Patents

Literature

119results about How to "Achieve passivation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyaniline-graphene composite based anticorrosive paint and preparation method thereof

InactiveCN102604533AAspect RatioExcellent metal corrosion protection performanceAnti-corrosive paintsEpoxy resin coatingsSolventPliability

The invention provides polyaniline-graphene composite based anticorrosive paint and a preparation method thereof. The polyaniline-graphene composite based anticorrosive paint comprises, by weight, 20-90 parts of film former, 0.1-20 parts of polyaniline-graphene composite, 1-10 parts of pigment, 1-10 parts of filler, 0.1-3 parts of sag-proof agent, 0.1-4 parts of dispersant, 0.01-2 parts of flatting agent, 0.01-2 parts of defoaming agent, and 1-50 parts of solvent. The paint has good physical anticorrosion as graphene is high in radius-thickness ratio and high in flexibility and has electromechanical anticorrosion by the aid of polyaniline loaded on the surface of the graphene, and under synergism of the polyaniline and the graphene, the paint has fine metal corrosion resistance. The anticorrosive paint achieves passivation and corrosion inhibition of metal substrates, avoids use of heavy metals causing environmental pollution, such as chromium and the like, and is simple to prepare, low in cost and easy in industrial batch production.

Owner:HARBIN ENG UNIV

Non-toxic polyaniline modified anti-corrosive coating and preparation method thereof

ActiveCN101643618AAchieve passivationImprove corrosion resistanceRubber derivative coatingsAnti-corrosive paintsAfter treatmentPhytic acid

The invention relates to coating technology, in particular to a non-toxic polyaniline modified anti-corrosive coating and a preparation method thereof to solve the problems that that prior antirust pigment has poor corrosion resistance, and the coating is matched with harmful lead-containing and chromate-containing pigment in the manufacturing process. The non-toxic polyaniline modified anti-corrosive coating comprises a film forming matter, polyaniline modified antirust pigment, and the like. A polyaniline coating layer is formed on the surface of the antirust pigment by an oxidative polymerization method; the antirust pigment after treatment has passivating effect on metal; and a phytic coating layer on the surface of the antirust pigment also has corrosion inhibiting effect on the metal. The non-toxic polyaniline modified anti-corrosive coating has strong corrosion resistance and permeability resistance, and can be applied to anti-corrosive projects such as petrochemical equipment,pipelines, offshore oil platforms, wharf facilities, shipping and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Environment-friendly polyaniline modified aluminium powder anti-corrosive coating and preparation method thereof

ActiveCN101643619AAchieve passivationImprove corrosion resistanceRubber derivative coatingsAnti-corrosive paintsPetrochemicalCorrosion

The invention relates to coating technology, in particular to an environment-friendly polyaniline modified aluminium powder anti-corrosive coating and a preparation method thereof to solve the problemthat the prior aluminium powder coating has poor corrosion resistance, and is matched with harmful lead-containing and chromate-containing pigment in the manufacturing process. The environment-friendly polyaniline modified aluminium powder anti-corrosive coating comprises a film forming matter, polyaniline modified aluminium powder and the like. A polyaniline coating layer is formed on the surface of the aluminium powder by an oxidative polymerization method; the treated aluminium powder has passivating effect on metal; and a phytic coating layer on the surface of the aluminium powder also has corrosion inhibiting effect on the metal. The environment-friendly polyaniline modified aluminium powder anti-corrosive coating has strong corrosion resistance and permeability resistance, and can be applied to anti-corrosive projects such as petrochemical equipment, pipelines, offshore oil platforms, wharf facilities, shipping and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Environmental-friendly polyaniline modified micaceous iron oxide anticorrosive coating and preparation method thereof

ActiveCN101643620AAchieve passivationImprove corrosion resistanceRubber derivative coatingsAnti-corrosive paintsPhytic acidPetrochemical

The invention relates to coating technology, in particular to an environmental-friendly polyaniline modified micaceous iron oxide anticorrosive coating and preparation method thereof, which solves theproblem that the prior micaceous iron oxide coating has poor anticorrosion performance, and needs to be matched with pigments containing lead and chromate during manufacturing. The environmental-friendly polyaniline modified micaceous iron oxide anticorrosive coating comprises film-forming material, polyaniline modified micaceous iron oxide, and the like. As polyaniline coating layers are formedon the surfaces of the micaceous iron oxide by an oxidative polymerization method, the treated micaceous iron oxide has the effect of passivating metal, and phytic-acid coating layers on the surfacesof the micaceous iron oxide play a role in inhibiting corrosion of metal. The environmental-friendly polyaniline modified micaceous iron oxide anticorrosive coating has strong corrosion resistance andpermeation resistance, can be applied to heavy-duty engineering of petrochemical equipment, pipelines, offshore oil platforms, wharf facilities, ships and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Polyaniline modified glass flake heavy-duty anti-corrosive coating and preparation method thereof

ActiveCN101643615AAchieve passivationImprove corrosion resistanceAnti-corrosive paintsPigment treatment with macromolecular organic compoundsEpoxyPhytic acid

The invention relates to coating technology, in particular to a polyaniline modified glass flake heavy-duty anti-corrosive coating and a preparation method thereof to solve the problems that when theprior glass flake anti-corrosive coatings are constructed, most of the glass flake anti-corrosive coatings require to coat primer on the surface of steel or other metal matrix to improve the corrosionresistance and prevent corrosion between the coat and the interface of the matrix, and the like. The polyaniline modified glass flake heavy-duty anti-corrosive coating comprises epoxy resin, a polyaniline modified glass flake, an amine curing agent and the like. A polyaniline coating layer is formed on the surface of the glass flake by an oxidative polymerization method; the glass flake after thetreatment has the passivating effect on metal; and a phytic coating layer on the surface of the glass flake also has the corrosion inhibiting effect on the metal. The polyaniline modified glass flakeheavy-duty anti-corrosive coating has strong corrosion resistance and permeability resistance, can be applied to heavy-duty anti-corrosive projects such as petrochemical equipment, pipelines, offshore oil platforms, wharf facilities, shipping and the like, and is particularly suitable for protecting wave splashing zones and tidal difference zones.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

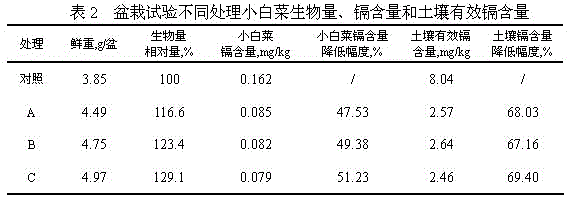

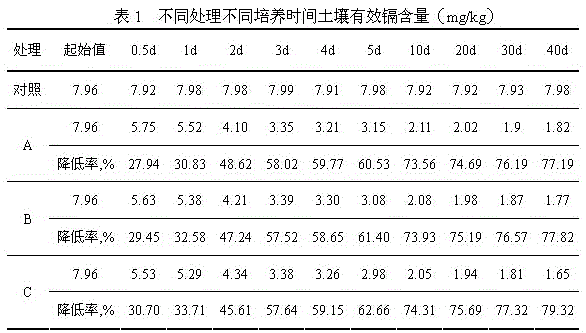

Method for restoring As-Cd-combined-polluted farmland soil through hyperaccumulator biomass charcoal combined system

The invention discloses a method for restoring As-Cd-combined-polluted farmland soil through a hyperaccumulator biomass charcoal combined system. The method comprises the following steps that the farmland soil is monitored and sampled at first, the varieties and planting modes of hyperaccumulators are determined, and enrichment of As and Cd is achieved; then a composite modifier mainly composed ofa microbial agent and a chelating agent is applied to the polluted farmland soil, and passivation and chelating of As and Cd are achieved; and a biomass charcoal-based restoring agent is applied to the surface of the farmland soil, soil is turned over and mixed evenly, and still standing is conducted, so that a treatment cycle is completed. Through the composite modifier, the biomass charcoal-based restoring agent and the hyperaccumulators are used for modifying and restoring the As-Cd-combined-polluted farmland soil, As-Cd heavy metal pollution of soil can be reduced and alleviated, the soilactivation and nutrients are improved, the soil structure is improved, plant growth is promoted, plant diseases and insect pests are suppressed, preparation is convenient, and the method is safe, reliable and suitable for large-area popularization.

Owner:SHENGSHI LANDSCAPE GRP CO LTD

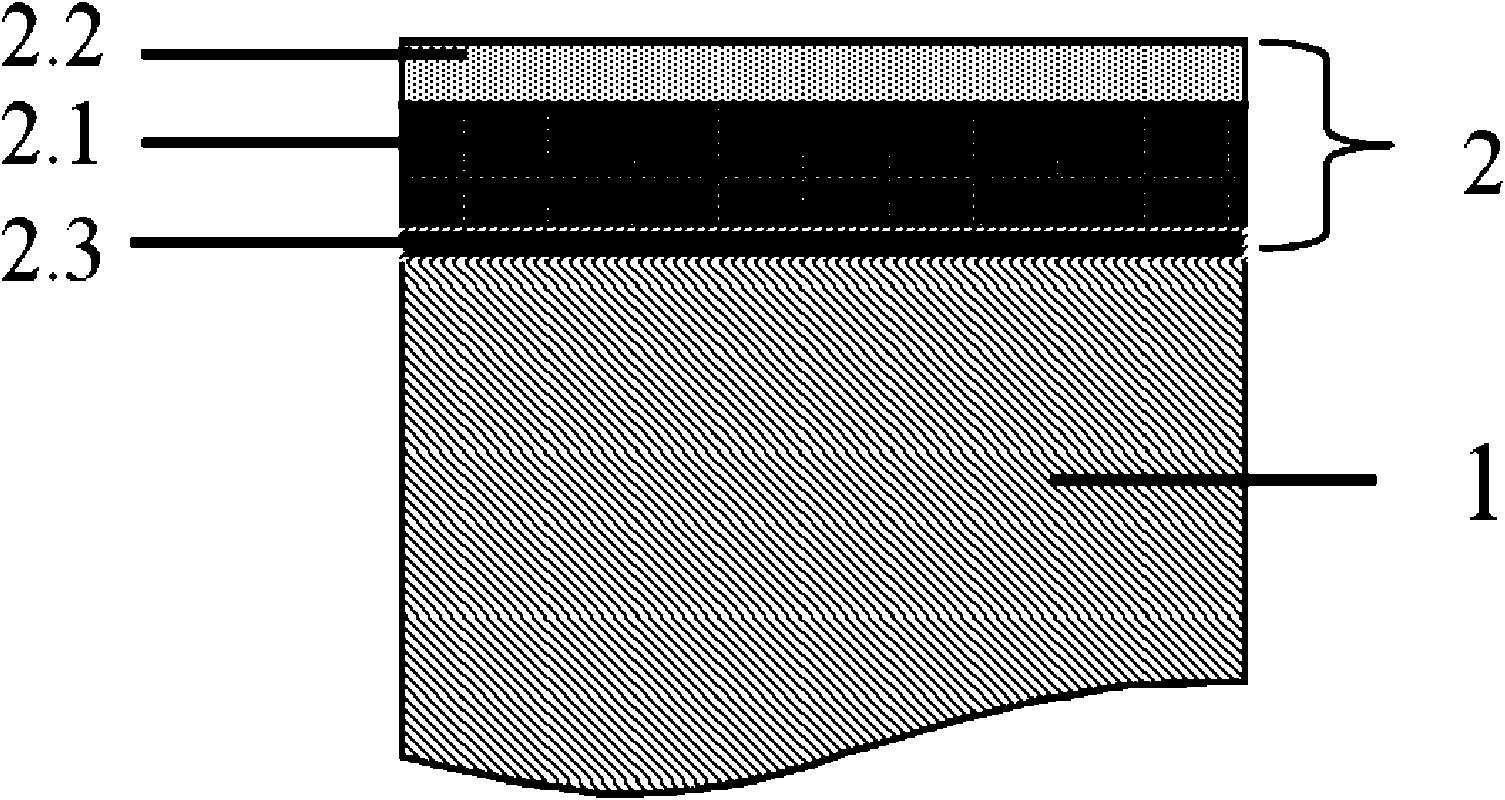

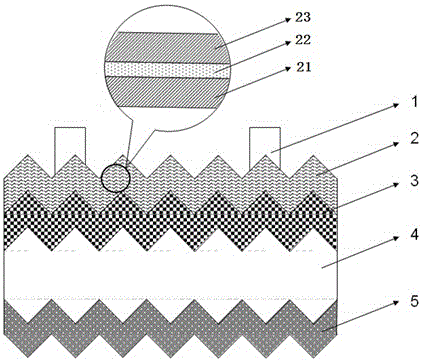

Double-layer anti-reflecting film of crystal silicon solar cell and preparation method thereof

InactiveCN101577294ALow costLow deposition temperatureFinal product manufacturePhotovoltaic energy generationSilver pasteSilicon based

The invention discloses a double-layer anti-reflecting film of a crystal silicon solar cell and a preparation method thereof. The double-layer anti-reflecting film is characterized in that the film consists of a loose layer TiO2 film, a compact layer TiO2 film and a SiO2 passivation layer in turn, wherein the SiO2 passivation layer is positioned between the compact layer TiO2 film and a silicon-based substrate. The preparation method comprises the following steps: depositing the compact layer TiO2 film and the loose layer TiO2 film on the right surface of the silicon-based substrate; and after electrode silver paste is printed, through conventional sintering at the temperature between 400 and 900 DEG C, forming the SiO2 passivation layer at an interface of the silicon-based substrate and the compact TiO2. A TiO2 / TiO2, quasi double-layer anti-reflecting film of the invention is finished once by changing the depositing condition, is optimized on the process and equipment, and has better anti-reflecting effect compared with a single-layer anti-reflecting film.

Owner:CENT SOUTH UNIV

Austenitic stainless steel cleaning and passivating agent

InactiveCN109487280AAccelerated corrosionLess corrosiveMetallic material coating processesPhosphoric acidYttrium

The invention discloses an austenitic stainless steel cleaning and passivating agent. The austenitic stainless steel cleaning and passivating agent is composed of, by mass, 30%-40% of citric acid, 0.1%-1% of ethylene diamine tetraacetic acid disodium, 1%-5% of 1-hydroxyethylidene-1,1-diphosphonic acid (HEDP), 3%-8% of glycollic acid, 3%-8% of phosphoric acid, 0.1%-2% of a non-ionic surface activeagent, 0.5%-3% of 322H, 0.5%-1% of sodium dodecylbenzenesulfonate, 0%-0.5% of yttrium nitrate, 0.1%-1% of corrosion inhibitor and the balance water. The prepared degreasing, rust removing and passivating agent has the characteristics of being environment-friendly, free of pungent smell and free of toxicity, harm to people and the environment can be remarkably reduced, and the production cost is effectively reduced.

Owner:安徽笃舜智能装备有限公司

Chemical repairing agent for farmland soil Cd pollution

ActiveCN105567249ALow toxicityReduce absorptionAgriculture tools and machinesContaminated soil reclamationAmmonium sulfateHumic acid

The invention discloses a chemical repairing agent for farmland soil Cd pollution. The chemical repairing agent is prepared from the following raw materials of 10 to 30 parts of humic acid, 10 to 30 parts of ammonium sulfate, 10 to 30 parts of potassium dihydrogen phosphate, 10 to 15 parts of citric acid, 5 to 15 parts of disodium dihydrogen pyrophosphate, 5 to 10 parts of biosurfactant, 5 to 10 parts of Cd chemical antidote and 5 to 10 parts of bentonite in a mixing way. The chemical repairing agent disclosed by the invention can be uniformly applied into soil along with soil tillage, the application amount per mu is 40 kg to 50 kg, and then water can be irrigated after the soil is uniformly raked. Cd in the soil is enabled to form a more stable chelation state of enabling the Cd not easy to absorb and utilize by a plant through activation, chelation and adsorption, the Cd in the soil can be changed from small molecules into big molecules, passivation of the Cd in the soil is realized, the toxicity of the Cd is reduced, and the chemical repairing agent is suitable for Cd pollution chemical repairing of limy farmland soil.

Owner:山西大地民基生态环境股份有限公司 +1

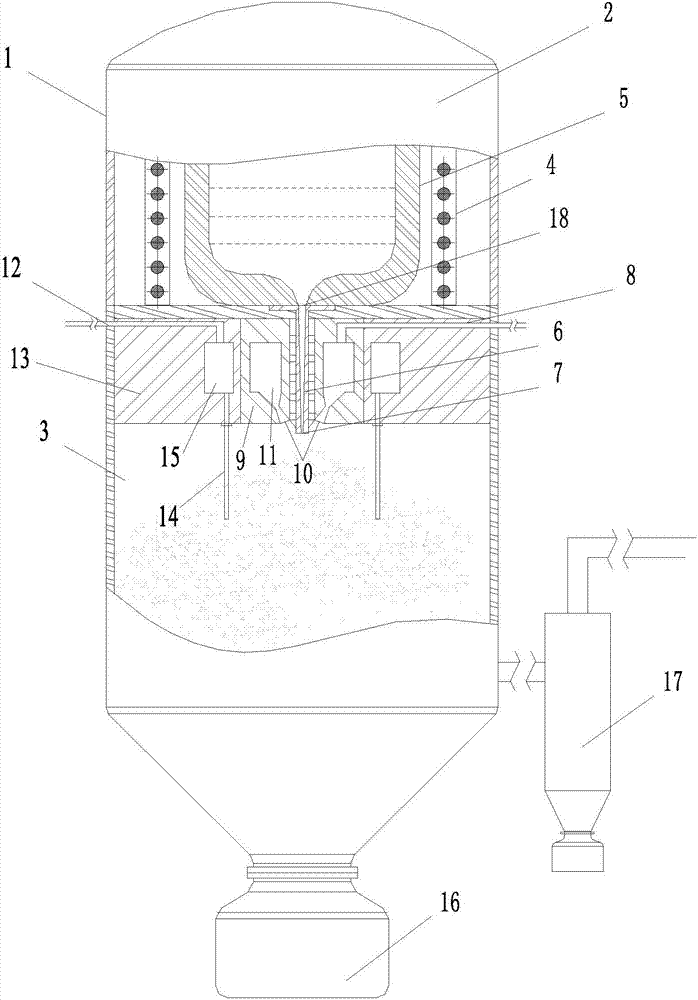

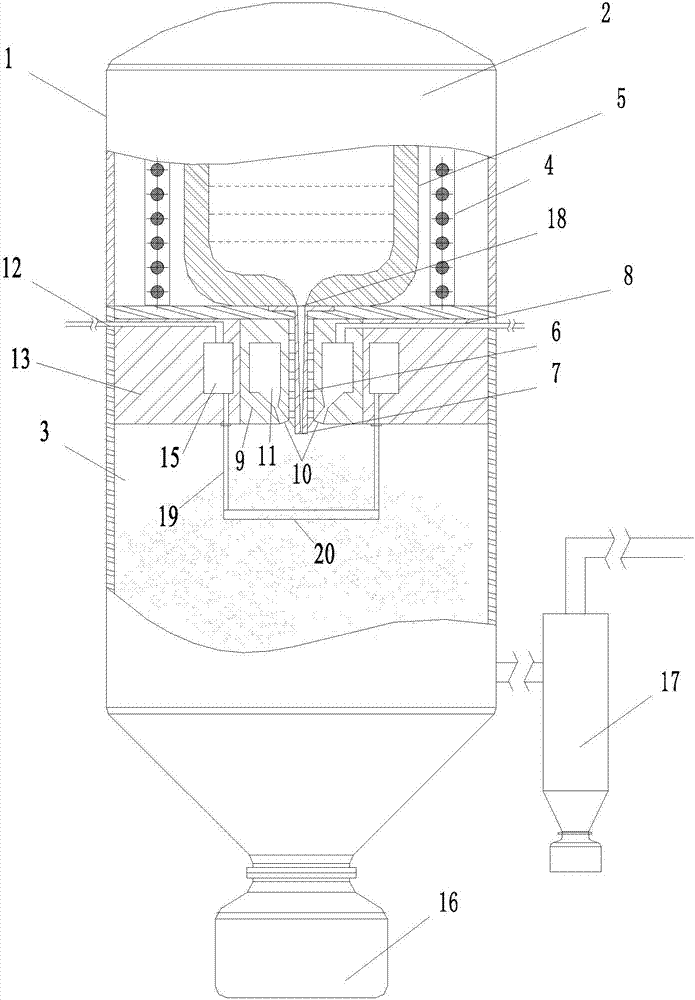

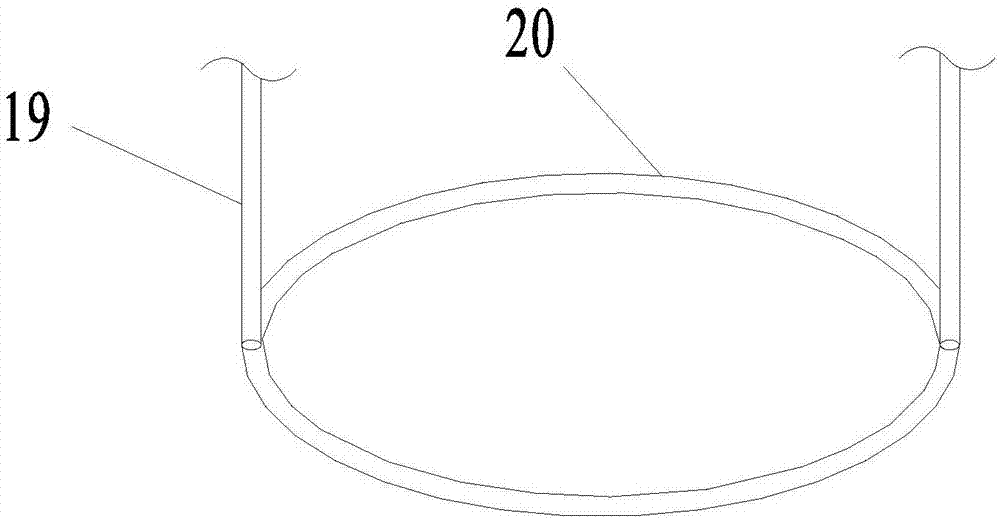

Atomization device for preparing alloy metal powder

PendingCN107377983AReduce stickingInhibition formationDispersed particle filtrationTransportation and packagingIndiumOxygen

The invention discloses an atomization device for preparing alloy metal powder. The atomization device comprises a body. A vacuum melting chamber and an atomization chamber are sequentially arranged in the body from top to bottom. A melting device and a heating device are arranged in the vacuum melting chamber. The heating device heats the melting device. The melting device comprises a liquid outlet. The liquid outlet communicates with the top of the atomization chamber through a diversion pipe. A gas spray nozzle is arranged in the atomization chamber and is connected with high-pressure inert gas through a pipeline. The gas spray nozzle sprays the high-pressure inert gas towards an outlet of the diversion pipe. An oxygen-containing gas pipeline and a gas inlet device connected with the oxygen-containing gas pipeline are arranged in the atomization chamber. The oxygen-containing gas pipeline conveys oxygen-containing gas into the atomization chamber through the gas inlet device. By means of the atomization device, the surface of the alloy metal powder can be passivated in the atomization process, and therefore the sphericity degree of copper, indium and gallium alloy powder and the phenomenon of the strong adhesion among the powder are controlled.

Owner:DONGJUN NEW ENERGY CO LTD

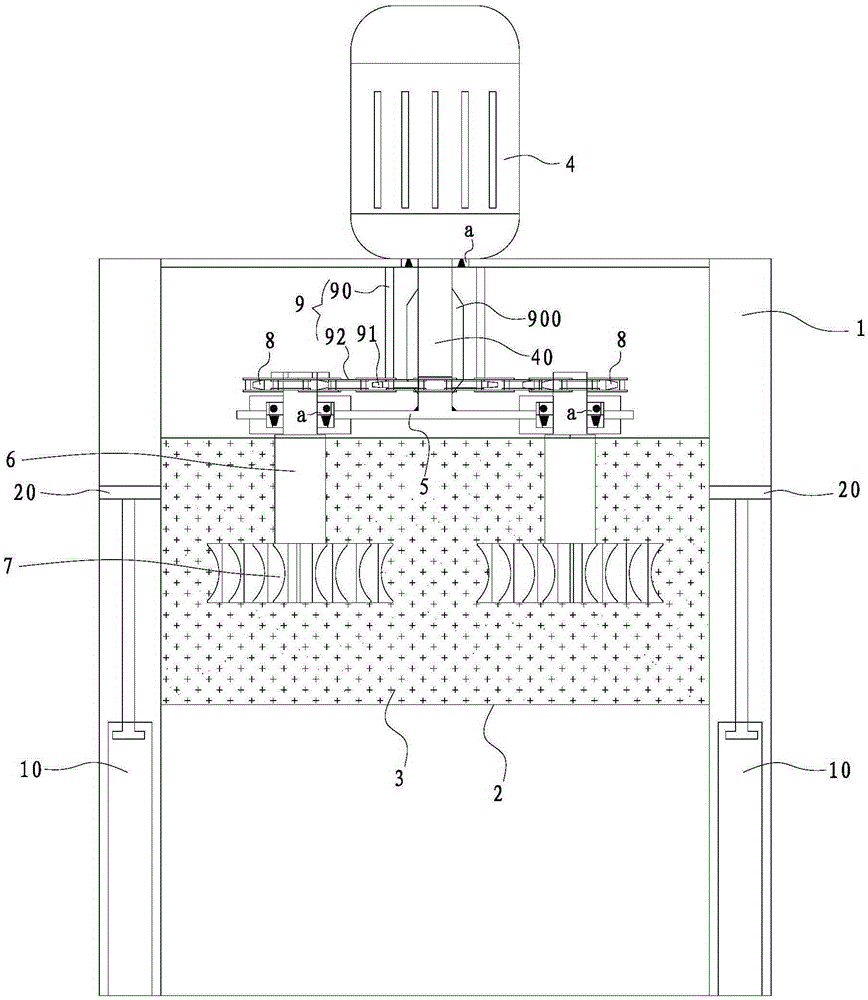

Cutter blunting machine

ActiveCN105290947AAchieve passivationSimple structureEdge grinding machinesPolishing machinesDrive motorEngineering

The invention relates to a cutter blunting machine, which comprise a rack, a grinding material tank, a grinding material, a drive motor, an output frame and rotating shafts, wherein the grinding material tank is capable of vertically moving along the height direction of the rack for adjustment; the grinding material is contained in the grinding material tank; the drive motor is arranged on the rack and an output shaft of the drive motor is vertically downward; the output frame is fixed to the lower end of the output shaft; the rotating shafts are arranged in parallel with the output shaft and rotatably arranged on the output frame around the respective axes; a to-be-blunted cutter is detachably mounted on the lower end parts of the rotating shafts; and when the cutter blunting machine works, the lower end parts of the rotating shafts and the to-be-blunted cutter stretch into the grinding material tank; the drive motor drives the rotating shafts to rotate and revolve on own axes, so that the cutter is blunted by the grinding material. According to the cutter blunting machine, the rotating shafts rotate around the output shaft of the drive motor and revolve on own axes, and the cutter is driven to rotate inside the grinding material tank provided with the grinding material, so that the cutter is blunted. The cutter blunting machine has the advantages that the structure is simple; the implementation is convenient; and the cost is low.

Owner:江苏仓环铜业股份有限公司

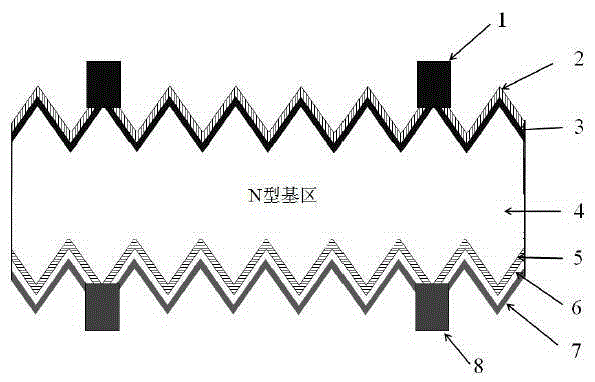

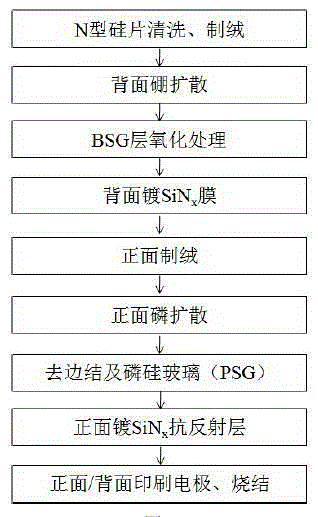

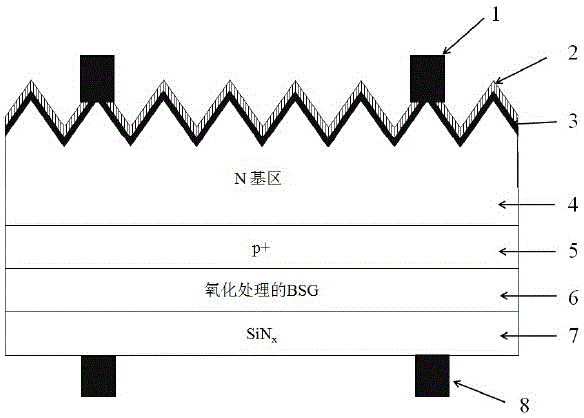

Back surface junction N-type double-sided crystal silicon cell and preparation method thereof

InactiveCN105206699AImprove life expectancyImprove efficiencyFinal product manufacturePhotovoltaic energy generationAg electrodeSunlight irradiation

The invention provides a back surface junction N-type double-sided crystal silicon cell and a preparation method thereof. The cell comprises a front surface Ag electrode, a front surface antireflection film, a phosphorus diffusion N+ front surface field layer, an N-type substrate, a boron diffusion emission electrode P+ layer, a back surface passivation composite film and a back surface AgAl electrode. The front surface and the back surface of the cell have a textured structure. The back surface passivation composite film comprises a borosilicate glass layer and a silicon nitride layer. The borosilicate glass layer is arranged on the boron diffusion emission electrode P+ layer. The silicon nitride layer is deposited on the borosilicate glass layer. Both of the front surface and the back surface of the cell can effectively receive sunlight irradiation for power generation so that comprehensive efficiency of the cell can be enhanced; and the laminated film of the borosilicate glass layer and the silicon nitride layer through oxidation treatment is adopted to act as a boron emission electrode passivation layer and a diffusion masking layer of subsequent phosphorus diffusion so that boron emission electrode passivation and diffusion masking functions can be realized simultaneously, and the process of multiple times of etching and mask deposition in the manufacturing process can be reduced. The back surface junction N-type double-sided crystal silicon cell is simple in technology, high in production efficiency and low in production technology cost.

Owner:中国东方电气集团有限公司

N-type back junction crystalline silicon cell and preparation method thereof

InactiveCN105097978AReduce the interfacial recombination rateImprove passivation effectFinal product manufacturePhotovoltaic energy generationPhysicsThin membrane

The invention provides an N-type back junction crystalline silicon cell and a preparation method thereof. The battery comprises a front surface Ag electrode, a front surface antireflection film, a phosphorus diffusion N+ front surface field layer, an N-type base, a boron diffusion emitter P+ layer, a back passivation composite film and a back AgAl electrode, wherein the PN junction is located on the back surface of the cell; a polishing structure is adopted by the back surface of the battery; the back passivation composite film comprises a borosilicate glass layer and a silicon nitride layer; the borosilicate glass layer is located on the boron diffusion emitter P+ layer; and the silicon nitride layer is deposited on the borosilicate glass layer; a boron emitter is passivated by the borosilicate glass layer and silicon nitride laminated film structure generated in the boron diffusion process; the polishing structure is adopted by the back surface; and the passivation effect of the boron emitter is further improved. The preparation technology of the battery is relatively simple, can be compatible with equipment of the current crystalline silicon cell production line, and is suitable for large-scale industrial production; and the cost can be reduced.

Owner:中国东方电气集团有限公司

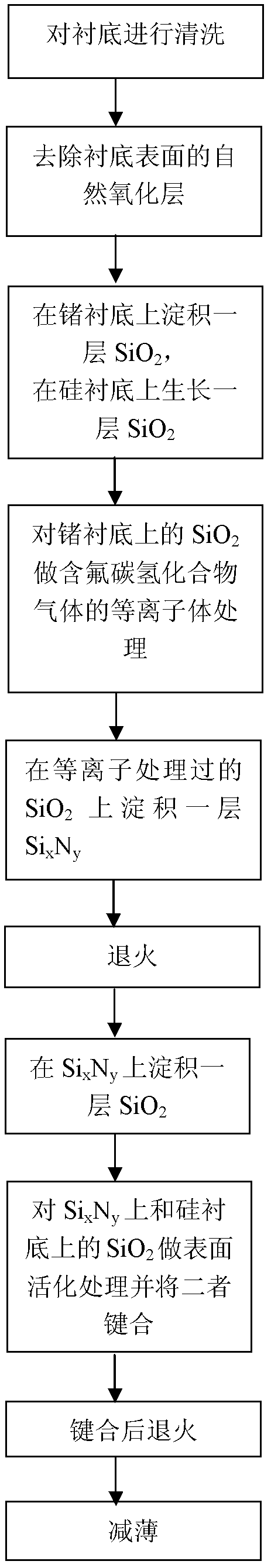

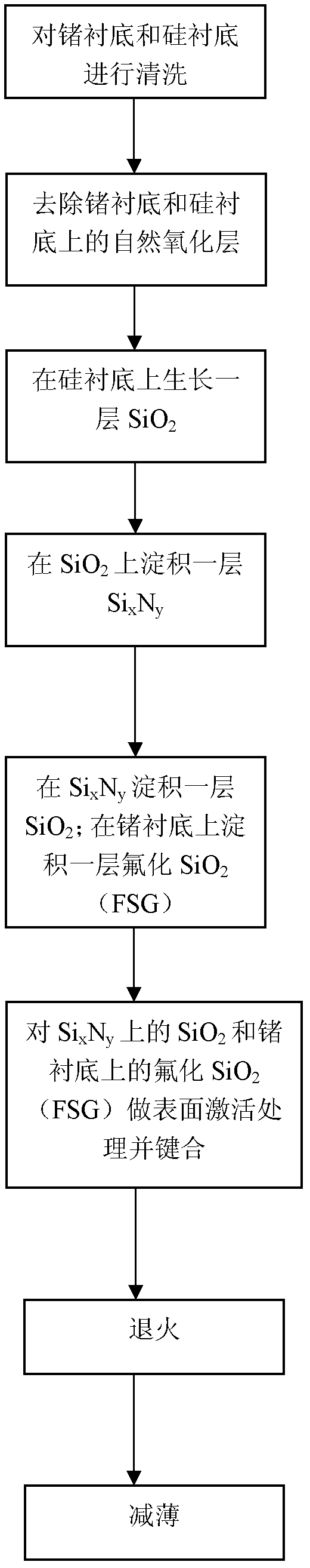

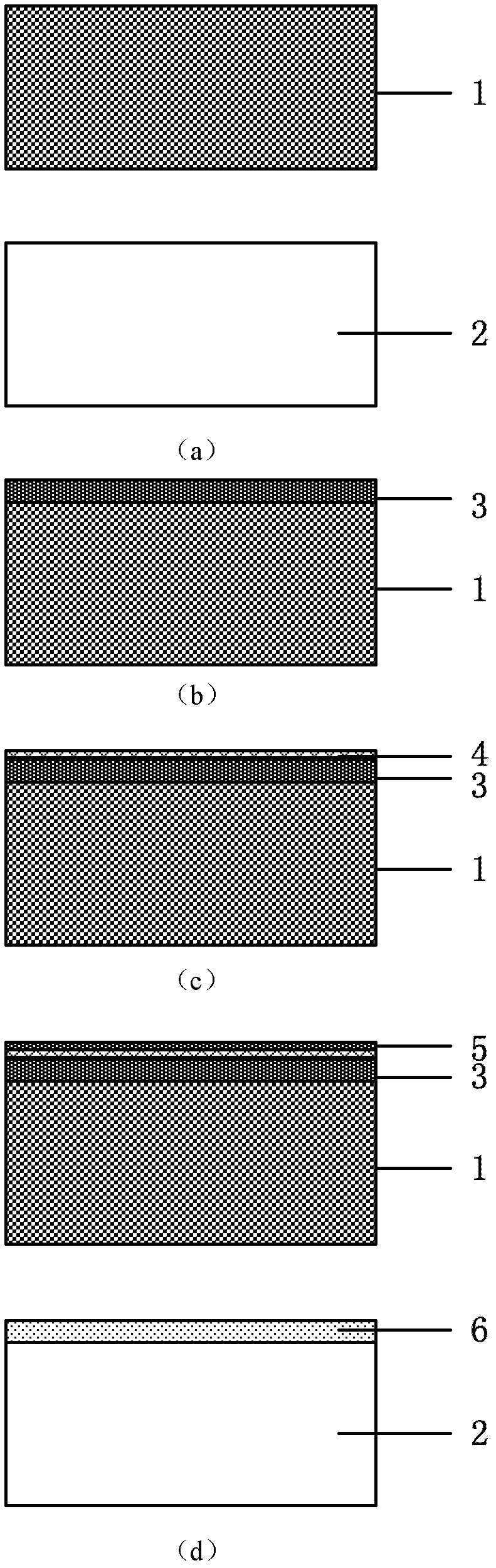

Preparation method for Ge-on-insulator substrate

InactiveCN102610553AImprove back interface qualitySuppression of short channel effectsSemiconductor/solid-state device manufacturingDevice materialOxygen

The invention discloses a preparation method for a Ge-on-insulator (GeOI) substrate and belongs to the field of semiconductor devices. Passvating treatment is realized on an interface of a Ge film of the upper layer and a buried oxygen layer in the process of preparing the GeOI substrate in the method, and thereby, the state density of the interface is reduced, and the quality of the back interface of the GeOI substrate is increased. The preparation method for the GeOI substrate is capable of effectively reducing the dielectric constant of the buried oxygen (BOX) layer and is favorable of restraining a short-channel effect of a metal-oxide-semiconductor field effect transistor (MOSFET) prepared based on the GeOI substrate.

Owner:PEKING UNIV

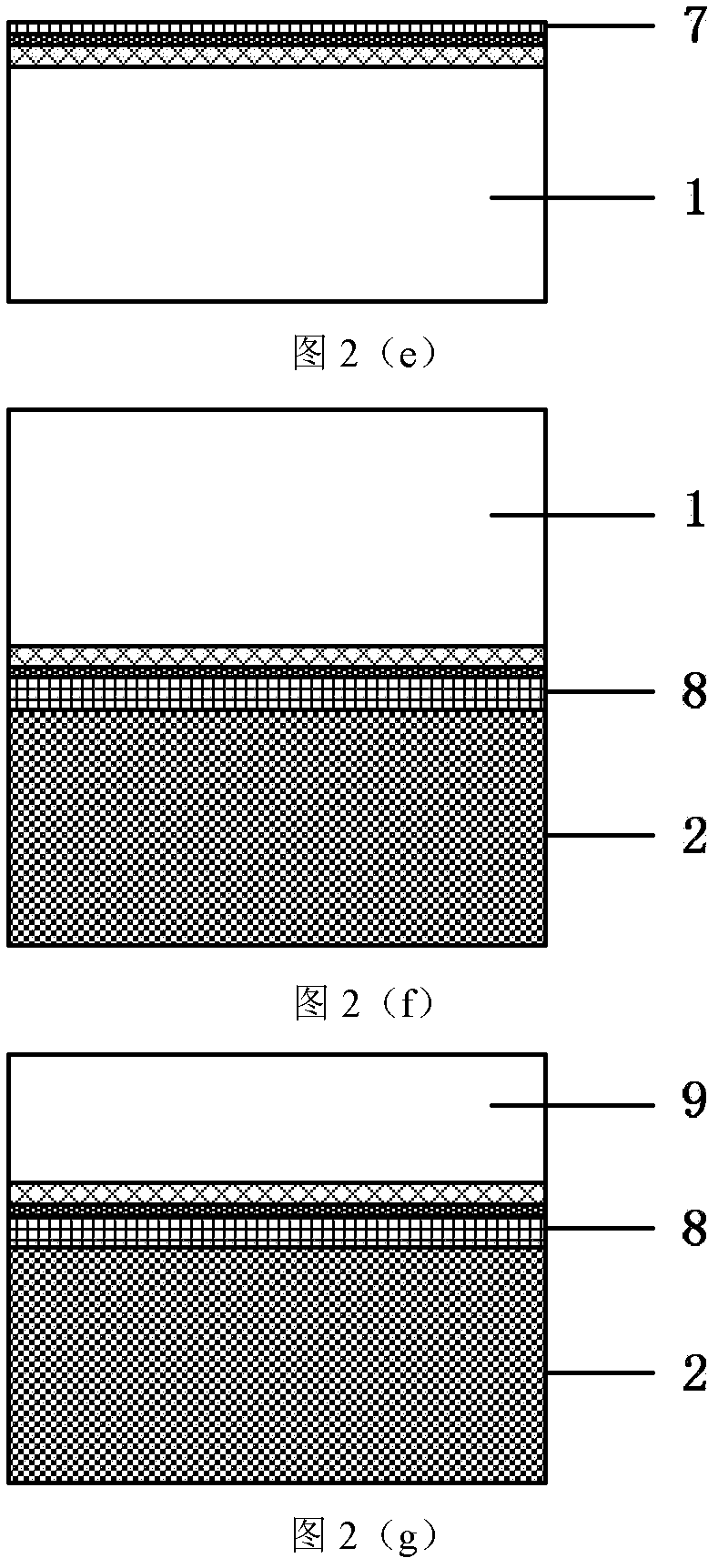

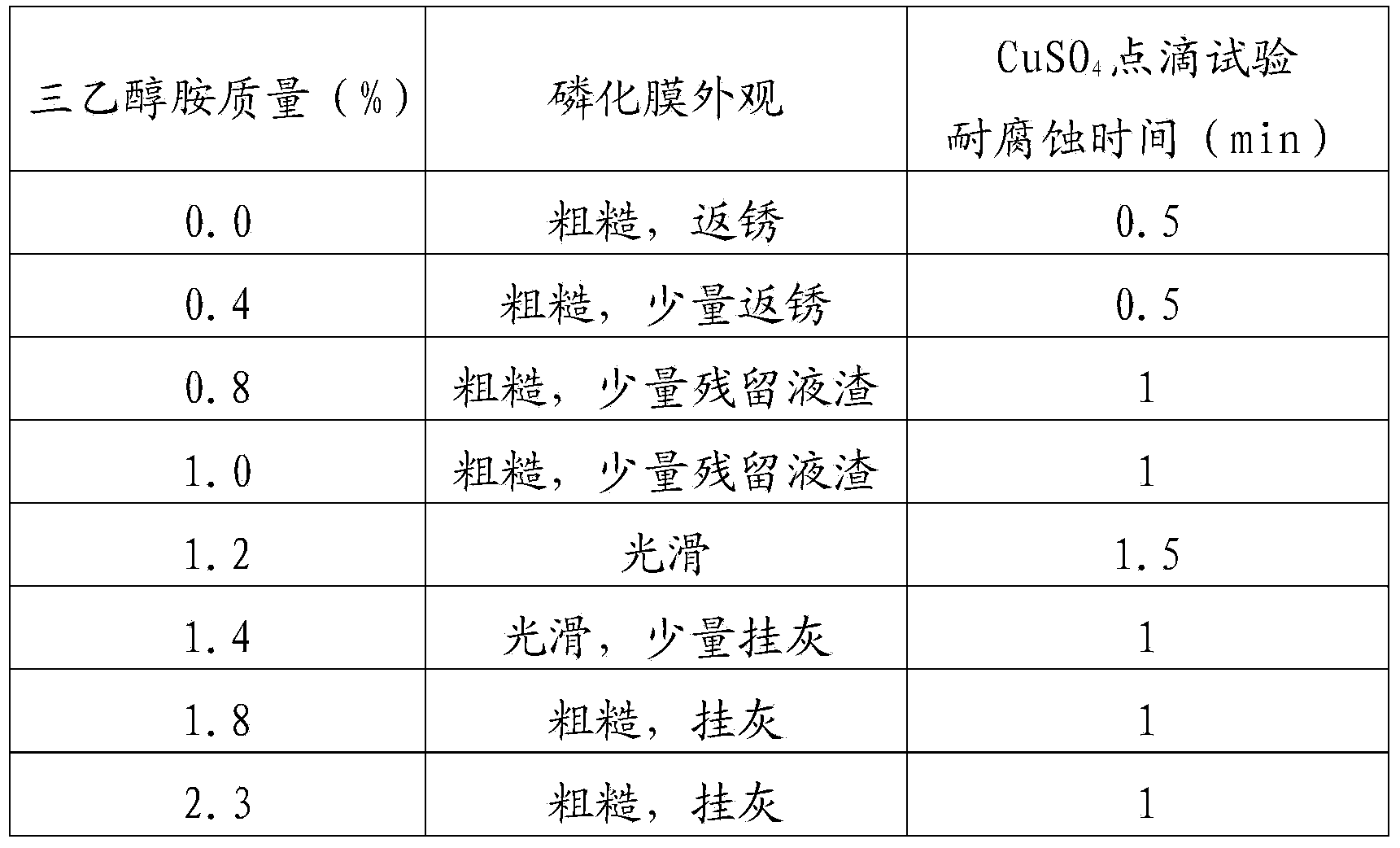

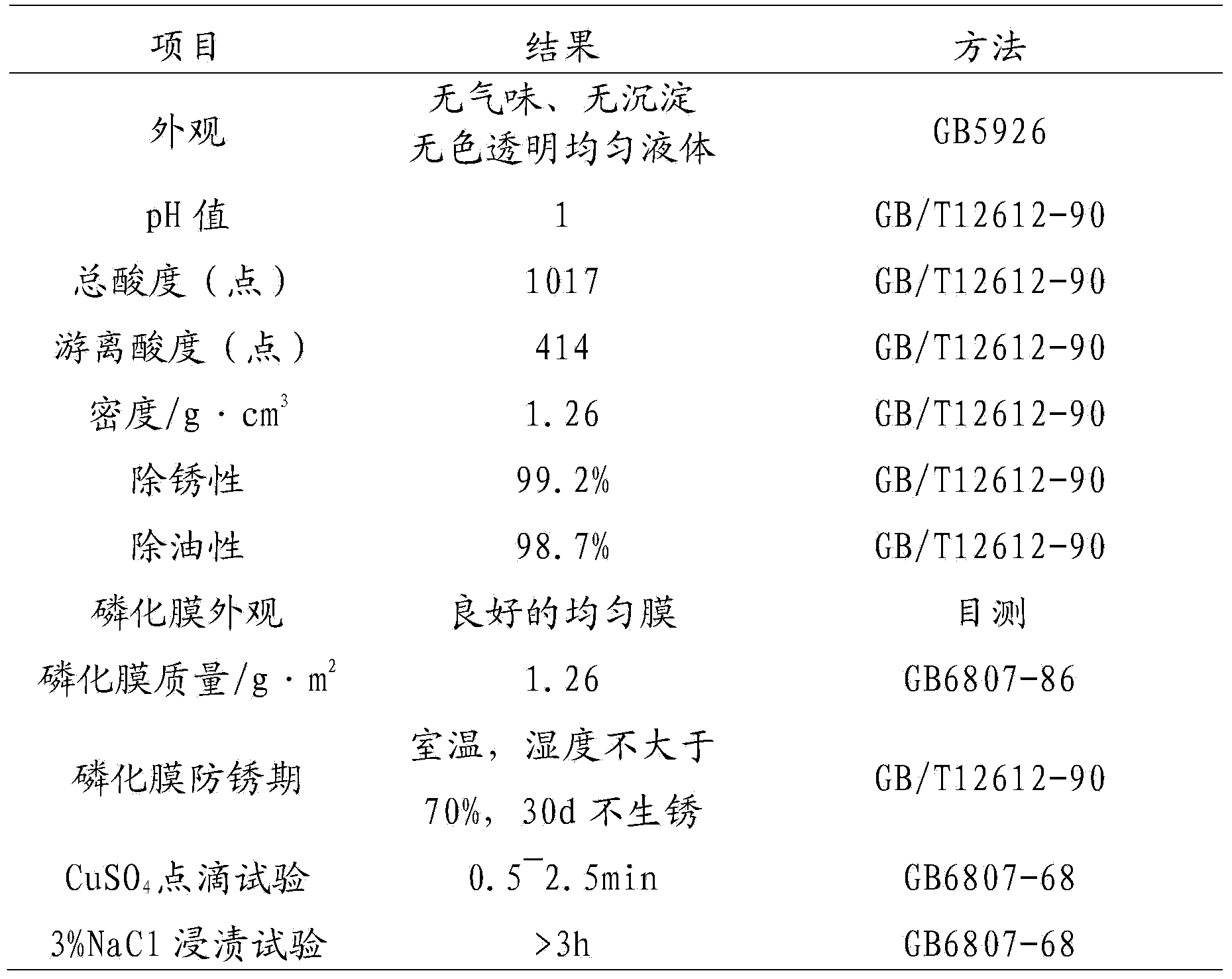

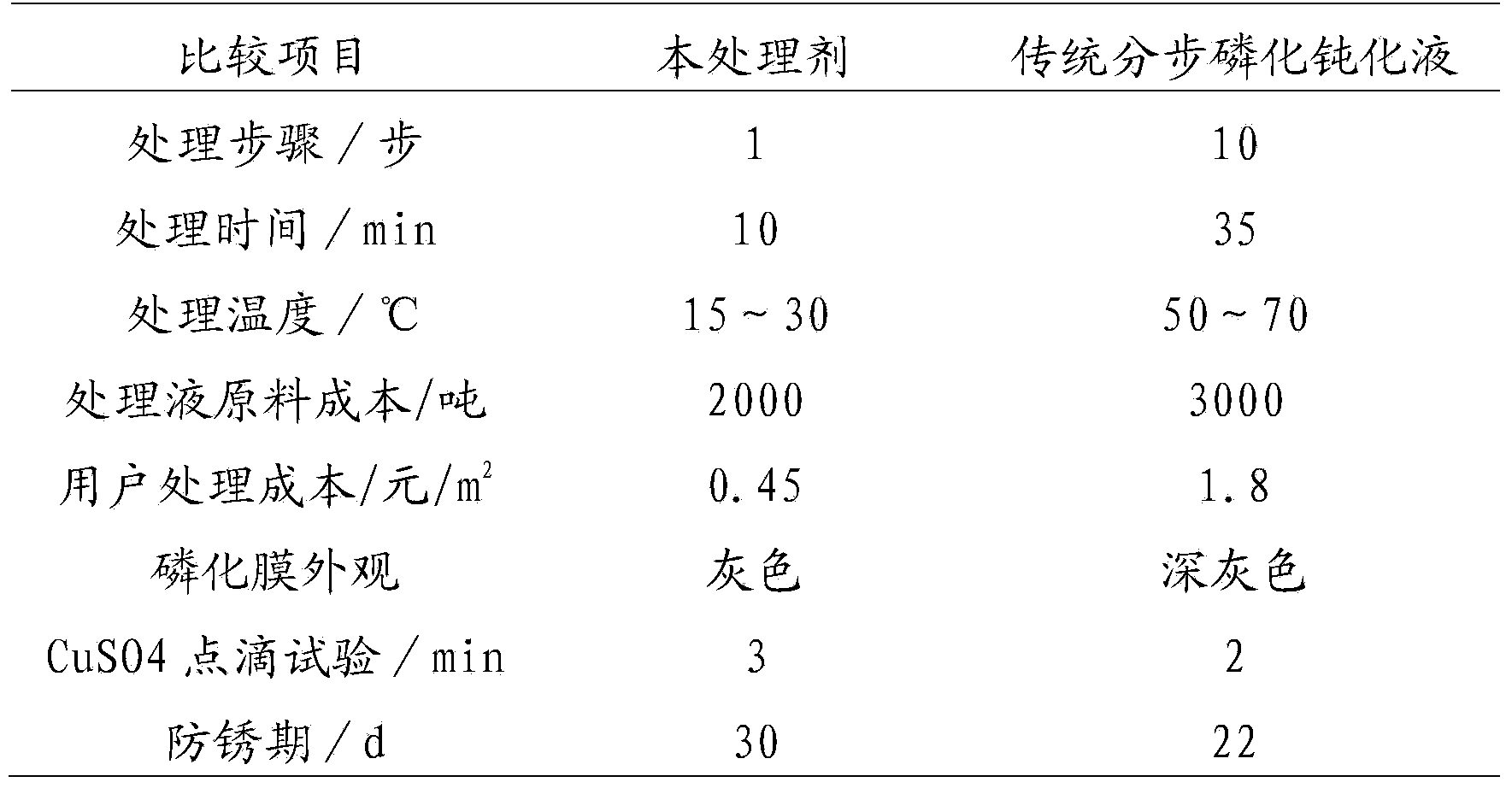

Comprehensive treatment agent and use method thereof

InactiveCN103436872AAvoid time costReduce processing costsMetallic material coating processesThioureaPhosphate

The present invention relates to a comprehensive treatment agent, which comprises, by mass, 25.0-30.0% of phosphoric acid, 1.0-3.0% of zinc oxide, 0.1-0.5% of sodium molybdate, 4.0-7.0% of zinc dihydrogen phosphate, 0.3-1.2% of potassium chlorate, 0.3-1.2% of a surfactant, 0.0-2.3% of triethanolamine, 0.8-2.3% of citric acid, 0.1-0.3% of thiourea, and 58.0-62.6% of water. According to the present invention, the treatment agent can be recycled, a treatment cost is low, and pollution on the environment can not be generated.

Owner:谢俊磊

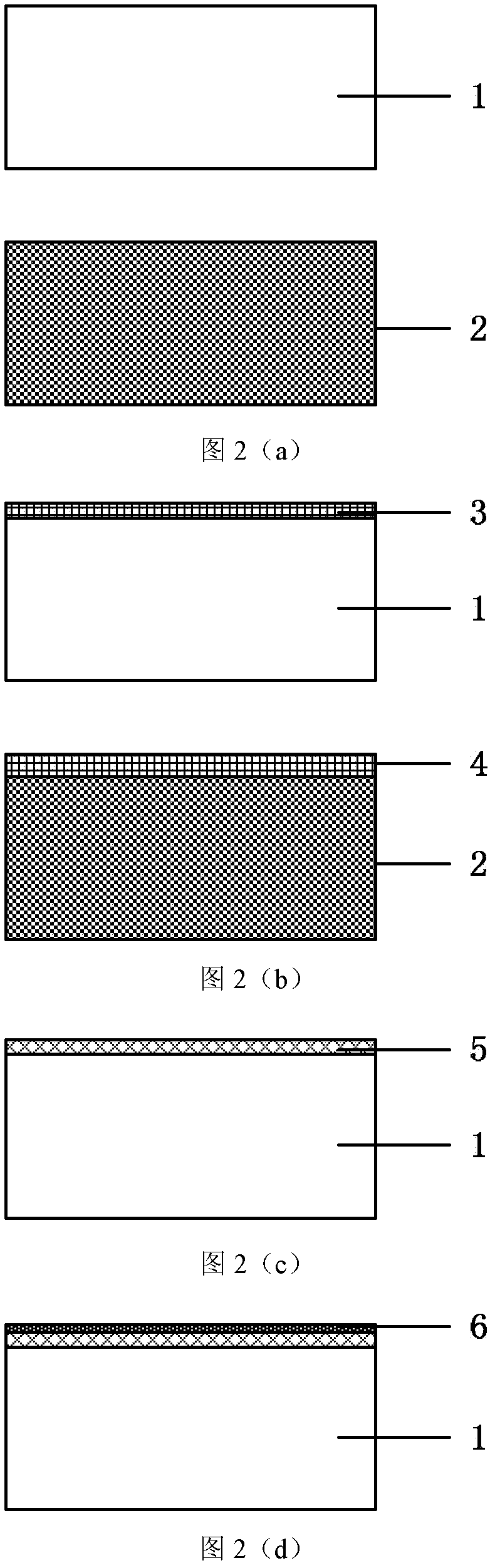

Method for preparing germanium-on-insulator (GeOI) substrate

InactiveCN102201364AImprove back interface qualityAchieve passivationSemiconductor/solid-state device manufacturingBiological activationSemiconductor

The invention discloses a method for preparing a germanium-on-insulator (GeOI) substrate. In the method, a back interface is passivated in the process of preparing the GeOI substrate; and the method comprises the following steps of: providing a semiconductor germanium substrate and a silicon substrate respectively, cleaning the germanium substrate and the silicon substrate, and removing natural oxide layers on the surfaces of the germanium substrate and the silicon substrate; growing a layer of SiO2 on the silicon substrate; depositing a layer of SixNy on the SiO2; depositing SiO2 for bonding on the SixNy, and depositing fluoridized SiO2 (FSG) for bonding on the germanium substrate; performing surface activation treatment on the SiO2 on the SixNy and the fluoridized SiO2 (FSG) on the germanium substrate, and performing alignment bonding along activated surfaces; annealing; and thinning. By the method, the quality of the back interface of the GeOI substrate can be improved.

Owner:PEKING UNIV

Improved high-temperature-resistant metal anti-corrosive paint

The invention relates to improved high-temperature-resistant metal anti-corrosive paint, which consists of the following components in parts by mass: 30-40 parts of GHNK high-temperature-resistant adhesive, 15-20 parts of polyaniline / graphene composite material, 15-20 parts of coloring pigment, 5-10 parts of superfine talcum powder, 5-10 parts of superfine mica powder, 5-10 parts of kaolin, 0.2-0.5 parts of SN-612 flatting agent, 0.3-0.5 parts of wetting agent X-405, 0.1-0.3 parts of dimethyl ethanolamine, 0.1-0.3 parts of anti-corrosive agent 981, 0.5-1 part of GHP 101 thickening agent, 0.1-0.3 parts of tributyl phosphate and 4-13 parts of water. The paint prepared by the invention has the advantages of excellent water-proof and anti-corrosive properties, high temperature resistance, alkaline resistance, weathering resistance, scrub resistance, artificial aging resistance and the like, passivation and corrosion inhibition of a metal base material can be realized, meanwhile, the use of heavy metals such as chromium which can cause environmental pollution is avoided, and the paint is easy to prepare, low in cost and is easy for industrial batch production.

Owner:冯斌

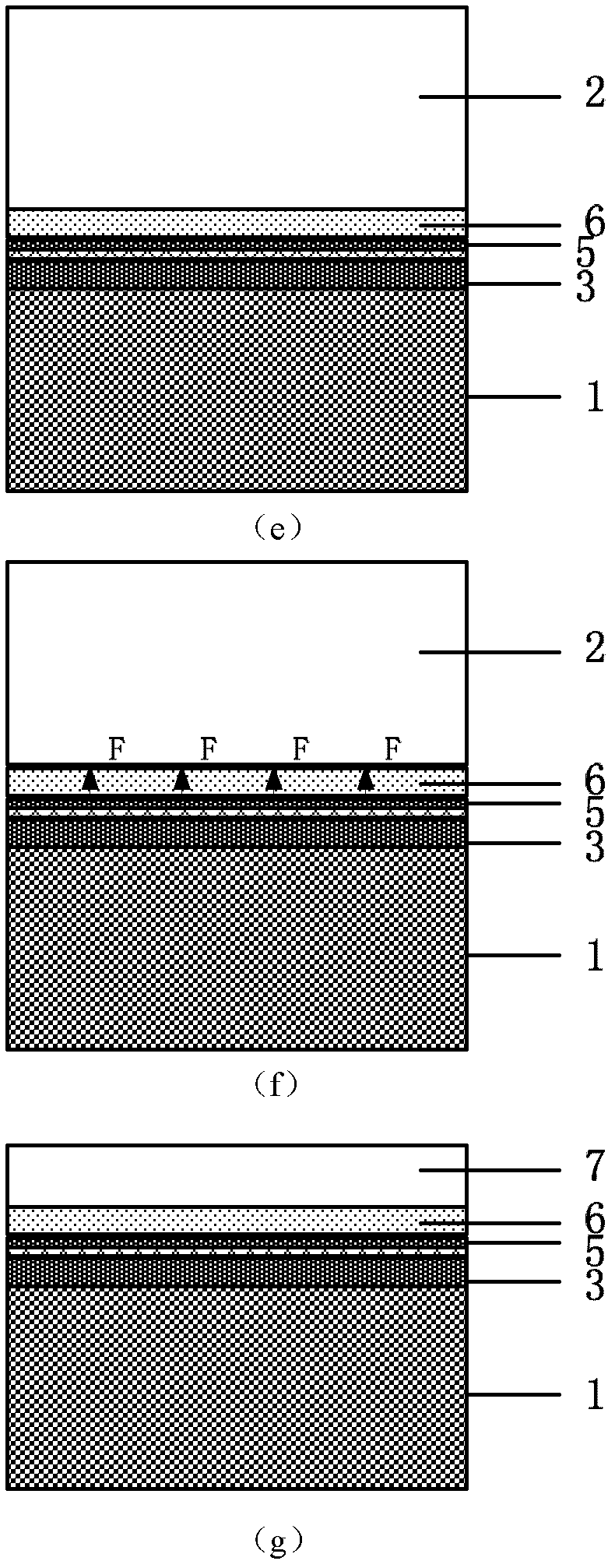

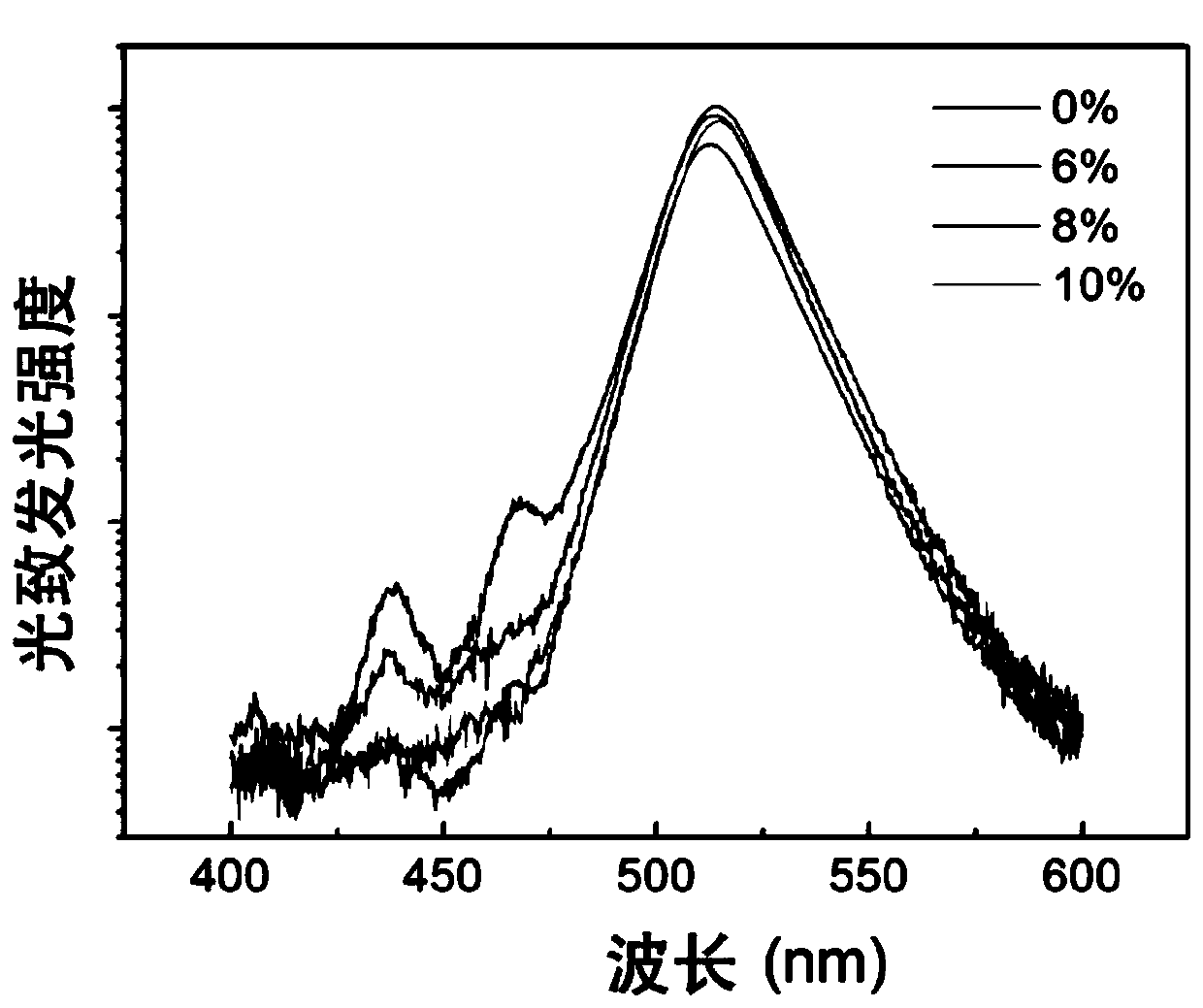

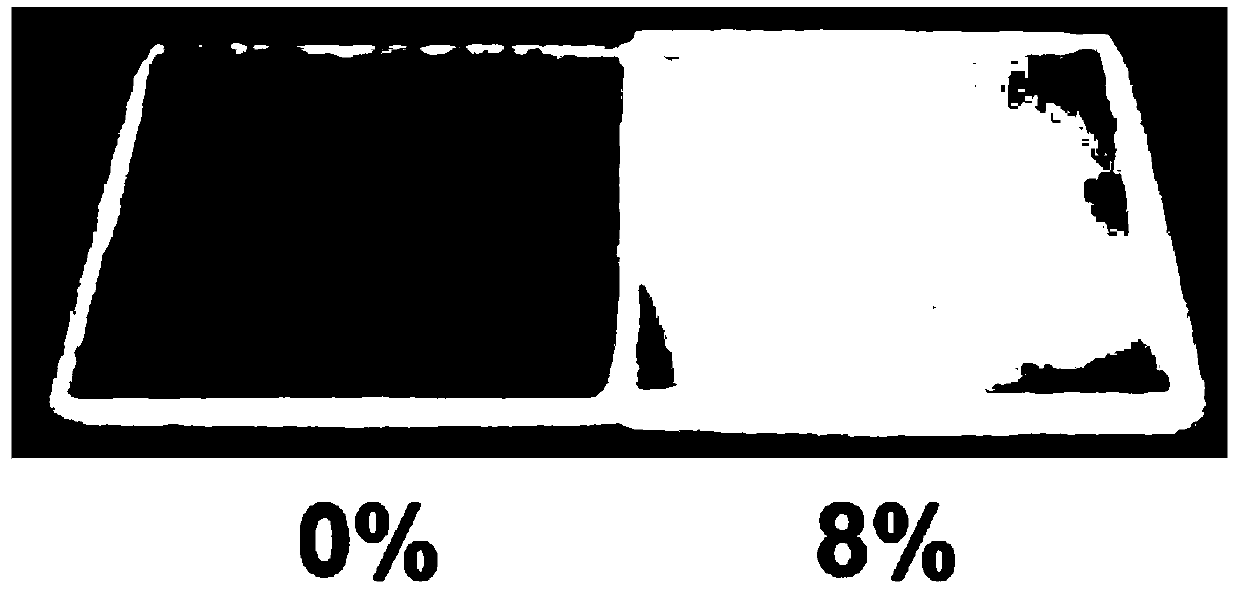

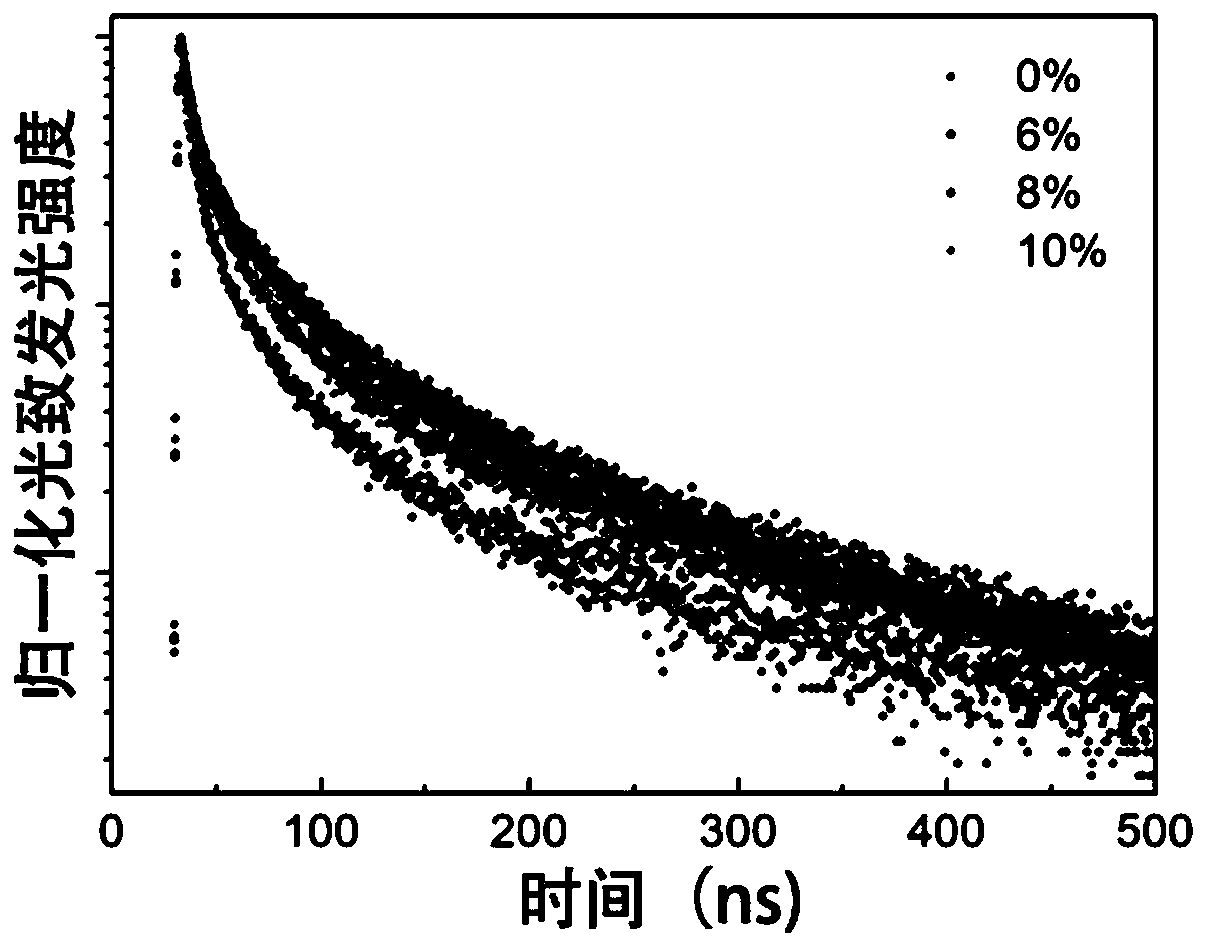

Preparation method of low-defect quasi-two-dimensional perovskite film based on methanesulfonic acid negative ion induction

ActiveCN110305660AEfficient deliveryEffective delivery pathLuminescent compositionsPhotovoltaic energy generationFilm baseMetal halides

The invention discloses a preparation method of a low-defect quasi-two-dimensional perovskite film based on methanesulfonic acid negative ion induction. According to the method, methanesulfonic acid (MeS) negative ions are led in an L2An-1MnX3n+1 perovskite precursor to adjust phase compositions, so that a more effective energy transfer way is generated. Crystal boundary and surface defect inactivation is achieved by the MeS negative ions, and non-radiative recombination is effectively restrained. The service life of an exciton of the prepared quasi-two-dimensional perovskite film is obviouslyprolonged, and three-dimensional perovskite crystal particles are obviously increased. CsMeS is added into quasi-two-dimensional metal halide perovskite precursor solution to adjust perovskite phasecompositions, so that more three-dimensional perovskite crystal particles are generated as compared with a traditional method, and the more effective energy transfer way is generated. According to themethod, mixing of perovskite crystal lattices in the used CsMeS is omitted, the crystal lattices only exist on the surfaces of the perovskite crystal lattices, crystal boundary and surface defect inactivation can be achieved by MeS negative ions in the CsMeS, and non-radiative recombination is effectively restrained.

Owner:SHANGHAI UNIV

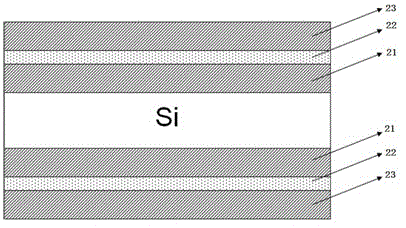

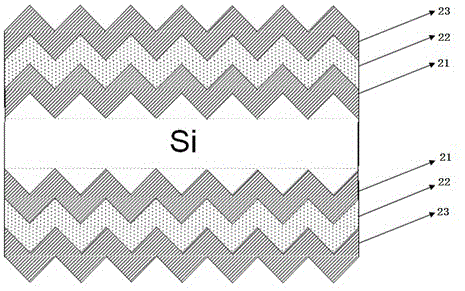

Crystalline silicon solar cell surface passivation layer having good conductive performance and passivation method

ActiveCN104992988ALow resistivityIncrease the carrier concentrationFinal product manufacturePhotovoltaic energy generationCrystallographyComposite film

The invention discloses a crystalline silicon solar cell surface passivation layer having good conductive performance. The surface passivation layer is a composite film lamination passivation layer which is disposed on the front surface and / or the back surface of a crystalline silicon solar cell and which has a dielectric-metal-dielectric structure, and the composite film lamination passivation layer comprises a first-layer medium film, a second-layer medium film and a metal film intermediate layer disposed between the first-layer medium film and the second-layer medium film. The surface passivation layer has the dielectric-metal-dielectric laminated structure and can achieve injection of current carriers into dielectrics, and the surface passivation layer has the good passivation effect and achieves a current transmission function of a surface passivation structure at the same time. The invention further discloses a method for achieving crystalline silicon solar cell surface passivation by utilizing the surface passivation layer enhancing conductivity.

Owner:江苏润阳世纪光伏科技有限公司

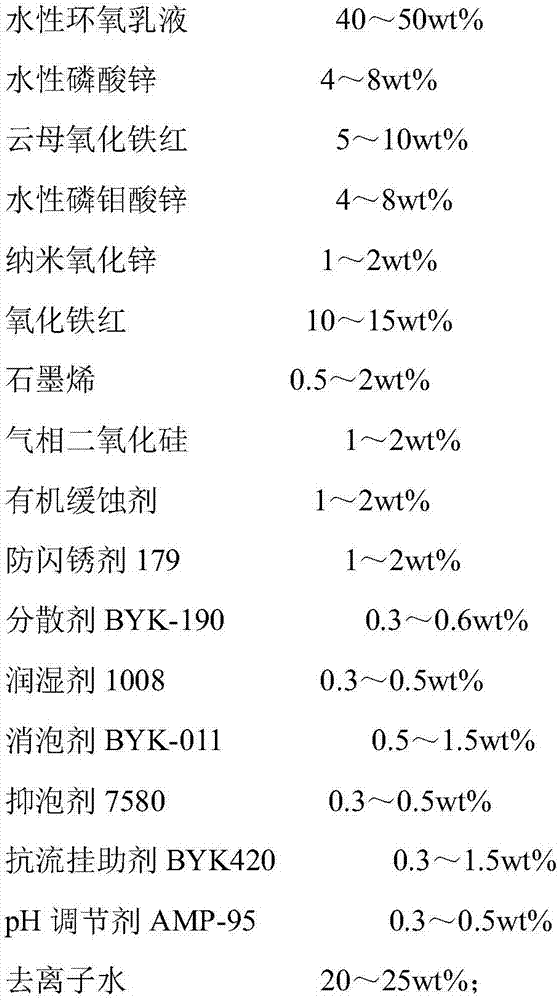

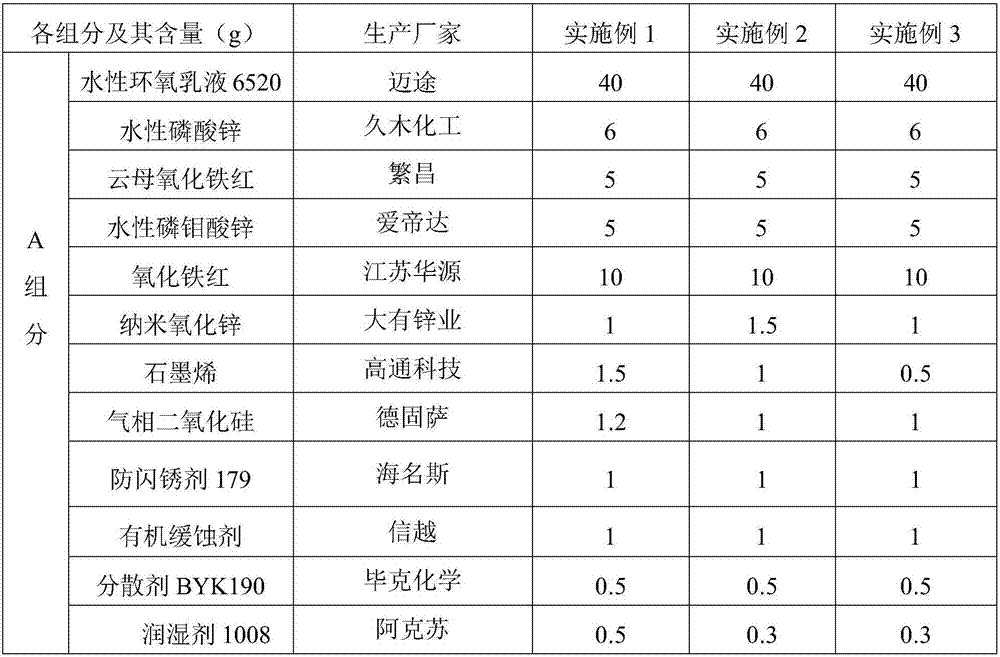

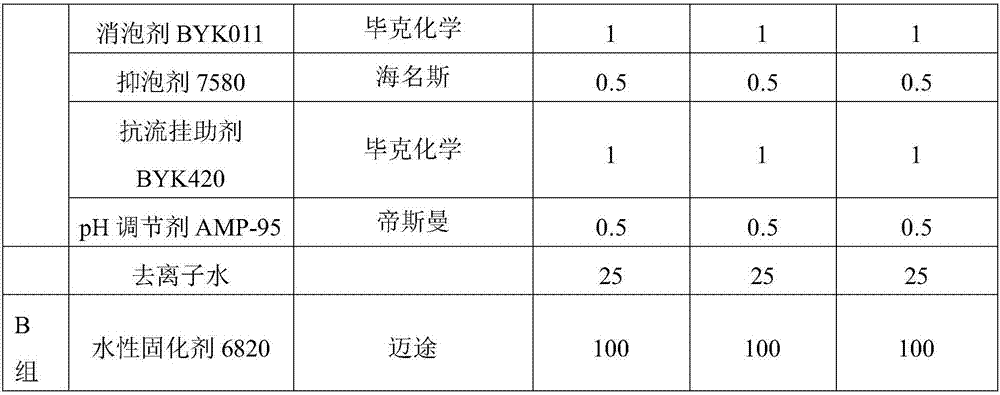

Graphene modified aqueous epoxy heavy anti-corrosion coating and detection method thereof

InactiveCN107400442AChemically stableFirm textureAnti-corrosive paintsEpoxy resin coatingsGas phaseWear resistant

The invention discloses a graphene modified aqueous epoxy heavy anti-corrosion coating which is prepared by mixing a component A and a component B in a weight ratio of 4:1, wherein the component A comprises 40-50 parts of a bisphenol A aqueous epoxy emulsion, 0.5-2 parts of graphene, 4-8 parts of aqueous zinc phosphate, 4-8 parts of aqueous zinc molybdate, 10-15 parts of iron oxide red, 1-2 parts of fumed silica, 1-2 parts of nano zinc oxide, 5-10 parts of mica iron oxide red, 1-2 parts of an organic corrosion inhibitor, 1-2 parts of a 179 anti-flash rust agent, 0.3-0.6 part of a 190 dispersant, 0.3-0.5 part of a 1008 wetting agent, 0.5-1.5 parts of a BYK-011 defoamer, 0.3-0.5 part of a 7580 foam inhibitor, 0.1-1.5 parts of a BYK420 anti-sagging auxiliary agent, 0.3-0.5 part of an AMP-95 pH regulator and some deionized water; the component B is a polyamine addition product aqueous epoxy curing agent. The coating disclosed by the invention has excellent physical property and excellent chemical resistance, in particular salt fog resistance; a film with the coating is firm and tenacious and wear-resistant, is high in adhesive force and construction adaptability and has very good environment-friendliness.

Owner:江苏纽克莱涂料有限公司

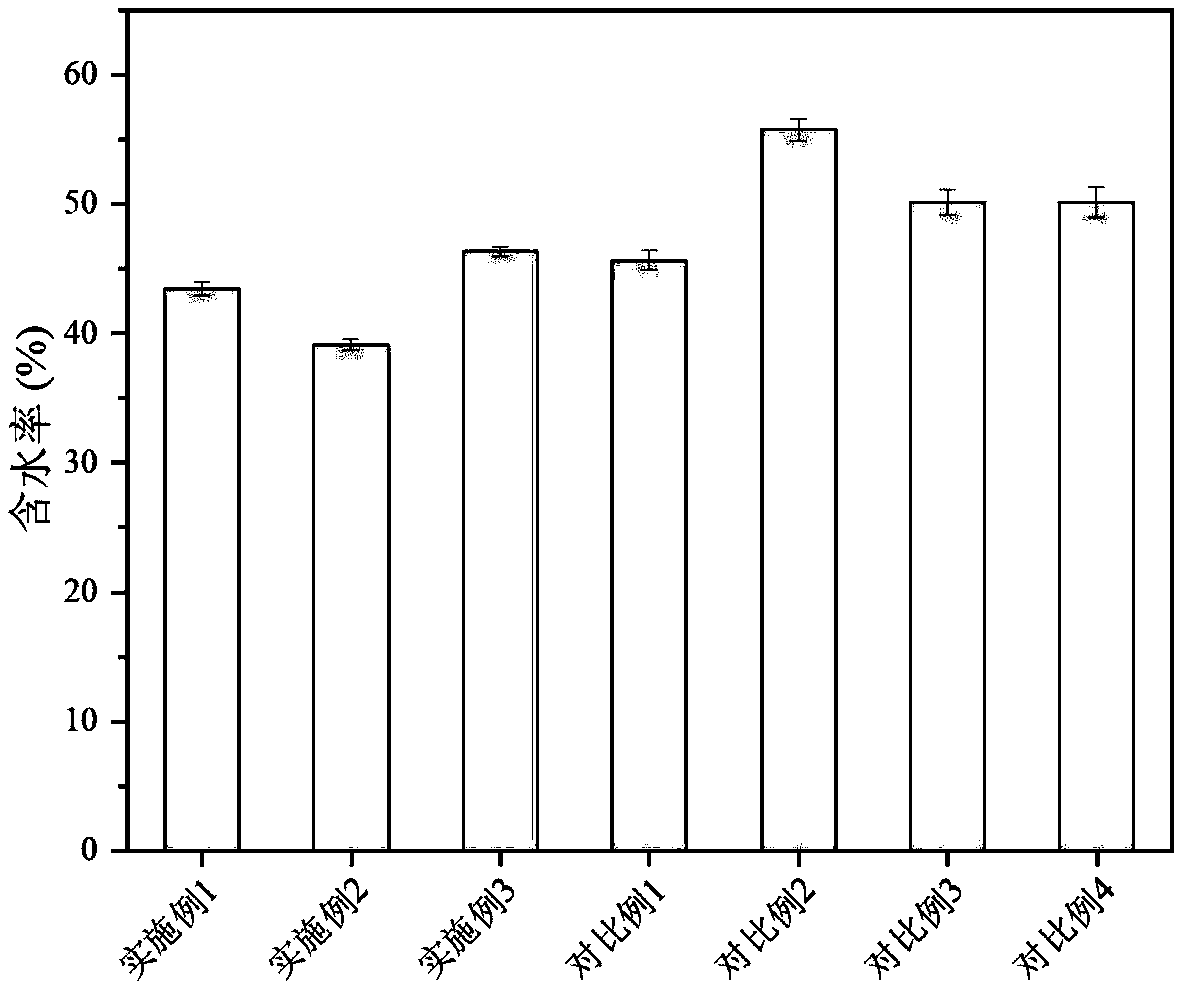

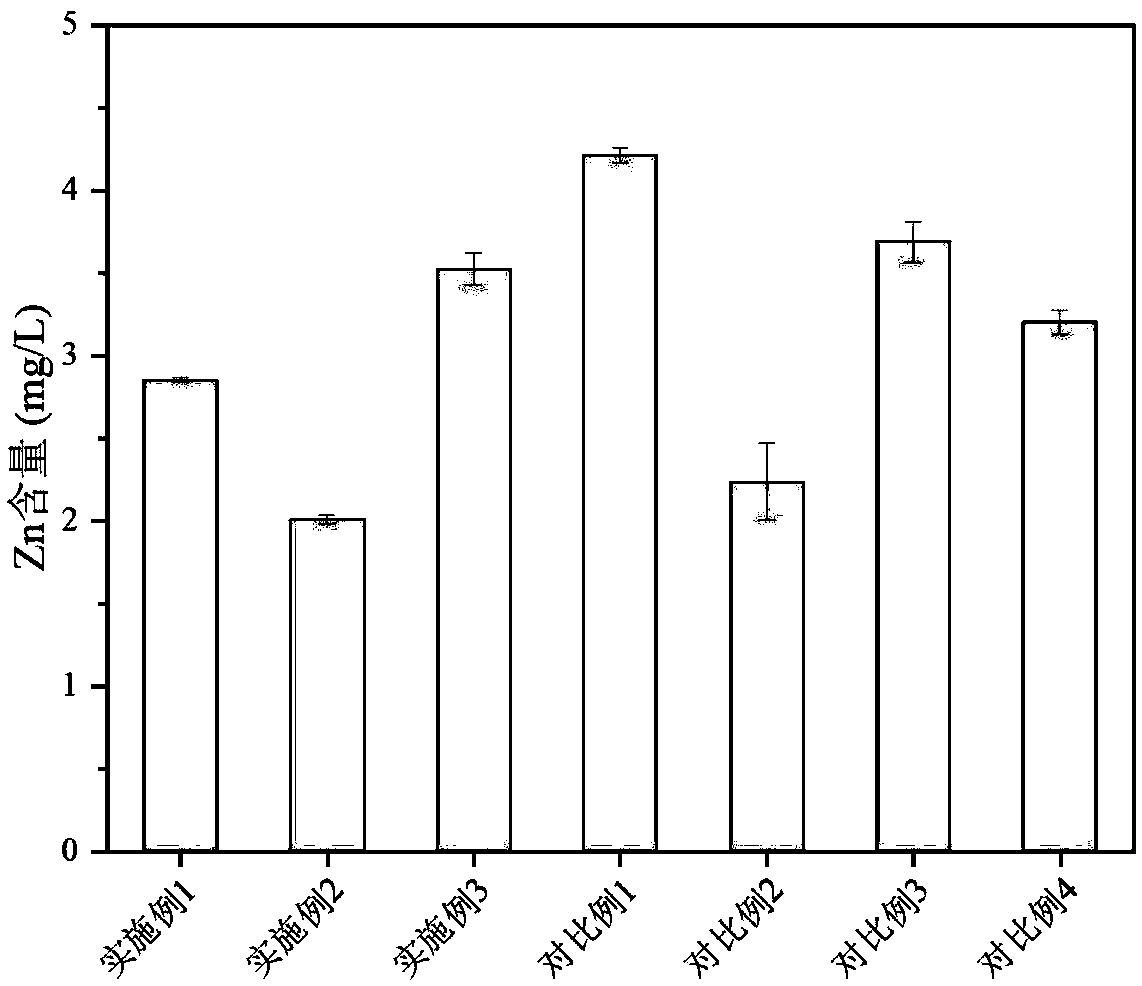

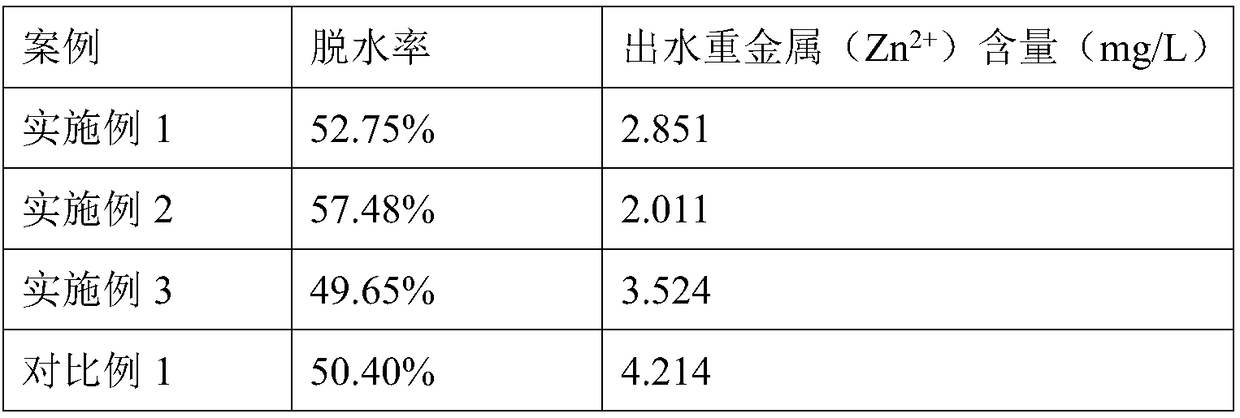

Sludge dewatering method

ActiveCN109368985AHigh degree of dehydrationImprove dehydration effectSludge treatment by de-watering/drying/thickeningReaction systemToxic industrial waste

The invention belongs to the technical field of sludge treatment, and particularly discloses a sludge dewatering method. The method comprises the following steps: performing pre-reaction on sludge anda conditioner M; adding a flocculating agent to the pre-reaction system, and performing hydrothermal reaction under the sealed condition; finally, performing solid-liquid separation to recover waterin the pre-reaction system to obtain dry sludge. The conditioner M comprises industrial waste residues and an activator. According to the method, the content of heavy metals in water removed from thesludge is lower, and harmless treatment and reduction of the sludge are achieved.

Owner:肇庆市珈旺环境技术研究院

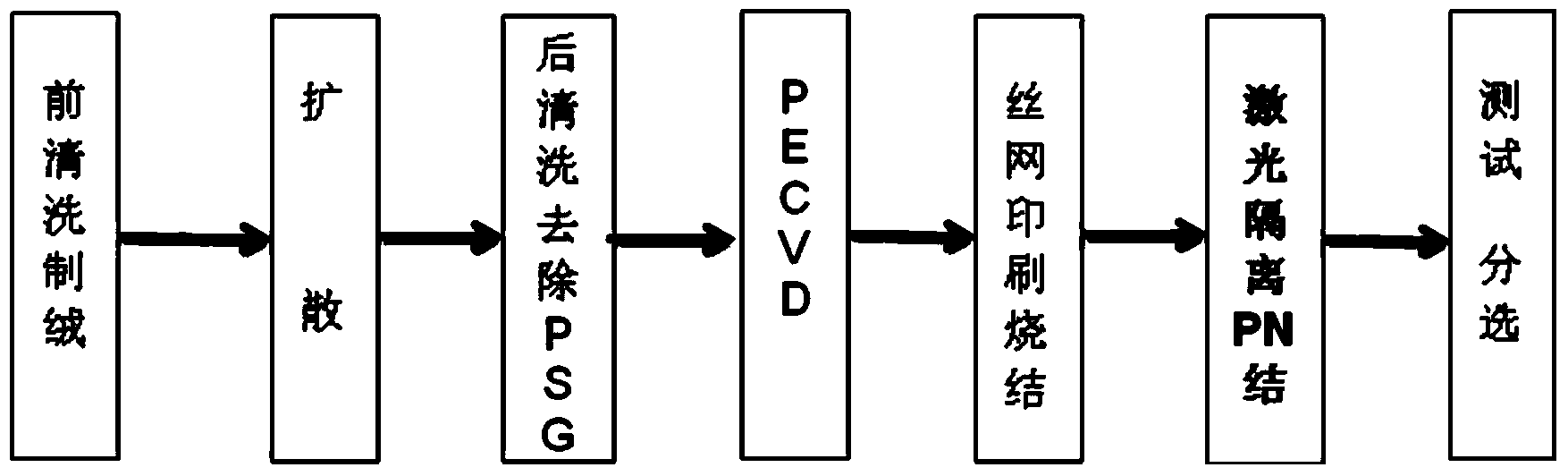

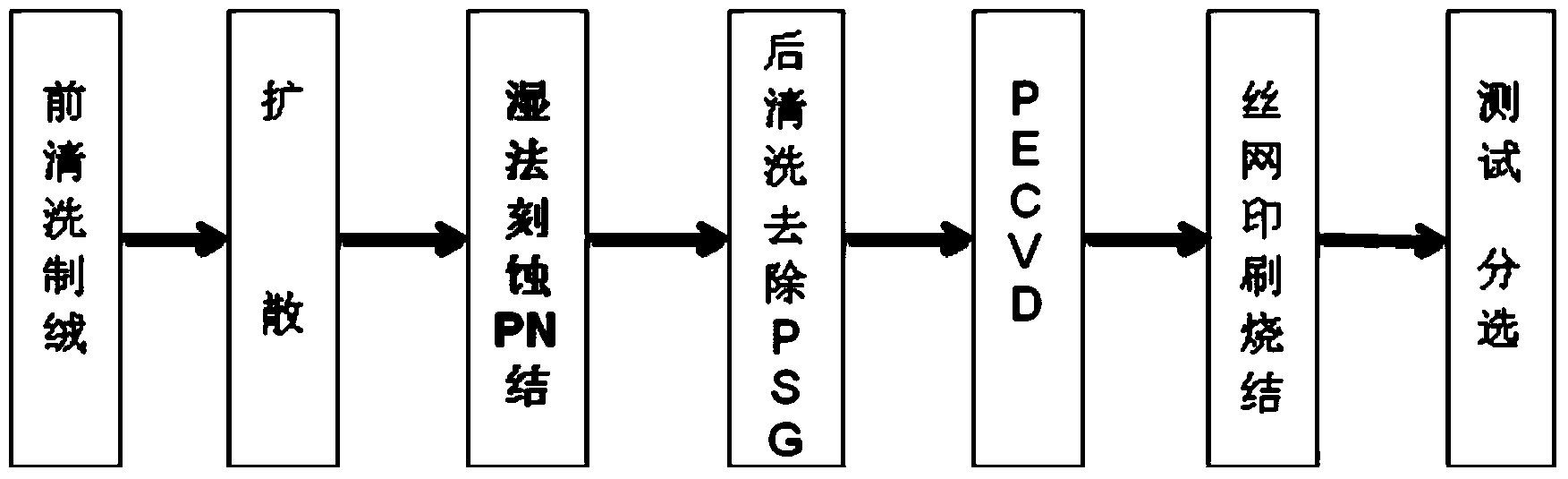

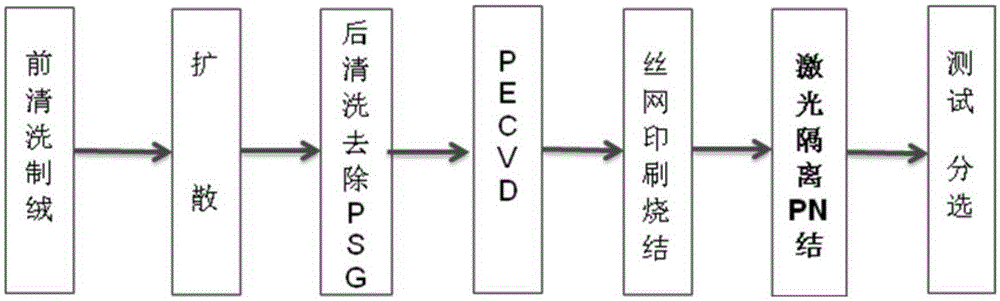

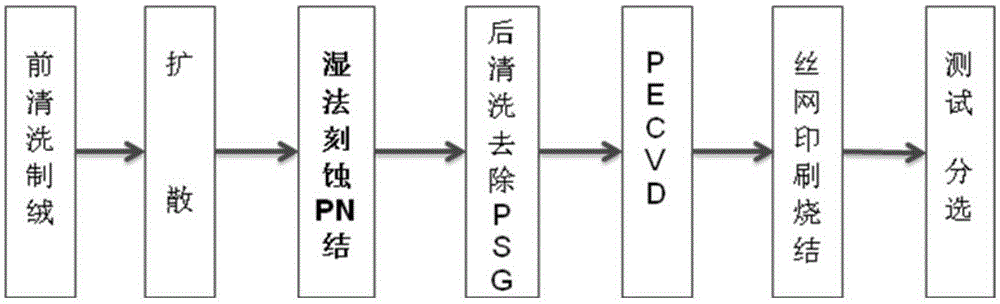

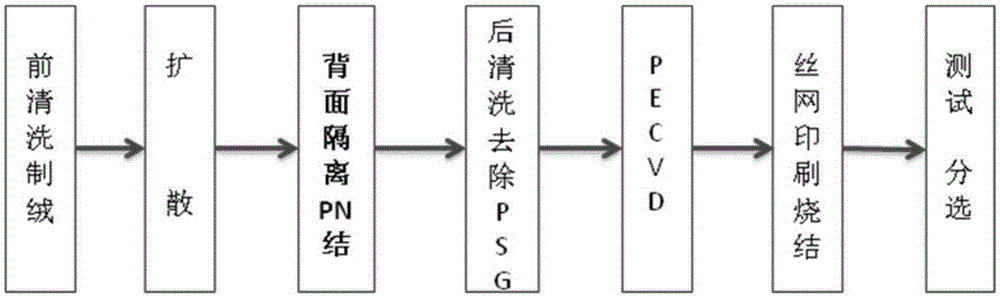

Laser PN isolation process for back surface field of solar cell

ActiveCN103400905AAchieve circuit breakMeet electrical performance parametersFinal product manufactureSemiconductor devicesScreen printingLaser etching

The invention discloses a laser PN isolation process for a back surface field of a solar cell. The process comprises steps as follows: front cleaning and texturing, diffusion, PN isolation, post cleaning, silicon nitride deposition with a plasma enhanced chemical vapor deposition method, screen printing and sintering, and testing and sorting, wherein the PN isolation adopts laser etching and specifically comprises steps as follows: edge slotting is performed on the back surface of the solar cell with a fiber laser at a line scribing speed of 100-120 mm / s by surrounding the surface of the back surface of a silicon wafer, the distance between a slotting edge and the silicon wafer edge is 0.5mm, and the slotting depth is 10-15 mu m, so that PN isolation is realized. According to the process, a traditional wet etching process is replaced with laser isolation, and a traditional laser etching process is improved, so that the process requirement of removing an edge PN junction during the production process of solar cells can be met.

Owner:REALFORCE POWER

Process of carrying out low-temperature chemical cleaning passivation on thermal power plant boiler by utilizing EDTA (Ethylene Diamine Tetraacetic Acid)

InactiveCN102425778AIncrease pHAdjust pH valueBoiler cleaning apparatusMetallic material coating processesEthylene diamineEngineering

The invention relates to a low-temperature chemical cleaning method for a thermal power plant boiler and in particular relate to a process of carrying out low-temperature chemical cleaning passivation by utilizing EDTA (Ethylene Diamine Tetraacetic Acid). The process comprises the following steps: A. connecting a chemical cleaning platform with a system which needs to be cleaned to form a cleaning system, and flushing with circulating water after the connected cleaning system is subjected to a hydraulic test until effluent is transparent and is free from impurities; B. heating the cleaning system cyclically; C. carrying out alkali wash, and flushing; washing by use of EDTA; and passivating. The process has the following characteristics: energy is saved, the consumption is reduced, the cleaning period is shortened, the cleaning cost is reduced, and the boiler can be cleaned and passivated in one step. After the thermal power plant boiler is cleaned by the EDTA at low temperature, a passivation process is added. An alkali substance is added into EDTA cleanout fluid to regulate the pH value of the EDTA cleanout fluid so as to passivate the cleaned boiler. The cleaning process disclosed by the invention is suitable for boilers of various specifications and is beneficial to implementation and popularization on site.

Owner:NINGXIA ELECTRIC POWER RES INST

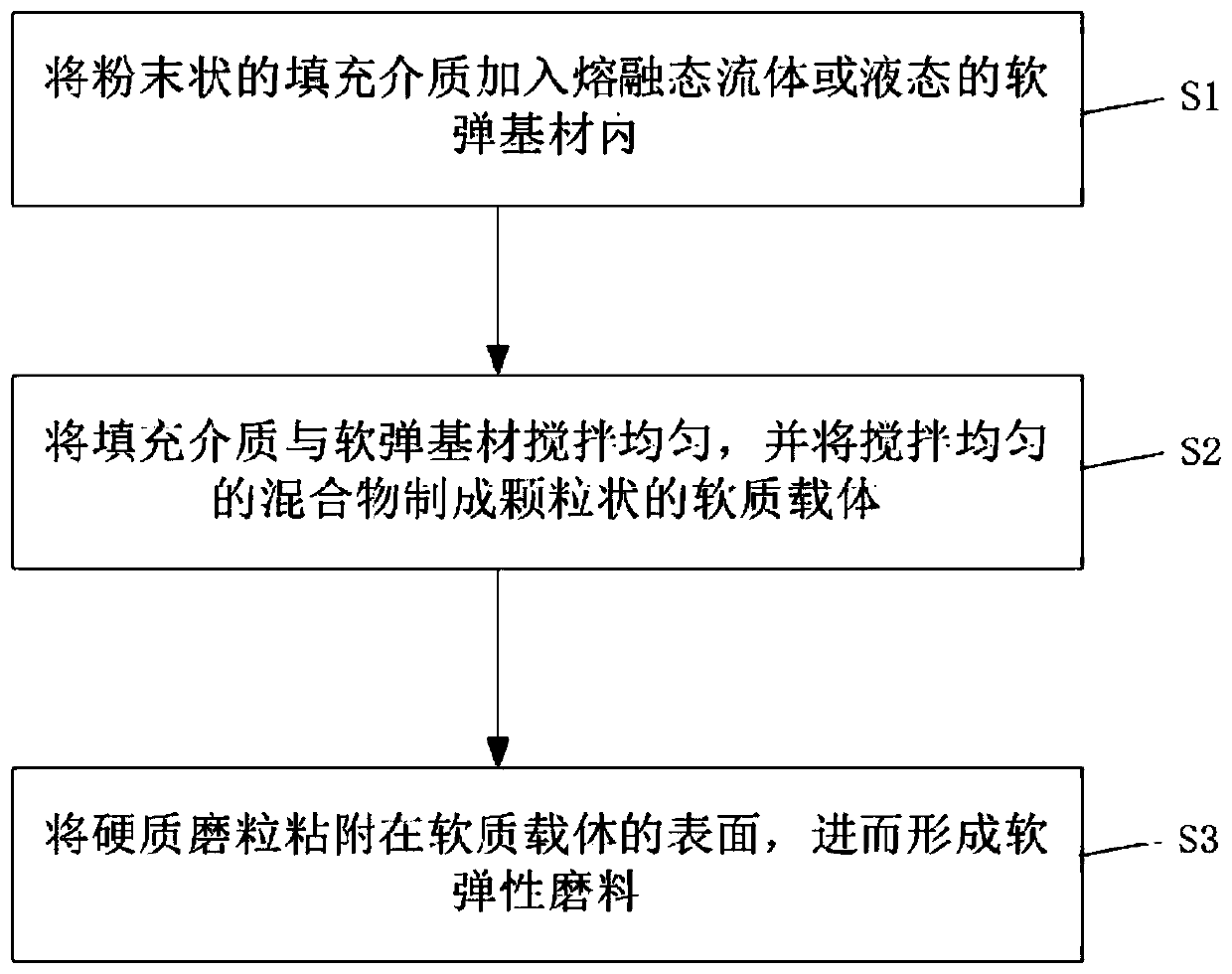

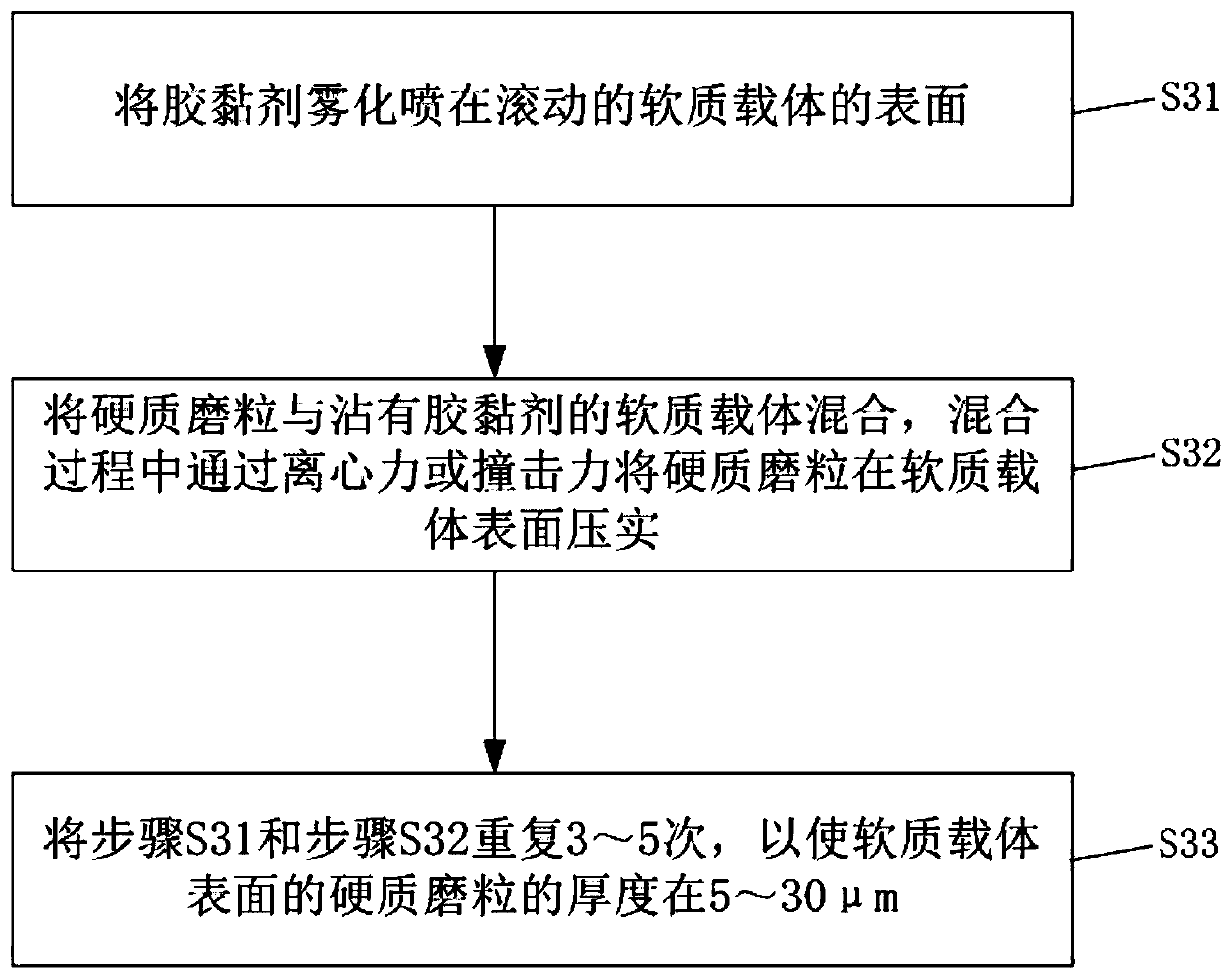

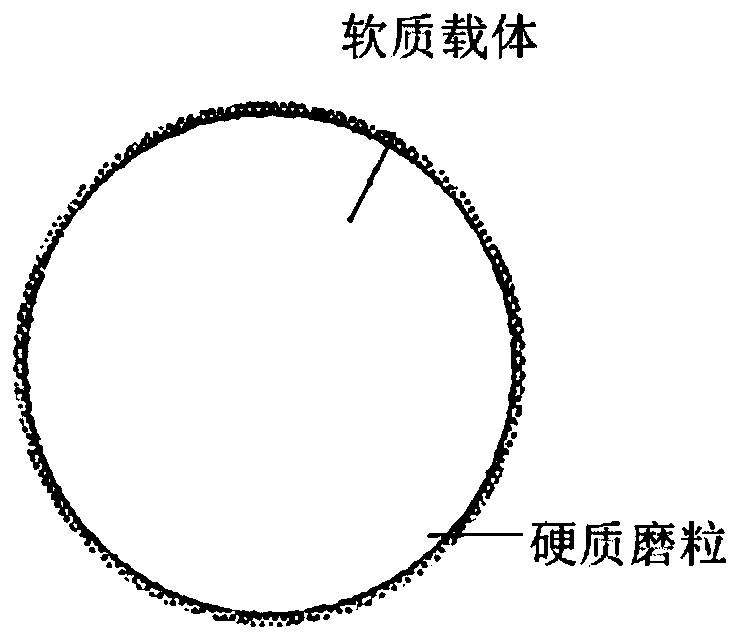

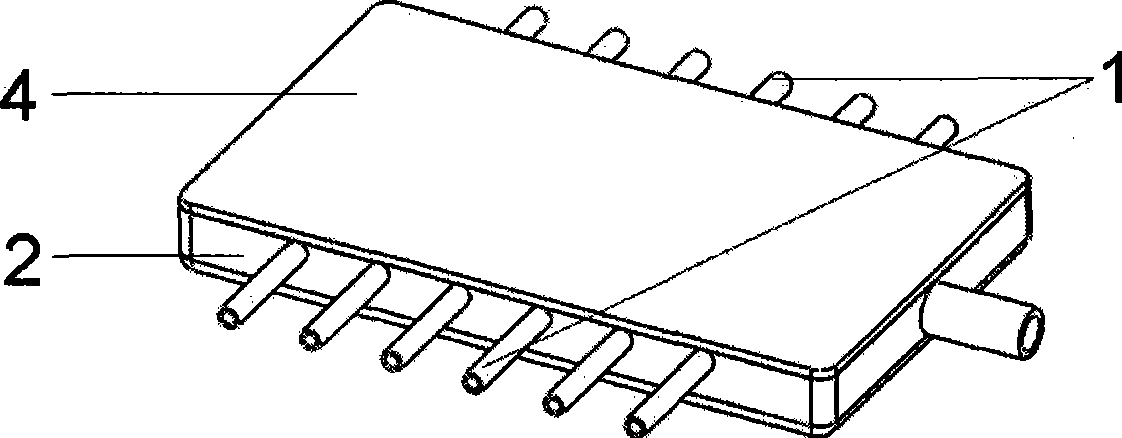

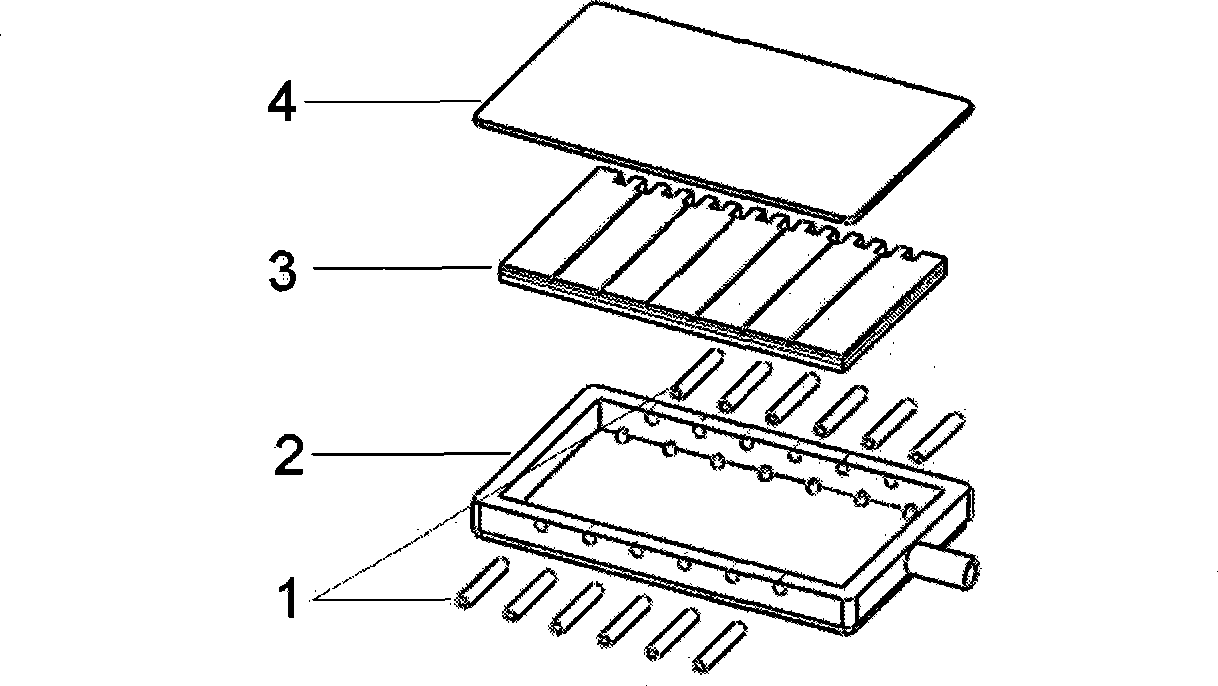

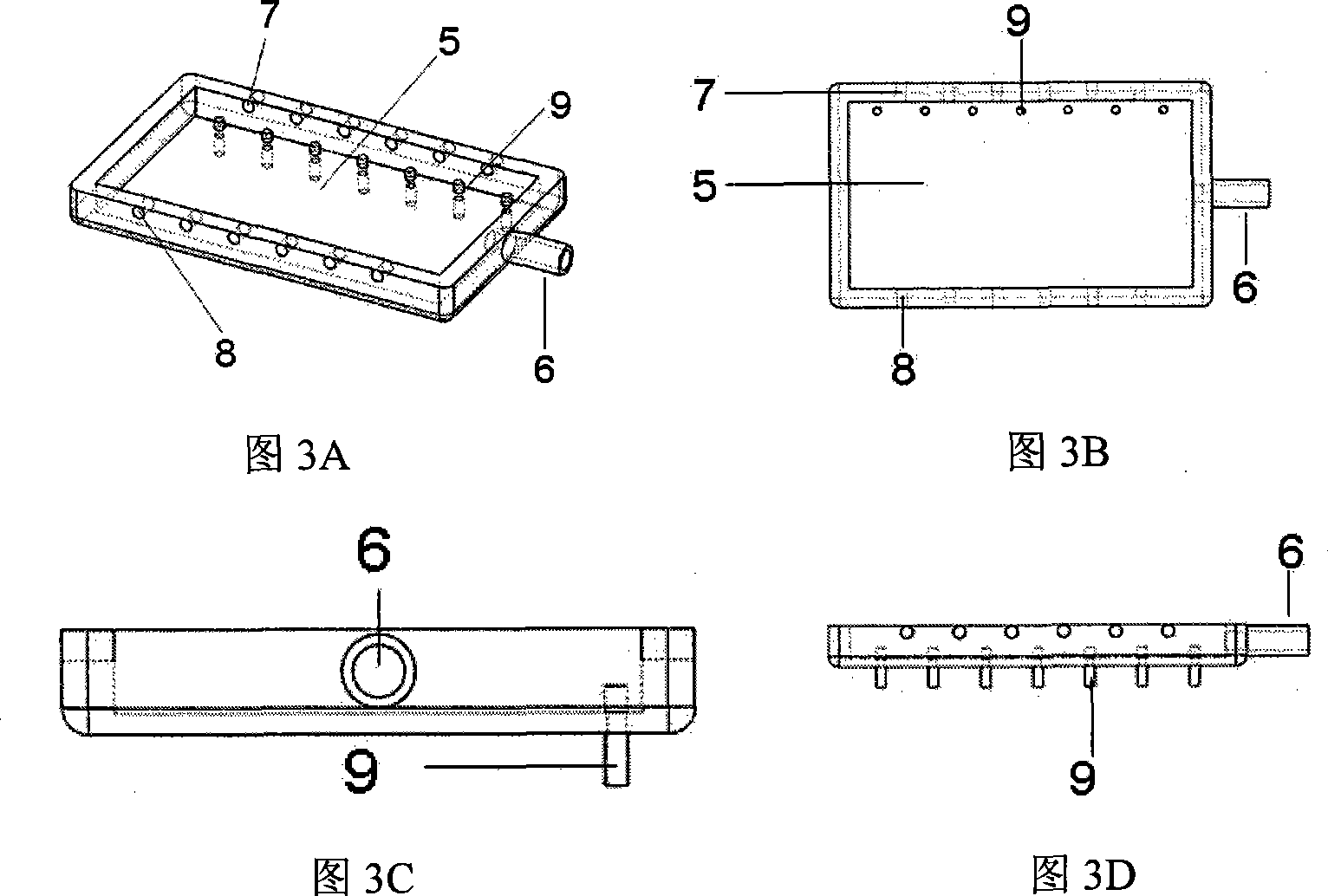

Method for manufacturing soft elastic abrasive, cutting tool and treatment method for mold

ActiveCN110387213AAchieve passivationMaximum scratch depthOther chemical processesAbrasion apparatusLiquid stateElastic substrate

The invention discloses a method for manufacturing a soft elastic abrasive. The method comprises: adding a powdery filling medium into a molten fluid or a liquid soft elastic substrate, wherein the filling medium has a particle size of 50 [mu]m or below and a density of 3.5 g / cm<3> or above, and the soft elastic substrate has a Shore hardness of 60HA or below; uniformly mixing the filling medium with the soft elastic substrate under stirring, and preparing a granular soft carrier from the uniformly mixed mixture, wherein the soft carrier has a particle size of 0.05-5 mm and a density of 2.0 g / cm<3> or above; and adhering hard abrasive grains onto the surface of the soft carrier to form the soft elastic abrasive, wherein the size of the hard abrasive grains is in a range of 0.25-10 [mu]m. The invention also discloses a cutting tool and a treatment method for a mold. The soft elastic abrasive of the invention can simultaneous realize passivation and polishing of a surface to be treated;and the soft elastic abrasive of the invention is reduced in requirements on ejection during surface treatment.

Owner:深圳市鑫意晟科技有限公司

Continuous flow cell electric amalgamation chip based on silicon structure on insulator

InactiveCN101368155AImprove uniformityImprove electrical performanceStress based microorganism growth stimulationPhysicsSilicon electrode

The invention discloses a cell-electrofusion chip of continuous flow based on silicone structure of an insulator and a processing technology thereof. The cell-electrofusion chip comprises a shell, a microelectrode array chip fixed in the shell, a sample input and output pipe communicating with the inside and the outside of the shell, and a silicone glass sheet encapsulated on the surface of the shell. The microelectrode array chip consists of a siliceous basal layer, a silicon dioxide insulating layer, a low-resistivity silicon electrode layer and a silicon dioxide protective film in turn from down to up. Using the micro machining technology, a groove is etched on the low-resistivity silicon electrode layer of silicon materials on the insulator till the silicon dioxide insulating layer forms a microelectrode structure. In virtue of microscale and arrangement of microchannel, external electric signals forms gradient field with sufficient intensity and increases cell-electrofusion efficiency. At the same time, a linear type microchannel constructed on the chip contributes for the flow of cell suspension and reduces cell adhesion in flow movement as low as possible. The development of the cell-electrofusion experiment of continuous flow can approximate to provide fusion cells with unlimited quantity.

Owner:CHONGQING UNIV

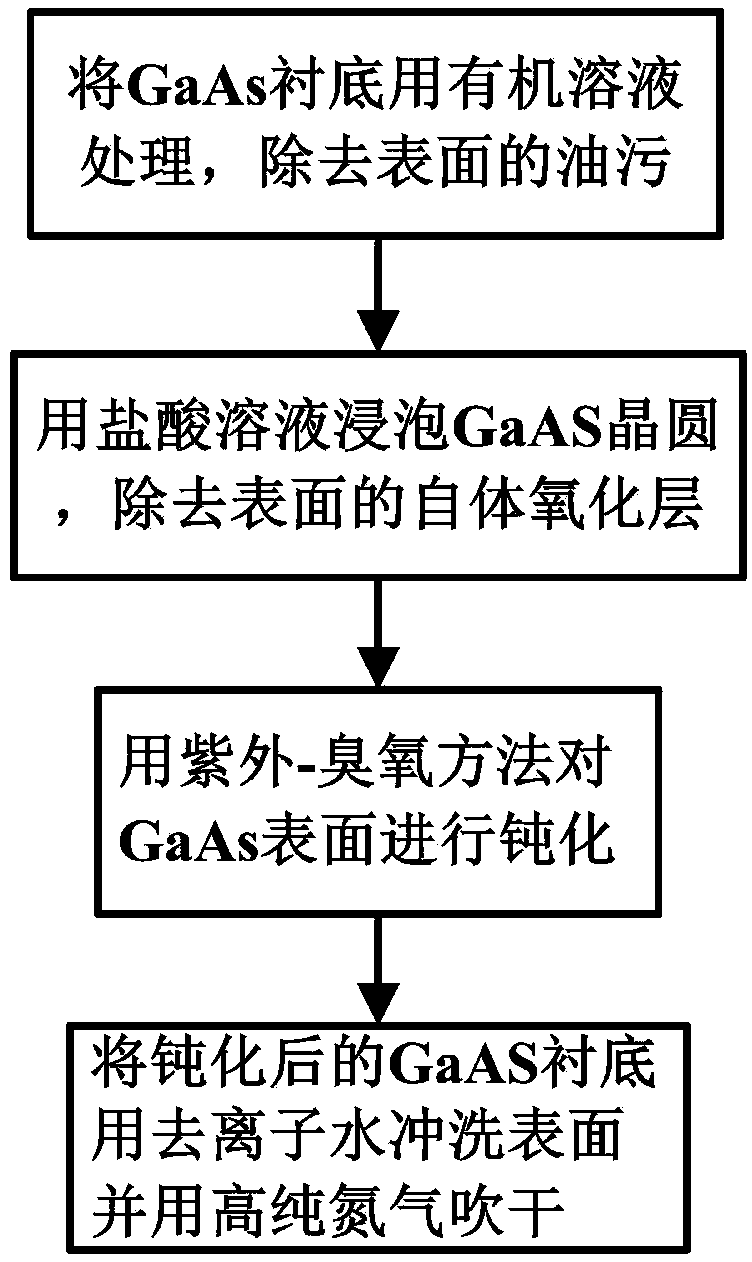

Method for cleaning passivated GaAs wafer surface

InactiveCN104392898AAchieve passivationAvoid n-type contaminationSemiconductor/solid-state device manufacturingSurface oxidationNitrogen

The invention relates to a method for cleaning a passivated GaAs wafer surface. According to the method, A GaAs wafer is processed by an organic solution to remove the surface oil contamination; a GaAs substrate is soaked by a hydrochloric acid solution to remove a surface oxidation layer; the GaAs surface is passivated by using an ultraviolet-ozone method; and deionized water is used for washing the surface of the passivated GaAs substrate and drying is carried out by using high-purity nitrogen. Therefore, the surface oxide of the processed wafer is closed to the surface characteristic of the wafer before processing; and the power characteristic, the gain characteristic, and especially the voltage withstanding characteristic of the device after passivation are substantially improved.

Owner:BEIJING UNIV OF TECH

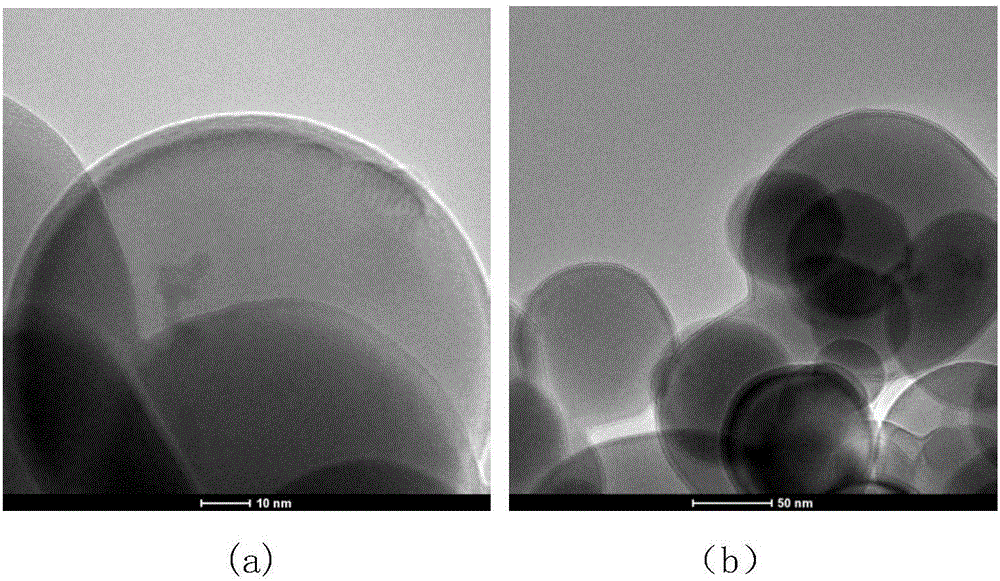

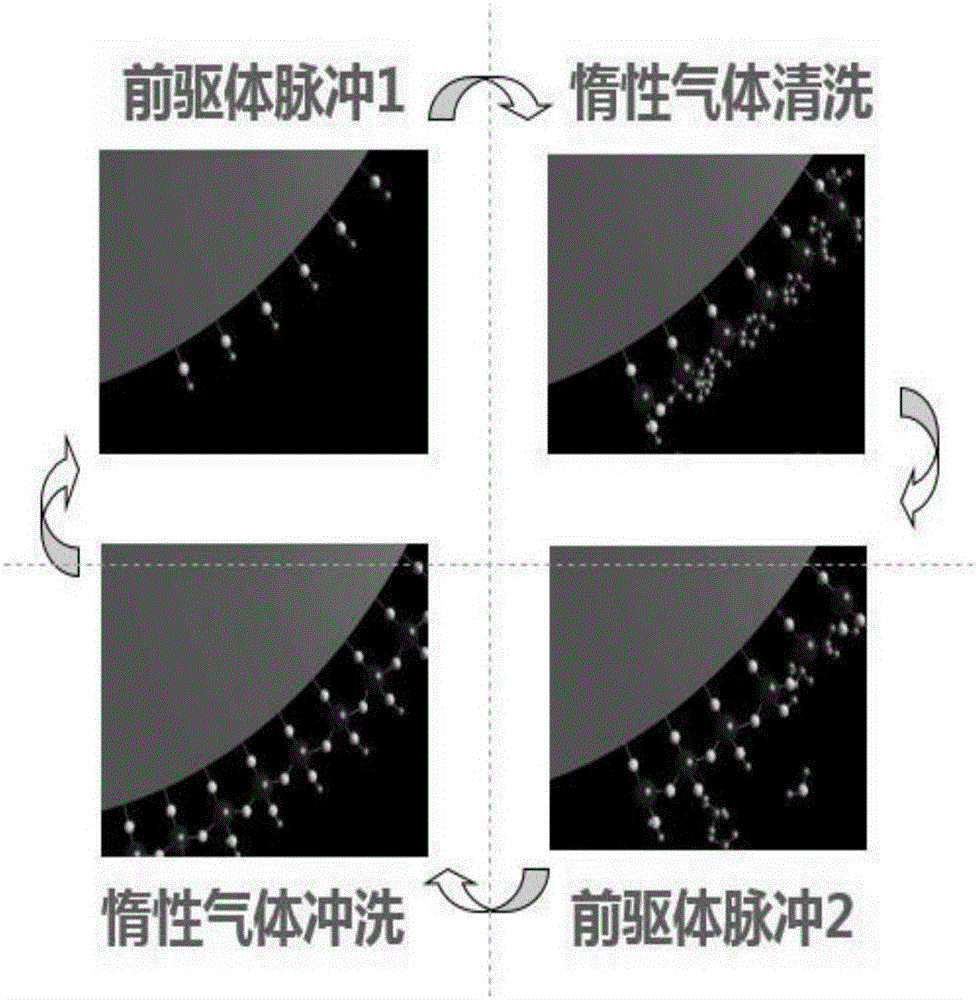

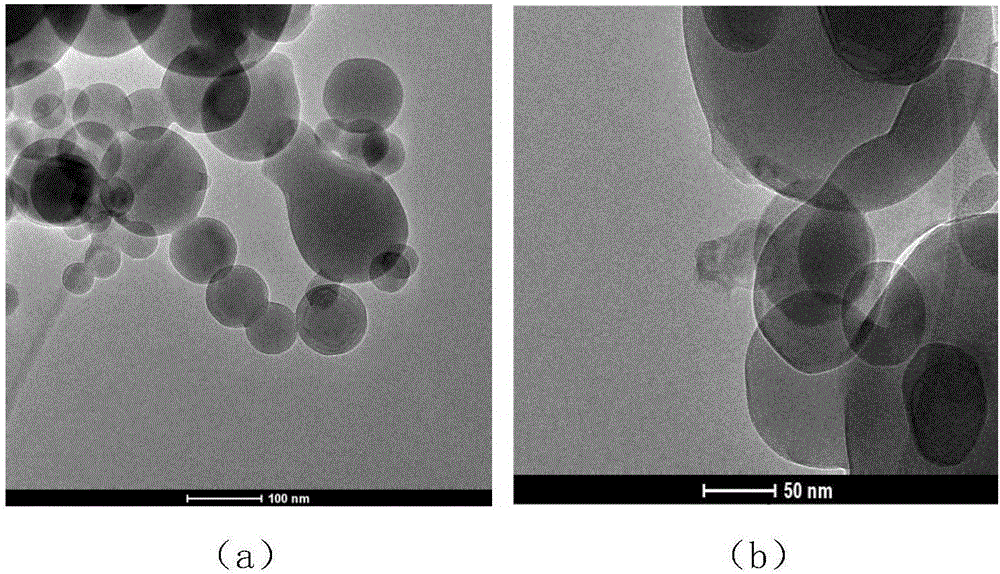

Method for achieving aluminum powder passivation by wrapping aluminum powder with zirconium oxide

ActiveCN106498365AAddress reactivitySolve the problem of changing its own chemical propertiesChemical vapor deposition coatingVacuum pumpingAluminium powder

The invention discloses a method for achieving aluminum powder passivation by wrapping aluminum powder with zirconium oxide. The method comprises the following steps that firstly, the aluminum powder needing to be wrapped is placed in a powder clamping device with the bottom provided with a filter net, and then the powder clamping device is placed in a cavity of an atom layer deposition reactor to be subjected to vacuum pumping; secondly, the cavity is heated, the cavity is constantly inflated with fluidization gas in the heating process, and the aluminum powder is pre-scattered; thirdly, when the cavity temperature reaches the preset temperature, the atom layer deposition reaction is started, and a layer of zirconium oxide film is deposited on the surface of the aluminum powder; and fourthly, the third step is repeatedly conducted, multiple layers of zirconium oxide films are deposited on the surface of the aluminum powder, and aluminum powder passivation is achieved. According to the method, the atom deposition technology is used for wrapping the surfaces of aluminum powder particles with a layer of zirconium oxide film with the nanometer thickness, aluminum powder passivation is achieved, and the beneficial effects that operation is convenient, and the technology is simple are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

Metal anticorrosive paint

ActiveCN103436141AGood waterproof and corrosion resistanceAchieve passivationAnti-corrosive paintsPolyether coatingsChemistryHeavy metals

The invention discloses a metal anticorrosive paint which is prepared by stirring the following raw materials in parts by weight: 100-110 parts of epoxy resin, 20-30 parts of benzoic acid resin, 10-15 parts of diphenyl ether resin, 15-18 parts of dimethylbenzene, 15-25 parts of cerium oxide, 6-10 parts of n-butanol, 8-12 parts of polybenzimidazole, 10-12 parts of KH-550, 10-15 parts of talcum powder, 3-8 parts of dimethylethanolamine, 6-10 parts of barium dinonylnaphthalene sulfonate and 50-60 parts of water. The commercial test proves that the prepared paint has the advantages of excellent water resistance and excellent corrosion resistance, can implement passivation and corrosion inhibition of the metal substrate, avoids using chrome and other heavy metals possibly causing environmental pollution, is simple to prepare and low in cost, and can be easily put into industrial production.

Owner:江苏悠谷未来科技有限公司

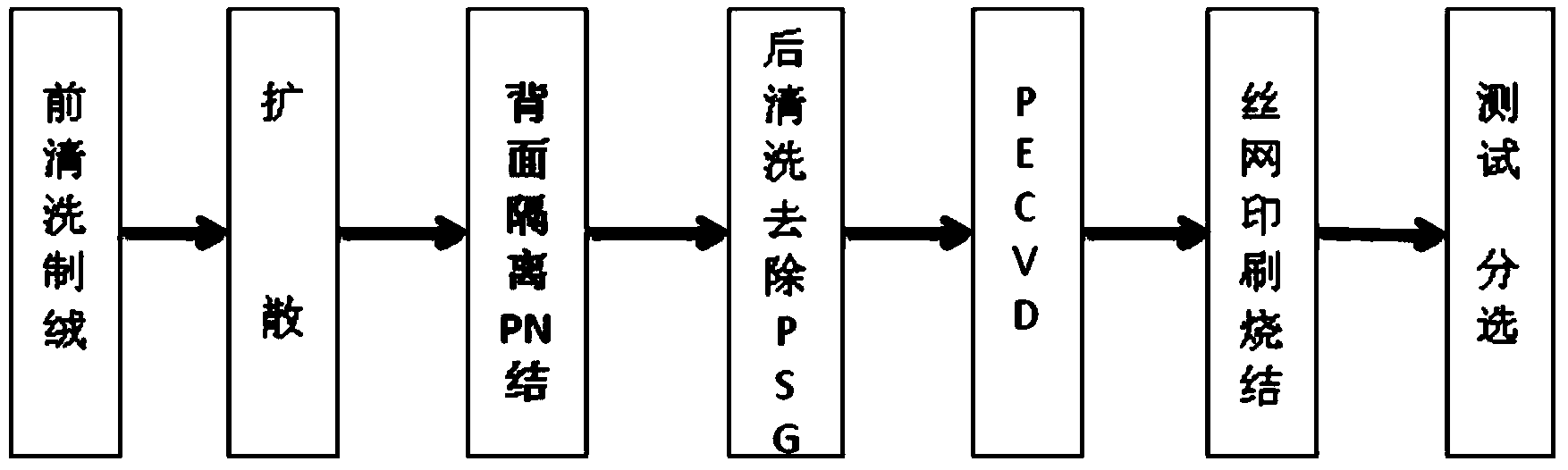

Solar cell back field laser pn isolation process

ActiveCN103400905BIncrease the generating areaBoost short currentFinal product manufactureSemiconductor devicesLaser etchingScreen printing

The invention discloses a laser PN isolation process for a back surface field of a solar cell. The process comprises steps as follows: front cleaning and texturing, diffusion, PN isolation, post cleaning, silicon nitride deposition with a plasma enhanced chemical vapor deposition method, screen printing and sintering, and testing and sorting, wherein the PN isolation adopts laser etching and specifically comprises steps as follows: edge slotting is performed on the back surface of the solar cell with a fiber laser at a line scribing speed of 100-120 mm / s by surrounding the surface of the back surface of a silicon wafer, the distance between a slotting edge and the silicon wafer edge is 0.5mm, and the slotting depth is 10-15 mu m, so that PN isolation is realized. According to the process, a traditional wet etching process is replaced with laser isolation, and a traditional laser etching process is improved, so that the process requirement of removing an edge PN junction during the production process of solar cells can be met.

Owner:微山县顺扬贸易有限公司

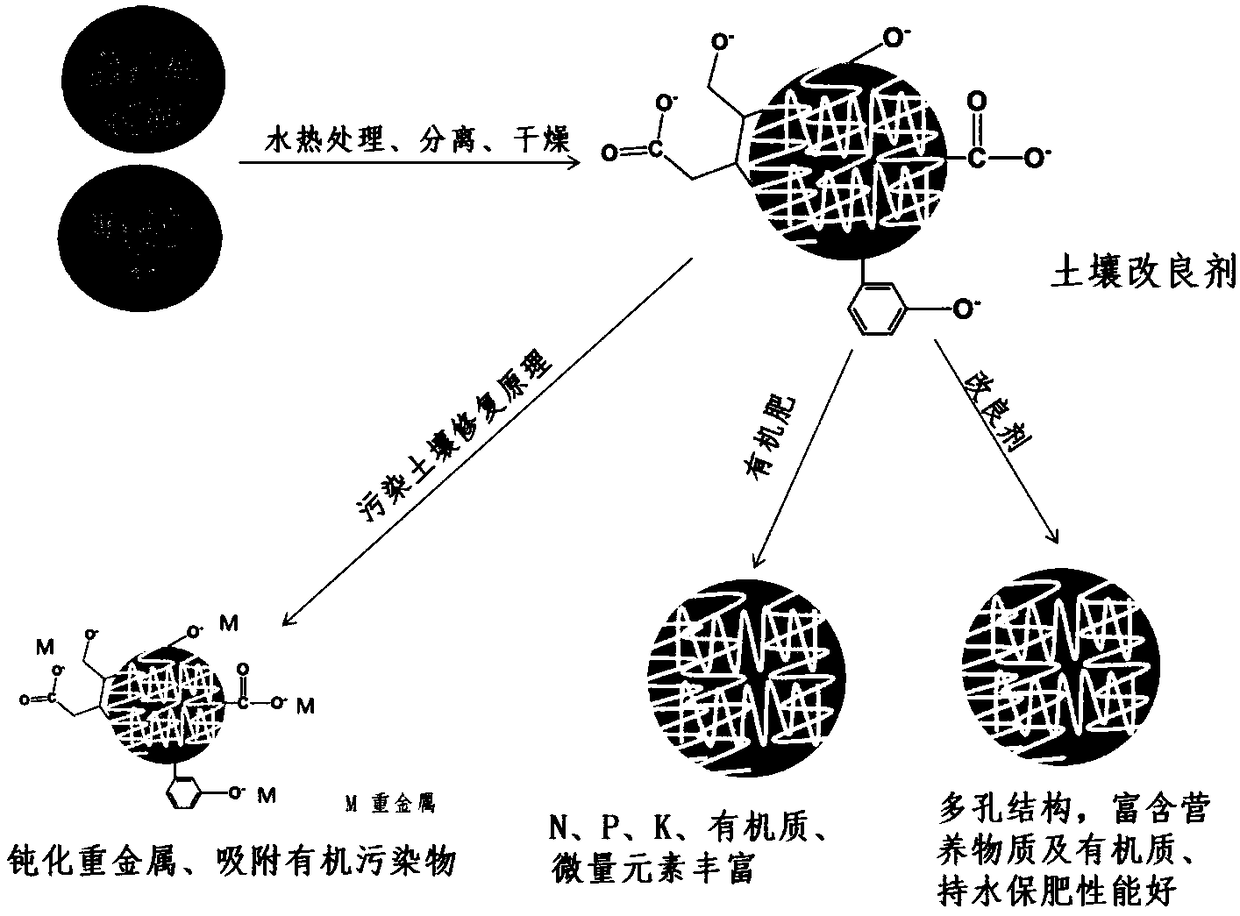

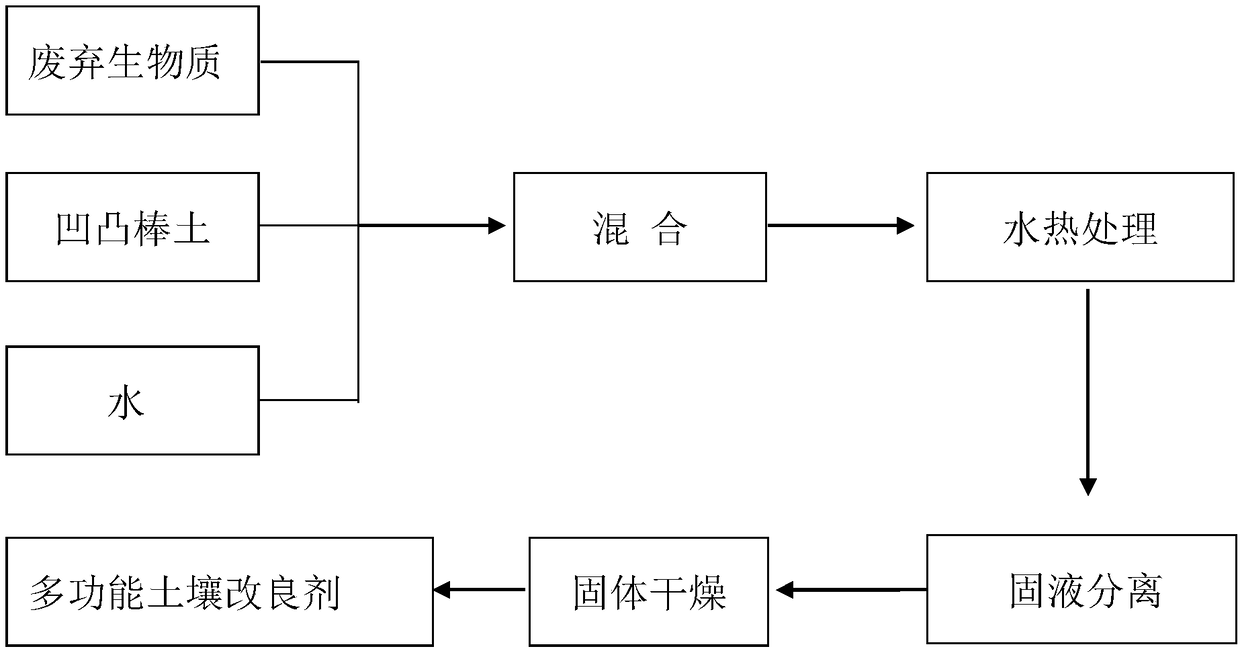

Preparation method and use of multifunctional soil improving agent

InactiveCN108752133AImprove water and fertilizer retention capacityImprove passivation effectExcrement fertilisersAgriculture gas emission reductionBiologyPollution

The high-strength utilization mode of the land in China accelerates the deterioration of a soil function, and soil pollution is very serious due to excessive application of chemical fertilizer and agricultural products. The crop yield declining and food safety incidents caused by soil degradation and soil pollution take place frequently and cause serious threats to people's health. The developmentof an eco-friendly, cheap and high-efficiency soil conditioner for improving soil fertility and reducing soil pollution is extremely urgent. The invention discloses a preparation method of a multifunctional soil improving agent. The preparation method comprises mixing waste biomass and a certain amount of attapulgite and modifying the mixture under specific conditions to obtain the multifunctional soil improving agent. The preparation method has simple processes. The multifunctional soil improving agent is renewable and eco-friendly, realizes a low cost, is rich in nutrients such as trace elements necessary for crop growth and can be used as organic fertilizer and a contaminated soil repairing agent.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com