Patents

Literature

710 results about "Virtual instrument" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

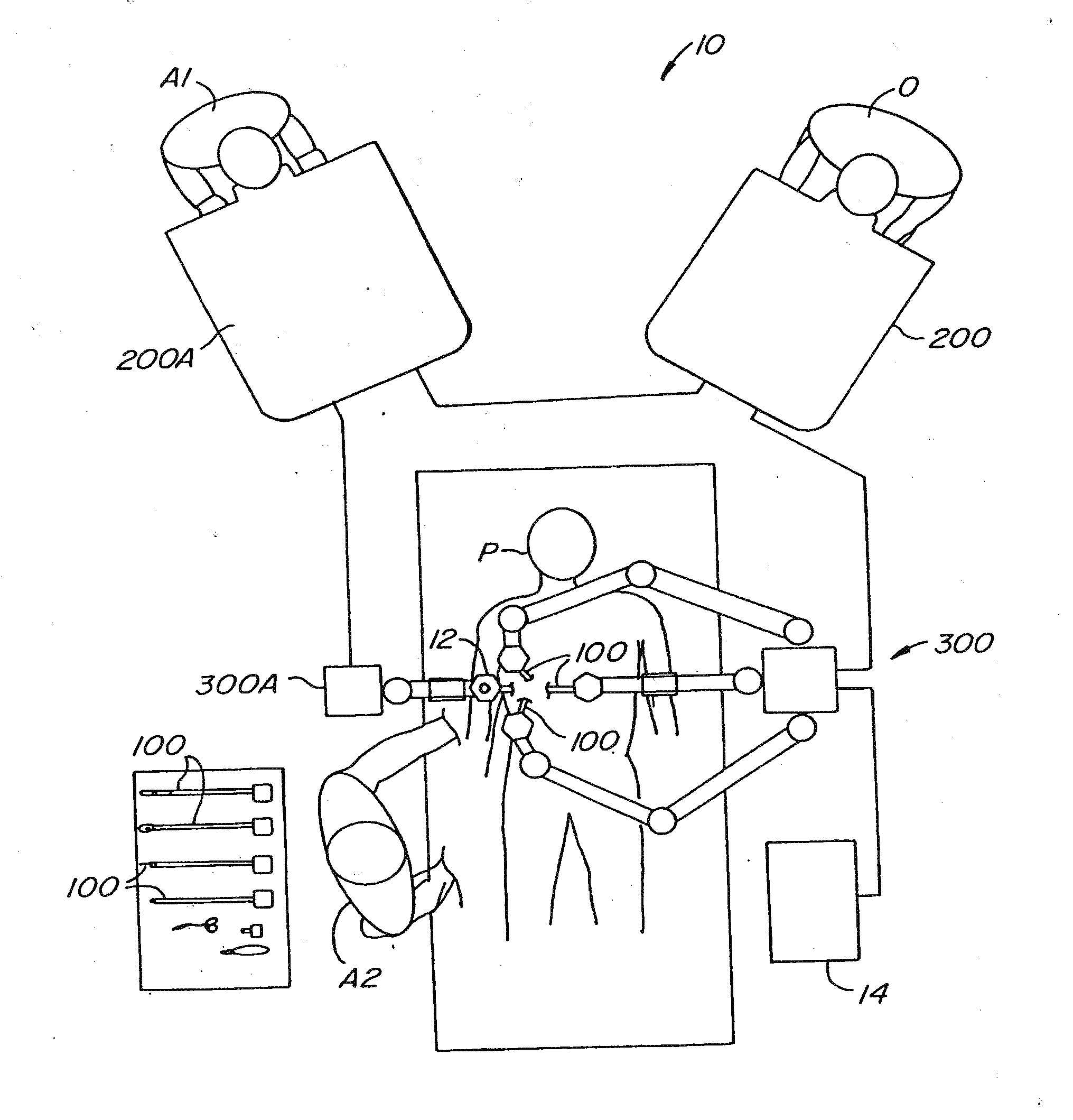

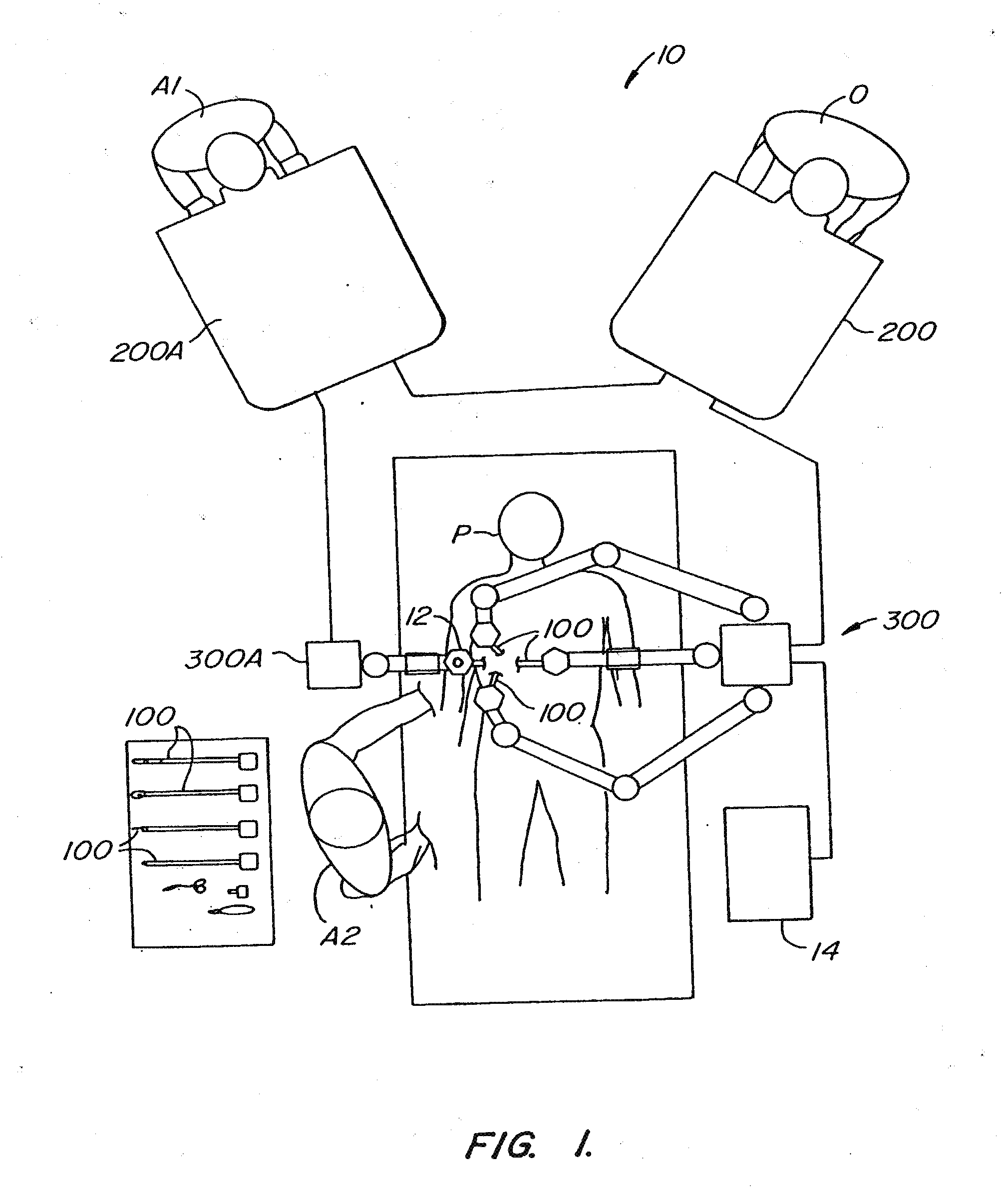

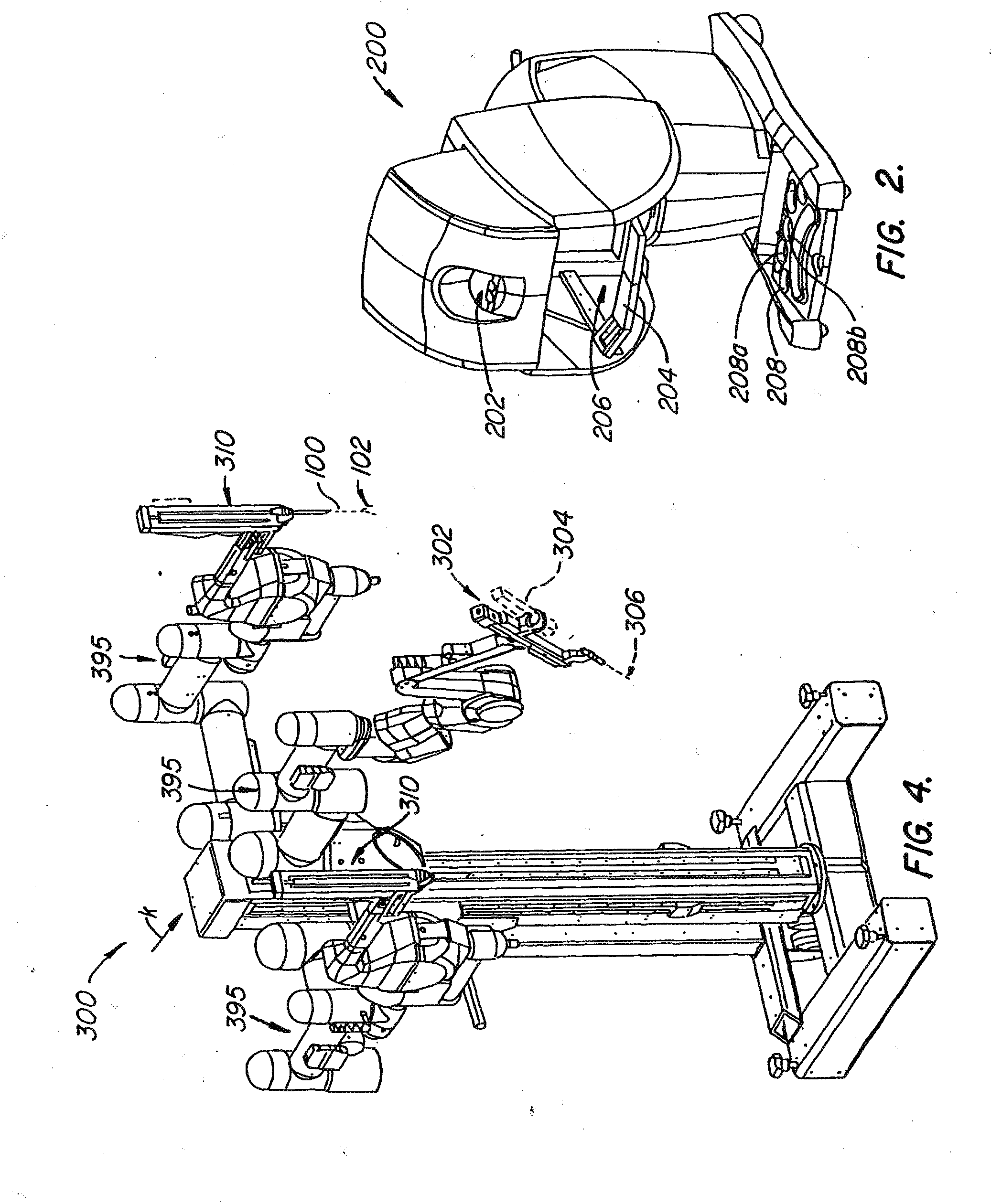

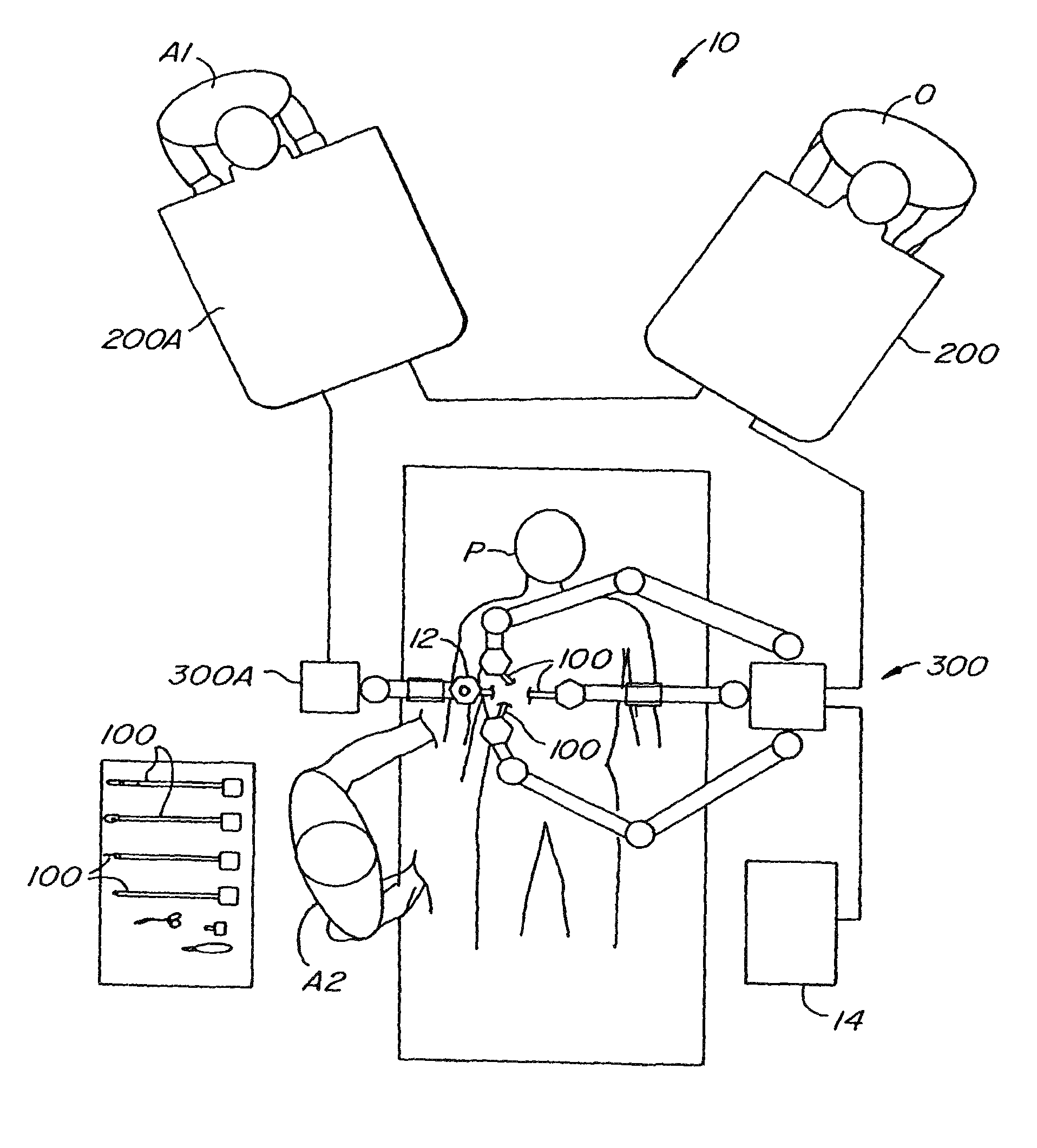

Medical robotic system with operatively couplable simulator unit for surgeon training

InactiveUS20100234857A1Easy to trainCost effectiveComputer controlSimulator controlRobotic armMedical robotics

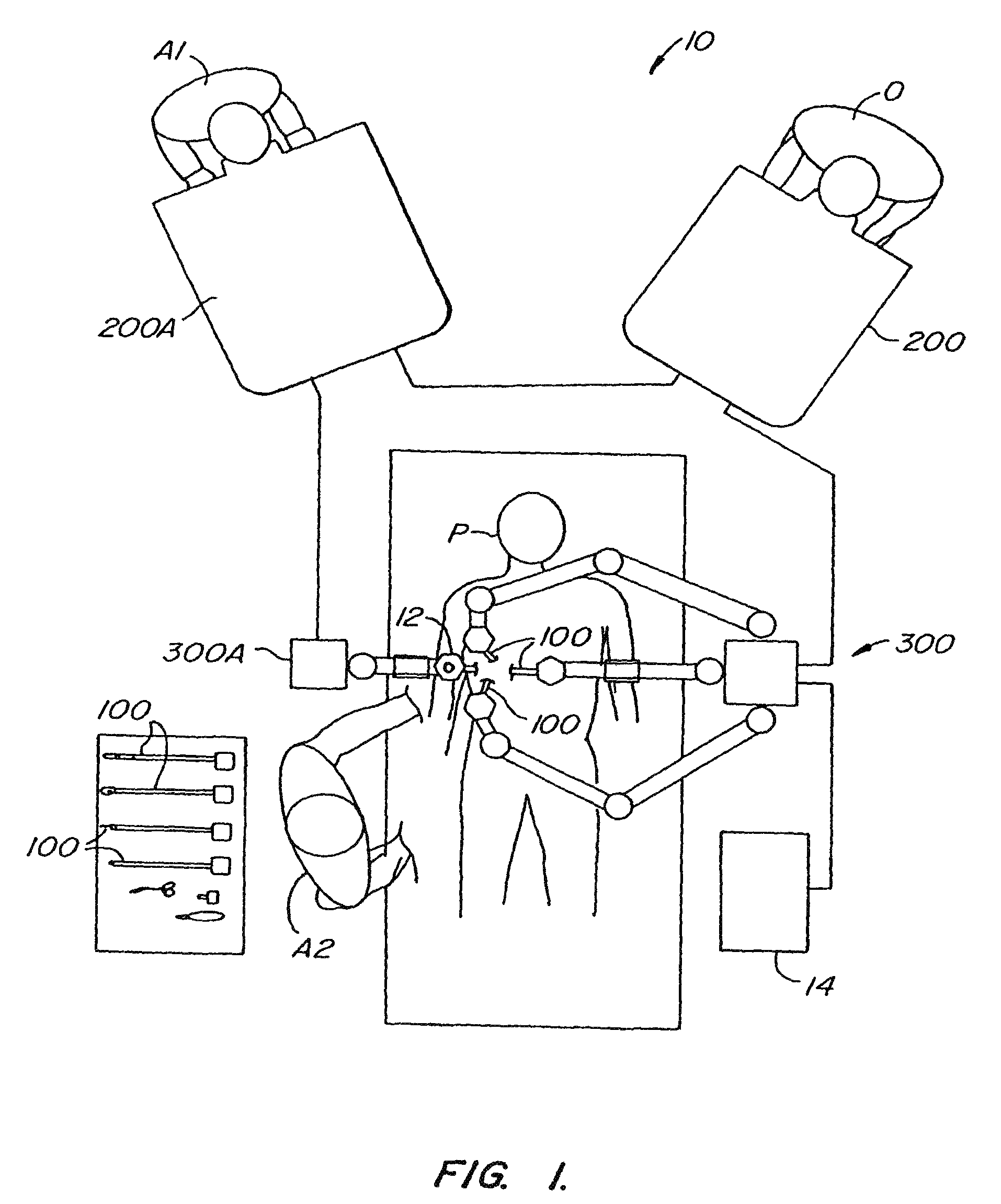

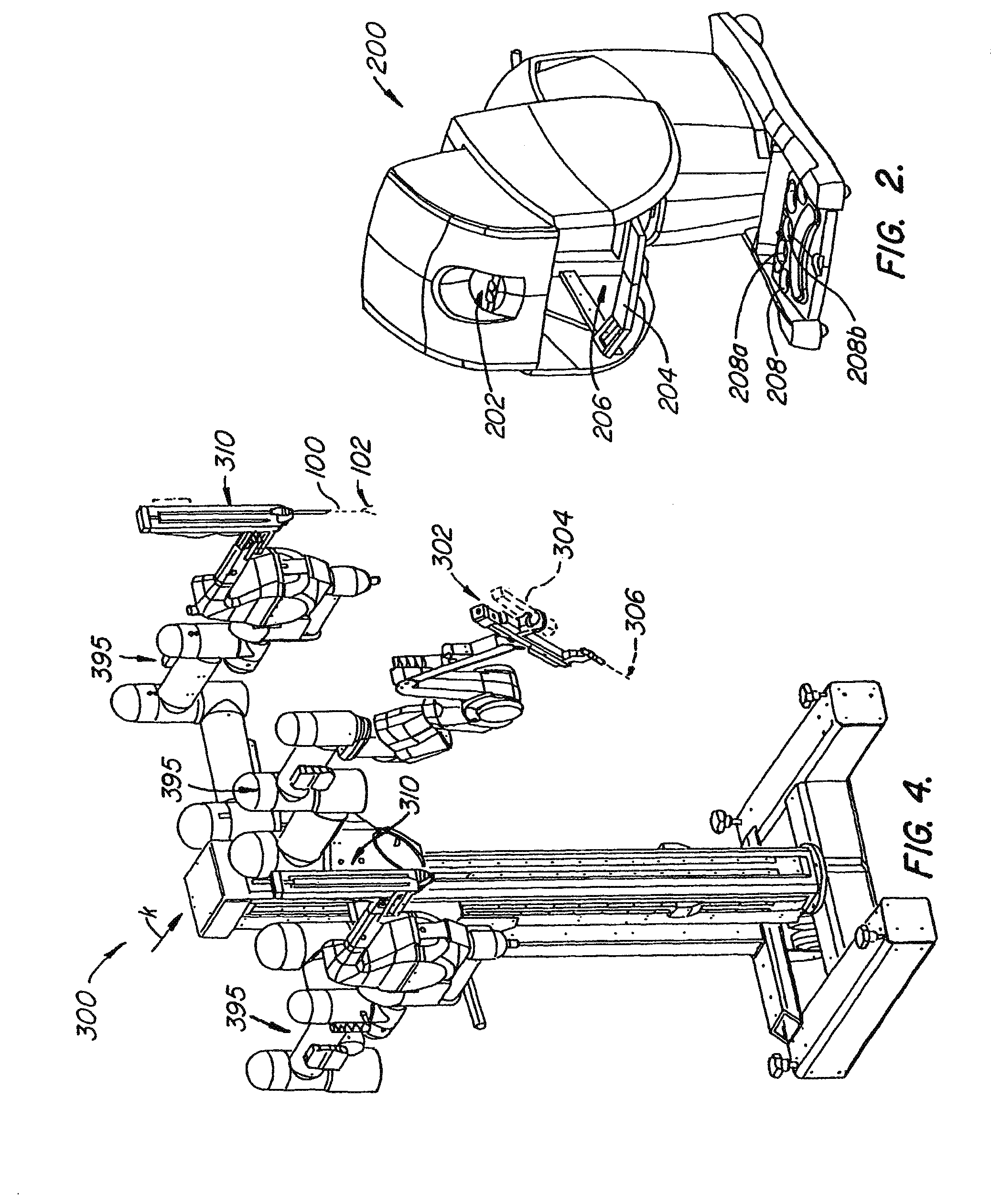

A medical robotic system has a surgeon console which is operatively couplable to a patient side unit for performing medical procedures or operatively couplable to a simulator unit for training purposes. The surgeon console has a monitor, input devices and foot pedals. The patient side unit has robotic arm assemblies coupled to instruments and an endoscope. When the surgeon console is coupled to the patient side unit, the instruments move in response to movement of the input devices to perform a medical procedure while captured images of the instruments are displayed on the monitor. When the surgeon console is coupled to the simulator unit, virtual instruments move in response to movement of the input devices to perform a user selected virtual procedure while virtual images of the virtual instruments are displayed on the monitor.

Owner:INTUITIVE SURGICAL OPERATIONS INC

Medical robotic system with operatively couplable simulator unit for surgeon training

InactiveUS8600551B2Easy to trainCost effectiveComputer controlSimulator controlRobotic armMedical robotics

A medical robotic system has a surgeon console which is operatively couplable to a patient side unit for performing medical procedures or operatively couplable to a simulator unit for training purposes. The surgeon console has a monitor, input devices and foot pedals. The patient side unit has robotic arm assemblies coupled to instruments and an endoscope. When the surgeon console is coupled to the patient side unit, the instruments move in response to movement of the input devices to perform a medical procedure while captured images of the instruments are displayed on the monitor. When the surgeon console is coupled to the simulator unit, virtual instruments move in response to movement of the input devices to perform a user selected virtual procedure while virtual images of the virtual instruments are displayed on the monitor.

Owner:INTUITIVE SURGICAL OPERATIONS INC

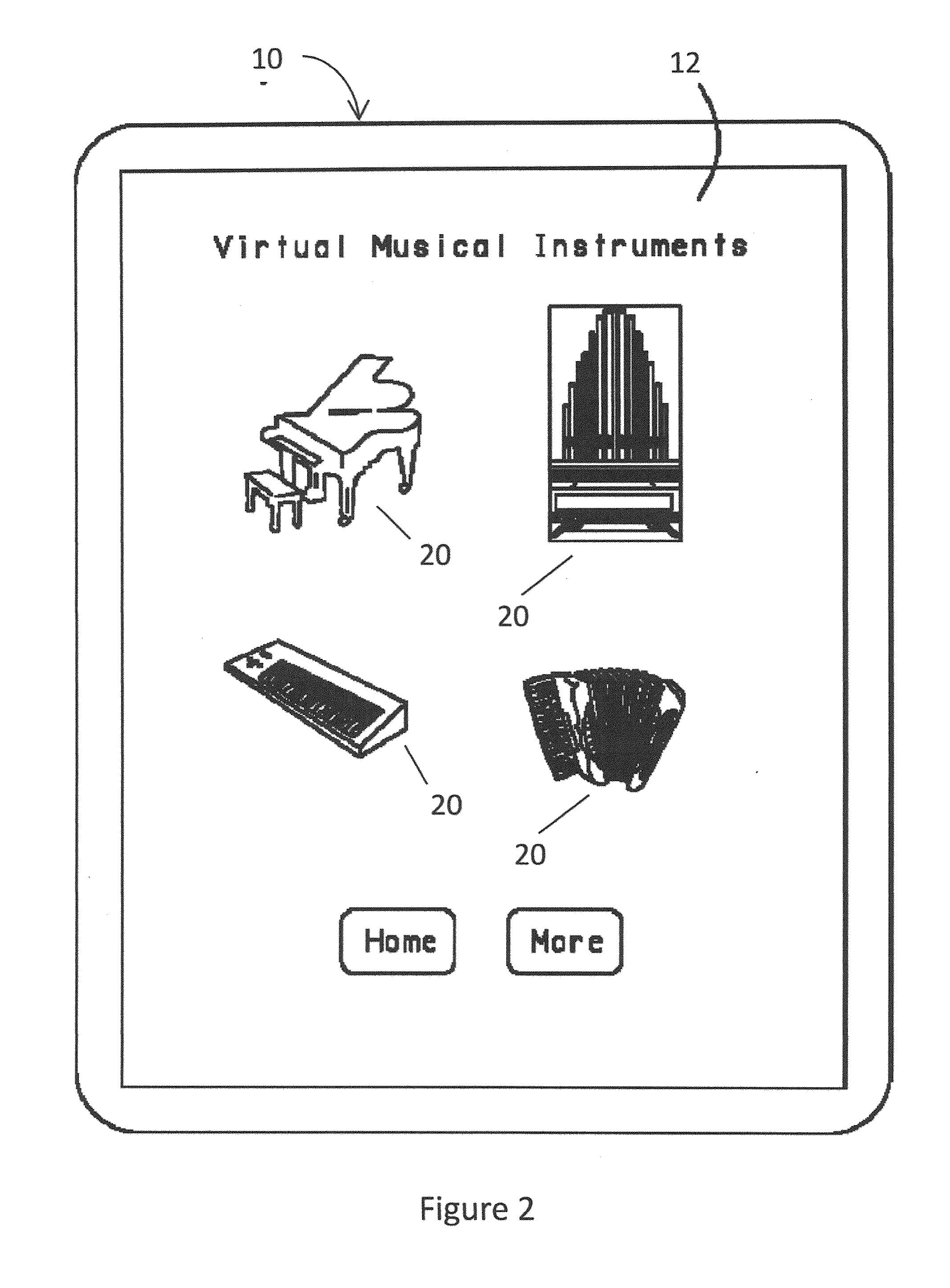

System and computer program for virtual musical instruments

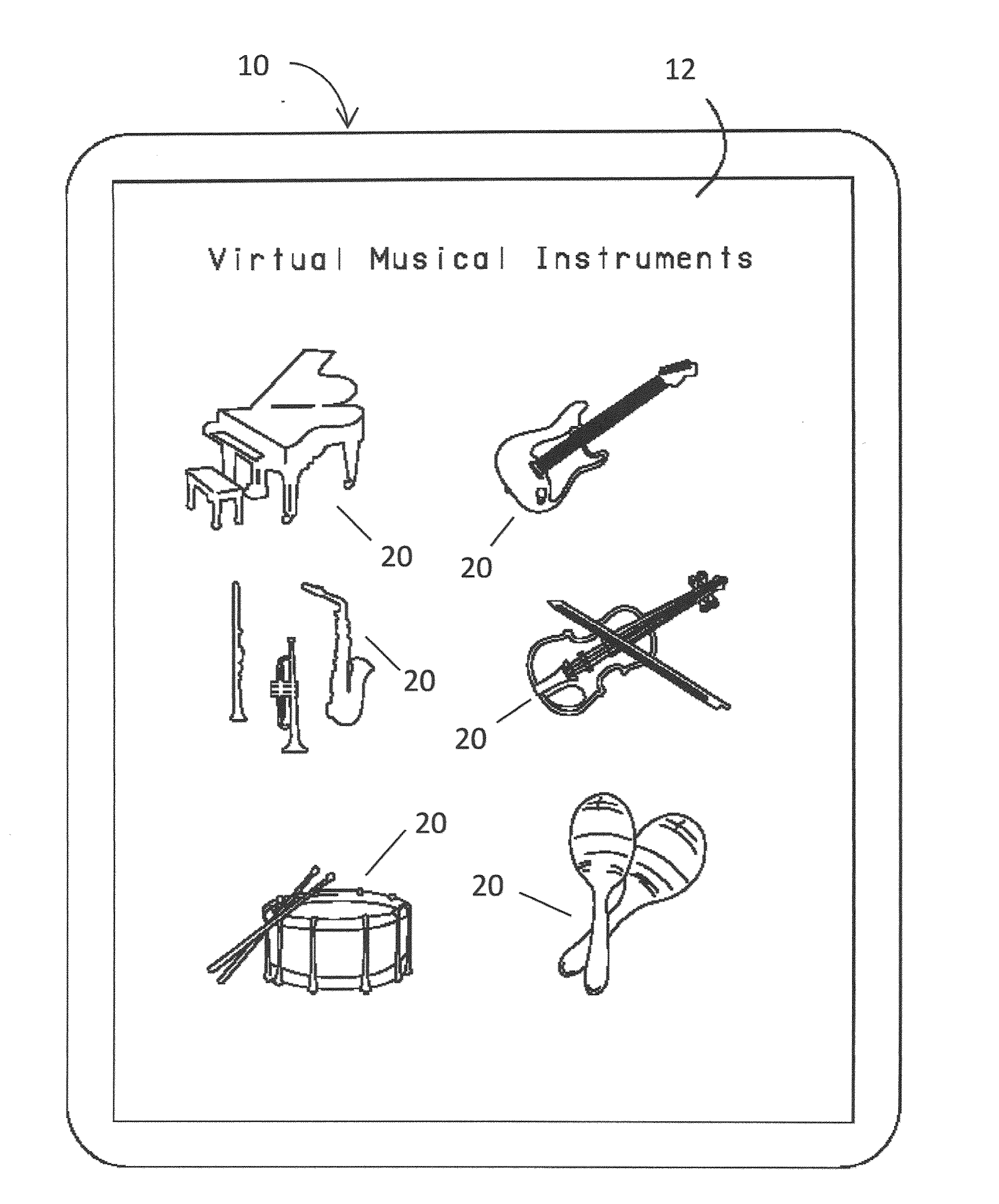

InactiveUS20110316793A1Electrophonic musical instrumentsInput/output processes for data processingInstrumentationComputer program

A system and computer program for virtual musical instruments includes a touch-sensitive screen; a selection interface that presents a list of virtual instruments on the screen for the user to select a virtual instrument; and a performance interface that presents a plurality of virtual instrument input elements on the screen for the user to play the virtual instrument by touching the screen. The system utilizes the location and speed of the user's touches to produce the sound, which may be a note produced with a sound effects library.

Owner:DIGITAR WORLD

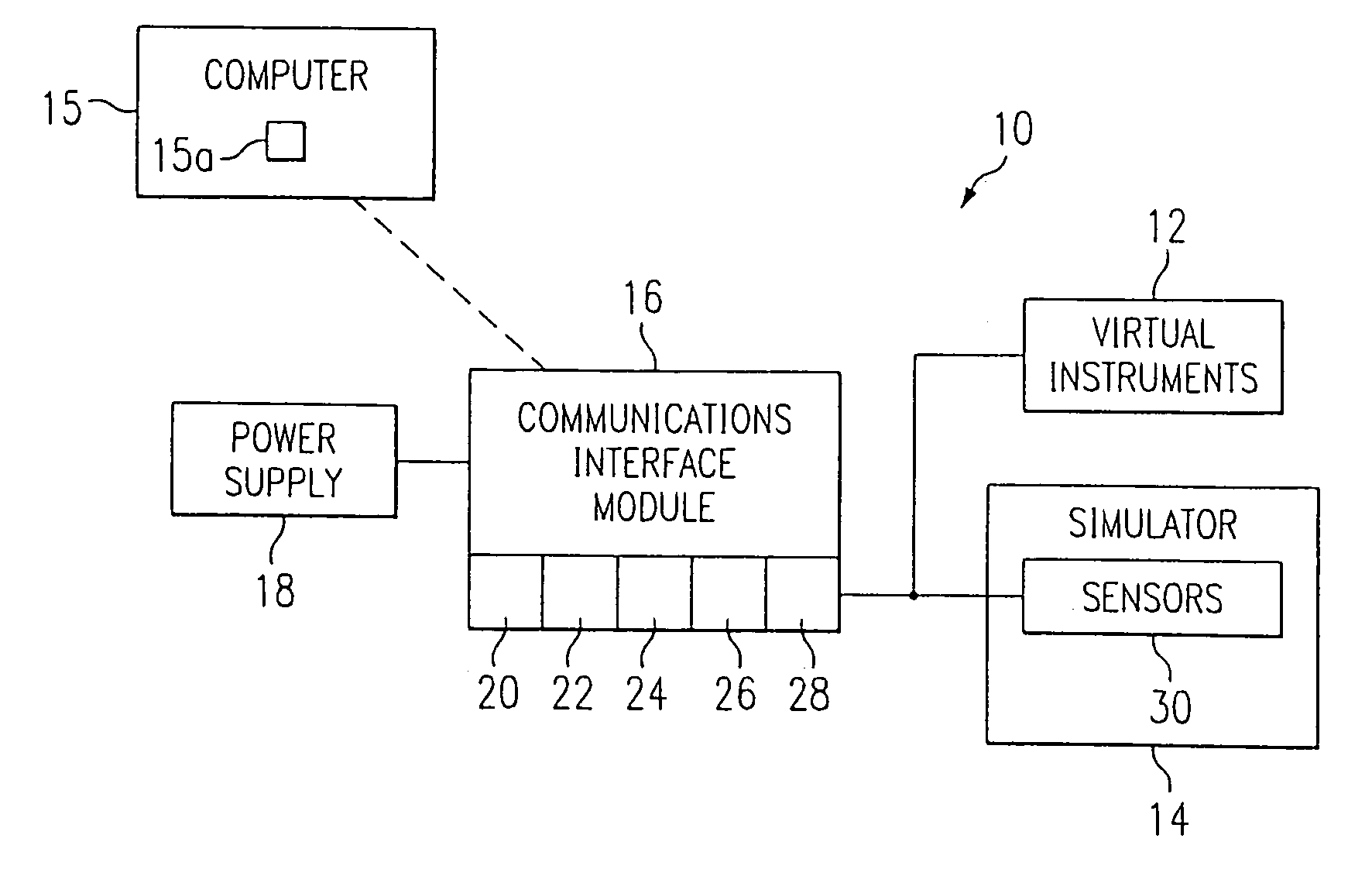

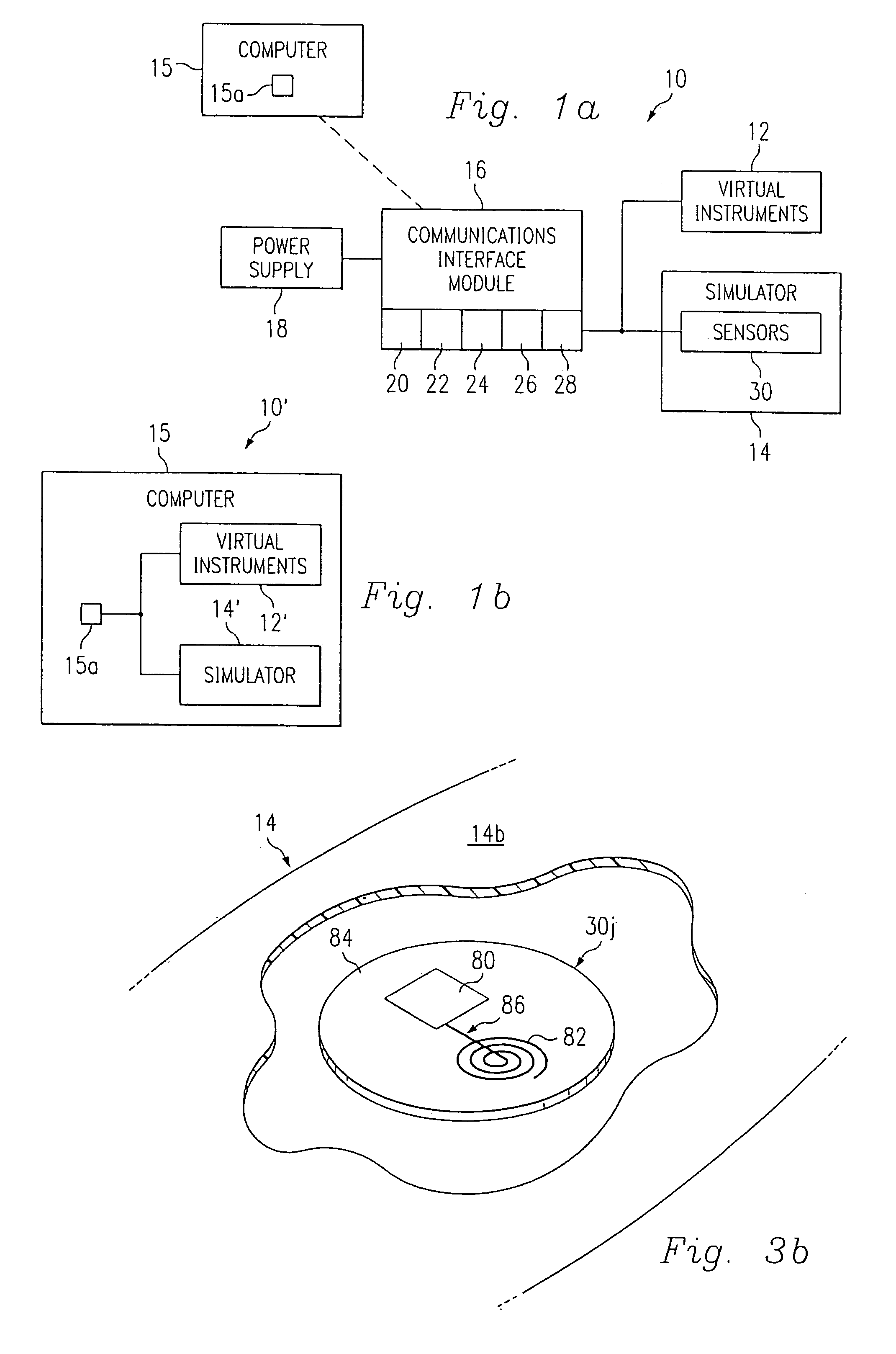

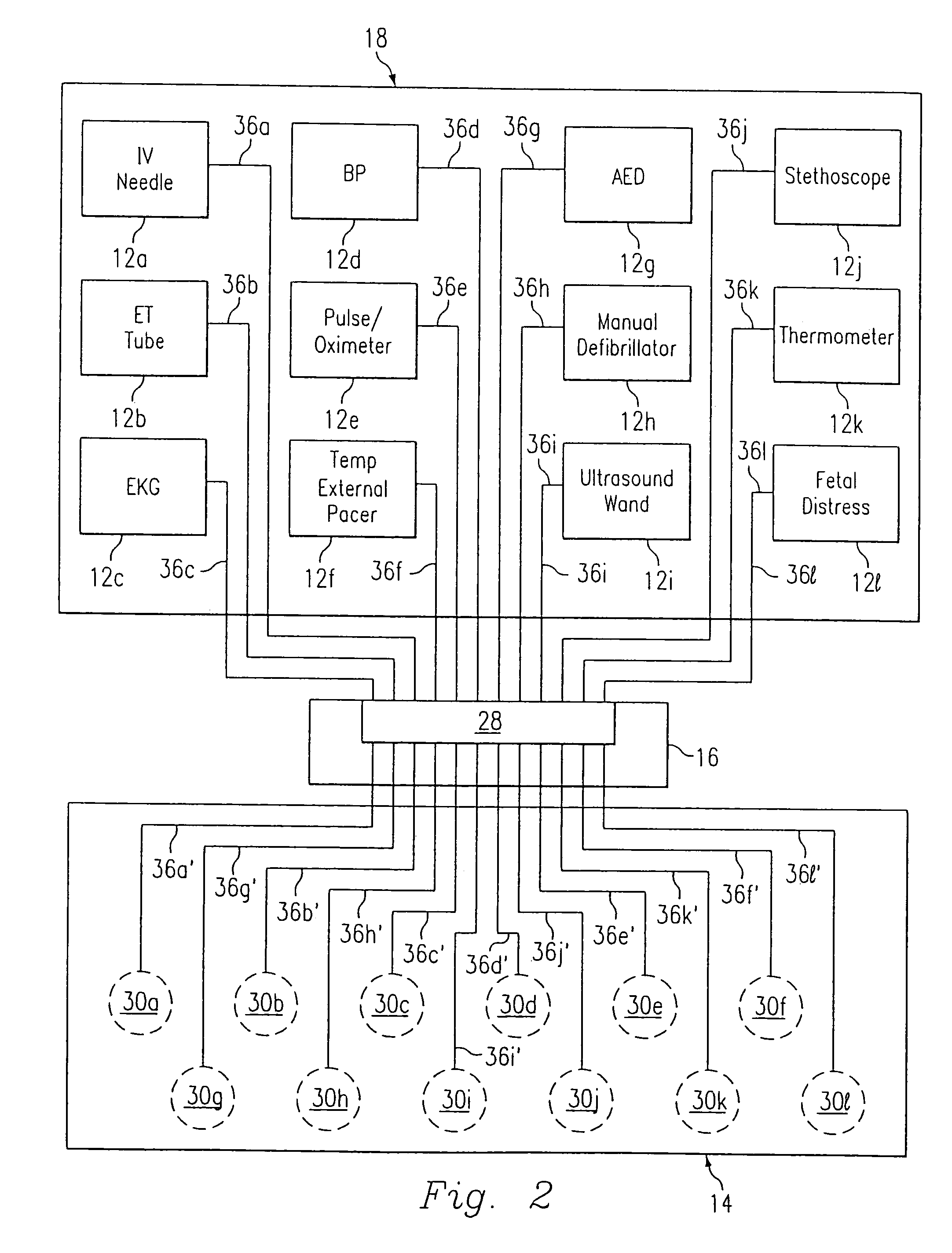

Interaction education system for teaching patient care

An interactive education system for teaching patient care to a user is described. The system comprises a patient simulator; a virtual instrument for use with the patient simulator in performing patient care activities; means for sensing an interaction between the virtual instrument and the simulator, and means for providing feedback to the user regarding the interaction between the virtual instrument and the simulator.

Owner:GAUMARD SCIENTIFIC

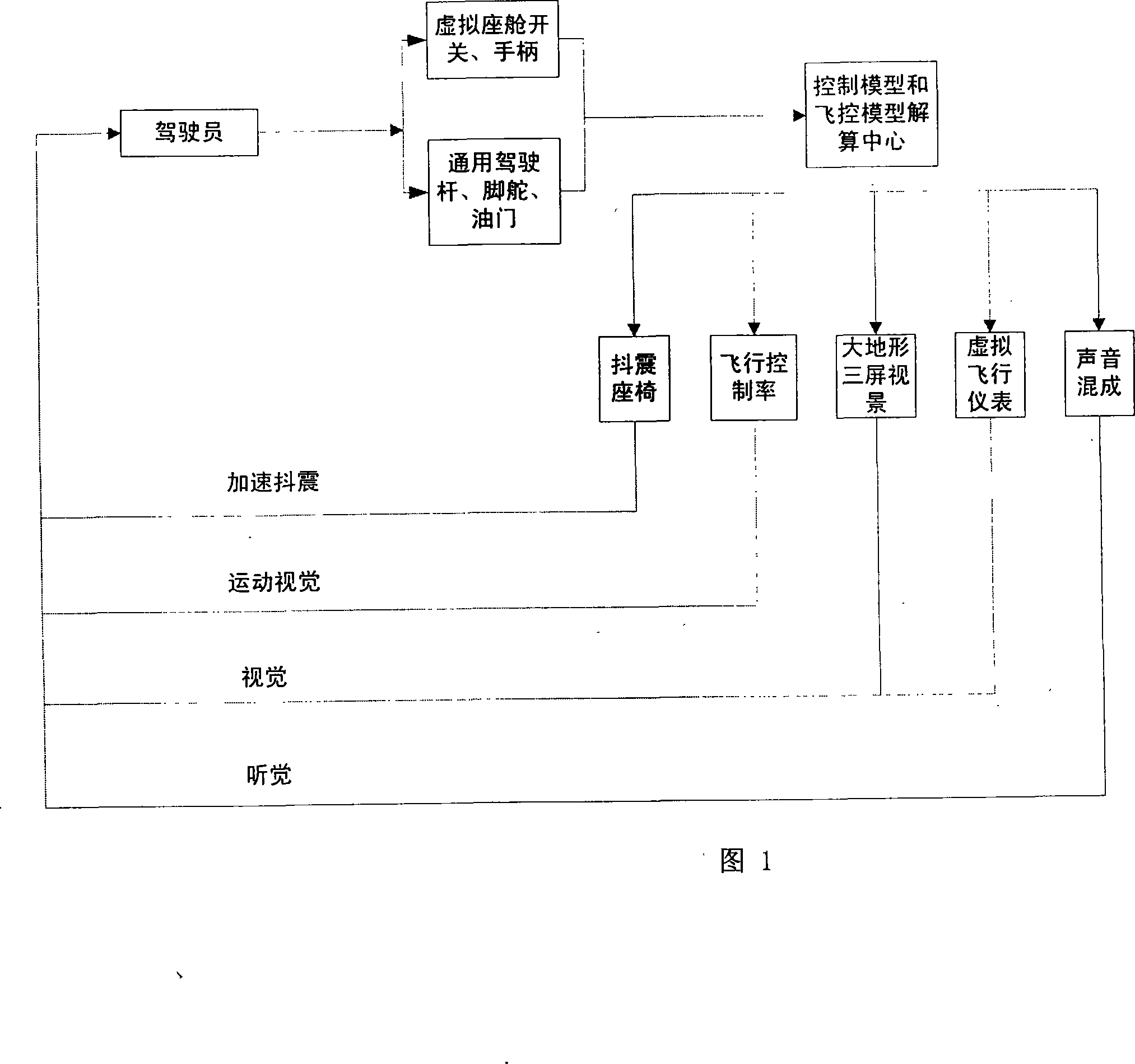

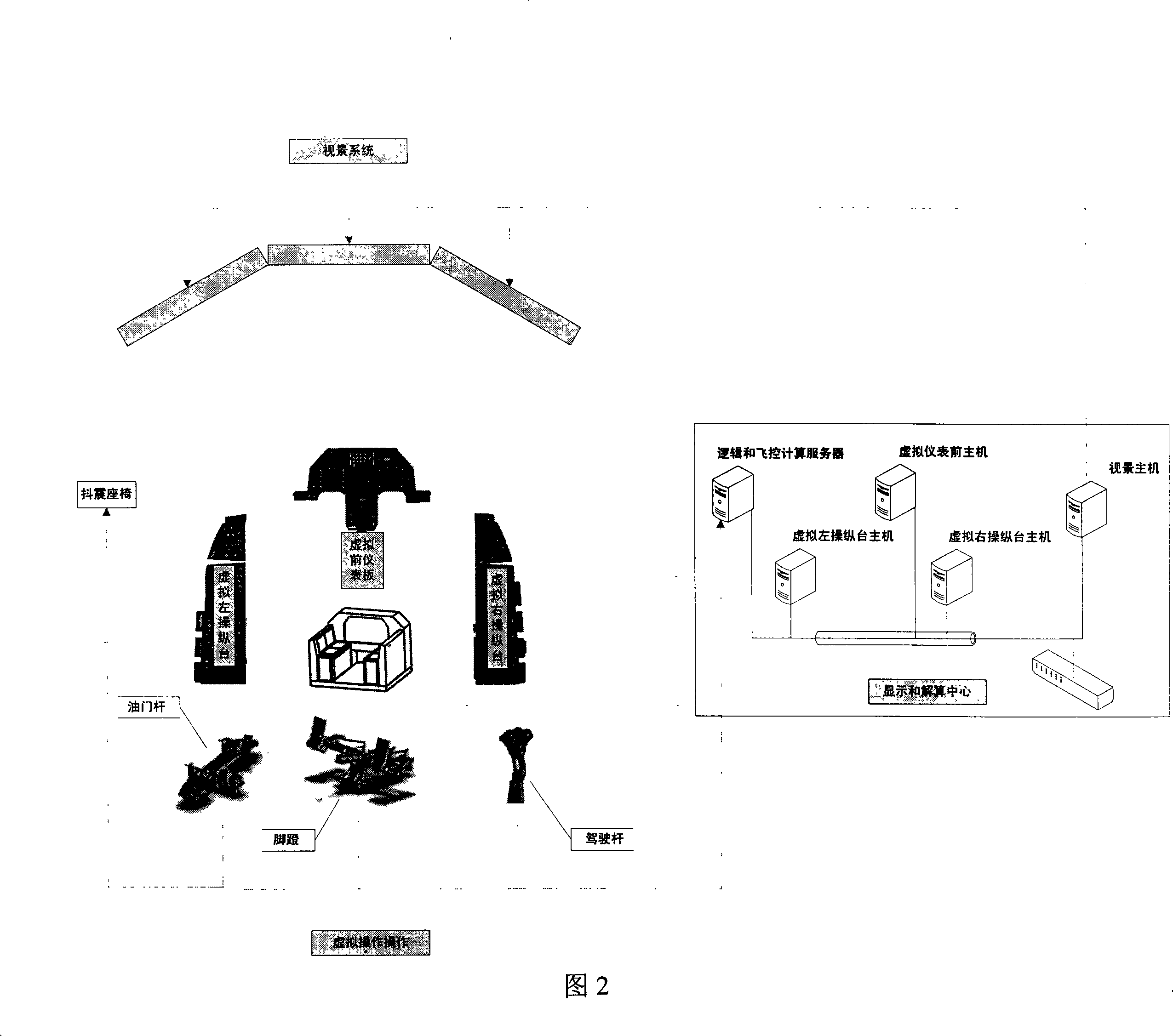

General-purpose aviation simulator based on virtual operation

InactiveCN101251959AFlexible switchingReduce volumeCosmonautic condition simulationsVideo gamesAviationGeneral purpose

The invention relates to a universal flight simulator based on virtual operation, which comprises footstools, a throttle lever, a steering column and a sound blending box arranged in a universal concept cabin of the virtual operation; the universal concept cabin also comprises a sight display system consisting of a back projection system, a virtual switch, a knob and a virtual instrument operated by using a touch mode, a displaying and resolving center for model resolving, flight control resolving and acceleration resolving and a buffeting chair seated by a driver. The universal flight simulator based on virtual operation uses a virtual operation switch and the virtual instrument to replace a real physical hardware switch and an instrument and can flexibly switch the virtual switch, the instrument software and a flight control model into various models for flight training and games. The universal flight simulator is small in size, light in weight, convenient to disassemble and assemble and suitable for use under the ordinary office condition, has vivid simulation, low price and strong universality through switching models by software and can be combined to a simulator set with different models for confronting training and games after being connected to the Internet.

Owner:于辉

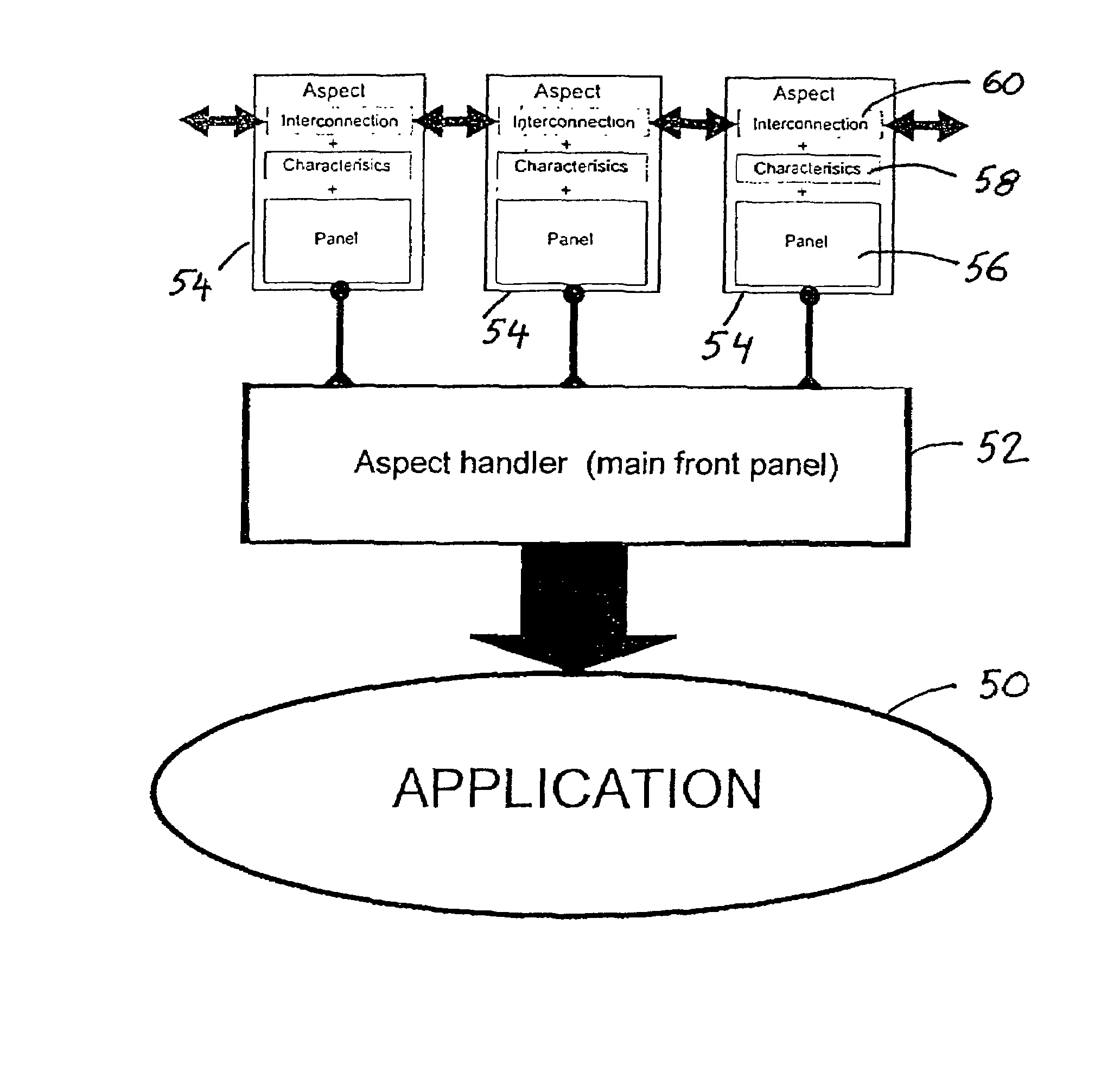

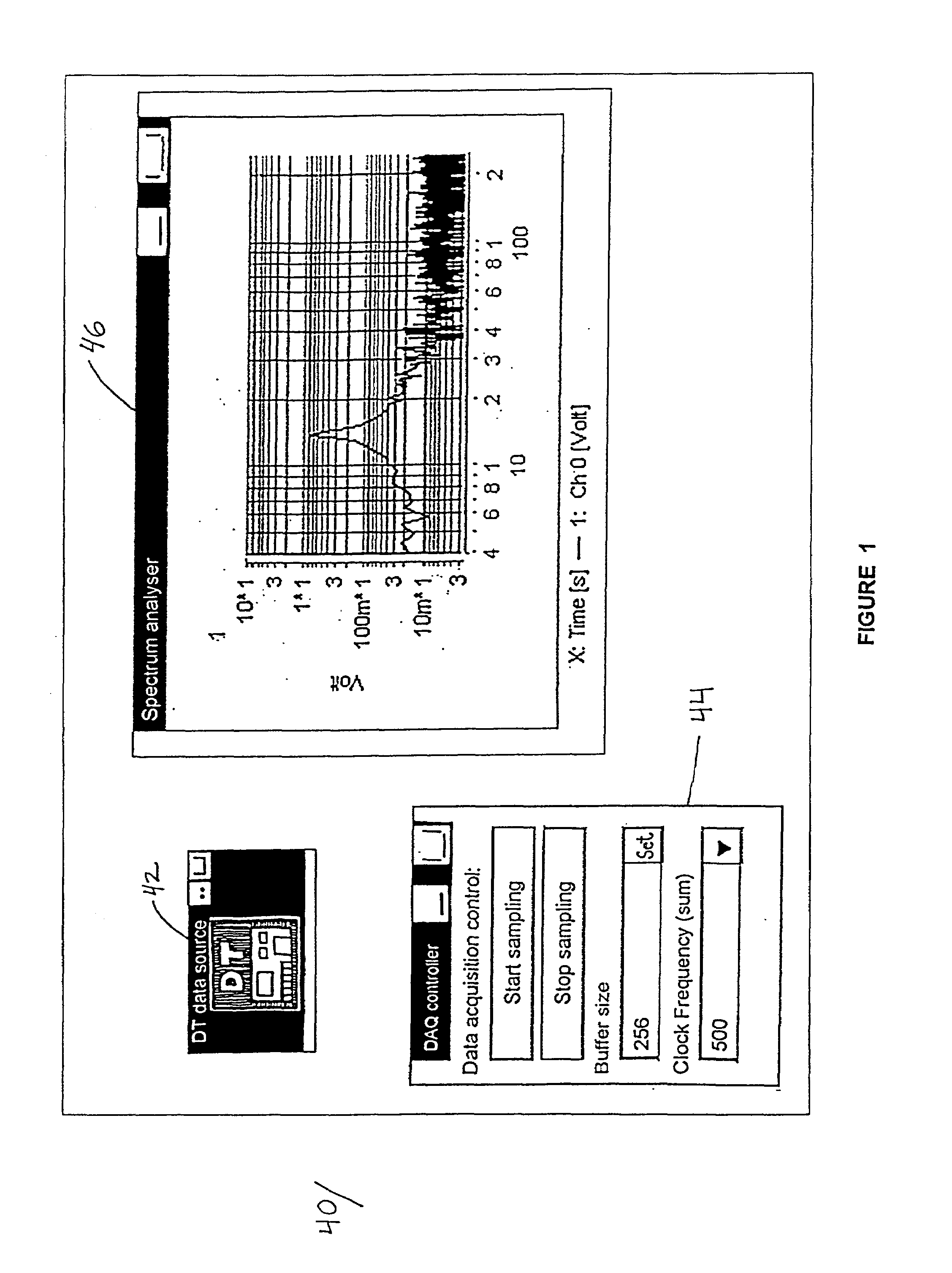

Graphical application development system for test, measurement and process control applications

InactiveUS7275235B2Easily employedGood saveDigital variable/waveform displaySpecific program execution arrangementsSoftware engineeringControl channel

A graphical application development environment is provided, for the development of test, measurement and process control applications. Said environment comprises thematically organized groups of “panels” representing components of virtual instruments, and said panels are combined and interconnected via data channels, control channels and event channels to form a complete instrument “front panel.” Each panel represents a quasi-autonomous “aspect” software object that has the attributes, properties and connectivities of the represented instrument component, and that is associated with executable code segments, including code segments that are usable by a plurality of aspects and are maintained in libraries accessible to an aspect handler for the construction of aspects. A representation of a user-developed application program, as created in a textual language, comprises an executable description of front panel aspects and their attributes and interconnections, and serves to invoke said associated code segments to run said user application.

Owner:MOLINARI ALFRED A +3

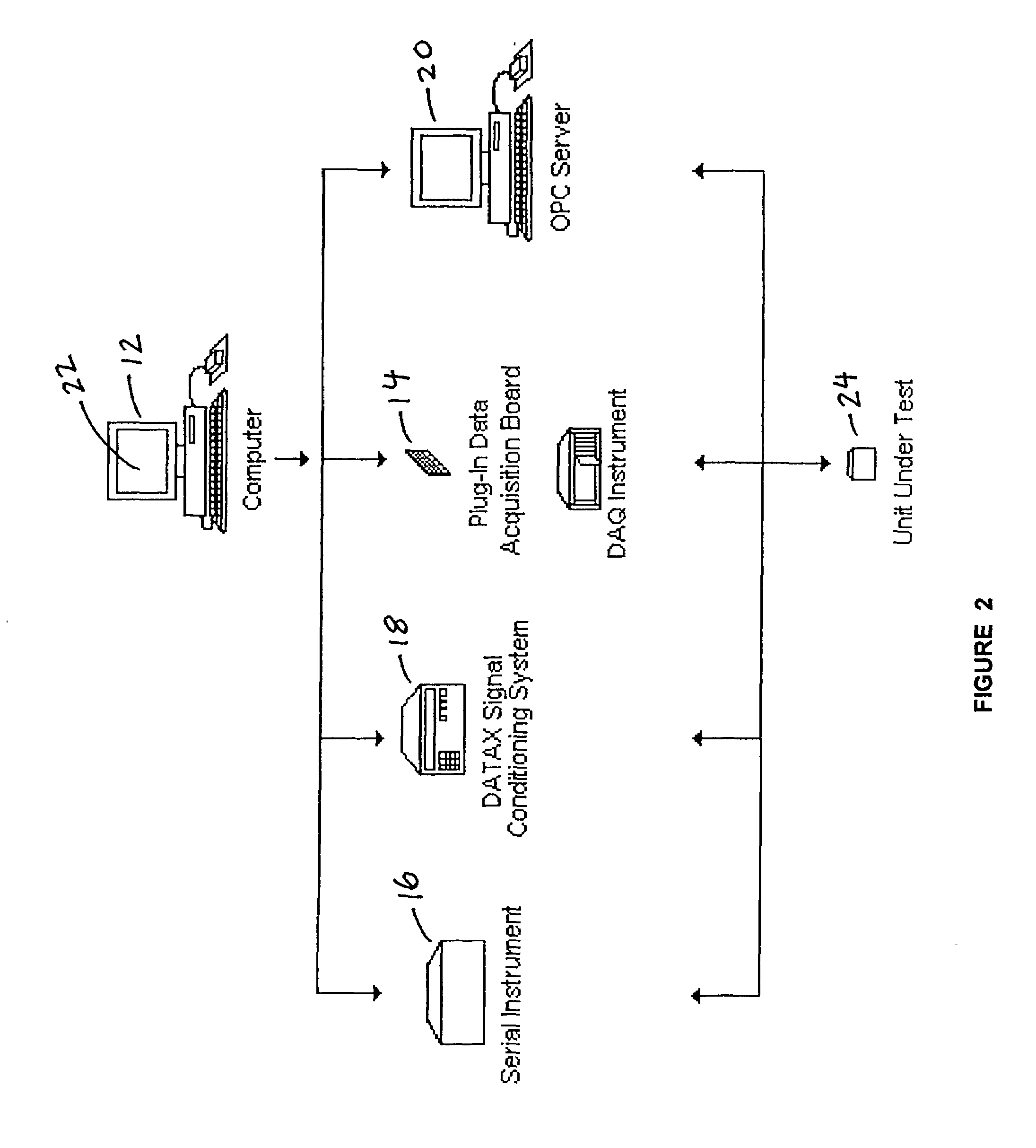

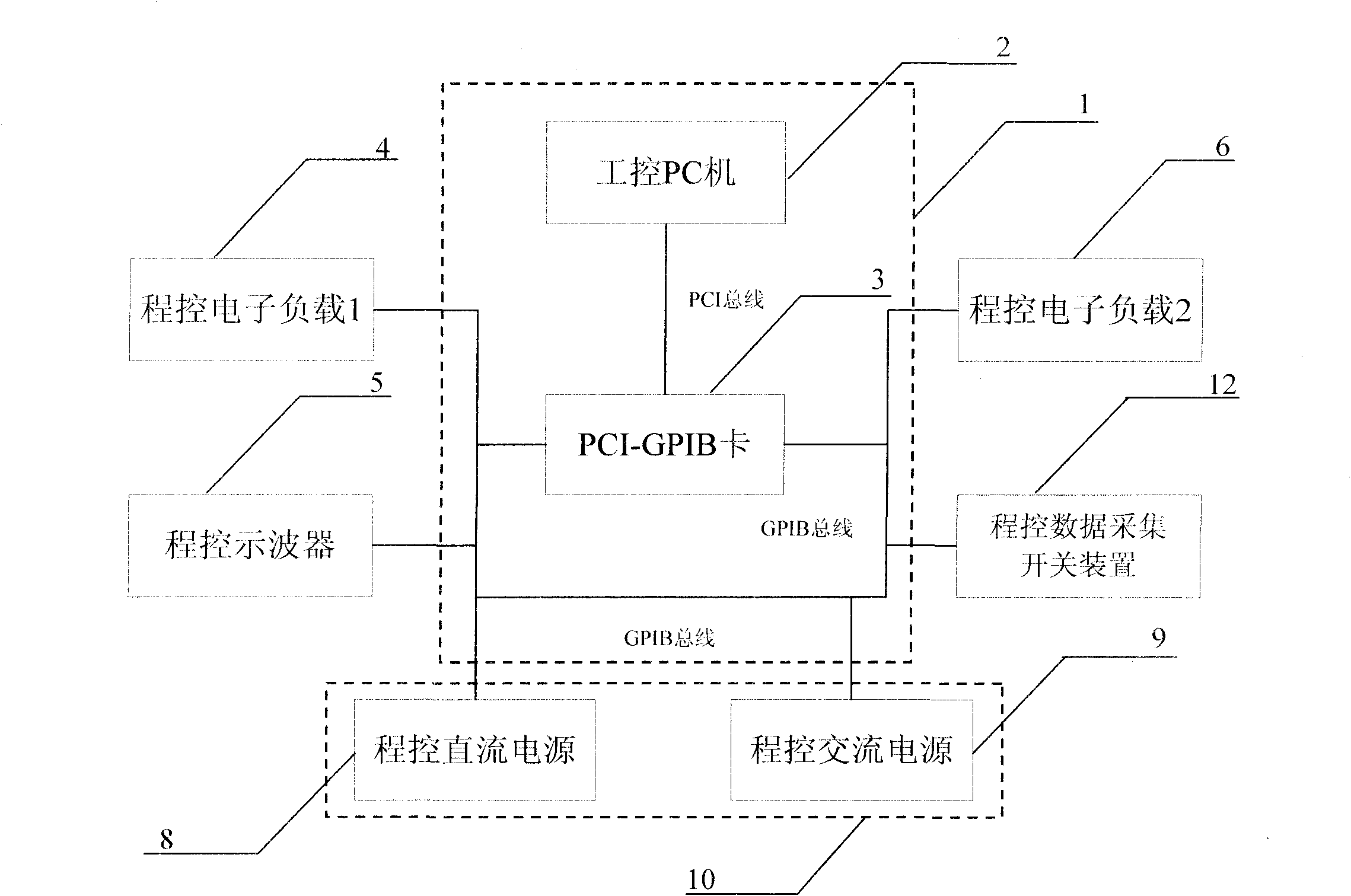

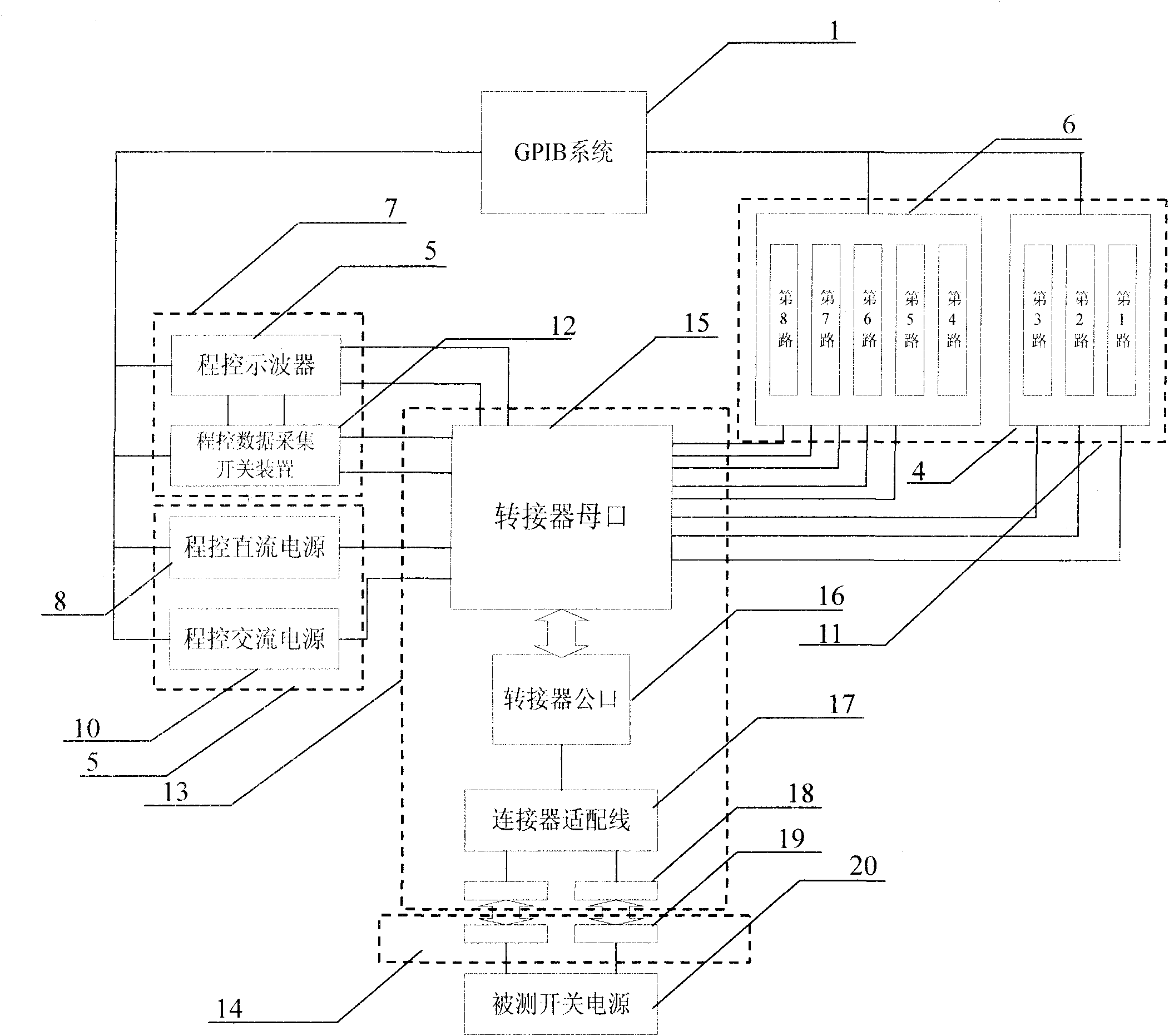

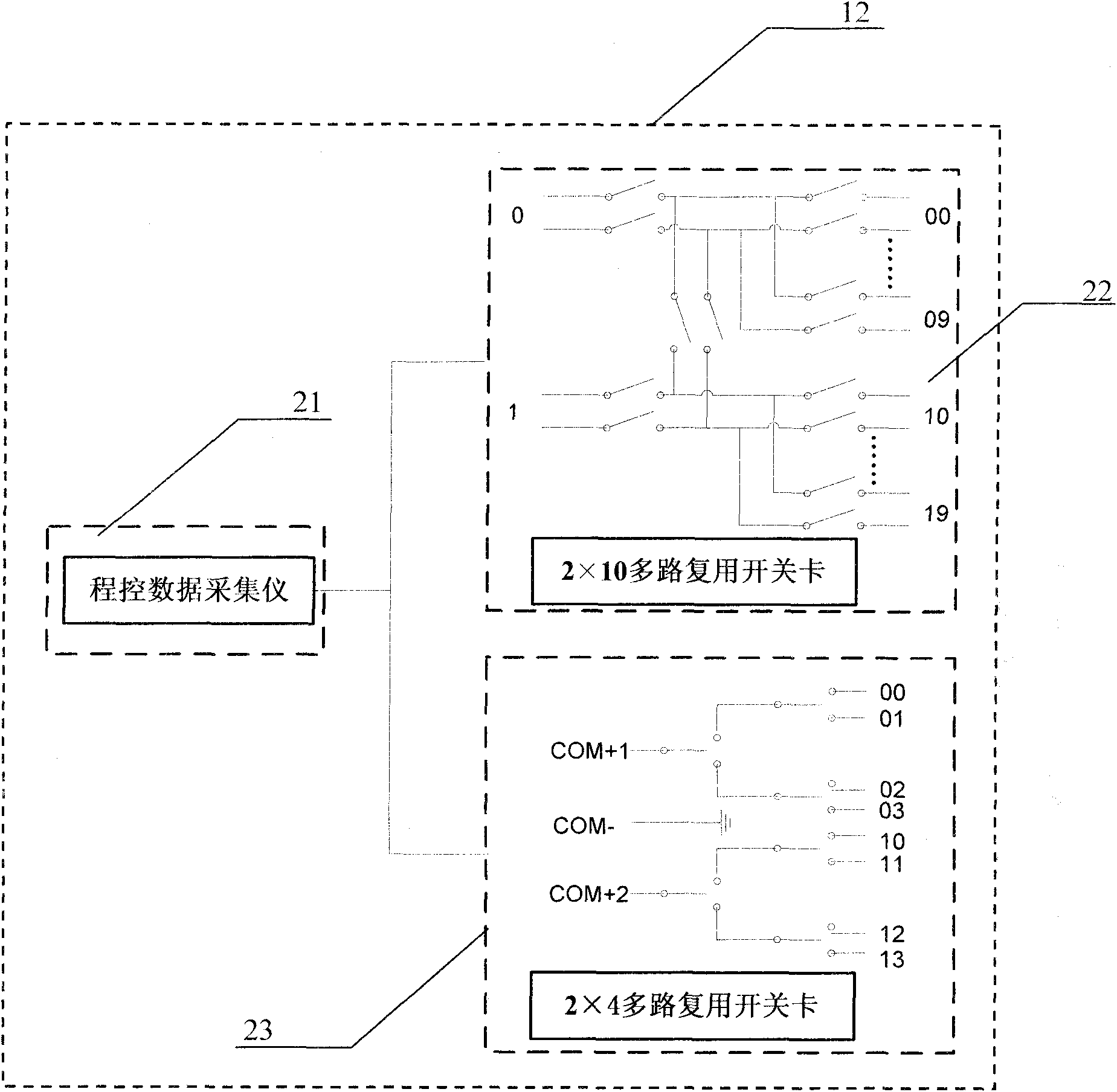

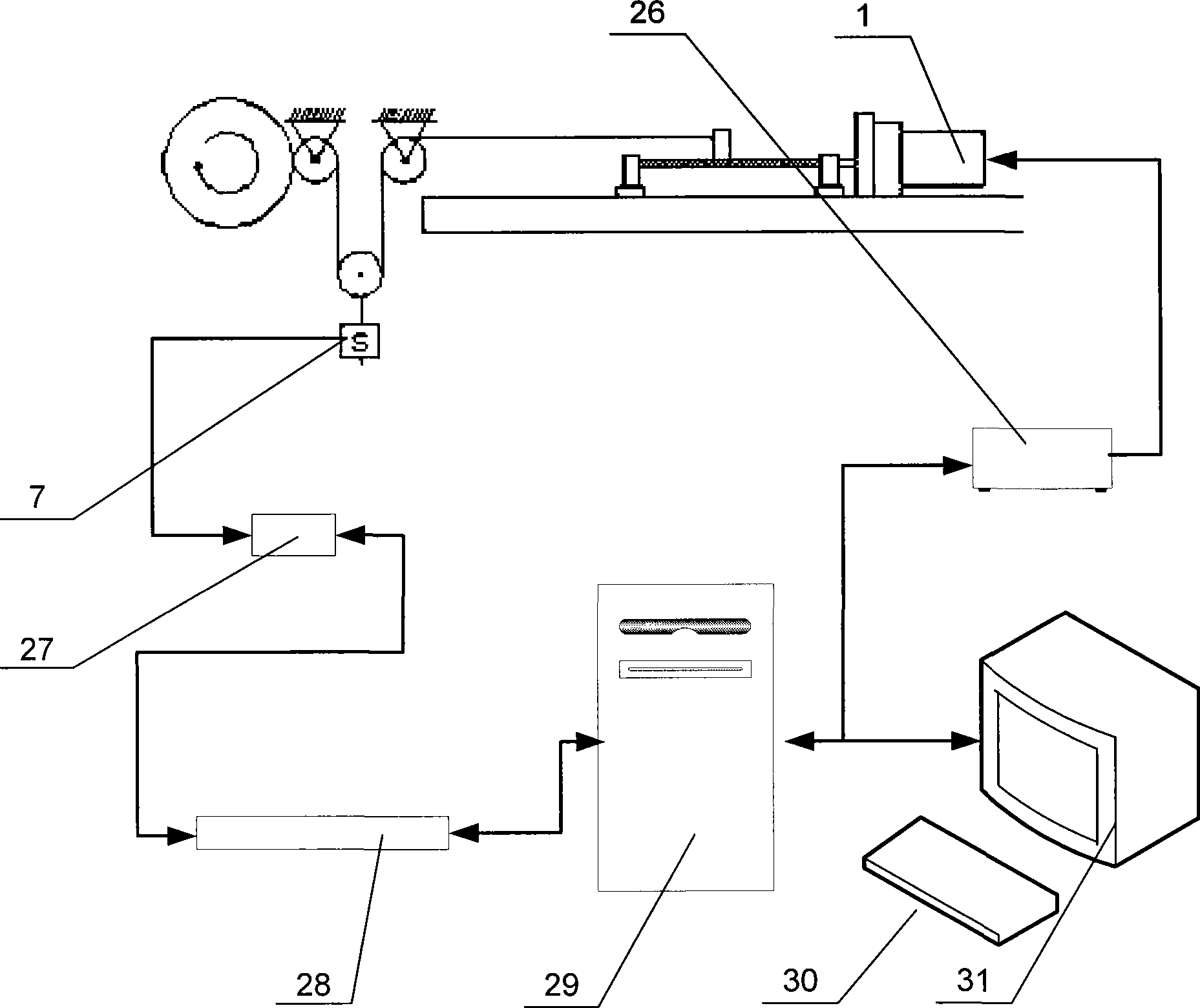

General-purpose automatic test system for locomotive switching power supply and method thereof

The invention relates to a general-purpose automatic test method for a locomotive switching power supply, and general-purpose automatic test system, and comprises a test control system, a programmable power supply unit, a programmable DC load unit and a programmable data acquisition unit, wherein the programmable power supply unit is connected with the test control system through a GPIB bus and provides excitation for the tested switching power supply; the programmable DC load unit is connected with the test control system through the GPIB bus and provides a load for the switching power supply to be tested; and the programmable data acquisition unit is connected with the test control system through the GPIB bus and acquires responses of the tested switching power supply. The output voltage, voltage regulation factor, load regulation factor and the like are tested by logging in virtual instrument software on a personal computer. The invention can well overcome the defects of insufficient compatibility, high complexity and low reliability of the test system in the prior art, and has the advantages of automation, general purpose, convenient operation and reliable performance.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

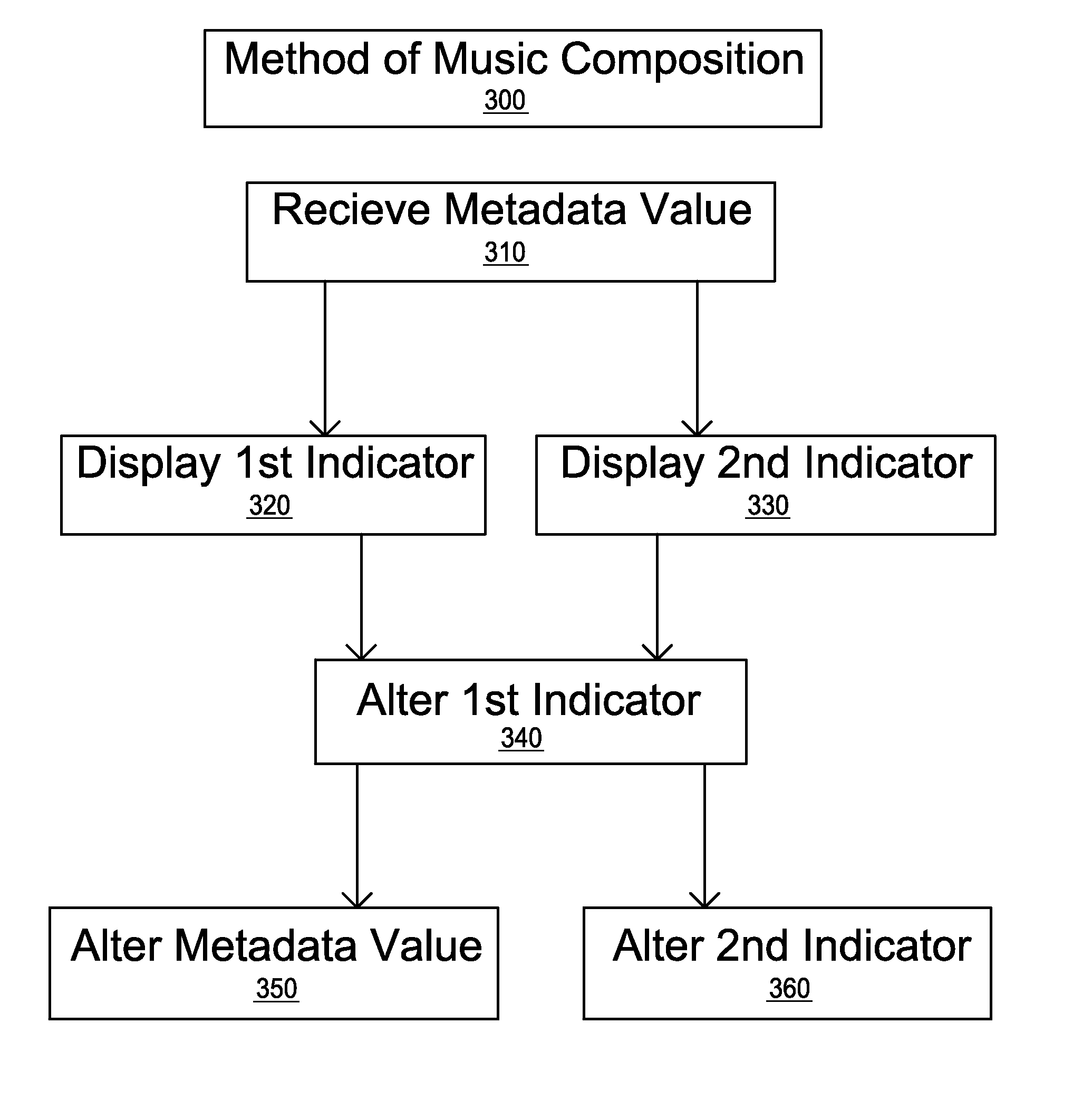

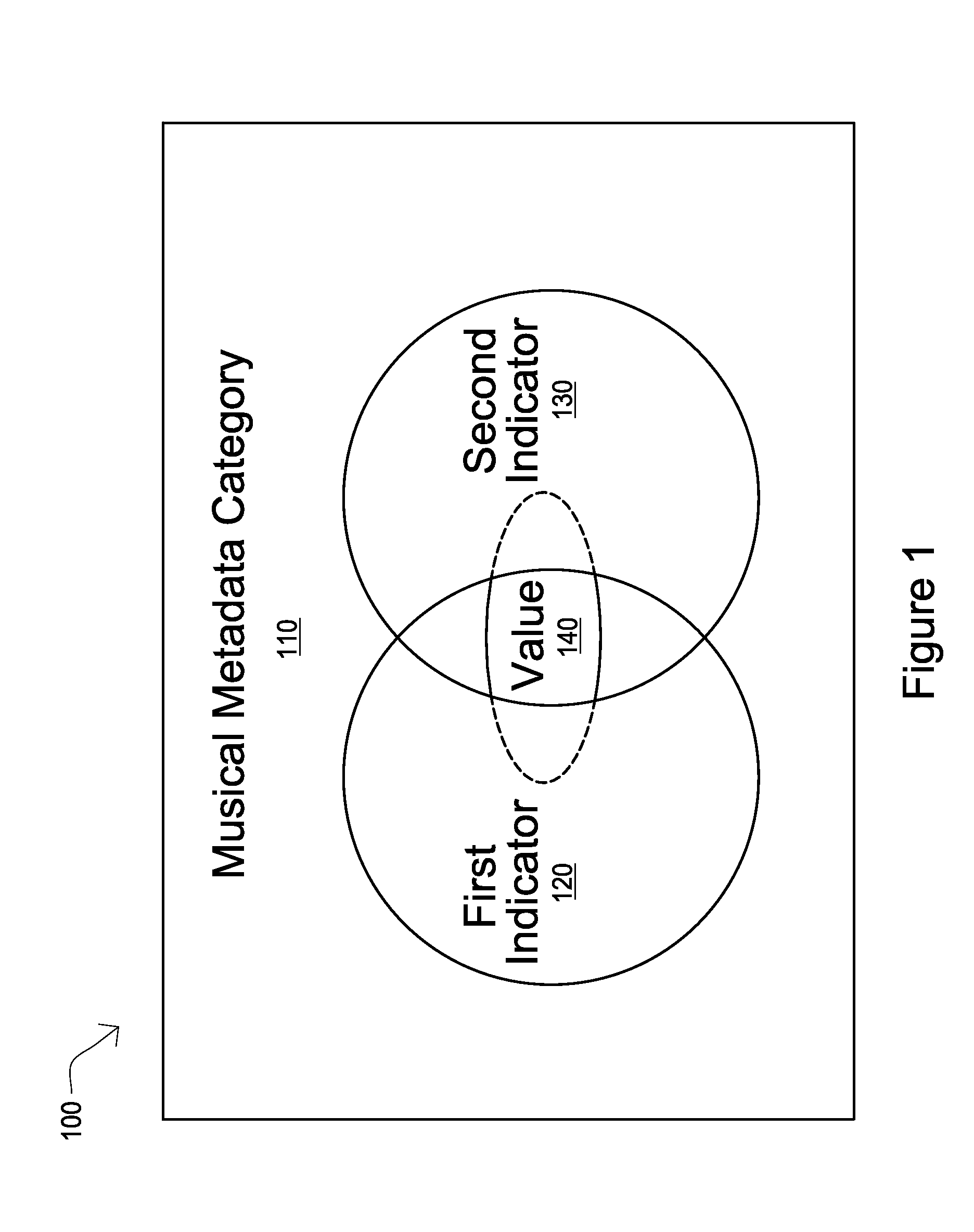

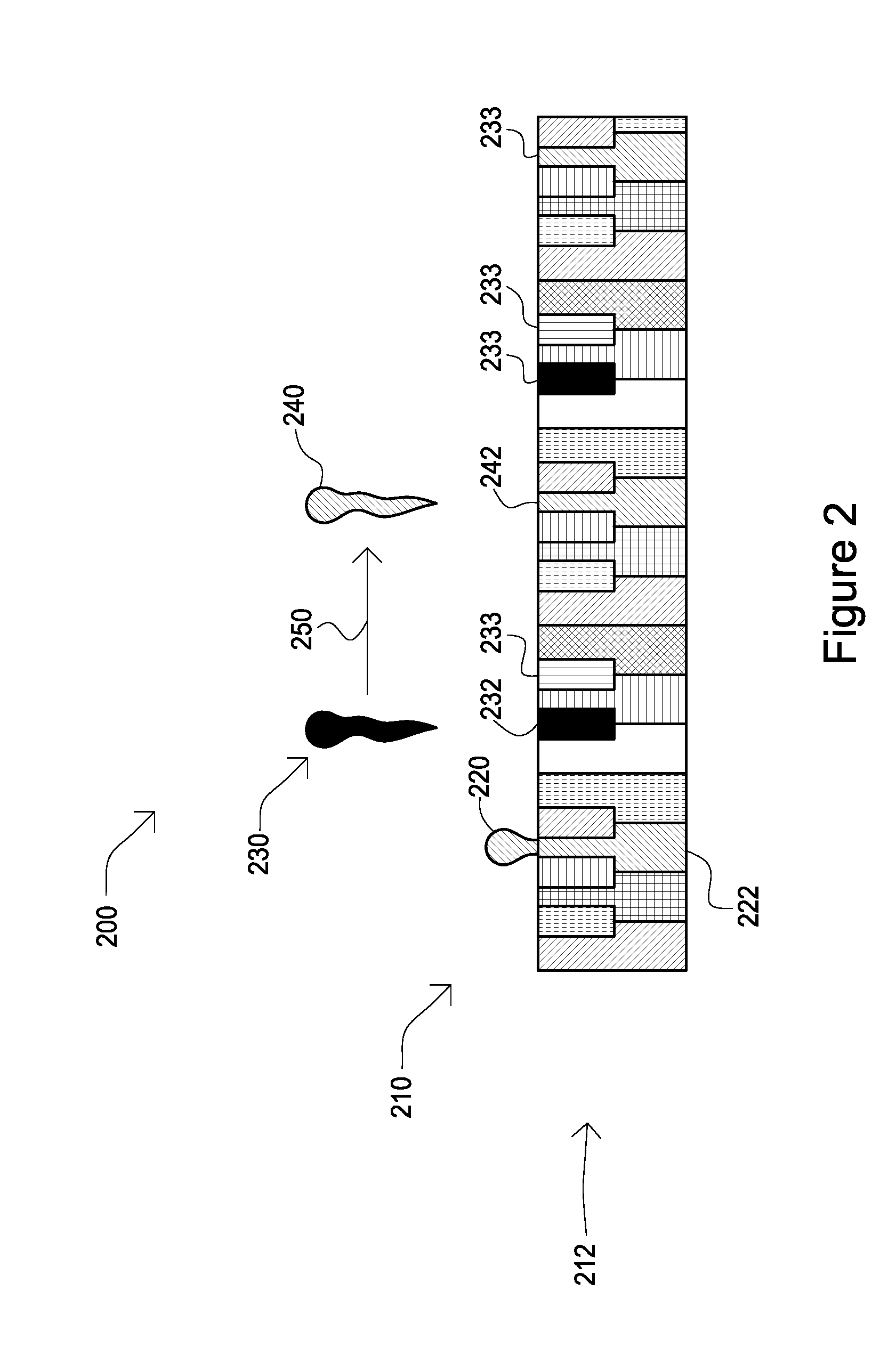

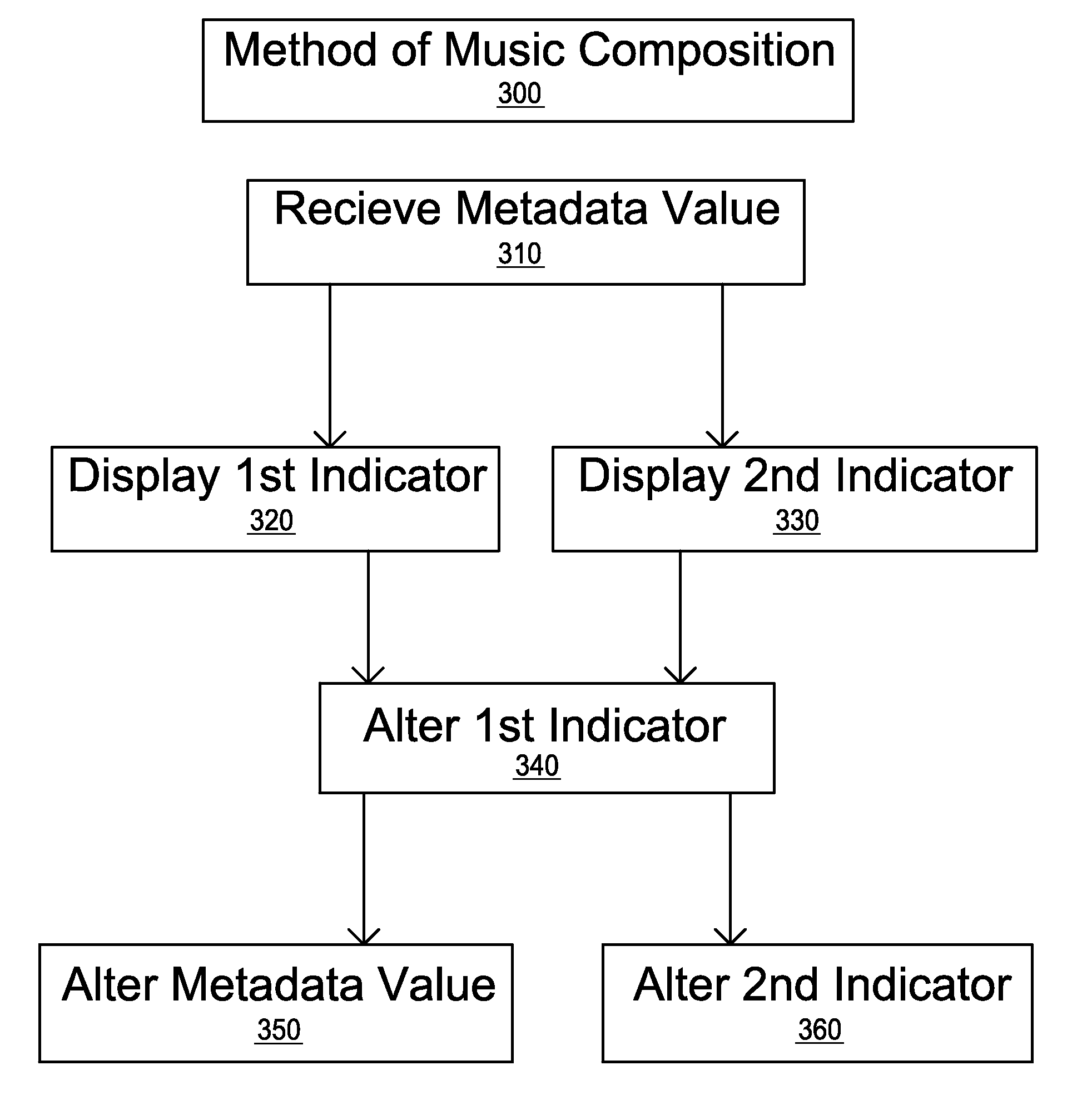

Music composition system and method

InactiveUS20080289477A1Simple, fun, and creativeElectrophonic musical instrumentsMusicGraphicsGraphical user interface

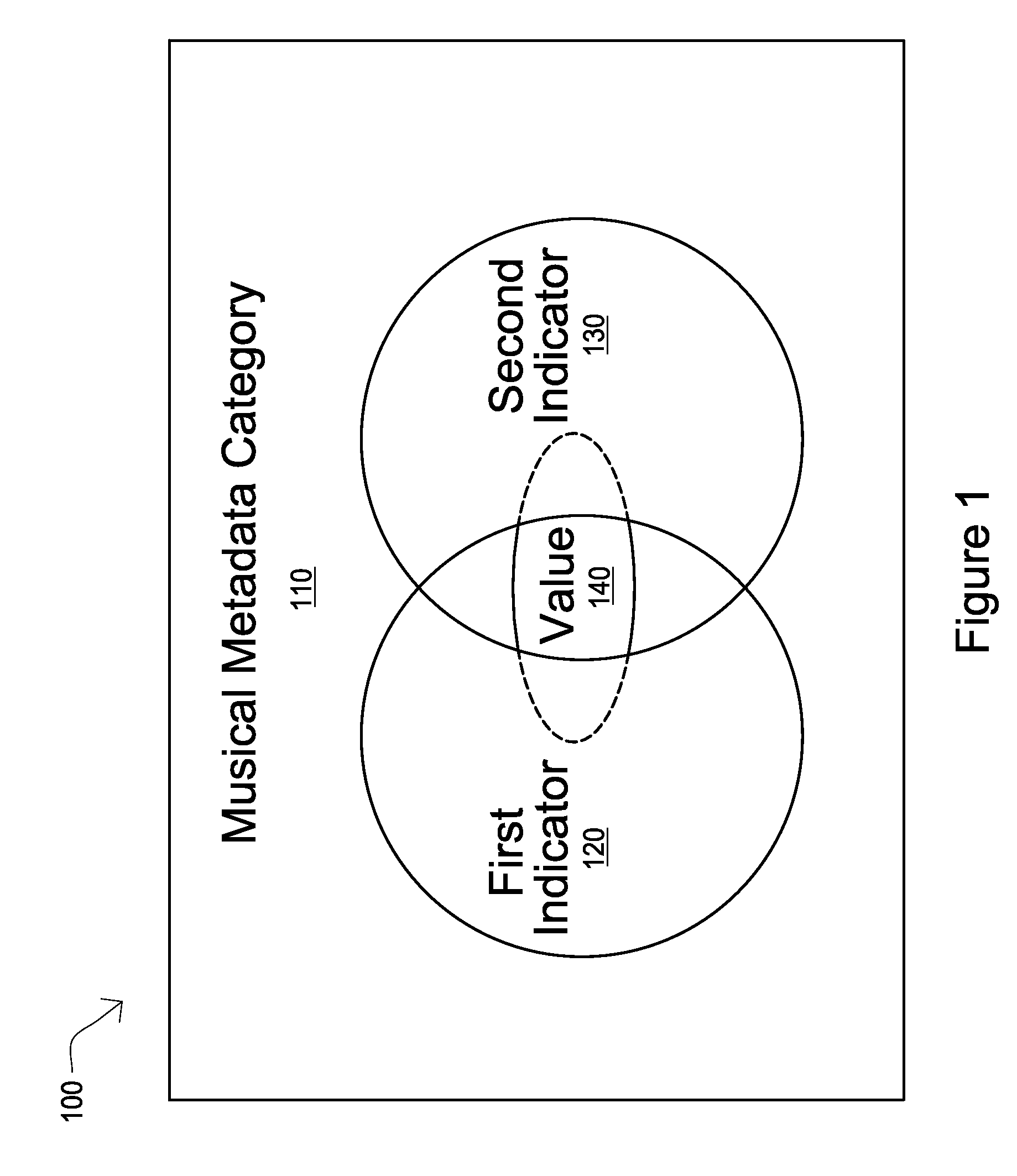

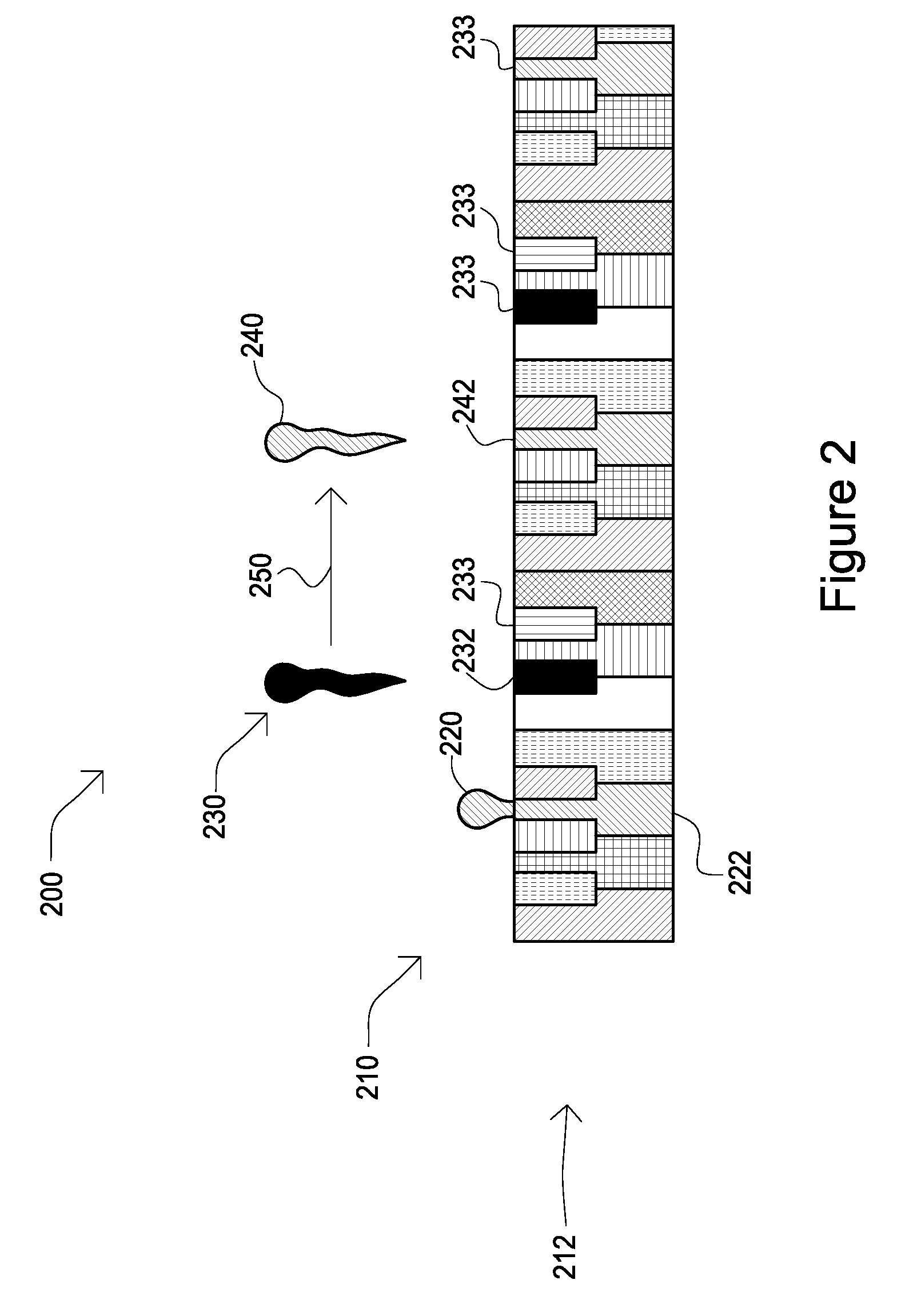

A system, program code, and method for music composition, comprising: displaying a composition object according to a first value, wherein the first value includes a musical event; displaying a first and second indicator, wherein the first and second indicator describes the first value; selecting the composition object; graphically altering the first indicator; changing the first value to a second value; and graphically altering the second indicator. The first indicator comprises the position of the composition object relative to a displayed virtual instrument. The second indicator is not keyed to shapes, rather comprises a color. The method and system further incorporates a graphical user interface including a virtual music instrument; the virtual music instrument includes a plurality of virtual keys, each key corresponding to a key on a performance module.

Owner:ALLEGRO MULTIMEDIA

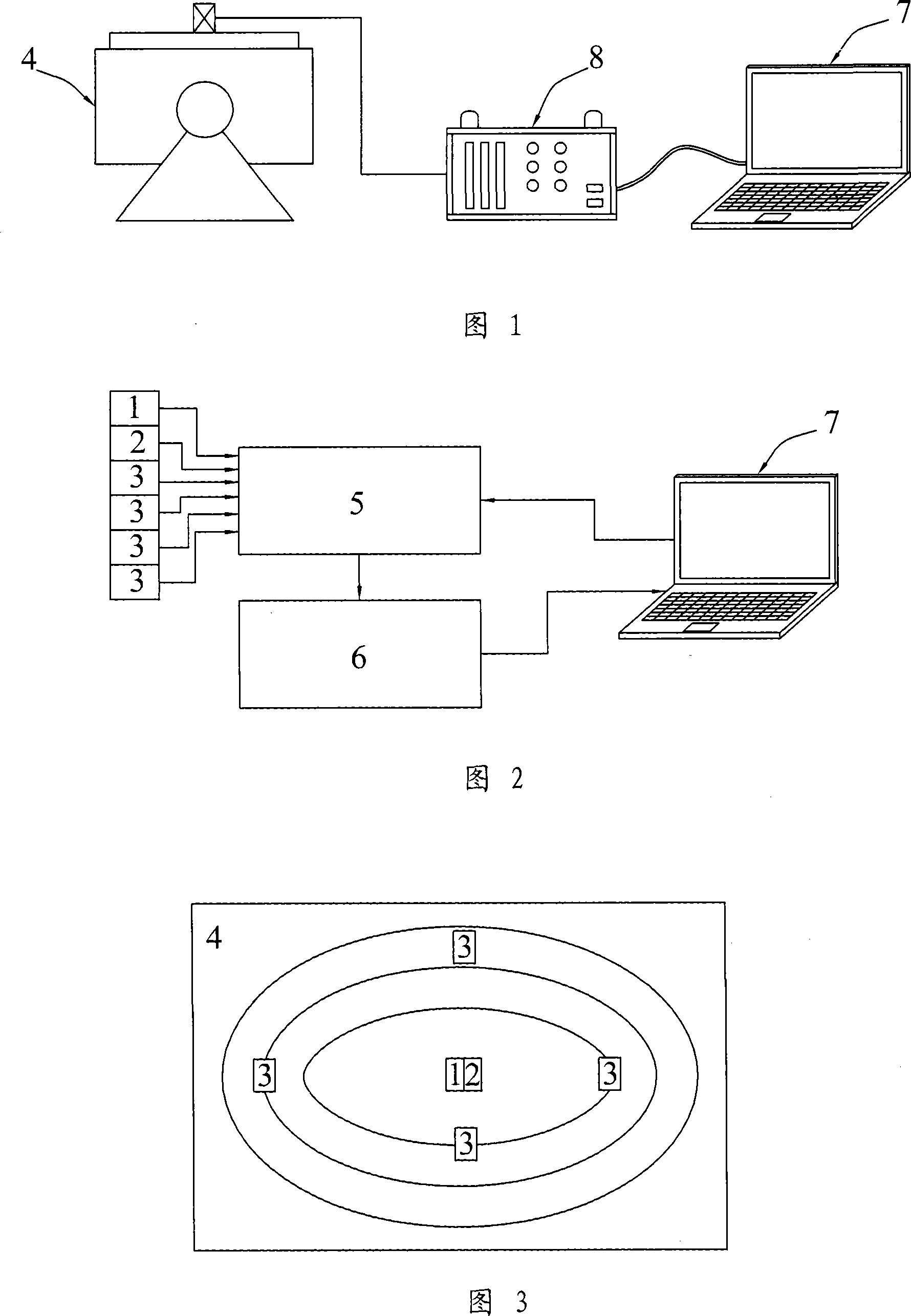

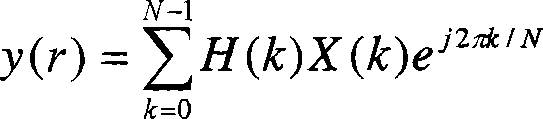

Virtual oscillating table detection signal processing method and equipment thereof

InactiveCN101113936AReduce testing costsGuaranteed test accuracyAcceleration measurement using interia forcesVibration testingElectricitySignal conditioning

The invention relates to a vibration table detection instrument field. In order to overcome the defects of the prior art, a signal processing approach is designed to allow a virtue instrument to be applied to the measurement field and an instrument suitable for measurement is designed accordingly on the basis of the signal processing approach. More particularly, the invention relates to a virtual vibration table detecting signal processing method and the instrument. The method comprises the processes: (1) the acceleration value of the vibration table is collected and converted into electric signals; (2) the signal is conditioned by a signal conditioning instrument; (3) the conditioned signal is collected by a data collecting card and transmitted to a computer; (4) the signal is preprocessed by the computer; (5) the preprocessed signal is discrete Fourier transformed and digital signal frequency domain filtered; (6) in the end, a speed component is output after the signal is integrated for one time; a displacement component is output after the signal is integrated for two times. The detection instrument comprises an acceleration sensor, a signal conditioning instrument, a data collecting card and a computer.

Owner:广州市计量检测技术研究院

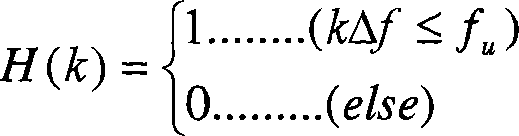

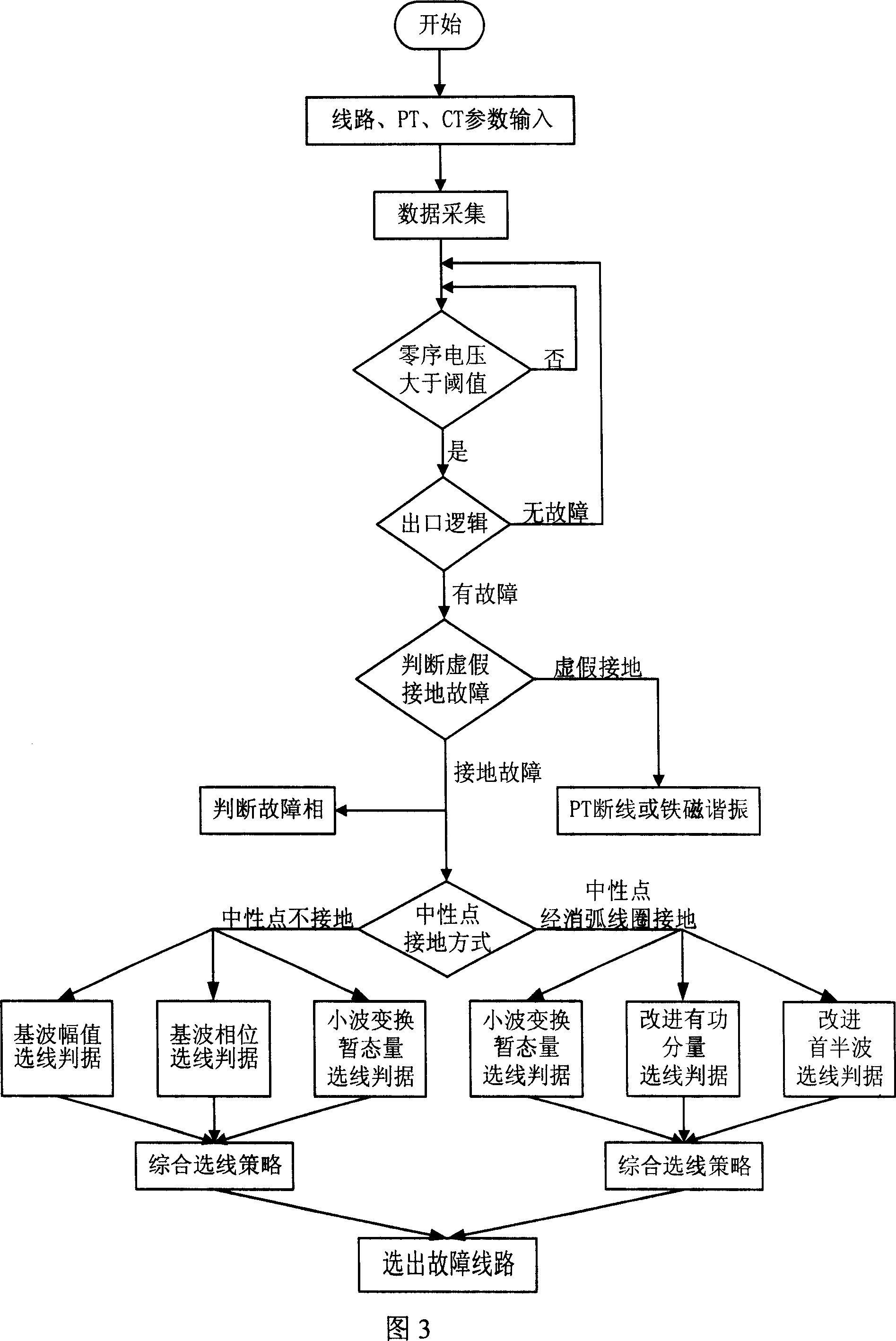

Small earthing current electric network single phase fault wire selecting method and apparatus

InactiveCN101022216AImprove reliabilityGuaranteed accuracyEmergency protective circuit arrangementsFault locationHuman–machine interfacePotential transformer

This invention discloses a method and a device for selecting single-phase fault of small earth current nets, which integratedly processes multiple kinds of fault signals based on the earth situation of the non-earth and arc-extinguishing coils, applies multiple kinds of line selention criteria to constitute quantification espressions showing that a line may be a fault one to get the final line selection result by integrated judgment, the selection device has good man-machine interface and is easily operated and installed, the hardware of the device is a PCI bus industrial control mainboard, and the selection algorithm is realized by virtual instrument technology to differentiate faults of single-phase earth, breakage of voltage mutual-inductors and ferromagnetic resonance and displayed by LCD.

Owner:YANSHAN UNIV

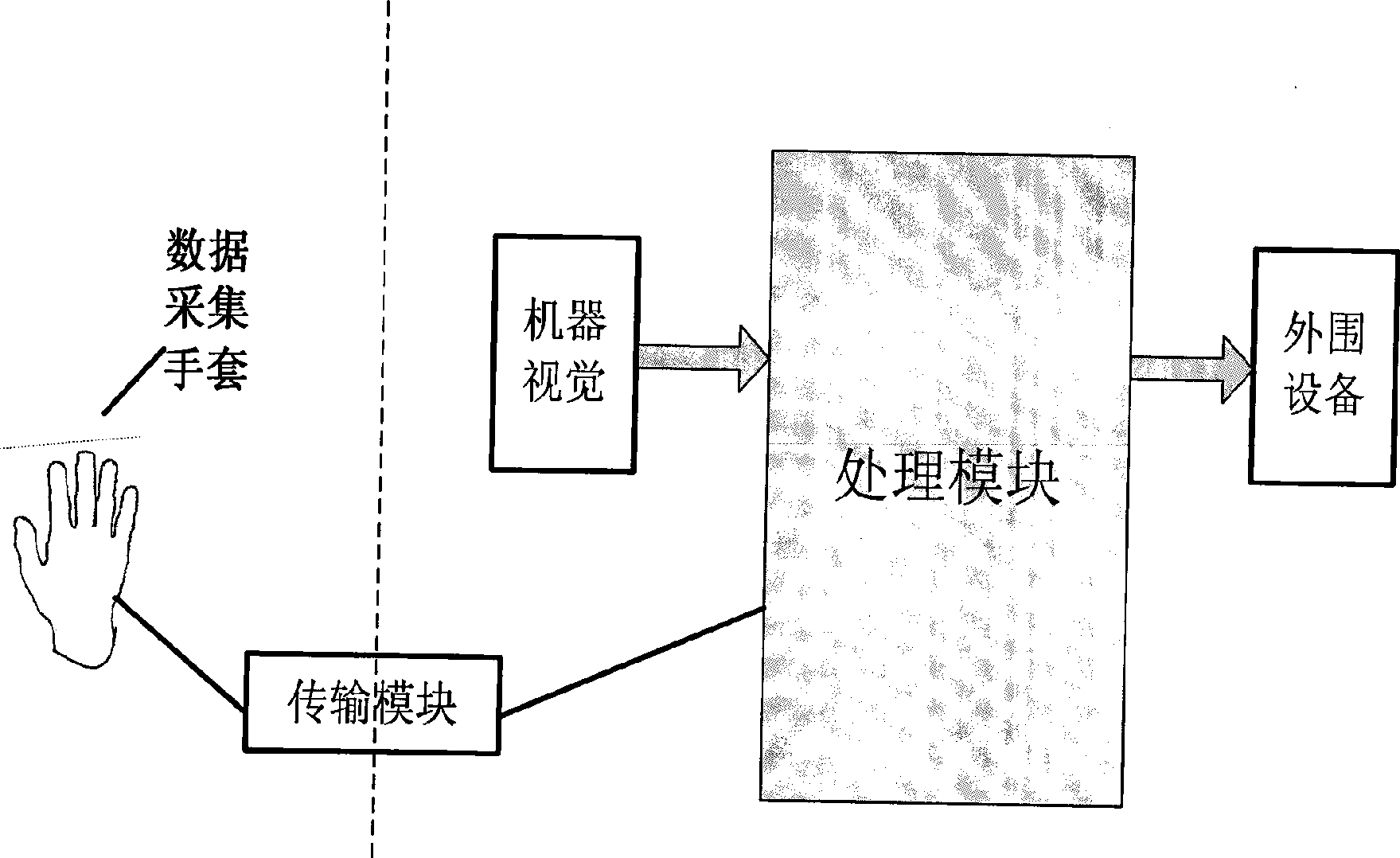

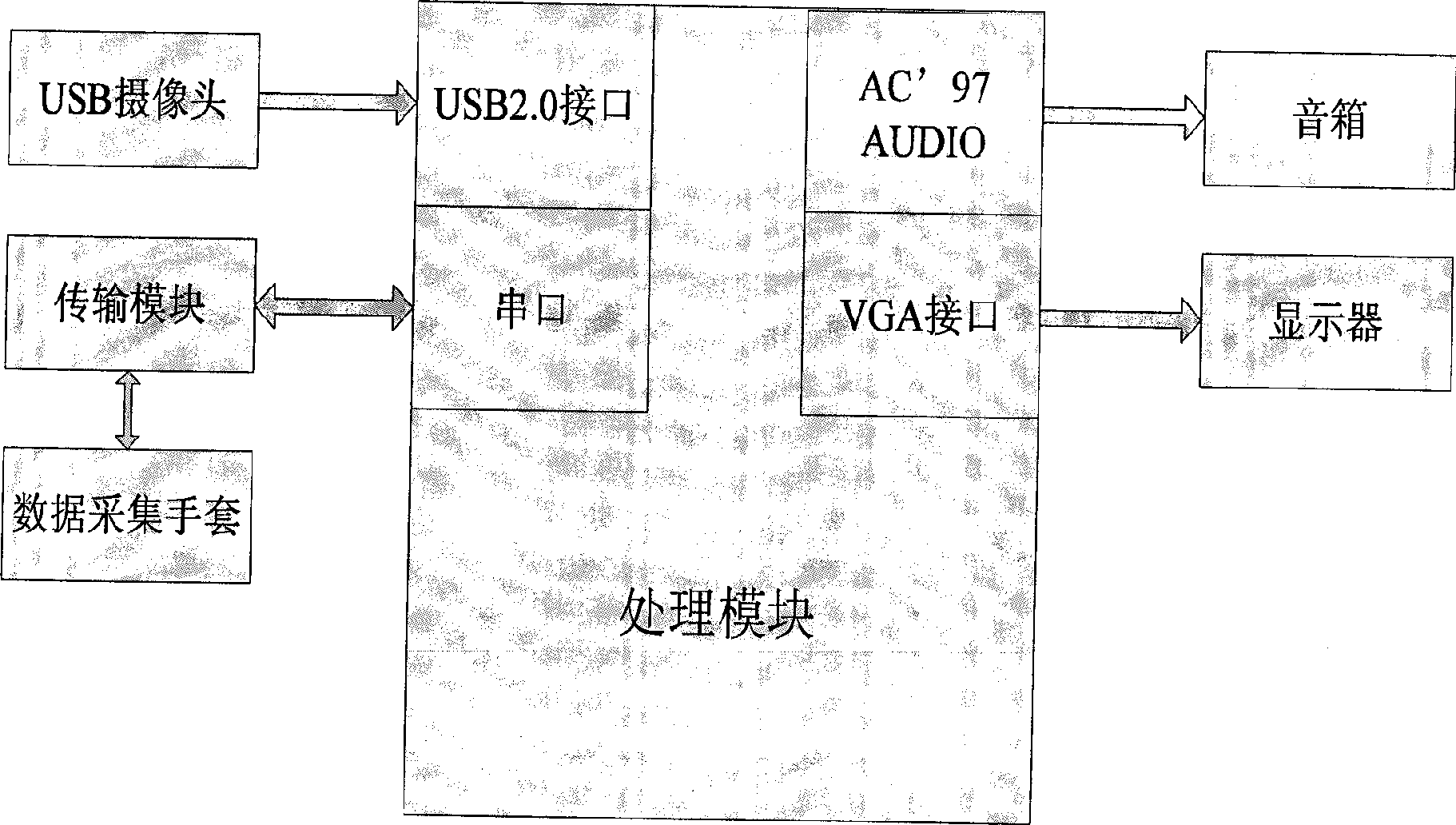

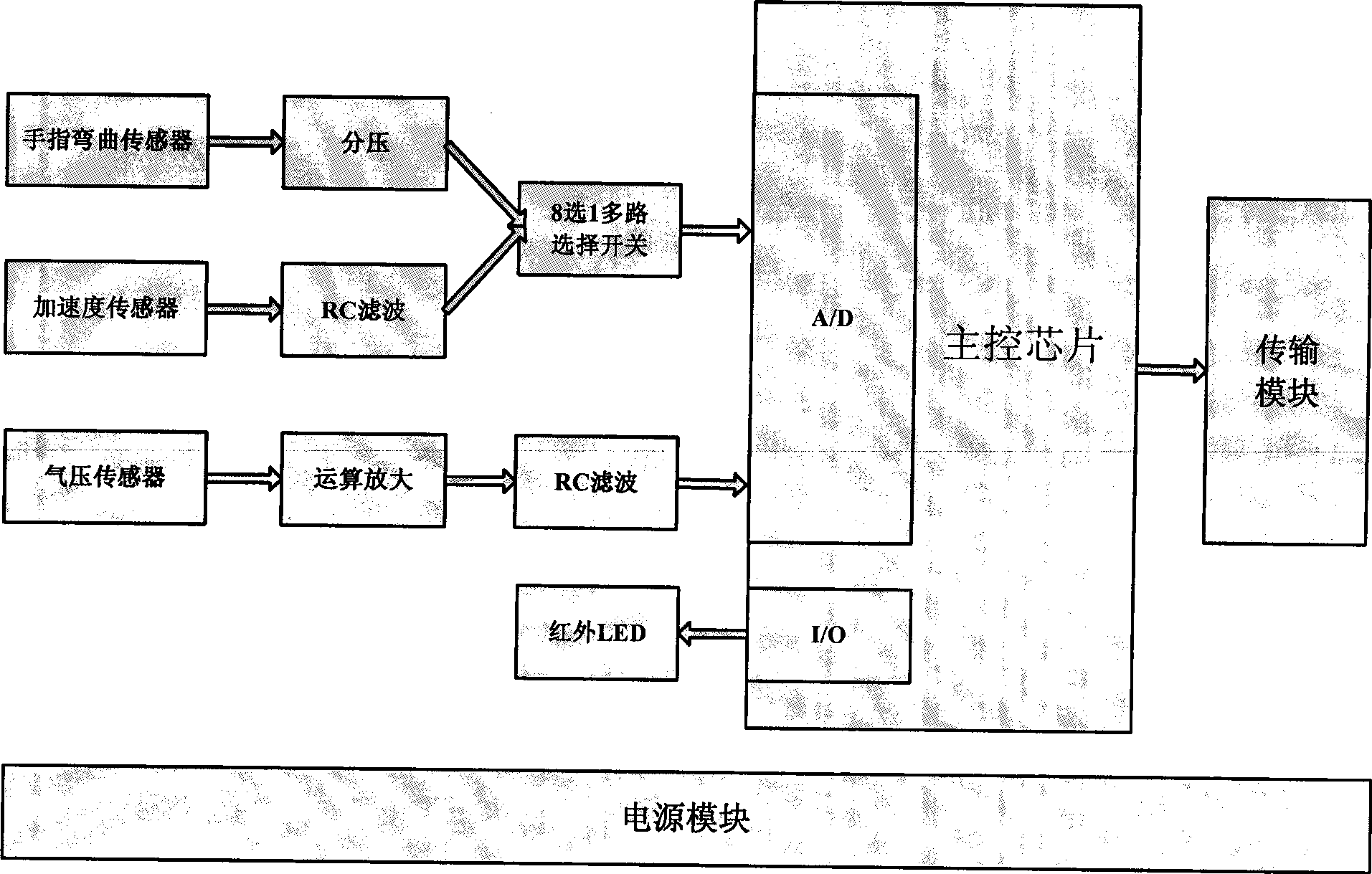

Virtual performance system based on hand motion sensing

InactiveCN101504832APlay directlyPlay natureInput/output for user-computer interactionElectrophonic musical instrumentsMachine visionHand parts

The invention relates to a set of virtual performance system based on hand motion induction, which comprises a data acquisition glove, a machine vision module, a transmission module, a processing module and a peripheral device, wherein the data acquisition glove induces hand motion; the machine vision module induces hand position information; the transmission module transmits information acquired by the data acquisition glove and the machine vision module to the processing module; the processing module identifies the motion performed by a musical instrument from the received hand information, and generates performance sound and specific scene of the musical instrument; and the peripheral device feeds back the sound and the scene to an operator. The invention provides a virtual musical instrument for carrying out human-computer interaction by using the glove, which has the same or similar play skill as a real musical instrument, so that the operator can naturally and flexibly carry out virtual performance; and simultaneously the performance sound and the specific scene of the musical instrument are fed back to the operator, so that the operator can carry out performance more directly and naturally.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

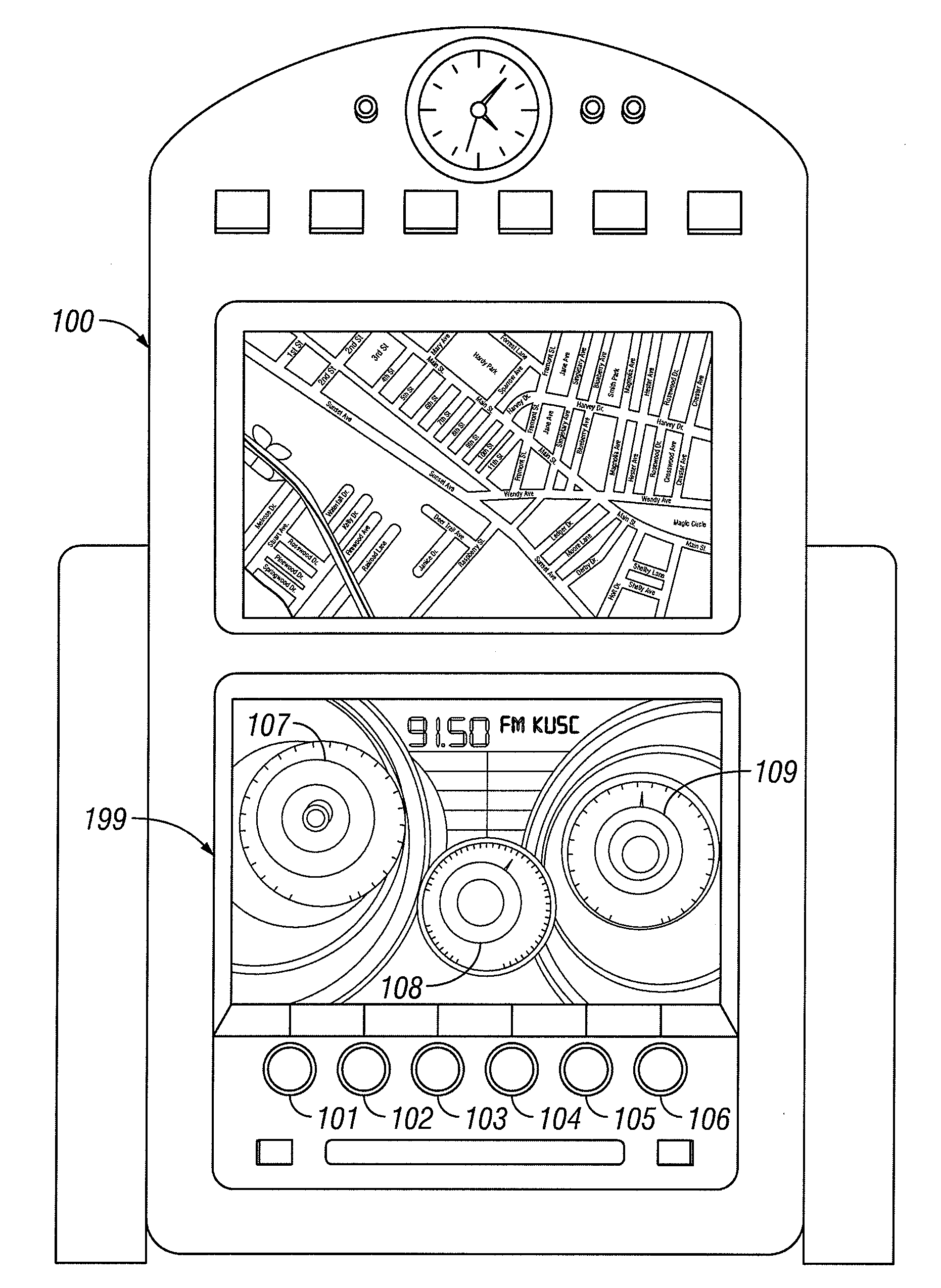

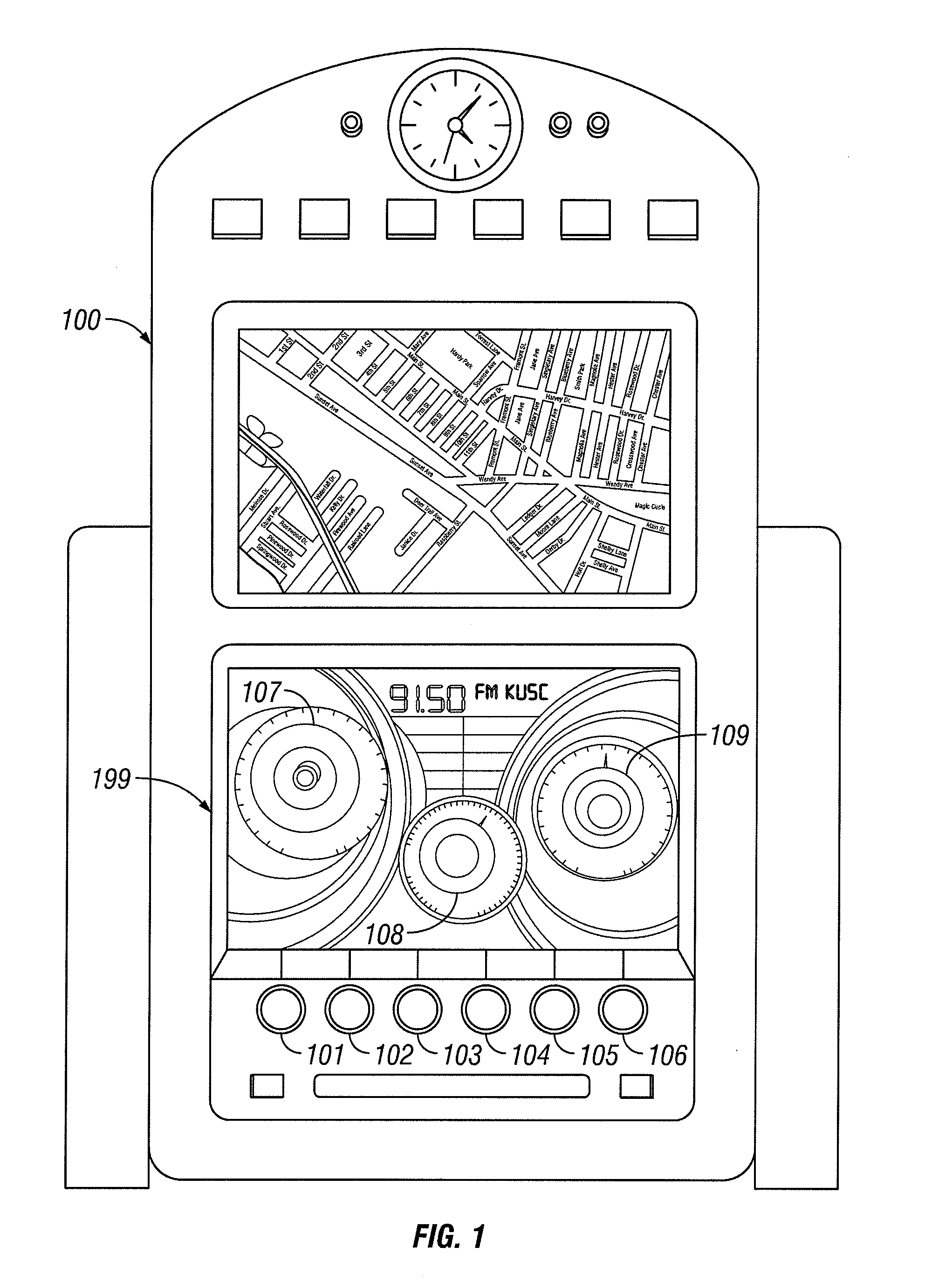

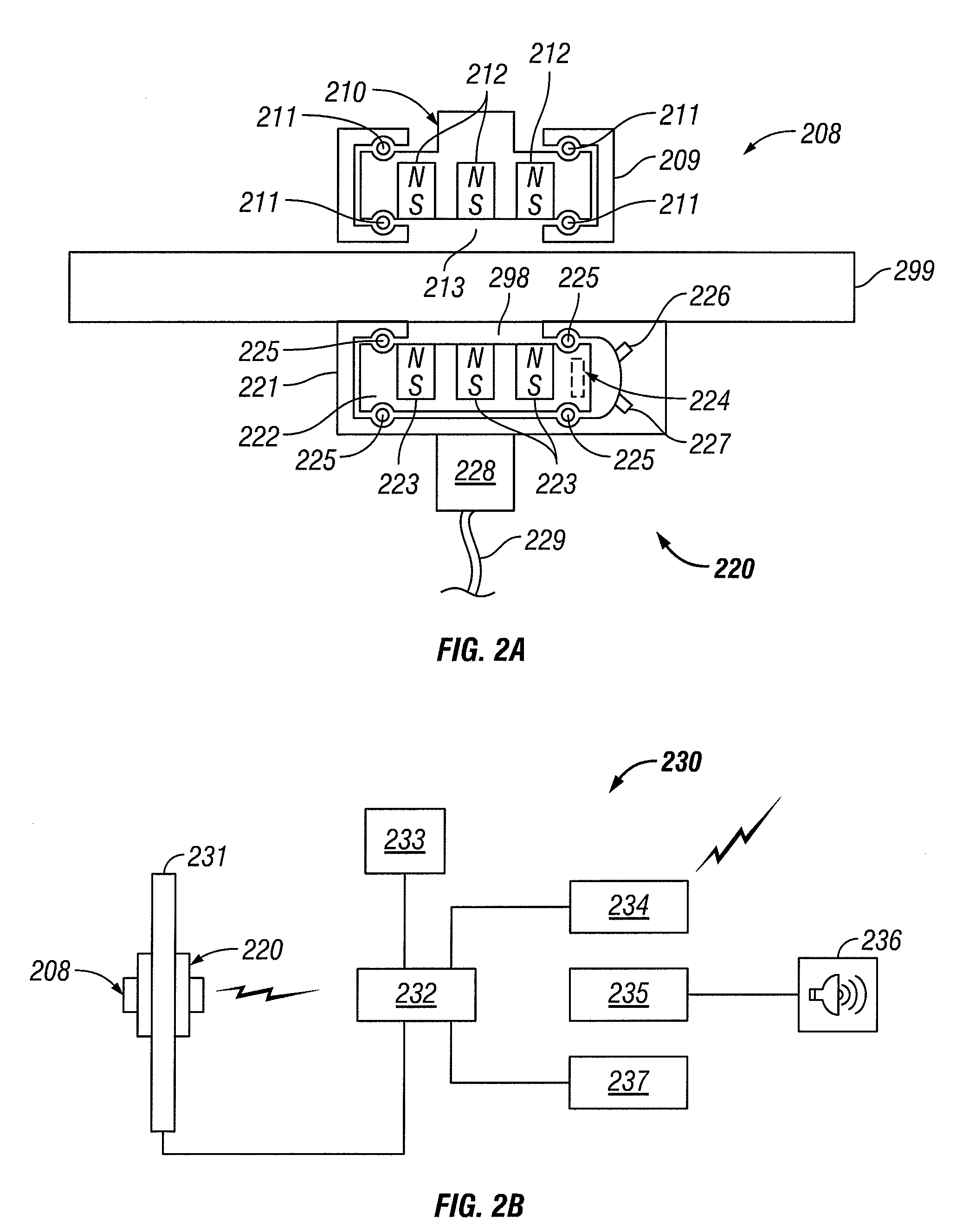

Customizable and reconfigurable virtual instrument panel

ActiveUS20100259375A1Easy to customizeEasy to reconfigureInput/output for user-computer interactionTelevision system detailsTactile sensationDisplay device

The invention provides an instrument control panel that is easily customized and reconfigured, and yet provides the familiar tactile sensation of physical knobs, sliders, and buttons. The instrument control panel comprises one or more interface components that are removably coupled to an interface display wherein the interface components communicate with one or more control components disposed behind the interface display. The present invention lends itself particularly well to an instrument panel.

Owner:APPLIED MINDS

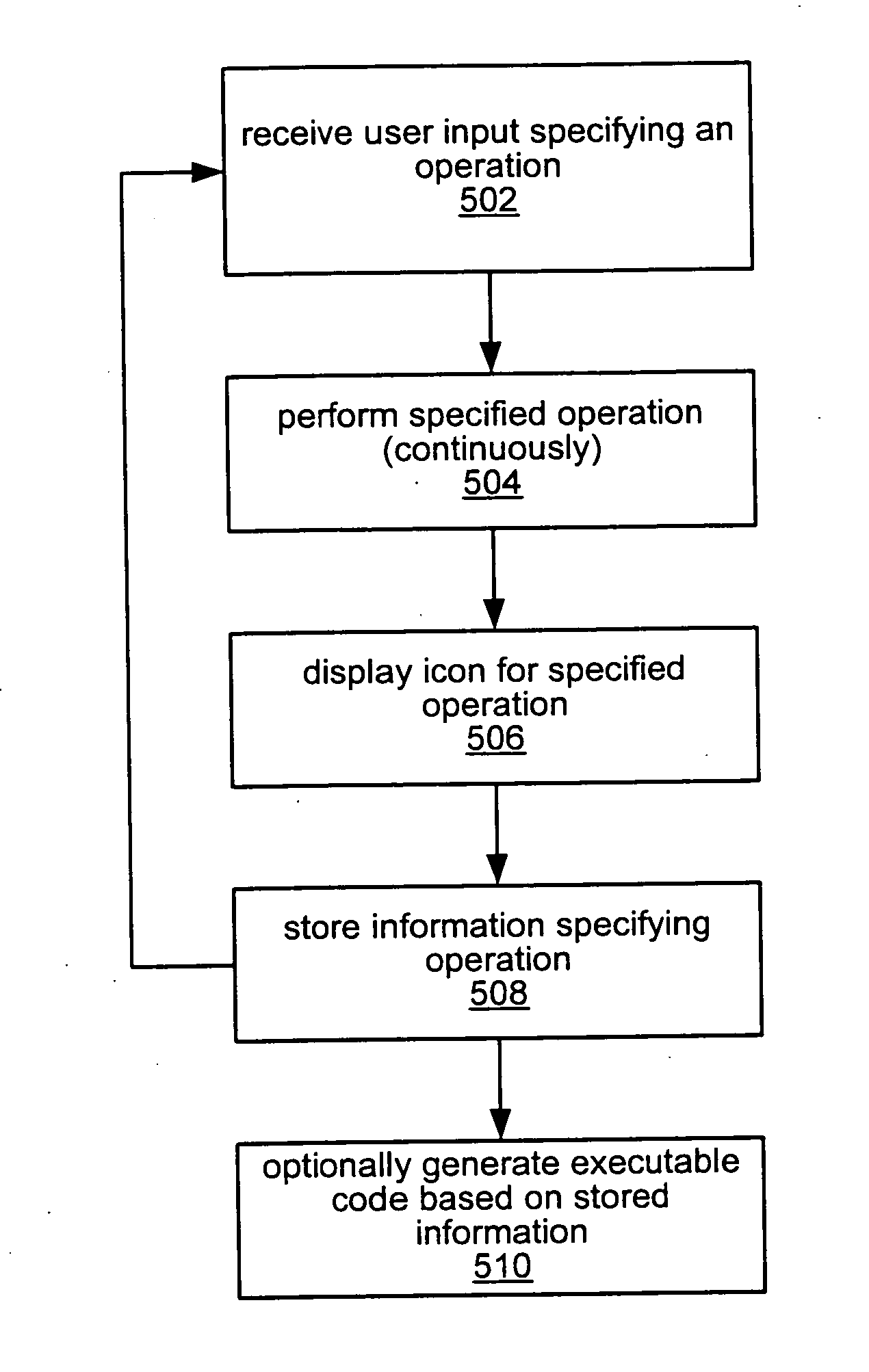

Signal analysis function blocks and method of use

ActiveUS20050039162A1Drawing from basic elementsData processing applicationsGraphicsProgram instruction

System and method implementing function blocks for specifying and performing a signal analysis function utilizing multiple instruments, including two or more virtual instruments (VIs). Each function block includes: a function block icon for display in a graphical user interface (GUI) of a signal analysis function development environment, that visually indicates a respective signal operation; and associated program instructions executable to perform the respective operation. Each function block is selectable from the function blocks by a user for inclusion in a set of function blocks, each operable to perform their respective signal operation continuously upon selection, and to provide a respective output, operable to be displayed in the GUI, provided as input to other function blocks, and / or exported to an external device. The set of function blocks is executable to perform the signal analysis function under the signal analysis function development environment using one or more of the multiple instruments.

Owner:NATIONAL INSTRUMENTS

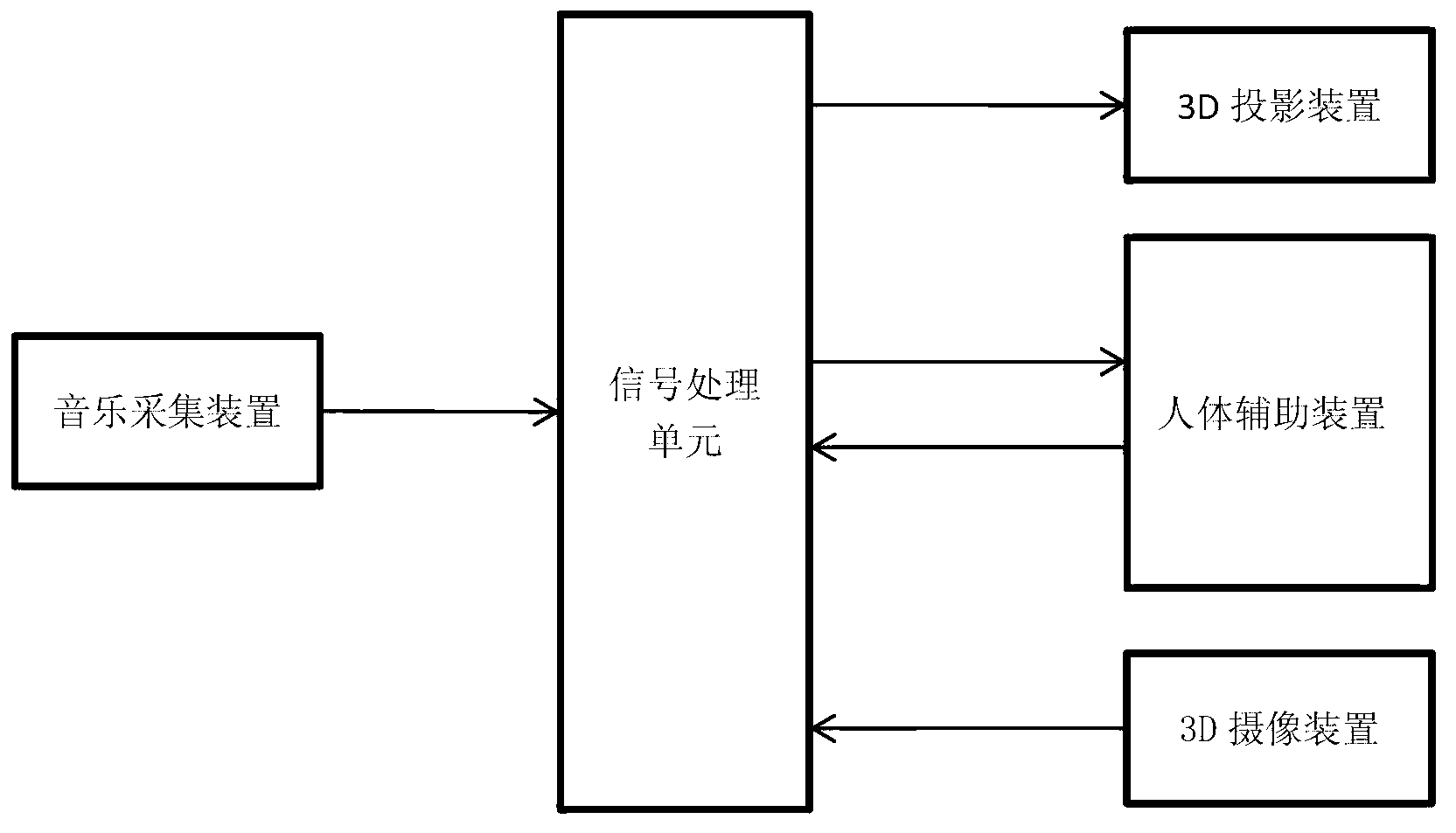

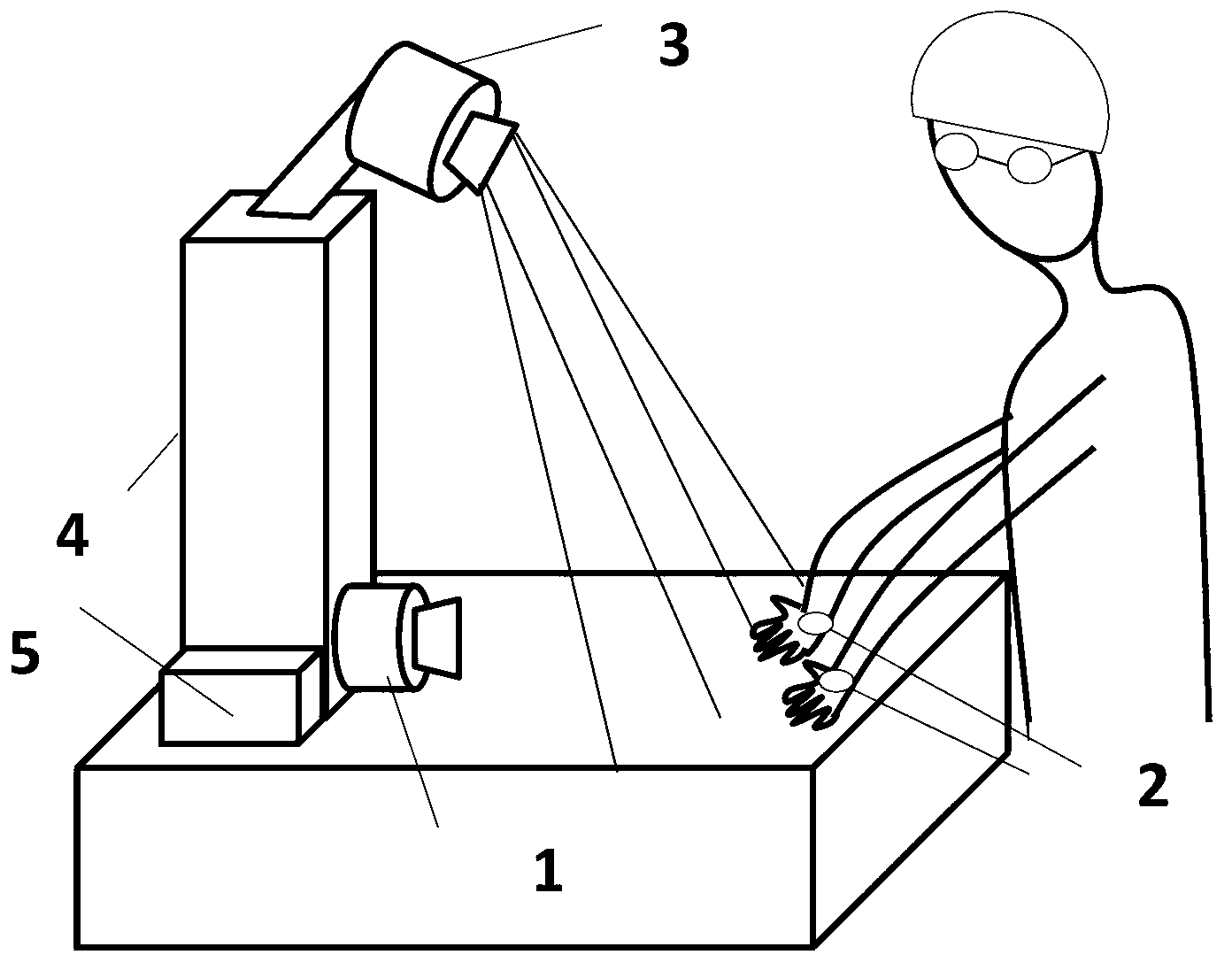

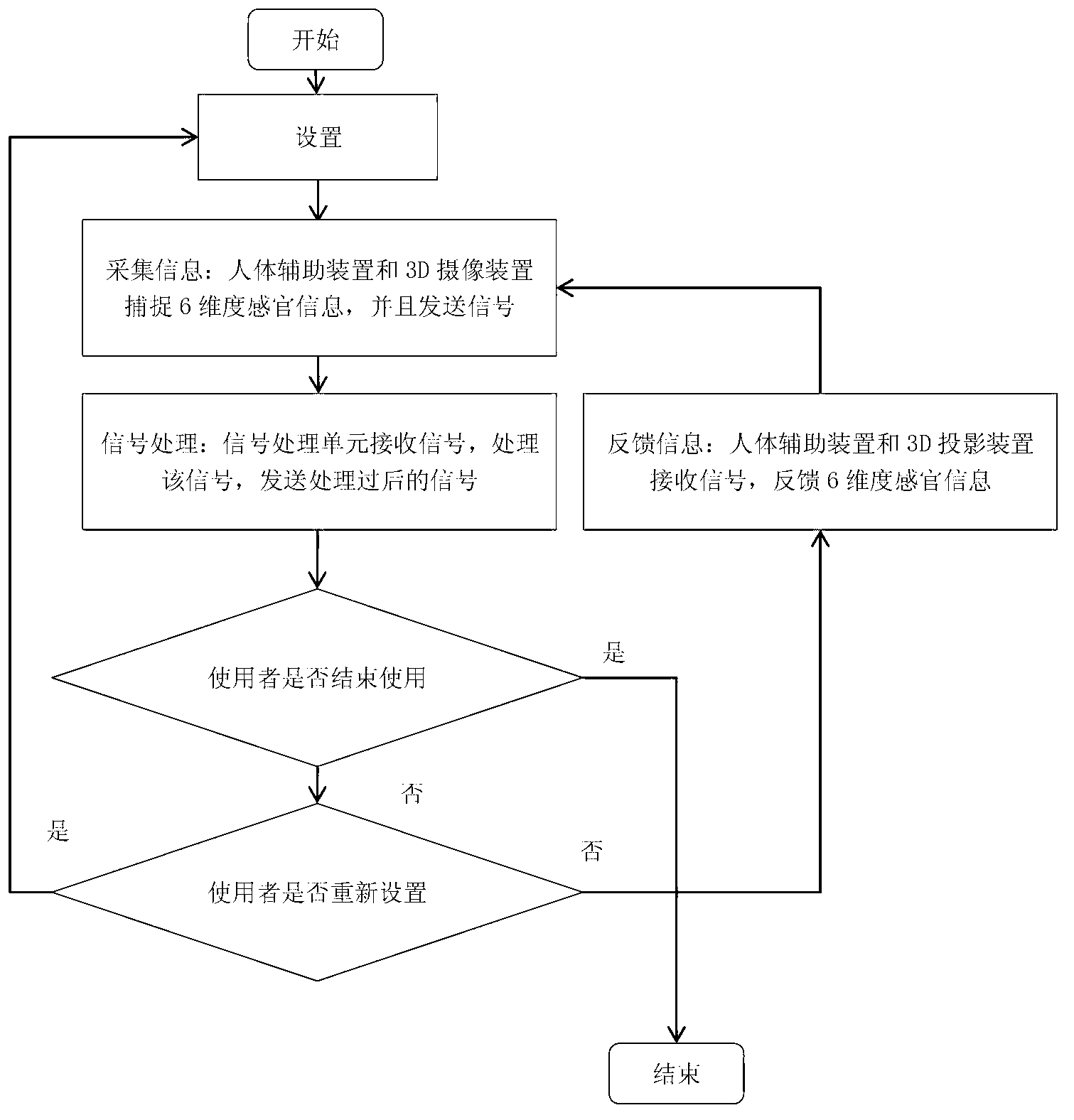

6-dimensional sensory-interactive virtual keyboard instrument system and realization method thereof

ActiveCN103235641AImprove experienceEasy to useInput/output for user-computer interactionMusicHuman bodyPiano

The invention provides a 6-dimentional sensory-interactive virtual keyboard instrument system and a realization method thereof. The 6-dimentional sensory-interactive virtual keyboard instrument system comprises a human body auxiliary device, a 3-dimentiaonal camera shooting device, a 3-dimentiaonal projection device, a signal processing unit and a music collection device. The system provided by the invention has various working modes, including a play mode, an optimal fingering prompting mode, a fingering correction mode and a teaching mode, not only can provides a basic play experience for a user, but also has the functions of fingering prompting, fingering correction and teaching demonstration. The 6-dimentional sensory keyboard instrument system provided by the invention is based on the 3-dimentiaonal vision, hearing, touch feeling and press feeling, and the provided virtual instruments comprises a piano, an electronic organ, an accordion, an organ and other keyboard instruments in species, so that the user can feel an interaction effect just like playing a real instrument; and moreover, the system can realize a powerful teaching function, is simple in use method, flexible and space-saving, is the huge breakthrough for a conventional keyboard instrument, and has a very broad application prospect.

Owner:ZHEJIANG UNIV

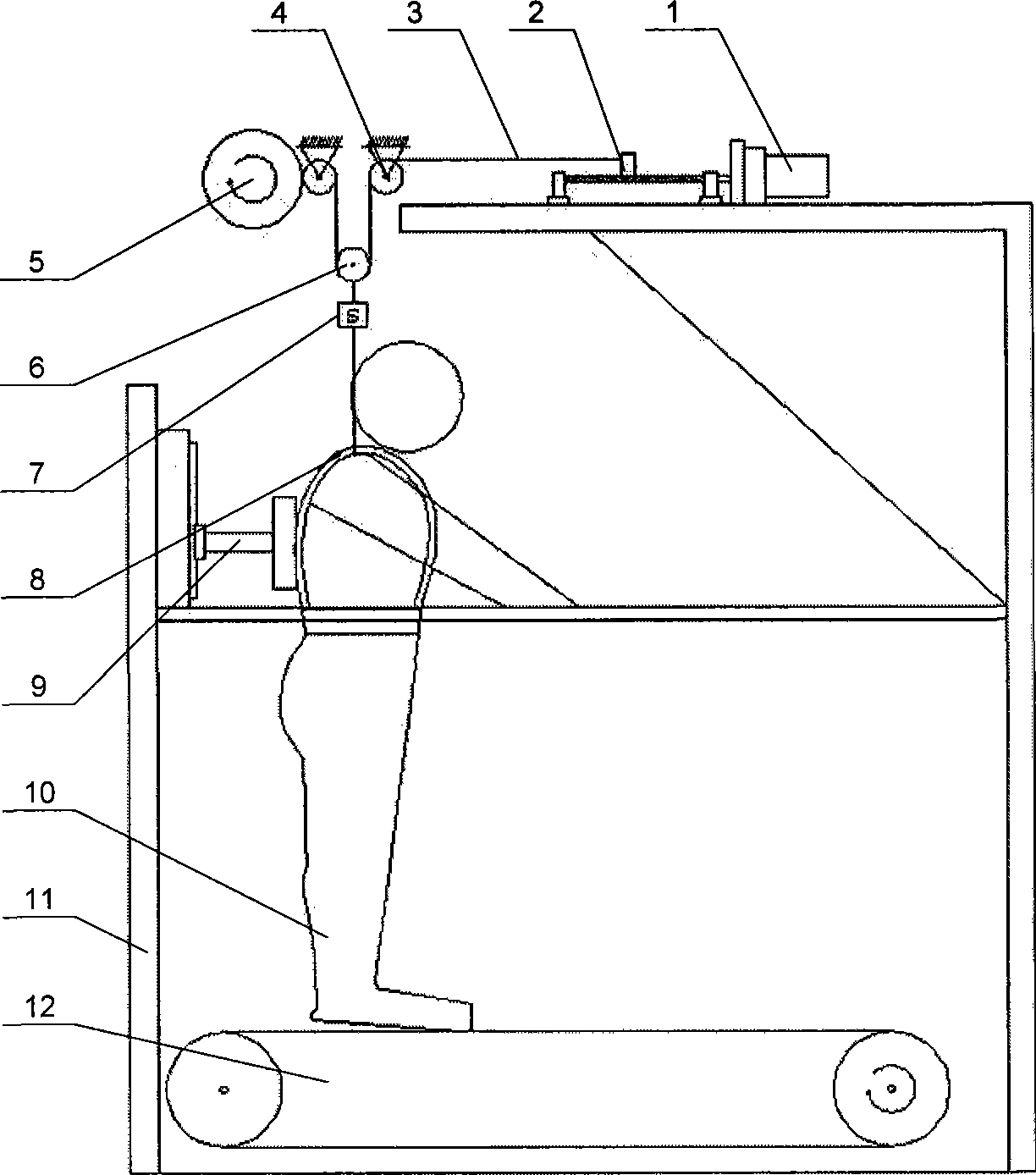

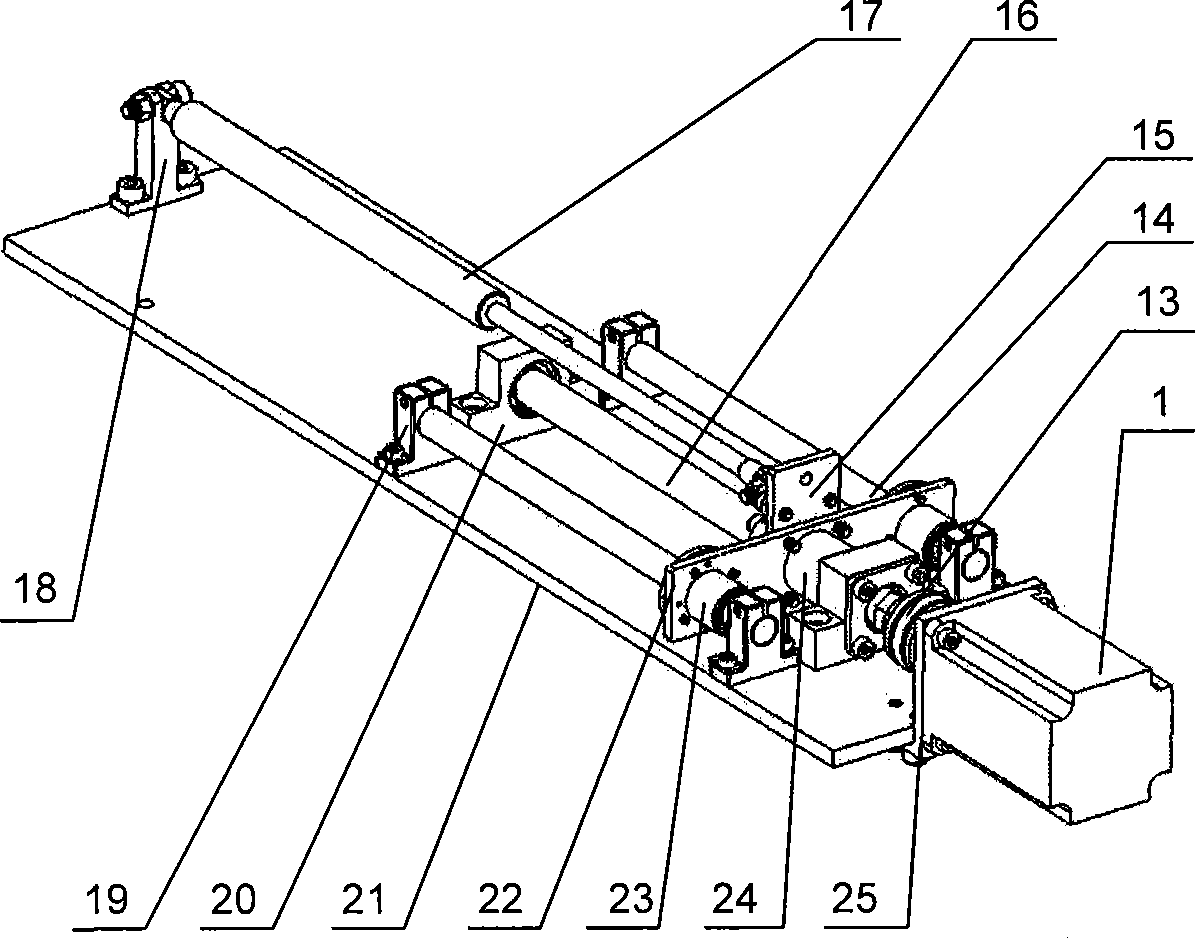

Active partial body weight support treadmill training device and active partial body weight support treadmill training method

InactiveCN101518490AReduce mistakesImproving the Effects of Weight Loss Walking TrainingChiropractic devicesMovement coordination devicesClosed loopEngineering

The invention relates to an active partial body weight support treadmill training device and an active partial body weight support treadmill training method. The device comprises a force sensor, a support, a treadmill, and a partial body weight support mechanism. During the training, a patient is positioned on the treadmill and is connected to a steel wire rope through a sling, one end of the steel wire rope is provided with a winch which can adjust the length of the steel wire rope according to the height of the patient, while the other end is connected to the partial body weight support mechanism which is used for providing a partial body weight support force, and the partial body weight support force can be given according to the requirement of a doctor. During the whole training process, the force sensor is used to detect the actual partial body weight support force and feed back the actual partial body weight support force to a virtual instrument to realize closed-loop control, so that the constancy of the partial body weight support force is ensured. The active partial body weight support method can effectively improve the effect of partial body weight support treadmill training, has simple operation, and is suitable for rehabilitation training in hospitals and families.

Owner:SHANGHAI UNIV

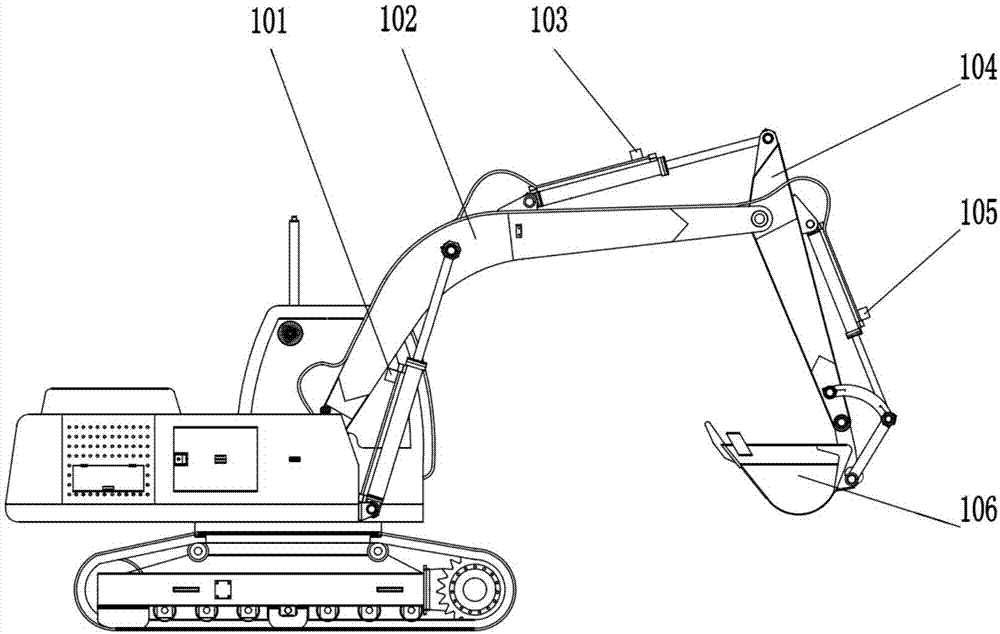

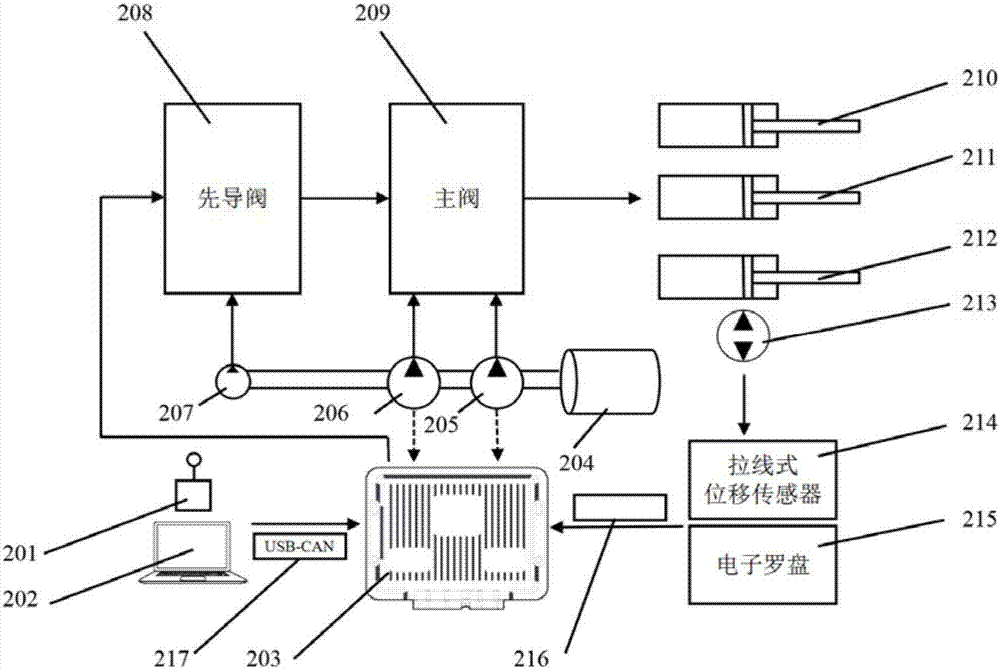

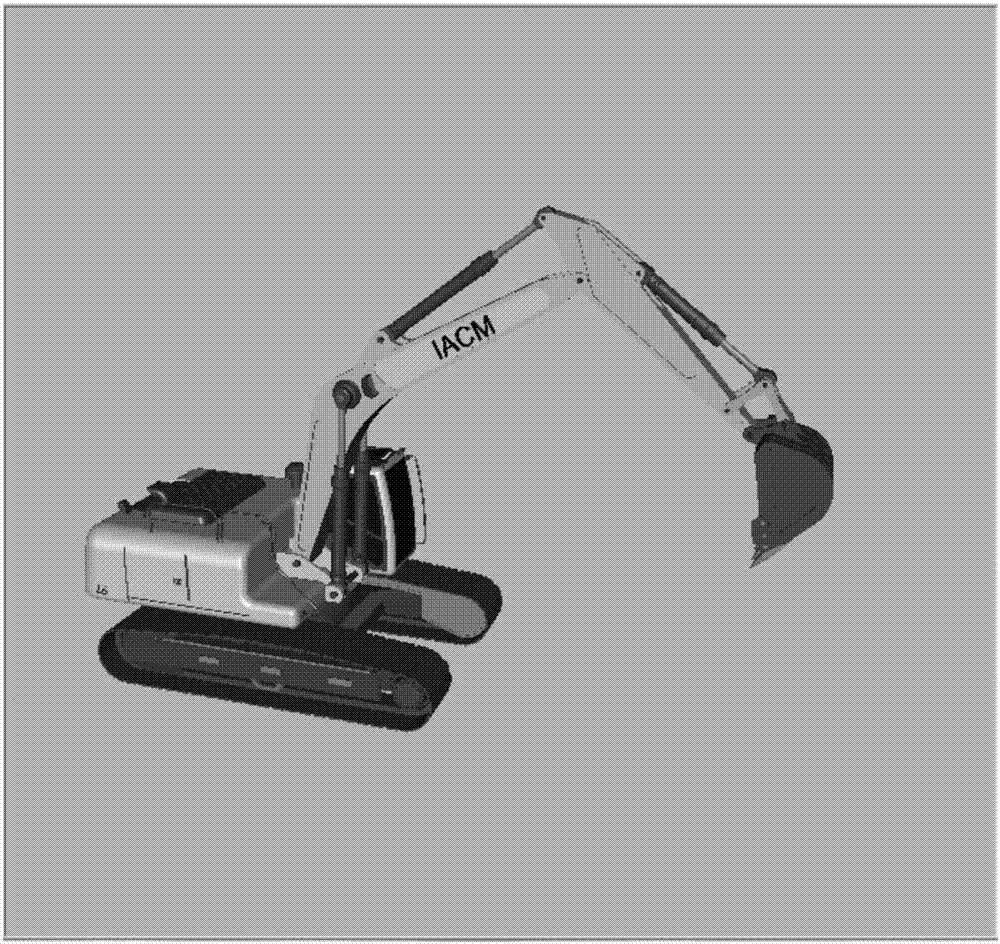

Three-dimensional attitude display and remote automatic control system of excavator

ActiveCN107882103ARealize remote automatic controlReal-time display of 3D animation simulation postureMechanical machines/dredgersAutomatic controlWeb service

The invention discloses a three-dimensional attitude display and remote automatic control system of an excavator. A pull line type displacement sensor is adopted to acquire a displacement signal of amoveable arm hydraulic cylinder, a bucket rod hydraulic cylinder and a scraper bucket hydraulic cylinder, and the displacement signal is sent to a computer through a data acquisition card; a car bodyrotation angle signal is acquired through an electronic compass, and the car body rotation angle signal is sent to the computer through an RS232 serial port; the computer is used for storing and processing data, so that a three-dimensional animated simulation attitude of the excavator is displayed in real time; an expected track of a scraper bucket tail end is planned; according to a practical displacement and car body rotation signal of a working device, a control algorithm is run by performing kinematic conversion on the practical displacement and car body rotation signal and comparing the practical displacement and car body rotation signal subjected to kinematic conversion with expected track data so as to correct the track; a CAN communication mode is adopted for realizing data communication between the computer and a special DSP controller of the excavator; operation state information is monitored in real time; operation track of tooth tips of X, Y and Z-axis scraper bucket and athree-dimensional displacement curve of the tooth tips of the scraper bucket are displayed in real time; and remote automatic control is realized through WEB service of a virtual instrument.

Owner:NANJING UNIV OF TECH +1

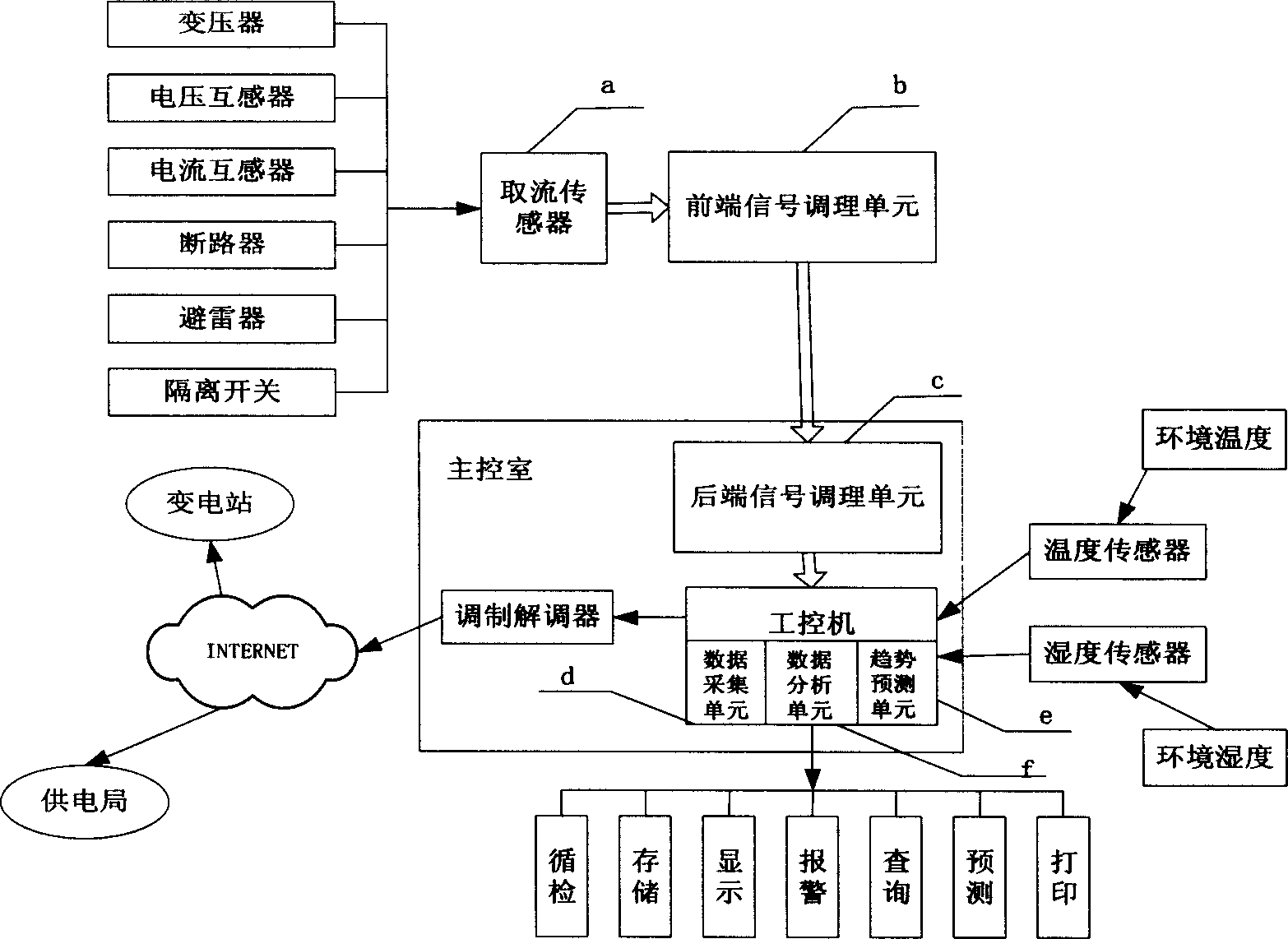

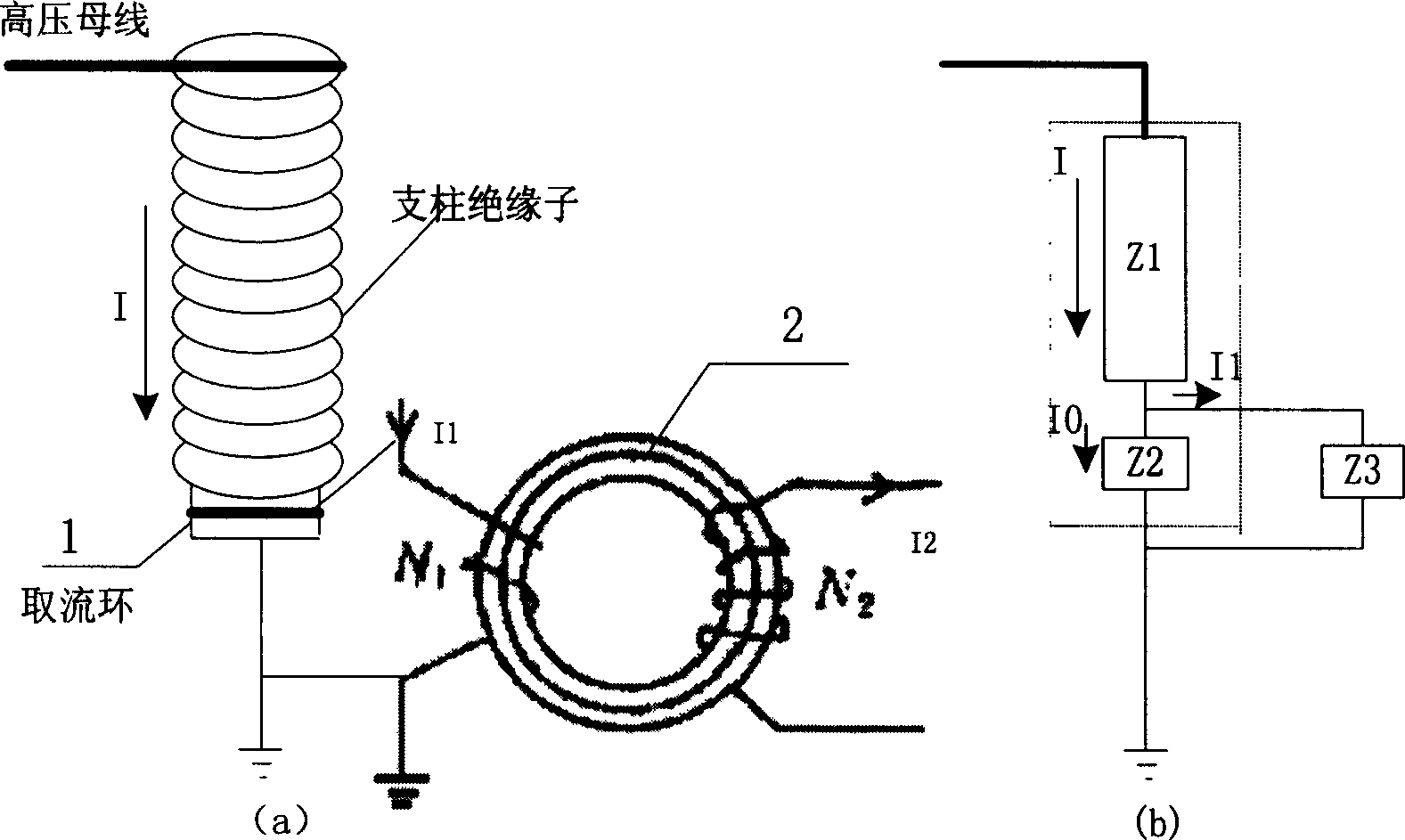

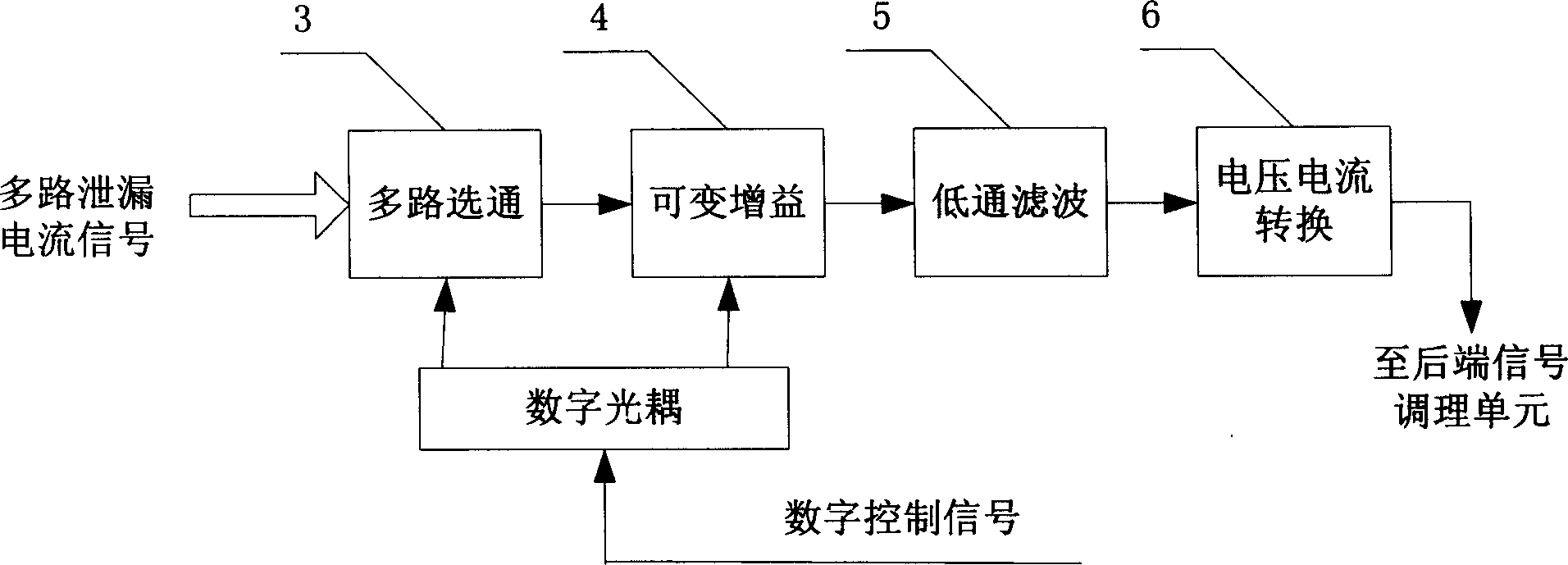

Electric power apparatus external insulative leakage current on-line monitoring system in converting station

InactiveCN1553206AHigh measurement accuracyImprove measurement stabilityElectrical testingEmergency protective arrangements for automatic disconnectionTrend predictionElectric power

The system is composed of flow taking transducer, regulation unit of front end signal, regulation unit of back end signal, data collection unit, data analysis unit and trend predictive unit. The present invention has developed software of remote monitoring, trend prediction, data processing, data analysing and circulation detecting for multiple equipment-multiple pollution leakage current by using virtual equipment and graphic programming language LabVIIEW with combining of SQLSERVER2000 databank system.

Owner:XI AN JIAOTONG UNIV

Music composition system and method

A system, program code, and method for music composition, comprising: displaying a composition object according to a first value, wherein the first value includes a musical event; displaying a first and second indicator, wherein the first and second indicator describes the first value; selecting the composition object; graphically altering the first indicator; changing the first value to a second value; and graphically altering the second indicator. The first indicator comprises the position of the composition object relative to a displayed virtual instrument. The second indicator is not keyed to shapes, rather comprises a color. The method and system further incorporates a graphical user interface including a virtual music instrument; the virtual music instrument includes a plurality of virtual keys, each key corresponding to a key on a performance module.

Owner:SALTER HAL C

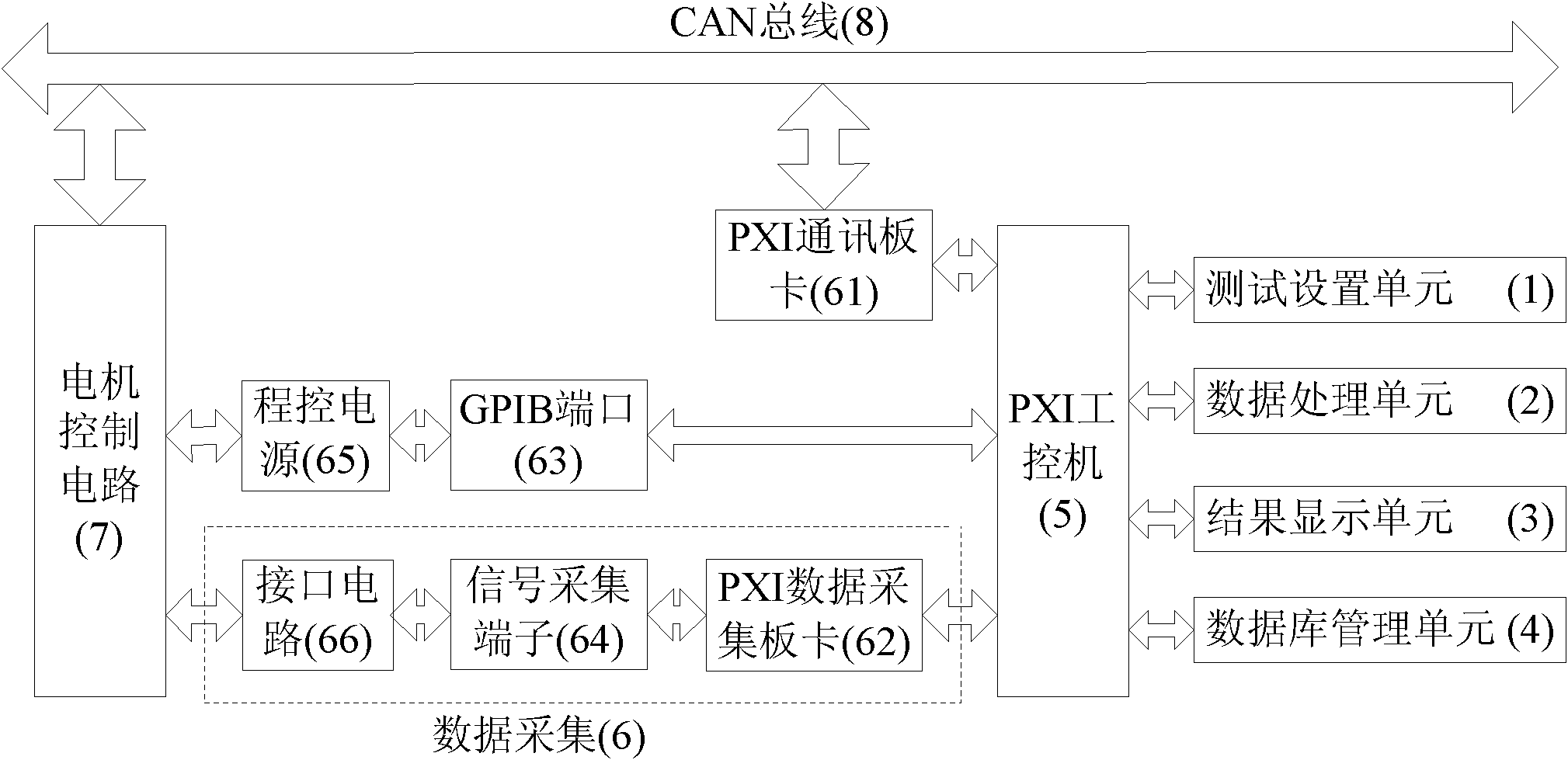

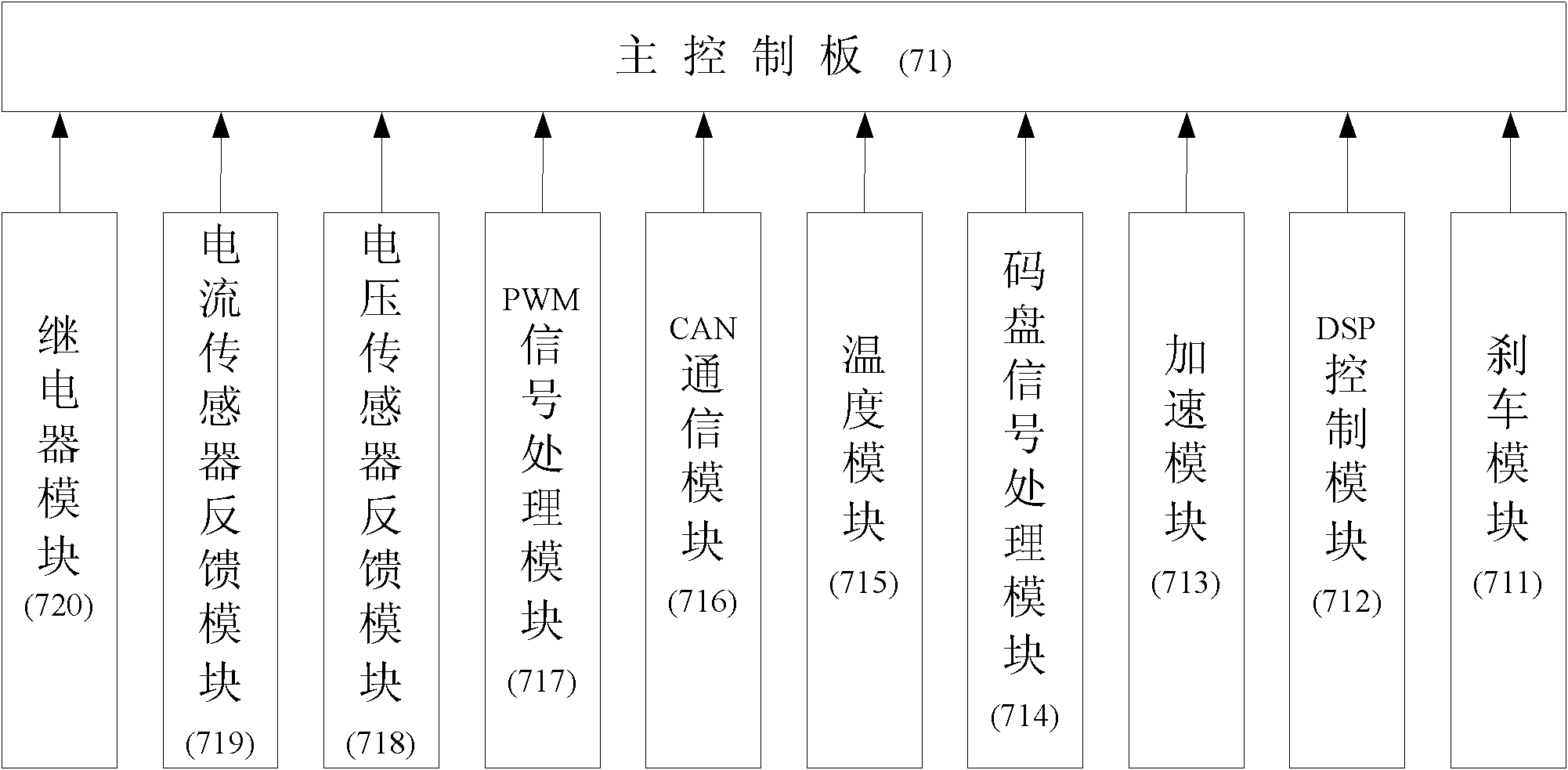

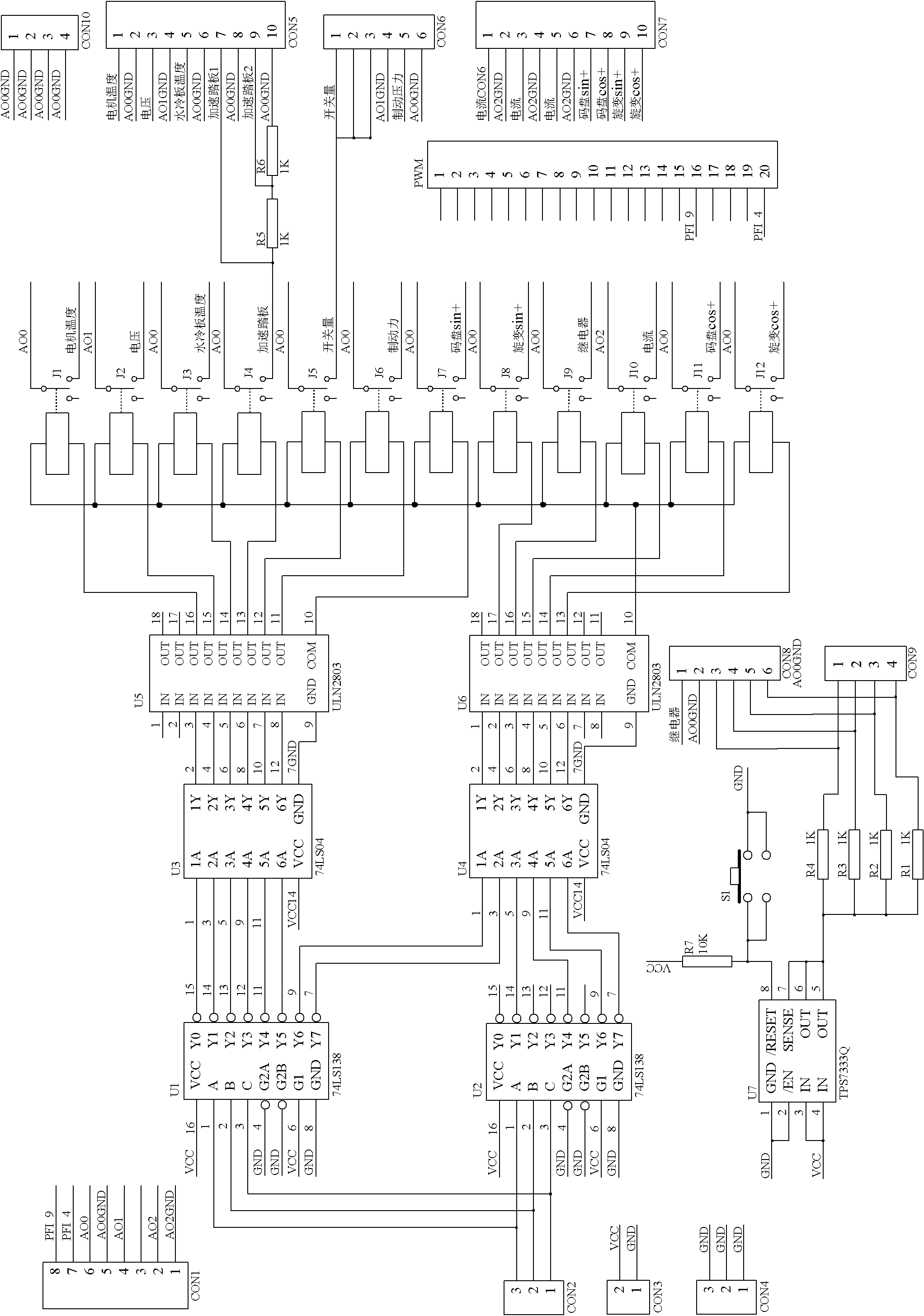

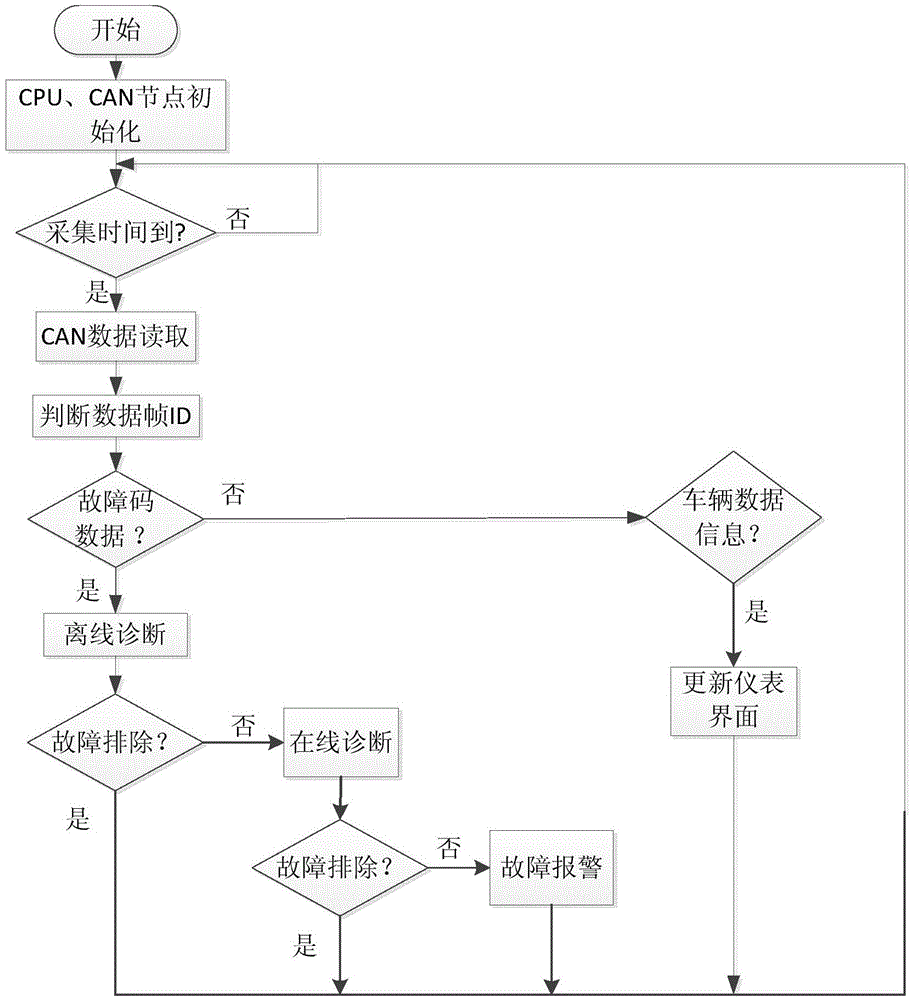

Virtual instrument-based motor control automatic testing system and method for electric automobile

ActiveCN102147619AGuaranteed synchronous samplingAcquisition speed is fastElectric testing/monitoringArea networkPCI eXtensions for Instrumentation

The invention provides a virtual instrument-based motor control automatic testing system and method for an electric automobile, wherein the system comprises an industrial personal computer and a CAN (controller area network) communication bus connected with the industrial personal computer, a test setting unit, a data processing unit, a result display unit and a database management unit which areall connected with the industrial personal computer, a data collecting unit respectively connected with a motor control circuit to be tested and the industrial personal computer, and a PXI (PCI Extensions for Instrumentation) communication card respectively connected with the industrial personal computer and the CAN communication bus; a programmable power supply is connected with the motor control circuit to be tested; and the motor control circuit to be tested is respectively connected with the data collecting unit and the CAN communication bus. The method comprises the steps of: selecting test items and setting parameters; collecting testing signals; analyzing and processing test data; displaying a testing result; and updating and managing a database. By the automatic testing system andmethod, the function detection and the collecting, processing and storing of the testing data of an electric automobile motor control circuit can be completed automatically; the synchronous sampling of the testing data is ensured; the automatic testing system and method have high testing precision and good the repeatability is good; the testing error is reduced; and the automatic level of the detection is improved.

Owner:TIANJIN QINGYUAN ELECTRIC VEHICLE

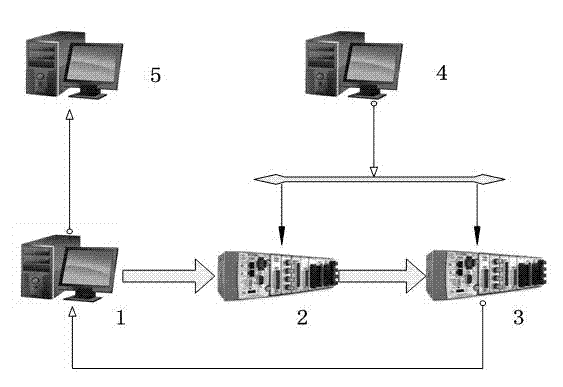

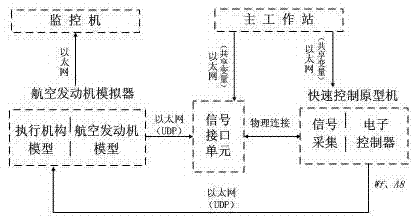

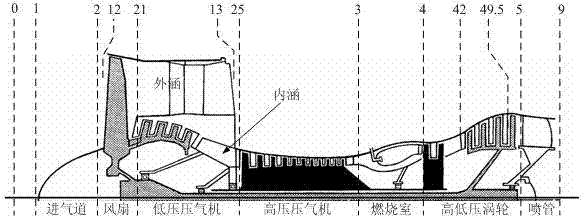

Rapid prototyping simulation method of aircraft engine control system

The invention discloses a rapid prototyping simulation method of an aircraft engine control system and belongs to the technical field of design of aircraft engine control systems. First, a control algorithm model is established, the prototype design of the control system is performed through the virtual instrument technology and a real-time hardware platform, the designed aircraft engine control algorithm model is compiled through the automatic code generation technology and downloaded to the real-time hardware platform, and a control algorithm prototype is established rapidly; second, the rapid control prototype is responsible for collecting output signals of an engine simulator after the engine simulator passes through a signal interface unit, relevant control quantities of an engine are calculated according to control instructions and sent to the engine simulator, and the closed loop control over the engine is achieved; finally, a control system designer observes the control effect in real time through a monitoring computer, keeps modifying the control algorithm model according to the requirements of the designer for performance of the control system and repeats the closed loop simulation process of the rapid control prototype till the requirements of the control system designer are met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

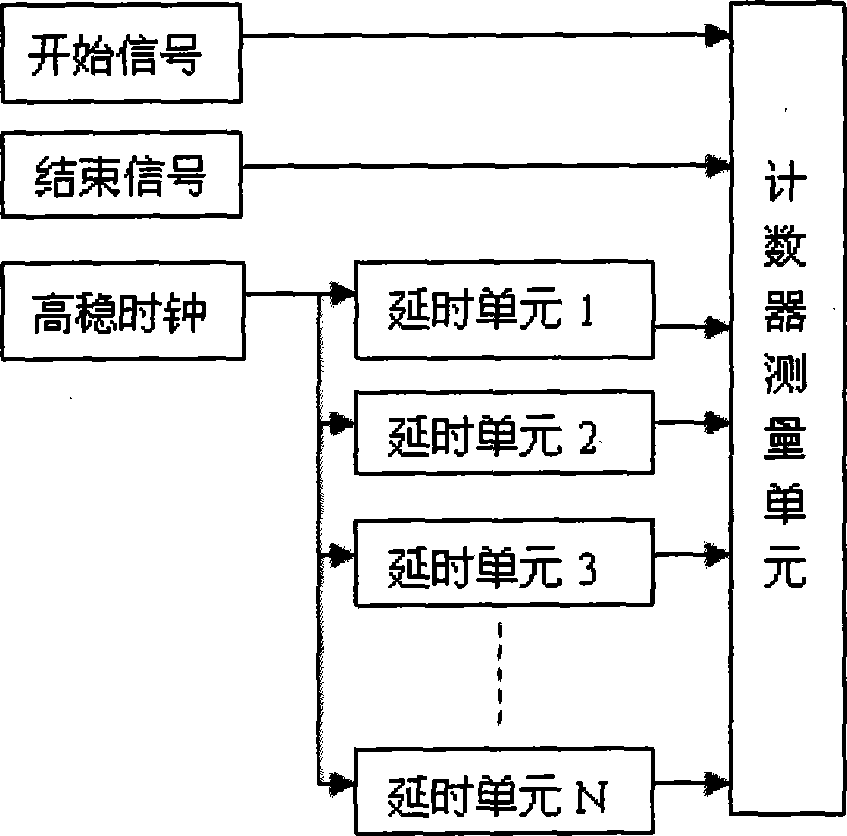

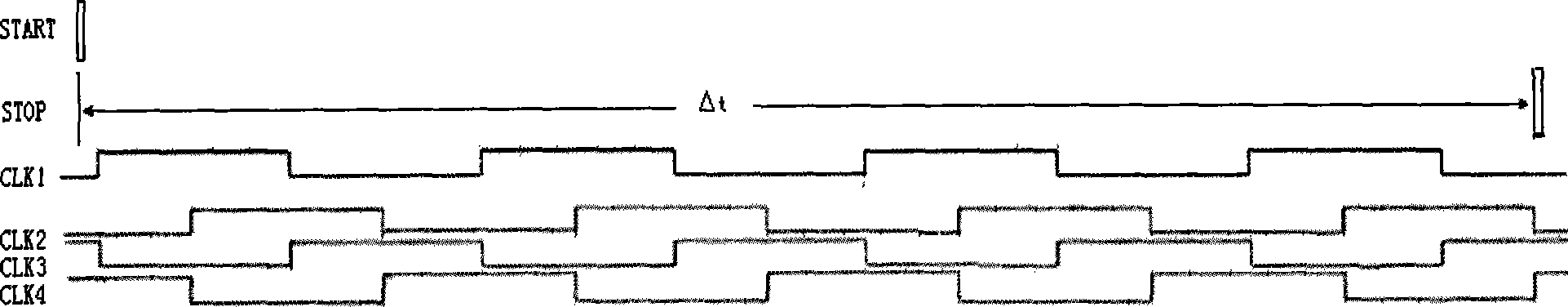

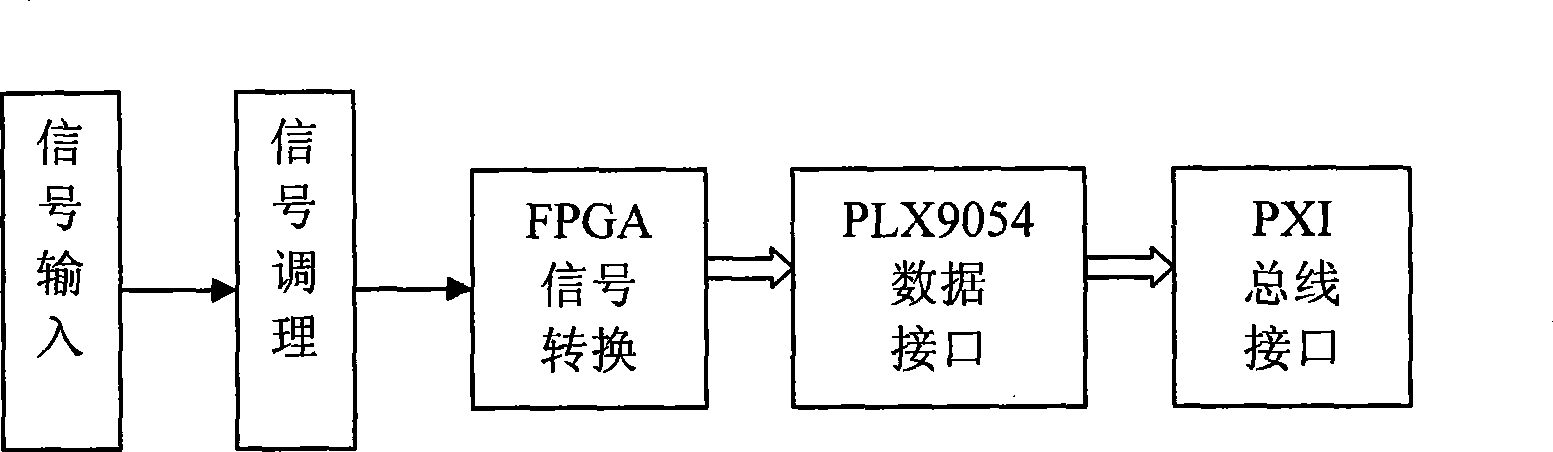

Time interval measuring instrument based on FPGA

InactiveCN101520640ASimple structureEasy to useElectric unknown time interval measurementPhase splittingMeasuring instrument

The invention provides a time interval measuring instrument based on FPGA. The time interval measuring instrument is designed into a virtual instrument by taking a PXI interface as a platform; a PXI system can be inserted with a plurality of PXI cards; each card carries out time interval measurement to signals of one initial channel and a plurality of stopping channels; simultaneously the pulse width of stop pulse is measured. The time interval measuring instrument utilizes phase-locked loop frequency doubling and time phase-splitting technology so that the measuring resolution can be up to 1ns and the measuring range can be up to 20ns to 200ms. As the virtual instrument structure is adopted, a PXI platform and a computer are combined to form an automatic measuring system; and the time interval measuring instrument has the advantages of simple structure, convenient use, high reliability, strong expandability and high measuring efficiency.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

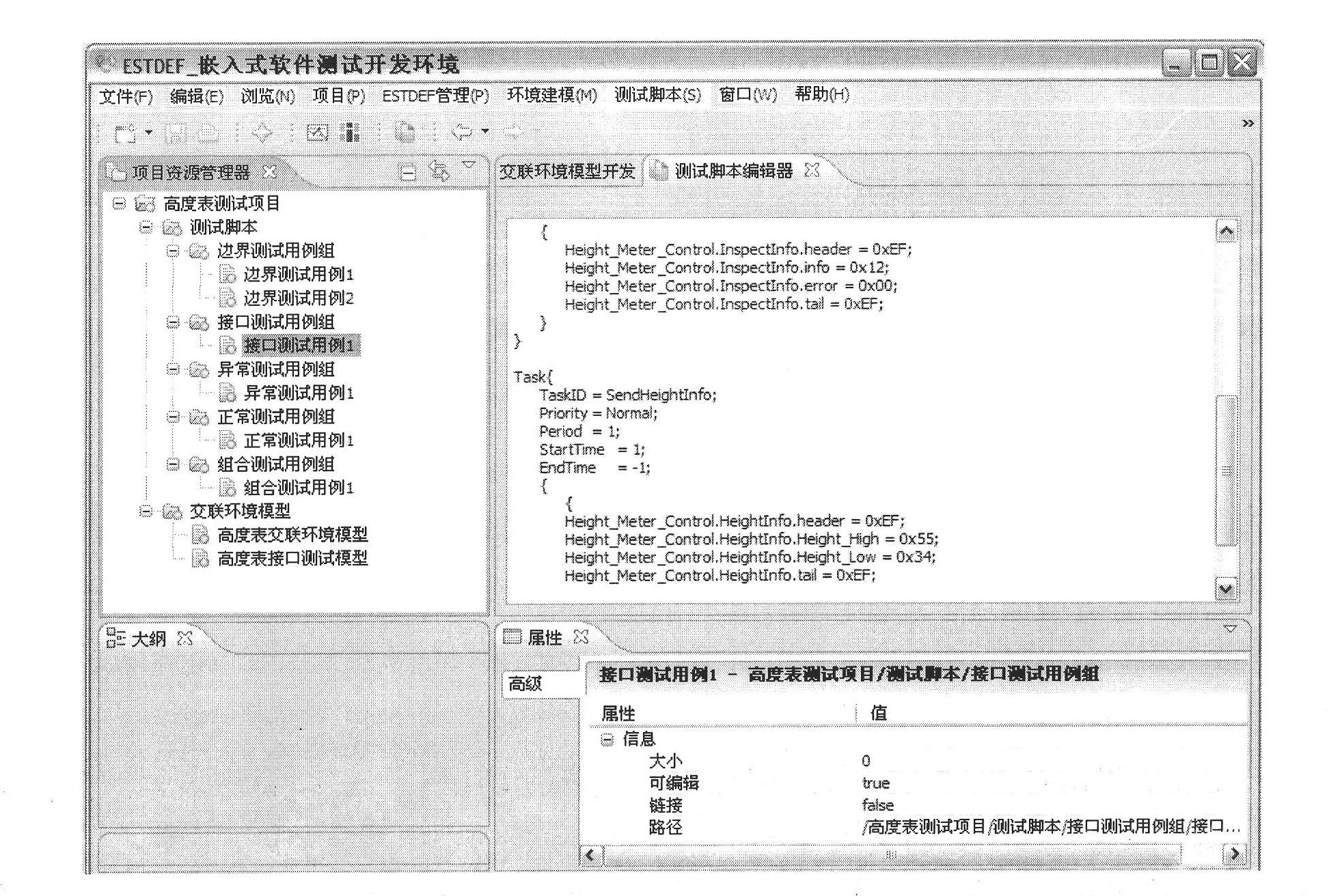

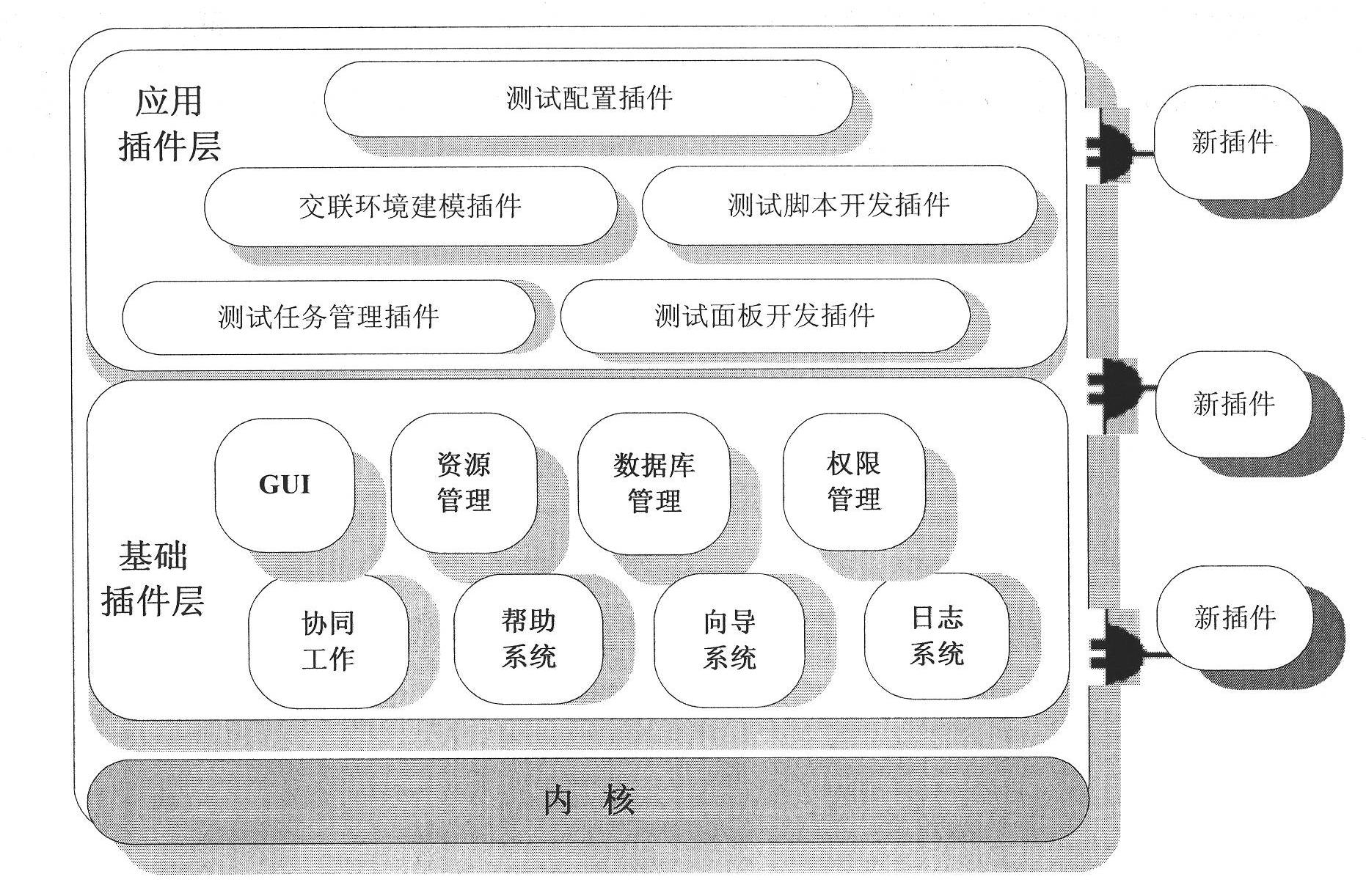

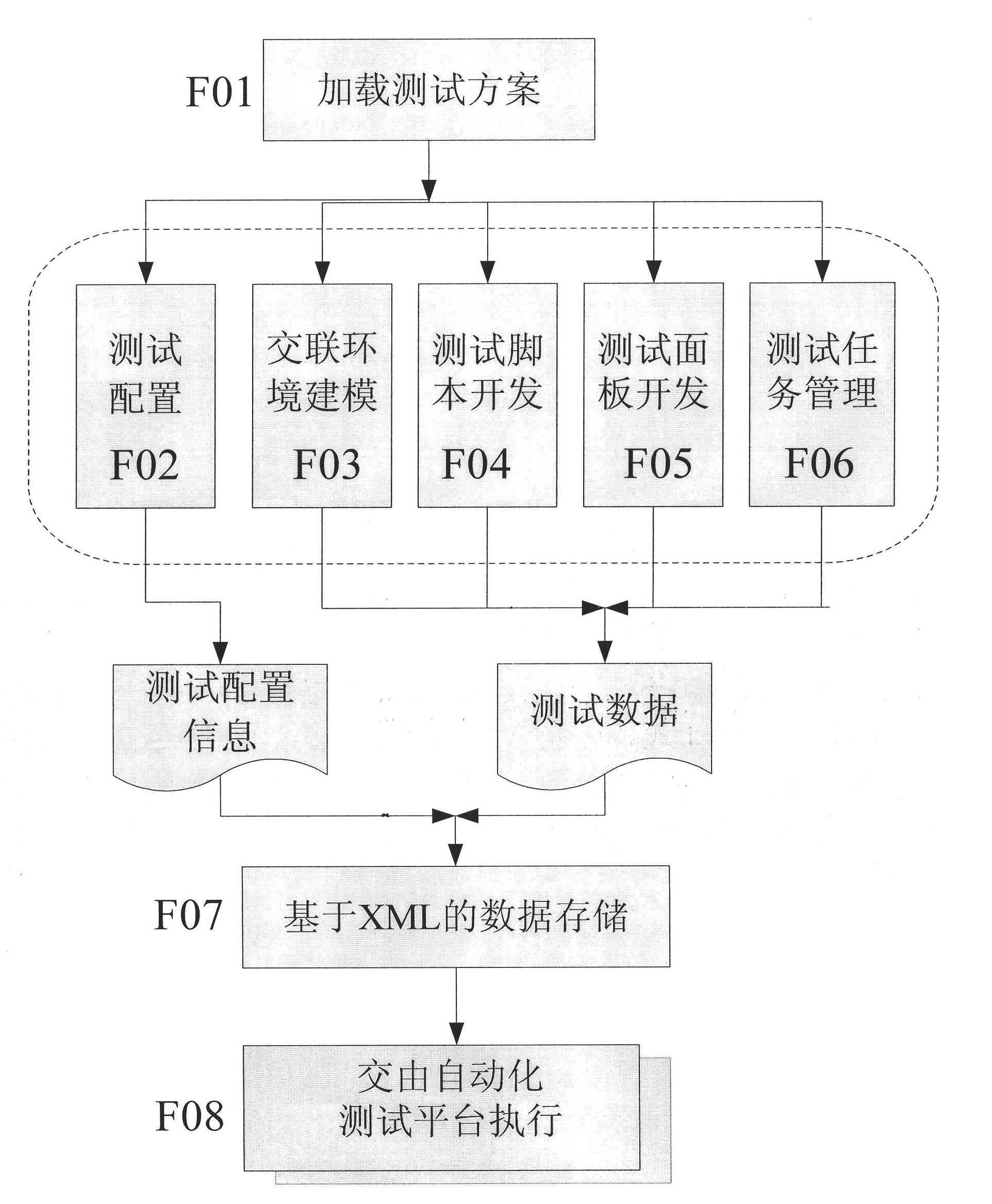

Reusable embedded software testing and developing method and system

The invention relates to a reusable embedded software testing and developing method and a reusable embedded software testing and developing system. The method comprises the following steps of: loading a test scheme; configuring a test environment; building a crosslinked environment model, and generating the information of the crosslinked equipment simulation model; organizing a test process through the development of a test script, selecting a test script language and generating a test script; using a test panel plug-in to allow a user to build a test display panel by drawing in a way of a visual virtual instrument; using a test task management plug-in to flexibly organize the information, such as a simulation model file, a test script file, a test panel file and the like, for each test in a test unit way; and generating the description of the test configuration information and test data based on an XML format, namely, loading the generated test configuration information and test data in the XML format onto a specific test platform. The method and the system can drive a test process to finish automation test of the embedded software.

Owner:BEIHANG UNIV

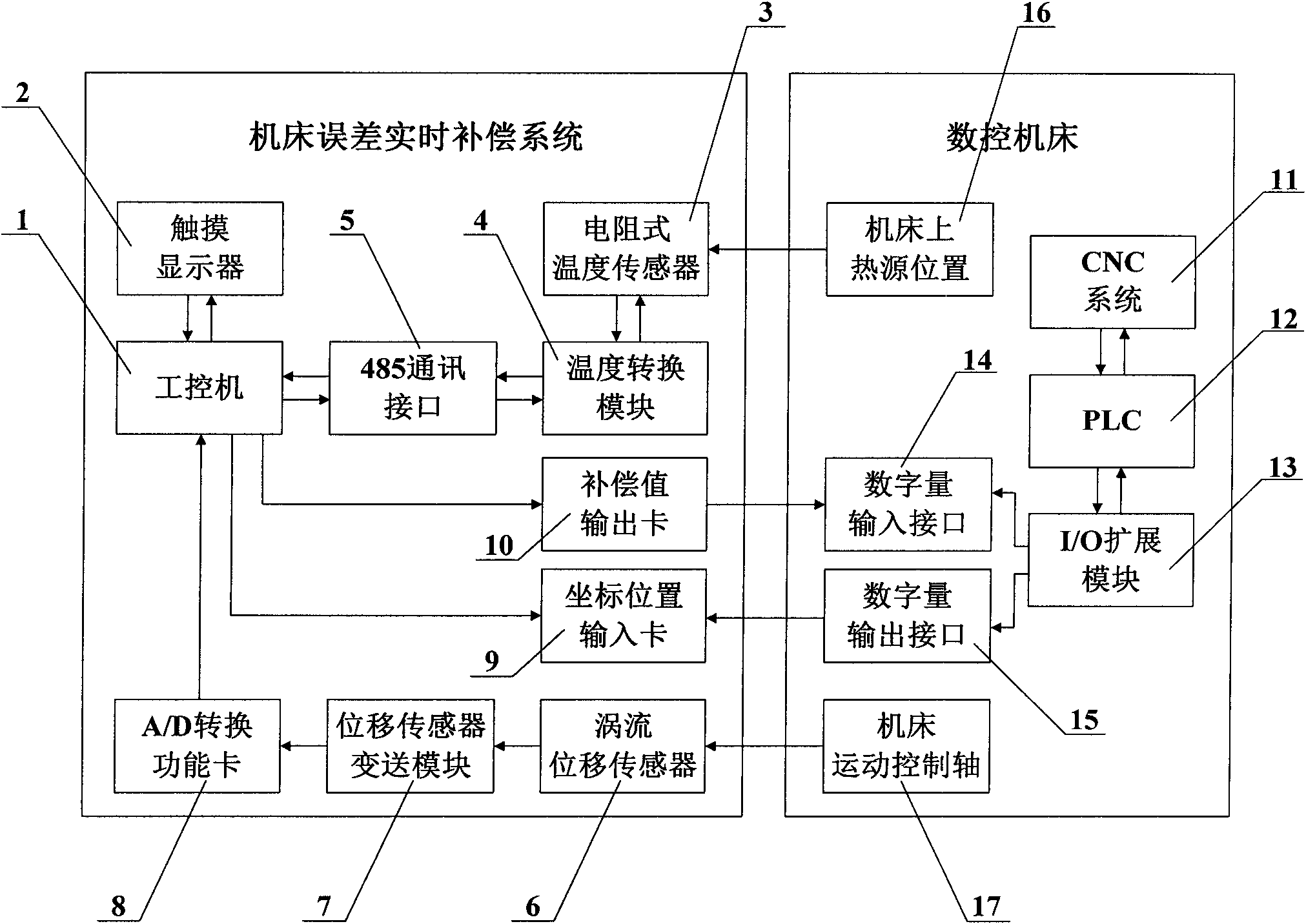

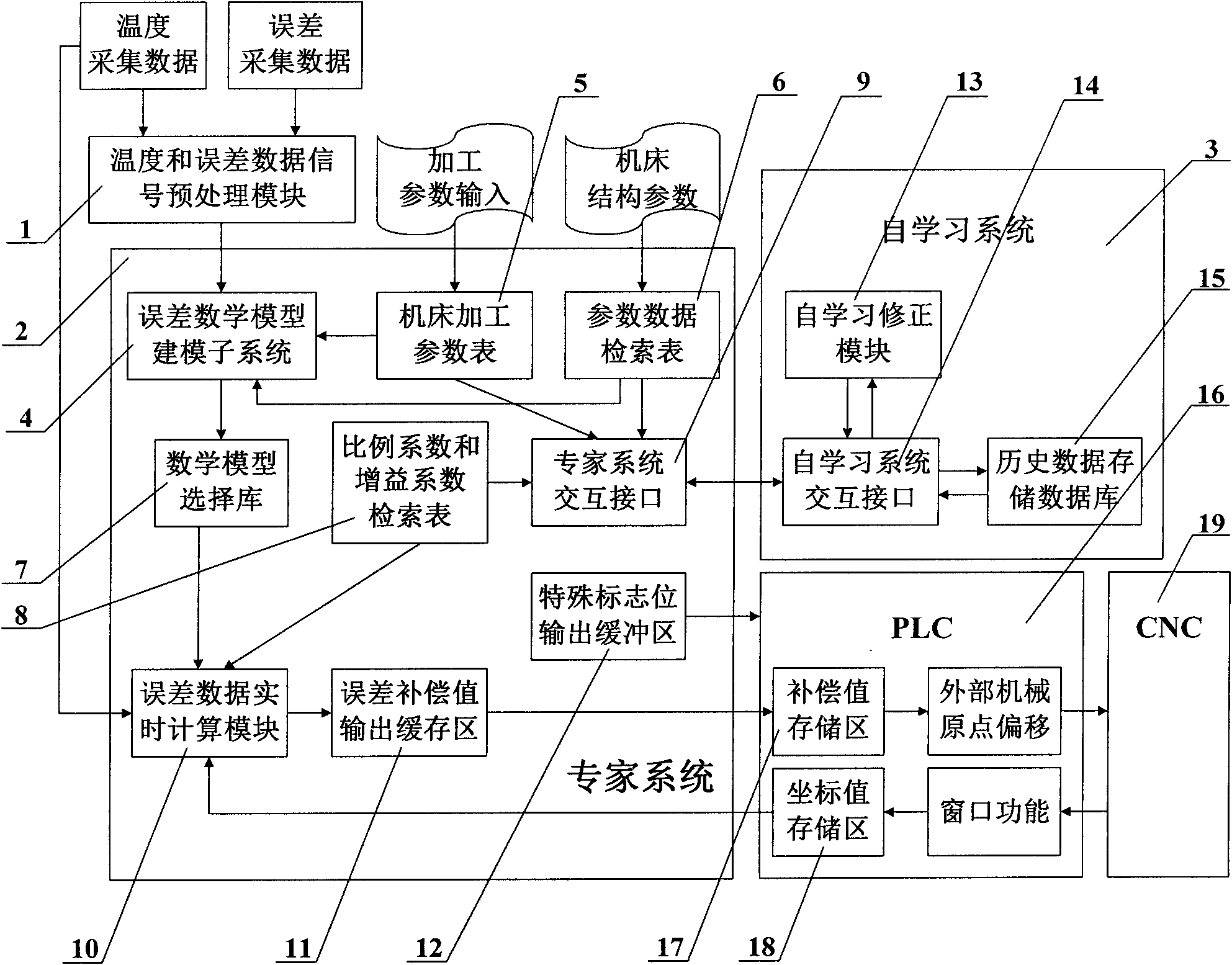

Numerical control machine tool error real-time compensation system based on virtual instrument

InactiveCN102736557AImprove the design levelImprove machining accuracyProgramme controlComputer controlNumerical controlSoftware system

The invention relates to a numerical control machine tool error real-time compensation system based on a virtual instrument, which belongs to the field of numerical control machine tool error compensation technology. According to the invention, an error compensation hardware system and a software system are comprised. As the carrier and the executive component of the software, the hardware system is for realizing the connection and communication of various function modules, data storage, and man-machine interaction. The software system based on virtual instrument programming is for realizing the preprocessing of temperature and an error data signal, the modeling of a machine tool error mathematical model, the real-time calculation of the error data, the data interaction between the compensation system and PLC, the optimization of an expert system, and the automatic identification and optimization of a self learning system. According to the invention, with the adoption of a method that combines a virtual instrument technology and a software compensation technology and with the collaborative work of the hardware system and the software system, the prediction and the real-time compensation of various processing errors of the numerical control machine tool is effectively realized, and the robustness and the reliability of the compensation system are improved based on the expert system and the self learning model, thus the system provided by the invention has the characteristics of simple operation and wide applicability.

Owner:上海睿涛信息科技有限公司

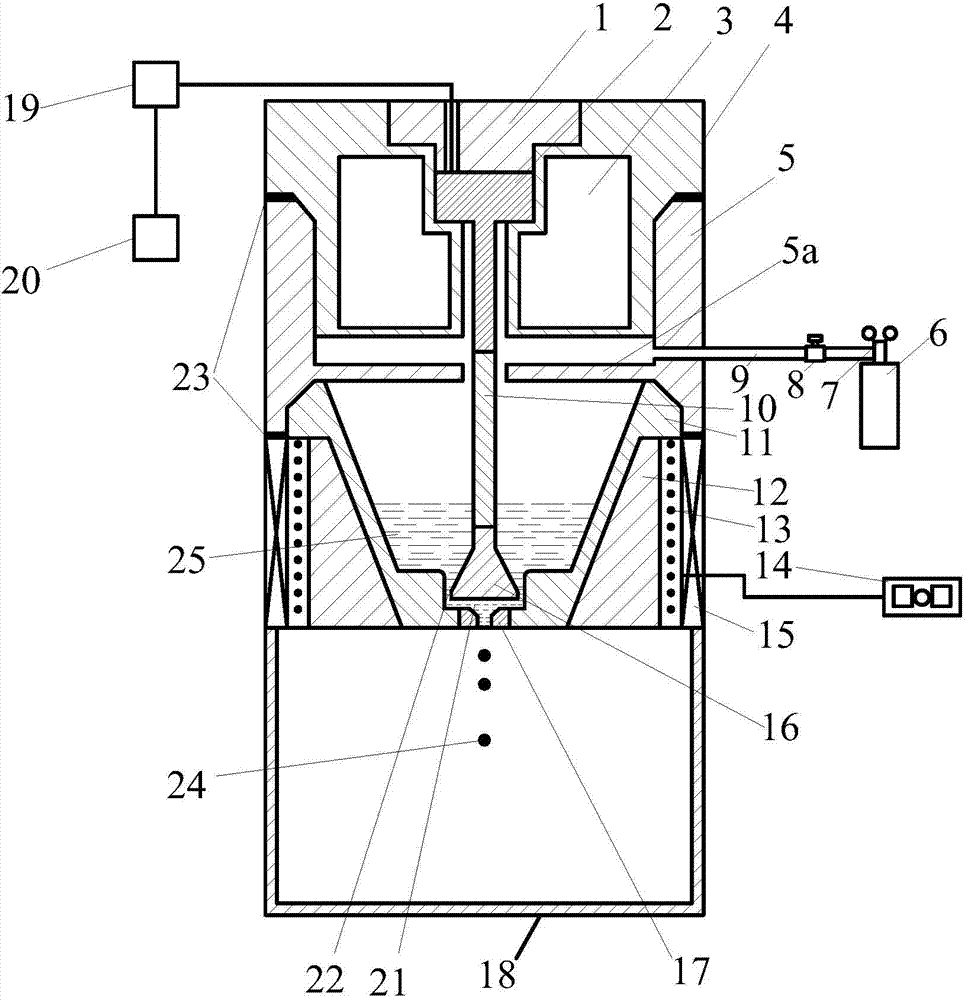

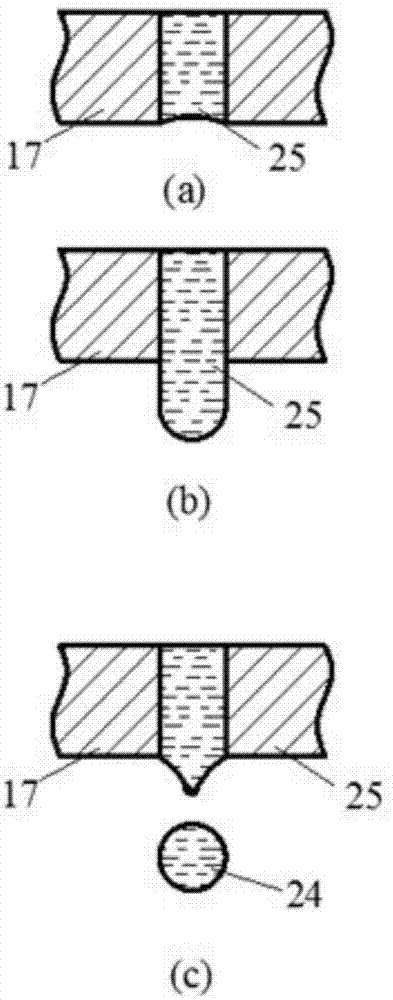

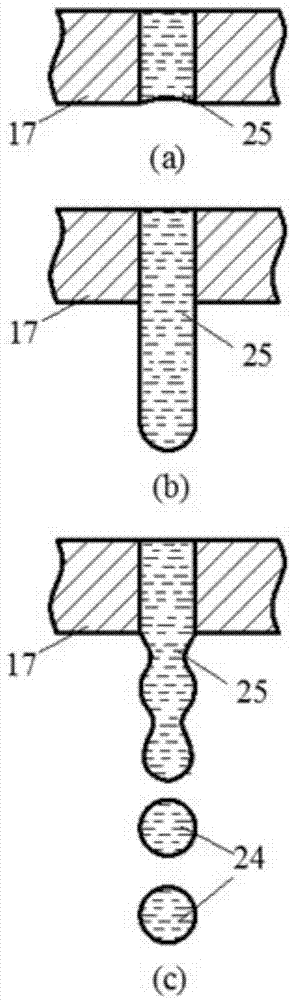

Jetting device and method for micro molten metal drops

The invention discloses a jetting device and method for micro molten metal drops. The device comprises a driving signal waveform generating device virtual instrument, a piezoelectric ceramic transducer, a crucible, heating elements and a micro-pressure adjustment valve and further comprises a vibration rod end which is replaceable and cylindrical and has conical surface transition, a vibration rod middle which is replaceable, a heat isolation protective cover and a conical surface crucible heating base. The bottom of the crucible and the installation position of a spray nozzle are matched with the vibration rod end, an inner diameter is adopted for forming a jetting containing cavity which is changeable in volume, and a large inner diameter is adopted for the upper portion of the crucible, so that the crucible is used for storing more molten metal, and the liquid level does not change tremendously; a gradual change structure is adopted for the vibration rod end, when corresponding to molten metal different in physical property, vibration rod ends different in diameter size can be replaced to precisely adjust the jetting structural size to be adaptive to molten bodies, and the micro molten drops are jet as needed under the action of driving signals as needed.

Owner:湖南哈工机器人研究院有限公司

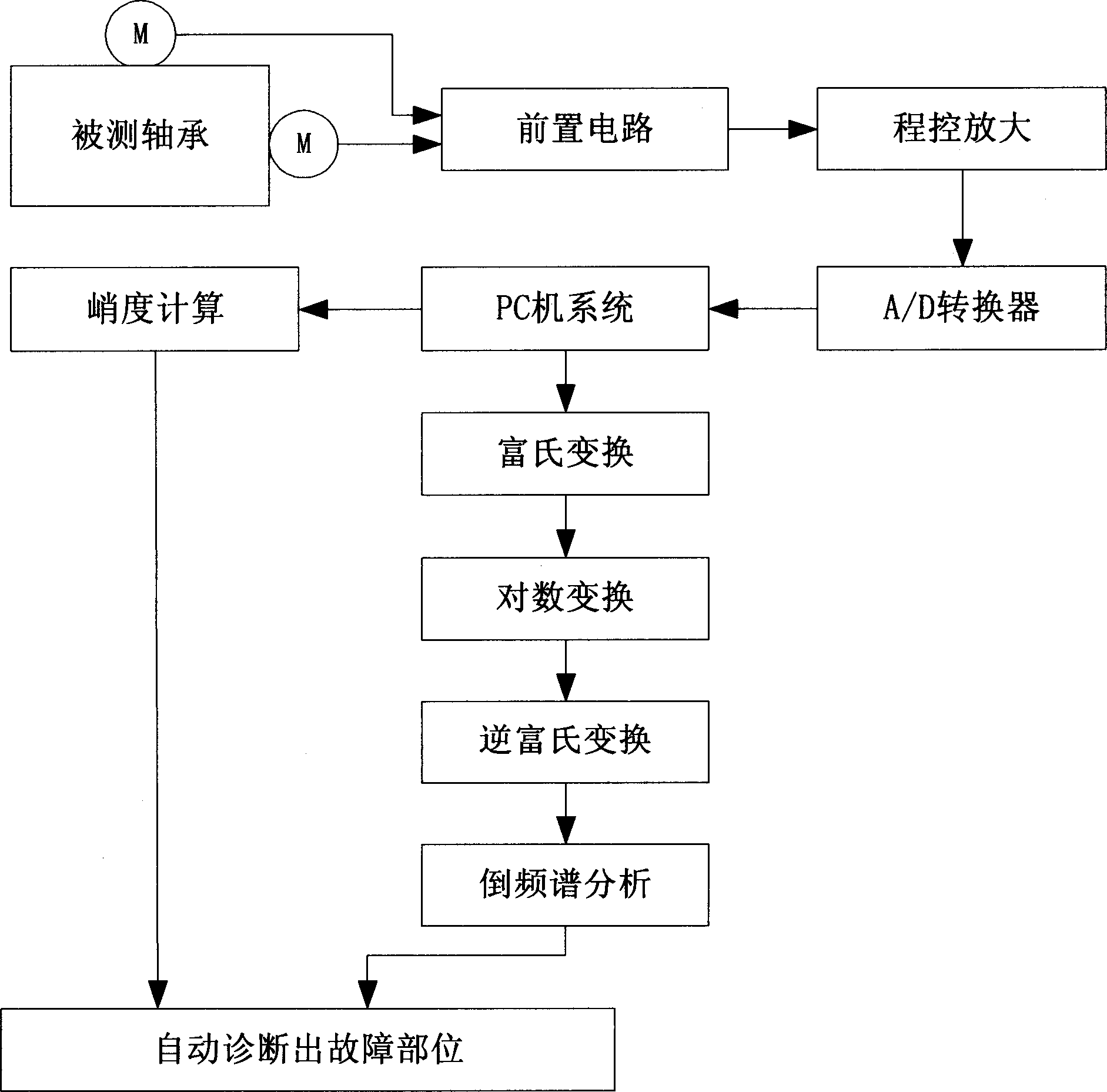

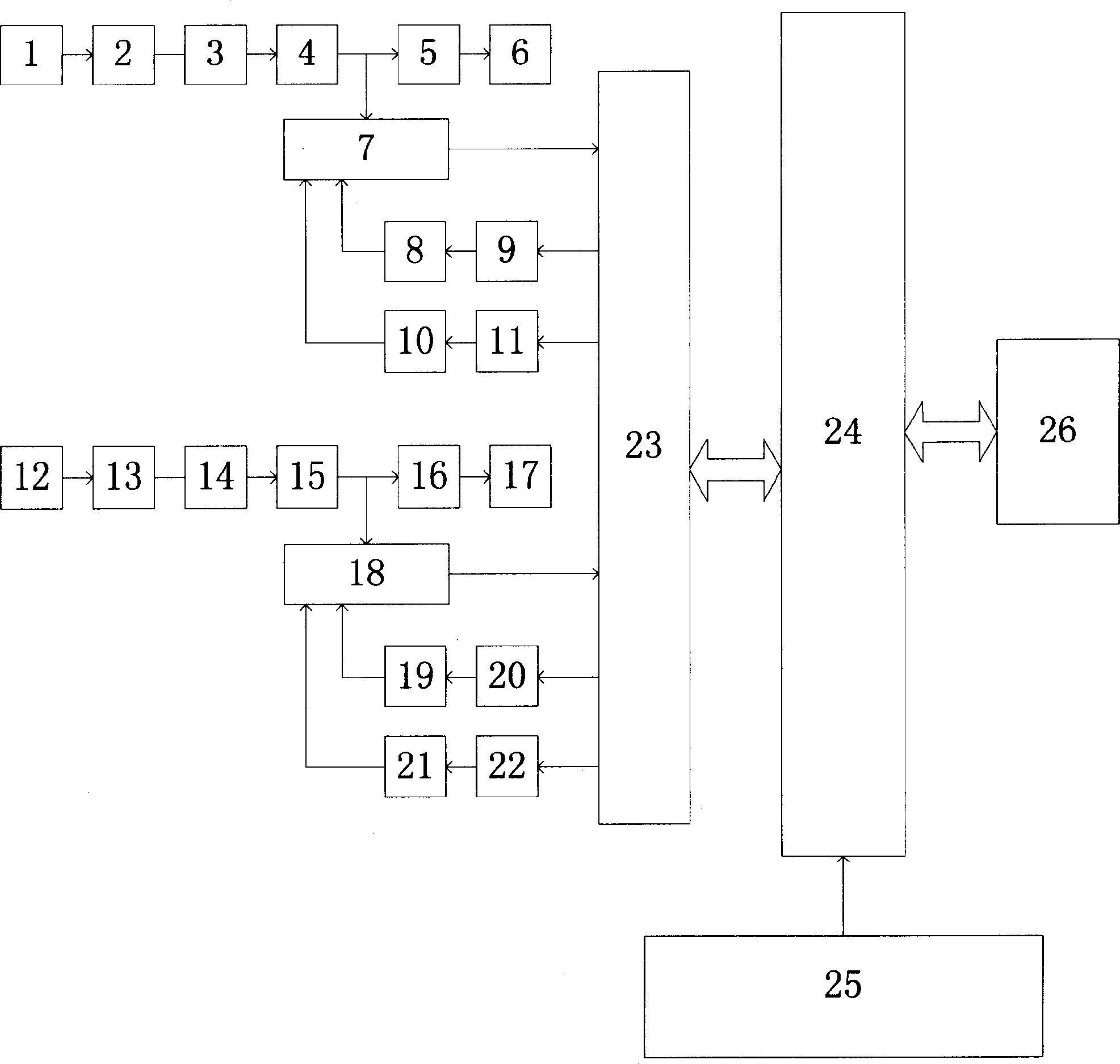

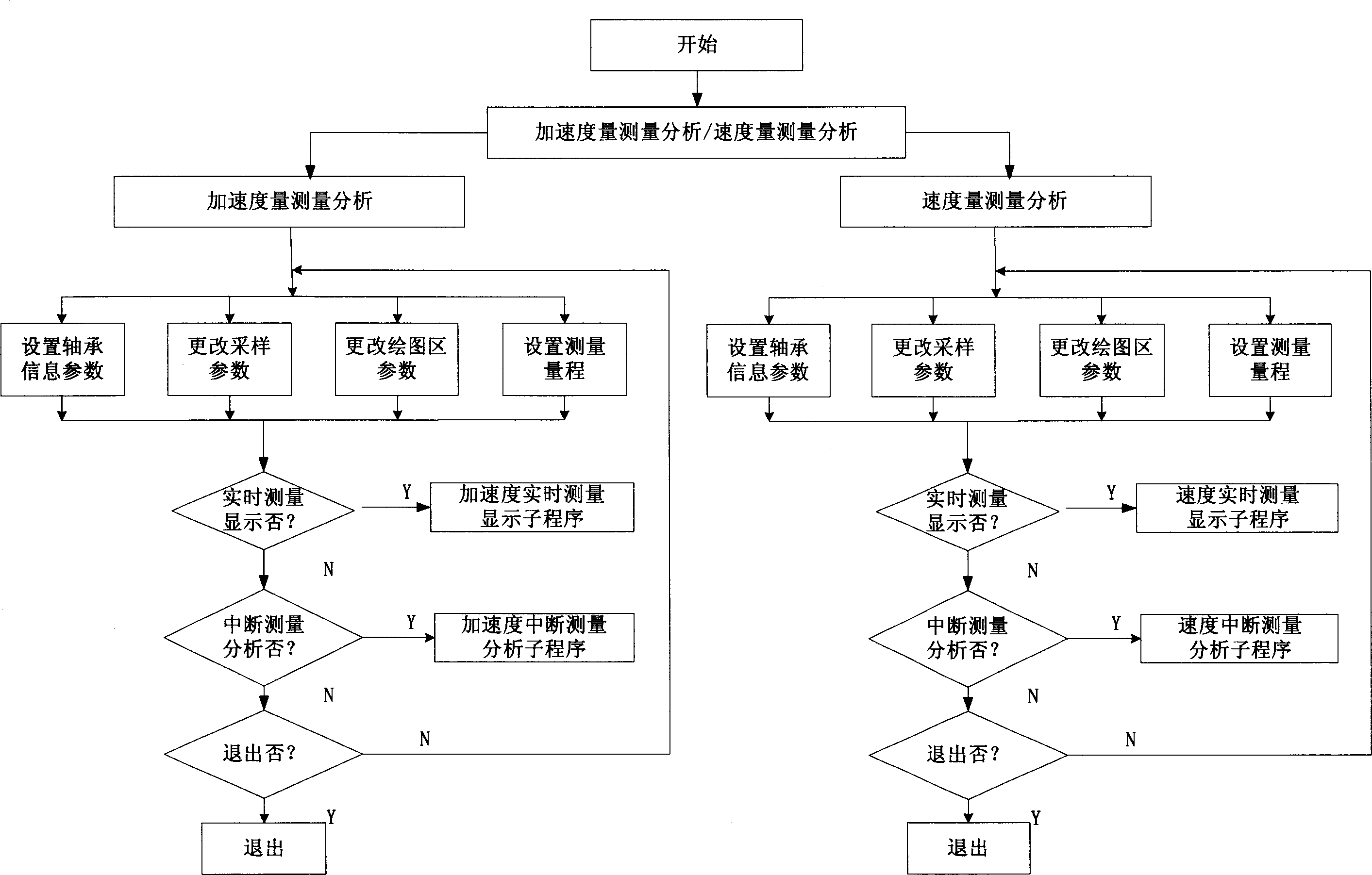

Automatic diagnosing system for rolling bearing fault

InactiveCN1825082AEasy to debugEasy maintenanceMachine bearings testingVibration testingDigital signal processingVibration acceleration

The invention relates to a rolling bearing error auto diagnose system. It takes testing analysis and kurtosis analysis to the bearing vibration, and calculates the kurtosis by virtual device and DSP, analyzes and compares the spectral configuration to accurately measure the acceleration and speed of bearing vibration, and achieve accurate analysis to automatically judge the place of the error.

Owner:LUOYANG BEARING SCI & TECH CO LTD

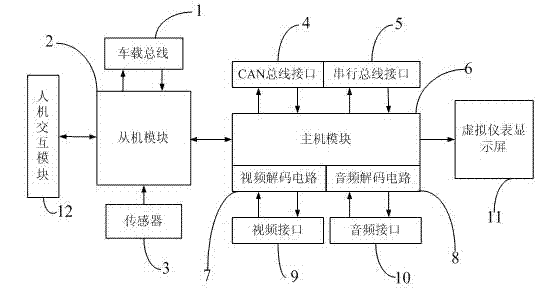

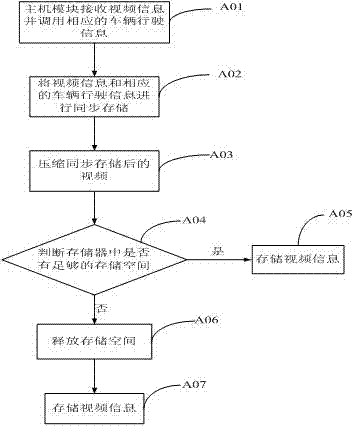

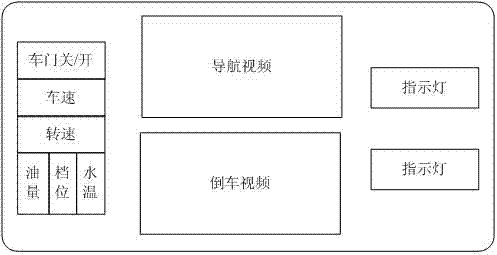

Intelligent virtual automobile instrument system and realizing method thereof

The invention discloses an intelligent virtual automobile instrument system and a realizing method thereof. The intelligent virtual automobile instrument system comprises a sensor for acquiring running information of a vehicle, a vehicle-mounted bus, a slave module, a host module, a virtual instrument display screen and a man-machine interaction module for man-machine interaction, wherein the slave module is electrically connected with the vehicle-mounted bus, the sensor, the man-machine interaction module and the host module; and the host module is electrically connected with the virtual instrument display screen, an audio interface and a video interface. According to the system, various running information and video information of the vehicle are centralizedly displayed on the virtual display screen after being processed by the slave module and the host module, and the space of an automobile instrument is effectively saved. The system realizes a man-machine interaction function, and the design of the system is very humanized. The system further realizes automatic display of various information, and the design of the system is more intelligent. With the adoption of the system, a driver can read related data more conveniently, and the automobile driving safety and comfortability are improved greatly.

Owner:FAURECIA CLARION ELECTRONICS (FOSHAN) LTD CO

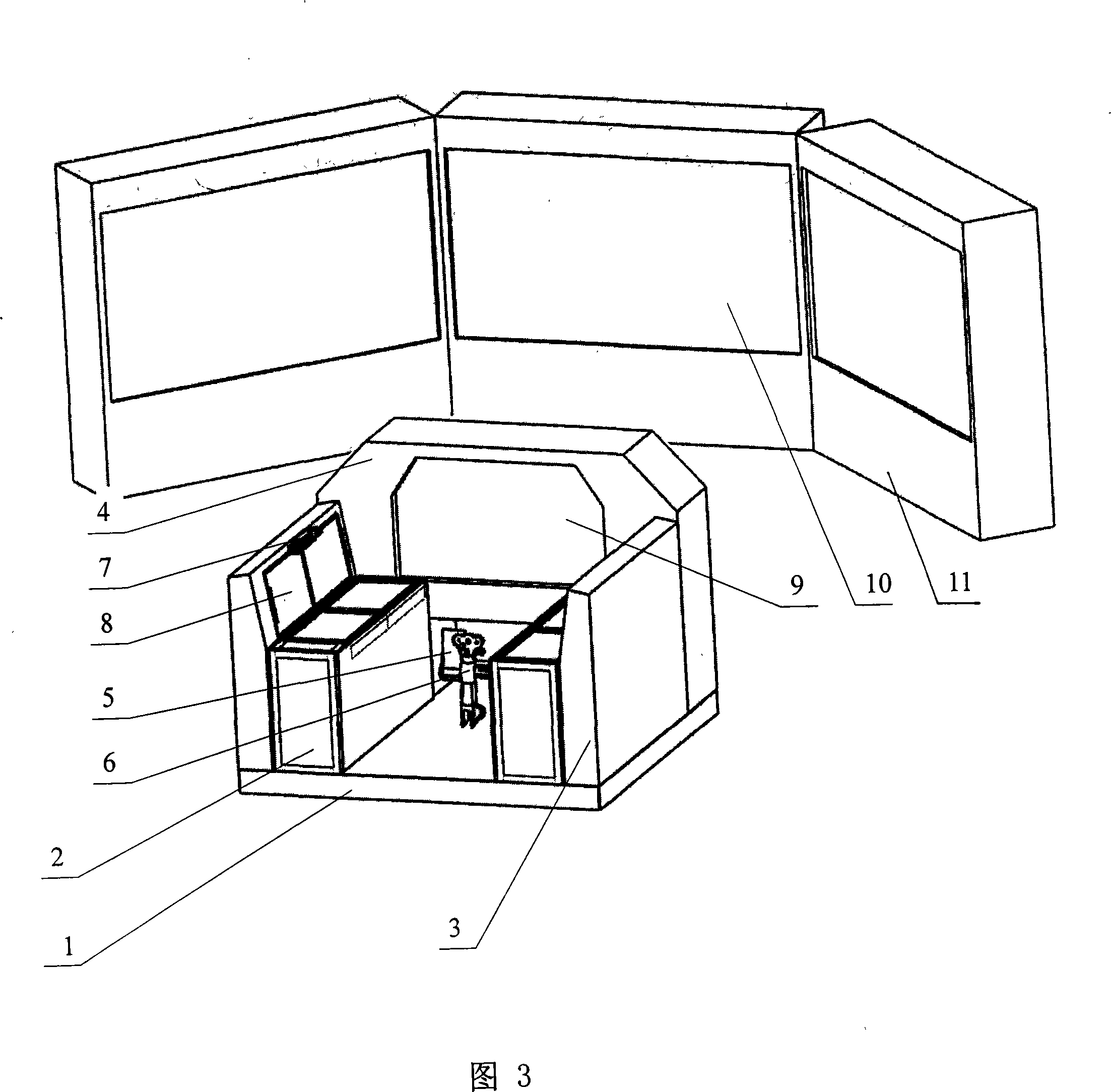

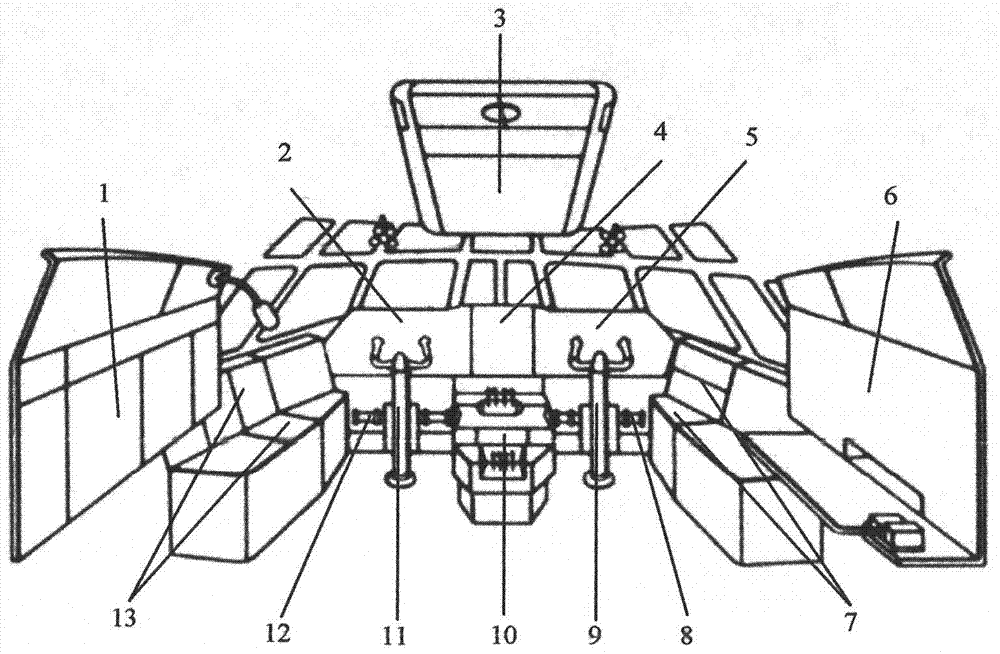

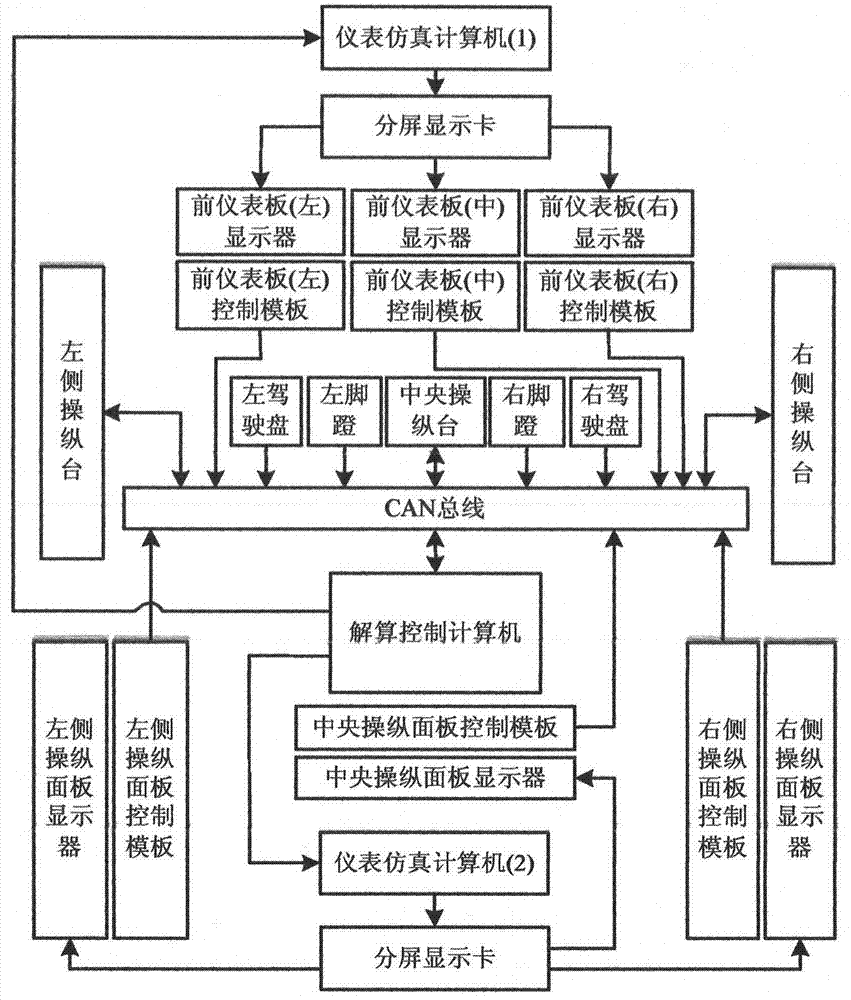

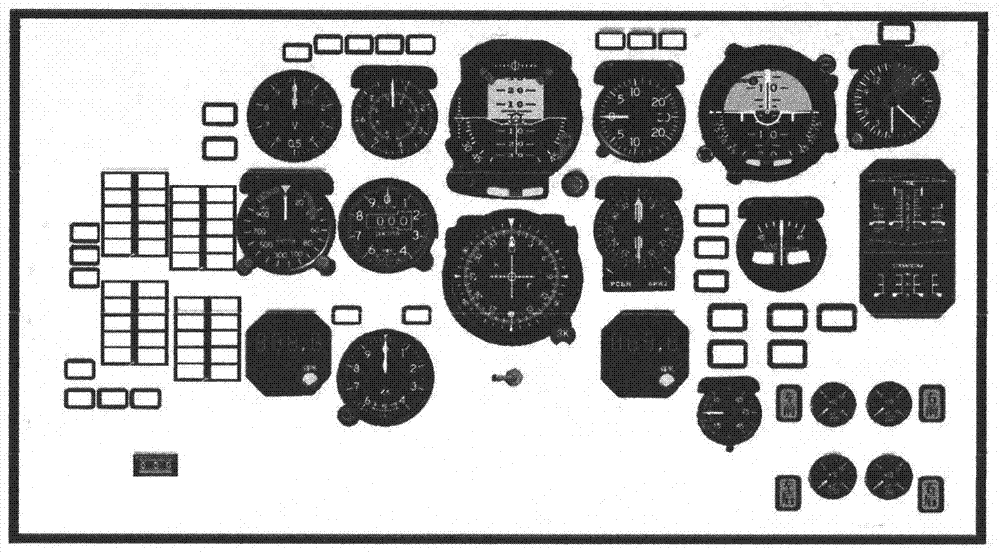

Low-cost flight simulator cabin display and control system

InactiveCN104269083ALow costEasy maintenanceCosmonautic condition simulationsSimulatorsControl systemControl signal

The invention discloses a low-cost flight simulator cabin display and control system which is a combined training simulator cabin display and control system used for large aircraft air-service and ground-service personal training. The low-cost flight simulator cabin display and control system is an interface for transmitting information between an operator and a flight simulator, is composed of a display part and a control part and is composed of a simulated cabin, control mechanisms, a resolving control computer, an instrument emulation computer, displayers and control templates. The displayers display instruments and various control signals, the control templates with integrated control knobs and switches are installed outside the displayers for achieving man-machine interaction, the control templates and the displayers are assembled according to the proportions of a true aircraft, and the simulated cabin is built. According to the low-cost flight simulator cabin display and control system, the method that the virtual instruments and the control templates are combined is used; compared with a full-hardware simulator based on solid instruments, the device structure of the simulator is simplified, the development cost is reduced, the development cycle is shortened, and the design change efficiency of the system is improved; meanwhile, the problem that the man-machine interaction fidelity of a virtual display and control system based on the touch technology is not high can be solved.

Owner:JINLIN MEDICAL COLLEGE

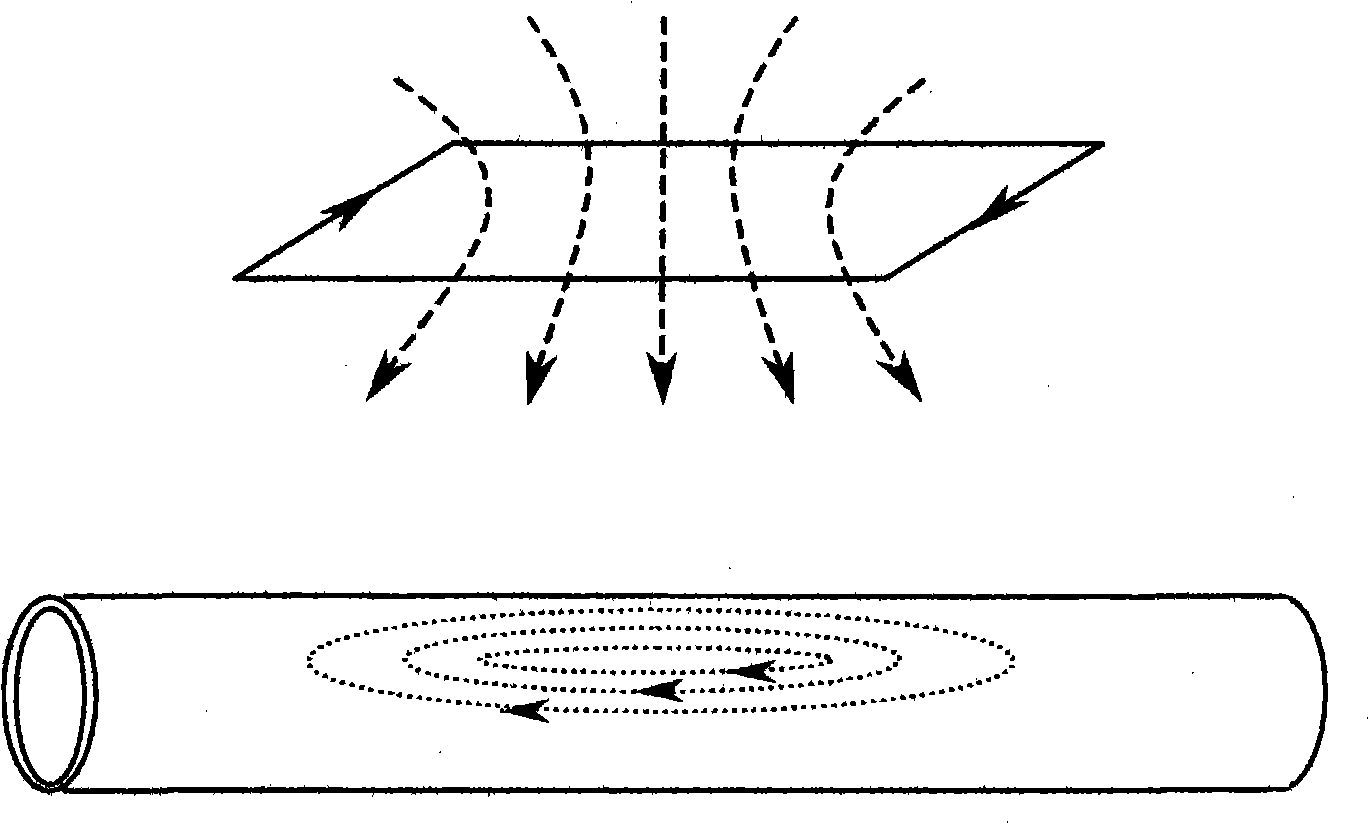

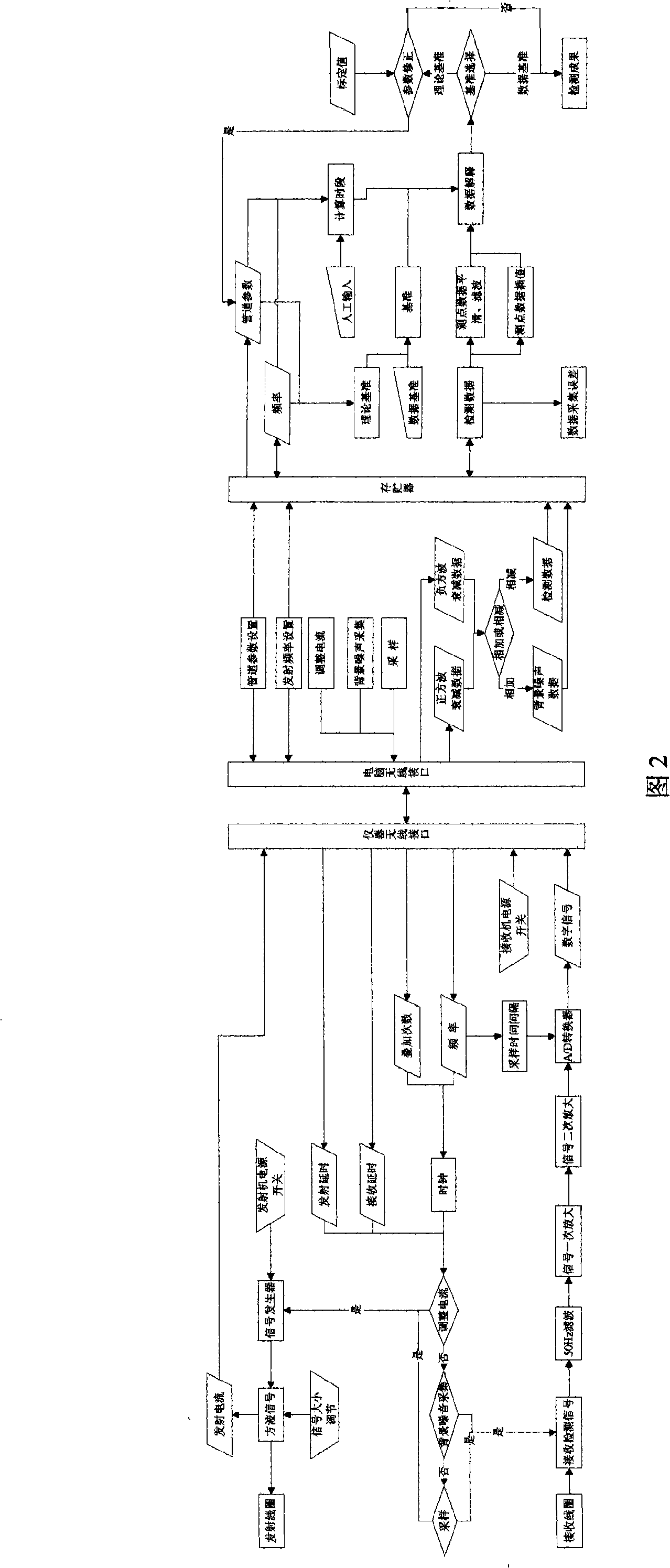

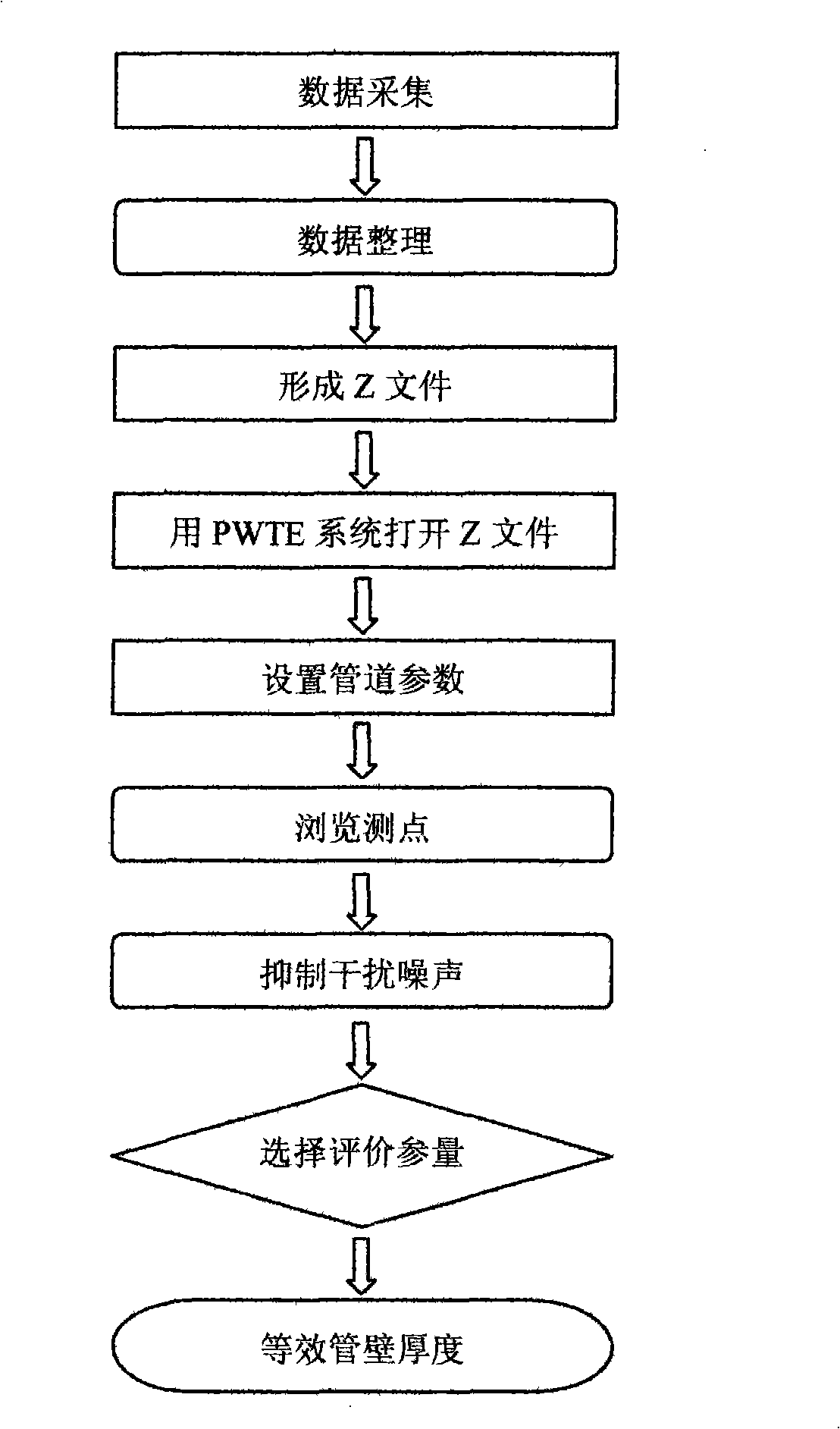

TEM detecting method for pipe wall thickness and intelligent detector for GBH pipe corrosion

ActiveCN101358827APipeline systemsElectrical/magnetic thickness measurementsPetrochemicalElectric power

The present invention relates to a corrosion examination and non-destructive examination method for a metal pipeline. The instant electromagnetic technology (TEM) is used to examine the average thickness of the wall of the pipeline under the condition that no dig is performed, no corrosion-prevention layer is damaged and the normal running of the pipeline is not influenced. The method is characterized in that when other conditions are the same, the metal pipeline with different wall thicknesses can have obvious time divisibility on a normalized pulse instant-changing responding curved line. The wall thickness of the measured section of the pipe can be obtained by the indication of the known wall thickness and the method of inversing modeling. The present invention also relates to a corrosion examination and non-destructive examination systematic device for the metal pipeline. A virtual instrument is designed and produced with the TEM examination method for the wall thickness of the metal pipeline; a data collector adopts the instant-changing electromagnetic instrument; the control of the instruments, the data processing and the results expression are realized by the software of the computer, so that the expansion property of the instrument is strengthened, and the renewing speed is accelerated, and the complicate data processing analysis can be performed instantly. The device can be widely used for examining the corrosion of the anti-corrosion heat-preservation pipeline in the industries such as the petroleum industry, the petrochemical industry, the fuel gas industry, the electric power industry, the water supply industry, and the like.

Owner:BAODING CHICHENGQIANLI SCI & TECH

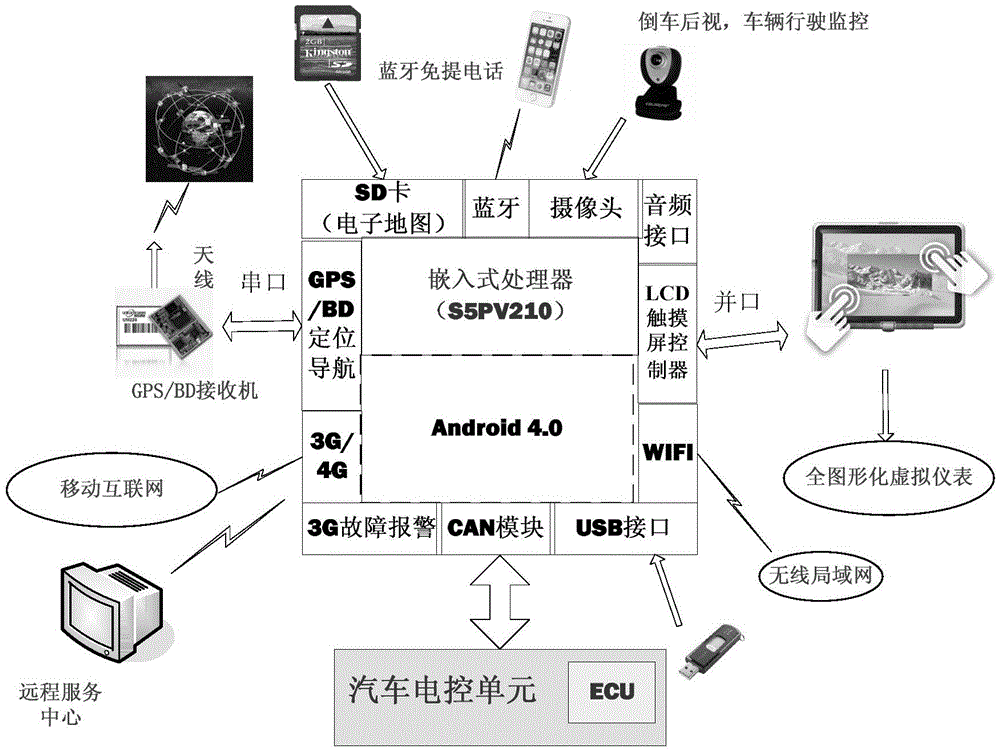

Integrated all-graphic virtual instrument type vehicle-mounted information service method and system

InactiveCN104536432AMeet needsRealize batch applicationElectric testing/monitoringTransceiverService domain

The invention relates to the field of automobile instruments and vehicle-mounted information services, and provides an intelligent vehicle-mounted system which integrates the all-graphic virtual instrument display function and vehicle information services. To provide a comfortable, easy and safe driving environment and multifunctional and comprehensive driving services for an owner, according to the technical scheme, the integrated all-graphic virtual instrument type vehicle-mounted information service system comprises an embedded ARM processor, a CAN communication device, an information acquisition device, a 3G / 4G module, a Bluetooth module, a Beidou / GPS module, a WIFI module, a multimedia device, a camera device and an LCD touch screen. The CAN communication device is composed of a controller and a transceiver and used for transmitting vehicle status data and sending complete vehicle running status information from the information acquisition device to the LCD touch screen through the embedded ARM processor. The integrated all-graphic virtual instrument type vehicle-mounted information service system is mainly applied to vehicle-mounted information services.

Owner:TIANJIN UNIV

Lidar three-dimensional imaging system based on virtual instrument

ActiveCN104049259AAchieve seamless integrationShorten the development cycleElectromagnetic wave reradiationMirror reflectionFull waveform

A lidar three-dimensional imaging system based on a virtual instrument comprises a three-dimensional scene modeling module, a lidar testing system simulation environment modeling module, a full-waveform signal processing module and a three-dimensional reconstruction module. The three-dimensional scene modeling module comprises a three-dimensional model loading element used for setting background colors, visual angle control, illumination, a projection mode, a display model and other basic scene projects. The lidar testing system simulation environment modeling module comprises four modeling sub-modules which are a laser pulse model, an atmospheric transmission model, an object interaction model and a receiving unit model. The laser pulse model is used for simulating a laser source according to the wavelength, pulse width, energy and other characteristics of a laser. The atmospheric transmission model is used for simulating a tested atmospheric environment, so that a noise model is generated for acting on the laser. The object interaction model is used for simulating effects of the laser and a detected object, and the effects comprise mirror reflection, diffuse reflection, surface reflection and speckles. The receiving unit model is used for simulating detector noise and amplifier noise which are generated after sensing.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com