Feldspar quarry beneficiation process

A feldspar mine and process technology, applied in the field of chemical metallurgy, can solve the problems of high cost and low impurity removal rate, and achieve the effects of low cost, reduced chemical content and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Crush the feldspar raw ore to -10mm, and then grind it in a wet conical ball mill, the grinding concentration is 60%, the grinding time is 15 minutes, and the grinding fineness is -200 mesh 80%, and the raw ore slurry is obtained ; The weight content of each component in the feldspar raw ore is respectively: SiO 2 64.82%, Al 2 o 3 28.13%, K 2 O 5.16% and Fe 2 o 3 1.89%;

[0022] Send the raw ore pulp into the SLon weak magnetic separator for weak magnetic separation to remove mechanical iron to obtain the first roughed ore pulp; wherein, the magnetic separation concentration is 25%, and the magnetic field strength is 1000 Oersted;

[0023] Send the first roughing pulp into the SLon high-gradient strong magnetic separator for strong magnetic separation to remove iron oxide to obtain the second roughing pulp; wherein, the magnetic separation concentration is 10%, and the magnetic field strength is 8000 Oersted;

[0024] Add 0.01% medicament of the second roughing p...

Embodiment 2

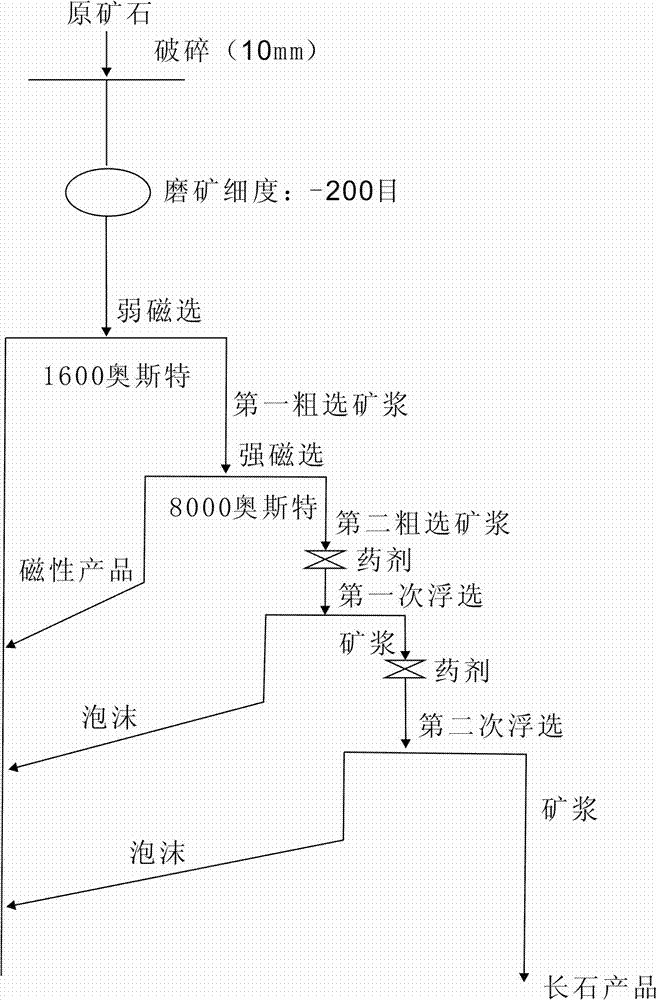

[0027] figure 1 It is the process flow chart of this embodiment, and the feldspar raw ore is beneficiated according to the process as follows: crush the feldspar raw ore to -10mm, and then grind it in a wet conical ball mill with a grinding concentration of 60%. The mining time is 15 minutes, the grinding fineness is -200 mesh 80%, and the raw ore slurry is obtained; the weight content of each component in the raw ore of the feldspar mine is: SiO 2 64.82%, Al 2 o 3 28.13%, K 2 O 5.16% and Fe 2 o 3 1.89%;

[0028] Send the raw ore pulp into the SLon weak magnetic separator for weak magnetic separation to remove mechanical iron to obtain the first roughed ore pulp; wherein, the magnetic separation concentration is 25%, and the magnetic field strength is 1600 Oersted;

[0029] Send the first roughing pulp into the SLon high-gradient strong magnetic separator for strong magnetic separation to remove iron oxide to obtain the second roughing pulp; wherein, the magnetic separa...

Embodiment 3

[0033] Crush the feldspar raw ore to -10mm, and then grind it in a wet conical ball mill, the grinding concentration is 60%, the grinding time is 15 minutes, and the grinding fineness is -200 mesh 80%, and the raw ore slurry is obtained ; The weight content of each component in the feldspar raw ore is respectively: SiO 2 64.82%, Al 2 o 3 28.13%, K 2 O 5.16% and Fe 2 o 3 1.89%;

[0034] Send the raw ore pulp into the SLon weak magnetic separator for weak magnetic separation to remove mechanical iron, and obtain the first roughed ore pulp; wherein, the magnetic separation concentration is 25%, and the magnetic field strength is 3000 Oersted;

[0035] Send the first roughing pulp into the SLon high-gradient strong magnetic separator for strong magnetic separation to remove iron oxide to obtain the second roughing pulp; wherein, the magnetic separation concentration is 10%, and the magnetic field strength is 8000 Oersted;

[0036] Add 0.05% medicament of the quality of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com