Method for preparing high-uniformity Nb-doped TiO2 transparent conducting thin film through atomic layer deposition

A technology of transparent conductive thin film and atomic layer deposition, which is applied in the direction of coating, metal material coating process, gaseous chemical plating, etc. Process parameters are easy to control, reduce experimental conditions and energy consumption, and achieve high uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

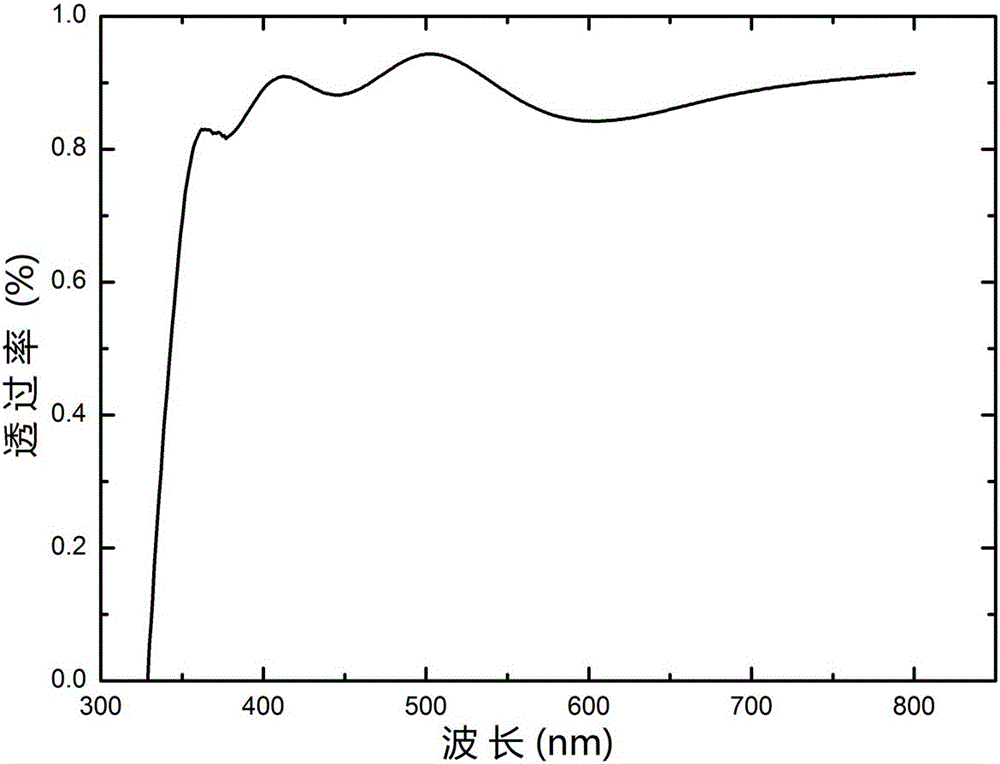

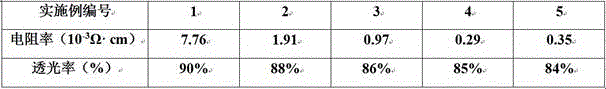

[0024] Load titanium tetrachloride, niobium tris(ethylmethylamino) tert-butyramide and high-purity water source on the machine, set the temperature of niobium tris(ethylmethylamino) tert-butyramide to 55°C; when the deposition chamber After heating to 200°C, place the glass substrate after ultrasonic cleaning with alcohol, acetone and deionized water in the deposition chamber; after vacuuming to 15hPa, perform TiO 2 cycle; that is, titanium tetrachloride / nitrogen / water / nitrogen = (0.4s / 6s / 0.2s / 4s); after 49 cycles, a niobium doping cycle is performed, that is, titanium tetrachloride / nitrogen / tri(B Base methyl amino) niobium tert-butyramide / nitrogen / water / nitrogen = (0.4s / 6s / 0.6s / 8s / 0.2s / 4s); the deposition is combined into a set of cycles, and this set of cycles is carried out for 40 groups; end Finally, the sample was taken out to make a Nb-doped TiO with a thickness of about 100nm. 2 film. After EDS mapping composition, the doping amount of Nb is about 0.65at.%; at this ti...

Embodiment 2

[0026] Load titanium tetrachloride, niobium tris(ethylmethylamino) tert-butyramide and high-purity water source on the machine, set the temperature of niobium tris(ethylmethylamino) tert-butyramide to 55°C; when the deposition chamber After heating to 220°C, place the glass substrate after ultrasonic cleaning with alcohol, acetone and deionized water in the deposition chamber; after vacuuming to 15hPa, perform TiO 2cycle; that is, titanium tetrachloride / nitrogen / water / nitrogen = (0.4s / 6s / 0.2s / 4s); after 24 cycles, a niobium doping cycle is performed, that is, titanium tetrachloride / nitrogen / tri(B Base methyl amino) niobium tert-butyramide / nitrogen / water / nitrogen = (0.4s / 6s / 0.6s / 8s / 0.2s / 4s); the deposition is combined into a set of cycles, and the set of cycles is carried out for 80 groups; end Finally, the sample was taken out to make a Nb-doped TiO with a thickness of about 100nm. 2 film. After EDS mapping composition, the doping amount of Nb is about 1.31at.%; at this time...

Embodiment 3

[0028] Load titanium tetrachloride, niobium tris(ethylmethylamino) tert-butyramide and high-purity water source on the machine, set the temperature of niobium tris(ethylmethylamino) tert-butyramide to 55°C; when the deposition chamber After heating to 240°C, place the glass substrate after ultrasonic cleaning with alcohol, acetone and deionized water in the deposition chamber; after vacuuming to 15hPa, perform TiO 2 cycle; that is, titanium tetrachloride / nitrogen / water / nitrogen = (0.4s / 6s / 0.2s / 4s); after 19 cycles, a niobium doping cycle is performed, that is, titanium tetrachloride / nitrogen / tri(B Base methyl amino) niobium tert-butyramide / nitrogen / water / nitrogen = (0.4s / 6s / 0.6s / 8s / 0.2s / 4s); the deposition is combined into a set of cycles, and the set of cycles is carried out for 100 groups; end Finally, the sample was taken out to make a Nb-doped TiO with a thickness of about 100nm. 2 film. According to the EDS mapping composition, the Nb doping amount is about 1.65 at.%; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com