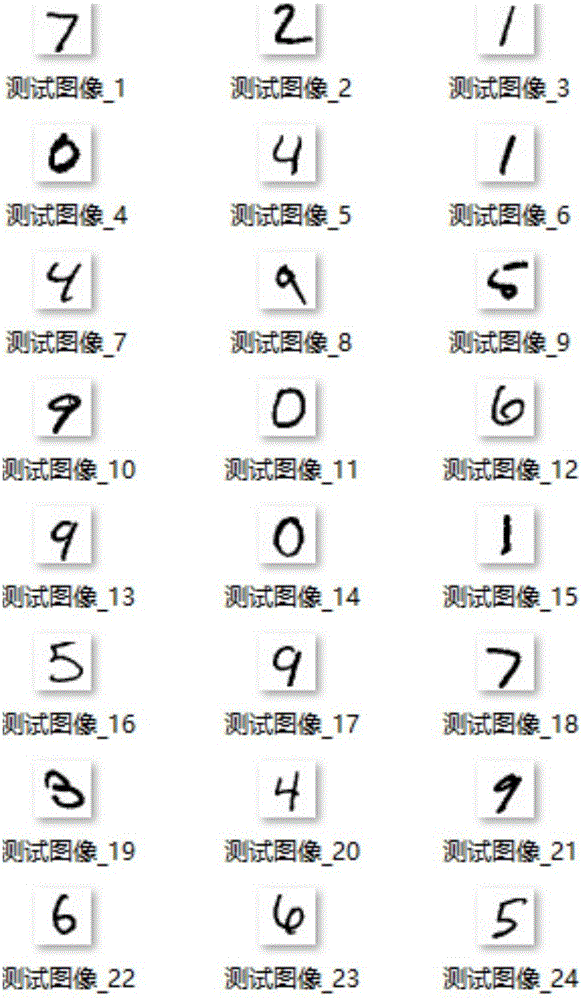

FPGA-based deep convolution neural network realizing method

ActiveCN106228240ASimple designReduce resource consumptionCharacter and pattern recognitionSpeech recognitionFeature vectorAlgorithm

The invention belongs to the technical field of digital image processing and mode identification, and specifically relates to an FPGA-based deep convolution neural network realizing method. The hardware platform for realizing the method is XilinxZYNQ-7030 programmable sheet SoC, and an FPGA and an ARM Cortex A9 processor are built in the hardware platform. Trained network model parameters are loaded to an FPGA end, pretreatment for input data is conducted at an ARM end, and the result is transmitted to the FPGA end. Convolution calculation and down-sampling of a deep convolution neural network are realized at the FPGA end to form data characteristic vectors and transmit the data characteristic vectors to the ARM end, thus completing characteristic classification calculation. Rapid parallel processing and extremely low-power high-performance calculation characteristics of FPGA are utilized to realize convolution calculation which has the highest complexity in a deep convolution neural network model. The algorithm efficiency is greatly improved, and the power consumption is reduced while ensuring algorithm correct rate.

Owner:FUDAN UNIV

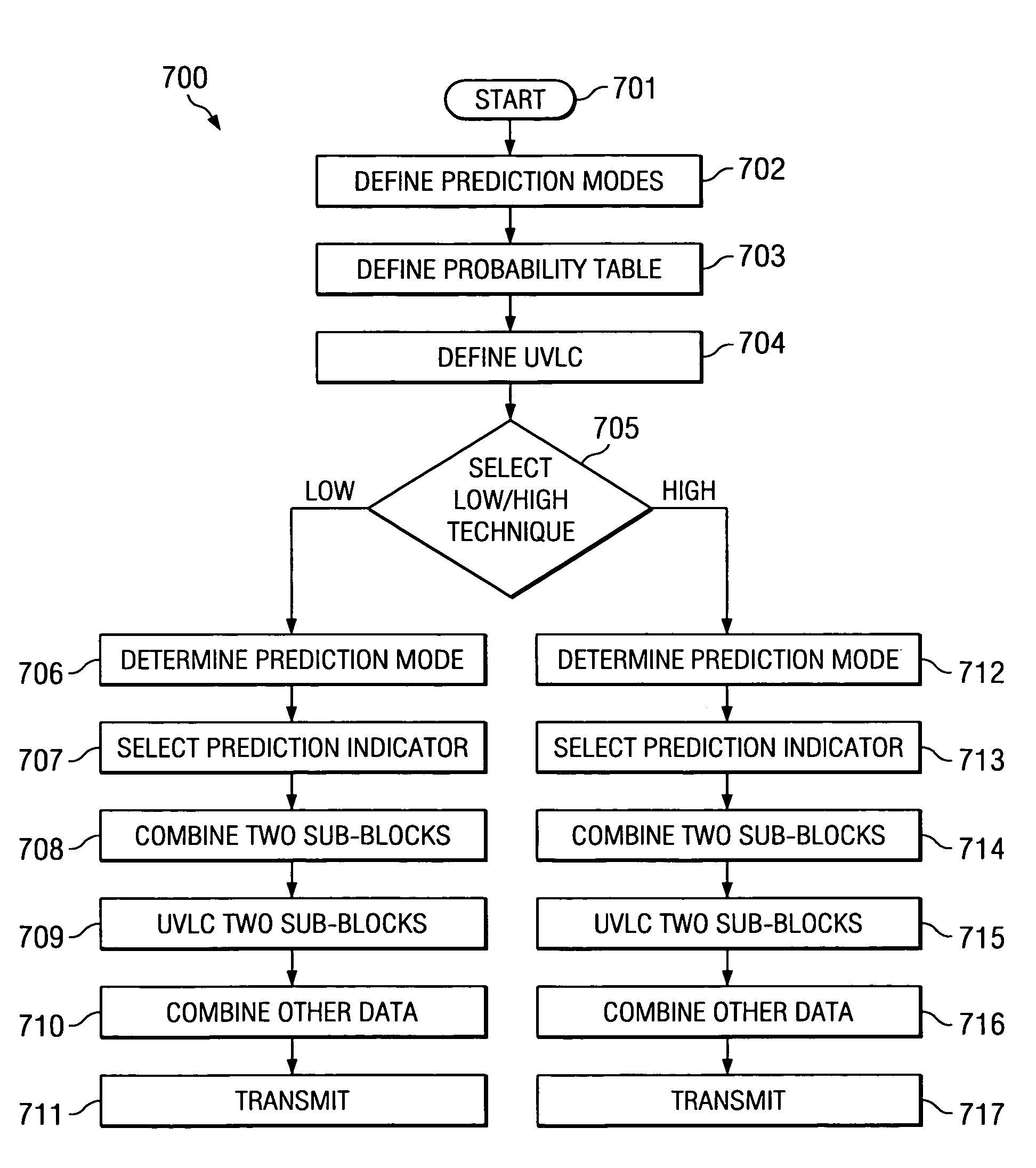

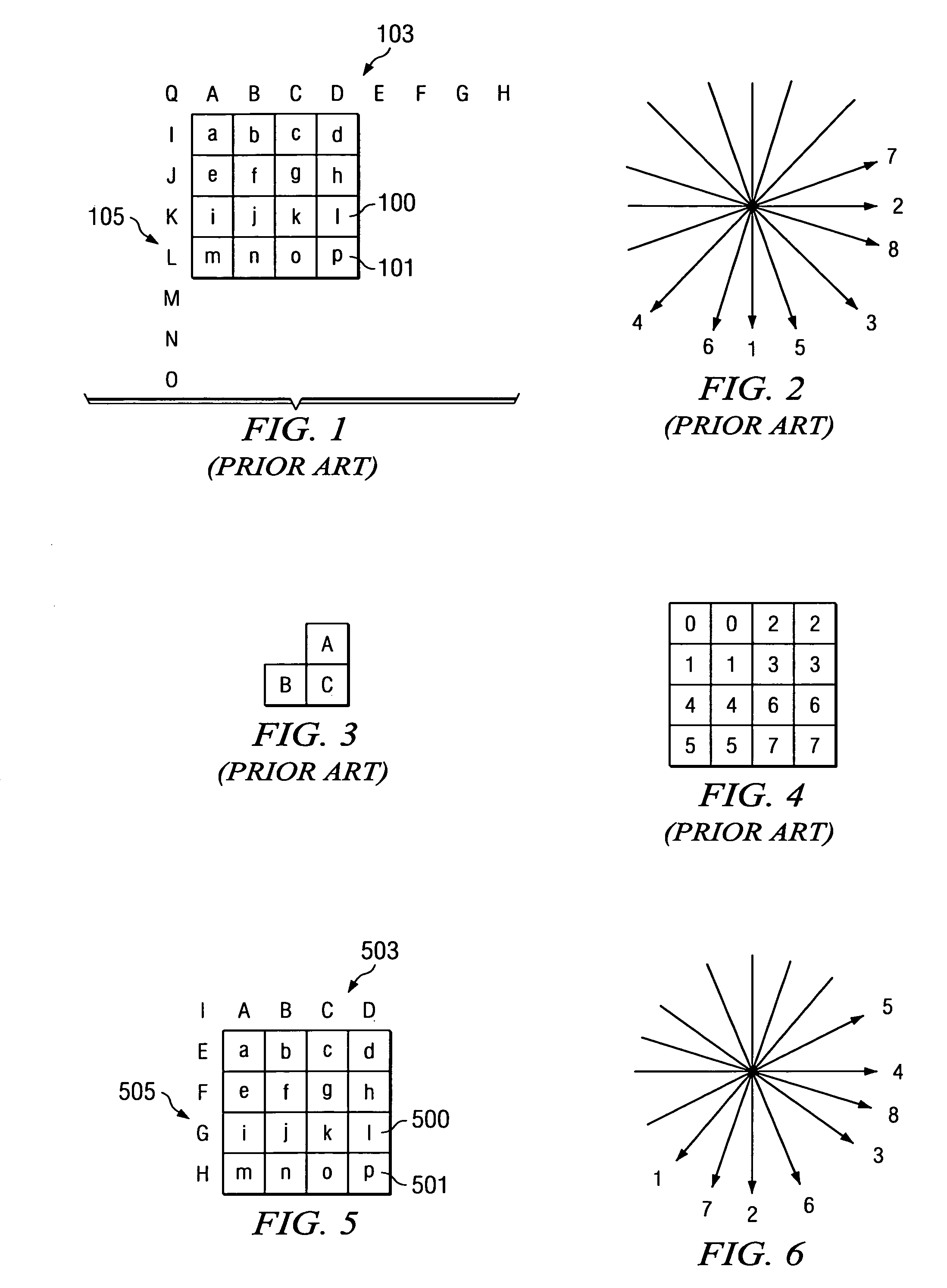

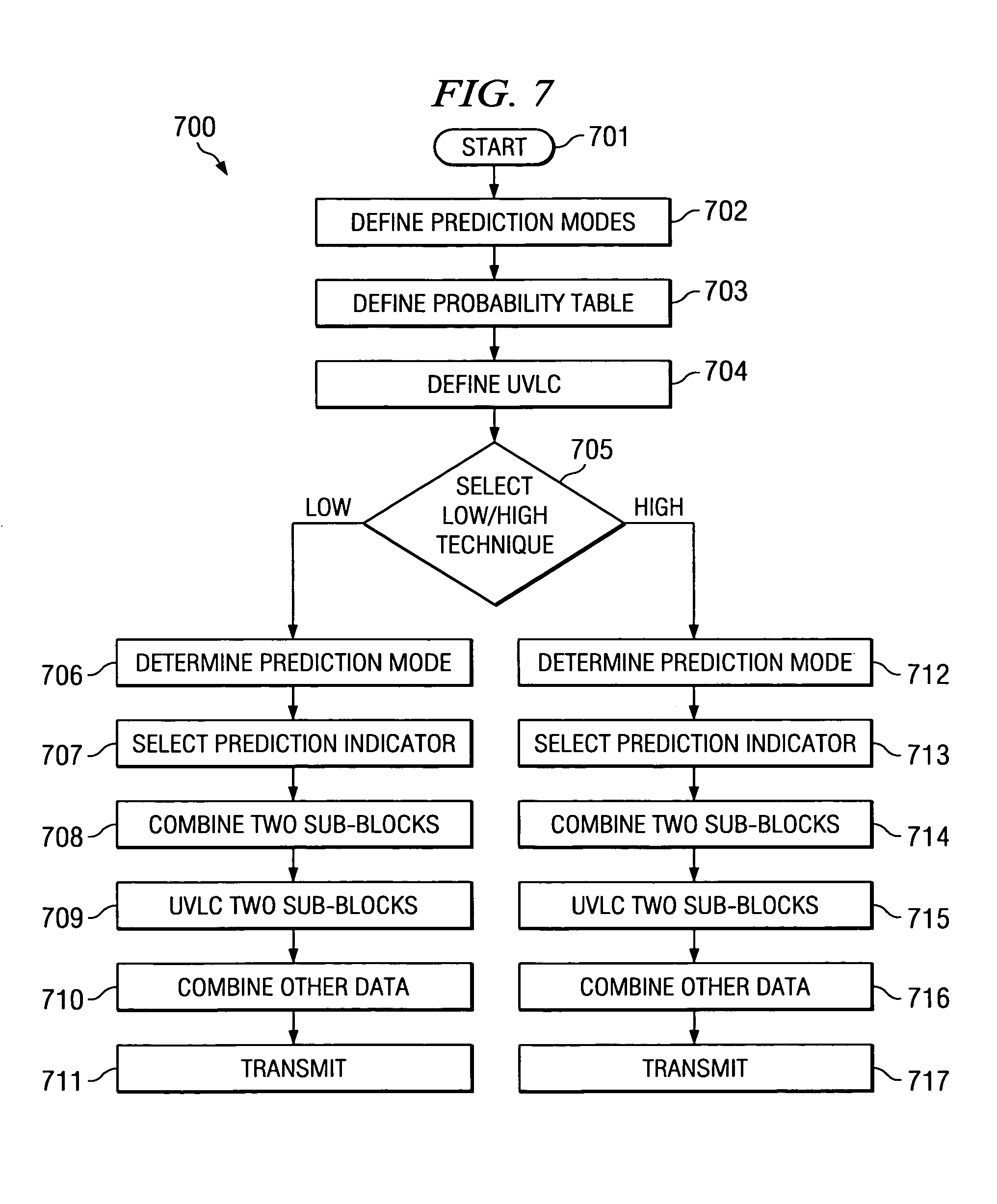

Complexity-scalable intra-frame prediction technique

ActiveUS7170937B2Color television with pulse code modulationColor television with bandwidth reductionTheoretical computer scienceIntra-frame

This invention is a method of encoding intra frames when encoding a motion picture. A set of intra frame prediction modes includes a low-complexity subset. A probability table relates the prediction mode of adjacent sub-blocks to the prediction mode of the current sub-block. For each combination of adjacent sub-blocks, the probability table includes a list of prediction modes in order of expected occurrence. The probability table is adjusted so that each list for prediction modes within the low-complexity subset include initial prediction modes of the low-complexity subset. Individual sub-blocks of intra frames are predictively coded in a low-complexity encoding the using the low-complexity subset or in a high-complexity encoding using any prediction mode. This permits a low-complexity decoder responsive to only the low-complexity subset.

Owner:TEXAS INSTR INC

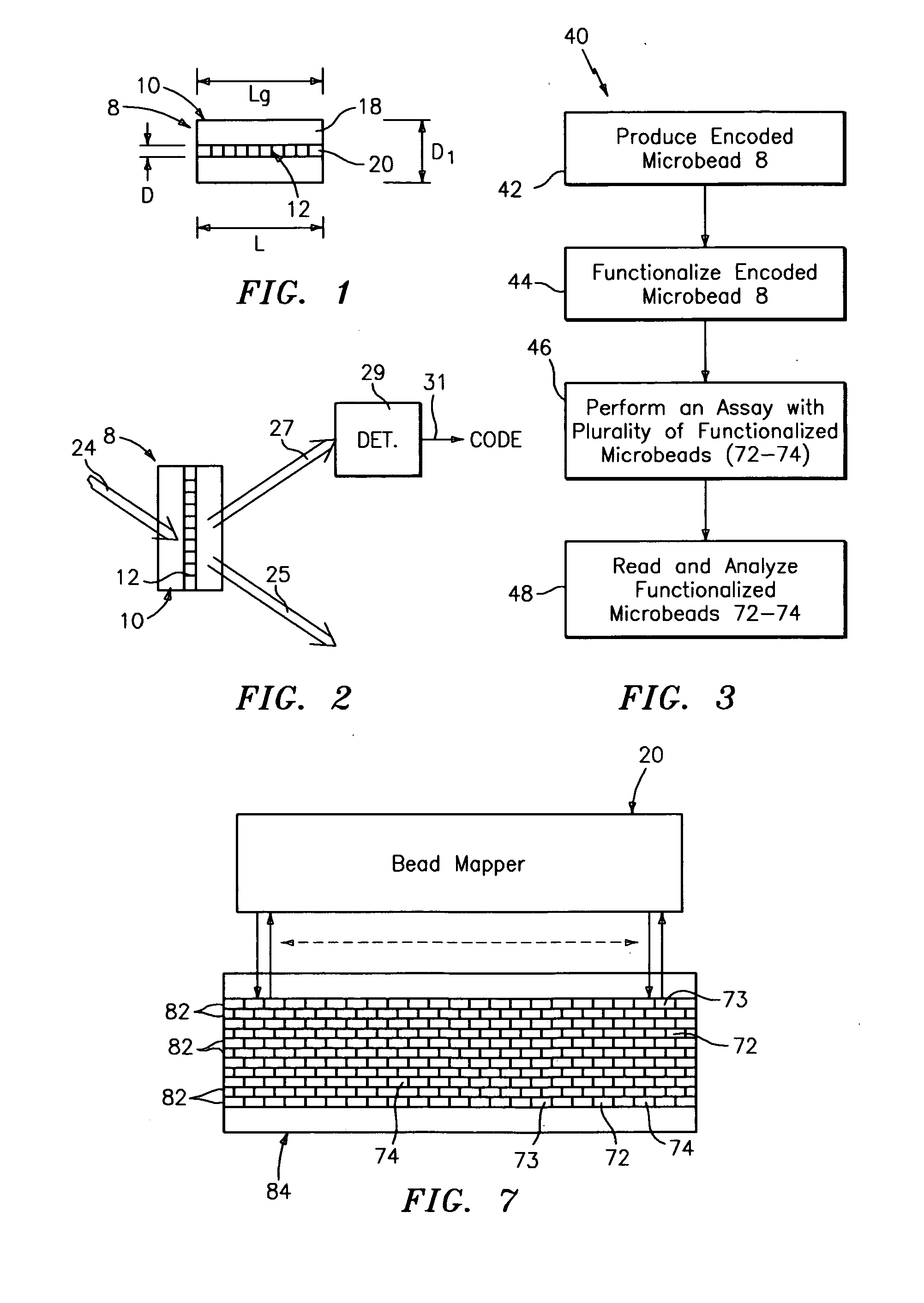

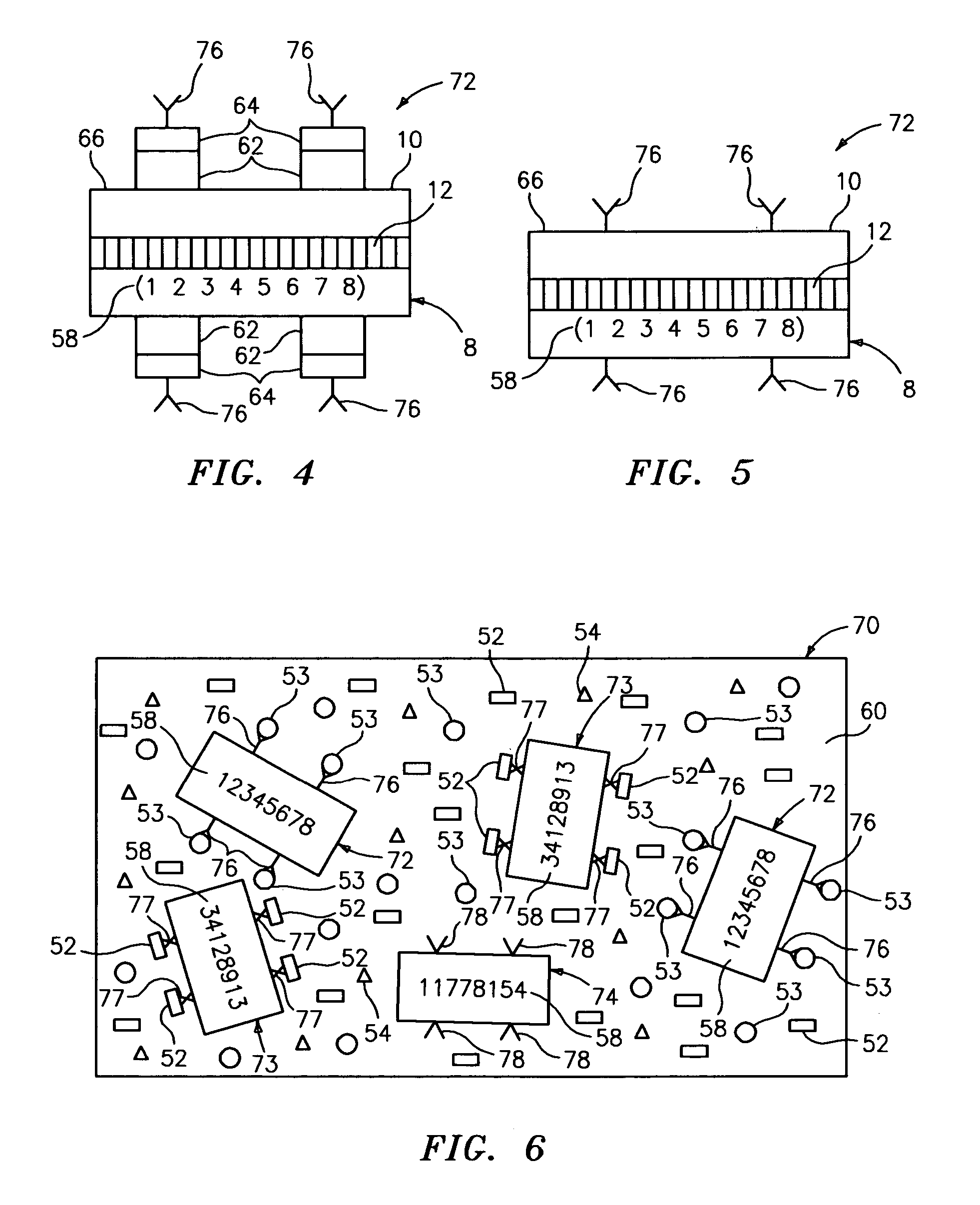

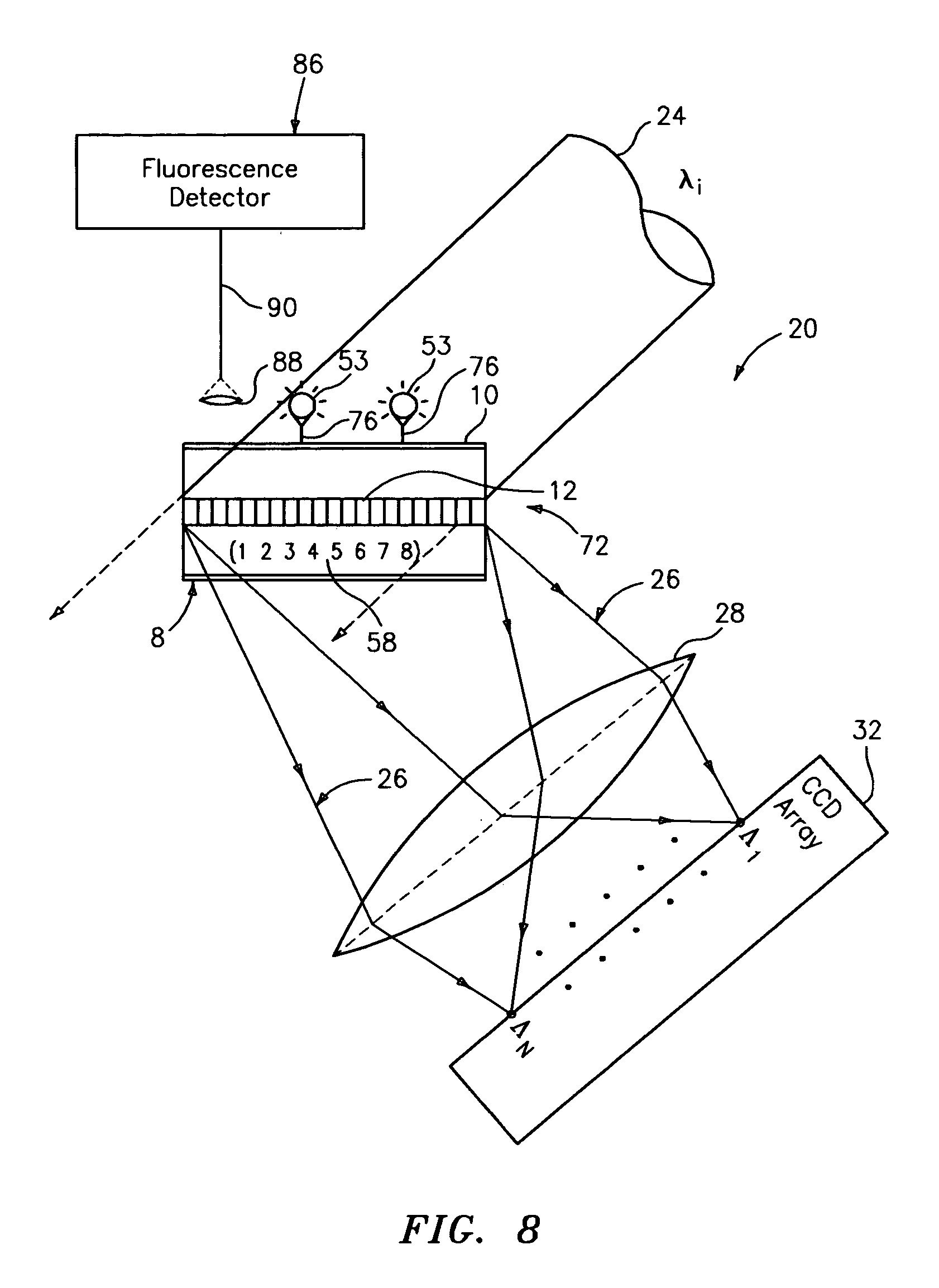

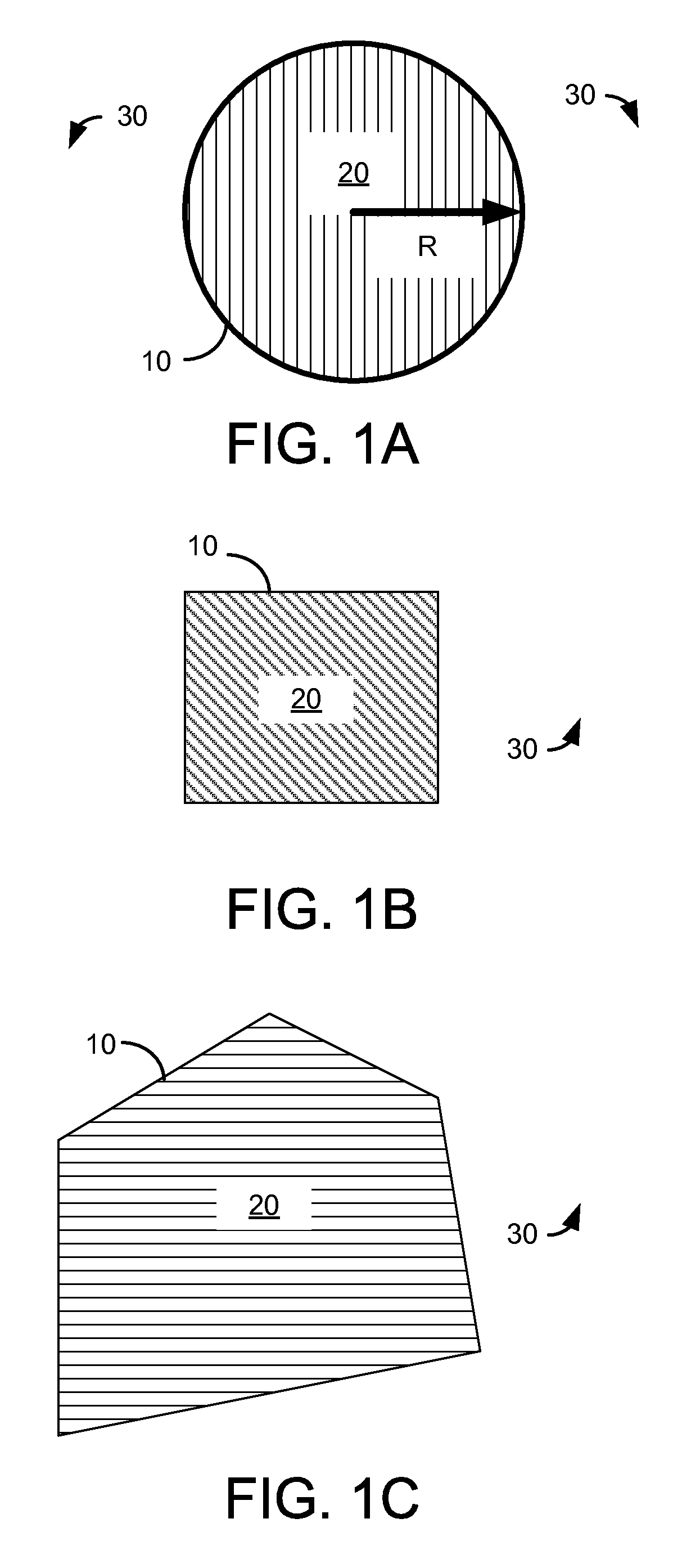

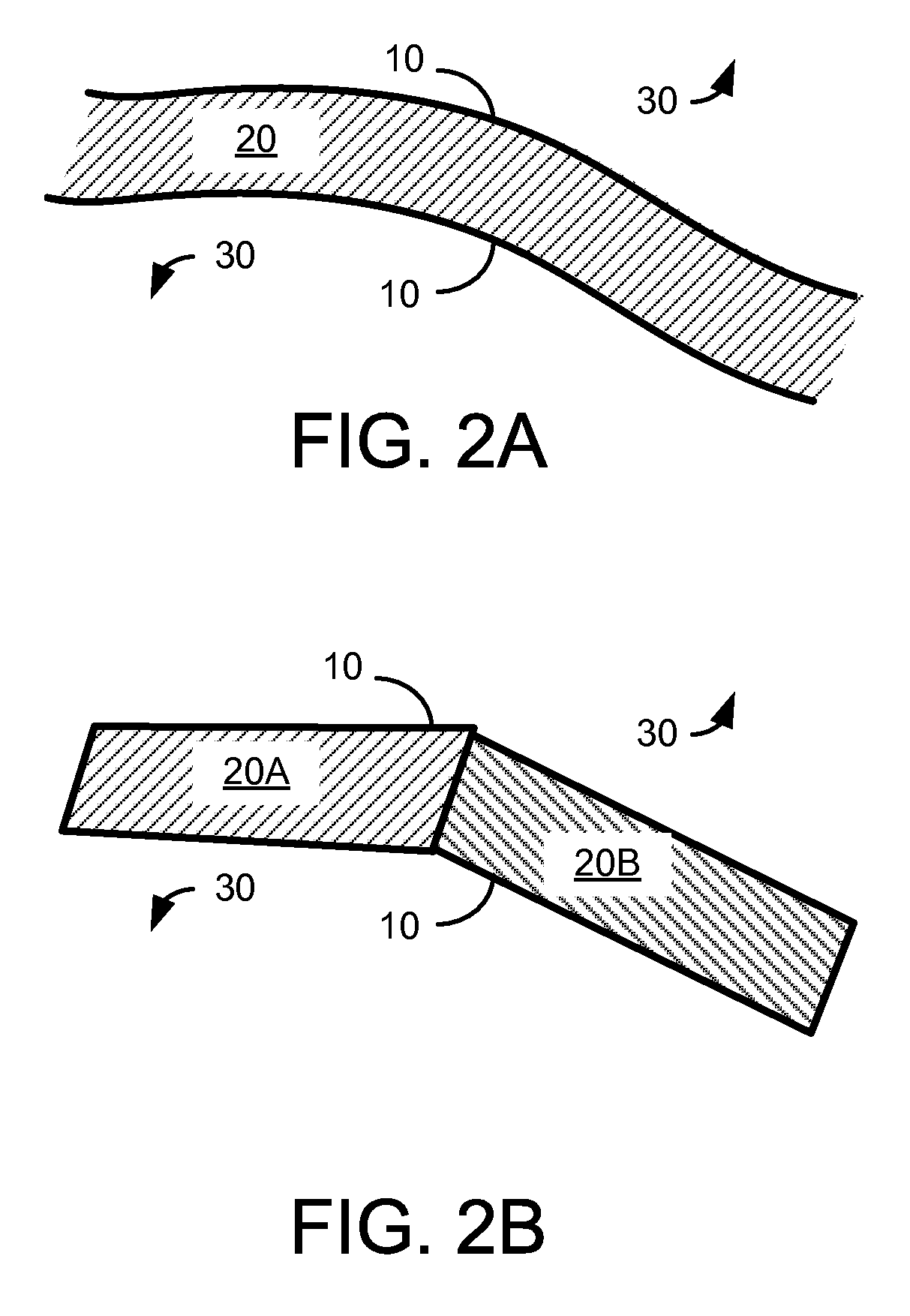

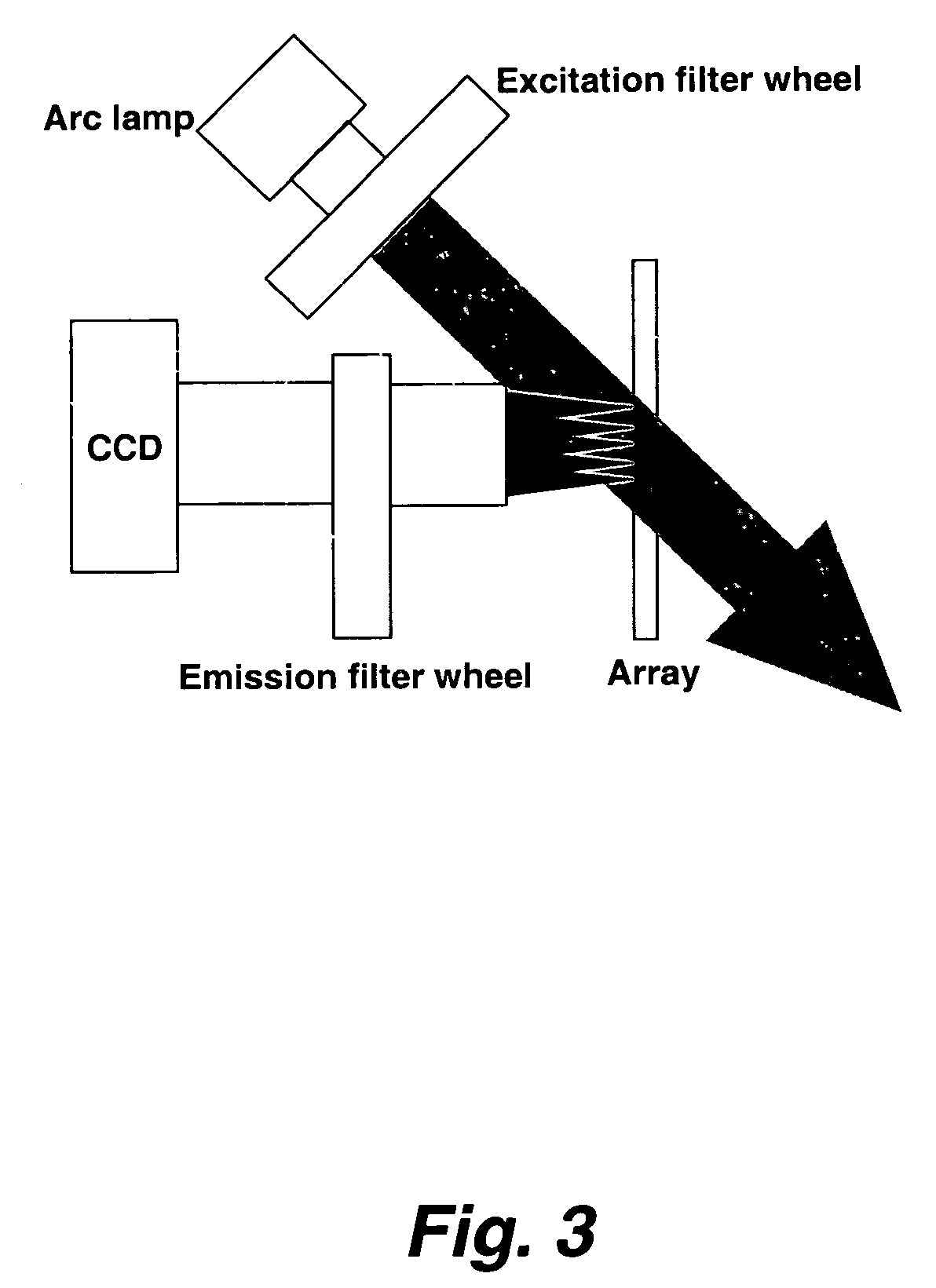

Diffraction grating-based encoded articles for multiplexed experiments

InactiveUS20050227252A1Easy to useBioreactor/fermenter combinationsBiological substance pretreatmentsMultiplexingAnalyte

The present invention provides methods and compositions directed toward assays of a broad range of analytes using specific targeting chemicals that bind to the analytes. The assays are founded on the use of coded assay articles to which the targeting chemicals are attached. Additionally the codes are such that they are interrogated and determined in real time. The target is analyzed as to identity, presence and quantity in real time. The methods and compositions of the invention are highly suitable for use in high-complexity multiplexed assay systems. All the methods and compositions are based on assay article that includes an optical substrate to which the chemical is bound, and in which is disposed at least one diffraction grating. The grating provides an output optical signal when illuminated by an incident light signal which is indicative of the code in the substrate. In general, coded assay article or sets thereof are employed in assay methods, including multiplexed assay methods, according to which a sample is contacted with an article or a set, and any analytes that bind to the attached chemical are identified according to the code, detected and / or quantitated.

Owner:ILLUMINA INC

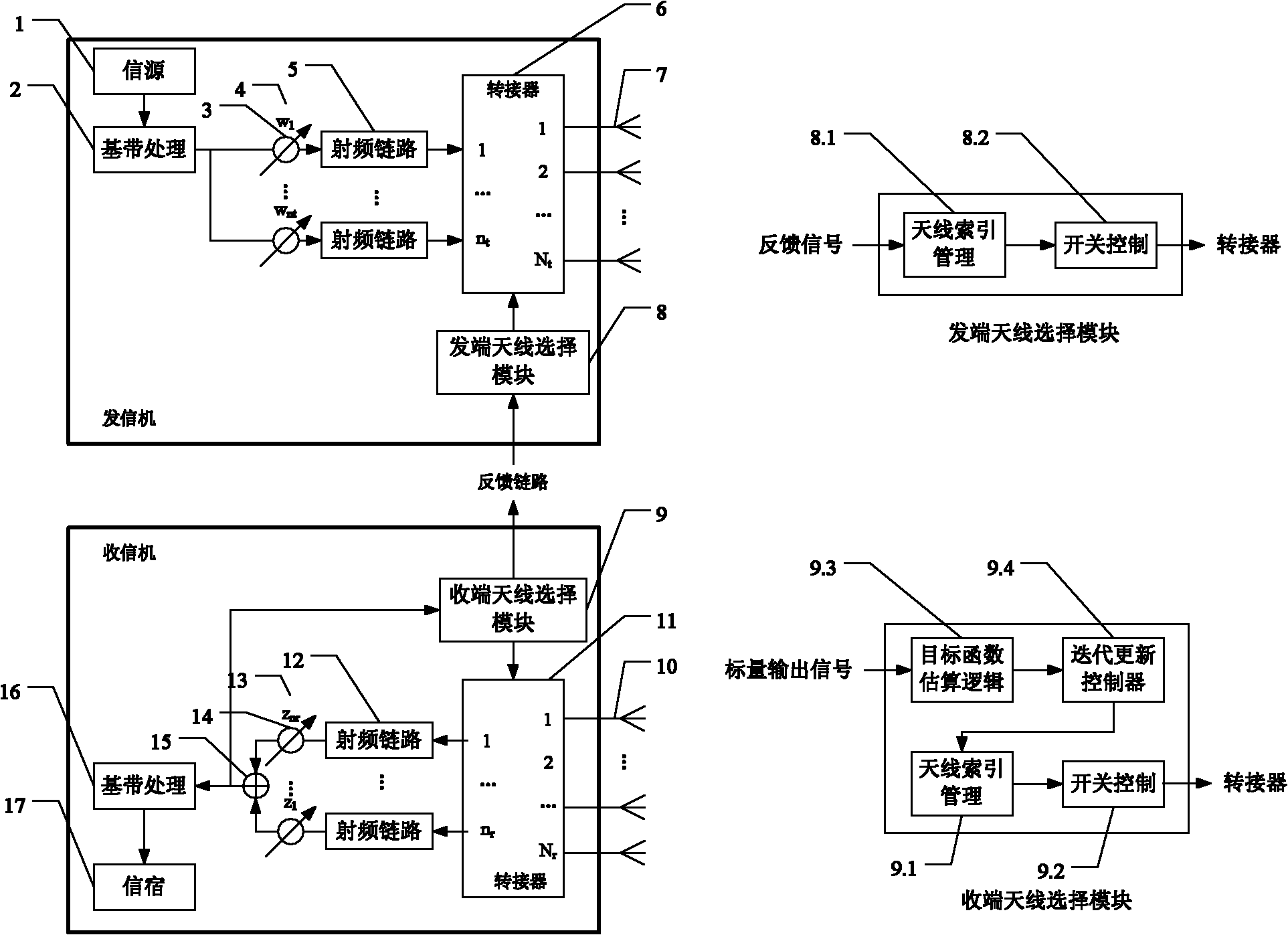

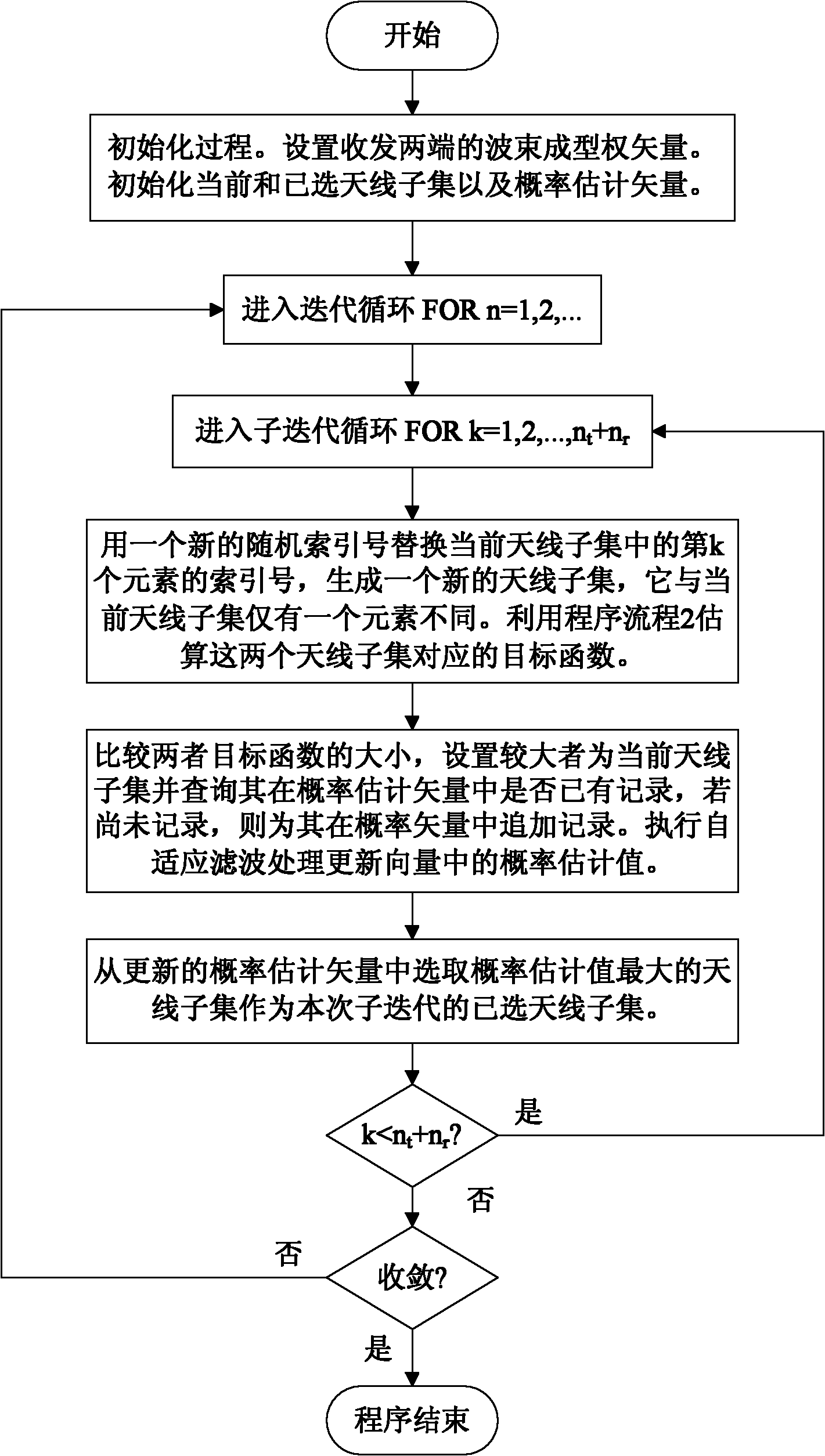

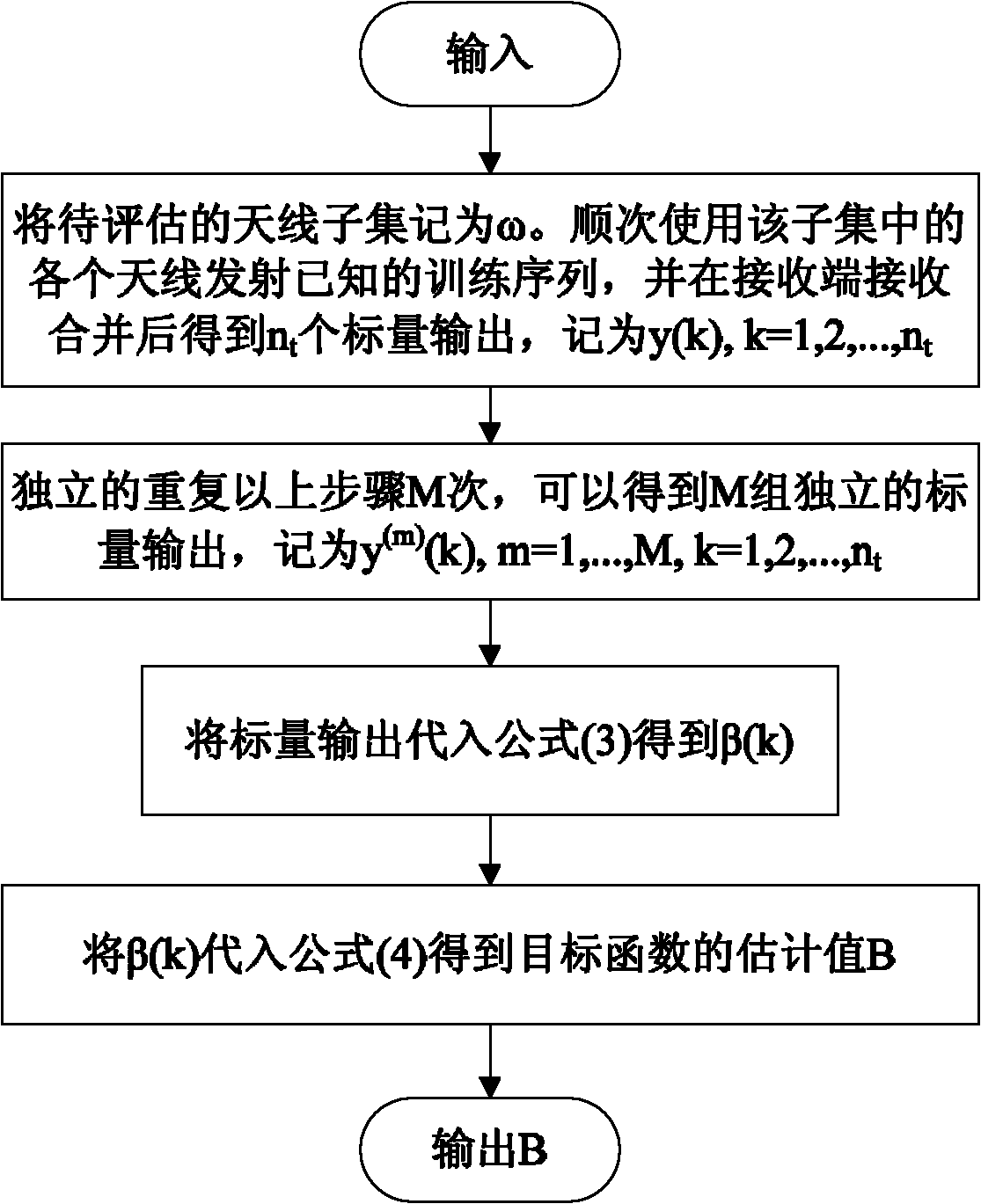

MIMO system and application method thereof for adaptive antenna selection

InactiveCN101867402AReduce complexitySpatial transmit diversityError prevention/detection by diversity receptionData transmissionSelf adaptive

The invention discloses an MIMO system and an application method thereof for adaptive antenna selection. The MIMO system comprises a transmitter, a receiver and a wireless channel; the process of the antenna selection which is realized in the MIMO system adopts an iterative feedback structure; a subset is selected quickly from a large amount of antenna sets by using the characteristic of 60 GHz channel without accurate channel estimation, so that a subchannel corresponding to an antenna subarray is optimal in the sense of a defined target function; and high speed data transmission is performed by using the selected optimal antenna subarray. The invention provides the rapid and efficient application method for the MIMO system along with low cost, and solves the technical problems of high complexity and low efficiency of the traditional antenna selection method in the large-scale the MIMO system. An experiment proves that: the adopted method can obtain good performance only through several iterations and low computational complexity; and the system can better support the application of the large-scale the antenna array.

Owner:XI AN JIAOTONG UNIV

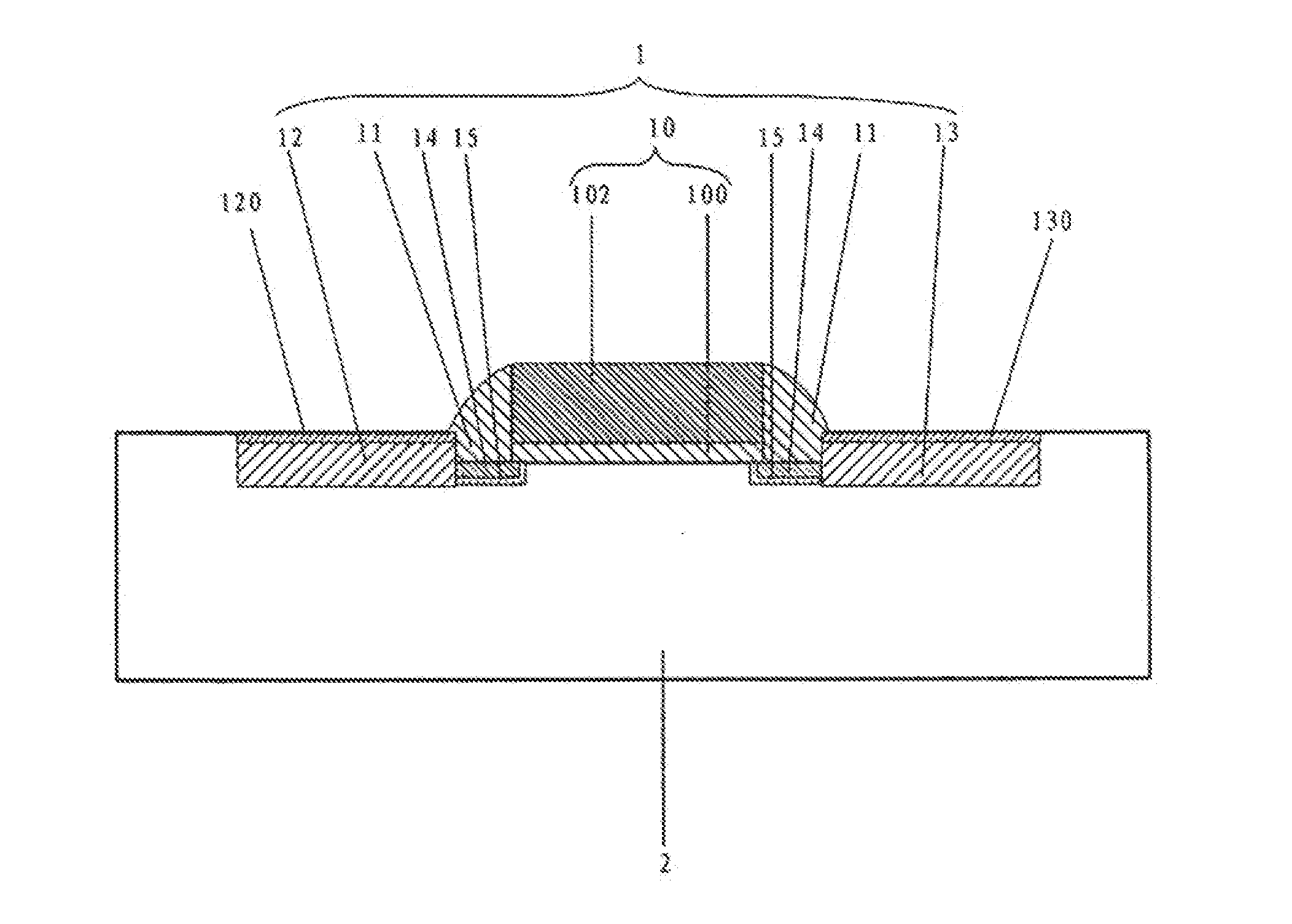

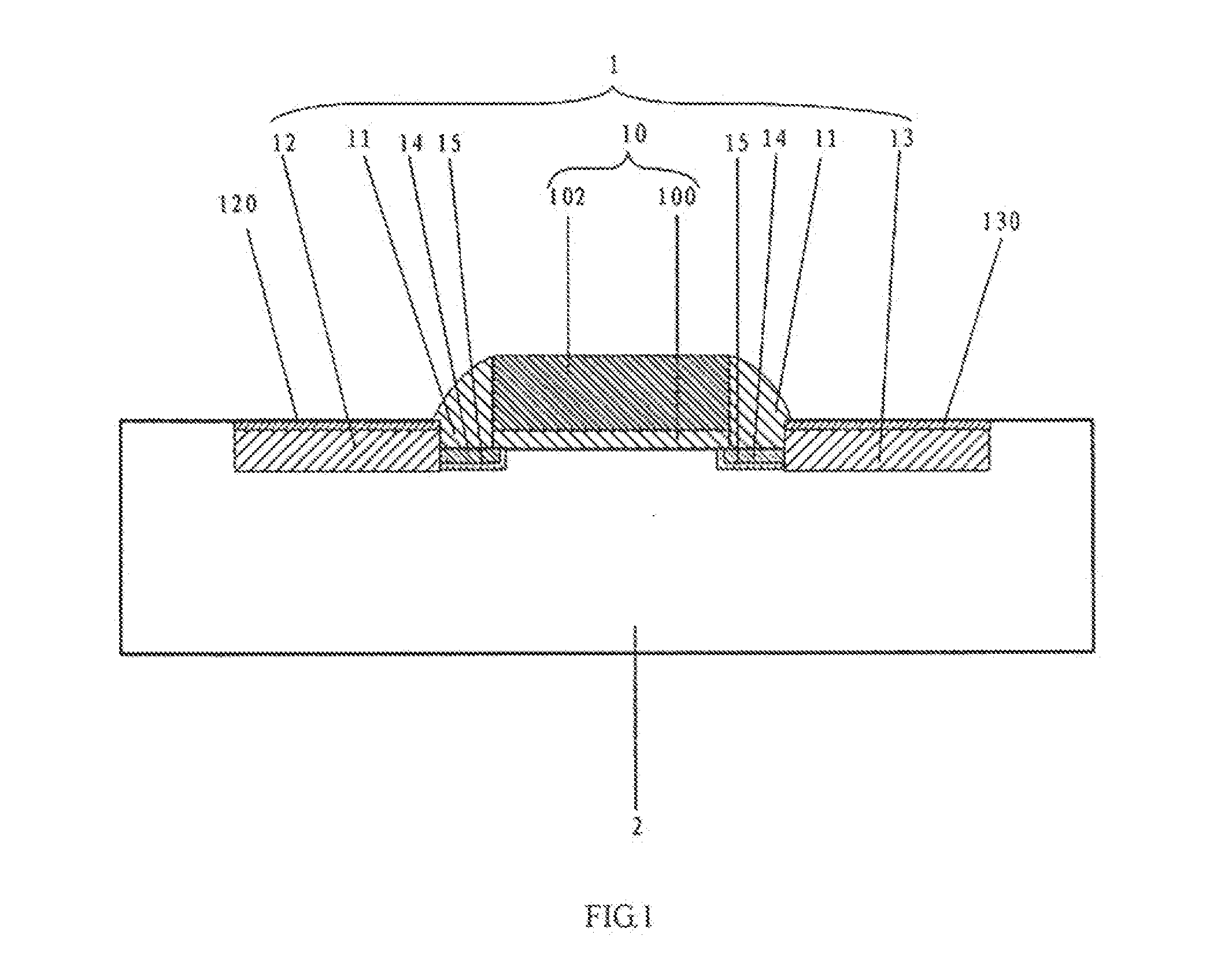

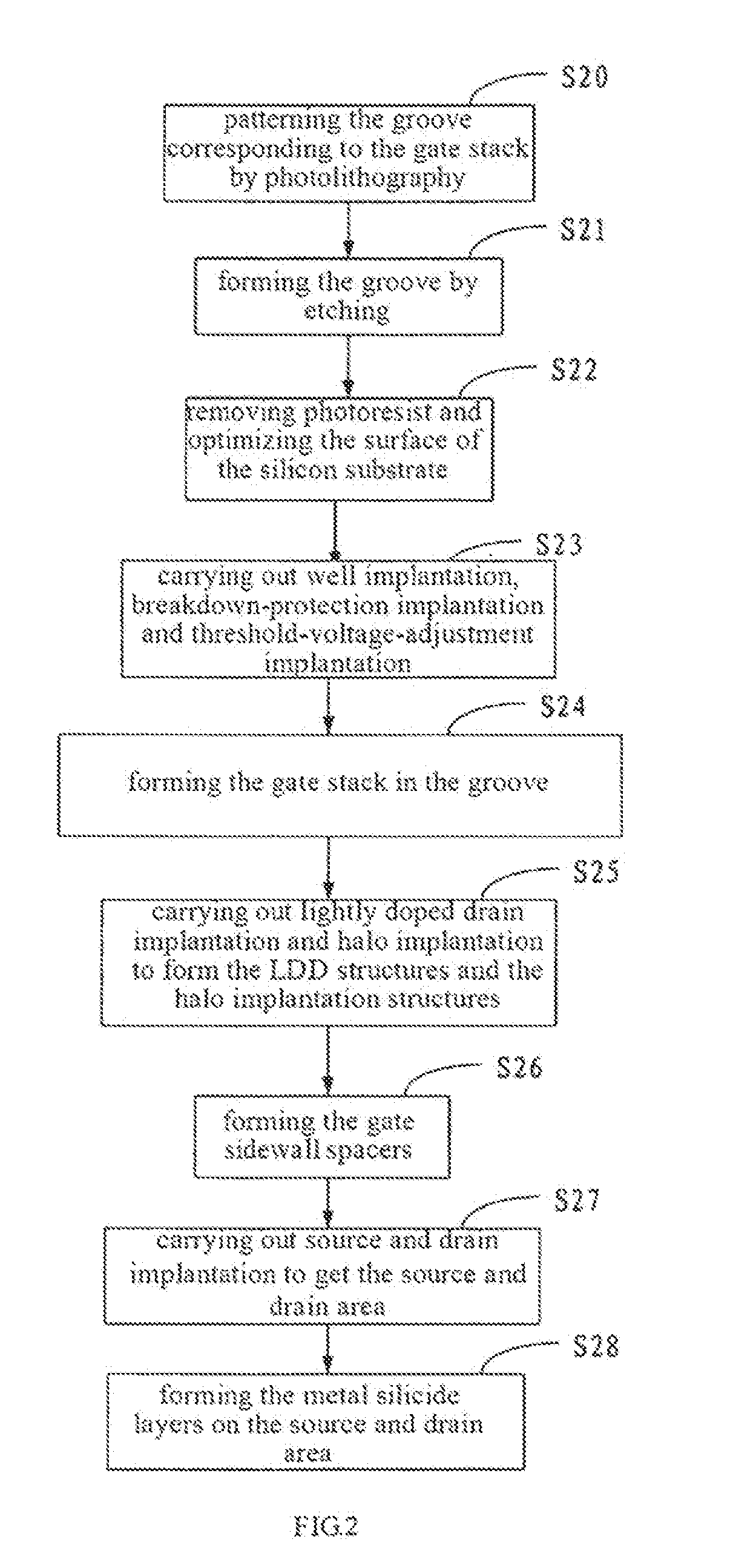

Mos transistor for reducing short-channel effects and its production

ActiveUS20110059588A1Suppression of short channel effectsReduce impactSemiconductor/solid-state device manufacturingSemiconductor devicesMetal silicideGate stack

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

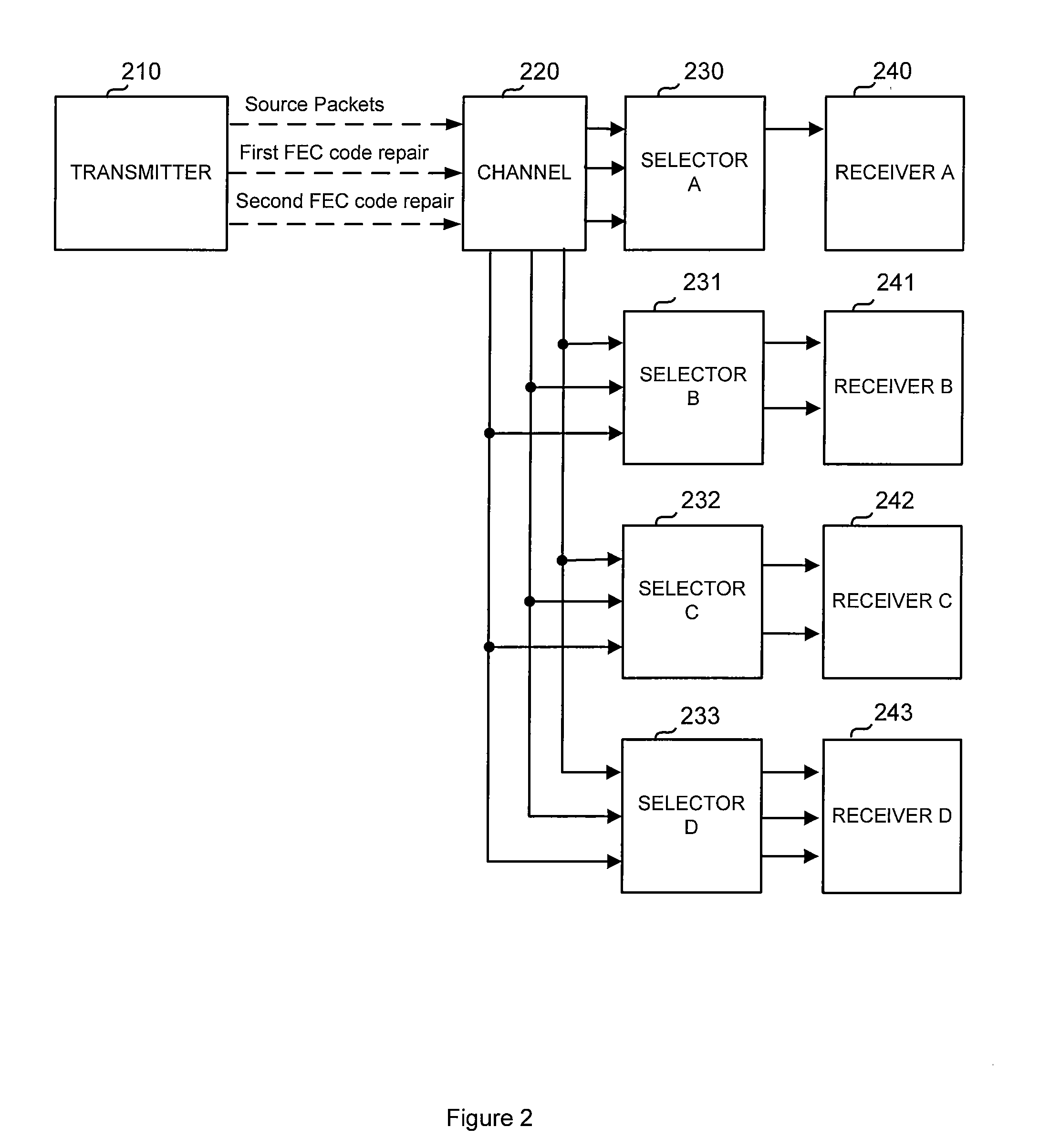

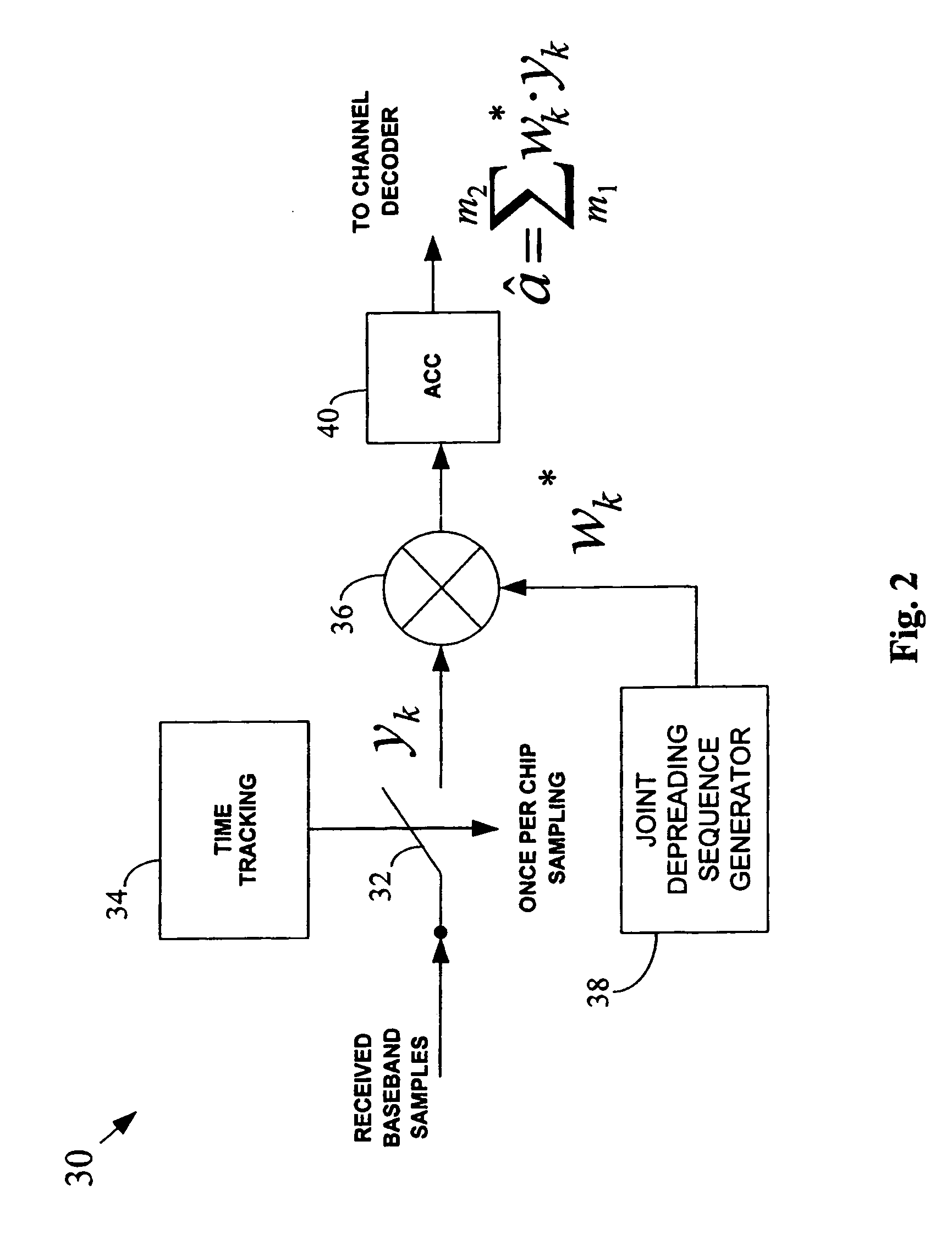

Code generator and decoder for communications systems operating using hybrid codes to allow for multiple efficient users of the communications systems

InactiveUS20070300127A1Error protectionImprove errorError preventionCode conversionComputer hardwareCommunications system

A method of encoding data for transmissions from a source to a destination over a communications channel is provided. The method operates on an ordered set of source symbols and may generate zero or more redundant symbols from the source symbols, wherein data is encoded in a first step according to a simple FEC code and in a second step, data is encoded according to a second FEC code, more complex than the first FEC code. The first FEC code and / or the second FEC code might comprise coding known in the art. These steps result in two groups of encoded data in such a way that a low-complexity receiver may make use of one of the groups of encoded data while higher complexity receivers may make use of both groups of encoded data.

Owner:QUALCOMM INC

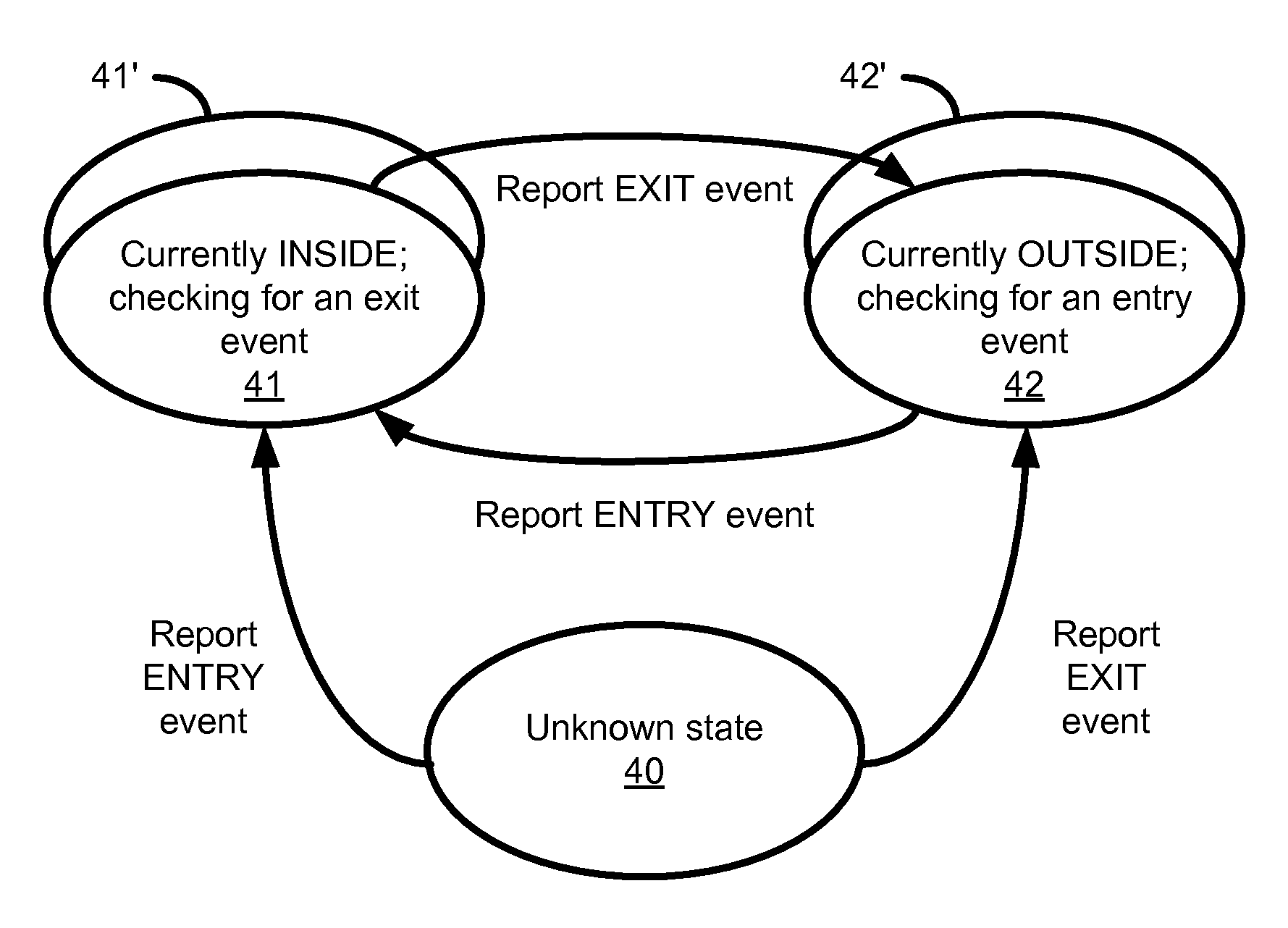

Geographical boundary based tracking

An apparatus, method and system for geographical tracking entry and / or exiting of an asset into and / or out of a defined geographical boundary and reporting the same. Entry and exit tests compare position fixes with various thresholds and parameters to determine if the asset has entered or exited the geographical boundary. Tests are sequenced such that tests having lower levels of complexity (lower order) are performed before tests having higher levels of complexity (higher order). In this way, most position fixes are processed using computations having a lower order of mathematical complexity than conventionally implemented.

Owner:QUALCOMM INC

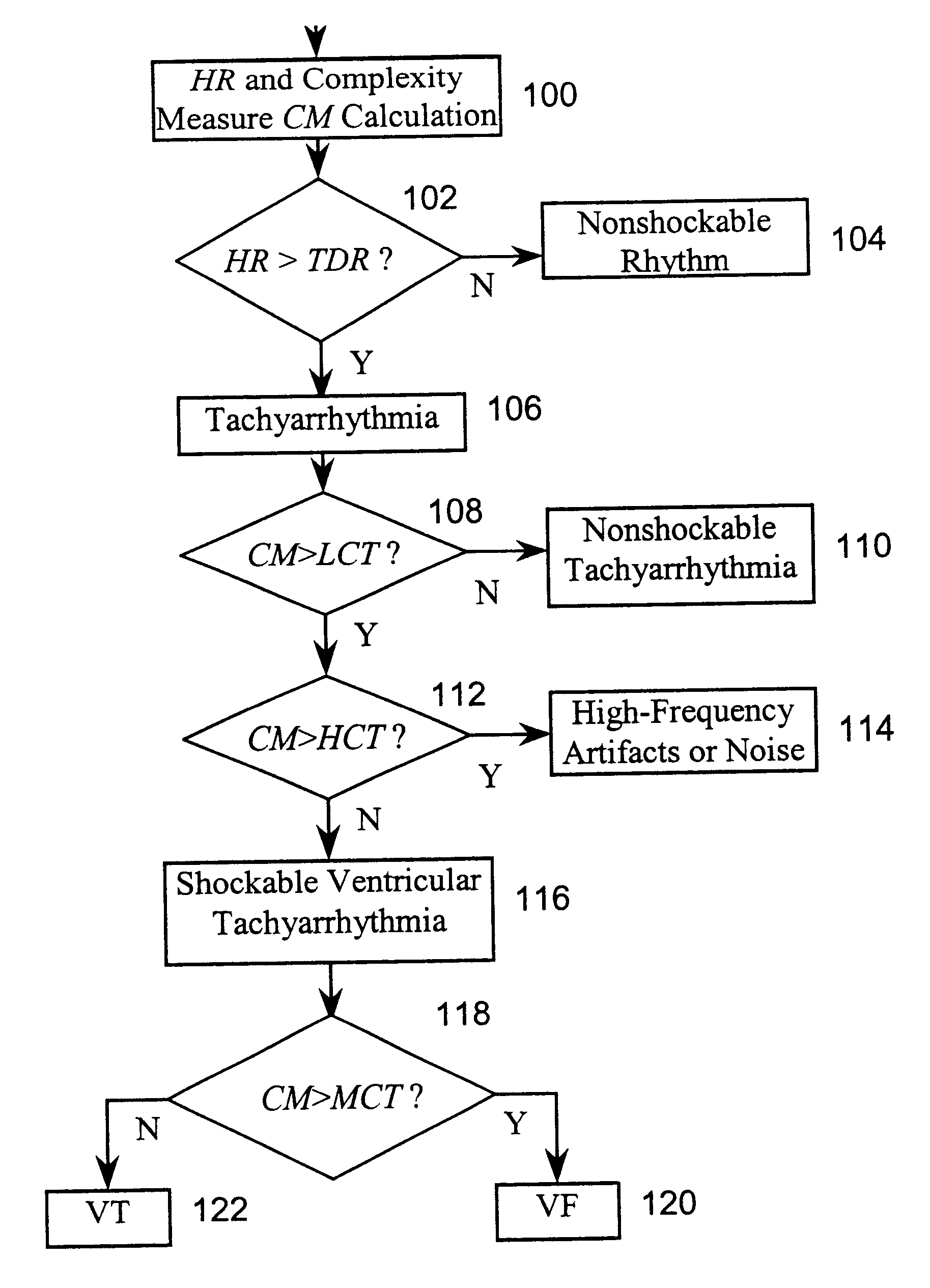

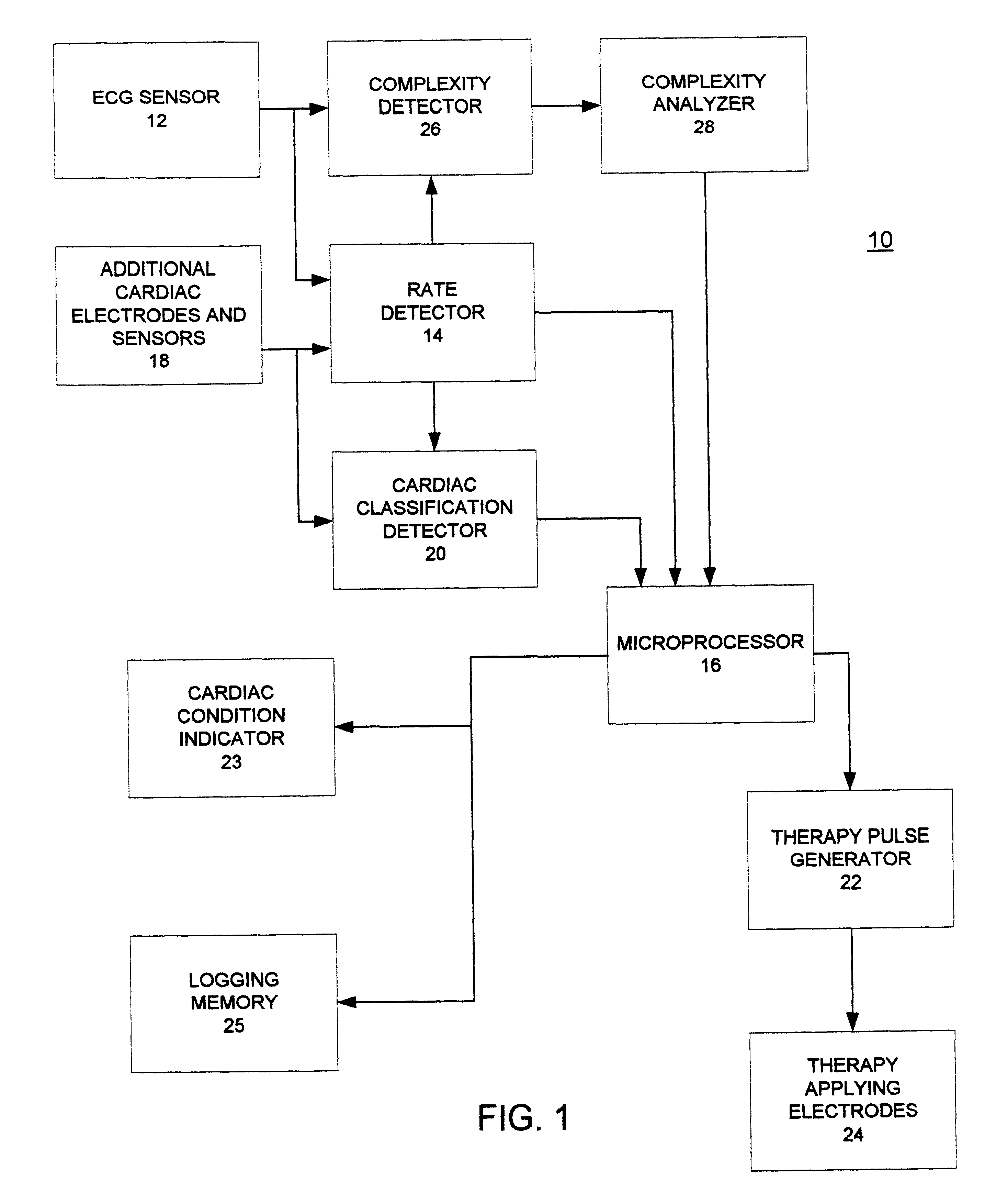

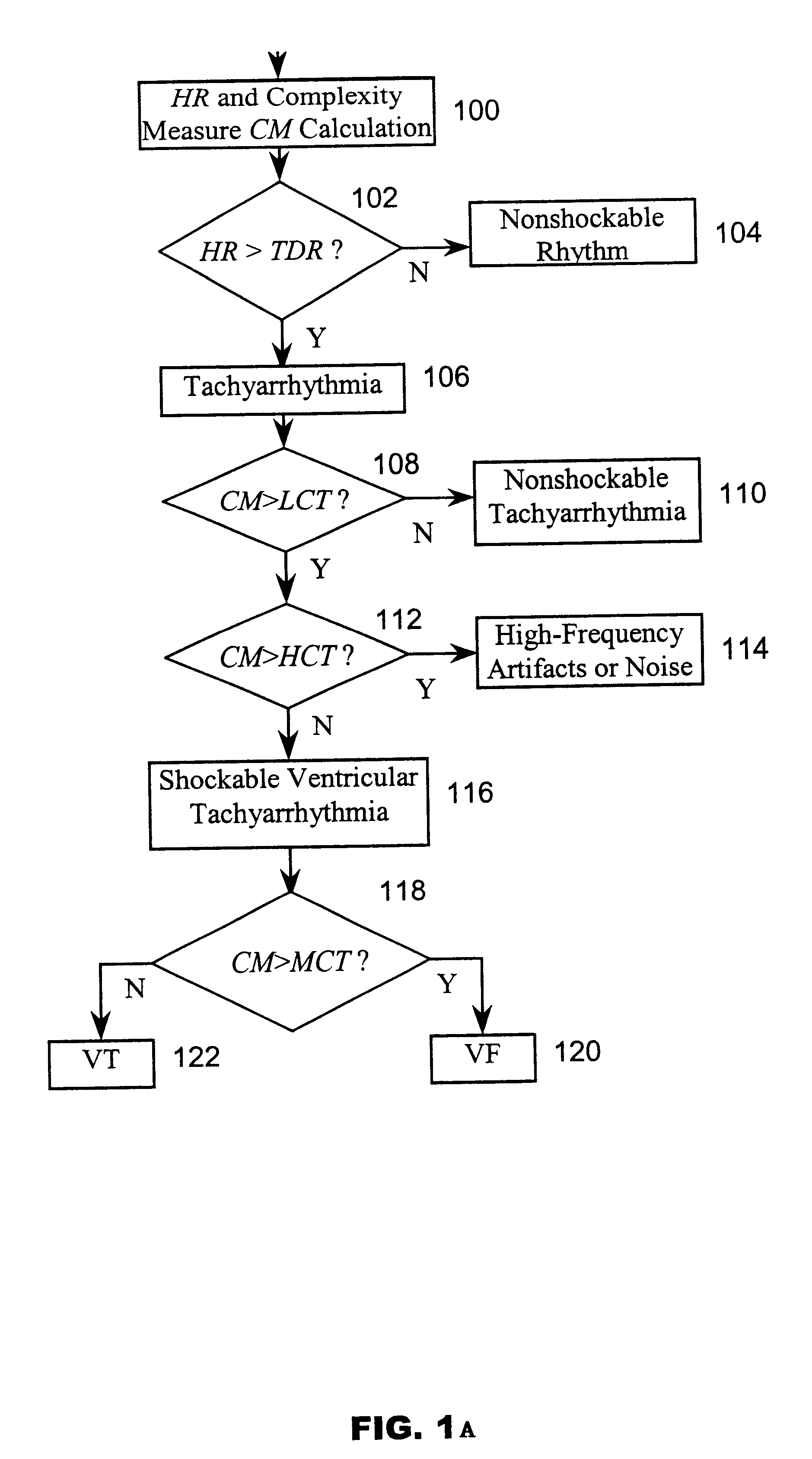

System and method for complexity analysis-based cardiac tachyarrhythmia detection

InactiveUS6490478B1Clearer and reliable indicationAvoids possible misidentificationsHeart defibrillatorsHeart stimulatorsEcg signalVentricular tachycardia

A system and method based on electrocardiogram (ECG) complexity analysis for real-time detecting shockable ventricular fibrillation (VF) and ventricular tachycardia (VT), and discriminating them from non-shockable tachyarrhythmia (e.g. supraventricular tachycardia (SVT) and atrial fibrillation (AF)) and high-frequency noise. In the disclosed invention, complexity measure CM (0 to 100), quantitatively characterizing the complexity nature of the non-linear dynamics underlying cardiac arrhythmia, is extracted from the sensed patient ECG signal using ECG complexity analysis. From the calculated complexity measure, by three thresholds (low complexity threshold (LCT), mediate complexity threshold (MCT), and high complexity threshold (HCT)), different kinds of tachyarrhythmia (i.e. heart rate (HR) above a preset rate threshold) and high-frequency noise are discriminated from each other: for non-shockable tachyarrhythmia, CM<=LCT; for VT, LCT<CM<=MCT; for VF, MCT<CM<=HCT; and for high-frequency noise, HCT<CM. The disclosed system and method can be used as a primary cardiac tachyarrhythmia detection scheme or as a backup system to reconfirm arrhythmia detection using conventional techniques.

Owner:ZOLL MEDICAL CORPORATION

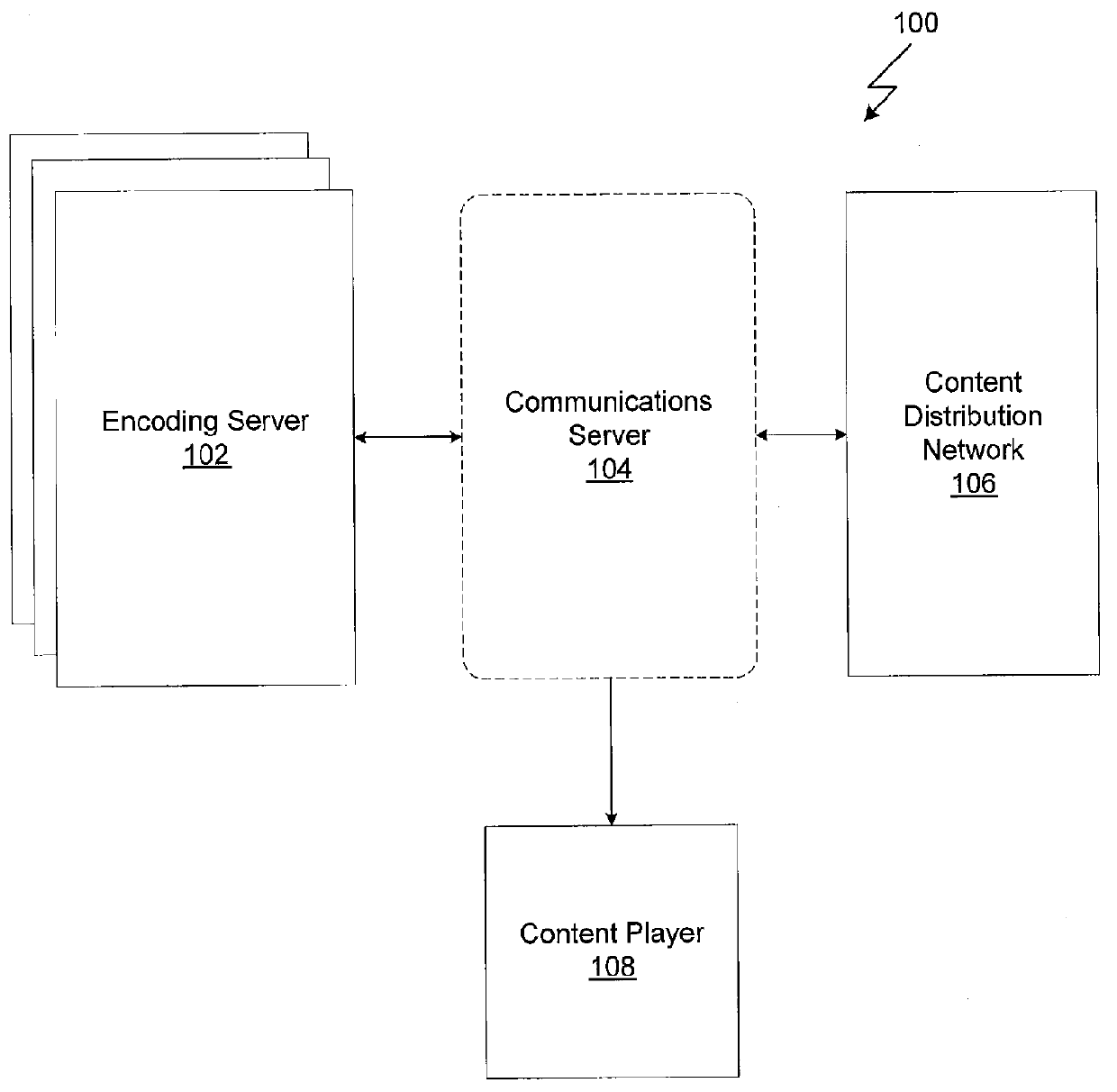

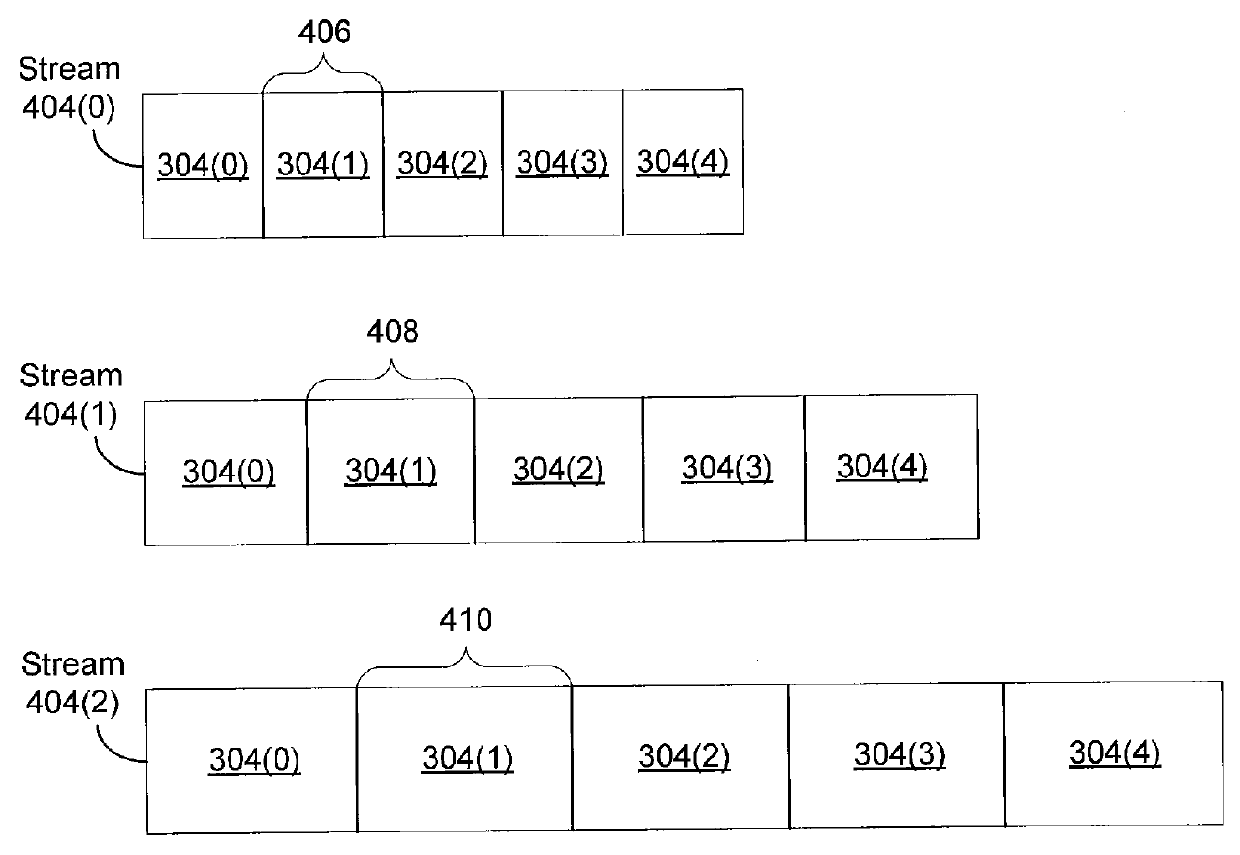

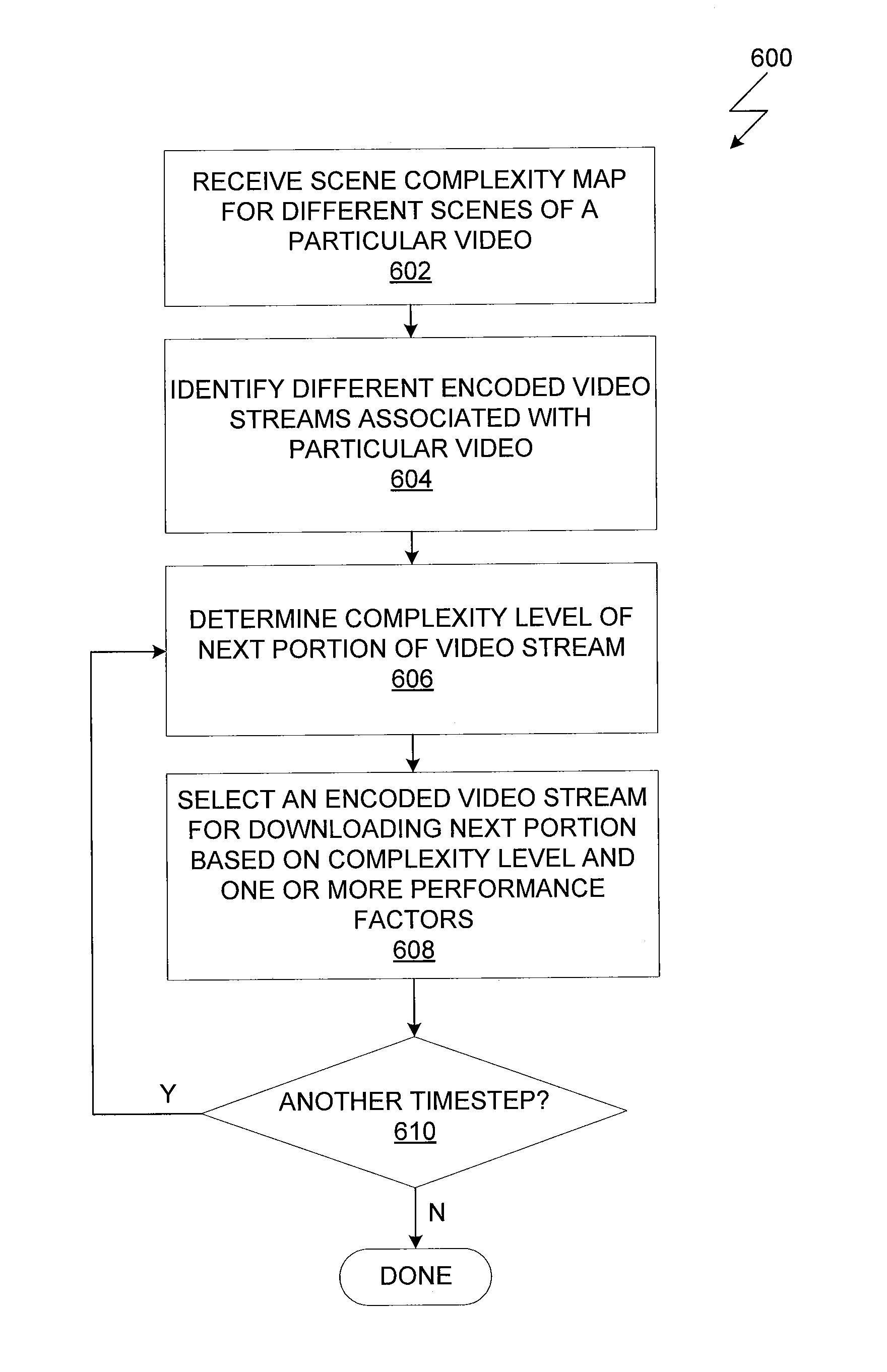

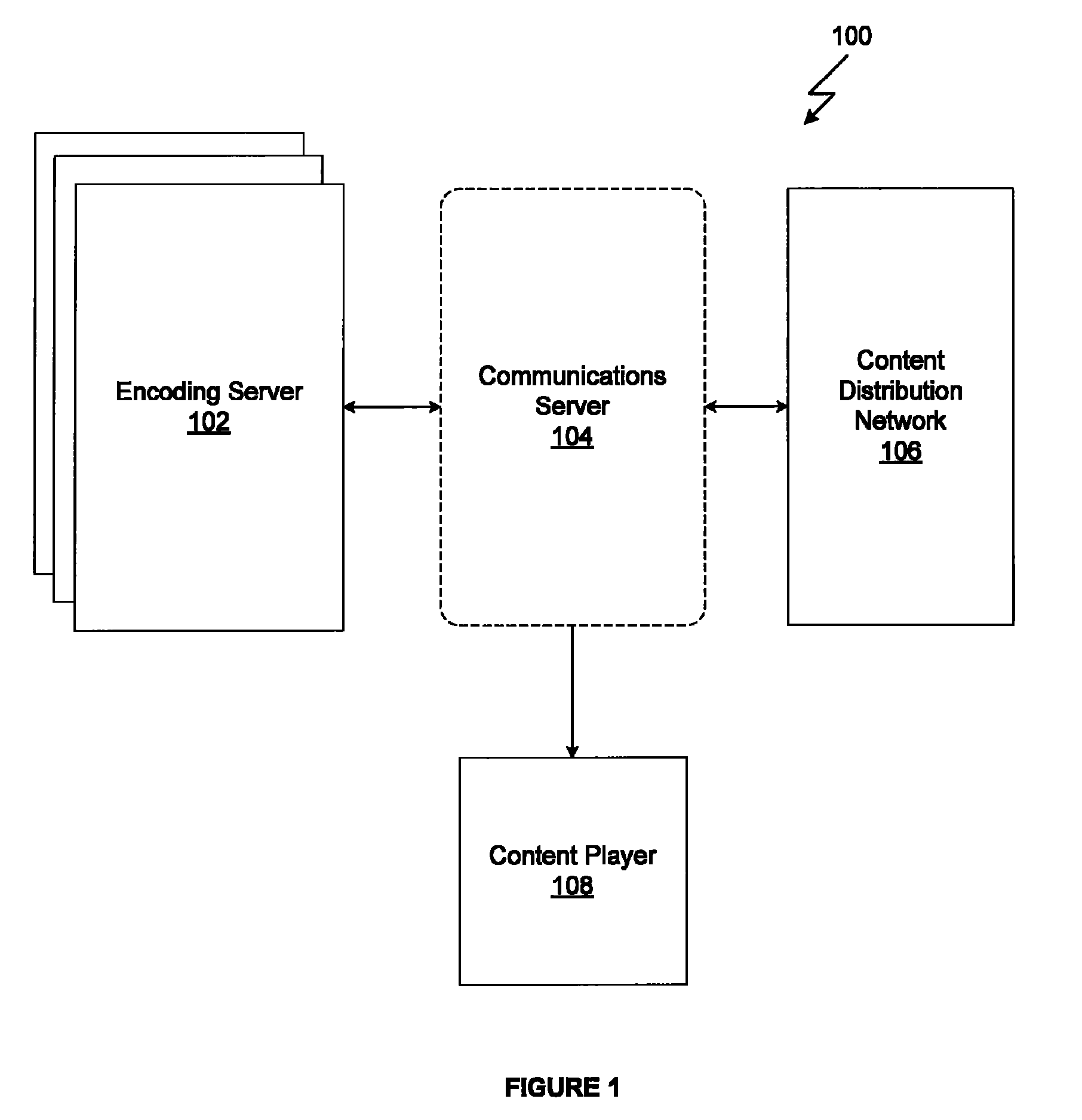

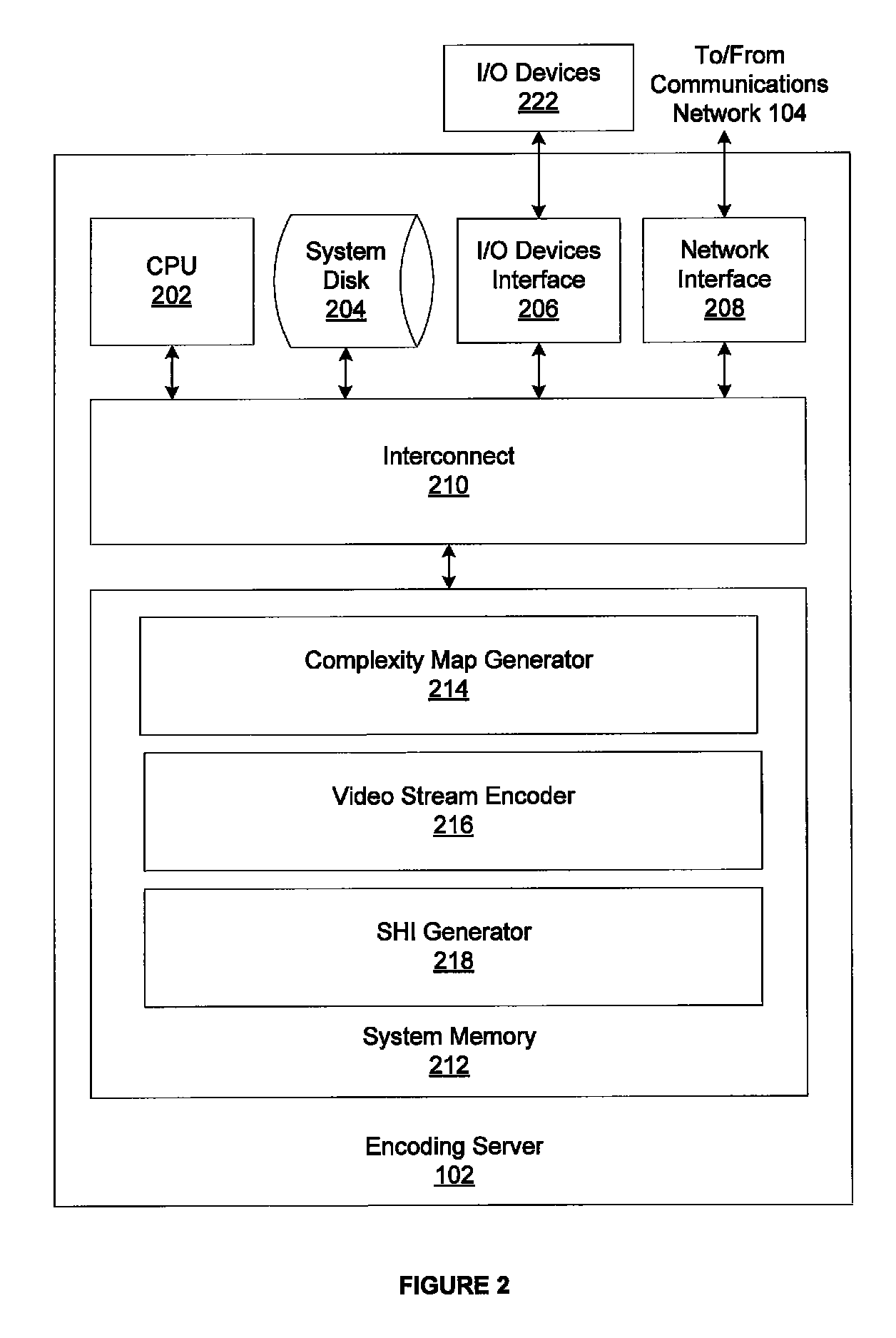

Variable Bit Video Streams for Adaptive Streaming

ActiveUS20120141089A1Improve playback qualityTelevision system detailsColor television signals processingComputer graphics (images)Network conditions

One embodiment of the present invention sets forth a technique for adapting playback bit rate in a content delivery system based on scene complexity of the video content as well as network conditions and other performance factors. A scene complexity map of the video content indicates the complexity levels of different scenes within the video content. Using the scene complexity map, a content player may download scenes of lower scene complexity levels from video streams encoded to lower bit rates to manage the bandwidth consumed to download the video content and allow for the downloading of scenes of higher complexity levels from video streams encoded to higher bit rates.

Owner:NETFLIX

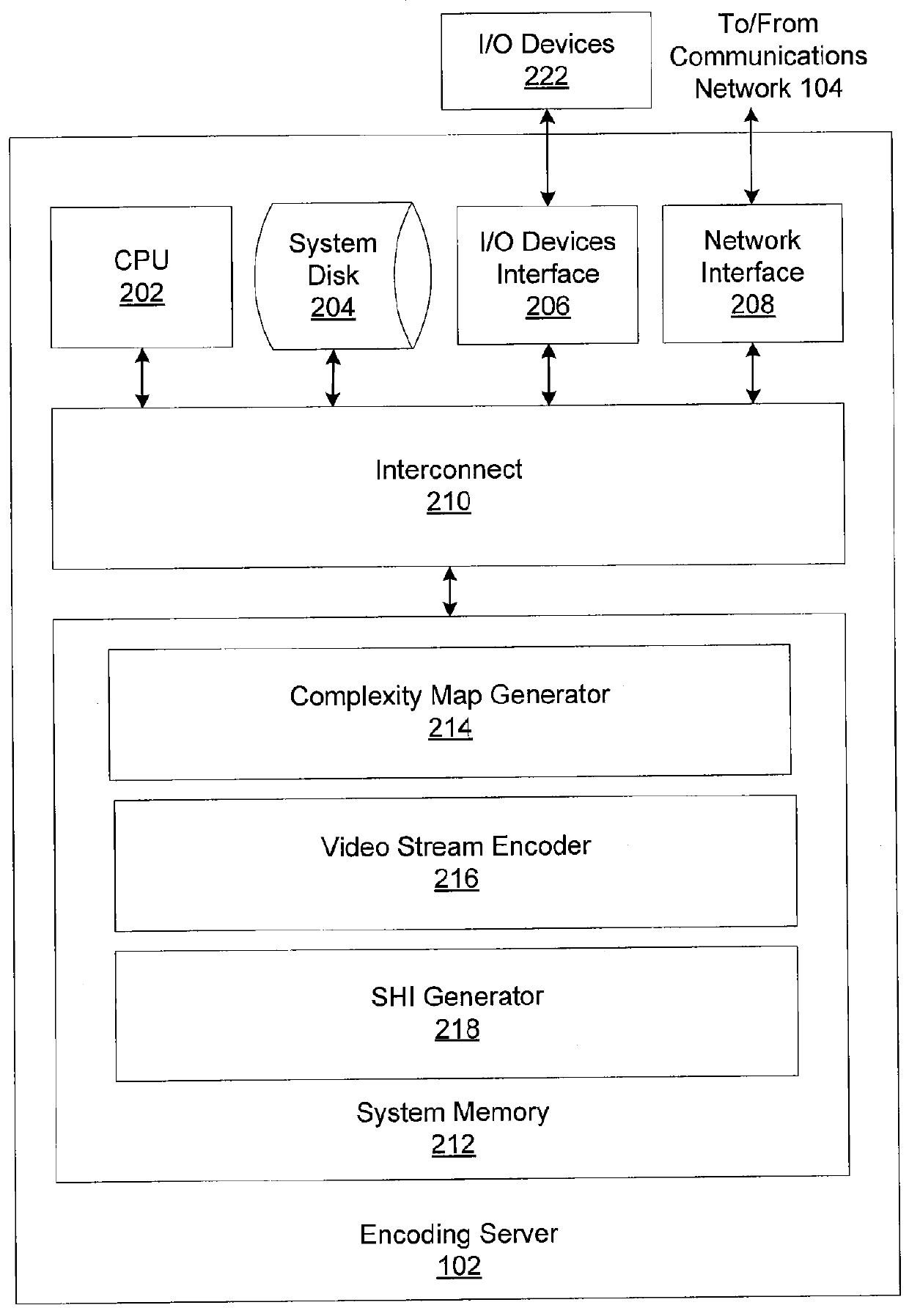

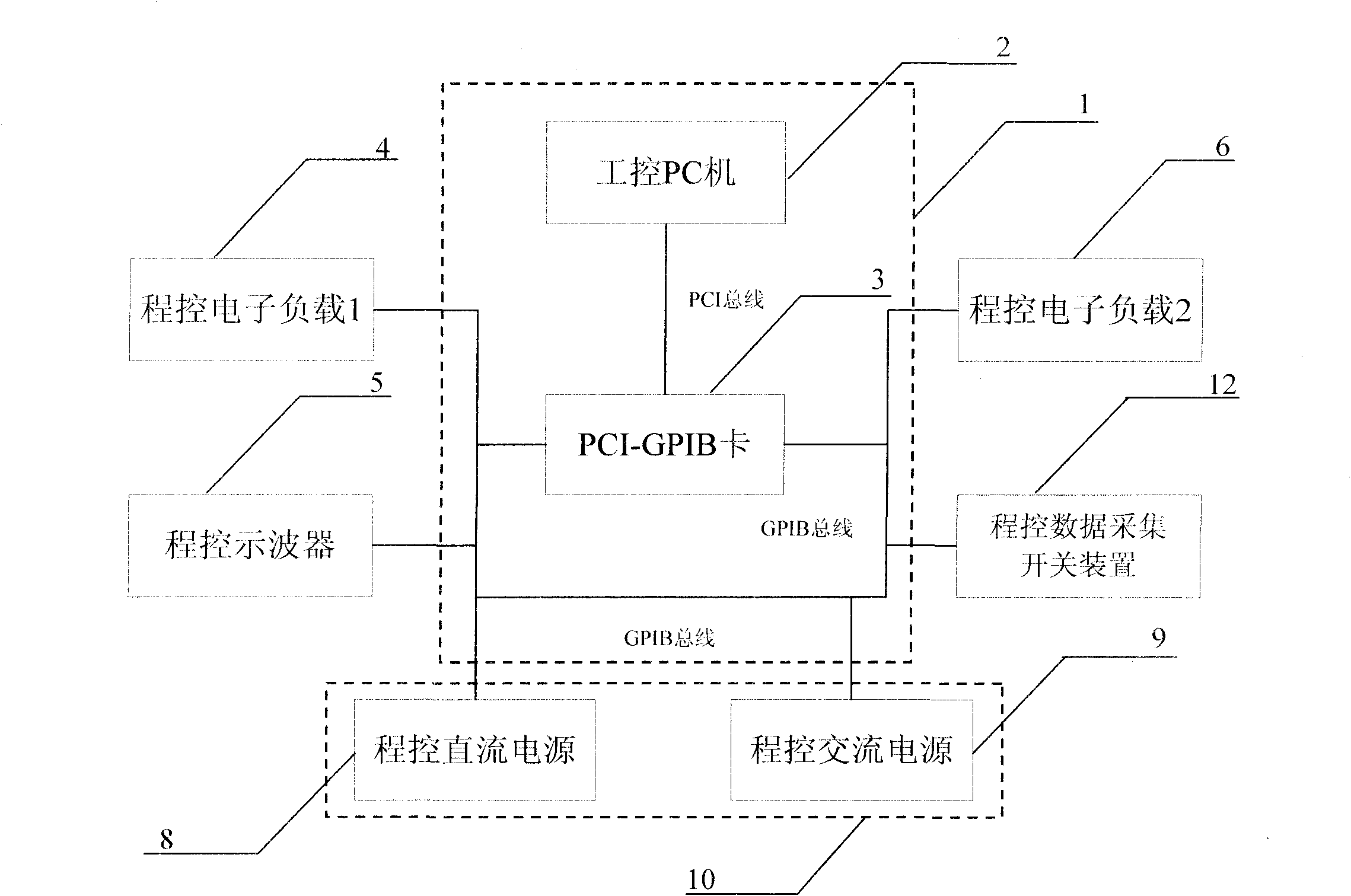

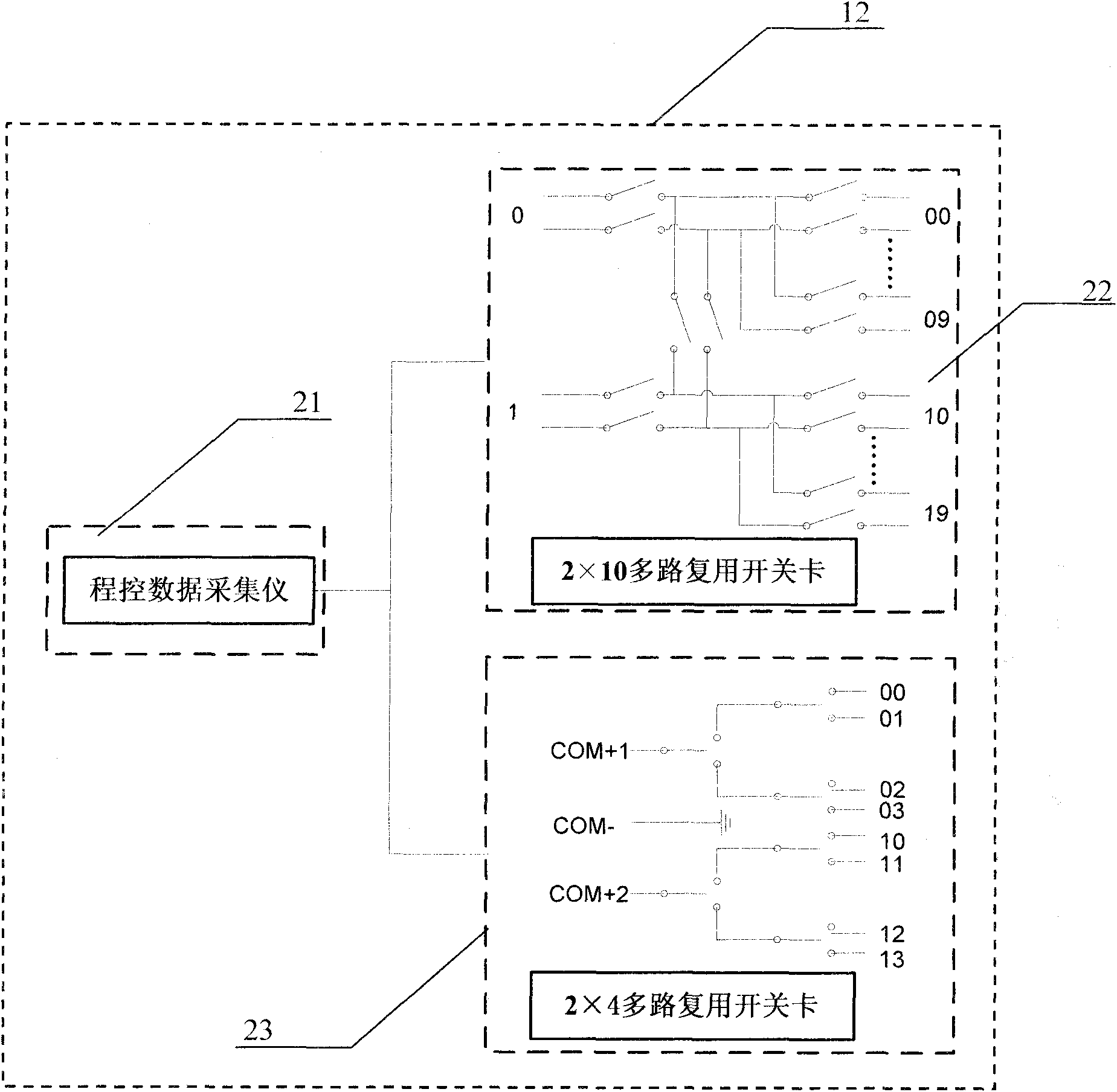

General-purpose automatic test system for locomotive switching power supply and method thereof

The invention relates to a general-purpose automatic test method for a locomotive switching power supply, and general-purpose automatic test system, and comprises a test control system, a programmable power supply unit, a programmable DC load unit and a programmable data acquisition unit, wherein the programmable power supply unit is connected with the test control system through a GPIB bus and provides excitation for the tested switching power supply; the programmable DC load unit is connected with the test control system through the GPIB bus and provides a load for the switching power supply to be tested; and the programmable data acquisition unit is connected with the test control system through the GPIB bus and acquires responses of the tested switching power supply. The output voltage, voltage regulation factor, load regulation factor and the like are tested by logging in virtual instrument software on a personal computer. The invention can well overcome the defects of insufficient compatibility, high complexity and low reliability of the test system in the prior art, and has the advantages of automation, general purpose, convenient operation and reliable performance.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

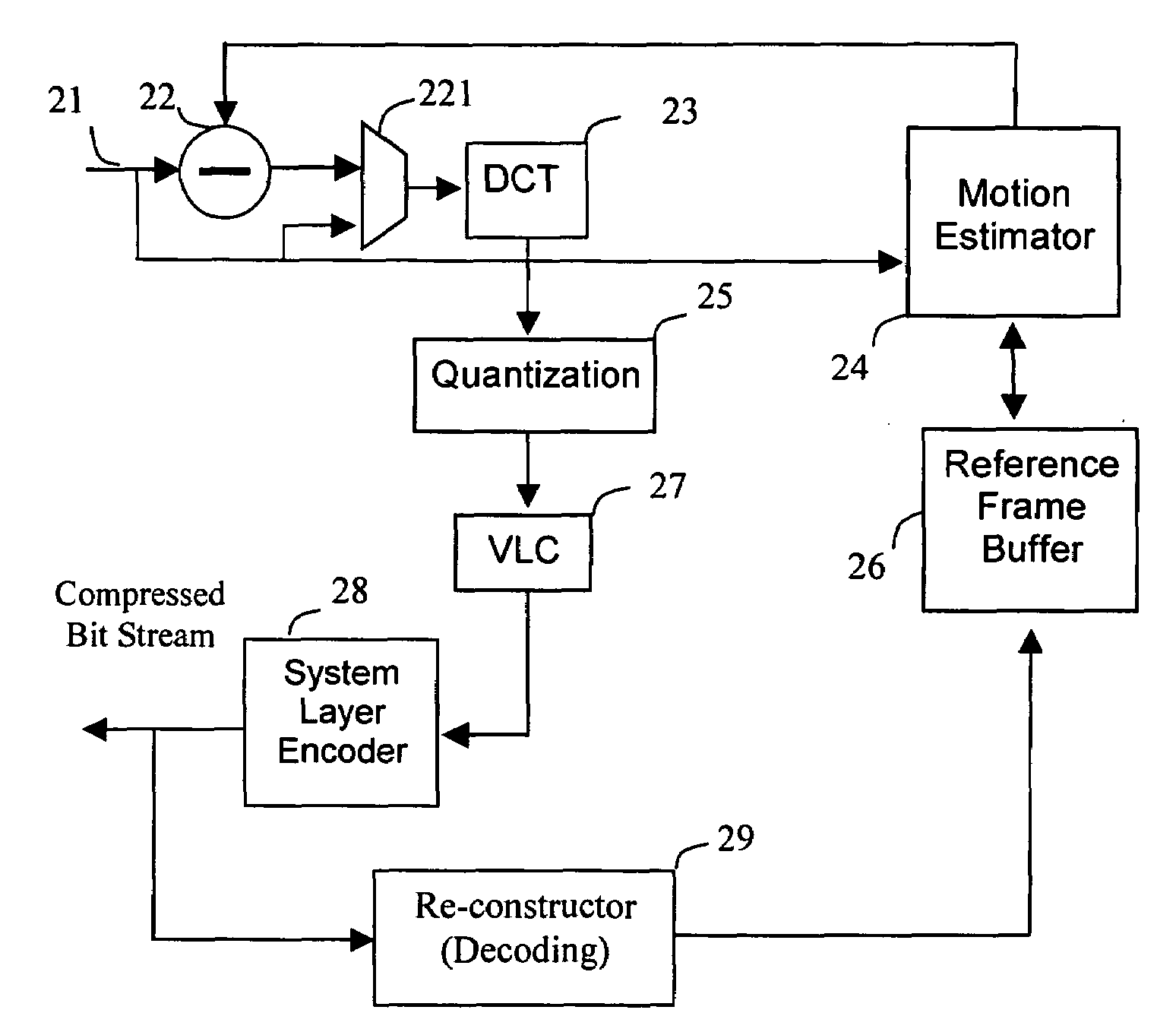

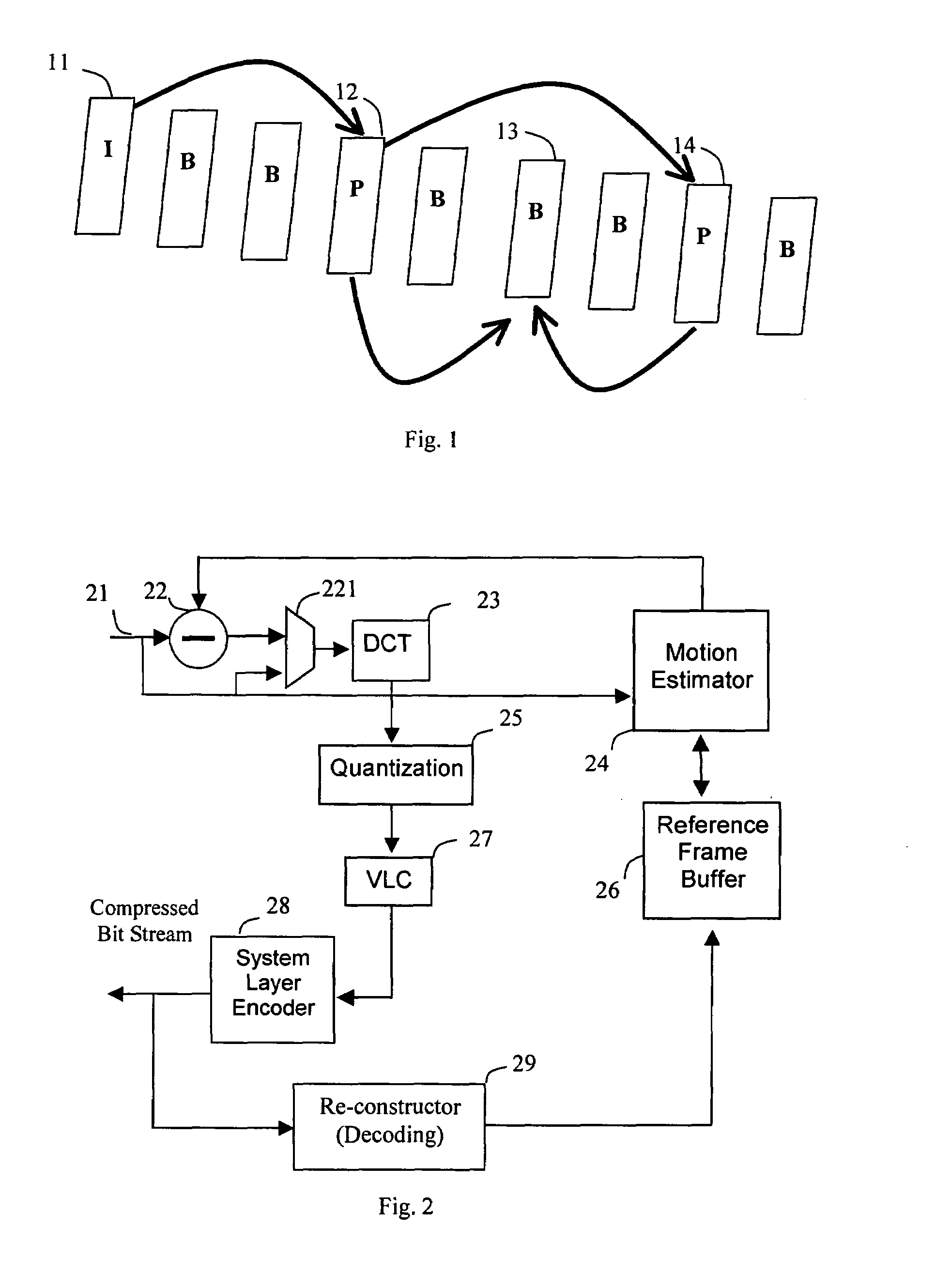

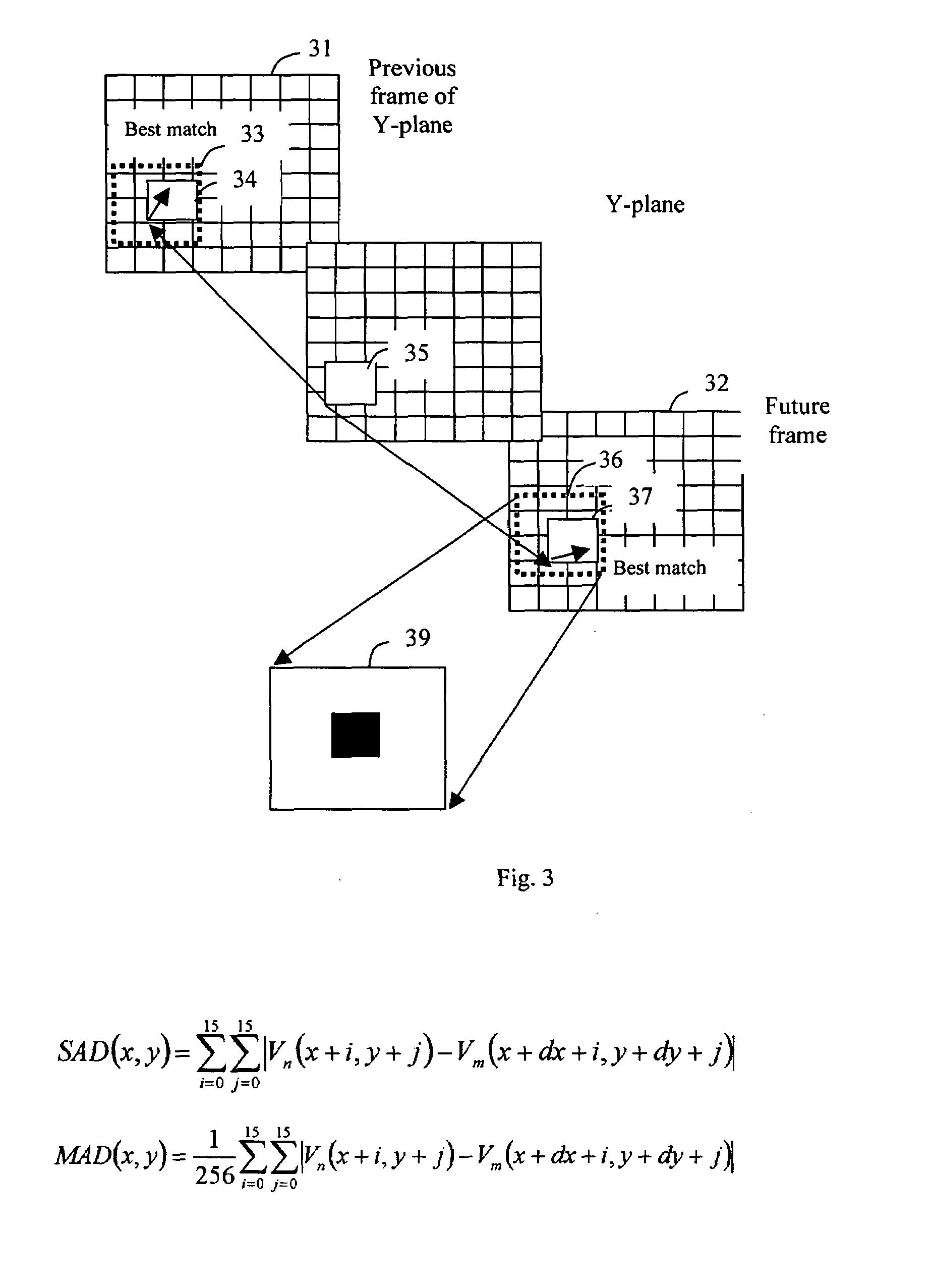

Method of digital video reference frame compression

ActiveUS20080170626A1High complexityAccelerated programColor television with pulse code modulationColor television with bandwidth reductionDigital videoLossless compression algorithm

The digital video referencing frame image is compressed block by block by applying lossless compression algorithm to pixel components with full length, or 1 bit, 2 bits, 3 bits or 4 bits LSB bits truncation. If a sub-block has high complexity which results in more than 3 bits error for most pixel components, a transfer algorithm with quantization and VLC coding is applied to compress this sub-block. Should the complexity is higher than a threshold or at least one sub-block having error of more than 3 bits for most pixel components, truncating 1 LSB bit of sub-block with simple pattern to save more bits to be allocate to code the sub-block with highest complex pattern.

Owner:TAIWAN IMAGINGTEK

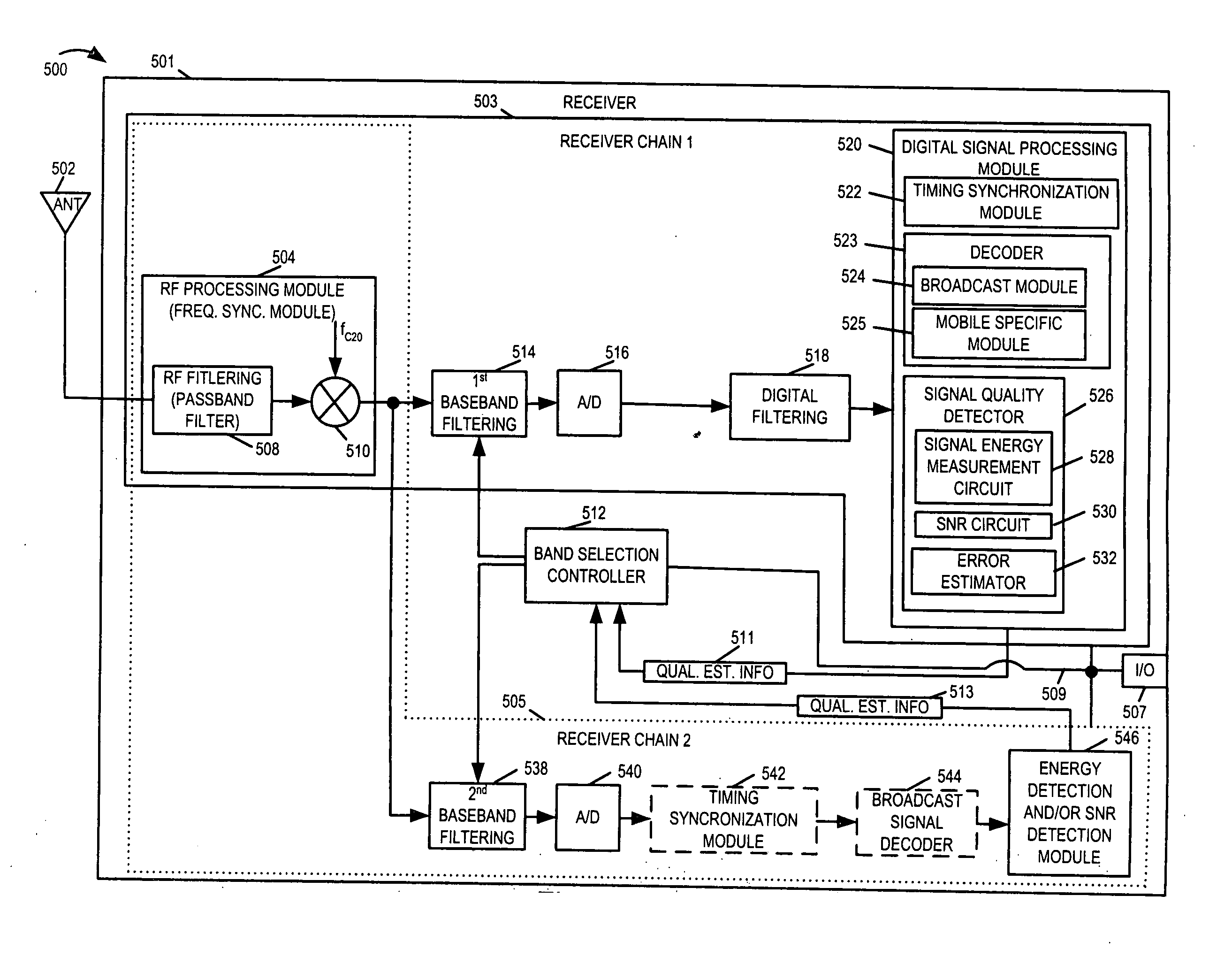

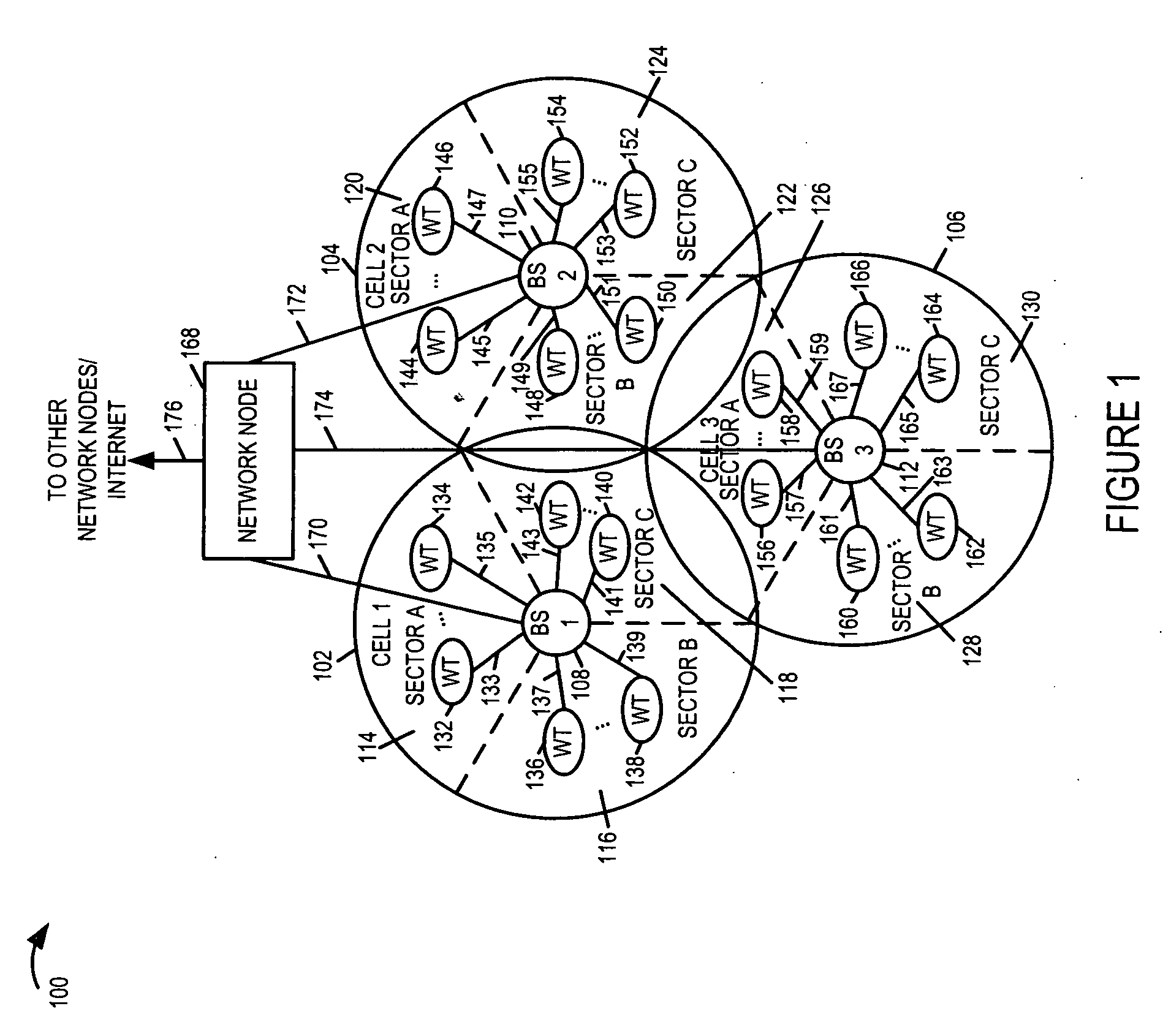

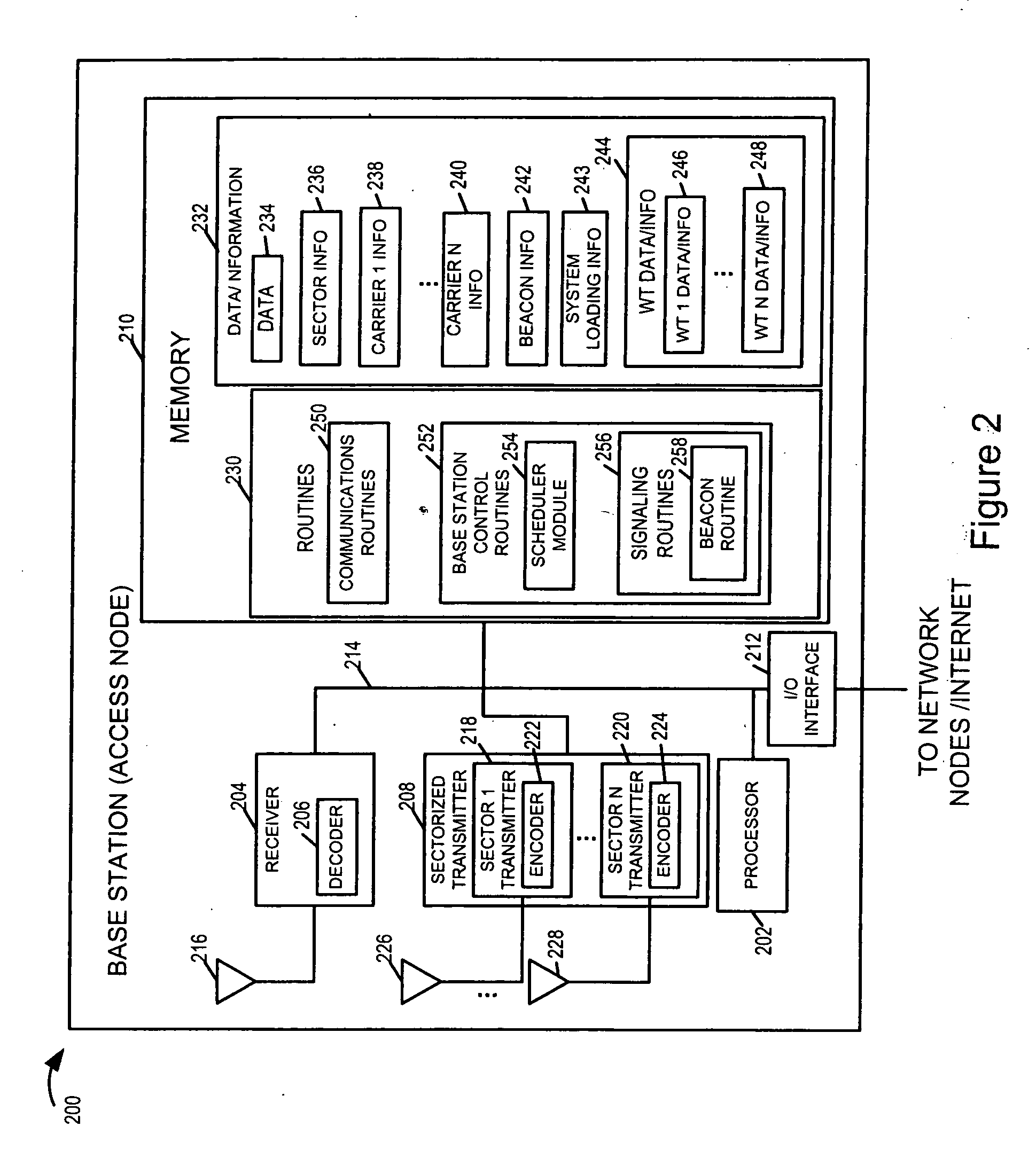

Methods and apparatus for selecting between multiple carriers using a receiver with multiple receiver chains

ActiveUS20050233716A1Implementation complexity is highSpatial transmit diversitySubstation equipmentCommunications systemCarrier signal

Receivers accommodating frequency band selection methods in wireless communications systems are described. Different frequency bands are associated with different alternative carrier frequencies and / or base station cell and / or sector transmitter connection alternatives. Mobile node receivers include two receiver chains, each chain processing signals corresponding to a carrier. In some embodiments, each receiver chain includes its own controllable RF module, and individual carrier band selection is performed in each RF module. In some embodiments, the two receiver chains share a common RF module; however, each chain includes its own controllable baseband filter. In various embodiments, the first chain has higher complexity than the second chain. In most embodiments, each chain uses the same technology, e.g., spread spectrum OFDM or CDMA. Each chain obtains a quality indicator value on a different band and a comparison of quality indicator values is used in selecting the channel and carrier band for downlink traffic signaling.

Owner:QUALCOMM INC

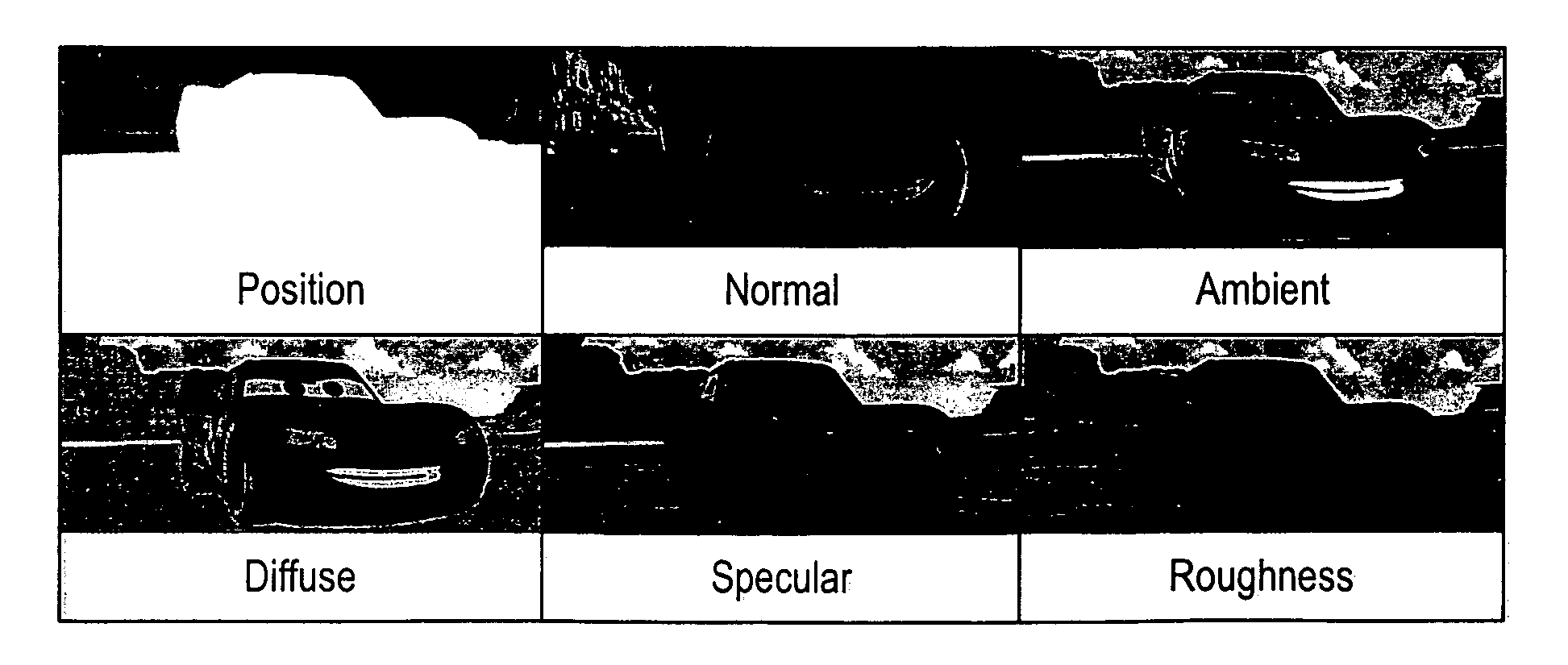

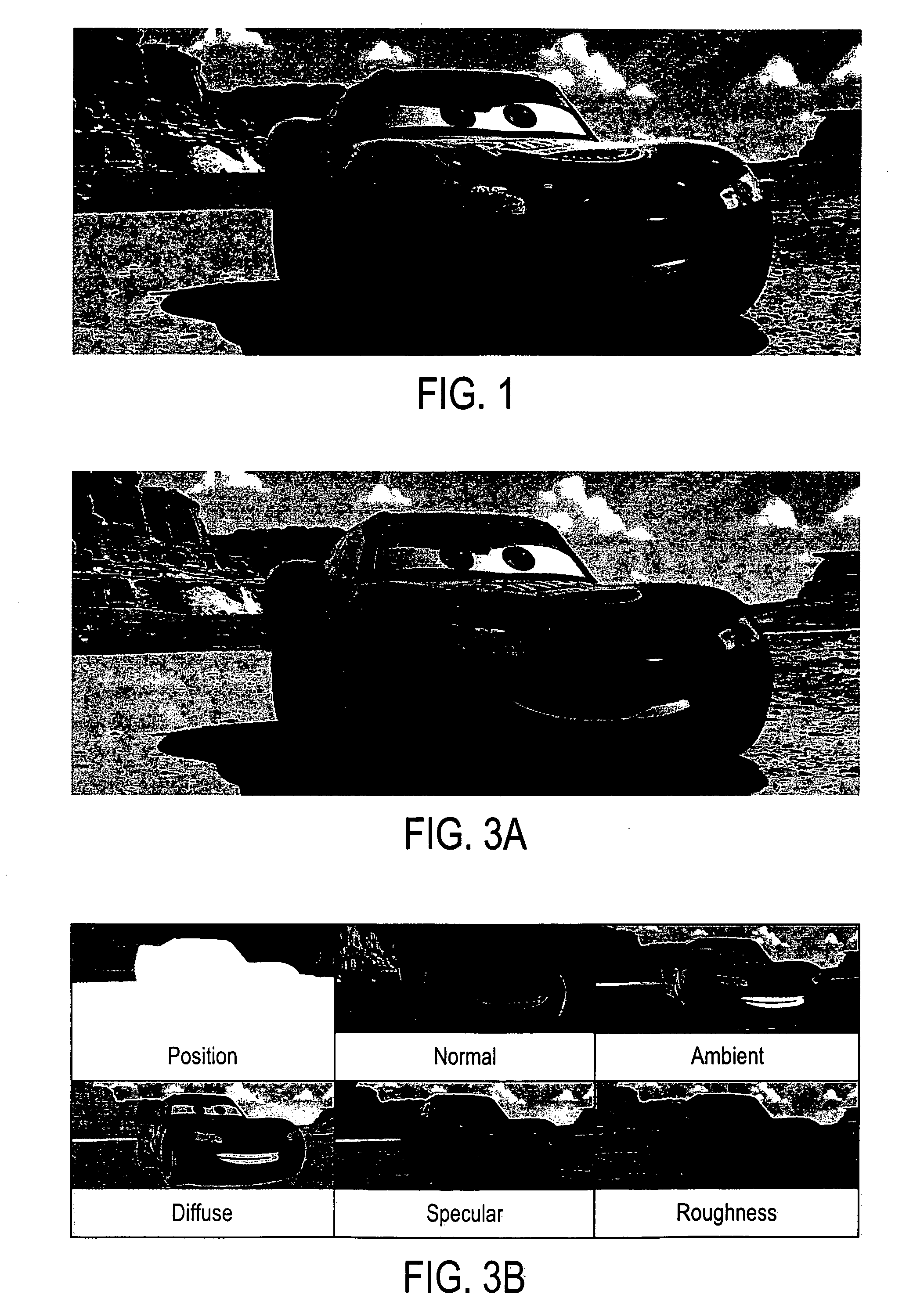

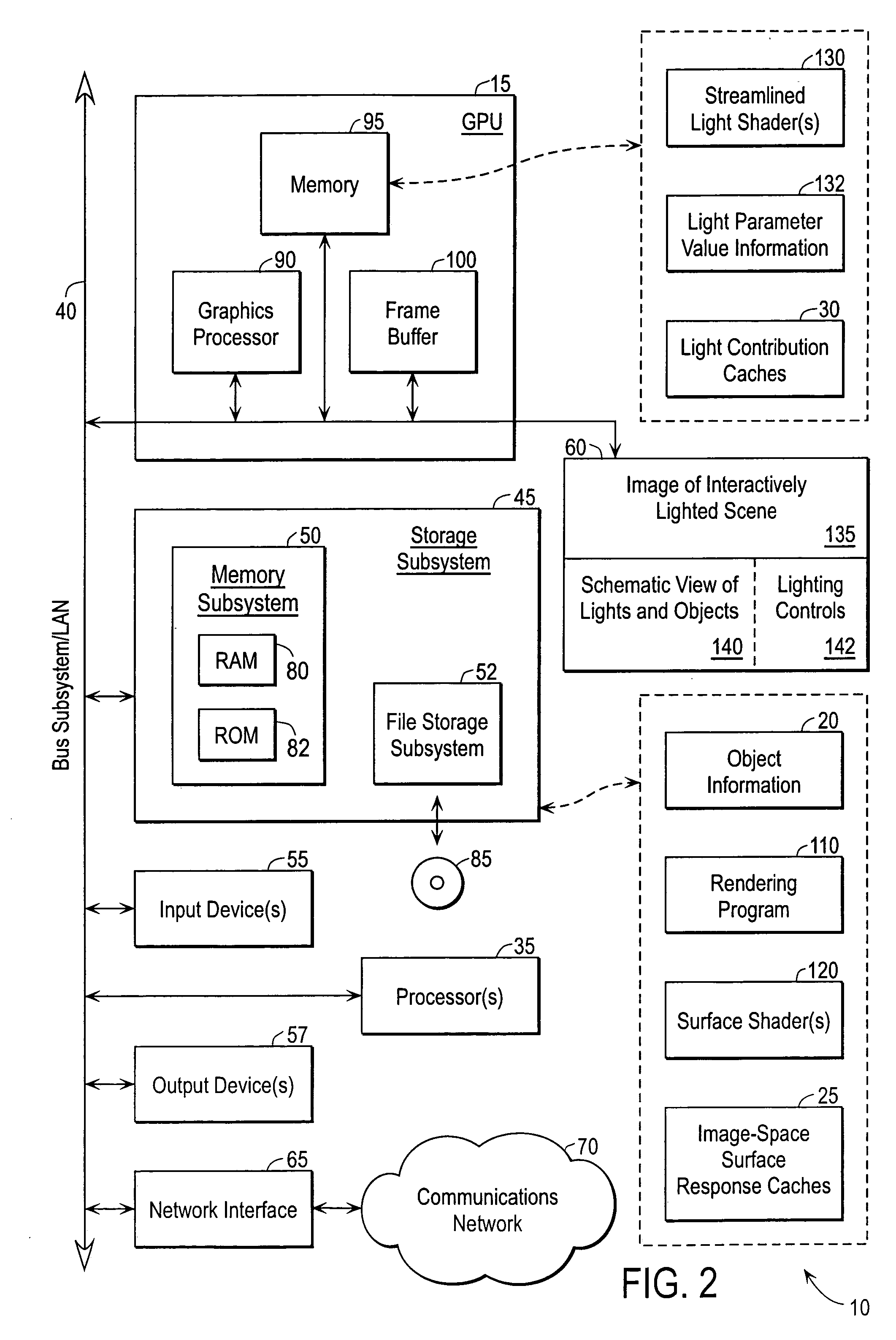

Hybrid hardware-accelerated relighting system for computer cinematography

ActiveUS20060209067A1Simple lightingIncrease speed3D-image renderingComputer animationDeferred shading

An interactive cinematic lighting system used in the production of computer-animated feature films containing environments of very high complexity, in which surface and light appearances are described using procedural RenderMan shaders. The system provides lighting artists with high-quality previews at interactive framerates with only small approximations compared to the final rendered images. This is accomplished by combining numerical estimation of surface response, image-space caching, deferred shading, and the computational power of modern graphics hardware.

Owner:PIXAR ANIMATION

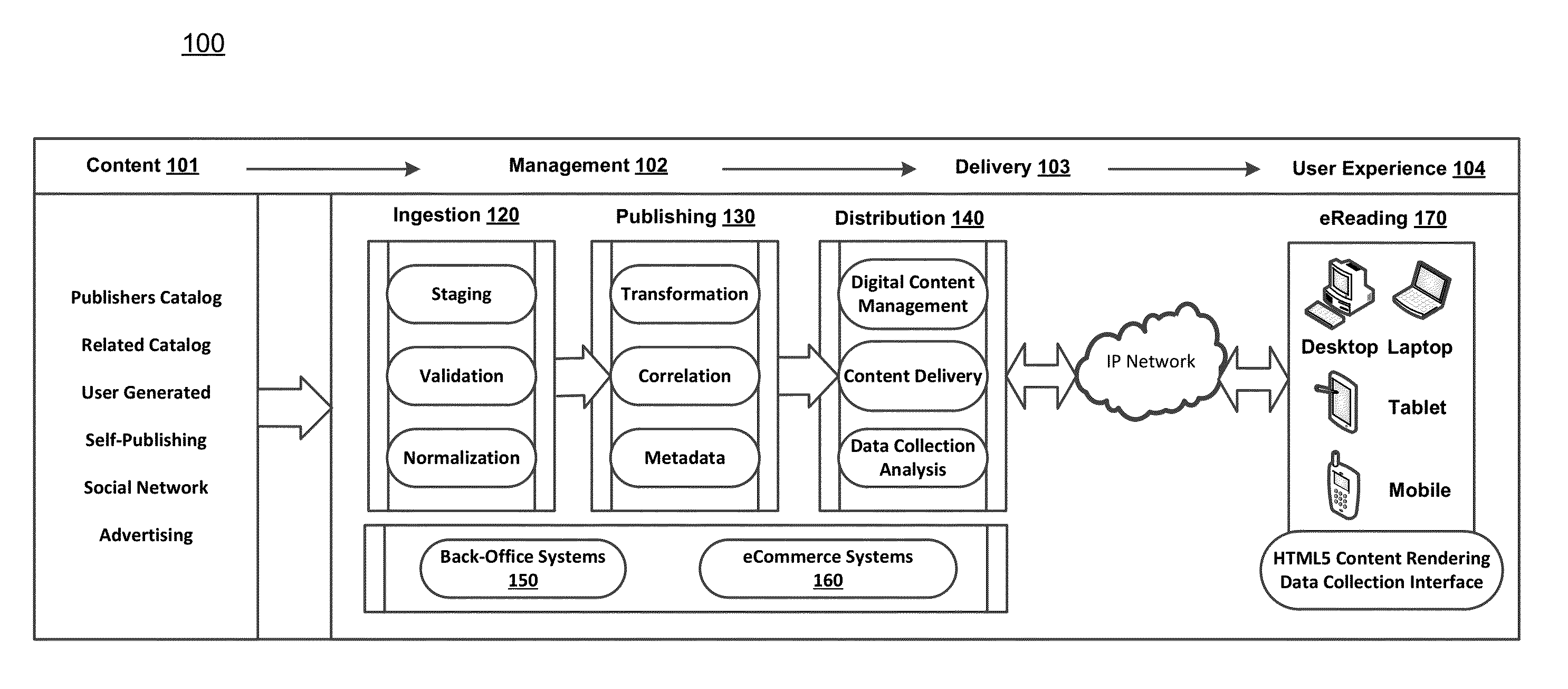

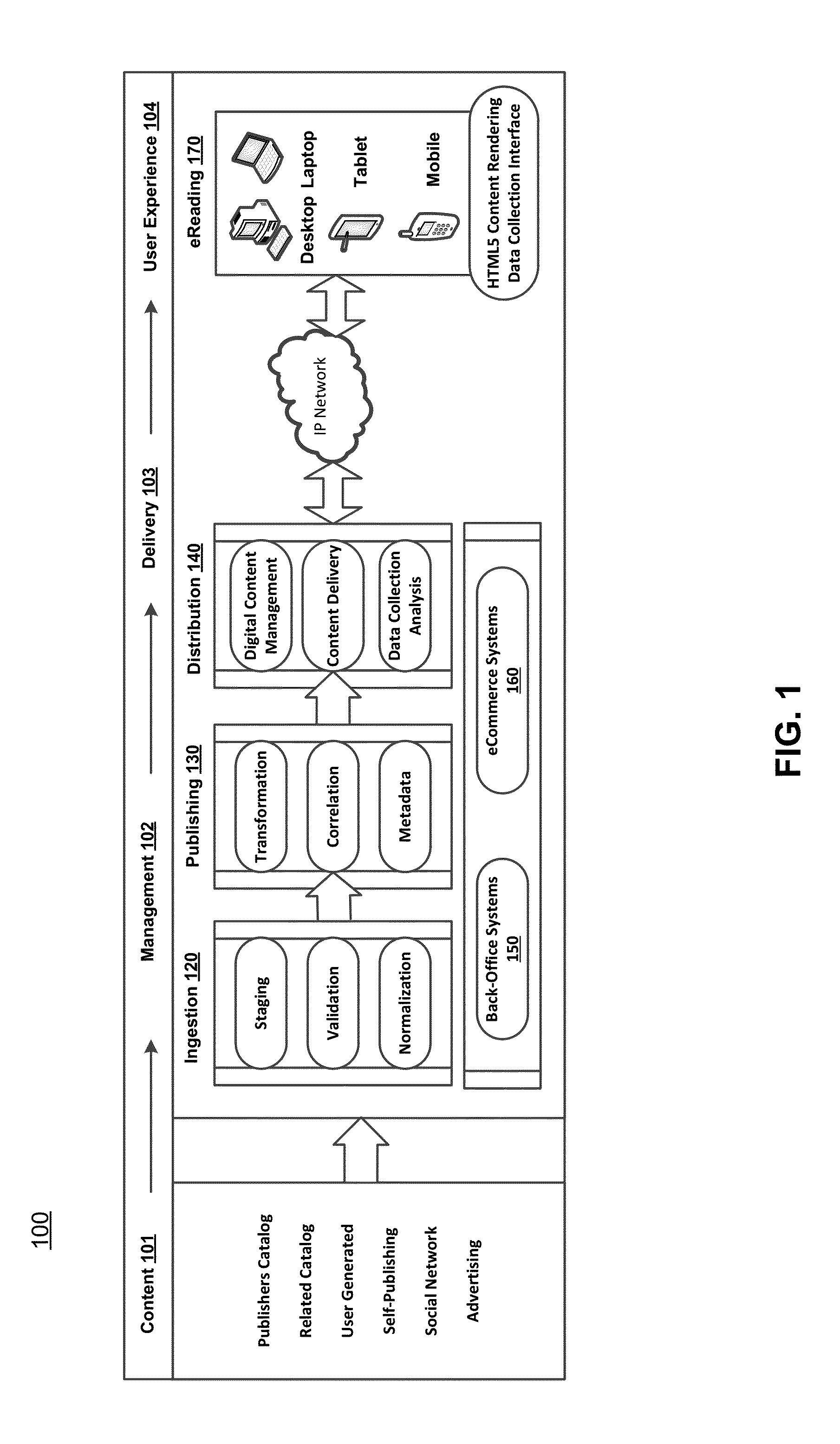

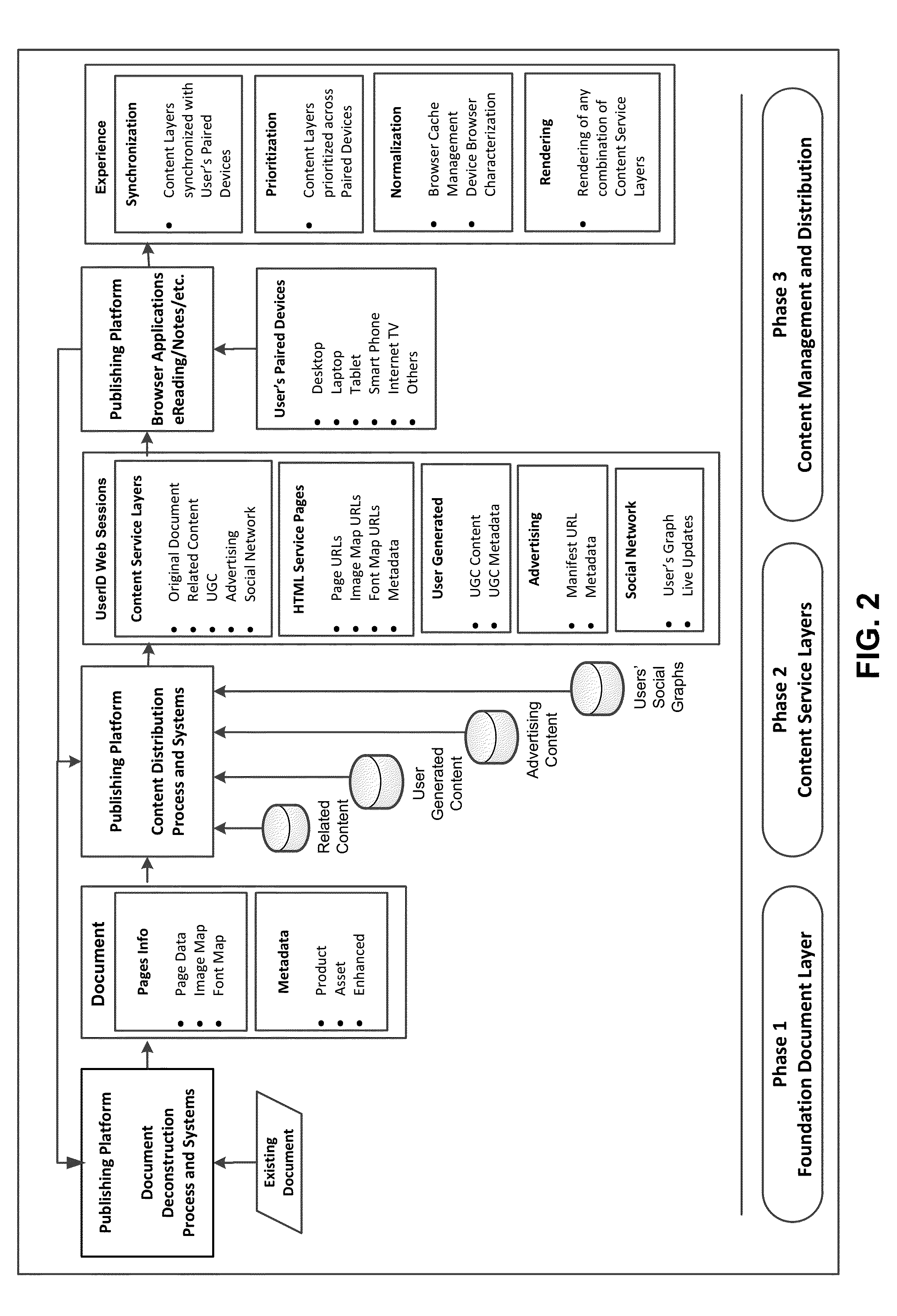

Building a Topical Learning Model in a Content Management System

ActiveUS20160147891A1Easy to browseHigh complexityDigital data processing detailsRelational databasesDocument preparationPairing

A content management system receives a plurality of topics extracted from documents stored by the system. Pairings between the topics are generated, where a pairing between two topics is generated responsive to the two topics appearing in proximity to one another in one or more of the documents. A complexity of each received topic is also determined. The content management system generates a progression of the topics based on the complexity of the topics and the pairings between the topics. The progression comprises a sequential ordering of paired topics, in which a topic in the ordering has a higher complexity than a preceding topic. Responsive to a user of the content management system accessing content associated with a topic in the progression, a next topic in the progression is recommended to the user.

Owner:CHEGG

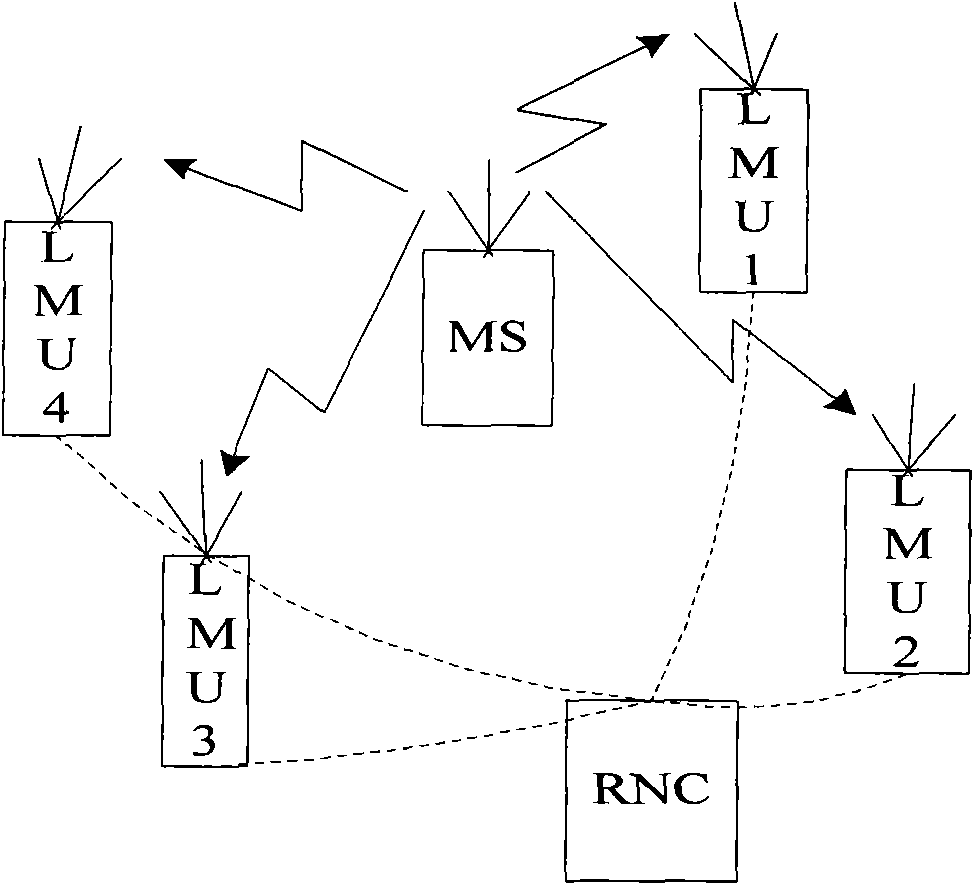

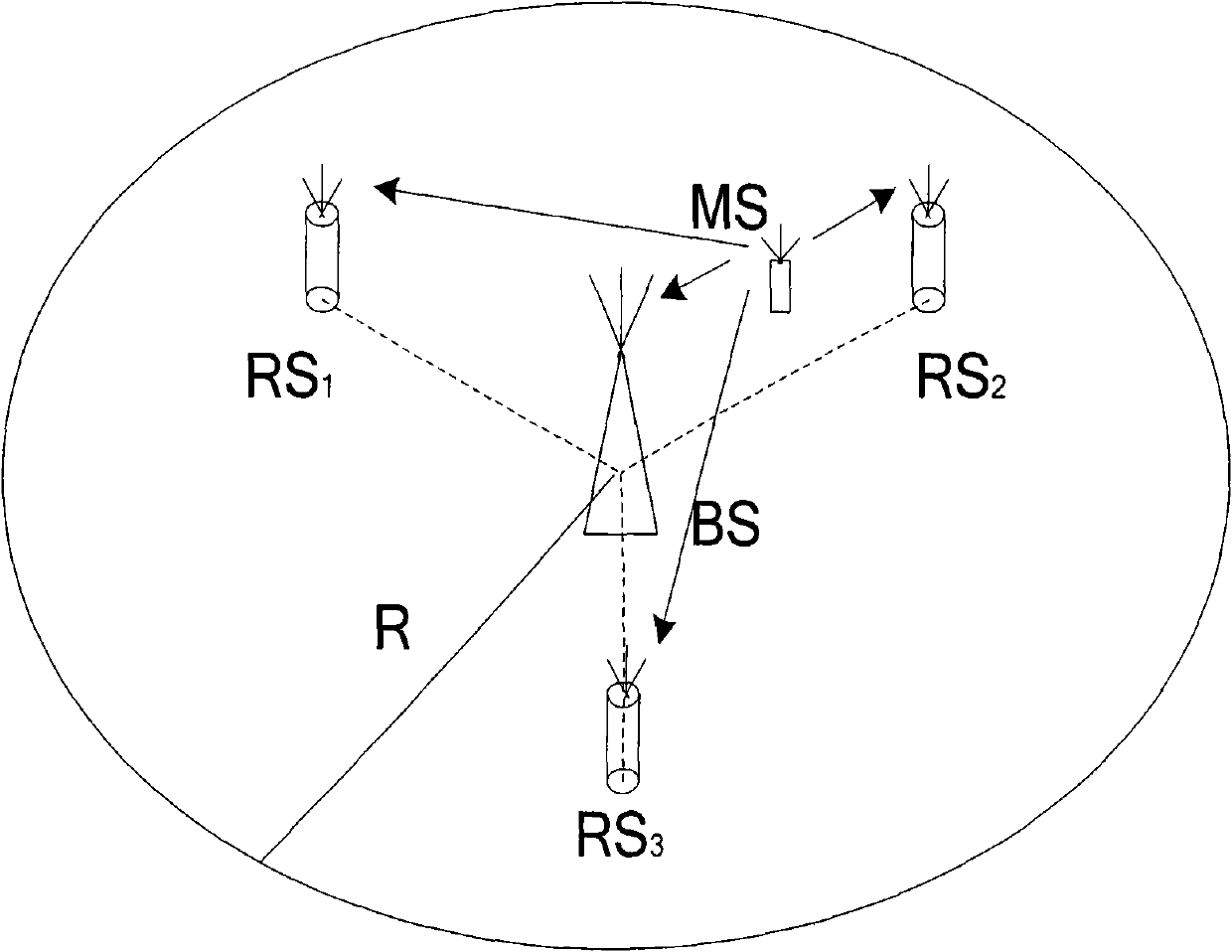

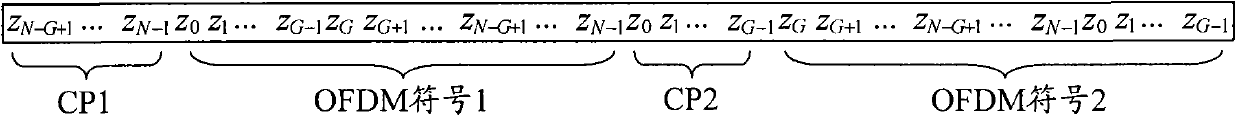

Method, system and device for estimating TDOA

InactiveCN101541078AReduce complexityInsensitive to timing errorsMulti-frequency code systemsWireless communicationMobile stationTime difference

The embodiment of the invention discloses a method, a system and a device for estimating time difference of arrival TDOA. The method for estimating the TDOA comprises the following steps that: time of arrival of data clustering estimated by a positioning reference point is received, and the time of arrival of the data clustering is detected at regular time by the positioning reference point according to a system precursor symbol, and is acquired by carrying out timing error estimation on an orthogonal frequency division multiplexing OFDM symbol containing a service LBS sequence based on positioning; and the TDOA is calculated according to the time of arrival of the data clustering estimated by different positioning reference points. Through the embodiment of the invention, the positioning reference point estimates the time of arrival of the data clustering, and a base station calculates the TDOA according to the time of arrival of the data clustering estimated by different positioning reference points so as to acquire specific position coordinates of a mobile station, thereby solving the problems of low accuracy and high complexity of the prior positioning algorithm.

Owner:HUAWEI TECH CO LTD +1

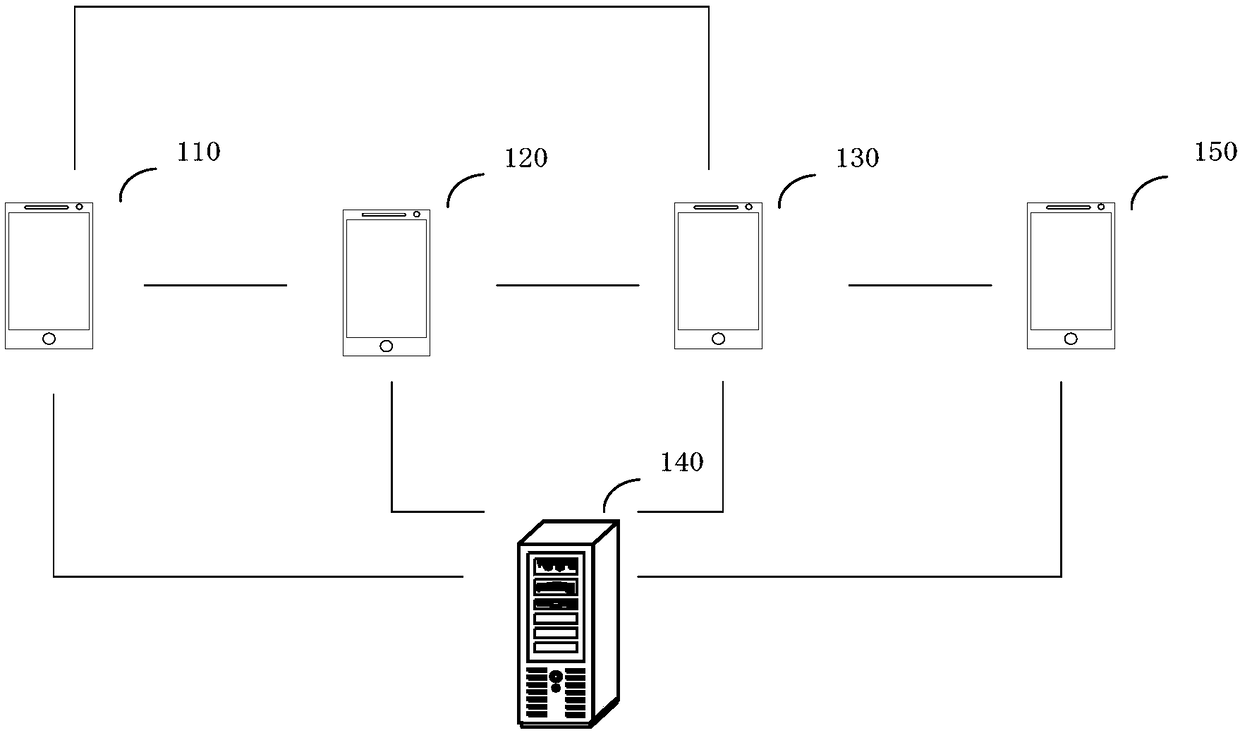

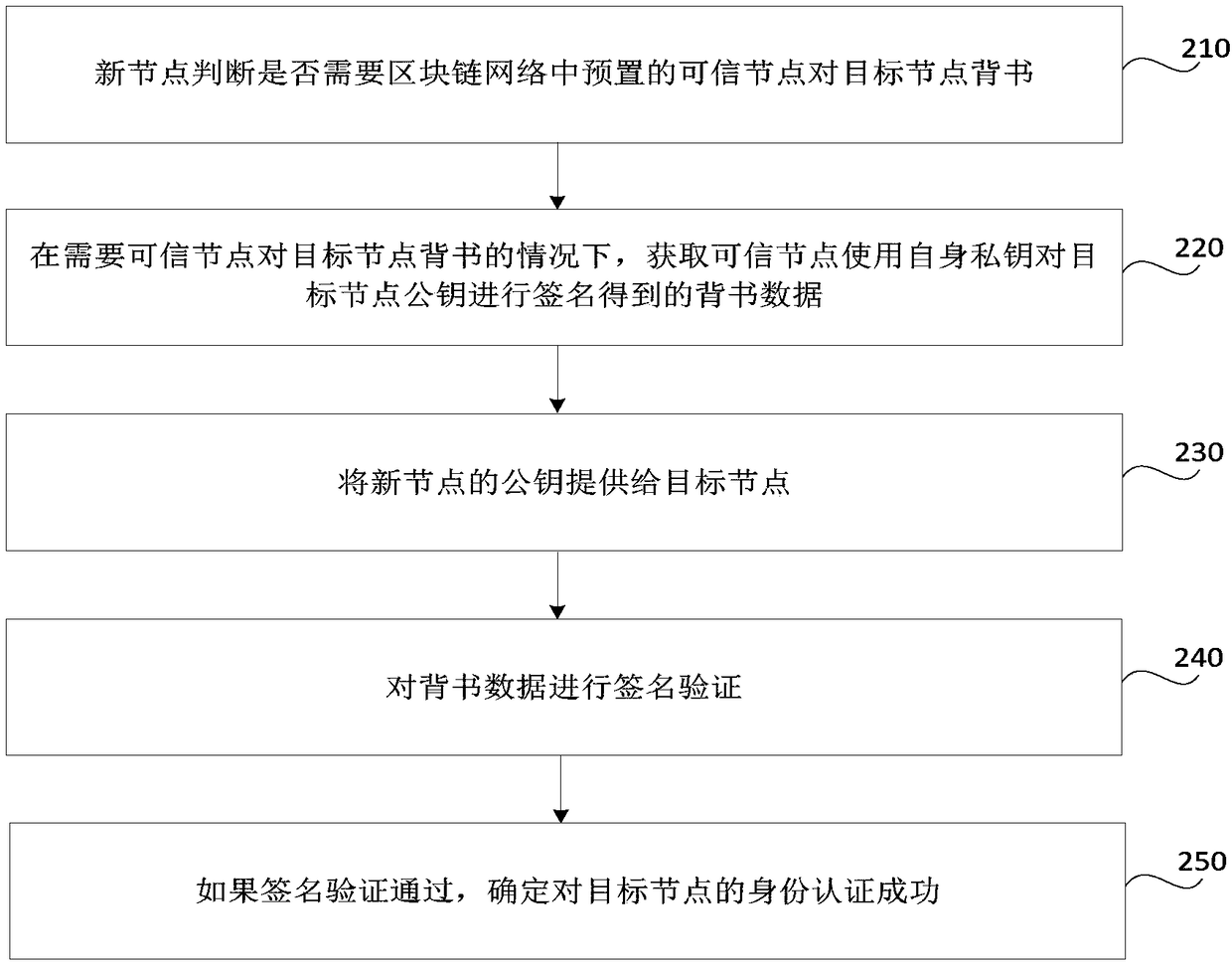

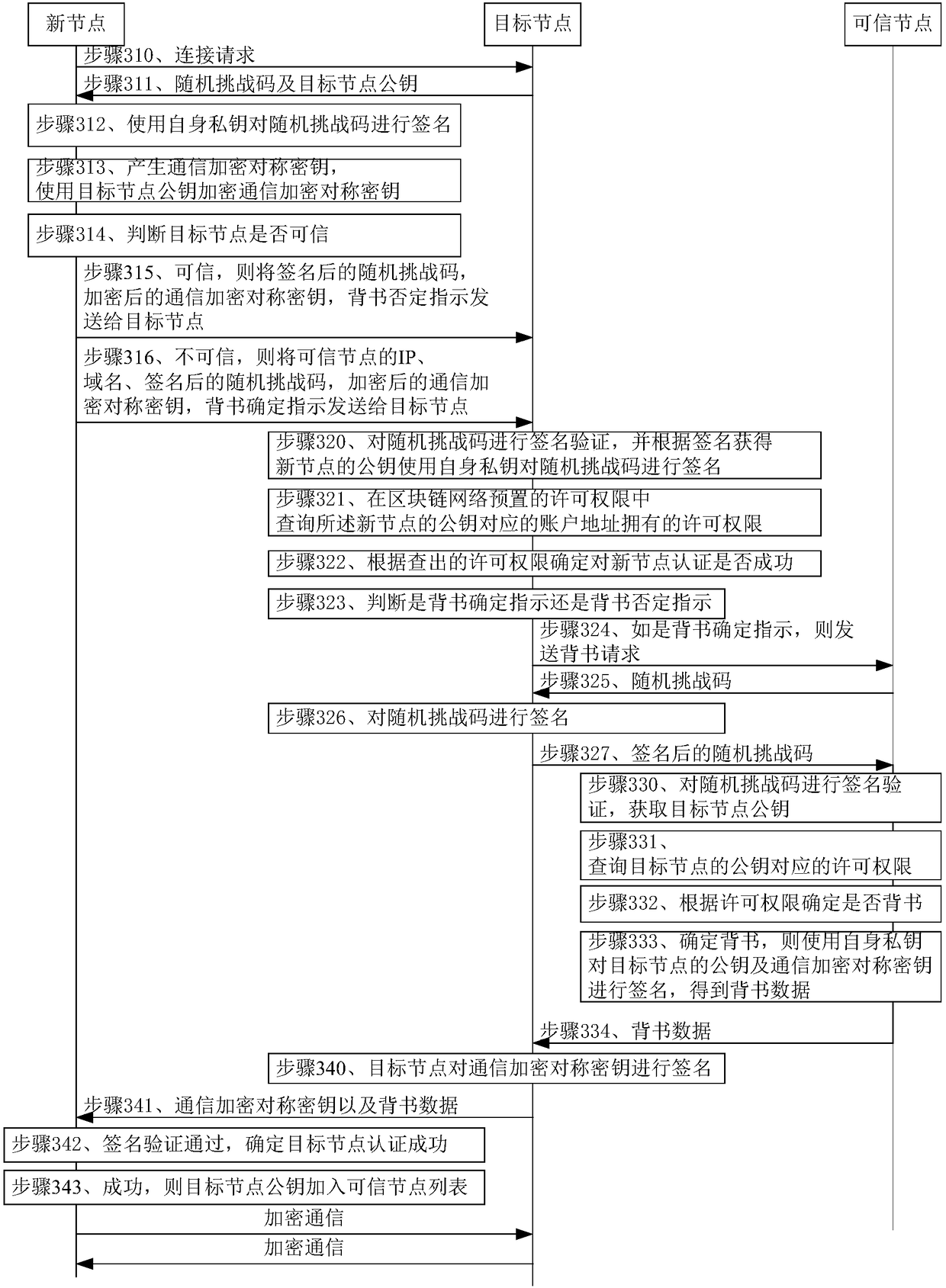

Method, apparatus, system, storage medium, and electronic device for securely accessing block chain

ActiveCN108235806AEnable secure accessReduce complexityUser identity/authority verificationThird partyChain network

The present disclosure proposes a method, an apparatus, a system, a storage medium, and an electronic device for securely accessing a block chain. The method comprises: preparing a new node accessingthe blockchain network to obtain endorsement data obtained by the trusted node preset in the block chain network using the private key to sign the target node public key, and performing signature verification on the endorsement data, if the signature After the verification is passed, it is determined that the identity authentication of the target node is successful, and the target node queries thepermission right of the new node's public key corresponding to the account address in the permission preset by the block chain network, and determines the new permission according to the checked permission. Whether the identity authentication of the node is successful. Therefore, the two-way authentication of the new node and the target node of the present disclosure directly utilizes the publicand private keys of the node of the block chain network node, and does not require a centralized third party to participate in the digital certificate, thereby avoiding the high complexity brought bythe digital certificate issuance. Secure access between nodes in the block chain network.

Owner:CLOUDMINDS SHANGHAI ROBOTICS CO LTD

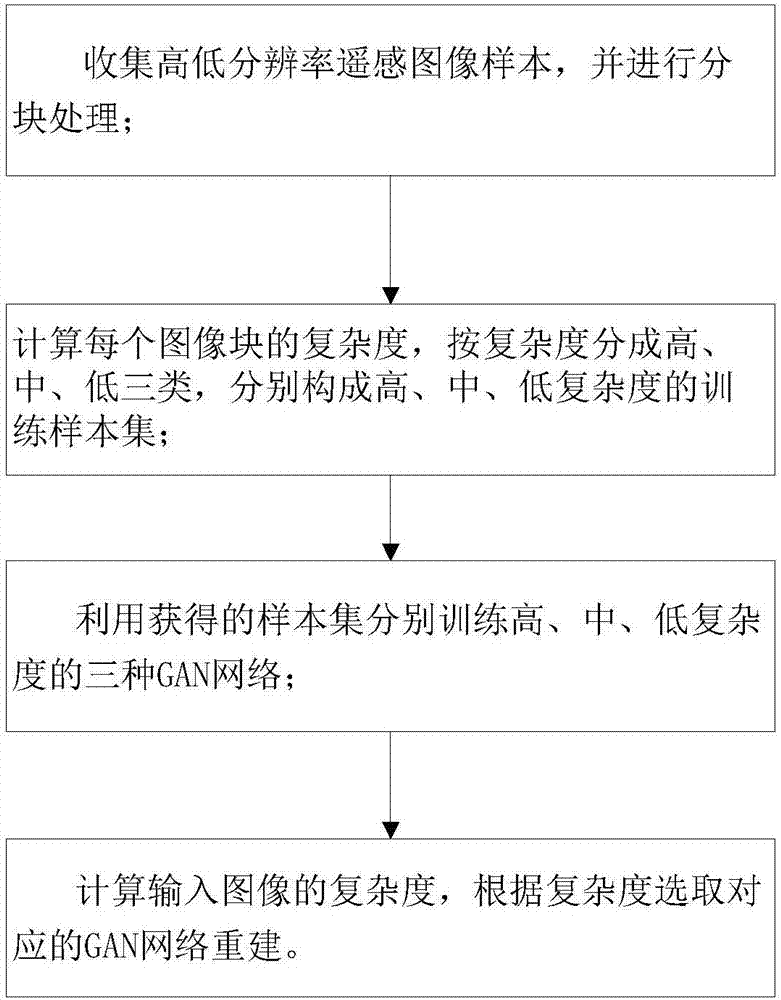

Content awareness deep learning network-based remote sensing image super-resolution reconstruction method

ActiveCN107194872AImproving the accuracy of super-resolution reconstructionOvercoming overfittingGeometric image transformationLearning basedReconstruction method

The invention discloses a content awareness deep learning network-based remote sensing image super-resolution reconstruction method. A comprehensive measurement index and a calculation method for content complexity of images are proposed; based on this, the sample images are classified by the content complexity; deep GAN models with low, medium and high complexity are built and trained; and according to the content complexity of the to-be-classified super-resolution input images, corresponding networks are selected for performing reconstruction. In order to improve learning performance of a GAN, an optimized loss function definition is given. The method overcomes the over-fitting and under-fitting contradiction ubiquitous in machine learning-based super-resolution reconstruction, and effectively improves the super-resolution reconstruction precision of the remote sensing images.

Owner:WUHAN UNIV

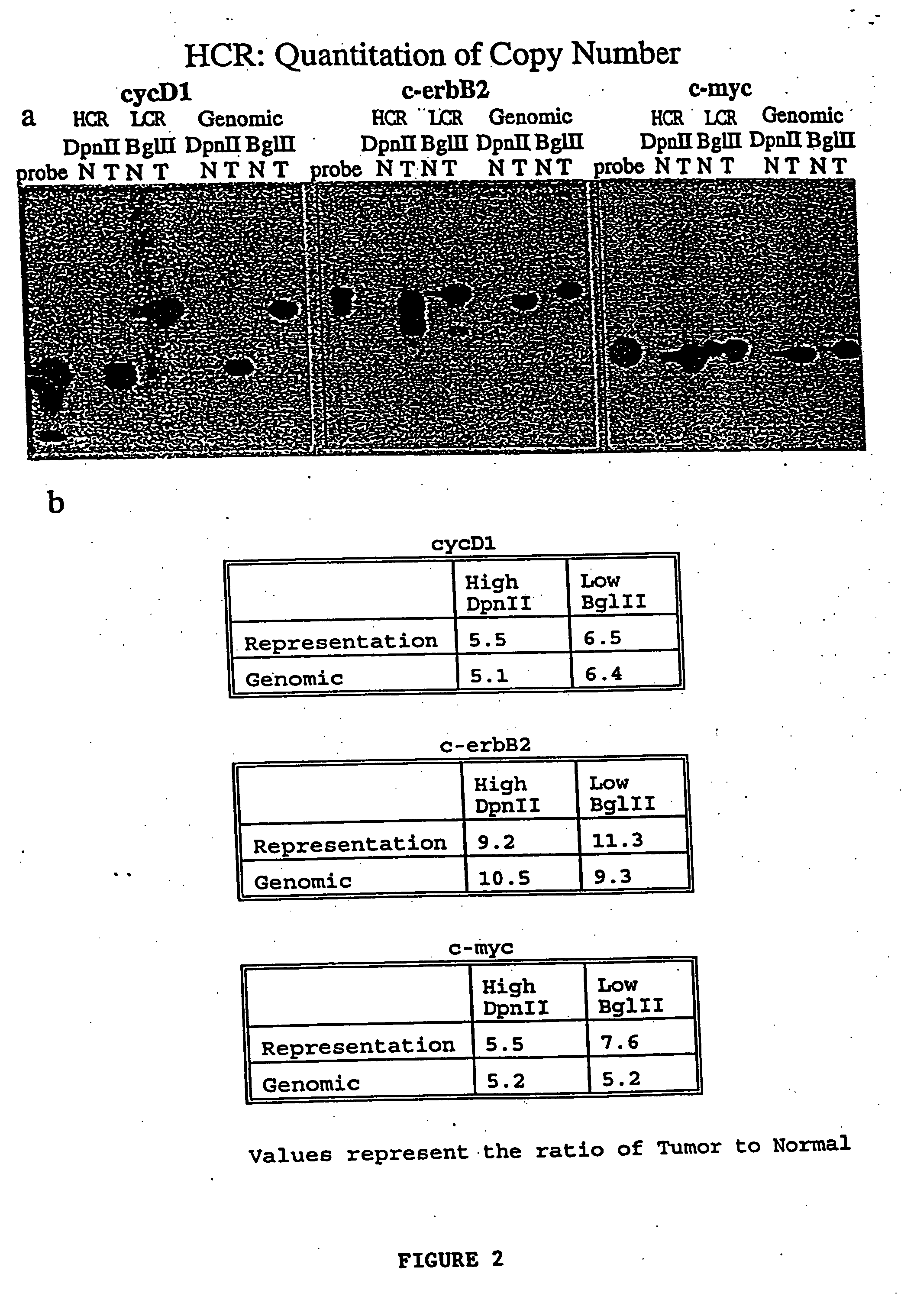

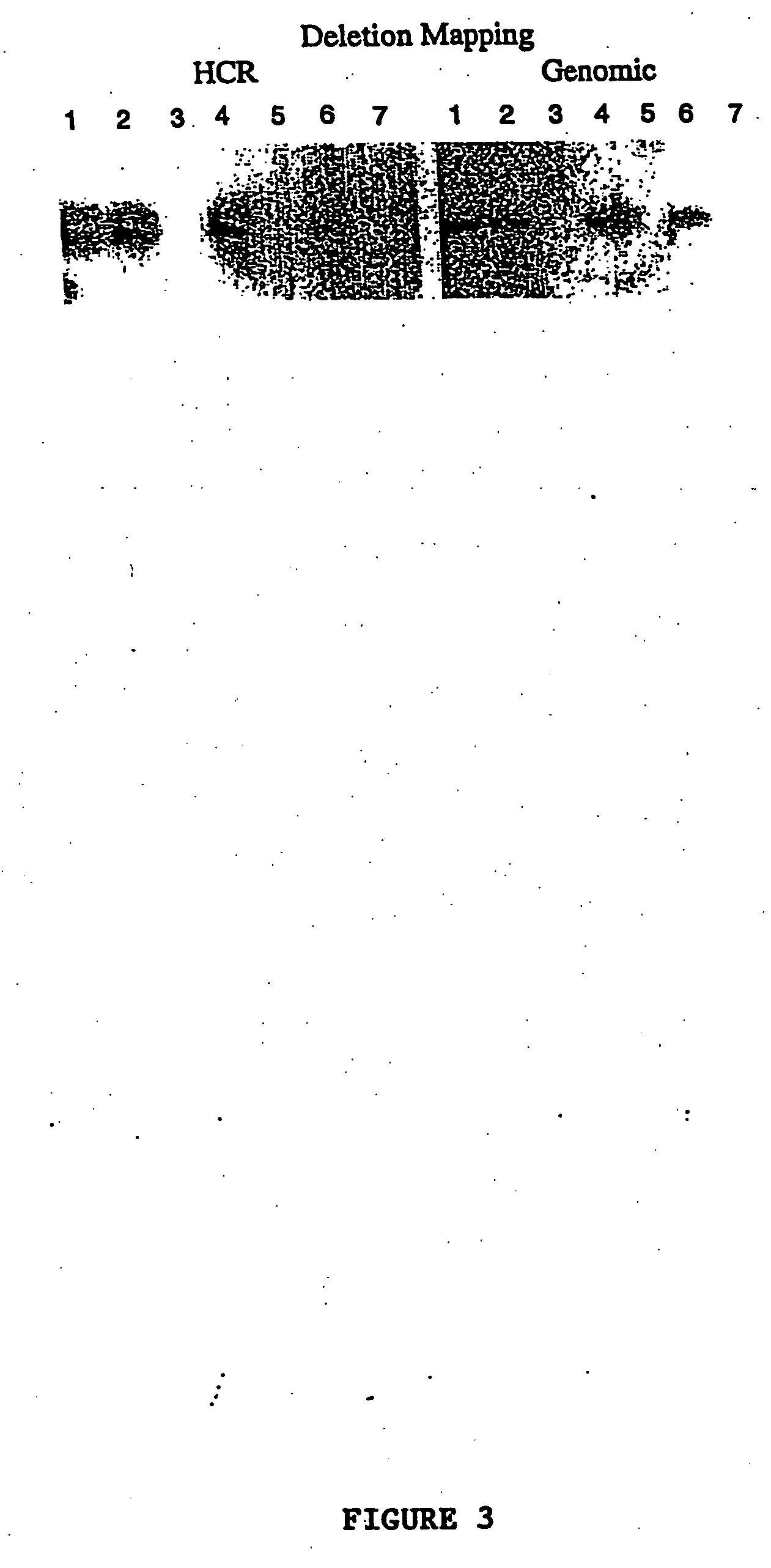

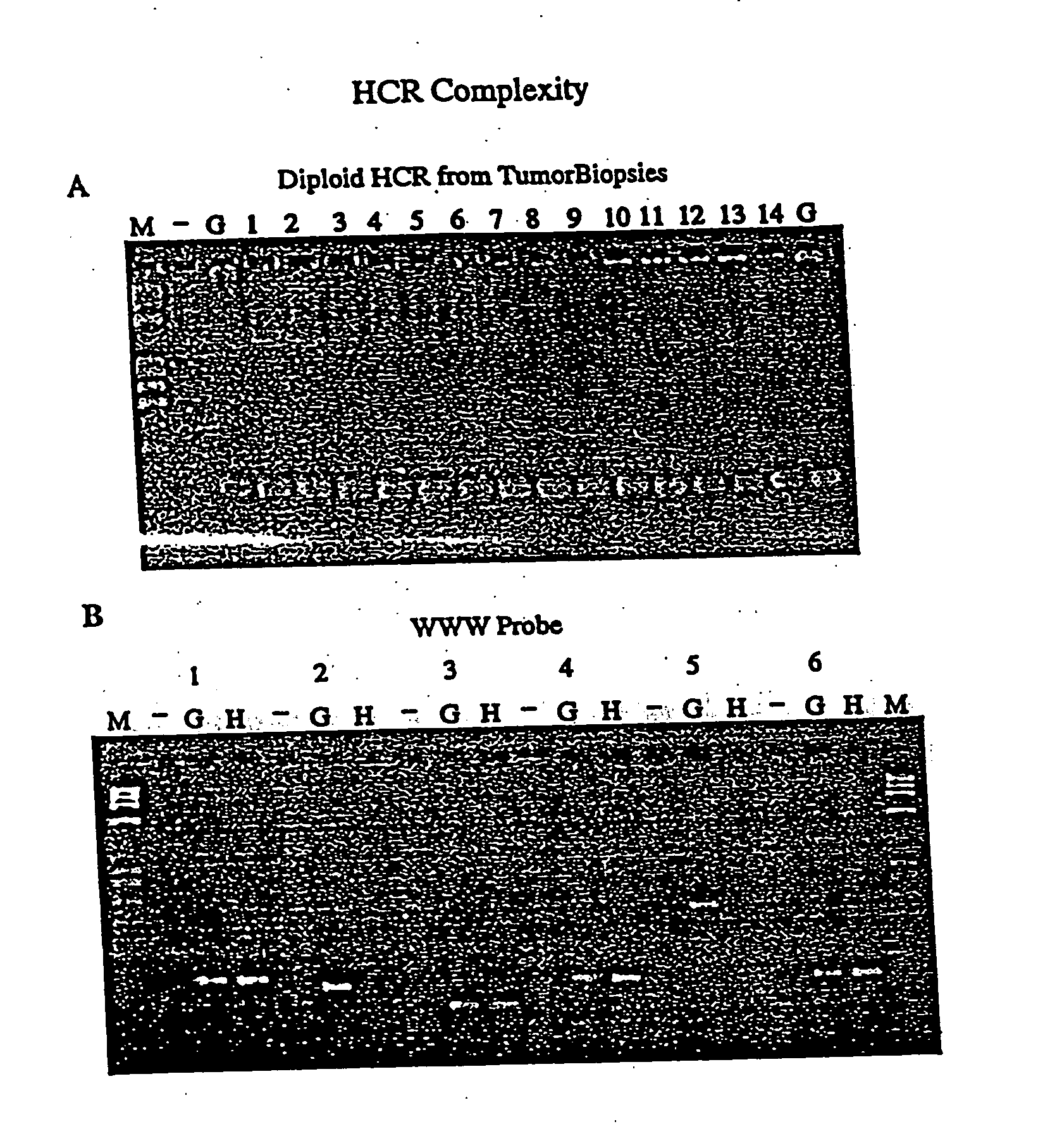

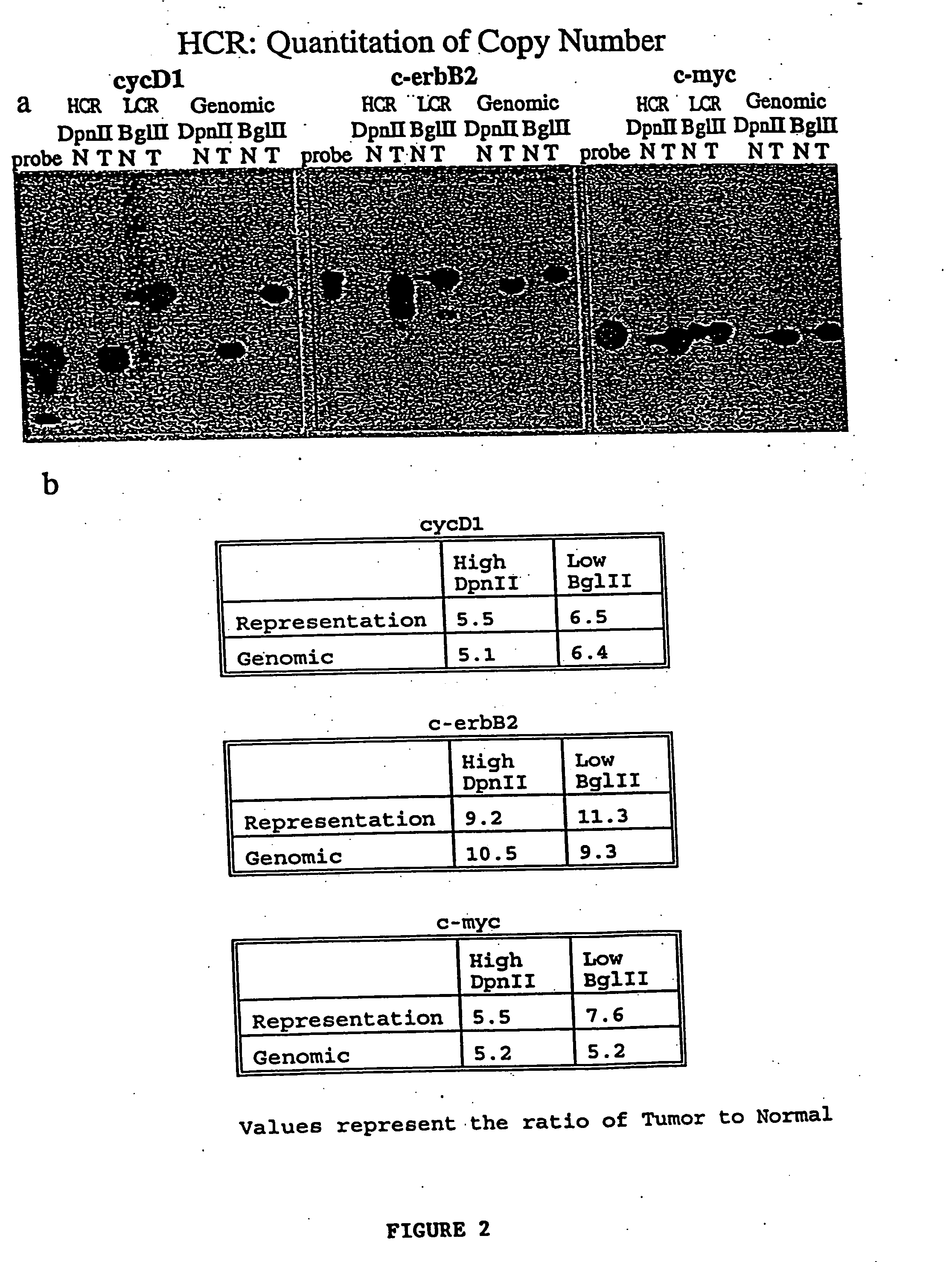

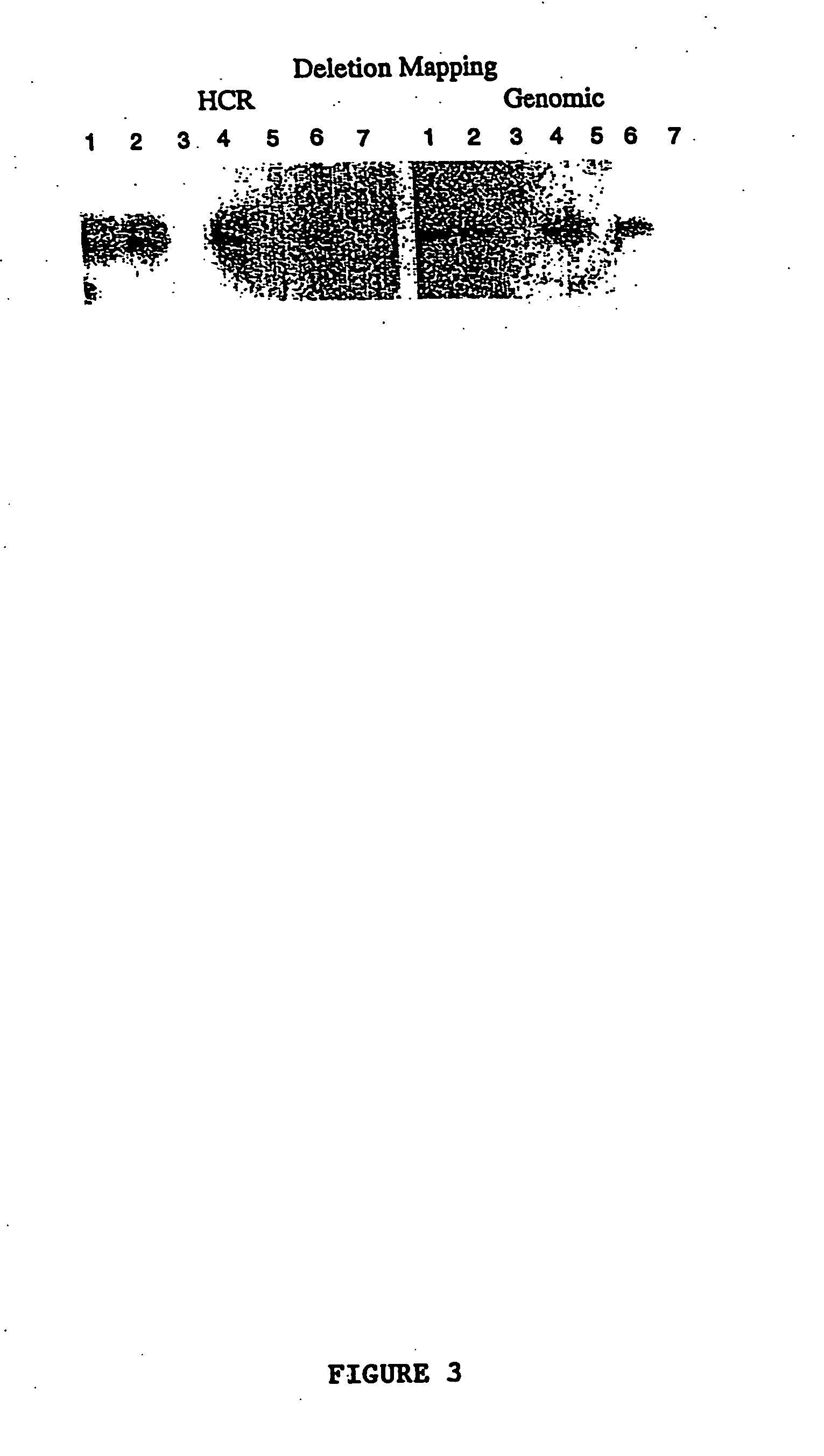

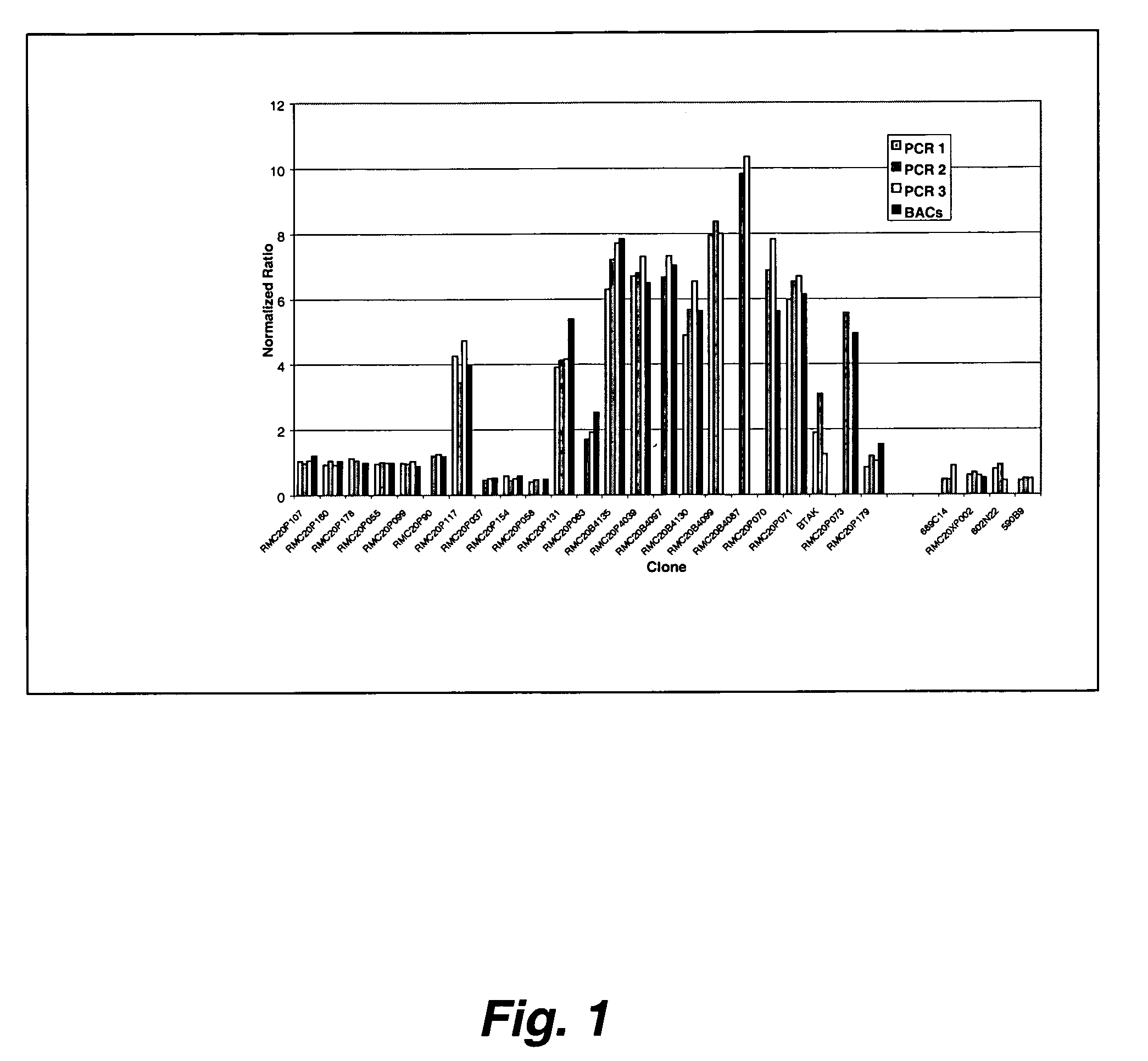

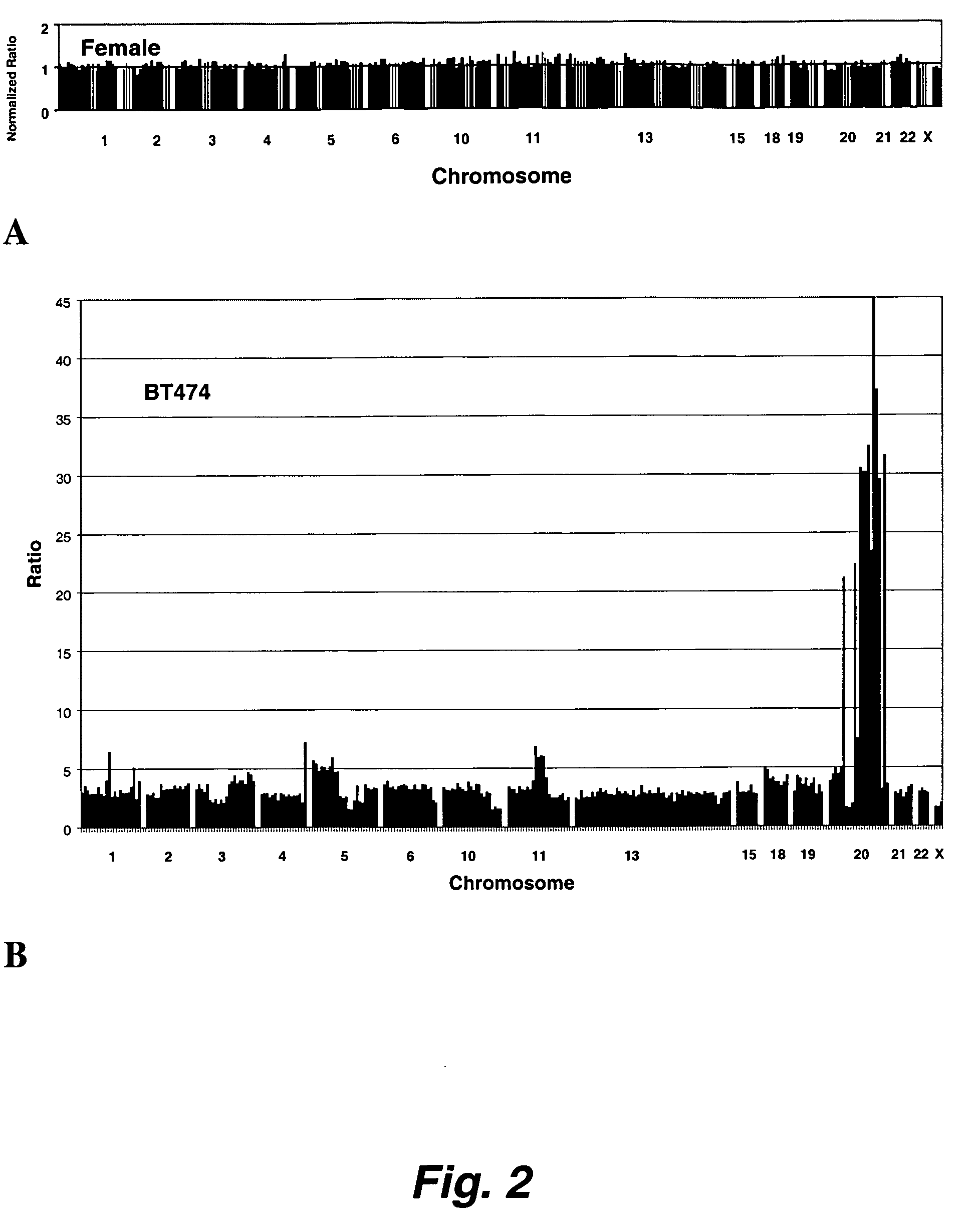

Use of representations of DNA for genetic analysis

InactiveUS20050266444A1Simplify complexityEfficient removalBioreactor/fermenter combinationsBiological substance pretreatmentsAnalysis dnaGenetic analysis

It is an object of the present invention to provide a solution to problems associated with the use of microarray technology for the analysis DNA. The present invention provides compositions and methods for the use of simple and compound representations of DNA in microarray technology. The present invention is also directed to methods for the production of High Complexity Representations (HCRs) of the DNA from cells.

Owner:COLD SPRING HARBOR LAB INC

Use of representations of DNA for genetic analysis

InactiveUS20050196799A1Simplify complexityEfficient removalBioreactor/fermenter combinationsBiological substance pretreatmentsAnalysis dnaGenetic analysis

It is an object of the present invention to provide a solution to problems associated with the use of microarray technology for the analysis DNA. The present invention provides compositions and methods for the use of simple and compound representations of DNA in microarray technology. The present invention is also directed to methods for the production of High Complexity Representations (HCRs) of the DNA from cells.

Owner:COLD SPRING HARBOR LAB INC

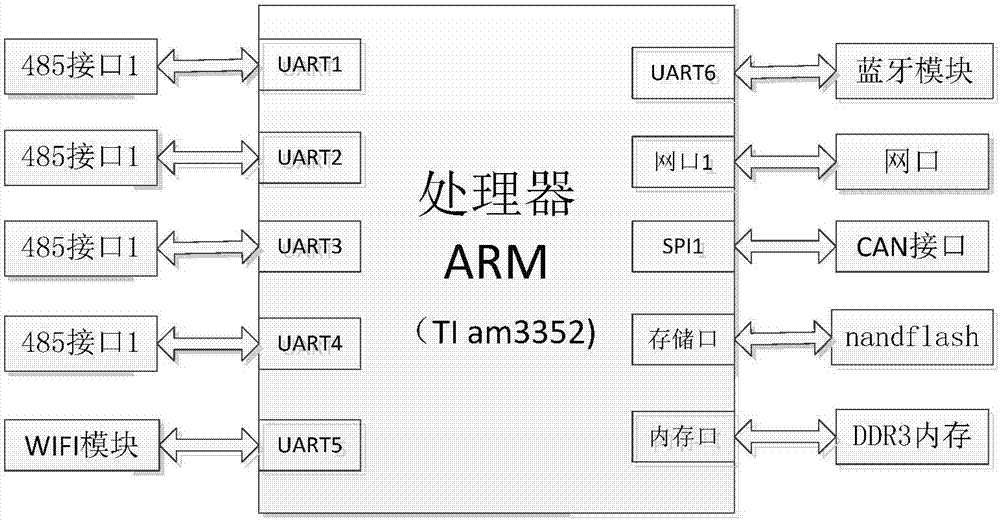

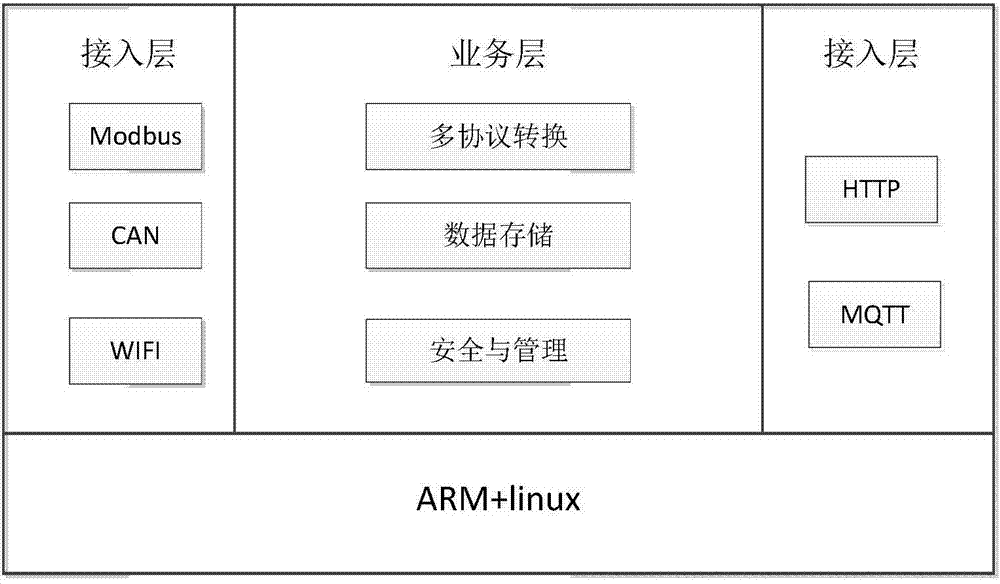

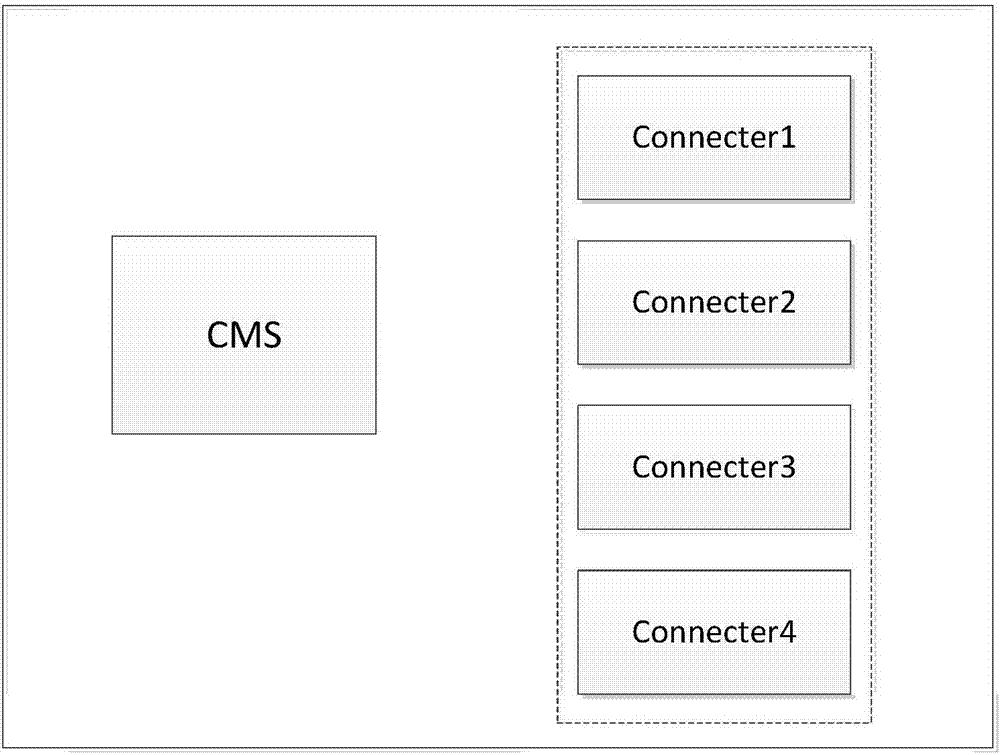

Internet of Things intelligent gateway for multi-data protocol conversion

ActiveCN106878163AExchange minimizationEfficient use ofNetwork connectionsThe InternetTechnical standard

The invention discloses an Internet of Things intelligent gateway for multi-data protocol conversion, and belongs to the technical field of the Internet of Things intelligent gateway. The intelligent gateway comprises the following functions: equipment management, multi-protocol accessing, protocol conversion and standard data format data transmission; the Internet of Things intelligent gateway comprises three parts: an embedded hardware platform, an operation system and application software. The intelligent gateway has the advantage that the predicament that multiple node and multiple protocol equipment is accessed into the Internet of Things cloud platform in low efficiency and high complexity is solved. The equipment access of multi-protocol is supported, and Internet of Things protocol data can be uploaded the cloud platform, thereby facilitating the popularization and transplanting of the intelligent gateway in the industrial and urban Internet of Things project. By adding an equipment management and configuration module, the use of the user is greatly facilitated.

Owner:AUTOMATION RES & DESIGN INST OF METALLURGICAL IND

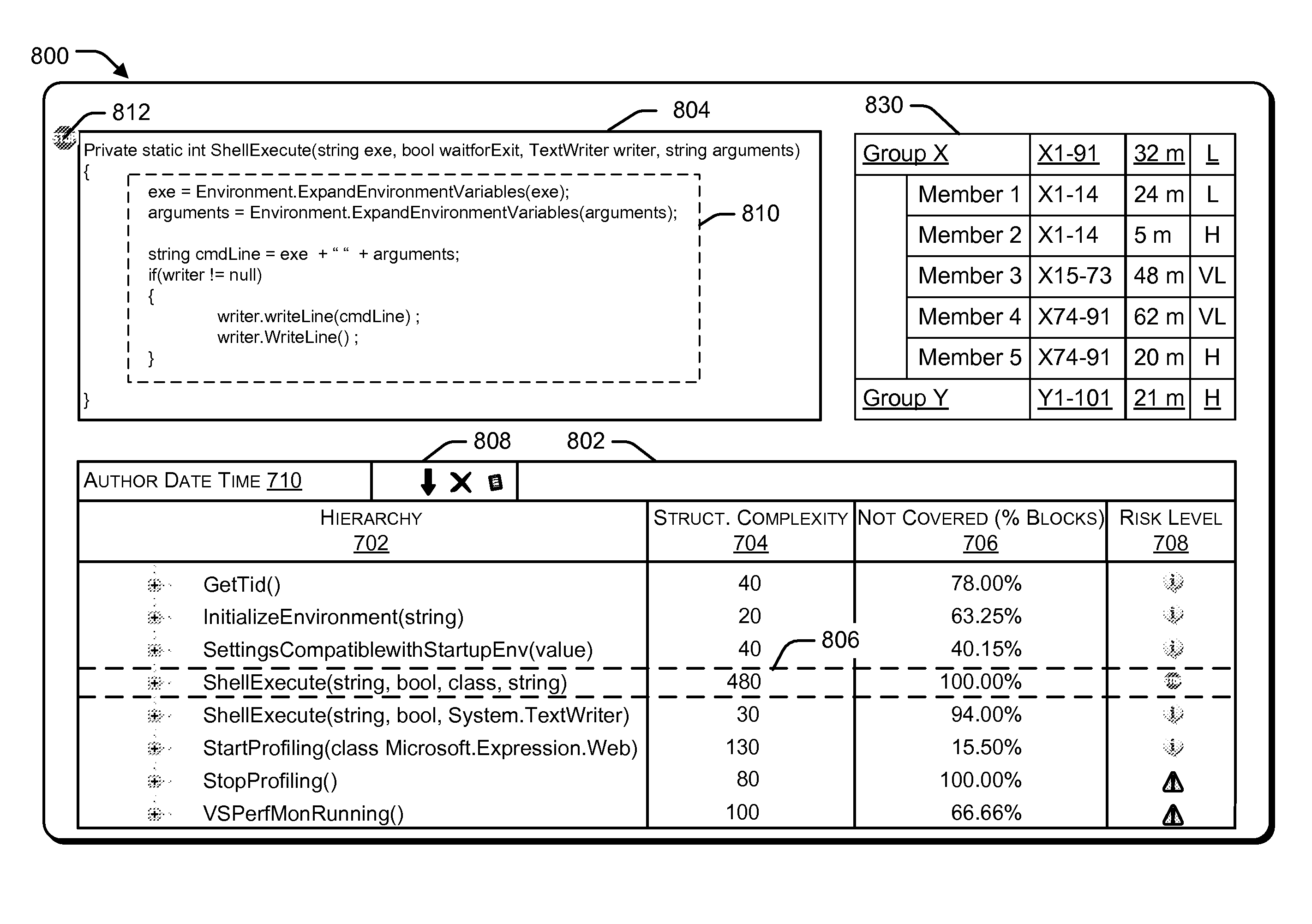

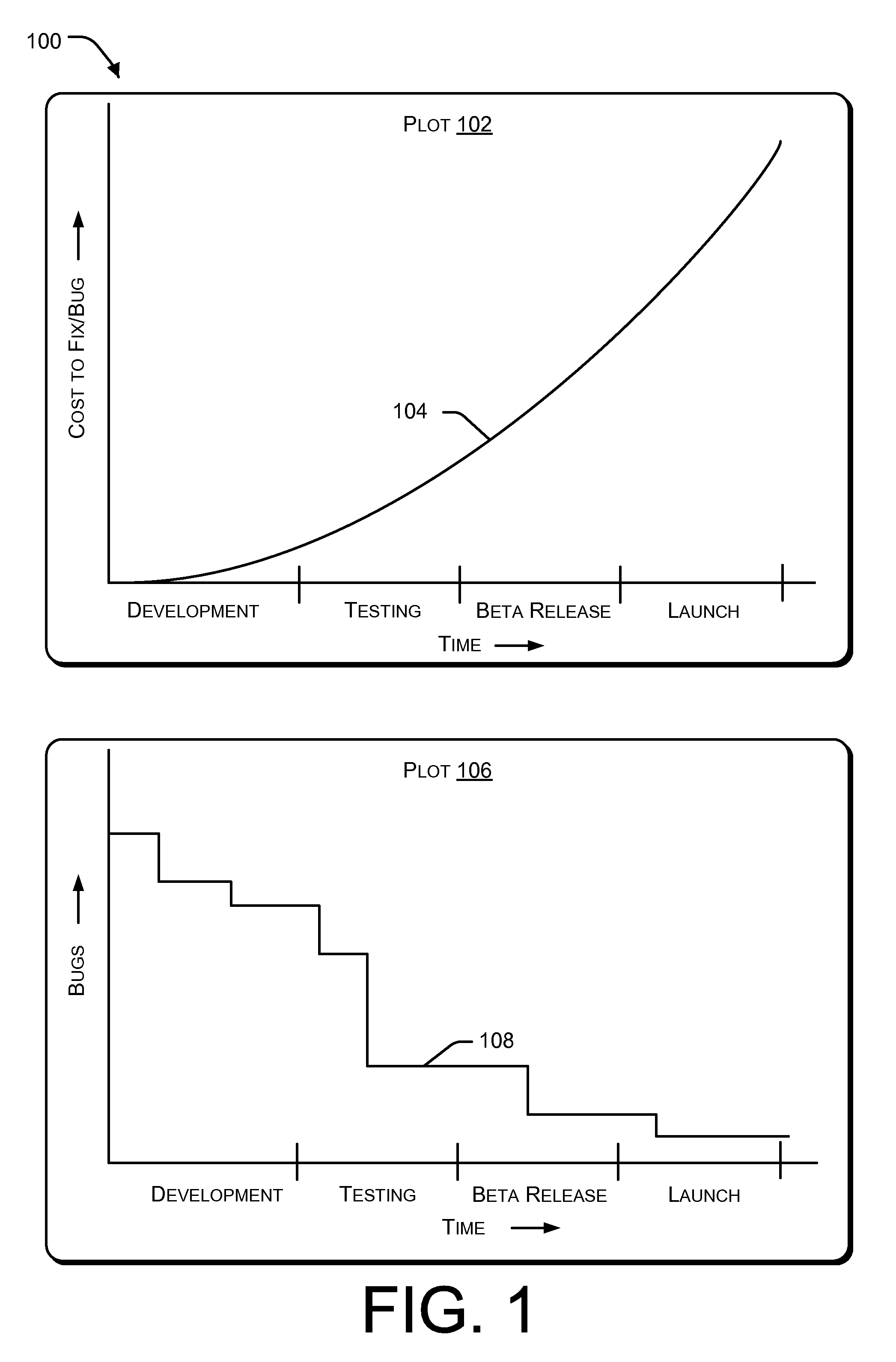

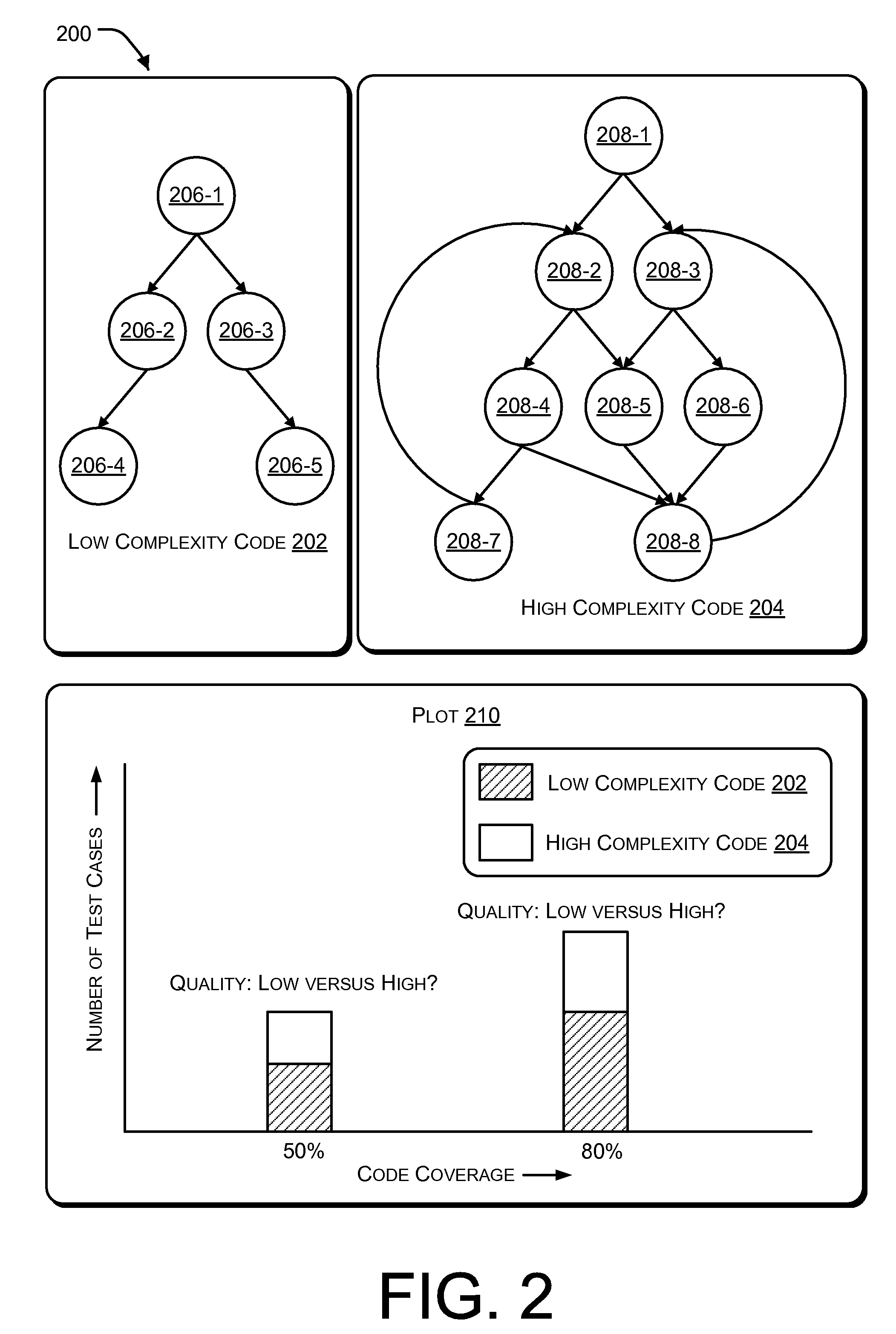

Prioritizing quality improvements to source code

ActiveUS8627287B2Simple conceptQuality improvementError detection/correctionReverse engineeringQuality levelParallel computing

An exemplary method includes receiving source code having a plurality of code segments, providing a desired level of quality for the source code, analyzing the source code to assign a complexity measure to each of the plurality of code segments and assigning a level of code coverage to each of the plurality of code segments based at least in part on the desired level of quality and the complexity measures. An exemplary system prioritizes quality improvements to source code based, in part, on a quality assessment. Such a system can improve code quality by assigning higher test coverage levels to modules with higher complexity.

Owner:MICROSOFT TECH LICENSING LLC

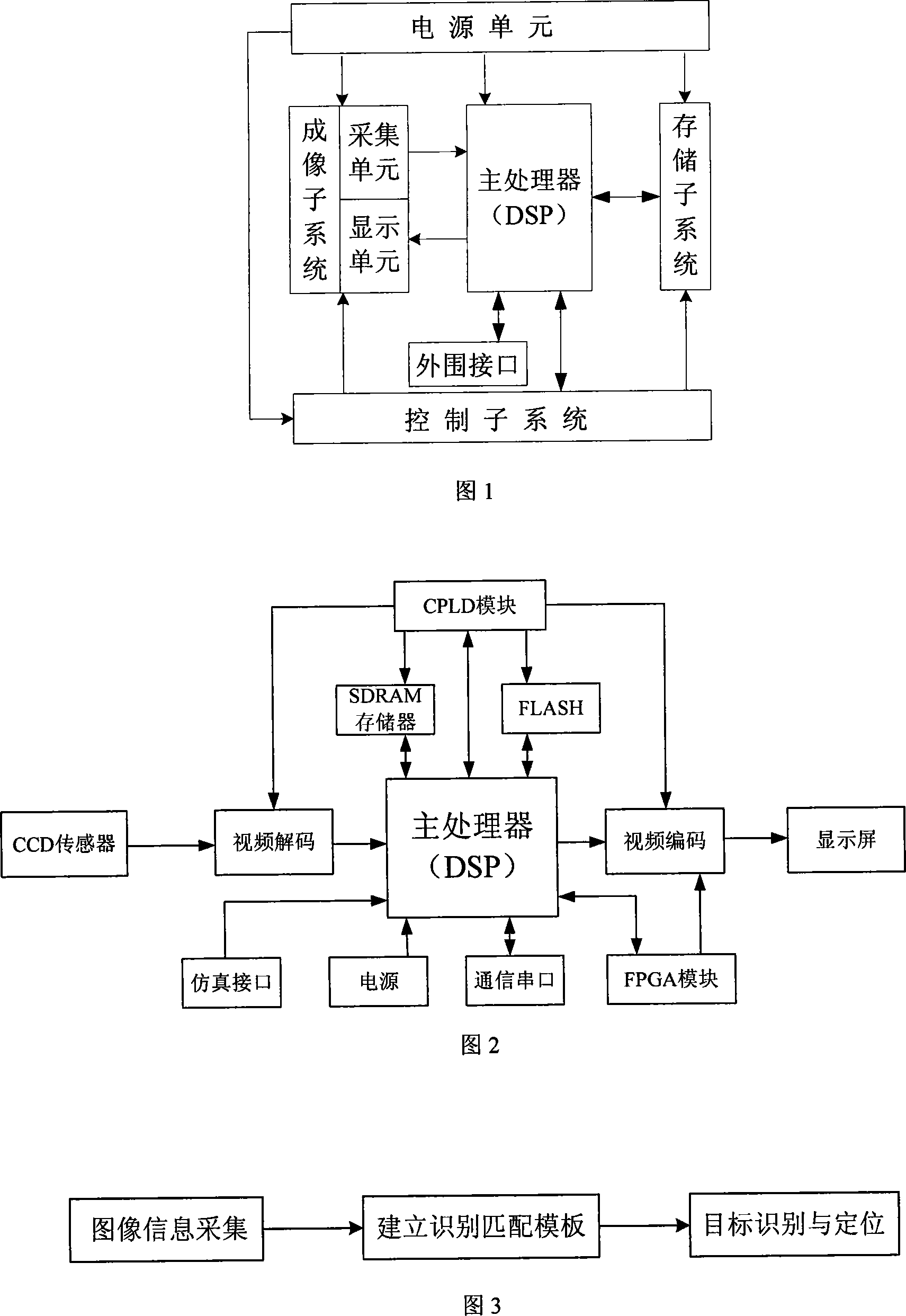

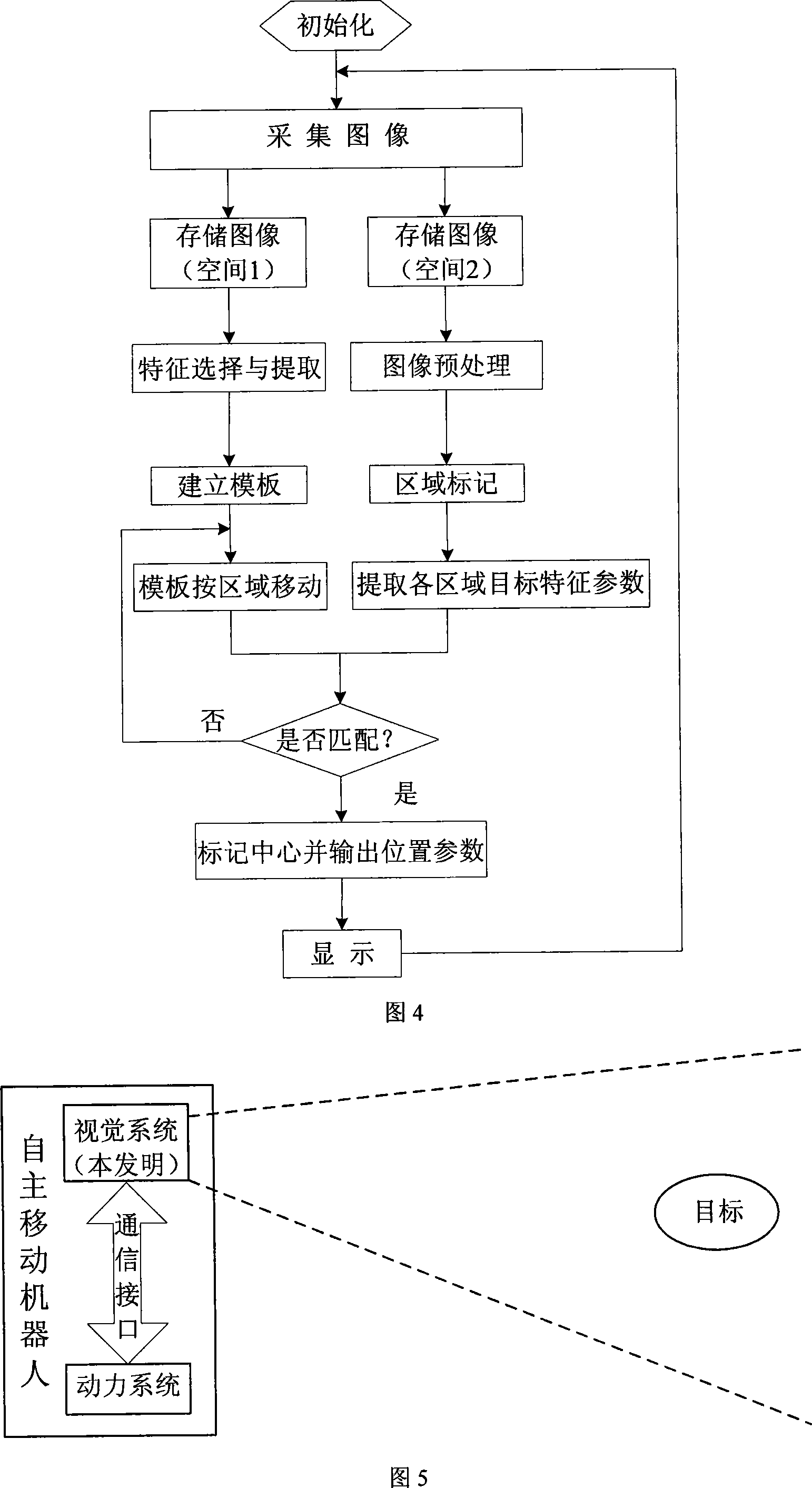

Quick target identification and positioning system and method

InactiveCN101145201ASimple structureHighly integratedCharacter and pattern recognitionImaging processingSystem structure

A rapid target-identification and positioning system and a method relate to DSP and CPLD, FPGA technologies, as well as to image processing and mode recognition technologies. The system comprises a power unit, an imaging subsystem, a main processor, a memory subsystem, a control subsystem and an external interface circuit. The system is characterized in that being the calculating core of the whole system, the main processor is connected with all subsystems; and the imaging subsystem and the memory subsystem are respectively connected with the control subsystem; the digital signal collected, converted and input by the collecting unit of the image subsystem is submitted into the main processor and displayed by the display unit of the image subsystem after being processed; the power unit which is connected with the imaging subsystem, the main processor, the memory subsystem and the control subsystem can be used for supplying working voltage for collecting, displaying and processing signal and for the control of processing; the system has simple structure, high complexity, small size, high processing speed, and high identification rate.

Owner:UNIV OF SCI & TECH BEIJING +2

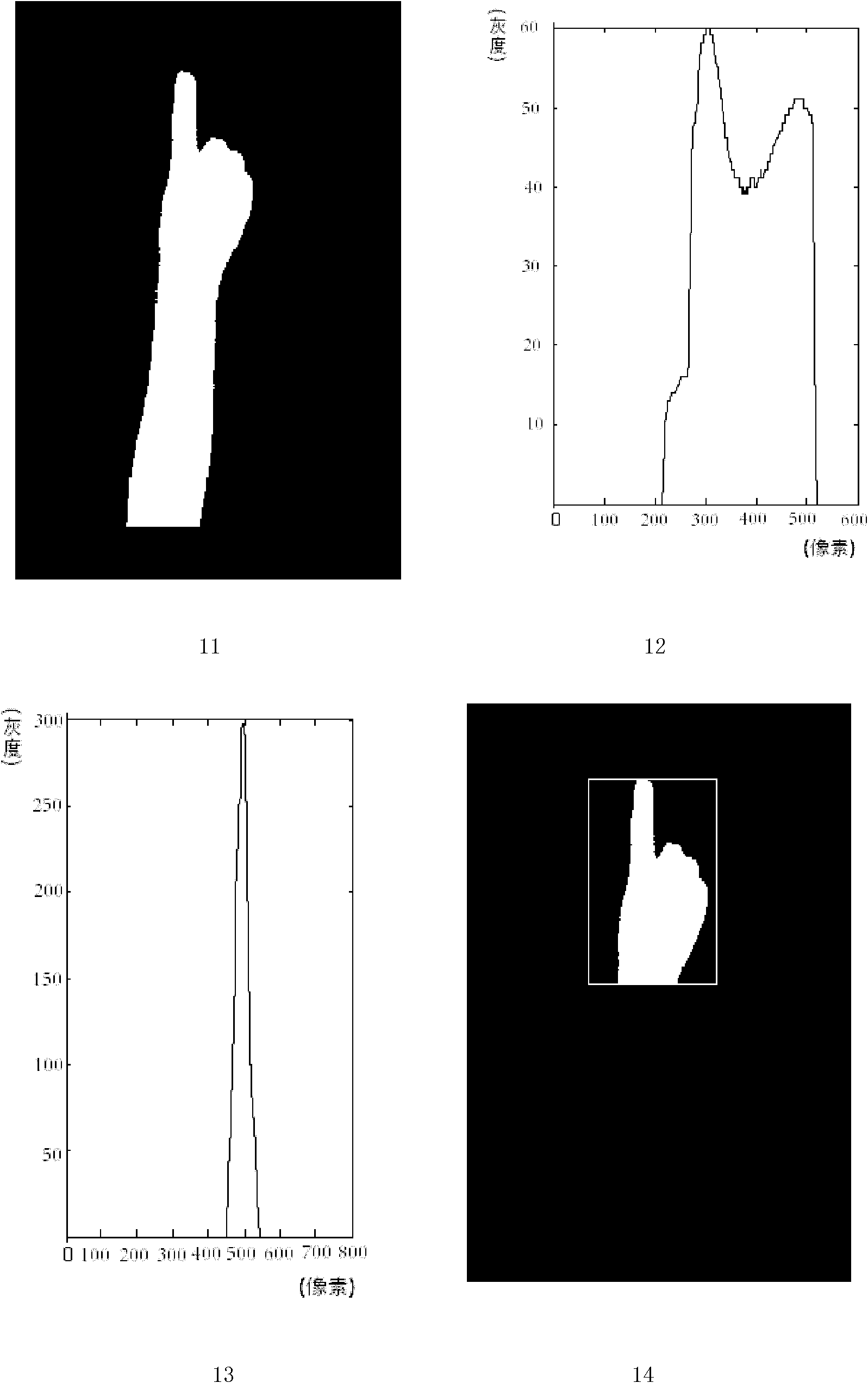

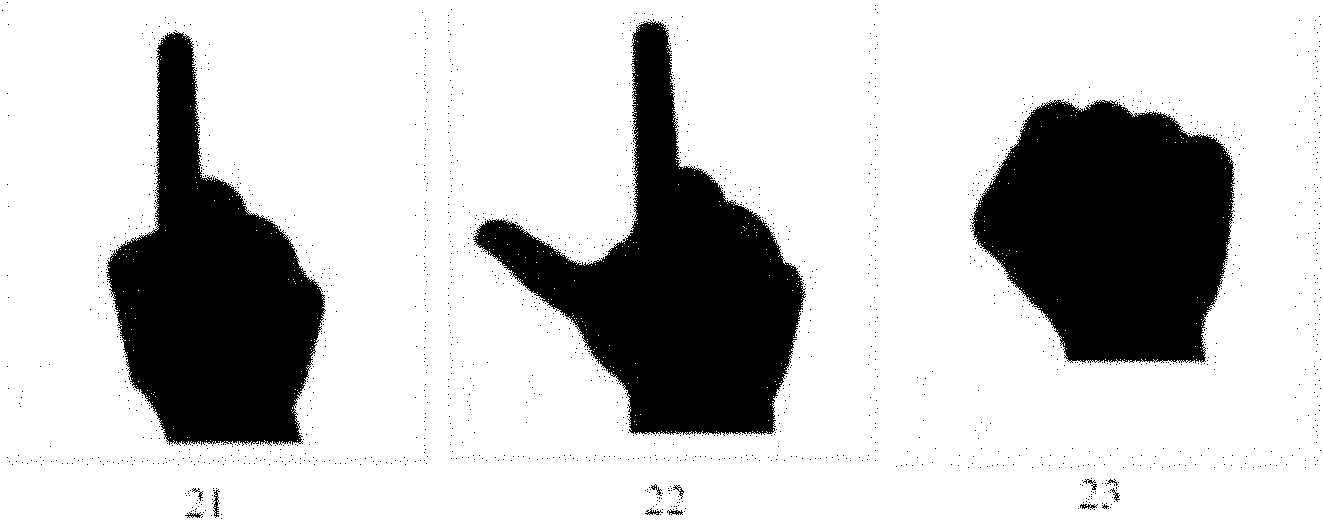

Dynamic gesture identification method in interactive system

ActiveCN102063618AOvercoming complexityOvercoming real-timeInput/output for user-computer interactionCharacter and pattern recognitionInteraction systemsGray level

The invention discloses a dynamic gesture identification method in an interactive system, comprising the following four steps of: acquiring an image, and obtaining a current image frame after denoising; obtaining a moving region of the image by calculating the difference of the current image frame and a reference image frame, and obtaining a binary image by a skin color detection method; carrying out gesture segmentation on the binary image by a gray level projection method to obtain a gesture region and a barycentric position; and obtaining a final identification result by a classification identification method according to the barycentric position and fingertip characteristics. The method can be used for overcoming the problems of high complexity, low real-time quality and low identification rate in traditional algorithms, has the advantages of simplicity in implementation, good real-time quality and high identification rate, and can be applied to the dynamic gesture identification very well. Moreover, the method can tolerate the translation of a definition gesture, the scale and the transformation of a rotation angle, and has a good robustness.

Owner:CHINA KEY SYST & INTEGRATED CIRCUIT

Detection of nucleic acid sequence differences by comparative genomic hybridization

InactiveUS20060063168A1Microbiological testing/measurementComparative genomic hybridizationNucleotide

The present invention provides a method of detecting nucleotide sequence differences between two nucleic acid samples. The method employs a comparative genomic hybridization (CGH) technique to analyze the sequence differences between the samples. This method permits the identification of small sequence differences (e.g., sequence divergence of 1% or less) in nucleic acid samples of high complexity (e.g., an entire genome).

Owner:RGT UNIV OF CALIFORNIA

Variable bit video streams for adaptive streaming

ActiveUS8689267B2Improve playback qualityPulse modulation television signal transmissionMultiple digital computer combinationsComputer graphics (images)Network conditions

One embodiment of the present invention sets forth a technique for adapting playback bit rate in a content delivery system based on scene complexity of the video content as well as network conditions and other performance factors. A scene complexity map of the video content indicates the complexity levels of different scenes within the video content. Using the scene complexity map, a content player may download scenes of lower scene complexity levels from video streams encoded to lower bit rates to manage the bandwidth consumed to download the video content and allow for the downloading of scenes of higher complexity levels from video streams encoded to higher bit rates.

Owner:NETFLIX

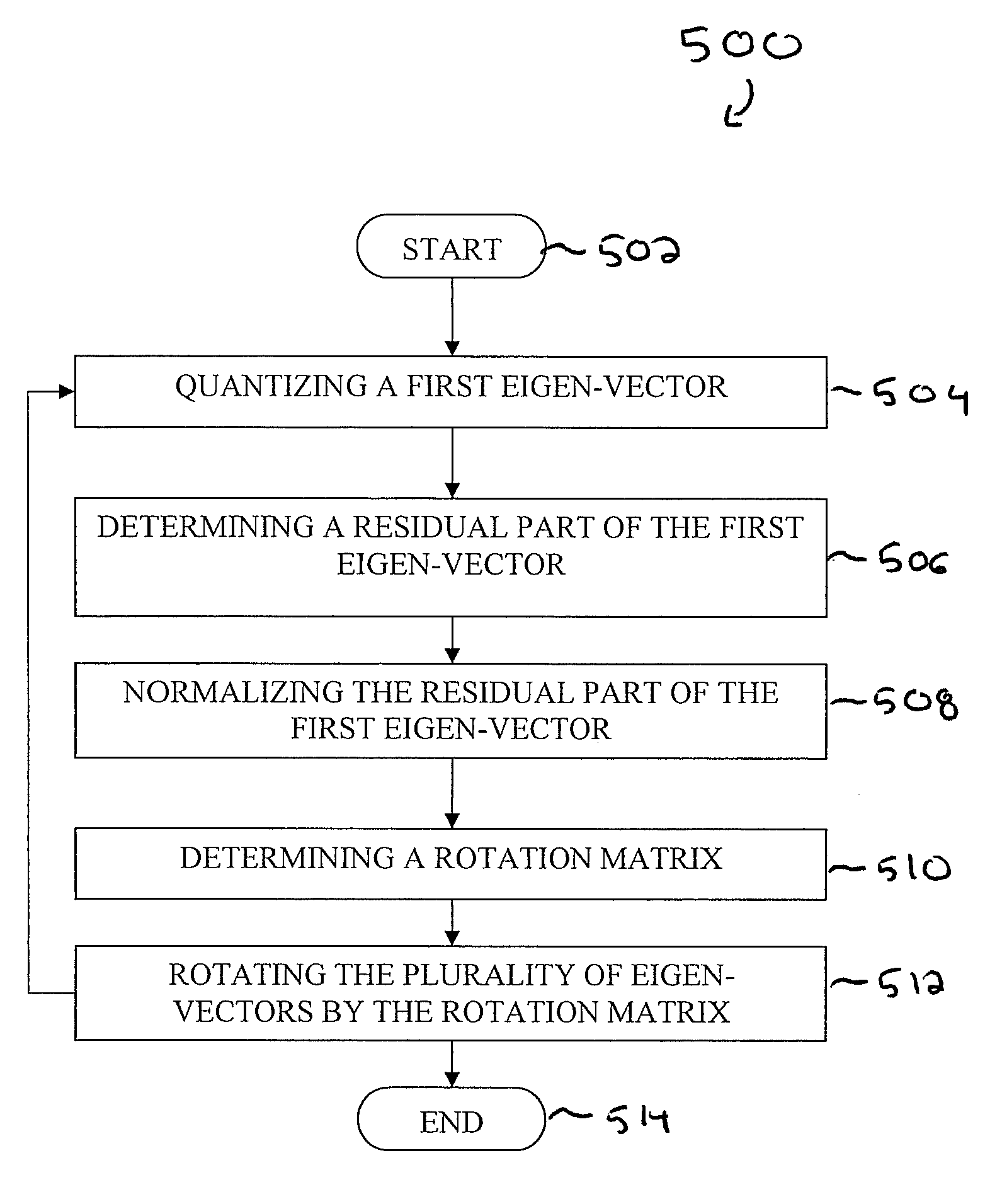

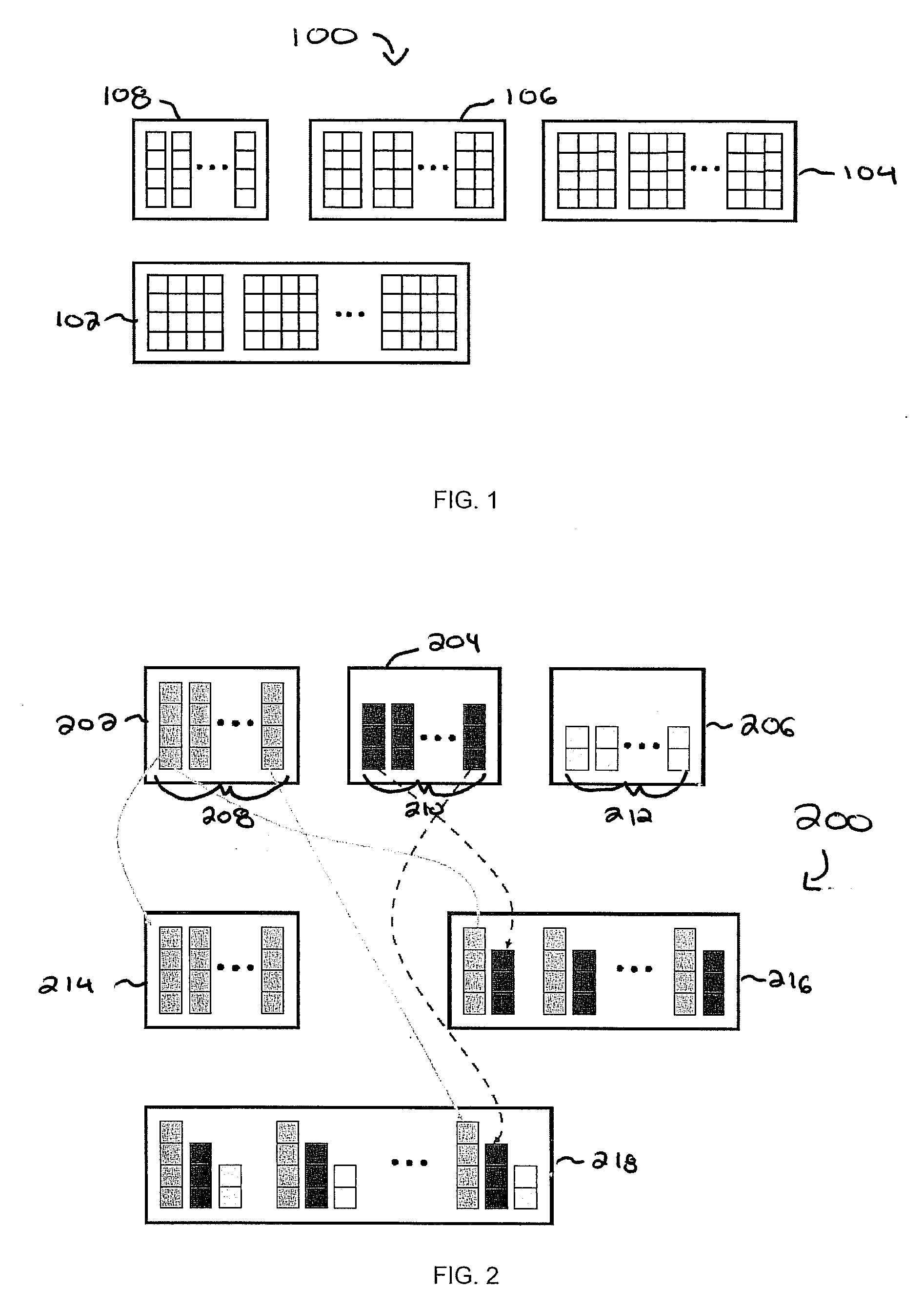

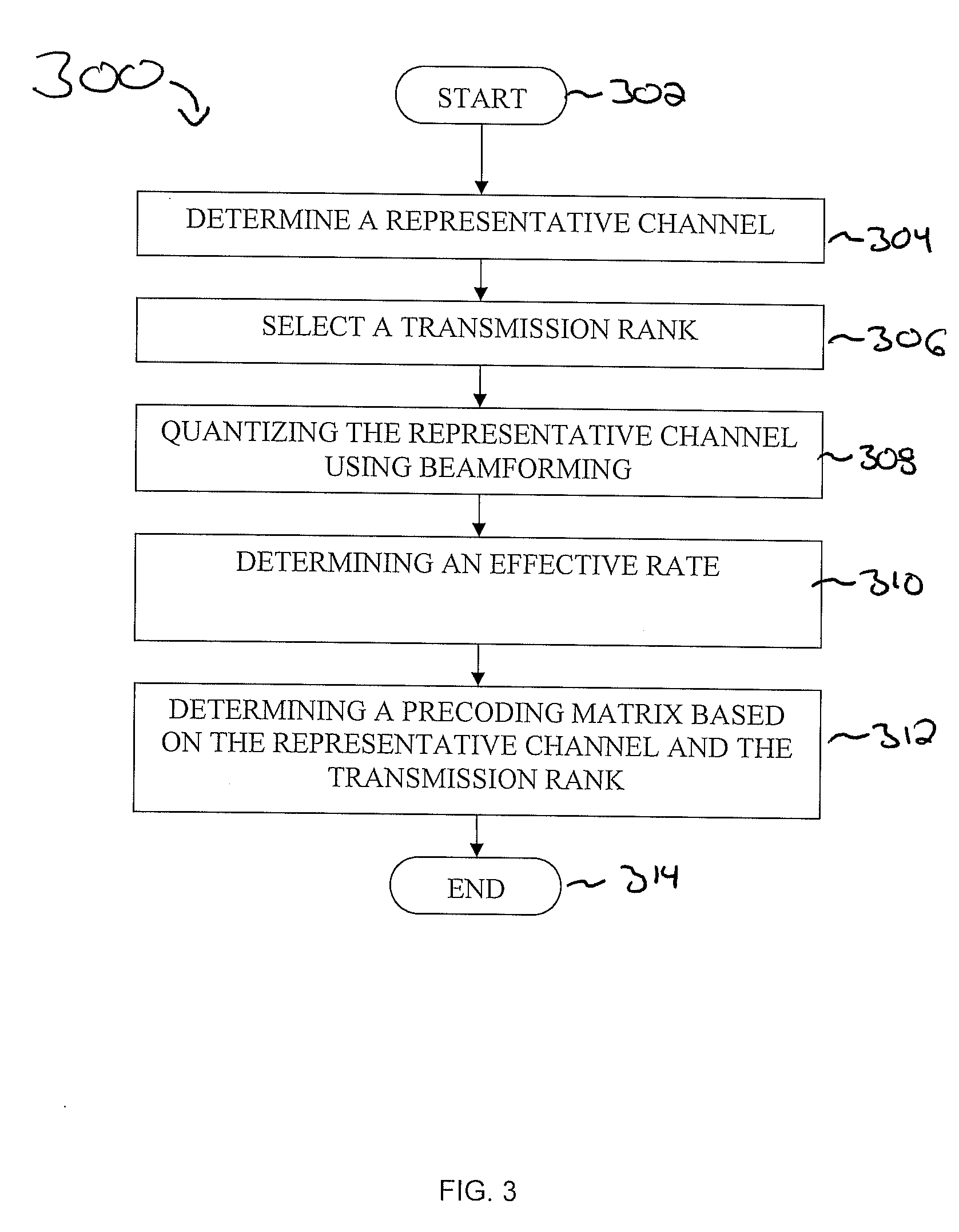

Quantized Precoding Over a Set of Parallel Channels

ActiveUS20080049596A1Reduce computational complexityImprove performanceFrequency-division multiplexRadio transmissionRound complexityEngineering

Methods and apparatus are disclosed for applying successive multi-rank beamforming strategies (e.g., successive preceding strategies) for the design of precoders over a set of parallel channels. Successive beamforming is applied to a narrow band channel model and is also applied for finer quantization of a single beamforming vector (e.g., recursive beamforming). A first embodiment provides the optimal approach with high complexity. An alternative embodiment provides successive beamforming for near optimal preceding selection with medium complexity. A low complexity method for precoder selection is also provided wherein a channel representative matrix for the set of parallel channels is determined and successive beamforming on the calculated channel representative is applied.

Owner:NEC CORP

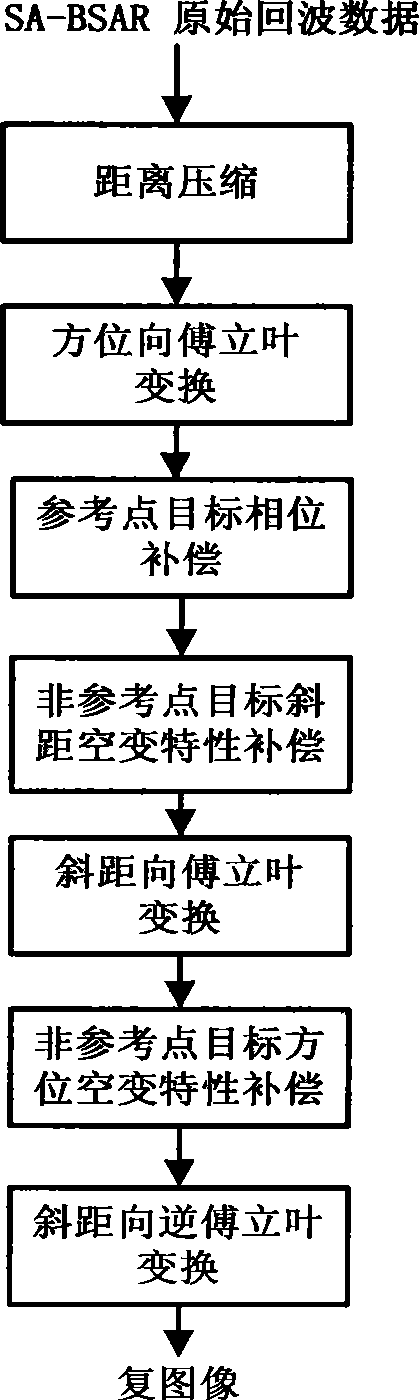

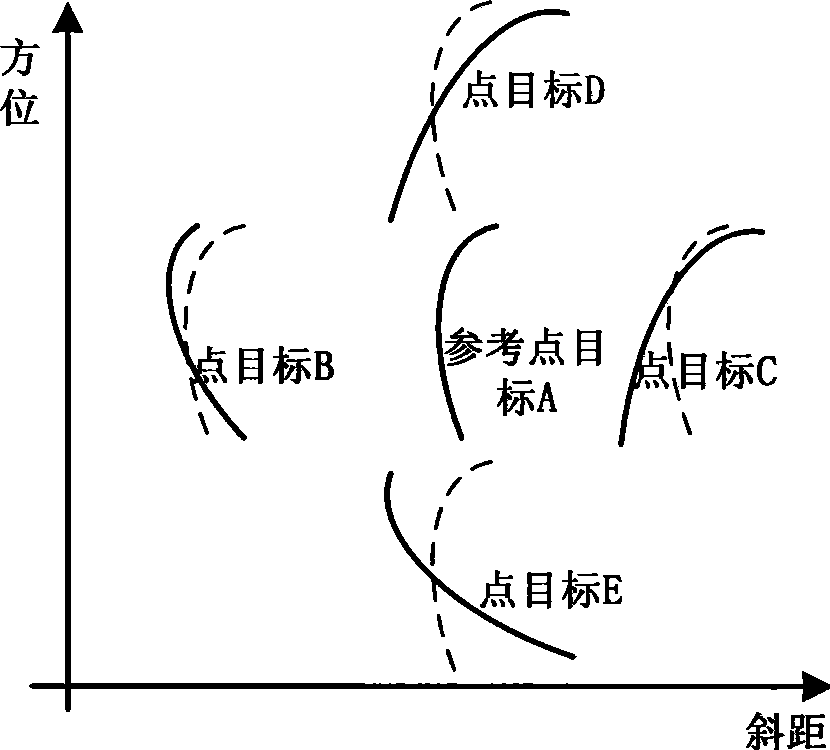

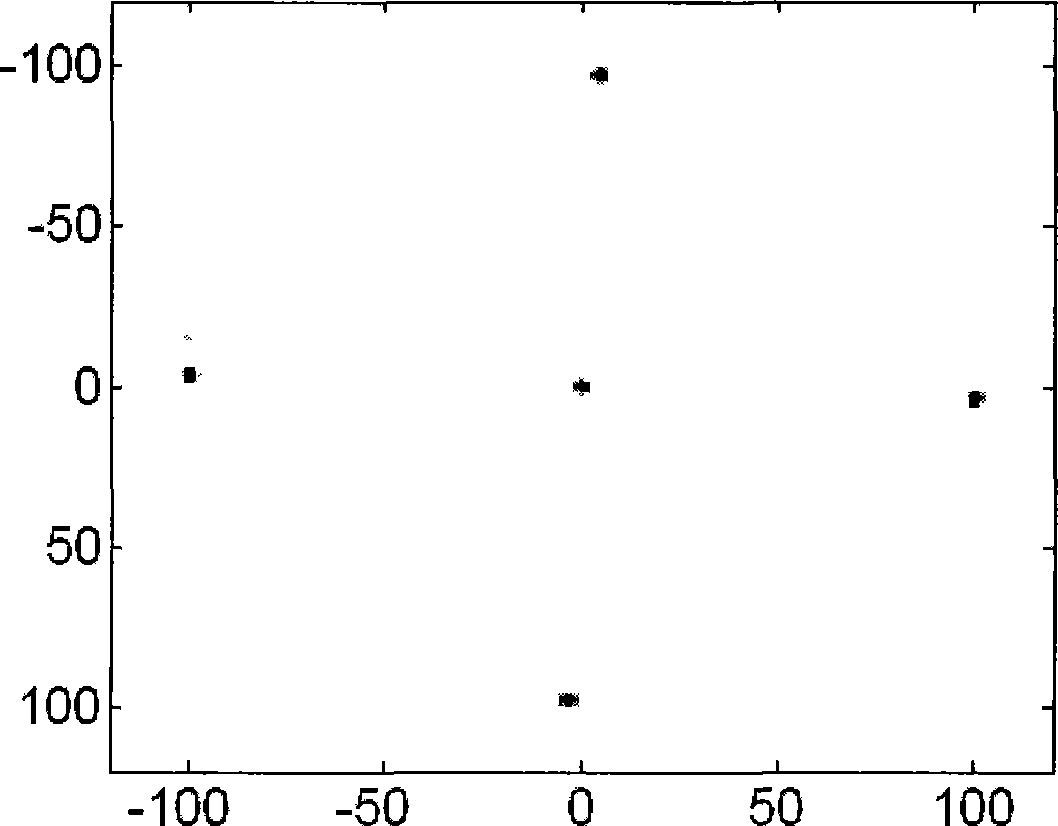

Satellite machine combined double-base synthetic aperture radar frequency domain imaging method

InactiveCN101369018AEasy to solveImprove computing efficiencyRadio wave reradiation/reflectionFrequency spectrumSynthetic aperture radar

The invention provides a satellite-machine combined frequency domain imaging method of Bistatic Synthetic Aperture Radar (Bistatic SAR), which utilizes characteristics of the SA-BSAR system to obtain the analytical expression of two-dimensional spectrum of the system, and then utilizes Omega-k algorithm thought to obtain SA-BSAR two-dimensional Stolt mapping relation according to the expression of the two-dimensional spectrum; finally, two-dimensional Stolt interpolation can be approximately achieved by using inverse scale Fourier transform and phase multiplication in frequency domain through studying the two-dimensional Stolt mapping relation, so as to complete the compensation for the two-dimensional space variance of the system; the method can avoid the problem of huge calculation and high complexity caused by two-dimensional Stolt interpolation, thereby effectively achieving SA-BSAR imaging with high resolution.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

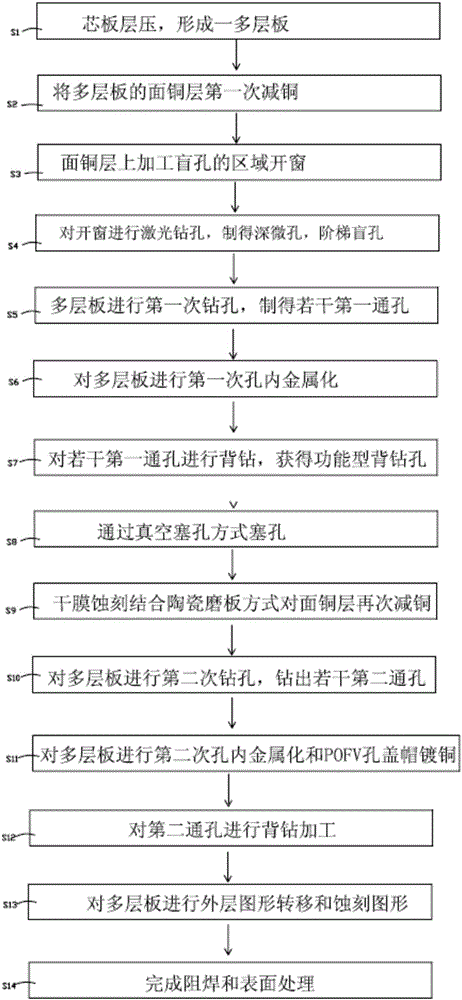

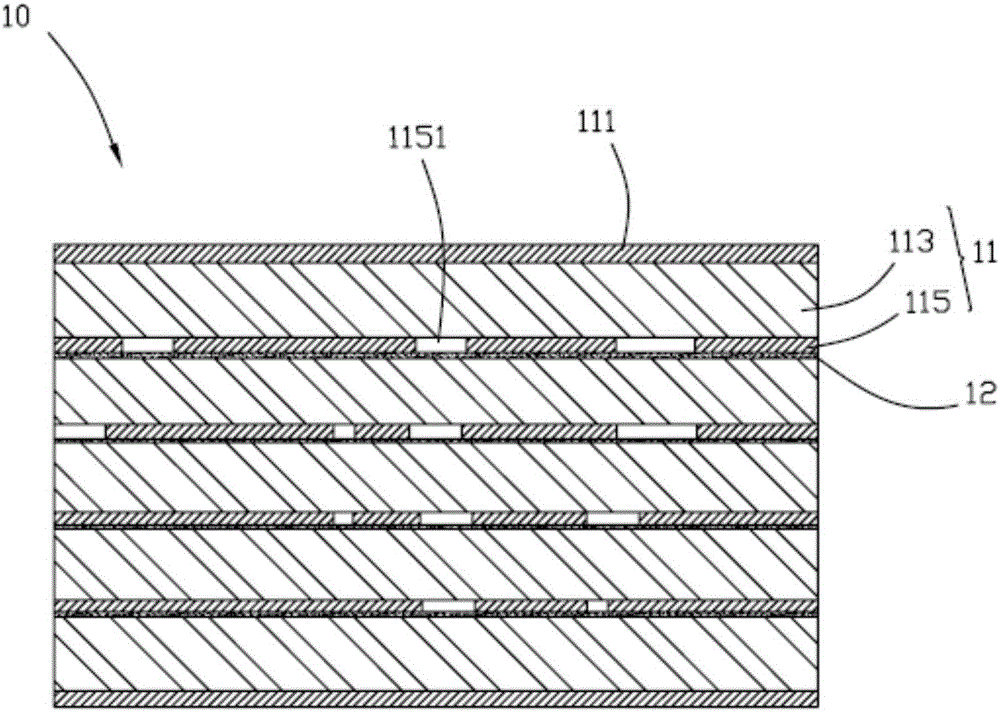

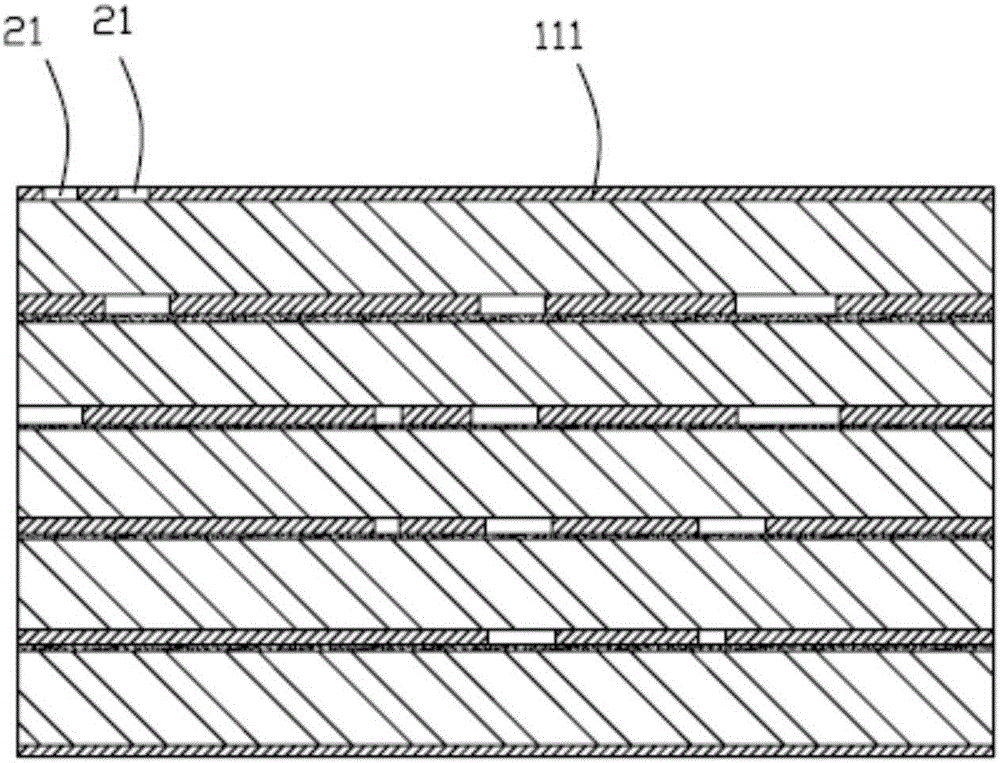

Manufacturing method of high-speed PCB and PCB

ActiveCN106793577AShort preparation cycleLow costPrinted circuit aspectsMultilayer circuit manufactureFine lineConnection type

The invention provides a manufacturing method of a high-speed PCB and the PCB. The manufacturing method includes the following steps that 1, lamination is carried out after a normal inner layer graph is manufactured; 2, copper reduction is carried out to achieve the size of 6 micrometers to 8 micrometers after lamination is completed; 3, +4.5 mil copper etching windowing is carried out on a deep micropore region and a first-order blind hole region overall; 4, laser drilling is carried out to complete deep micropore and first-order blind hole machining; 5, through holes needing resin hole plugging are mechanically drilled for the first time; 6, the interiors of the holes are metalized for the first time; 7, the through holes are back-drilled for the first time; 8, vacuum hole plugging is carried out; 9, the holes are covered with dry films, single side +5 mil dry film covering is carried out on deep micropores, first-order blind holes and the first through holes; 10, chemical copper reduction and ceramic grinding plate copper reduction are carried out to achieve the size of 20 micrometers to 25 micrometers; 11, second through holes are mechanically drilled; 12, the interiors of the holes are metalized for the second time, and POFV blocking is carried out; 13, the second through holes are back-drilled, and connection type functional holes are machined; 14, an outer layer graph is transferred, and a fine line graph is etched; 15, solder resisting and surface treatment are completed. The high-complexity high-speed PCB can be manufactured, the manufacturing period is short, and the cost is low.

Owner:DONGGUAN SHENGYI ELECTRONICS

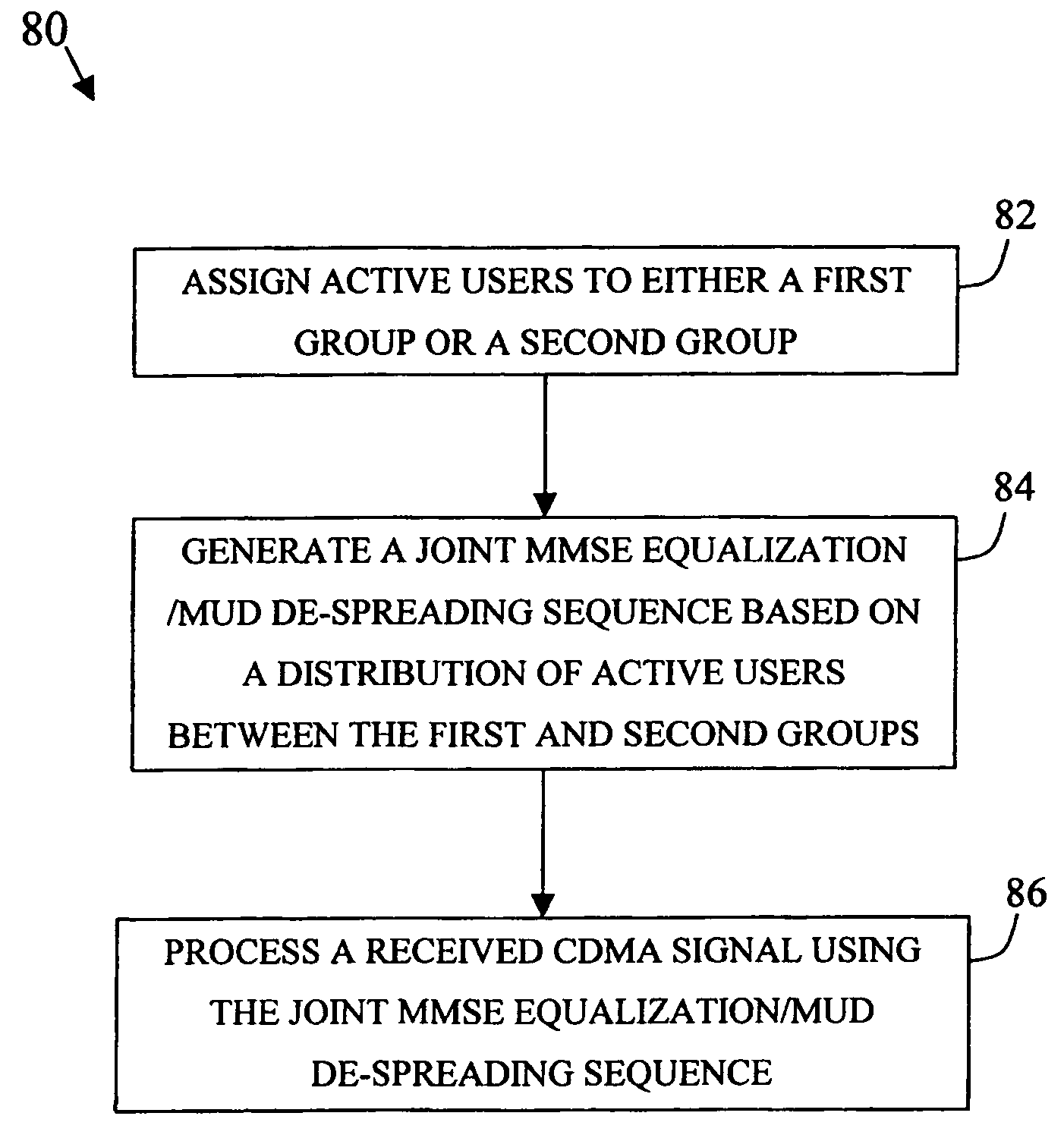

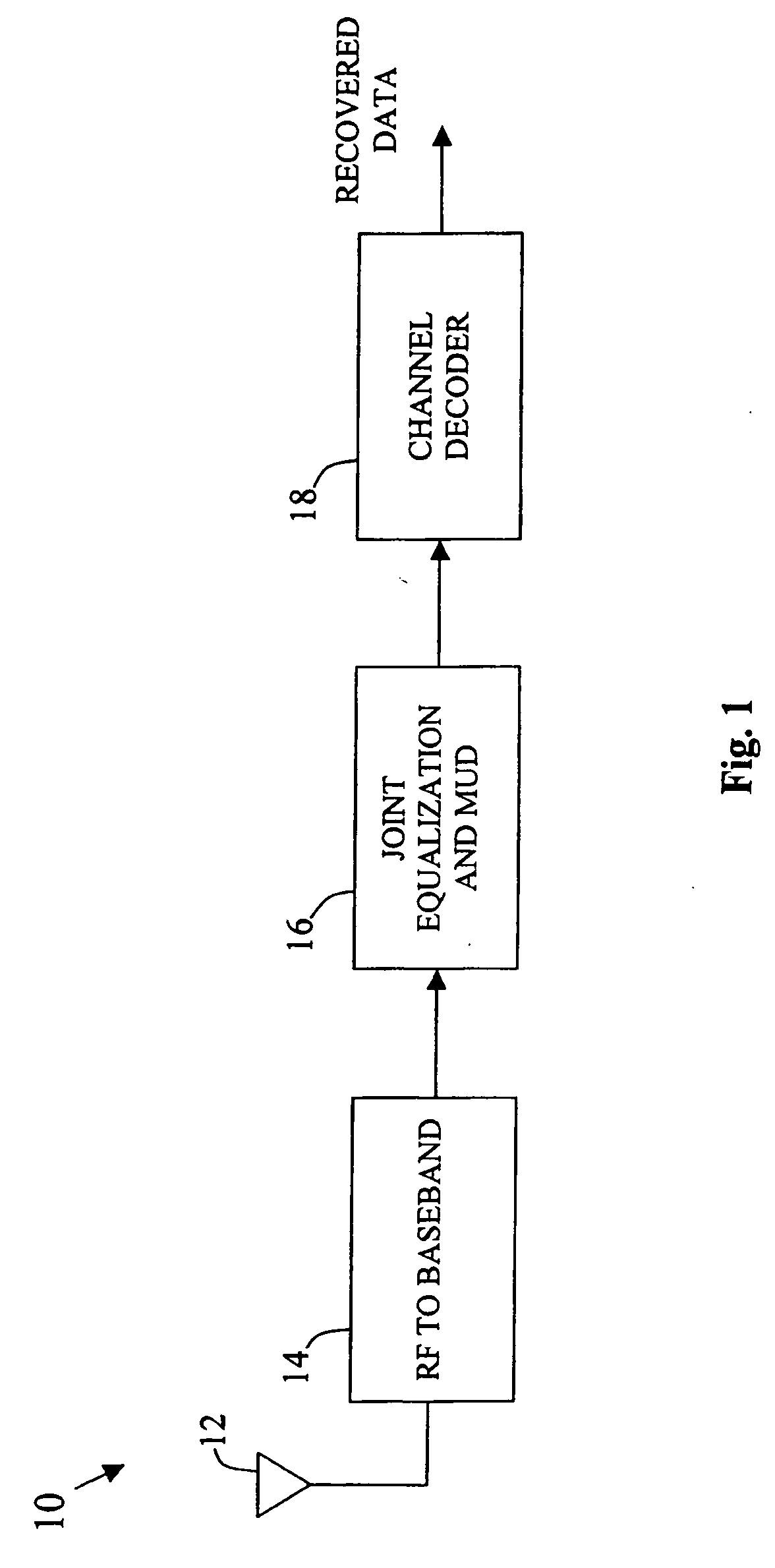

Unified MMSE equalization and multi-user detection approach for use in a CDMA system

ActiveUS20050094713A1Radio transmissionTransmitter/receiver shaping networksFir systemMulti user detection

A unified minimum mean square error (MMSE) equalization / multi-user detection (MUD) approach for demodulating direct sequence CDMA (DS-CDMA) signals is described. In at least one embodiment, the unified approach is capable of generating a variety of cost-effective receiver demodulation techniques that may range from, for example, a low cost linear MMSE equalization technique to a relatively high complexity MMSE MUD.

Owner:MARVELL ASIA PTE LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com