Patents

Literature

140 results about "Glass industry" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glass Industry. the industry producing sheet glass, optical glass, glass fiber, household glassware, glass containers, various glass items and materials, and the glass used in construction, illuminating engineering, and electrical engineering. The production of glass began in antiquity, and glassmaking became a craft in the Middle Ages.

Purification method in process of production of high-pure quartz sand as raw material of quartz glass

InactiveCN101337767AHigh purityHigh activitySilicaGlass shaping apparatusPurification methodsImpurity

The invention discloses a purification method in the production of high-purity quartz sand applied to the raw materials of quartz glass. Through effectively eliminating hydroxyl group and gaseous-liquid inclusion in a natural quartz, the raw material of the quartz glass hyphen, the high-purity quartz sand produced by a common vein quartz, is realized, thereby achieving the effective control to key quality indexes such as air bubbles and air lines in a quartz glass product, and breaking the high dependency to the quality of an ore in the prior process art, so that the availability of vein quartz resources in a quartz glass industry is improved to above 80 percent from about 5 percent; the content of the high-purity quartz sand SiO2 produced by the common vein quartz ore reaches above 99.99 percent; and the total amount of the foreign impurities of thirteen metallic elements is less than 25 to 30 ppm.

Owner:江苏阳山硅材料科技有限公司

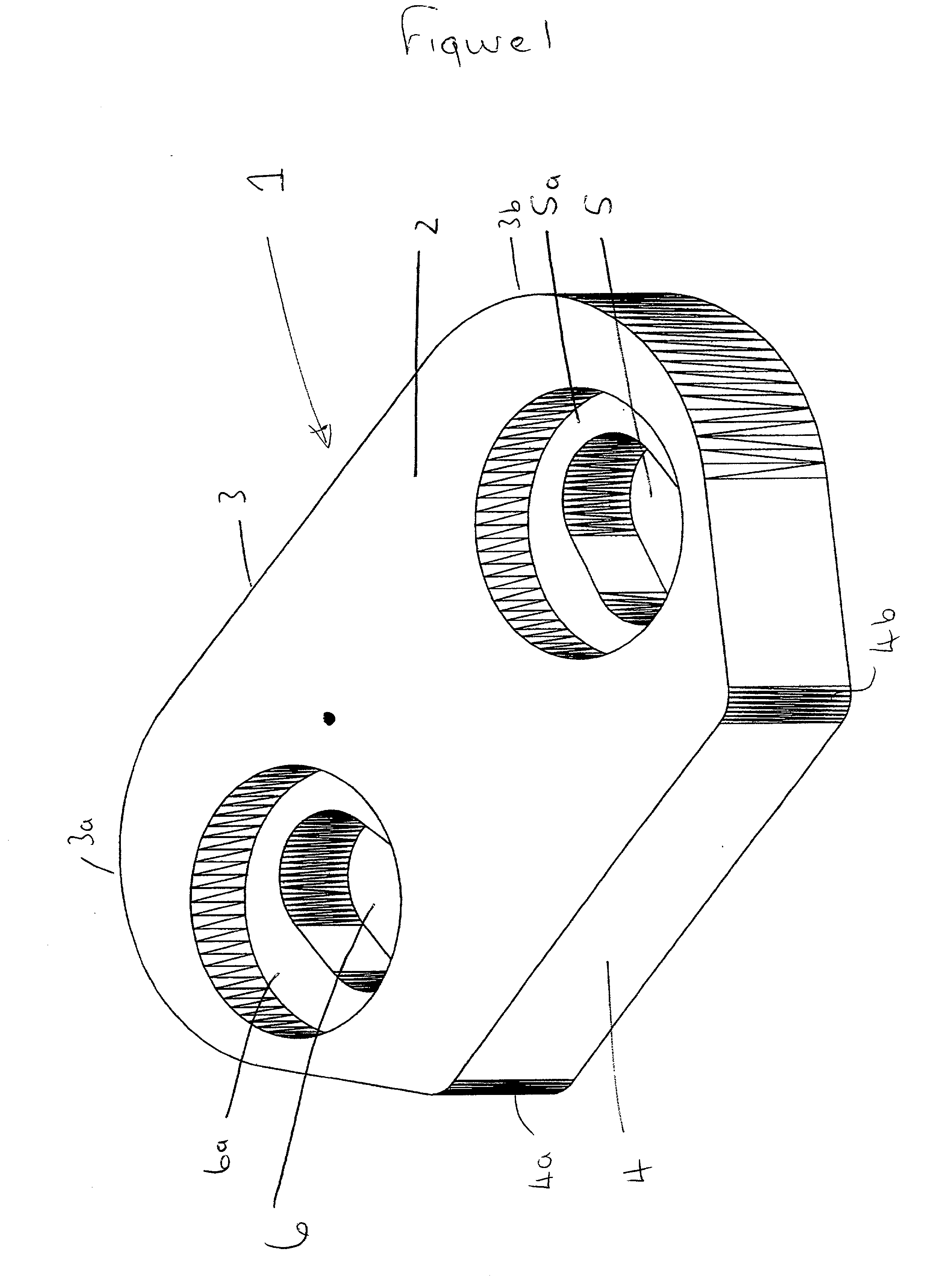

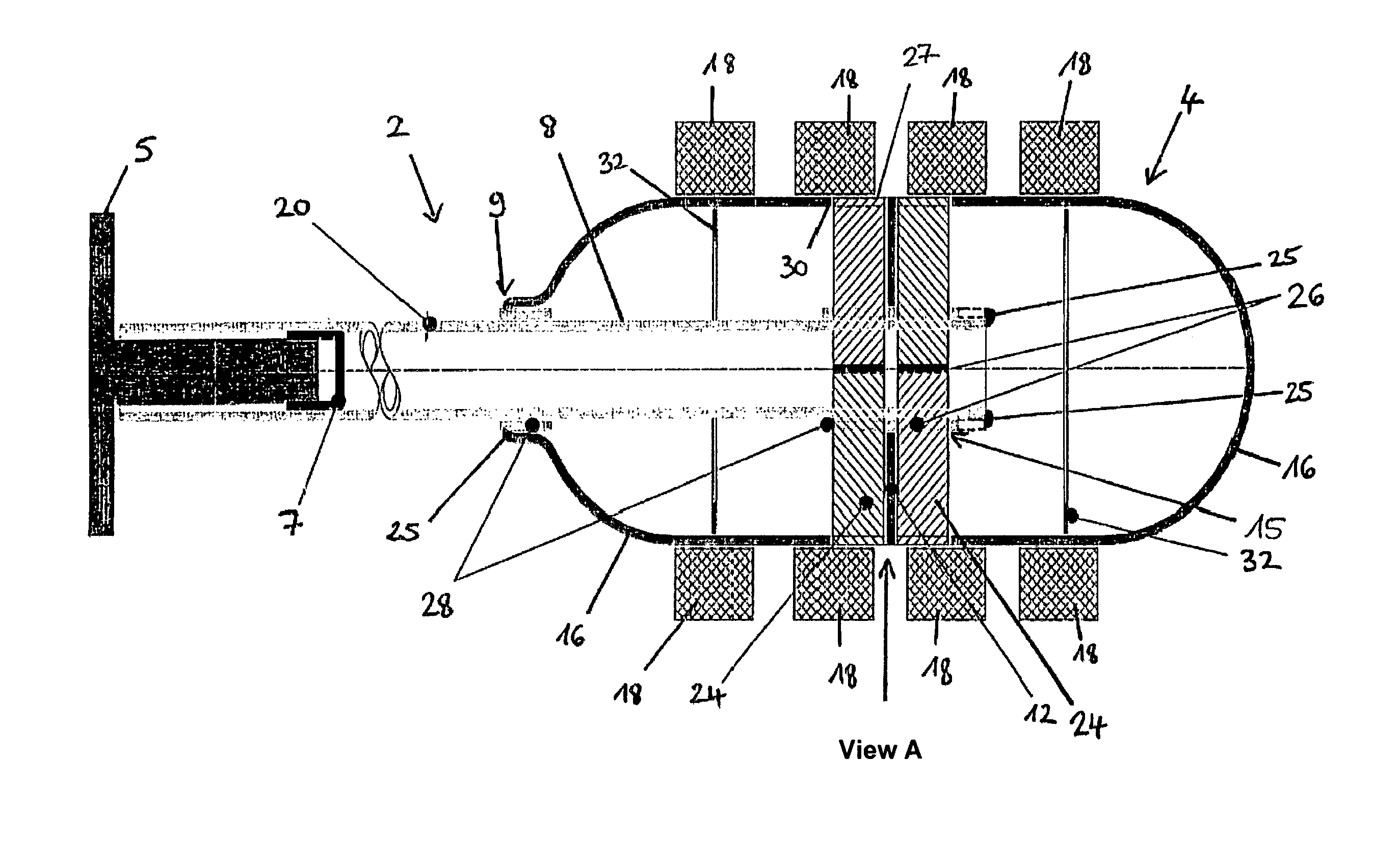

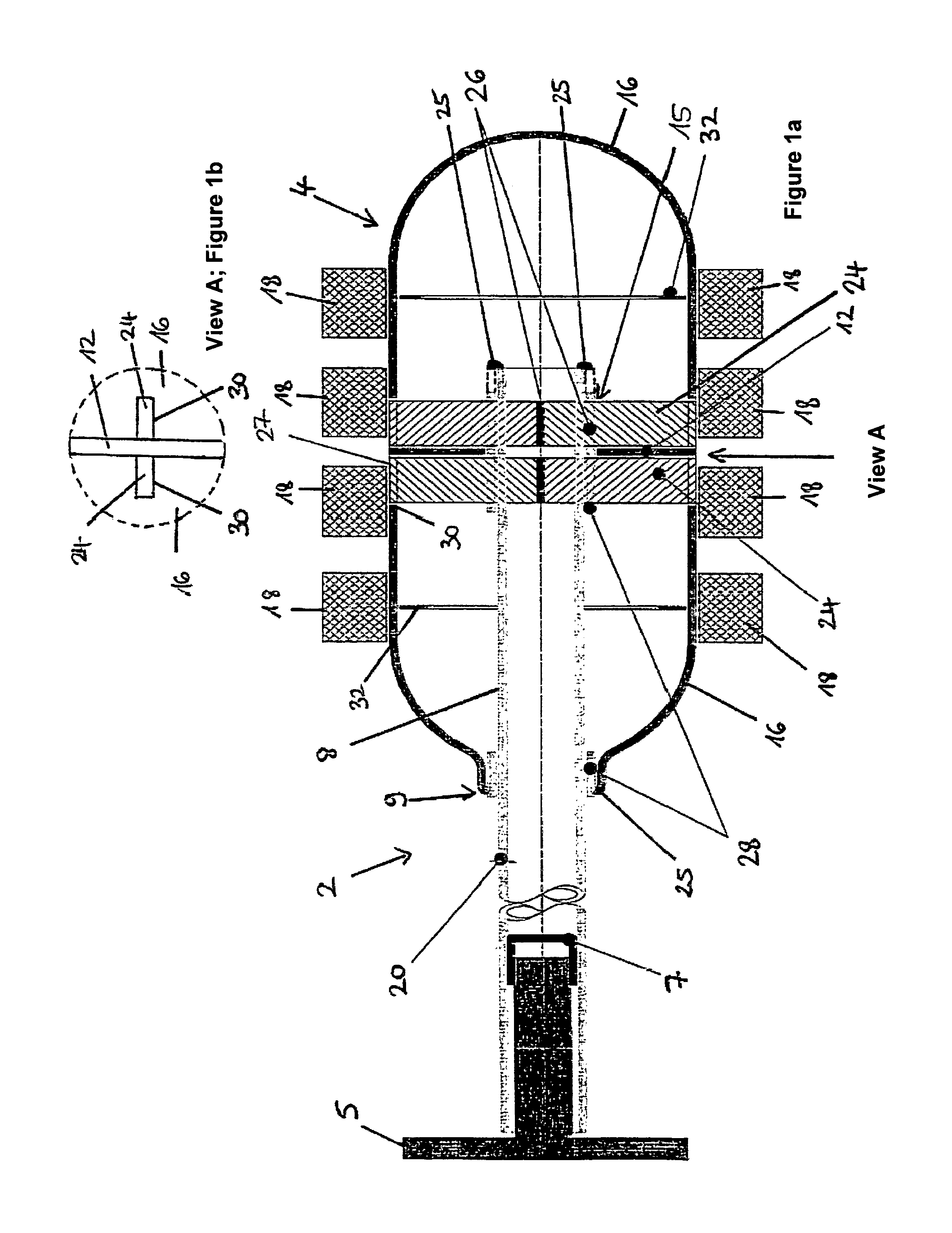

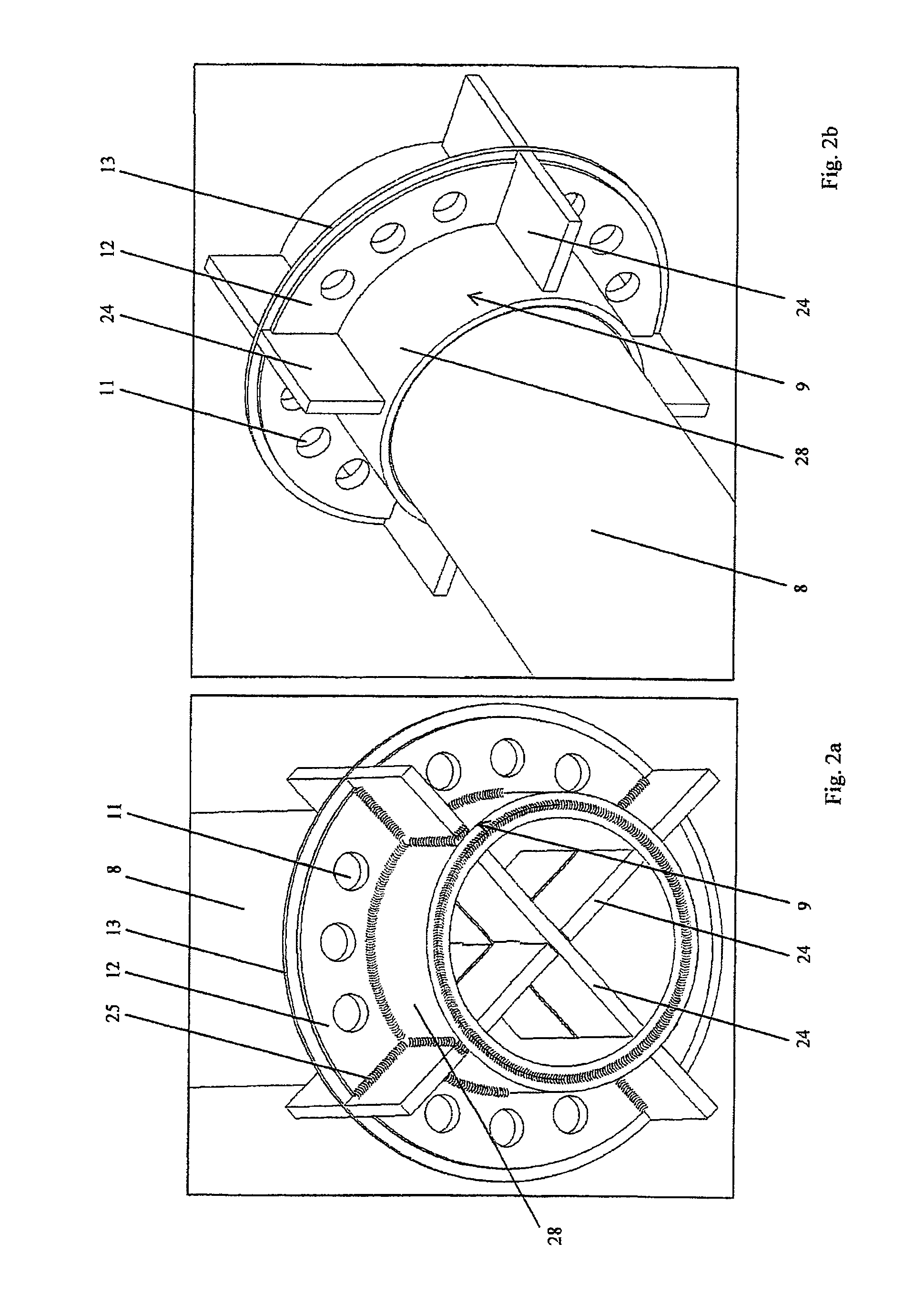

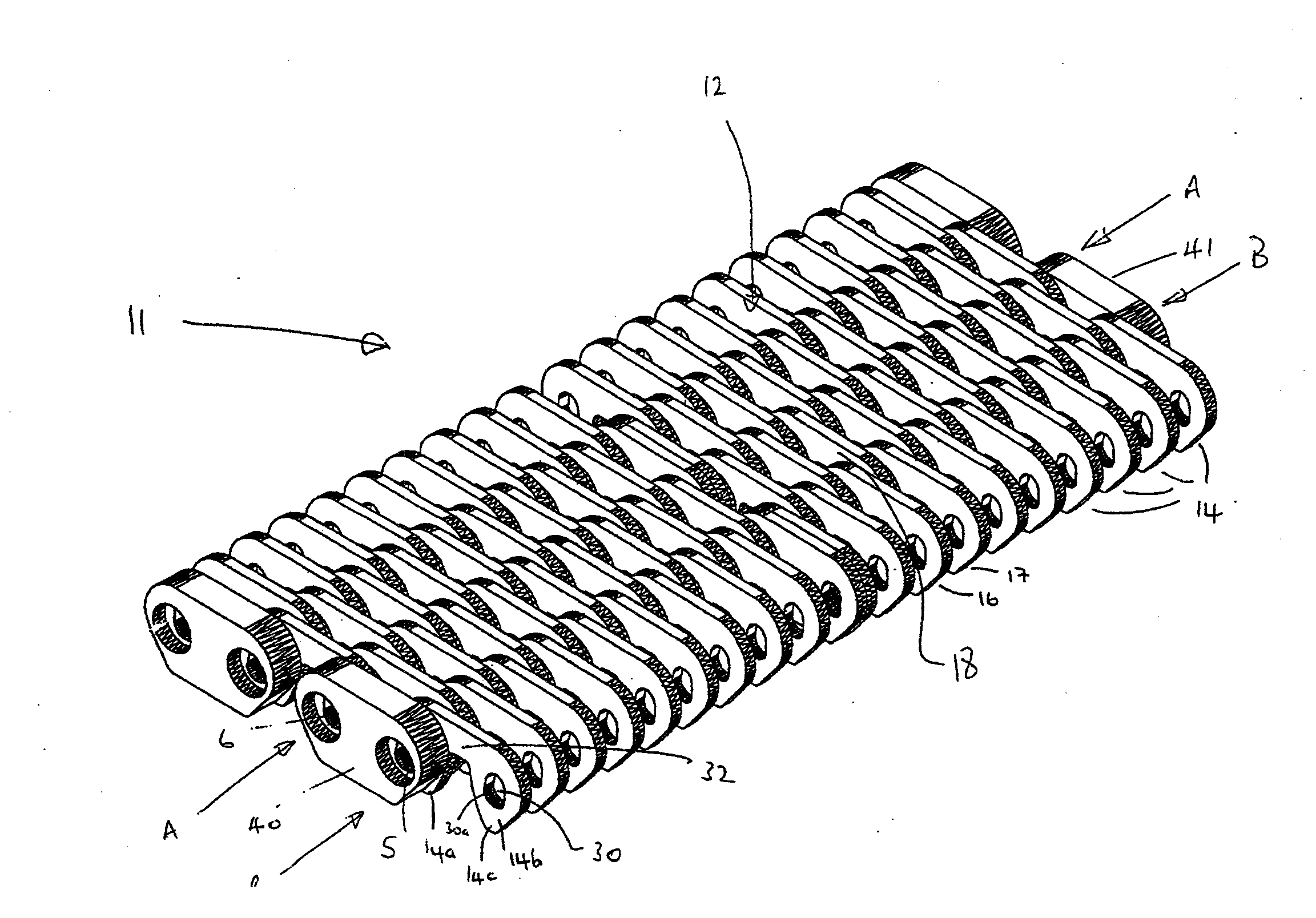

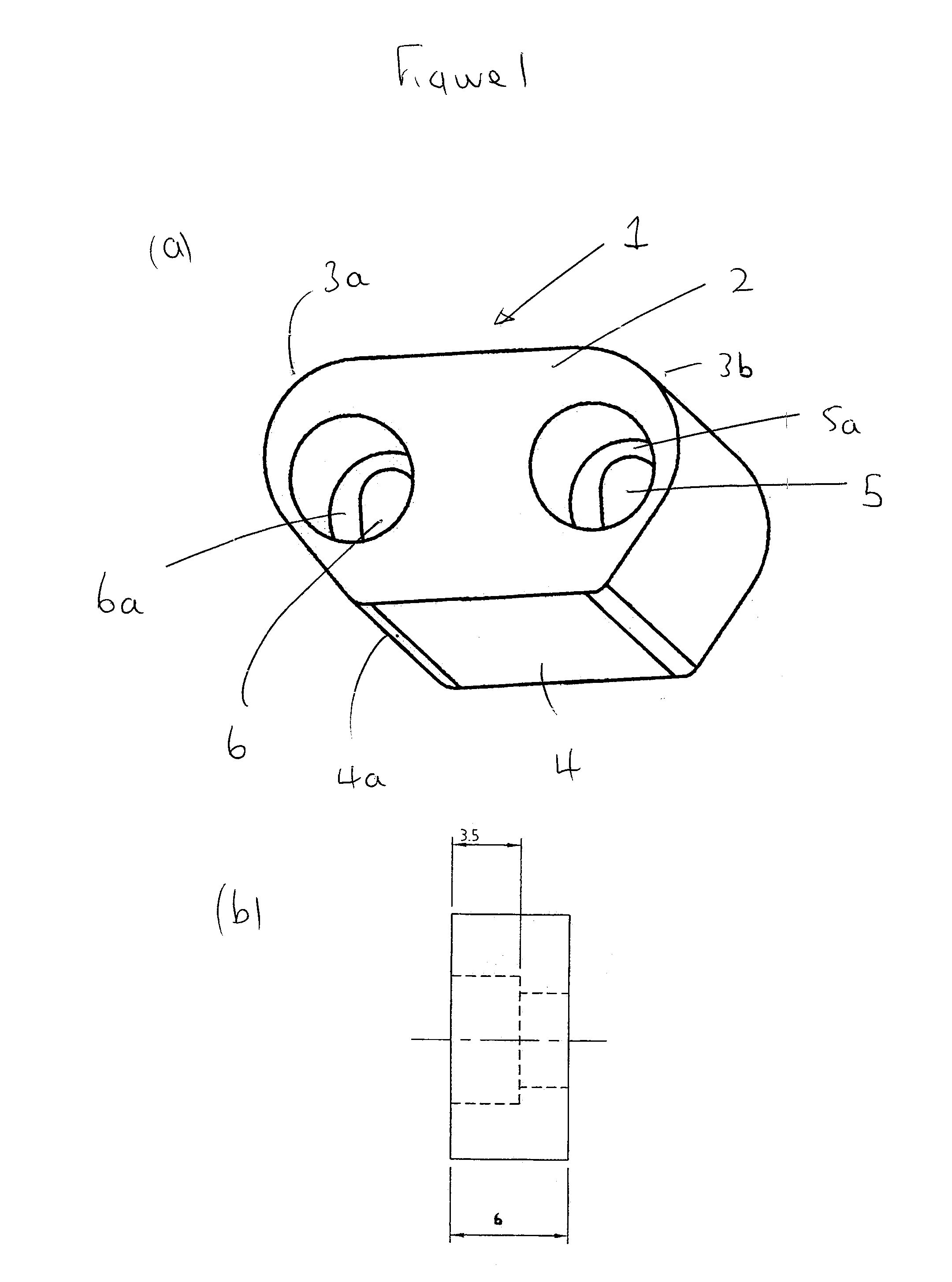

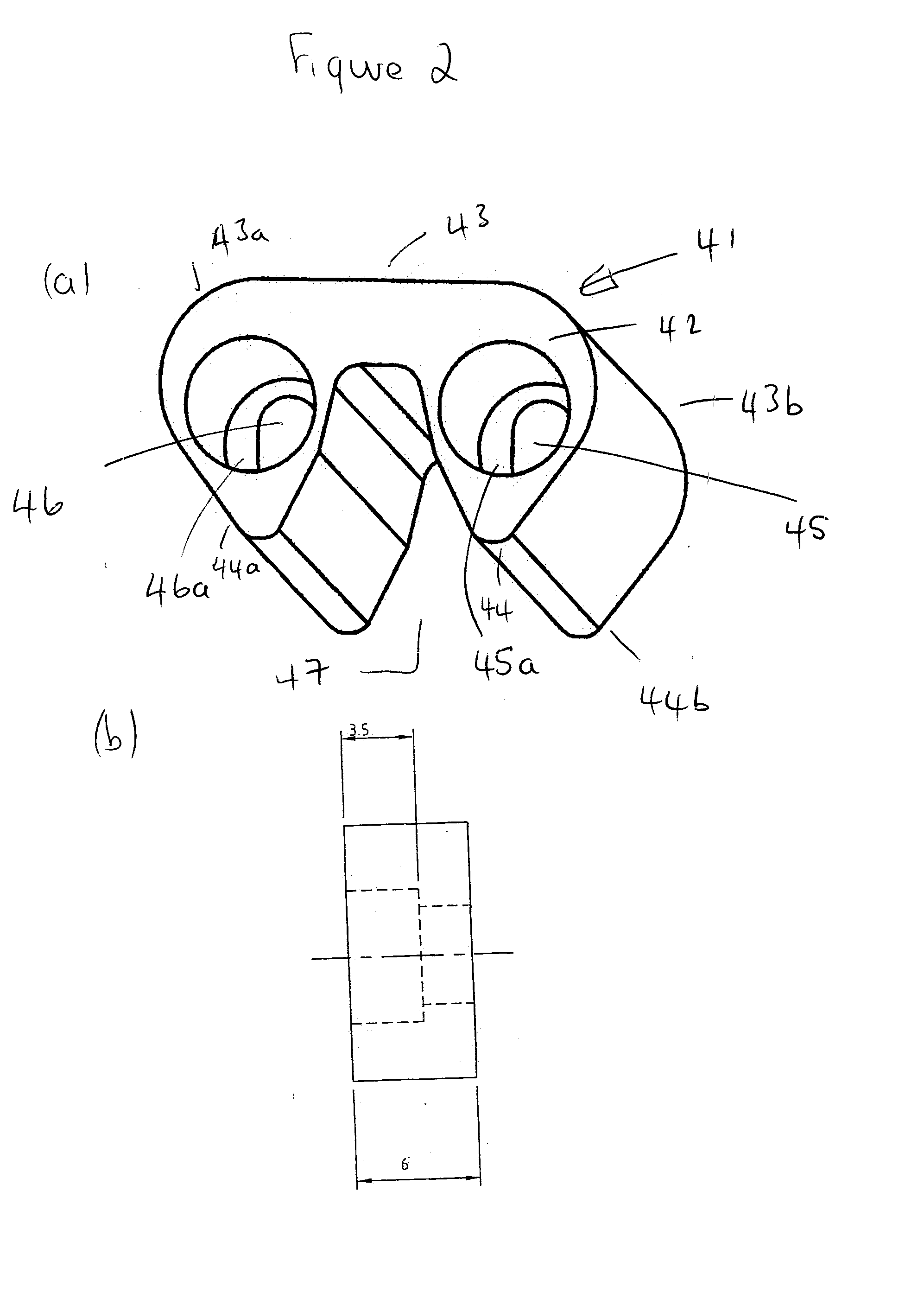

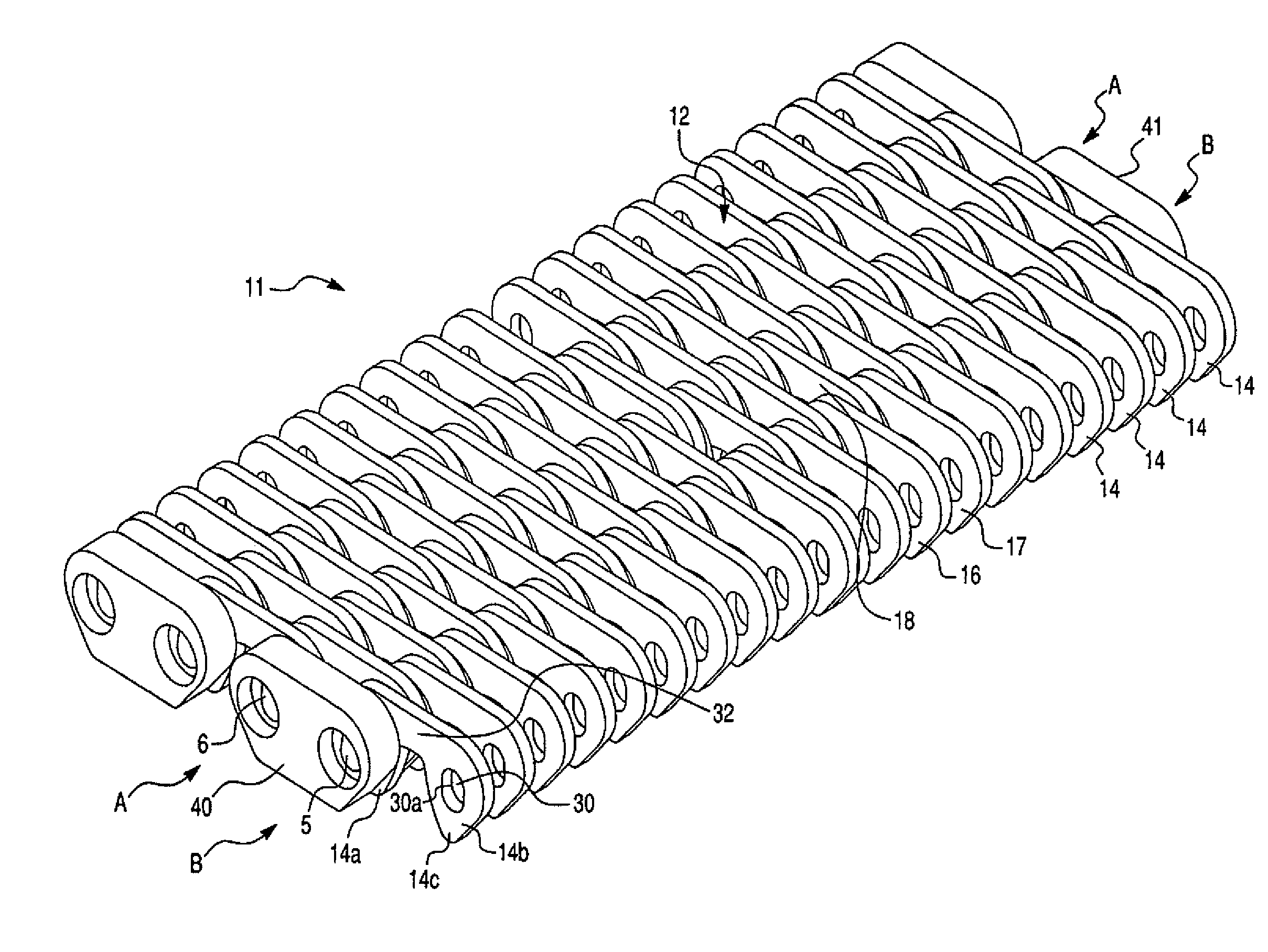

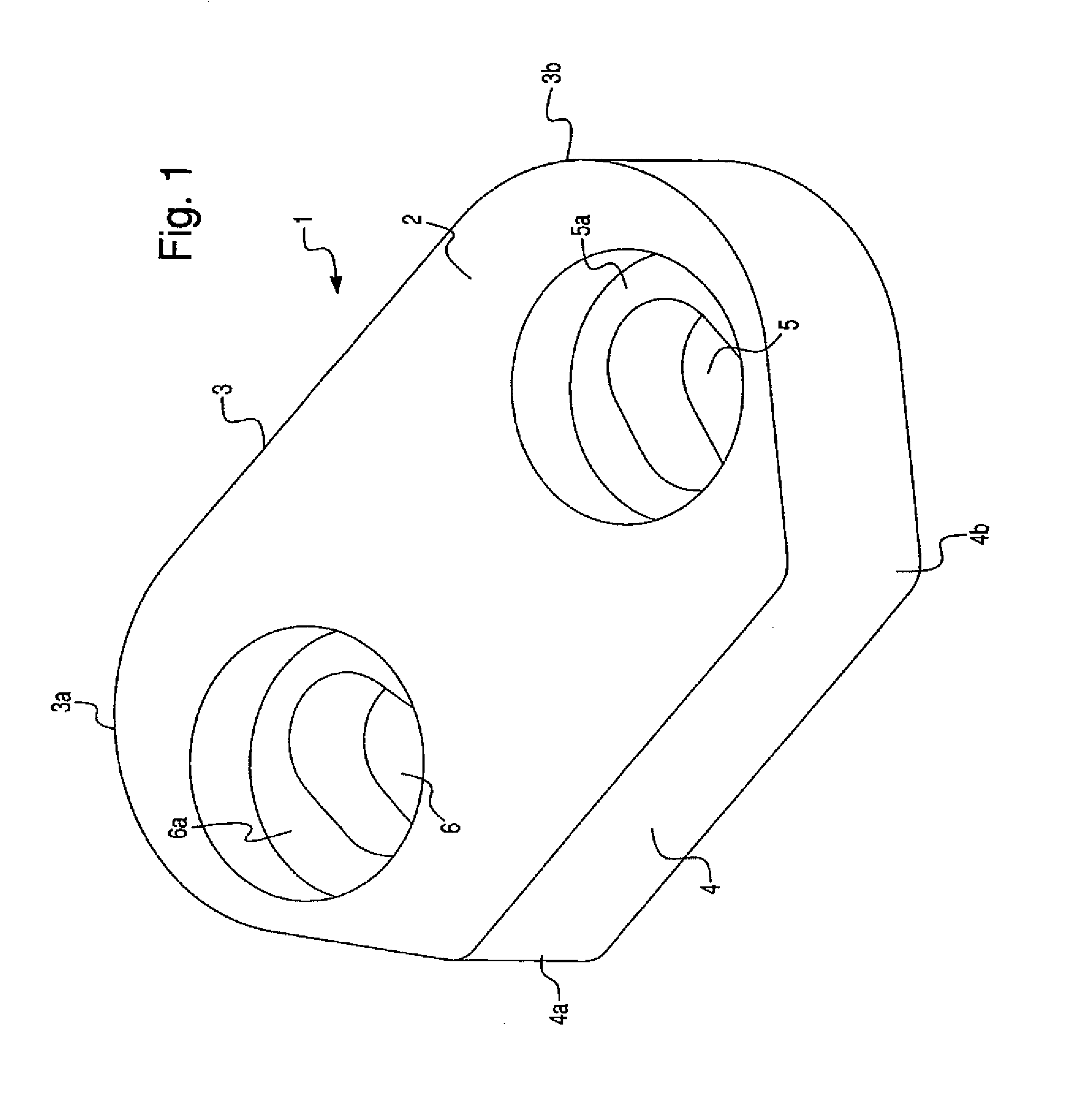

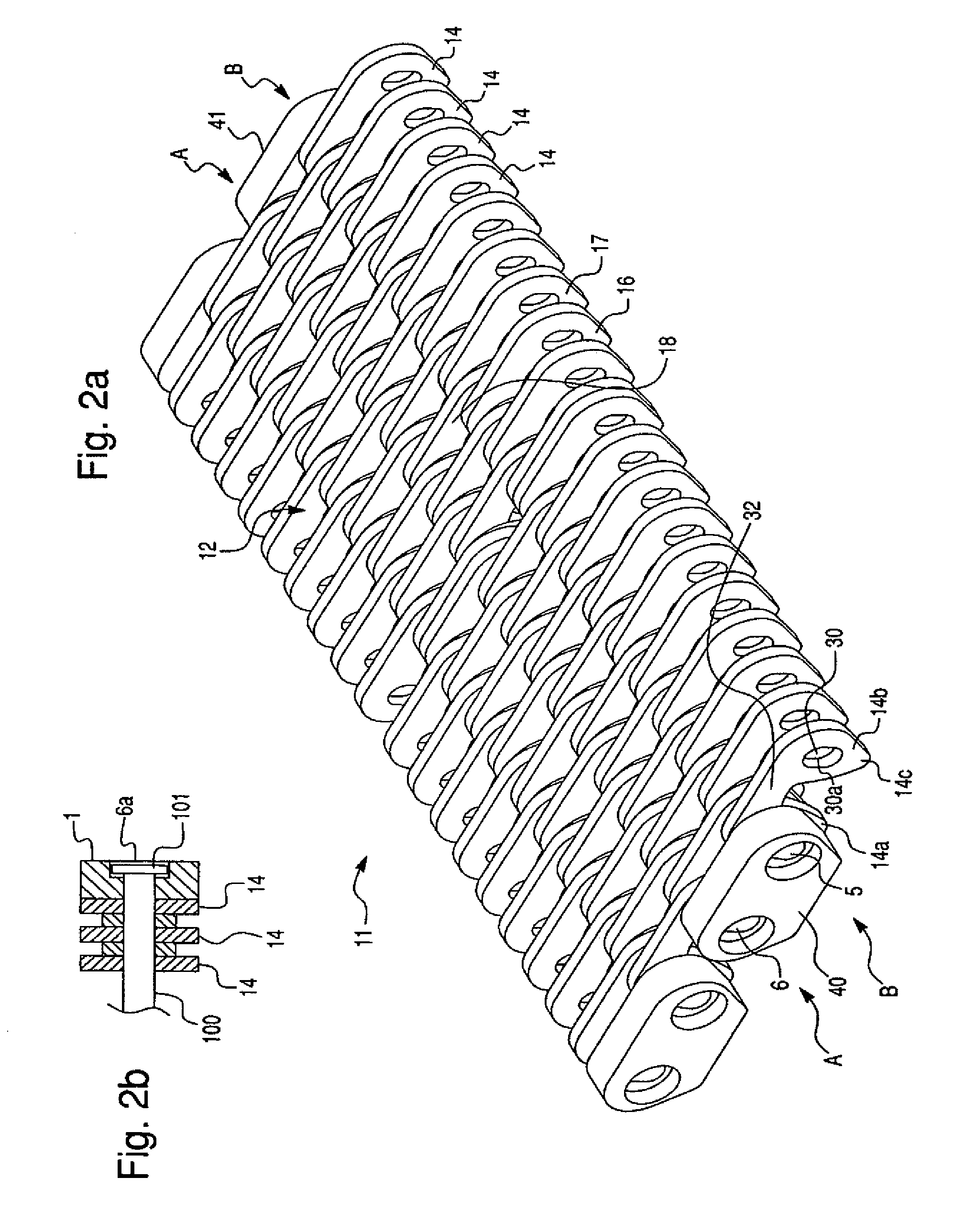

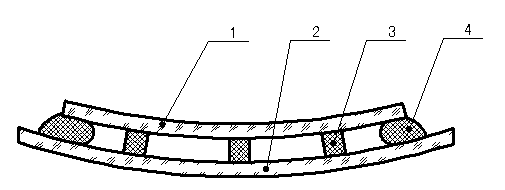

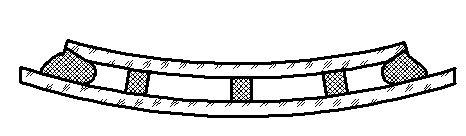

Enclosure member, and multi-link conveyor chain

InactiveUS20020129732A1Improve integrityEasy to wearConveyorsTrain hauling devicesMechanical engineeringIndustrial engineering

The present invention relates to a multi-link conveyor chain which may be used (for example) in the glass industry, in particular to an enclosure member for protecting the integrity of the multi-link conveyor chain during use and to a method for manufacturing the multi-link conveyor chain incorporating the enclosure member.

Owner:PENNINE INDAL EQUIP

Heat-transfer-printing color tape capable of being printed with high-temperature-resistant marks and manufacturing method thereof

The invention discloses a heat-transfer-printing color tape capable of being printed with high-temperature-resistant marks, comprising a PET (polyethylene terephthalate) tape base and a heat-transfer-printing oil-ink layer adhered on the PET tape base. The heat-transfer-printing color tape is characterized in that the heat-transfer-printing oil-ink layer comprises the following materials in partsby weight: 5-35 parts of ionic liquid, 20-45 parts of composite inorganic binding agent, 5-40 parts of inorganic filler, 1-8 parts of organic silicon resin, 5-40 parts of high-temperature-resistant pigment, 0-5 parts of processing aid and 0-20 parts of solvent; and the ionic liquid is solid in normal temperature, is liquid when being heated in heat transfer printing, and is solid due to being decomposed at the temperature of higher than 300 DEG C. The heat-transfer-printing oil-ink layer is coated on a base film by adopting a blade coating or roll coating process. Compared with the prior art,the marks printed on the color tape disclosed by the invention such as characters, images and barcodes can resist high temperature without casting, deformation and blurring. The heat-transfer-printing color tape can be used for the industrial fields with high-temperature treatment procedures such as the ceramic industry, the iron-making and steel-making industry, the metal casting and forging industry, the glass industry and the like.

Owner:HEBEI UNIV OF ENG

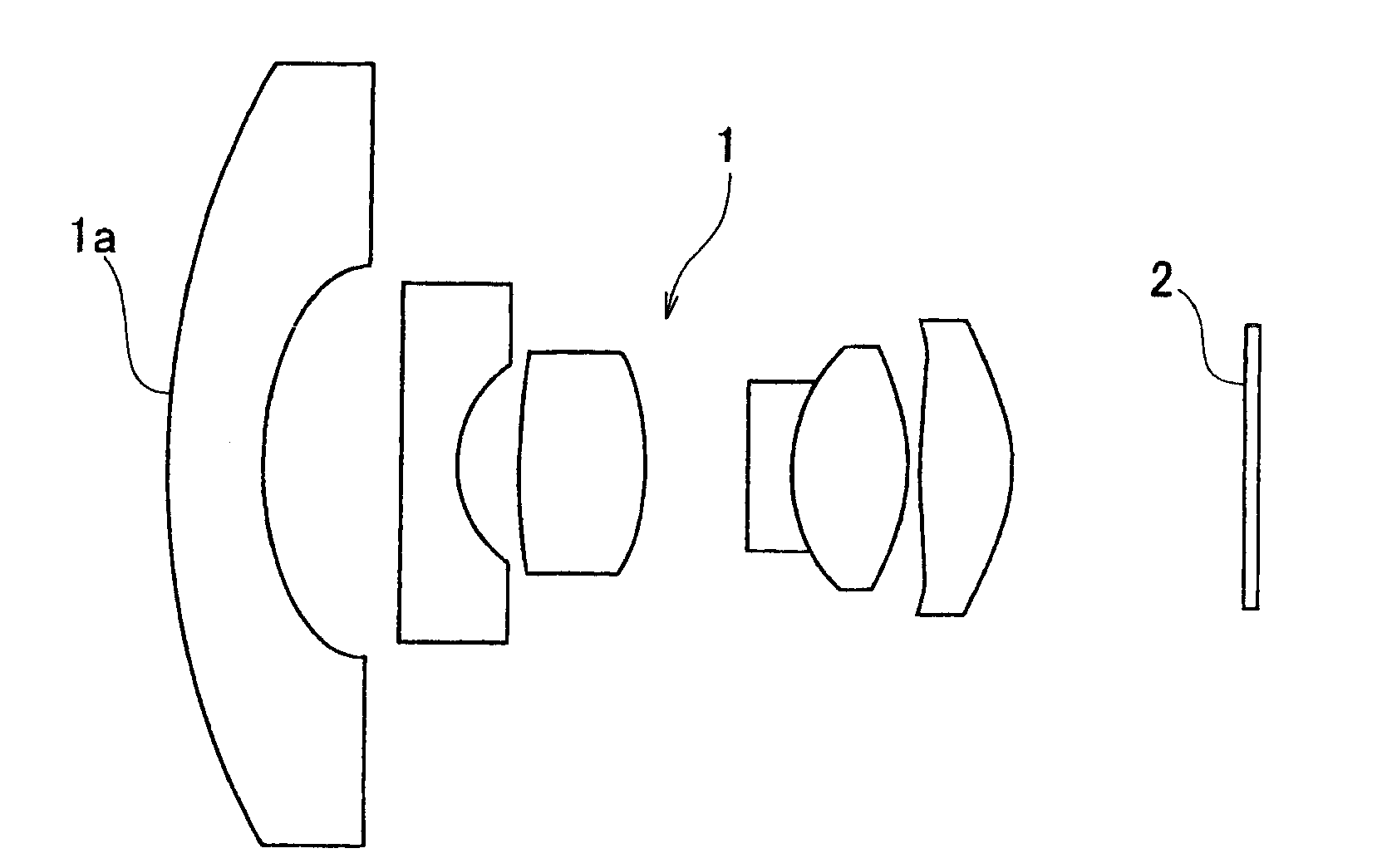

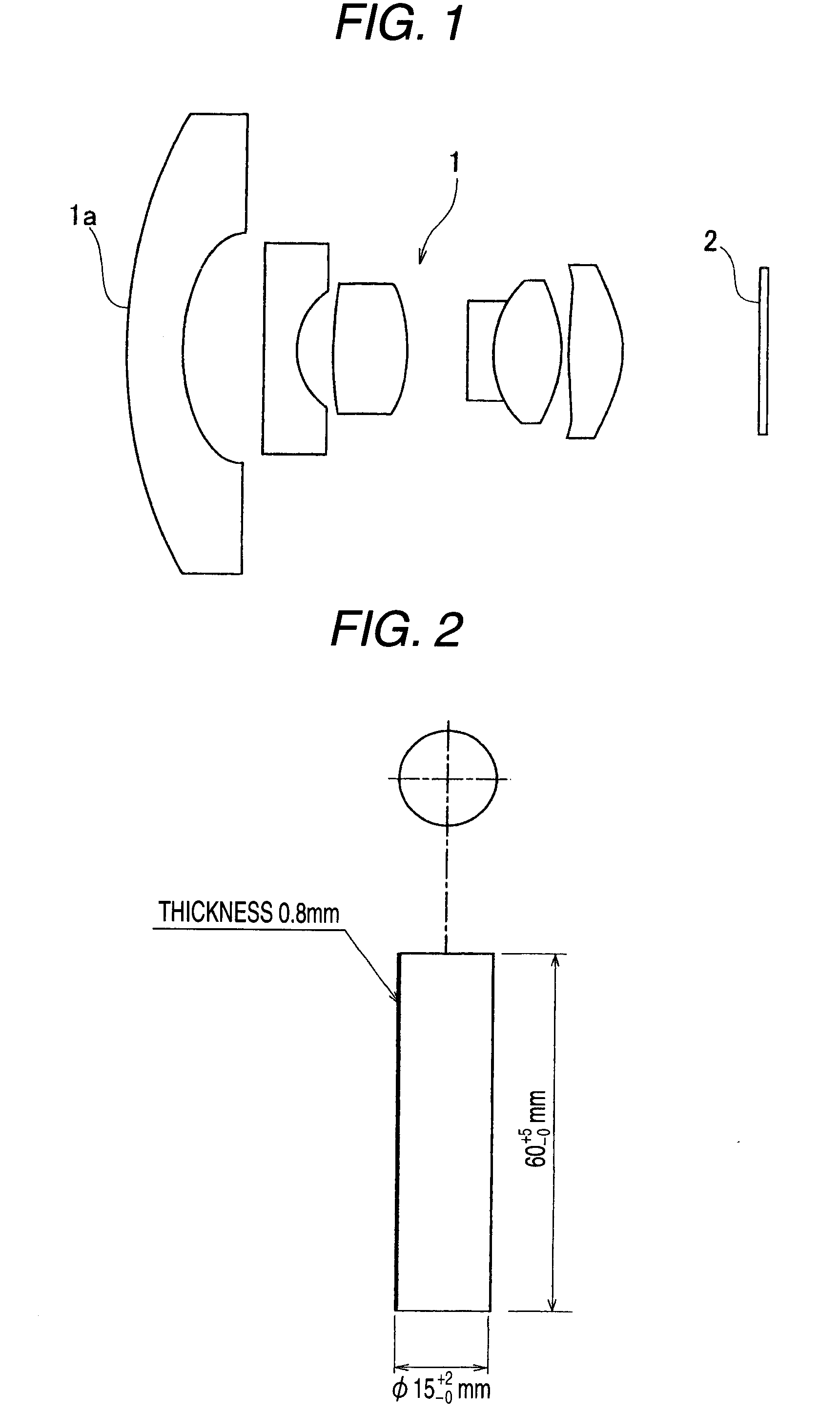

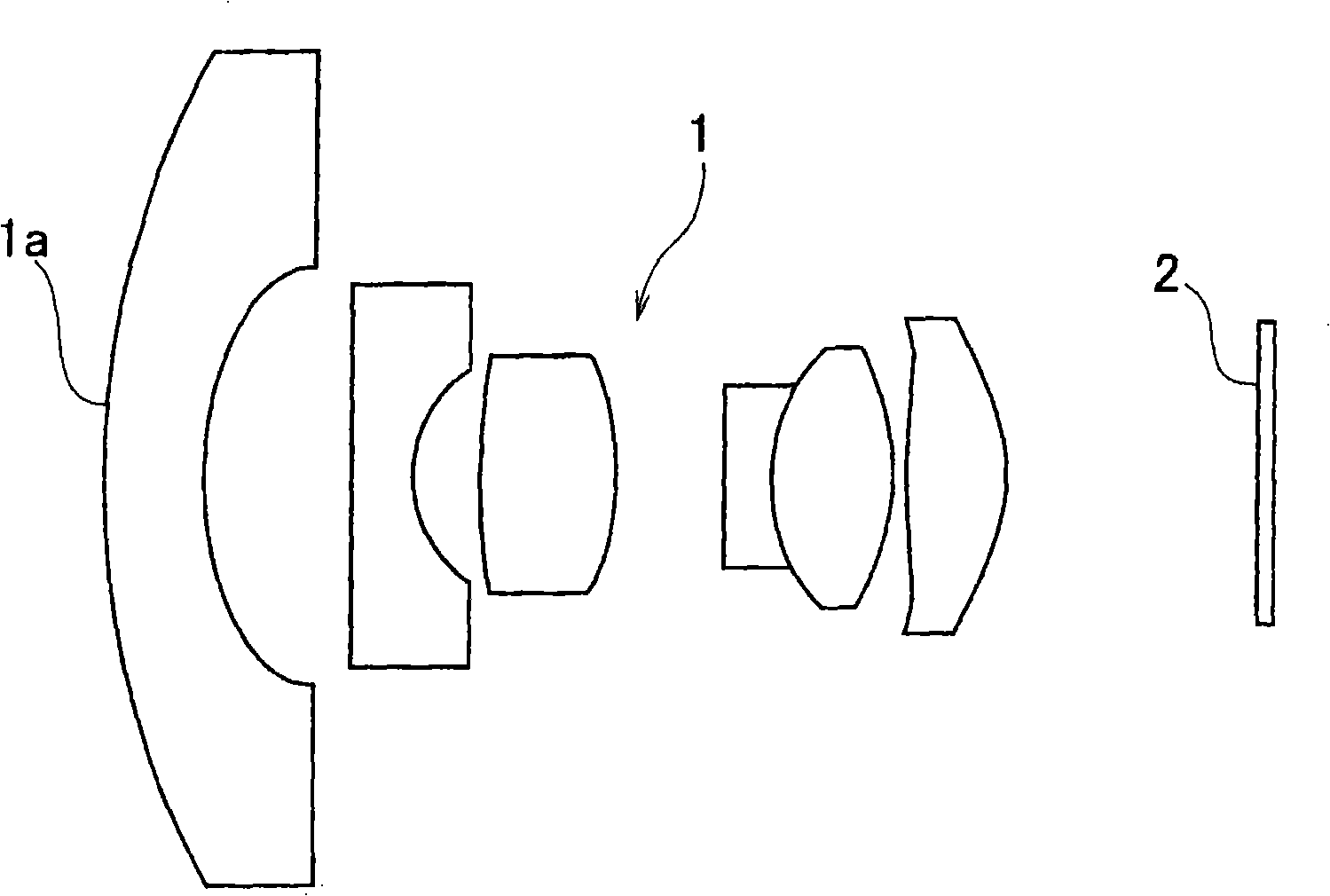

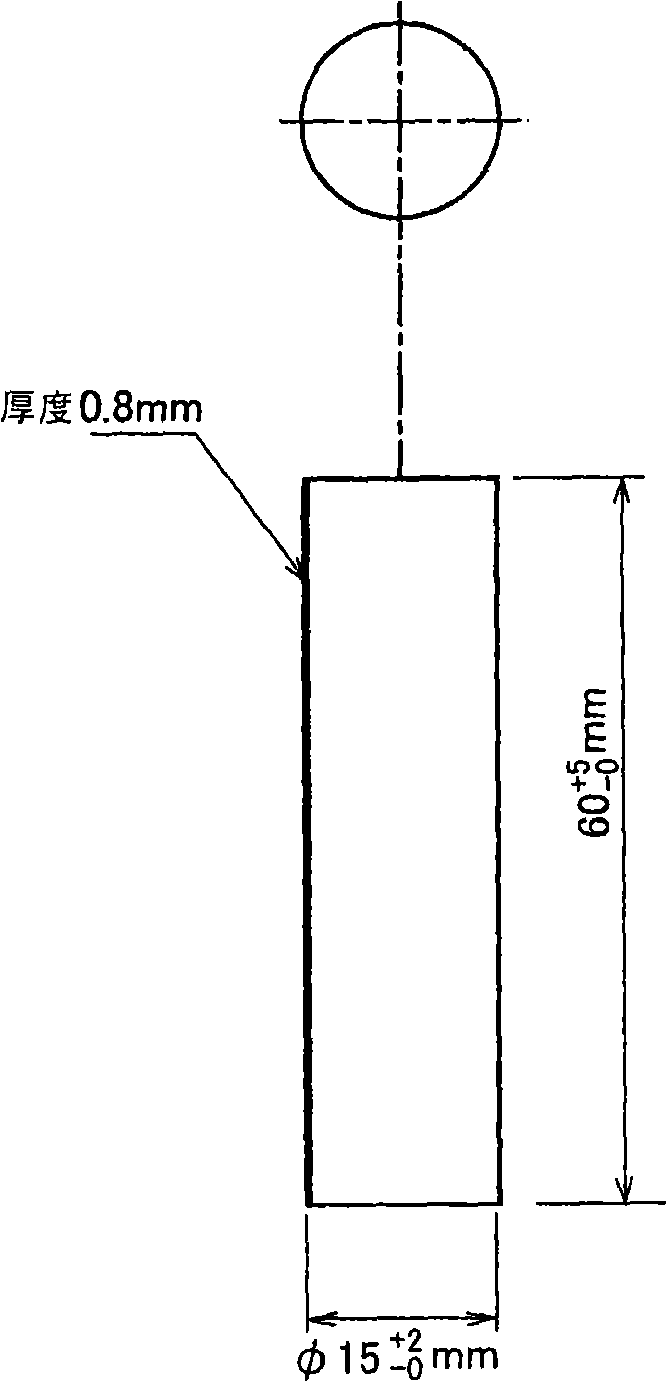

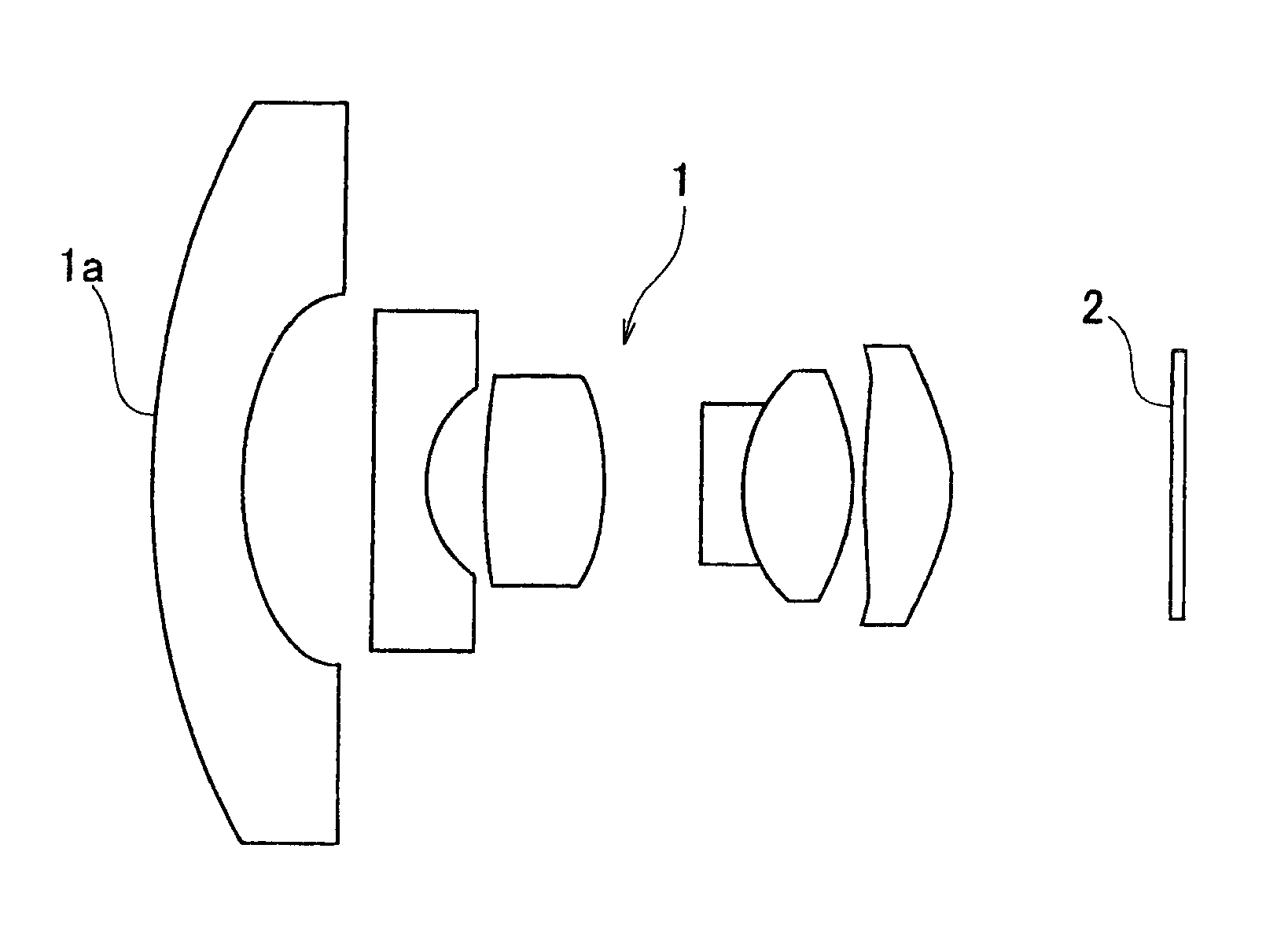

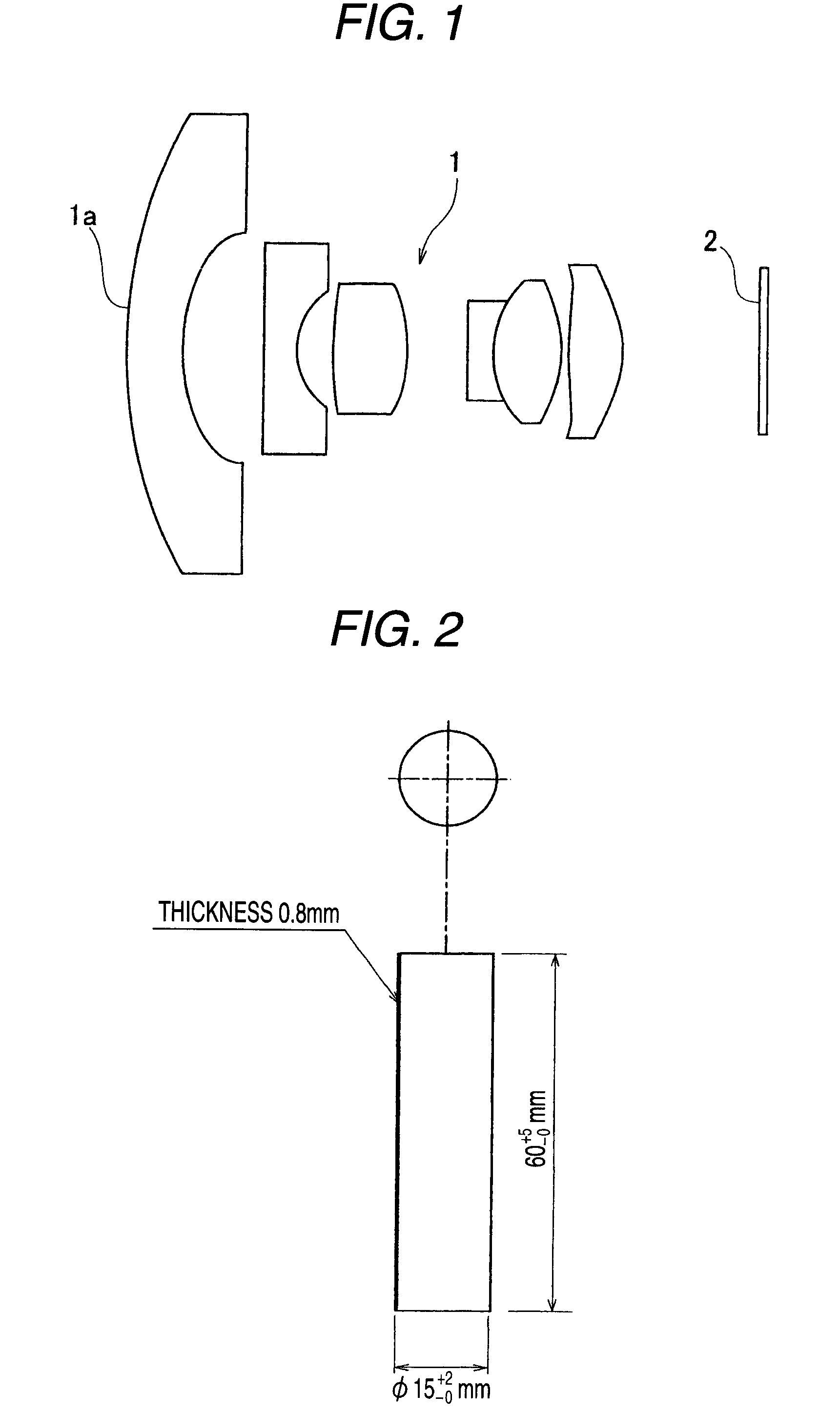

On-vehicle camera lens glass material and on-vehicle camera lens

ActiveUS20080231972A1Improve the immunityLess deteriorationOptical viewingLensCamera lensPowder method

An on-vehicle camera lens glass material satisfies at least one of conditions in which a measurement result in water resistance based on a powder method prescribed by Japanese Optical Glass Industrial Standard is 1st Class, a measurement result in Knoop hardness based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is 6th Class or higher, a measurement result in solarization based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is 2% or less, and a measurement result in average linear expansion coefficient based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is 100×10−7° C.−1 or less.

Owner:HOYA CORP

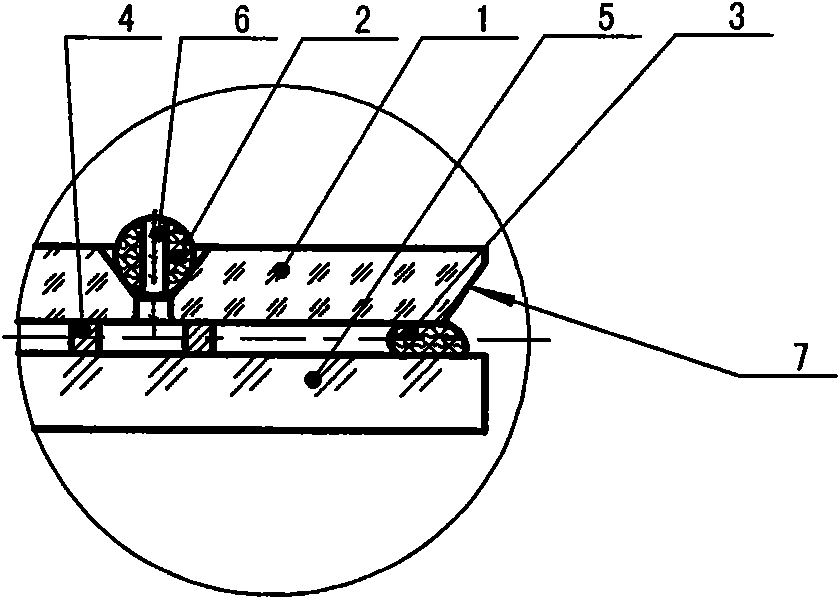

Apparatus for use in the glass industry and method for processing molten glass

ActiveUS8434329B2Extended service lifeReduce stepsRotary stirring mixersGlass furnace apparatusMaterials scienceMolten glass

Apparatus, which is suitable for being surrounded by molten glass, the apparatus having a shank which has at least one at least partially seamless tube consisting of an oxide dispersion-strengthened PGM material, the shank having at least one thickened portion on which an actuating device is arranged.

Owner:UMICORE AG & CO KG

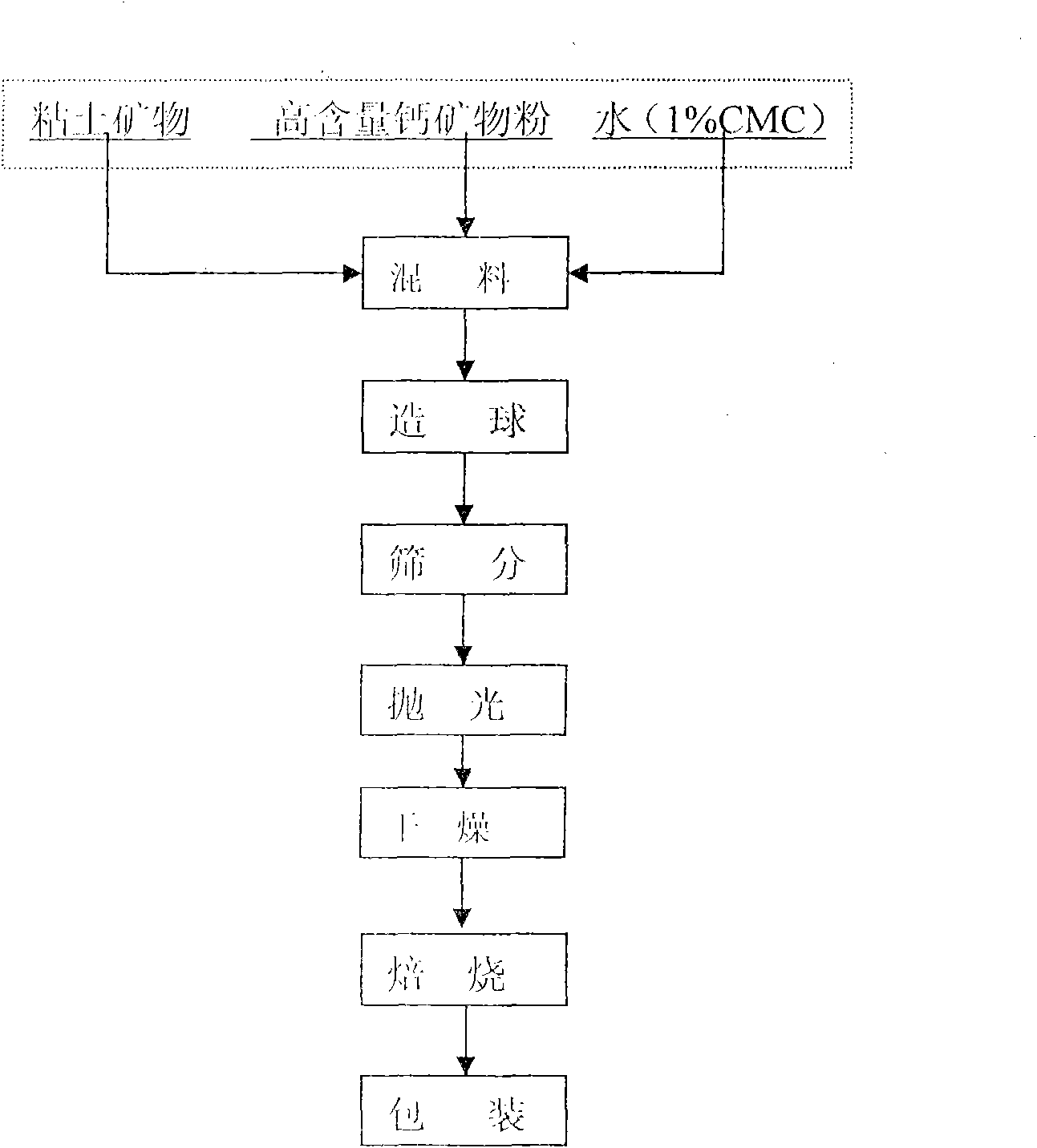

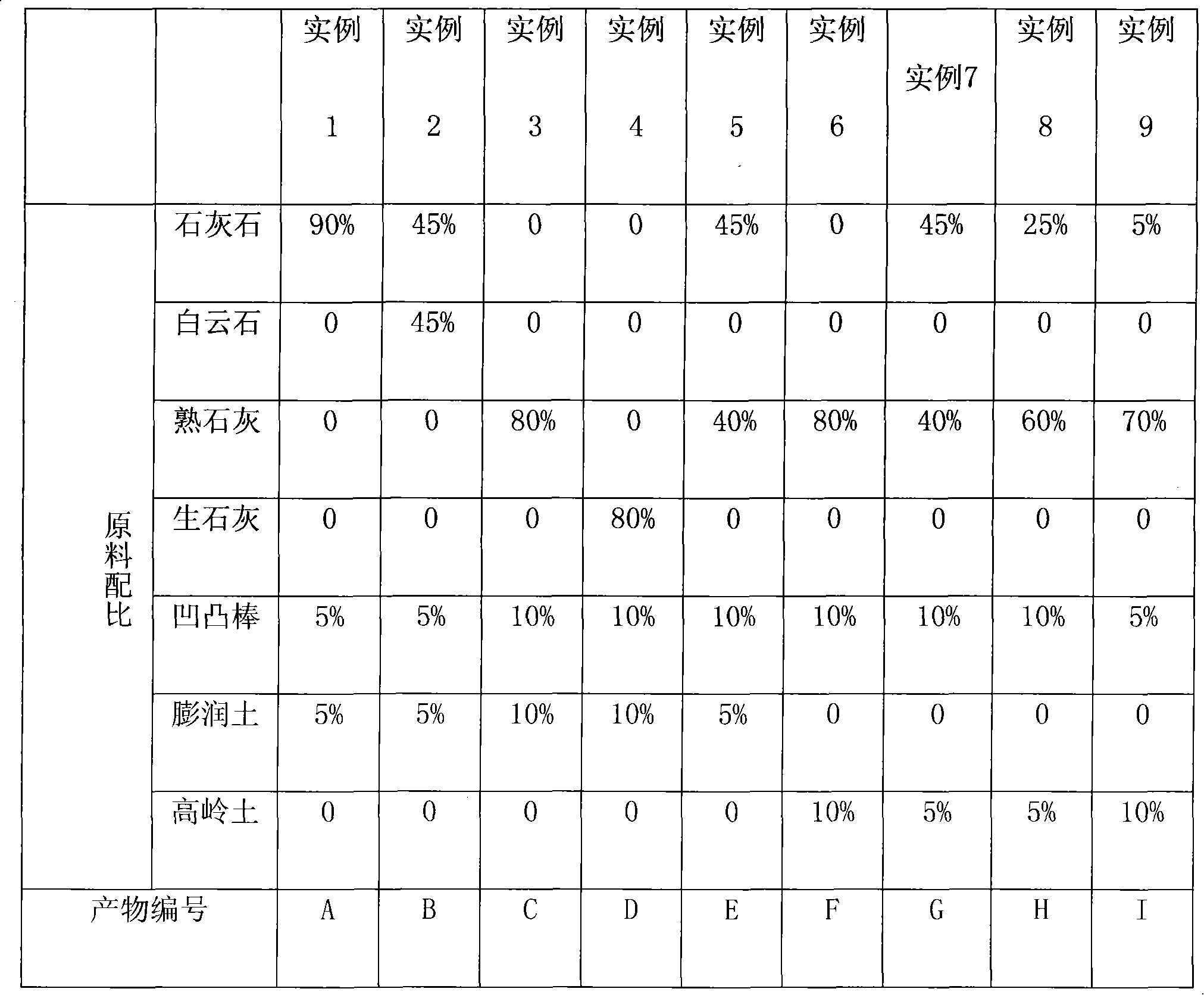

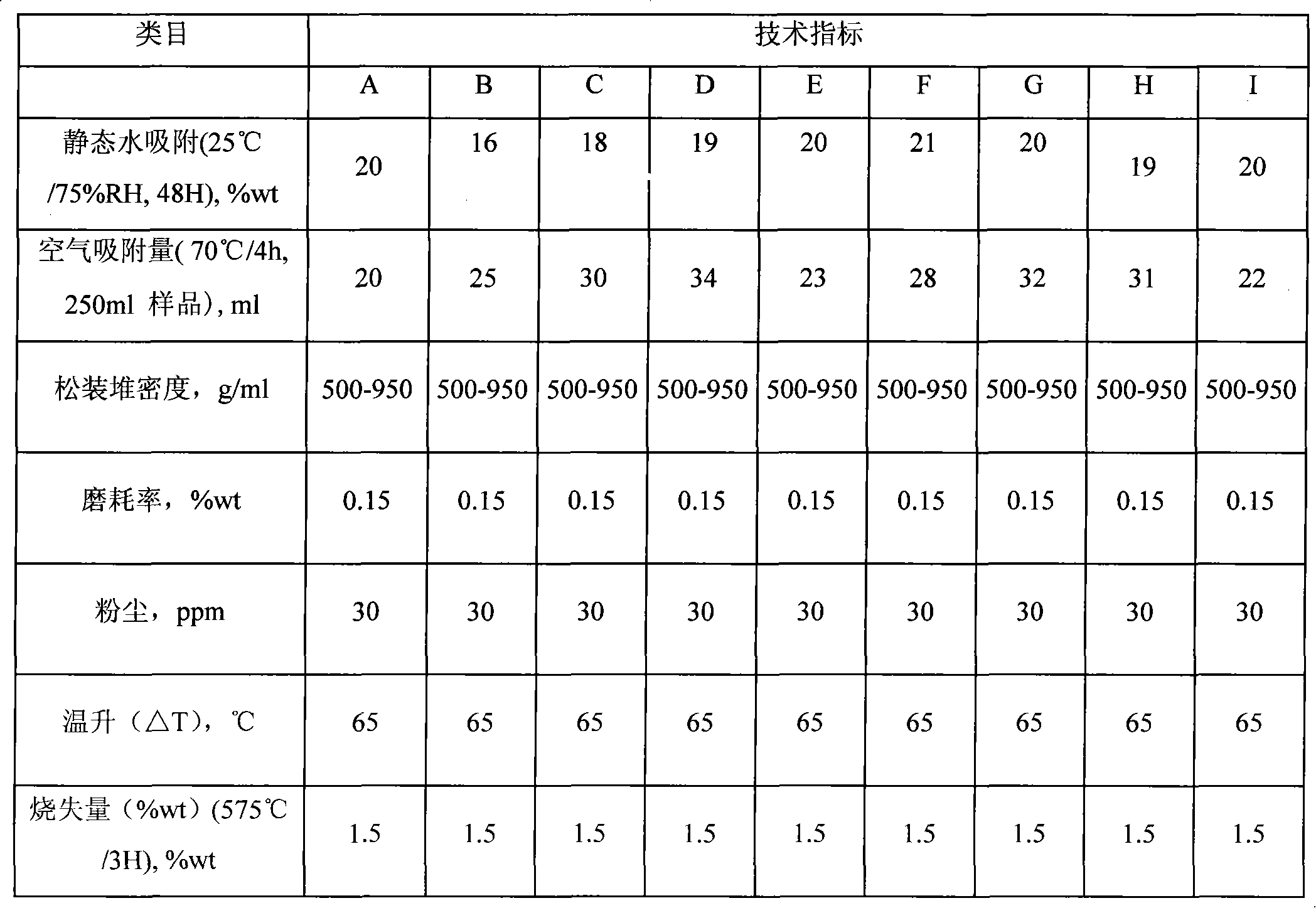

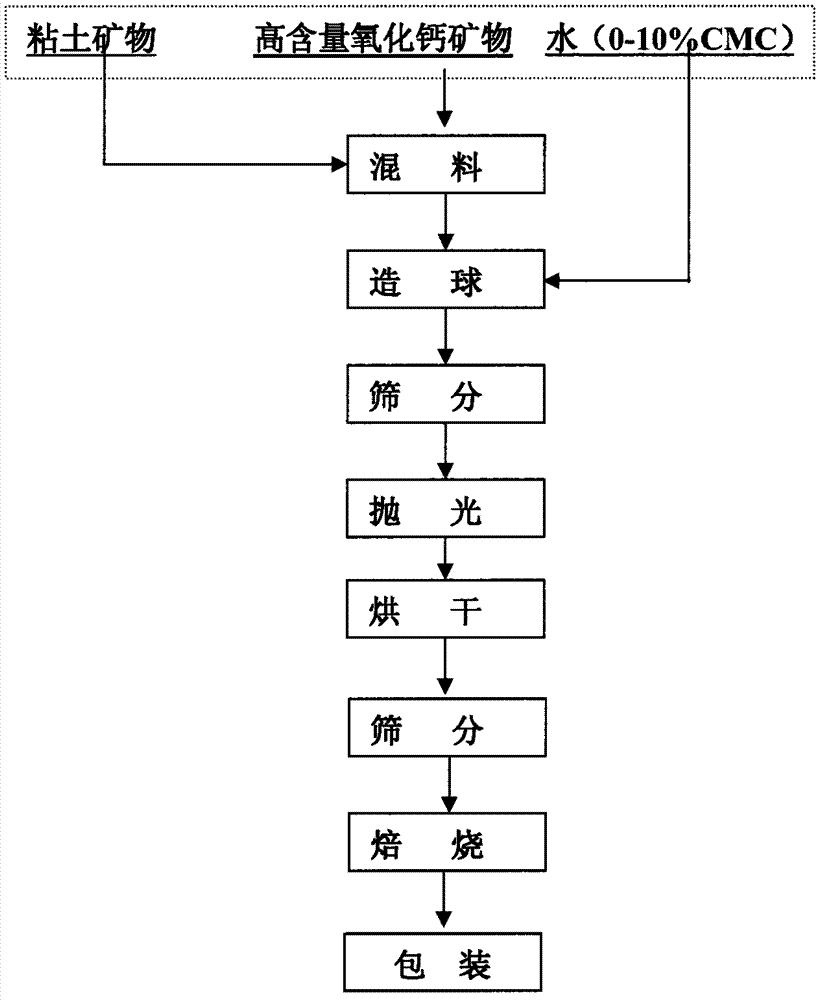

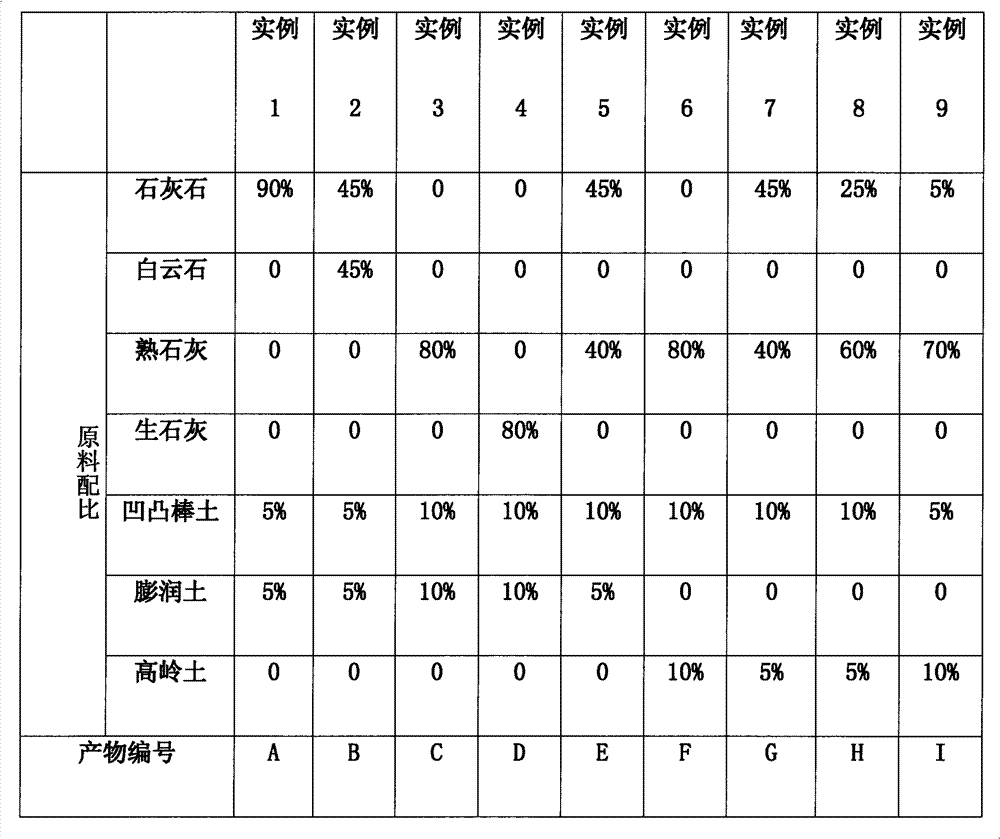

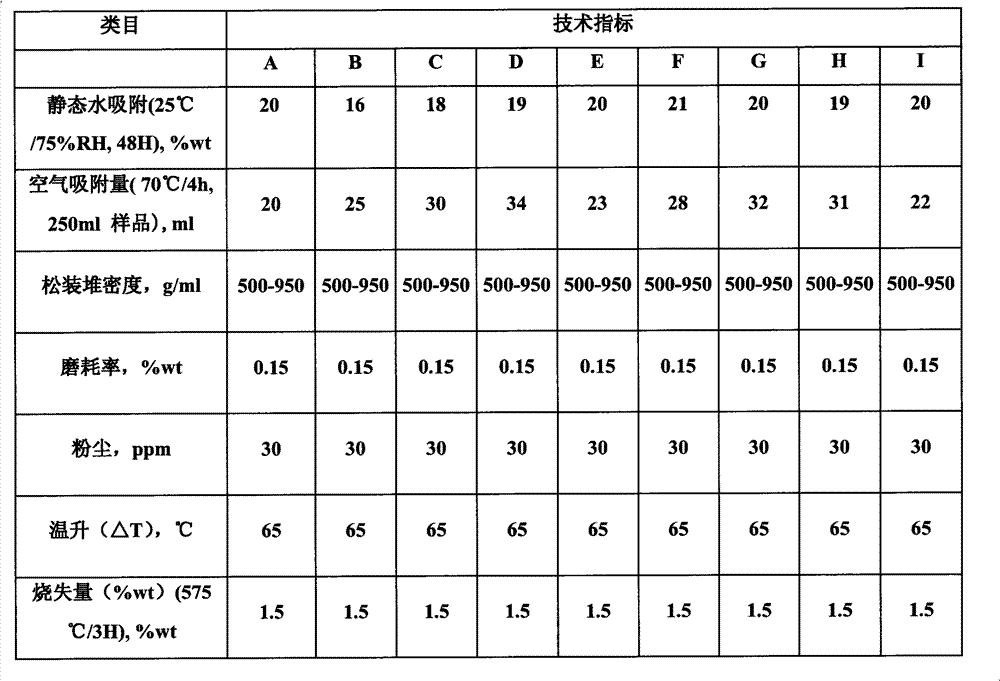

Spherical calcium oxide adsorbent and preparation method thereof

InactiveCN101628221AImprove water absorptionReduce manufacturing costOther chemical processesClay mineralsSorbent

The invention discloses a spherical calcium oxide adsorbent and a preparation method thereof. High-content calcium oxide mineral and clay mineral are used as main raw materials, and the materials are mixed according to the following mixture ratio (in percentage by weight): 50 to 95 percent of the high-content calcium oxide mineral, and 10 to 50 percent of the clay mineral. The preparation method comprises the following steps: mixing the two minerals, molding the mixture in a spherical granulator by using 0 to 1 percent CMC water solution as assistant, screening out spherical granules with certain granularity range by using a two-layer sieve, and further drying, roasting and packing the spherical granules to obtain the spherical calcium oxide adsorbent. The spherical calcium oxide adsorbent comprises the following chemical components: 40 to 90 percent of calcium oxide, 0 to 50 percent of magnesium oxide, 5 to 30 percent of silicon dioxide, 5 to 30 percent of aluminum oxide, and 0 to 30 percent of sodium oxide. The adsorbent has good selective adsorption property and abrasion-resistant property, can be used as a drying agent in the hollow glass industry, can adsorb acid gases such as hydrogen sulfide, hydrogen chloride, sulfur dioxide, chlorine and the like, and can purify industrial waste gases.

Owner:郑州天祥无机材料有限公司 +1

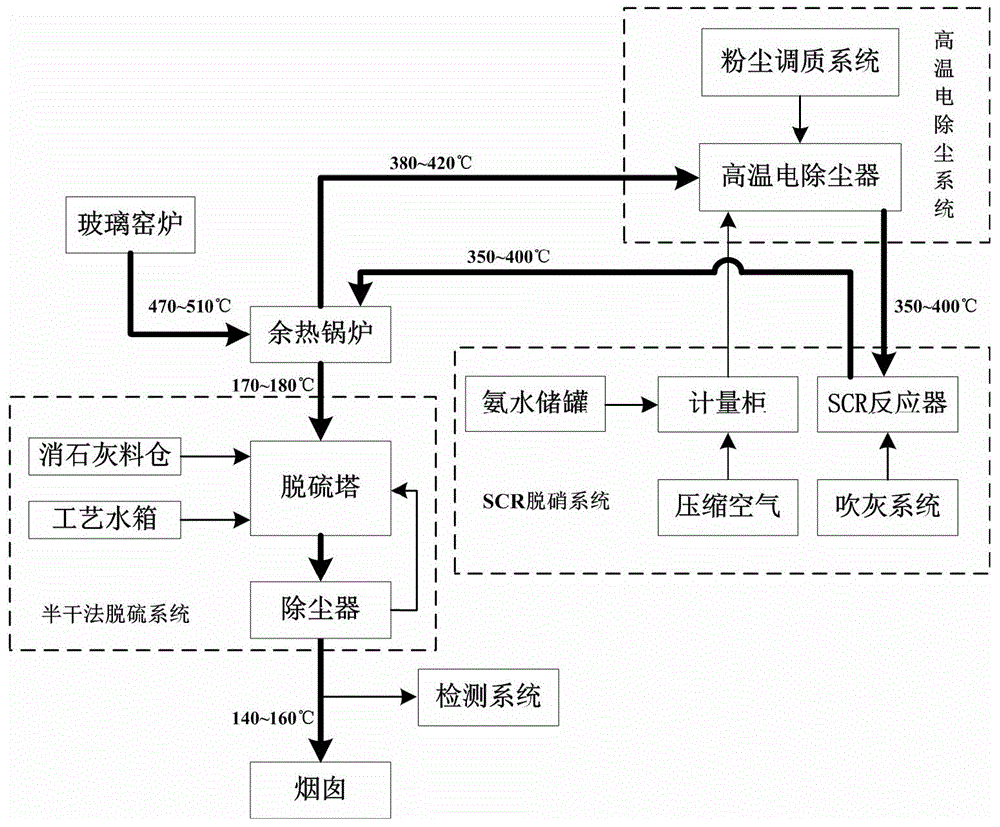

Comprehensive purification process of glass kiln smoke

InactiveCN104984640AImprove dust removal efficiencyHigh temperature resistantDispersed particle separationIncreasing energy efficiencyAtmospheric airEngineering

The invention discloses a comprehensive purification process of glass kiln smoke. The comprehensive purification process comprises the process flows of performing waste heat recovery on high-temperature smoke generated by a glass kiln through a waste heat boiler, leading the smoke into a high-temperature electric precipitator system for high-temperature smoke dust removal treatment in the section of the waste heat boiler at 380 to 420 DEG C, cooling the standard smoke after dust removal to 350 to 400 DEG C, so as to satisfy the requirement of the best active temperature of an SCR denitration catalyst, then leading the smoke after dust removal into an SCR denitration system for removing NOx, leading the smoke after denitration back to the waste heat boiler for waste heat recovery, and leading the smoke into a desulfurization system with a semidry method after the smoke in the waste heat boiler is cooled to 170 to 180 DEG C, so that the standard smoke after desulfurization is cooled to 140 to 160 DEG C and then is discharged into the atmospheric environment through a chimney. The glass kiln smoke after process treatment by adopting the comprehensive purification process reaches the regulations of related national environmental protection discharge standards of a glass industry, the dust discharge concentration is lower than 50 mg / m<3>, the NOx discharge concentration is lower than 700 mg / m<3>, and the SO2 discharge concentration is lower than 400 mg / m<3>.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

On-vehicle camera lens glass material and on-vehicle camera lens

InactiveCN101271165AExcellent chemical durabilityImprove resistance to damageOptical viewingOptical elementsCamera lensRefractive index

This invention provides an on-vehicle camera lens glass material with excellent resistance to acid rain or medicine and full hardness, which comprises high reflection ratio through reducing the characteristic deterioration caused by ultraviolet ray, and is suitable for composing optical components such as on-vehicle camera lens on the on-vehicle camera which can be exposed under cruel environment, additionally, this invention provides an on-vehicle camera lens made of this on-vehicle camera lens glass material. The on-vehicle camera lens glass material satisfies at least one of conditions in which a measurement result in water resistance based on a powder method prescribed by Japanese Optical Glass Industrial Standard is the first class; a measurement result in Knoop hardness based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is sixth class or higher; a measurement result in solarization based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is 2% or less; and a measurement result in average linear expansion coefficient based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is less than 100*10(-7) DEG C (-1).

Owner:HOYA CORP

Spherical calcium oxide adsorbent and preparation method thereof

InactiveCN102949978AImprove water absorptionReduce manufacturing costOther chemical processesDispersed particle separationClay mineralsSorbent

The invention relates to a spherical calcium oxide adsorbent and a preparation method of the spherical calcium oxide adsorbent. The spherical calcium oxide adsorbent takes a high content calcium oxide mineral and a clay mineral as main raw materials. The spherical calcium oxide adsorbent is prepared from materials in percentage by weight: 50-95% of high content calcium oxide mineral, and 5-50% of clay mineral. The preparation method of the spherical calcium oxide adsorbent comprises the steps of: mixing the high content calcium oxide mineral and the clay mineral, taking a CMC (carboxyl methyl cellulose) aqueous solution in the concentration of 0-10% as an assistant, molding in a spherical pellet granulator, screening spherical particles in a certain particle size range by two layers of sieves, further drying, roasting and packaging the spherical particles to obtain the spherical calcium oxide adsorbent. The spherical calcium oxide adsorbent is chemically prepared from 40-95% of calcium oxide, 0.5-49.5% of magnesium oxide, 3-30% of silicon dioxide, 1-30% of aluminum oxide, 0-30% of sodium oxide, and 0.5-5% of ferric oxide. The spherical calcium oxide adsorbent has favorable selective adsorption performance and wear-resistant performance. Moreover, the spherical calcium oxide adsorbent can be used as a desiccant used in the hollow glass industry, and also can adsorb acid gases such as hydrogen sulfide, hydrogen chloride, sulfur dioxide and the like to purify the industrial waste gases.

Owner:金松

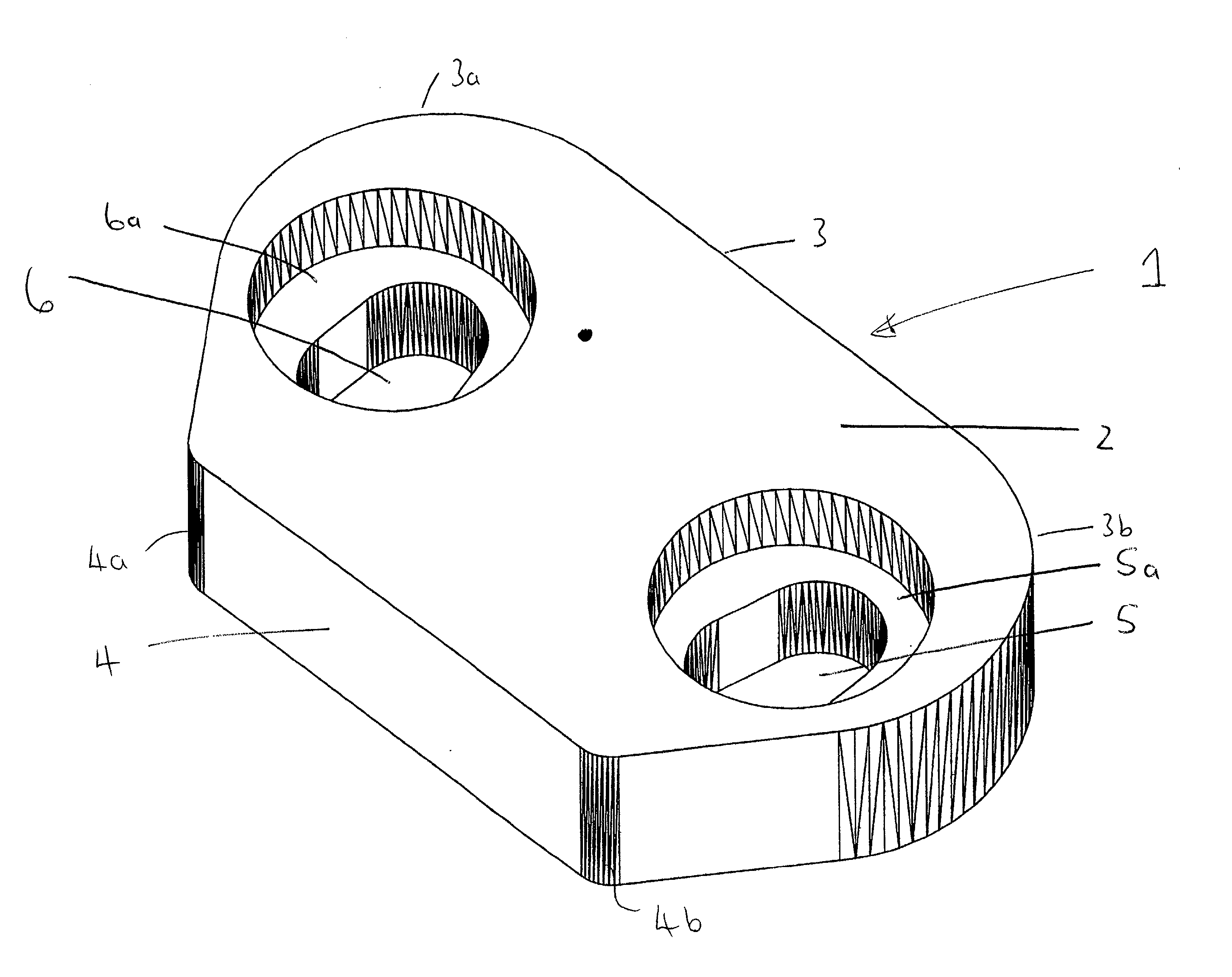

Enclosure member

The present invention relates to a multi-link conveyor chain which may be used (for example) in the glass industry and to an enclosure member for use in the multi-link conveyor chain.

Owner:PENNINE INDAL EQUIP

Novel multi-layer coating angularly heterochrome interference color pearlescent pigment

The invention discloses a novel multi-layer coating angularly heterochrome interference color pearlescent pigment, which takes a transparent or a semitransparent sheet as a substrate. High refractive index coating and low refractive index coating are repeatedly coated on the outer surface of the substrate in sequence in an alternating manner, wherein, the number of the coating is at least three layers; the low refractive index coating is arranged between two high refractive index coatings; intermediate transitional coatings with gradually changed refractive indexes are arranged between the high refractive index coating and the low refractive index coating, and between the low refractive index coating and the high refractive index coating; the intermediate transitional coating is composed of metallic silicate, metallic aluminate and mixture composed of the metallic silicate, the metallic aluminate, high refractive index metallic oxide and low refractive index compound. Because of the existence of the intermediate transition coating, the pigment provided by the invention enables the color-changing transition region color variability to be more clear and obvious, and the color saturation to be higher. The pigment can be used in automobile paint, cosmetic formula, paint, printing ink, plastics and glass industries.

Owner:林一中

Sea water desalting device for heating sea water by using residual heat of waste gas

ActiveCN104150671AImprove heat utilizationNo emissionsGeneral water supply conservationSeawater treatmentEvaporationEngineering

Owner:孔令斌

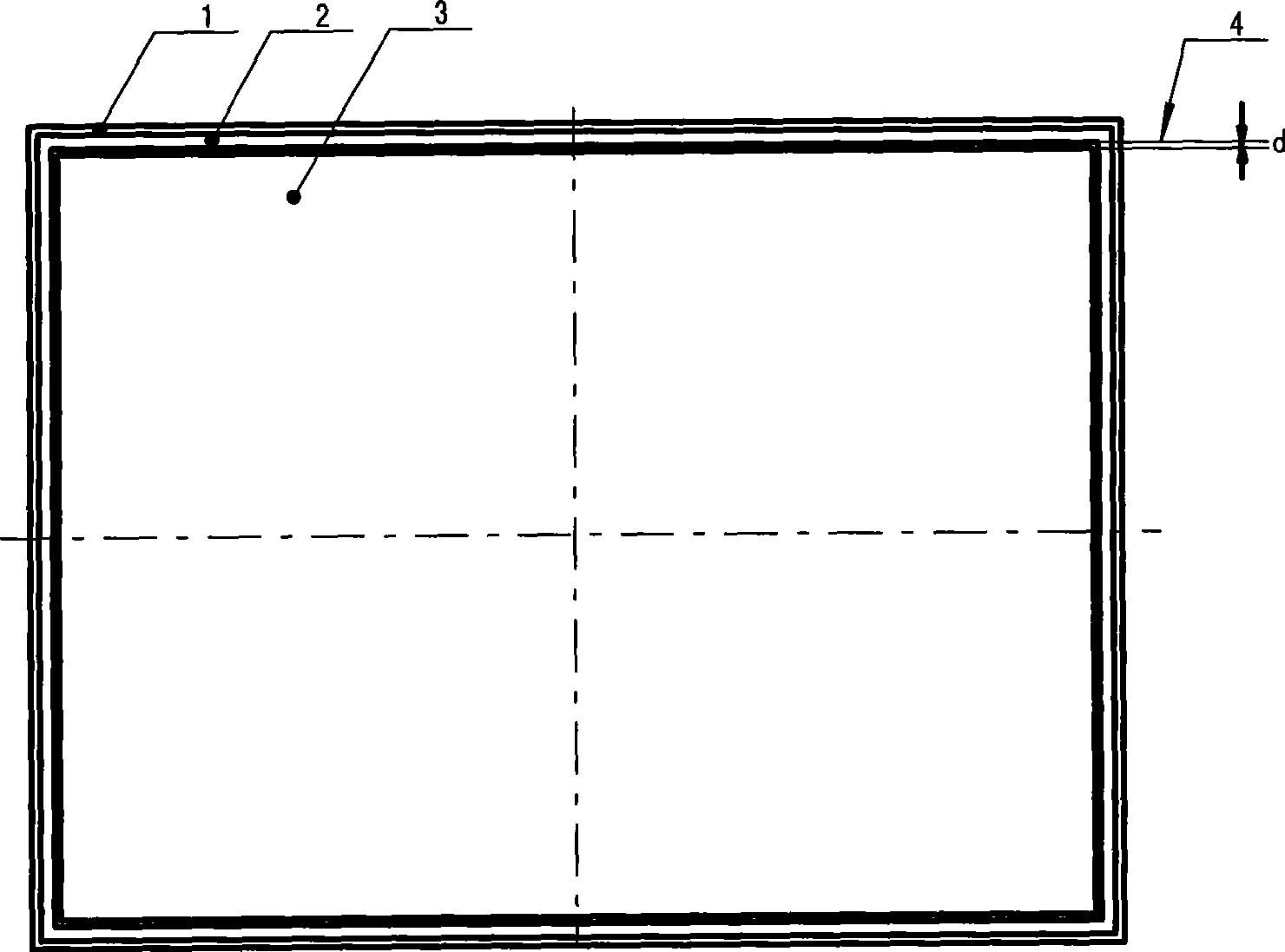

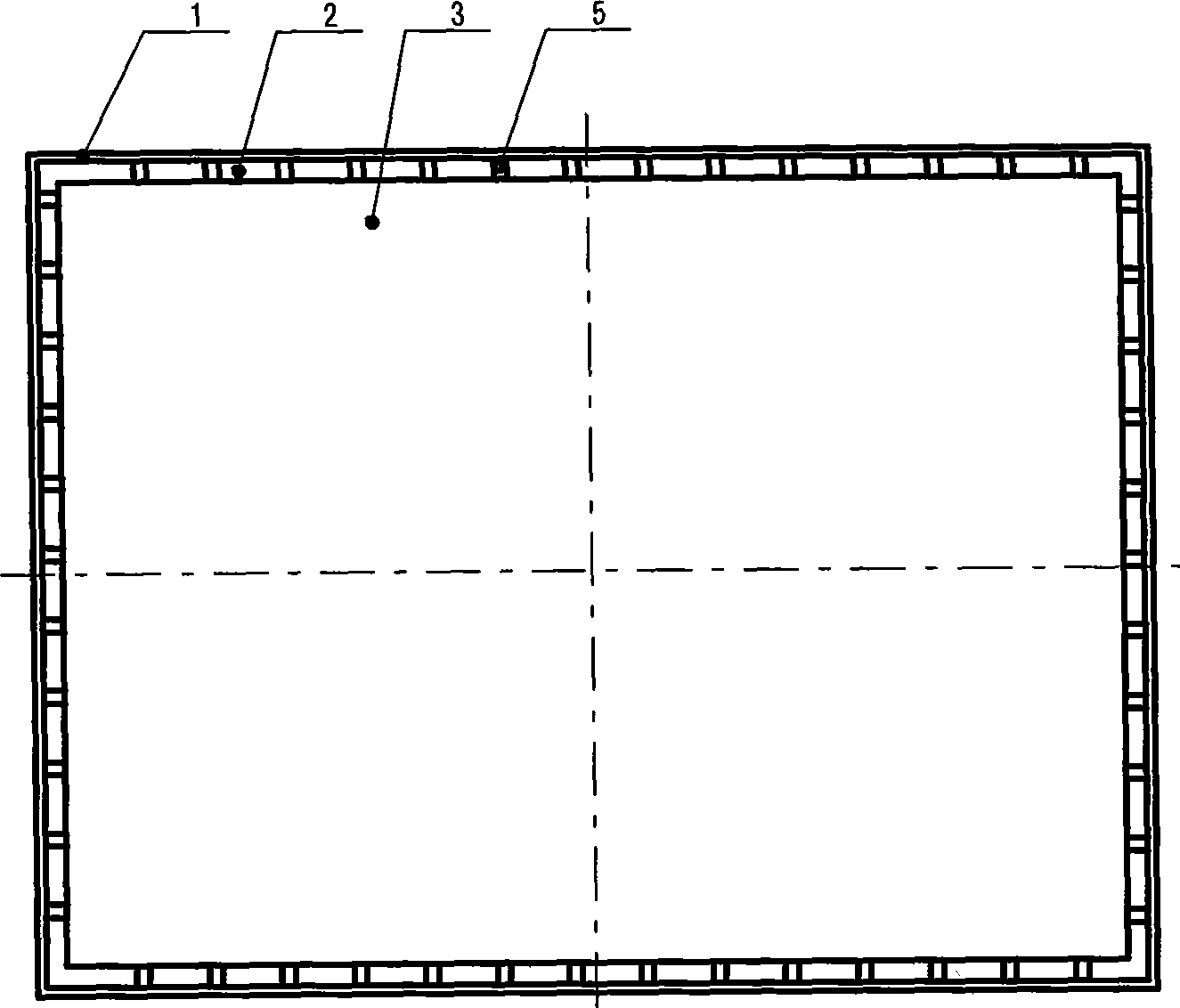

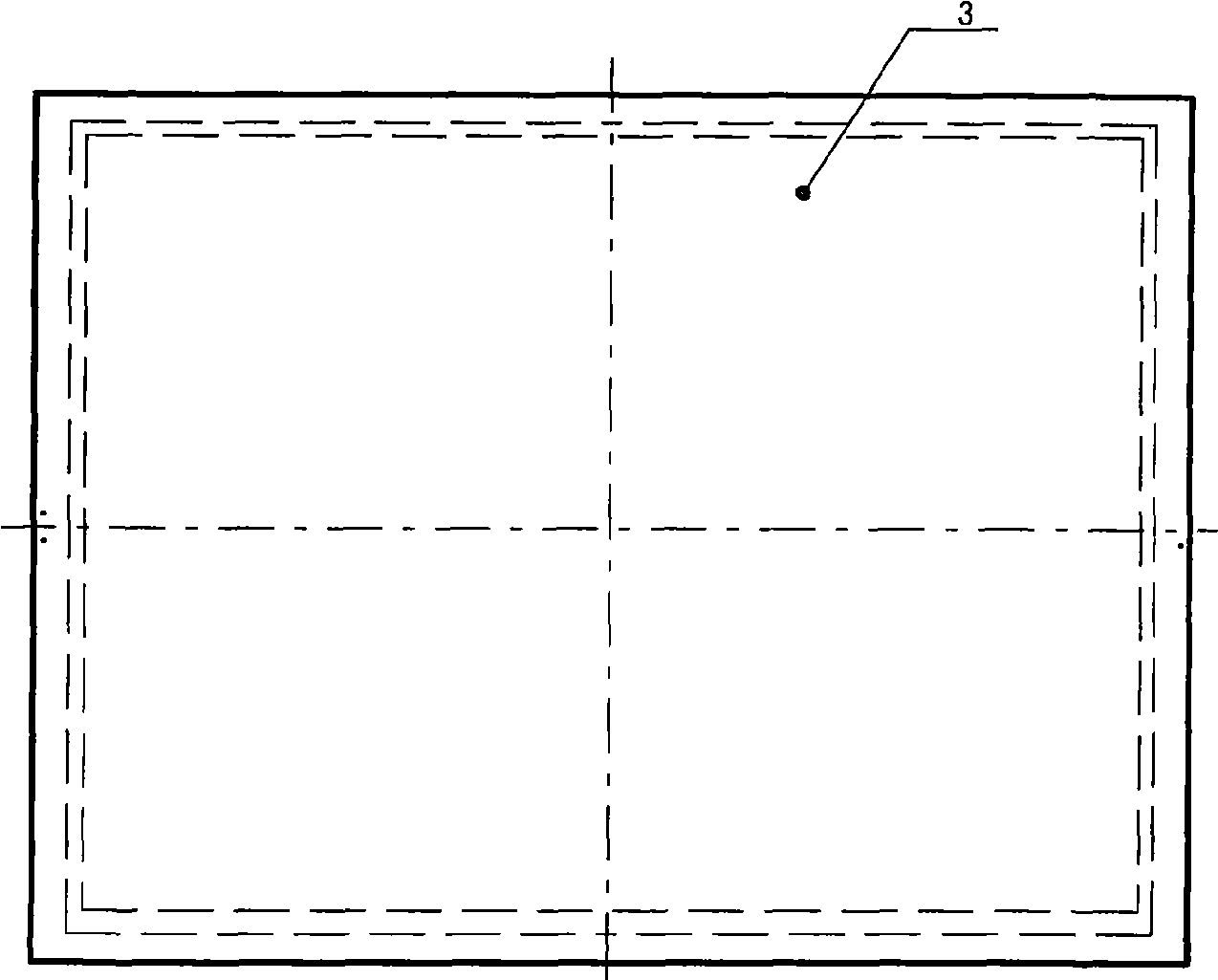

Automatic edge sealing process for vacuum glass

InactiveCN101481205AImprove the effect of edge bandingBeautiful edge bandingGlass reforming apparatusHeating furnaceAir tightness

The invention relates to an automatic edge sealing technology for vacuum glass, which comprises the following steps of arranging supporters on basal board glass, arranging upper plate glass on the basal board glass, using low melting-point glass powder between the upper plate glass and the basal board glass for sealing edges, placing the upper plate glass and the basal board glass into a vacuum heating furnace to be heated and taking out upper plate glass and the basal board glass to get a finished vacuum glass, wherein in the step of using the low melting-point glass powder for sealing the edge, a section bar of low melting-point glass powder or the low melting-point glass powder is arranged on the basal board glass, and a gap of air escaping in the evacuation in the heating furnace is left in a chamber formed between the basal board glass and the upper plate glass. The invention has simple integrated structure, greatly shortens the evacuation time, increases the work efficiency, has reliable automatic evacuation and sealed package, good air tightness, little air leakage hazard, attractive appearance and production technology simplification, greatly promotes the development of the vacuum glass industry, and is particularly suitable for the industrialized, the scale and the standardized production of the vacuum glass.

Owner:左树森

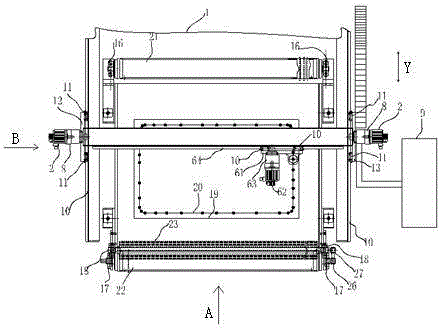

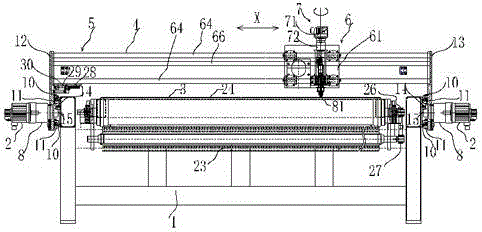

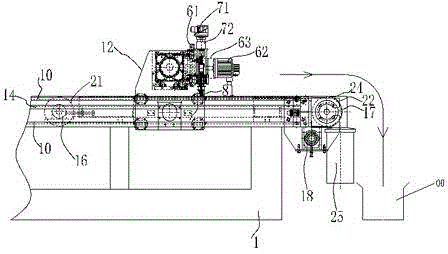

Automatic glass cutting machine

The invention relates to a cutting machine, particularly an automatic glass cutting machine. Both sides of a machine frame (1) are respectively provided with a Y-direction guide rail (10); the Y-direction guide rail (10) is provided with a Y-direction mobile device (5); the Y-direction mobile device (5) makes a Y-direction reciprocating motion under the driving action of a Y-direction mobile servomotor installed beside the Y-direction guide rail (10); the Y-direction mobile device (5) comprises an X-direction cross beam (4) and an X-direction rack (66) which are installed between two fixed ends (13); and the X-direction cross beam (4) is fixedly provided with an X-direction mobile device (6). By adopting the double-drive automatic-cutting mode, the unique structure and control method of the cutting tool bit and the effective filter unit for glass residues, the automatic glass cutting machine improves the condition that the products processed by most cutting machine devices in automobile glass industry have the defects of low yield and low speed.

Owner:GUANGDONG NORTHGLASS ZHENXING GLASS TECH IND CO LTD

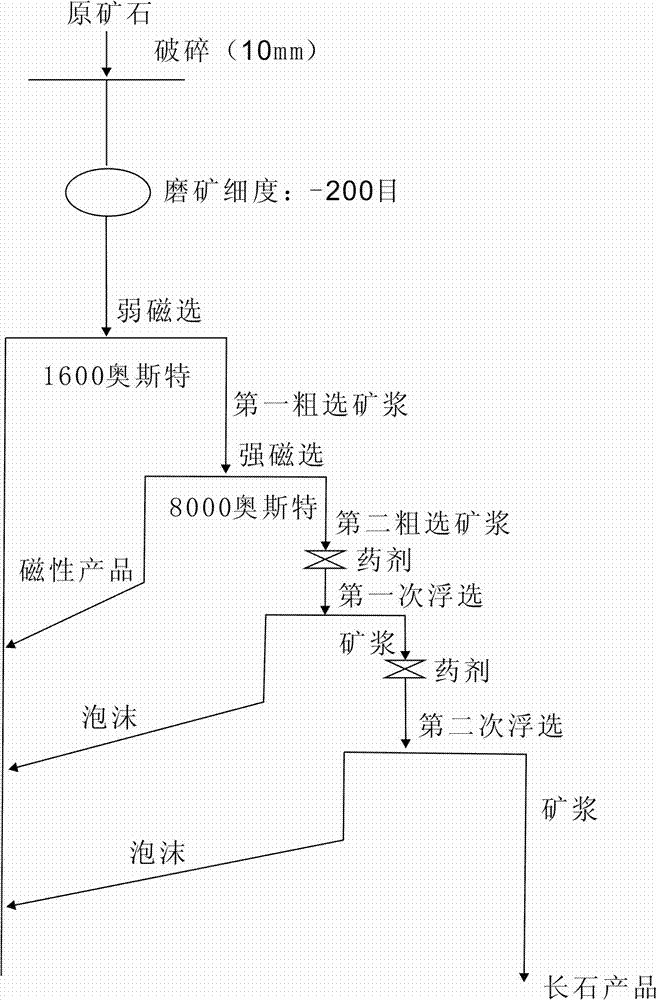

Feldspar quarry beneficiation process

The invention discloses a feldspar quarry beneficiation process which includes conducting breaking and grinding on feldspar quarry raw ore, adopting SLon magnetic separators to conduct strong magnetic separation and weak magnetic separation, then conducting secondary floatation to obtain feldspar concentrate with the content of Fe2O3 smaller than 0.1%. The beneficiation process is characterized in that under the condition that the raw ore is ground to certain fineness, a weak SLon magnetic separator and a strong SLon magnetic separator are sequentially adopted to conduct magnetic separation, then floatation is conducted under the specific process condition to enable the content of iron in the feldspar quarry raw ore to be reduced to below 0.1% to obtain good feldspar quarry and reach the use standard in the glass industry. The process turns waste into wealth, adopts the mode that magnetic separation is conducted first and then floatation is conducted, the content of medicament added later is greatly reduced, the pollution is small, and the cost is lower.

Owner:四川南江新兴矿业有限公司

Method for drilling vacuum glass

ActiveCN101671111AImprove quality levelImprove shape look and feelGlass reforming apparatusQuality levelHeating furnace

The invention relates to a method for drilling vacuum glass, which comprises the following steps: setting supporters; combining glass sheets and setting edge sealing; heating the glass in a heating furnace; vacuumizing the glass; and sealing. Glass holes are arranged on substrate glass and upper glass, and are subjected to edge sealing by adopting low melting-point glass powder or the low melting-point glass powder is distributed in a drilling area between the substrate glass and the upper glass firstly before the glass sheets are combined. The drilling method has a simple process and scientific design, changes the convention assembly mode that a framework is sealed on the edge of the vacuum glass, improves the firmness and stability of connecting assembly between vacuum glass, has good look and feel, high quality level, high strength and long service life, is easy for realizing industrial mass production, is a revolutionary innovation for the vacuum glass manufacture process, and hasgreat promoting effect for the development of the vacuum glass industry.

Owner:TIANJIN GUSHANG VACUUM GLASS MFG

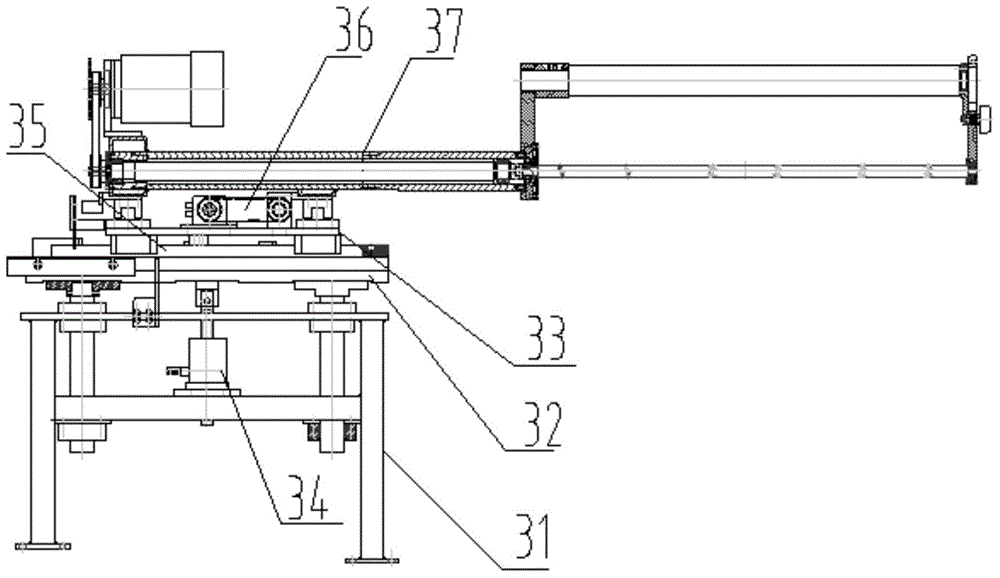

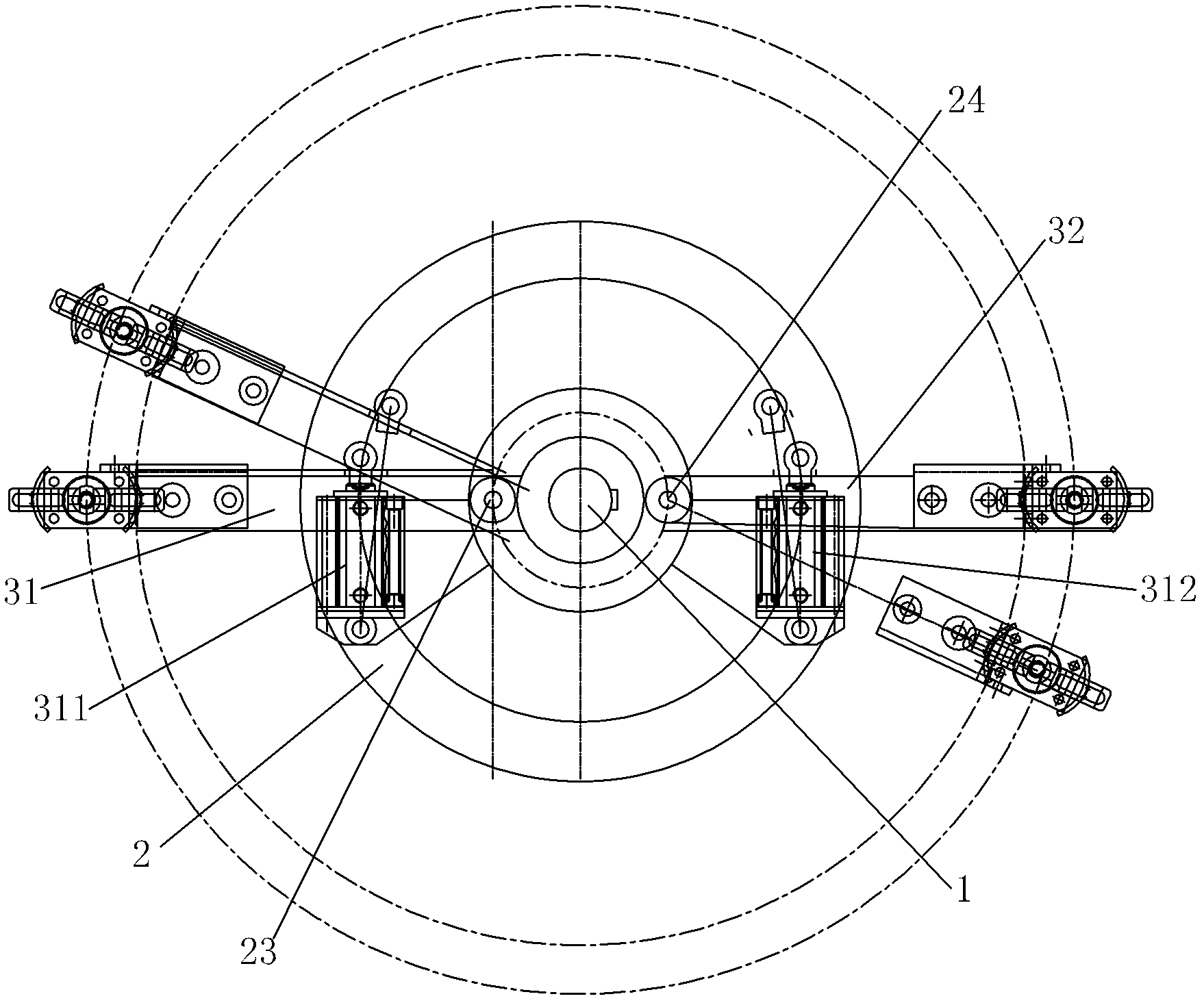

Novel high-speed glass fiber indexing cake winder

The invention relates to a novel high-speed glass fiber indexing cake winder. The cake winder comprises a rack as well as a tube unloading mechanism, an arranging mechanism, a fiber stopping mechanism, a water pipe, an impeller, a spindle and a turnover mechanism which are mounted on the rack, wherein the tube unloading mechanism is mounted at the lower part of the rack, and the arranging mechanism is mounted in the middle of the rack; the fiber stopping mechanism is mounted at the top of the rack, and the water pipe is mounted on one side of the upper part of the rack through a locknut; the spindle is mounted on the rack through a turn plate, the impeller is mounted at one end of the spindle, and the other end is in transmission connection with the turnover mechanism; the turnover mechanism is fixed at the bottom of the rack. After successful research and development of the project, the domestic blank can be filled up, and the project can reach the international advanced level; according to the packaged technology of the project, the bottleneck problem for development of the industry can be solved effectively, the production of the glass fiber drawing machines of China as well as glass fiber drawing production technology and the automation degree is increased, and the whole glass fiber industry can be pushed forwards by a large step.

Owner:泰安佳成机电科技有限公司

On-vehicle camera lens glass material and on-vehicle camera lens

An on-vehicle camera lens glass material satisfies at least one of conditions in which a measurement result in water resistance based on a powder method prescribed by Japanese Optical Glass Industrial Standard is 1st Class, a measurement result in Knoop hardness based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is 6th Class or higher, a measurement result in solarization based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is 2% or less, and a measurement result in average linear expansion coefficient based on a measurement method prescribed by Japanese Optical Glass Industrial Standard is 100×10−7° C.−1 or less.

Owner:HOYA CORP

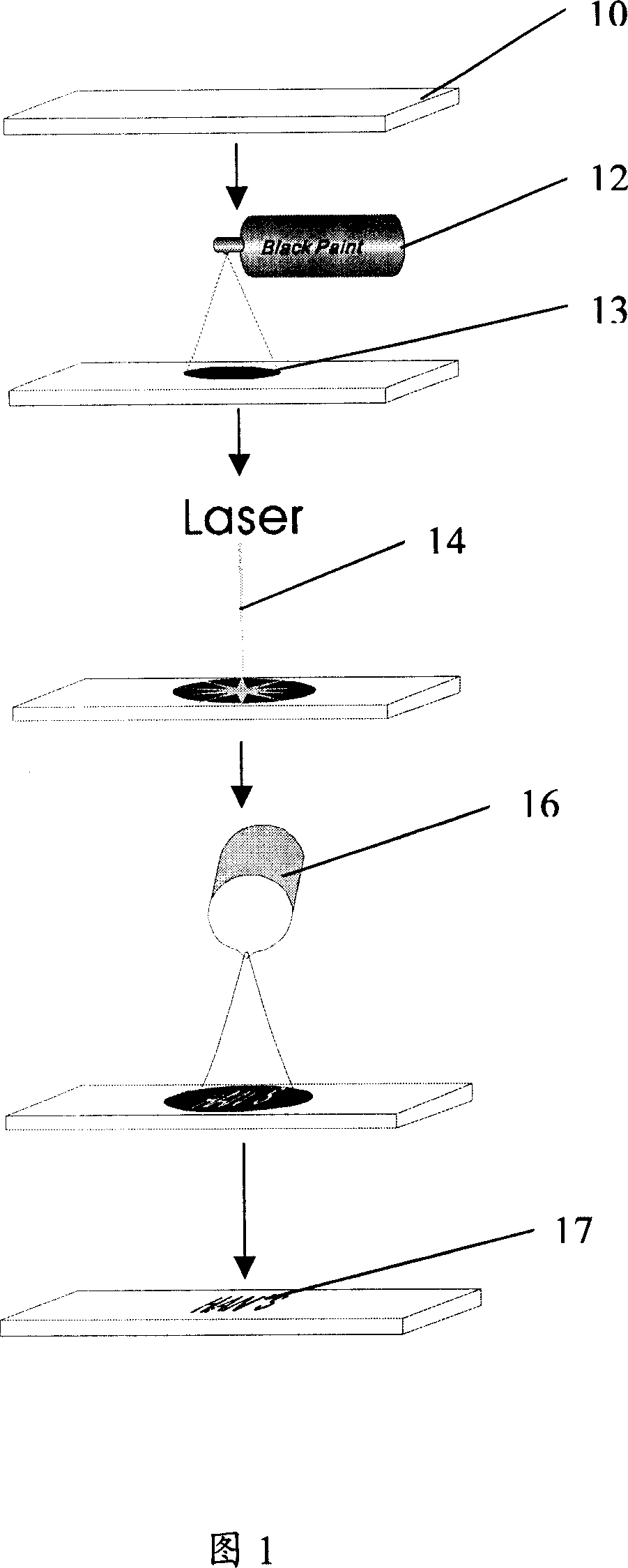

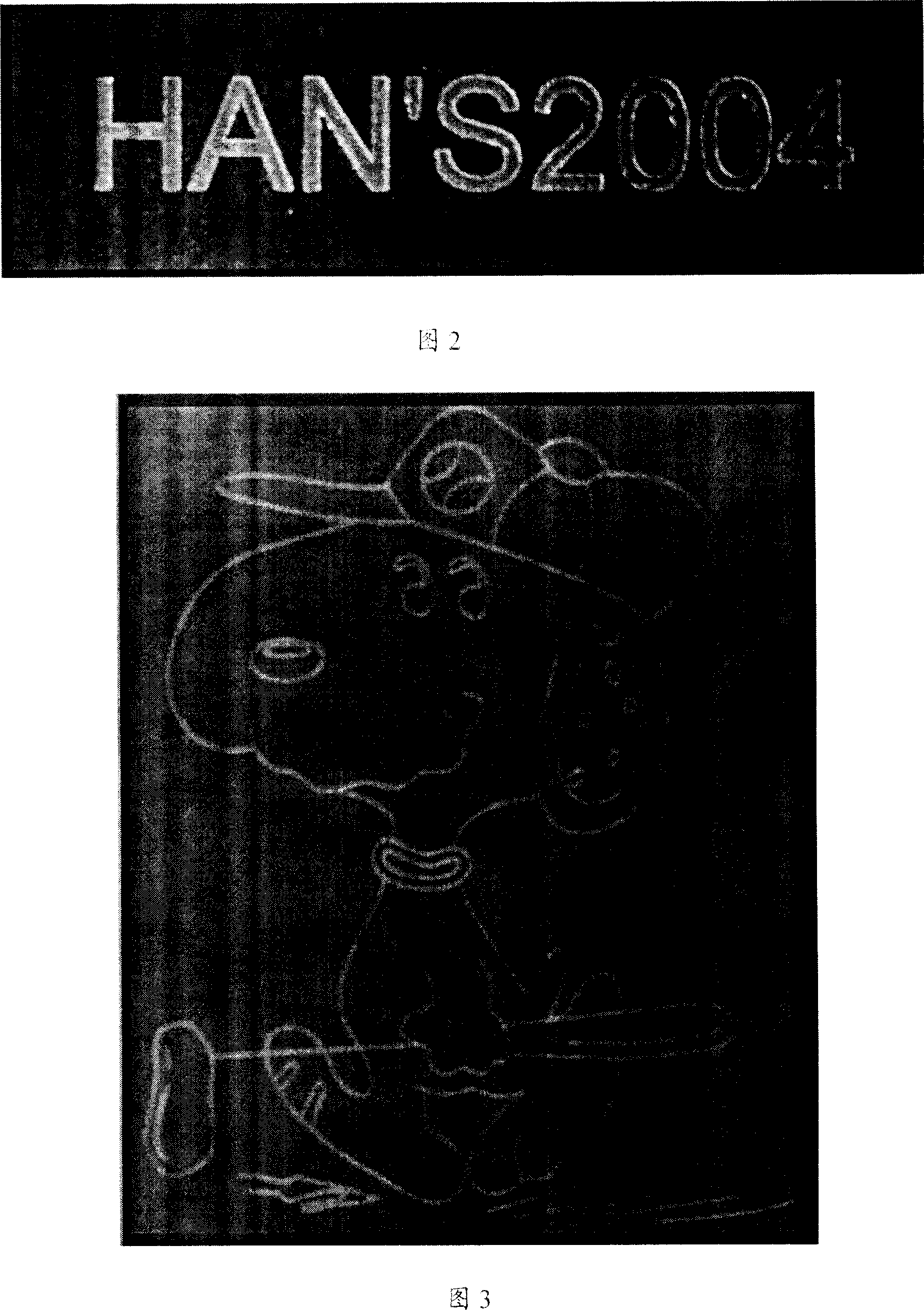

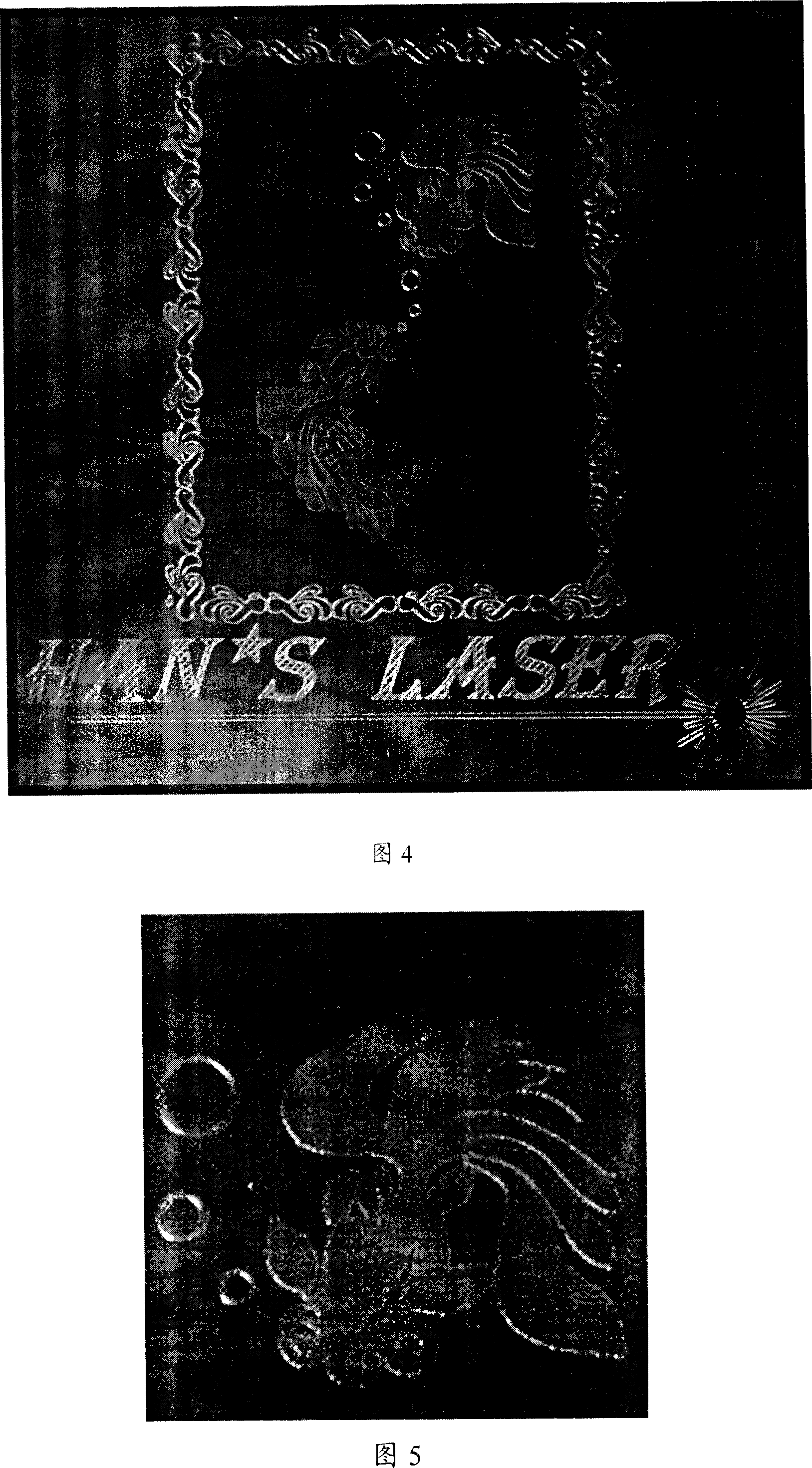

Method for marking on glass by YAG laser

The invention discloses a method of marking on a glass with YAG laser. The steps of the invention is that: first, a glass needed to be marked is chosen; second, a position needed to be marked on the glass by alignment is sprayed with black paint or black ink; third, lasers emitted by the YAG laser are used to mark on the position needed to be marked on the glass; fourth, the marked position is cleaned by means of cleaning fluid. The invention can increase the absorptivity of glass surfaces to near infrared laser and will greatly accelerate the application of the YAG laser on the glass industry.

Owner:HANS LASER TECH IND GRP CO LTD

Water dispersable glass fiber sizing material

The invention discloses a water dispersing sizing material for chopped glass fiber comprising, mixture dispersing agent including two nitrogen-containing organic compounds, protective agent formed by one or more polyhydroxy or carbonyl alcohols, esters and acyl polymers, humectant, lubricating agent, common silicane coupling agent in glass fiber industry including multicomponent alcohol mixture, and deionized water or distilled water for the rest. The sizing material can be applied to the dispersion of various alkali-free, medium alkali glass fiber in aqueous medium.

Owner:章峻

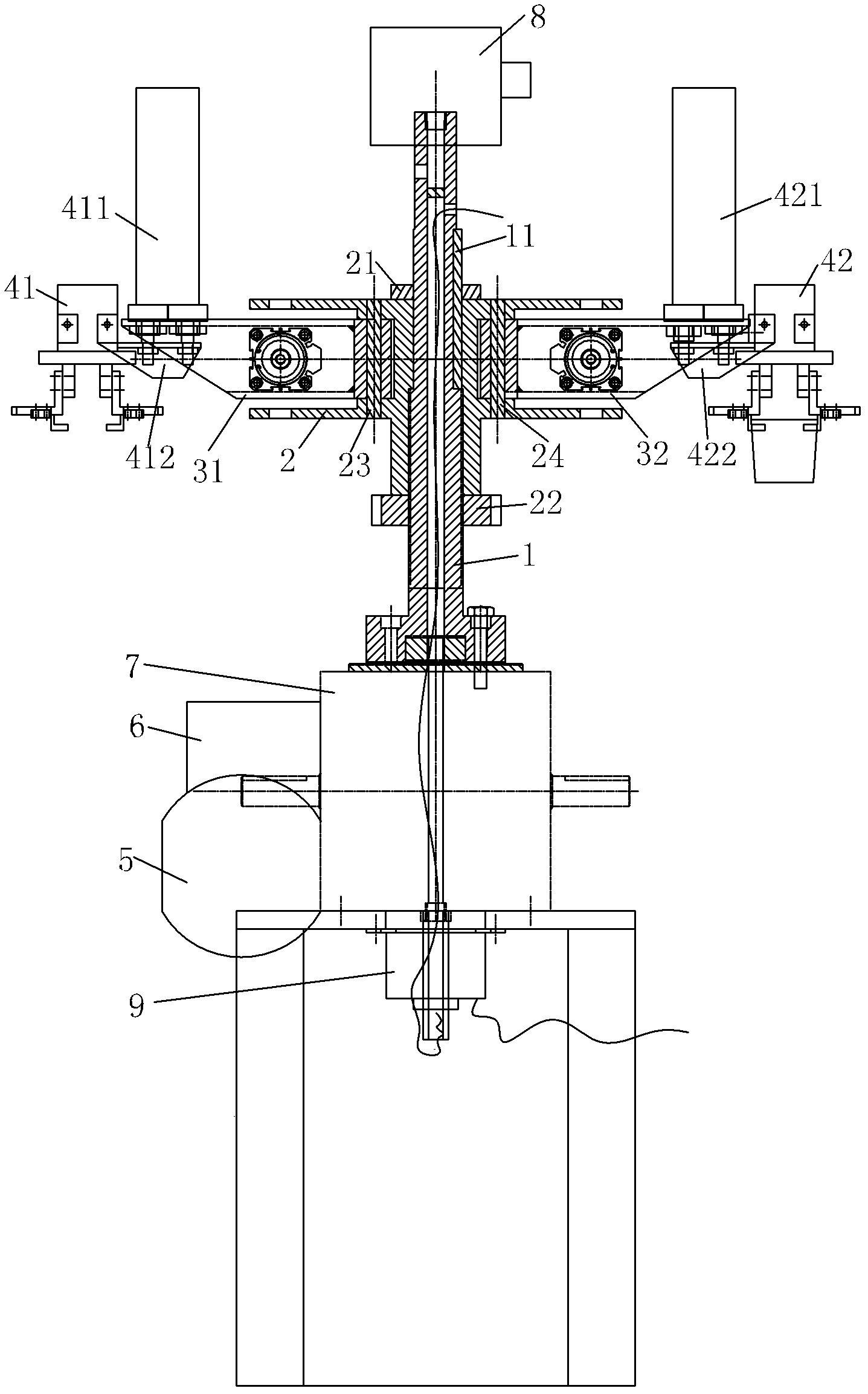

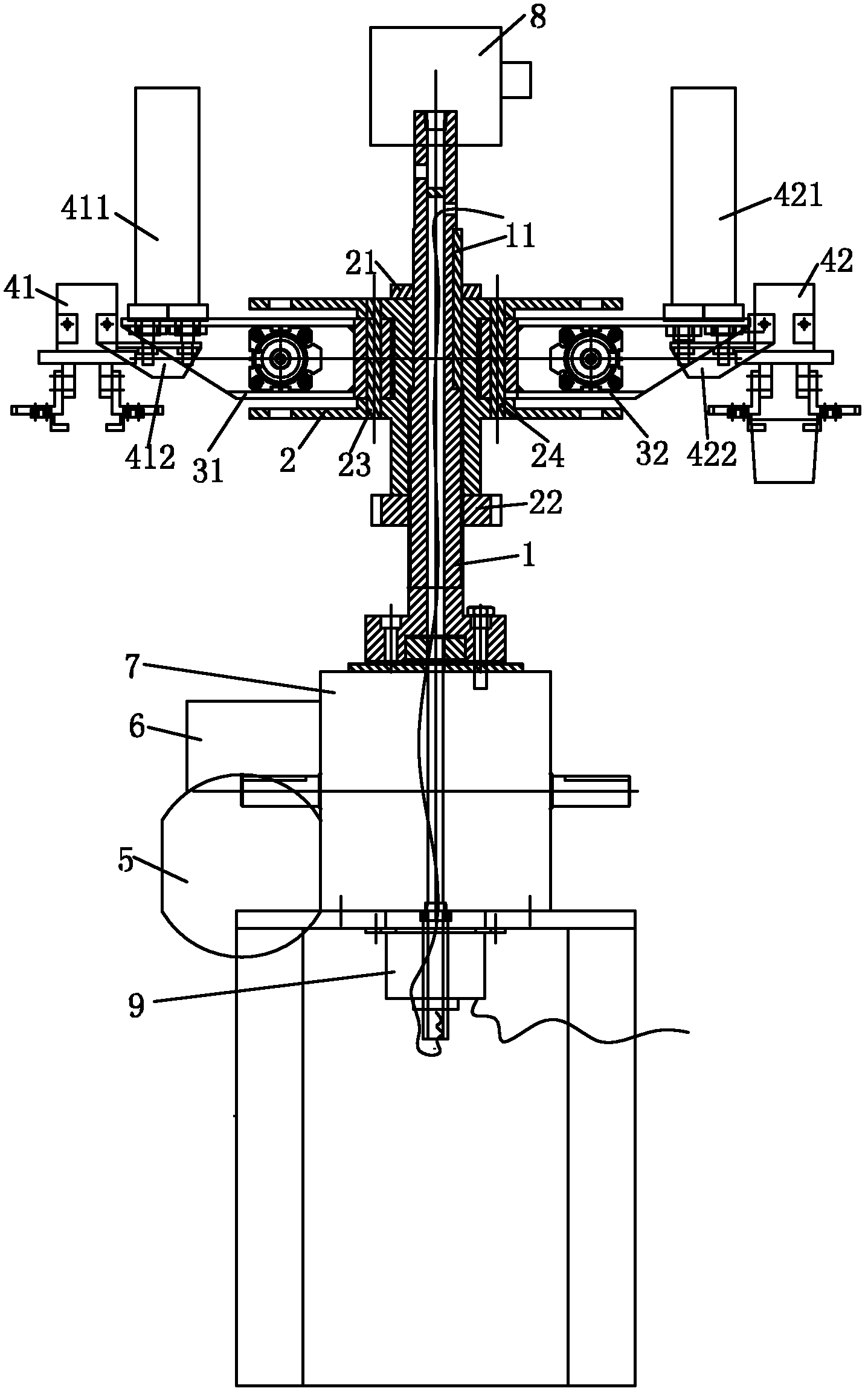

Cup fetching machine

A cup fetching machine belongs to the technical field of glass industries, and comprises a rotary center shaft, a sliding sleeve, first and second mechanical arms, first and second pneumatic fingers, a driving motor, an intermittent drive device, a rotary joint and a conductive slip ring, wherein the sliding sleeve is sleeved on the rotary center shaft; the first and the second mechanical arms are respectively connected to the sliding sleeve; first and second double bar extending cylinders are respectively fixed at free ends of the first and the second mechanical arms; the first and the second pneumatic fingers are respectively fixed on piston rods of the first and the second double bar extending cylinders; the intermittent drive device is connected with one end of the rotary center shaft; the rotary joint is connected with the other end of the rotary center shaft; the first and the second double bar extending cylinders are respectively connected with electromagnetic directional valves; compressed air source pipelines of the electromagnetic directional valves are connected with a rotating connector on the rotary joint; a static connector on the rotary joint is connected with a compressed air pipe network; circuit parts of the electromagnetic directional valves are respectively connected with a rotor part of the conductive slip ring; and a stator part of the conductive slip ring is connected with a control device. The cup fetching machine has the advantages that the cup fetching efficiency is greatly improved.

Owner:刘亢

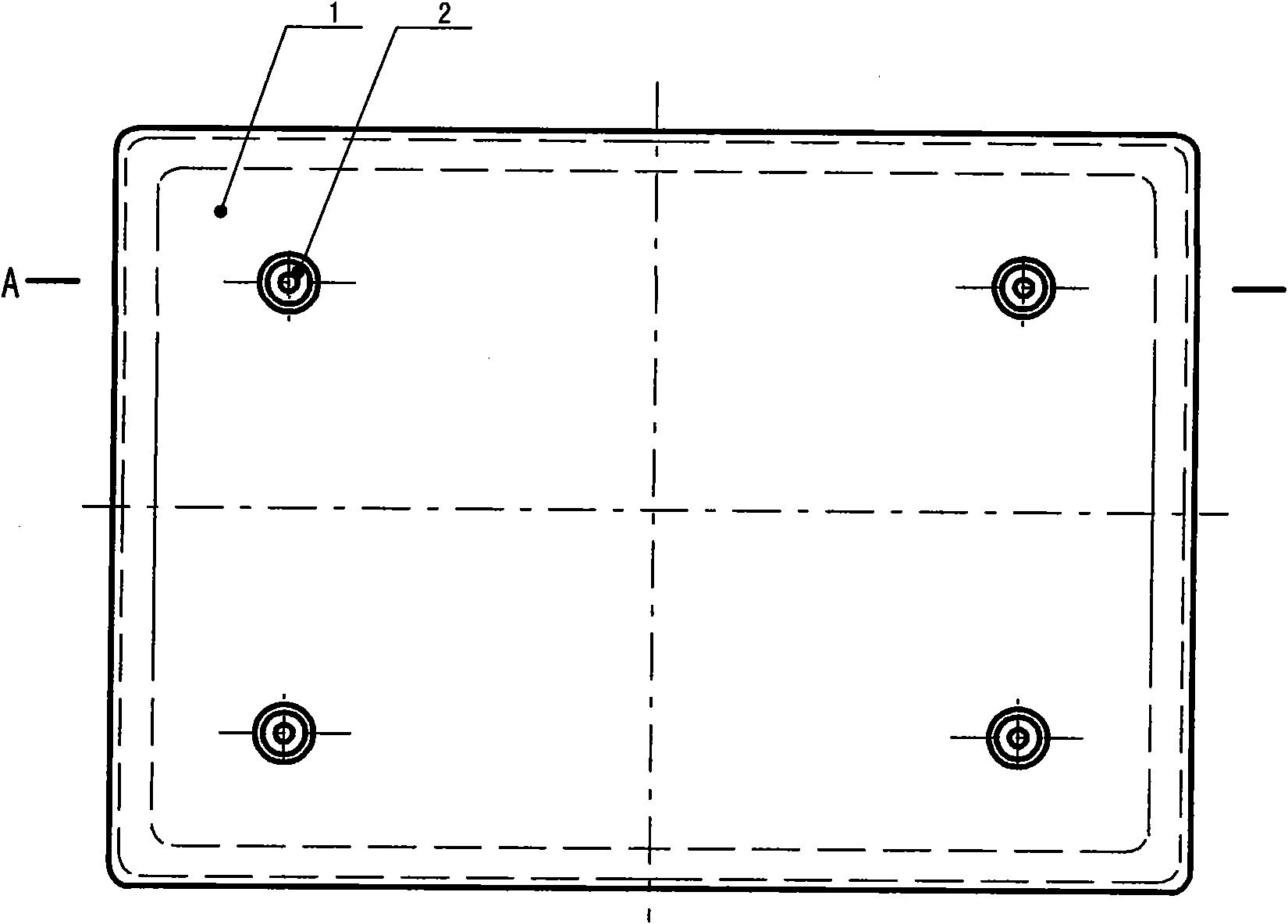

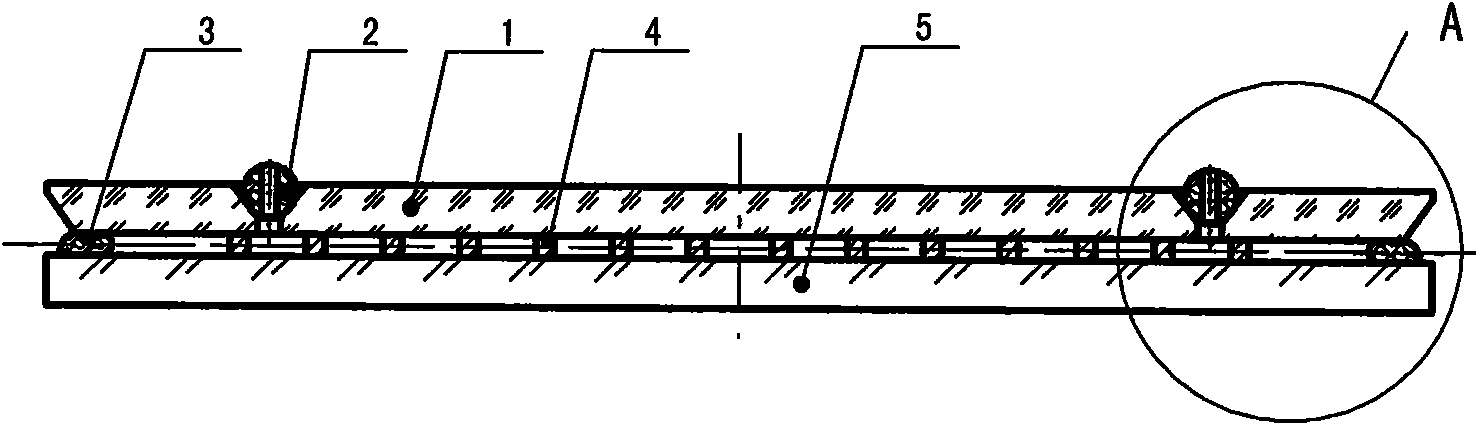

Fabricating method of vacuum glass with uniform stress

InactiveCN101565268AIncrease the support areaAvoid crackingGlass reforming apparatusBreakage rateHeating furnace

The invention relates to a fabricating method of vacuum glass with uniform stress, which comprises the following steps: firstly, arranging bonding points on substrate glass; secondly, bonding low melting glass powder and solid support; thirdly, combining sheet and arranging a seal edge; fourthly, heating the sheet in a heating furnace; and fifthly, vacuumizing and sealing so that the vacuum glass can be obtained. The invention has simple process, convenient operation, low cost, high yield and high production efficiency, reduces the breakage rate to be less than 10 percent and is easy to realize the industrial massive production. The fabricated vacuum glass has uniform and consistent stress, good quality, high strength and long service life, is the creative development on the fabricating process of the vacuum glass, and has great promotion function on the development of the vacuum glass industry.

Owner:左树森

Method for manufacturing vacuum glass

InactiveCN101555095AStress reliefExtended service lifeGlass reforming apparatusMetallurgyGlass manufacturing

The invention relates to a method for manufacturing vacuum glass, which comprises the following steps: (1) processing the upper part of an upper piece of glass into an opened pumping through hole; (2) putting support objects on the upper plane of a lower piece of glass and placing the upper piece of glass on the lower piece of glass; (3) sealing vacuum glass edges and glass powder at the pumping through hole; (4) putting the sealed vacuum glass into a vacuum heating chamber for vacuumization at the vacuum degree of 10-10 Pa and steady heating at 300-500 DEG C for 10-60 minutes in a curve way; and (5) obtaining finished vacuum glass after the sealed vacuum glass is taken out of the furnace when temperature in the vacuum heating chamber slowly drops below 60 DEG C. The invention effectively overcomes the defects of the prior art, simplifies the process, improves the quality of appearance, reduces the manufacture cost of the vacuum glass, is a revolutionary innovation for vacuum glass manufacturing process and greatly promotes the development of the vacuum glass industry.

Owner:左树森

Enclosure member and multi-link conveyor chain

A multi-link conveyor chain suitable for use in the glass industry is provided. The conveyor chain includes an enclosure member having a non-tapered counterbore for retaining and protecting a pin head of an elongate pin thereby ensuring that the integrity of the multi-link conveyor chain during use is maintained. Also provided is a method for manufacturing the multi-link conveyor chain incorporating the enclosure member.

Owner:MARSHALL CHRISTOPHER

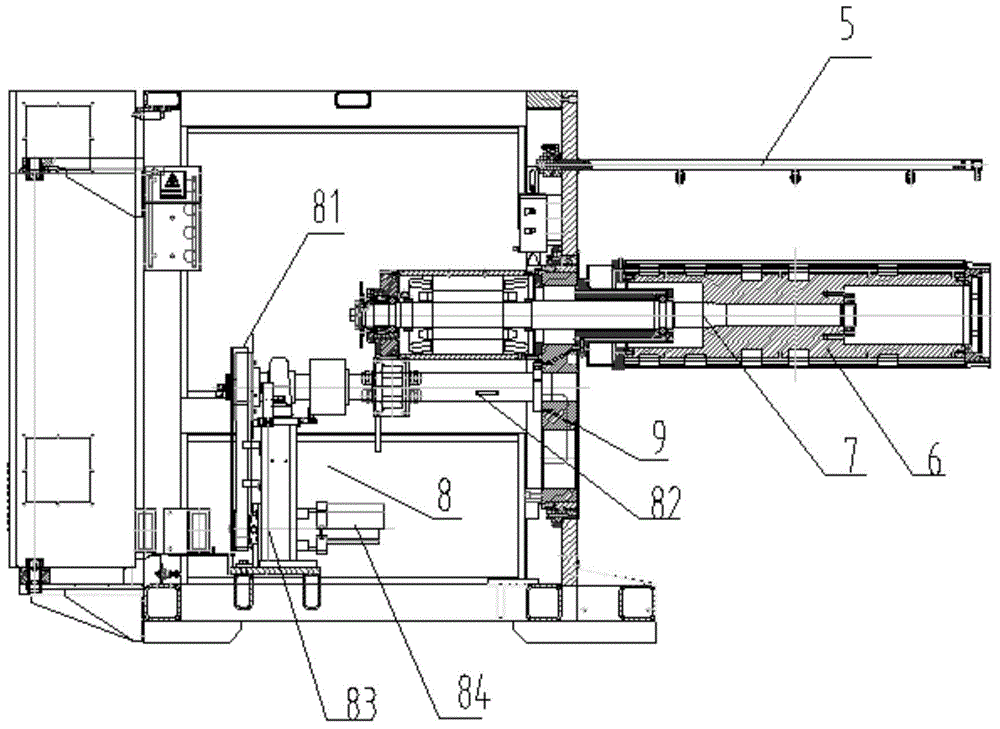

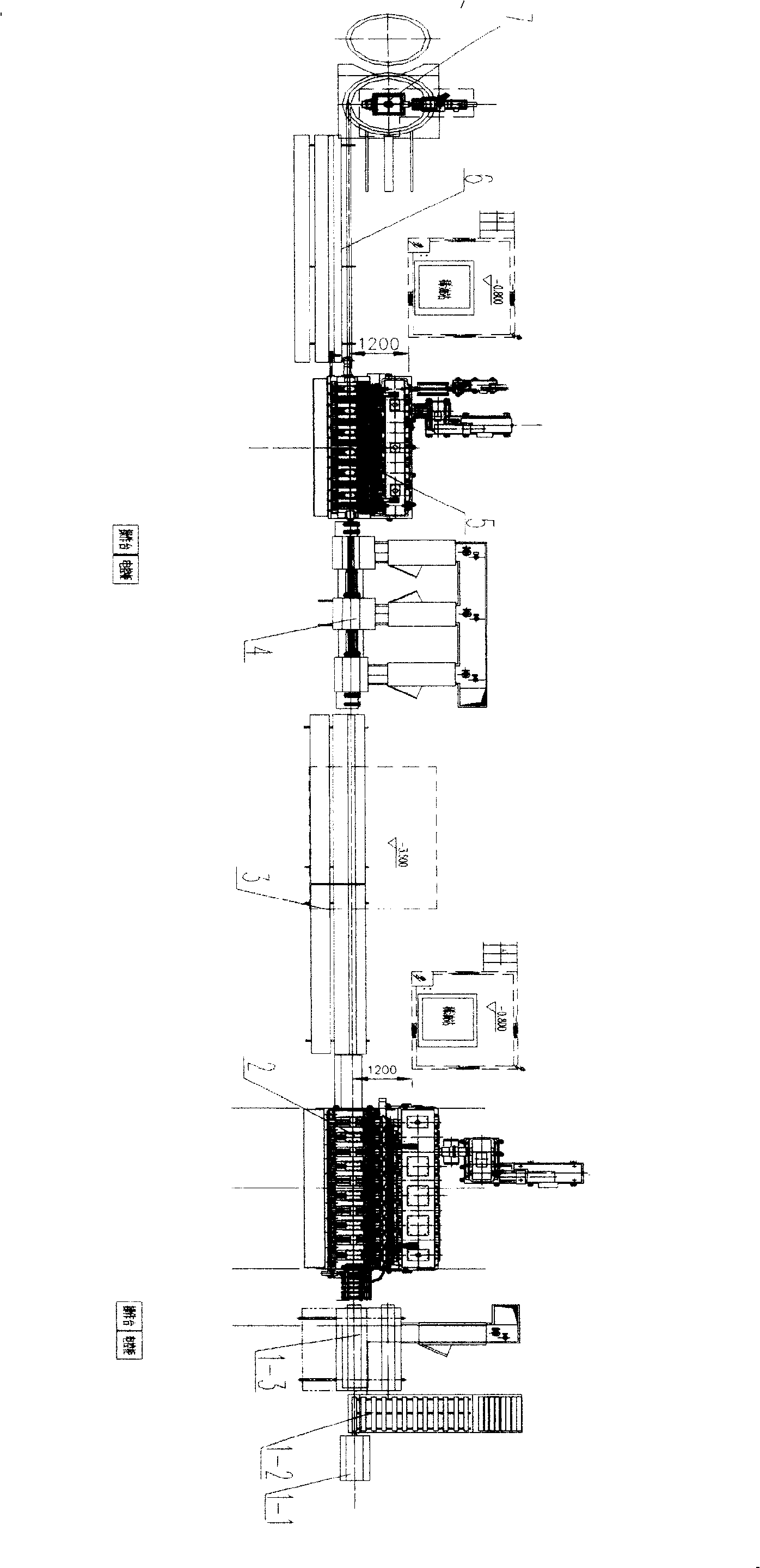

Large piece weight molybdenum, tungsten, titanium stick and wire coil blank

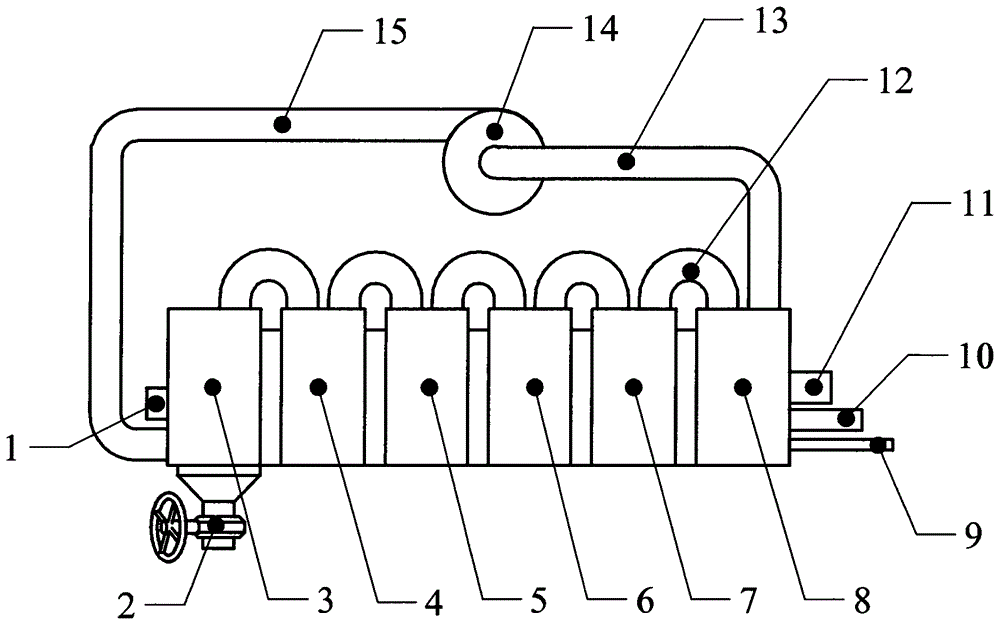

InactiveCN101294263AReapply extensionIncrease productivityTemperature control deviceElectric controlTubing types

The invention relates to a large unit heavy molybdenum, tungsten and titanium bar and a wire coil proximate matter, and adopts the manufacture method that heavy ingot cogging is adopted, on-line continuous heating and rolling is adopted without stop during the machining process, and long wire drawing is adopted during the finish rolling process. The invention mainly comprises an automatic bar material feeding machine, a medium-frequency induction sintering bar heating furnace, a feed adding mechanism, a three-roll Y type 10 stand roughing mill group, a tube-type conveying mechanism, an on-line three section superaudio induction heating furnace, a three-roll Y type 12 stand finishing mill group, the tube-type conveying mechanism, a recoiling machine, and an electronic control and fume extraction system. The large unit heavy molybdenum, tungsten and titanium bar and the wire coil proximate matter are the important raw material in the electric light source industry, the automotive industry, the glass industry and the machinery manufacturing industry.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

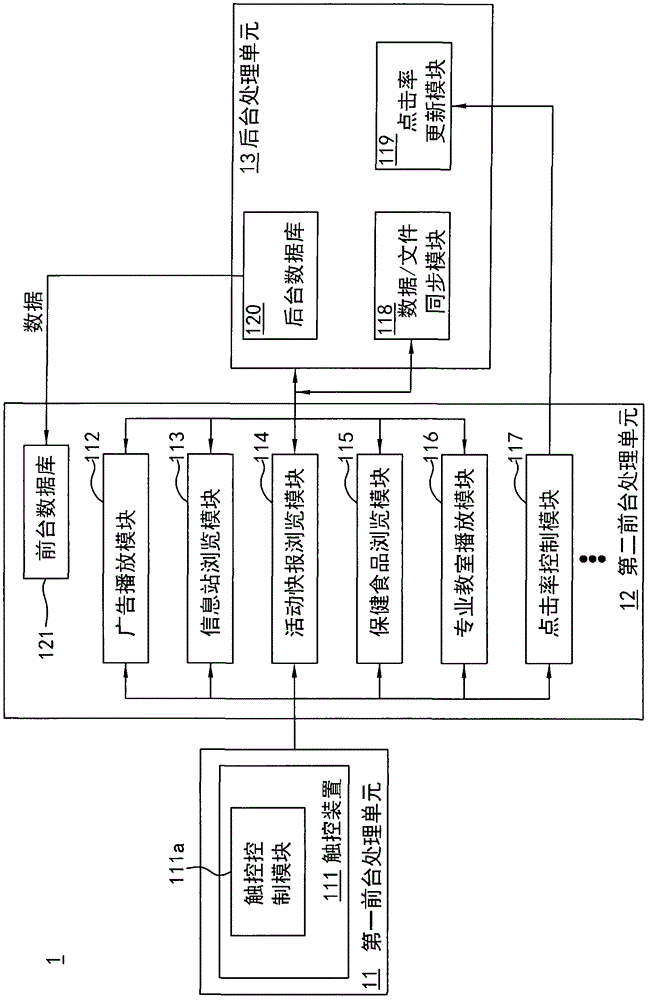

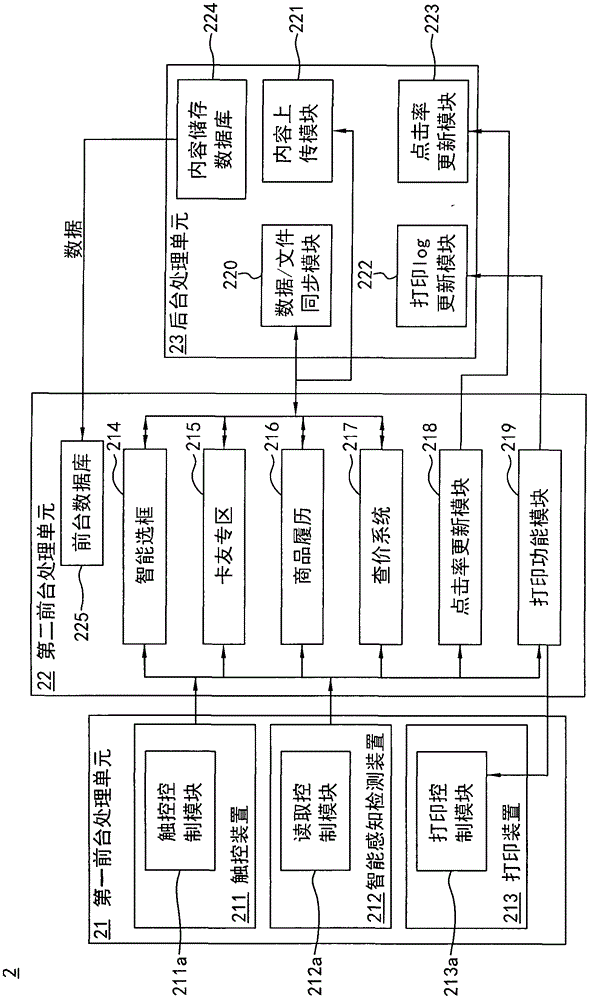

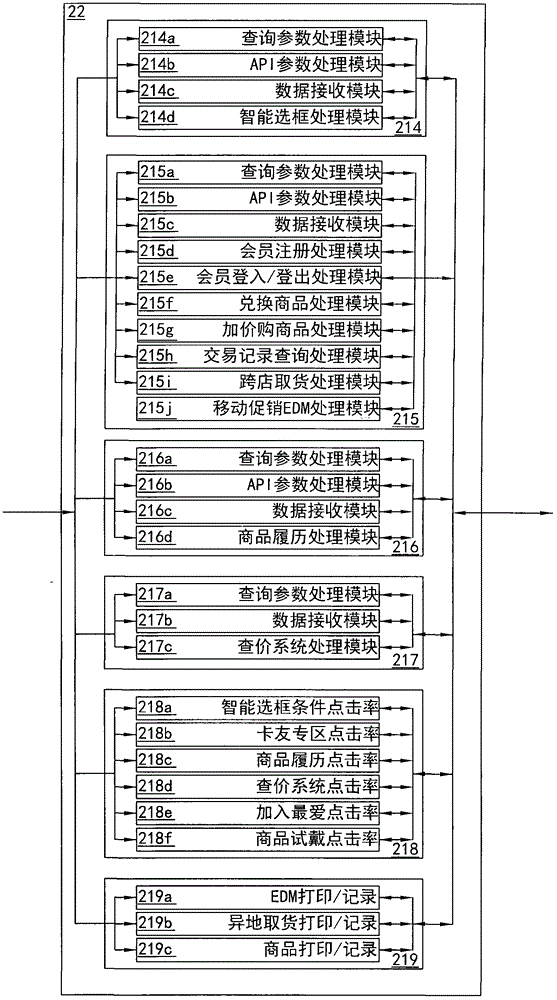

Intelligent machine interactive system service platform

InactiveCN103064579AMarketingInput/output processes for data processingHuman–computer interactionIntelligent machine

The invention discloses an intelligent machine interactive system service platform which is applied in the commodity marketing and member interaction service of the glasses industry. The intelligent machine interactive system service platform comprises a first foreground processing unit, a second foreground processing unit and a background processing unit, wherein the first foreground processing unit is used for providing a plurality of options for at least one user to choose, the second foreground processing unit is used for arranging and showing a plurality of information options corresponding to the selected option for the browsing of the user and playing at least one image in accordance with the option chosen by the user, and the background processing unit which comprises a plurality of option contents is used for transmitting and playing the option contents corresponding to the information options in accordance with the information options output by the second foreground processing unit, and is further used for managing and updating the plurality of option contents.

Owner:SOLUTIONS +1

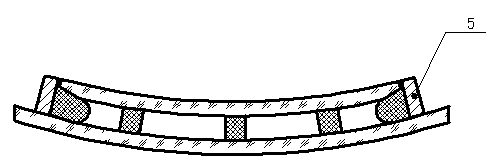

Manufacturing method of bent vacuum glass

The invention relates to a manufacturing method of bent vacuum glass. The method comprises the steps such as that: supports are arranged for supporting the bent glass; two glass pieces are closed; a filling material is adopted as a sealing material for sealing; vacuum pumping is carried out; an air pumping port is sealed. The method provided by the invention is innovative in that: an upper glass piece and a lower glass piece are hot-bent in a heating furnace; hot-bending is carried out on a mold with a certain deflection; the bending degrees of the two glass pieces forming the bent vacuum glass are kept similar; an adhesive is uniformly printed on the opposing inner surfaces of the two bent glass pieces; the supports are then arranged; and edge sealing and vacuum pumping are carried out, such that the bent vacuum glass is manufactured. The bent vacuum glass has a simple integral structure. The manufacturing process is reasonable. With the invention, a vacancy in glass industries is filled, and supports are provided for the developments of glass industries.

Owner:左树森

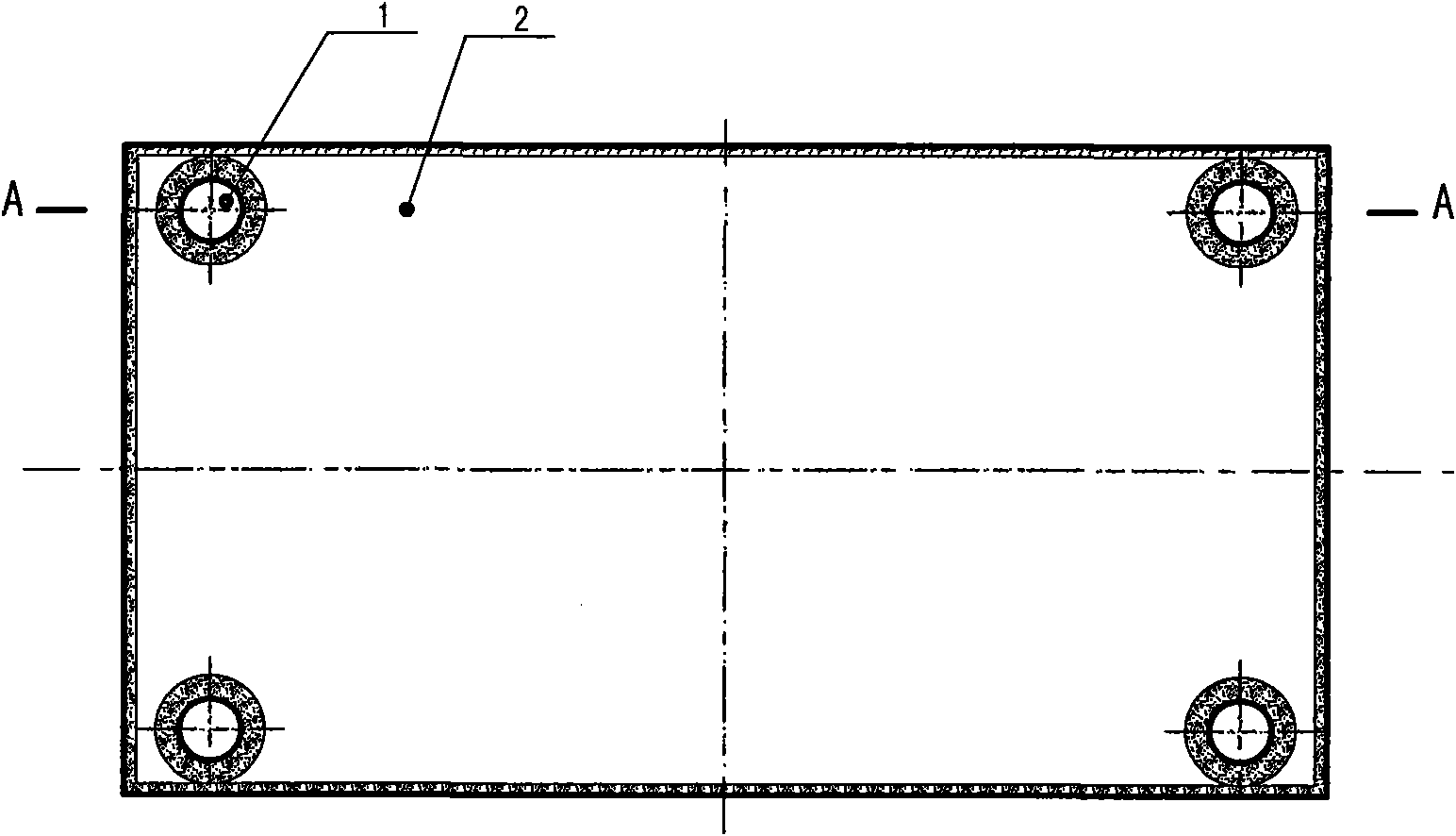

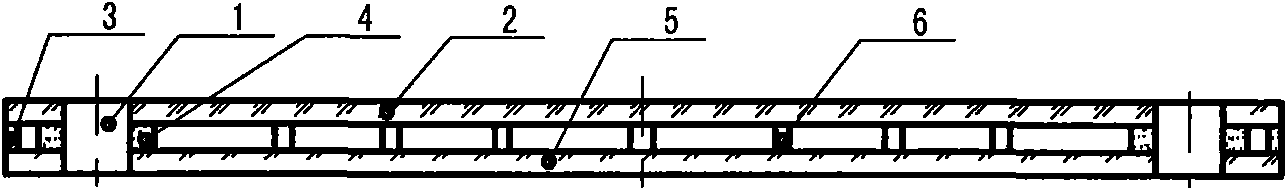

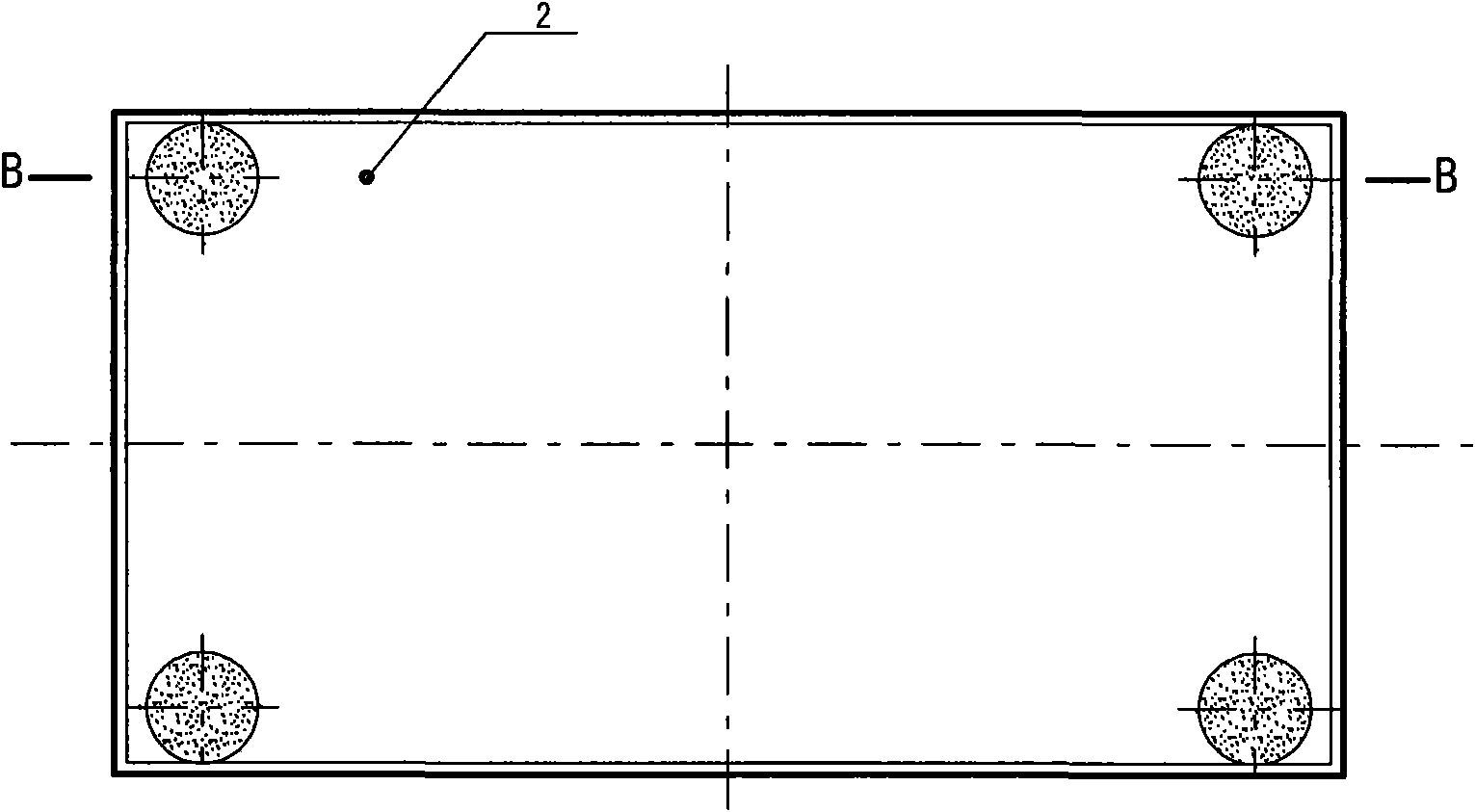

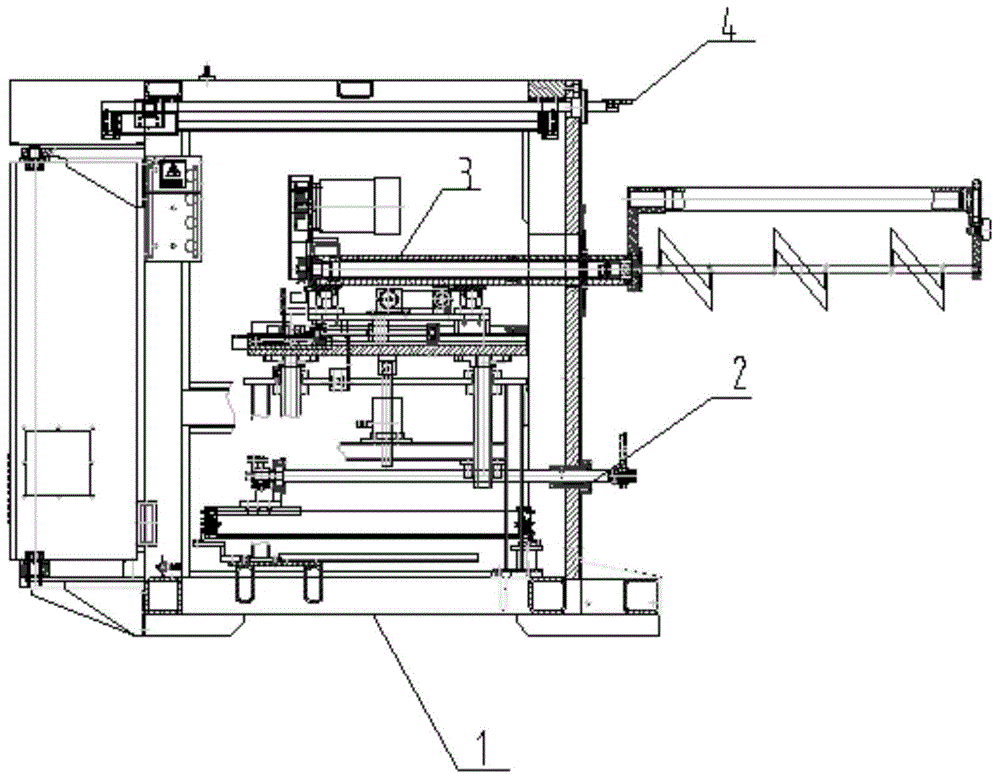

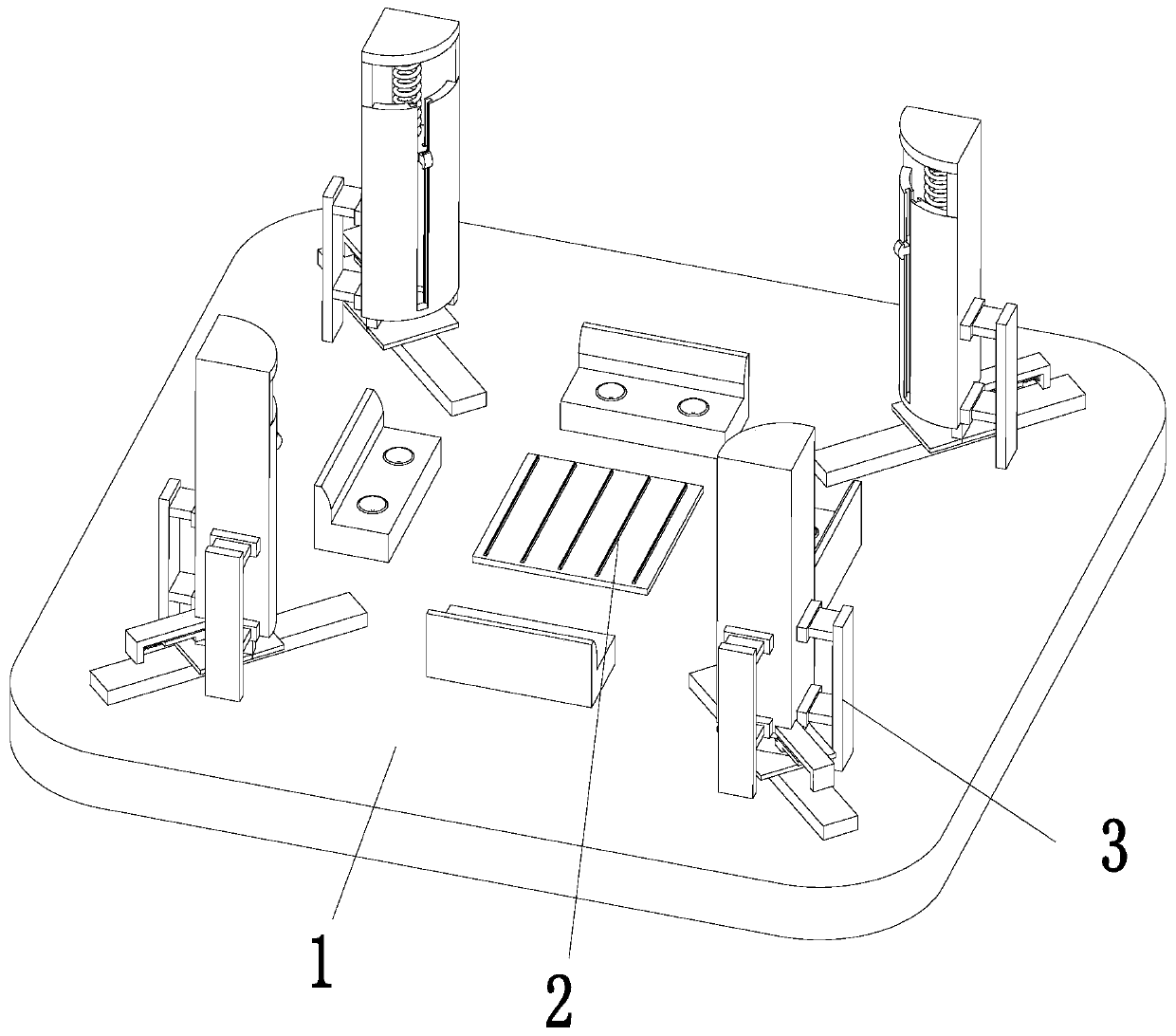

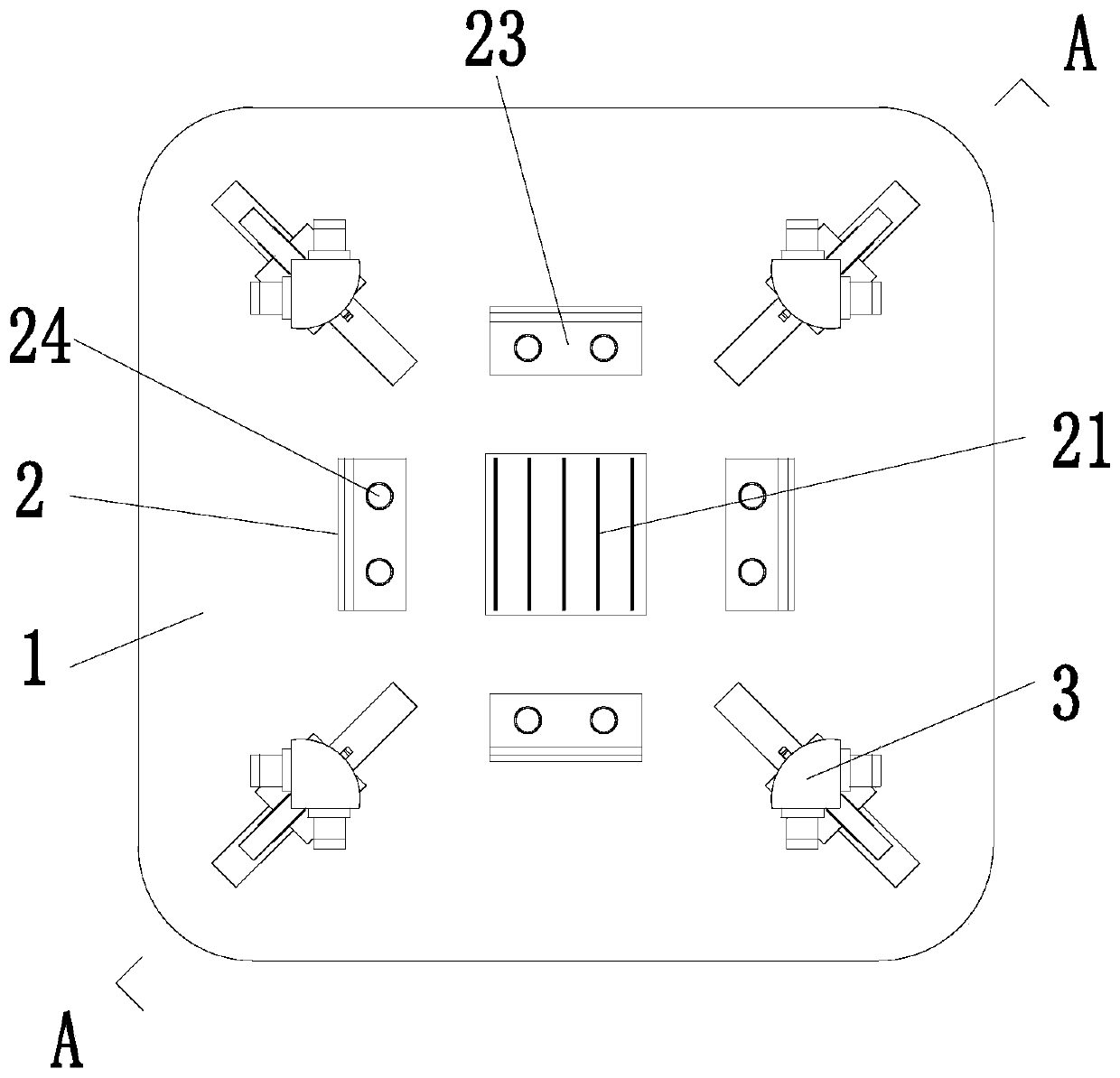

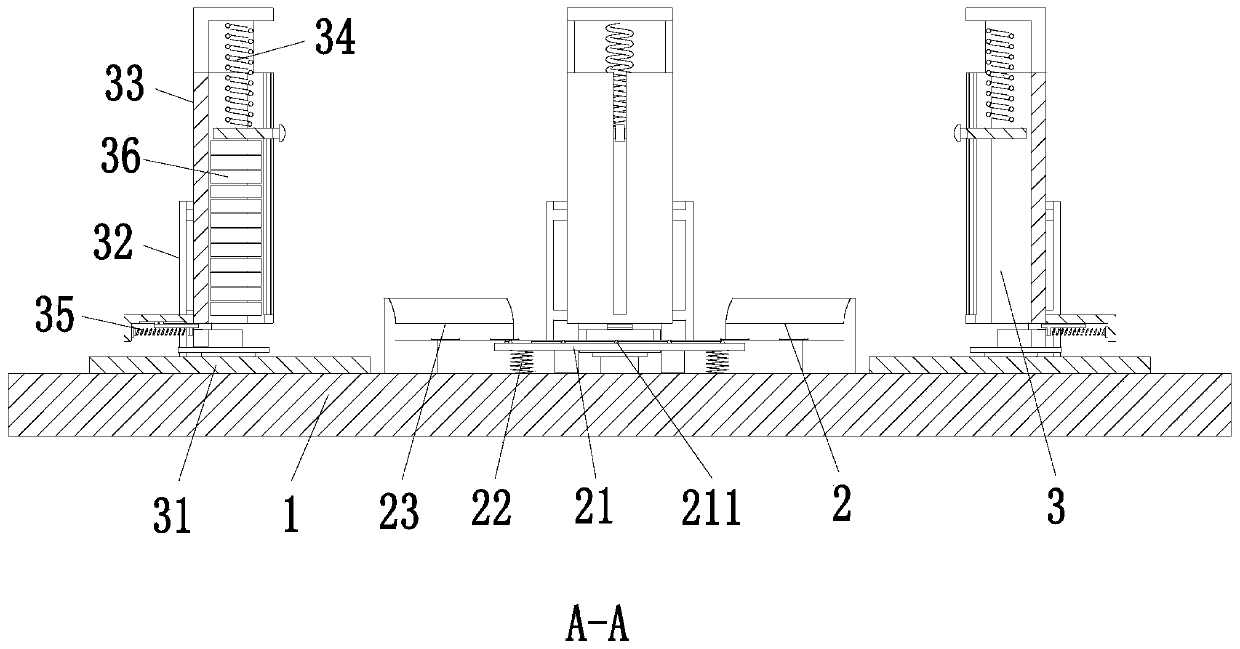

Glass industrial production protective packaging automatic equipment

ActiveCN110155410AImprove the installation effectReduce manual labor intensityShock-sensitive articlesEngineeringUltimate tensile strength

Owner:阜阳市正大玻璃科技有限公司

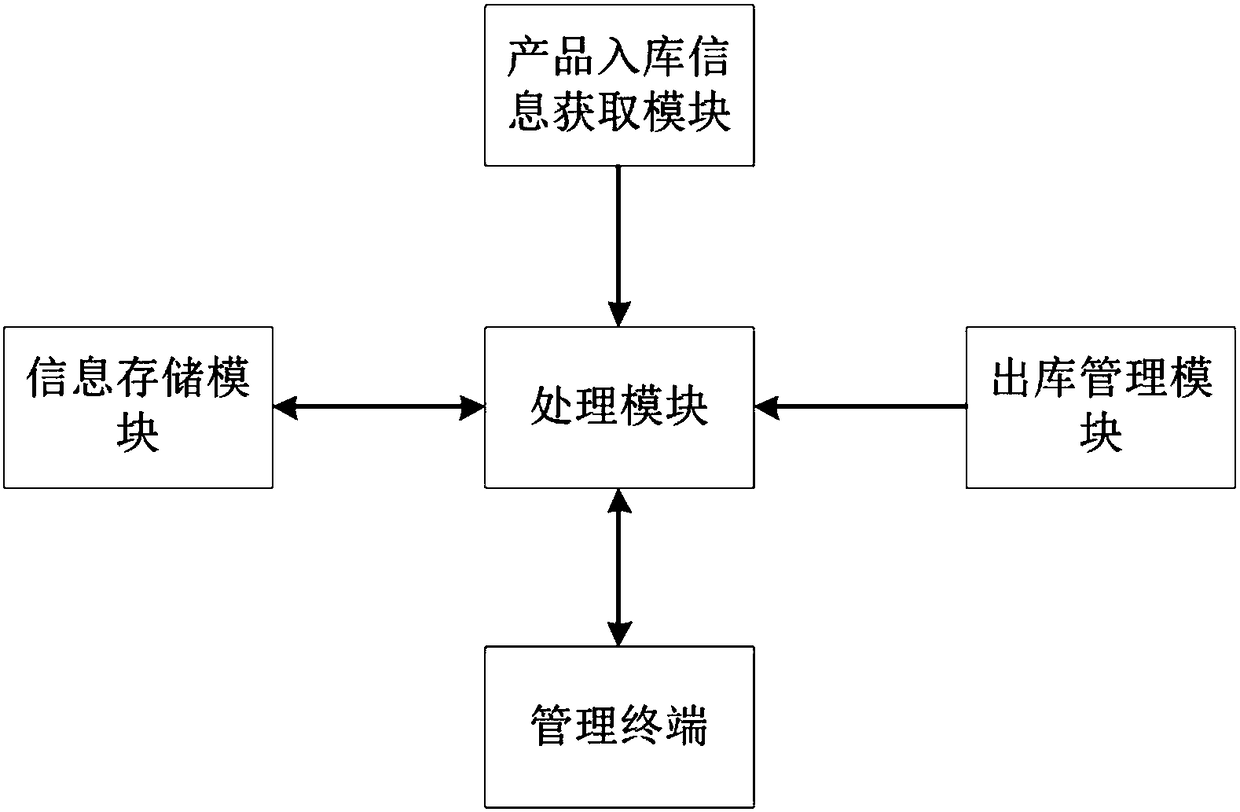

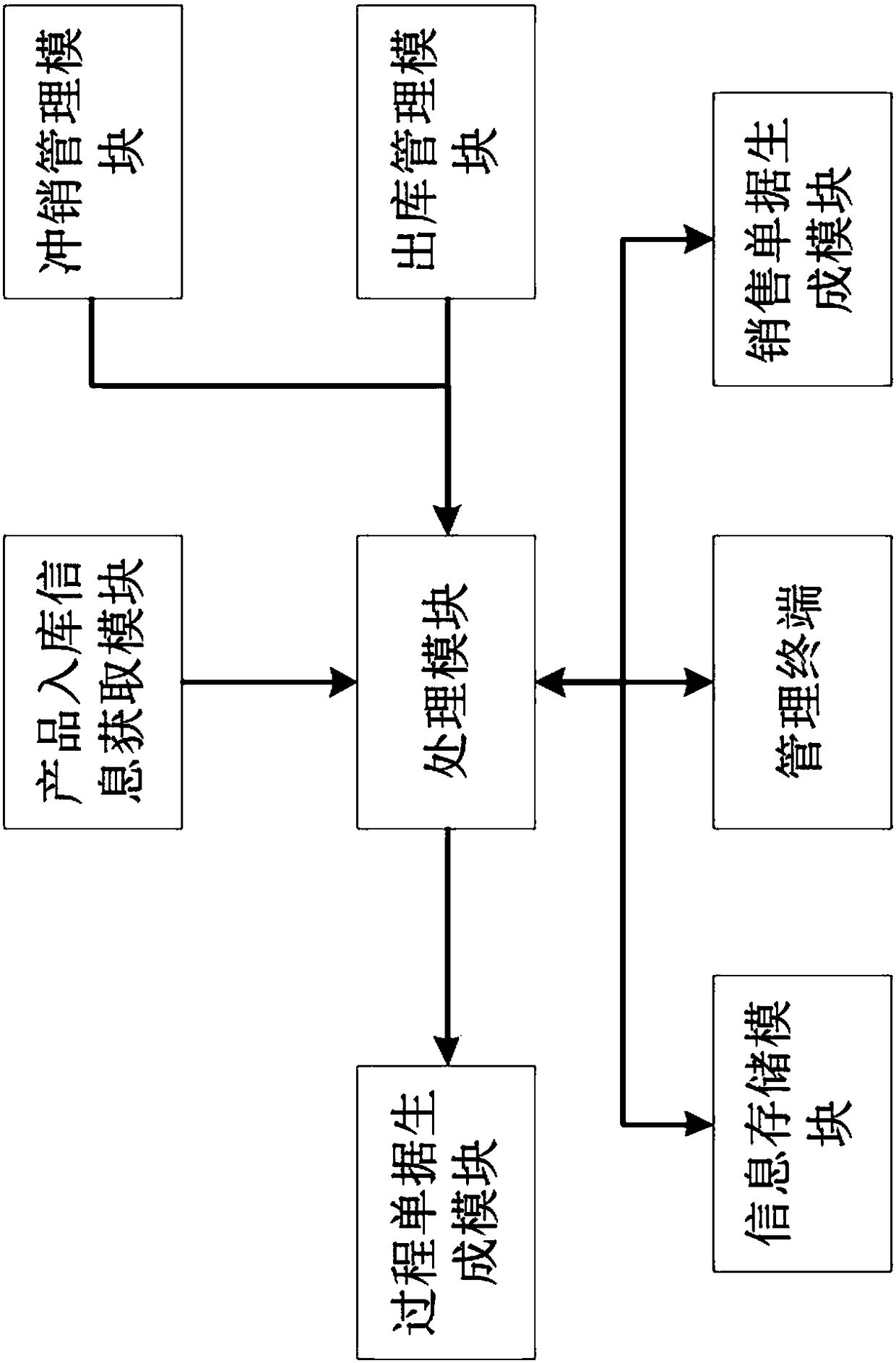

Management information system for class-III medical instruments in glasses industry

The invention relates to the field of commodity purchase-sales-inventory management and provides a management information system for class-III medical instruments in the glasses industry to solve thetechnical problems that existing management systems in the glasses industry are bloated and inefficient and cannot help dealers to timely return commodities near the expiry date. The management information system comprises a product storage information acquisition module, a processing module, an information storage module, a delivery management module and a management terminal, wherein the productstorage information acquisition module is used for acquiring feature information of stored products and the number of the stored products and sending the feature information and the number to the processing module, and the feature information comprises expiry date information; the processing module is used for generating an internal code corresponding to the feature information according to the feature information of the stored products, sending the internal code to the information storage module and sending the number of the stored products to the information storage module; the informationstorage module is used for storing and updating the feature information, the internal code and the number of the stored products to inventory information.

Owner:千叶眼镜连锁股份公司

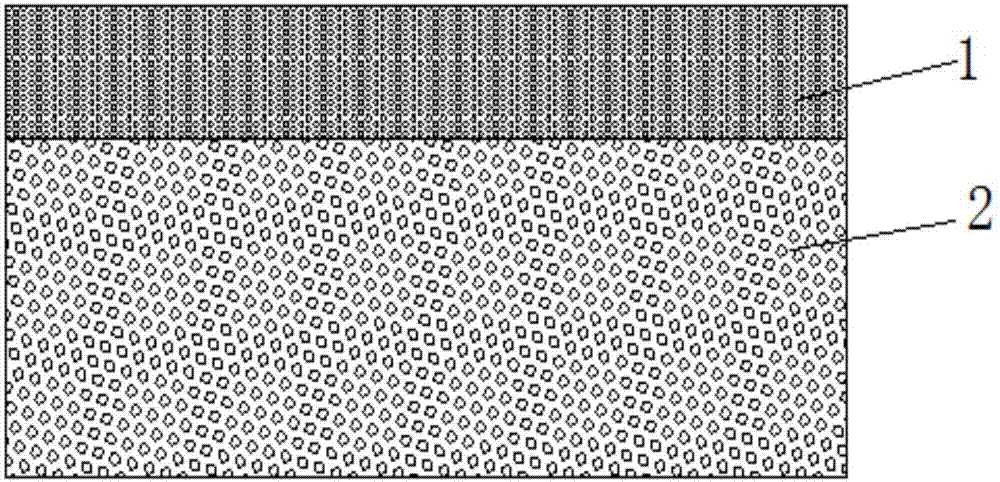

Color-changing water-permeable brick with gradient pore structure and preparation method of color-changing water-permeable brick

ActiveCN107141011AMeet the needs of building a sponge cityImprove the decorative effectCeramic shaping apparatusCeramic materials productionSurface layerBrick

The invention belongs to the technical field of building materials and particularly relates to a color-changing water-permeable brick with a gradient pore structure and a preparation method of the color-changing water-permeable brick. The color-changing water-permeable brick comprises a color-changing surface layer and a matrix layer, wherein the color-changing surface layer is prepared from inorganic solid waste particles, color-changing glass particles, clay, albite and a water glass solution; and the matrix layer is prepared from the inorganic solid waste particles, the clay, the albite and the water glass solution. The color-changing water-permeable brick has two remarkable advantages: (1) the water-permeable brick has an effect of changing colors along the change of environmental illumination or temperature, so that the decoration effect of the water-permeable brick is enriched, and meanwhile, the water-permeable brick can be used for carrying out warning monitoring on the environmental illumination or temperature; and (2) glass waste in the color-changing glass industry can be adequately used for preparing color-changing particles.

Owner:淄博天之润生态科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com