TEM detecting method for pipe wall thickness and intelligent detector for GBH pipe corrosion

A pipe and pipe wall technology, which is applied in the field of corrosion detection of the average pipe wall thickness of metal pipes, and can solve problems such as strong environmental requirements around the pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

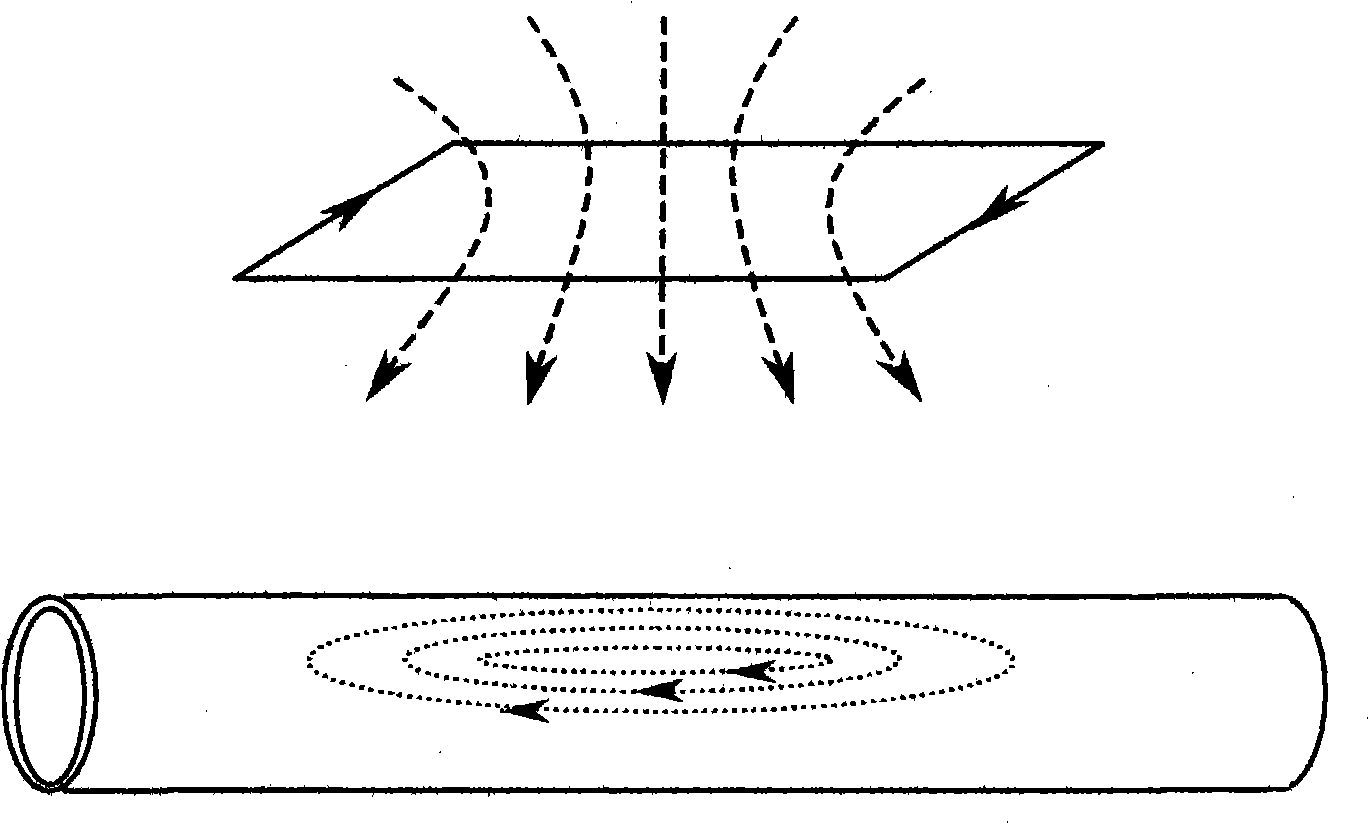

[0045] In order to illustrate the feasibility of the TEM method for the thickness of the metal pipe wall, the expression of the electromagnetic response of the circular cylinder in the harmonically variable field is firstly derived. like Figure 4 As shown, the outer radius of the circular cylinder is a, the wall thickness is d, the center depth is h, and the electromagnetic parameters in the column and inside the column are respectively σ G , μ G , σ J , μ J .

[0046] When the transmitting loop passes a transient pulse square wave signal, the normalized electromotive force excited in the receiving loop can be expressed by the following mathematical formula:

[0047] U ( t ) I = 8 μ D π ( a ...

Embodiment 2

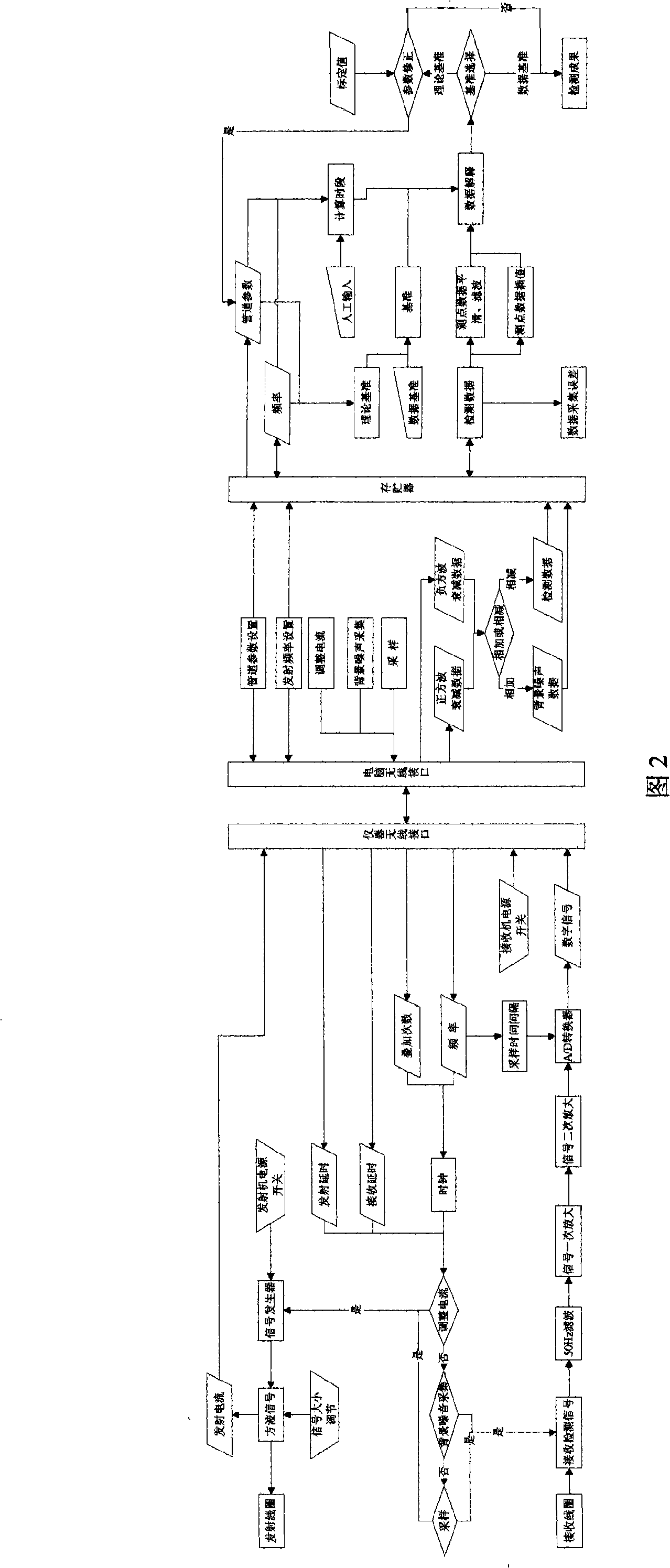

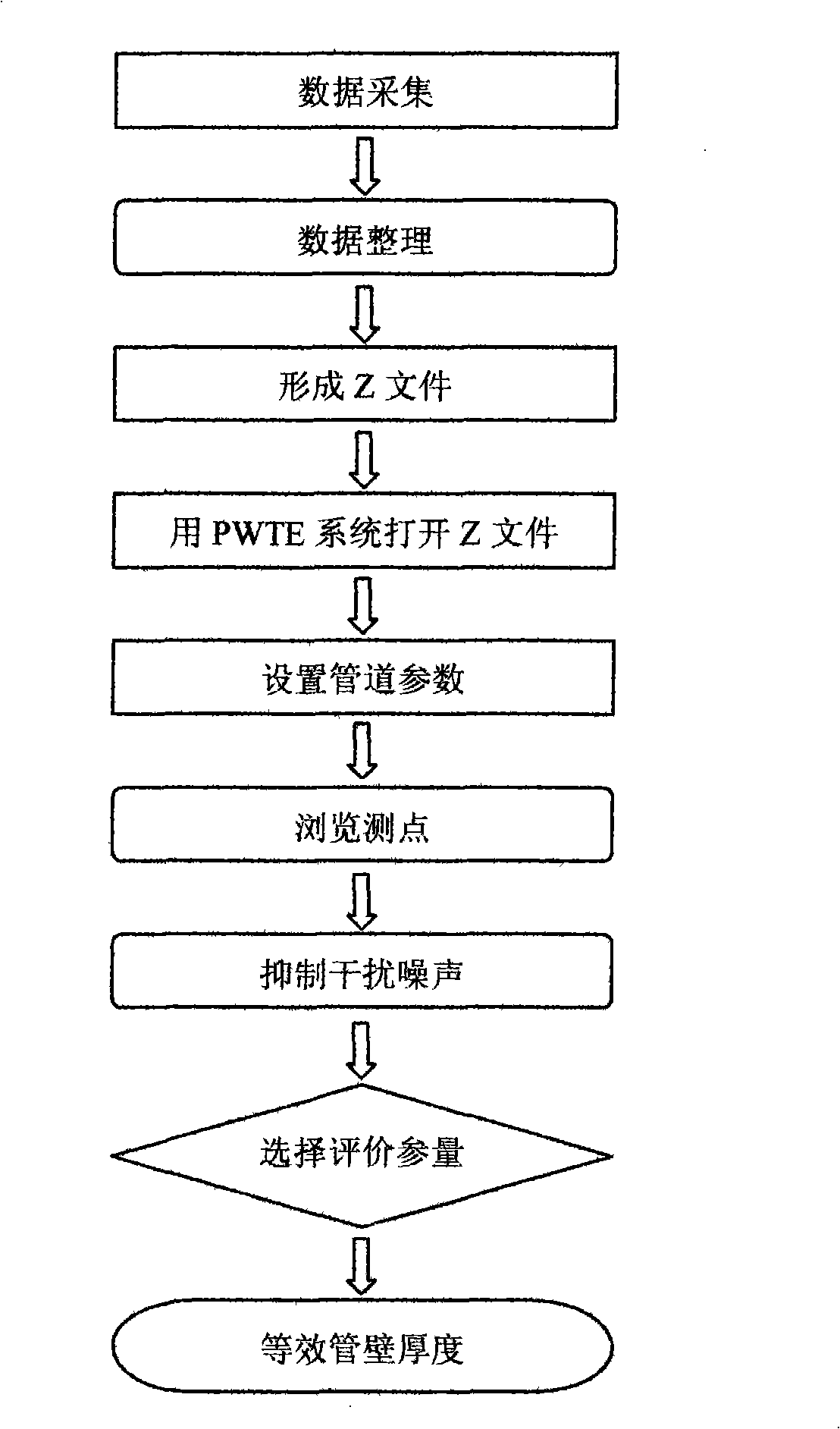

[0072] In order to better illustrate the actual application effect of the pipeline wall thickness TEM detection method and the GBH pipeline corrosion intelligent detector, the following examples are provided. The ground test pipeline in the joint station of the oil production plant is Φ219×7mm, threaded steel pipe, and the detection section is 20m. Follow the steps below to detect:

[0073] 1) Preparation before detection: According to the site conditions, determine that the distance between the detection points is 1 meter, the size of the sensor is 0.5 meters, and the number of coil turns is 50 turns. Make a mark at the measuring point;

[0074] 2) The sensor is placed horizontally directly above the center of the pipeline, and cables are used to connect the transmitting loop and the transmitting end of the data collector, and the receiving loop and the receiving end of the data collector;

[0075] 3) Turn on the data collector transmitter, receiver, and control computer for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com