Crystalline silicon solar cell surface passivation layer having good conductive performance and passivation method

A technology of solar cells and electrical conductivity, applied in the field of solar cells, can solve the problems of large series resistance of batteries, affect short-circuit current and fill factor, weaken the protective effect of passivation film, etc., and achieve good ductility and stress fatigue resistance. Effect of increasing mechanical stress and tensile strength, enhancing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The general implementation steps of the inventive method are:

[0033] (1) Select silicon wafers, after chemical polishing or acid-base texturing treatment, use RCA cleaning steps to clean the surface of silicon wafers to remove pollution such as metal ions, organic matter and particulate matter, and finally use hydrofluoric acid to remove the surface of silicon wafers the oxide layer;

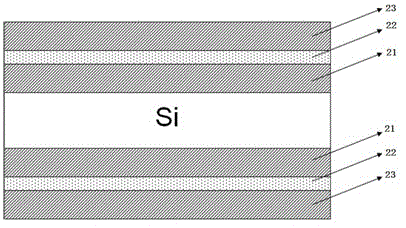

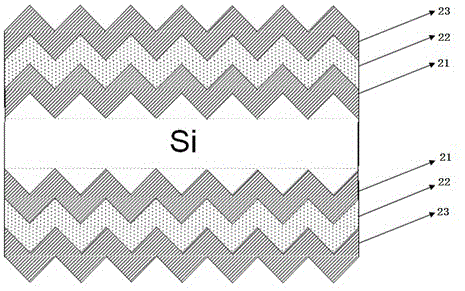

[0034](2) Prepare a composite thin film laminated passivation layer with a dielectric-metal-dielectric structure on the front and rear surfaces respectively. First, prepare a first layer of dielectric film 21 with a thickness of 1 nm to 800 nm. The materials of the dielectric layer include silicon dioxide, trioxide One or more of aluminum, silicon nitride, silicon oxynitride, and hydrogenated amorphous silicon, and then prepare a metal thin film intermediate layer with a thickness ranging from 1 nm to 400 nm by means of evaporation, sputtering, spin coating, and printing 22 , the metal...

Embodiment 2

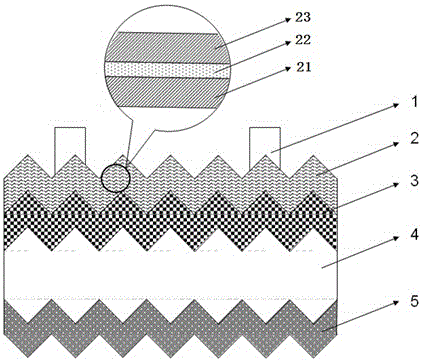

[0036] (1) Select crystalline silicon 4, crystalline silicon 4 can be p-type or n-type silicon wafers, and silicon wafers can be single crystal silicon, polycrystalline silicon or microcrystalline silicon, which are cleaned and textured in sequence to form p-n by high-temperature diffusion Junction 3, use plasma etching to remove the edge after removing the back junction;

[0037] (2) Prepare a composite thin-film laminated passivation layer 2 with a dielectric-metal-dielectric structure on the front surface. First, prepare a first layer of dielectric film 21 with a thickness of 1 nm to 800 nm. The dielectric layer material includes silicon dioxide, dioxide One or more of aluminum, silicon nitride, silicon oxynitride, and hydrogenated amorphous silicon, and then prepare a metal thin film intermediate layer with a thickness ranging from 1 nm to 400 nm by means of evaporation, sputtering, spin coating, and printing 22 , the metal here includes one or more of gold, silver, copper...

Embodiment 3

[0040] (1) Select crystalline silicon 4, which is a p-type silicon wafer with a resistivity of 1~3 Ω·cm, use 20%wt NaOH solution to polish at 80°C for 10 minutes, and then use alkaline solution to make texture to obtain a pyramid structure Finally, use RCA to clean and remove metal ions, organic matter, and particle pollutants on the surface, then use hydrofluoric acid to remove the surface oxide layer, put the silicon wafer into a tubular diffusion furnace and use phosphorus oxychloride for high-temperature diffusion at 850 ° C to form p-n Junction 3, the silicon wafer is de-junctioned after diffusion;

[0041] (2) On the front surface of the p-n junction solar cell, the ordinary SiN with a thickness of 80 nm and a refractive index of 2.1 was prepared by PECVD x : H thin film 6 is used as anti-reflection and passivation film, prepares the composite thin film lamination passivation layer 2 with dielectric-metal-dielectric structure on the rear surface of solar cell, prepares 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com